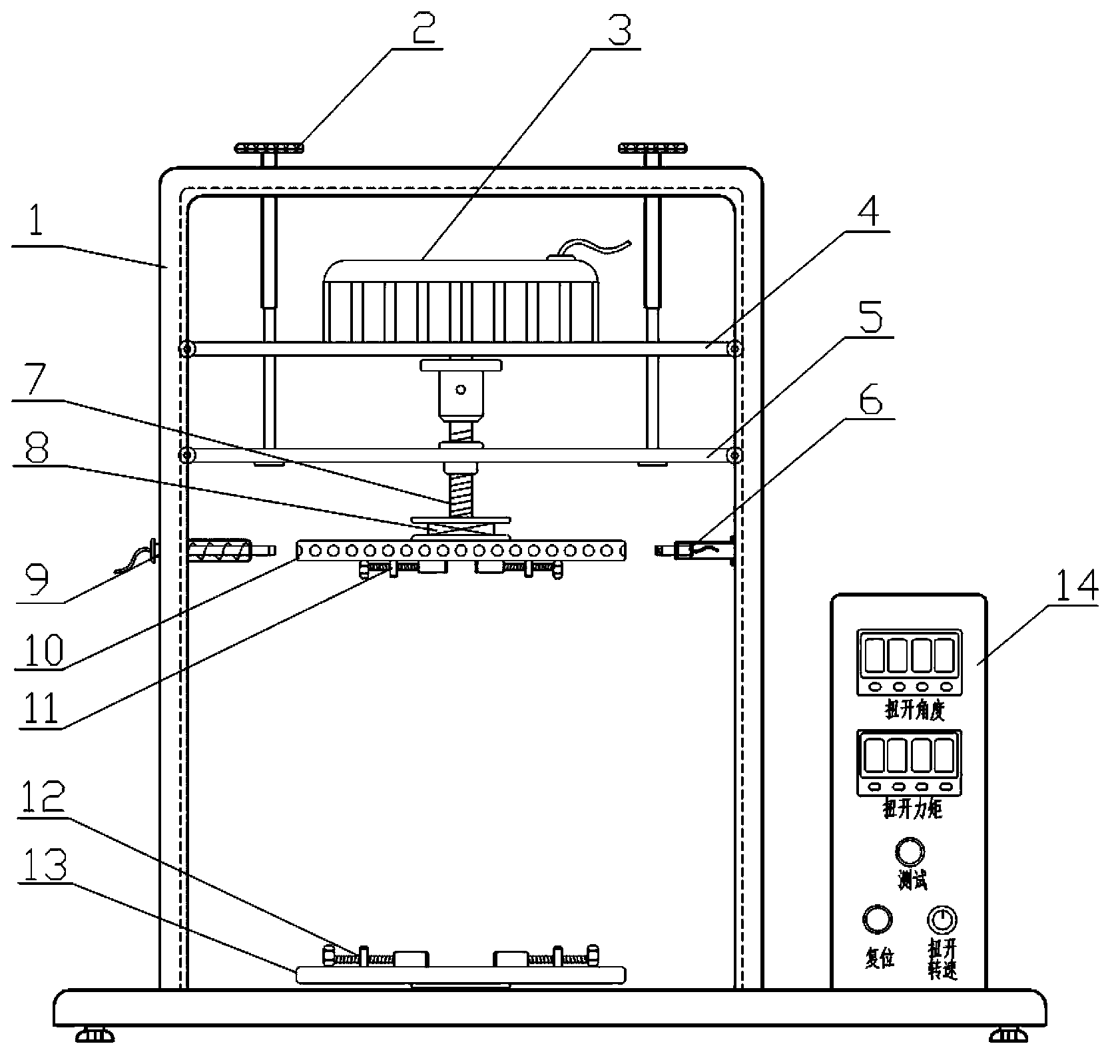

Turn-on performance testing device and testing method thereof

A testing device and performance technology, applied in measuring devices, measuring torque/torsion force during tightening, instruments, etc., can solve the detection of bottle cap torsion angle, the influence of accuracy, precision and automation without considering problems such as low level, to achieve the effect of compact structure, wide application and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment is used to illustrate the test process and results of the twist-off performance of a disposable packaging plastic bottle cap package using the bottle cap twist-off performance test device provided by the present invention.

[0055] The disposable packaging plastic bottle cap package in this embodiment is a commercially available 500ml carbonated beverage bottle cap package, the bottle cap is a polypropylene plastic bottle cap, and the height of the bottle body is 24.5cm.

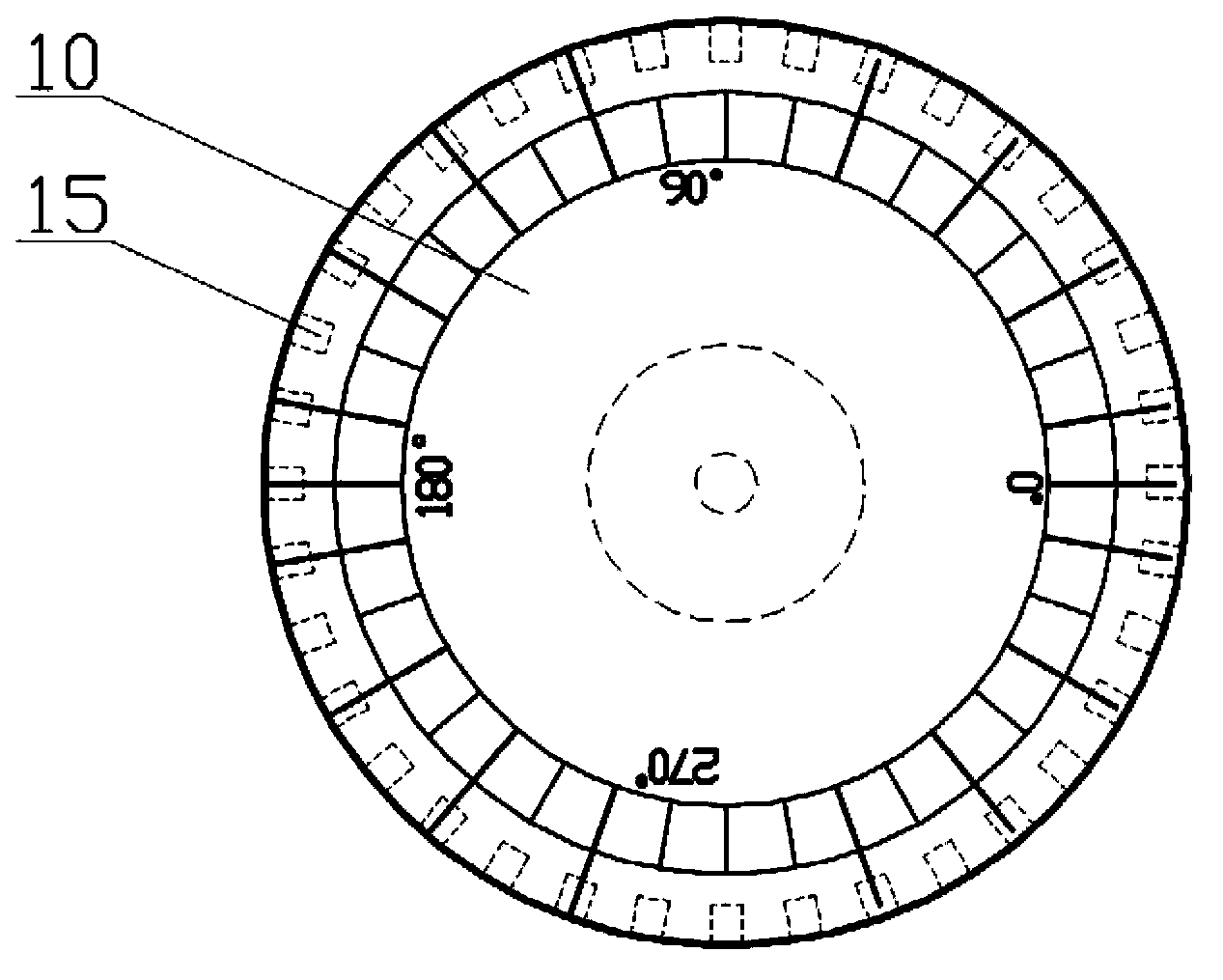

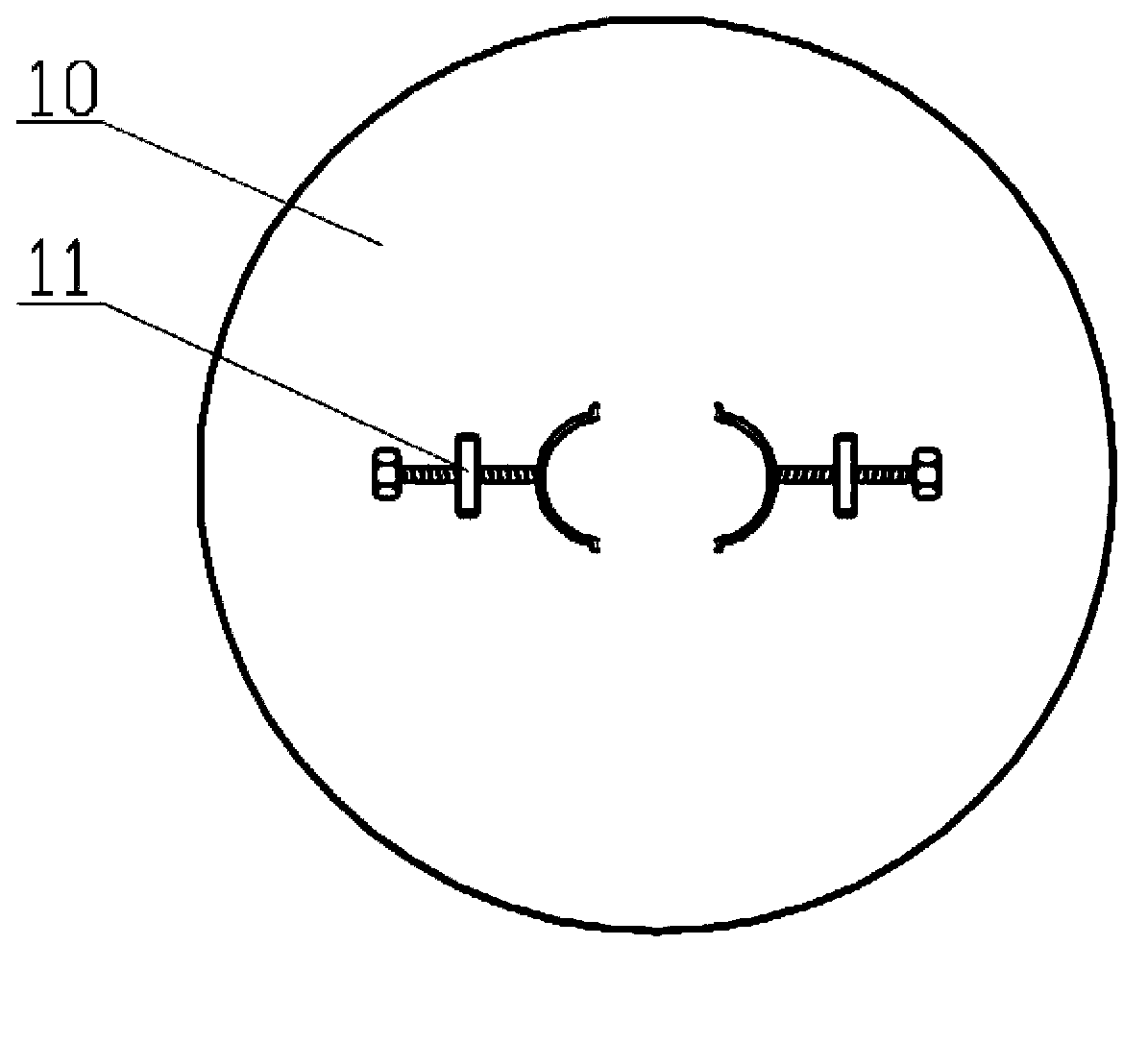

[0056] When the twist-off performance of this bottle cap package was tested, the distance between the twist-off part 10 and the fixed part 13 of the device of the present invention was adjusted to 24.5 cm, and the measured bottle cap package was placed between the twist-off part 10 and the fixed part 13. Between, and the cap body part of the bottle cap is clamped by the first clamping part 11 on the unscrewed part 10, and the bottom part of the bottle is clamped by the second clamping p...

Embodiment 2

[0059] This embodiment is used to illustrate the test process and results of the twist-off performance of a disposable packaging plastic bottle cap package using the bottle cap twist-off performance test device provided by the present invention.

[0060] The disposable packaging plastic bottle cap package in this embodiment is a commercially available bottle cap package for 330ml drinking water, the bottle cap is a polypropylene plastic bottle cap, and the height of the bottle body is 15cm.

[0061] The twist-off performance test of the bottle cap package adopts the method of Example 1, the difference is that the distance between the twist-off part 10 and the fixed part 13 is adjusted to 15 cm, and the test twist-off rotation rate is set to 90 degrees / s.

[0062] The test of this bottle cap packaging unscrew performance, adopts the method that respectively gets 5 bottle cap samples and carries out parallel test, to verify the test stability performance of the device of the pres...

Embodiment 3

[0066] This embodiment is used to illustrate the test process and results of the twist-off performance of a disposable packaging metal bottle cap package using the bottle cap twist-off performance test device provided by the present invention.

[0067] The disposable packaging metal bottle cap package in this embodiment is a bottle cap package of a commercially available 400ml fruit juice drink, the bottle cap is a metal aluminum bottle cap, and the height of the bottle body is 17cm.

[0068] The twist-off performance test of the bottle cap package adopts the method of Example 1, the difference is that the distance between the twist-off part 10 and the fixed part 13 is adjusted to 17 cm, and the test twist-off rotation rate is set to 5 degrees / s.

[0069] Finally, through the test of the device of the present invention, it is obtained that the twist-off angle of the disposable packaging metal cap package is 50 degrees, and the twist-off torque is 2.0 N·M.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com