Porous insulation board and preparation method thereof

A technology of thermal insulation board and firing temperature, applied in clay products, ceramic products, other household appliances, etc., can solve the problems of poor durability and fire resistance of EPS boards and XPS boards, easy water absorption of rock wool boards, and high construction requirements. Achieve good thermal insulation effect, high compressive and flexural strength, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a porous insulation board, which comprises the steps of:

[0032] 1) Raw material selection:

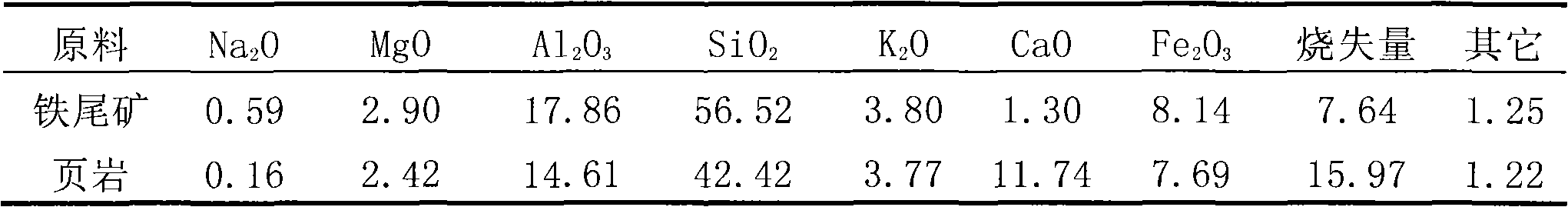

[0033] The particle size of iron tailings after crushing and screening is less than 75 μm; the particle size of shale after crushing and screening is less than 75 μm;

[0034] The foaming component is a mixture of coal powder and calcium phosphate, and the mass percentages of the foaming components accounted for by each raw material are: coal powder 30%, calcium sulfate 70%, and the particle size of the foaming component is less than 75 μm (after crushing and screening rear).

[0035] The fluxing component is feldspar, and the particle size of feldspar (fluxing component) after crushing and screening is less than 75 μm; the toughening component is mica, and the particle size of mica (toughening component) after crushing and screening is less than 300μm;

[0036] According to the mass percentage of each component: iron tailings: 20%, shale: 70%, foami...

Embodiment 2

[0043] A preparation method of a porous insulation board, which comprises the steps of:

[0044] 1) Raw material selection:

[0045] The particle size of iron tailings after crushing and screening is less than 75 μm; the particle size of shale after crushing and screening is less than 75 μm;

[0046]The foaming component is a mixture of calcium carbonate and silicon carbide. The mass percentages of the foaming components accounted for by each raw material are: calcium carbonate 60%, silicon carbide 40%, and the particle size of the foaming component is less than 75 μm (through crushing and screening. rear).

[0047] Feldspar is selected as the fluxing component, and the particle size of the fluxing component after crushing and screening is less than 75 μm;

[0048] The toughening component is selected from mica, and the particle size of the toughening component after crushing and screening is less than 300 μm;

[0049] According to the mass percentage of each component: iro...

Embodiment 3

[0056] A preparation method of a porous insulation board, which comprises the steps of:

[0057] 1) Raw material selection:

[0058] The particle size of iron tailings after crushing and screening is less than 75 μm; the particle size of shale after crushing and screening is less than 75 μm;

[0059] The foaming component is a mixture of calcium carbonate, coal powder and calcium phosphate. The mass percentages of the foaming components of each raw material are: 40% calcium carbonate, 30% coal powder, and 30% calcium phosphate. The diameter is less than 75 μm (after crushing and screening).

[0060] Feldspar is selected as the fluxing component, and the particle size of the fluxing component after crushing and screening is less than 75 μm;

[0061] Fluorite is selected as the toughening component, and the particle size of the toughening component after crushing and screening is less than 300 μm;

[0062] According to the mass percentage of each component: iron tailings: 40%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com