Patents

Literature

204results about How to "Meet the clamping needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

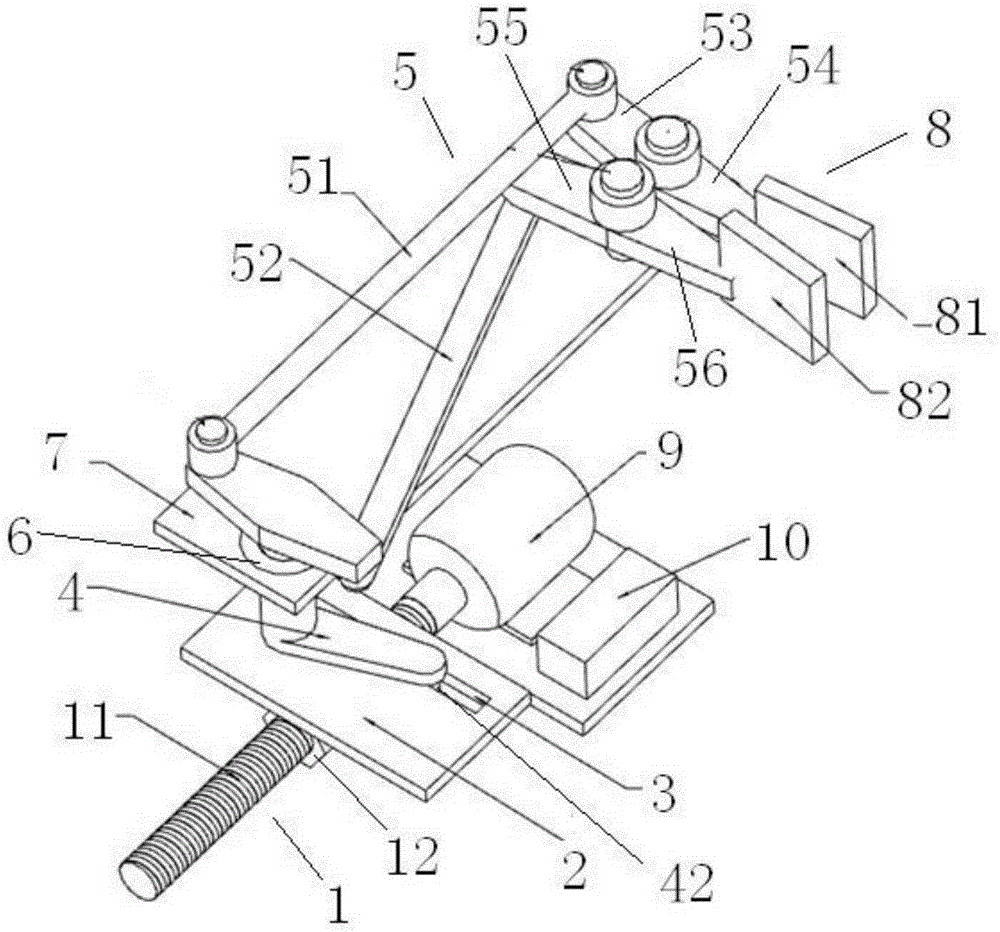

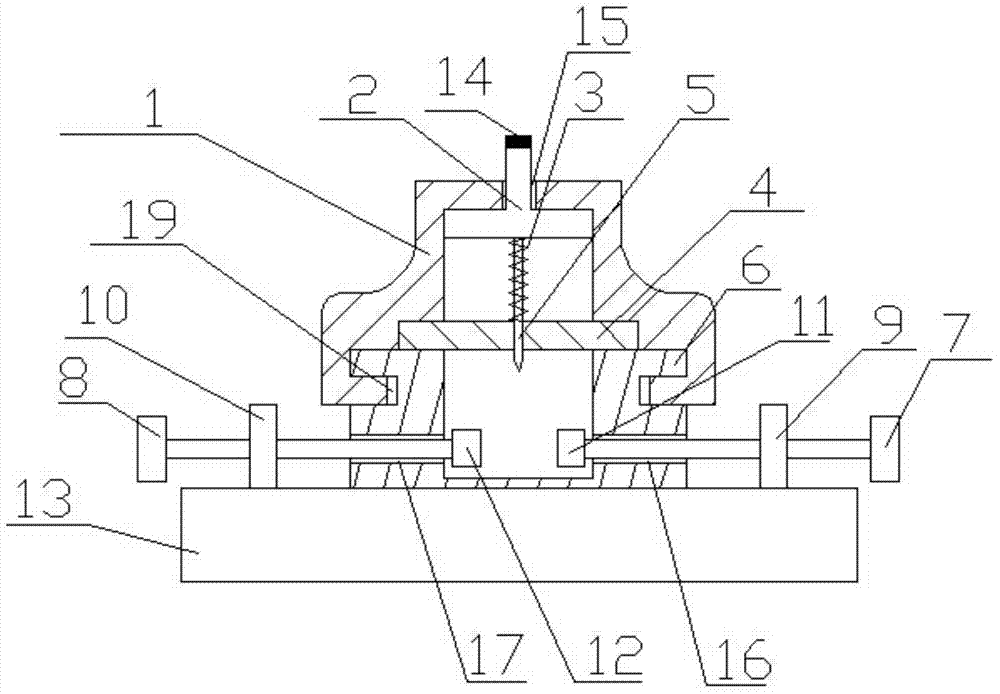

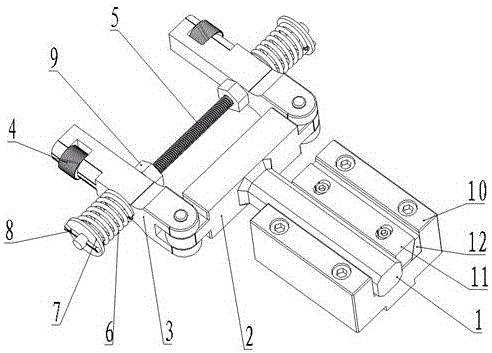

Flexible fixture device and operation method thereof

InactiveCN101570008APrecise positioningNo displacementWork holdersPositioning apparatusEngineeringMachining process

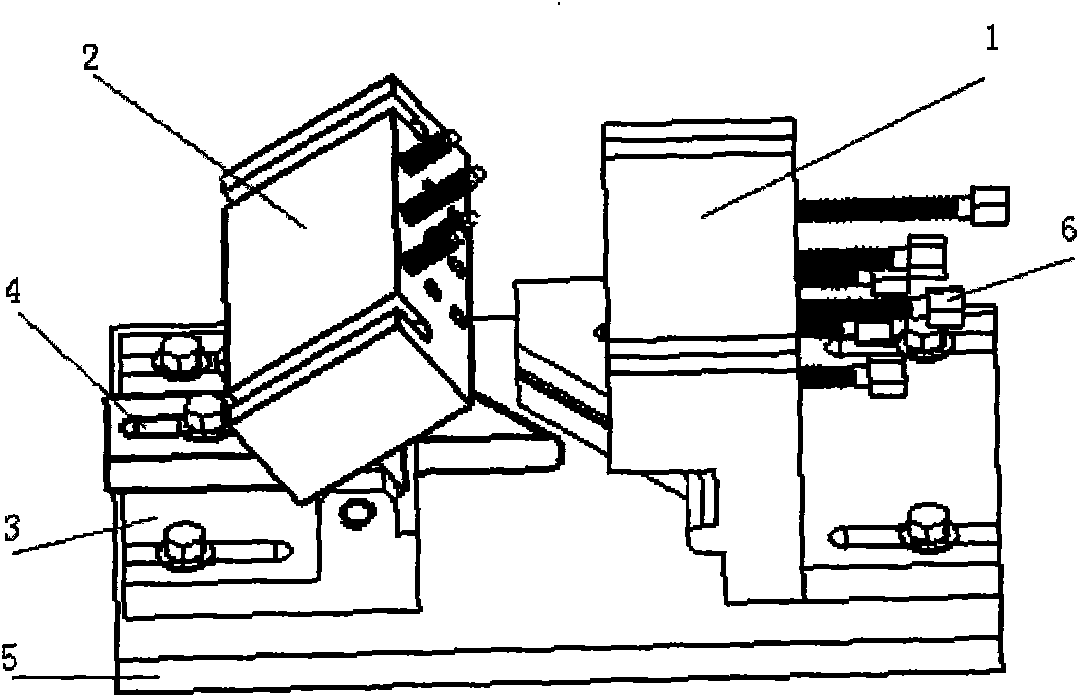

The invention provides a flexible fixture device and an operation method thereof. The device comprises a root pre-tightening block, an adjustable fixture block, an adjustable fixture support, a clamping block, a base and a clamping fixed piece, wherein the root pre-tightening block and the adjustable fixture support are fixed on two sides of the base respectively through a position regulating mechanism thereon; the clamping block is fixed on the adjustable fixture support through a position regulating mechanism thereon; the adjustable fixture block is hinged on the adjustable fixture support; the root pre-tightening block and / or the adjustable fixture block are / is provided with through holes back and forth respectively; and the through holes are inserted into the clamping fixed piece which performs flexible clamping on the surfaces of processed parts, ensures that the processed parts can obtain effective and even clamping force, and prevents the loosening and shifting during processing. Because the adjustable clamping block and clamping screws are adopted to clamp and position the roots and planes of vanes respectively, the reliable positioning of the vanes is ensured during processing, and shifting is avoided. The whole fixture device has simple structure, reliability, durability and simple operation, and provides good basis for processing and repairing vane parts in high quality.

Owner:GUANGDONG UNIV OF TECH

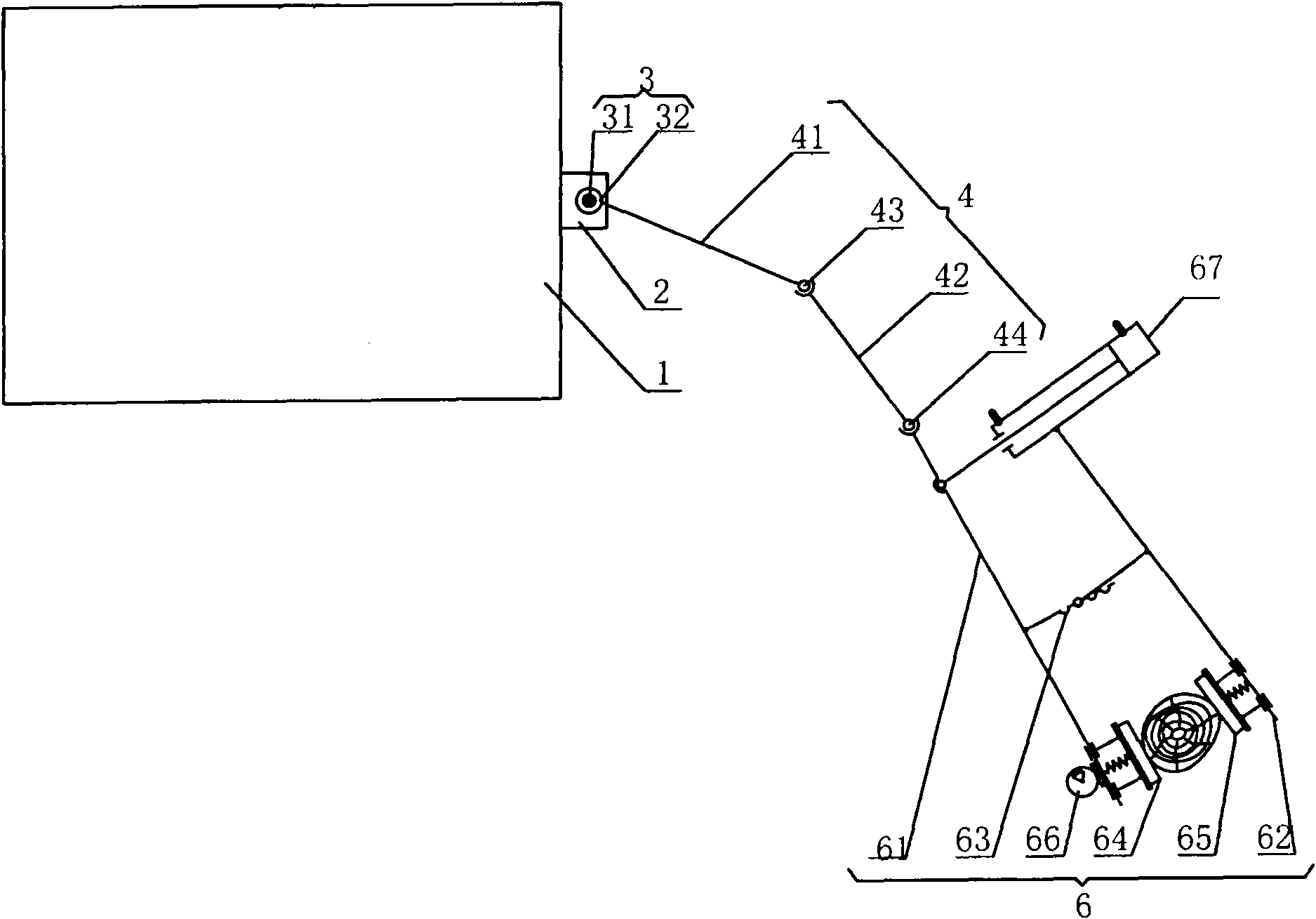

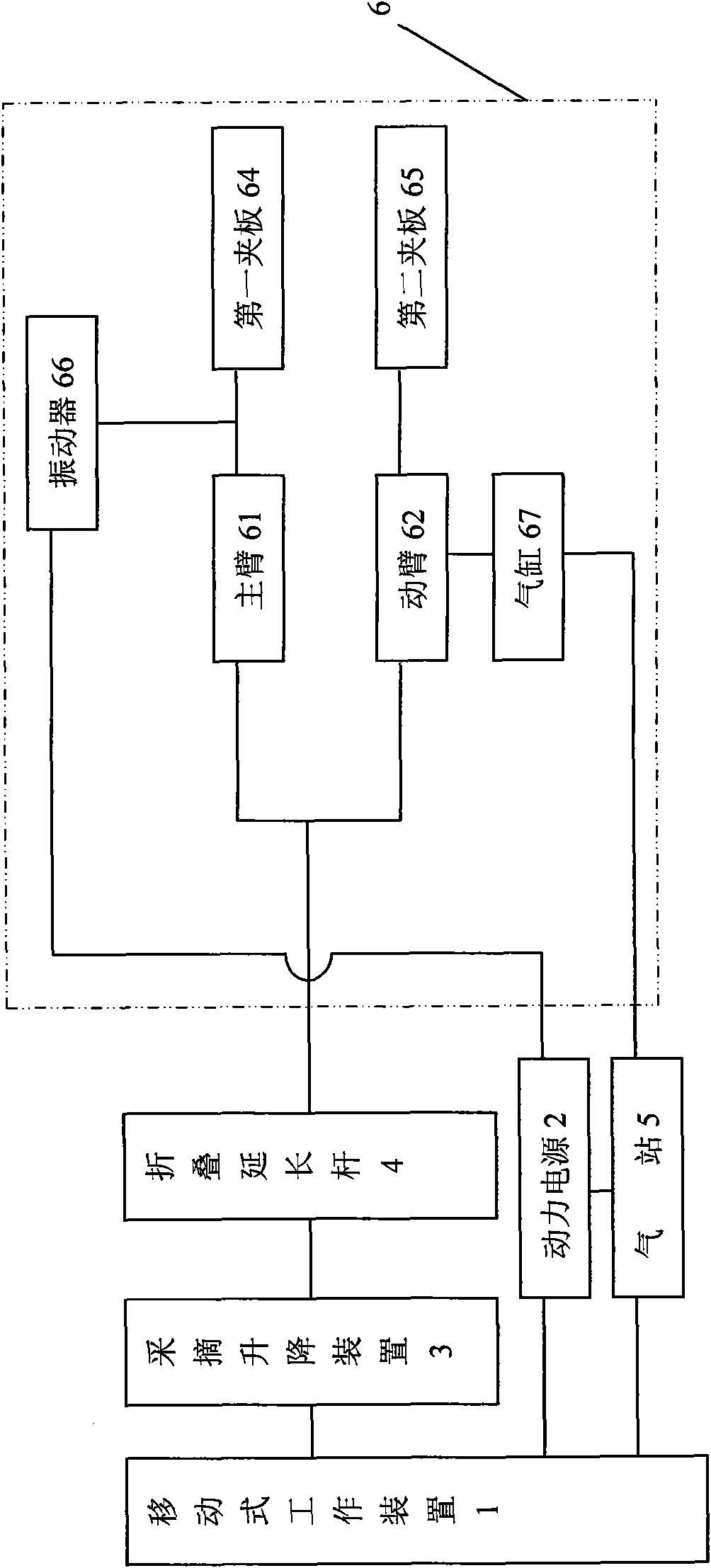

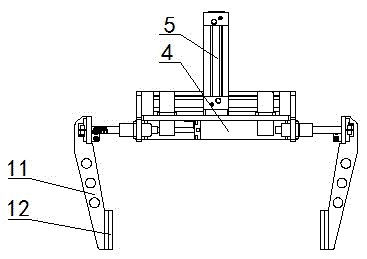

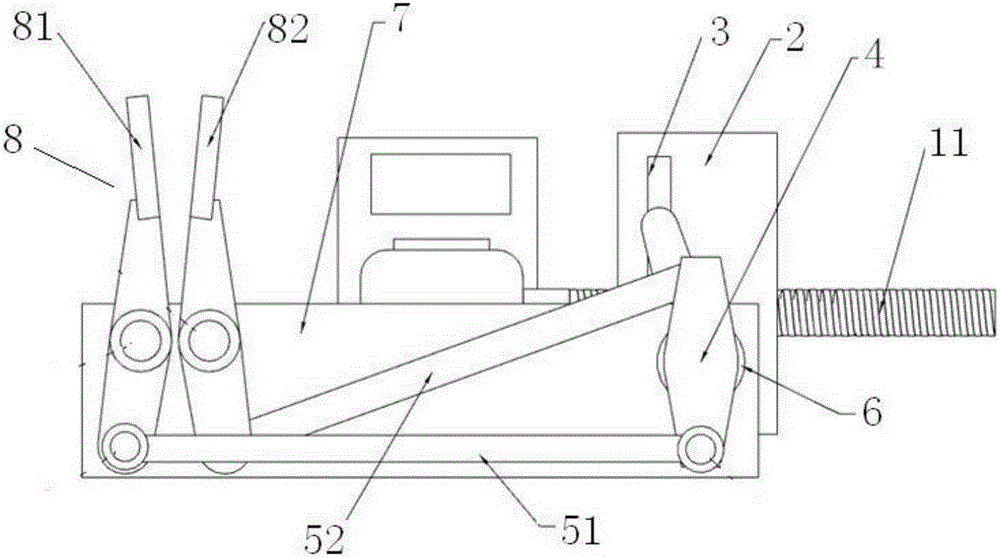

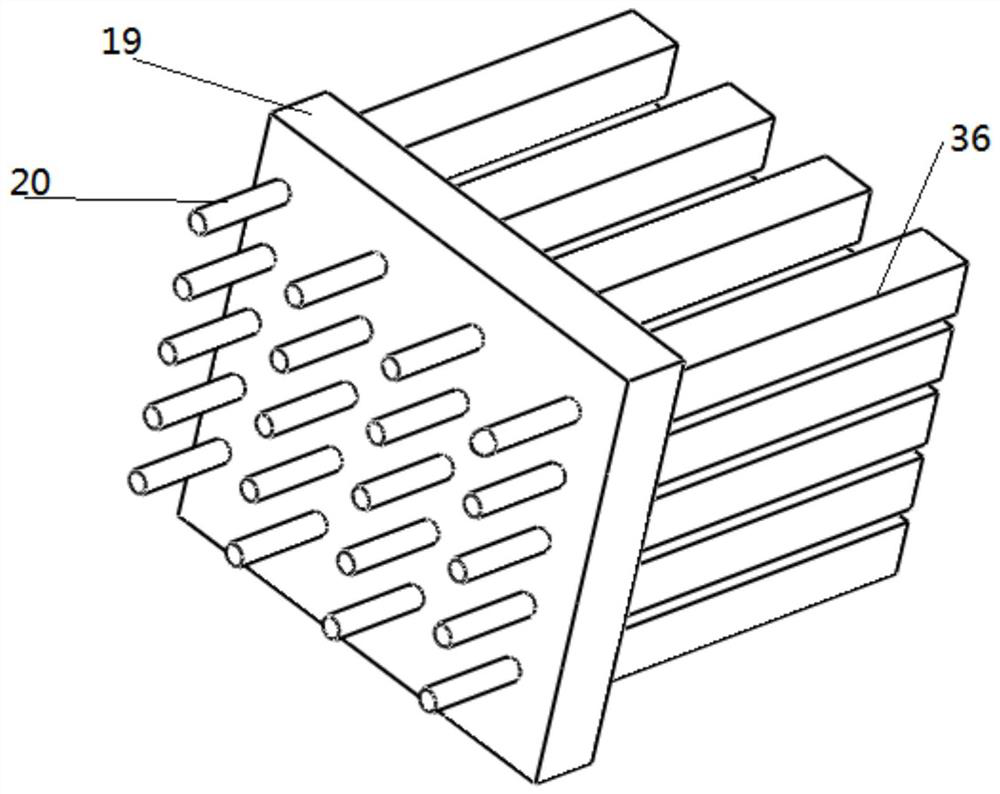

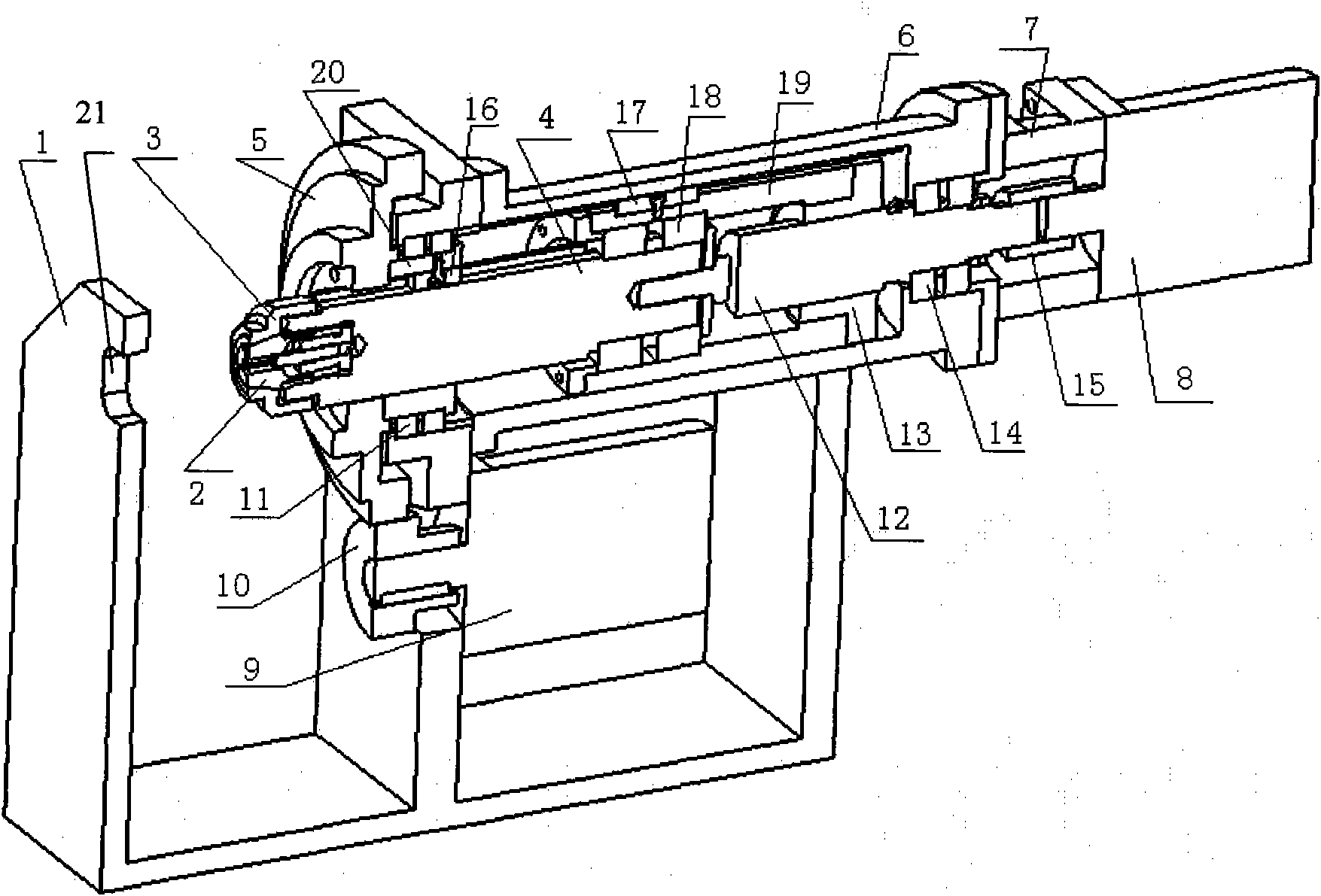

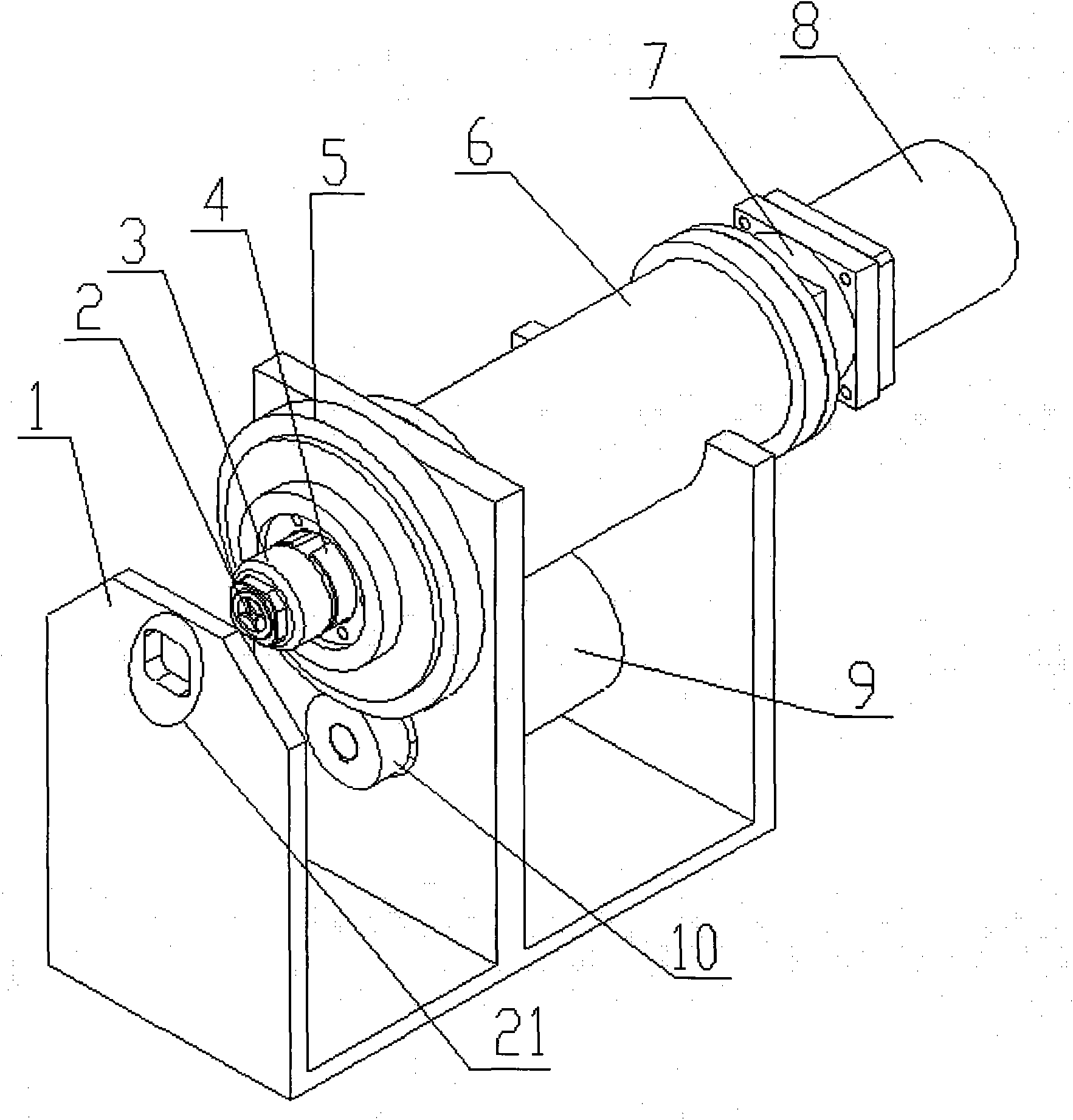

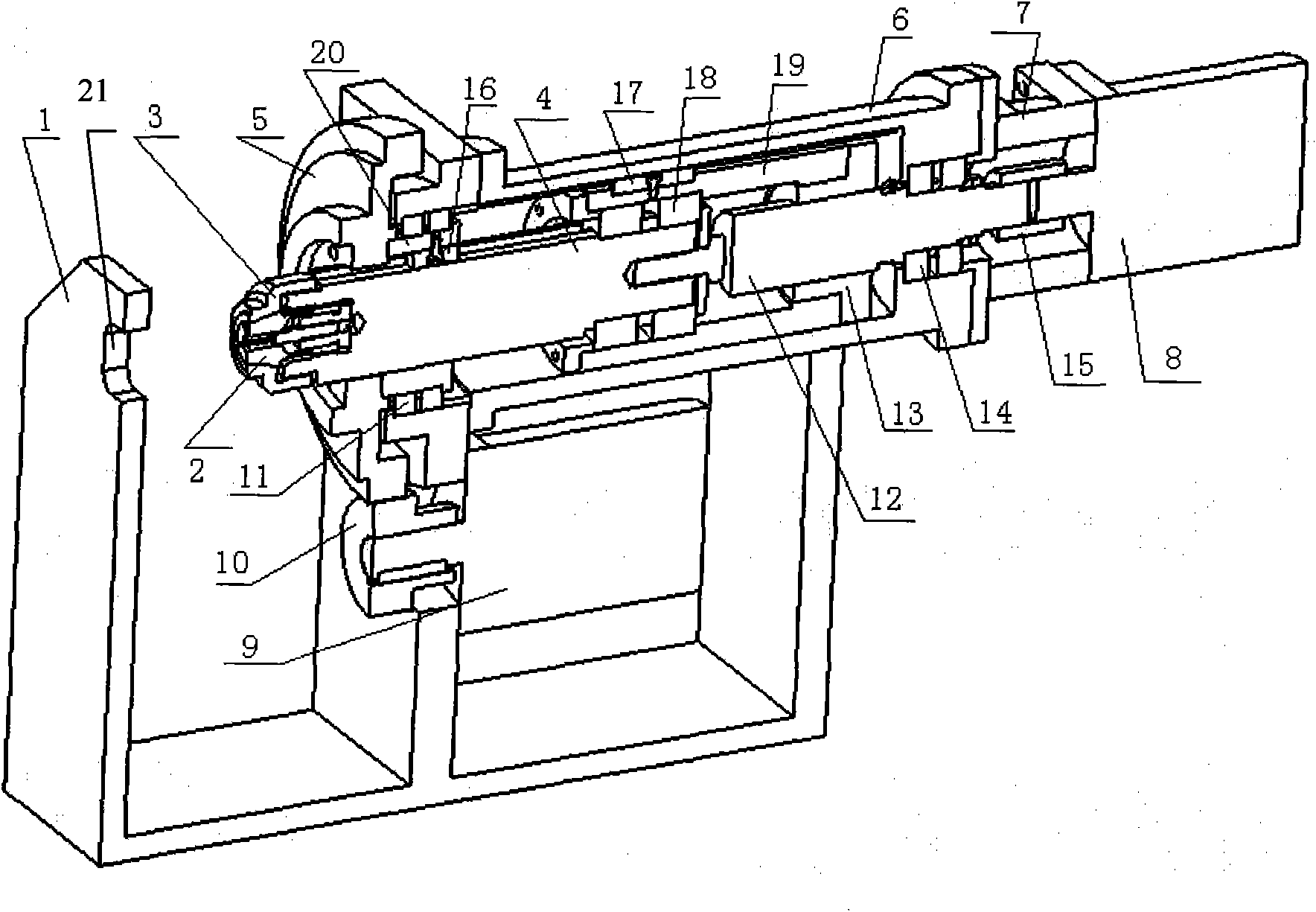

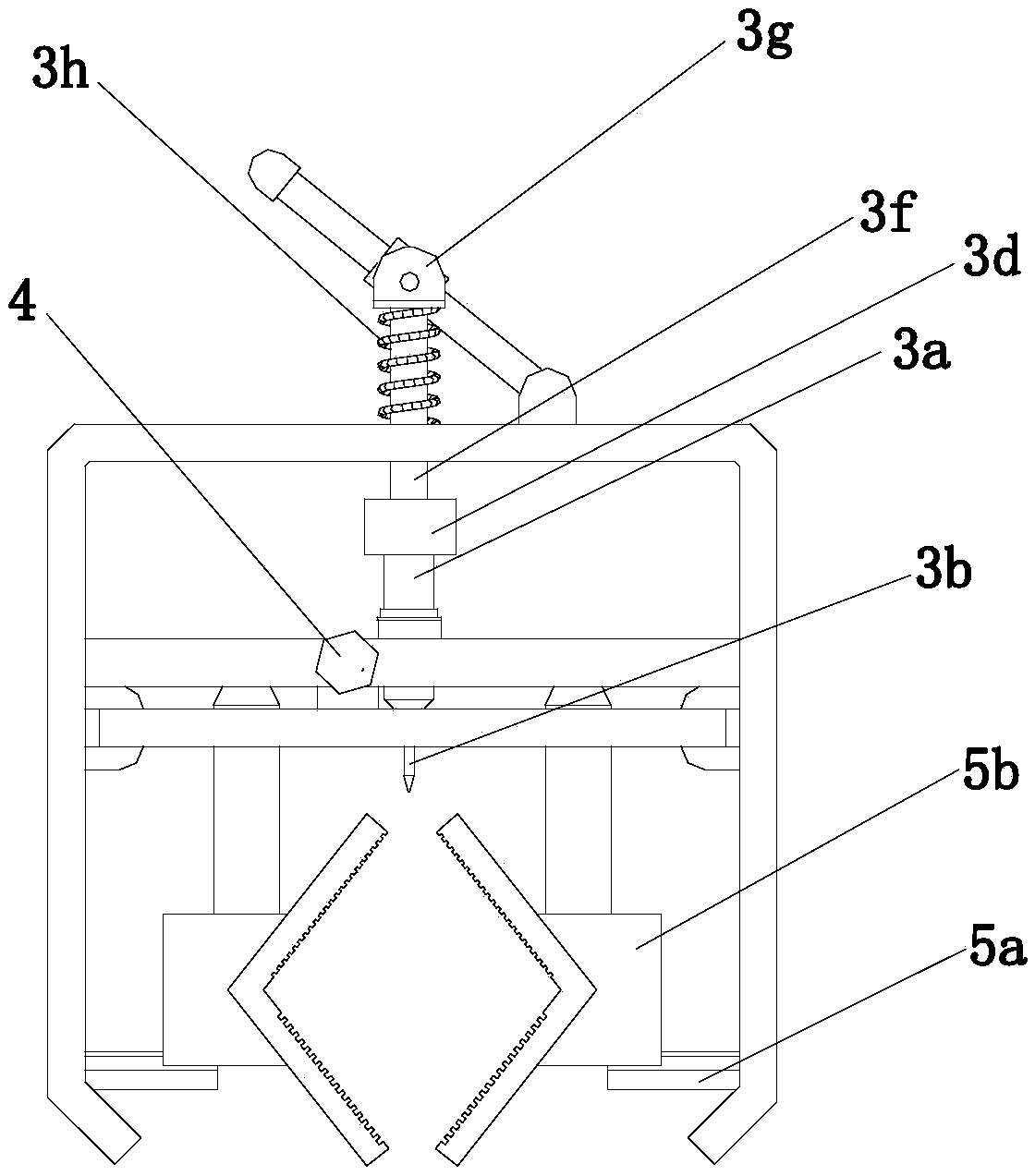

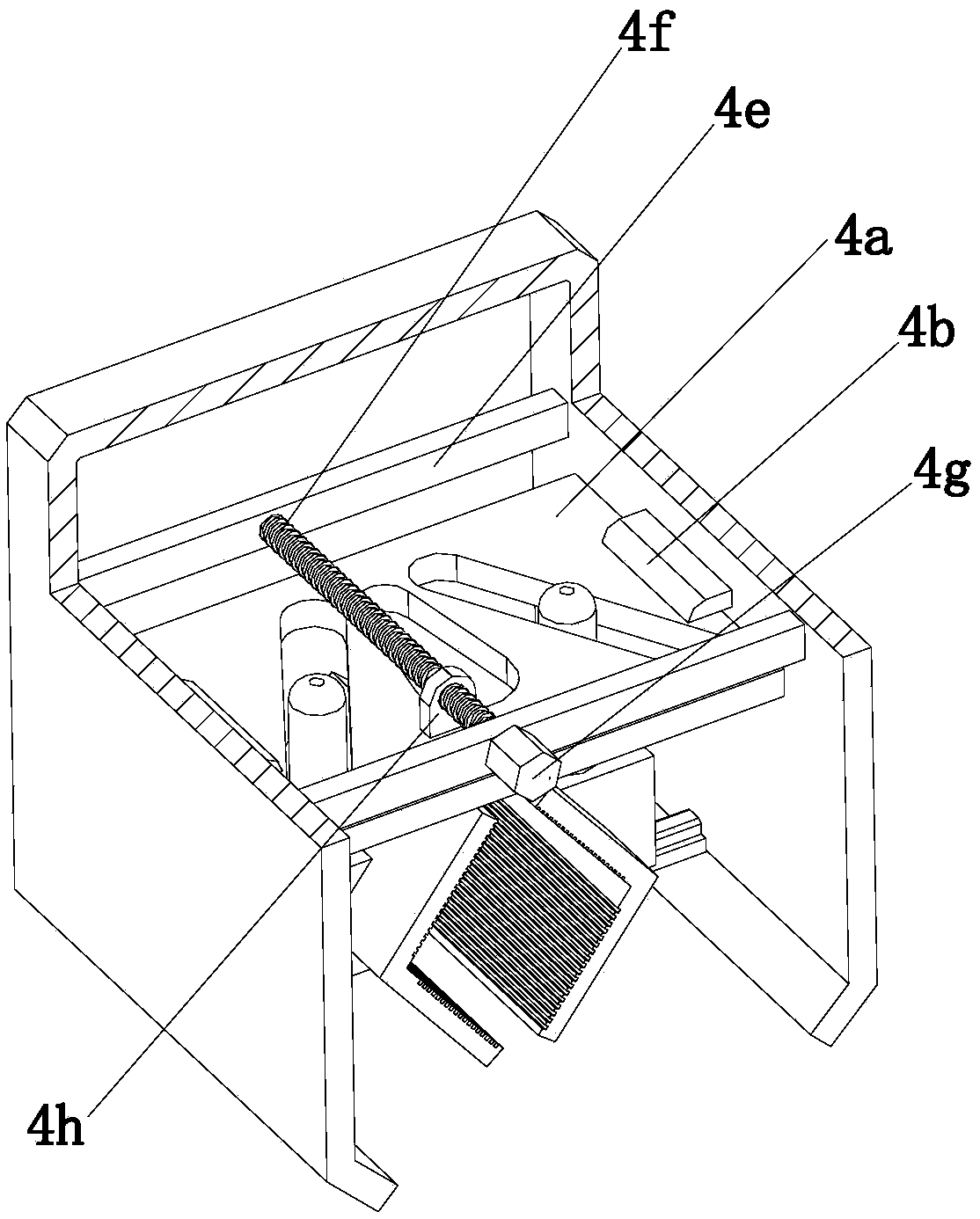

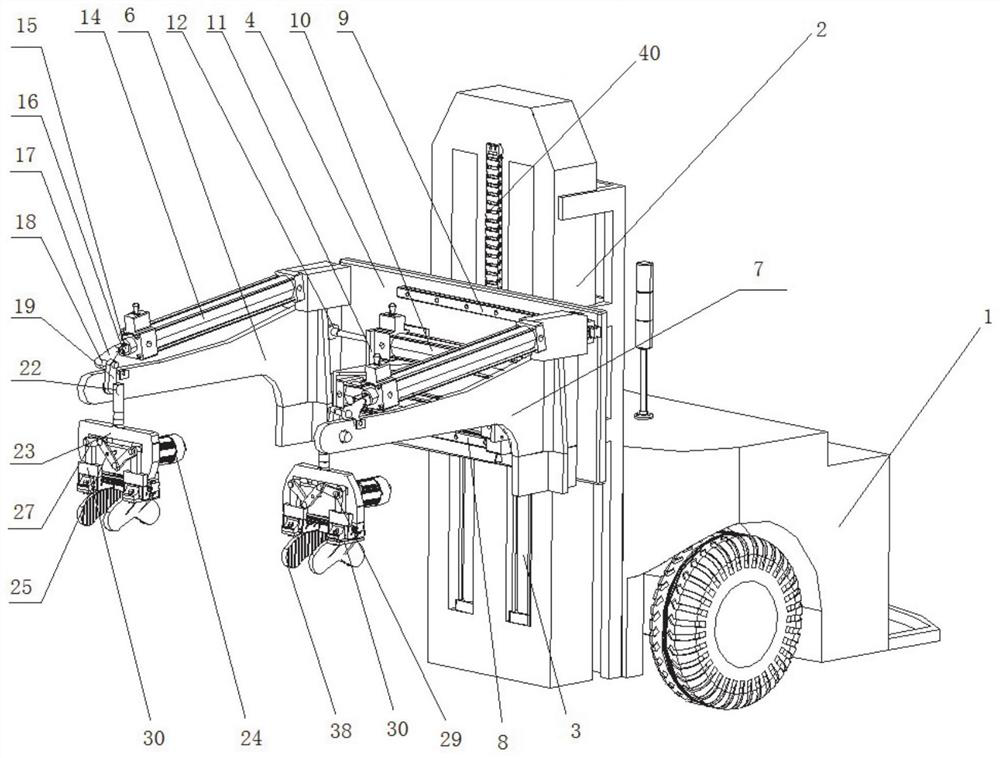

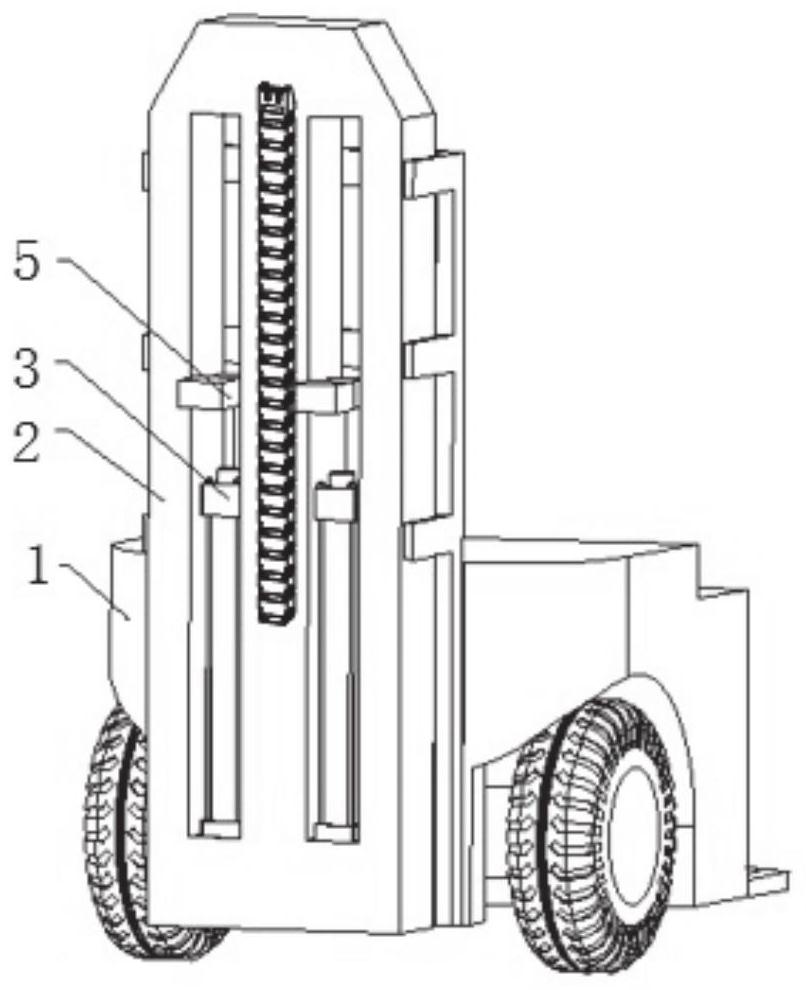

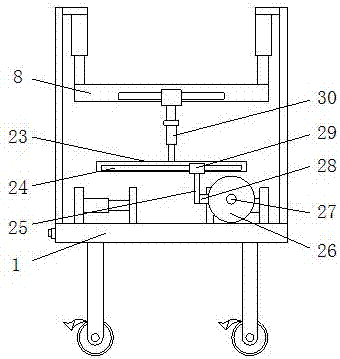

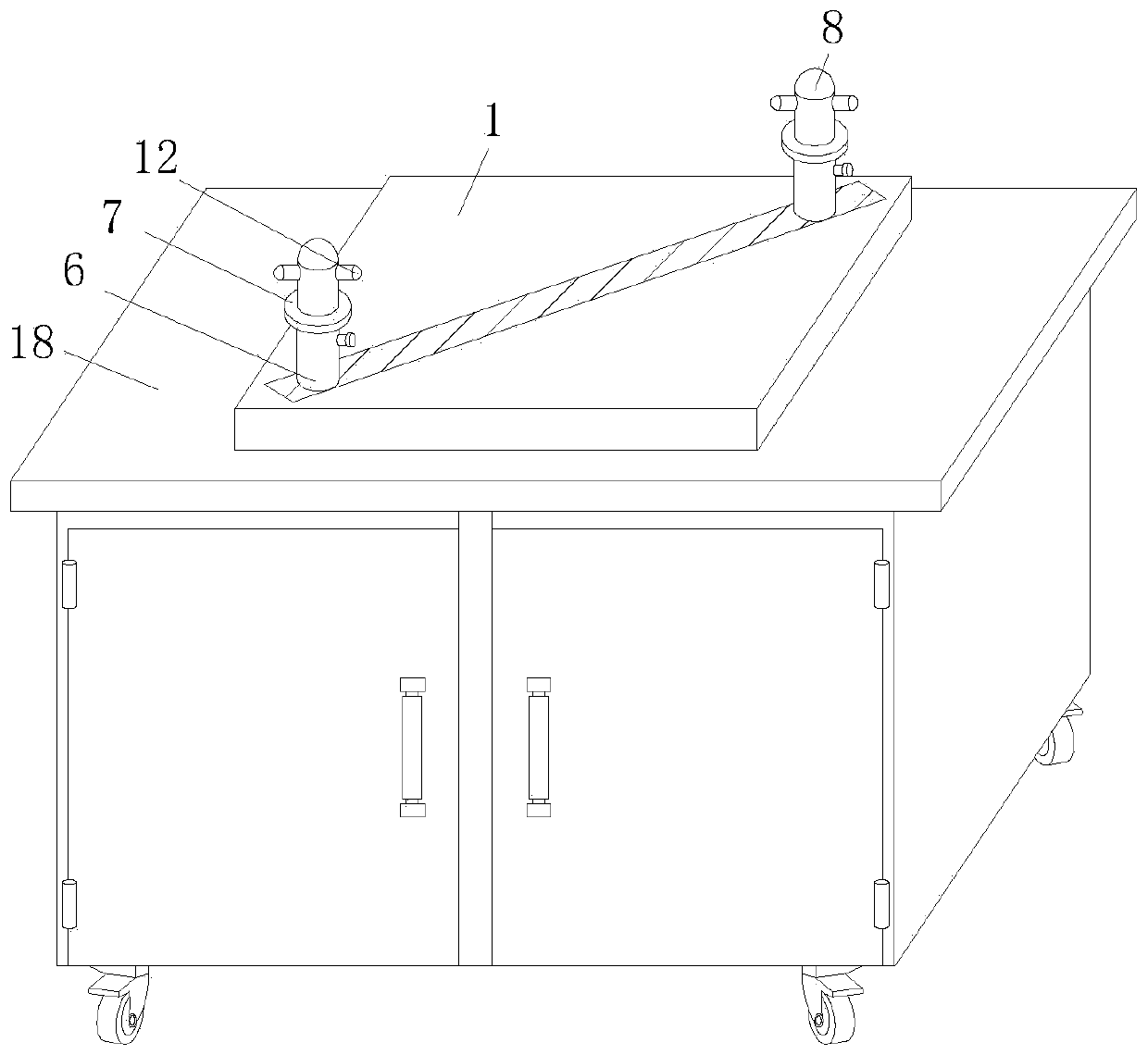

Fruit picking machine

InactiveCN101982039AMeet the clamping needsFulfilling clamping requirementsPicking devicesFruit treeWorking space

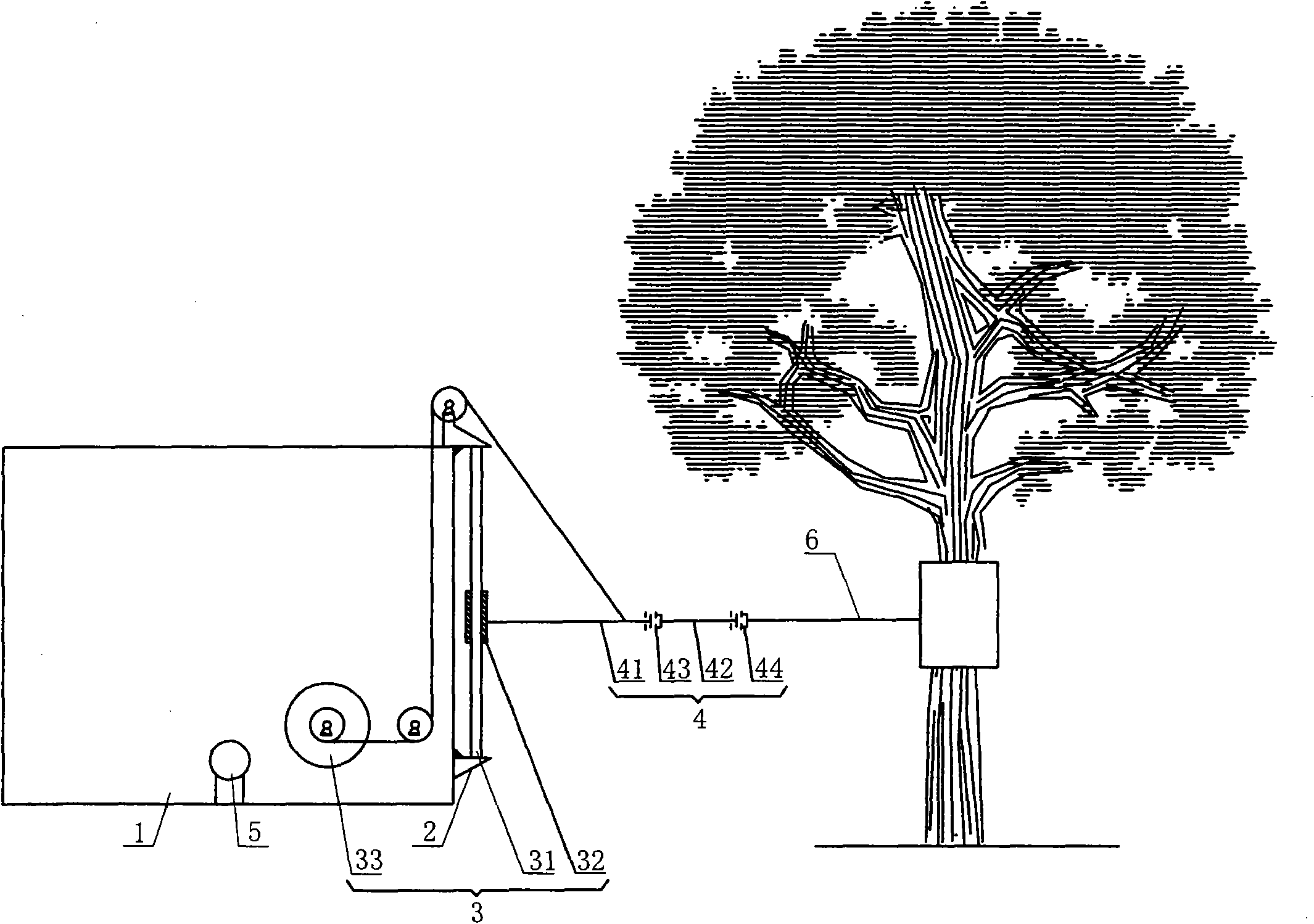

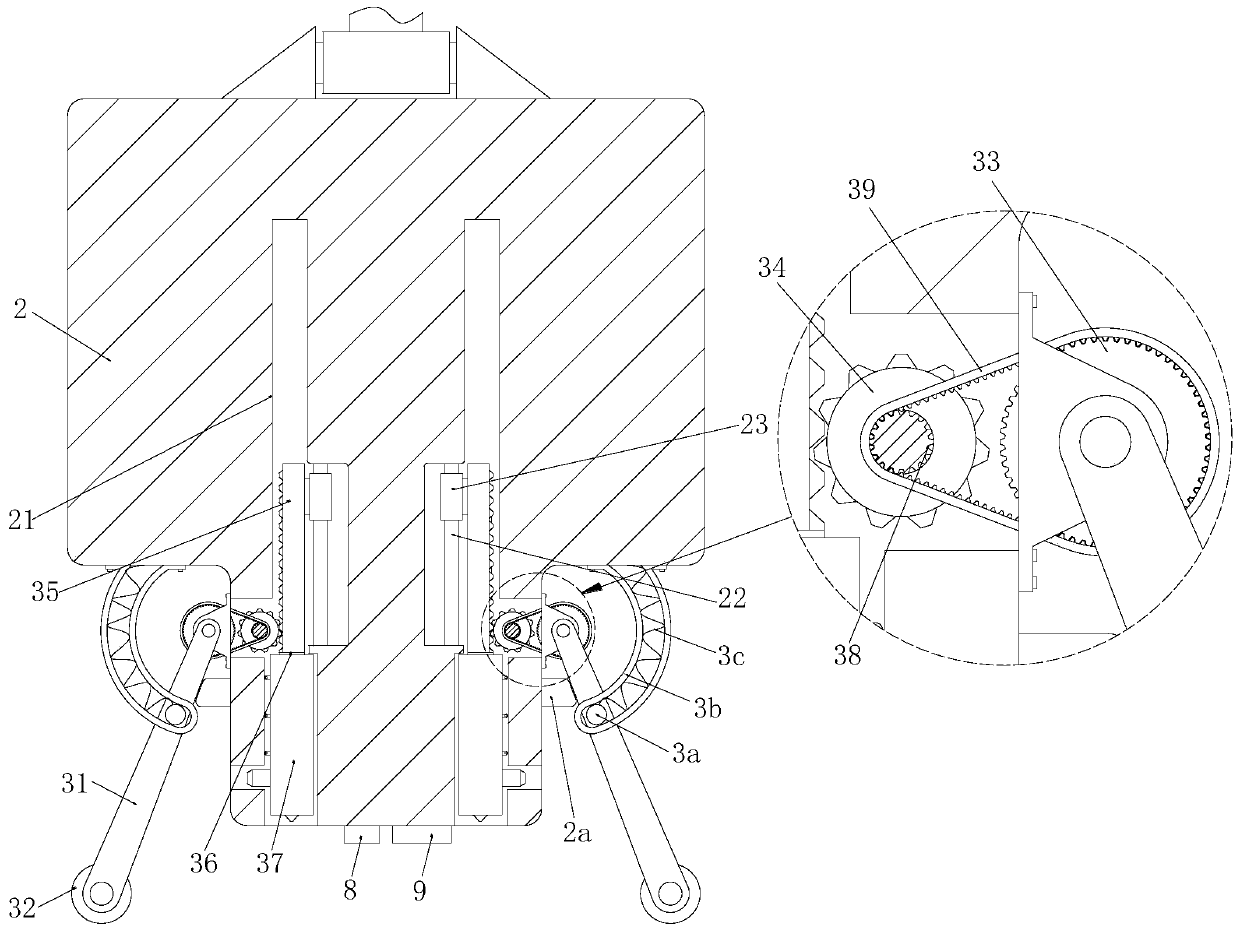

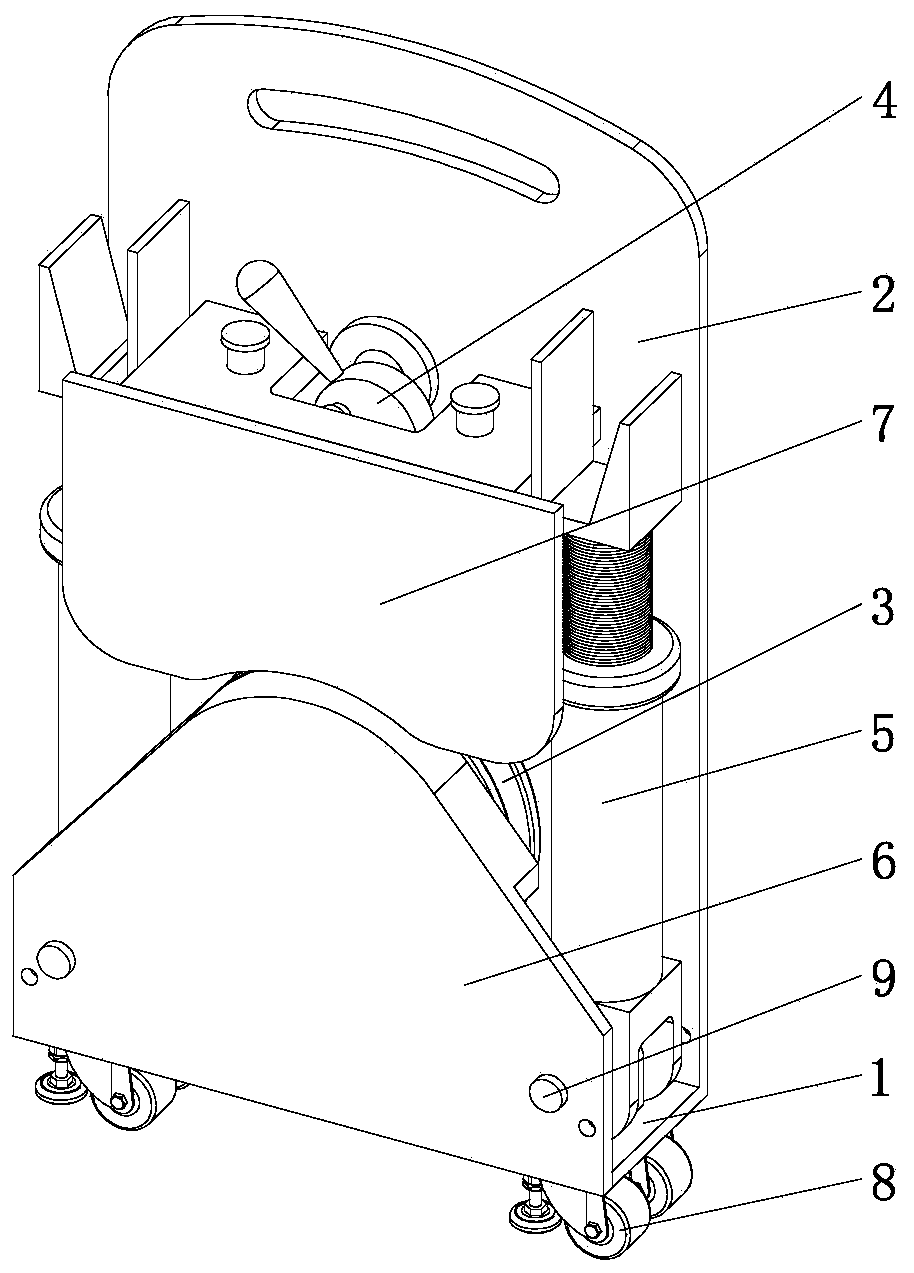

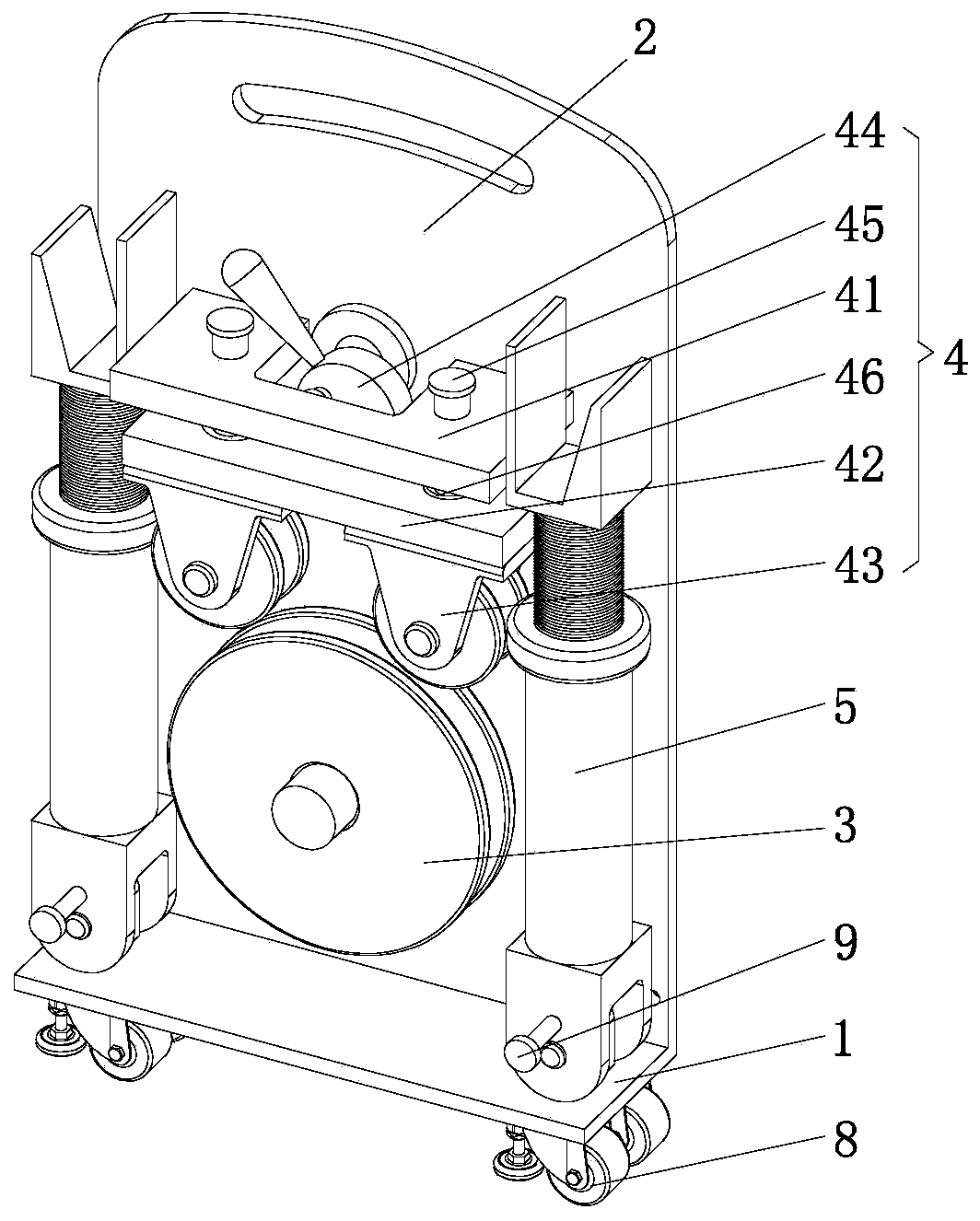

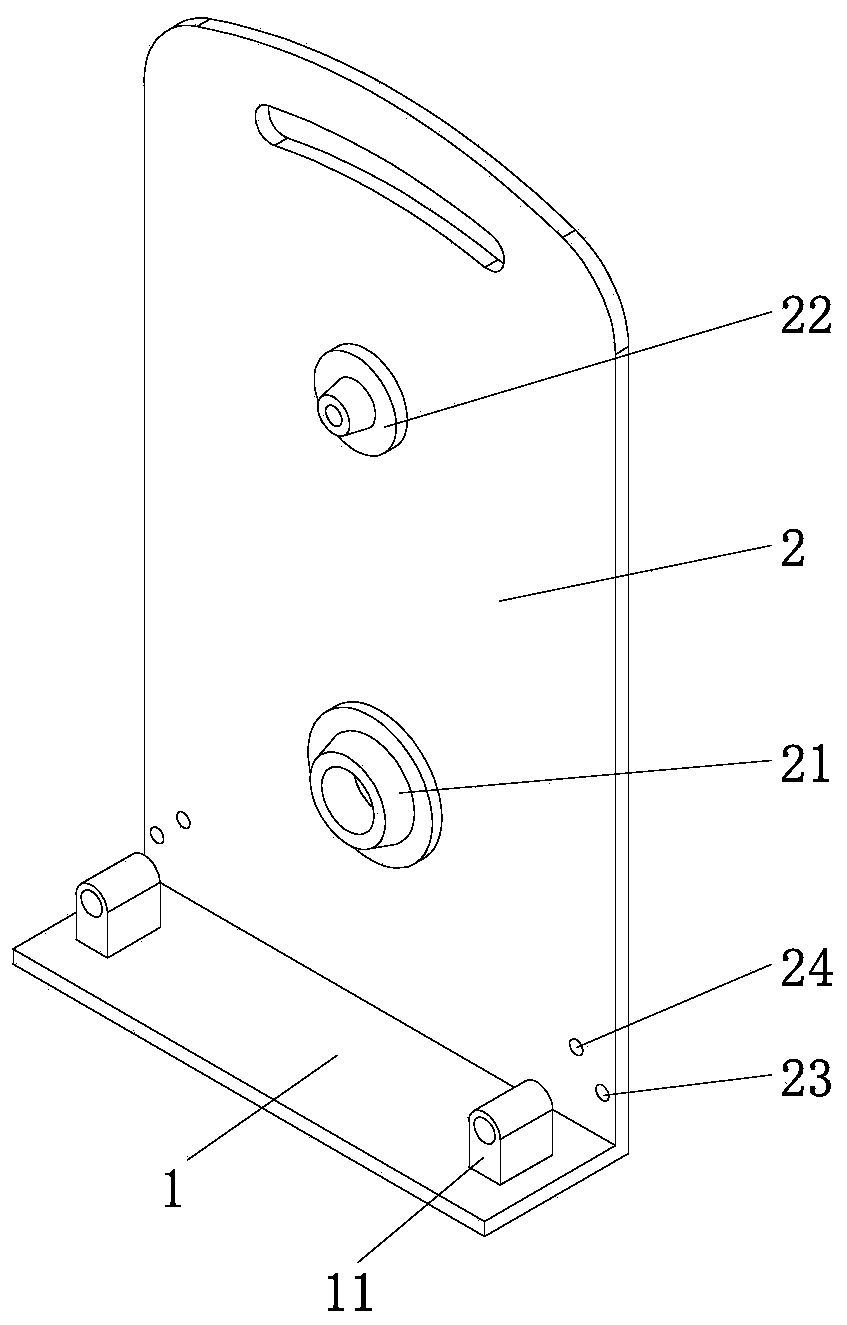

The invention discloses a fruit picking machine comprising a movable travelling gear (1), a power supply (2), a lifting gear (3) for picking, a foldable extension rod (4), a gas station (5) and a vibration picking device (6), wherein the power supply (2), the lifting gear (3) for picking and the gas station (5) are installed on the movable travelling gear (1), the foldable extension rod (4) is hinged with the lifting gear (3) for picking, and the vibration picking device (6) is hinged with the foldable extension rod (4). The vibration picking device of the fruit picking machine can clamp fruit trees of different position distances and heights. Because of adopting a crawler-type travelling gear, the invention is suitable for picking fruit in hill countries, in particular to working face with big gradient of mountain roads. The machine is flexible and has high work efficiency, small requirement on working space and high harvest efficiency.

Owner:NANTONG GUANGYI ELECTROMECHANICAL CO LTD

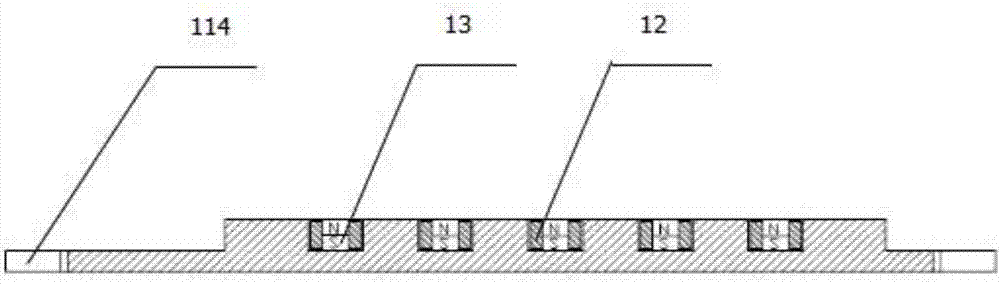

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

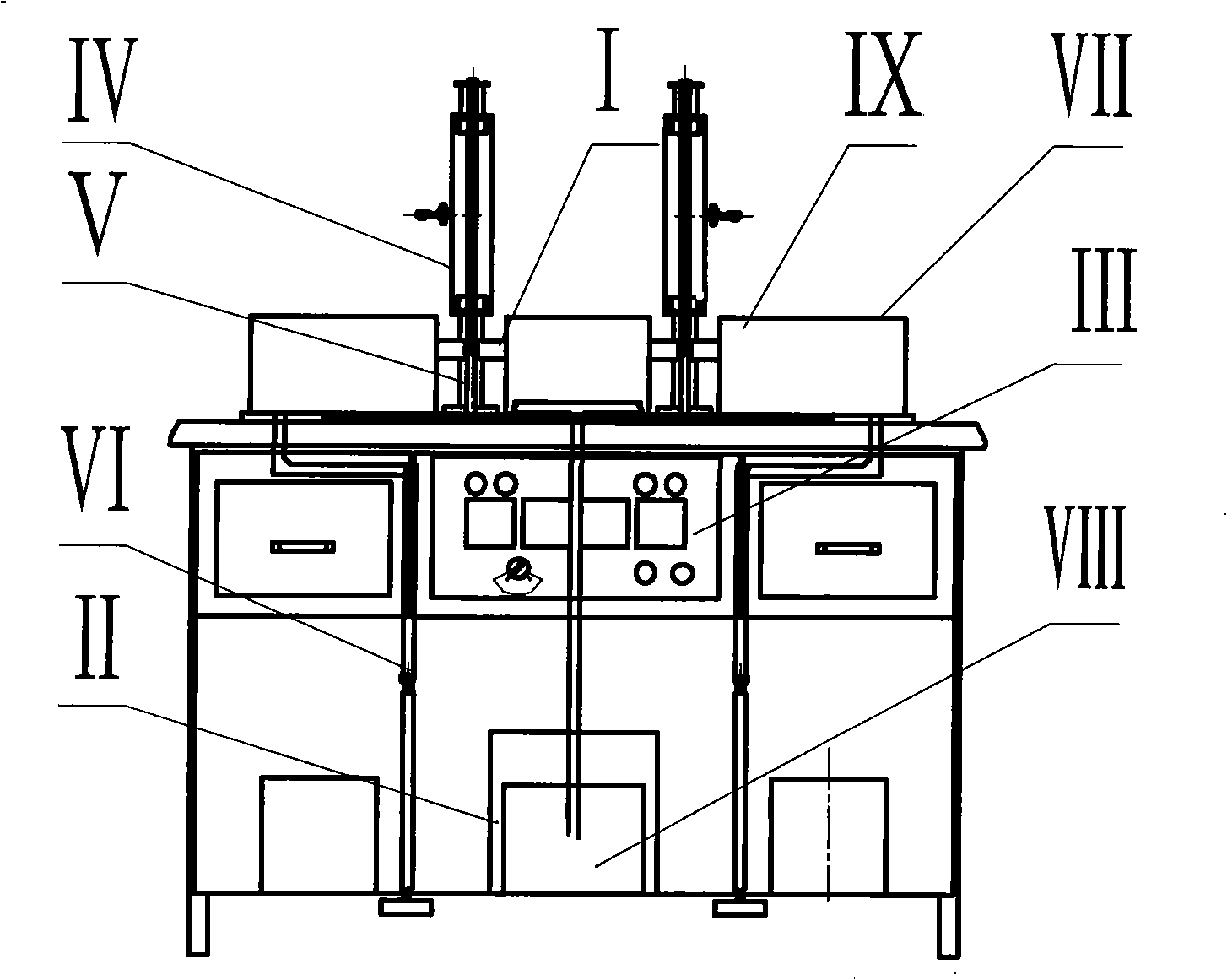

Cable and pin tube cavity contact pair as well as apparatus and method for brazing cable connector

InactiveCN101355220AFirmly connectedGuarantee welding qualityLine/current collector detailsSoldering apparatusElectrical resistance and conductanceGraphite electrode

The invention provides a device and a method for brazing cables and pin tube cavity contact pairs as well as cable joints, belonging to the technical field of cable connection in the electric power industry. The device is characterized in that: the device comprises a pair of graphite or graphitized electrodes I used for elastically clamping a weldment matrix, an electric control system III generating low voltage and high current, as well as a brazing operation table IX; a voltage between 2 and 15 V and a current between 50 and 500 A are transmitted to a welded piece matrix through the graphite electrodes I with the resistance between 5 and 60 omega, and solder in a pin tube cavity or a wiring hole of the welded piece matrix is heated to be between 130 and 600 DEG C, so as to complete the brazing connection of the cables and the pin tube cavity contact pairs or the cable joints. The device has the advantages that the good connection among the cables, the pin tube cavity contact pairs or the cable joints is realized, and brazing equipment is high in machining efficiency, good in safety protection property, high in automation degree, convenient to operate and good in agreeableness.

Owner:DALIAN UNIV OF TECH

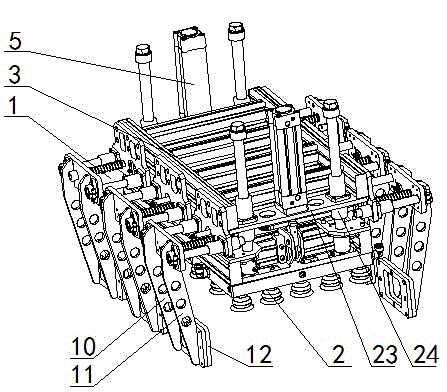

Clamping device of manipulator

The invention discloses a clamping device of a manipulator. The clamping device comprises a floating clamping mechanism (1) and an adsorption mechanism (2), wherein the floating clamping mechanism (1) comprises a frame (3) which is located on the upper end face of the adsorption mechanism (2); clamping groups in pairs are arranged on the frame (3); a cylinder A (4) for driving the clamping groups to stretch and close is arranged on the upper end face of the frame (3); a cylinder B (4) for driving the adsorption mechanism to move up and down is vertically arranged on the upper end face of the frame (3). The clamping device of the manipulator has the advantages of simple structure and high reliability; the clamping device of the manipulator is capable of freely adjusting the clamping position and meeting the requirements of clamping; a mechanical finger mechanism A and a mechanical finger mechanism B are used for clamping workpieces to meet the requirements of the clamping; a sucker group is arranged to attach the workpieces and achieve the requirement of stability.

Owner:CHONGQING JIANGDONG MACHINERY

Double-rocker clamping mechanism

InactiveCN105351302ASimple structureThe transmission method is simple and reliableWork holdersFriction grip releasable fasteningsSmall footprintEngineering

Owner:GUANGXI UNIV

Adjustable sheet material clamping jaw

The invention discloses an adjustable sheet material clamping jaw which comprises a fixed rack and sliding plates arranged on two sides of the fixed rack, wherein a control cylinder is arranged on the fixed rack; a fixed clamping jaw and a first adjustment sliding rail are arranged at two ends of the fixed rack; the control cylinder is matched with a screw rod; the screw rod is matched with a guide sleeve; guide rods are arranged at two lateral parts of the guide sleeve and are in sliding fit with the sliding plates; an elastic deboosting part is arranged between each guide rod and the corresponding sliding plate; movable clamping jaws and second adjustment sliding rails are arranged on the sliding plates; wedge blocks matched with each other are arranged on the sliding plates and the fixed rack. According to the adjustable sheet material clamping jaw, the fixed rack is matched with the oblique planes of the wedge blocks on the sliding plates, and the sliding plates are matched with the guide sleeve through the elastic deboosting part, so that the control cylinder can control the movable clamping jaws to move towards the outer side and sink simultaneously or to withdraw towards the inner side and rise simultaneously through one-time action; the control manner is simple, and the working efficiency is high; the fixed clamping jaw and the movable clamping jaws can be adjusted in a sliding manner to meet the demand of clamping different sheet materials.

Owner:SUZHOU SHUNYI HARDWARE

Fixture

The invention discloses a fixture. The fixture comprises a fixture body and a slide rod; the slide rod is connected with the fixture body; the fixture body is C-shaped, and consists of a slide rod connecting part and a clamping part; a connecting hole is formed in the end of the slide rod connecting part; a locking mechanism is mounted on the slide rod connecting part; the slide rod connecting part and the clamping part directly pass through a length adjusting rod; a fixing head is mounted at the end, making contact with the clamping part, of the slide rod; a return device is mounted between the fixing head and the slide rod connecting part; and an extension handle is mounted at the end, opposite to the fixing head, of the slide rod. Through the mode, the length of the fixture can be adjusted to satisfy the clamping demands of workpieces with different sizes, so that the generality of the fixture is greatly increased.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

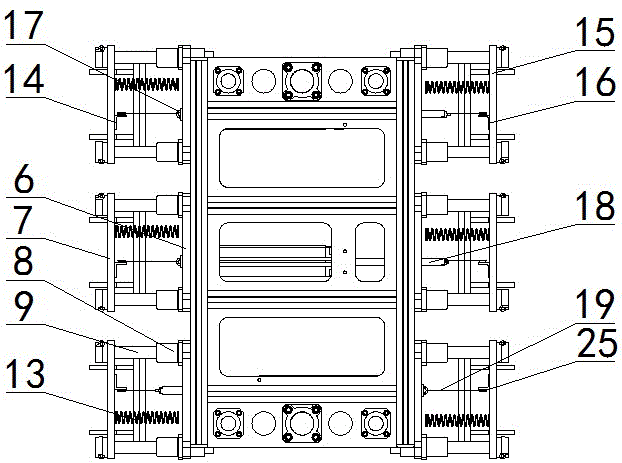

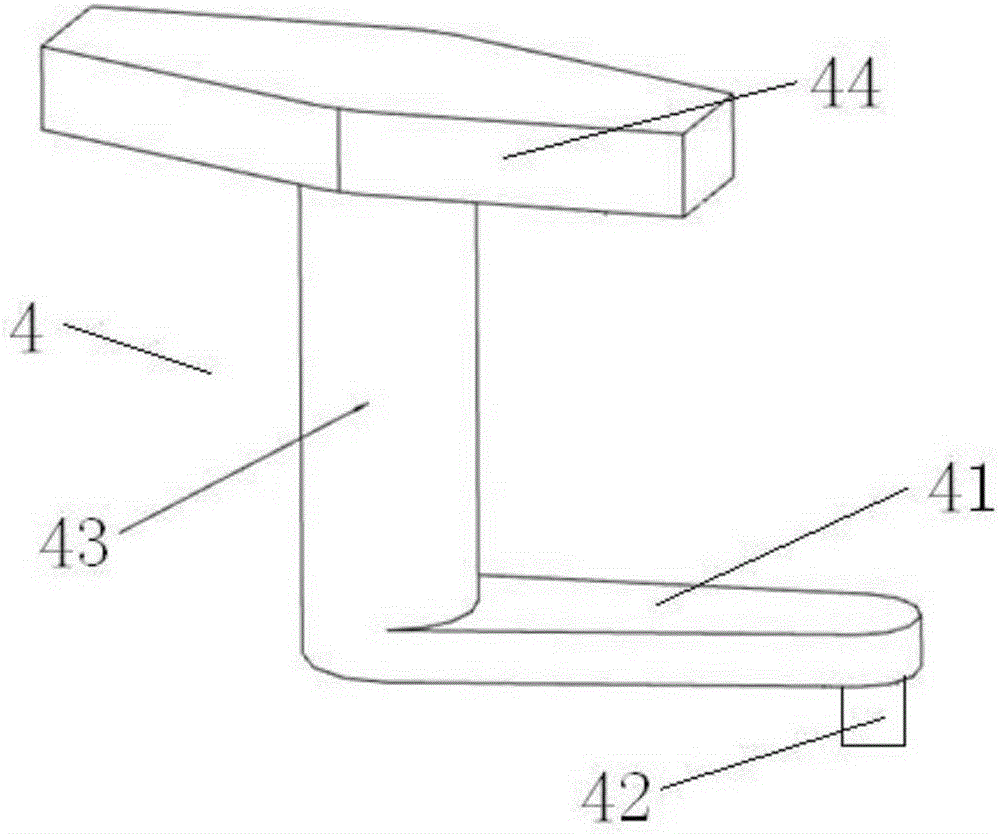

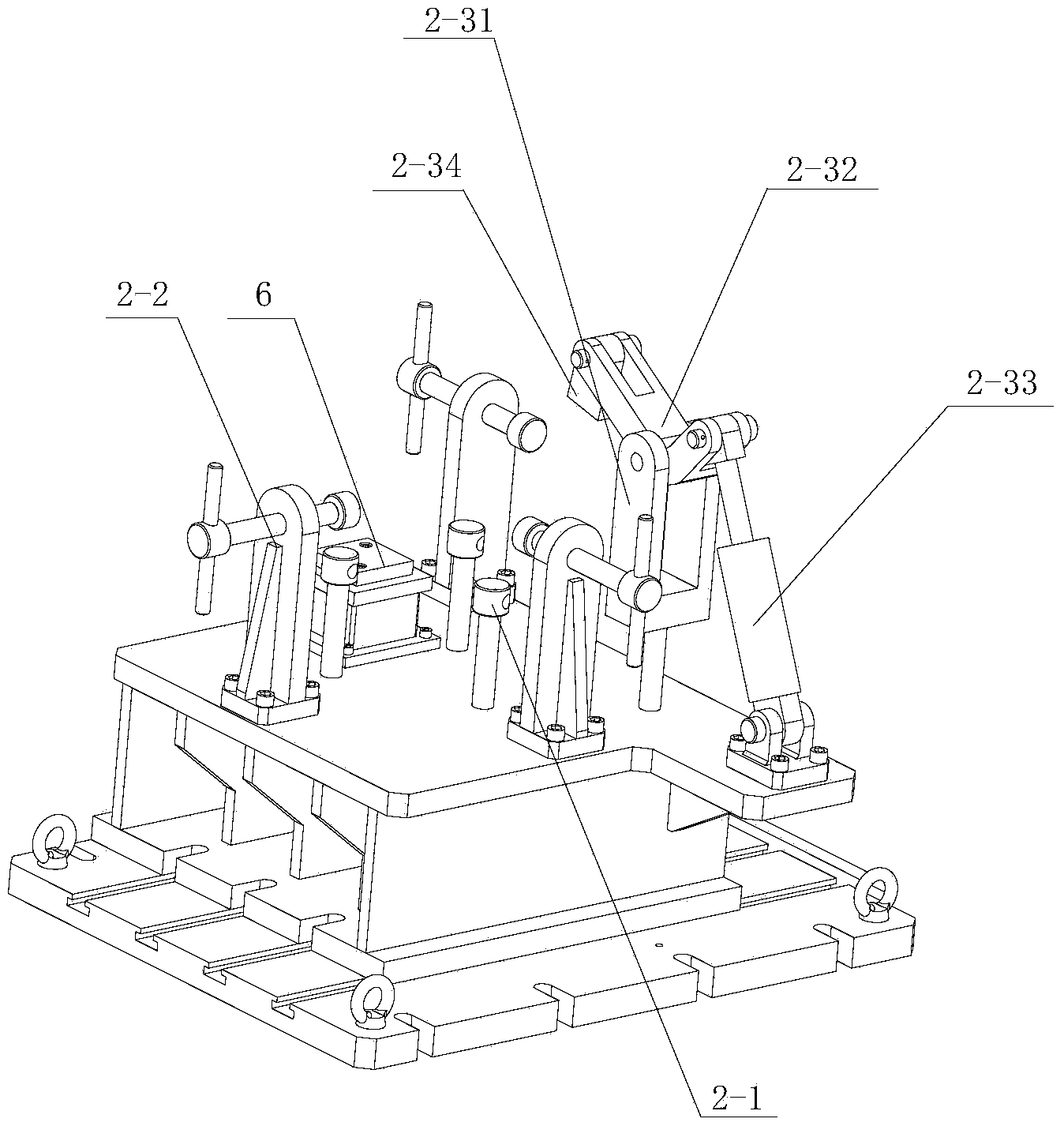

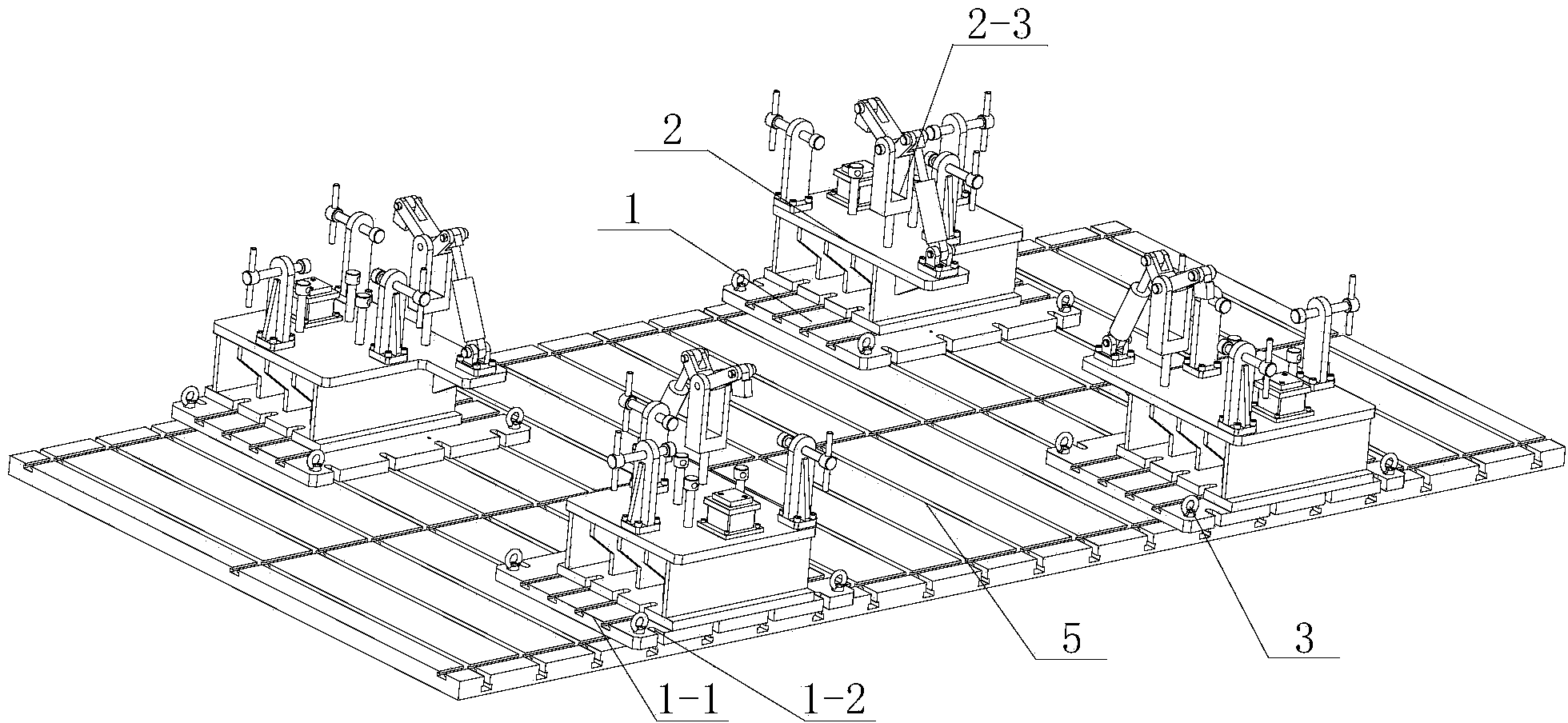

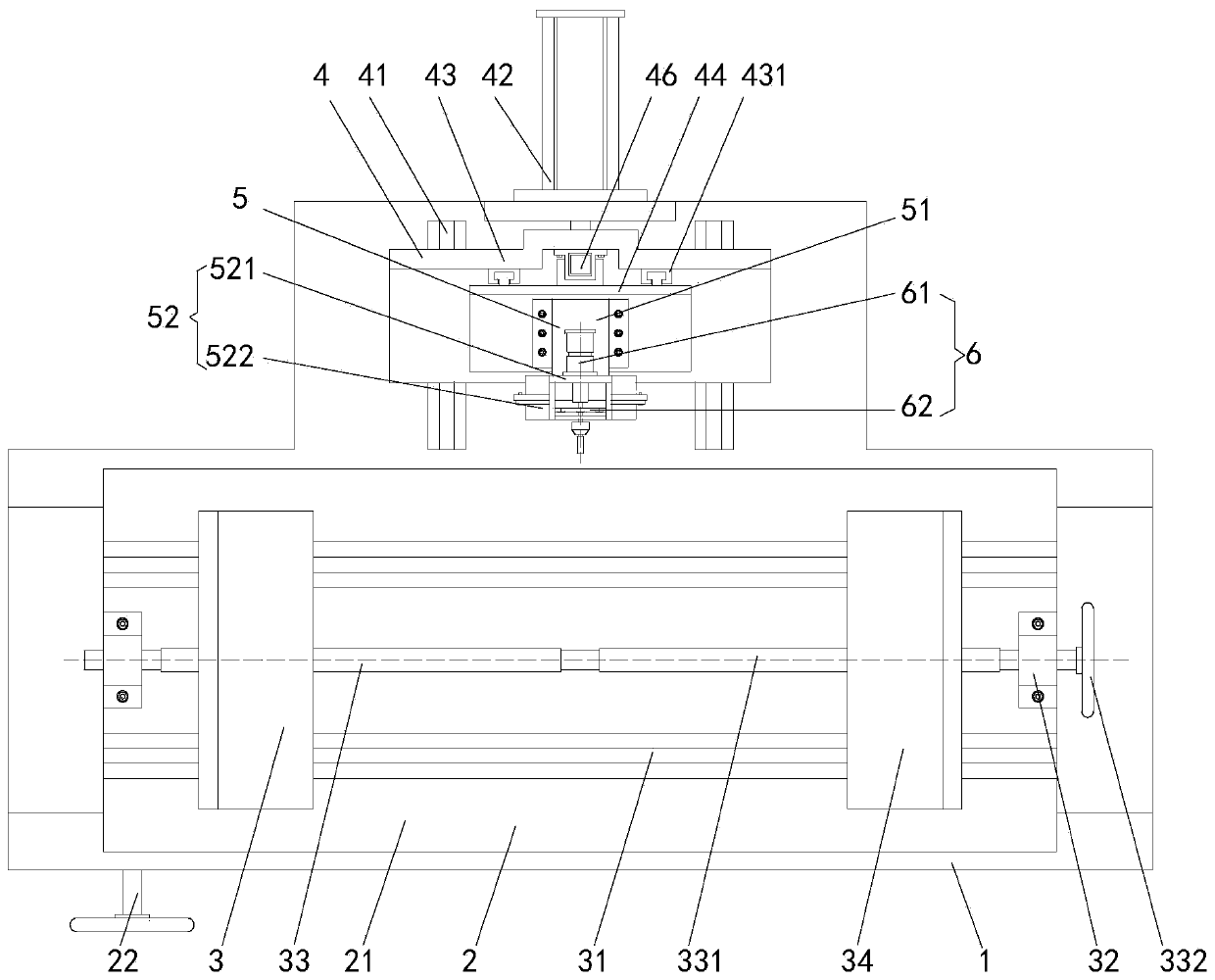

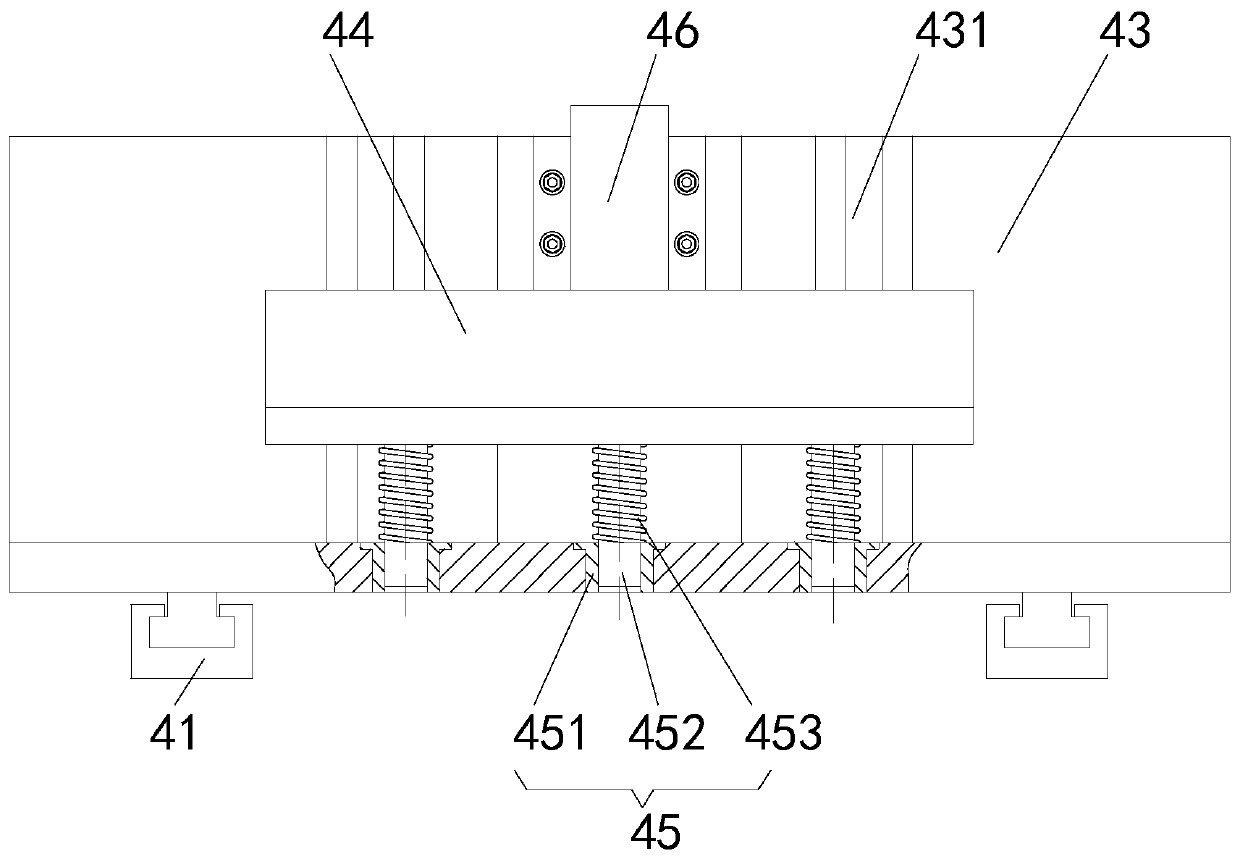

Universal hydraulic tool for framework machining

ActiveCN103406793AMeet clamping needsImprove clamping efficiencyPositioning apparatusMetal-working holdersHydraulic ramMachining

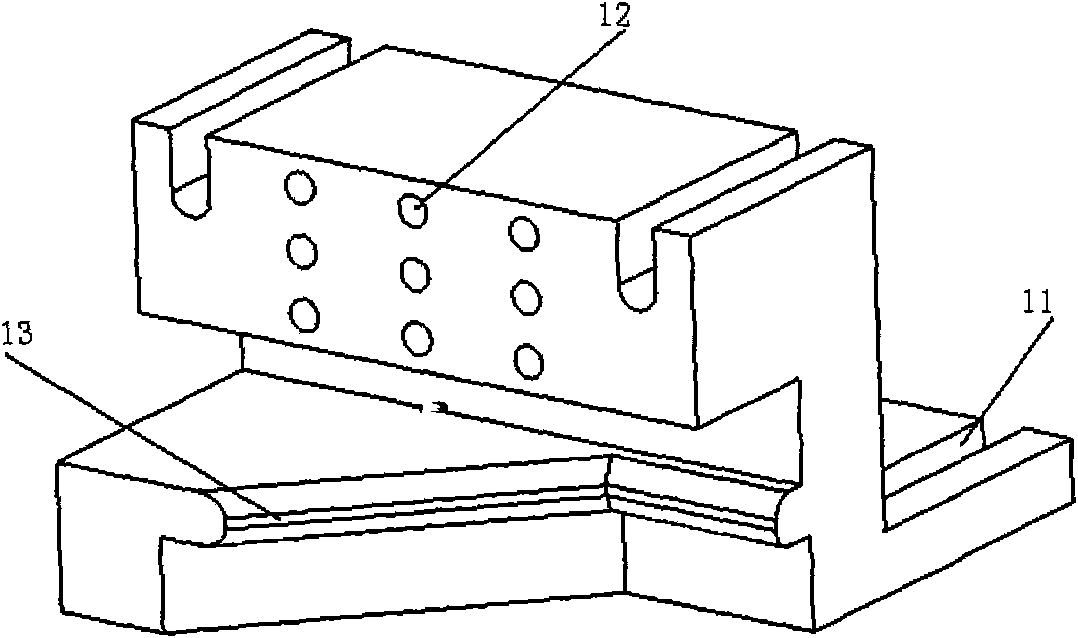

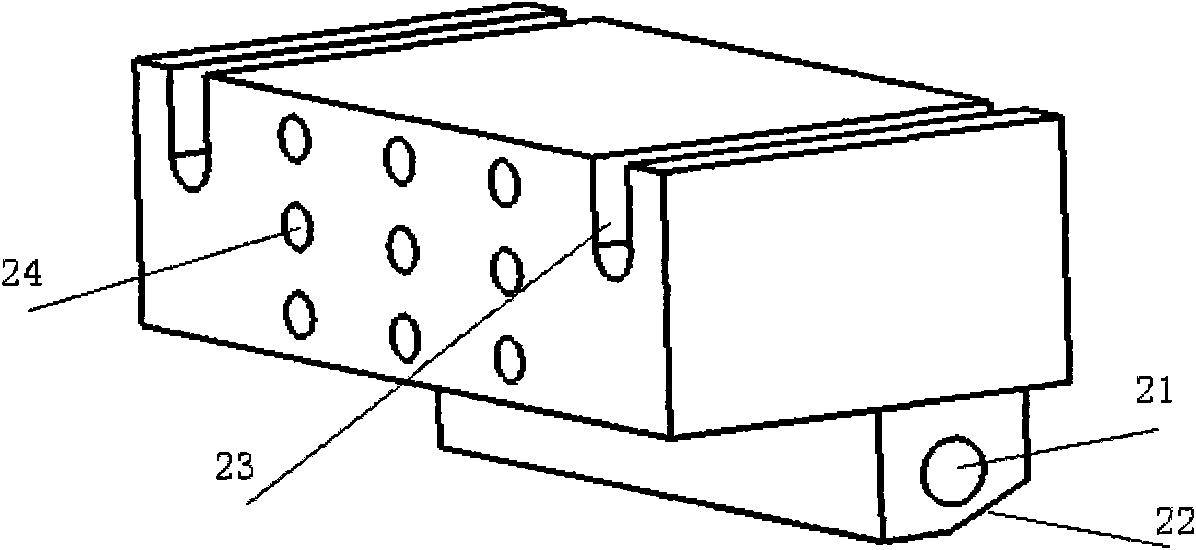

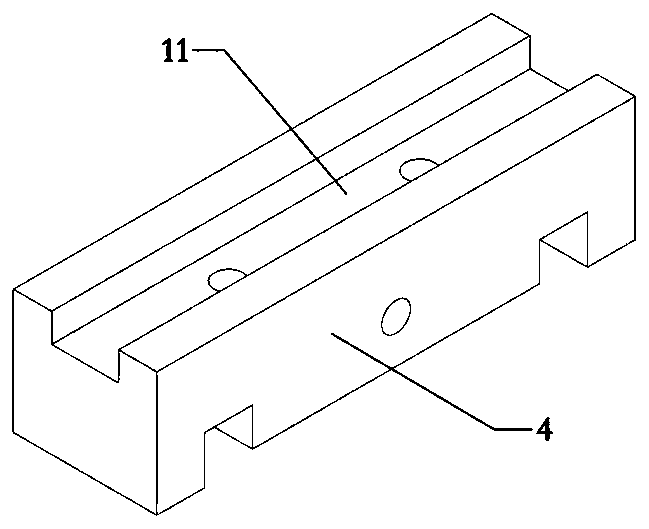

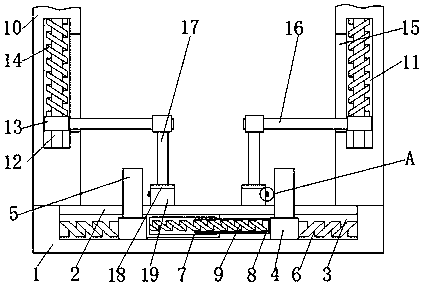

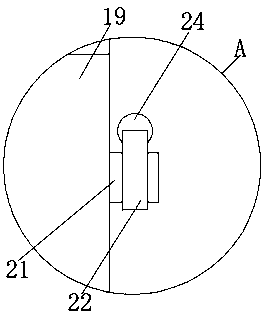

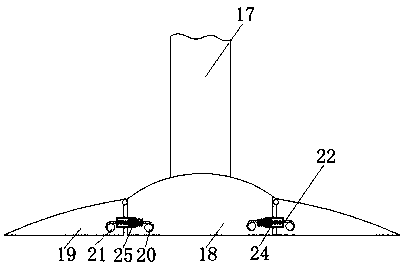

The invention relates to a universal hydraulic tool for shaft bracket machining, and belongs to the technical field of machining equipment. The universal hydraulic tool structurally comprises workbench connecting modules and at least four tool modules arranged on the workbench connecting modules, Y-direction H-shaped grooves are formed in the upper surfaces of the workbench connecting modules, the tool modules comprise locating devices, adjusting devices and clamping devices, the locating devices, the adjusting devices and the clamping devices are arranged on tool supports, and the locating devices are composed of Z-direction locating faces, Y-direction locating faces and X-direction locating faces. The adjusting devices are composed of Y-direction adjusting bolts and X-direction adjusting bolts. The middle portions of the clamping force arms of the clamping devices are movably arranged at the top ends of clamping supports through pin shafts, one ends of the clamping force arms are connected with hydraulic oil cylinders arranged on the tool supports, and clamping press blocks are movably arranged at the other ends of the clamping force arms. The universal hydraulic tool can reduce the investment of new projects in tool machining and lower production cost, meanwhile, a hydraulic system is adopted to clamp machined workpieces, the stability and the reliability of clamping force are ensured, and workpiece clamping efficiency is improved.

Owner:CRRC NANJING PUZHEN CO LTD

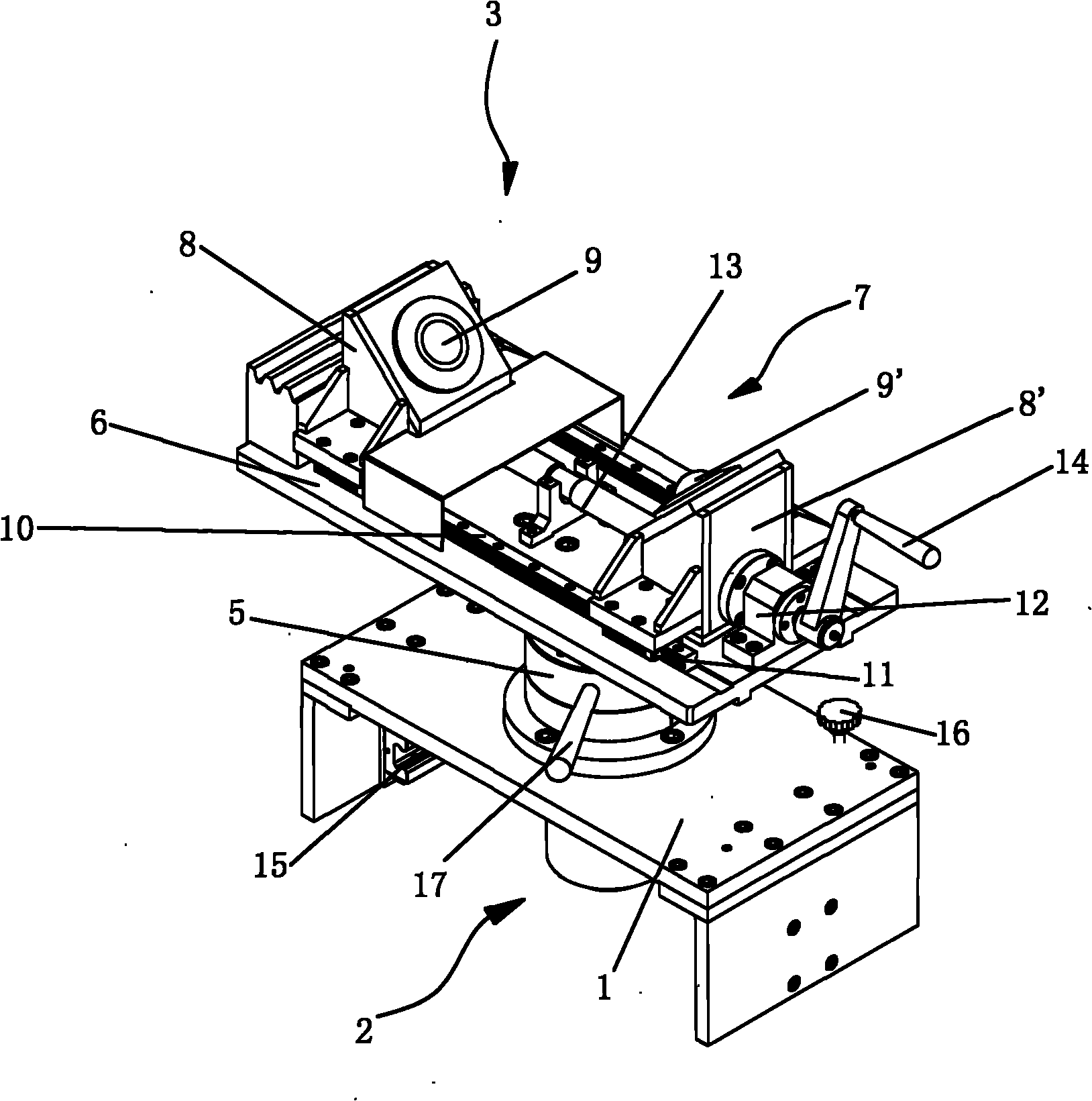

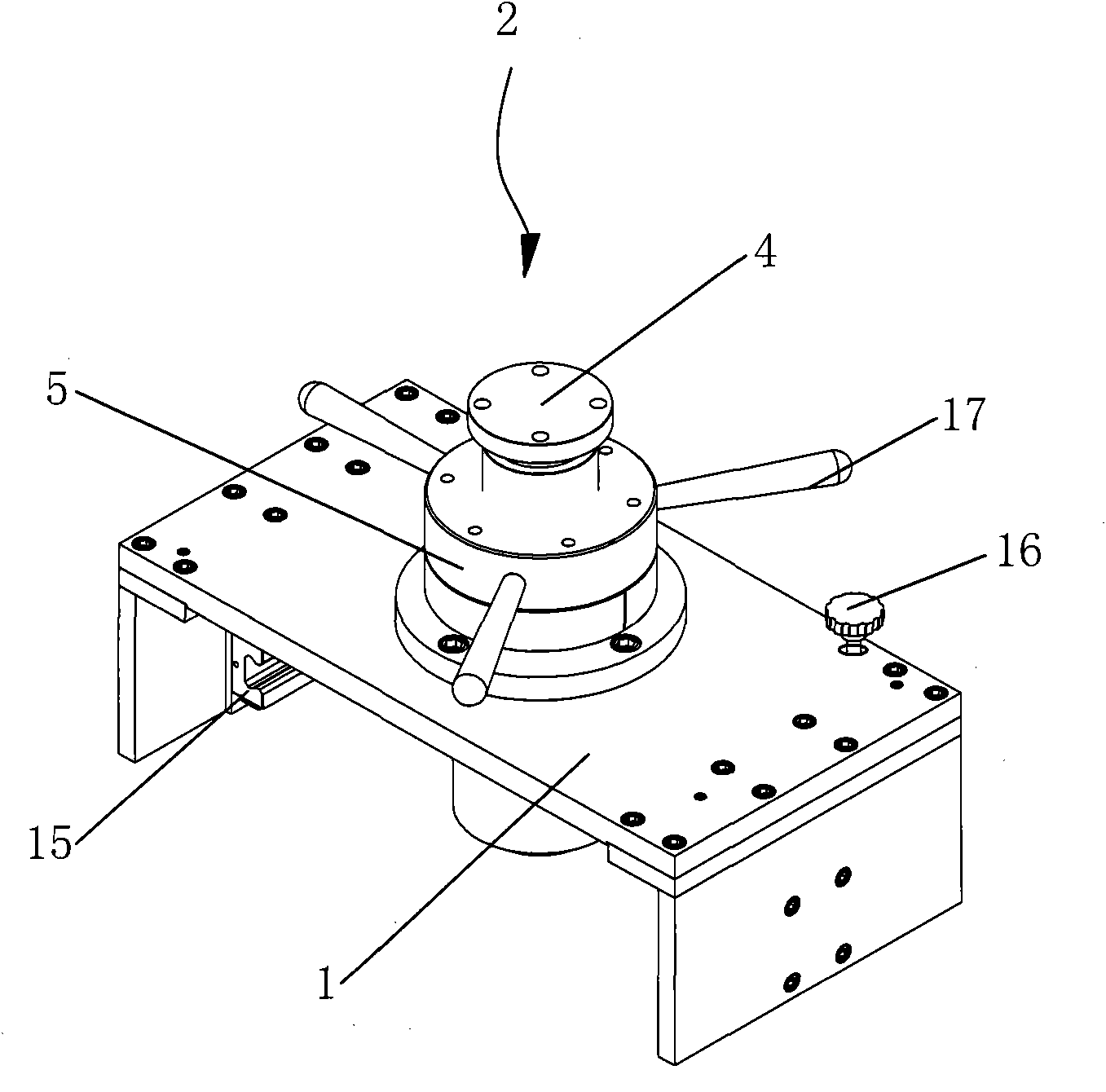

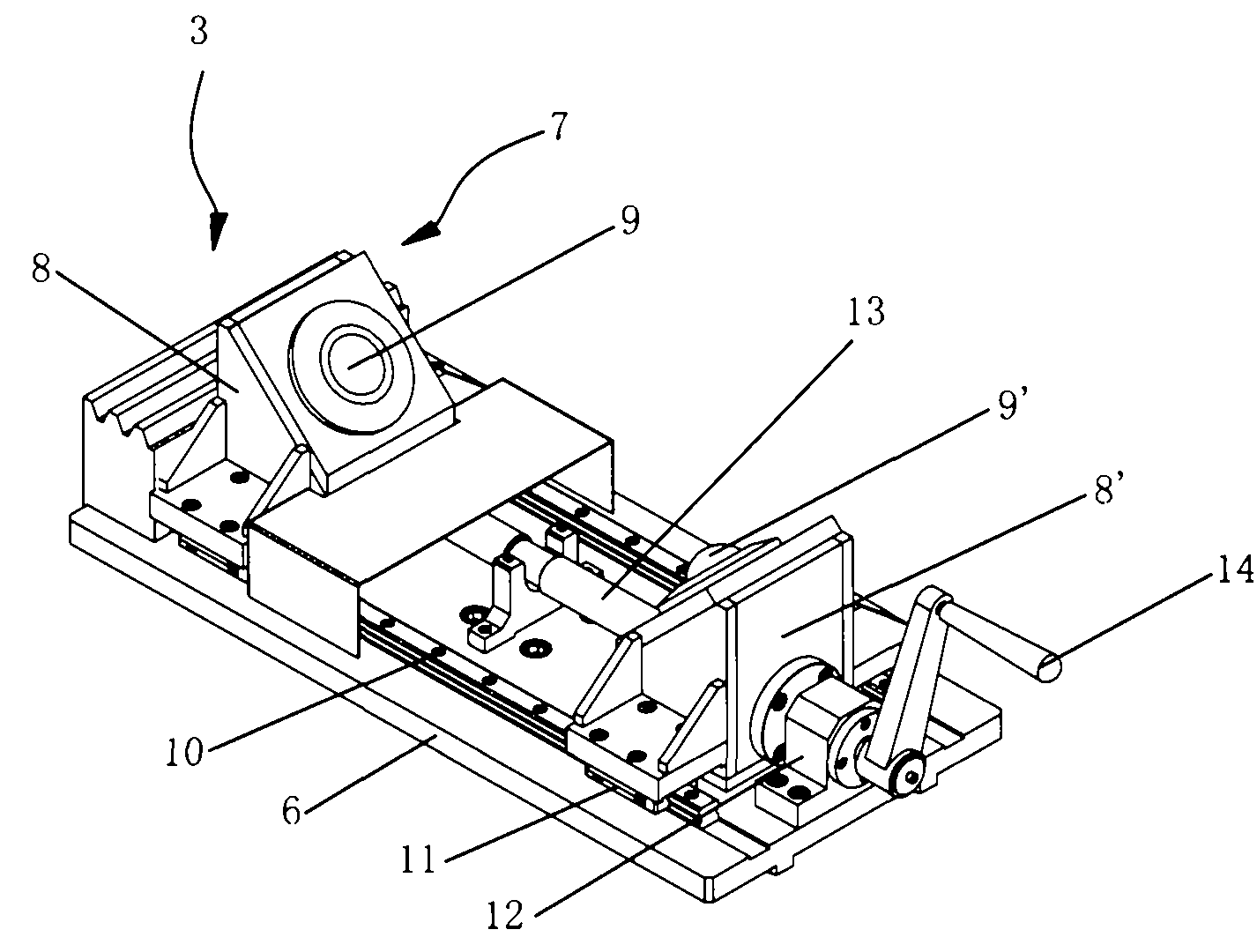

Convenient-to-adjust positioning device for machine tool accessory mold and method

InactiveCN112518389AMeet the clamping needsPracticalPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a convenient-to-adjust positioning device for a machine tool accessory mold and a method. The positioning device comprises a fixed base arranged at the machining position of amachine tool in a sliding mode, wherein plane position adjusting pieces used for adjusting the position of the fixed base are arranged at the two sides of the fixed base; a supporting table used for supporting a workpiece is arranged in the middle of the upper end of the fixed base; a rotary driving piece used for driving the supporting table to rotate is arranged at the upper end of the fixed base; a clamping piece used for clamping the workpiece is arranged at the upper end of the supporting table; the clamping piece comprises mounting plates symmetrically arranged at the two sides of the upper end of the supporting table; and the lower ends of the two mounting plates are connected to a clamping pushing piece used for driving the two mounting plates to get close to each other or get awayfrom each other. The positioning device is designed for overcoming the defects of an existing device, the horizontal position of the workpiece can be adjusted, and the workpiece can be rotationally adjusted; and in addition, the shape of the clamping face can be adjusted, the clamping requirements of the workpieces of various shapes are met, and the practicability is high.

Owner:GUANGYUAN BORUI PRECISION TECH CO LTD

Method and device for automatically clamping workpieces

InactiveCN102107368AEffective clampingRealize automatic clampingPositioning apparatusMetal-working holdersEngineering

The invention discloses a method and device for automatically clamping workpieces, which are characterized in that workpieces are clamped by two sets of servo systems, a fixed clamp hole is a non-circular hole, and the shape and size of an external outline of a lock nut are consistent with the shape and size of the fixed clamp hole so as to ensure the lock nut and the fixed clamp hole can be matched with each other; a set of servo system is used for driving a clamping chuck to get into (or get out of) the fixed clamp hole, so that the lock nut can be matched with the clamp hole or separated from the clamp hole; and the other set of servo system is used for adjusting the phase position of the lock nut, and driving a main shaft to have gyroscopic motion when the lock nut and the clamp hole are mutually matched, thereby achieving the purpose of clamping workpieces. By using the method and device disclosed by the invention, the clamping torque can be controlled accurately, the torque can be adjusted, the clamping position can be remembered, and the clamping operation can be completed quickly.

Owner:贵州省机电装备工程技术研究中心有限公司 +1

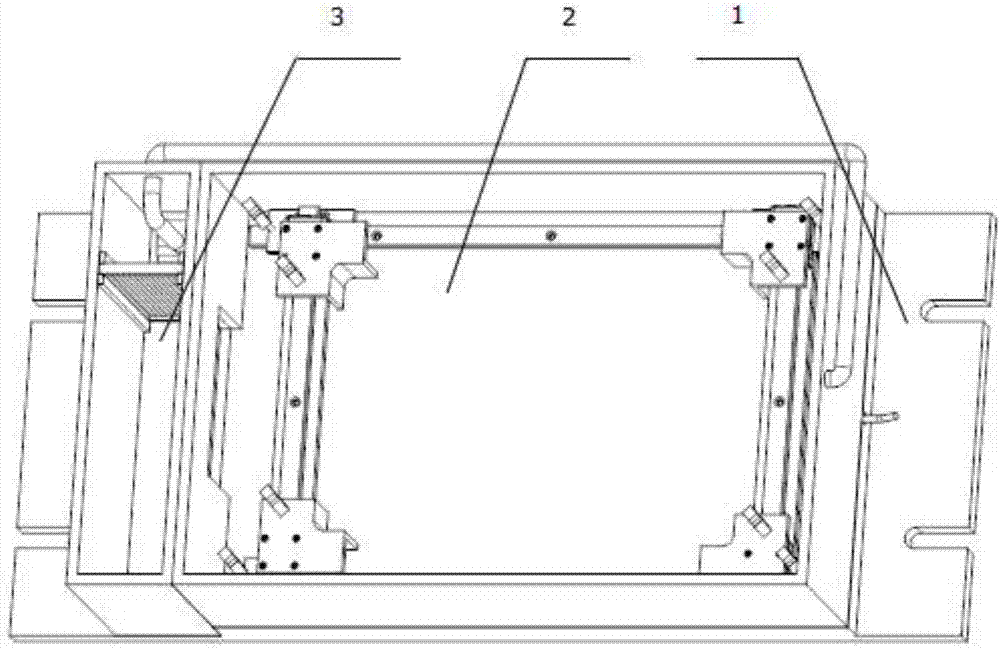

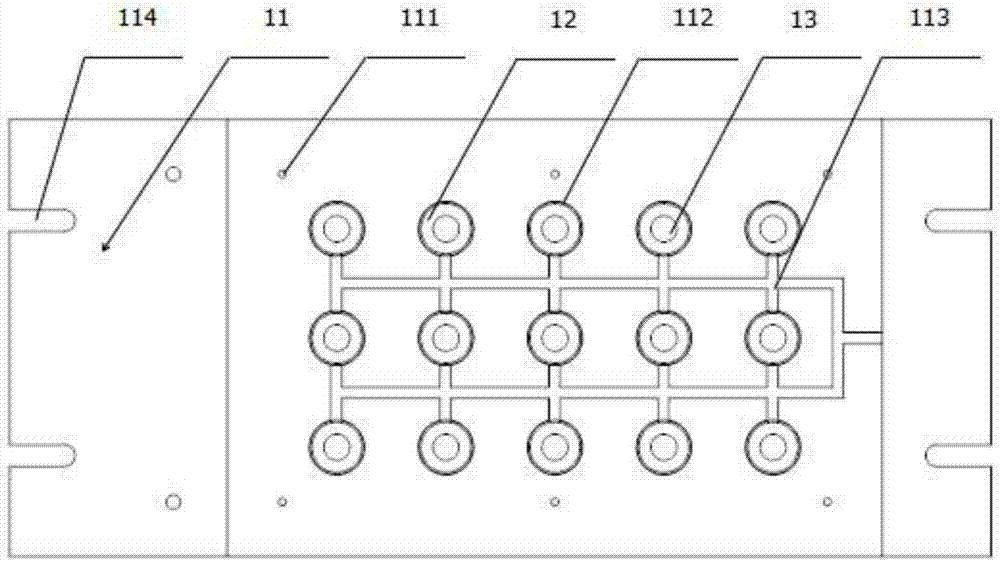

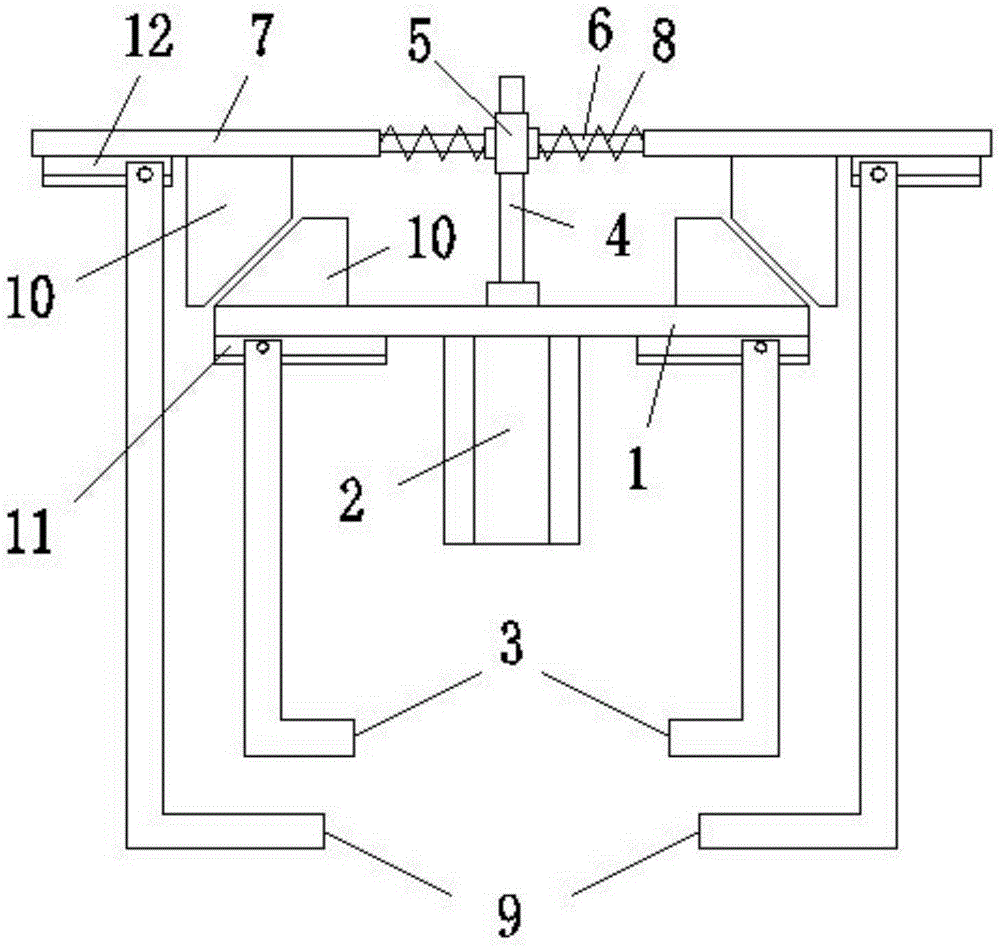

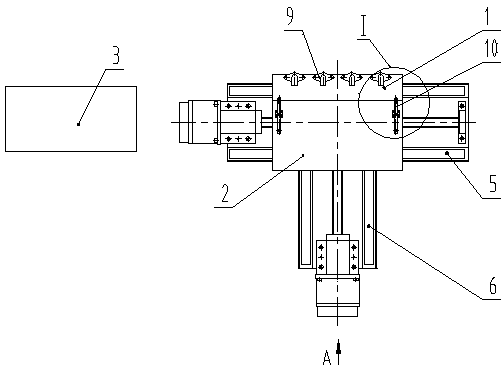

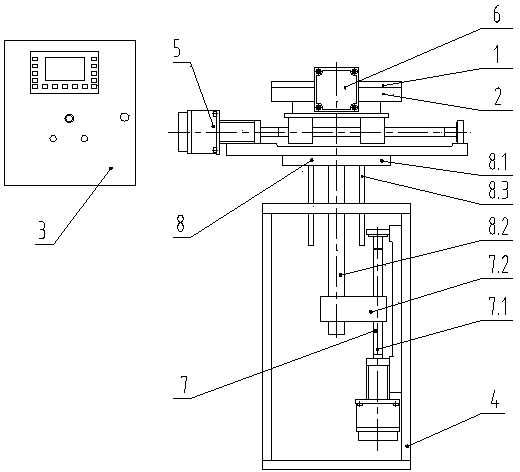

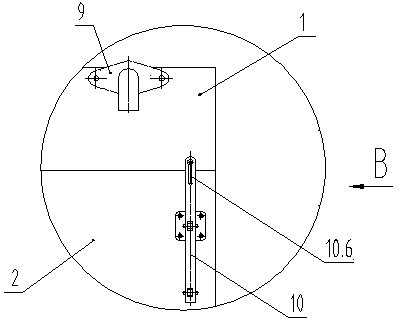

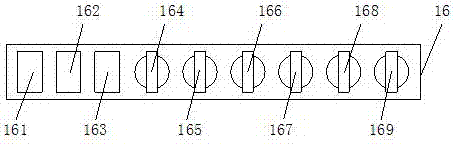

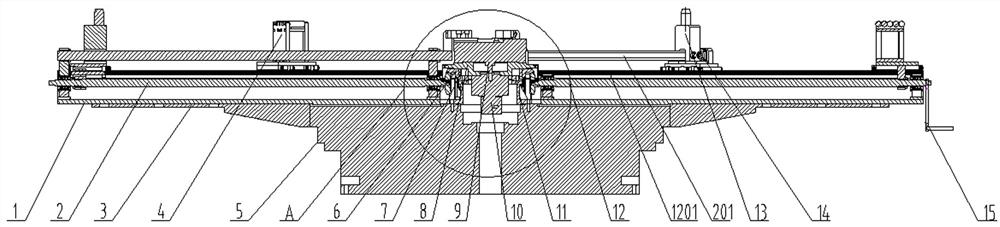

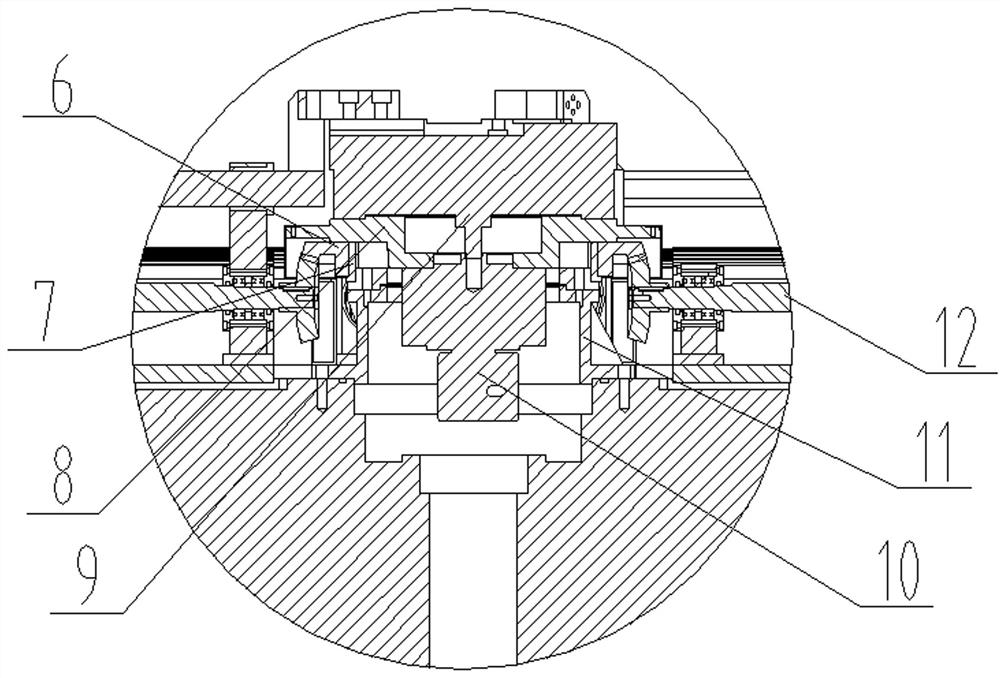

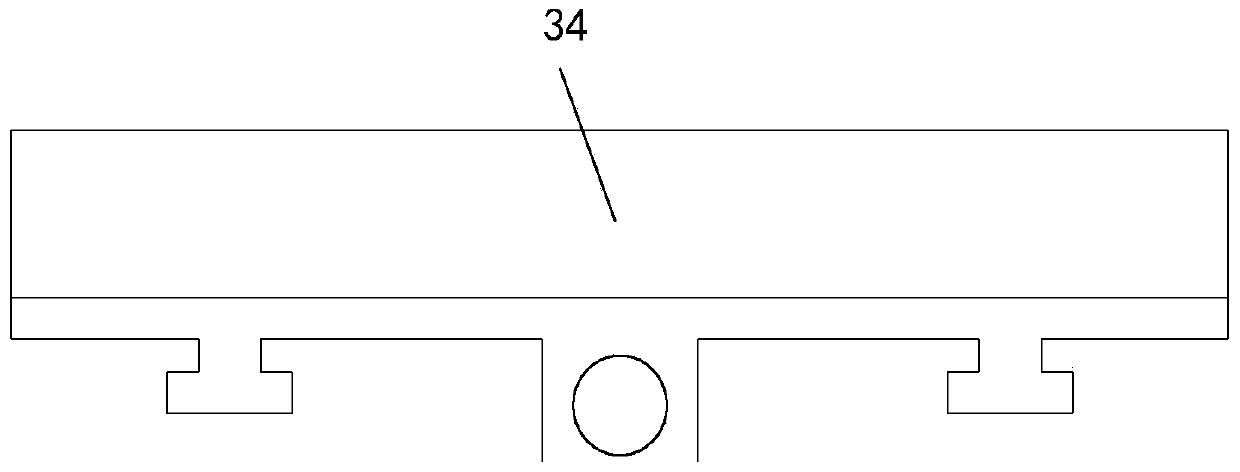

Numerical-control working platform for precision casting sprue grinding

InactiveCN104385098AAccurate quality controlIncrease productivityGrinding carriagesBelt grinding machinesNumerical controlElectrical control

The invention discloses a numerical-control working platform for precision casting sprue grinding. The working platform comprises a fixture, a working platform body, a support, a transverse numerical-control sliding table, a longitudinal numerical-control sliding table and an electric control assembly, wherein the fixture is mounted on the upper end surface of the working platform body; the support is arranged at the lower part of the working platform body; the transverse numerical-control sliding table and the longitudinal numerical-control sliding table are arranged between the working platform body and the support; each of the transverse numerical-control sliding table and the longitudinal numerical-control sliding table comprises a guide rail and a motor-driven lead screw driving mechanism (I); the working platform body is supported on the guide rail of the longitudinal numerical-control sliding table supported on the transverse numerical-control sliding table; the electrical control assembly is electrically connected with motors and electrical control elements on the transverse numerical-control sliding table and the longitudinal numerical-control sliding table. The numerical-control working platform is characterized by further comprising a lifting mechanism and a lifting numerical-control moving mechanism; the fixture is connected with the upper end surface of the working platform body through a positioning pin. The numerical-control working platform is high in production efficiency, high in safety and low in labor intensity, and the quality of ground sprue surfaces is good.

Owner:TAIZHOU XINYU PRECISION MFG CO LTD

Plate scribing device

ActiveCN104493807AMeet clamping needsSolve the need for drawing linesOther workshop equipmentEngineeringMechanical engineering

The invention discloses a plate scribing device. The plate scribing device comprises a workbench, a positioning mechanism, a slide block and a scribing pen, wherein a first slide rail and a second slide rail are arranged in parallel on the workbench; an accommodating groove for accommodating plates is formed between the first slide rail and the second slide rail; the bottom end of the first slide rail is provided with a first through hole; the bottom end of the second slide rail is provided with a second through hole; the positioning mechanism comprises a first jackscrew which is arranged on the workbench close to the first slide rail and passes through the first through hole, a second jackscrew which is arranged on the workbench close to the second slide rail and passes through the second through hole, a first positioning block which is arranged in one side of the accommodating groove and is fixed together with the first jackscrew, and a second positioning block which is arranged in the other side of the accommodating groove and is fixed together with the second jackscrew; the slide block is arranged on the first slide rail and the second slide rail in a sliding way; the scribing pen is arranged at the top end of the slide block in an extension and contraction way; the scribing pen can extend into the bottom of the accommodating groove. Scribing of plates of different specifications is realized, and meanwhile the clamping demands of plates of different thicknesses are met.

Owner:邓州市新艺木业有限责任公司

New energy automobile hub machining clamping device

InactiveCN110434631AMeet clamping needsSolve the problem of inconveniencePositioning apparatusMetal-working holdersNew energyThreaded rod

The invention discloses a novel energy automobile hub machining clamping device. The device comprises a base and a second threaded rod, wherein a fixed rod is fixedly connected to the middle end of aninner cavity of the base, a first forward and reverse motor bottom plate is fixedly connected to the lower end of the left side of the base, a first forward and reverse motor is fixedly connected tothe top of the first forward and reverse motor bottom plate, and an output shaft of the first forward and reverse motor is fixedly connected with a first threaded rod through a movable shaft. According to the device, the first forward and reverse motor bottom plate is fixedly connected to the lower end of the left side of the base, the first forward and reverse motor is fixedly connected to the top of the first forward and reverse motor bottom plate, and through the functions of a second forward and reverse motor, a second forward and reverse motor bottom plate, the first threaded rod, a second threaded rod, a threaded sleeve, a supporting rod, a first clamping block, a groove, an electric telescopic rod and a second clamping block, the problem that an existing hub clamping device cannot meet the clamping requirements of hubs with different sizes and brings inconvenience to users during use thereof is solved.

Owner:江苏久久车轮有限公司

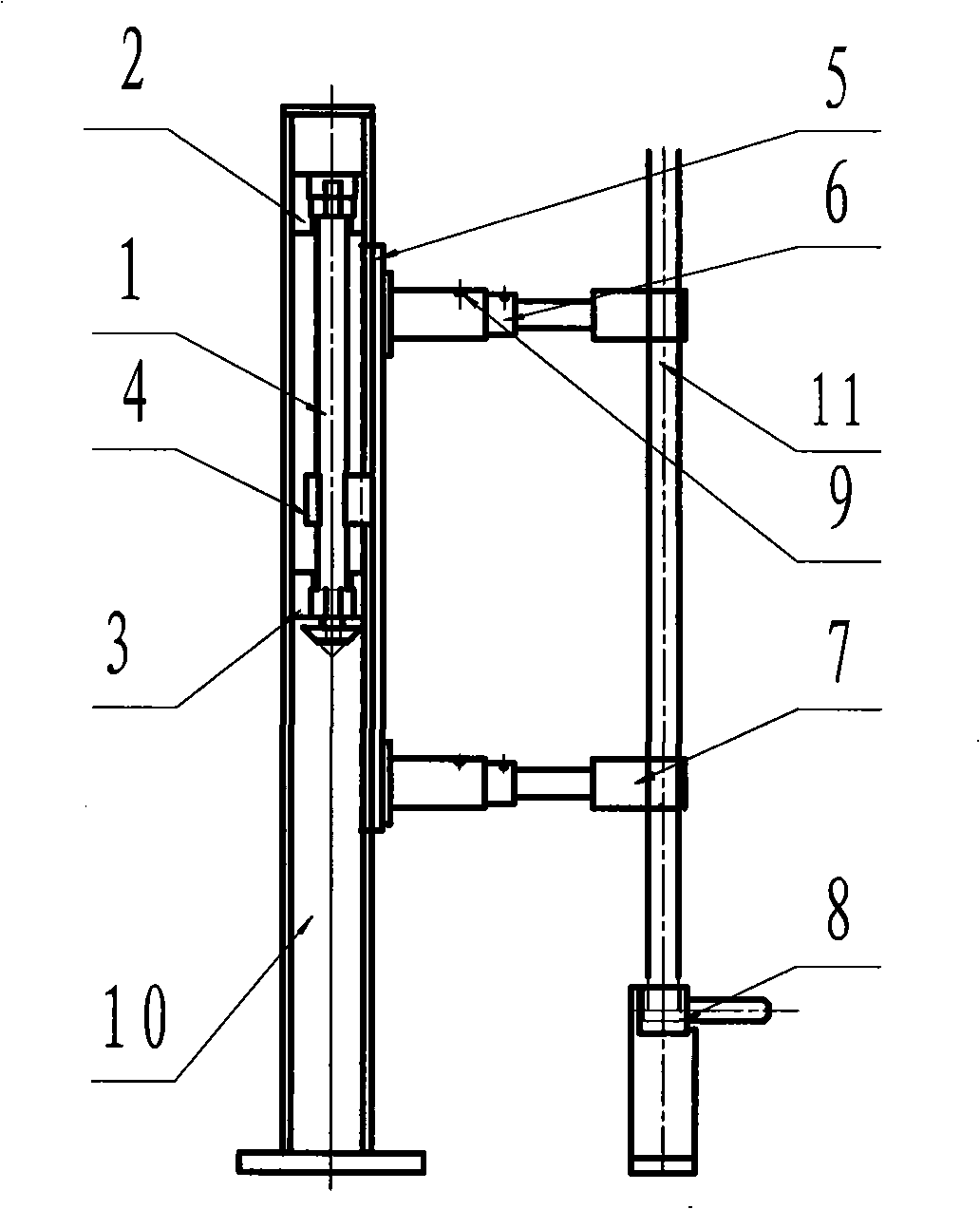

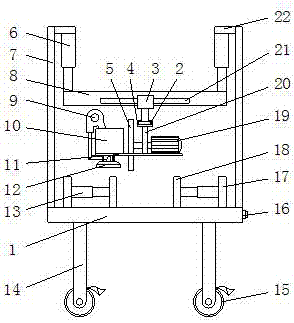

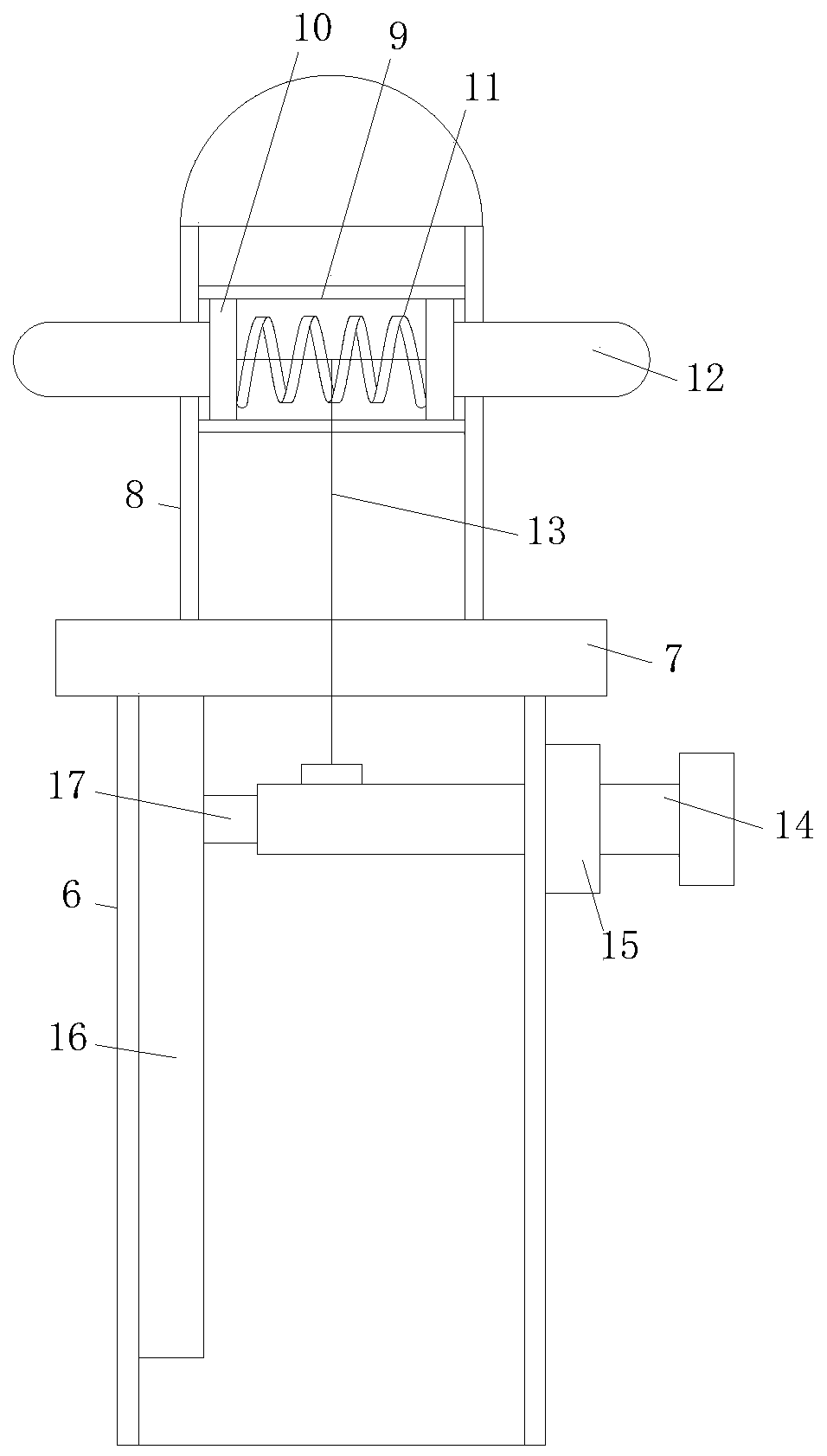

Auxiliary bracket

ActiveCN101829872AMeet the clamping needsEasy to useWelding/cutting auxillary devicesAuxillary welding devicesBall bearingScrew thread

The invention relates to an auxiliary bracket comprising a bracket body, an elevator mechanism arranged on the bracket body and an adjusting mechanism installed on the elevator mechanism. The elevator mechanism comprises a lifting screw arranged on the bracket body and a nut connected on the lifting screw by screw threads, wherein when the nut is rotated, the lifting screw is ascended and descended vertically. The adjusting mechanism comprises a substrate fixedly installed on the top end of the screw and a clamping unit arranged on the upper surface of the substrate, wherein the clamping unit comprises a pair of universal ball bearing brackets which can move relative to each other on the substrate, universal ball bearings are installed on each universal ball bearing bracket, and a workpiece can be clamped between one pair of universal ball bearings. By adopting the universal ball bearings as a clamping part, the auxiliary bracket can meet the requirement of clamping workpieces with different diameters and different shapes. Since the adjusting mechanism and the elevator mechanism are combined together, the auxiliary bracket is convenient, quick, safe and reliable to use.

Owner:XUZHOU HUAHENG ROBOT SYST

High-voltage electric cable detection device

The invention discloses a high-voltage electric cable detection device, and belongs to the technical field of electric power detection. The high-voltage electric cable detection device comprises a fixing frame, an electric cable clamping assembly and a voltage detection assembly. The fixing frame is of a U-shaped structure, the electric cable clamping assembly comprises a driving component and twoclamping plates, the two clamping plates are of V-shaped structures, antislip layers are arranged on two opposite ends of the two clamping plates, support assemblies are arranged on two sides of thefixing frame, and the two clamping plates are arranged on the two support assemblies. The high-voltage electric cable detection device has the advantages that workers can manually clamp electric cables with different diameters by the aid of the electric cable clamping assembly and can quickly fix or detach the electric cables by the aid of an adjusting head, and accordingly the high-voltage electric cable detection device is high in practicality; the workers can quickly puncture and detect the electric cables by the aid of the voltage detection assembly, accordingly, the time and labor can besaved as compared with the traditional methods, the high-voltage electric cable detection device can bring convenience for the workers, and the detection efficiency of the workers can be improved.

Owner:浙江亘古电缆股份有限公司

Automatic material frame clamping, overturning and transporting device and working method

PendingCN112408259AImplement automatic placementEasy to placeLifting devicesControl engineeringControl theory

Owner:山东大学日照智能制造研究院 +1

Shifting fork drilling fixture

ActiveCN104097082AMeet clamping needsReasonable designWork clamping meansPositioning apparatusMechanical engineeringEngineering

Owner:青岛海博双木机械有限公司

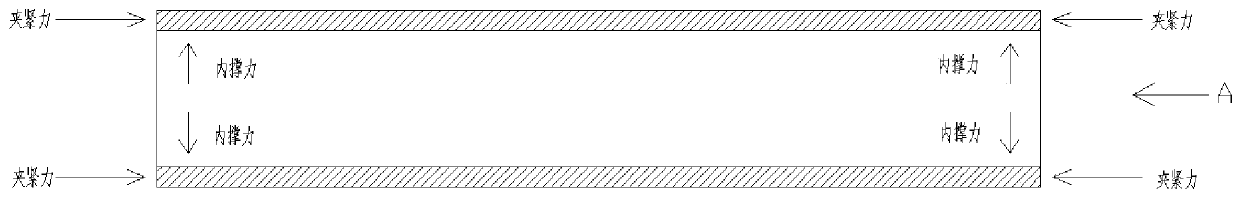

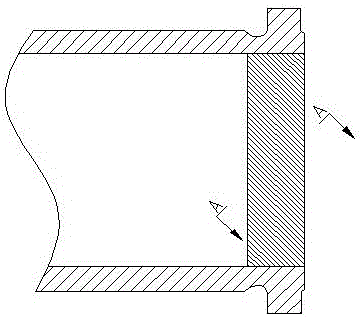

Clamping method and clamp for thin-wall cylindrical part turning as well as processing device

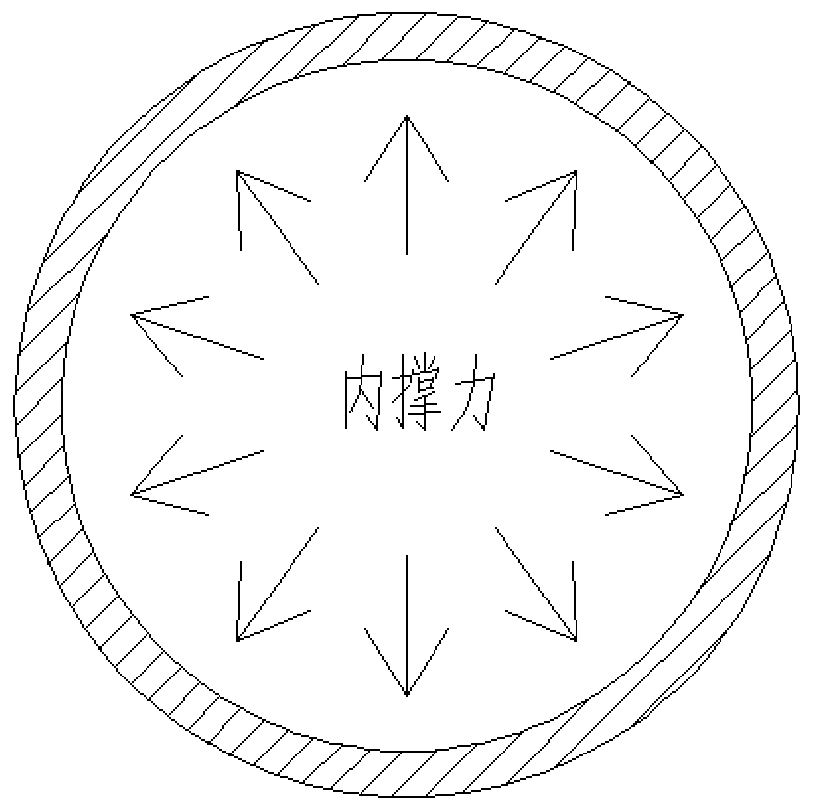

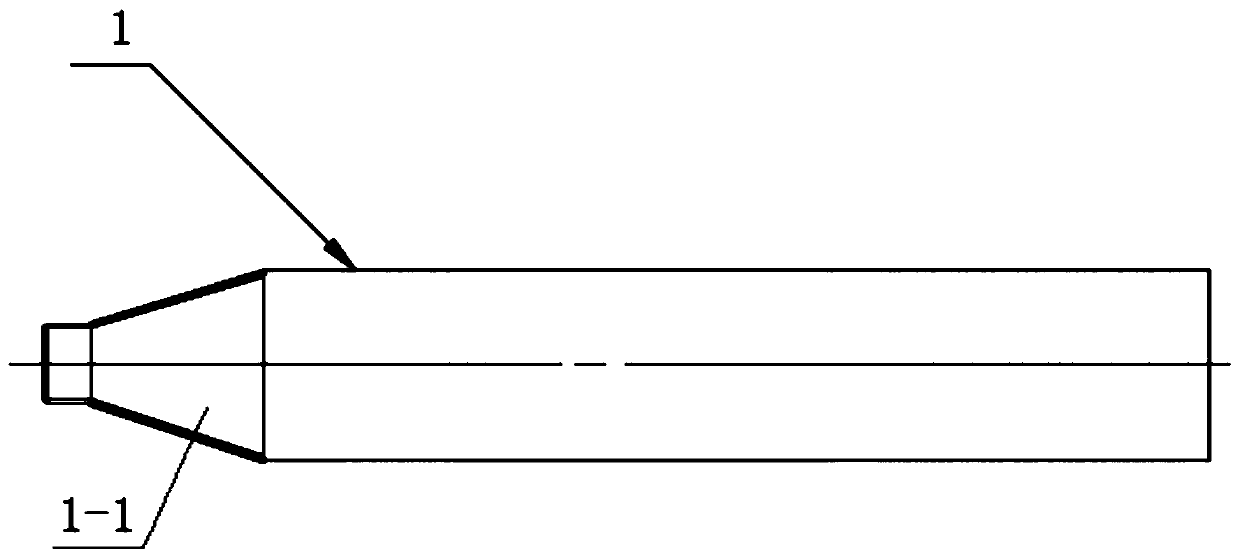

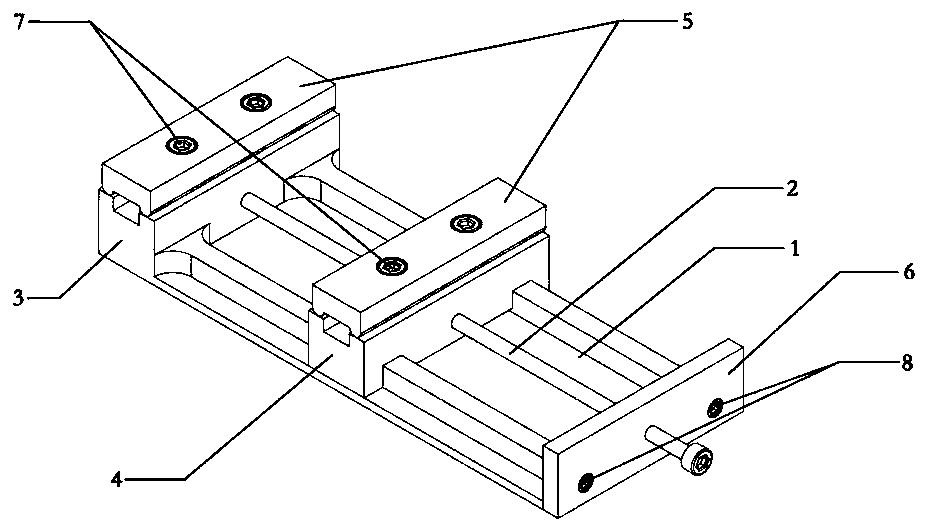

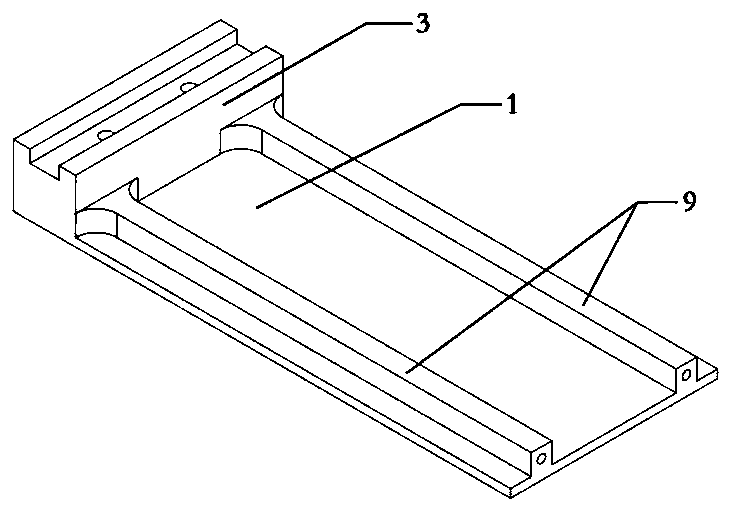

ActiveCN109822123ASolve the accuracy problemSimple structureExpansion mandrelsMechanical engineeringThin walled

The invention relates to a clamping method and a clamp for thin-wall cylindrical part turning as well as a processing device. The clamp comprises a first supporting shaft and a second supporting shaft, wherein one end of the first supporting shaft and one end of the second supporting shaft are connected to a tightening mechanism; the tightening mechanism is used for applying inner supporting forceto the two ends of a thin-wall cylindrical part; a limiting structure is arranged on the tightening mechanism; and the limiting structure is used for limiting axial movement of the thin-wall cylindrical part. The clamping method and the clamp disclosed by the invention avoid the problem that a workpiece has clamping deformation and chattering, and improve processing precision.

Owner:SHANDONG UNIV

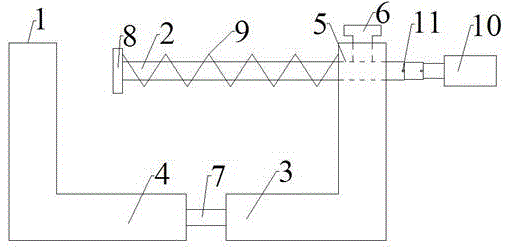

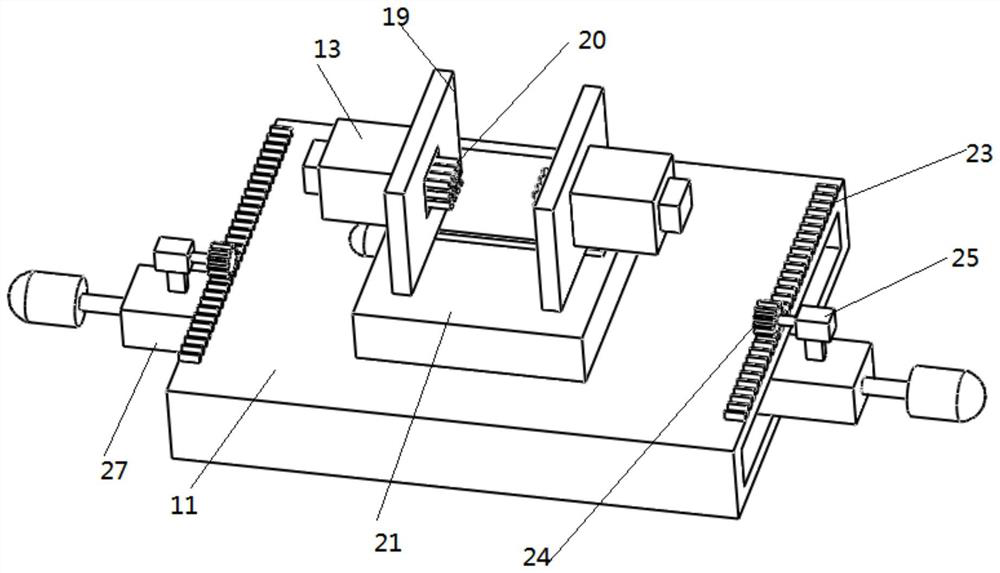

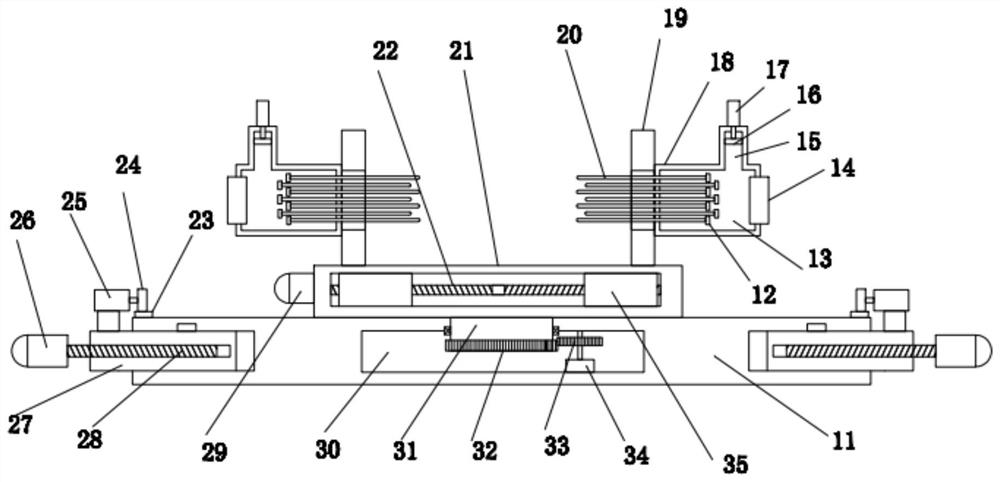

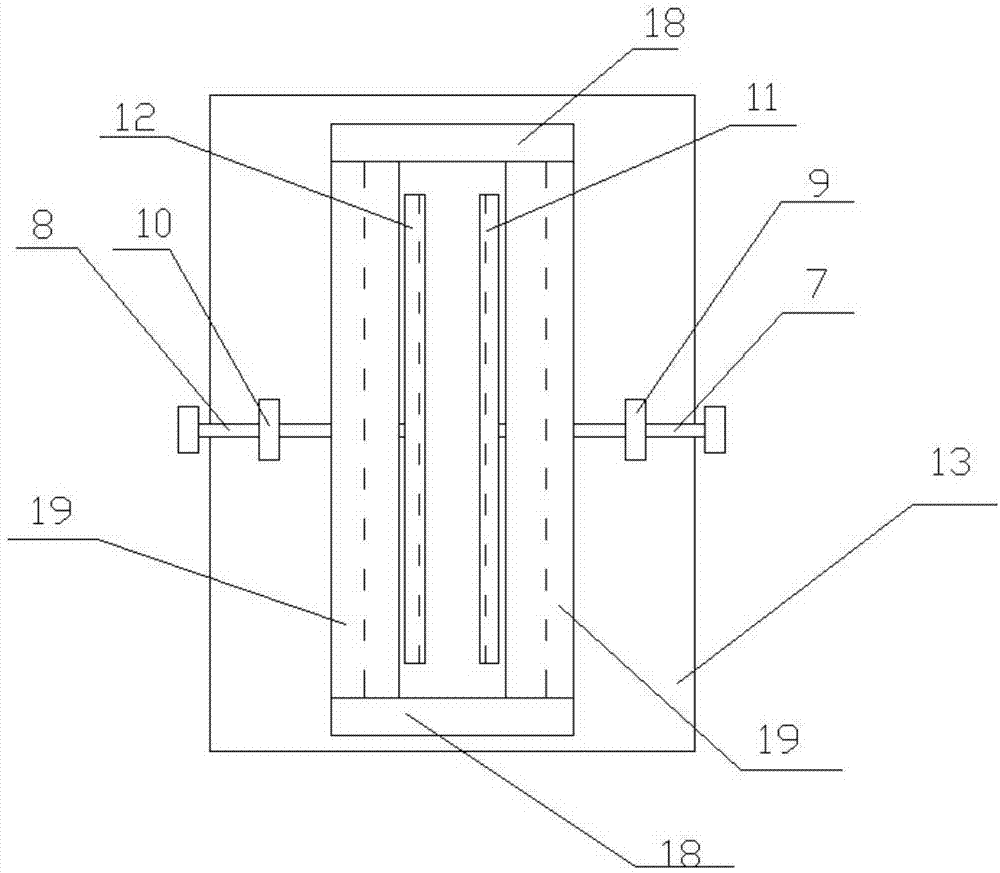

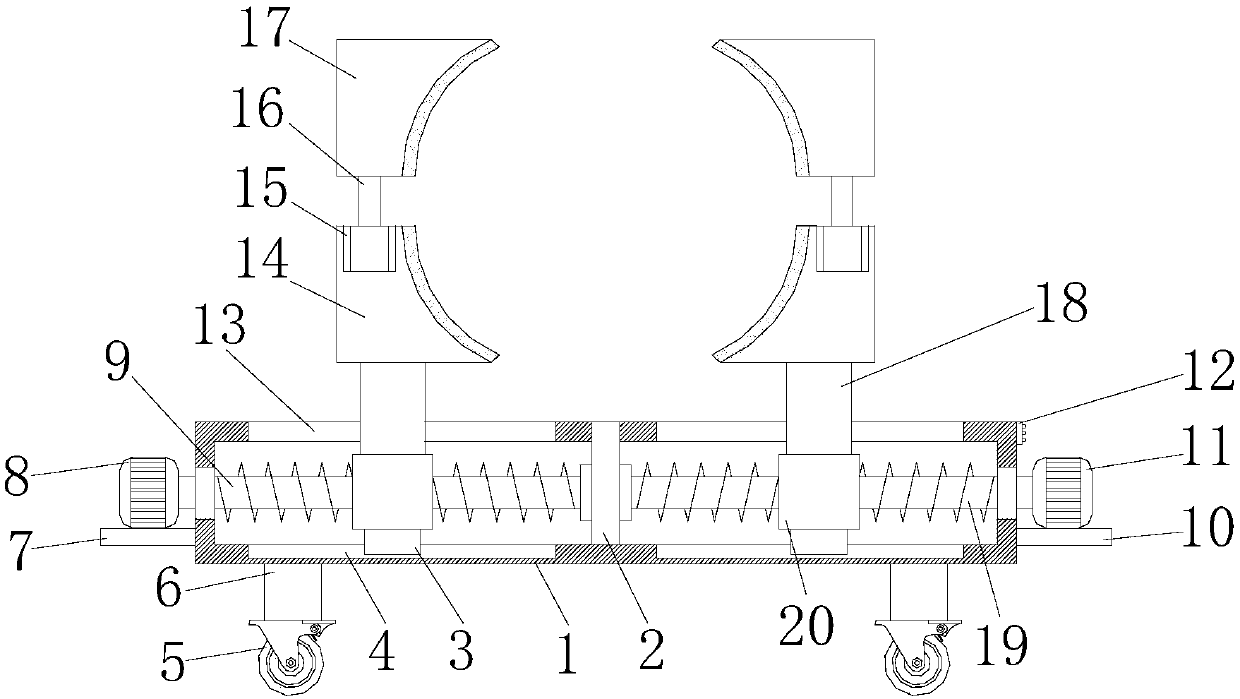

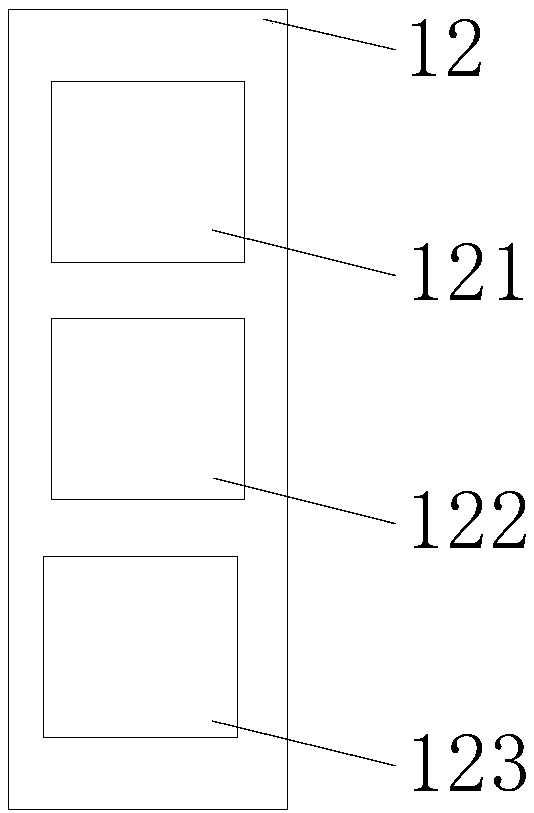

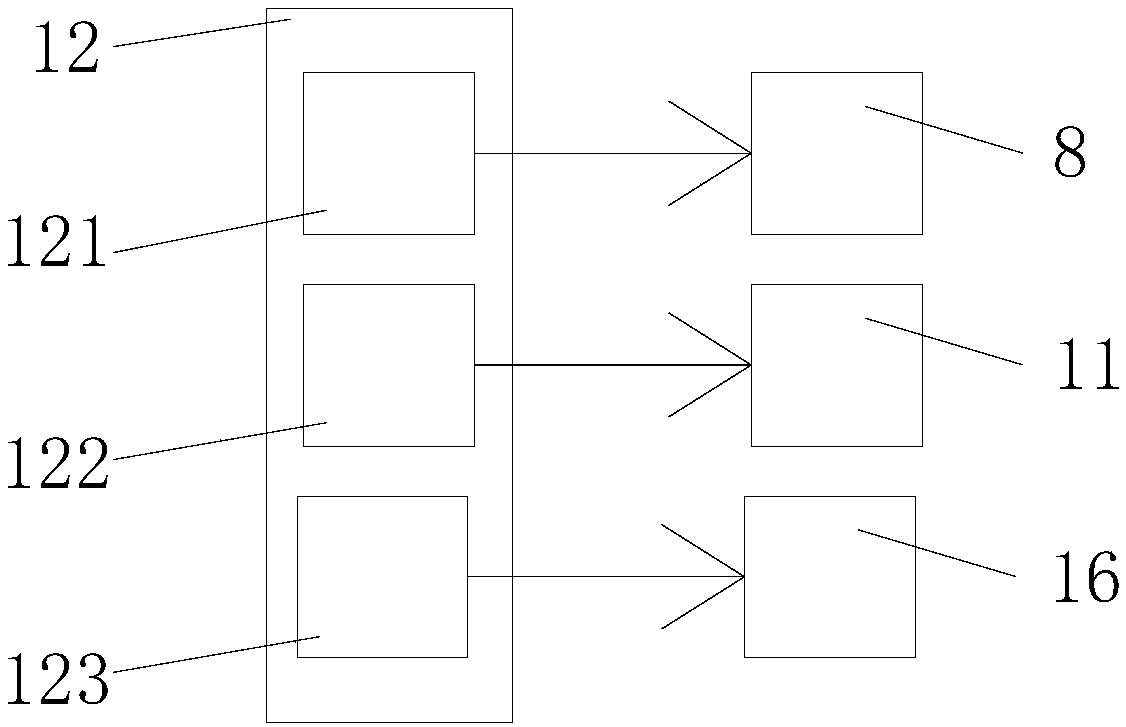

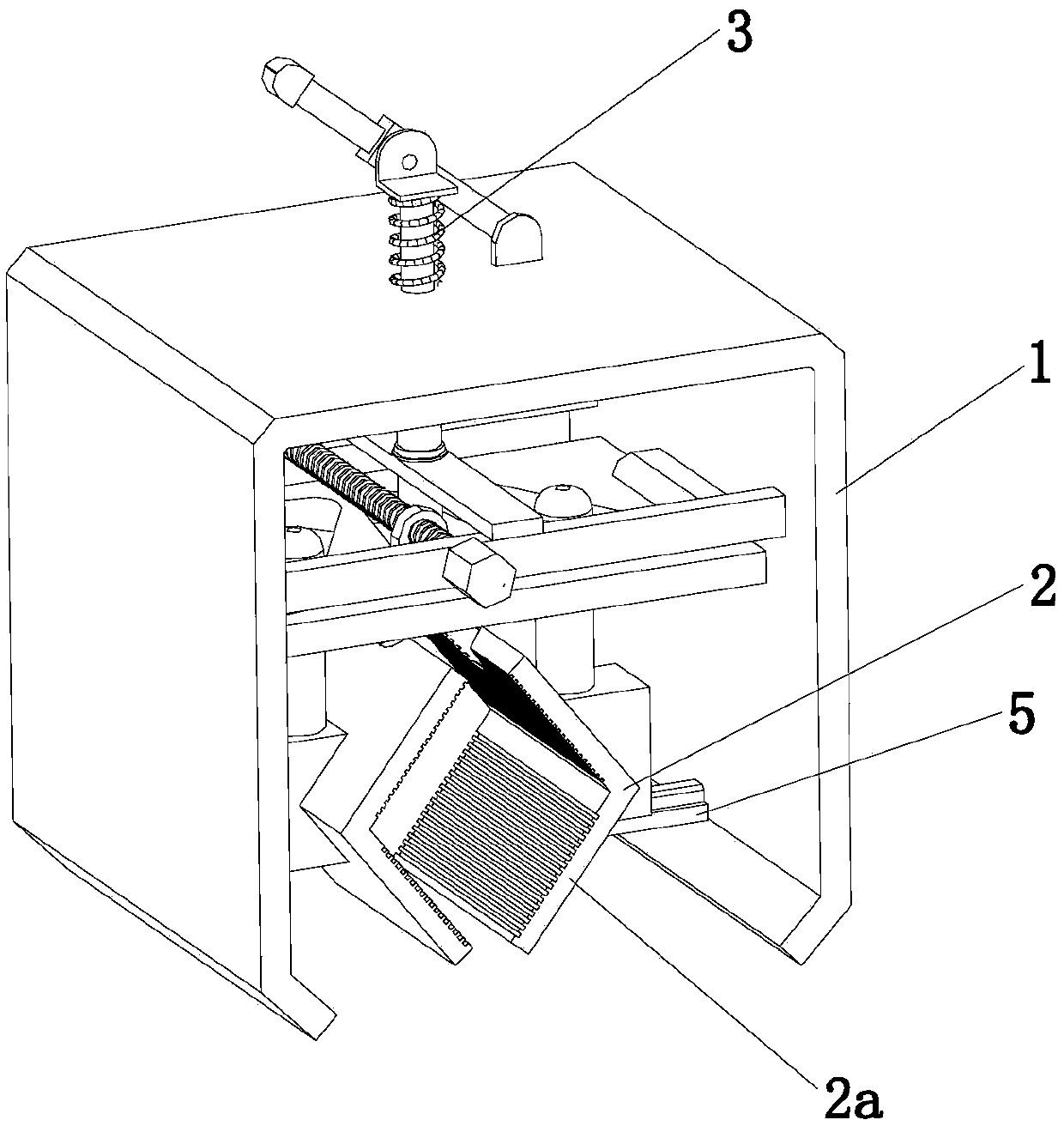

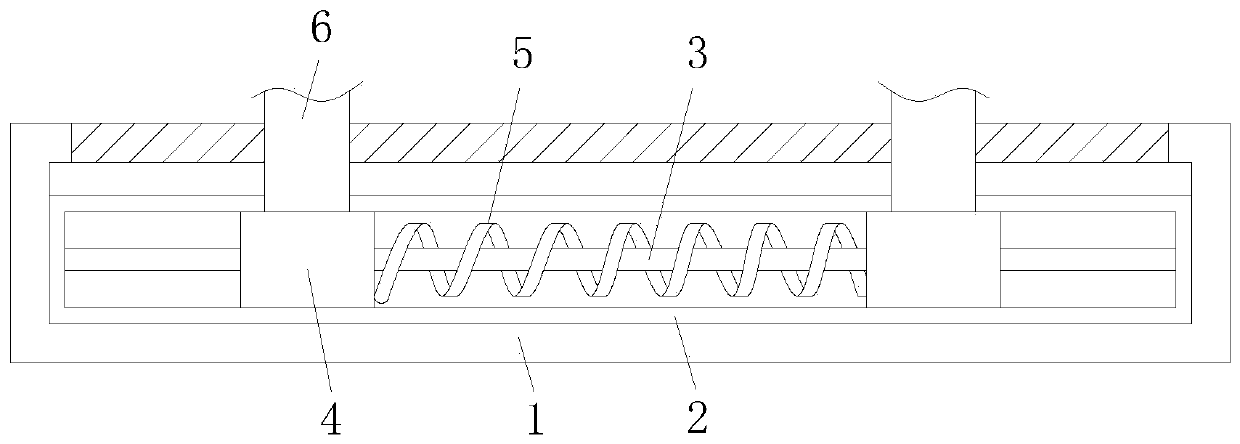

Device for preparing gratings with different periods and using method thereof

ActiveCN111175870AMeet the clamping needsSatisfies the requirement of batch duplicating gratings with different period sizesDiffraction gratingsGratingAdhesive

The invention discloses a device for preparing gratings with different periods and a using method thereof, and relates to the field of micro-machining. The device comprises a guide rail base, a transmission shaft, a bearing slide block, a PDMS fixed cover plate and a limiting side plate. When the device is used, the structured surface of the grating PDMS soft template is upwards fixed on the device bearing part, the bearing slide block moves away from the fixed part by adjusting the transmission shaft; the PDMS soft template is stretched so that the size of the periodic structures on the softtemplate is increased. The structured surface of the PDMS soft template is coated with the curing adhesive, a substrate is placed on the curing adhesive, then the adhesive is cured through a heating or exposure method, and the PDMS soft template is stripped after the adhesive is cured so as to obtain a grating structure with a required period on the substrate. Grating structures with different period sizes can be obtained by changing the stretching amount of the soft template. The device is easy to operate and convenient to use and can meet the requirement of copying gratings with different periodic sizes in batches at low cost.

Owner:LUDONG UNIVERSITY

Machine tool with stable clamping function

InactiveCN109746713AMeet the needs of clampingInhibit sheddingPositioning apparatusMetal-working holdersMachine toolEngineering

The invention discloses a machine tool with a stable clamping function, and relates to the technical field of machine tool equipment. The machine tool with the stable clamping function comprises a base, a groove is formed in the upper surface of the base, a sliding groove is formed in the bottom of the inner wall of the groove, two sliding blocks are arranged inside the sliding grooves in a sleevemode, the tops of the sliding blocks are fixedly connected with pressing plates, the tops of the pressing plates sequentially penetrate through the sliding groove and the groove from bottom to top and extend to the position above the base, the two opposite sides of the two sliding blocks are movably connected through first springs, and the first springs are connected to the interior of the sliding groove in a sleeve mode. According to the machine tool with the stable clamping function, the base, the groove, the sliding chute, first sliding blocks, the pressing plates, the first springs, an outer sleeve, an inner sleeve and a second spring are arranged, a part is placed on the upper surface of the base, the two pressing plates are pulled outwards so as to drive the first sliding blocks tomove, the first sliding blocks slide inside the sliding groove and compresses the first springs, and the inner sleeve and the outer sleeve are stressed to move outwards.

Owner:扬州市龙腾焦化设备有限公司

Wood molding processing device

PendingCN107415014AMeet the needs of line processing in different positionsMeet cutting needsProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringWood plank

The invention discloses a wood molding processing device. The wood molding processing device comprises a supporting base. A controller is fixedly mounted on the right side of the supporting base. Fourth supporting plates are fixedly connected with the top end of the supporting base through second supporting plates. A first sliding base is movably connected with the bottoms of the fourth supporting plates through second electric telescopic rods. The front side and the rear side of the outer surface of the first sliding base are provided with first sliding grooves. First sliders are slidably connected with the outer surfaces of the first sliding grooves. The first sliders are slidably connected with the outer surfaces of the first sliding grooves, through the action of a third sliding base and third sliders, the demand of people for molding processing of different positions of planks can be met, meanwhile, through the action of third electric telescopic rods, a second sliding base, second sliding grooves and second sliders, the demand of people for cutting the processed planks can be met, the automation degree of the wood molding processing device is increased, and production operation of people is greatly facilitated.

Owner:湖州南浔森发木制品厂

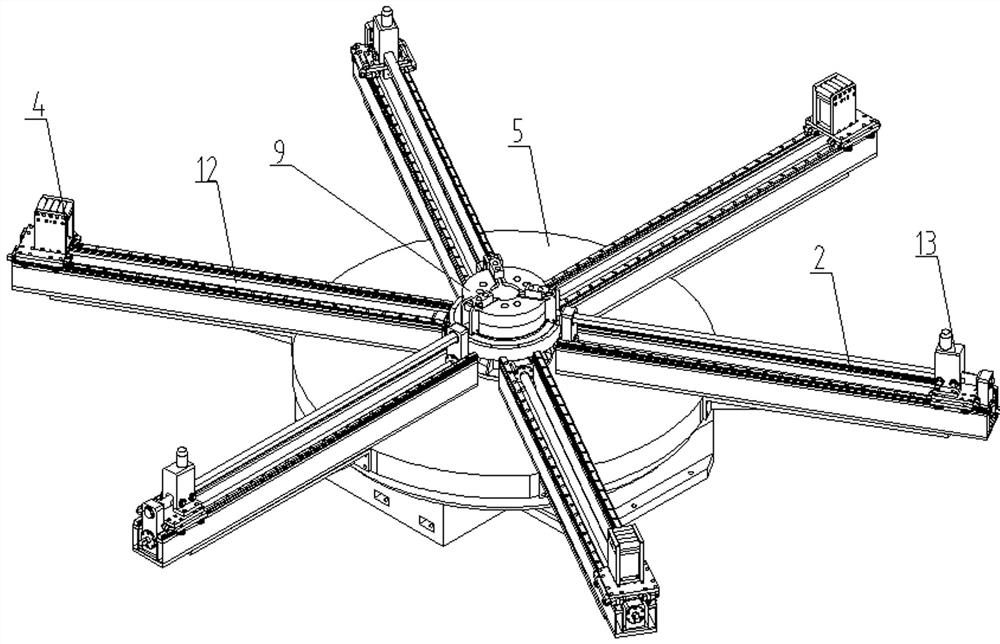

Hydraulic clamping device for large ferrule parts

ActiveCN113528770AMeet the clamping needsGuaranteed unchangedFurnace typesIncreasing energy efficiencyHydraulic cylinderStructural engineering

The invention discloses a hydraulic clamping device for large ferrule parts. The hydraulic clamping device is characterized in that a supporting moving assembly or a clamping moving assembly acts by rotating an adjusting hand wheel, and other supporting moving assemblies and clamping moving assemblies act together through transition of a bevel gear wheel, therefore, positions of a supporting base and clamping bases are adjusted in the radial direction of a rotating table till the supporting base is adjusted to a target position and the clamping bases are adjusted to the position close to the to-be-clamped side wall of a part, then power is transmitted to a power chuck through a hydraulic cylinder, action of the power chuck is achieved, the power chuck transmits the power to the m clamping bases through pull rods, and the m clamping bases move along first guide rails thererof in the same direction at the same distance so as to clamp the part and ensure that the center of the part is unchanged all the time. According to the hydraulic clamping device, radial positions of the supporting bases and the clamping bases are rapidly and concentrically adjusted according to diameters of ferrule parts;and rapid clamping of the ferrule parts is achieved, and automatic centering of the ferrule parts and the rotating table is achieved.

Owner:LUOYANG SHENGHUA INDUCTION HEATING

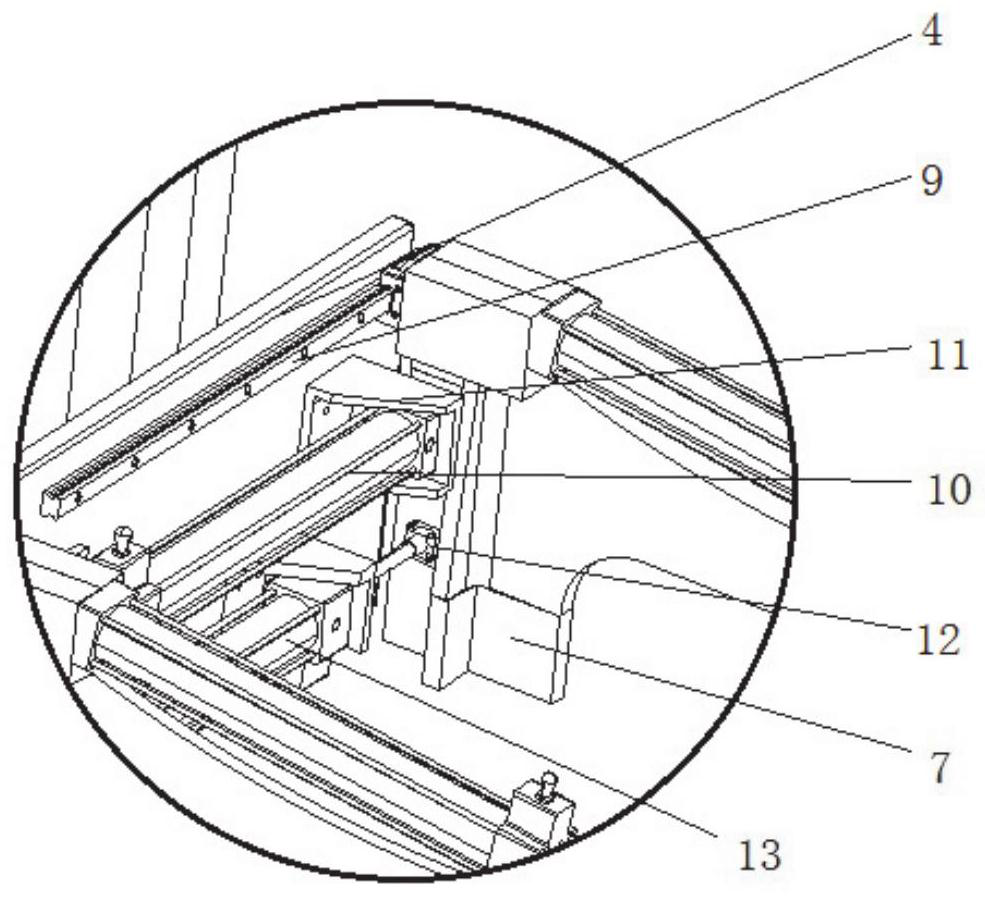

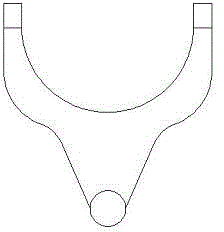

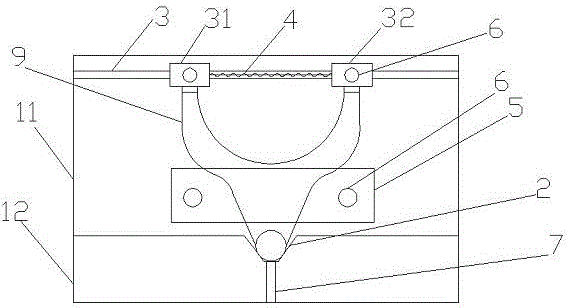

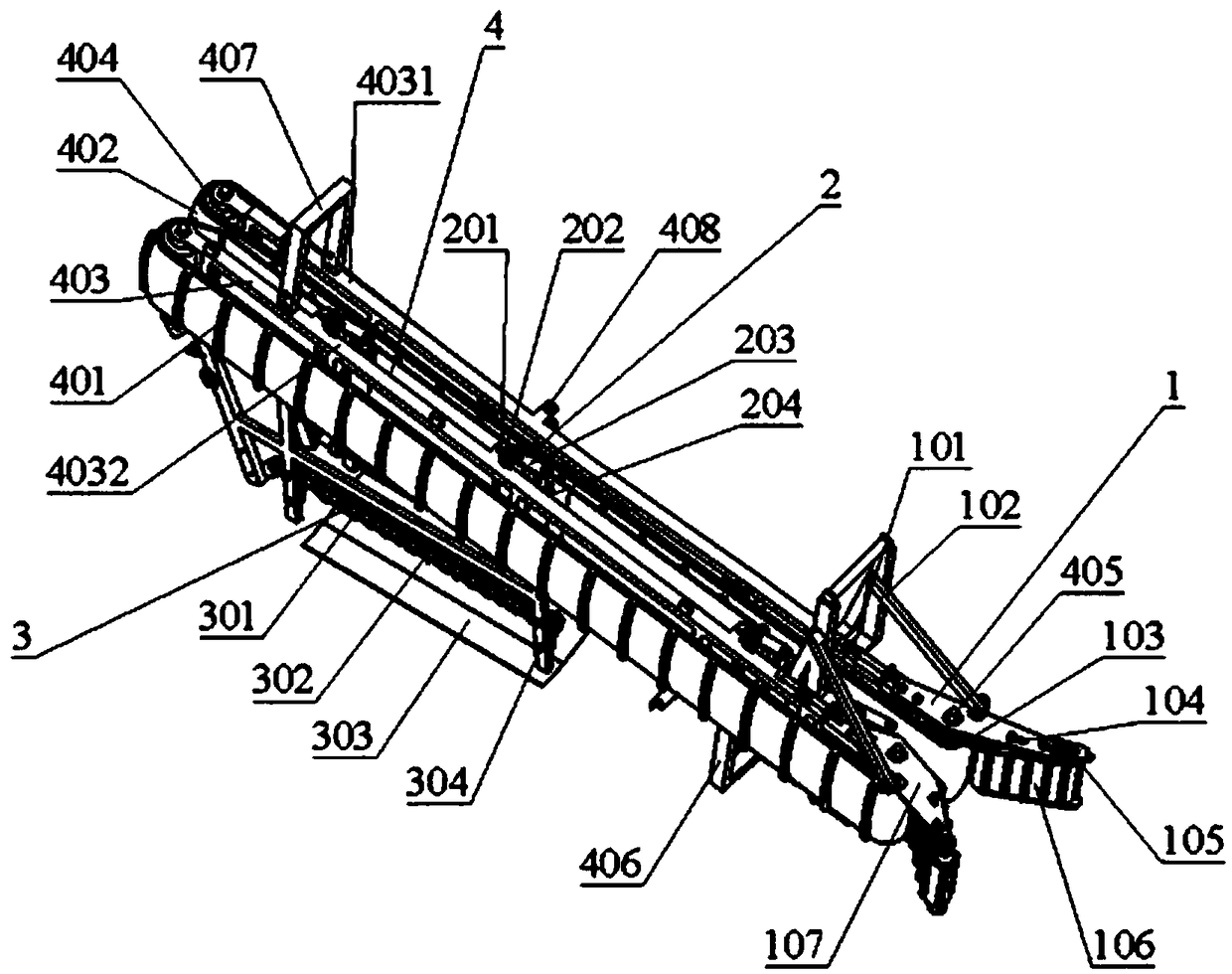

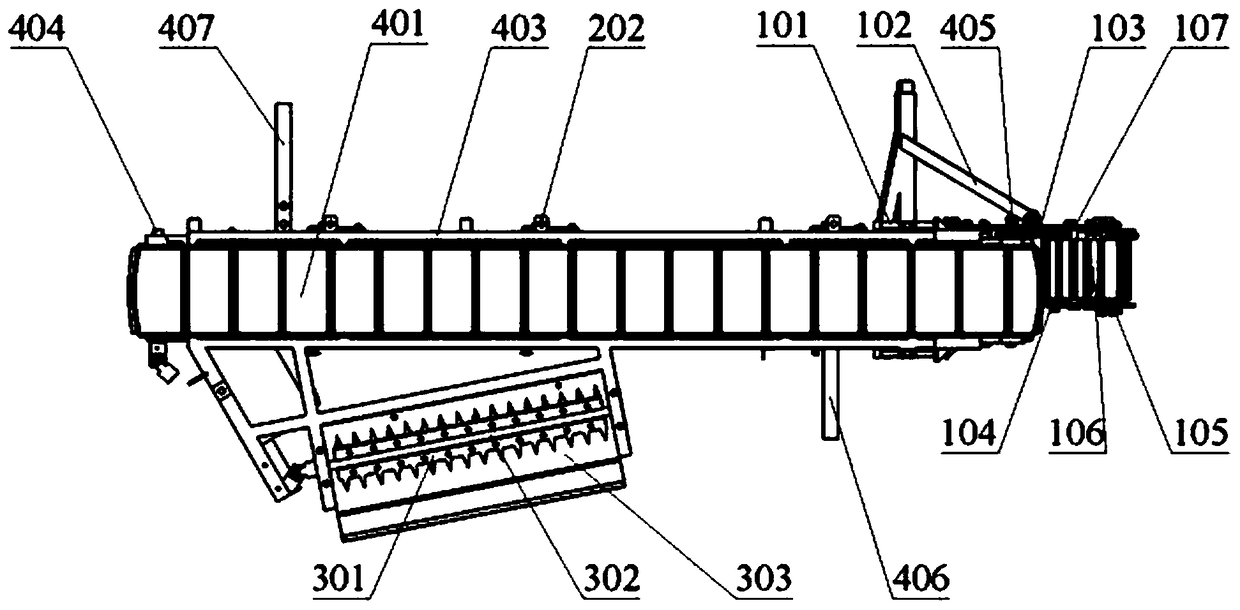

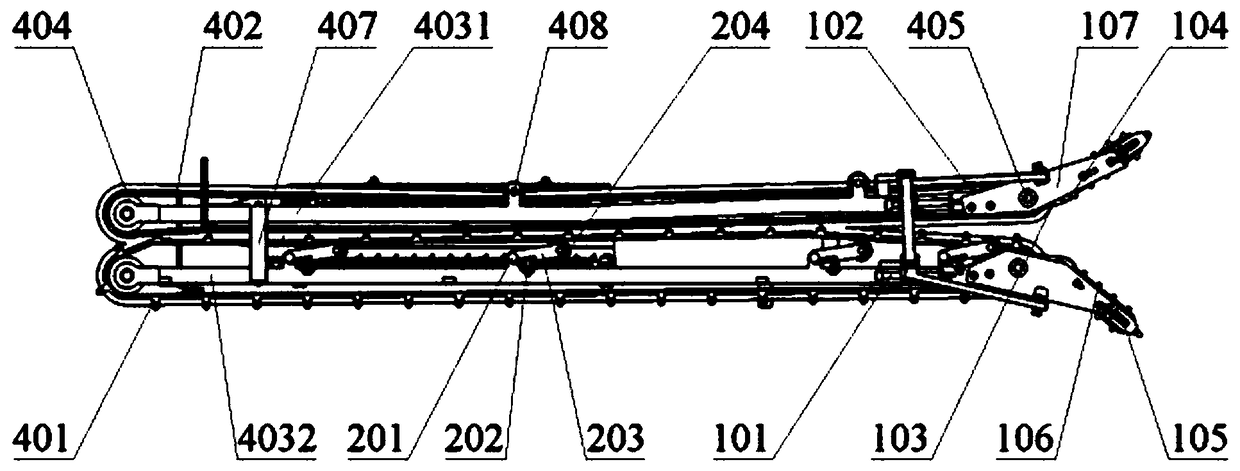

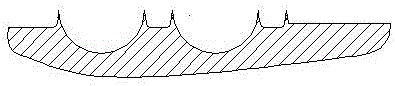

Flexible clamping conveying impurity-removing device of combined harvester of Allium fistulosum L.var. giganteum Makion and application method of flexible clamping conveying impurity-removing device

The invention relates to a flexible clamping conveying impurity-removing device of a combined harvester of Allium fistulosum L.var. giganteum Makion and an application method of the flexible clampingconveying impurity-removing device. The flexible clamping conveying impurity-removing device comprises a left clamping rack and a right clamping rack which are arranged side by side, wherein flexibleclamping conveyor belts are separately installed on the left clamping rack and the right clamping rack, support feeding devices are fixedly connected to input ends of the left clamping rack and the right clamping rack, and a tensioning device is arranged at the inner side of the flexible clamping conveyor belt on the right clamping rack. The flexible clamping conveying impurity-removing device canadapt to harvest of Allium fistulosum L.var. giganteum Makion of different growth conditions through arrangement of the support feeding devices, so that it is ensured that Allium fistulosum L.var. giganteum Makion is smoothly sent between the two flexible clamping conveyor belts, and the versatility of the harvester of Allium fistulosum L.var. giganteum Makion is improved; through arrangement ofthe flexible clamping conveyor belts, flexible clamping and conveying of Allium fistulosum L.var. giganteum Makion can be ahcieved, damage to Allium fistulosum L.var. giganteum Makion is reduced, andthe harvest quality is ensured; and through arrangement of the tensioning device, the spacing of the two flexible clamping conveyor belts can be adjusted so as to adapt to change of the diameter of Allium fistulosum L.var. giganteum Makion stems, and the reliable and continuity of clamping transportation are ensured.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Advertisement board clamping device for advertisement printing and working method thereof

InactiveCN103481652AMeet the clamping needsWide adaptabilityRotary pressesMirror imageIndustrial engineering

The invention relates to the technical field of media devices, in particular to an advertisement board clamping device for advertisement printing and a working method thereof. A rectangular through hole for an advertisement board to penetrate is arranged in the middle of an operating platform, the upper portion and the lower portion of the operating platform are provided with two clamping devices for mirror image configuration, and the clamping device located at the upper portion of the operating platform comprises two parallel first air cylinders fixed on the operating platform. The ends of telescopic rods of the two first air cylinders are connected through a fixing plate, one side of the fixing plate away from the operating platform is provided with a support, a second air cylinder is arranged on the support, a telescopic rod of the second air cylinder penetrates the fixing plate, and a pressing block is arranged at the end of the telescopic rod of the second air cylinder. The advertisement board clamping device for the advertisement printing limits two sides of the advertisement board through the two clamping devices. The clamping demands of different types and sizes of advertisement boards can be met under the condition that the first air cylinders and the second air cylinder work, and the application range is wide.

Owner:铜陵市长江彩色印刷有限责任公司

Plastic bag forming manufacturing method

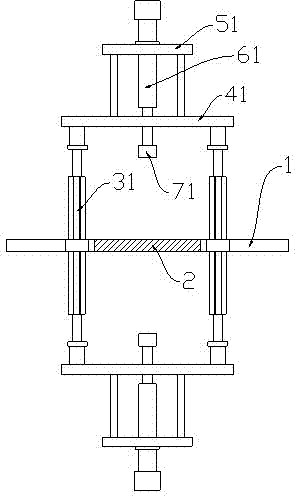

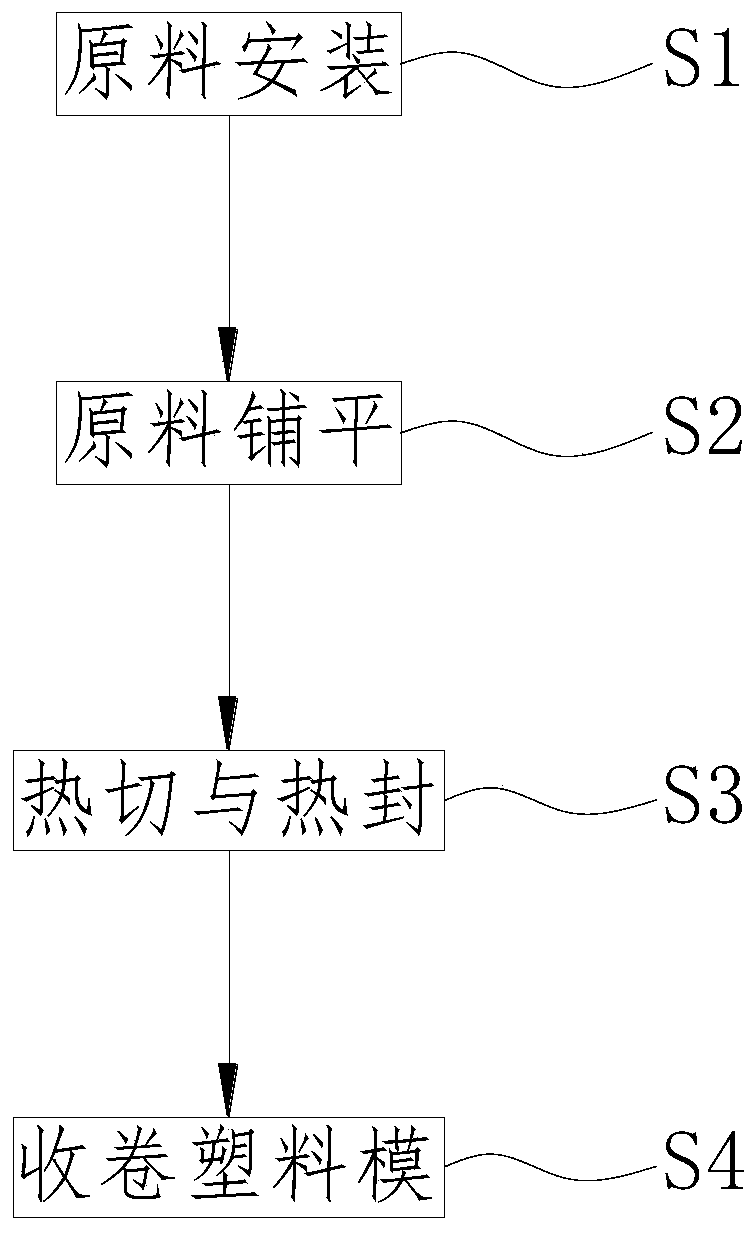

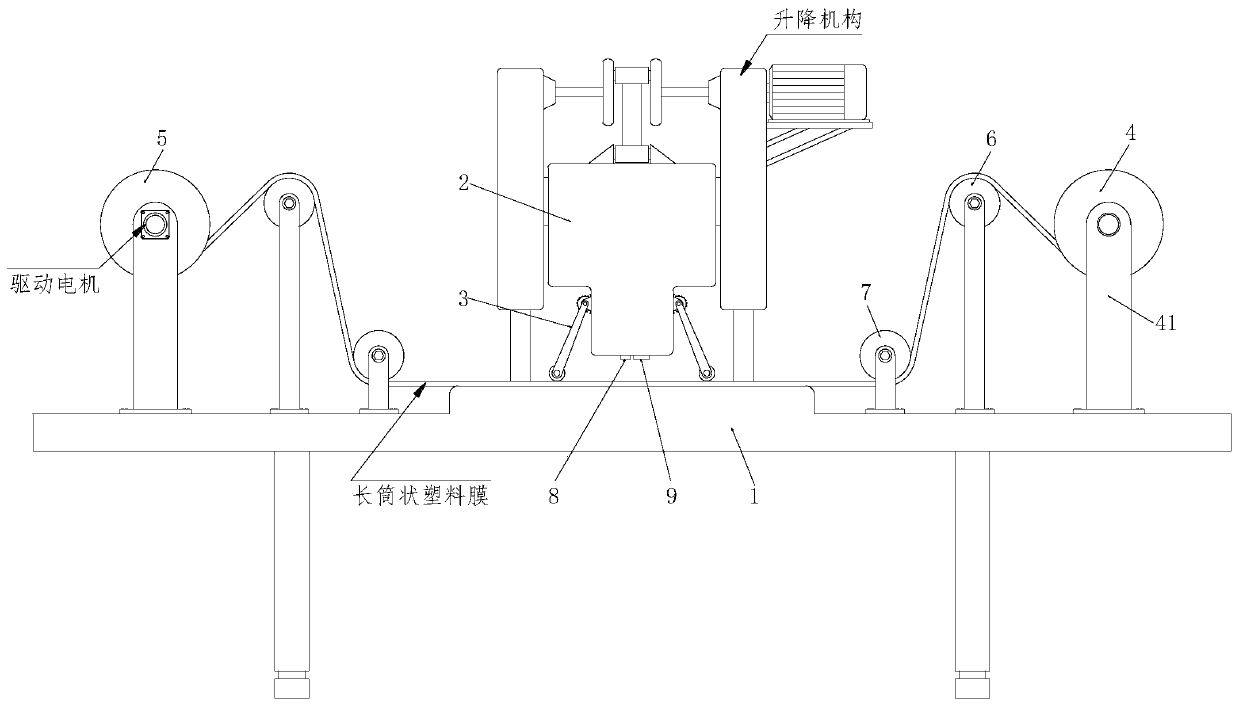

InactiveCN111590963AGuarantee processing qualityChange radiusBag making operationsPaper-makingStructural engineeringPlastic bag

The invention relates to a plastic bag forming manufacturing method which comprises a placing platform, a movable block, a paving mechanisms, a placing mechanism, a winding mechanism, a first positioning roll shaft, a second positioning roll shaft, a hot cutting end and a heat-seal end; a movable block is arranged right above the placing platform; the top of the movable block is connected with a lifting mechanism; the paving mechanisms are symmetrically mounted on the two side walls of the bottom of the movable block; the hot cutting end is arranged on the lower end face of the movable block;the heat-seal end is arranged on the lower end face of the movable block and on the right side of the hot cutting end; the first positioning roll shaft and the second positioning roll shaft are symmetrically mounted on the left and right sides of the movable block and on the upper end face of the placing platform; the winding mechanism is mounted at the left end of the top of the placing platformthrough a bolt; the placing mechanism is mounted at the right end of the top of the placing platform through a bolt; the placing mechanism and the winding mechanism are components with the same structure; and a mounting groove is formed in the movable block. The plastic bag forming manufacturing method has the characteristics of being high in processing quality and practicality.

Owner:合肥新胜塑料科技有限公司

Steel-wire-rope traction device

PendingCN110271981ARealize clamping and fixingImprove versatilityWinding mechanismsLocking mechanismEngineering

The invention discloses a steel-wire-rope traction device which comprises a baseplate, a mounting frame plate, a traction wheel and a position-locking mechanism, wherein the mounting frame plate is fixed on one side of the top surface of the baseplate; the bottom of one side face of the mounting frame plate is rotationally connected with the traction wheel in which a steel wire rope is embedded; the position-locking mechanism for locking the position of the steel wire rope in the traction wheel is arranged over the traction wheel and fixed at the upper part of one side face of the mounting frame plate; two sides of the top face of the baseplate are respectively and rotationally connected with clamping assemblies located respectively on two sides of the traction wheel; and a plurality of wheels are mounted on the bottom face of the baseplate. According to the steel-wire-rope traction device, by arranging the position-locking mechanism over the traction wheel, the problem of the release of the steel wire rope from the traction wheel can be effectively avoided; the folding clamping assemblies provide convenience for the erection of the steel-wire-rope traction device on an inspection shaft and can meet the needs of clamping the steel-wire-rope traction device to inspection shaft lids of different types and specifications, so that the steel-wire-rope traction device has wide application range and good universality; and the steel-wire-rope traction device is compact in overall structure, small in size, and convenient to carry and move.

Owner:XUANCHENG POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

PCB online semiconductor device testing system

ActiveCN111044885AMeet the clamping needsSimple structurePrinted circuit testingMeasurement instrument housingDevice materialClassical mechanics

The invention relates to the technical field of PCBs and especially relates to a PCB online semiconductor device testing system. The system comprises a placement table, a sliding rod, sliding sleeves,a telescopic spring, a movable rod, a limiting plate, an insertion column, a sliding rail, a sliding block, an extrusion spring, a limiting column, a rope, an adjusting screw rod, a locking nut, a guide rail, a movable block, a needle bed and a testing system. A sliding groove is arranged in a bottom of an inner wall of the placement table, middle positions of the two sides of the inner wall of the sliding groove are fixedly connected with two ends of the sliding rod correspondingly, the two sliding sleeves are connected with an outer surface of the sliding rod in a sleeving mode correspondingly, and the sliding sleeves are slidably connected with the sliding rod. In the invention, a purpose that the system is suitable for clamping and positioning PCBs of different models and sizes is achieved; and meanwhile, an overall structure is simple and convenient, automatic change can be performed according to the size, and a mode that clamps need to be replaced according to models in the pastwhen the PCB is detected is replaced so that detection efficiency is improved, a detection procedure is simplified, and a clamping requirement in a PCB detection process is met.

Owner:深圳市瑞福自动化设备有限公司

Multifunctional plate slotting machine for customized production of furniture

ActiveCN110466017AReduce the number of assembliesEasy to switchPolishing machinesGrinding drivesMechanical engineeringSlot machine

The invention relates to a multifunctional plate slotting machine for customized production of furniture. The multifunctional plate slotting machine comprises a working table, a horizontal moving platform arranged on the working table, a plate clamping mechanism arranged on the horizontal moving platform, a moving platform mechanism arranged on the top of the working table, a slotting mechanism installed on the horizontal moving platform, and a regulating mechanism installed on the slotting mechanism. According to the plate slotting machine provided by the invention, a plate is slotted under the condition that the plate is clamped effectively, and the slotting accuracy is high; not only can the slotting be finished, but also the surface of a formed slot can be further cleaned, simply polished and deburred; and the assembly quality of the customized furniture is ensured.

Owner:LAOMUJIANG WOOD IND XIANGCHENG DIST ZHANGZHOU CITY

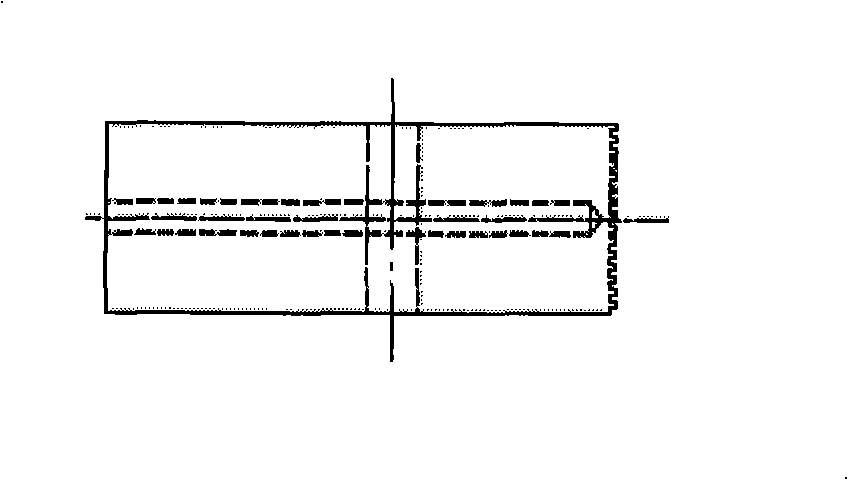

Tool and method for machining comb lines on inner wall of cylinder liner

The invention discloses a tool and method for machining comb lines on an inner wall of a cylinder liner, and belongs to the field of machining. The tool for machining the comb lines on the inner wall of the cylinder liner comprises a knife holder and a comb line knife. The comb line knife comprises a hilt, a crossbeam, auxiliary hilts and rollers, a U-shaped groove is formed in each auxiliary hilt, and directions of openings of the U-shaped grooves in the two auxiliary hilts are opposite to each other. Each U-shaped groove is connected with the corresponding roller through a corresponding hinge pin, and outer circle surfaces of the two rollers are higher than the tops of the corresponding U-shaped grooves. A threaded rod is mounted in the middle of each of the two auxiliary hilts, and each auxiliary hilt is connected with the corresponding threaded rod through a corresponding fixing device. In addition, the method for machining the comb lines on the inner wall of the cylinder liner comprises the following steps: step A, mounting a clamp and a knife; step B, adjusting the clamp and the knife; step C, rolling the comb lines; step D, removing burrs; and step E, cleaning and polishing the comb lines. The special tool is used for machining the comb lines, damage to a machine tool is small, and machining steps are simple; and the machined cylinder liner can adsorb carbon deposits and is high in strength.

Owner:HEBEI HUABEI DIESEL ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com