Patents

Literature

473results about How to "Less slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

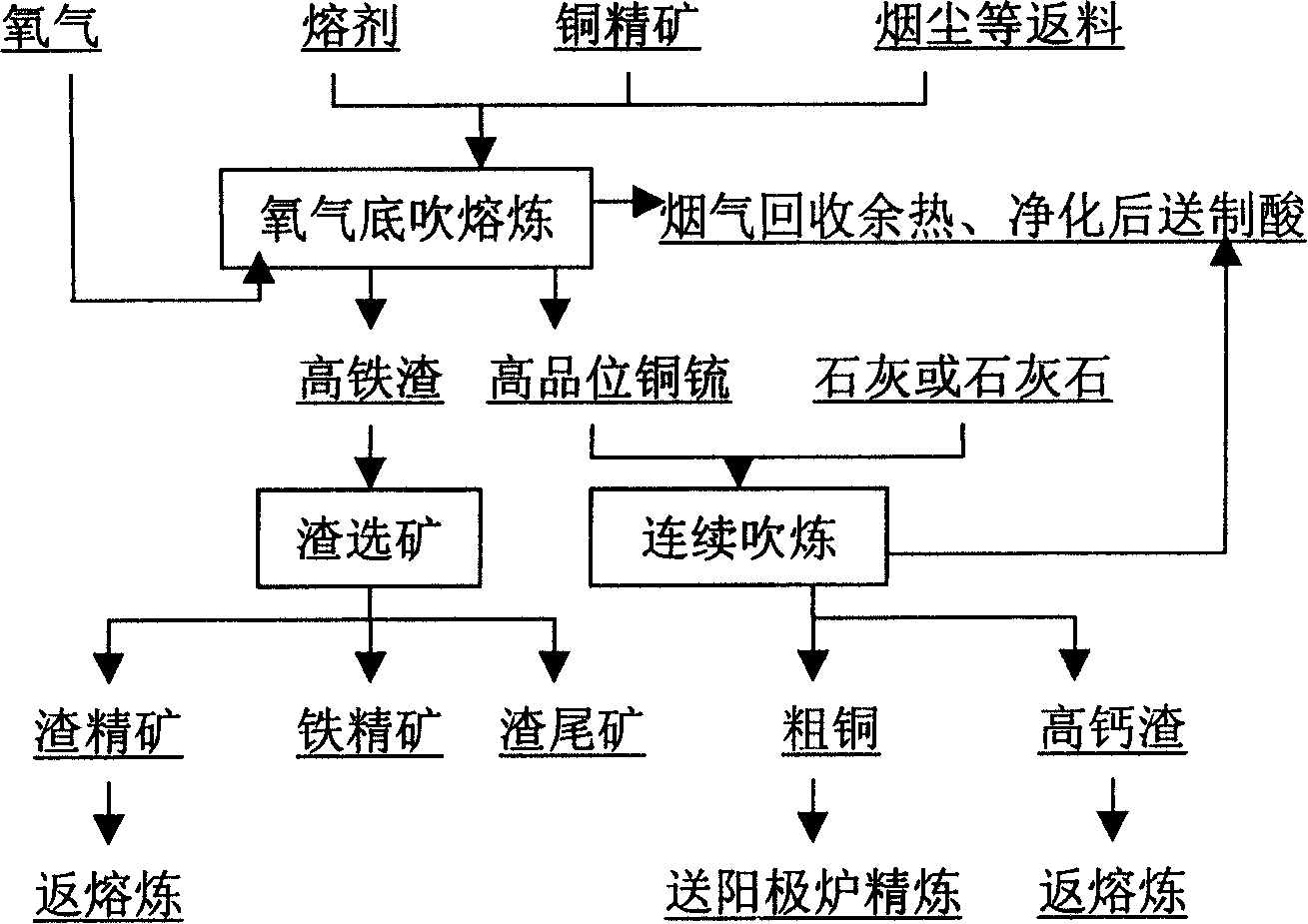

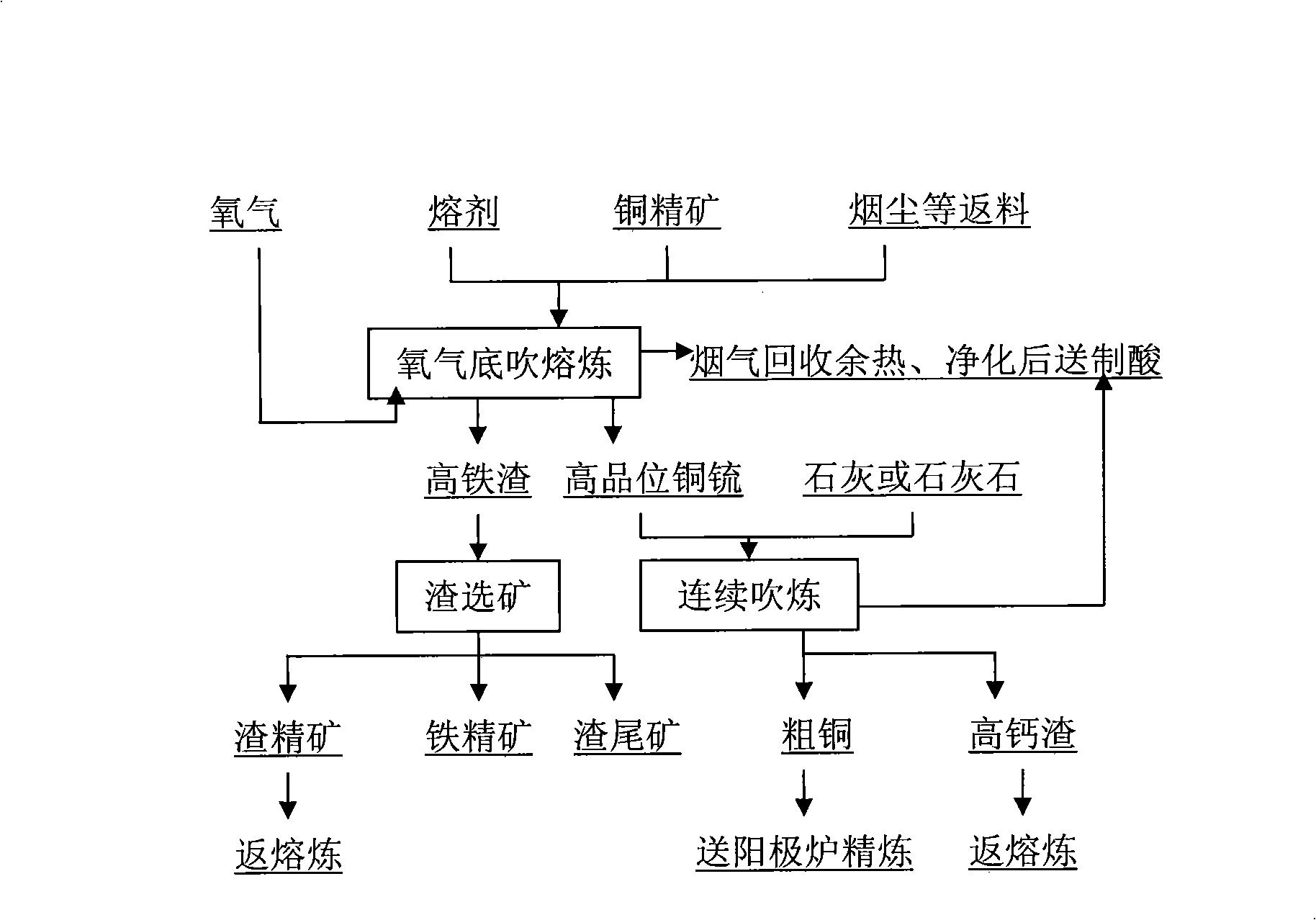

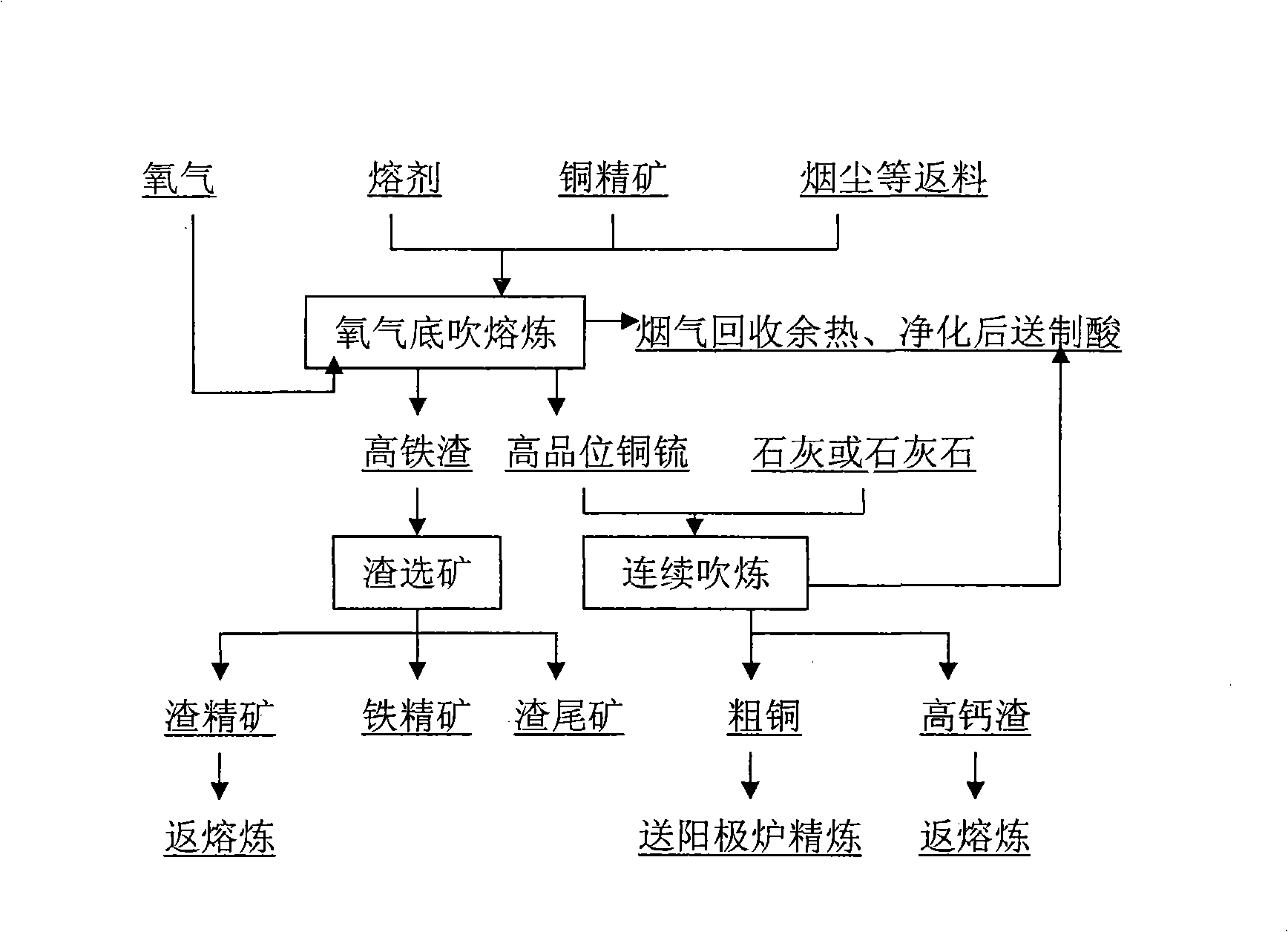

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

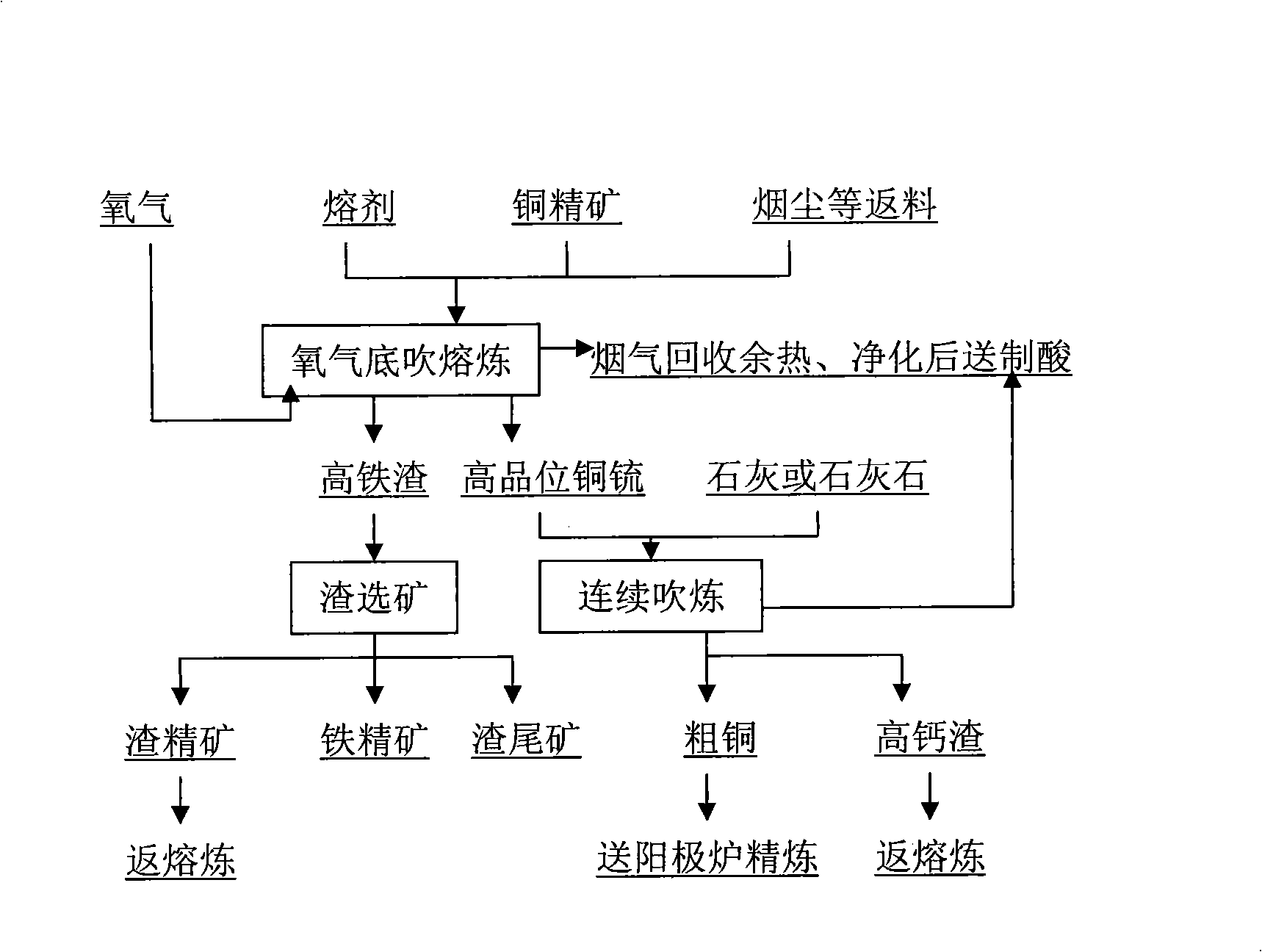

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

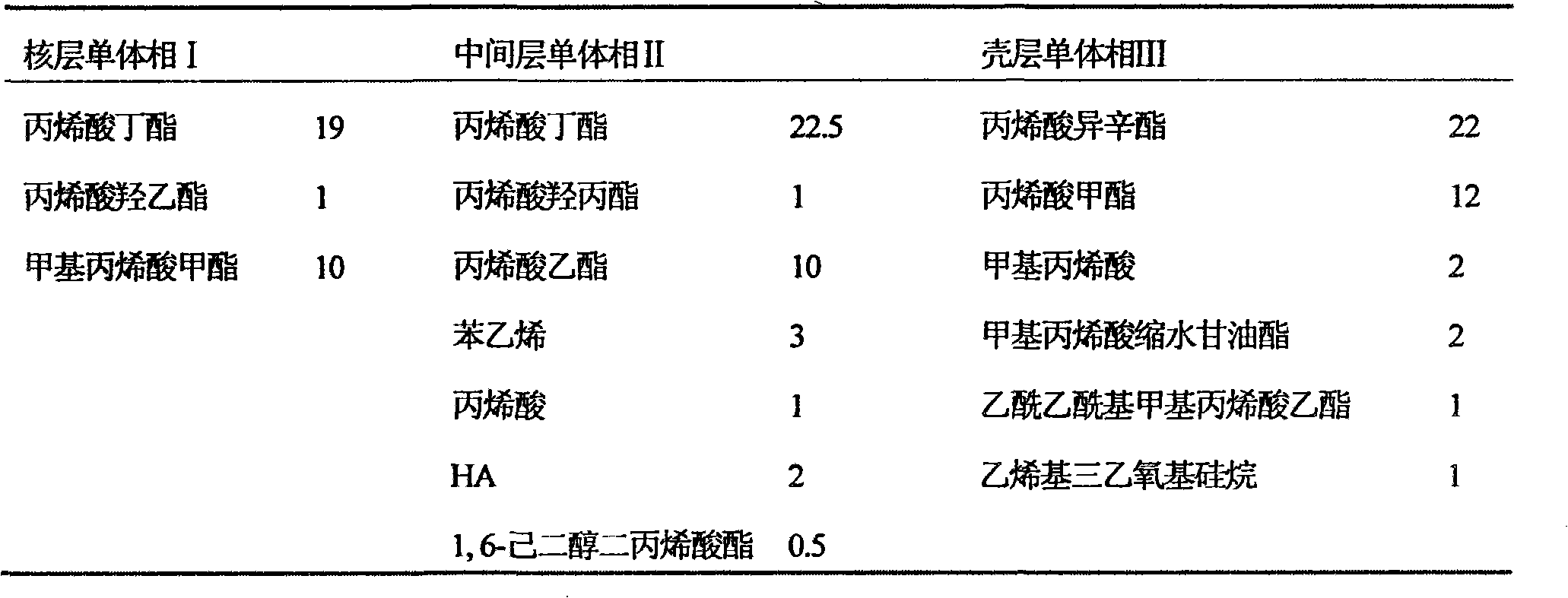

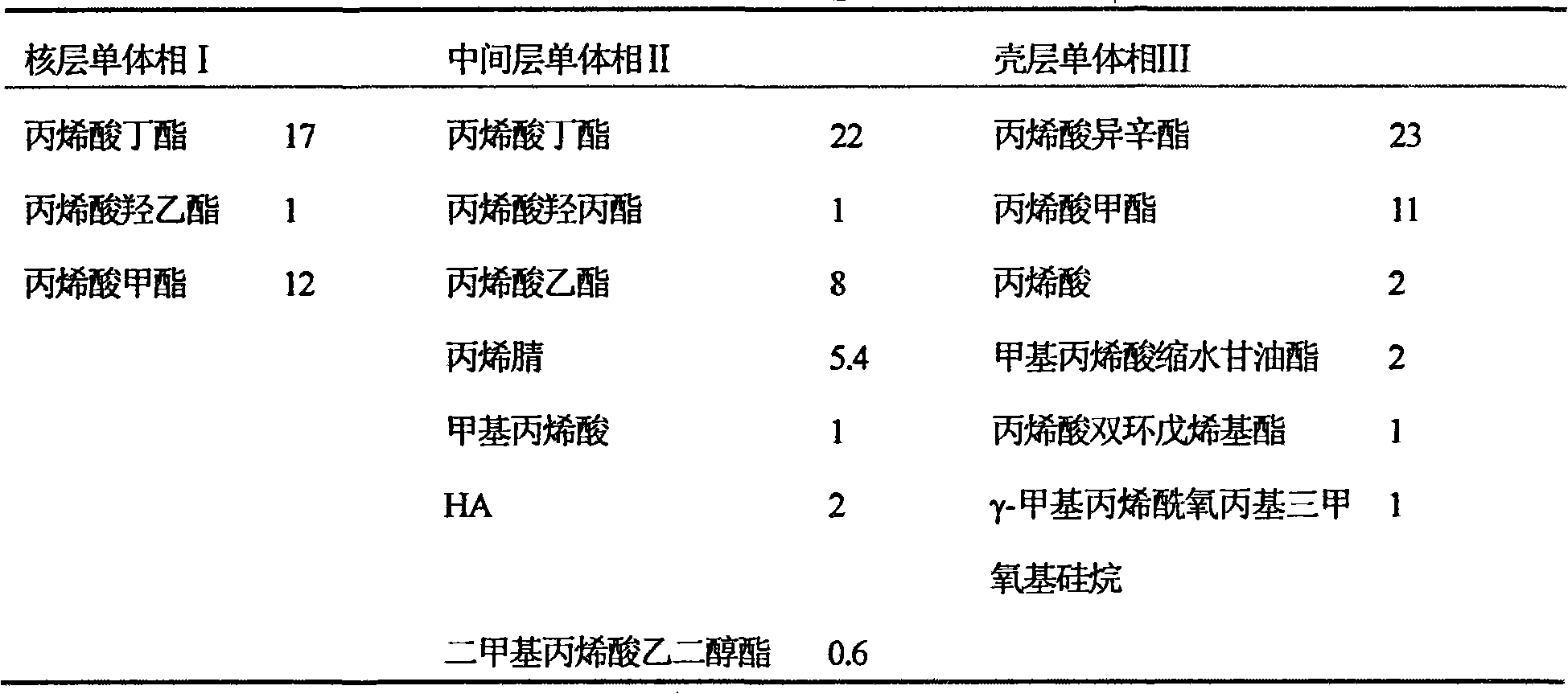

Single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and preparing method thereof

InactiveCN101928534ALess slagHigh affinityNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention discloses a single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and a preparing method thereof. The raw materials of the self-crossing emulsion adhesive comprise the following components in part by weight: 100-150 parts of de-ionized water, 0.8-3.0 parts of emulsifier, 20-40 parts of nuclear layer monomer, 30-50 parts of interlayer monomer, 20-40 parts of shell layer monomer, and 0.2-0.6 part of initiator. The invention uses a small amount of anionic emulsifier to prepare nuclear emulsion, uses polymerisable emulsifier to prepare interlayer and shell layer pre-emulsion, and adopts semi-continuous seeded low emulsion polymerization process to prepare emulsion particles that have a three-layer core-shell microstructure to obtain the exquisite and stable emulsion. The product has no organic solvent, and does not release methanal, contains no APEO and no phthalate; the film coating has high transparency, high water resistance and high heat and humidity resistance; and the emulsion adhesive is applied to plastic and paper compounds, has high adhesive strength, peel strength and permanent adhesion, is also compatible to oil and ink and has high oil / ink transferring rate.

Owner:SOUTH CHINA UNIV OF TECH

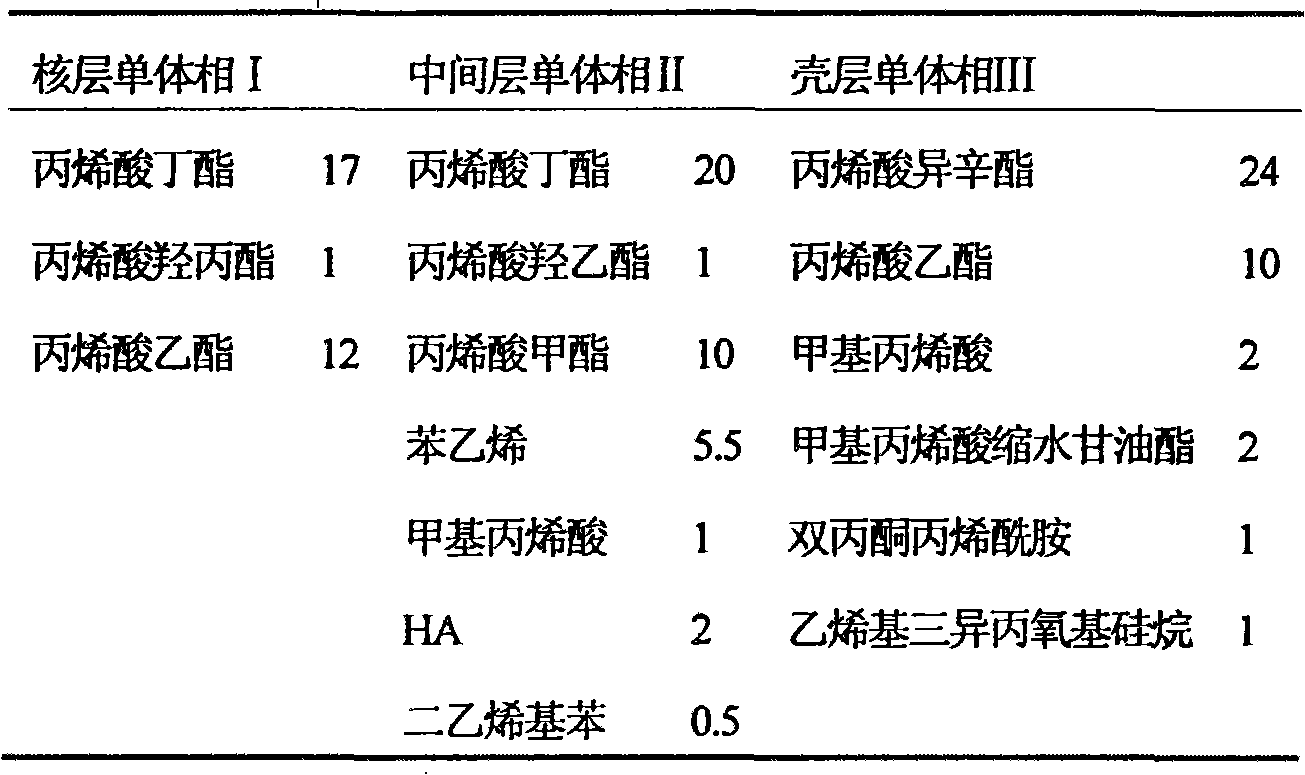

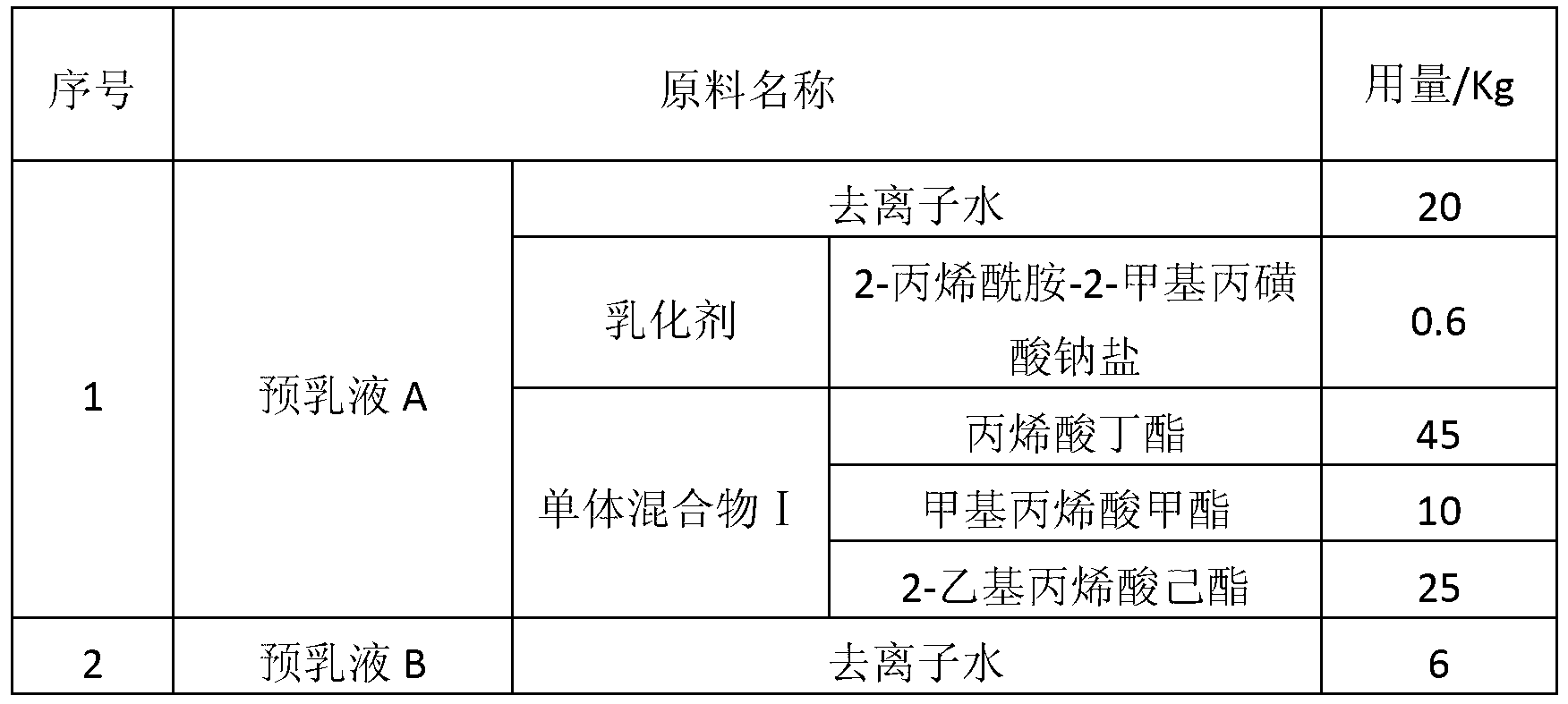

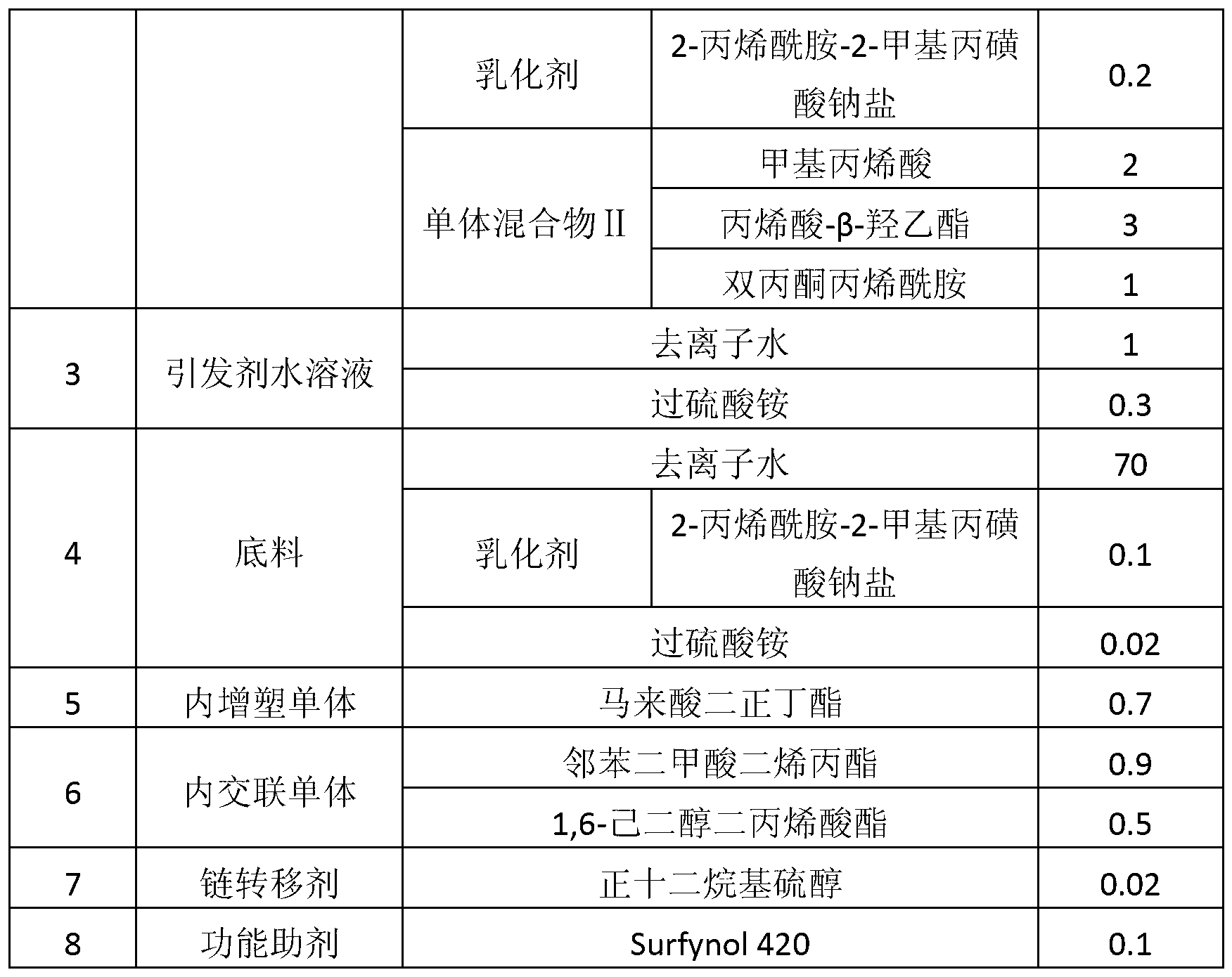

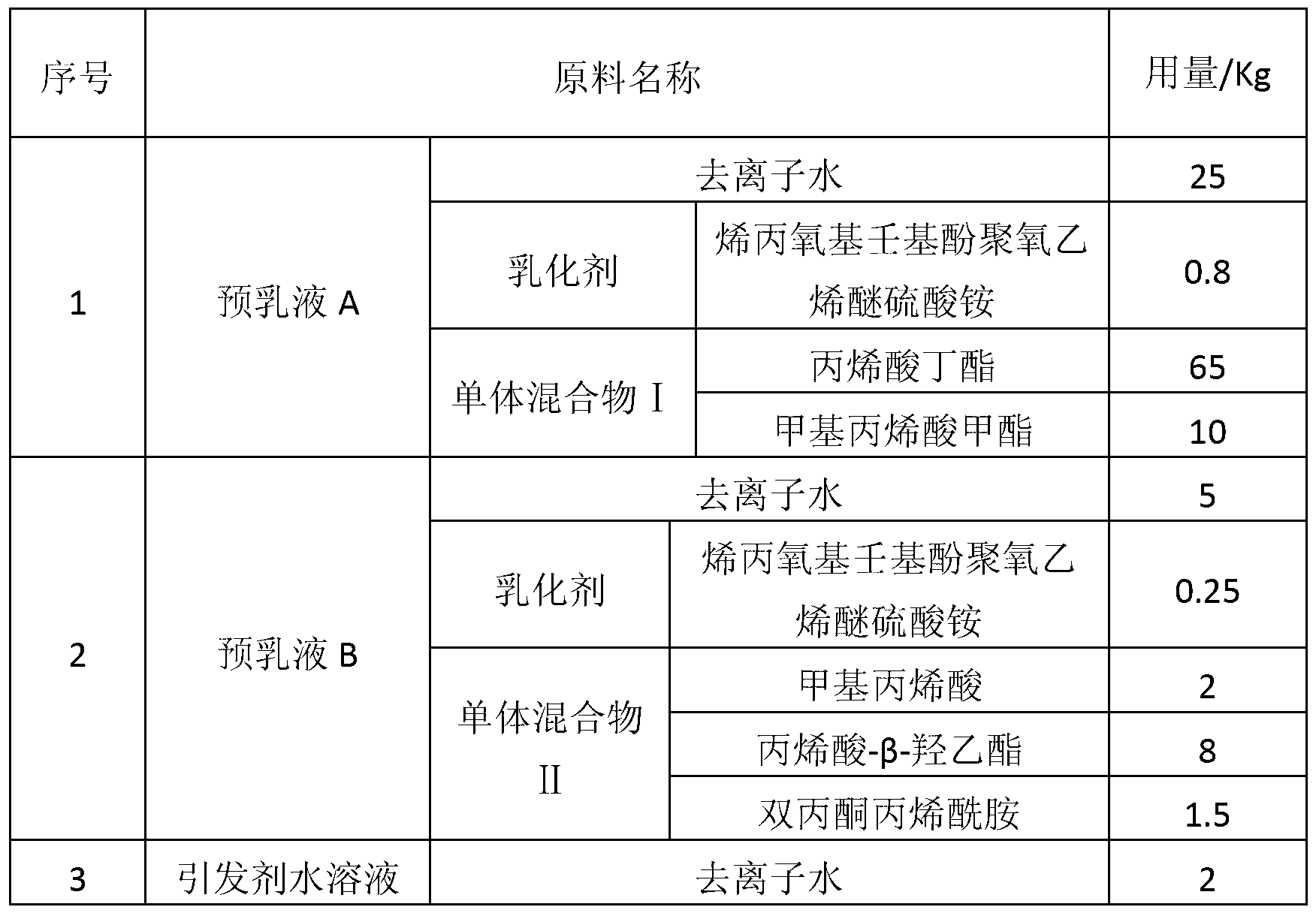

Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

ActiveCN103059784AHigh bonding strengthImprove stabilityEster polymer adhesivesWater basedPolyurethane adhesive

The invention discloses a water-based plastic-plastic compound adhesive for food and drug flexible packages and a preparation method thereof. The preparation method comprises the following steps of: carrying out pre-emulsification by using 20-30 parts by weight of deionized water, 0.4-1.0 part by weight of emulsifying agents and 75-90 parts by weight of monomer mixtures to obtain a pre-emulsion A; then carrying out the pre-emulsification by using 5-8 parts by weight of the deionized water, 0.2-0.3 part of the emulsifying agents and 3-20 parts by weight of the monomer mixtures to obtain a pre-emulsion B; preparing an initiator water solution C by using 1-3 parts by weight of the deionized water and 0.2-0.8 part by weight of initiators; and dropping the monomer mixture I with lower polarity and the monomer mixture II with higher polarity step by step by adopting a pre-emulsification seed emulsion polymerization process to obtain the water-based plastic-plastic compound adhesive for the food and drug flexible packages. The water-based plastic-plastic compound adhesive disclosed by the invention has the advantages of no organic solvent, no formaldehyde release, good adhesivity and high stripping strength and permanent adhesion and can be applied to a flexible package industry and substitute for a solvent type two-component polyurethane adhesive maturely applied to the present market.

Owner:DONGGUAN STAR COSM POLYMER

Copolymer, process for producing the same, and resist composition

InactiveUS6706826B1Improve adhesive propertyImprove resistance propertyOriginals for photomechanical treatmentPhotosensitive materials for photomechanical apparatusSolventResist

The present invention relates to a copolymer for use in paints, resists, and the like; a method for manufacturing the same; and a resist composition using the same. The copolymer according to the present invention is obtained by means of polymerizing at least one monomer containing an alicyclic structure and one monomer containing a lactone structure, and the distribution of the copolymer composition of said monomer containing a lactone structure in said copolymer is in the range of -10 to +10 mol % of the average copolymer composition of said monomer containing a lactone structure in said entire copolymer. In addition, the copolymer according to the present invention is obtained by means of polymerizing a monomer containing an alicyclic structure, a monomer containing a lactone structure, and another vinyl monomer comprising a higher polarity than said monomer containing an alicyclic structure, but a lower polarity than said monomer containing a lactone structure. The copolymer according to the present invention exhibits superior adhesion properties to surfaces possessing a high polarity, such as metal surfaces and the like, in addition to excellent hydrophobic and thermal resistance properties, and also displays a favorable solubility in solvents used for paints, resists, and the like.

Owner:MITSUBISHI CHEM CORP

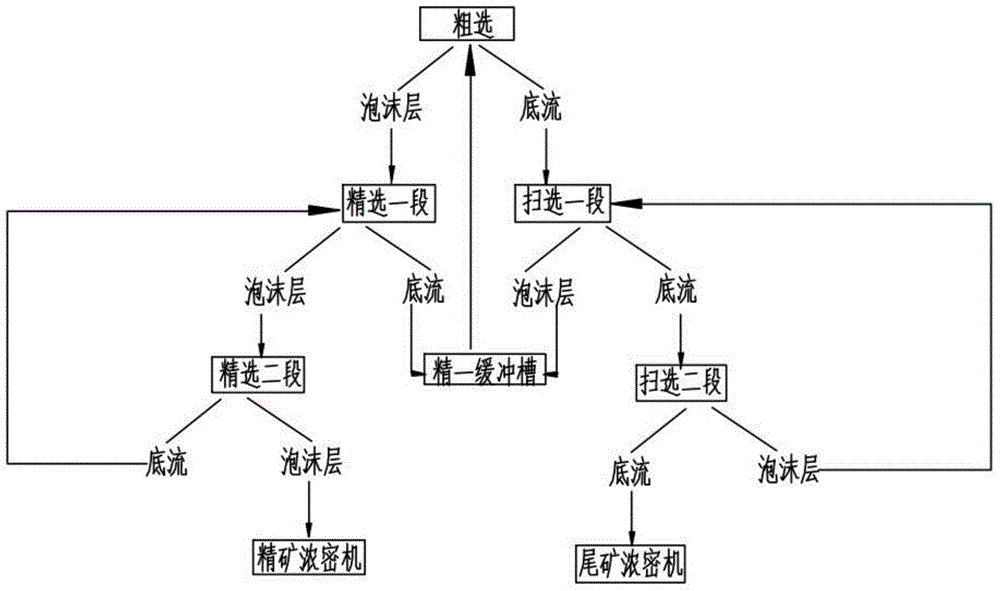

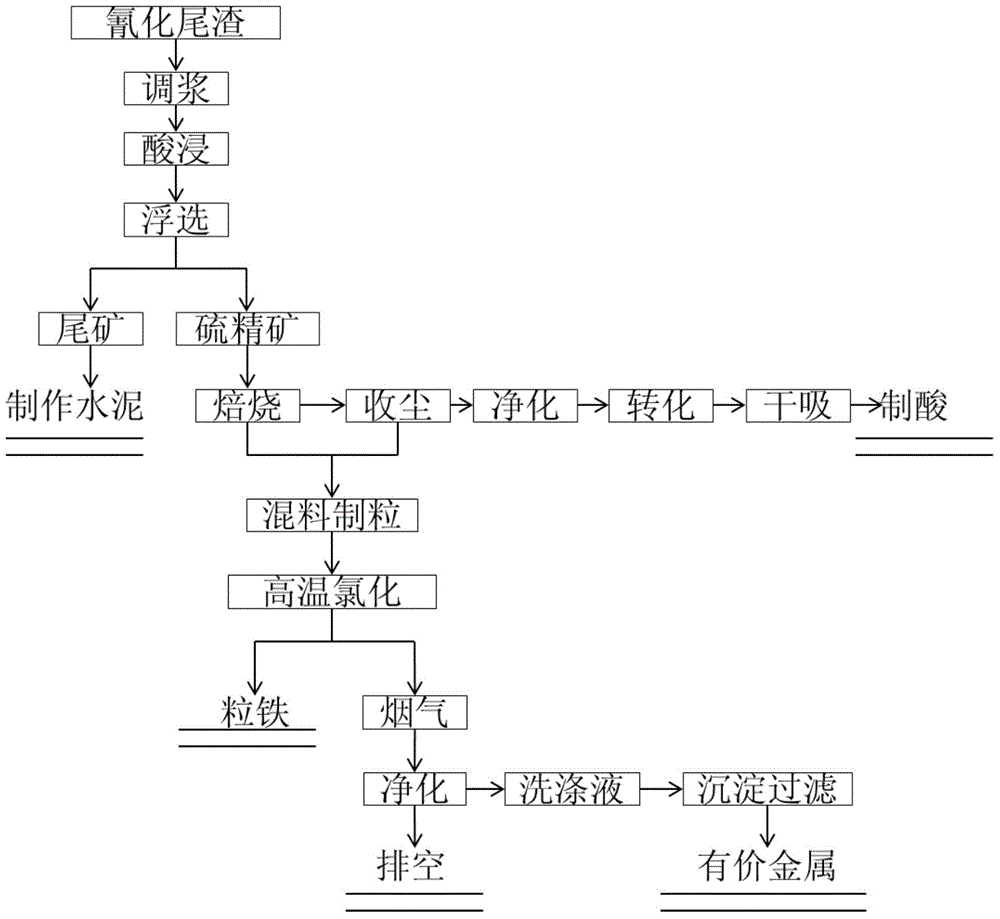

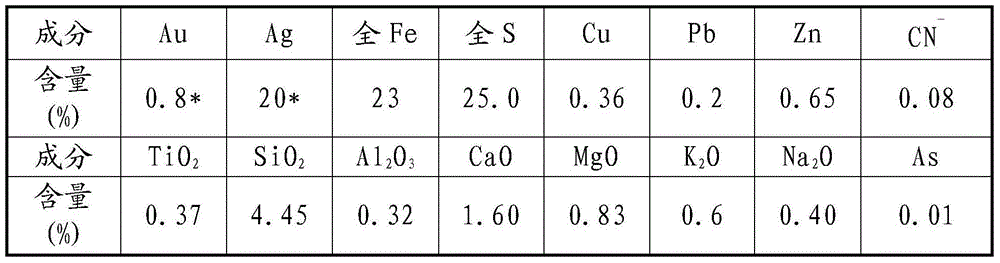

Comprehensive recycling method of cyanide tailing slag

ActiveCN103981370AEfficient separation and recoveryImprove utilization efficiencySolid waste managementSulfur compoundsCyanideSulfur

The invention belongs to the technical field of metallurgical waste slag recovery and in particular relates to a comprehensive recycling method of cyanide tailing slag. Cyanide tailings is floated to obtain sulfur concentrate and tailing, sulfur concentrate is roasted by weak oxygen to obtain sulfuric acid, and pyritic slag is subjected to chlorination roasting to enable valuable elements to be recycled. By virtue of the comprehensive recycling method disclosed by the invention, the valuable elements can be efficiently separated and recovered from cyanide tailing slag, and cyanide tailing slag is utilized to a maximum extent, the comprehensive utilization efficiency of resources is improved and the pollution of cyanide tailing slag to the environment is reduced.

Owner:ZHAOJIN MINING +1

Smelting method of low-phosphorus steel

InactiveCN101423879ALess slagShorten converter smelting cycleManufacturing convertersSlagLiquid steel

The invention provides a smelting method for efficiently producing low-phosphorous liquid steel through one-time slagging in a converter. The method comprises converter smelting and ladle refining. The method is characterized in that the temperature of converter smelting liquid steel is higher than or equal to 1,680 DEG C; the phosphorous content of the liquid steel is less than 0.012 percent; activity oxygen in the liquid steel is controlled to account for 0.1 to 0.13 percent; before converter tapping, deep dephosphorization agents are put into a ladle; in a converter tapping process, slag stopping control is performed so as to ensure that the amount of outflow slag is less than or equal to 3 kilograms per ton of steel, and the liquid steel in the ladle is subjected to weak deoxidation treatment; after the tapping is over, the deep dephosphorization agents are put into the ladle again; then ladle bottom blowing and argon stirring are carried out; and finally, steel slag in the ladle is eliminated by use of a ladle slagging-off device. Compared with other methods, the low-phosphorous liquid steel smelting method reduces slag amount by more than 20 percent and shortens converter smelting period by more than 5 percent. As slagging is carried out only once in a converter, the method is little in the erosion of a converter lining, and rephosphorization phenomena can not occur in a secondary refining process of the liquid steel.

Owner:ANGANG STEEL CO LTD

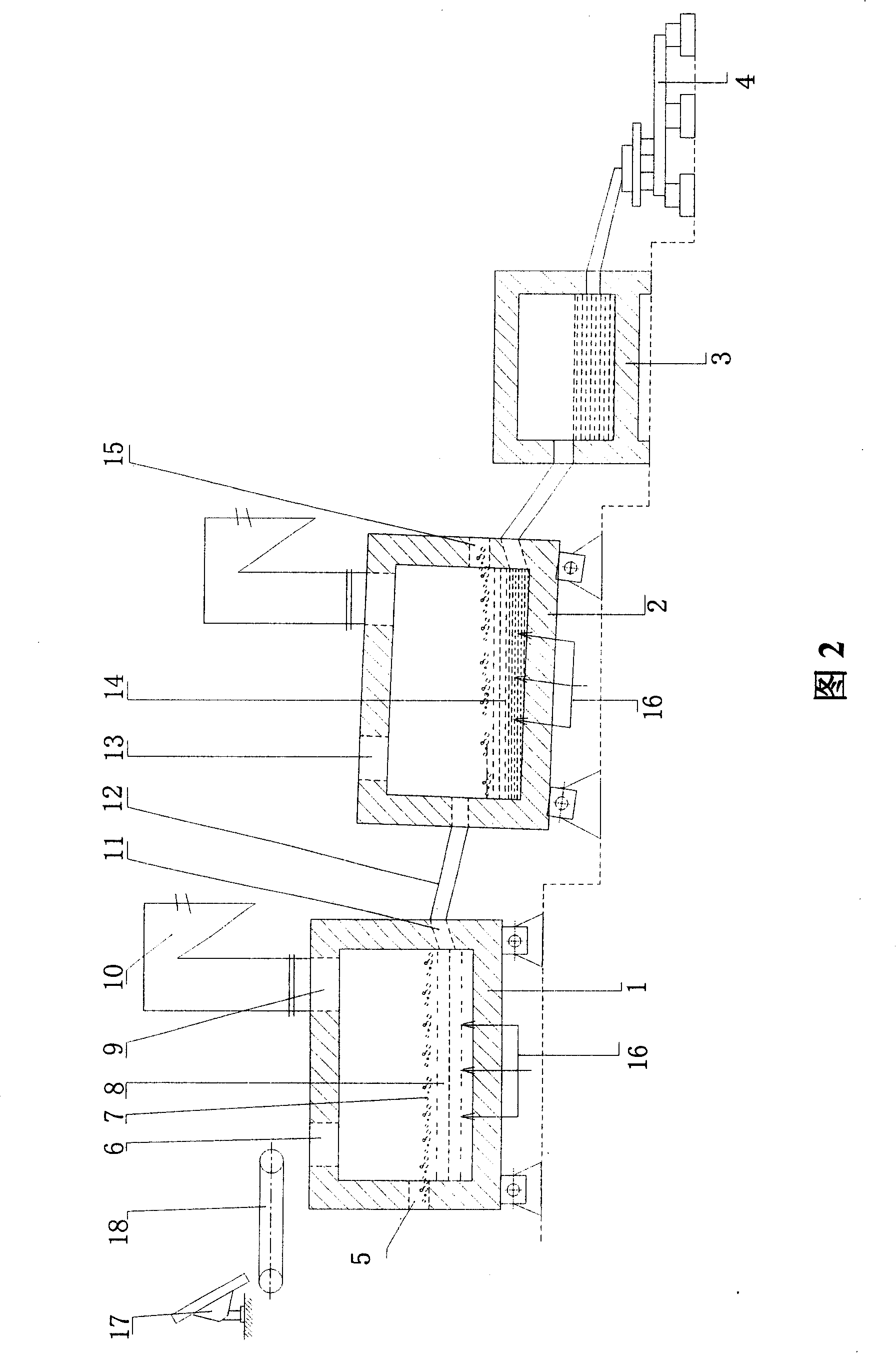

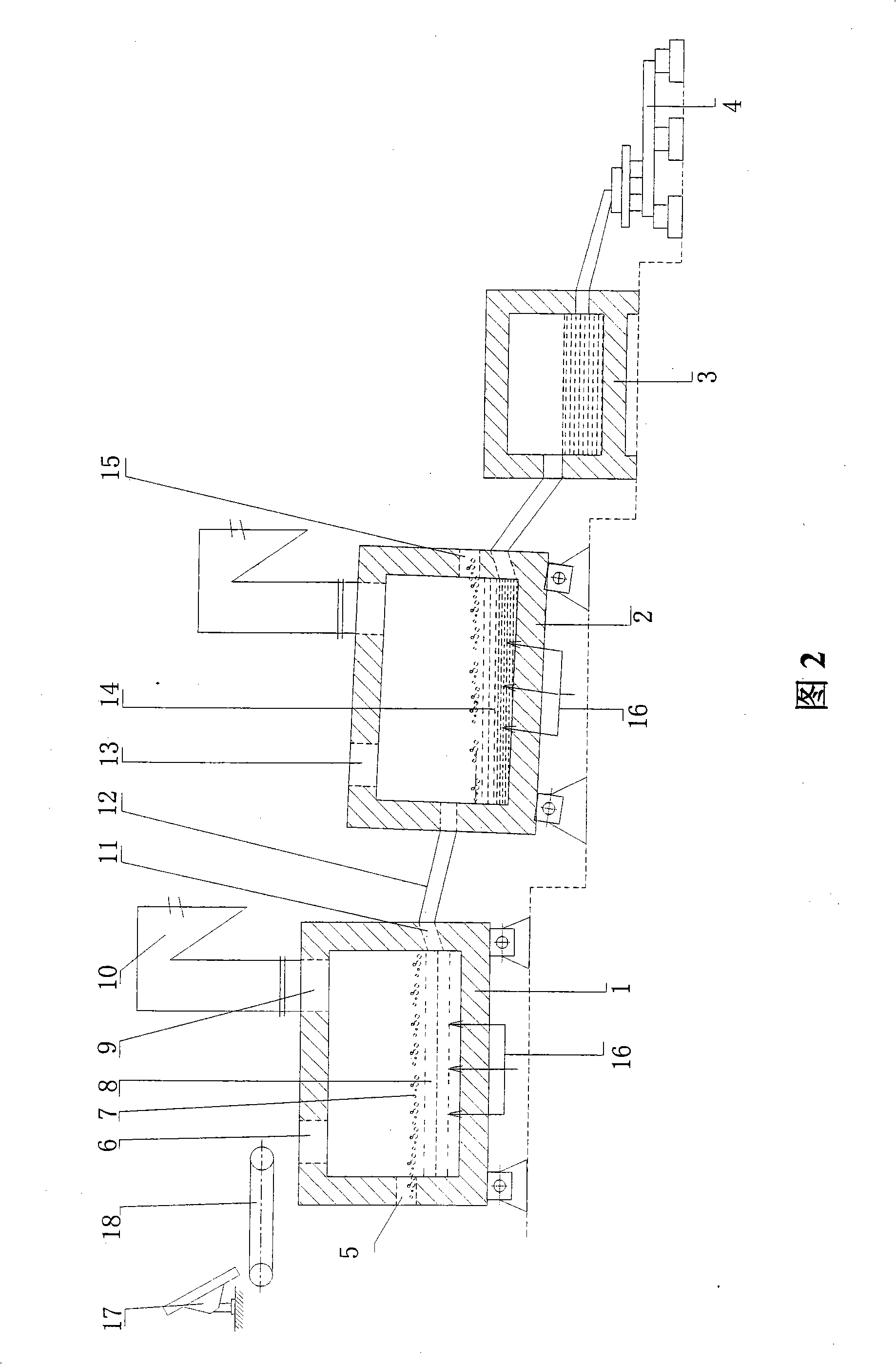

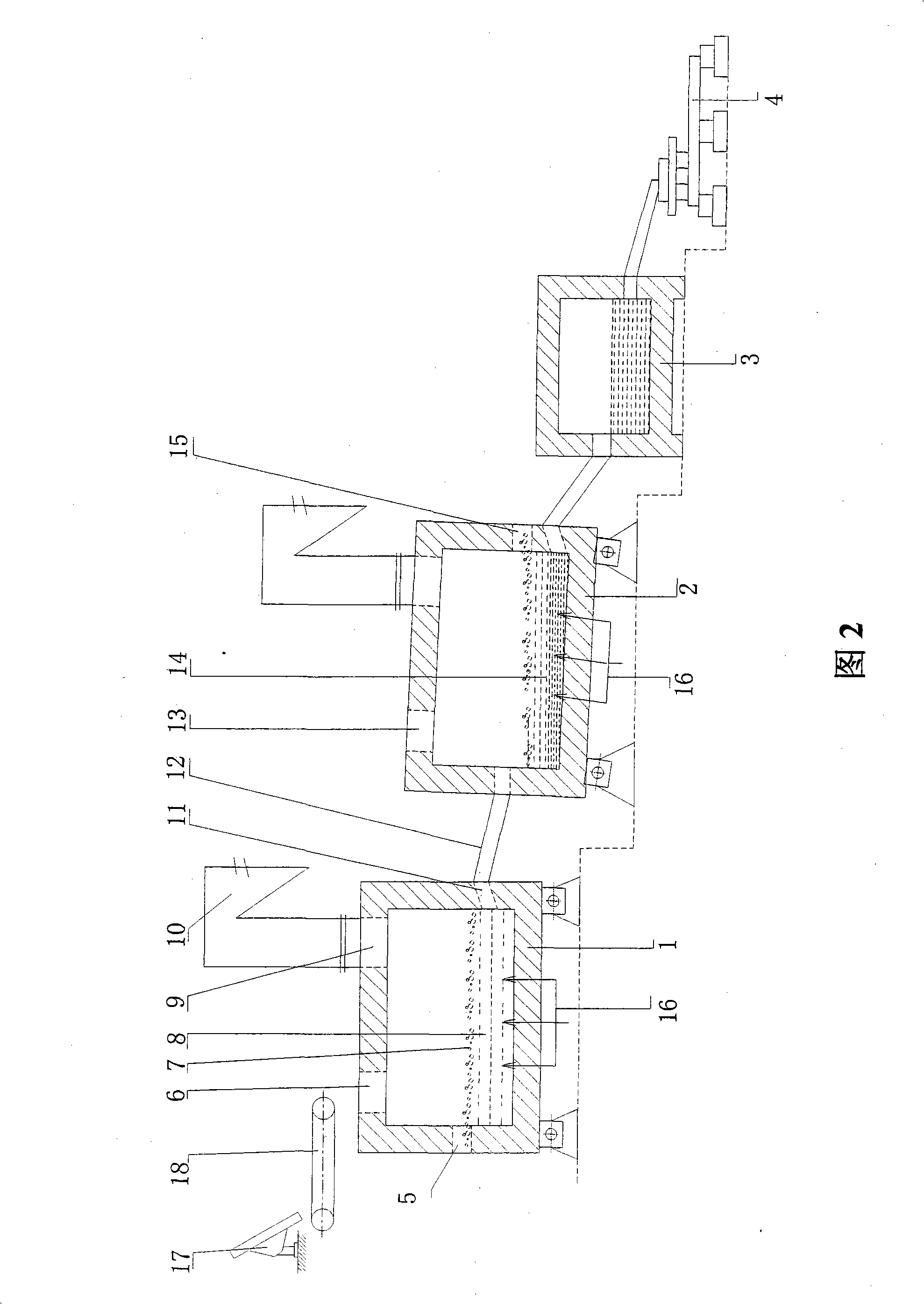

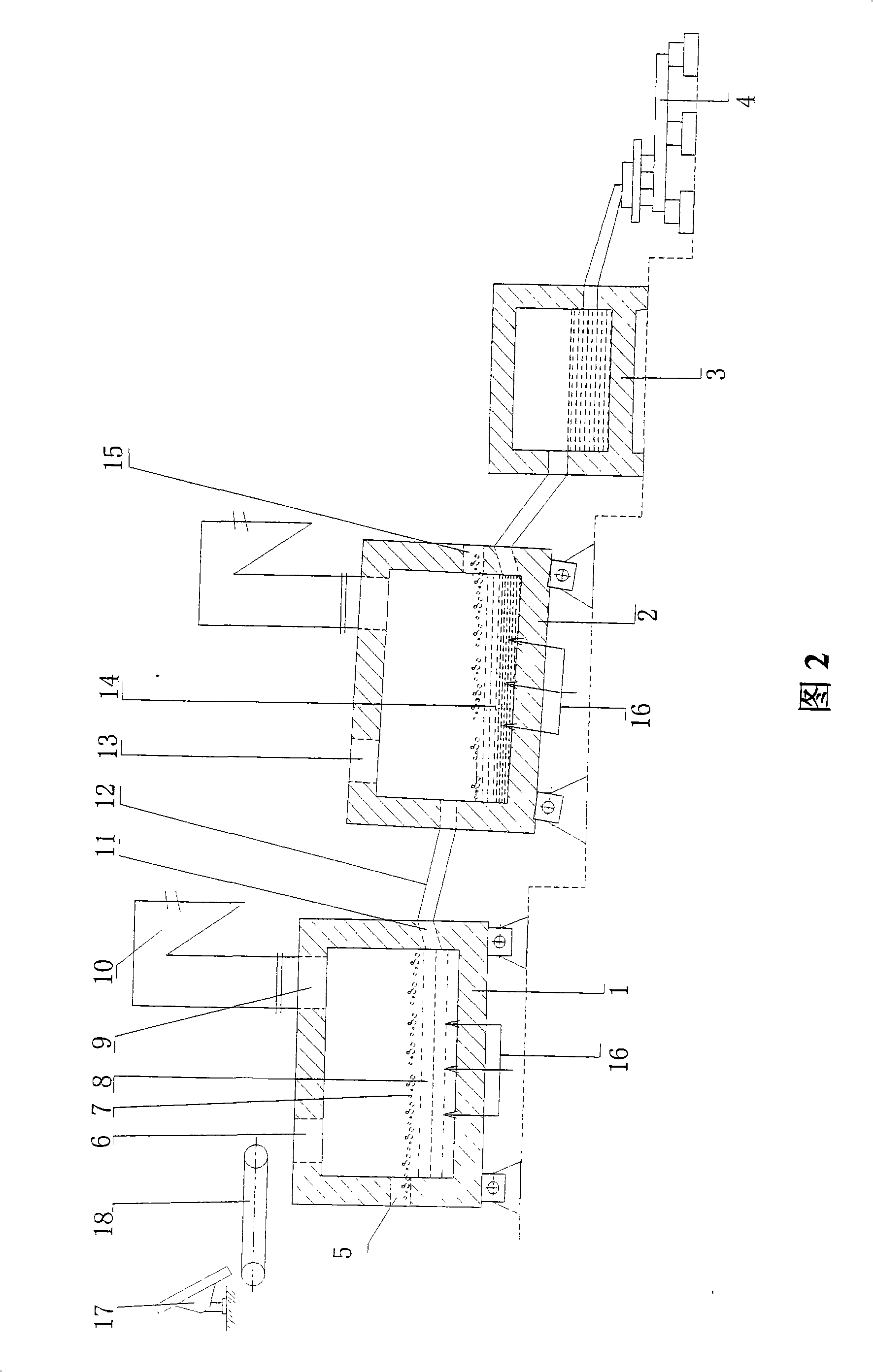

Oxygen bottom blowing continuous copper smelting apparatus

InactiveCN101328543ALess slagHigh yieldRotary drum furnacesCrucible furnacesSmelting processLiquid copper

The invention provides an oxygen bottom blowing continual copper smelting device used in the continual copper smelting process. The device is characterized in that the device comprises an oxygen bottom blowing smelting furnace, an oxygen bottom blowing converting furnace, an anode furnace and an anode plate casting machine, wherein the oxygen bottom blowing smelting furnace and the oxygen bottom blowing converting furnace are connected by a first chute, so that liquid copper matte smelted by the oxygen bottom blowing smelting furnace can be continuously injected into the oxygen bottom blowing converting furnace through the first chute to obtain coarse copper by the continuous converting of the oxygen bottom blowing converting furnace; the oxygen bottom blowing converting furnace and the anode furnace are connected by a second chute, so that the coarse copper can flow in the anode furnace through the second chute and is subjected to refining by the anode furnace to obtain anode copper; and the anode furnace and the anode plate casting machine are connected by a third chute, so that the anode copper can flow into the anode plate casting machine through the third chute and is subjected to casting by the anode plate casting machine to obtain the copper anode plate.

Owner:CHINA ENFI ENGINEERING CORPORATION

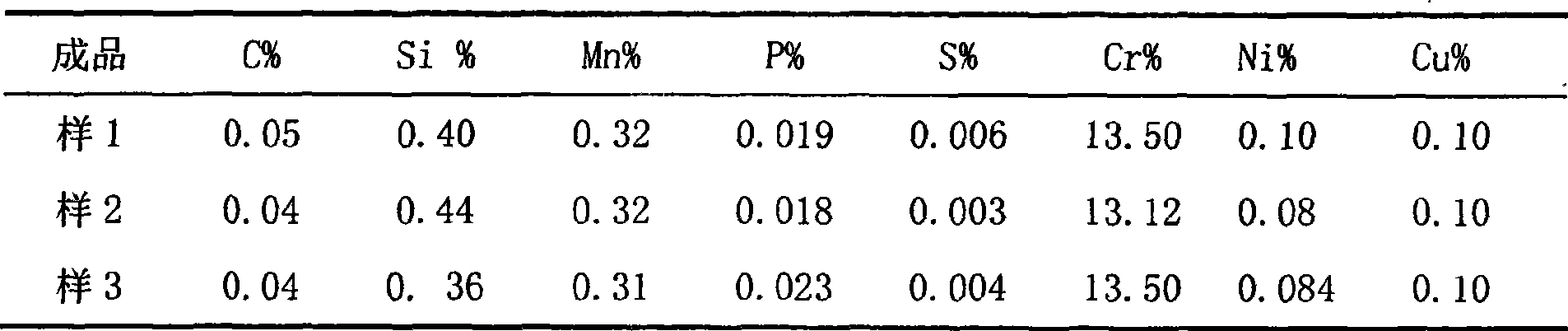

Two-step stainless steel smelting method

ActiveCN101457272AHigh recovery rateReduce consumptionProcess efficiency improvementElectric furnacePresent methodChromium nickel

The invention relates to a stainless steel smelting method by a two-step process. The method comprises the following steps: (1) smelting dephosphorized molten iron; (2) smelting semisteel; (3) lifting the semisteel to a deslagging station for deslagging treatment; (4) adding the semisteel to a GOR refining furnace for air refining; (5) refining; (6) continuous casting and (7) finishing, thinning and then rolling. Compared with the present method for producing the stainless steel by smelting, the method has the advantages of wide application scope of raw materials, low energy and resource consumption, strong variety development capacity, high recovery rate of chromium-nickel metal, high production efficiency and the like. Sulfide, oxide, silicate and punctiform non-metallic inclusion in the steel have low grade, the dephosphorized molten iron is provided by a top-bottom combined blowing converter and smelting is performed by the two-step process in an EAF+GOR refining furnace, thus the method has relatively low production cost and relatively large cost advantage, and the performance of a rolled finished product is consistent with a user quality standard.

Owner:SHANDONG TAISHAN STEEL GROUP

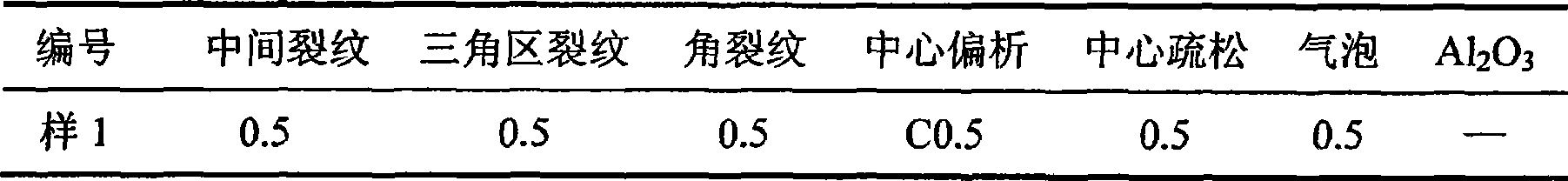

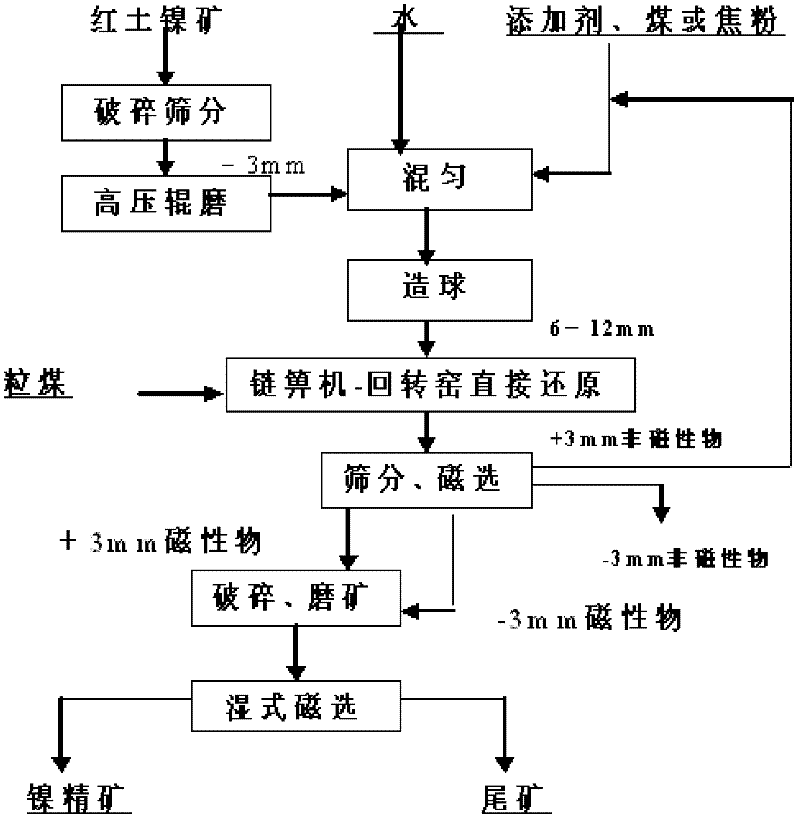

Method for preparing high-nickel concentrate from low-grade red soil nickel ore

InactiveCN102242252ALarge specific surface areaGood ball formingMagnetic separationMass ratioHigh pressure

The invention discloses a method for preparing a high-nickel concentrate from a low-grade red soil nickel ore, which comprises the following steps of: drying the low-grade red soil nickel ore until water content is 13 to 16 percent, crushing to ensure that the size of all particles is less than 3mm, grinding by using a high-pressure roller mill to ensure that particles with the size of less than 0.074mm account for 80 percent and specific surface area is not less than 2,000cm<2> / g, adding 15 to 20 percent of composite binder and 1 to 5 percent of coal powder, and pelletizing by using a disc pelletizer to obtain green pellets with the size of 6 to 16mm; drying and preheating the green pellets on a chain grate for water removal and solidification to ensure that each piece of pellet entering a kiln has the compression strength of over 500N; directly adding the preheated and solidified pellets into a rotary kiln, and reducing at the temperature of between 1,100 and 1,250 DEG C for 60 to 120 minutes by using pea coal as a reducing agent in a mass ratio of the reducing coal to the pellets of 0.8-1.0; and cooling a reduction product, sieving, performing magnetic separation to obtain a magnetic product, crushing, grinding, and performing magnetic separation to obtain the high-nickel concentrate, wherein the composite additive comprises the following components: Na2CO3 and CaO, iron oxide powder, the coal powder and sodium humate in a ratio of (30-60):(20-30):(20-30):(5-10). The method is high in adaptability and nickel recovery rate and suitable for mass production.

Owner:CENT SOUTH UNIV

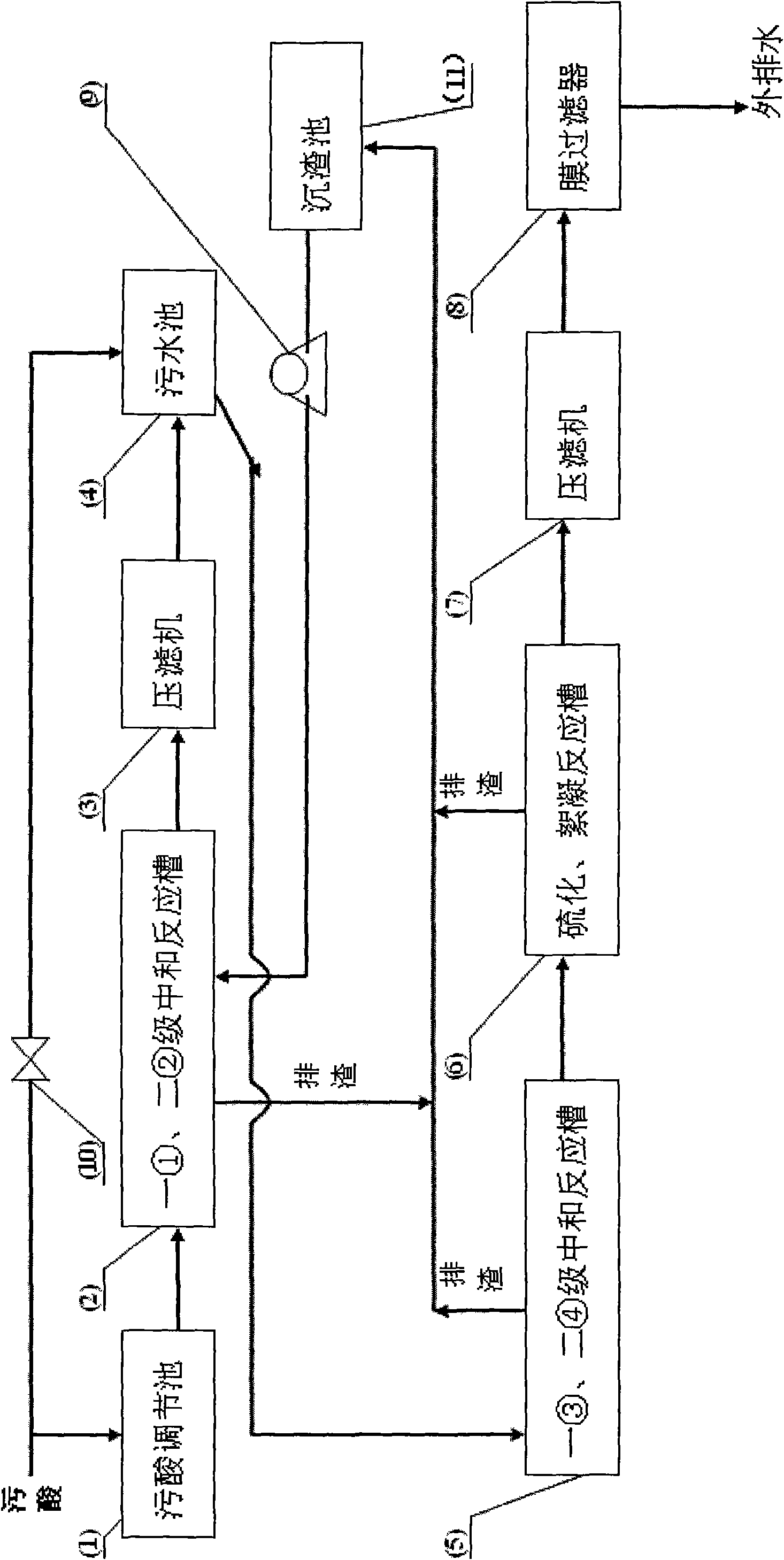

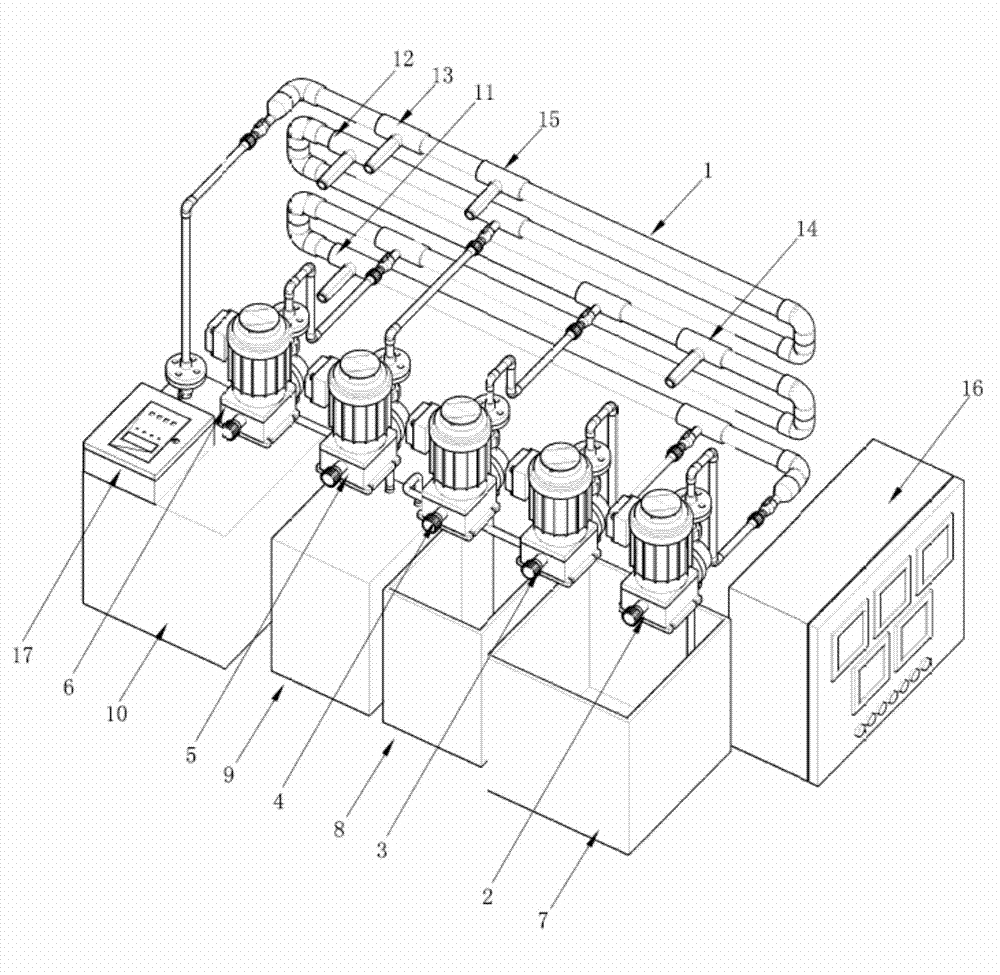

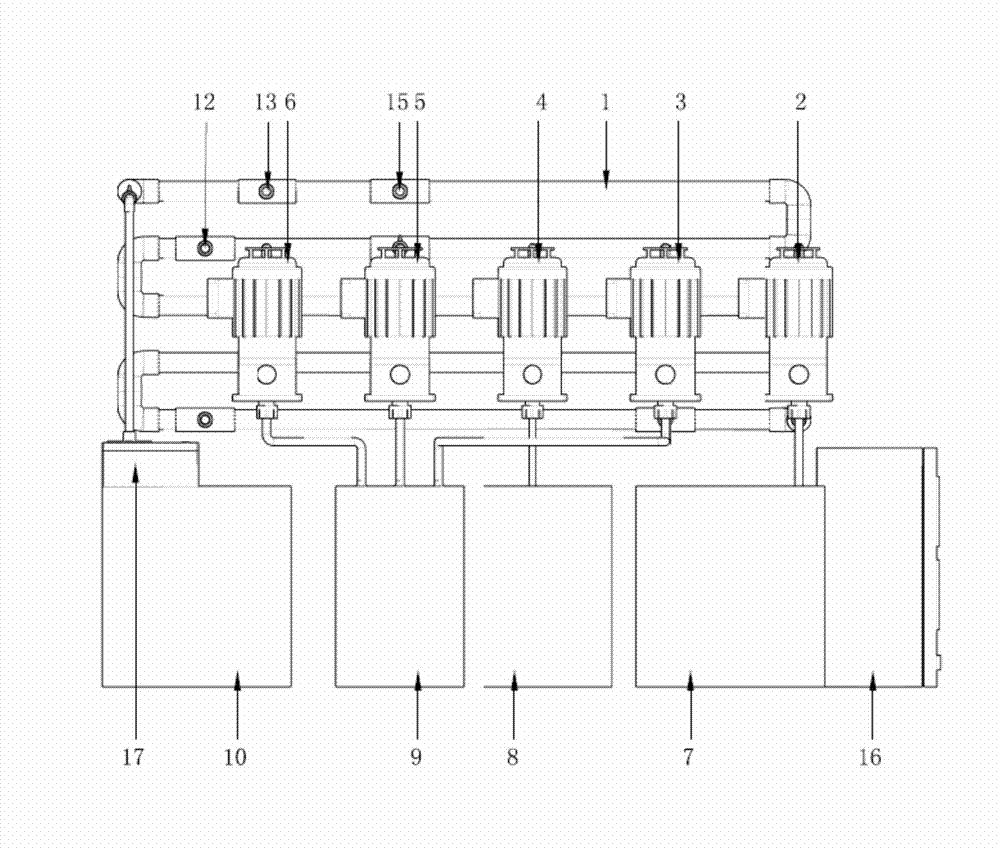

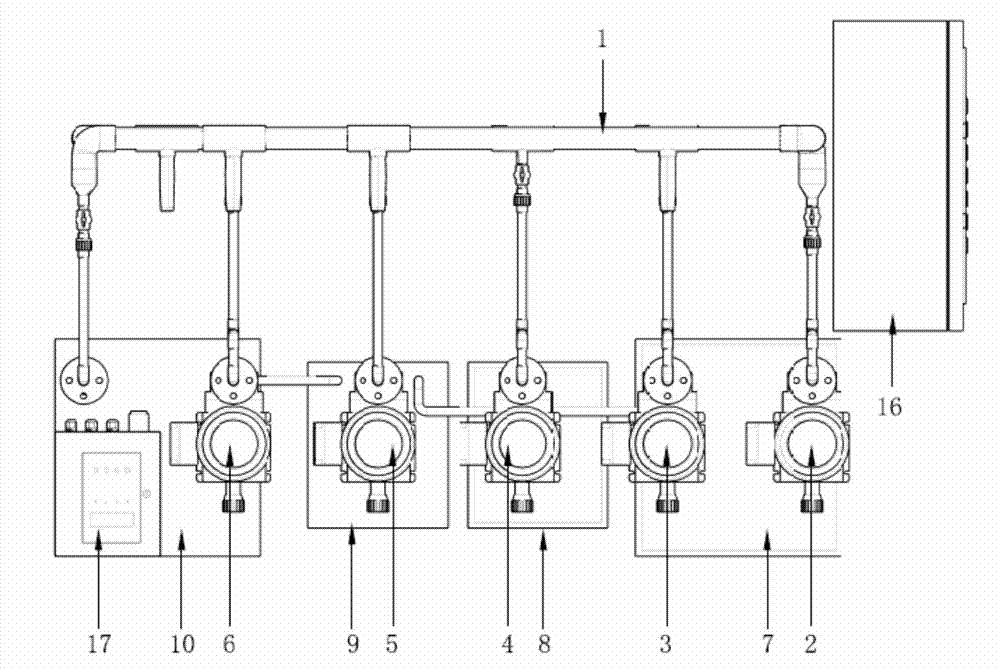

Processing equipment and technique for waste acid and water

InactiveCN101628763AAchieve separationEasy to achieve precise adjustmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFlocculationVulcanization

The invention relates to waste acid and water processing equipment and a technique for processing acidic sewage generated in the process of purification of an acid making system. The technique comprises the following steps: pumping the waste acid into a first-level neutralizing reaction tank in the first stage; adding calcium carbide slag to adjust the pH value between 1 and 6; adding calcium carbide slag to adjust the pH value between 5 and 6, when the liquid overflows into a second-level neutralizing reaction tank in the first stage; carrying out solid-liquid separation; entering a sewage pool; pumping the liquid in the sewage pool into a first-level neutralizing reaction tank in the second stage; adding lime milk to adjust the pH value between 6 and 7; adding lime milk to adjust the pH value between 7 and 8, when the liquid gravitationally flows into a second-level neutralizing reaction tank in the second stage; adding 7% of sodium sulphide and 15% of ferrous sulfate according to weight percentage into a vulcanization and flocculation reaction tank, when the liquid gravitationally flows into the vulcanization and flocculation reaction tank; carrying out solid-liquid separation of fine particles on the liquid by a filter press and a film filter; discharging the liquid, thus the continuous up-to-standard discharging of effluent water is easily realized.

Owner:HENAN YUGUANG ZINC IND

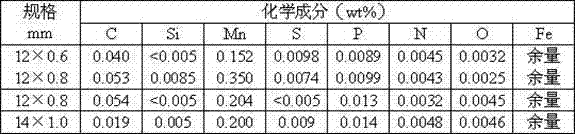

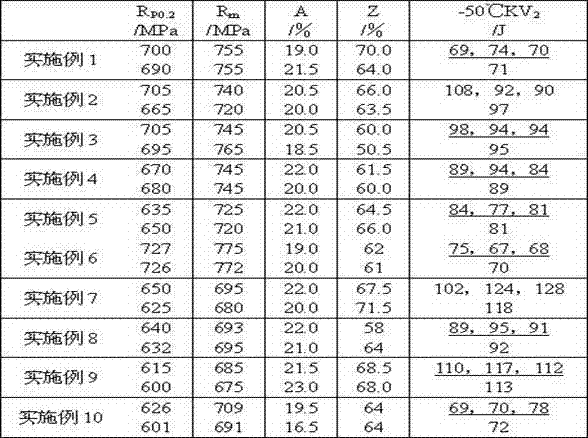

High-strength and high-toughness metal powder type flux-cored wire with no need of being pre-heated before welded

ActiveCN103028864AGood welding performanceGood workmanshipWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a high-strength and high-toughness metal powder type flux-cored wire with no need of being pre-heated before welded. Steel skin is 79-84% of a total weight of a welding wire and a flux core is 16-21% of the total weight of the welding wire. The steel skin is manufactured by using a cold rolling carbon steel strip and comprises the following components: 0.02-0.055% of C, 0.005-0.0085% of Si, 0.15-0.35% of Mn and the balance of iron; and the flux core comprises the following components: 12-18% of nickel powder, 2-4% of manganese powder, 3-7% of silicon iron, 2-6% of ferro-molybdenum, 0.8-2.5% of ferrotitanium, 1-5% of mid-carbon ferromanganese, 0.8-2.5% of potassium fluosilicate and rear earth oxide in sum, and the balance of iron powder. The flux-cored wire provided by the invention has the advantages of good welding process, high melting efficiency and less slag quantity; the yield strength of deposited metal can be more than 590 MPa; the impact rigidity at a temperature of -50 DEG C can be more than 70J; and the diffusible hydrogen is in an ultralow hydrogen level.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

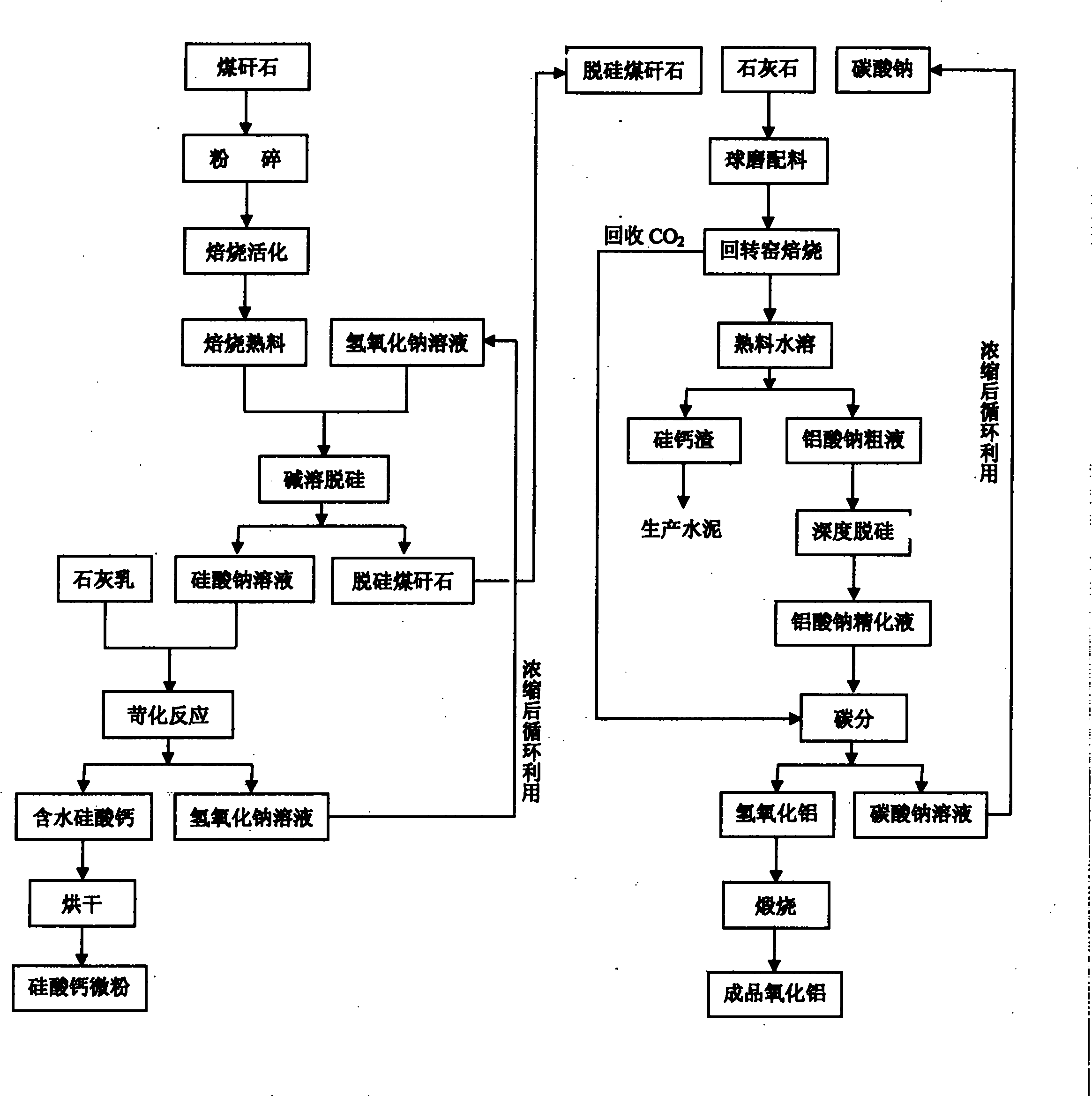

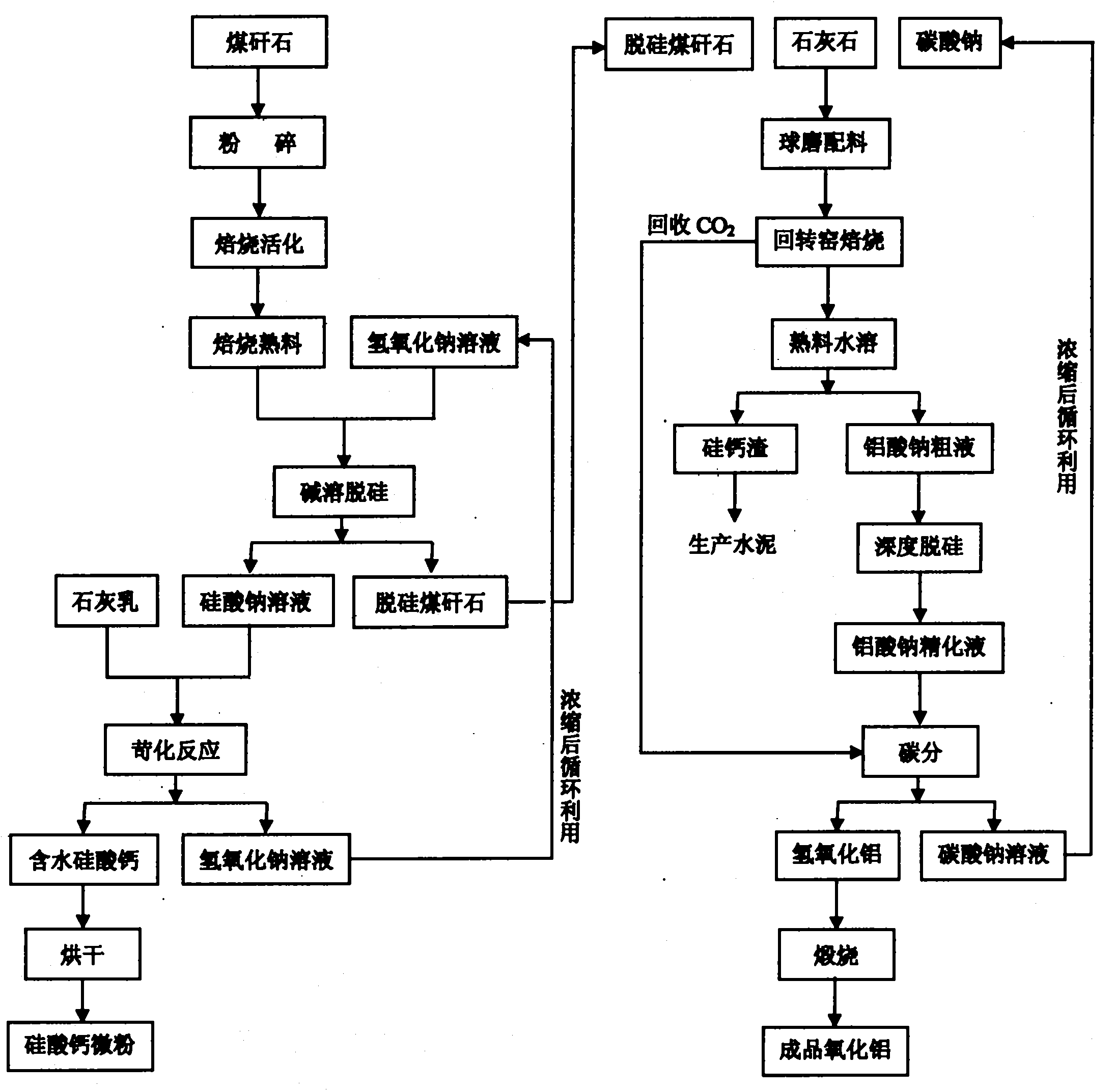

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725ALow firing temperatureHigh activityAlkaline-earth metal silicatesCement productionCoal gangueAluminium oxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon and calcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxide to obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

Method and device for producing crude antimony trioxide by smelting of rich oxygen side-blown volatile molten pool

The invention discloses a method and a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The method comprises the following steps: by taking an antimonial material as a raw material, blind coal or coke or a natural gas or a coal gas and the like as supplement fuel, and iron ore and lime as fluxes, blowing oxygen-enriched air, entering a furnace to react after metering a charging material, so as to produce high-temperature smoke and melt; condensing and dedusting the high-temperature smoke, and then feeding the smoke to an acid making system to prepare an acid, wherein the condensed powder is a crude antimony trioxide product to feed to the next procedure to process; respectively discharging the high-temperature melt after settling and layering in a hearth; quenching the slag to be directly used as a waste slag, and returning a little of produced antimony matte and crude antimony; and feeding noble antimony to the next procedure to process and extract gold. The invention also comprises a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The device has the advantages of being strong in raw material adaptability, low in energy consumption, high in smoke SO2 concentration, high in direct recovery rate and recovery rate of antimony and noble metal, clean and environment-friendly to produce, low in production cost and the like, and the acid can be directly prepared.

Owner:锡矿山闪星锑业有限责任公司 +3

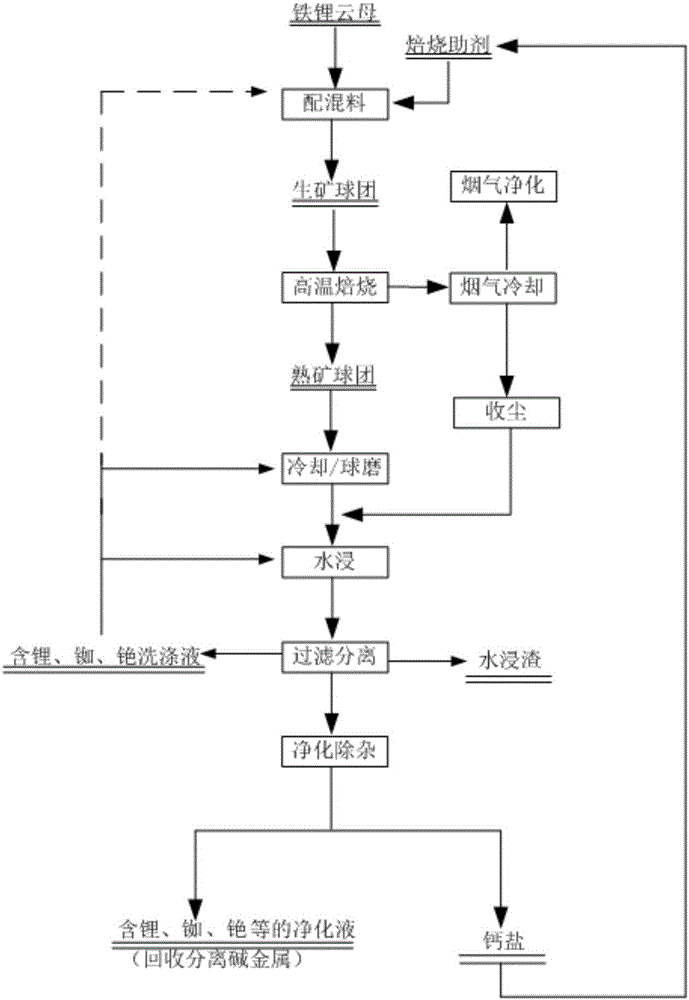

Method for extracting lithium, rubidium and cesium in zinnwaldite

The invention discloses a method for extracting lithium, rubidium and cesium in zinnwaldite. The method includes the following steps that S1, the zinnwaldite and a roasting addition agent are evenly mixed and pelletized, and thus raw ore pellets are obtained; the roasting addition agent is a compound addition agent which is composed of sulfate and / or calcium carbonate and / or calcium hydroxide and / or calcium oxide; S2, the raw ore pellets are roasted, so that clinker ore pellets are obtained; S3, the clinker ore pellets are ground, the ground clinker ore pellets are immersed by water, filtering is performed, and thus leach liquor is obtained; and S4, calcium oxide and / or calcium hydroxide are / is added into the leach liquor, performing is performed, and thus a purified solution containing water-soluble lithium salt, water-soluble rubidium salt and water-soluble cesium salt is obtained. According to the lithium extracting method, the compound roasting addition agent is creatively used, the extraction efficiency of alkali metal like the lithium, rubidium and cesium is improved, and cost is reduced.

Owner:道县亿林矿业有限公司 +1

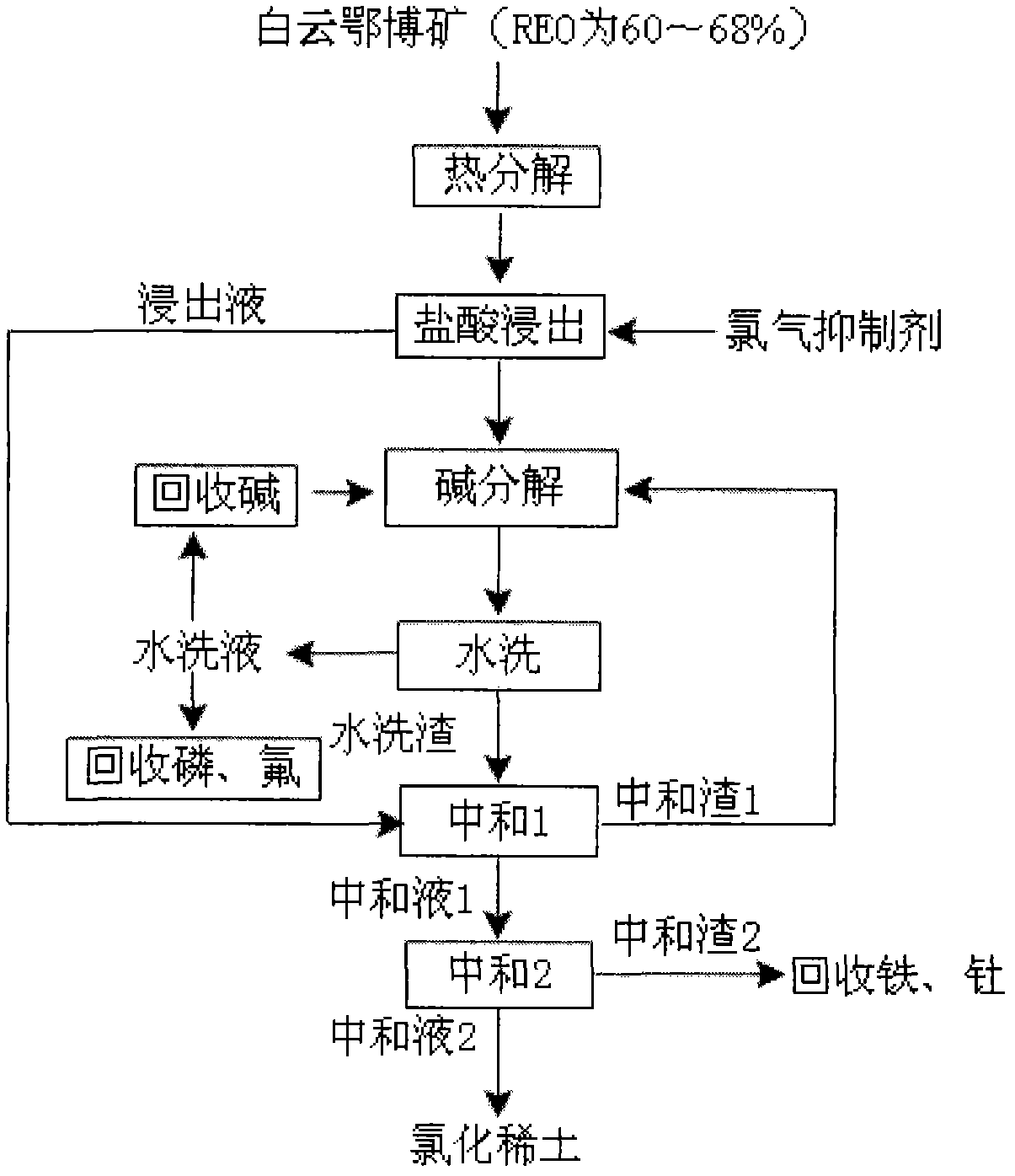

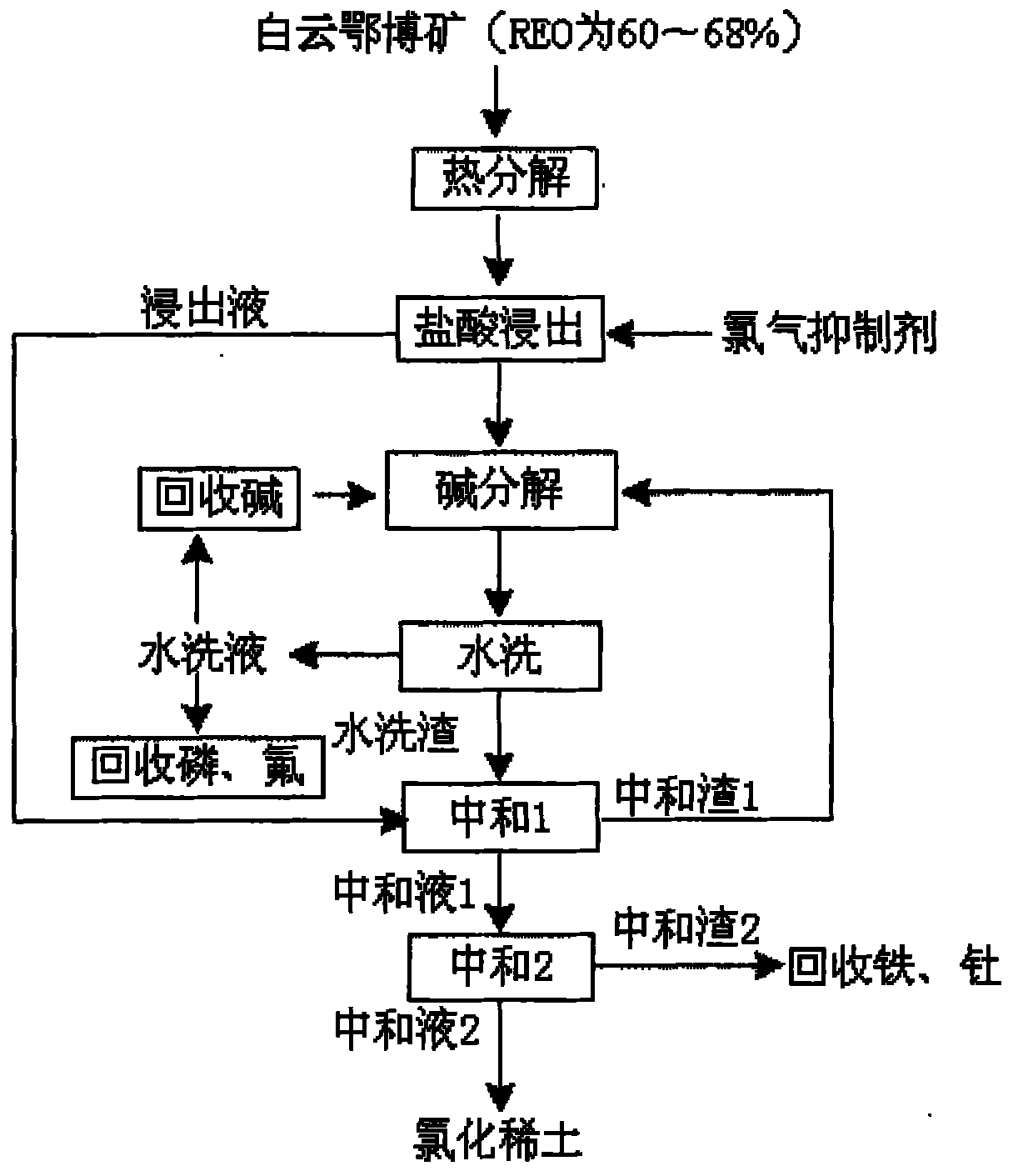

A New Method for Preparing Rare Earth Chloride from Baiyun Obo Rare Earth Concentrate

The invention relates to a new method for preparing rare earth chloride by using Baiyunebo rare earth concentrate and belongs to the field of wet-process metallurgy. The invention comprises the following steps: performing thermal decomposition, wherein a raw material used is Baiyunebo mixed rare earth concentrate with a grade of 60 to 80 percent; leaching in hydrochloric acid, namely leaching oreobtained after thermal decomposition in hydrochloric acid; performing alkaline decomposition, namely decomposing filter residue obtained after leaching in hydrochloric acid with solution of sodium hydroxide; washing, namely washing the ores obtained after alkaline decomposition with water till the pH value is 7 to 9, and recovering fluorine and phosphorus from washing solution; performing primaryneutralization, namely mixing hydrochloric acid leachate and water washing residue, and neutralizing till the pH value is 0.5 to 2.5; and performing secondary neutralization, namely neutralizing the filtrate obtained by the primary neutralization till the pH value is 4 to 5, wherein the filtrate of the secondary neutralization is solution of rare earth chloride. The method has the advantages of facilitating recovery of other elements, avoiding waste gas, waste water and waste residue, along with small alkali consumption, stable process and high rare earth recovery rate of more than or equal to 95 percent.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Treatment method of arsenic wastewater

ActiveCN103112974AShort process routeShort construction periodMultistage water/sewage treatmentFlocculationResource recovery

The invention discloses a treatment method of arsenic wastewater. The treatment method comprises the following steps: optionally adding acid liquor into the arsenic wastewater to adjust the pH value to 0-5; introducing the arsenic wastewater into a reaction unit, continuously removing arsenic by adding sulfide in multistage manner; carrying out solid-liquid separation on the effluent after reaction, recycling the separated arsenic slag; adding alkali into the separated effluent to perform electrochemical advanced treatment, wherein the electrochemical advanced treatment includes an electrolytic coagulation step, an electrolytic flotation step and an electrolytic oxidation reduction step, in the electrolytic coagulation, cations are generated by the electrolyzation of a soluble anodic iron plate for flocculation; carrying out aerated oxidation on the effluent after flocculation to generate floc and micelle sediment including ferric ions, and then carrying out solid-liquid separation, wherein the liquid supernatant after separation can be recycled or reach the standard and drain outwards. The treatment method of arsenic wastewater has the advantages of simple technology, low investment, low cost and high resource recovery and recycling rate, and being green and environment-friendly, and being capable of treating continuously and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

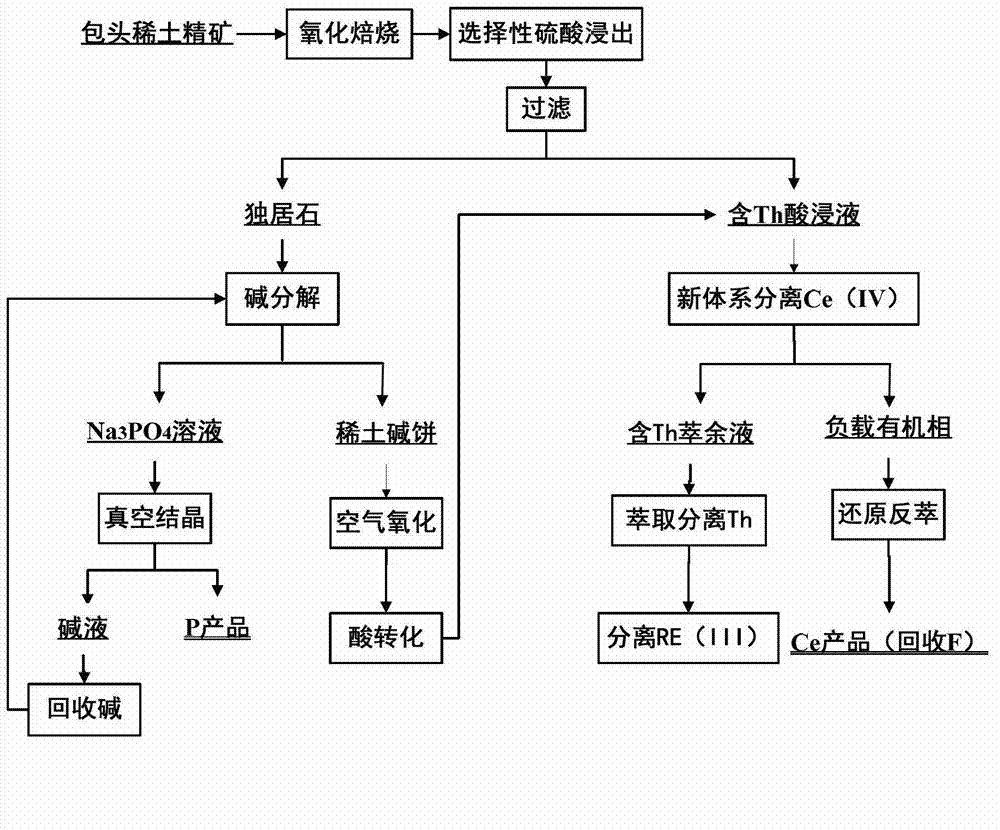

Technique for decomposing Baotou rare-earth ores

InactiveCN103045851AReduce stockpilesReduce processingProcess efficiency improvementPregnant leach solutionSodium phosphates

The invention relates to a technique for decomposing Baotou rare-earth ores. The invention solves the technical problems of environmental pollution and resource loss caused by the rare-earth ore separation technique in the prior art. The technique comprises the following steps: carrying out oxidizing roasting on mixed rare-earth concentrate; leaching the roasted ores with an H2SO4 solution to obtain a leach solution and urdite; extracting and separating Ce (IV), F and Th as well as single RE (III) from the sulfuric acid leach solution; and carrying out alkali conversion on the urdite to obtain a rare-earth alkali cake, carrying out size mixing, filtering, and crystallizing the alkaline solution to recover sodium phosphate, wherein the residual alkali liquor is used for cyclically leaching urdite slag. When being used for treating the mixed rare-earth concentrate, the technique provided by the invention can implement multi-step extraction of bastnaesite and urdite in the mixed ores. Besides, the invention is beneficial to further effectively recovering Th, F and P from baotite, thereby avoiding environmental pollution, enhancing the rare-earth yield, saving the cost and implementing clean production and comprehensive resource utilization in deed.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

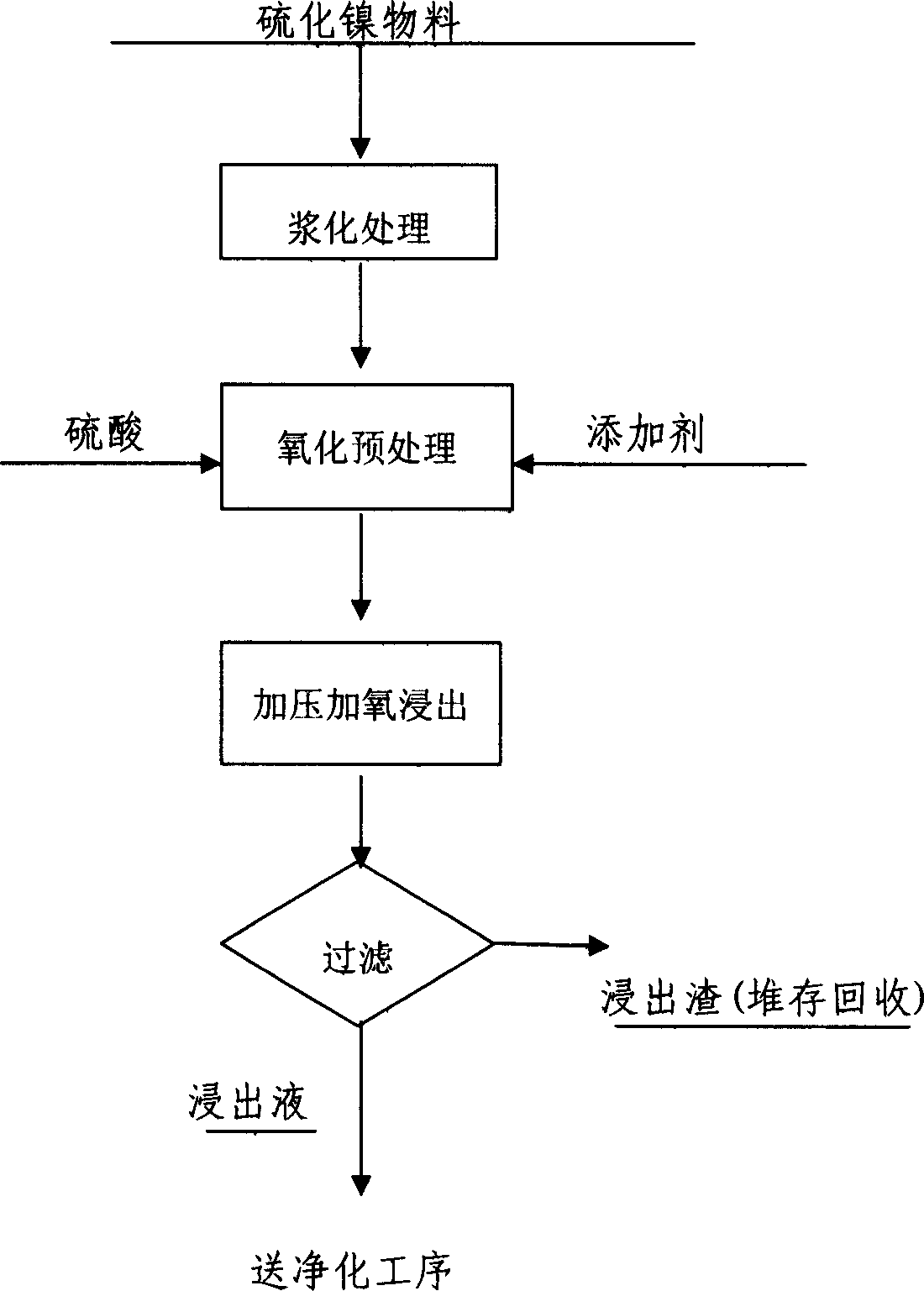

Wet treatment method of iron containing nickel sulfide material

The invention relates to a wet treatment method extracting nickel from iron containing nickel sulfide material. Its features are after slurring and oxidizing pretreatment to the iron containing nickel sulfide material; adopting pressurizing, adding oxygen, and additive method to effectively lixiviate nickel cobalt and restrain iron, reduce purifying deferrization reagent consumption and iron slag, reduce nickel losing, use sodium hydroxide to sink nickel after leaching solution, use sulphuric acid to dissolve nickel hydroxides, and gaining bright nickel sulphate solution after extracting and reclaiming cobalt. The nickel sulfate solution is produced out nickel sulfate by condensing crystallizing, or electricity nickel products by electro deposit, and both of them are according with GB.

Owner:云锡元江镍业有限责任公司

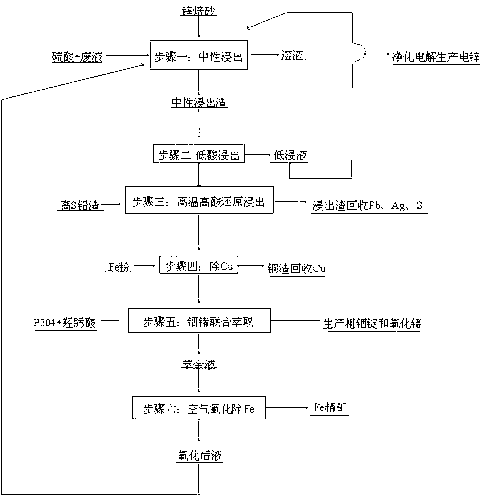

Method for comprehensively recovering iron and germanium from zinc calcine containing high iron and high indium

InactiveCN102703695AShort processSimple methodPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for comprehensively recovering iron and germanium from zinc calcine containing high iron and high indium. The method comprises the following steps of: leaching the zinc calcine containing the indium, the germanium and zinc by using a sulfuric acid, sending a solution to electrolyze the zinc, leaching a leaching residue by using a low acid, merging with a high-lead residue together to leach by using a high-temperature high acid, adding a hydroximic acid and P204 kerosene to synergistically extract the indium and the germanium to respectively acquire an indium ingot and a germanium concentrate, and recycling extracting liquid after the iron is recovered. By using the method, the germanium and the indium can be extracted from slag with a lower grade; a procedure is simple; the operation is easy; and fewer pollutants are discharged.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

Electrochemical method for treating industrial wastewater

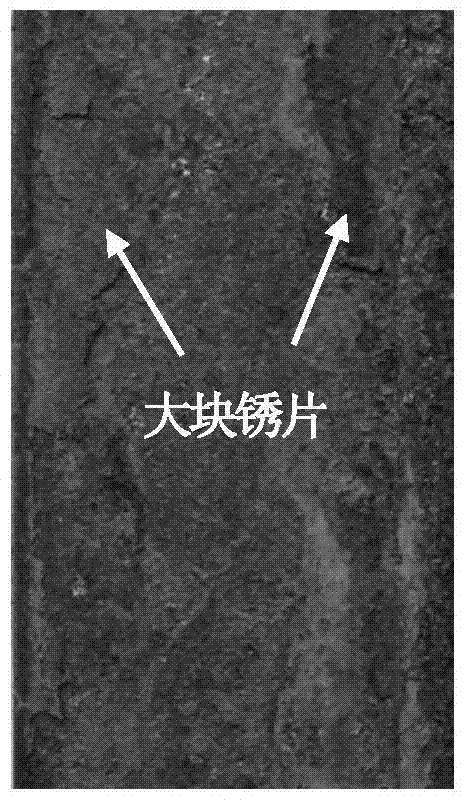

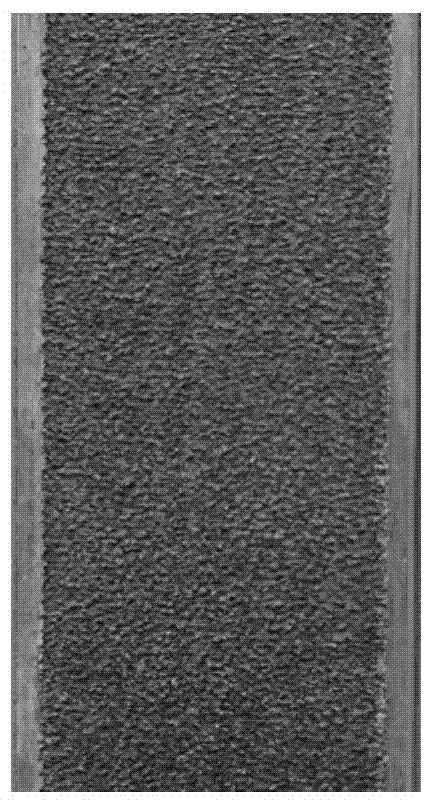

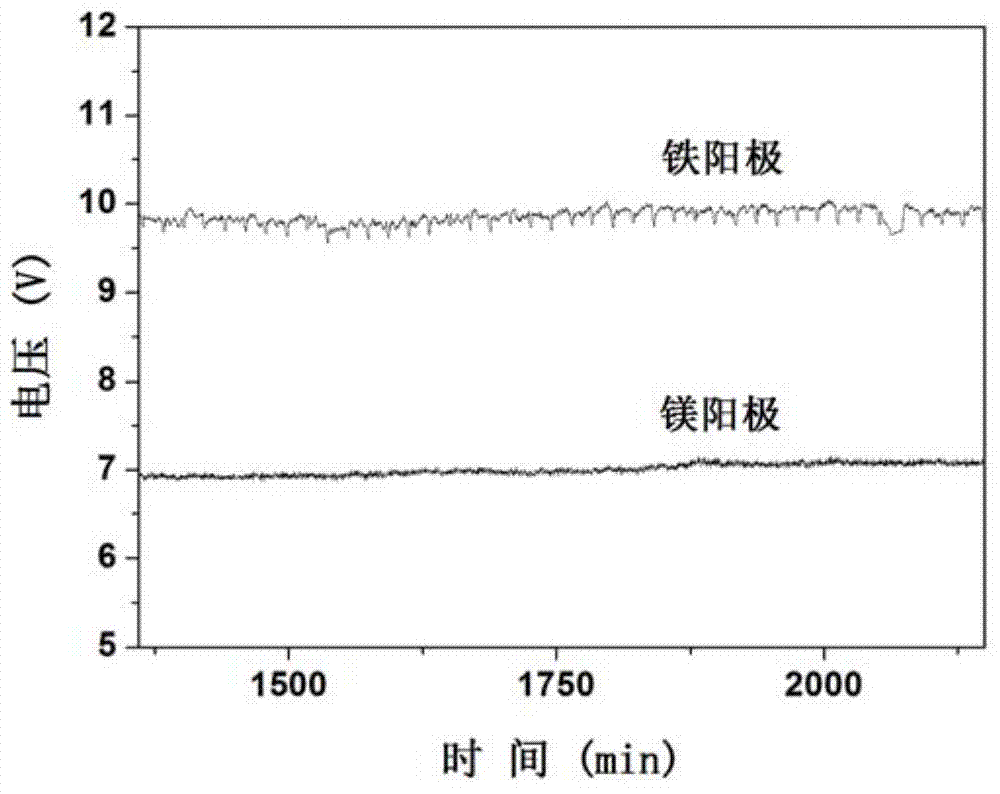

InactiveCN103936105AUniform oxide filmStable voltageWater/sewage treatment by electrochemical methodsIonHeavy metals

The invention belongs to the technical field of water treatment and relates to an electrochemical method for treating industrial wastewater. The electrochemical method can be used for effectively removing heavy metal elements in industrial wastewater by taking magnesium or magnesium alloy as an anode. High-activity magnesium hydroxide generated by a magnesium anode under electrochemical action can efficiently adsorb heavy metal ions in wastewater and is combined with suspended substances in water, and finally, the solid-liquid separation is realized through precipitation, so that the aim of purifying the wastewater is achieved. The method can be used for simultaneously removing heavy metal ions such as zinc, cadmium, copper, arsenium and the like in the industrial wastewater, and the removal rate can be up to more than 95%. Compared with the traditional iron and aluminum anode electrochemical devices, a magnesium anode electrochemical device has the advantages of no easiness for passivation of polar plates, low power consumption, low waste residue quantity and the like, and is suitable for treating wastewater generated in the industries such as metallurgy, mining, electroplating, metal processing and the like.

Owner:江阴和悦鑫环保科技有限公司

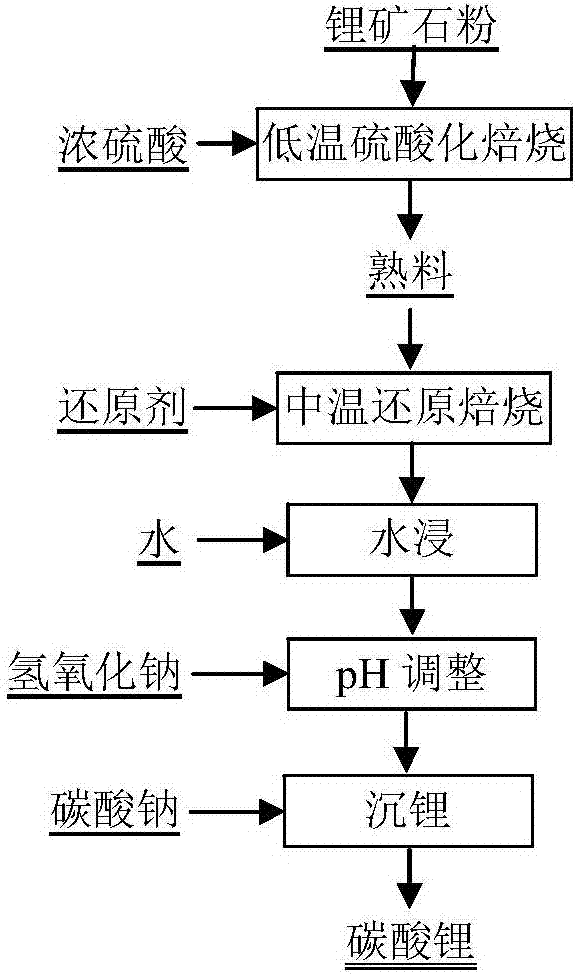

Method for preparing lithium carbonate through two-stage conversion of lithium ore

InactiveCN107089673AHigh recovery rateAchieve recyclingLithium carbonates/bicarbonatesSolubilityCalcination

The invention discloses a method for preparing lithium carbonate through two-stage conversion of lithium ore and belongs to the technical field of lithium metallurgy. The method comprises the steps: mixing lithium ore powder and concentrated sulfuric acid, performing low-temperature sulfation calcination under condition of 150 to 400 DEG C to convert lithium in the lithium ore into lithium sulfate with good water solubility and meanwhile converting fluorine into hydrogen fluoride gas to be removed to finish first-stage conversion; then performing medium-temperature reduction calcinations on a clinker under 550 to 900 DEG C to convert sulfate of iron, aluminum and the like into aluminum oxide and ferric oxide, which are difficult to dissolve in water, in the clinker to finish second-stage conversion, wherein generated sulfur dioxide flue gas can be used for preparing acid; soaking reduced calcine with water to extract lithium, leaving impurities of iron, aluminum and the like in leaching residues and filtering water-soaked ore pulp to directly obtain a purer lithium sulfate solution. The method not only achieves separation of the lithium from the aluminum and the iron in a leaching process, but also achieves regeneration cycle of sulfuric acid, reduces consumption of chemicals of sulfuric acid, neutralizing alkali and the like and has high lithium recovery rate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Converting process of bottom blowing converting furnace continuous copper smelting

The invention provides a converting process for continuous copper smelting by a bottom blowing converting furnace. The process is characterized in that liquid copper matte generated from a bottom blowing smelting furnace passes through a chute to be continuously injected into the oxygen bottom blowing smelting furnace, and oxygenized air is continuously blown in from the bottom part of the converting furnace to continuously convert the copper matte; simultaneously, lime flux or limestone is continuously added from an opening at the top of the converting furnace for slag making by a material bin and a measuring belt feeder according to the required quantity measured, or the top part of the converting furnace is not provided with the opening, the lime flux or the limestone is crushed into powder and fed together with oxygen gas in the furnace for slag making through an oxygen lance by the material bin and the measuring belt feeder; one end of the furnace has an upper part provided with an opening used for discharging smelting slag and a lower part provided with an opening used to be provided with a siphoning installation for discharging coarse copper, thereby realizing continuous addition of the copper matte, continuous converting, continuous addition of the flux, continuous slag making, continuous slag discharge and continuous coarse copper discharge and furthering realizing the continuous converting process.

Owner:CHINA ENFI ENGINEERING CORPORATION

Compound iron melt desulfurizing agent and method of preparing the same

The invention relates to a composite type molten iron desulfurizer and a preparation method thereof, which relates to a novel desulfurizer used for desulfurizing of molten iron or molten steel and a manufacturing process thereof. The components and the weight percentage ratio of the composite type molten iron desulfurizer are: 70.0 to 75.0 percent of CaO, 2.0 to 3.0 percent of TMg, 10.0 to 12.0 percent of CaC2, 8.0 to 10.0 percent of NaHCO3, 0.5 to 1.5 percent of Al, C 1.0 to 4.0 percent of C, 0 to 5.0 percent of CaF2, less than and equal to 0.18 percent of S, less than and equal to 0.10 percent of P and the rest of impurities; the finished product of the desulfurizer is powdery. The preparation method of the sulfurizer is that lime, passivated magnesium powders, calcium carbide, alkali carbonate additives, aluminum powders, graphite or charcoal, fluorite, etc. are utilized as the raw materials and are mixed evenly according to a certain weight percentage, dried and pretreated; passivated liquid is prepared; then the passivated liquid is poured into the materials to be stirred till the materials are dried, and the materials are cooled naturally and ground to make into powdery finished product. Compared with the prior art, the composite type desulfurizer and the preparation method thereof of the invention have the following advantages: short time required by the desulfurizing treatment, small quantity of slags, small temperature drop and good desulfurizing effect; low comprehensive using cost; simple production process and wide resources of the raw materials; improvement of slag forms during molten iron desulfurizing and reduction of iron loss of the molten iron. The calcium carbide, especially the magnesium powders (particles) are the products of high energy consumption, the effect of energy saving is achieved because the composite type molten iron desulfurizer of the invention correspondingly lowers the using amount of CaC2 or Mg.

Owner:PANZHIHUA DONGPAN IND & TRADE

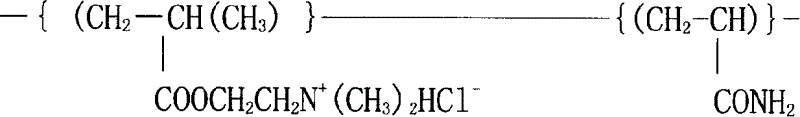

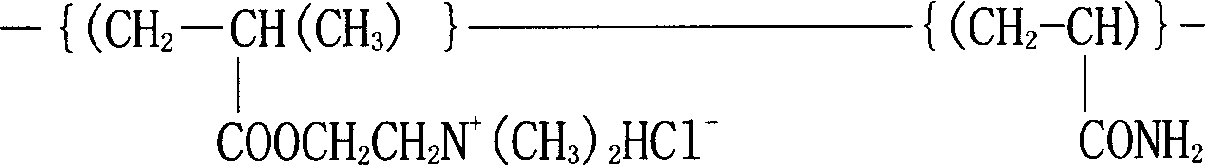

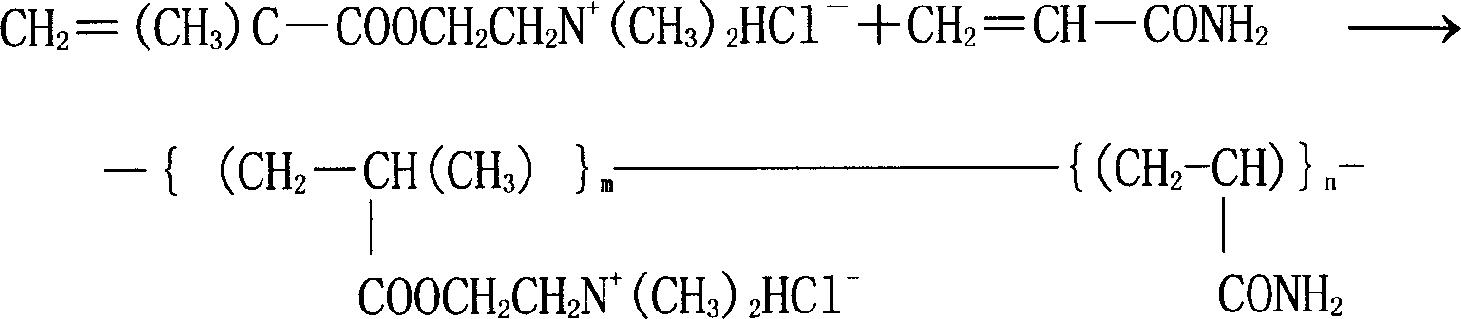

Cation type polymer flocculating agent and its preparation method

InactiveCN1597550AShort reaction timeGood flocculation effectWater/sewage treatment by flocculation/precipitationSludgeSewage

A high-molecular cationic flocculant is prepared from acrylamide, dimethylaminoethyl methylacrylate, hydrochloric acid and deionized water through polymerizing reaction in aqueous solution mode under the action of trigger.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing waste acid generated in process of preparing acid from metal smelting fume

InactiveCN102115270AIncrease consumptionIncrease processing costWater contaminantsMultistage water/sewage treatmentLiquid wasteSmelting process

The invention relates to a method for processing waste acid generated during preparing acid from fume generated in the smelting process of metal sulphide ore. In the method, the waste acid generated in process of preparing the acid from the metal smelting fume is processed by adopting a ferrous sulfate-lime neutralization method. The method comprises a sulfuration step and a neutralization step and is characterized in that a neutralizer used in the neutralization step is calcium carbide neutralizer slurry prepared from calcium carbide. In the invention, improvement is carried out aiming at the problems that in industrial application, the ferrous sulfate-lime neutralization method is large in the consumption of the calcium material lime of the neutralizer and high in processing cost; through fully utilizing the characteristic that the content of effective CaO in carbide slag is high, the carbide slag is used as a calcium material to replace the lime, thereby greatly reducing the cost, achieving the environment-friendly effect of treating the waste liquid by utilizing the waste slag, creating a novel way for use of calcium carbide and achieving the purpose of using wastes to treat wastes.

Owner:ZHUZHOU SMELTER GRP

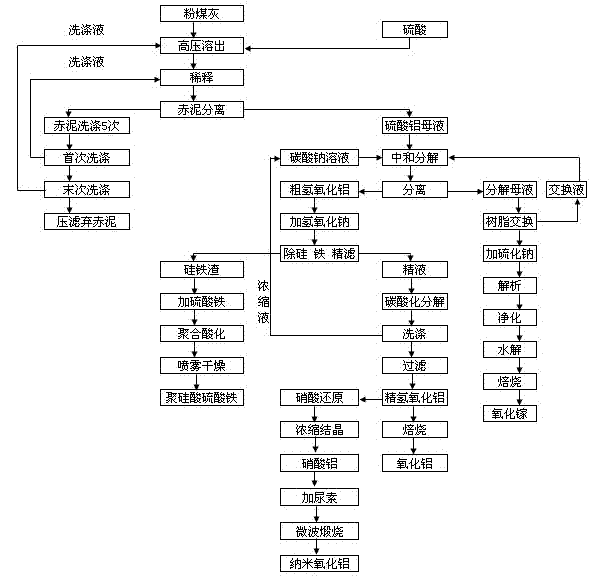

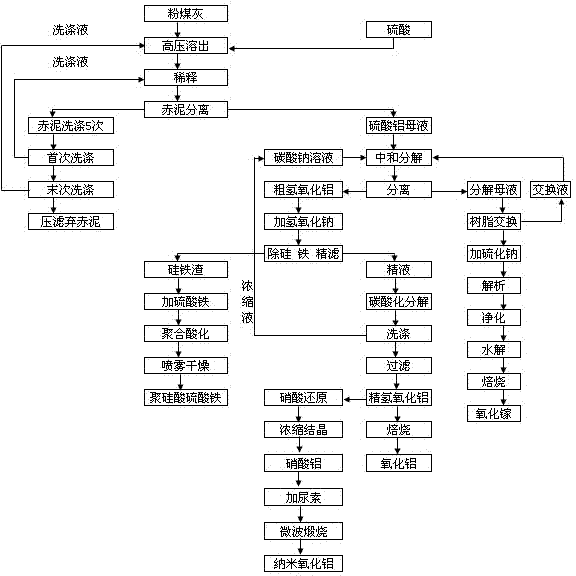

Method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate

InactiveCN102515220AImprove use valueReduce manufacturing costSolid waste disposalGallium/indium/thallium compoundsSlurryMaterials science

Provided is a method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate. Pulverized fuel ash and sulfuric acid are sent to a high-pressure autoclave to react by heating and pressurizing so as to generate slurry, and after dilution separation, neutralization desilicication of iron, carbonation decomposition, washing and dehydration and roasting, aluminum oxide is obtained. Nitric acid is added to the prepared aluminium hydroxide for reduction to prepare aluminium nitrate. The aluminium nitrate is added with carbamide and enters a microwave oven to be roasted to ashes, and aluminum oxide nanometer is obtained. Aluminum sulfate solution which has subjected to separation is added to sodium carbonate for neutralization and decomposition, and filtrated stock is sent to an ion resin exchange column to extract gallium oxide. Aluminum hydroxide is added to sodium hydroxide, and then silicon iron filter residue is obtained by filtering. Ferric sulfate is added for polymerization reaction to obtain polymeric ferric silicate sulfate. By adopting the technique of decomposing pulverized fuel ash with sulfuric acid in a high-temperature high-pressure mode, a plurality of industrial products are can be obtained respectively. Compared with an existing hydrochloric acid decomposition method, the method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate increases comprehensive utilization value of pulverized fuel ashand has great economic benefits.

Owner:潘安标

Process of oxygen bottom blowing continuous copper smelting

The invention provides a process adopting the oxygen bottom blowing continual copper smelting. The process is characterized in that an oxygen bottom blowing smelting furnace is utilized to smelt copper-containing materials into liquid copper matte, and the oxygen bottom blowing converting furnace is utilized to continuously convert the liquid copper matte into coarse copper.

Owner:CHINA ENFI ENGINEERING CORPORATION

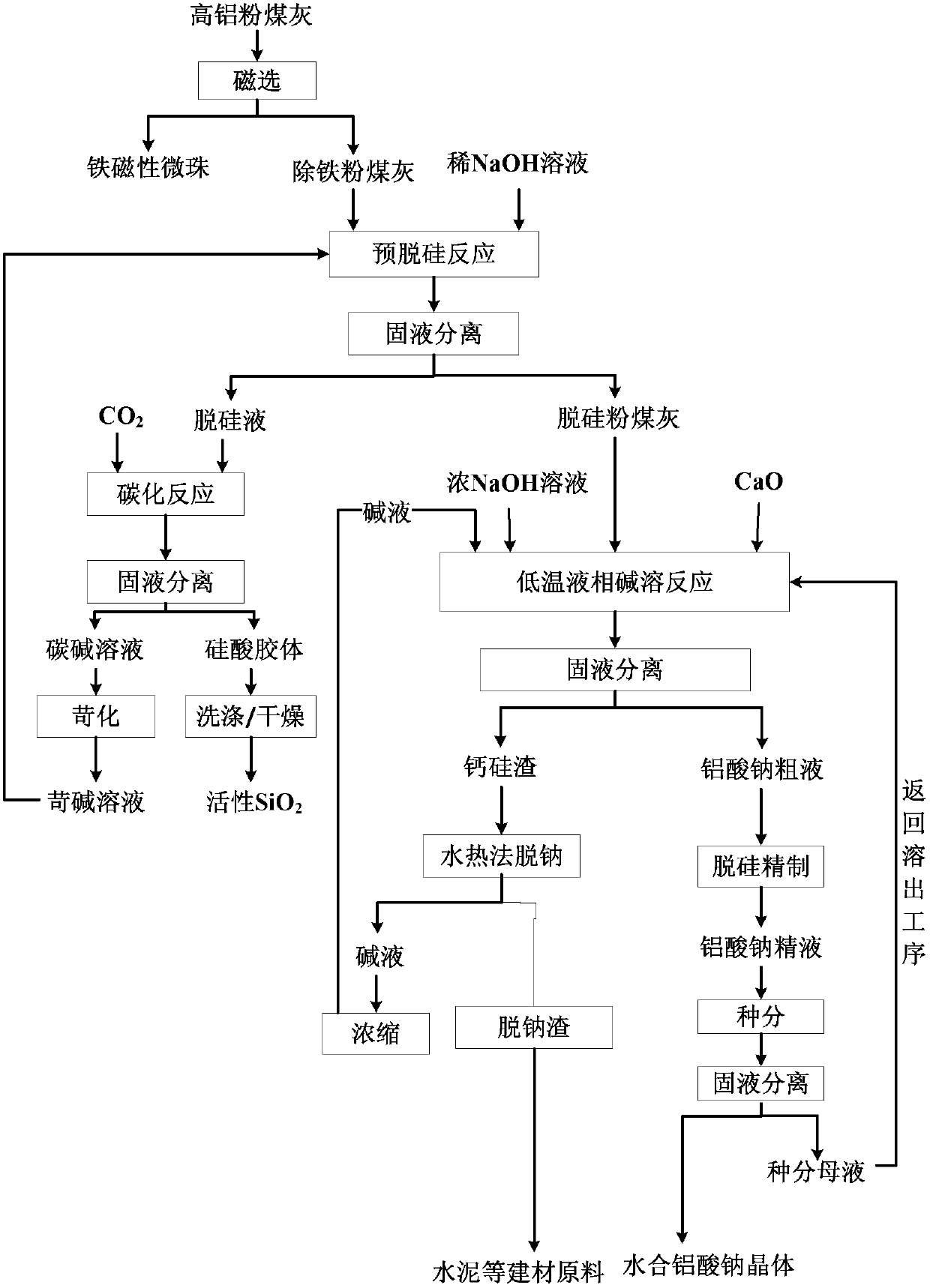

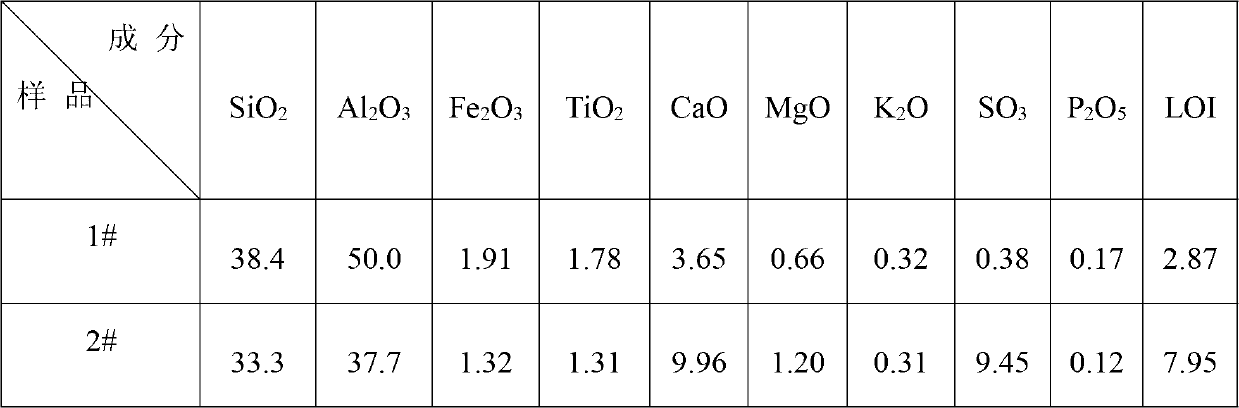

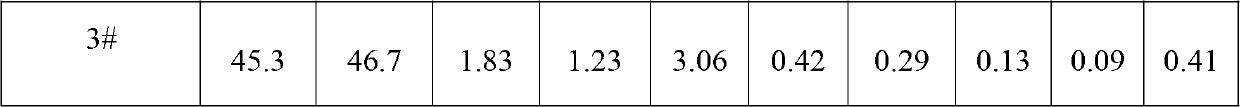

Method for linked preparation of sodium aluminate and production of silica-based material by means of high-alumina fly ash low-temperature liquid-phase alkali dissolving

ActiveCN103303952AIncrease added valueWide variety of sourcesSilicaSolid waste disposalCalcium silicateSlag

The invention discloses a method for linked preparation of sodium aluminate and production of silica-based material by means of high-alumina fly ash low-temperature liquid-phase alkali dissolving. The method comprises the following steps of: 1) obtaining fine iron ore sand and iron-removed fly ash by separation; (2) reacting the iron-removed fly ash with a dilute NaOH solution to obtain desiliconized fly ash and a desilication solution; (3) reacting the desiliconized fly ash with calcium hydroxide and the NaOH solution to obtain a crude solution of sodium aluminate and calcium silicate slag; (4) diluting the crude solution of sodium aluminate, adding calcium oxide into the diluted solution, and desiliconizing the resulting solution to obtain a refined solution of sodium aluminate; (5) adding a sodium aluminate crystal into the refined solution of sodium aluminate, and decomposing the seed crystal to obtain a sodium aluminate crystal hydrate and a seed precipitation mother solution; (6) introducing CO2 into the desilication solution for carbonation to obtain active silicon dioxide; (7) reacting calcium silicate slag with water to obtain sodium-removed slag. The method disclosed by the invention is wide in raw material resources, mild in reaction condition, less in operation step, capable of fully utilizing the raw materials, less in slag amount, high in product added value, and wide in purpose.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

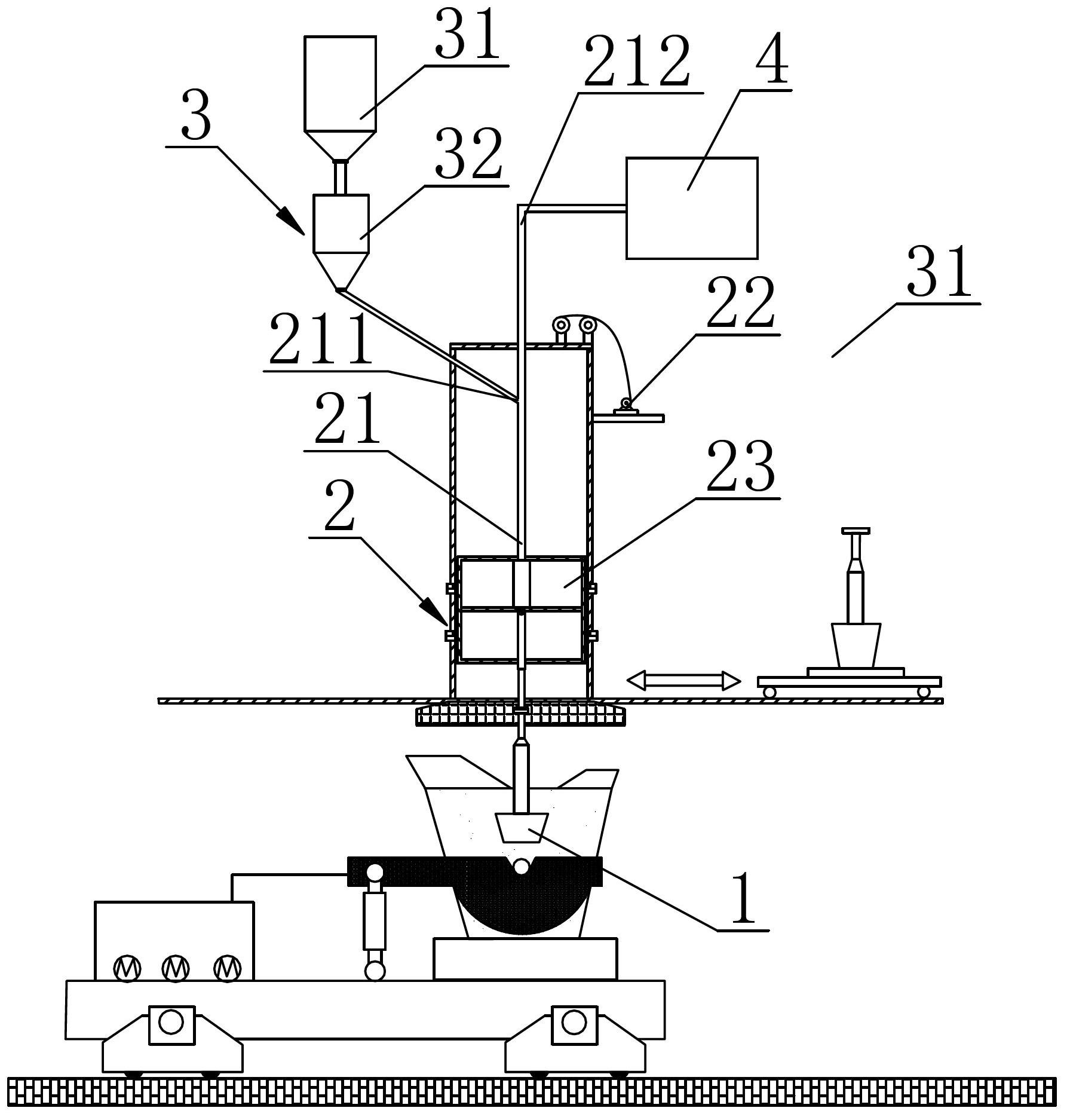

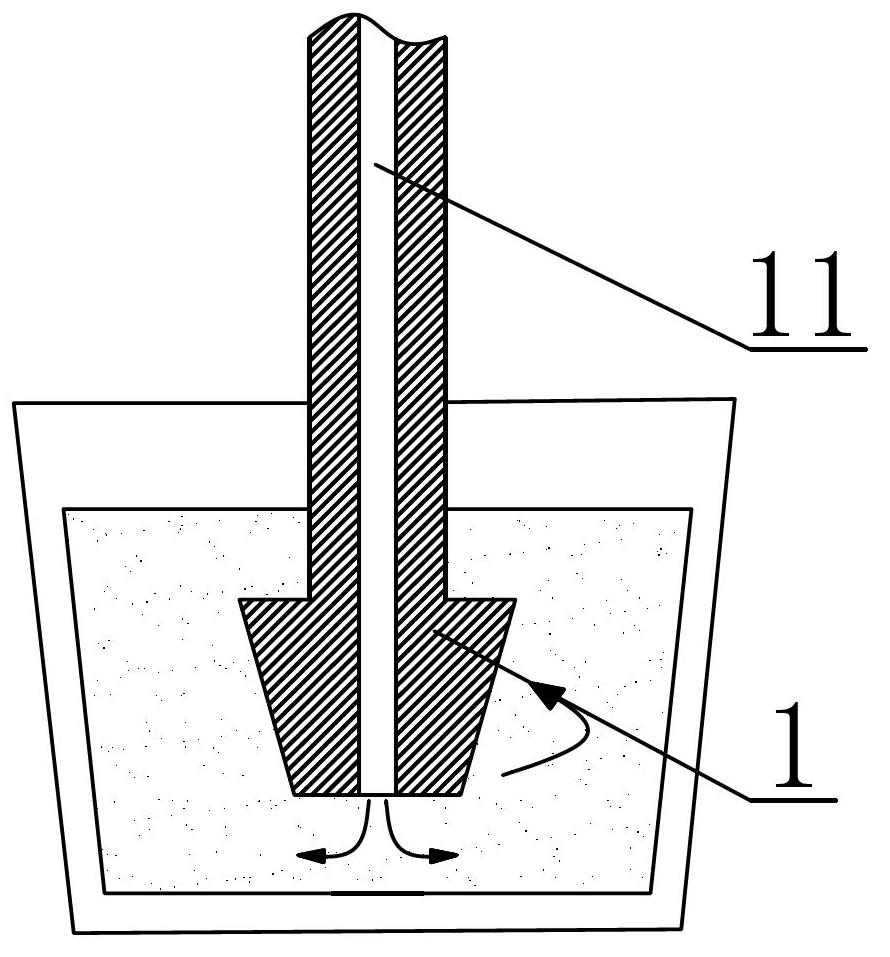

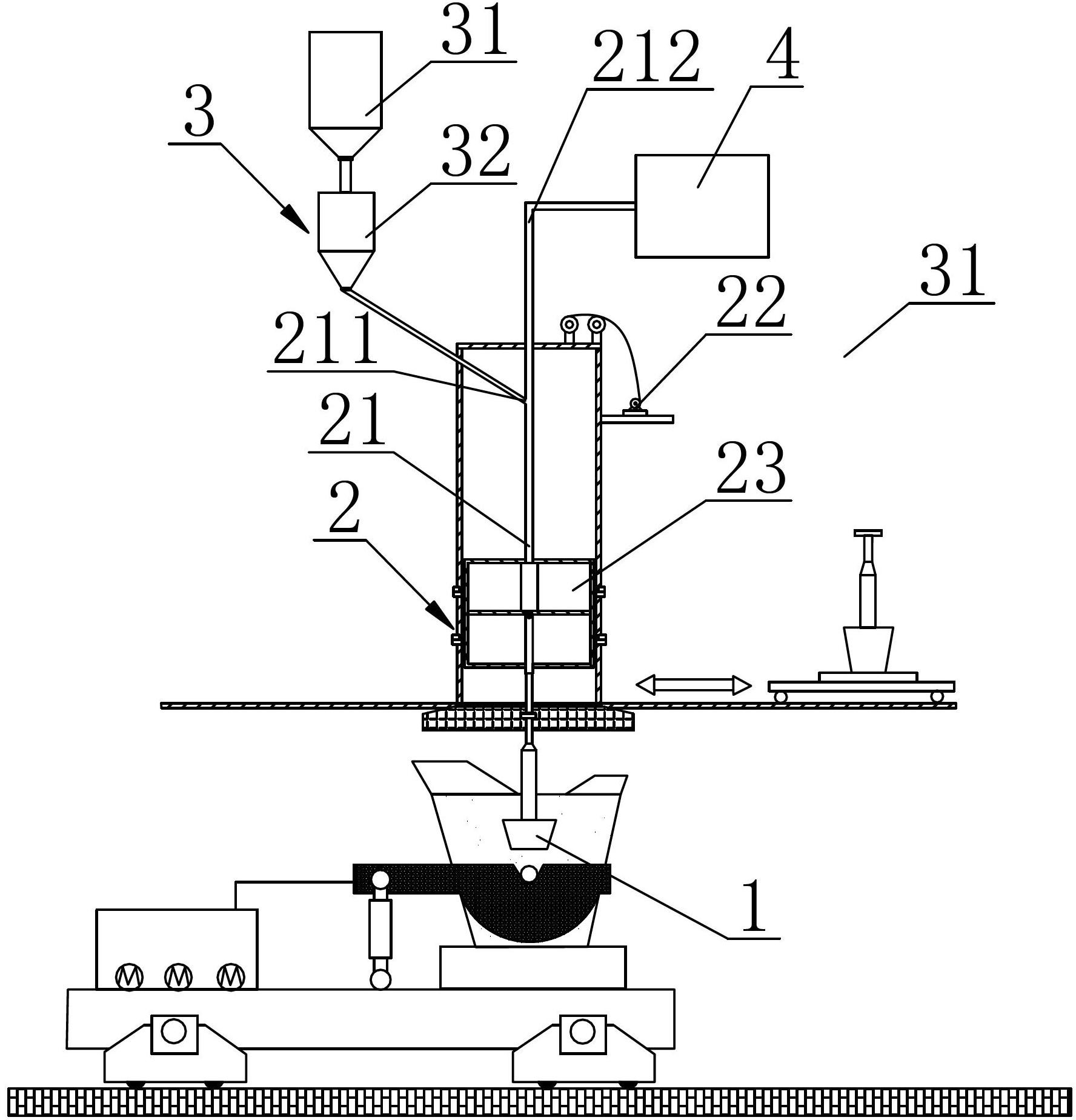

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

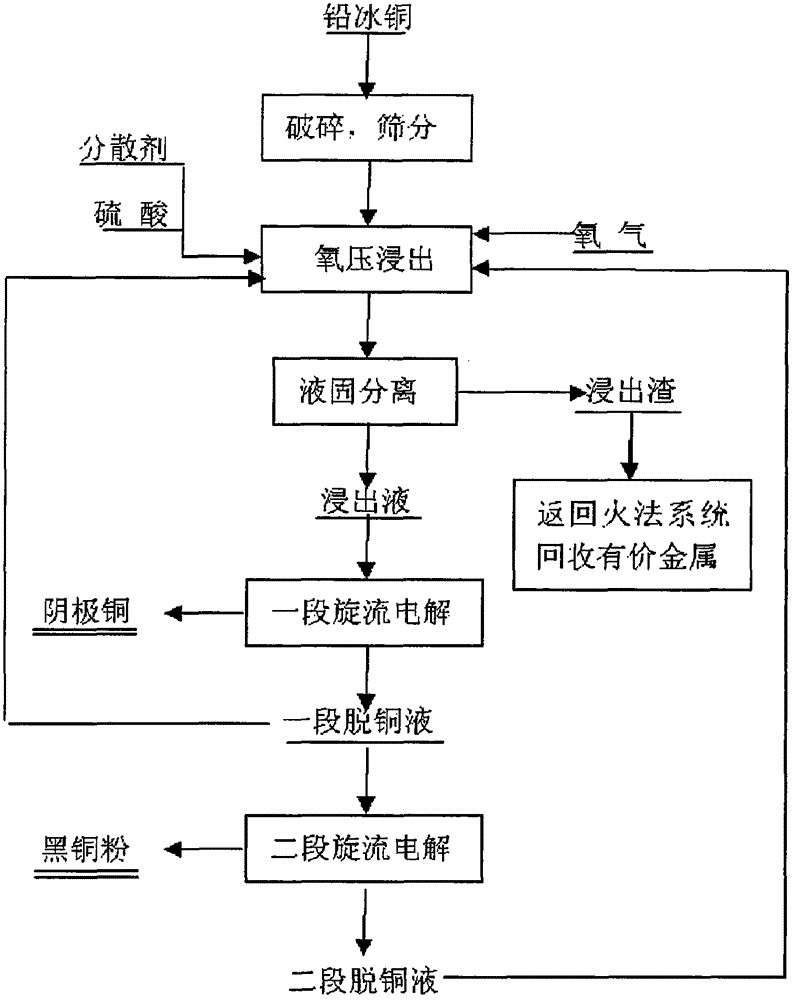

Process of efficiently recovering copper from lead matte according to oxygen pressure acid leaching and vortex electrolysis techniques

InactiveCN104831064AAdaptableImprove leaching ratePhotography auxillary processesProcess efficiency improvementElectrolysisHydrometallurgy

The invention belongs to the field of nonferrous metal hydrometallurgy and discloses a process of efficiently recovering copper from lead matte according to oxygen pressure acid leaching and vortex electrolysis techniques. The method includes: taking lead matte as a raw material, crushing and grinding the lead matte, screening through a 100-mesh sieve, adding into a high-pressure autoclave along with sulfuric acid and a dispersing agent, feeding oxygen for leaching, carrying out liquid-solid separation to obtain solution containing copper sulfate, subjecting the solution containing copper sulfate to vortex electrolytic decopperation to obtain cathode copper, and returning after-electrodeposition liquid to the leaching procedure to replace sulfuric acid serving as the leaching agent. High efficiency in copper recycling can be realized, electrodeposition of copper can be selectively carried out according to the vortex electrolysis techniques, and high current level and current efficiency, low reagent consumption, reduction of production cost and improvement of enterprise benefits are realized. In addition, due to closed cycle of solution, harmful gas emission is avoided, and current concepts of circular economy and environment protection are met.

Owner:XIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com