Patents

Literature

82results about How to "Avoid clamping deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

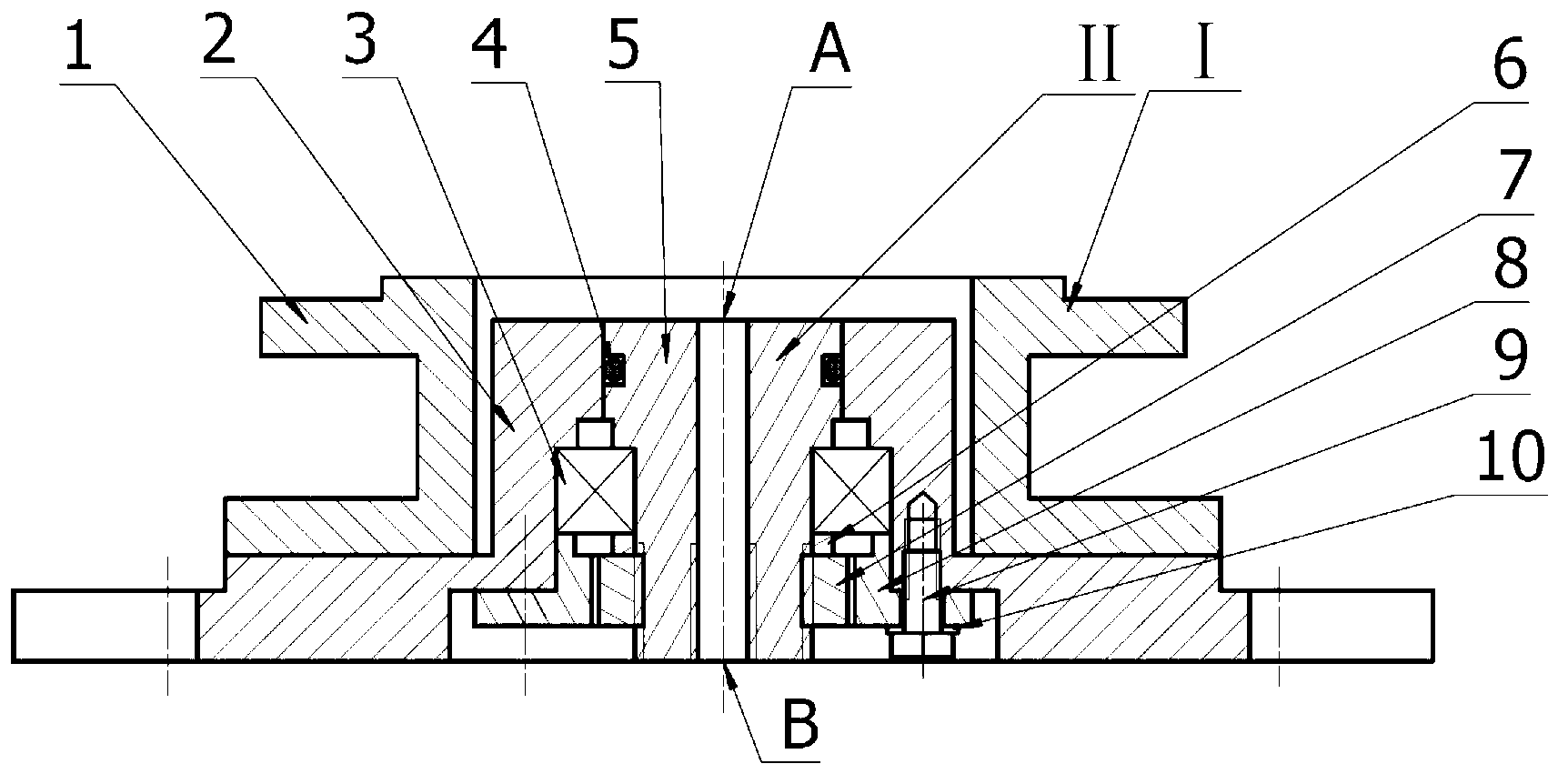

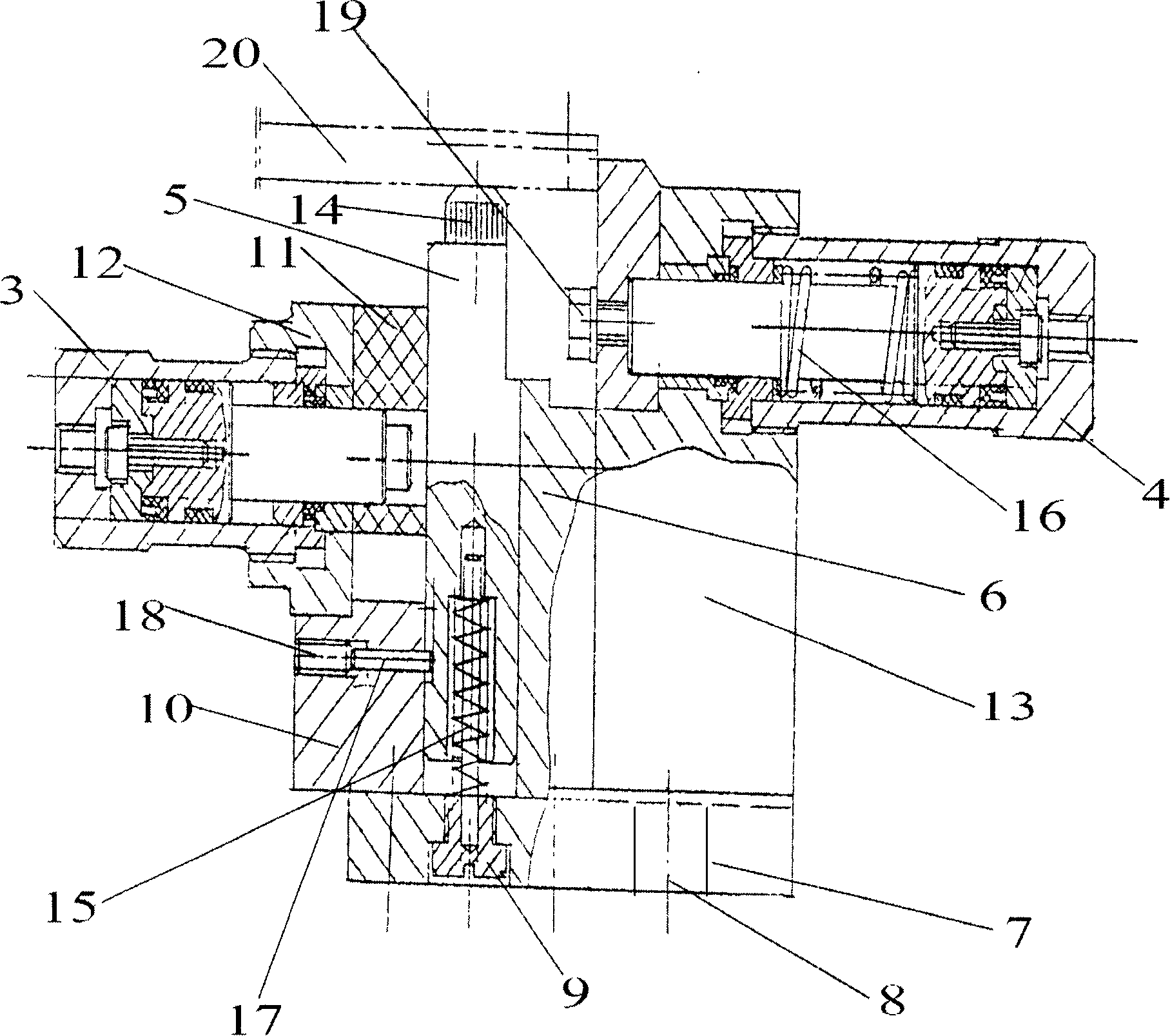

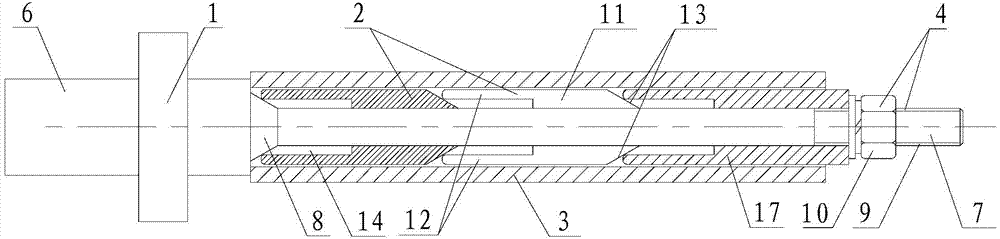

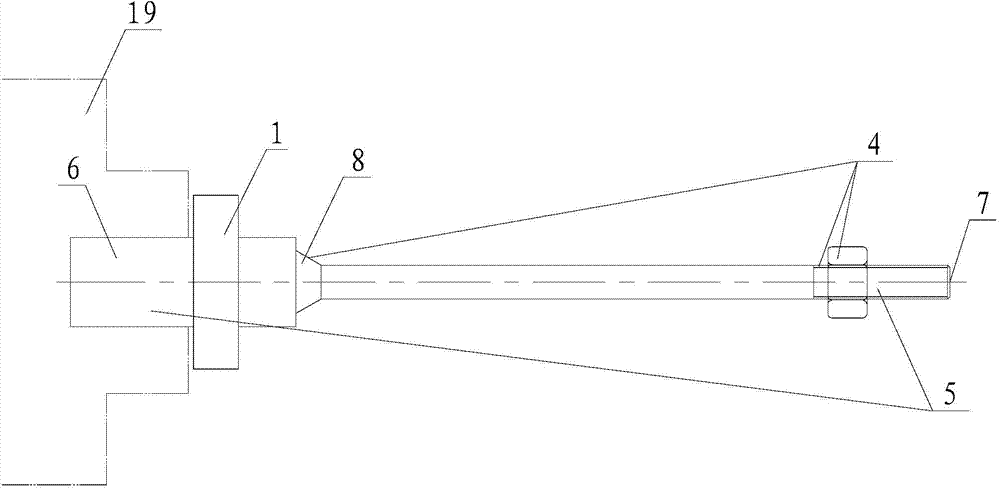

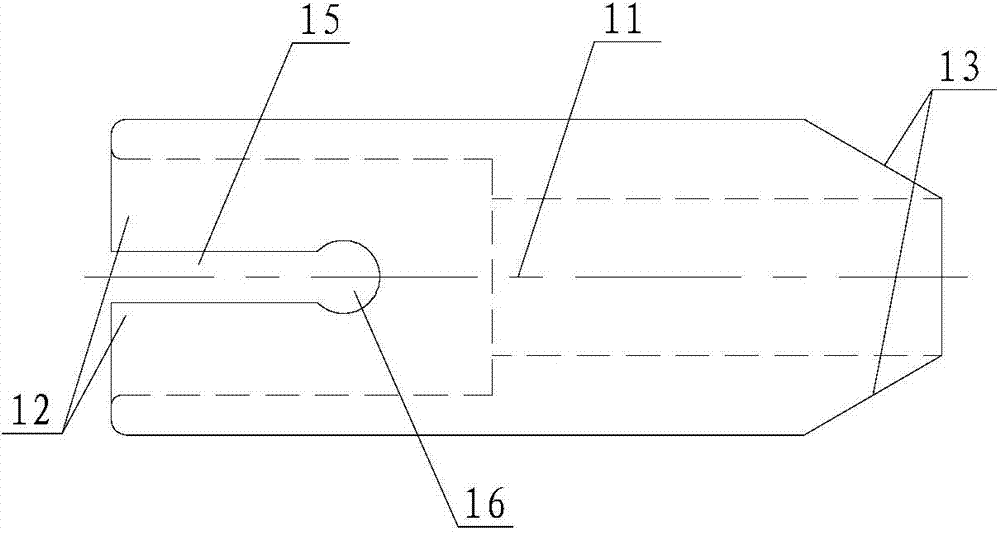

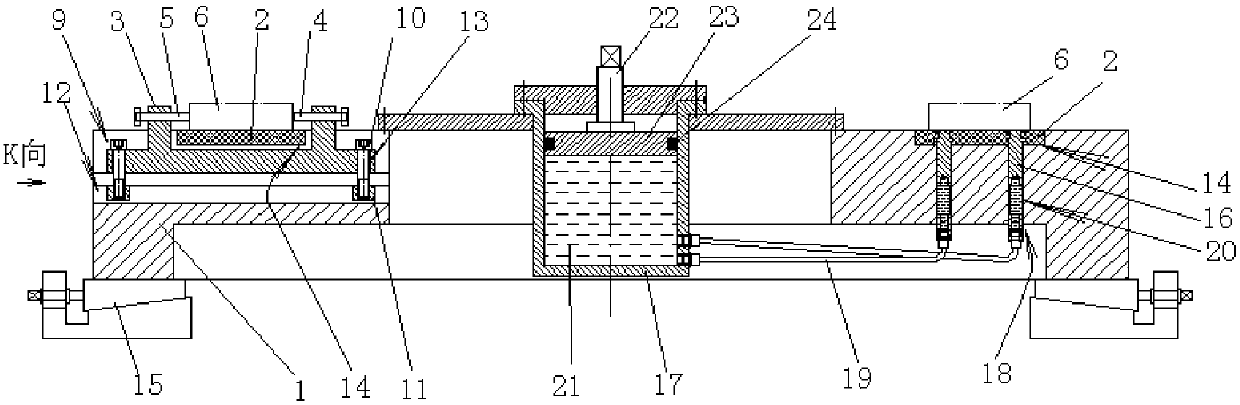

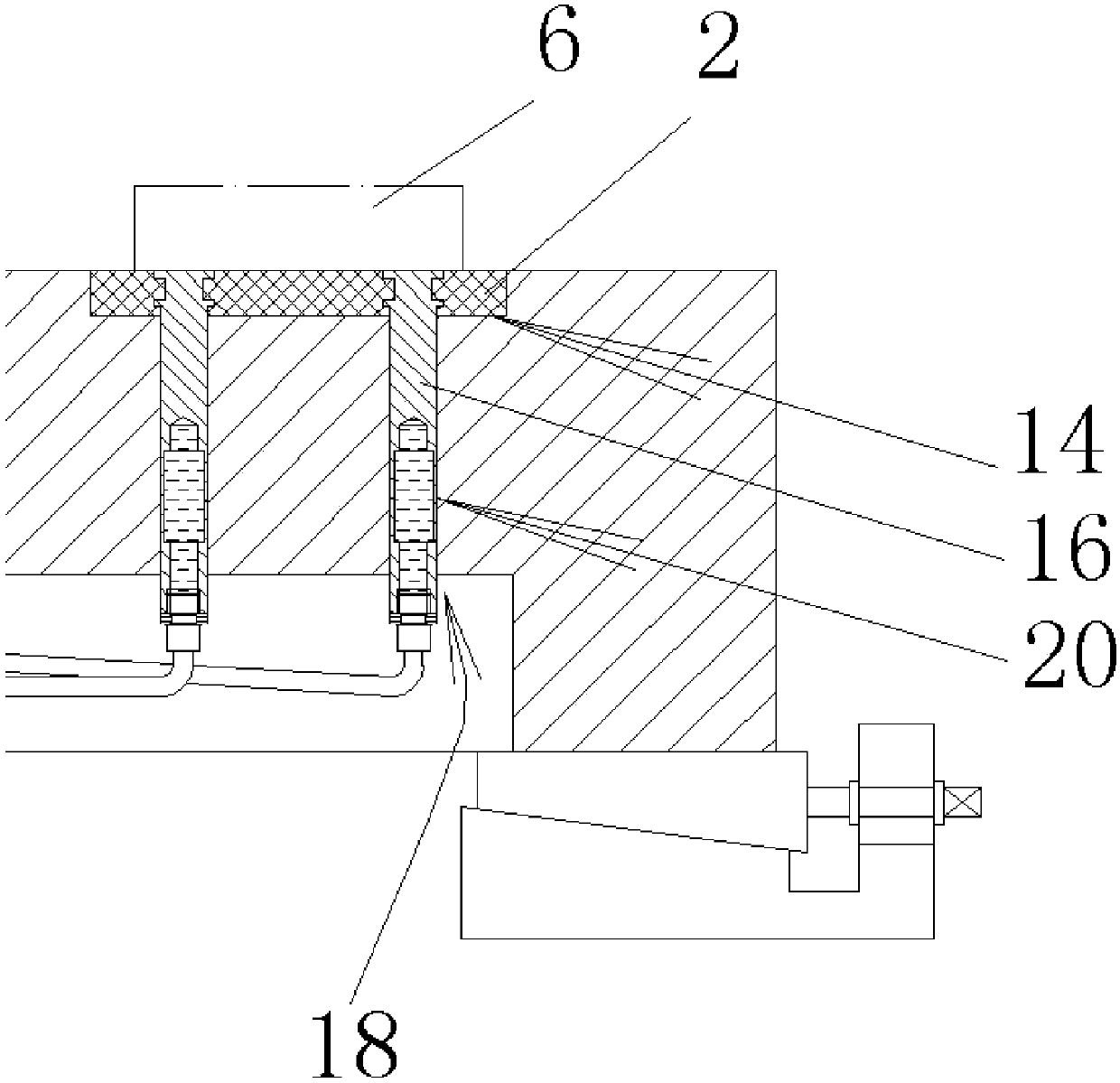

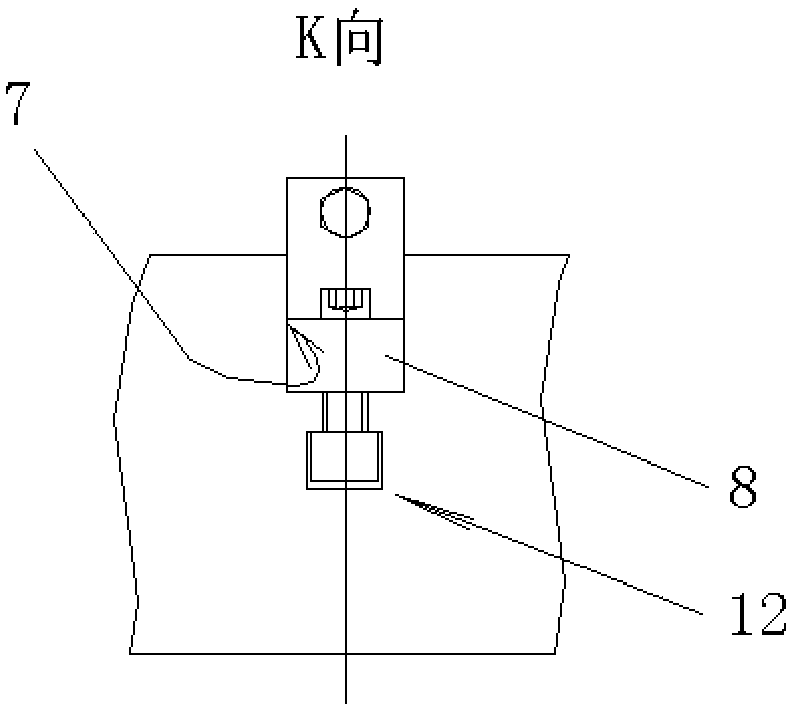

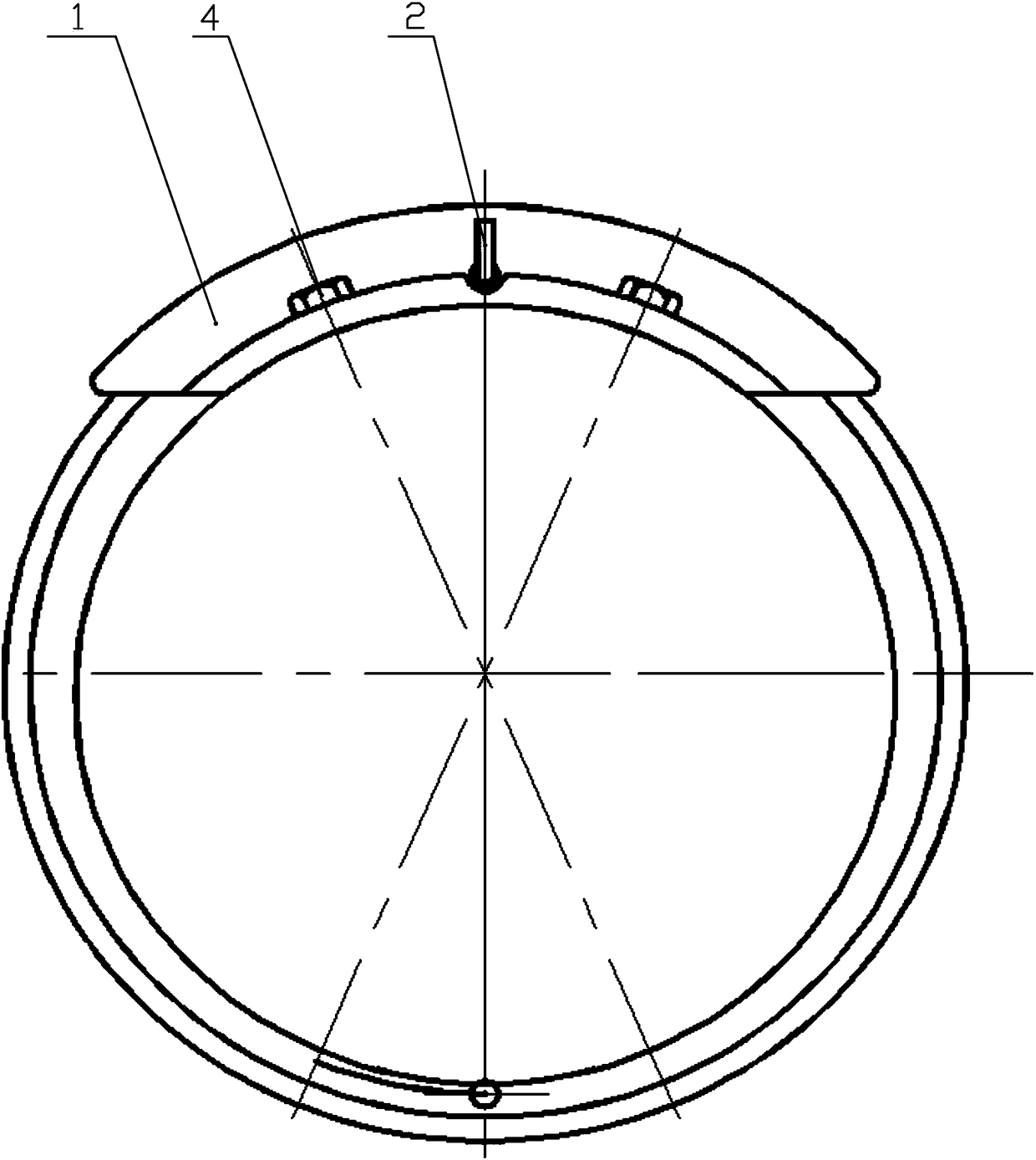

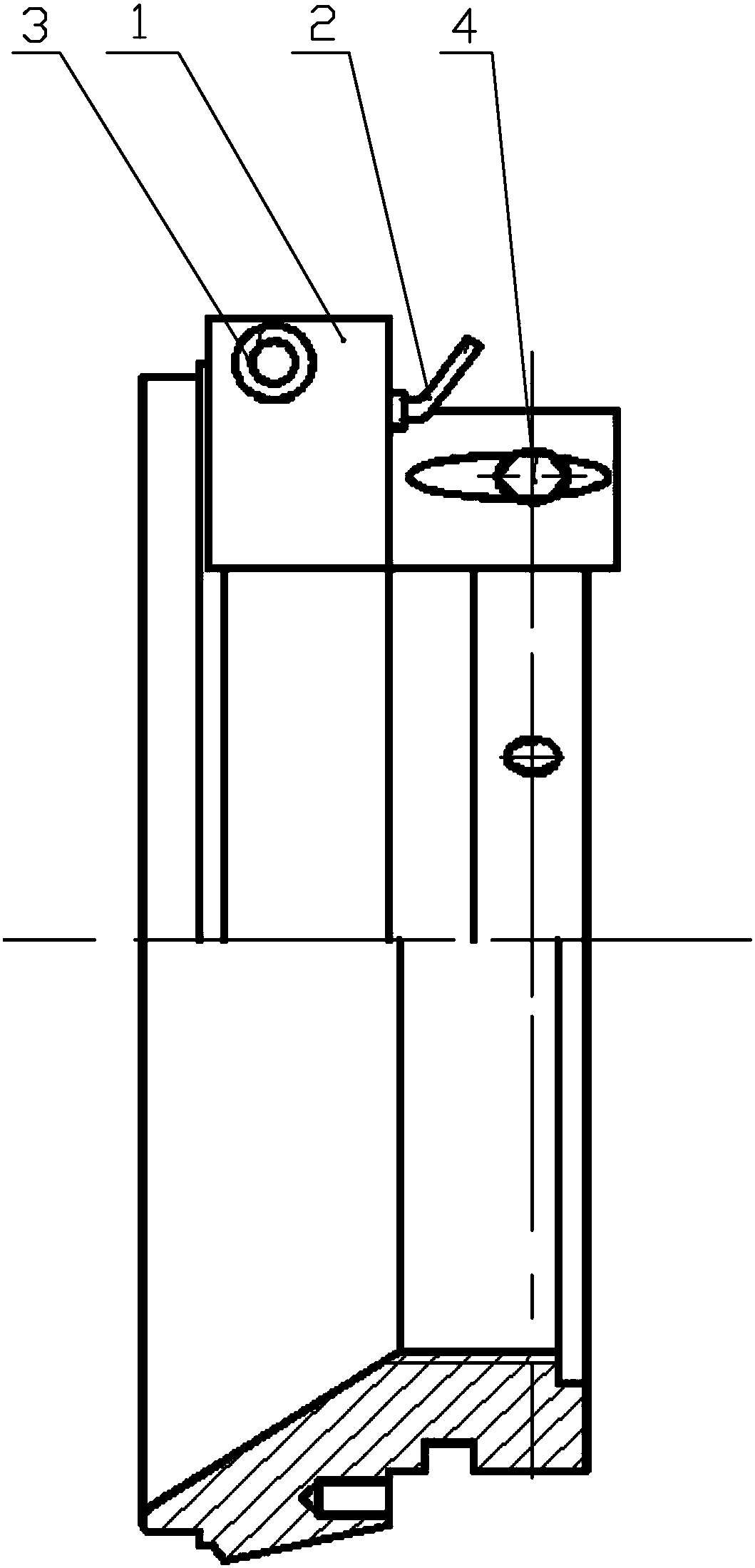

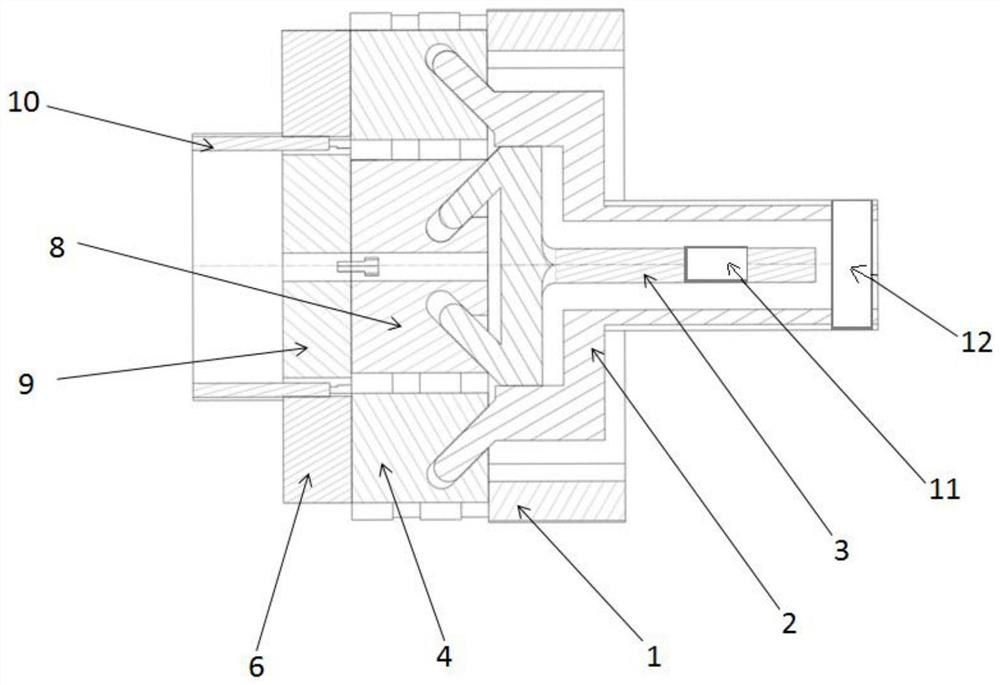

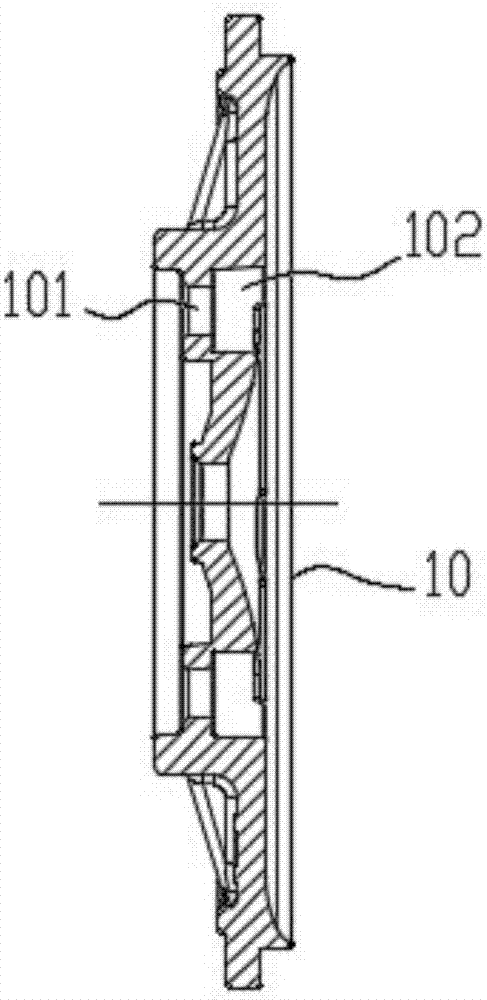

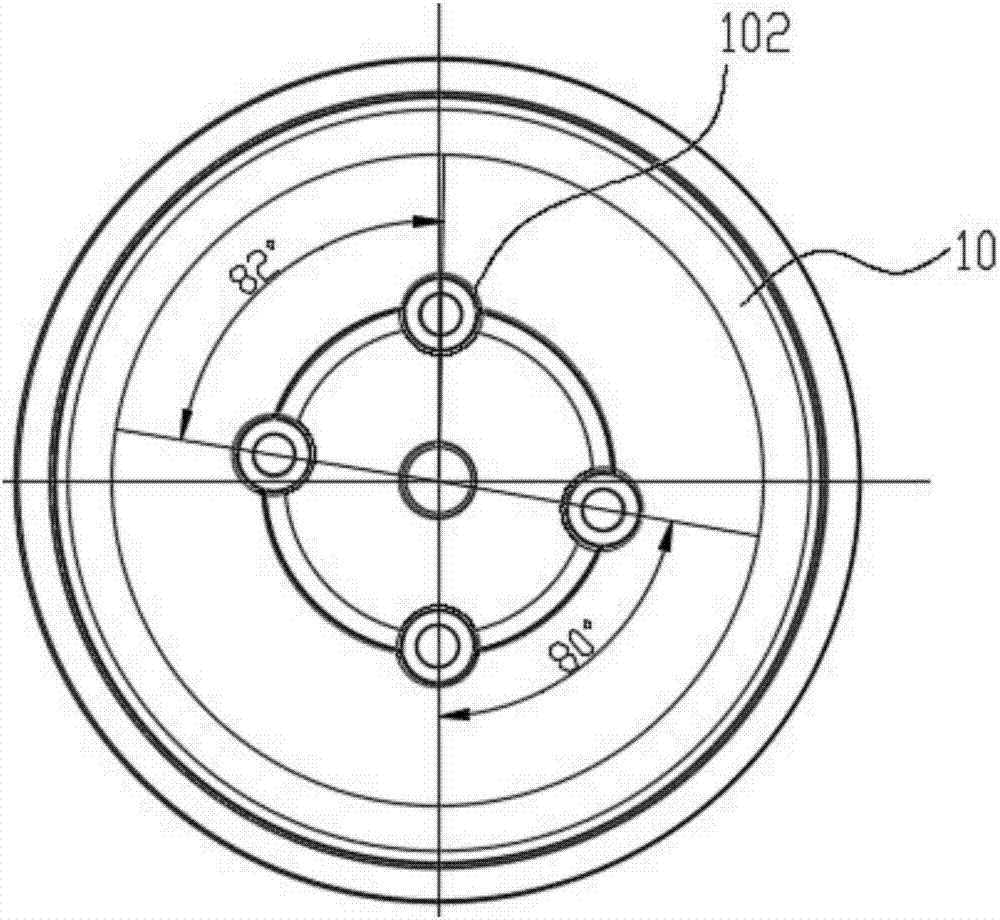

Pneumatic precise clamping device of low-rigidity thin-wall cavity part

ActiveCN103264303APrecise positioningAvoid clamping deformationPositioning apparatusMetal-working holdersHardnessEngineering

The invention discloses a pneumatic precise clamping device of a low-rigidity thin-wall cavity part, belongs to the field of machining and particularly relates to a precise clamping device of a low-hardness thin-wall cavity coated part. The pneumatic precise clamping device has a function of performing reliable clamping and precise positioning on parts on a two-dimensional rotary working table and is composed of a primary positioning part, a pneumatic clamping part and a precise adjusting part. The primary positioning part is composed of an upper clamp body and a lower clamp body, the clamping part adopts the vacuum adsorption technology, and the precise adjusting part is composed of four annular supports surrounded on the lower clamp body, four spiral micro feeding mechanisms and a fixed support. The pneumatic precise clamping device integrates the clamping device and the adjusting device, performs pneumatic adjusting on clamping force according to mechanical properties of workpiece materials, and is convenient to install, compact in structure and high in centering accuracy.

Owner:DALIAN UNIV OF TECH

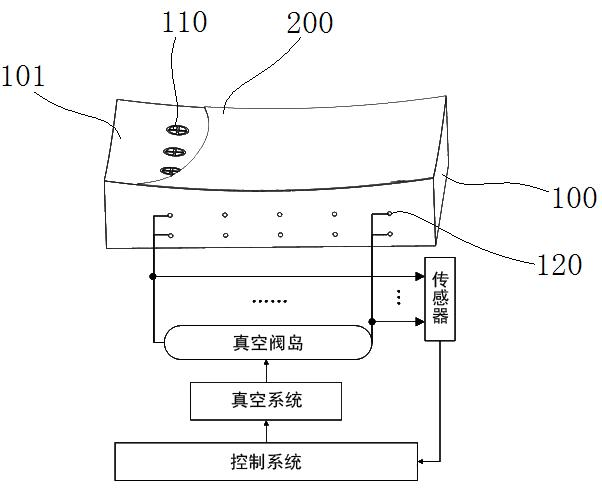

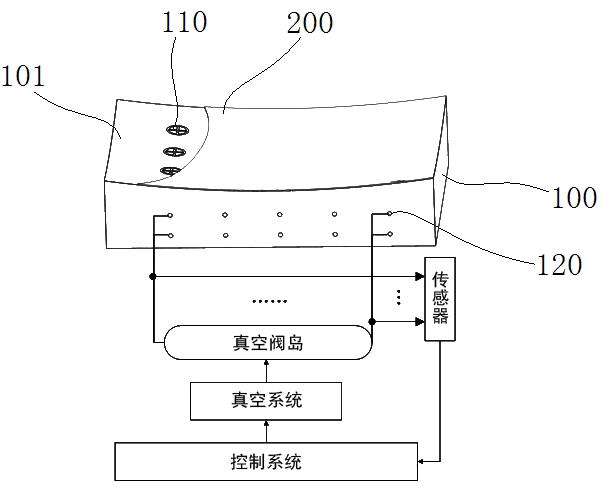

Multipoint profiling rigid clamp and method for processing thin-wall workpiece by using same

InactiveCN102179708ASolve rigid problemsSolve Vibration ProblemsPositioning apparatusMetal-working holdersControl systemSurface type

The invention discloses a multipoint profiling rigid clamp, comprising a clamp body. The clamp body is provided with a positioning surface for positioning a processed workpiece; the positioning surface is provided with a vacuum sucker; the clamp body is internally provided with a vacuum hole channel; one end of the vacuum hole channel is connected with the vacuum sucker, and the other end of the vacuum hole channel is connected with a vacuum valve island arranged at the outer part of the clamp body; the vacuum valve island is connected with a vacuum system connected with a control system; andthe vacuum hole channel is also connected with the control system by a vacuum sensor. A method for processing a thin-wall workpiece by using the multipoint profiling rigid clamp comprises the steps of: modeling, analyzing, determining and optimizing key positioning points, arranging the vacuum sucker, processing the positioning surface of the clamping body and finally carrying out processing on the thin-wall workpiece. The multipoint profiling rigid clamp is used for a high-speed milling finish processing stage of the complex profile of the thin-wall workpiece, the positioning surface of the clamp is consistent to the surface type of the processed workpiece, the uniform distribution of a clamping force is guaranteed and the clamping and the deformation of the thin-wall workpiece are avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

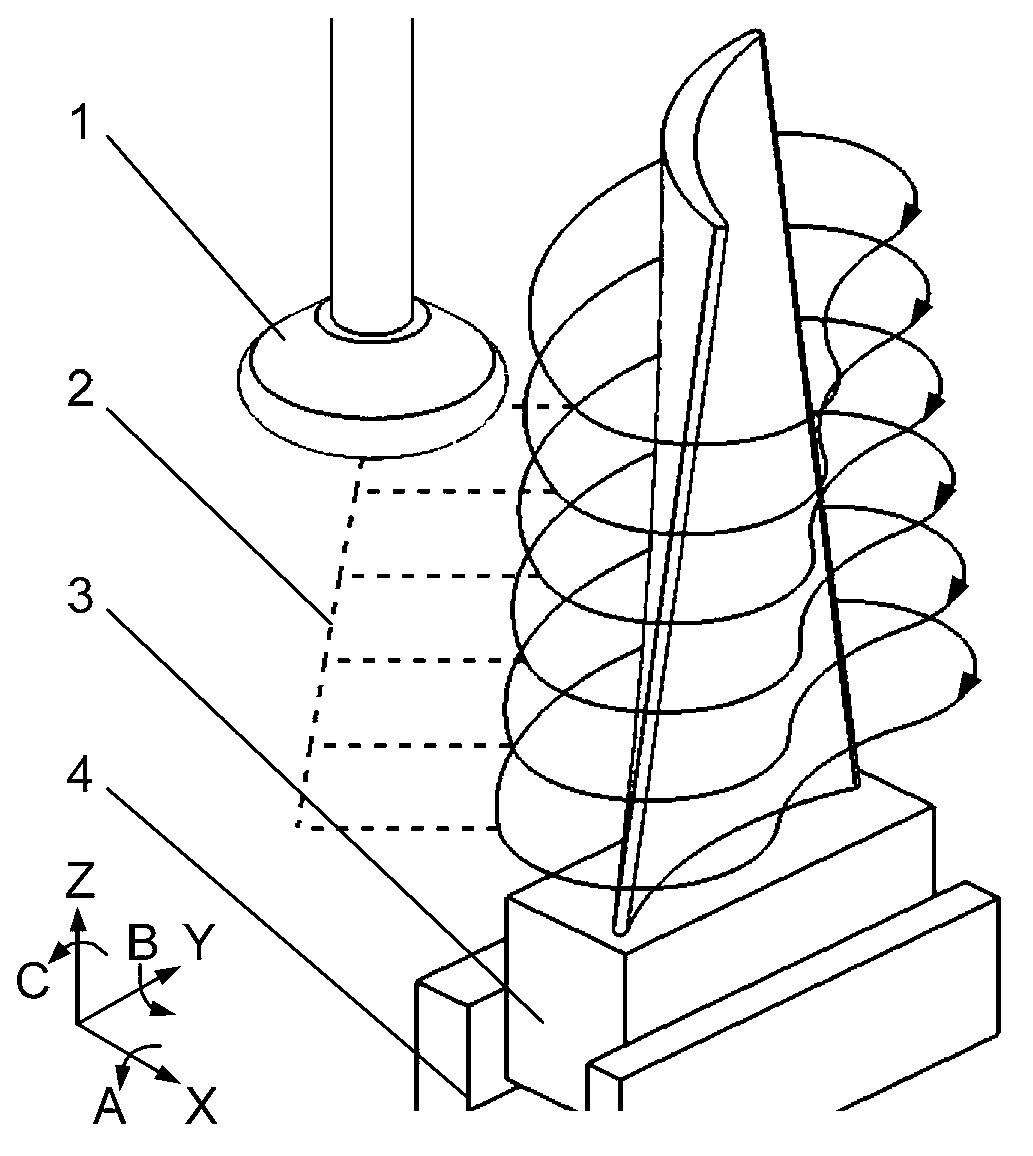

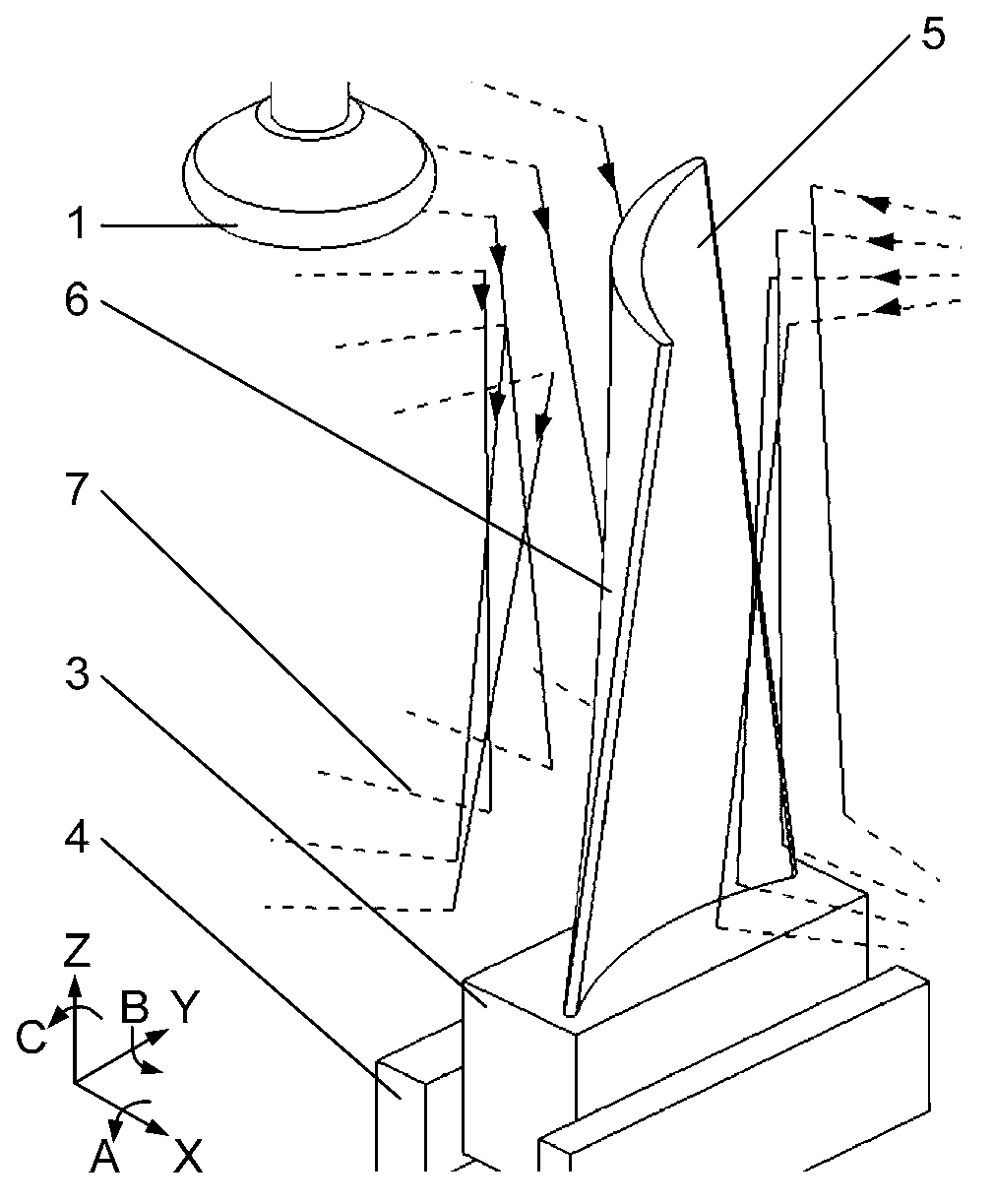

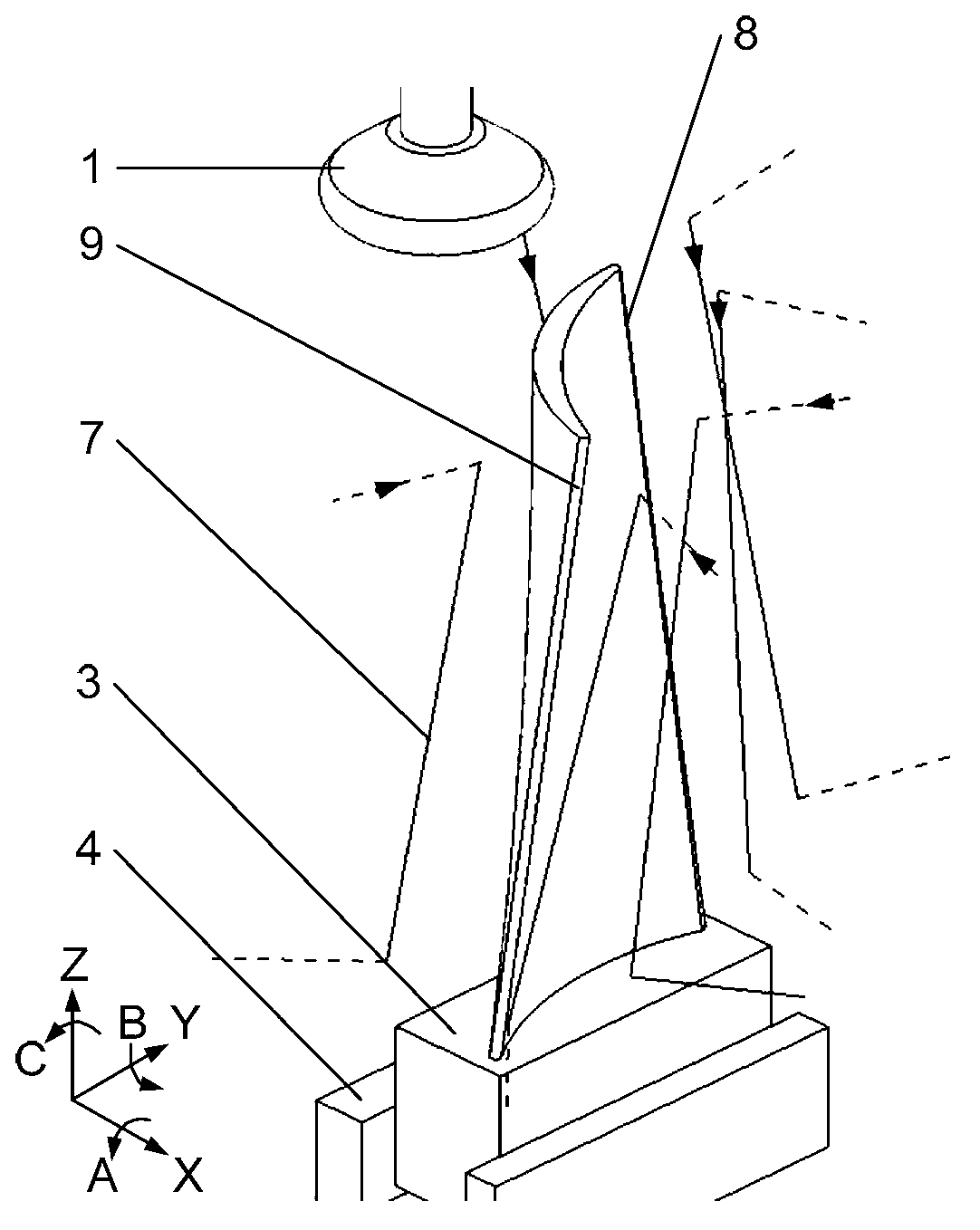

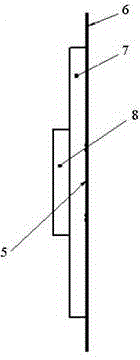

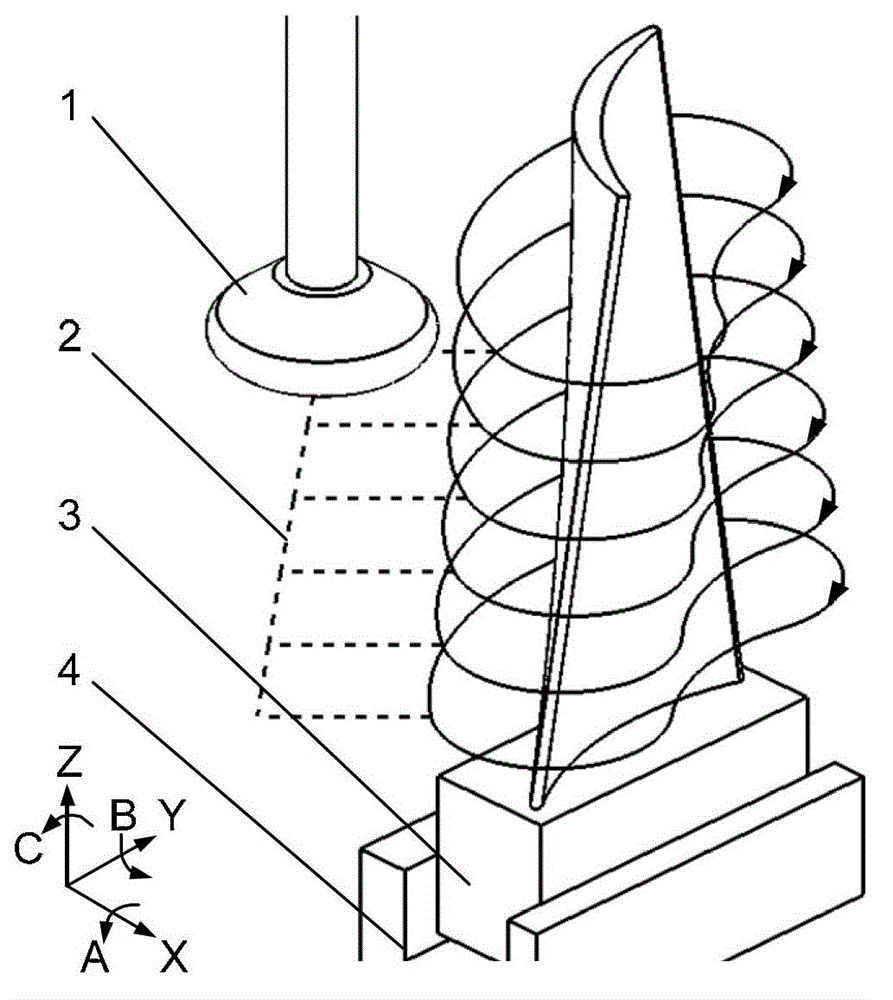

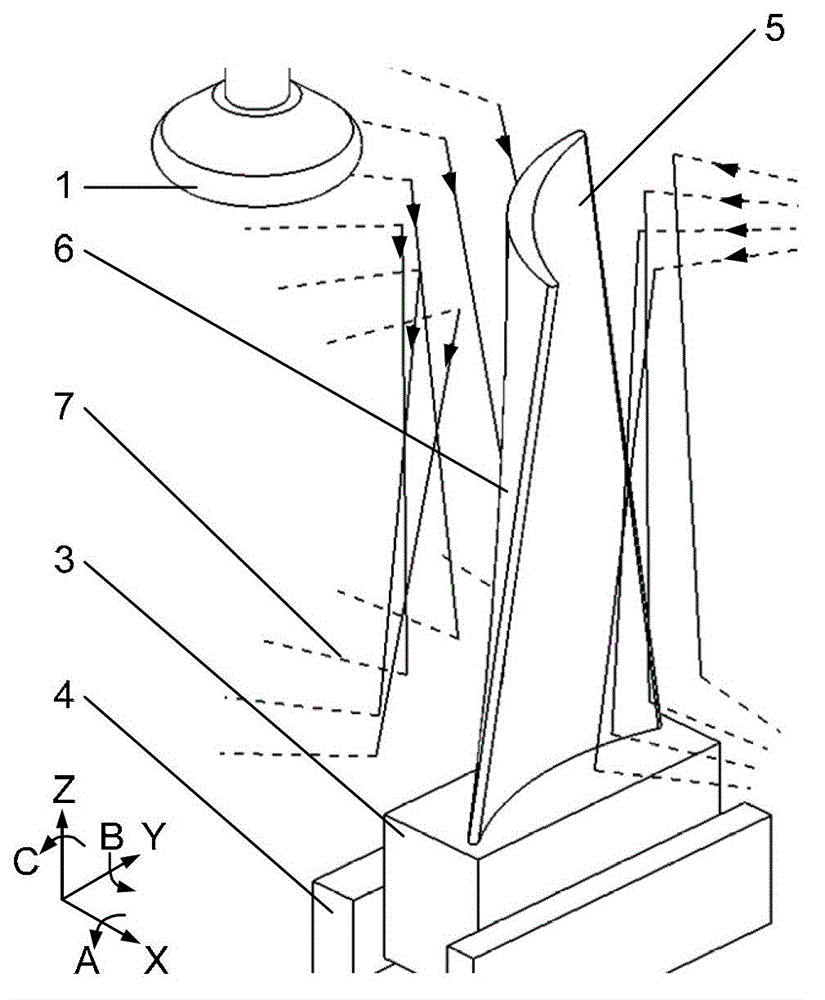

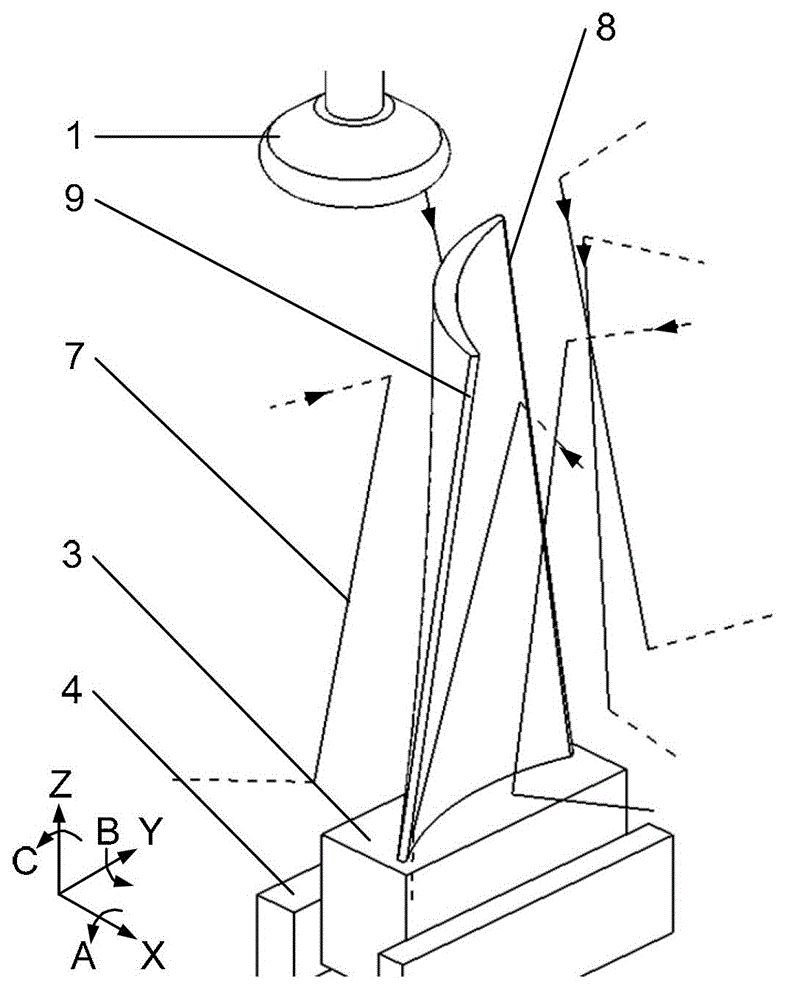

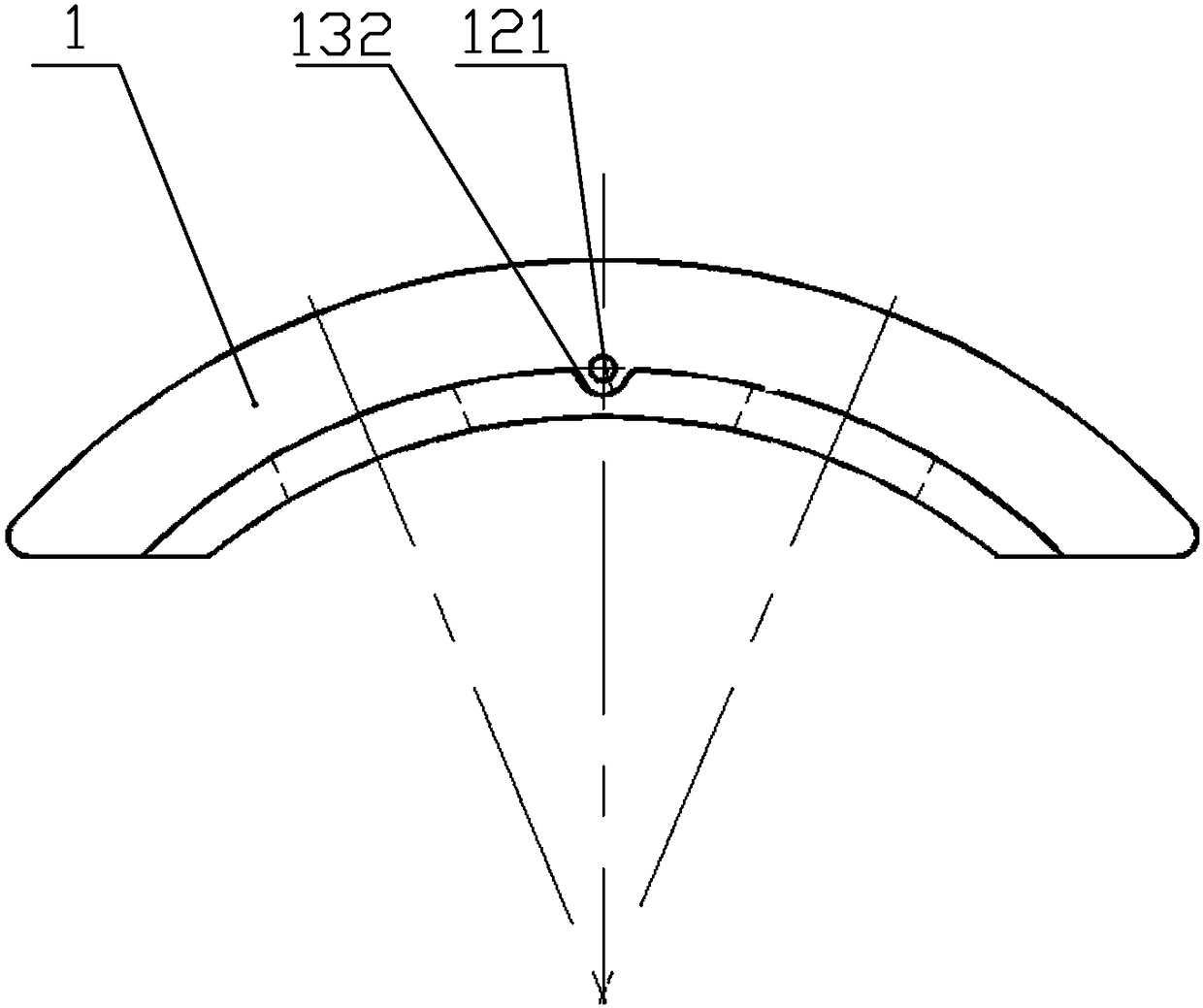

Cantilever grinding machining method for vane using three-axis linkage interpolation

InactiveCN103100950AAvoid clamping deformationReduce adverse factorsGrinding machinesGrinding work supportsNumerical controlLinear motion

A cantilever grinding machining method for a vane using three-axis linkage interpolation comprises four steps: (1) ascertaining the grinding method of a vane-shaped face according to the structure type and the motion mode of a machine tool and the structure form of the vane; (2) clamping a tenon or a installation reference block of the vane through a single end of a fixture to enable the vane to be firmly fixed on an operating platform of the machine tool and keeping the vane-shaped face portion needing machining in a cantilever state on the numerical control machine tool; (3) selecting three machine tool motion axes suitable for the grinding machining of the vane-shaped face and a grinding wheel to composite a digital control program, and driving the three linear motion axes X, Y and Z, or the axis X, the axis Z and axis C, or the axis Y, the axis Z and the axis C to conduct the three-axis linkage interpolation motion by the digital control program to form a motion trail of the grinding wheel when the vane is in a grinding machining; and (4) enabling the grinding wheel to rotate at a high speed under the driving of a main shaft of the machine tool and move along the motion trail of the three-axis linkage interpolation of the machine tool to achieve the three-axis linkage interpolation cantilever grinding machining of the vane-shaped face.

Owner:BEIHANG UNIV

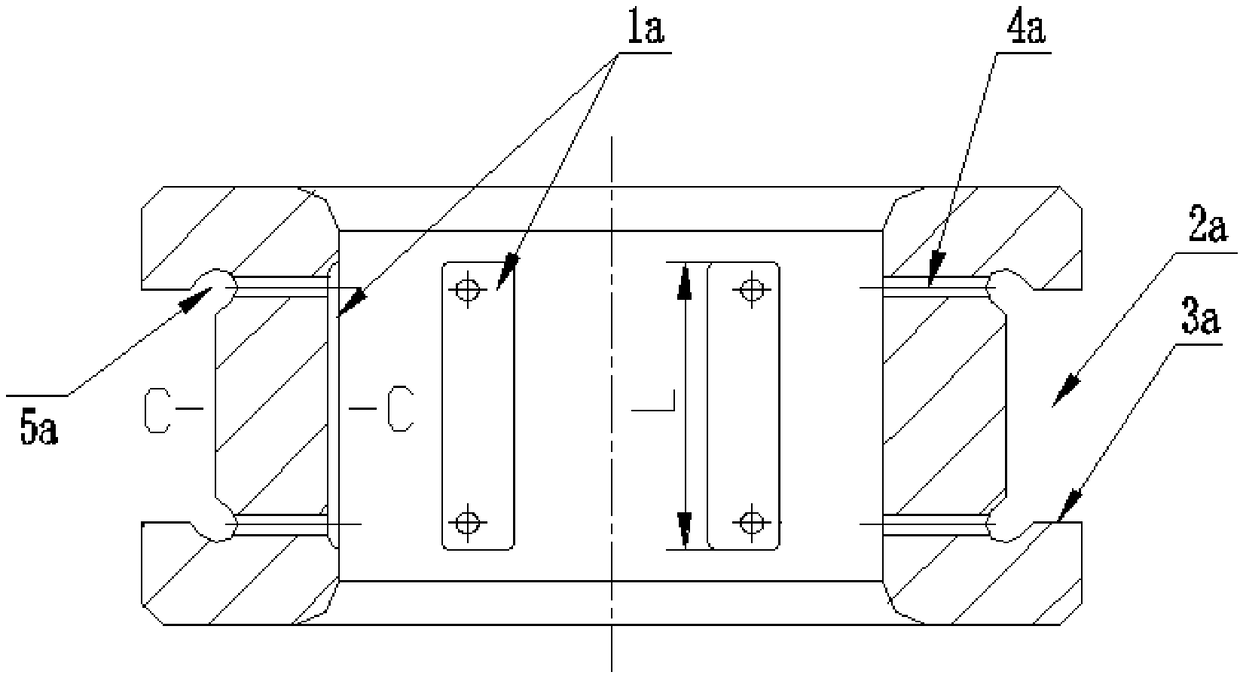

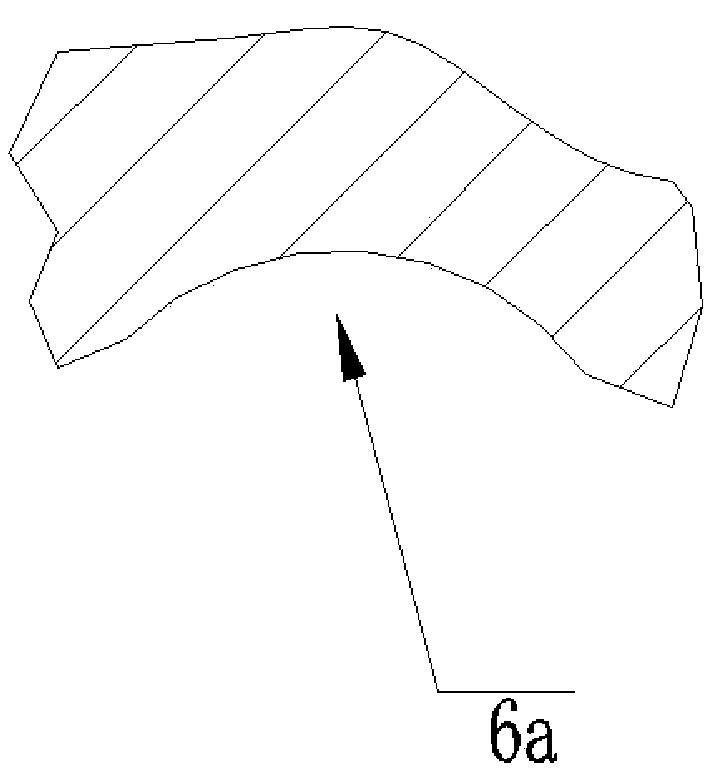

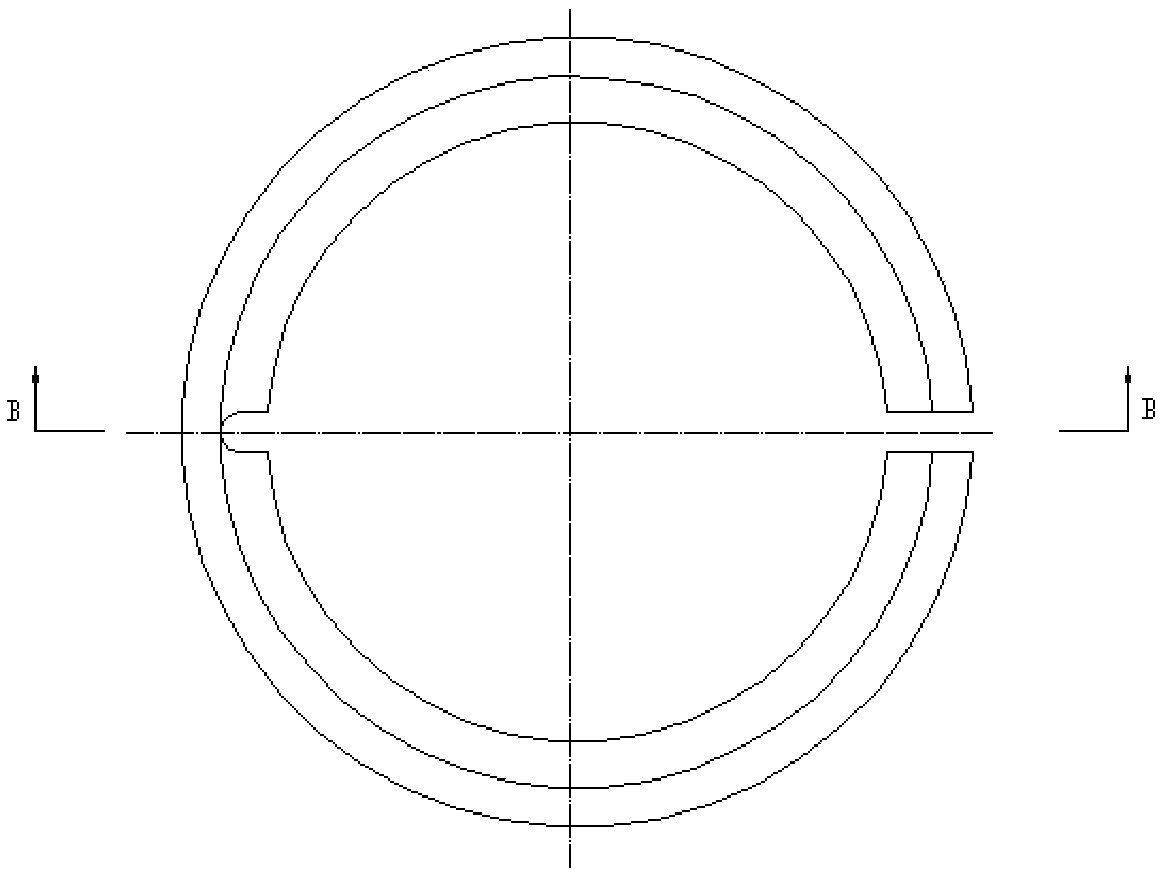

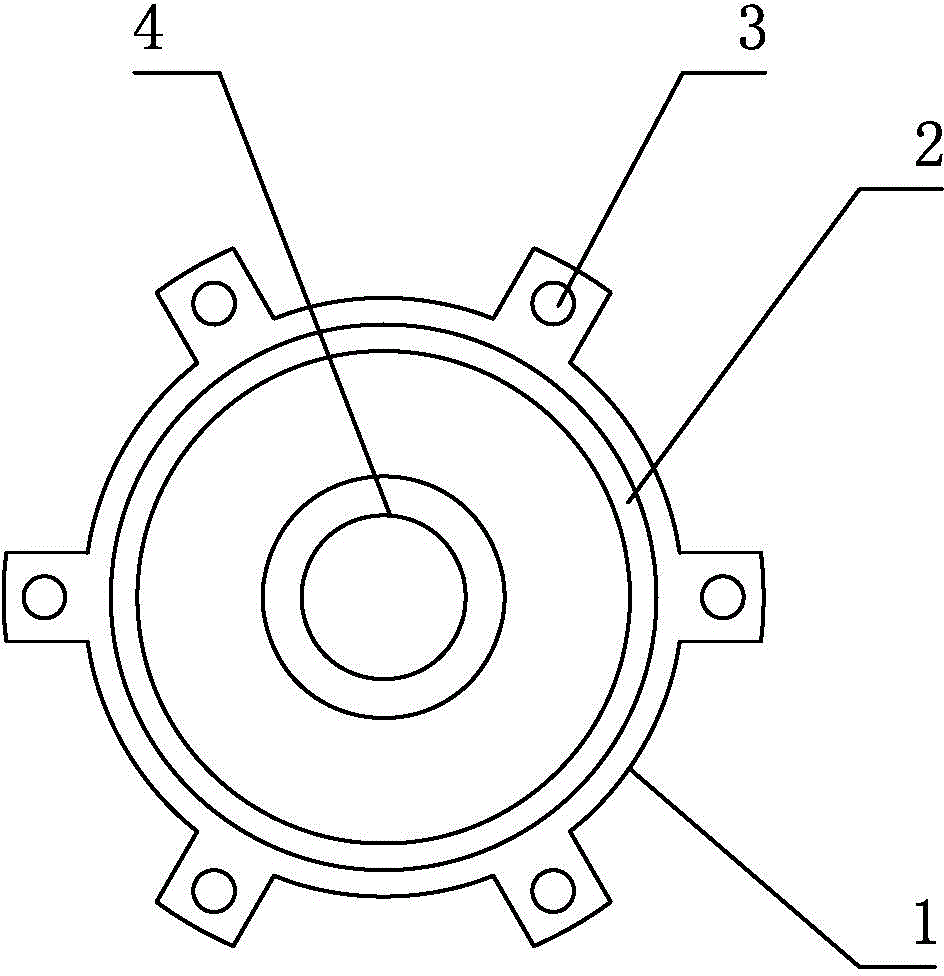

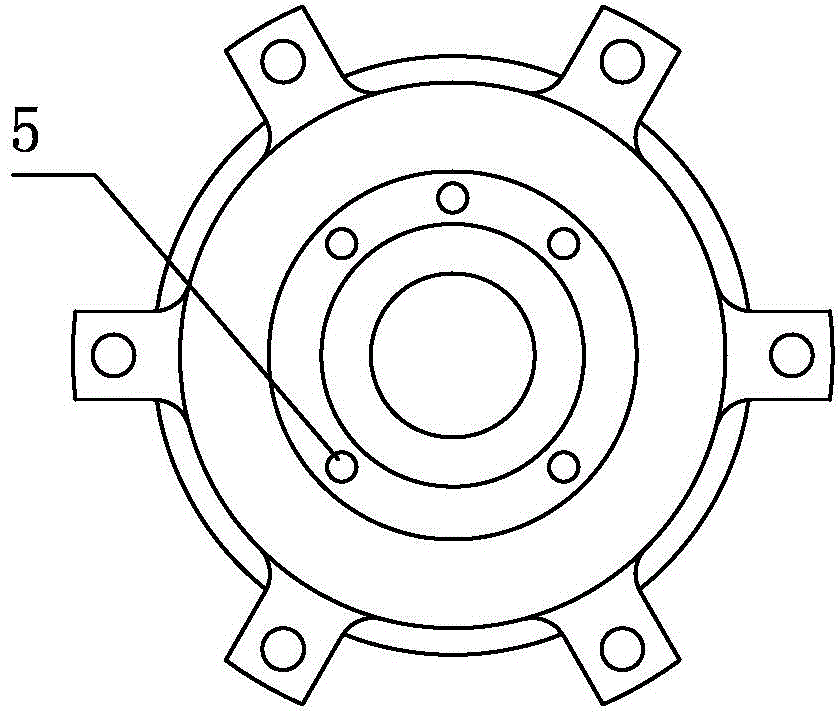

Mould for machining engine main shaft bearing inner ring with inner diameter oil groove and machining method

ActiveCN109483262ATight depth toleranceGuaranteed machining accuracyWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to a mould for machining an engine main shaft bearing inner ring with an inner diameter oil groove and a machining method, and relates to a mould for machining a bearing inner ring and a machining method. The problem of poor machining accuracy of the inner diameter of a bearing inner ring and the size of an inner diameter oil groove is solved. The mould is composed of a mouldbase, a pressing plate and a connecting bolt; and a ring-shaped flange is arranged on a bearing plane. The machining method comprises the steps that an outer circumferential surface is milled softlybefore an inner circumferential surface is turned finally, the outer circumferential surface of an inner ring and one end face of the bearing inner ring are used as a positioning datum to machine theinner circumferential surface of the inner ring; milling of the inner diameter oil groove is performed after the finally turning of the inner circumferential surface of the inner ring; the bearing support flat face of the mould is used for positioning one end face of the bearing inner ring; and the outer circumferential surface positioned by the inner surface of the ring-shaped flange of the baseis used for machining the inner diameter oil groove. According to the mould for machining the engine main shaft bearing inner ring with the inner diameter oil groove, deformation caused by tightly clamping can be avoided, the machining method ensures the machining accuracy of the inner diameter oil groove, and the method is suitable for machining the engine main shaft bearing inner ring with the inner diameter oil groove.

Owner:AVIC HARBIN BEARING

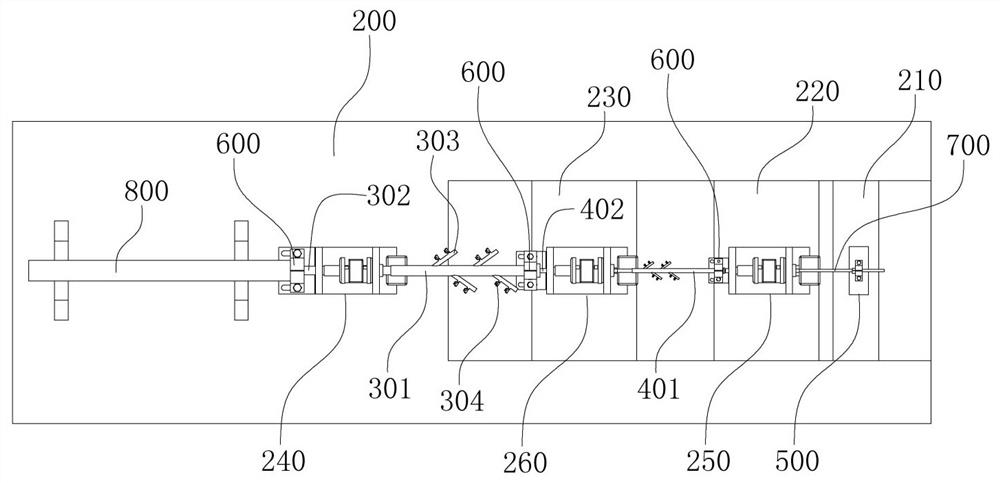

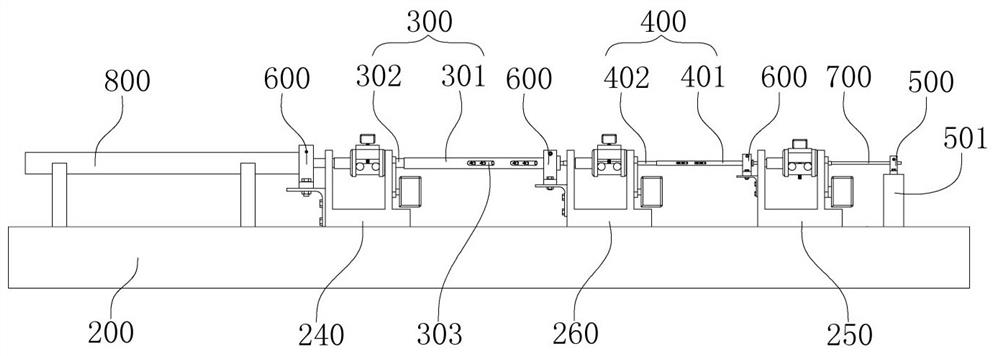

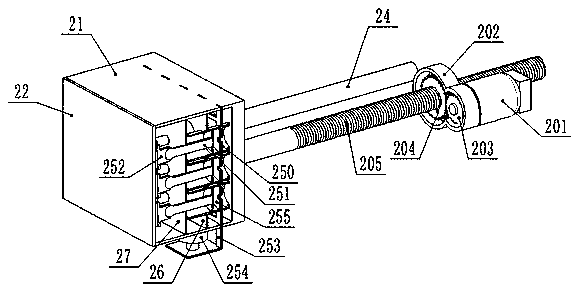

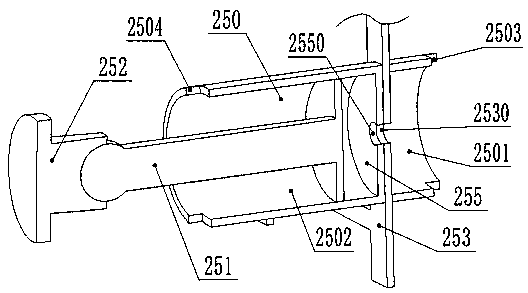

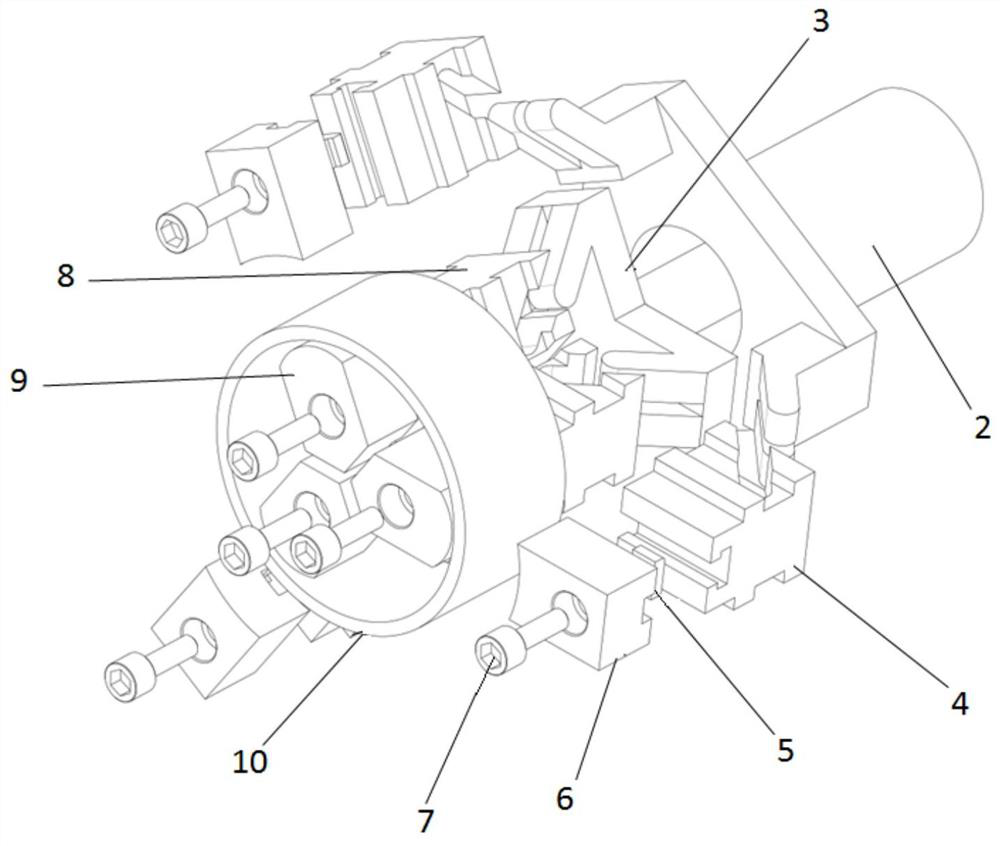

Rotary pushing device and interventional operation robot

The invention belongs to the technical field of medical equipment. The invention discloses a rotary pushing device for controlling a catheter or a guide wire and comprises a base, a rotary table, a pushing unit and a pushing driving part, the rotary table is arranged on the base through two hollow pivot shafts, and a rotary driving part for driving the rotary table to rotate is arranged on the base; the pushing unit is arranged on the rotary table, the pushing unit comprises an upper pushing roller and a lower pushing roller which are correspondingly arranged up and down, and at least part of the upper pushing roller and the lower pushing roller are arranged up and down in a staggered mode; and the pushing driving part drives the pushing unit to act. The invention further discloses an interventional surgical robot. Stable pushing of the guide wires or the catheters can be effectively improved, the product structure is simplified, modularization of the rotary pushing device is achieved, assembling is more convenient, tensioning of the guide wires or the catheters can be achieved through a new transmission mode, the accuracy of surgical actions is guaranteed, and practicability is higher.

Owner:王利

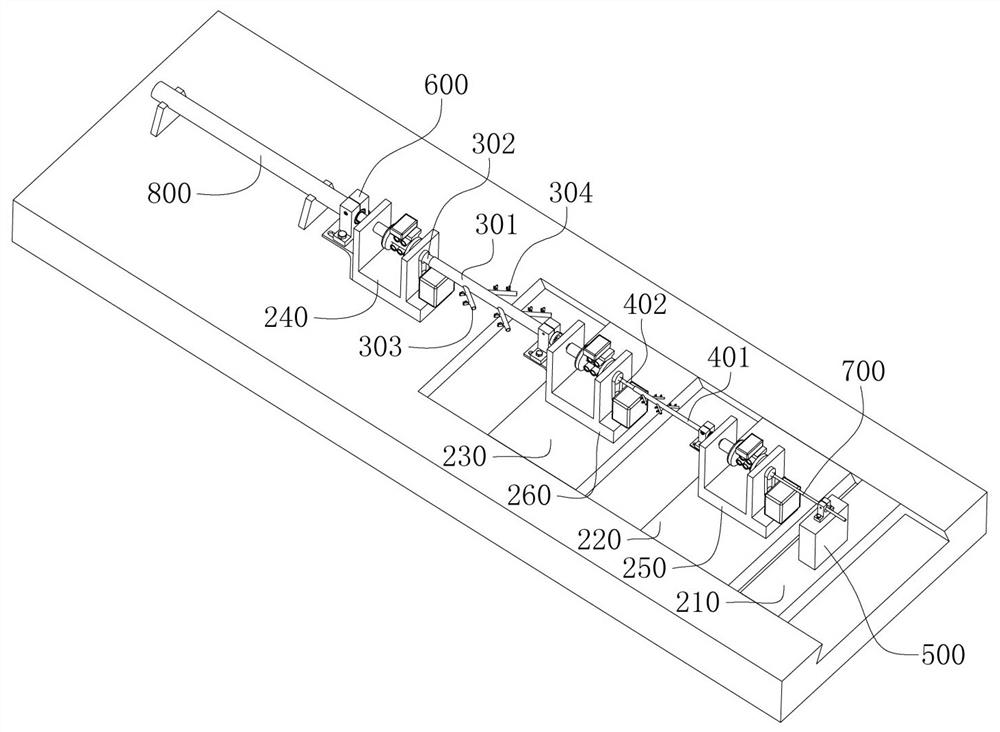

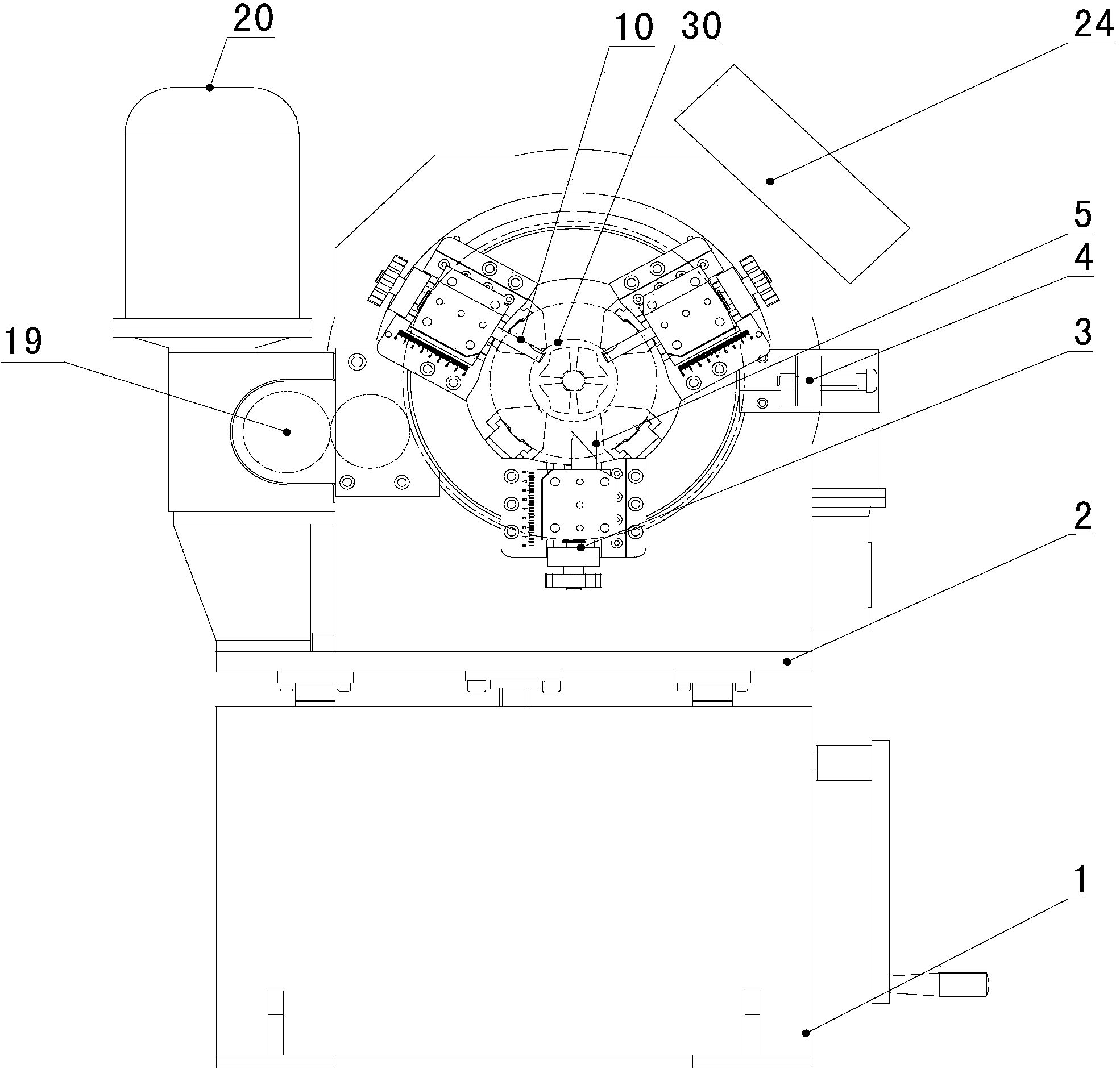

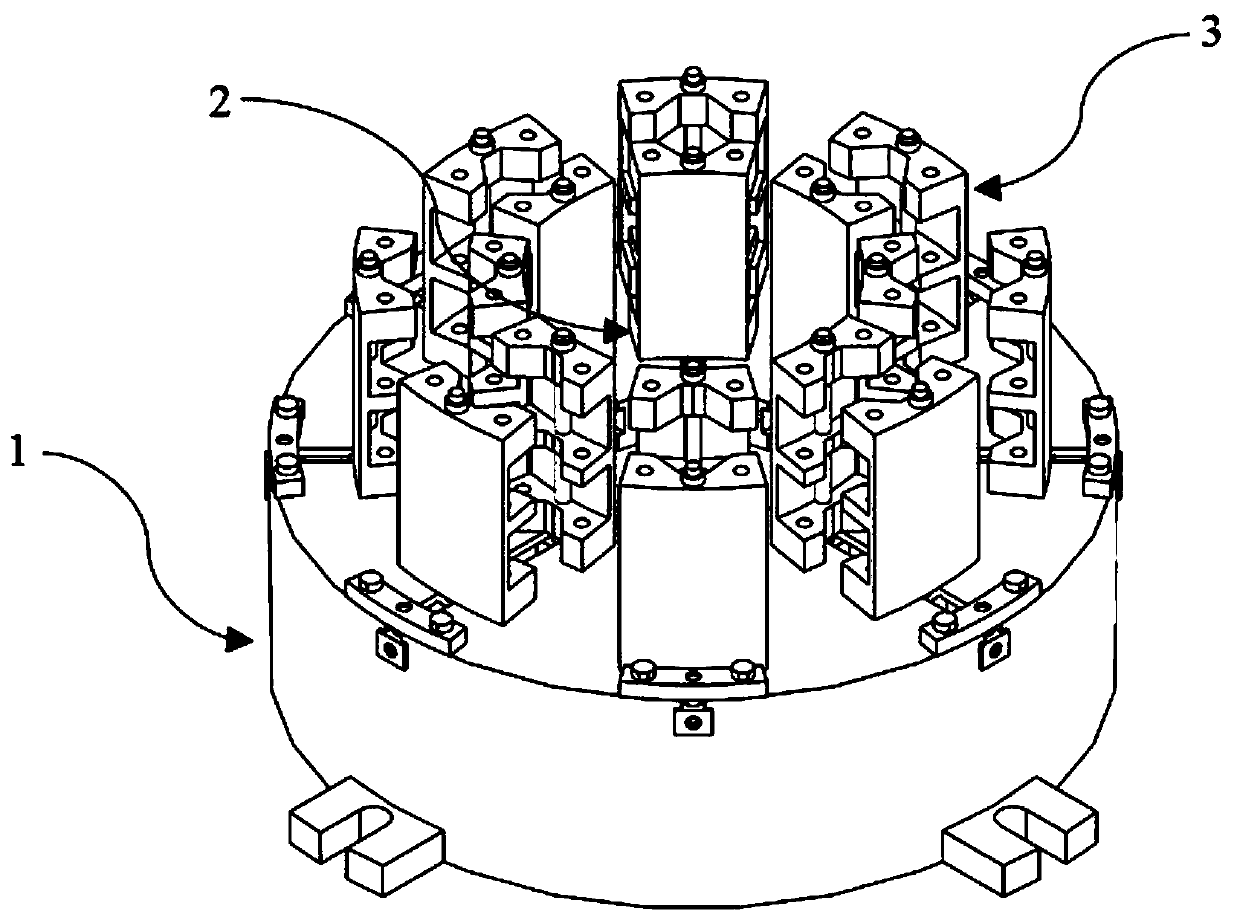

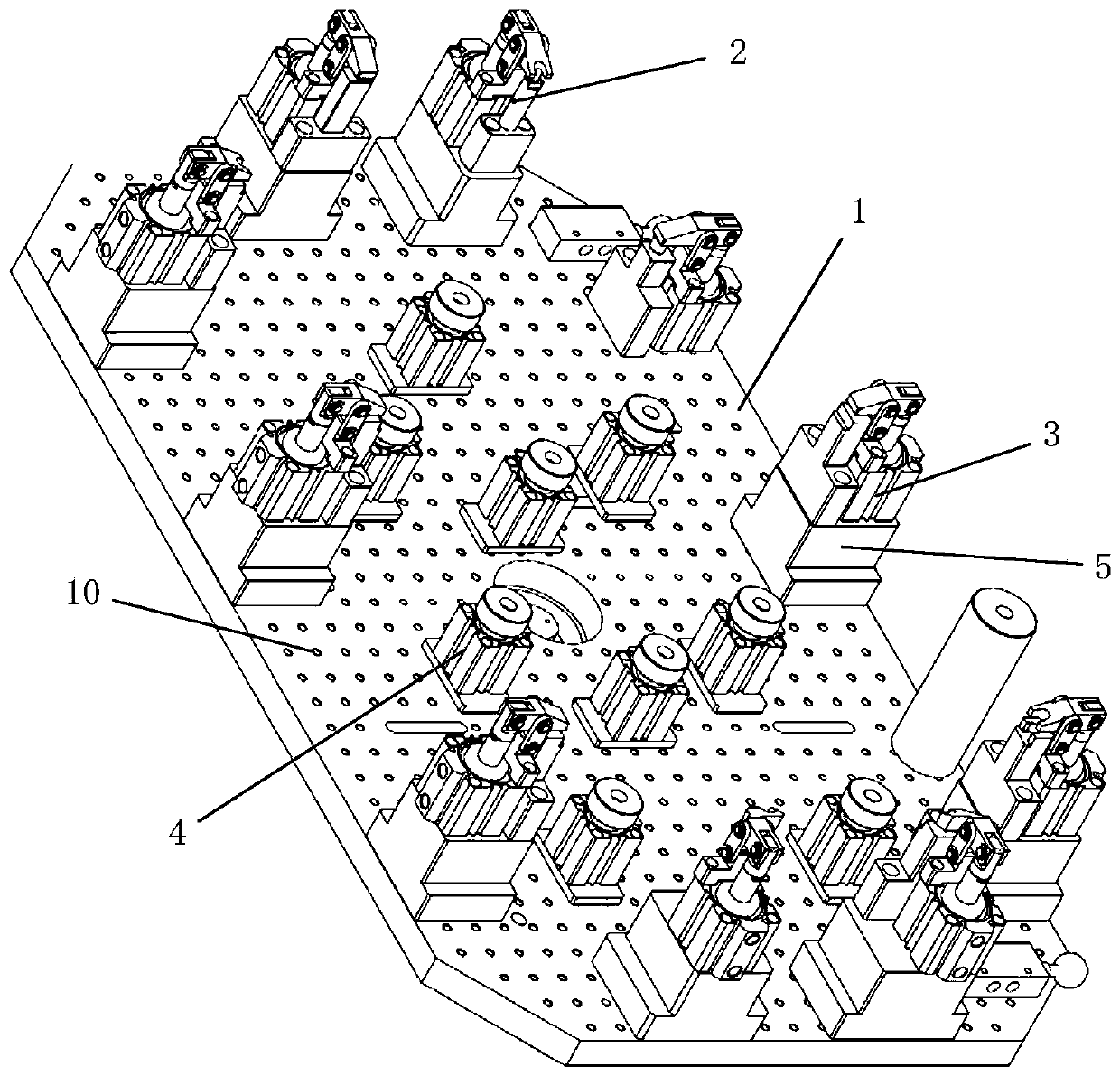

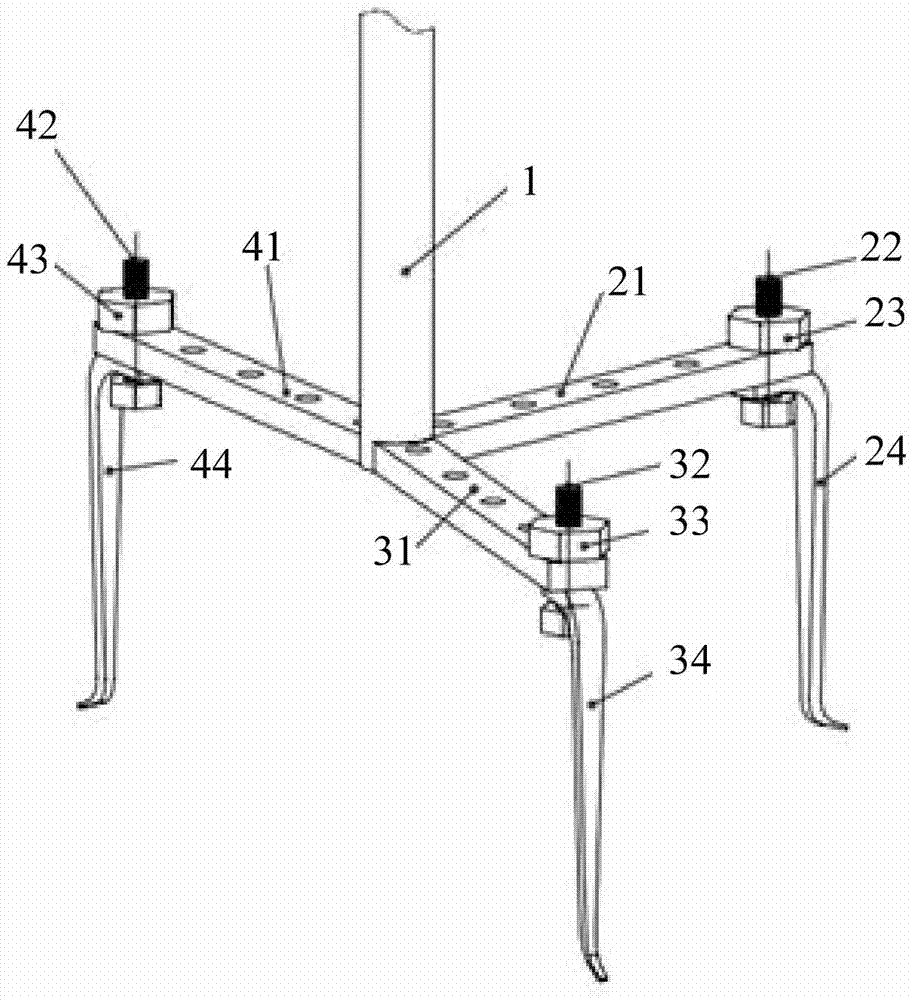

Adjustable hydraulic frock

ActiveCN101200037AAvoid deformationHigh clamping precisionWork holdersPositioning apparatusEngineeringHydraulic equipment

Disclosed is an adjustable hydraulic fixture, which is structured by an installation platform and 18 supporting devices. The supporting devices are arranged on the installation platform along the circumference by equal circumference divisions; the supporting device is structured by each free end bearing seat which is equipped with an elevating seat; the elevating seat is equipped with a lifting poker; both sides of the elevating seat are equipped with an stretching oil cylinder and a pressure-keep cylinder, etc. The piston rod of the stretching oil cylinder is equipped with a pressure spring. The front end of the piston rod of the stretching oil cylinder is equipped with a stretching claw; the pressure-keep oil cylinder is connected with an hydraulic oil-channel connector through a pipeline. Eighteen hydraulic equipments are arranged in the fixture structure as the supporting points in the invention, and the clamping force at each point can be regulated to equal by hydraulic system; meanwhile, a pressure spring is arranged in hydraulic equipment for workpiece pre-fixing, and the parts deformation is avoided. The invention has the advantages of convenient installation and regulation, and can improve the clamping precision and reliability of the workpiece.

Owner:SHANGHAI PEITONG MACHINERY

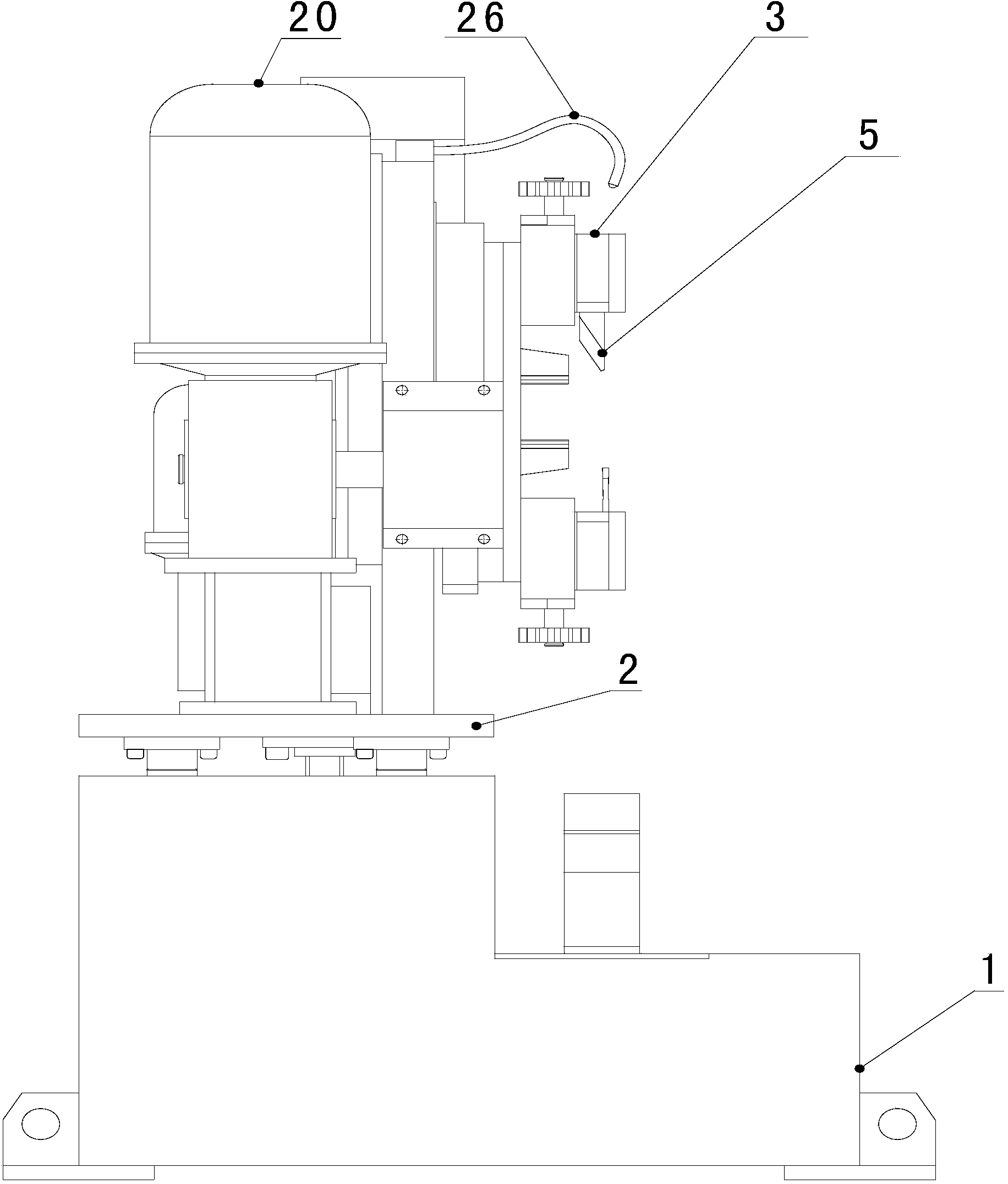

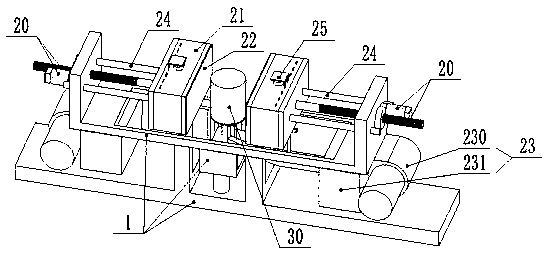

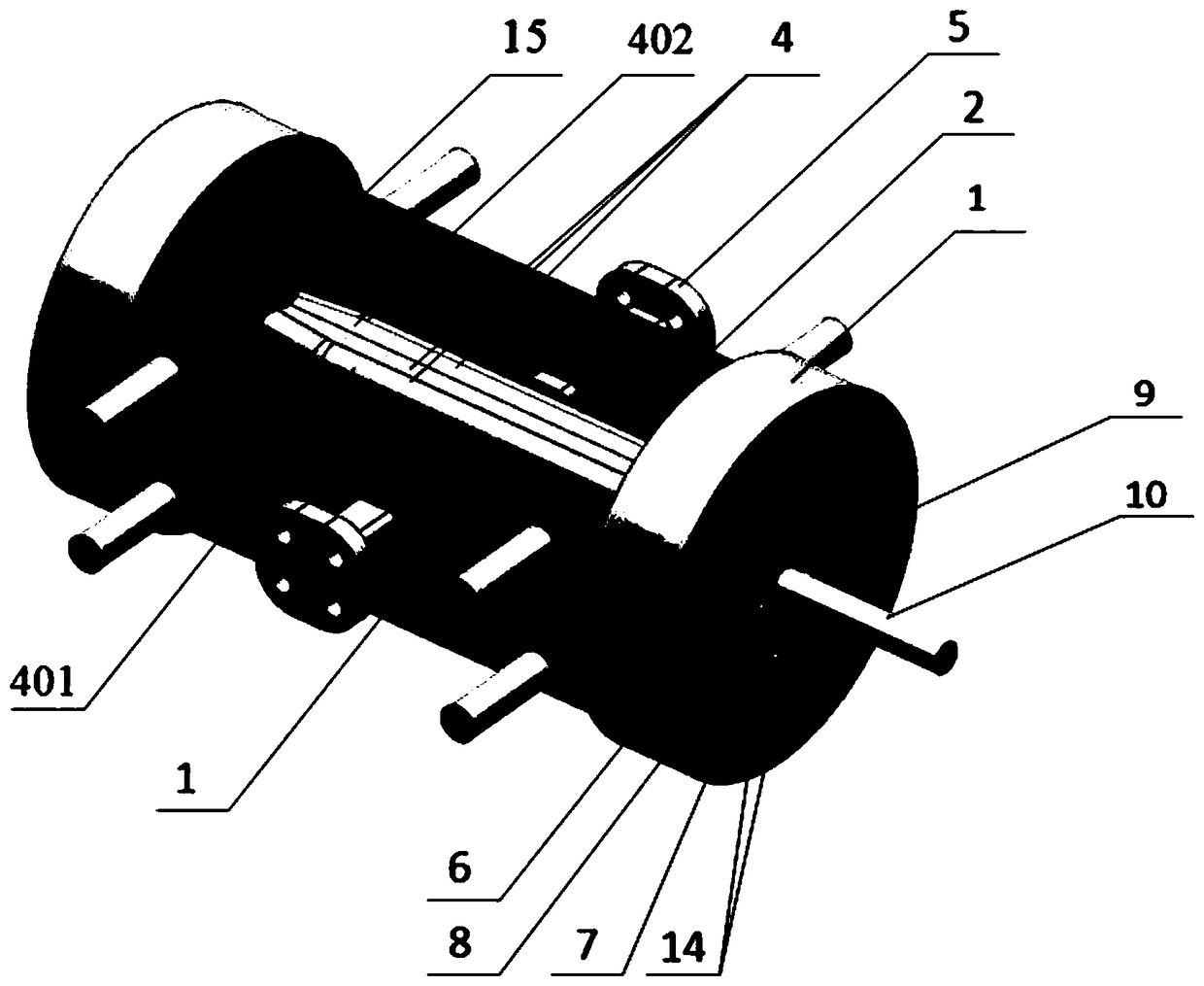

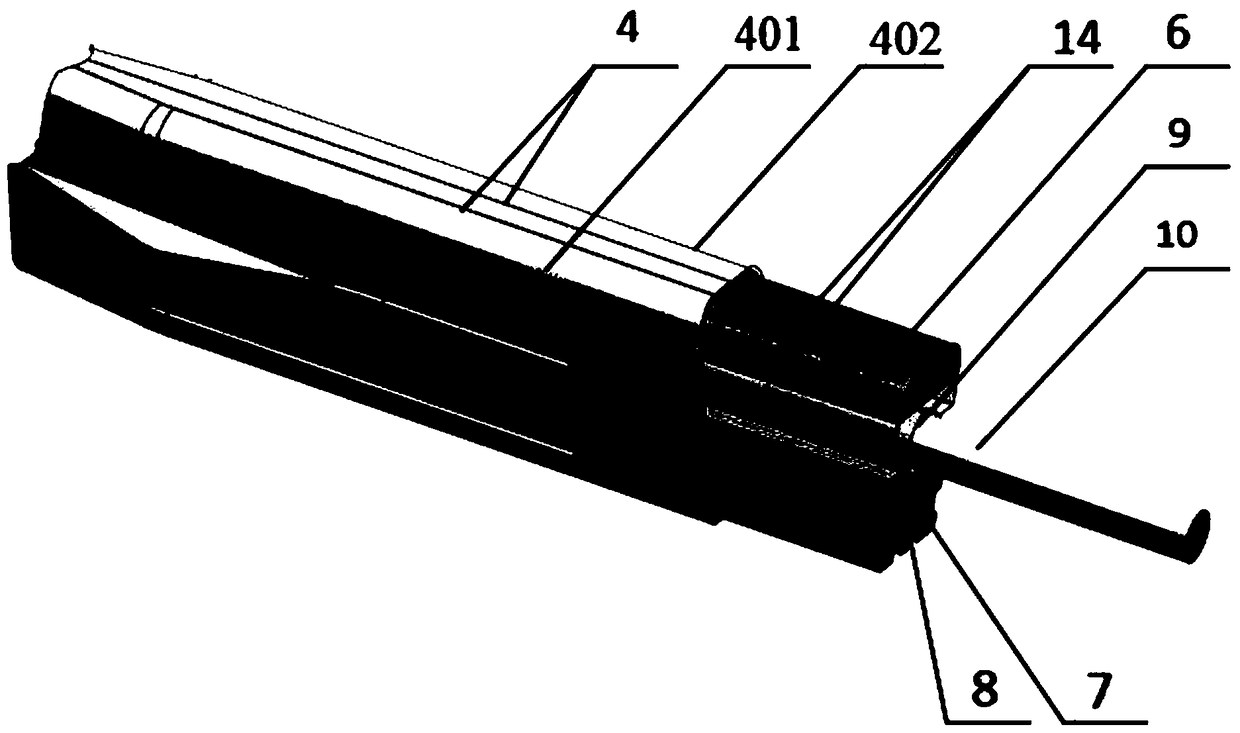

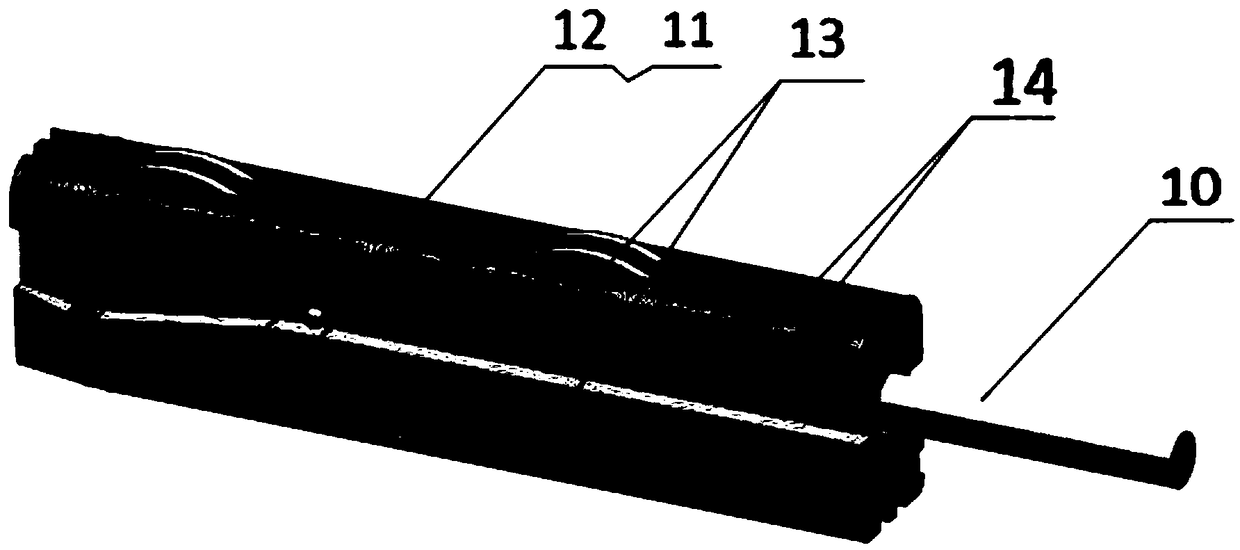

Pipe beveling machine

ActiveCN104028841AAvoid clamping deformationImprove reliabilityFeeding apparatusPositioning apparatusCooling effectEngineering

The invention relates to a beveling machine, and discloses a pipe beveling machine. The pipe beveling machine comprises a base, a clamping device, a cutter disc, a cutter holder and cutters, wherein the clamping device is arranged on the base can be freely lifted, the beveling end of a pipe is clamped by the clamping device, and the cutters comprise the cutting-off cutter and the beveling cutter which are fixedly arranged on the cutter holder. According to the pipe beveling machine, the beveling end of the pipe is clamped by the clamping device, and the pipe is effectively prevented from deforming when clamped; rotary cutting off and beveling are performed on the pipe through the cutting-off cutter and the beveling cutter, so that the end face is vertical and the chute surface of the beveled edge is free of burrs and deformation; a water pump cooling system is good in cooling effect; the clearance amount of the beveling machine in the radial direction is extremely small, and the pipe beveling machine performs machining by being attached to the wall of the pipe, and is high in reliability and automation degree, easy to operate, suitable for the on-line pipe and first-aid repair, simple and compact in structure, small in occupied area and light in weight.

Owner:聊城市翔达钢管有限公司

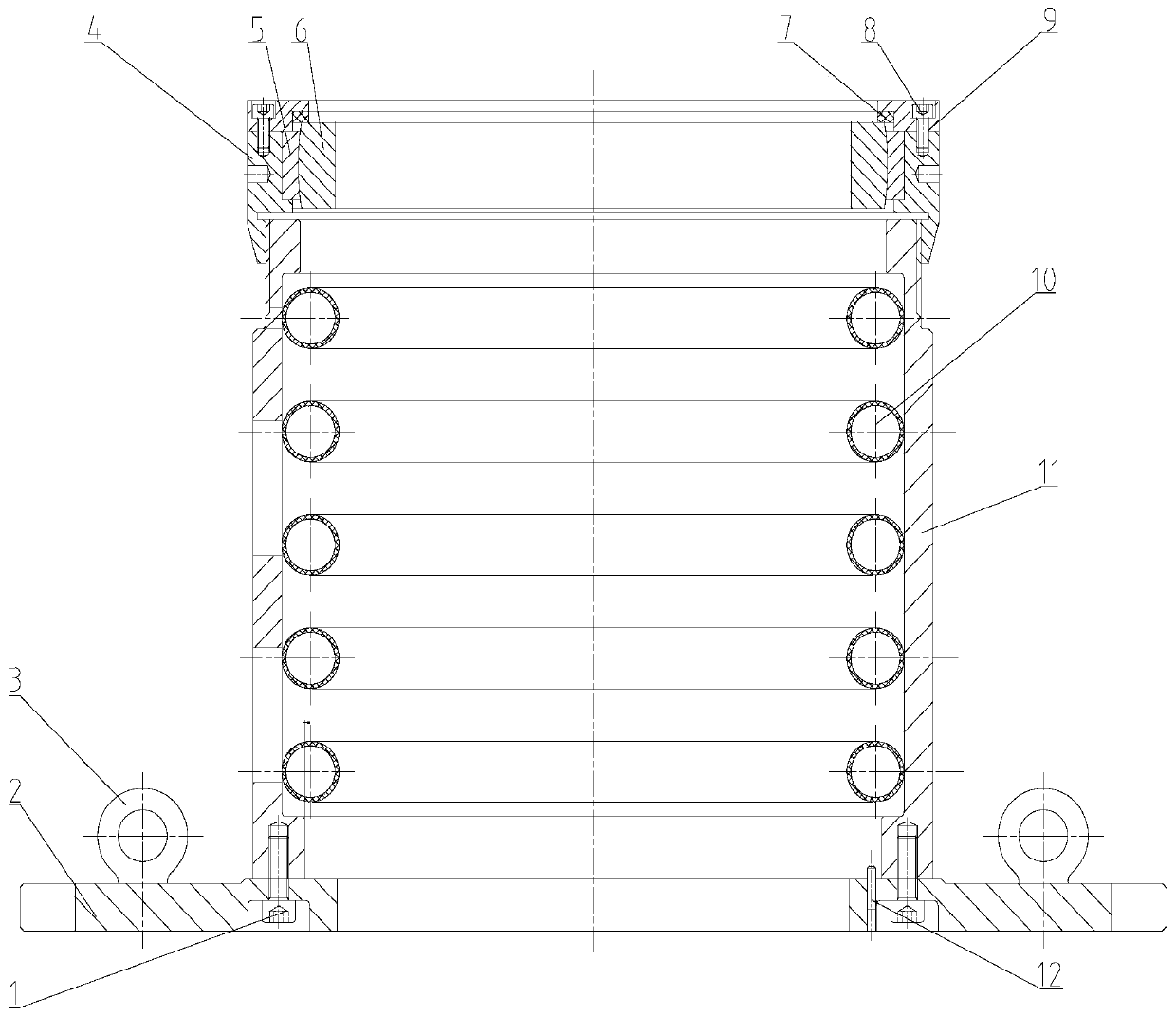

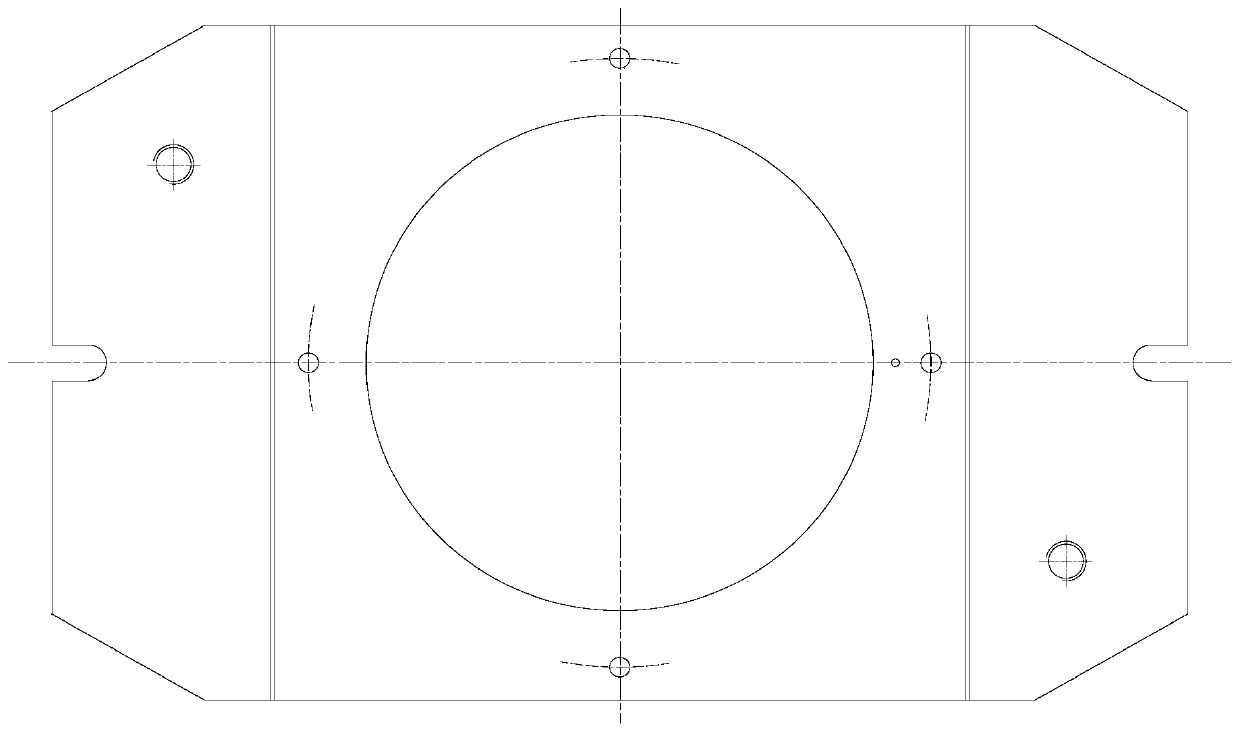

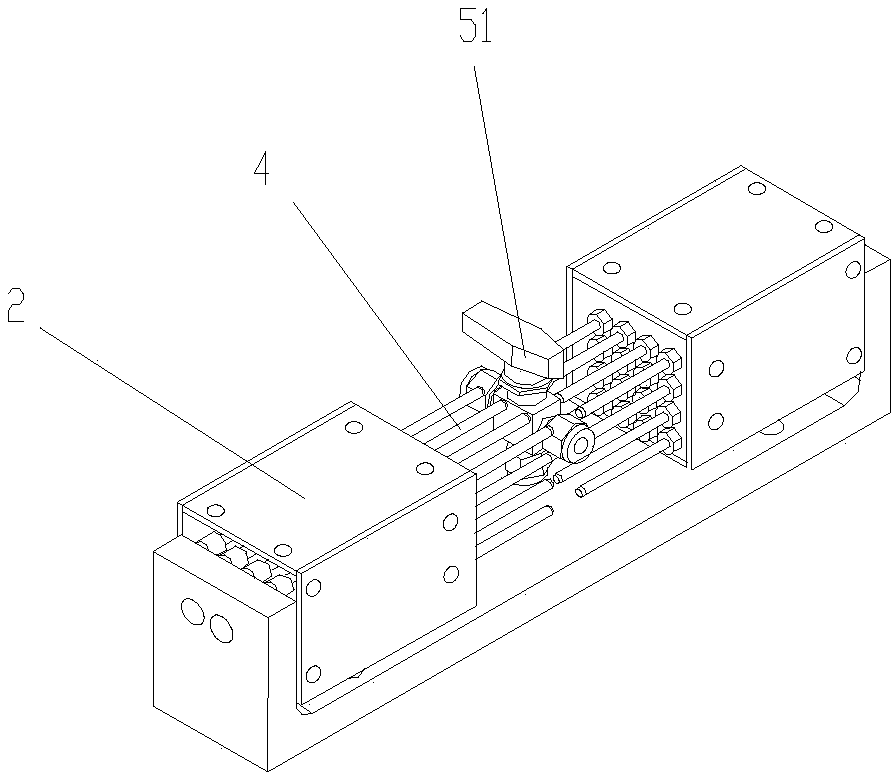

Machining tool used for thin-wall barrel type part

ActiveCN104759653AAvoid clamping deformationWorkpiecesBoring/drilling apparatusManufacturing technologyEngineering

The invention discloses a machining tool, in particular to a machining tool used for a thin-wall barrel type part and belongs to the technical field of machining technology, assembly, design and manufacturing. By means of the machining tool used for the thin-wall barrel type part, large machining errors in the machining process of the thin-wall part due to clamping reasons can be effectively avoided. The machining tool comprises a base frame and clamping support components, and the base frame is sleeved with the clamping support components in an expansible and contractible mode in the radial direction; the thin-wall barrel type part is fixed onto the machining tool in an expansible mode through the clamping support components, and the machining tool is installed on machining equipment for the thin-wall barrel type part in a clamped mode through the base frame.

Owner:CHINA 19TH METALLURGICAL CORP

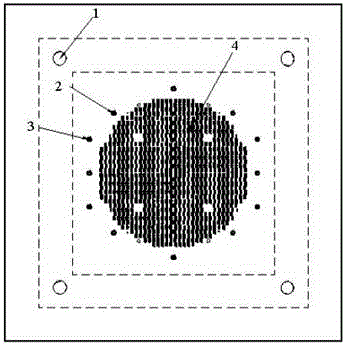

Method for producing millimeter wave antenna slot array sheet

InactiveCN103331471AAvoid clamping deformationReduce stressMilling equipment detailsEngineeringMaterials processing

The invention discloses a method for producing a millimeter wave antenna slot array sheet. The production method selects tooling equipment suitable for clamping a large-area super-thin sheet, can be used for realizing the reliable clamping of a slot array sheet during high-speed machining by matching with a corresponding clamping pressure plate and a reasonable clamping method, and reasonably selects a micro-diameter cutting tool formed by machining a corresponding material as well as a system tool environment and related parameters which conform to the machining of a slot array so as to ensure that a high-speed and high-precision machining process can be realized. The production method can be used for realizing the production of the slot array in the large-area super-thin sheet, and the high-speed machining of high-precision multi-slot graphs.

Owner:SHANGHAI RADIO EQUIP RES INST

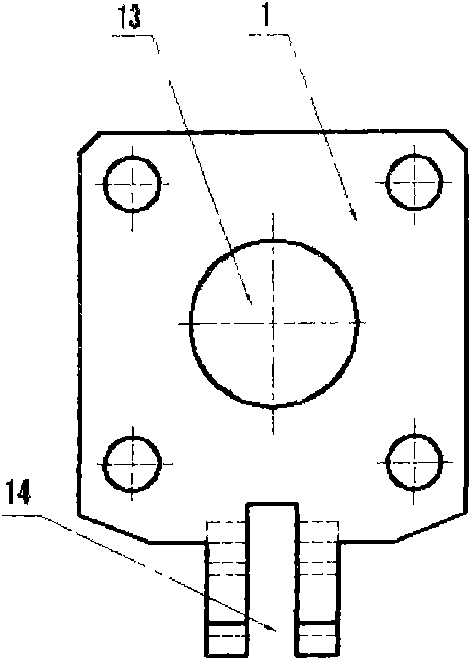

Clamping structure for fixture

InactiveCN102145461ACompact structureAvoid loadPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses a clamping structure of a fixture. A hydraulic cylinder and a base are fixed on a fixture plate, the lower end of a connecting rod is fixed on the hydraulic cylinder after penetrating through a connecting plate, and the connecting rod is provided with a groove at the upper end and pin holes in the side face; the bottom of a crank is arranged in the connecting plate and connected by using pins at clamping parts; one end of the crank is a square block, and the side face at the other end of the crank is provided with a square groove; the square block of the crank is arranged in the groove of the connecting rod and is provided with a U-shaped groove, and the pins penetrate through the pin holes; one end of a pressing plate is embedded into the crank through the square groove; the upper end of the base is provided with two orienting holes; one end of a first compression rod is in contact with the pressing plate, and the other end of the first compression rod is fixedly connected with one end of a first push rod after penetrating through one of the orienting holes in the base; and one end of a second compression rod is in contact with the pressing plate, and the other end of the second compression rod is fixedly connected with a second push rod after penetrating through the other oriented hole in the base. In the invention, the accurate compaction on two pressing points with a small spacing can be realized by using a single hydraulic cylinder, the traditional hinge-type floating dual-pressing point structure is replaced, and orienting devices are arranged on the pressing points to accurately orient the positions of the pressing points.

Owner:HUBEI HANDAN MECHATRONICS CO LTD

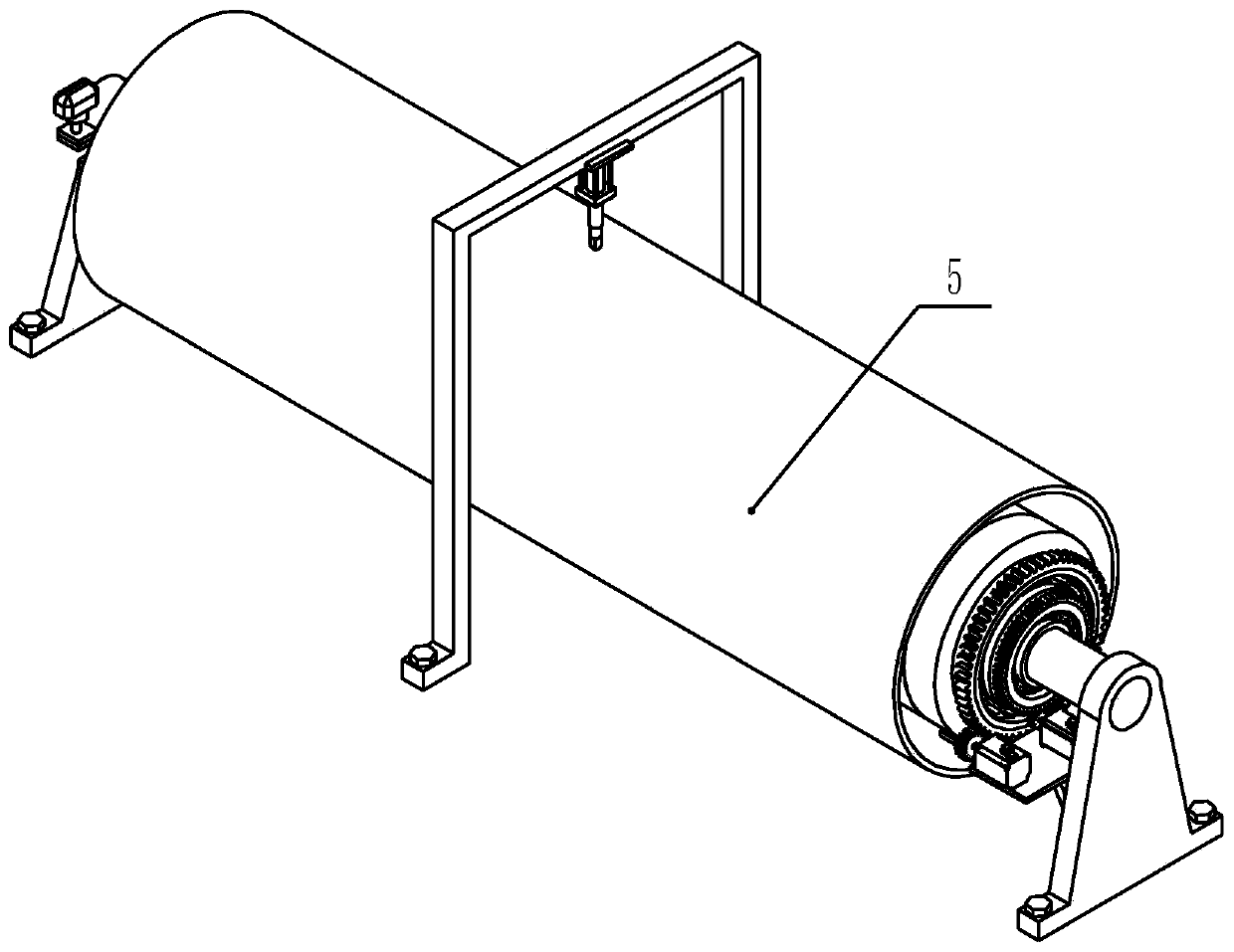

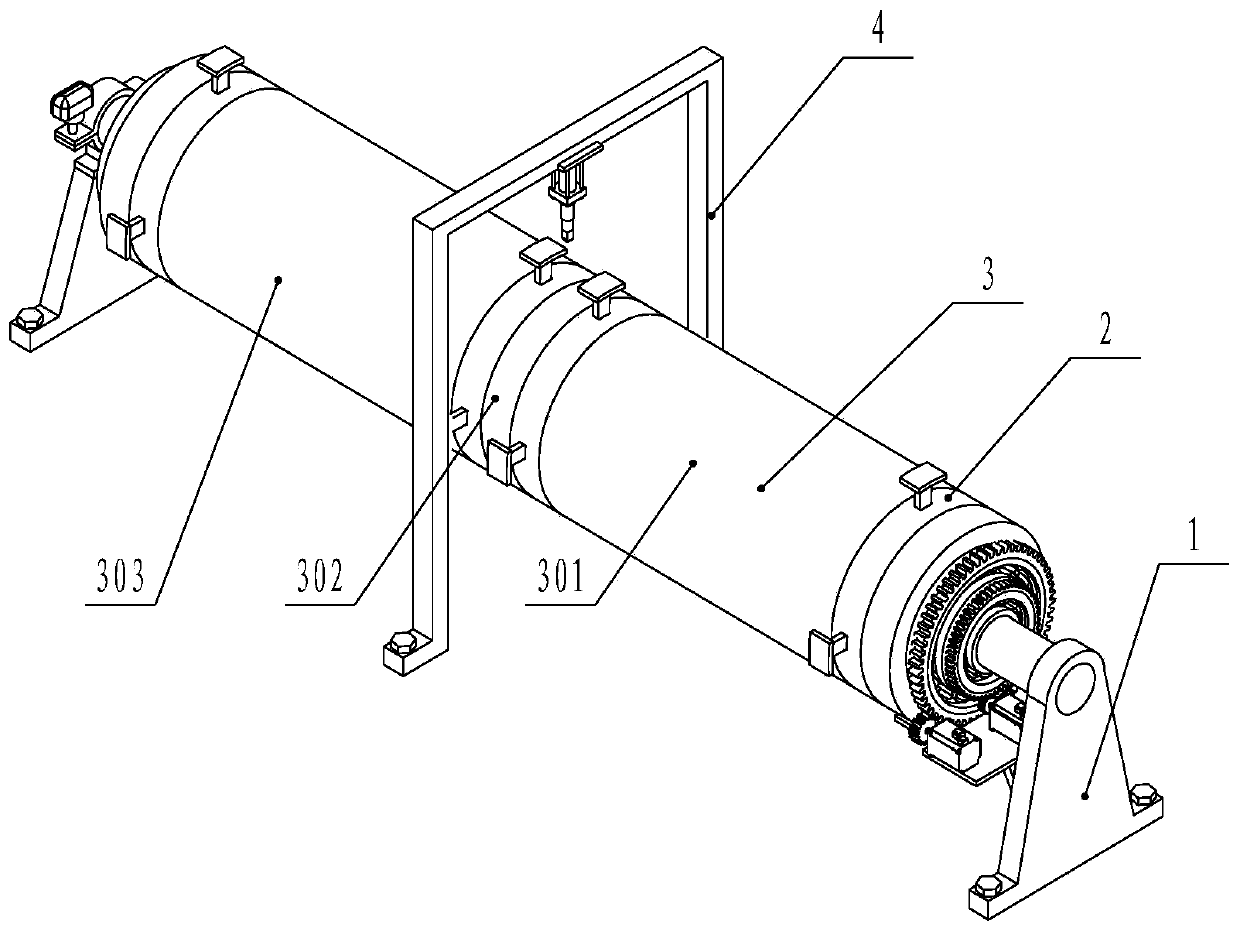

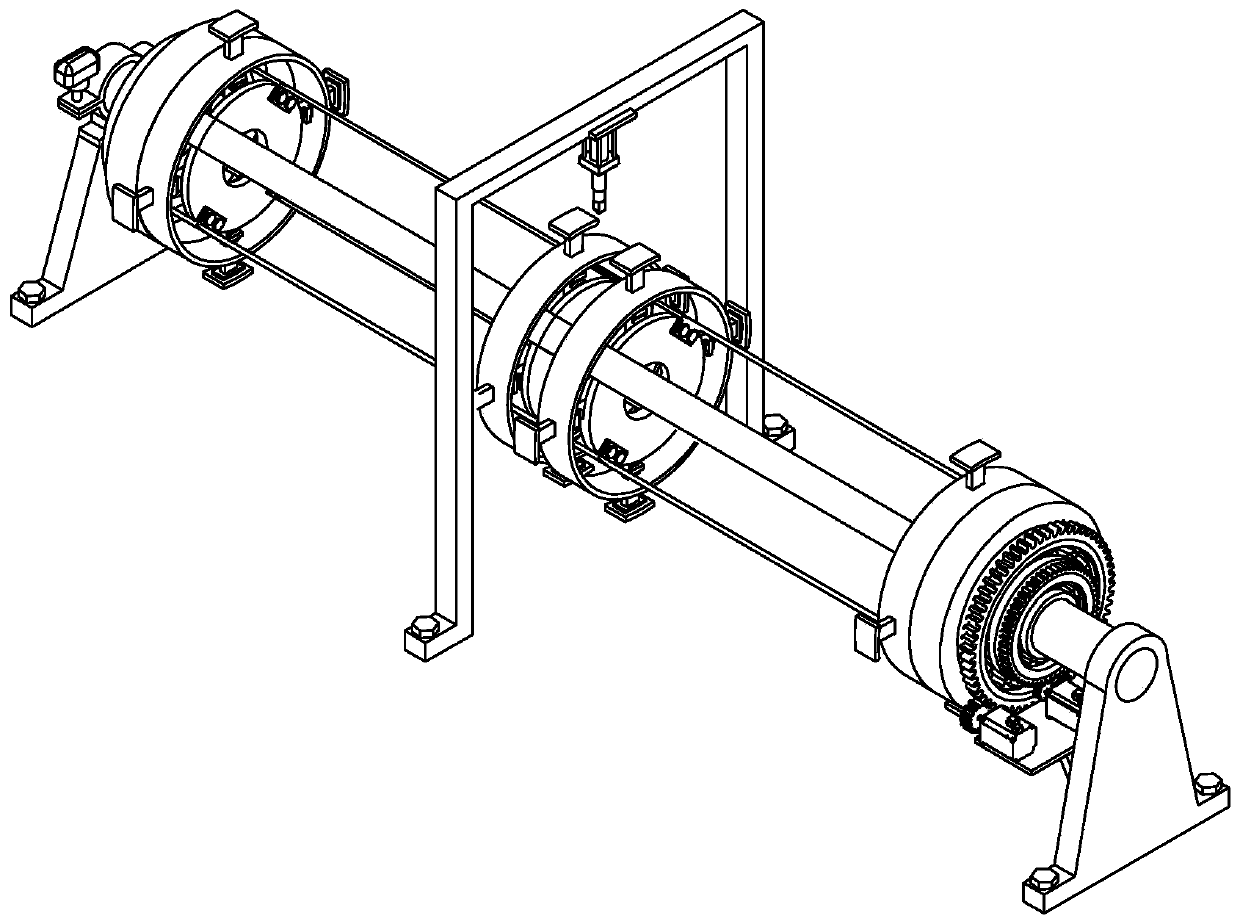

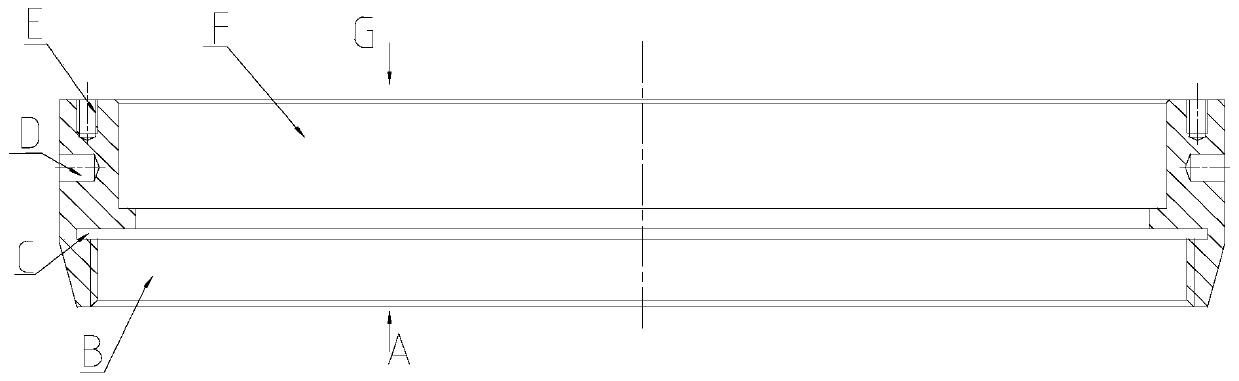

Chuck expansion type metal hard tube rotary cutting machine

InactiveCN110064790AUniform clamping forceAvoid clamping deformationTube shearing machinesShearing machine accessoriesEngineeringGrinding wheel

The invention provides a chuck expansion type metal hard tube rotary cutting machine. The rotary cutting machine comprises a supporting device, a sleeve device, a cutting device and at least four expansion devices, wherein a plurality of expansion devices are sequentially connected and arranged on the same axis through connecting frames, two expansion devices located at two ends are connected withthe supporting device, every two adjacent expansion devices are connected by sleeve pipes of the sleeve device in a sleeving mode, and the cutting device is arranged between two adjacent expansion devices. The expansion devices can expand from the inside of the metal hard tube to achieve the purpose of fixing the metal hard tube, and all lengths of the metal hard tube can be fixed, so that an existing equipment which can only clamp and fix the cut part is replaced, the clamping force is more uniform, and the clamping deformation is prevented; the expansion devices can drive the metal hard tube to rotate together, and then the cutting wall thickness distance can be achieved through feeding movement of a cutting knife, so that the cutting task can be completed, a cutting mode that an existing cutting grinding wheel pieces enter the inner part of the metal hard tube is replaced, and the situation that a cut surface is burned and worn is avoided.

Owner:HEBEI UNIV OF TECH

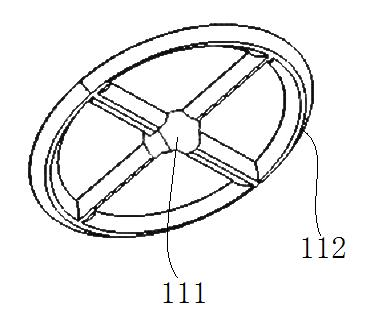

Titanium alloy hollow thin-wall long-shaft component machining method

InactiveCN108213874AEliminate roundness errorsAvoid clamping deformationNumerical controlPosition tolerance

The invention relates to a titanium alloy hollow thin-wall long-shaft component machining technology method. High-precision numerical control equipment is adopted for machining the component outer profile, and boundary dimension precision and shape precision are guaranteed. An annular clamp is used for fine machining of centre holes in the two ends of a component, and the roundness error caused tothe centre holes due to clamping force is eliminated. A centre is used for tightly jacking and fixing the component for fine machining of the outer profile, and clamping deformation caused when a three-jaw chuck or a four-jaw chuck is used for clamping the component is effectively avoided. According to the titanium alloy hollow thin-wall long-shaft component machining technology method, finally,after the titanium alloy hollow thin-wall long-shaft component is machined, the dimensional precision of the component is smaller than or equal to 0.01 mm, the position tolerance of the component is smaller than or equal to 0.008 mm, and the inner and outer profile wall thickness error is smaller than or equal to 0.05 mm.

Owner:HARBIN DONGAN ENGINE GRP

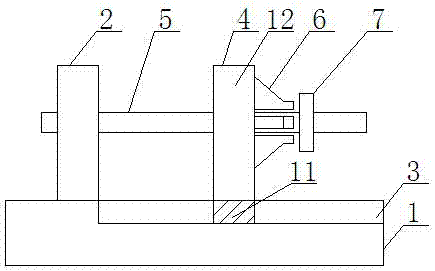

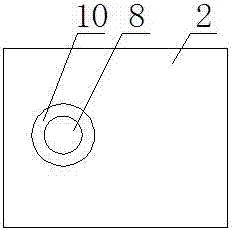

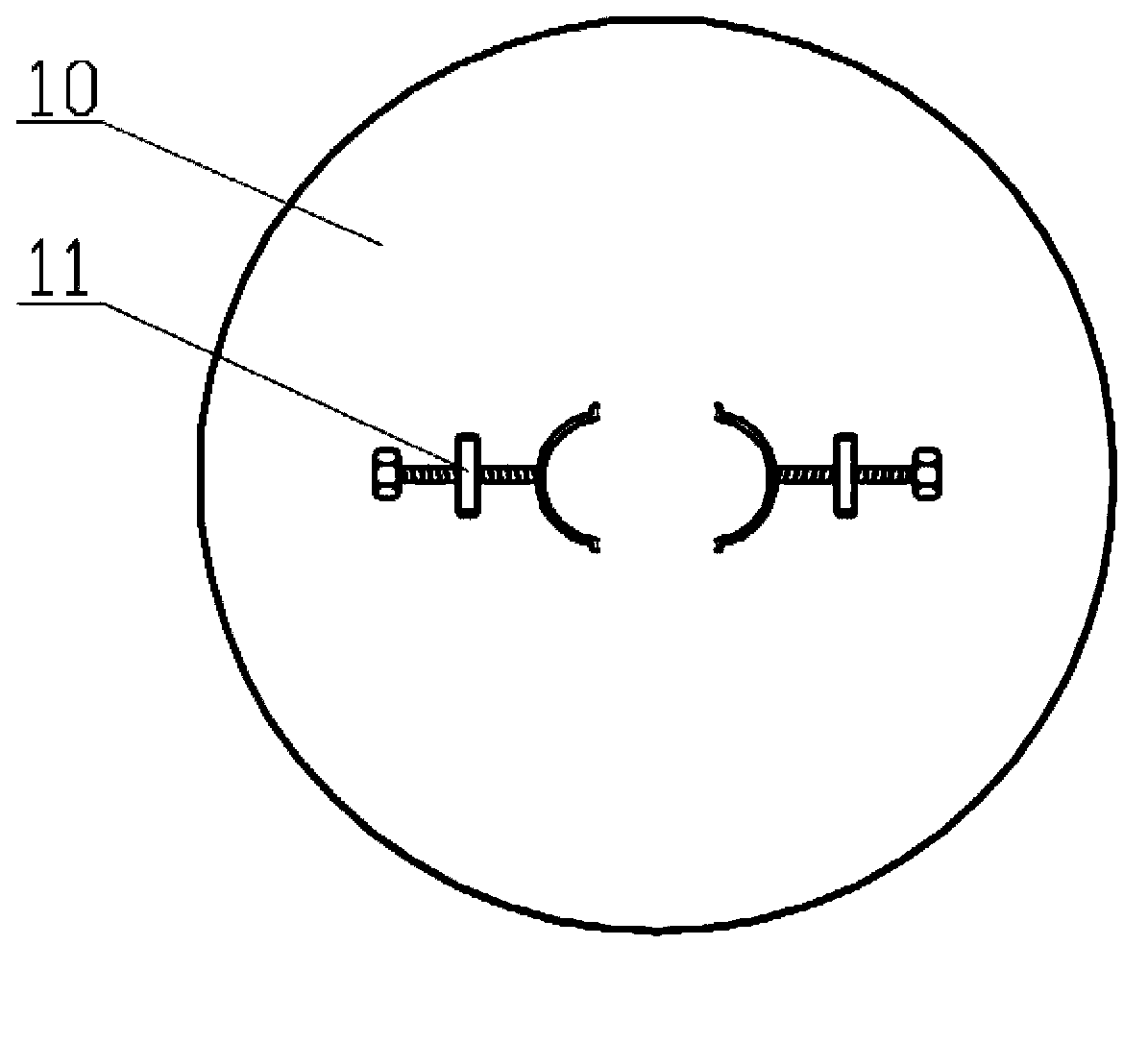

Auxiliary tool for preventing large-diameter thin-wall part inner hole from deforming during honing

ActiveCN110561270AEasy to repair and replaceAvoid clamping deformationHoning machinesGrinding work supportsEngineeringAtmospheric pressure

The invention belongs to the technical field of mechanical manufacturing, and particularly relates to an auxiliary tool for preventing a large-diameter thin-wall part inner hole form deforming duringhoning. The tool comprises a bottom plate (2), a compressing assembly, an inflatable ring (10) and a placing barrel (11). According to the tool, a relatively comprehensive auxiliary supporting structure is used for preventing the large-diameter thin-wall part inner hole from deforming during honing, and a flexible supporting structure and a multi-axial full compressing structure are added; in theusing process, the compensation of the cutting force of a cutter by small allowance is realized through air pressure, and meanwhile, auxiliary supporting is exerted on other thin-wall parts, and the rigidity is increased; deforming during clamping of a thin-wall part caused by rigid auxiliary supporting is also avoided; and meanwhile, the clamping structure is simple, the clamping performance is reliable, the parts are easy to maintain and replace, the practicability of a clamp is improved, and the problems of stress deformation, lack of stress compensation and the like brought by a supportingscheme are overcome.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

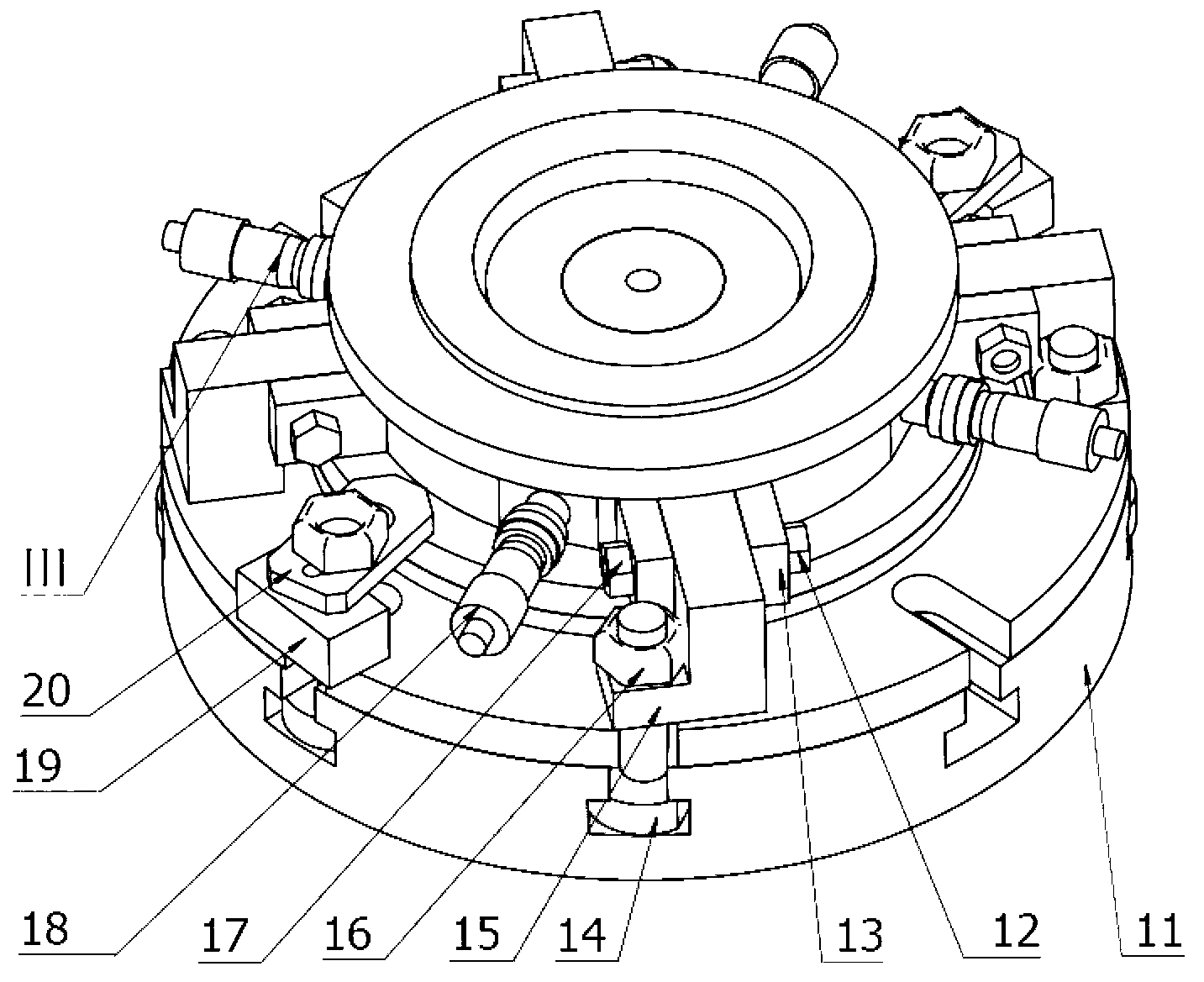

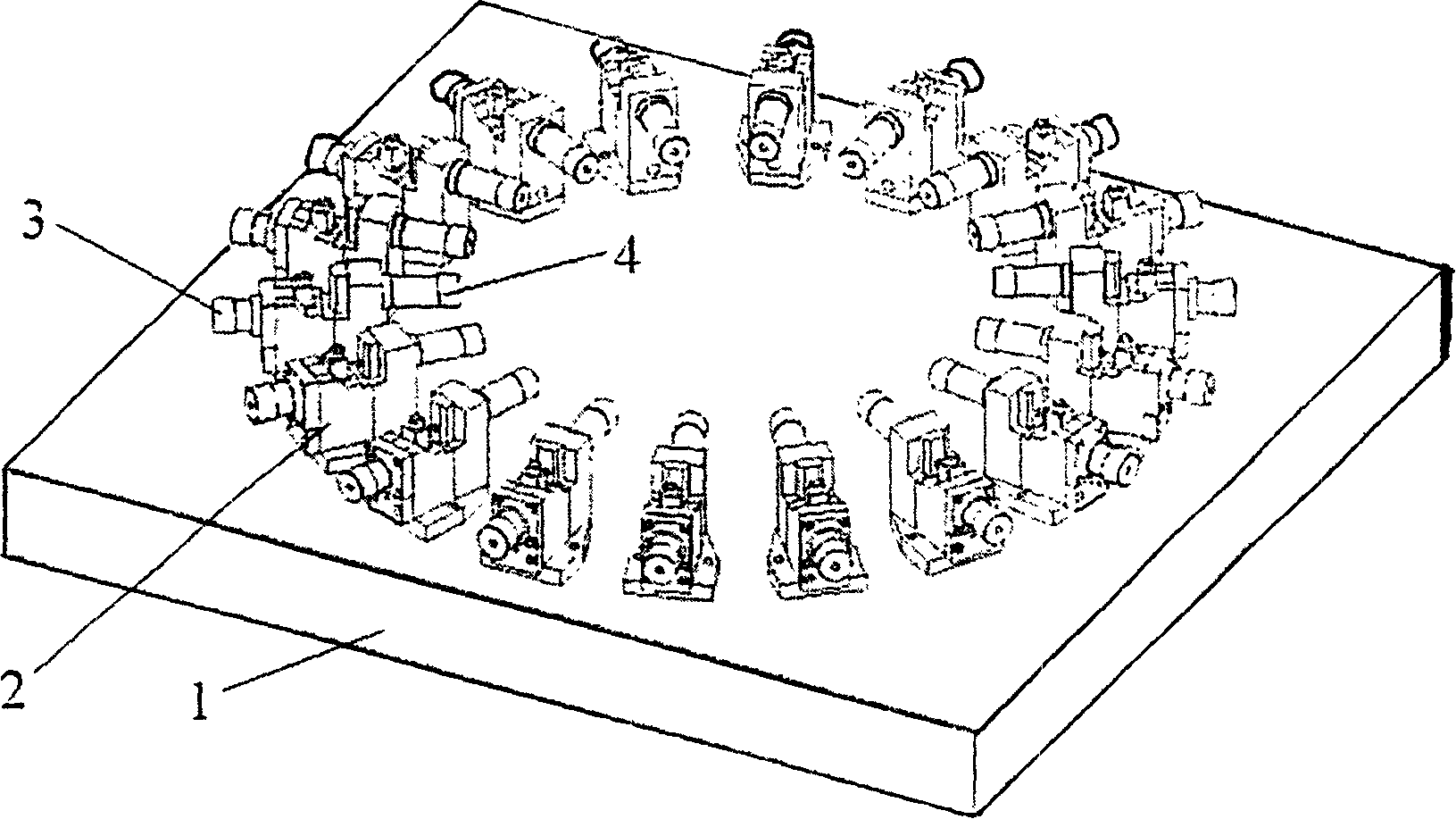

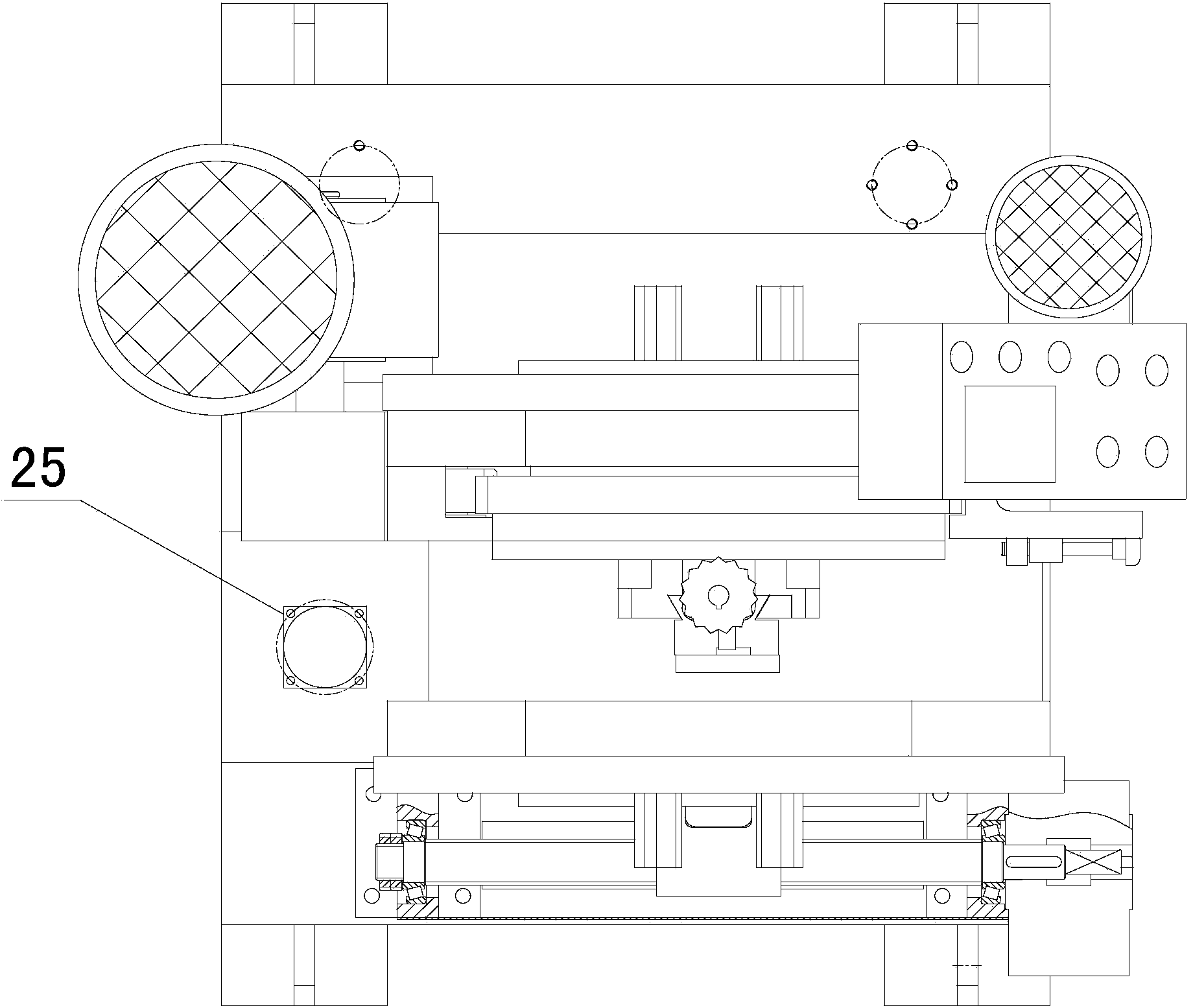

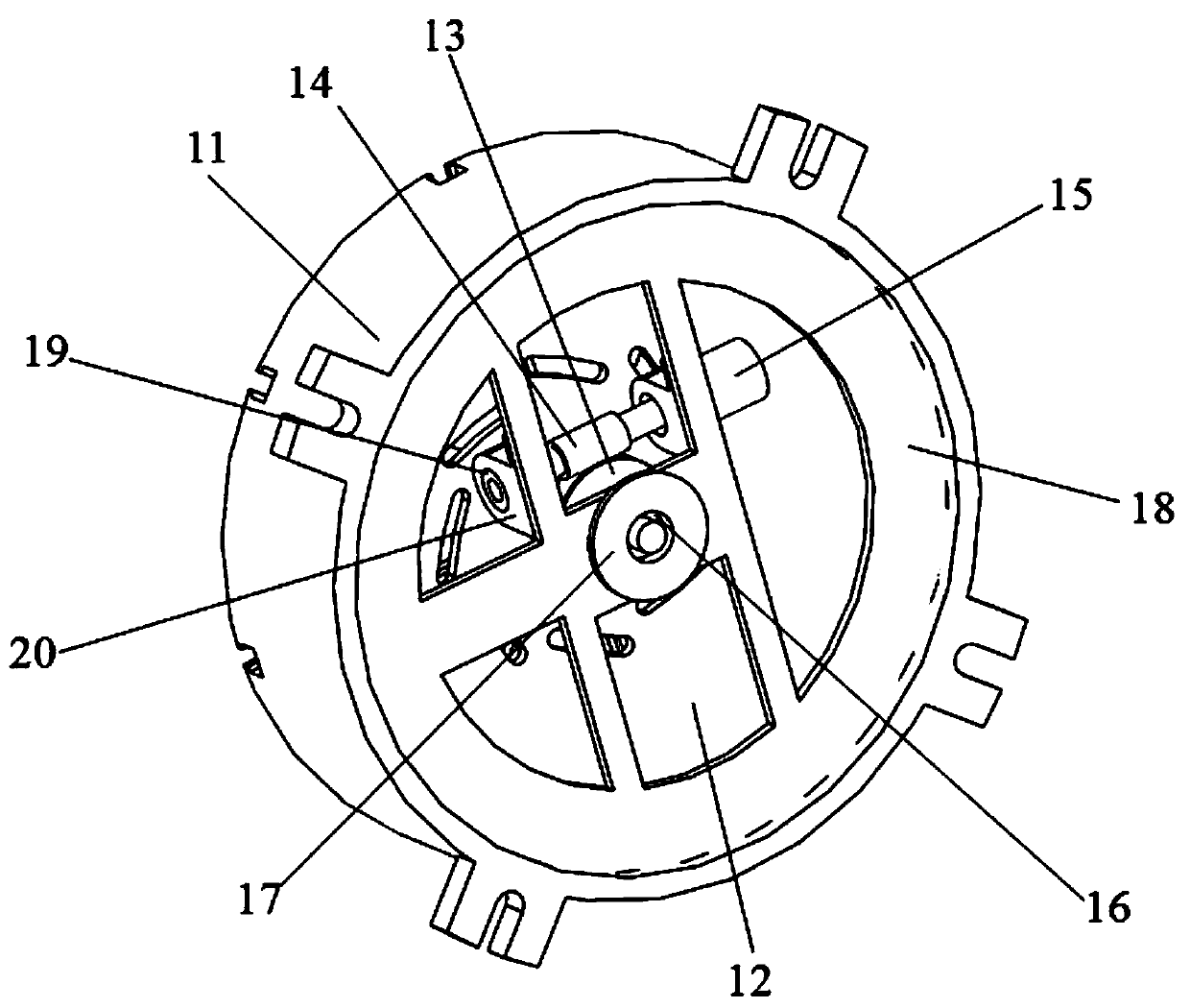

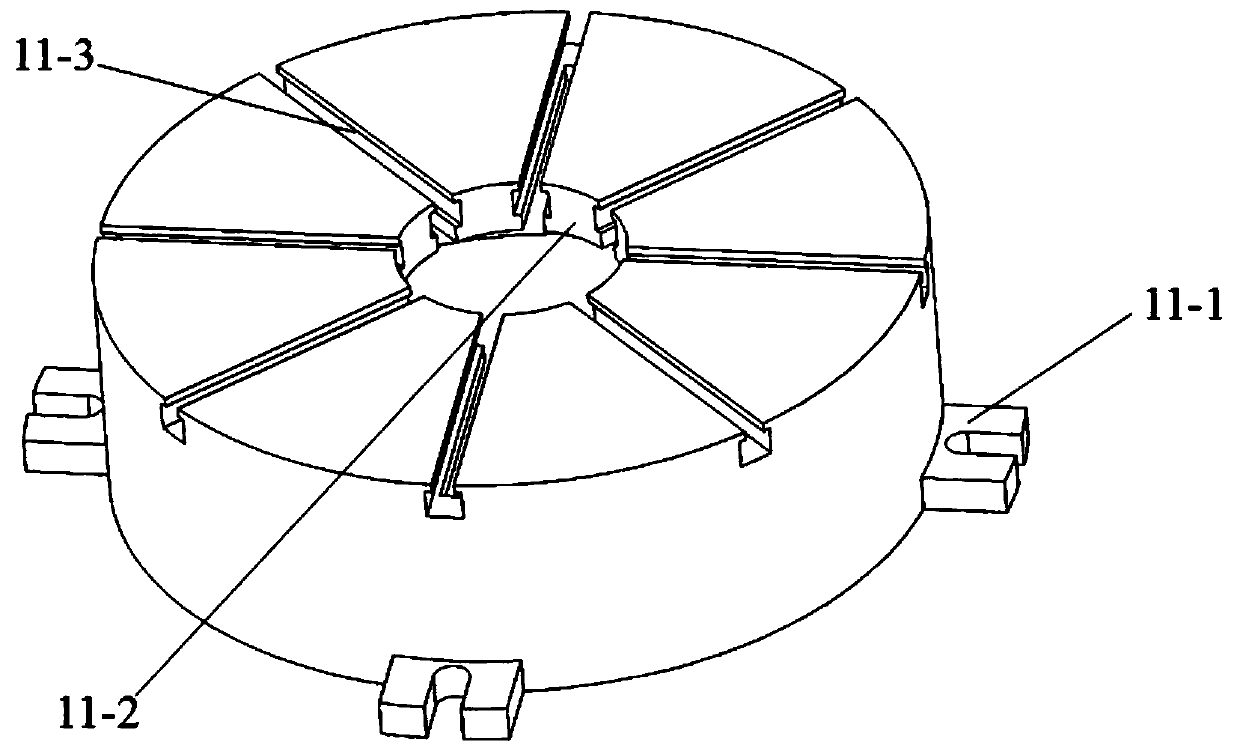

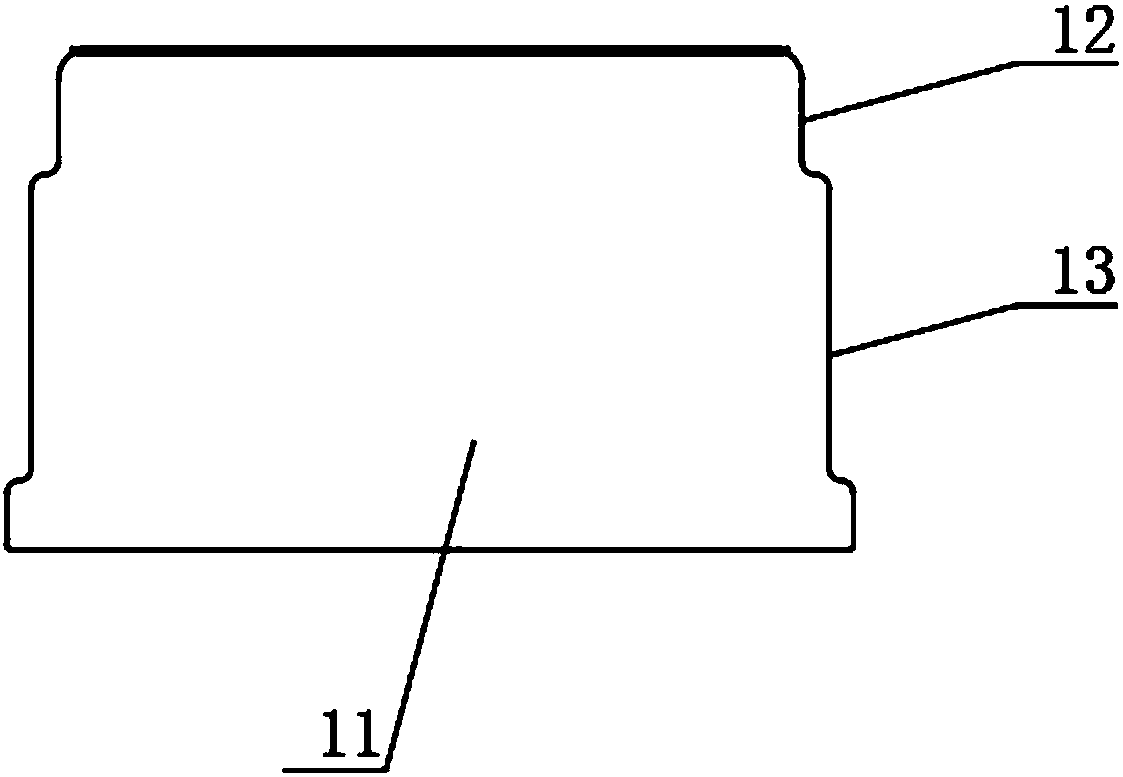

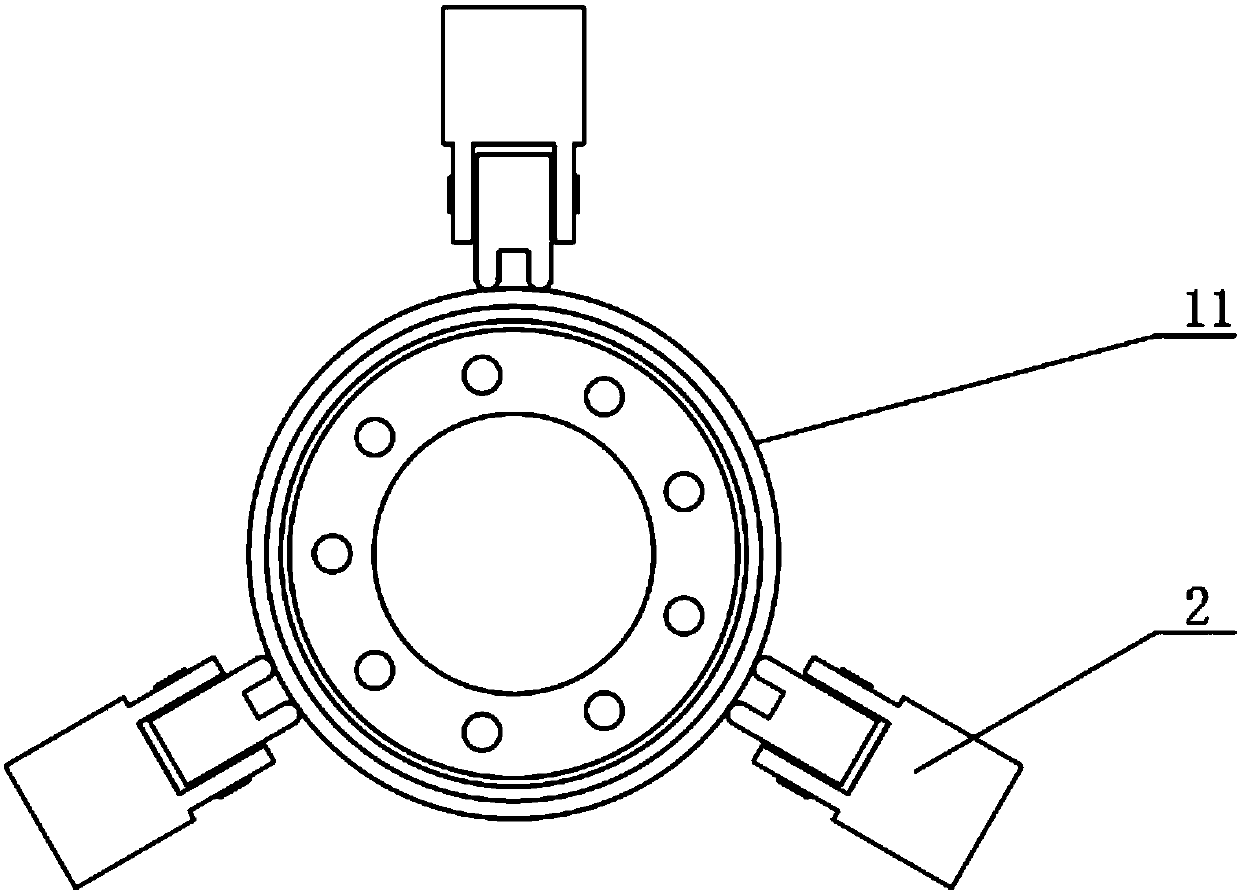

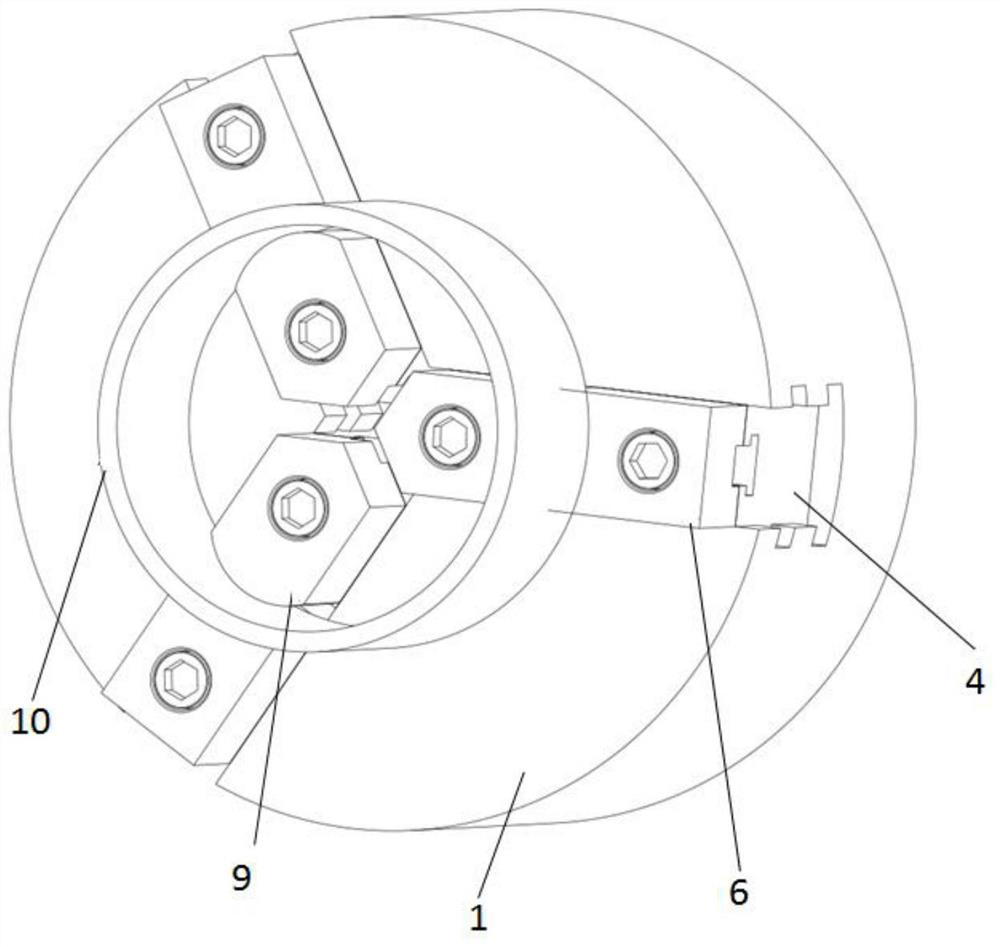

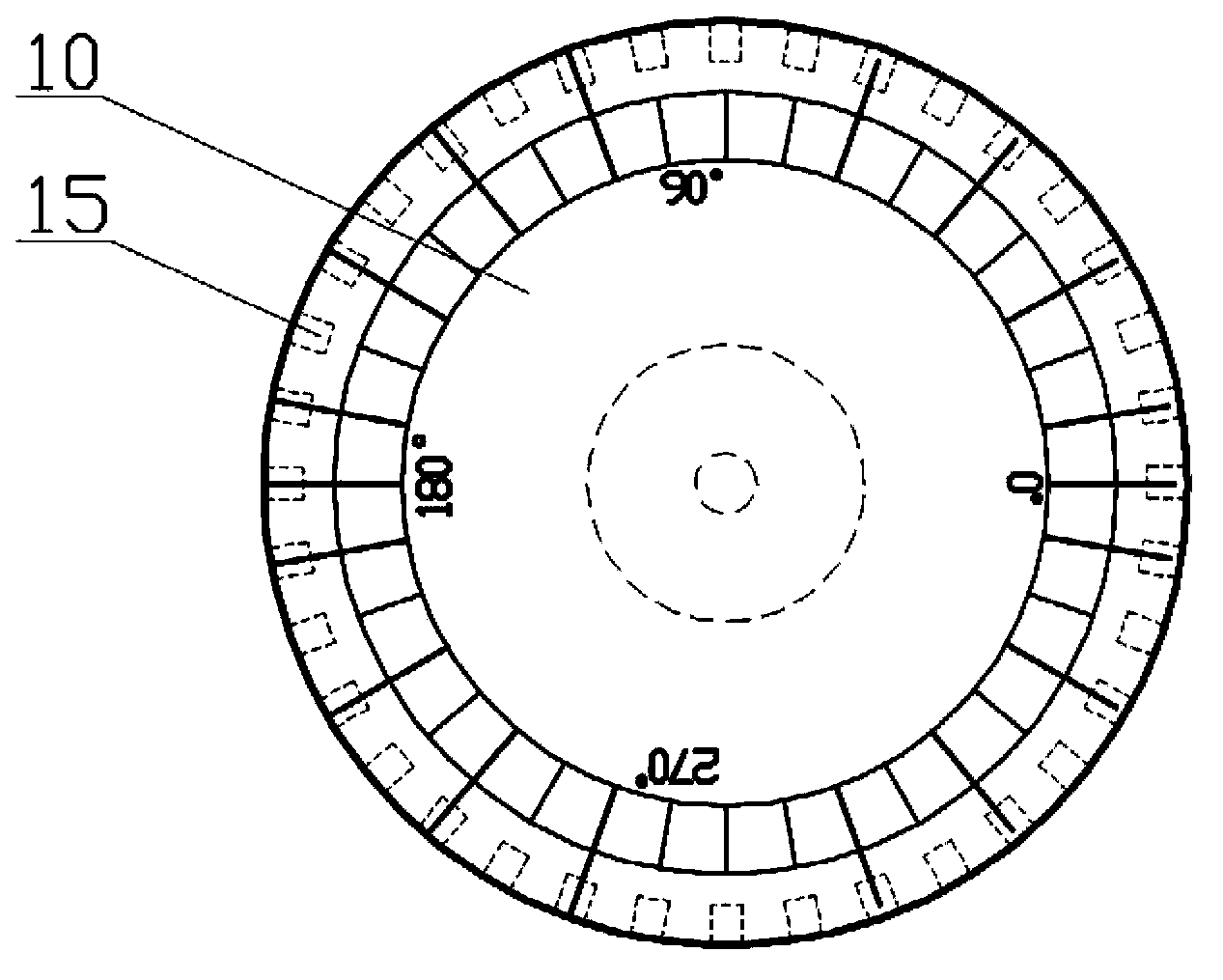

Multi-directional linkage pipe clamp for self-adaptively clamping thin-wall pipes

PendingCN110394741AAvoid clamping deformationEasy to control clamping deformationVicesMechanical engineeringMulti directional

The invention discloses a multi-directional linkage pipe clamp for self-adaptively clamping thin-wall pipes. The multi-direction linkage pipe clamp comprises a clamping driving mechanism and a plurality of clamp body units, wherein the clamping driving mechanism is horizontally arranged, and the plurality of clamp body units are arranged on the clamping driving mechanism and are annularly arranged. The multi-direction linkage pipe clamp for self-adaptively clamping the thin-wall pipes have the advantages that due to the arrangement of floating clamp bodies, certain retraction displacement canbe generated when the pipes are clamped, and clamping deformation caused by overlarge clamping force of the pipes is avoided; and the multi-direction driving clamp bodies are simultaneously controlledthrough a rotary disc, so that the consistency of an outer thrust of each driving clamp body can be effectively controlled, and the clamping deformation of each thin-wall pipe can be conveniently controlled. The multi-direction linkage pipe clamp is formed through the multi-direction driving clamp bodies and the floating clamp bodies, so that the plurality of thin-wall pipes can be clamped at a time.

Owner:NANJING COLLEGE OF INFORMATION TECH

Special clamp structure for large-power brake drum

InactiveCN107662115AEvenly distributedAvoid clamping deformationPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a special fixture structure for a large power brake drum, including a chuck seat, a claw bracket, a claw, a claw seat, a claw body, a rubber contact and a hinge shaft; the bottom of the claw bracket is connected to on the chuck seat; the claw is hinged on the claw bracket through a hinge shaft; the claw includes a claw seat and a claw body. In the present invention, the clamping force of the claws on the brake drum is distributed on 12 claw bodies, and rubber contacts are provided on the contact surface between the claw bodies and the brake drum, so that the distribution of the clamping force is more uniform and avoids Solved the problem of clamping deformation of thin-walled parts. The present invention can complete the processing content of rough turning and finishing turning in one clamping, and the rotation angle of the jaws is limited within 0-30°, which avoids the excessive rotation of the jaws and affects the efficiency of the next clamping, and the auxiliary time is less and the processing efficiency is improved. high. The clamping of the invention has good adjustability and strong versatility, and can meet the processing requirements of various varieties.

Owner:十堰市宏昌达工贸股份有限公司

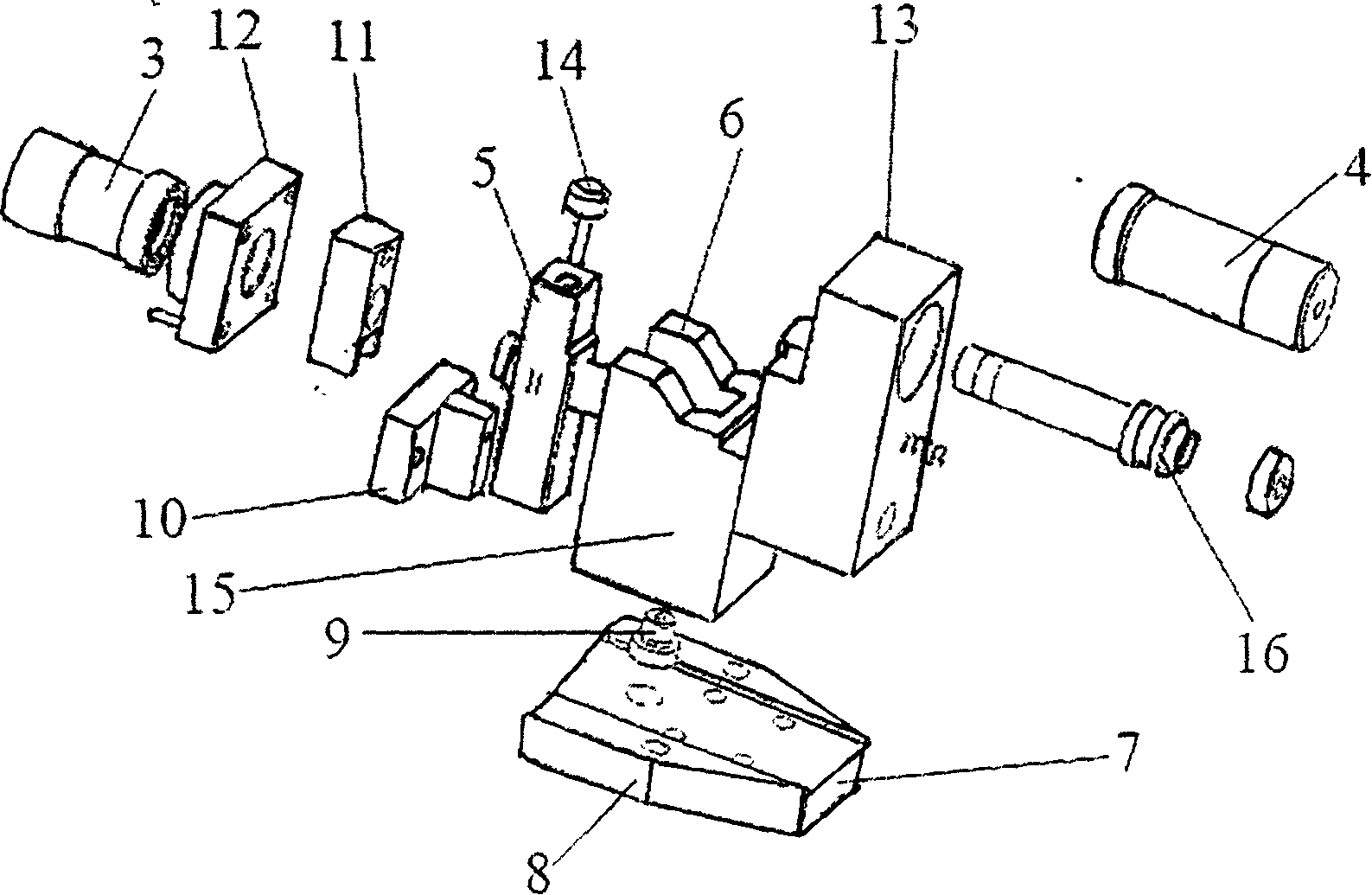

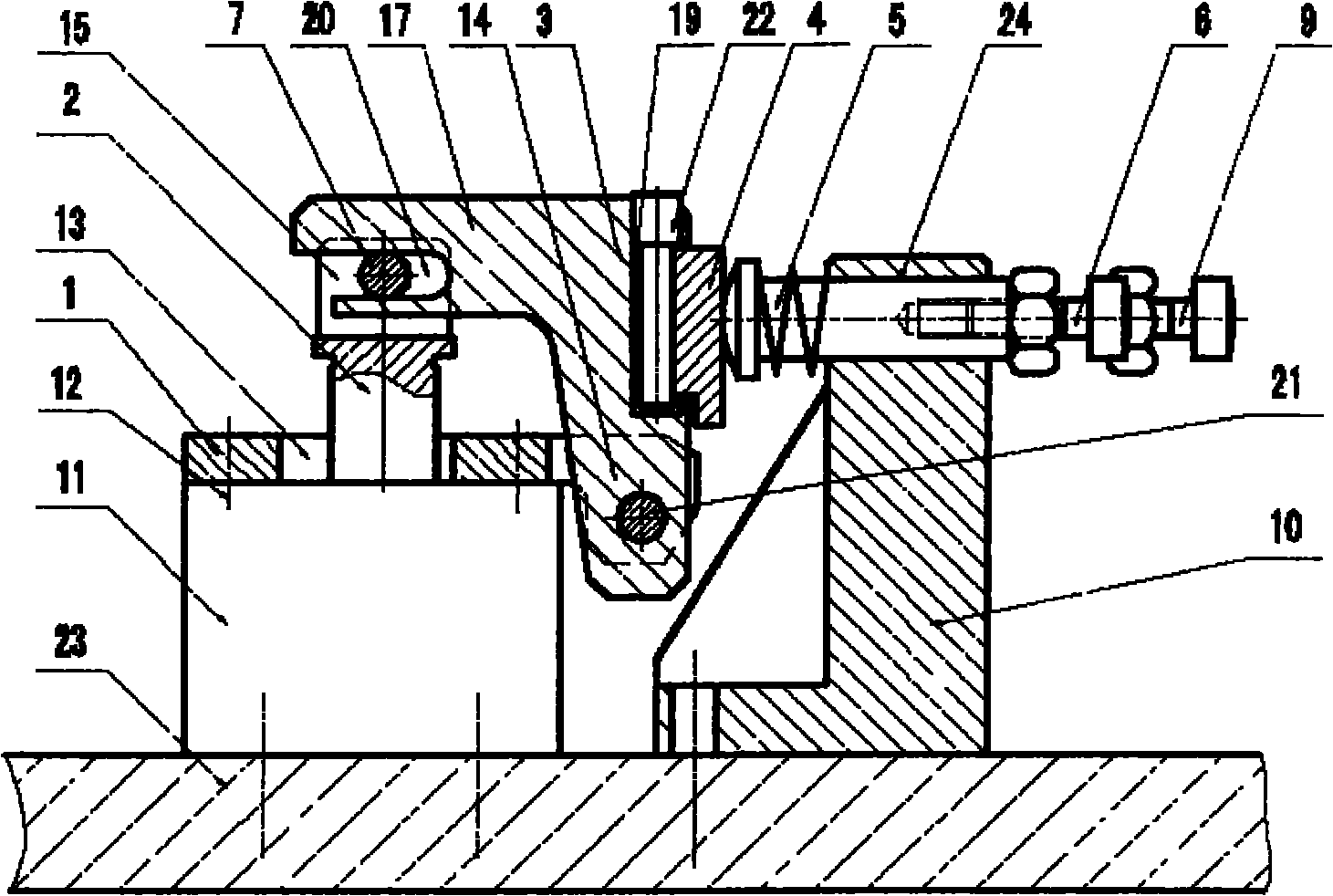

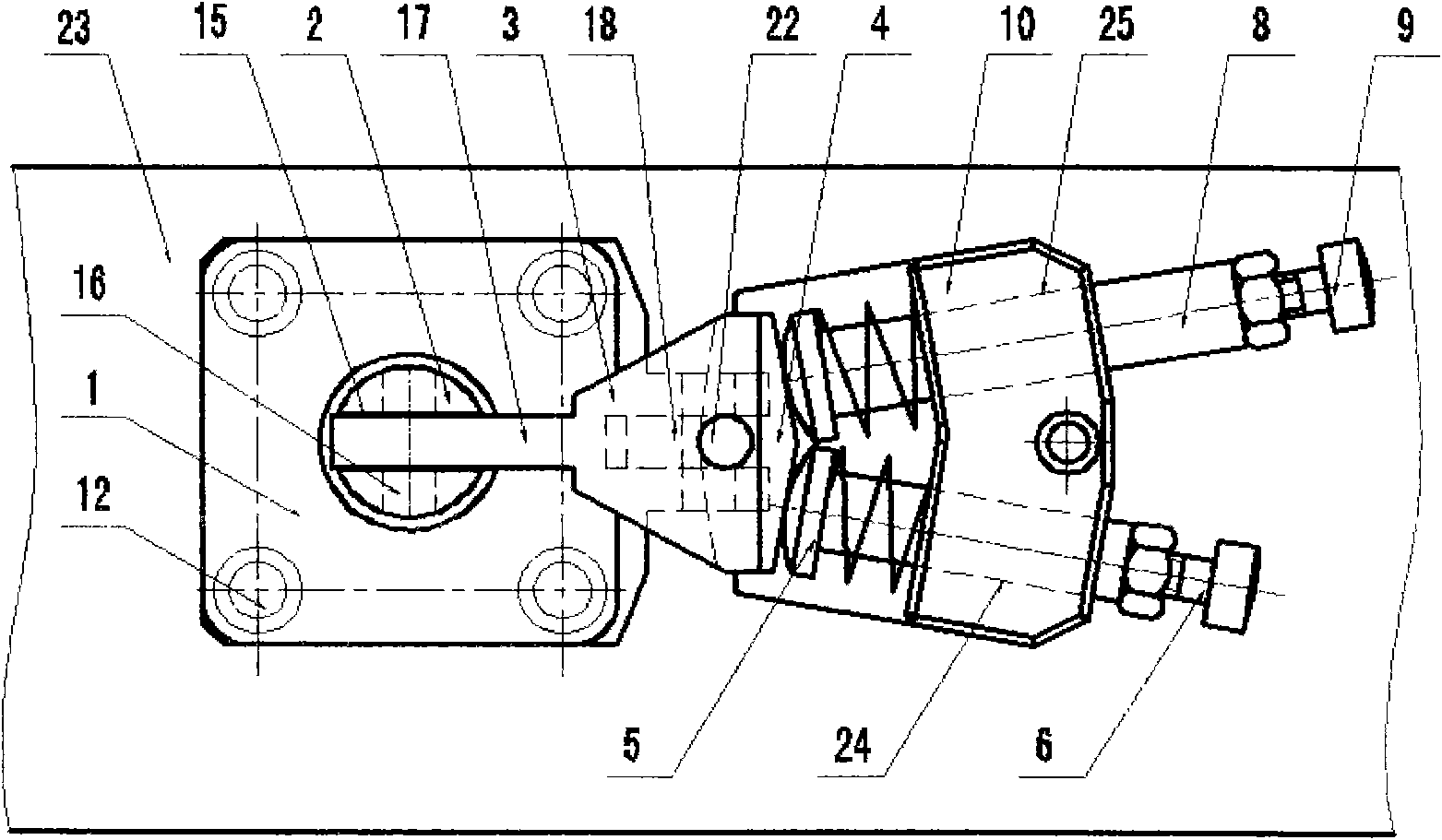

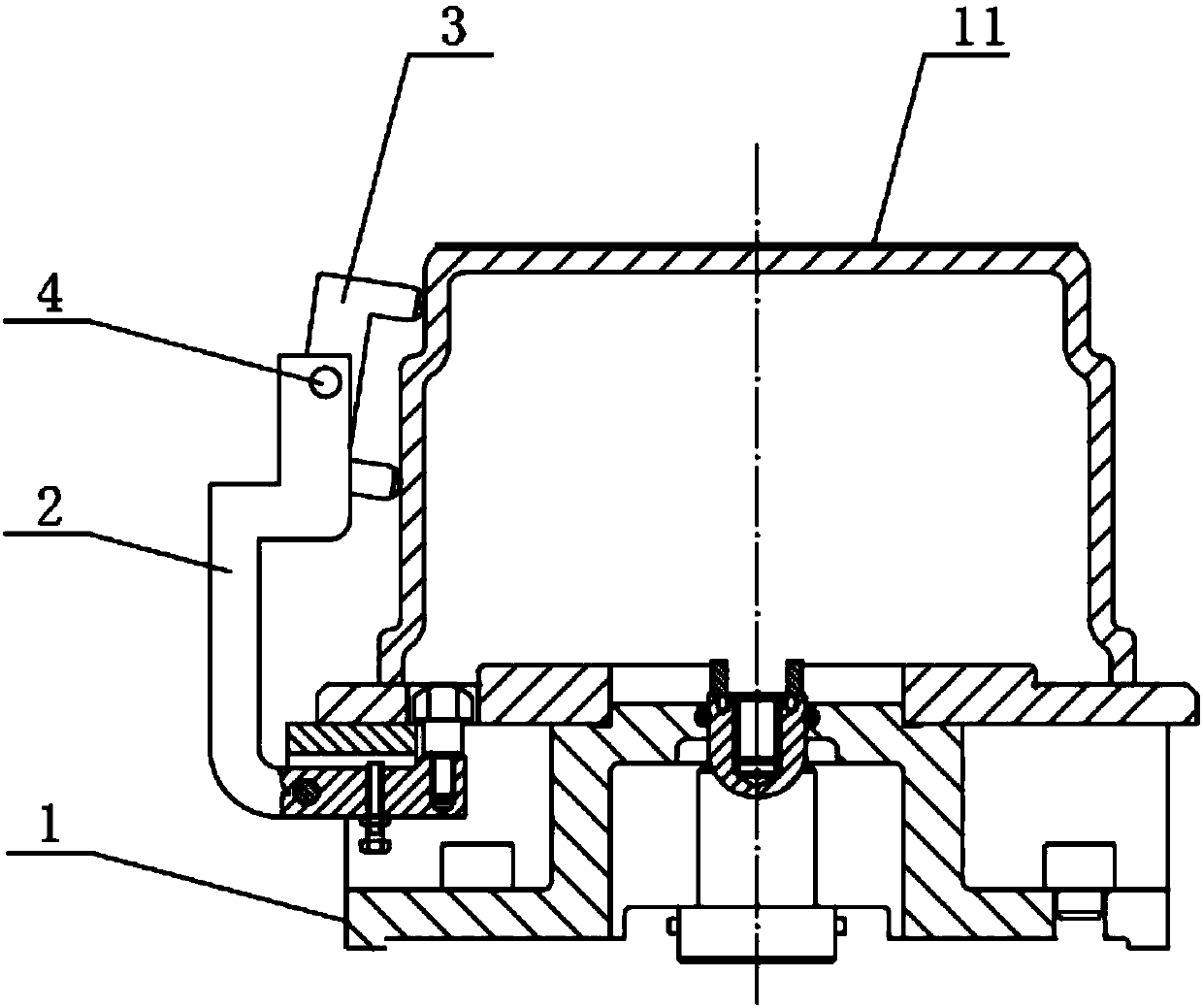

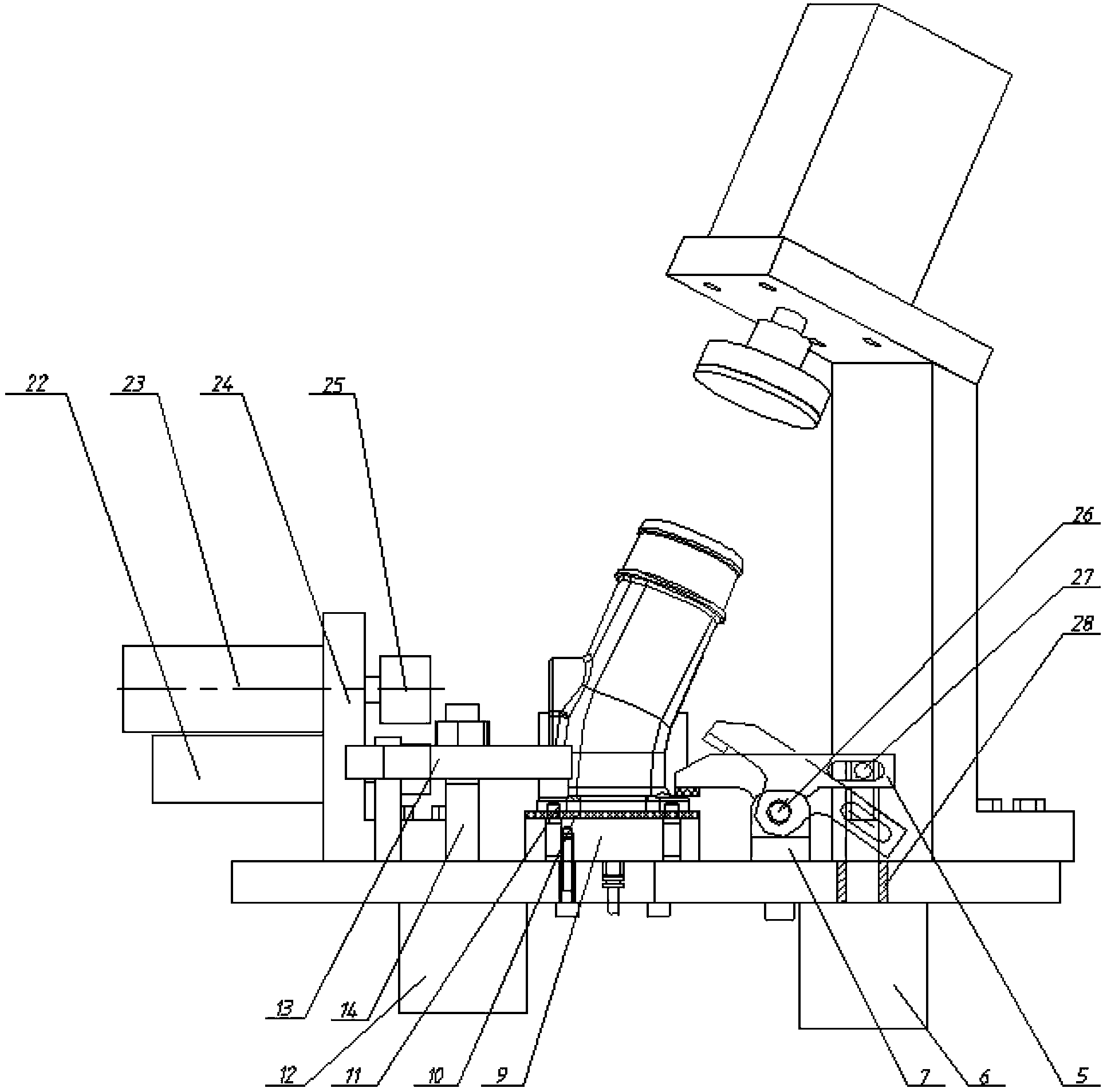

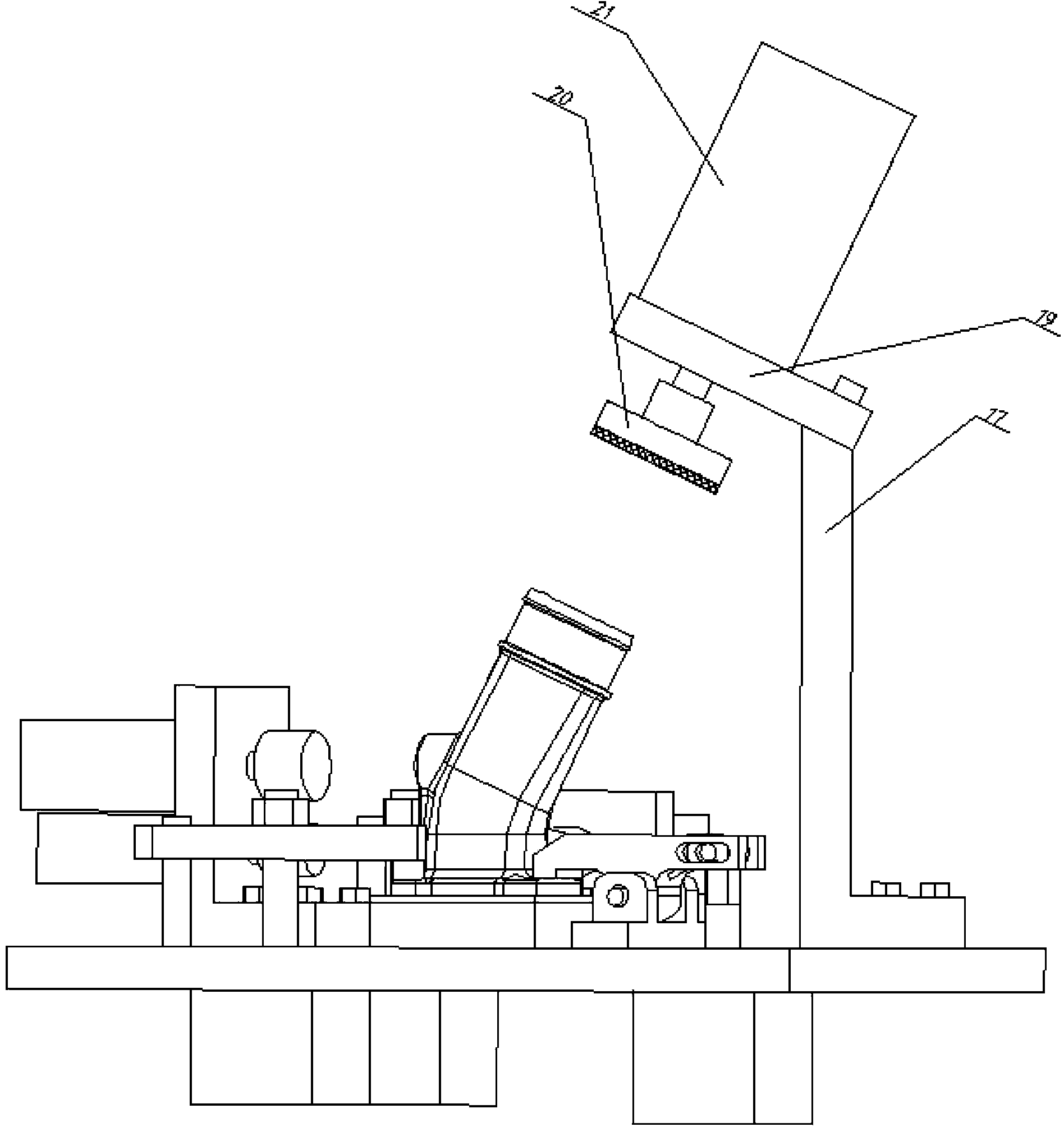

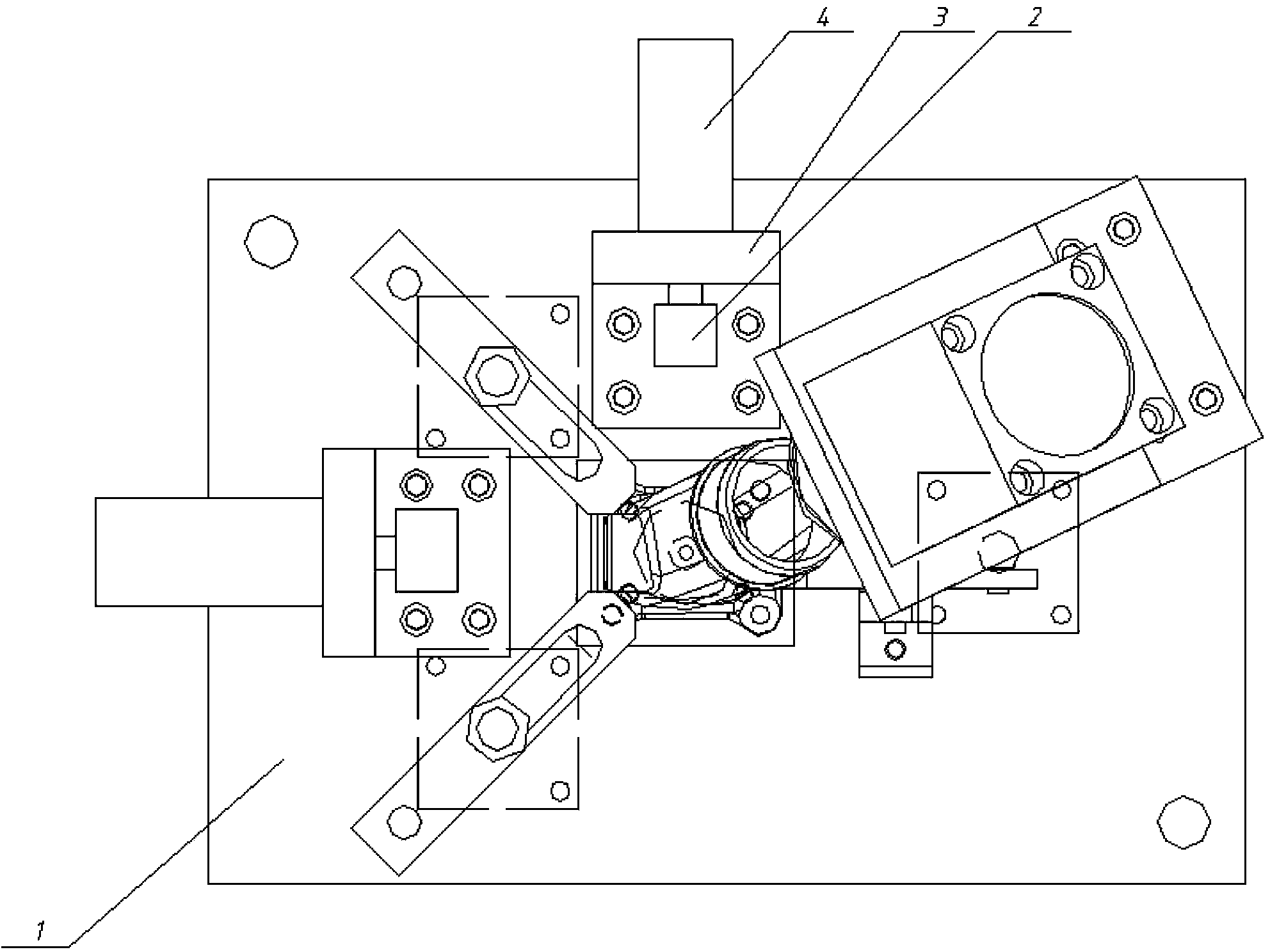

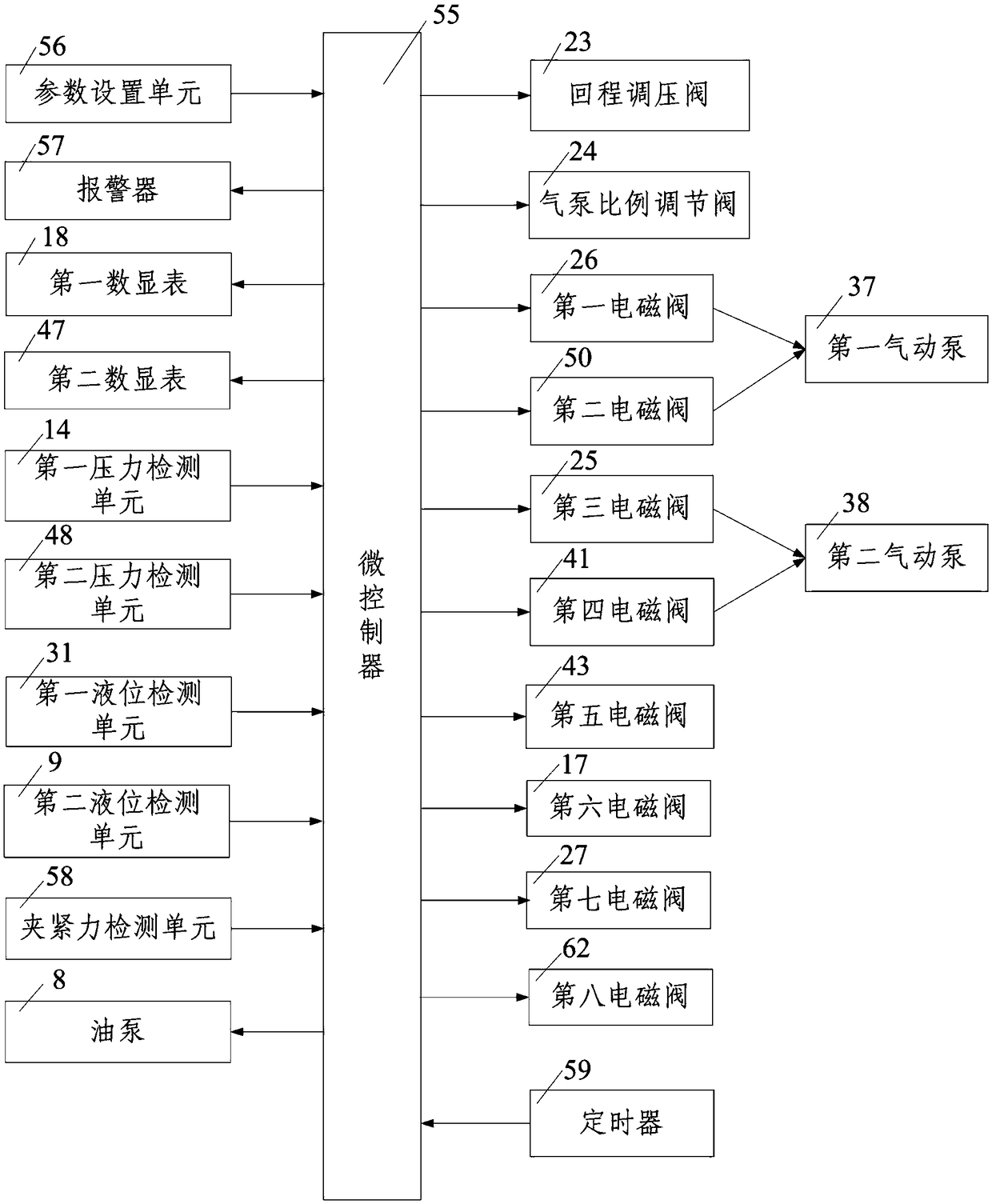

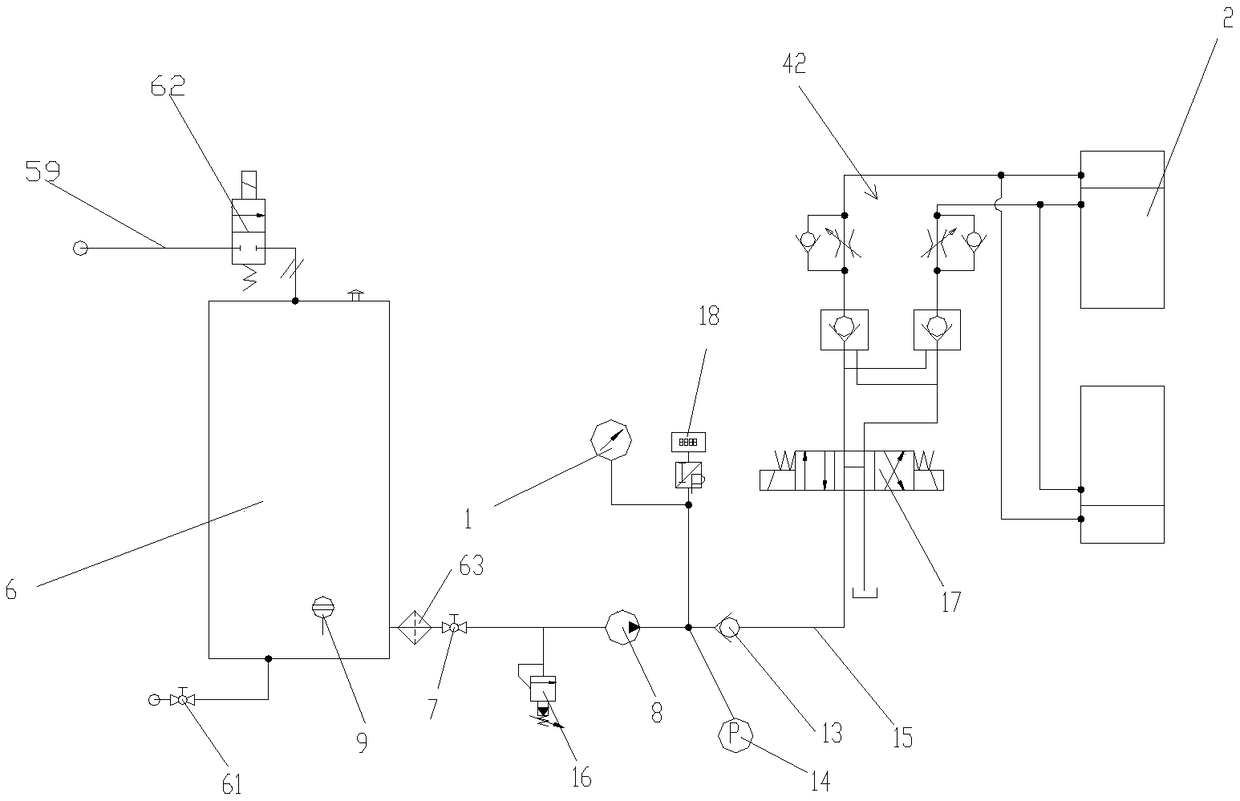

Pneumatic air-tight test device for water inlet pipe

ActiveCN103439057AQuality improvementReduce setup timeDetection of fluid at leakage pointPneumatic circuitAir tightness

The invention discloses a pneumatic air-tight test device for a water inlet pipe. The pneumatic air-tight test device for the water inlet pipe is characterized in that the pneumatic air-tight test device for the water inlet pipe comprises a base plate (1), a first round plug (2), a first angle block (3), a first cylinder (4), a second angle block (17), a cylinder supporting plate (19), a round platen (20) and a fourth cylinder (21). According to the pneumatic air-tight test device for the water inlet pipe, positioning and sealing are achieved step by step by the adoption of the multiple cylinders, clamping can be achieved without manual operation, therefore, clamping time is greatly shortened, and production efficiency is improved; meanwhile, the detects of clamping deformation and crushing caused by manual clamping are overcome, and quality of parts is improved. The pneumatic air-tight test device for the water inlet pipe plays an importance role in improving pneumatic air-tight test techniques of other products, improving production efficiency and saving cost and is quite popular with customers.

Owner:临沂高新自来水有限公司

Cantilever grinding machining method for vane using three-axis linkage interpolation

InactiveCN103100950BAvoid clamping deformationReduce adverse factorsGrinding machinesGrinding work supportsNumerical controlLinear motion

A cantilever grinding machining method for a vane using three-axis linkage interpolation comprises four steps: (1) ascertaining the grinding method of a vane-shaped face according to the structure type and the motion mode of a machine tool and the structure form of the vane; (2) clamping a tenon or a installation reference block of the vane through a single end of a fixture to enable the vane to be firmly fixed on an operating platform of the machine tool and keeping the vane-shaped face portion needing machining in a cantilever state on the numerical control machine tool; (3) selecting three machine tool motion axes suitable for the grinding machining of the vane-shaped face and a grinding wheel to composite a digital control program, and driving the three linear motion axes X, Y and Z, or the axis X, the axis Z and axis C, or the axis Y, the axis Z and the axis C to conduct the three-axis linkage interpolation motion by the digital control program to form a motion trail of the grinding wheel when the vane is in a grinding machining; and (4) enabling the grinding wheel to rotate at a high speed under the driving of a main shaft of the machine tool and move along the motion trail of the three-axis linkage interpolation of the machine tool to achieve the three-axis linkage interpolation cantilever grinding machining of the vane-shaped face.

Owner:BEIHANG UNIV

Combined clamp

InactiveCN111390792AExtend the life cycleReduce manufacturing costWork holdersStructural engineeringControl valves

The invention provides a combined clamp. The combined clamp comprises a locating base plate, multiple locating pin press bases and multiple locating face press bases. Multiple installation holes are formed in the locating base plate in an array mode at equal intervals, the locating pin press bases are detachably installed on the locating base plate through the installation holes, and the locatingface press bases are detachably installed on the locating base plate through the installation holes. According to the combined clamp, the positions of the locating pin press bases and the locating face press bases can be adjusted according to products with different shapes and specifications, and therefore the application range of the combined clamp can be effectively broadened, the service life can be prolonged, and the production cost can be reduced; and supporting air cylinders with air control valves are utilized to support the suspended portion of a product to be processed, and thereforethe product is prevented against clamping deformation, the problem of machining cutter vibration is effectively solved, and the product quality and the yield are improved.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Flexible locating and combined locking type rough turning clamp of large thin-wall flange

ActiveCN108015569AEven by forceNo clamping deformationPositioning apparatusMetal-working holdersFree stateEngineering

The invention relates to a turning clamp, in particular to a flexible locating and combined locking type rough turning clamp of a large thin-wall flange. The flexible locating and combined locking type rough turning clamp comprises a bottom disc, a flexible locating device used for locating the end face of a flange blank, a floating type clamping device used for clamping an inner hole and an outercircle of the flange at the same time and a combined locking device used for fixing the flexible locating plane of the flexible locating device. The flexible locating device comprises a soft rubber locating disc and multiple rigid guide columns perpendicular to the end face of the soft rubber locating disc, wherein the soft rubber locating disc and the multiple rigid guide columns are mounted onthe bottom disc. The upper end parts of the rigid guide columns and the soft rubber locating disc are connected into a whole. The combined locking device is connected with the lower ends of the rigidguide columns so as to be used for locking and loosening the rigid guide columns. According to the flexible locating and combined locking type rough turning clamp, the flange is located and fixed in afree deformation-free state, the planeness of the machined flange plane is good, and the flange plane can be used as a high-quality locating datum plane during subsequent finish machining.

Owner:JIANGYIN HENGRUN RING FORGING

Clamp special for cavity-like part bevel drilling

ActiveCN108580979AAvoid clamping deformationSimple structurePositioning apparatusDrill jigsDrillEngineering

The invention discloses a clamp special for cavity-like part bevel drilling, and belongs to the technical field of mechanical clamps. According to the clamp special for cavity-like part bevel drilling, the problems that an existing workpiece is inconvenient to mount and clamp, and consequently the workpiece is likely to deform, the position precision of to-be-machined holes is poor, and accordingly the machining quality of the workpiece is poor are solved. The central axis of a drill jig body coincides with the central axis of a workpiece, the inner arc surface of a first arc-shaped positioning section closely makes contact with the outer wall of the circular table section of the workpiece, the inner arc surface of a second arc-shaped positioning section closely makes contact with the outer wall of the second cylindrical section of the workpiece, and the left side wall of an arc-shaped plate closely makes contact with the small end of the circular table section of the workpiece; and the arc-shaped plate is fixedly connected with the workpiece through a positioning pin closely mounted in a penetrating mode in a first through hole, the second arc-shaped positioning section is fixedlyconnected with the workpiece through two fixing screws correspondingly mounted in a penetrating mode in two positioning holes, a through groove is formed in the outer arc surface of the second arc-shaped positioning section in the axis direction of the second arc-shaped positioning section, and two second through holes are coaxial with the two to-be-machined holes of the workpiece correspondingly. The clamp special for cavity-like part bevel drilling is used for large cavity-like part bevel drilling.

Owner:HARBIN JIANCHENG GRP

Quick-change aluminum alloy anodic oxidation hanging tool

InactiveCN104762649AAvoid clamping deformationLow costAnodisationElectrolysis componentsAlloyMaterials science

The invention relates to a quick-change aluminum alloy anodic oxidation hanging tool which comprises a hanging tool body and adjusting support strips, wherein the plurality of adjusting support strips are vertically arranged at the bottom end of the hanging tool body and are horizontally fixed; the plurality of adjusting support strips are evenly distributed relative to the circumference of the hanging tool body; vertical through holes are distributed in each adjusting support strip at intervals; and elastic pins are respectively installed at the vertical through holes of the adjusting support strips. All the elastic pins are arranged at the corresponding holes of the adjusting support strips by compression bolts according to the inner diameter of a part to be hung; the elastic pins of the hanging tool are adjusted to be fixed at the holes with the proper distance according to the size of an inner hole of the part to be produced, and the inner hole of the part is supported by the elastic pins with the adjusted distance. After the structure of the three adjusting support strips is adopted, the phenomenon that the hanging points of the elastic pins are not even on the circumference can be avoided, and the problem that the part is deformed by clamping is solved. The design of the movable elastic pins is adopted, so that the range can be adjusted according to the inner diameter of the part to be hung, and the function that one tool serves multiple purposes can be realized.

Owner:苏州市新鸿基精密部品有限公司

Tool for high-speed numerical control milling machining of thin-walled part

InactiveCN111390617AEffective fitAvoid clamping deformationPositioning apparatusMetal-working holdersNumerical controlThermoplastic

The invention discloses a tool for high-speed numerical control milling machining of a thin-walled part. The tool comprises a support, a support and two follow-up clamping devices oppositely arrangedon the support, wherein each follow-up clamping device comprises a first linear driving mechanism, a hollow shell, a heating mechanism, a gas supply mechanism, a deformation mechanism and a floating clamp, each deformation mechanism comprises a planar thermoplastic layer and an elastic outer layer wrapping the planar thermoplastic layer, and each floating clamp comprises cylinder bodies, floatingchucks, pistons, a second linear driving mechanism and a closed partition plate. According to the tool, the flexible clamping of the thin-walled part is realized, the thin-walled part can be effectively attached, the clamping deformation of the thin-walled part is effectively avoided, the machining quality of the thin-walled part is improved, clamping of different thin-wall parts can be realized,and the application range is wide.

Owner:HUNAN IND POLYTECHNIC

Aluminum alloy magazine welding deformation control device and method

ActiveCN109128538AAvoid clamping deformationReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesPre deformationWelding deformation

The invention provides an aluminum alloy magazine welding deformation control device and method. The aluminum alloy magazine welding deformation control device comprises an outer mold for positioningthe outer contour of a magazine, a core mold for positioning the inner contour of the magazine and a turnover mechanism for turning over the magazine. The control method include the steps that left and right molds are pushed relative to each other until a left half and a right half of the magazine have a welding seam spacing of 0.07-0.12mm; pushing and pressing mechanisms are pushed relative to each other, and the left half and the right half of the magazine are subjected to pre-deformation; when the temperature is detected greater than 80 DEG C during welding, normal temperature high-purity argon gas is immediately introduced into an argon gas passage, and the introduction of the argon gas is stopped until a temperature sensor detects that the temperature is lower than 80 DEG C; and afterturning over, a welding seam on the lower surface of magazine is welded, and vibrating ageing treatment is performed on the magazine after the welding is completed. The deformation amount in the direction, perpendicular to the welding seam, on the plane on which the aluminum alloy magazine welding seam is located can be controlled to be 0.02-0.05mm / 50mm, the deformation amount in the direction, parallel to the welding seam, on the plane on which the welding seam is located is controlled to be 0.04-0.08mm / 50mm, and the welded part cannot be oxidized and cannot absorb moisture.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Clamping device for machining of thin-wall part

InactiveCN111940772ASame clamping forceAvoid clamping deformationChucksPositioning apparatusEngineeringMachining

The invention belongs to the technical field of machined parts, and particularly relates to a clamping device for machining of a thin-wall part. Multiple inner claws are glidingly connected inside a main body; each inner claw can slide in the radial direction of the main body; the outside of the main body is glidingly connected with multiple outer claws corresponding to the inner claws; each outerclaw can slide in the radial direction of the main body; and the right end of an inner claw pulling rod is sleeved with an outer claw pulling rod; the right end of each inner claw is connected with one slope at the left end of the inner claw pulling rod in a matched manner, so that the inner claw can slide along the slope at the left end of the inner claw pulling rod; the right end of each outerclaw is connected with one slope at the left end of the outer claw pulling rod in a matched manner, so that the outer claw can slide along the slope at the left end of the outer claw pulling rod; andpressure sensors are arranged on the inner claw pulling rod and the outer claw pulling rod respectively. The technical problems that a revolving body thin-wall part is prone to deformation in the clamping process and the part falls off due to the insufficient clamping force can be solved.

Owner:CHINA FIRST AUTOMOBILE

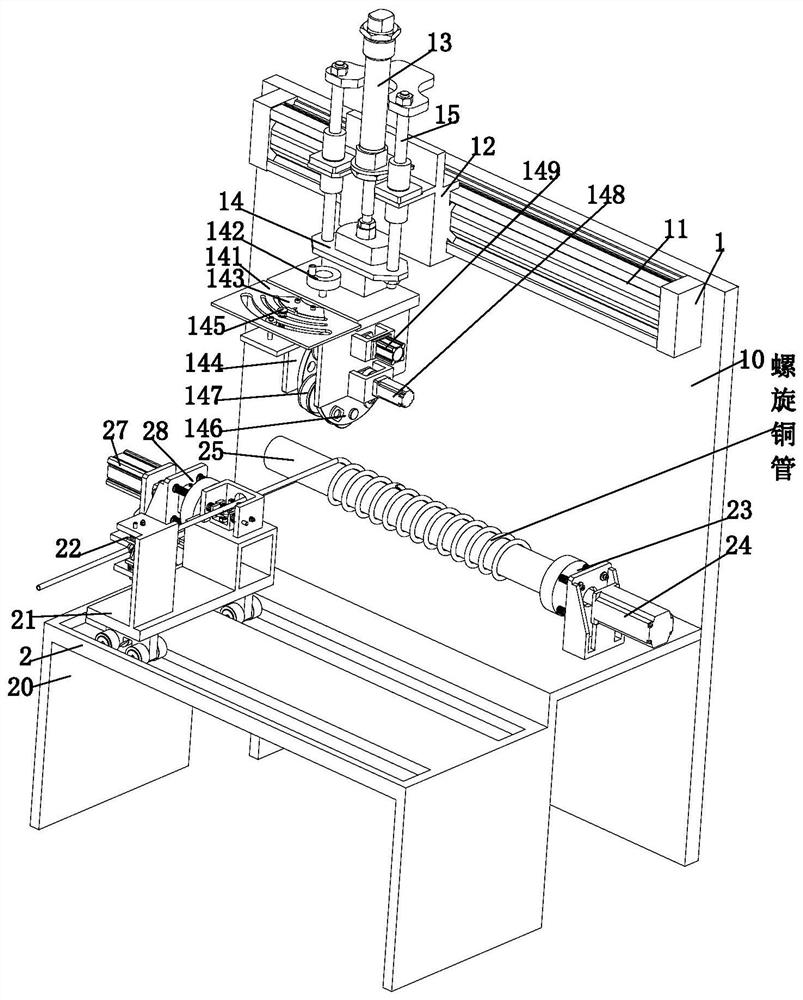

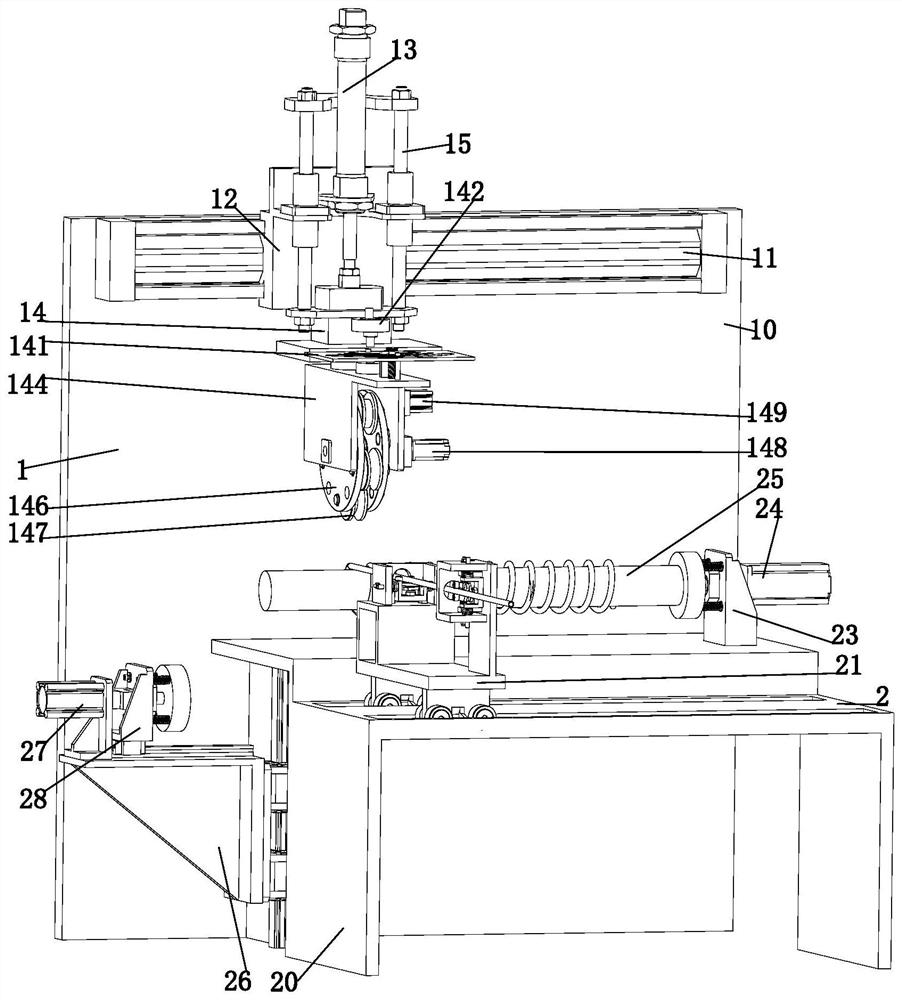

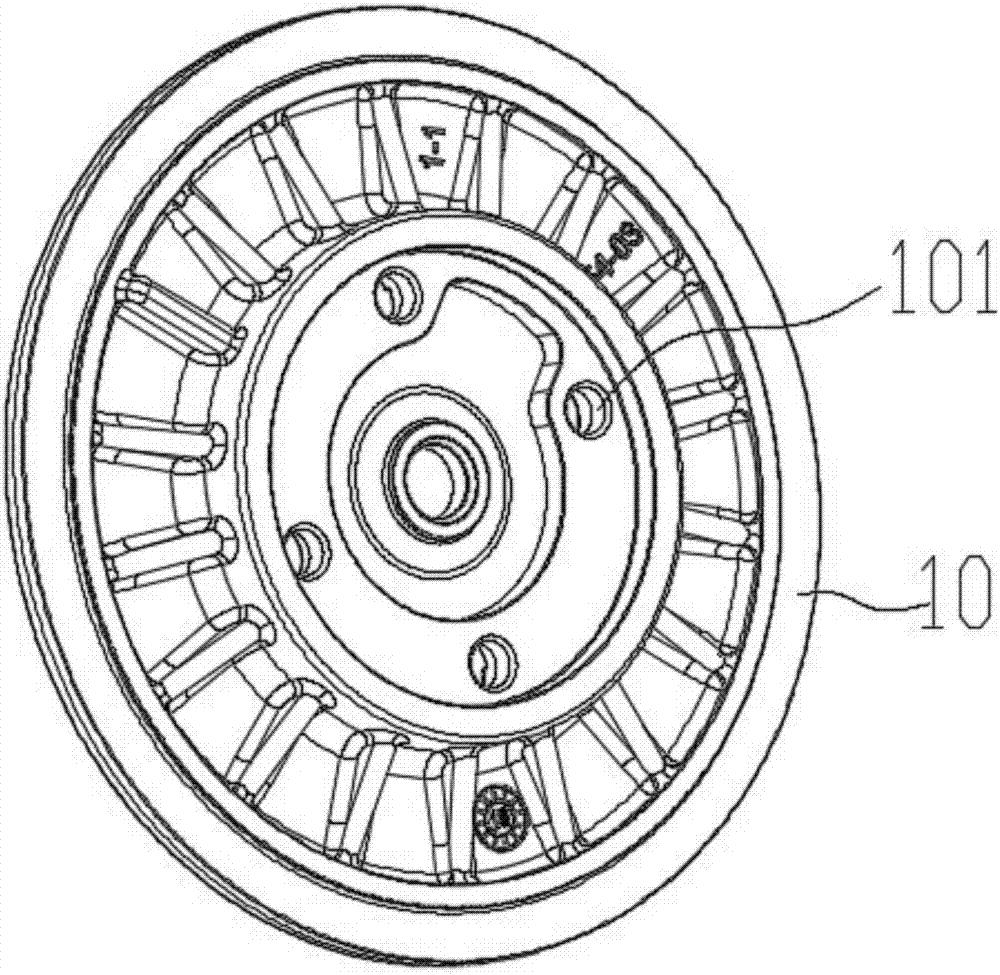

Manufacturing process of air conditioner condenser copper pipe

InactiveCN111804780AGuaranteed accuracyEliminate loosenessHeat exchange apparatusMetal working apparatusMolding machineMachining process

The invention provides a manufacturing process of an air conditioner condenser copper pipe. The process involves a pressing mechanism and a forming mechanism, wherein the pressing mechanism is installed on the outer wall of the forming mechanism, and the pressing mechanism is positioned over the forming mechanism. The problems that the copper pipe is in a long round pipe state after being producedin a factory mode, the long copper pipe needs to be bent so as to be applied to a condenser refrigerating system, an existing method of bending the copper pipe into a spiral shape comprises the stepof manually winding and the copper pipe on a cylinder, but the method has high requirements on workers, the copper pipe is likely to be flattened due to uneven stress in the winding process, therefore, the copper pipe is deformed, meanwhile, spiral pitches obtained after winding are different, and use requirements cannot be met are solved.

Owner:孙大慧

Internal expansion type tensioning fixture for end cover sealing plate

PendingCN107052847AAvoid clamping deformationImprove machining accuracyPositioning apparatusMetal-working holdersStructural engineeringCircular disc

The invention discloses an internal expansion type tensioning fixture for an end cover sealing plate. The internal expansion type tensioning fixture comprises a machine base, wherein a pull rod is arranged at the center of the machine base; a sliding seat is connected to the upper end of the pull rod and arranged in a sliding groove in the upper end of the machine base; a fixing seat is fixedly arranged at the top end of the machine base; the fixing seat comprises a disc-shaped base plate and a fixing pillar at the center of the upper end of the base plate; positioning pillars matched with counter bores in the bottom surface of the end cover sealing plate are arranged on the upper end edge of the fixing pillar; a sliding inclined groove is formed in each of the positioning pillars; a sliding ring is connected onto the fixing pillar in a sleeving manner; clamping rods matched with the positioning pillars are arranged on the sliding ring; a clamping inclined block matched with the sliding inclined grooves is arranged on each of the clamping inclined blocks; the sliding ring is connected with the sliding seat through long bolts; a pin bush is arranged on each of the long bolts; a dustproof ring is arranged on the base plate; the sliding ring is positioned in the dustproof ring; limiting pillars are uniformly arranged on the base plate. According to the internal expansion type tensioning fixture for the end cover sealing plate, the end cover sealing plate can be clamped stably and reliably, the machining precision is improved, the disassembly and assembly is quick and convenient, and the machining efficiency of the end cover sealing plate is improved.

Owner:CHANGSHA BODA MACHINERY PARTS CO LTD

Dual-purpose fixture

InactiveCN107138982ALow costReduce labor intensityPositioning apparatusMetal-working holdersEngineeringDual purpose

The invention discloses a dual-purpose clamp, which comprises a bottom plate, a vertical plate is arranged on the bottom plate, an adjustable screw rod is arranged on the vertical plate, a chute is arranged on the bottom plate, a sliding plate is arranged on the chute, and an adjustable screw rod is arranged on the sliding plate. The screw holes for the screw rods are provided with nuts on the adjustable screw rods on the right side of the slide plate, the slide plate is locked on the adjustable screw rods through the nuts, and a rib plate is provided on one side of the slide plate. The present invention can hold plate-type and cylinder-type parts, can clamp the cylinder-type parts from the inside, has high processing efficiency, low production cost and high processing quality.

Owner:四川利丰航空科技有限公司

Machining technique for explosion-proof motor end cover

InactiveCN105710605AEliminate turning chatterSolve the problems of large clamping deformation in turning and vibration during turningPerformance indexEngineering

The invention relates to a machining technique for an explosion-proof motor end cover and belongs to the field of production and manufacturing of motor end covers. The machining technique comprises the following steps that (1) a workblank is clamped and aligned by means of a three-jaw chuck, and an outer circle is turned; (2) the end face of the outer circle is positioned, the outer circle is aligned and clamped, and a big-end-face seam and a big-face hole are turned; (3) the big-end-face seam is positioned, clamping and aligning are conducted, and a small-face hole is turned; (4) the big-face hole is drilled and tapped; (5) an oil duct hole is drilled and tapped; (6) a circumferential hole is drilled and tapped; and (7) hydrostatic testing is conducted on the whole end cover. According to the machining technique, the process is stable, the rate of finished products is high, the machining precision of the explosion-proof motor end cover can be completely guaranteed, the explosion-proof end cover with performance indexes meeting requirements is obtained, and the production requirements of explosion-proof motors are met.

Owner:SHANDONG YUANTONG MASCH CO LTD

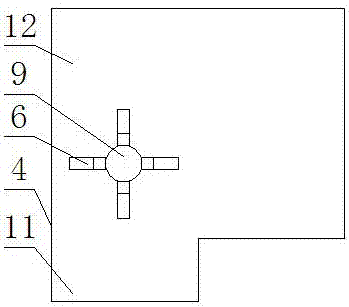

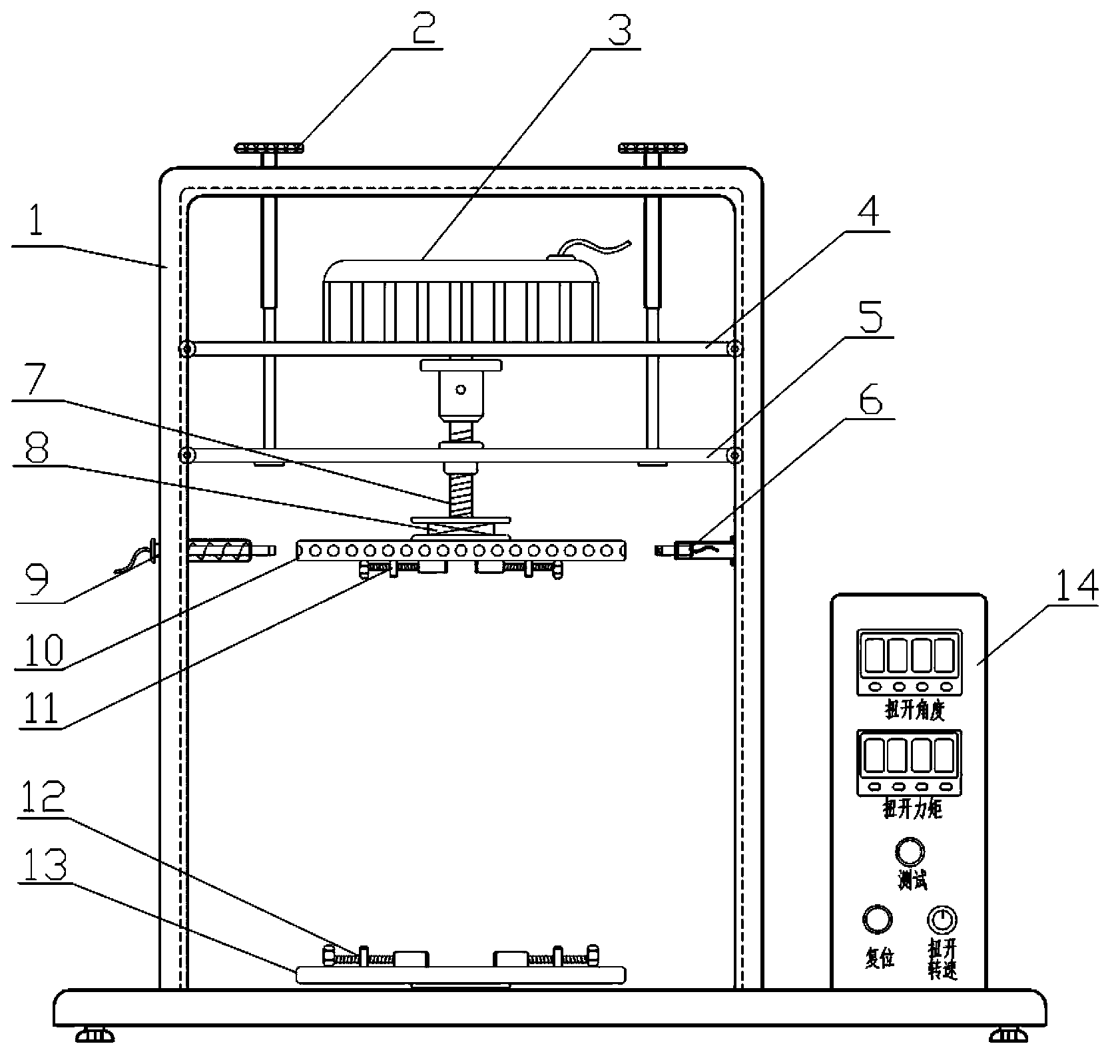

Turn-on performance testing device and testing method thereof

InactiveCN103674388AAvoid clamping deformationPrevent affecting test accuracyMeasurement of torque/twisting force while tighteningExperimental researchEngineering

The invention discloses a turn-on performance testing device and testing method thereof. The testing device comprises a bracket, a testing mechanism, a driving mechanism and a detection mechanism, and has the advantages of small size, precise design, compact structure, simplicity and convenience in operation and high degree of automation, can accurately quantify and test the turn-on performance of a tested object, greatly eliminates uncertain factors of a current manual testing method, and is good in accuracy and repeatability. The testing device is not only suitable for quick detection of product encapsulation quality of bottle cover encapsulation manufacturers, but also can be used for scientific organizations for experiment research for bottle cover encapsulation technology and the raw materials adopted, and therefore is wide in application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydraulic drive type clamping heterotype valve explosion pressure test system and test method

The invention discloses a hydraulic drive type clamping heterotype valve explosion pressure test system and test method. The hydraulic drive type clamping heterotype valve explosion pressure test system includes a hydraulic drive type clamping device, a quick connector plug, an explosion pressure testing device and a monitoring device, wherein the explosion pressure testing device includes a watersupply box, a liquid supply pipe, a pressurization mechanism and a pressure release mechanism. The hydraulic drive type clamping heterotype valve explosion pressure test method includes the followingsteps: 1) preparing before testing; 2) defining a heterotype valve and determining a clamped area of the heterotype valve; 3) determining the number of clamping rods contacting the clamped area; 4) clamping the heterotype valve and connecting a quick connector plug; 5) determining whether clamping of the tested heterotype valve is stable; 6) testing the explosion pressure of the heterotype valve;and dismounting the heterotype valve. The hydraulic drive type clamping heterotype valve explosion pressure test system and test method have the advantages of being reasonable in design, being simplein operation, being stable in clamping of the heterotype valve so as to prevent the heterotype valve from deformation, guaranteeing accuracy of the explosion pressure test of the heterotype valve, and being high in practicality.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com