Technique for decomposing Baotou rare-earth ores

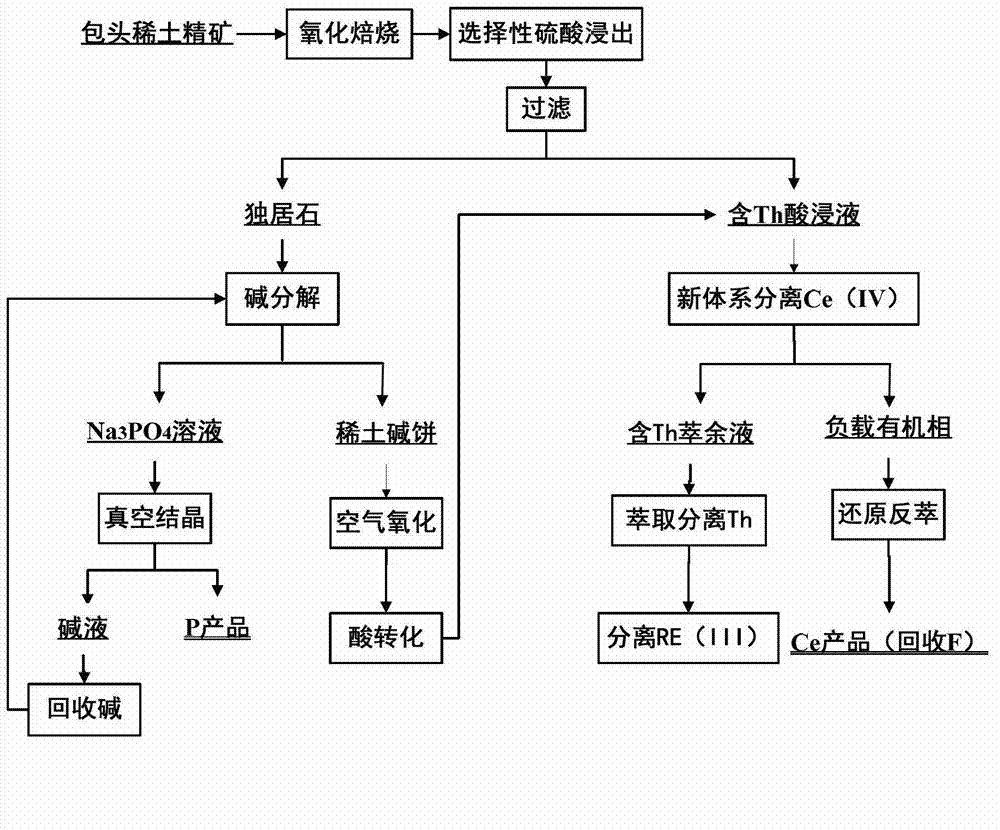

A technology of Baotou rare earth and process method, which is applied in the field of decomposing Baotou rare earth mine, which can solve problems such as environmental pollution and resource loss, and achieve the effects of avoiding waste gas, waste water and waste residue, reducing the amount of treatment, and reducing the amount of residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 500g of Baotou rare earth mixed ore and roast it in a muffle furnace at 400°C for 2h. Baotou rare earth mixed roasting mine with 2.5M H 2 SO 4The solution was leached at 80°C for 30 minutes and then filtered to obtain Th-acid-containing leach solution and filter cake (monazite). The REO content in the leachate is 60g / L. Add 40wt% NaOH solution to the filter cake and react at 150°C for 3h. After the reaction, use hot water at 80°C to slurry, filter, and wash for 1 to 2 times to obtain an alkali-containing solution and a rare-earth alkali cake. When leaching with sulfuric acid solution, the leaching rate of REO reaches 66%, and the Ce:F in the obtained leaching solution is about 1:1 (mol), wherein the concentration of REO is 50.67g / L, and the concentration of F is 3.76g / L. The obtained filter cake (monazite) REO content is 44.18%, F content is 8.12%. In the alkali conversion process with NaOH solution, about 99.81% of REO remained in the rare earth alkali cake, ...

Embodiment 2

[0040] Take 500g of Baotou rare earth mixed ore and roast it in a muffle furnace at 450°C for 2h. 2M H for Baotou Rare Earth Mixed Roasting Mine 2 SO 4 The solution was leached at 80°C for 60 minutes and then filtered to obtain Th-acid-containing leachate and filter cake (monazite). The REO content in the leachate is 57g / L. Add 50wt% NaOH solution to the filter cake and react at 180°C for 3h. After the reaction, the slurry is mixed with hot water and filtered, and then the filter cake is washed with water for 1 to 2 times to obtain an alkali-containing solution and a rare earth alkali cake. When leaching with sulfuric acid solution, the leaching rate of REO reaches 64.84%, and the Ce:F in the obtained leaching solution is about 1:1 (mol), wherein the concentration of REO is 52.46g / L, and the concentration of F is 3.85g / L. The obtained filter cake (monazite) REO content is 42.12%, F content is 7.54%. In the alkali conversion process with NaOH solution, about 98.95% of RE...

Embodiment 3

[0042] Take 500g of Baotou rare earth mixed ore and roast it in a muffle furnace at 300°C for 6h. Baotou rare earth mixed roasting mine with 3M H 2 SO 4 The solution was leached at 100°C for 12 minutes and then filtered to obtain Th-acid-containing leachate and filter cake (monazite). The REO content in the leachate is 60g / L. Add 50wt% NaOH solution to the filter cake and react at 150°C for 5h. After the reaction, the hot water at 80°C is slurried and filtered, and then the filter cake is washed with water for 1 to 2 times to obtain an alkali-containing solution and a rare earth alkali cake. When leaching with sulfuric acid solution, the leaching rate of REO reaches 67.10%, and Ce:F in the obtained leaching solution is about 1:1 (mol), wherein the concentration of REO is 54.46g / L, and the concentration of F is 3.90g / L, and the filter cake ( monazite) REO content is 42.12%, F content is 7.56%. During the alkali conversion process with NaOH solution, about 99.25% of REO rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com