Numerical-control working platform for precision casting sprue grinding

A working platform and precision casting technology, which is applied in the direction of grinding workpiece support, grinding frame, grinding bed, etc., can solve the problems of high labor intensity, low production efficiency, non-uniform size, etc., to reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

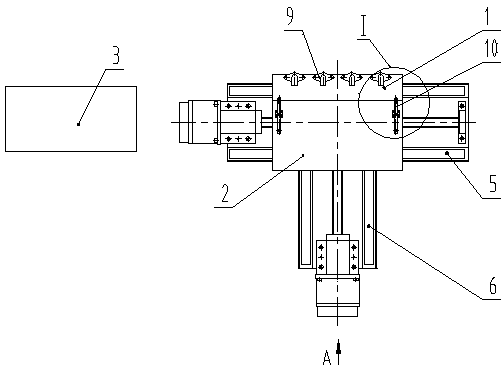

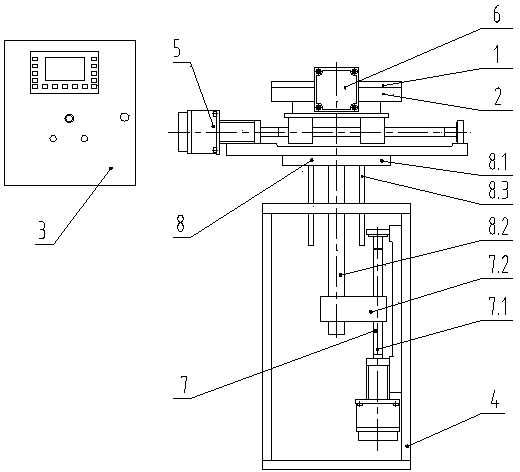

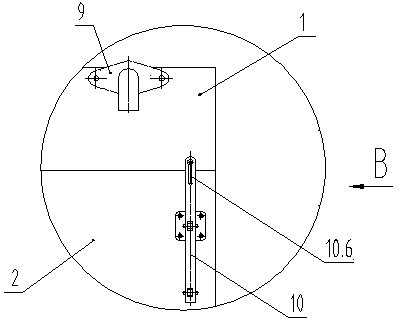

[0024] The CNC working platform for gate grinding of precision castings shown in the attached figure includes fixture 1, working platform 2, bracket 4, horizontal CNC slide table 5, vertical CNC slide table 6, electrical control components 3, lifting mechanism 8, and lifting CNC moving mechanism 7. Fixture 1 is a plate-like member, installed on the upper end of working platform 2; bracket 4 is set at the lower part of working platform 2; horizontal CNC sliding table 5 and vertical numerical control sliding table 6 are set between working platform 2 and bracket 4, which can be driven The working platform 2 realizes the movement in the horizontal and vertical directions in the horizontal plane; the horizontal CNC slide table 5 and the vertical CNC slide table 6 both include guide rails and motor-driven screw transmission mechanism I; the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com