Patents

Literature

177results about How to "Increase the critical current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

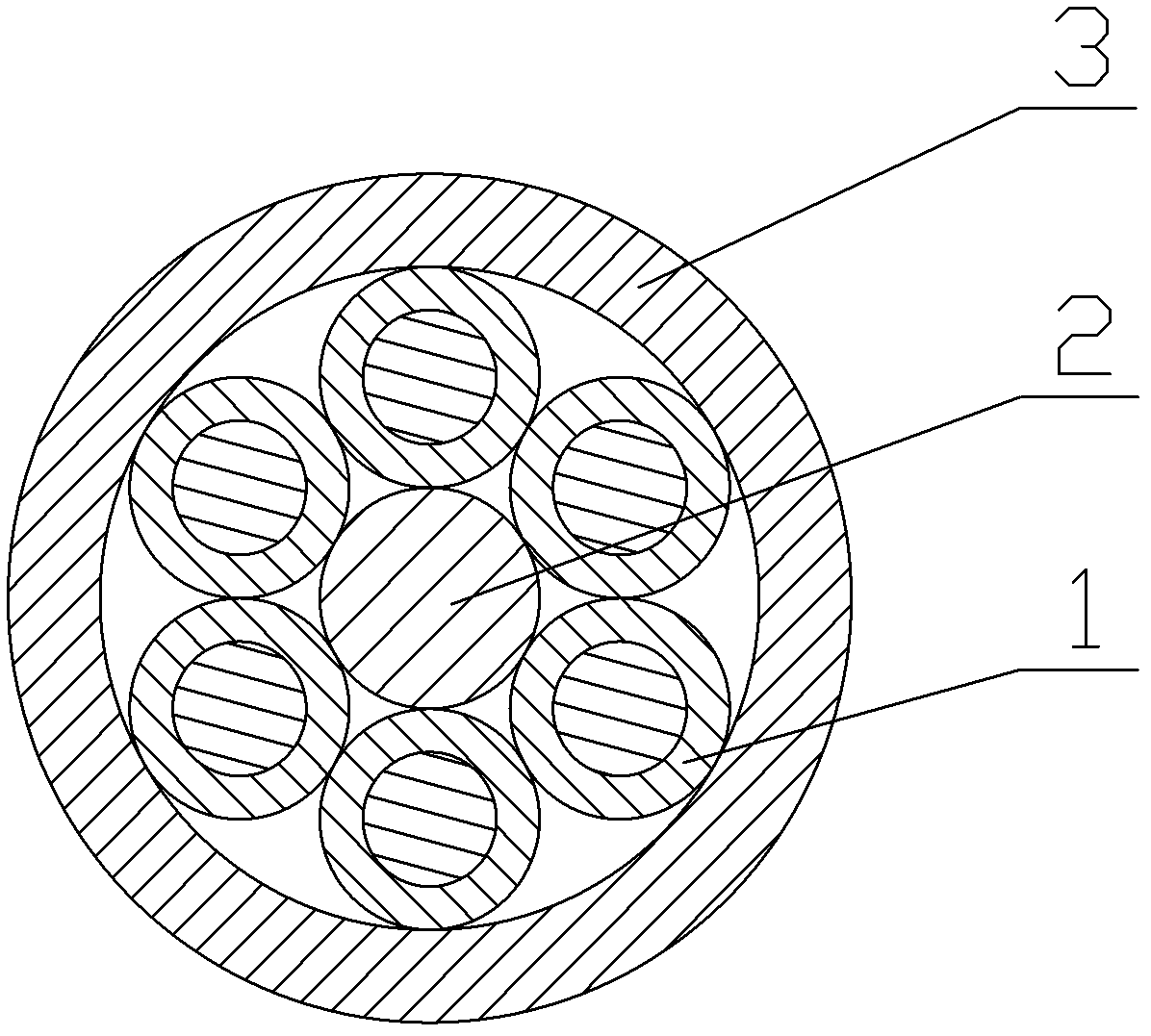

Method for manufacturing NbTi-CuNi-Cu superconductive composite wire rod

ActiveCN103956219AReduce manufacturing costFacilitate hot extrusion and cold drawing processingSuperconductors/hyperconductorsSuperconductor devicesExtension methodMaterials science

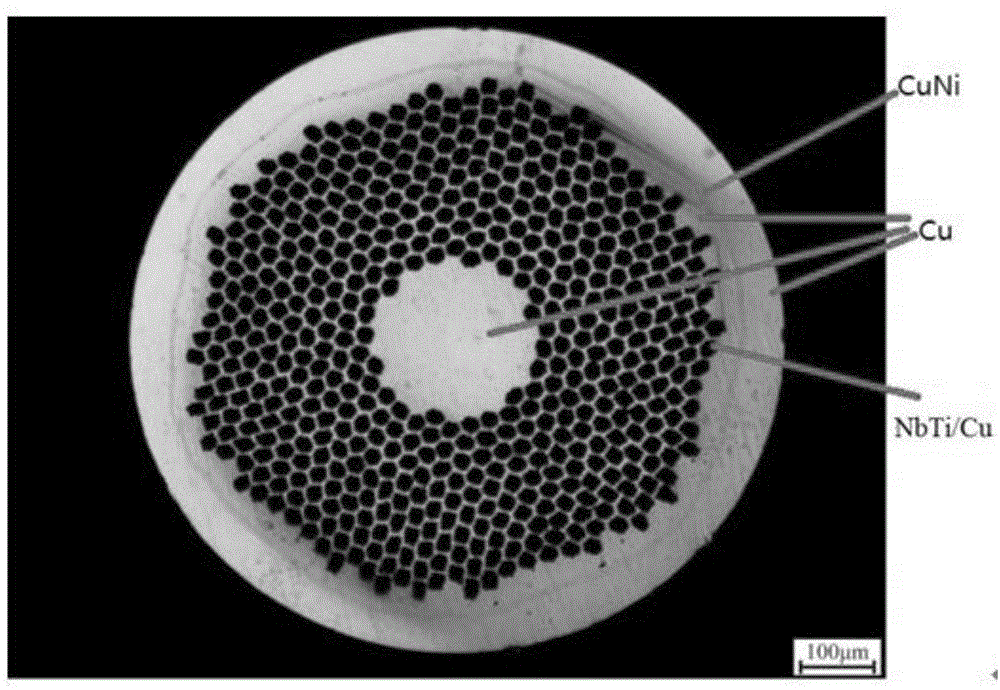

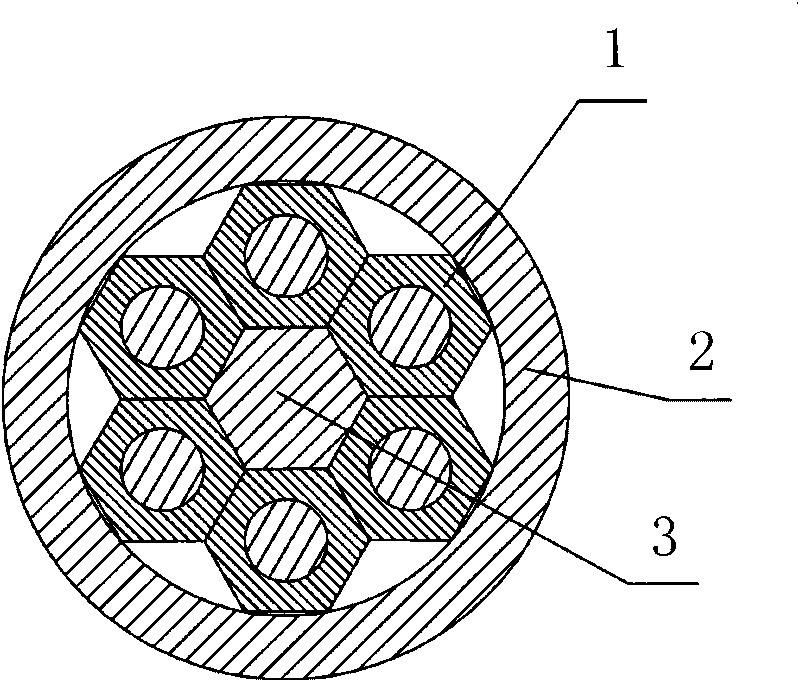

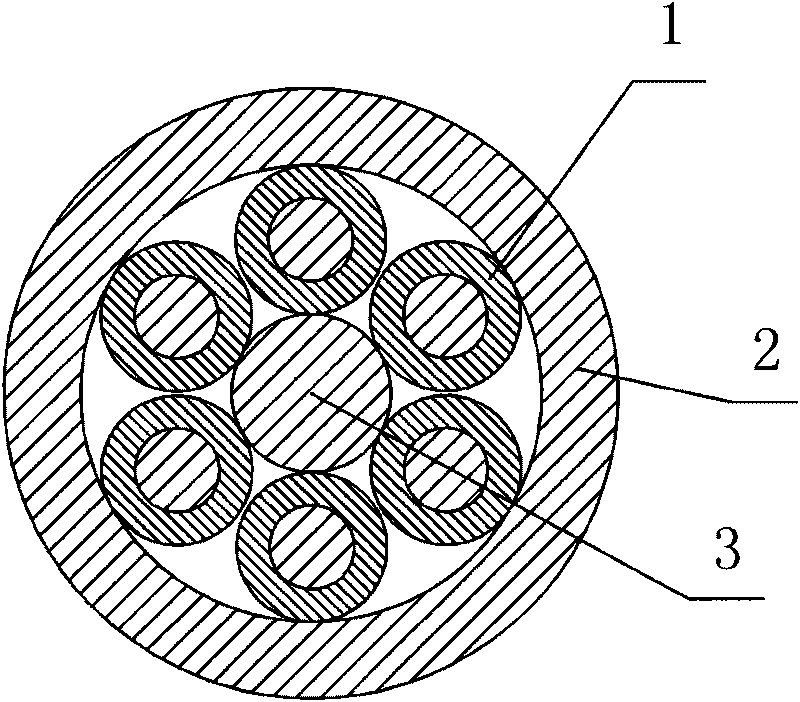

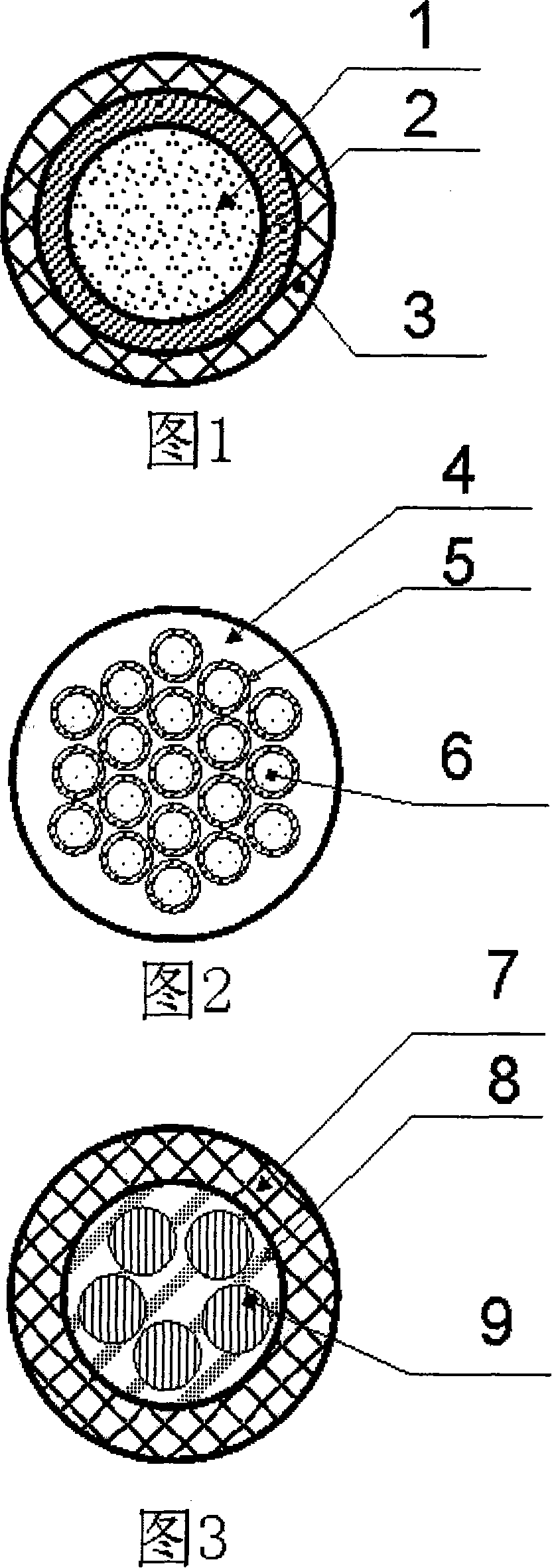

The invention discloses a method for manufacturing an NbTi-CuNi-Cu superconductive composite wire rod. The method comprises the following steps of putting an NbTi alloy rod into a Cu tube, and obtaining an NbTi-Cu single-core composite rod blank through a hot extrusion or sleeve extension method; extending the NbTi-Cu single-core composite rod blank to a hexagonal rod to obtain an NbTi-Cu single-core composite rod, putting the NbTi-Cu single-core composite rod into a copper tube to manufacture an NbTi-Cu multi-core composite rod; putting the NbTi-Cu single-core composite rod or the NbTi-Cu multi-core composite rod into a copper tube, sleeving a CuNi tube with the copper tube, sleeving another copper tube with the CuNi tube, and sealing two ends of the copper tube; reducing space in the copper tube through a hot isostatic pressure method and performing hot extrusion to obtain an NbTi-CuNi-Cu composite rod; performing multiple cold extension and aging treatment on the NbTi-CuNi-Cu composite rod to obtain the superconductive composite wire rod with the required dimension and shape. By means of the method, alternating current loss of the NbTi superconductive composite wire rod is reduced, production processes are simplified, and production cost is reduced.

Owner:西部超导材料科技股份有限公司

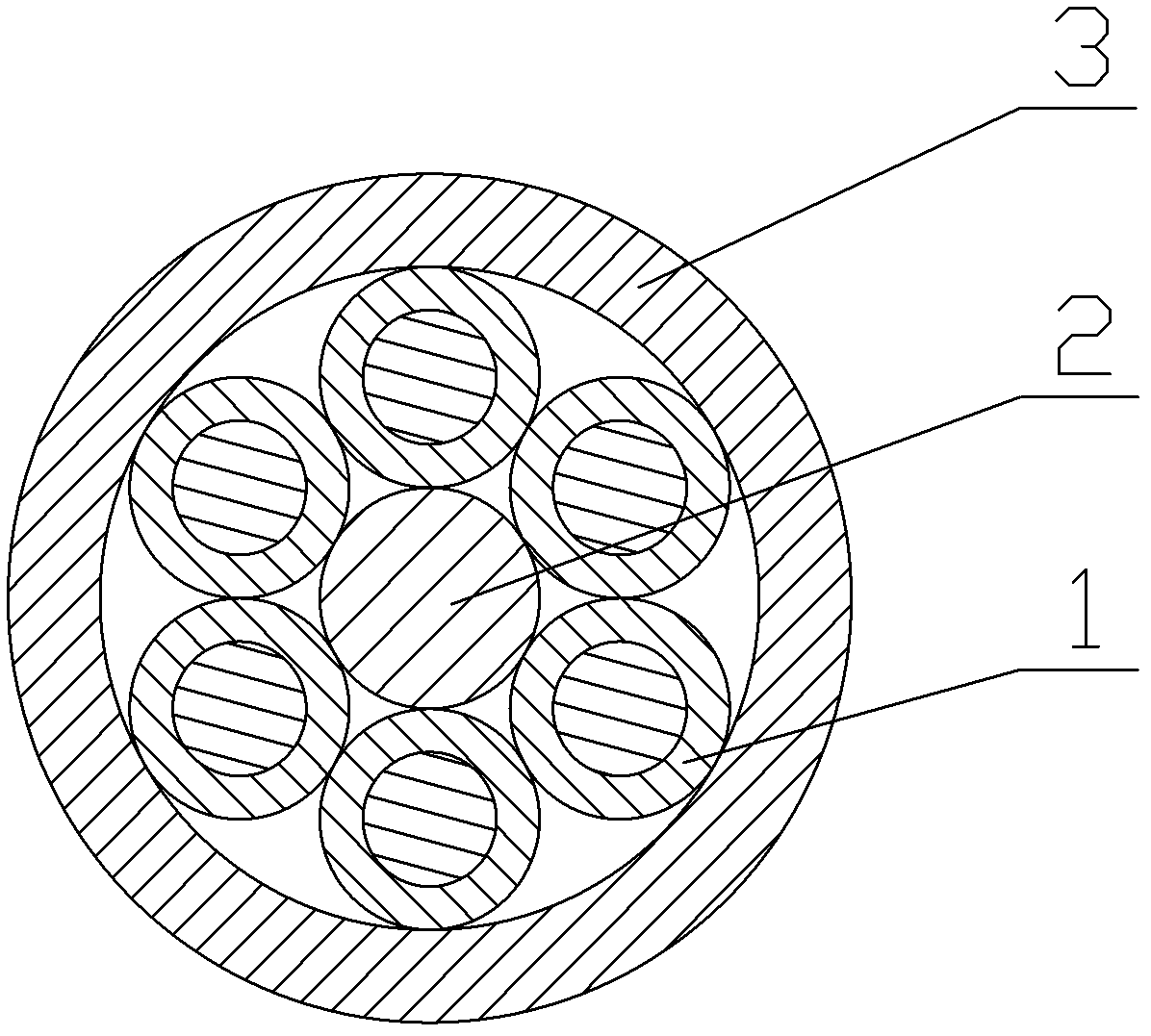

Preparation method for multi-core MgB2/Fe/Cu superconducting wire

ActiveCN102693785AIncrease the critical current densityImprove current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesPower flowNiobium

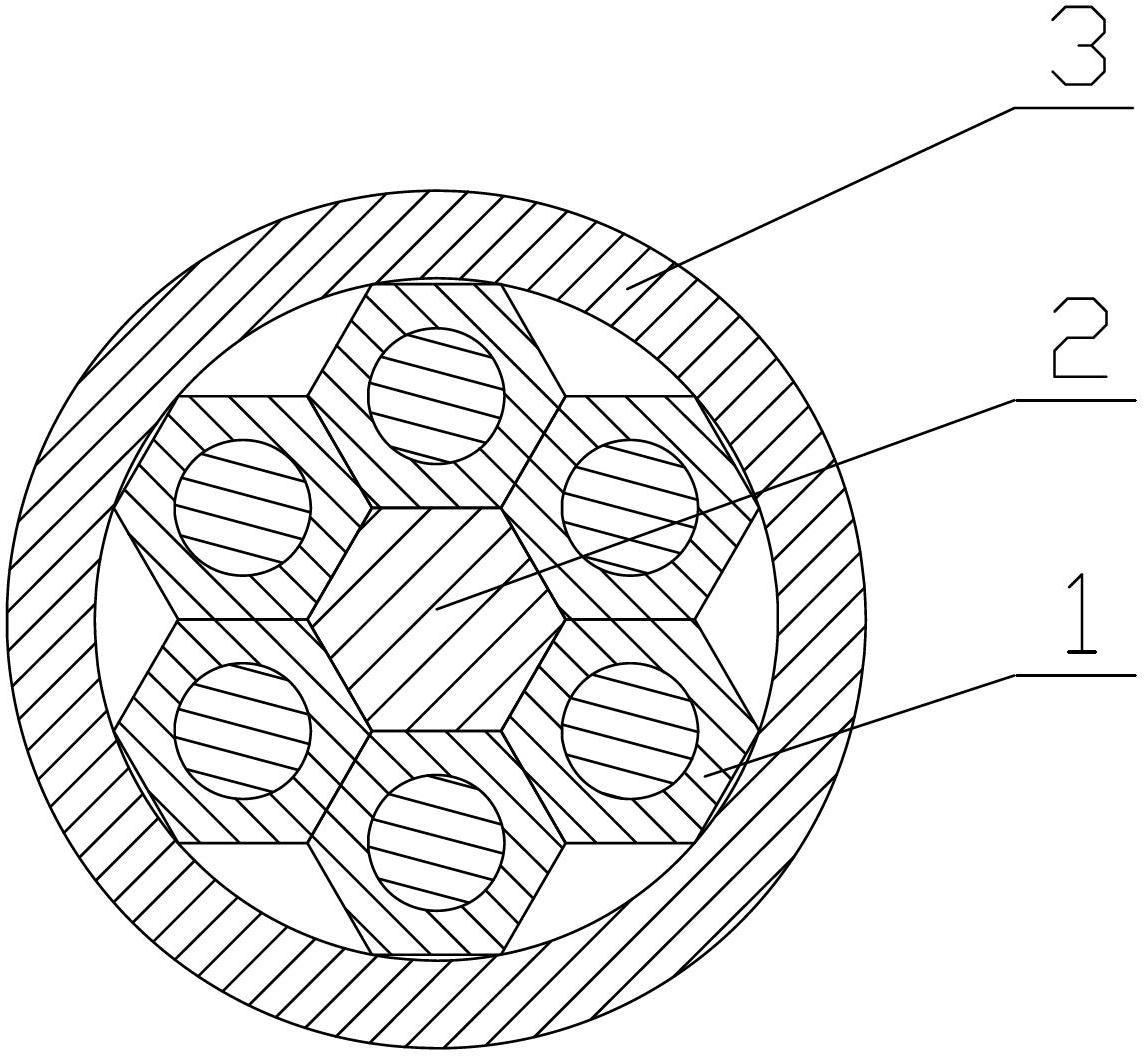

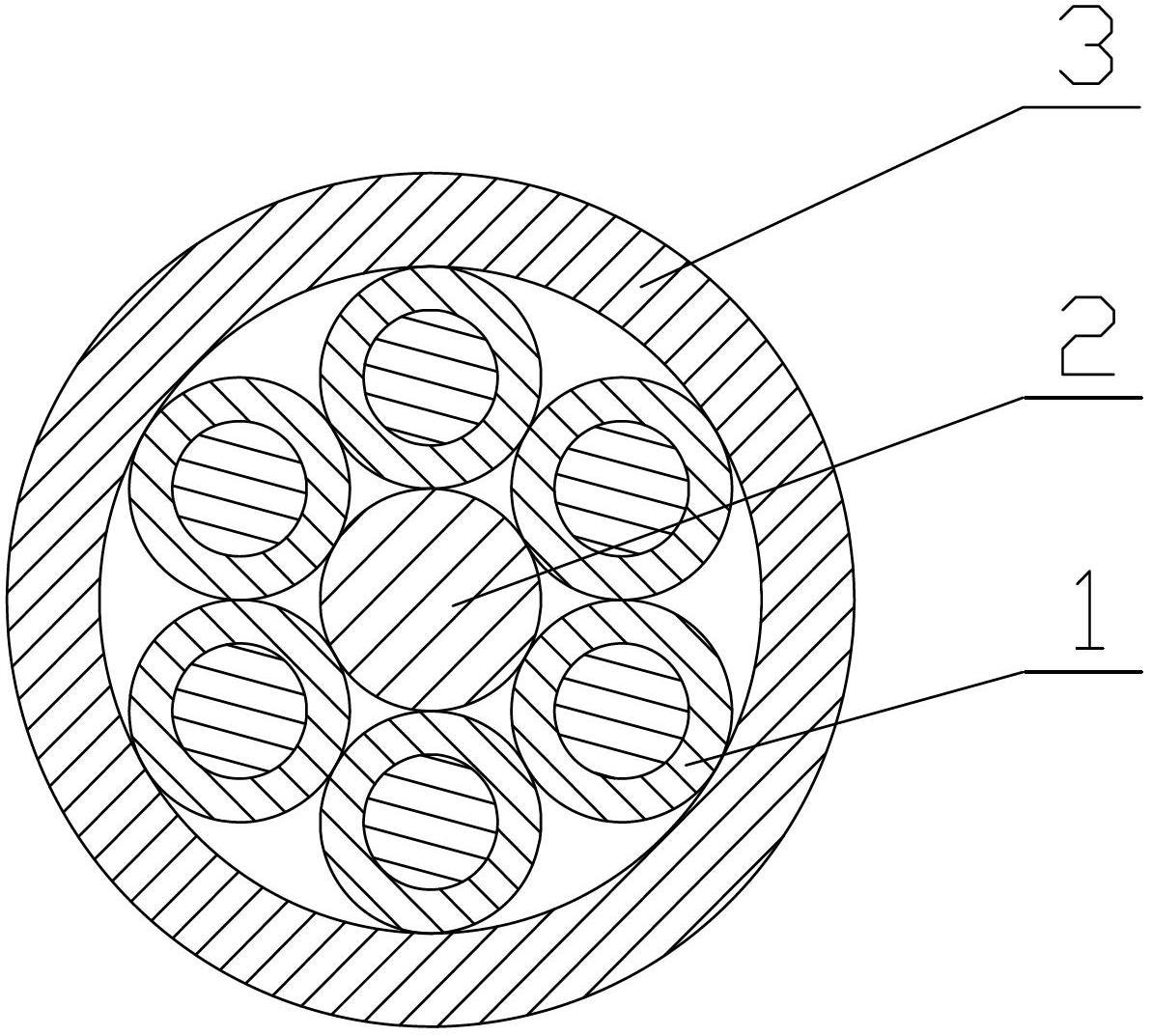

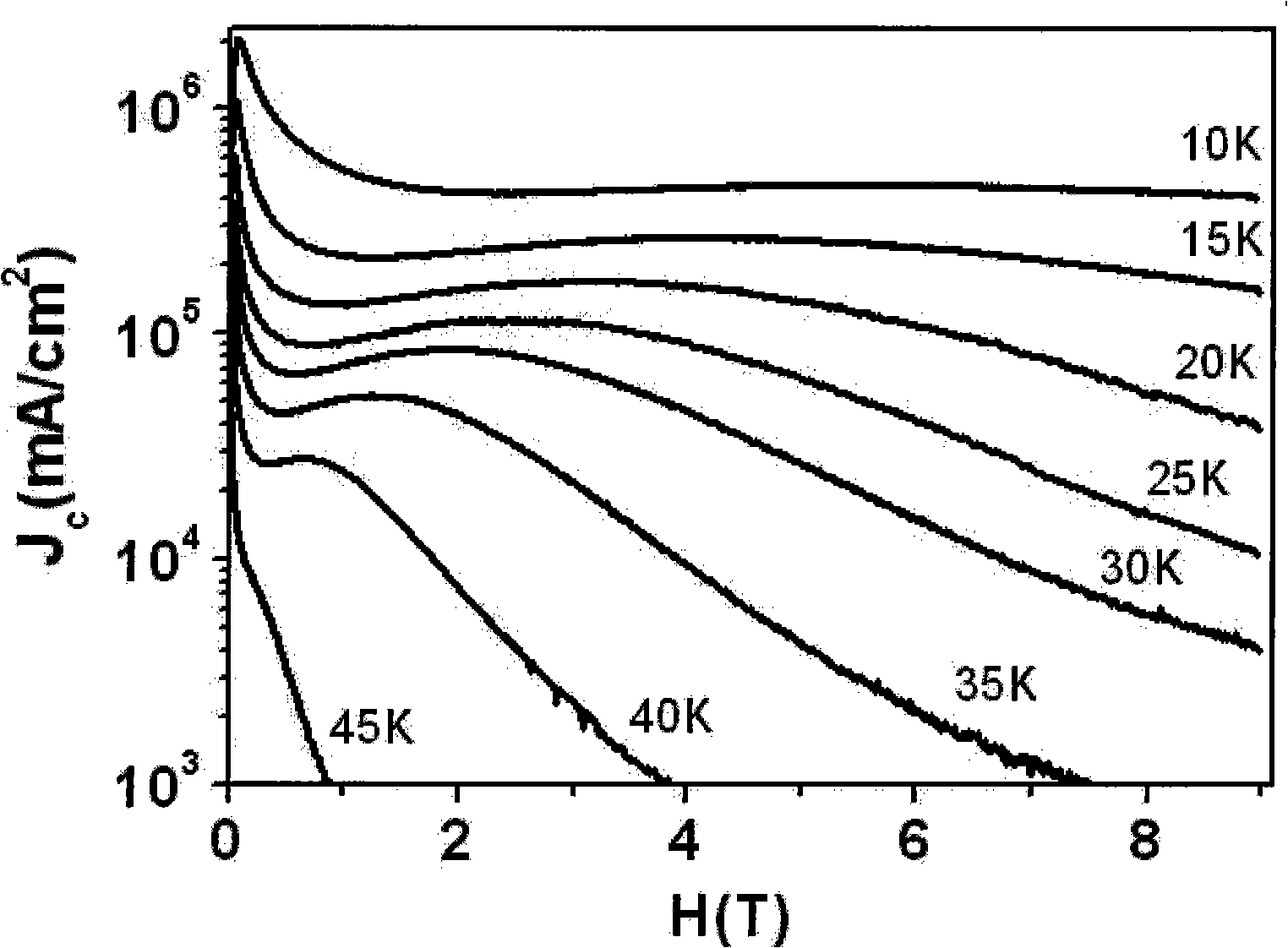

The invention discloses a preparation method for a multi-core MgB2 / Fe / Cu superconducting wire. The preparation method comprises the following steps of: 1, preparing precursor powder; 2, filling the precursor powder into a pure iron tube, and placing the pure iron tube into a first oxygen-free copper tube to obtain a tubulated composite; 3, performing rotary forging and drawing treatment on the tubulated composite to obtain single-core wires; 4, placing a copper-niobium composite rod and six single-core wires into a second oxygen-free copper tube, performing secondary assembly to obtain a second composite rod, and performing rotary forging and drawing and grooving rolling treatment on the second composite rod to obtain a multi-core MgB2 / Fe / Cu wire; and 5, sealing the two ends of the wire, placing the sealed wire into a vacuum furnace, and performing vacuum sintering to obtain the multi-core MgB2 / Fe / Cu superconducting wire. The multi-core MgB2 / Fe / Cu superconducting wire has critical current density Jc reaching 1.8*10<4>A / cm<2> under 20 K and 1T, and a requirement for the practicability of the multi-core MgB2 / Fe / Cu superconducting wire is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

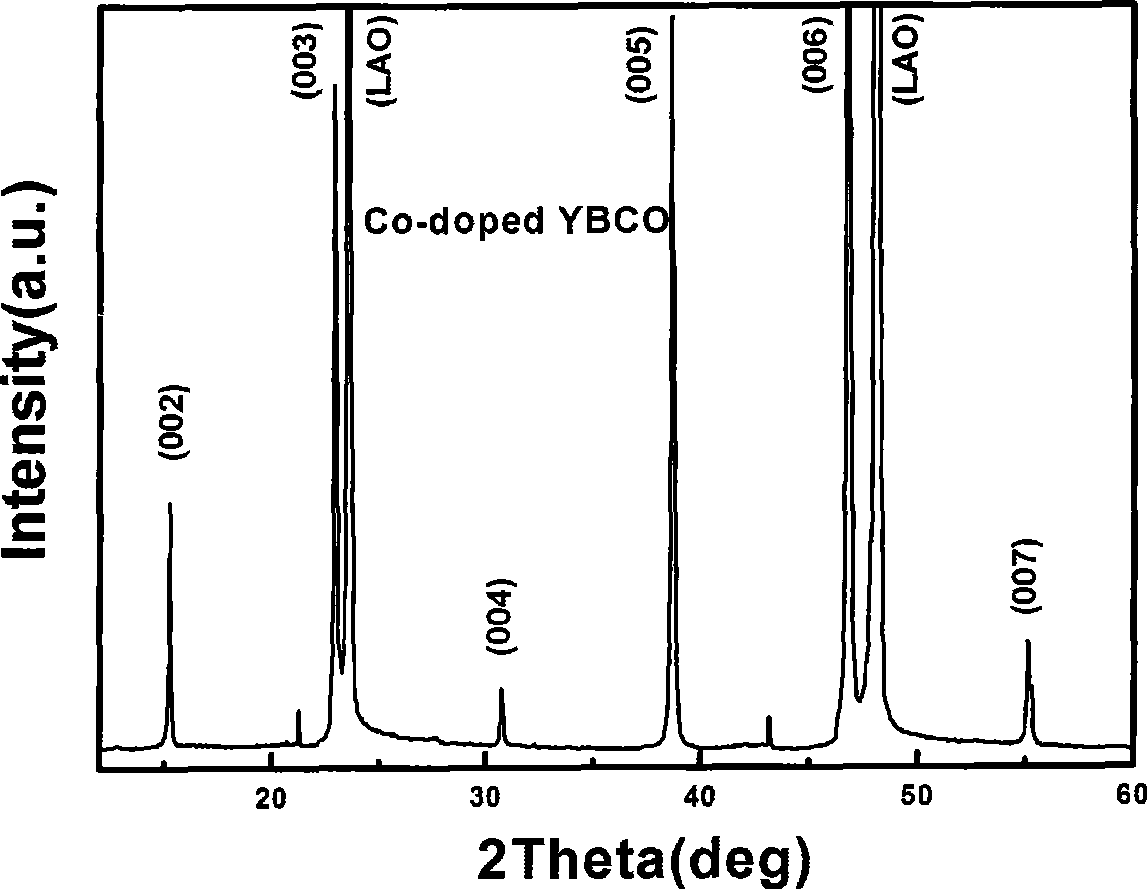

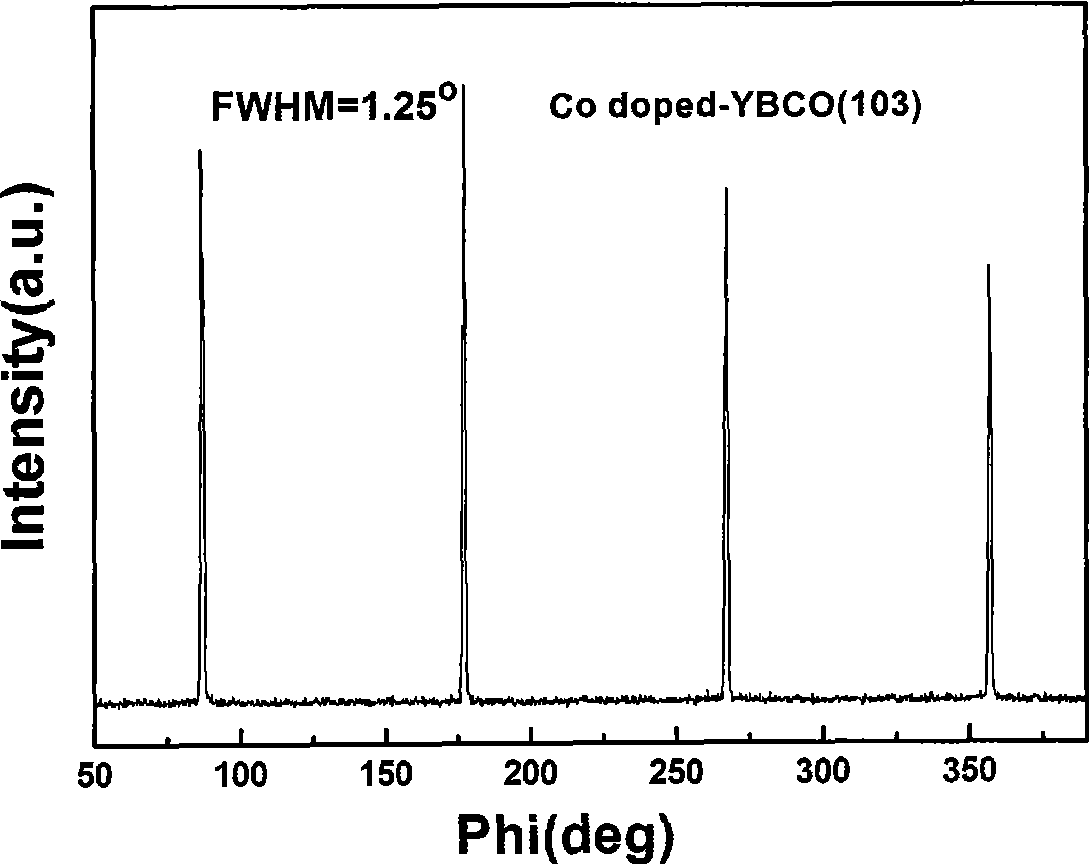

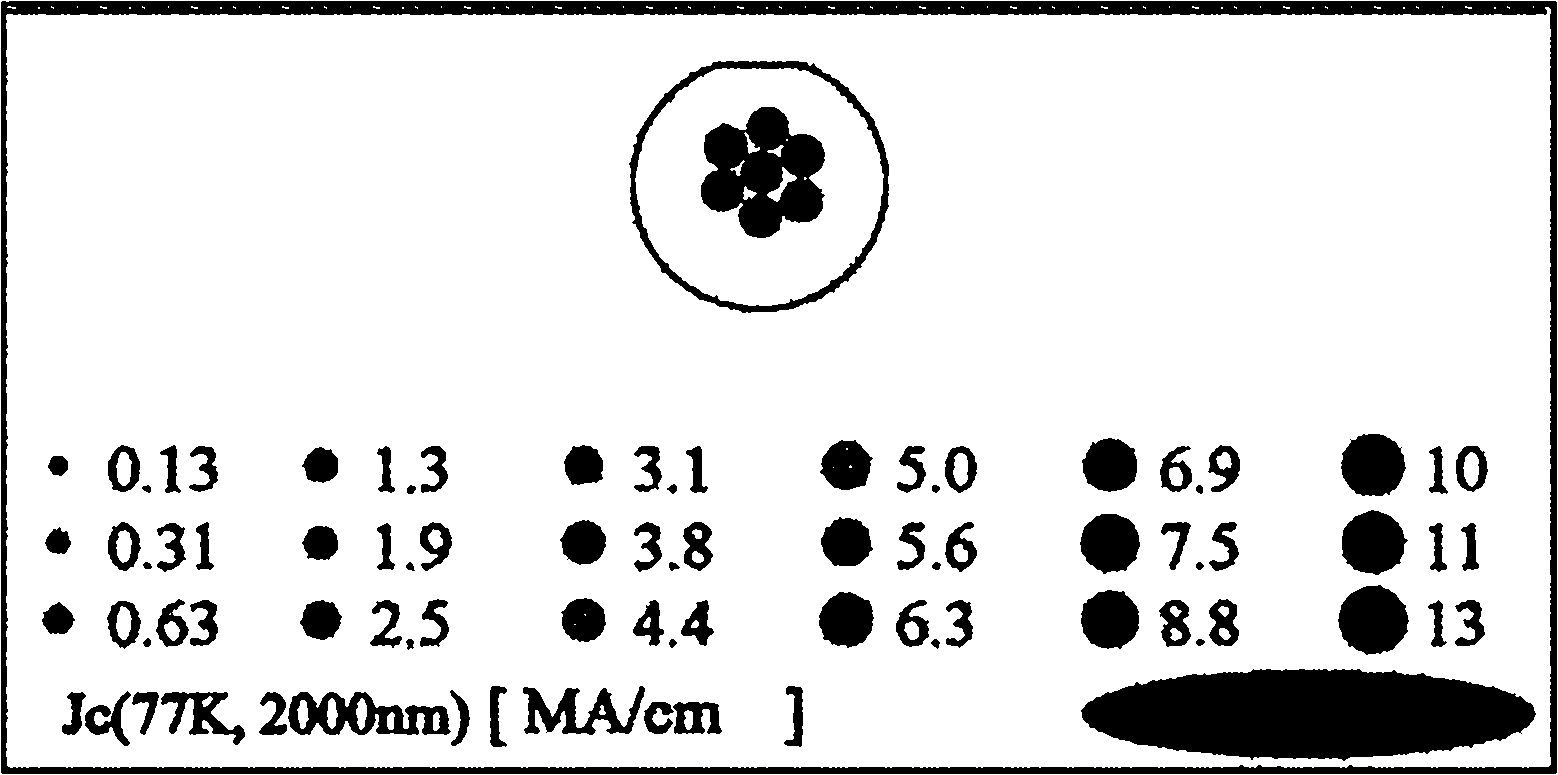

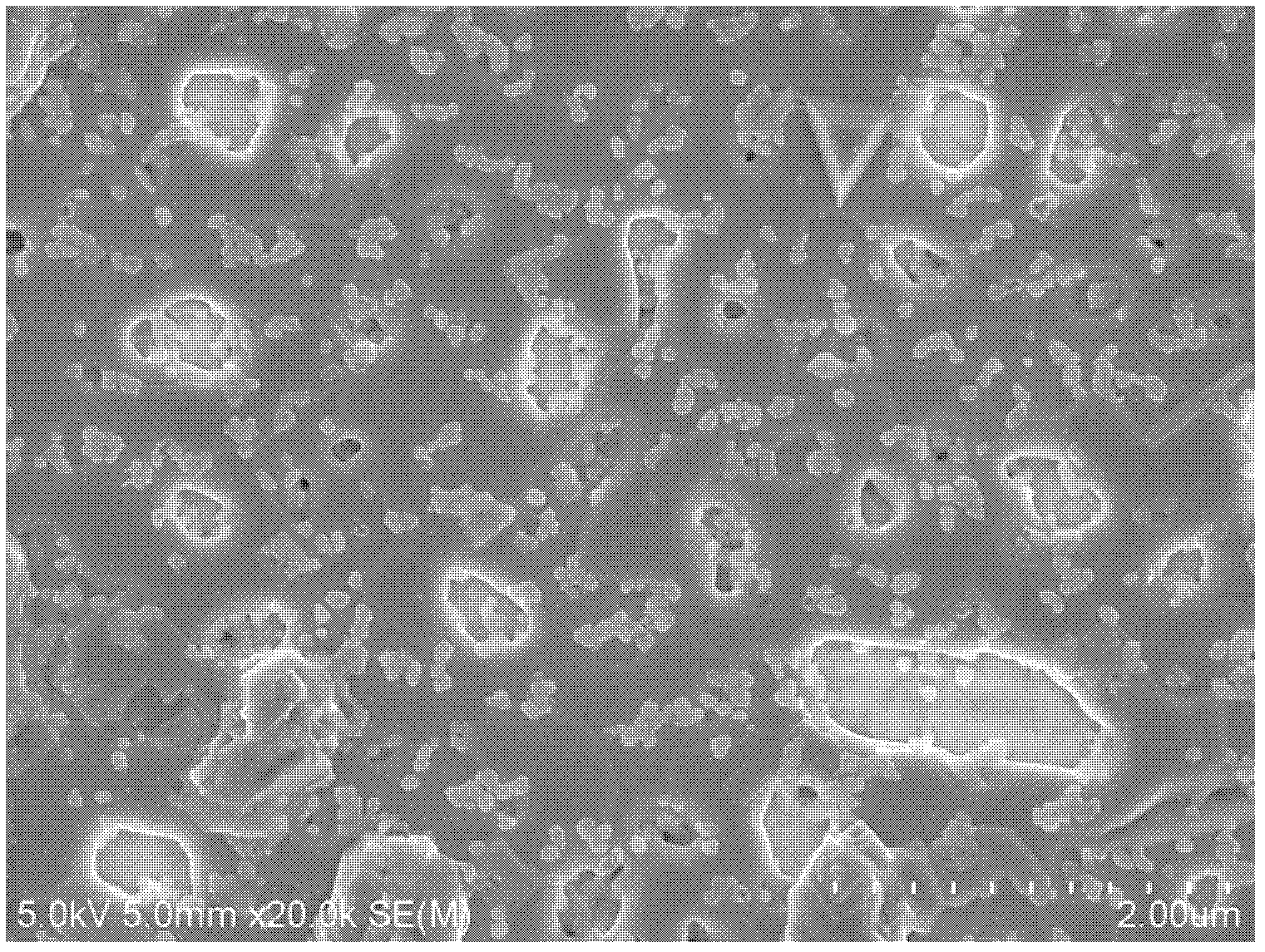

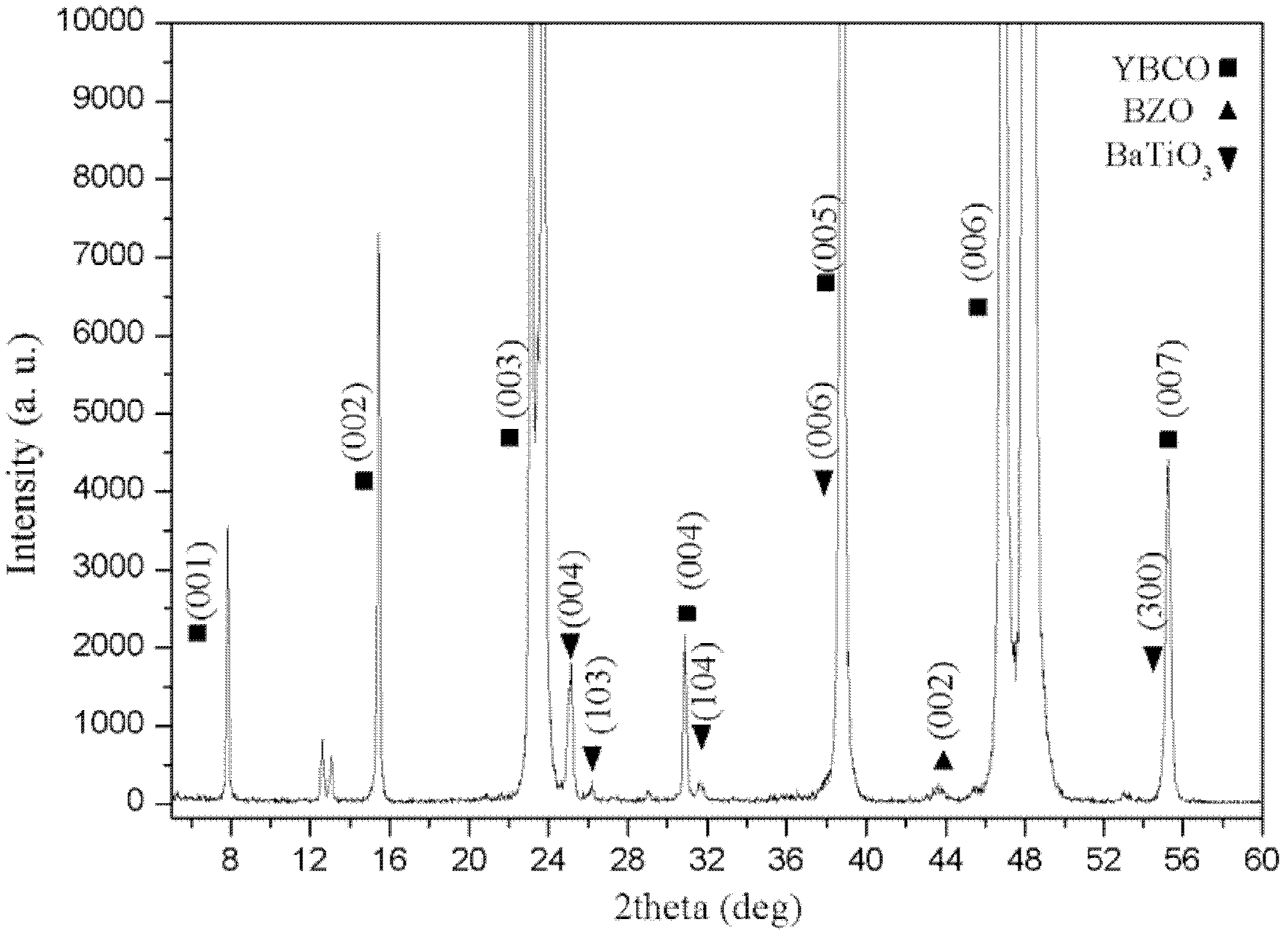

Method for preparing high critical current density yttrium barium copper oxide superconducting film

InactiveCN101456726ASimple processShorten the timeSuperconductors/hyperconductorsSuperconductor devicesPolyvinyl butyralPropanoic acid

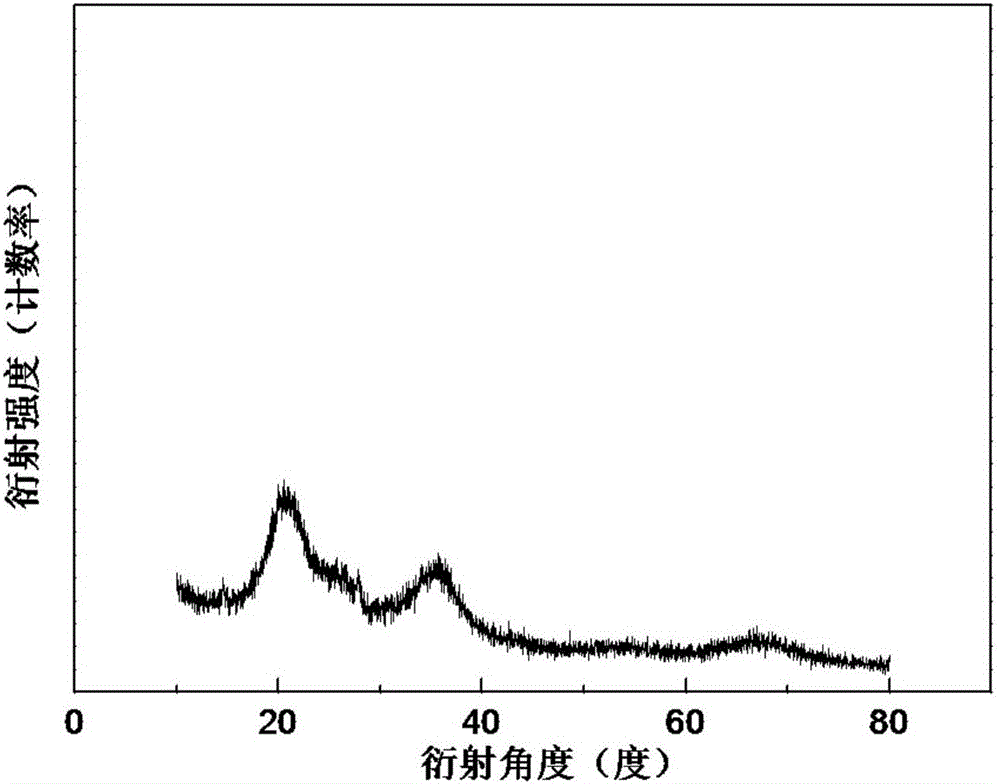

The invention discloses a method for preparing a yttrium barium copper oxide superconducting film with high critical current density, which comprises the following concrete steps: a, preparing a precursor solution, which is to dissolve yttrium acetate, barium acetate, copper acetate and acetate of an impurity element into propionic acid according to the proportion that the stoichiometric ratio of yttrium: barium: copper: impurity element is 1: 2: 3-X: X (the X is more than or equal to 0.0002 and less than or equal to 0.008) to obtain the precursor solution, and the impurity element is one of Co, Fe, Zn, Ni, and Li; b, adding a polymer material polyvinyl butyral (PVB) into the precursor solution obtained in a step to obtain a coating colloid; c, coating and drying the coating colloid on a substrate to form a film; and d, performing thermal decomposition treatment on the substrate with the film prepared in c step and then imaging thermal treatment to obtain the YBCO superconducting film. The yttrium barium copper oxide superconducting film prepared by the method has high biaxial texture, smooth and compact surface, high critical current density under a magnetic field, low cost, and simple process, and is suitable for mass industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

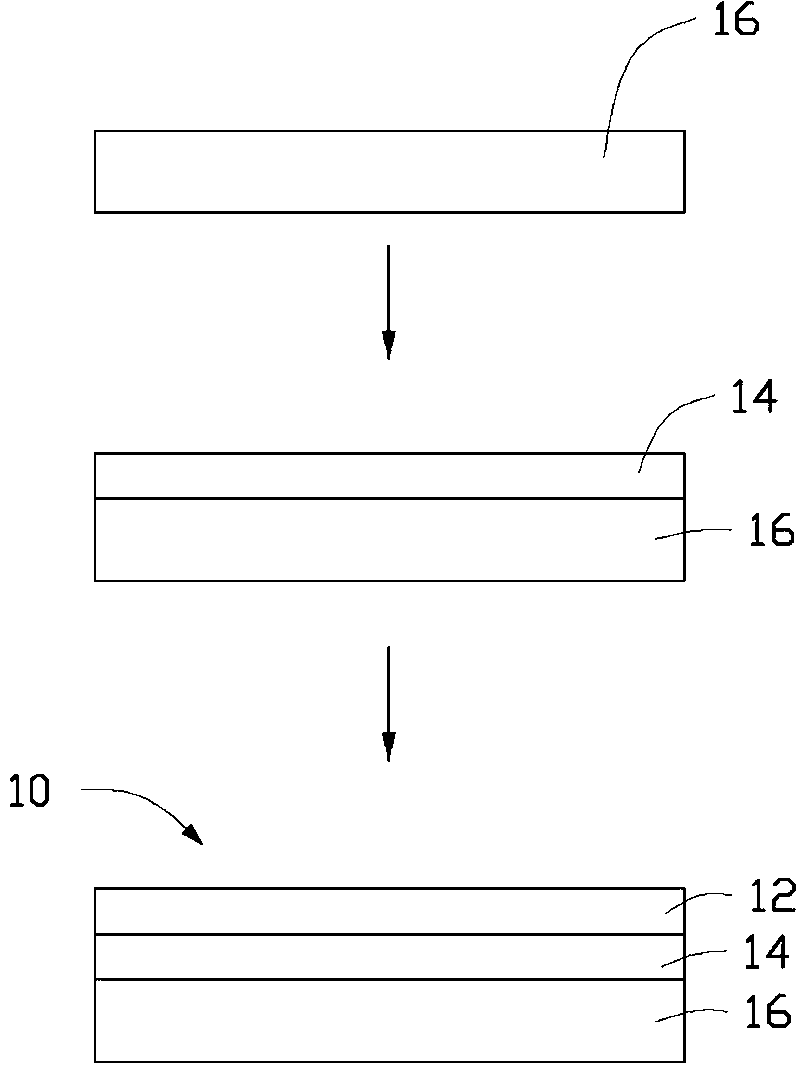

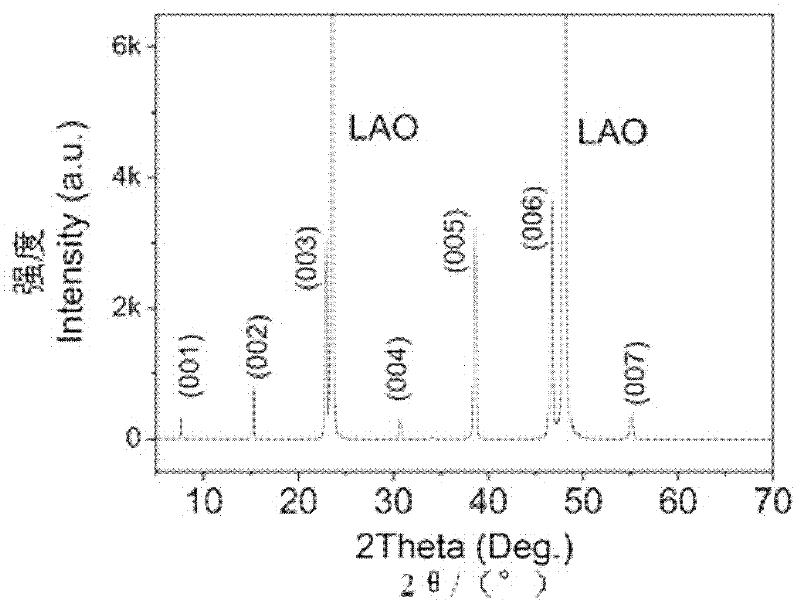

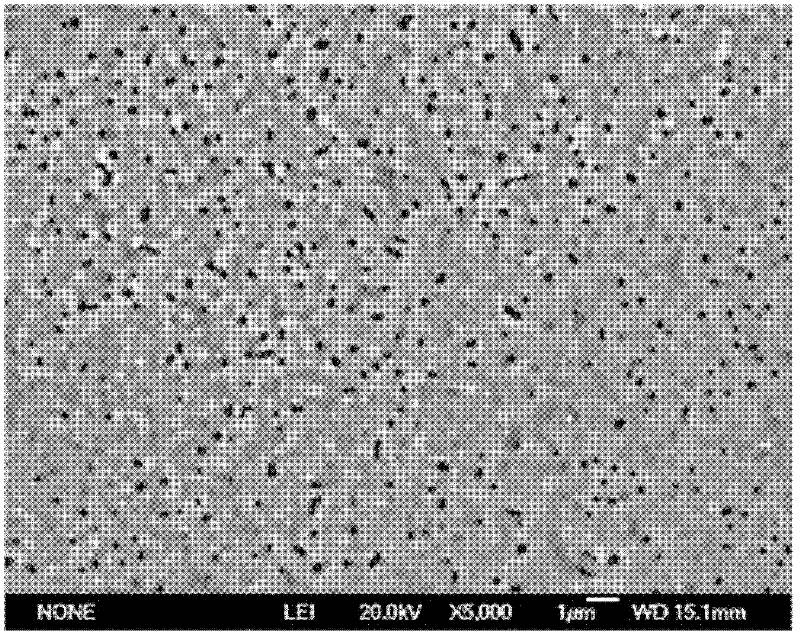

Preparation method of high-temperature superconducting thin film

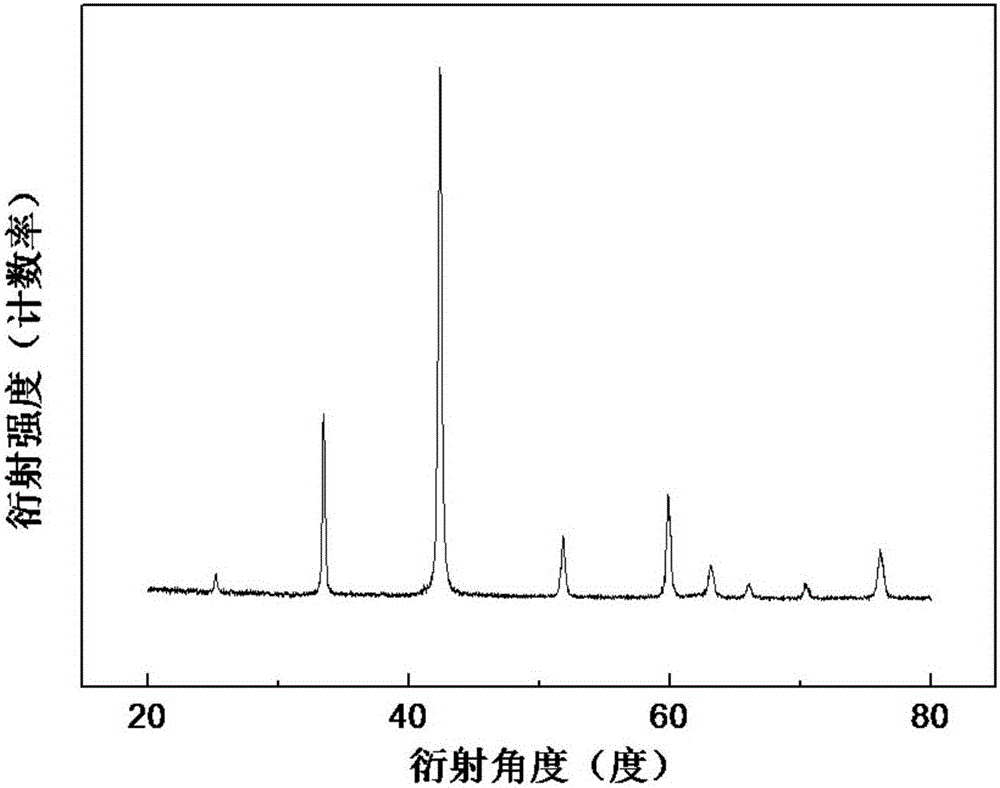

ActiveCN103184513AGuaranteed 2D epitaxial growthAtomic level flatteningPolycrystalline material growthFrom chemically reactive gasesCrystal structureCondensed matter physics

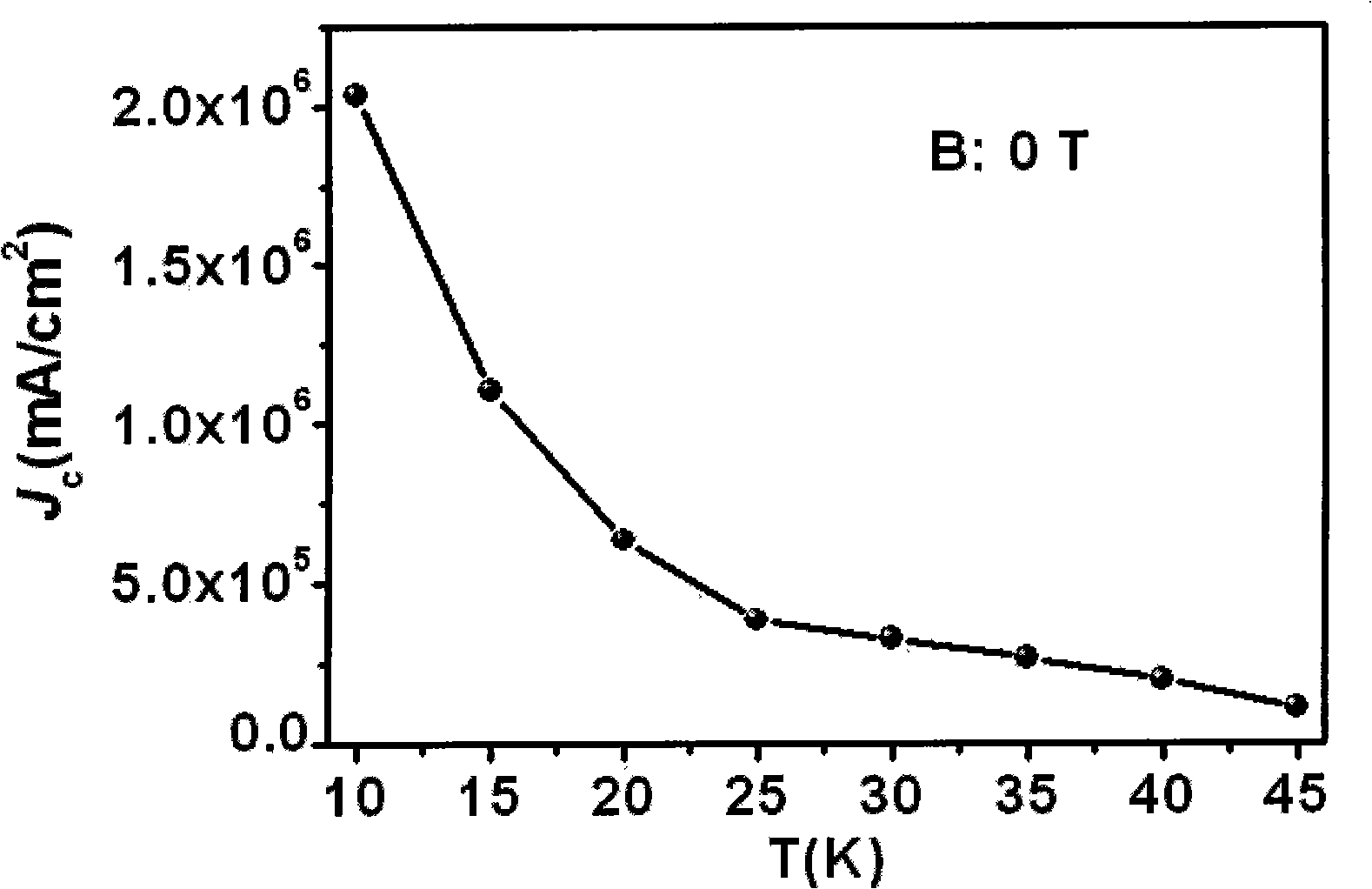

The invention relates to a preparation method of a high-temperature superconducting thin film. The method specifically comprises steps as follows: providing an SrTiO3 substrate and placing the SrTiO3 substrate in a super-high vacuum system, growing an FeSe monocrystal layer on the surface of the SrTiO3 substrate by adopting a molecular beam epitaxy growing technology, and growing a protective layer with a layered crystal structure by adopting the molecular beam epitaxy growing technology and covering the surface of the FeSe monocrystal layer with the protective layer. By means of the method, the high-quality and ultrathin high-temperature superconducting thin film can be prepared, the starting temperature of superconducting transition of the thin film is above 54K, and the critical current density is higher than 106A / cm<2> when the starting temperature of superconducting transition of the thin film is 12K.

Owner:TSINGHUA UNIV +1

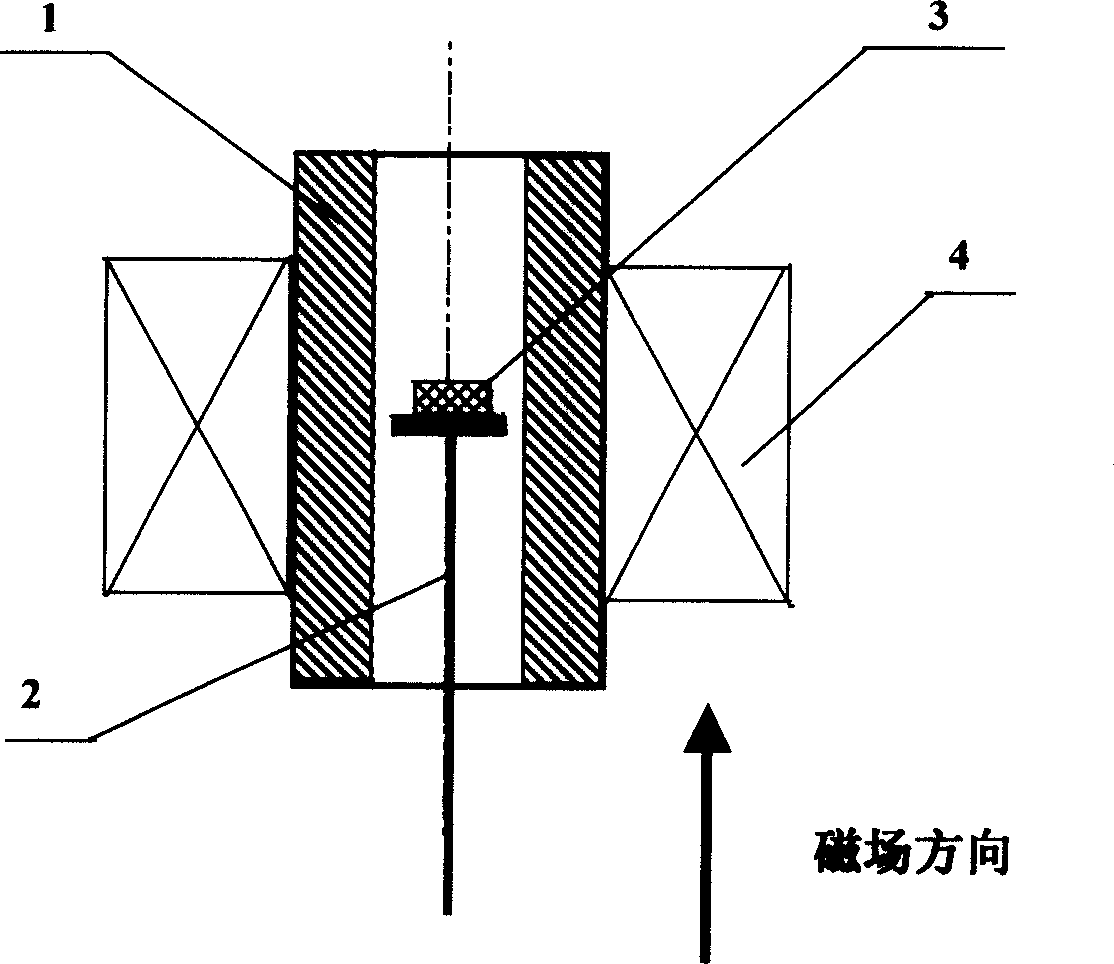

Process for preparing magnesium diboride superconductor

The preparation process of magnesium diboride superconductor features that magnesium diboride superconductor is prepared in strong magnetic field. Magnesium powder and boron powder in stoichiometric ratio are mixed homogeneously, the mixture is prepared into lump or belt sample, and the lump or belt sample is set heating furnace with Ar atmosphere and strong magnetic field and maintained at magnetic field of 0-30 tesla and temperature of 600-950 deg.c for 1-3 hr before the power source for the strong magnetic field and heating is turned off and the sample is cooled to room temperature inside the furnace. The present invention has effectively improved crystal grain connectivity and greatly raised clinical current structure of the magnesium diboride superconductor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for preparing magnesium diboride superconducting wire with graphene coated boron powder

ActiveCN105931750ACombine tightly and evenlyInhibition of contractionSuperconductors/hyperconductorsSuperconductor devicesRoom temperatureMagnesium diboride

The invention discloses a method for preparing a magnesium diboride superconducting wire with graphene coated boron powder. The method comprises the steps of: 1, adding the spherical nano boron powder to graphene oxide solution, filtering after stirring uniformly to obtain filter residue and carrying out vacuum drying on the filter residue to obtain mixed powder; 2, carrying out heat treatment on the mixed powder to obtain the graphene coated boron powder; 3, after mixing the graphene coated boron powder with magnesium powder, grinding to obtain tubing precursor powder; 4, putting the tubing precursor powder into an Nb / Cu composite tube which is processed by acid pickling to obtain a tubing complex; 5, processing the tubing complex into a single-core wire; 6, processing into a multi-core wire by employing a bundle-drawing technology; and 7, carrying out phase-forming heat treatment, and cooling to room temperature with a furnace to obtain the magnesium diboride superconducting wire. According to the method disclosed by the invention, through adding the spherical boron powder to the graphene oxide solution, the single-layer graphene coated boron powder is realized; after the heat treatment, the graphene has no agglomeration and can be combined with the boron powder tightly and uniformly; and the phenomena of graphene contraction and nonuniformity in the traditional method are inhibited.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Yttrium barium copper oxide superconducting thin film mixed with samarium and manufacture method thereof

InactiveCN102491740AGood c-axis textureGood in-plane and out-of-plane textureYttrium barium copper oxideChemical composition

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Heat treatment method for iron base MgB2 superconductor wire and belt

InactiveCN1865457AIncrease the critical current densitySuperconductors/hyperconductorsFurnace typesMagnesium diborideJoule

The invention discloses a heat disposal method of iron-base magnesium diboride superconductive wire, which is characterized by the following: disposing the core superconductive material through joule heat of current flow; blending magnesite powder and boron powder evenly according to chemical gauge rate; filling the mixture in the iron pipe after grinding; producing iron-base leptctene and fasciola material with magnesite powder and boron powder in the middle through rotating, drawing and rolling; connecting two ends of leptctene or fasciola with blaster fuse in the Ar quartz tube; controlling the heating speed at 45-900 deg.c per min and heat disposal temperature at 600-900 deg.c; keeping temperature for 10-60 min; cooling at 30-300 deg.c per min to approach indoor temperature. The invention can improve the heating and cooling speed in the heat disposal course, which increases the marginal current density value of magnesium diboride superconductive wire.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

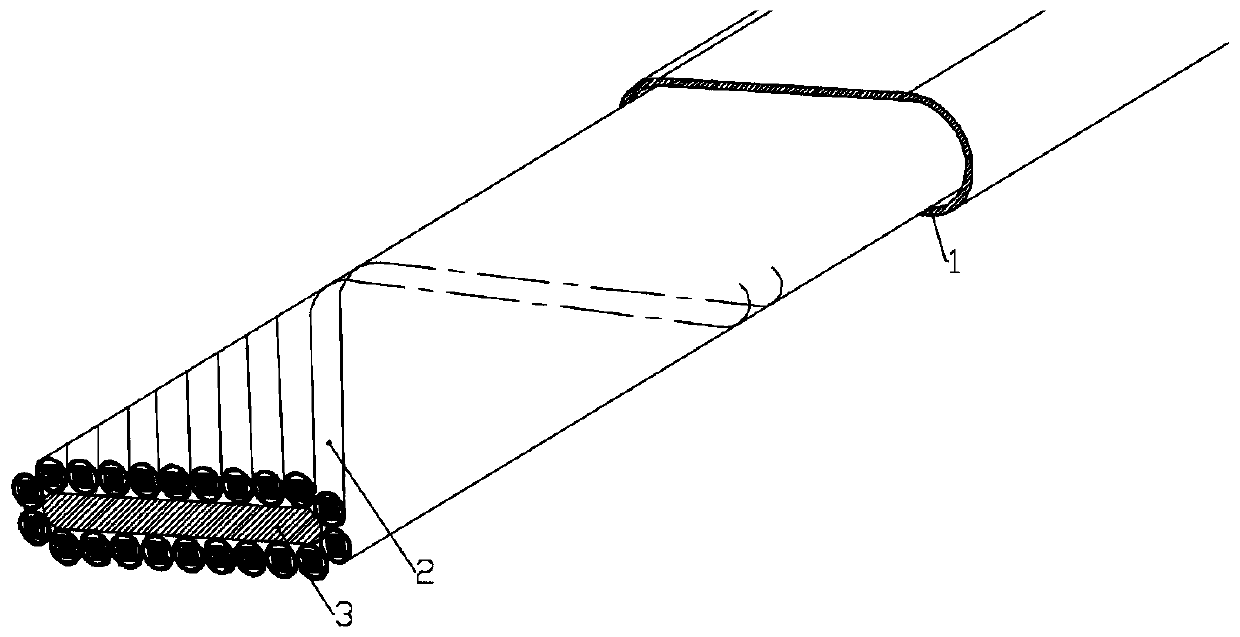

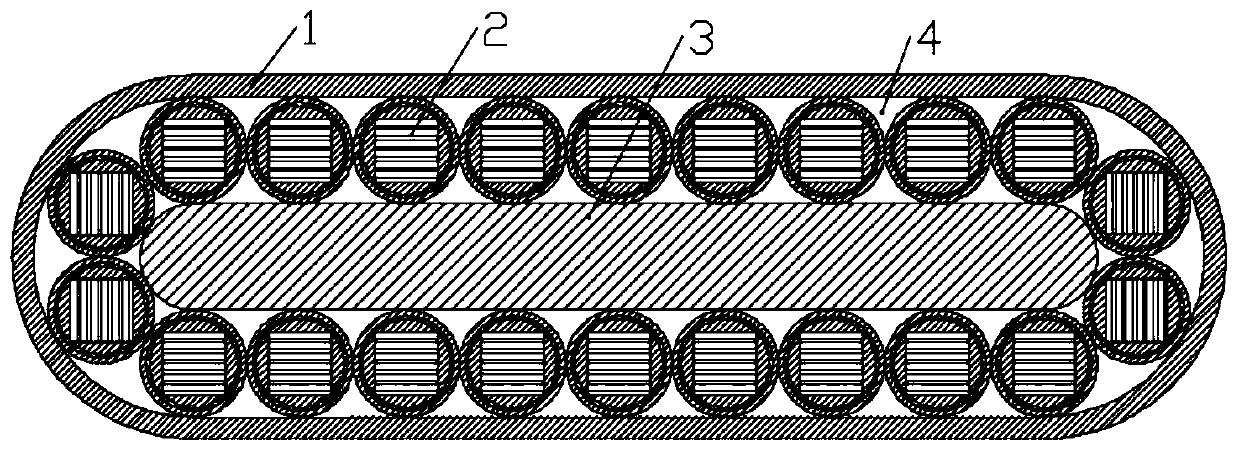

Preparation method of multi-core MgB2 superconducting wire

ActiveCN102522153AHigh degree of compoundHigh densitySuperconductors/hyperconductorsSuperconductor devicesSwagingUltimate tensile strength

The invention discloses a preparation method of a multi-core MgB2 superconducting wire. The method comprises: first, precursor power is prepared; second, the precursor power is placed in a Ta tube to prepare a tubulation complex; third, groove rolling is carried out on a single core wire; fourth, a NbTi / Cu composite rod and a plurality of single core wires are placed in an oxygen-free copper tubefor assembling so as to obtain a secondary composite rod; fifth, rotary swaging and drawing are carried out on the secondary composite rod, groove rolling is carried out and rotary swaging and drawing are carried out again, so that a multi-core wire is obtained; and sixth, heat treatment is carried out on the multi-core wire to obtain a multi-core MgB2 superconducting wire. According to the invention, processes of rotary swaging, drawing and groove rolling are combined and employed; therefore, not only is density of the multi-core wire improved, but also connectivity between crystal grains can be improved; it is beneficial to prepare a multi-core MgB2 superconducting wire with high performances; and the prepared wire has high mechanical strength and can bear great stress and strain without obvious reduction of the superconductive current carrying performance, so that a superconducting wire practical requirement can be well met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

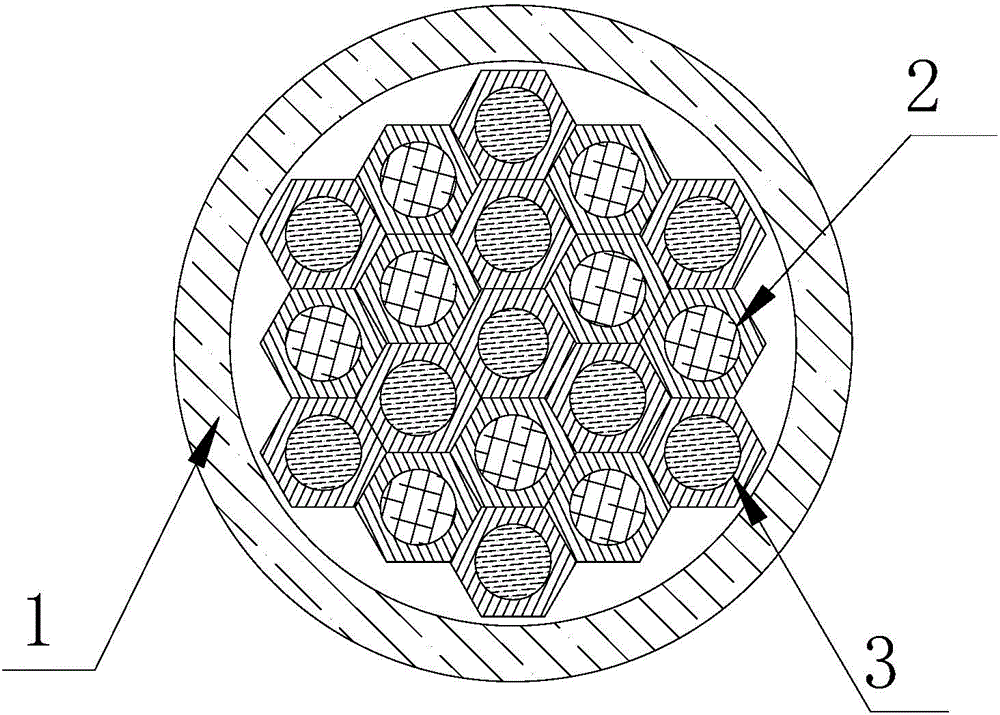

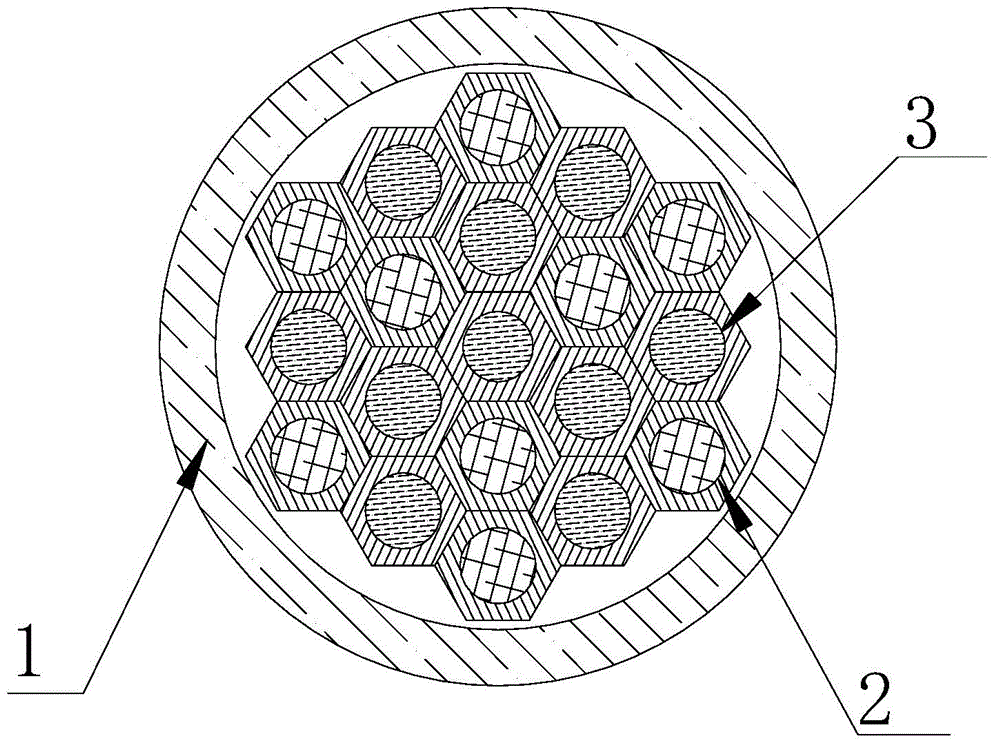

High-temperature superconductive Rutherford cable

InactiveCN110246625AImprove thermal conductivityImproved magnetothermal stabilitySuperconductors/hyperconductorsSuperconductor devicesHigh-temperature superconductivityElectrical conductor

The invention discloses a high-temperature superconducting Rutherford cable. The cable comprises a conductor, a plurality of superconductive strands and a metal sheath. The plurality of superconductive strands are tightly and spirally wound on the outer wall of the conductor. The metal sheath is of a hollow structure, the conductor and the superconductive strands are arranged in the metal sheath, and the outer walls of the superconductive strands make contact with the inner wall of the metal sheath. A gap formed between the inner wall of the metal sheath and the outer wall of the conductor is filled with a cooling medium. The high-temperature superconducting Rutherford cable provided by the invention has the advantages that the thermal stability of the cable can be effectively improved, the installation space is saved and the cost is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

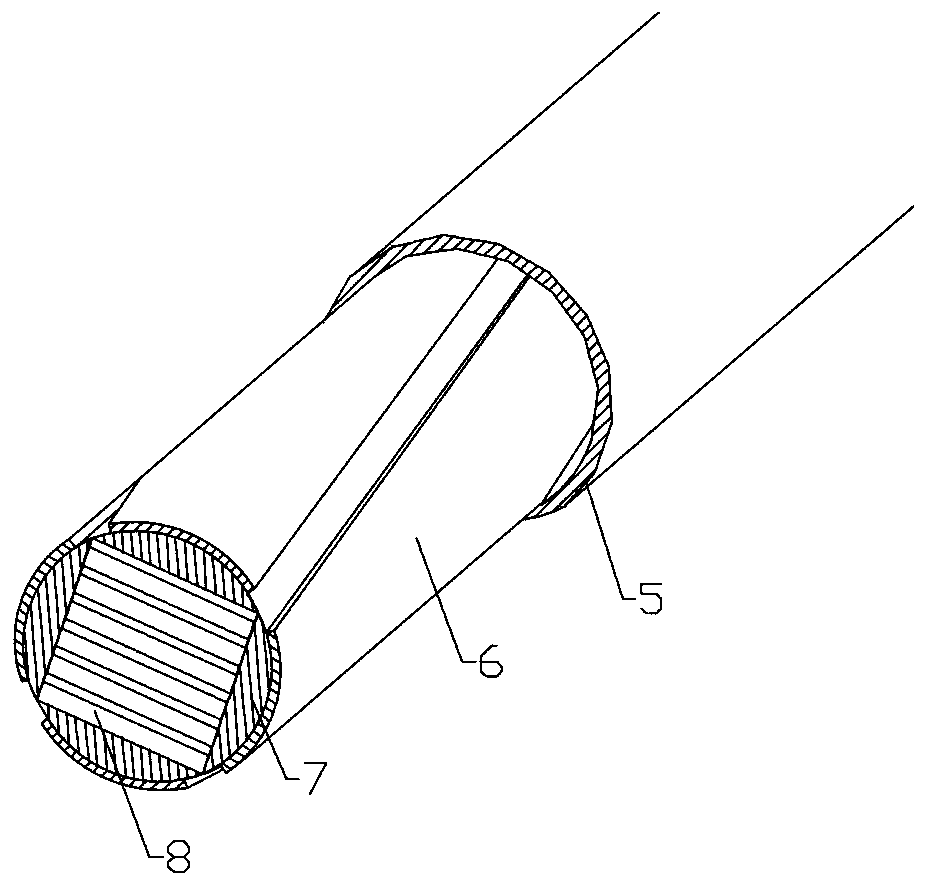

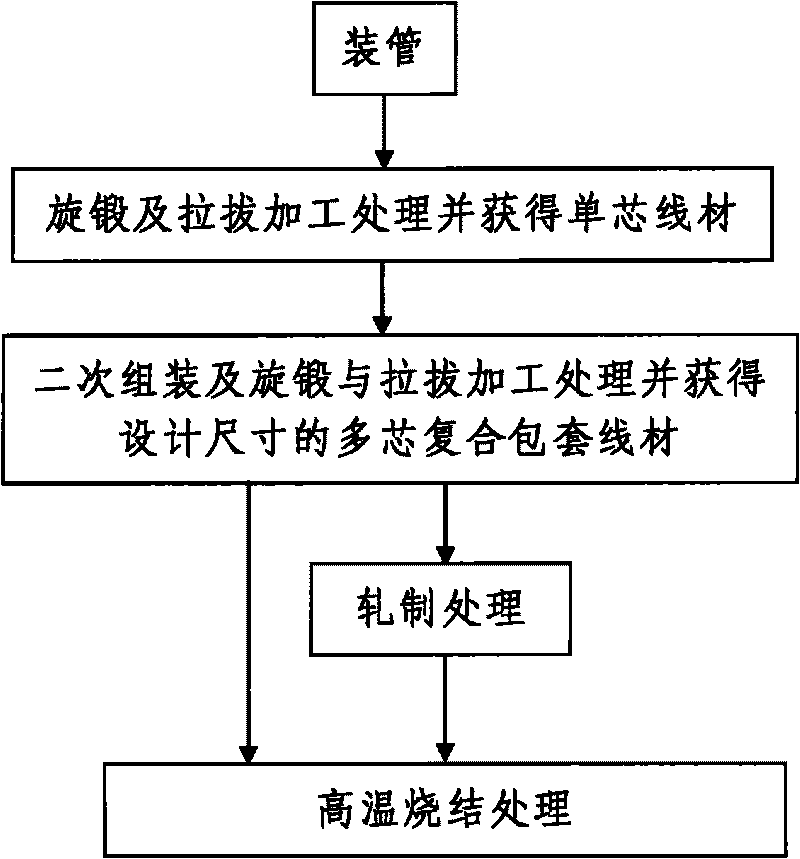

Method for preparing multicore TiC doped with MgB2 superconductive material by in situ method

ActiveCN101728028AThe process steps are simpleSimple and fast operationSuperconductors/hyperconductorsMetal boridesWire rodTitanium carbide

The invention discloses a method for preparing multicore TiC doped with MgB2 superconductive material by in situ method, including the following steps: firstly, tabulation, dry magnesium powder, high purity crystal state boron powder and nano titanium carbide powder are fully mixed to be uniform in atom quantity ratio of 1:(2-x):x, thus obtaining a tabulation compound body, wherein x is more than or equal to 0.02 and less than or equal to 0.10; secondly, rotary swaging and drawing processing are carried out to obtain single core wire rod; thirdly, secondary packaging and rotary swaging and drawing processing are carried out to obtain multicore compound sheathed wire rod in designed dimension; fourthly, high temperature sintering is carried out. The invention is reasonable in design, simple in technological step and convenient to realize, is applicable to preparing MgB2 superconductive wire rod with high critical current density in any length, reaction between superconducting phase and sheathed material is greatly reduced, and the critical current density is higher.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

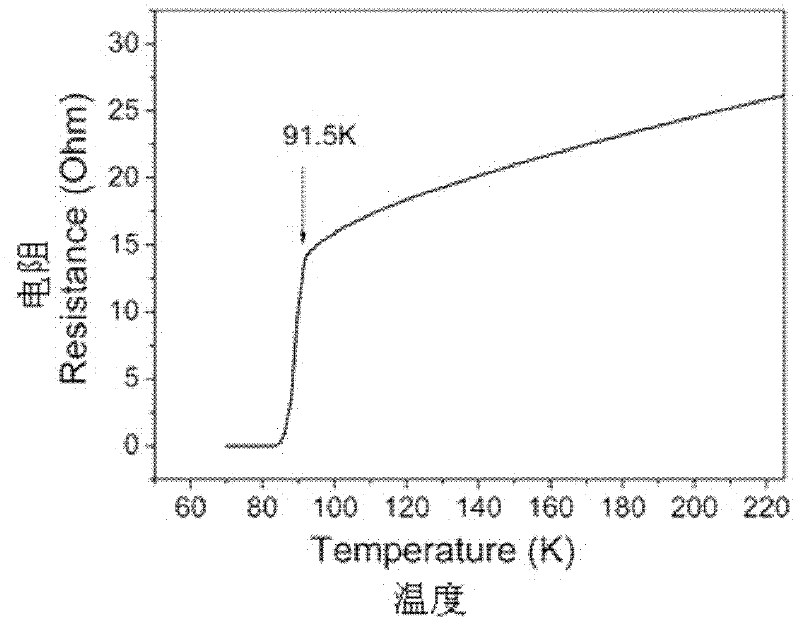

Preparation method iron based SmFeAsO1-xFx superconducting wire

InactiveCN101345103AEvenly distributedIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesCritical magnetic fieldSuperconducting transition temperature

The invention provides a preparation method of an iron-based SmFeAsO<1-x>Fx superconducting wire, comprising the steps as follows: a: material preparation: the material is prepared according to the stoichiometry of the iron-based superconducting material SmFeAsO<1-x>Fx (wherein, x is not more than 0.35 and not less than 0.15, the raw materials such as SmAs, Fe, Fe2O3 and FeF3 are weighed, grinded, uniformly mixed, arranged into a Tantalum pipe, fully fixed and compacted; the two ends of the Tantalum pipe are sealed; b: wire preparation: the Tantalum pipe is sheathed into a copper pipe and rotatablely forged; subsequently, the wire with the diameter of 1.8-2.2mm is formed by pulling and drawing; c: burning: the wire is arranged in a quartz pipe and sealed in vacuum and then put into a sintering furnace; under the protection of inert gas, the temperature of the wire is increased to 1150-1170 DEG C at the speed of 100-150 DEG C / hour, the temperature is kept for 36-50 hours and the wire is cooled with the furnace. The method of the invention has the advantages of simple technology and facilitating industrial production, and the compactness, high purification, stable superconducting performance, high superconducting conversion temperature and high critical magnetic field of the prepared iron-based SmFeAsO<1-x>Fx superconducting wire.

Owner:SOUTHWEST JIAOTONG UNIV

High performance Fe/Cu wrapping structure magnesium diboride multiple core superconductive wire preparation method

InactiveCN101150004AGuaranteed thermal stabilityHigh critical current density valueSuperconductors/hyperconductorsSuperconductor devicesMagnesium diborideNon doped

This invention relates to a preparation method for MgB2 multi-core super-conductive wires with Fe / Cu jacket structure including the following steps: putting Mg and B powder in the mol ratio of 1 : 2 and Mg, B powder and doped material in the mol ratio of 1 : 2 : 0.5 into a Fe / Cu composite pipe to be pressed and sealed to get a single-core lead with Fe / Cu composite jacket after swaging, pass rolling and drawing, then a processed hardened layer of the single-core structure is eliminated and aligned to assemble the doped and non-doped single-core wires tightly in a seamless Cu pipe to be swaged and drawn to a MgB2 wire of multi-core Fe / Cu jacket structure to be processed for 0.5-5h under 650-950deg.C to become a MgB2 multi-core superconductive wire in the high performance Fe / Cu jacket.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

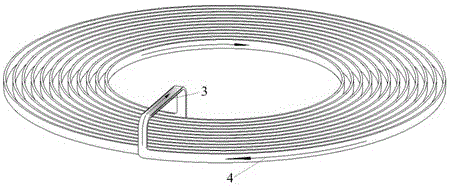

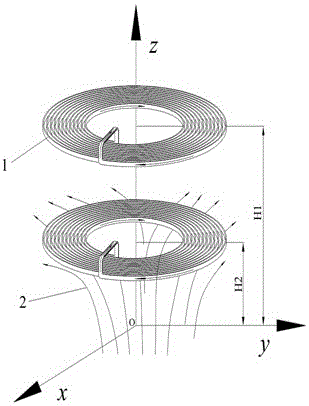

Method for realizing magnetic suspension state through adoption of closed loop constant current high-temperature superconducting coil

ActiveCN106059394AReduce dependenceReduce construction costsPermanent magnetsSuperconducting magnets/coilsClosed loopEngineering

The present invention provides a method for realizing magnetic suspension state through adoption of a closed loop constant current high-temperature superconducting coil which takes places of the novel superconductive suspension mode of high-temperature superconductor materials. The high-temperature superconductor materials are wound on a coil framework through a certain winding method (a drying winding method and a wet winding method), a closed loop structure is formed by employing the superconduction welding technology; and the closed loop high-temperature superconducting coil (1) is disposed in the low-temperature container and is located at the upper portion of a high-intensity magnetic field source, and field cooling enters the superconducting state. The superconducting coil has zero resistance property in the superconducting state, the induced current forms a constant current state in the closed loop high-temperature superconducting coil and maintains the interaction between an induced magnetic field and the high-intensity magnetic field source so as to realize passive and self-stable suspension similar to the high-temperature superconductor materials suspension.

Owner:SOUTHWEST JIAOTONG UNIV

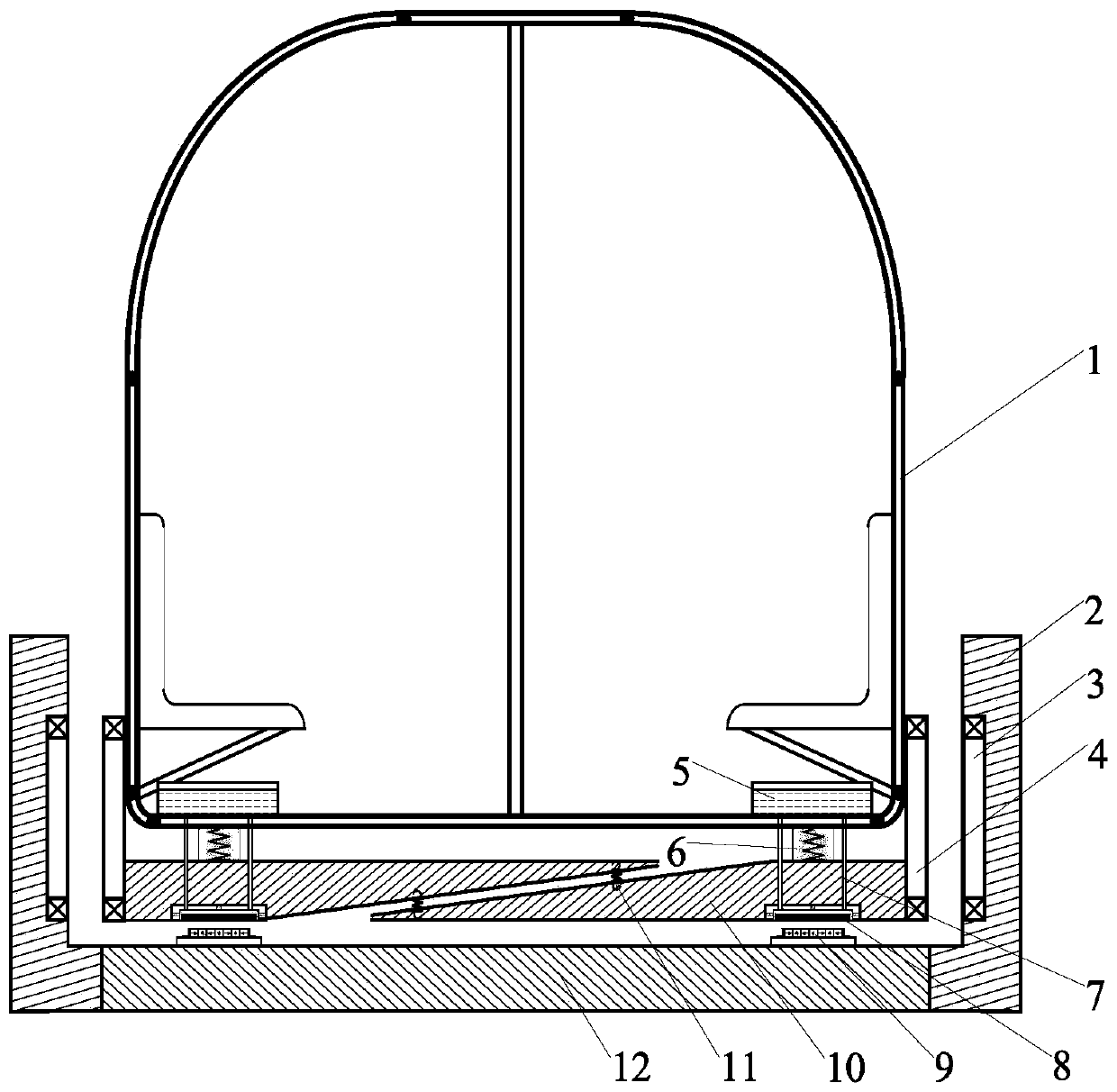

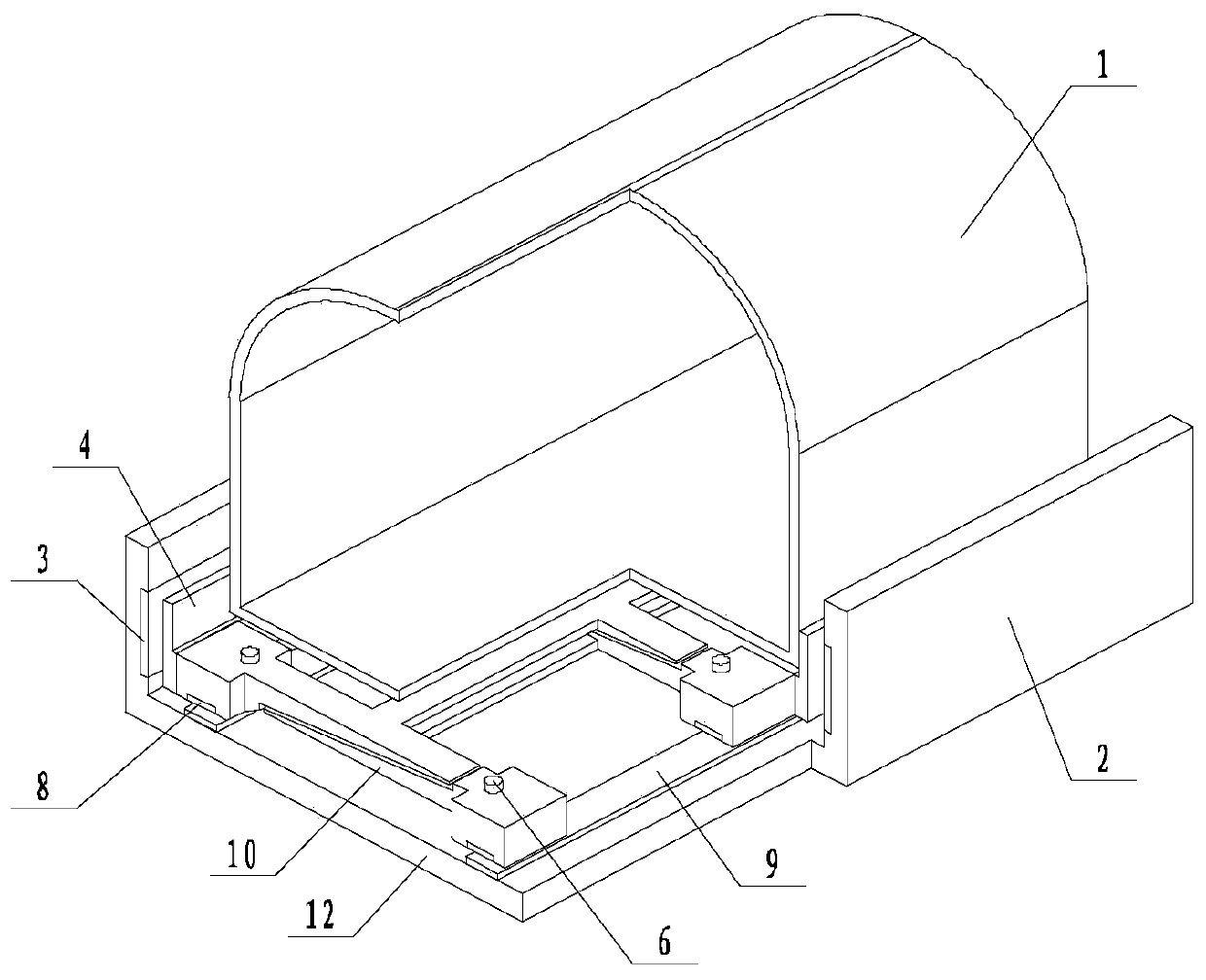

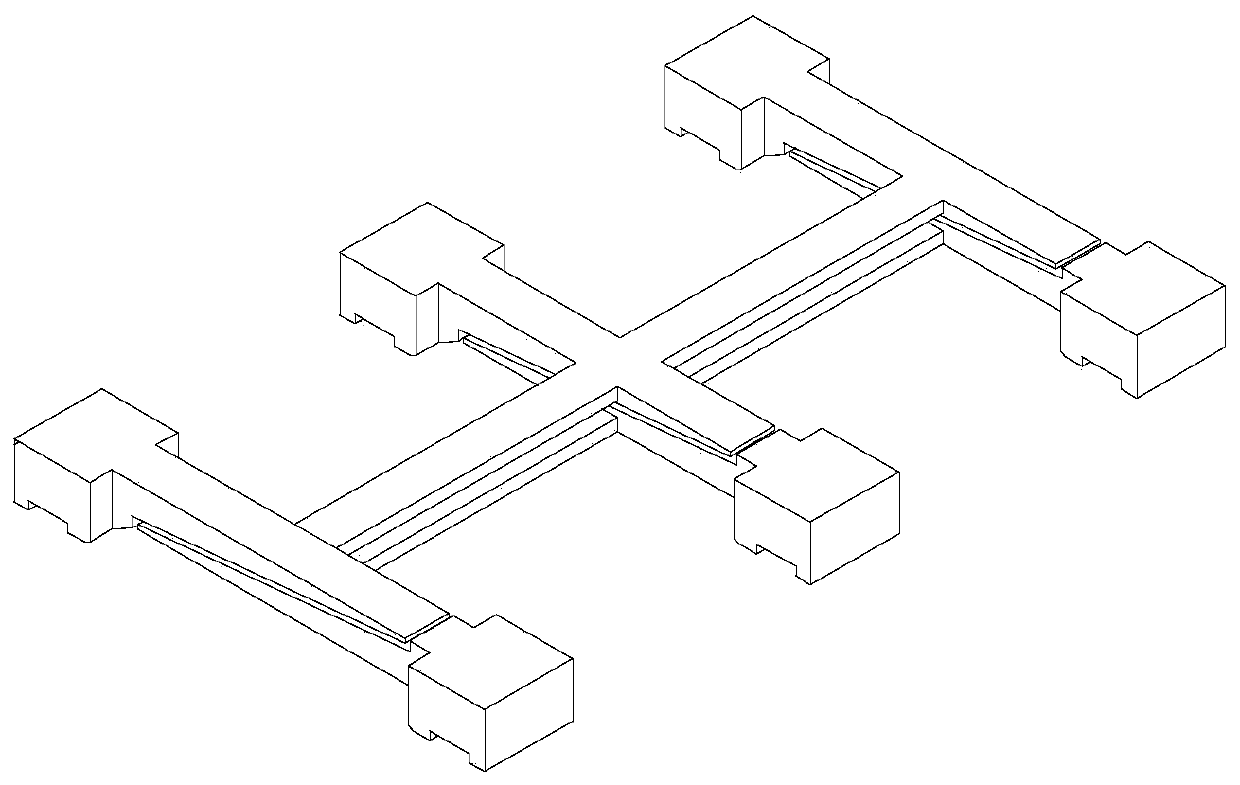

High-temperature superconducting magnetic suspension structure and high-temperature superconducting strip magnetic suspension train

ActiveCN110356243AImprove stabilityImprove decoupling abilitySuperconducting magnets/coilsElectric propulsionHigh temperature superconductingElectric machinery

The invention discloses a high-temperature superconducting magnetic suspension structure and a high-temperature superconducting strip magnetic suspension train. The high-temperature superconducting magnetic suspension structure comprises a permanent magnetic rail, a suspension frame and a traction linear motor, wherein the suspension frame is located above the permanent magnetic rail, the bottom of the suspension frame is opposite to a suspension dewar of the permanent magnet rail. The suspension dewar comprises two wedge-shaped blocks, wherein inclined surfaces of the wedge-shaped blocks areopposite, and the inclined surfaces of the wedge-shaped blocks are connected through a plurality of elastic members. The permanent magnetic rail is fixed on a rail bed, the suspension frame is provided with carriages, wherein the carriages are connected with the two wedge-shaped blocks. The traction linear motor is used for driving the suspended frame to move on the traction linear motor. The invention aims to provide the high-temperature superconducting magnetic suspension structure and the high-temperature superconducting strip magnetic suspension train. Compared to a traditional rigid connection structure, the suspension frame has higher stability and decoupling performance, and the suspension capability is superior to a high-temperature superconductor block magnetic suspension system in the prior art, and therefore the structure and the train have higher engineering application value and advantages.

Owner:成都睿逸谷科技有限责任公司

Preparation method of MgB2-NbTi composite superconducting wire

ActiveCN103606423AIncrease the critical current densityImprove current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesSingle-coreSizing

The invention provides a preparation method of a MgB2-NbTi composite superconducting wire. The preparation method comprises the following steps: A, preparing a MgB2 single-core wire; B, sizing, cutting and acid pickling a NbTi single-core wire and the MgB2 single-core wire; C, assembling the NbTi single-core wire, the MgB2 single-core wire and a Cu pipe to obtain a MgB2-NbTi tube composite body; D, adopting a machining route combining drawing and hole-pattern rolling, and carrying out the appropriate annealing treatment, thereby obtaining the MgB2-NbTi composite wire; E, carrying out the phase treatment and time-efficiency treatment, thereby obtaining the MgB2-NbTi composite superconducting wire. The MgB2 single-core wire is assembled with the NbTi single-core wire, a machining technology combining the drawing and hole-pattern rolling and a heat treatment technology are adopted, the MgB2-NbTi superconducting wire with excellent superconducting performance is finally prepared, and the preparation method is promising in application prospect.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

Low-fluorine solution deposition and heat treatment process of YBCO (Yttrium Barium Copper Oxide) superconducting thin film

InactiveCN102443792AIncrease the critical current densityAvoid crackingLiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingFurnace temperatureMoisture

The invention provides a low-fluorine solution deposition and heat treatment process of a YBCO (Yttrium Barium Copper Oxide) superconducting thin film. The low-fluorine solution deposition and heat treatment process comprises the following steps of: firstly, preparing a low-fluorine YBCO solution; secondly, preparing and drying a gel thin film and pre-treating the dried film; and finally, carrying out final treatment on the dry film: using mixed gas of moisture oxygen gas and inert gas and keeping the mixed gas at the furnace temperature of 790-810DEG C for 1-2 hours; switching the atmosphereinto the mixed gas of dry oxygen gas and inert gas with the same oxygen partial pressure; continuously keeping the mixed gas at the furnace temperature of 790-810DEG C for 10-30 minutes; and finally,naturally cooling the mixed gas along with the furnace, switching the atmosphere into dry O2 after the temperature is reduced to 400-500 DEG C, preserving the heat for 2-4 hours, finally naturally cooling to room temperature along with the furnace and taking out a sample. The YBCO superconducting thin film which is finally obtained in the invention has a high c-axle texture and critical current density Jc as high as (1-5)*106A / cm<2> at the liquid nitrogen temperature.

Owner:XIAN UNIV OF TECH

Method for preparing high temperature superconducting thin film by chemical process

ActiveCN101752035AIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesRare-earth elementEvaporation

The invention provides a method for preparing high temperature superconducting thin film by chemical process. The method comprises the following steps: firstly preparing a precursor solution, by mixing Y(CH3COO)3, RE(CH3COO)3, Ba(CH3COO)2 and Cu(CH3COO)2 with ratio of (Y+RE) to Ba to Cu equaling to 1:2:3 (wherein RE is Nd, Sm, Eu, Gd and Dy) and dissolving in 20-30 mol percent aqueous trifluoroacetic acid solution; stirring to be uniform, performing vacuum drying by evaporation to the solvent to obtain gel; then adding methanol, stirring to be uniform, performing drying by evaporation to the solvent to obtain gel; then adding proper amount of methanol to prepare the precursor solution with the total concentration of metal ions of Y, RE, Ba and Cu being 0.8-3.0mol / L; then coating the precursor solution on a substrate; performing low temperature heat treatment at 400-410 DEG C to the coated thin film to decompose trifluoroacetic acid salt; and finally performing high temperature heat treatment at 800-850 DEG C and annealing process at 490-510 DEG C to form YBCO thin film doped with rare-earth element.

Owner:GRIMAT ENG INST CO LTD

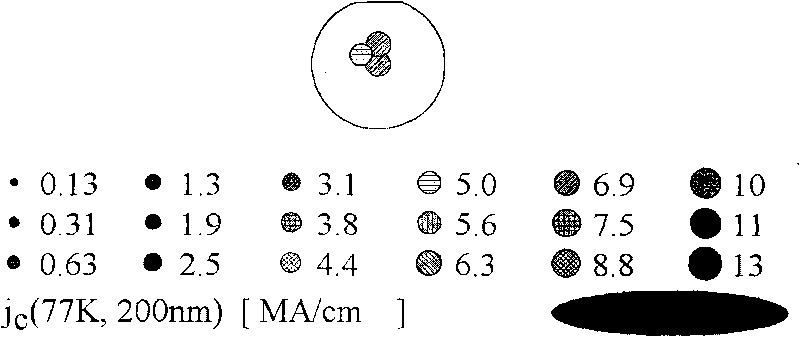

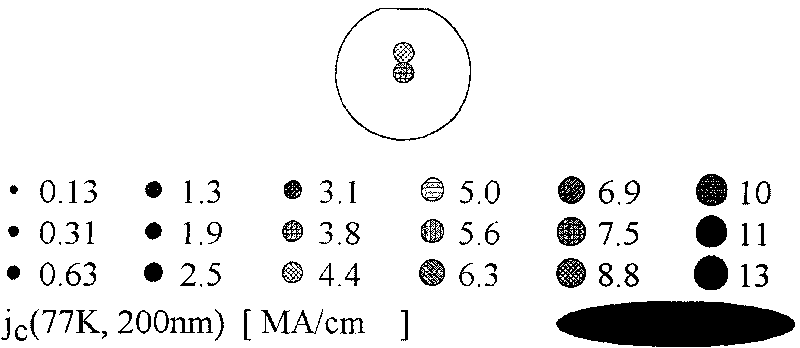

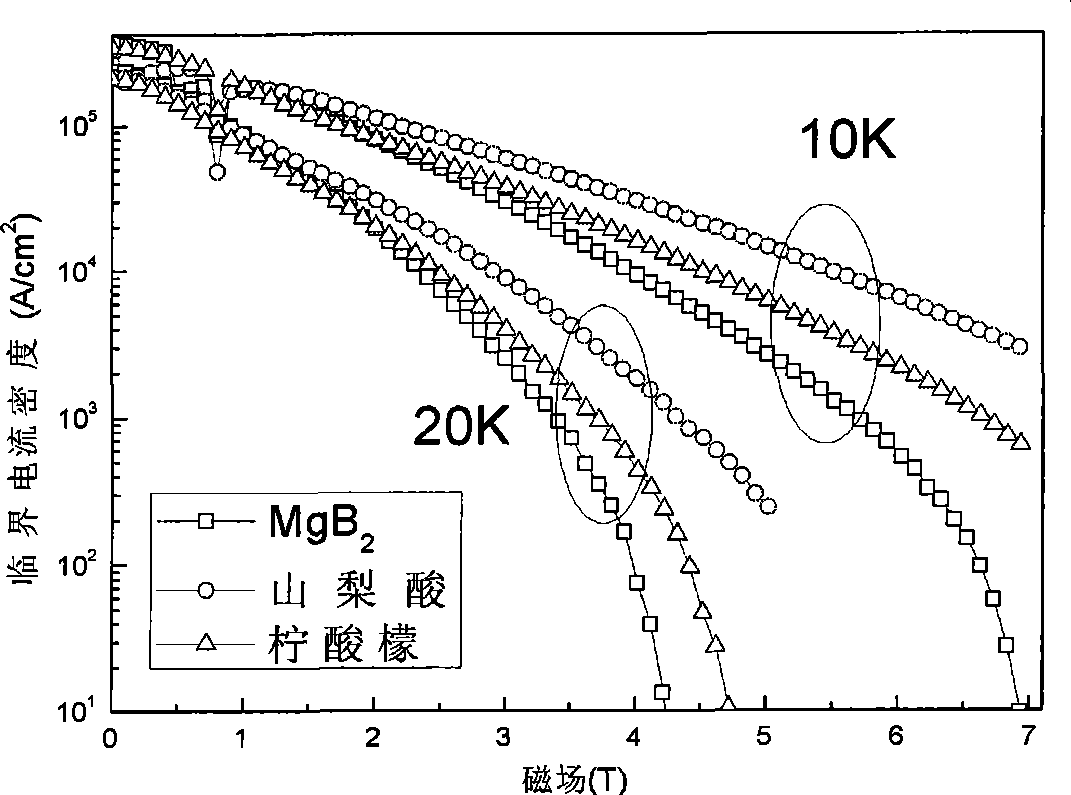

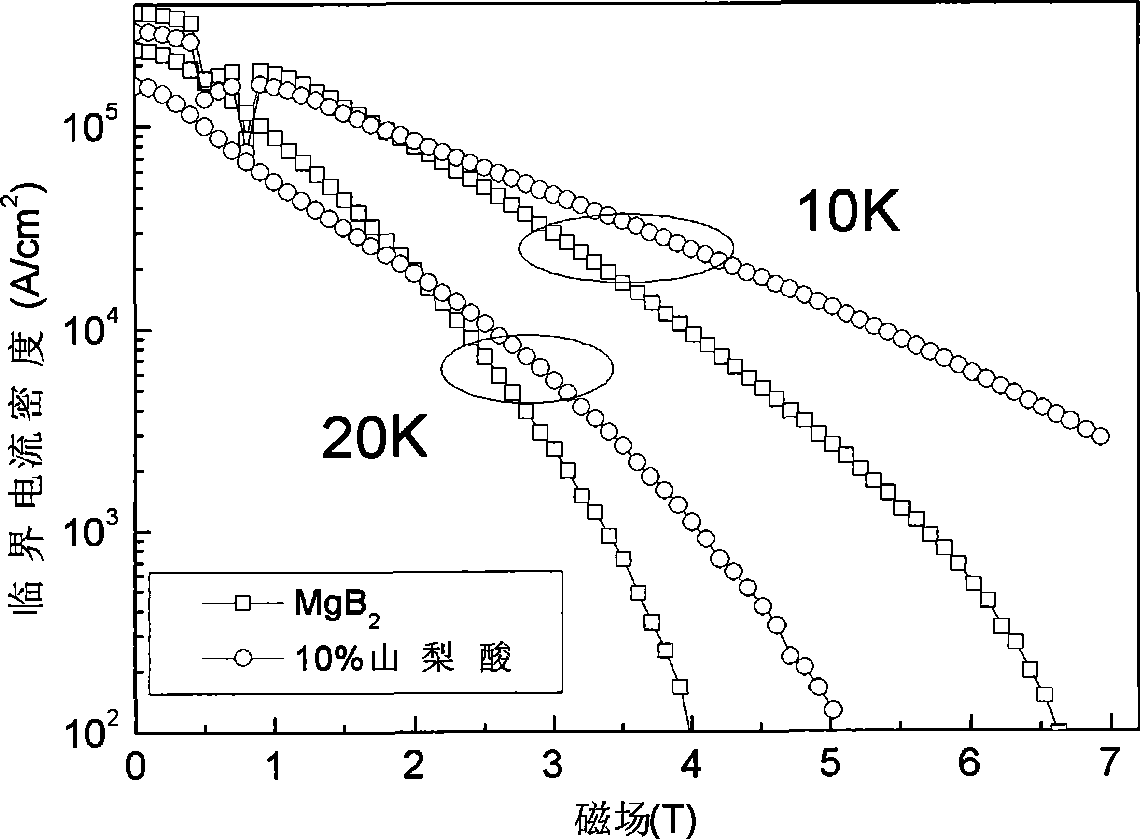

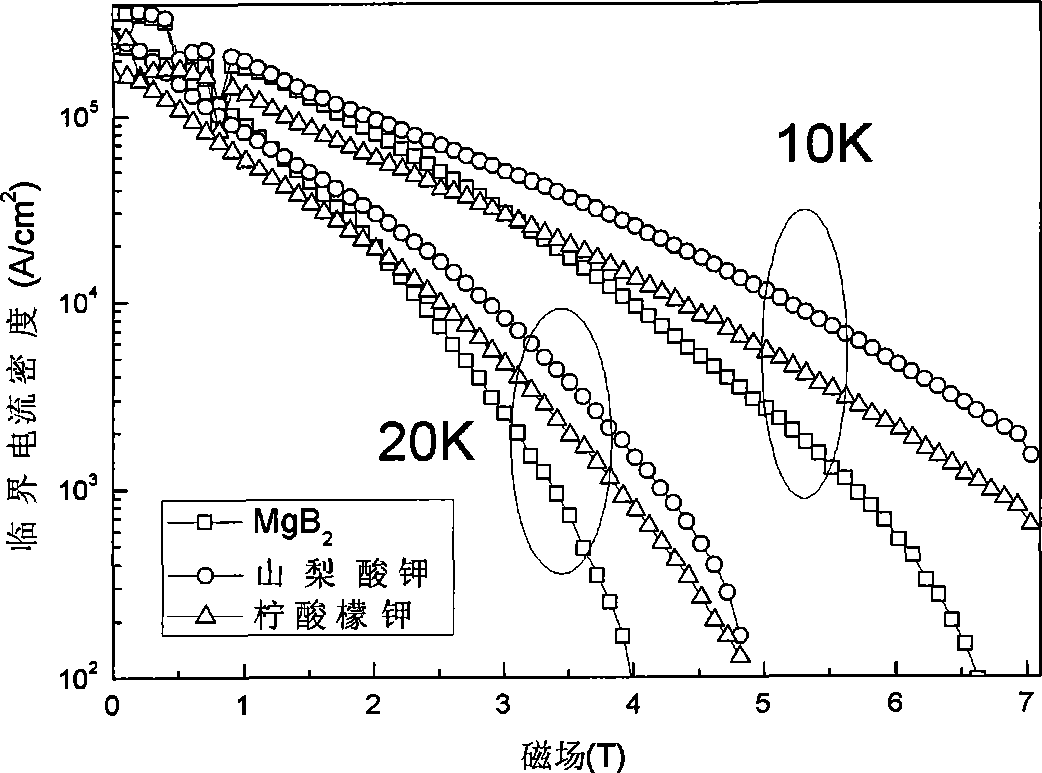

Preparation of magnesium boride doped superconduction material

InactiveCN101462881ALow reaction temperatureShorten the timeSuperconductors/hyperconductorsSuperconductor devicesDopantArgon atmosphere

A preparation method of a magnesium diboride-doped superconducting material comprises the following steps: respectively weighing magnesium powder and boron powder based on a mol ratio of 1:0.7-2.5; weighing a dopant based on the ratio of the total mass of the magnesium powder and the boron powder to the mass of the dopant of 1:0.01-1, wherein, the dopant is one of sorbic acid or sorbate; evenly mixing the magnesium powder, the boron powder and the dopant powder to obtain mixed powder; and sintering the mixed powder under the protection of argon atmosphere at the sintering temperature of 600 DEG C-1200 DEG C, and keeping the temperature for 0.5-12 hours, thus obtaining the superconducting material. The method has the advantages of short preparation time, low reaction temperature, high efficiency and low cost, and is especially suitable for industrialized production. The magnesium diboride superconducting material obtained by the method has obviously increased critical current density especially very high critical current density in a high magnetic field, which is beneficial to the application of the superconducting material to the high magnetic field; and the superconducting material has strong practicability.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of YBa2Cu3O7-x(YBCO) high-temperature superconductive thick film

InactiveCN102173820AIncrease the critical current densityImprove current carrying capacityEvaporationSolvent

The invention a preparation method of a YBa2Cu3O7-x(YBCO) high-temperature superconductive thick film. The preparation method comprises the following steps of: preparing precursor liquid; mixing yttrium acetate [Y(CH3COO)3], barium acetate [Ba(CH3COO)2] and copper acetate [Cu(CH3COO)2] according to the molar ratio of Y to Ba to Cu of 1:2:3; dissolving the mixture into aqueous solution of 10 to 30molar percent trifluoroacetic acid; stirring uniformly and drying the solvent by evaporation under vacuum to obtain gel; adding methanol and stirring uniformly; drying the solvent by evaporation to obtain gel; adding a proper amount of methanol and terpineol to prepare solution, wherein the total concentration of three kinds of metal ions of Y, Ba and Cu is 1.5 to 3.0 mol / L; stirring the solutionuniformly; adding titanium acetylacetonate in an amount which is 5 to 10 percent of the total molar concentration of the three kinds of metal ions to prepare precursor liquid; coating the precursor liquid on a substrate; perform low-temperature thermal treatment on the substrate coated with the precursor liquid at the temperature of between 300 and 500 DEG C to decompose trifluoroacetic acid salt; and performing high-temperature thermal treatment at the temperature of between 750 and 850 DEG C and annealing at the temperature of between 450 and 550 DEG C to form a nano titanium oxide-containing YBCO thick film. The critical current of the prepared YBCO thick film reaches 1,000 A / cm.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

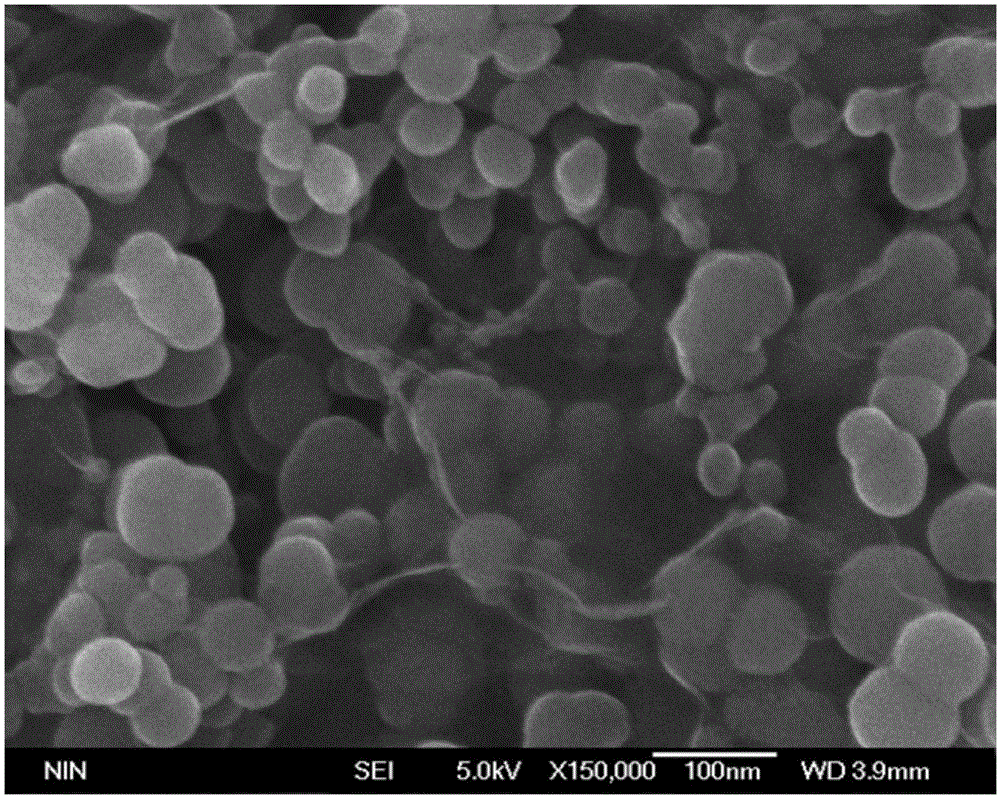

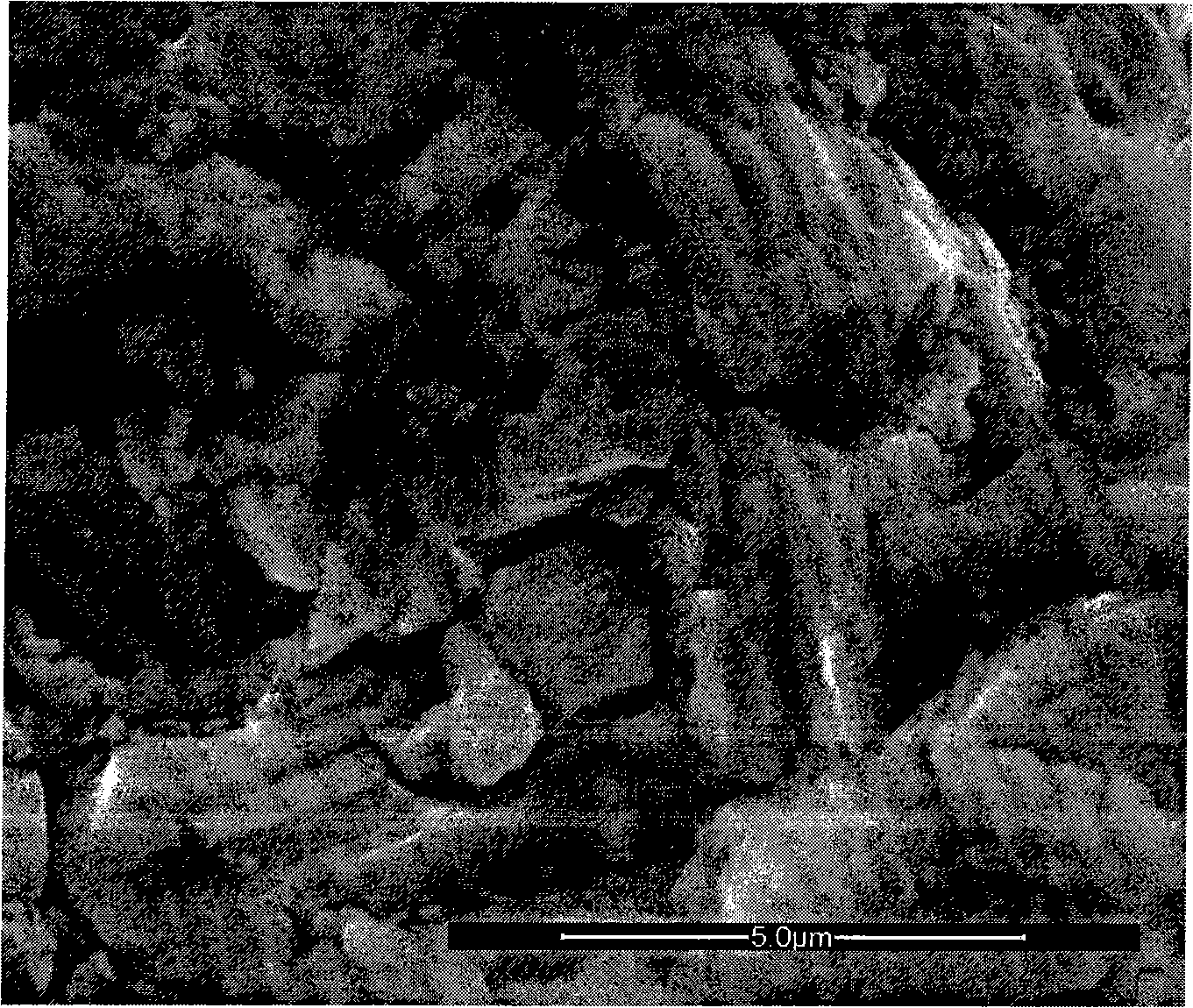

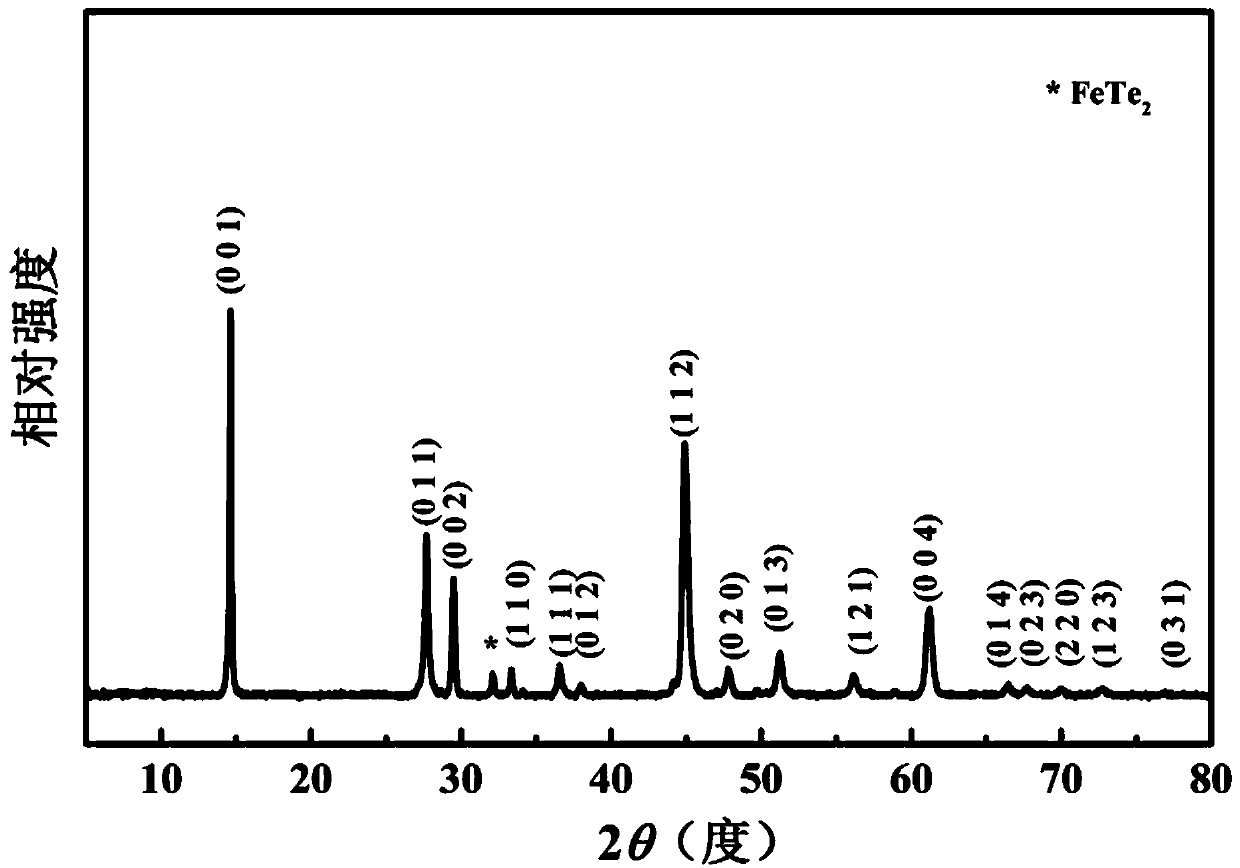

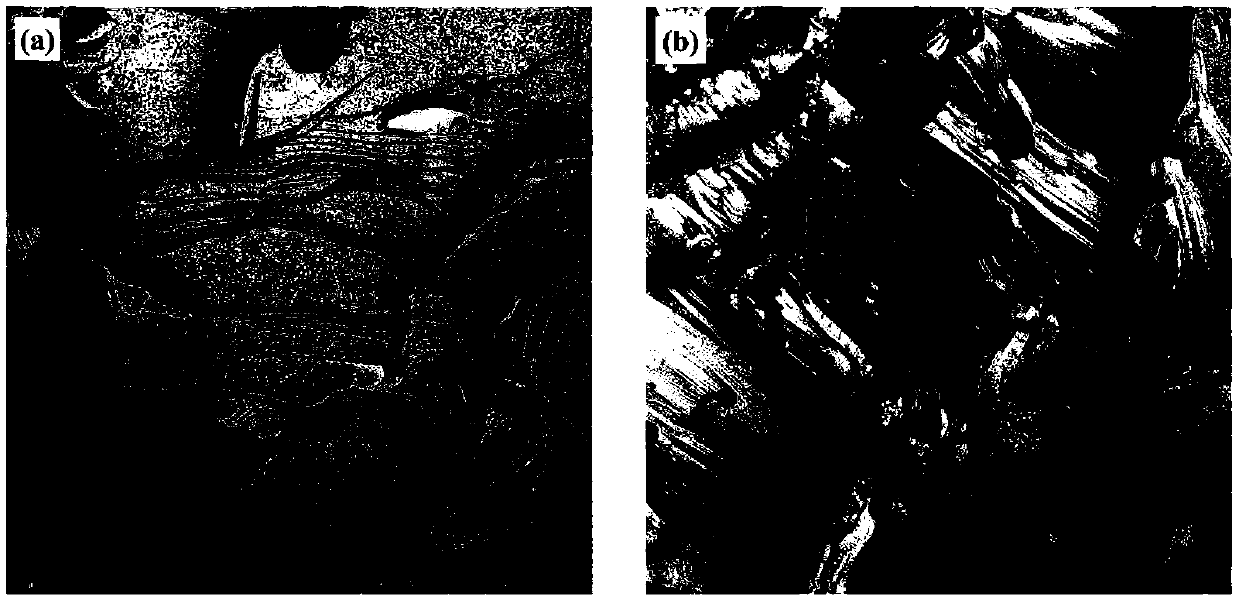

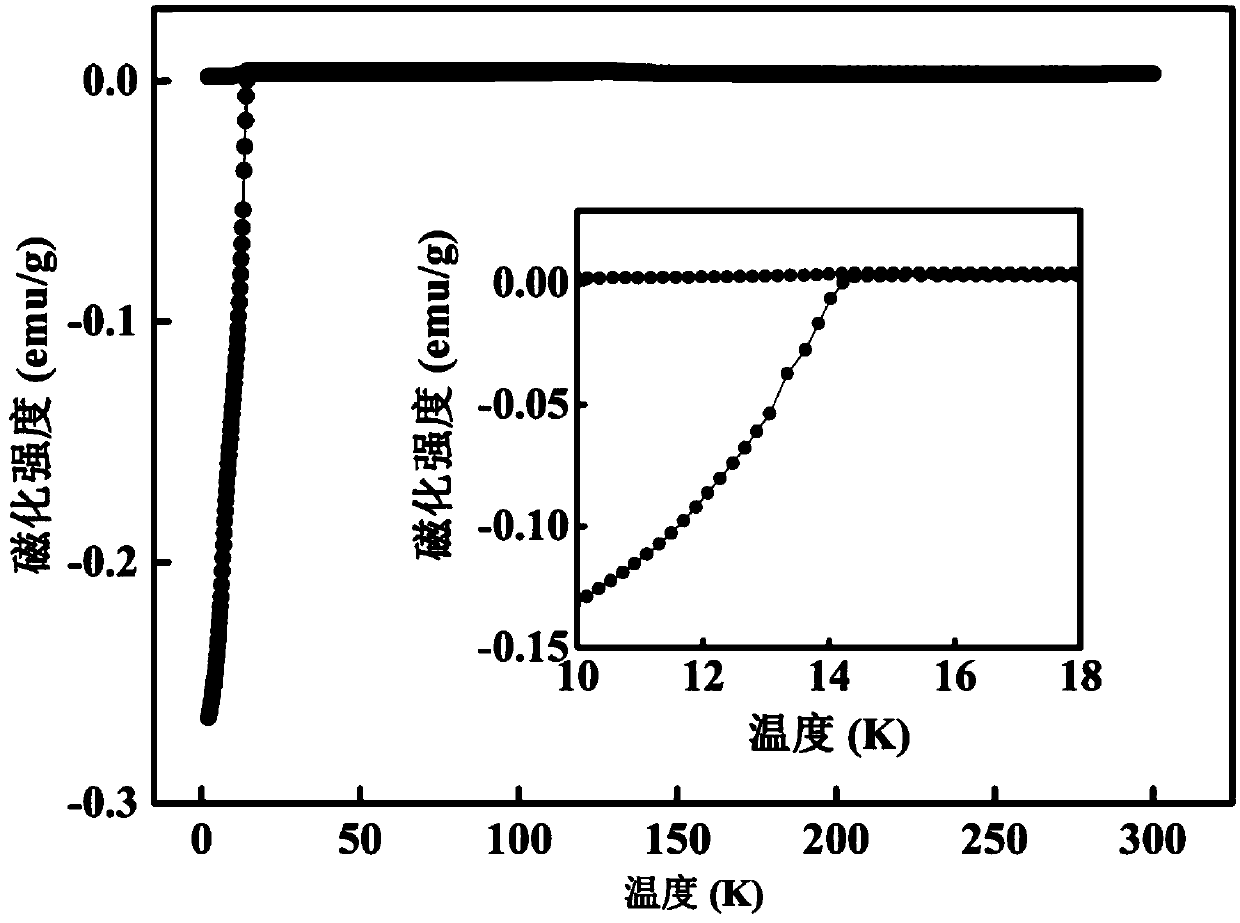

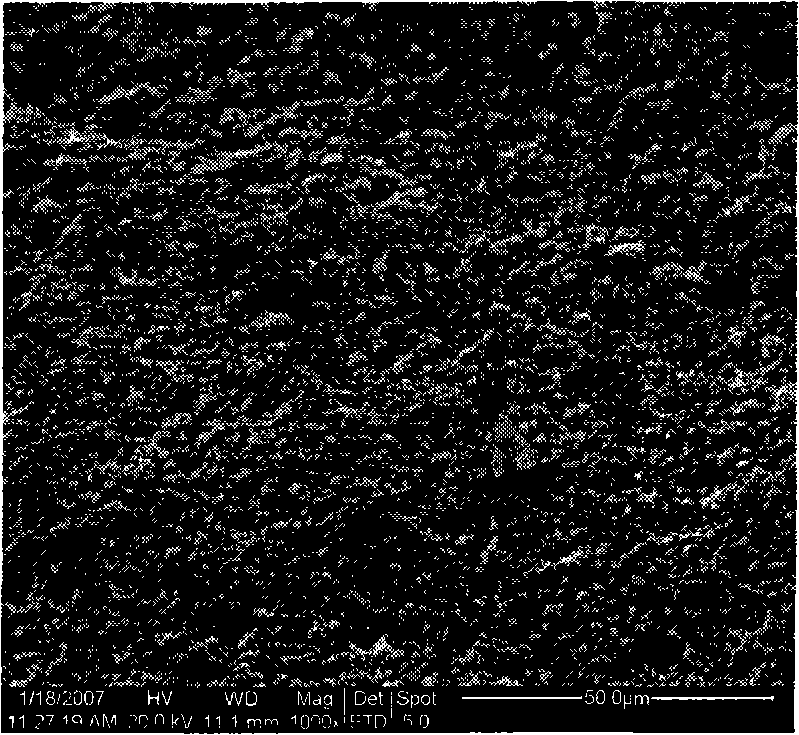

Preparation method of FeTeSe polycrystalline superconductor

ActiveCN110970170AIncrease the critical current densityImprove practicalitySuperconductors/hyperconductorsSuperconductor devicesMaterial synthesisHeating furnace

The invention provides a preparation method of a FeTe1-xSex polycrystalline superconductor. The preparation method comprises the following steps: (1) proportionally mixing and sufficiently grinding Fepowder, Te powder and Se powder, performing tabletting, putting the mixture into a quartz tube of which one end is sealed, vacuumizing the quartz tube, and sealing the other end of the quartz tube; (2) adopting microwave heating, and after cooling, obtaining a FeTe1-xSex polycrystalline blank; and (3) putting the FeTe1-xSex polycrystalline blank in a heating furnace for annealing, and cooling theFeTe1-xSex polycrystalline blank to obtain a FeTe1-xSex polycrystalline superconductor. According to the method, energy consumed in the preparation process of the FeTe1-xSex superconducting materialis reduced through the rapid synthesis characteristic of microwaves, and the cost is saved. Due to the fact that heat is almost concentrated on the raw materials in the microwave in-situ heating process, the influence of the high temperature on other materials is avoided when the raw materials are compounded to other materials or workpieces. In addition, the grain boundary connection performance is improved through the non-thermodynamic effect of microwaves in the material synthesis process, and the material density is improved, so that the FeTe1-xSex superconducting material with very high critical current density is obtained, and the practicability of the FeTe1-xSex superconducting material is greatly promoted.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for preparing compound MgB2 superconductor

The invention discloses a method for preparing compound MgB2 superconductor, and belongs to the technical field of MgB2 superconductor preparation. The method comprises the following steps: taking magnesium powder, boron powder and white phosphorus, milling with anhydrous ethanol, freezing into blocks with liquid nitrogen, conducting pulverization and sieving, then conducting stirring and preheating, adding an ignited magnesium rod, then heating, keeping heat and stirring, filtering to obtain a filtered matter, washing with a hydrochloric acid solution and distilled water, drying, mixing and grinding with graphene, conducting cold drawing to obtain a compound superconductor wire rod, and keeping heat in the xenon condition so as to prepare the compound MgB2 superconductor. The method has the benefits that the preparation steps are simple, the effective pinning center of the superconductor is effectively improved, the critical current density is increased by 12-16%, and the purity is increased by 25.6% or above; the fragility of the obtained product is less, the MgB2 core wire has no crack in the production process, and the material performance is good.

Owner:陈建峰

Method for preparing magnesium diboride superconductive wire and strip

InactiveCN101279740AImprove compactnessFirmly connectedSuperconductors/hyperconductorsMetal boridesHigh magnesiumDiboride

The invention relates to a method for preparing a magnesium boride superconducting line and belt material. The preparation method is that a. preparation of precursor powder: high magnesium diboride MgBx powder is taken as the precursor powder, wherein, x is more than or equal to 4 and less than or equal to 12; or magnesium powder and amorphism boron powder are mixed according to 1:3-20 of stoichiometric ratio between magnesium and boron to form the precursor powder; b. putting into a magnesium pipe: the precursor powder is put into a magnesium pipe, compacted and sealed; c. putting into a canning pipe: the magnesium pipe is put into a metal canning pipe and is sealed after the metal canning pipe is fully filled with metal powder as a barrier layer; or the magnesium pipe is first put into a barrier layer metal pipe and then is put into the metal canning pipe and the metal canning pipe is sealed; d. moulding treatment: the metal canning pipe is produced into line and belt material; e. heat treatment: the metal canning pipe is put into a pipe typed furnace and under the protection of argon, the temperature is raised to 700-1200 DEG C by the speed of 1-10 DEG C / minute, preserved for 1-30 hours and then cooled to room temperature. The MgB2 superconducting line and belt material prepared by the method has high compactability, good grain connectivity and even cross section.

Owner:SOUTHWEST JIAOTONG UNIV

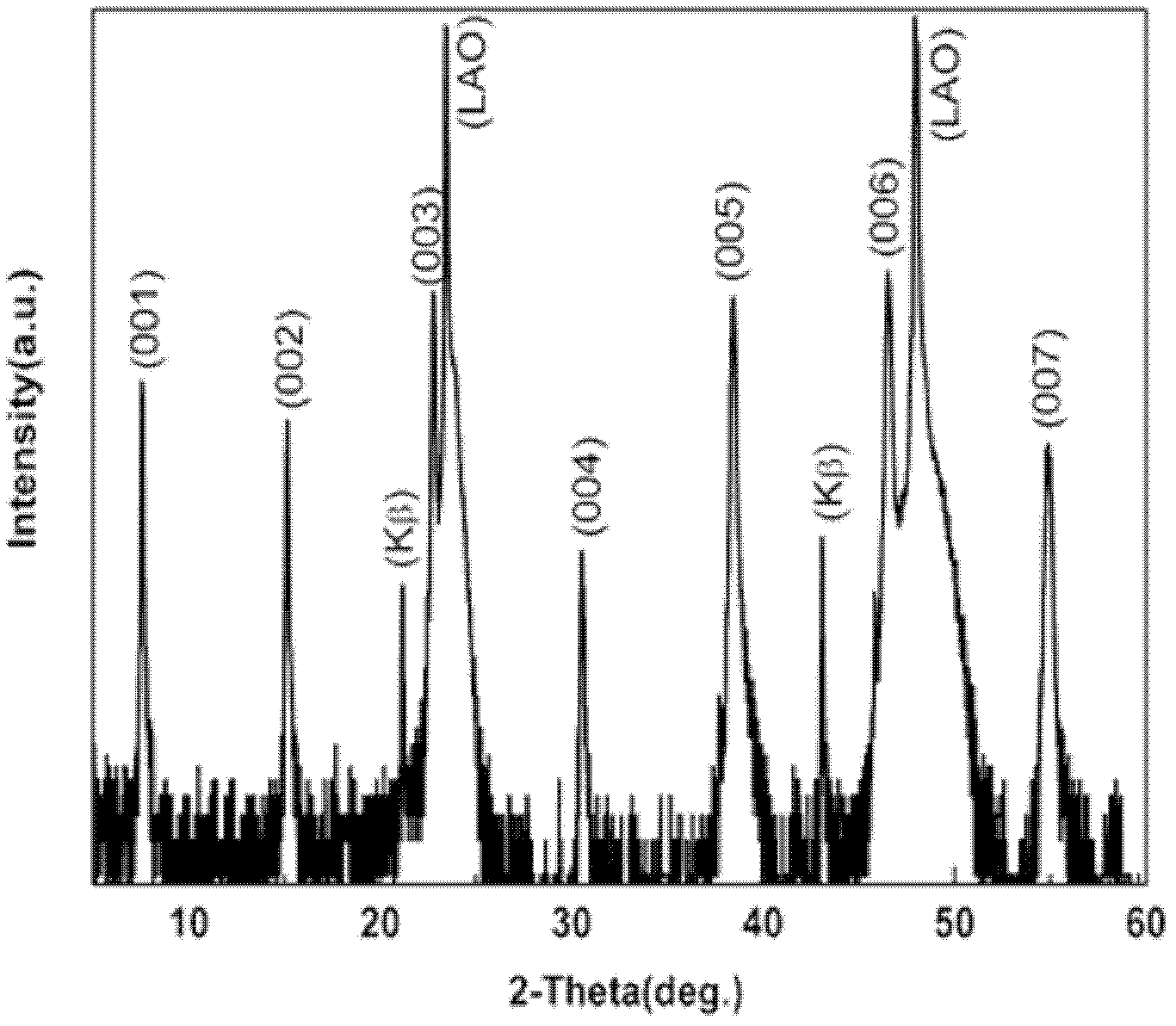

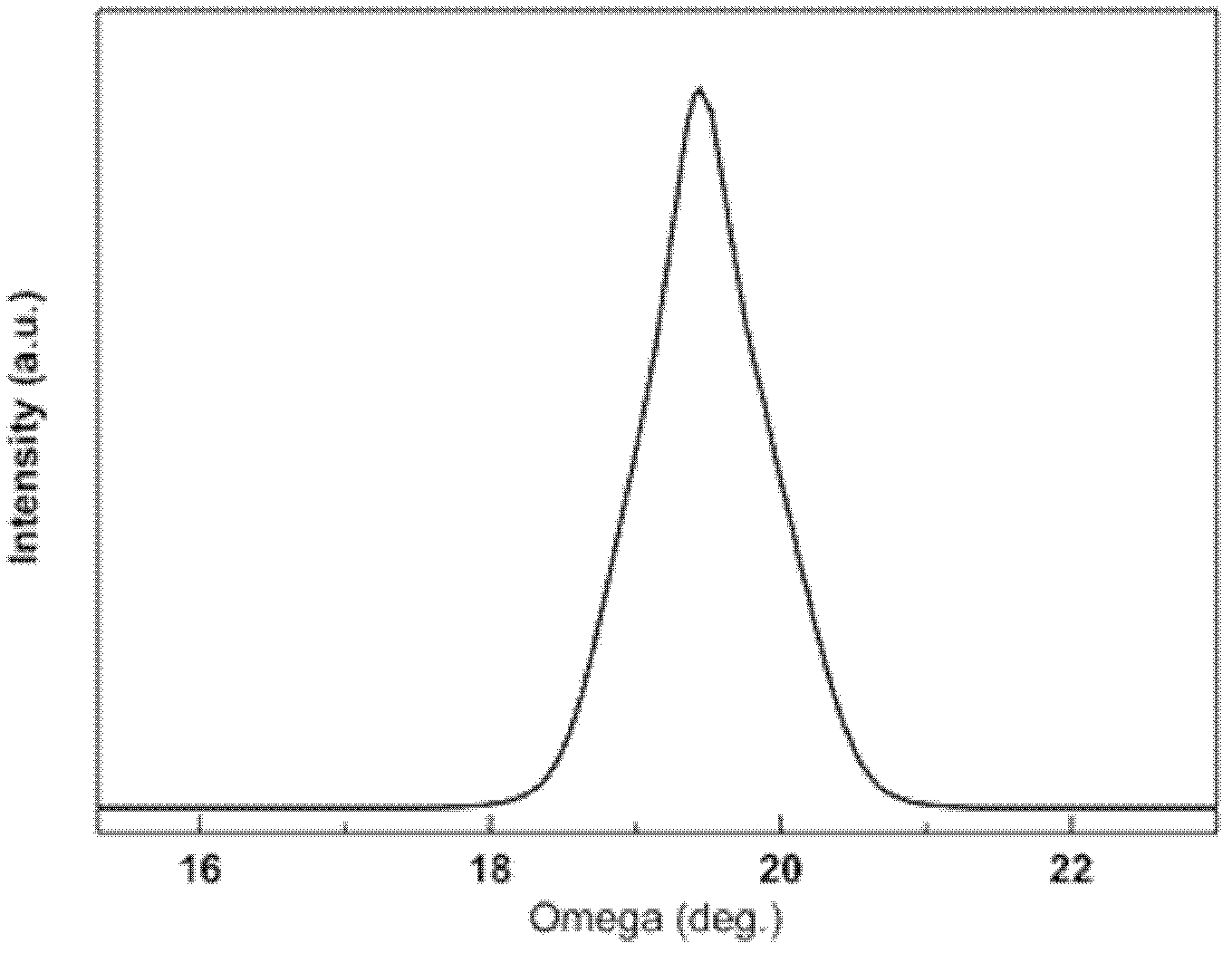

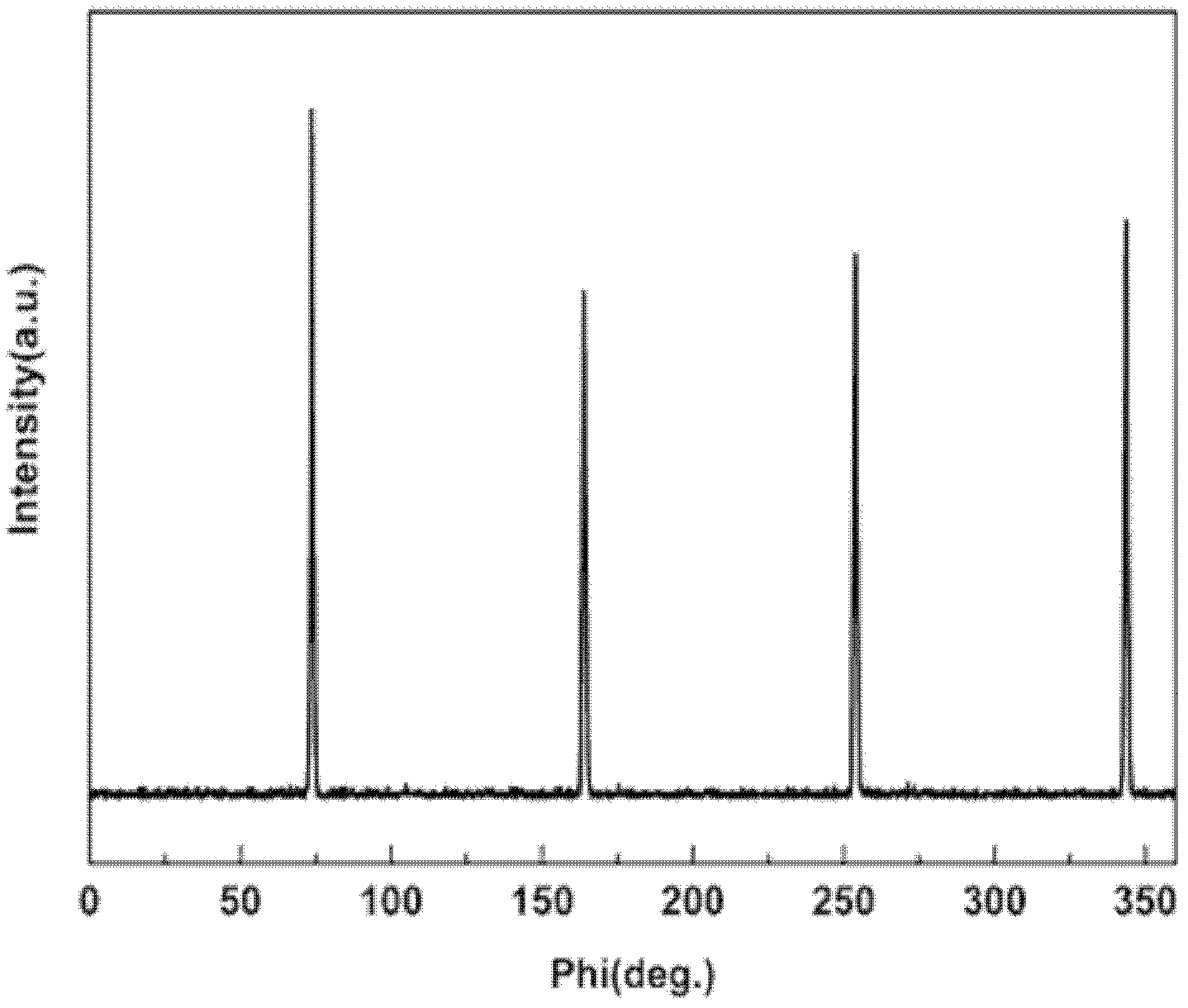

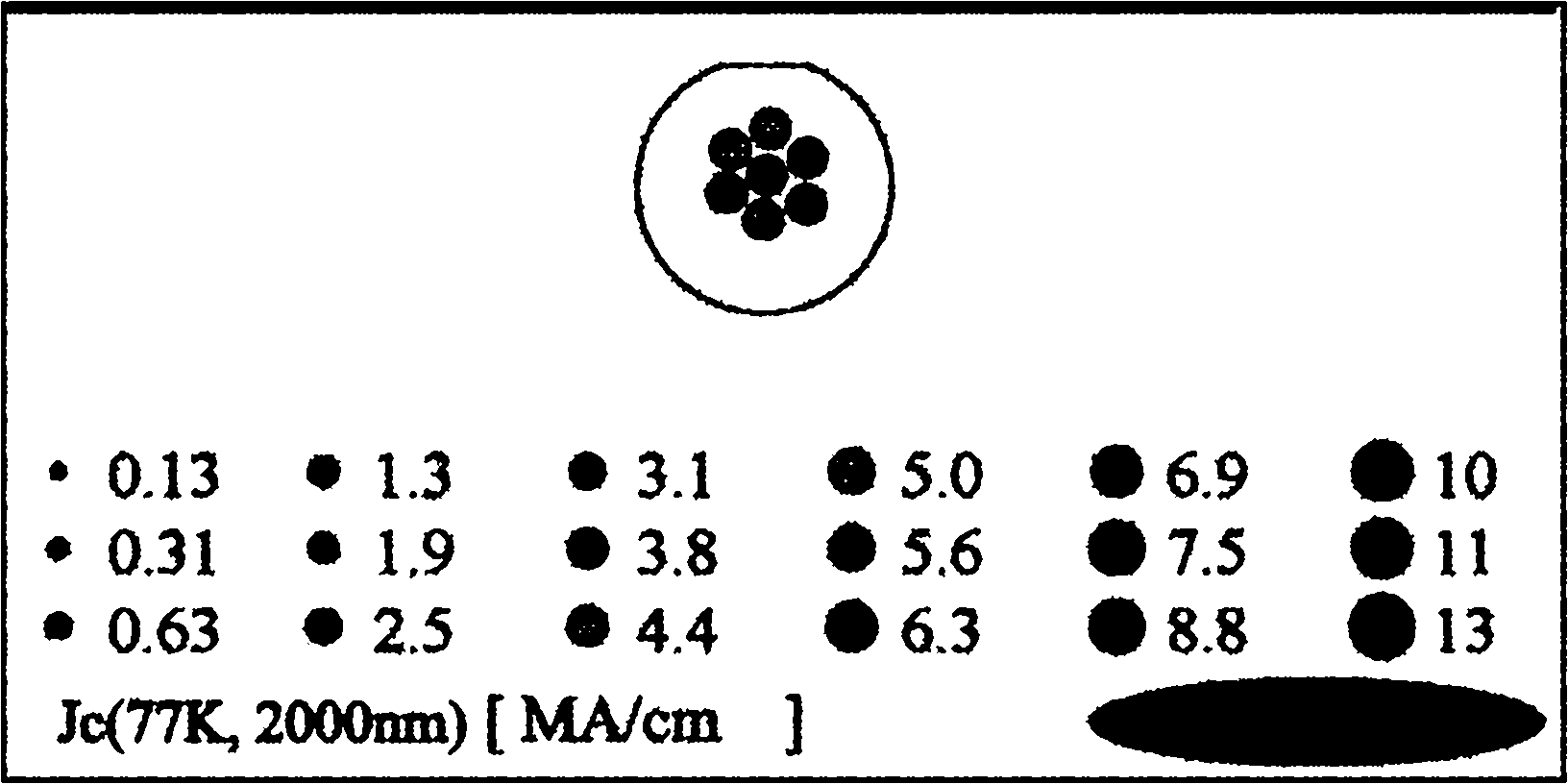

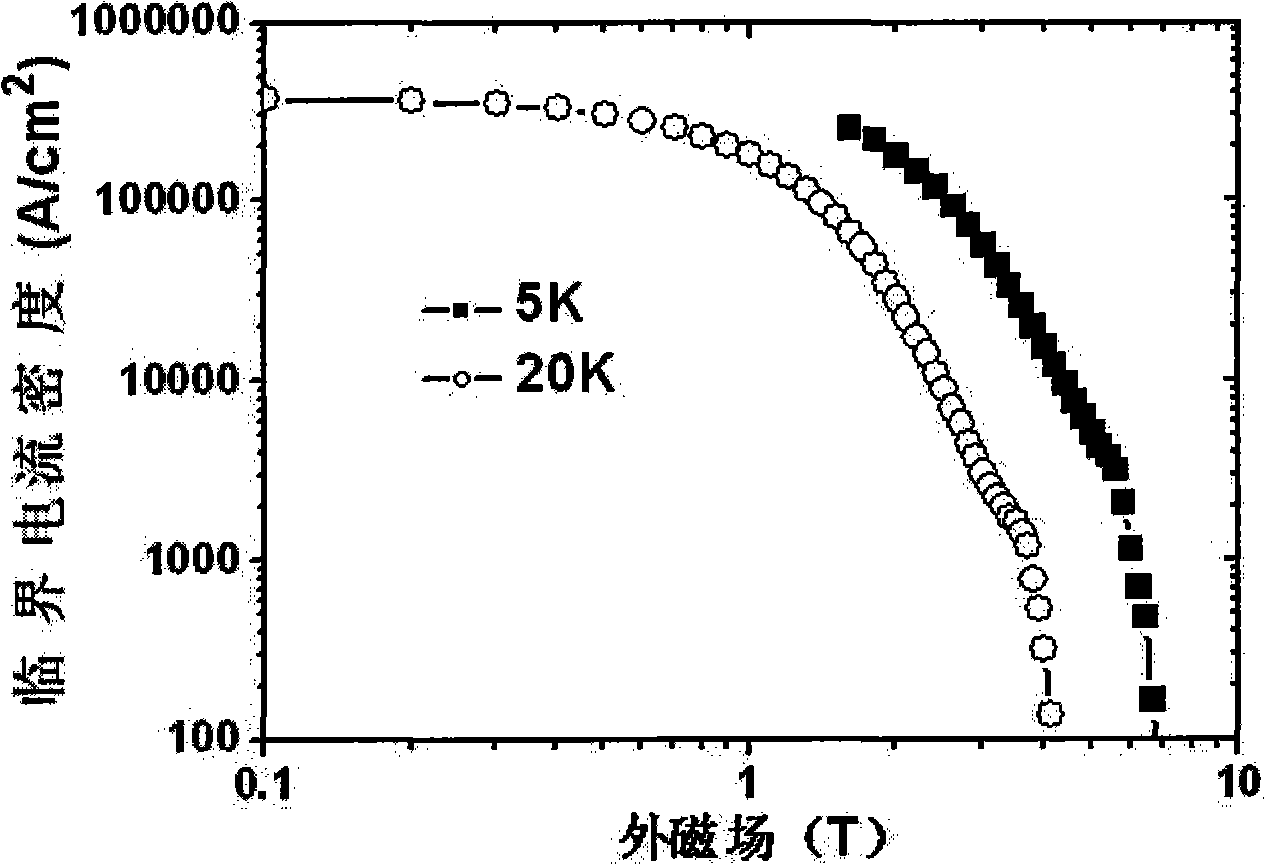

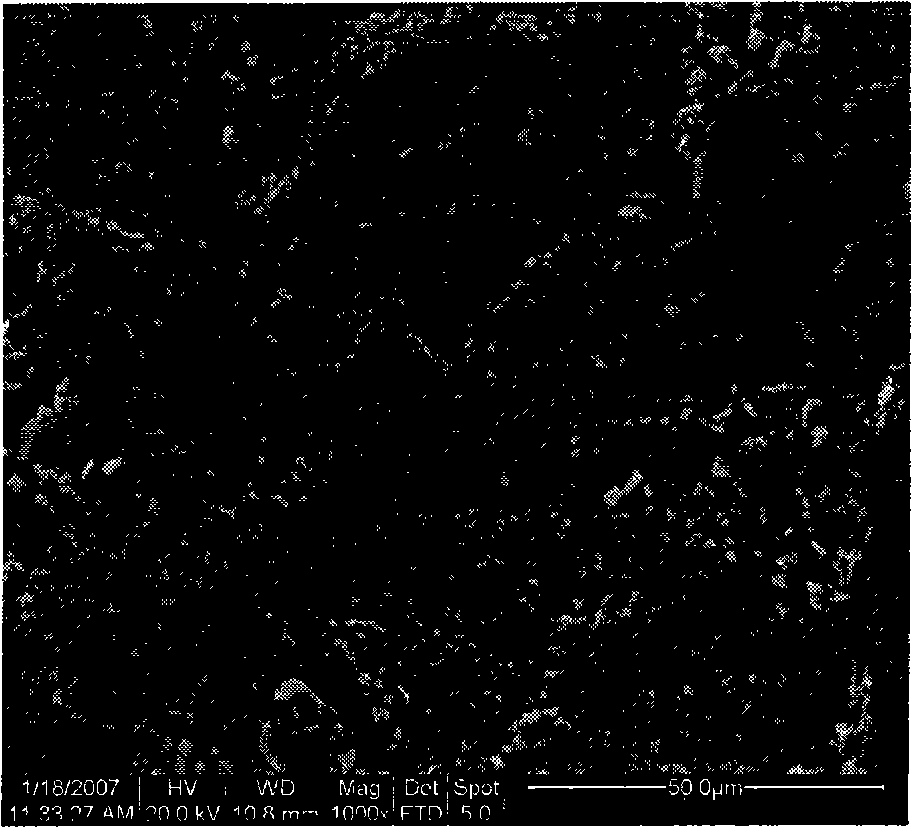

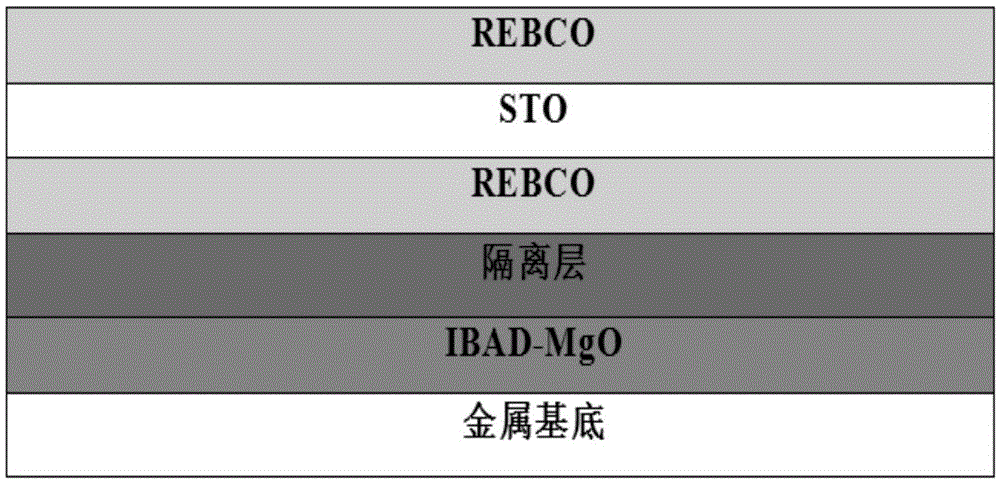

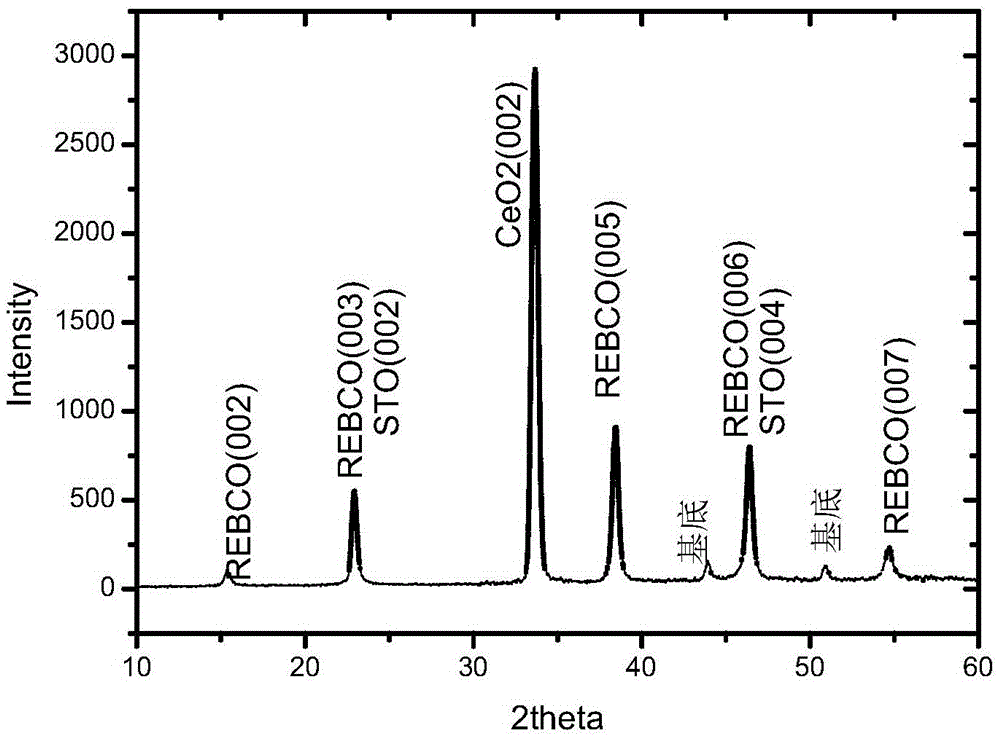

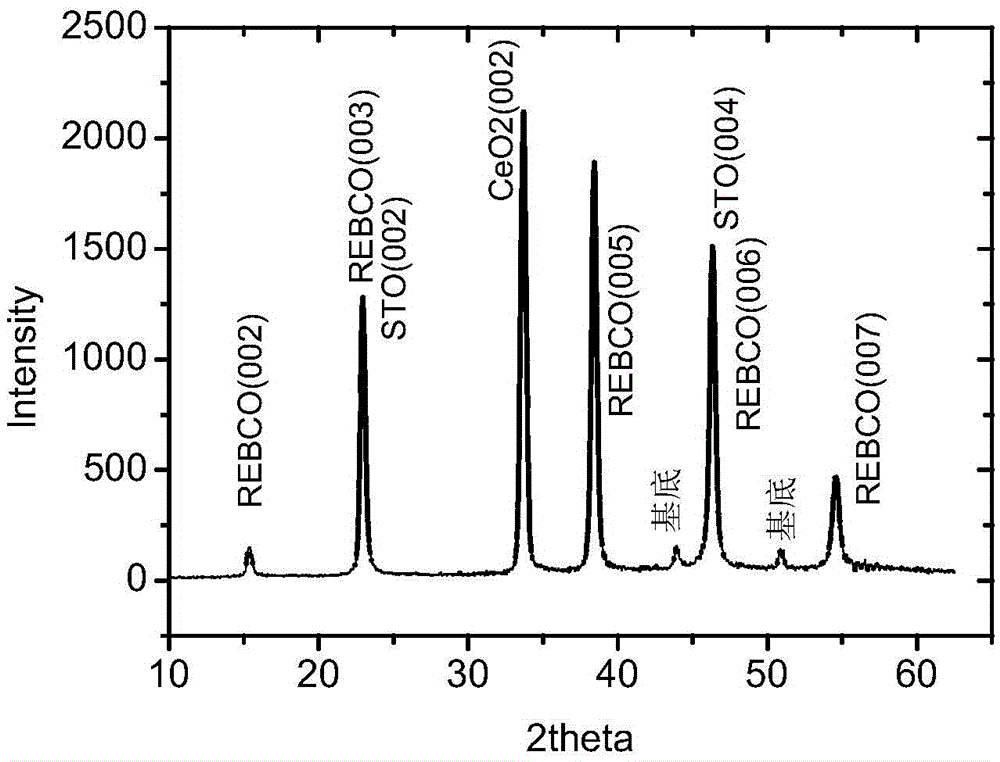

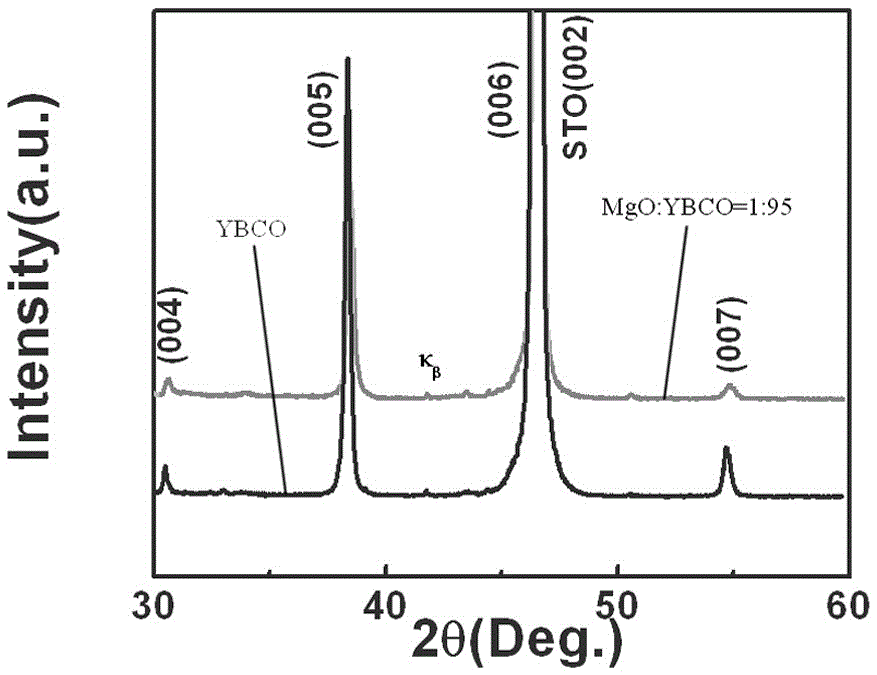

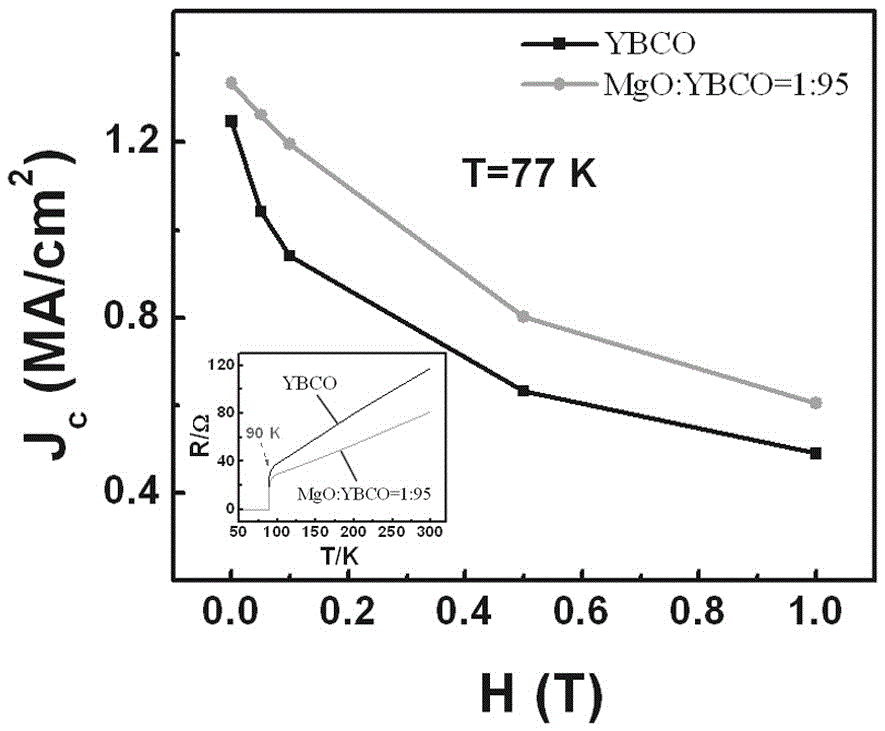

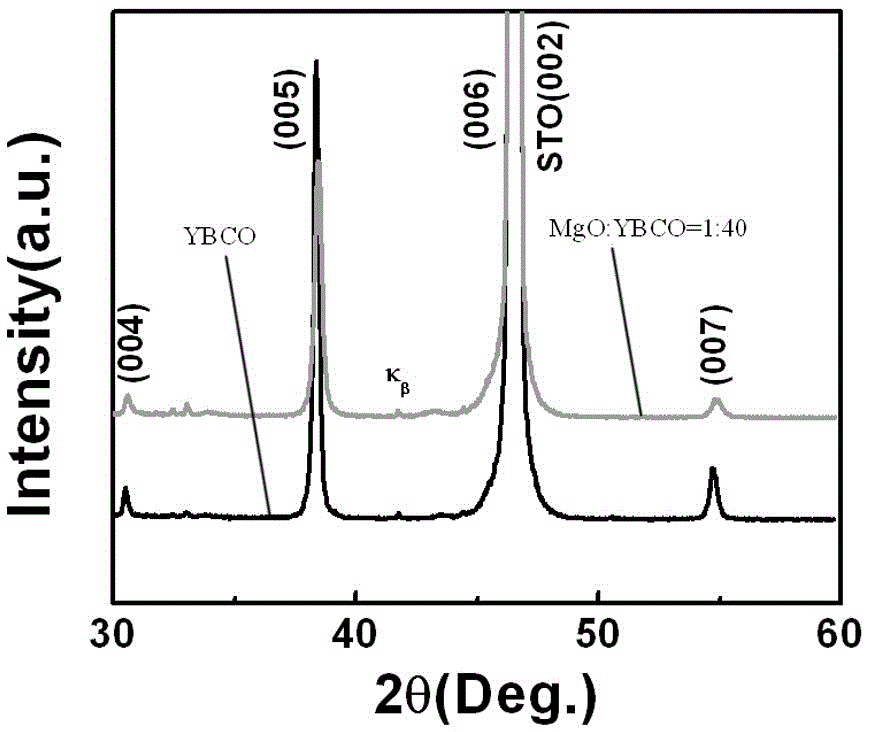

High-performance REBCO multilayer film, application and preparation method for high-performance REBCO multilayer film

ActiveCN105648401AHigh shape stability and repeatabilityIncrease the critical current densityVacuum evaporation coatingSputtering coatingBinding forceElectrical conductor

The invention relates to the technical field of yttrium barium copper oxide coating conductors, in particular to a high-performance REBCO multilayer film, application and a preparation method for the high-performance REBCO multilayer film. The high-performance REBCO multilayer film is composed of a REBCO thin film layer and an STO interlayer. The invention further relates to the application of the high-performance REBCO multilayer film during preparing of a high-temperature superconductive belt material and relates to the preparation method for the high-performance REBCO multilayer film. The preparation method comprises the following steps that an IBAD-MgO base belt plated with an isolated layer is taken, and the high-performance REBCO multilayer film is prepared through a multi-target multi-channel pulse laser method. The prepared high-performance REBCO multilayer film prepared has a pure C-axis orientation, a smooth compact surface and a high critical current density, and the critical current density reaches up to 5 MA / cm<2>. The REBCO multilayer film has high critical current under a self field or a magnetic field, has the high binding force, can meet the application requirements for a superconducting cable and the like and is suitable for industrialization production.

Owner:SHANGHAI JIAO TONG UNIV

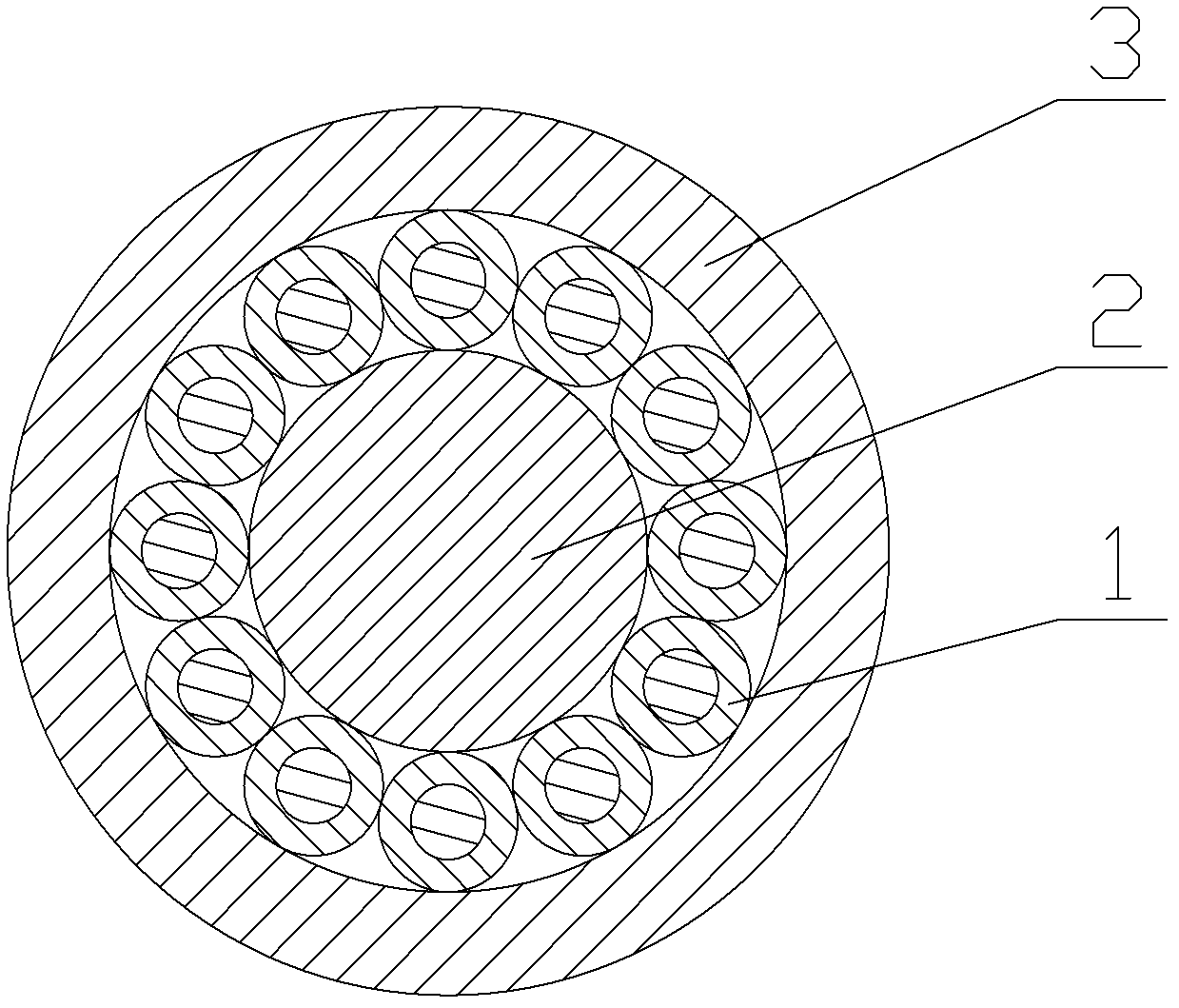

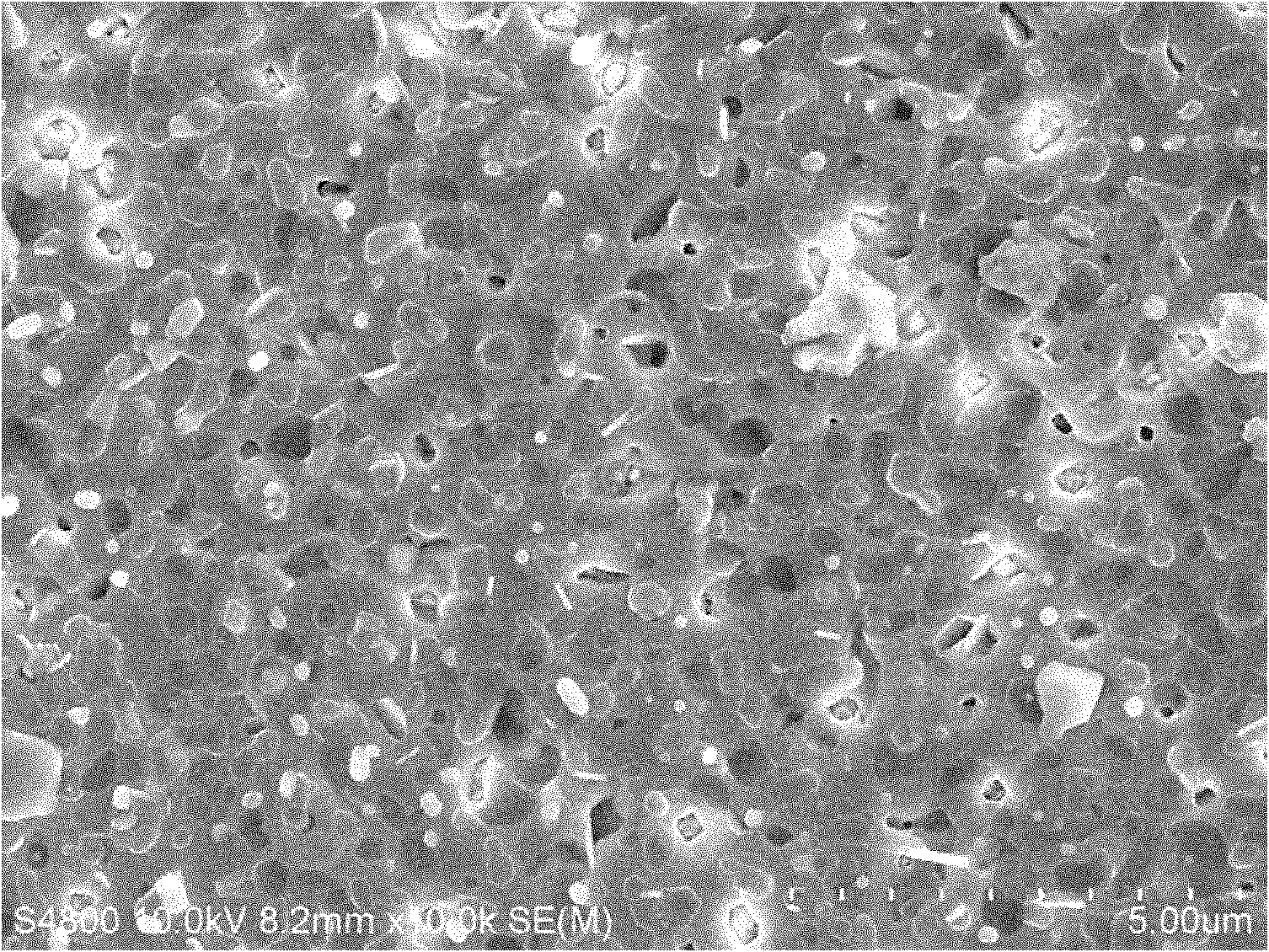

Method for preparing multicore MgB2 superconductive wire material

InactiveCN106784292AHigh densityImprove uniformitySuperconductor device manufacture/treatmentOxygenBoron

The invention discloses a method for preparing a multicore MgB2 superconductive wire material. The method comprises the specific steps: mixing magnesium powder with amorphous powdered boron so as to obtain precursor powder, loading the precursor powder to a Nb / Cu composite tube, and carrying out drawing, so as to obtain single-core bars; putting non-oxygen copper bars, Nb / Cu composite bars and the single-core bars in an oxygen-free copper tube for secondary assembly, so as to obtain a secondary composite; carrying out static hydraulic extrusion on the secondary composite, so as to obtain a multicore bar material; carrying out drawing on the multicore bar material so as to obtain a multicore wire material, and carrying out heat treatment, thereby obtaining the multicore MgB2 superconductive wire material. According to the method, the multicore MgB2 superconductive wire material is prepared by adopting a static hydraulic extrusion process on the basis of the traditional powder tubing method, so that the density of powder in core wires is remarkably improved, meanwhile, the uniformity and crystal grain connectivity of the core wires are improved, and the obtaining of high critical current density is facilitated. The method is simple in process, is applicable to the preparation of MgB2 superconductive wire material with the length of greater than 2,000 meters and has a very good application prospect.

Owner:西部超导材料科技股份有限公司

Preparation method for MgB2 based composite element doped cryogenic conductor

ActiveCN101343184AIncrease the critical current densityImproved Flux PinningSuperconductors/hyperconductorsSuperconductor devicesFlux pinningHydrogen

The invention provides a preparation method of an MgB2 matrix composite element doped superconductor, and the preparation process comprises: firstly mixing dried magnesium powder, boron powder and Ti3SiC2 powder fully according to a certain proportion for 1 to 2 hours, and molding the mixed powder by compression; then putting the mixture into a vacuum annealing furnace, and preserving the heat of the furnace for 1 to 10 hours at a temperature of between 700DEG C and 1000DEG C under the protection of a gas mixture of pure argon gas or argon gas and hydrogen; and finally cooling the mixture to the room temperature, so as to prepare the MgB2 matrix composite element doped superconductor with high critical current density. The adoption of the MgB2 matrix superconductor prepared by the preparation method can introduce the second phase particle as an effective pinning center while changing the crystal structure of the MgB2 matrix superconductor, and the acquired MgB2 matrix superconductor has high critical current density in the background magnetic field of over 3-Tesla, and can realize the low-cost preparation of the MgB2 matrix superconductive material, and effectively improve the flux pinning of the MgB2 matrix superconductor.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

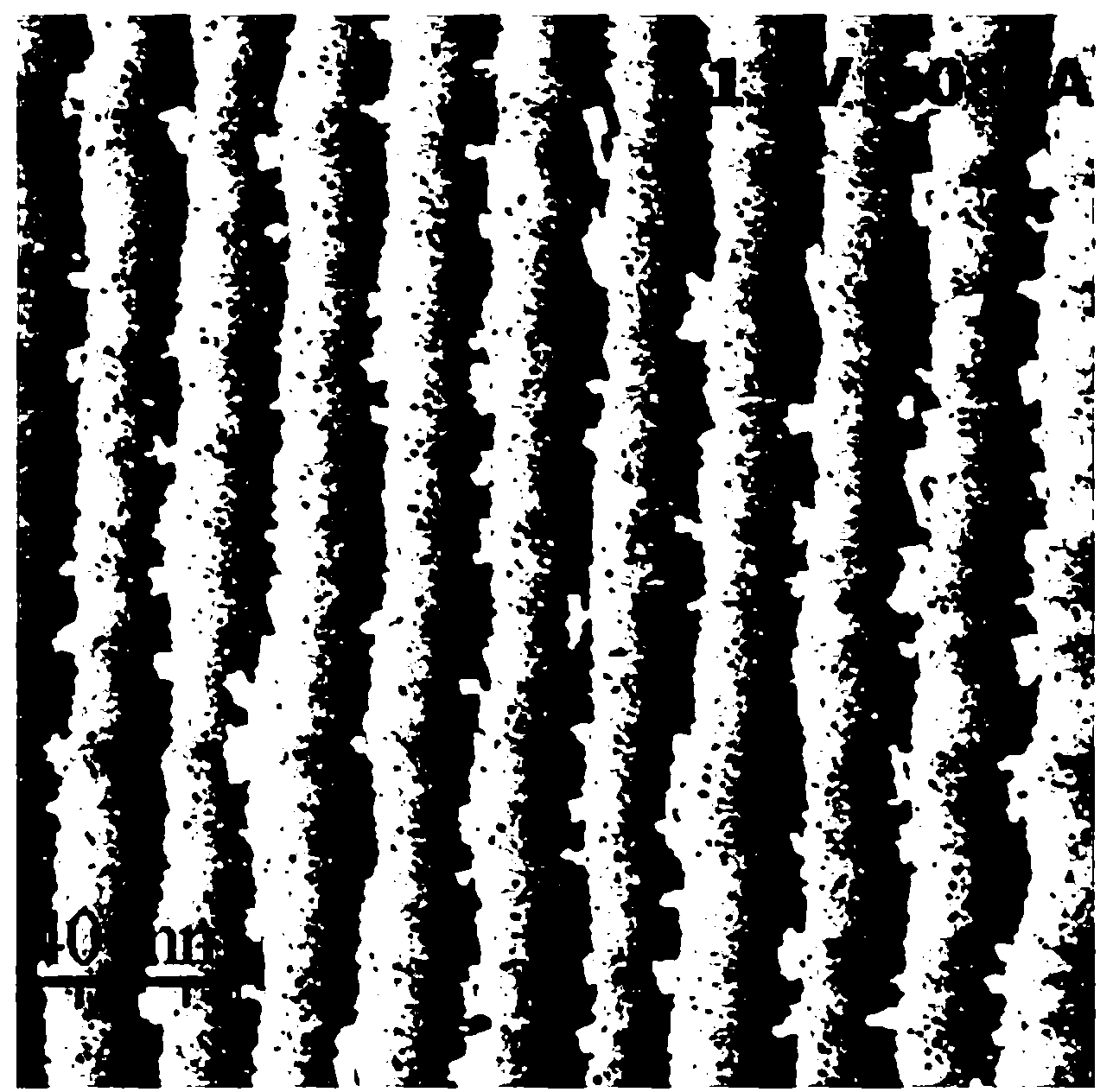

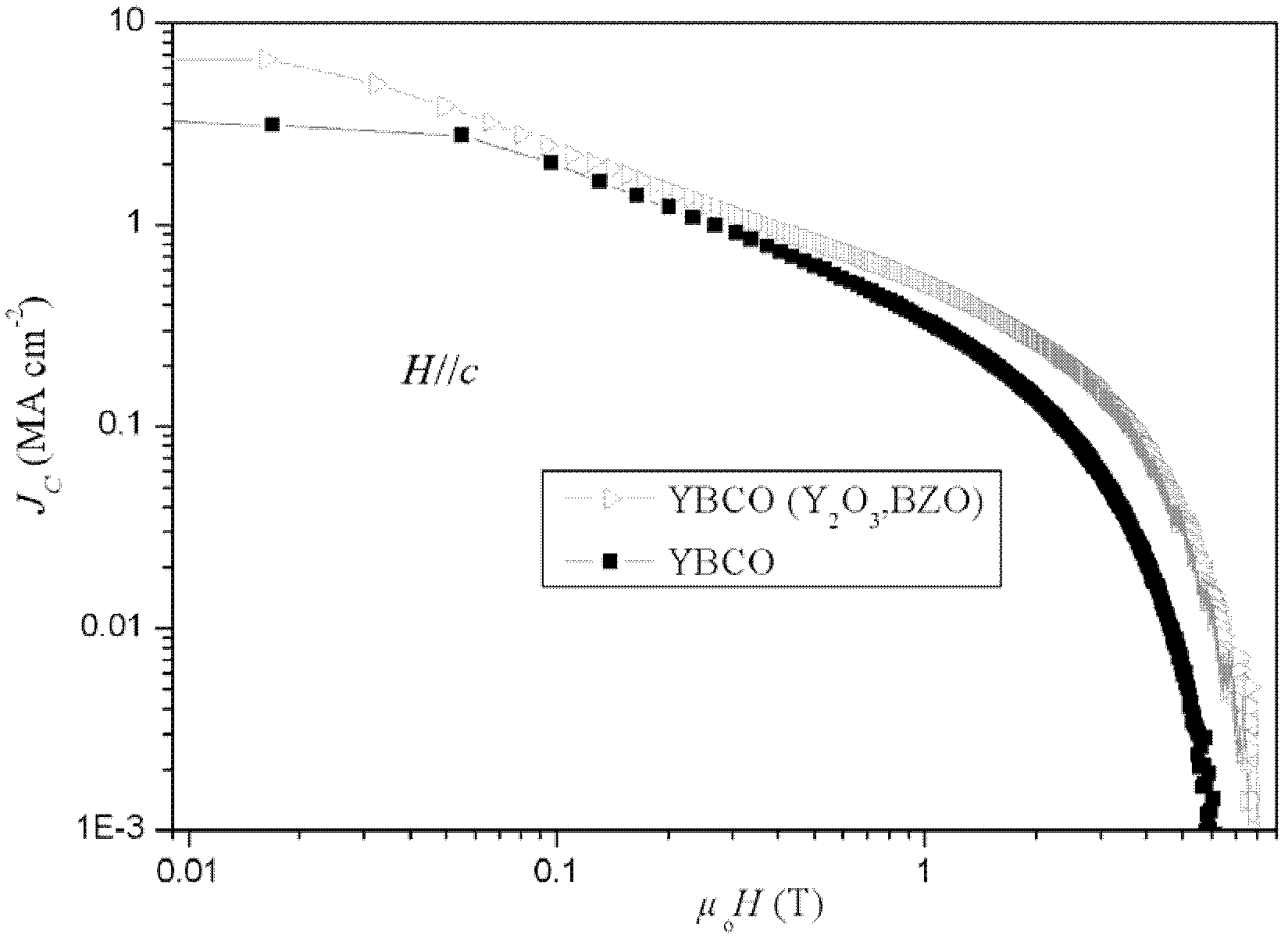

Nanostructures superconducting composite film and preparation method thereof

ActiveCN105741971AImprove abilitiesReal-time adjustment of doping concentrationMaterial nanotechnologySuperconductors/hyperconductorsMicro structureRare-earth element

The invention provides a nanostructures superconducting composite film and a preparation method thereof. The nanostructures superconducting composite film provided by the invention is formed by co-depositing a superconducting material and a non-superconducting nano material on a substrate through a magnetron and pulsed laser codeposition technology; the substrate is an SrTiO3, LaAlO3, MgO or flexible metal base band and the like; the superconducting material is REBa2Cu3O(7-x) (RE is rare-earth elements of Y, Gd, Nd, Sm and the like) or (LaSr)2CuO4 and the like; and the non-superconducting nano material is at least one of MgO, CeO2, Y2O3, BaZrO3 and BaSnO3. Through a magnetron and pulsed laser co-sputtering method, control on introduced defect distribution condition is achieved by adjusting magnetron and laser sputtering parameters in real time in the film growth process; and the target of adjusting and controlling the micro-structure and the superconducting property of the superconducting composite film is finally achieved.

Owner:北京安泰可科技有限公司

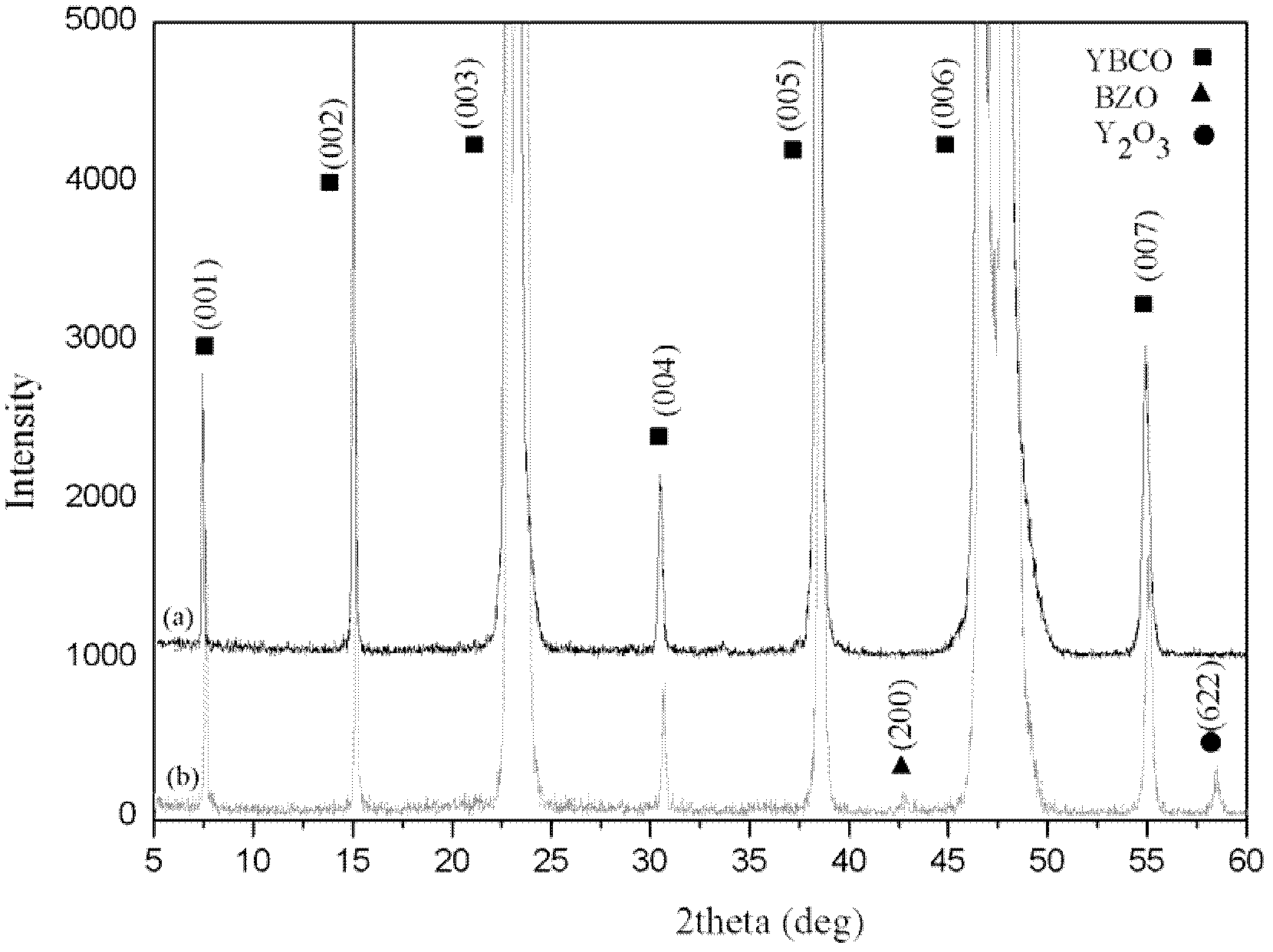

Method for preparing yttrium barium copper oxide (YBCO) superconductive composite film

InactiveCN102584204AIncrease the critical current densityImprove current carrying capacitySolventIon

Provided is a method for preparing an yttrium barium copper oxide (YBCO) superconductive composite film. Firstly, a precursor solution is prepared, namely yttrium acetate Y(CH3COO)3, barium acetate Ba(CH3COO)2 and cupric acetate Cu(CH3COO)2 are mixed and dissolved in a water solution containing 10-30 mol% of trifluoroacetic acid according to the molar ratio of Y to Ba to Cu being 1 to 2 to 3. The solvent is evaporated in a vacuum mode to obtain gel after even stirring. Carbinol is further added into the gel to be stirred evenly and then the solvent is dried to obtain gel. Afterwards, an appropriate amount of carbinol and terpineol are added into the solution to prepare a solution with 1.5-3.0 mol / L of total ion concentration of metal Y, metal Ba and metal Cu, after even stirring, zirconium acetylacetonate and titanium acetylacetonate which have 10%-15% of total ion molar concentration of metal Y, metal Ba and metal Cu are added into the solution to prepare the precursor solution. After that, the precursor solution is coated on a substrate. A coated film is first subjected to low temperature thermal decomposition at the temperature of 300-500 DEG C to decompose trifluoroacetic acid salt. Finally, the coated film is subjected to high temperature heat treatment at the temperature of 800-880 DEG C and annealing process at the temperature of 450-550 DEG C to form the YBCO superconductive composite film containing nanometer barium titanate and nanometer barium zirconate. The critical current density of the YBCO superconductive composite film reaches 7 MA / cm<2> (77K, 0T).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Preparation method of YBCO (Yttrium Barium Copper Oxide) superconducting thin film

InactiveCN102255041AActs as flux pinningIncrease the critical current densitySuperconductor device manufacture/treatmentSolventYttrium

The invention discloses a preparation method of a YBCO (Yttrium Barium Copper Oxide) superconducting thin film. The method comprises the following steps of: preparing a precursor solution, mixing yttrium acetate Y(CH3COO)3, barium acetate Ba(CH3COO)2 and copper acetate Cu(CH3COO)2 in the molar ratio (1.2-1.5):2:3 and dissolving the mixture into 10-30 mole percent aqueous solution of trifluoroacetic acid; uniformly stirring and evaporating a solvent in vacuum to obtain gel; adding methanol, uniformly stirring and evaporating a solvent to obtain gel; adding an appropriate amount of methanol andterpineol to obtain a solution in which the total concentration of metal ions such as Y, Ba and Cu is 1.5-3.0 mol / L, uniformly stirring and adding zirconium acetylacetonate in which the total ion molar concentration of three metals is 5-10 percent to obtain a precursor solution; coating the precursor solution on a substrate; thermally treating a coated thin film at the low temperature 300-500 DEGC and decomposing trifluoroacetates; and thermally treating at high temperature 750-850 DEG C and annealing at the temperature 450-550 DEG C to form the YBCO superconducting thin film containing nanometer yttrium oxide and nanometer barium zirconate. The critical current density of the YBCO thin film is 6 MA / cm<2> (77K, 0T).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

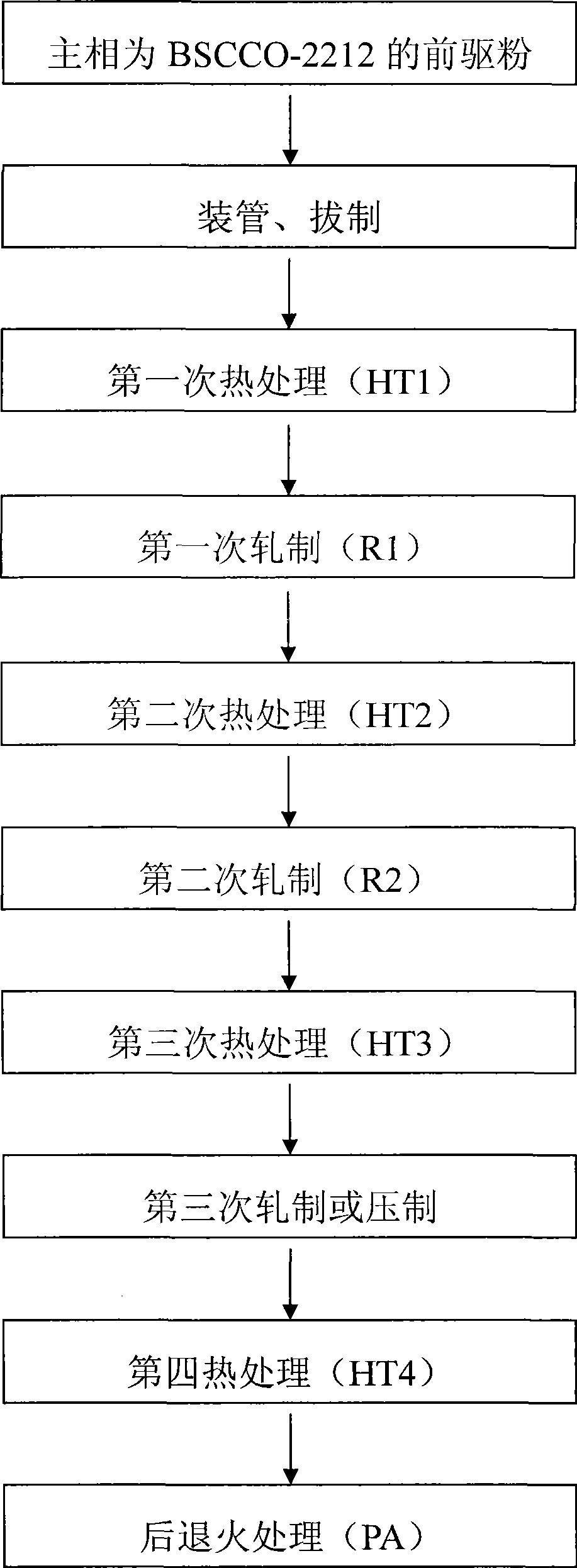

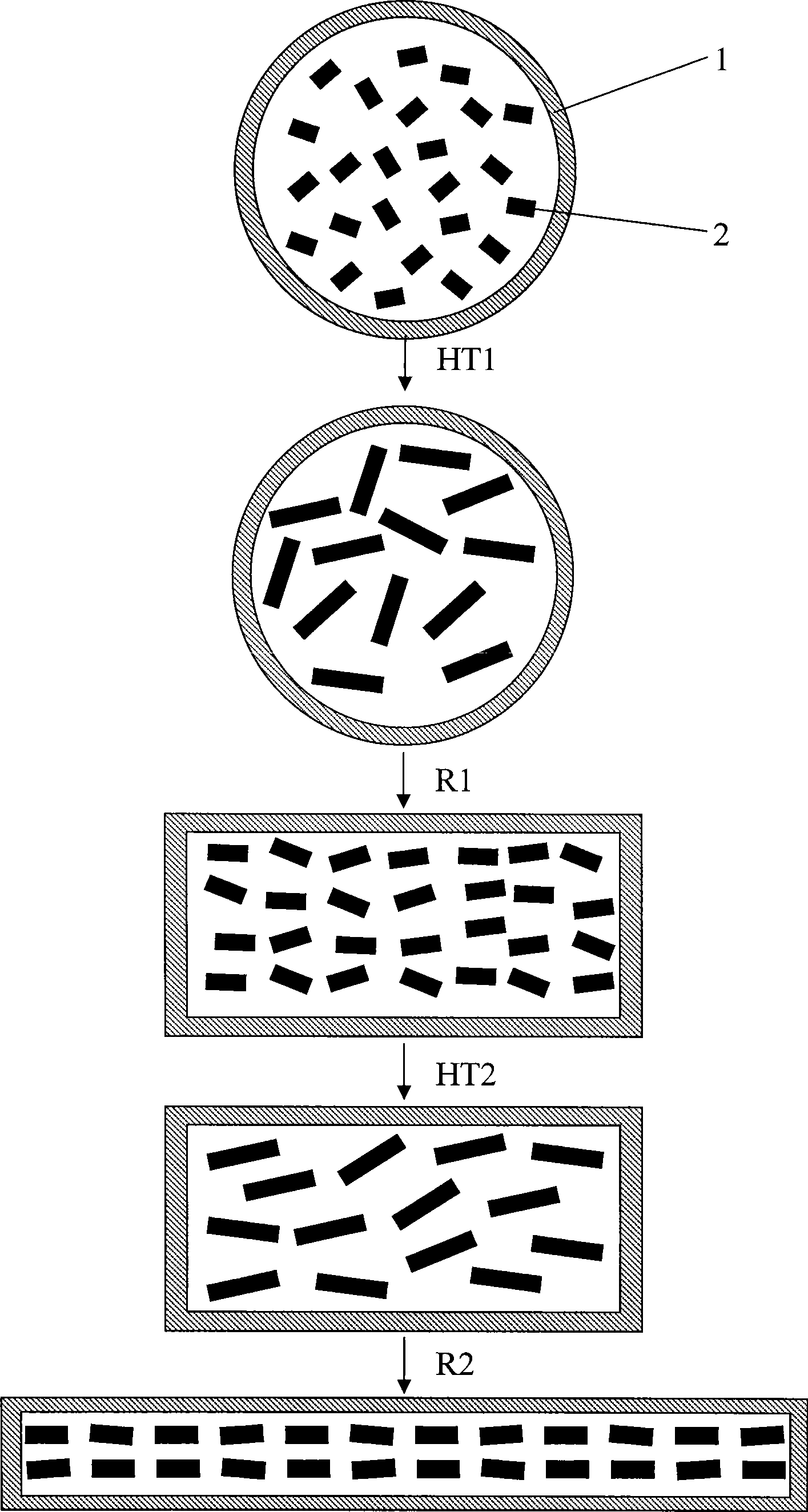

High-performance bismuth series high-temperature superconducting strip and preparation method thereof

InactiveCN101465178AEasy alignmentFirmly connectedSuperconductors/hyperconductorsSuperconductor devicesHigh temperature superconductingAlloy

The invention relates to a bismuth system high temperature superconducting tape and the preparation method thereof. The tape consists of a metal sheath and a superconducting core positioned in the metal sheath; the main phase of the superconducting core is (Bi, Pb)2Sr2Ca2Cu3Oy; the weight percentage content of the main phase is 75 to 98 percent of the superconducting core; the second phase is any two among CuO, (Ca, Sr)2CuO3, (Ca, Sr)14Cu24O41, Bi2Sr2CuO6, Ca2PbO4, SrCaCuO, CaCuO and Pb3Sr2.5Bi0.5Ca2CuOy, or more than two combinations; the weight percentage content of the second phase is 2 to 25 percent of the superconducting core; and the material of the metal sheath is silver or silver alloy. By adopting the method, the prepared bismuth system high temperature superconducting tape has the advantages of high performance and relative high critical current density.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com