Push-pull type water-seepage-proof plastic-steel door and window

A steel door and window, push-pull technology, applied in the field of push-pull anti-seepage water plastic steel doors and windows, can solve the problems of poor anti-seepage effect, ground water seepage, deformation of sealing strips, etc., to improve user experience, improve user experience, and good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0036] It is understood that these descriptions are exemplary only, and are not intended to limit the scope of the invention.

[0037] A push-pull anti-seepage water plastic steel door and window provided by some embodiments of the present invention will be described below with reference to the accompanying drawings.

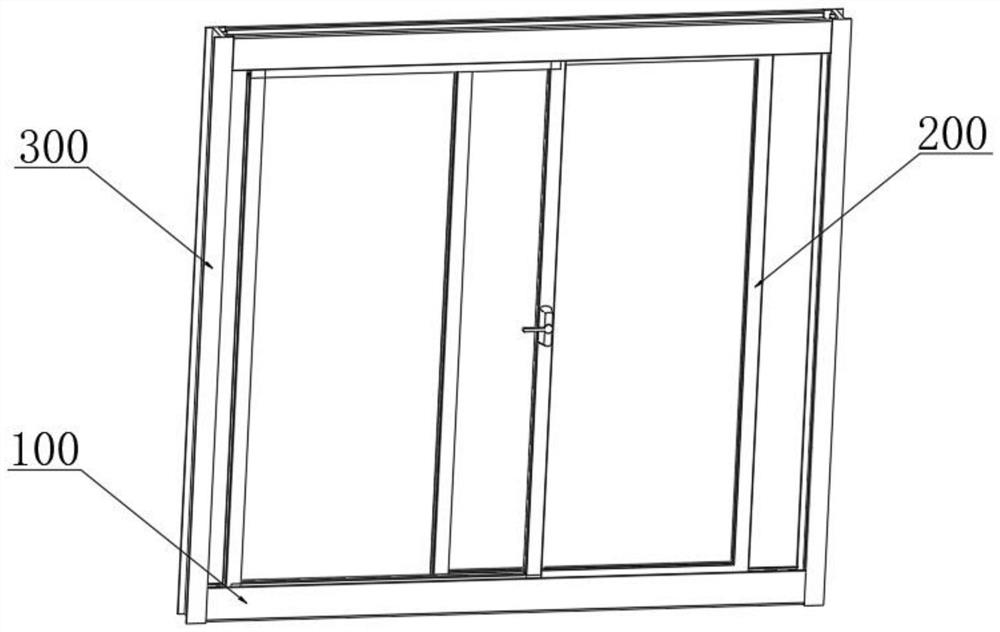

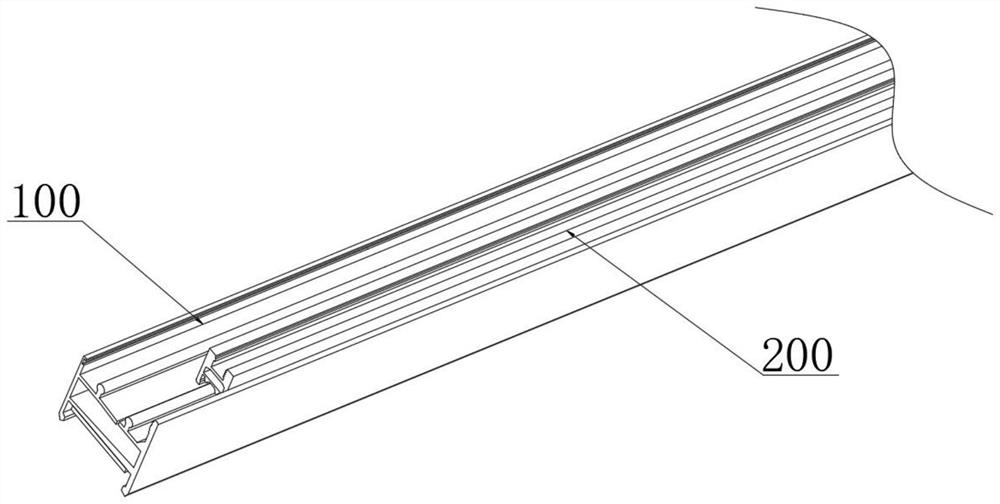

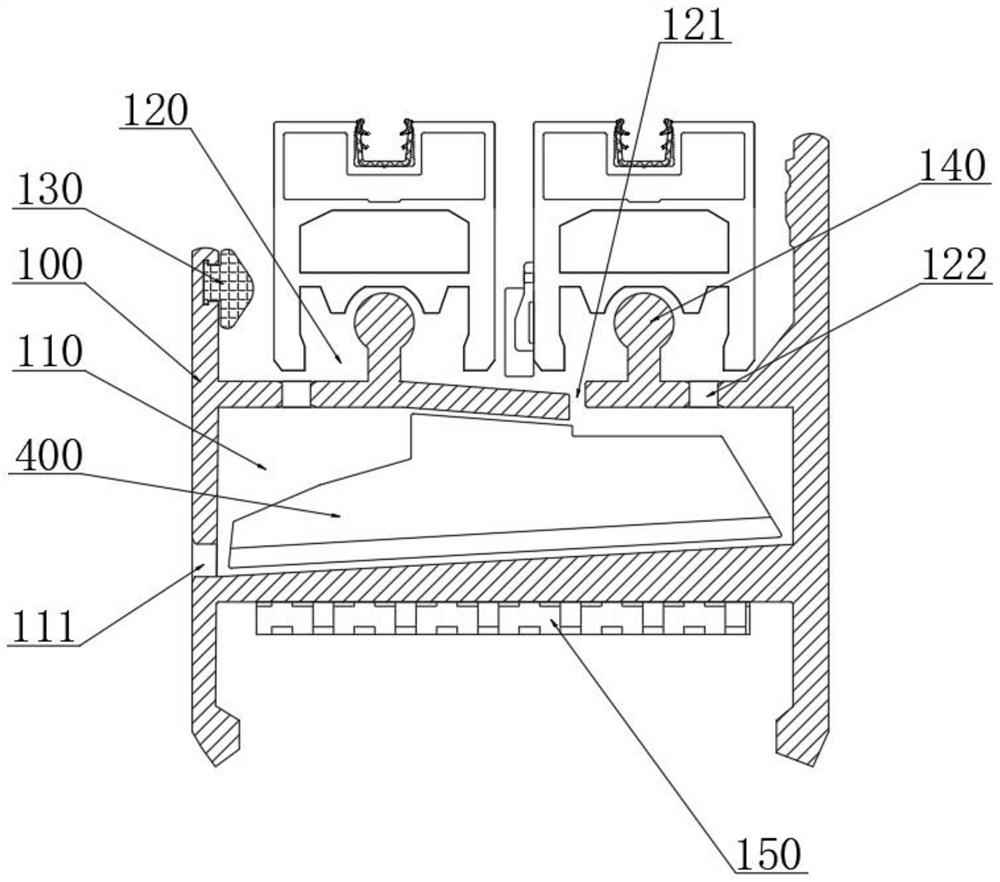

[0038] combine Figure 1-7As shown, a push-pull anti-seepage plastic-steel door and window provided by the present invention includes: a slide profile 100, a window blade 200, a window frame profile 300, and a piston cleaning mechanism 400 slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com