Patents

Literature

613 results about "Soot blower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sootblower is a device for removing the soot that is deposited on the internal furnace tubes of a boiler during combustion to prevent plugging of the gas passes and maintain boiler efficiency.

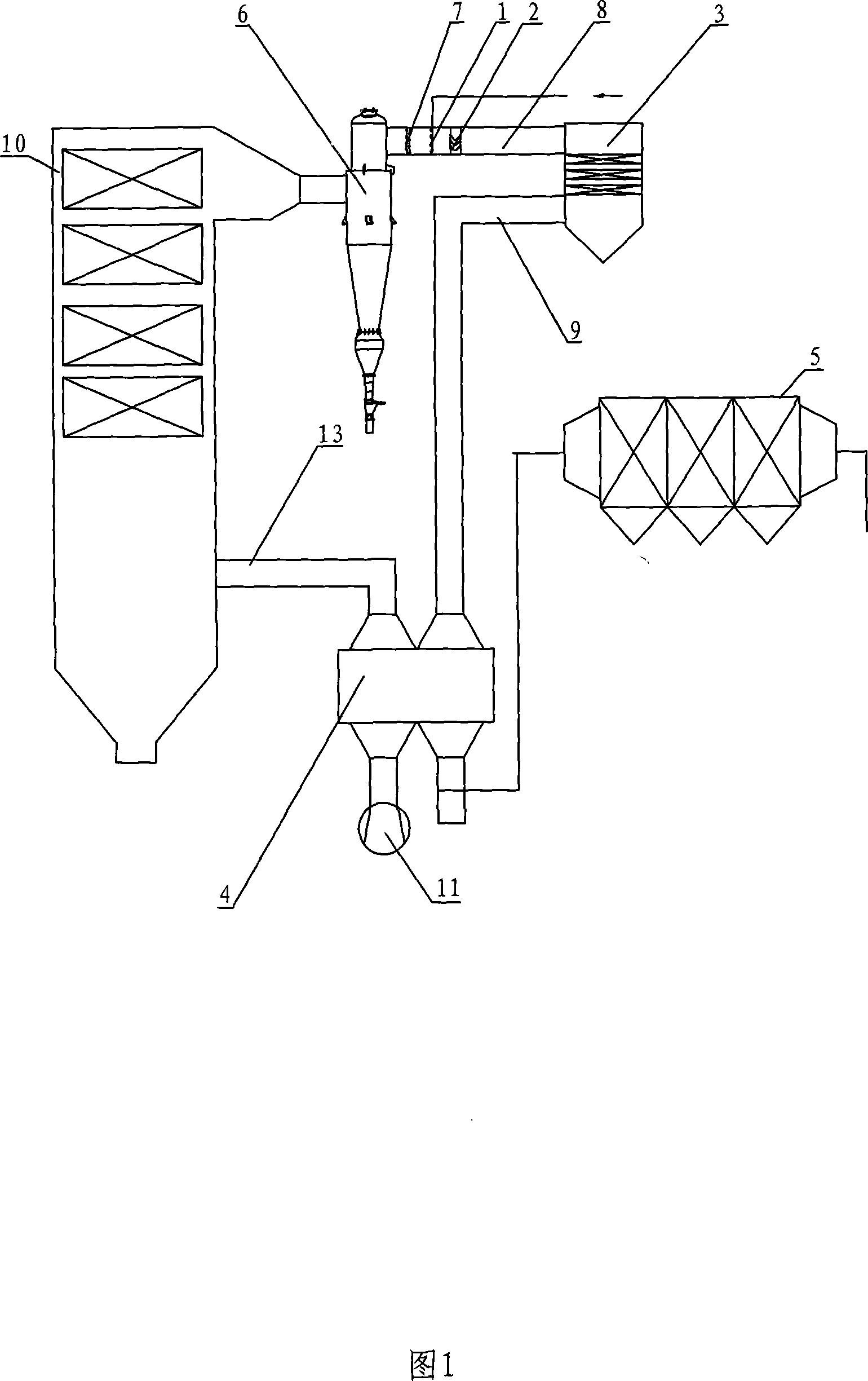

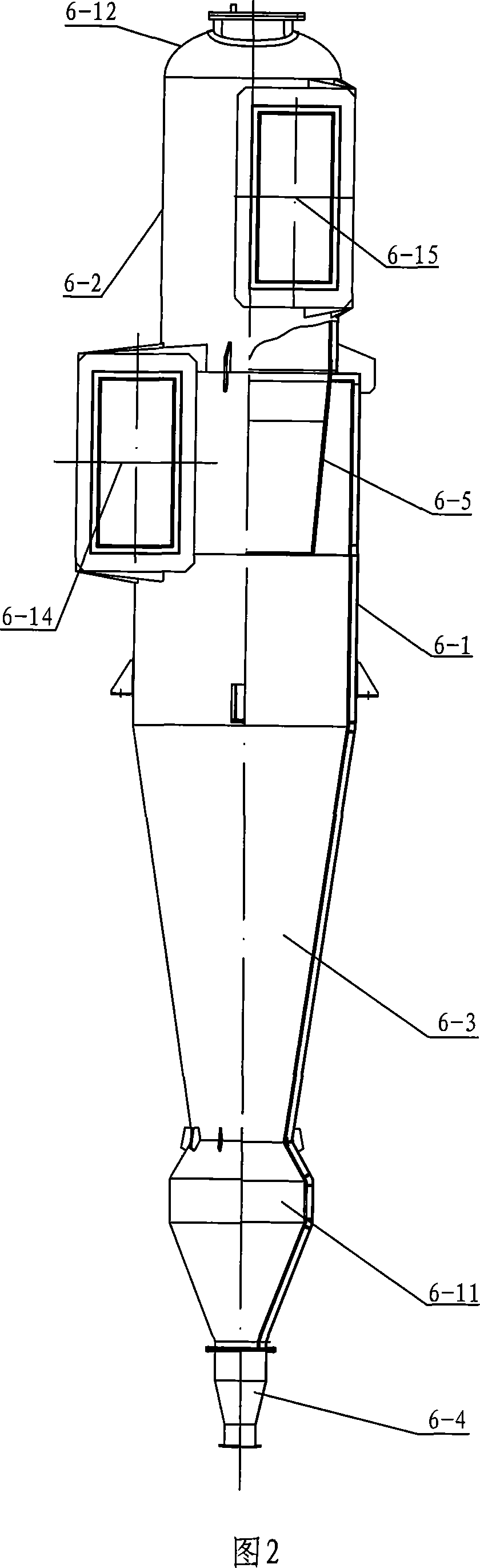

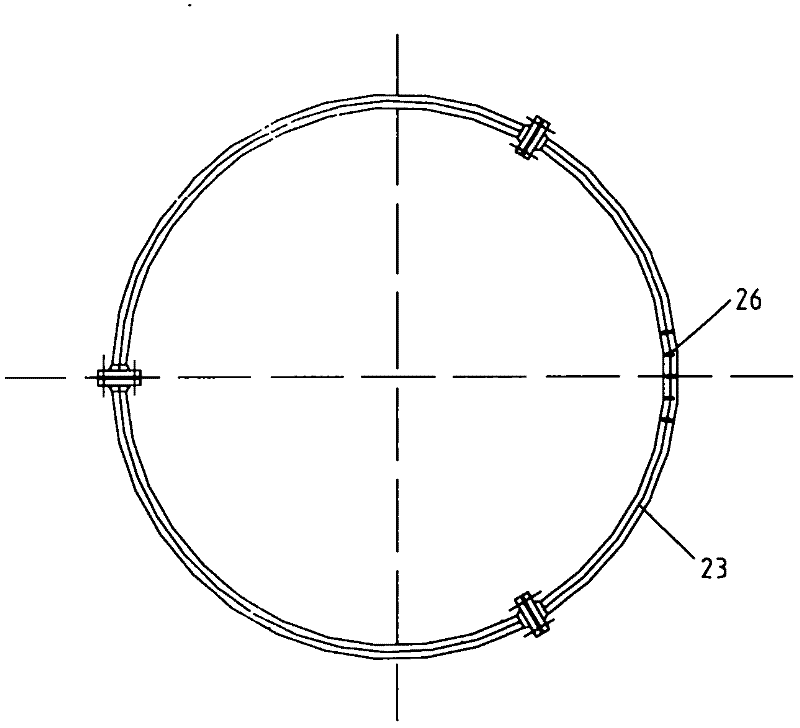

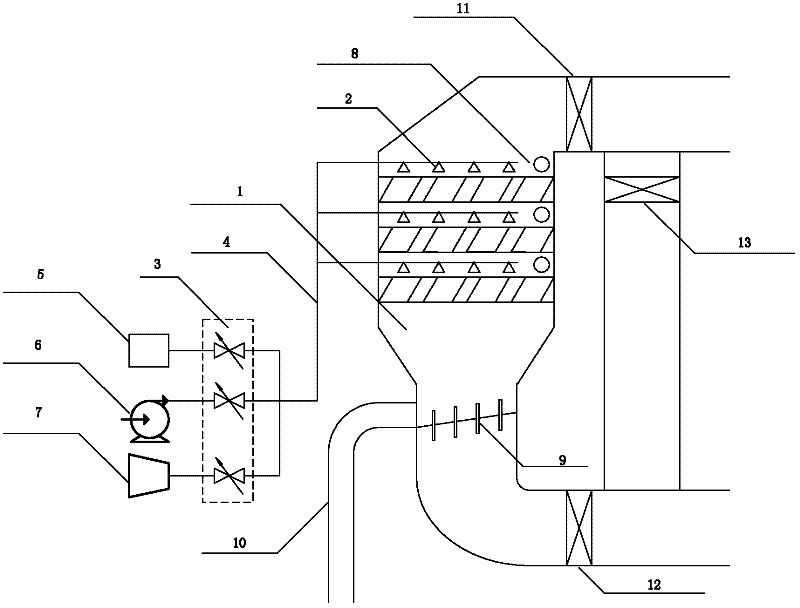

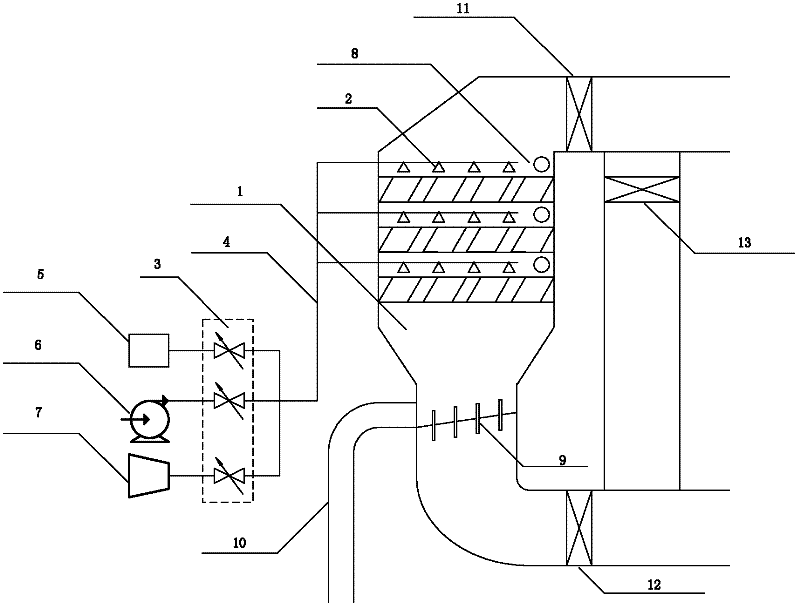

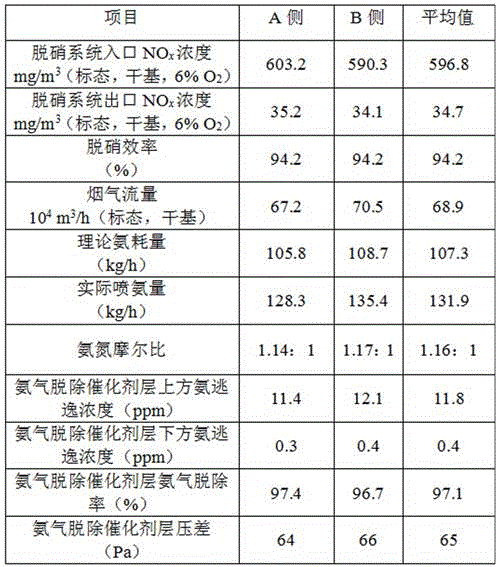

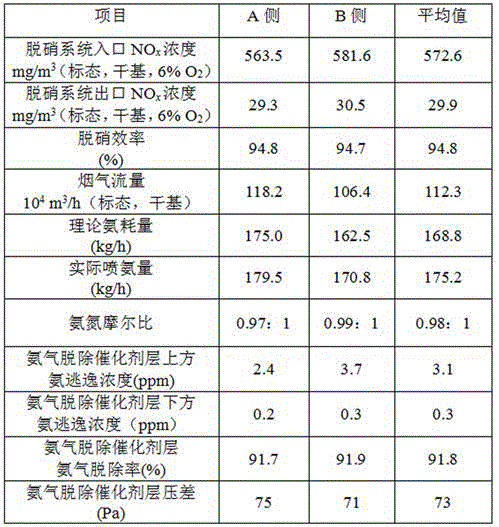

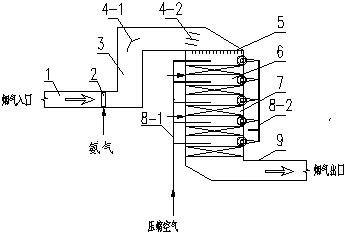

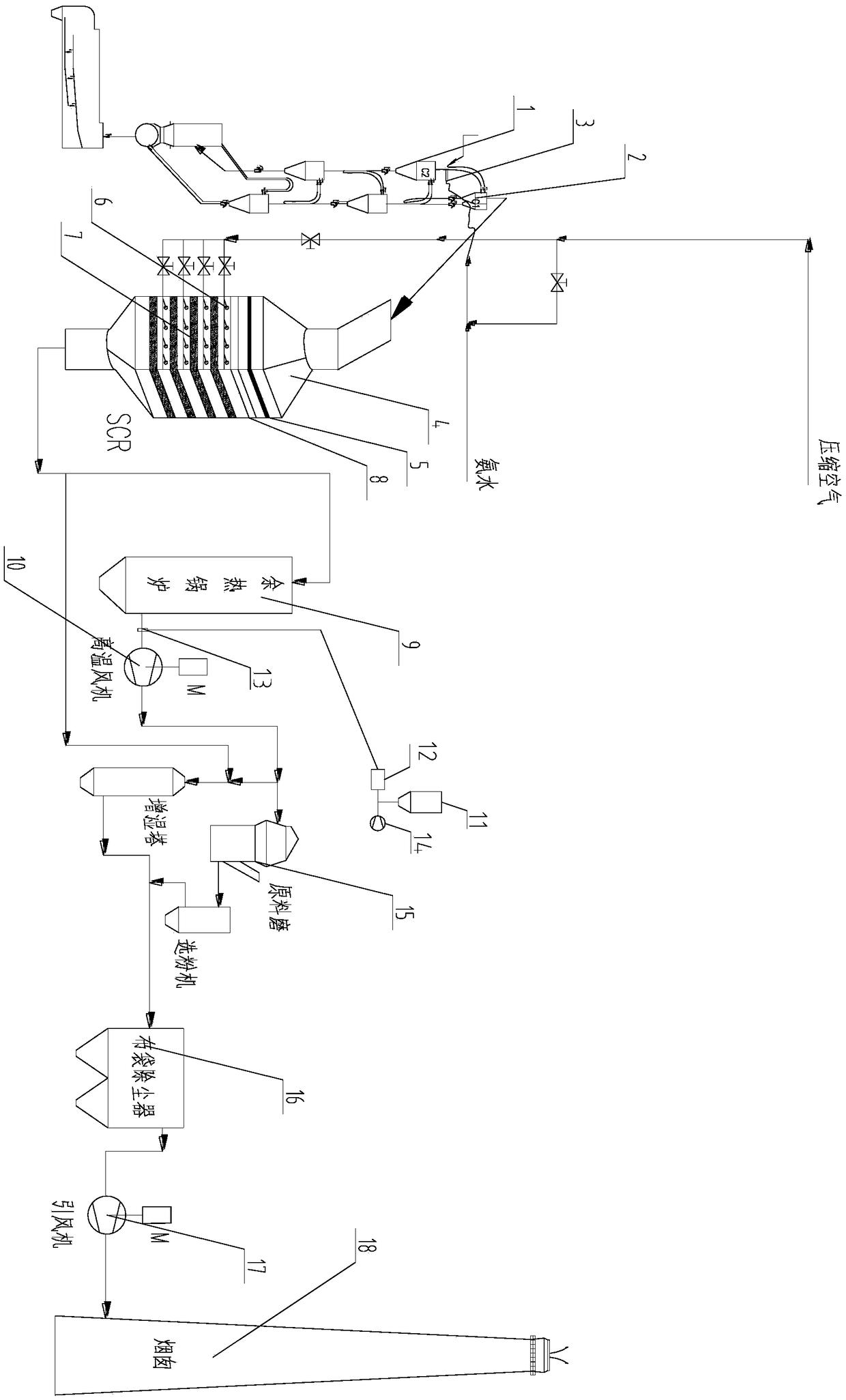

Flue gas denitrating technique with preposed whirlwind beforehand dust removal SCR

The invention discloses a preposing cyclone pre-dedusting SCR flue gas denitration technique. The flue gas extracted from a boiler economizer (12) primarily passes through a high temperature resistant cyclone separator (6), then passes through a flue gas current equalizer (7) and a static mixer (2) to unify the flow direction of the flue gas evenly; meanwhile, the flue gas after being mixed evenly with ammonia is preprocessed before reacting with a catalyst of an SCR reactor (3); finally, the flue gas is output after the temperature is reduced through an air preheater (4) and the flue gas is dedusted through an electrical precipitator (5). The invention reduces the volume of the catalyst and the SCR reactor, reduces the requirements of the support, eliminates an SCR bypass and greatly reduces engineering cost of the SCR; meanwhile, the invention also prolongs the service life of the catalyst and the cleaning period of the air preheater without installing a soot blower or prolonging the period of sootblowing.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Double-barrel water cooled wall type radiation waste boiler with adjusting function and industrial application thereof

InactiveCN102213409AImprove utilization efficiencySmall sizeSteam boilersSteam boilers componentsSlagHigh pressure water

The invention discloses a recycling technology for sensible heat of high-temperature and high-pressure gasified products which are coal-gasified by an entrained flow bed, is particularly applicable for a waste boiler flow gasification furnace or a half waste boiler flower gasification furnace of a gasification island of an integrated gasification combined cycle (IGCC) power generation system, and provides a double-barrel water cooled wall type radiation waste boiler with an adjusting function. The double-barrel water cooled wall type radiation waste boiler consists of a flange connected with the gasification furnace, a shell for bearing high temperature and high pressure, an inner-layer water cooled wall, an outer-layer water cooled wall, a screen type water cooled wall, a soot blower and a slag pool positioned at the bottom, and comprises a water-spraying temperature reduction device with the adjusting function. Dust and slag which are carried by most air flows are caught and collected by the slag pool, and synthesized gas flows out from the single side of the radiation waste boiler. High-pressure water entering the radiation waste boiler recycles the sensible heat of the high-temperature and high-pressure gasified products and is converted into saturated high-pressure steam discharged from the outlet of the water cooled wall. By the double-barrel water cooled wall type radiation waste boiler, the high-position sensible heat of the gasified products can be recycled effectively, so the whole energy utilization efficiency can be improved; the double-barrel water cooled wall type radiation waste boiler has the characteristics of safe running, reliability and controllability, and is a clean and efficient energy recycling technology.

Owner:EAST CHINA UNIV OF SCI & TECH

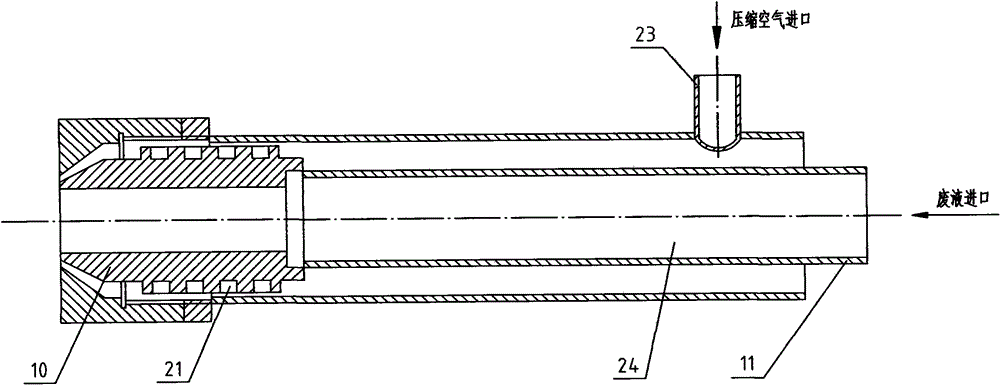

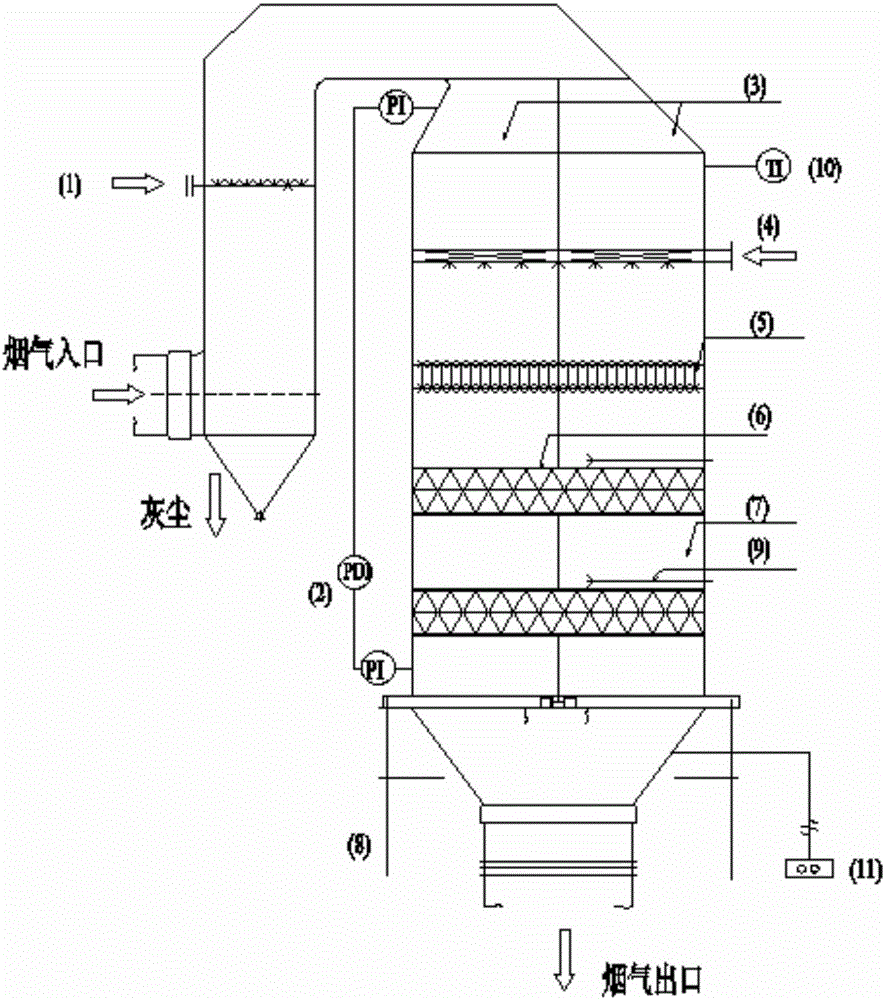

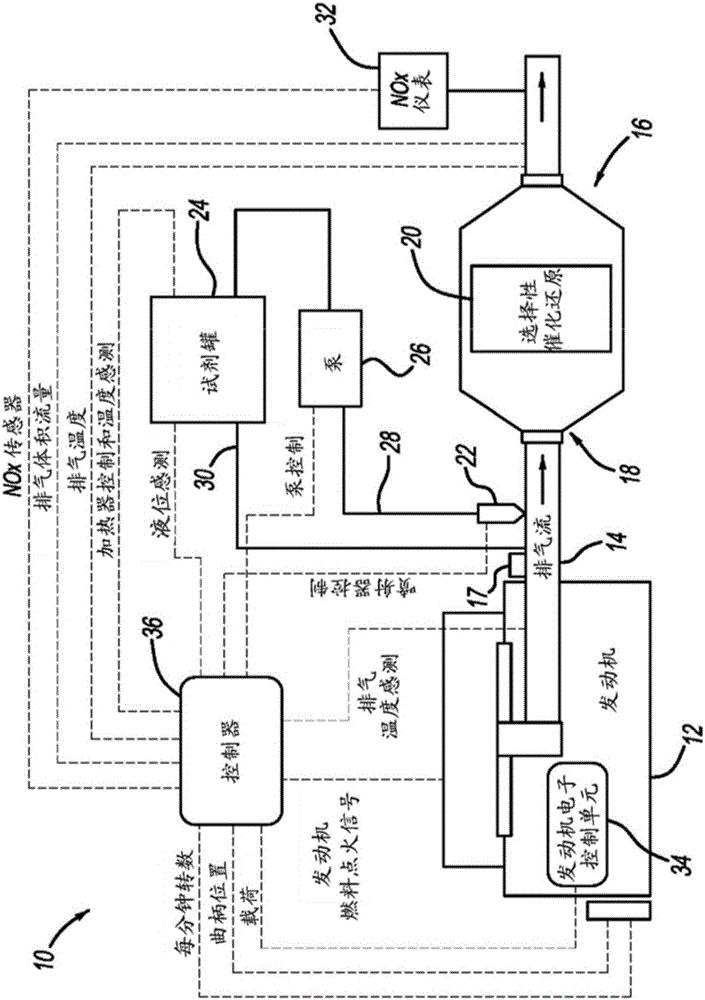

Device for on-line cleaning of selective catalyctic reduction (SCR) denitration catalyst and cleaning process thereof

ActiveCN102389838AShort cycleLow running costCatalyst regeneration/reactivationPtru catalystNitrogen oxides

The invention relates to a device for on-line cleaning of a selective catalyctic reduction (SCR) denitration catalyst and a cleaning process thereof. The device is formed through integrating a soot blower, a cleaning device, a waste liquid collecting device and a hot air drying device, in addition, the on-line cleaning on the catalyst is carried out in the early period of the catalyst invalidation, and catalyst surface sediments, pore blockage substances, alkali metal and other soluble toxic substances are removed. The technology has the advantages that the catalyst activity is improved, the service life of the catalyst is prolonged, the denitration efficiency is improved, the nitrogen oxide discharge is reduced, simultaneously, the cleaning process of the catalyst is simplified, the dismounting and handling work is not needed, the unnecessary loss caused by the dismounting and handling work is avoided, the catalyst cleaning period is shortened, and a large amount of operation cost issaved for enterprises using the SCR denitration catalyst.

Owner:XI AN JIAOTONG UNIV

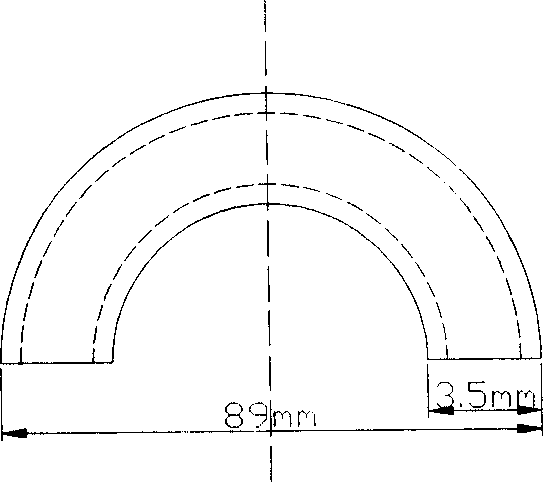

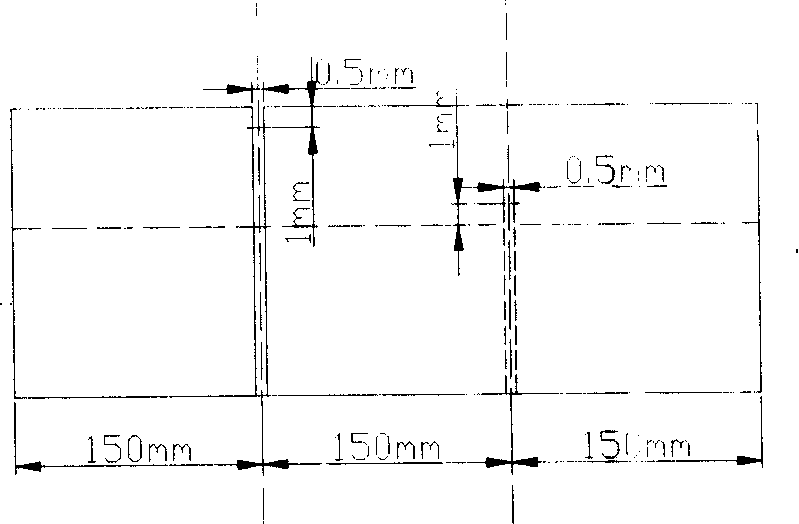

Ultrathin wall sootblower outer sleeve weld joint ultrasound detection method

InactiveCN101236180AReduce security risksDoes not affect power productionAnalysing solids using sonic/ultrasonic/infrasonic wavesWeld seamEngineering

The invention relates to an ultrasonic method for detecting an ultrathin wall (T less than 4mm) soot blower outer casing welding seam ultrasonic which is not stipulated in the prior ultrasonic testing standards comprises the following steps of adopting a comparison test block and a choice device for probe selection and adjustment, and selecting a K3.5 probe; adopting a Hanwei HS-600a digital ultrasonic defect detector with a crack height measurement function, adjusting scanning rate, preparing DAC curves and determining the sensitivity. The soot blower outer casing welding seam ultrasonic detecting method has the advantages that: the ultrasonic method can detect the ultrathin wall soot blower outer casing welding seam sensitively, correctly, simply and conveniently; the method replaces the ray detection without impacting electricity generation during the detection process; the method can improve the detectable rate, reduce the hidden trouble during the operation of a work piece, ensure an inspection result, find smaller cracks and guarantee safety in electricity generation.

Owner:天津诚信达金属检测技术有限公司

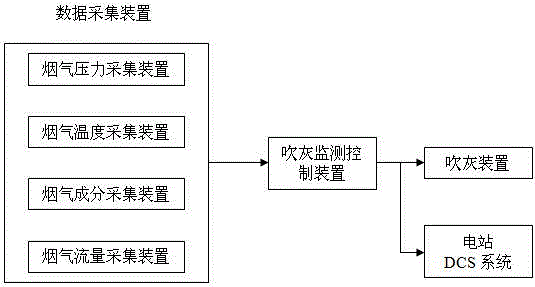

System for online monitoring of gathered dust on convection heating surface of boiler

InactiveCN103604132AReal-time calculation of ash deposit thicknessTake advantage ofMeasurement devicesSolid removalPower stationControl signal

The invention discloses a system for online monitoring of gathered dust on a convection heating surface of a boiler. The system comprises a data acquisition device, a dust blowing monitoring control device and a dust blowing device. The system is used for directly monitoring and calculating the thickness of the gathered dust on the convection heating surface in real time and comparing the thickness of the gathered dust with a critical thickness of the gathered dust, and if the thickness of the gathered dust is more than or equal to the critical thickness of the gathered dust, the system outputs a dust blowing control signal to realize intelligent monitoring and control of the gathered dust on the convection heating surface. The system for online monitoring of the gathered dust can calculate the thickness of the gathered dust in real time no matter how the running state of the boiler changes; the data acquisition device is simple in structure, and the current data acquisition device of a power station boiler can be fully used; dust blowing can be performed on the convection heating surface of the boiler accurately in real time; the thickness data of the gathered data, which is calculated in real time, can be uploaded to a DCS (distributed control system) of a power station to provide technical data for optimization of the running of the boiler.

Owner:TAIYUAN UNIV OF TECH +1

Novel SCR denitration system based on ammonia escape catalytic removal

InactiveCN106178948AMinor changesEasy constructionDispersed particle separationProcess engineeringAmmonia

The invention discloses a novel SCR denitration system based on ammonia escape catalytic removal. The novel SCR denitration system comprises an SCR denitration reactor, a denitration system inlet flue arranged on the top of the SCR denitration reactor, and a denitration system outlet flue arranged on the bottom of the SCR denitration reactor, wherein the denitration system inlet flue is connected with an economizer outlet flue of a boiler system, and the denitration system outlet flue is connected with an inlet of the air pre-heater of the boiler system; the denitration system inlet flue comprises a horizontal flue body and a vertical flue body, an ash bucket is arranged on the bottom of the vertical flue body, and an ammonia spraying grating is arranged in the vertical flue body; guide vanes, a rectification grating, an SCR denitration catalyst layer and an ammonia removal catalyst layer are arranged in the SCR denitration reactor from top to bottom in sequence, and the SCR denitration catalyst layer and the ammonia removal catalyst layer are provided with soot blower systems. By the adoption of the novel SCR denitration system, construction is easy, cost is low, ammonia removal rate can reach 90-99%, and ammonia escape concentration at an outlet of the denitration system can be controlled to be below 3 ppm.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

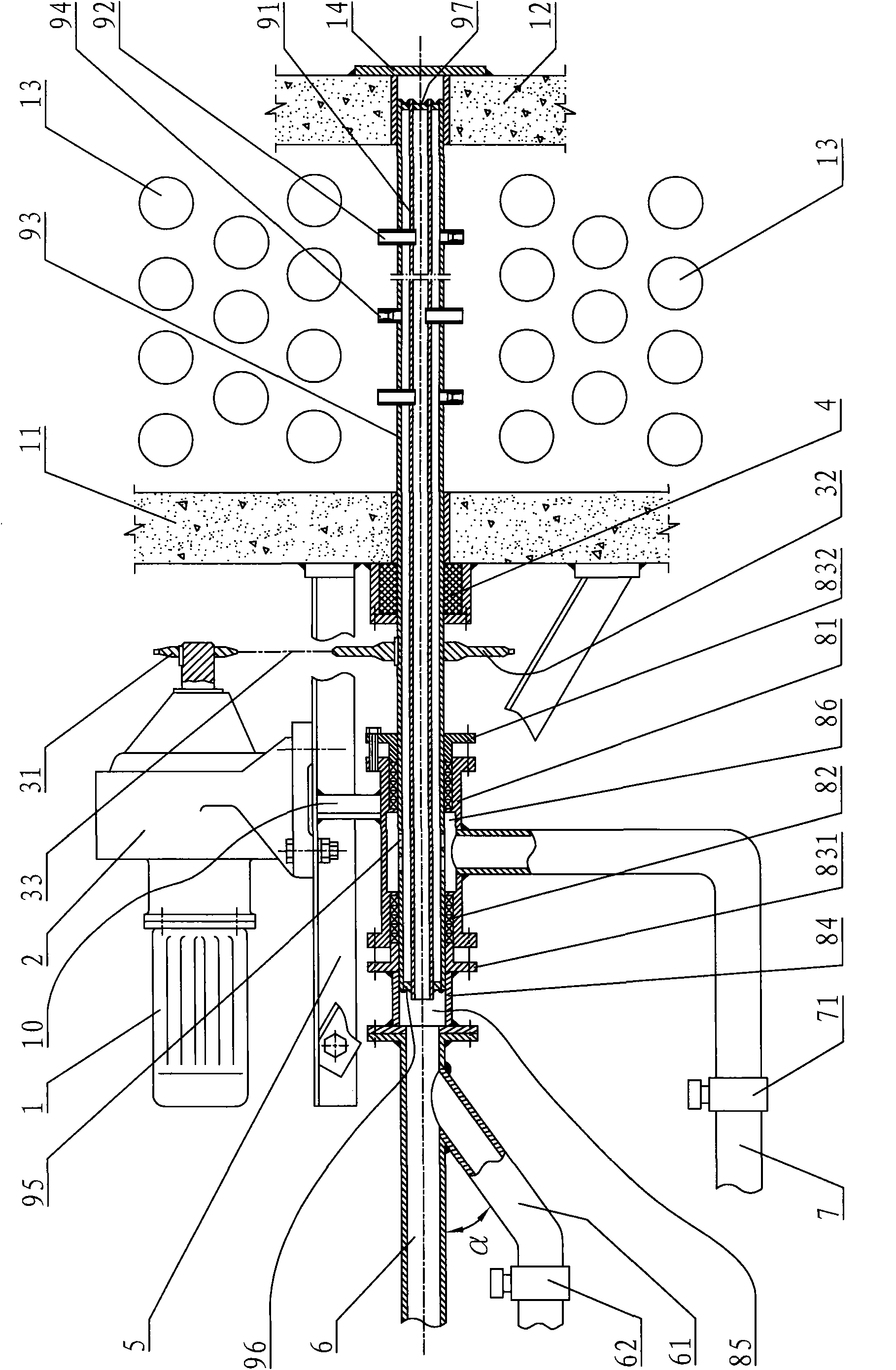

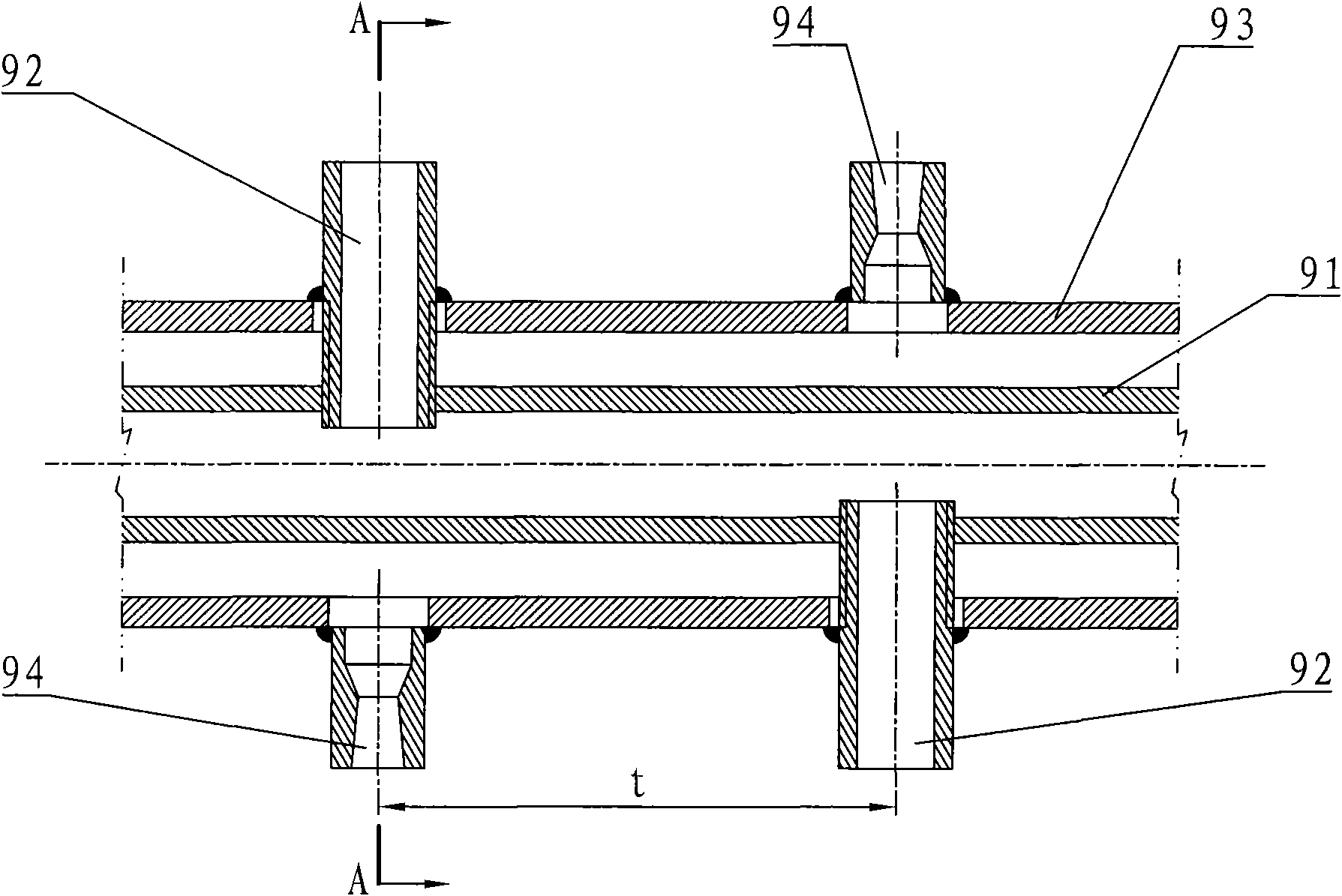

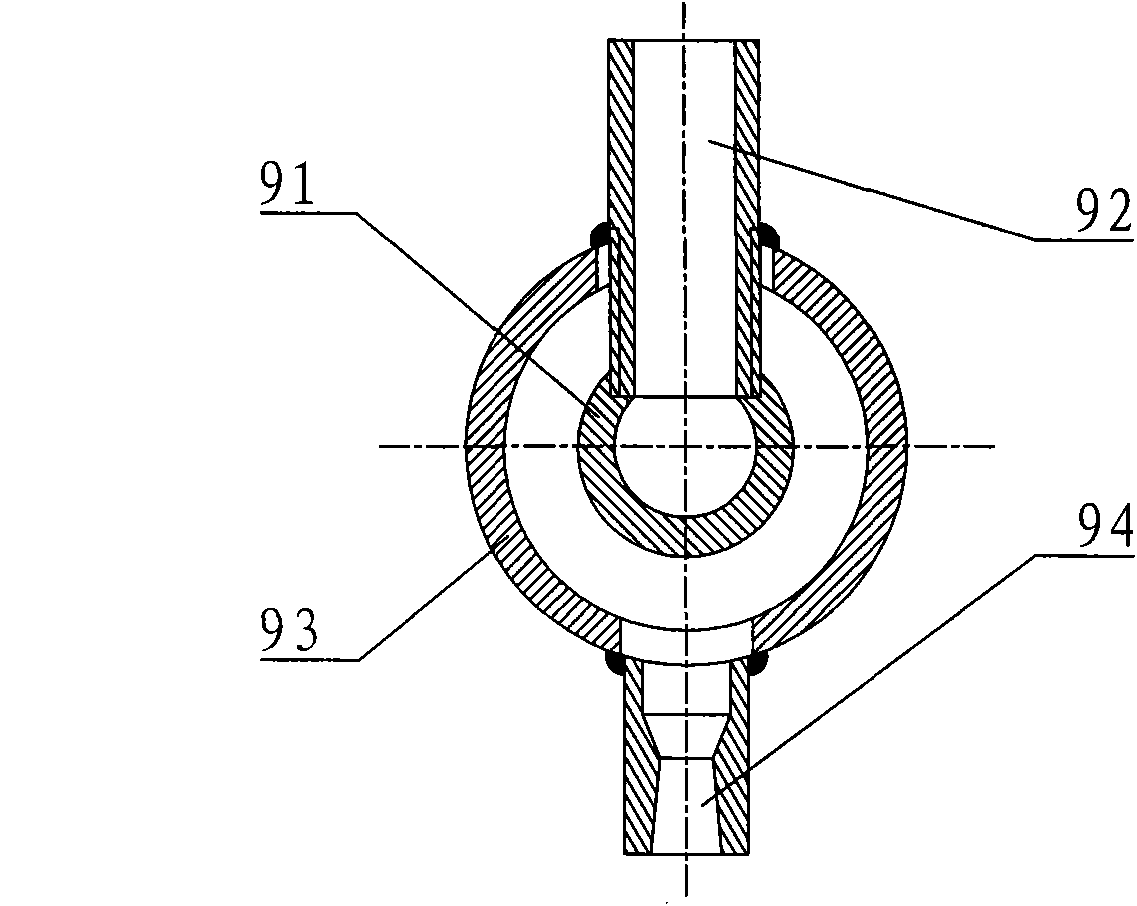

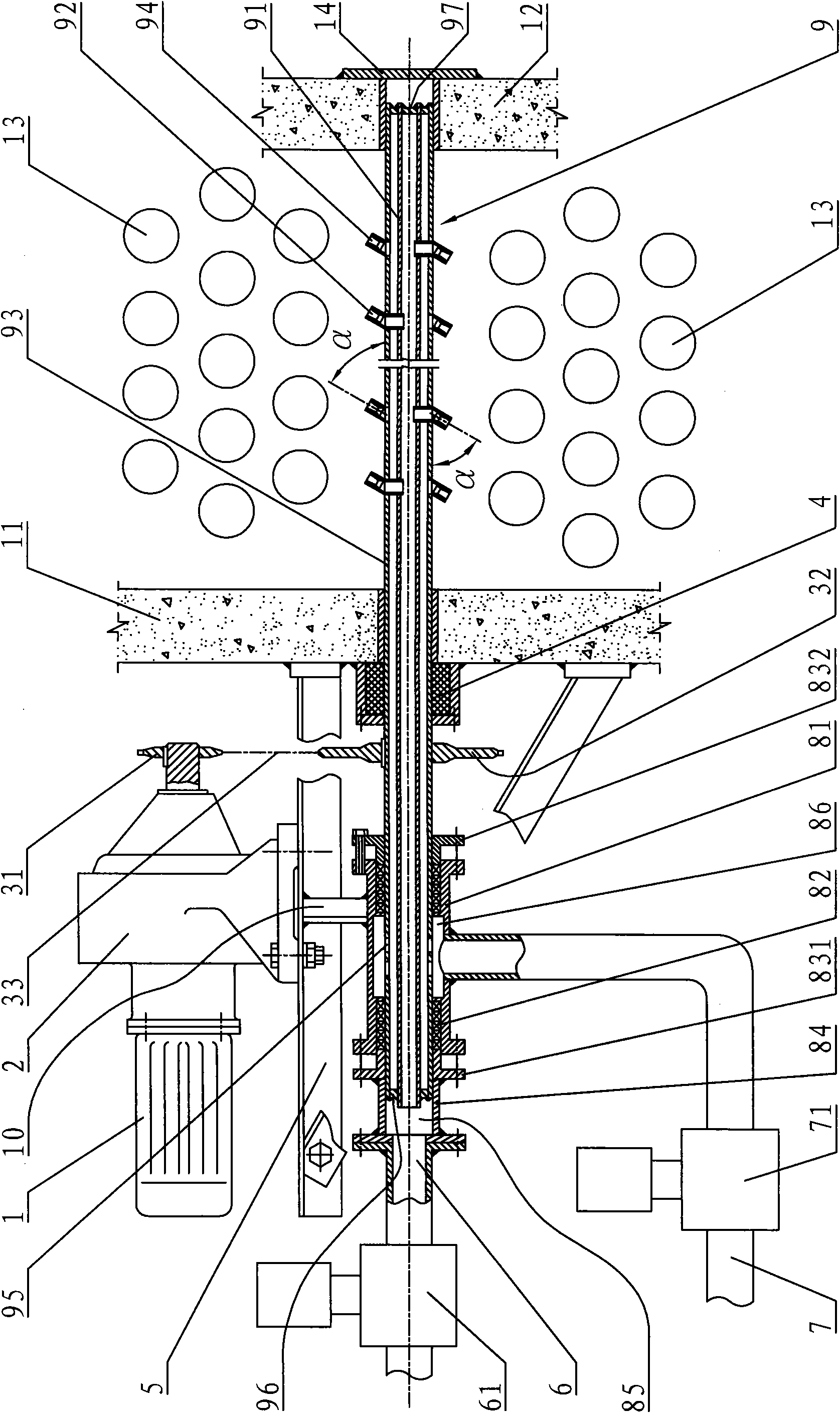

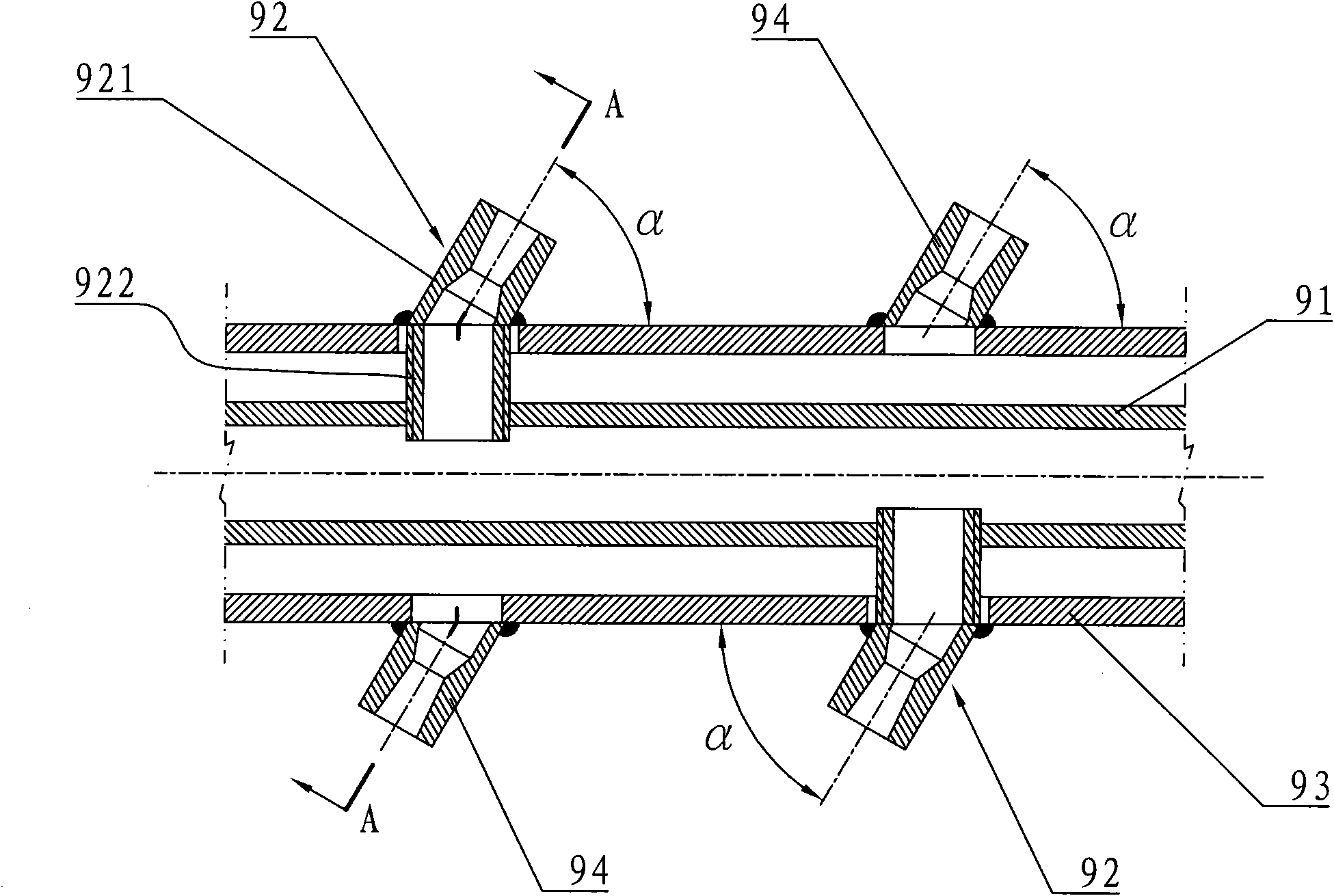

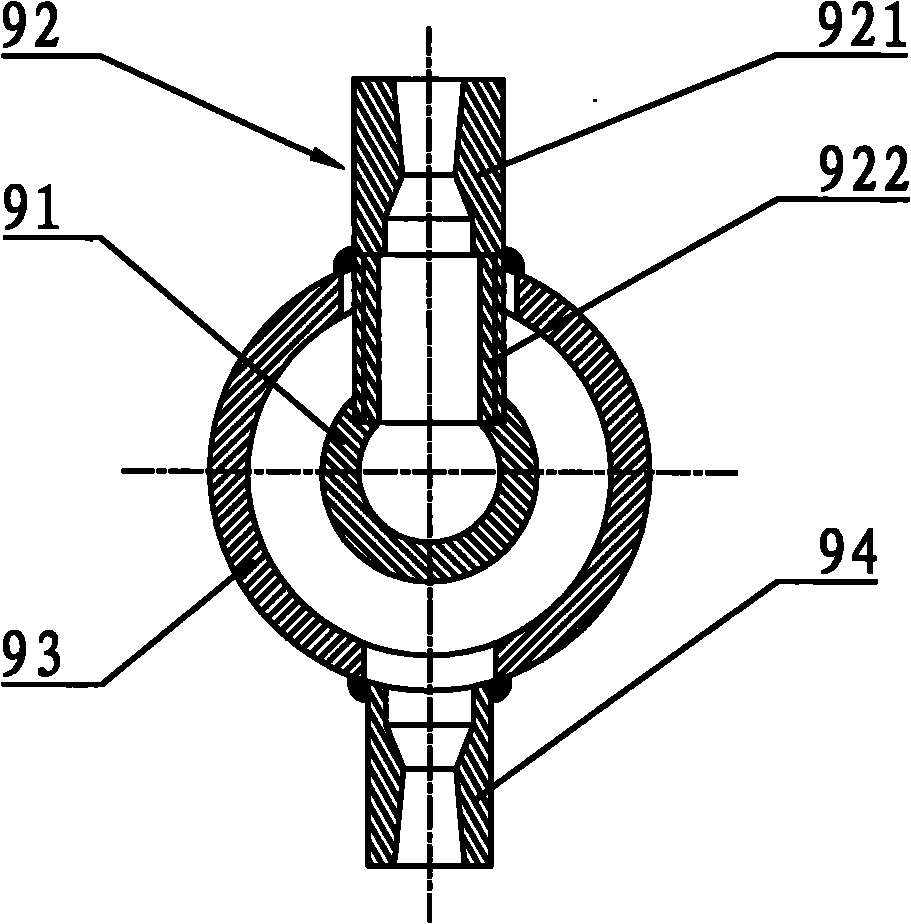

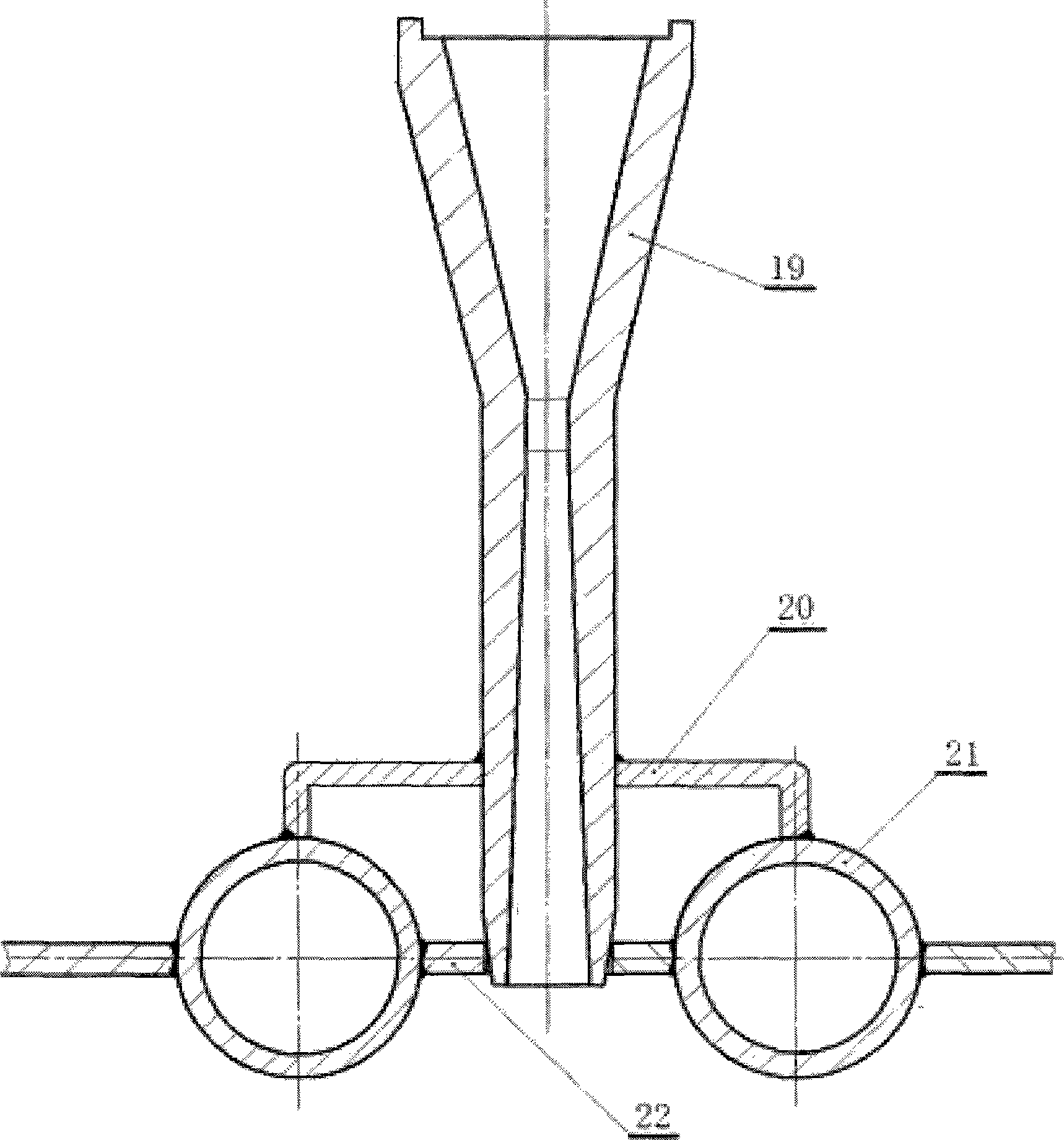

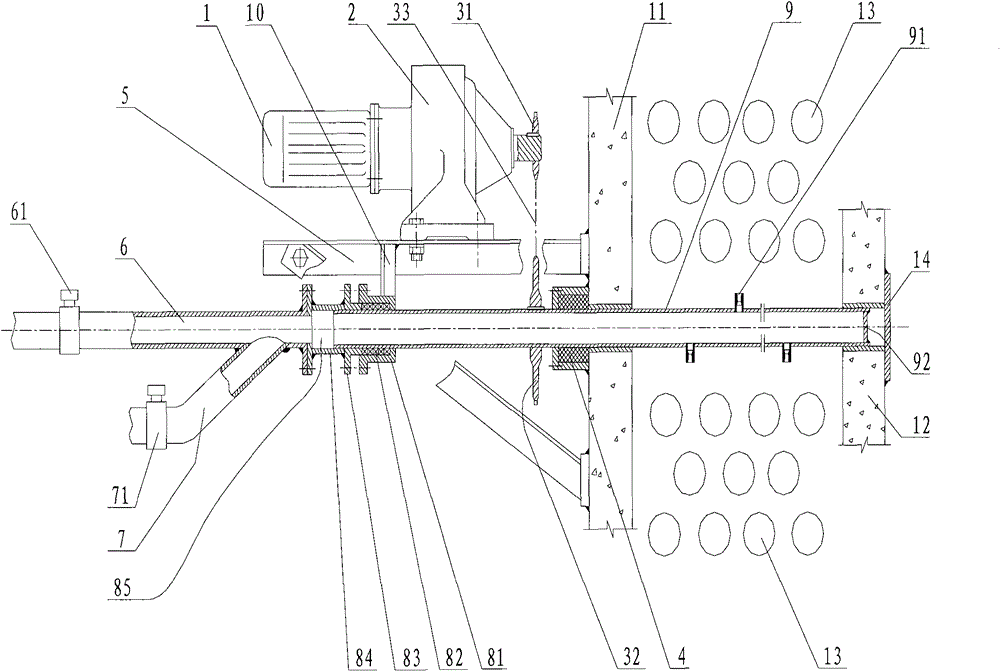

Soot blower

ActiveCN101876447AEasy to peel offReduce the degree of cohesive dust accumulationSolid removalAir preheaterEngineering

The invention discloses a soot blower. The invention aims to solve the problem that the existing soot blower and soot remover spray system can not well clean adhesive soot deposited on furnace tubes in a convection section of a tube heating furnace and heat exchange tubes in an air preheater. The soot blower of the invention is provided with an air intake system, a transmission system, a soot blowing tube (93) and a bracket (5), wherein the soot blowing tube is provided with two rows of soot blowing nozzles (94) in the axial direction, and a soot remover spray tube (91) is coaxially arranged in the soot blowing tube; the soot remover spray tube is axially provided with two rows of soot remover nozzles (92), and the upper part of each soot remover nozzle extends out of the wall of the soot blowing tube; each soot remover nozzle row and the corresponding soot blowing nozzle row are in the same row, and the soot blowing nozzles and soot remover nozzles in each row are alternately arranged; and the air inlet section of the soot blowing tube is provided with an air inlet (95). The invention is mainly used in tube heating furnaces in the fields of petroleum refining and petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-dust smoke SCR (selective catalytic reduction) denitrification device applied to cement kiln

InactiveCN105498531AConsistent flow rateUniform velocity distributionGas treatmentDispersed particle separationAmmoniaCement kiln

The invention provides a high-dust smoke SCR (selective catalytic reduction) denitrification device applied to a cement kiln. The device comprises an inlet flue, an ammonia injection grid, a connecting flue, a flow equalizing-guiding plate, a rectification grid, a reactor shell, a catalytic layer, a combined soot blower and an outlet flue. The inlet flue, the connecting flue, the reactor shell and the outlet flue are sequentially connected along the smoke direction; the ammonia injection grid is arranged on the inlet flue; the flow equalizing-guiding plate and the rectification grid are both arranged in the connecting flue; the rectification grid is positioned below the flow equalizing-guiding plate; the catalytic layer is arranged in the reactor shell; the combined soot blower is positioned in the corresponding position of the reactor shell. The high-dust smoke SCR denitrification device applied to the cement kiln has the advantages that the denitrification efficiency under the high-dust smoke characteristics can be guaranteed, the ammonia escape is reduced, and the blockage of the catalytic layer is prevented.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

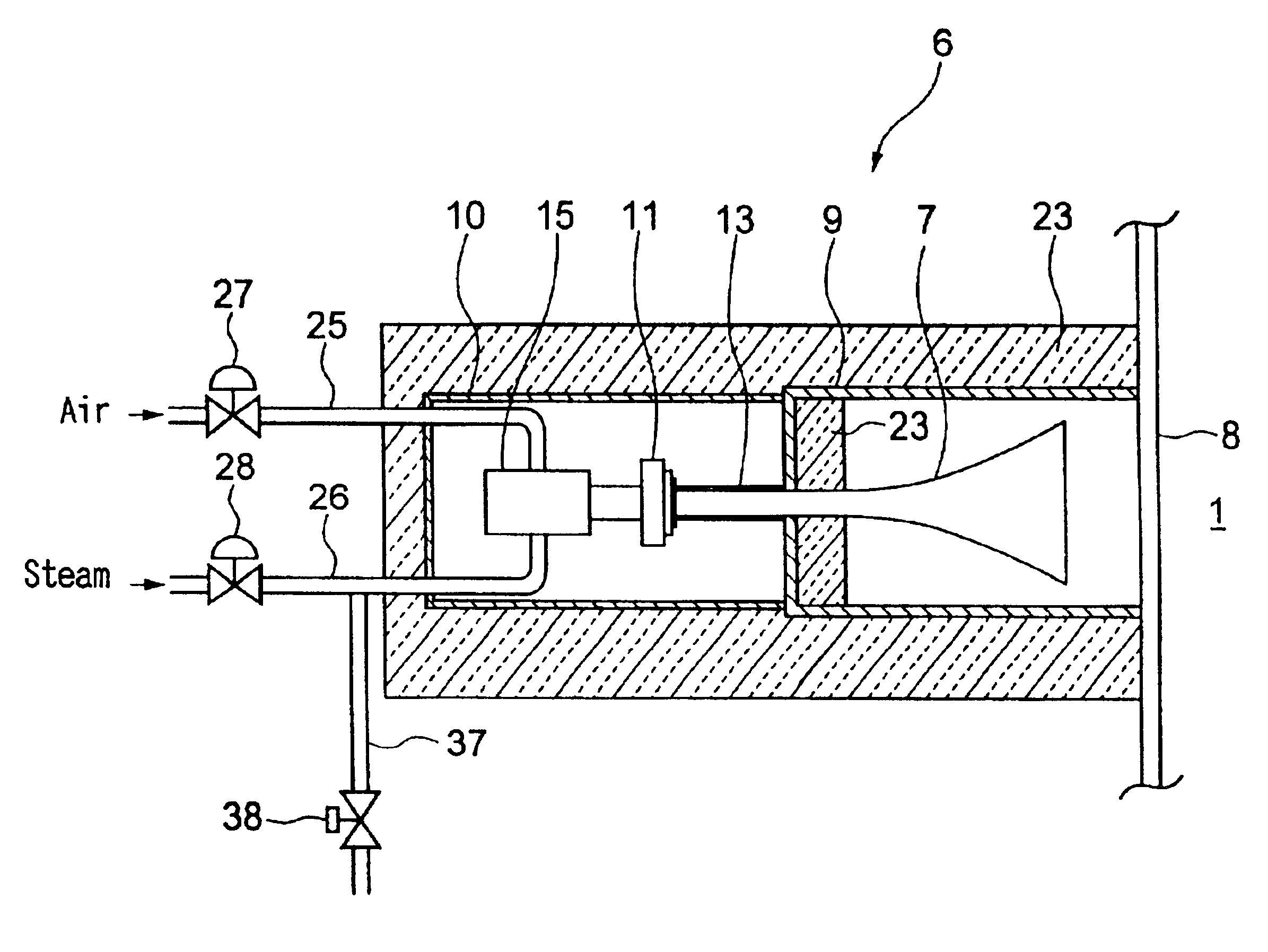

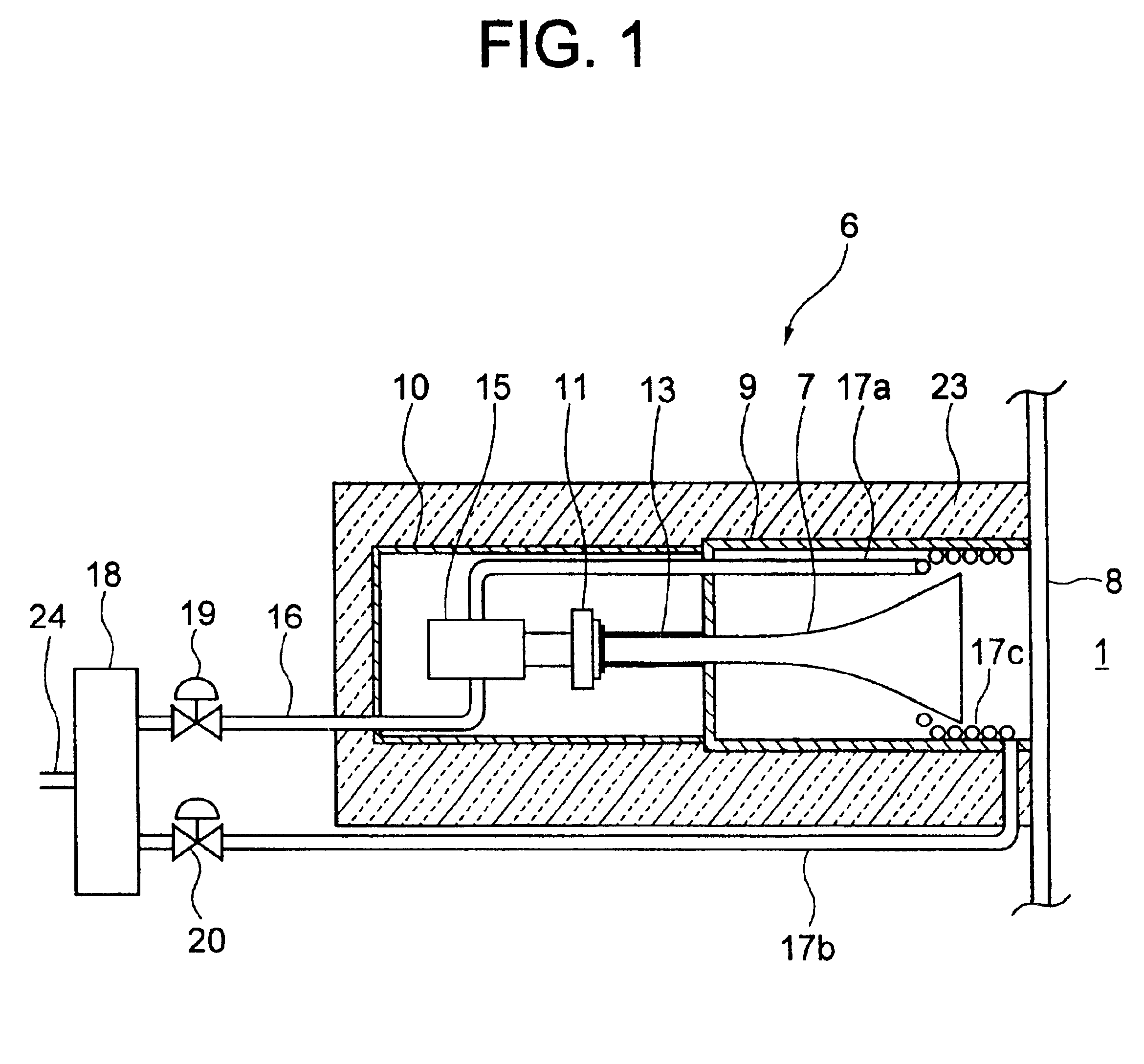

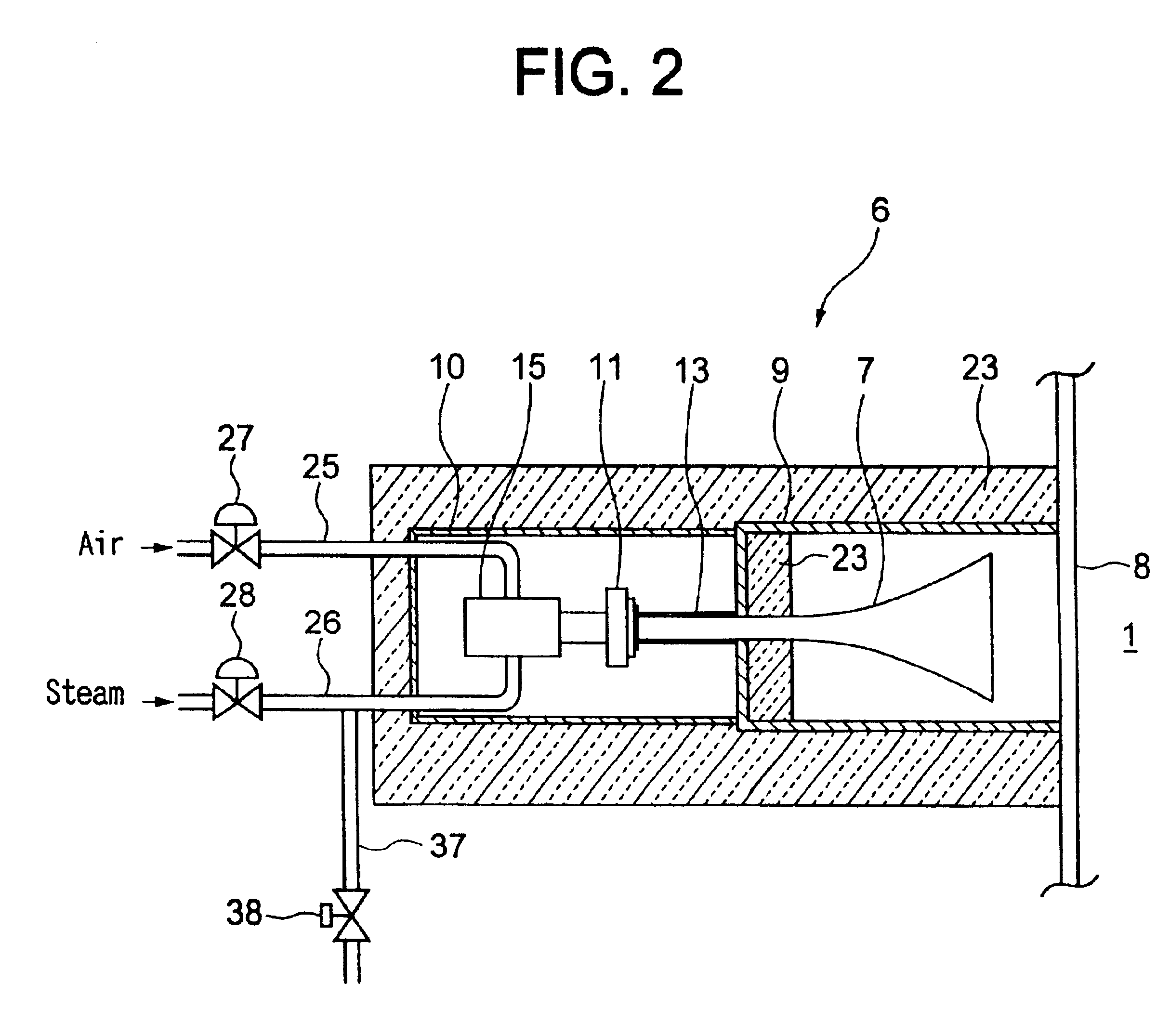

Acoustic soot blower, and method for operating the same

The sonic soot blower includes a sonic wave oscillator that oscillates sonic waves by compressed air or steam, a frequency-regulating portion that varies the frequencies of the sonic waves oscillated by the above-described sonic wave oscillator, a resonance tube that resonates the oscillated sonic waves, and a horn that amplifies the same, wherein powdery dust adhered to members installed inside a boiler furnace, etc., are removed, and are prevented from adhering to the above-described members. The above-described frequency-regulating portion is a gas mixer which is connected to the upstream side of the sonic wave oscillator and is provided with two or more gas conducting flow channels for conducting a compressive gas whose temperatures and / or densities are different from each other, or a slide mechanism that varies the length of the above-described resonance tube. Since the sonic soot blower is able to oscillate sonic waves while regulating the oscillation frequency so as to be suited to the operating conditions of the boiler, it becomes possible to effectively remove ash from the heat transmission tubes and to effectively prevent the same from adhering thereto over a wide range of operating conditions of soot blower-installed equipment (such as a boiler).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

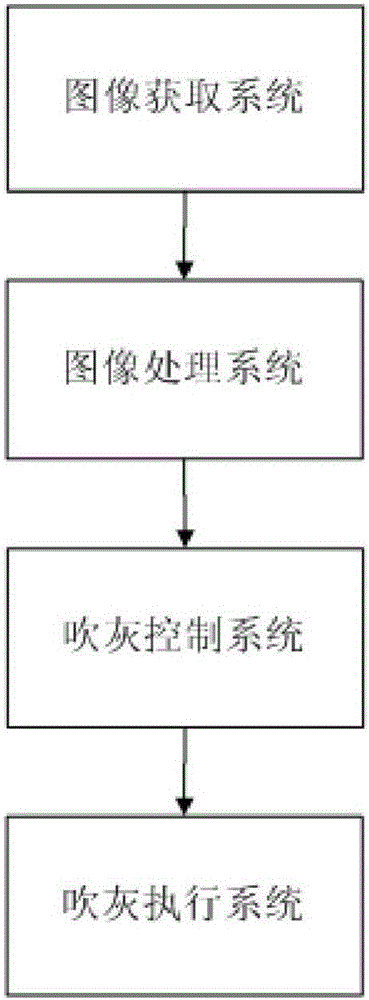

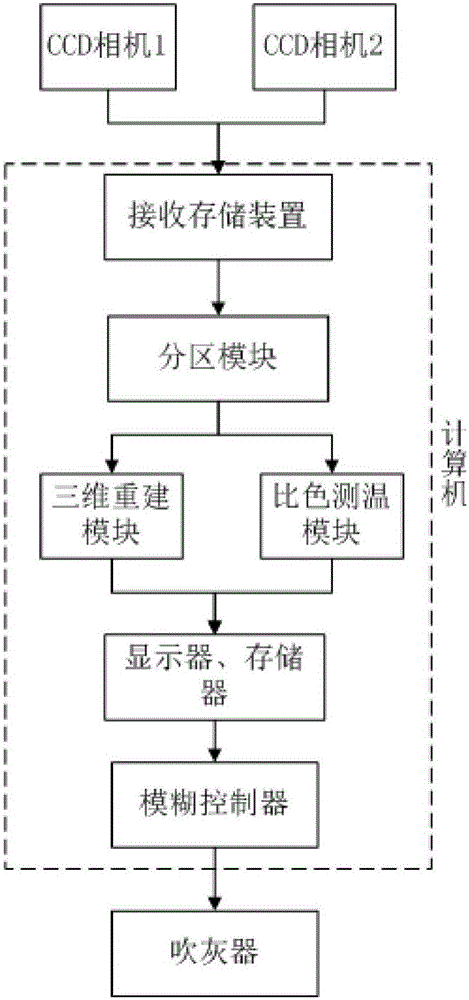

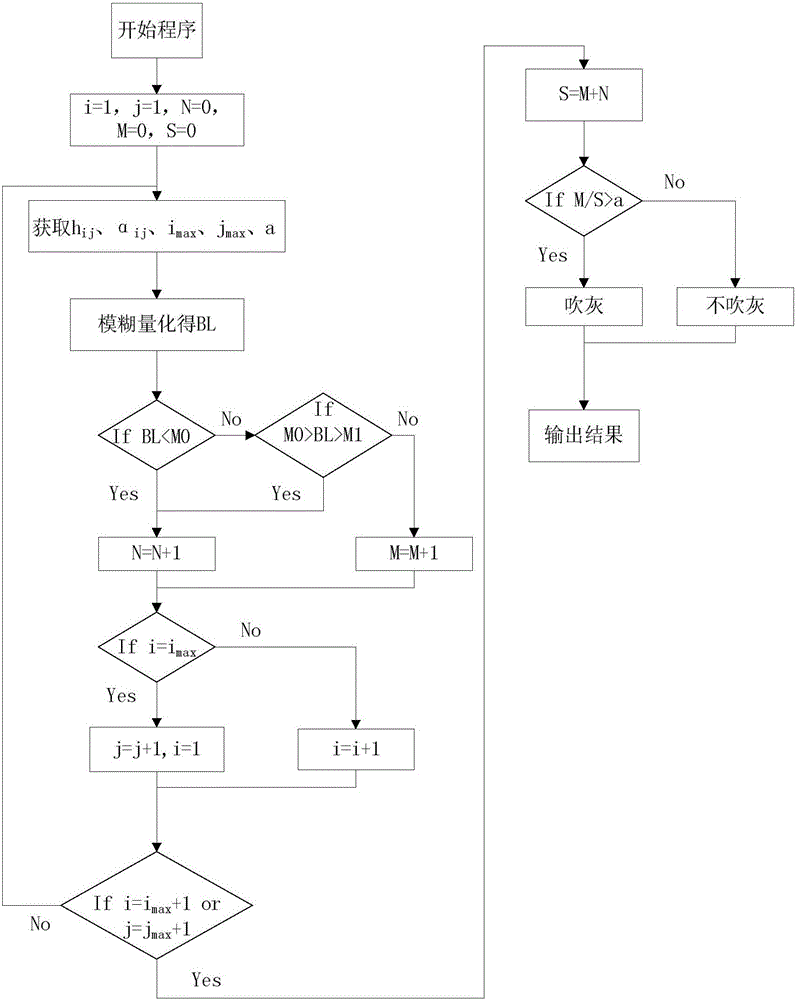

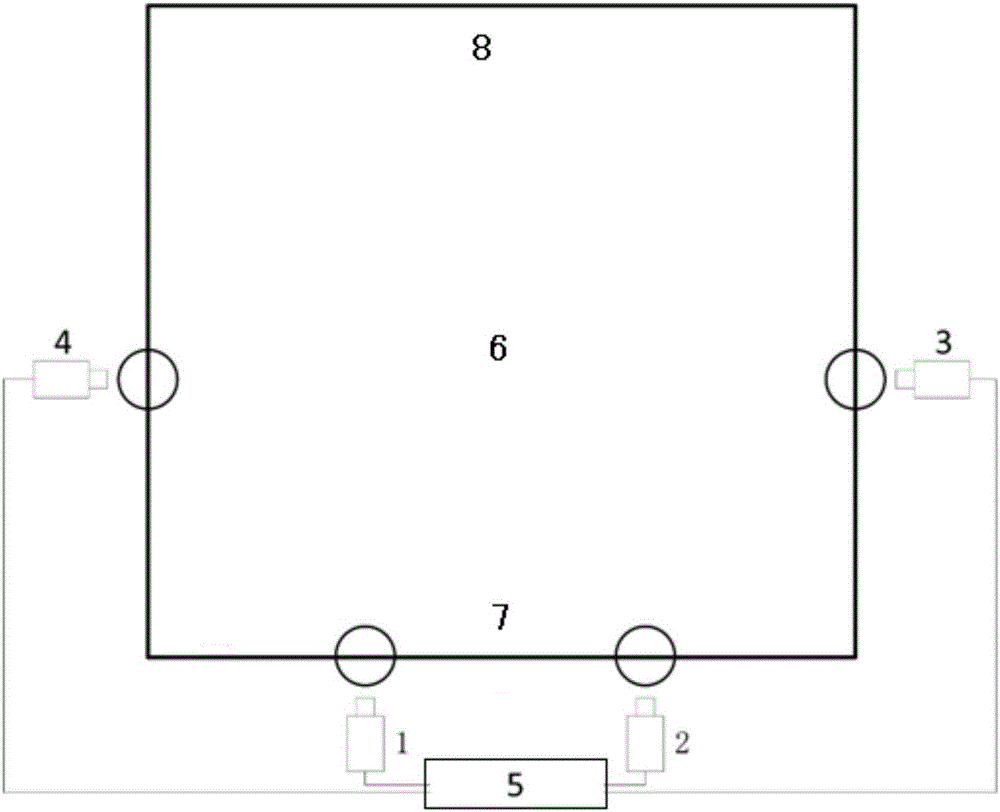

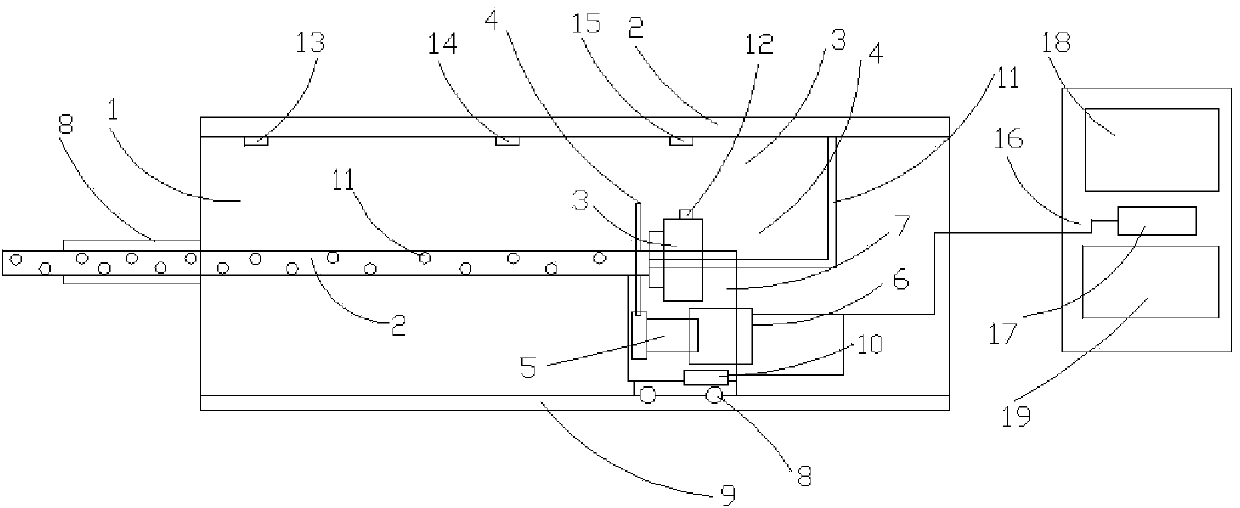

CCD-based intelligent soot blowing system for formed soot and bonded slag on boiler heating surface

ActiveCN106093062AGet thickness in real timeEliminate environmental problemsLighting and heating apparatusOptically investigating flaws/contaminationImaging processingBoiler furnace

The invention discloses CCD-based intelligent soot blowing system for formed soot and bonded slag on a boiler heating surface. The system comprises an image acquiring system, an image processing system, a soot blowing controlling system and a soot blowing executing system; the image acquiring system is arranged on a boiler wall and used for acquiring two-dimensional images and transmitting and storing the images to a computer through a receiving and storing device; the image processing system is used for conducting three-dimensional reconstruction and colorimetric temperature measurement on the two-dimensional images to obtain the thickness of a soot slag layer and the relative temperature of the heating surface; the soot blowing controlling system is used for conducting fuzzy processing on the thickness of the soot slag layer and the relative temperature of the heating surface and sending out an instruction; the soot blowing executing system conducts targeted intelligent soot blowing according to the instruction. According to the system, the heating surface is partitioned according to a soot blower, the thickness of the soot slag layer and the relative temperature of the heating surface are taken as input variables of fuzzy control, and therefore the whole boiler heating surface is accurately monitored; soot blowing is conducted on the local heating surface as needed, therefore, soot blowing loss is reduced, and the overall heat efficiency of a boiler is improved.

Owner:SOUTH CHINA UNIV OF TECH

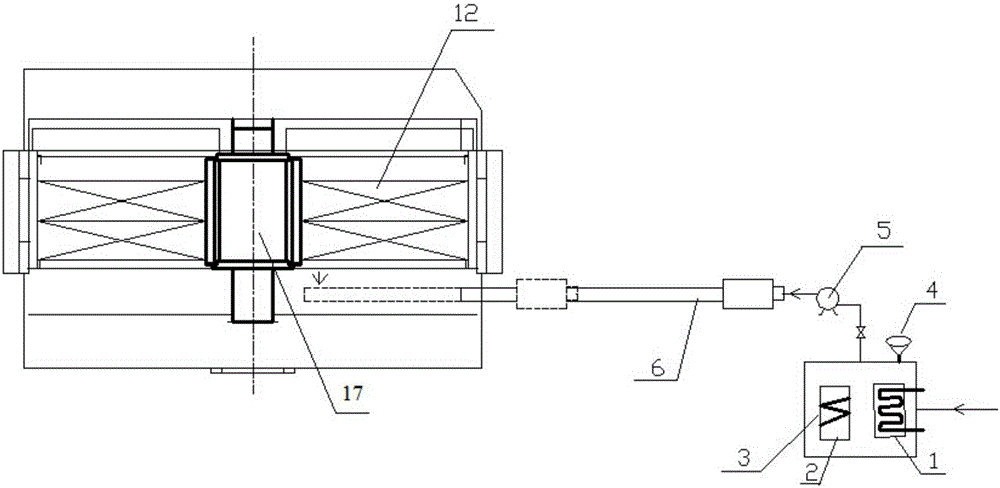

High-pressure-head low-flow non-isolated online cleaning device for rotary air preheater

InactiveCN105758253AReduce uneven expansionLower smoke temperatureFlush cleaningSolid removalAir preheaterElectricity

The invention provides a high-pressure-head low-flow non-isolated online cleaning device for a rotary air preheater.The device comprises a steam heating device, an electric heating device, a water tank, an agentia adding device, a high-pressure water pump and a soot blower, wherein the water tank, the agentia adding device, the high-pressure water pump and the soot blower are sequentially connected, and the steam heating device and the electric heating device are both arranged in the water tank.The device is simple in structure, convenient to implement, small in influence on unit operation, and capable of efficiently cleaning a heat exchanging element of the rotary air preheater under the online non-isolated condition.

Owner:GUODIAN SCI & TECH RES INST +1

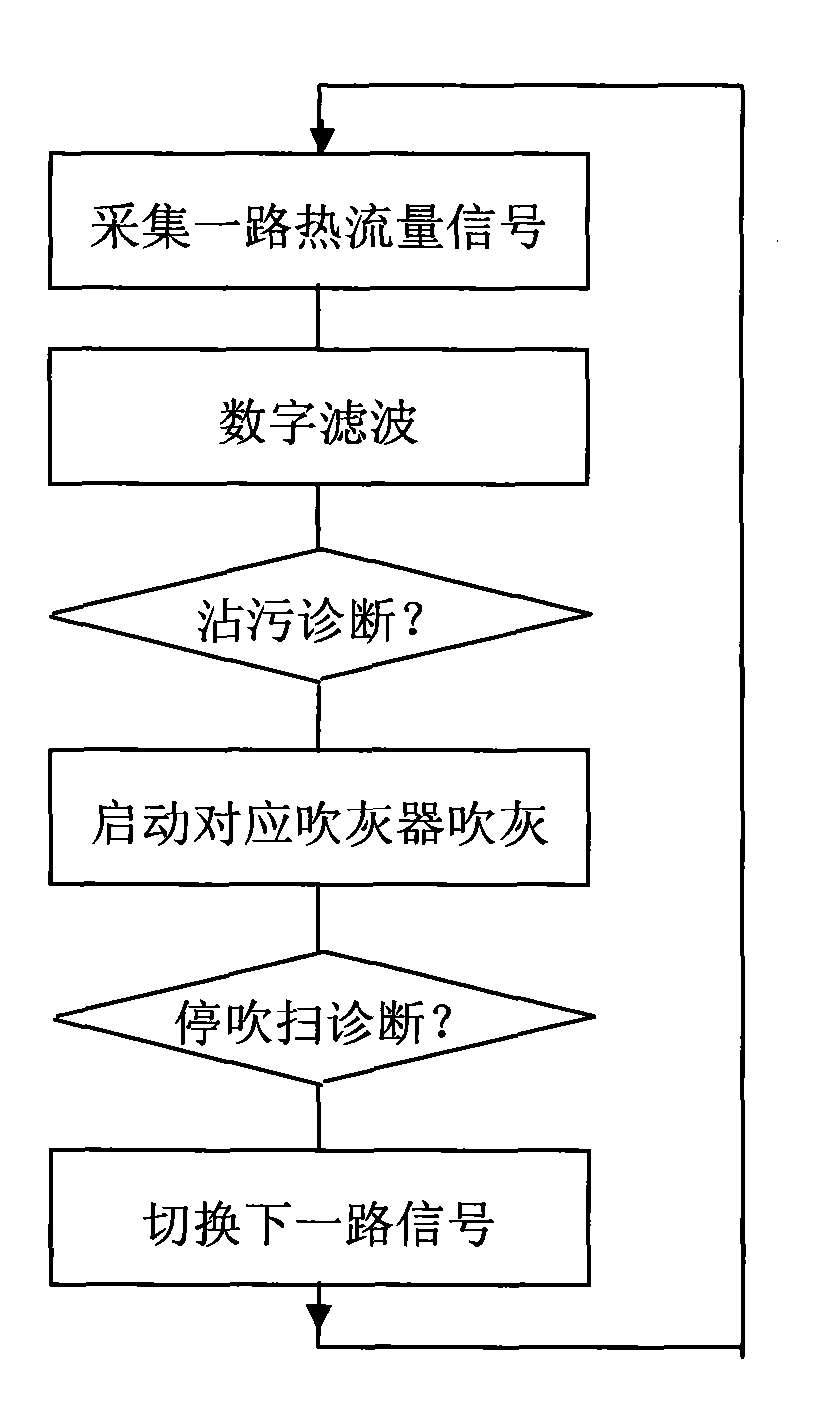

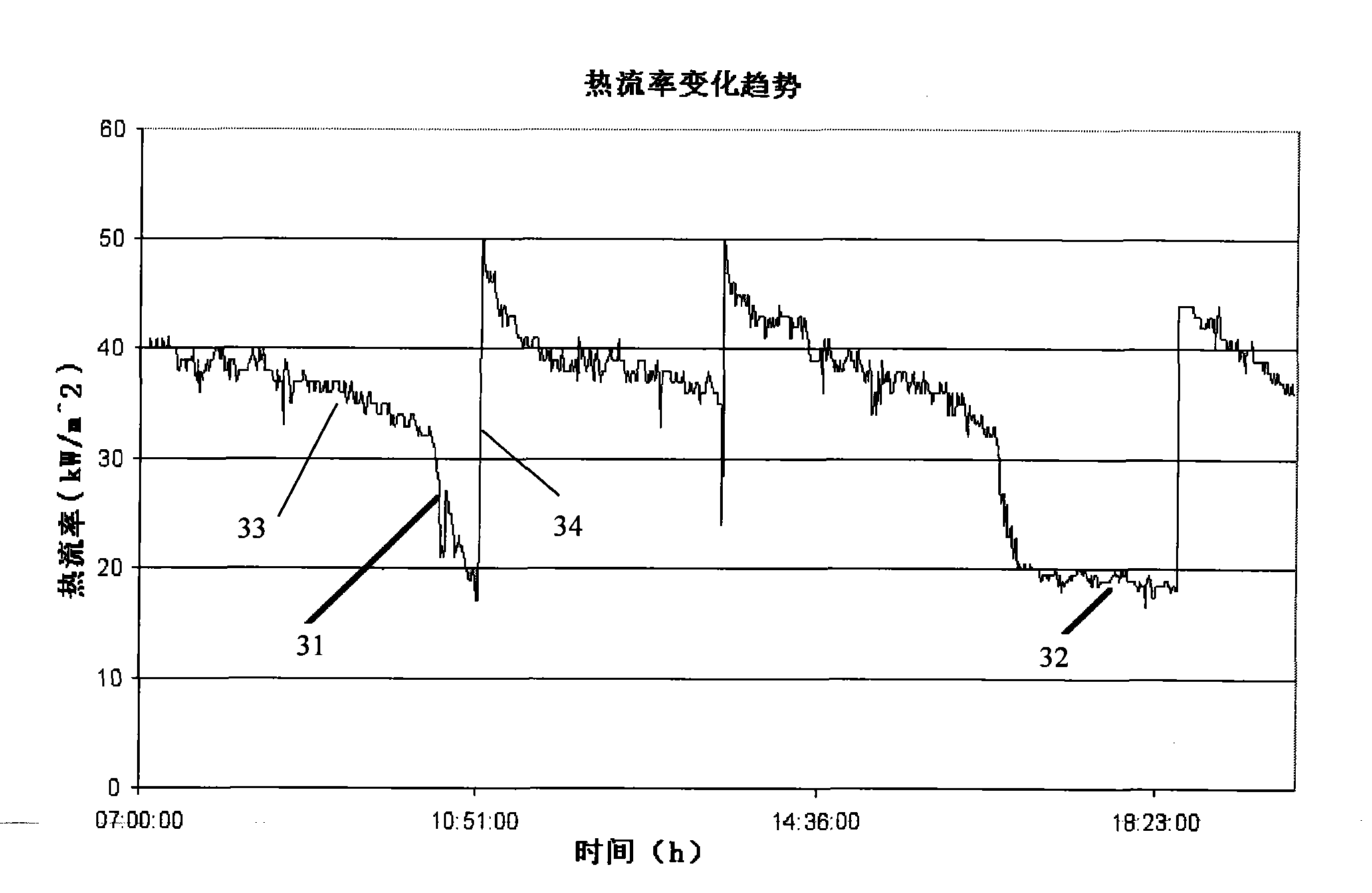

Soot-blowing control device and method for boiler furnace based on heat flow online measurement

InactiveCN101975400AImprove accuracyImprove real-time performanceBoiler controlData acquisitionEngineering

Owner:SOUTHEAST UNIV

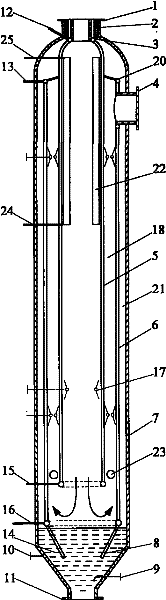

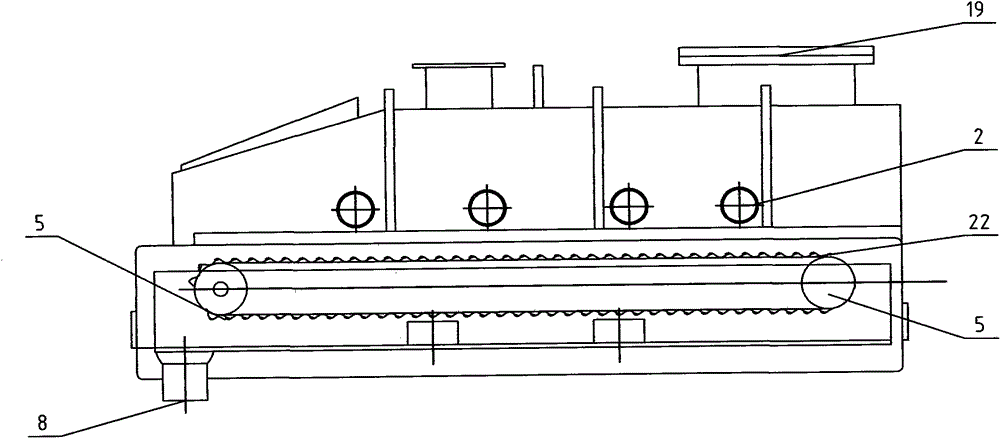

Soot blower

The invention discloses a soot blower in order to solve the problems that the existing soot blower has higher operating failure rate, unreachable blowing area and poor blowing effect. The transmission system of the soot blower of the invention comprises a motor, a reducer and a chain transmission device, wherein the reducer is particularly a cycloidal pin-wheel reducer. The soot blower is provided with an internal soot blower and an external soot blower, and an internal soot blower nozzle and an external soot blower nozzle are arranged on the internal soot blower and the external soot blower respectively; the inclined section of the internal soot blower nozzle is arranged in a way that the inclined section thereof is inclined relative to the axis of the soot blower; an air inlet is formed on the inlet section of the external soot blower; the air inlet system of the soot blower is provided with an air inlet tube, and a second air inlet chamber arranged in the middle of the air inlet tube is communicated with the air inlet and a second air inlet pipe; a first air inlet chamber is arranged at the end part of the inlet section of the internal soot blower and communicated with the end part of the inlet section of the internal soot blower and the first air inlet pipe; a first electromagnetic valve is arranged on the first air inlet pipe; and a second electromagnetic valve is arranged on the second air inlet pipe. The invention is mainly applicable to tubular heating furnaces in the field of petroleum refining and petroleum chemical engineering.

Owner:CHINA PETROCHEMICAL CORP +1

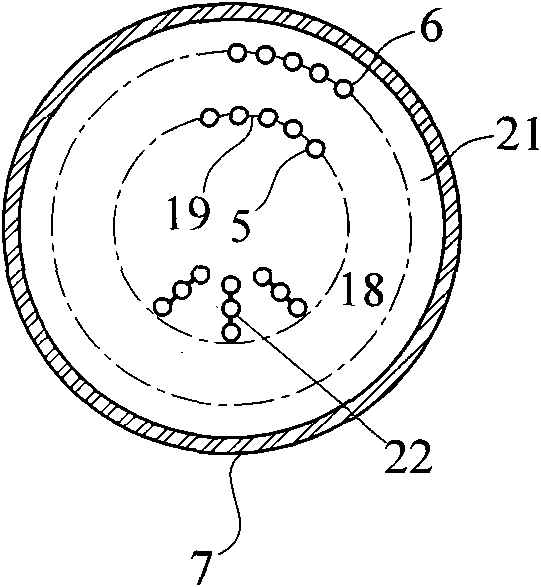

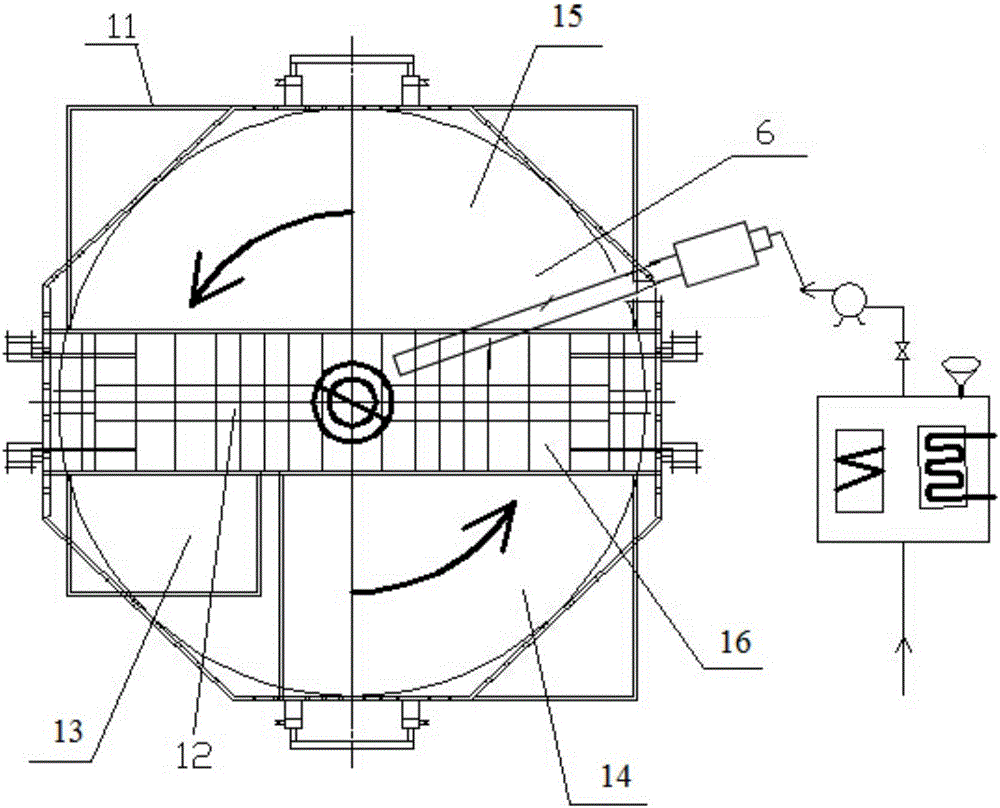

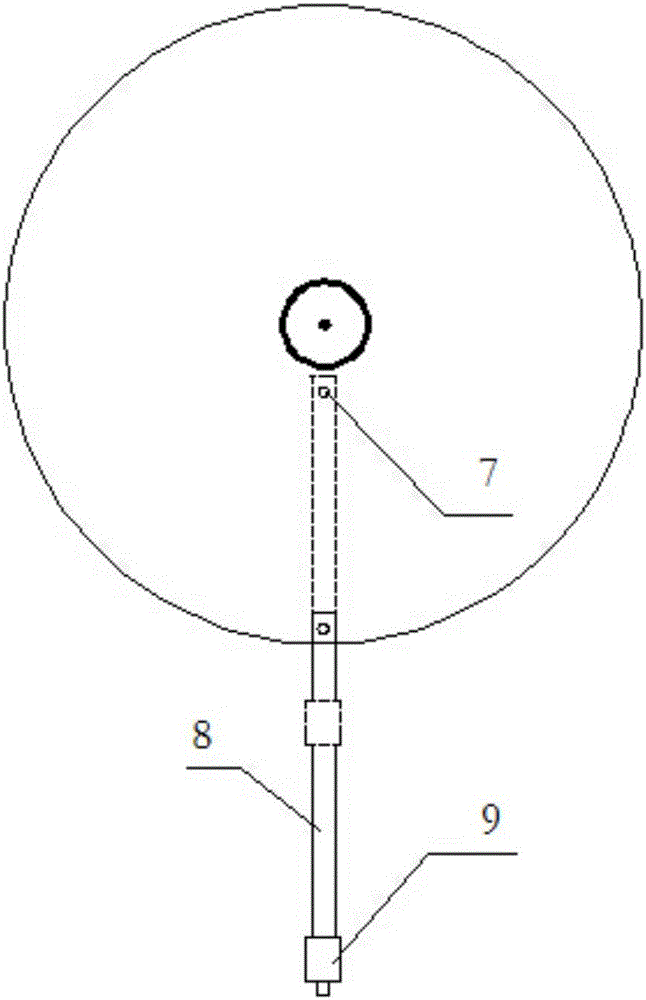

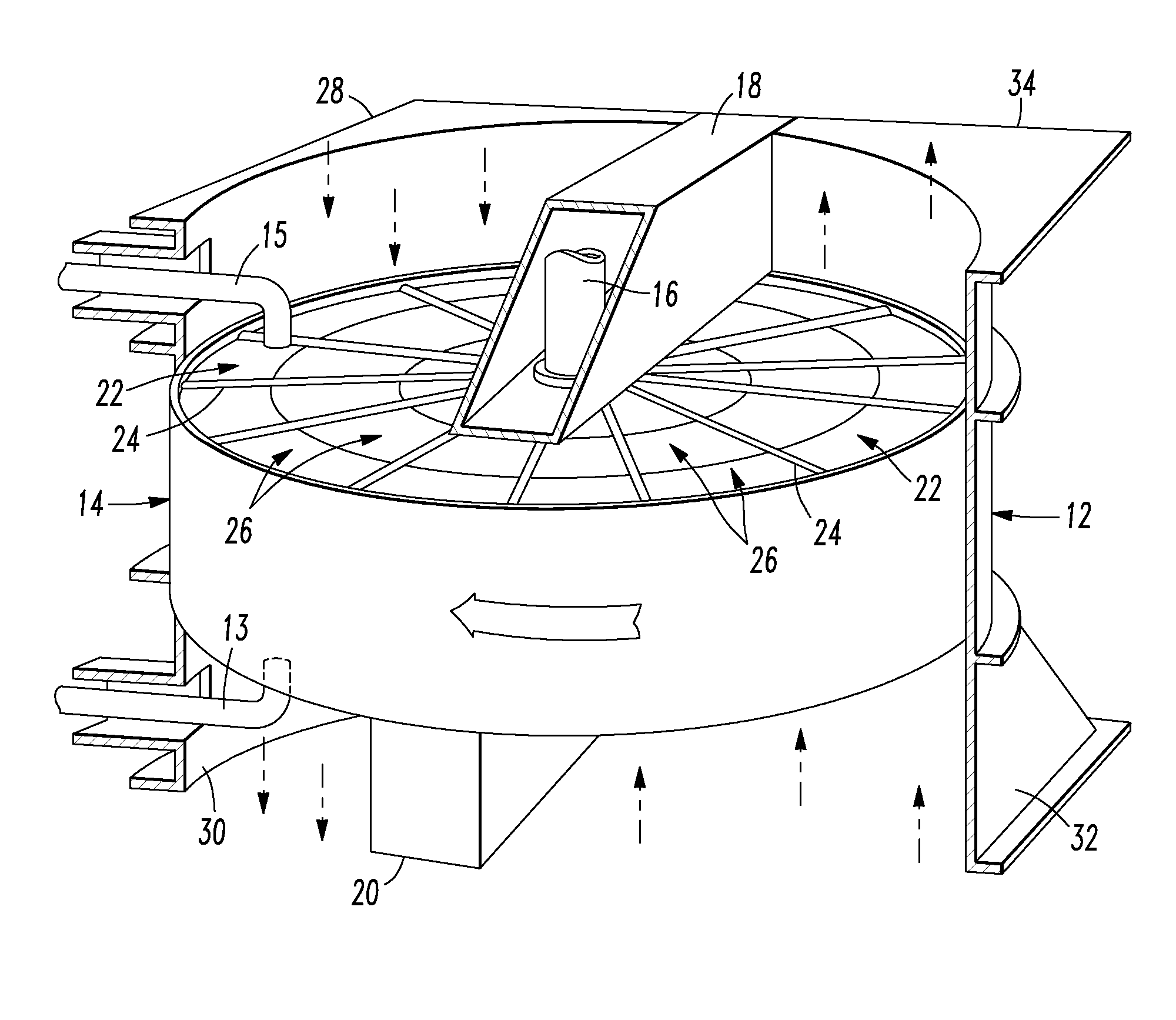

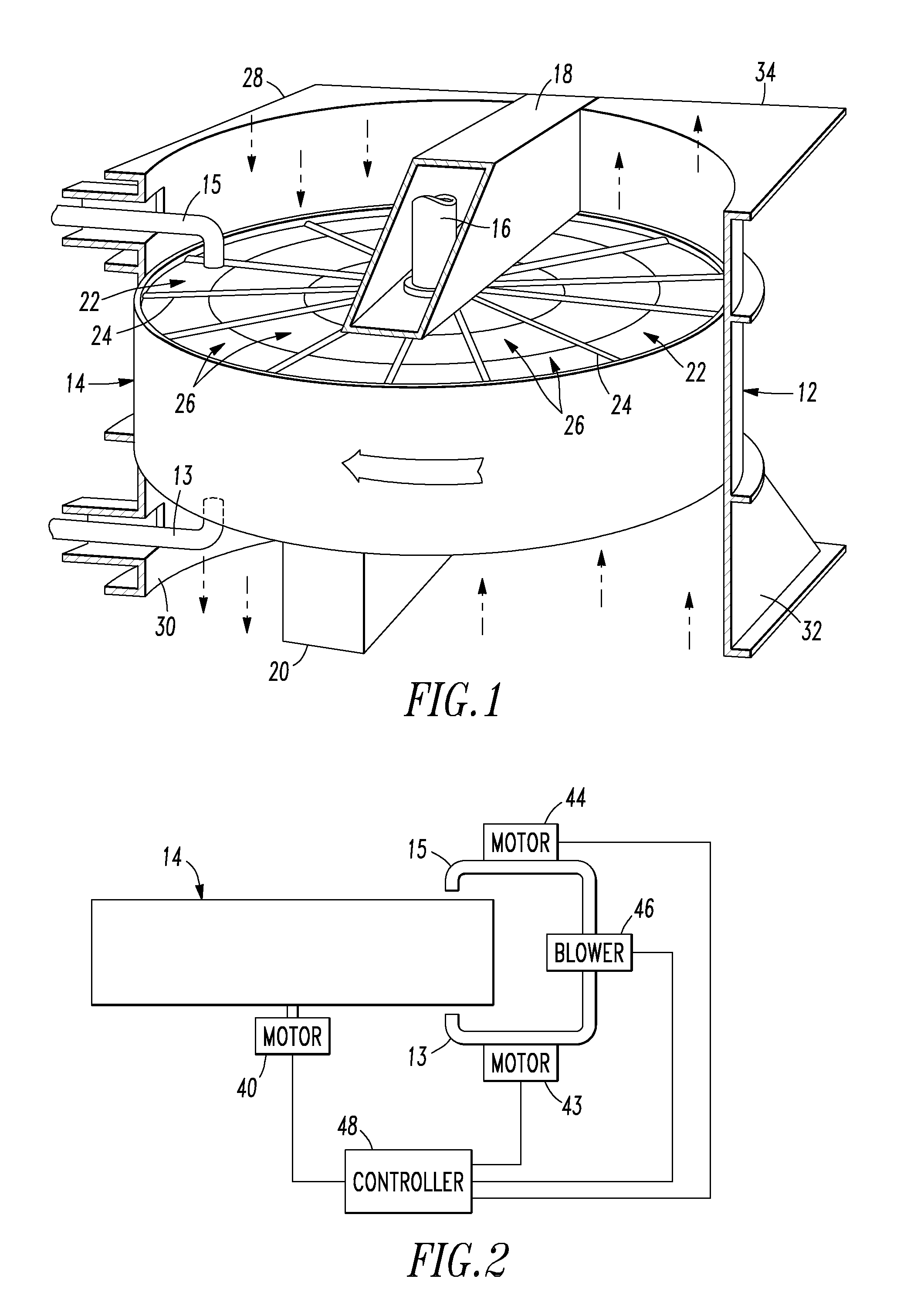

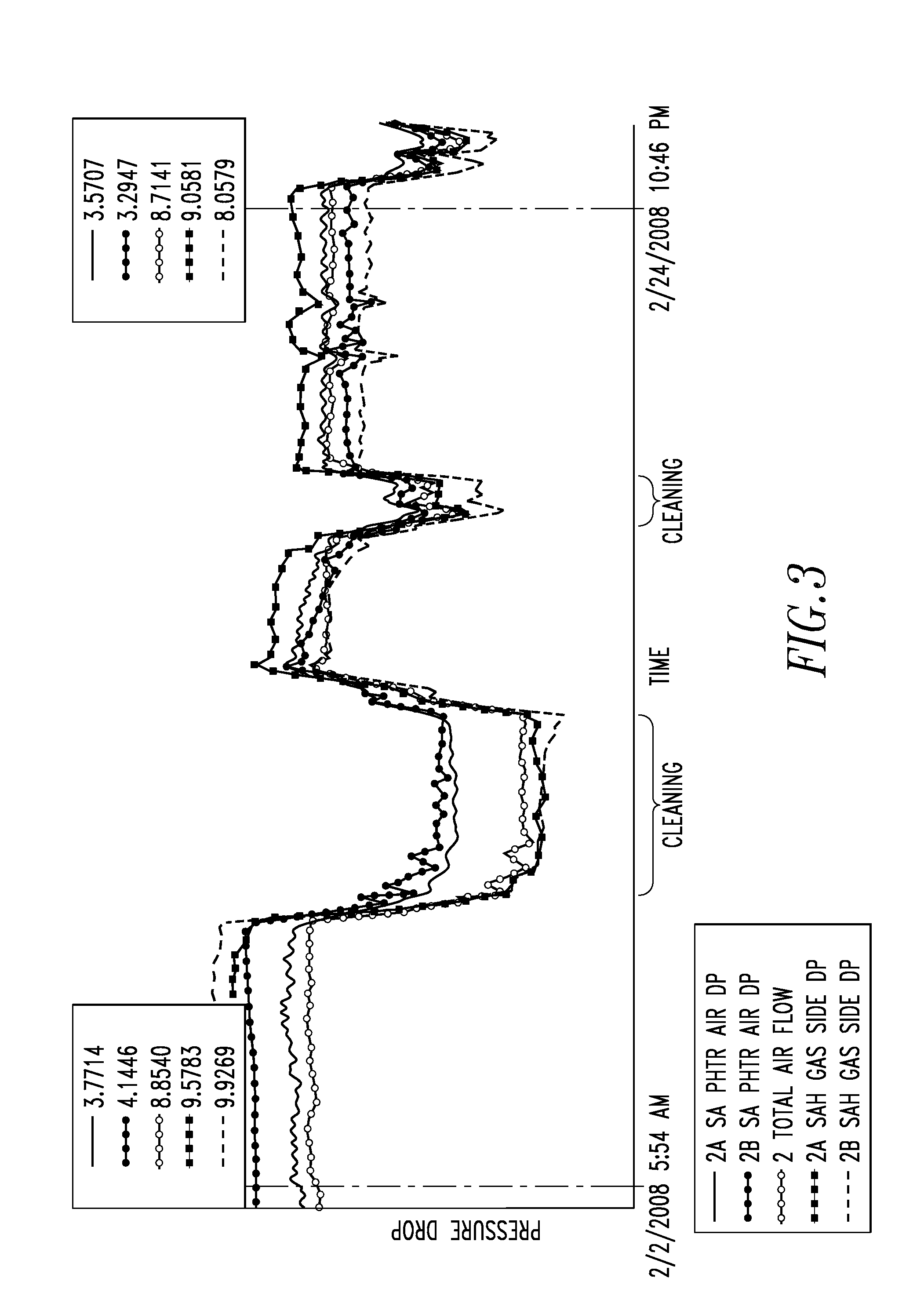

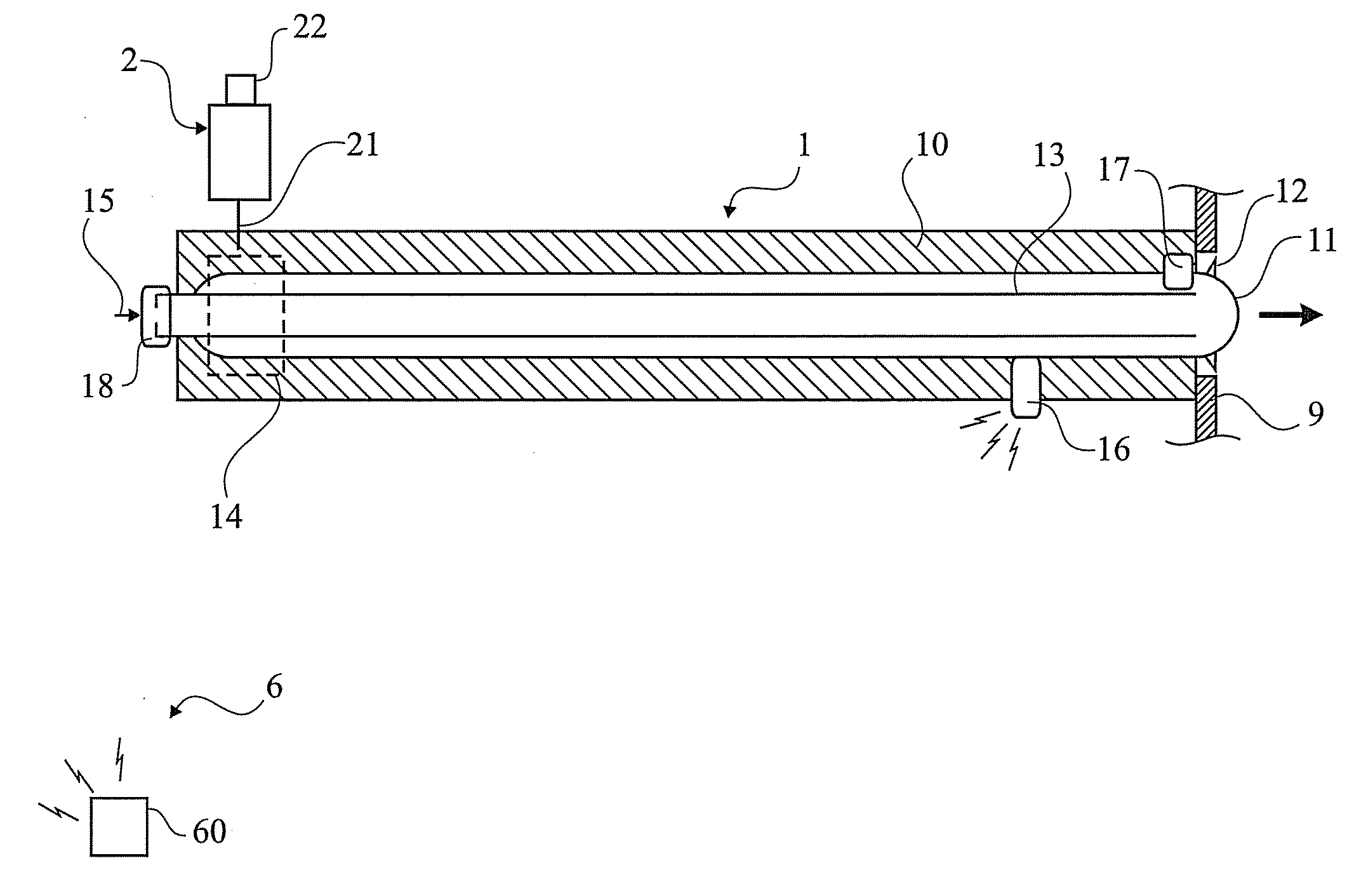

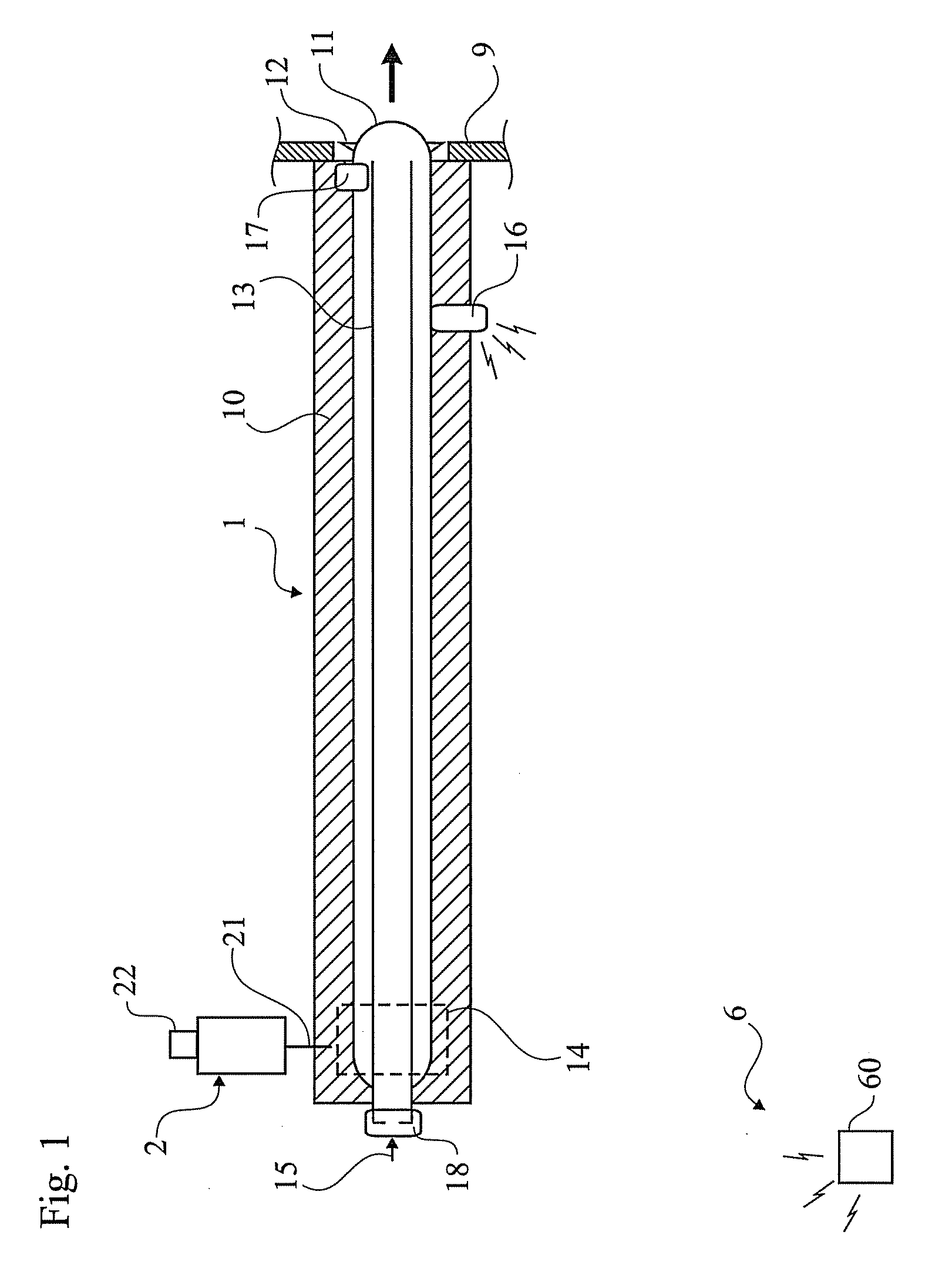

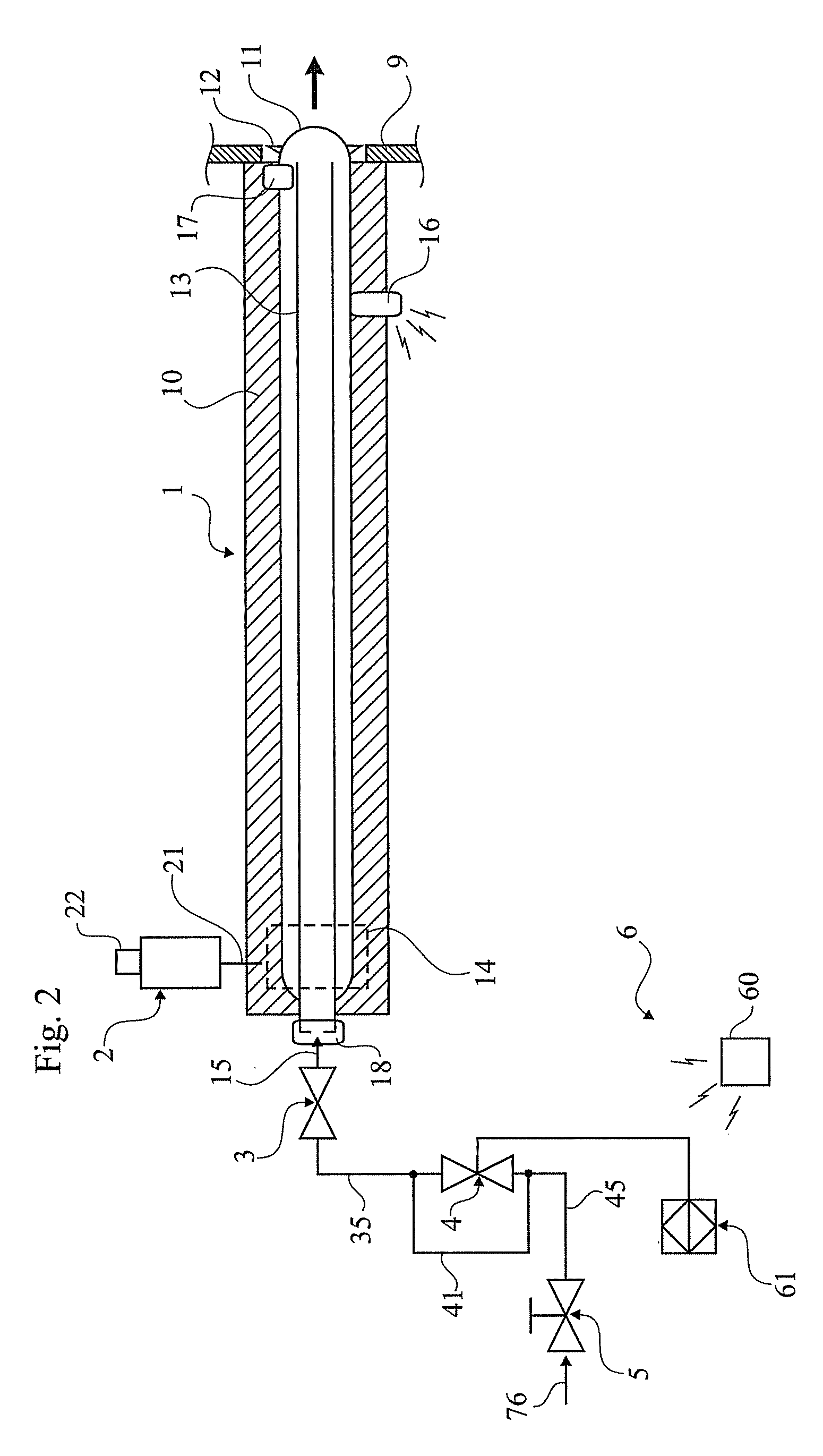

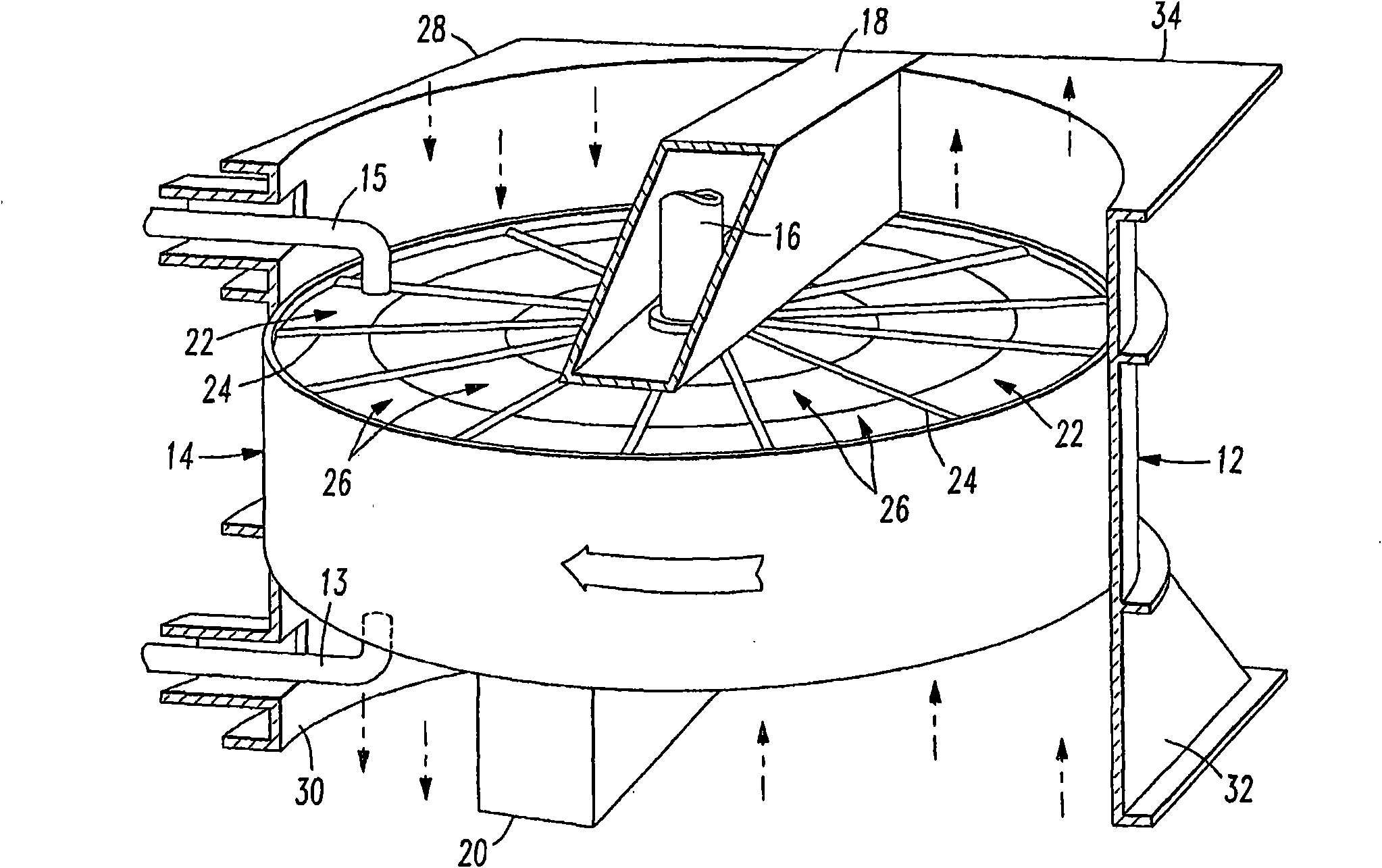

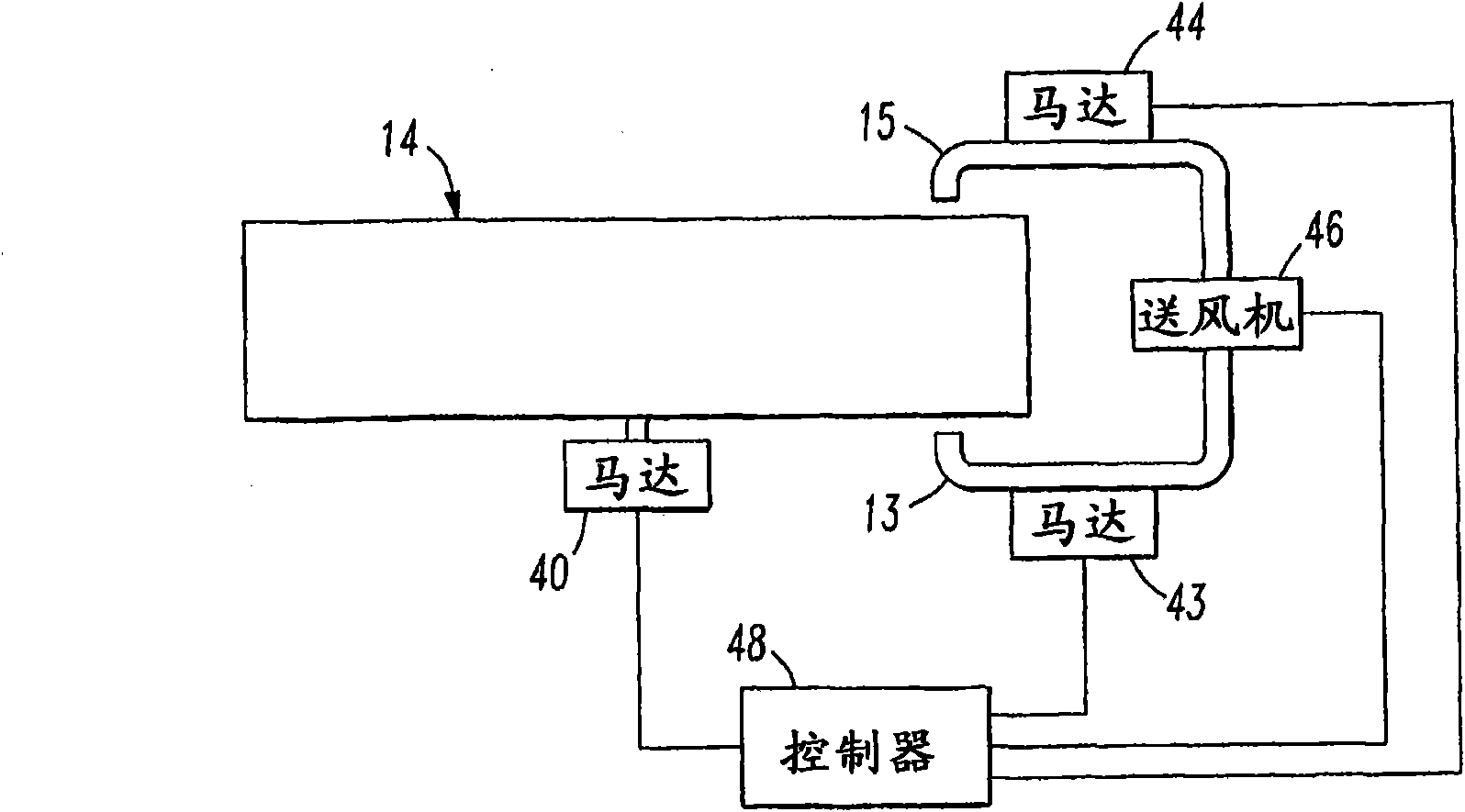

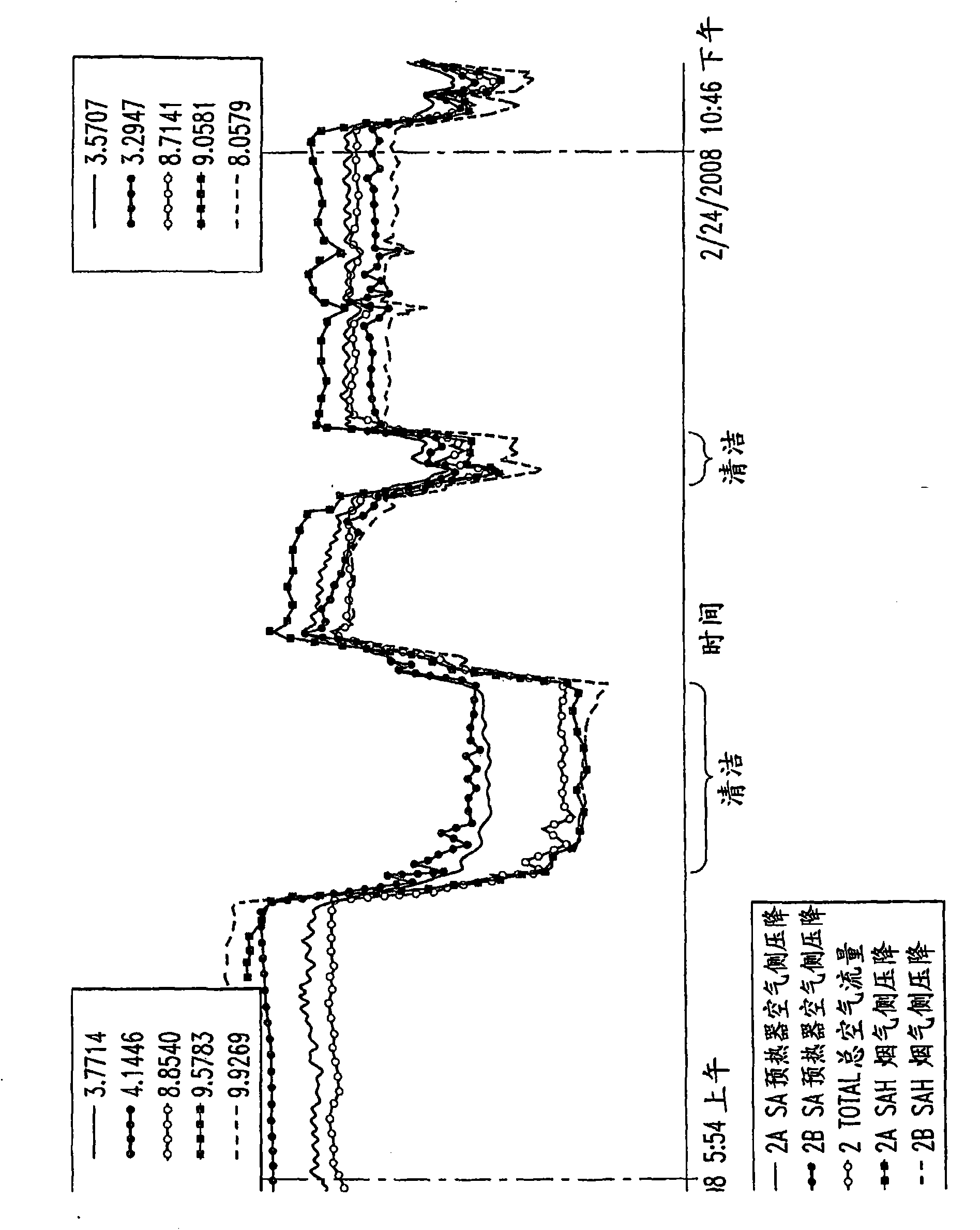

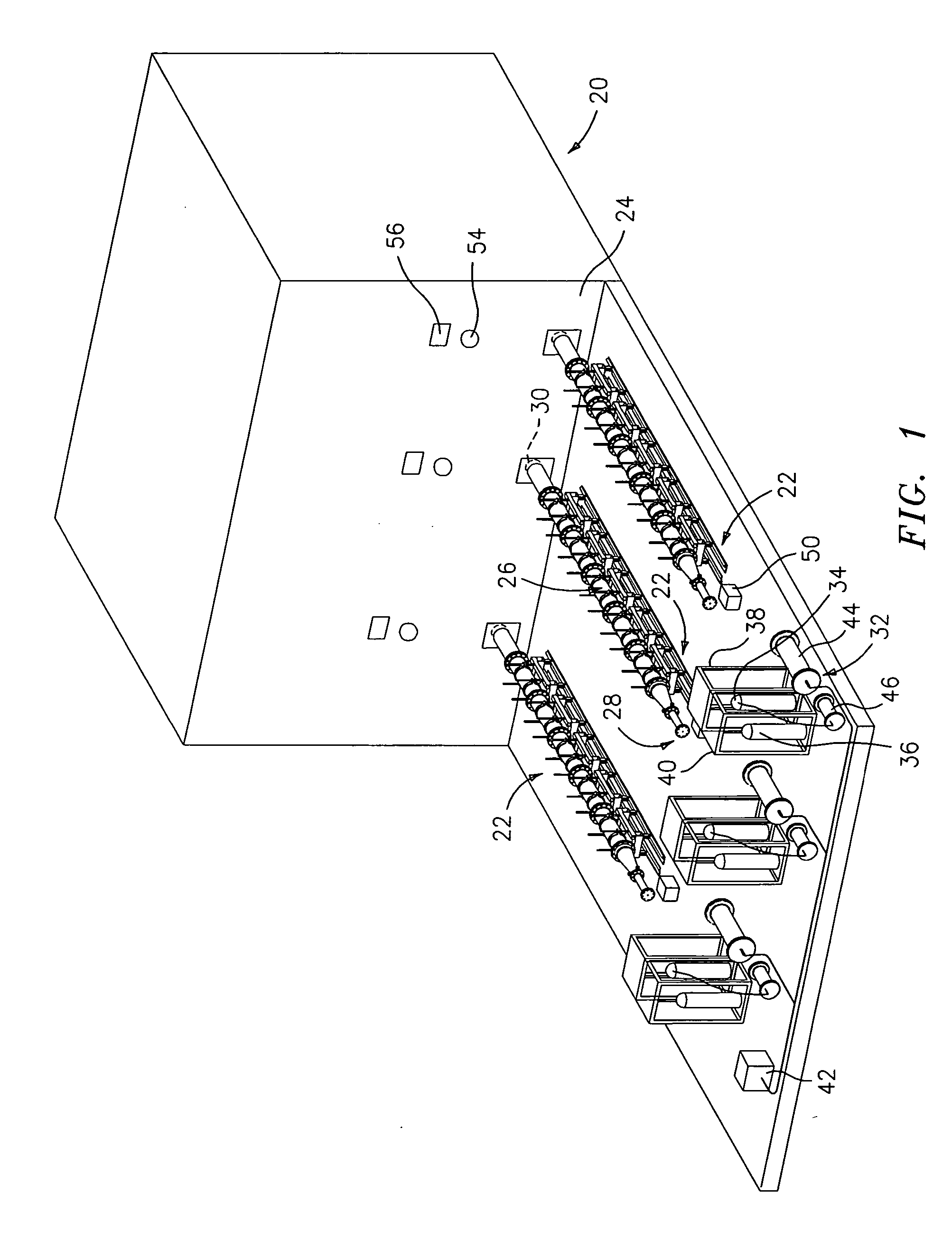

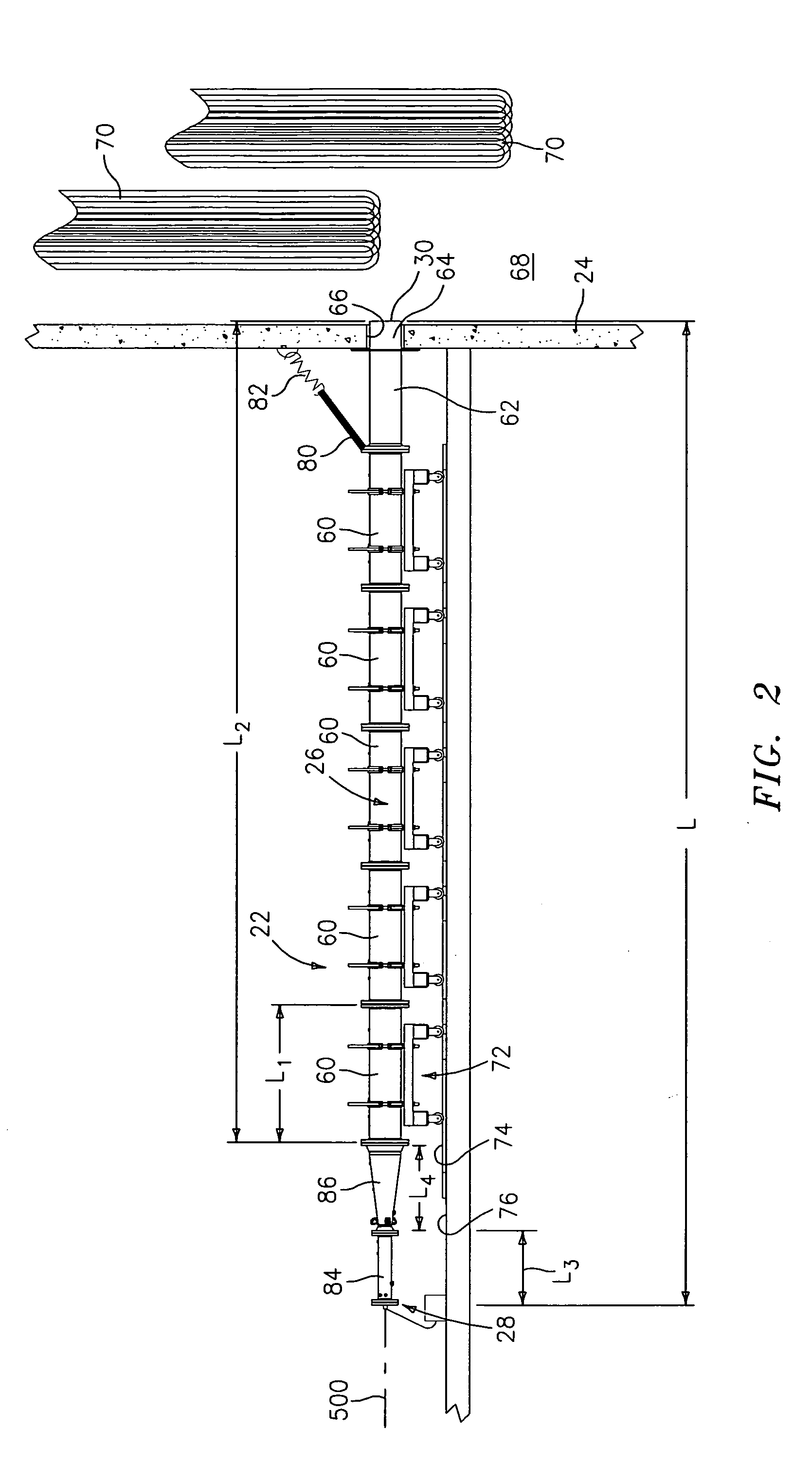

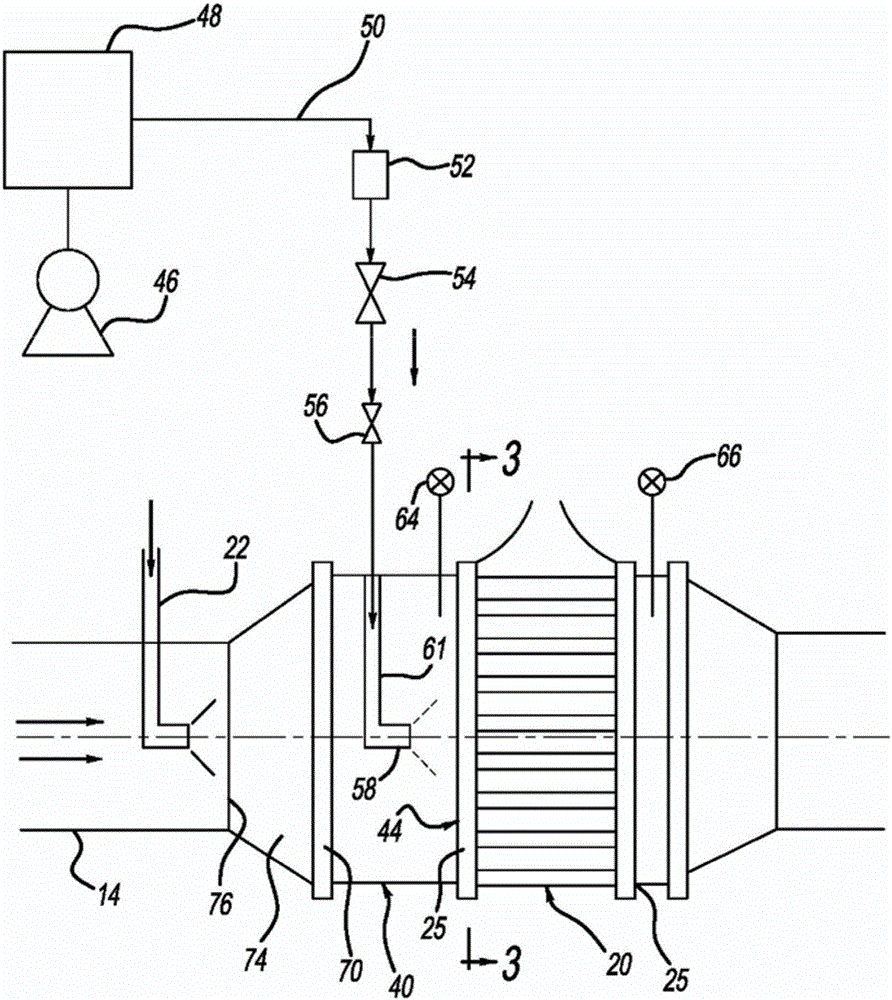

Method for Online Cleaning of Air Preheaters

InactiveUS20110005706A1Reduced accumulation of depositReduce accumulationCombustion processFlush cleaningAir preheaterPresent method

A method of cleaning air preheaters of the type having a rotor which passes through a stream of flue gas and a stream of intake combustion air is disclosed. A soot blower is operated in step-wise fashion to blow a soot blowing medium through passageways in the rotor. The passageways are arranged in concentric rings and move at a tangential velocity which depends on the speed of the rotor and the location of the passageway relative to the center of the rotor. In the present method the speed of the rotor is adjusted in accordance with the position of the soot blower so that every passageway moves over the soot blower at the same or substantially the same tangential velocity.

Owner:BREEN ENERGY SOLUTIONS

Cement kiln flue gas dry desulfurization and high dust SCR denitration device and process

PendingCN109364741AExtend your lifeReduce maintenance costsGas treatmentDispersed particle filtrationFlue gasProcess engineering

The invention relates to a cement kiln flue gas dry desulfurization and high dust SCR denitration device, which comprises a preheater C1 and a preheater C2, a high dust SCR denitration reactor, a waste heat boiler at the cement kiln tail, a high temperature fan and a desulfurizer grinding and conveying system, wherein a desulfurizer dosing device is arranged between a waste heat boiler outlet andthe high temperature fan; the desulfurizer dosing device is connected with the desulfurizer grinding and conveying system; a gas outlet of the preheater C1 is connected with a gas inlet of the high dust SCR denitration reactor; a gas outlet of the high dust SCR denitration reactor is connected with a gas inlet of the waste heat boiler; a double fluid atomization spray gun for a denitration agent ammonia atomization jet is arranged between the preheater C1 of a cement kiln and the preheater C2 of the cement kiln; the high dust SCR denitration reactor comprises a flue gas flow equalizer, a highdust SCR catalyst layer, a soot blower and a catalyst reserve layer; the desulfurizer grinding and conveying system comprises a desulfurizer pulverizer and a Roots blower; and a desulfurizer powder bin is arranged between the desulfurizer pulverizer and the Roots blower.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Method for measuring conditions in a power boiler furnace using a sootblower

ActiveUS20110056313A1Most efficientRecovery can be controlledFurnace componentsMeasurement devicesBoiler furnaceEngineering

The present invention relates to a method for measuring the conditions inside a power boiler wherein a sootblower is used as a measuring probe. The invention also relates to a system for measuring the conditions in a power boiler, comprising a control unit, at least one sensor and a measuring probe placed inside said furnace, wherein said probe is arranged on a soot blower.

Owner:SOOTTECH AB

Eastern-Junggar-coal fired double-reheat steam power plant boiler

InactiveCN104075309ASave huge investmentClear thermostat logicSteam superheatersSteam boilersEngineeringSupersonic speed

The invention discloses an eastern-Junggar-coal fired double-reheat steam power plant boiler, and relates to a double-reheat steam power plant boiler which can be used by a thermal power station for a long time, and is safe, economical, and completely eastern-Junggar-coal fired. A tail flue is divided into a front flue, a middle flue and a rear flue by division walls, and the three flues all adopt structural supports; an ejector primary hot wind regulation baffle opens when the boiler is at middle or lower load, and the opening of the ejector primary hot wind regulation baffle is controlled to enable double reheat steam temperature to be kept at a rated value in the range of 40% to 100% BMCR; sequence and quantity of temperature-regulation air-flue ejectors along the width direction of the boiler are changed, so that thermal deviations of high-temperature heating surfaces along the width direction of the boiler can be compensated and reduced; a strong directional supersonic steam flow soot blower system is arranged on the ceiling, DCS controls continuous soot blowing time and interval time of each supersonic steam flow nozzle set, and thereby the thermal deviation of each high-temperature heating surface can be further compensated; the low thermal deviations effectively relieve the growing process of an oxide skin on the inner side of each high-temperature heating surface, so that operational reliability is significantly improved.

Owner:章礼道

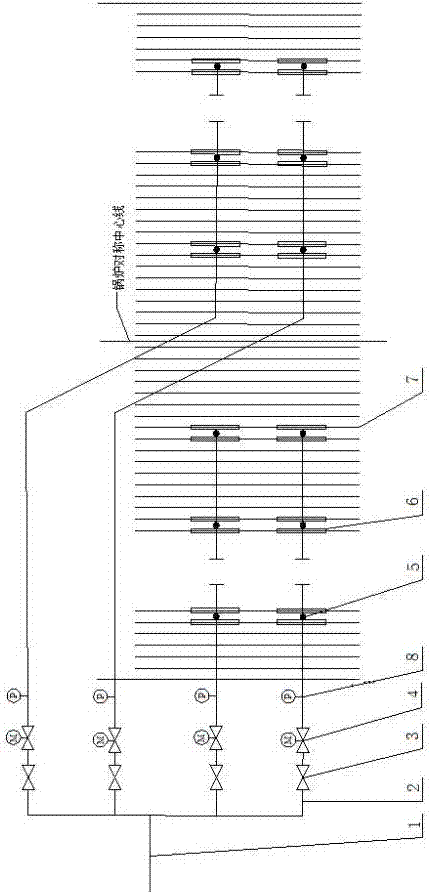

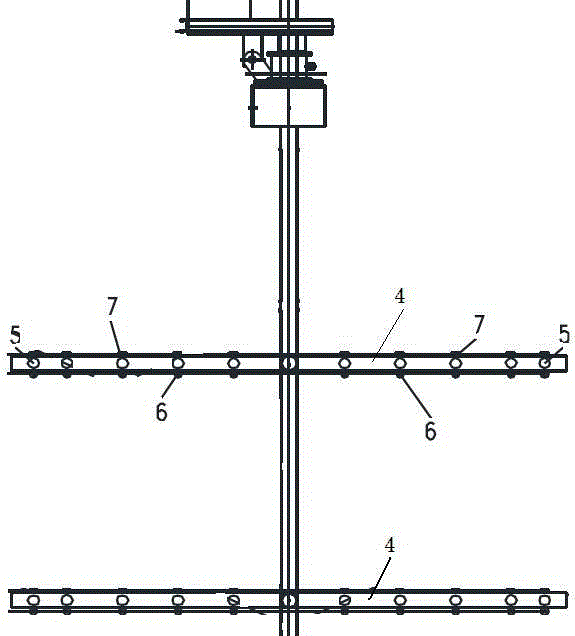

Soot blowing system and method used for boiler horizontal flue

PendingCN107143867ASolve the problem of dust accumulationDust accumulation problem preventionSolid removalEffective solutionEngineering

The invention relates to a soot blowing system and method used for a boiler horizontal flue. The soot blowing system and method are mainly used in a coal-fired boiler. The soot deposition phenomenon is serious at the furnace arch of the coal-fired boiler horizontal flue, and no effective solution exists at present. The soot blowing system comprises a compressed air main pipe and a plurality of soot blowing units. Each soot blowing unit comprises a compressed air branch pipe, a manual brake valve, an electromagnetic valve, a pressure gauge, a plurality of air caps and a plurality of anti-abrasion tiles. The soot blowing system is characterized in that the compressed air branch pipes are connected with the compressed air main pipe; the manual brake valves, the electromagnetic valves and the pressure gauges are all installed on the compressed air branch pipes so that each compressed air branch pipe can achieve the function of blowing soot alone; the manual brake valves, the electromagnetic valves and the pressure gauges are all located outside the boiler; the air caps are directly fixed to two adjacent fins of two adjacent water cooling wall pipes in the boiler; the air caps and the compressed air branch pipes are connected; and the anti-abrasion tiles are installed on the water cooling wall pipes in a sleeving mode. According to the soot blowing system and method used for the boiler horizontal flue, adjusting is convenient, and the soot blowing effect is good.

Owner:HANGZHOU HUADIAN ENERGY ENG

Method for online cleaning of air preheaters

A method of cleaning air preheaters of the type having a rotor which passes through a stream of flue gas and a stream of intake combustion air is disclosed. A soot blower is operated in step-wise fashion to blow a soot blowing medium through passageways in the rotor. The passageways are arranged in concentric rings and move at a tangential velocity which depends on the speed of the rotor and the location of the passageway relative to the center of the rotor. In the present method the speed of the rotor is adjusted in accordance with the position of the soot blower so that every passageway moves over the soot blower at the same or substantially the same tangential velocity.

Owner:BREEN ENERGY SOLUTIONS

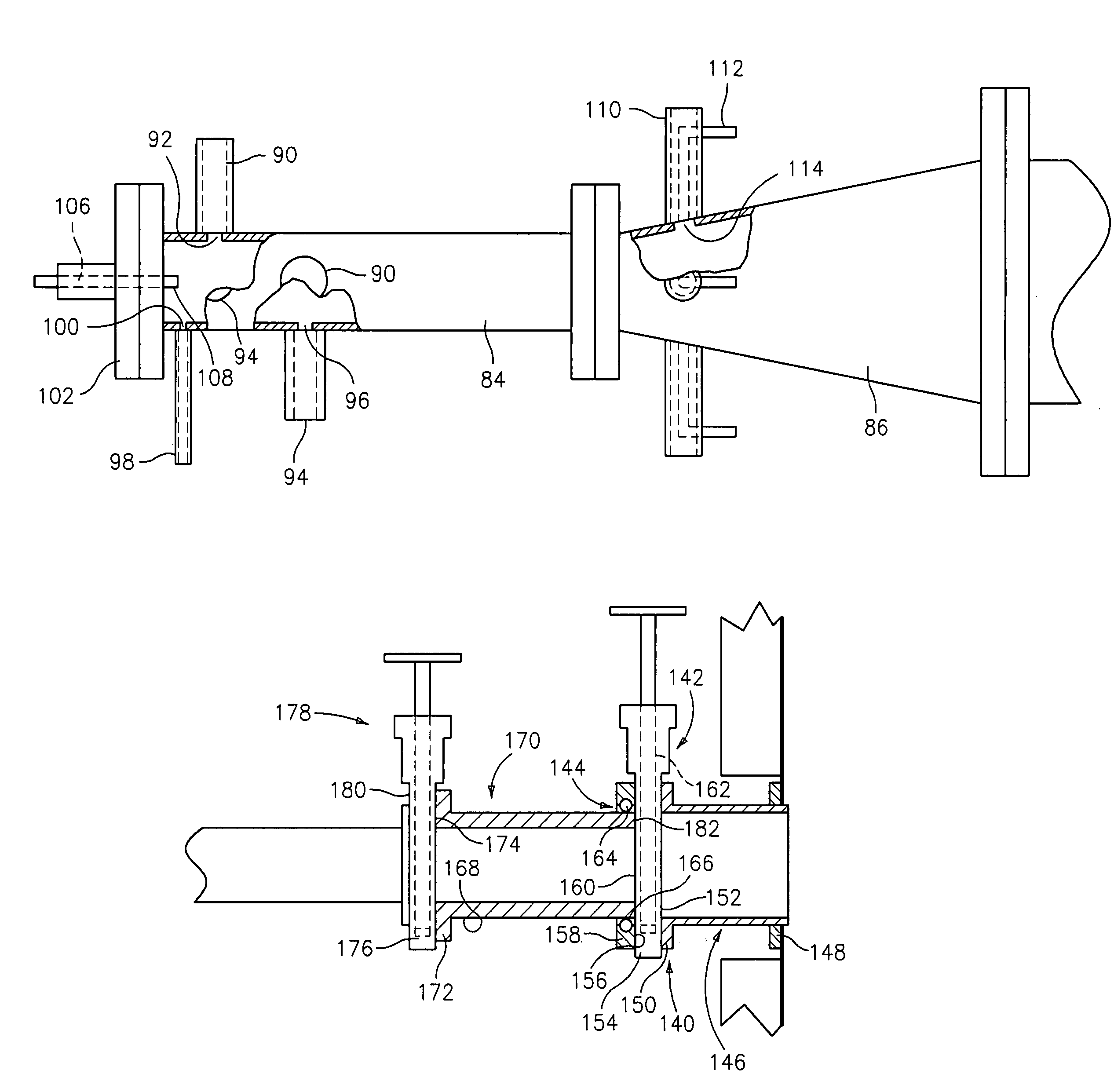

Soot blower access apparatus

An apparatus for providing detonative cleaning through a vessel wall has a first conduit extending through the wall. A first valve has an open condition permitting communication through the first conduit and a closed condition. A second conduit has an insertion portion dimensioned to be received within a receiving portion of the first conduit. A second valve has an open condition permitting communication through the second conduit and a closed condition.

Owner:SHOCKSYST

Air soot blower

InactiveCN102748766AReduce manufacturing costImprove operational reliabilitySolid removalInlet channelSolenoid valve

The invention provides an air soot blower which comprises a transmission device, an air inlet device, a filler sealing device, a soot blowing pipe and a support, wherein one end of the filler sealing device is connected with the air inlet device, and the other end of the filler sealing device is connected with the soot blowing pipe. The air inlet device comprises a soot blowing medium pipe, a soot blowing medium solenoid valve, a soot removing agent pipe, a soot removing agent pipe solenoid valve and an air inlet pipe, wherein the soot blowing medium pipe and the soot blowing medium solenoid valve form a first air inlet channel, the soot removing agent pipe and the soot removing agent pipe solenoid valve form a second air inlet channel, an air inlet cavity is formed in the air inlet pipe, the soot removing agent pipe is connected with the air inlet pipe through a flange, the soot blowing medium pipe is welded with the soot removing agent pipe, and an included angle formed by axes of the soot blowing medium pipe and the soot removing agent pipe is an acute angle. Compared with the existing air soot blowing structures, the air soot blower is greatly simplified in structure, obviously reduced in manufacture cost and reduced in air leakage points, can effectively remove accumulated soot on a furnace pipe and a heat exchange pipe, keeps heat transfer efficiency on a high level and accordingly reduces fuel consumption.

Owner:CHINA PETROLEUM & CHEM CORP +2

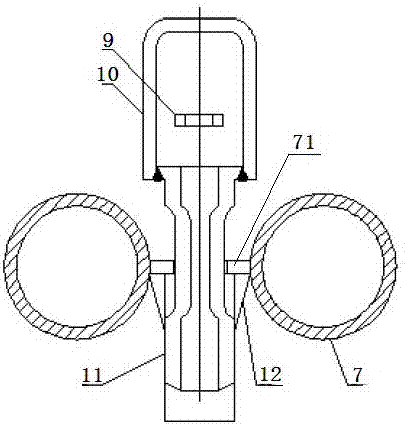

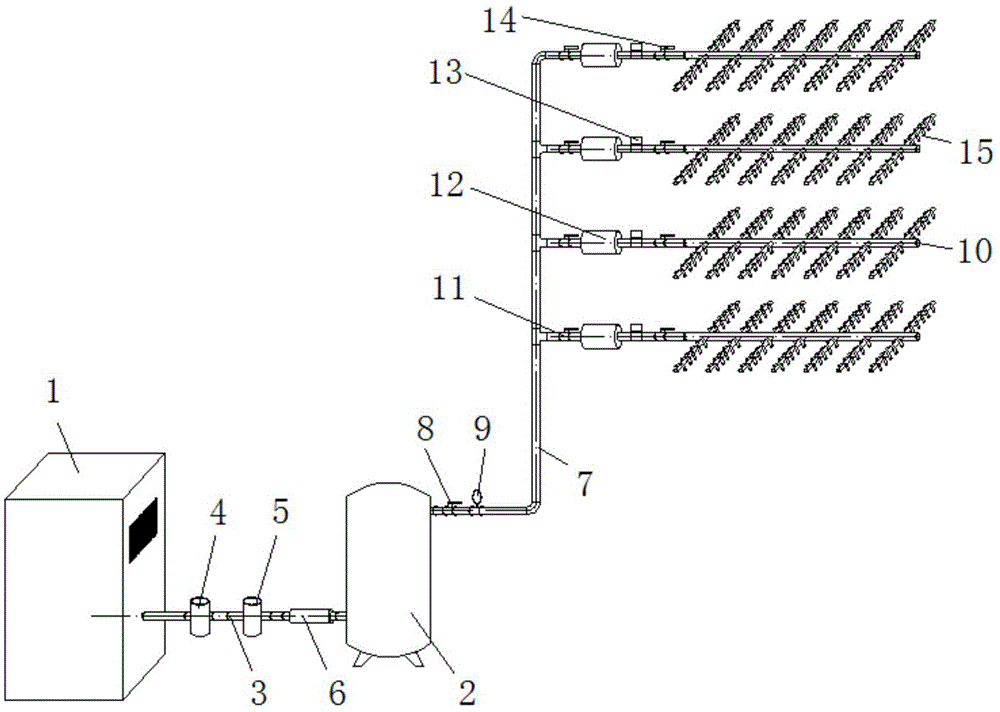

Movable impulse type compressed air soot blower and using method thereof

InactiveCN105478009AService life is not affectedGood effectGas treatmentDispersed particle separationPressure stabilizationElectromagnetic pulse

The invention discloses a movable impulse type compressed air soot blower and a using method thereof. The movable impulse type compressed air soot blower comprises an air compressor and an air storage tank, wherein an air outlet of the air compressor is communicated with an air inlet of the air storage tank through a communication pipe, a refrigeration dryer, a filter and a heater are sequentially installed on the communication pipe, an air feeding header pipe bent upwards is communicated with the upper end of the outer wall of the air storage tank, a manual main control valve and a pressure sensor are installed on the horizontal section of the air feeding header pipe from left to right in sequence, a plurality of air feeding branch pipes which are horizontally distributed at intervals are communicated with the longitudinal section of the air feeding header pipe, a first manual branch control valve, a pressure stabilization air chamber, an electromagnetic pulse valve and a second manual branch control valve are installed on each air feeding branch pipe from left to right in sequence, a plurality of blowing components which are distributed in parallel at intervals are perpendicularly communicated with the portion, at the right side of the second manual branch control valve, of each air feeding branch pipe in a penetrating mode, and the blowing components conduct blowing facing the space above an SCR reactor catalyst. By the adoption of the movable impulse type compressed air soot blower, ash removal can be achieved automatically, the effect is stable, and the service life of the catalyst is not affected.

Owner:HEFEI CEMENT RES DESIGN INST

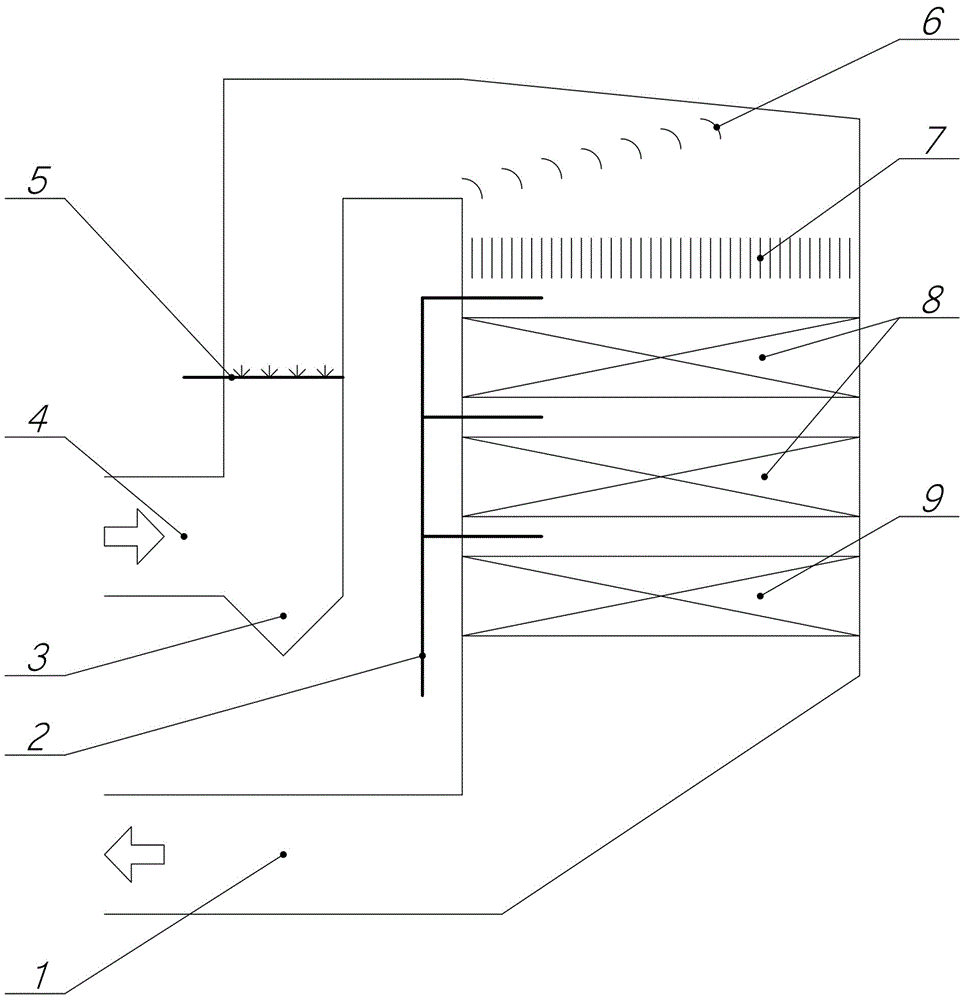

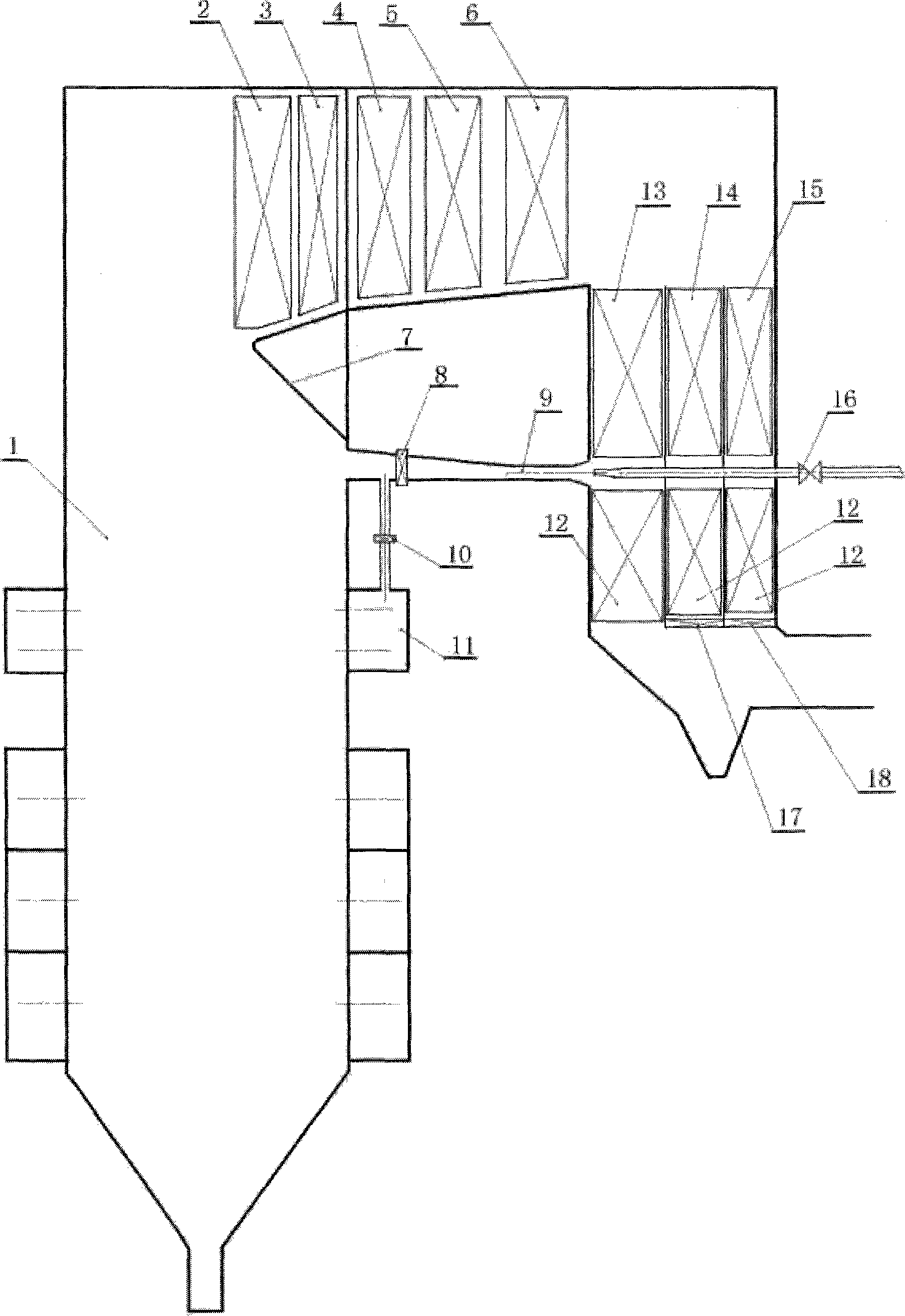

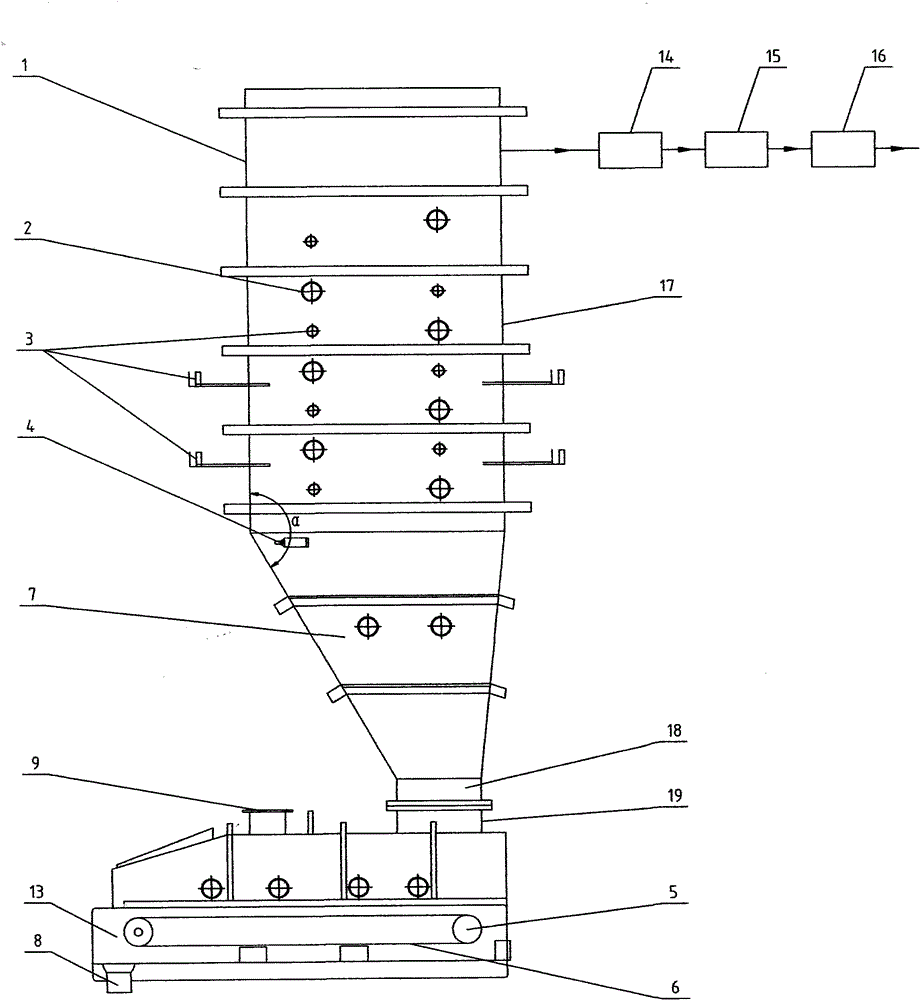

Two-part type incinerator and incineration system

ActiveCN103062777ASolve the problem of easy to block the muzzleSolve the problem of processing powerIncinerator apparatusFlue gasPart type

The invention provides a main device for a phosphorus containing waste incineration disposal process. A two-part type incinerator forms an L-shaped furnace body by connecting a vertical furnace (1) and a horizontal furnace (13). The vertical furnace (1) is composed of a cuboid combustion area (17) and a cone depression area (7). Waste liquid atomization guns (2) and fuel combustion guns (3) are alternately arranged along the wall of the cuboid combustion area (17). Soot blowers (4) are arranged in the connection position of the cone depression area (7) and the cuboid combustion area (17) along the front side wall of the furnace from top to bottom. The fuel combustion guns (3) are arranged in the middle portion of the cone depression area (7). An exit (18) of the cone depression area (7) is communicated with a feed inlet (19) of the vertical furnace (13). The vertical furnace (13) utilizes a scale circulation type fire grate (6). A feed outlet is arranged at the front end of the fire grate. Combustion tail gas passes through an exit (20) which is formed in the top portion of the vertical furnace (1) and passes through a secondary combustion settling chamber (14), a heat exchanging unit (15) and a flue gas cleaning device (16) in sequence.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP +1

Low temperature continuous denitrification process for coke oven smoke and reactor thereof

InactiveCN106334444ARestore activityMeet regeneration requirementsGas treatmentDispersed particle separationDecompositionInlet valve

The invention discloses a low temperature continuous denitrification process for coke oven smoke and reactor thereof. The reactor is divided into 2-9 individual regions, in between the regions are installed with heat insulation facilities, inside each of the regions are arranged with denitrification catalyst, a rectification grille, a soot blower, a pressure difference transmitter, an air inflow pipe for coke oven smoke, and more. When ammonium bisulfate, ammonium sulfate and other sticky substances generated by the reaction of SO2 and NH3 in the oven smoke, consolidate by large amount on the catalyst surface, causing the drop of catalyst activity in certain region of the reactor, the air intake valve is closed for smoke in the associated region, and hot air supply is plugged into the associated region, speeding up the decomposition by heat of ammonium bisulfate, ammonium sulfate and other substances, the denitrification catalyst is regenerated, with no effect on the running of denitrification devices in the remaining regions. The present invention is simple to operate, safe and reliable, with less area occupied, and low operating cost.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

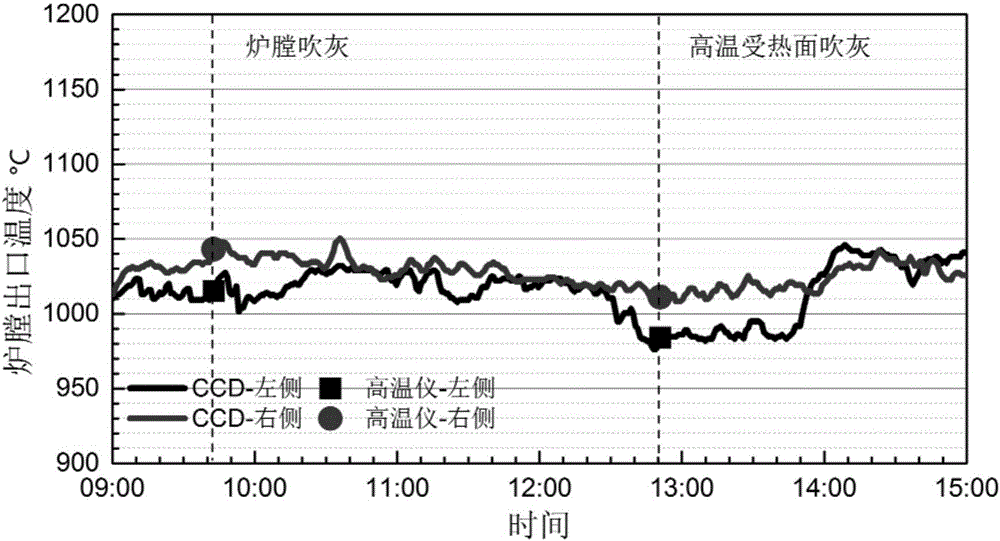

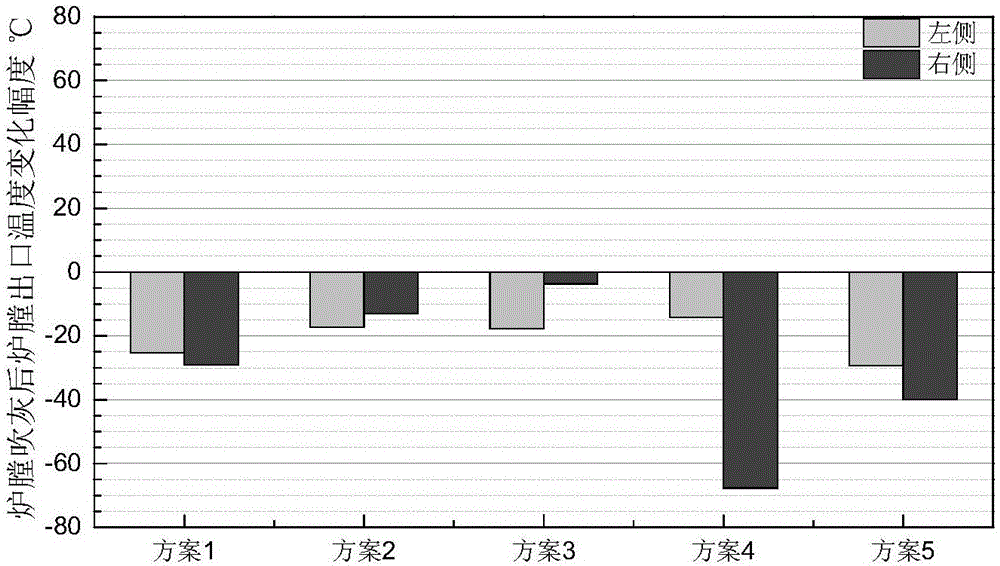

Boiler slagging condition monitoring and controlling methods based on outlet temperature of combustion chamber

ActiveCN106247308ACleanliness reflectsReflect slagging characteristicsBoiler indication operationsBoiler controlCombustion chamberBoiler slag

The invention discloses a boiler slagging condition monitoring method based on the outlet temperature of a combustion chamber. The monitoring method includes the steps of 1, detecting the outlet temperature of the combustion chamber; 2, calculating the temperature change before and after soot blowing and the temperature rising rate after soot blowing of an outlet of the combustion chamber according to detection in the step 1; and 3, judging that combusted coal tends to form slag when the temperature change is greater than 50 DEG C and the temperature rising rate is greater than 5 DEG / h, and judging that the combusted coal is not suitable for long-term combustion and adjusting the coal type when the temperature change is greater than 80 DEG C and the temperature rising rate is greater than 10 DEG / h. The invention further provides a boiler slagging condition controlling method based on the outlet temperature of the combustion chamber. According to the monitoring method and the controlling method, scientific use of a soot blower can be effectively guided, the outlet temperature of the combustion chamber can be continuously recorded, the temperature change before and after soot blowing and the temperature rising rate after soot blowing of the combustion chamber can be calculated, the use time of the soot blower can be further obtained, and the cleanliness degree of a water-cooled wall and the slagging characteristics of the coal type can be reflected.

Owner:ZHEJIANG UNIV

Novel soot blower

InactiveCN103994450AExtended service lifeReduce the impact of high temperatureSolid removalAir pumpReducer

The invention discloses a novel soot blower which comprises a fixed box. A telescopic soot blowing pipe is arranged in the fixed box and comprises a pipe body, an air pump is connected to the port position of the pipe body, a chain wheel is formed on the outer wall of a port and connected with a rotating motor through a speed reducer, the pipe body is welded on a fixed table, the fixed table is arranged on guide rails at the bottom of the fixed box through pulleys arranged at the bottom, and one pulley is connected with a driving motor. The soot blowing pipe comprises the pipe body, and soot blowing holes are spirally arranged on the inner wall of the pipe body. The novel soot blower can achieve telescopic operation control according to actual operation requirements, meanwhile improves the soot blowing radiation area and efficiency and reduces the using cost of enterprises.

Owner:姜建勇

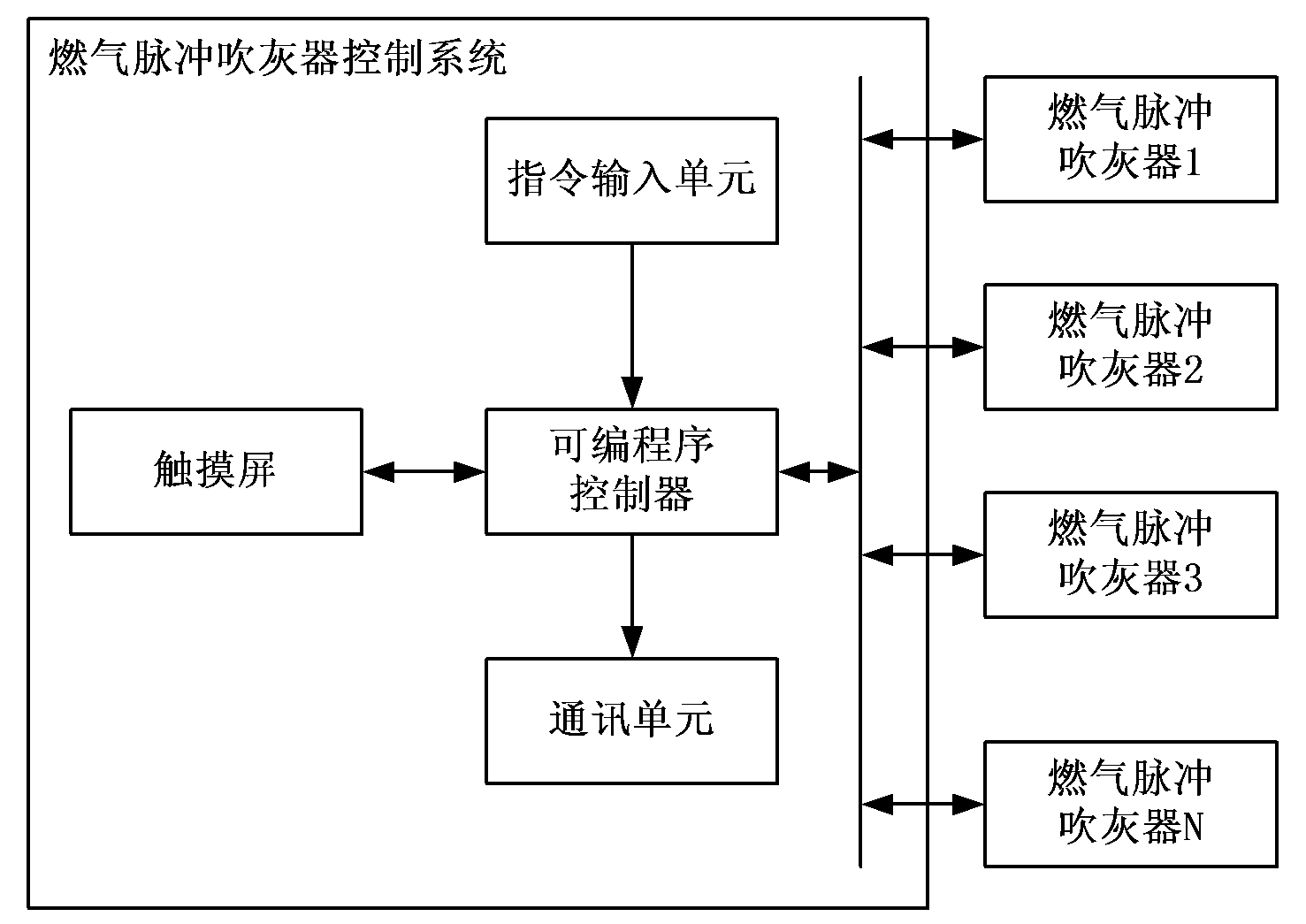

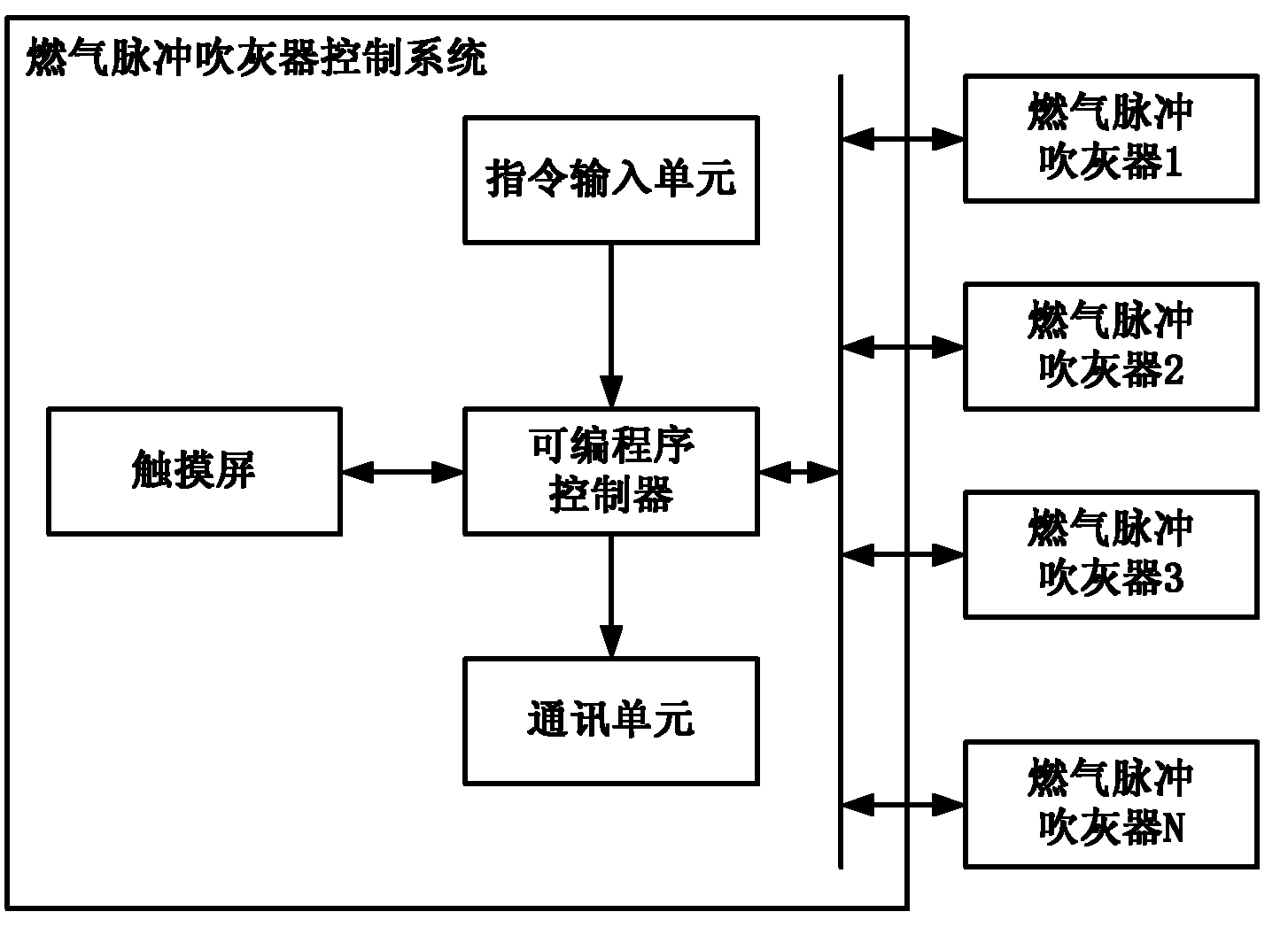

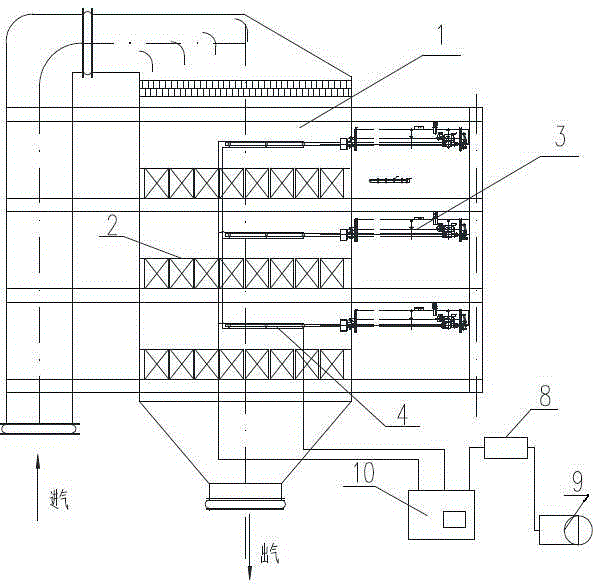

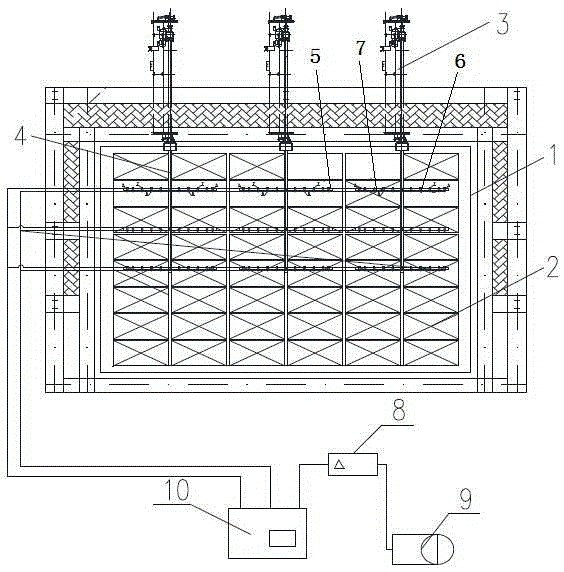

Operation control system for combustion gas pulse soot blower

InactiveCN102183912AReduce intensityEasy to controlProgramme control in sequence/logic controllersSolid removalCommunication unitProgrammable logic controller

The invention discloses an operation control system for combustion gas pulse soot blowers, which is used for controlling multiple groups of combustion gas pulse soot blowers. The system comprises a touch screen, a programmable controller, an input unit, a communication unit, a temperature sensor, a pressure transducer, an ash production amount weighing device and a corresponding connecting circuit, wherein the touch screen is connected with the programmable controller, the touch screen displays running states of the multiple groups of combustion gas pulse soot blowers; and the temperature sensor is arranged in the multiple groups of combustion gas pulse soot blowers, and is connected with the programmable controller. The operation control system further comprises an instruction input unitconnected with the programmable controller, and an operator can input a control instruction to the programmable controller according to a time curve of temperature to pressure. In the operation control system for combustion gas pulse soot blowers provided by the invention, the touch screen and the programmable controller are adopted to conduct direct, convenient and precise control on the multiple groups of combustion gas pulse soot blowers, and to arrange reasonable control conditions.

Owner:BEIJING FANYUANXING SCI & TECH

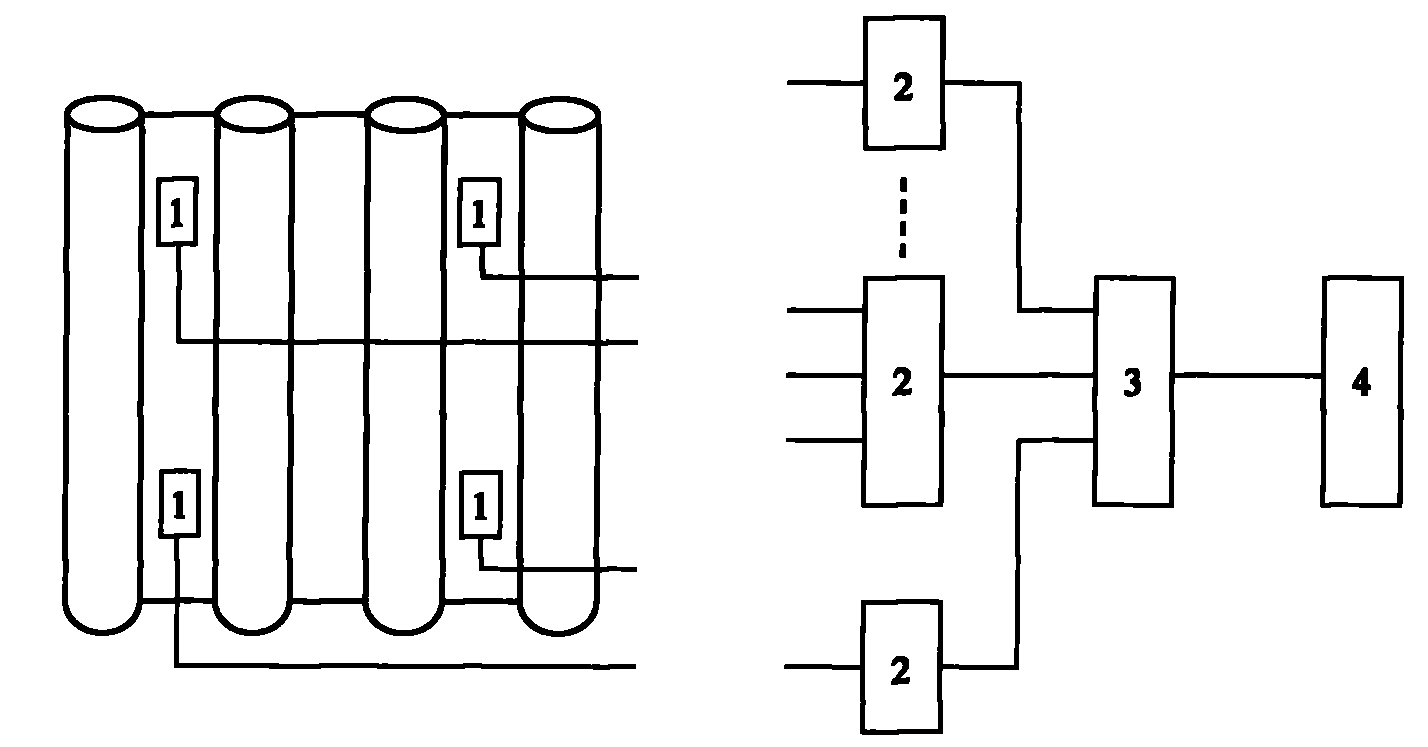

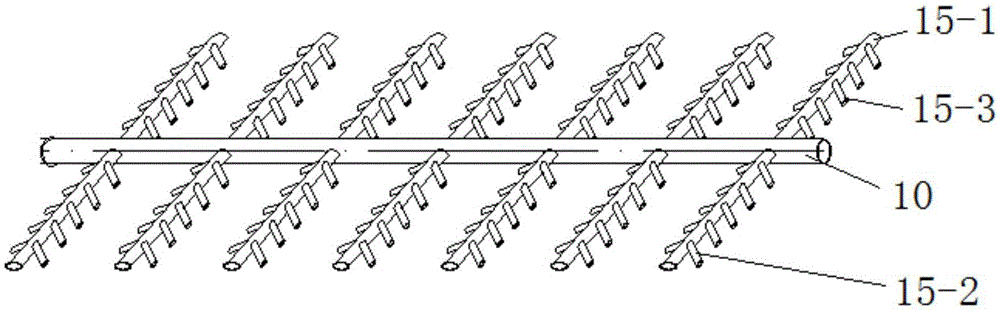

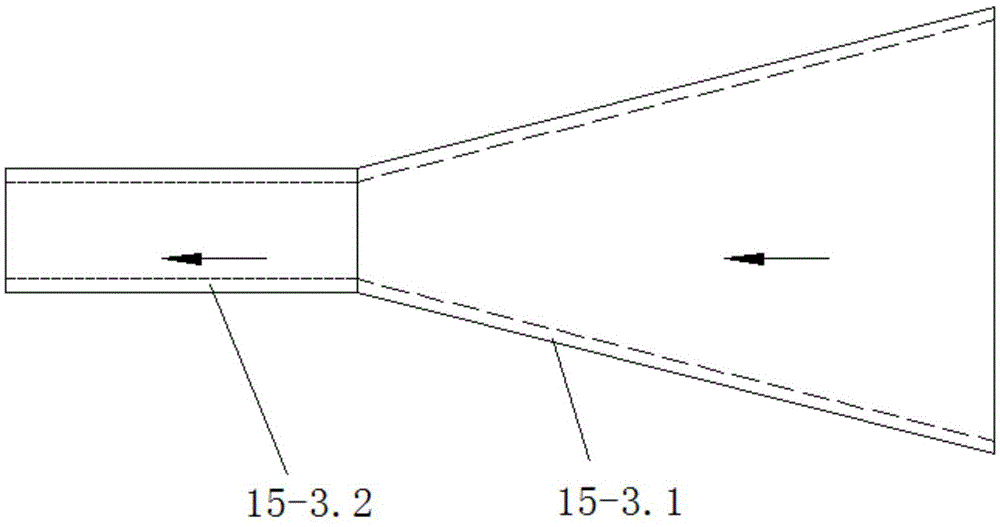

Online denitration catalyst regeneration device and method

ActiveCN105311958ASolve the problem of offline regenerationImprove applicabilityDispersed particle separationCatalyst regeneration/reactivationControl systemMaterial resources

The invention relates to an online denitration catalyst regeneration device and method. At present, offline operation is usually adopted, and lots of manpower and material resources and financial resources are needed to be input. The online denitration catalyst regeneration device includes a denitration device and rake type steam soot blowers and is characterized by further including ultrasonic transmitters, pressure sensors, an ultrasonic generator and a central control system, wherein the ultrasonic transmitters and the pressure sensors are both fixed to steam branch pipes of the rake type steam soot blowers. The method comprises the following steps that if the difference of upper-layer and lower-layer pressure parameters in the denitration device is larger, no obvious improvement is obtained before and after the rake type steam soot blowers operate and the denitration effect of the denitration device is reduced somewhat, it means that a denitration catalyst is blocked and inactive, and an ultrasonic system is started to perform online denitration catalyst regeneration till the regeneration effect meets the requirements. The online denitration catalyst regeneration device is simple in structure, reasonable in design, low in cost and capable of saving energy and reducing the consumption.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

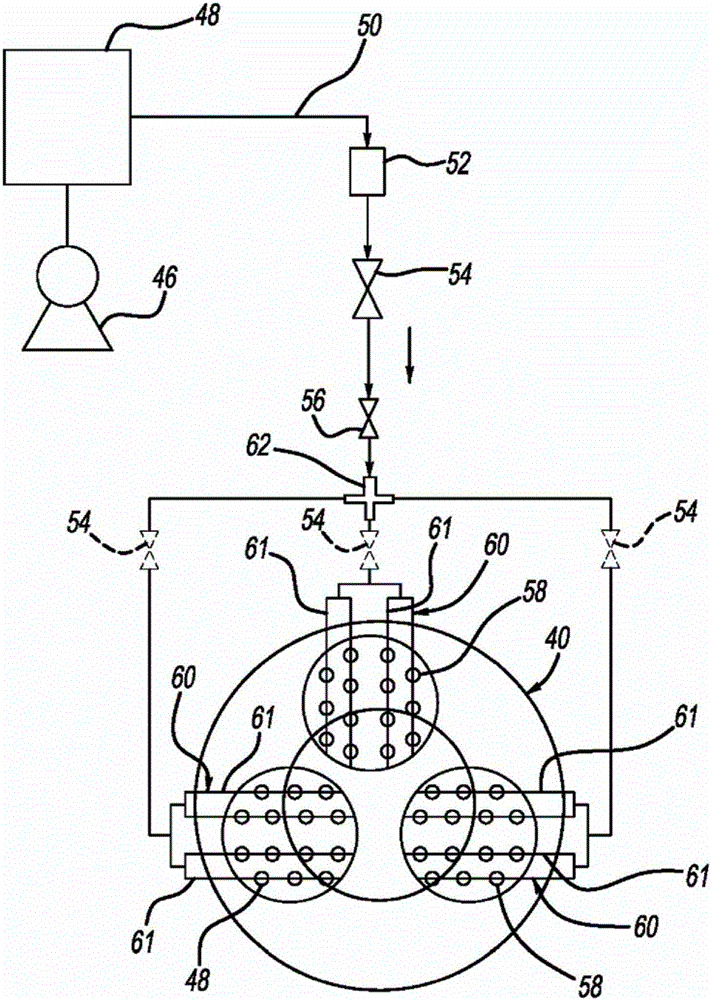

Multi-lobed soot blower

An exhaust after-treatment system including at least one exhaust treatment component (18); and a particulate matter dispersion device (40) located upstream of the exhaust treatment component (18). The particulate matter dispersion device (40) includes at least one nozzle line (61) having a plurality of nozzles (58) formed therein, and the particulate matter dispersion device (40) is operable to inject compressed gas towards the exhaust treatment component (18) to substantially minimize build-up of particulate matter at the exhaust treatment component (18).

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

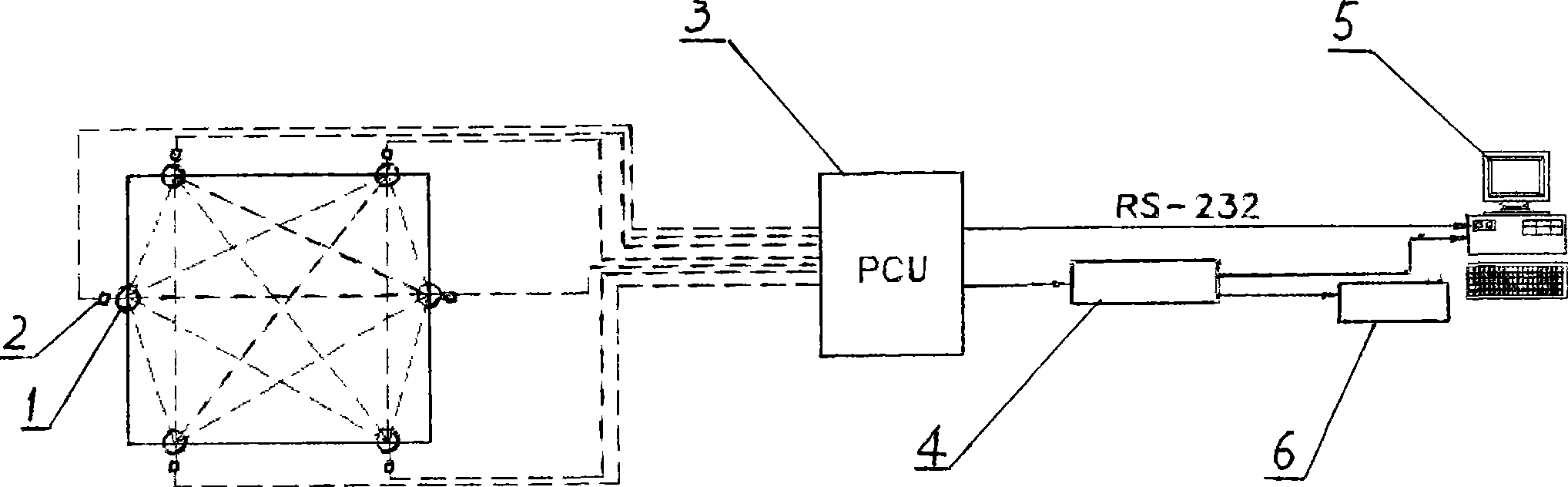

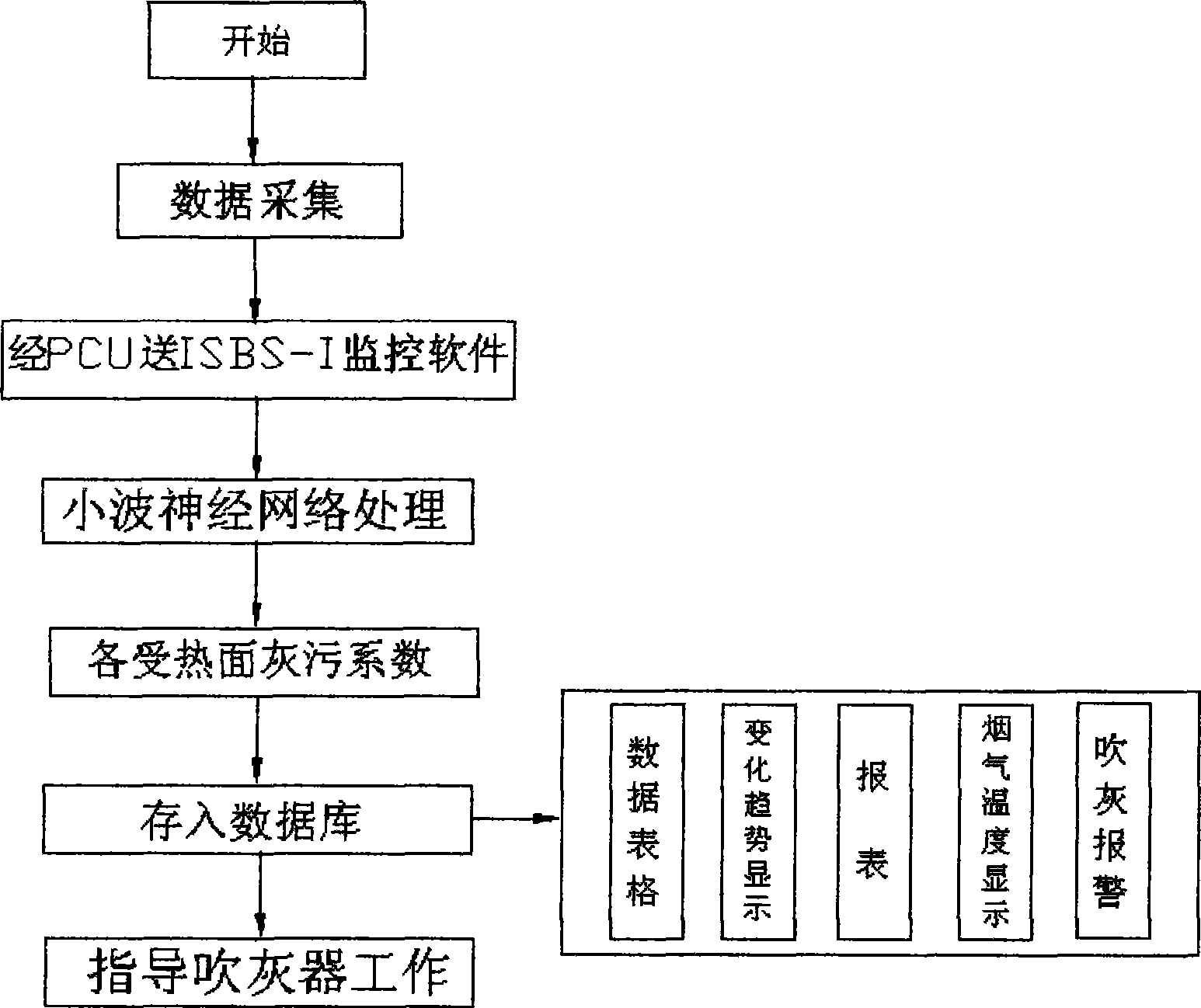

Intelligent ash blowing control system based on sound wave gas temperature field measuring technique

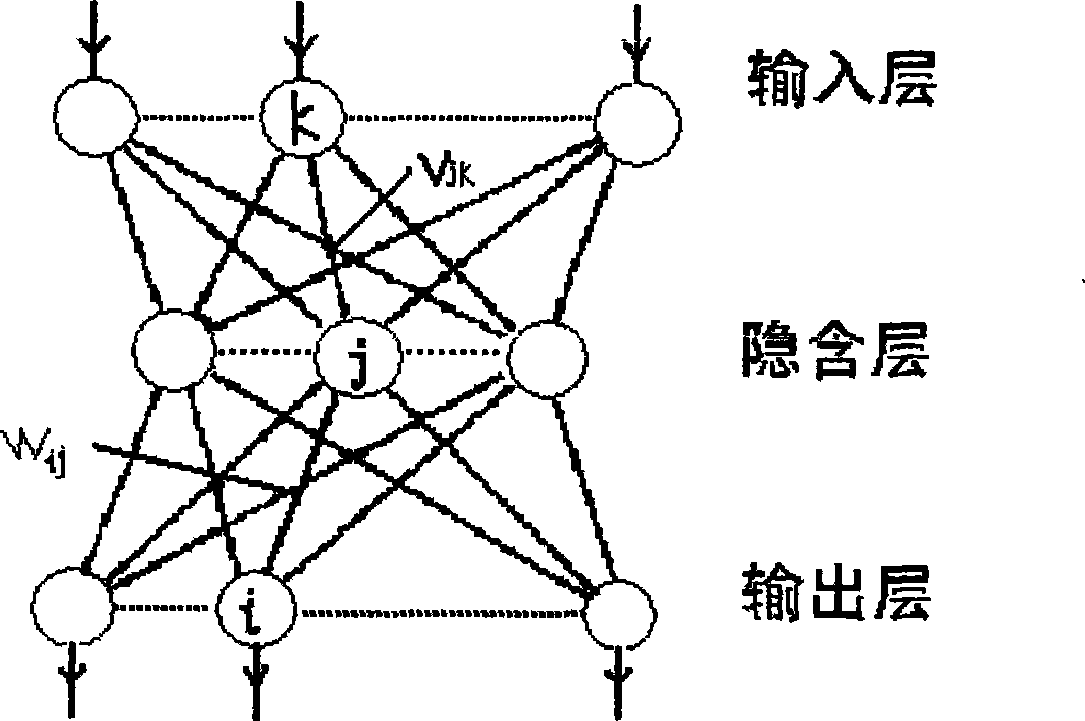

The invention relates to an intelligent soot-blowing control system on the basis of a sound wave gas temperature field measuring technique, which consists of a plurality of sound wave transmitting / receiving sensors arranged on the peripheral side of a heating surface of a thermal power generating unit boiler, preamplifier boxes correspondingly connected with each sound wave transmitting / receiving sensor, a process control unit (PCU), an intelligent soot-blowing controller and an industrial computer, wherein the amplifying signal output end of the preamplifier box is connected to the process control unit, the output end of the process control unit is connected with the corresponding input ends of the intelligent soot-blowing controller and the industrial computer, and the output end of the intelligent soot-blowing controller is externally connected to a DCS control system which guides the work of a boiler soot blower. The industrial computer is loaded with a software system on the basis of a wavelet neural network computational method, computes and processes data signals entering the intelligent soot-blowing controller through the software system, and then transmits soot-blowing optimization guidance information to the DCS control system so as to optimize and guide the boiler soot blower to blow soot as required.

Owner:陕西午禾科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com