Patents

Literature

171results about How to "Reduce stockpiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

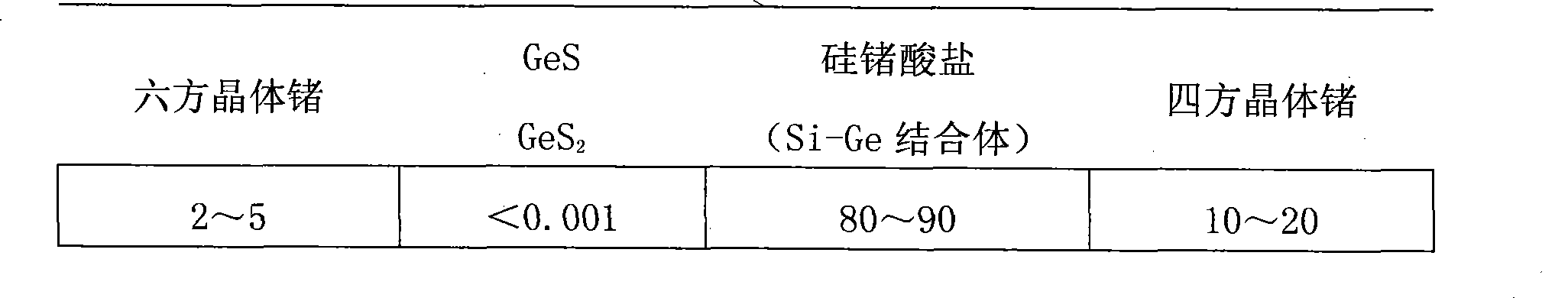

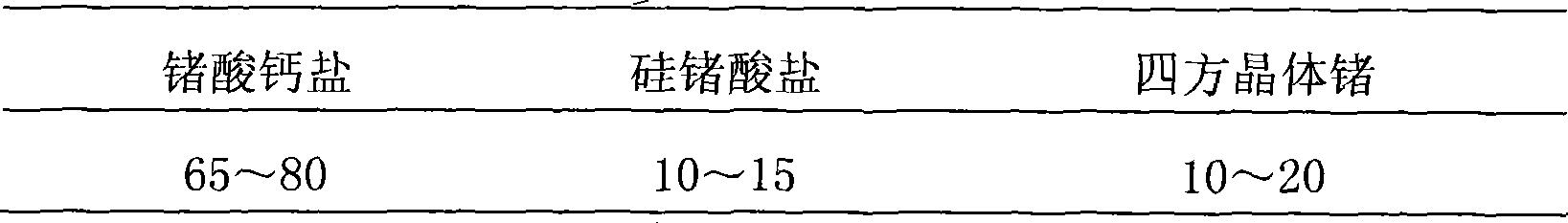

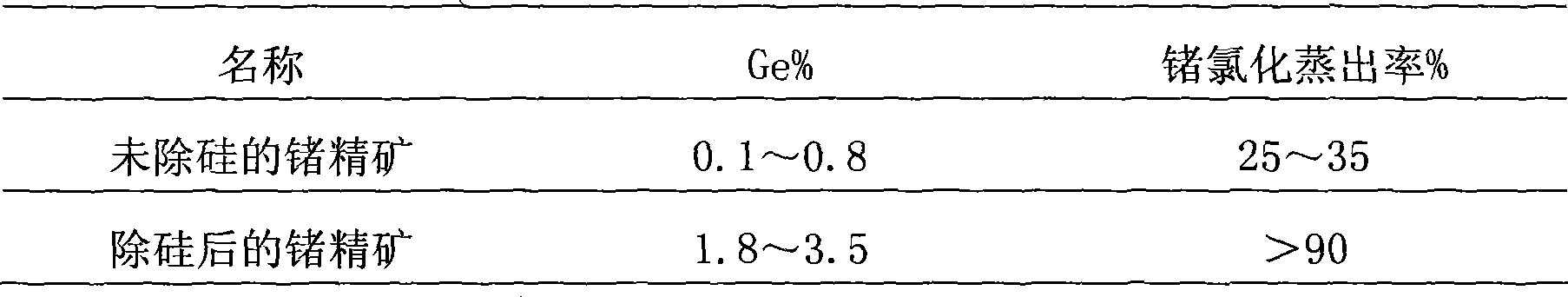

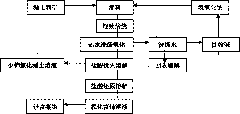

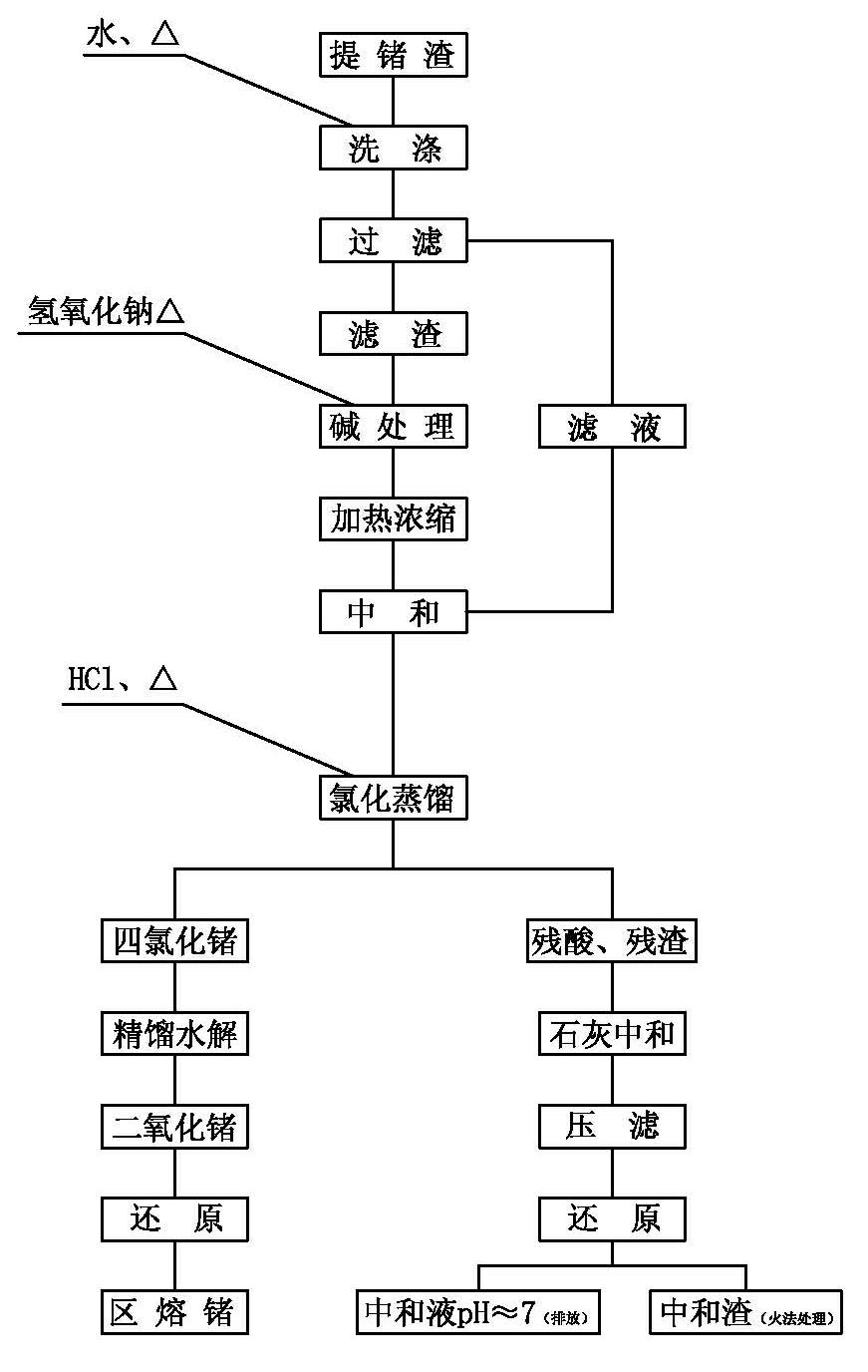

Method for extracting germanium from chlorinated distillation slag

The invention relates to a method for extracting germanium from chlorination distillation slag. The method comprises the following processes: primary alkaline leaching, secondary alkaline leaching, desiliconization, the alkaline leaching of silica residue, germanium precipitation, drying and ignition, chlorination and distillation, and the like. The germanium leaching efficiency is above 85 percent, the desiliconization rate is above 95 percent, the germanium precipitation rate is above 95 percent, and the recovery rate of germanium is above 70 percent. The method for extracting the germanium can annually process more than 2,000 tons of chlorination slag, recover more than 1 ton of germanium (by Ge in GeCl4), and obtain 4.5 million RMB of profit payment and tax turnover. The method solves the problems of the silicon germanium separation in alkaline liquid, germanium precipitation technology, and the like. The method opens up a reasonable path to extract the germanium from the chlorination distillation slag, reduces the piling amount of the waste slag, reasonably utilizes the resources, reduces the working time, and indirectly reduces the production cost. The cost of germanium precipitation is reduced from 695 RMB / kg Ge which is the cost of germanium precipitation through the prior tannin extract (high price) to 370 RMB / kg Ge.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND

Liquid alkali roasting decomposition extraction process of mixed rare earth concentrates

ActiveCN101824554AReduce consumptionEliminate pickling and decalcification processDecompositionRare earth

The invention relates to a liquid alkali roasting decomposition extraction process of mixed rare earth concentrates, which comprises the following steps of: (1) mixing mixed rare earth concentrates and sodium hydroxide (prepared solution) in the weight ratio of 1:0.5 to 1.5; (2) roasting the rare earth ore mixed with the sodium hydroxide at the roasting temperature of between 150 and 500 DEG C for 0.5 to 4 hours; (3) performing size mixing on roasted ore hot water obtained by roasting, adding oxidant simultaneously for oxidation, and performing washing until the mixture is neutral after the oxidation; (4) dissolving trivalent rare earth preferentially in washed alkali cakes in hydrochloric acid, and controlling the pH value to be between 4 and 5 to prepare rare earth chloride solution with less cerium; and (5) performing reductive dissolution of the hydrochloric acid on cerium dregs dissolved preferentially in the hydrochloric acid, and controlling the pH value to be between 4 and 5 to prepare cerium-rich chloride solution. The mixed rare earth concentrates are processed by adopting the extraction process, so that the continuous production of the alkali-decomposing mixed rare earth ore can be realized, cerium-rich products are extracted preferentially, the treatment capacity of the follow-up extraction separation is relieved, and the pollution-free production and comprehensive utilization of resources are realized.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

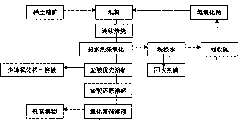

Technique for decomposing Baotou rare-earth ores

InactiveCN103045851AReduce stockpilesReduce processingProcess efficiency improvementPregnant leach solutionSodium phosphates

The invention relates to a technique for decomposing Baotou rare-earth ores. The invention solves the technical problems of environmental pollution and resource loss caused by the rare-earth ore separation technique in the prior art. The technique comprises the following steps: carrying out oxidizing roasting on mixed rare-earth concentrate; leaching the roasted ores with an H2SO4 solution to obtain a leach solution and urdite; extracting and separating Ce (IV), F and Th as well as single RE (III) from the sulfuric acid leach solution; and carrying out alkali conversion on the urdite to obtain a rare-earth alkali cake, carrying out size mixing, filtering, and crystallizing the alkaline solution to recover sodium phosphate, wherein the residual alkali liquor is used for cyclically leaching urdite slag. When being used for treating the mixed rare-earth concentrate, the technique provided by the invention can implement multi-step extraction of bastnaesite and urdite in the mixed ores. Besides, the invention is beneficial to further effectively recovering Th, F and P from baotite, thereby avoiding environmental pollution, enhancing the rare-earth yield, saving the cost and implementing clean production and comprehensive resource utilization in deed.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

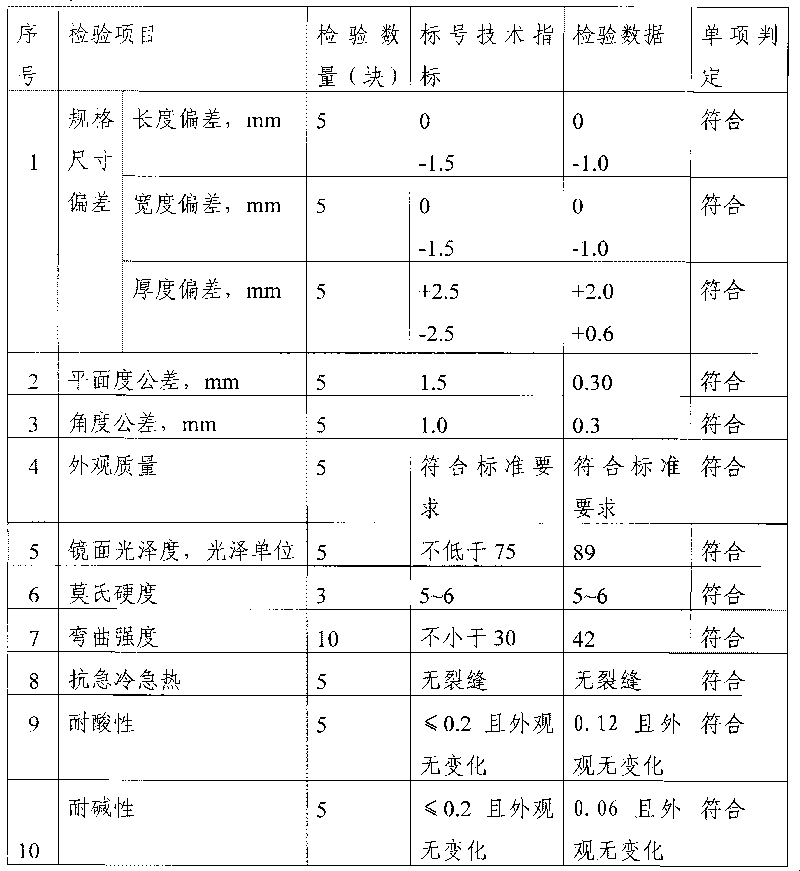

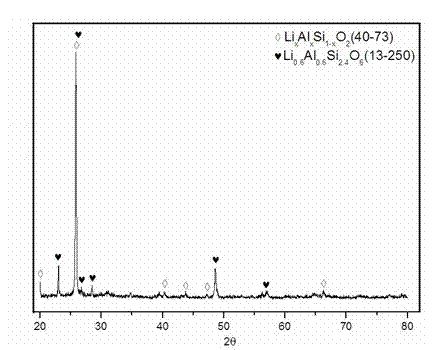

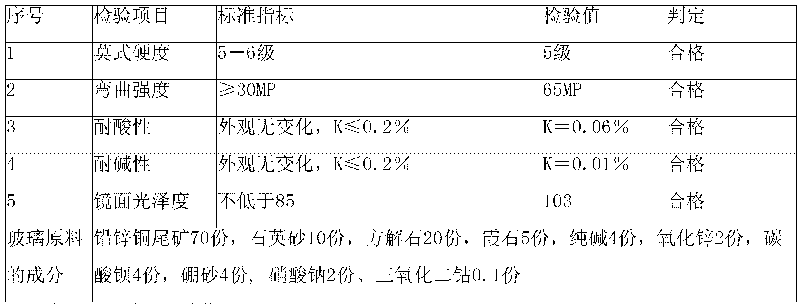

Low-expansion glass-ceramics with lithia ore tailings as principal raw material and manufacturing method thereof

The invention relates to low-expansion microcrystalline glass which takes spodumene tailings as a main raw material and a manufacturing method thereof. The raw materials of the low-expansion microcrystalline glass comprise alumina and lithium carbonate. The low-expansion microcrystalline glass is characterized in that the mixing proportion of the compositions by weight percentage is as follows: the content of the spodumene tailings which are taken as the main raw materials is between 70 and 80, the content of the alumina is between 9 and 14, and the content of the lithium carbonate is between 5 and 10; the sum of the addition of four compositions of zinc oxide, barium carbonate, a boric acid and magnesia is between 2 and 5; the sum of the addition of titanium oxide and zirconia is between 3 and 5; and quartz sand can replace partial spodumene tailings. The invention solves the problem of manufacturing the low-expansion microcrystalline glass by utilization of a large quantity of waste spodumene tailings, and the low-expansion microcrystalline glass has the characteristics of reducing environmental pollution, improving the product performance and reducing the production cost.

Owner:中国地质科学院尾矿利用技术中心

Method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste

InactiveCN108525843AValue cost enhancementGreat benefitWet separationMechanical material recoveryNiobiumSlag

The invention discloses a method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste. The method is characterized in that the difficult-to-treat mine solid waste is taken as a raw material, wherein the difficult-to-treat mine solid waste is a valuable component material containing a trace of (Ta, Nb)2O5, lepidolite and feldspar, and themethod comprises the step of recovering the tantalum-niobium concentrate, the feldspar powder and the lepidolite, recovering of the tantalum-niobium concentrate is achieved though the following steps,the series-connection technology of weak magnetism, medium magnetism and strong magnetism is carried out on the difficult-to-treat mine solid waste raw material for separation of iron slag, magneticminerals and non-magnetic mineral so that the influence of iron minerals on the reselection of the tantalum-niobium ore can be eliminated, a tantalum-niobium ore waste stone raw material is obtained,the tantalum-niobium ore waste stone raw material undergoes classification by adopting a stage grinding-stage separation process method, coarse grains enter a ball mill for ore grinding, a high-frequency vibration fine sieve is adopted for carrying out intensifying classification on the fine fraction, and then the tantalum-niobium concentrate and the feldspar-lepidolite mixture with tailings beingiron-tantalum-niobium contained weak-magnetic impurities are prepared. The method has the advantages that the technology is simple, the efficiency is high, the economic and technical benefits are obvious, and the recovery rate of the tantalum-niobium and other mineral resource products is high.

Owner:江西金辉再生资源股份有限公司

Liquid alkali low-temperature roasting decomposition process of caustic soda liquid of mixed rare earth concentrates

InactiveCN101824531AEliminate pickling and decalcification processRealize continuous roasting decompositionDecompositionRare earth

The invention relates to a liquid alkali low-temperature roasting decomposition process of caustic soda liquid of mixed rare earth concentrates, which comprises the following steps of: (1) mixing mixed rare earth concentrates and sodium hydroxide in the weight ratio of 1:0.5 to 1.5; (2) roasting the mixed rare earth ore at the roasting temperature of between 150 and 550 DEG C for 0.5 to 4 hours; (3) washing roasted ore water obtained by roasting until the water is neutral; (4) dissolving washed alkali cakes in hydrochloric acid, and controlling the pH value to be between 4 and 5 to prepare rare earth chloride solution; (5) after washing thorium enrichment dissolved by the hydrochloric acid, performing sealing pile-up or extracting thorium and rare earth through further dissolution. The mixed rare earth concentrates are processed by adopting the low-temperature roasting decomposition process, so that the continuous production of the alkali-decomposing mixed rare earth ore can be realized, no waste gas or ammonia nitrogen waste water is generated in the process, and the pollution-free production and comprehensive utilization of resources are realized.

Owner:BAOTOU RES INST OF RARE EARTHS

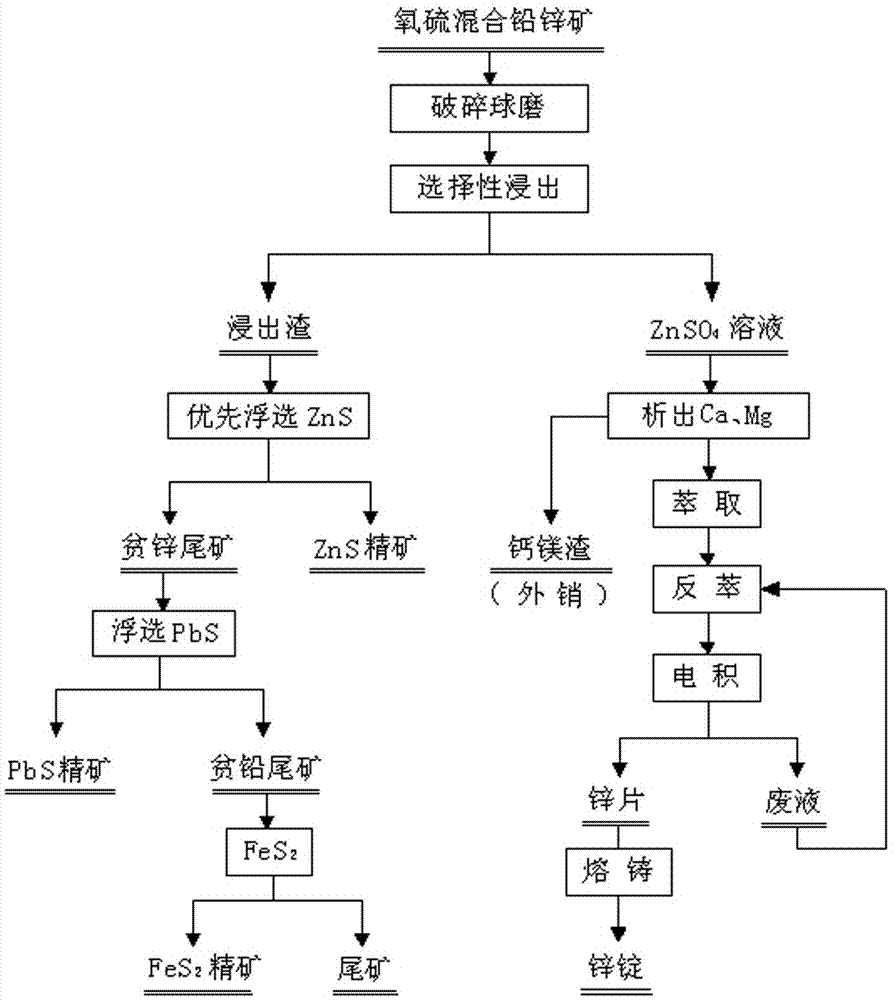

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

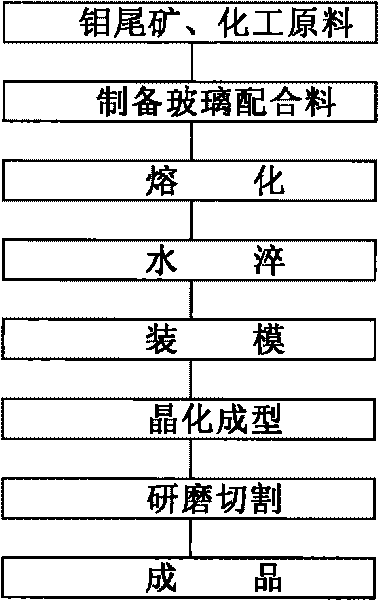

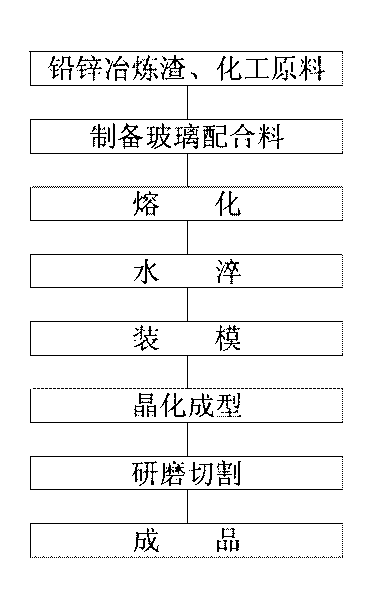

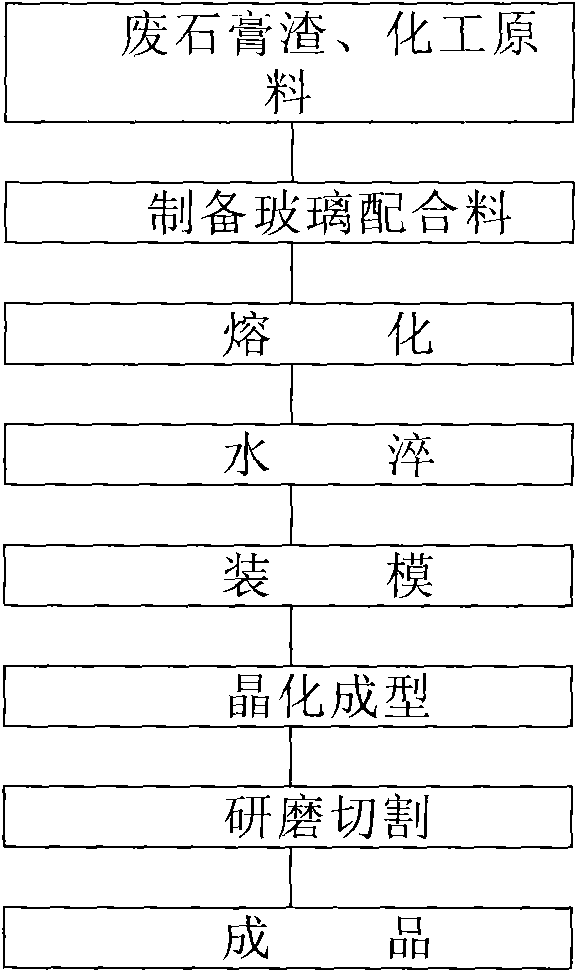

Method for manufacturing black microcrystalline glass plates from molybdenum tailings

The invention discloses a method for manufacturing black microcrystalline glass plates from molybdenum tailings, which comprises the following steps: mixing a certain part by weight of molybdenum tailings, quartz sand, lime stone, sodium carbonate, zinc oxide, barium carbonate, ferric oxide, manganese dioxide, nickel oxide and cobalt oxide to prepare a glass batch; melting the glass batch into molten glass, and then, pouring the molten glass into water to form glass particles; horizontally laying the glass particles in a fire-resistant mold for crystallization heat treatment; and grinding and cutting black microcrystalline glass crude products after crystallization heat treatment to form finished products. By using the molybdenum tailings for manufacturing black microcrystalline glass plates, the invention not only reduces the stockpiling amount of tailings and relieves the environmental pollution, but also can improve the product performance and reduce the production cost, thereby having good social benefit and economic benefit.

Owner:陕西乾盛环保建材工程有限公司

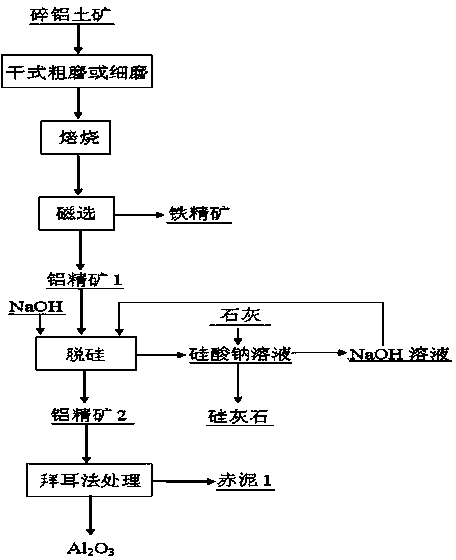

Bauxite comprehensive utilization method

InactiveCN104163445AReduce production alkali consumptionEasy to separate by magnetic separationAlkaline-earth metal silicatesProcess efficiency improvementWollastoniteSodium silicate

The invention discloses a bauxite comprehensive utilization method, relates to an alumina production method and iron-containing mineral utilization and especially relates to a low-grade high-iron bauxite comprehensive utilization method. The bauxite comprehensive utilization method comprises the following steps of 1, grinding bauxite into mineral powder, 2, roasting the mineral powder in a reduction atmosphere, 3, carrying out magnetic separation on the roasted mineral powder to obtain iron concentrate and aluminum concentrate, 4, carrying out desilicication treatment on the aluminum concentrate by an alkali liquid to obtain silicon-free aluminum concentrate and a sodium silicate-containing alkali liquid, 5, adding lime into the sodium silicate-containing alkali liquid, carrying out regeneration treatment, carrying out solid-liquid separation and recycling the regenerated alkali liquid, washing the silicon-free dregs by water, and drying the silicon-free dregs to obtain a wollastonite product, and 6, dissolving the silicon-free aluminum concentrate by a Bayer process so that alumina is produced. The bauxite comprehensive utilization method greatly reduces alkali loss of alumina production. Wollastonite as a silicon-removal by-product and iron concentrate obtained by magnetic separation iron-removal can be sold as products and thus high economic and environmental benefits are obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

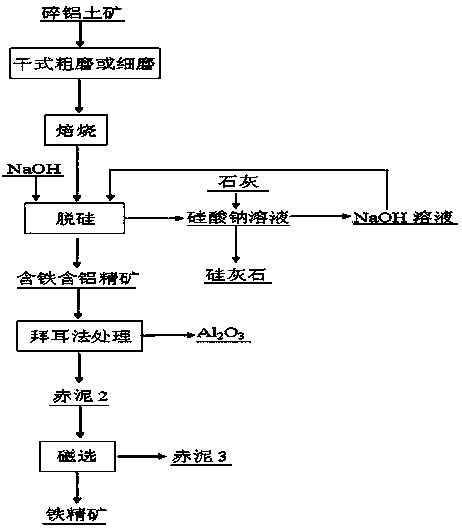

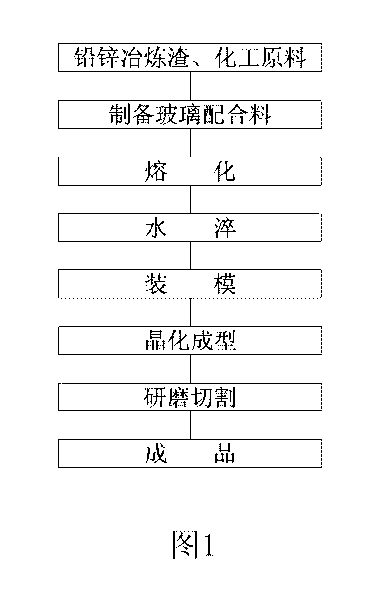

Green glass-ceramic plate made from lead-zinc smelting slag and manufacturing method thereof

The invention relates to a green glass-ceramic plate made from lead-zinc smelting slag and a manufacturing method thereof. The glass raw material is prepared from the following components in parts by weight: 40 to 60 parts of lead-zinc smelting slag, 26 to 38 parts of quartz, 15 to 24 parts of lithium feldspar, 2 to 4 parts of soda ash, 2 to 3 parts of zinc oxide, 2 to 5 parts of barium carbonate, 1 to 3 parts of borax, 2 to 2.5 parts of chromium oxide, 0 to 0.2 part of copper oxide and 0.04 to 0.2 part of carbon powder. The invention is not only in line with the common glass-ceramic produced by completely adopting industrial materials on the aspect of the performance, but also can realize waste utilization, reduce the environmental pollution, the product cost and the melting temperature of glass, improve the melting speed and the melting furnace efficiency of the glass, decrease the energy consumption and can be widely applied to building decoration materials, especially applied in various building decoration engineering, such as inside and outer walls, floors, pillars, table boards of the building, and the like.

Owner:FENGXIAN SANLIAN BUILDING MATERIALS

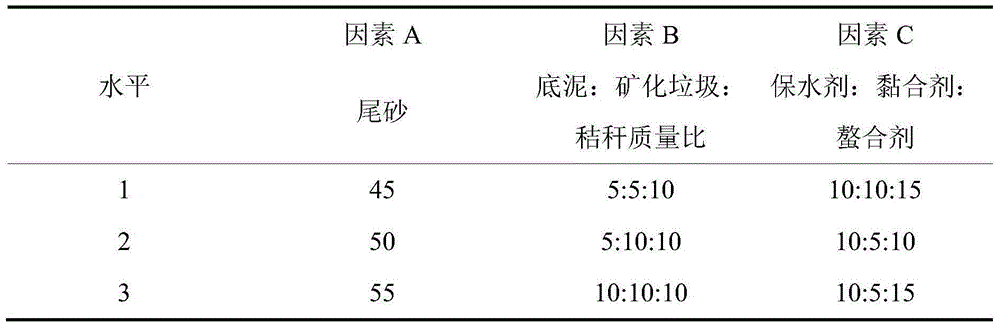

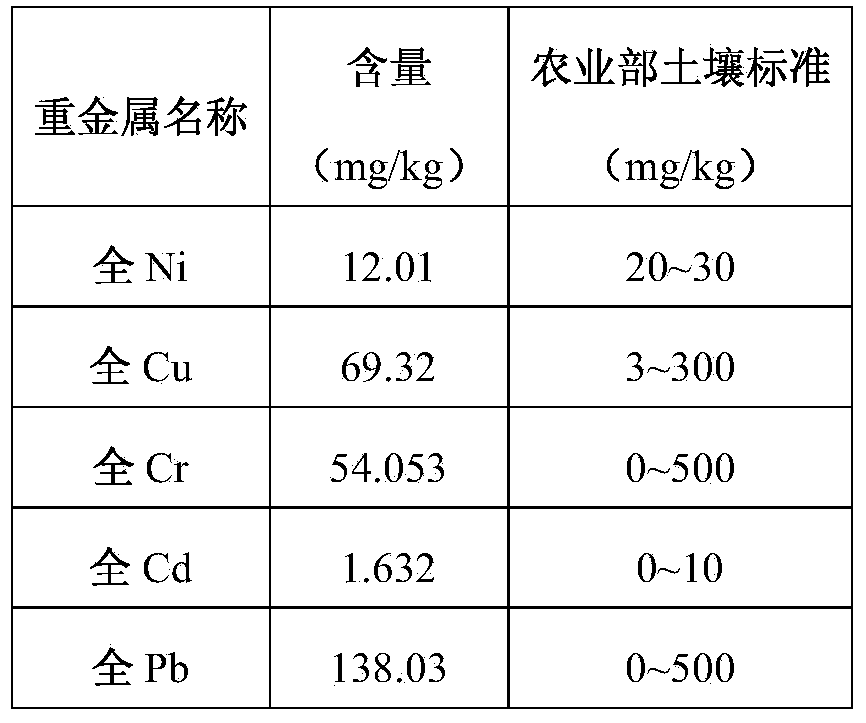

Ecological restoration matrix of lead-zinc tailing reservoir and preparation method and application thereof

ActiveCN104987260APollution controlImprove the living environmentFertilizer mixturesAdhesiveDecomposition

The invention discloses an ecological restoration matrix of a lead-zinc tailing reservoir. The matrix comprises, by mass, 45-55 parts of tailing reservoir tailings, 20-30 parts of organic matter and 25-35 parts of tailing conditioning agents; the organic matter comprises 20-33 parts of city watercourse sediment, 25-40 parts of mineralized refuse and 33-50 parts of agricultural waste; the tailing conditioning agents comprise 28.6-40 parts of water-retaining agents, 16.7-28.6 parts of adhesives and 40-50 parts of chelating agents; the tailing reservoir tailings are dry beach sediment formed after the surface of the lead-zinc tailing reservoir is dried, and the particle diameter is 0.07-0.15 mm; the city watercourse sediment is products fermented by high temperature composting through a municipal sewage plant, and the water ratio is 30-40 percent; the mineralized refuse is products screened and fermented by the municipal sewage plant; the agricultural waste is smashed until the particle diameter is below 1 cm, and decomposition is performed by adding decomposition agents and water. According to the ecological restoration matrix of the lead-zinc tailing reservoir and a preparation method and application thereof, the rapid ecological restoration of the lead-zinc tailing reservoir is achieved through an ecological restoration technology, therefore, the environmental pollution of the tailing reservoir to surrounding soil can be governed, and the dwelling and living environment of neighboring residents can be improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

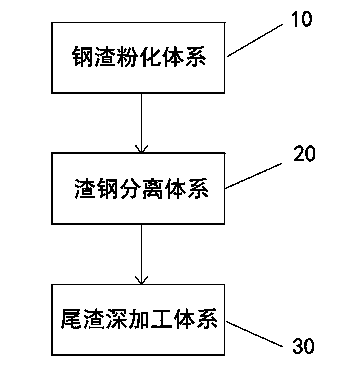

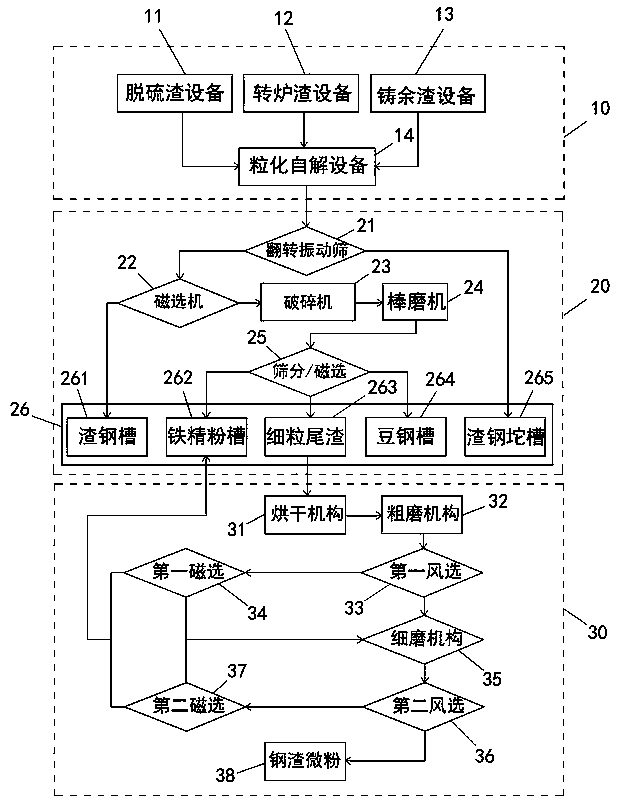

System and method for converting steel slag into renewable resources

ActiveCN103555867AEfficient use ofShort processRecycling and recovery technologiesProcess efficiency improvementSlagMagnetic separator

The invention discloses a system and a method for converting steel slag into renewable resources. The system comprises a steel slag powdering system, a steel slag separating system and a tail slag deep processing system, wherein the steel slag powdering system comprises desulphurization slag equipment, converter slag equipment, casting residue equipment and granulation self-extracting equipment which is communicated with the desulphurization slag equipment, the converter slag equipment and the casting residue equipment respectively; the steel slag separating system is connected with the granulation self-extracting equipment and comprises overturn vibration equipment, a magnetic separator, a crushing machine, a rod mill, screening / magnetic separation equipment and material storage equipment, wherein the overturn vibration equipment, the magnetic separator, the crushing machine, the rod mill, and the screening / magnetic separation equipment are led to the material storage equipment; the tail slag deep processing system is connected with a fine tail slag device and comprises a drying mechanism, a coarse grinding mechanism, a fine grinding mechanism, a first winnowing mechanism, a second winnowing mechanism, a first magnetic separation mechanism, a second magnetic separation mechanism and a steel slag fine powder groove. By the combination of the structures of the system, the design construction of the system for converting the steel slag into the renewable resources, which is clean and environment-friendly and reduces occupation space, is realized.

Owner:WISDRI ENG & RES INC LTD

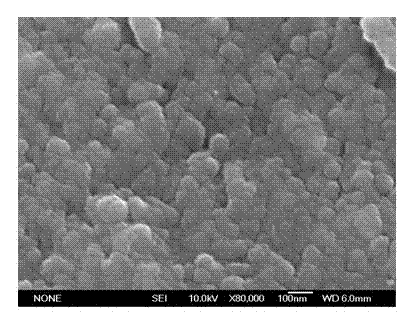

Method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings

ActiveCN103086602AIncrease the amount of participationReduce stockpilesThermal dilatationHeat stability

The invention relates to a method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings. The low-swelling microcrystalline glass comprises the following raw materials in percentage by weight: 40-50% of gold tailings, 20-25% of quartz, 13-18% of aluminum oxide, 5-13% of lithium carbonate, 2-4% of magnesium oxide, 2-4% of titanium oxide, 0.5-1% of zirconium oxide and 1-3% of borax. The method comprises the following steps: evenly mixing the raw materials, placing into an aluminum oxide crucible, and melting by microwave heating, thus obtaining glass metal; and transferring the molded glass metal into an industrial microwave oven, annealing, and performing crystallization treatment to obtain the product. According to the invention, the mining waste gold tailings are used as the main raw material, and the waste is changed into a valuable substance, thereby realizing the comprehensive utilization of the waste; a one-step heat treatment process is adopted, and the production cycle is shortened; the industrial microwave oven is used for heating in the melting, annealing and crystallization processes, thereby ensuring high heating speed and no pollution; for the obtained sample, grains are refined, the structure is uniform, and energy is saved; and the obtained microcrystalline glass is low in heat expansion coefficient and high in heat stability.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

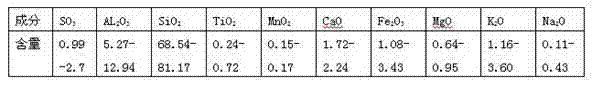

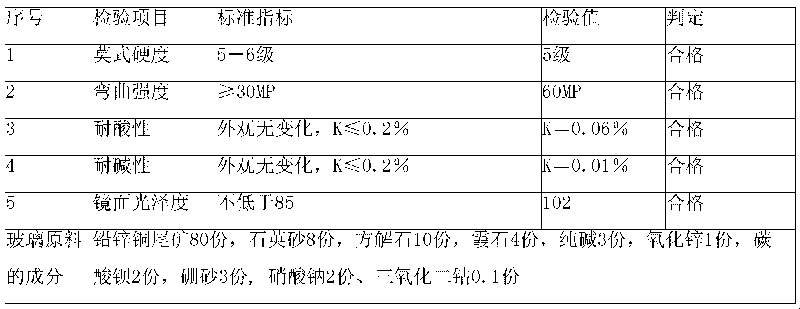

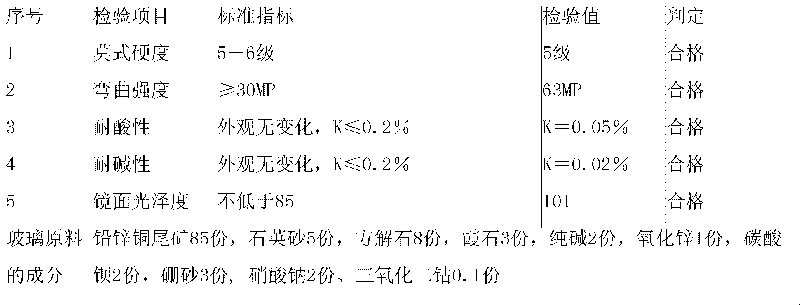

Black micro-crystal glass plate manufactured from lead-zinc-copper tailings and manufacturing method thereof

The invention relates to a black micro-crystal glass plate manufactured from lead-zinc-copper tailings, which is manufactured from the following raw materials in parts by weight: 60-90 parts of lead-zinc-copper tailings, 5-10 parts of quartz sand, 8-20 parts of calcite, 3-7 parts of nepheline, 2-4 parts of soda, 1-6 parts of zinc oxide, 2-8 parts of barium carbonate, 2-5 parts of borax, 2-6 parts of sodium nitrate and 0.1-0.5 part of cobalt oxide. The manufacturing method of the black micro-crystal glass plate comprises the following steps: grinding the lead-zinc-copper tailings, the quartz sand, the calcite and the nepheline into powder; removing cyanides from the lead-zinc-copper tailings by using an ion exchange method; weighing in proportion and preparing into a mixture; melting at 1250 DEG C-1350 DEG C; pouring the mixture into water for water quenching to obtain glass particles; horizontally laying the glass particles into a fire-resistant mold for crystallization treatment; and grinding and cutting black micro-crystal glass samples. The invention can relieve the harm of the tailings to the environment, reduce the cost of raw materials, and improve the product quality.

Owner:君达环保科技(宝鸡)有限公司

Iron tailing residue reclaimed soil and preparation method thereof

The invention provides iron tailing residue reclaimed soil and a preparation method thereof. The reclaimed soil is obtained by curing a reclaimed mixture. The reclaimed mixture comprises air-dried particles of the iron tailing residue and air-dried particles of sludge from a tap water plant which accounts for 20-30% of the mass of the air-dried particles of the iron tailing residue. Since the reclaimed soil provided by the invention comprises the iron tailing residue and the sludge from the tap water plant, various bacteria contained in the sludge from the tap water plant can improve the amount of bacteria in the iron tailing residue, and meanwhile, bacteria contained in the sludge from the tap water plant have the effect in decomposing harmful substances in the residue and the farming performance of the reclaimed soil is the same as or close to that of the conventional soil. Due to adoption of the preparation method, the utilization ration of the residue can be improved and the problem of the stockpiling of the residue can be alleviated. The soil is simple in composition and the stockpiling amount of the existing residue can be effectively reduced.

Owner:湖南鑫生矿冶废弃物综合利用科技有限公司

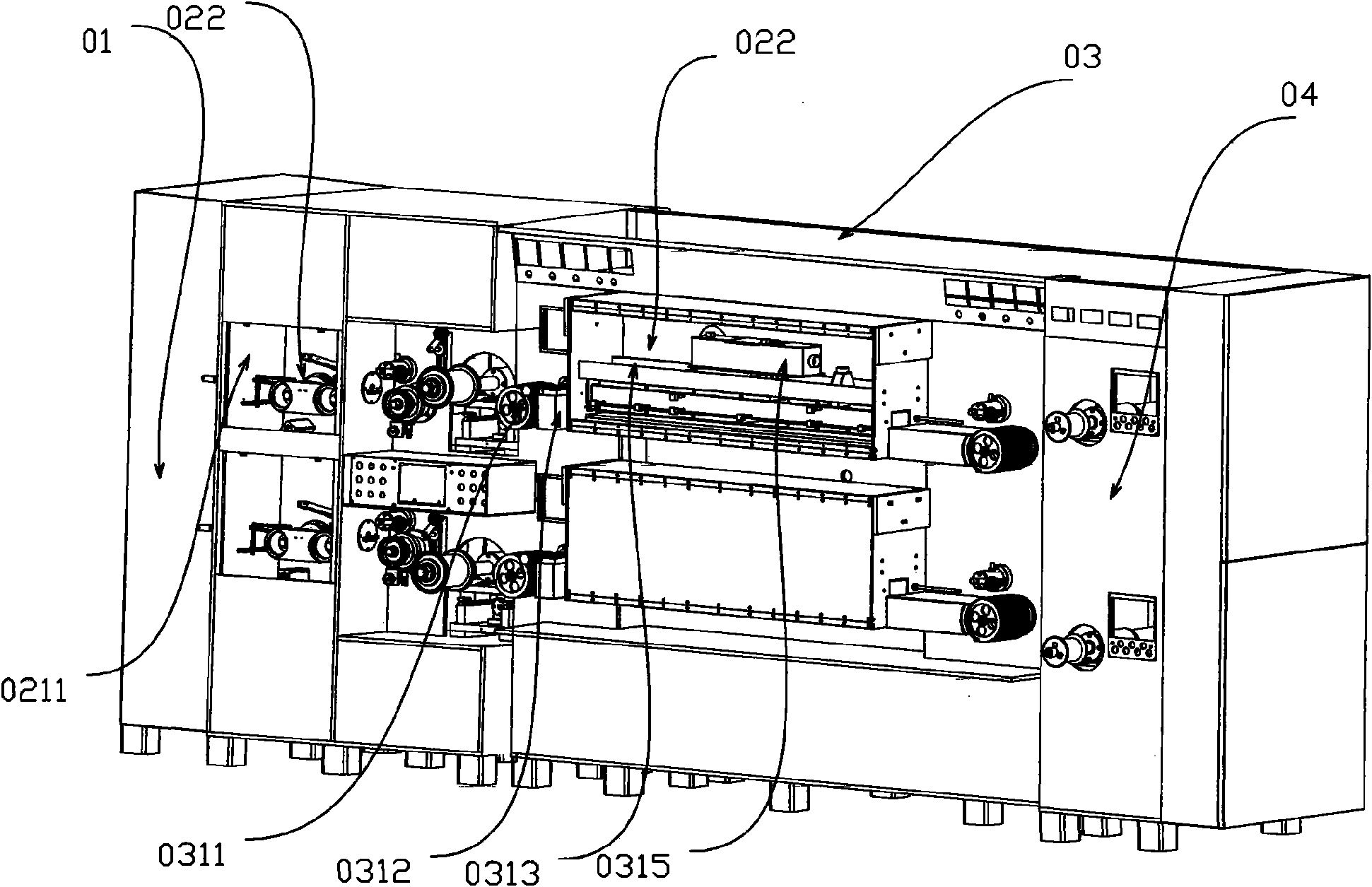

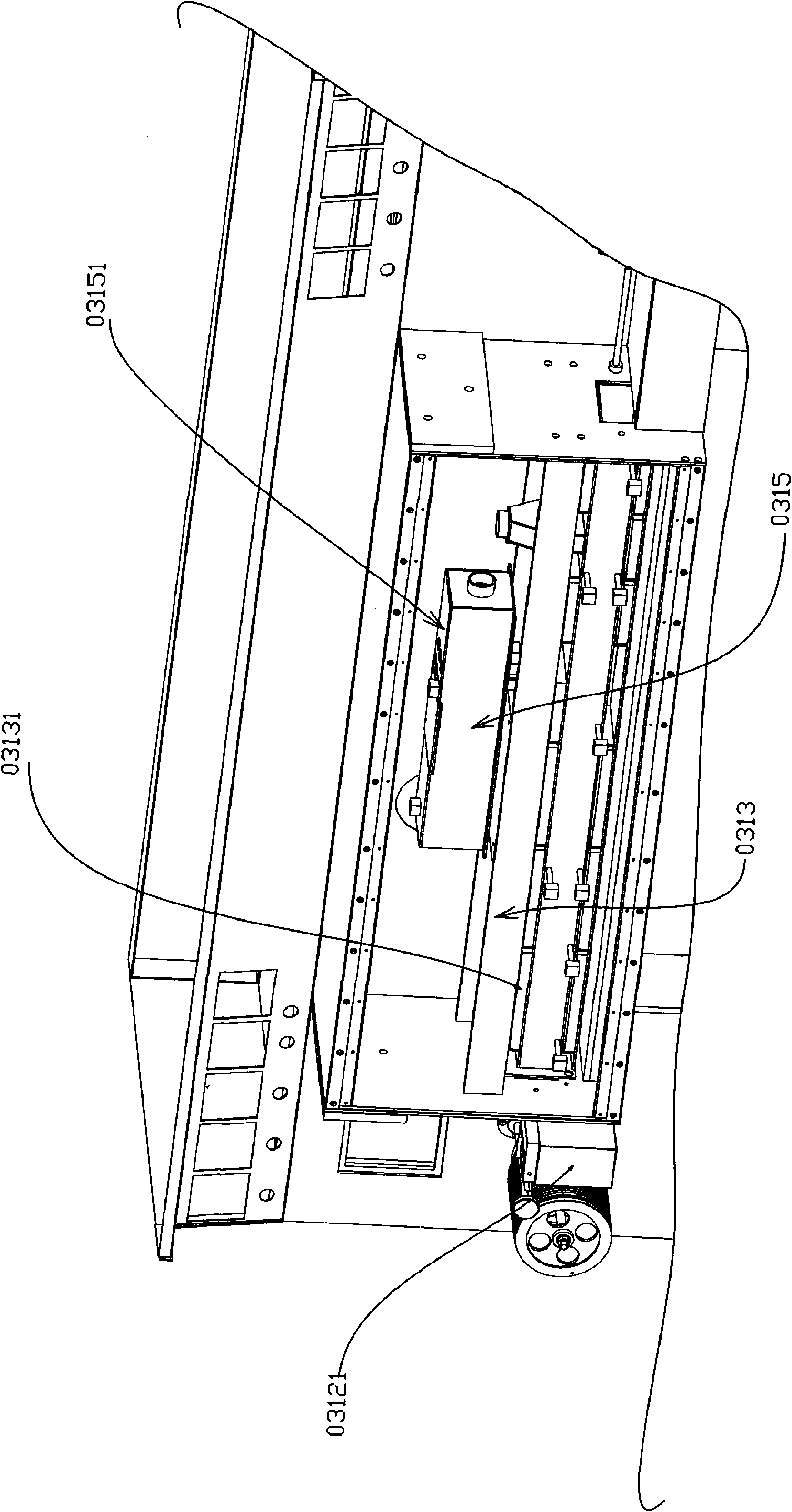

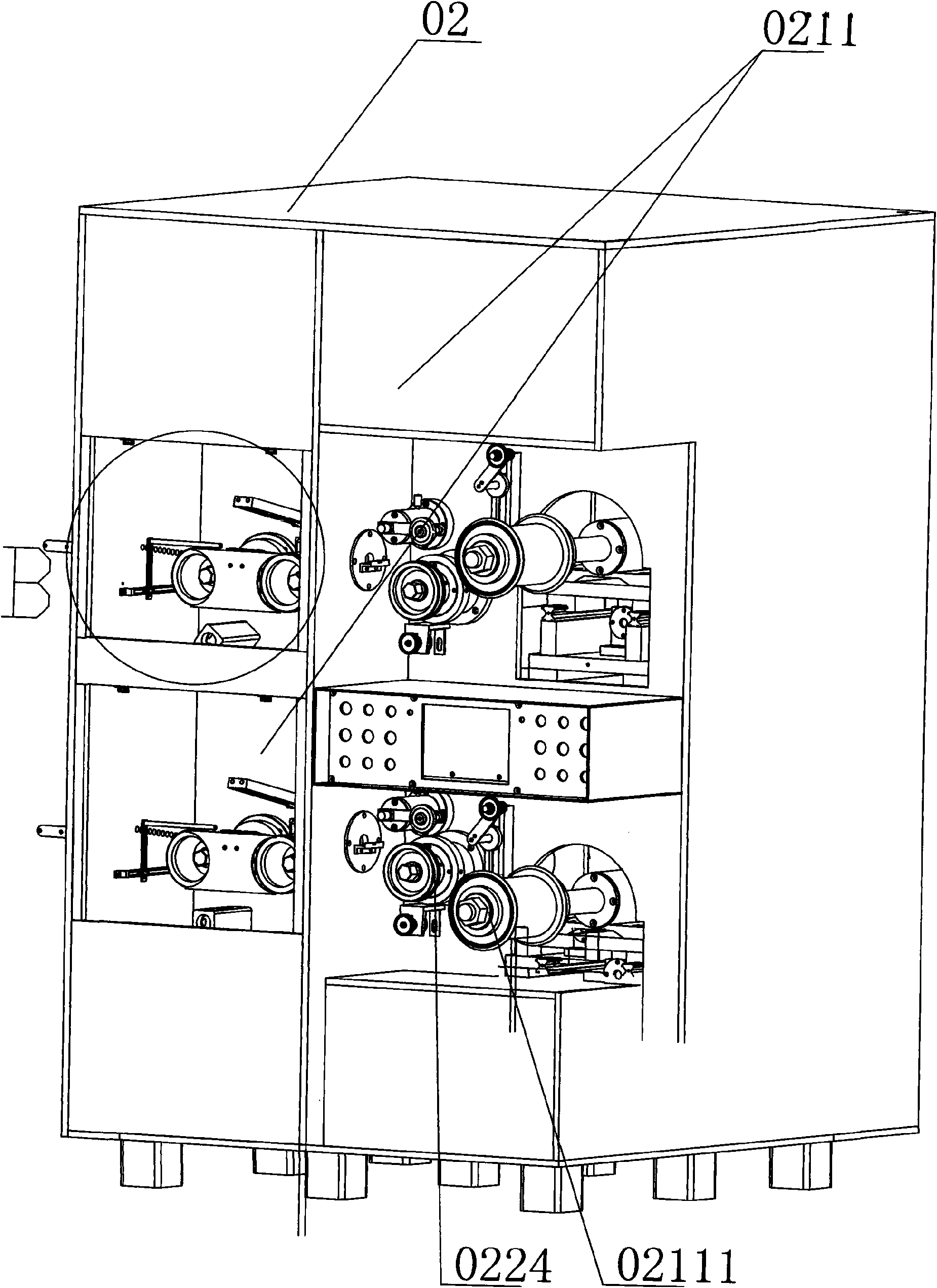

Equipment for producing bonding wire for packaging semiconductor

InactiveCN101572135AReduce volumeCompact structureLine/current collector detailsSemiconductor/solid-state device manufacturingThin metalSemiconductor package

The invention discloses equipment for producing a bonding wire for packaging a semiconductor, which comprises a wire releasing device, a wire-drawing machine, a quenching and tempering device and a take-up device, wherein a metal wire in the wire releasing device is sent to the wire-drawing machine through a leading mechanism; the wire-drawing machine is arranged on one side of a wire outlet of the wire releasing device and comprises a wire-drawing component; the metal wire led out of the leading mechanism of the wire releasing device is connected to a wire-drawing component capable of gradually drawing the outer diameter of the metal wire small; the quenching and tempering device is arranged on one side of a wire outlet of the wire-drawing machine and comprises a wire sending device, a washing device, a coating device, an annealing device and a roasting oven; a thin metal wire conforming to specifications and pulling out of the wire-drawing machine is sent to the washing device through the wire sending device; the washed metal wire enters the annealing device for annealing; the annealed metal wire enters the coating device for coating; the coated metal wire enters the roasting oven for drying and then enters a cooling device for cooling; the wire take-up device is provided with a wire containing tray for collecting a finished wire, and the wire containing tray is connected with a driving device and driven by the driving device.

Owner:袁毅

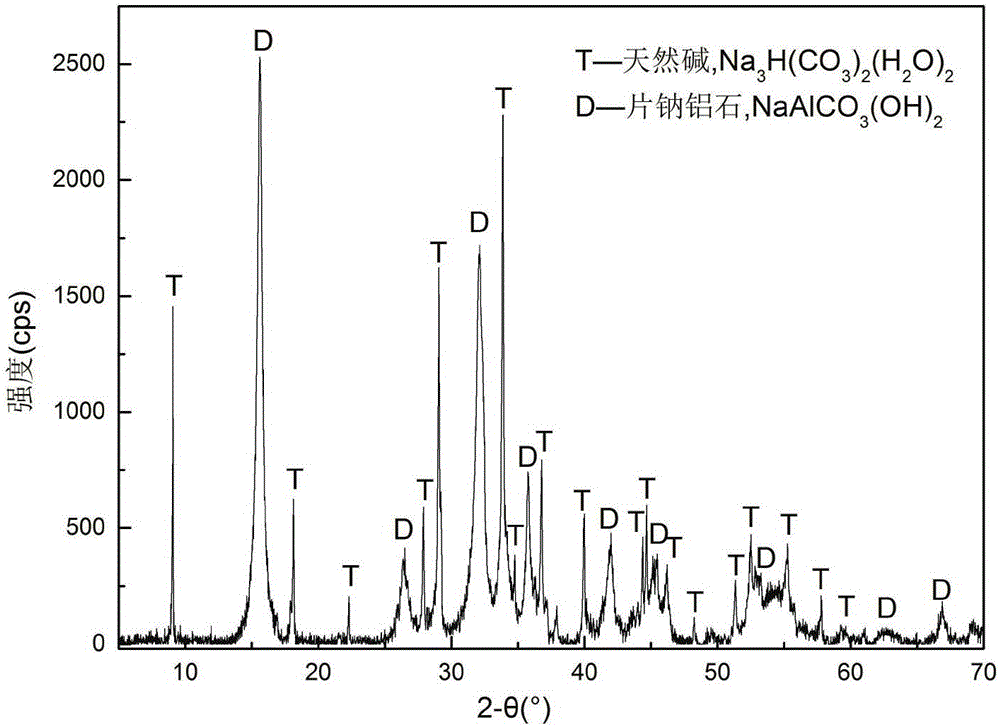

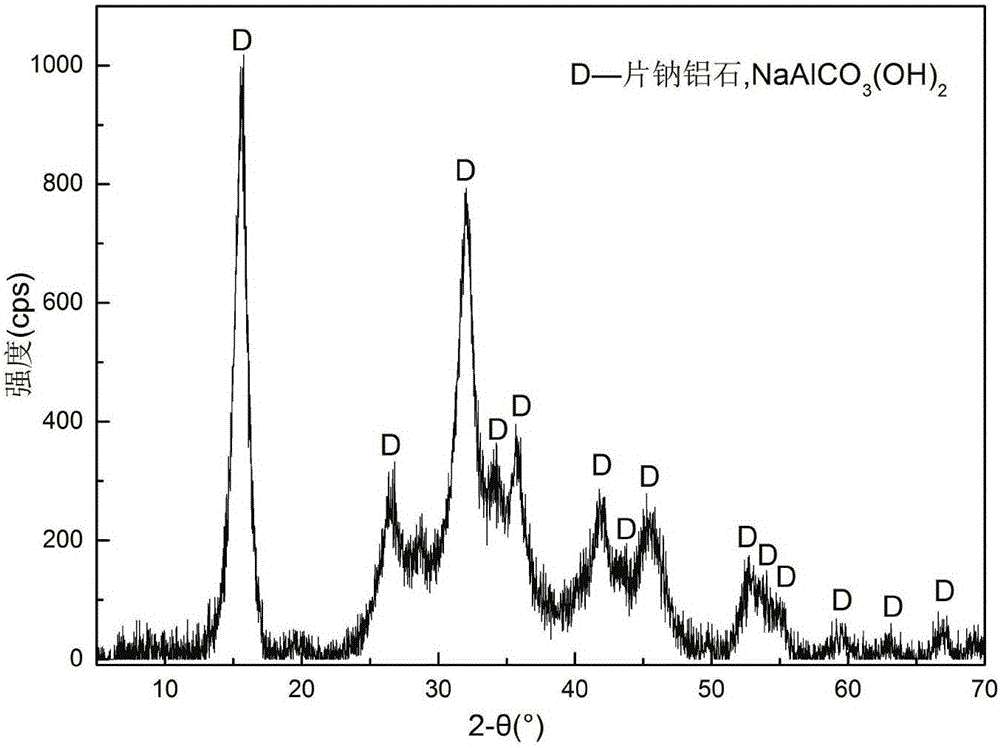

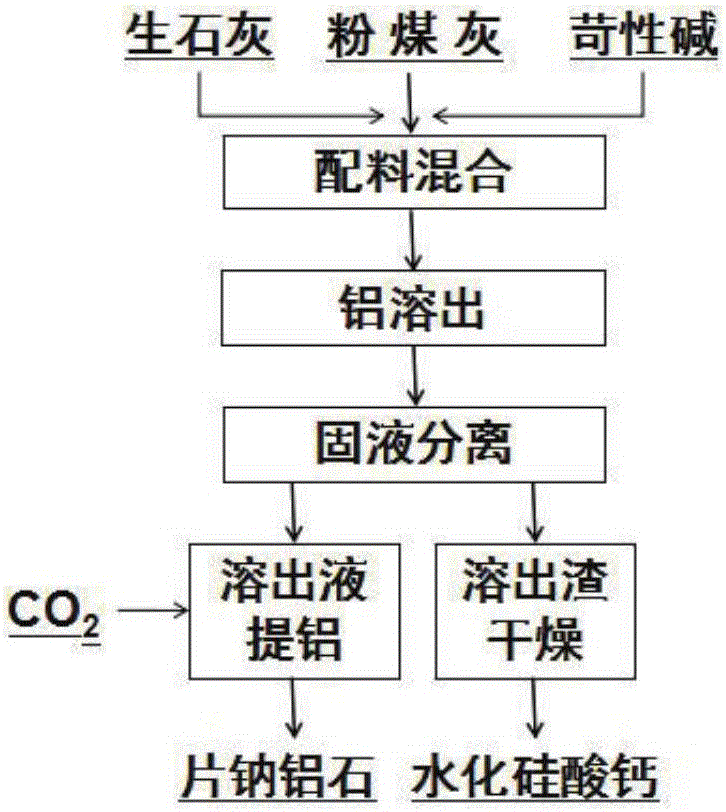

Method for co-producing dawsonite and tobermorite from fly ash

ActiveCN106542551AHigh activityHigh purityAluminium compoundsAlkaline-earth metal silicatesCalcium silicateSlag

The invention provides a method for extracting alumina from fly ash. According to the mol ratio of CaO to SiO2 being 0.3 to 1.5 and the liquid-to-solid ratio being 5ml / g to 50ml / g, quick lime, fly ash and water ingredients are mixed; 5g / L to 100g / L of NaOH is added for regulating the pH value of slurry; the reaction is performed for 0.5h to 12h in a high-pressure sealed container with the temperature being 120 DEG C to 260 DEG C; through solid-liquid separation, digestion solution containing sodium metaaluminate as main ingredients and digestion slag containing tobermorite as main ingredients are obtained; then, CO2 gas with the volume concentration being 10 percent to 100 percent is introduced into the digestion solution; along with the reduction of the pH of the solution, aluminum oxide compounds are separated out in a crystal form; when the pH is 9.5 to 8.0, the gas introduction is completed; then, through the solid-liquid separation operation, crystals containing the dawsonite as the main ingredients are obtained. The method has the advantages that the low-cost recovery and utilization on aluminum resources in the fly ash can be realized; the obtained dawsonite can be used for producing aluminum salt chemical products, or can be used for producing metallurgy grade aluminum oxide and the like after being purified; the obtained tobermorite is used as ingredients for producing cement and concrete, and the product intensity can be improved.

Owner:CENT SOUTH UNIV

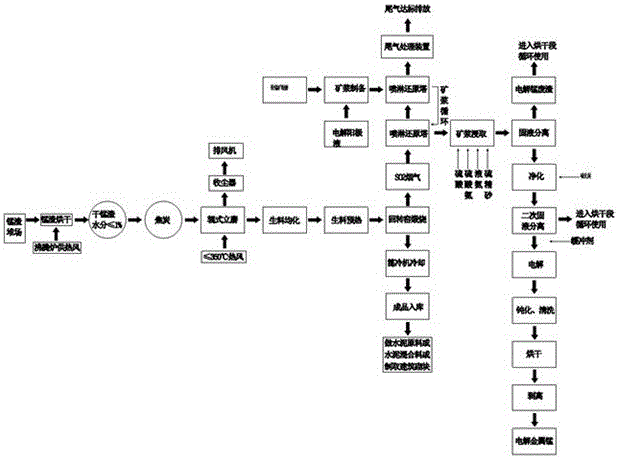

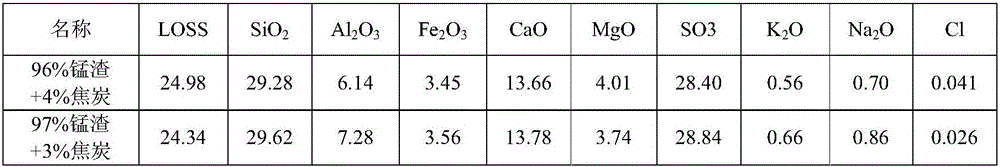

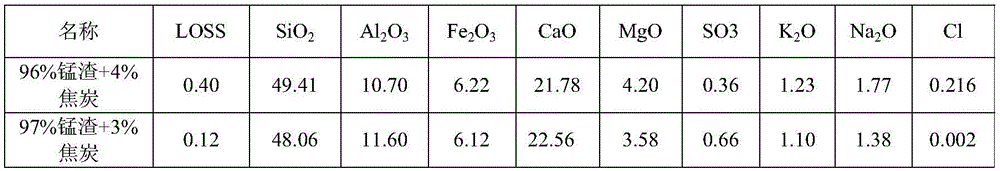

Method for producing electrolytic manganese metal by comprehensively utilizing electrolytic manganese residues

InactiveCN106756001AReduce manufacturing costActivePhotography auxillary processesCement productionSocial benefitsElectrolysis

The invention discloses a method for producing the electrolytic manganese metal by comprehensively utilizing electrolytic manganese residues, and relates to improvement for a method for producing the manganese metal in a wet process electrolysis mode. The producing process comprises the steps that ore pulp is subjected to leaching and solid-liquid separation; a solid-liquid separated liquid is subjected to purification and electrolysis to produce electrolytic manganese; the electrolytic manganese residues are obtained through solid-liquid separation; according to the characteristic of the method, the electrolytic manganese residues are obtained after solid-liquid separation and subjected to calcination, and SO2 smoke generated during calcination of the electrolytic manganese residues are subjected to spraying and reduction and then used for manganese sulfate pulp preparation through ore pulp leaching; and the calcinated electrolytic manganese residues are used for production of cement. According to the method, the electrolytic manganese residues are further treated, sulfur in the electrolytic manganese residues are effectively recovered, the production cost of the electrolytic manganese is lowered, the calcinated electrolytic manganese residues have activity and can serve as a raw material for production of building materials, stockpiling of solid waste is reduced, damage of electrolytic manganese production to the environment is effectively reduced, and the production economic and social benefits are increased.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

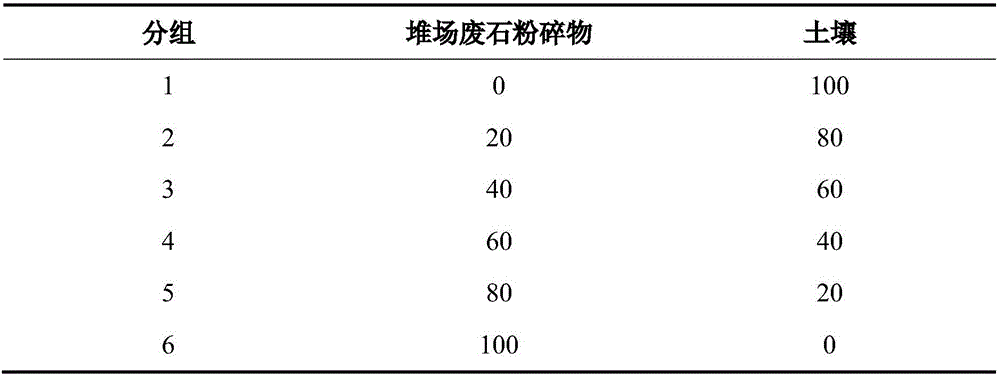

Ecological recovery matrix for vanadium ore waste rock stockyard, preparation method and application thereof

ActiveCN106064980AImprove physical and chemical propertiesReduce stockpilesExcrement fertilisersFertilizer mixturesEdaphicEnvironmental engineering

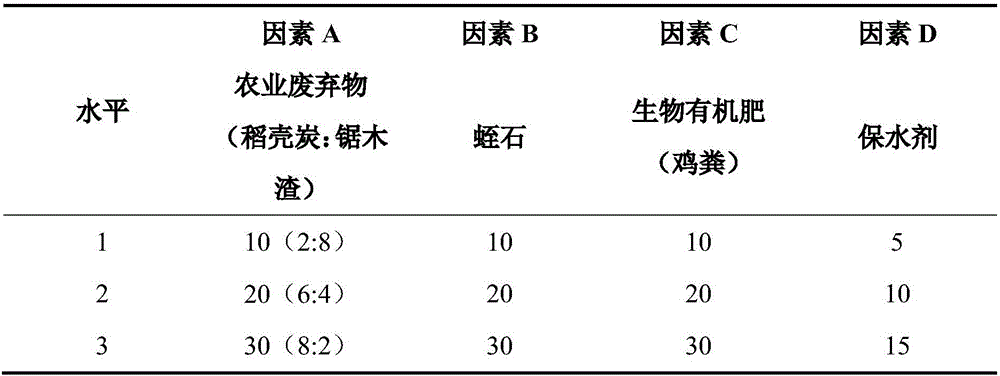

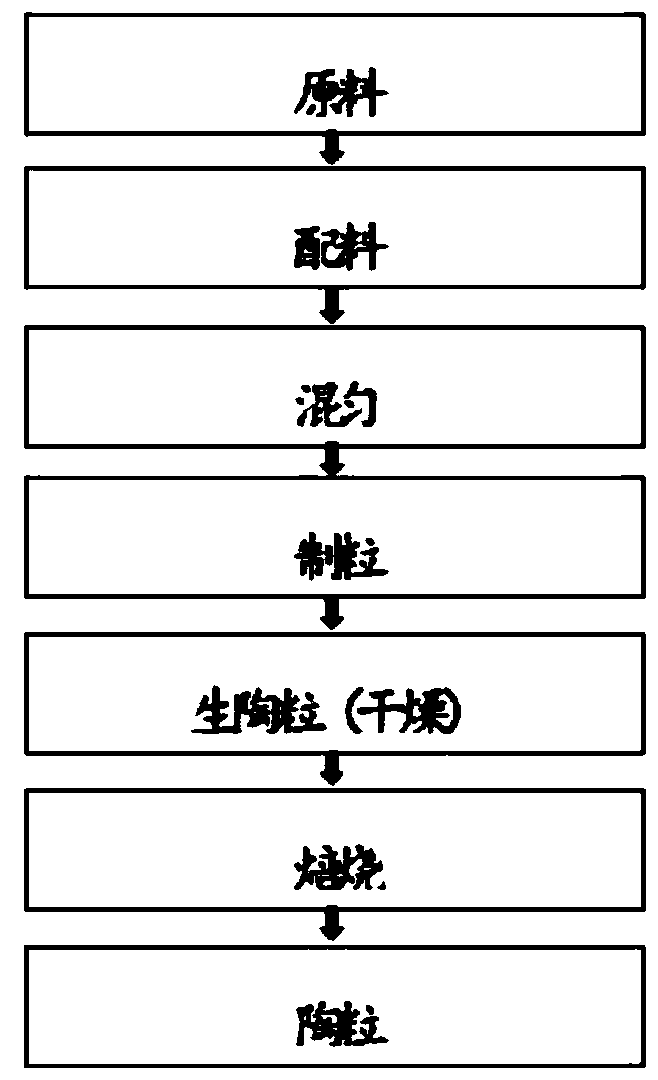

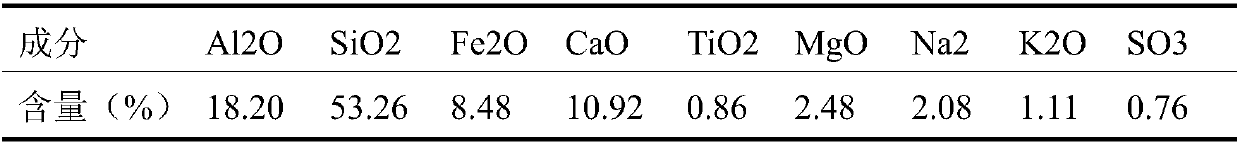

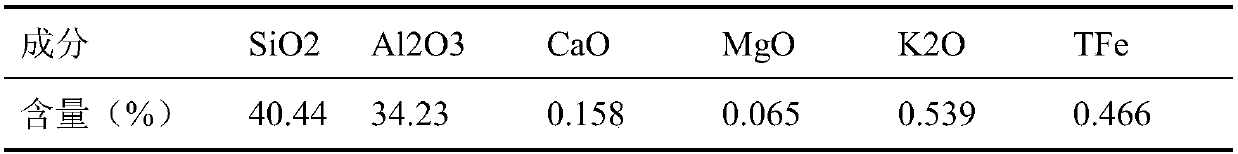

The present invention discloses an ecological recovery matrix for vanadium ore waste rock stockyard. The ecological recovery matrix comprises, by weight, 0-100 parts of crushed stockyard waste rock, 0-100 parts of soil portions, and a matrix additive accounting for 1.75-5.25 wt.% of the total weight of crushed waste rock and soil; the matrix additive includes 0.5-1.5% of agricultural wastes, 0.5-1.5% of vermiculite, 0.5-1.5% of biological organic fertilizer, and 0.25-0.75% of a water-retaining agent. The agricultural waste contains 20-80% of rice husk carbon and 20-80% saw wood residue. The invention realizes the fast recovery of the ecological waste vanadium ore yard through ecological restoration technology. In order to achieve the environmental pollution on the surrounding soil management of waste rock yard, improve the surrounding habitat Living and living environment of the people.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Olive-leaf foods and its preparation method and use

The present invention discloses an olive leaf food with health-care function its preparation method and use. Said food not only comprises olive leaf 10-100 weight portions, but also comprises ginkgo leaf 5-50 weight portions of ginkgo leaf extract. Said product possesses several health-care functions of raising immunity of human body, resisting thrombosis, curing hypertension and arteriosclerosis, reducing blood sugar, delaying senility, preventing cancer, resisting cancer and regulating internal secretion, etc. and has no toxic side effect.

Owner:北京华源生命科贸发展有限公司

Light fly ash ceramsite and preparation method thereof

ActiveCN110862270ASmall bulk densityReduce stockpilesCeramic materials productionCeramicwareKaolin clayExpanded clay aggregate

The invention belongs to the technical field of solid waste recycling, and particularly discloses a preparation method of light fly ash ceramsite, which comprises the following steps: mixing fly ash,kaolin, kieselguhr and expanded perlite raw material, pelletizing, and roasting the obtained green pellets at 1210-1230 DEG C to obtain the light fly ash ceramsite. Wherein the weight ratio of the flyash to the kaolin to the kieselguhr is (75-85): (12-18): (4-6); and the expanded perlite accounts for 7-12wt% of the sum of the weight of the fly ash, the kaolin and the kieselguhr. According to theinvention, the synergism of the components in percentage by weight is further matched with the control of the roasting temperature, so that the technical problems of high ceramsite bulk density and incapability of meeting the quality requirement of ultralight ceramsite caused by high-proportion fly ash can be solved, the bulk density of the prepared ceramsite can be unexpectedly and remarkably reduced, and the quality of the ultralight ceramsite can be improved, and the bulk density of the lightweight aggregate is superior to the relevant provisions of the Test Method for Lightweight AggregateGB / T17431.2-2010.

Owner:湖南中大再生资源与环保工程有限公司

Stone-plastic wallboard

InactiveCN107244868AHigh activityIncrease activationAnti-corrosive paintsElectrically-conductive paintsFiberCrack resistance

The invention provides a stone-plastic wallboard which comprises 50-80 parts of calcite powder, 40-60 parts of PVC (Polyvinyl Chloride) resin, 20-30 parts of chloroprene rubber, 33-43 parts of butadiene-acrylonitrile rubber, 3-5 parts of conductive fibers, 30-50 parts of marble powder, 4-8 parts of processing aids, 4-8 parts of a modifier, 1-3 parts of a stabilizer, 2-5 parts of a foaming agent, 1-5 parts of a lubricating agent, 90-100 parts of semi-hydrated gypsum, 1-3 parts of bamboo charcoal fibers, 2-5 parts of methyl cellulose, 3-7 parts of ethyl cellulose, 20-30 parts of a stone-like coating and 3-6 parts of polyvinyl alcohol. According to the stone-plastic wallboard disclosed by the invention, the calcite powder, the marble powder, the semi-hydrated gypsum, the PVC resin, chloroprene rubber and the butadiene-acrylonitrile rubber are mixed, so that the prepared stone-plastic wallboard has excellent mechanical strength, tensile strength and crack resistance, the activity of the semi-hydrated gypsum is improved, the content of soluble impurities in the semi-hydrated gypsum is reduced, a pulverization phenomenon on the surface of a gypsum base material is further avoided, and the strength and toughness of the semi-hydrated gypsum base material are improved, so that the gypsum is applied to the field of building materials in a wide range, the inventory of phosphogypsum in the natural world is reduced, and the environmental pollution is reduced.

Owner:合肥易美特建材有限公司

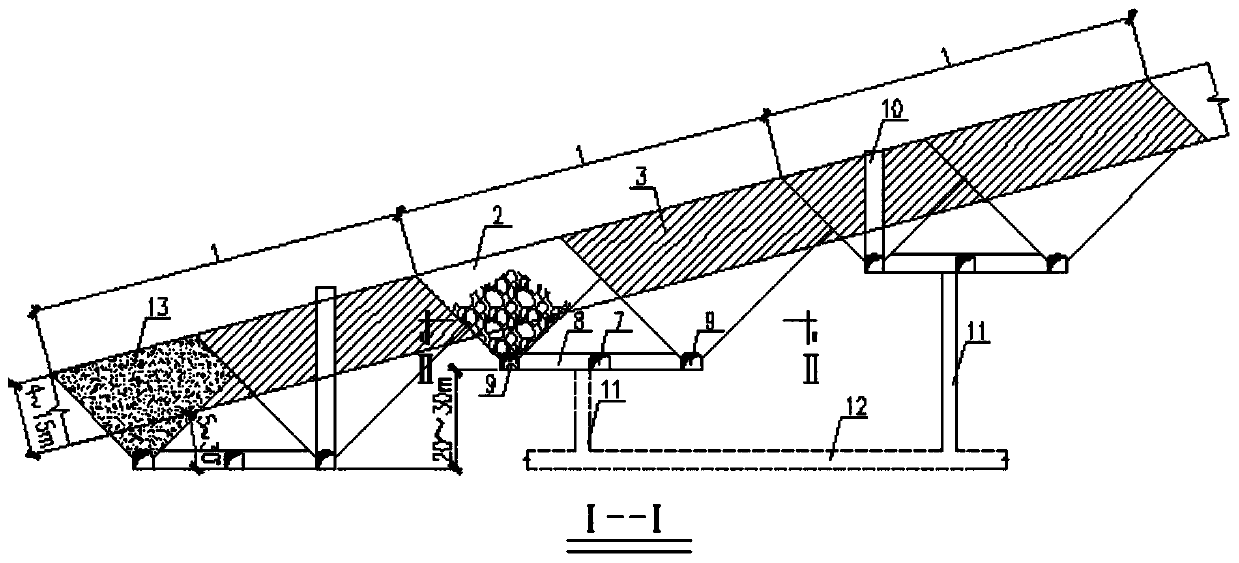

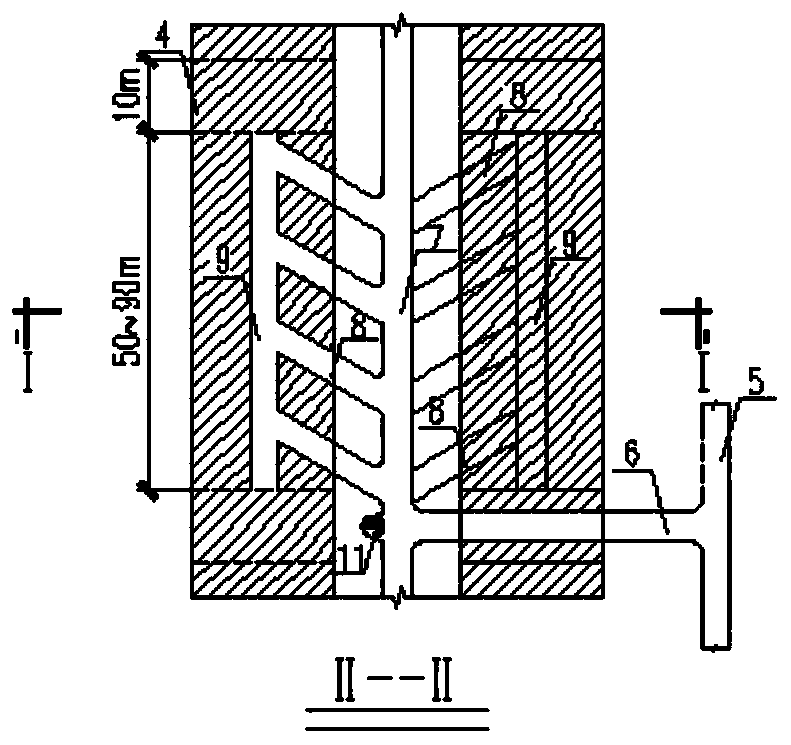

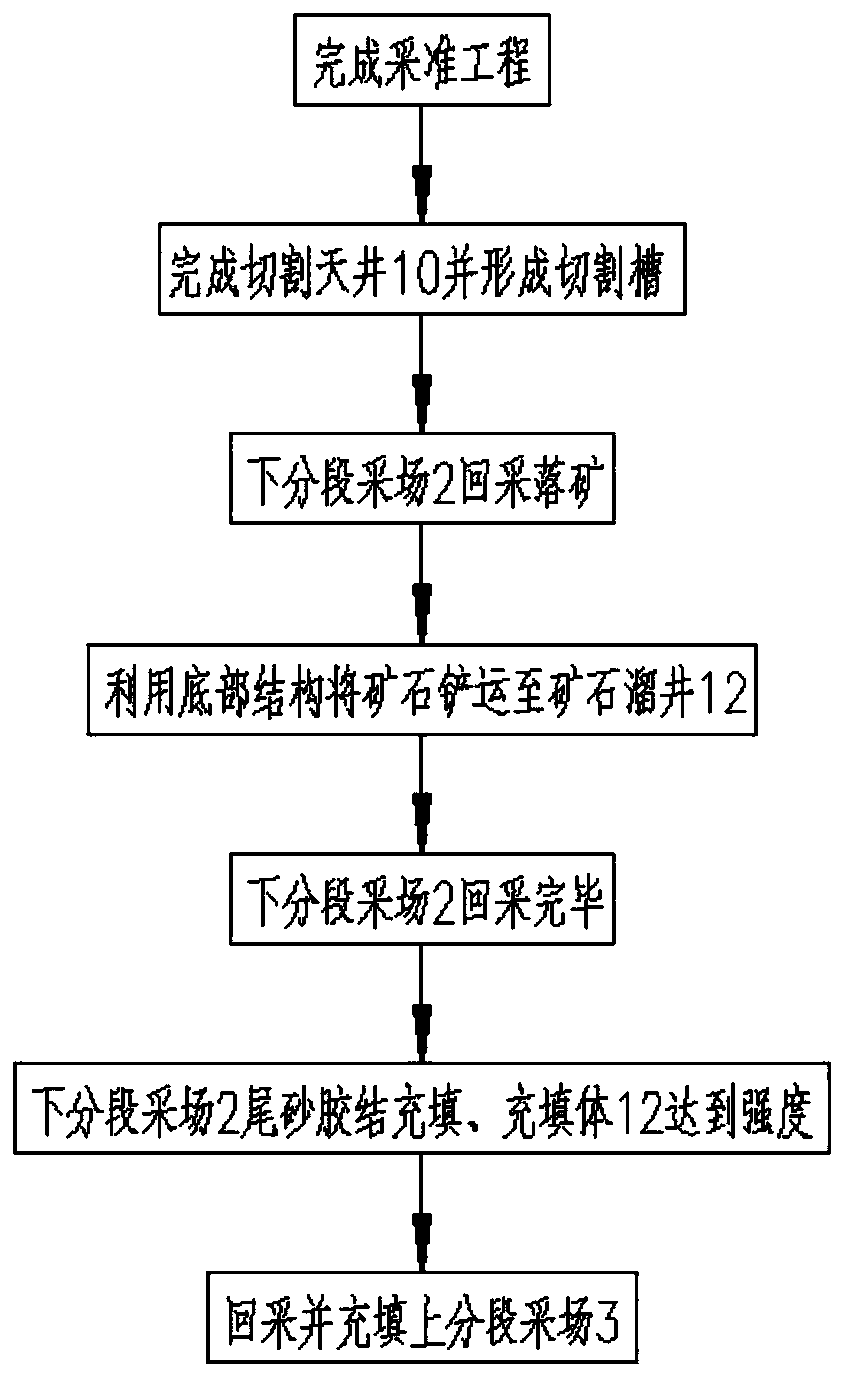

Gentle dip medium-thick ore body safety and low-cost combined segmented mining method

ActiveCN110359914AAvoid direct accessGuarantee job securityUnderground miningSurface miningEngineeringYard

The invention discloses a gentle dip medium-thick ore body safety and low-cost combined segmented mining method. Lower segmented stopes (2) and upper segmented stopes (3) are alternately arranged in the ore body vertical direction at each interval of 10-15 m, one recovery unit (1) is formed through combination of each lower segmented stope (2) and the corresponding upper segmented stope (3), and studs (4) are scratched at the end portions of the recovery units (1). In each lower segmented stope (2), a cutting groove is formed with a cutting open yard (10) as the free face, and ore falls into atrench (9). A shoveling and conveying machine is utilized for conducting ore loading in an ore loading access road (8), carries the ore into an ore drop shaft (11) through an ore discharging roadway(7) and then lowers the ore into a conveying roadway (12) for car loading and conveying-out. According to the gentle dip medium-thick ore body safety and low-cost combined segmented mining method, every two segmented stopes are gathered into one recovery unit for exploitation, the ore discharging roadway, the ore drop shaft, a slope ramp linking way and other projects are commonly used, the stopepreparation cost is reduced, the preparing time for the stope preparation work is saved, and the exploitation efficiency is improved. Exploited waste stone can be machined into building materials to be sold, and the stockpiling space is additionally arranged for tailing filling.

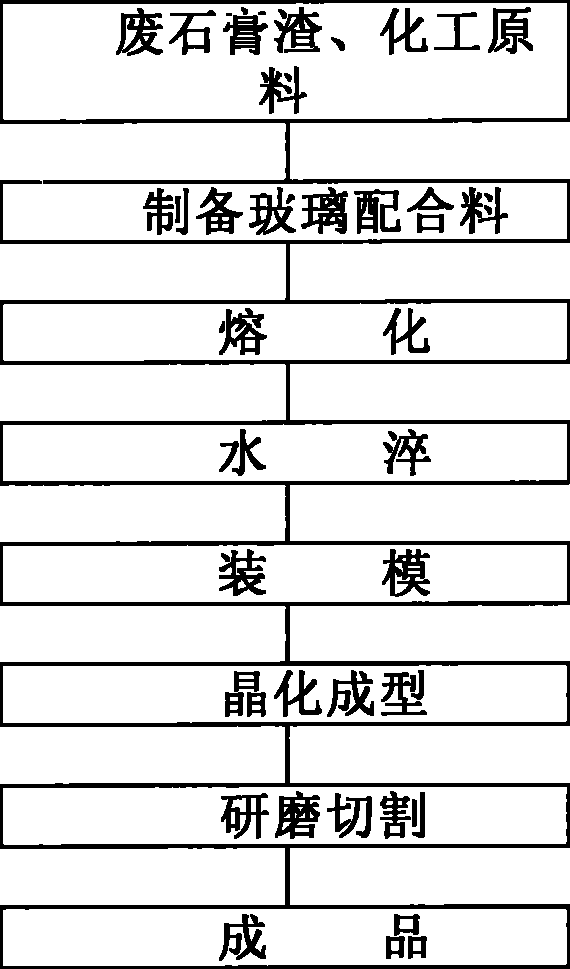

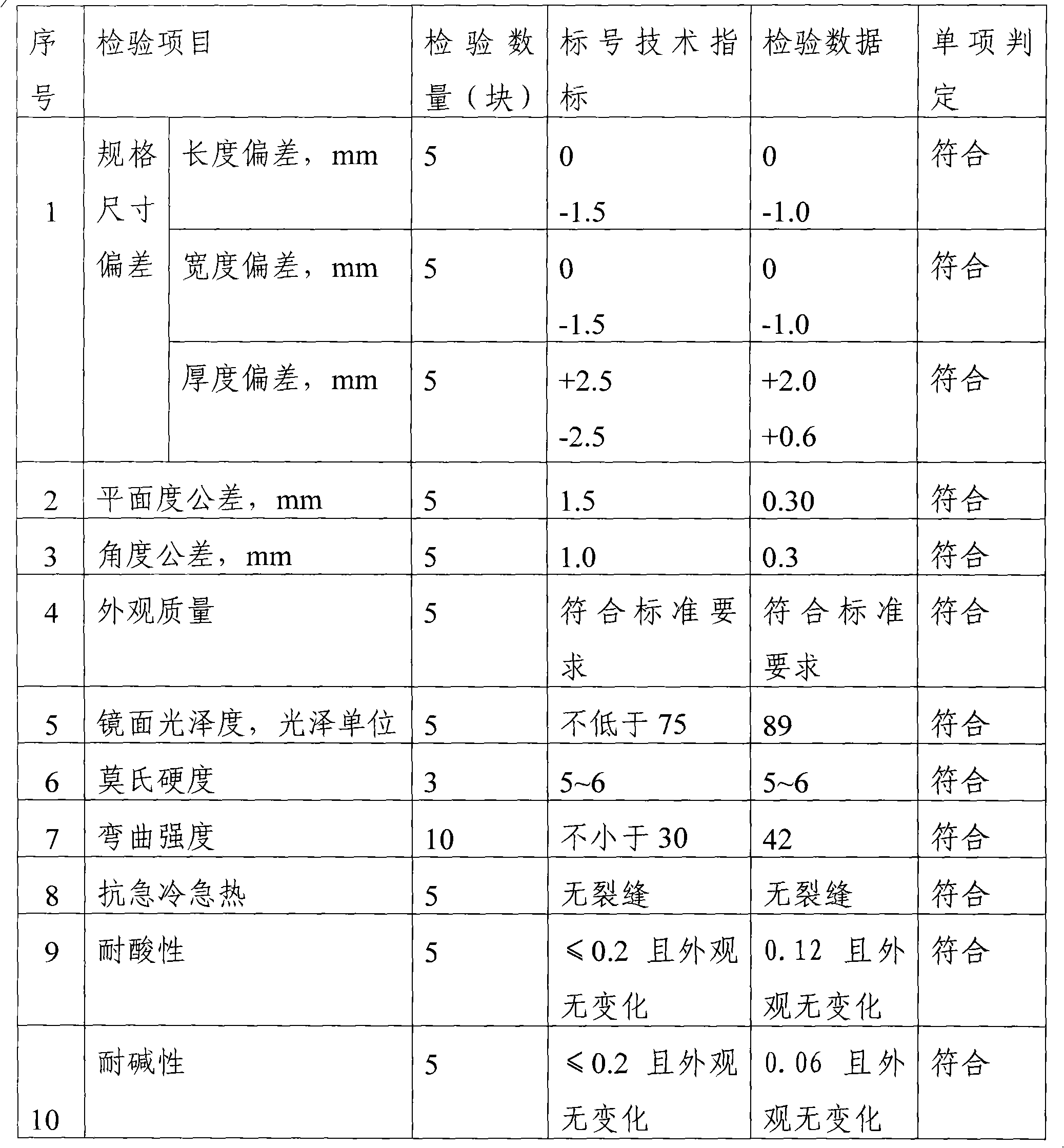

Method utilizing waste gypsum slag to manufacture green microcrystalline glass plate material

The invention discloses a method utilizing waste gypsum slag to manufacture a green microcrystalline glass plate material. The method includes the following steps: the waste gypsum slag, quartz sand, petalite, soda ash, zinc oxide, barium carbonate, chromic oxide, copper oxide and carbon powder are mixed together according to certain parts by weight to prepare a glass batch mixture; the glass batch mixture is molten into liquid glass; the liquid glass is poured into water to obtain glass particles; the glass particles are laid in a fireproof mould to carry out crystallization heat treatment; finally, the rough green microcrystalline glass is ground and cut after the crystallization heat treatment so as to obtain the finished glass. The method in the invention utilizes the waste gypsum slag to manufacture the green microcrystalline glass plate material, which not only reduces the stacking quantity of industrial waste slag and lessens environmental pollution, but also improves the product performance and reduces the production cost. Therefore, the method in the invention has good social and economic benefits.

Owner:陕西乾盛环保建材工程有限公司

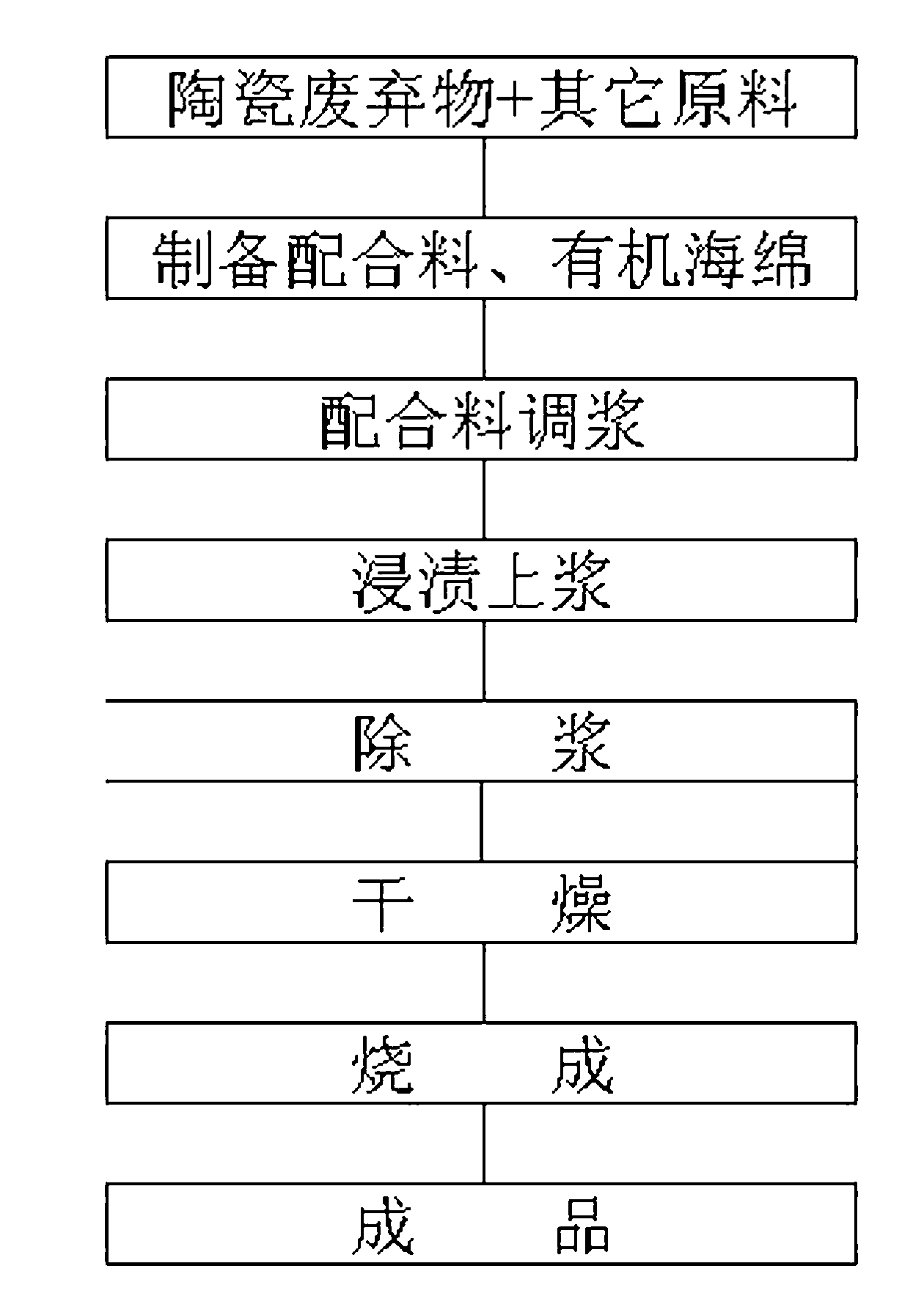

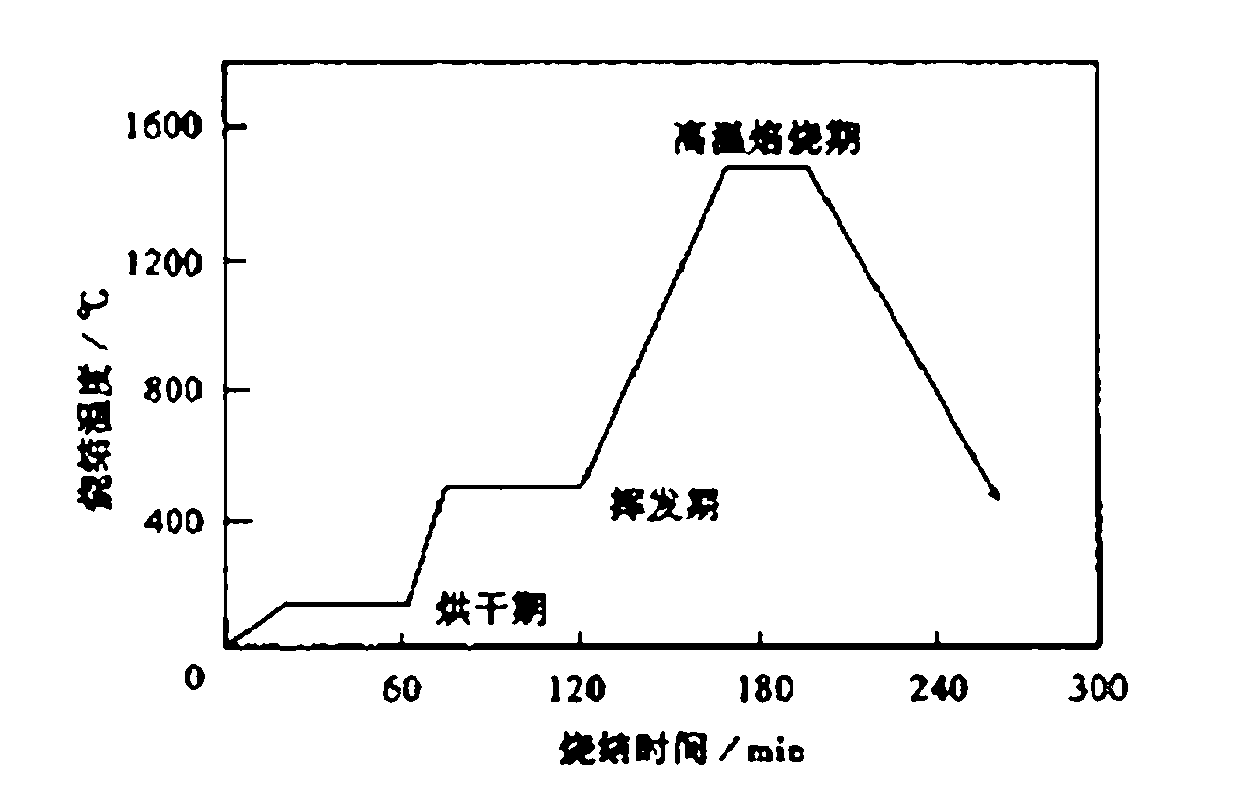

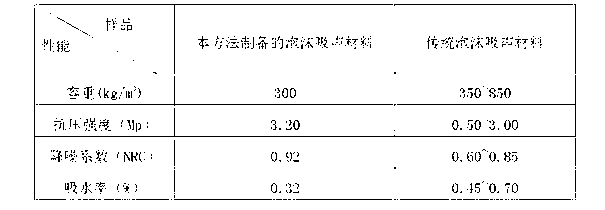

Foam sound absorption material produced by using ceramic waste and production method of foam sound absorption material

ActiveCN102936151AReduce manufacturing costLow costSolid waste disposalCeramicwareNoise barrierKaolin clay

The invention discloses a foam sound absorption material and a production method of the foam sound absorption material. A ceramic waste serves as a main raw material in production. The foam sound absorption material comprises, by weight, 55-85 parts of the ceramic waste, 15-30 parts of superfine kaoline, 0.2-0.6 part of a suspending agent and 0-6 parts of zirconium oxide. An organic precursor-dipping high-temperature sintering process is used for producing the foam sound absorption material, the disadvantages that a convention sound absorption material is low in noise reduction coefficient, short is service life and easy to deliquesce and produce secondary pollution are overcome, the material is light in weight, acid-resisting, alkali-resisting, fire-proof and high temperature-resisting and can be used in noise-elimination noise barriers in urban streets, railways, subways, construction sites, central air-conditioner rooms and the like, and also can be used in public places such as hospitals, libraries, convention centers, exhibition halls, lecture halls, music halls, movie theaters, gymnasiums, commercial buildings, public houses, hotels and office buildings. The waste serves as the production raw material, the production cost is reduced, the dumped amount of the ceramic waste is reduced at the same time, environmental pollution is controlled, and the resourcization recycling utilization of the waste is achieved.

Owner:张金青

Copper mine raffinate treatment method

ActiveCN105565395AReduce stockpilingImprove maximum utilizationIron sulfatesProcess efficiency improvementIron(III) sulfateCalcium hydroxide

The invention discloses a copper mine raffinate treatment method. The copper mine raffinate treatment method includes steps: (1) adding iron powder into copper mine raffinate to realize copper recovery and acquisition of iron-containing waste liquid; (2) adding sodium hydrosulfide or sodium sulfide into the iron-containing waste liquid to realize deep removal of harmful elements and acquisition of aftertreatment liquid; (3) adding aluminium hydroxide, calcium hydroxide or sodium hydroxide into the aftertreatment liquid to realize catalytic oxidation, hydrolysis and polymerization to obtain an oxidation product; (4) subjecting the oxidation product to ageing, and drying to obtain a qualified solid polymeric ferric sulfate product. The iron powder is taken as a raw material for copper recovery pretreatment of the raffinate, then the sodium sulfide or the sodium hydrosulfide is added for deeply removing the harmful elements such as copper, arsenic, cadmium and chromium, and the treated iron-containing liquid is subjected to catalytic oxidation, hydrolysis, polymerization and ageing to obtain the qualified polymeric ferric sulfate which is a water treatment agent.

Owner:厦门紫金矿冶技术有限公司

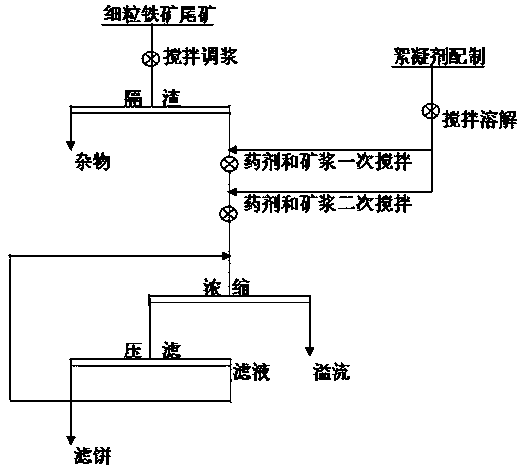

Concentration and dehydration process of very fine tailings

The invention relates to a concentration and dehydration process of very fine tailings. The process is characterized by comprising the following steps: (1) stirring and slurrying the tailings ore pulpto obtain suspended ore pulp; (2) carrying out slag separation on the slurried ore pulp to remove impurities; (3) preparing a flocculating agent and adding into the ore pulp subjected to slag separation, and evenly stirring and mixing twice; (4) mixing the flocculating agent with and the ore pulp, and concentrating the ore pulp by using a high-efficiency thickener; (5) conveying the concentratedunderflow to a filter press for carrying out pressure filtration, and overflowing and clarifying to enable the effluent to be used as industrial circulating water. After the scheme is adopted, the water content of the tailings is greatly reduced; a filter cake is good in looseness, does not need to be scattered, does not stick to a bucket when being shoveled by a forklift, does not stick to a truck bed when being transported by a truck and unloaded, and does not drip and leak in transit; furthermore, the concentration and dehydration process meets the quality requirements of an iron correctorused in cement industry, and increases the utilization rate of tailings resources.

Owner:NANJING MEISHAN METALLURGY DEV +1

Method for recovering germanium from germanium extraction residues

ActiveCN102181649AEfficient recyclingTake advantage ofProcess efficiency improvementChemistryPre treatment

A method for recovering germanium from germanium extraction residues relates to the technical field of wet process metallurgy, in particular to a method for extracting germanium for a second time from distillation residues after germanium extraction by wet process treatment. The method is implemented by the following technical steps: washing of germanium extraction residues for deacidification, heating pretreatment of sodium hydroxide, solution treatment by concentrated alkali, sodium chlorate oxidation and hydrochloric acid distillation to separate germanium, and preparation of germanium dioxide and the like. The method is used for recovering germanium from germanium extraction residues and germanium tetrachloride at the rate up to over 75%. The successful research of the germanium extraction technology has actually positive significance in high-efficiency recovery of germanium in the residues, full utilization of rare germanium resource, reduction of residue pileup, environmental protection and other aspects.

Owner:LINCANG JIECAIBA COAL IND

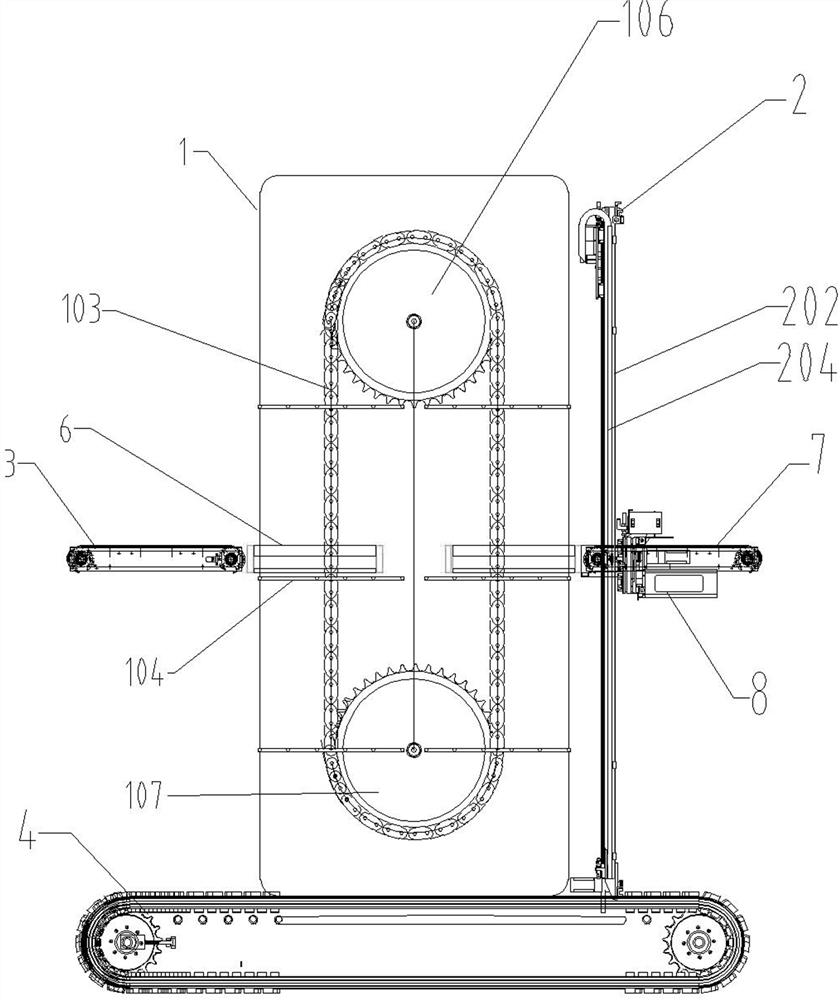

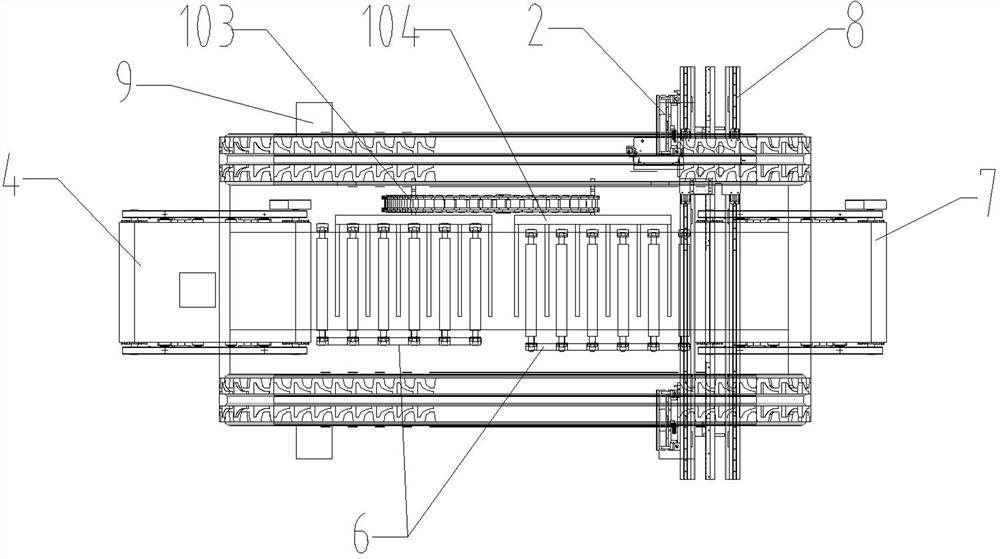

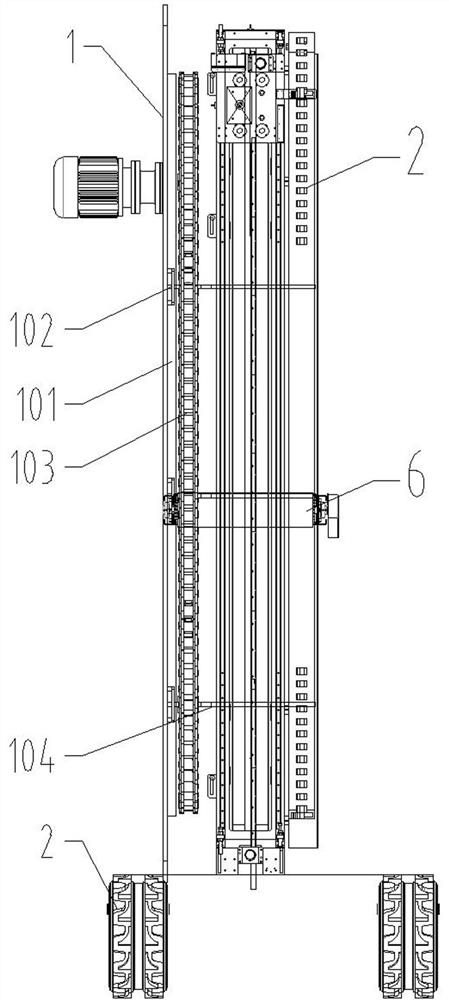

Automatic loading device

PendingCN113200373AMeet the requirements of stackingShorten the lifting timeControl devices for conveyorsStacking articlesControl engineeringMachine

The invention relates to an automatic loading device, and belongs to the field of automatic stacking and loading. According to the technical scheme, a circulating lifting conveyor and a material taking and placing elevator are arranged on the rear portion of a main conveyor. The circulating lifting conveyor comprises a long-circle-shaped vertical circulating rail, a chain lifting structure running along the circulating track and a circulating operation table, the long-circle-shaped end of the rail is provided with a semicircular rerail with the same radius as the long circle, the rerail communicates with the track, a plurality of vertical sliding blocks moving along the rail are arranged on a chain, and the vertical sliding blocks are provided with at least two sets of idler wheels. The two idler wheels move in the circulating rail and the rerail and are kept in a vertical state, and a circulating operation table is further arranged on the vertical sliding blocks. Materials on the conveyor are transferred to a stacking and lifting mechanism through the circulating lifting mechanism, and the stacking and lifting mechanism can move left and right along with a lifting machine and the materials can be placed at the required position, so that the requirement of stacking is met.

Owner:三维汉界机器(山东)股份有限公司

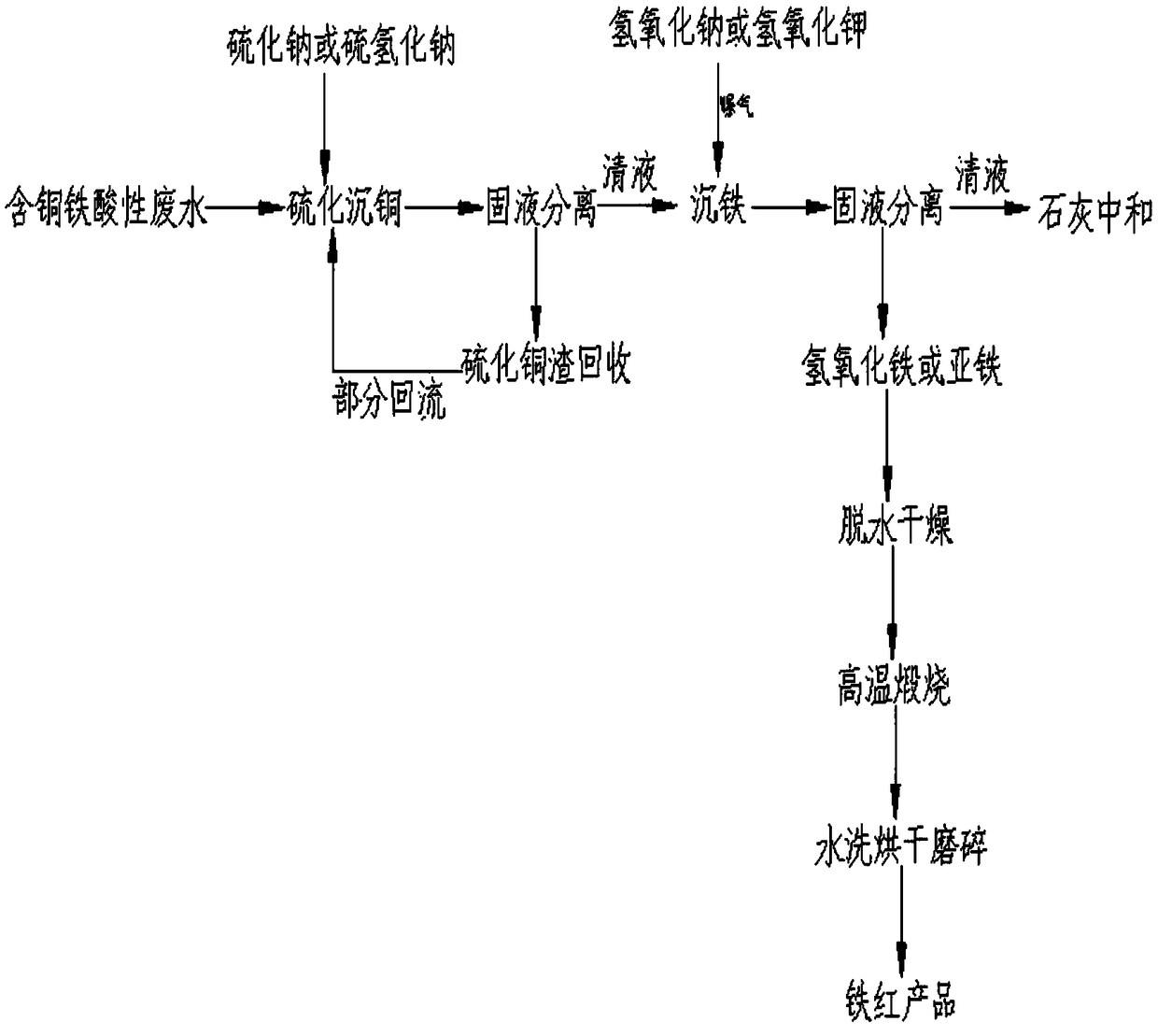

Method for recycling mine acid wastewater

InactiveCN109234536ASimple processReduce investmentFerric oxidesProcess efficiency improvementFerric hydroxideVulcanization

The invention provides a method for recycling mine acid wastewater. The method comprises the following steps: vulcanization for copper deposition: injecting a sodium sulfide or sodium sulfhydrate solution into acid wastewater containing copper and iron to perform copper deposition reaction for 0.5-1.5h, performing solid-liquid separation to obtain clear liquid containing iron and underflow containing copper sulfide slag, and performing press filtration on the underflow containing copper sulfide slag by a plate and frame filter press to obtain a copper concentrate product and waste liquid containing ferrous iron; aeration for iron deposition: adding sodium hydroxide or potassium hydroxide to the clear liquid containing iron to perform aeration for iron deposition, and performing solid-liquid separation to obtain ferric hydroxide or a ferrous iron product and residual liquid; high-temperature calcination: performing high-temperature calcination on the ferric hydroxide or the ferrous ironproduct to obtain a high-temperature calcination product; and washing, drying and grinding: washing, drying and grinding the high-temperature calcination product to obtain a high-purity iron red product. The method provided by the invention is simple in process and low in equipment investment, is capable of performing harmless treatment on acid wastewater and capable of recovering copper concentrate and high-purity iron red products, reduces the accumulation of solid wastes in mines, increases the resource utilization rate, is beneficial to sustainable and healthy development of the mines, and is suitable for application in the hydrometallurgical industry.

Owner:ZIJIN MINING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com