Variable section end head unwarming armored heater and preparation method thereof

An armored heater with variable cross-section technology, applied in the direction of the shape of the heating element, can solve problems such as heater failure, poor contact, and burnout of the heating element material, and achieve the effect of simplifying the manufacturing process and ensuring the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

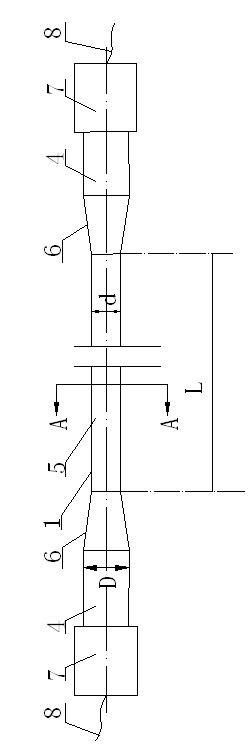

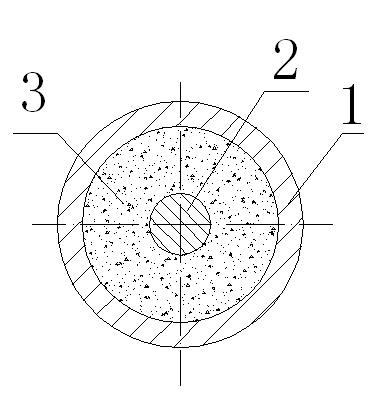

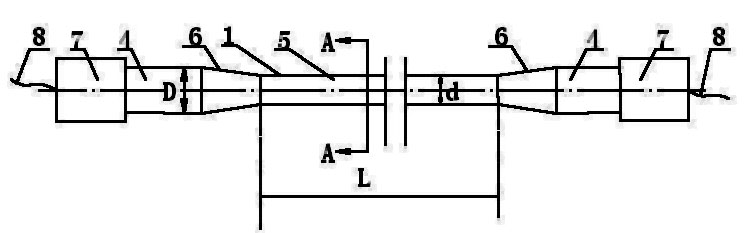

[0032] see figure 1 , figure 2 , a non-heating armored heater with a variable cross-section end, including a metal sleeve 1, a resistance heating wire 2, the resistance heating wire 2 is placed on the axis of the metal sleeve 1, and between the metal sleeve 1 and the resistance heating wire 2 The gap is filled with insulating material 3, and the left and right ends of the metal casing 1 are connected with a simple cap 7, and the resistance heating wire 2 passes through the end of the simple cap 7 to connect with the heating traction rod 8, and the simple cap 7 is filled with sealant , characterized in that: the two ends of the metal sleeve 1 are heating ends 4, the middle part of the metal sleeve 1 is an intermediate heating section 5, and the diameter D of the heating end 4 is greater than the diameter d of the intermediate heating section 5.

[0033] The diameter D of the heating end 4 is φ10.0mm, and the diameter d of the middle heating section 5 is φ3.3mm.

[0034] A co...

Embodiment 2

[0049] Others are the same as in Embodiment 1, the diameter D of the heating end 4 is φ10.0mm, and the diameter d of the middle heating section 5 is φ6.7mm.

[0050] The resistance heating wire 2 is Cr30Ni70 alloy wire.

[0051] The metal sleeve 1 is made of stainless steel. The stainless steel material is 304 alloy.

[0052] The insulating material 3 is a cylindrical ceramic column made of MgO with a through hole on the axis.

[0053] The length L of the middle heating section 5 is 10m.

[0054] The preparation method of the non-heating armored heater at the end of the variable cross-section is the same as that in Example 1, except that the amount of cold deformation in step a drawing is 10%, and the amount of cold deformation in step b swaging is 5%. In step c, the mechanical connection between the simple cap 7 and the heating end 4 is an interference connection; in step d, the heating drawing rod 8 and the resistance heating wire 2 are connected by welding, and the weldi...

Embodiment 3

[0056] Others are the same as in Embodiment 1, the diameter D of the heating end 4 is φ10.0mm, and the diameter d of the middle heating section 5 is φ5.0mm.

[0057] The resistance heating wire 2 is Cr15Ni60 alloy wire.

[0058] The metal sleeve 1 is made of stainless steel. The stainless steel material is 316 alloy.

[0059] The insulating material 3 is a cylindrical ceramic column made of MgO with a through hole on the axis.

[0060] The length L of the middle heating section 5 is 10m.

[0061] The preparation method of the non-heating armored heater at the variable cross-section end is the same as that in Example 1, except that the amount of cold deformation in step a drawing is 20%, and the amount of cold deformation in step b swaging is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com