Machining technique for explosion-proof motor end cover

A motor end cover and processing technology technology, applied in the field of explosion-proof motor end cover processing technology, can solve the problem that the special quality requirements of the explosion-proof motor end cover cannot be met, the verticality shape and position accuracy of the end face cannot be guaranteed, and the explosion-proof end cover turning Clamping deformation and other problems, to achieve safe and reliable motor operation, significant energy saving effect, eliminating the effect of turning chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

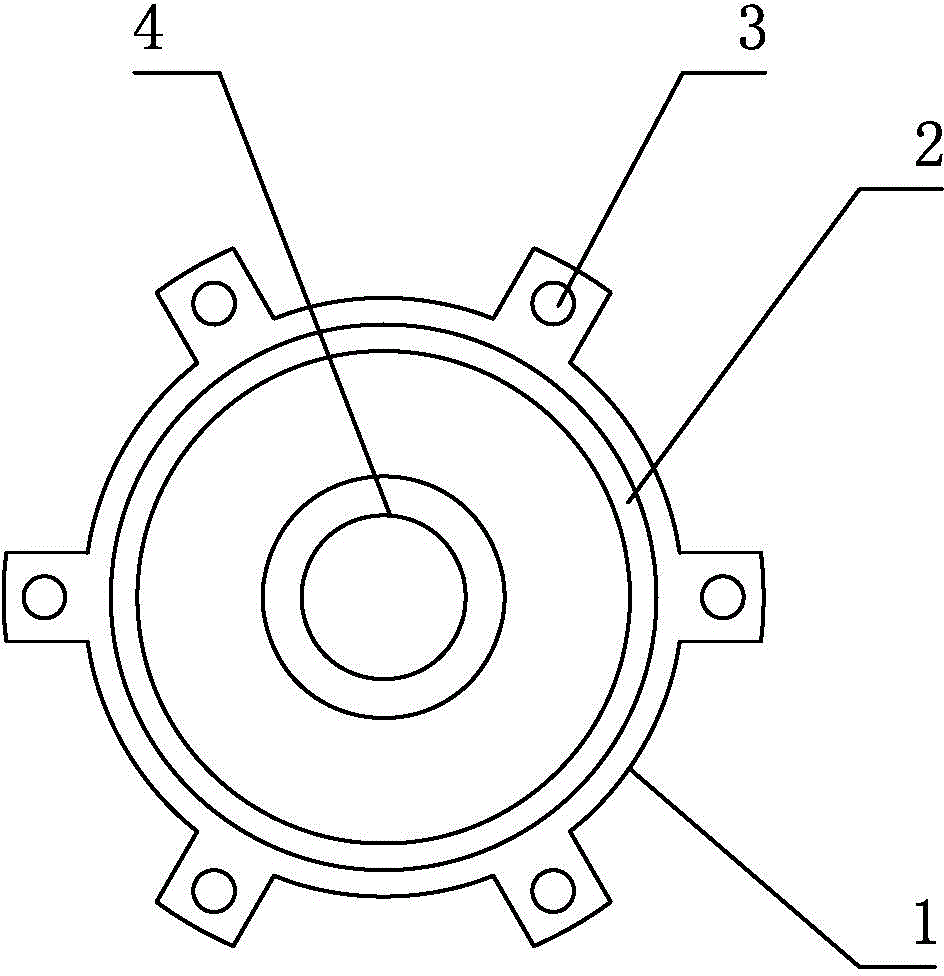

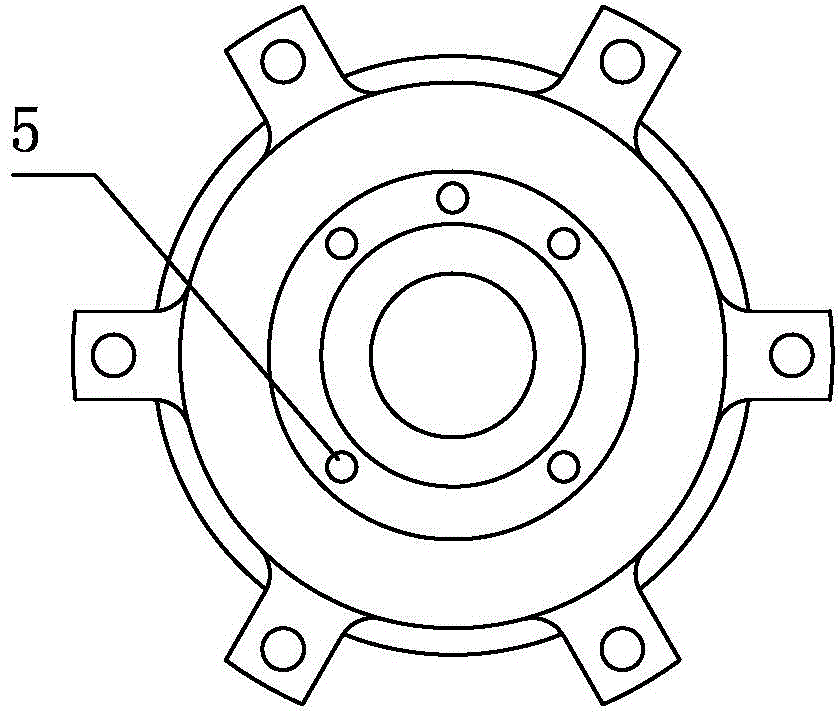

[0019] Such as Figure 1~2 As shown, a type 200 explosion-proof motor end cover of ABB in Finland is assembled with the explosion-proof motor shell to form an explosion-proof motor, replacing the traditional ordinary motor. The material of the end cover is gray iron HT200, and it is required to process a large end face 2 diameter tolerance +0.3 -0.1 , Perpendicularity 0.1, coaxiality ∮ 0.1, notch depth 26.5, to ensure the assembly requirements of explosion-proof motors.

[0020] 1) Use a three-jaw chuck to clamp and align the blank, the outer circle of the car is 1, the diameter of the outer circle 1 is controlled to ∮287±0.5, and the depth is 7±0.5.

[0021] 2) Using a C630 lathe, locate the end face of the outer circle 1, align and clamp the outer circle 1, turn the big end face 2 and the big face 3, and control the diameter of the big end face 3 ∮334.8 +0.3 -0.1 , depth tolerance 26.5±0.2, large face 3 diameter ∮174.2 +0.1 -0.3 .

[0022] 3) Using a C630 lathe, locat...

Embodiment 2

[0028] A type 225 explosion-proof motor end cover of ABB in Finland, which is assembled with an explosion-proof motor casing to form an explosion-proof motor, replacing the traditional ordinary motor. The material of the end cover is gray iron HT200, and it is required to process a large end face with a diameter tolerance of 2. +0.3 -0.1 , Perpendicularity 0.1, coaxiality ∮ 0.1, notch depth 26.5, to ensure the assembly requirements of explosion-proof motors.

[0029] 1) Use a three-jaw chuck to clamp and align the blank, the outer circle of the car is 1, the control is ∮311±0.5, and the depth is 9±0.5.

[0030] 2) Use a C630 lathe to locate the end face of the outer circle, align and clamp the outer circle 1, turn the big end face seam 2 and the large face hole 3, and the diameter of the large end face seam 2 is ∮376.8 +0.3 -0.1 , depth tolerance 26.5±0.2, large face 3 diameter ∮200.2 +0.1 -0.3 .

[0031] 3) Using a C630 lathe, locate the seam 2 of the large end face, cla...

Embodiment 3

[0037] A type 250 explosion-proof motor end cover of ABB in Finland, which is assembled with an explosion-proof motor casing to form an explosion-proof motor, replacing the traditional ordinary motor. The material of the end cover is gray iron HT200, and it is required to process a large diameter tolerance of the end face. +0.3 -0.1 , Perpendicularity 0.1, coaxiality ∮ 0.1, notch depth 26.5, to ensure the assembly requirements of explosion-proof motors.

[0038] 1) Use a three-jaw chuck to clamp and align the blank, turn the outer circle, control ∮350±0.5, and the depth dimension is 9±0.5.

[0039] 2) Use a C630 lathe to locate the end face of the outer circle, align and clamp the outer circle, turn the big end face 2 and the big face 3, and the diameter of the big end face 2 is ∮424.8 +0.3 -0.1 , depth tolerance 26.5±0.2, large face 3 diameter ∮209.2 +0.1 -0.3 .

[0040] 3) Using a C630 lathe, locate the seam 2 of the large end face, clamp and align, turn the small face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com