Patents

Literature

186 results about "Barium zirconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium zirconate. Zirconate has excellent dielectric, temperature and chemical properties, and is widely used in ceramic capacitors, PTC thermistors, filters, microwave devices, plastics modification, solders, brake pads and organic properties improvement.

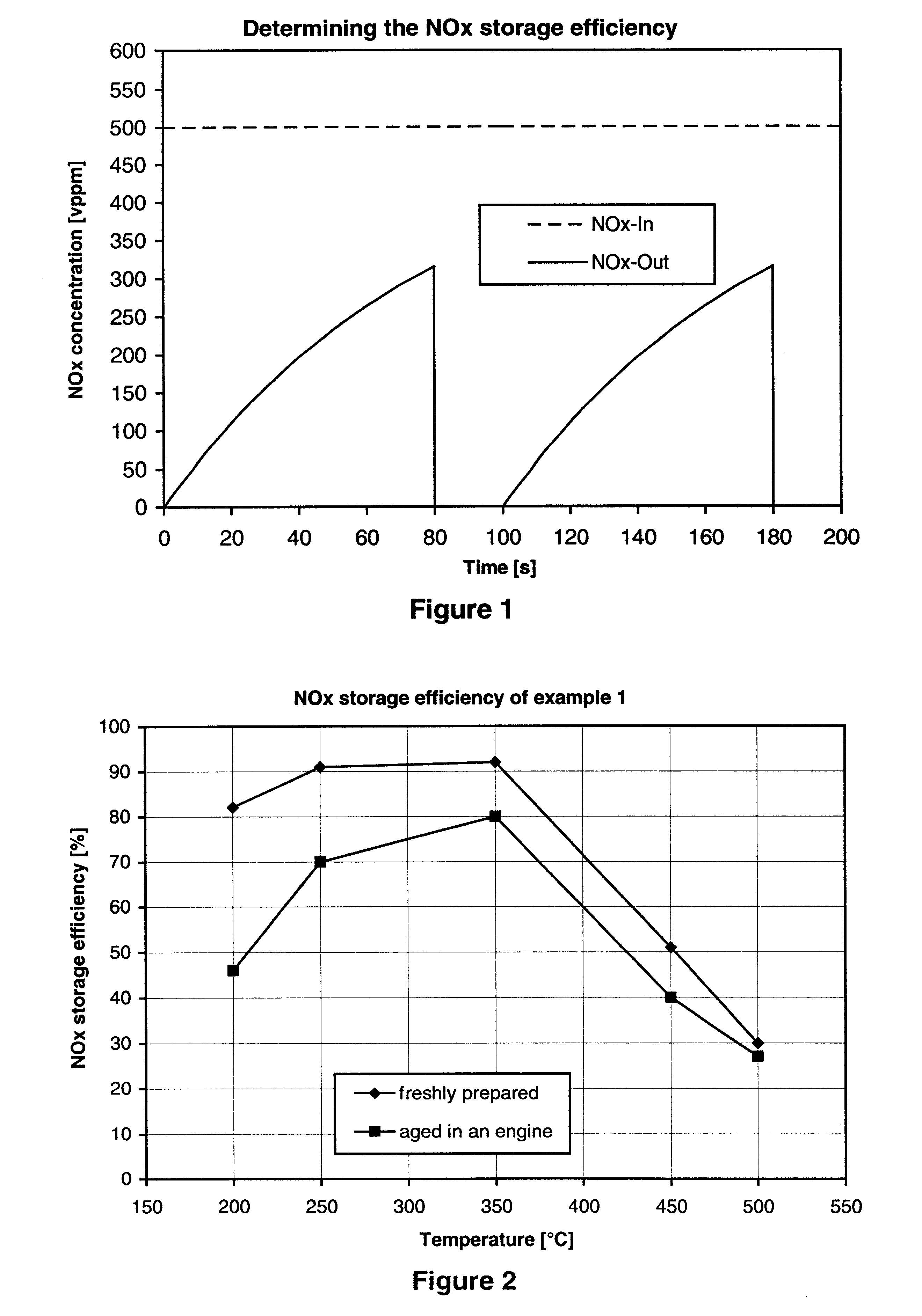

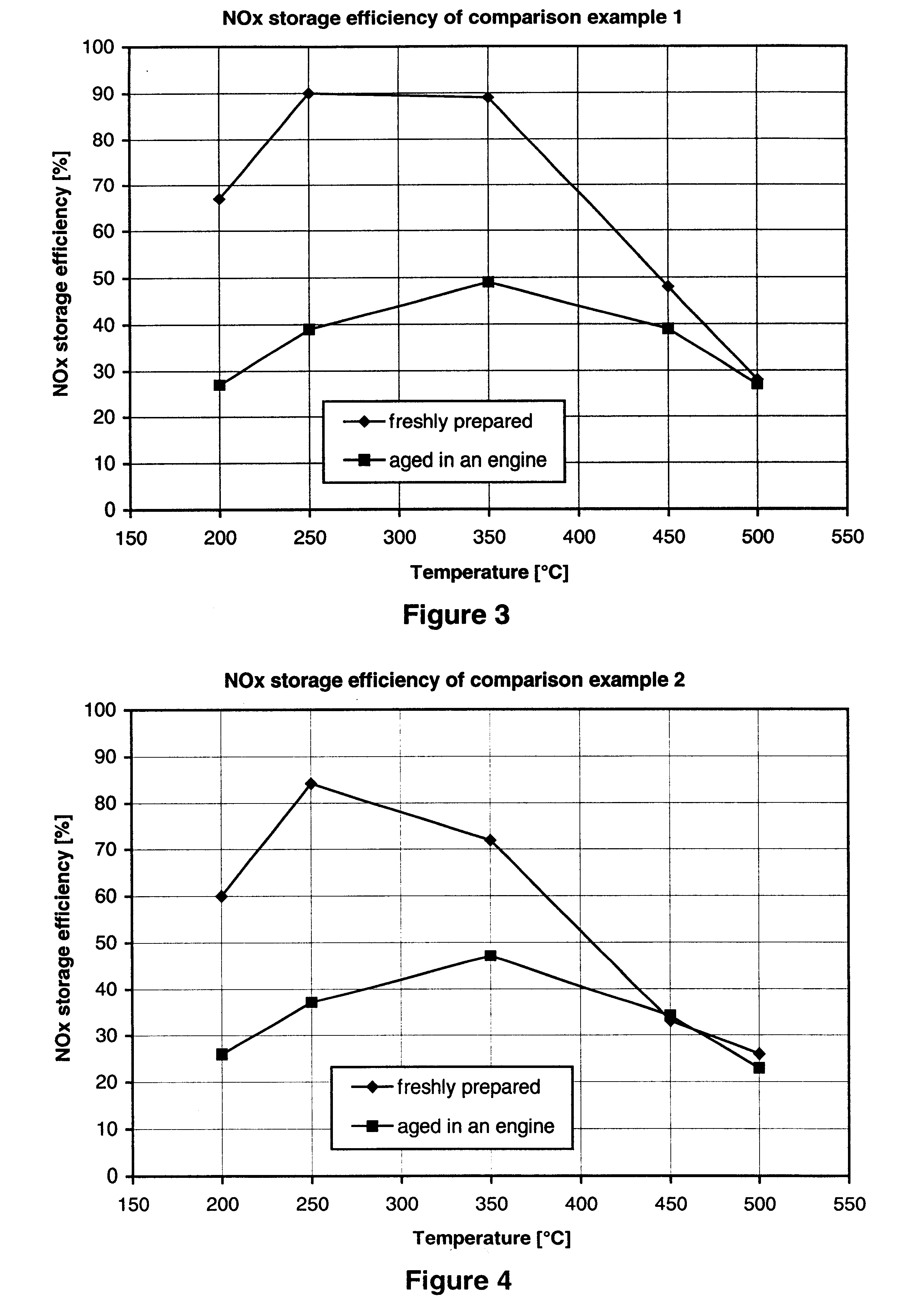

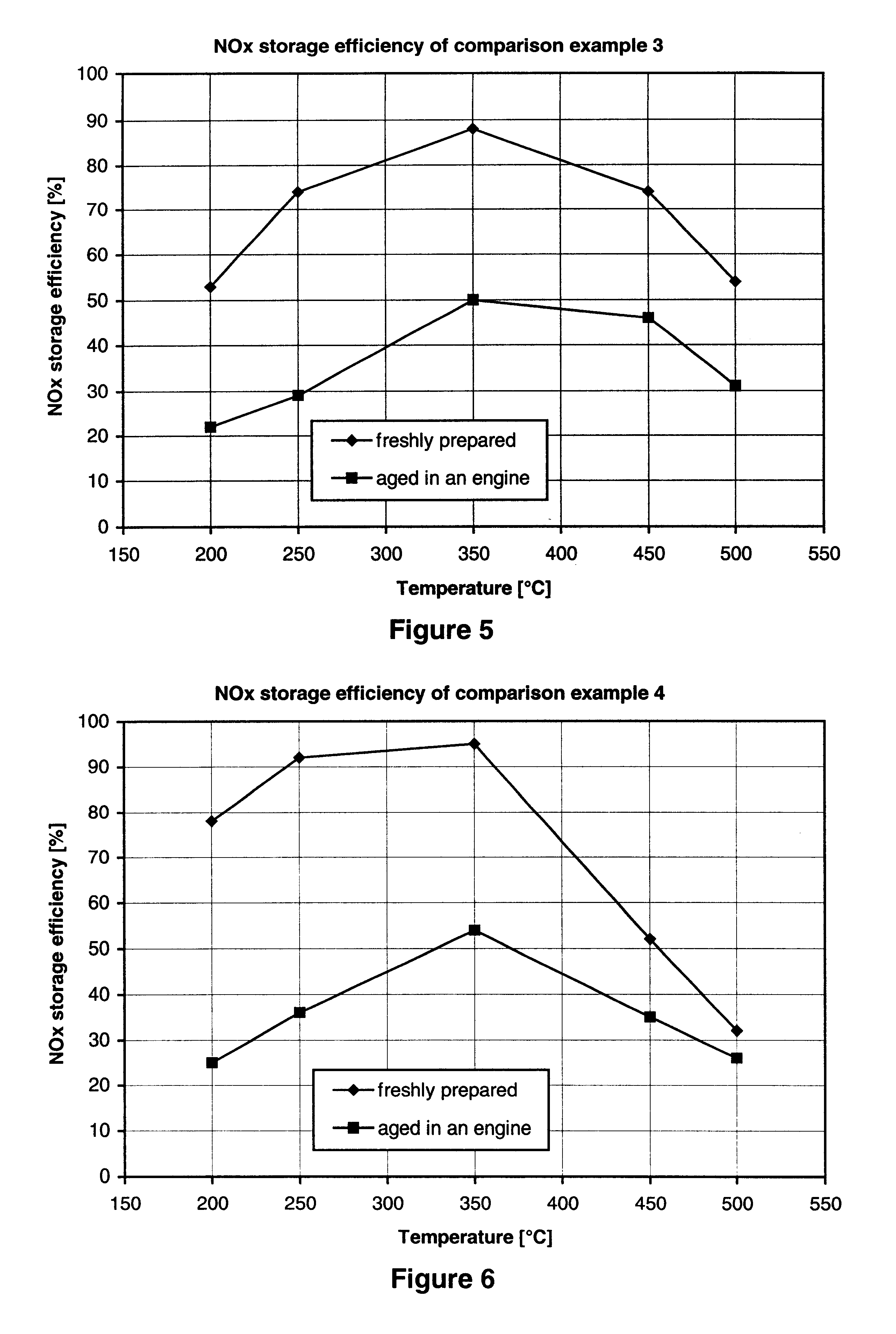

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

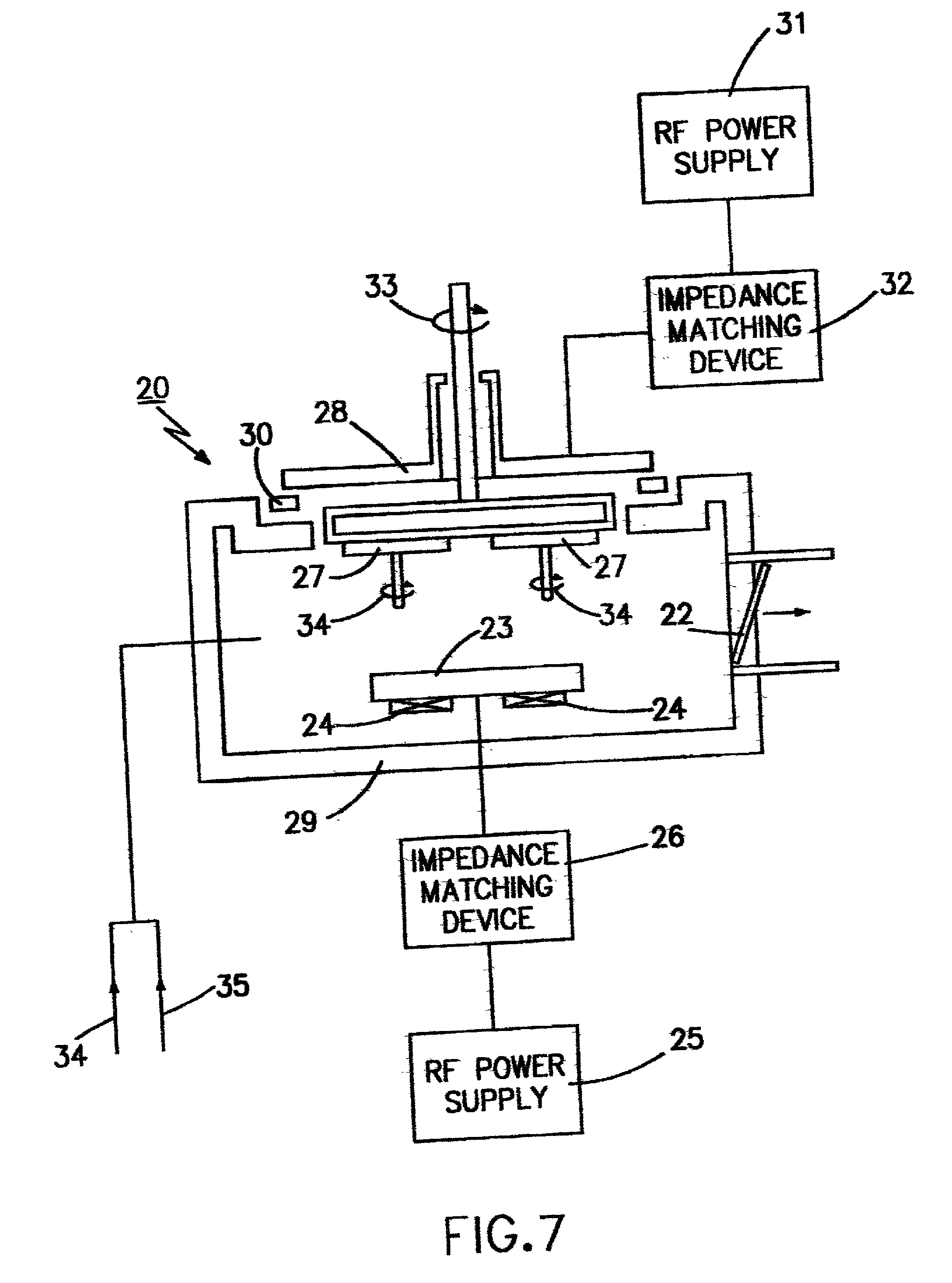

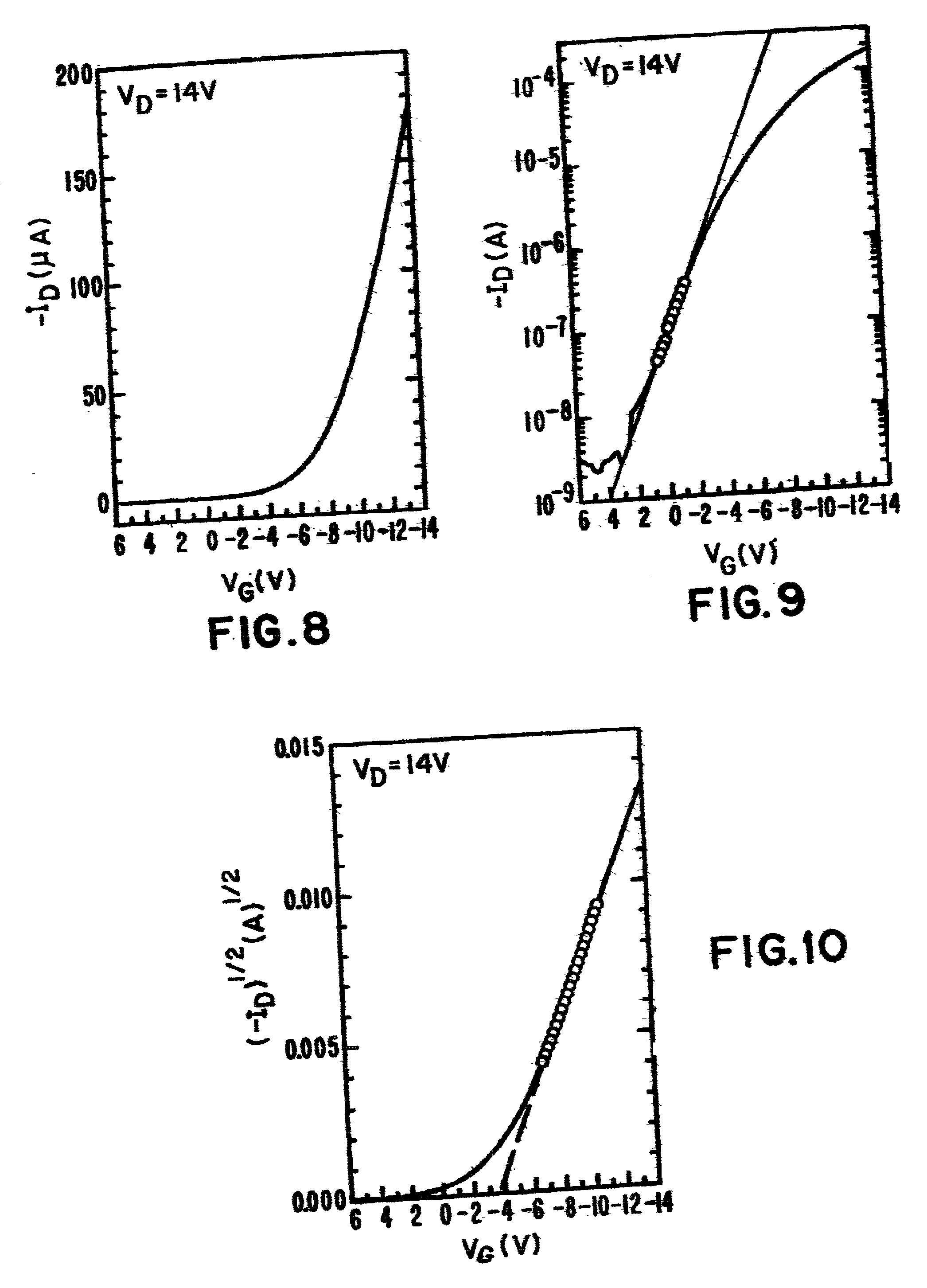

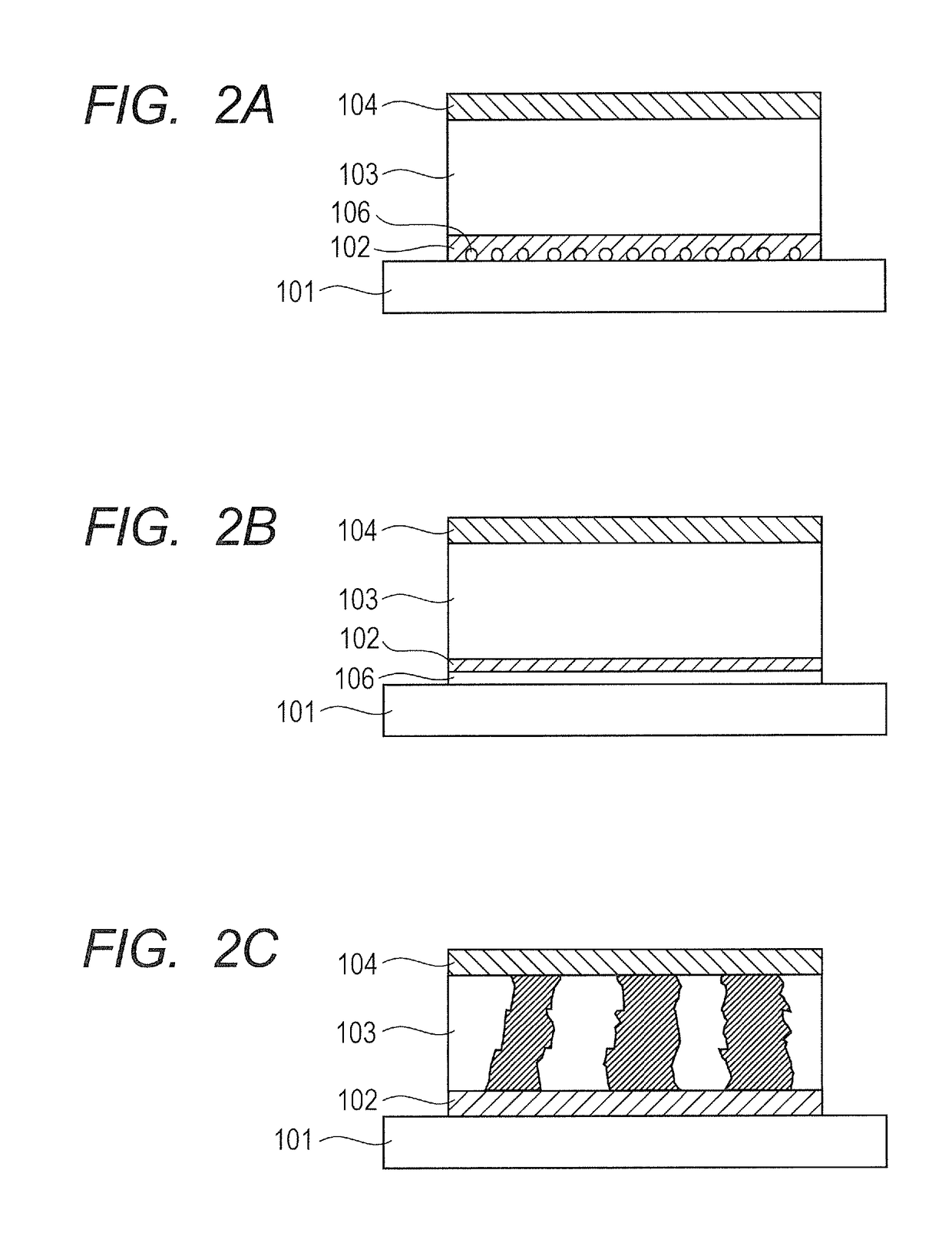

Low temperature thin film transistor fabrication

The invention broadens the range of materials and processes that are available for Thin Film Transistor (TFT) devices by providing in the device structure an organic semiconductor layer that is in contact with an inorganic mixed oxide gate insulator involving room temperature processing at up to 150 degrees C. A TFT of the invention has a pentacene semiconductor layer in contact with a barium zirconate titanate gate oxide layer formed on a polycarbonate transparent substrate employing at least one of the techniques of sputtering, evaporation and laser ablation.

Owner:GLOBALFOUNDRIES INC

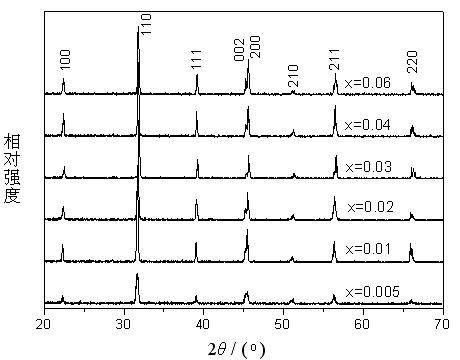

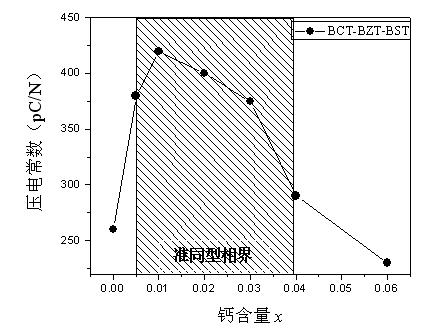

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

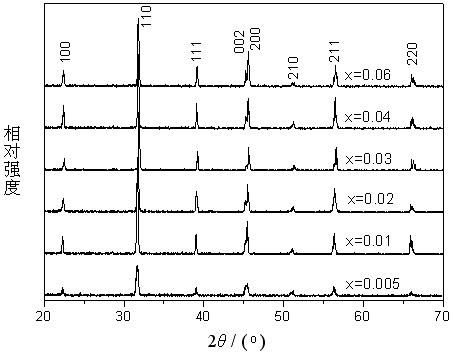

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

Sodium bismuth phthalate-barium zirconium phthalate leadless piezoelectric ceramic and its preparation method

InactiveCN1623954AExcellent piezoelectric propertiesReduce leakage currentPiezoelectric/electrostrictive/magnetostrictive devicesHigh densitySodium titanate

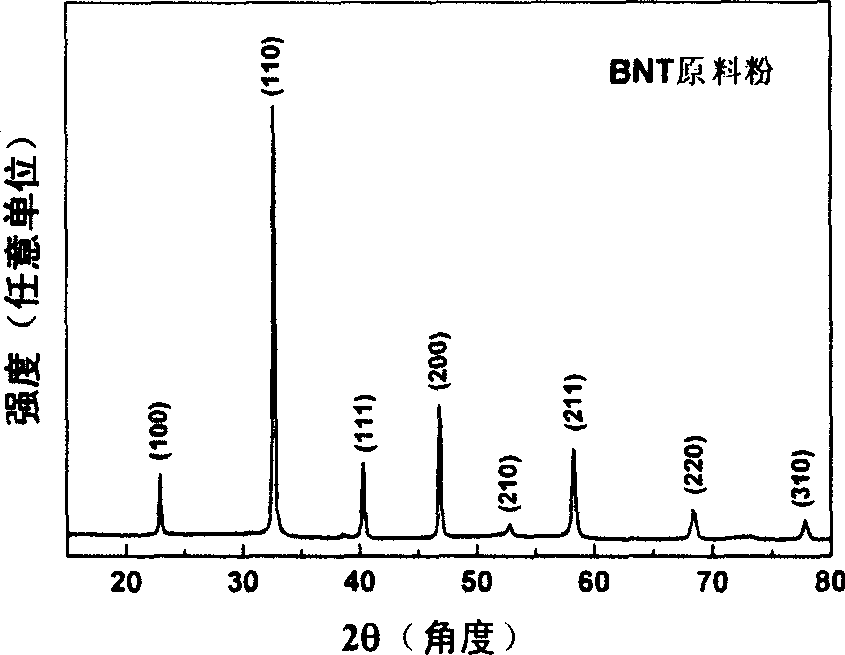

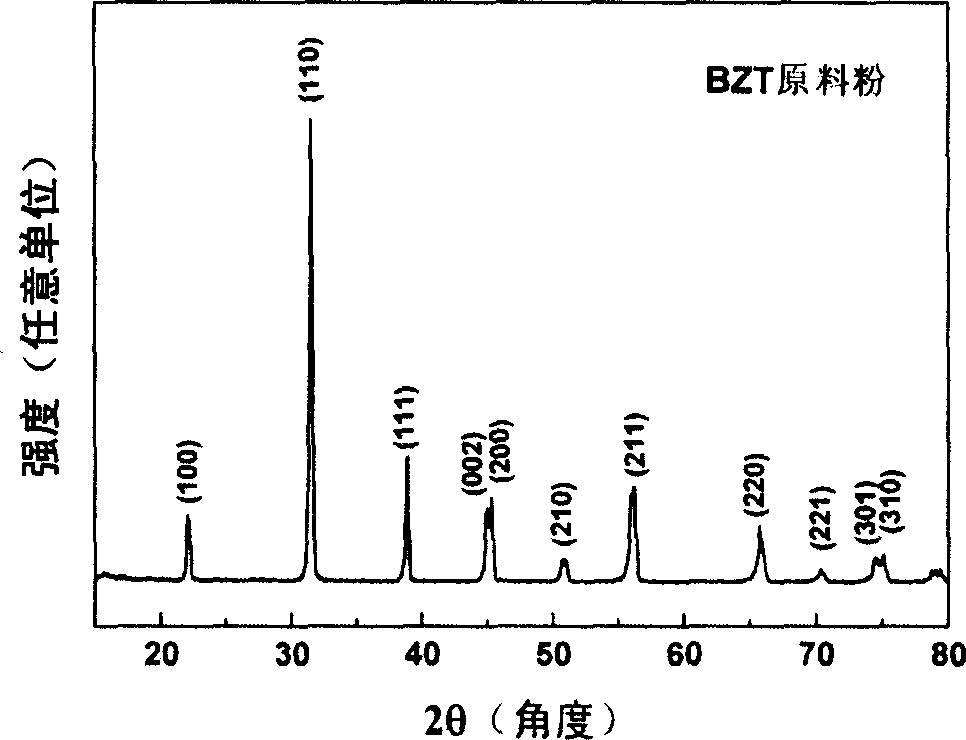

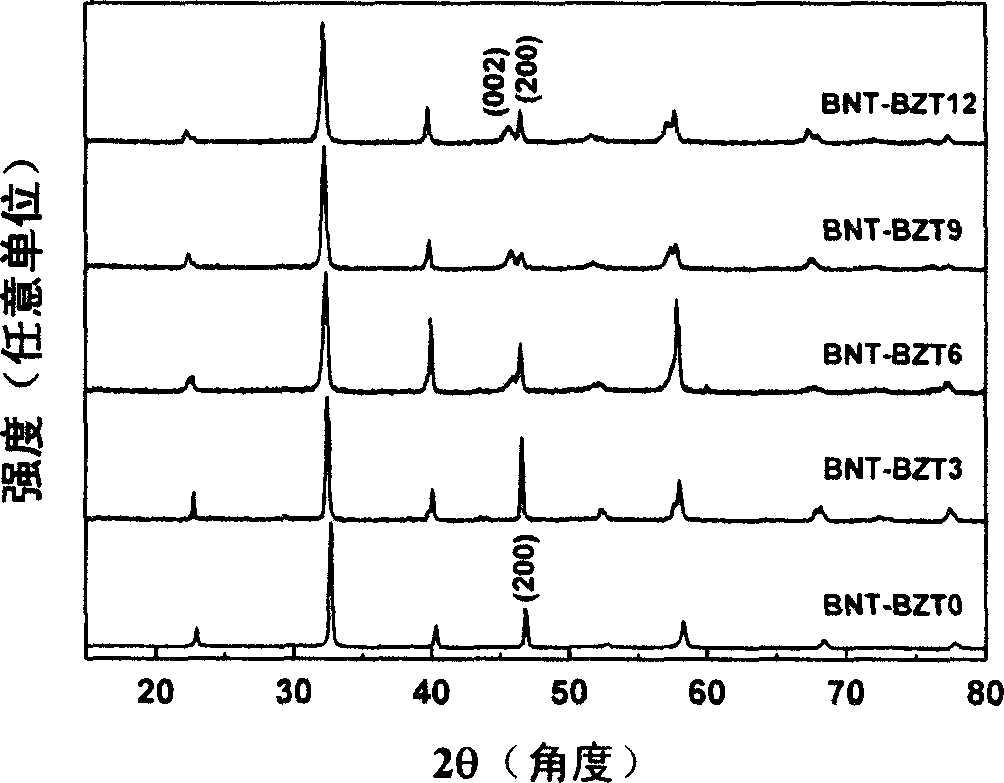

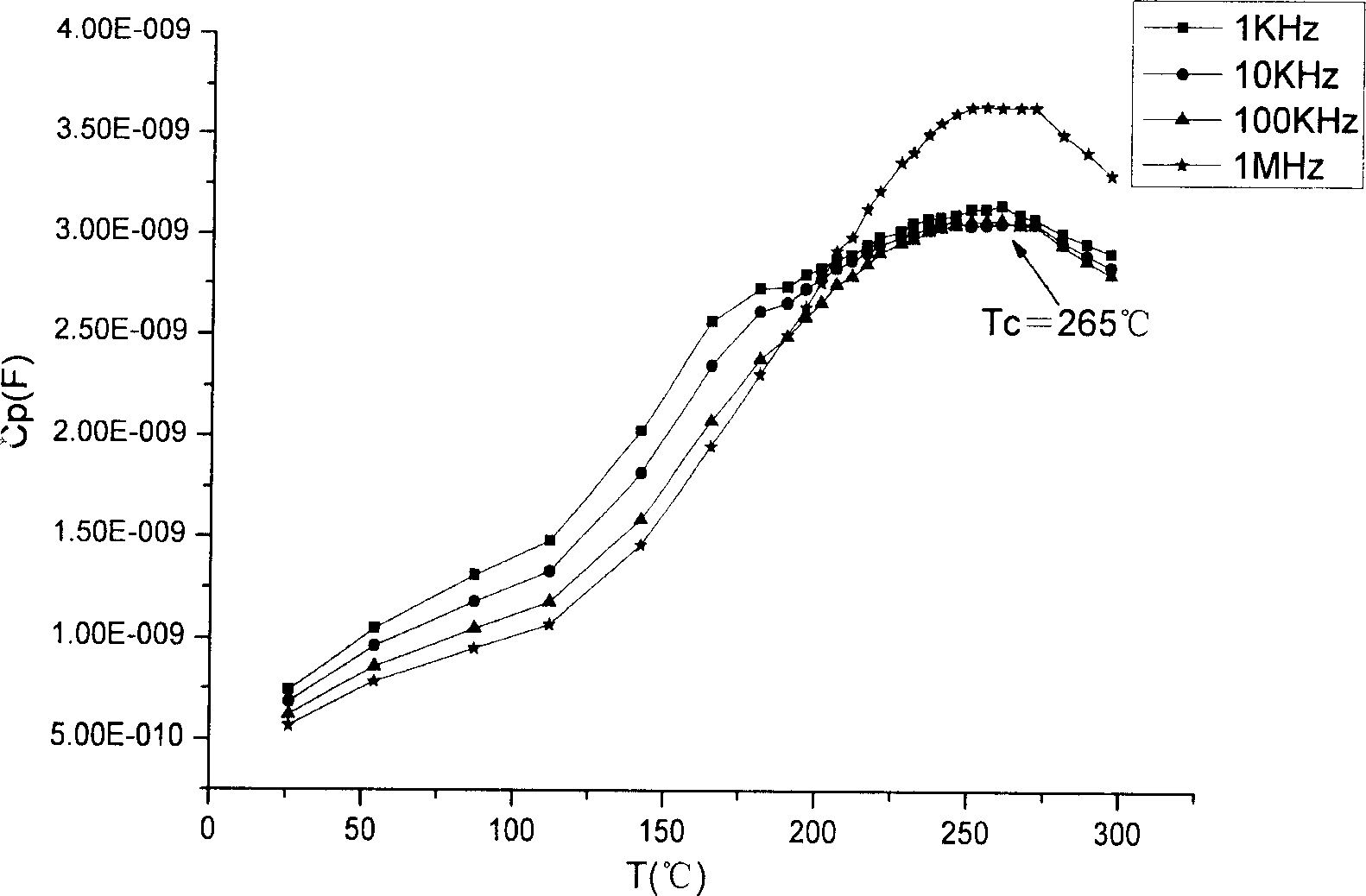

A non-Pb piezoelectric bismuth sodium titanate-barium zirconate titatate ceramics, (Bi0.5Na0.5)TiO3-xBa(Ti1-yZry)O3 (BNT-BZT), is prepared by two-step sinter method. Its advantages are high density, low leakage current in polarizing procedure, and high piezoelectric and ferroelectric performance.

Owner:TSINGHUA UNIV +1

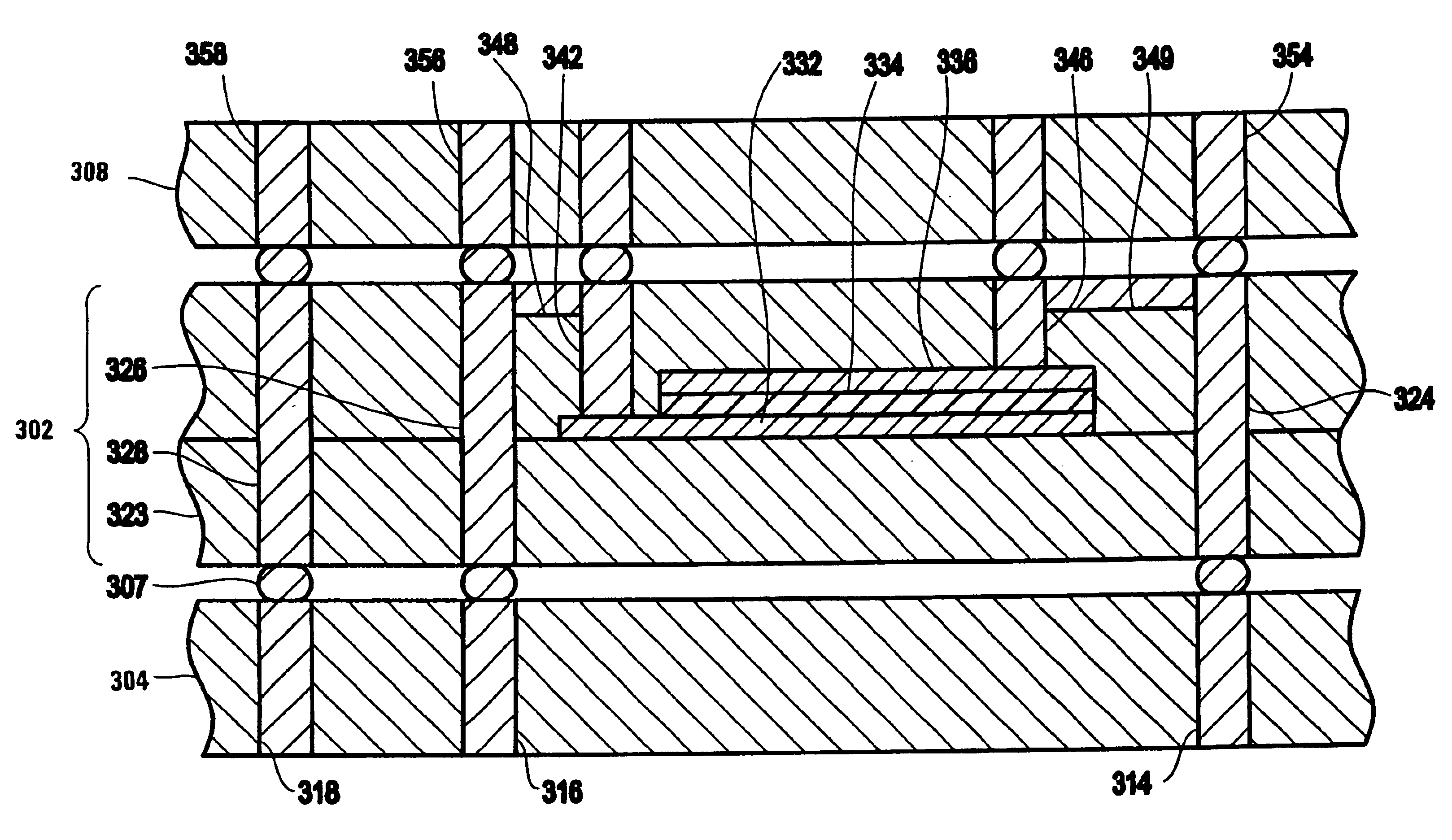

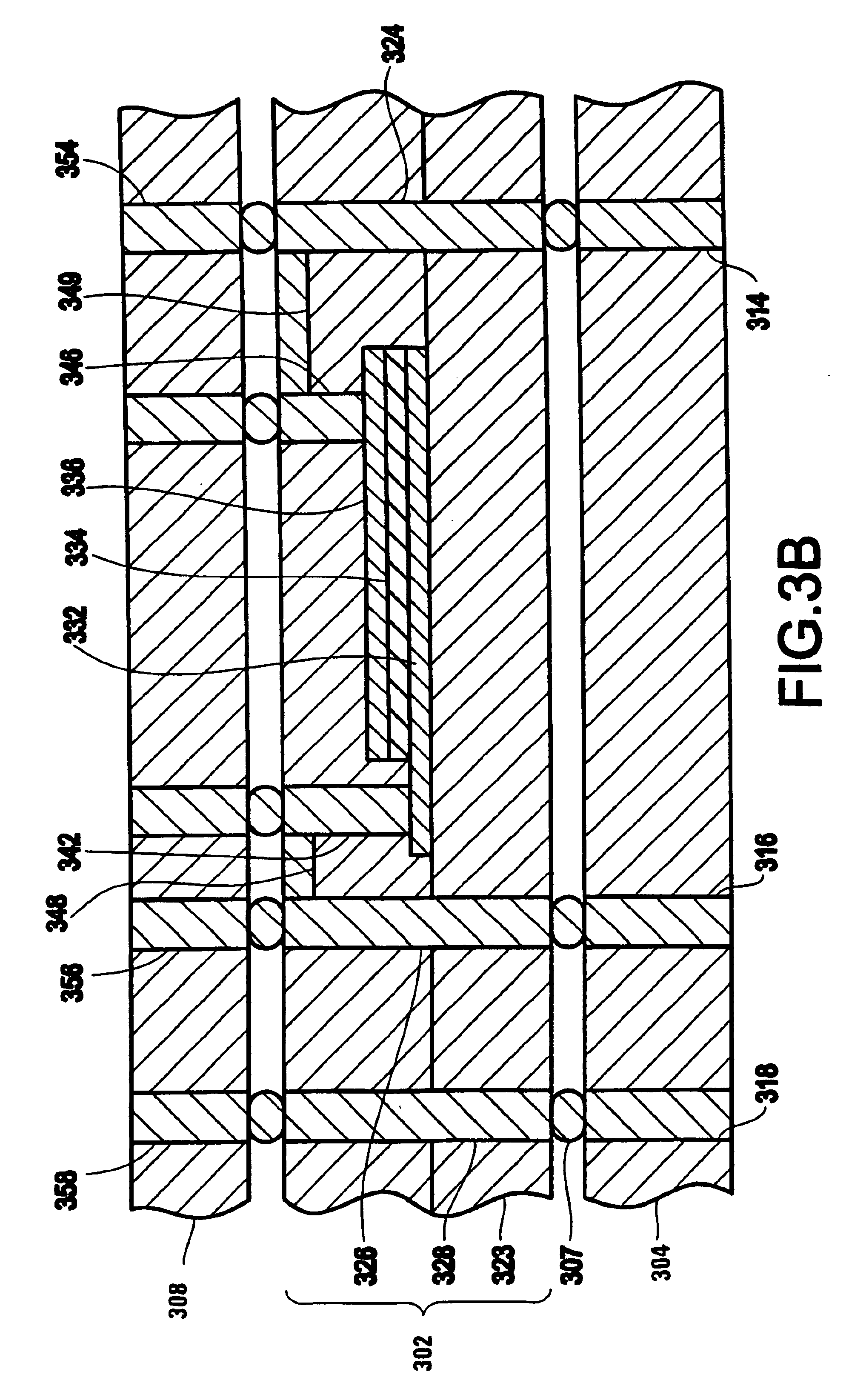

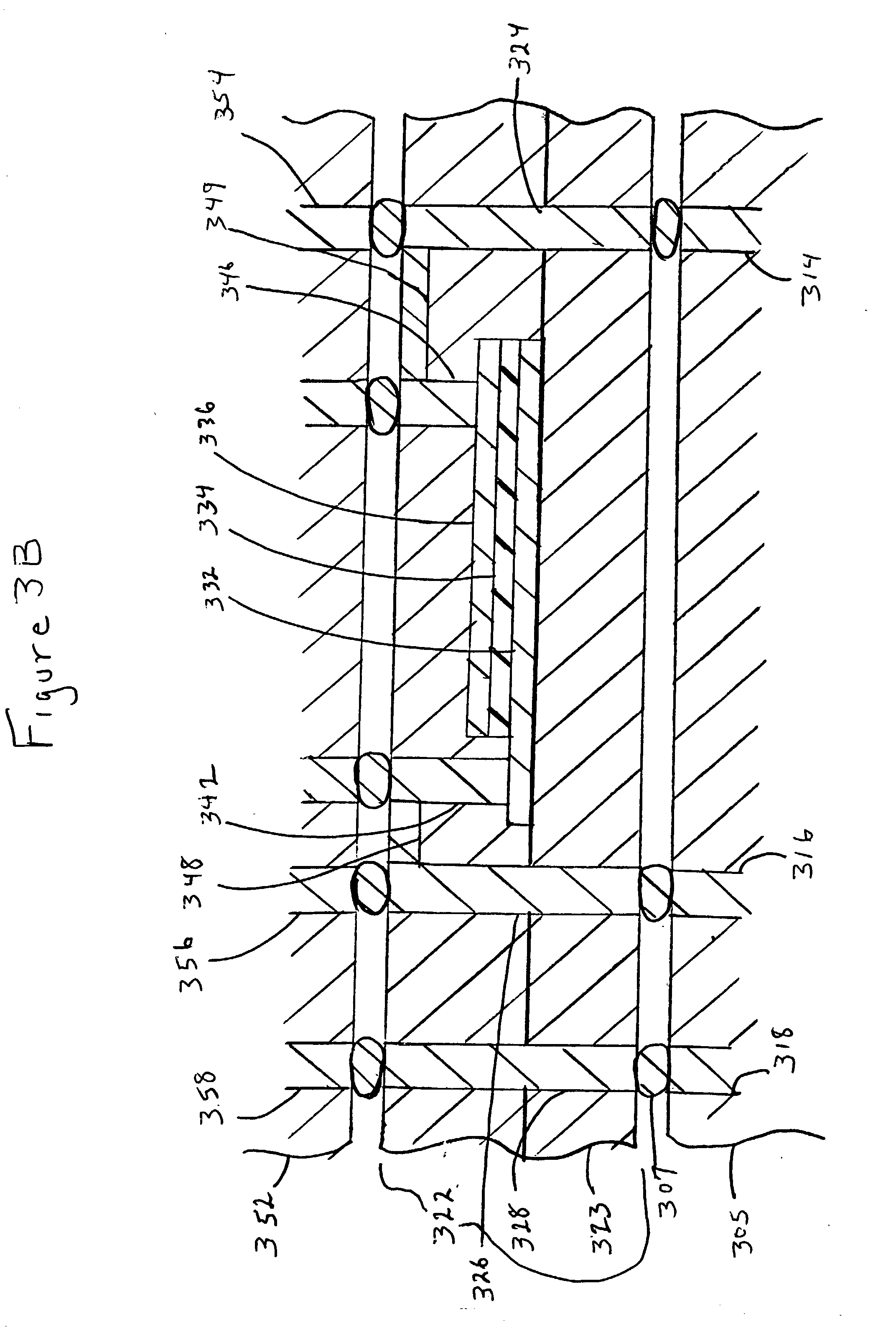

Interposer capacitor built on silicon wafer and joined to a ceramic substrate

InactiveUS6791133B2Improve performanceHigh yieldTransistorSemiconductor/solid-state device detailsLead zirconate titanateBarium strontium titanate

An interposer, located between an integrated circuit having power, ground and signal connections and a ceramic substrate having power, ground and signal connections, that includes an oxide layer formed on a polished surface of a silicon substrate, a thin film dielectric capacitor formed on the oxide layer, a plurality of metallized that electrically connect to either of the electrodes of the thin film dielectric capacitor, and vias than conduct power, ground and signals between a the ceramic substrate and the integrated circuit. The interposer connects the metallized vias to the integrated circuit by solder connections and also connects the vias conducting power, ground and signals from the ceramic substrate to the interposer by solder connections. The dielectric of the thin film dielectric capacitor may be selected from the group of high-K titanates, such as, barium zirconate titanate, barium strontium titanate, pure barium titanate, barium titanate modified with Pb, Nb, W, Ca, Mg, and Zn, lead titanate, lead zirconate titanate, and polycrystalline lanthanum-modified lead zirconate titanate, or other high-K dielectrics, such as, lead niobate and its derivatives, and lead tungstate and its derivatives.

Owner:GLOBALFOUNDRIES US INC

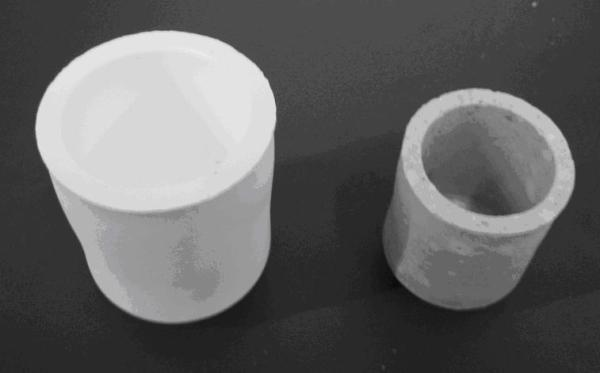

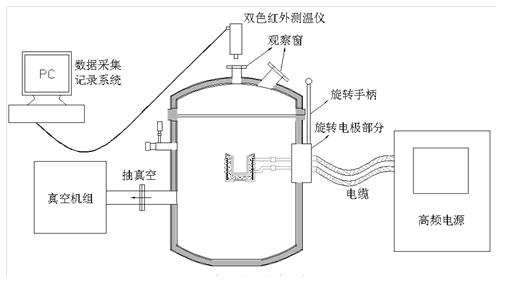

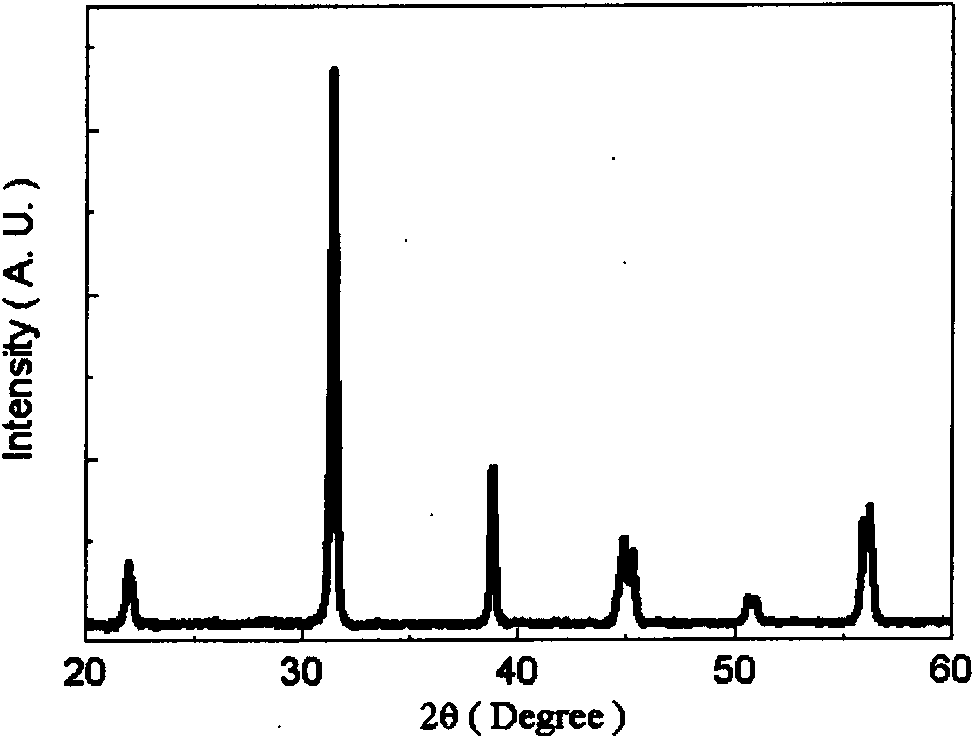

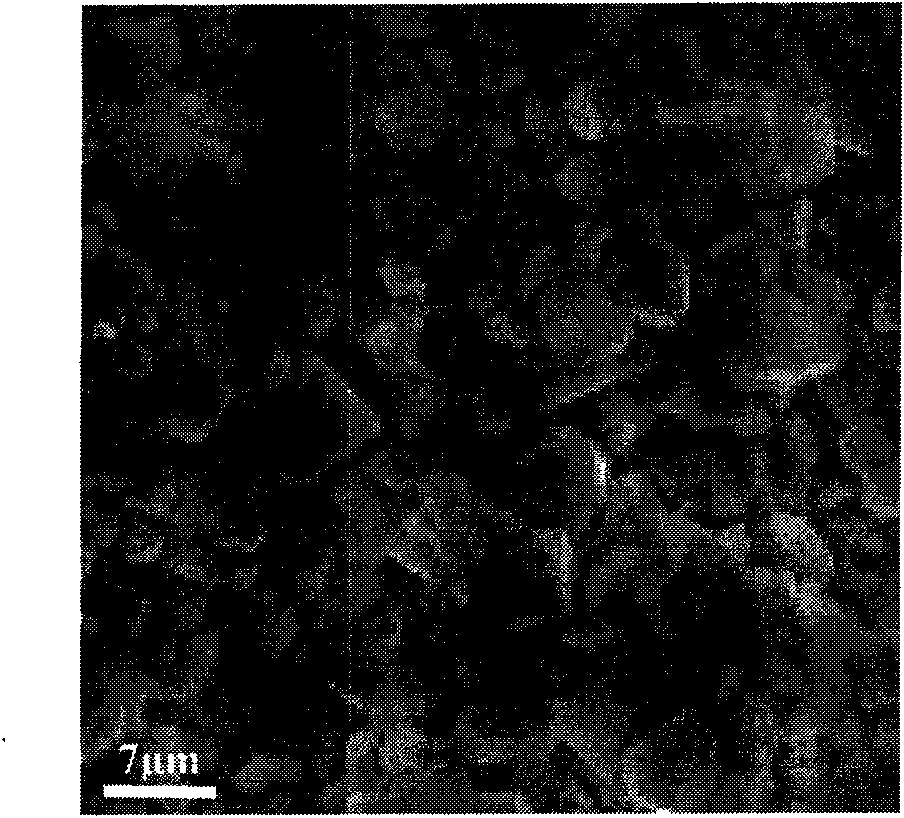

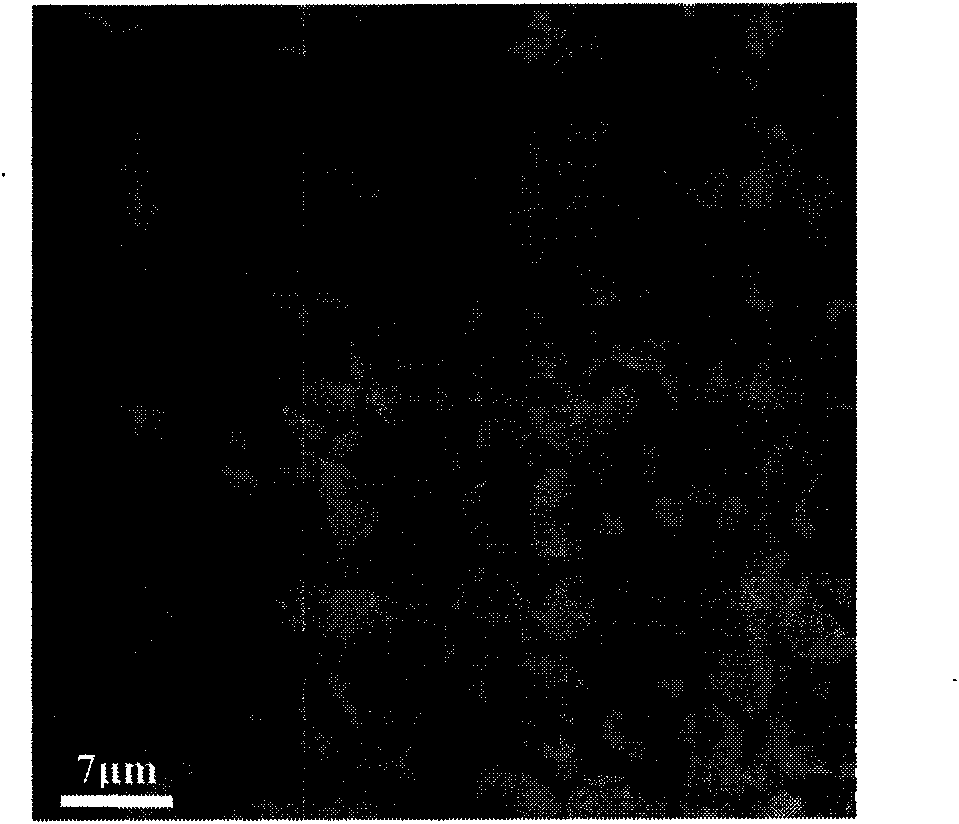

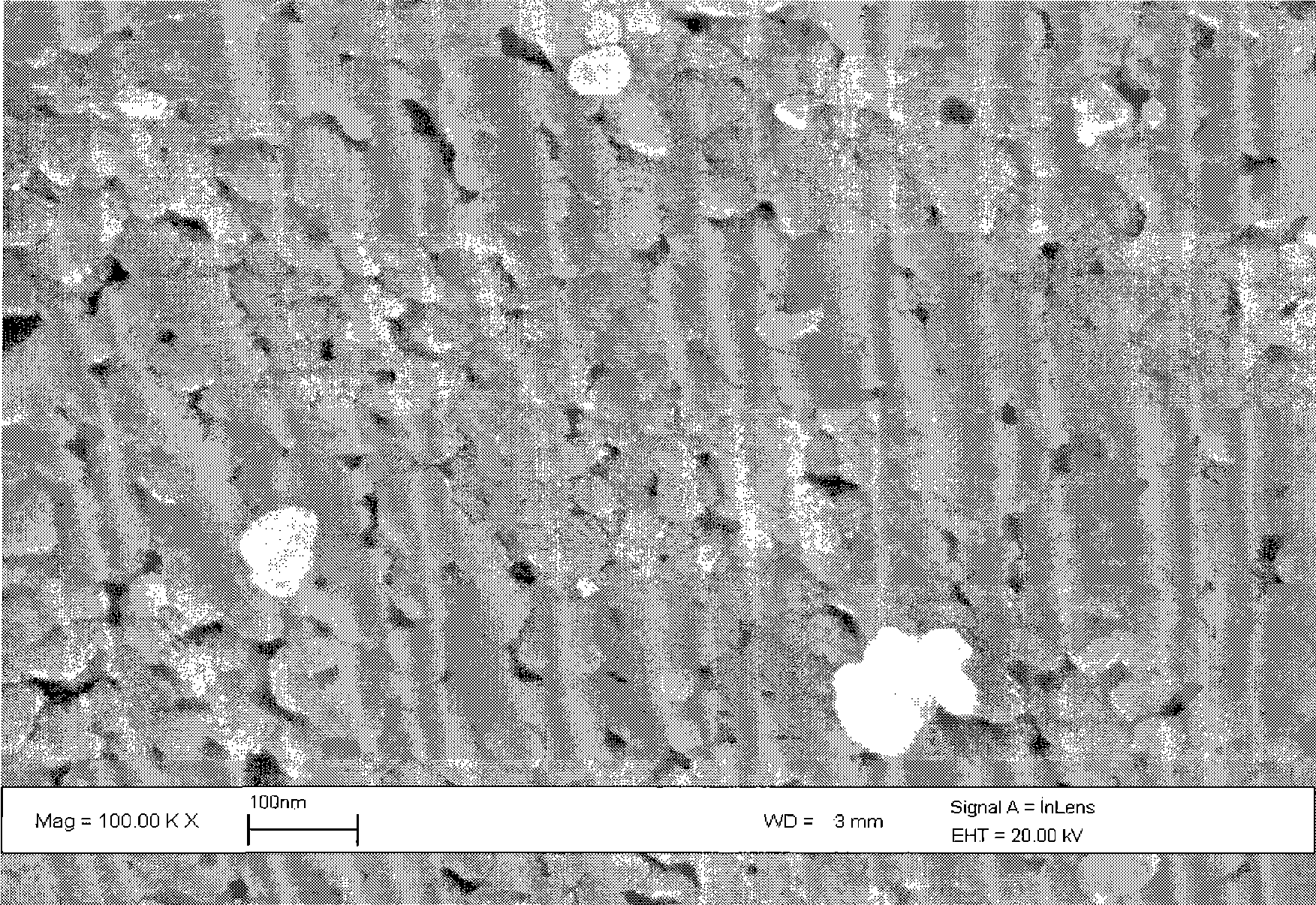

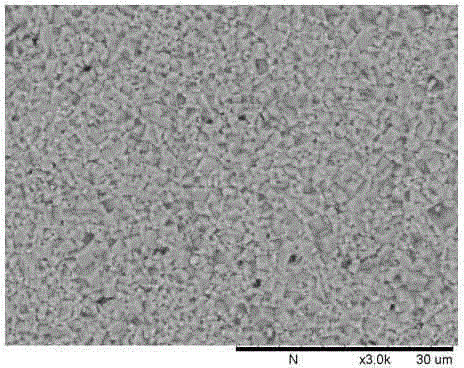

BaZrO3 refractory material for smelting titanium alloy and preparation method of crucibles

The invention discloses a BaZrO3 refractory material of a titanium and titanium alloy smelting crucible and a crucible preparation method. The preparation method comprises the steps of: using BaCO3 and ZrO2 as raw materials, repeatedly sintering the raw materials at 1200-1400 DEG C to synthesize barium zirconate (BaZrO3) crystal powder; adding a proper dosage of additive and adhesive in the barium zirconate material, performing such procedures as pre-treating, forming, pre-sintering and sintering, and the like to prepare a crucible. The BaZrO3 crucible is used as a container for smelting titanium alloy at a temperature of 1650-1750 DEG C in a vacuum environment; the internal and external surfaces of the crucible are intact after the smelting process and no reaction is generated with the titanium alloy, no obvious interface layer exists, and as shown in the detection, no crucible material exists on the external surface of the metal, and the oxygen content in the alloy is low, so that the purity and performance of the titanium alloy are guaranteed.

Owner:SHANGHAI UNIV

Calcium barium zirconate titanate base piezoceramics and preparation method thereof

InactiveCN101648807ALower coercive fieldLow equipment requirementsPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateZirconium dioxide

The invention discloses calcium barium zirconate titanate base piezoceramics and a preparation method thereof. The chemical formula of the calcium barium zirconate titanate base piezoceramics is (1-x-y)BaTiO3-xCaTiO3-yBaZrO3, wherein x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions. The preparation method comprises the following steps: mixing barium carbonate, calcium carbonate, titanium dioxide and zirconium dioxide according to the stoichiometric proportion (1-x-y)BaTiO3-xCaTiO3-yBaZrO3 (x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions), ball-milling, calcining, ball-milling for the second time, granulating, moulding, removing the binder, high-temperature sintering and the like so as to finally prepare the calcium barium zirconate titanate base piezoceramics with high piezoelectric performance. The method greatly enhances the piezoelectric performance of the lead-free piezoceramic system and the technical stability of the material, so that the lead-free piezoceramics in the barium titanate system achieve the practical level in the aspectsof components and technique.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

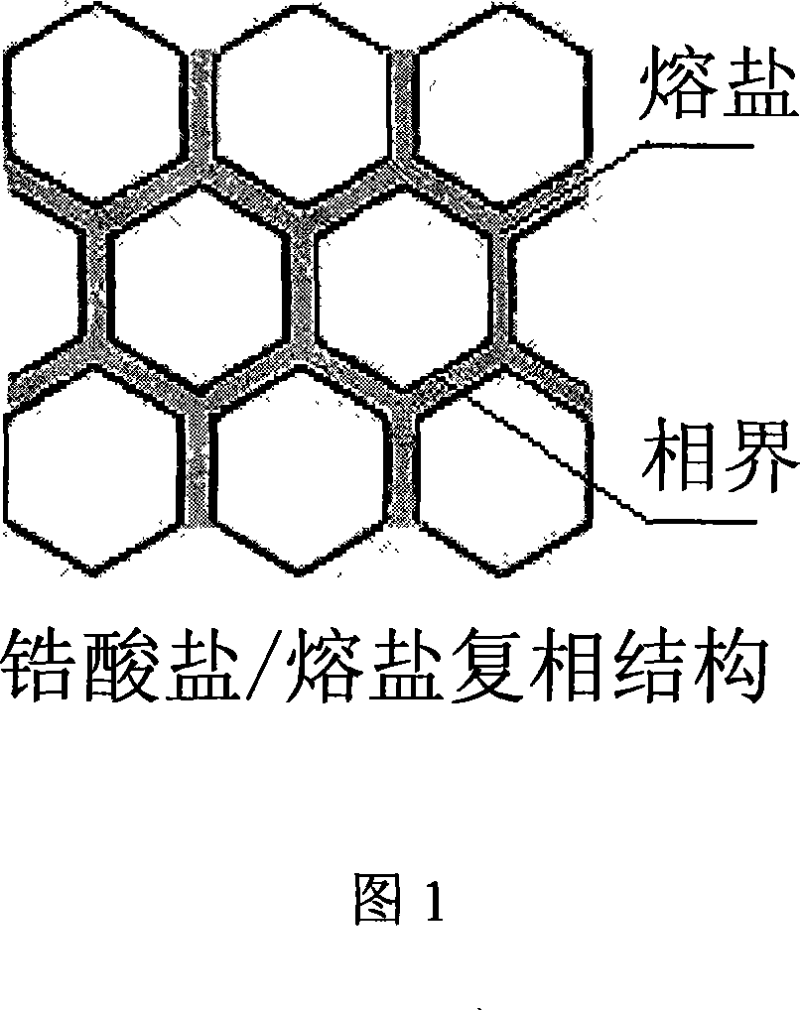

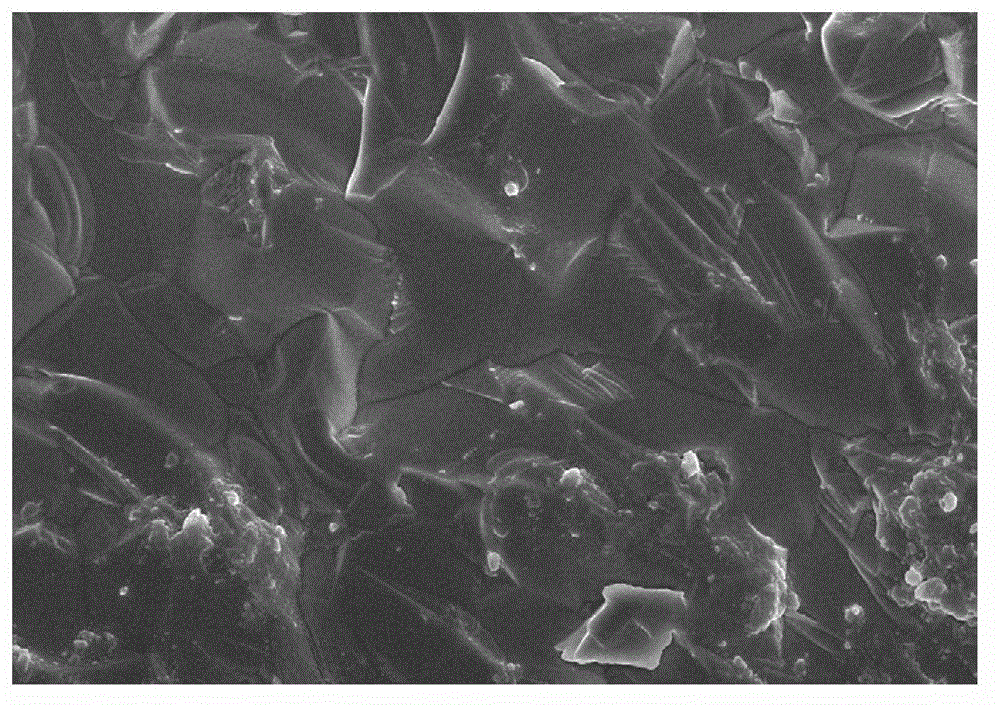

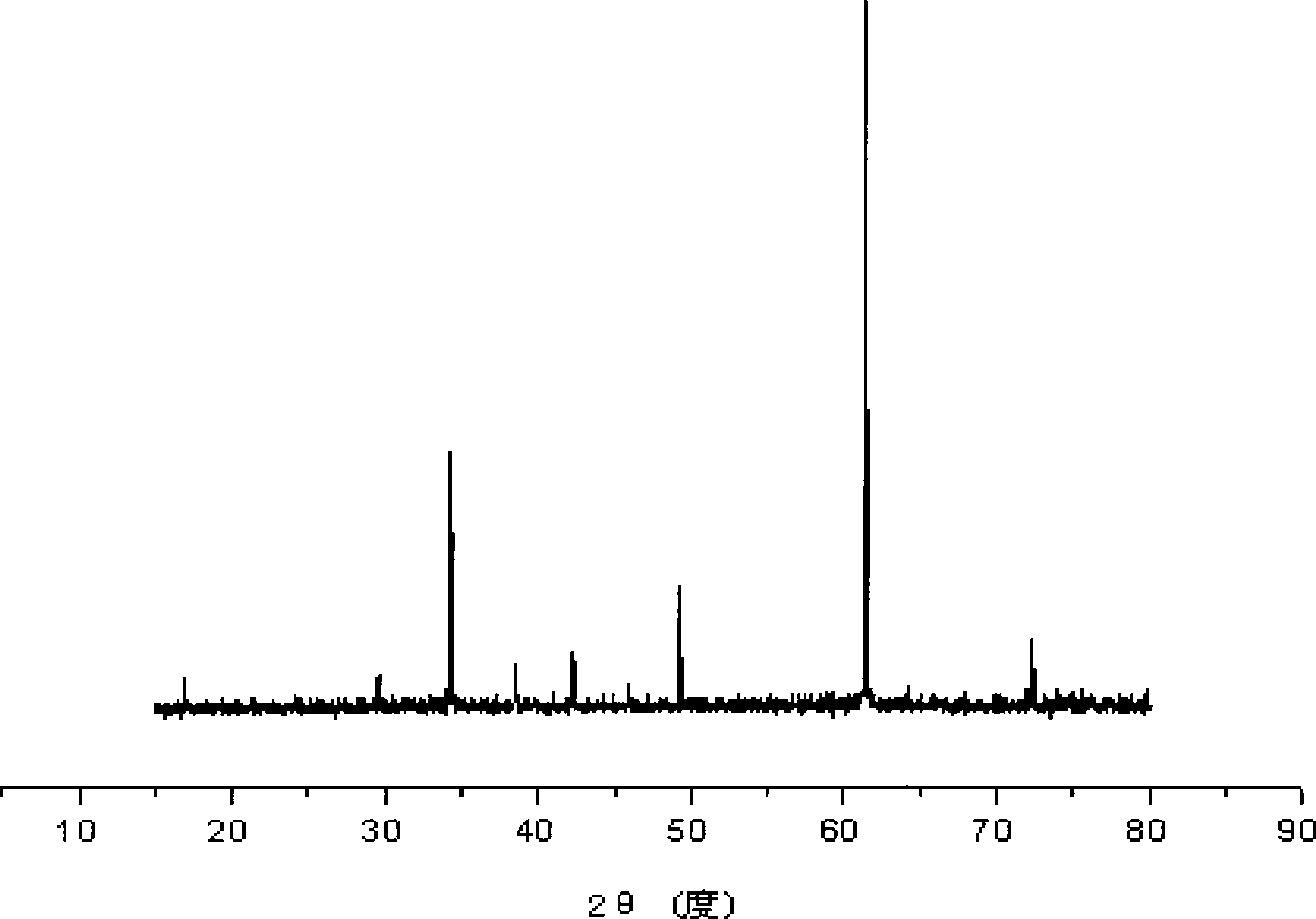

Multi-phase structure designed high-conductive electrical zirconate barium proton conductor and preparation method thereof

InactiveCN101037331AImprove conductivityImprove migration speedConductive materialElectrical conductorConcentration cell

The invention relates to a barium zirconate proton conductor designed by complex phase structure with a high electric conductivity and its manufacturing method. The invention is coating a layer of NaOH or sulfate around the crystal grain of the barium zirconate. The manufacturing method is: taking the BaCO3, ZrO2 and Y2O3 as raw material, water as medium, ball milling mixing for 4-10 hours, calcining for 4-12 hours in 1200-1400 DEG C; then adding 1-10% molar ZnO, ball milling mixing for 4-10 hours, adding 5-50% mol NaOH or K2SO4 or Na2SO4 or Li2SO4 in a way of hand lapping to make the mixture uniform; putting the mixing material into the die and dry pressing molding under a pressure of 50-120 MPa, and then isopressing under 200-350 MPa; sintering in the air of 1200-1500 DEG C with a heating rate of 2-10 DEG C / minute and keeping warm for 2-10 hours, then cooling to the room temperature to produce the barium zirconate proton conductor material with a high electric conductivity. The invention adopts the new designing thought of complex phase structure to establish a foundation for exploiting hydrogen gas and vapor sensor, hydrogen pump and concentration cell electrolyte material.

Owner:TIANJIN UNIV

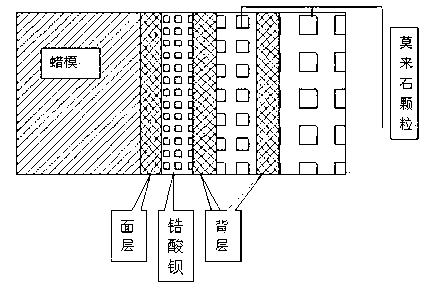

Shell for titanium and titanium alloy precision casting and preparation method thereof

The invention discloses a shell for titanium and titanium alloy precision casting and a preparation method thereof, and belongs to the technical field of the alloy precision casting. Through taking barium zirconate as packing, and taking zirconium acetate or yttrium sol which does not react with titanium as a binder, the shell disclosed by the invention is prepared through the steps of: pre-treating, molding, hardening, sintering, and the like. The extent of the reaction between the shell and the titanium as well as titanium alloys is small, and the thickness of a sticky dirty layer formed on the surface of a casting piece is small; the barium zirconate ceramic shell is high in strength, and the roughness of the surface of the casting piece is high; and in addition, a barium zirconate containing coating is stable and uneasy to gelatinize, good in suspension property, and long in retention time.

Owner:SHANGHAI UNIV +1

Barium zirconate titanate-potassium sodium niobate piezoelectric ceramics and preparation method thereof

The invention discloses barium zirconate titanate-potassium sodium niobate piezoelectric ceramics and a preparation method thereof. The general formula of the chemical composition of the barium zirconate titanate-potassium sodium niobate piezoelectric ceramics is (1-x-y) BaTiO3-xCaTiO3-yBaZrO3, wherein the x is more than 0 and less than 0.5, the y is more than 0 and less than 0.5, and the x and the y are both mole fractions. The preparation method comprises the following steps: dosing barium carbonate, calcium carbonate, titanium dioxide and zirconium dioxide by the stoichiometric ratio of the (1-x-y) BaTiO3-xCaTiO3-yBaZrO3, and then carrying out the procedures of ball milling, calcination, secondary ball milling, pelleting, moulding, glue discharging, high-temperature sintering and the like to finally prepare the calcium barium zirconate titanate piezoelectric ceramics with high piezoelectric performance. The method in the invention greatly improves the piezoelectric performance of lead-free piezoelectric ceramic systems and the process stability of materials and makes the lead-free piezoelectric ceramics of the barium titanate system achieve the practical level at two aspects of the components and the process.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Insulation material, film, circuit board and method of producing them

ActiveUS7700185B2Increase volumeHigh dielectric constantPlastic/resin/waxes insulatorsFixed capacitor dielectricStrontium titanium oxideBarium titanate

There is provided an insulation material having a dielectric constant of 10 or more, comprising a filler having a dielectric constant of 50 or more and having two peaks in different particle size ranges in a particle size distribution and an insulating resin combined with each other; an insulation material having a dielectric constant of 10 or more comprising, as essential components, 1) at least one filler selected from the group consisting of barium titanate, strontium titanate, potassium titanate, magnesium titanate, lead titanate, titanium dioxide, barium zirconate, calcium zirconate and lead zirconate, 2) an insulating resin and 3) a dispersant containing a carboxylic group; or an insulation material comprising a filler having a dielectric constant of 50 or more, a dispersant for dispersing the filler and an insulating resin as essential components, wherein an extract of a cured product of the insulation material obtained by extraction with water at 120° C. for 20 hours using a pressure vessel has a pH of 6 or higher.

Owner:RESONAC CORPORATION

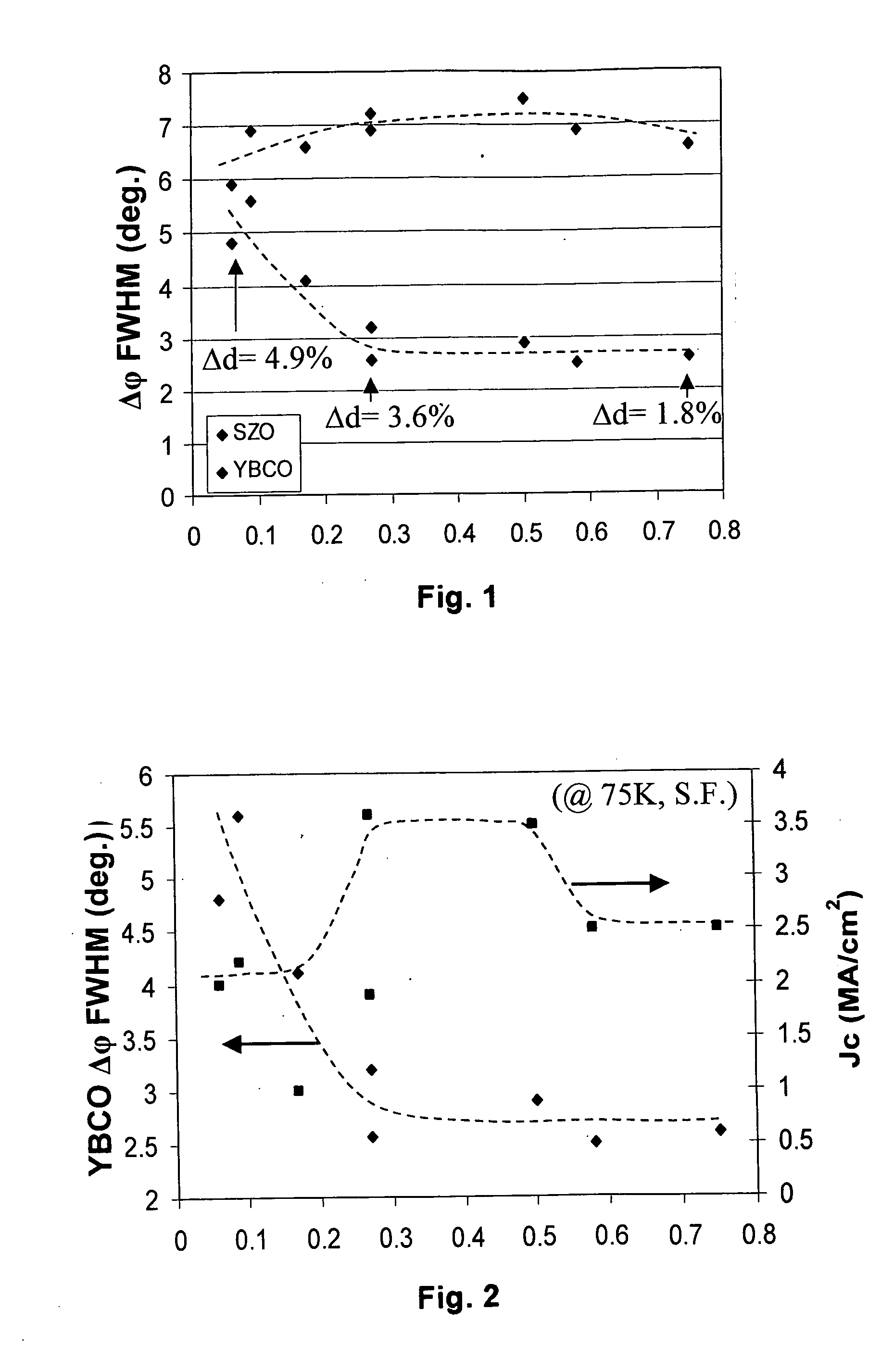

Coated conductors

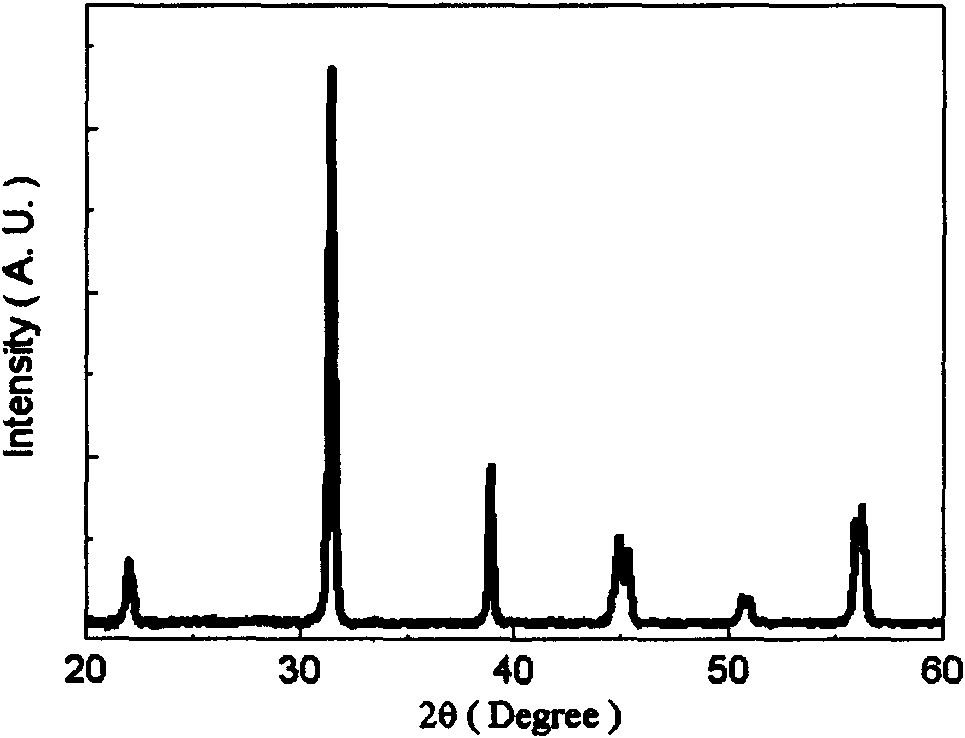

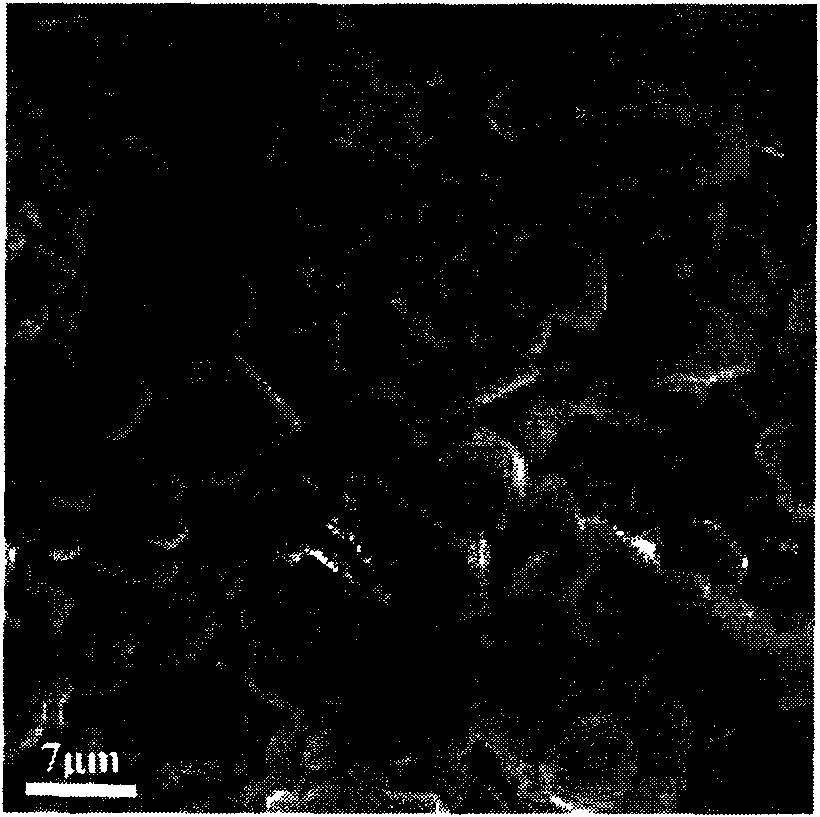

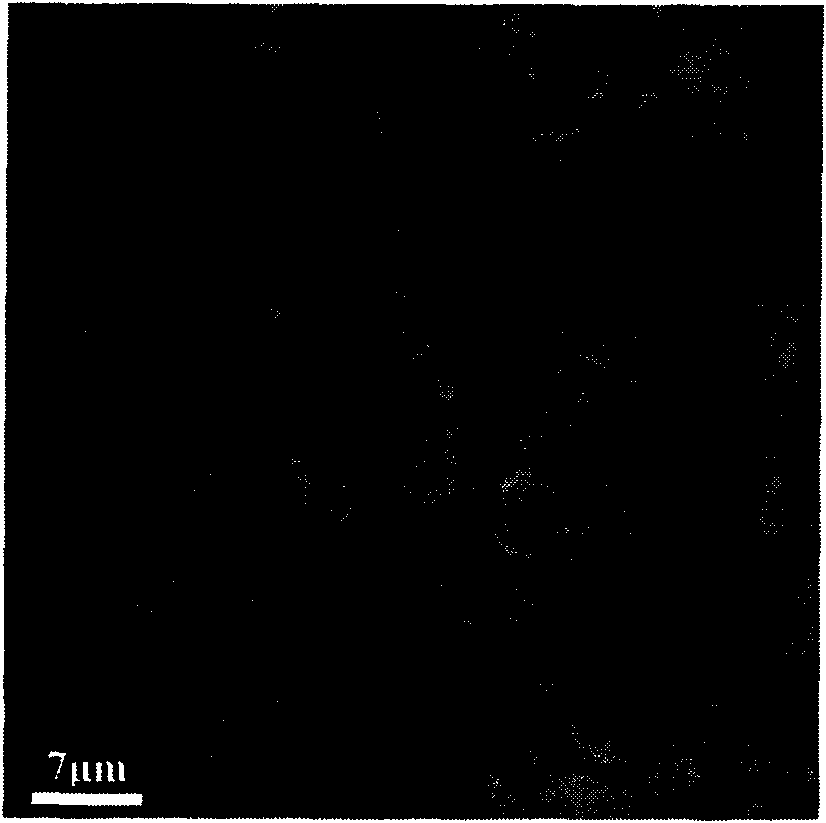

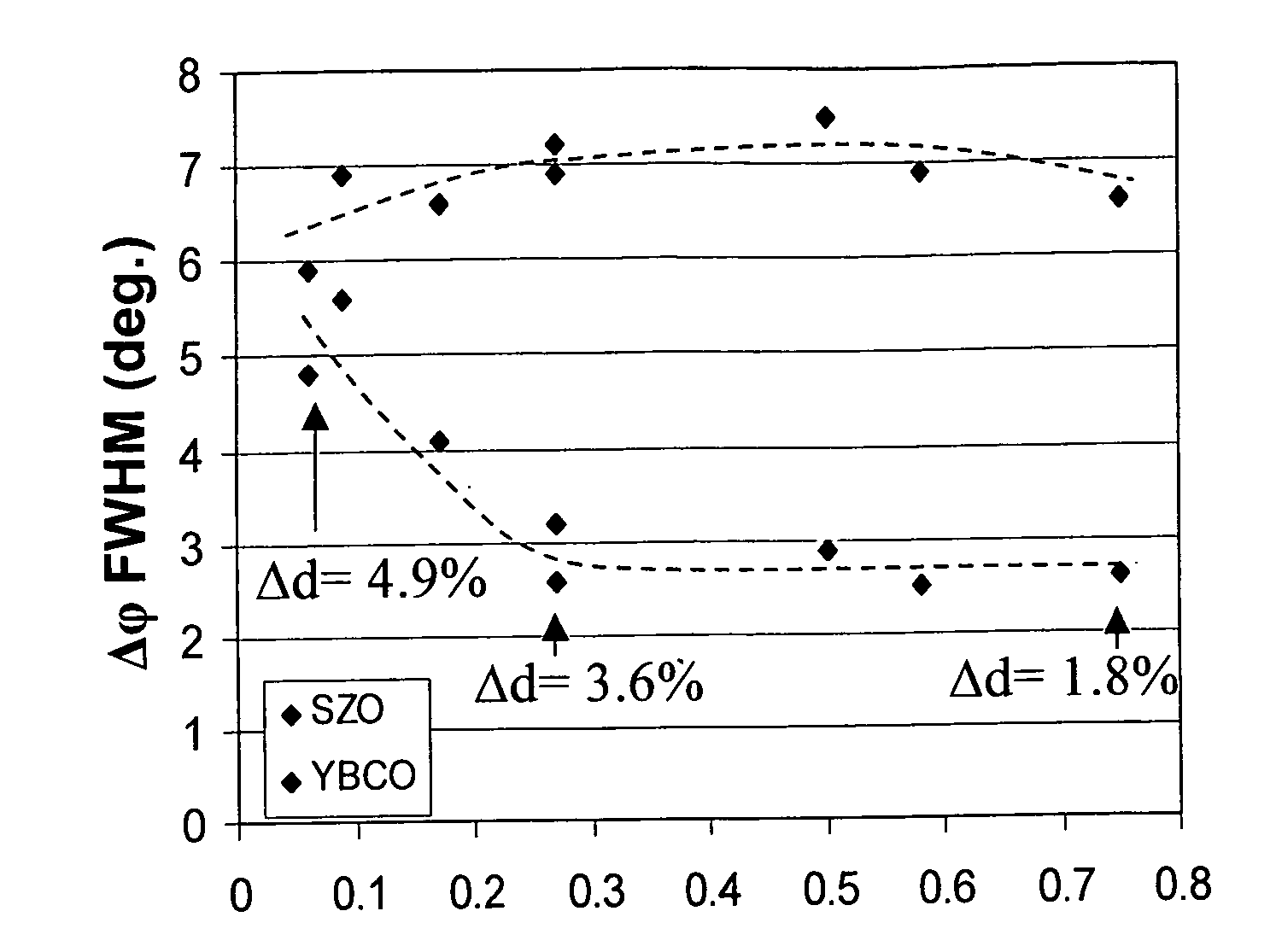

ActiveUS20070012975A1Semiconductor/solid-state device manufacturingSuperconductor devicesBarium strontium titanateElectrical conductor

Articles are provided including a base substrate having a layer of an IBAD oriented material thereon, and, a layer of barium-containing material selected from the group consisting of barium zirconate, barium hafnate, barium titanate, barium strontium titanate, barium dysprosium zirconate, barium neodymium zirconate and barium samarium zirconate, or a cubic metal oxide material selected from the group consisting of rare earth zirconates and rare earth hafnates upon the layer of an IBAD oriented material. Such articles can further include thin films of high temperature superconductive oxides such as YBCO upon the layer of barium-containing material selected from the group consisting of barium zirconate, barium hafnate, barium titanate, barium strontium titanate, barium dysprosium zirconate, barium neodymium zirconate and barium samarium zirconate, or a cubic metal oxide material selected from the group consisting of rare earth zirconates and rare earth hafnates.

Owner:TRIAD NAT SECURITY LLC

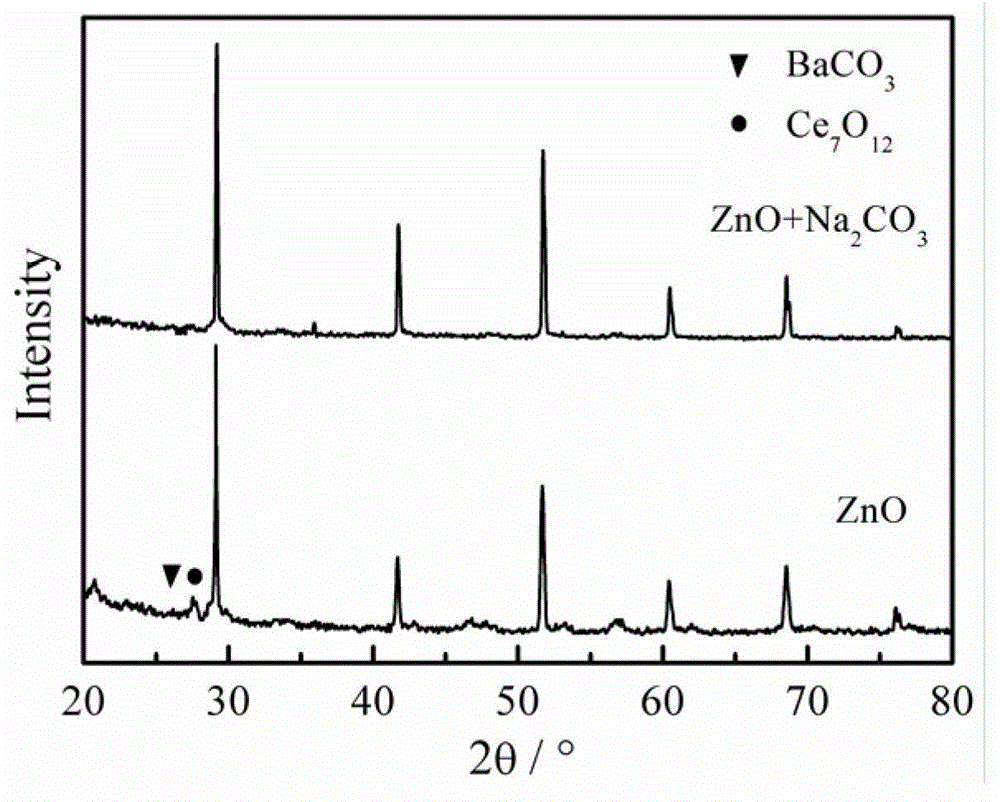

Zinc oxide-carbonate co-doped cerium barium zirconate proton conductor material and preparation method thereof

InactiveCN102942364AGood chemical stabilityImprove conductivityFinal product manufactureSolid electrolyte fuel cellsSupporting electrolyteElectrical conductor

The invention relates to a zinc oxide-carbonate co-doped cerium barium zirconate proton conductor material and a preparation method thereof, belonging to the field of solid oxide fuel cells. The method disclosed herein comprises the following steps: firstly synthesizing yttrium oxide-doped cerium barium zirconate proton conductor powder by solid phase method, then mixing with zinc oxide and carbonate or composite carbonate, conducting dry pressing and isostatic compaction, then conducting high temperature burying sintering to obtain the zinc oxide-carbonate co-doped cerium barium zirconate proton conductor material. An anode-supported electrolyte part is prepared by lamination co-press technology, then a Ba0.5Sr0.5Co0.8Fe0.2O2.9 cathode slurry is coated on one side of the electrolyte, and an anode-supported unit cell is assembled to test. According to the invention, the invention provides a preparation method of a medium and low temperature solid oxide fuel cell electrolyte material, has the characteristics of low cost of raw materials and preparation and simple process, on the premise that the conductivity of the material is guaranteed at medium and low temperature, the material has good chemical stability, the unit cell has good output performance, and the method lays a foundation for developing solid oxide fuel cells.

Owner:TIANJIN UNIV

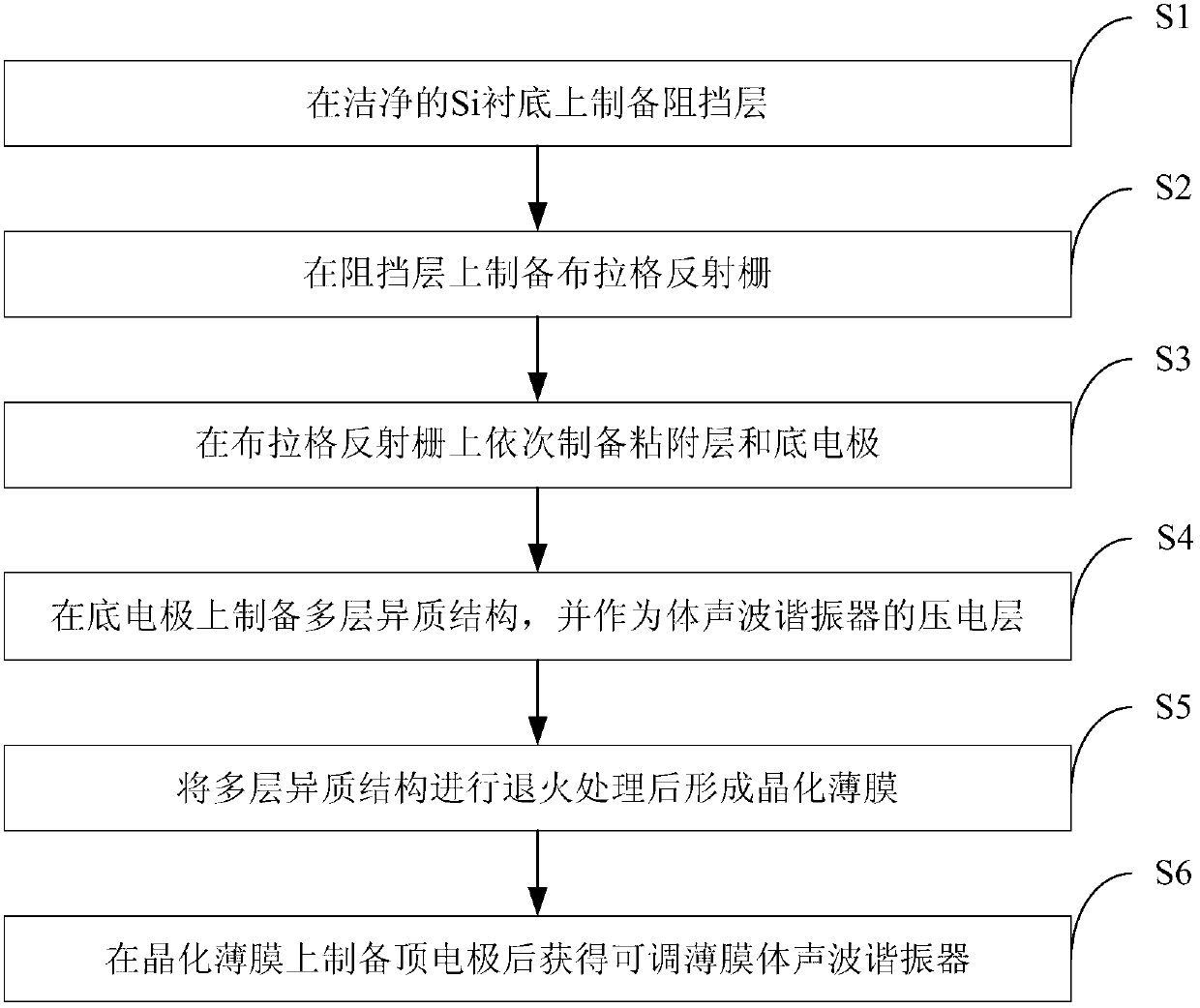

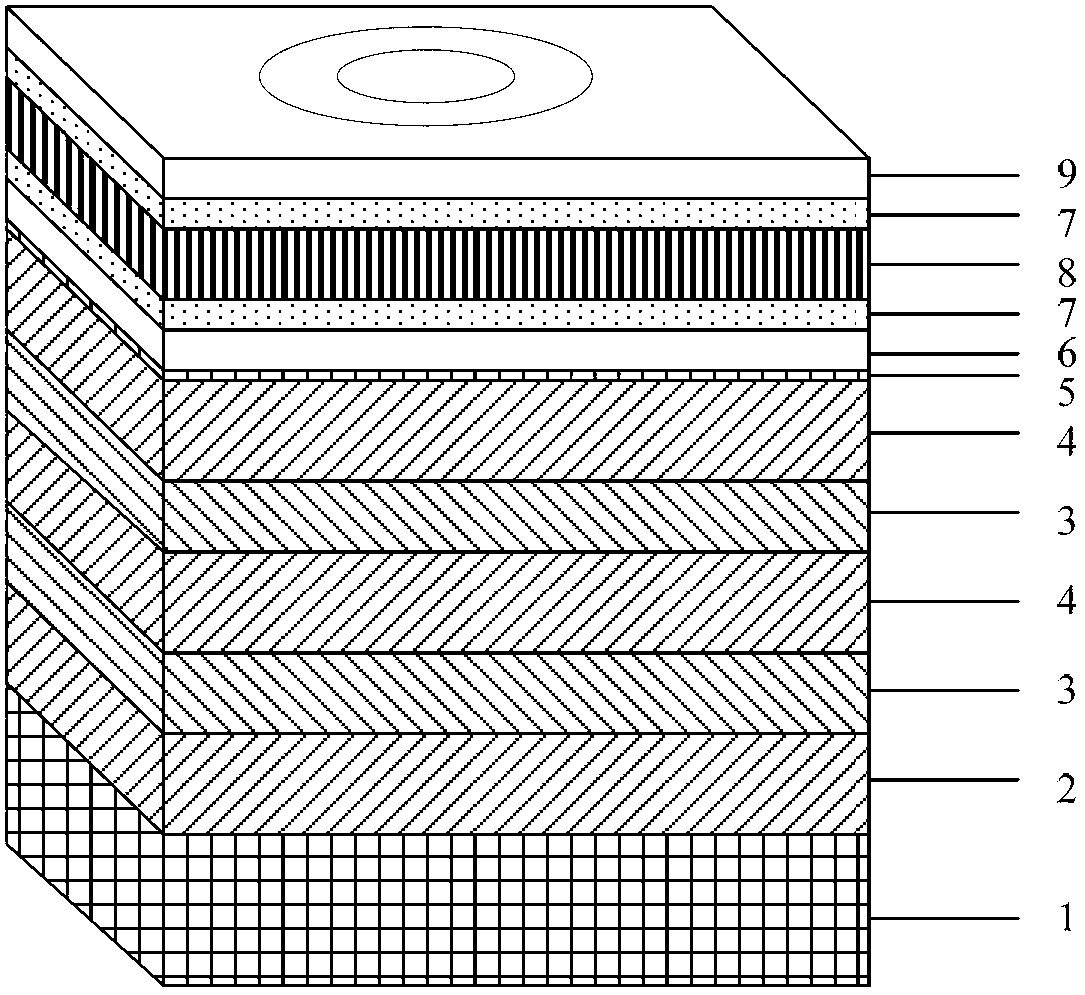

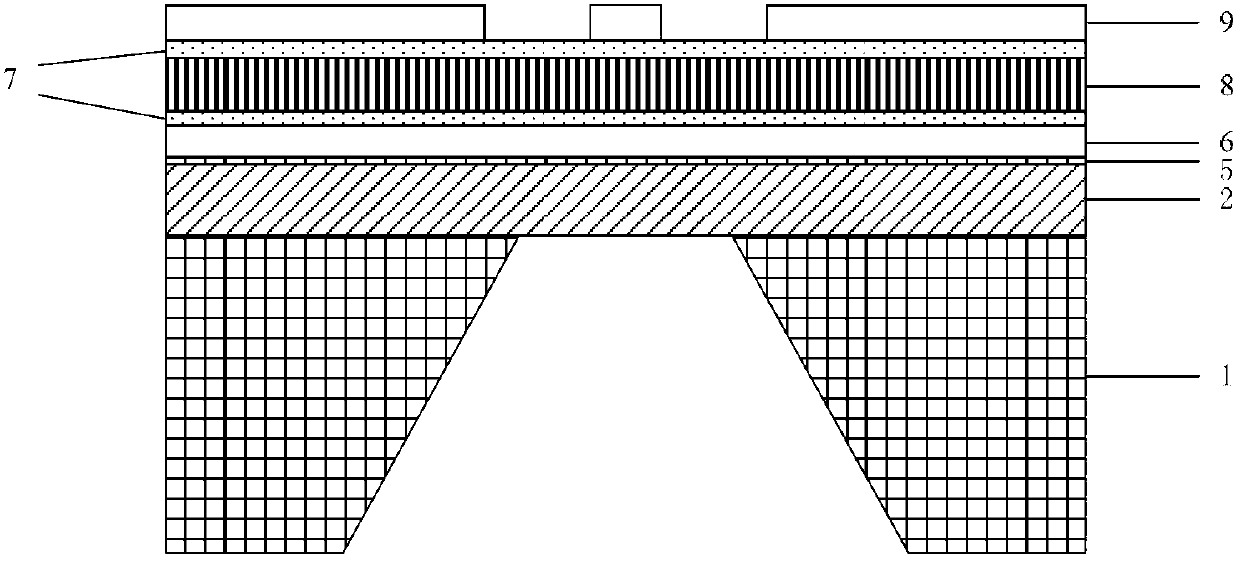

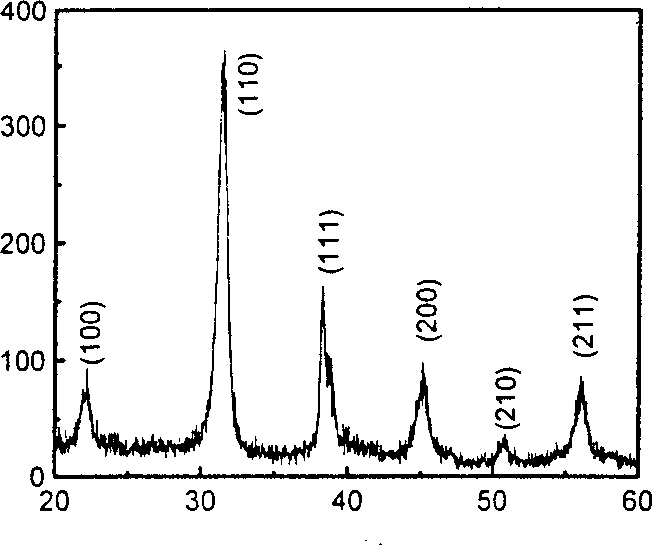

Adjustable film bulk acoustic wave resonator and preparation method thereof

ActiveCN102946236AImprove leakage currentLow dielectric lossImpedence networksThin-film bulk acoustic resonatorGrating

The invention discloses an adjustable film bulk acoustic wave resonator and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a blocking layer on a clean Si substrate; S2, preparing a Bragg reflecting grating on the blocking layer, wherein the Bragg reflecting grating consists of different acoustic wave impedance films; S3, preparing an adhesion layer and a bottom electrode on the Bragg reflecting grating sequentially; S4, preparing a multi-layer heterogeneous structure on the bottom electrode to serve as a piezoelectric layer of the bulk acoustic wave resonator, wherein the multi-layer heterogeneous structure consists of a barium strontium titanate (BST) film, a barium zirconate titanate (BZT) film or a bismuth zinc niobate (BZN) film; S5, annealing the multi-layer heterogeneous structure to form a crystallized film; and S6, preparing a top electrode on the crystallized film to obtain the adjustable film bulk acoustic wave resonator. The multi-layer heterogeneous structure serves as the piezoelectric layer, so that the bulk acoustic wave resonator has relatively low dielectric loss and leak current, relatively moderate dielectric constant, relatively high adjustability and large optimum value at room temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

Insulation material, film, circuit board and method of producing them

ActiveUS20070060672A1Increase volumeEasy to operatePlastic/resin/waxes insulatorsFixed capacitor dielectricStrontium titanateBarium titanate

There is provided an insulation material having a dielectric constant of 10 or more, comprising a filler having a dielectric constant of 50 or more and having two peaks in different particle size ranges in a particle size distribution and an insulating resin combined with each other; an insulation material having a dielectric constant of 10 or more comprising, as essential components, 1) at least one filler selected from the group consisting of barium titanate, strontium titanate, potassium titanate, magnesium titanate, lead titanate, titanium dioxide, barium zirconate, calcium zirconate and lead zirconate, 2) an insulating resin and 3) a dispersant containing a carboxylic group; or an insulation material comprising a filler having a dielectric constant of 50 or more, a dispersant for dispersing the filler and an insulating resin as essential components, wherein an extract of a cured product of the insulation material obtained by extraction with water at 120° C. for 20 hours using a pressure vessel has a pH of 6 or higher.

Owner:RESONAC CORP

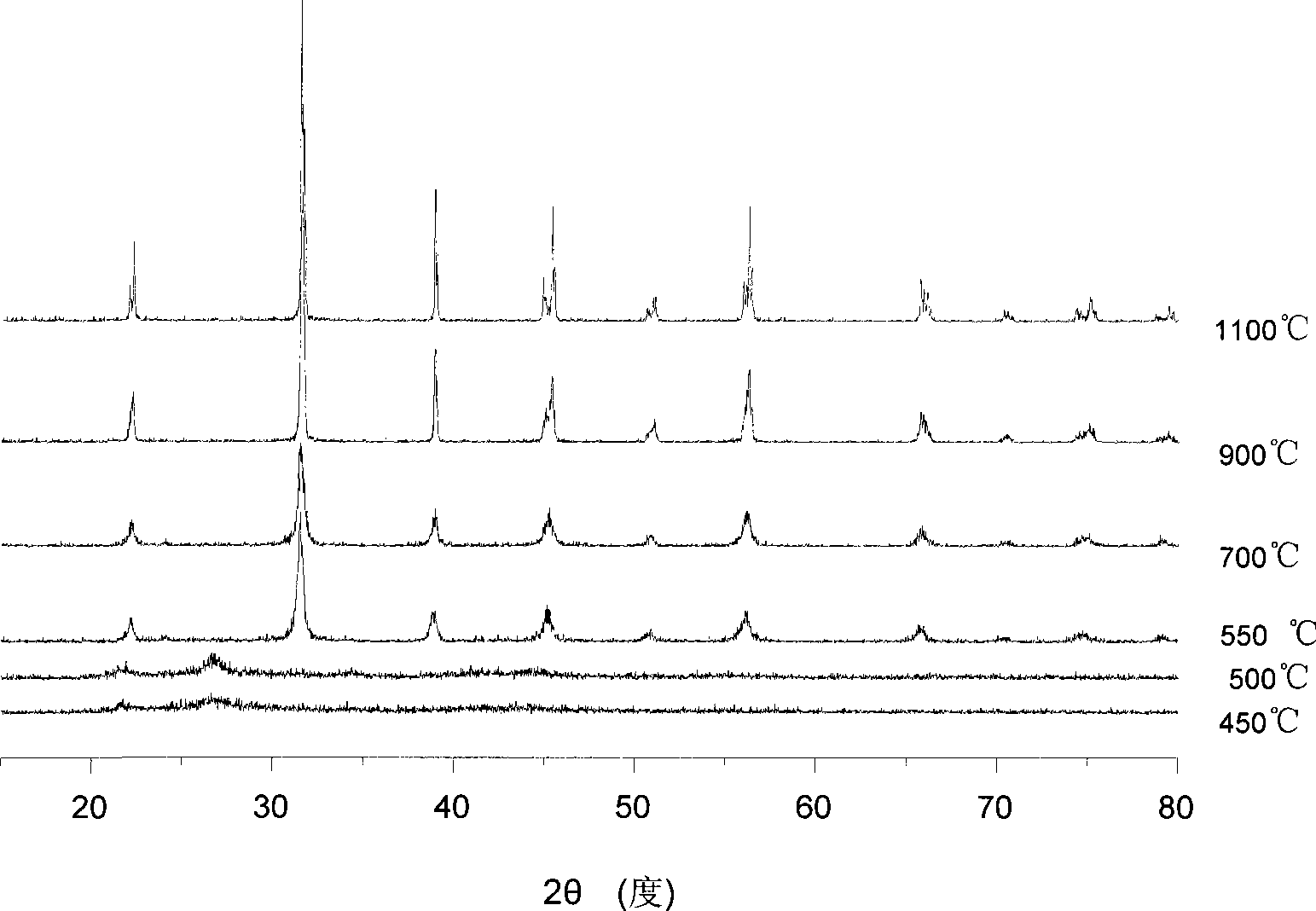

Wet chemical prepn process of leadless functional barium titanate ceramic film

InactiveCN1350071AGood dielectricExcellent ferroelectricPiezoelectric/electrostrictive device manufacture/assemblyLiquid/solution decomposition chemical coatingBarium titanateSolvent

The method for preparing barium zirconate titanate (BZT) film belongs to the field of functional ceramic film. Its precursor liquor for preparing BZT is made up by using barium acetate, zirconium propylate and butyl titanate as raw material, using glycol methyl ether as solvent and using acetylacetone and glacial acetic acid as stabilizing agent according to the gran molecular concentration mixing ratio of Ba:Zr:Ti=I:X:1-X (X is greater than or equal to O and is less than or equal to 1), and its concentration is 0.2-0.3M. The above-mentioned precursor is undergone the process of filting, film-forming, whirl coating (its speed is 3000-4000 rpm and time is 30 sec.), pretreating, multiple film-forming, pretreating and film-forming to reach to required thickness, and annealing at 650-750 deg.c so as to obtain the invented product. The lead-free BZT functional film prepared by said ivnention possesses good dielectric feeraelectric and piezoelectric properties.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Piezoelectric element, piezoelectric actuator, and electronic apparatus

Provided is a piezoelectric element containing no lead therein and having a satisfactory piezoelectric constant and a small dielectric loss tangent at room temperature (25° C.) In order to attain this, the piezoelectric element includes a substrate, a first electrode, a piezoelectric film, and a second electrode. The piezoelectric film contains barium zirconate titanate, manganese, and trivalent bismuth. The piezoelectric film satisfies 0.02≦x≦0.13, where x is a mole ratio of zirconium to the sum of zirconium and titanium. A manganese content is 0.002 moles or more and 0.015 moles or less for 1 mole of barium zirconate titanate, and a bismuth content is 0.00042 moles or more and 0.00850 moles or less for 1 mole of barium zirconate titanate.

Owner:CANON KK

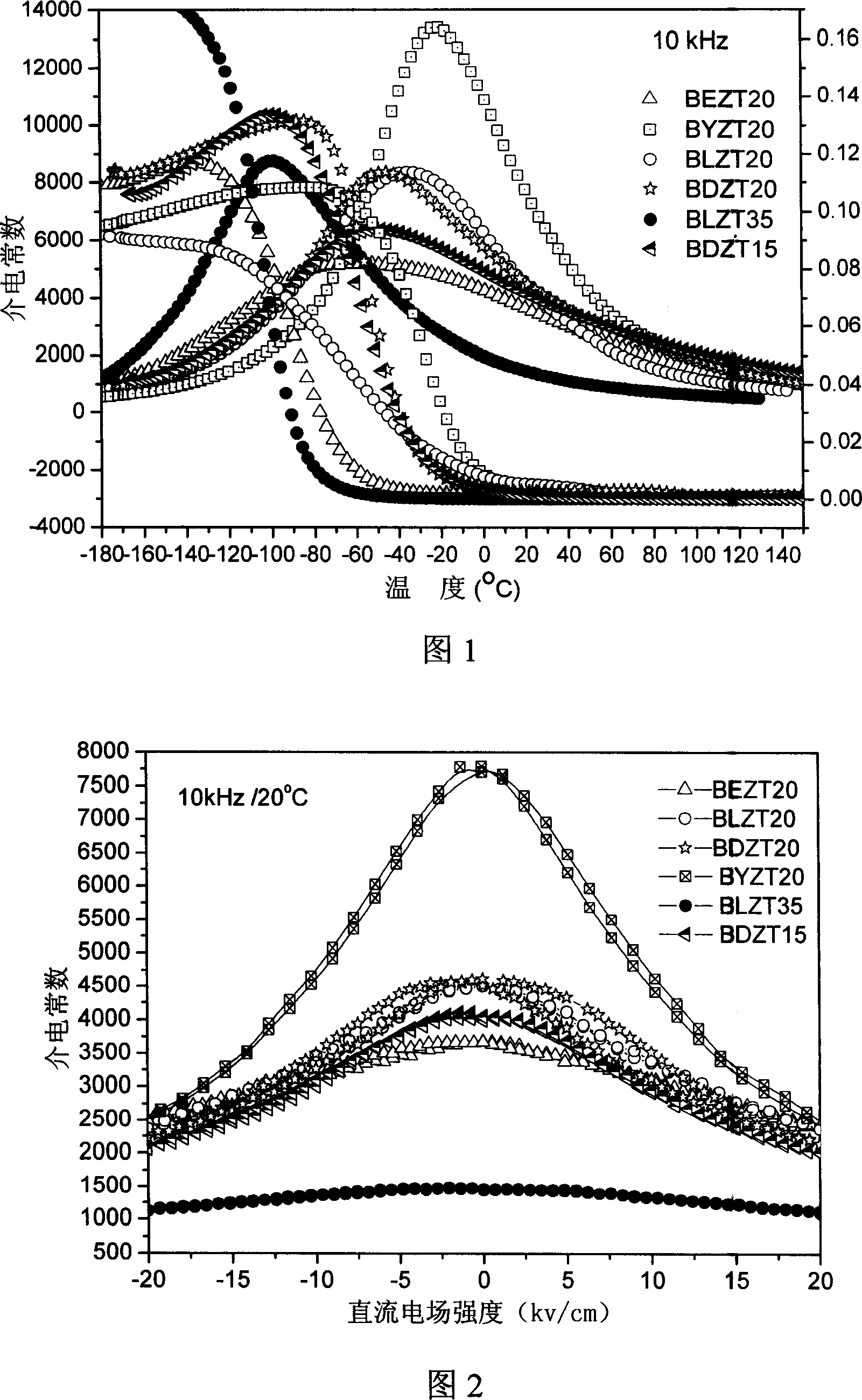

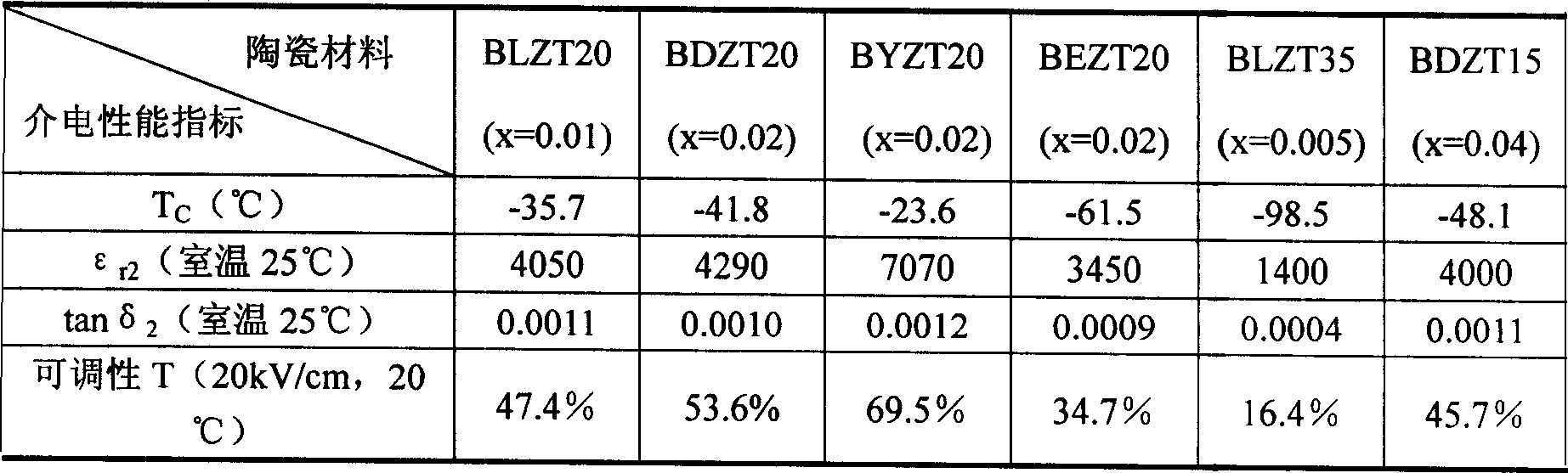

Rare earth oxide doped and modified barium zirconate titanate dielectric adjustable ceramic material and its preparation method

InactiveCN101007737ALow dielectric lossHigh dielectric tunabilityPiezoelectric/electrostrictive/magnetostrictive devicesRare-earth elementCapacitor

The invention discloses an electric adjustable ceramic material of barium zirconate titanate of doped modified rare earth oxide as well as making method, whose molecular formula is Ba1-xMx (Ti1-y-0.25xZry) O3, wherein N is rare earth element; x is between 0.001 and 0.05; y is 0.1-0.5.

Owner:TONGJI UNIV

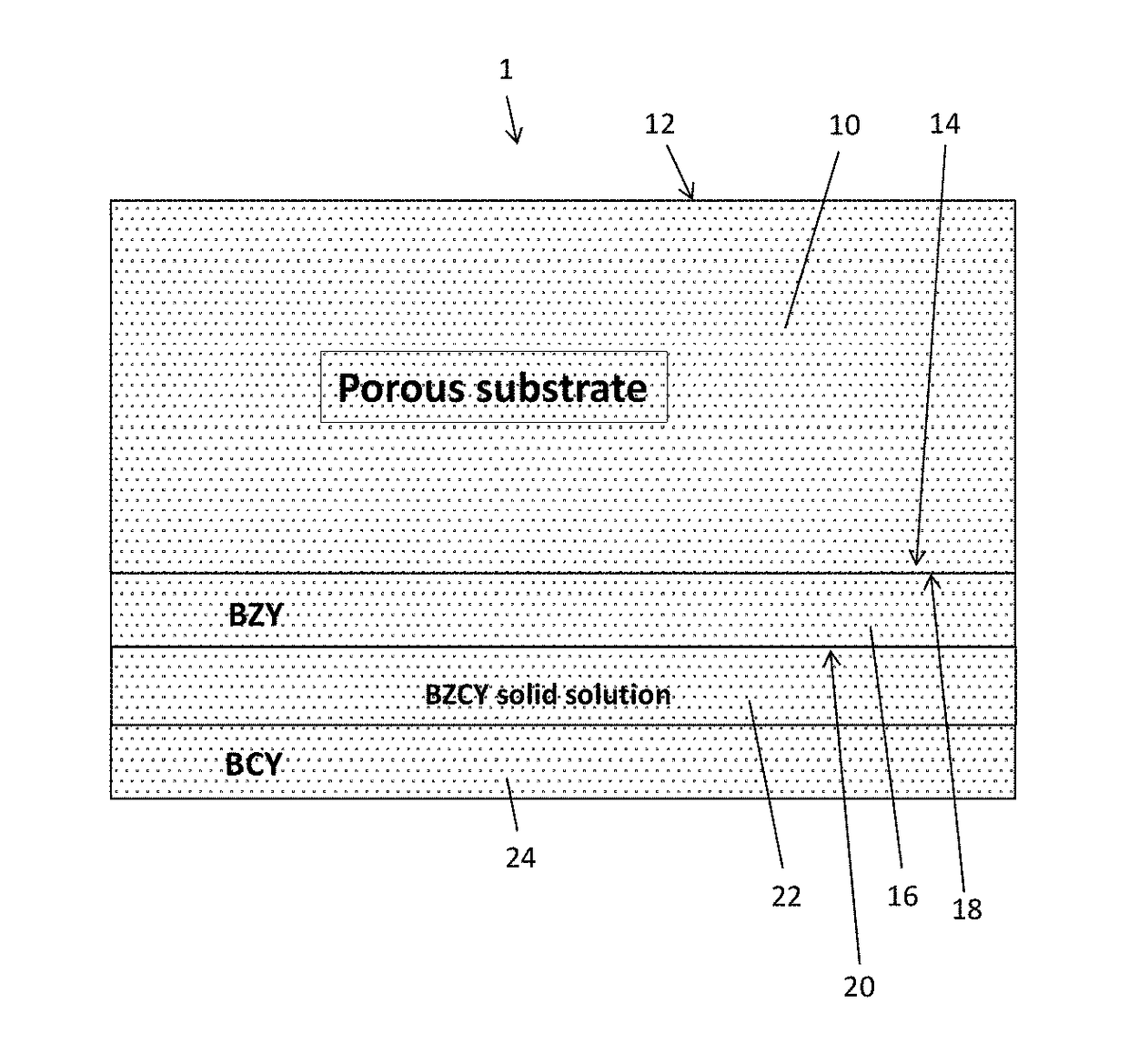

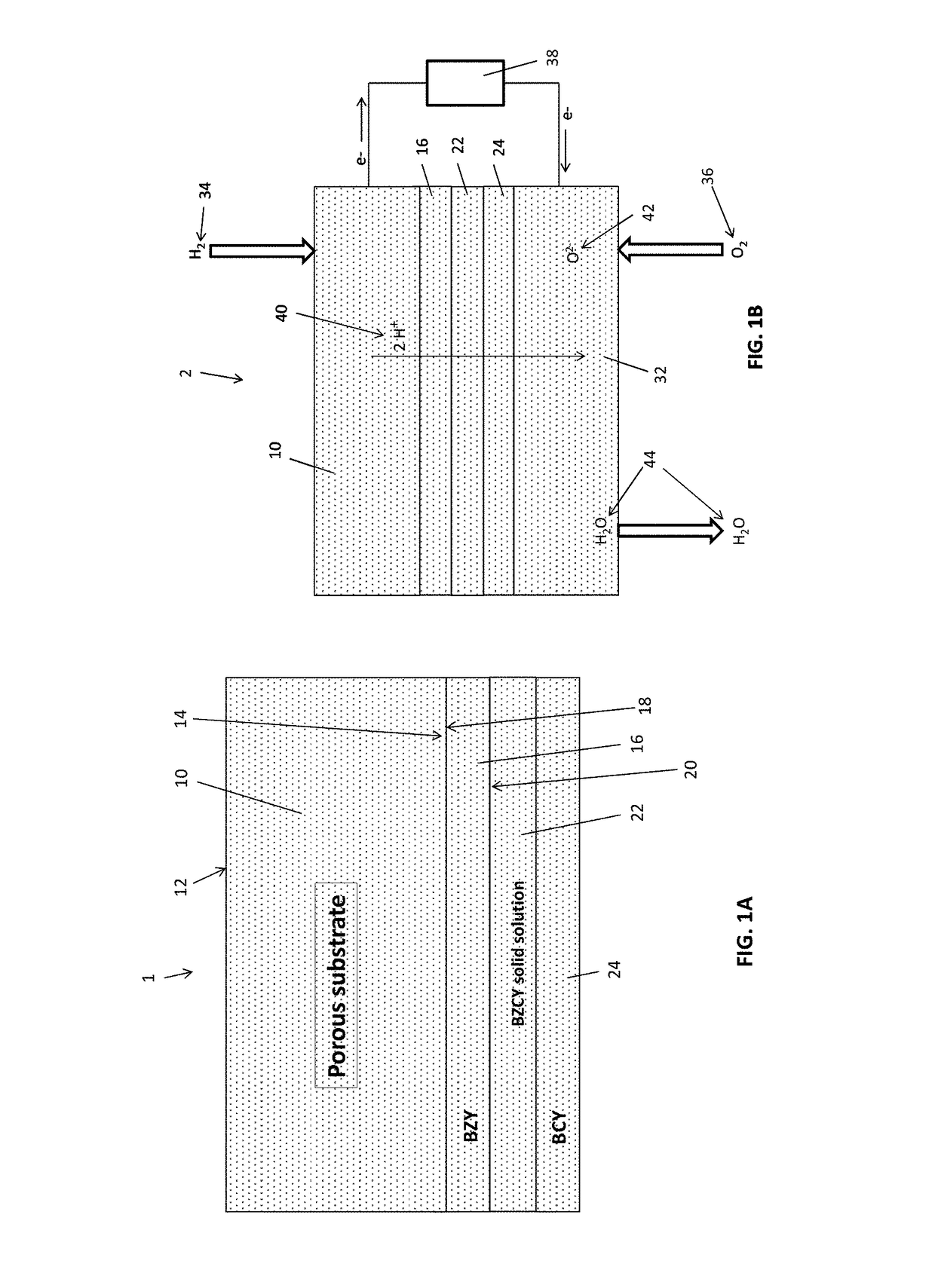

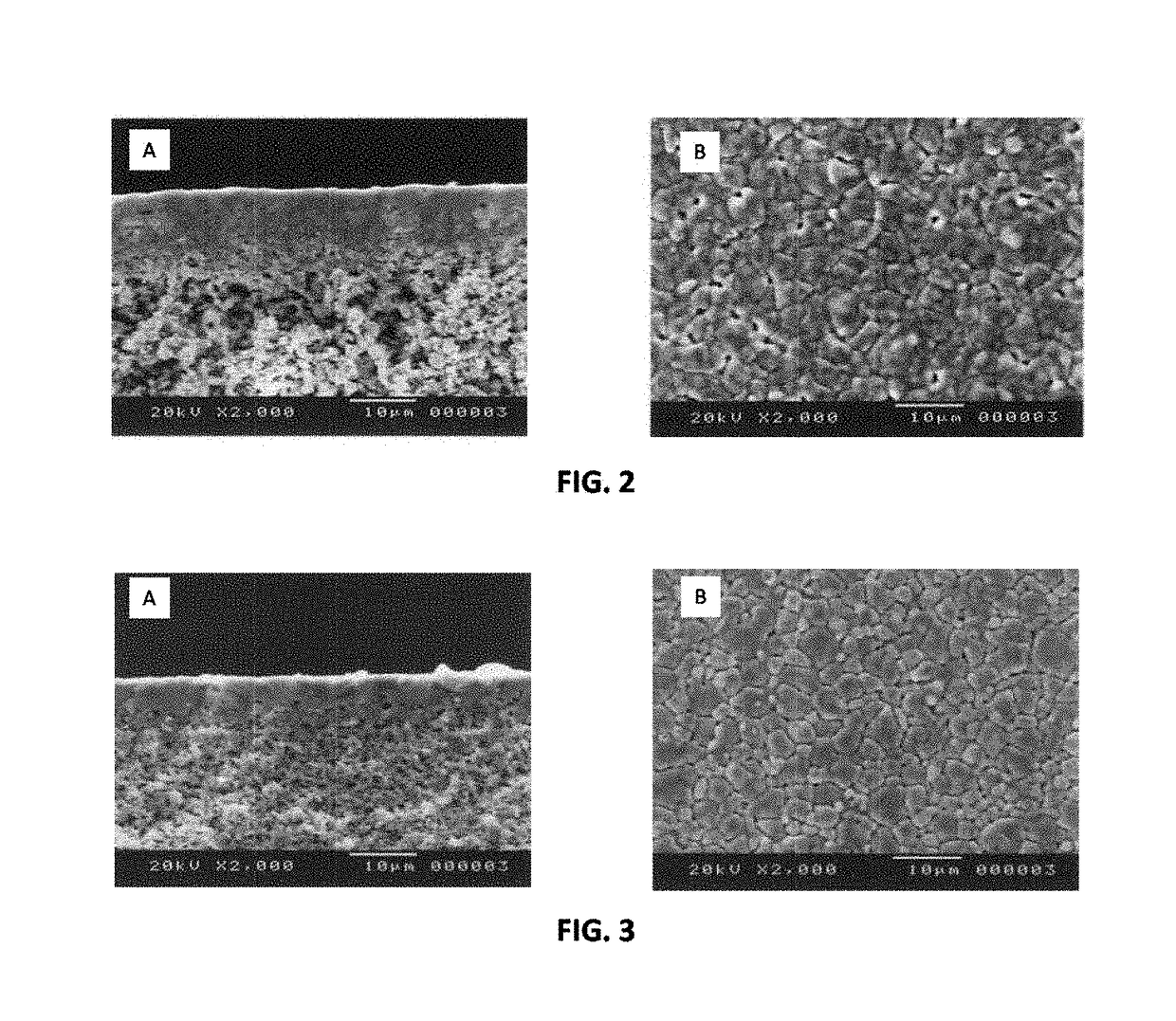

Multi-layered proton-conducting electrolyte

ActiveUS9692075B1Improve proton conductivityGood chemical stabilityCell electrodesFinal product manufactureLanthanideYttrium

The present invention provides a multilayer anode / electrolyte assembly comprising a porous anode substrate and a layered solid electrolyte in contact therewith. The layered solid electrolyte includes a first dense layer of yttrium-doped barium zirconate (BZY), optionally including another metal besides Y, Ba, and Zr (e.g., a lanthanide metal such as Pr) on one surface thereof, a second dense layer of yttrium-doped barium cerate (BCY), and an interfacial layer between and contacting the BZY and BCY layers. The interfacial layer comprises a solid solution of the BZY and BCY electrolytes. The porous anode substrate comprises at least one porous ceramic material that is stable to carbon dioxide and water (e.g., porous BZY), as well as an electrically conductive metal and / or metal oxide (e.g., Ni, NiO, and the like).

Owner:UCHICAGO ARGONNE LLC

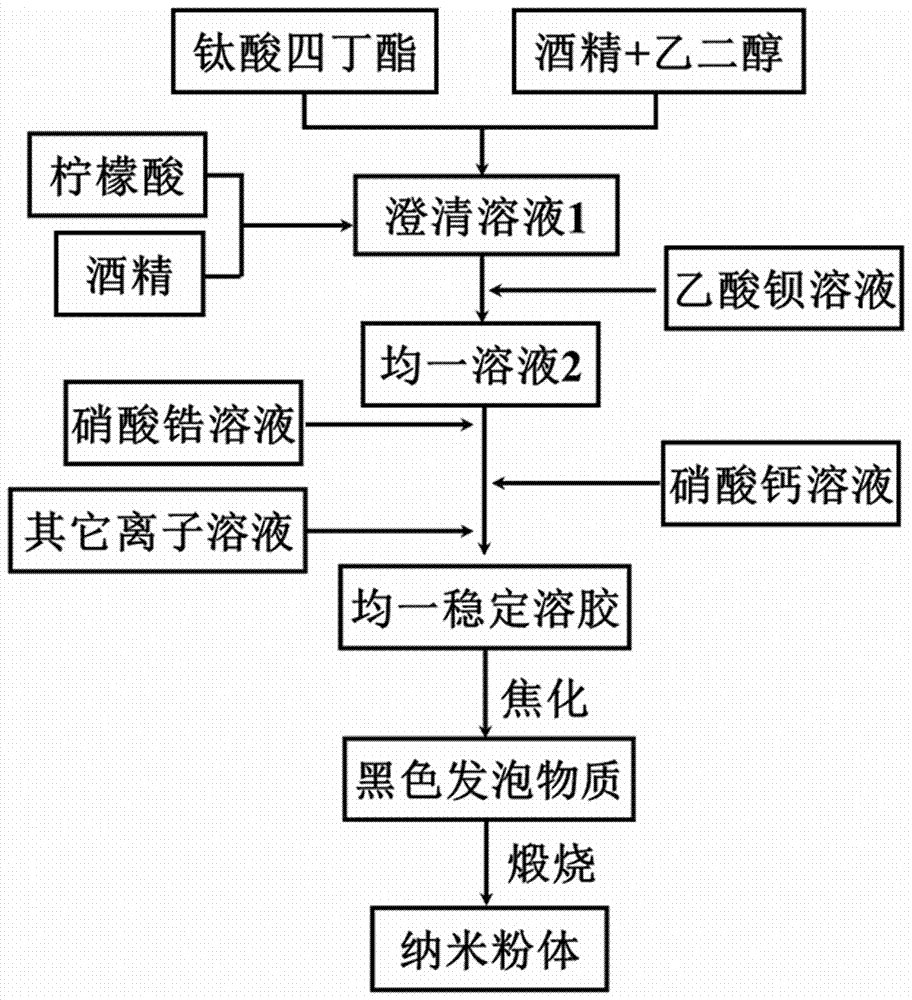

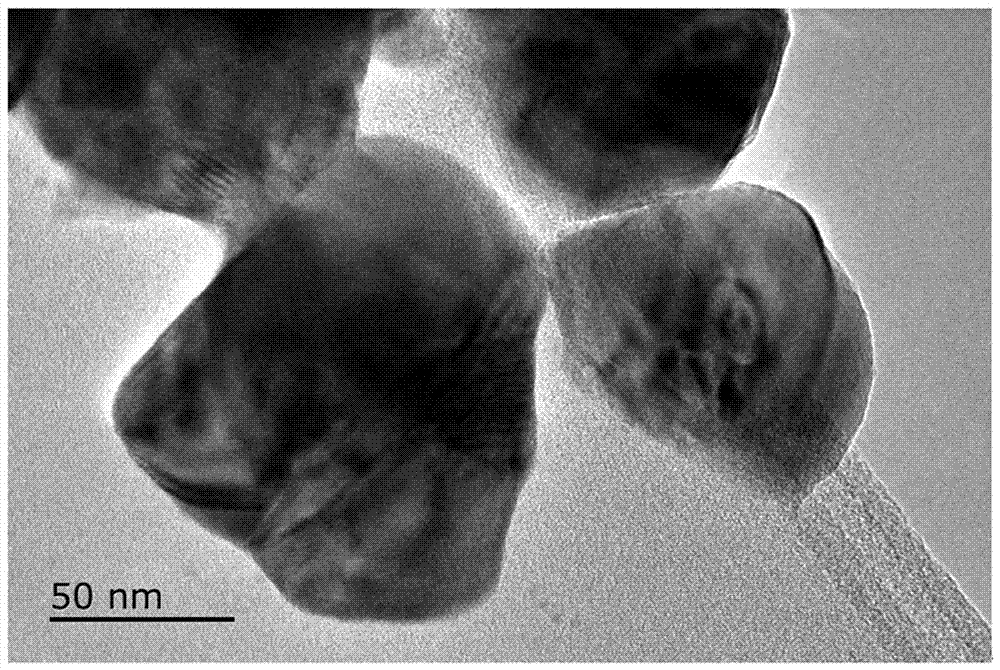

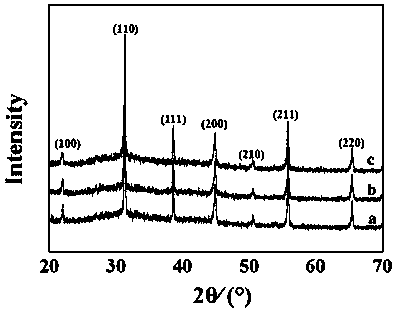

Barium zirconate titanate calcium-based piezoelectric ceramic and preparation method thereof

InactiveCN106986634AHigh degree of densificationImprove performanceElectronic componentSilver coating

The invention relates to barium zirconate titanate calcium-based piezoelectric ceramic and a preparation method thereof, belonging to the technical field of piezoelectric ceramic electronic components and devices. The ceramic has a chemical constitution represented by a general formula as follows: Ba1-xCaxTi1-yZryO3. The preparation method comprises the following steps: preparing chelate sol from tetrabutyl titanate, citric acid, barium acetate, calcium nitrate, zirconium nitrate, glycol, alcohol and the like in a molar mass / volume ratio, and coking and calcining the sol, so as to obtain nano-powder; and carrying out granulation, dry-pressure formation and glue discharging on the nano-powder, heating to 1250-1290 DEG C, stopping heating, and carrying out furnace cooling until the sintering temperature is 1150-1250 DEG C, so as to obtain the ceramic. After the ceramic is subjected to polishing, silver coating and polarization, measurement shows that the ceramic has excellent electrical properties: the piezoelectric coefficient d33 is equal to 479pC / N-634pC / N, and the maximum relative dielectric constant epsilonr is equal to 12328-13582.

Owner:XINYANG NORMAL UNIVERSITY

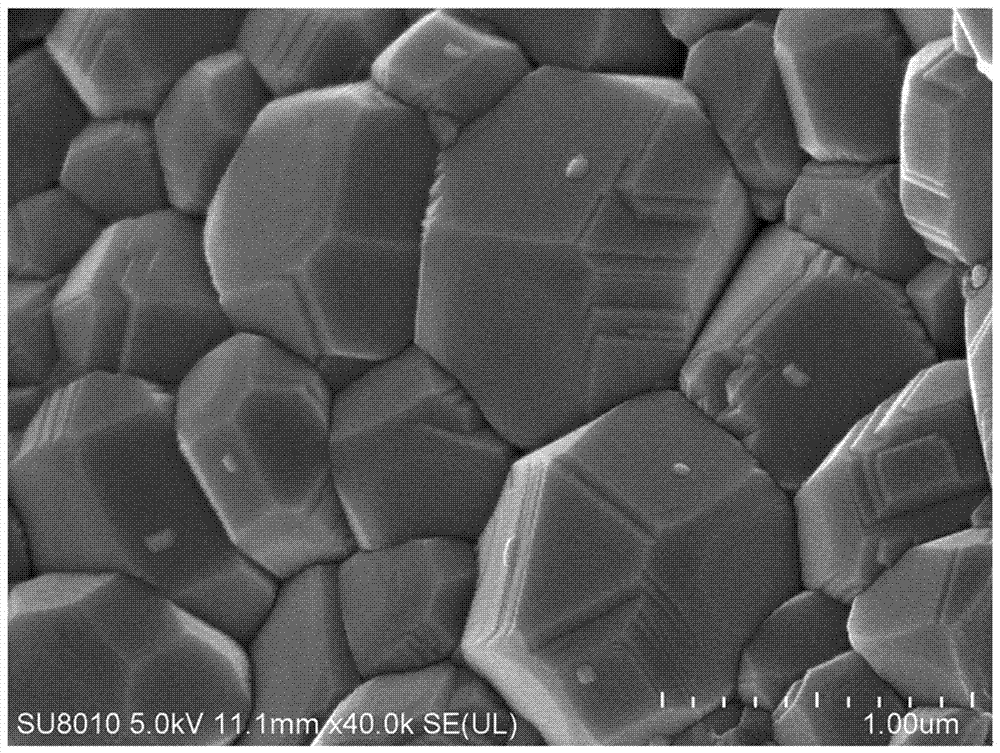

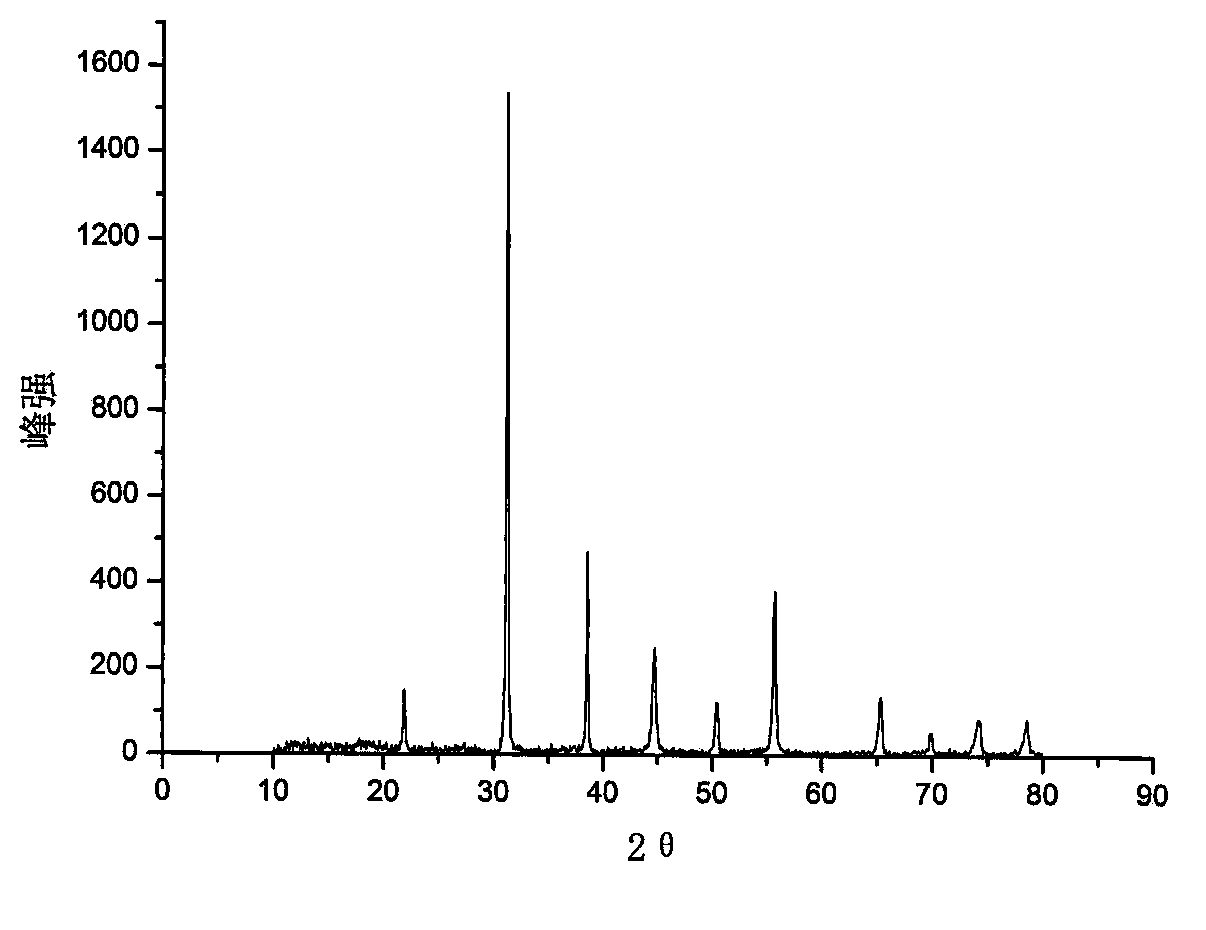

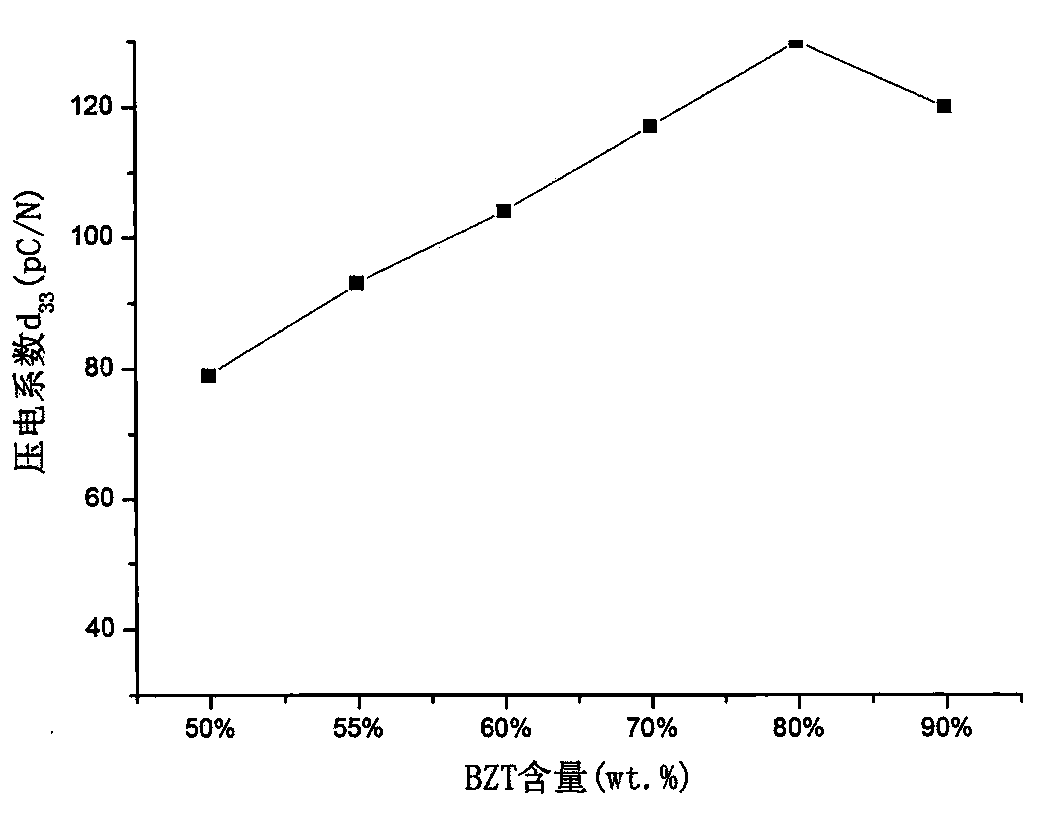

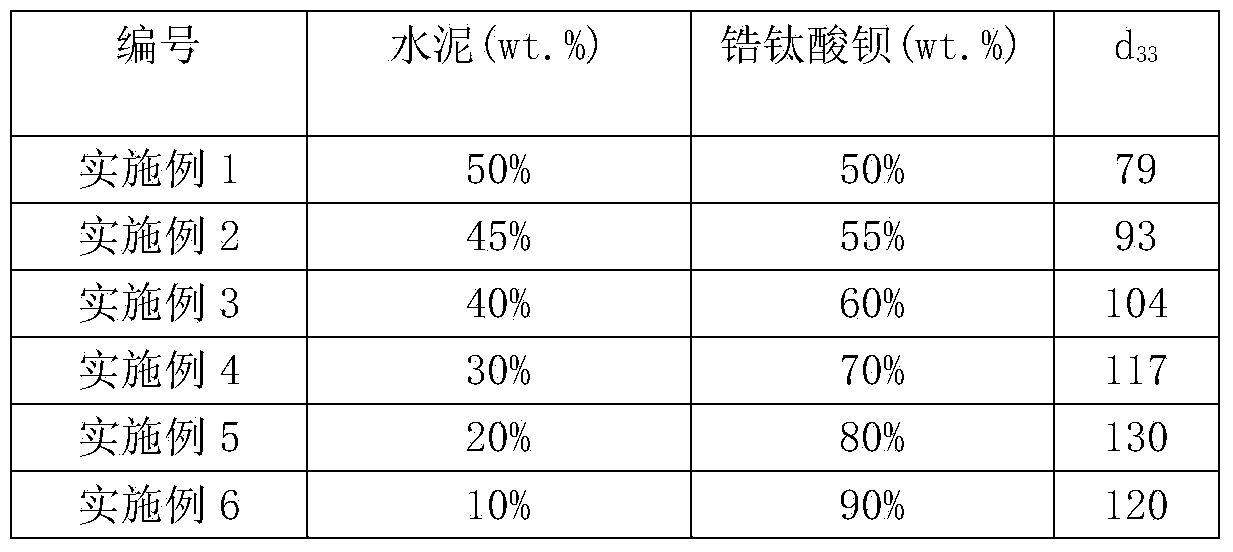

Lead-free cement-based piezoelectric composite material and preparation method thereof

The invention relates to a lead-free cement-based piezoelectric composite material and a preparation method thereof. The composite material is prepared from silicate cement and pure-phase barium zirconate titanate ceramic particles. The preparation method comprises the following steps: ball-milling and mixing the silicate cement and pure-phase barium zirconate titanate ceramic particles by using absolute ethyl alcohol as a medium, adding water to sufficiently stir, press-forming, conserving and polarizing to obtain the composite material, wherein after standing for 24 hours, the piezoelectric coefficient of the composite material can achieve 130PC / N, the composite material is 0-3 type structure, environment-friendly, good in piezoelectric response performance, simple in preparation process, low in cost, convenient to spread, and capable of maintaining good piezoelectric performance under a high temperature. The cement-based piezoelectric material is environment-friendly, good in piezoelectric response performance, simple in preparation process, low in cost and convenient to spread.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

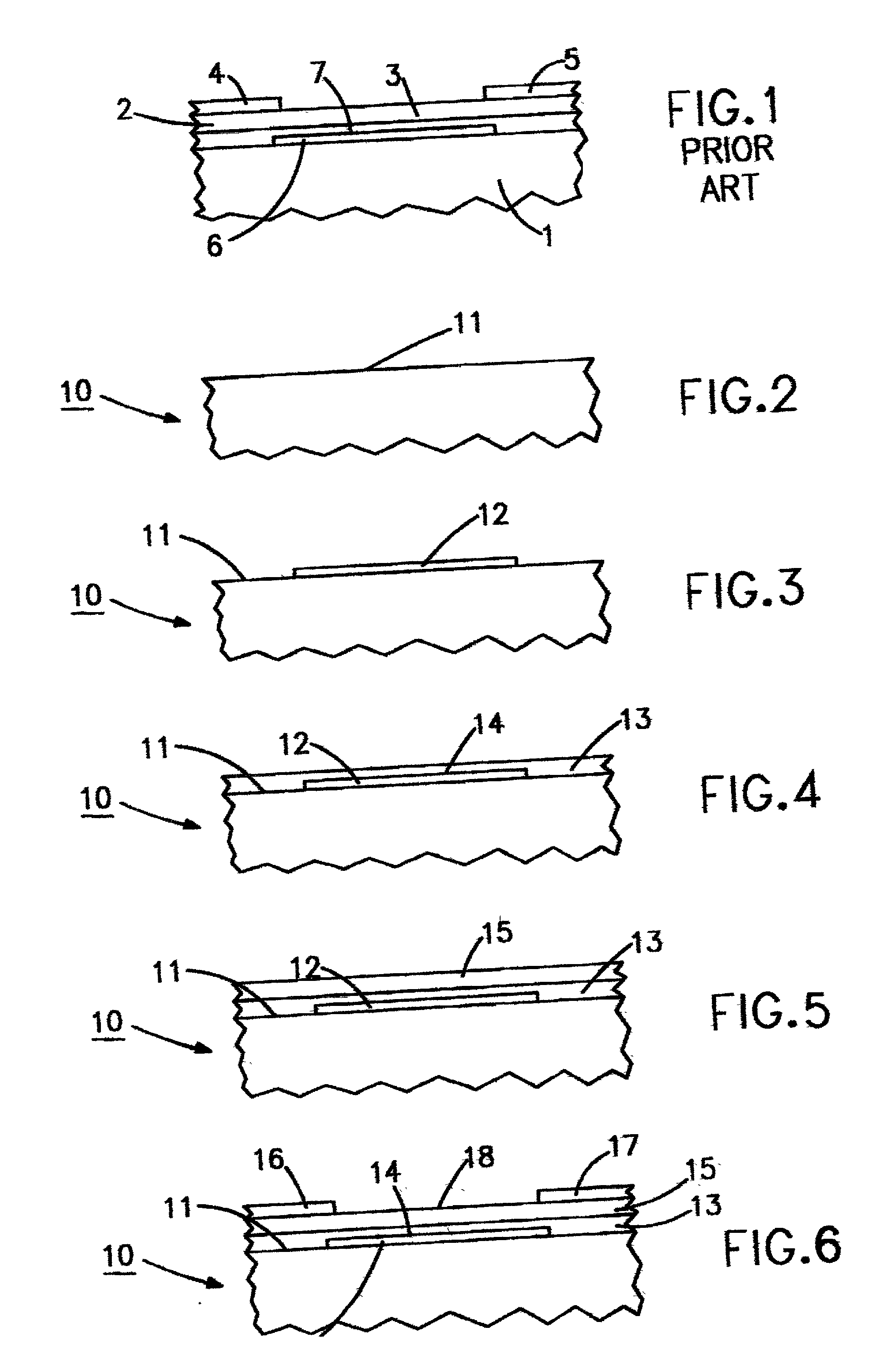

Interposer capacitor built on silicon wafer and joined to a ceramic substrate

InactiveUS20040014313A1Improve performanceHigh yieldTransistorSemiconductor/solid-state device detailsLead zirconate titanateBarium strontium titanate

An interposer, located between an integrated circuit having power, ground and signal connections and a ceramic substrate having power, ground and signal connections, that includes an oxide layer formed on a polished surface of a silicon substrate, a thin film dielectric capacitor formed on the oxide layer, a plurality of metallized that electrically connect to either of the electrodes of the thin film dielectric capacitor, and vias than conduct power, ground and signals between a the ceramic substrate and the integrated circuit. The interposer connects the metallized vias to the integrated circuit by solder connections and also connects the vias conducting power, ground and signals from the ceramic substrate to the interposer by solder connections. The dielectric of the thin film dielectric capacitor may be selected from the group of high-K titanates, such as, barium zirconate titanate, barium strontium titanate, pure barium titanate, barium titanate modified with Pb, Nb, W, Ca, Mg, and Zn, lead titanate, lead zirconate titanate, and polycrystalline lanthanum-modified lead zirconate titanate, or other high-K dielectrics, such as, lead niobate and its derivatives, and lead tungstate and its derivatives.

Owner:GLOBALFOUNDRIES US INC

Bismuth-sodium titanate-bismuth potassium titanate barium zirconate titanate lead free piezoelectric ceramics

InactiveCN1715242AExcellent piezoelectric ferroelectric propertiesProcess stabilityStrontium titanateBarium titanate

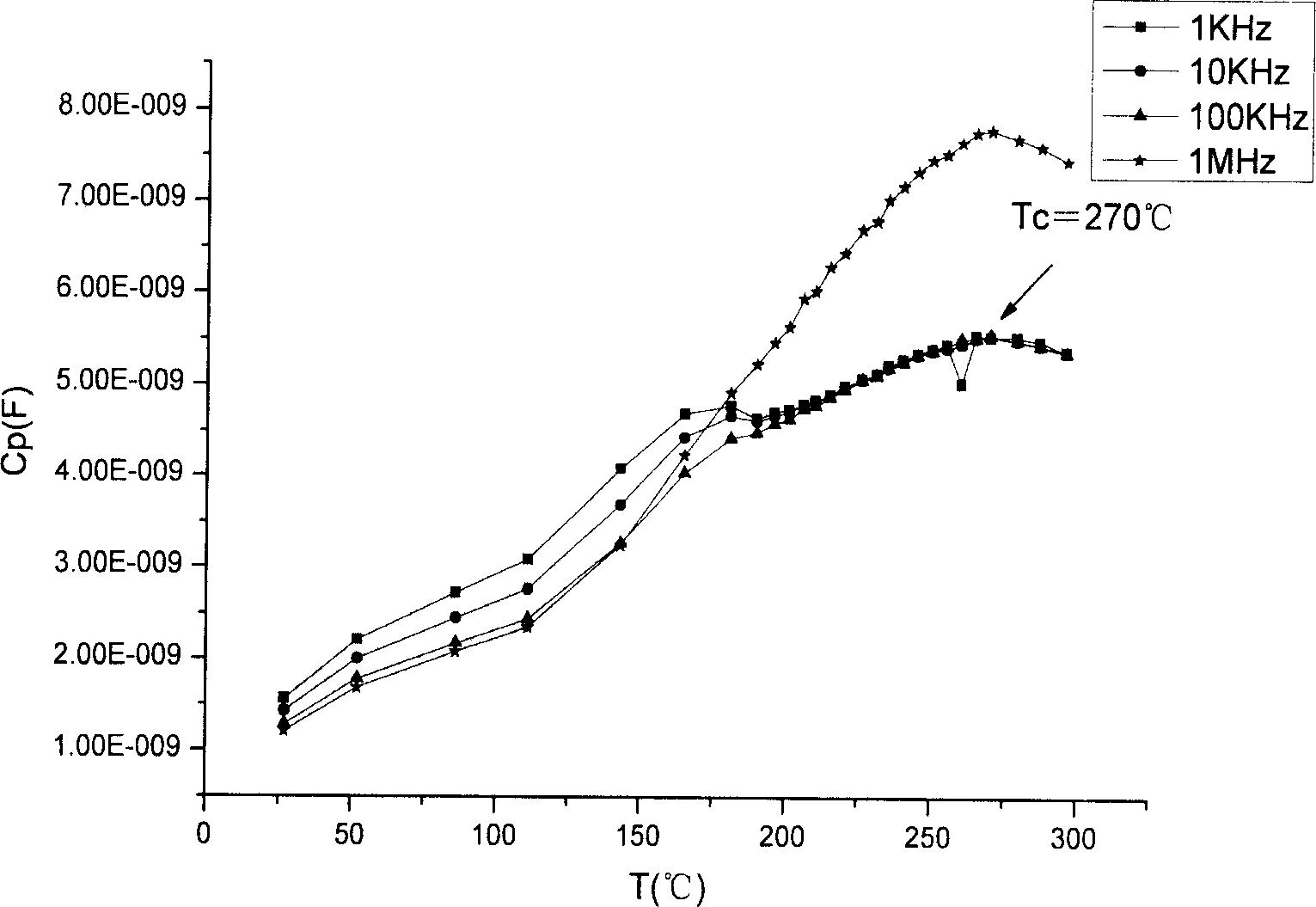

The present invention discloses a kind of environment friendly lead-free bismuth sodium titanate-bismuth potassium tatanate-barium zirconate titanate piezoelectric ceramic in functional ceramic preparing technology. The lead-free piezoelectric ceramic has the general expression of (1-x)Bi1 / 2(Na1-zKz)1 / 2TiO3-xBa(ZryTi1-y)O3, where, x is BZT molar content, y is atom number of Zr to replace Ti in BaTiO3, z is atom number of K to replace Na in BaNaO3, x is 0-0.1, y is 0-0.10 and z is 0-0.05. The lead-free piezoelectric ceramic may be prepared with industrial materials and through traditional piezoelectric ceramic preparing technological process. The lead-free piezoelectric ceramic has d33 up to 16pC / N, Curie temperature up to 270 deg c and practical application value.

Owner:TSINGHUA UNIV

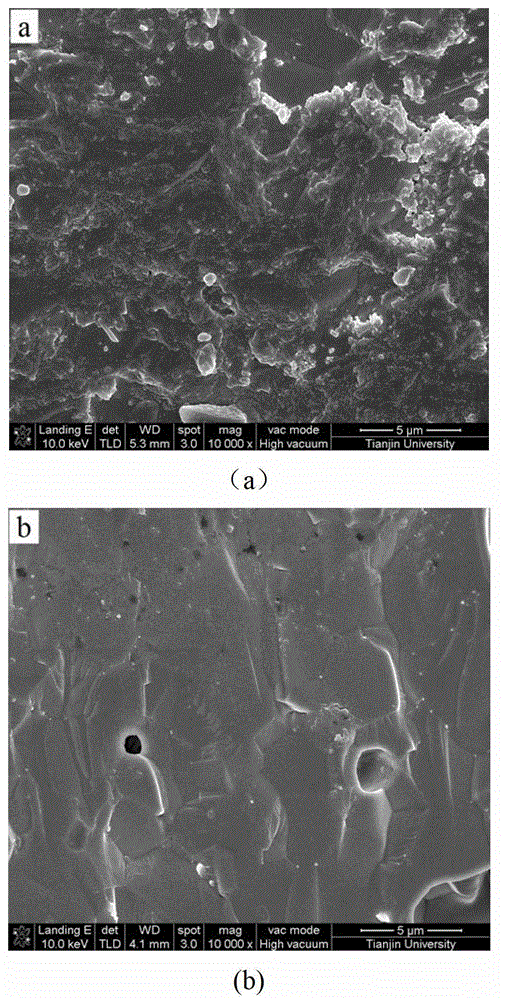

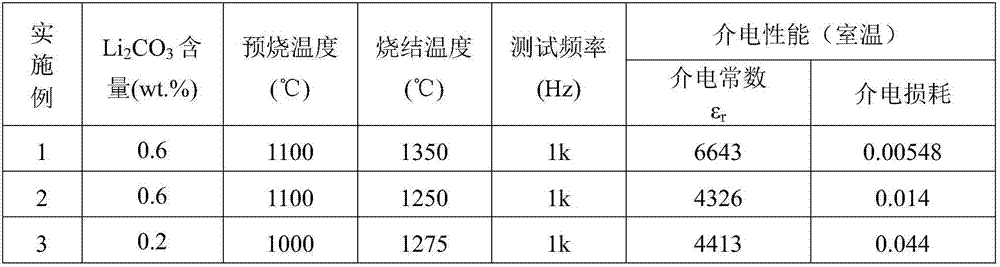

Lithium carbonate modified cerium barium zirconate proton conductor material and preparation method thereof

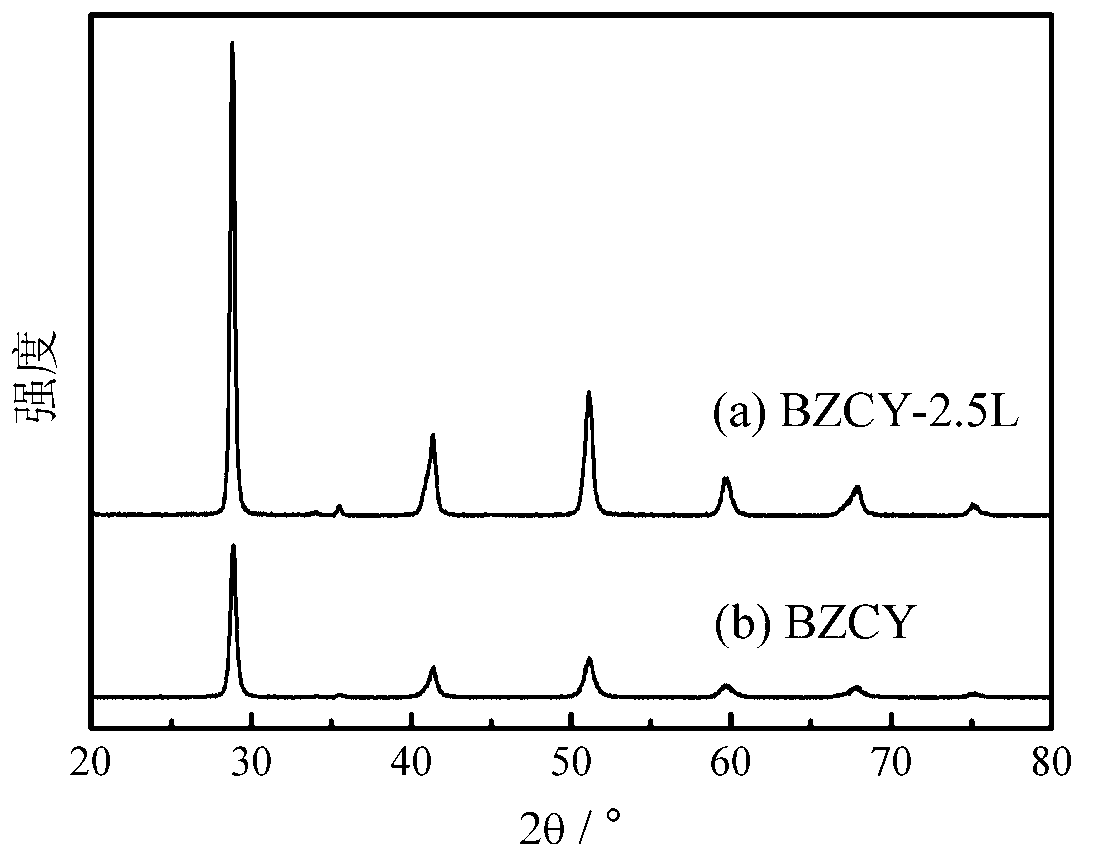

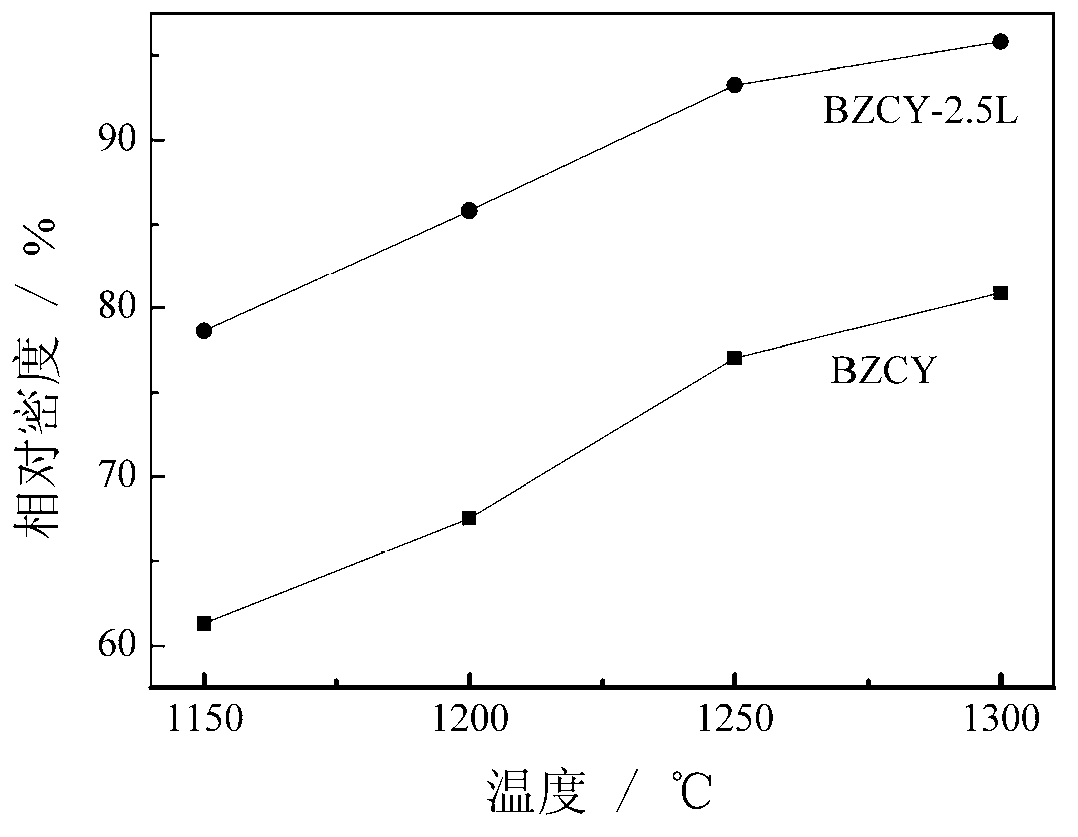

The invention discloses a lithium carbonate modified cerium barium zirconate proton conductor material. Raw material components and molar ratio percentage content thereof are BaCe0.7Zr0.1Y0.2O3-delta, and on the basis, 0%-7.5% by mass of lithium carbonate and 0%-4% by mole of zinc oxide are added. BaCe0.7Zr0.1Y0.2O3-delta powder is synthesized by a nitrate-citric acid gel auto-combustion method; then an inorganic salt sintering aid lithium carbonate zinc oxide are added in the power; the powder is shaped by dry pressing and sintered at a temperature of 1,150-1,300 DEG C. The raw materials of the lithium carbonate modified cerium barium zirconate proton conductor material are low in cost; the preparation process is simple and time-saving; relatively high conductivity can be obtained under the premise of increasing sintering performance of the materials; and the lithium carbonate modified cerium barium zirconate proton conductor material provides a foundation for low temperature development of solid oxide fuel cells.

Owner:TIANJIN UNIV

Method for preparing composite inorganic metal oxide

The invention discloses a method for preparing a composite inorganic metal oxide, which comprises the following steps: firstly, preparing a precursor of the composite inorganic metal oxide; and then, treating the precursor by a calcining or burning method, wherein the precursor is a homogeneous liquid substance formed by mixing liquid polylol and more than two metal organic salts, and the contentratio of all metal elements in the precursor accords with the requirement of forming the composite inorganic metal oxide. The method can prepare powder of various composite inorganic metal oxides of nano-scale crystal grains, which comprise barium titanate, calcium copper titanate, lithium titanate, strontium titanate, barium zirconate or strontium zirconate and the like.

Owner:MICROVAST POWER SYST CO LTD

Gradient composite technology ceramic tile and preparation method thereof in field of glass kilns

ActiveCN112225558AGood Thermal Gradient Reduction CapabilitiesLow thermal conductivityFiberZirconate

The invention discloses a gradient composite technology ceramic tile in the field of glass kilns, which is prepared by the following steps of on the basis of taking zirconium dioxide as a base material, compounding with other components to form a first-layer material with the mass percentage of 100%, gradually changing the content of the material by sections in a gradient manner and gradually increasing the content of other materials until a trace amount of zirconium dioxide exists, progressively increasing two or more than two other materials in a gradient manner and changing different components to form a plurality of layers of components in percentage by mass of 100 for implementing material distribution, so that gradual change from one side to the other side in a continuous gradient manner is realized. The ceramic tile comprises the following components: zirconium dioxide Zr02, silicon dioxide SiO2, yttrium oxide Y203, calcium zirconate eutectic CaZrO3, barium zirconate eutectic BaZrO3, magnesium-zirconium eutectic MgZrO3, corundum alpha-Al2O3, alumina powder alpha-Al2O3, alumina fiber whisker alpha-Al2O3, silicon carbide SiC, silicon nitride Si3N4 and magnesium oxide MgO. Thepreparation method is convenient to operate and comprises the following steps of 1, preparing raw material components, 2, carrying out process treatment on each layer of components, and d, sintering amolded product.

Owner:ZHENGZHOU FANGMING HIGH TEMPERATURE CERAMIC NEW MATERIAL CO LTD

Constant pressure hydro-thermal preparation method for barium zirconate titanate powder

Disclosed is a normal-pressure hydrothermal preparation method for barium zirconate titanate powder. Pure titanium tetrachloride is used as the source of titanium; zirconia oxygen dichlorohydrate is used as the source for zirconium; barium chloride is used as the barium source; sodium hydroxide is taken as the reaction agent; in conjunction with technology, the reaction conditions are timely and strictly controlled, thus the reaction speed is greatly accelerated and the sodium chloride and other remnants left after the reaction are easy to be washed to cause less pollution on environment. The reaction of the invention is carried through in normal-pressure and low-temperature environment, thus the various parameters in the reaction process can be easily adjusted and controlled. The barium zirconate titanate powder prepared through the invention has the advantages of integral grains, even granularity distribution, non-reunion, high activity and low cost, which can fully meet the requirements on the high-performance of barium zirconate titanate in the electronic industry.

Owner:仙桃市中星电子材料有限公司

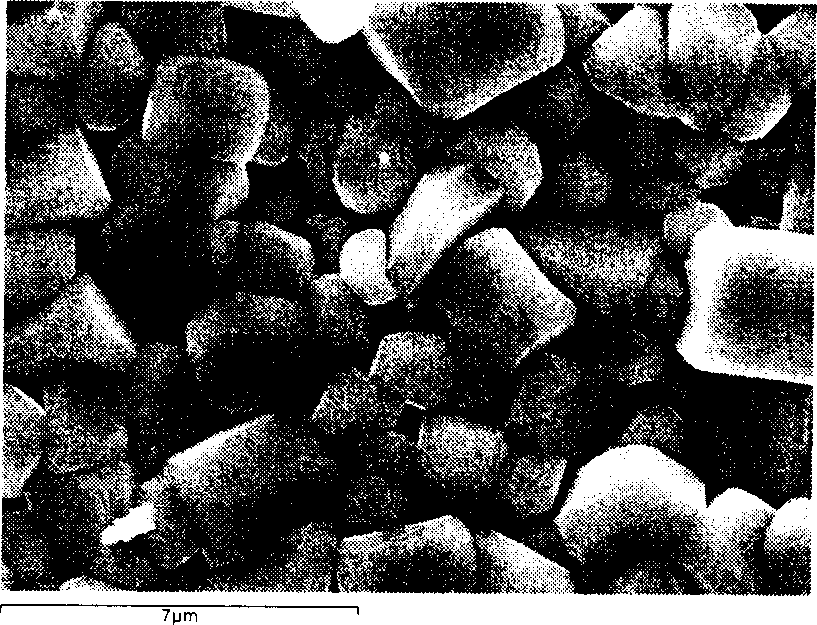

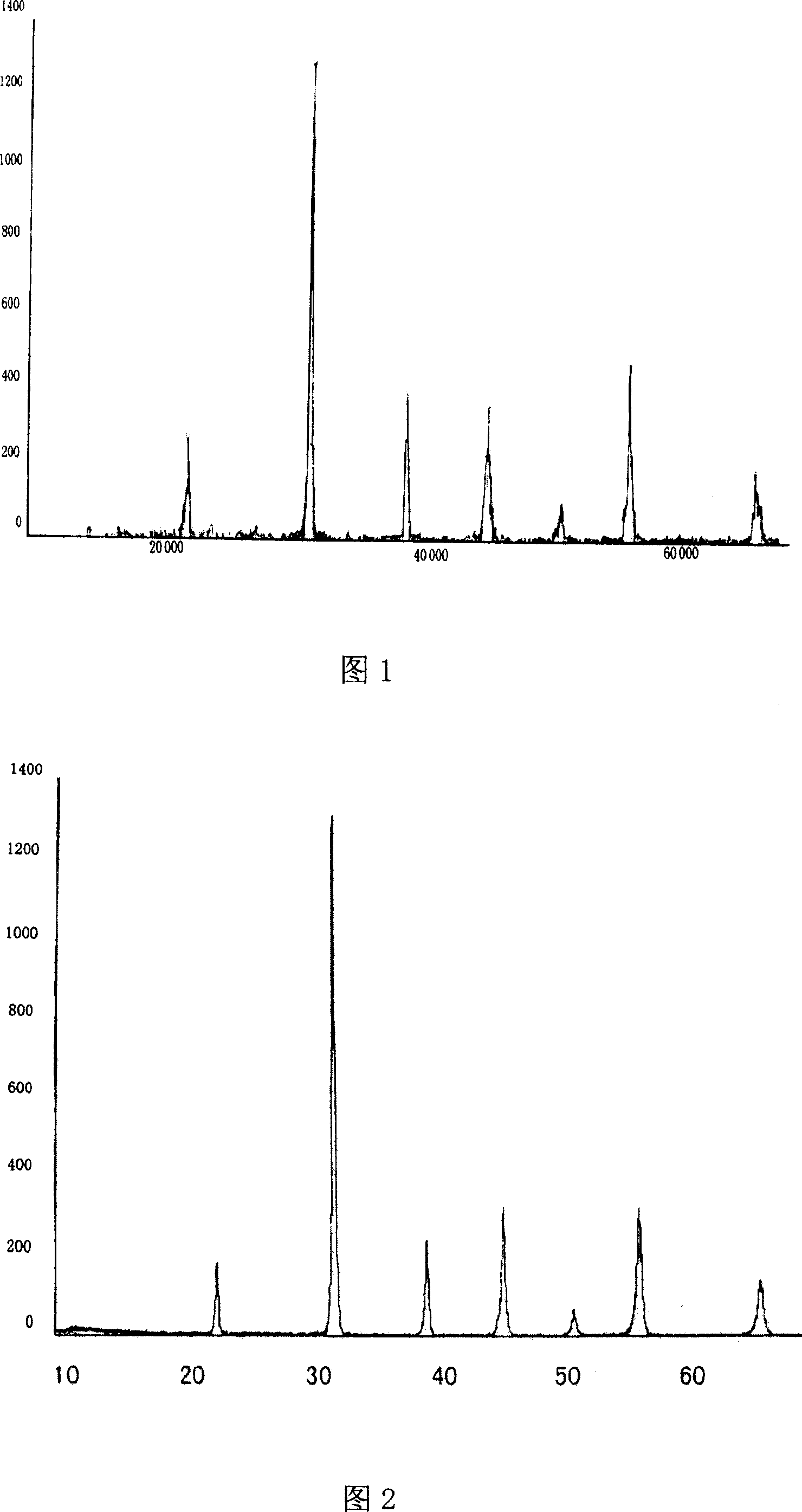

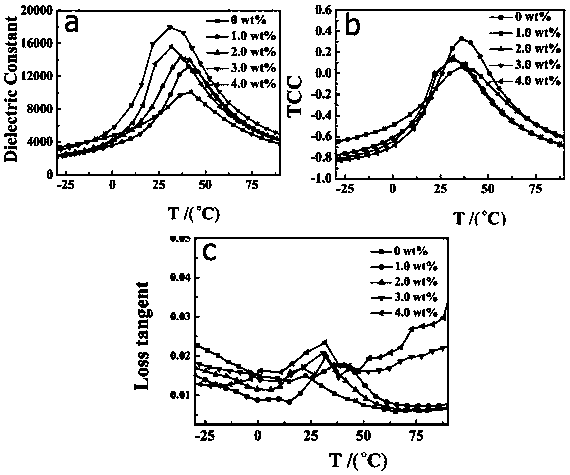

Low-temperature sintering high-dielectric-property Y5V type ceramic capacitor dielectric material and preparation method thereof

The invention discloses a low-temperature sintering high-dielectric-property Y5V type ceramic capacitor dielectric material and a preparation method thereof. Barium zirconate titanate which is prepared by a sol-gel method serves as a main component and is sintered to obtain ceramic with maximum dielectric constant being 15950, heat temperature change rate being -82% to 22%, indoor temperature dielectric loss smaller than 0.5%, and ceramic grain size being 0.8 micrometer to 7.6 micrometers. With sintering aids added, the Y5V type dielectric material having excellent dielectric performance and microscopic structure, high electric constant and low dielectric loss is obtained. The low-temperature sintering high-dielectric-property Y5V type ceramic capacitor dielectric material has the advantages of being environmental friendly and cheap, is suitable to be used for manufacturing high-capacity, small-sized high-performance multi-layer ceramic capacitors, and has wide industrialized application prospect.

Owner:NORTHWEST UNIV

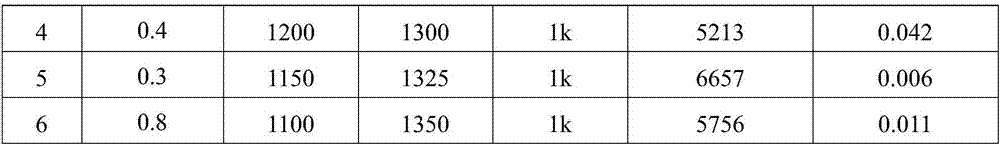

Barium zirconate titanate ceramic material with low dielectric loss and preparation method thereof

The invention discloses a barium zirconate titanate ceramic material with low dielectric loss. The chemical formula of the barium zirconate titanate ceramic material is Ba0.9Ca0.1Ti0.8Zr0.2O3+0.2-0.8wt.% Li2CO3 and is abbreviated as BCTZL. A preparation method of the barium zirconate titanate ceramic material includes: preparing BaCO3, CaCO3, TiO2 and ZrO2 according to the stoichiometric formula Ba0.9Ca0.1Ti0.8Zr0.2O3, performing ball milling, drying and sieving, pre-sintering at 1000-1200 DEG C, mixing the pre-sintered powder with 0.2-0.8wt.% Li2CO3, performing ball milling in a ball milling tank, drying, sieving, performing compression molding to obtain a green body, and sintering the green body at 1250-1325 DEG C to obtain the barium zirconate titanate ceramic material with low dielectric loss. The barium zirconate titanate ceramic material and the preparation method thereof have the advantages that the dielectric loss of the material is low and reaches 0.00548, the high dielectric constant of the material is high and reaches 6643, the sintering temperature (1250-1325 DEG C) of the preparation method is moderate, and the material can meet the needs, for constantly developing towards low power consumption, of electronic devices.

Owner:TIANJIN UNIV

Method for preparing barium zirconate crucible by slip casting

The invention discloses a method for preparing a barium zirconate crucible by slip casting, comprising the following steps: a) calcining a commercial barium zirconate powder; b) carrying out ball milling on the calcined powder for 24h and drying for later use; c) adding distilled water and a solution of Arabic gum into the dried powder, mixing for 2-5h, sieving through a 200-mesh sieve, and removing large particle impurities in the slurry; d) injecting the slurry into a plaster mold until a certain thickness is reached, pouring out the residual slurry, placing the plaster mold in the air, demoulding, pouring out a biscuit, drying in an environment of 30-40 DEG C, carrying out fettling, and naturally drying; and 3) heating at the rate of 1-20 DEG C / min to 1600-1800 DEG C, and carrying out thermal insulation for 2-12 h so as to obtain the barium zirconate crucible. The invention has advantages as follows: raw materials are cheap and easily available; the technology is simple; costs are low; and the method is suitable for large-scale production. The prepared barium zirconate crucible has characteristics of high strength, high thermal shock resistance, high density and the like, can be used in a high-temperature environment, and provides a good material foundation for crystal growth and other applications.

Owner:EAST CHINA NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com