Application of molybdenum-based catalyst to prepare organic chemicals from lignin

A molybdenum-based catalyst and organic chemical technology, applied in recycling technology, plastic recycling, etc., can solve problems such as decomposition difficulties, and achieve the effects of good atomic economy, high product yield, and high added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

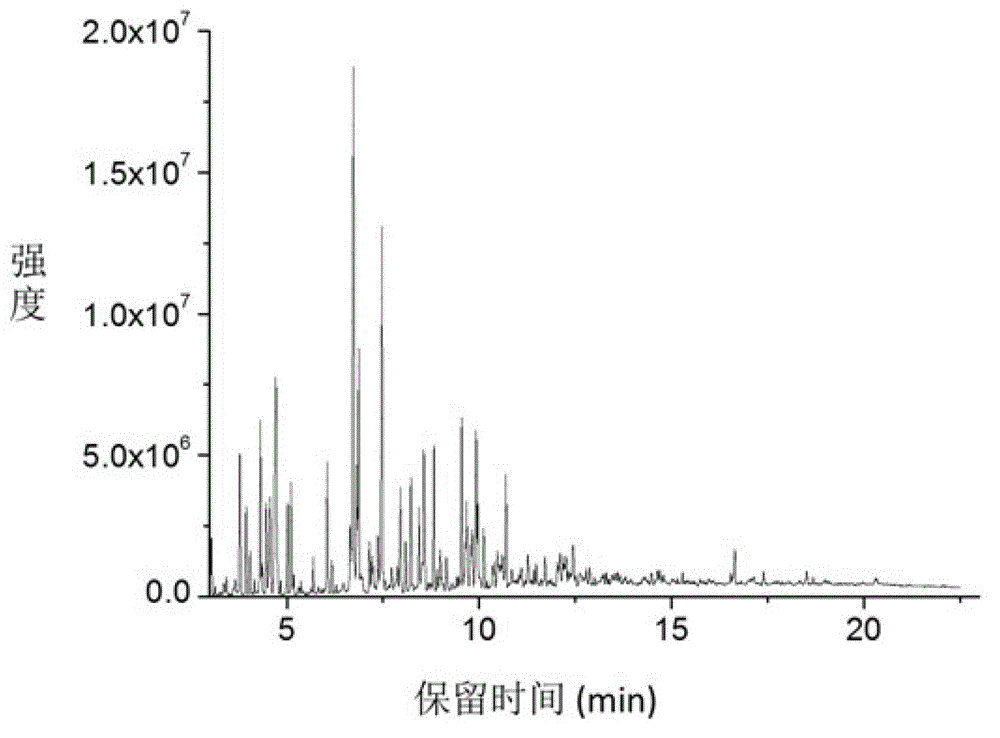

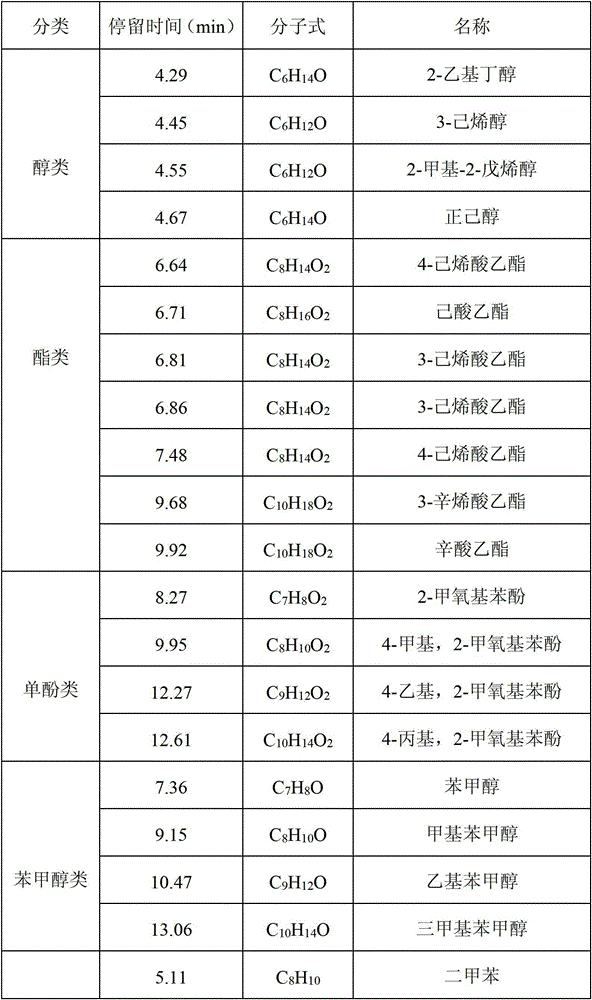

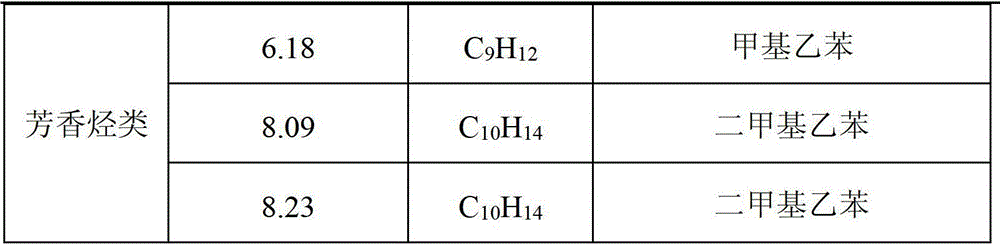

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 catalyst

[0041] Weigh ammonium heptamolybdate and dissolve it in ammonia solution, then impregnate the same volume on the acidified activated carbon (AC) carrier, and after drying in an oven at 120°C for 12 hours, the catalyst precursor is subjected to a temperature-programmed carbonization reaction. The specific reaction process is as follows: in H 2 In the atmosphere, 0.5g of the precursor was placed in a quartz reaction tube and the temperature was raised to 350°C and kept for 12h. The gas was then switched to 15% CH by volume 4 / H 2 , the temperature was raised to 590°C, kept for 2h, and then rapidly lowered to room temperature 25°C. The resulting catalyst with a molybdenum loading of 30 wt%, expressed as Mo 2 C / AC (30wt%Mo 2 C / AC).

Embodiment 2

[0042] The preparation of embodiment 2 catalyst

[0043] The preparation method of the catalyst is the same as in Example 1, and the difference from Example 1 is that the concentration of ammonium molybdate in the impregnating solution can be changed, or catalysts with different loads can be obtained through multiple impregnations. For example, the loading of Mo is 1wt%, 5wt%, 10wt%, 15wt%, 20wt%, 30wt%, 50wt% and 80wt% Mo 2 C / AC catalyst.

Embodiment 3

[0044] The preparation of embodiment 3 catalyst

[0045] Catalyst preparation method is the same as embodiment 1, and the difference with embodiment 1 is that activated carbon (AC) carrier is replaced by alumina (Al 2 o 3 ), silicon dioxide (SiO 2 ) or silicon carbide (SiC) supports, catalysts supported on different supports can be obtained. Such as Mo 2 C / Al 2 o 3 、Mo 2 C / SiO 2 、Mo 2 C / SiC catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com