Patents

Literature

764results about How to "Meet the requirements of sustainable development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ethanediol from polyhydroxy compounds

ActiveCN101735014ARaw material resources are renewableMeet the requirements of sustainable developmentOrganic compound preparationCatalyst activation/preparationHydrogen pressureCobalt

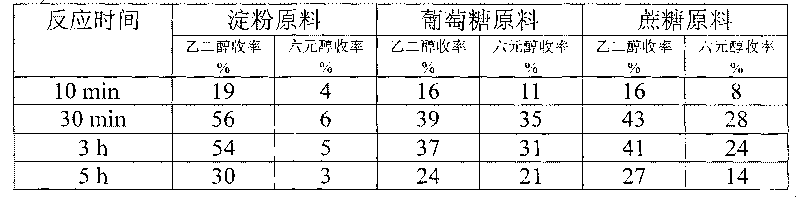

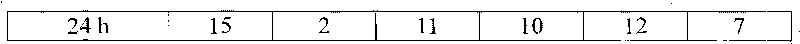

The invention provides a method for preparing ethanediol from polyhydroxy compounds comprising starch, hemicellulose, cane sugar, glucose, fructose and fructosan. The method comprises the following steps of: taking the polyhydroxy compounds as reaction raw materials, and taking metals, carbides, nitrides, and phosphides of transition metals in families VIII, IX and X, such as ferrum, cobalt, nickel, ruthenium, rhodium, palladium, iridium, platinum, molybdenum and tungsten as catalytic active components to form a polymetallic catalyst; and performing further catalytic conversion under a hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13 MPa to prepare the ethanediol from the polyhydroxy compounds with high efficiency, high selectivity and high yield. The method for preparing the ethanediol from the polyhydroxy compounds has the outstanding advantages of renewable raw materials, environment-friendly reaction process, and atom economical efficiency. Simultaneously, compared with other techniques taking biomasses as the raw materials, the method has the advantages of simple process and high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing ethylene glycol from cellulose

ActiveCN101723802ALow costWide variety of sourcesOrganic compound preparationCatalyst activation/preparationHydrogen pressurePolyethylene glycol

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Application of tungsten-based catalyst in lignin catalytic hydrogenation for producing aromatic compound

ActiveCN102476980AWide variety of sourcesLow costCatalyst carriersOrganic compound preparationIridiumHydrogen pressure

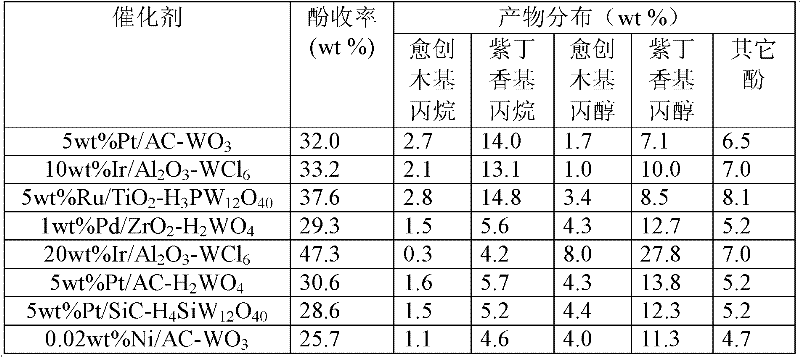

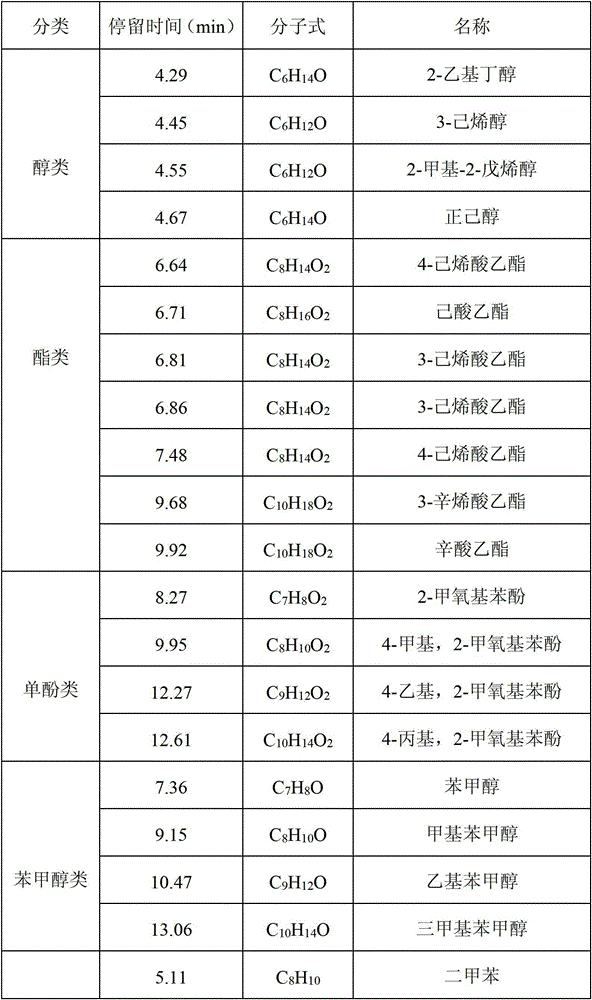

The invention relates to hydrocracking of lignin, and specifically relates to a method for applying a tungsten-based catalyst to catalyze lignin hydrocracking for producing an aromatic compound. The catalyst comprises a main active component of non-zero-valent tungsten, and a second metal component of a small amount of one or more transition metals selected from zero-valent nickel, cobalt, ruthenium, iridium, palladium, platinum, iron, and copper. According to the method, raw materials such as lignin, biomass hydrolysis residue, lignosulfonate, and alkaline lignin are subject to catalytic hydrogenation under a hydrothermal condition with a temperature of 120 to 450 DEG C and a hydrogen pressure of 1 to 20MPa; the raw materials are cracked into C6-C9 phenolic compounds with high selectivity. A maximal phenol yield reaches 55.6%. Compared to existing technologies, according to the invention, renewable natural biomasses are adopted as raw materials, such that the raw materials are cheap, and have wide sources; inorganic acid and alkali are not required, such the production of a large amount of alkaline solution in traditional lignin catalysis is avoided; the tungsten-based catalyst is cheap; the reaction process is green, and has atom economical characteristics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin

InactiveCN104744204AWide variety of sourcesRaw materials are renewableHydrocarbon from oxygen organic compoundsEthylene productionIridiumPtru catalyst

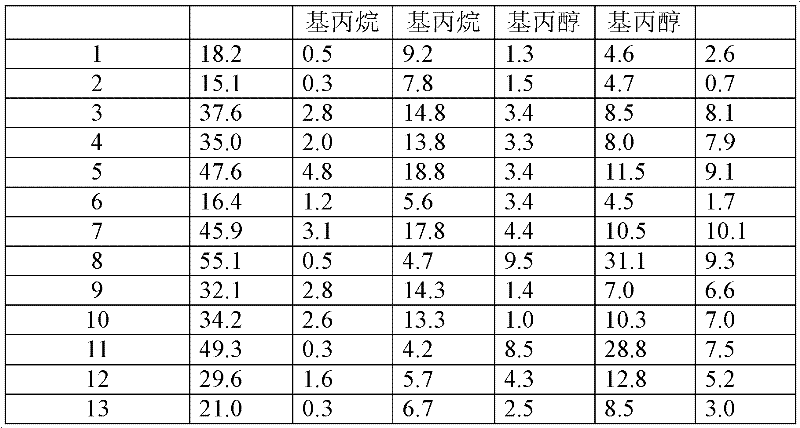

The invention relates to a method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin. A catalyst used in the method provided by the invention comprises two active components, namely an acid site being one or combination of more than one of transition metal elements niobium, tantalum, zirconium, molybdenum, tungsten and rhenium and a hydrogenation or hydrogen transfer active site being one or more than one of ruthenium, platinum, palladium, iridium, iron, cobalt, nickel and copper. According to the method provided by the invention, a phenol group, a guaiacol group, a syringa phenolic group compound, natural lignin and industrial lignin are taken as raw materials, water is taken as a solvent, high selectivity catalytic hydrodeoxygenation is carried out at the temperature of 180-350 DEG C and hydrogen pressure of 0.1-5MPa or with methyl alcohol, isopropyl alcohol and formic acid as hydrogen sources, so that C6-C9 aromatic hydrocarbon is obtained, the highest mass yield of aromatic hydrocarbon is 10%, and content of aromatic hydrocarbon in product oil can be up to more than 75%. The method provided by the invention has the advantages that reproducible natural biomass can be used as a raw material, and the raw material is cheap and available; the water is taken as the solvent, so that a reaction process is environment-friendly; and content of aromatic hydrocarbon in the product is high, and reaction conditions are mild.

Owner:EAST CHINA UNIV OF SCI & TECH

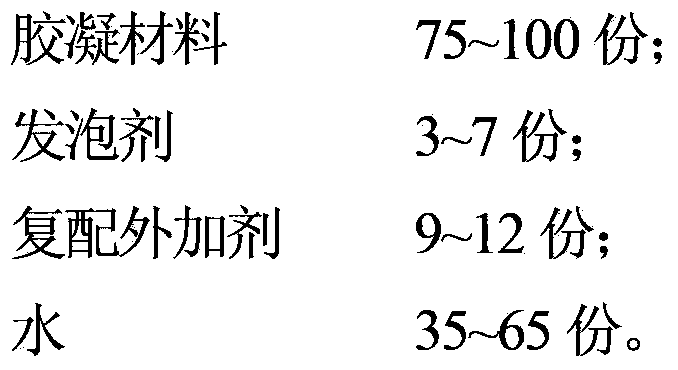

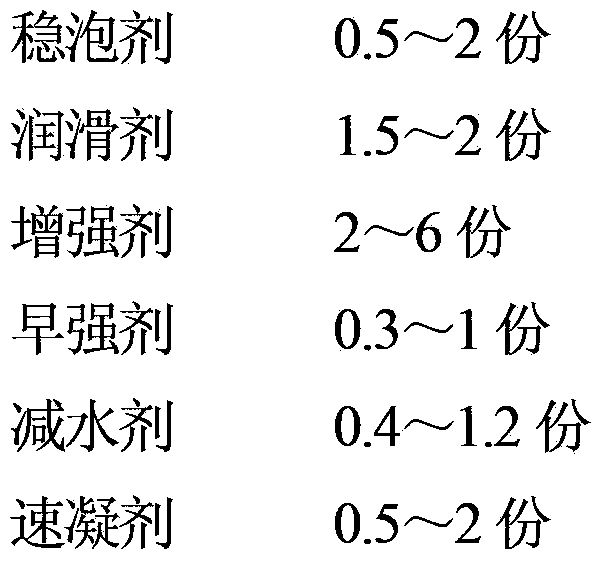

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

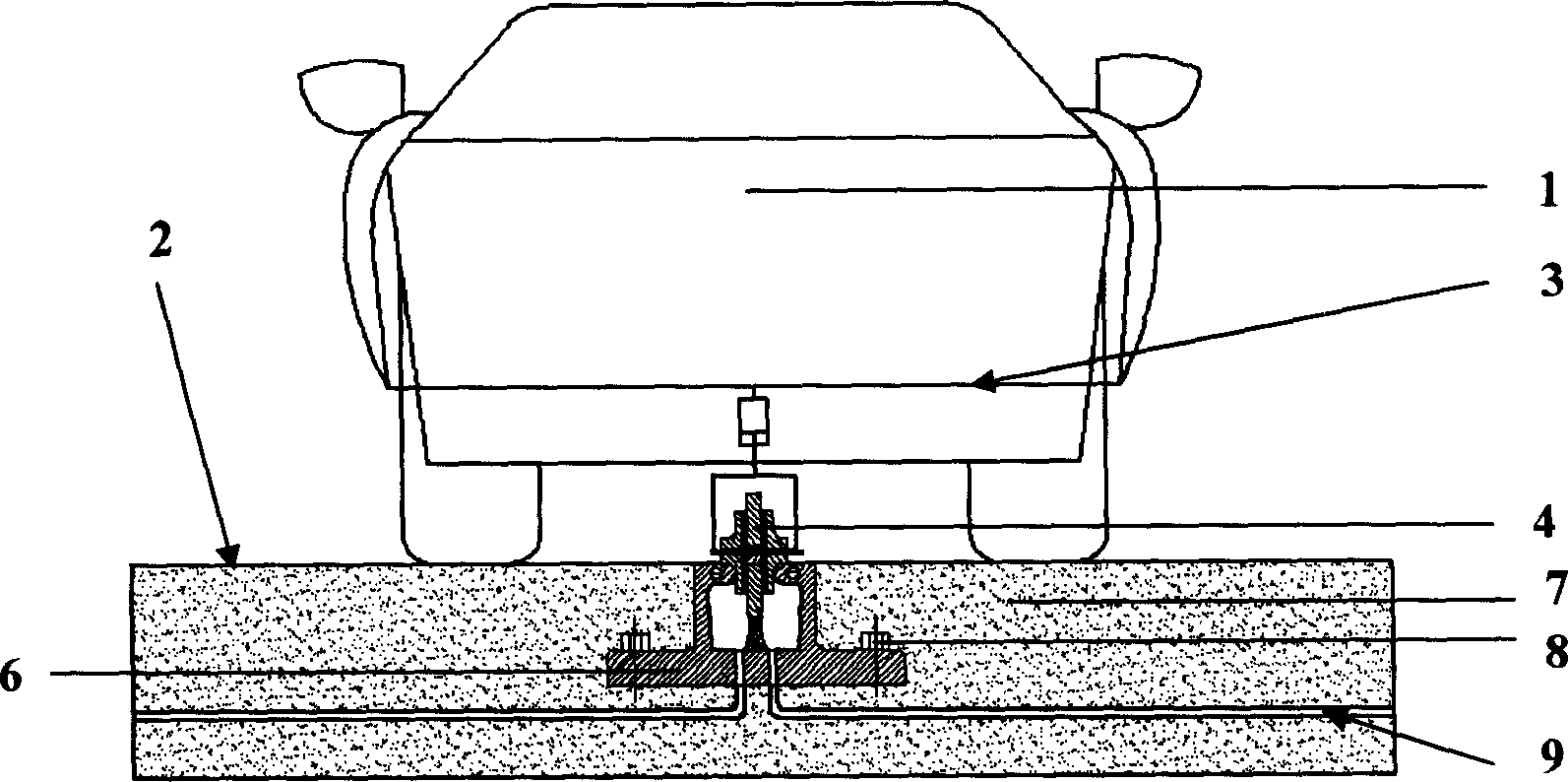

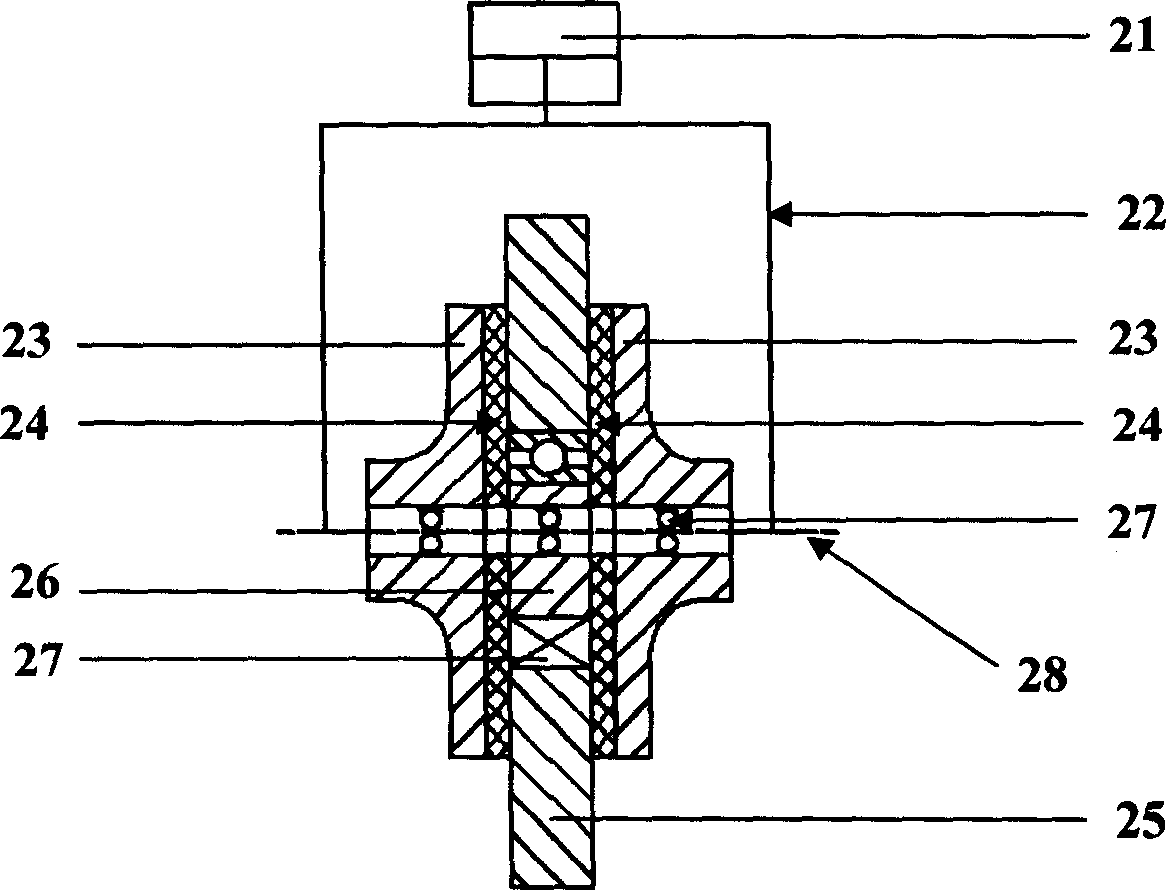

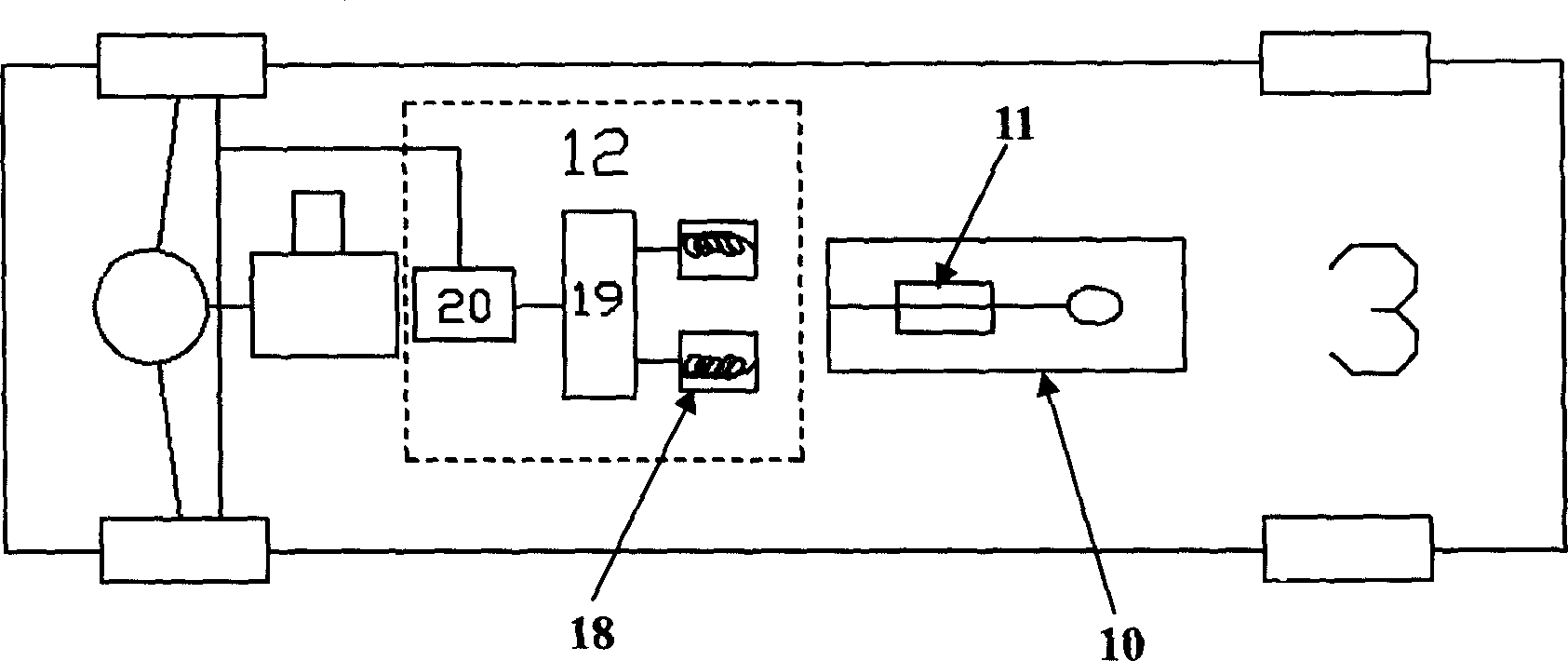

Power road electric closer car

InactiveCN1718457ASimple structureImprove battery lifeRail and road vehiclesPower railsAutomotive engineeringSubgrade

A combination of electric car and power road features that each electric car has a chassis, an electric receiving wheel unit arranged in the chassis and an automatic drive system, and said power road is characterized by that each lane on the road has a concave electric power supplying rail matched with said electric receiving wheel unit of each car.

Owner:SHANGHAI JIAO TONG UNIV

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

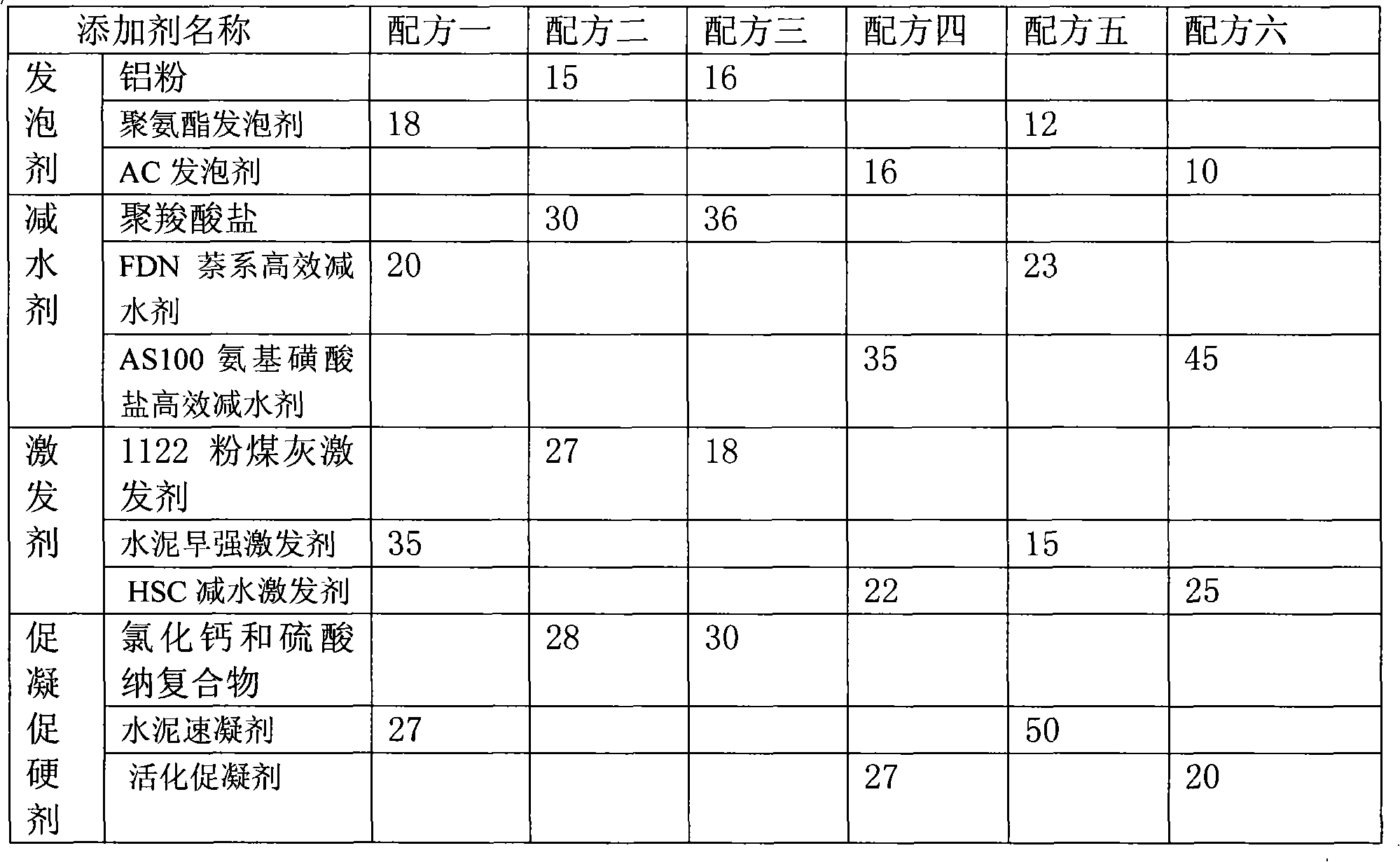

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

Flue gas desulfurization process

InactiveCN102068876AEasy to recycle and reuseRealize resourcesDispersed particle separationFlue gasTower

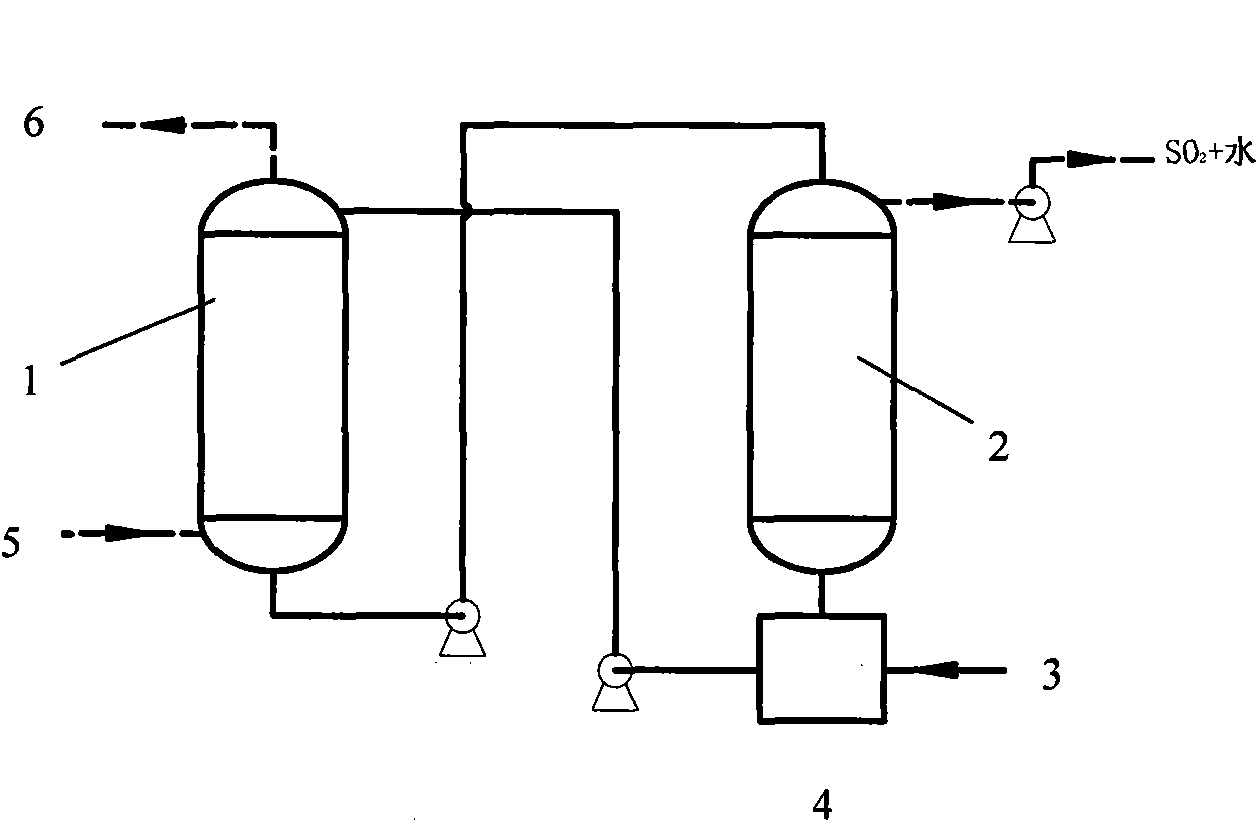

The invention provides a flue gas desulfurization process employing an ionic liquid. In the process, the ionic liquid is used as an absorbent, different types of absorption towers are adopted to absorb SO2 in the flue gas at the temperature of 0-200 DEG C under the pressure of 0.09-5.0 MPa, wherein gas-liquid countercurrent contact is adopted, various types of towers are adopted to improve a mass transfer effect so as to realize the emission of flue gas reaching the standard. The ionic liquid after absorbing the SO2 is pumped into a desorber through a pump and is subjected to deabsorption by adopting a heating and / or decompressing method, and SO2 is recovered. The desorbed ionic liquid enters the absorption towers to be reused. The process provided by the invention can be used for effectively removing the SO2 in the flue gas and recovering the SO2.

Owner:BEIJING UNIV OF CHEM TECH

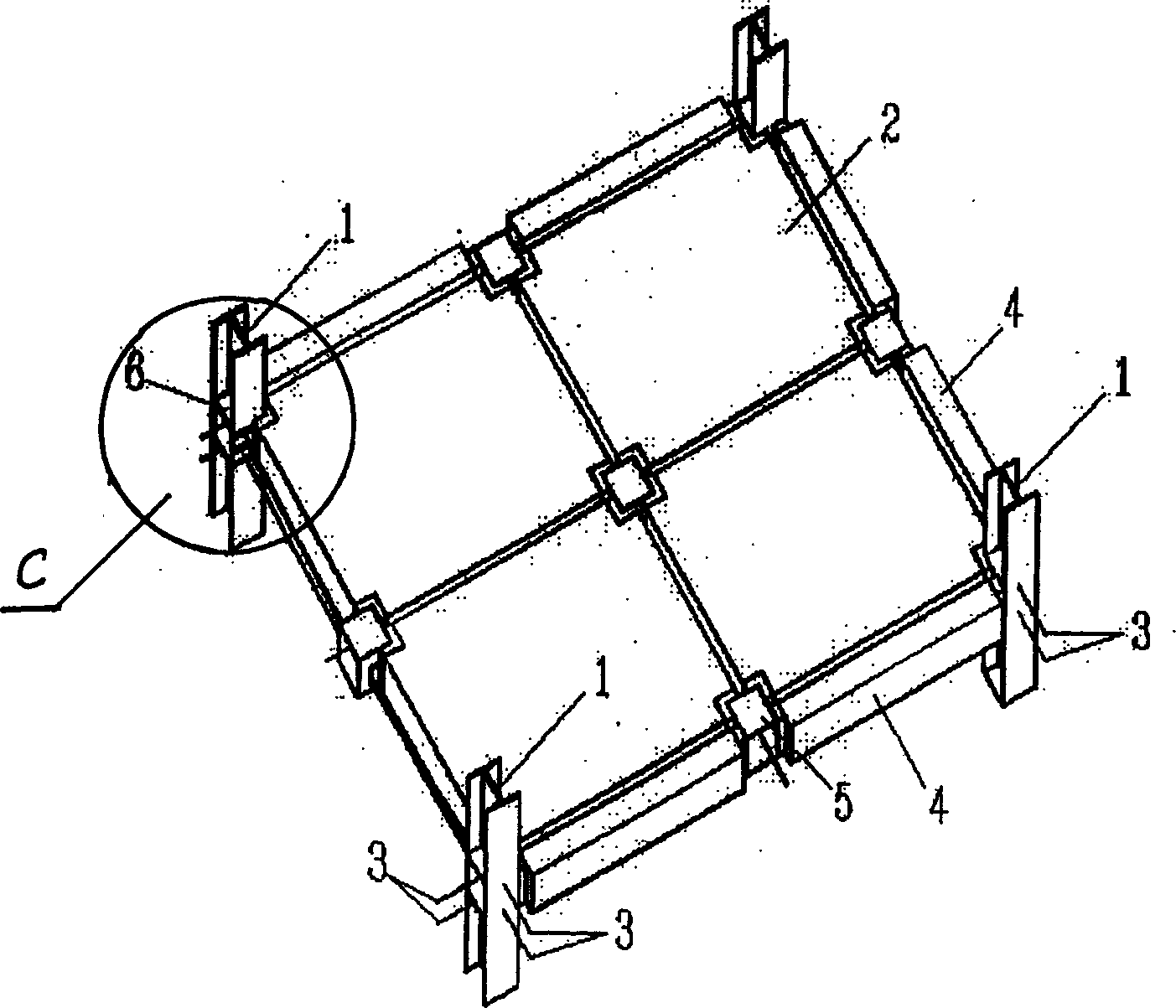

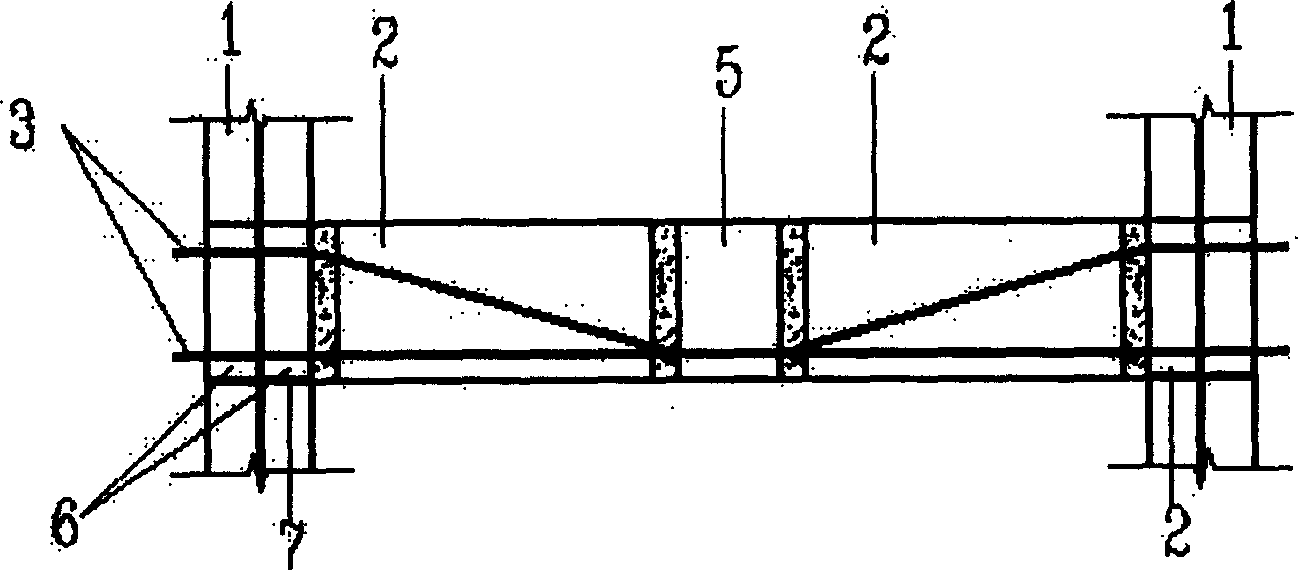

Steel-steel concrete fully prefabricated assembling structure

InactiveCN1554839AEnsure safetyImprove bearing capacityBuilding constructionsHigh strength concreteFloor slab

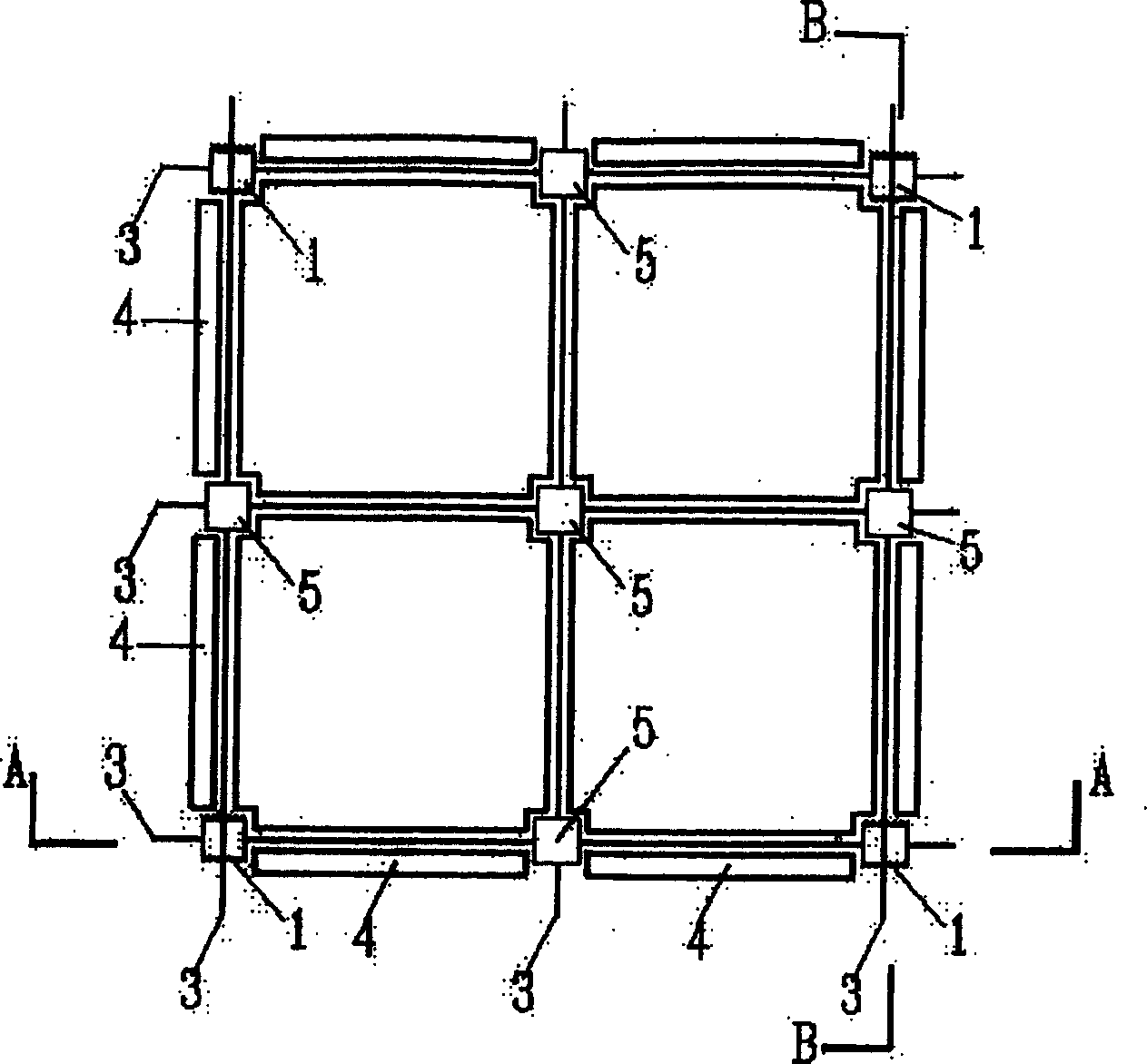

The fully prefabricated assembled steel-steel concrete structure includes two kinds of assembling forms. The first one is fully prefabricated assembled steel column-steel concrete structure, and its prefabricated steel column consists of H-shaped steel column, reinforcing concrete ribs, supporting steel plate and prestress-shearing force friction nodes with shear resisting strips. The second one is fully prefabricated assembled prefabricated steel pipe-concrete column-steel concrete structure, and the prefabricated steel pipe-concrete column consists of steel pipe with square cross section, micro expanding high strength concrete cast inside the steel pipe and shear resisting strips attached to the outer wall of the steel pipe to form preshearing force-friction type nodes. The present invention has raised antiseismic performance, area utilization, construction efficiency, fireproof performance, low cost and small member size, and is suitable for various buildings.

Owner:KUNMING UNIV OF SCI & TECH

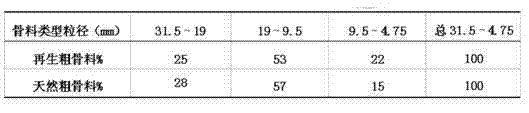

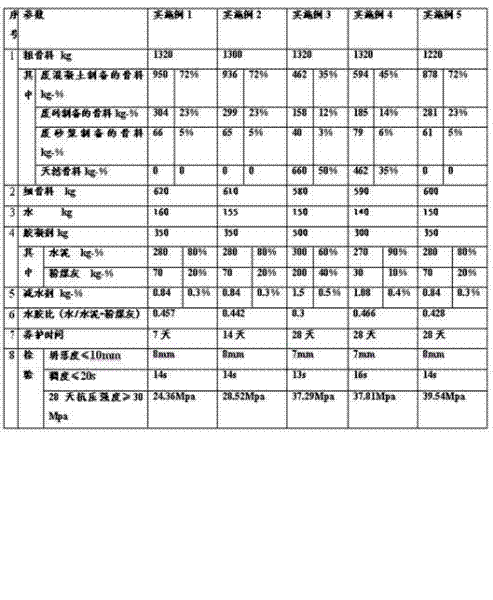

Recycled aggregate medium-dry hard concrete prepared by using building waste and preparation method of recycled aggregate medium-dry hard concrete

The invention discloses a recycled aggregate medium-dry hard concrete prepared by using building waste, which comprises the following raw materials of coarse aggregate, fine aggregate, a gelatinizing agent, a water reducing agent and water, wherein the gelatinizing agent comprises cement and coal ash, and the coarse aggregate comprises 50-100 percent of recycled coarse aggregate prepared from thebuilding waste. A preparation method of the recycled aggregate medium-dry hard concrete comprises the following steps of: pretreating the building waste, removing impurities, remaining waste concrete, waste bricks and the like; crushing and screening to prepare the recycled coarse aggregate; mixing the recycled coarse aggregate, natural sand, cement and water according to the proportion, adding the coal ash and the water reducing agent, stirring uniformly to obtain a mixture; and squeezing and forming the mixture, curing for 2 days to obtain the recycled aggregate medium-dry hard concrete. The invention solves the problems of worsening ecological environment and the like caused by difficulty in treating the building waste; and the building wastes are used for manufacturing the recycled aggregate for replacing natural aggregate, the increasingly deficient natural aggregate and damage degree to the ecological environment are reduced, and the living environment of human beings is protected. The recycled aggregate medium-dry hard concrete prepared by using the method has high strength and high abrasive resistance, and can be used for building base installations such as city roads, housing constructions and the like.

Owner:云南华威废弃物资源化有限公司

Rubber seed oil polyalcohol and preparation method thereof

ActiveCN101906016AReduce dependenceIncrease added valuePreparation by alcoholysisEpoxyReaction temperature

The invention relates to rubber seed oil polyalcohol and a preparation method thereof. The method comprises the following steps of: mixing rubber seed oil, hydrogen peroxide and a catalyst serving as raw materials in a weight ratio of 1:0.5-1.5:0.01-0.05, putting the mixture into a reaction kettle, stirring the mixture and raising temperature to 50 to 80 DEG C, keeping reaction temperature for 3 to 8 hours, lowering the temperature to 30 DEG C, separating acid water out, washing the mixture with aqueous solution of sodium carbonate until the pH of the mixture is between 5 and 6, washing the mixture to be neutral with saturated sodium chloride and water, and performing pressure reduction and water removal at the temperature of between 50 and 90 DEG C for 2 to 5 hours to obtain epoxy rubberseed oil; and adding the epoxy rubber seed oil, methanol, isopropanol and fluoboric acid into the reaction kettle in a weight ratio of 1:1-5:1-5:0.002-0.01, raising the temperature to 75 to 100 DEG C, performing a reaction for 0.5 to 3 hours, washing the reaction product with the aqueous solution of the sodium carbonate until the pH of the reaction product is between 5 and 6, washing the reaction product to be neutral with water, and performing vacuum pumping at the temperature of between 50 and 120 DEG C for 2 to 5 hours to obtain the rubber seed oil polyalcohol. In the method, the conventional petroleum chemical is replaced by a non-edible plant oil resource, so that the dependence of polyurethane industry on petroleum chemicals is reduced, and the added value of the rubber seed oil is increased.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Method for preparing Ag:ZnIn2S4 luminescent quantum dots and photocatalyst

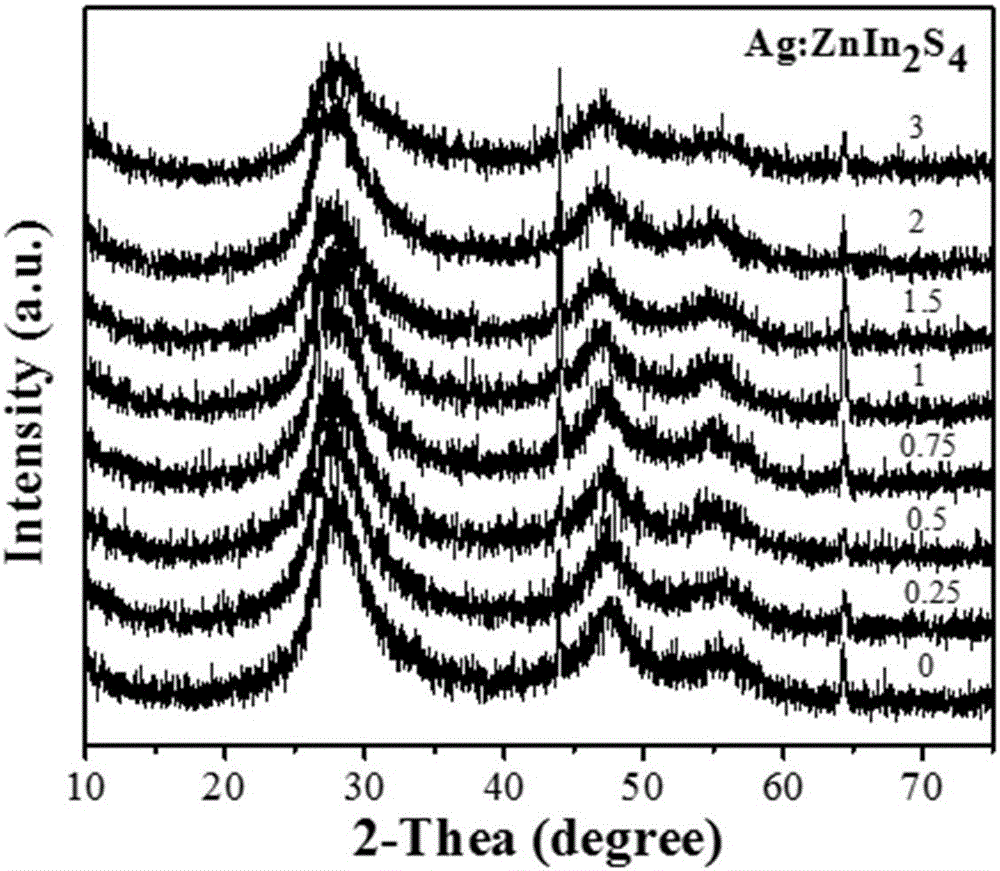

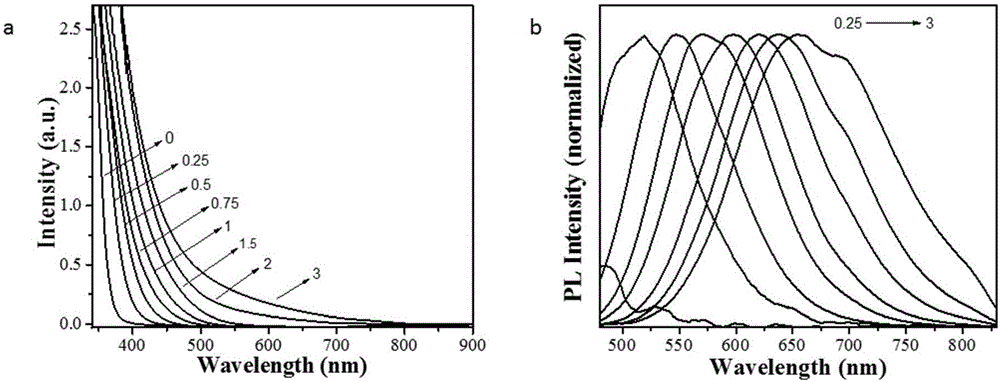

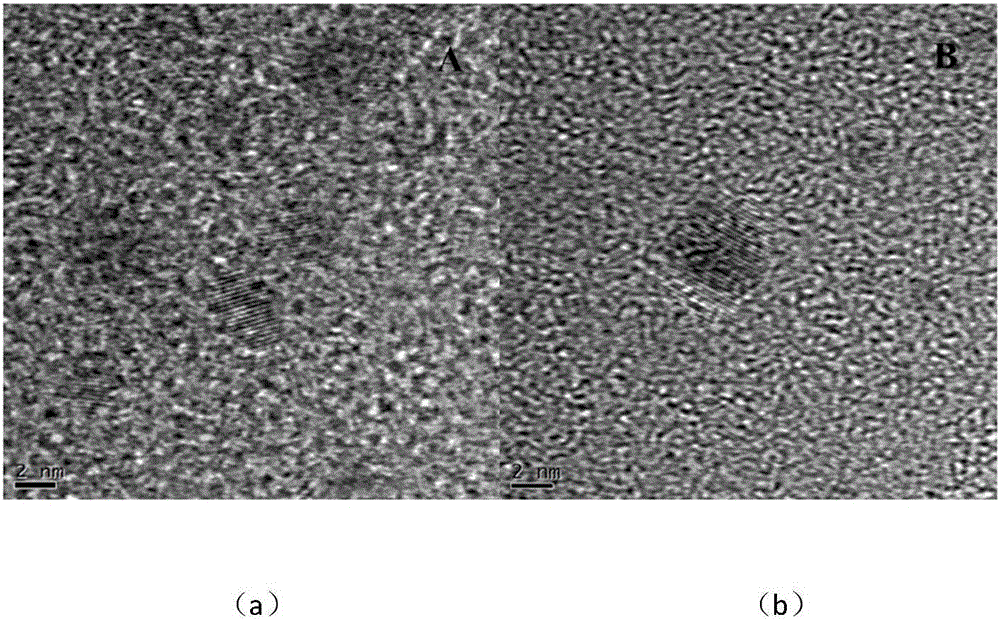

InactiveCN105950140AFully crystallizedGood dispersionMaterial nanotechnologyPhysical/chemical process catalystsFluorescenceZinc Acetate Dihydrate

The invention relates to the field of synthesis of nano-materials and particularly relates to a method for synthesizing a series of Ag:ZnIn2S4 luminescent quantum dots by using a simple and rapid hydrothermal method in one step. Fluorescence is adjustable in the range of 460nm to 830nm, the fluorescent life is relatively long, and the luminescent quantum dots can be applied to water-decomposed hydrogen production under visible light. The method comprises the steps of firstly, mixing and dissolving silver nitrate, indium nitrate, zinc acetate dihydrate and L-cysteine in an aqueous solution, adjusting the pH value of the solution to 8.5 by using NaOH, adding thioacetamide into the solution, carrying out ultrasonic stirring, then, carrying out a hydrothermal reaction for 4 hours at the temperature of 110 DEG C, and carrying out centrifugal drying after the reaction ends, thereby obtaining Ag@ZnIn2S4 nanocrystals of different ratios. Proven by a photocatalytic hydrogen production experiment under the visible light, the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

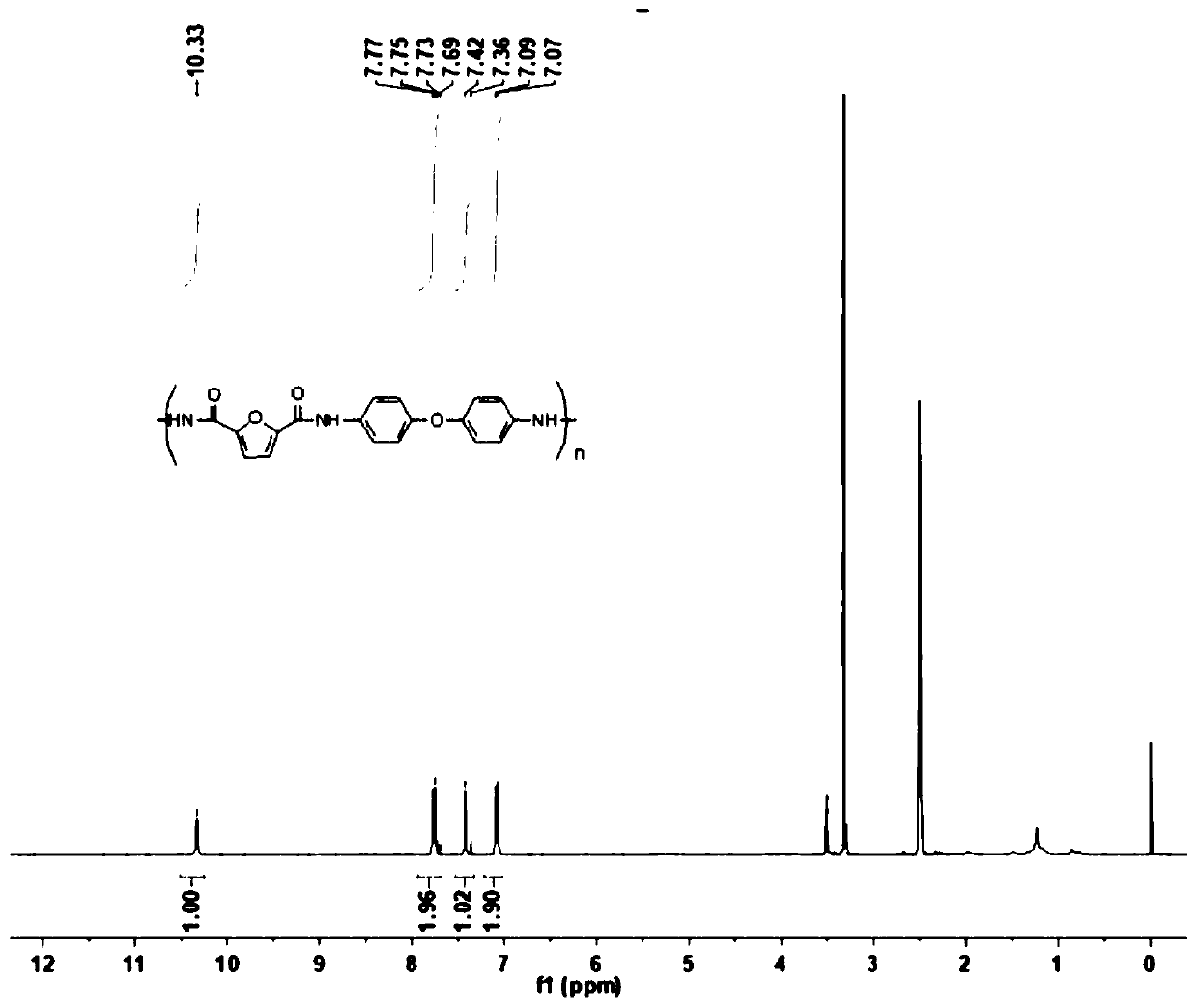

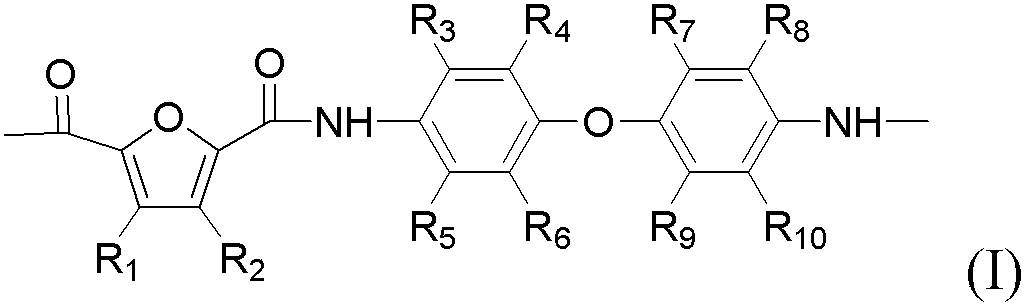

High-molecular-weight furyl aromatic polyamide, preparation method and application thereof

ActiveCN110256668AImprove mechanical propertiesImprove thermal stabilityWet spinning methodsMonocomponent polyamides artificial filamentFuranDiaminodiphenyl ether

Owner:UNIV OF SCI & TECH OF CHINA

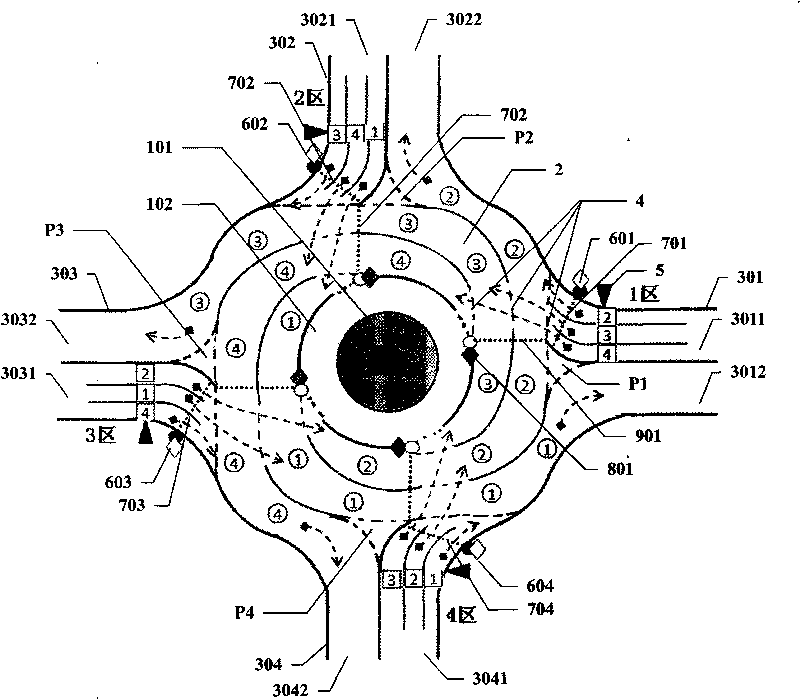

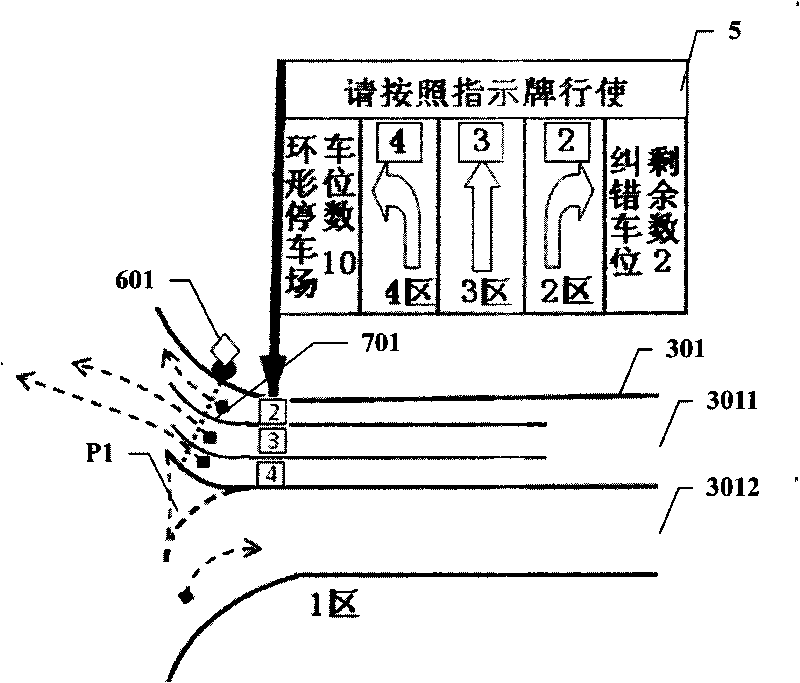

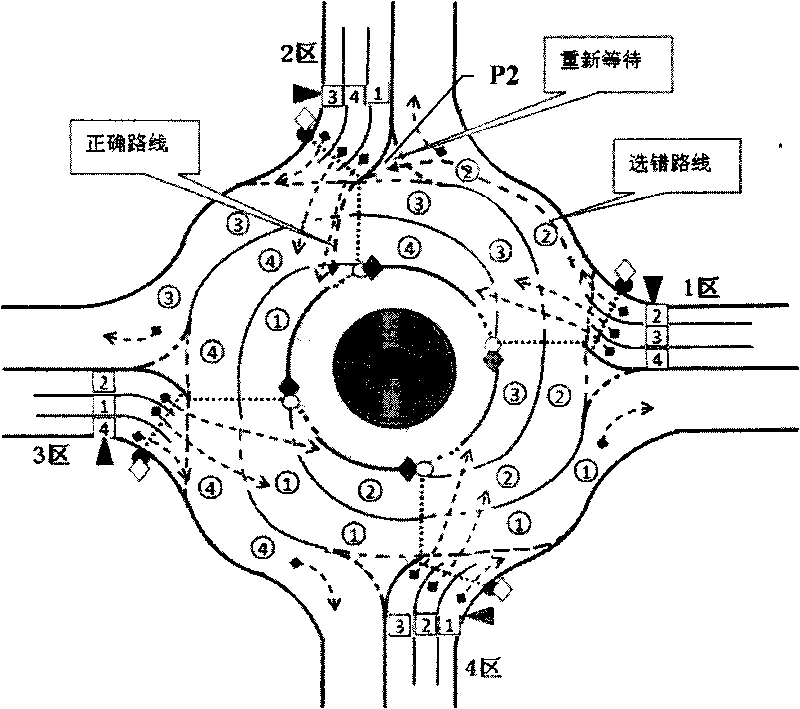

Traffic diverging system for roundabout

The invention discloses a traffic diverging system for a roundabout. An annular road comprises four helical lanes, which start from a central roundabout opposite to the centre line of four arterial roads respectively, then, extend outwards gradually around the roundabout until surrounding three fourths of turn to the outermost layer of the annular road. The four helical lanes are connected with four lanes of the four arterial roads away from the roundabout. The helical lanes are dotted lines at the intersection with the arterial roads to permit vehicles to drive in. The arterial roads are divided into a left turn lane, a through lane, and a right turn lane, which are jointed with corresponding helical lanes respectively. A sign is arranged at the roundabout respectively for indicating the vehicles to turn left, go through or turn right to drive in the helical lanes. After driving in the roundabout, the vehicles enter the left turn lane, the through lane, or the right turn lane, namely a helical lane corresponding to a destination exit. The helical lanes can lead to each destination exit so as to avoid the conflict during leaving the roundabout. The vehicles only need to drive along the helical lanes, and drive away from the roundabout when reaching the destination exit.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

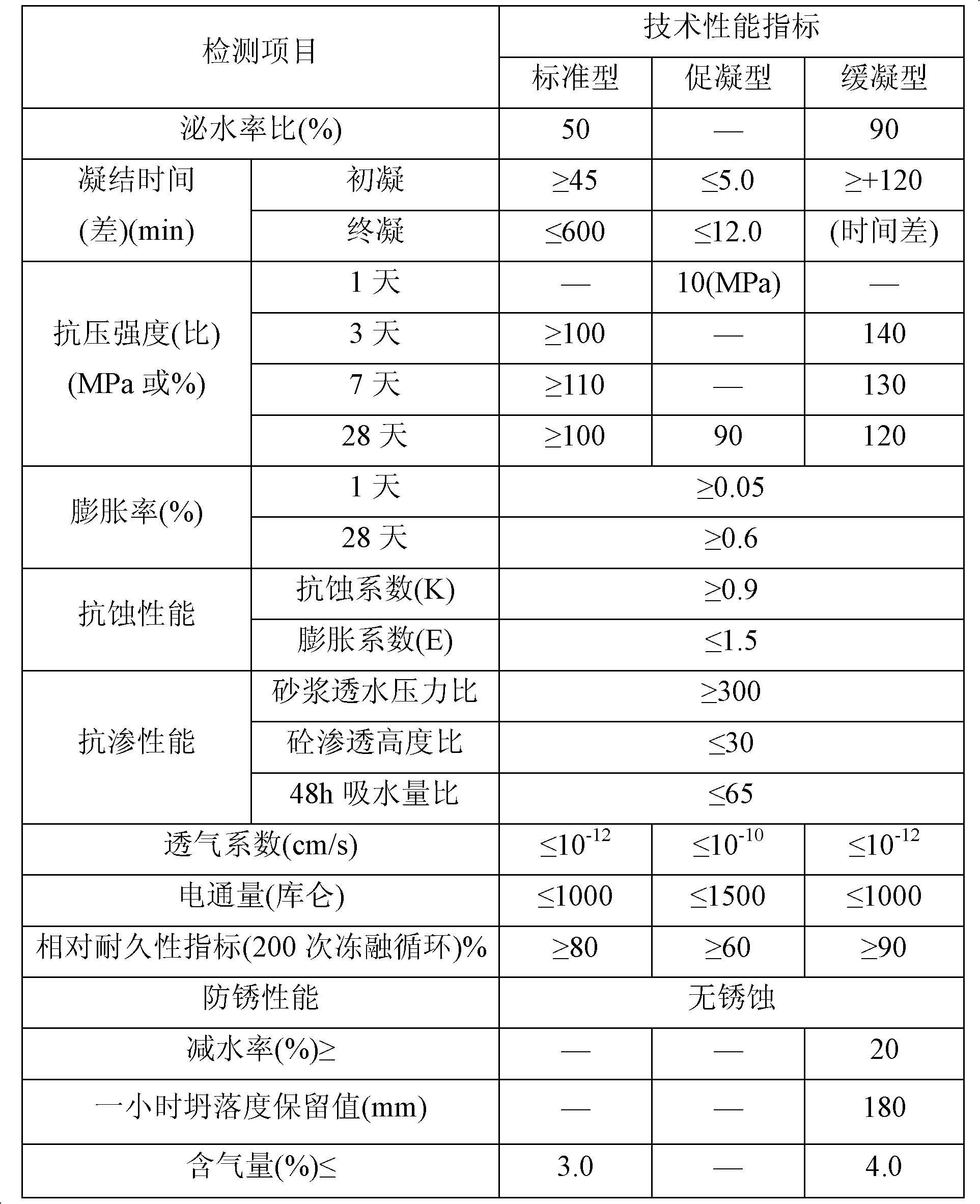

Anticorrosion expansion compacting agent composition and preparation method thereof

The invention relates to an anticorrosion expansion compacting agent composition and a preparation method thereof; the composition comprises the following components by weight: 15-35% of aluminium-containing compounds, 0-8% of zirconium-containing compounds, 2-10% of magnesium salts, 0-3% of titanium dioxide compounds, 0-6% of lithium salts, 2-6% of alkanolamine salts, 0-10% of super-plasticizers, 0-10% of solidification adjusting agents, 0-5% of acids, and the balance of carriers. The components are reacted in a reaction vessel at 80 DEG C+ / -5 DEG C for 3 hours, and then cooled to 45 DEG C+ / -5 DEG C; thermal insulation is performed for one hour; and anticorrosion expansion compacting agents of a standard type, a solidification-promoting type, or a pumping slow-solidifaction type are obtained according to the added solidification adjusting agents with different types and amounts.

Owner:苏琳

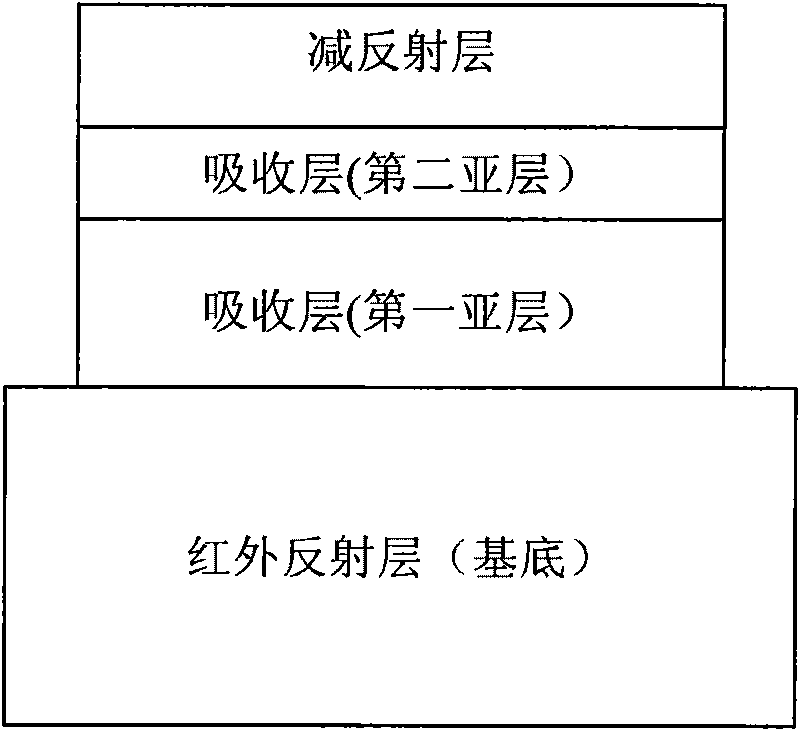

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN101737983AImprove thermal stabilityMeet the requirements of sustainable developmentSolar heat devicesLayered productsRefractive indexAlloy

The invention relates to a solar spectrum selective absorbing coating which is prepared by adopting magnetron sputtering technology. The absorber of the coating comprises the following three layers of films from substrate to top: a first layer adopts copper with infrared reflectivity or aluminium substrate as an infrared reflecting layer; a second layer uses a metalloid layer and a medium type layer which have different refractive indexes and thicknesses; and a third layer uses SiON film as an antireflection layer. The preparation method comprises the following steps: the first layer (infrared reflecting layer): cleaning copper or aluminium sheets with ultrasonic wave or polishing the copper or aluminium sheets; the metalloid layer of second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the medium type layer of the second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the third layer (antireflection layer): uses SiN as target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting radio frequency power source to perform reactive sputtering; and finally obtaining the absorber.

Owner:安徽科鑫光热技术有限公司

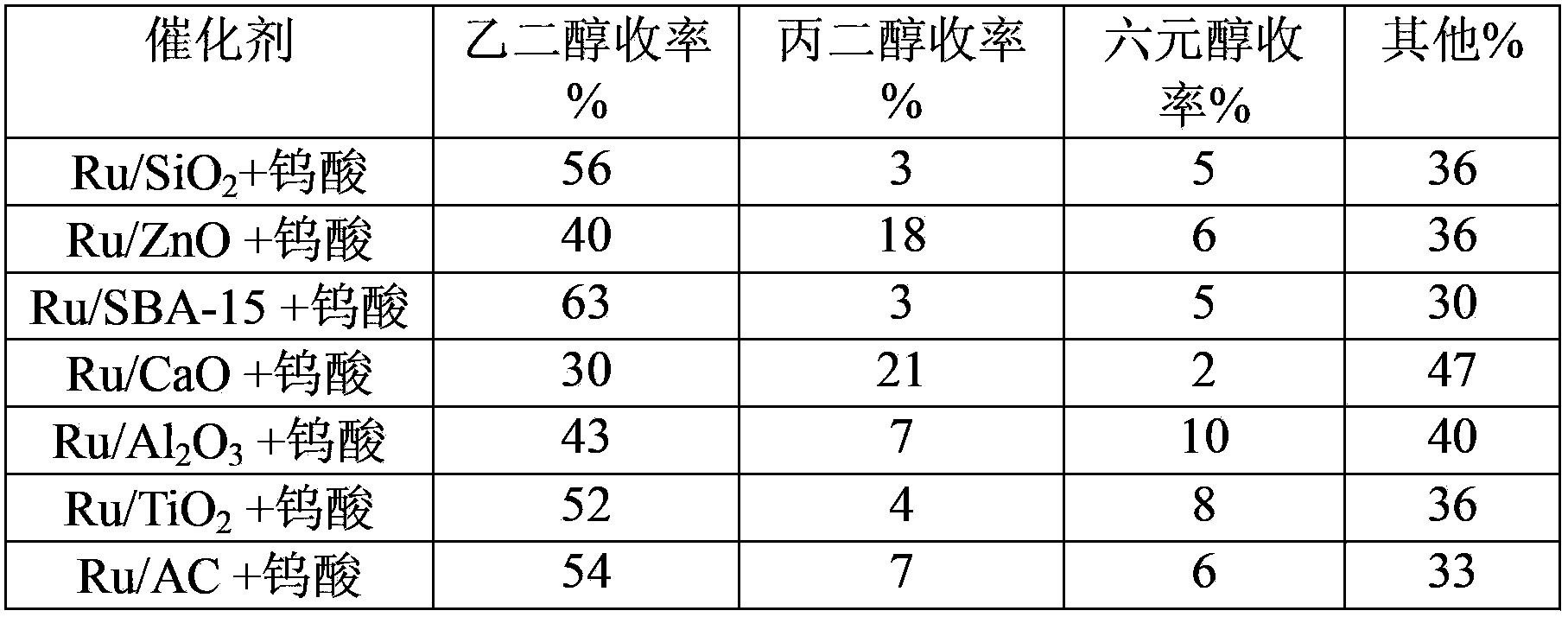

Method of low metal loading catalyst for preparing glycol from carbohydrate

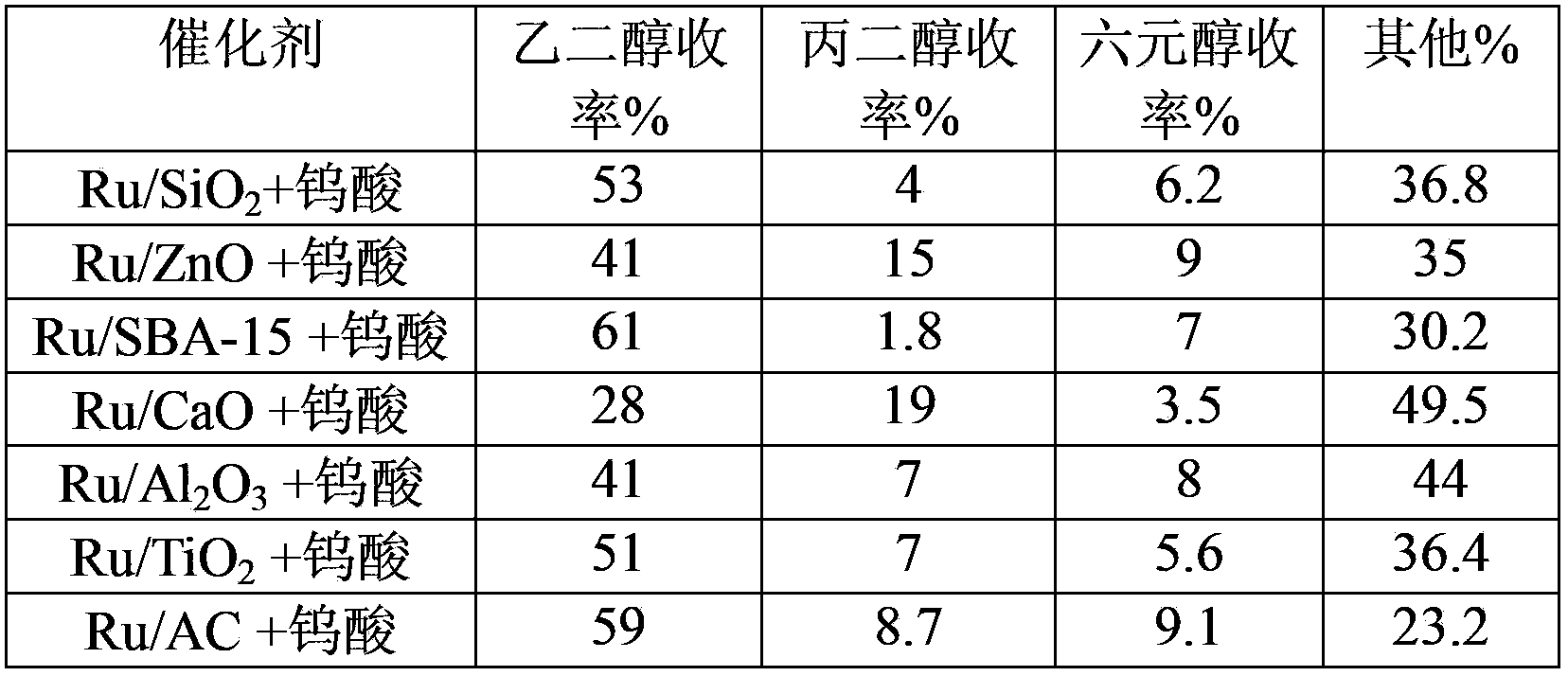

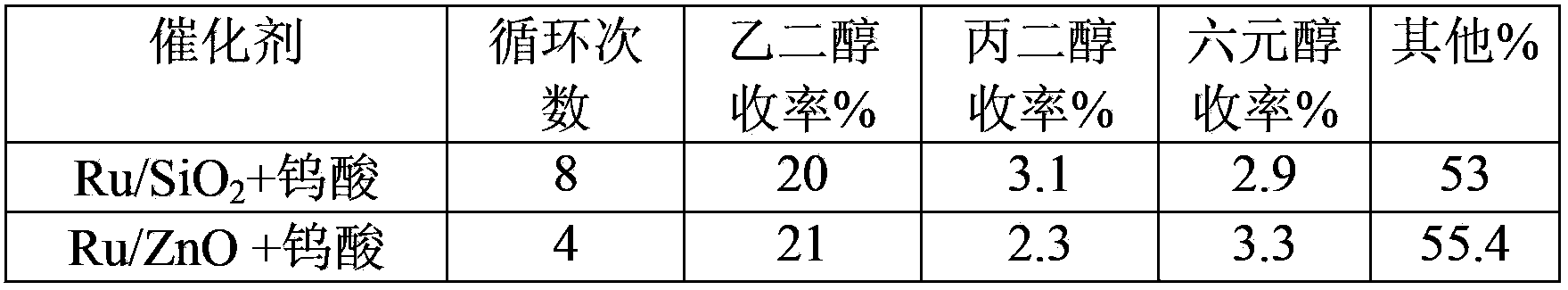

ActiveCN103420797ARaw material resources are renewableMeet the requirements of sustainable developmentMolecular sieve catalystsOrganic compound preparationHydrogen pressureInorganic compound

The invention provides a method of applying a low metal loading catalyst for preparing glycol and propylene glycol from carbohydrate, including cellulose, starch, semi-cellulose, cane sugar, glucose, fructose, fructosan, xylose, and soluble xylo oligosaccharide. In the method, carbohydrate is taken as the raw material, the compound catalyst is composed of catalytic active components selected from one or more components from following components: highly-disperse and low-loading ruthenium, inorganic compounds, organic compounds, and complex of tungsten, or simple substance tungsten, then one-step catalytic conversion process is carried out under the hydrothermal conditions: temperature of 60 to 350 DEG C, and hydrogen pressure 0.1 to 15 MPa, and the high-efficient, high-selective and high yield preparation of glycol and propylene glycol from carbohydrate is achieved. The method takes highly-disperse and high stability low loading Ru-based catalyst as the reaction catalyst, so the usage amount of value metals is reduced, the loss of catalyst carrier is slowed down, and the recycle rate of Ru-base catalyst is increased. The catalyst has the prominent advantages of high activity, high selectivity, and very high cyclicity. Compared to other technologies, which prepare polyol from carbohydrate, the method has the advantages of simple reaction process, high efficiency, good stability of catalyst, and multi-circulation, and has very vast industrial application value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

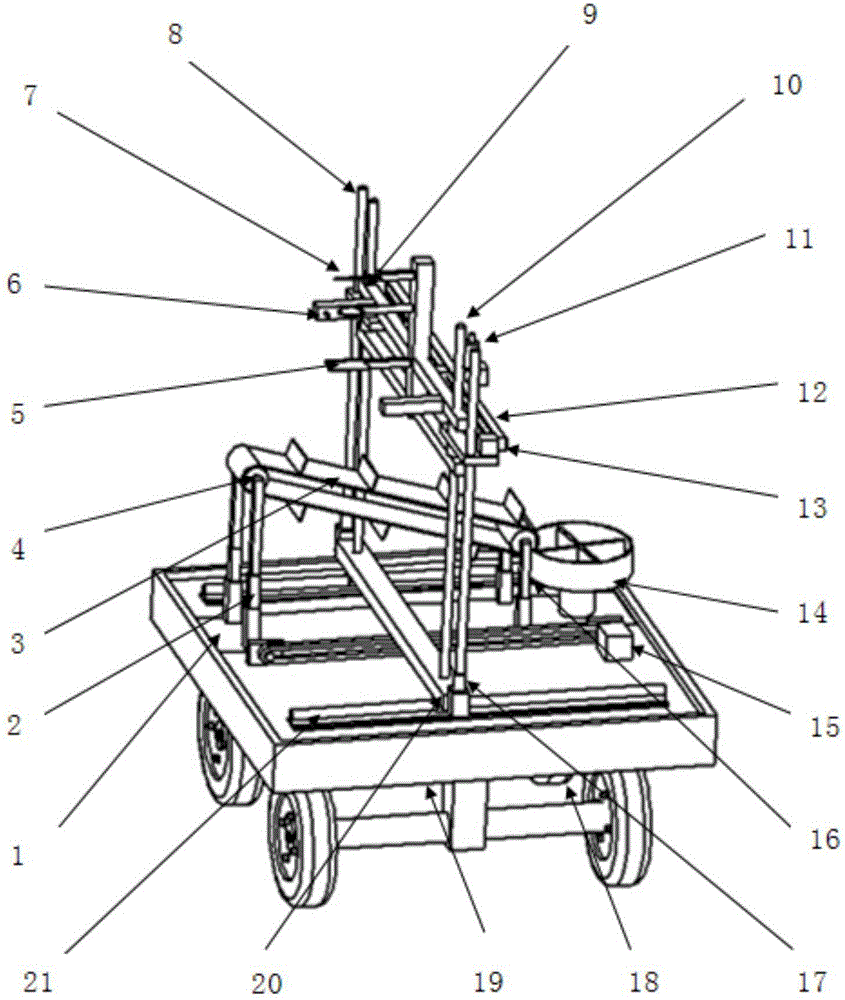

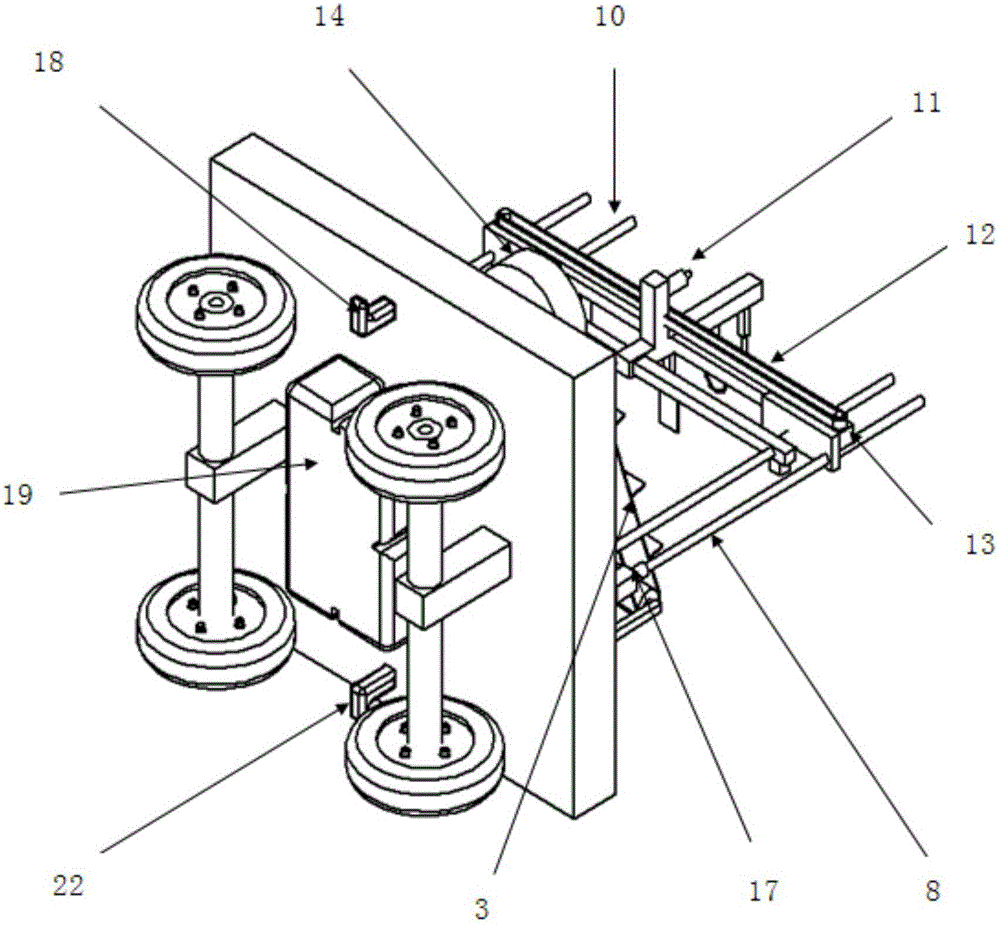

Intelligent integrated machine for intactly picking and grading table grapes and control method thereof

ActiveCN105900610AMeet the requirements of sustainable developmentAvoid secondary damageFood treatmentPicking devicesImage detectionEngineering

The invention provides an intelligent integrated machine for intactly picking and grading table grapes and a control method thereof. The intelligent integrated machine comprises a three-dimensional motion platform, a picking point positioning system, a picking system and a grading and subpackaging system. The three-dimensional motion platform comprises a walking motor controller, a position sensor and the like; the picking point positioning system is composed of a grading image detecting camera, system software and a data transmission module; the picking system is a top end structure of the three-dimensional motion platform and is composed of an infrared geminate transistor set, a picking cutter, a net bag and a rotary buffering plate; the grading and subpackaging system is composed of a conveying belt front lifting device, a conveying crawler belt, a conveying belt driving motor, a grading image detection camera and a controllable rotary box. The grape pickup integrated machine improves grape pickup efficiency and grading accuracy, reduces secondary damage to the grapes, ensures freshness and has wide market popularization prospects.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

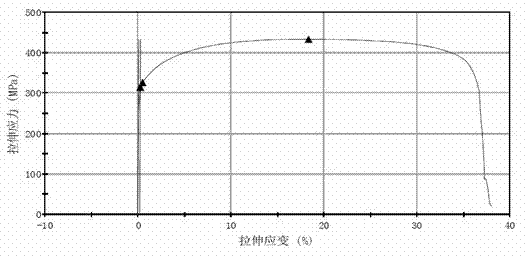

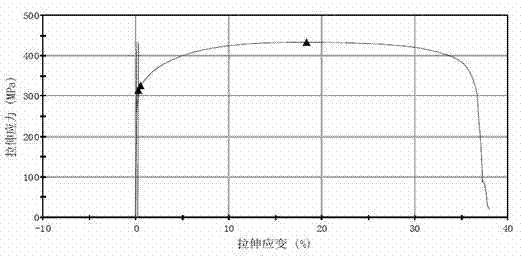

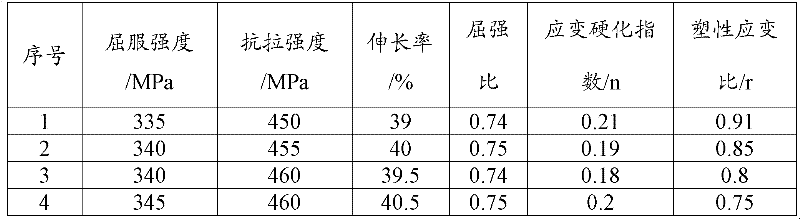

Hot-rolled pickled sheet with low yield ratio and production method thereof

ActiveCN102409223AAchieving the requirement of low yield ratioIn line with the concept of green steelChemical compositionTrace element

The invention discloses a hot-rolled pickled sheet with a low yield ratio. The hot-rolled pickled sheet comprises the following chemical components in percentage by mass: 0.04-0.12 of C, 0.005-0.05 of Si, 0.8-1.5 of Mn, less than or equal to 0.020 of P, less than or equal to 0.020 of S, 0.01-0.08 of Al, 0.0005-0.003 of B and the balance of Fe and trace elements. The invention also discloses a method for producing the hot-rolled pickled sheet with the low yield ratio. According to the hot-rolled pickled sheet with the low yield ratio and the production method thereof, a proper element content proportion is given through analog computation of influence of each element on yield strength and tensile strength by utilizing a common C-Mn component system, and the content of the alloy elements isless, thus production cost can be greatly reduced; a hot rolling process window is wide, which is convenient for production and implementation; and the property of a finished product is excellent, and the yield ratio reaches the requirement of a cold plate. The production method provided by the invention is an economical and effective hot-rolled pickled sheet production method and meets the requirements of green steel and low-carbon economy.

Owner:BEIJING SHOUGANG CO LTD

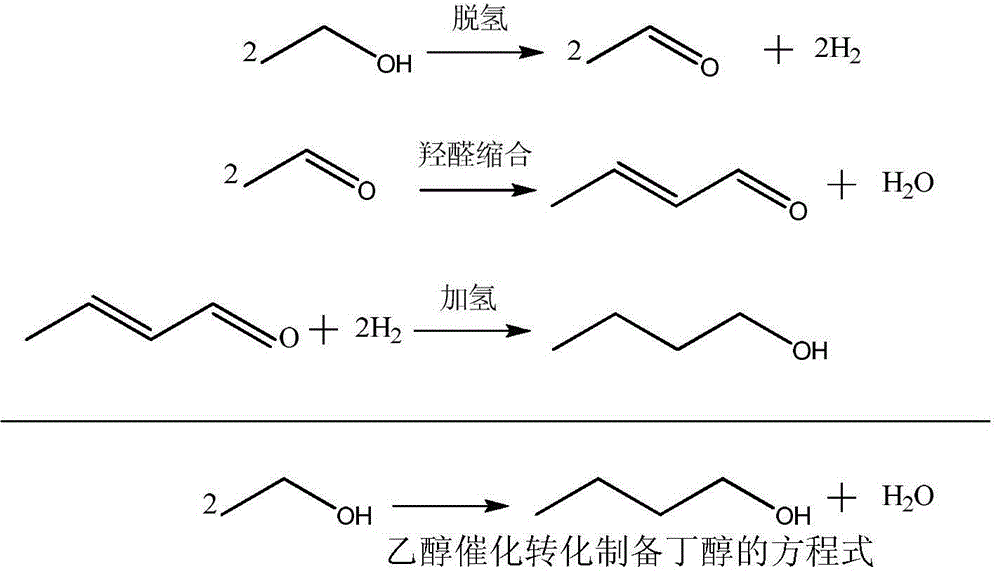

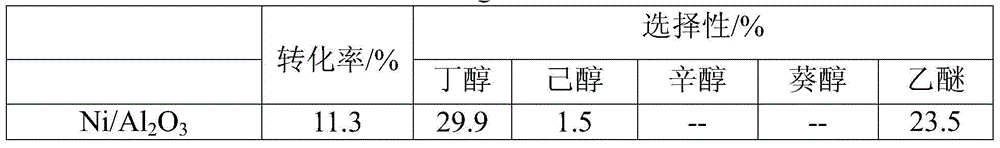

Method for producing high-carbon primary alcohols by catalytic conversion of ethanol

InactiveCN105712840AIncrease productionSufficient sourceOrganic compound preparationHydroxy compound preparationOxideFixed bed

The present invention provides a method for producing high-carbon primary alcohols by catalytic conversion of ethanol. Even-number-carbon primary alcohols are prepared in a fixed bed by catalytic conversion of ethanol by use of transition metal-compound oxide as a catalyst prepared by co-precipitation method. Compared with the prior art, a raw material used in the method is bio-ethanol, the bio-ethanol has the advantages of being rich in reserves, environmentally friendly, green, pollution-free and the like, the prepared even-number-carbon primary alcohols include butanol, hexanol and octanol, and have the advantages of being highly-economical, wide in use ways, and the like. In addition, in the process, the catalyst is low in price, the reaction selectivity is high, stability is good, products are easy to separate, and the method has important economic value and potential industrial prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of super-hydrophobic super-oleophylic sponge

The invention provides a preparation method of super-hydrophobic super-oleophylic sponge. The preparation method mainly comprises the steps of (1) carrying out physical and chemical pretreatment on the sponge material; (2) respectively dip-coating a nanometer material and a long carbon chain alkyl silane material on the pretreated sponge material; and (3) carrying out an environment-friendly post-treatment process to obtain the super-hydrophobic super-oleophylic sponge. The preparation method is economical, environment-friendly, simple and efficient, and the prepared functional sponge material not only has good compression resistance, but also has excellent capability of separating oil or organic solvent from water, and has good adsorptive selectivity to oily liquid, which is higher than 97.5%.

Owner:东莞市腾崴塑胶制品有限公司

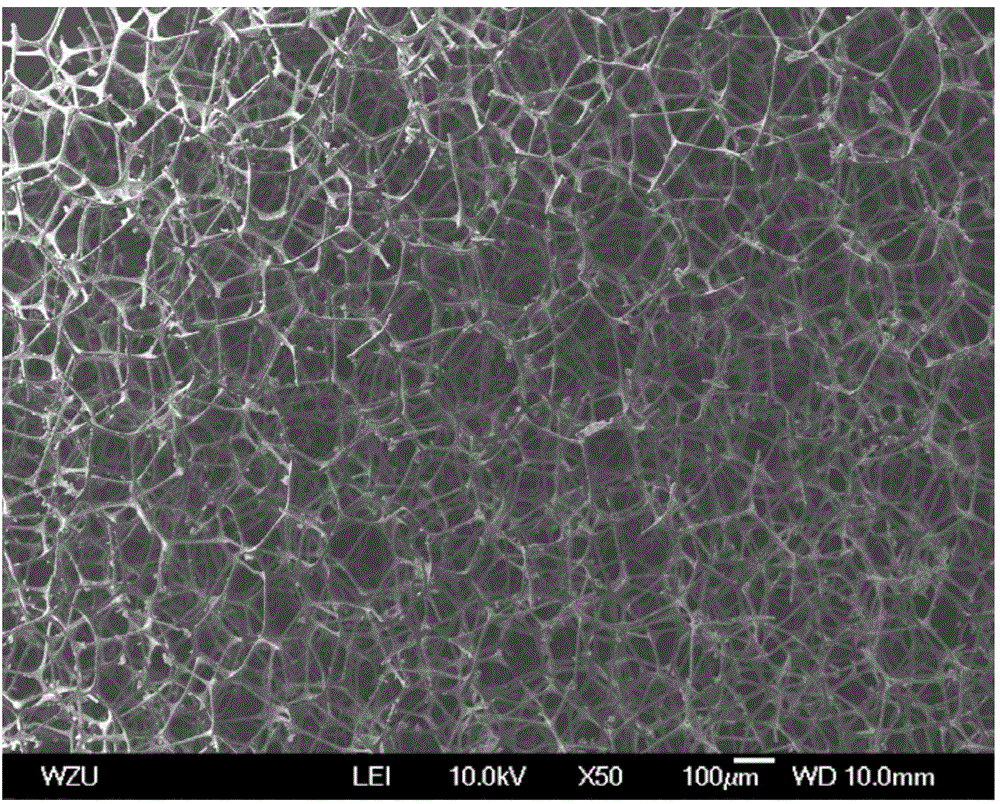

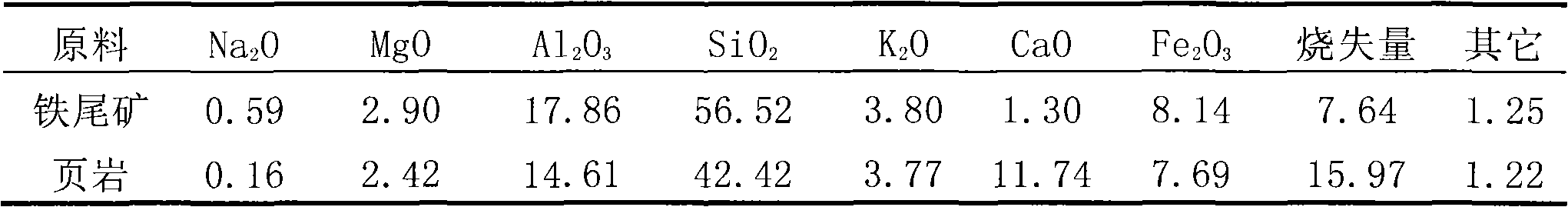

Porous insulation board and preparation method thereof

InactiveCN101805166AHigh compressive strengthImprove flexural strengthCeramic materials productionCeramicwareBreaking strengthBuilding energy

The invention relates to a porous insulation board and a preparation method thereof. The porous insulation board is characterized in that the porous insulation board is prepared by carrying out mixing, granulating and roasting on iron tailings, shale, foaming components, fluxing components and toughening components; the raw materials comprise the following components in percentage by weight: 20-60% of the iron tailing, 30-70% of the shale, 0.5-5% of the foaming component, 3-20% of the fluxing components and 3-15% of the toughening components. The insulation board prepared by the method of the invention has high compression strength and breaking strength, low water absorption, low volume density and excellent heat insulation effect, simultaneously greatly utilizes industrial tailings, and conforms to the sustainable development requirements and building energy saving requirements of China.

Owner:WUHAN UNIV OF TECH +1

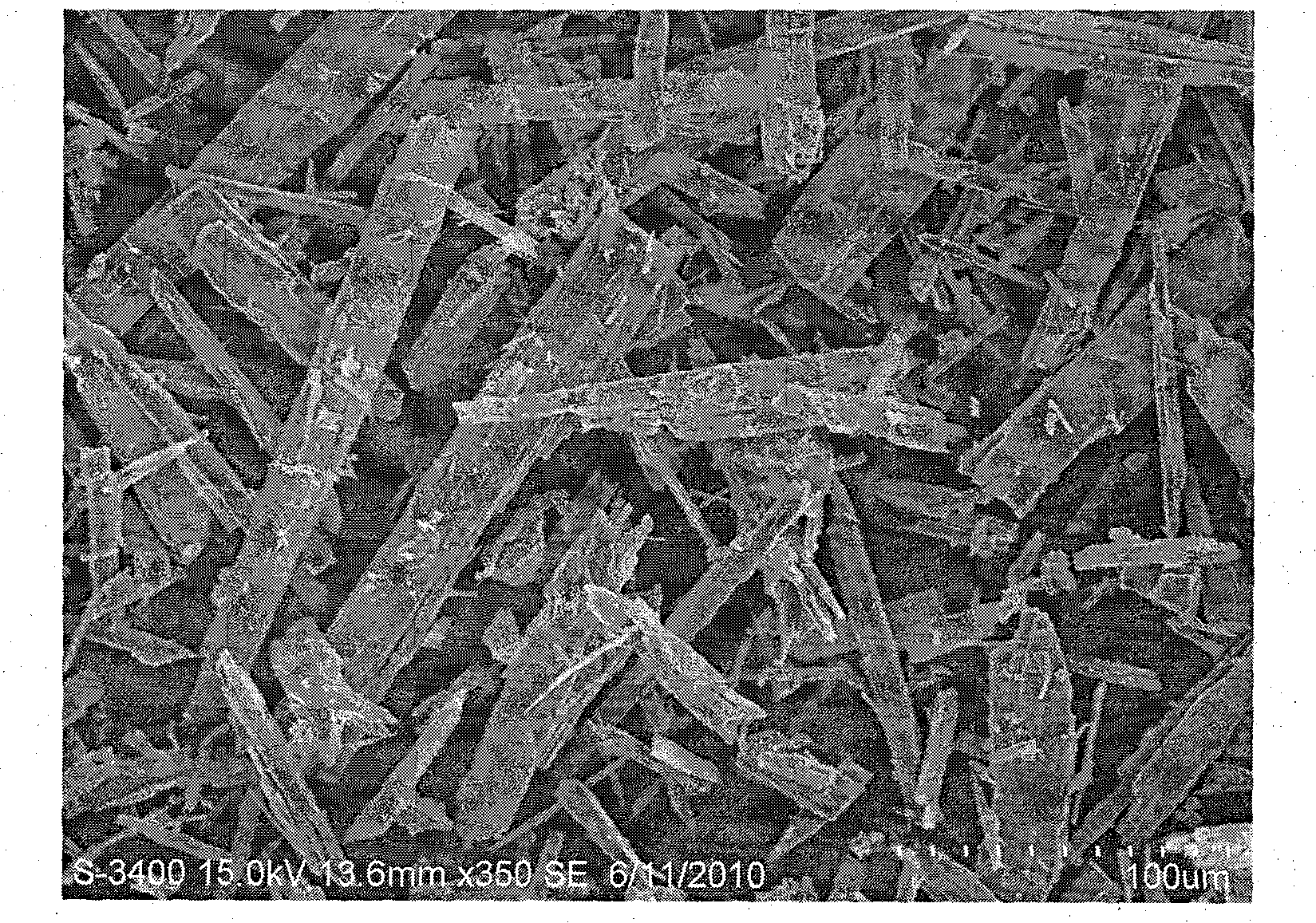

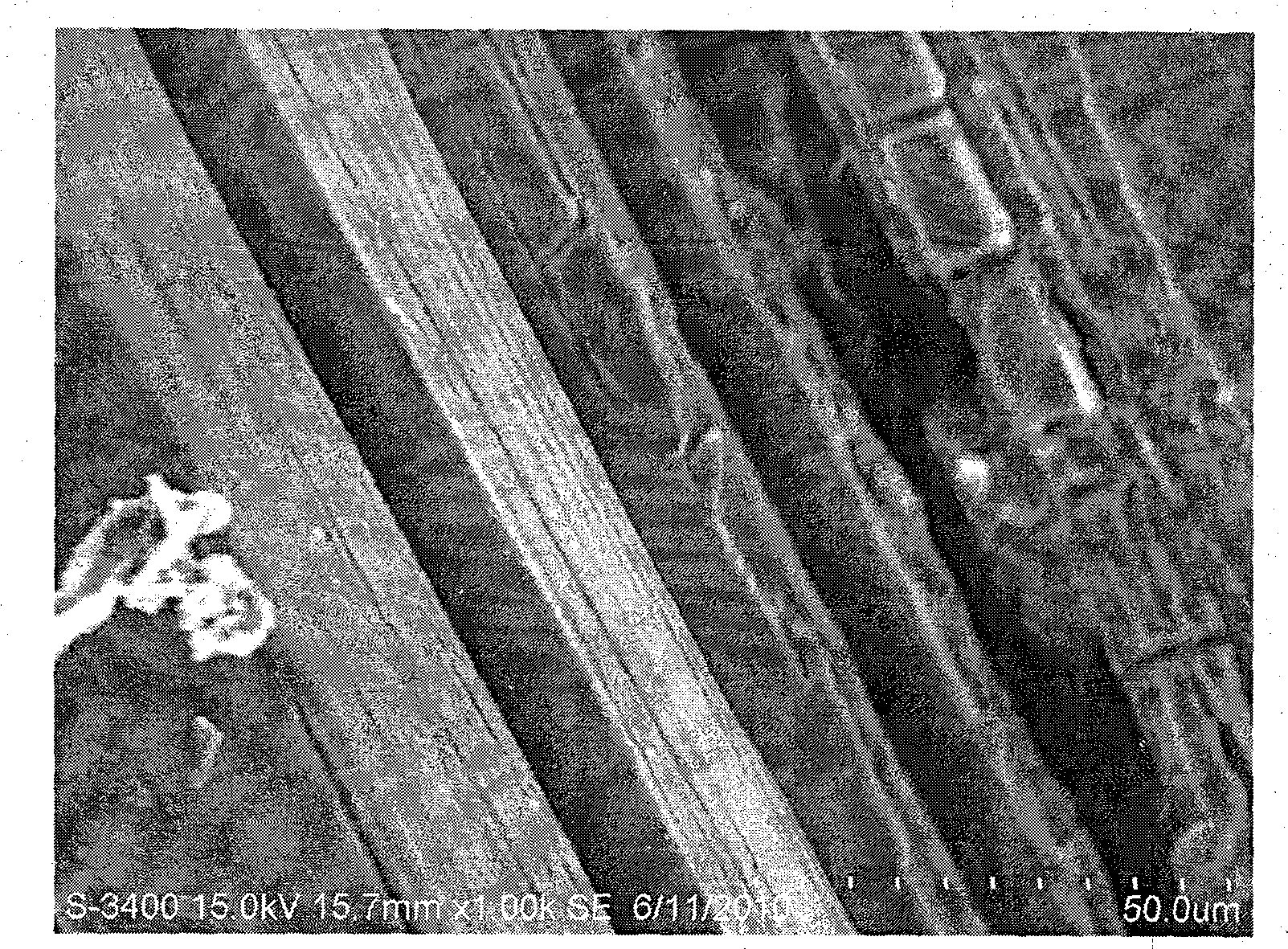

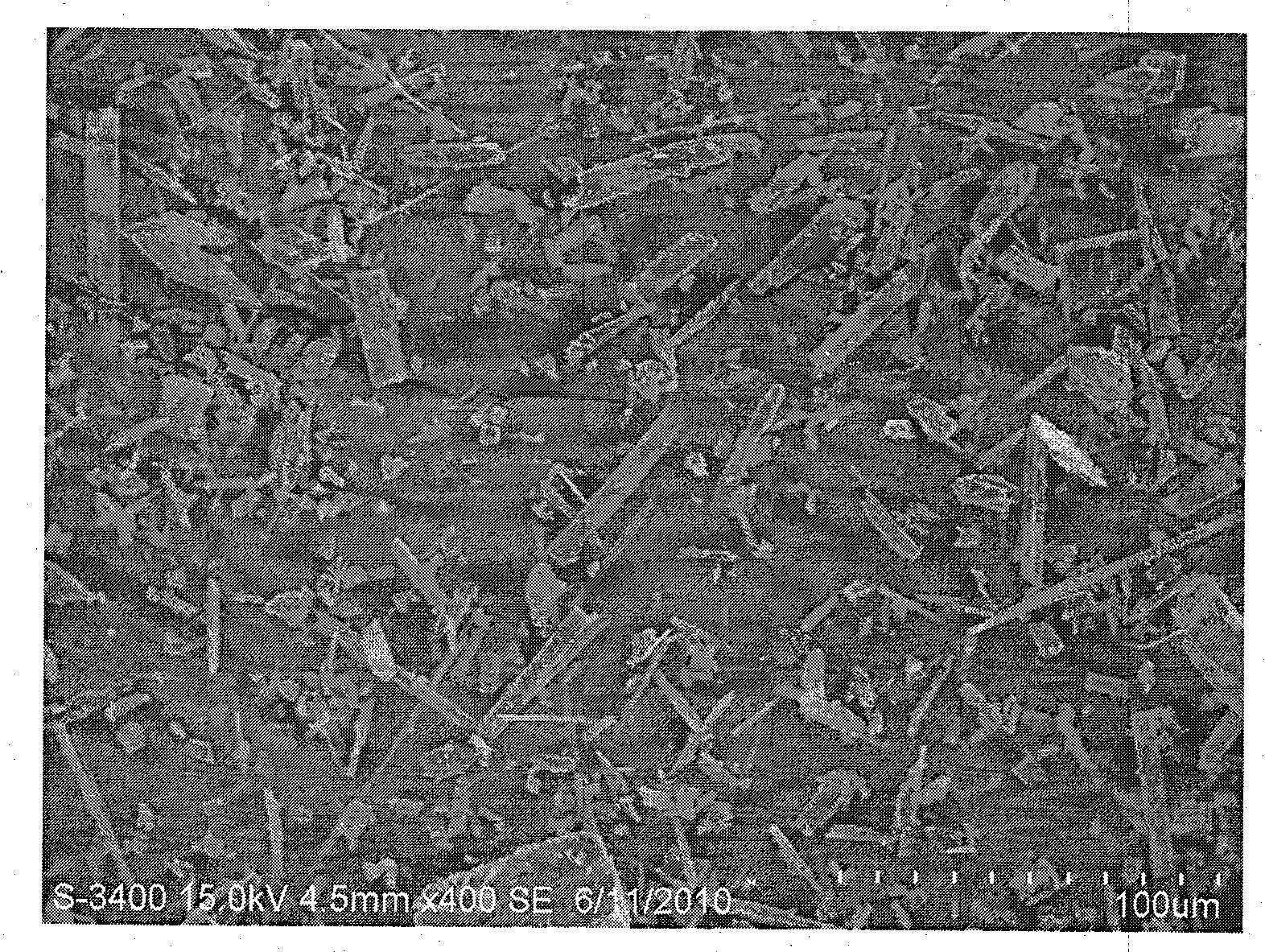

High-efficiency and energy-saving potassium titanate whisker preparation method

ActiveCN101962808AIncrease profitShorten the timePolycrystalline material growthFrom normal temperature solutionsThermal insulationCorrosion prevention

The invention discloses a high-efficiency and energy-saving potassium titanate whisker preparation method, which comprises: firstly, mixing and grinding a titanium raw material and a potassium raw material, and preheating; and secondly, calcining, crushing, absorbing and desorbing moisture, converting potassium ions, forming and obtaining pure white potassium titanate whiskers. In the invention, potassium dititanate is crushed by a machine, the moisture absorption and desorption speed is improved, and the production efficiency is improved considerably; through heat recycling, the energy consumption is reduced greatly; heat generated in a high-temperature area is used in a preheating kiln and a constant-temperature moisture absorption and desorption kiln, the structural integrity of the crystals and the utilization rate of raw materials are improved, and the high-efficiency and energy-saving preparation of potassium titanate whisker is realized; and a quantitative injection mode is used to realize the quantitative digestion conversion of the potassium ions, so the effective control of different whiskers is realized and the obtained whisker products have complete crystal structure and contain white crystals with flaky, lamellar or needle-like shapes. The product can be widely used in fields of thermal insulation, reinforcement, corrosion prevention, toughening and the like.

Owner:马玉馨

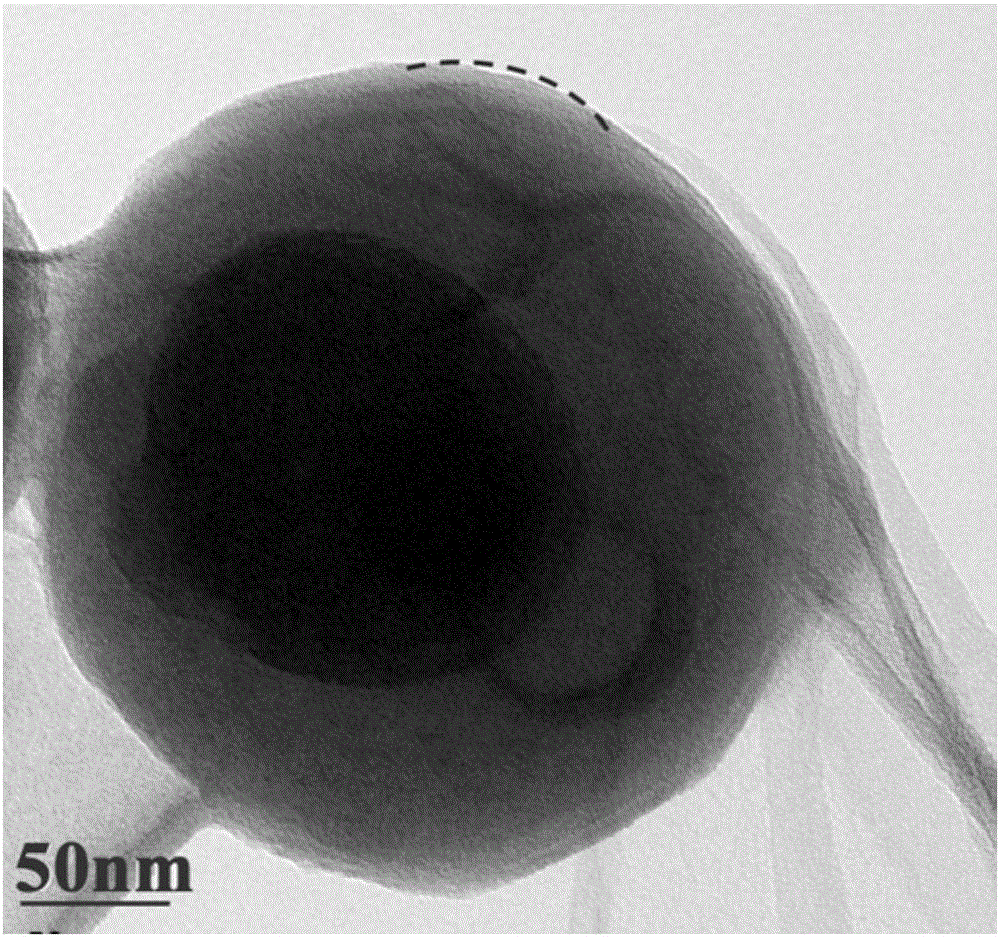

Porous carbon coated ZnO nanometer composite material and preparing method thereof

InactiveCN105964238ALow priceExcellent photodegradation catalytic performanceMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsPorous carbonCarbon nanocomposite

The invention discloses a porous carbon-coated ZnO nanocomposite material and a preparation method thereof. The present invention adopts a simple method of coating and calcining to synthesize porous carbon-coated ZnO nanocomposite material, and the preparation process is simple. First, 2-methylimidazole and ZnO nanoparticles are used as raw materials to construct ZnO heterostructure material, and then The obtained material is calcined to obtain a layer of porous carbon nanocomposite material supported on the ZnO surface. That is, the porous carbon-coated ZnO nanocomposite material is obtained; the prepared material has great application prospects in the field of degrading organic dyes.

Owner:NINGBO UNIV

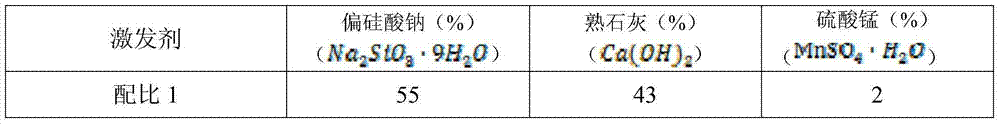

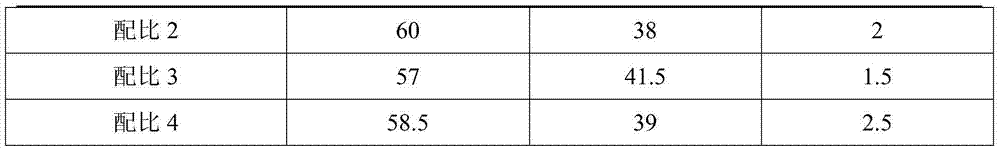

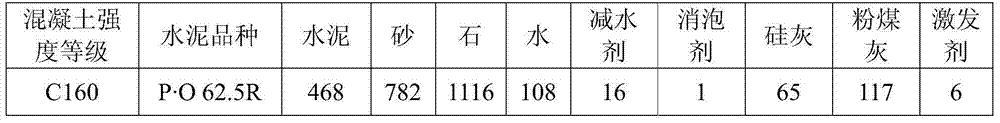

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

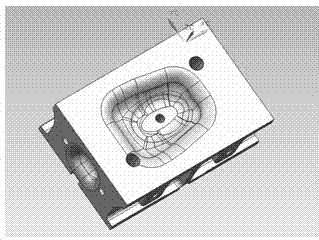

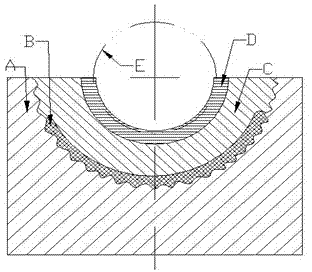

Sandwich layer forging die and preparation method of forging die sandwich layer surfacing

ActiveCN104741499AExtended service lifeImprove performanceArc welding apparatusForging/hammering/pressing machinesSoft materialsHigh pressure

The invention discloses a sandwich layer forging die and a preparation method of forging die sandwich layer surfacing. The sandwich layer forging die is used for surfacing a layer of sandwich layer soft welding material which is better in plasticity and lower in yield strength than a cast steel substrate and a double-metal gradient surfacing material between the cast steel substrate and the double-metal gradient surfacing material; the preparation method of the forging die sandwich layer surfacing comprises the following steps of taking cast steel as the cast steel substrate, and welding a sandwich layer soft material on a substrate layer; surfacing a transition layer material on a substrate of a sandwich layer welded, welding and covering all sandwich materials to form a surfacing transition layer; welding a high-temperature wearing layer material; tempering to distress after the completion of the welding, and then mechanically processing to obtain a mould. The sandwich layer forging die provided by the invention is long service life and high in loading capacity of the cast steel substrate. According to the method provided by the invention, the critical bottleneck problems that the forging die is low in life and the die is high in manufacturing cost can be solved thoroughly, the die forging forming of various materials can be supported at high temperature and high pressure, and a brand new manufacturing method can be provided for forging die manufacturing.

Owner:CHONGQING UNIV +2

Method for preparing polyol by using bio-oil and application

ActiveCN104341297AWide variety of sourcesPromote degradationOrganic compound preparationPolyureas/polyurethane adhesivesPtru catalystPotassium fluoride

The invention discloses a method for preparing polyol by using bio-oil. The method comprises the following steps: firstly performing methyl esterification, namely, performing ester exchange on biolipid and methanol under the catalysis of potassium fluoride loaded magnesium oxide solid alkali, converting the obtained product into fatty acid methyl ester with small molecular weight and byproduct glycerol, filtering to recycle the catalyst, and separating lower-layer glycerol; performing epoxidation on upper-layer fatty acid methyl ester in 30% of hydrogen peroxide under the catalysis of ionic liquid so as to form epoxidized fatty acid methyl ester.; then adding the glycerol in the methyl esterification process, continuously performing alkoxide ring-opening under the catalysis of ionic liquid, introducing hydroxyl, and finally separating liquid to recycle the ionic liquid catalyst, reducing pressure and distilling the upper-layer to remove water so as to obtain low-viscosity bio-oil-based polyol. The raw material is easily available, recyclable and good in biodegradability, the preparation process is environmental friendly, the industrial three-waste emission is small, the product structure and a hydroxyl value are adjustable, the application range is wide, and the environment influence level is low.

Owner:ZHEJIANG HENGFENG NEW MATERIAL

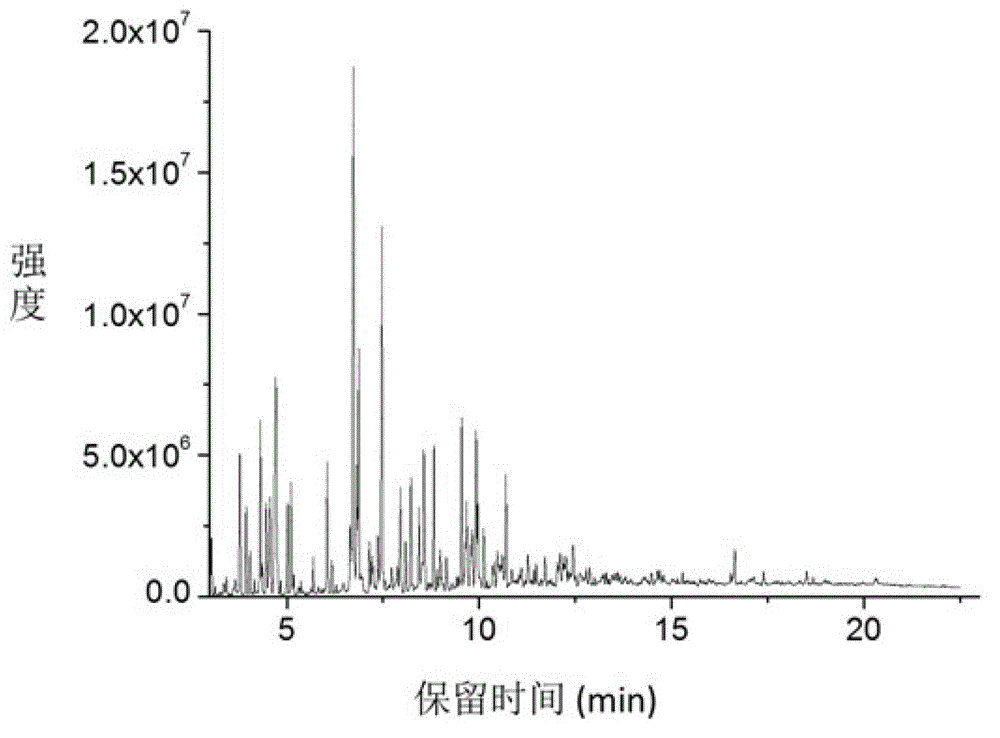

Application of molybdenum-based catalyst to prepare organic chemicals from lignin

The invention discloses a method for preparing organic chemicals from lignin. The method comprises: taking a catalyst employing a transition metal molybdenum as an active site to perform catalysis on reactions, heating to 230-350 DEG C, stirring to react for 0.5 h-12 h, after the reaction is finished, filtering out the solid catalyst, and performing rotary evaporation to obtain liquid products. The catalytic process of the technical scheme has extremely high product efficiency, the product total yield is up to 90%, the products comprise monophenols and other aromatic compounds used in large scale in industry, the added value is high, and the application has extremely good industrial application prospect.

Owner:TIANJIN UNIV

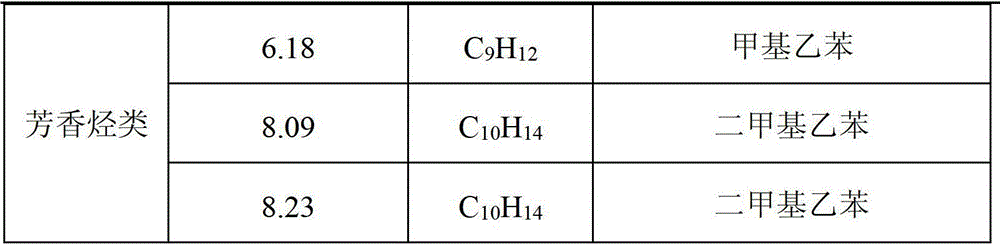

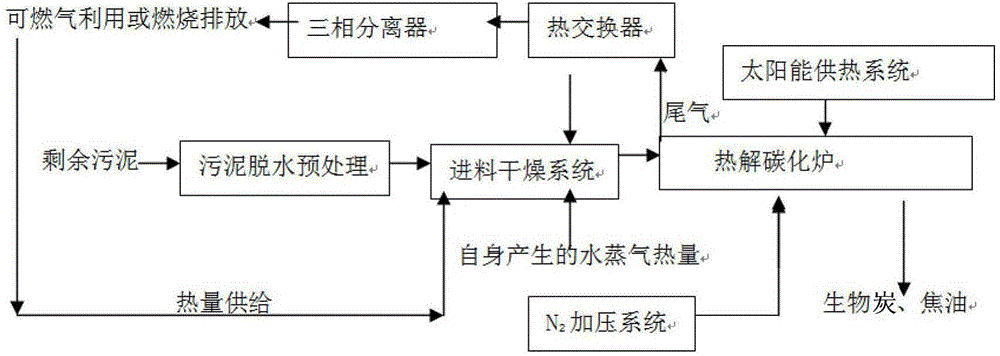

Sludge treatment method using solar pyrolysis carbonization technology

ActiveCN104671628ANot easily migrated and absorbed by plantsRealize resource utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCarbonationMunicipal sewage

The invention discloses a sludge treatment method using a solar pyrolysis carbonization technology. The method comprises the following steps: adding the sludge produced by municipal sewage treatment into a pyrolysis carbonization furnace, carrying out a series of reactions, including vaporization, pyrolysis, dehydrogenation, pyrocondensation and carbonation, in a sealed, oxygen-free and non-burning state, wherein a heat source of the pyrolysis carbonization furnace is provided by a solar heat supply system, the reaction condition is high temperature and normal pressure, or high temperature and high pressure, or moderate-high temperature and high pressure, the high temperature is 500-800 DEG C, the moderate-high temperature is 200-400 DEG C and the high pressure is 1-16MPa. With the method provided by the invention, thorough treatment disposal of the sludge in a sewage plant is realized, secondary pollution is avoided, energy utilization rate is high, operation cost is very low, renewable resources is recycled, and reduction, stabilization, reutilization and resource utilization of sludge treatment disposal are really implemented completely.

Owner:北京金泥华牛科技有限公司

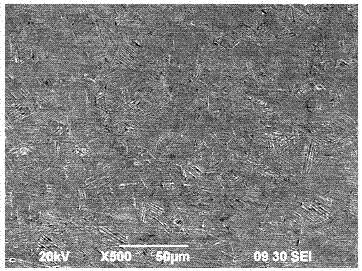

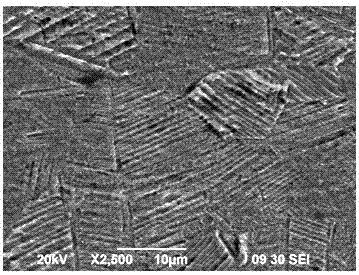

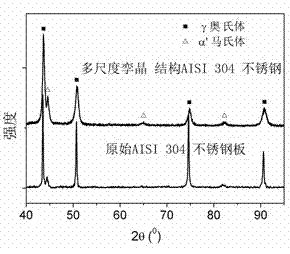

Steel with multi-scale twin-crystal structure and preparation method of steel

The invention discloses steel with a multi-scale twin-crystal structure and a preparation method of the steel. The steel with the multi-scale twin-crystal structure is of a complex microstructure, i.e., a multi-scale twin-crystal and complex phase structure, and the hardness of the steel is reduced in a gradient way from the surface to the center. The preparation method comprises the step of preparing the steel by taking austenitic stainless steel, TRIP (Transformation-Induced Plasticity) steel or TWIP (Twinning Induced Plasticity) steel as materials by using a high strain rate deformation method or high strain rate deformation and temperature deformation treatment combined method. The twin-crystal density of the multi-scale twin-crystal structure ranges from 10% to 90% and changes along with the change of depth, and the twin-crystal density of a surface layer of the multi-scale twin-crystal structure ranges from 30% to 85%, and the twin-crystal density of the center of the multi-scale twin-crystal structure ranges from 10% to 50%. The strength and the plasticity of the steel with the multi-scale twin-crystal structure, disclosed by the invention, are synchronously enhanced; and meanwhile, the favorable ductility is kept. The steel has the highest yield strength of 900-1800MPa, the tensile strength of 1000-2000MPa and the breaking elongation of 30-50%.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com