Patents

Literature

135results about How to "Reduce adverse factors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

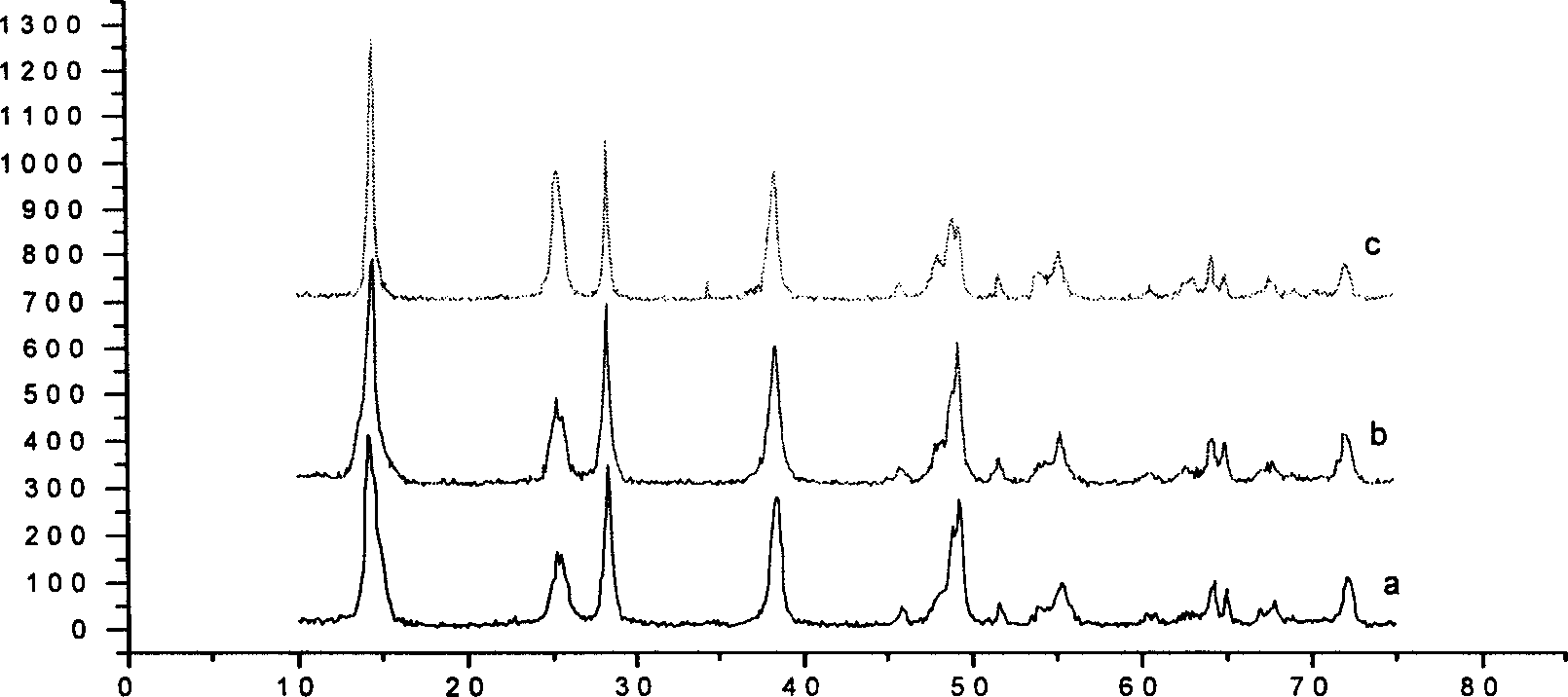

Aluminium alloy for vehicle hub and preparation method thereof

The invention provides an aluminium alloy for a vehicle hub and a preparation method thereof. The alloy comprises the following components by weight percent: 4.5-6.3% of Zn, 1.4-2.5% of Mg, 0.5-0.9% of Cu, 0.12-0.3% of Zr, 0.05-0.15% of Ti, 0.05-0.2% of Cr, 0.1-0.3% of Sc and the balance of Al. The preparation method of the aluminium alloy comprises the following steps: weighting raw materials, melting the raw materials except for magnesium blocks, adding a covering agent, then adding the preheated magnesium blocks, stirring, injecting nitrogen or argon to degas, filtering with a ported ceramic plate, reducing the temperature, standing for 20 minutes, and adopting a liquid forging mould and a liquid forging forming method to prepare the hub. The prepared vehicle hub has high strength, impact toughness and corrosion resistance; and the mechanical properties of the aluminium alloy hub can be ensured, the production cost can be reduced and the large-scale production of the hub is easy to perform.

Owner:ZHEJIANG GKO ALUMINUM

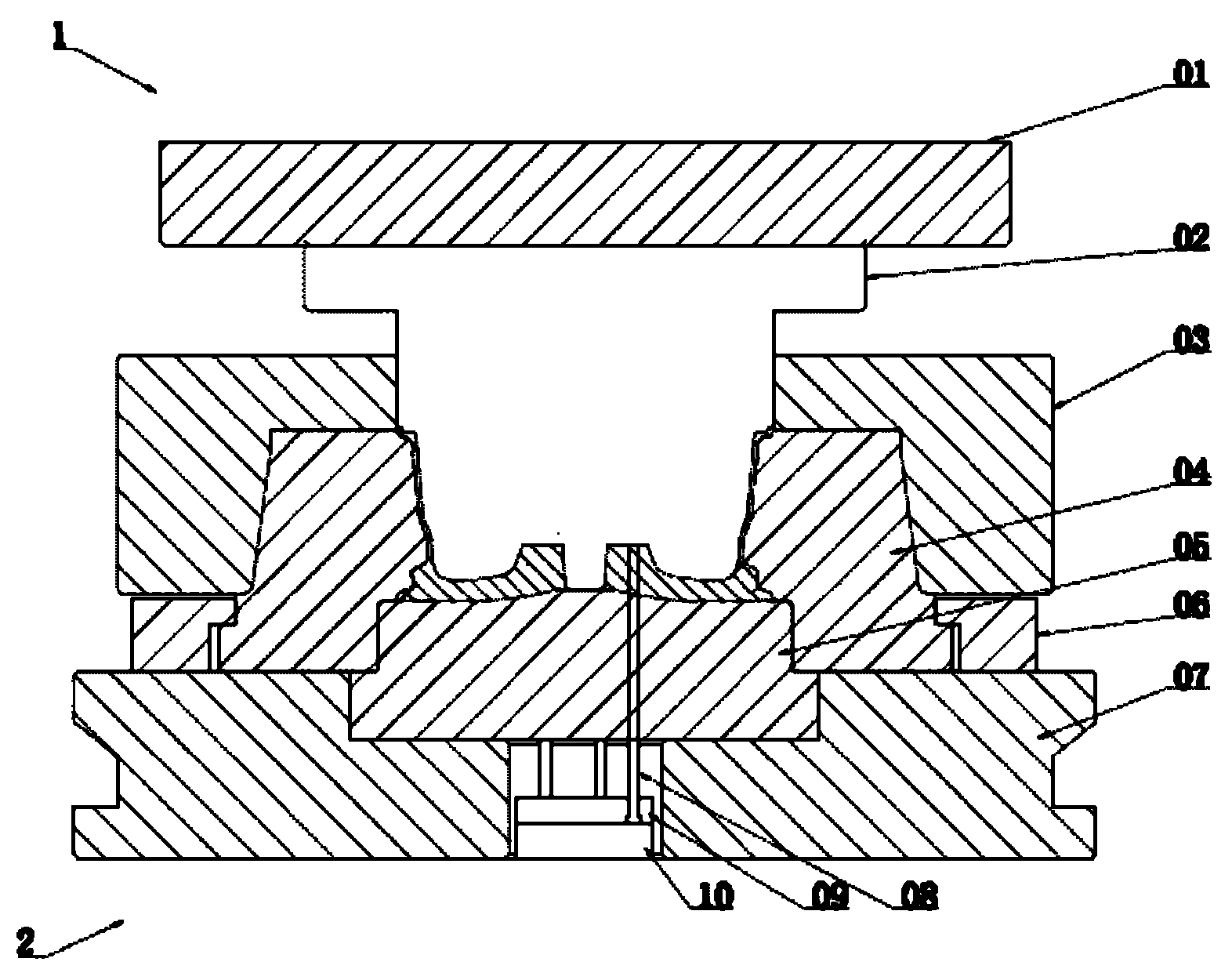

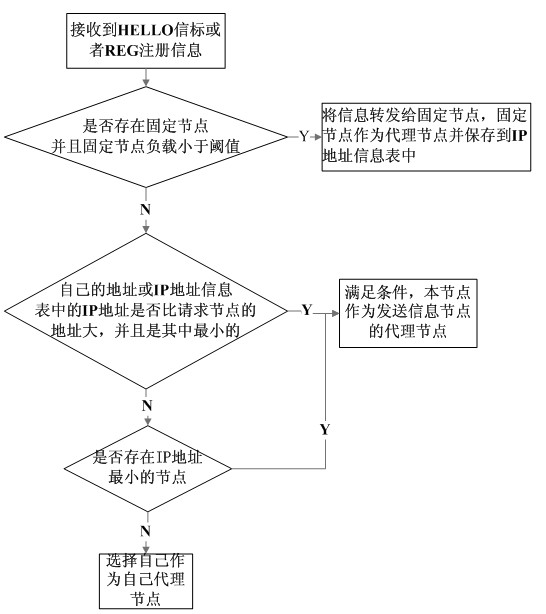

Method of automatically assigning ip address based on geographic location in mobile ad hoc network

The invention discloses an automatic IP (Internet protocol) address allocation method based on geographical position in mobile ad hoc network, wherein the network is divided into grid structures of multiple layers, and a temporary IP address field is pre-defined for each grid. The allocation method comprises the following steps: when a node joins the network, randomly selecting a temporary IP address from the temporary IP address field of the grid in which the node is located, and performing DAD repeated address detection to avoid conflict with the selected temporary IP address for sure; after the temporary IP address of the node is successfully configured, sending an IP inquiry message, avoiding IP address conflict, and configuring a formal IP address; after successful configuration, if the formal IP address is different from the temporary IP address, releasing the temporary IP address; and finishing the selection of a proxy node through an HELLO beacon and REG registration information by the node. The method provided by the invention has small system overhead and good expansibility, and can realize recovery of IP address and avoid address leakage.

Owner:SOUTH CHINA UNIV OF TECH

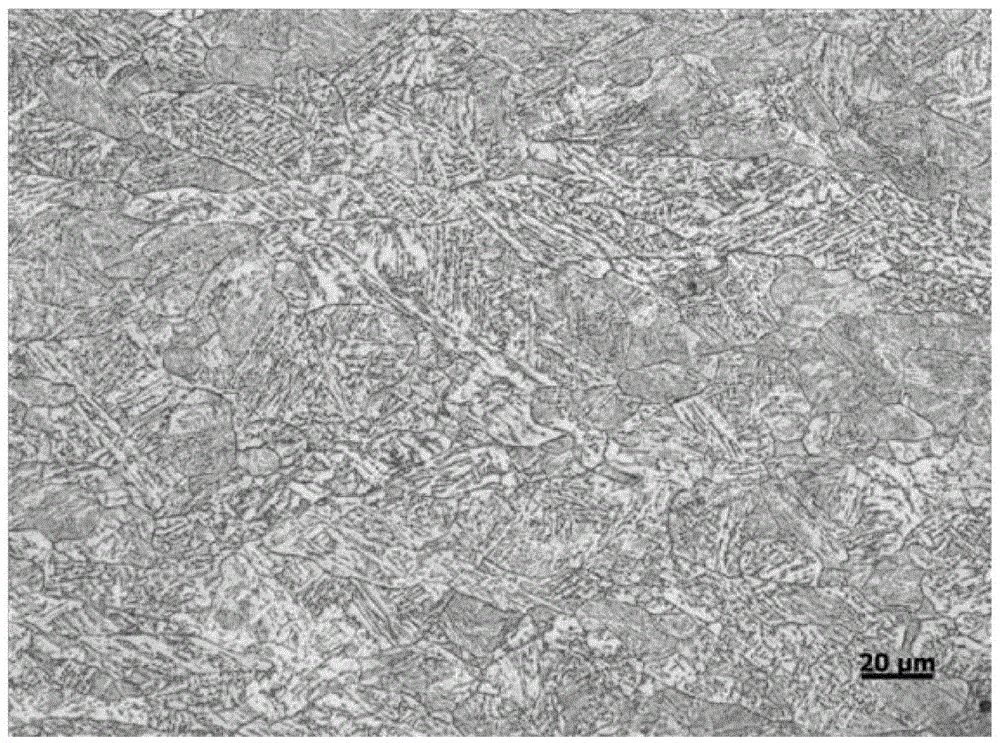

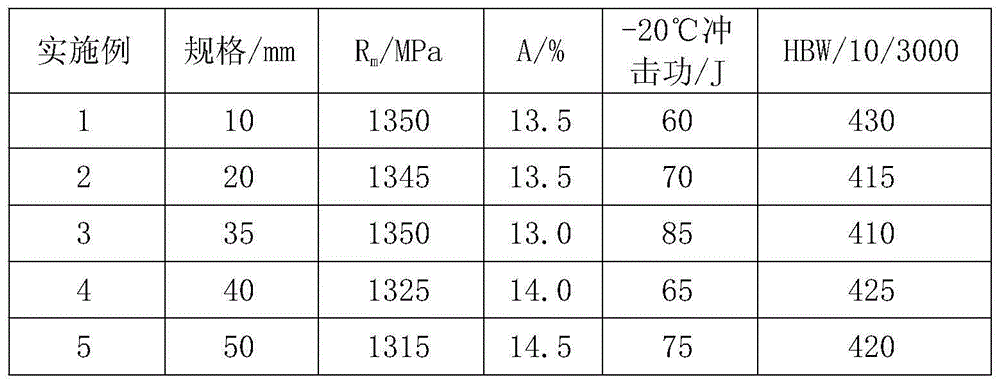

Low-cost HB400-grade wear-resisting steel and production method thereof

The invention discloses low-cost HB400-grade wear-resisting steel and a production method thereof. The low-cost HB400-grade wear-resisting steel comprises the following chemical components in percentage by weight: 0.08-0.19 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.015 percent of S, 0.30-0.65 percent of Cr, 0.02-0.05 percent of Nb, 0.005-0.025 percent of Ti, 0.001-0.005 percent of B, 0.010-0.040 percent of Als and the balance of Fe and a trace amount of impurity elements. According to a steel plate, the thickness specification range is 10mm to 50mm; Rm is larger than or equal to 1300MPa; the percentage elongation is larger than or equal to 15%; the Akv is larger than or equal to 47J at -20 DEG C; the HBW / 10 / 3000 is larger than or equal to 400. The low-cost HB400-grade wear-resisting steel has the advantages that the manufacturing cost is greatly lowered, the problems of high strength and poor plasticity of wear-resisting martensite steel are solved, and the steel plate can be delivered directly. Therefore, the low-cost HB400-grade wear-resisting steel has quite high market competitiveness, wide application prospect and obvious economic benefits and social benefits.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

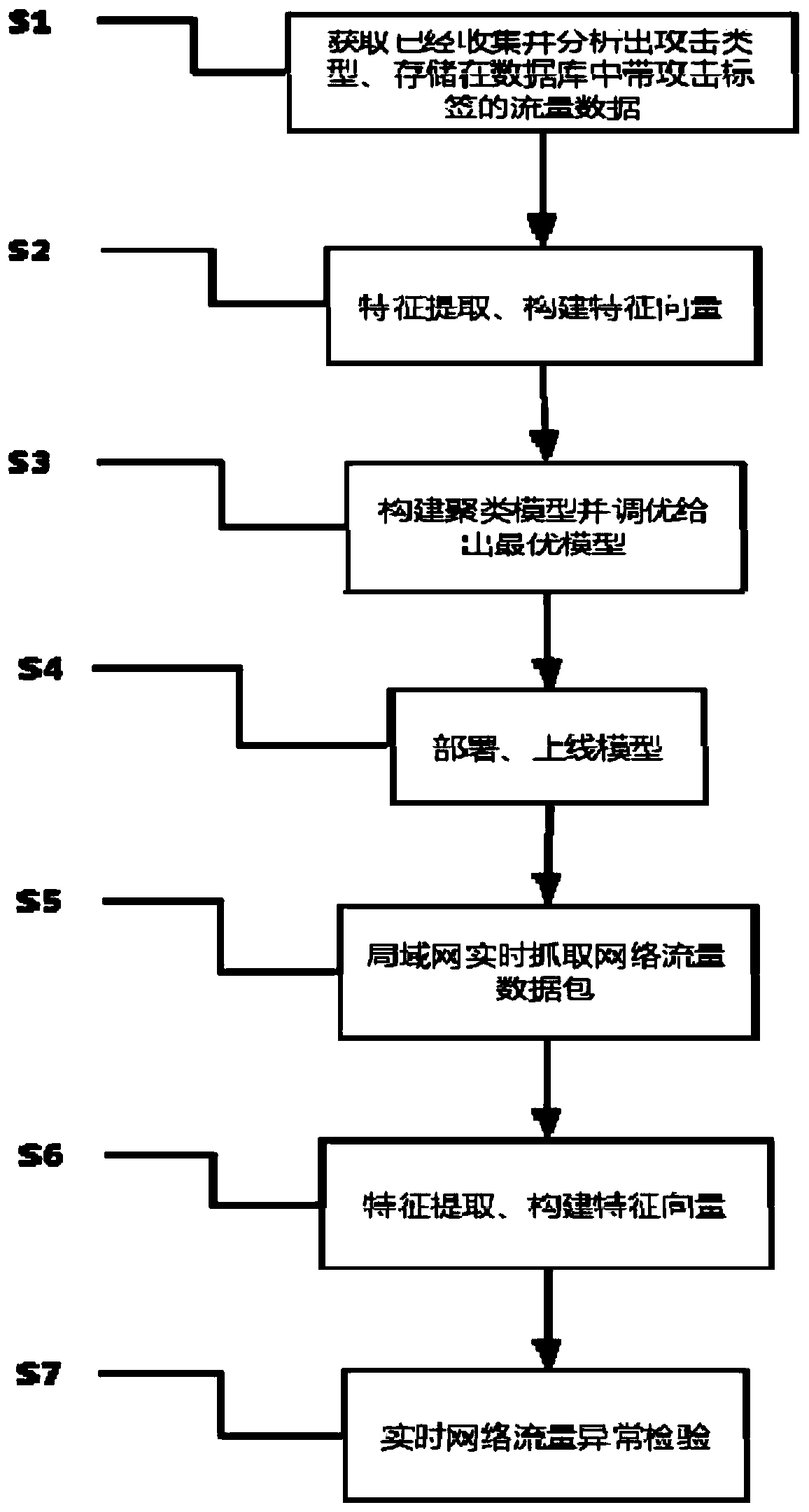

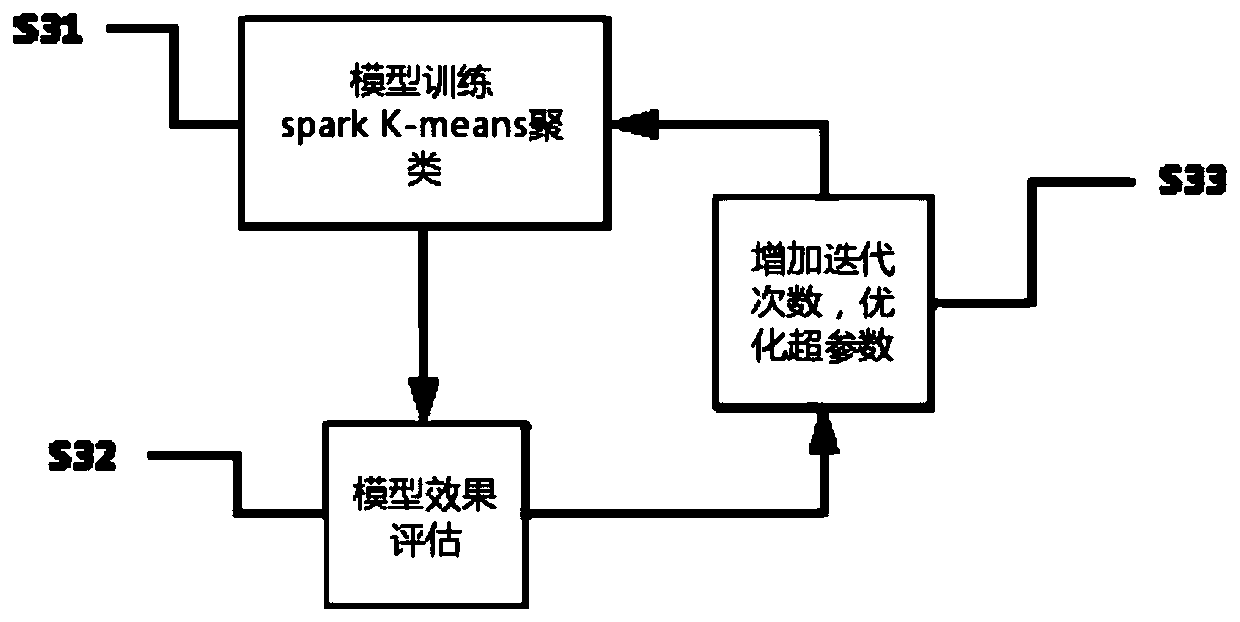

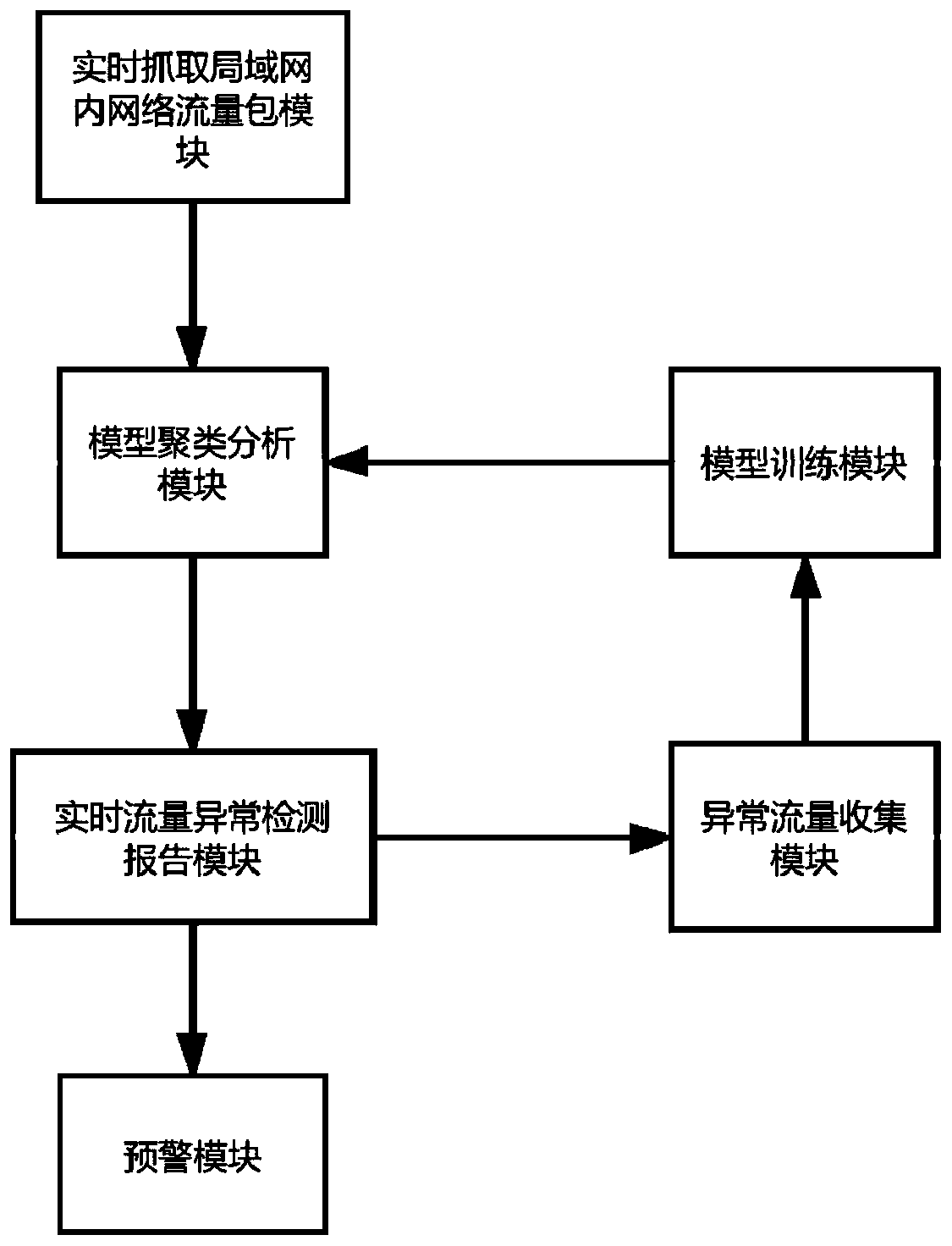

Real-time network flow anomaly detection method based on big data

InactiveCN111107102AReduce threatReal perception detectionData switching networksInternet trafficAttack

The invention discloses a real-time network flow anomaly detection method based on big data, which comprises the following steps: S1, obtaining collected and analyzed historical flow data with attacktags stored in a database to obtain attack types; S2, performing data feature preprocessing on the historical traffic data in the S1, and constructing a first class of feature vectors; S3, constructing a clustering model based on the first class of feature vectors in the S2, and obtaining a target model meeting a preset condition by utilizing model evaluation and optimization; S4, storing the target model obtained in S3 and deploying the target model online; S5, capturing and collecting real-time network data flow packet information transmitted in a local area network; S6, performing data feature preprocessing on the real-time network data traffic packet in S5, and constructing a second type of feature vectors; and S7, according to the target model in the S3 and the second type of featurevectors in the S6, performing real-time online analysis and detection, and judging whether the current real-time network data traffic is abnormal traffic or normal traffic.

Owner:SHANGHAI MARITIME UNIVERSITY

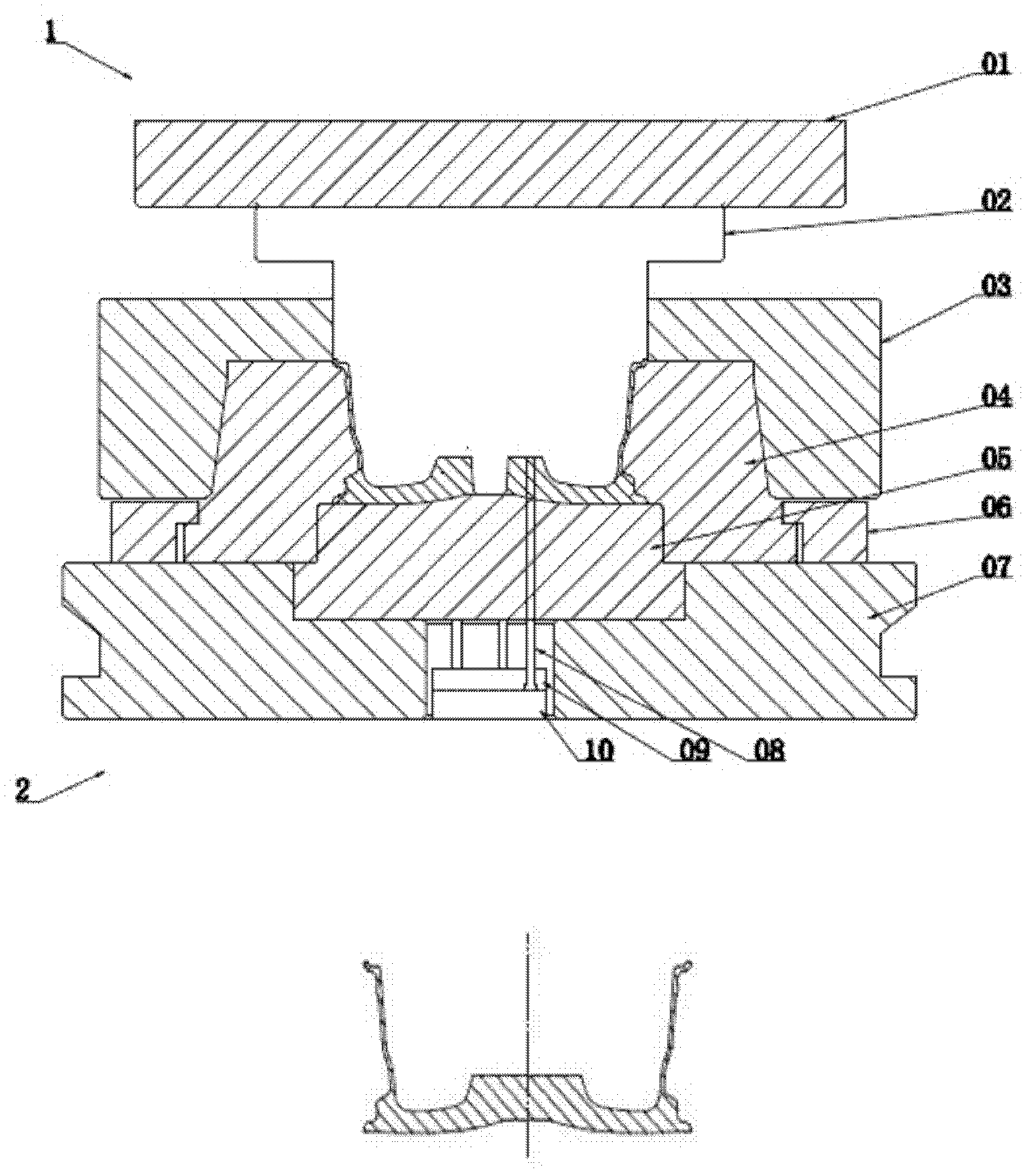

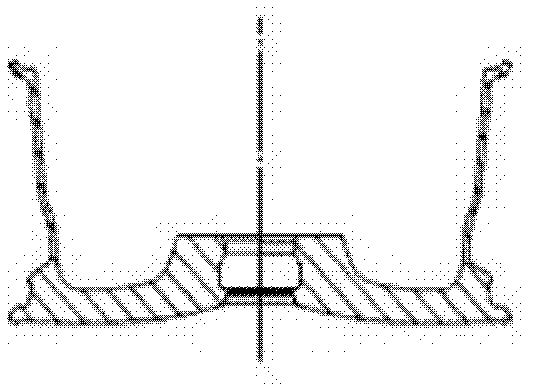

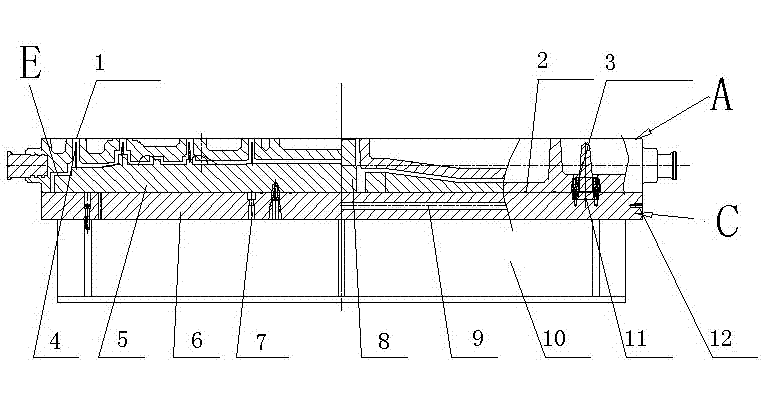

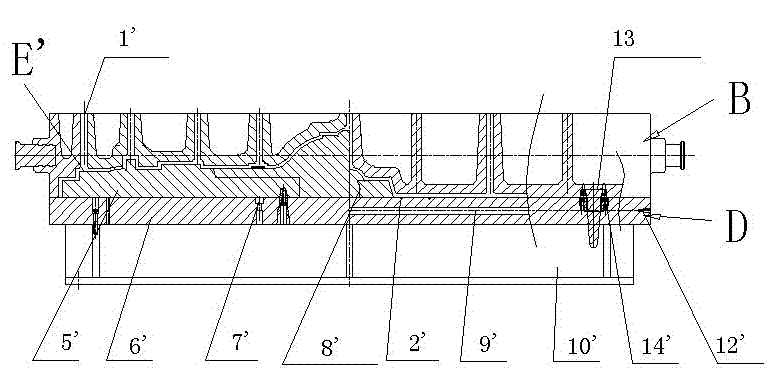

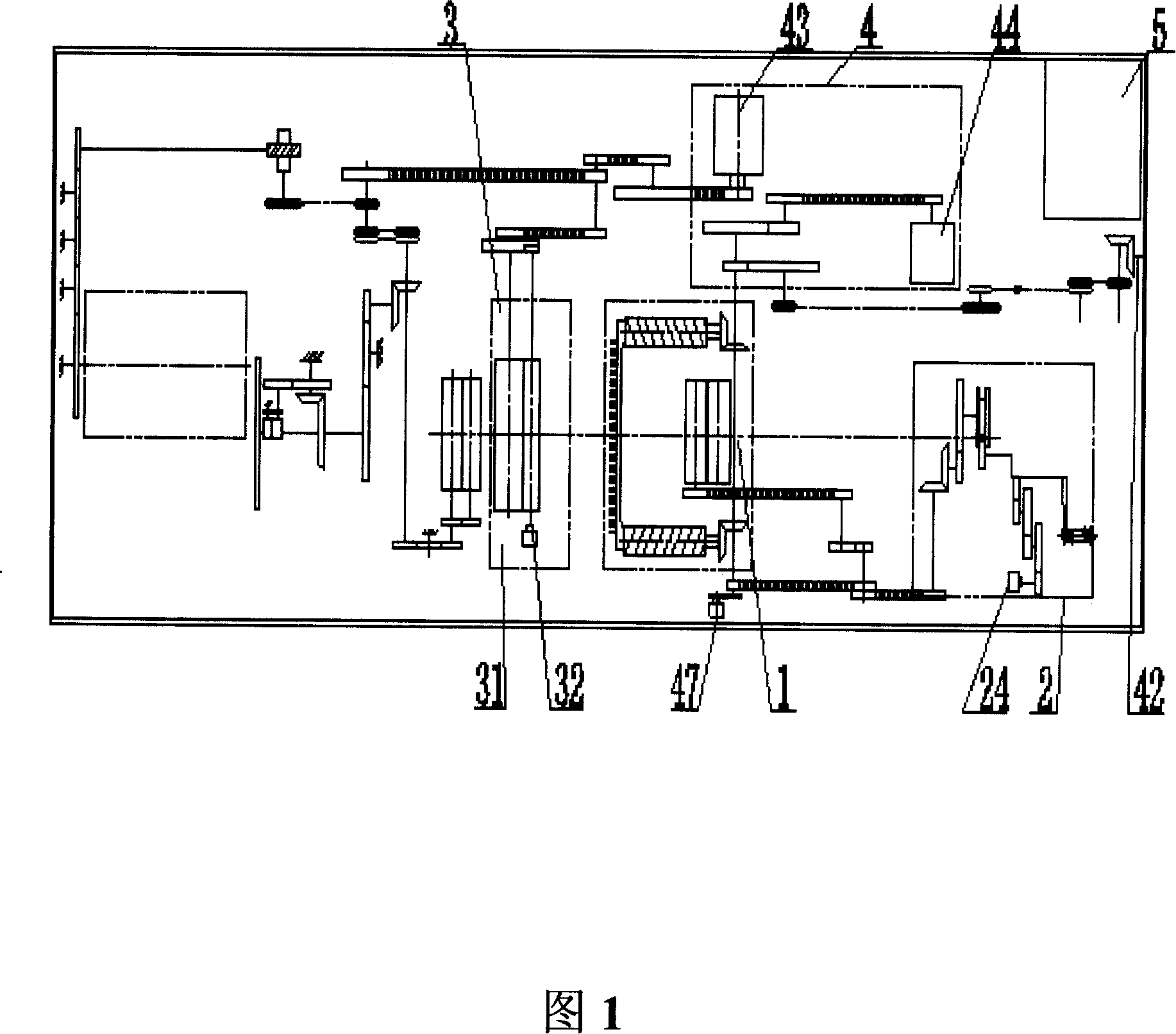

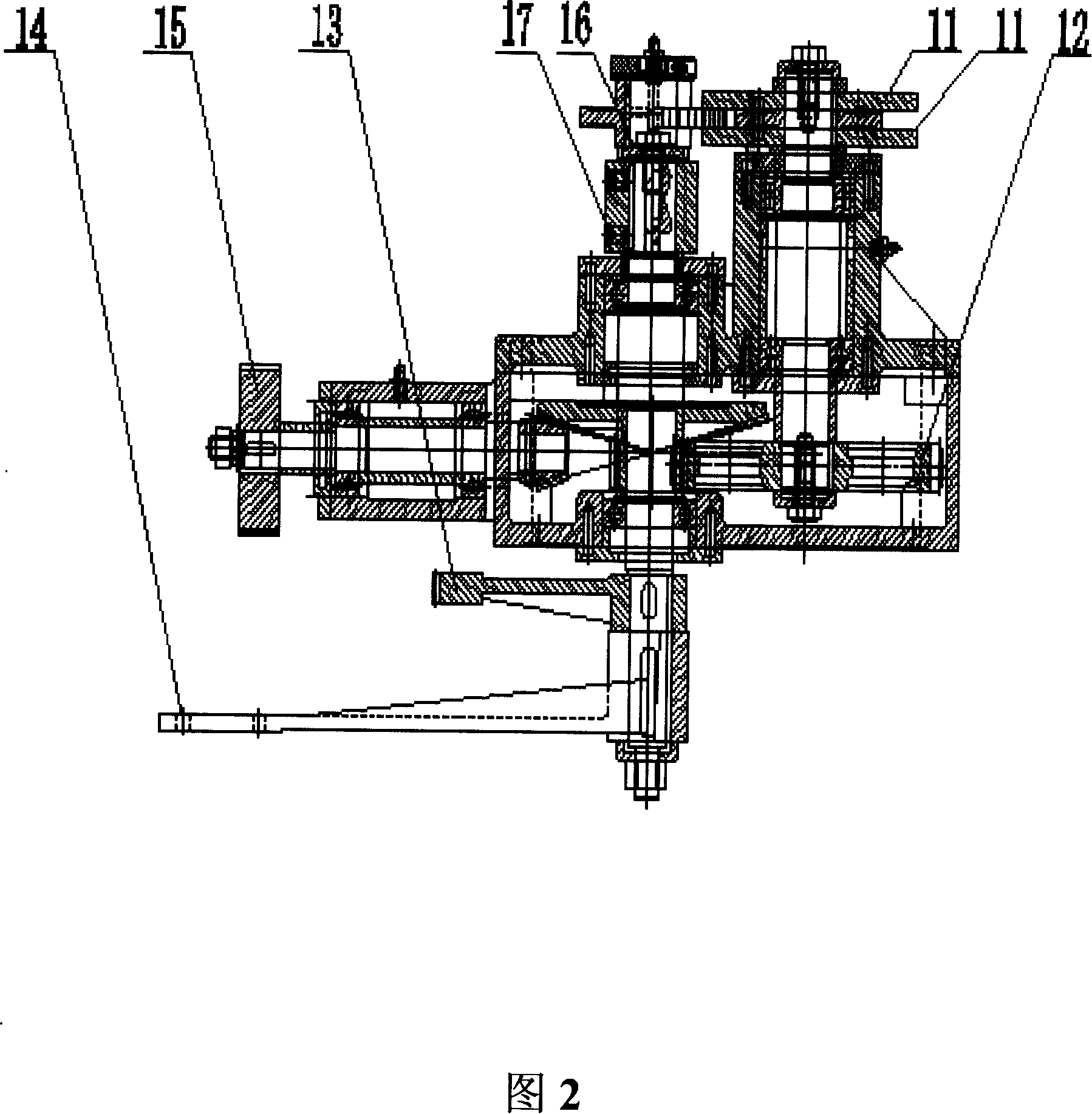

Device and production method for manufacturing automobile rear axle cast through metal mold with sand lining

ActiveCN102380586AHigh dimensional accuracyImprove surface qualityFoundry mouldsMoulding machinesTemperature controlMetallurgy

The invention discloses device and production method for manufacturing an automobile rear axle cast through the sand lining process of a metal mold. The device is characterized in that a mud core component is arranged in a mold cavity formed after an upper iron mold and a lower iron mold are assembled, positions of sand shooting holes of the upper iron mold and the lower iron mold are in one-to-one correspondence, gas needles are arranged on an upper mold plate, the gas needles and the sand shooting holes of the upper iron mold are in one-to-one correspondence, a plurality of heating pipes are respectively and uniformly distributed in mold plates of the upper mold plate and a lower mold plate, a temperature control meter of the heating pipes is connected with a temperature sensor, a plurality of exhaust bosses are further uniformly distributed on the peripheries of the mold plates of the upper mold plate and the lower mold plate, water-cooling bases are respectively arranged on the upper mold plate and the lower mold plate, and a plurality of exhaust grooves are arranged on the parting surface of the upper iron mold and the parting surface of the lower mold plate. The automobile rear axle cast manufactured by adopting the device and the method is good in quality, high in size precision, high in process yield, low in production cost, good in a working environment and low in energy consumption.

Owner:浙江省机电设计研究院有限公司

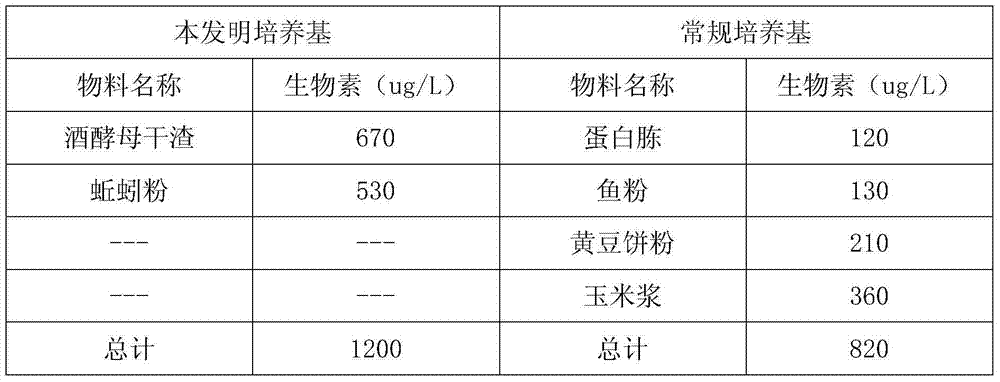

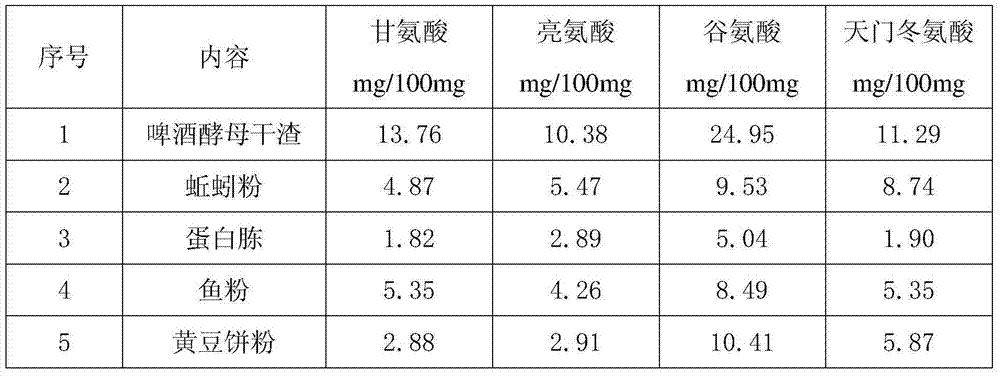

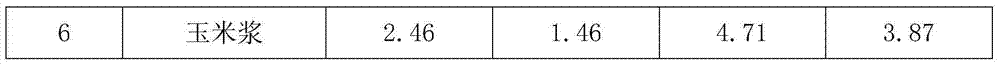

Culture medium for fermentation production of spectinomycin through streptomyces spectabilis and fermentation method

ActiveCN103484509AReduce dosageReduce typesMicroorganism based processesFermentationBiotechnologySpectinomycin

The invention relates to a culture medium for fermentation production of spectinomycin through streptomyces spectabilis and a fermentation method. A primary seed culture medium, a secondary seed culture medium and a fermentation culture medium all contain corn oil, maltose, beer yeast dry residues and earthworm meal. According to the invention, maltose replaces glucose, beer yeast dry residues and earthworm meal replace fish meal, peptone, soybean cake meal and corn steep liquor, and the culture medium formula is optimized, so that the problem of high costs of raw materials is solved, the environmental effect on the source of the raw materials is reduced to the utmost extent, sufficient supply of the raw materials is guaranteed, and stable and efficient production of spectinomycin is realized. Meanwhile, the culture medium can improve the fermentation unit and shorten the fermentation period.

Owner:宁夏泰瑞制药股份有限公司

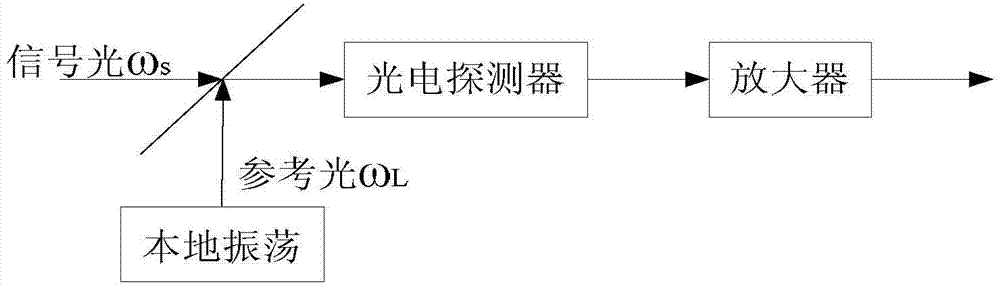

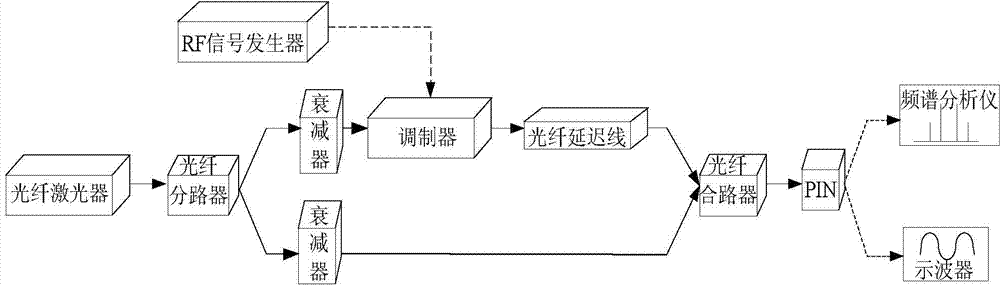

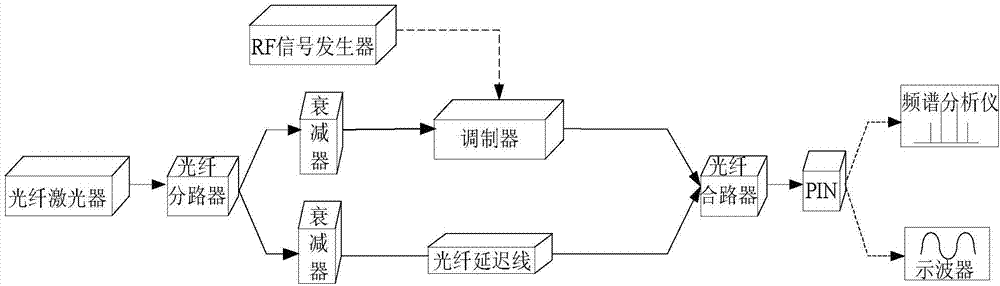

Coherent light detection system and method for optical fiber delay line phase control

ActiveCN103575408ASmall ups and downsGuaranteed frequency stabilityOptical measurementsSignal-to-noise ratio (imaging)Phase difference

The invention discloses a coherent light detection system and method for optical fiber delay line phase control. The output end of an optical fiber laser device is connected with the input end of an optical fiber branching unit. A first output end of the optical fiber branching unit is connected with an input end of a modulator. The other input end of the modulator is connected with an external RF signal generator. The output end of the modulator is connected with an input end of an optical fiber combiner. A second output end of the optical fiber branching unit is connected with the other input end of the optical fiber combiner. An optical fiber delay line is connected in series between the output end of the modulator and an input end of the optical fiber combiner, or the optical fiber delay line is connected in series between the second output end of the optical fiber branching unit and the other input end of the optical fiber combiner. The output end of the optical fiber combiner is connected with the input end of a photoelectric detector. According to the coherent light detection system and method for optical fiber delay line phase control, phase control can be achieved through the optical fiber delay line, and phase difference between reference light and a signal light branch is compensated, so that receiving sensitivity, the signal to noise ratio and system output stability are improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

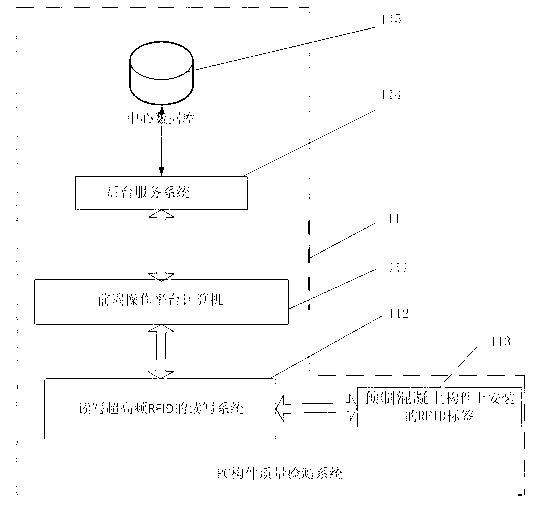

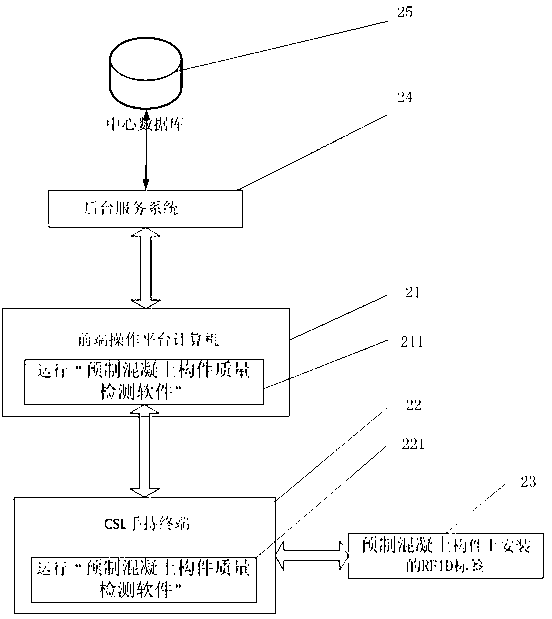

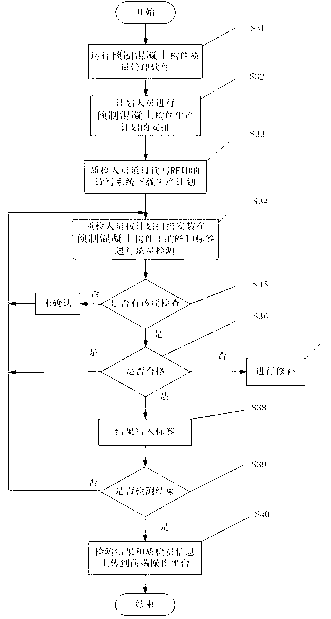

Precast concrete member production quality detection system

ActiveCN103020679ALow costImprove work efficiencyCo-operative working arrangementsPrecast concreteUltrahigh frequency

The invention relates to a precast concrete member production quality detection system. The precast concrete member production quality detection system is applied to quality detection in precast concrete member production process or other production quality detection systems capable of mounting ultrahigh frequency passive radio frequency identification devices (RFID) labels on products. The precast concrete member production quality detection system (11) is composed of a read-write system (112) and a backstage service system (114), read-write system (112) is arranged on a precast concrete member and reads and writes ultrahigh frequency RFID of an RFID label (113), the backstage service system (114) is connected with a front-end operation platform computer (111), and the backstage of the backstage service system (114) is provided with a central data base (115). The precast concrete member production quality detection system has the advantages of greatly improving working efficiency of quality detection operators during precast concrete member production on one hand, reducing engagement of people in product production on the other hand, and really achieving the aim of 'managing human by machine'.

Owner:SHANGHAI UNIV

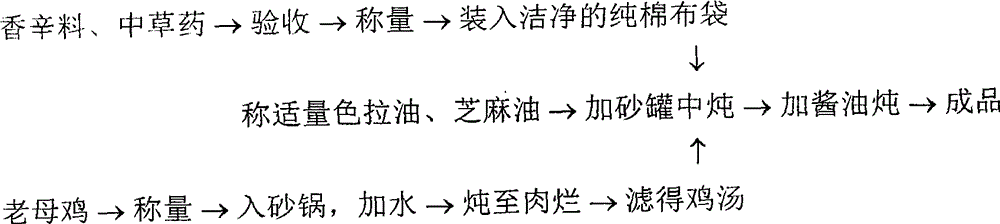

Formula of marinade and preparation method of marinade

The invention relates to a formula of marinade and a preparation method of the marinade. An inventor develops the special marinade for preparing spiced-food from pure natural raw materials by an in-depth research according to traditional local cuisine secret recipes; meat prepared from the marinade is unique in flavor, and fragrant but not greasy, does not rot easily, and has certain health efficacies; in addition, the preparation method is simple; large or small scale operation both can be realized; and popularization and application are facilitated.

Owner:郝涤非

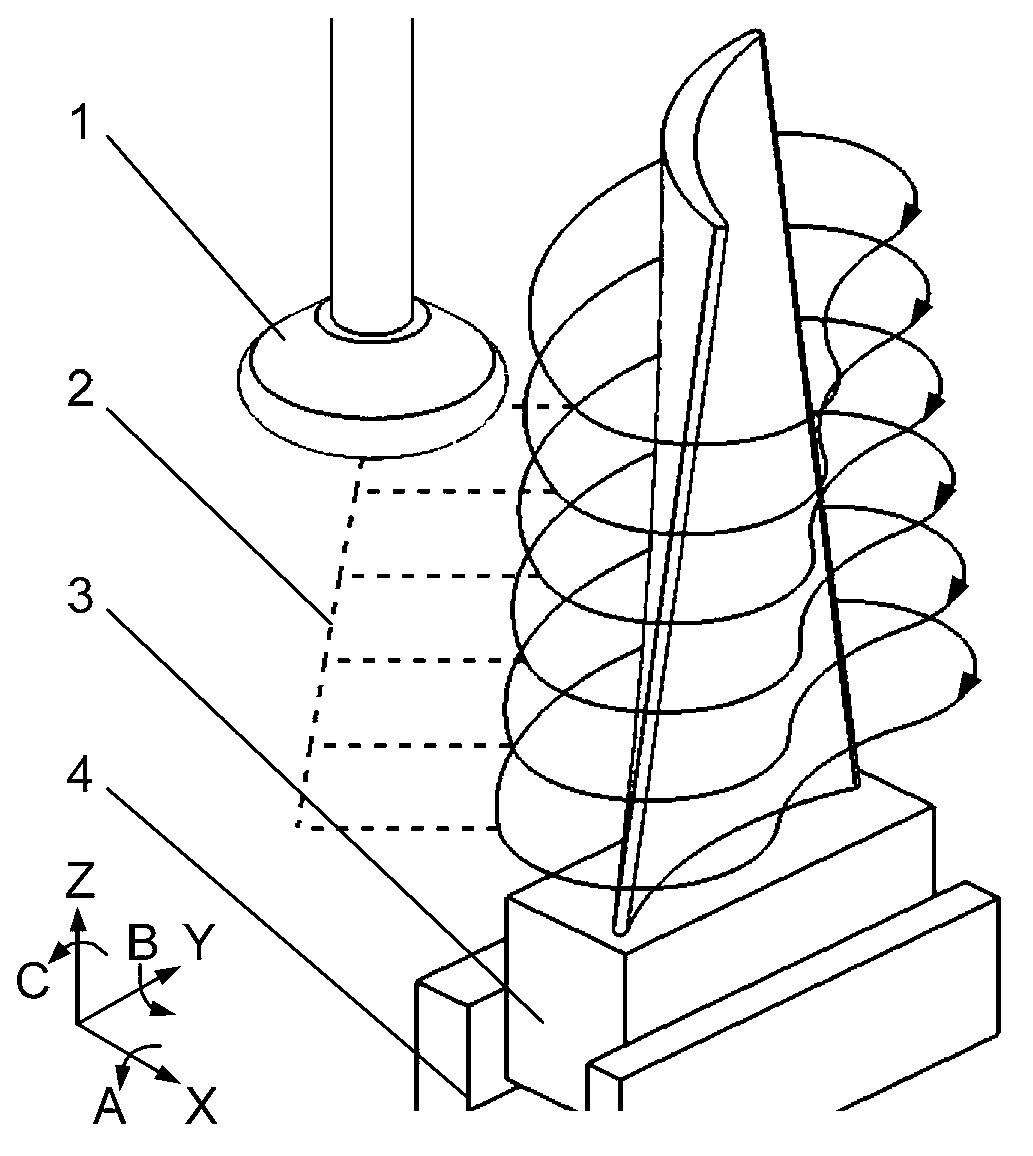

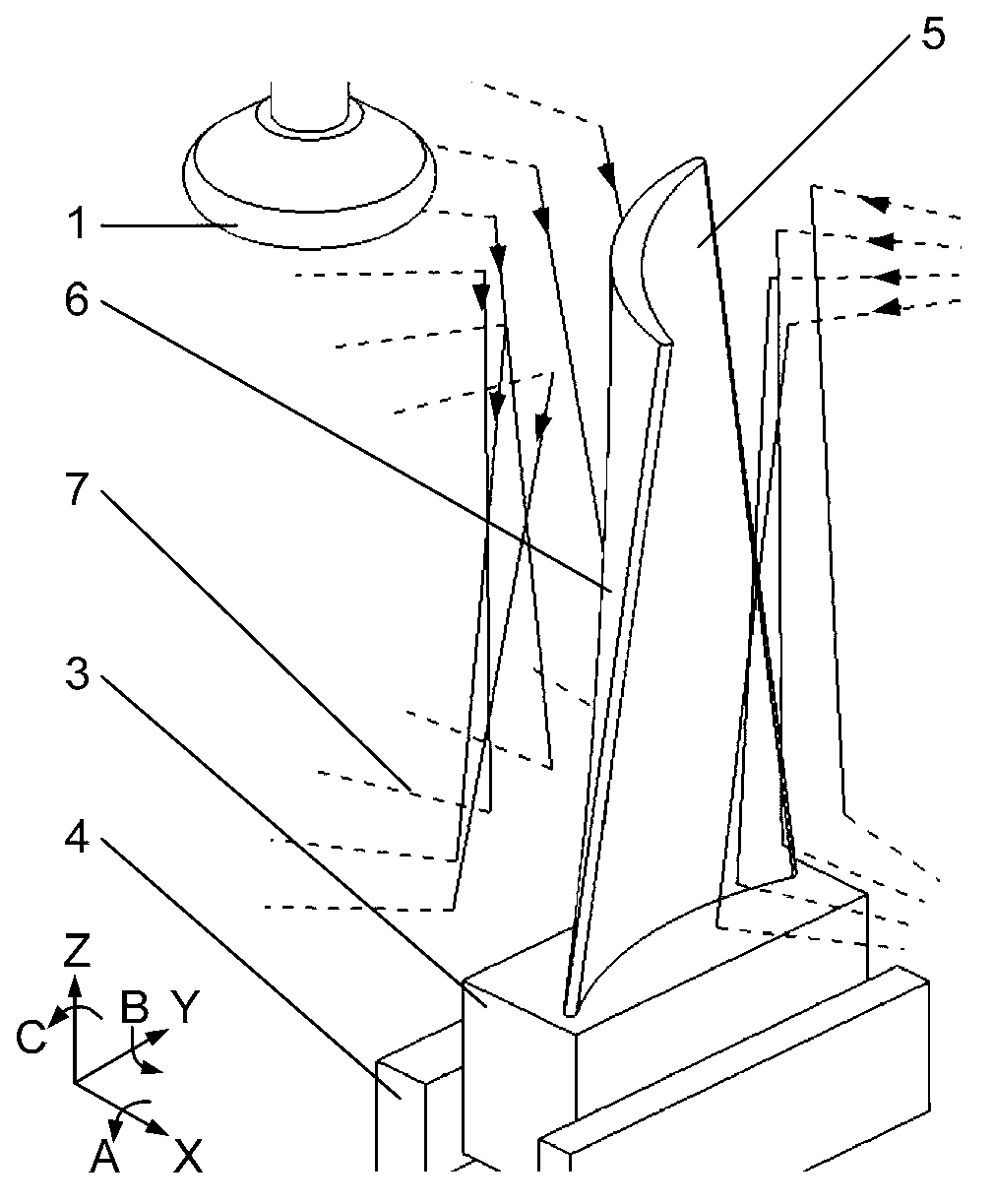

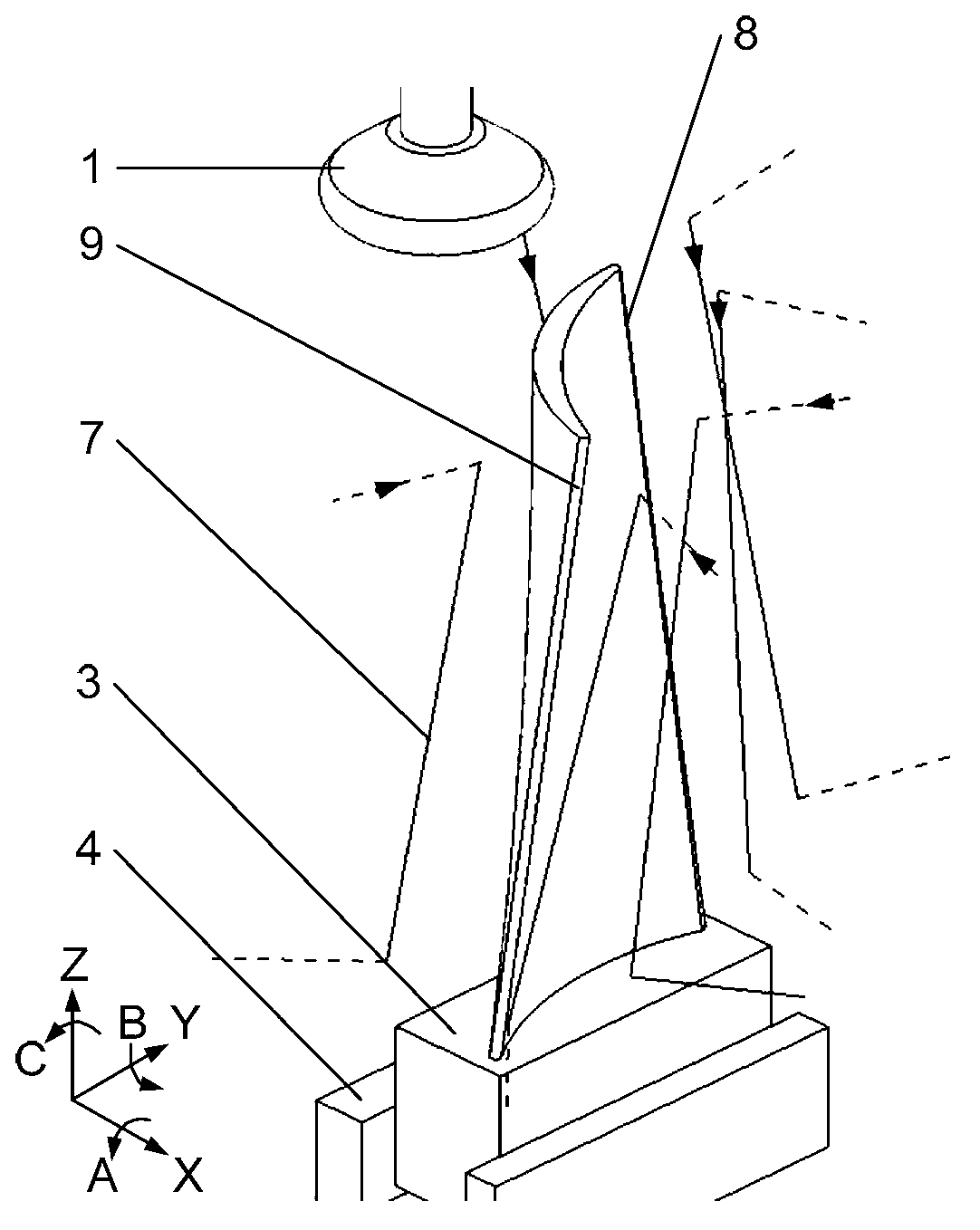

Cantilever grinding machining method for vane using three-axis linkage interpolation

InactiveCN103100950AAvoid clamping deformationReduce adverse factorsGrinding machinesGrinding work supportsNumerical controlLinear motion

A cantilever grinding machining method for a vane using three-axis linkage interpolation comprises four steps: (1) ascertaining the grinding method of a vane-shaped face according to the structure type and the motion mode of a machine tool and the structure form of the vane; (2) clamping a tenon or a installation reference block of the vane through a single end of a fixture to enable the vane to be firmly fixed on an operating platform of the machine tool and keeping the vane-shaped face portion needing machining in a cantilever state on the numerical control machine tool; (3) selecting three machine tool motion axes suitable for the grinding machining of the vane-shaped face and a grinding wheel to composite a digital control program, and driving the three linear motion axes X, Y and Z, or the axis X, the axis Z and axis C, or the axis Y, the axis Z and the axis C to conduct the three-axis linkage interpolation motion by the digital control program to form a motion trail of the grinding wheel when the vane is in a grinding machining; and (4) enabling the grinding wheel to rotate at a high speed under the driving of a main shaft of the machine tool and move along the motion trail of the three-axis linkage interpolation of the machine tool to achieve the three-axis linkage interpolation cantilever grinding machining of the vane-shaped face.

Owner:BEIHANG UNIV

Method for producing sodium hypophosphite

ActiveCN101172591AHigh recovery rateImprove operating conditionsHypophosphorous acidSlagNitrogen gas

The invention is a method for producing sodium hypophosphite, which is characterized in that the process steps include batching, reaction, filtration, first concentration, adjustment, second concentration, cooling and crystallization, and centrifugal packaging. Advantages: Put the measured liquid caustic soda into the lime milk tank, mix it with water and quicklime, and pump it into the reaction kettle together. In this way, it is not necessary to disassemble the liquid alkali pipeline frequently, thereby reducing the unfavorable factors affecting normal production; the reactor is emptied with nitrogen, which should be evacuated with steam, which is easy to operate and does not require additional equipment; replace the old-fashioned plate with a diaphragm press filter Frame filter. The water content of the filter cake is reduced from 45-50% to 35-40%, and the filter cake content of 1-1.5% sodium hypophosphite is reduced to 0.4-0.8%. The reduction of the water content of the filter cake not only improves the recovery rate of sodium hypophosphite, but also improves the operating conditions of slag unloading; the ratio of yellow phosphorus per kettle is changed from 90 to 100kg to 150kg, which greatly increases the output of a single device.

Owner:江苏和纯化学工业有限公司

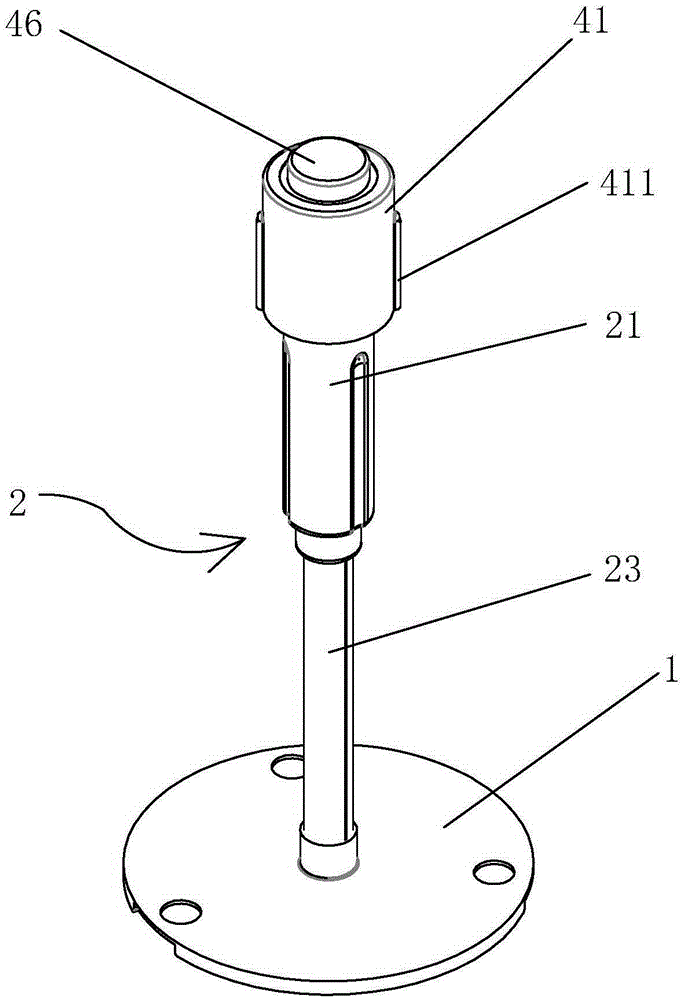

Novel temperature sensor

ActiveCN105318977ADetect trueReduce adverse factorsThermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

The invention discloses a novel temperature sensor which comprises a fixed disk, wherein the top of the fixed disk is connected with a lining with an opening in the top; a probe seat is arranged at the opening of the lining; a unidirectional heat conduction assembly is arranged between the probe seat in the lining and the fixed disk; the top of the probe seat is connected with a thermocouple and a probe in sequence from bottom to top; the thermocouple is connected with a wire passing through the fixed disk. The novel temperature sensor is a temperature sensor which can really sense the temperature in a heated pot body under a complicated heating environment and a long-time working state.

Owner:VATTI CORP LTD

Yield and quality improving method used in wild peach planting

InactiveCN105900775AMeet moisture needsPromote recoveryFertilising methodsCultivating equipmentsPesticide residueInsect pest

The invention discloses a yield and quality improving method used in wild peach planting. The yield and quality improving method comprises the steps that land sterilization and weeding are performed after land is selected according to the planting requirements of peach trees, moisture absorption with quick lime and air drying make the temperature in a film rise to kill worm eggs and weed seeds and decrease adverse factors of later planting, stone powder having strong water absorption and water-retaining properties is added to field planting holes so as to meet the moisture demands of the peach trees at a juvenile stage, the transplanted fruit trees can rapidly revive and rejuvenate, the method facilitates trace elements and growth hormones are directly added by utilizing tree barks, efficient utilization of the trace elements, the stress resistance of the peach trees is strong in the later growth process, plant diseases and insect pests are decreased, pesticide residues are decreased, and the quality of peach tree fruits is improved.

Owner:WUHU FEIGAO AGRI CO LTD

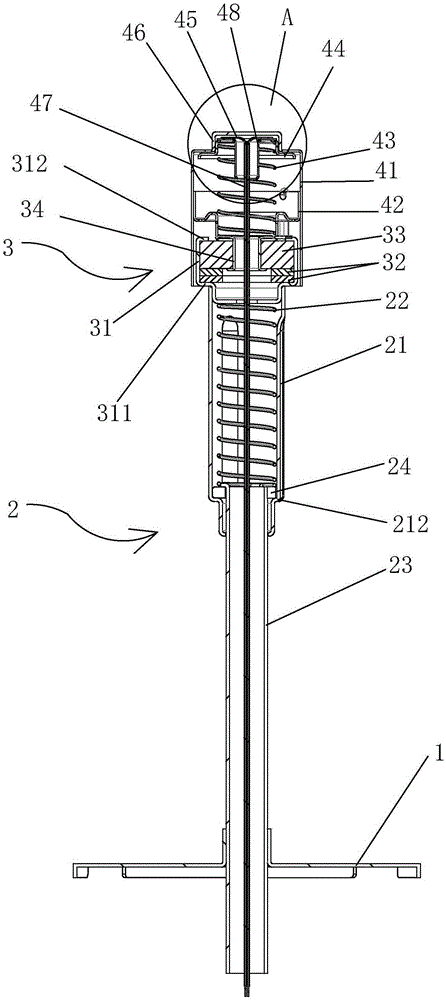

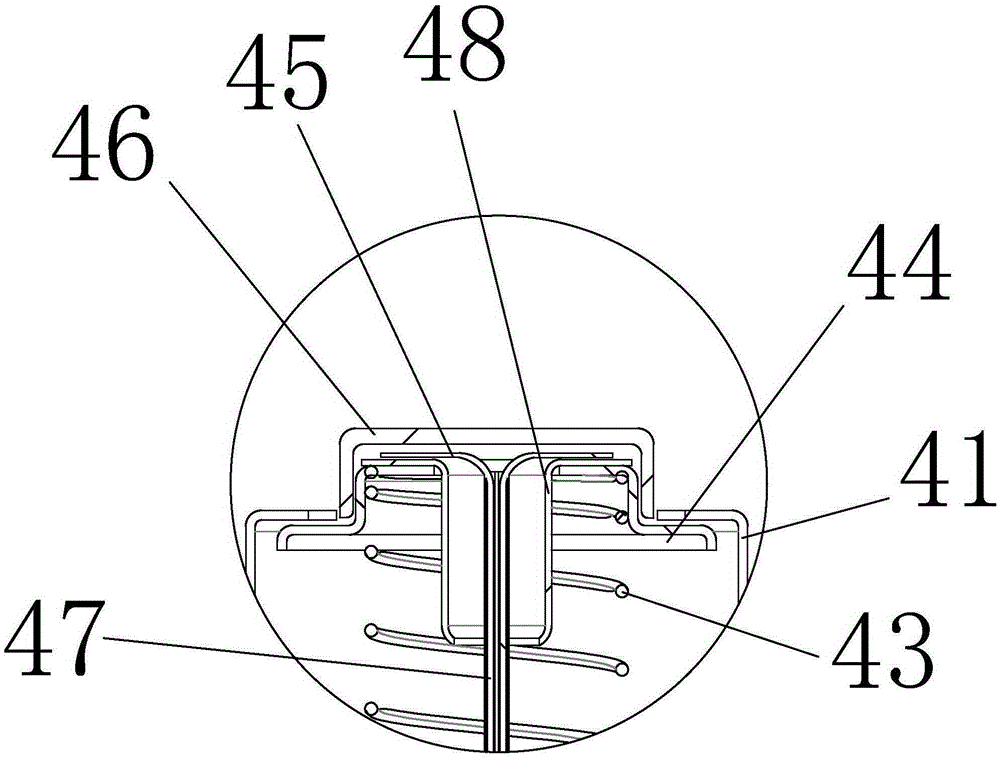

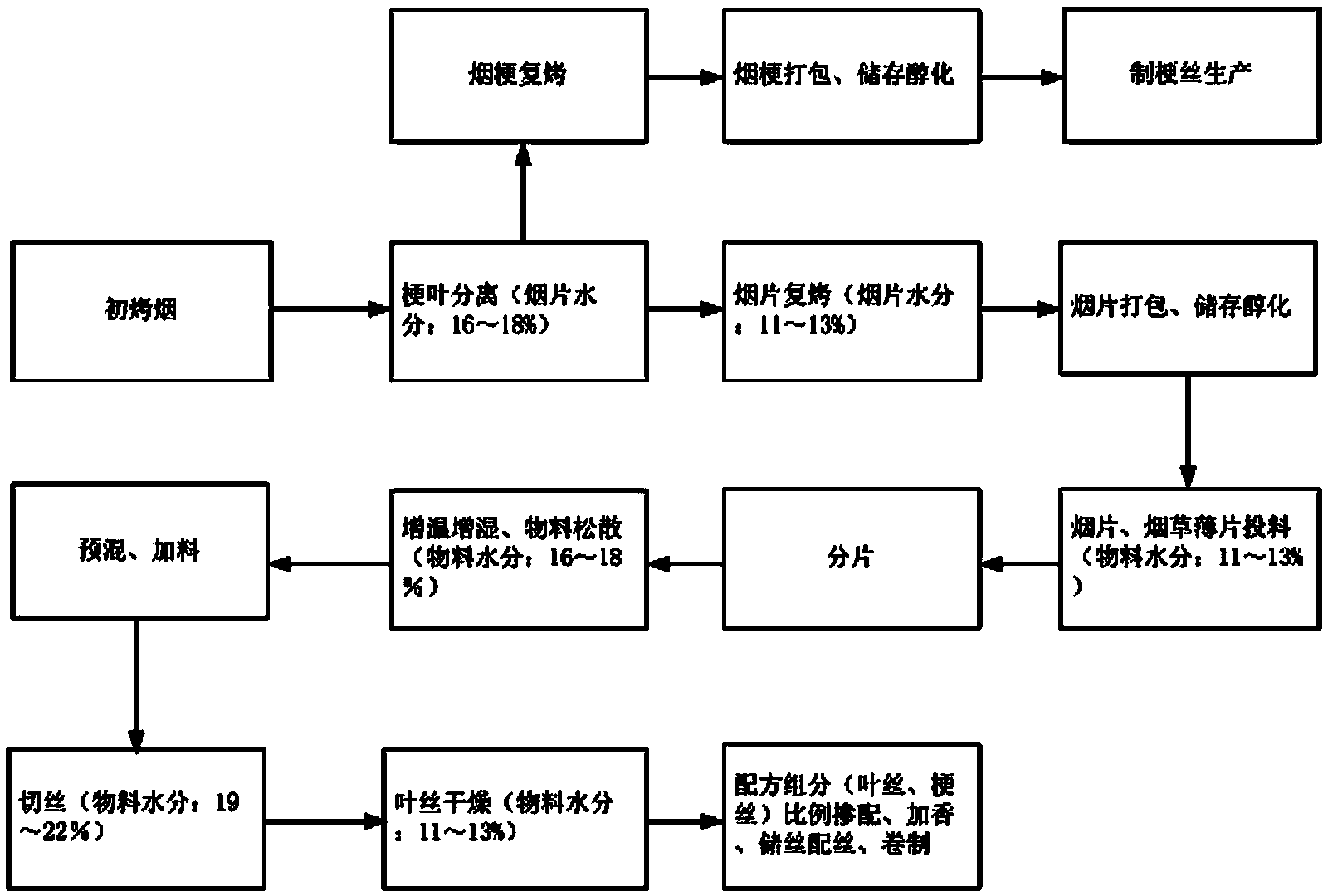

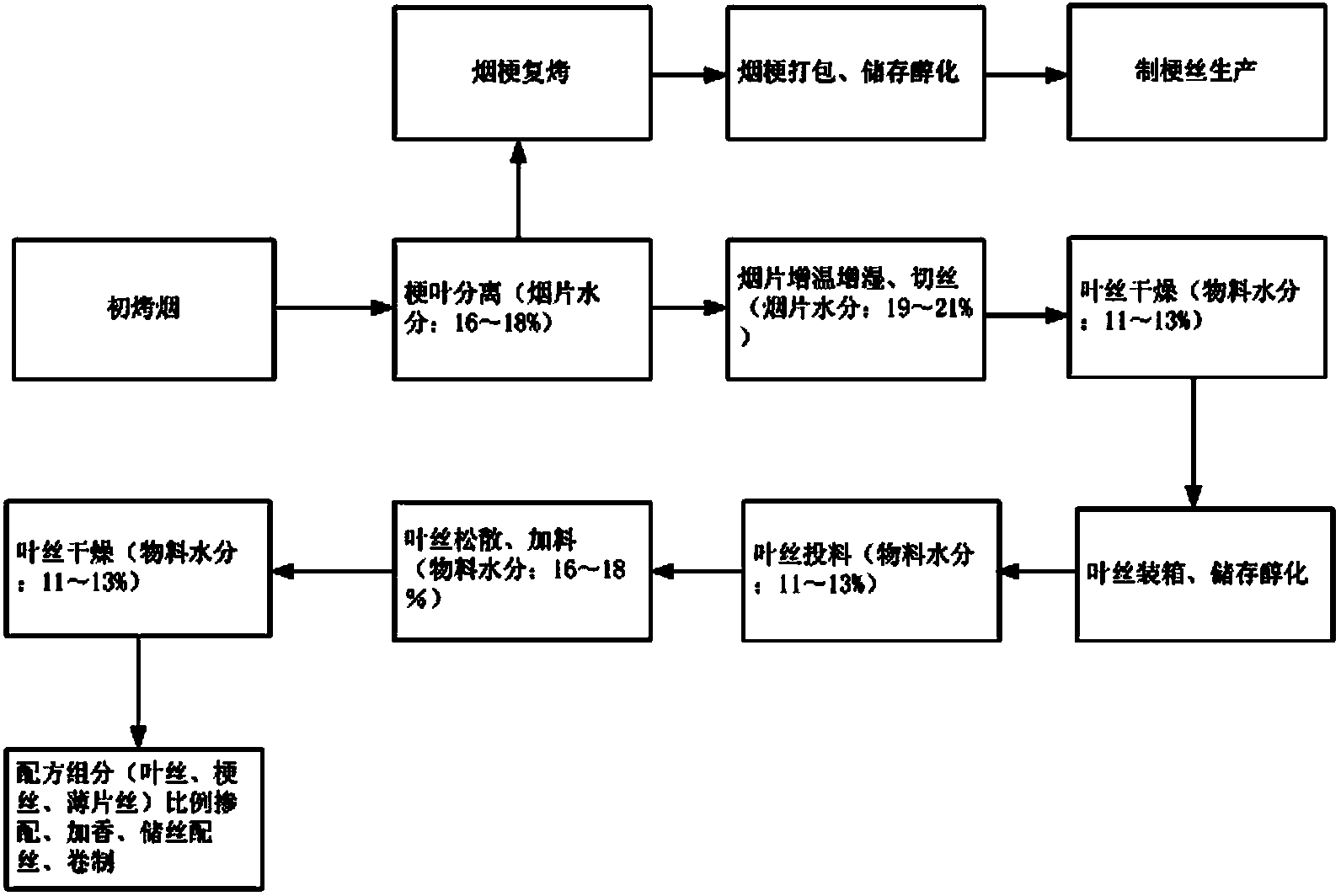

Technology for cigarette production

InactiveCN103704865AExcellent mechanical processing strengthIncrease lossTobacco preparationTobacco treatmentEngineeringMoisture

The invention discloses the technology for cigarette production, belongs to a technology for cigarette production, and particularly relates to a method for leaf-beating redrying production, cut leaf storage alcoholization and cut leaf production. According to the technology, the leaf beating redrying production technical process, the storage alcoholization production technical process and the cut leaf production technical process in the prior cigarette production mode are integrated; tobacco flakes obtained after leaves are separated from stems in the redrying process are humidified to the degree that the moisture content is, by weight, 19%-21%; after the tobacco leaves are cut, the tobacco leaves are dried to the degree that the moisture content is, by weight, 11%-13%; the cut tobacco is boxed, stored and alcoholized for 6 months to 24 months in the storage environment that the temperature is lower than or equal to 32 DEG C and the humidity is smaller than or equal to 70% RH; the alcololized cut leaves are processed in a loosened mode; feed liquid is added until the degree that the moisture content is, by weight, 16%-18%; the flow of the cut leaves is controlled and the cut leaves enter a drying device for dehydration to the degree that the moisture content is 11% to 13%; blending, flavoring, cut tobacco storage and matching and coil making are conducted according to a factory formula. The method can effectively simplify production, reduce unreasonable consumption of energy sources and raw materials and improve the economical efficiency of cigarette production.

Owner:HONGTA TOBACCO GRP

Preparation method for synthesizing nucleocapsid TiO2/Al2O3 nano powder by one-step hydrothermal process

This invention discloses one step hydrothermal method synthesizing nucleocapsid style TiO2 / Al2O3 nm powder body preparation method. It includes following procedures first ammonia water is added into material TiC14 solution to control pH value between 8.5 and 9.0 to fully deposit Ti4+ in the solution to make predecessor Ti(OH)4 of Ti02, then AlCl3 solution is added to Ti(OH)4, and ammonia water is added to Ti(OH)4 at the same time, pH value is adjusted to 8.8-9.5, then Al(OH)3 envelope is formed on surface of Ti(OH)4 to get predecessor. The predecessor is filled into high pressure tank as Ti(OH)4 / Al(OH)3 style to take part in hydrothermal reaction, then it is filtrated after the reaction, and then it is alcohol water exchanged by absolute ethyl alcohol, finally TiO2 / Al2O3 nm powder body is got after dried. There is no need to prepare nm level Ti02 core, and then enveloping in this method. Because water heat method is used in this invention, complex powder particles are uniform, envelope is integrated, agglomeration is few, and its preparation cost is reduced, technological line is facilitated, so it has wide industrial application prospect.

Owner:GUANGDONG UNIV OF TECH

Multi-station polishing machine capable of improving efficiency

InactiveCN106064342ASimple structureSimple control methodPolishing machinesGrinding drivesEngineeringMechanical engineering

A multi-station polishing machine capable of improving efficiency comprises a rack, a polishing mechanism mounted on the rack as well as a workpiece loading and synchronous rotating control working table arranged below the polishing mechanism, wherein the polishing mechanism comprises a polishing fixing beam and at least two polishing heads mounted on the polishing fixing beam at an interval; and the workpiece loading and synchronous rotating control working table comprises a loading fixing base, at least two workpiece clamping mechanical arms rotationally mounted on the top surface of the loading fixing base as well as a synchronous driving device for controlling all the workpiece clamping mechanical arms to rotate synchronously and swing synchronously. With the machine, all workpieces can be polished in the same environment at the same time, the polishing consistency of products is greatly improved, product polishing differences caused by polishing condition deviations are reduced, differences of polishing effects of the same batch of workpieces can be reduced to a certain extent, unified production is facilitated, meanwhile, the control method is simple and easy to implement, and the product polishing accuracy can be improved.

Owner:FUJIAN CHANGJIANG IND

Polyether esters as flame retardants for polyurethane flexible foams

InactiveCN1648146AReduce dosageReduce adverse factorsPedestrian/occupant safety arrangementPolyolFire retardant

Flexible polyurethane foams that satisfy the requirements of FMVSS 302 are produced by reacting a polyisocyanate with a polyol component that includes: (1) from 90 to 99 parts by weight of a polyether polyol having an OH value of from 20 to 200 mg KOH / g and functionality of from 2 to 4 and (2) from 1 to 10 parts by weight of a polyether ester polyol having an OH value of from 150 to 450 mg KOH / g and a functionality of from 2 to 3 in the presence of a blowing agent, catalyst and stabilizer. The foams thus produced are useful as cushioning for furniture and automotive applications.

Owner:BAYER MATERIALSCIENCE AG

Low cholesterol eggs rich in conjugate linoleic acid, and its prodn. method

InactiveCN1751601AHigh in conjugated linoleic acidLower cholesterol levelsFood processingAnimal feeding stuffBiotechnologyNutritive values

A low-cholesterol egg rich in conjugated linoleic acid (CLA) is disclosed. Its productive method features that the feed of fowls is prepared from the composition of CLA or conjugated linoleate and basic feed through proportional mixing.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Chip automatic detection method

InactiveCN105572147AFully automatedImprove detection efficiencyOptically investigating flaws/contaminationSortingEngineeringWaste material

The invention belongs to the technical field of integrated circuit chip production, processing, and detection, and discloses a chip automatic detection method. The method comprises the following steps: loading material discs into a feeding chamber, delivering the material discs to a feeding station, taking pictures of the material discs and sending the chip position by a visual camera, sending a feeding signal by a chip detection box, catching the chips in the material disc by a robot, catching the chips that have been detected by a suction disc claw, placing the chips into a chip detection box by the suction disc claw to detect the chips, delivering the detected chips to a material disc or a waste material box, delivering the material disc that has been detected to a discharge chamber, and detecting all material discs in the feeding chamber. The method has the advantages that the chip detection becomes automatic, the detection efficiency is high, and the unfavorable factors brought by artificial intervention are reduced.

Owner:上海恒浥智能科技股份有限公司

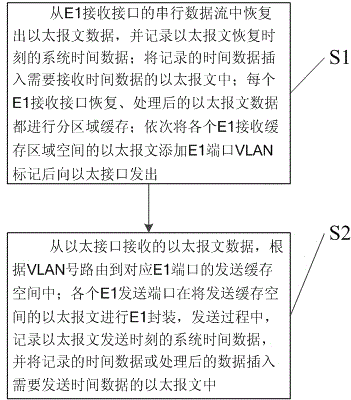

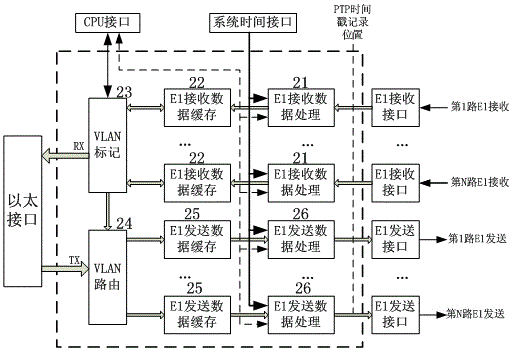

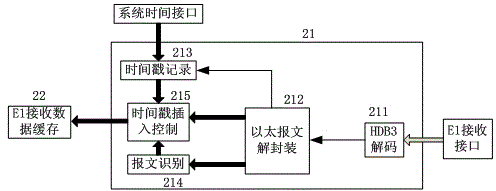

Ethernet data and multi-channel E1 data processing method and system

ActiveCN104660360AImplement the application requirements for the buildMeet the application needs of the buildTime-division multiplexTimestampSystems design

The invention discloses an Ethernet data and multi-channel E1 data processing method and system. The positions of receiving and sending timestamps of PTP (Precision Time Synchronization Protocol) event messages are located at E1 interfaces, and the influence that as the circuit time delay change is brought by uncertain time delay in the protocol conversion process of the Ethernet and the E1, the time service precision of the PTP is reduced is eliminated; the Ethernet messages of the Ethernet interface and the multiple E1 interfaces are interacted through a port VLAN mark, not only is bandwidth utilization ratio of the Ethernet interface improved, but also the effective bandwidth of an E1 link circuit is improved, the application requirements meeting multi-node long-distance time synchronous system network creation are realized, and the technical effects of optimizing and simplifying systems design, reducing adverse factors of time service precision, improving time service precision and meeting application requirements of multiple E1 interface time service are achieved.

Owner:电信科学技术第五研究所有限公司

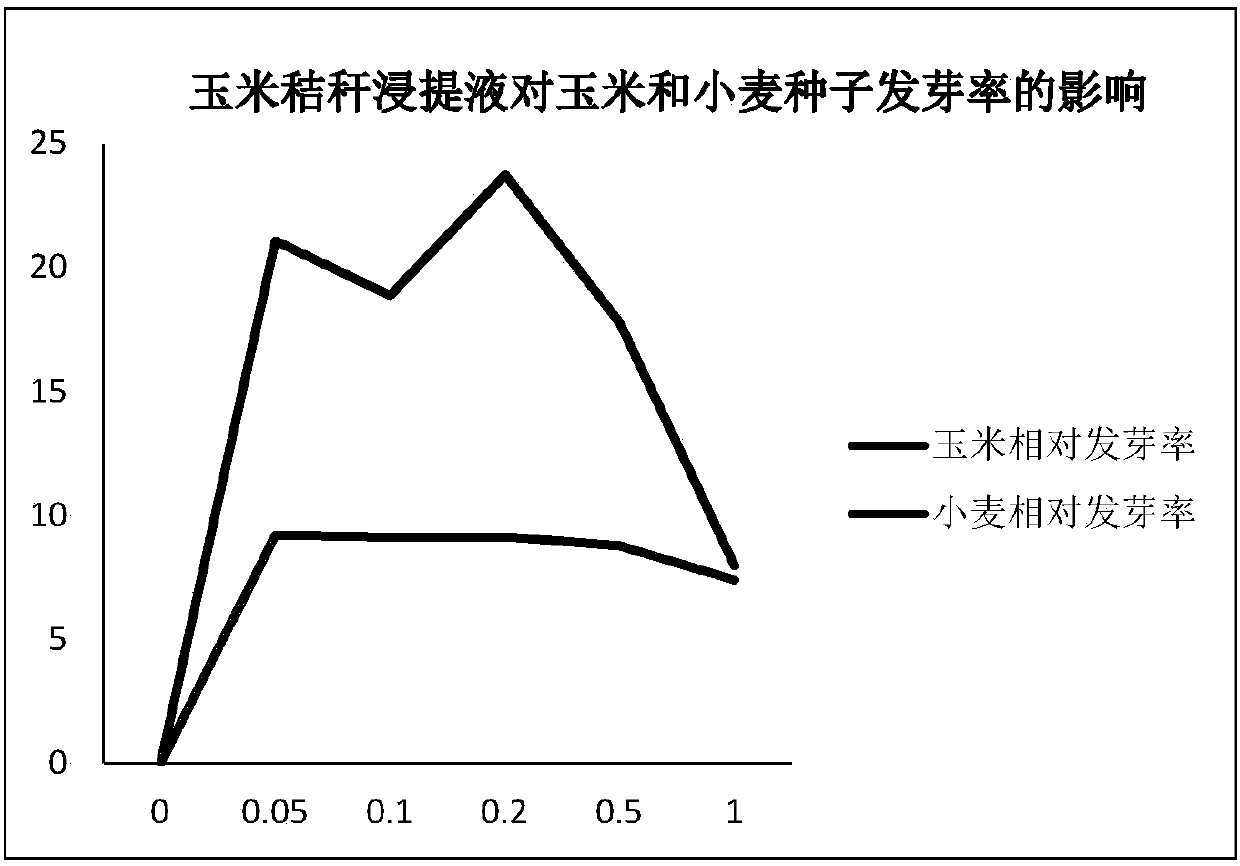

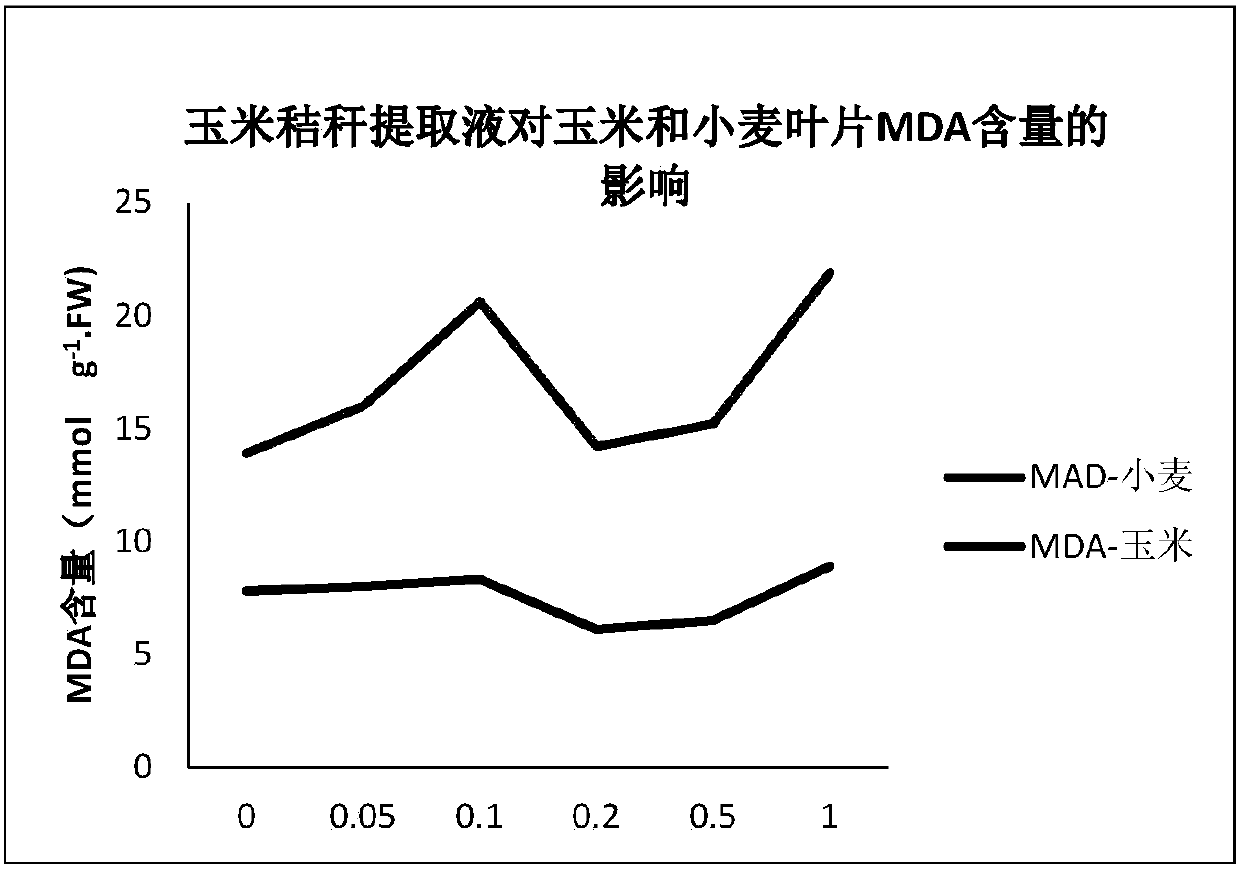

Method for increasing utilization rate of nutrient elements after straw returning to field

The invention relates to a method for increasing the utilization rate of nutrient elements after straw returning to field, comprising the following steps: reserving crop straws after harvest for strawreturning to field; broadcasting a fertilizer and a straw maturing multiple species inoculant and then performing deep ploughing, wherein the straw maturing multiple species inoculant contains trichoderma reesei, aspergillus oryzae, trichoderma, white rot fungi, bacillus subtilis, dietary fiber clostridium, sporogenes dietary fiber fungi, streptomyces, bacillus aceticus and photosynthetic bacteria. According to the method, partial straw returning to field is adopted, so as to promote germination of seeds of afterreap crops and growth of seedlings, and increase favorable factors in crop allelopathic effect; by adopting combination of the fertilizer and the straw maturing multiple species inoculant after straw returning to field, the contents of alkali-hydrolyzale nitrogen, rapidly available phosphorus and rapidly available potassium in soil can be increased; use of the fertilizer is reduced while ensuring yield, so as to avoid the problems of soil nutrient saturation, surplus nutrientloss and water pollution caused by excessive application of the fertilizer. The invention provides reference for existing application of straw returning to field and has important practical application value.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT NINGXIA ACAD OF AGRI & FORESTRY SCI NINGXIA KEY LAB OF SOIL & PLANT NUTRITION

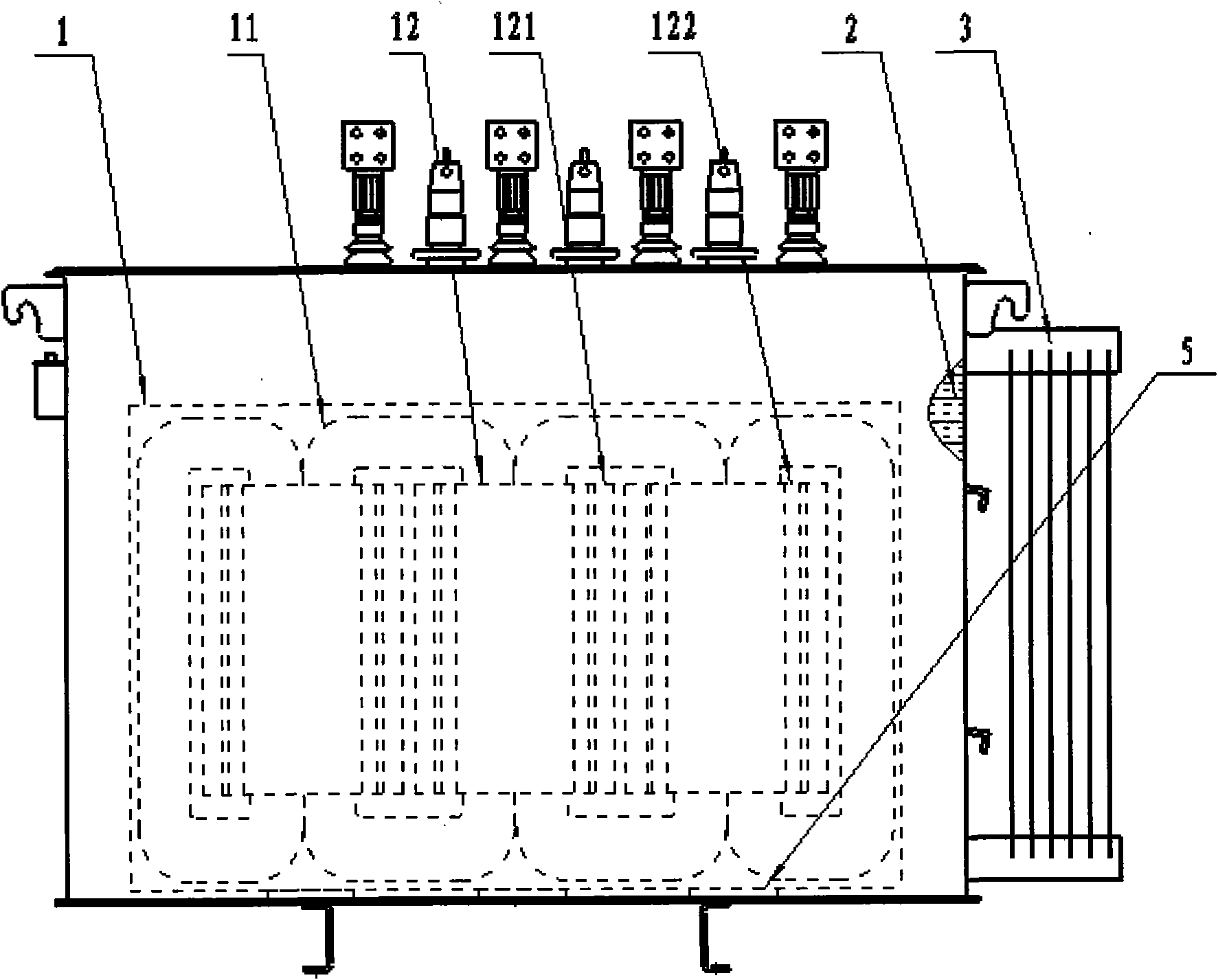

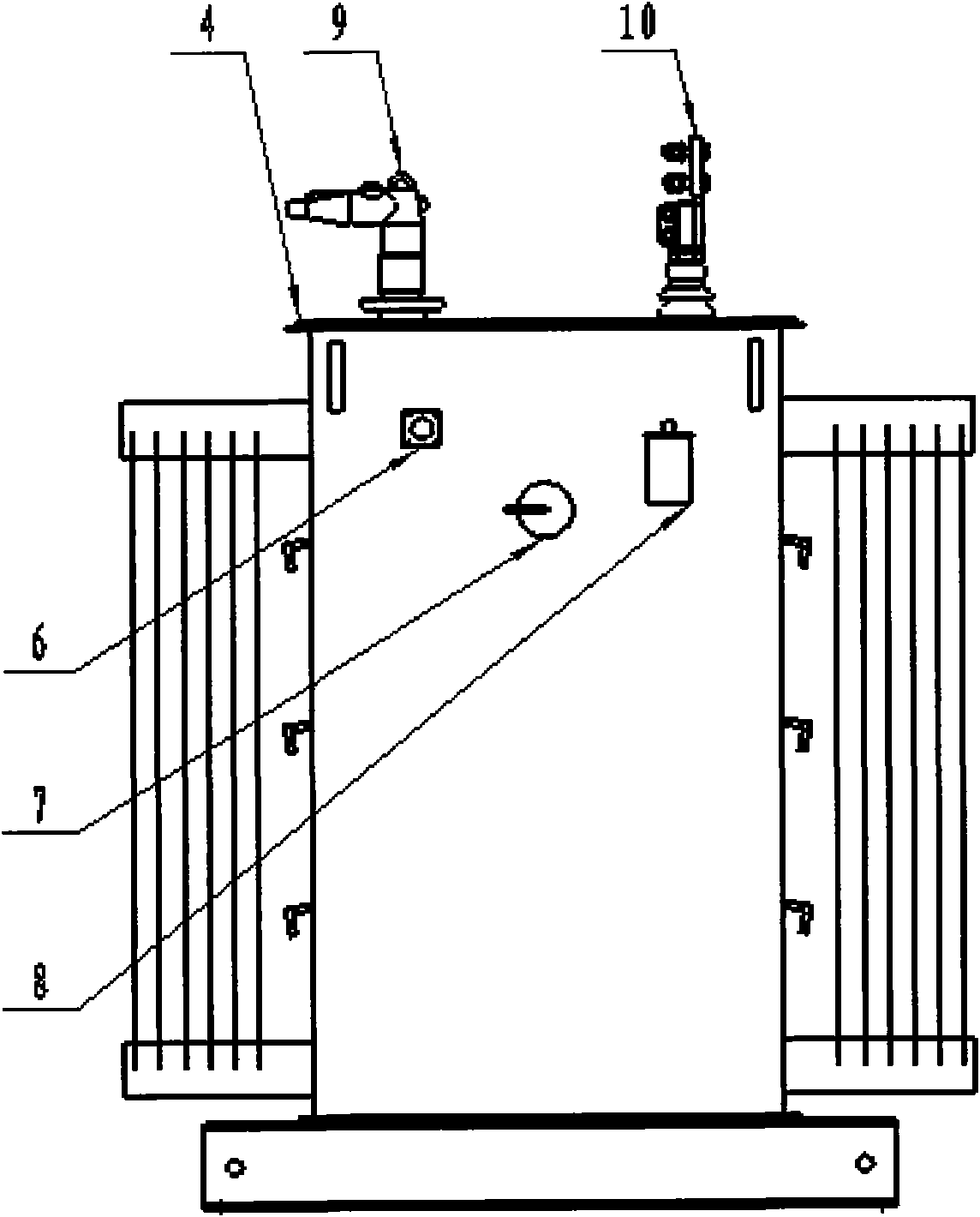

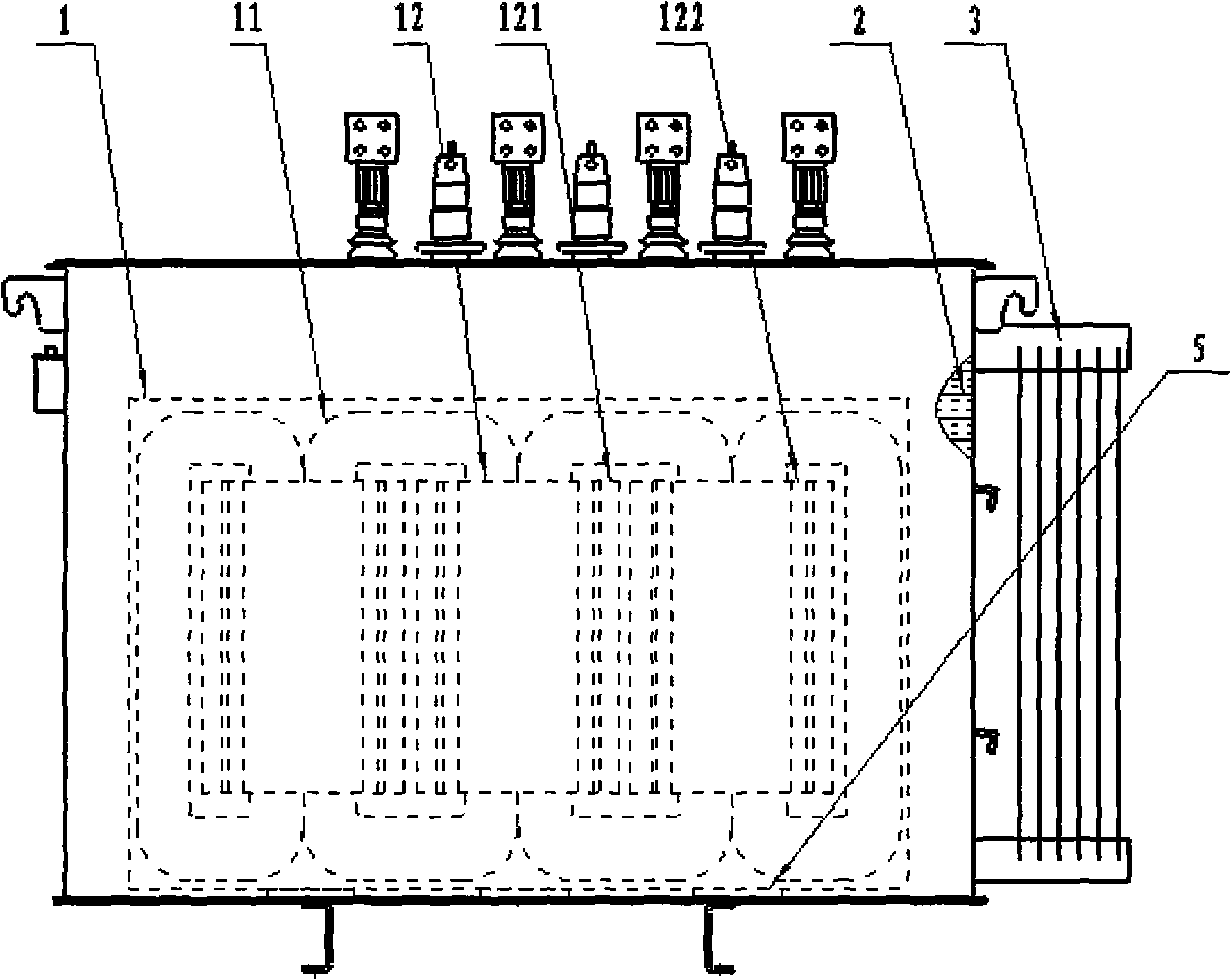

Amorphous alloy 10kV oil-immersed type transformer for wind power generation

InactiveCN101996754AExtended service lifeImprove securityTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEngineeringAlloy

The invention discloses an amorphous alloy 10kV oil-immersed type transformer for wind power generation, wherein the no-load loss of the amorphous alloy 10kV oil-immersed type transformer is 30% of the traditional silicon sheet iron-core transformer. The amorphous alloy 10kV oil-immersed type transformer comprises a transformer body, a tank body and transformer oil, wherein the transformer body comprises an iron core and a coil winding; the tank body comprises an oil tank and a tank cover; the transformer oil is filled in the tank body; the transformer body is installed in the tank body and immersed in the transformer oil; the iron core is made of amorphous alloy material and is in a four-frame and five-post type structure; and the oil tank and the tank cover are welded into a whole to form a fully-closed structure.

Owner:SHANGHAI ZHIXIN ELECTRIC +2

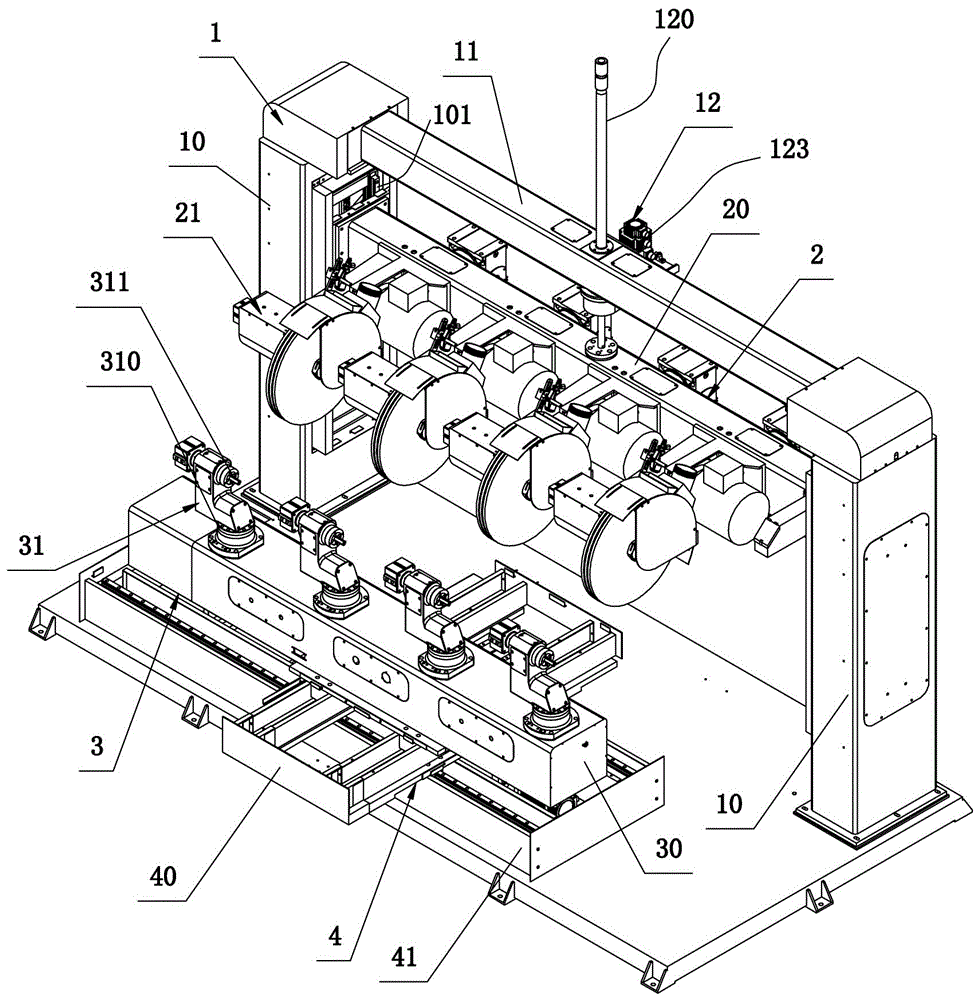

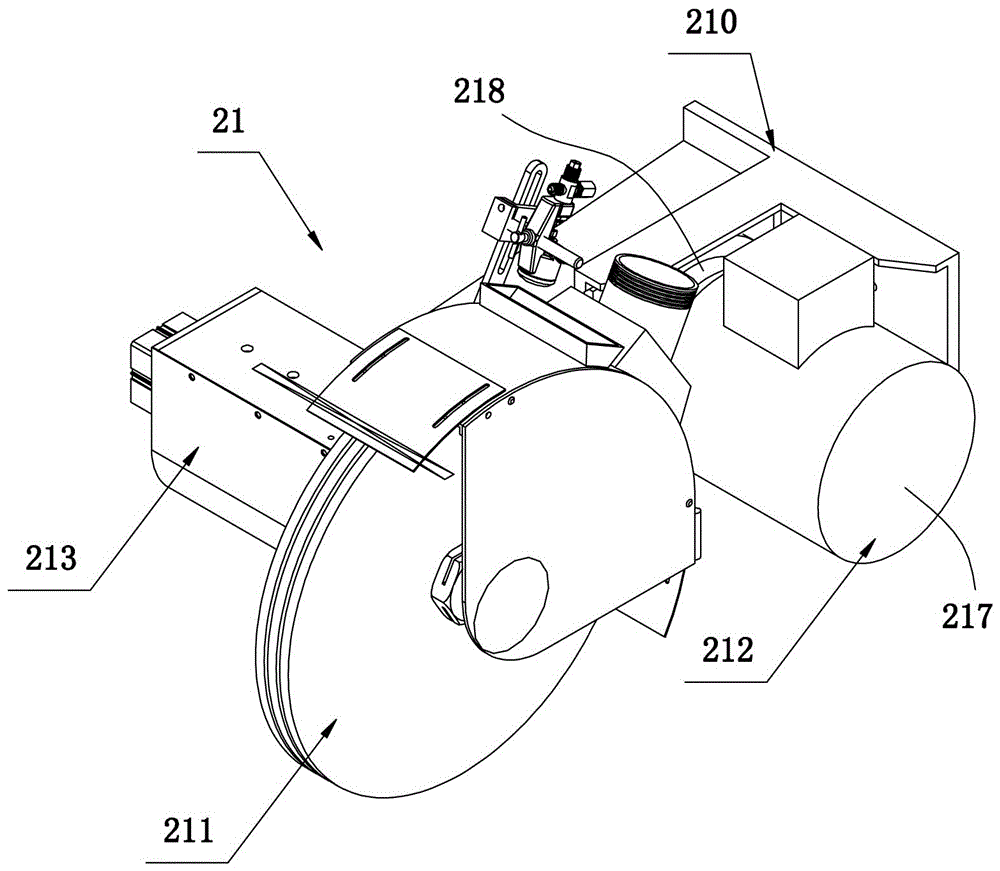

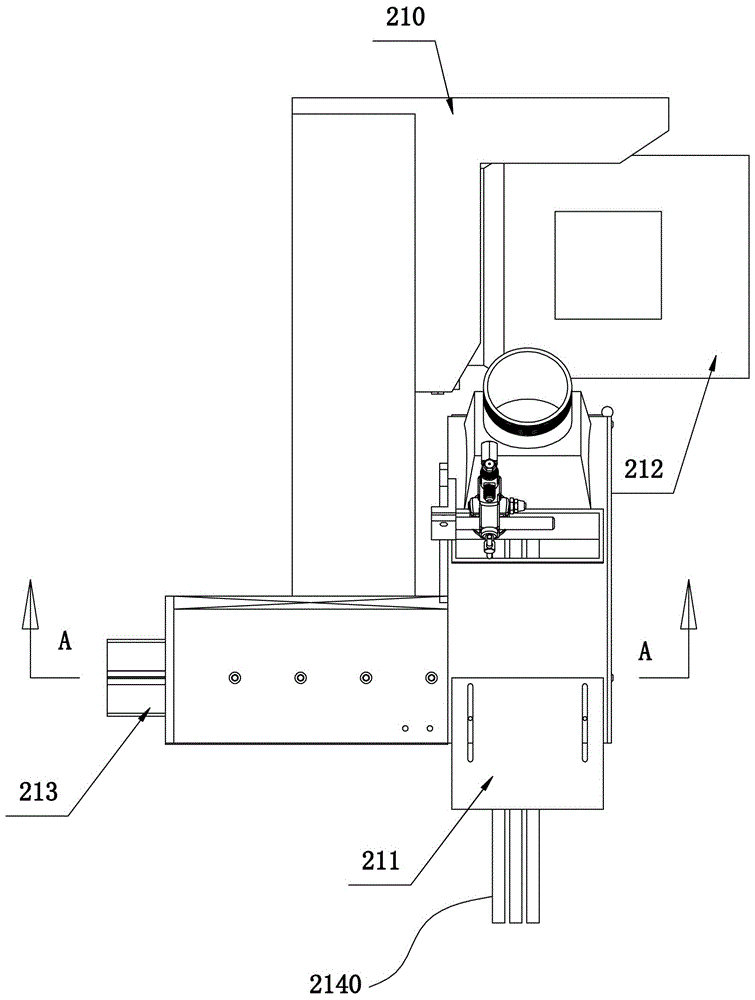

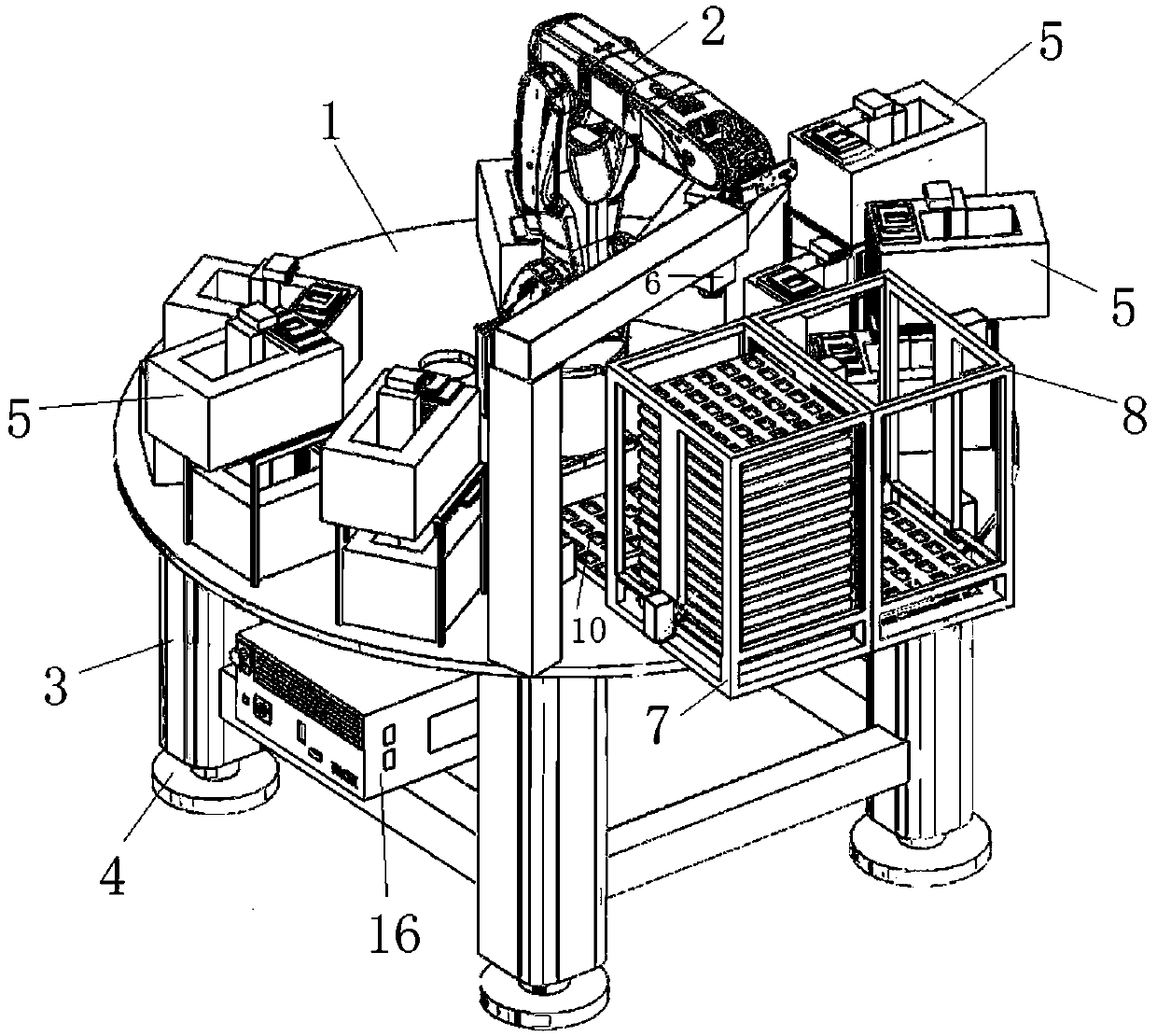

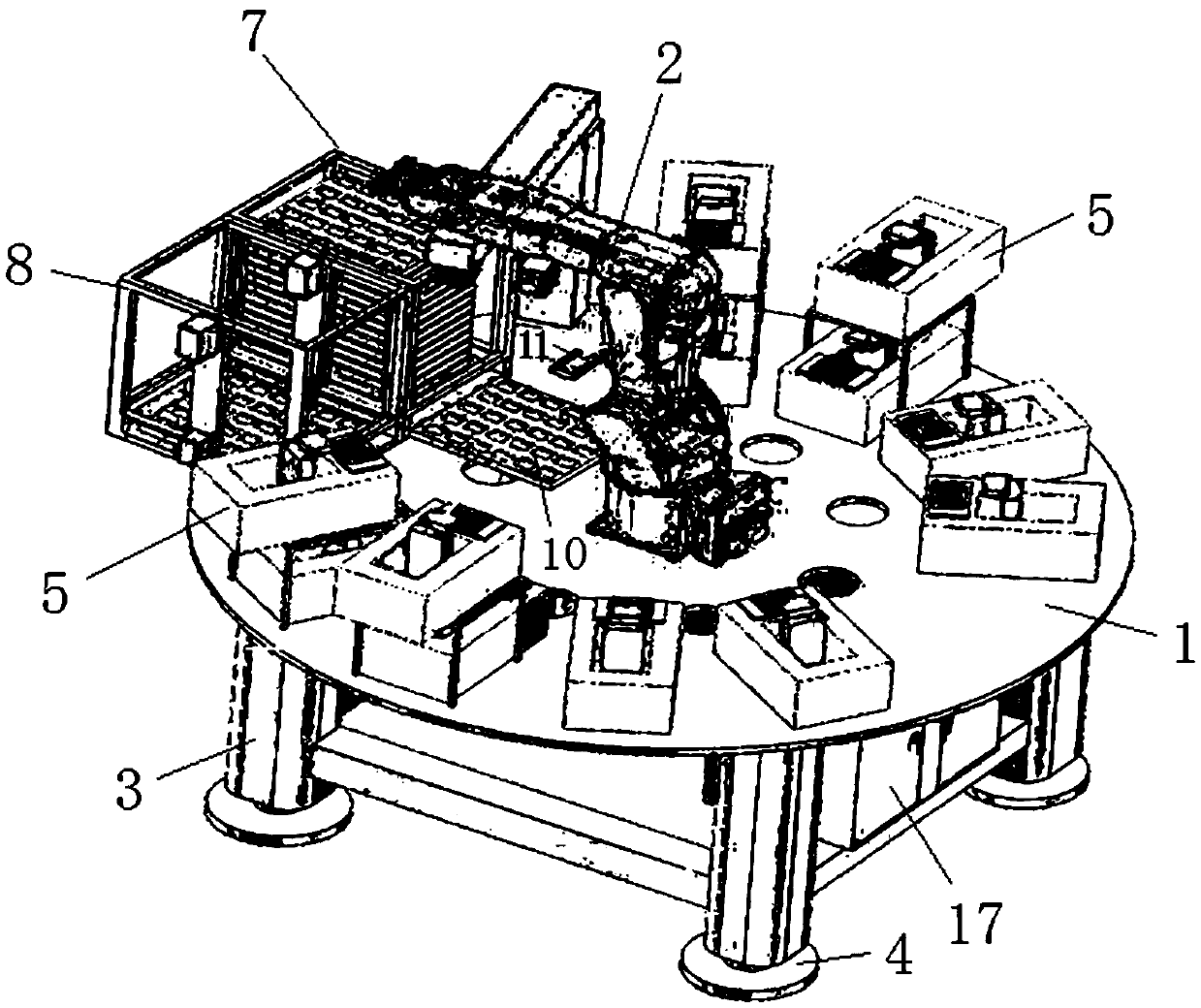

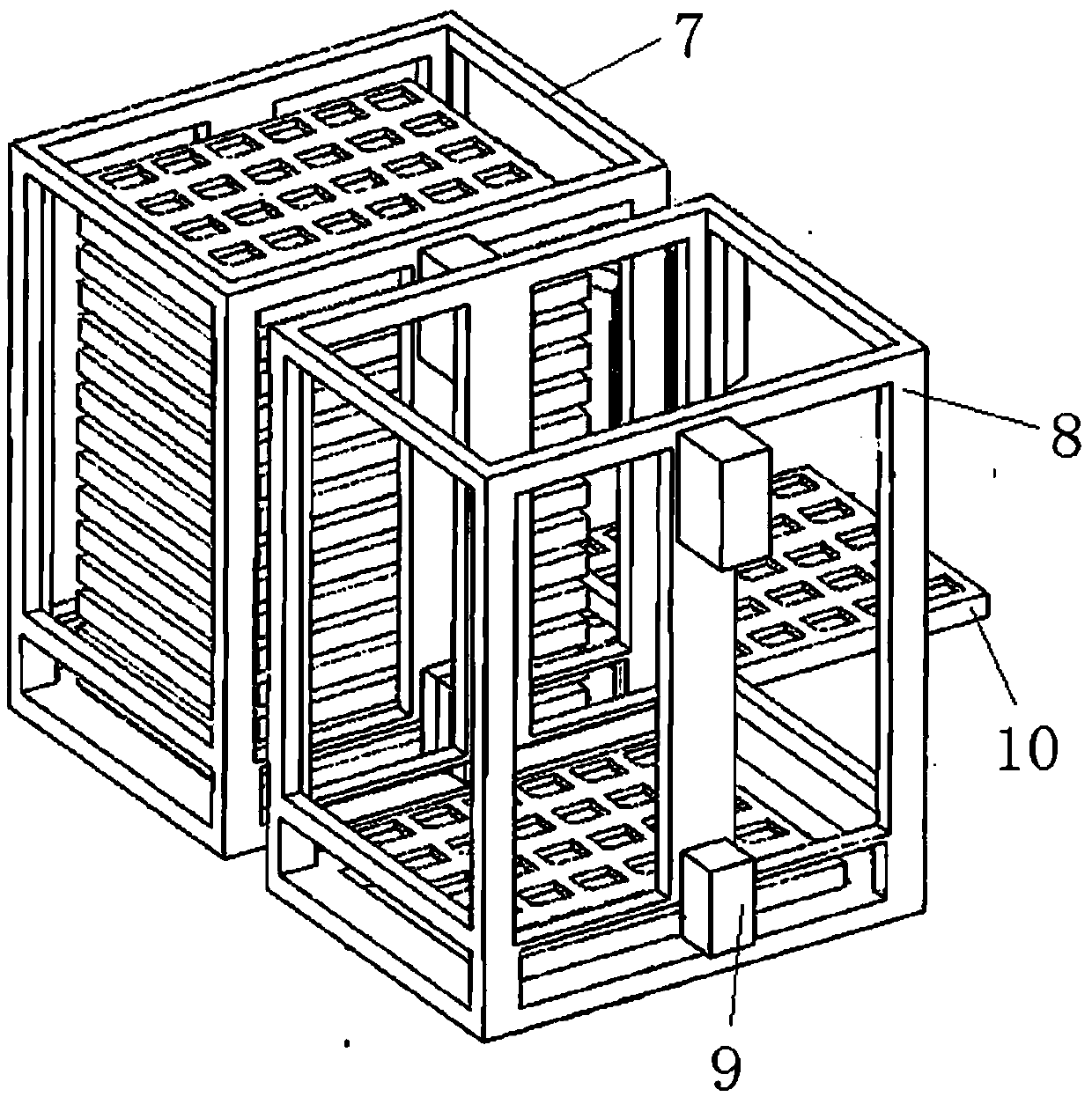

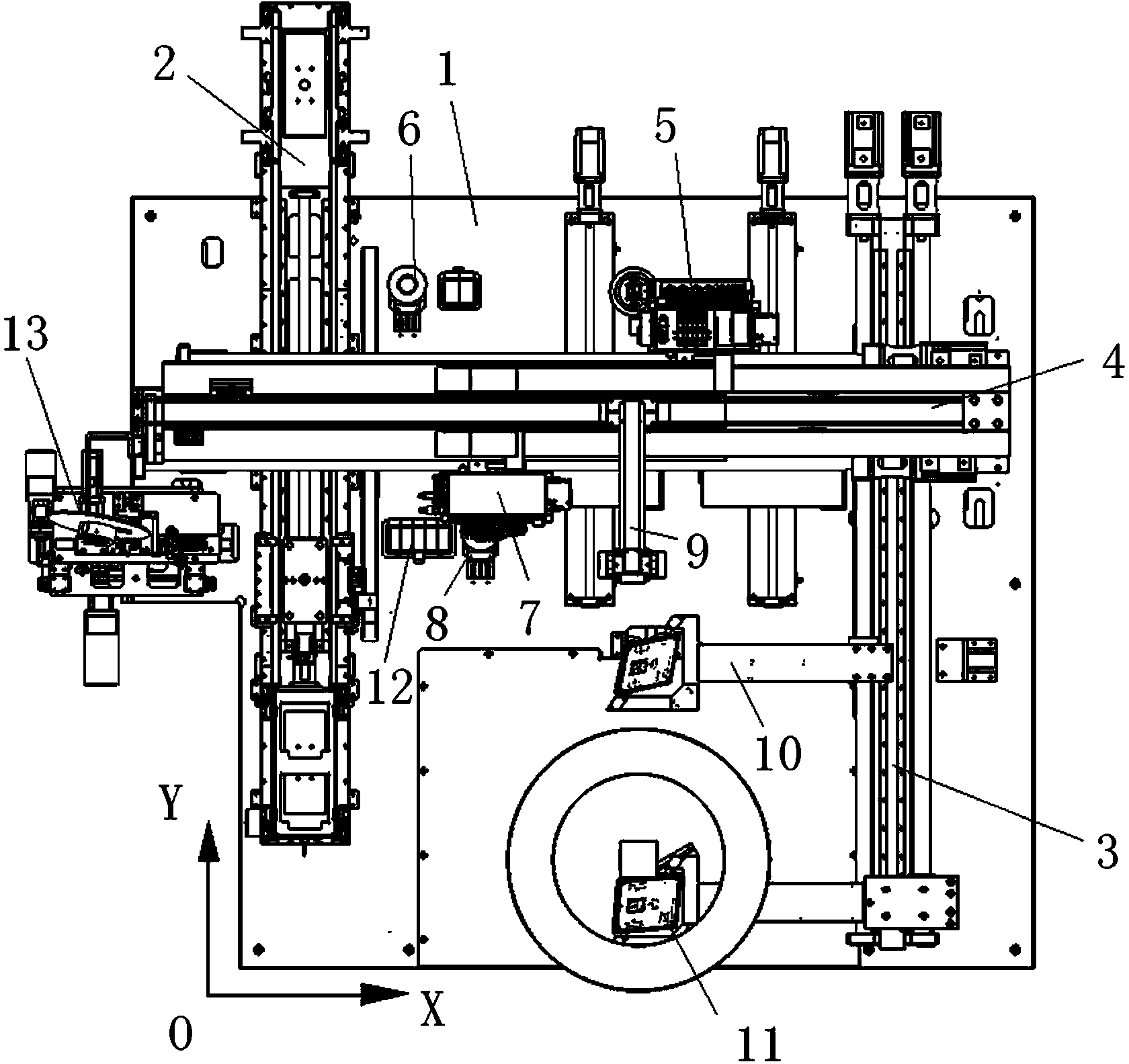

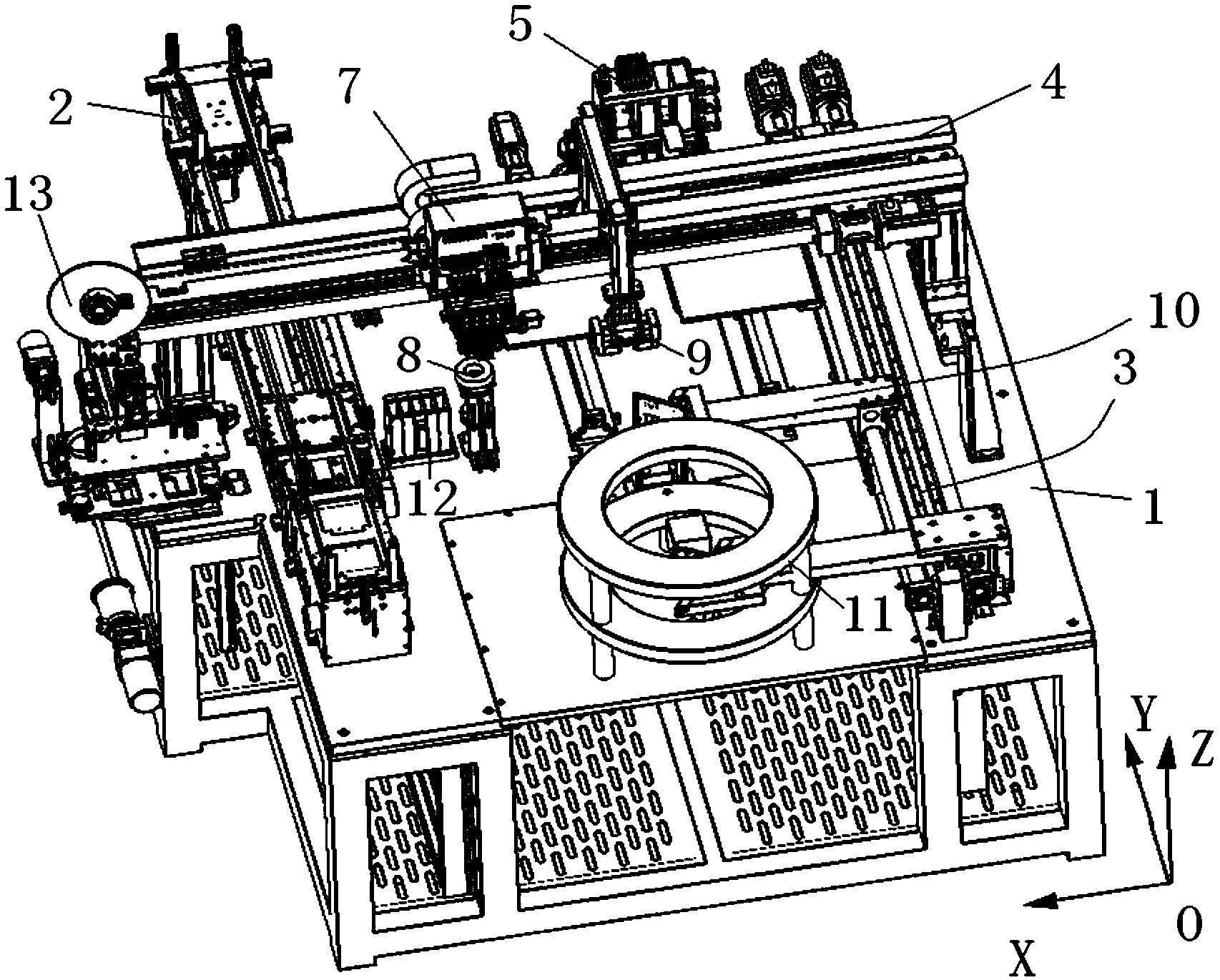

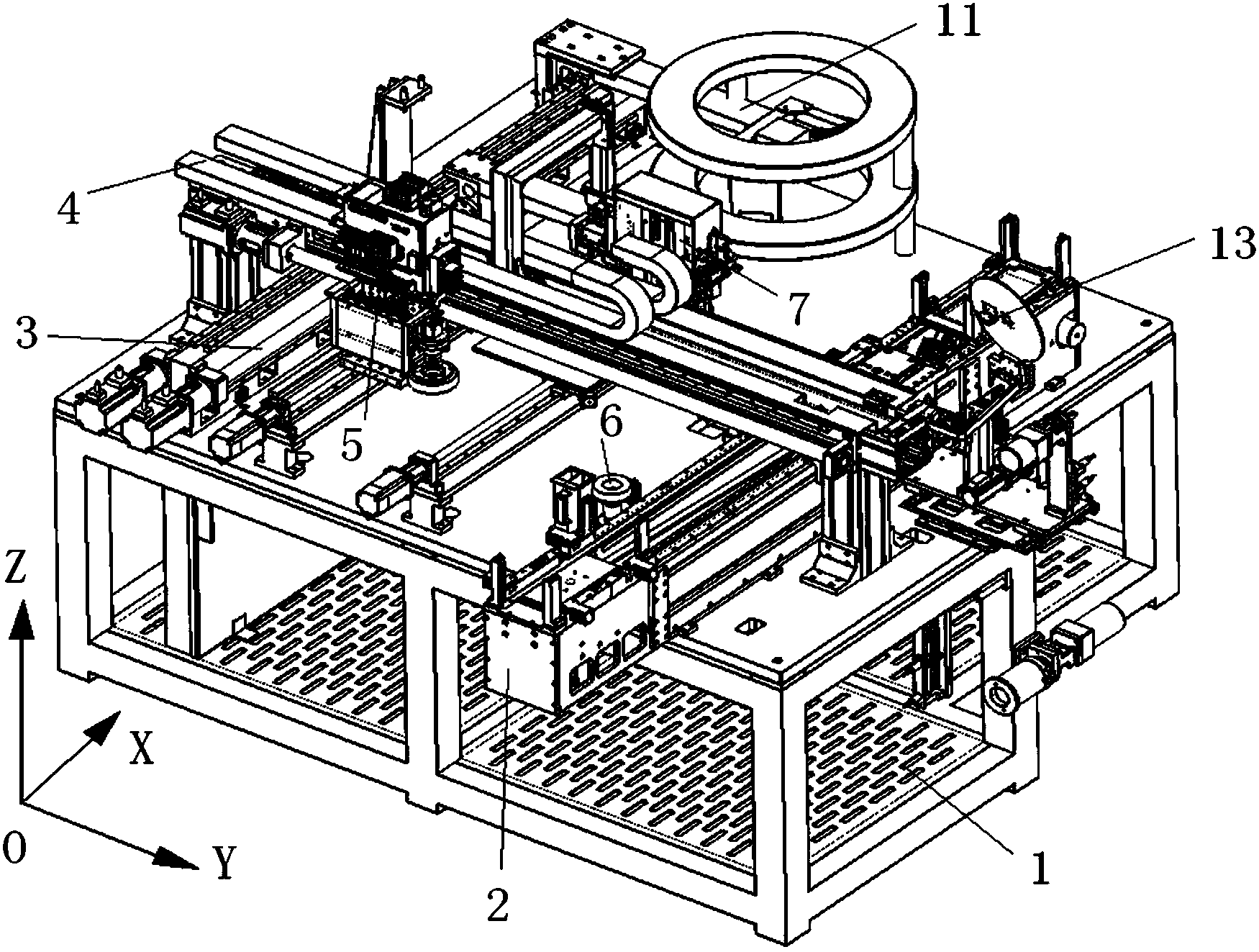

Test machine for finished chips

ActiveCN103454576AImprove detection efficiencyReduce adverse factorsElectronic circuit testingStep detectionIntegrated circuit

The invention relates to the technical field of processing of integrated circuit chips, and discloses a test machine for finished chips. A chip conveying device is arranged on the first side of a base, an inspection device is arranged on the second side of the base, the chip conveying device and the inspection device are both provided with longitudinal guide rails along the side edges of the base, a transverse guide rail is arranged on the base and located above the two longitudinal guide rails in an erecting mode, an angle pickup device is arranged on the transverse guide rail, a pickup arm of the angle pickup device is located on the left side of the transverse guide rail, a first camera detection device is arranged on the base and located on the left side of the transverse guide rail, a displacement pickup device is arranged on the transverse guide rail, a pickup arm of the displacement pickup device is located on the right side of the transverse guide rail, and a second camera detection device, an uncovering and covering device, an air cylinder turnover device and a final angle locating device are arranged on the base and located on the right side of the transverse guide rail. The test machine for the finished chips achieves automation of step-by-step detection for the chips, is high in detection efficiency and reduces adverse factors caused by manual intervention.

Owner:JIAXING JINGYAN INTELLIGENT EQUIP TECH

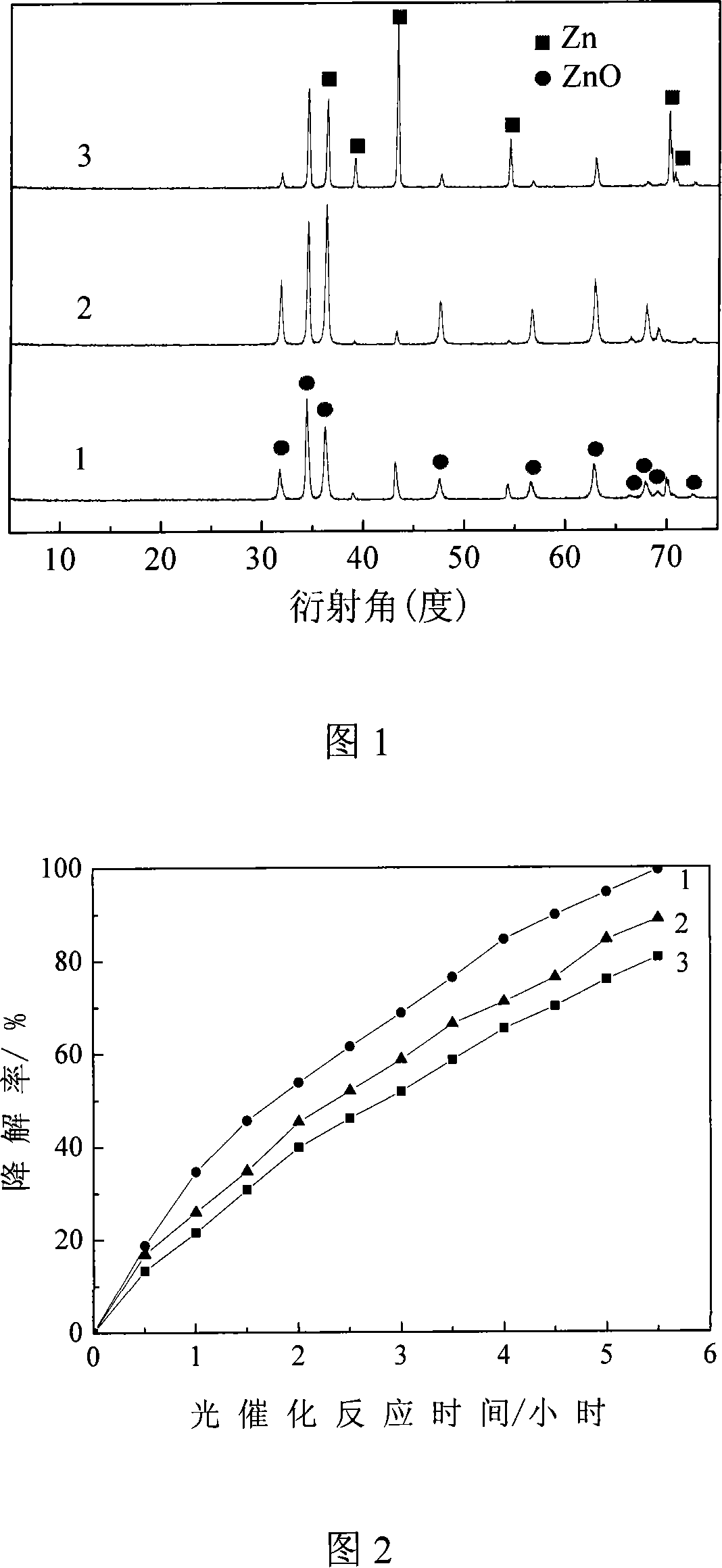

Preparation method of zinc oxide thin film photocatalyst

InactiveCN101138716AReduce adverse factorsHigh sample purityMetal/metal-oxides/metal-hydroxide catalystsThin membranePolytetrafluoroethylene

The present invention discloses a preparation method of a zinc oxide thin-membrane photo-catalyst. With the method, a zinc metal sheet is put into the excessive distilled water to have a hydrothermal reaction under the temperature of 100 to 180 centigrade degrees for 4 to 48 hours. After the water is cooled down, the zinc sheet is taken out and dried, and the nanometer zinc oxide thin-membrane photo-catalyst is got. The hydrothermal reaction is carried out in a high-pressure kettle, which is provided with a poly-tetrafluoroethylene liner. Before the reaction, the zinc sheet is cleaned with distilled water, absolute ethanol and acetone in the ultrasonic way. The present invention uses the hydrothermal reaction method to synthesize the nanometer zinc oxide thin-membrane photo-catalyst. The synthesis method is simple and no acid, alkali or organic solvent is involved in the reaction. Compared with other wet chemical methods, the present invention is provided with the advantage that the present invention is environment-friendly, requires a low temperature, and needs no calcination, and so on. Moreover, the zinc oxide thin-membrane got with the present invention is provided with a higher photo-catalysis activity.

Owner:SUN YAT SEN UNIV

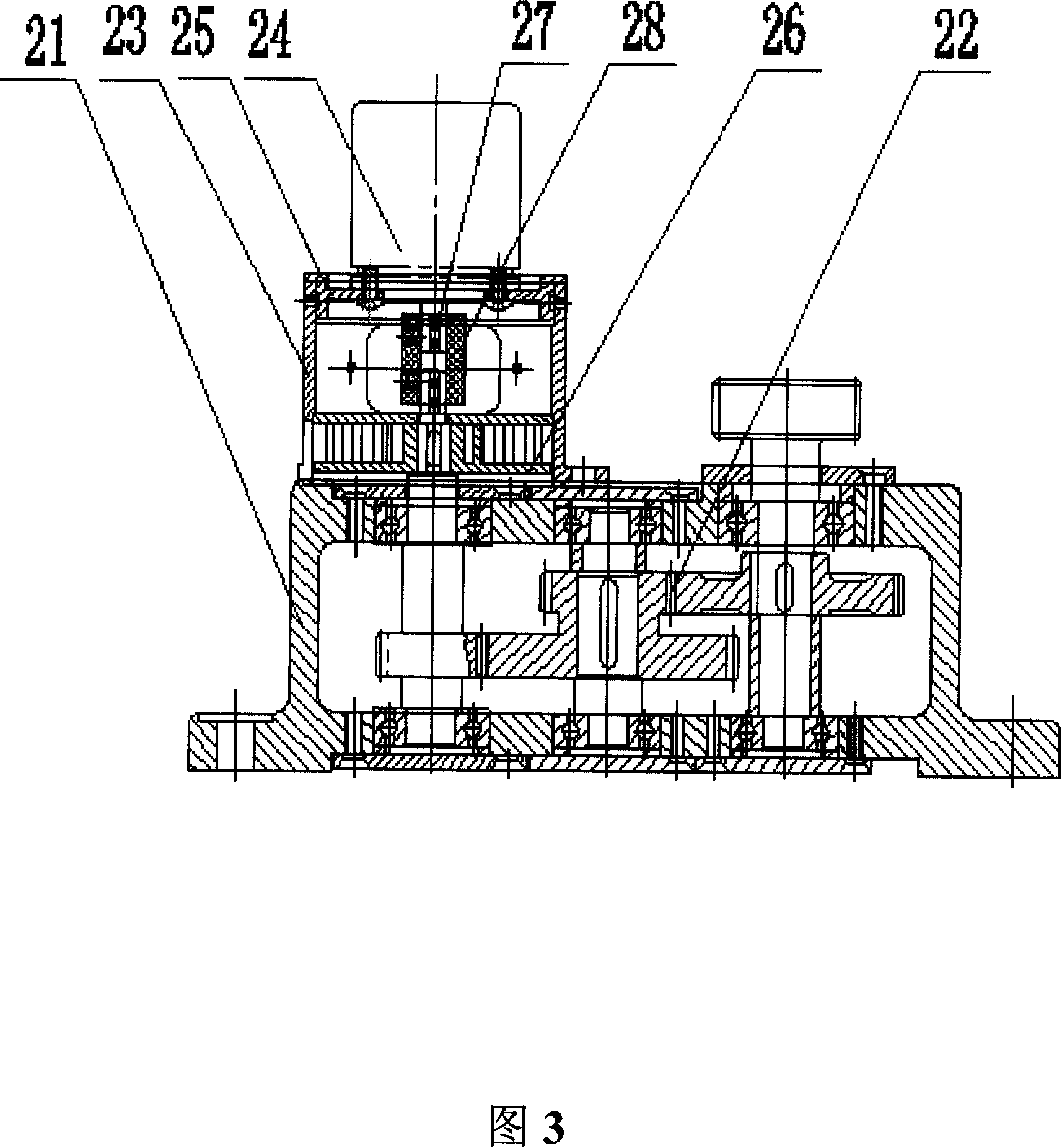

High-speed numeric control automatic regulating gill

InactiveCN101139753AReduce the burden onImproved mechanical levelingCarding machinesEngineeringSignal amplification

The invention discloses a high-speed numerically-controlled autoleveller gill box. The box comprises a feeding roller test mechanism, a roller displacement signal amplification test mechanism, a pulling roller test mechanism, a drive mechanism and a control mechanism. The feeding roller test mechanism is composed of a pair of symmetrically arranged front rollers and test transmission gear sets; the input end of the test transmission gear set is connected with the drive mechanism; the output end of the test transmission gear set is linked to the roller displacement signal amplification test mechanism; the pulling roller test mechanism comprises a roller pulling device and a rotary encoder; the rotary shaft on the rotary encoder is connected with a main shaft of the roller pulling device; the roller displacement signal amplification test mechanism, the drive mechanism and the pulling roller test mechanism are respectively linked to the control mechanism. The invention is a high-speed numerically-controlled autoleveller gill box with advantages of high automation, simple and convenient operation, production efficiency and high product quality.

Owner:长沙策源科技开发有限公司

Acid-resistant pipeline steel and pipe making method

The invention discloses acid-resistant pipeline steel and a pipe making method, and relates to the field of steel and iron materials. The acid-resistant pipeline steel comprises the chemical compositions of, by mass, 0.014%-0.024% of C, 0.10%-0.35% of Si, 0.60%-0.80% of Mn, less than or equal to 0.012% of P, less than or equal to 0.0010% of S, 0.030%-0.070% of Nb, 0.006%-0.020% of Ti, 0.10%-0.30%of Ni, 1.00%-1.10% of Cr, 0.15%-0.20% of Mo, 0.10%-0.30% of Cu, 0.010% of V, 0.015%-0.050% of Al, and the balance Fe and impurities. According to the acid-resistant pipeline steel and the pipe makingmethod, unique composition design is adopted, pipe making is carried out through edge milling, prebending, forming, welding, flaw detection, hole enlargement and hydraulic testing and other processesto meet the pipe making requirements of the acid-resistant pipeline steel.

Owner:NANJING IRON & STEEL CO LTD

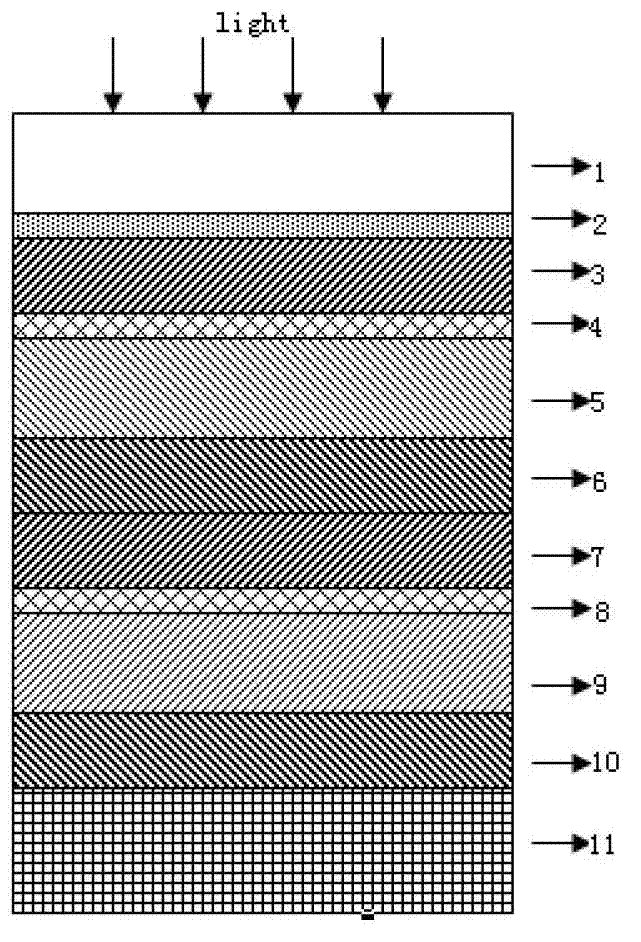

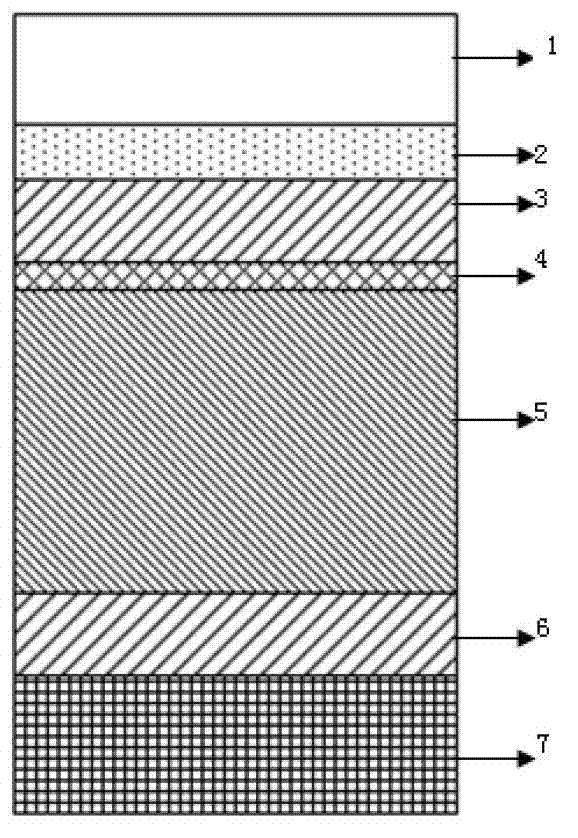

Amorphous silicon solar cell with multiple longitudinally distributed adsorption layers

InactiveCN102856399AImprove conversion efficiencyReduce adverse factorsPhotovoltaic energy generationSemiconductor devicesAmorphous silicon solar cellSolar energy conversion efficiency

The invention discloses an amorphous silicon solar cell with a plurality of longitudinally distributed adsorption layers, belongs to the technical field of solar energy utilization and relates to an amorphous silicon solar cell structure. Compared with an existing unijunction amorphous silicon solar cell, the amorphous silicon solar cell with a plurality of longitudinally distributed adsorption layers, which is provided by the invention, has a similar structure, however, the amorphous silicon light adsorption layers in the amorphous silicon solar cell are of a composite multilayer structure and are formed by sequentially laminating a plurality of amorphous silicon light adsorption sub layers from top to bottom along the longitudinal direction, wherein the widths of optical band gaps of the amorphous silicon light adsorption sub layers are sequentially decreased. According to the invention, the solar spectrum utilization rate of the amorphous silicon solar cell can be further improved, the solar conversion efficiency is improved, the light-induced degradation effect is also reduced and the influence of N-P reversed junctions is eliminated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of straw organic fertilizer

InactiveCN105418328AGood fertilizer effectReduce pollutionBio-organic fraction processingExcrement fertilisersAgricultural engineeringPeanut meal

The invention discloses a preparation method of a straw organic fertilizer. The preparation method includes the steps of 1) boiling soybean meal, peanut meal and rapeseed meal, performing solid-liquid separation and cooling, and uniformly mixing meal solids, meal nutrient liquids, corn straw powder and EM bokashi, and sealing the mixture; 2) crushing straw and mixing the straw with a fermentation material A to perform fermentation; 3) dissolving an EM stock solution and molasses in water to prepare an EM fermentation liquid; and 4) mixing a fermentation material B with the EM fermentation liquid, performing fermentation in a gradient fermentation manner. In the straw organic fertilizer, farmland straw wastes are fully utilized. The fermentation technology is simple and high-effective. The EM organic fertilizer has excellent effects, can be used for replacing chemical fertilizers and reduces the environment pollution caused by the chemical fertilizers and also reduces air pollution caused by straw combustion. In addition, the straw organic fertilizer can improve soil structure in certain degree, and especially, solve a problem of soil hardening due to large use quantity of chemical fertilizers.

Owner:范明月

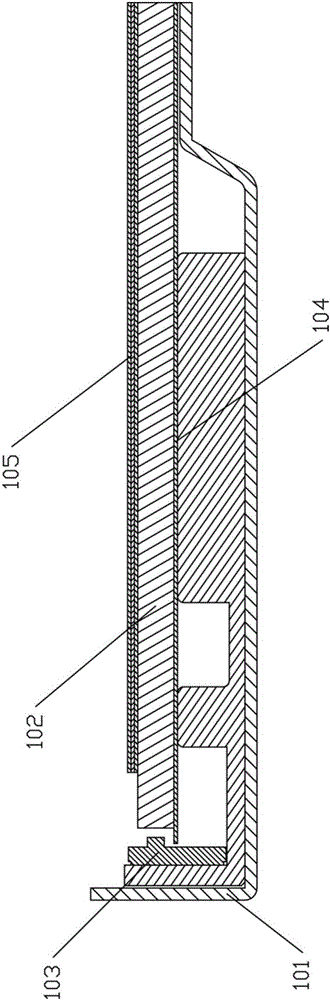

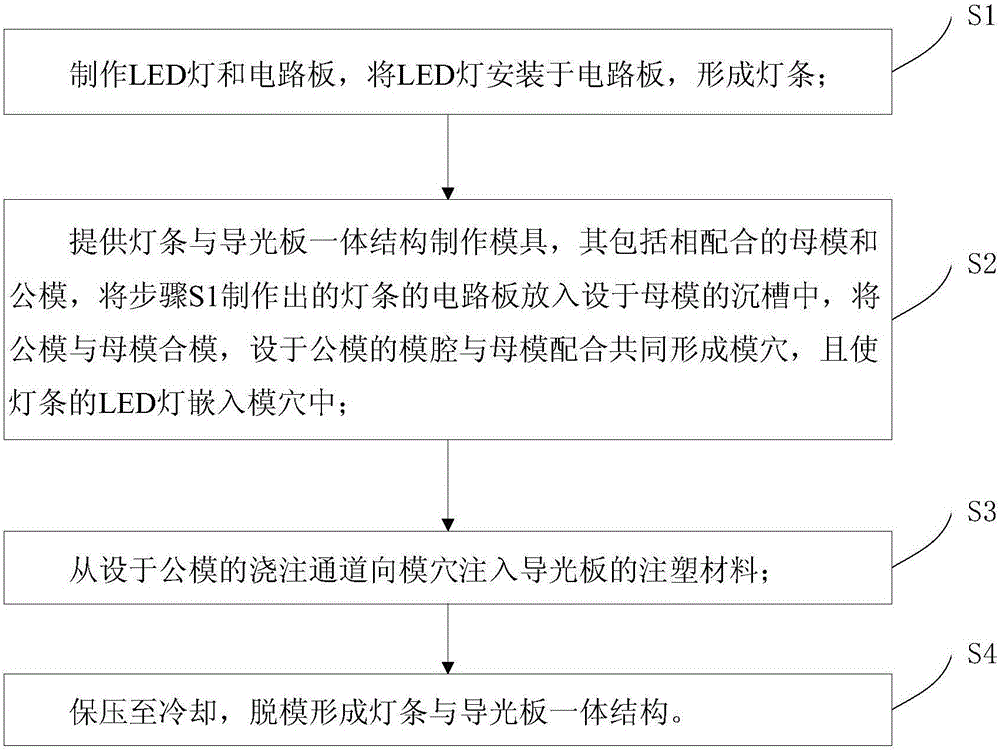

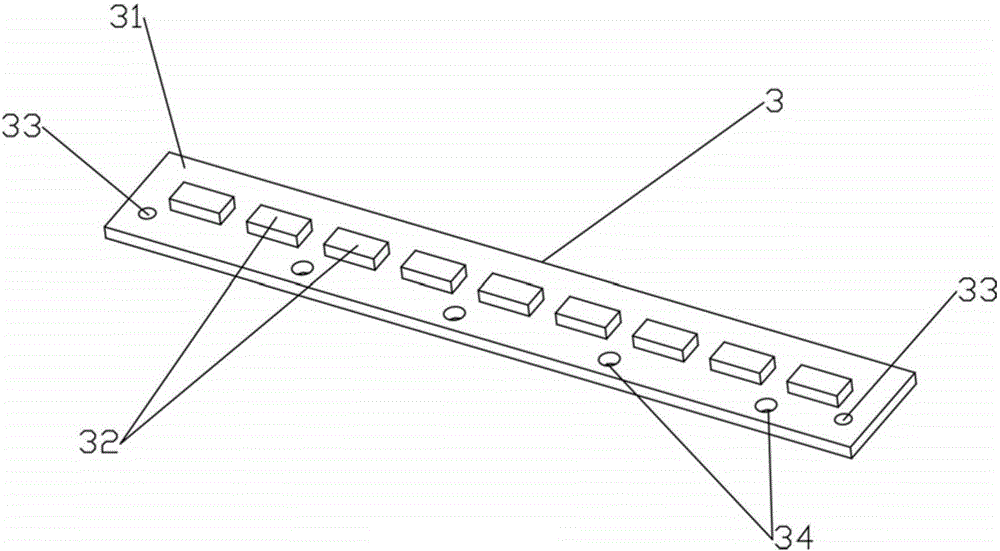

Method for manufacturing lamp bar and light guide board integrated structure, as well as mold and backlight module

ActiveCN105066014AReduce foulingReduce labor intensityMechanical apparatusPoint-like light sourceLight guideEngineering

The invention relates to the field of manufacture of backlight modules and discloses a method for manufacturing a lamp bar and light guide board integrated structure. The method comprises the following steps: S1, manufacturing LED lamps and a circuit board, and arranging the LED lamps on the circuit board so as to form a lamp bar; S2, providing a mold for manufacturing the lamp bar and light guide board integrated structure, wherein the mold comprises a female mold and a male mold which are matched with each other; putting the circuit board of the lamp bar manufactured in S1 in a sinking groove of the female mold, and assembling the male mold and the female mold, wherein a cavity of the male mold is matched with the female mold to form mold holes together, and the LED lamps of the lamp bar are embedded in the mold holes; S3, injecting injection molding materials of light guide boards into the mold holes from an injection molding channel of the male mold; and S4, keeping the pressure until the structure is cooled, and demolding to form a finished lamp bar and light guide board integrated structure. The lamp bar and light guide board integrated structure manufactured by adopting the method disclosed by the invention can be used for solving the problem that the process of sticking the lamp bar and the light guide board is complex in assembly of the backlight module. The invention further provides the mold for manufacturing the lamp bar and light guide board integrated structure, and the backlight module.

Owner:HEFEI BOE DISPLAY LIGHT +1

Preparation method of crop straw organic fertilizer

InactiveCN105085113AGood fertilizer effectReduce pollutionBio-organic fraction processingClimate change adaptationEffective microorganismAgricultural engineering

The invention discloses a preparation method of a crop straw organic fertilizer, which comprises the following steps: (1) boiling bean pulp and soybean, and carrying out solid-liquid separation; uniformly mixing the boiled bean pulp soybean, bean pulp soybean water, rice bran, corn straw powder and EM (effective microorganism) bokashi, and fermenting in a sealed environment to obtain a fermentation material a; (2) pulverizing the straw, mixing with the fermentation material a, and fermenting to obtain a fermentation material b; (3) dissolving an EM stock solution and molasses in water to prepare an EM fermentation liquid; and (4) mixing the fermentation material b and EM fermentation liquid, and fermenting by a gradient fermentation process. The crop straw organic fertilizer fully utilizes the farmland straw waste, and is simple and efficient in the fermentation technique. The EM organic fertilizer has favorable fertilizer efficiency, can be used instead of the chemical fertilizer to reduce the environmental pollution caused by the chemical fertilizer and also reduce the air pollution caused by straw combustion, can improve the soil structure to some extent, and especially can improve the soil hardening caused by abundant use of the chemical fertilizer.

Owner:范明月

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com