Catalyst for selective catalytic reduction of nitric oxide and preparation method of catalyst

A technology for nitrogen oxides and catalysts, which is applied in the field of catalysts for selective catalytic reduction of nitrogen oxides and their preparation, can solve the problems of poor high-temperature stability, narrow active temperature window, poor low-temperature activity, etc., and achieves improved low-temperature activity and preparation method. Simple and easy to use, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

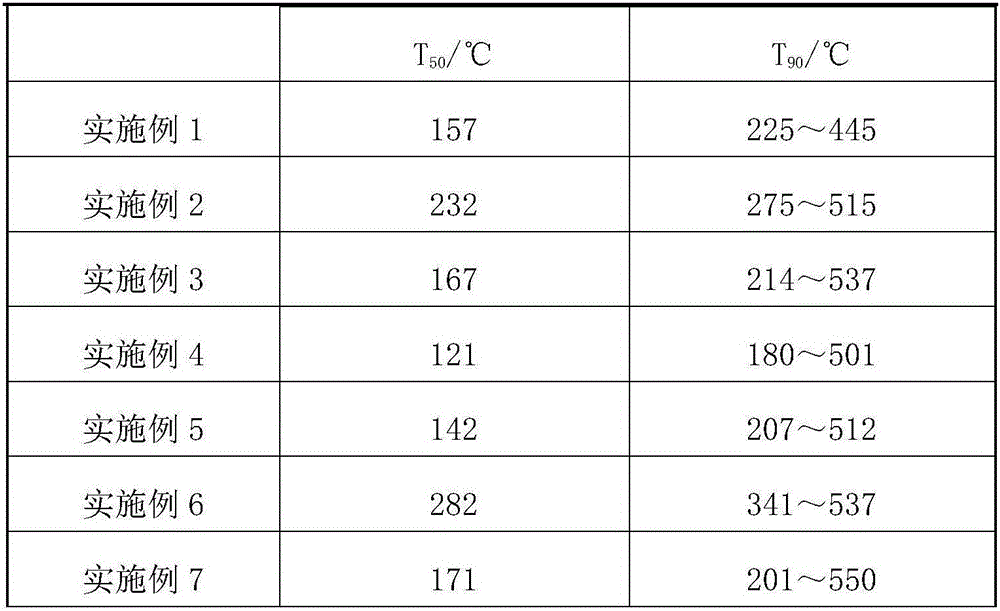

Examples

Embodiment 1

[0023] This embodiment is a catalyst for selective catalytic reduction of nitrogen oxides, wherein: the catalyst comprises SAPO-34 molecular sieve and Cu metal supported on the molecular sieve, and is made of SAPO-34 molecular sieve and copper nitrate, wherein the Cu metal is The mass ratio of the mass to the SAPO-34 molecular sieve was 0.01. Among them, molecular sieve BET specific surface area ≥ 500m 2 / g.

[0024] The preparation method is as follows:

[0025] 1) drying the SAPO-34 molecular sieve at a temperature of 100 ° C for 2 hours to remove the moisture adsorbed by the molecular sieve;

[0026] 2) mixing copper nitrate with water, stirring and dissolving to obtain a solution, the volume of which is the mass×specific pore volume of the pretreated molecular sieve in step 1);

[0027] 3) Stir and mix the copper nitrate solution prepared in step 2) and the pretreated SAPO-34 molecular sieve in step 1), place it in an oven to dry at a temperature of 100° C. for 2 hours,...

Embodiment 2

[0030] The present embodiment is a catalyst for selective catalytic reduction of nitrogen oxides, wherein: the catalyst includes beta molecular sieve and Fe and Ce metals supported on the molecular sieve, and is made of beta molecular sieve, ferric nitrate and cerium nitrate, wherein Fe metal The mass ratio to Ce metal is 1:4, and the mass ratio of the total mass of Fe metal to Ce metal to β molecular sieve is 0.10. Among them, molecular sieve BET specific surface area ≥ 500m 2 / g.

[0031] The preparation method is as follows:

[0032] 1) drying the beta molecular sieve at a temperature of 120 ° C for 4 hours to remove the moisture adsorbed by the molecular sieve;

[0033] 2) mixing ferric nitrate and cerium nitrate with water, stirring and dissolving to obtain a solution, and the volume of the solution is the mass×specific pore volume of the molecular sieve after the pretreatment in step 1);

[0034] 3) Stir and mix the ferric nitrate and cerium nitrate mixed solution pre...

Embodiment 3

[0037] This embodiment is a catalyst for selective catalytic reduction of nitrogen oxides, wherein: the catalyst includes SSZ-13 molecular sieve and Cu metal supported on the molecular sieve, and is made of SSZ-13 molecular sieve and copper nitrate, wherein the Cu metal is made of SSZ-13 molecular sieve and copper nitrate. The mass ratio of mass to SSZ-13 molecular sieve is 0.03. Among them, molecular sieve BET specific surface area ≥ 500m 2 / g.

[0038] The preparation method is as follows:

[0039] 1) drying the SSZ-13 molecular sieve at a temperature of 105 ° C for 3 hours to remove the moisture adsorbed by the molecular sieve;

[0040] 2) mixing copper nitrate with water, stirring and dissolving to obtain a solution, the volume of which is the mass×specific pore volume of the pretreated molecular sieve in step 1);

[0041] 3) Stir and mix the copper nitrate solution prepared in step 2) and the pretreated SSZ-13 molecular sieve in step 1), place it in an oven to dry at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com