High-dust smoke SCR (selective catalytic reduction) denitrification device applied to cement kiln

A technology of cement kiln and flue gas, which is applied in the direction of gas treatment, membrane technology, and separation of dispersed particles. It can solve the problems that are difficult to deal with the characteristics of flue gas with high dust concentration in cement kilns, and achieve long-term high-efficiency and stable operation, uniform concentration distribution, and Avoid local clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

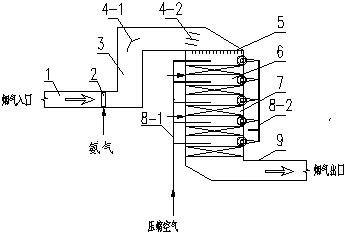

[0021] This specific embodiment provides an SCR denitration device for high-dust flue gas in cement kilns, including an inlet flue 1, an ammonia injection grille 2, a connecting flue 3, a flow equalizing deflector 4, a rectifying grille 5, and a reactor Shell 6, catalytic layer 7, combined soot blowing device 8, outlet flue 9. The inlet flue 1, the connecting flue 3, the reactor shell 6, and the outlet flue 9 are sequentially connected along the flue gas direction, the ammonia injection grille 2 is arranged on the inlet flue 1, the flow equalization deflector 4 and the rectification grille 5 are all placed in the connecting flue 3, the rectifying grille 5 is under the flow equalization deflector 4, the catalytic layer 7 is placed in the reactor shell 6, and the combined soot blowing device 8 is located at the corresponding position of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Arc length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com