Boiler soot deposit and coking synergistic treatment device and work method thereof

A technology of ash accumulation and coking, which is applied in the direction of combustion method, combustion product treatment, lighting and heating equipment, etc. It can solve the problems of reducing boiler service life, fluctuating furnace negative pressure, reducing boiler thermal efficiency, etc., to avoid clogging of nozzle holes, Large sweeping area and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

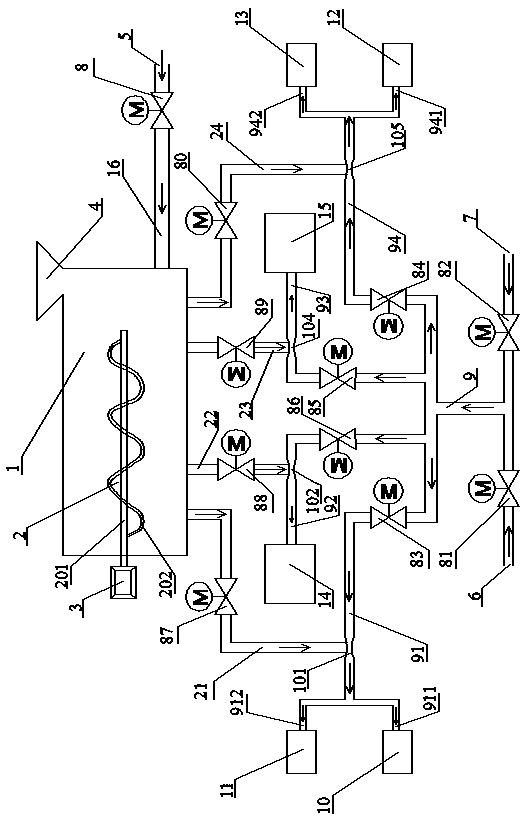

[0027] see figure 1 , a device for synergistically treating boiler soot and coking, including a decoking agent storage tank 1, an agitator 2, a drive motor 3, a decoking agent inlet 4, a replenishing water inlet 5, a compressed air inlet 6, and soot blowing steam Inlet 7, water supply solenoid valve 8, main pipe 9, short soot blower 10 on the left side of the furnace, short soot blower 11 on the right side, short soot blower 12 on the front wall of the furnace, short soot blower 13 on the rear wall, left side Wall length soot blower 14, right wall length soot blower 15, water supply connection pipe 16, decoking agent first pipeline 21, decoking agent second pipeline 22, decoking agent third pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com