Deep drawing process for battery box body

A battery box and box technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven bottom surface of products, fast feeding, water leakage of electric packs, etc., to achieve beautiful appearance, reduce production costs, and eliminate electricity. The effect of leaking water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

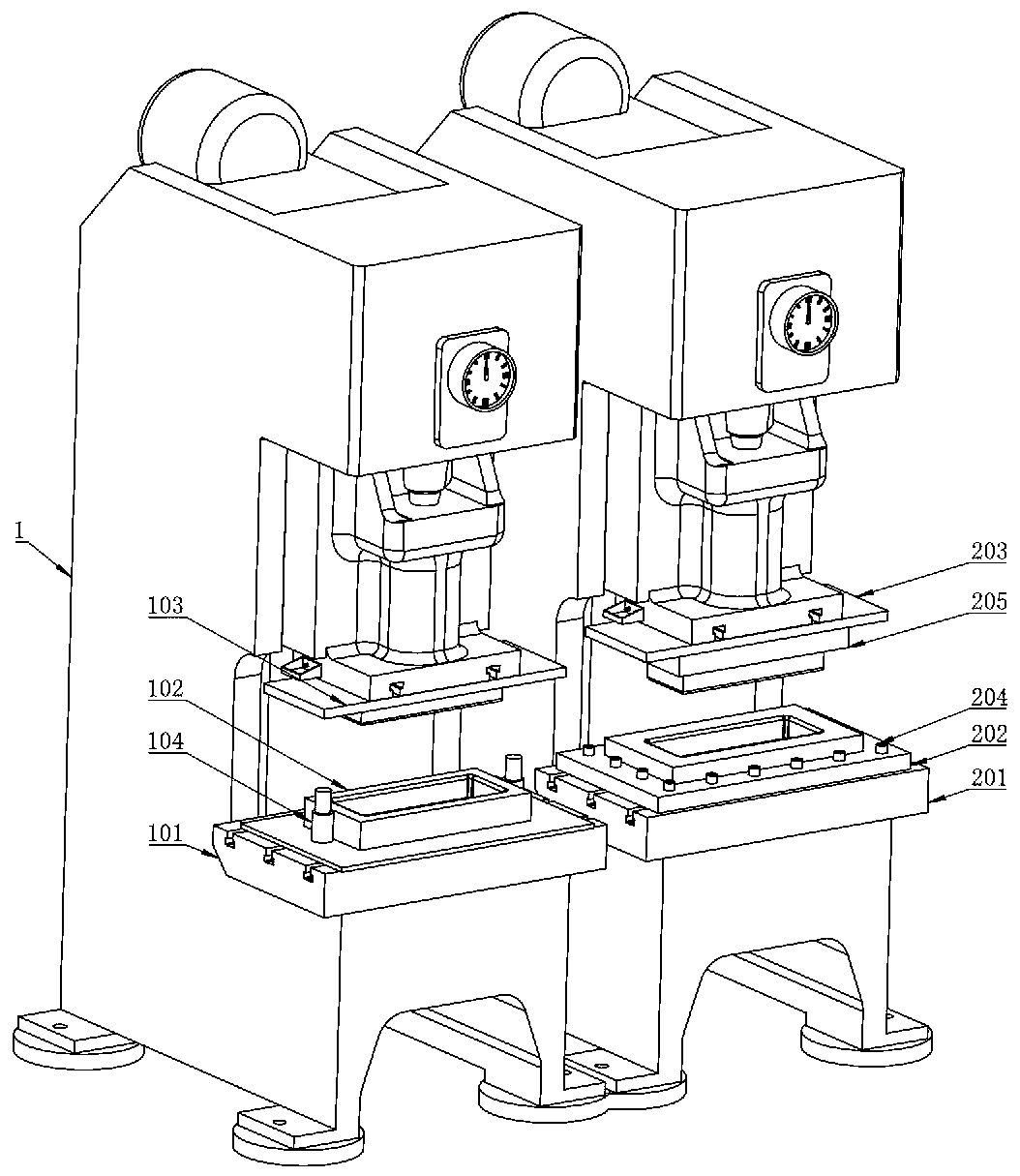

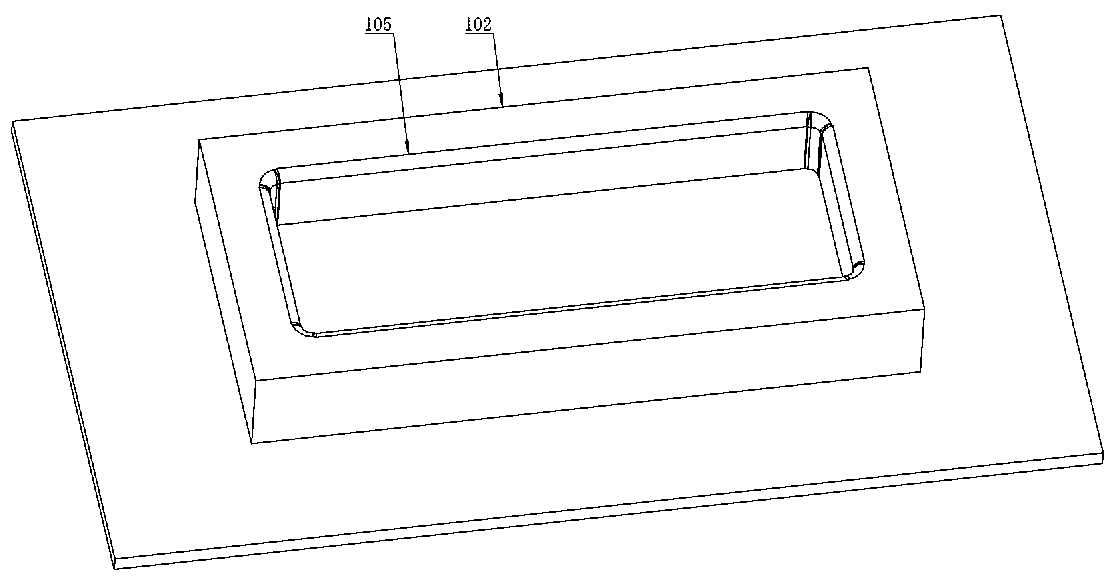

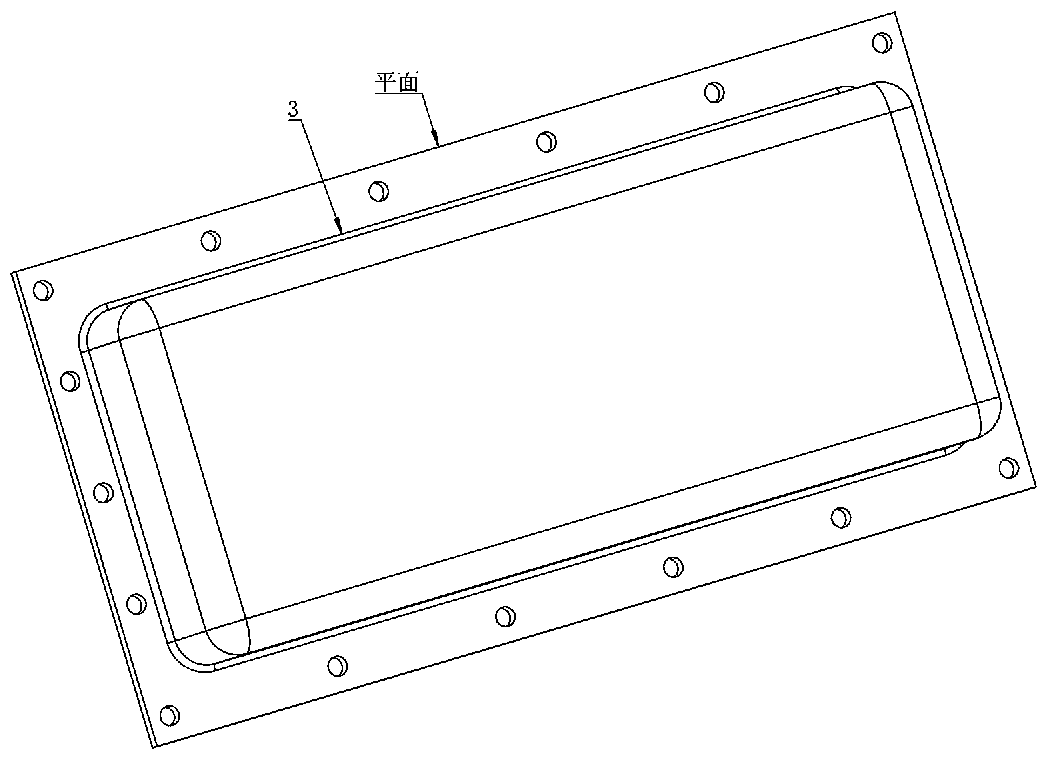

[0025] Specific implementation mode one: combine Figure 1-3 As shown, the battery box deep drawing process is characterized in that it includes a forming pneumatic press 1, a shaping pneumatic press 2 and a battery box 3; the shaping press 2 is arranged on the side of the forming press 1; the forming pressure The middle part of the machine 1 is provided with a forming platform 101; the forming platform 101 is provided with a lower forming die 102; above the lower forming die 102, an upper forming die 103 is arranged on the forming pneumatic press 1; the lower forming die 102 has two The air ejector rod 104 is arranged on the side; the shaping platform 201 is arranged in the middle of the shaping pneumatic press 2; the lower shaping mold 202 is arranged on the shaping platform 201; There is an upper shaping die 203; when making the battery box 3, the steel plate is first stretched by the forming pneumatic press 1, and then shaped by the shaping pneumatic press 2; the lower sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com