Patents

Literature

421 results about "Swaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Swaging (/ˈsweɪdʒɪŋ/) is a forging process in which the dimensions of an item are altered using dies into which the item is forced. Swaging is usually a cold working process, but also may be hot worked.

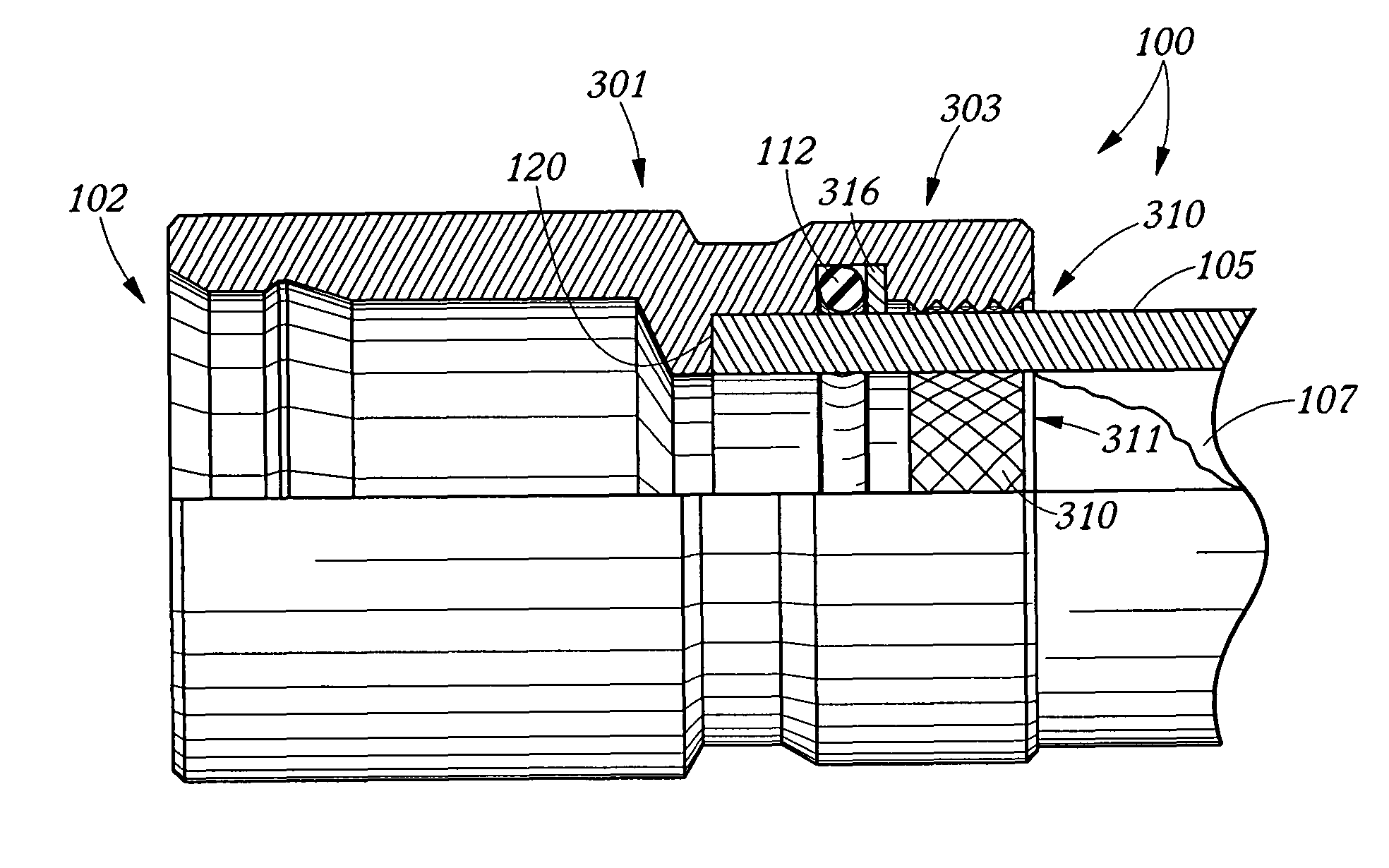

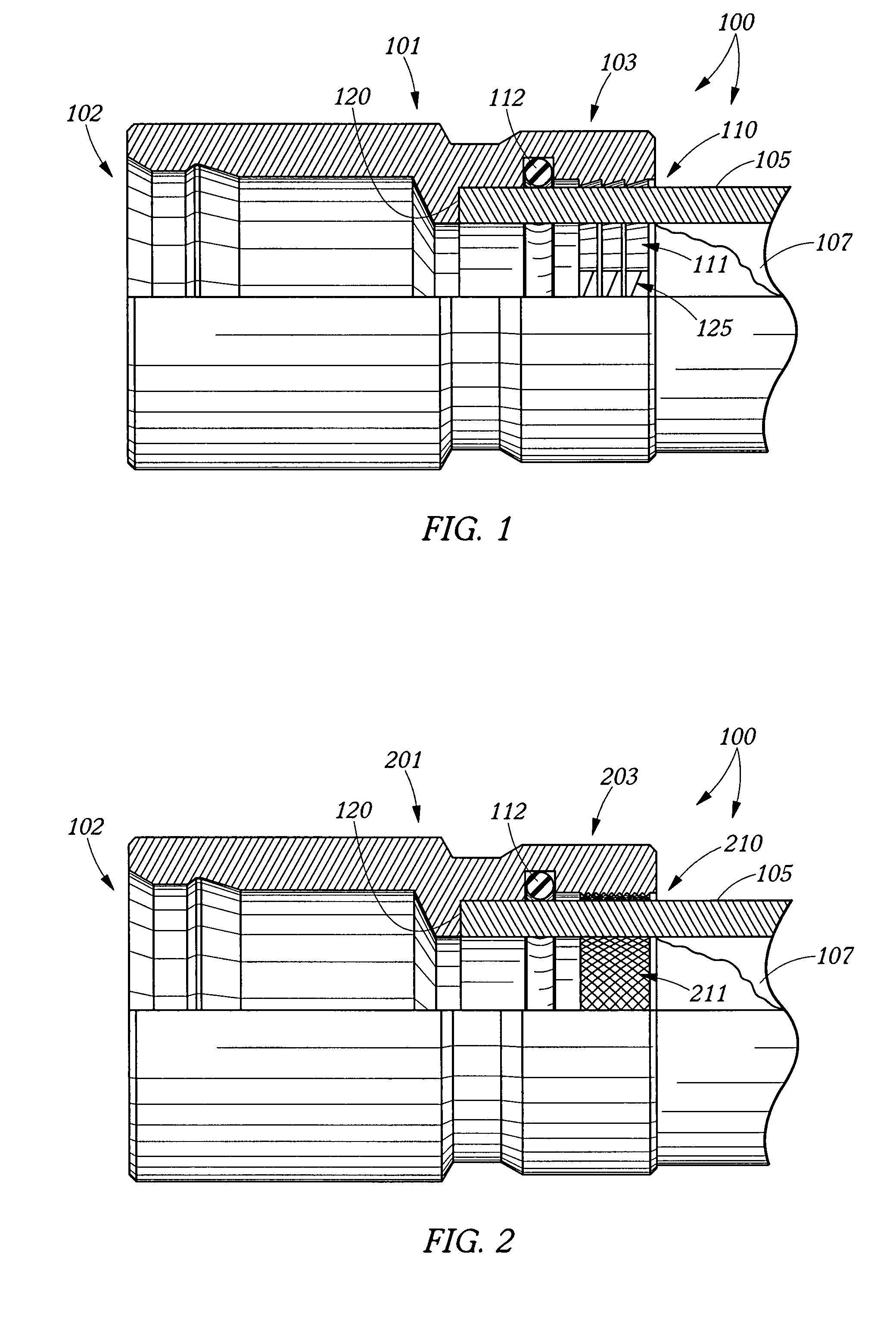

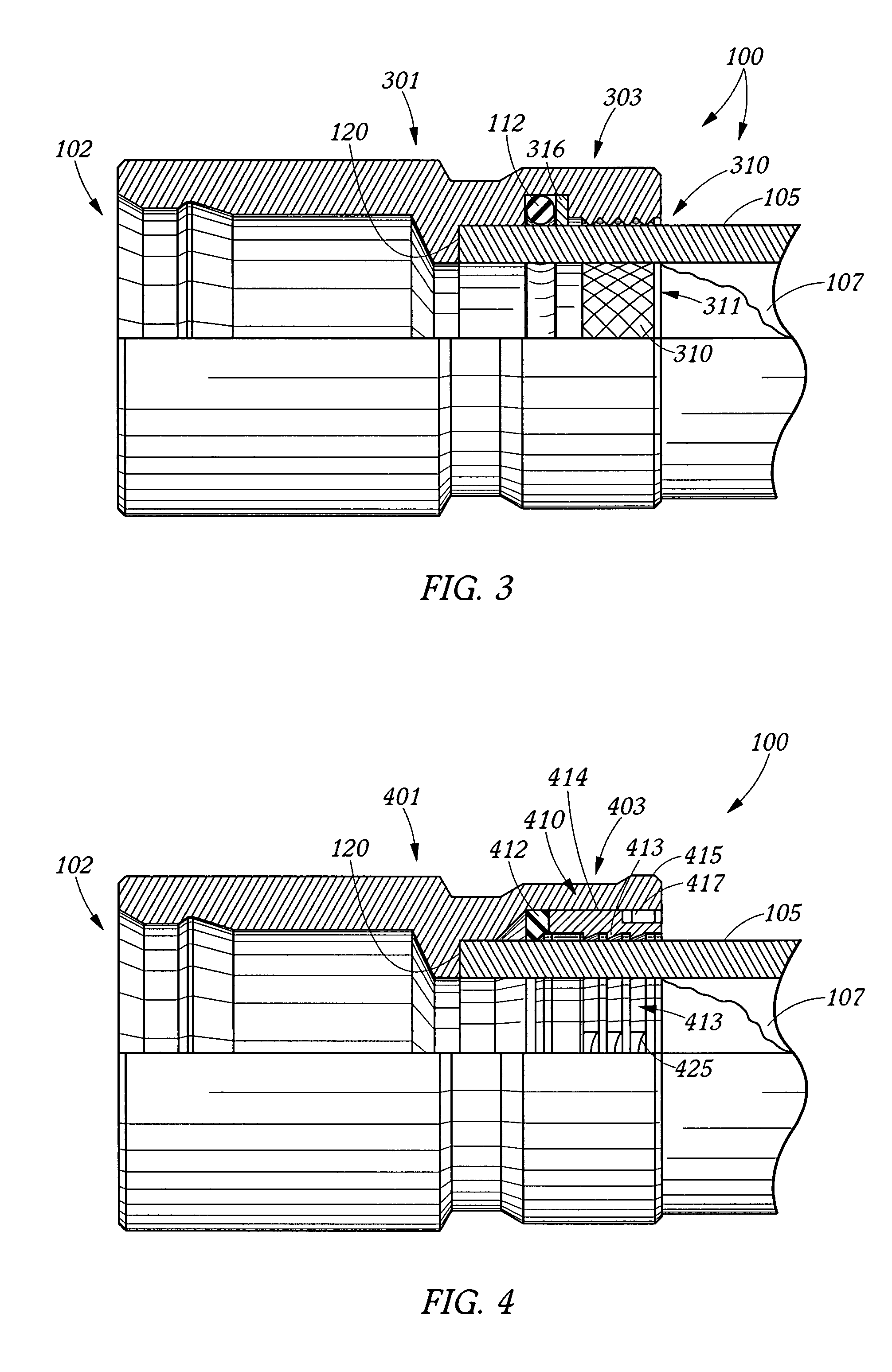

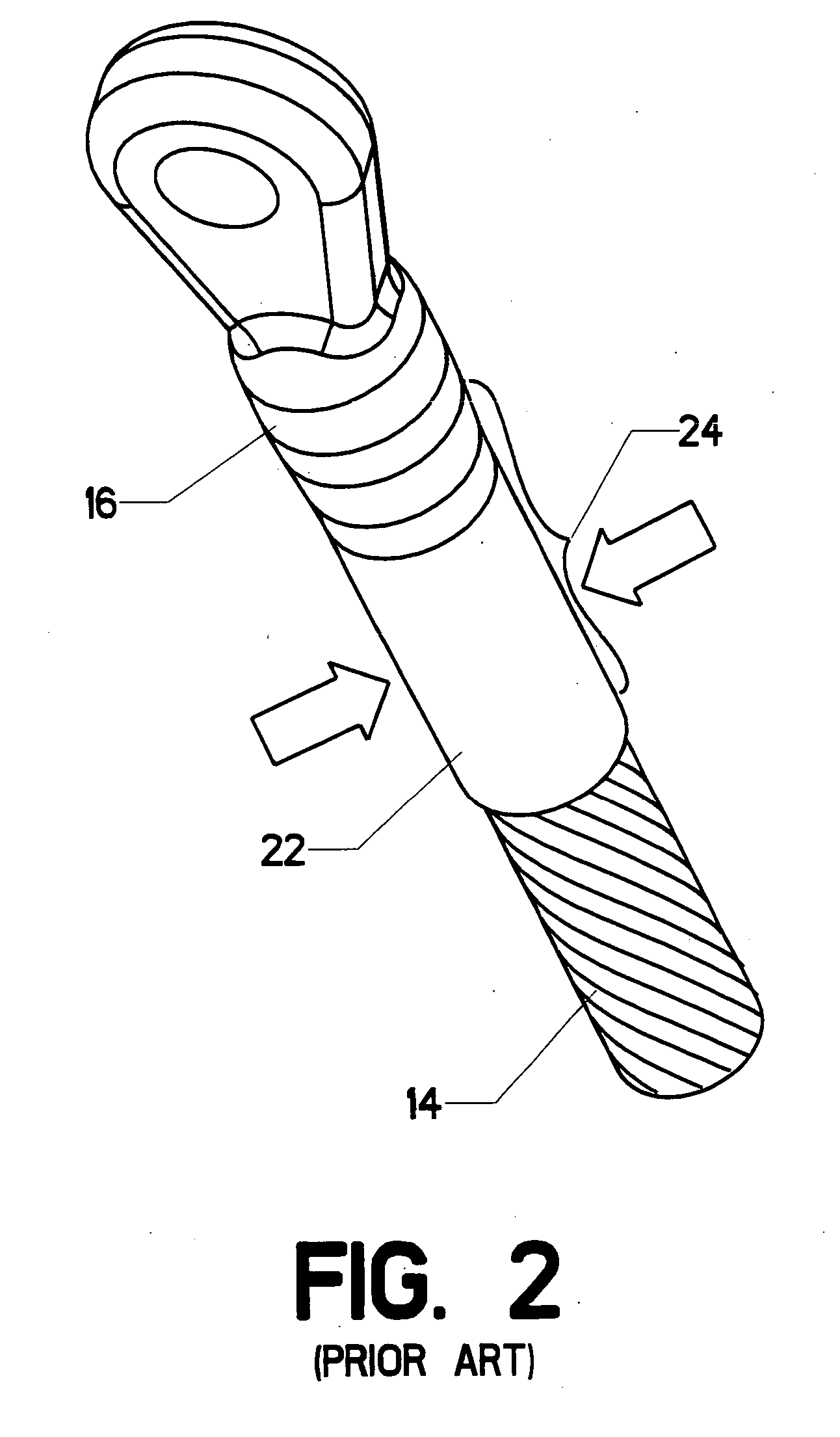

Device for altering the angle between the shaft and the head of a golf club

InactiveUS6270425B1Easy to removeSolve the complicated replacementGolf clubsRacket sportsInterference fitAdhesive

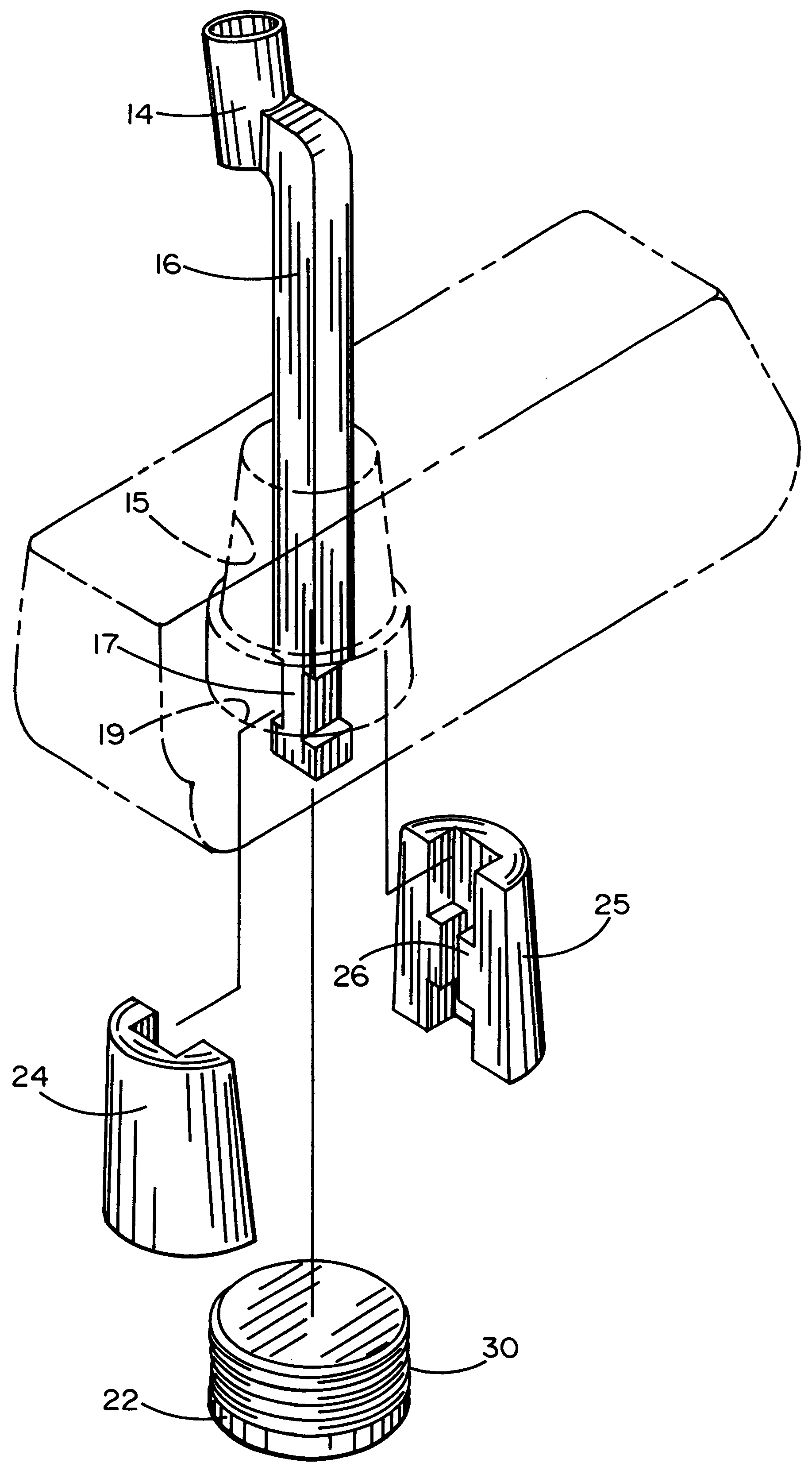

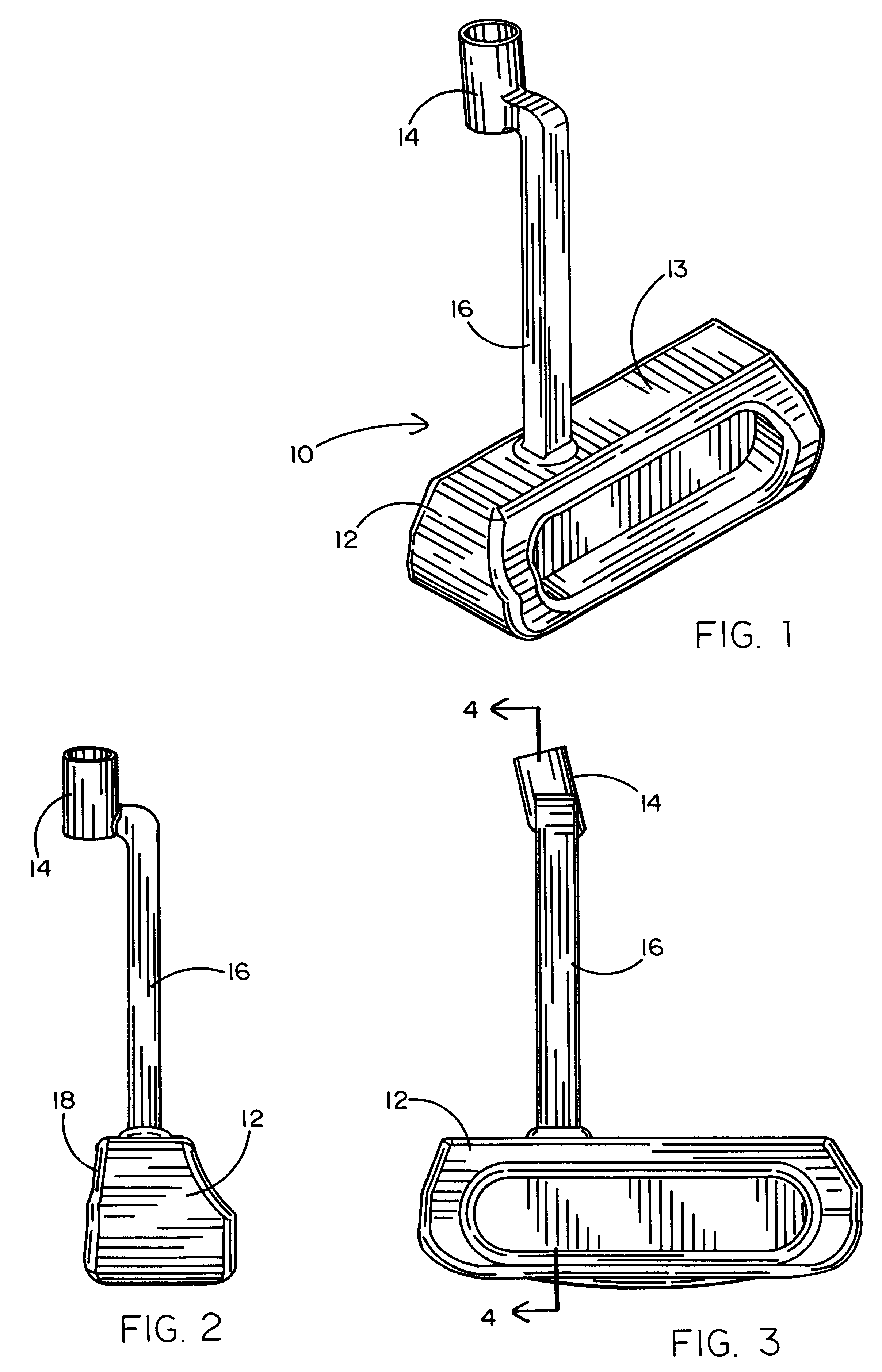

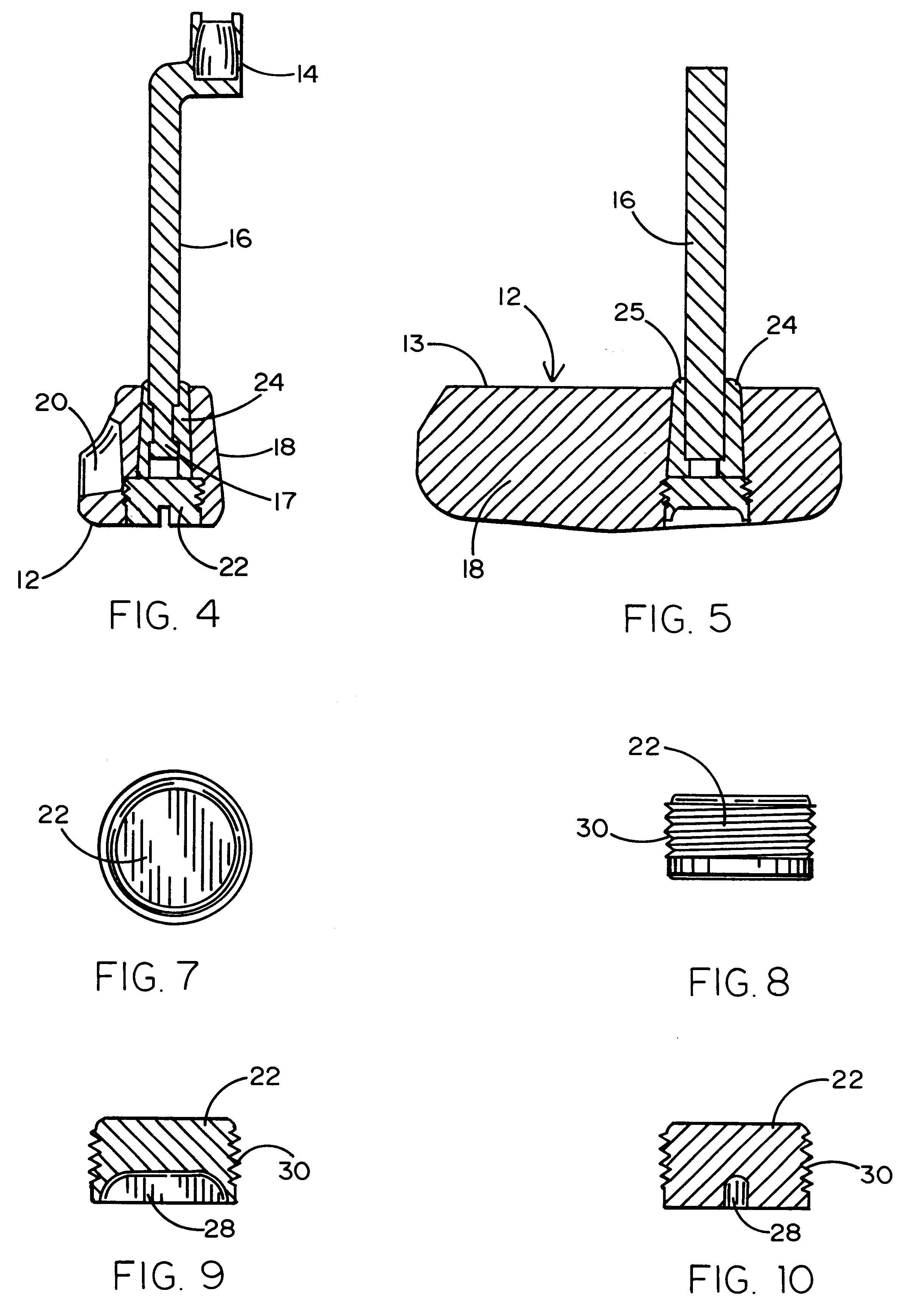

A device for altering the angle between the shaft and the head of a golf club. The preferred embodiment of the invention utilizes a plurality of inserts which are configured to be inserted into a tapered hole in the golf club head for receiving a shaft or a hosel for mating with the shaft. Each such insert is designed to provide a different angle between head and shaft so that the golfer merely selects one of the plurality of inserts which will be best for his or her hitting accuracy. The inserts are positioned in the club head in such a way as to create a swaging of the insert into the club head and the insert onto the shaft tip. Swaging is the interference fit of two components with two or more surfaces that are forced together in a locking condition, for instance a tapered pin into a tapered hole. A swaging screw is utilized to drive the insert into a tapered swage condition with the club head and thus squeeze onto the shaft to ensure a strong bond without utilizing an adhesive. The disclosed embodiment relates to a golf club putter, but other golf clubs, such as metalwood head golf clubs would employ the invention as well.

Owner:NIRVANA GRP L L C THE

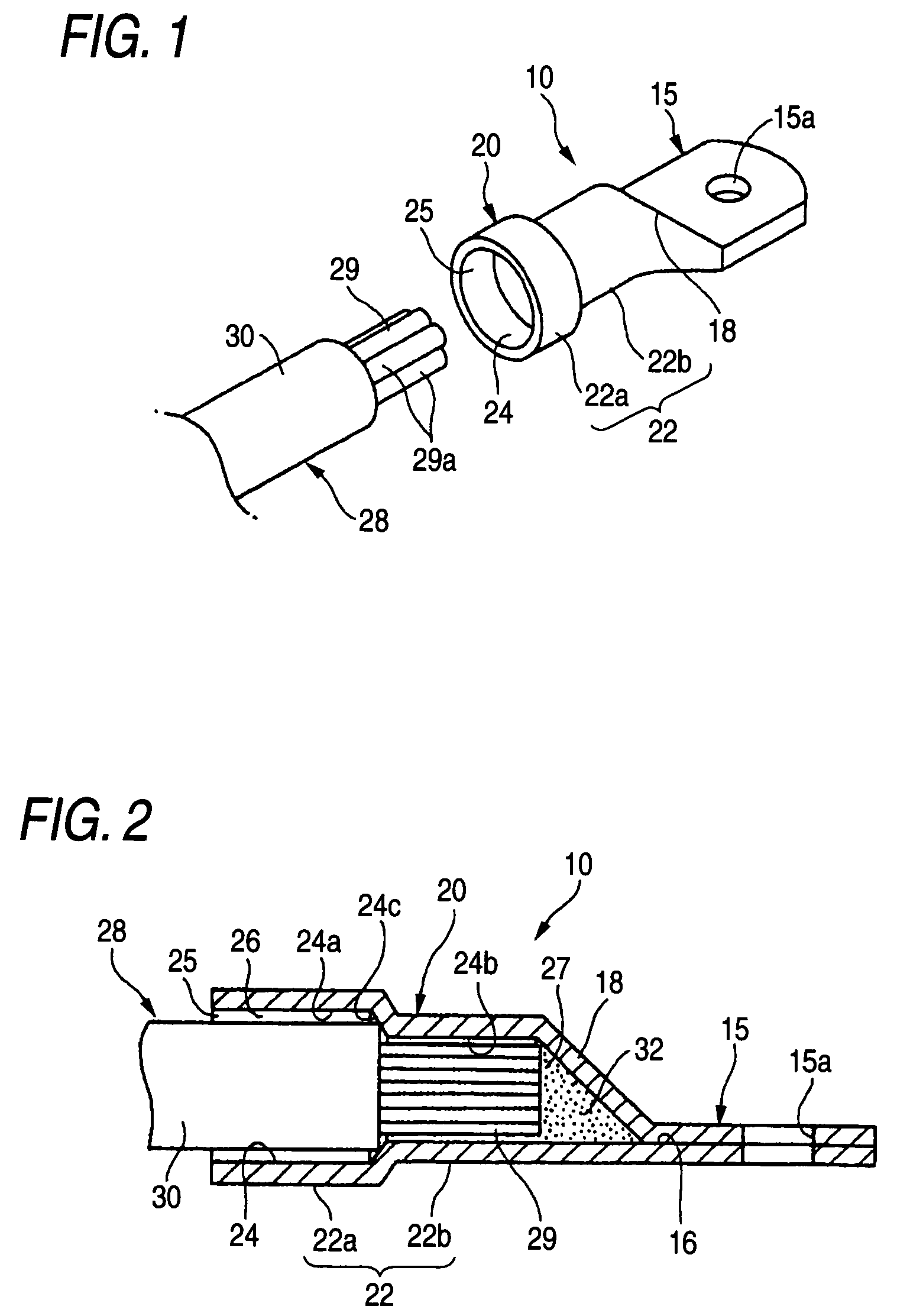

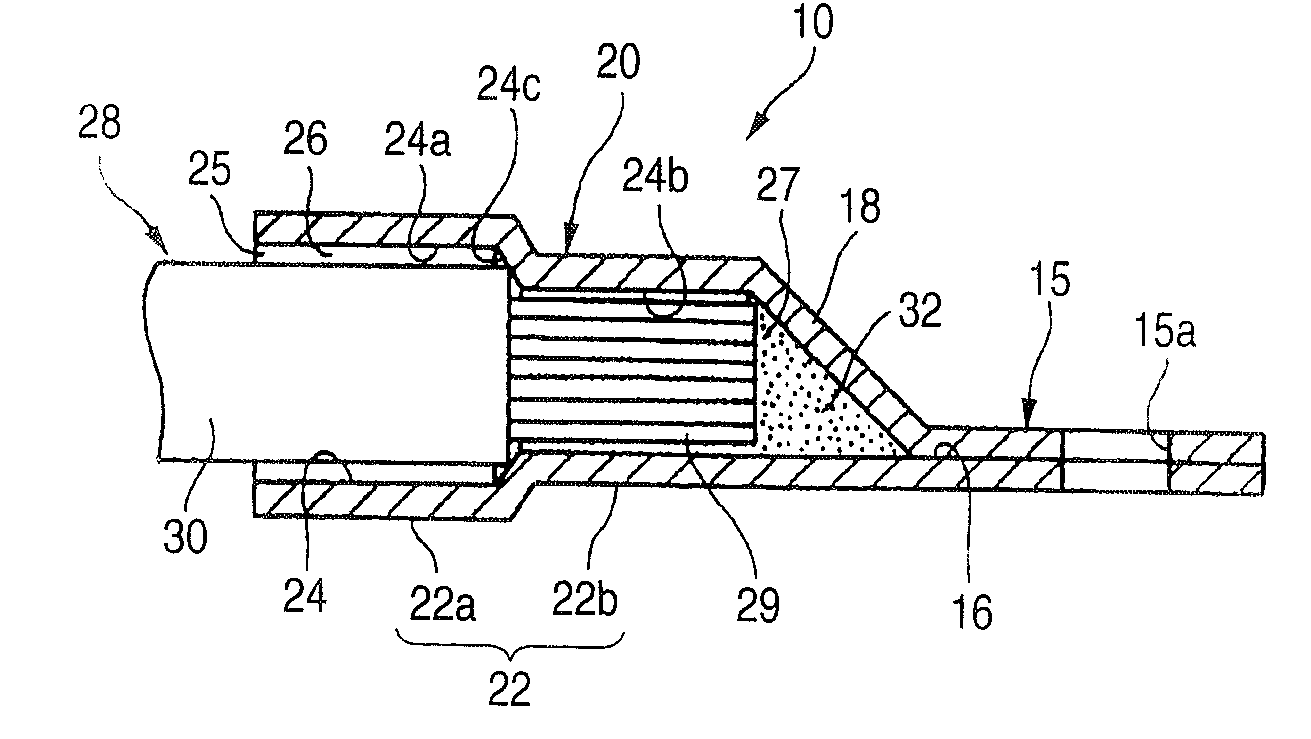

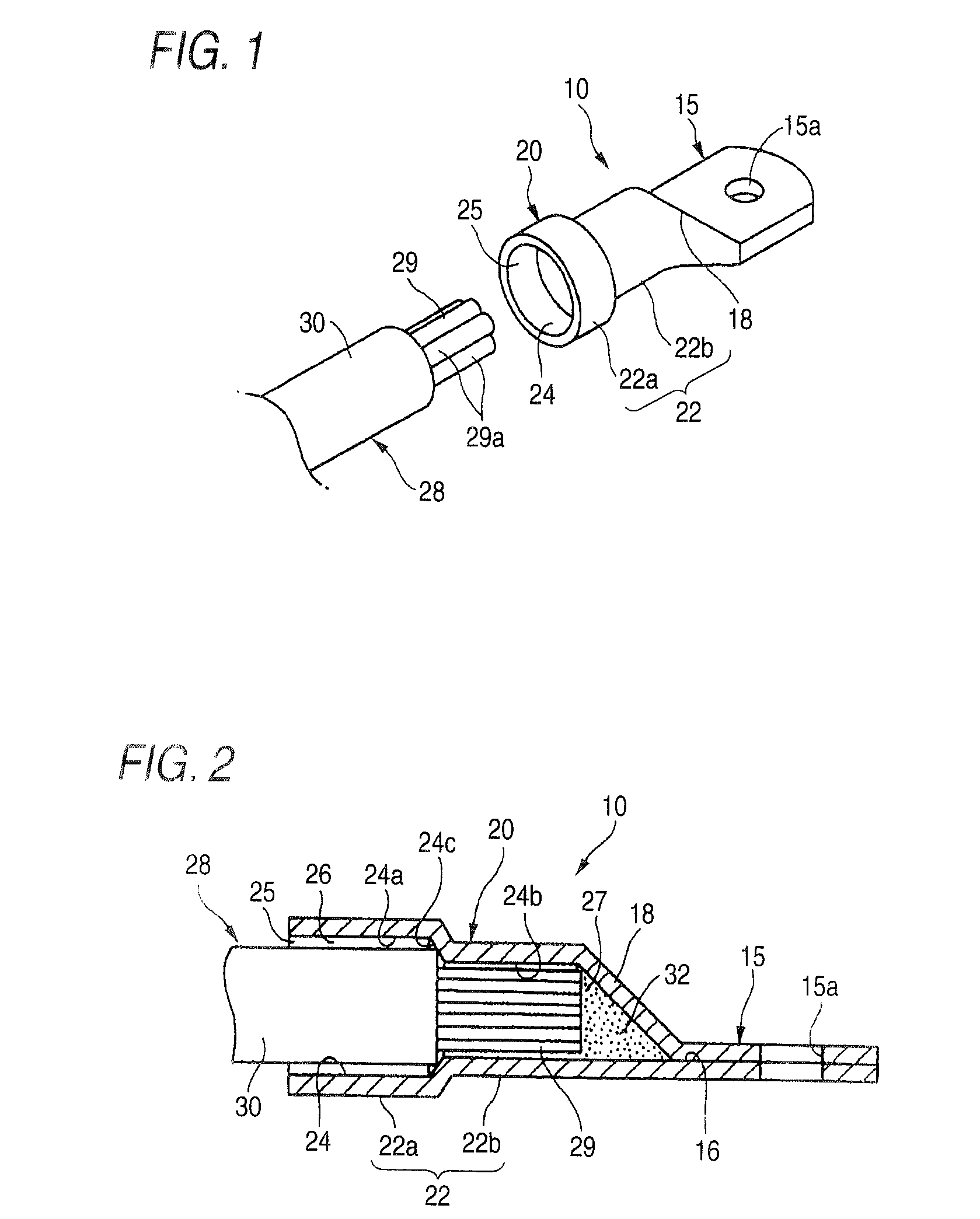

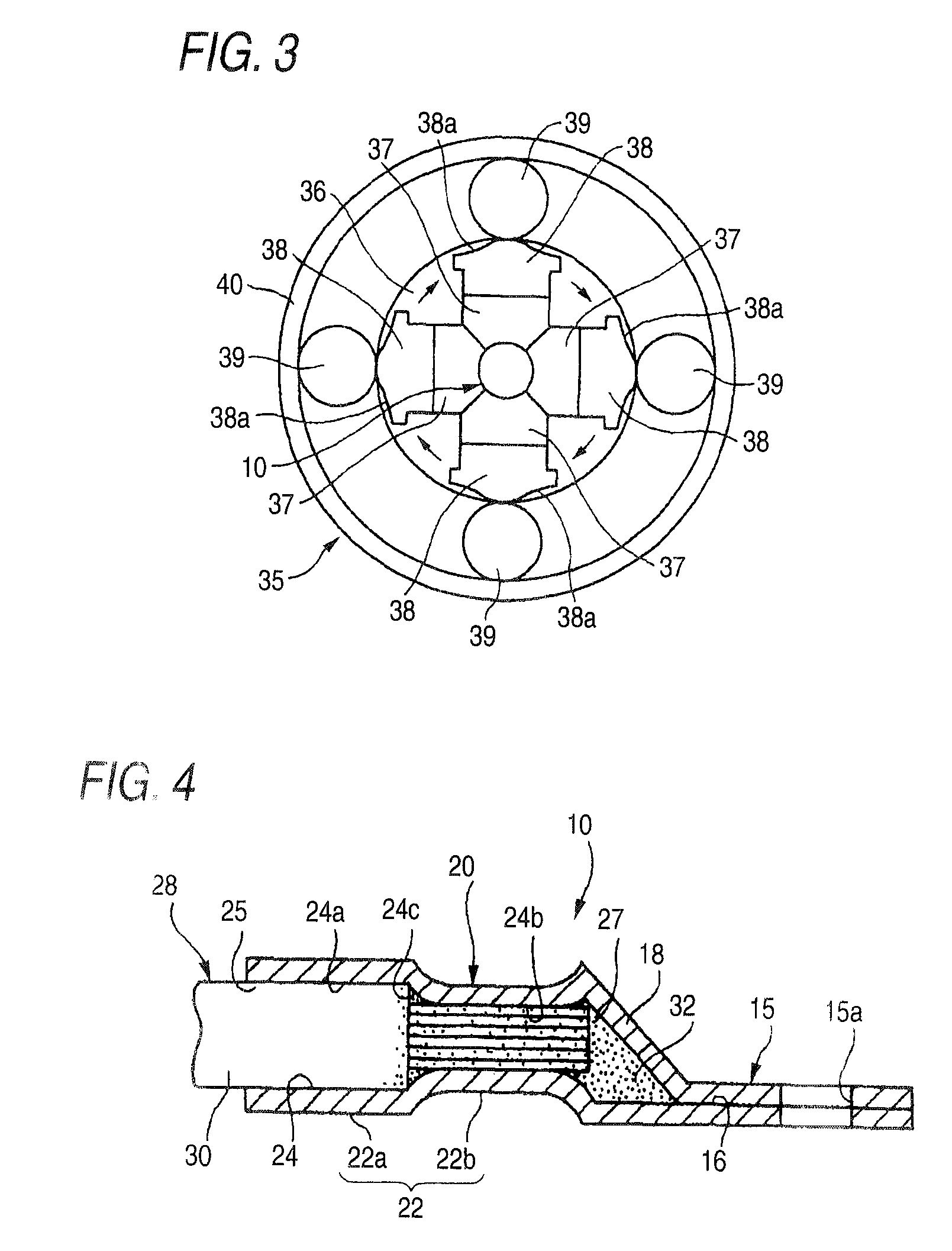

Method of connecting terminal and electric wire

ActiveUS7174633B2Few partsLow costPrinted circuit assemblingElectrically conductive adhesive connectionsEpoxyElectricity

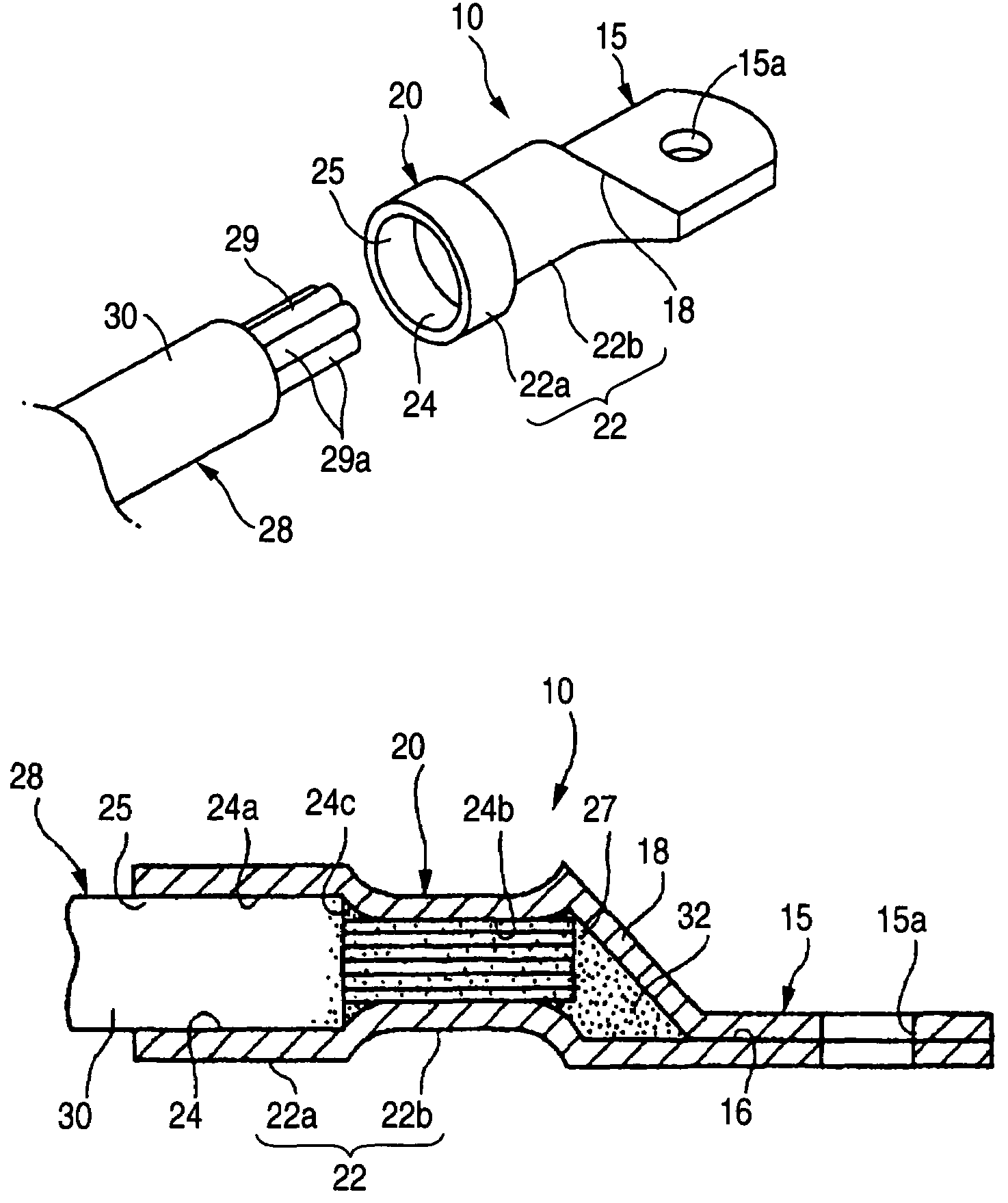

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

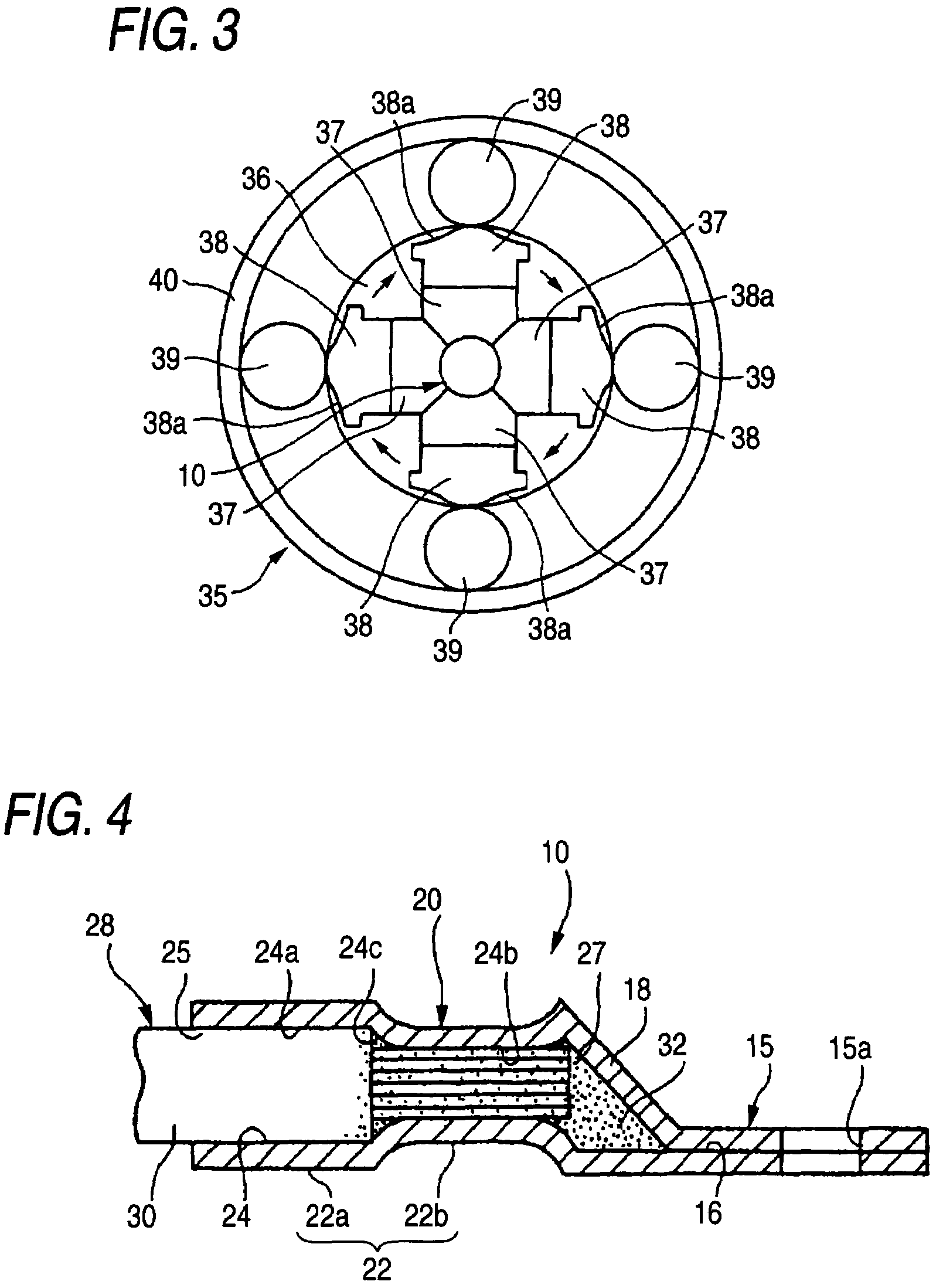

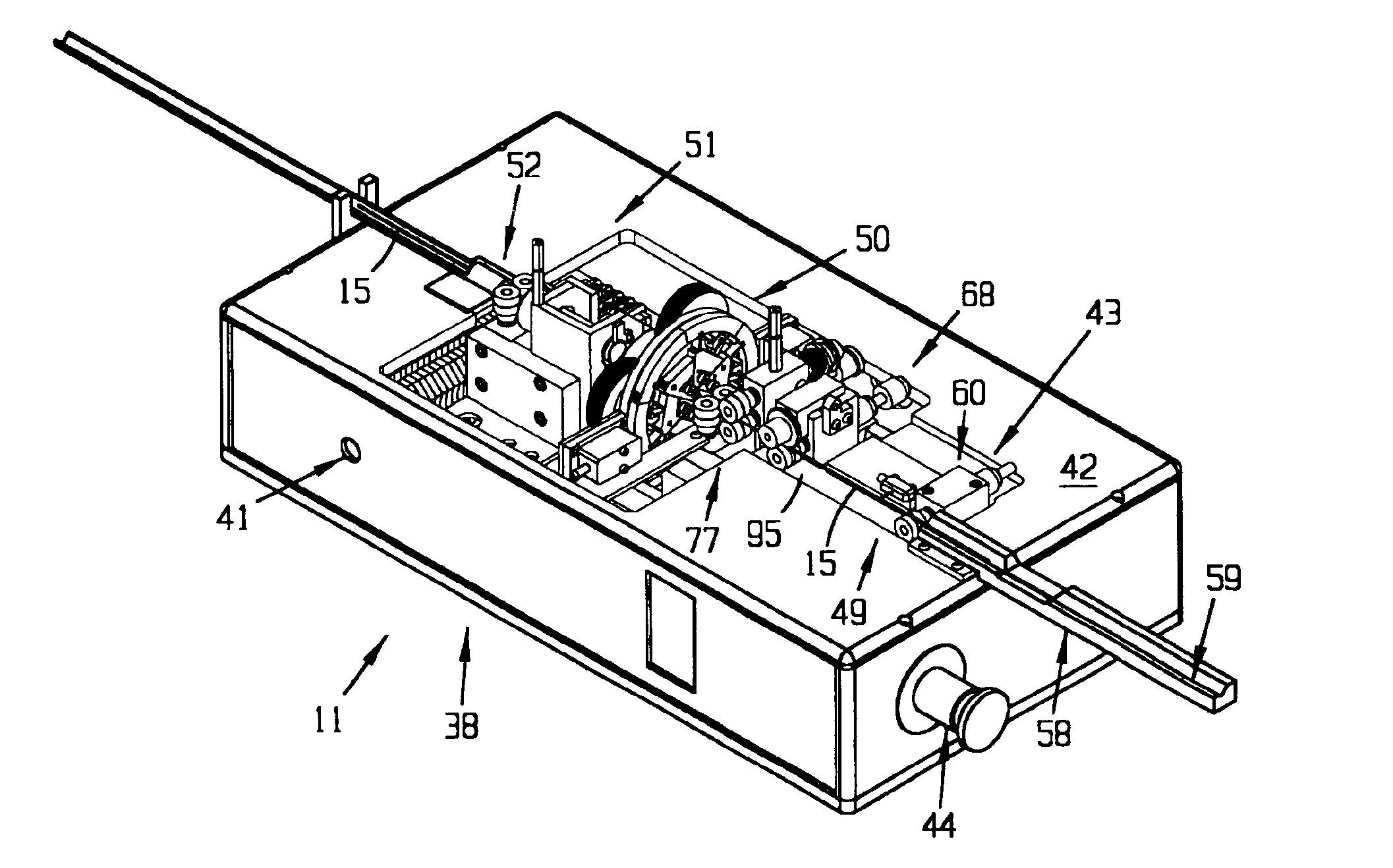

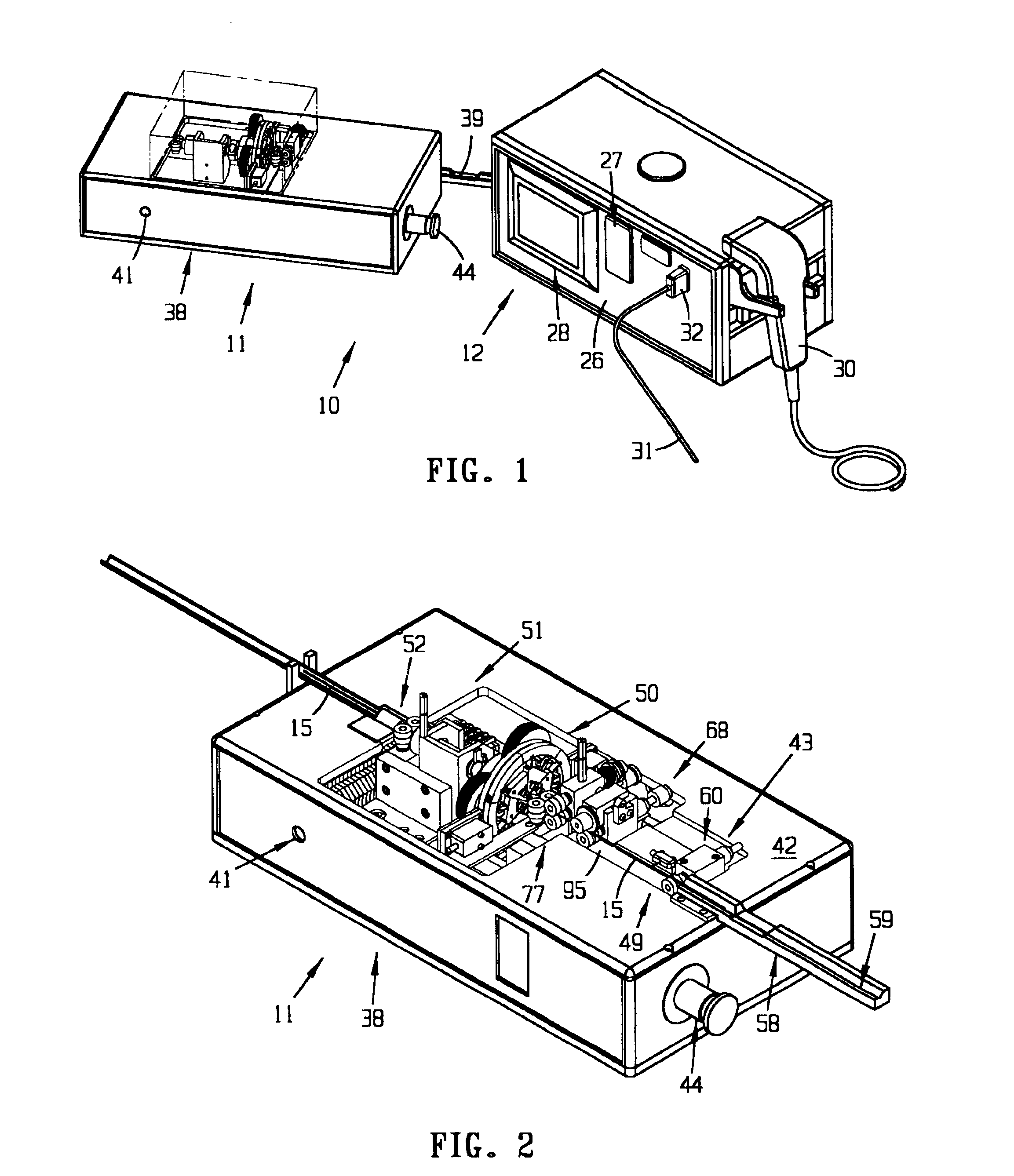

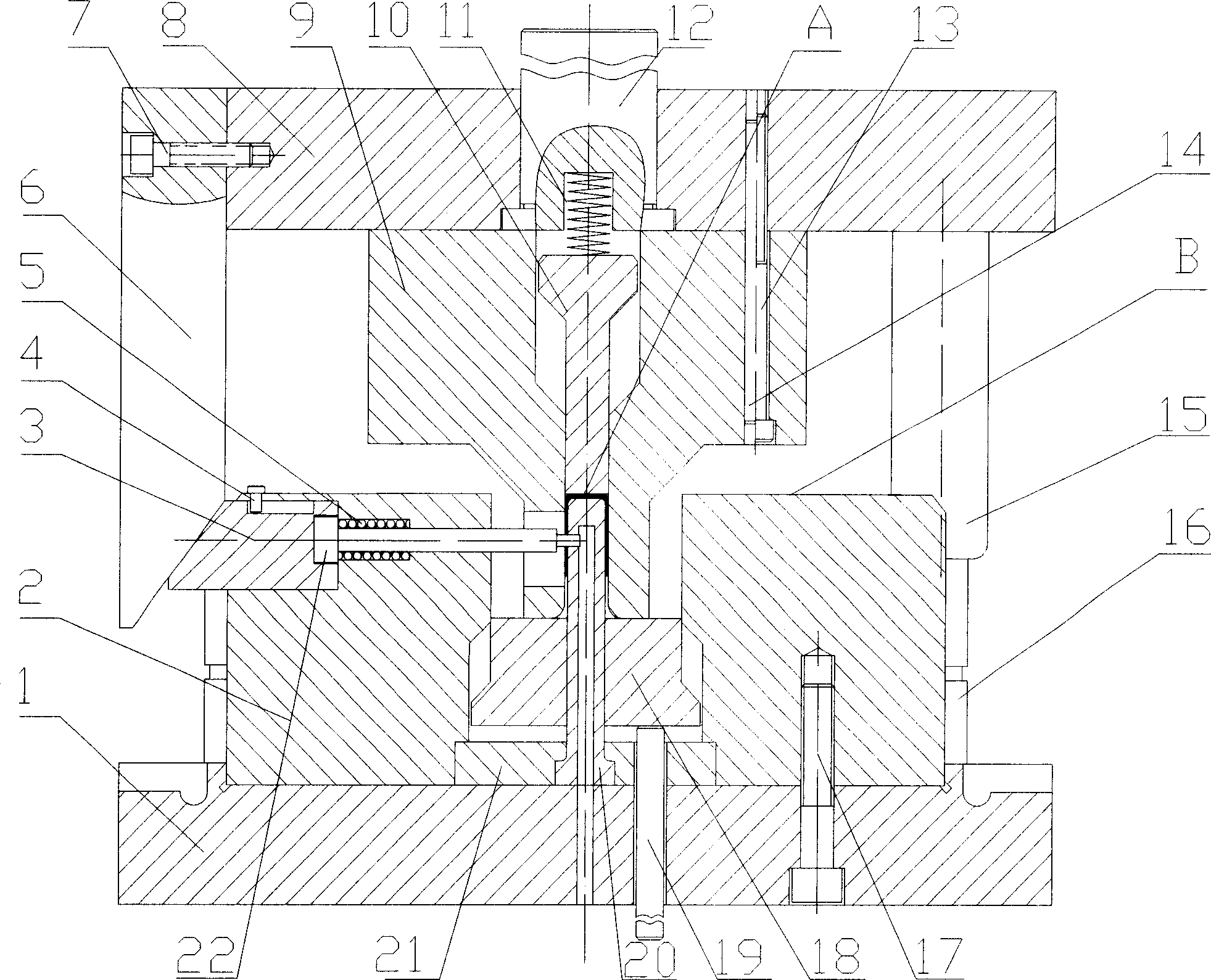

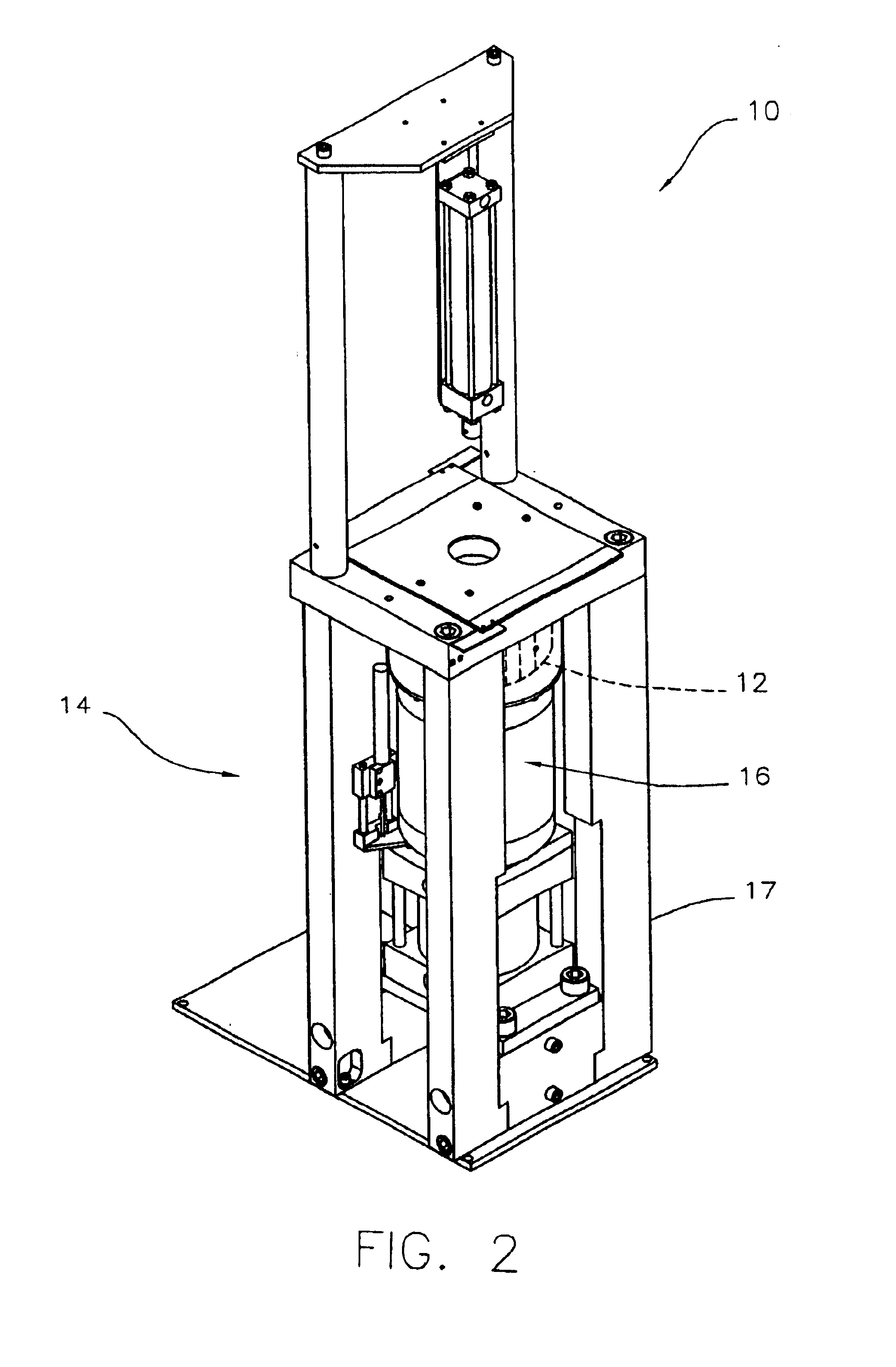

Swaging technology

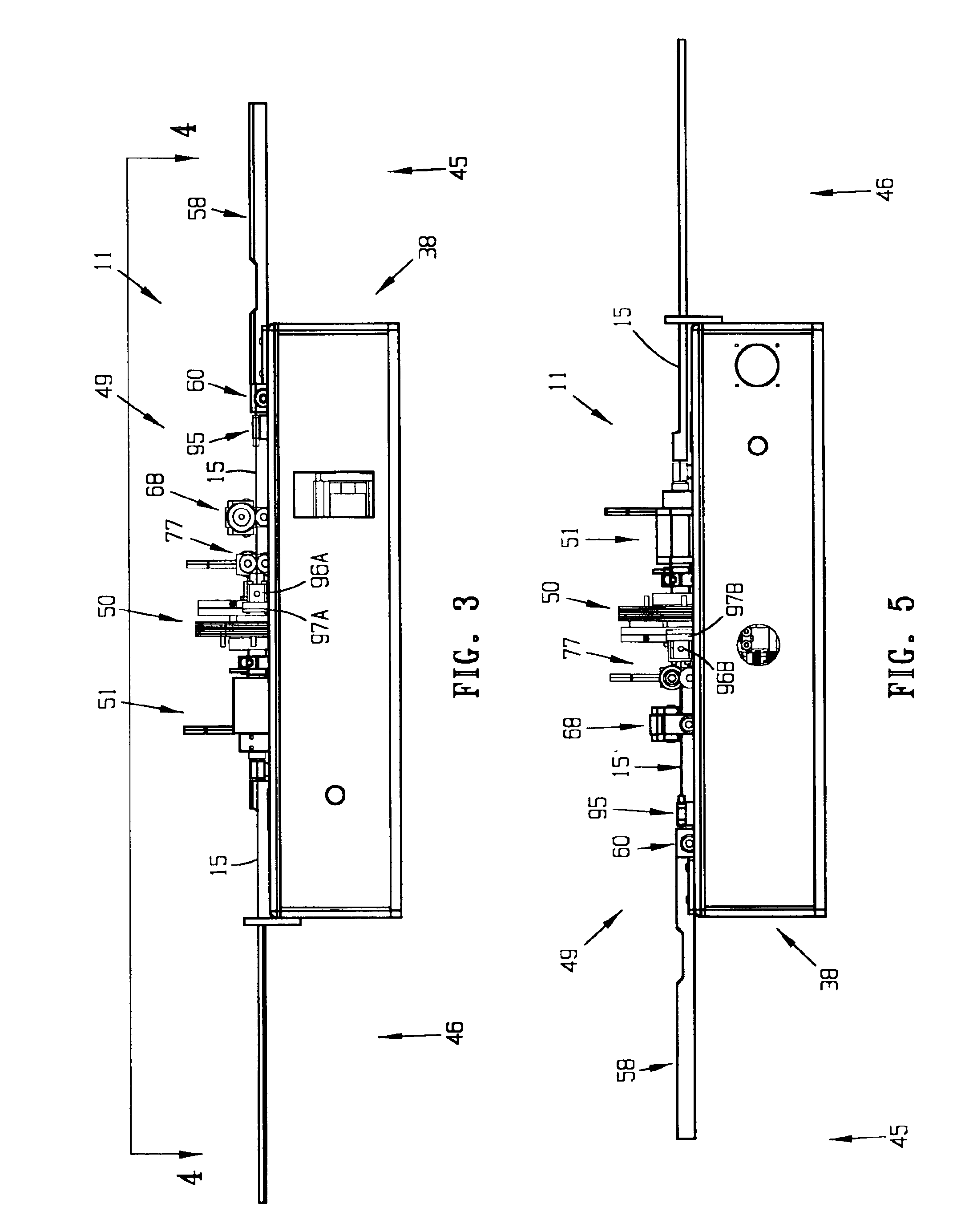

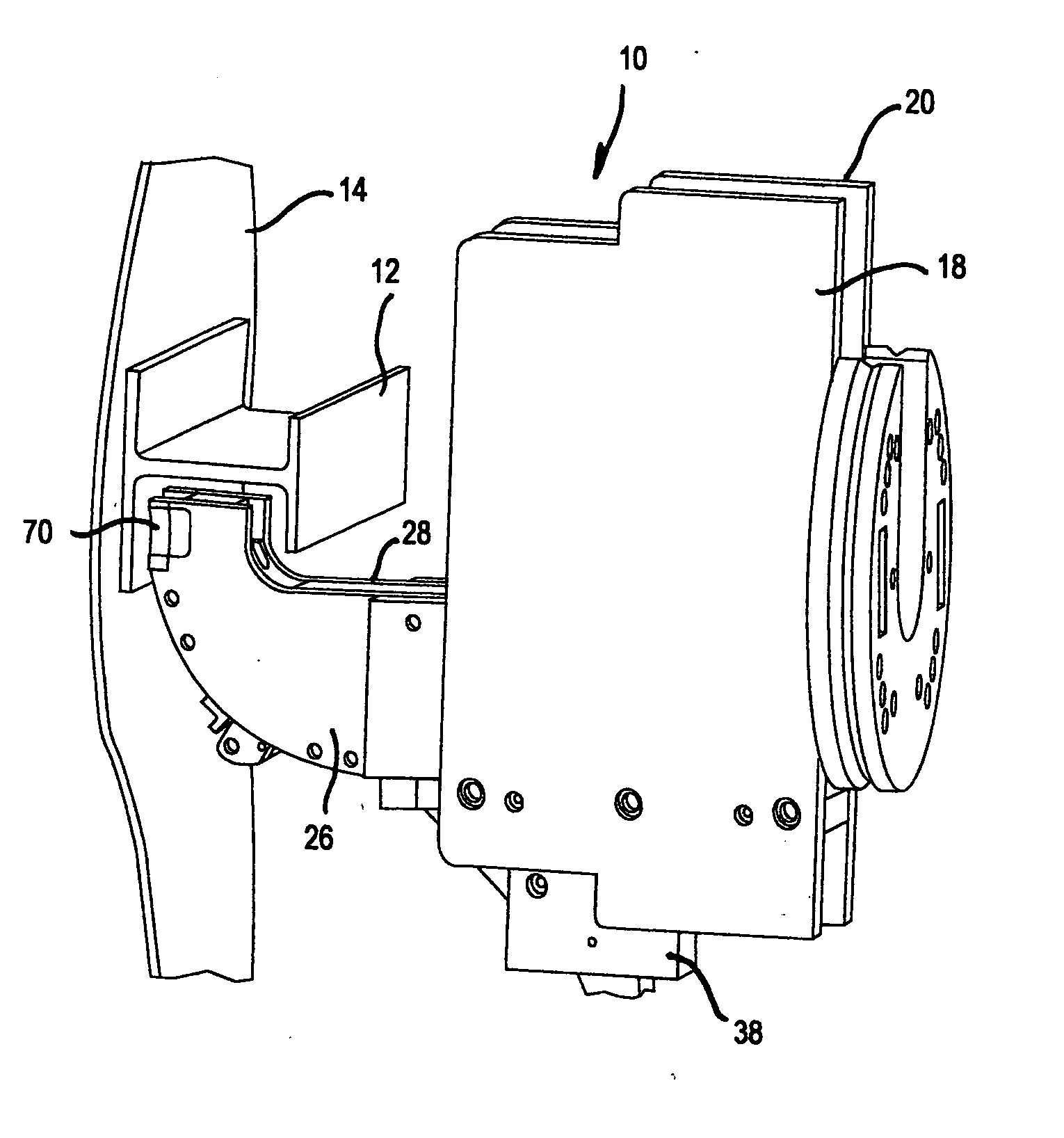

InactiveUS6931899B2Practical and reliable and accurate and efficientForging hammersShaping safety devicesEngineeringCatheter

A swager for swaging marker bands to a medical catheter, comprises an article input mechanism, the article input mechanism having a first input roller assembly for receiving and conveying an article, a first sensor for detecting a predetermined aspect of the article, a second input roller assembly for receiving and conveying the article, a positioning roller assembly for precisely aligning the article with respect to the swaging head, and a second sensor all constructed and arranged in a streamwise orientation. The swager also has a radial compression swaging head with a central swaging aperture, the swaging head being aligned and communicatively coupled with the input mechanism to receive an input article from the article input mechanism and to swage the article, the swaging head being rotatable and including (i.) a unitary die plate including a plurality of die segments movably coupled to each other to provide a radial compressive force to the article disposed in the central swaging aperture; and (ii.) a closing plate pivotally coupled with respect to each other. The swager also has an output mechanism aligned and communicatively coupled with the swaging head to receive the swaged article. A swaging head and die are also disclosed.

Owner:MACHINE SOLUTIONS

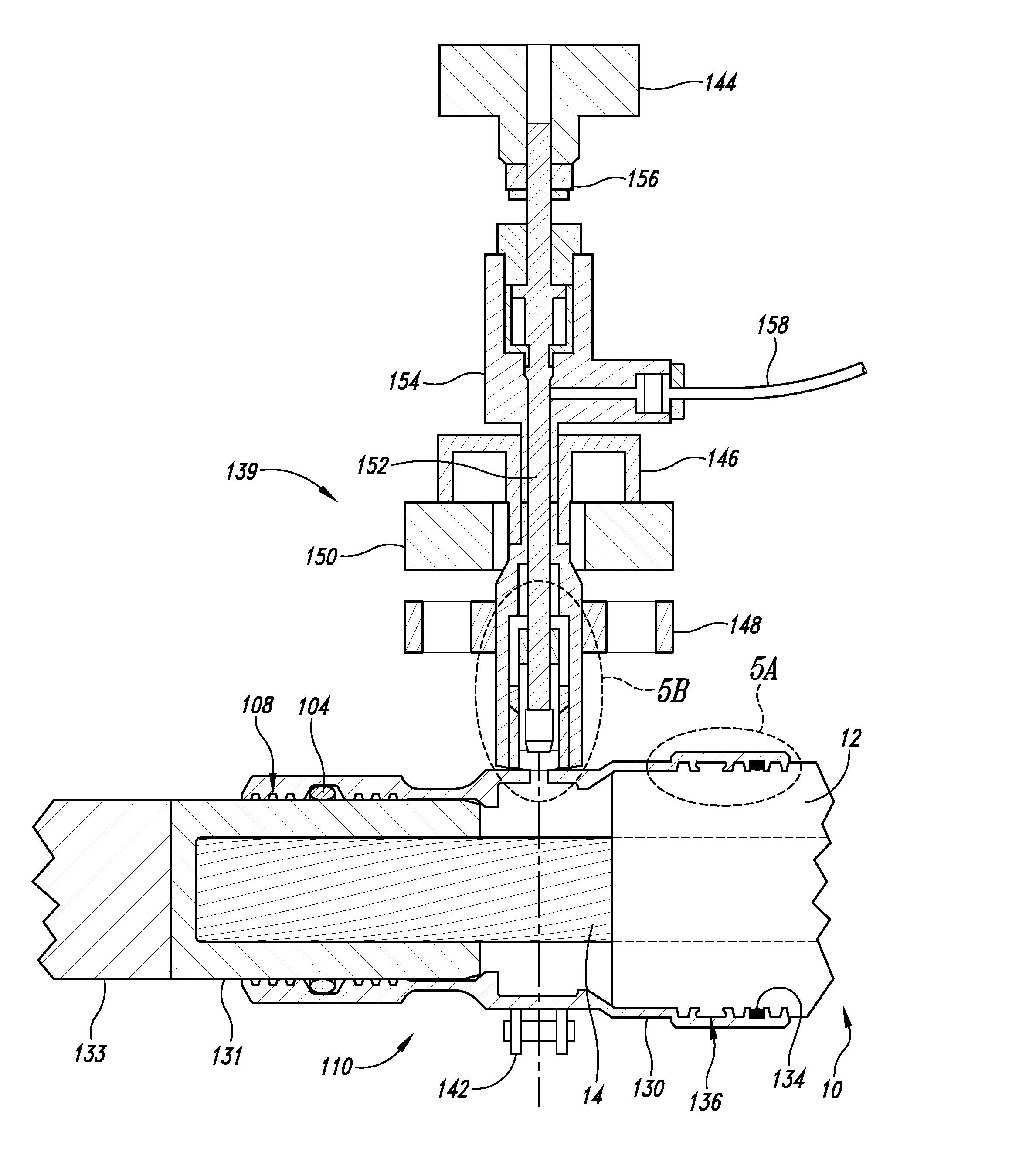

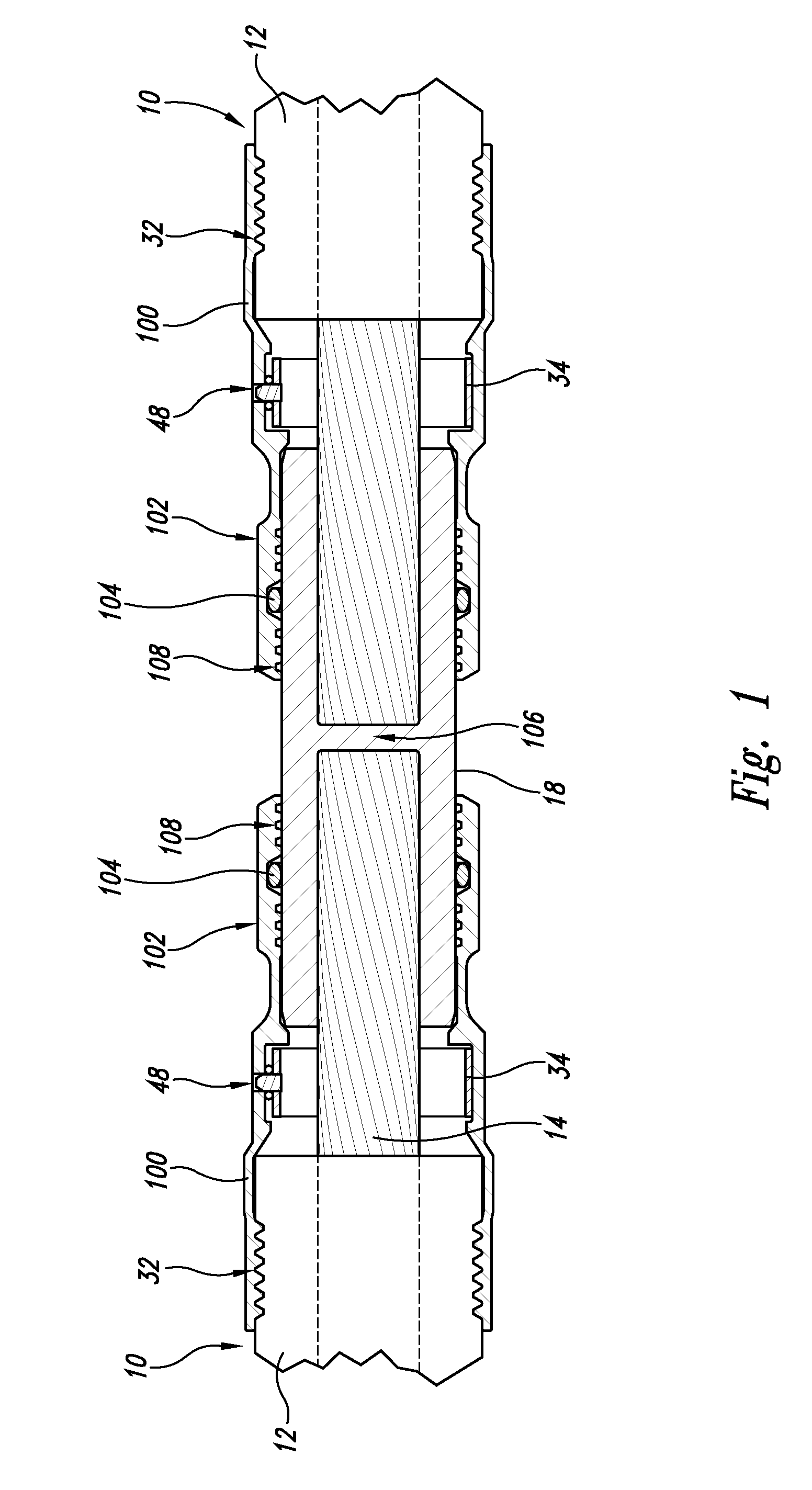

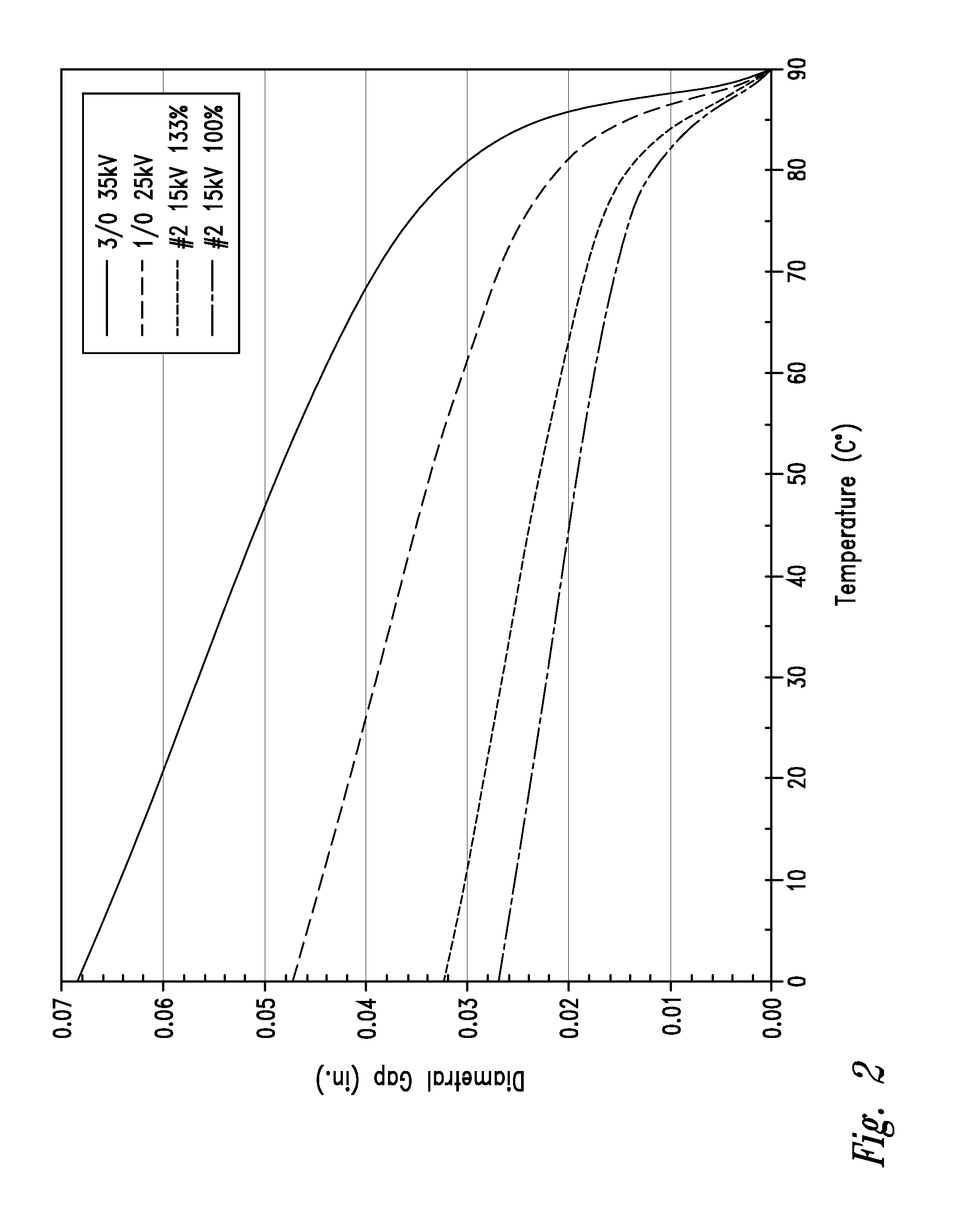

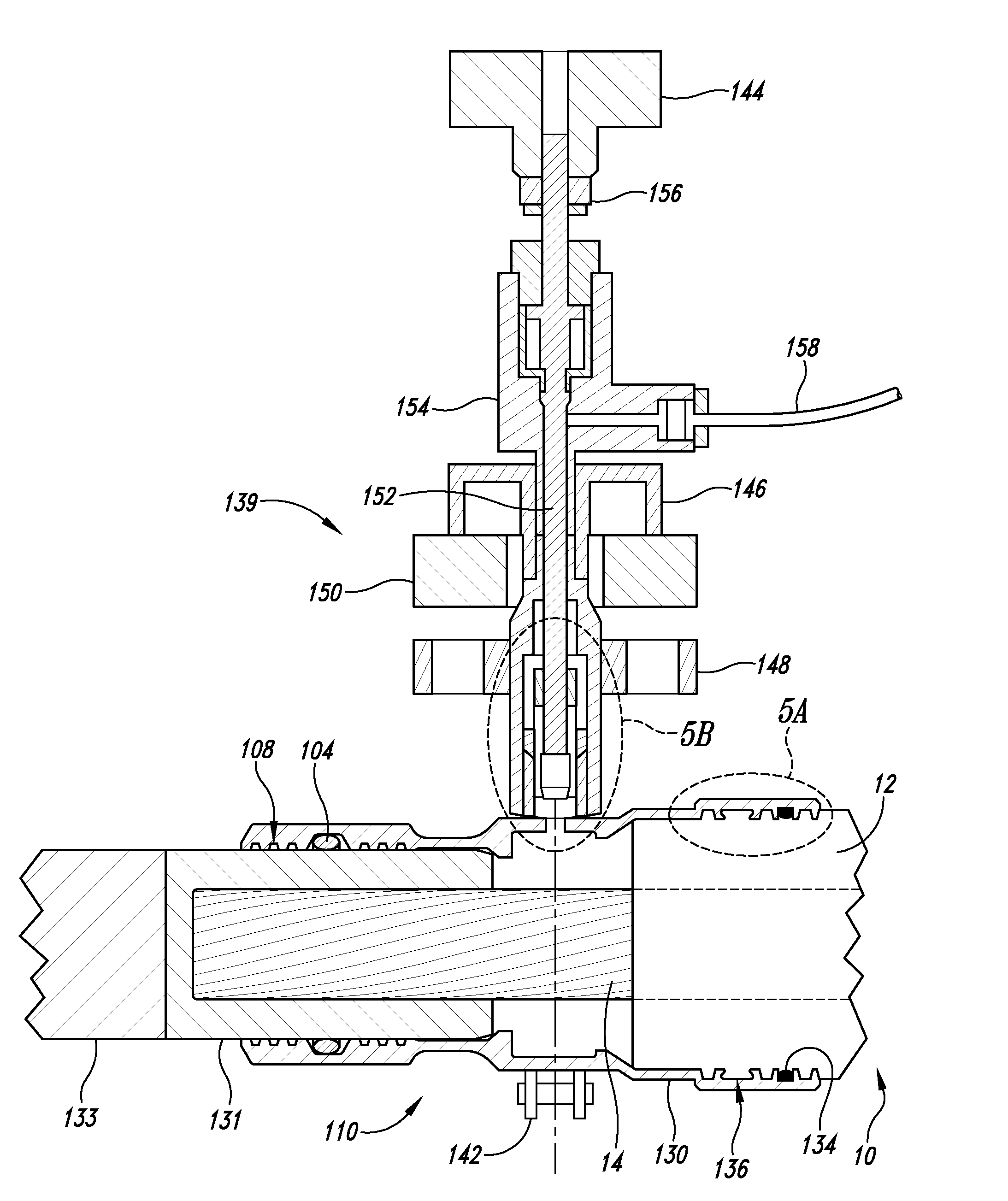

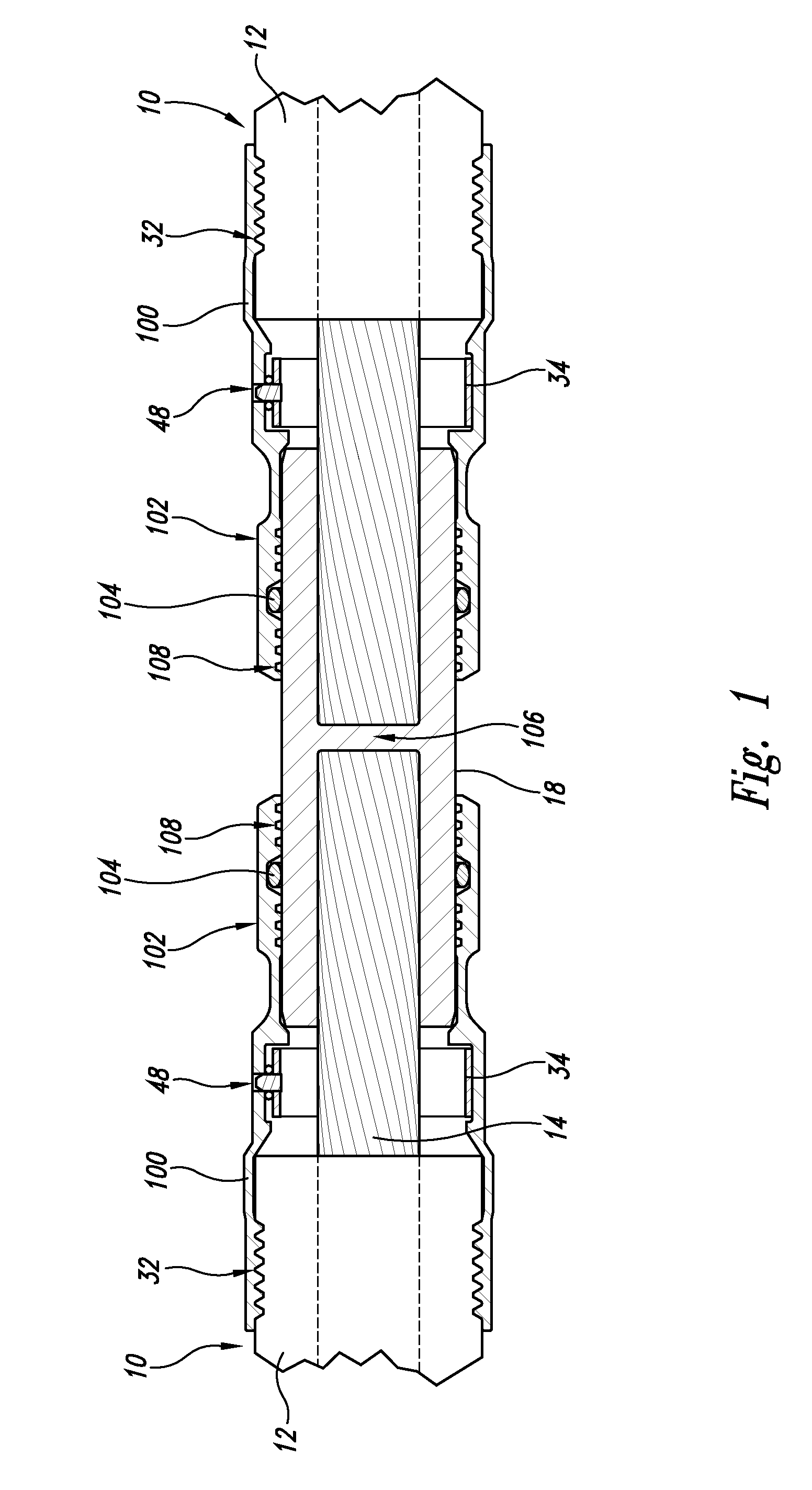

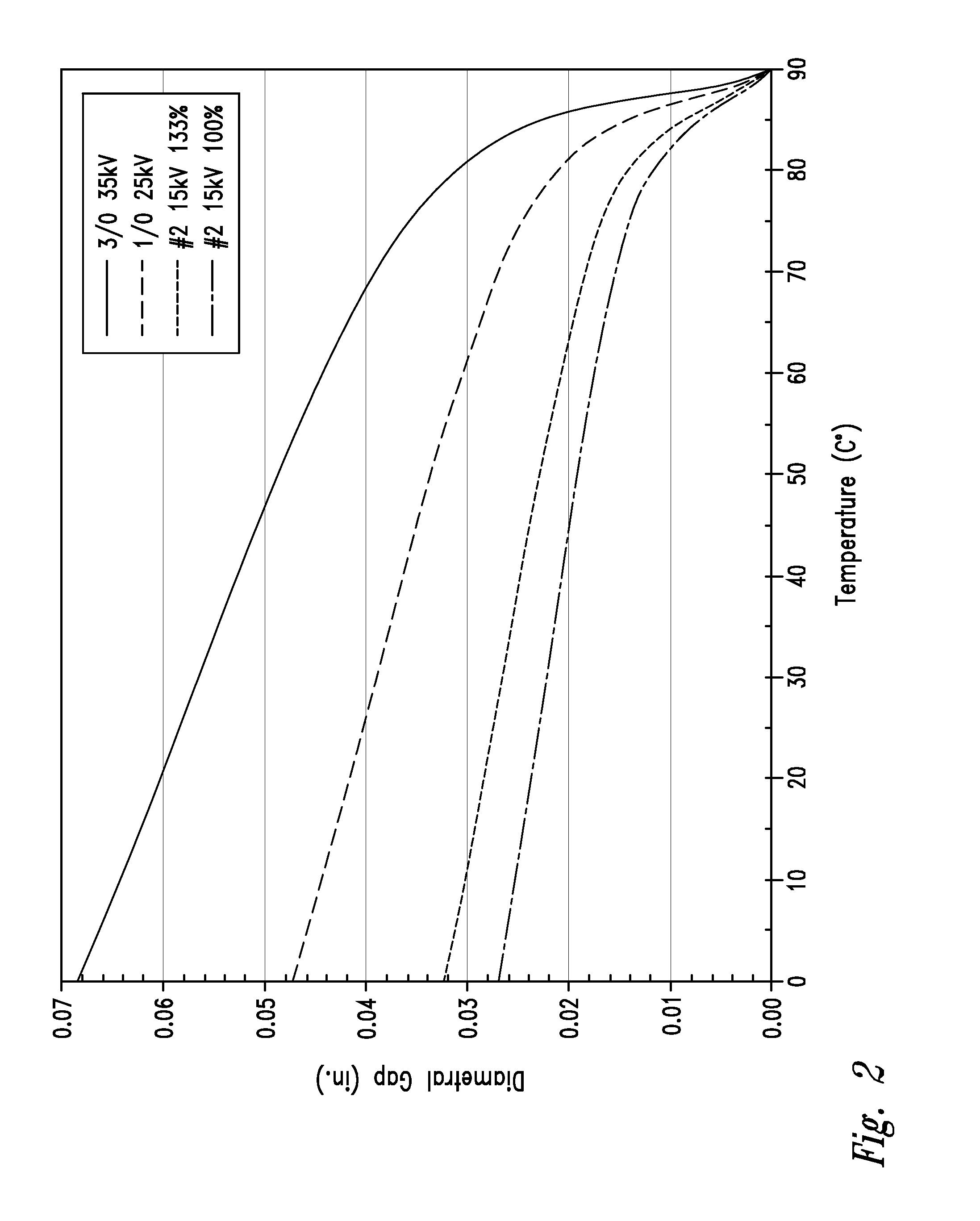

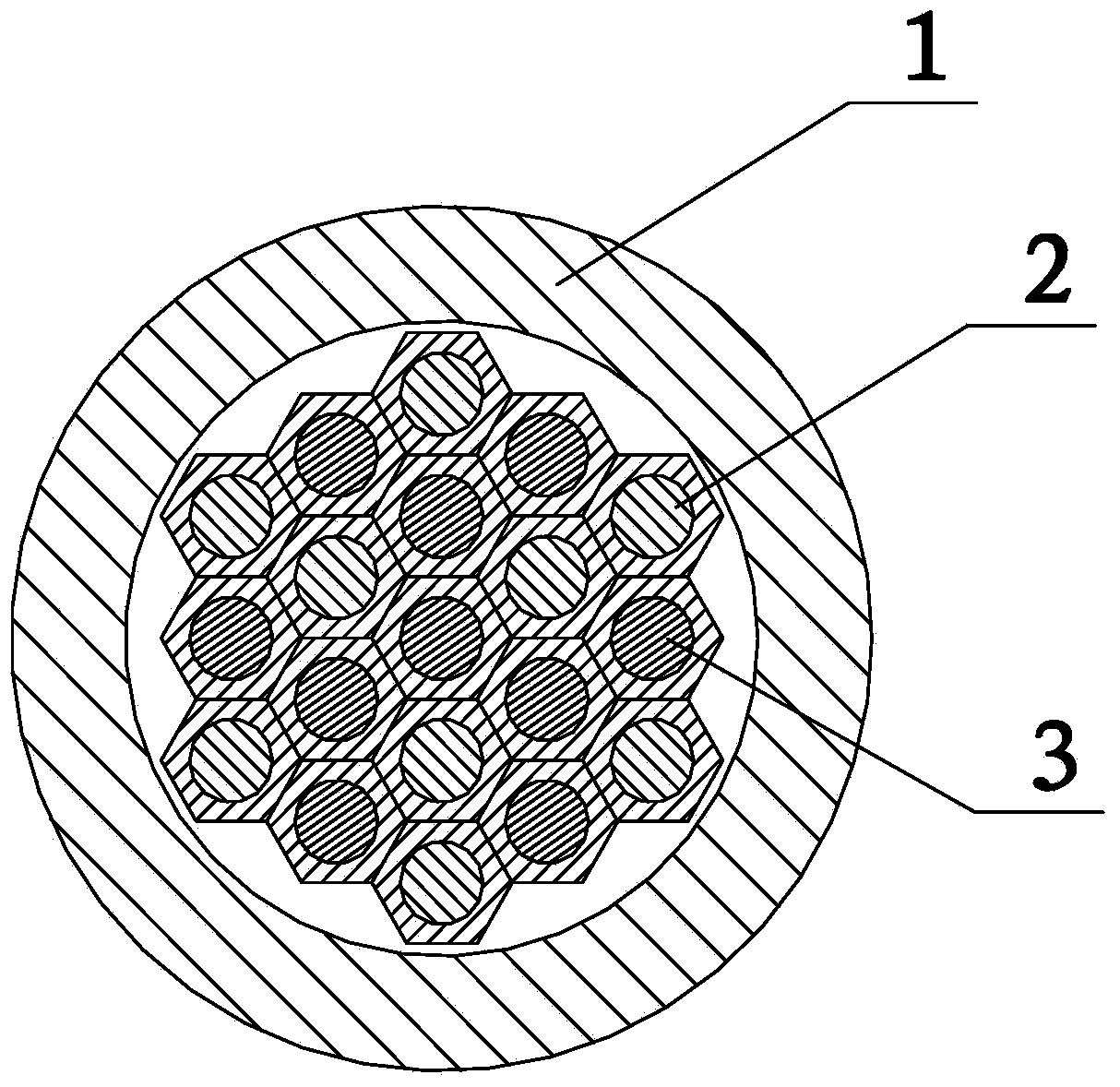

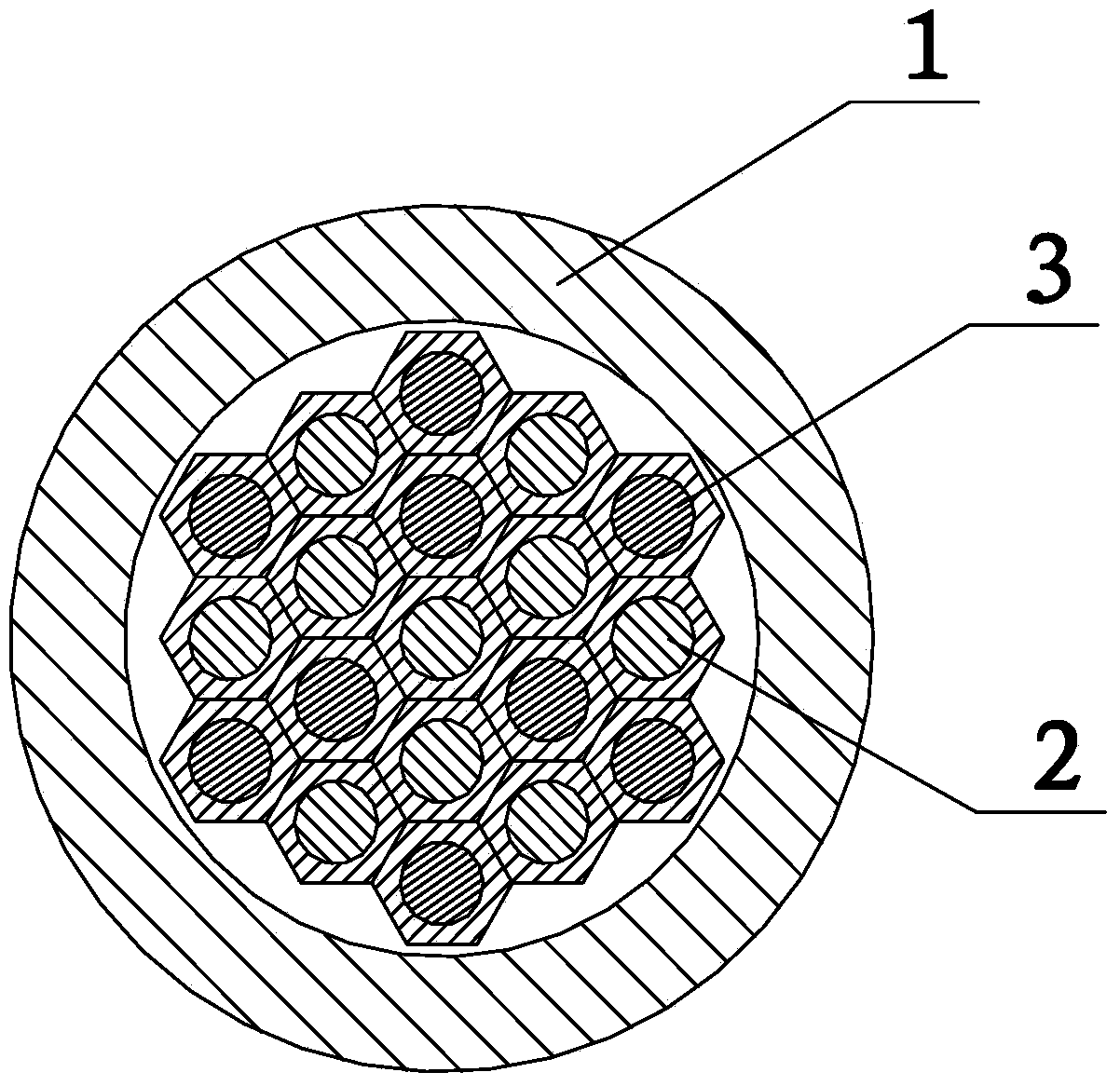

Swagable high-pressure cable connectors having improved sealing means

A high-pressure connector for an electrical power cable section having a central stranded conductor encased in a polymeric insulation jacket and having an interstitial void volume in the region of the stranded conductor, the high-pressure connector being suited for confining a fluid within the interstitial void volume at a residual pressure above atmospheric, but below the elastic limit of the polymeric insulation jacket, the high-pressure connector comprising a housing having a wall defining an interior chamber configured to be in fluid communication with the interstitial void volume and an end portion sized to receive the insulation jacket within the interior chamber and to overlap at least a portion of the insulation jacket at an end thereof with the cable section extending from the housing end portion and at least a portion of the stranded conductor positioned within the interior chamber. The housing wall of the housing end portion has an engagement portion comprised of a swagable material to secure the housing wall to the insulation jacket in fluid-tight sealed engagement therewith upon inward swaging of the engagement portion of the housing wall of the housing end portion to the insulation jacket to confine the fluid at the residual pressure within the interior chamber and the interstitial void volume. The housing includes at least one axially-projecting engagement member located within the interior chamber at the engagement portion of the housing wall of the housing end portion.

Owner:NOVINIUM LLC

Crimped/swaged-on tubing terminations and methods

InactiveUS7954861B2Quick and straightforwardGood “bite”Joints with sealing surfacesNon-disconnectible pipe-jointsEngineeringSwaging

A tubing termination comprises a termination portion adapted to make a fluid connection and a tube attachment portion, adapted to receive a tube and to be crimped or swaged. The tube attachment portion comprises a retention mechanism that is adapted to be manipulated during crimping or swaging to bite the tube so as to lock the tube attachment portion relative to the tube. This retention mechanism may take the form of a deformable bite ring, a deflectable c-insert, irregularities defined on an inner surface of the tube attachment portion, and / or the like. The tube attachment portion also may include a resilient sealing mechanism adapted to provide a seal between the tube and the tube attachment portion, and thereby a fluid-tight connection between the tube and the termination portion.

Owner:THE GATES CORP

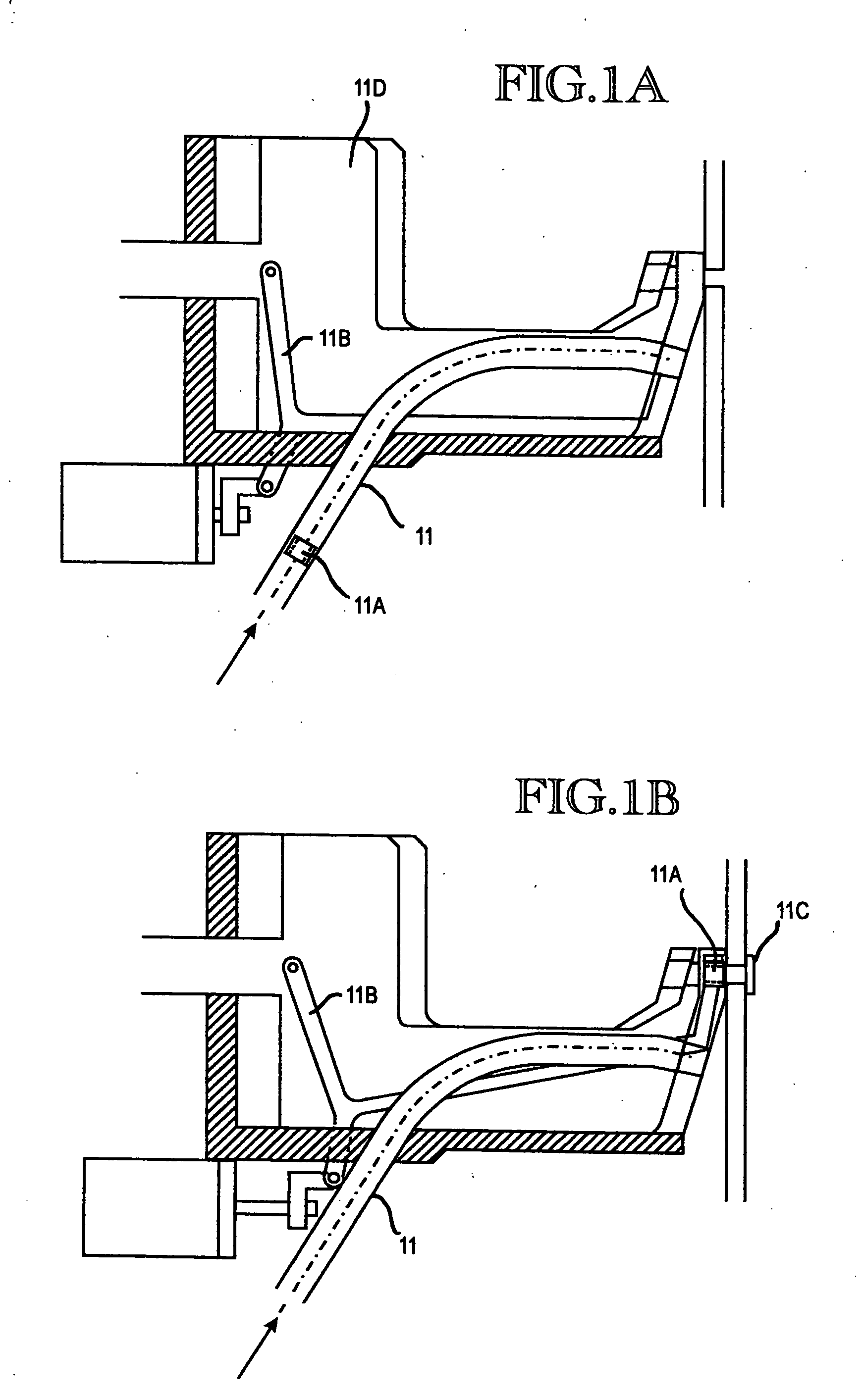

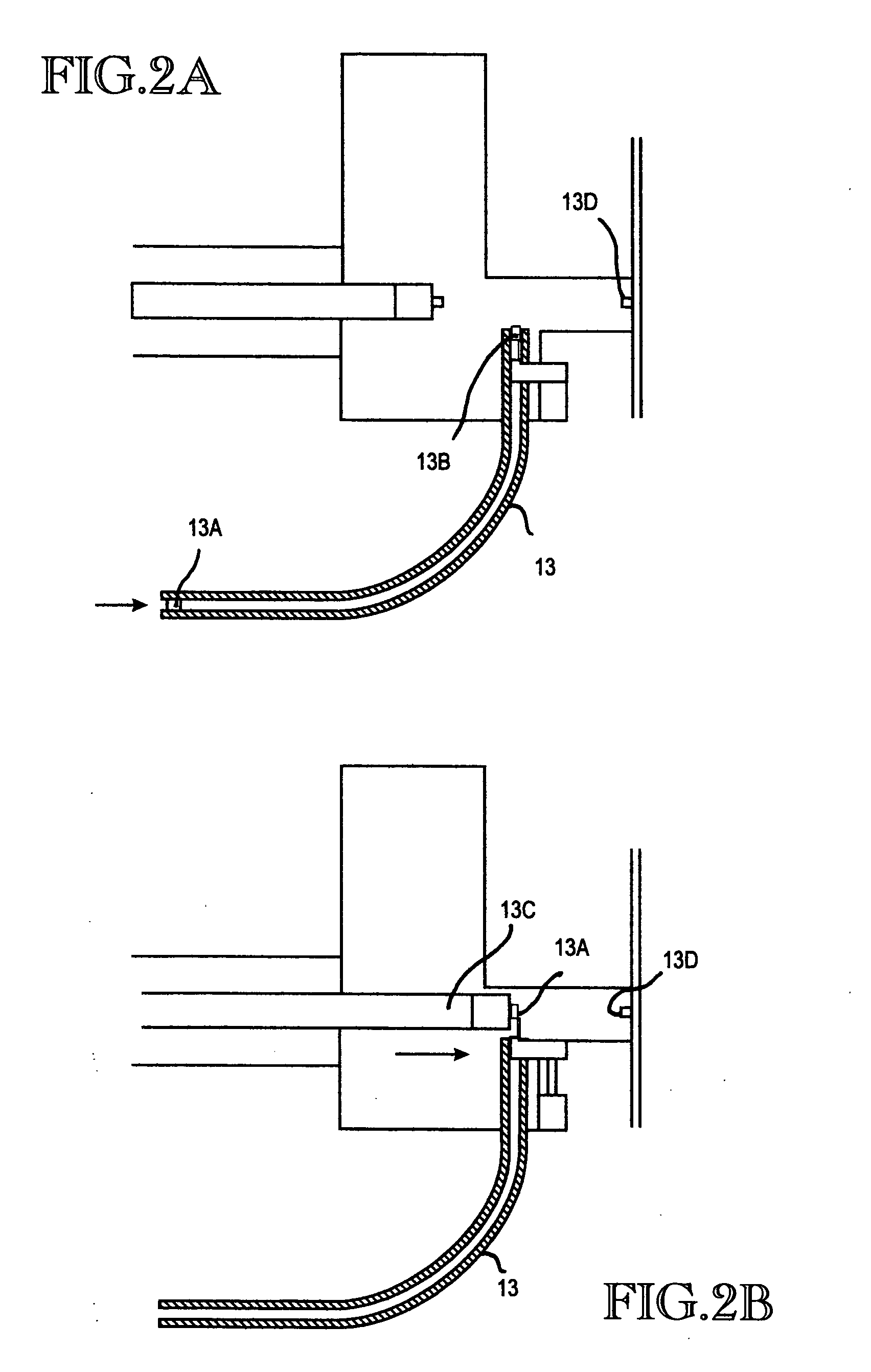

Self-aligning collar swaging system for airplane panel bolts

ActiveUS20070157453A1Prevent rotationStapling toolsAutomatic control devicesJet aeroplaneEngineering

A system and method for feeding collar members to an attachment system for assembly of aircraft and similar large scale mechanical assemblies. Collars are fed sideways along a tube having a rectangular internal cross-section to a collar pathway defined by an clamp fork and swaging ram combination. The collar pathway is curved to present the collar to a receiving element mounted on a swaging die in a proper orientation relative to an attachment bolt which is moved through an opening in the workpiece and then through the collar. As the bolt is moved into the collar, the collar, receiving element and swaging die move together laterally to come into alignment with the bolt.

Owner:ELECTROIMPACT

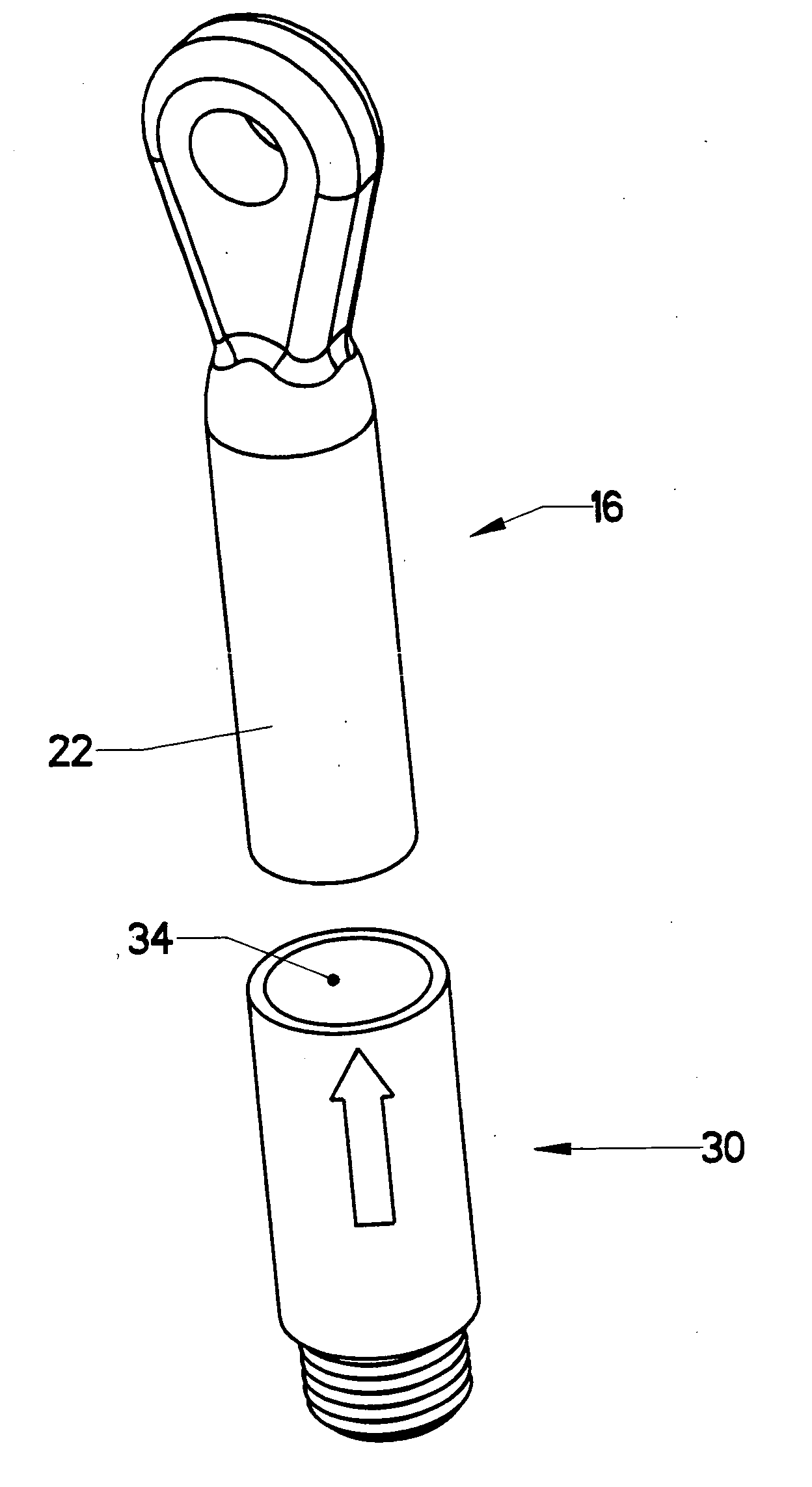

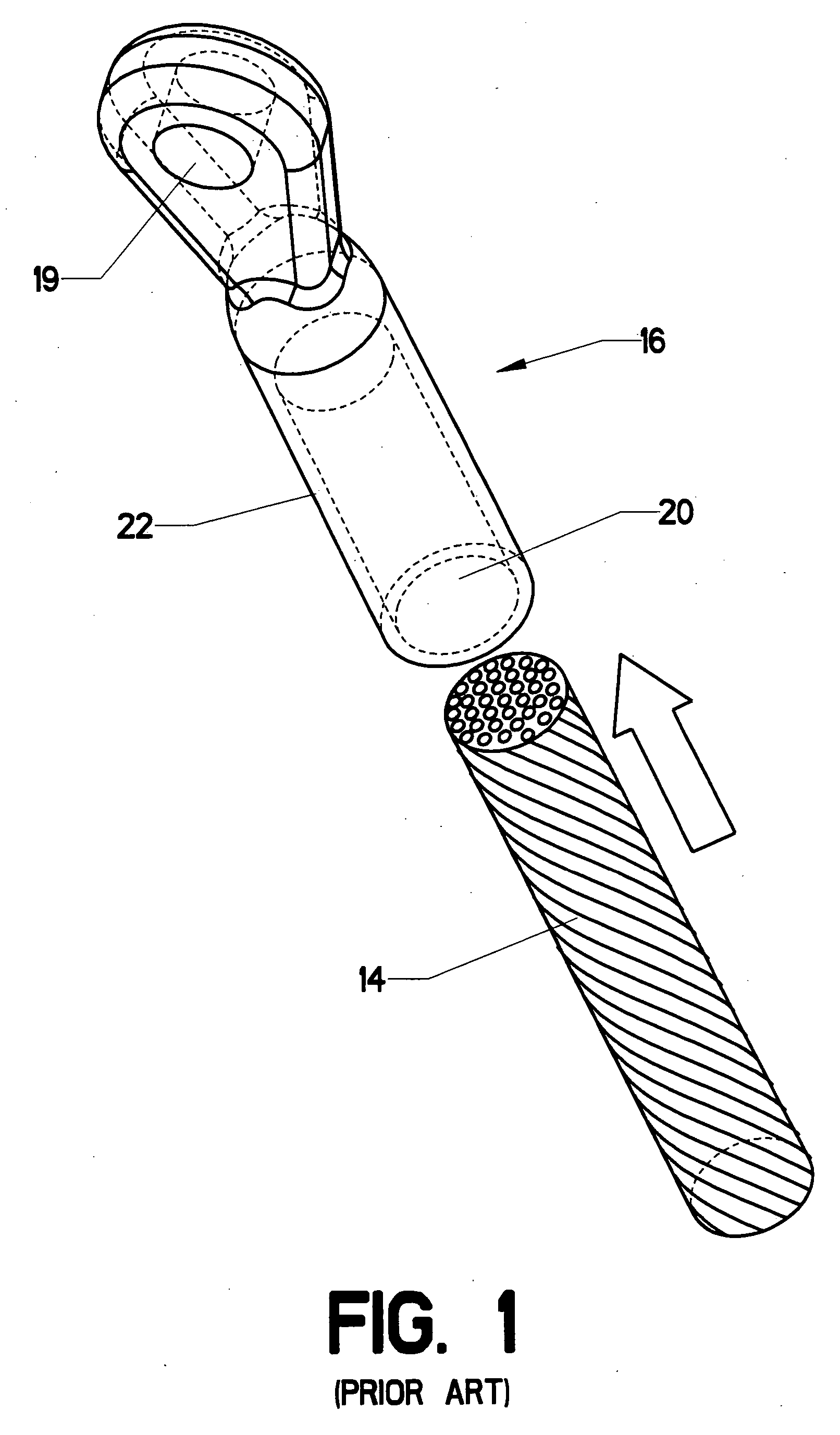

Swaged synthetic cable terminations

ActiveUS20060160435A1Engagement/disengagement of coupling partsRopes and cables for vehicles/pulleySwagingScrew thread

A connecting system which allows a standard rigging fixture to be connected to a synthetic cable termination by swaging. The cable termination is provided with a swaging sleeve. When the standard rigging fixture is placed next to the termination, this swaging sleeve is swaged over a portion of the standard rigging fixture in order to lock the standard rigging fixture to the termination. The provision of the swaging sleeve on the termination is accomplished using a variety of approaches, including forming the swaging sleeve as part of an anchor, providing a separate swaging sleeve attached by threads, and forming the anchor and swaging sleeve with two separate swaging operations.

Owner:BRIGHT TECH CO LTD

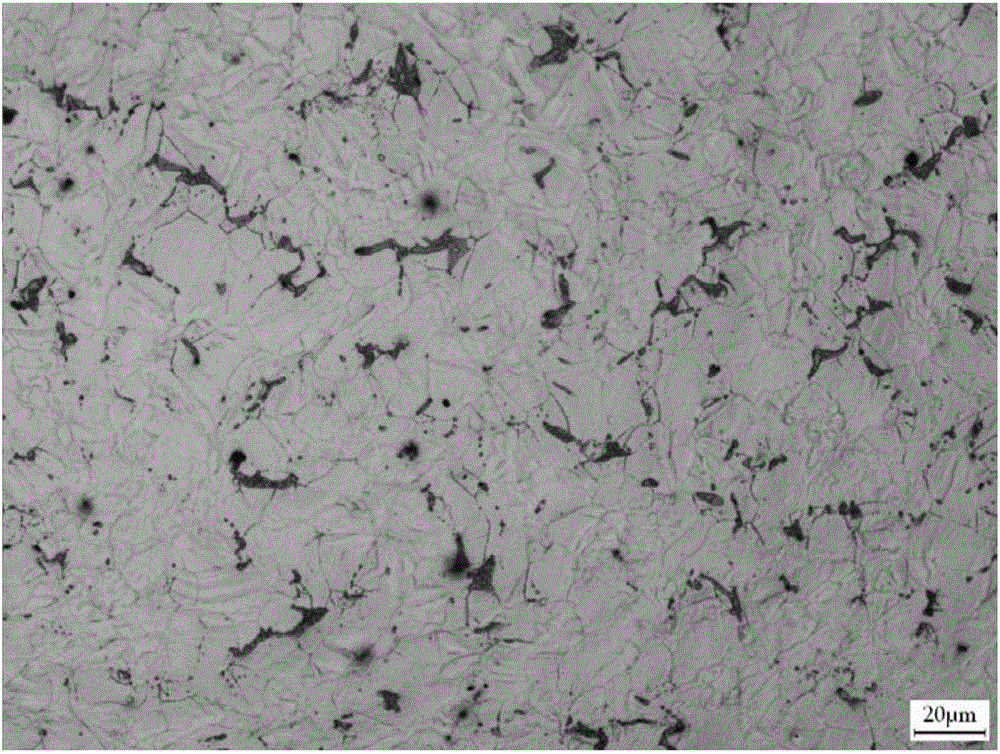

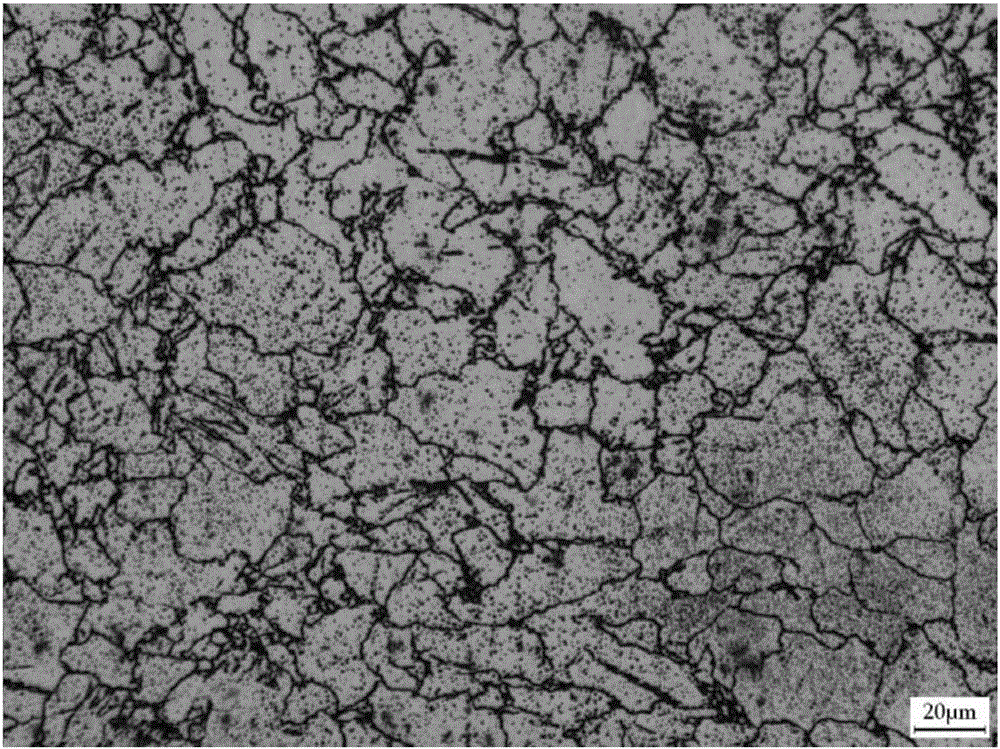

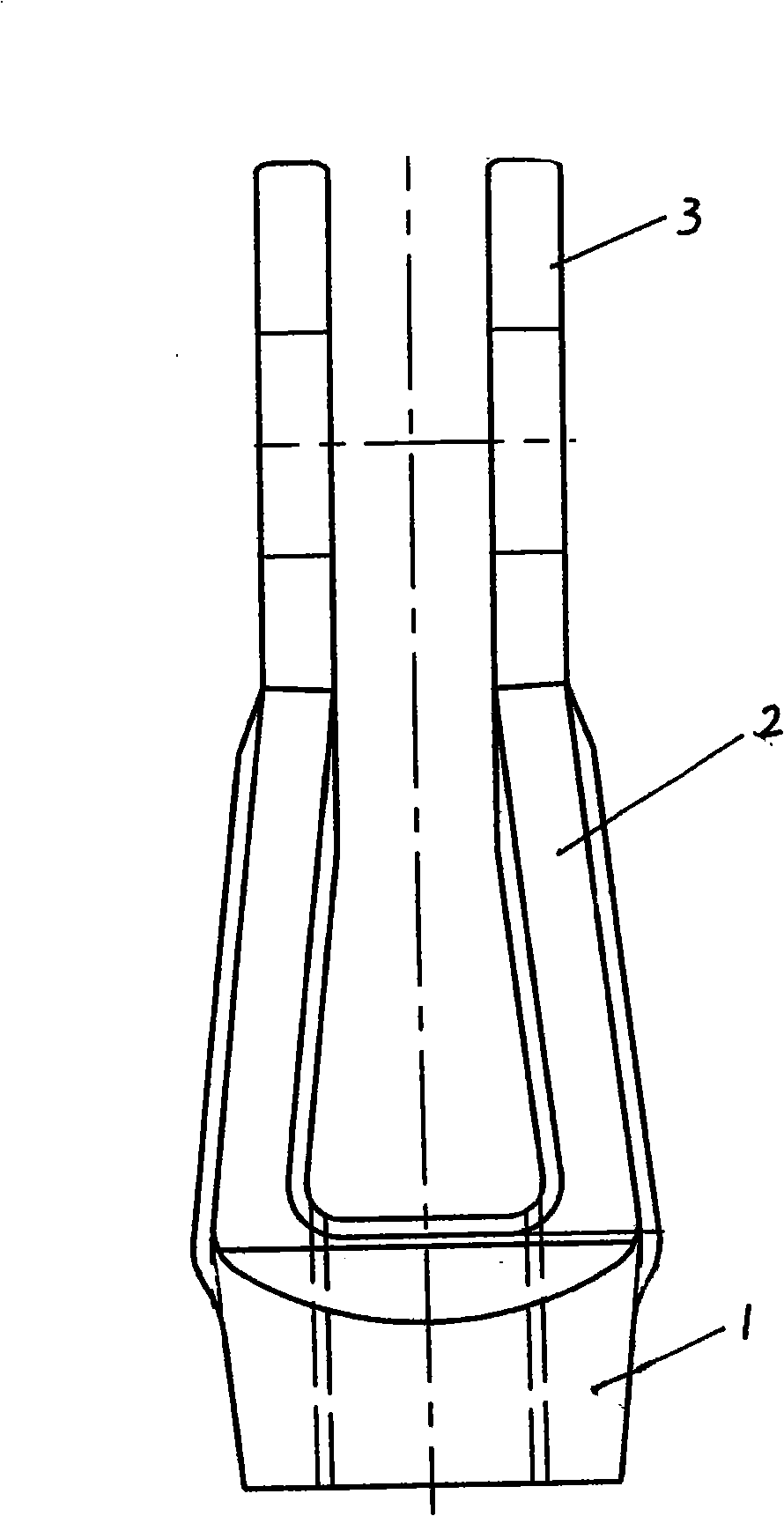

Machining method of small-specification high-strength magnesium alloy bars

The invention discloses a machining method of small-specification high-strength magnesium alloy bars. The method comprises the steps as follows: magnesium alloy bar blanks are subjected to multi-pass hot-swaging at a certain temperature, magnesium alloy bars with the diameter not larger than 10 mm are obtained and have the tensile strength larger than 290 MPa, the yield strength larger than 250 MPa and the cumulative compression rate ranging from 60% to 98%, intermediate annealing treatment is performed when the cumulative compression rate of hot-swaging exceeds 70%, and the cumulative compression rate between two adjacent times of intermediate annealing treatment ranges from 70% to 85%. The small-specification magnesium alloy bars are machined with the online heating and continuous hot-swaging method, and the method has the characteristics of being accurate in temperature control, high in heat efficiency, uniform and stable in bar performance and high in linearity. Besides, if the magnesium alloy bars are machined with the method, the single-pass compression rate of the bar can be increased, grains can be refined, and the second phase can be crushed, so that the strength of the bars can be substantially improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Loose metal litter briquetting machine and processing method

InactiveCN102101364AImprove compression efficiencyImprove work efficiencyPressesHigh densityReciprocating motion

The invention relates to a loose metal litter briquetting machine. A vertical main cylinder is arranged at the top of a stand, a piston of the main cylinder is connected with a punch in up-and-down reciprocating motion in a final pressure swaging bucket, a soleplate for sealing the bucket bottom is arranged at the bottom of the swaging bucket and controlled by a horizontally arranged knife gate cylinder, the middle of the swaging bucket is horizontally provided with a pushing cabin which is in sealed connection and vertical intersection with the swaging bucket; the tail end of the pushing cabin is provided with a pushing head connected with a piston of a pushing cylinder piston, the pushing cabin is provided with an open side which is communicated with the bottom of a feeding hopper, a precompression pushing head is arranged at the other side of the bottom of the feeding hopper and connected with a piston of a precompression cylinder. The precompression cylinder, the pushing cylinder and the main cylinder provided by the invention respectively extrude materials in the three directions of the X axis, the Y axis and the Z axis to effectively improve the compression efficiency of the materials and finally obtain high-density litter cakes while cutting coiled wires and separating litter liquid and have high degree of automation and good economic benefits.

Owner:JIANGYIN RUIFENG HYDRAULIC MACHINE CO LTD

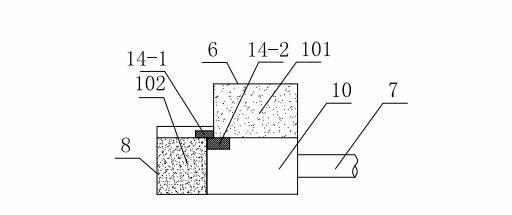

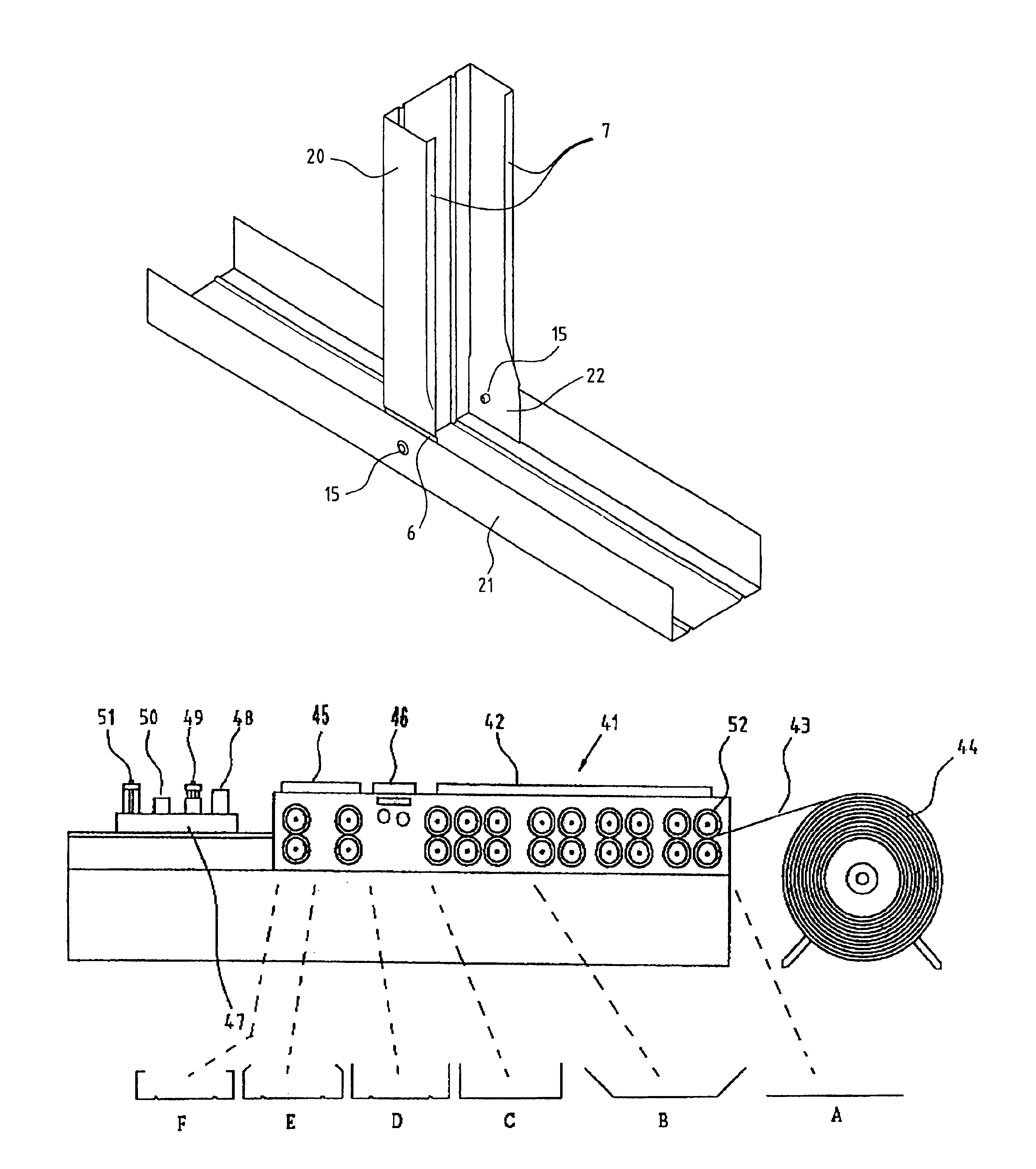

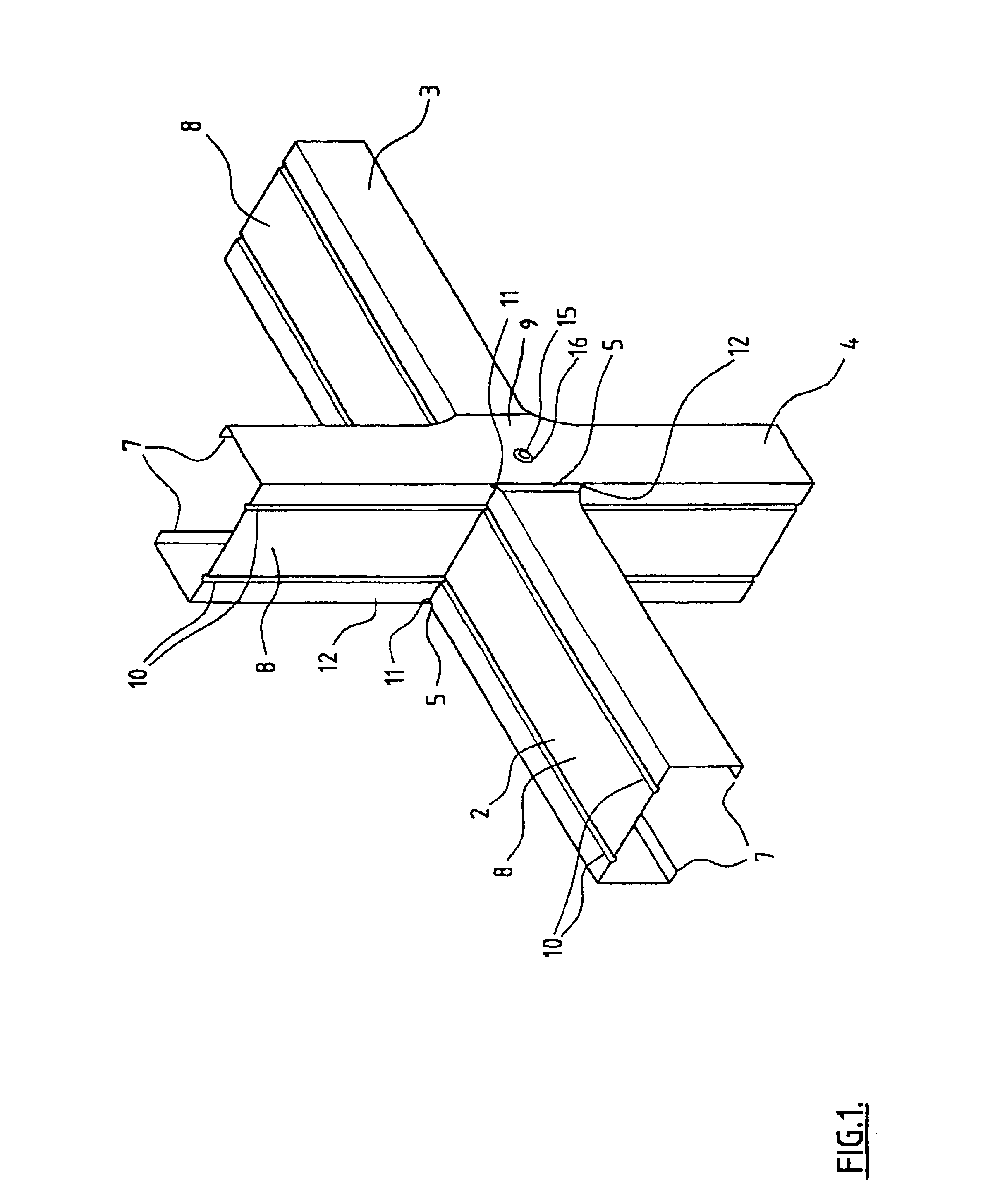

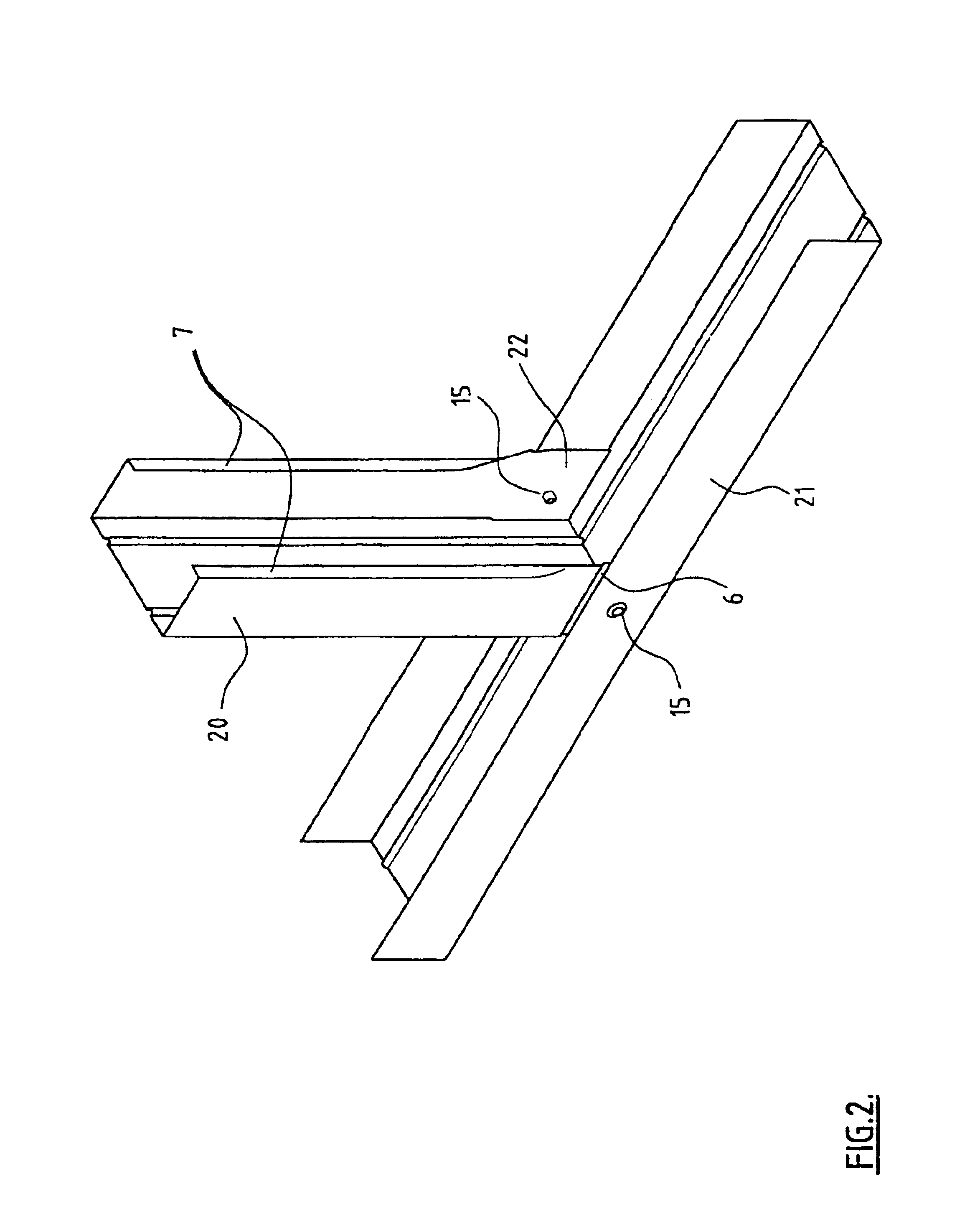

Method of making a frame member into U-section and C-section panel profiles

This invention relates to metal framing (2, 3, 4), in particular steel framing for building construction. The invention also relates to a method of constructing a metal frame assembly (2, 3, 4) and roll forming apparatus (41) for producing metal framing for building construction. The individual components of the metal frame (2, 3, 4), and assembly made from these components is adapted to provide for a substantially even planar surface without deformations, to which a cladding may be attached with a preferred even finish. The invention also includes roll forming apparatus (41) adapted for producing metal framing (2, 3, 4) of this type, and particularly adapted to produce metal frame members (2, 3, 4) having a predominantly C-section profile (7), with one or more portions of a U-section profile (9, 6), the U-section (9, 6) and C-section (7) profiles formed simultaneously on the same sheet metal strip (43). The apparatus (41) is also adapted to form narrowing or swaging of the channel at same or all U-section portions (6). The overall method of constructing a building frame assembly of the invention includes recording data defining a unit area in which a frame assembly is to fit, processing the data to design a frame assembly to fit that unit area, and controlling operation of roll forming apparatus (41) by a computing means using the processed data, to produce frame members (2, 3, 4) cut and formed ready for assembly to produce the required design of frame assembly.

Owner:FRAMEMAX INC

Rotary swaging forming method for automobile aluminum alloy wheel hubs

The invention relates to a rotary swaging forming method for automobile aluminum alloy wheel hubs. By utilizing the capability of deformation allowance of a material under a certain temperature, and by the aid of the rotary swaging forming method, an aluminum alloy material is forced to form a shape according to a preset mould shape. The rotary swaging forming method includes: preparing a rough material, cleaning, preheating the rough material (enabling the rough material to be semi-solid), forging and pressing to form a shape, expanding an opening, and rotating and pressing to form a shape. The automobile aluminum alloy wheel hubs manufactured by the rotary swaging forming method are high in yield and stable in mechanical property, mechanical processing quantity and energy consumption for the wheel hubs are obviously lowered, raw material is saved, and production efficiency is improved.

Owner:金刚

Processing method of nickel-titanium memorial alloy tube with thin diameter and thick wall

The invention discloses a processing method of a nickel-titanium memorial alloy tube with a thin diameter and a thick wall and belongs to the field of material processing. The processing method of the nickel-titanium memorial alloy tube with thin diameter and thick wall includes: manufacturing a nickel-titanium memorial alloy tube blank according to actual use requirements and adopting a method of three-roller cold rolling to roll the inner diameter into 3 to 8 millimeters according to a gate working rate of 10% to 25%; and then enabling the inner diameter to nearly reach a final size by conducting rotary swaging, wherein rotary swaging is conducted at a working rate of not more than 30% of gate deformation; processing the outer diameter into a needed size on the premise of guaranteeing that the inner diameter reaches an appropriate size by drawing, wherein the gate deformation is 5% to 15%; and finally obtaining a finished product of the tube with the thick wall and the thin diameter by correcting and cylindrical grinding. According to the processing method of the nickel-titanium memorial alloy tube with thin diameter and thick wall, the nickel-titanium memorial alloy tube with the thin diameter of lower than 3 millimeters and the thick wall of 1millimeter to 3 millimeters can be manufactured. The nickel-titanium memorial alloy tube with the thin diameter and the thick wall has the advantages of possessing an appropriate organization and an axial structure and being particularly suitable for preparing the nickel-titanium memorial alloy thin diameter tube connector with high recoverability.

Owner:GRIMAT ENG INST CO LTD

Copper-nickel-tin alloy bar and manufacturing method thereof

The invention discloses a copper-nickel-tin alloy bar. The copper-nickel-tin alloy bar comprises, by mass, 14%-16% of nickel, 7%-9% of tin, 0.05%-0.3% of yttrium, 0.8%-1.0% of aluminum, 0.2%-1.0% of niobium, and the balance copper and other impurities. The invention further discloses a manufacturing method of the copper-nickel-tin alloy bar. The method comprises the steps that alloy powder is prepared according to the ingredients and the mass percentages through a gas atomization method, then an alloy ingot blank is prepared through the methods of cold isostatic pressing molding, vacuum sintering and ingot blank covering, and finally the high-quality copper-nickel-tin alloy bar is obtained through the processes of water-sealing hot extrusion, cold rotary swaging, aging treatment and the like. By means of the method, the problems of composition segregation and the like generated in the casting process of a copper-nickel-tin alloy can be avoided, and the yield is high; the copper-nickel-tin alloy bar can have high strength, high toughness and excellent abrasion and corrosion resistance at the same time, and the overall performance is higher than that of beryllium bronze. The copper-nickel-tin alloy bar can be widely applied to manufacturing of bearings, shaft sleeves, bearing bushes and other wear-resisting components which are used in high-load, high-speed and high-corrosion environments like space flight and aviation and oil drilling platforms.

Owner:CENT SOUTH UNIV +1

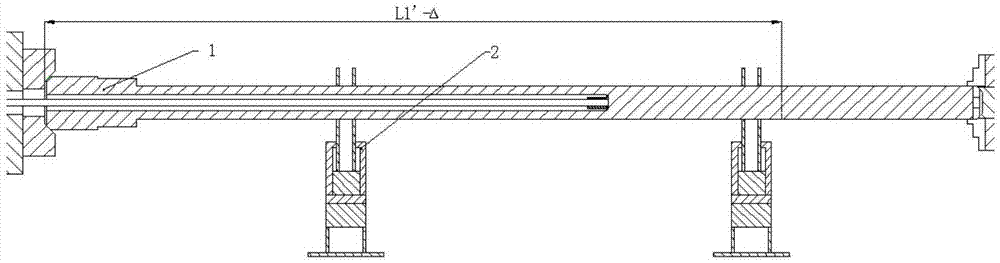

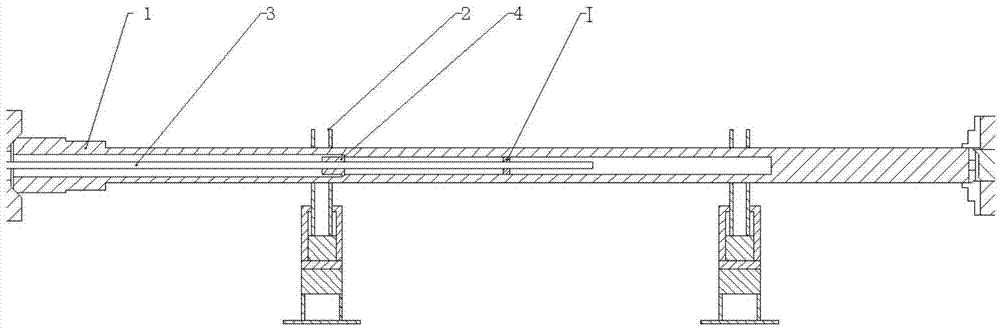

Machining process and tool for shaft with inner step hole with large depth-diameter ratio

ActiveCN104723045AImprove straightnessIncrease stiffnessLarge fixed membersPositioning apparatusDiameter ratioEngineering

The invention provides a machining process and tool for a shaft with an inner step hole with a large depth-diameter ratio. The process includes the steps of preparing a workpiece blank first, drilling a middle hole, finely boring the middle hole, honing the middle hole, boring on a large hole in a push mode, drilling a small hole, conducting rotary swaging shaping, machining the outer circle, and finally drawing out a combined core shaft, wherein the combined core shaft is formed by connecting a large-end core shaft, a middle core shaft and a small-end core shaft through threads. Through the machining process and tool, hole drilling straightness is improved remarkably, the reject rate is reduced, and meanwhile mechanical properties of a workpiece are enhanced.

Owner:XI AN JIAOTONG UNIV

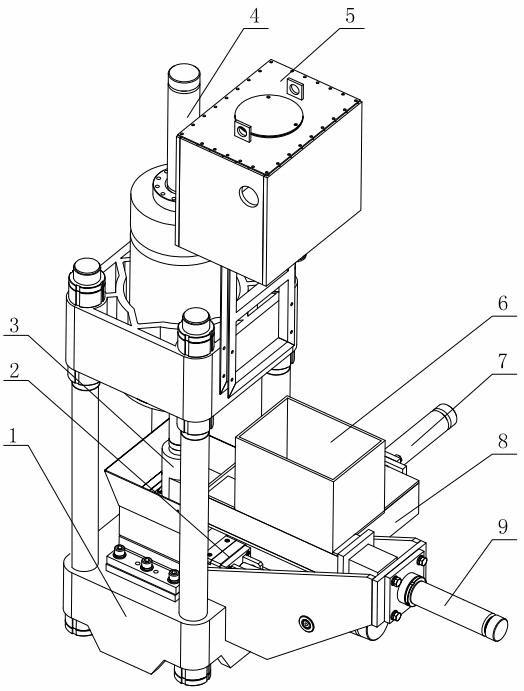

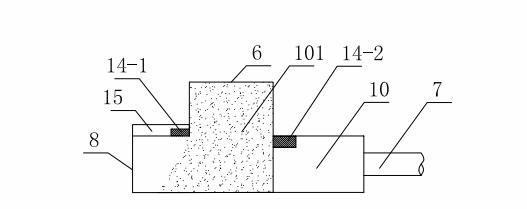

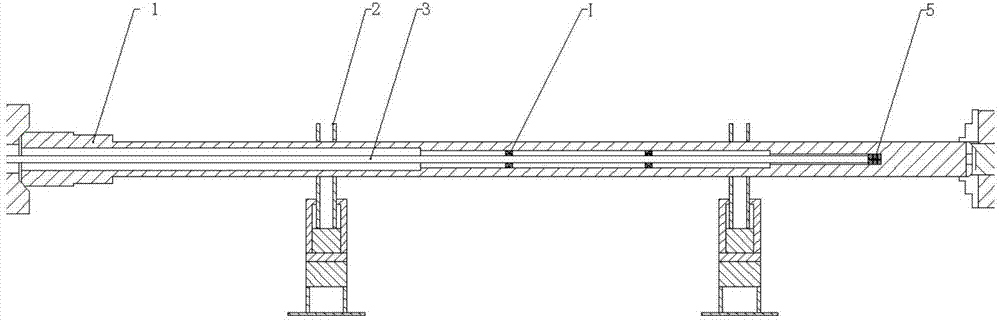

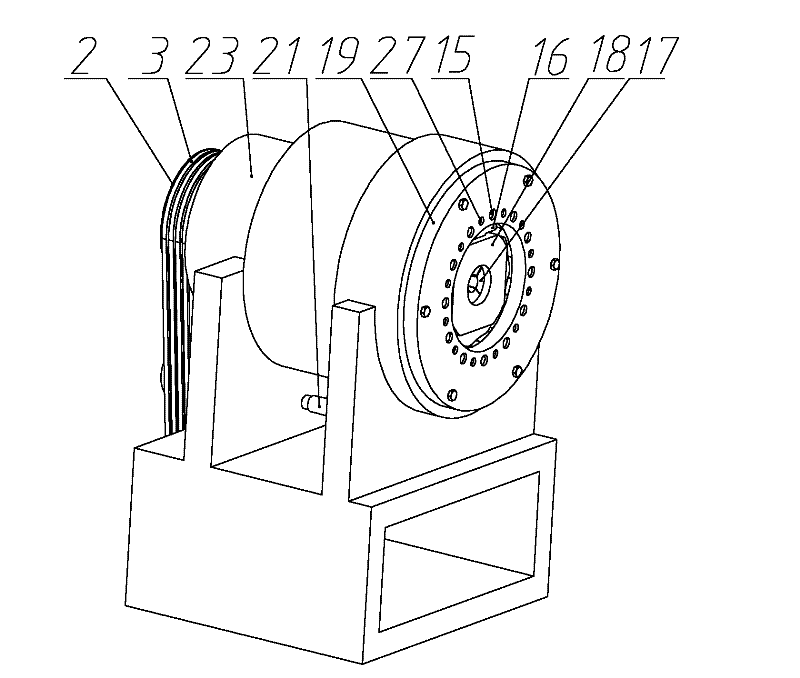

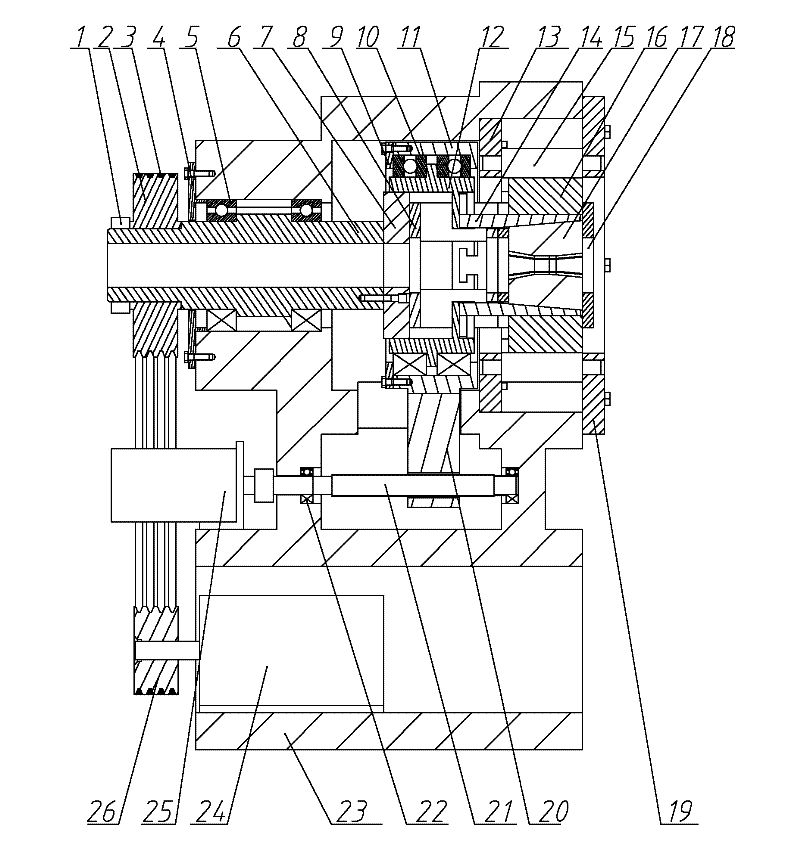

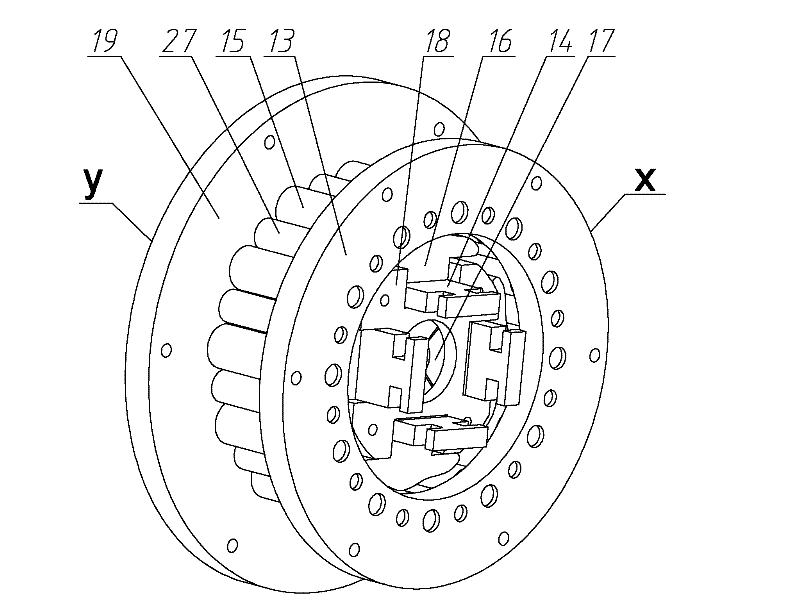

Rotary swaging forming equipment

ActiveCN102218491AGood continuity of motion accelerationSmall shock and vibrationForging/hammering/pressing machinesForging press detailsEngineeringSwaging

Owner:XI AN JIAOTONG UNIV

Method of connecting terminal and electric wire

InactiveUS20070184715A1Low costImprove conductivitySecuring/insulating coupling contact membersElectrically conductive adhesive connectionsAdhesiveSwaging

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

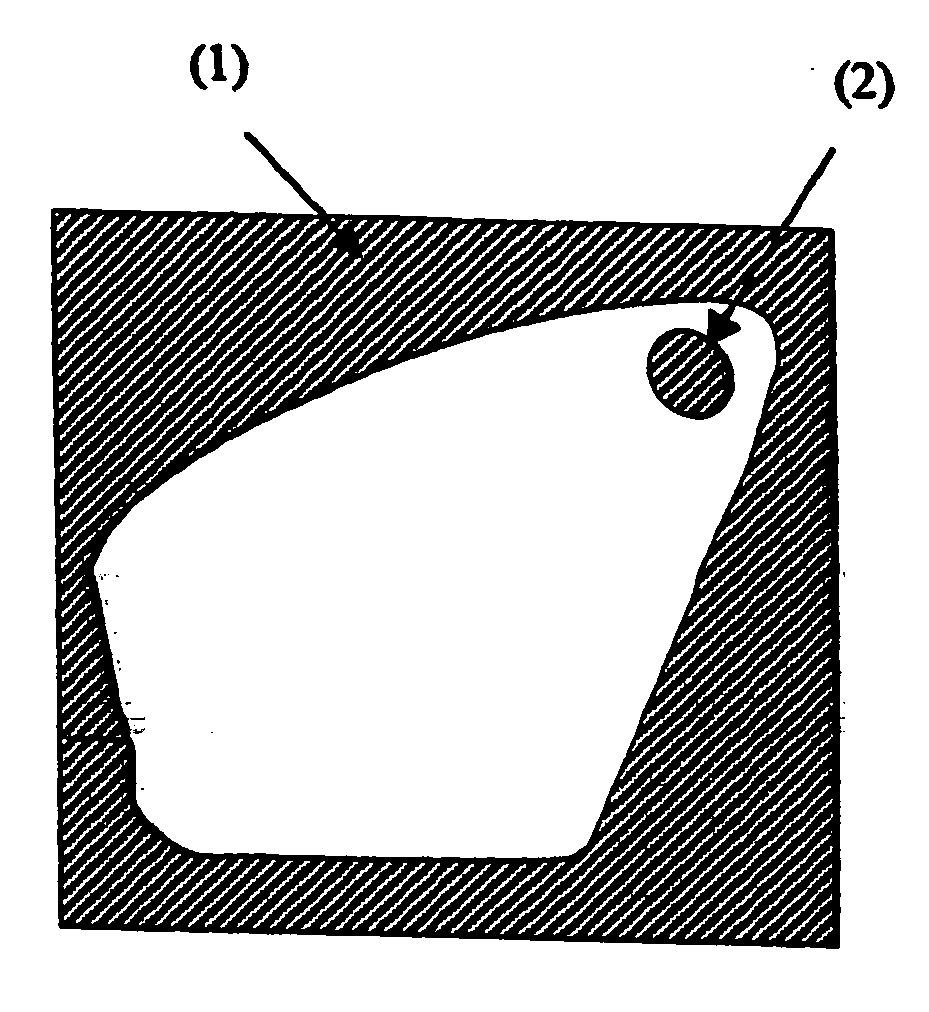

Punching-pressing composite mould

This complex press mould comprises upper and lower moulds. Wherein, the lower mould comprises base with arranged locating block, dead plate for convex mould on base center by block with bending convex mould of top end surface lower 2~3 blank thickness than the locating block 's, lower backing-out punch on edge of bending convex mould, towbar and guide pole both arranged directly on base, and sideslip pole, horizontal press head, reset spring and limiting pin all arranged in locating block; the upper mould comprises base with shank on base center by locating hole, swaging spring on shank, bending concave mould below base center with swaging block, wedge and guide sleeve both arranged on base side by bolt and locating plot; wherein, the upper is matched with lower mould by guide sleeve and guide pole.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

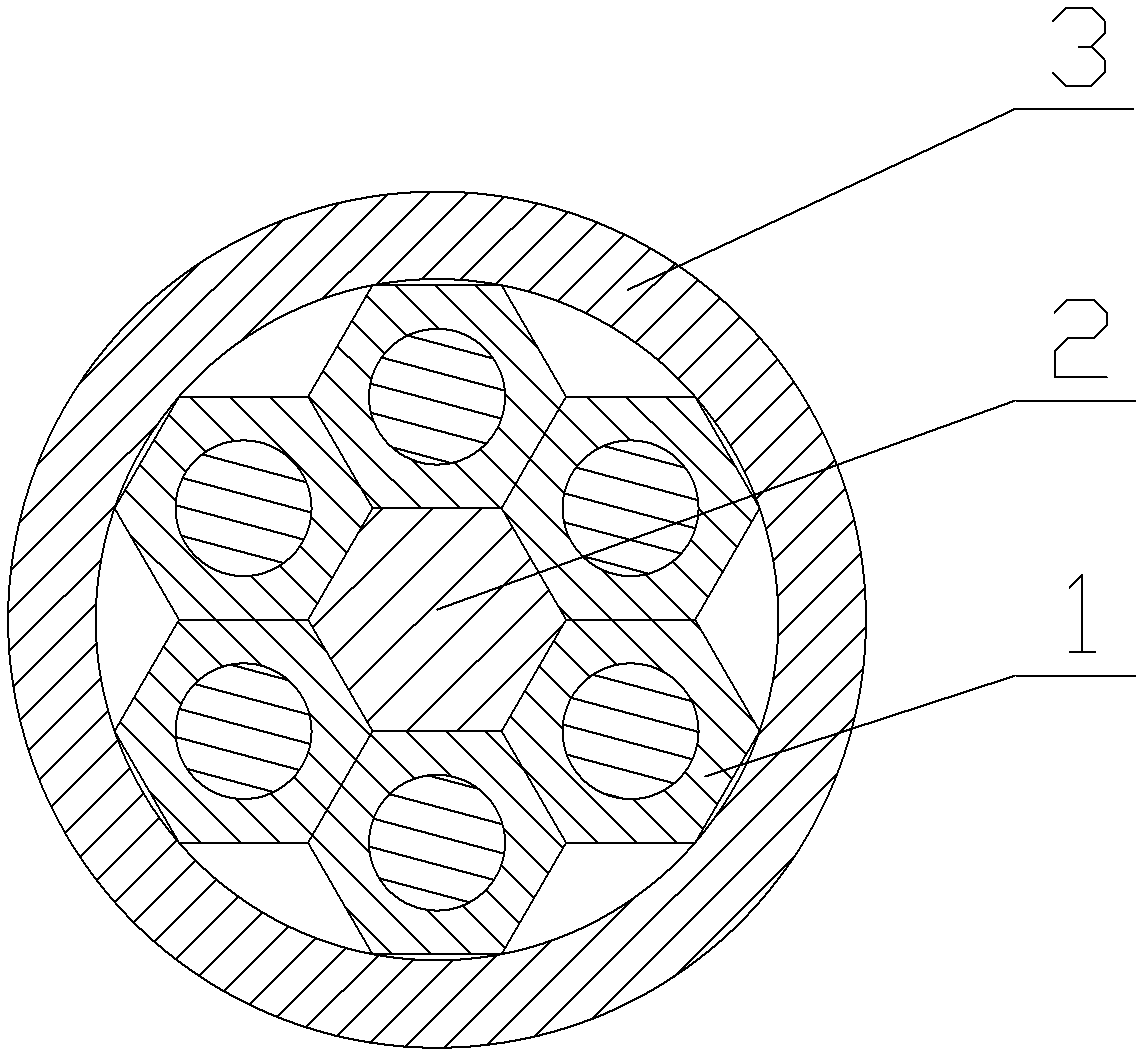

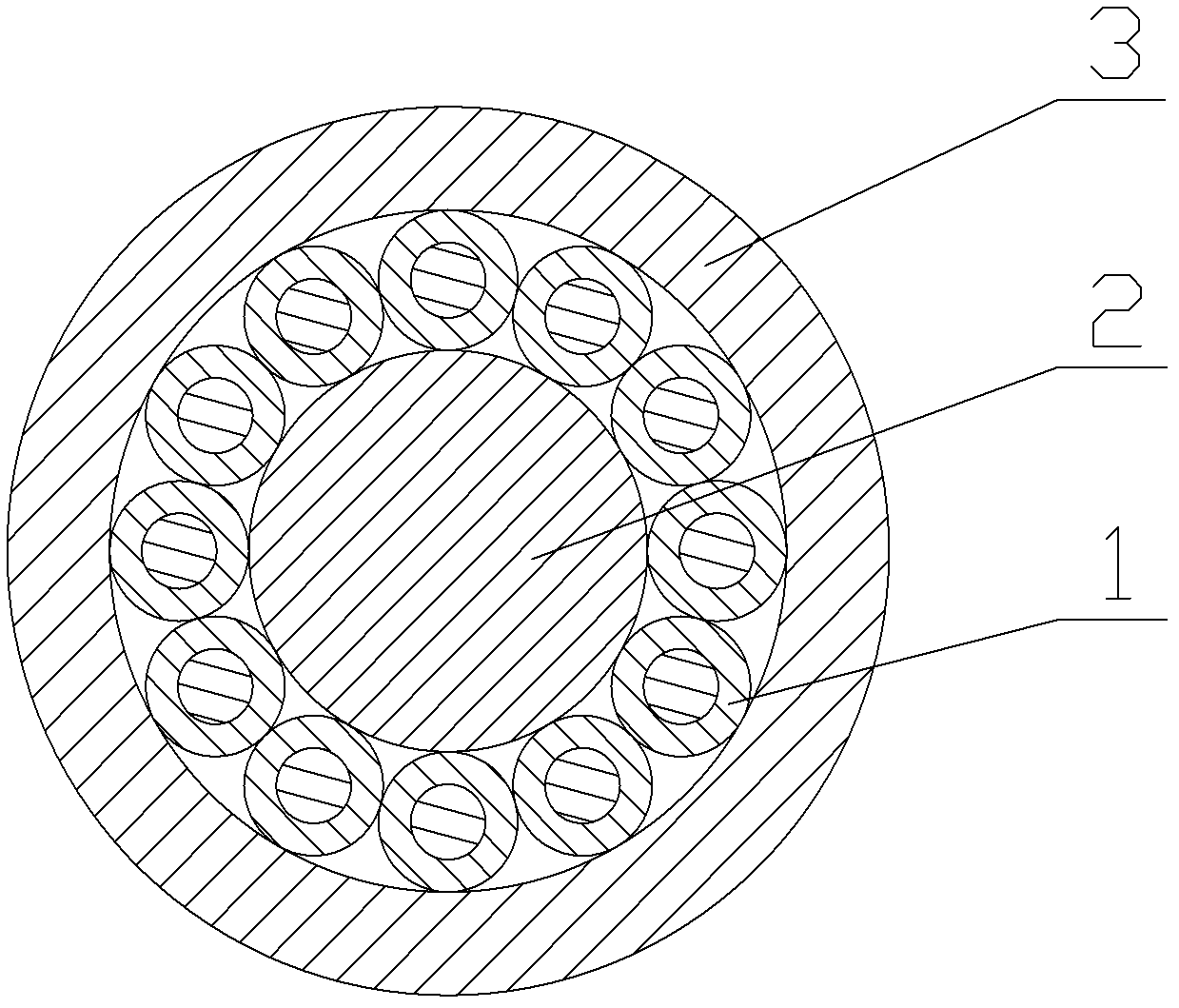

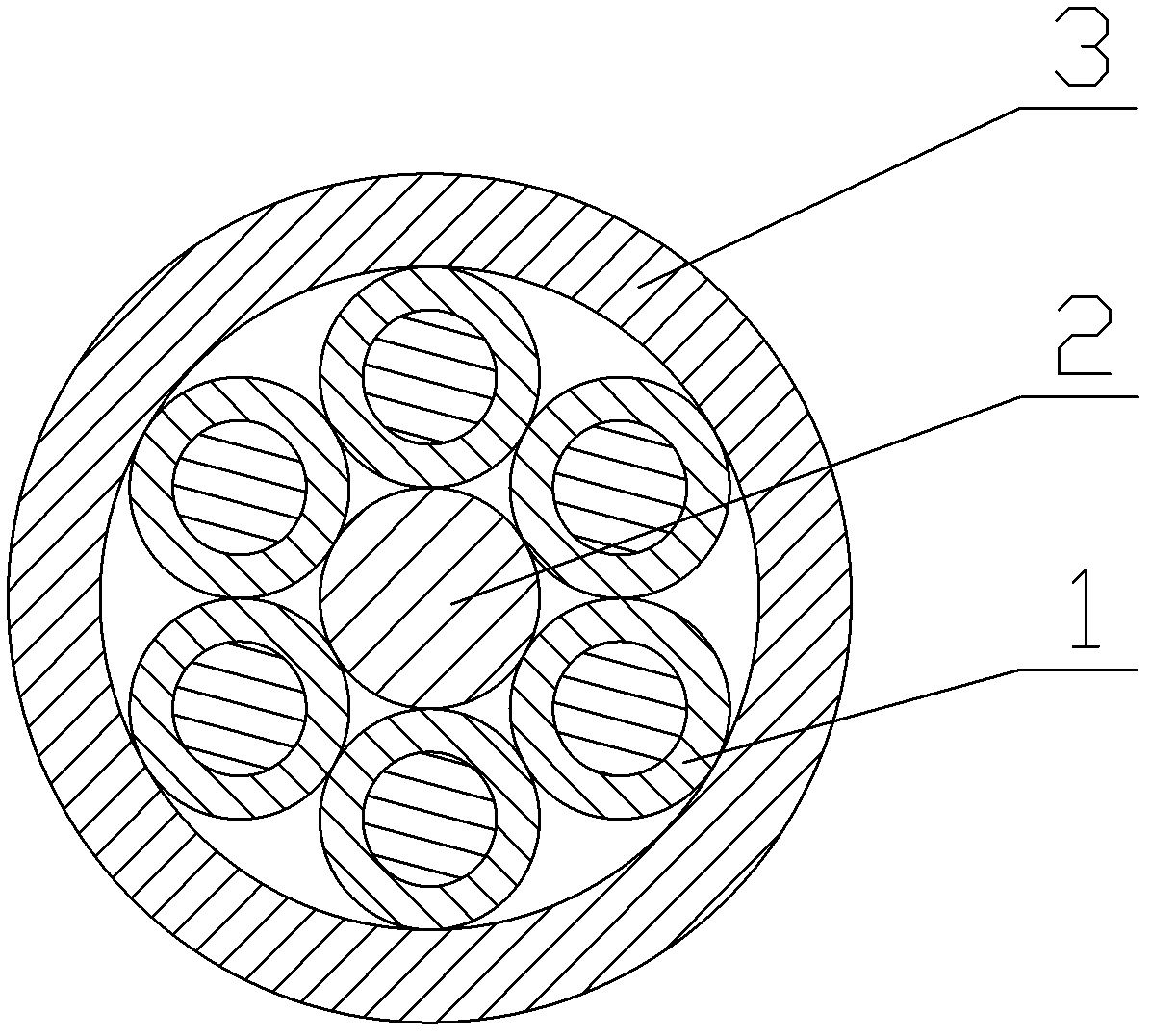

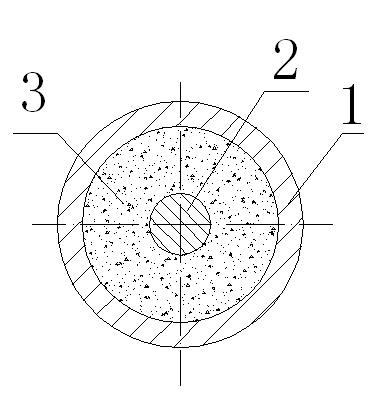

A kind of preparation method of multi-core mgb2 superconducting wire/tape

ActiveCN102280198AIncrease the critical current densityHigh densitySuperconductors/hyperconductorsMetal boridesElectrical conductorNiobium

The invention discloses a preparation method for a multi-core MgB2 superconducting wire / band. The method comprises the following steps of: 1, preparing precursor powder; 2, feeding the precursor powder into a Nb / Cu composite metal tube to obtain a tubing complex; 3, performing rotary swaging and drawing treatment, and thus obtaining single-core wires; 4, placing a copper-niobium composite rod anda plurality of single-core wires into an anaerobic copper tube for secondary assembly to obtain a secondary composite rod, performing the rotary swaging and drawing treatment, and thus obtaining multi-core wires; and 5 sintering in vacuum, and thus obtaining the multi-core MgB2 superconducting wire; or rolling into multi-core bands, then sintering in vacuum, and thus obtaining the multi-core MgB2superconducting band. By the preparation method, powder is subjected to high-temperature heat treatment, so that the condition that high-activity carbon which is decomposed from SiC can better replace boron can be ensured, and the improvement on the critical current density of the wire / band in a magnetic field is better facilitated. Due to the adoption of a center copper-niobium composite bar enhanced conductor structure, the improvement on the density of the MgB2 superconducting wire is facilitated, the connectivity of MgB2 crystal grains is enhanced, and the critical current density of the wire / band is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Casting and hot spinning process of aluminum alloy wheel

The invention discloses a casting and hot spinning process of an aluminum alloy wheel, which comprises a casting process and a spinning process. The casting and hot spinning process is characterized in that the content of Mg in aluminum liquid for casting accounts for 0.30-0.40 percent of total mass; a spinning blank is processed by adopting the casting process; a spoke is only cast by the blank; a rim is preformed and a material required for the rim is reserved by the preformed rim according to an isovolumetric deformation principle; the deformation ratio of the performing of the rim to the final forming is between 0.8 and 1; and then the performing part of the blank rim is spun and formed by adopting the spinning process. The invention uses traditional common cast equipment, so the cost of products is greatly reduced as comparison with a rotary swaging process, the rim formed by casting has strong shape change adaptability and relatively-complicated models can be finished; and meanwhile, casting defects such as the loosening and the shrinkage in the spinning and forming process disappear by spinning and the rim strength can be remarkably improved.

Owner:BAODING CITY LIZHONG WHEEL MFG

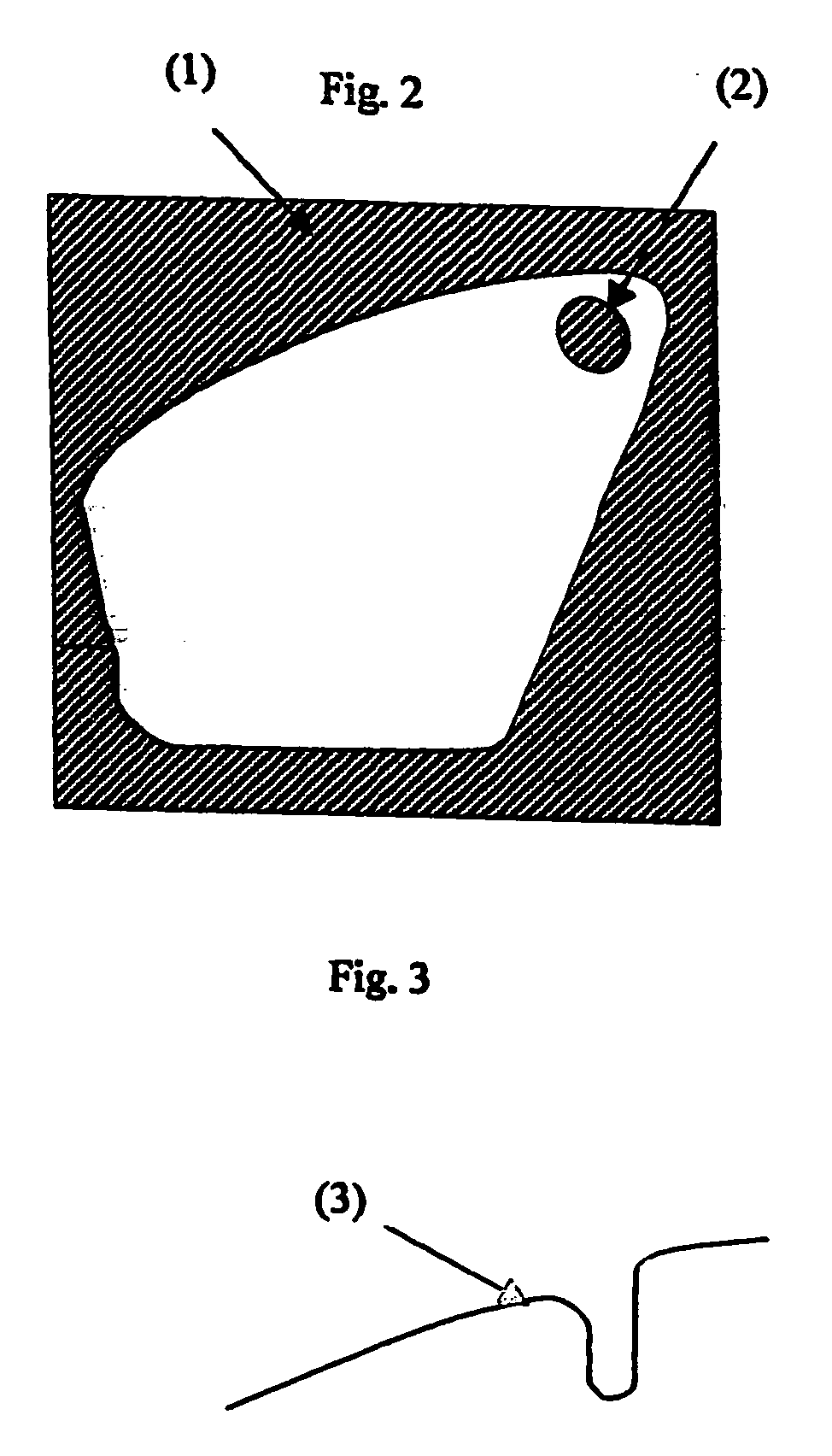

Method for warm swaging al-mg alloy parts

A method for the production of swaged aluminum alloy parts, by production of a 0.5 mm-5 mm thick alloy strip made of 1-6 wt. % Mg, <1.2 wt. % Mn, <1 wt. % Cu, <1 wt. % Zn, <3 wt. % Si, <2 wt. % Fe, <0.4 wt. % Cr, Zr<0.3, other elements <0.1 each, total of <0.5, the remainder being Al, cutting a blank from the strip, locally or totally heating the blank at a temperature of 150-350° C. for <30 secs, and swaging the heated blank with the aid of heated tools, at least partially, at a temperature of 150-350° C. in the presence of a lubricant which is compatible with later operations. The swaged parts are automotive body work parts.

Owner:CONSTELLIUM NEUF BRISACH

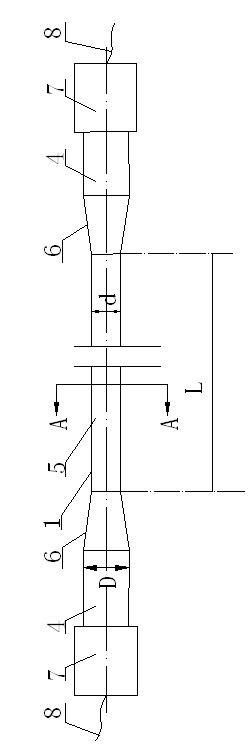

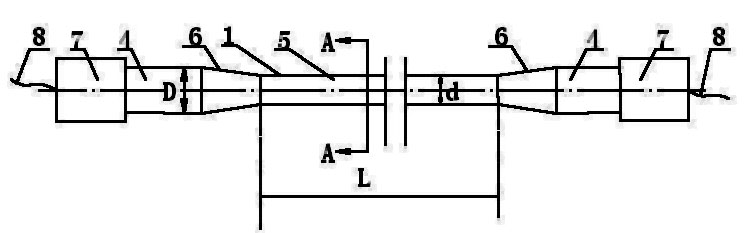

Variable section end head unwarming armored heater and preparation method thereof

ActiveCN102361522ASimple manufacturing processGuaranteed performanceHeating element shapesSwagingPhysics

The invention discloses a variable section end head unwarming armored heater and a preparation method thereof. The heater comprises a metal casing and a resistance heating wire, wherein the resistance heating wire is arranged on the axis of the metal casing; an insulating material is filled between the metal casting and the resistance heating wire; left and right ends of the metal casting are connected with a simple and easy cap respectively; the resistance heating wire passes through the end part of the simple and easy cap to connect a heating traction rod; and an organic seal gum is filled in the simple and easy cap. The heater is characterized in that: two ends of the metal casing are heating ends, the middle part of the metal casing is a middle heating section, and the diameter D of the heating ends is greater than the diameter d of the middle heating section. The preparation method comprises the following steps of: a) drawing; b) rotary swaging; c) end head manufacturing; and d) heating traction rod welding. By designing an armored heating element with a reasonable structure, the heat aggregated at the end head is as low as possible to achieve an effect that the end head is not heated, so a manufacturing process for the end head can be simplified, and the overall performance, particularly the reliability of the heating element can be ensured.

Owner:CHONGQING MATERIALS RES INST

Molybdenum-yttrium alloy wire preparation method

InactiveCN101642812AImprove performance consistencyImprove uniformityHydrogenHigh volume manufacturing

The invention provides a molybdenum-yttrium alloy wires preparation method and is characterized in that the preparation method comprises the following steps: immersing molybdenum dioxide powder in yttrium nitrate solution, drying, mixing evenly, reducing with hydrogen at 800-1000 DEG C to obtain molybdenum powder doped with rare earth oxide Y2O3, isostatic pressing the obtained molybdenum powder at 160-200MPa to prepare rods, then sintering the rods at high temperature and finally rotary swaging and drawing to obtain molybdenum wires. The method of the invention effectively increases the uniformity of doping elements and can be used in mess production, the uniformity of the processed molybdenum-yttrium alloy wires is good and the rolled molybdenum foil strip has good using effect.

Owner:金堆城钼业光明(山东)股份有限公司

Swagable high-pressure cable connectors having improved sealing means

A high-pressure connector for an electrical power cable section having a central stranded conductor encased in a polymeric insulation jacket and having an interstitial void volume in the region of the stranded conductor, the high-pressure connector being suited for confining a fluid within the interstitial void volume at a residual pressure above atmospheric, but below the elastic limit of the polymeric insulation jacket, the high-pressure connector comprising a housing having a wall defining an interior chamber configured to be in fluid communication with the interstitial void volume and an end portion sized to receive the insulation jacket within the interior chamber and to overlap at least a portion of the insulation jacket at an end thereof with the cable section extending from the housing end portion and at least a portion of the stranded conductor positioned within the interior chamber. The housing wall of the housing end portion has an engagement portion comprised of a swagable material to secure the housing wall to the insulation jacket in fluid-tight sealed engagement therewith upon inward swaging of the engagement portion of the housing wall of the housing end portion to the insulation jacket to confine the fluid at the residual pressure within the interior chamber and the interstitial void volume. The housing includes at least one axially-projecting engagement member located within the interior chamber at the engagement portion of the housing wall of the housing end portion.

Owner:NOVINIUM LLC

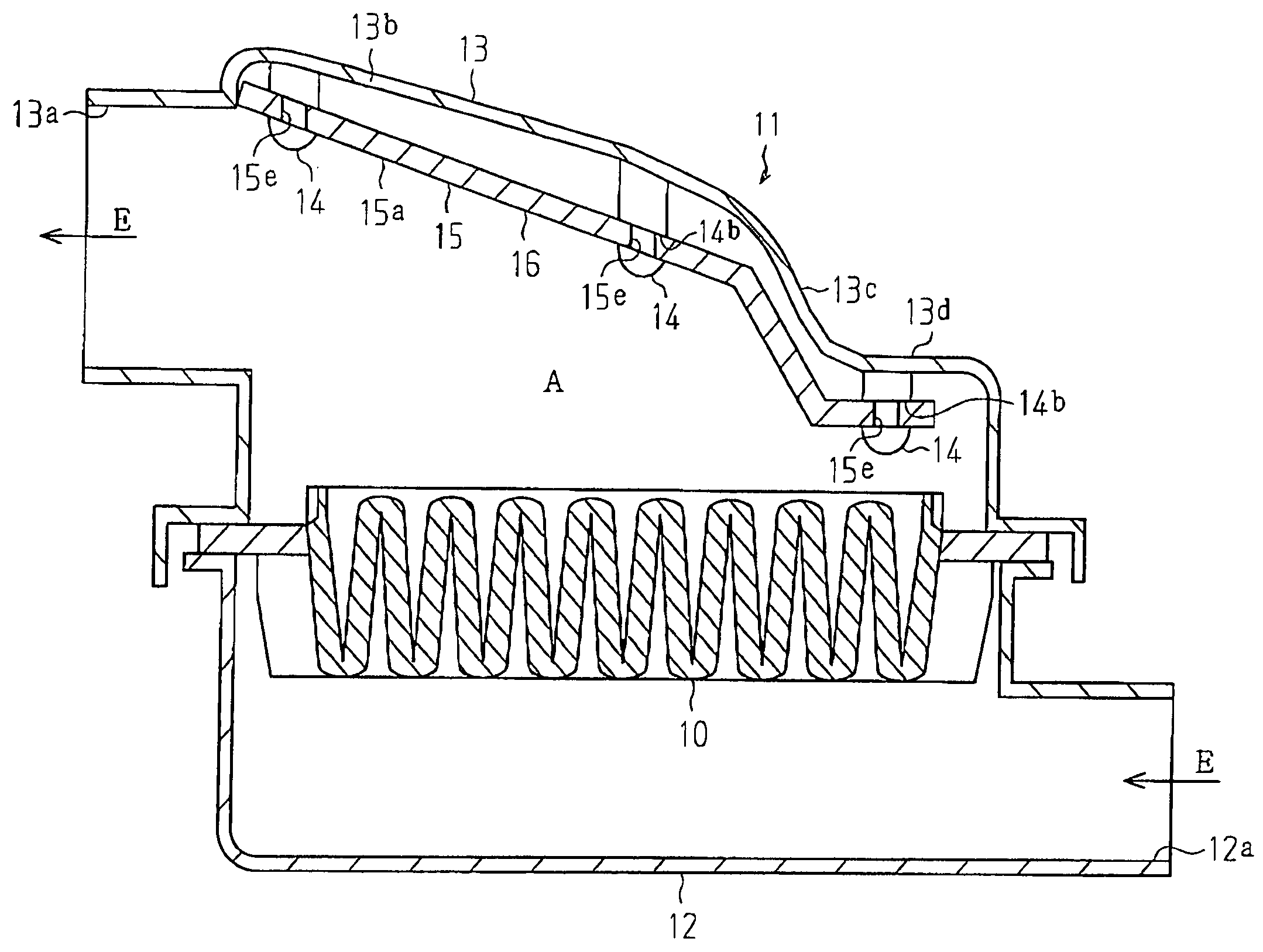

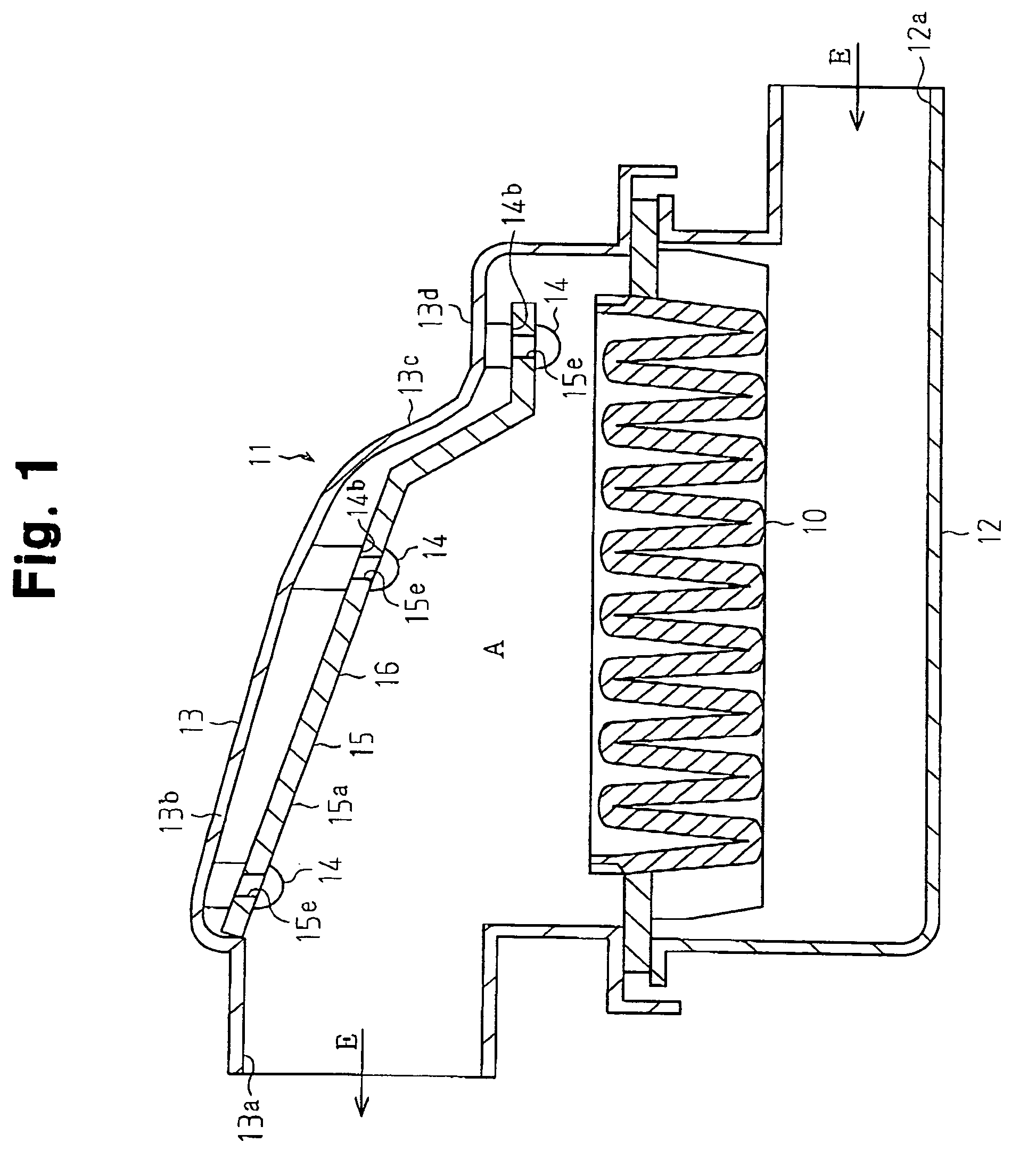

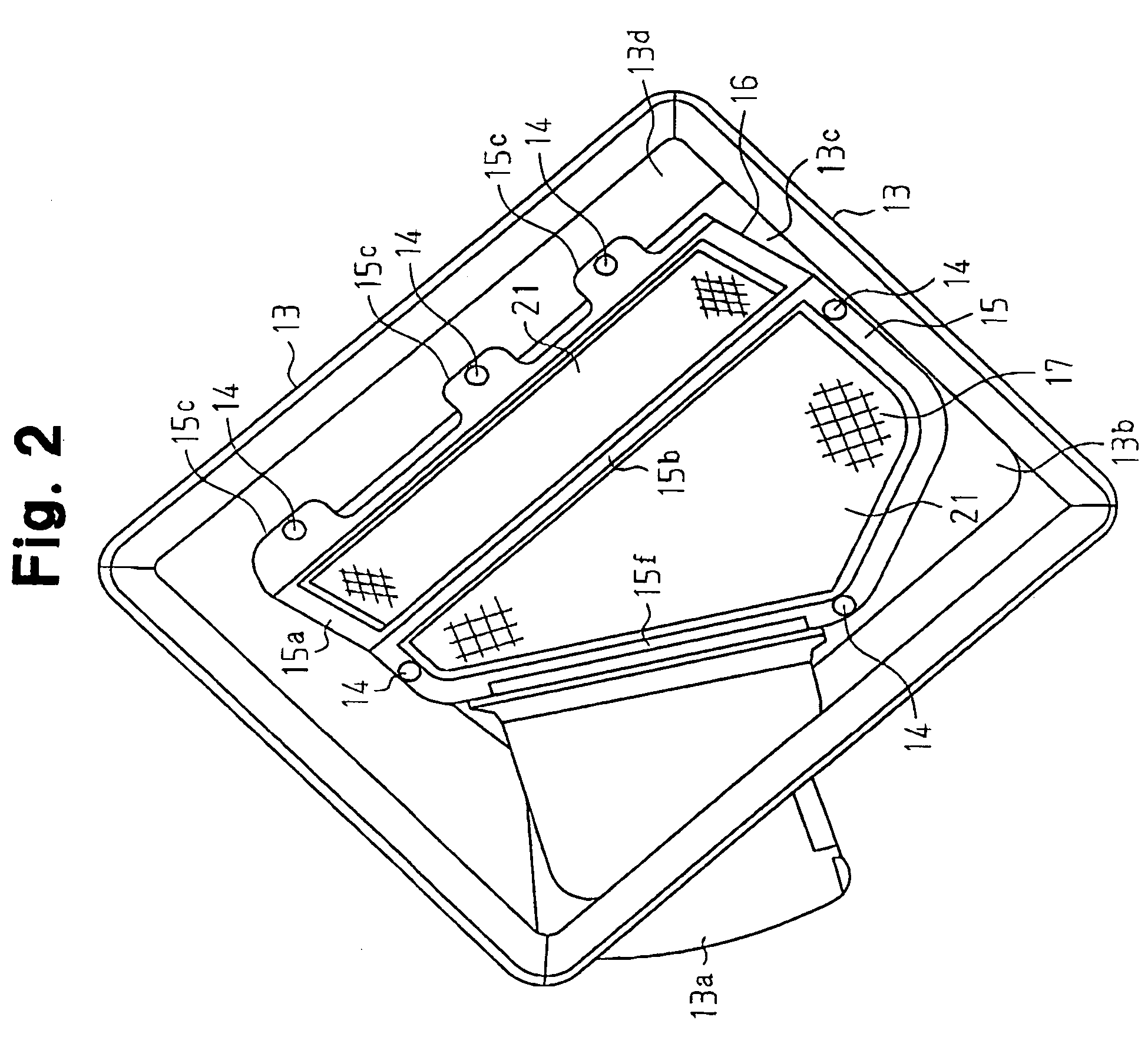

Air cleaner

InactiveUS7507279B2Avoid damageReduce resistanceNon-fuel substance addition to fuelDispersed particle filtrationActivated carbonSwaging

A fuel adsorption member 16 is fixed to an inner surface of a housing 13 by fixing pins 14. A fuel vapor leaking from an intake system of an engine is adsorbed by an active carbon included in an adsorption sheet member of the fuel adsorption member 16. The fuel adsorption member 16 is arranged along an inner surface of the housing 13. Accordingly, when an engine is operated, the fuel adsorption member 16 can reduce a ventilation resistance without being adversely affecting an intake air E. Further, the fuel adsorption member 16 is fixed to an inner surface of the housing 13 in accordance with a swaging of the fixing pins 14. Therefore, it is possible to prevent a damage of the fuel adsorption member 16 caused by a vehicle vibration, a fluctuation of an intake pressure or the like, and a reduction of a fuel adsorbing function caused by a wear of the active carbon.

Owner:TOYOTA BOSHOKU KK

Lanthanum-doped molybdenum alloy wire for thermal spraying and preparation method thereof

The invention relates to a lanthanum-doped molybdenum alloy wire for thermal spraying and a preparation method thereof, and is characterized in that La2O3 is contained in the lanthanum-doped molybdenum alloy wire, and the weight content is as follows: 0.1-0.8 percent of La, and the balance of Mo and inevitable impurities. The lanthanum-doped molybdenum alloy wire for thermal spraying has better high temperature strength, hardness and oxidation resistance, and is more advantageous compared with pure molybdenum wires, thereby being expected to be the substitute of pure molybdenum wires in the aspect of thermal spraying. No harm is generated to the body of an operator during preparation; the production process is easy to control, the operation is simple and convenient, safe and reliable, vast investment and transformation on equipment is not needed, and the lanthanum-doped molybdenum alloy wire is applicable to production in large scale; as a liquid-solid doping method is adopted, the added alloy elements are uniformly distributed in the material, and the production consistency is good; and as the pressure machining processes of rolling, rotary swaging and drawing are adopted, the product loss is low and the recovery rate is high.

Owner:金堆城钼业光明(山东)股份有限公司

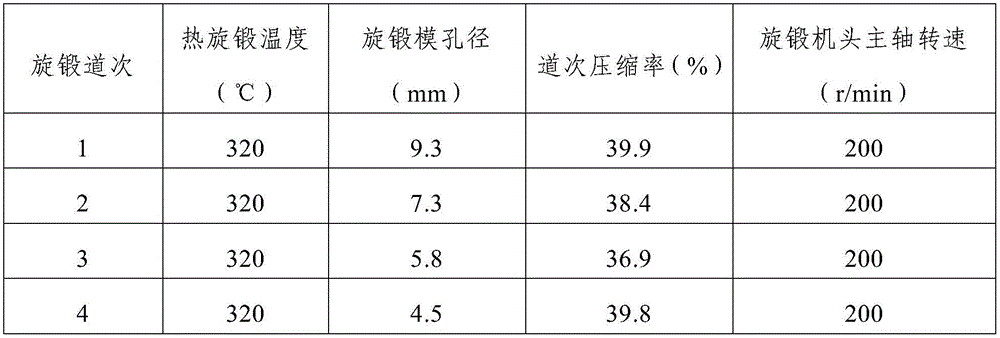

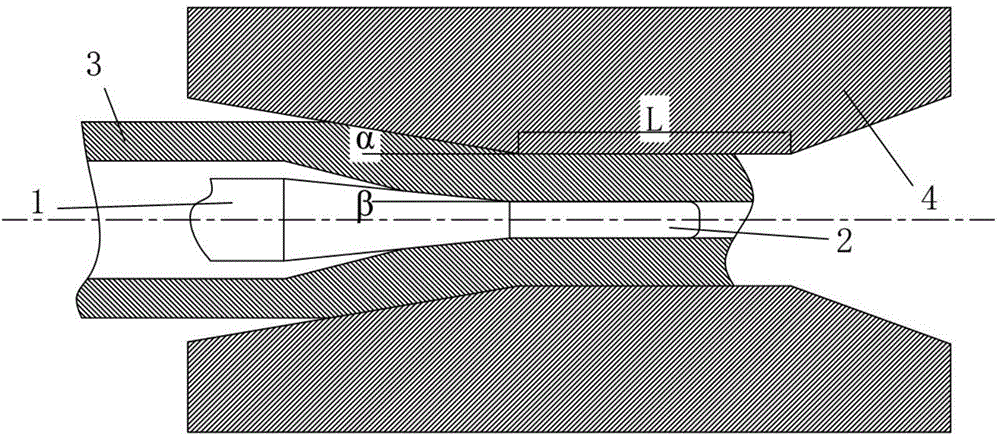

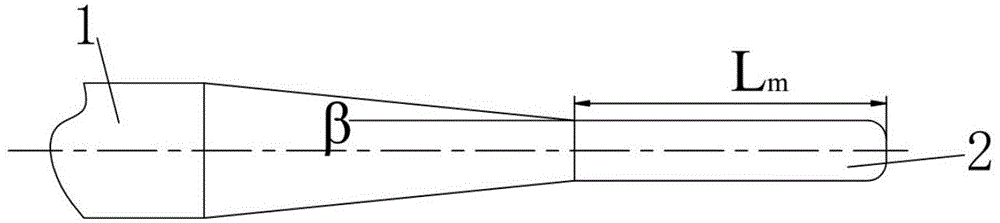

Rotary swaging preparation method for high-strength magnesium alloy wire

InactiveCN101745592AImprove plastic deformation abilityImprove performanceForging hammersNonferrous metalHigh intensity

The invention relates to a rotary swaging preparation method for a high-strength magnesium alloy wire, and belongs to the technical field of nonferrous metal plastic molding. The method comprises the following steps: carrying out heat preservation on magnesium alloy bars for 1 to 15 minutes at the temperature of between 120 DEG C and 200 DEG C, and clamping the bars by a special fixture of a rotary swaging machine to carry out rotary swaging; and after the rotary swaging is finished, replacing a rotary swaging mold with smaller bore diameter to repeat the steps until the magnesium alloy wire with required diameter is obtained, wherein in the process of rotary swaging, the feeding speed is controlled to between 6 and 10m / min; the pass compression ratio is controlled to between 18 and 45 percent; and the coning angle of the rotary swaging mold is controlled to between10 and 26 degrees. The method uses the three-dimensional compressive stress state and the pulse loading mode provided by the rotary swaging to realize plastic-deformation induced dispersion-strengthening phase precipitation and grain refinement so as to fulfill the aim of improving mechanical properties. The prepared magnesium alloy has excellent performance, the yield strength thereof is 25 to 53 percent higher than that of the magnesium alloy wire prepared through extrusion, and the tensile strength thereof is 18 to 23 percent higher than that of the magnesium alloy wire prepared through extrusion. The method has the advantages of no need of special on-line insulating device, simple equipment, high production efficiency and easy operation.

Owner:BEIJING UNIV OF TECH

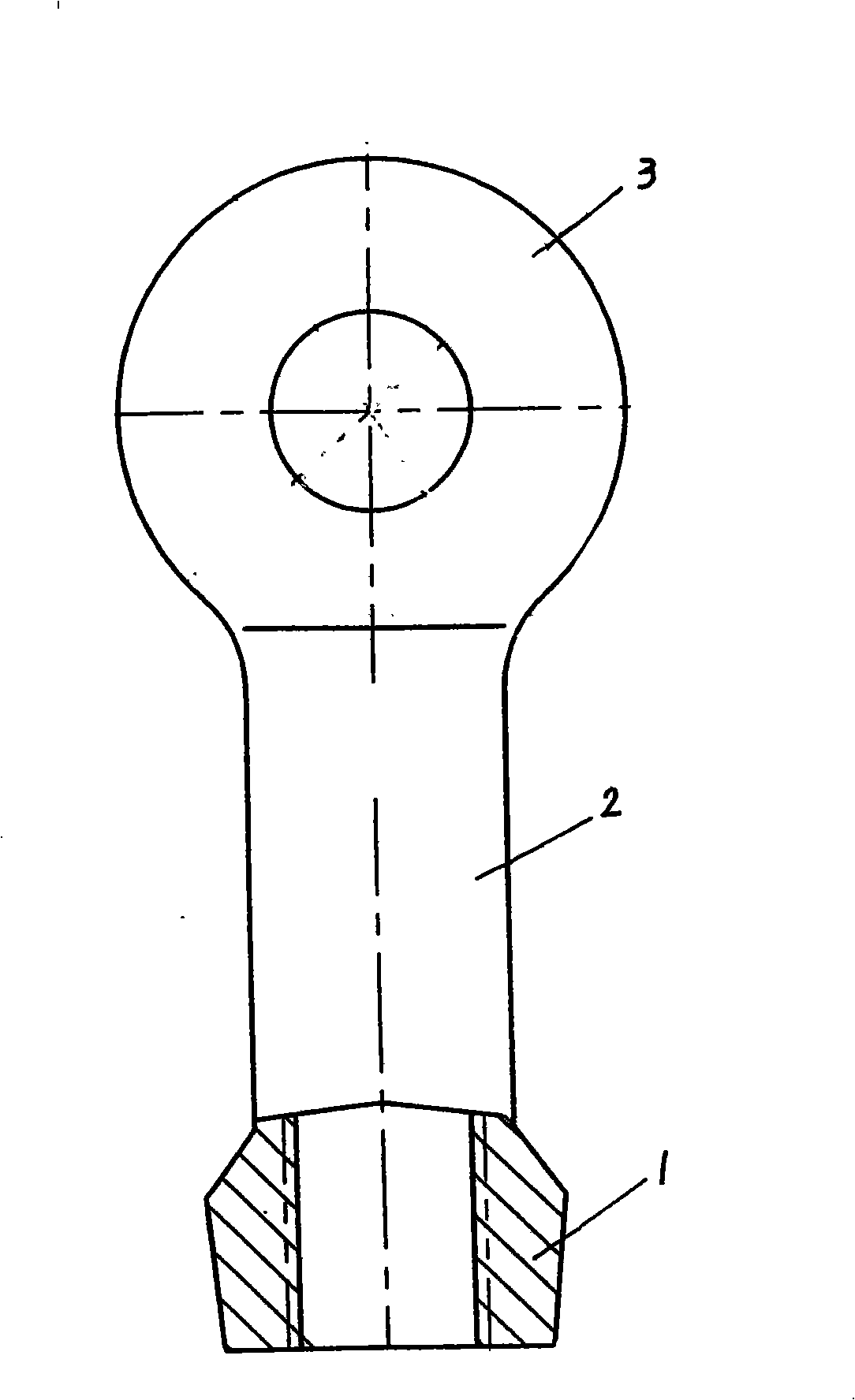

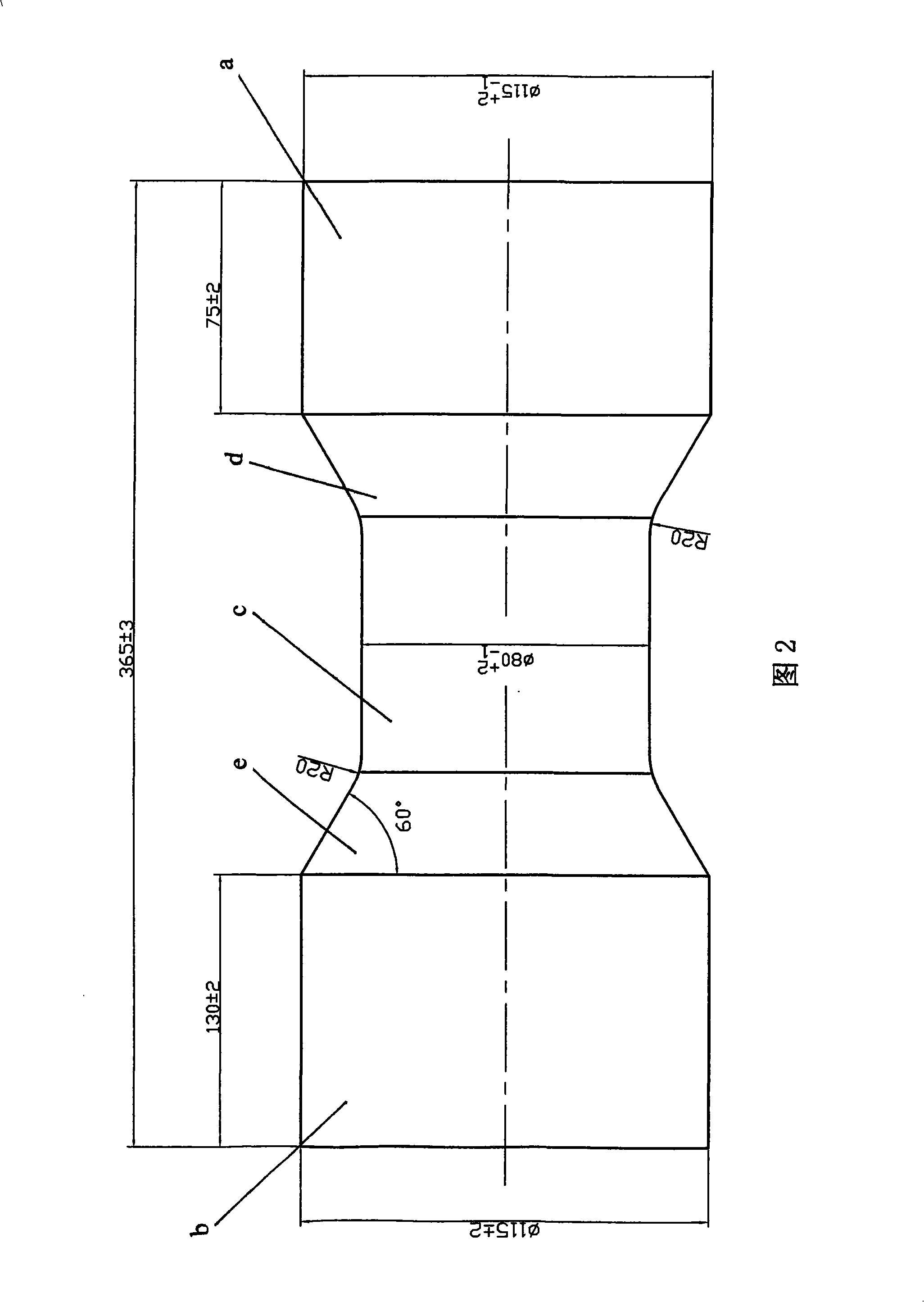

U shaped suspension clamp swaging technique

InactiveCN101269398AReasonable and practical process stepsReasonable and practical conditionsForging/hammering/pressing machinesEngine componentsPower stationEconomic benefits

The invention discloses a mould forging process used on a U-shaped hanging folder as a component of a hanging boiler in the manufacturing process of a power station boiler. A forging die and a trimming die are manufactured, the cavity outline of the forging die is fundamentally identical to the outline of the U-shaped hanging folder, and the forging die has a forging margin and a draft; firstly, material are forged into blank which is then arranged in the mould cavity for forging molding, at last the raw edges are removed by the trimming die; the sub-forging die of the mould forging is positioned at the central line of the U-shaped hanging folder, with an outer draft of 7 DEG and an inner draft of 5 DEG; the bridge part of the forging die is provided with a choke trough; the blank presents a dumbbell shape. The mould forging process provided by the invention has the advantages that the die, the blank structure and the technics steps are reasonable and practical; the U-shaped hanging folder forge piece is forged and molded at one go, the lifting lug dispenses with bending, the quality of products is acceptable, the production efficiency is high, the minimum output per shift is more than 200, and the economic benefit is good.

Owner:四川振强锻造有限责任公司

Technology for preparing small-bore and thick-wall metal tubes by rotary swaging technique

ActiveCN104475479AAvoid prone inner wall cracksAvoid pittingMetal-working apparatusEngineeringSwaging

The invention provides a technology for preparing small-bore and thick-wall metal tubes by a rotary swaging technique and belongs to the technical field of metal working. The technology comprises the following processes: (1) an appropriate tube blank is selected, the tube blank undergoes descaling, and cut-to-length is carried out; (2) the tube blank is installed onto a feeding mechanism, and it is ensured that a mandrel unit passes through an inner bore of the tube blank; (3) the mandrel unit is fed to a fixed position, and a mandrel head part is positioned inside a die sizing area; (4) the feeding mechanism sends the tube blank into a rotary swaging case for rotary swaging; and (5) the processes from (2) to (4) are repeated, and the forming process is finished after 1-3 passes. The technology is simple and easy to do. Size precision of the product is high (+ / -0.02 to + / -0.08mm). Defects such as inner-wall crack, pit, folding and the like which are easy to happen to small-bore and thick-wall metal tubes prepared by the present drawing technology are avoided. The technology provided by the invention can be used for molding of various small-bore and thick-wall metal tubes.

Owner:UNIV OF SCI & TECH BEIJING +1

Preparation method of rectangular multicore composite superconductive strip

ActiveCN103440931AEvenly distributedNo reunionSuperconductors/hyperconductorsSuperconductor devicesAlloySlurry

The invention discloses a preparation method of a rectangular multicore composite superconductive strip. The preparation method comprises the following steps of step one. preparing mixed slurry by using amorphous boron powder, magnesium powder and a malic acid ethanol solution; step two. preparing tubing precursor powder; step three. tubing, carrying out rotary swaging, and drawing, thus obtaining a Cu-Nb-MgB2 single-core rod; step four. placing the Cu-Nb-MgB2 single-core rod and a Cu-NbTi single-core rod in a Cu-Ni alloy tube for secondary packaging, thus obtaining a secondary complex; five. processing the secondary complex into a wire rod, then carrying out rotary swaging and drawing so as to obtain a rectangular multicore composite strip; step six. winding a high-silica glass fiber to form a disk, and clamping the two ends of the disk to be flat; and step seven. carrying out thermal treatment so as to obtain the rectangular multicore composite superconductive strip. Compared with a single MgB2 and NbTi superconducting material, the composite superconductive strip prepared by the method is relatively wide in temperature using range and has relatively high using magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

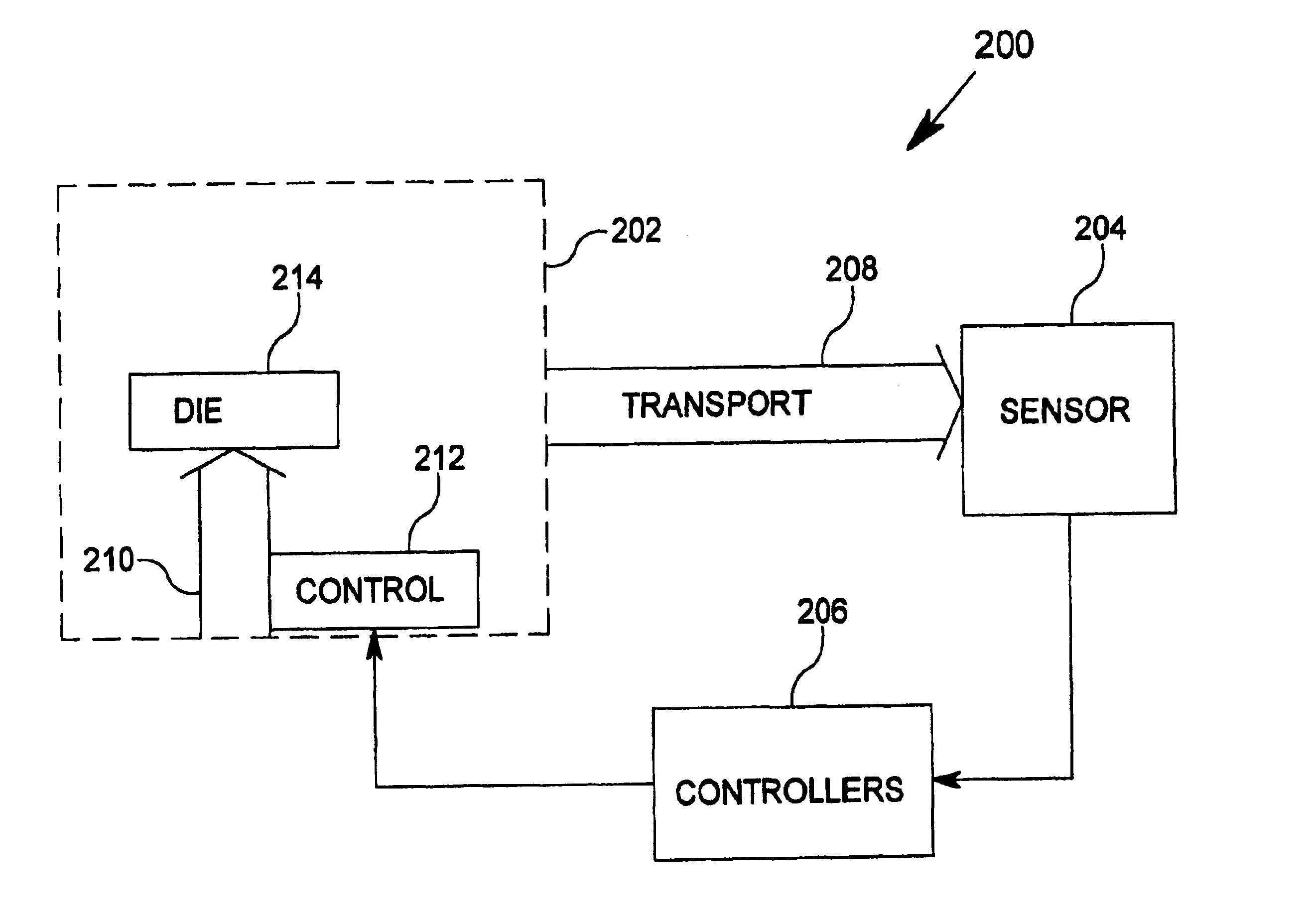

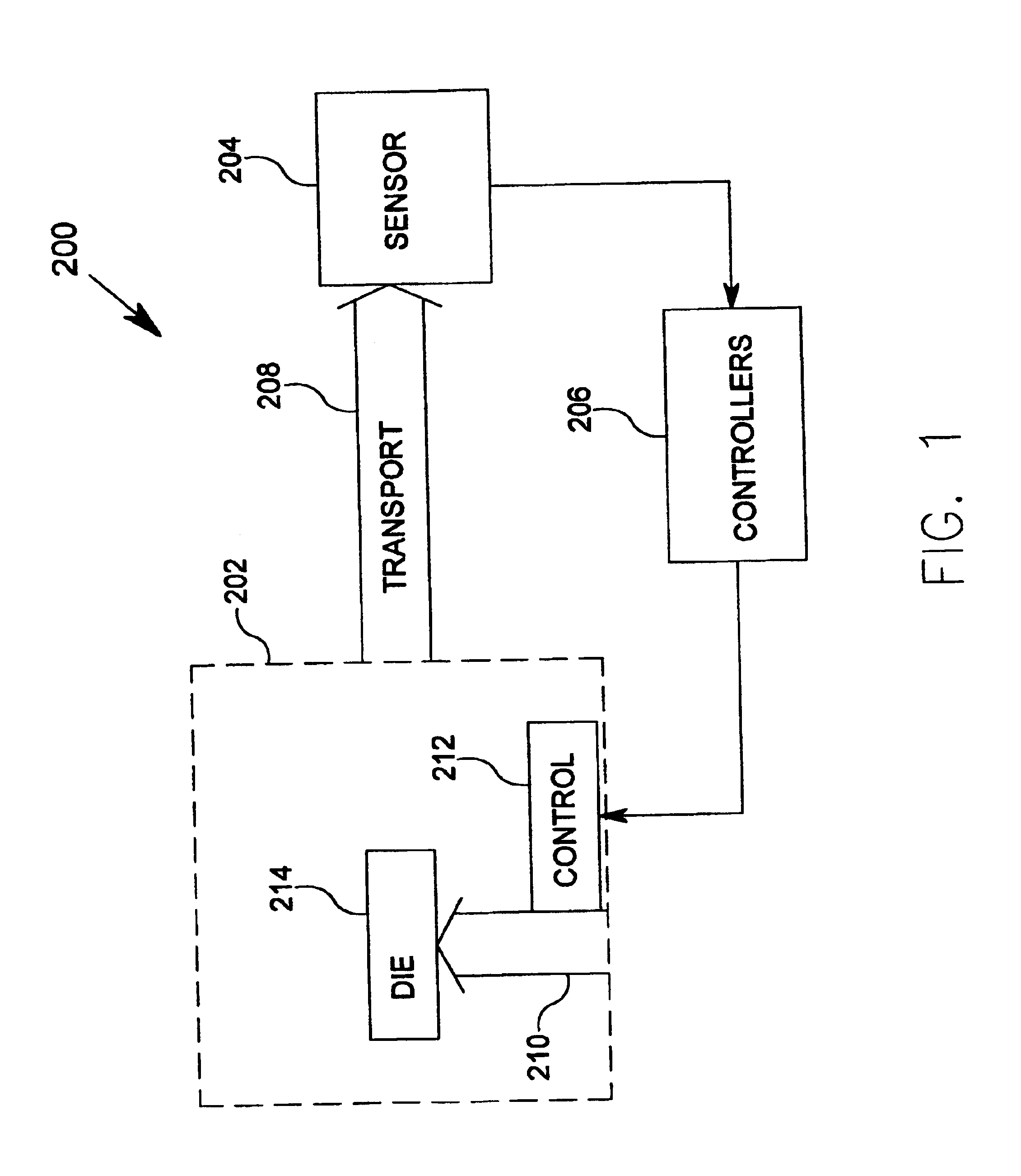

Swaging feedback control method and apparatus

A swaging system includes a swaging assembly, a sensor, and a controller. The swaging assembly includes a movable tool, the movable tool operate to exert force on a die. The die is configured to reduce a dimension of a work piece responsive to the exerted force, the dimension reduction having a relationship to a stroke of the movable tool. The sensor is operable to obtain information including a measurement of the reduced dimension of the work piece. The sensor is operable to generate a measurement signal representative of the obtained information. The controller is operably coupled to receive the measurement signal from the sensor, and is operable to cause adjustment the stroke of the movable tool responsive to the measurement signal.

Owner:BARTROM MICHAEL A +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com