Loose metal litter briquetting machine and processing method

A processing method and technology of a briquetting machine, which can be applied to presses, manufacturing tools, etc., can solve the problems of continuous production, low compression efficiency, low production efficiency, etc., so as to reduce equipment costs, improve compression efficiency, and improve density and output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

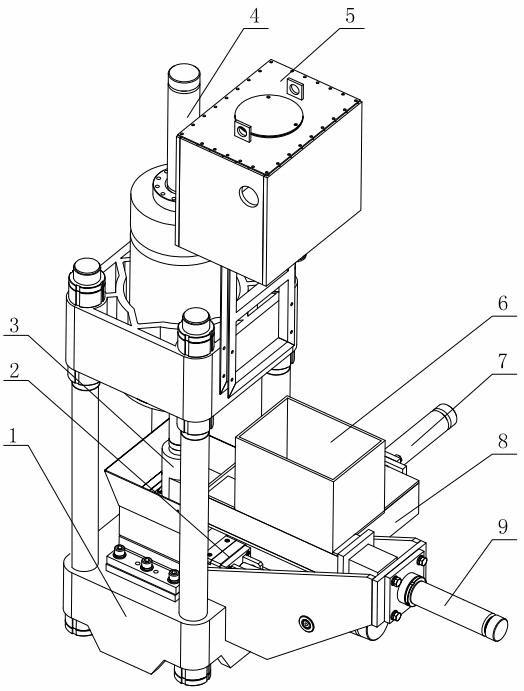

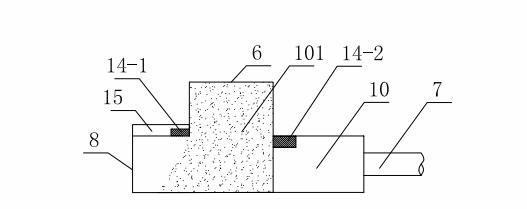

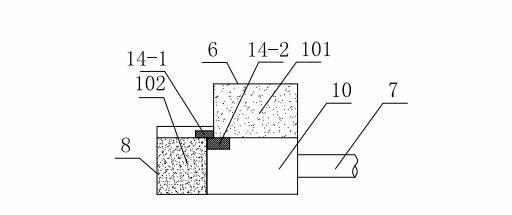

[0027] The specific implementation of the equipment and processing method of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 , Figure 4 As shown, the loose metal waste briquetting machine according to the present invention is provided with a vertical master cylinder 4 and an oil tank 5 on the top of the frame 1, and the piston of the master cylinder 4 is connected to reciprocate up and down in the final pressing material barrel 3 The punch 12 is provided with a high-strength mold sleeve at the mouth of the final pressing barrel 3, and the bottom is provided with a bottom plate 13 that closes the bottom of the barrel. The bottom plate 13 is controlled by a horizontally arranged pumping plate oil cylinder 2 to complete the closed or open barrel. Bottom action. A pushing bin 8 is arranged horizontally on the height of the middle part of the pressing barrel 3. The pushing bin 8 of the present invention is ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com