Method and apparatus for flattening bamboo wood without flaws

A crack-free bamboo technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of bamboo inner wall cracking, difficult to meet, difficult to flatten bamboo boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

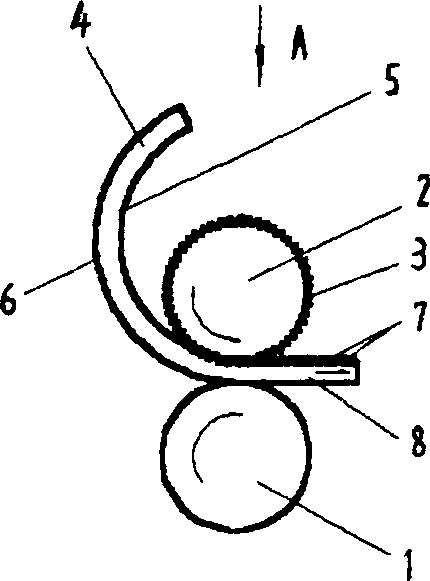

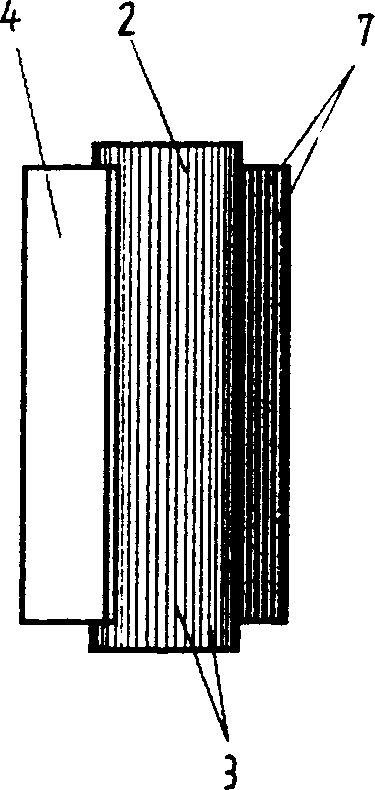

[0011] Embodiment one, in figure 1 and figure 2 Among them, there are two axially parallel rolls, the lower one is the smooth roll 1, the upper one is the toothed roll 2, the circumferential surface of the toothed roll 2 is evenly covered with the teeth 3, and the length direction of the teeth 3 is The longitudinal direction of the roll is equal to the length of the roll. The cross-sectional shape of the roller teeth 3 is preferably an isosceles triangle. The tooth pitch of two adjacent roller teeth is preferably less than or equal to 3 millimeters, and the tooth height is preferably less than or equal to 2 millimeters. The tooth surface roller 2 is like a triangular spline shaft. Will remove bamboo green, outer section; split; remove bamboo yellow, inner section; , Note that the inner wall surface 5 (ie concave surface) of the bamboo material 4 is contacted with the tooth surface roller 2, and the outer wall surface 6 (ie convex surface) of the bamboo material 4 is conta...

Embodiment 2

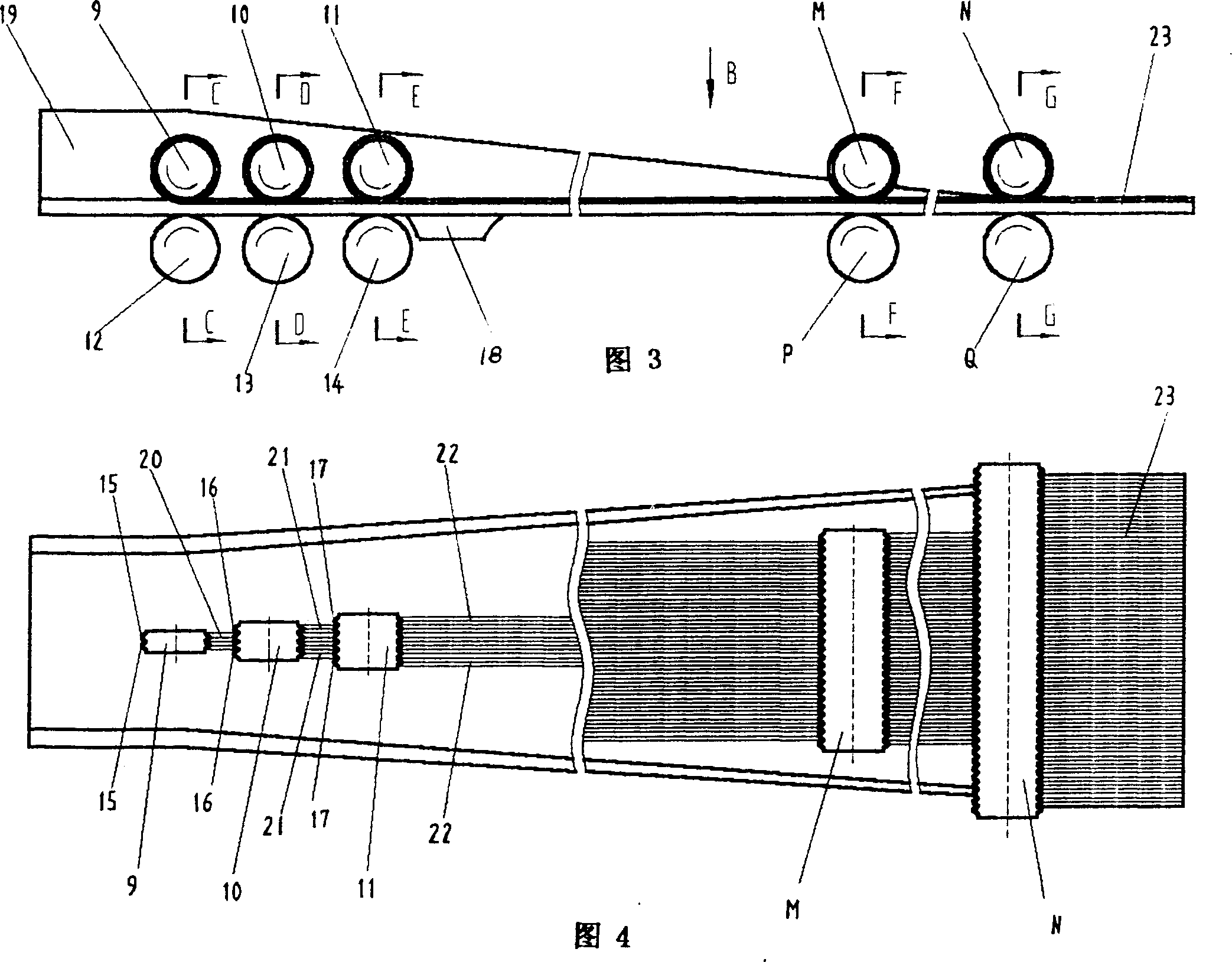

[0013]Embodiment two, in Fig. 3 and Fig. 4, there are upper and lower two rows of rolls 9, 10, 11, ... M ... N and 12, 13, 14, ... P ... Q, the rolls axes are parallel to each other. The upper and lower rows of rolls correspond to each other one to one, that is, the upper row of rolls 9 and the lower row of rolls 12 form a corresponding pair, the upper row of rolls 10 and the lower row of rolls 13 form a pair of corresponding pairs, and the upper row of rolls 9 and the lower row of rolls 13 form a corresponding pair. The roll M of the row and the roll P of the lower row form a pair corresponding to each other, and the roll N of the upper row and the roll Q of the lower row form a pair corresponding to each other. The working sides of each row of rolls are adjusted on the same plane, and the lower row of rolls 12, 13, 14, ... P...Q are all smooth rolls, and their axial lengths are preferably the same as the axis of the last roll Q. Equal to the length, also can be equal to or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth pitch | aaaaa | aaaaa |

| Tooth height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com