Method for preparing yttrium barium copper oxide (YBCO) superconductive composite film

A technology of composite thin film and superconducting thin film is applied in the field of preparation of second-generation high-temperature superconducting tapes to achieve the effects of broadening the scope of application, improving current-carrying capacity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

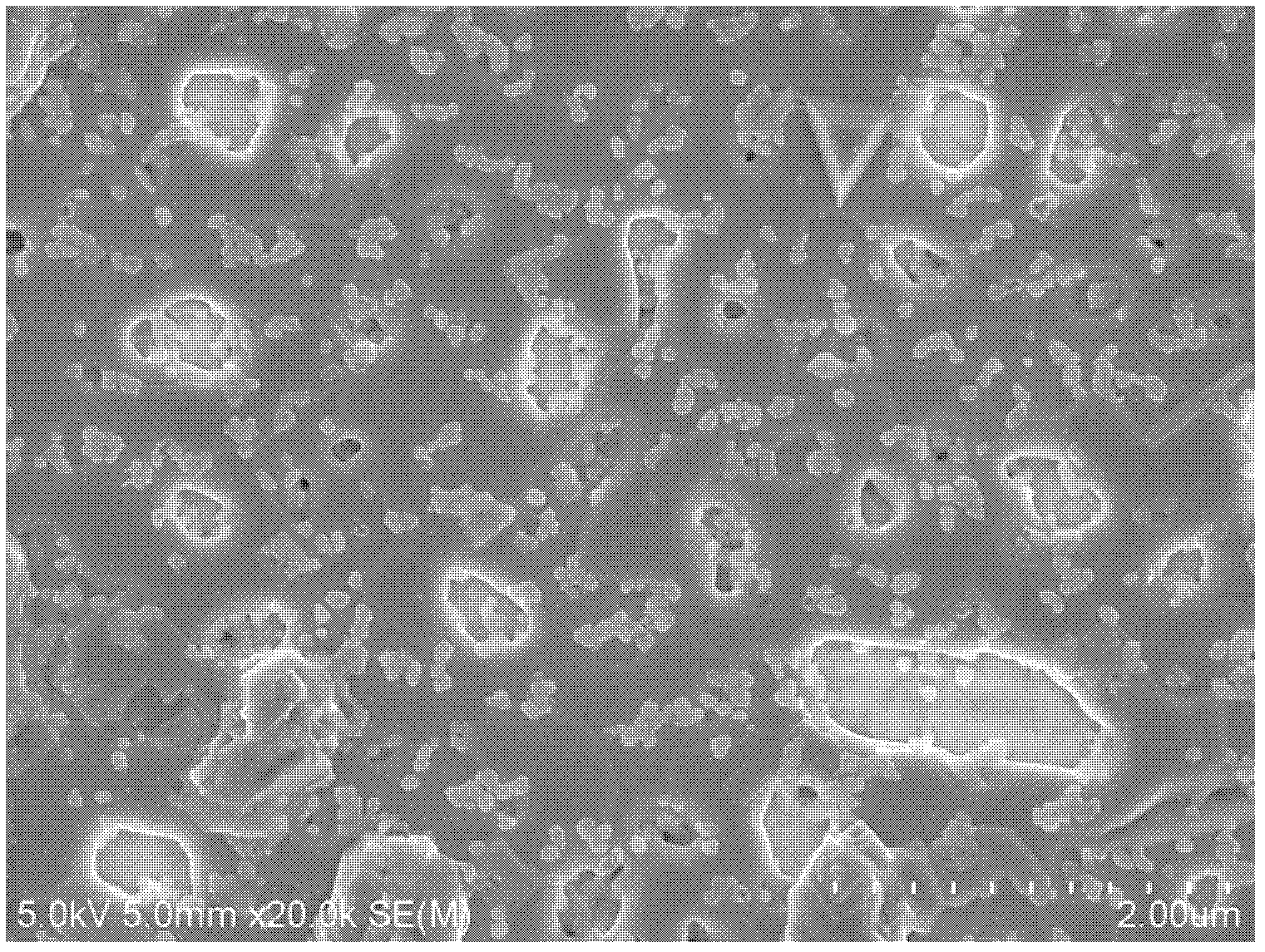

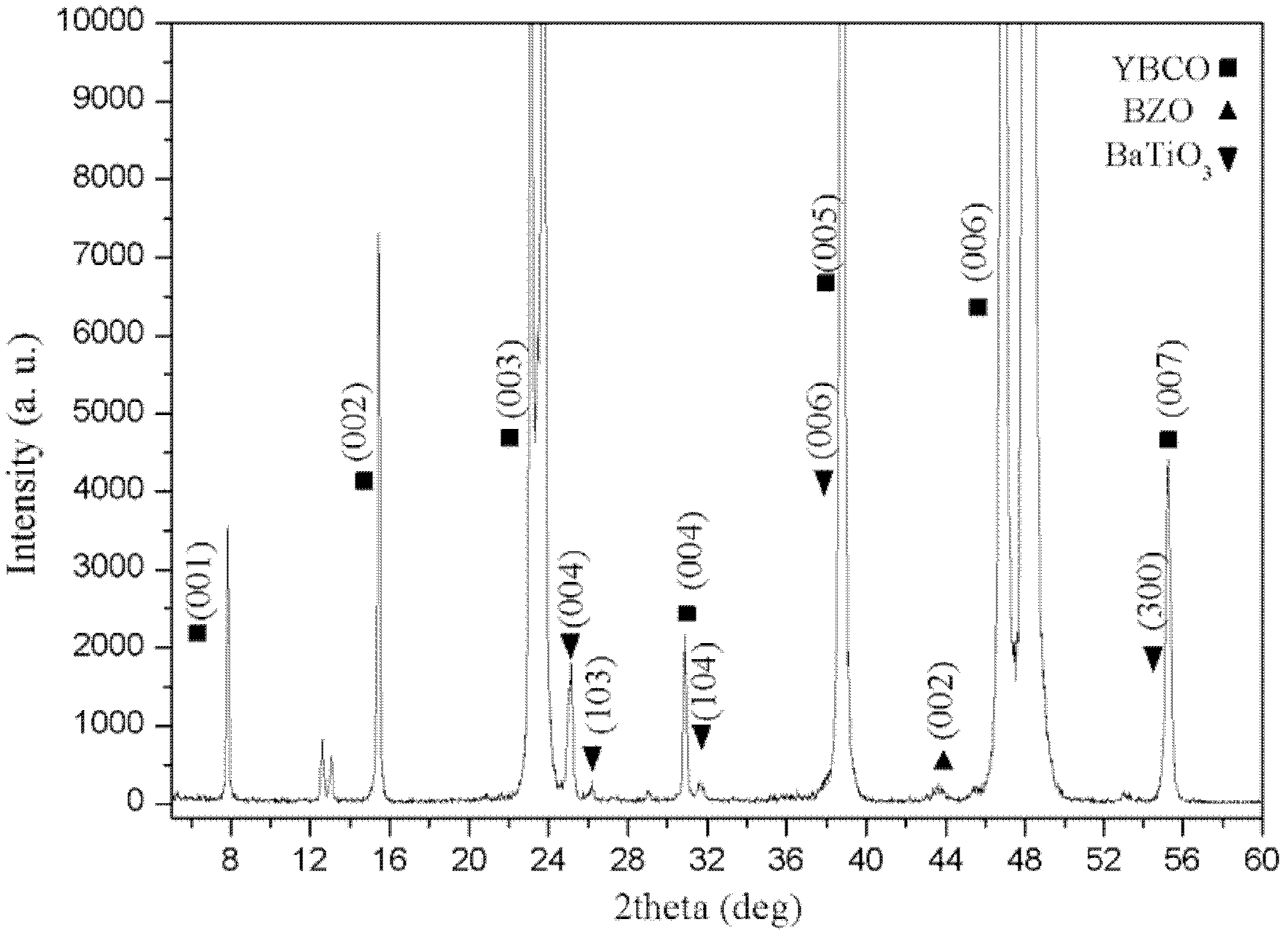

Image

Examples

Embodiment 1

[0025] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.005mol, 0.01mol and 0.015mol respectively, mix yttrium acetate, barium acetate and copper acetate and dissolve them in deionized water containing 10mol% trifluoroacetic acid to prepare Solution, wherein the molar ratio of solute and solvent in the solution is 1: 100;

[0026] (2) After the solution prepared in step (1) was stirred by a magnetic stirrer for 1 h, the solvent was evaporated by a rotary evaporator to obtain a gel;

[0027] (3) 1.55mol of methanol is added to the gel obtained in step (2), and then stirred by a magnetic stirrer for 0.5h, and then the solvent is evaporated by a rotary evaporator to further remove impurities such as moisture to obtain a very pure gel Gel, wherein the molar ratio of sol and methanol is 1:50;

[0028] (4) The gel prepared in step (4) is added to the mixed solution of 10.3ml methanol and 10.3ml terpineol, and the volume ratio of the methanol and terpineol is 1:1...

Embodiment 2

[0034] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.01mol, 0.02mol and 0.03mol respectively, mix yttrium acetate, barium acetate and copper acetate and dissolve in deionized water containing 20mol% trifluoroacetic acid to prepare Solution, wherein the molar ratio of solute and solvent in the solution is 1: 100;

[0035] (2) After the solution prepared in step (1) was stirred for 2 hours by a magnetic stirrer, the solvent was evaporated by a rotary evaporator to obtain a gel;

[0036] (3) 3.175 mol of methanol was added to the gel obtained in step (2), stirred by a magnetic stirrer for 1 hour, and then the solvent was evaporated by a rotary evaporator to further remove impurities such as moisture to obtain a very pure gel, Wherein the molar ratio of sol and methanol is 1: 50;

[0037] (4) The gel prepared in step (3) is added to the mixed solution of 15.8ml methanol and 15.8ml terpineol, the volume ratio of the methyl alcohol and terpineol is 1: 1 to ma...

Embodiment 3

[0044] (1) Take by weighing yttrium acetate, barium acetate and copper acetate to be 0.015mol, 0.03mol and 0.045mol respectively, after mixing yttrium acetate, barium acetate and copper acetate, be dissolved in 1 deionized water containing 30mol% trifluoroacetic acid to prepare into a solution, wherein the molar ratio of solute and solvent in the solution is 1: 100;

[0045] (2) After the solution prepared in step (1) was stirred for 3 hours by a magnetic stirrer, the solvent was evaporated by a rotary evaporator to obtain a gel;

[0046] (3) Add 4.875 mol of methanol to the gel prepared in step (2), stir with a magnetic stirrer for 1.5 hours, and then use a rotary evaporator to remove the solvent to further remove impurities such as water to obtain a very pure gel. Glue, wherein the molar ratio of sol and methanol is 1:5;

[0047] (4) The gel prepared in step (3) is added to the mixed solution of 16.25ml methanol and 16.25ml terpineol, the volume ratio of the methanol and te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com