Machining tool used for thin-wall barrel type part

A thin-walled cylinder and parts technology, which is applied in the field of machining process assembly design and manufacturing, can solve the problems of difficult control of workpiece size, inability to process thin-walled parts, low coaxiality, etc., and achieve the effect of avoiding machining errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

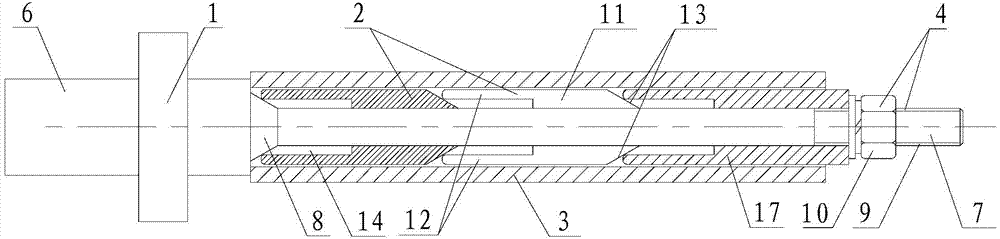

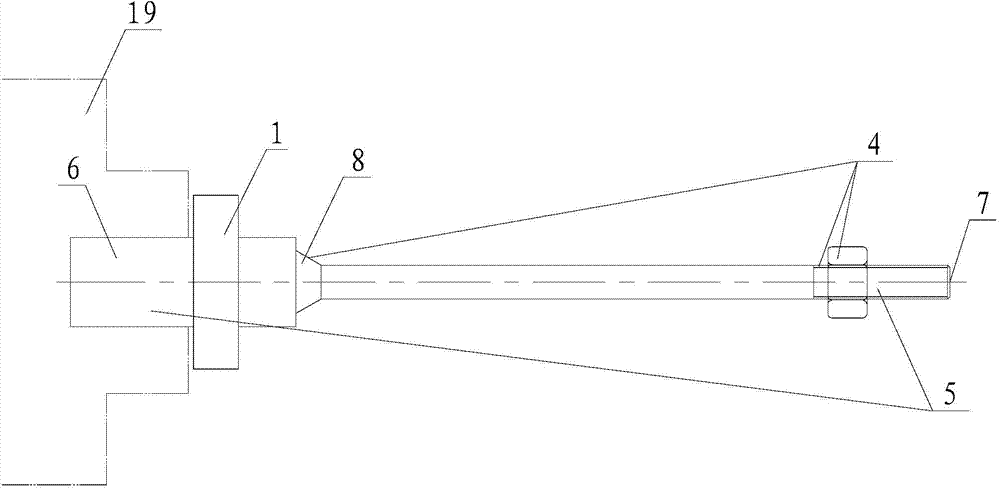

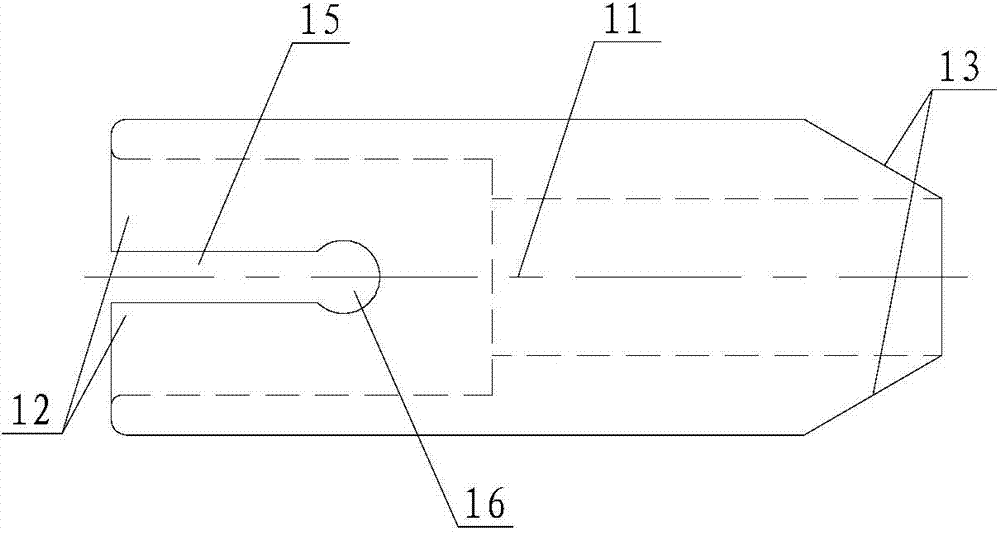

[0026] Such as Figure 1 to Figure 6 Shown is a processing tool for thin-walled cylindrical parts provided by the present invention that can effectively avoid large processing errors in the processing of thin-walled parts due to clamping. The processing tool includes a base frame 1 and a clamping support assembly 2, and the clamping support assembly 2 is sleeved on the base frame 1 in a radially expandable and contractible manner; the thin-walled cylindrical parts 3 The clamping support assembly 2 is expanded and fixed on the processing tool, and the processing tool is clamped on the processing equipment 19 for processing the thin-walled cylindrical parts 3 through the base frame 1 . A set of processing tools including a base frame 1 and a clamping support assembly 2 is provided, and the clamping support assembly 2 is radially expandable and contractible sleeved on the base frame 1 . In this way, when the thin-walled cylindrical part 3 to be processed is clamped by the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com