BaZrO3 refractory material for smelting titanium alloy and preparation method of crucibles

A technology for refractory materials and titanium alloys is applied in the field of preparation of refractory materials and crucibles, and can solve the problems of being unsuitable for large-scale use, high price, and increasing the cost of titanium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

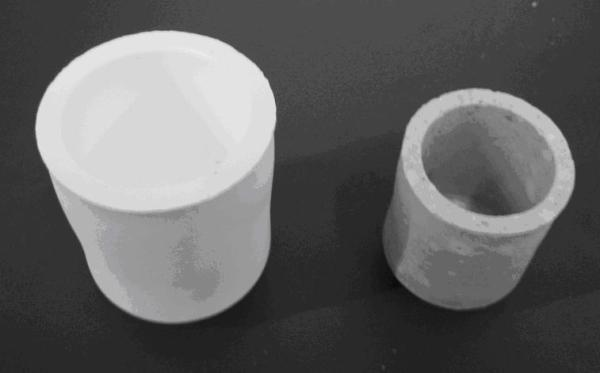

[0023] (1) BaZrO 3 Preparation of refractories

[0024] Using high-purity barium carbonate and zirconia as raw materials, the molar ratio of the two is BaCO 3 : ZrO 2 =1:1; in addition, add 0.5~5.0 mol% TiO 2 Flux sintering accelerator; the batch is repeatedly sintered at 1300°C to make BaZrO 3 refractory material.

[0025] (2) BaZrO 3 Preparation of the melting crucible

[0026] The manufacturing process and steps of melting crucible are as follows:

[0027] 1) Ingredients: High-purity barium carbonate and zirconia are used as raw materials, the molar ratio of the two is 1:1, and 2.0 mol% of TiO is added 2 ;

[0028] 2) Ball milling: add an appropriate amount of absolute ethanol to the prepared material, add zirconia balls, and ball mill for 20 hours;

[0029] 3) Drying: The ball-milled material is placed in a drying box and dried at 100~110°C;

[0030] 4) Molding: add a binder to the dried material, the binder is paraffin, the addition amount is 4wt%, and press it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com