Flexible clamping conveying impurity-removing device of combined harvester of Allium fistulosum L.var. giganteum Makion and application method of flexible clamping conveying impurity-removing device

A combine harvester and flexible clamping technology, applied in excavator harvesters, harvesters, applications, etc., can solve problems such as poor adaptability and versatility, low degree of mechanized harvesting, and inability to apply green onion harvesting to ensure reliability. and continuity, labor saving, injury reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

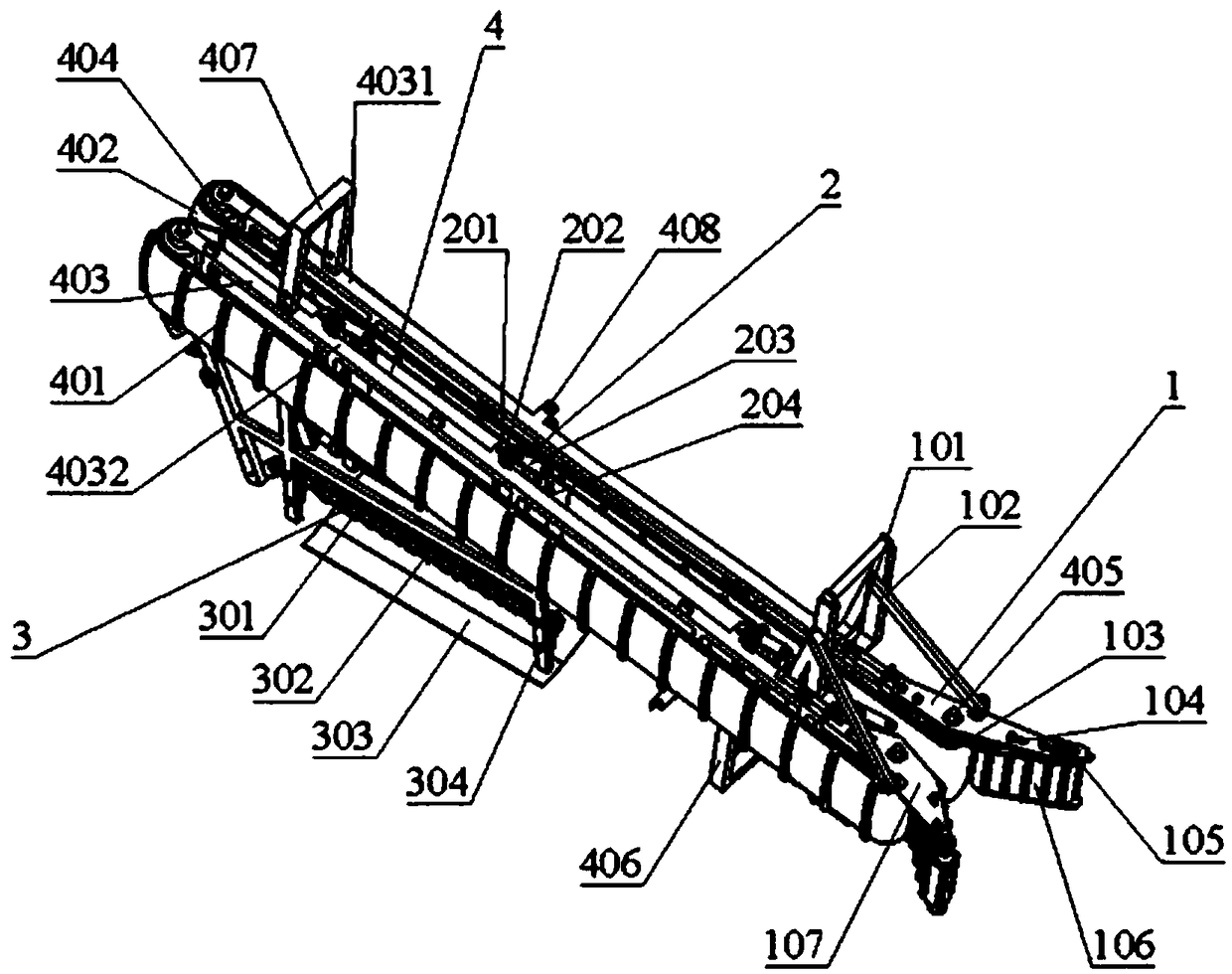

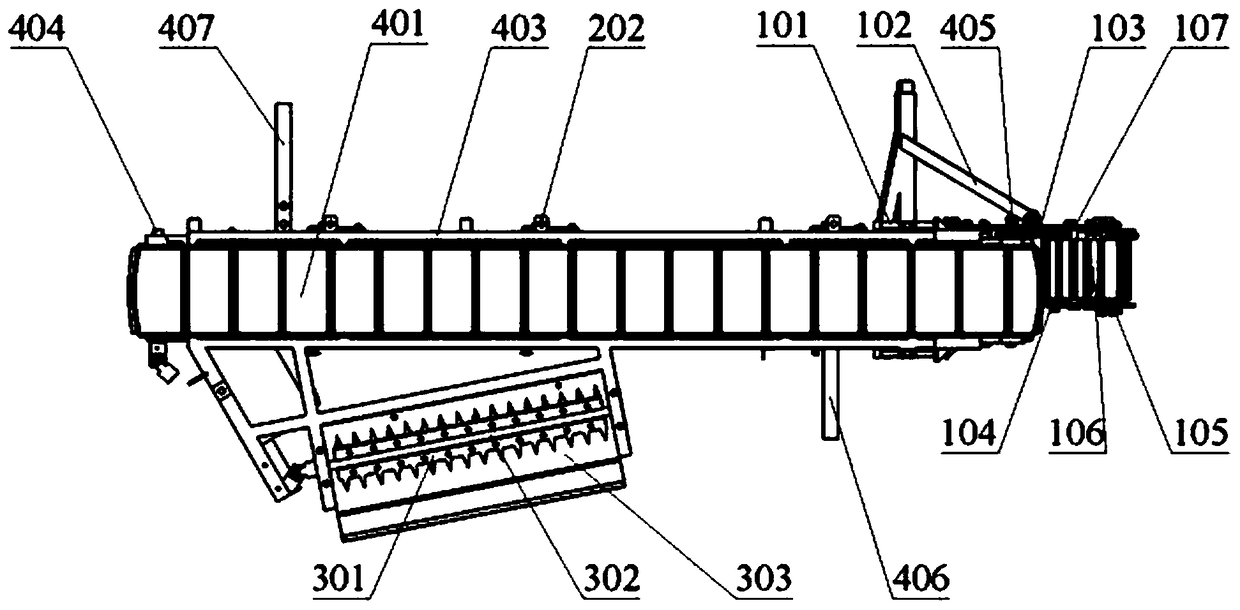

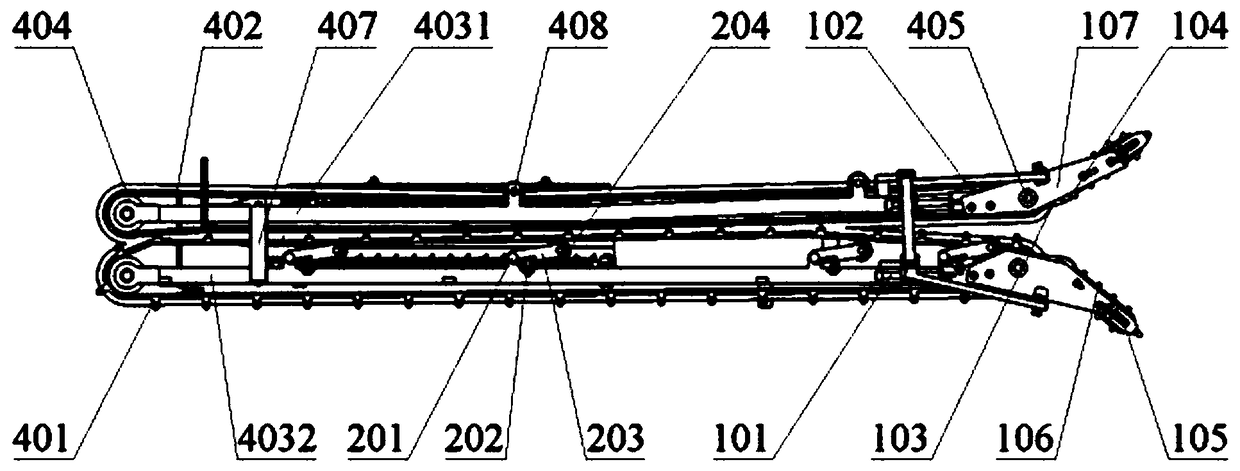

[0032] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0033] Such as figure 1 Shown is a flexible clamping and conveying cleaning device for a scallion combine harvester, including a supporting feeding device 1, a tensioning device 2 and a flexible clamping and conveying device 4, and the supporting and feeding device 1 is installed on the clip of the flexible clamping and conveying device. On the frame 403, the scallion combine harvester is a self-propelled scallion combine harvester.

[0034] The clamping frame 403 comprises a left clamping frame 4031 and a right clamping frame 4032 arranged side by side, and the installation distance between the left clamping frame 4031 and the right clamping frame 4032 is 150mm, and is fixedly connected by an upper connecting rod 407 and a lower connecting rod 406 Together, the lower connecting rod 406 and the upper connecting rod 407 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com