Patents

Literature

56results about How to "Realize cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

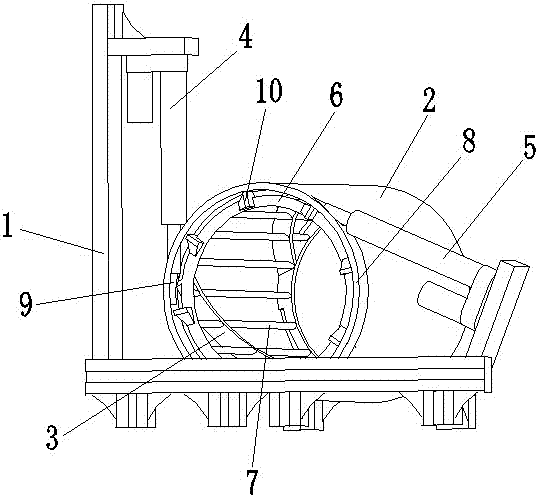

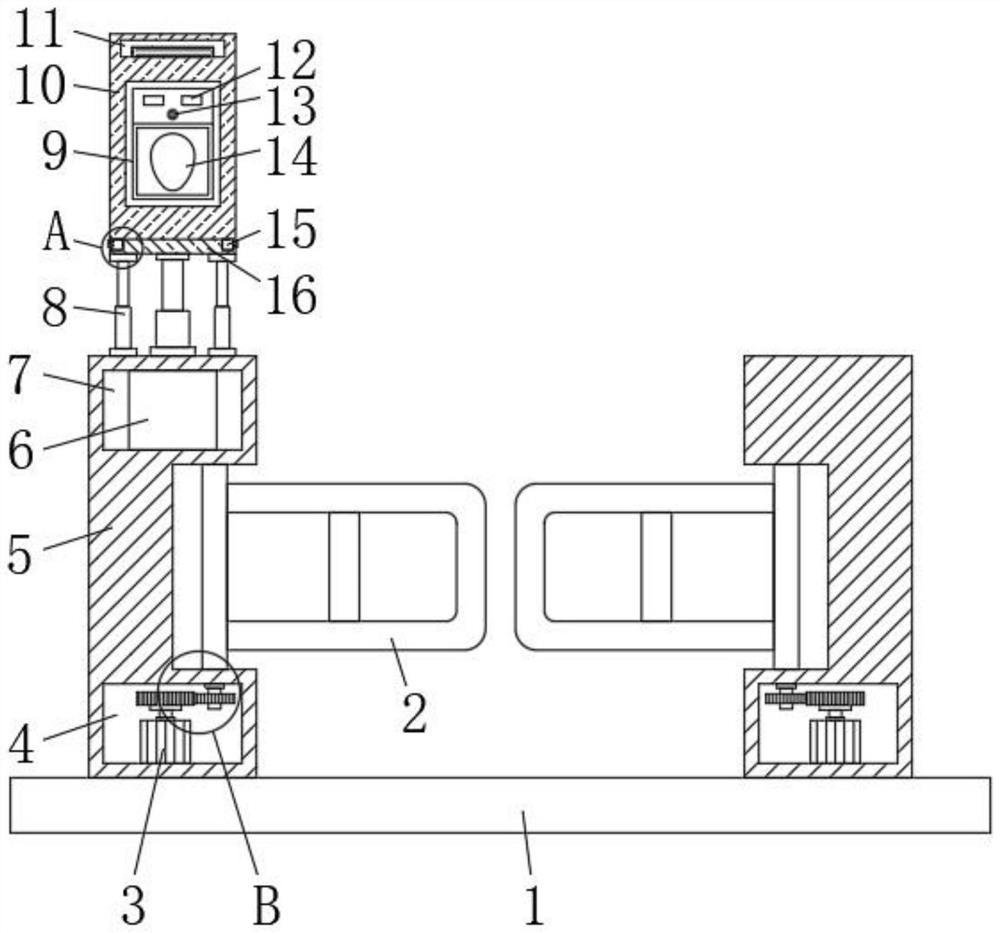

Central air conditioner cleaning device

ActiveCN103639161ARealize cleaningCompact structureHollow article cleaningMechanical engineeringElastic rods

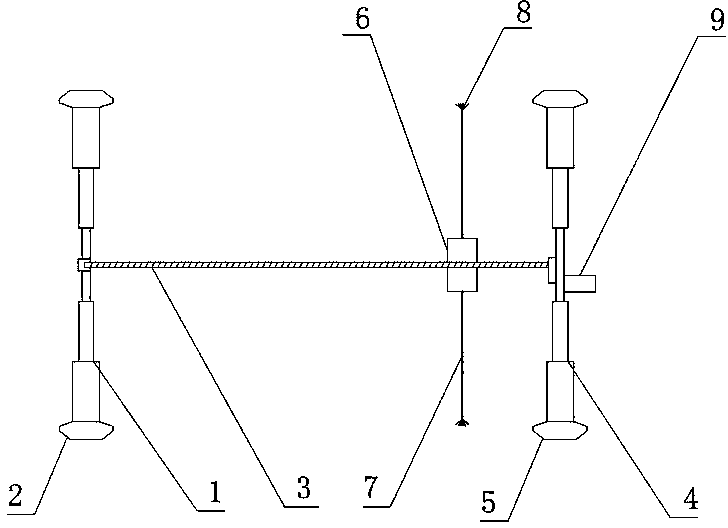

The invention discloses a central air conditioner cleaning device. The central air conditioner cleaning device comprises a first supporting arm and a second supporting arm which are distributed in the radial direction of a ventilation pipe of a central air conditioner. A first crawler belt is installed at one end of the first supporting arm, a second crawler belt is installed at one end of the second supporting arm, a lead screw is installed between the center of the first supporting arm and the center of the second supporting arm, the lead screw is in transmission linkage with a power device, the lead screw is sleeved with a lead screw nut, a radial elastic rod is installed on the lead screw nut, and a brush is installed at one end of the elastic rod. The central air conditioner cleaning device has the advantages of being compact in structure, good in cleaning effect and the like.

Owner:靖江市纳川空调设备有限公司

All-dimensional computer surface ash removing machine

ActiveCN105817435ARealize cleaningRealize sponge wipeCleaning using toolsLiquid-crystal displaySlide plate

The invention relates to the field of notebook computers, in particular to an all-dimensional computer surface ash removing machine. The all-dimensional computer surface ash removing machine comprises a body mechanism, a keyboard cleaning device, an advancing mechanism and a screen cleaning device. The body mechanism comprises a left side plate, a right side plate, four supporting air cylinders and two rodless air cylinders; the keyboard cleaning device comprises a sliding plate, front and back screws, front and back motors, a moving plate, a keyboard cleaning motor, a keyboard cleaning machine, a hairbrush, a keyboard cleaning air cylinder and a dirty removing sponge; and the screen cleaning device comprises a fixed plate, left and right screws, left and right motors, a screen cleaning block, a screen cleaning air cylinder, a rotary supporting air cylinder and a screen cleaning sponge. By means of the all-dimensional computer surface ash removing machine, a computer keyboard can be subject to automatic hairbrush cleaning and sponge wiping; in addition, automatic cleaning of a liquid crystal display can be achieved, the automatic degree is high, manual work is not needed, the structural design is ingenious, and the manpower is saved.

Owner:江苏弘汉生物科技有限公司

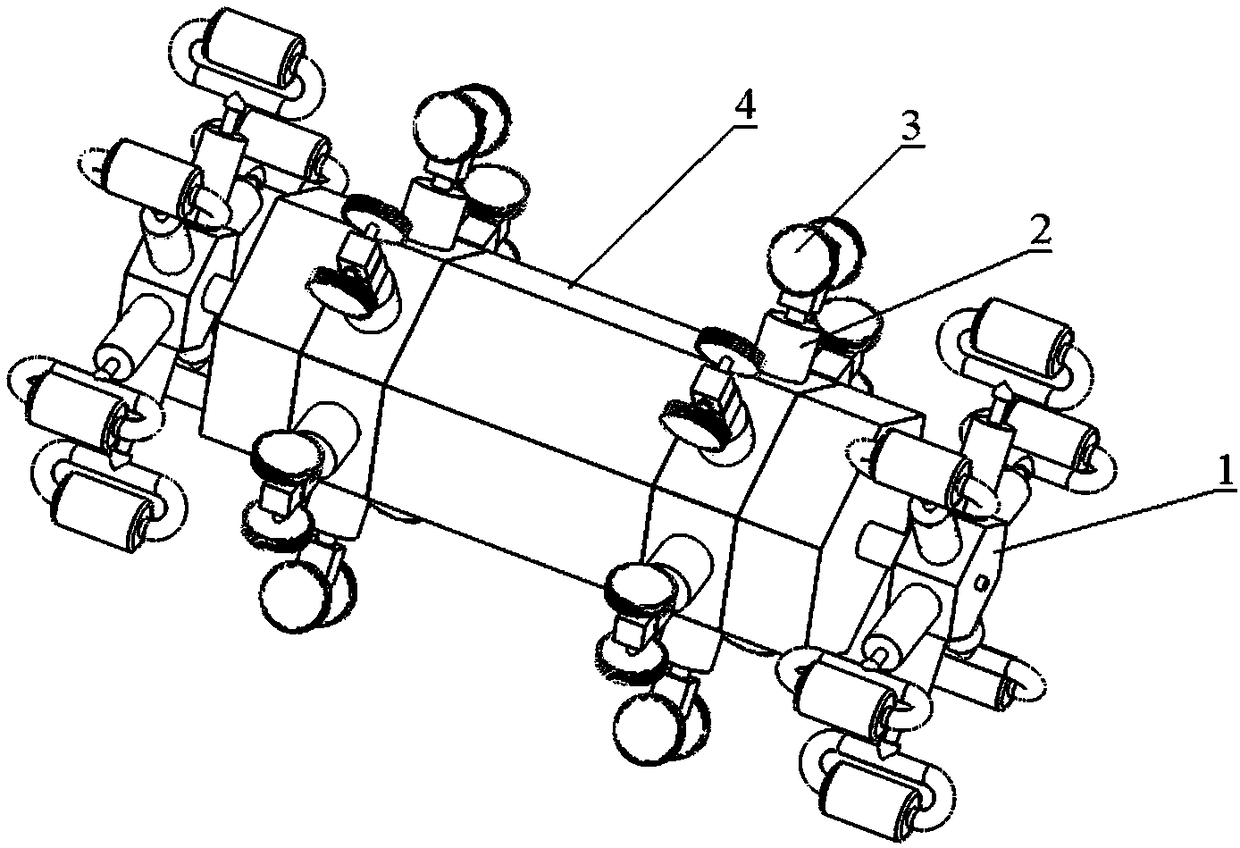

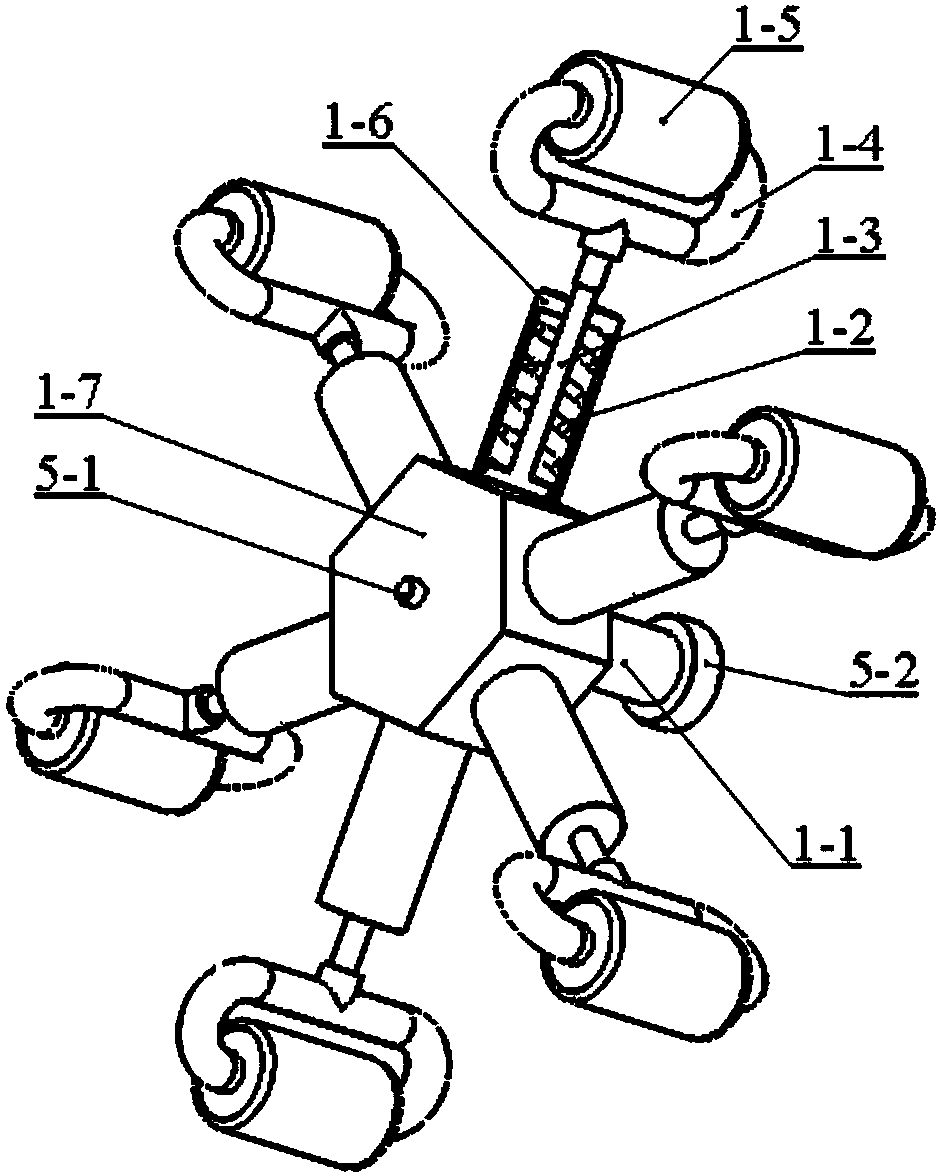

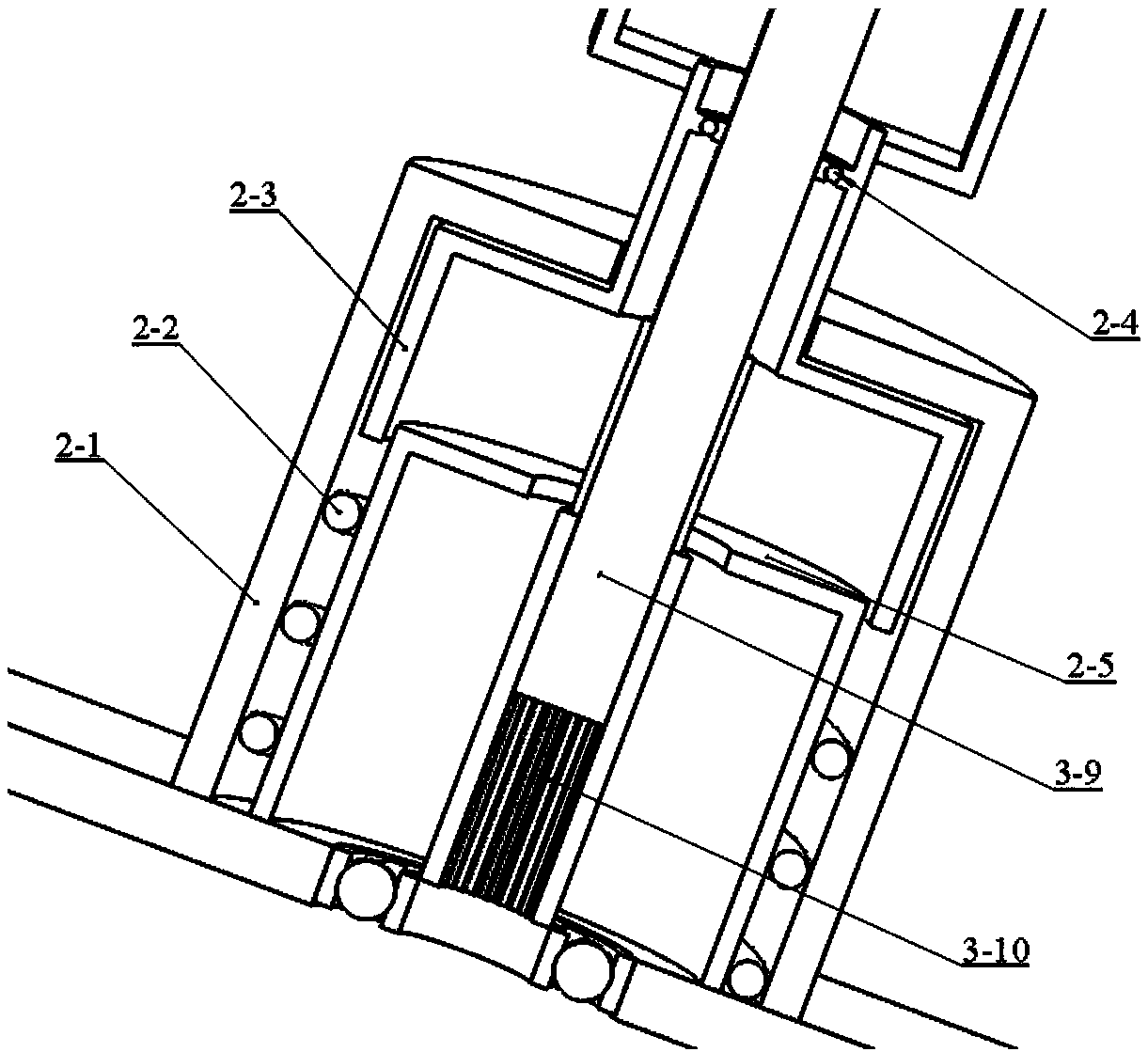

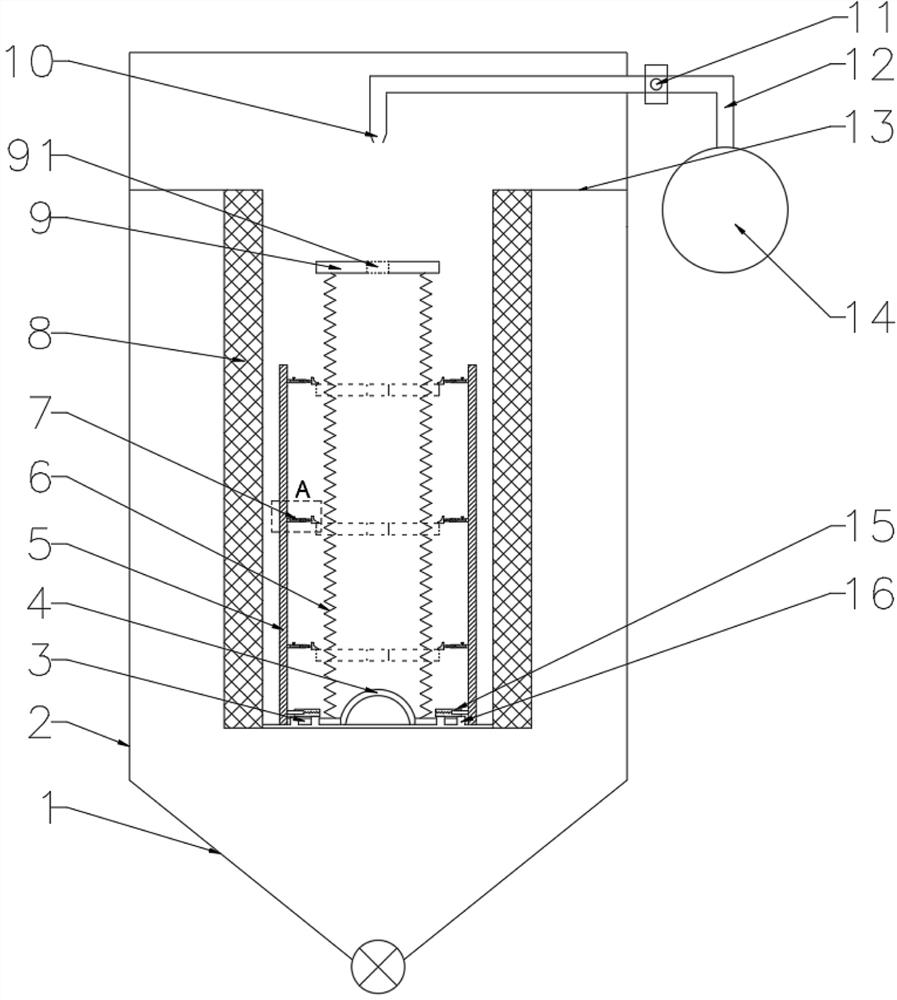

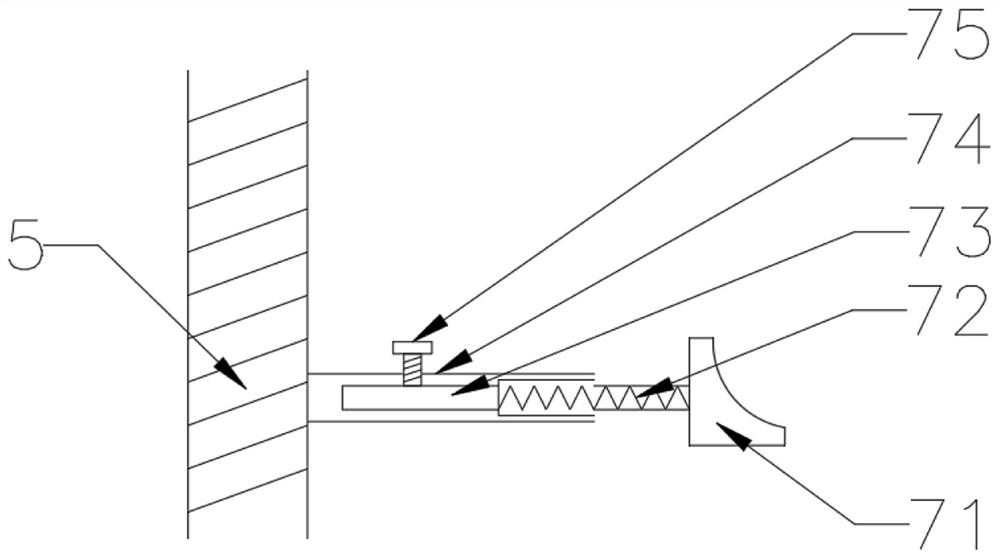

Single chip microcomputer control based automatic soot cleaning device for soot pipeline

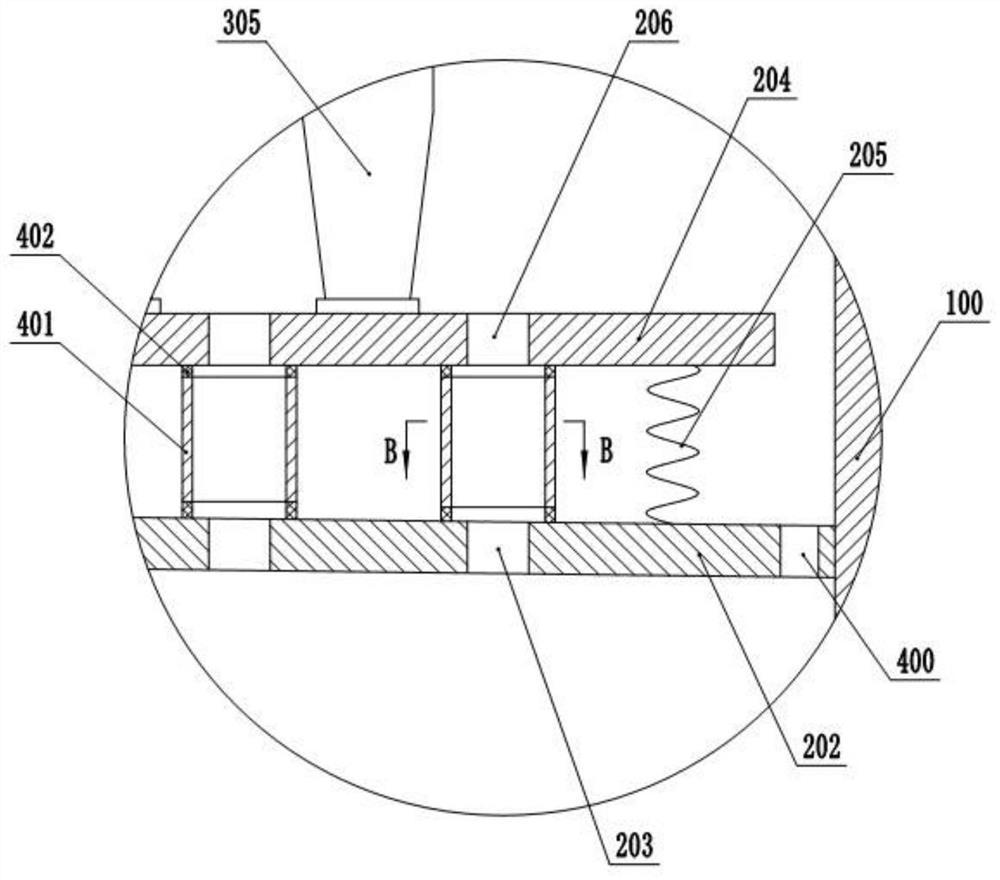

PendingCN108160633ACompact structureImprove cleanlinessProgramme-controlled manipulatorHollow article cleaningMicrocontrollerRemote control

The invention relates to a single chip microcomputer control based automatic soot cleaning device for a soot pipeline. The single chip microcomputer control based automatic soot cleaning device is characterized by comprising a housing, telescoping mechanisms, travelling mechanisms, soot cleaning mechanisms, a control device and a power supply device, wherein the soot cleaning mechanisms are symmetrically mounted at the two ends of the housing; the travelling mechanisms and the telescoping mechanisms are mounted together and are symmetrically arranged at the two ends of the surface of the housing; the power supply device and the control device are mounted inside the housing; the control device is connected with the telescoping mechanisms, the travelling mechanisms and the soot cleaning mechanisms; the control device is connected with a remote-control module outside the housing in a wireless mode; and the remote-control module is used for sending a control instruction to the control device, and the control device controls operation of the telescoping mechanisms, the travelling mechanisms and the soot cleaning mechanisms. The single chip microcomputer control based automatic soot cleaning device adopts the hexagonal-prism housing, and the telescoping mechanisms and the travelling mechanisms are arranged on the housing, so that a soot cleaning function for pipelines of different diameter lengths can be realized, and therefore, the single chip microcomputer control based automatic soot cleaning device is compact in structure, is good in soot cleaning effect, is high in working efficiency, is matched with the internal control device, saves manual soot cleaning trouble, and is wide in range of application.

Owner:HEBEI UNIV OF TECH

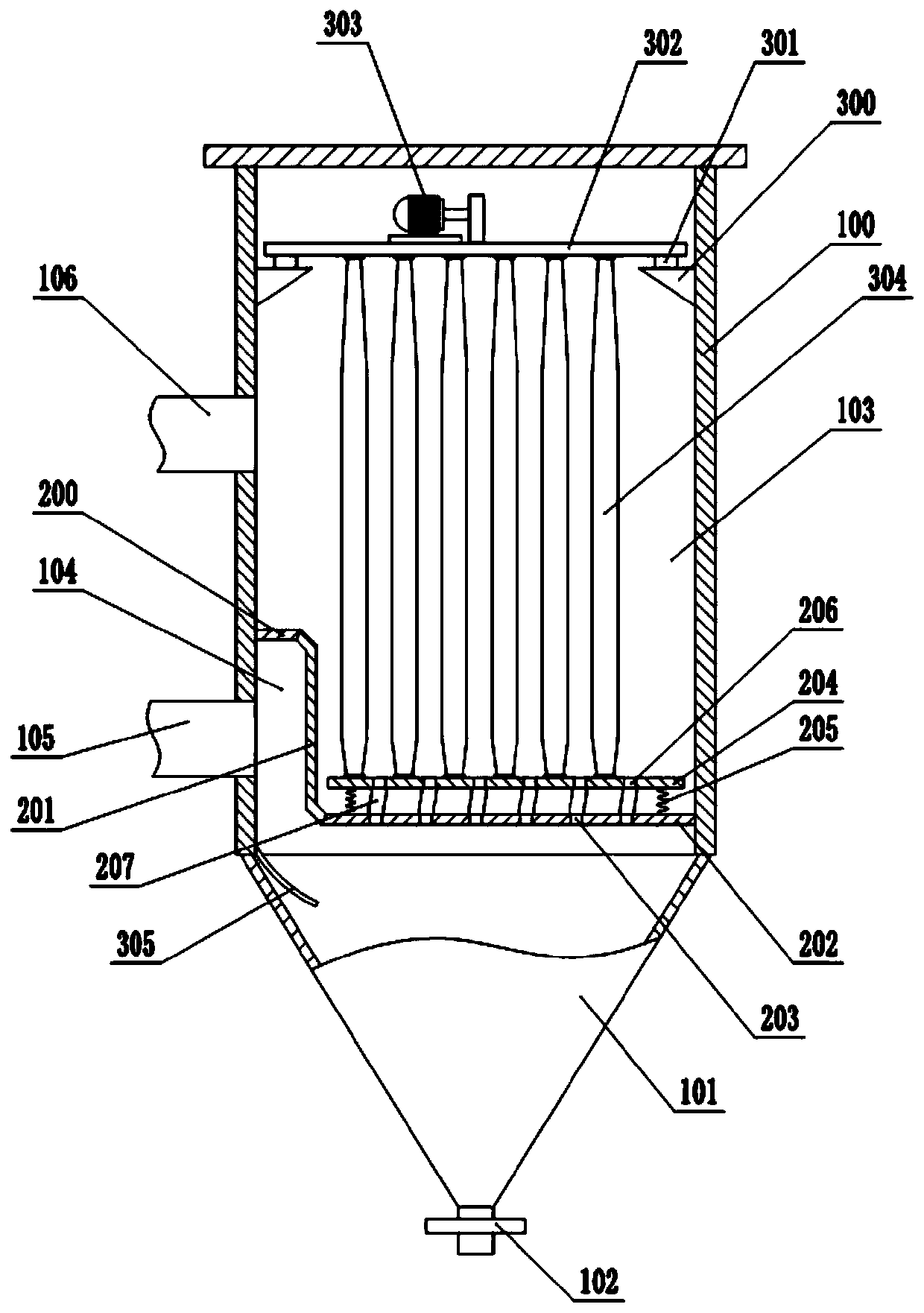

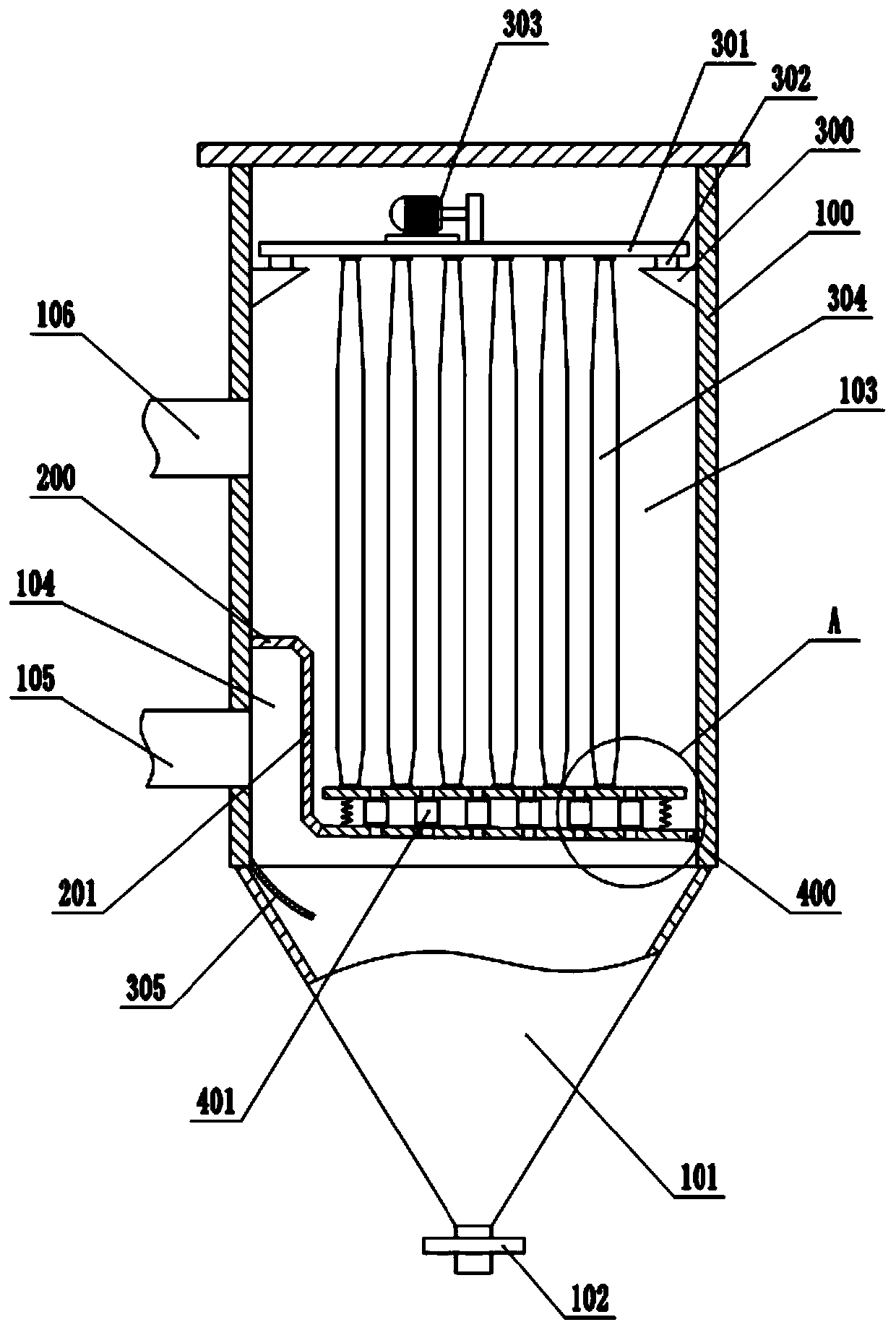

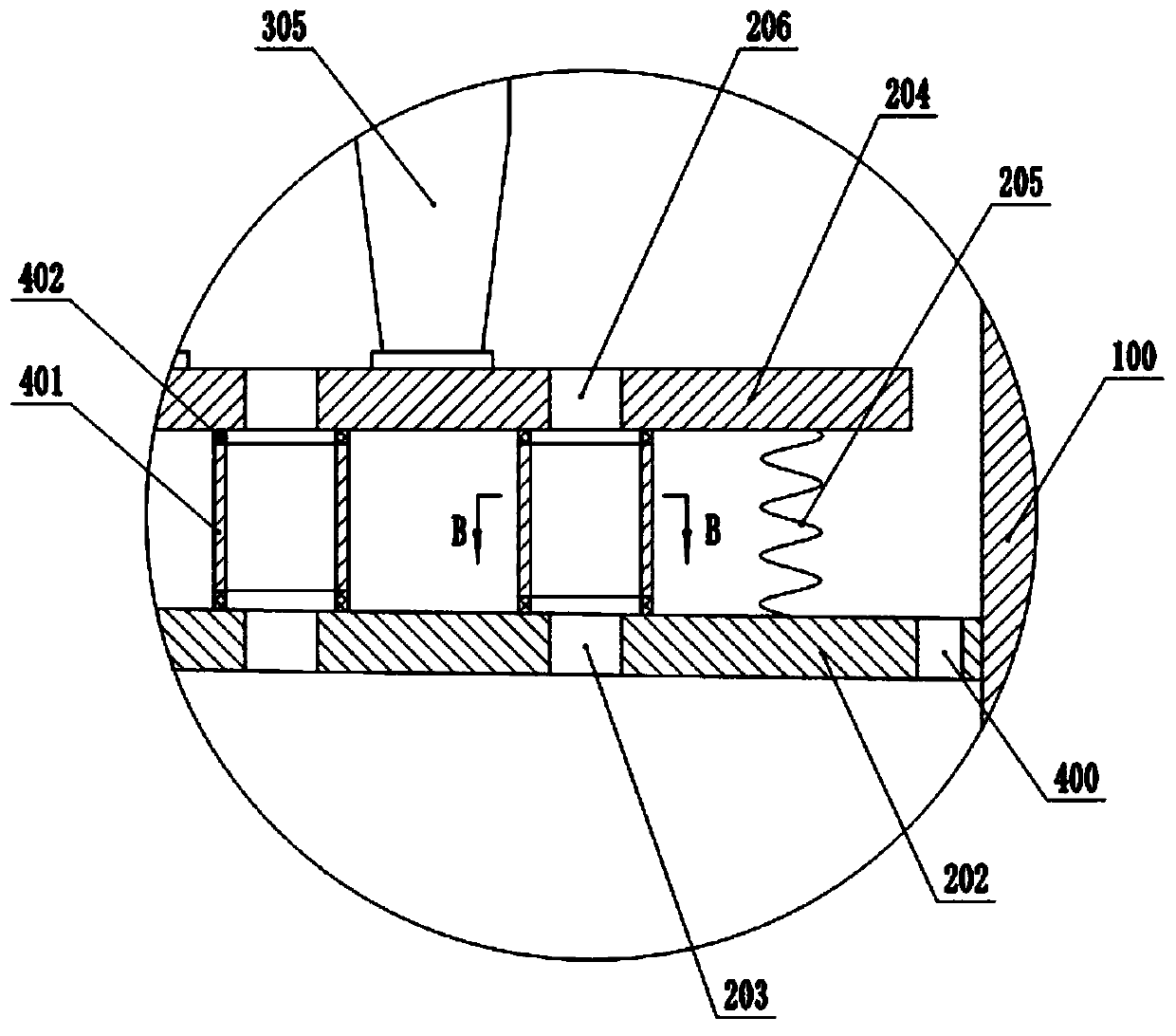

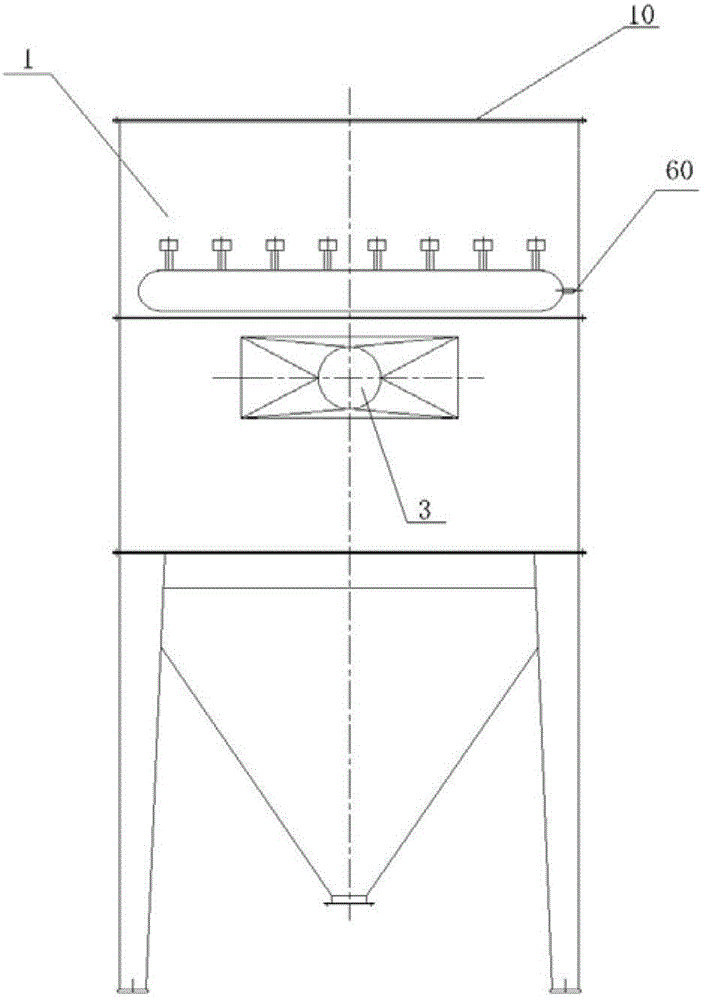

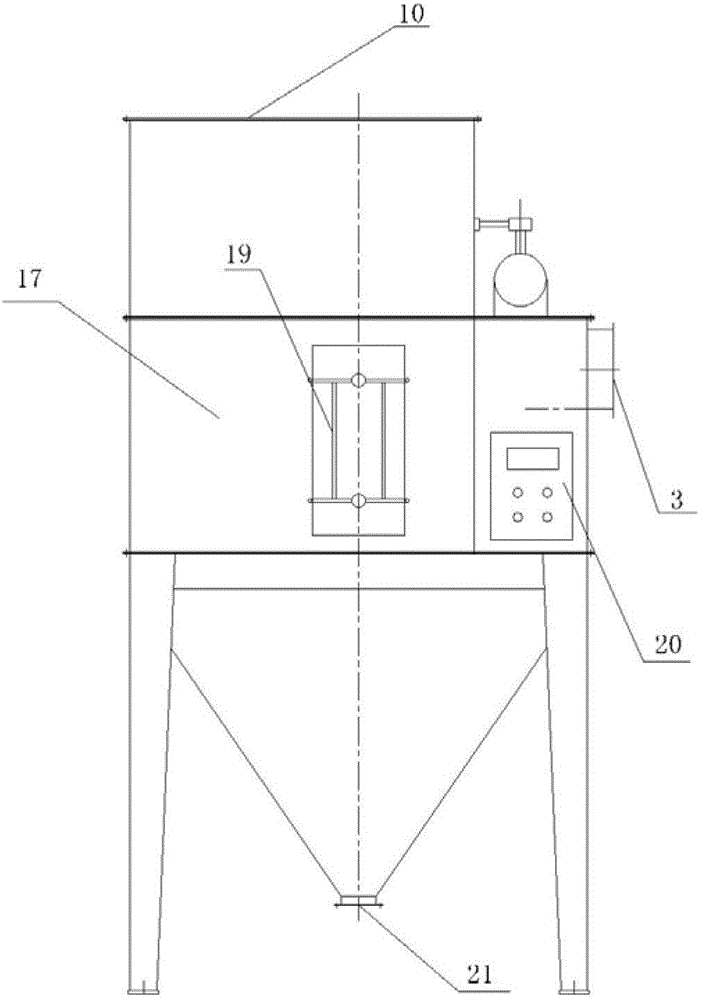

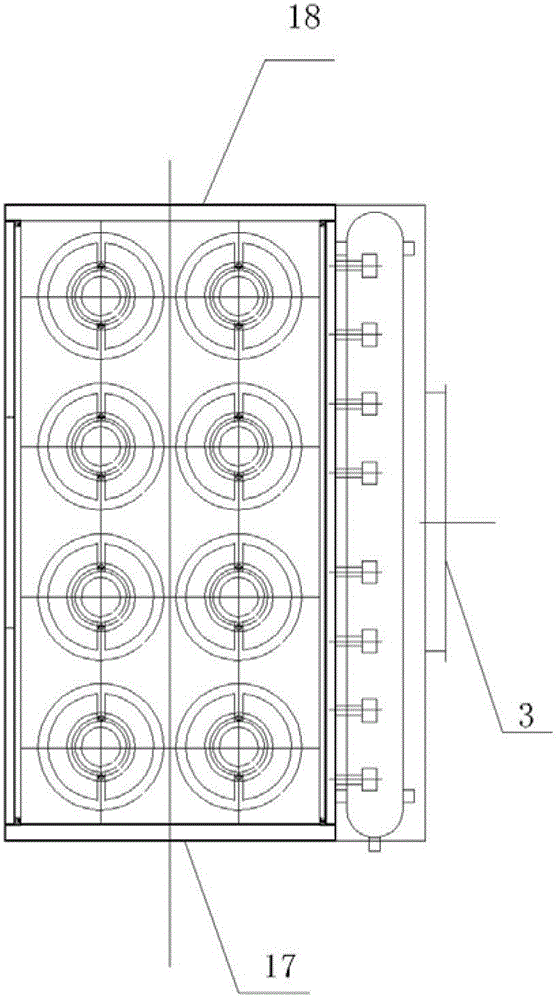

Dust remover for dumping furnace self-baking electrode volatile matter

ActiveCN110339640AExtended service lifeReduce pulling forceCombination devicesDispersed particle filtrationEngineeringElectrode

The invention relates to the technical field of waste-gas treatment equipment, and particularly discloses a dust remover for dumping furnace self-baking electrode volatile matter. The dust remover comprises a box body and an ash hopper; a partition plate is laterally fixed in the box body, the partition plate divides the box body into a purification chamber and a cleaning chamber, and the partition plate is provided with a plurality of through holes I; the box body is provided with a gas inlet communicating with the purification chamber and a gas outlet communicating with the cleaning chamber,a plurality of filter bags located above the partition plate is vertically arranged in the box body, and a vibrating unit vibrating the filter bags is arranged in the box body; and a buffer plate isarranged above the partition plate, the bottoms of the filter bags are fixed on the buffer plate, the baffle plate is connected with the partition plate through elastic parts, the buffer plate is provided with a plurality of through holes II, and each middle pipe communicates with one corresponding through holes I and one corresponding through holes II. The dust remover provided by the invention can solve the problem that connection positions of filter bags and a partition plate are broken because the connection positions are pulled during vibration in the prior art.

Owner:重庆市赛特刚玉有限公司

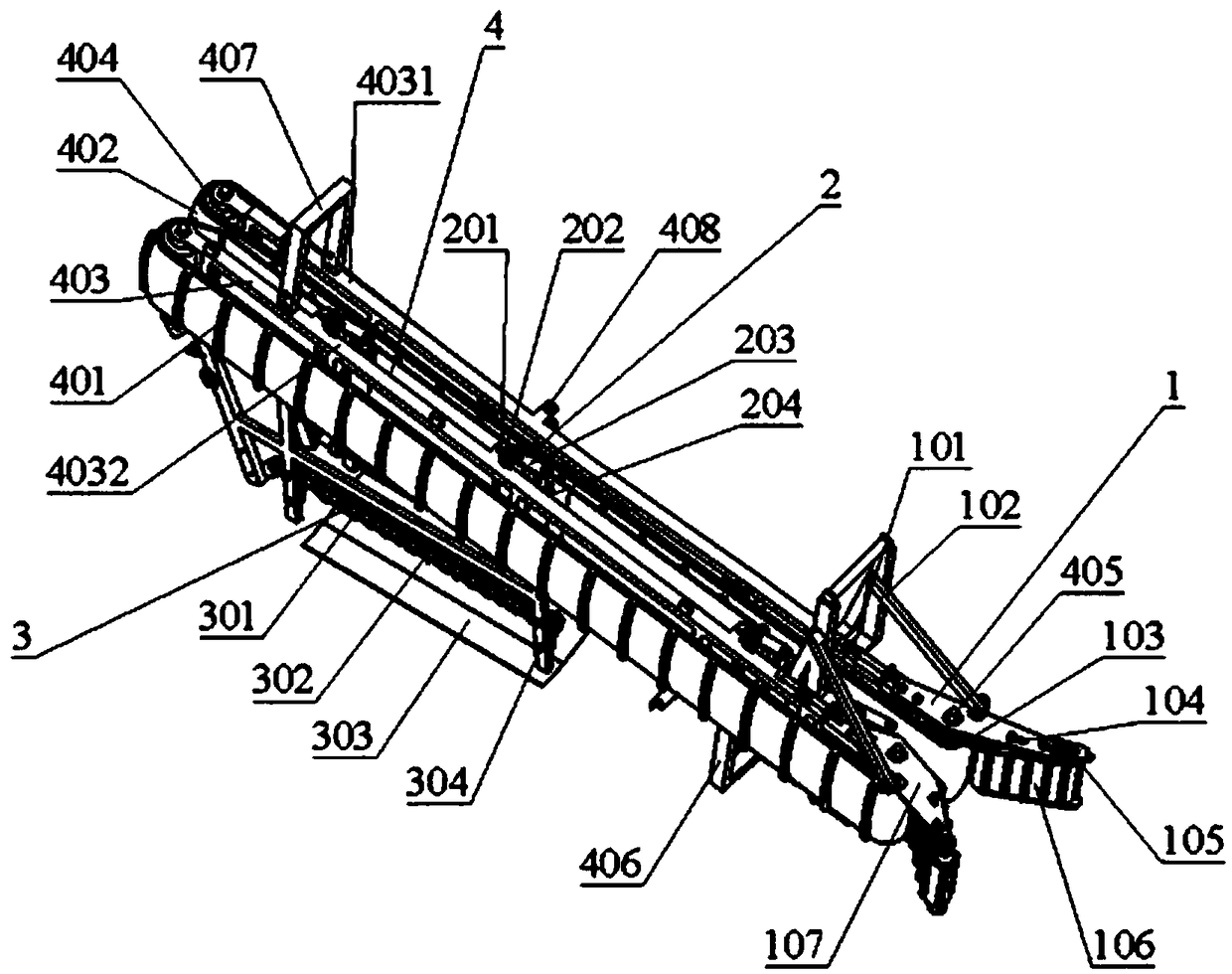

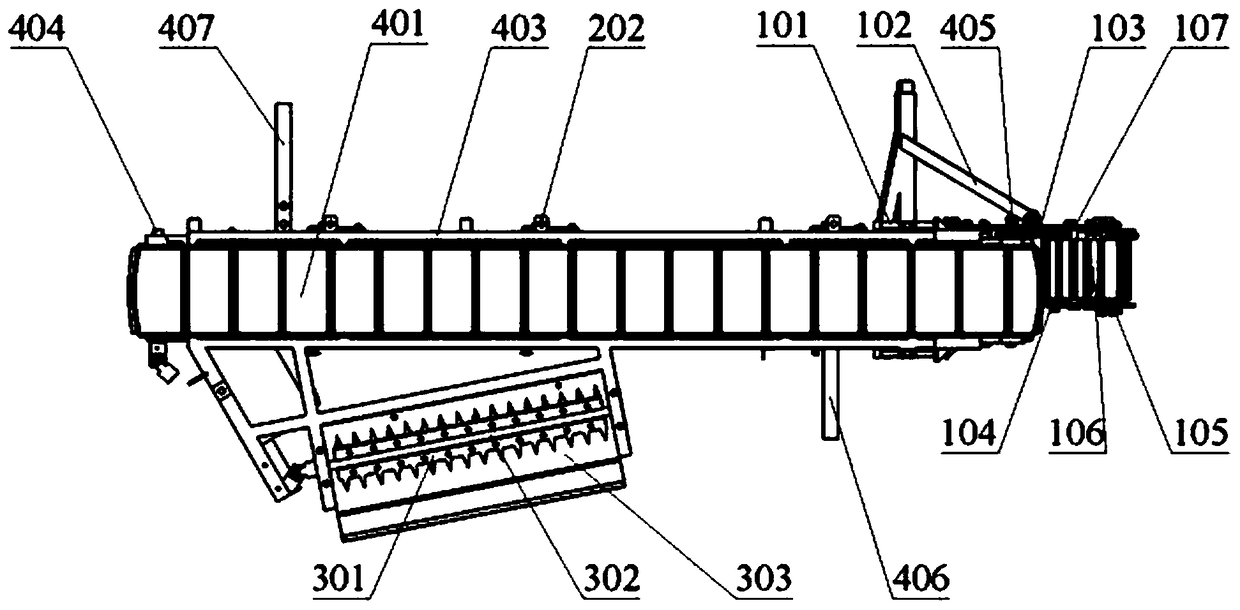

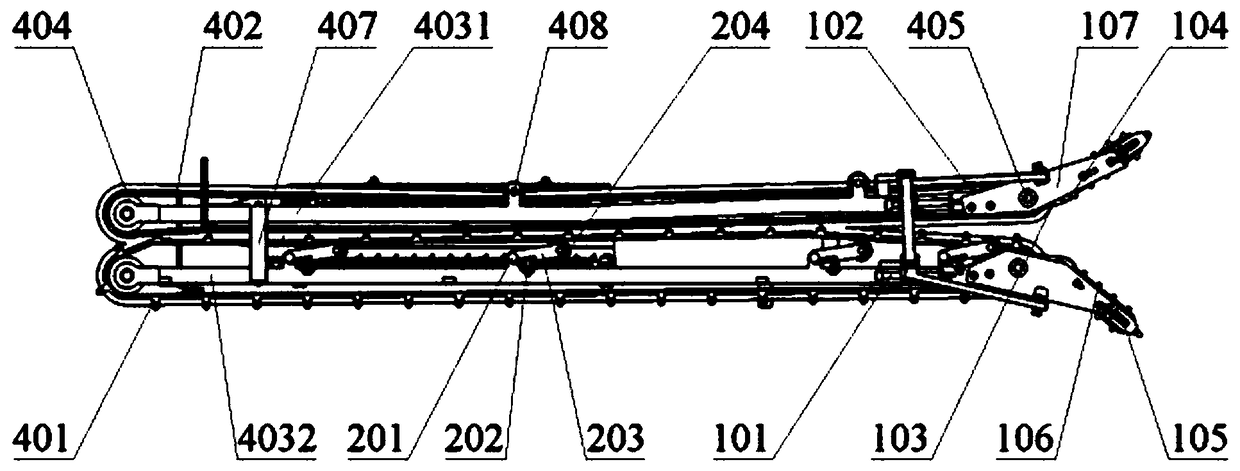

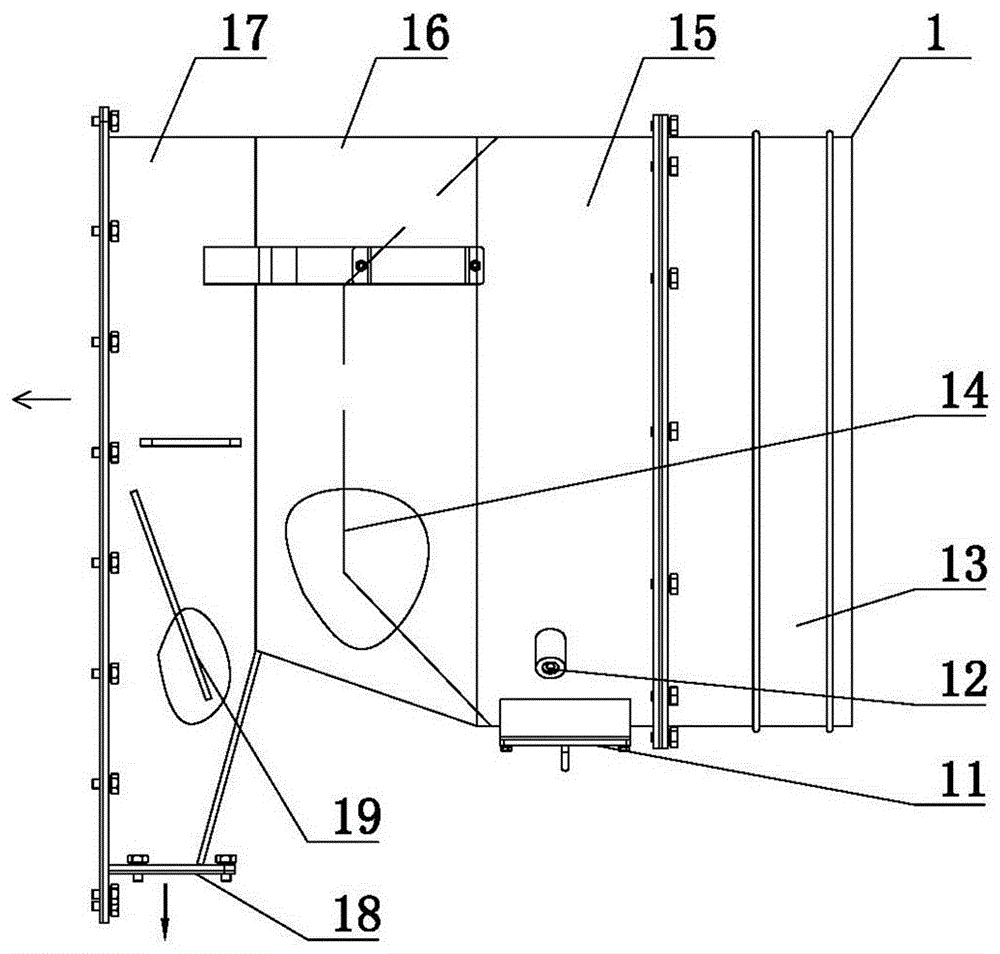

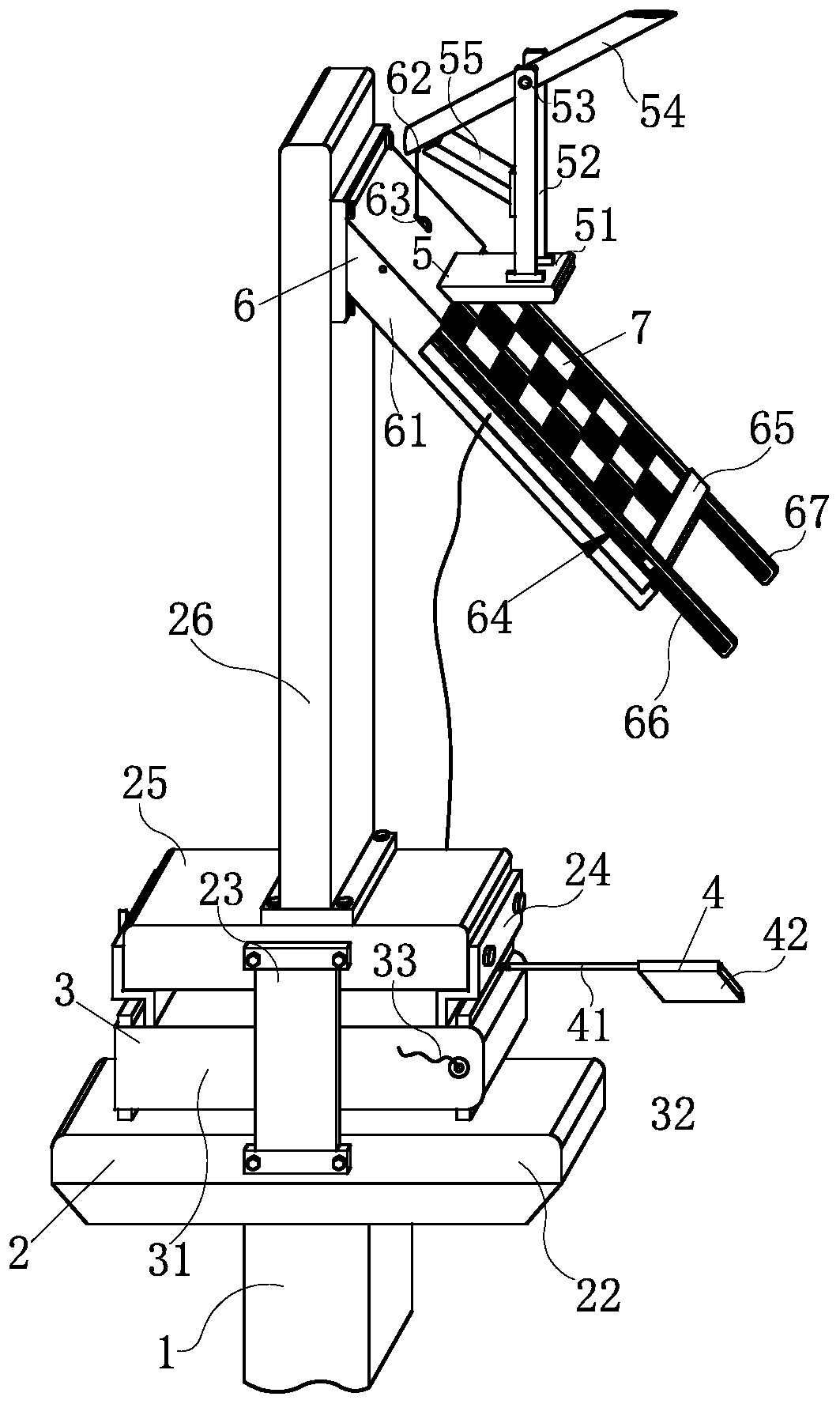

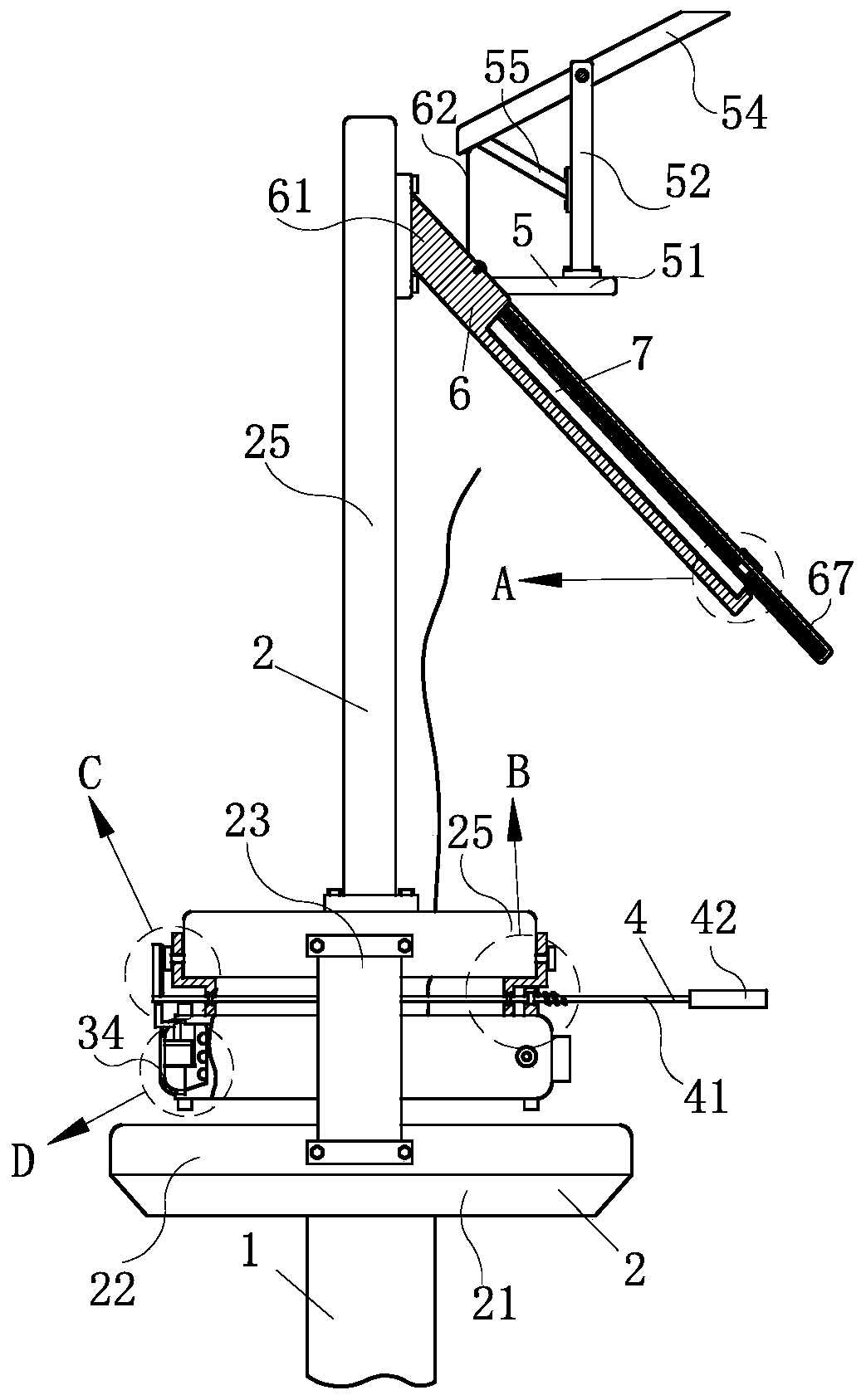

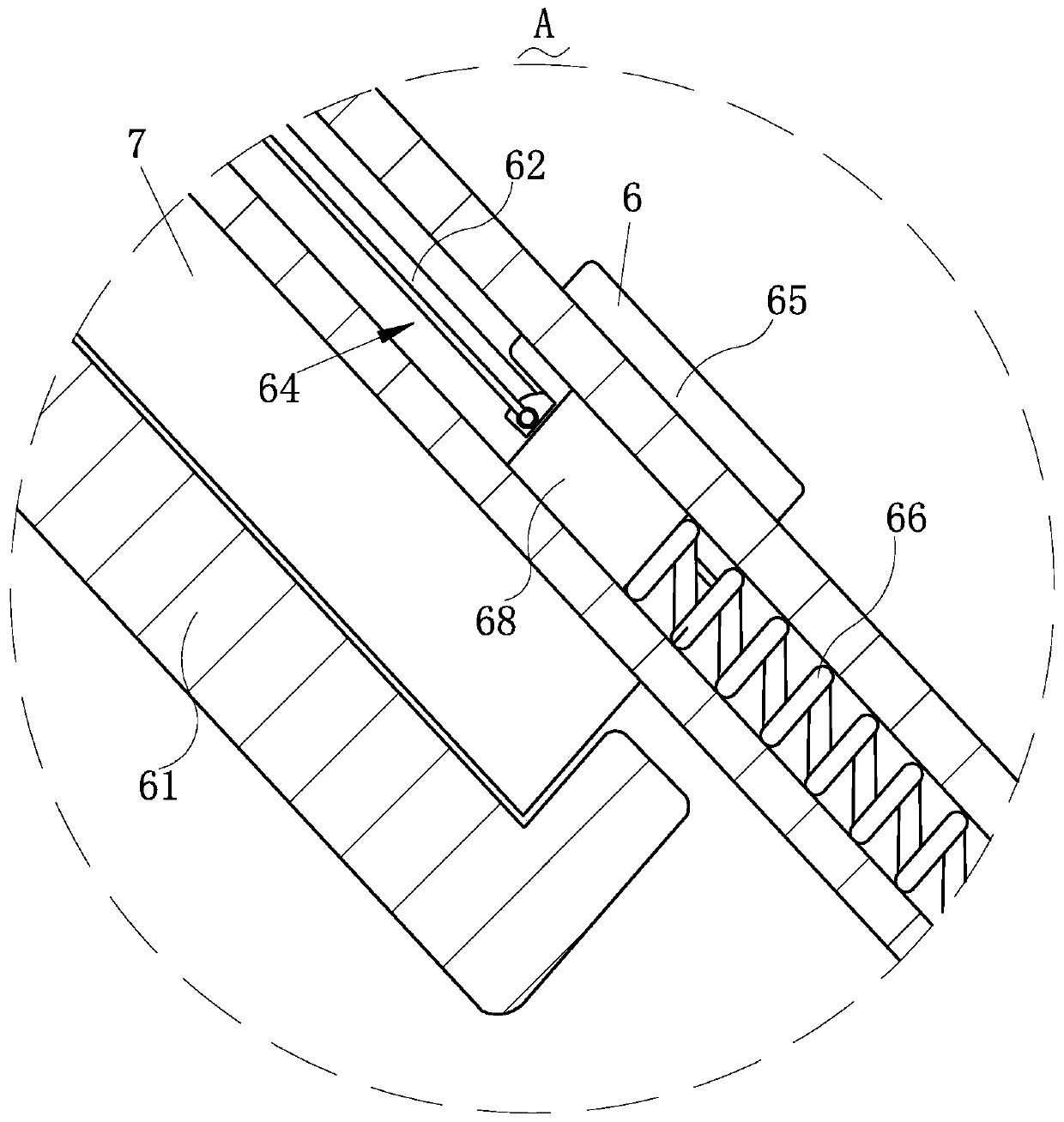

Flexible clamping conveying impurity-removing device of combined harvester of Allium fistulosum L.var. giganteum Makion and application method of flexible clamping conveying impurity-removing device

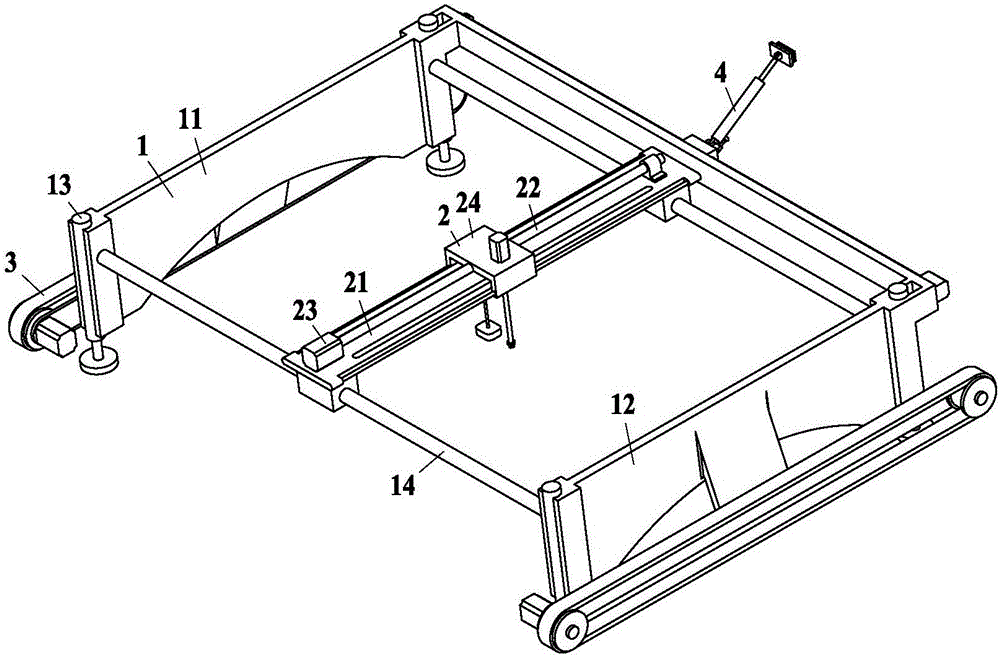

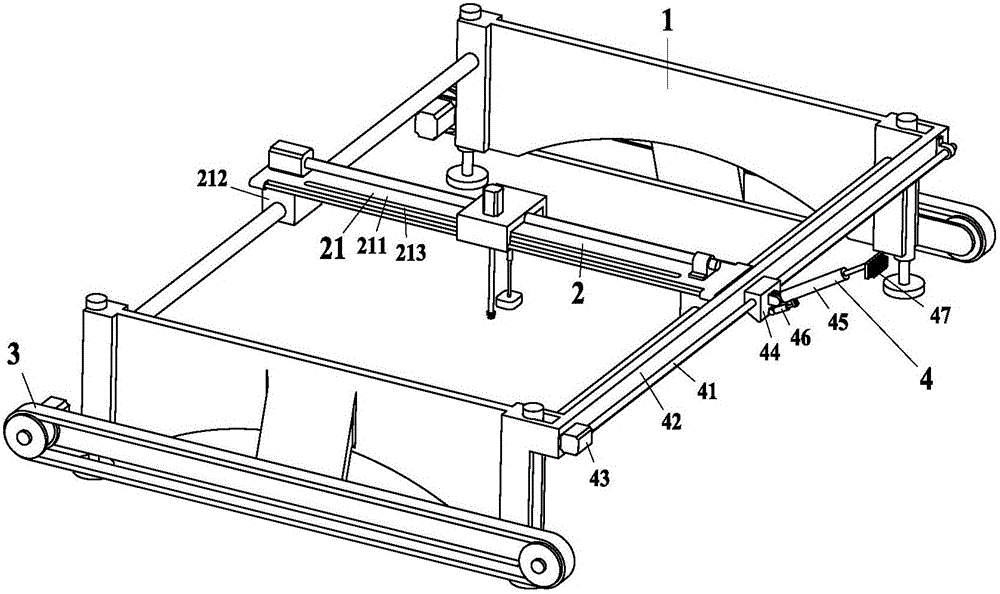

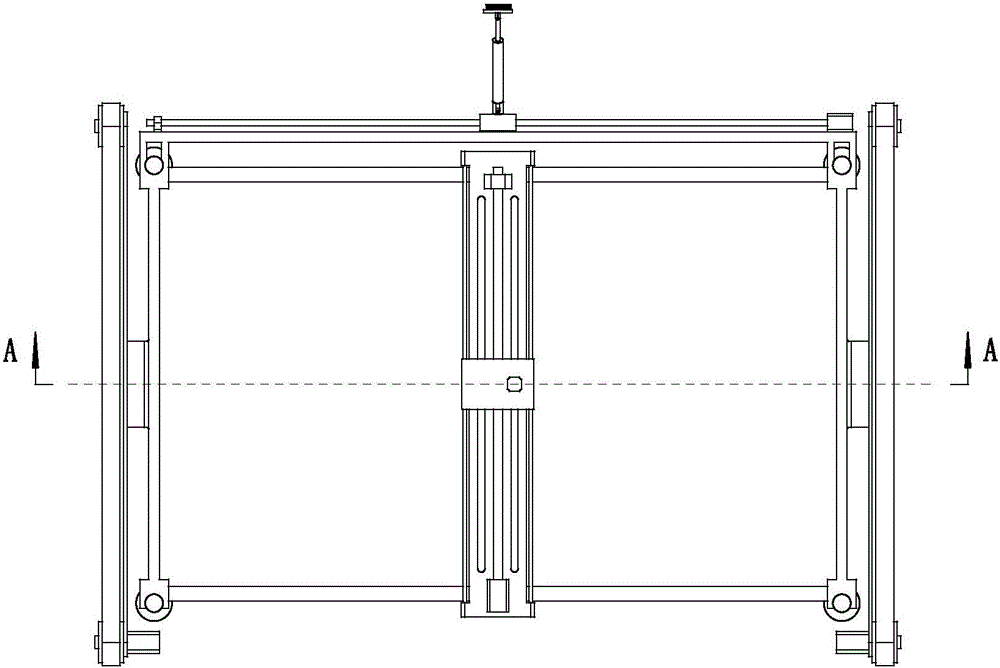

The invention relates to a flexible clamping conveying impurity-removing device of a combined harvester of Allium fistulosum L.var. giganteum Makion and an application method of the flexible clampingconveying impurity-removing device. The flexible clamping conveying impurity-removing device comprises a left clamping rack and a right clamping rack which are arranged side by side, wherein flexibleclamping conveyor belts are separately installed on the left clamping rack and the right clamping rack, support feeding devices are fixedly connected to input ends of the left clamping rack and the right clamping rack, and a tensioning device is arranged at the inner side of the flexible clamping conveyor belt on the right clamping rack. The flexible clamping conveying impurity-removing device canadapt to harvest of Allium fistulosum L.var. giganteum Makion of different growth conditions through arrangement of the support feeding devices, so that it is ensured that Allium fistulosum L.var. giganteum Makion is smoothly sent between the two flexible clamping conveyor belts, and the versatility of the harvester of Allium fistulosum L.var. giganteum Makion is improved; through arrangement ofthe flexible clamping conveyor belts, flexible clamping and conveying of Allium fistulosum L.var. giganteum Makion can be ahcieved, damage to Allium fistulosum L.var. giganteum Makion is reduced, andthe harvest quality is ensured; and through arrangement of the tensioning device, the spacing of the two flexible clamping conveyor belts can be adjusted so as to adapt to change of the diameter of Allium fistulosum L.var. giganteum Makion stems, and the reliable and continuity of clamping transportation are ensured.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

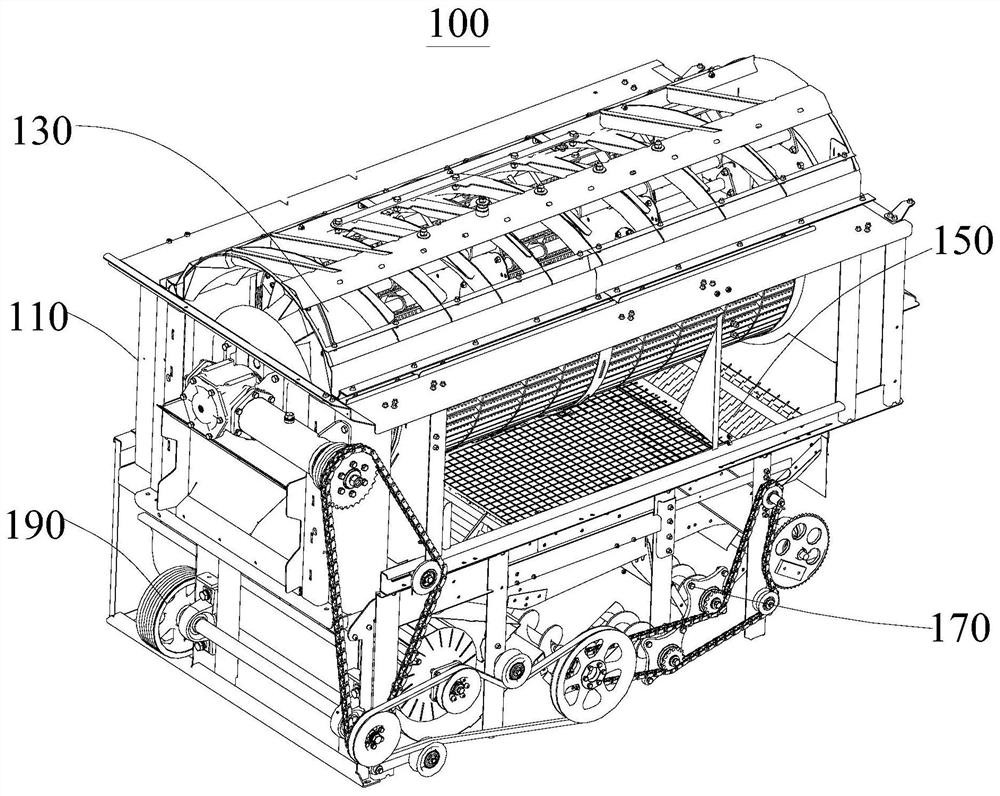

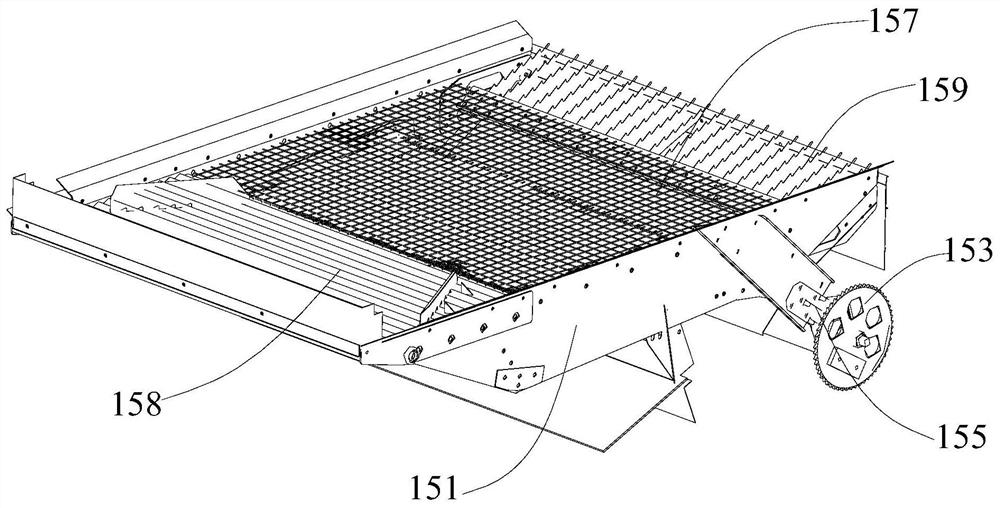

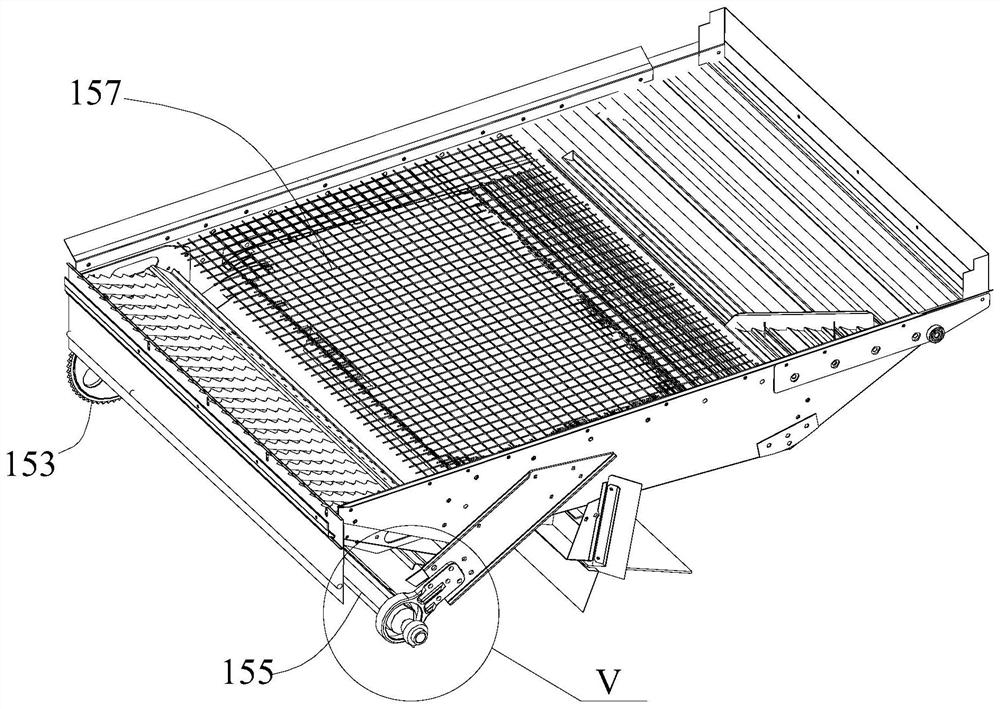

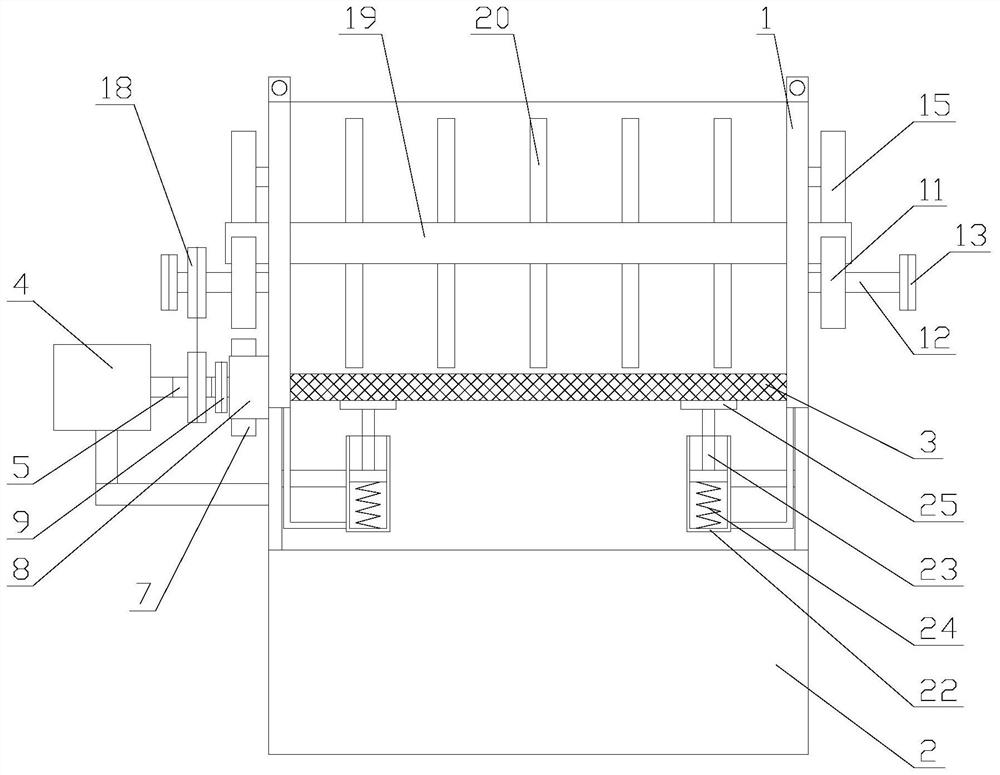

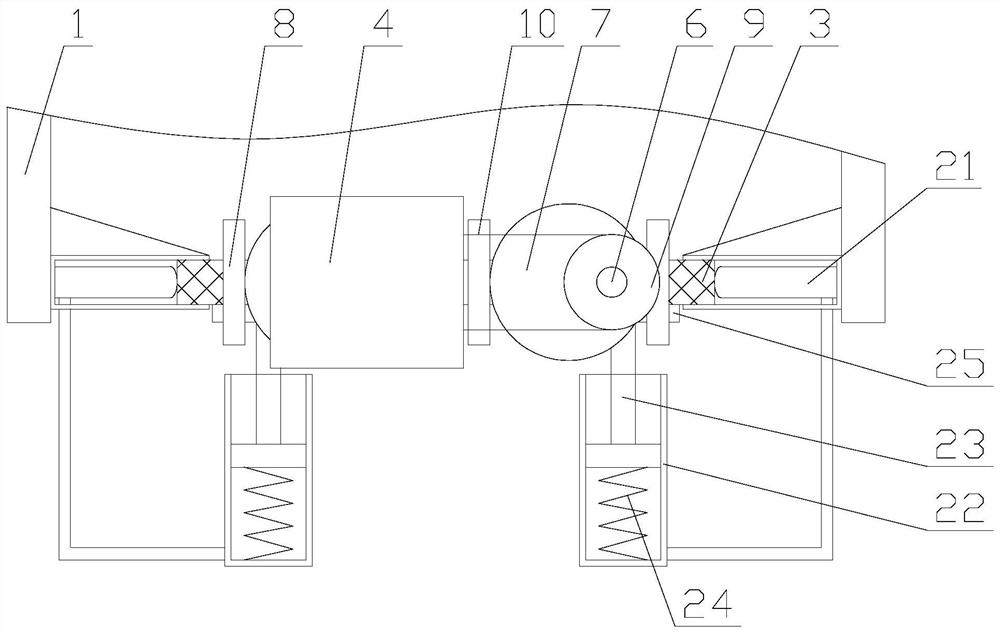

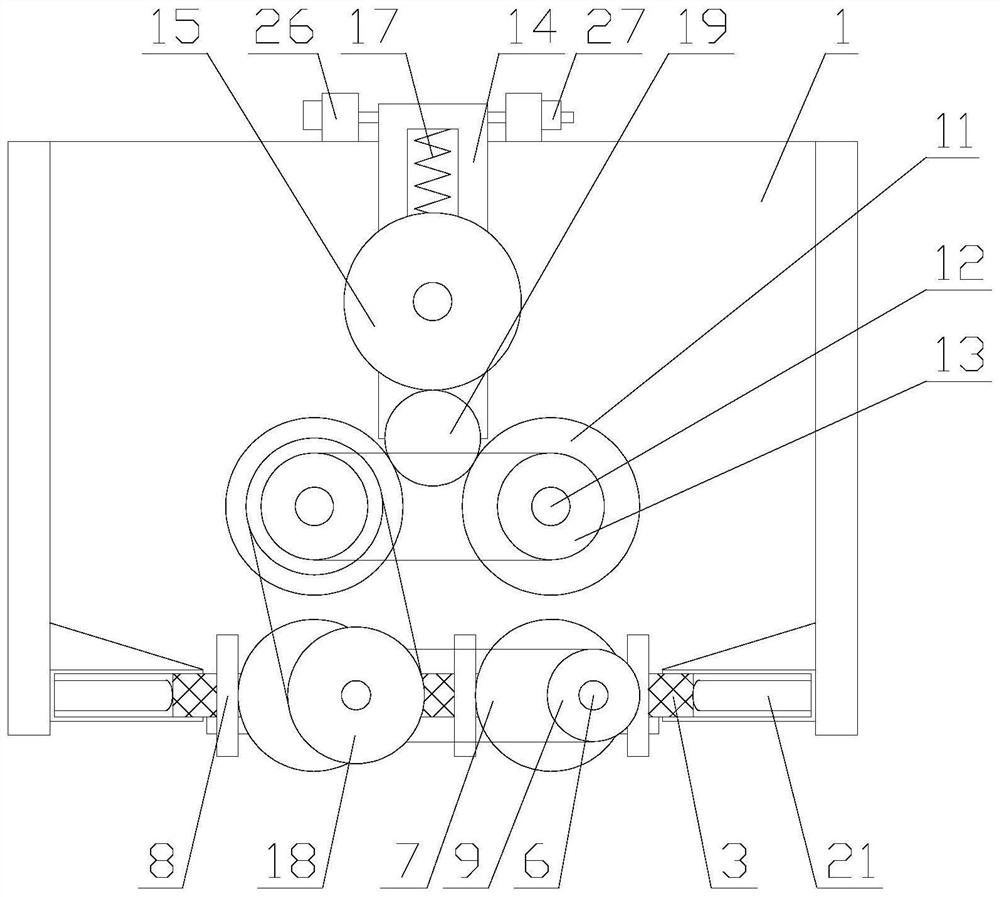

Seed threshing and cleaning device

PendingCN111742717AReduce impurityThreshing achievedThreshersAgricultural scienceAgricultural engineering

The embodiment of the invention provides a seed threshing and cleaning device, and relates to the field of agricultural machinery. The seed threshing and cleaning device comprises a rack, a roller threshing mechanism, a vibration screening mechanism, a material conveying mechanism and a driving mechanism, wherein the roller threshing mechanism is arranged at the top of the rack, the vibration screening mechanism is arranged in the middle of the rack and located below the roller threshing mechanism, the material conveying mechanism is arranged at the bottom of the rack and located below the vibration screening mechanism, and the driving mechanism is arranged on one side of the rack and is in transmission connection with the roller threshing mechanism, the vibration screening mechanism and the material conveying mechanism. Compared with the prior art, the seed threshing and cleaning device can achieve the function of threshing, cleaning and conveying forage grass seed; and meanwhile, thecleaning effect can be improved by adopting a multi-layer vibration woven screening mode, and the rate of impurities in the seeds is low.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

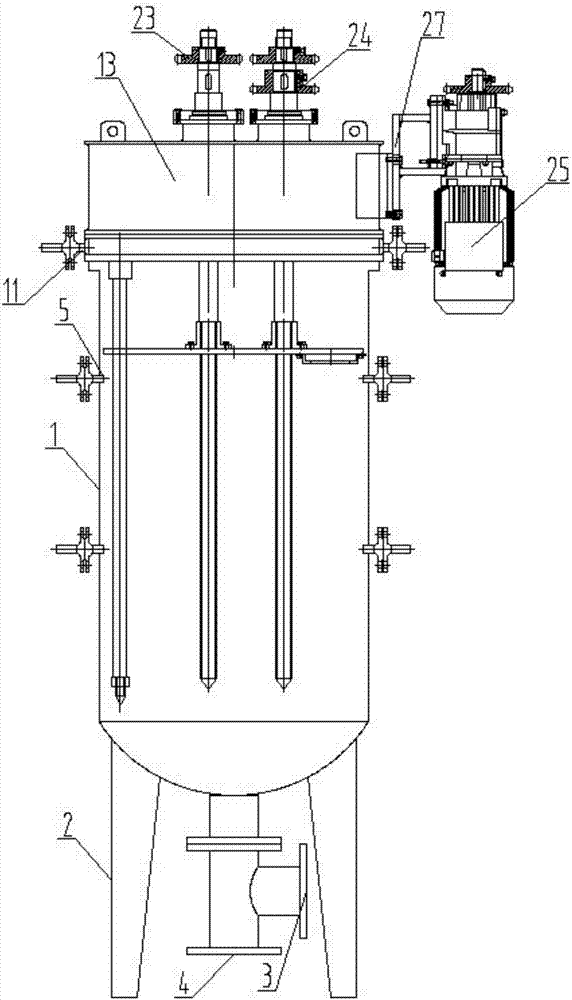

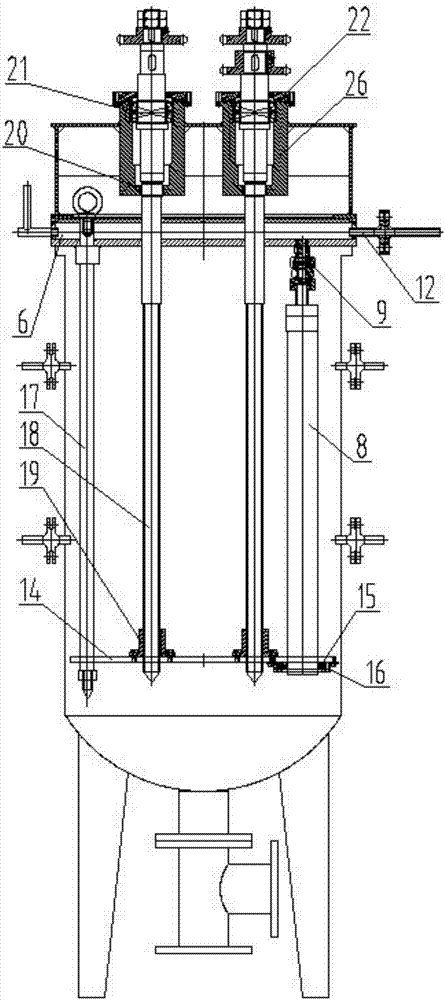

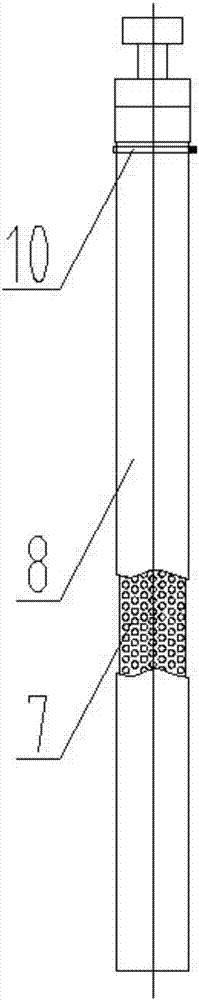

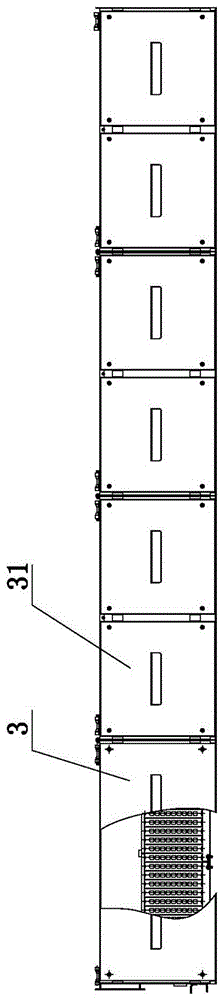

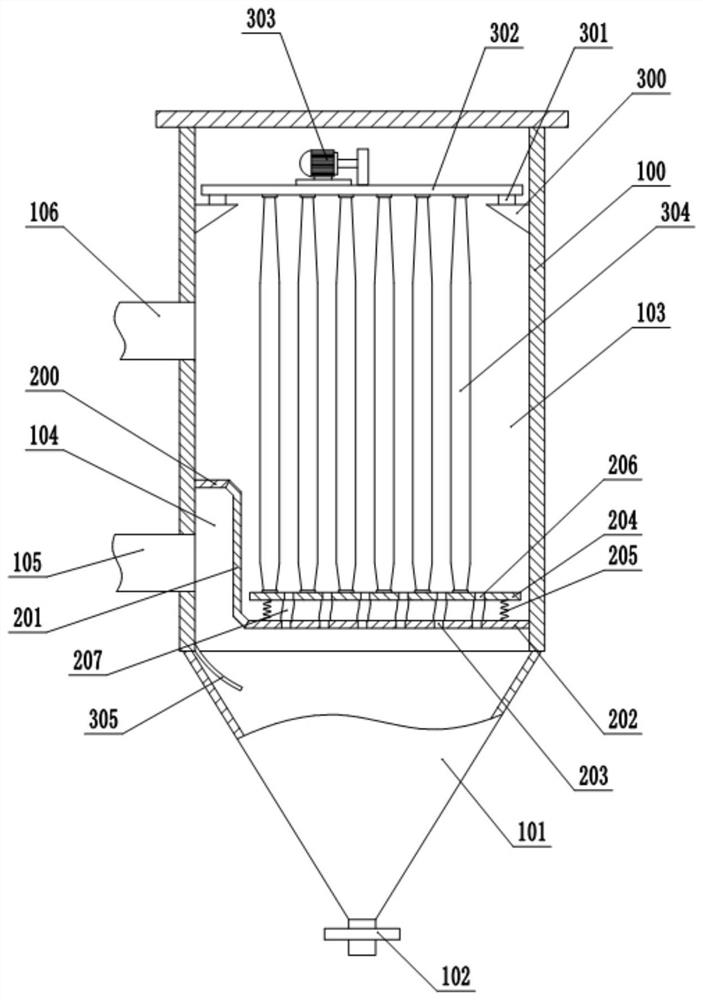

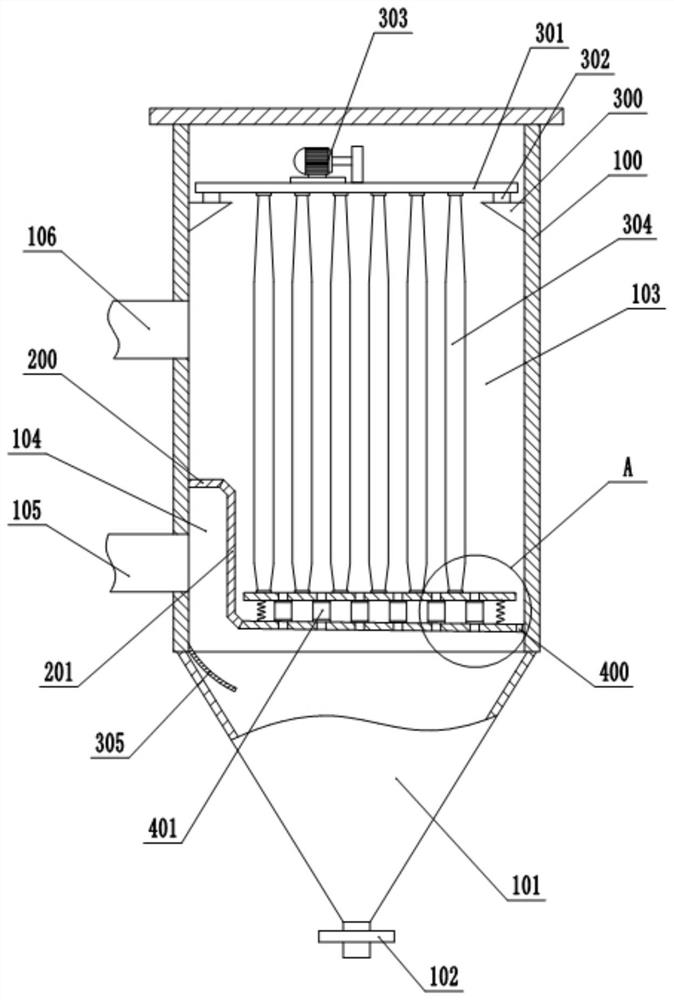

Self-cleaning tank type filtering separator

ActiveCN107080994ACompact structureSpeed up filteringStationary filtering element filtersWaste managementSelf adaptation

The invention discloses a self-cleaning tank type filtering separator which comprises a tank, a filtering assembly and a self-cleaning assembly. The filtering assembly comprises a filter pipe, a filter bag and the like. A filter hole is formed in the filter pipe, the upper end of the filter pipe is communicated with the interior of a water tank through a spherical pipe joint, and the filter pipe is sleeved with the filter bag which is fixed in a clamped mode. A water box and the tank are fixed. The self-cleaning assembly comprises a tank cover, a scraper blade, a scraping ring, a lead screw and the like; the tank cover is provided with a bearing pedestal and fixedly connected with the water box; the scraping ring is clamped into the scraper blade and provided with a movable clearance; the scraping ring penetrates through the filter bag and the filter pipe; a lead screw nut and the scraper blade are fixed; one end of the lead screw and the lead screw nut form a screw pair, and the other end of the lead screw is provided with a movable sealing ring, a bearing and a chain wheel and the like and assembled with the tank cover; under the drive the forward and backward rotation of the motor, the chain wheel and the chain, the lead screw automatically rotates synchronously, the scraper blade is driven by the lead screw nut to horizontally move up and down, self-adaptation adjustment of the scraping ring on the scraper blade is achieved, and the filter bag is scraped and cleaned. The self-cleaning tank type filtering separator has the advantages that the structure is novel and reasonable, the sealing performance is good, the filtering capability is high, various self-cleaning modes are adopted, and long-term automatic operation can be achieved easily.

Owner:HUBEI JUNJI WATER TREATMENT

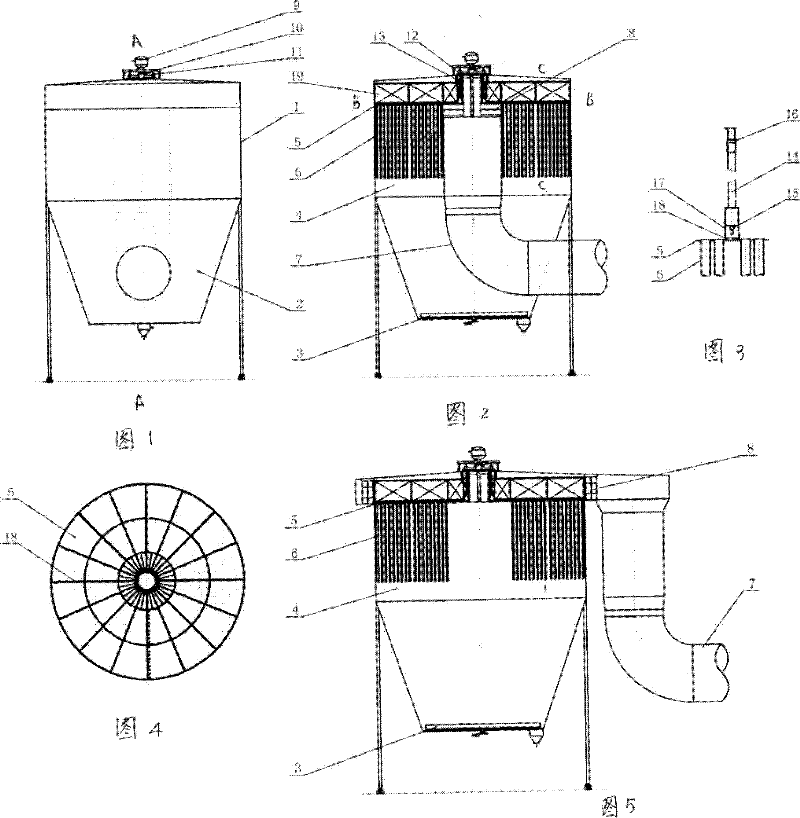

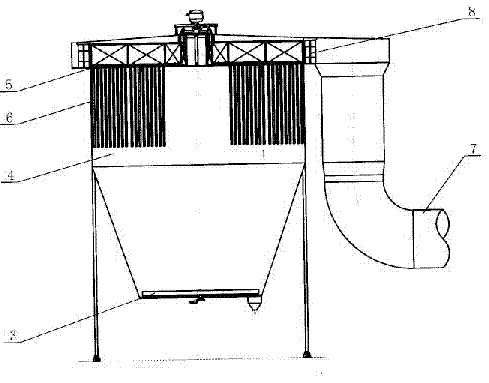

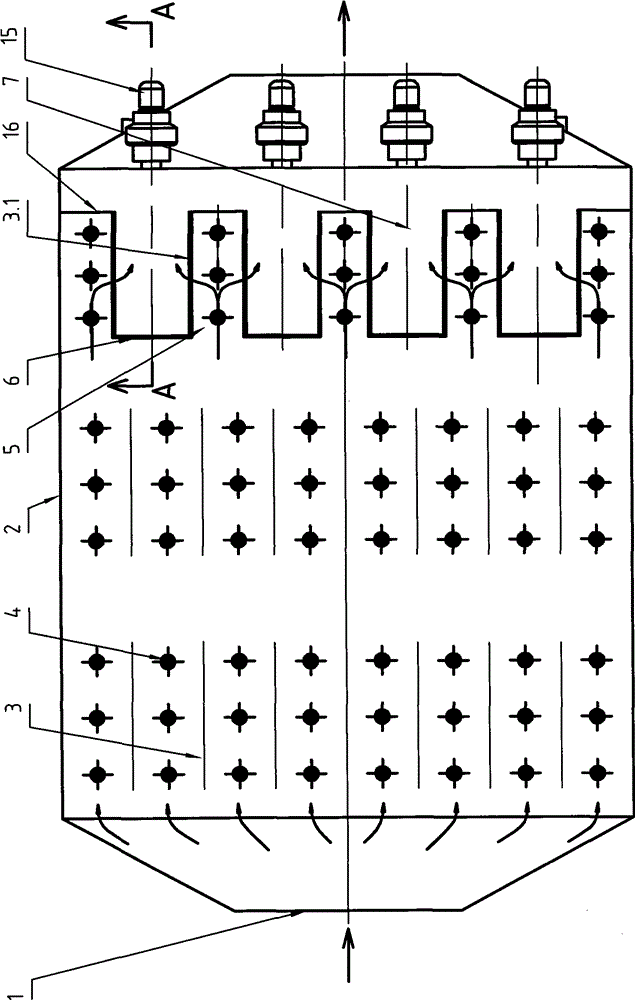

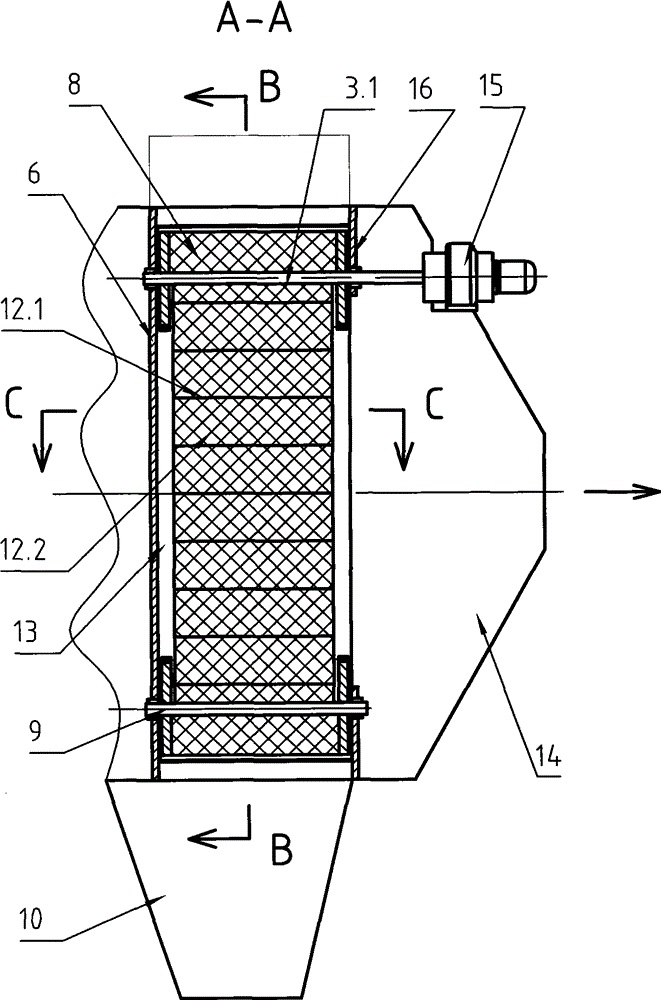

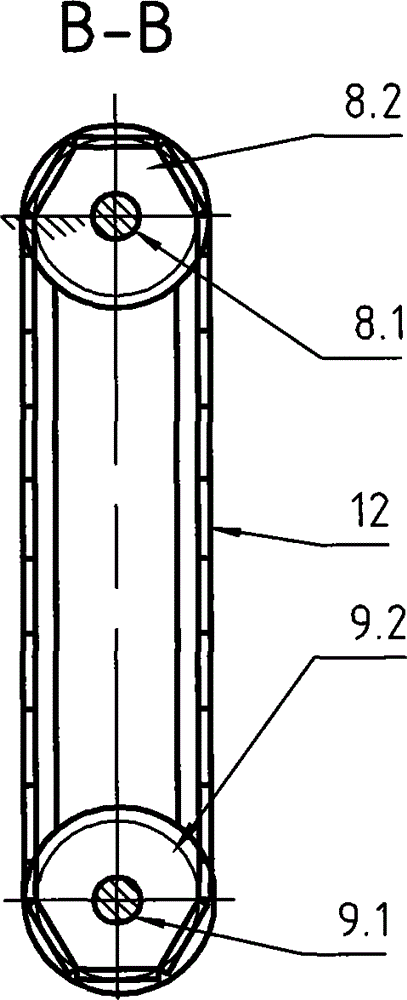

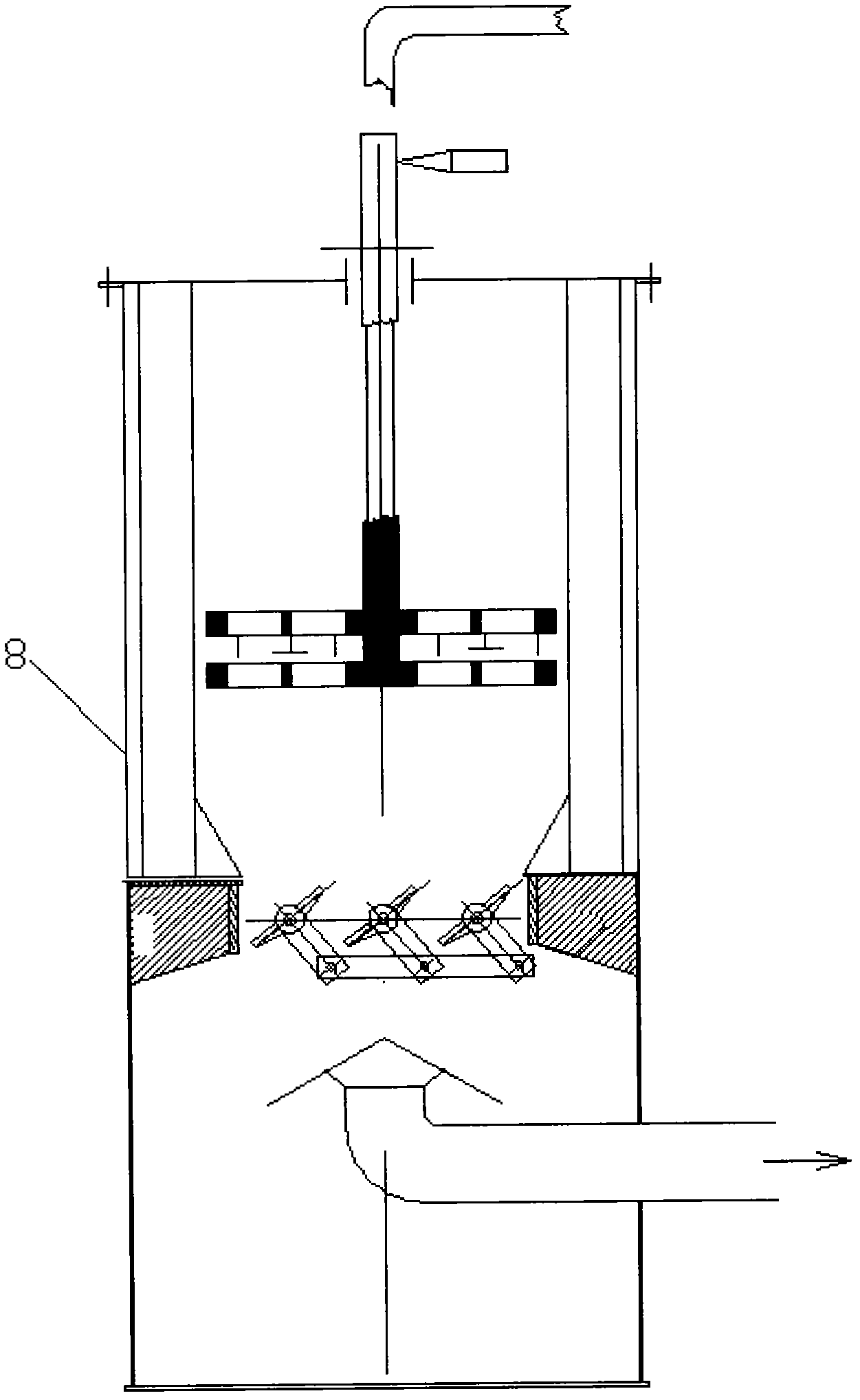

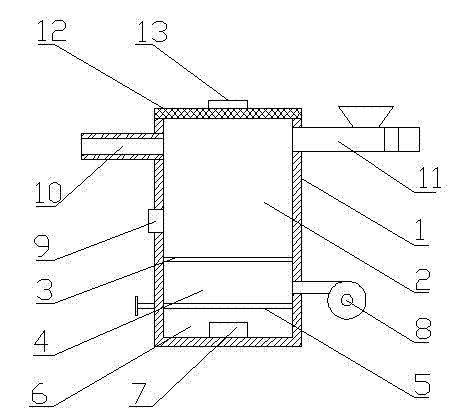

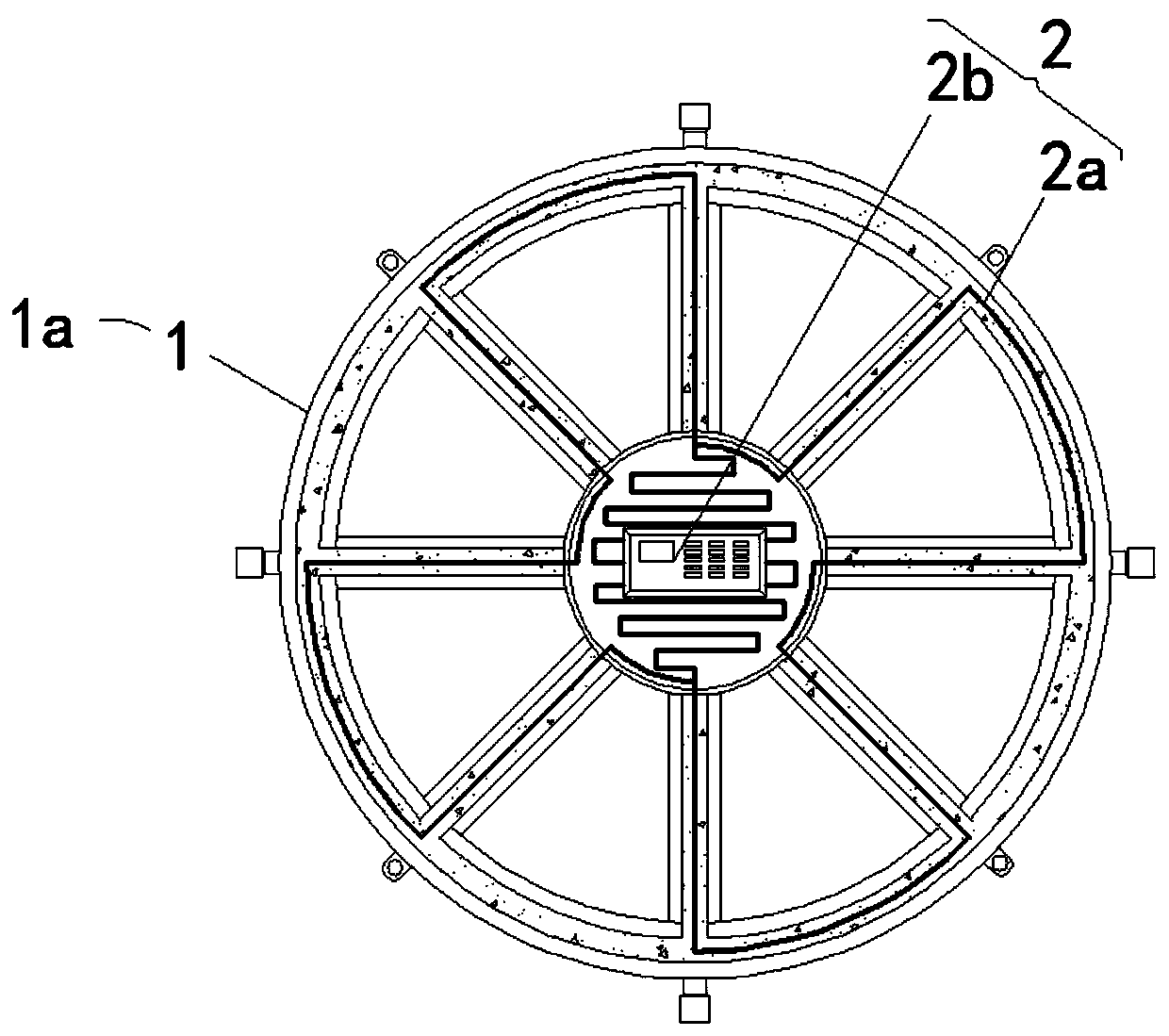

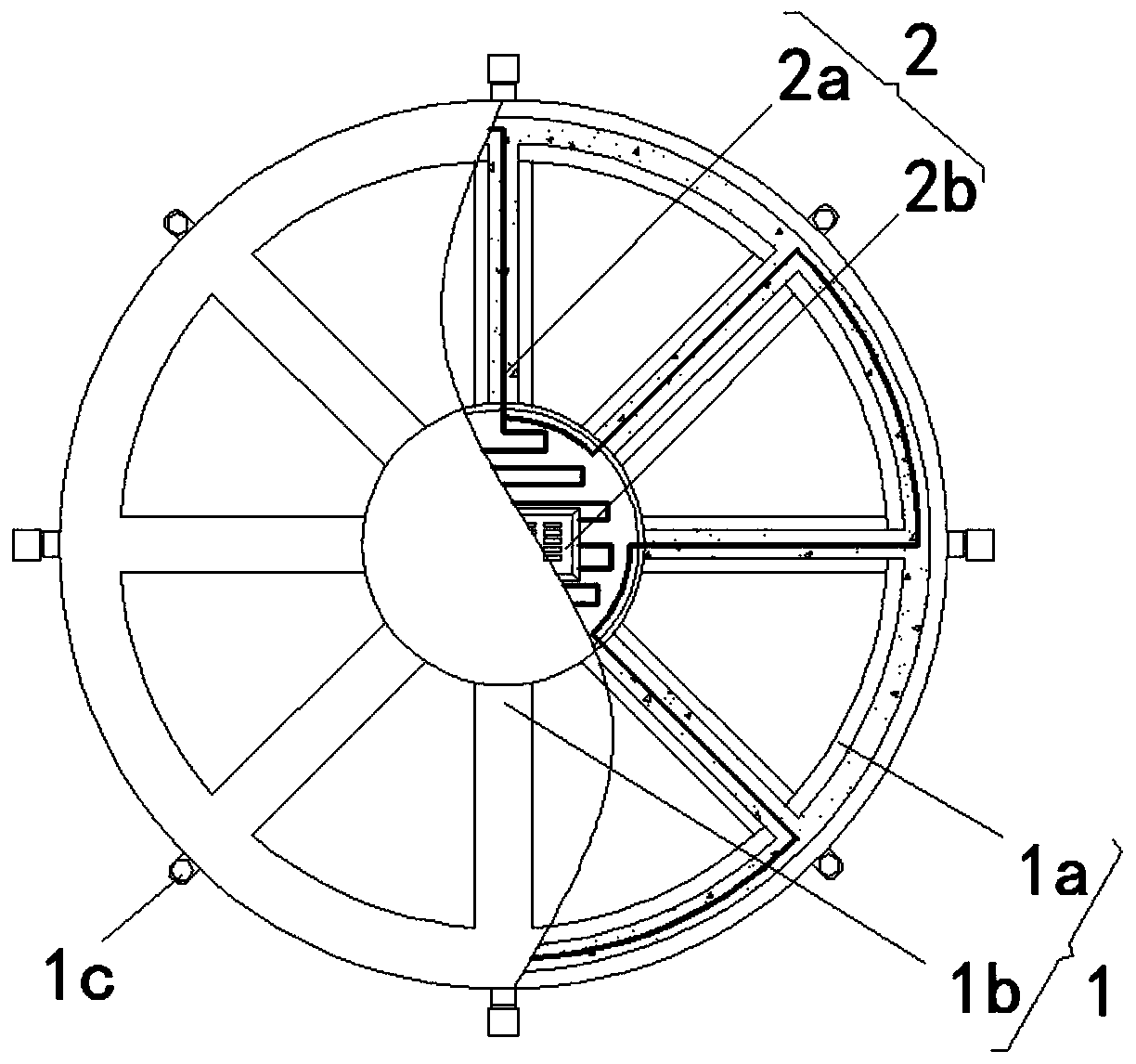

Offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher

InactiveCN102430299ALower installation heightSmall resistanceDispersed particle filtrationBaghouseElectrical and Electronics engineering

The invention relates to an offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher, which comprises a cylindrical main shell, an ash discharger, a filter chamber, a tube nest, filter bags and an annular clean air chamber, wherein a fixed air storage bag, pulse valves, a compressed air distributor, a rotary driving device and a plurality of rotary pulse blowing pipes are arranged in the center of the main shell; a plurality of insulating plate structures of which the peripheries are provided with sealing devices are arranged above the rotary pulse blowing pipes; offline ash removal hoods are arranged on two sides of each pulse blowing pipe; the tube nest (5) is arranged on the top of the filter chamber (4); the filter bags (6) are arranged between the tube nest (5) and the filter chamber (4) in a concentric circle; an air outlet valve is arranged at an air outlet corresponding to each fan-shaped clean air chamber; and an air outlet pipe is arranged at the periphery of the inside or outside of the main shell. By the offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher, the offline ash removal and online maintenance of the dust catcher can be realized, the ash removal of all filter bags can be completed by a plurality of pulse valves; the installation height of the dust catcher can be reduced effectively; the drag loss of the dust catcher can be reduced; and the running power consumption can be reduced.

Owner:WUXI HONGCHENG ENVIRONMENTAL TECH

Special dust collection device for spring grinder

InactiveCN104097148AImprove purification efficiencyLarge gas handling capacityGrinding/polishing safety devicesFiltrationProduct gas

The invention discloses a special dust collection device for a spring grinder, which is characterized by comprising a cavity body, a spring grinder dust suction inlet and a filter cartridge type dust collection unit, wherein the cavity body is formed by front and rear shells and left and right shells; the spring grinder dust suction inlet is opened on the front shell; the filter cartridge type dust collection unit is arranged on the rear shell and the front shell; the front shell is convex to form a cavity so as to form a centrifugal separation chamber; the spring grinder dust suction inlet is mounted on the lateral surface of the centrifugal separation chamber in the tangential direction; the lower parts of the front shell and the rear shell are provided with funnel-shaped dust collection units which are reduced gradually; an outlet of the filter cartridge type dust collection unit is formed on a purified air exhaust passage and the passage is provided with a fan assembly. The special dust collection device for the spring grinder has the beneficial effects that dust is automatically removed by pulses, purification efficiency is high, gas processing capacity is high and performance is stable; a filter cartridge adopts submicron-order filtration and a clean space is created; automatic online pulse dust removal can be implemented; equipment can collect and process gas with dust, which is generated by the spring grinder, on site; the structural design of the special dust collection device for the spring grinder has the characteristic of convenience for operation and maintenance.

Owner:HANGZHOU SOURCE PURIFICATION EQUIP

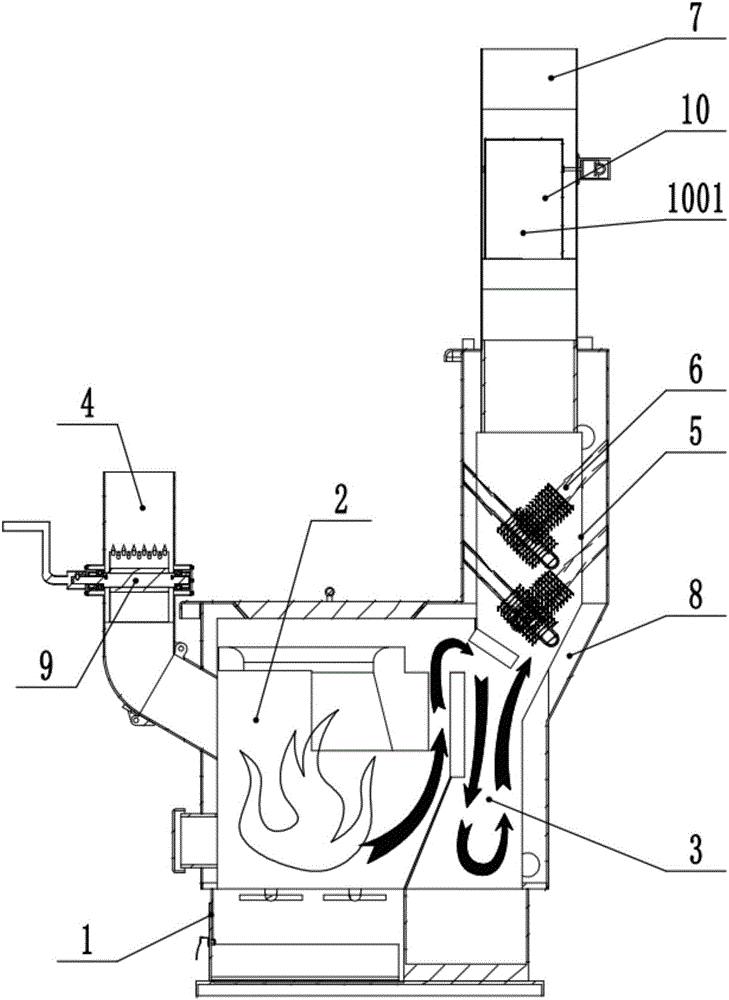

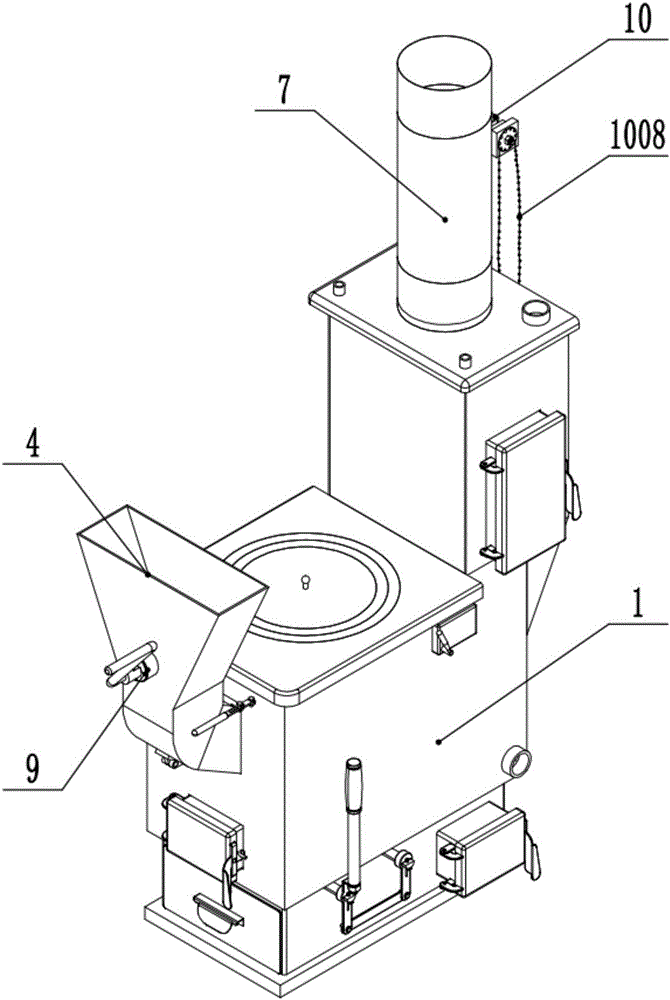

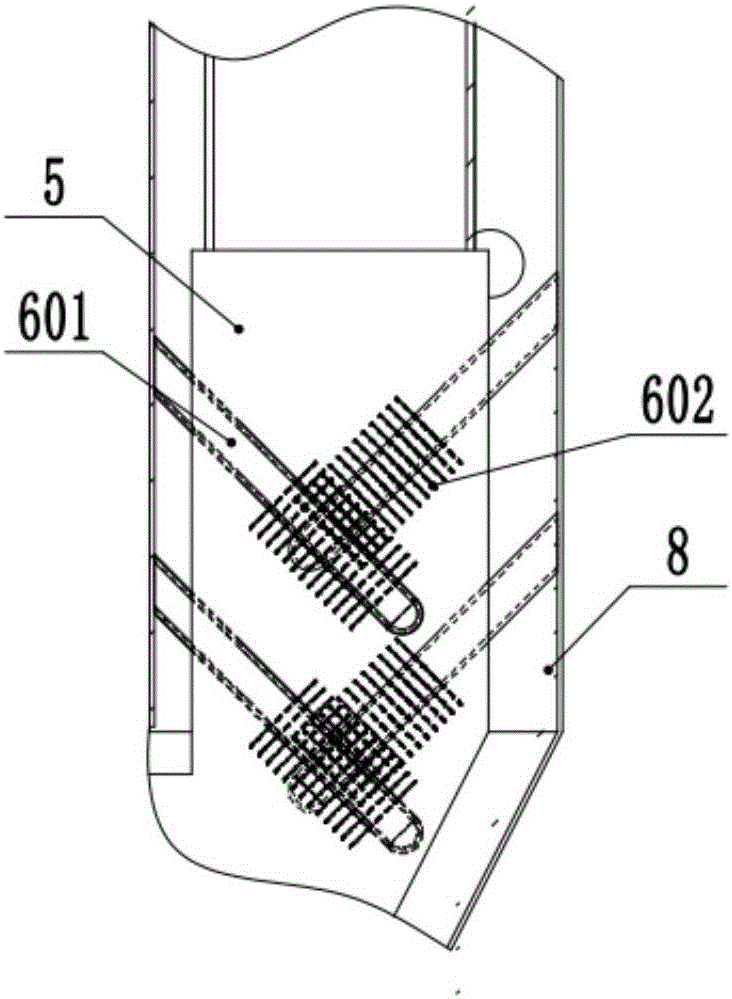

Novel domestic energy-saving and environmental-friendly heating stove

ActiveCN106439923AImprove combustion efficiencyAvoid low heat transfer efficiencyDispersed particle filtrationStove/ranges for heating waterCombustion chamberEngineering

The invention discloses an energy-saving and environmental-friendly heating stove which comprises a stove body. The stove body is internally provided with a hearth and a multi-return-stroke reversal combustion chamber communicating with the hearth and is provided with a fuel feeding inlet leading to the hearth and a smoke box leading to the reversal combustion chamber. The smoke box is internally provided with smoke waste heat recovery devices and is provided with a smoke discharge barrel leading to the outside. The stove body is further provided with a water jacket wrapping the outsides of the hearth, the multi-return-stroke reversal combustion chamber and the smoke box. According to the energy-saving and environmental-friendly heating stove, the purpose of energy saving and environmental protection is achieved through fuel granularity control and smoke waste heat recovery, tail gas is filtered, pollution is reduced, and the energy-saving and environmental-friendly heating stove is simple in structure, low in cost and convenient to use.

Owner:XUHAI COLLEGE CHINA UNIV OF MINING & TECH +1

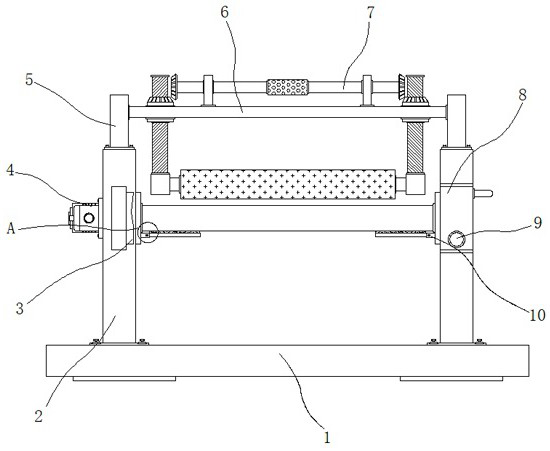

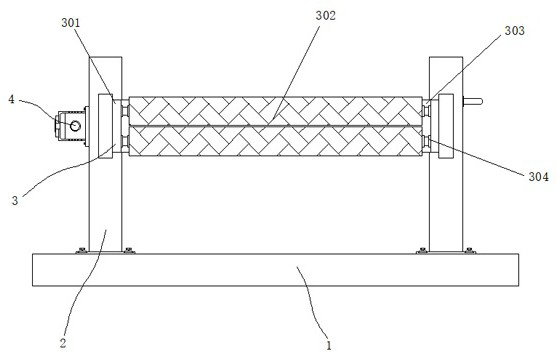

Movable electric dust removing device achieving filtration through dust collecting electrodes

The invention belongs to the field of environment protection and provides a movable electric dust removing device achieving filtration through dust collecting electrodes. The device comprises a gas inlet, a shell, anodes, cathodes, a gas outlet, a dust hopper, a power supply system and the like. In the flowing direction of dusty gas, at least part of the rear portion of each dust collecting electrode is a meshed dust collecting electrode. The meshed dust collecting electrodes are arranged in parallel and connected with baffles to constitute meshed dust collecting electrode gas inlet spaces and meshed dust collecting electrode gas outlet spaces. The cathodes are arranged in the meshed dust collecting electrode gas inlet spaces between the meshed dust collecting electrodes. Each meshed dust collecting electrode comprises an upper rotating part, a lower rotating part, a filtration body annularly surrounding the upper rotating part and the lower rotating part, and the like, wherein the upper rotating part rotates to drive the lower rotating part and the filtration body to rotate. According to the device, electric dust removal and filtration dust removal are combined effectively, and the dust removal efficiency is greatly improved; dust removal of the meshed dust collecting electrodes is effectively achieved through rotation of the filtration bodies; the device is suitable for newly building and transforming projects.

Owner:SHANDONG SHENGHUA INVESTMENT

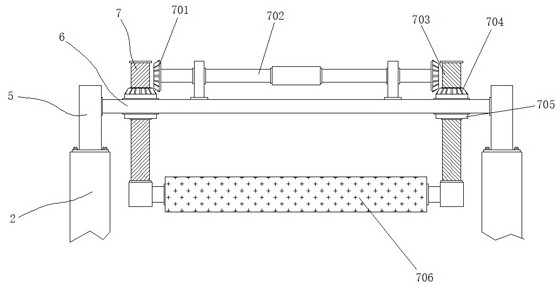

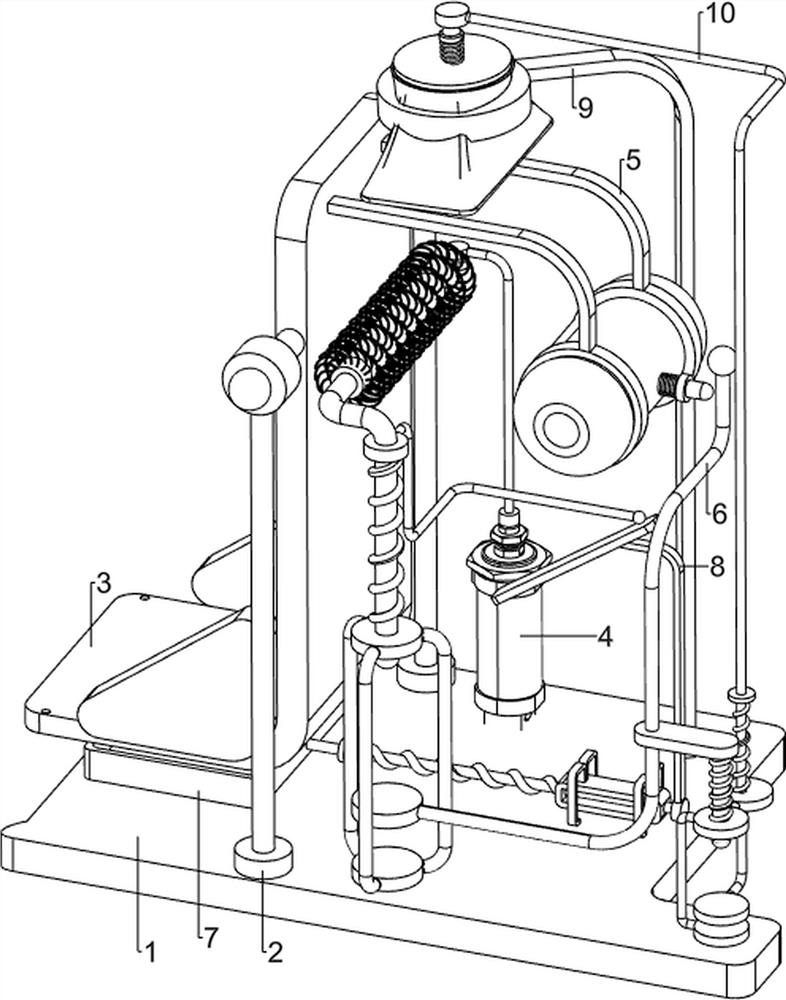

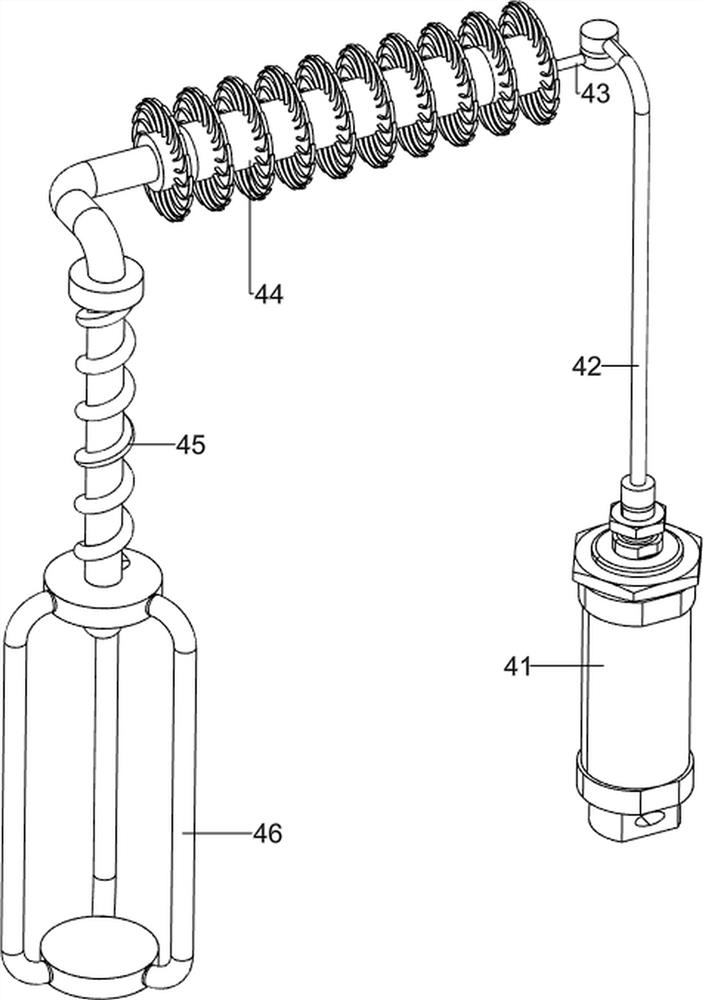

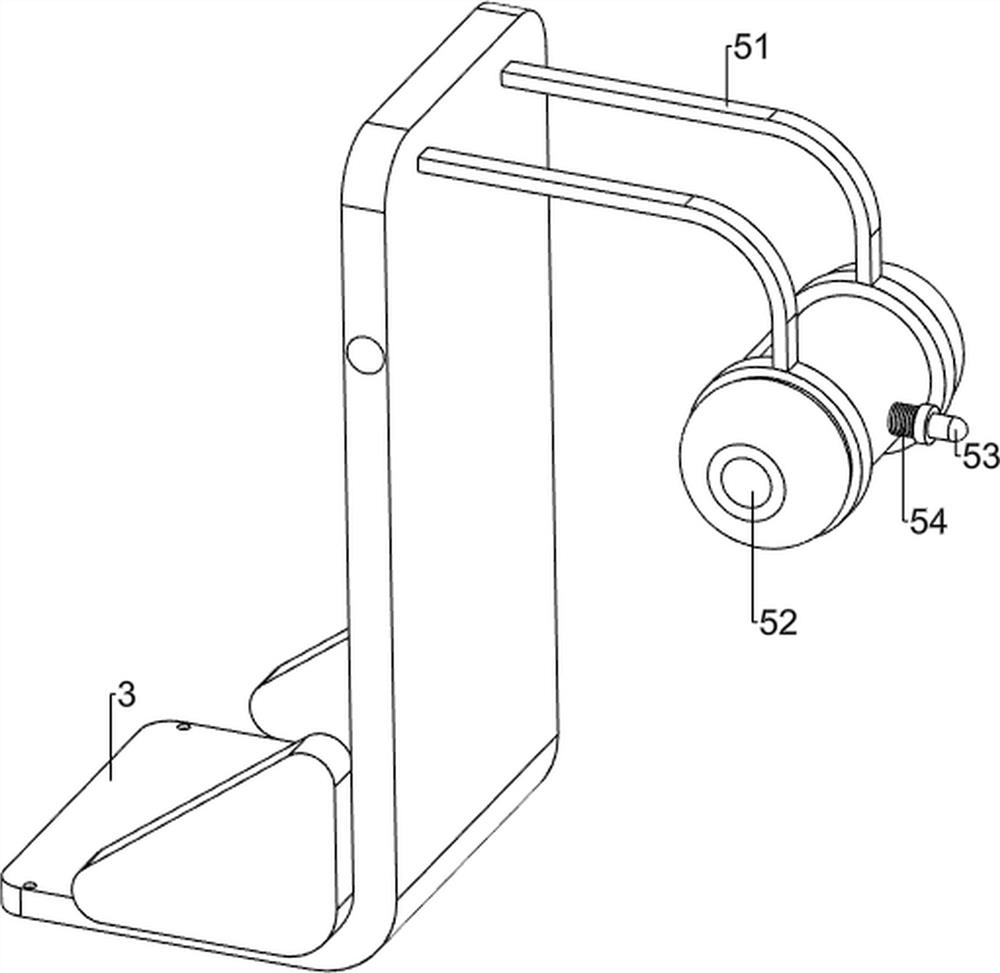

Winding equipment used for building waterproof films

InactiveCN112897133ARealize cleaningEasy to replaceCleaning using toolsWebs handlingArchitectural engineeringThin membrane

The invention discloses winding equipment used for building waterproof films, and particularly relates to the technical field of winding equipment. The winding equipment used for the building waterproof films comprises a base, side plates, connecting plates and a top plate, wherein the side plates are fixedly connected with two sides of the top end of the base respectively, a brushing structure is arranged between one side of one end of one side plate and one side of one end of the other side plate, one corresponding connecting plate is fixedly connected with one end of the top of each side plate, the top plate is fixedly connected between one side of one connecting plate and one side of the other connecting plate, an arrangement structure is arranged in the top plate, and a winding mechanism is arranged between the inner sides of the side plates. According to the winding equipment used for the building waterproof films, the winding mechanism is arranged between the inner sides of the side plates, the winding mechanism comprises a servo motor, a handle is held to turn a turning plate outwards by 90 degrees, a winding shaft is stuffed between one side of one shaft sleeve and one side of the other shaft sleeve, the handle is loosened to make the turning plate reset under the resilience of a first spring shaft, and then clamping pieces, connected through second spring shafts, in hinge bases are shifted, so that the thin films are clamped and fixed through silica gel pads at the tops of the clamping pieces, and the purpose of facilitating replacement and installation of the winding shaft is achieved.

Owner:HENAN YUZHUO INFORMATION TECH CO LTD

Convenient-to-clean rocking chair in garden pavilion

InactiveCN112570319ARealize cleaningRealize the operationDirt cleaningCleaning using toolsStructural engineeringMechanical engineering

The invention relates to a rocking chair in a garden pavilion, in particular to a convenient-to-clean rocking chair in a garden pavilion The convenient-to-clean rocking chair in the garden pavilion liberates two hands and is automatically cleaned. The convenient-to-clean rocking chair in the garden pavilion comprises first supporting assemblies, a seat and a brushing mechanism. The first supporting assemblies are symmetrically arranged on a bottom plate. The seat is arranged between the first supporting assemblies. The brushing mechanism is arranged in the middle of the bottom plate. An air cylinder telescopic rod drives a first pressing rod to move up and down, and therefore a brush supporting rod moves downwards in a first stable support in a sliding manner, a first spring is compressed,and the rocking chair is brushed; a first switch button is manually pressed, and therefore a second spring is compressed, water in a water tank is jetted to the rear part of the rocking chair, and operation of sprinkling water to the rocking chair is achieved; and by manually moving a collecting frame backwards, a fourth spring is compressed, and the dirt collecting effect is achieved.

Owner:林云平

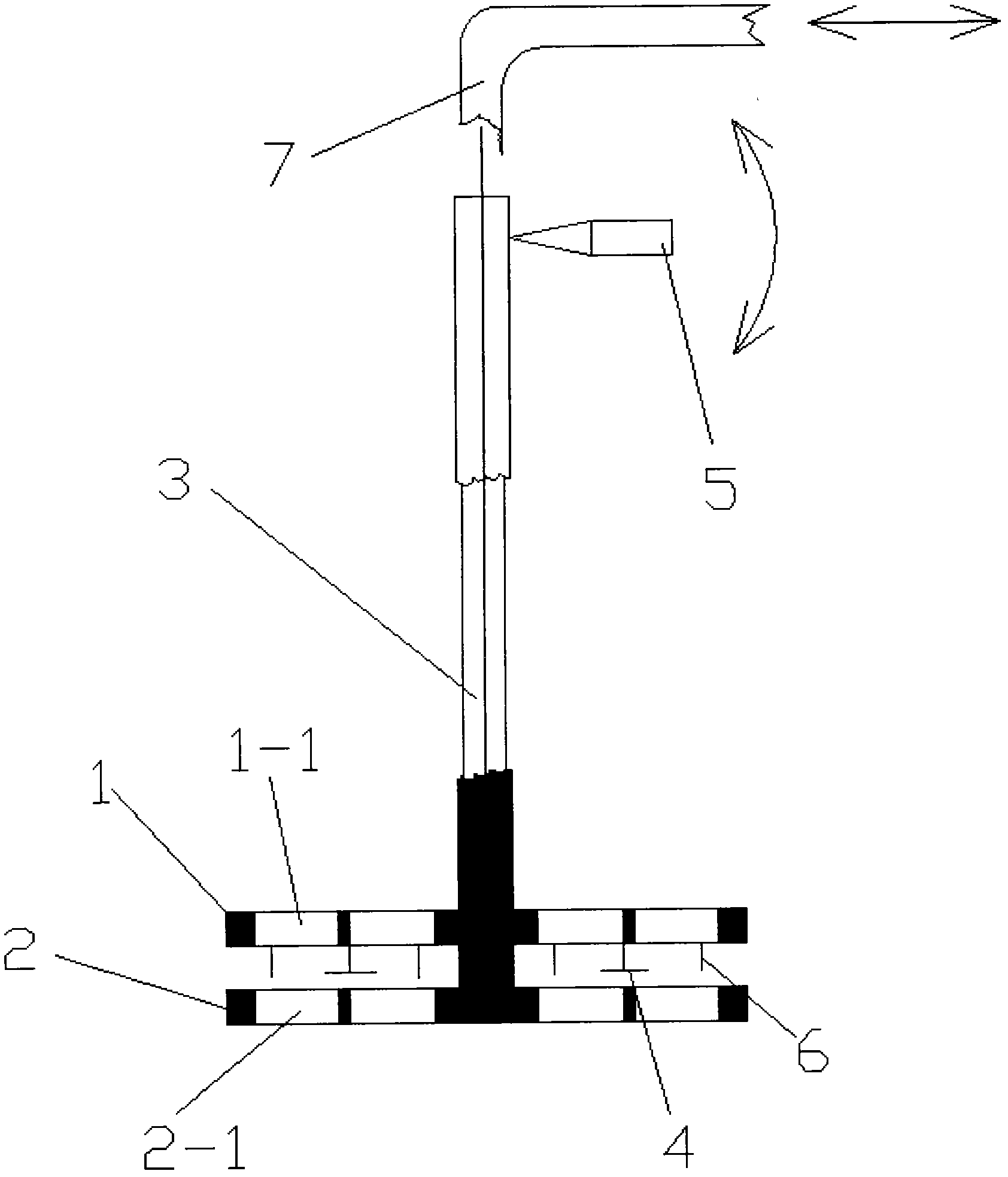

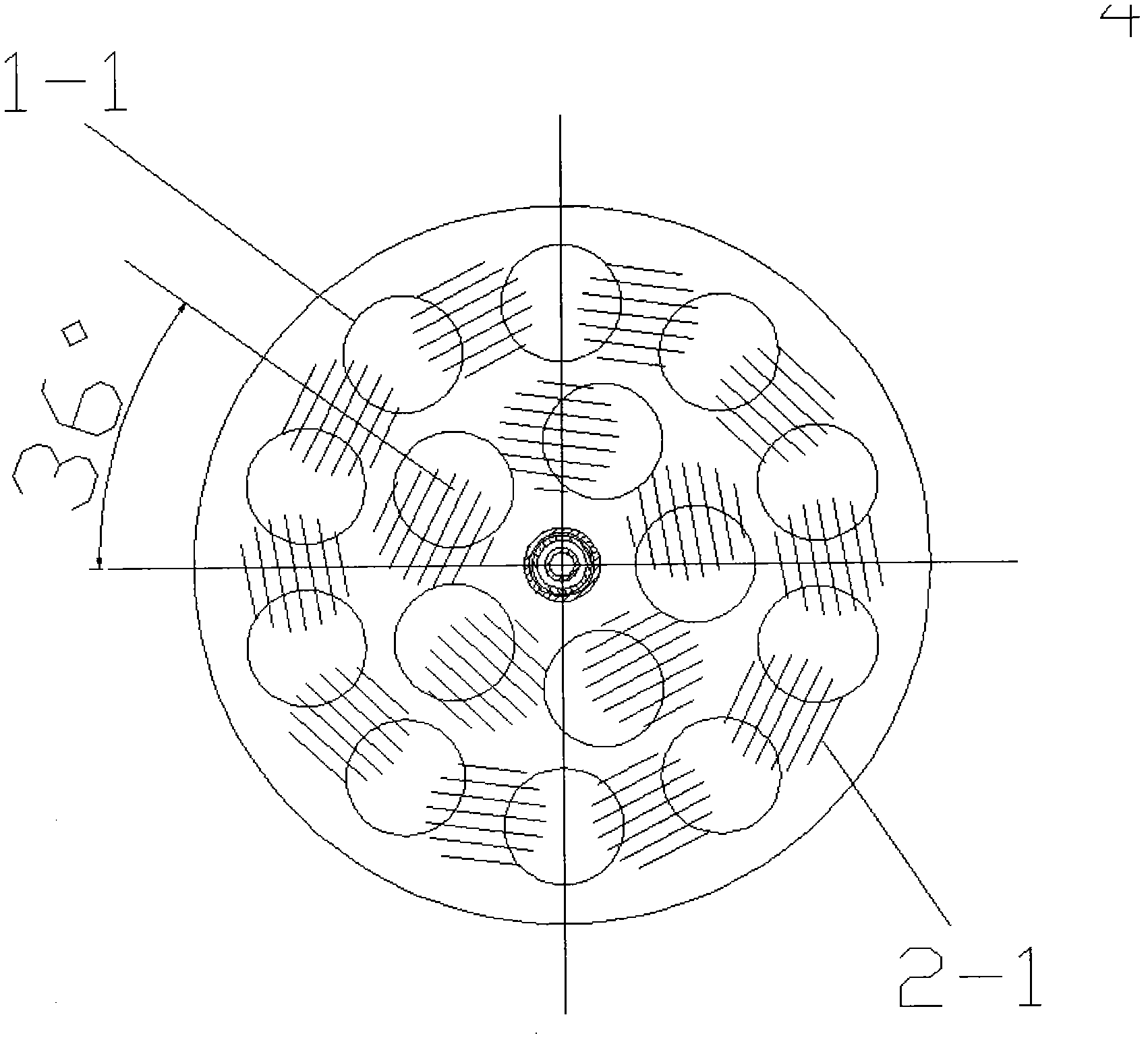

Steam spraying device of biomass gasification furnace

InactiveCN102634375AEasy to operateApplicable operationCombustible gas productionTemperature controlCircular disc

The invention discloses a steam spraying device of a biomass gasification furnace. The device comprises an upper hanging scaffold, a lower hanging scaffold, a steam pipeline and steam nozzles which are communicated with the steam pipeline, wherein the upper hanging scaffold and the lower hanging scaffold are the same in size and structure and are circular discs; material discharging holes are uniformly distributed on each circular disc; the lower hanging scaffold is fixedly arranged and the upper hanging scaffold is connected with a rotary handle to freely rotate the upper hanging scaffold within a range of 36 degrees; and the bottom face of the upper hanging scaffold and the upper side of the lower hanging scaffold are provided with a plurality of the steam nozzles and a temperature control probe. The steam spraying device of the biomass gasification furnace is mounted in a low-suction type gasification furnace, is used for injecting water steam in straw combustion and gasification processes, and is provided with a temperature control device, thus the purpose of spraying certain amount of steam while setting the temperature can be achieved, the operation is convenient and simple, and the steam spraying device is very suitable to be used in operation of straw gasification furnaces.

Owner:永清中希光电科技发展有限公司

Boiler soot deposit and coking synergistic treatment device and work method thereof

ActiveCN109028114AAchieve dust removalAchieving the synergistic effect of decokingSolid removalTherapeutic effectEngineering

The invention relates to a boiler soot deposit and coking synergistic treatment device and a work method of the boiler soot deposit and coke synergistic treatment device. Boiler soot deposit and coking mutually accelerate and influence each other, in the prior art, boiler soot deposit and the coking are both independently treated, and the treatment effect is poor. According to the boiler soot deposit and coking synergistic treatment device, a compressed air inlet and a soot blowing steam inlet are connected with a main pipe. The main pipe is connected with a left hearth short soot blower, a right hearth short soot blower, a front wall hearth short soot blower and a back wall hearth short soot blower through connection pipes. A decoking agent storage box is connected with the four hearth short soot blowers through connection pipes. The boiler soot deposit and coke synergistic treatment device removes soot first of all and then conducts decoking, the soot removal and decoking synergisticeffect is achieved, the decoking agent is sprayed into a boiler through the soot blowers, the feature that the blowing area of the soot blowers is large is utilized to achieve that the decoking agentcan be in full and uniform contact with all the positions of the boiler wall, and targeted focused decoking according to the coking condition in the boiler can be achieved; all electromagnetic valvesare controlled by a DCS, and full automation of soot removal and decoking can be achieved; and therefore the boiler soot deposit and coking synergistic treatment device is easy and convenient to useand high in efficiency and saves energy.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Hindering collision type pulse-jet dust removal filter cartridge dust removal device

PendingCN112915675ARealize cleaningUniform cleaning effectGas treatmentDispersed particle filtrationFiltrationDust control

The invention relates to the field of dust filtration, in particular to a hindering collision type pulse-jet dust removal filter cartridge dust removal device which comprises a sliding plate, an elastic reset plate, supports, springs I, buckles, a collision plate, a damper and a sliding way II. The sliding plate is mounted in the sliding way II in a sleeving mode, the damper is fixed to the sliding way II, the elastic reset plate is arranged in the middle of the sliding plate, springs I are arranged on the sliding plate on the two sides of the elastic reset plate, the collision plate is supported by the springs I and located in the filter cylinder, the axis of the collision plate coincides with the axis of the filter cylinder, supports are arranged at the two ends of the sliding plate, and buckles are installed on the supports. Hindering collision can be generated on blown airflow, dynamic pressure energy of the blown airflow is forcibly converted into static pressure energy in a preset area, the ash removal effect with concentrated energy is generated area by area, finally, overall uniform ash removal is completed, the problem of poor ash removal is solved, and an ash removal dead area is avoided; the collision plate can be rebounded and reset at the bottom; the structure is simple, no extra power is needed for auxiliary operation, and the automation performance is good.

Owner:NANCHANG UNIV

Combustor convenient for cleaning ash

InactiveCN102818273AGuaranteed continuous operationIncrease productivitySolid removalContinuous operationCombustion chamber

The invention discloses a combustor convenient for cleaning ash. The combustor comprises a shell, a combustion chamber, a grate, an ash deposition chamber, an ash cleaning opening, a furnace cover, a handle, a fire outlet barrel, a feed system, a fire observation window, a rotatable stop plate and an ash cleaning chamber, wherein the combustion chamber is arranged in the shell, the grate is arranged in the combustion chamber, the ash deposition chamber is arranged below the grate, the ash cleaning opening is arranged at the bottom of the ash deposition chamber, the furnace cover is arranged at the top of the combustion chamber, the handle is arranged on the furnace cover, the fire outlet barrel and the feed system are connected with the combustion chamber, the fire observation window is arranged on the side wall of the combustion chamber, and the ash cleaning chamber is arranged below the rotatable stop plate which is arranged in the ash deposition chamber. By the means, the ash can be cleaned without stopping fire, continuous operation of equipment is guaranteed, and production efficiency of enterprises is improved.

Owner:郭丰亮

Grain screening device with good effect

InactiveCN112246621ARealize online mixingRealize cleaningSievingScreeningVertical vibrationReciprocating motion

The invention relates to a grain screening device with a good effect. The grain screening device with the good effect comprises a box body, a recovery box, a screen, a vibration mechanism and a stirring mechanism, wherein the box body is arranged above the recovery box; the vibration mechanism is arranged at one side of the box body; and the stirring mechanism is arranged in the box body. According to the grain screening device with the good effect, the reciprocating motion of the screen is realized through the vibration mechanism; the vertical vibration of the screen is realized through a knocking assembly, and the good screening effect is realized; meanwhile, the screen is prevented from being blocked, grains are stirred through the stirring mechanism, and therefore the better screeningeffect is realized; and compared with an existing screening device, the vibration mechanism and the stirring mechanism of the device are in linkage, online stirring and screening for the grains are realized, and a pure mechanical mechanism is adopted for the linkage, so that the stability of the device is improved, and the service life of the device is prolonged; and compared with an existing stirring mechanism, the stirring mechanism is detachable, and a stirring rod and a filter screen are convenient to clean, so that the practicability is improved.

Owner:科曼空气技术(深圳)有限公司

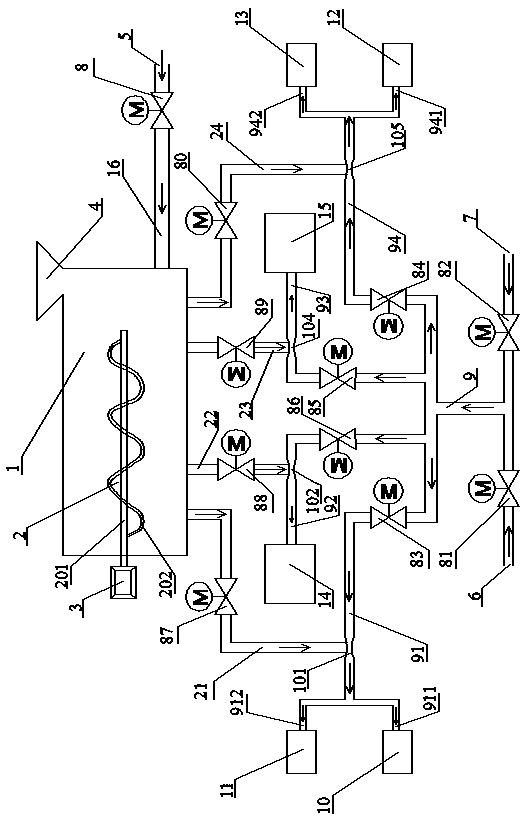

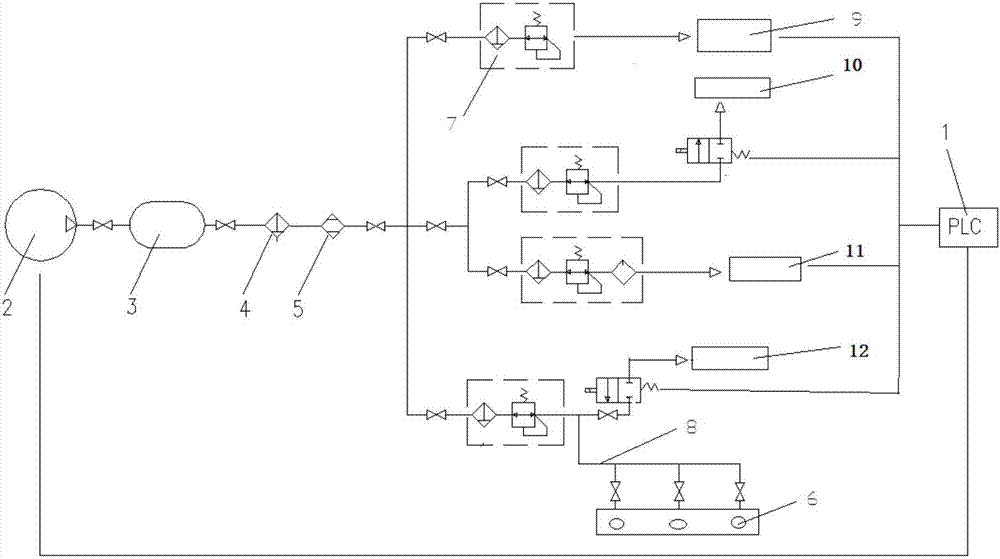

Pneumatic control system of machine-made sand making device

PendingCN107511001ADestroy the effect of dust removalEasy to assembleDispersed particle filtrationControl systemSolenoid valve

The invention discloses a pneumatic control system of a machine-made sand making device. The pneumatic control system comprises an air compressor, a gas storage tank connected to the air compressor, a main pipe filter connected to the gas storage tank, a forth filter pressure reducing valve connected to the main pipe filter, a pulse valve and a lifting valve for controlling dedusting of a dust remover, wherein the pulse valve and the lifting valve are respectively connected to an outlet of the forth filter pressure reducing valve, a first solenoid valve connected to the main pipe filter and used for controlling discharge of a powder tank, a second solenoid valve connected to the main pipe filter and used for controlling opening and closing of a blowing device for removing dust in a coarse material recovery pipe, and PLC connected to a control end of the air compressor, wherein the PLC has an output end respectively connected to the pulse valve, the first solenoid valve and the second solenoid valve. The dust remover, the powder tank and the coarse material recovery pipe share a gas source and assembling and control are convenient.

Owner:CHINA RAILWAY CONSTR HEAVY IND

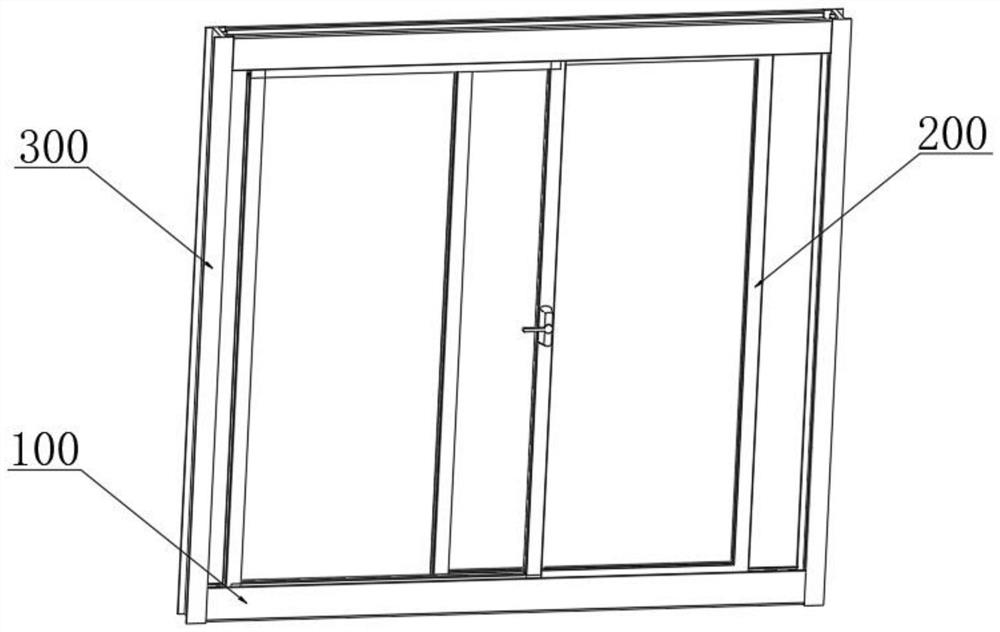

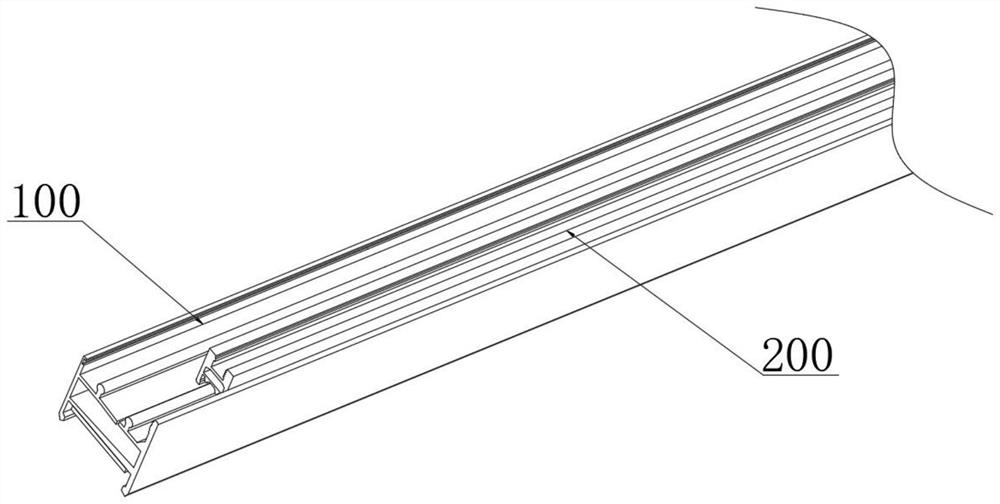

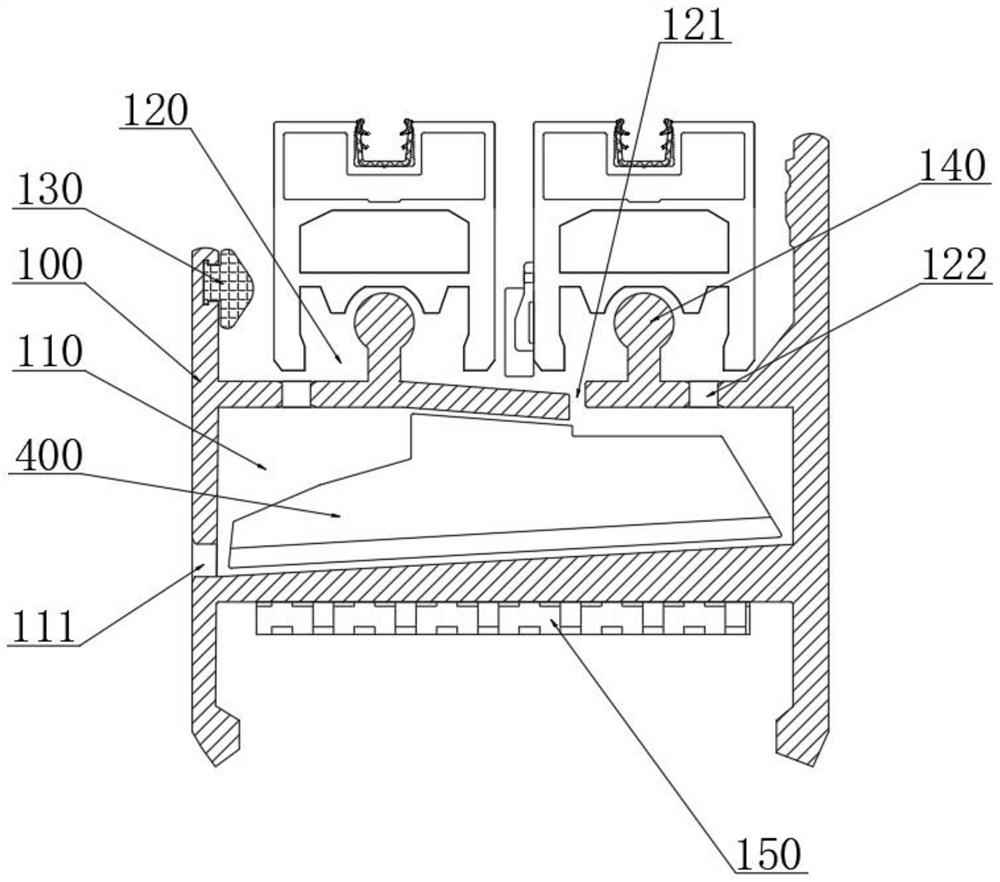

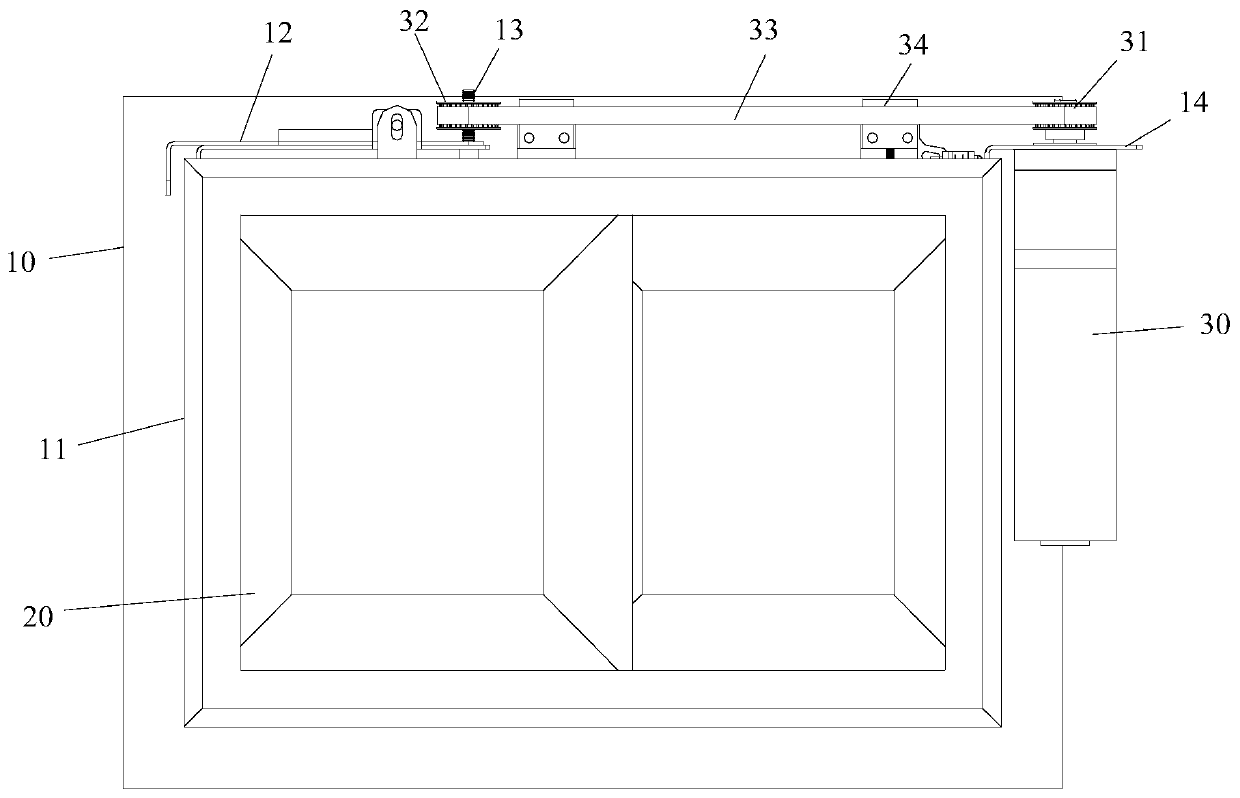

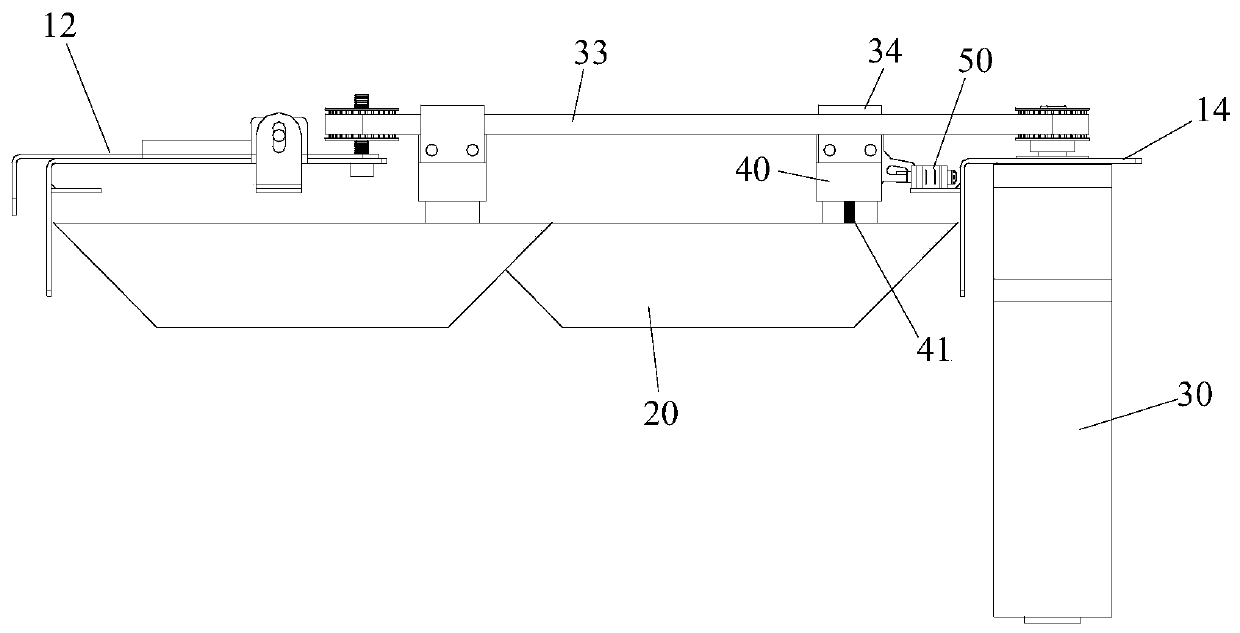

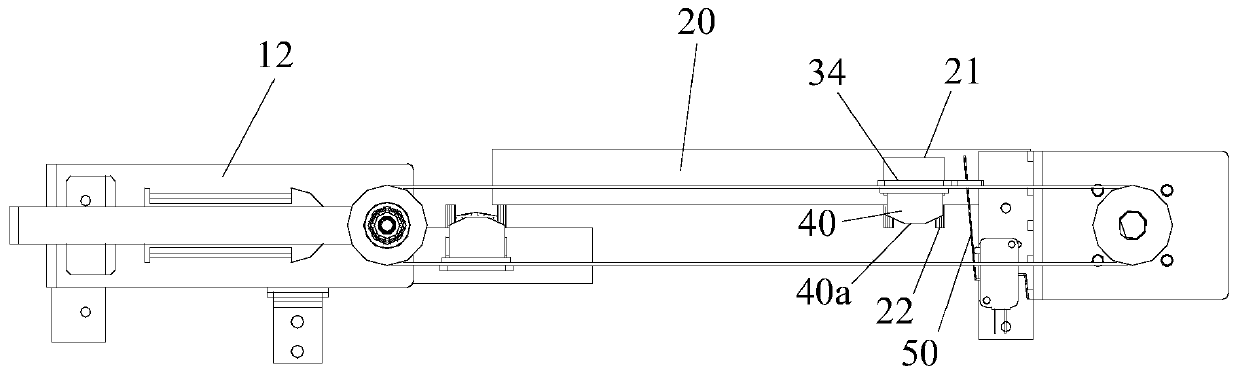

Push-pull type water-seepage-proof plastic-steel door and window

PendingCN113818787APrevent infiltrationKeep dryBuilding braking devicesCondensed water drain-offStructural engineeringMechanical engineering

The invention discloses a push-pull type water-seepage-proof plastic-steel door and window. The push-pull type water-seepage-proof plastic-steel door and window comprises a sliding way sectional material, a window body leaf plate, window frame sectional materials and a piston cleaning mechanism slidably installed in the sliding way sectional material, and the window frame sectional materials are correspondingly located at the two ends of the sliding way sectional material and fixedly connected through bolts; and the window body leaf plate comprises a sectional material base strip and a glass panel, the sectional material base strip wraps the periphery of the glass panel, the window leaf plate is slidably installed on the surface of the slide way sectional material, an anti-seepage guide cavity is formed in the slide way sectional material, a slide way groove is formed in the top surface of the slide way sectional material, and a supporting guide strip is arranged on the top surface of the slide way groove. According to the push-pull type water-seepage-proof plastic-steel door and window, the novel infiltration drainage profile structure is arranged, water is infiltrated and drained in time through infiltration guide grooves and drainage holes in the surface of the slide way sectional material, dryness of the interior of a slide way groove is kept, the water is prevented from infiltrating into a room, a liquid guide pipe can be connected to avoid polluting the surface of a wall, and the practicability and the user experience of the window body structure are improved.

Owner:徐州华展门窗工程股份有限公司

Spiral type ash clearing device driven by dual-electric push rod and working method thereof

ActiveCN106989406APrevent impact on air qualityGood cleaning effectSolid removalStructural engineeringMechanical engineering

The invention relates to a spiral type ash clearing device driven by dual-electric push rod and a working method thereof. The spiral type ash clearing device comprises a rack and a flue pipe which is arranged on the rack; a rolling cage is arranged in the flue pipe; a spiral type scraper which is laminated with the inner wall of the flue pipe is arranged on the cage wall of the rolling cage along an axial direction; a first electric push rod mounted on the rack is vertically arranged on one side of the front end of the rolling cage; a second electric push rod which is inclined upwards and mounted on the rack is arranged on the other side of the front end of the rolling cage; the first electric push rod and the second electric push rod alternatively resist against the front end of the rolling cage to move so as to realize that the rolling cage drives the spiral type scraper to rotate along the whole circle of the inner wall of the flue pipe; the rolling cage is matched with the spiral scraper to clear ash in the flue pipe; meanwhile, the scrapped dust is discharged out of the flue pipe by the spiral type scraper along a spiral line to complete an ash clearing process of the flue pipe. The spiral type ash clearing device has good and complete ash clearing effect, improves the using efficiency of the flue pipe and extends the service life of the flue pipe.

Owner:FUJIAN AGRI & FORESTRY UNIV

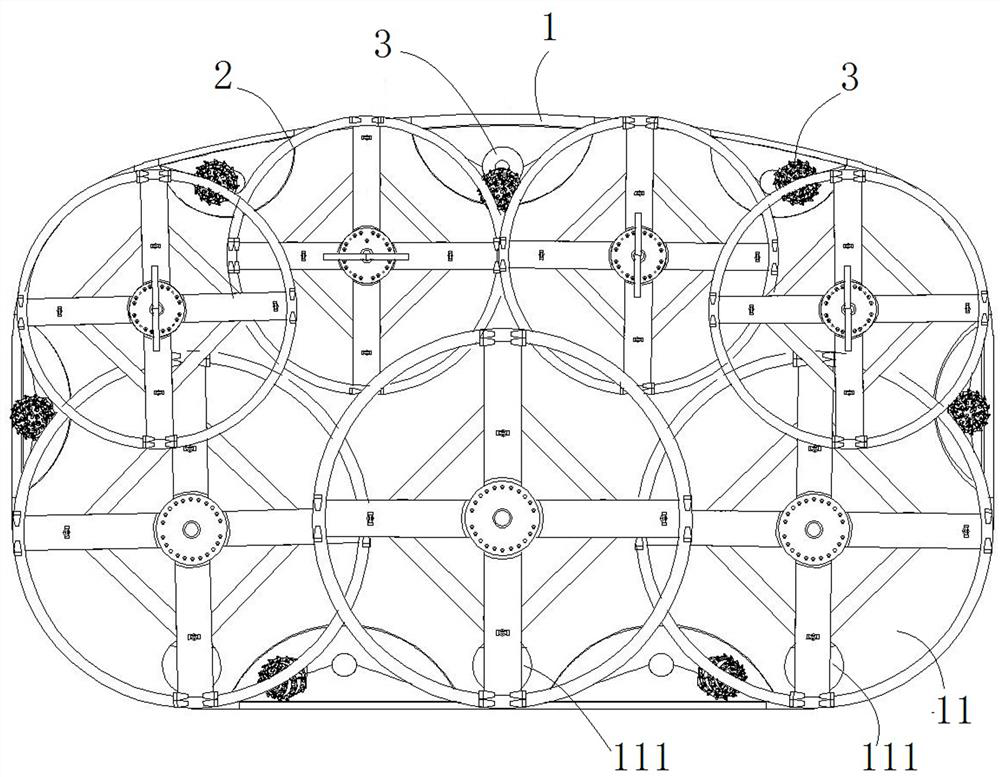

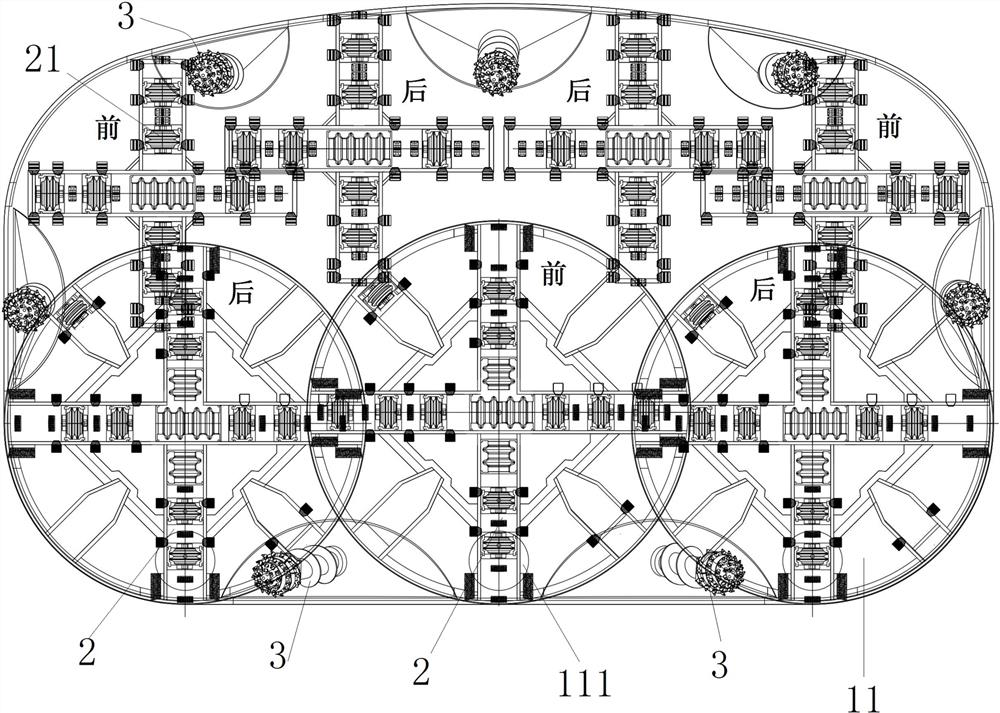

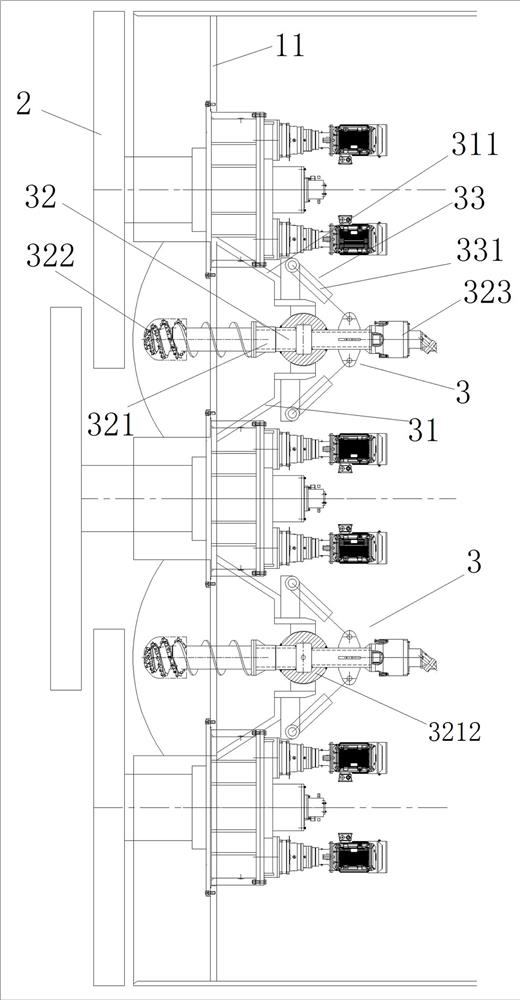

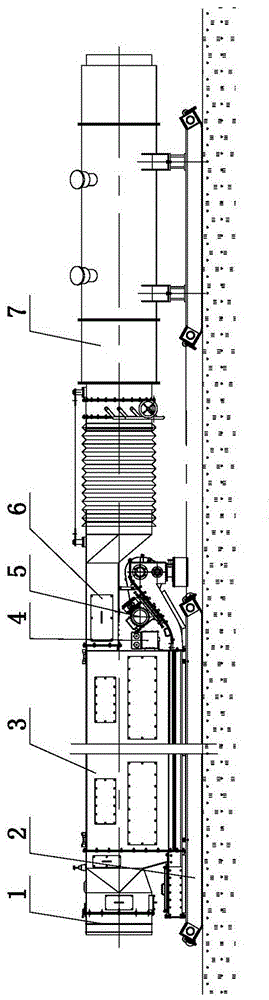

Non-circular tunnel boring machine and auxiliary excavation device for tunnel boring machine

The invention relates to the field of tunneling equipment with drilling or cutting tools. The invention discloses a non-circular tunnel boring machine and an auxiliary excavation device for the tunnelboring machine. The auxiliary excavation device for the tunnel boring machine comprises an installation seat, a crushing device and an adjusting mechanism, wherein the installation seat is used for being installed on a rack of the tunnel boring machine; the crushing device comprises a device base, a crushing head rotationally arranged on the device base and a driving device for driving the crushing head to rotate, the device base is movably assembled on the installation seat, and the crushing head is used for crushing an excavation blind area of the tunnel boring machine; and the adjusting mechanism is used for exerting acting force on the device base to enable the device base to move when the crushing head is driven by the driving device to work, so that the position of the crushing headis changed to sweep the excavation blind area. Through cooperation of the crushing device and the adjusting mechanism, the excavation blind area can be swept away, the influence of the excavation blind area on the tunnel boring machine is reduced, and the excavation efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

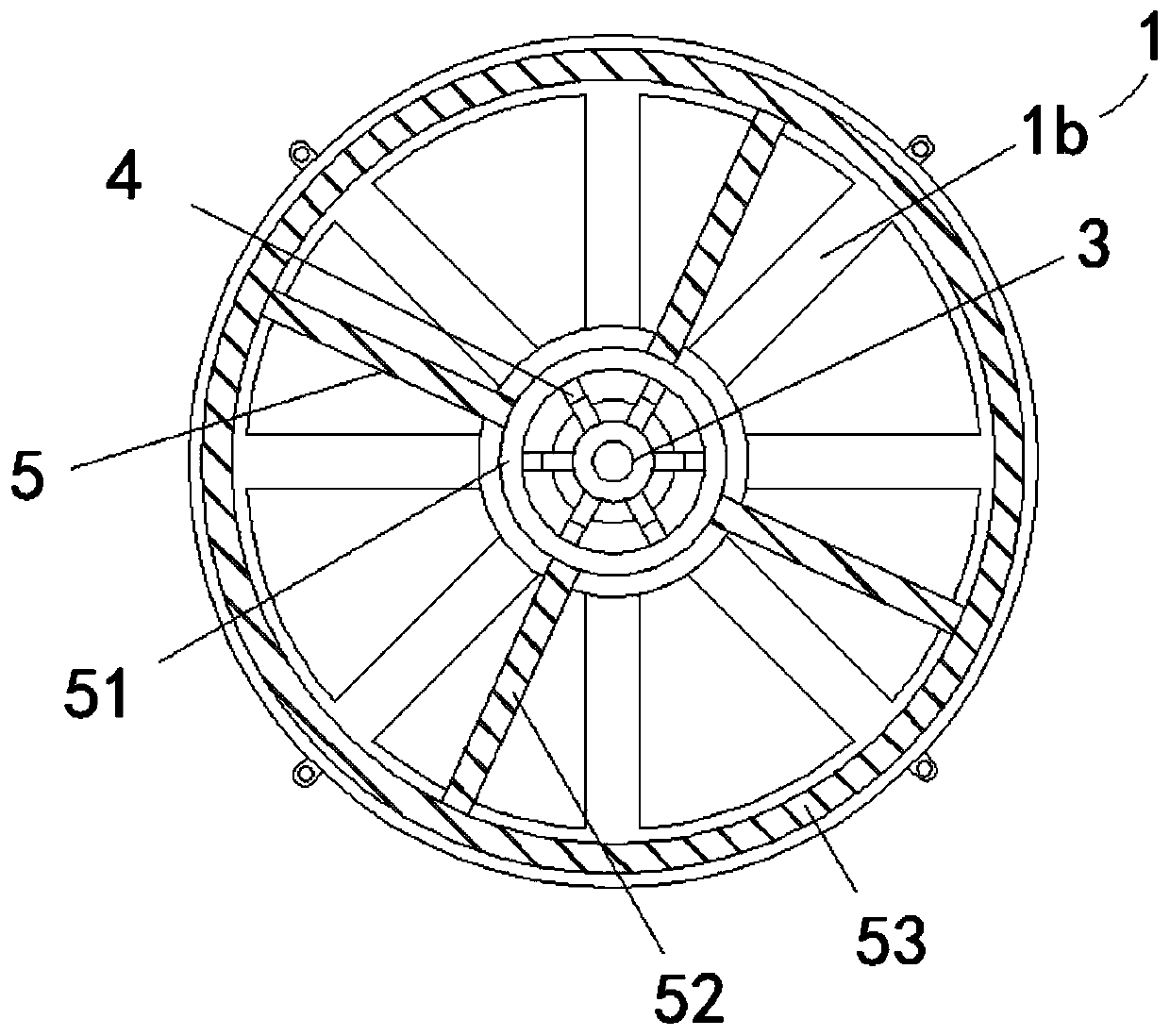

Condensate fan mesh enclosure with snow prevention and snow removal function

PendingCN110905861AIncrease temperatureGuaranteed uptimeAir-treating devicesPump componentsSnow removalTemperature control

The invention relates to a condensate fan mesh enclosure with snow prevention and snow removal function. The condensate fan mesh enclosure comprises a mesh enclosure body formed by assembling a mesh enclosure base and a mesh enclosure top base. A mounting cavity is formed in the mesh enclosure base, and a heating part is arranged in the mounting cavity. The beneficial effects are that: when the mesh enclosure of a condensation fan is covered with accumulated snow, heating is carried out by the heating part to make the temperature of the mesh enclosure base and the mesh enclosure top base rapidly increased, so that the accumulated snow can be quickly melted; after the accumulated snow is removed, the air conditioner condensate fan can be normally started, and normal operation of the heatingfunction of an air conditioner is guaranteed; a temperature control device controls the heating wires to emit heat, the heating wires are distributed in the installation cavity in a fan-shaped surrounding mode, the heat conduction performance of the heating wires is improved, and therefore, it is guaranteed that the temperature of the mesh enclosure base and the mesh enclosure top base can be stably and efficiently increased.

Owner:荆州市楚泰新能源科技有限公司

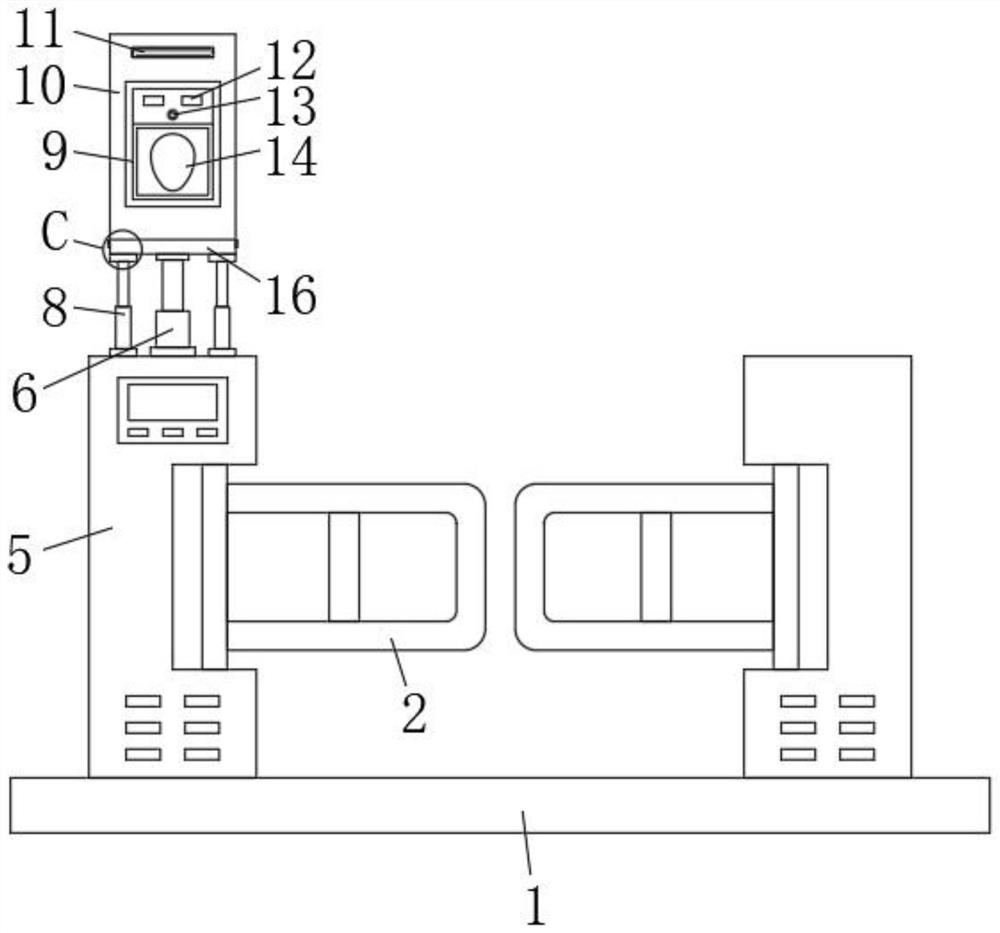

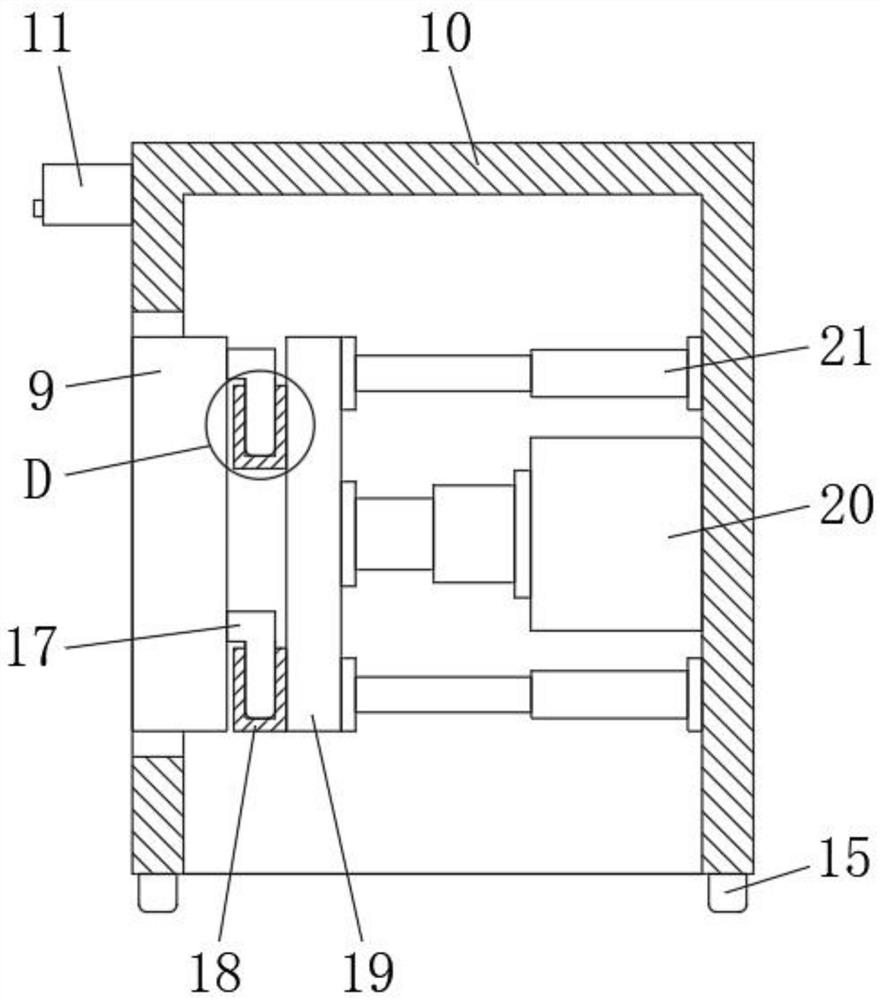

Library face recognition all-in-one machine with protection structure

InactiveCN113112667ARealize cleaningEasy to useCleaning using toolsIndividual entry/exit registersEngineeringMechanical engineering

The invention discloses a library face recognition all-in-one machine with a protection structure, which relates to the technical field of face recognition all-in-one machines. The library face recognition all-in-one machine with the protection structure comprises a gate assembly and a face recognition device, wherein the middle of the gate assembly is provided with a channel convenient for readers to pass through; the face recognition device is arranged above the gate assembly, the face recognition device comprises a protection assembly, a face recognition assembly and a cleaning assembly, the protection assembly comprises a protection box, the protection box is used for achieving protection of the face recognition assembly, and theface recognition assembly is mounted in the protection box. Through the arrangement of the cleaning assembly, the face recognition assembly can be cleaned and brushed, so that dust removal of the face recognition assembly is realized in a library with a large personnel flow, and dust accumulation on the face recognition assembly is effectively prevented; and normal use of the face recognition assembly is facilitated.

Owner:SHANGLUO UNIV

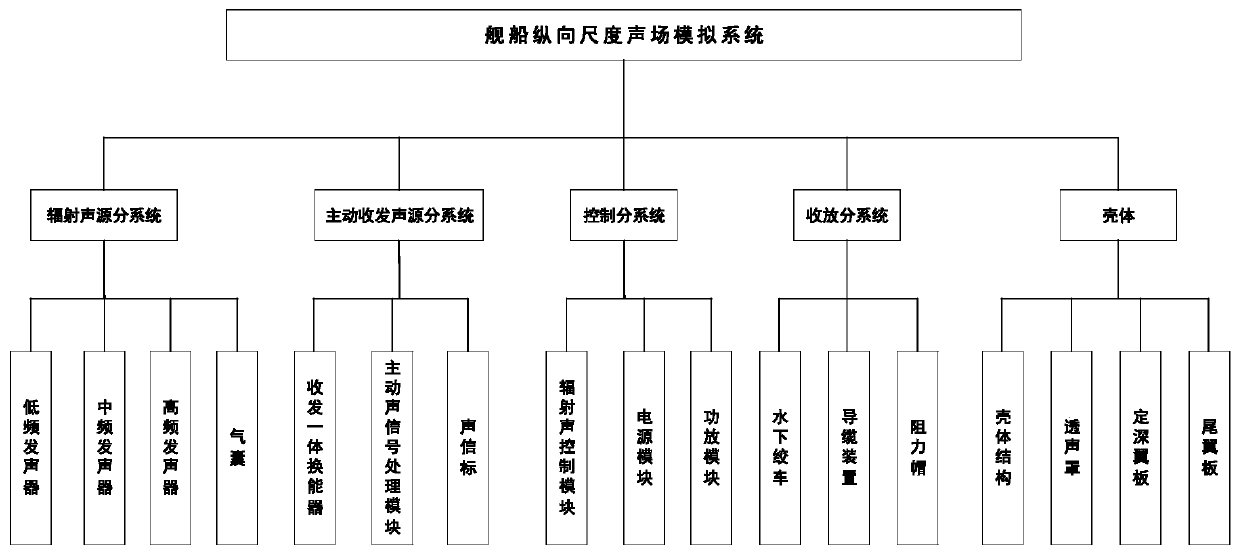

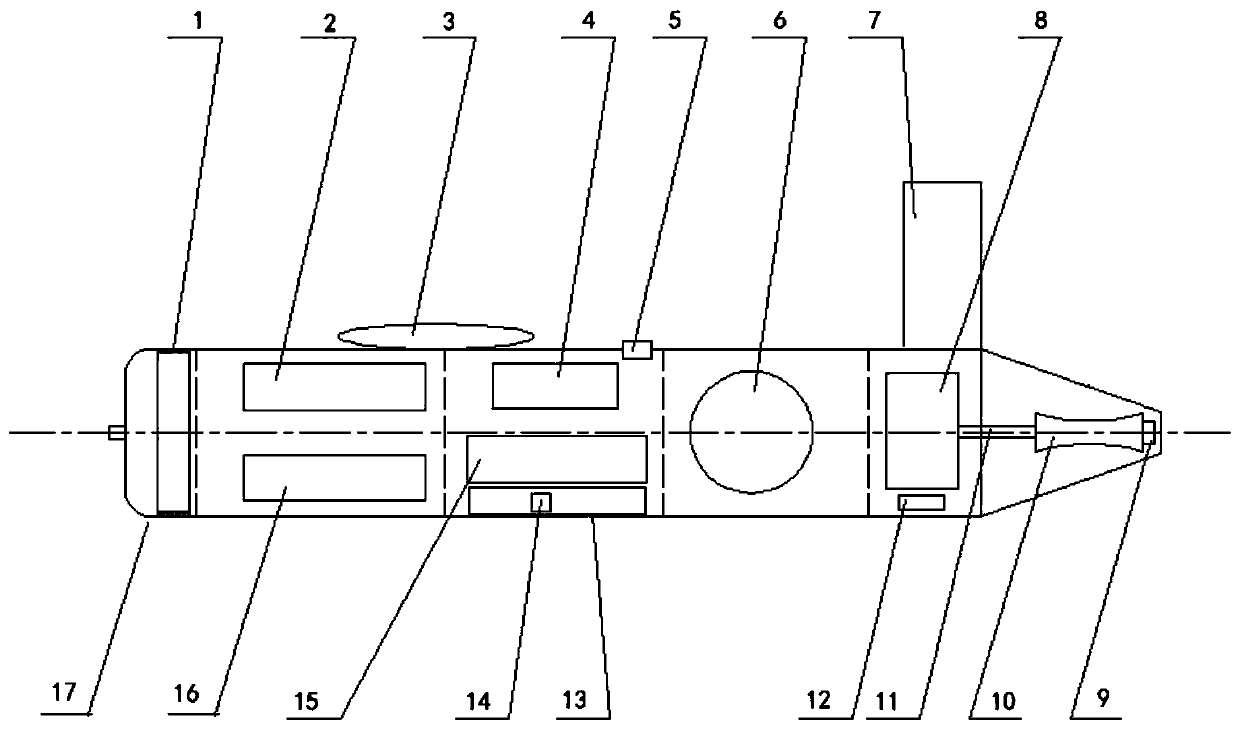

Longitudinal scale sound field simulation system of ship

ActiveCN109765560AEasy to operateFlexible useSustainable transportationAcoustic wave reradiationSound sourcesEngineering

The invention discloses a longitudinal scale sound field simulation system of a ship. A longitudinal scale sound field characteristic of a ship is added on the basis of a traditional ship simulation,a scale of a simulated ship can be adjusted, and ships withthedifferent longitudinal scale sound field characteristic can be simulated. According to the longitudinal scale sound field simulation system of the ship, a point sound source located in the tail part of a casing is distributed and recycled through a retracting system, so that length of the point sound source laid out along the length direction of the ship changes, thus sound fields of the ships with the different longitudinal length characteristics can be simulated, operation is convenient, and using is flexible; and an active acoustic fuze signal can be received and reconstructed by adopting an active acoustic simulation segment, a reconstructed signal is emitted through an independent emitting unit, and emission intensity is controllable, and simulationof different ship target strengths and different ship speeds can be realized.

Owner:CSIC NO 710 RES & DEV INST

Intelligently controlled multifunctional sow obstetric table

The invention relates to an intelligently controlled multifunctional farrowing bed for sows, comprising an intelligent monitoring module, a cleaning information collection module, a feeding and feeding service module, and a sanitation and epidemic prevention module, wherein the intelligent monitoring module and the cleaning information collection module are connected wirelessly , the feeding and feeding service module is connected to the cleaning information collection module, and the sanitation and epidemic prevention module is connected to the feeding and feeding service module. The intelligent monitoring module is provided with a communication module, and the communication module in the intelligent monitoring module and the health and epidemic prevention module realize short-distance control, and the control is realized by WIFI or Bluetooth. The system can effectively use the intelligent monitoring module to sample sow breeding epidemic prevention data and related mobile data records, and release the data in time, use the feeding and feeding service module to realize feeding and control, and realize the sow farrowing bed The cleaning, monitoring, drinking water, ventilation, and sterilization functions have greatly improved the immune effect.

Owner:界首市颍南东生家庭农场

Translational window opening device

ActiveCN108119001BAchieve closureRealize cleaningInorganic/elemental detergent compounding agentsDetergent solventsDrive wheelElectric machine

The invention discloses a translating window opening device which comprises an outer frame, an inner frame and windows. The inner frame is provided with a driving mechanism, and the driving mechanismcomprises a driving motor, a driving wheel and a driven wheel. A belt is arranged between the driving wheel and the driven wheel. A traction end is fixedly disposed on the belt, one side of the windowclose to the belt is provided with a traction end matching groove, and the traction end is fixedly connected with the traction end matching groove. The number of the windows is two, a gap is formed between the windows, one side of each window close to the gap is provided with hairbrushes, the number of the hairbrushes on each window is two groups, the groups of hairbrushes are parallel to each other, the arrangement position of each hairbrush corresponds to the traction end matching groove, and a window body sponge layer is arranged between the hairbrushes on the same window. In the translating window opening device, the hairbrush and the window body sponge layer are matched with each other, window dust can be removed while the windows are automatically opened and closed, and the translating window opening device has the advantage that the problem of potential safety hazard generated by manual dust removal is solved.

Owner:奋安铝业股份有限公司

Mine dry dust removal device

The mine dry dust removal device relates to dust collector technology, in particular to the mine dry dust removal device in coal mine roadways and explosive hazardous areas. The invention provides a mine-used dry dust removal device with high dust removal efficiency, easy dust removal, no secondary pollution, good equipment stability, convenient operation and maintenance, and safe and reliable operation. The present invention includes a base, which is characterized in that: a filter box is arranged above the base, an ash delivery tank is provided at the bottom of the filter box, an ash delivery mechanism is arranged on the base corresponding to the ash delivery tank, and an air exhaust port is provided at the tail end of the filter box; The air outlet is connected with the fan on the base.

Owner:SHENYANG NORTH MINING MACHINERY

A dumping furnace self-baking electrode volatile dust collector

ActiveCN110339640BExtended service lifeReduce pulling forceCombination devicesDispersed particle filtrationExhaust fumesDust collector

Owner:重庆市赛特刚玉有限公司

Organic waste gas monitoring device based on Internet of Things

InactiveCN111289699AAchieve pullRealize cleaningFouling preventionPhotovoltaicsWater storageDust control

The invention relates to the field of environmental monitoring, in particular to an organic waste gas monitoring device based on the Internet of Things. The device comprises a support rod, a support mechanism, a monitoring mechanism, a pressurizing mechanism, a water storage mechanism, a dust removal mechanism and a solar cell panel, wherein a water storage mechanism for storing water in rainy days is mounted at the edge of the top of the supporting mechanism; after the water amount in the water storage mechanism reaches a certain amount, the water is poured out, so the dust removal mechanismis pulled; after the dust removal mechanism is pulled, dust removal of the solar cell panel is realized, heat absorption of solar energy is facilitated, continuous power supply to the monitoring mechanism is realized, and environment detection is facilitated; the top of the monitoring mechanism is rotationally connected with a pressurizing mechanism; when water in the water storage mechanism is poured out, the pressurization mechanism on the top of the monitoring mechanism is pressed, so the pressurization mechanism promotes air circulation of the monitoring mechanism, the rainwater is prevented from making contact with the monitoring mechanism, the air circulation is promoted, and the situation that the monitoring effect is affected by rainwater flowing is avoided.

Owner:卢敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com