Clothes hanger type non-woven fabric melt-blow mold

A non-woven fabric and hanger-type technology, which is applied in the field of mold manufacturing, can solve problems such as inconsistent injection pressure, uneven thickness of non-woven fabrics, and poor quality, and achieve the effects of increasing feed resistance, consistent flow rate, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

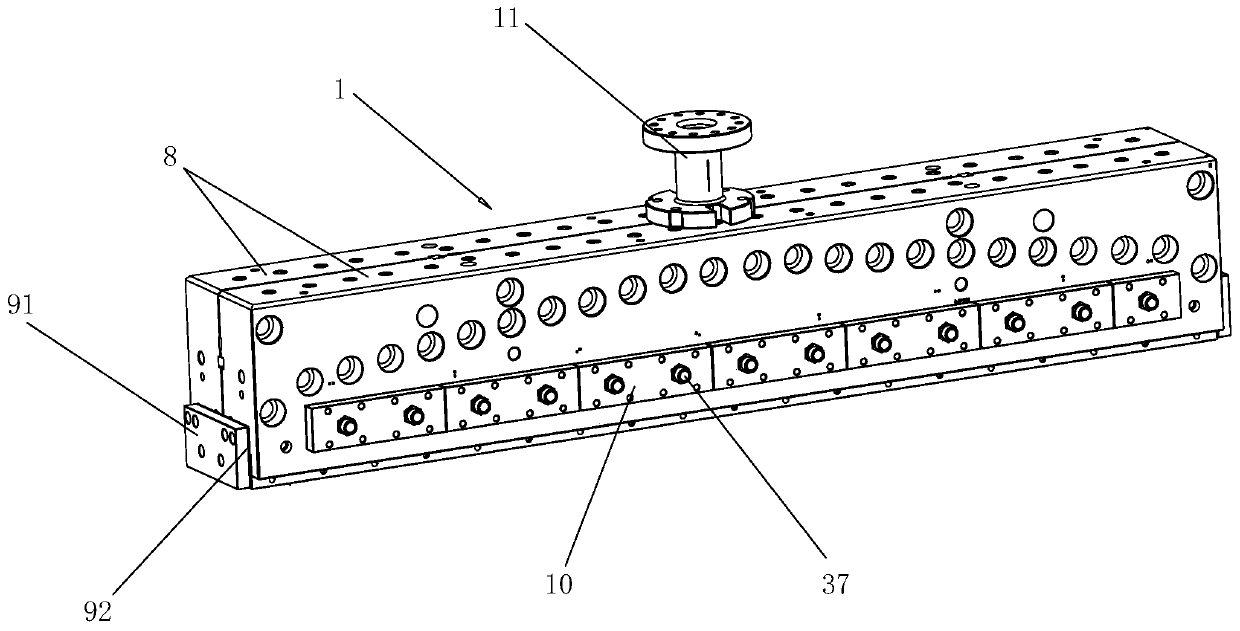

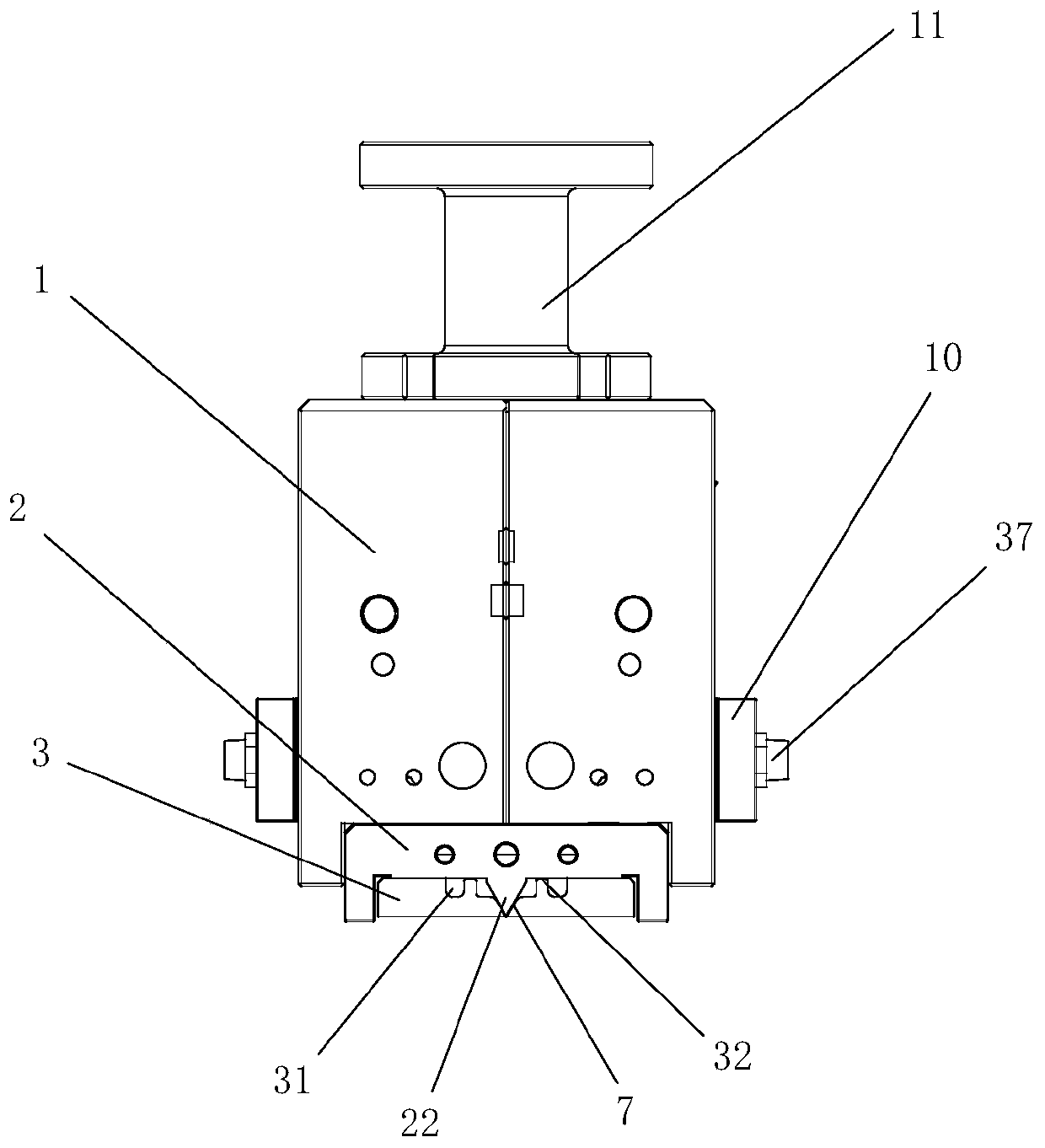

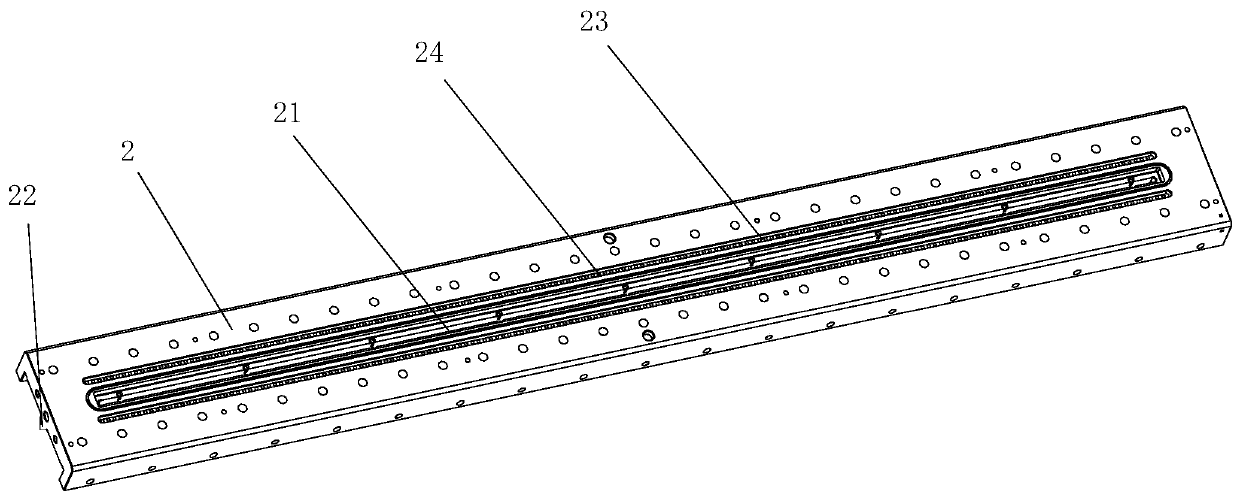

[0039] combine Figure 1 to Figure 7 , a hanger-type non-woven fabric melt-blown mold, including a die head 1, a spinneret 2 and an air knife 3, the die head 1 is a rectangular structure, the die head 1 is horizontally arranged along its length direction, and the spinneret The plate 2 is a rectangular plate structure made of steel, the spinneret 2 is located under the die head 1, and is fixed on the bottom of the die head 1 by bolts. The inside of the die head 1 is provided with a feed cavity of a hanger type structure, and the top of the die head 1 is provided with a sprue sleeve 11, and the sprue sleeve 11 is connected to the middle position of the upper end of the feed cavity, and the sprue sleeve 11 is preferably It is fixedly connected with the top bolt of the die head 1 in a vertical manner.

[0040] The feed cavity includes a main feed channel 12 , a distribution chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com