Hydraulic drive type clamping heterotype valve explosion pressure test system and test method

A technology of burst pressure and hydraulic clamping, which is applied in the testing of machines/structural components, impact testing, measuring devices, etc., and can solve the problems of clamping valve extrusion deformation, inconvenient operation, low versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

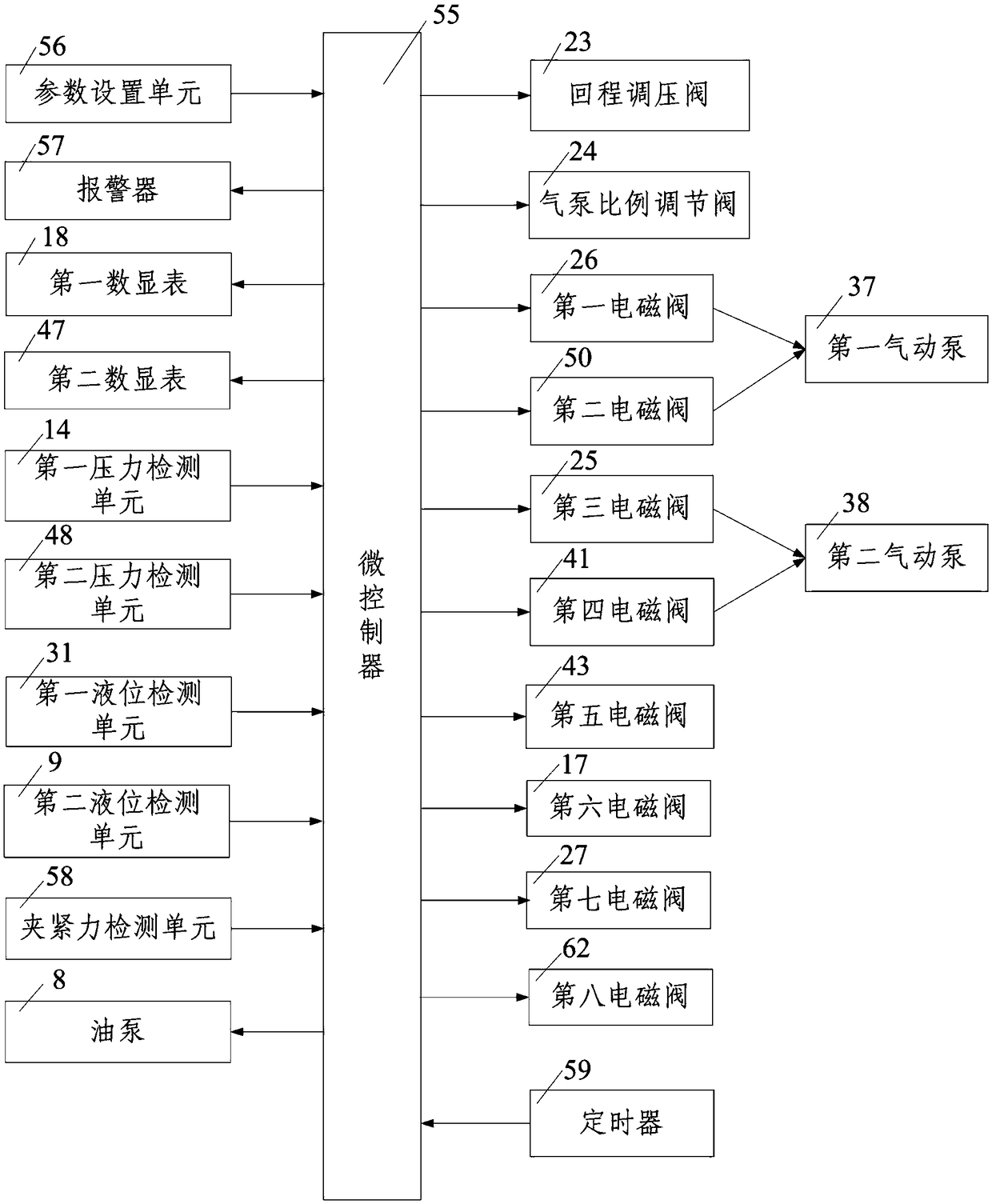

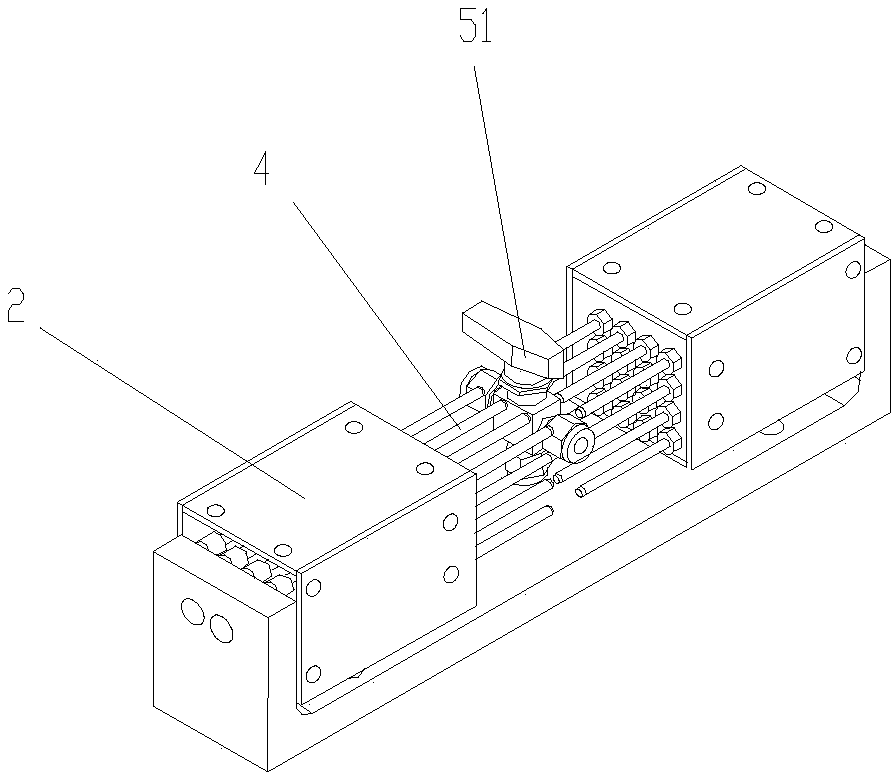

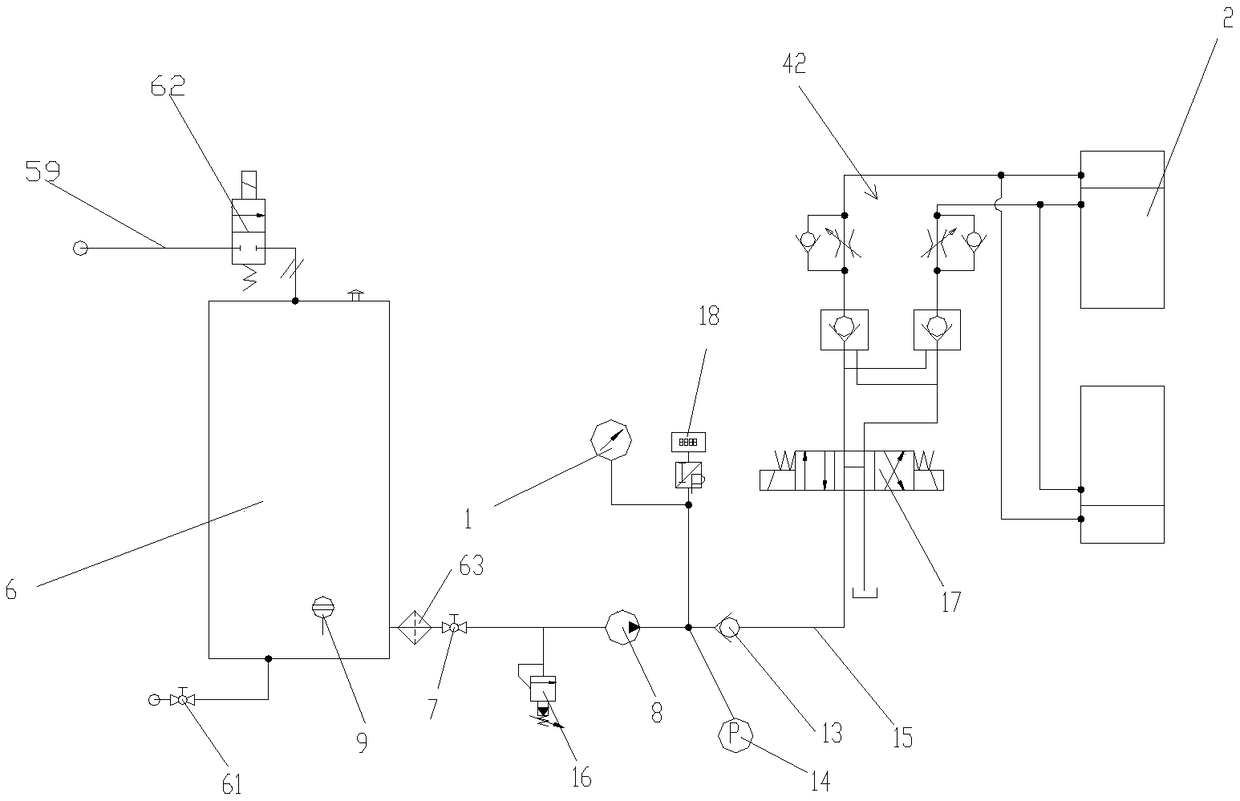

[0132] Such as Figure 1-Figure 4 The burst pressure test system for a hydraulically driven clamping special-shaped valve is shown, including a hydraulic clamping device for clamping the special-shaped valve 51 to be tested, a quick connector connected with the special-shaped valve 51 to be tested, a A burst pressure test device for testing the burst pressure of 51 and a monitoring device for monitoring the hydraulic clamping device and the burst pressure test device. The burst pressure test device includes a liquid supply tank 30 connected to the liquid supply tank 30 The liquid supply pipe and the pressurization mechanism arranged on the liquid supply pipe and the pressure relief mechanism connected with the outlet end of the liquid supply pipe, the pressurization mechanism includes an air supply mechanism, and outputs to the air supply mechanism The air pump proportional regulating valve 24 and the return pressure regulating valve 23 for adjusting the driving air pressure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com