Light fly ash ceramsite and preparation method thereof

A technology of fly ash ceramsite and fly ash, which is applied to ceramic products, clay products, and other household appliances. It can solve the problems of high packing density of ceramsite and low amount of fly ash, and achieve good cylinder compressive strength, The effects of protecting cultivated land, good economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

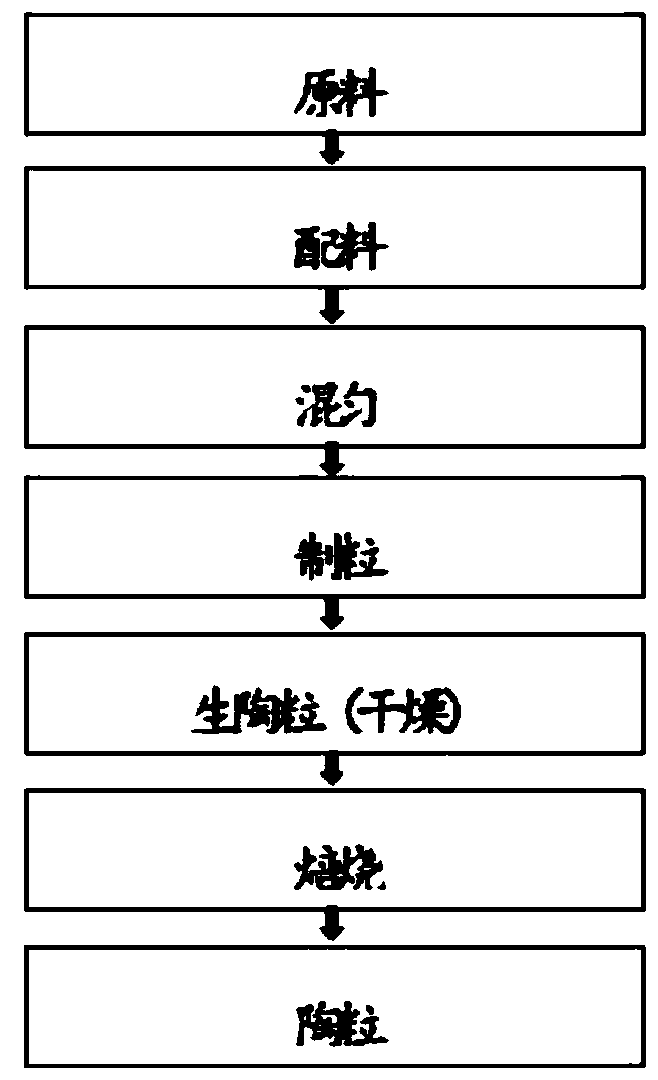

Method used

Image

Examples

Embodiment 1

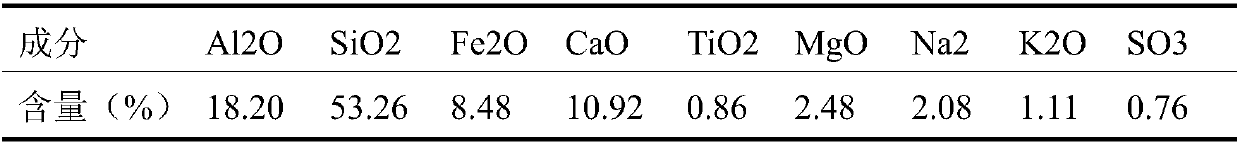

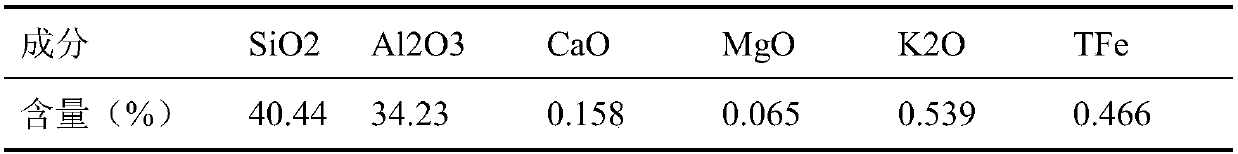

[0052] With the fly ash of 80 weight parts, the kaolin of 15 weight parts, the diatomite of 5 weight parts and the expanded perlite that mixes 9% (based on the weight sum of fly ash, kaolin and diatom earth) The raw materials are stirred and mixed, and an appropriate amount of water is continuously added during the stirring process (the mass ratio of liquid to solid is 1:4) to ensure that the materials in the system are evenly mixed, and the pellets are granulated by a pelletizer to control the diameter fluctuation of the green pellets between 10-15mm. Then put the molded ceramsite into a drying oven at a temperature of 100°C and let it stand for 2 hours to obtain raw ceramsite. Then put the dried raw ceramsite into the muffle furnace, bake at 1220°C for 10-12 minutes, and cool naturally. properties such as strength and bulk density.

[0053] The bulk density of the obtained product is 338.25kg / m3, the cylinder compressive strength is 1.02MPa, the cylinder compressive strengt...

Embodiment 2

[0055] Compared with Example 1, the mass ratio of fly ash, kaolin and diatomite in the raw material is 76: 18: 6, and the usage amount of expanded perlite is the weight sum of fly ash, kaolin and diatomite 10% of. The bulk density of the prepared ceramsite is 352.24kg / m3, and the cylinder compressive strength is 1.31MPa.

Embodiment 3

[0057] Compared with Example 1, the mass ratio of fly ash, kaolin and diatomite in the raw material is 84: 12: 4, and the usage amount of expanded perlite is the weight sum of fly ash, kaolin and diatomite 9%. The bulk density of the prepared ceramsite is 343.13kg / m 3 , The cylinder compressive strength is 1.21MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com