Patents

Literature

103results about How to "High yield preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

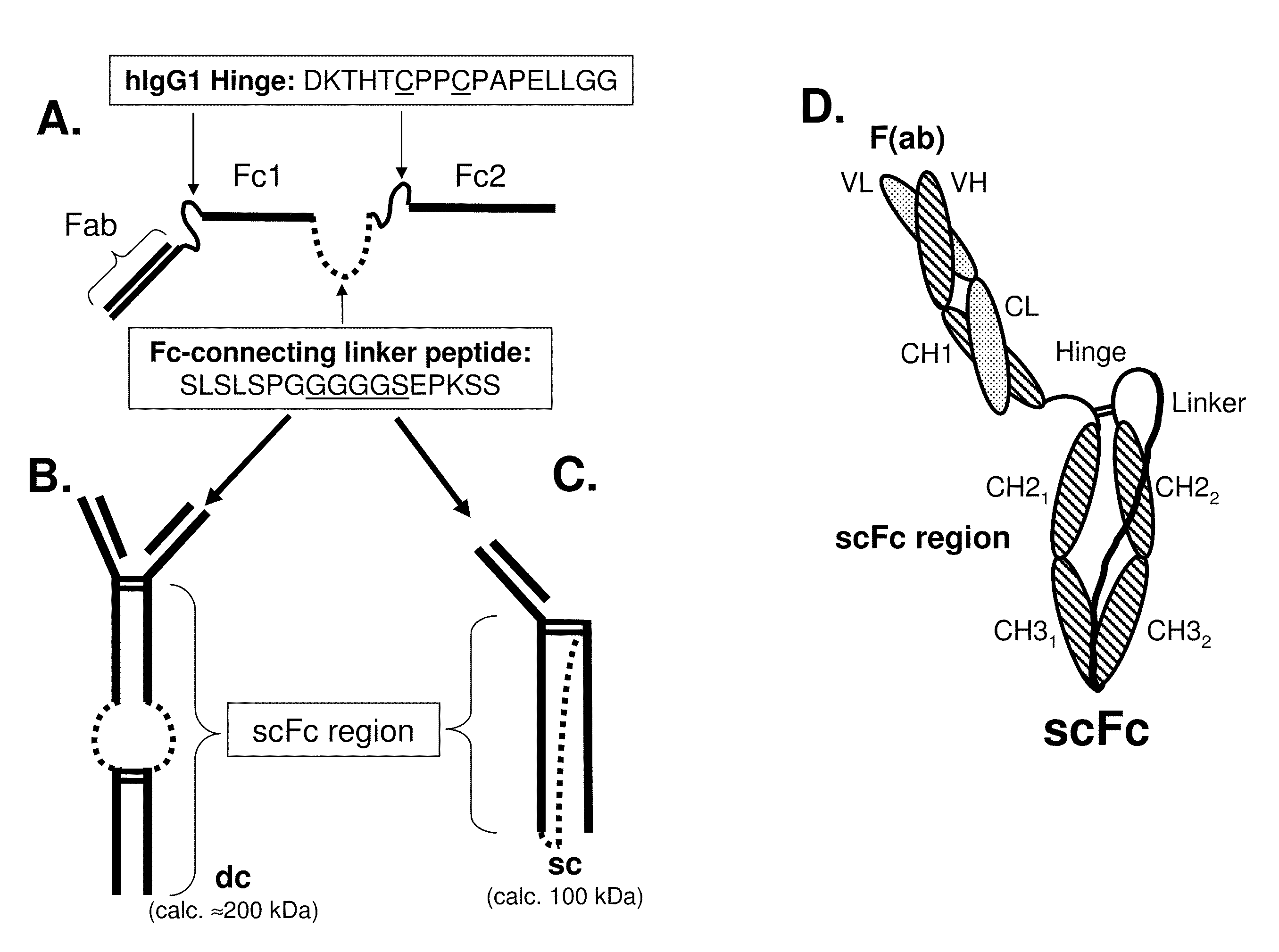

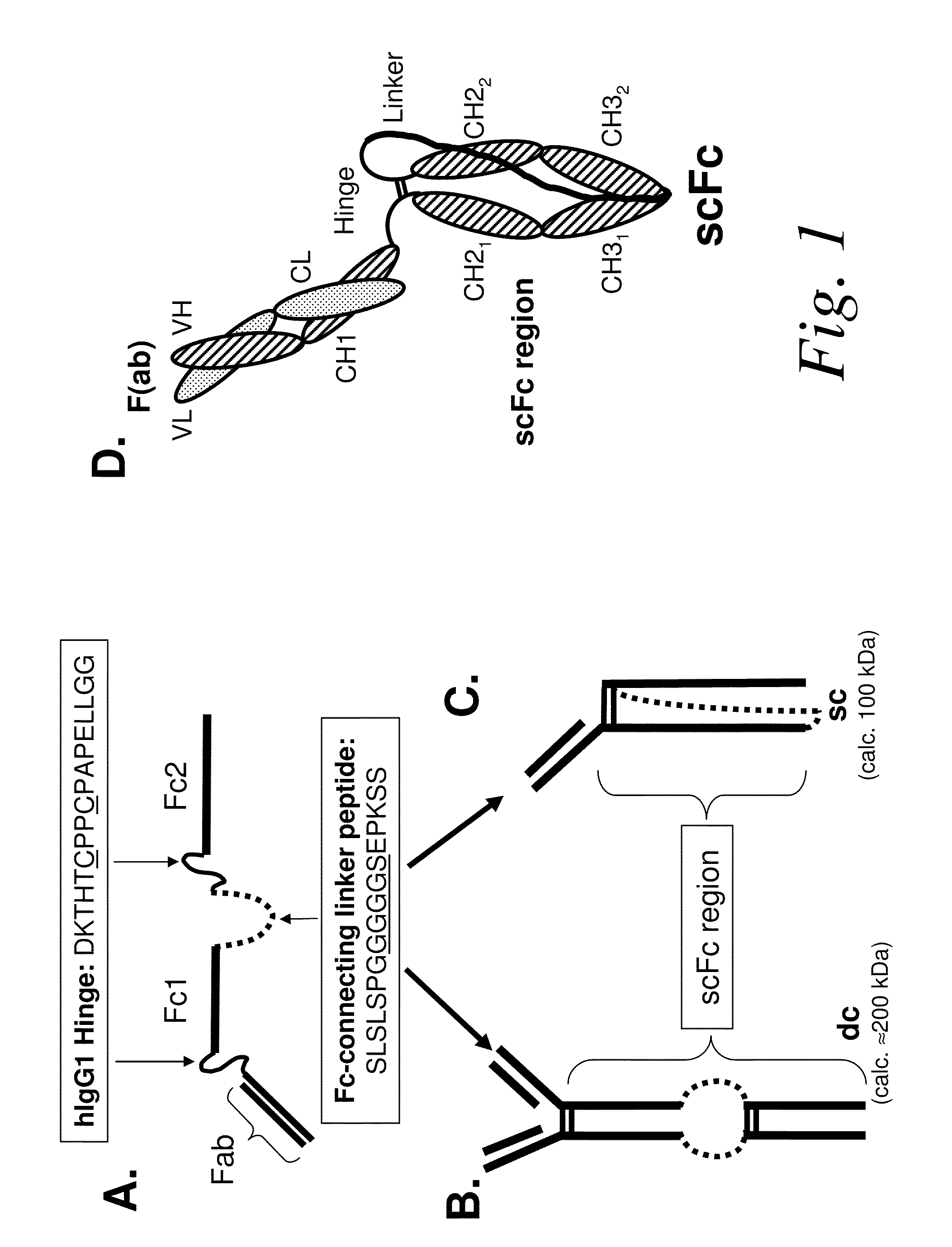

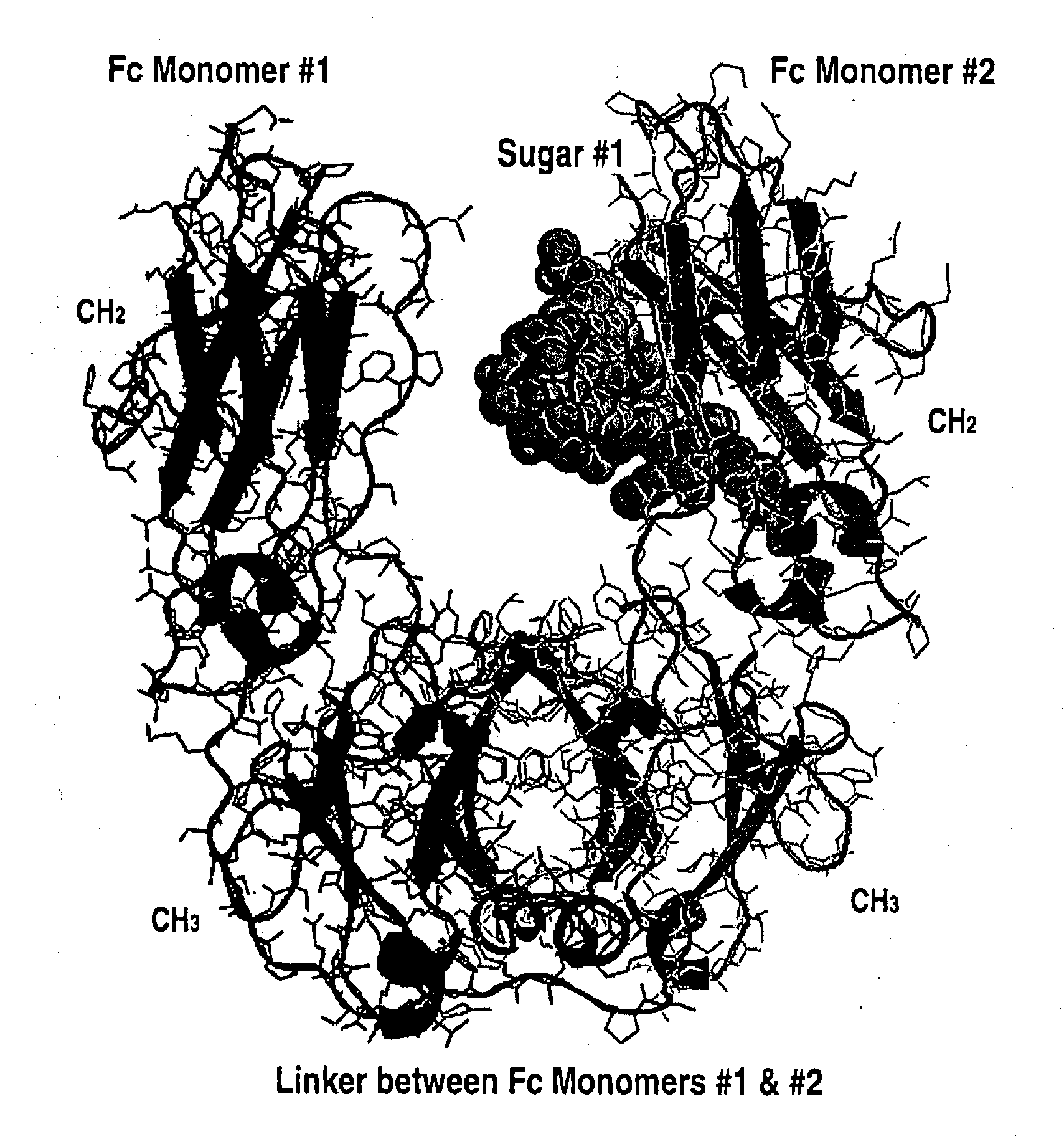

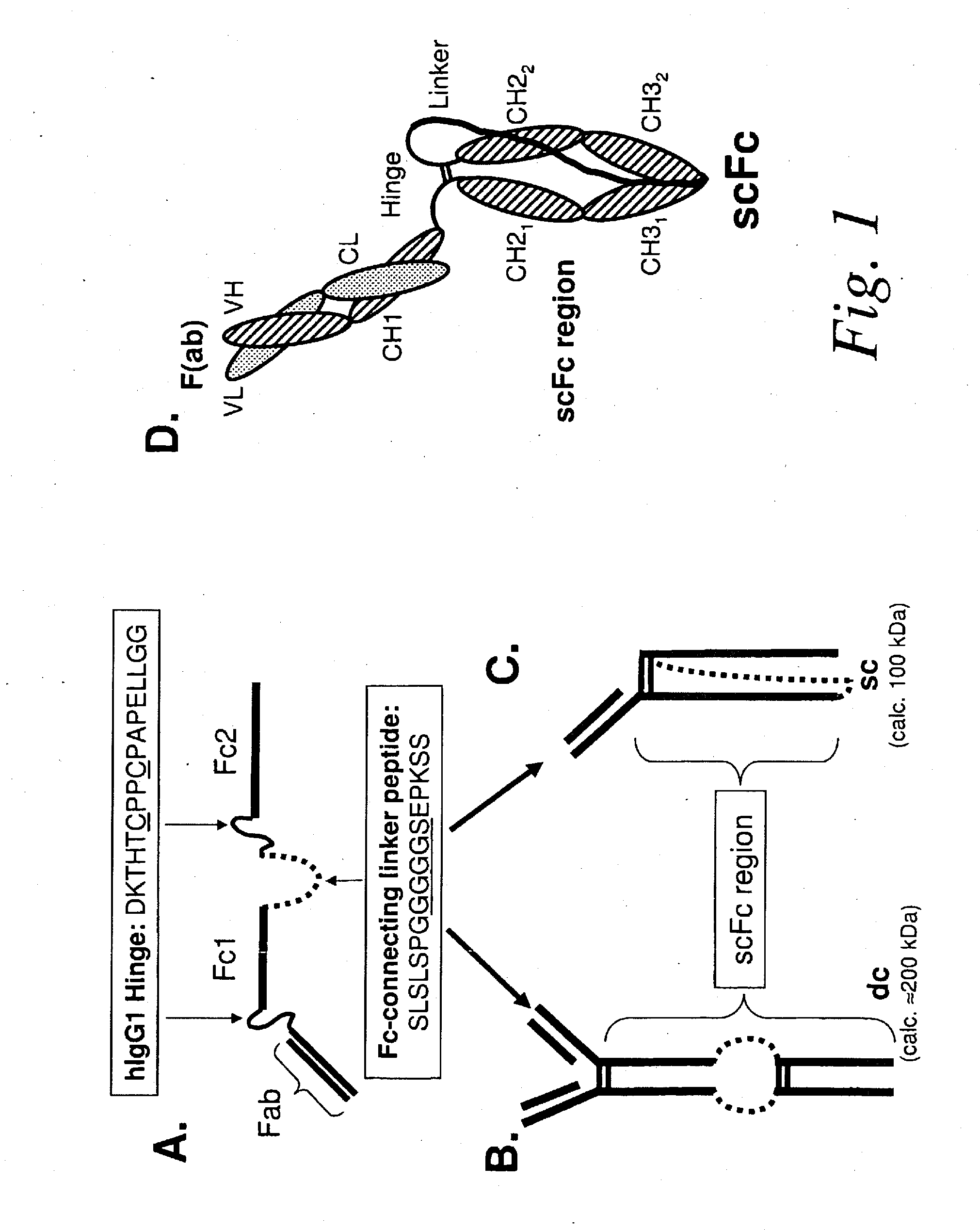

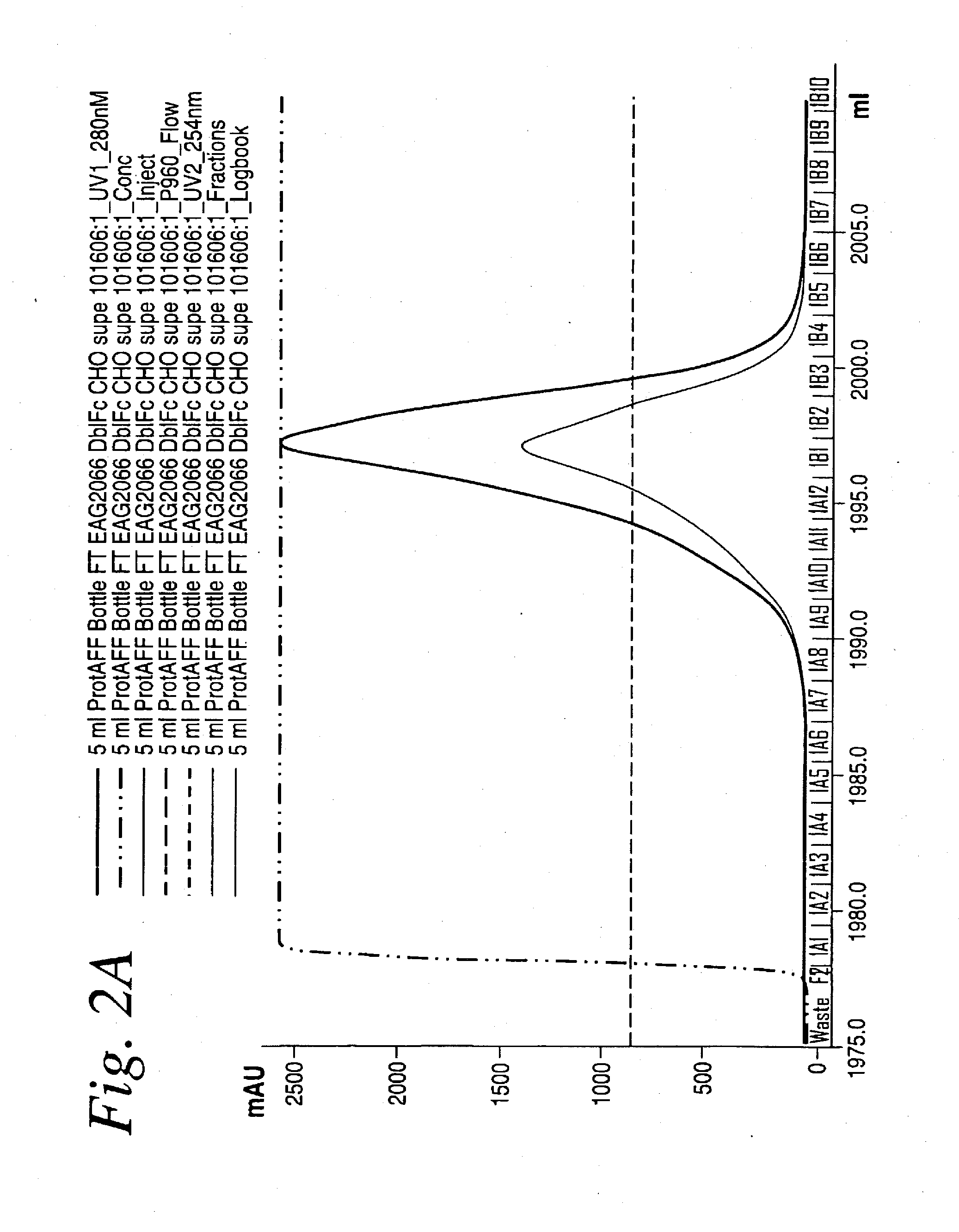

Single-chain Fc (scFc) regions, binding polypeptides comprising same, and methods related thereto

InactiveUS20090252729A1Fine-tune such effector functionHigh expressionNervous disorderAntibody mimetics/scaffoldsDiseaseChemistry

The present invention features inter alia polypeptides comprising an Fc region comprising genetically-fused Fc moieties. In addition, the instant invention provides, e.g., methods for treating or preventing a disease or disorder in subject by administering the binding polypeptides of the invention to said subject.

Owner:BIOGEN MA INC

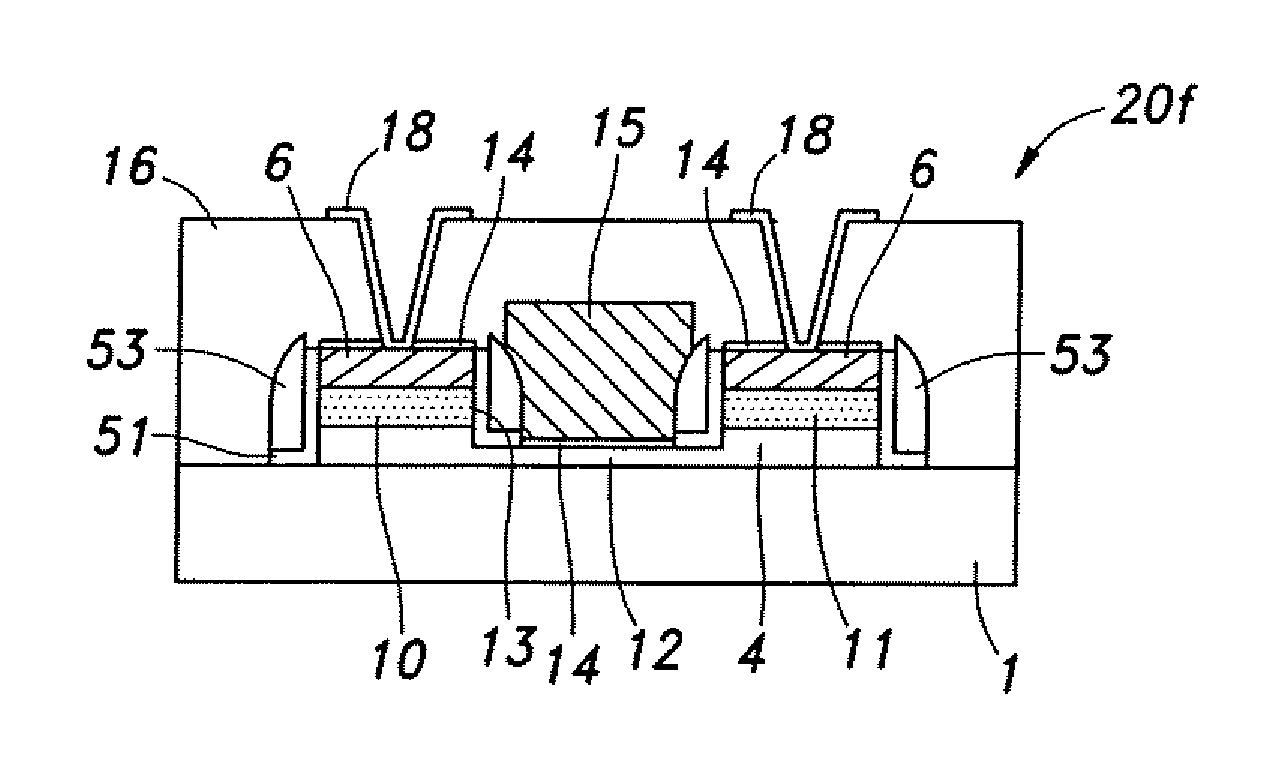

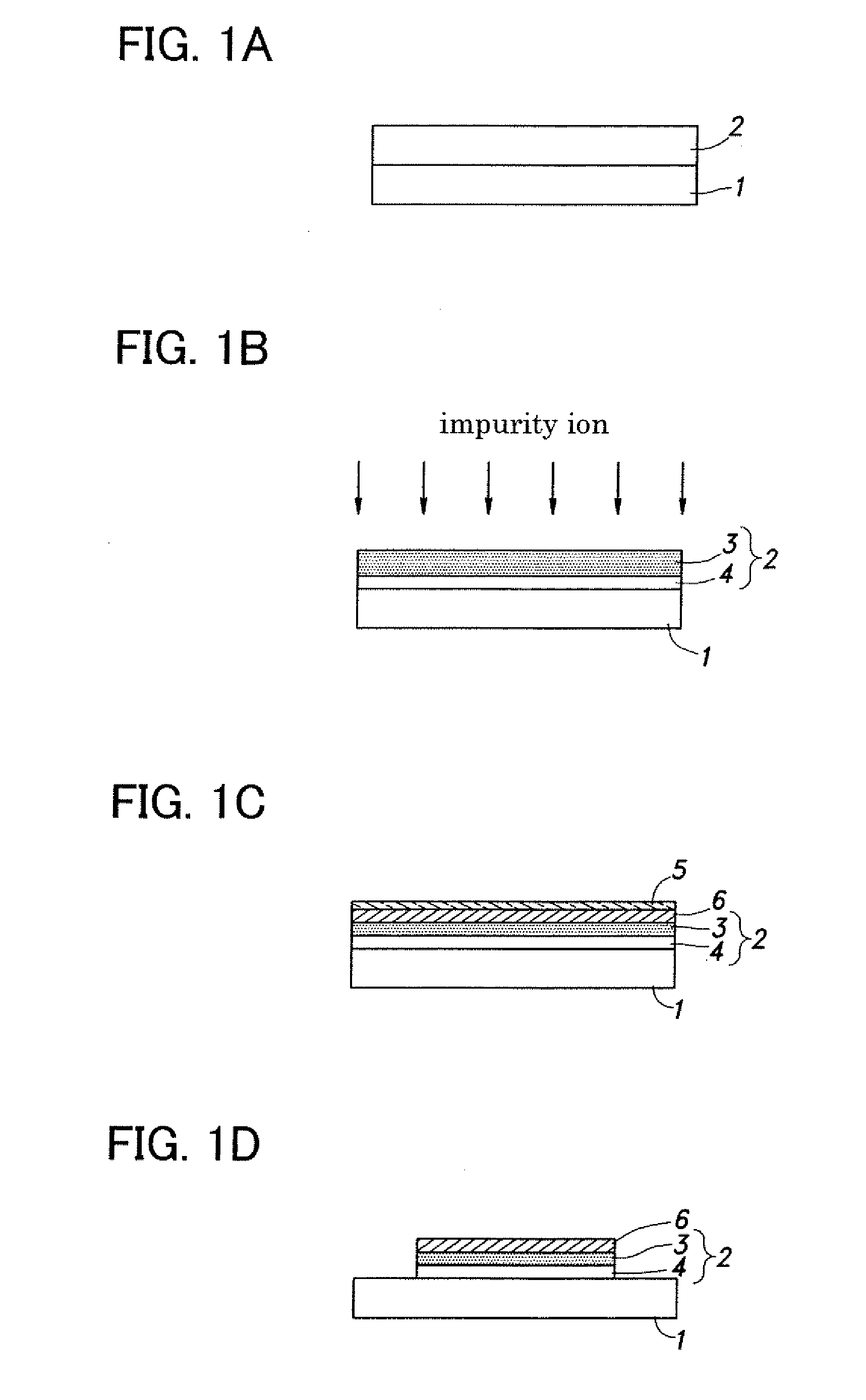

Semiconductor device and manufacturing method thereof

InactiveUS20090096024A1Less heatConsumes less powerSolid-state devicesSemiconductor/solid-state device manufacturingMetal silicideSemiconductor

In a method for manufacturing a semiconductor device, a semiconductor film formed over an insulator is doped with an impurity element to a depth less than the thickness of the semiconductor film, thereby forming an impurity doped layer; a metal silicide layer is formed on the impurity doped layer; the metal silicide layer and the semiconductor film are etched to form a recessed portion; and a layer which is not doped with the impurity element and is located at the bottom of the recessed portion of the semiconductor film is thinned to make a channel formation region. Further, a gate electrode is formed in the recessed portion over the thinned non impurity doped layer, with an insulating film interposed therebetween.

Owner:SEMICON ENERGY LAB CO LTD

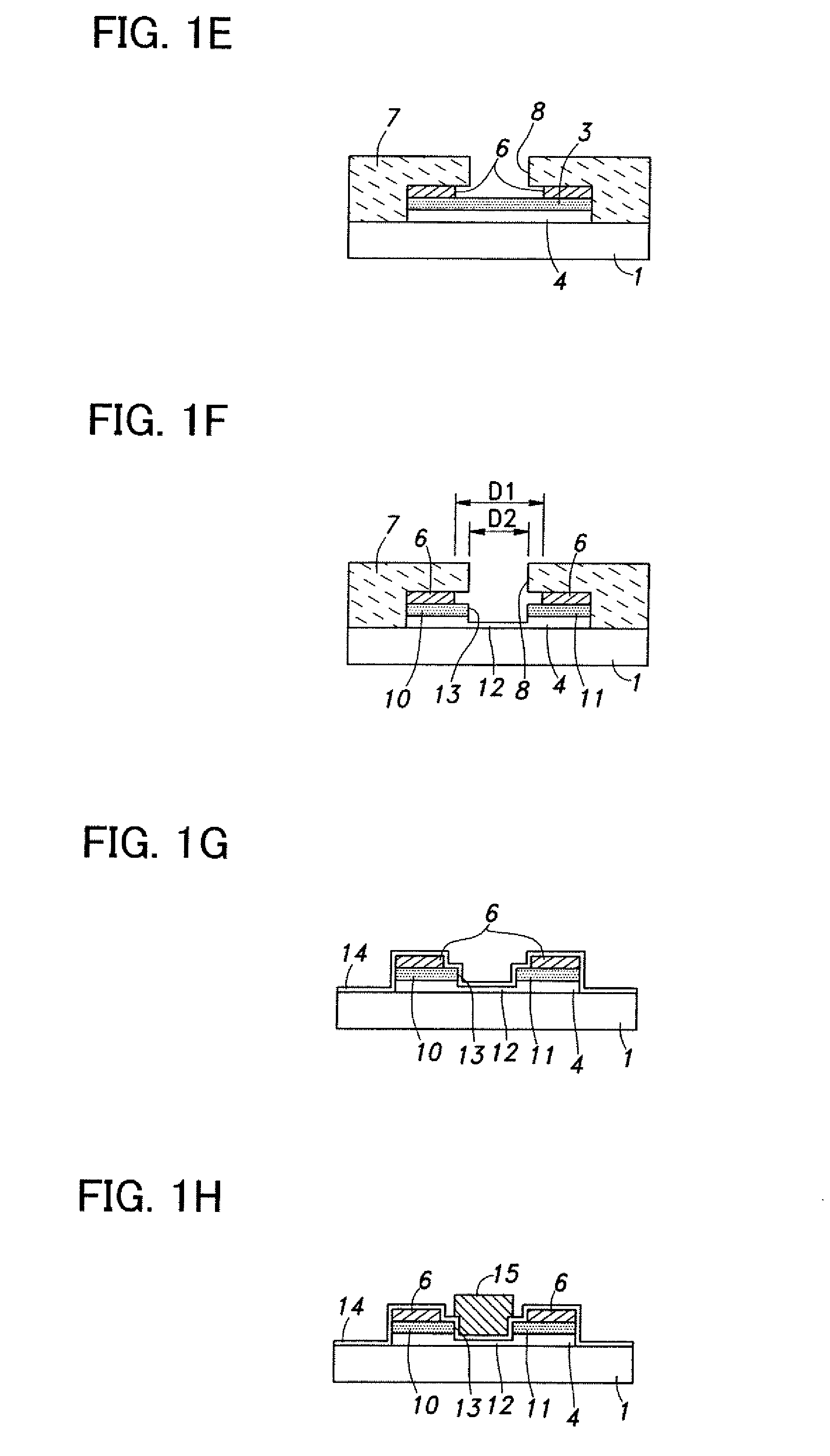

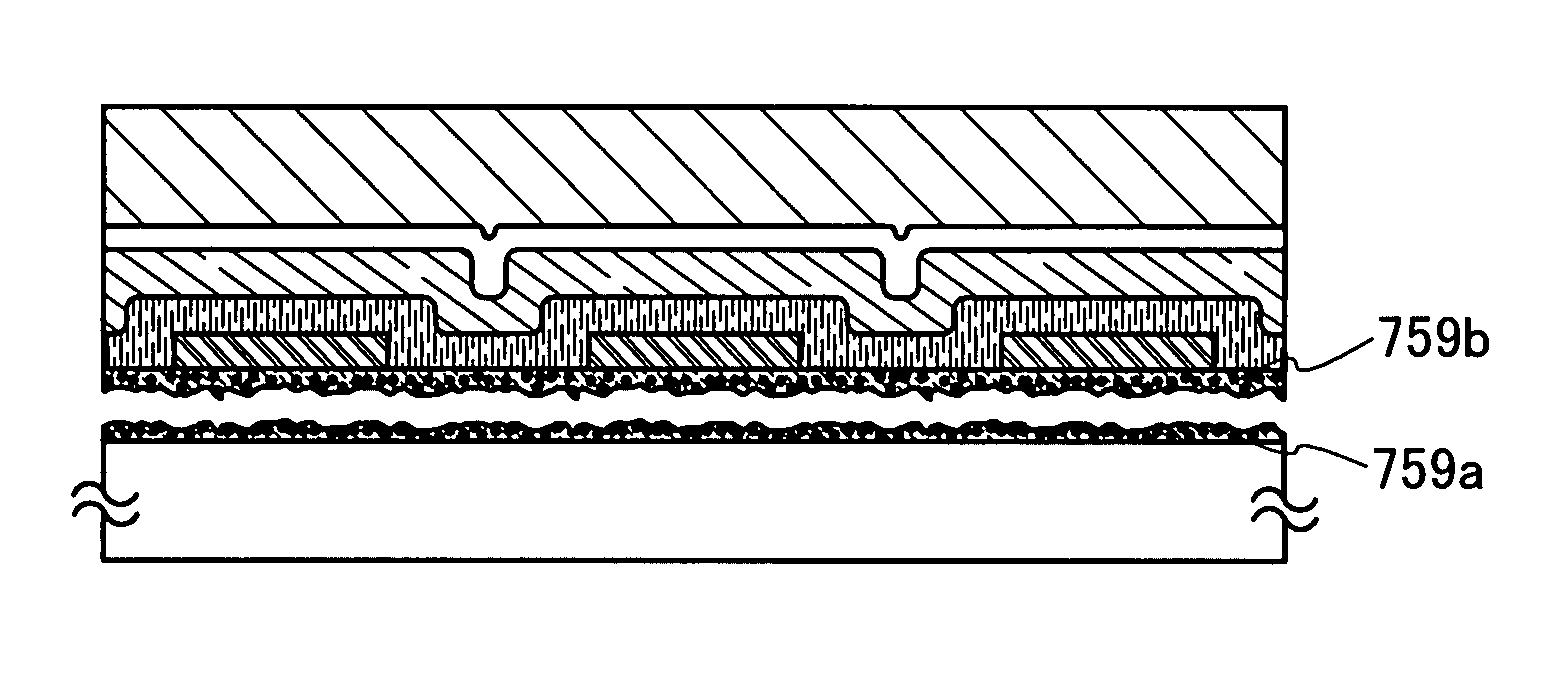

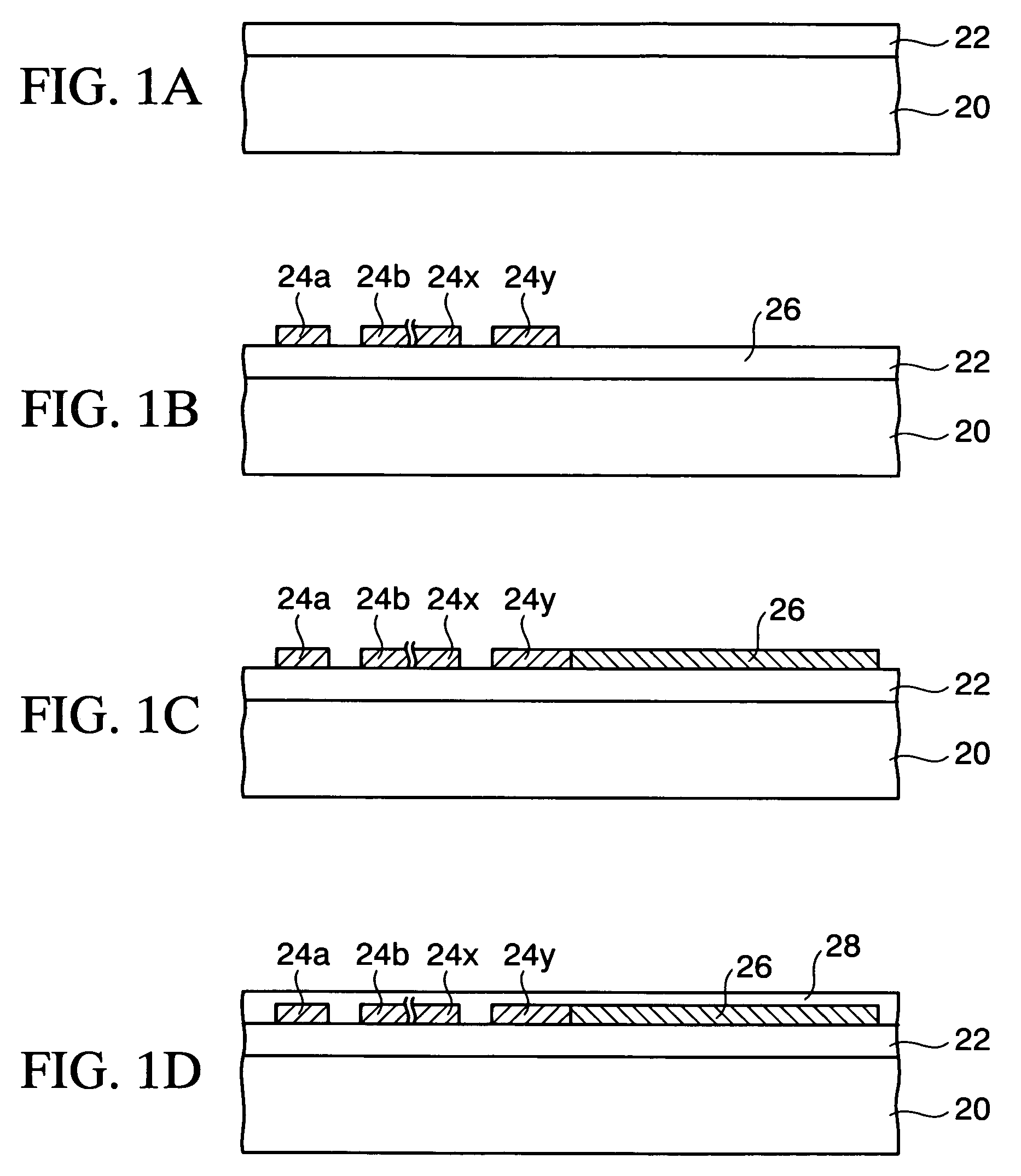

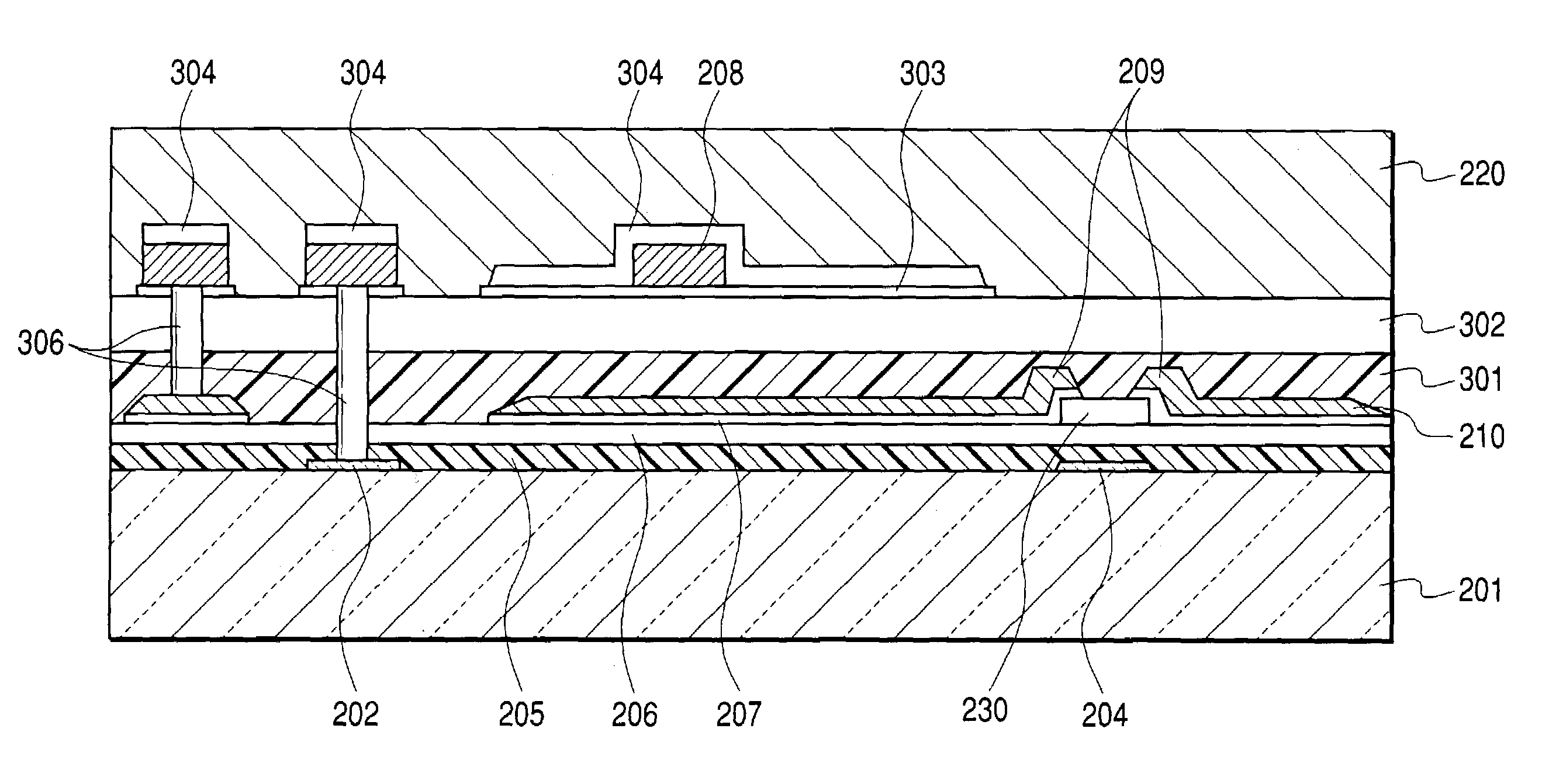

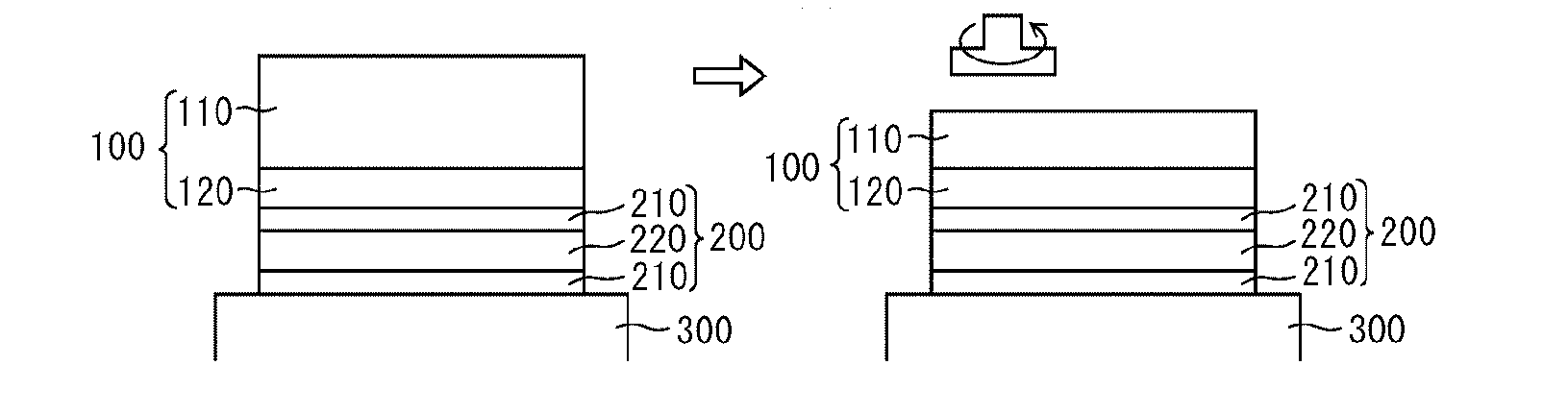

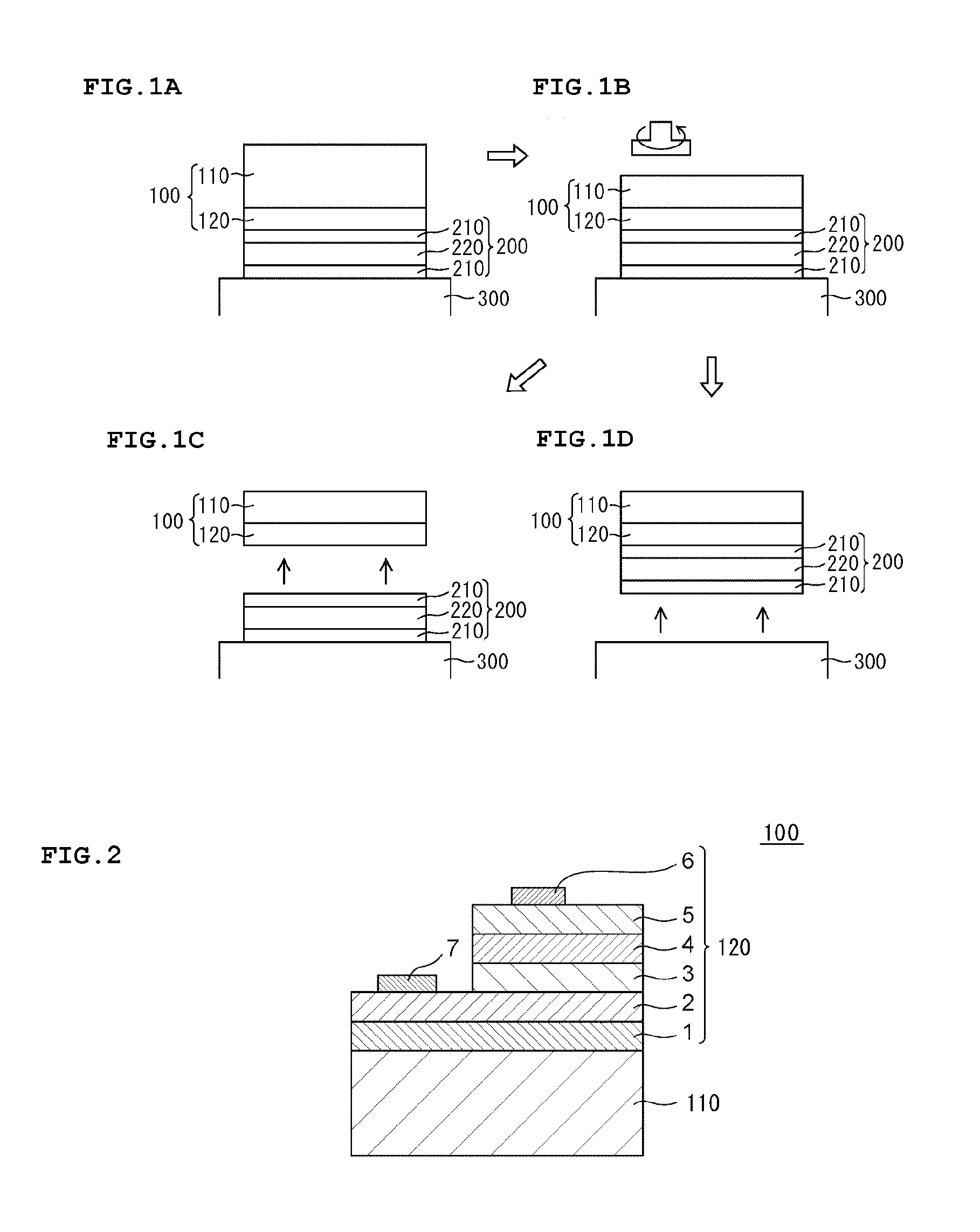

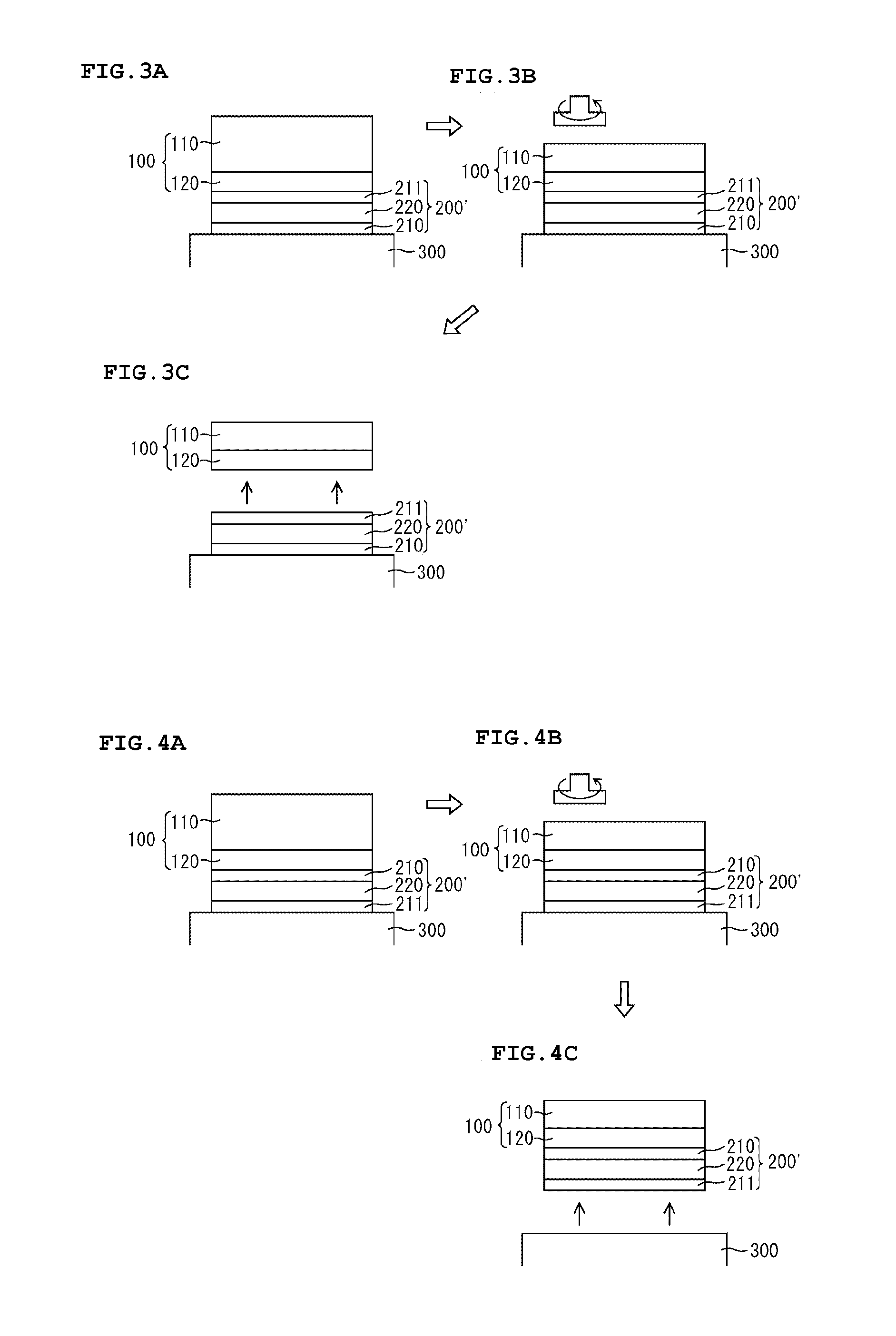

Method for manufacturing semiconductor device

ActiveUS20070295973A1Easily and freely transferHigh yieldFinal product manufactureSolid-state devicesEngineeringOrganic compound

The present invention provides a manufacturing technique of a semiconductor device and a display device using a peeling process, in which a transfer process can be conducted with a good state in which a shape and property of an element before peeling are kept. Further, the present invention provides a manufacturing technique of more highly reliable semiconductor devices and display devices with high yield without complicating the apparatus and the process for manufacturing. According to the present invention, an organic compound layer including a photocatalyst substance is formed over a first substrate having a light-transmitting property, an element layer is formed over the organic compound layer including a photocatalyst substance, the organic compound layer including a photocatalyst substance is irradiated with light which has passed through the first substrate, and the element layer is peeled from the first substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing ethylene glycol from cellulose

ActiveCN101723802ALow costWide variety of sourcesOrganic compound preparationCatalyst activation/preparationHydrogen pressurePolyethylene glycol

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

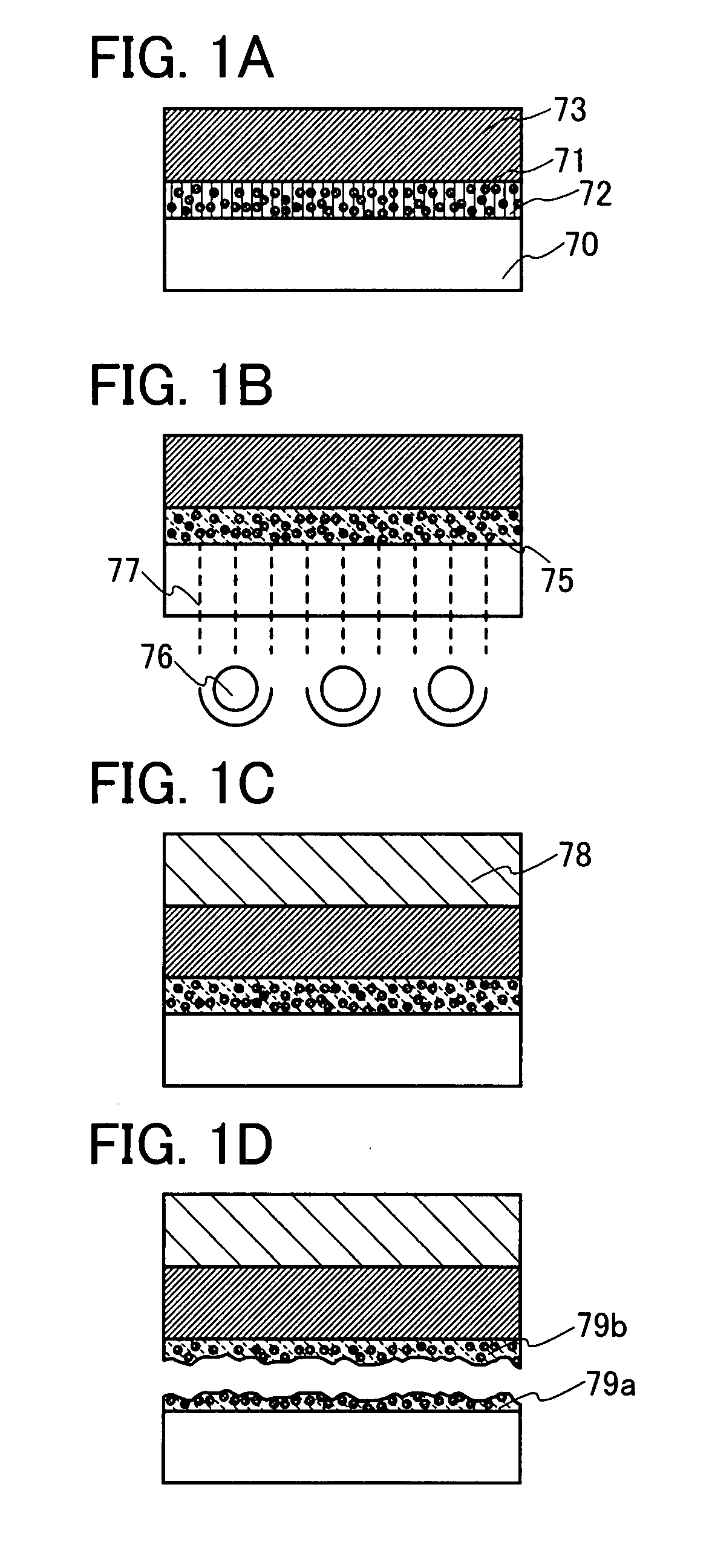

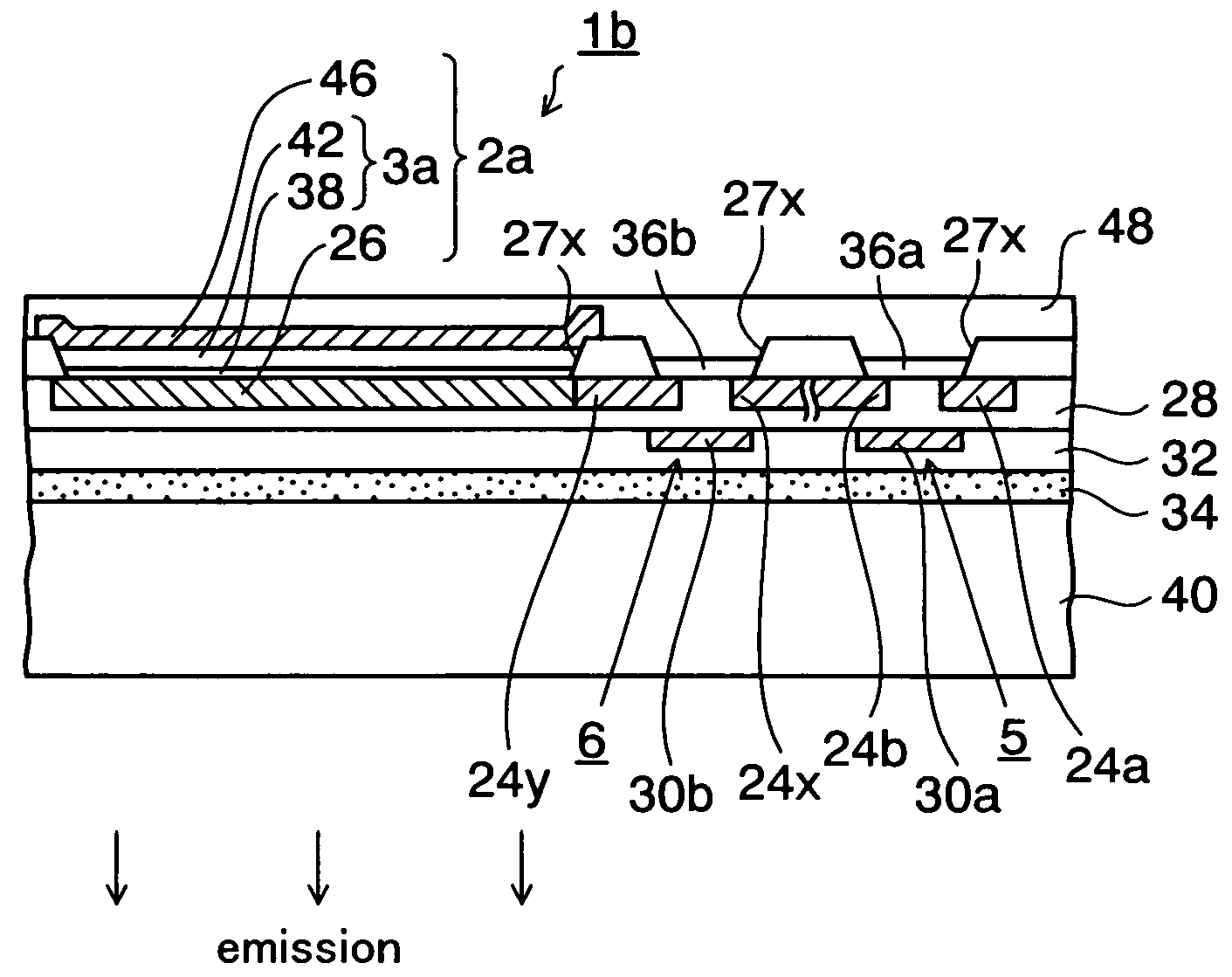

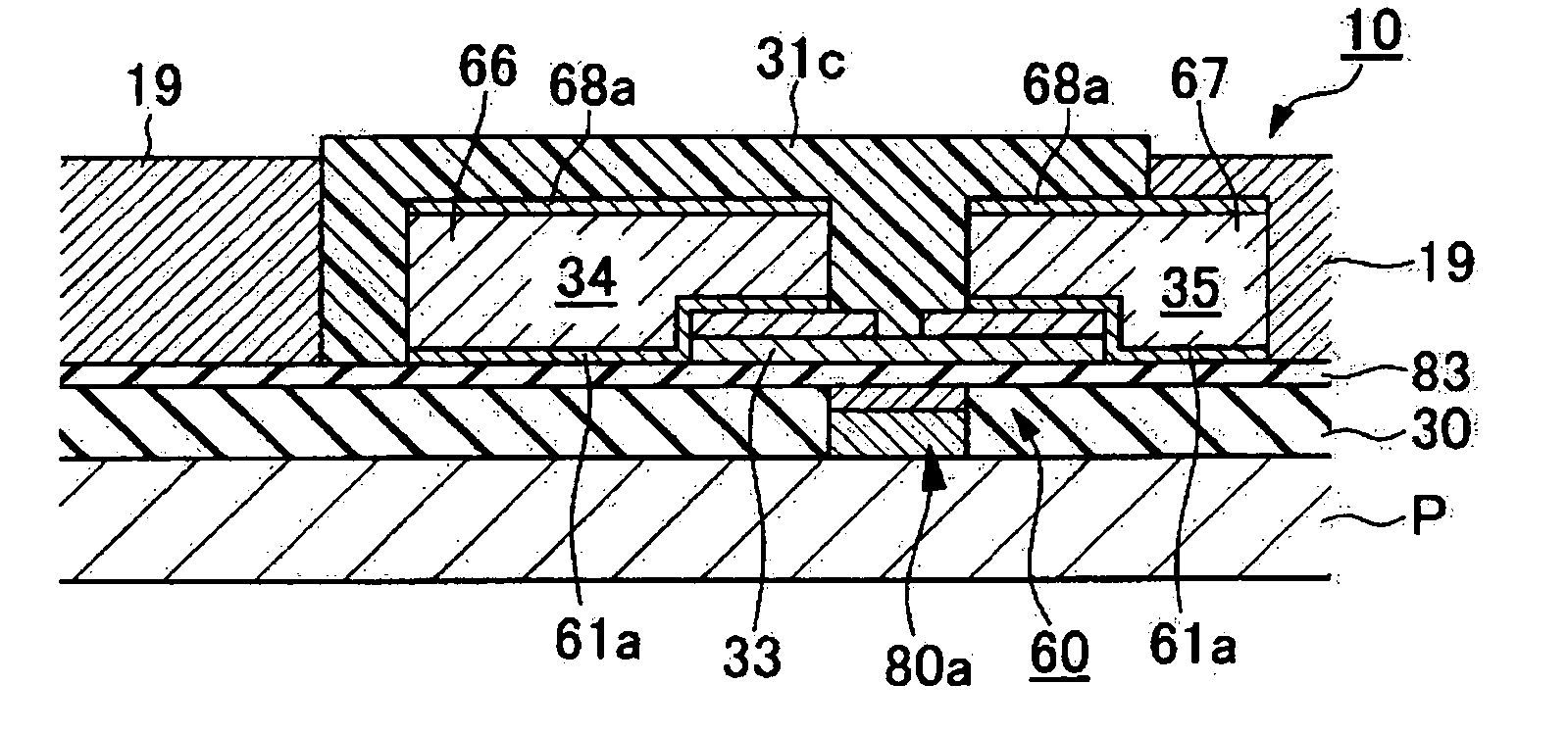

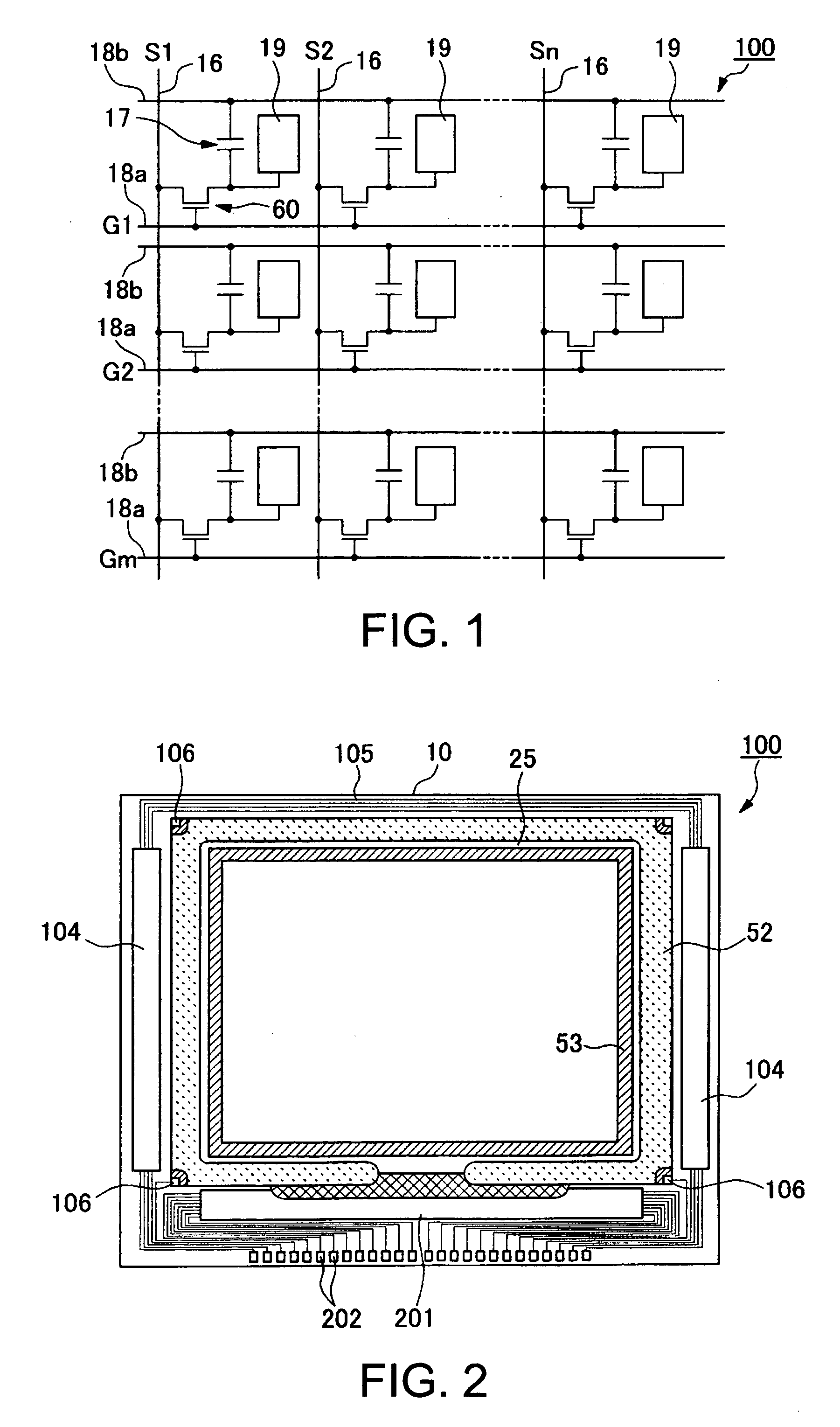

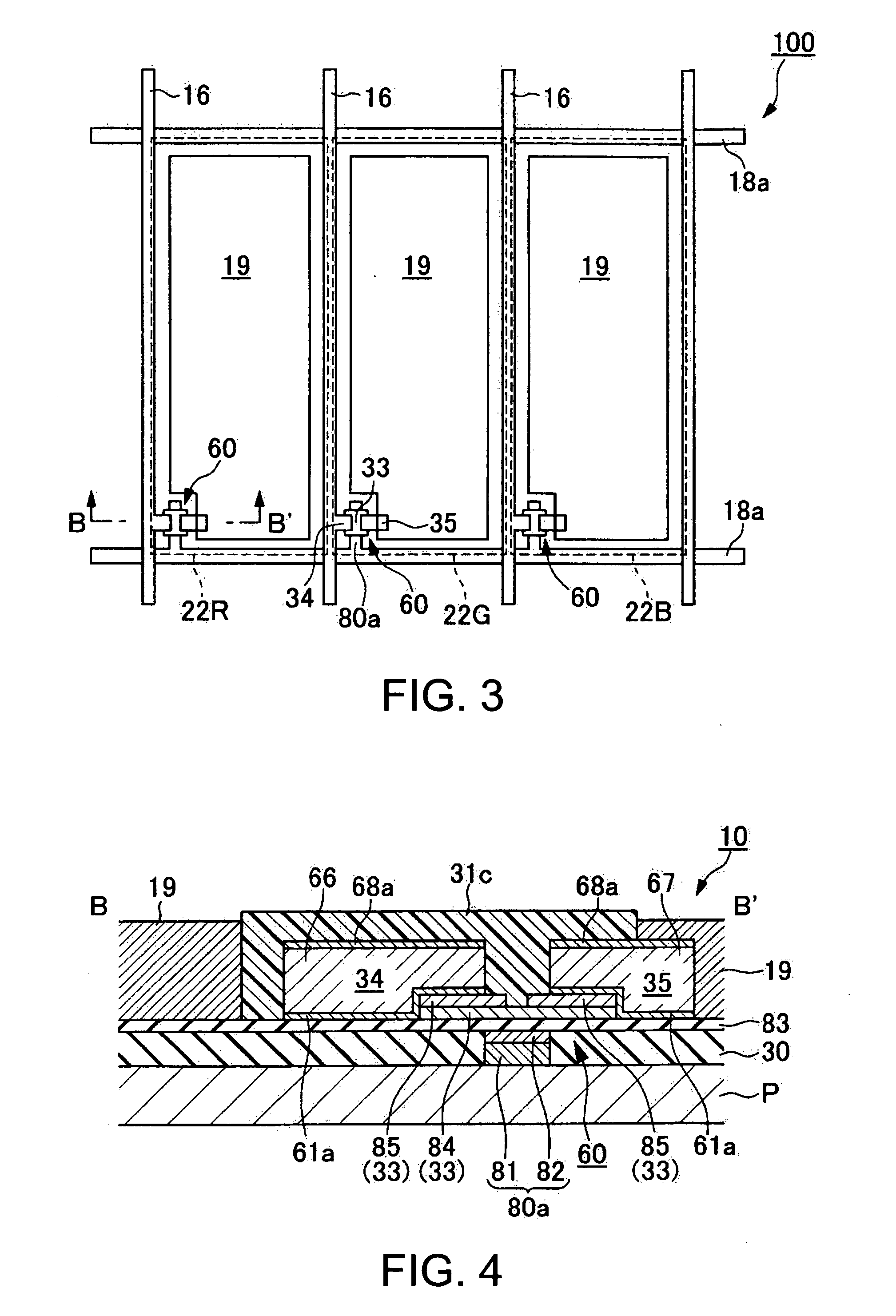

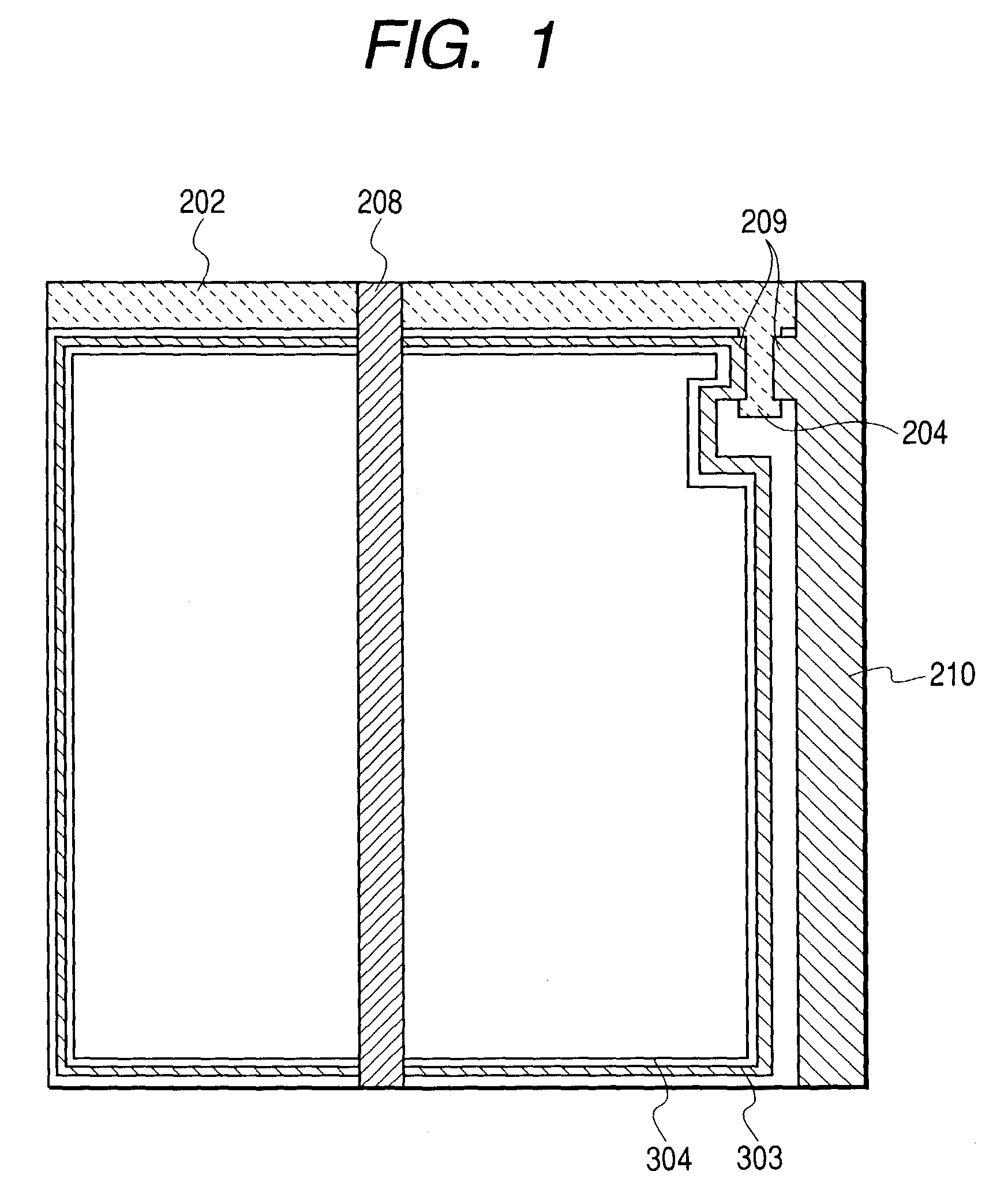

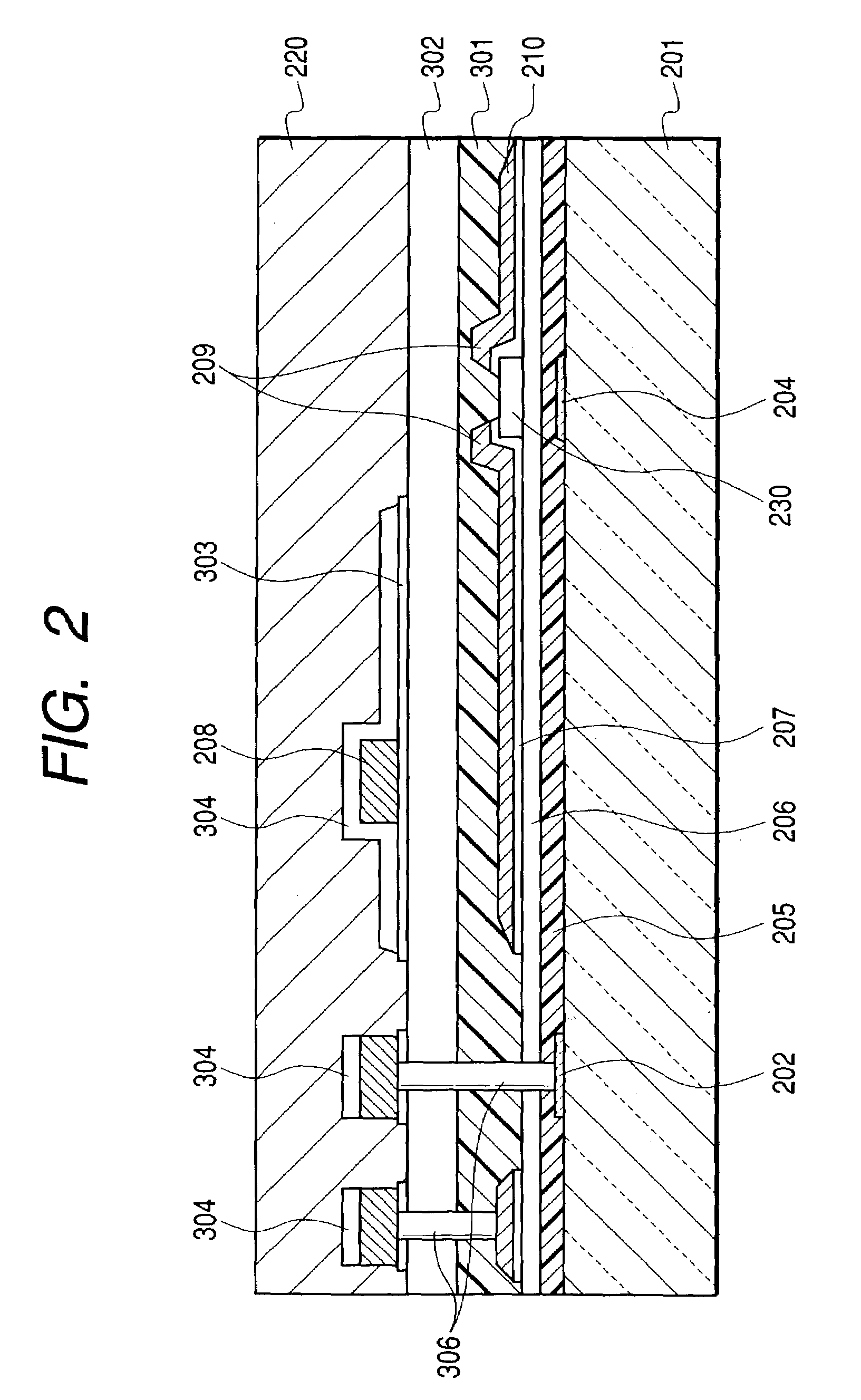

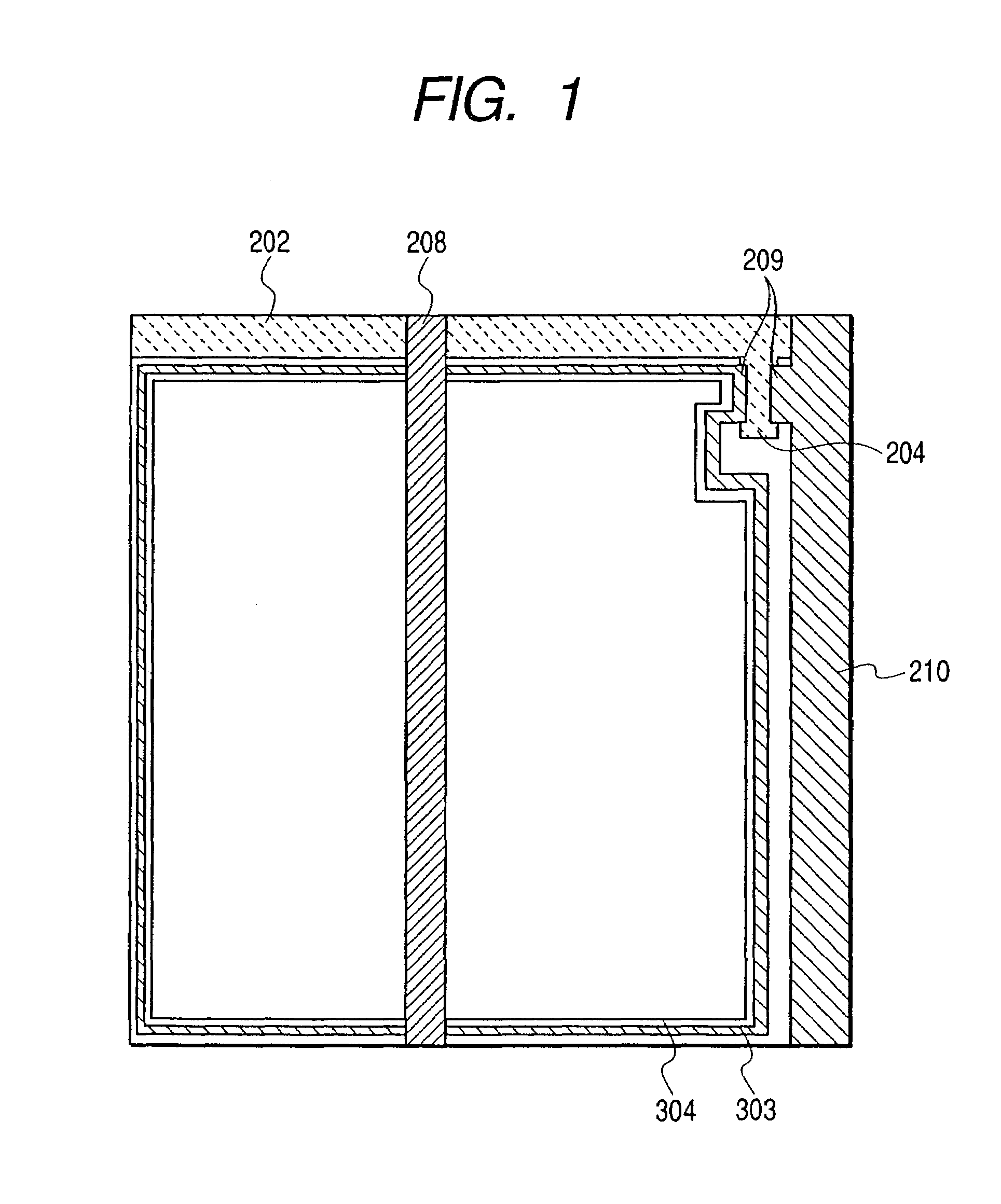

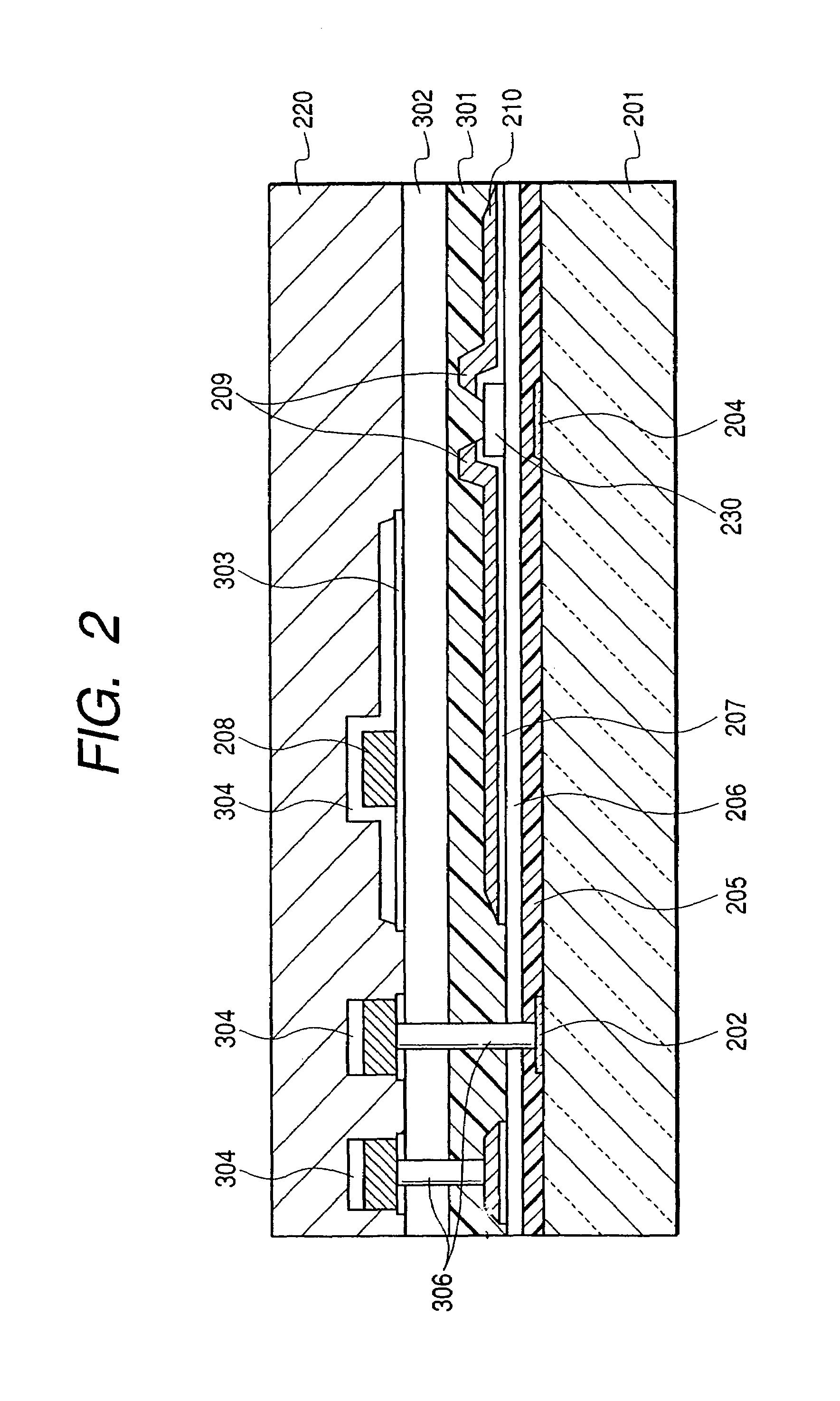

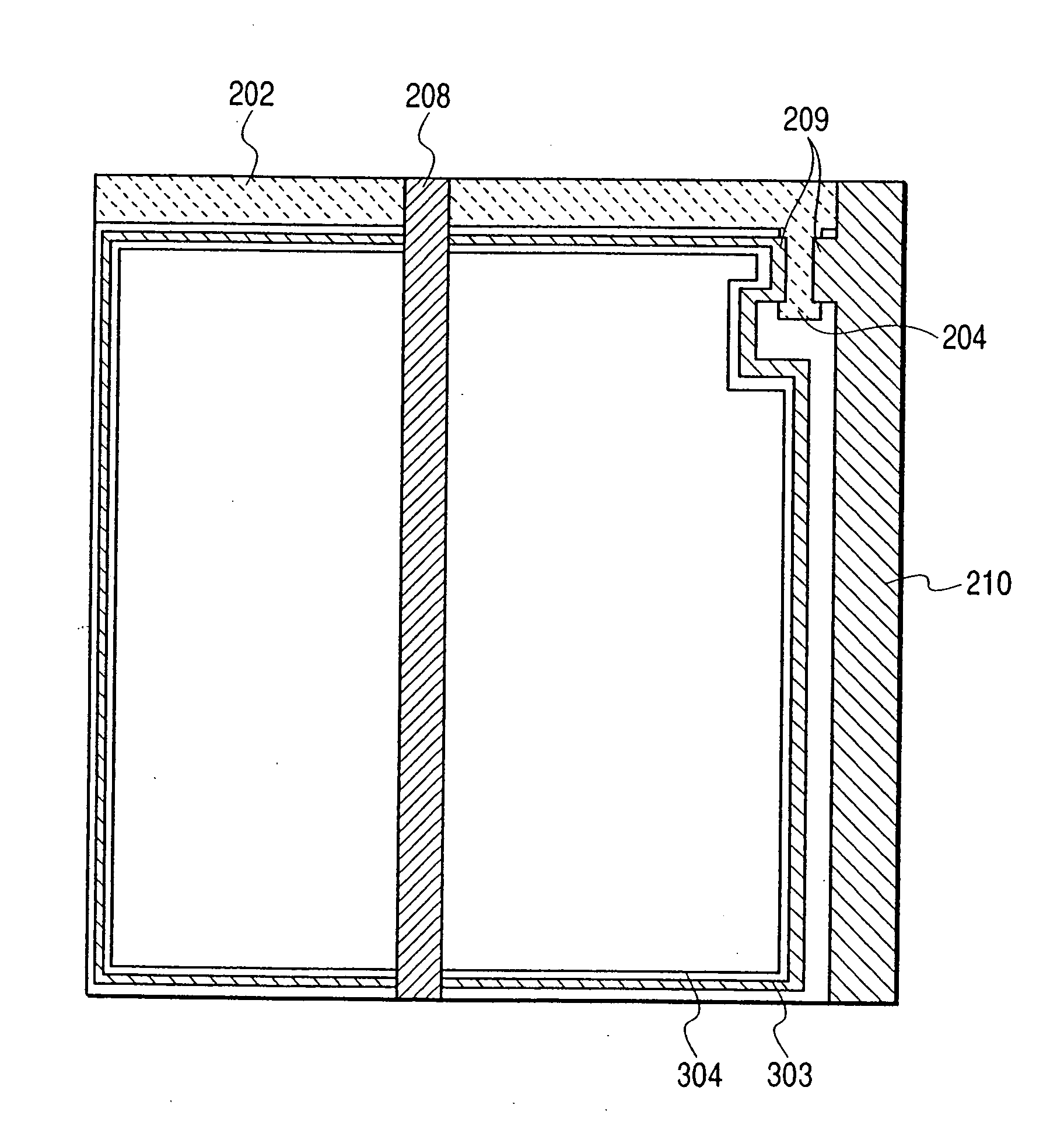

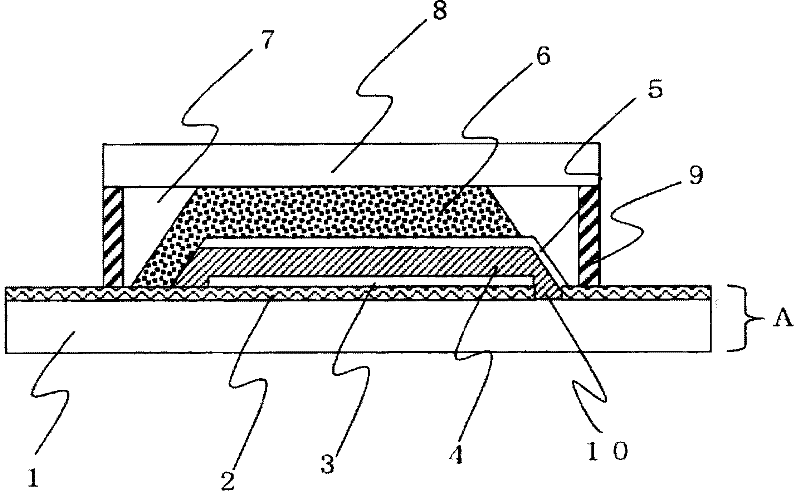

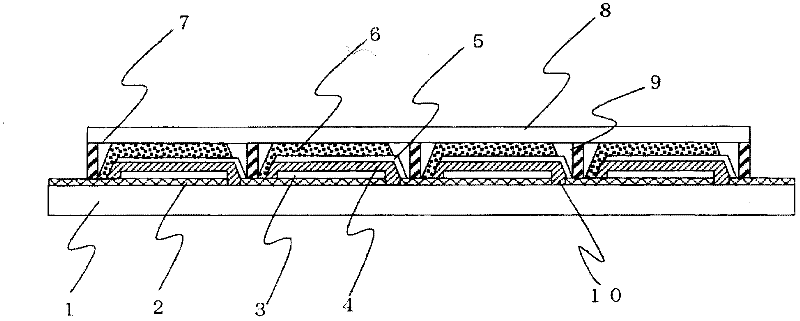

Flexible display and manufacturing method thereof

InactiveUS7825582B2High yieldHigh yield preparationTransistorDischarge tube luminescnet screensActive matrixDisplay device

A flexible display of the present invention is an active matrix flexible display in which a TFT is provided for each pixel. In the flexible display, an adhesive layer, a protective layer, a gate electrode for the TFT, which is buried in the protective layer, a gate insulating layer for the TFT, source and drain electrodes for the TFT, a pixel electrode electrically connected to the drain electrode, an organic active layer for the TFT, an organic EL layer including a red (R) emitting layer, a green (G) emitting layer and a blue (B) emitting layer, which are formed on a plurality of the pixel electrodes, a metal electrode, and a sealing layer are formed on a plastic film.

Owner:KYODO INSATU KK KYODO PRINTING CO LTD +1

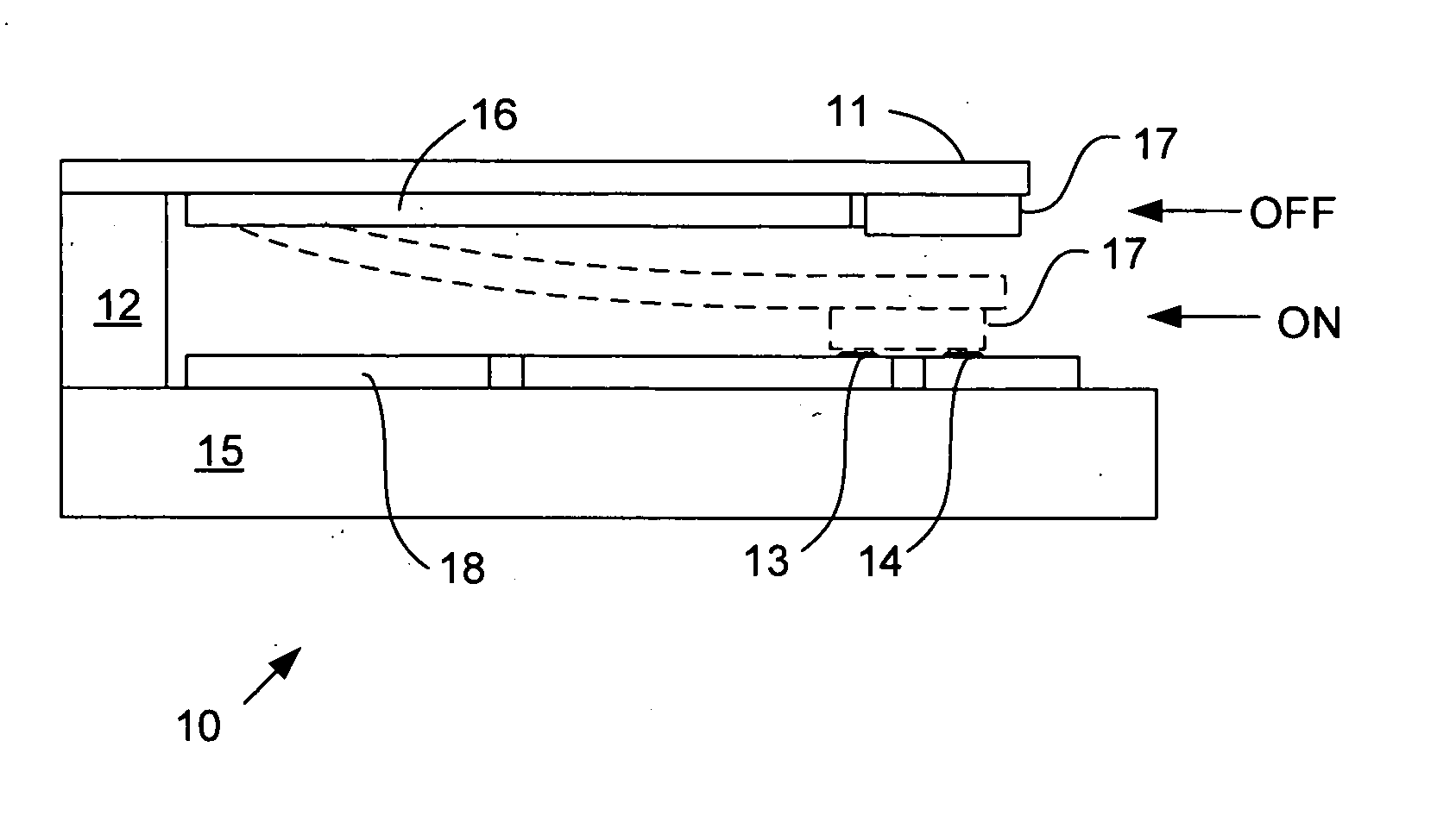

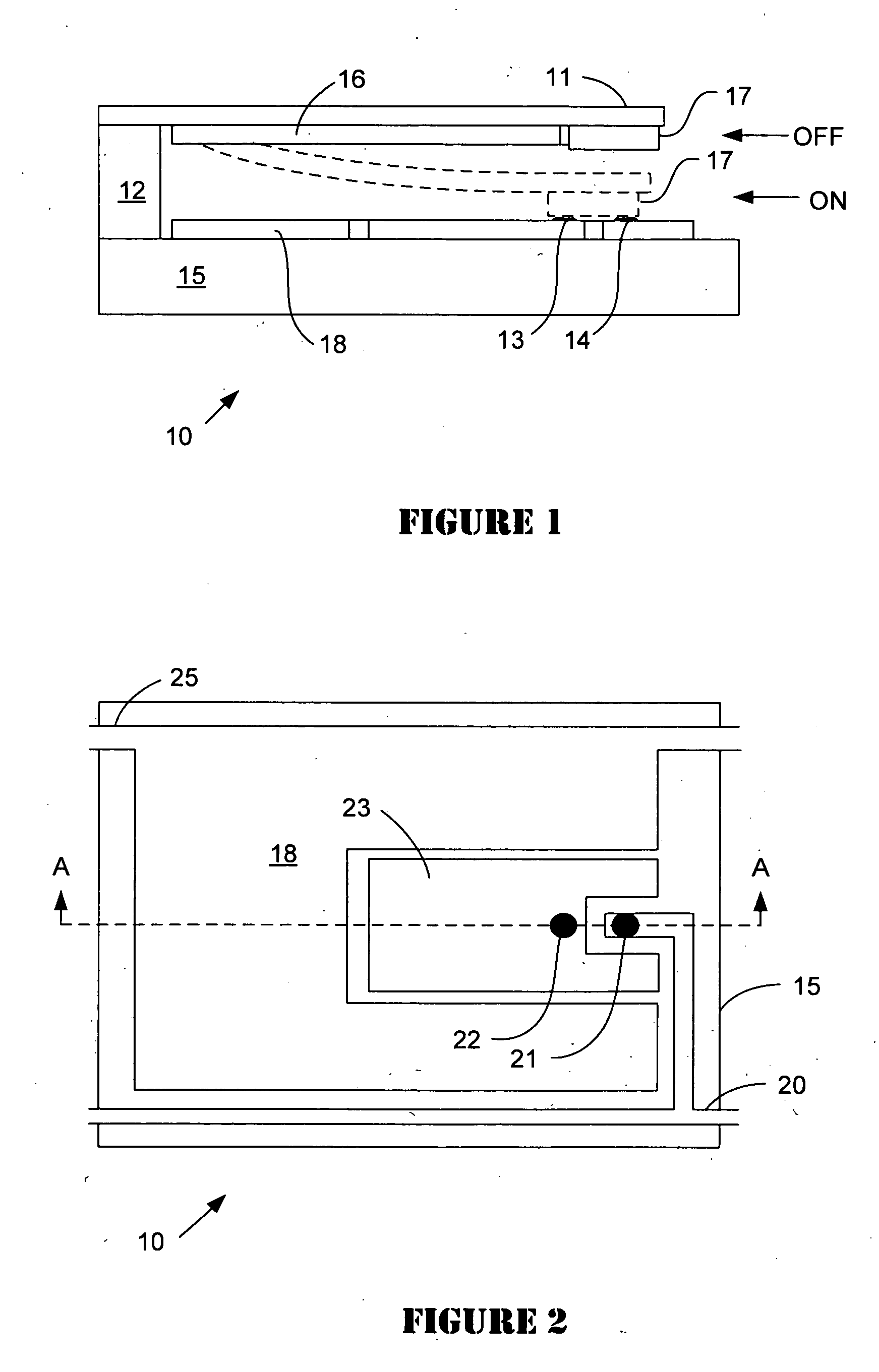

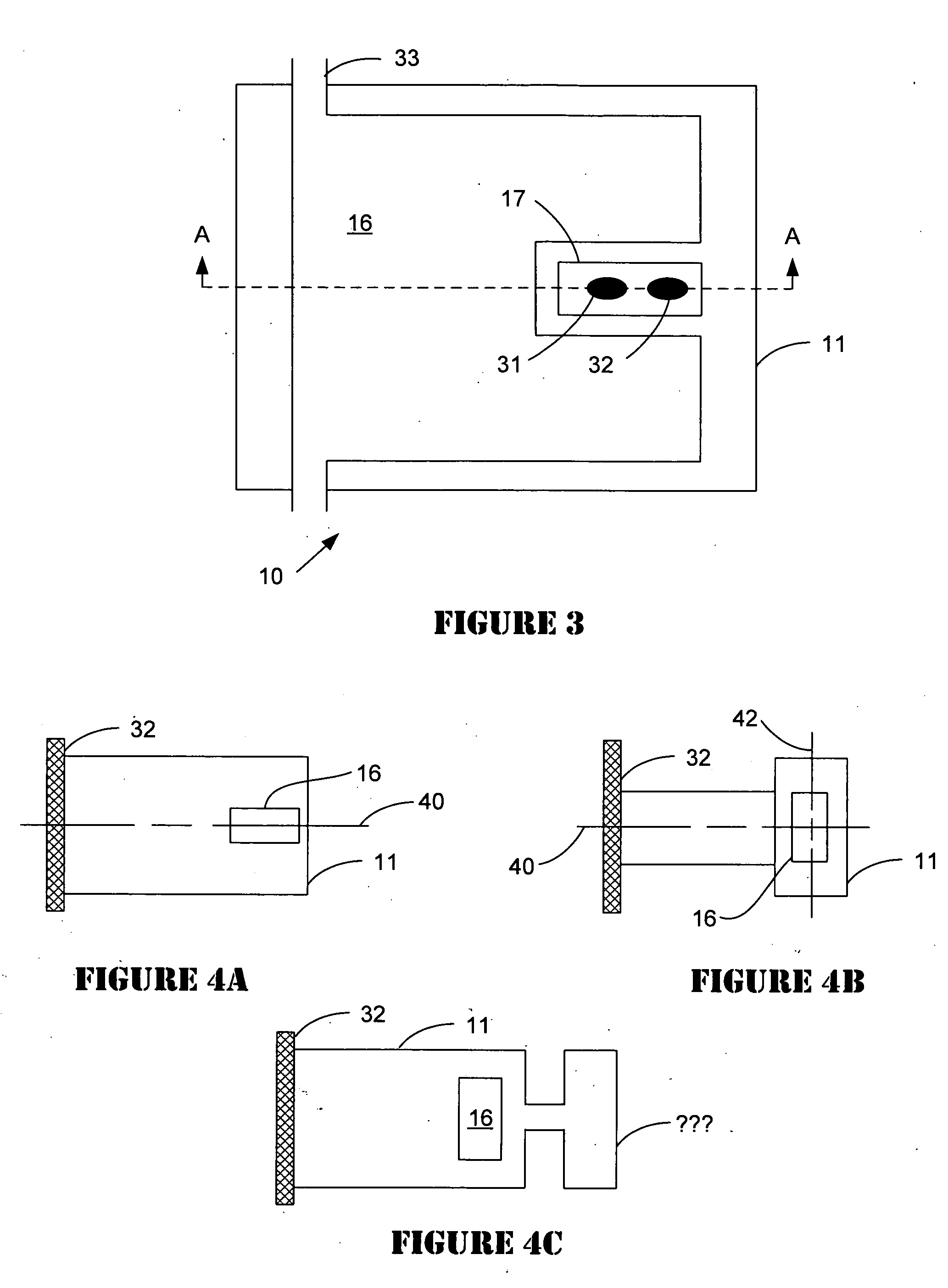

Cantilevered micro-electromechanical switch array

InactiveUS20050244099A1Low costLow-cost techniqueElectrostatic/electro-adhesion relaysCoupling light guidesDisplay deviceEngineering

A flexible micro-electromechanical switch having a cantilevered platform for forming an electrical circuit. A latching mechanism maintains the platform in a biased position after the biasing voltage is removed. The flexible micro-electromechanical switch can be formed into large area arrays and used as the backplane of display devices.

Owner:SEERTECH CORP

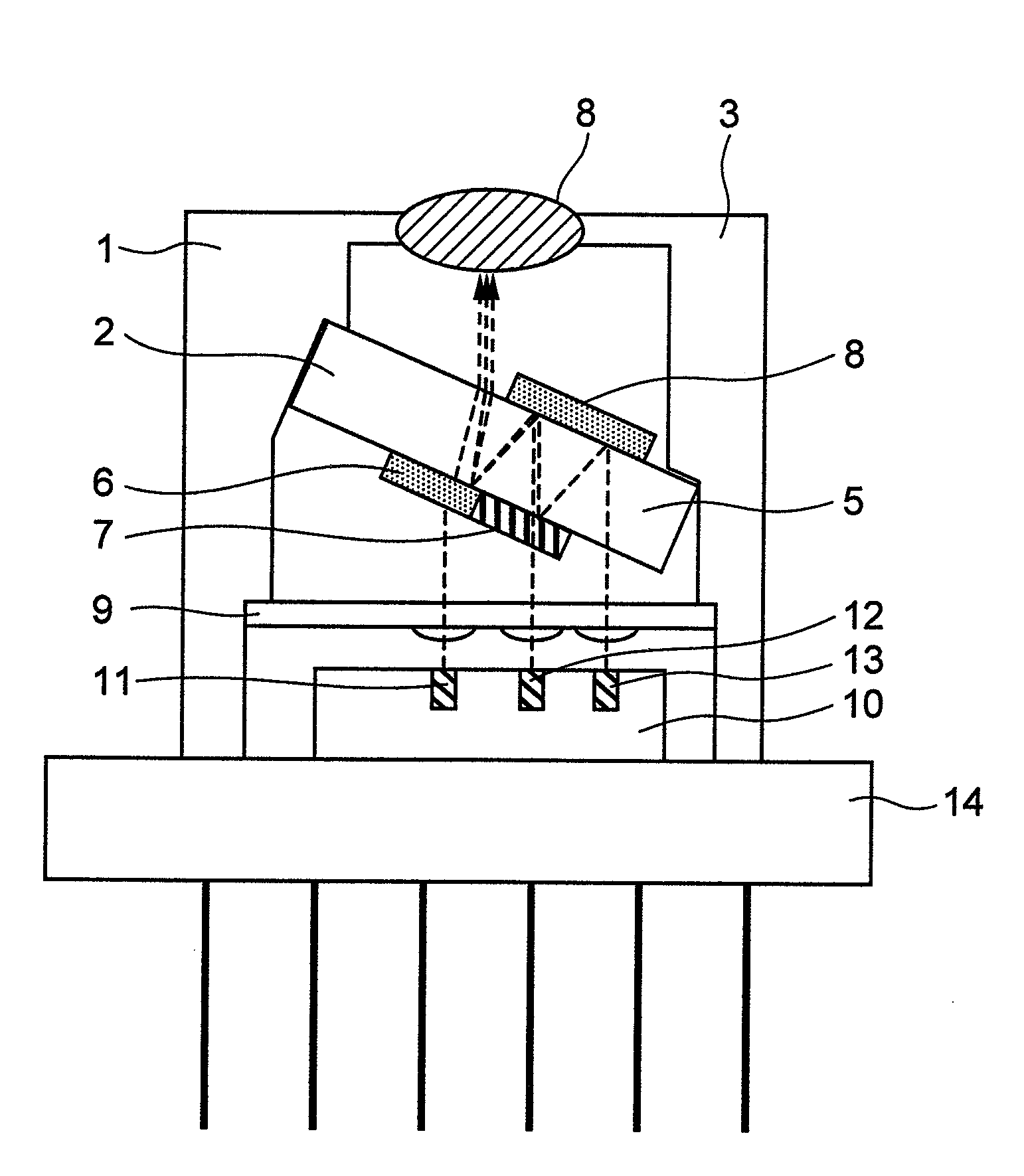

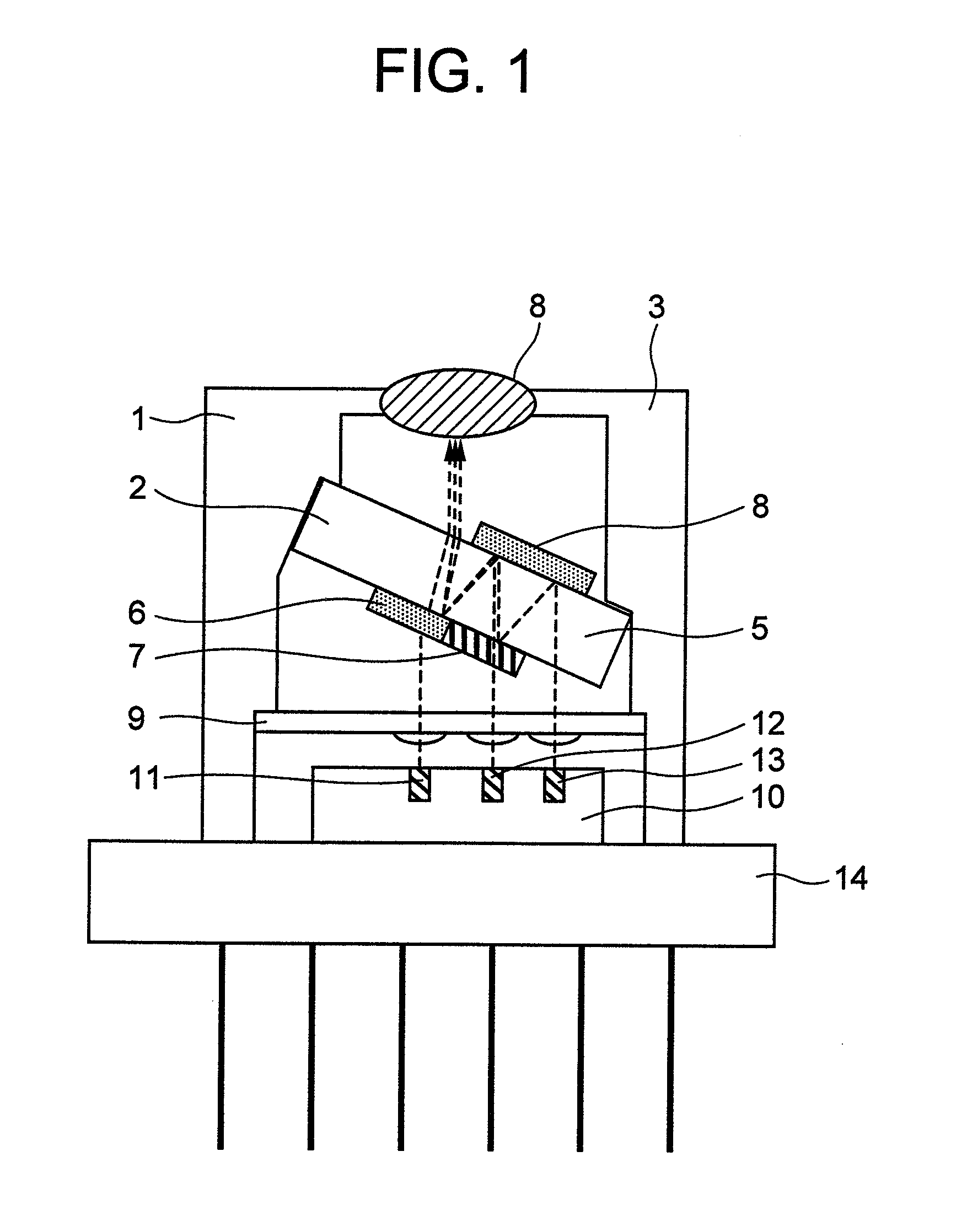

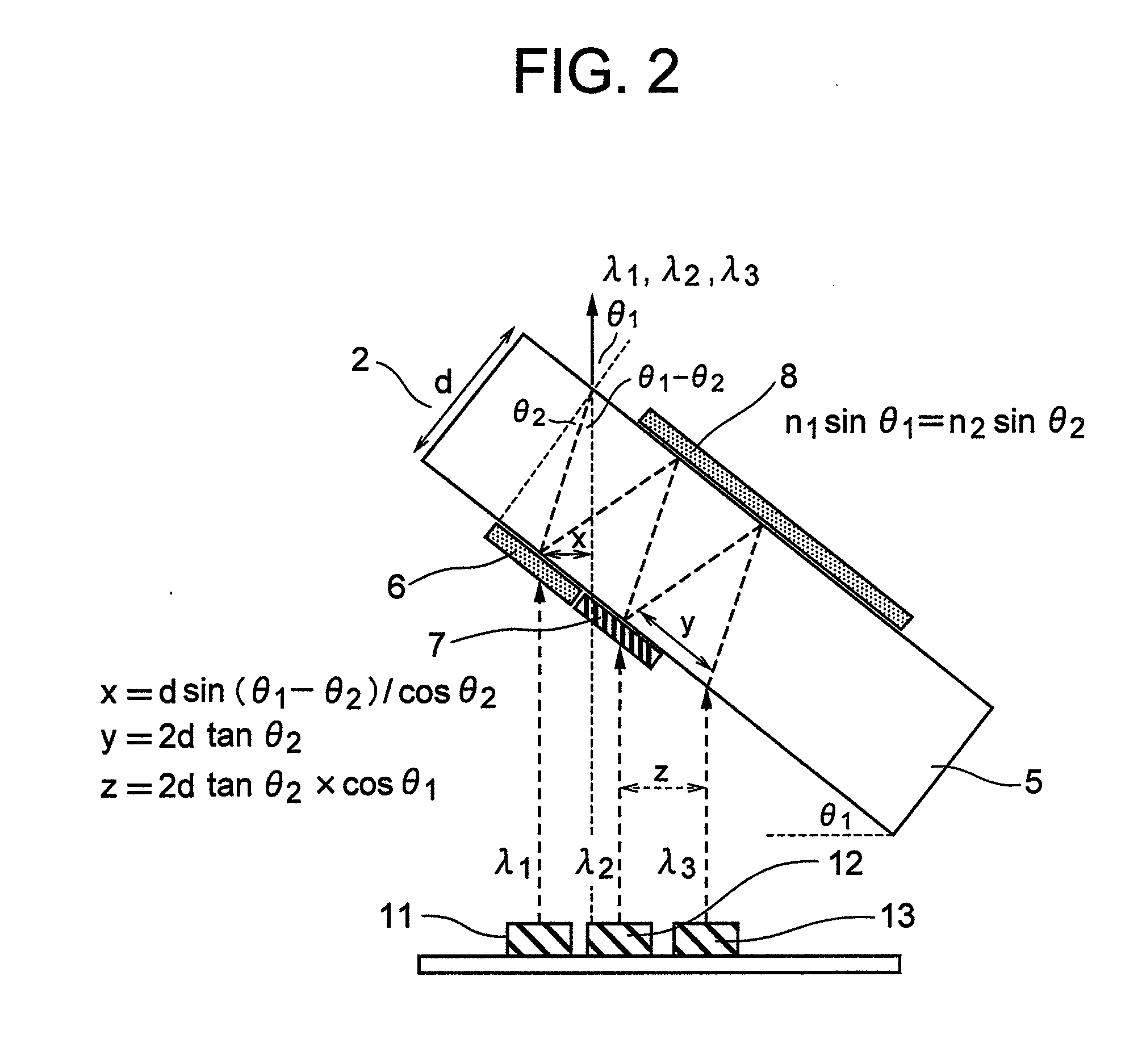

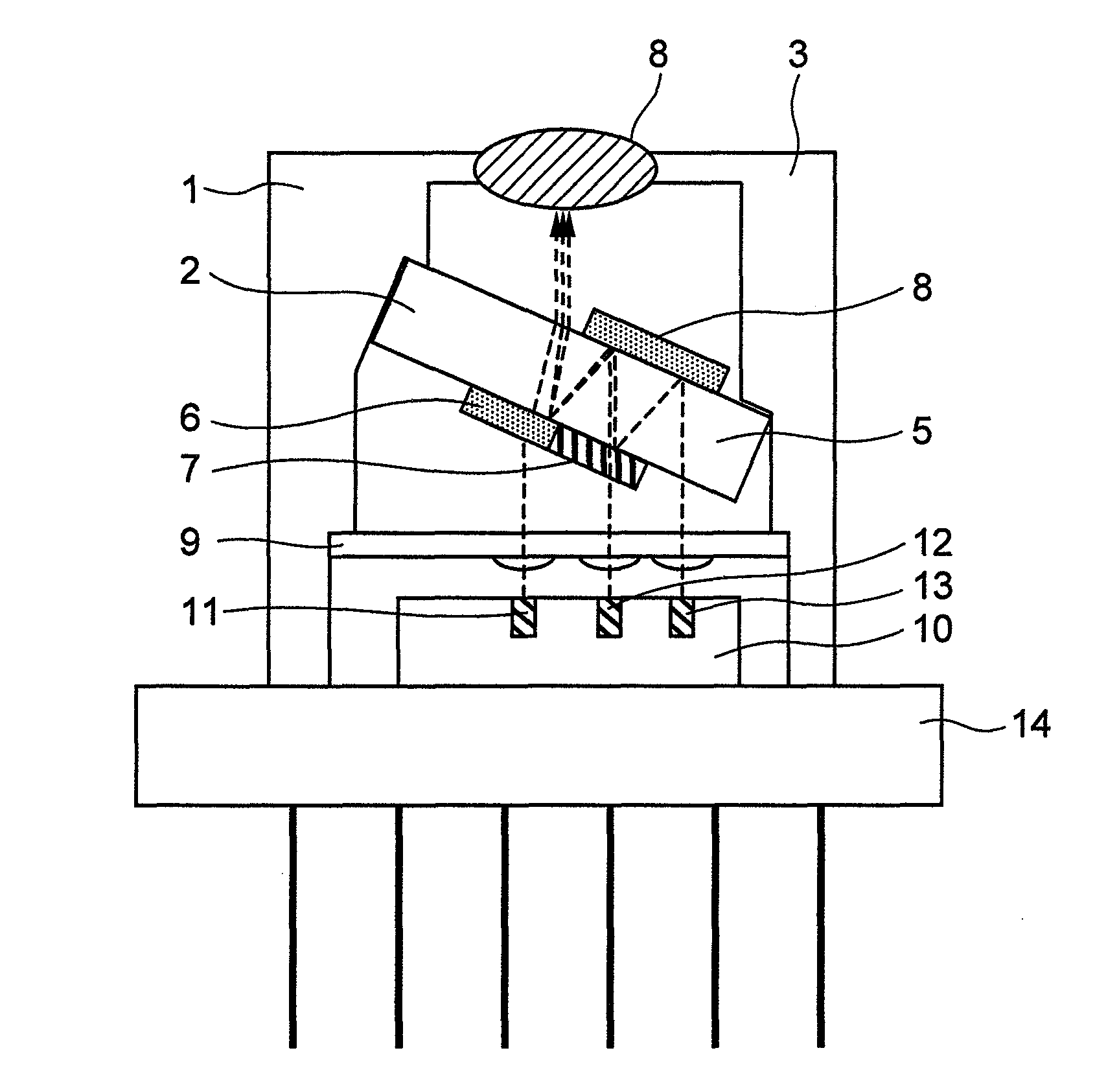

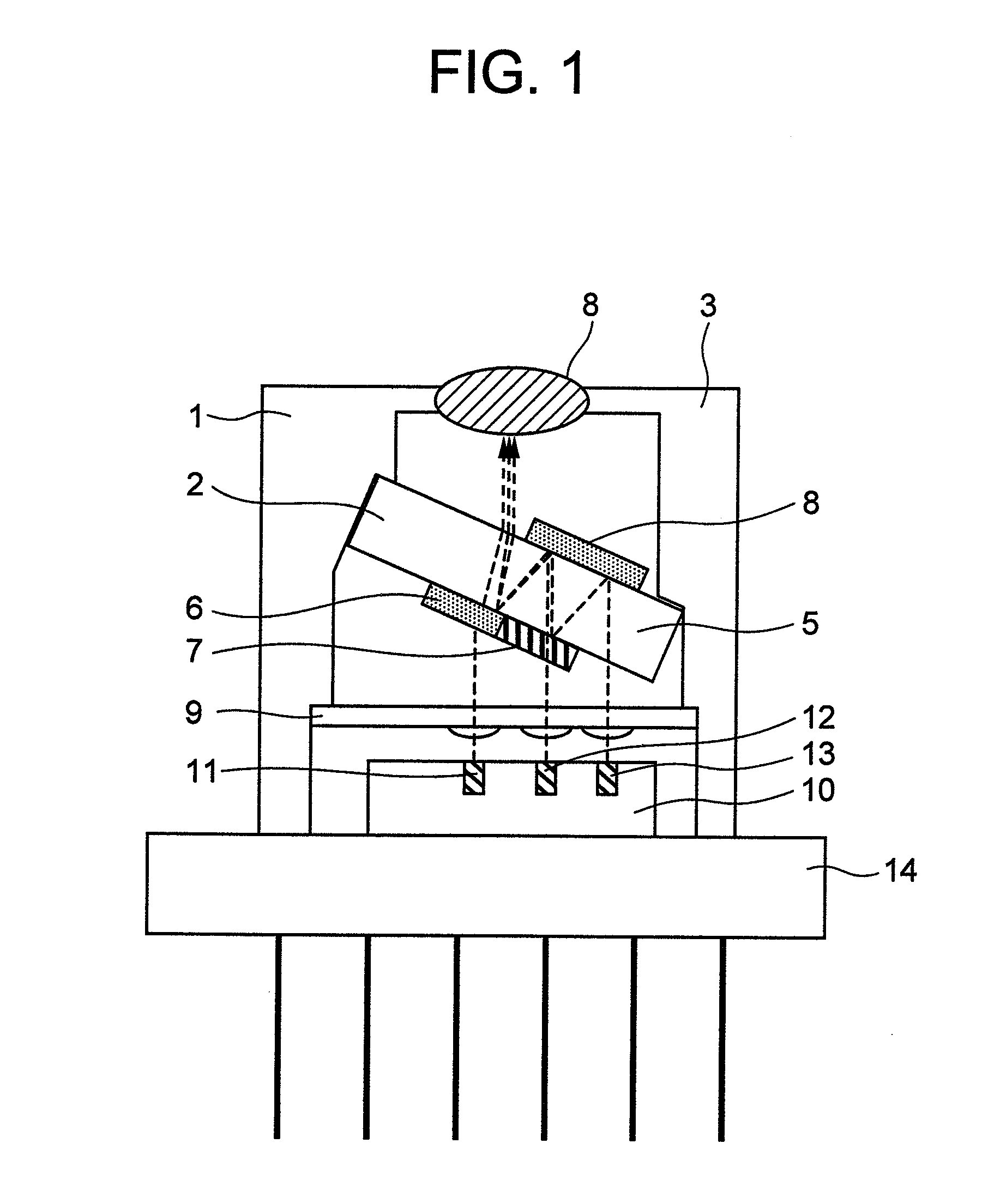

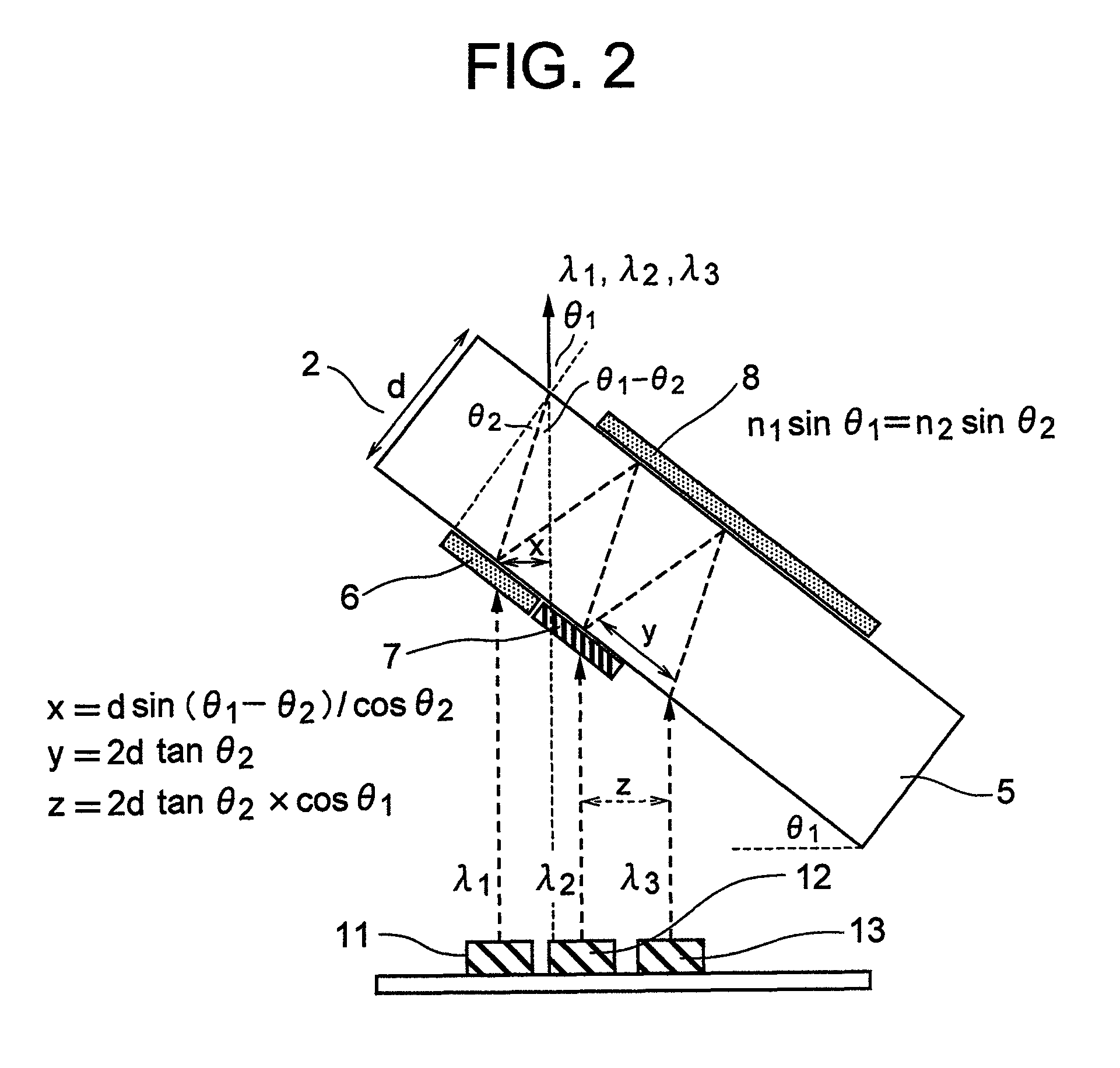

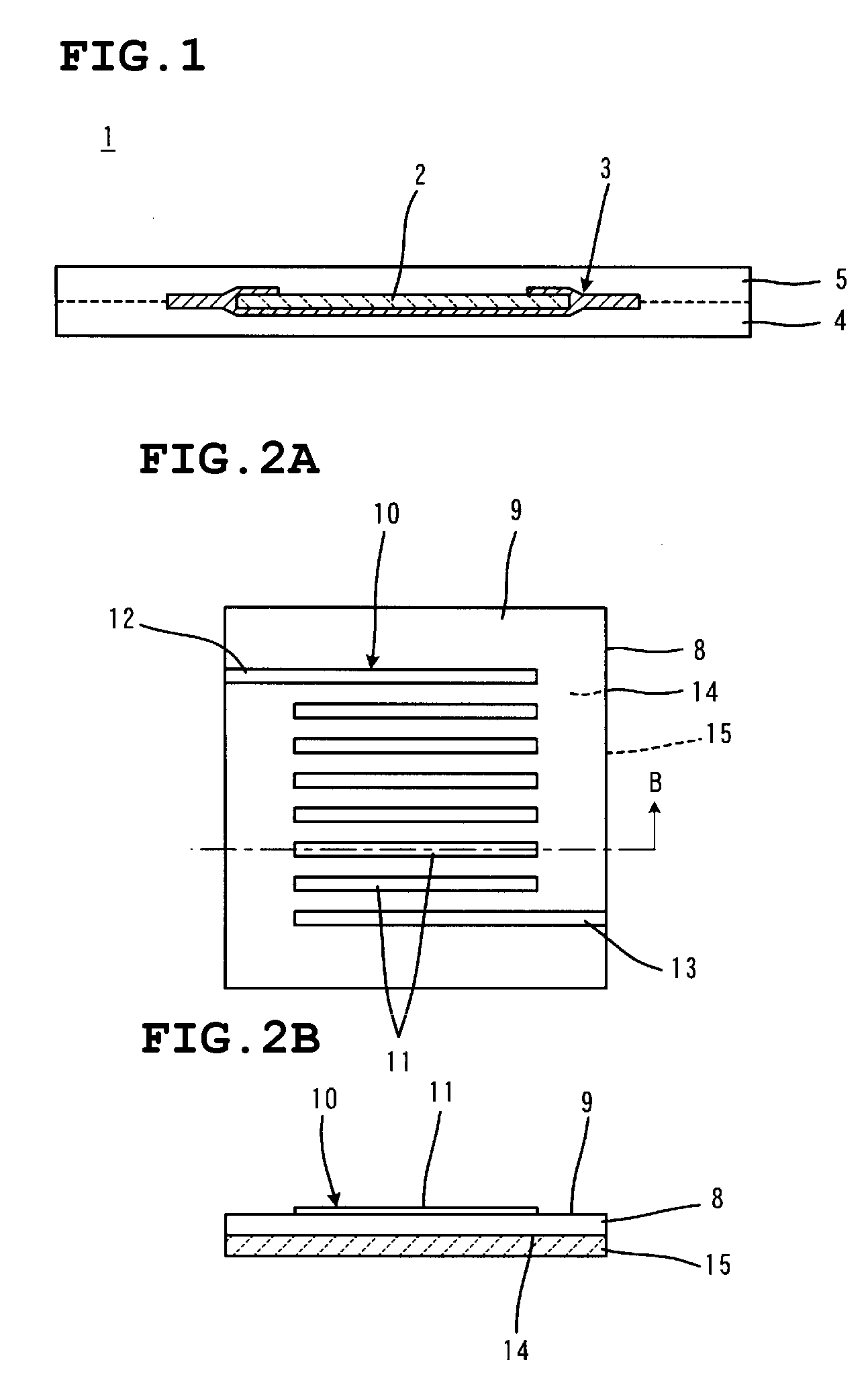

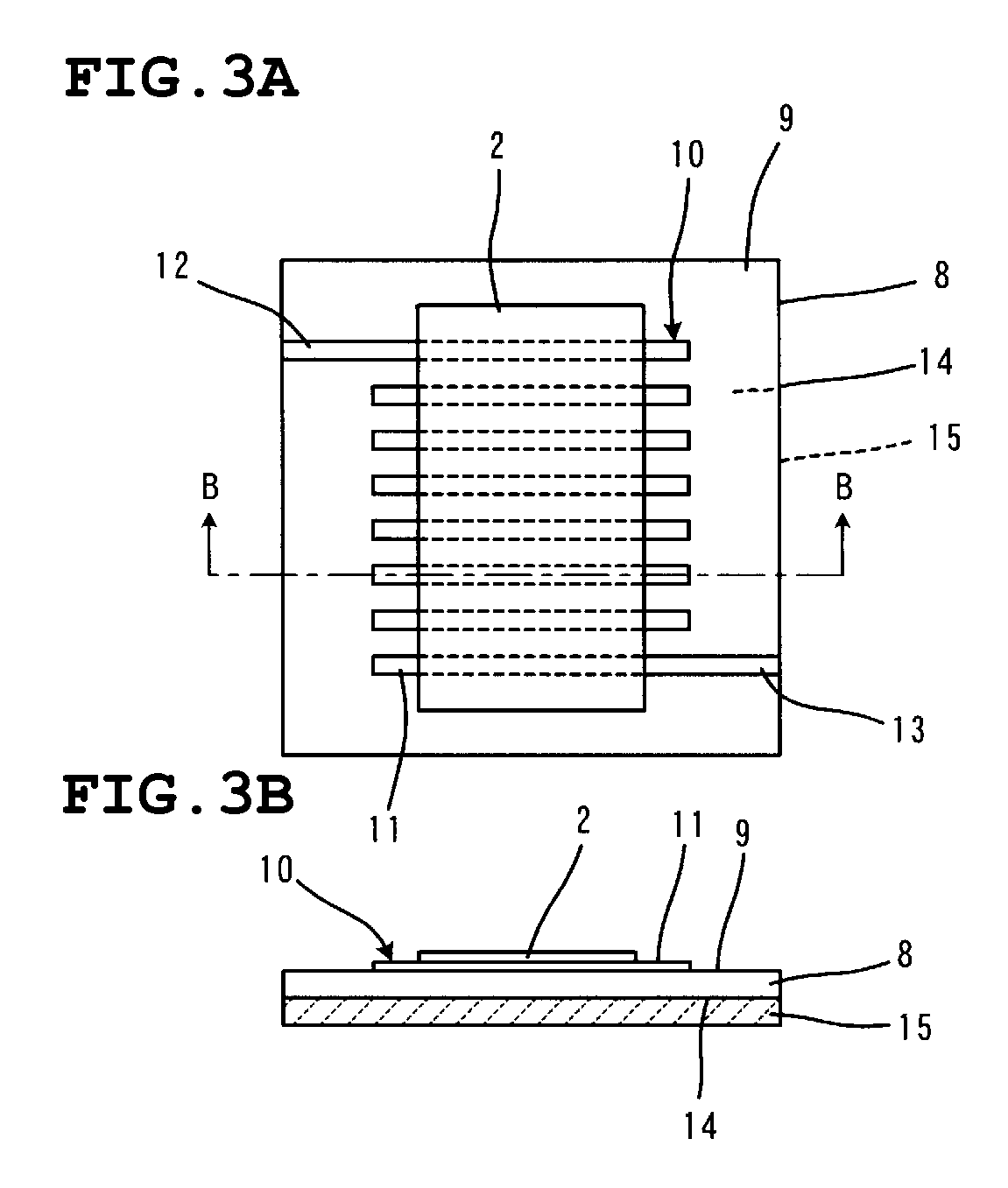

Optical Transmitter/Receiver Module

InactiveUS20090103923A1High yieldReduce in quantityWavelength-division multiplex systemsCoupling light guidesMultiplexingOptical axis

An optical element mounting substrate where a plurality of light emitting elements have been mounted on the same plane, a lens array for collimating a plurality of light emitted from the plurality of light emitting elements, and a wavelength multiplexing / demultiplexing device are prepared. The wavelength multiplexing / demultiplexing device has typically mounted both a wavelength selecting filter and a mirror on front and rear planes of a transparent substrate. These three components are mounted within a package at a desirable angle position. Optical axes of respective wavelengths of the wavelength multiplexing / demultiplexing device are determined based upon a thickness and an angle of the light emitting element mounting substrate, and are arrayed on a straight line of a horizontal plane. As a consequence, if the respective light emitting elements are arranged on the optical axes which are exclusively determined by a design work, then optical multiplexing / demultiplexing operations can be carried out.

Owner:HITACHI LTD

SINGLE CHAIN Fc (ScFc) REGIONS, BINDING POLYPEPTIDES COMPRISING SAME, AND METHODS RELATED THERETO

InactiveUS20110243966A1High expressionFine-tune such effector functionsFungiNervous disorderDiseaseMoiety

The present invention features inter alia polypeptides comprising an Fc region comprising genetically-fused Fc moieties. In addition, the instant invention provides, e.g., methods for treating or preventing a disease or disorder in subject by administering the binding polypeptides of the invention to said subject.

Owner:BIOGEN MA INC

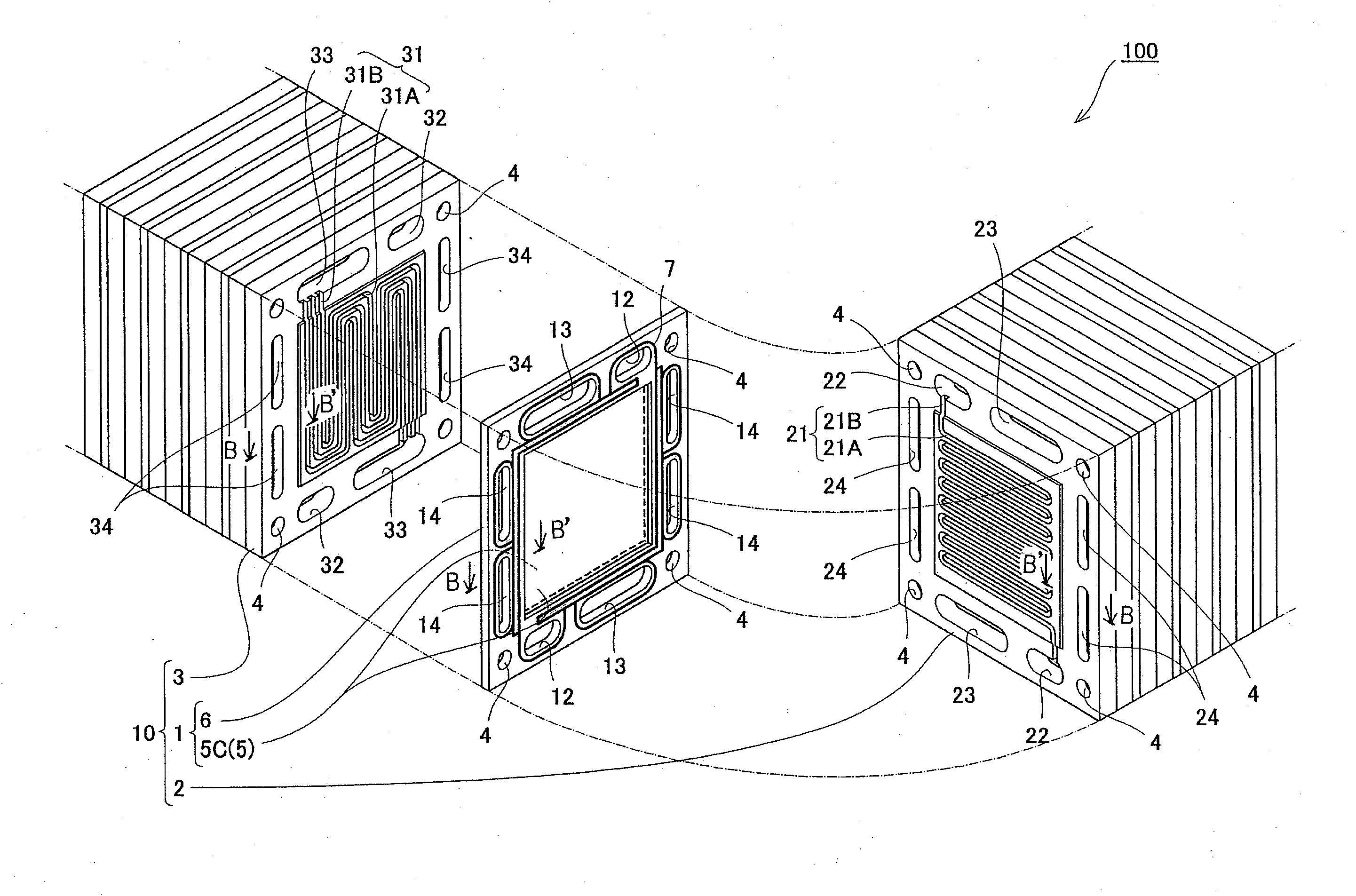

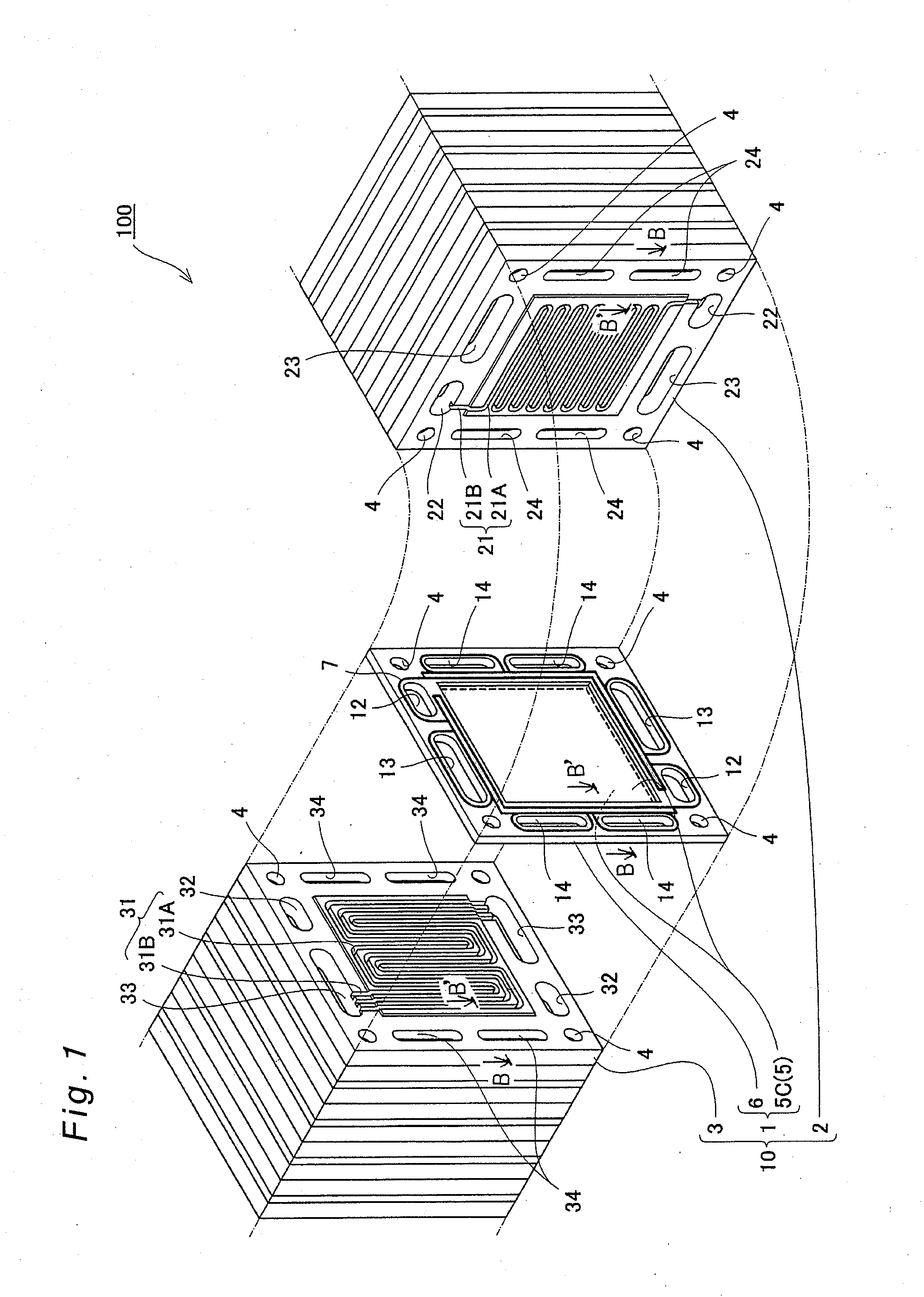

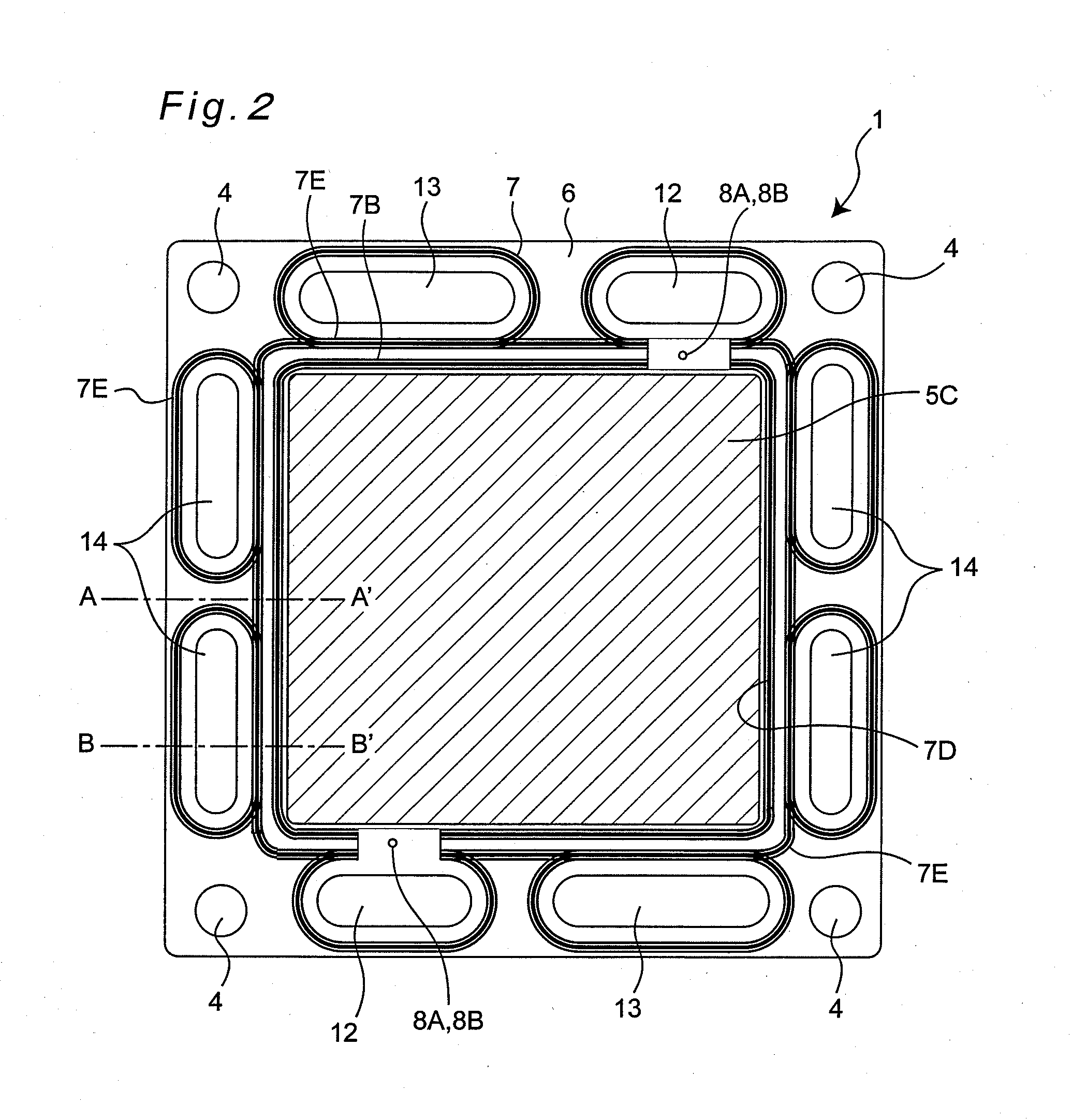

Electrode-membrane-frame assembly for fuel cell, polyelectrolyte fuel cell and manufacturing method therefor

ActiveUS20080305384A1Facilitated releaseYield in manufacturing can be improvedFinal product manufacturePrimary cellsPolyelectrolyteFuel cells

An electrode-membrane-frame assembly for a polyelectrolyte fuel cell which is held between one pair of separators and constitutes an electric cell module in the fuel cell is constituted of a membrane electrode assembly, a first frame body which has a separator-side surface on which a sealing member for sealing between the member and one separator and a membrane-side surface located on one surface of the peripheral edge portion of the membrane electrode assembly and is formed of a thermoplastic resin material, and a second frame body that has a separator-side surface on which a sealing member for sealing between the member and the other separator and a membrane-side surface located on the other surface of the peripheral edge portion of the membrane electrode assembly and is formed of a thermoplastic resin material and fitted to the first frame body holding the peripheral edge portion of the membrane electrode assembly between the second frame body and the first frame body.

Owner:PANASONIC CORP

Method for manufacturing semiconductor device

ActiveUS8222116B2Highly reliable semiconductor devicesHigh yieldFinal product manufactureSolid-state devicesSimple Organic CompoundsPower semiconductor device

The present invention provides a manufacturing technique of a semiconductor device and a display device using a peeling process, in which a transfer process can be conducted with a good state in which a shape and property of an element before peeling are kept. Further, the present invention provides a manufacturing technique of more highly reliable semiconductor devices and display devices with high yield without complicating the apparatus and the process for manufacturing. According to the present invention, an organic compound layer including a photocatalyst substance is formed over a first substrate having a light-transmitting property, an element layer is formed over the organic compound layer including a photocatalyst substance, the organic compound layer including a photocatalyst substance is irradiated with light which has passed through the first substrate, and the element layer is peeled from the first substrate.

Owner:SEMICON ENERGY LAB CO LTD

Optical transmitter/receiver module

InactiveUS8036533B2Increase the number ofLow costWavelength-division multiplex systemsCoupling light guidesMultiplexingOptical axis

An optical element mounting substrate where a plurality of light emitting elements have been mounted on the same plane, a lens array for collimating a plurality of light emitted from the plurality of light emitting elements, and a wavelength multiplexing / demultiplexing device are prepared. The wavelength multiplexing / demultiplexing device has typically mounted both a wavelength selecting filter and a mirror on front and rear planes of a transparent substrate. These three components are mounted within a package at a desirable angle position. Optical axes of respective wavelengths of the wavelength multiplexing / demultiplexing device are determined based upon a thickness and an angle of the light emitting element mounting substrate, and are arrayed on a straight line of a horizontal plane. As a consequence, if the respective light emitting elements are arranged on the optical axes which are exclusively determined by a design work, then optical multiplexing / demultiplexing operations can be carried out.

Owner:HITACHI LTD

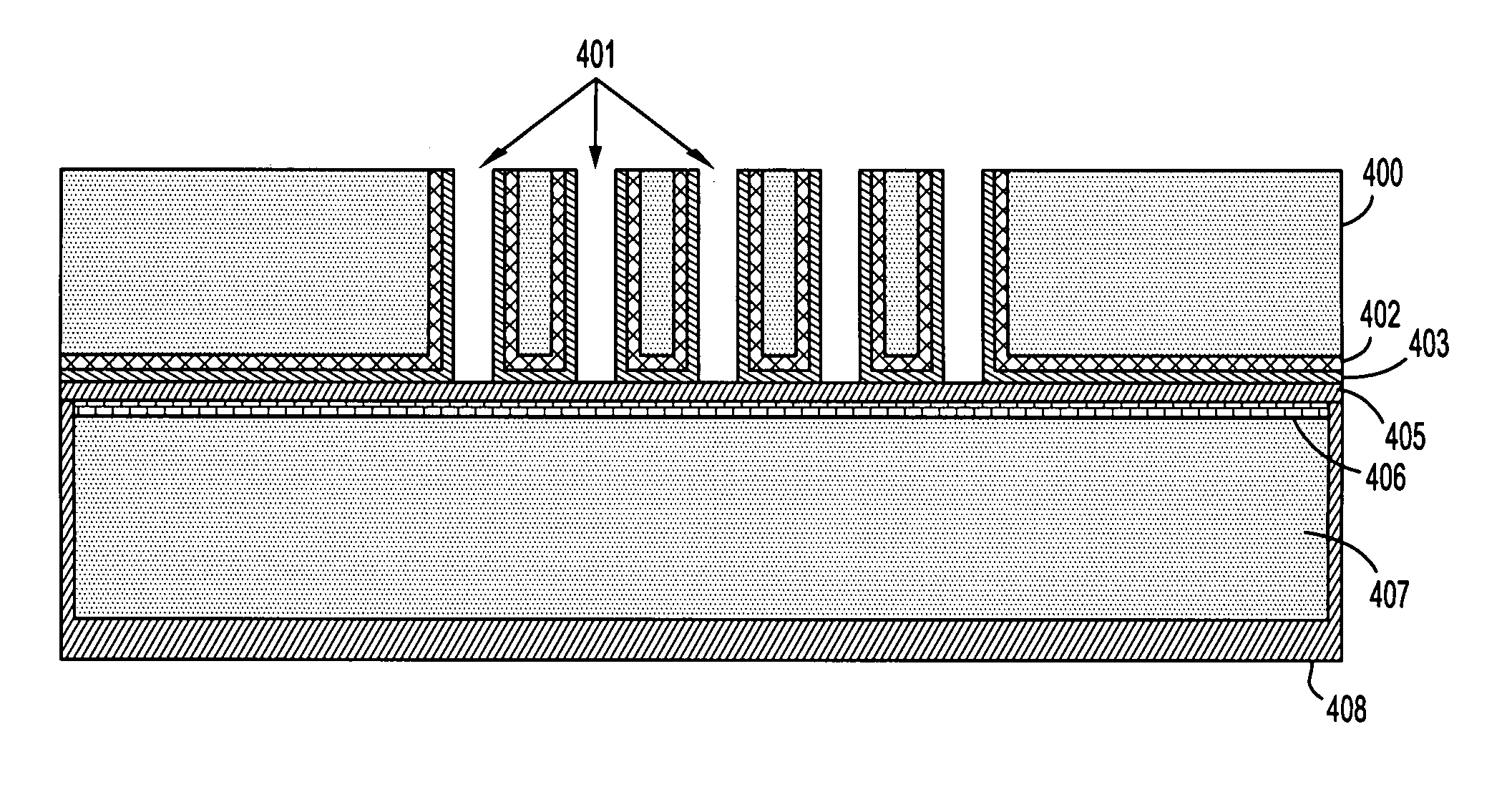

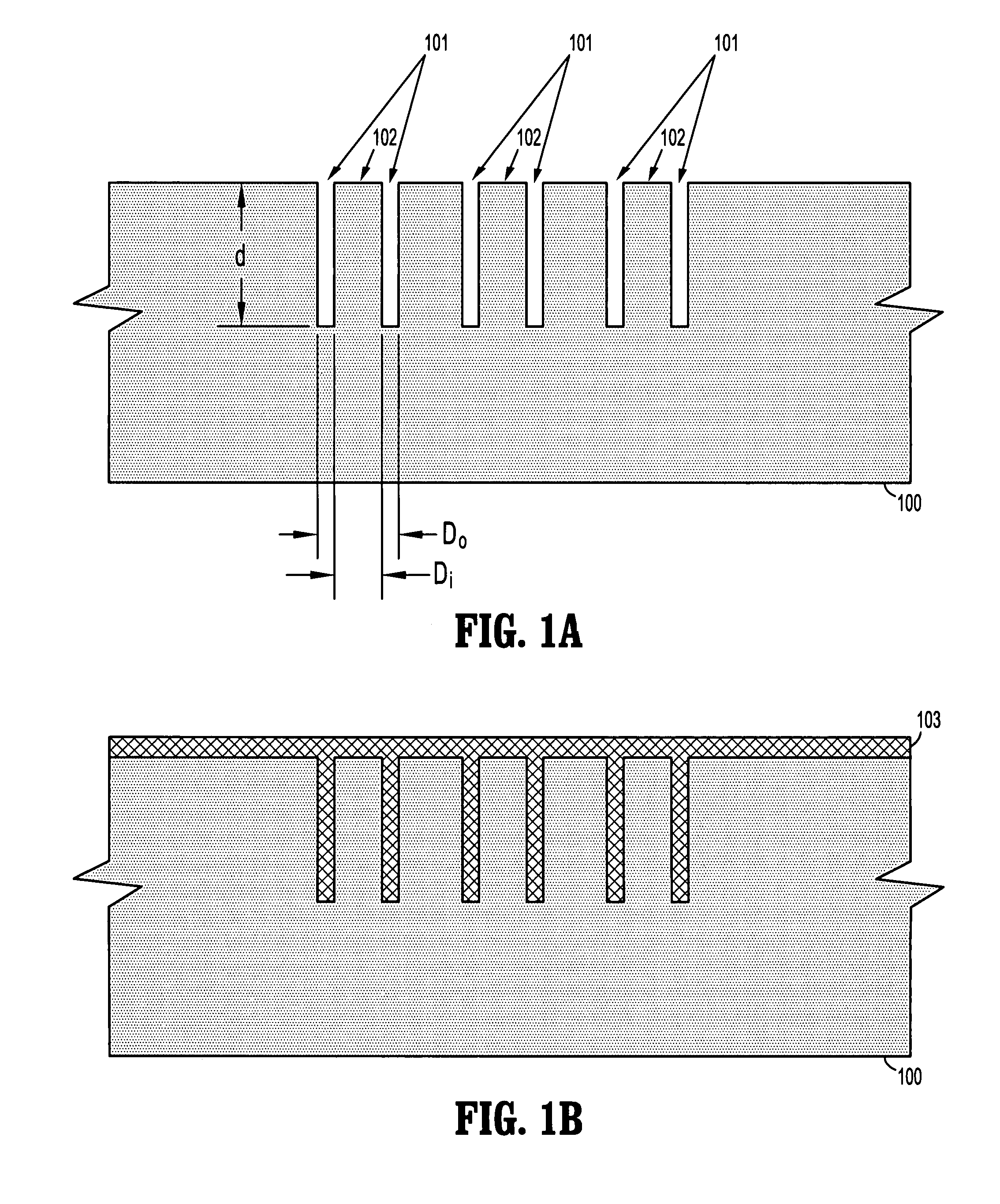

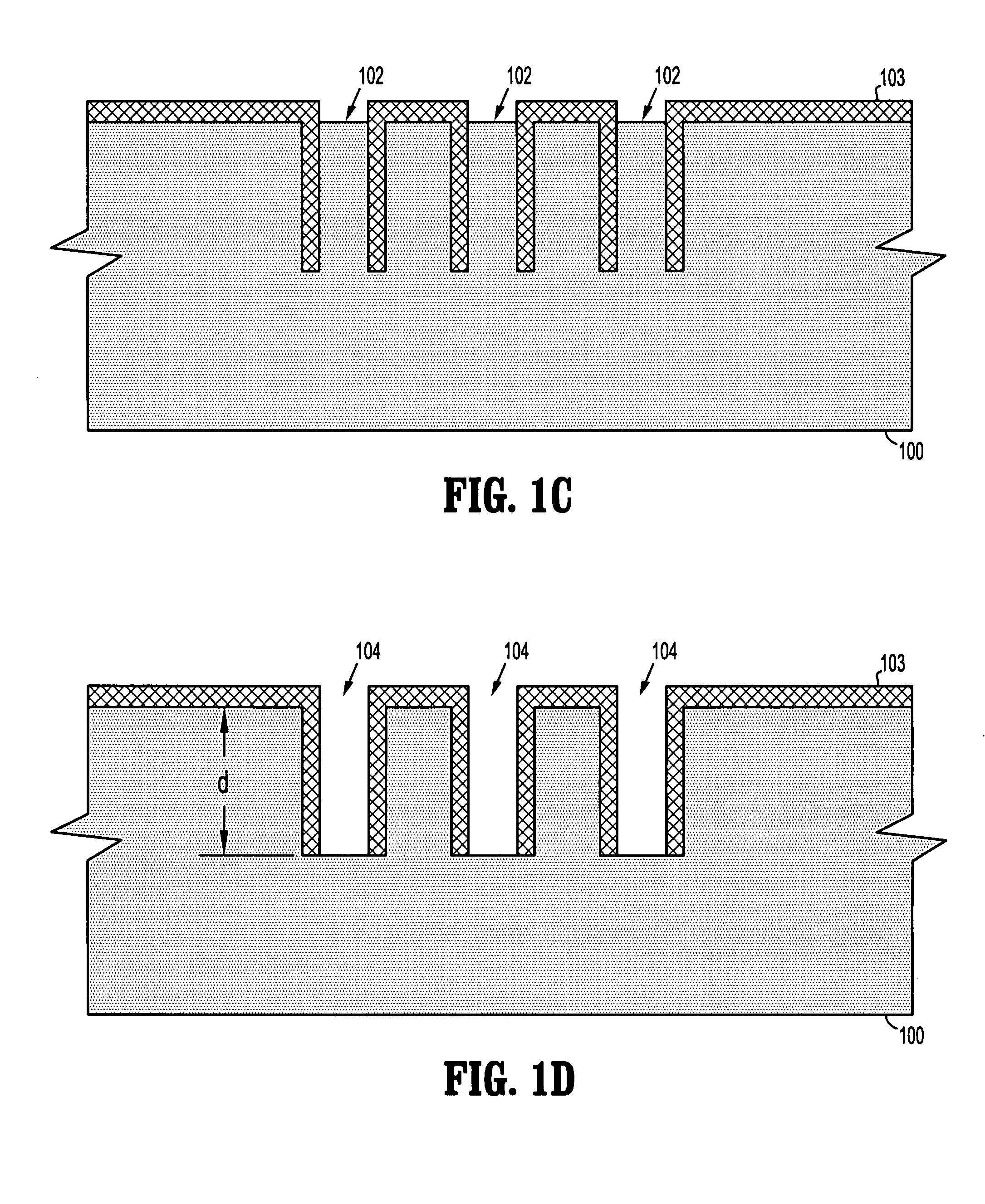

Methods for fabricating silicon carriers with conductive through-vias with low stress and low defect density

InactiveUS7863189B2High-density packagingHigh-yieldSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMicrometer

Methods are provided for fabricating silicon carriers with conductive through-vias that allow high-yield manufacture of silicon carrier with low defect density. In particular, methods are provided which enable fabrication of silicon carries with via diameters such as 1 to 10 microns in diameter for a vertical thickness of less than 10 micrometers to greater than 300 micrometers, which are capable robust to thermal-mechanical stresses during production to significantly minimize the thermal mechanical movement at the via sidewall interface between the silicon, insulator, liner and conductor materials.

Owner:GLOBALFOUNDRIES U S INC

Thin film transistor, electro-optical device and electronic apparatus

InactiveUS20060086978A1Lower performance requirementsReduce manufacturing costSolid-state devicesNon-linear opticsSurface layerMetallic materials

A thin film transistor includes a semiconductor layer formed over a substrate, and an electrode member formed over the substrate by a liquid phase method. The electrode member includes a base layer composed of a metal material and an outer surface layer deposited on at least one surface of the base layer. The outer surface layer is formed of a metal material that is less susceptible to being dissolved in silicon and a silicon compound compared with the metal material constituting the base layer.

Owner:SEIKO EPSON CORP

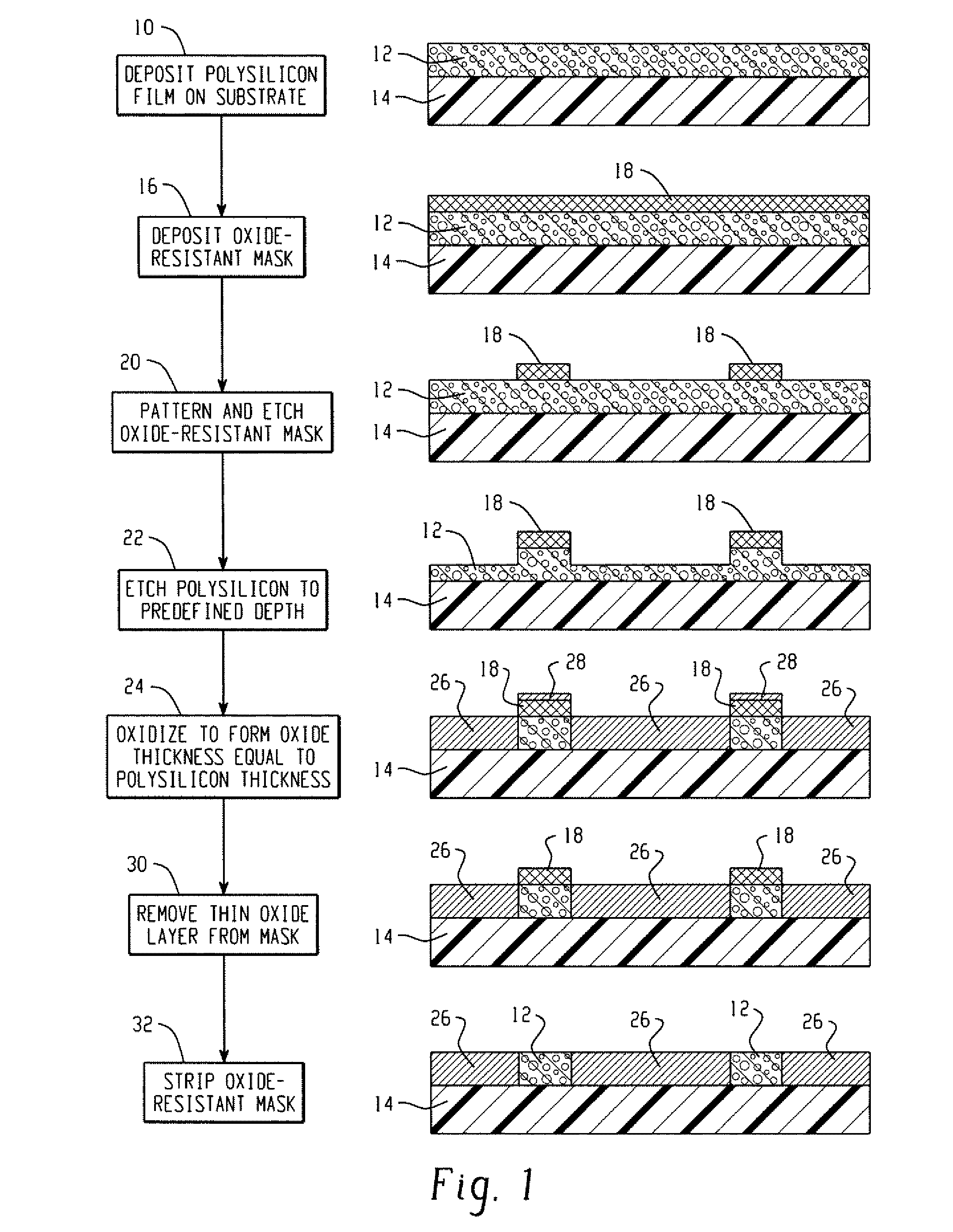

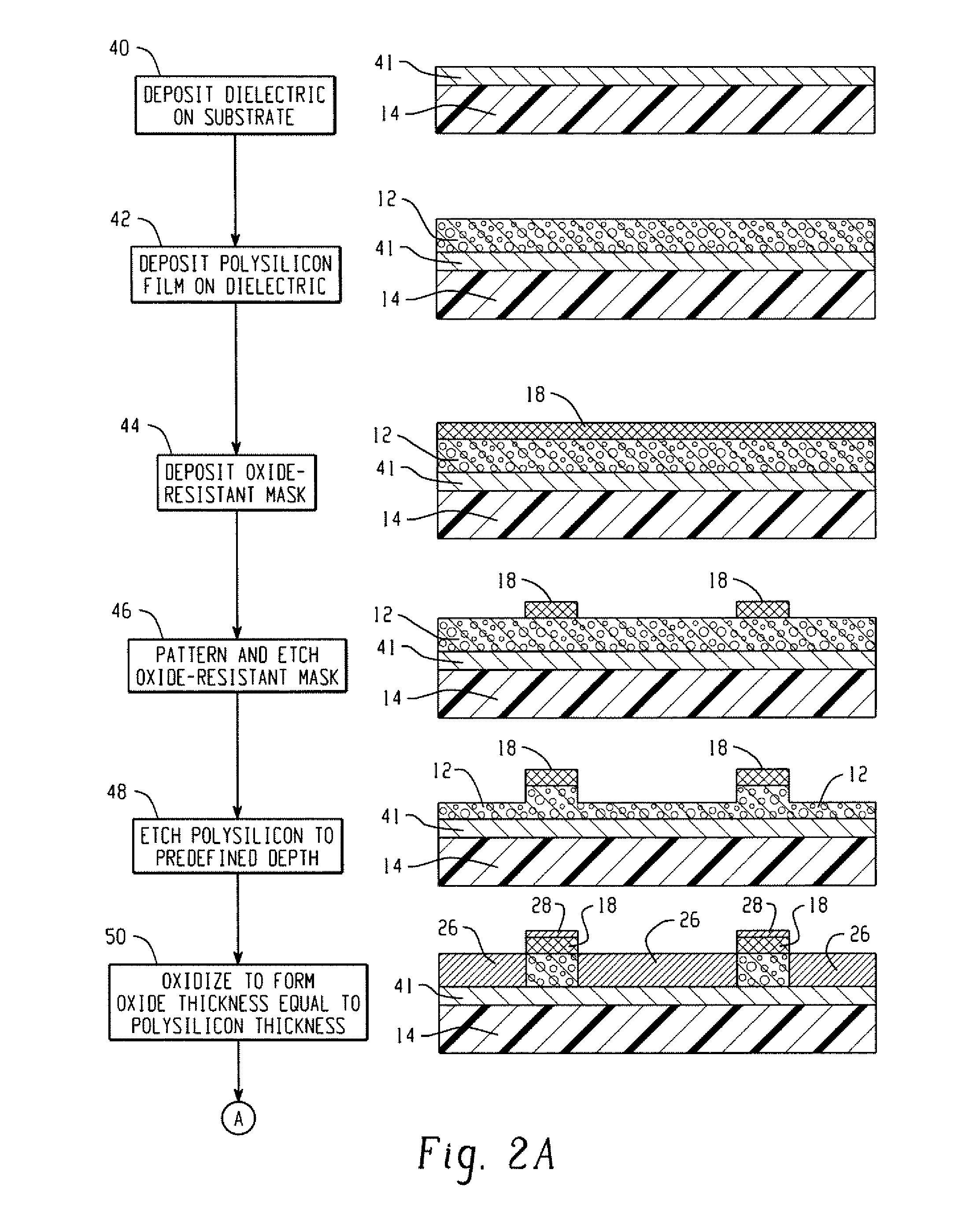

Local Oxidation of Silicon Planarization for Polysilicon Layers Under Thin Film Structures

ActiveUS20090017591A1Reduce eliminateHigh yield preparationThin/thick film capacitorFixed capacitor dielectricFilm structurePolycrystalline silicon

In accordance with the teachings described herein, a method for fabricating a patterned polysilicon layer having a planar surface may include the steps of: depositing a polysilicon film above a substrate material; depositing an oxide-resistant mask over the polysilicon film; patterning and etching the oxide-resistant mask to form a patterned mask layer over the polysilicon film, such that the polysilicon film includes masked and unmasked portions; etching the unmasked portions of the polysilicon film for a first amount of time; oxidizing the etched polysilicon film for a second amount of time to form an oxide layer that defines the patterned polysilicon layer; and removing the patterned mask layer; wherein the first and second amounts of time are selected such that the oxide layer and the patterned polysilicon layer have about the same thickness and form a planar surface.

Owner:NXP USA INC

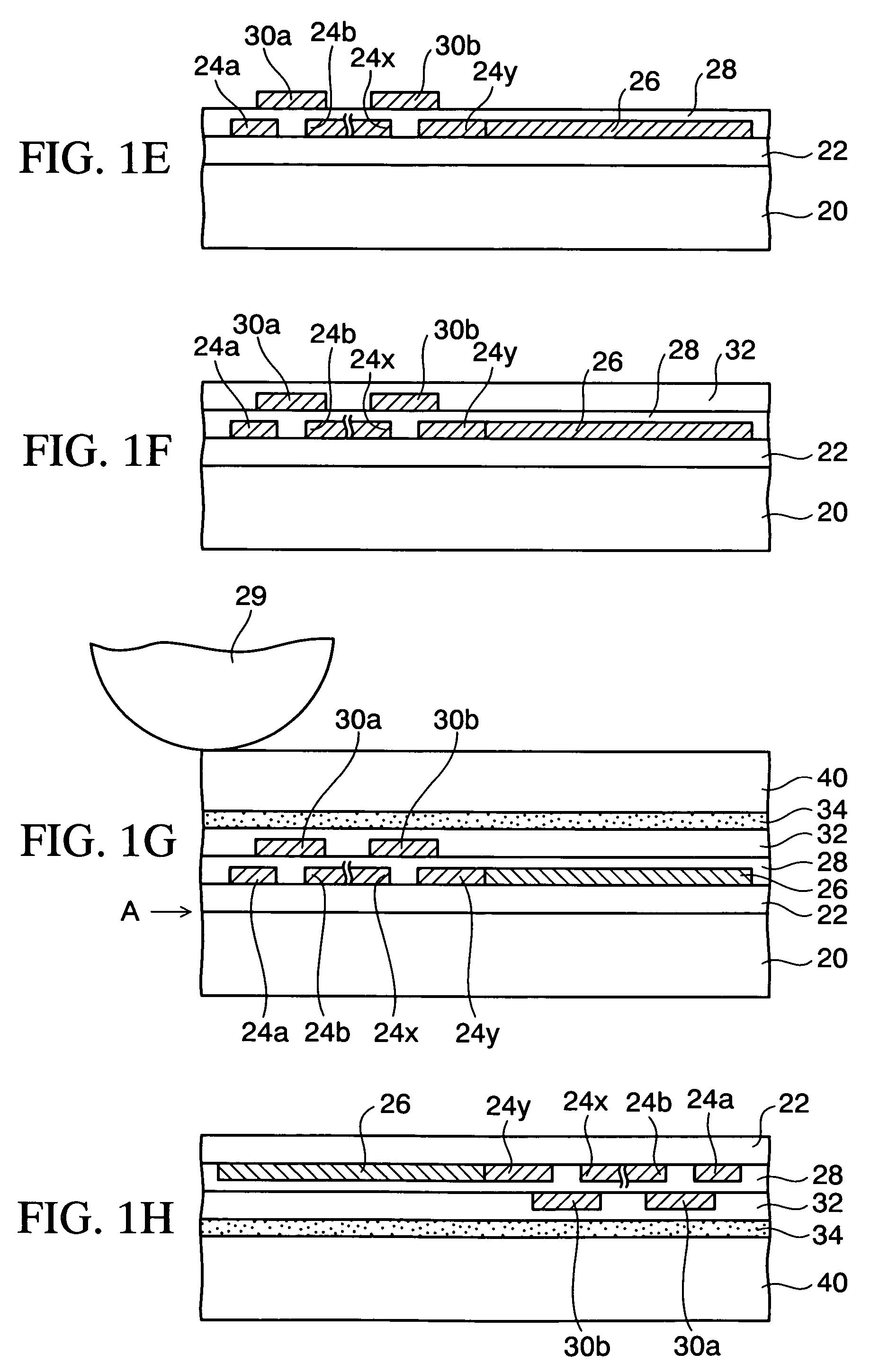

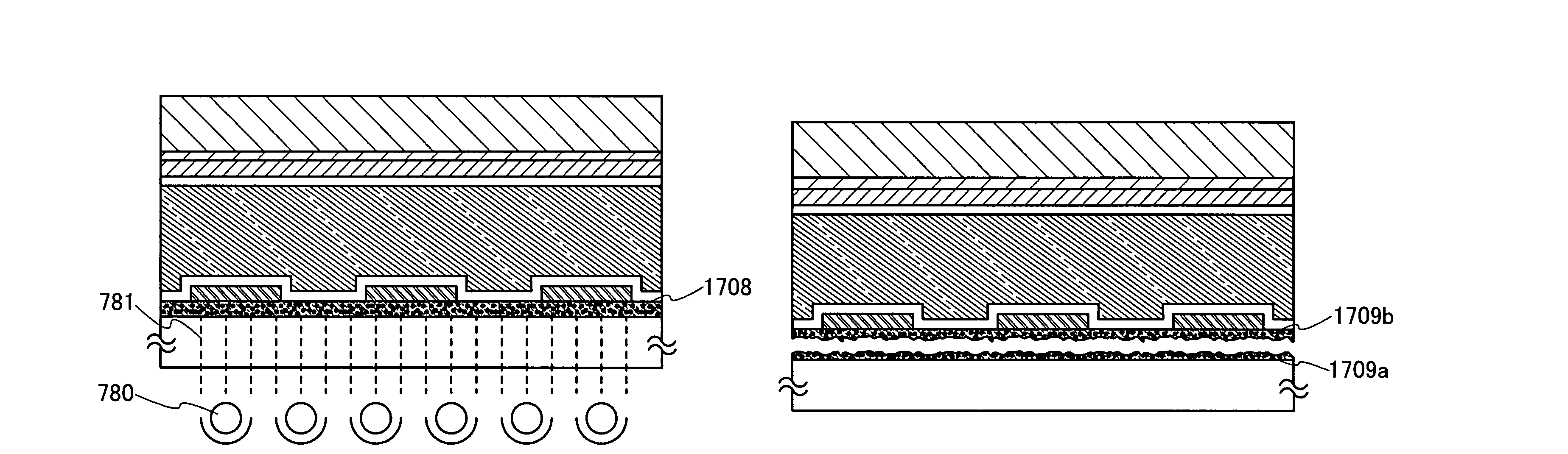

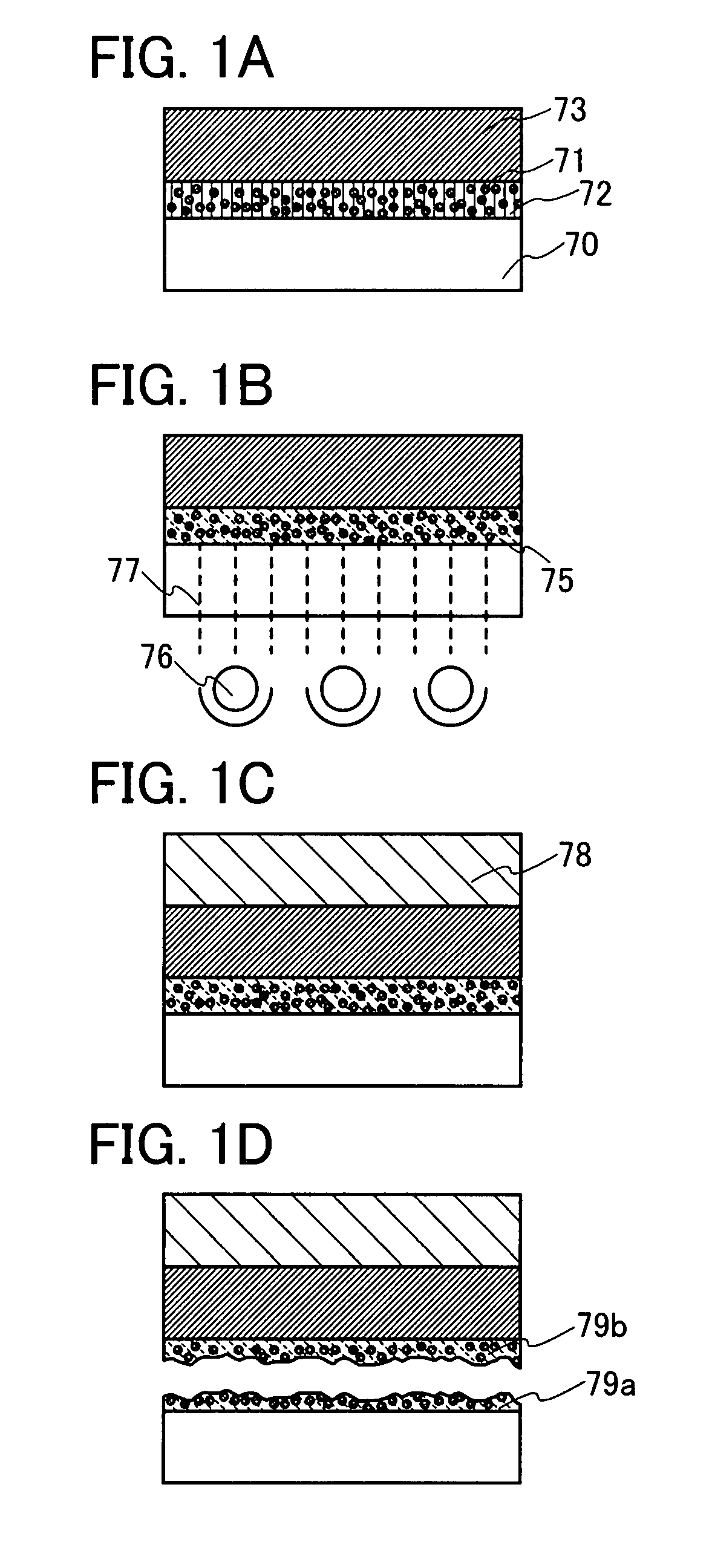

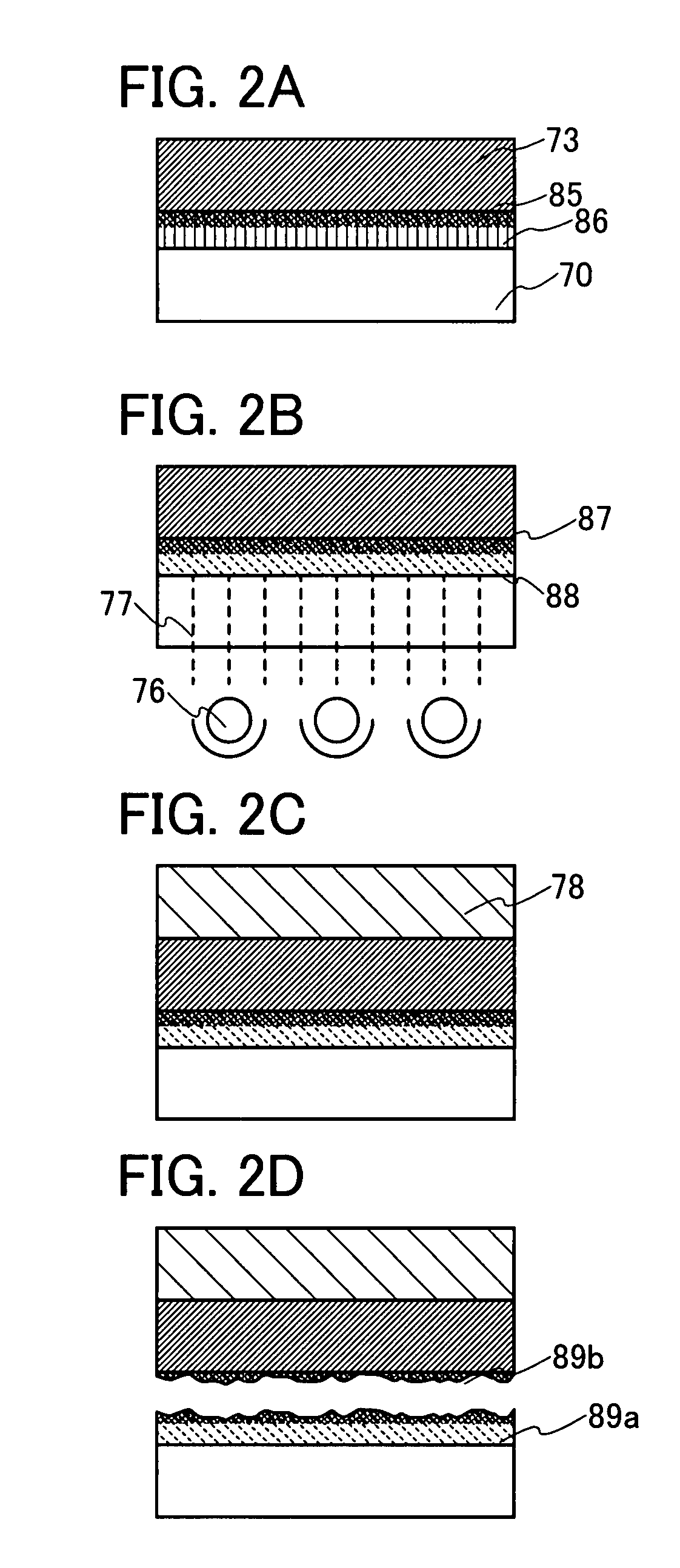

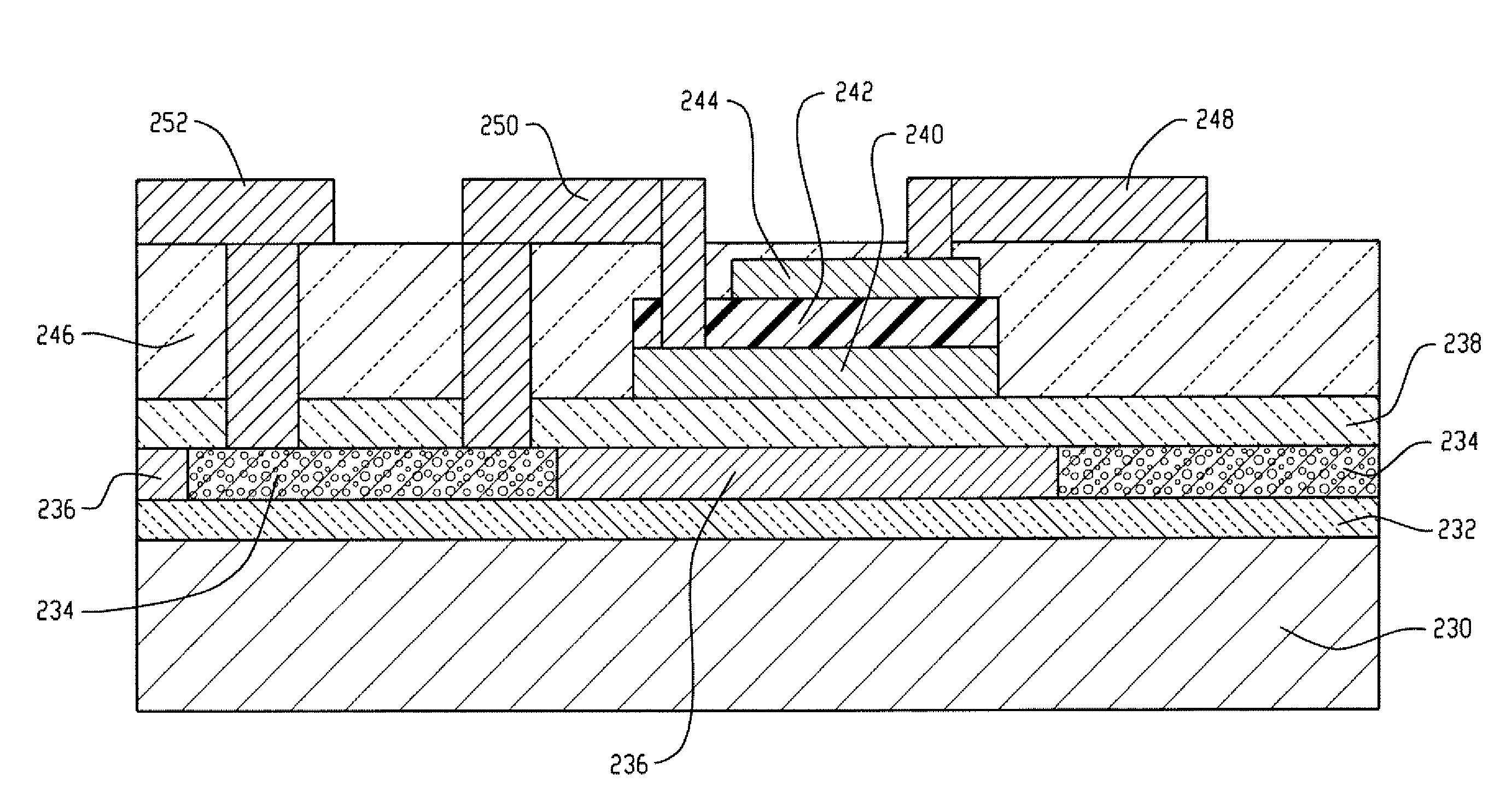

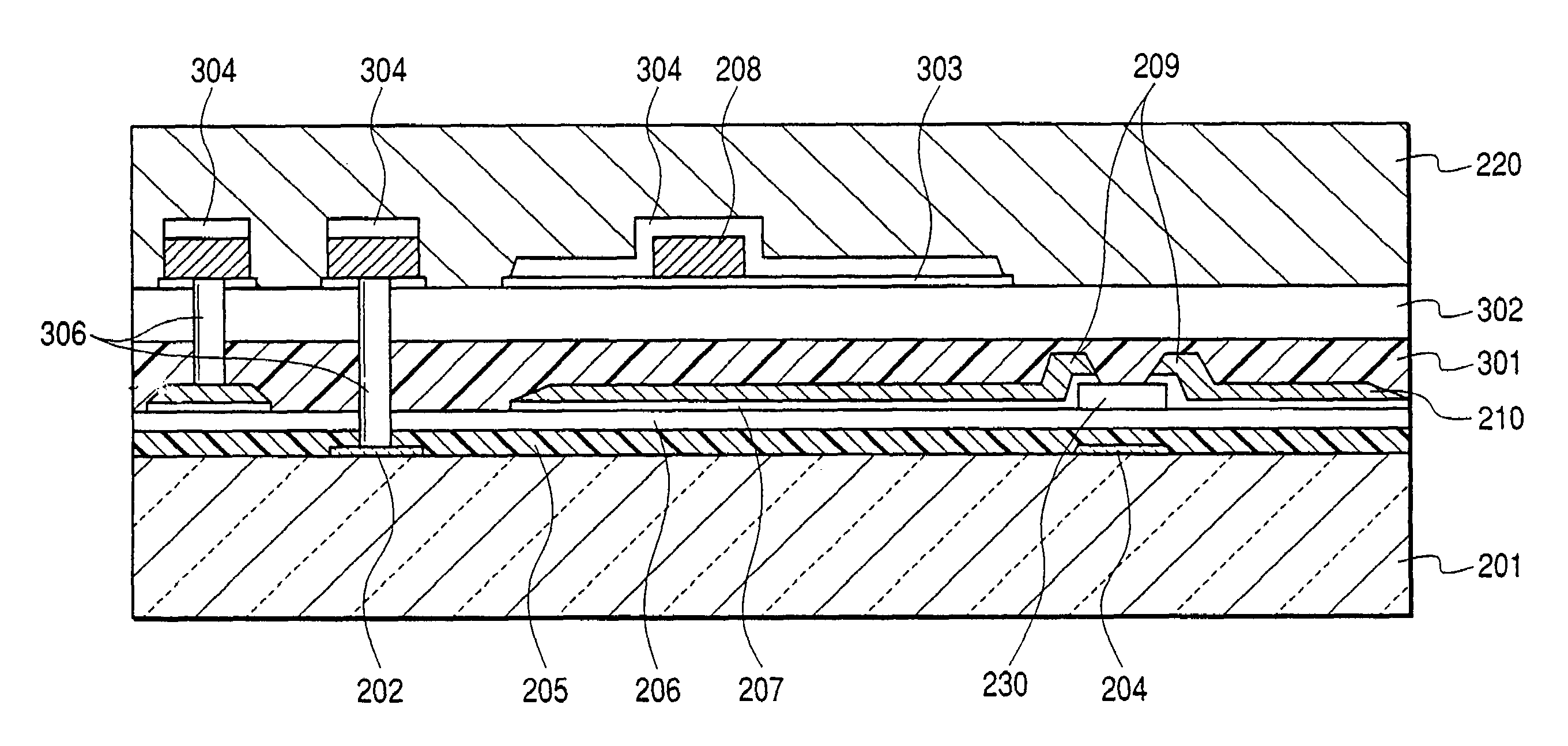

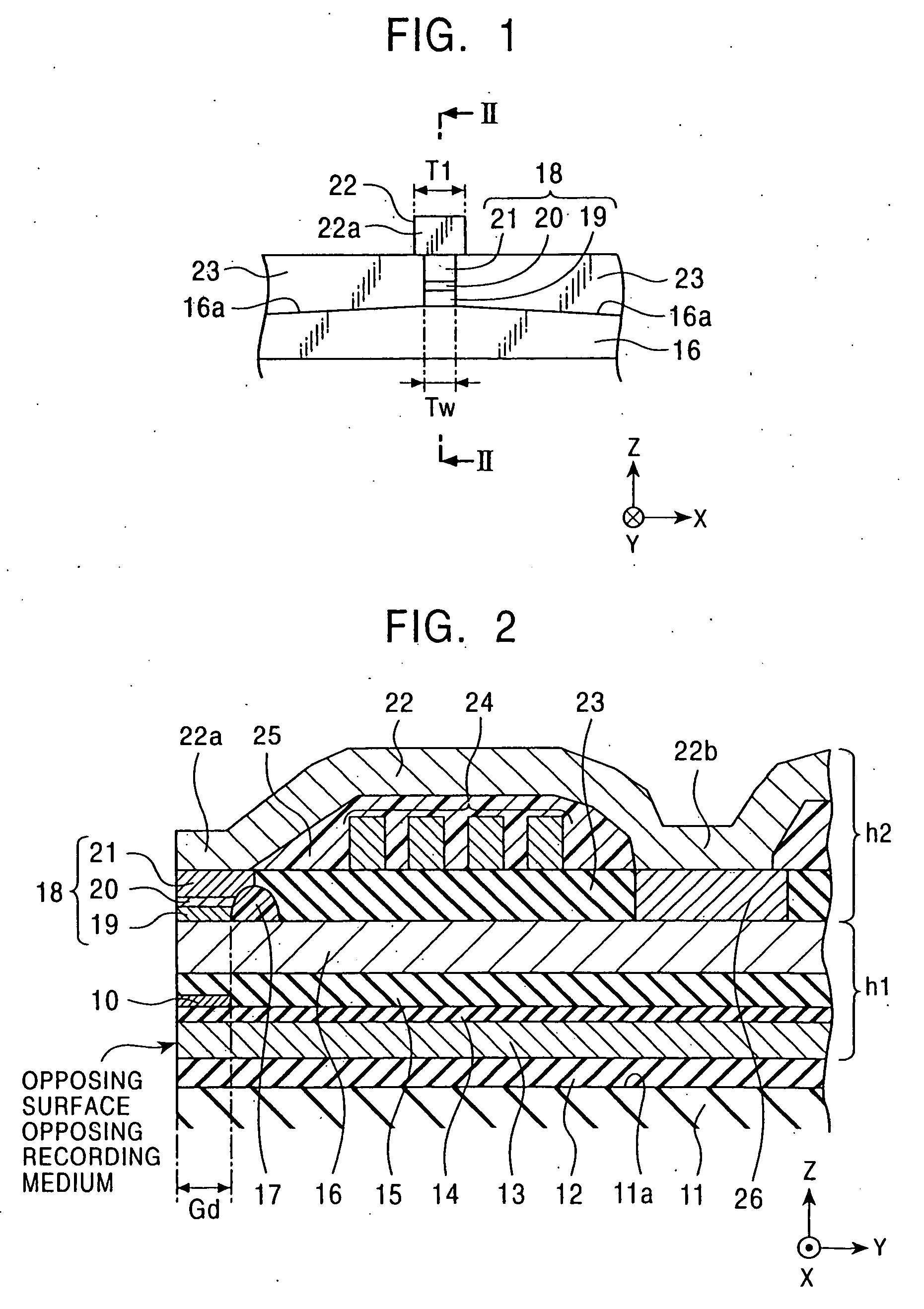

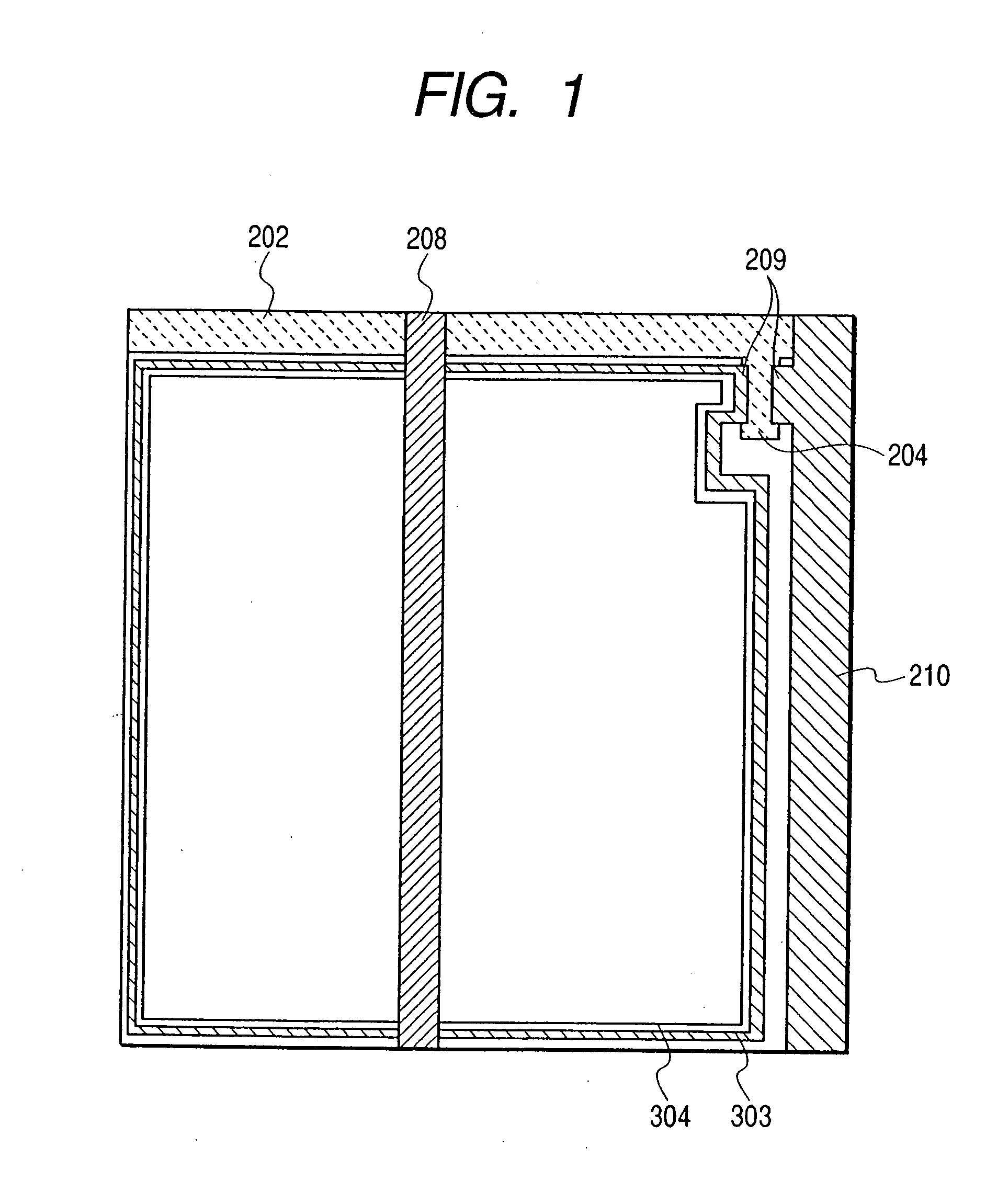

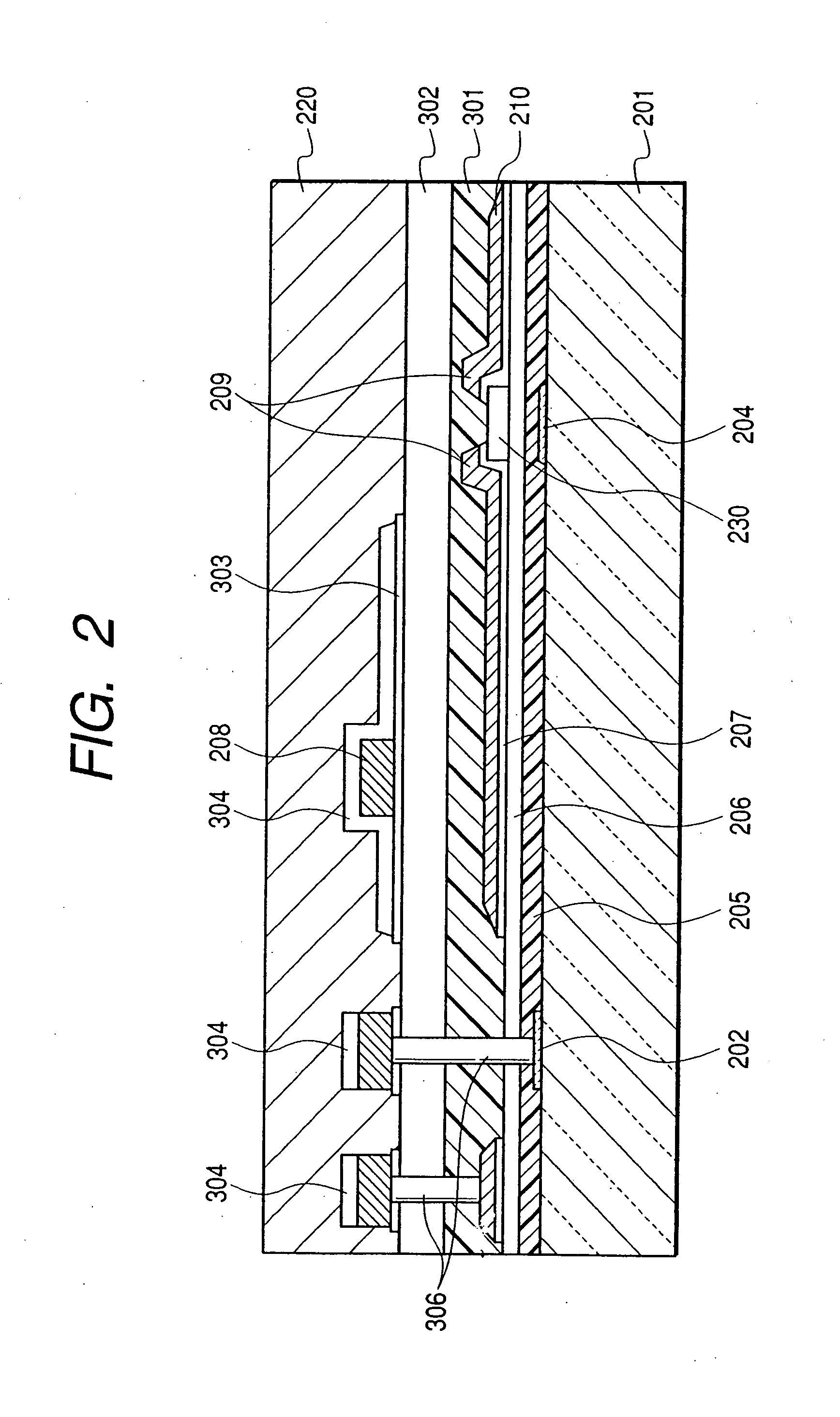

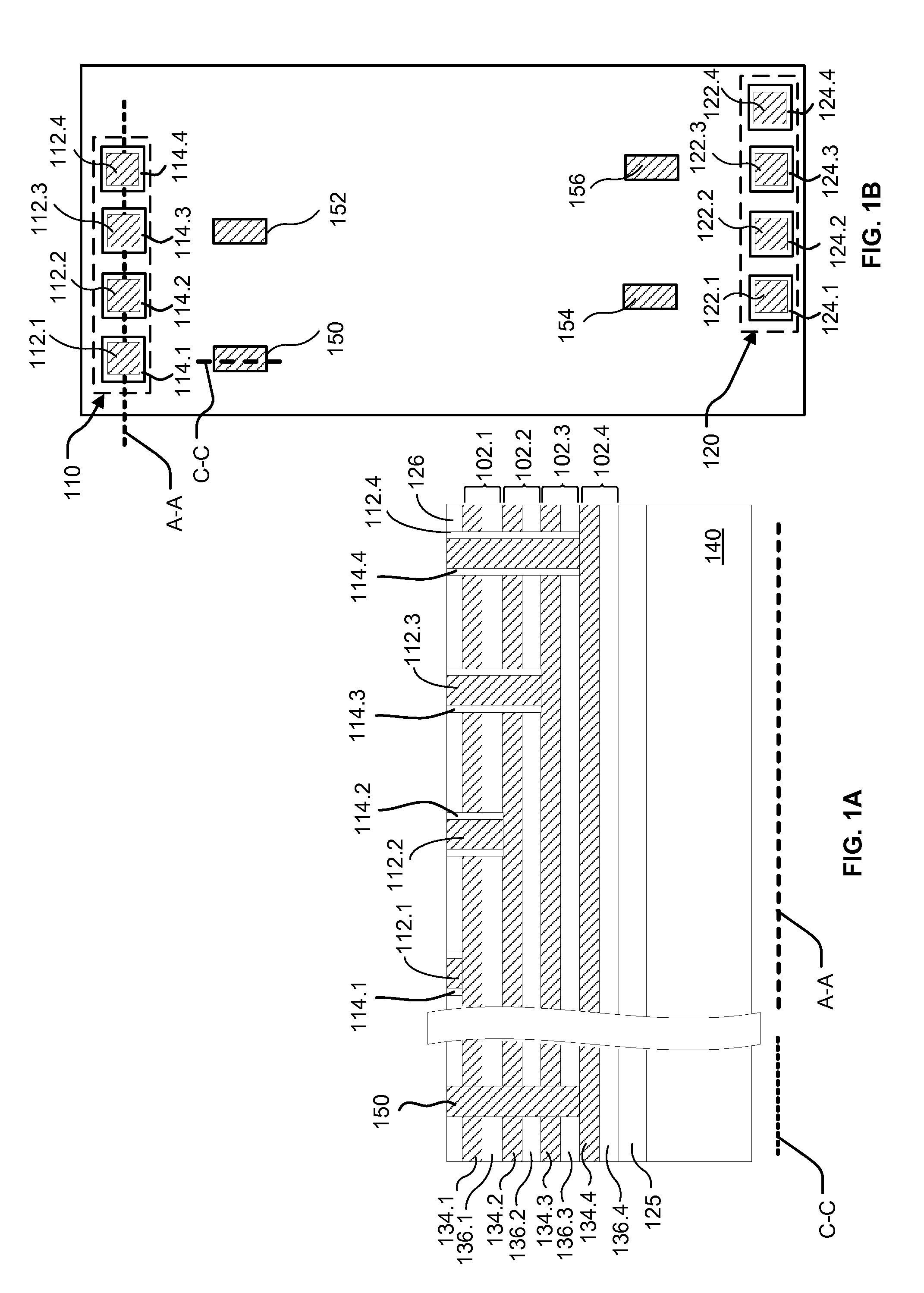

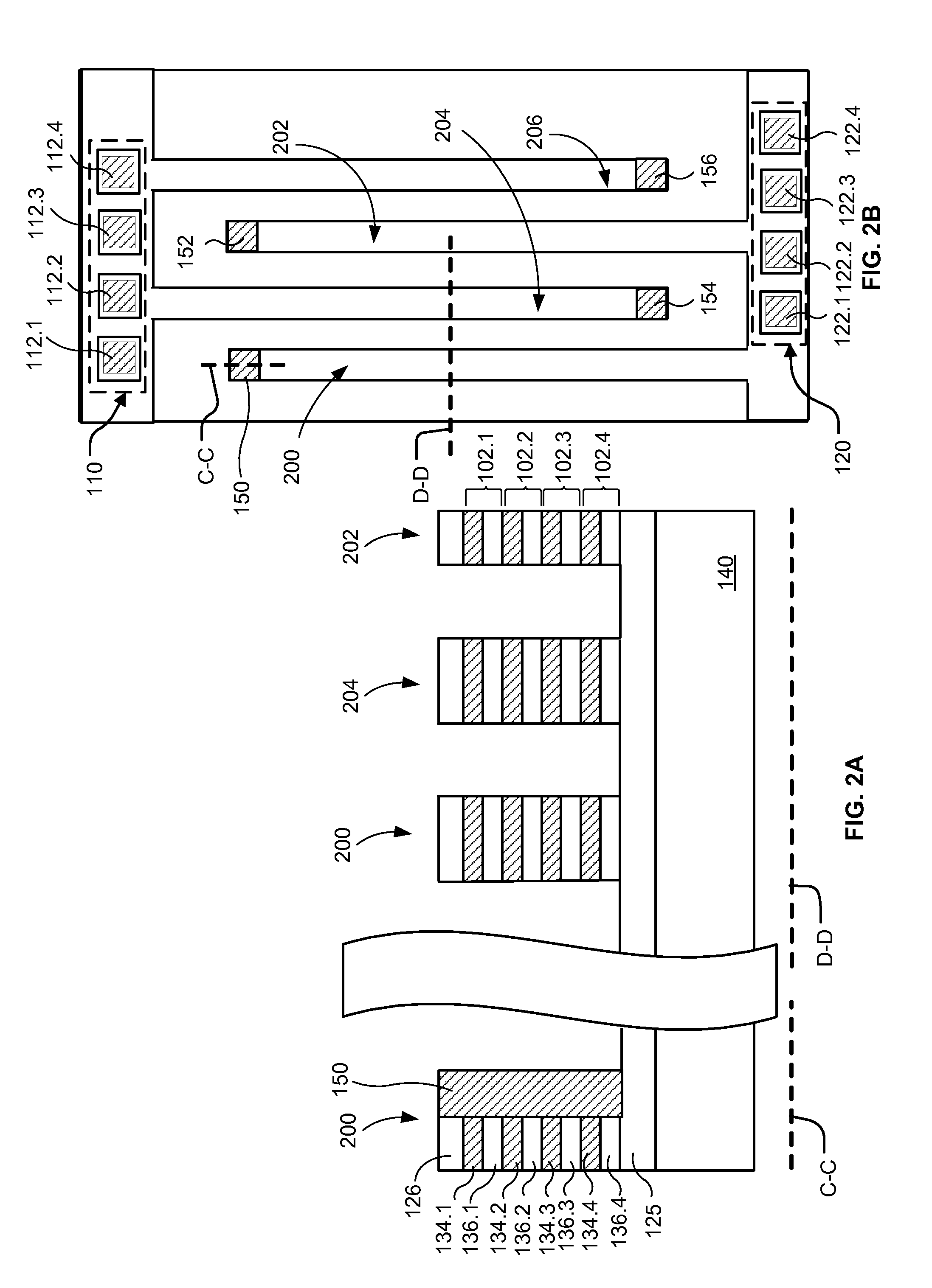

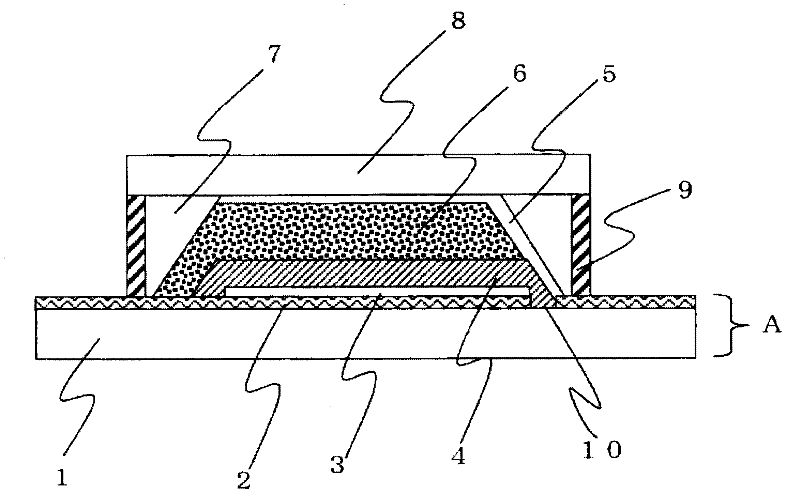

Radiation detecting apparatus, manufacturing method therefor, and radiation image pickup system

ActiveUS7214945B2High yield preparationHigh sensitivityPhotometrySolid-state devicesElectrical conductorOhmic contact

A radiation detecting apparatus having a radiation conversion element arranged on a switch TFT is provided. The apparatus includes a gate electrode of the switch TFT; a first insulating layer, a first semiconductor layer, and an ohmic contact layer, which are arranged on the gate electrode in order; and a source / drain electrode of the switch TFT arranged on the ohmic contact layer, which all constitute the switch TFT. The apparatus also includes a lower electrode of the radiation conversion element formed from the same layer as the source / drain electrode, a second insulating layer, a second semiconductor layer, and a second ohmic contact layer, which are arranged on the lower electrode in order, and a bias wiring for applying a bias voltage to the radiation conversion element.

Owner:CANON KK

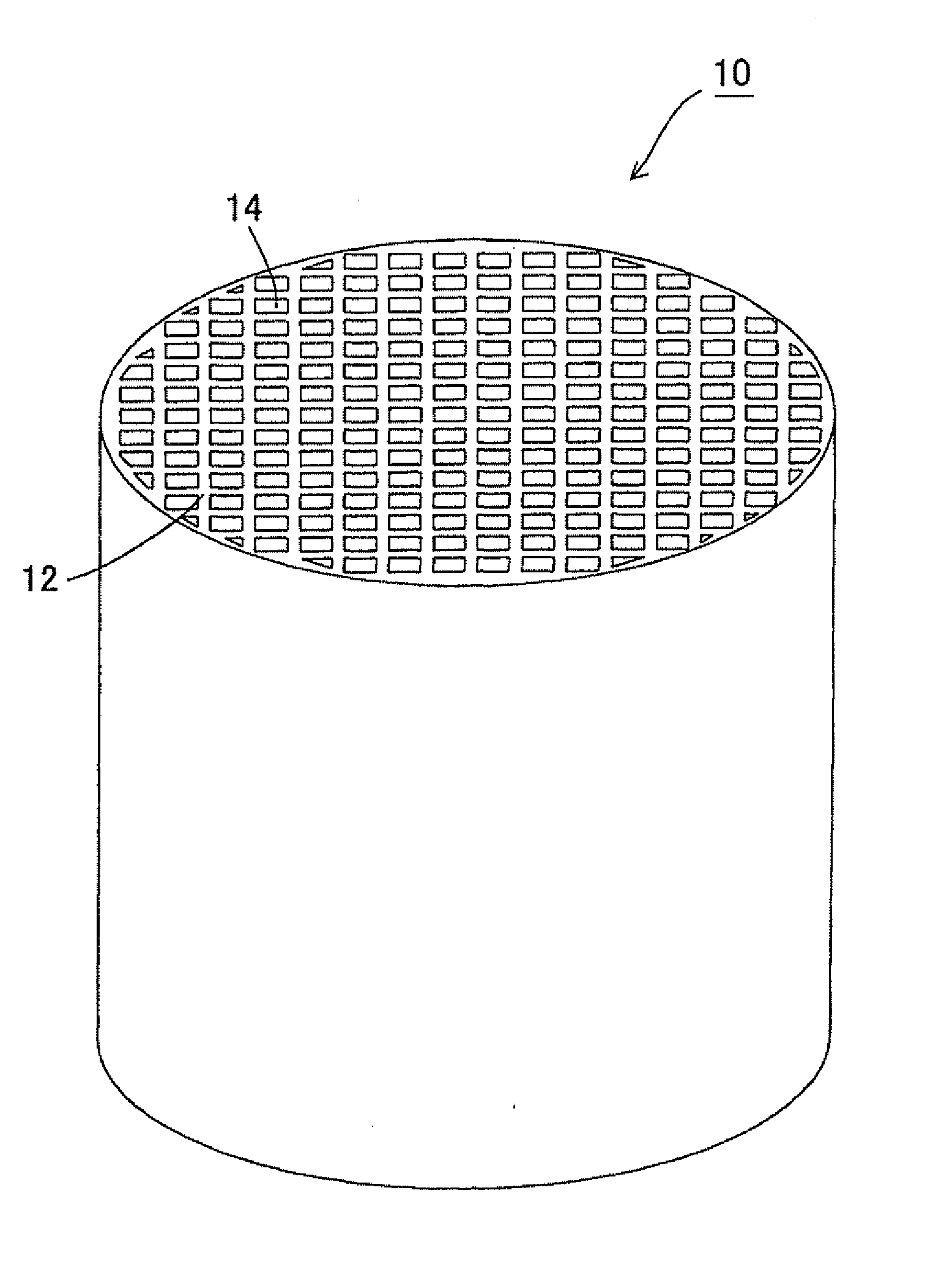

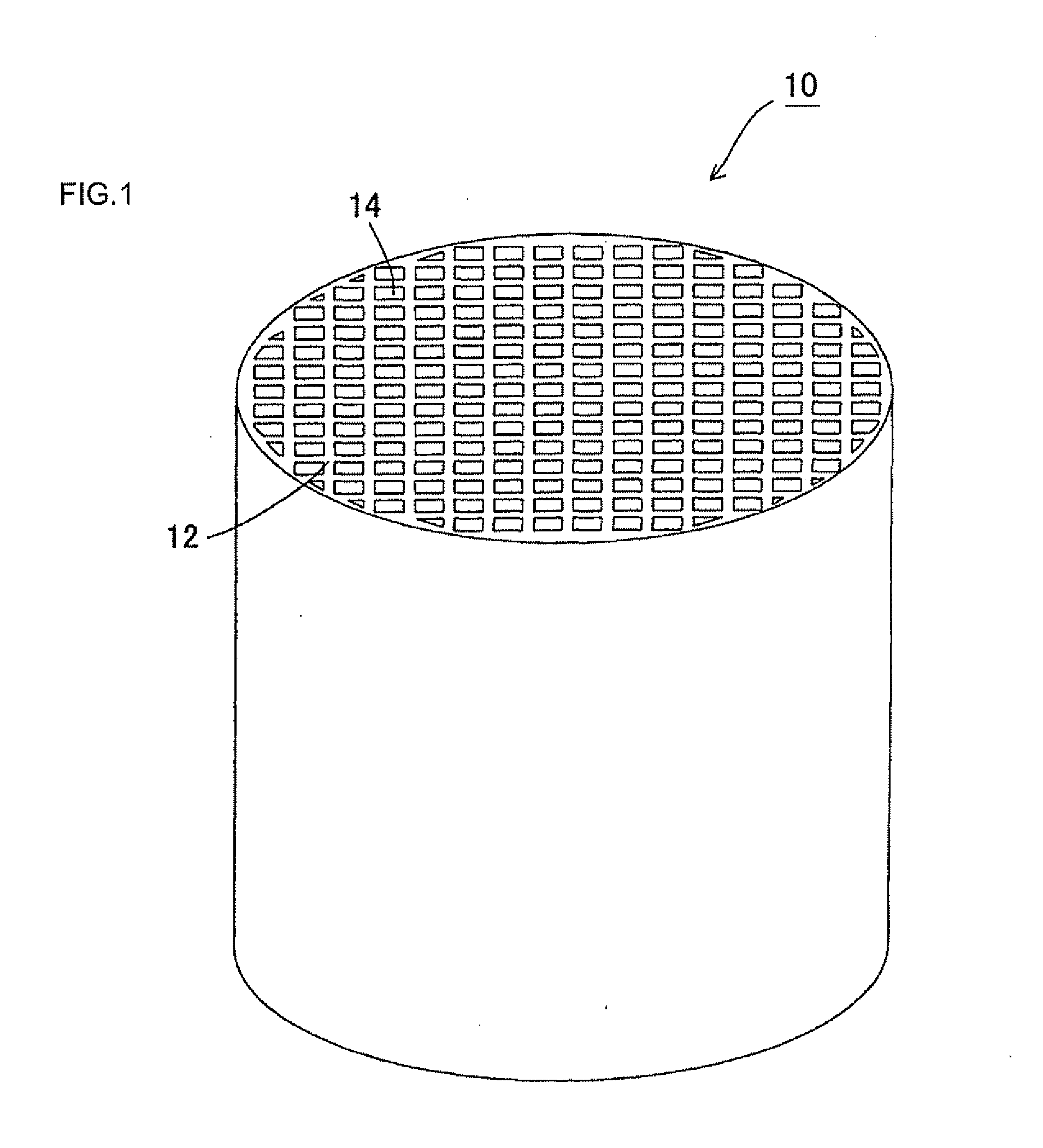

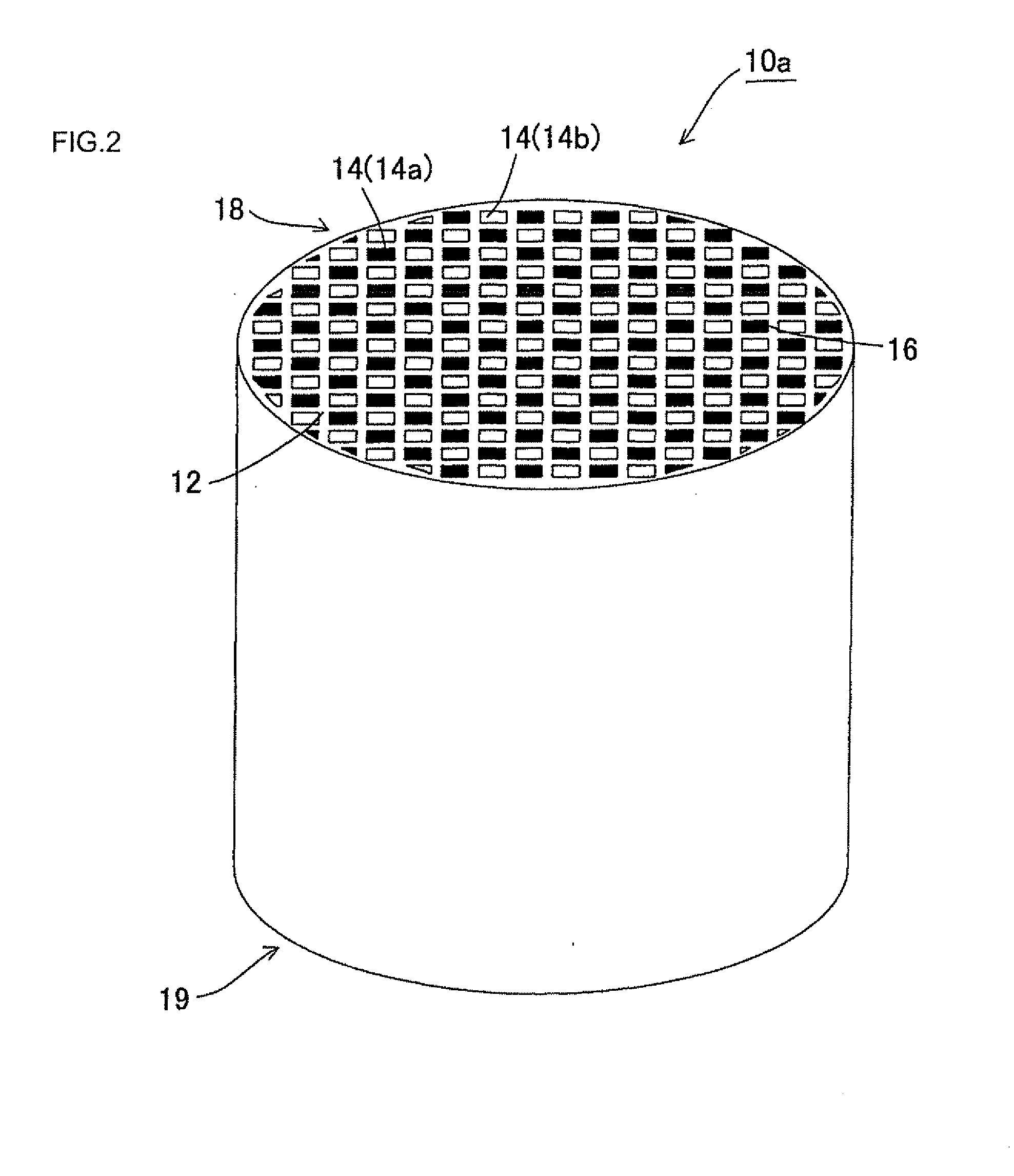

Honeycomb structure and method for manufacturing the same

ActiveUS20100086731A1Large average pore sizeThinning of partition wallPhysical/chemical process catalystsExhaust apparatusCordieriteHoneycomb structure

A honeycomb structure 10 of the present invention is provided with porous partition walls 12 made of a ceramic material containing cordierite as a main crystal phase and separating and forming a plurality of cells 14 functioning as fluid passages. The partition walls 12 contain sodium at 0.08 to 0.15 mass % in terms of sodium oxide. A honeycomb structure having a large average pore size can be provided.

Owner:NGK INSULATORS LTD

Method for manufacturing monolithic ceramic electronic component, and multilayer composite

InactiveUS20070180684A1Reduce manufacturing costReduce pointsTransformers/inductances coils/windings/connectionsVariable inductances/transformersMetallurgyElectronic component

A multilayer composite including a core made of a magnetic ceramic sintered compact disposed therein, and shrinkage restraining layers including an inorganic powder that is not substantially sintered at the sintering temperature of the green ceramic layers are sintered in order to reduce the difference in shrinkage behavior during firing between the core and the green ceramic layers.

Owner:MURATA MFG CO LTD

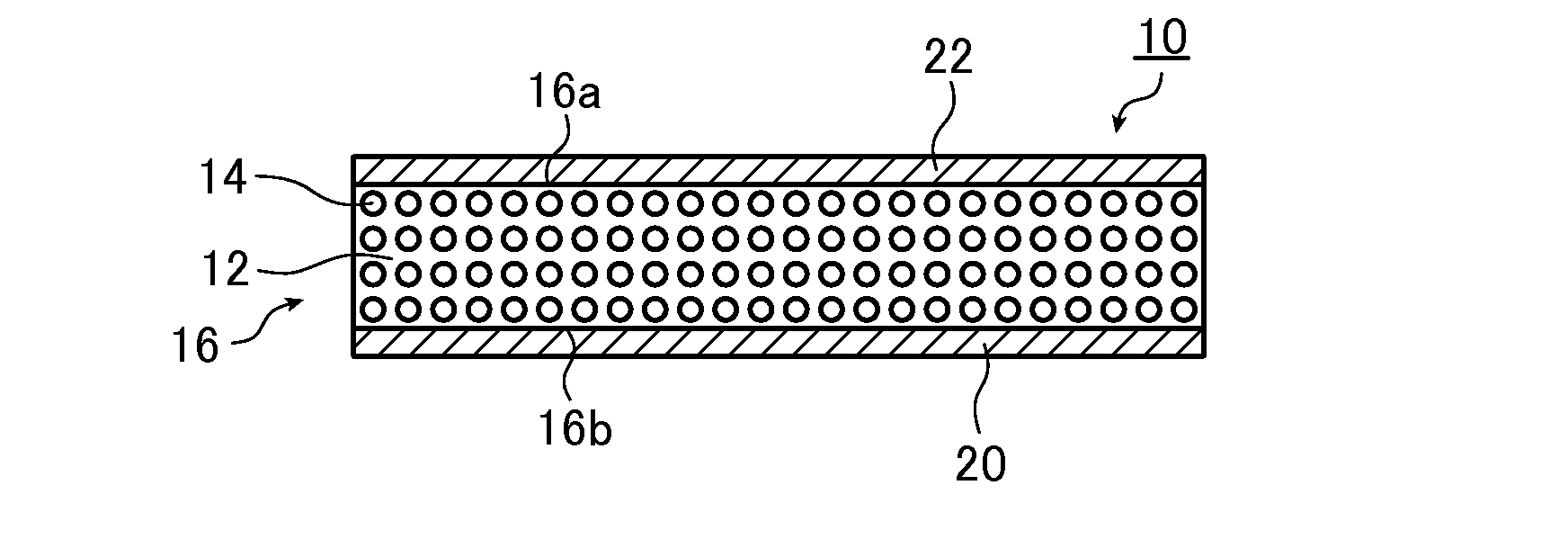

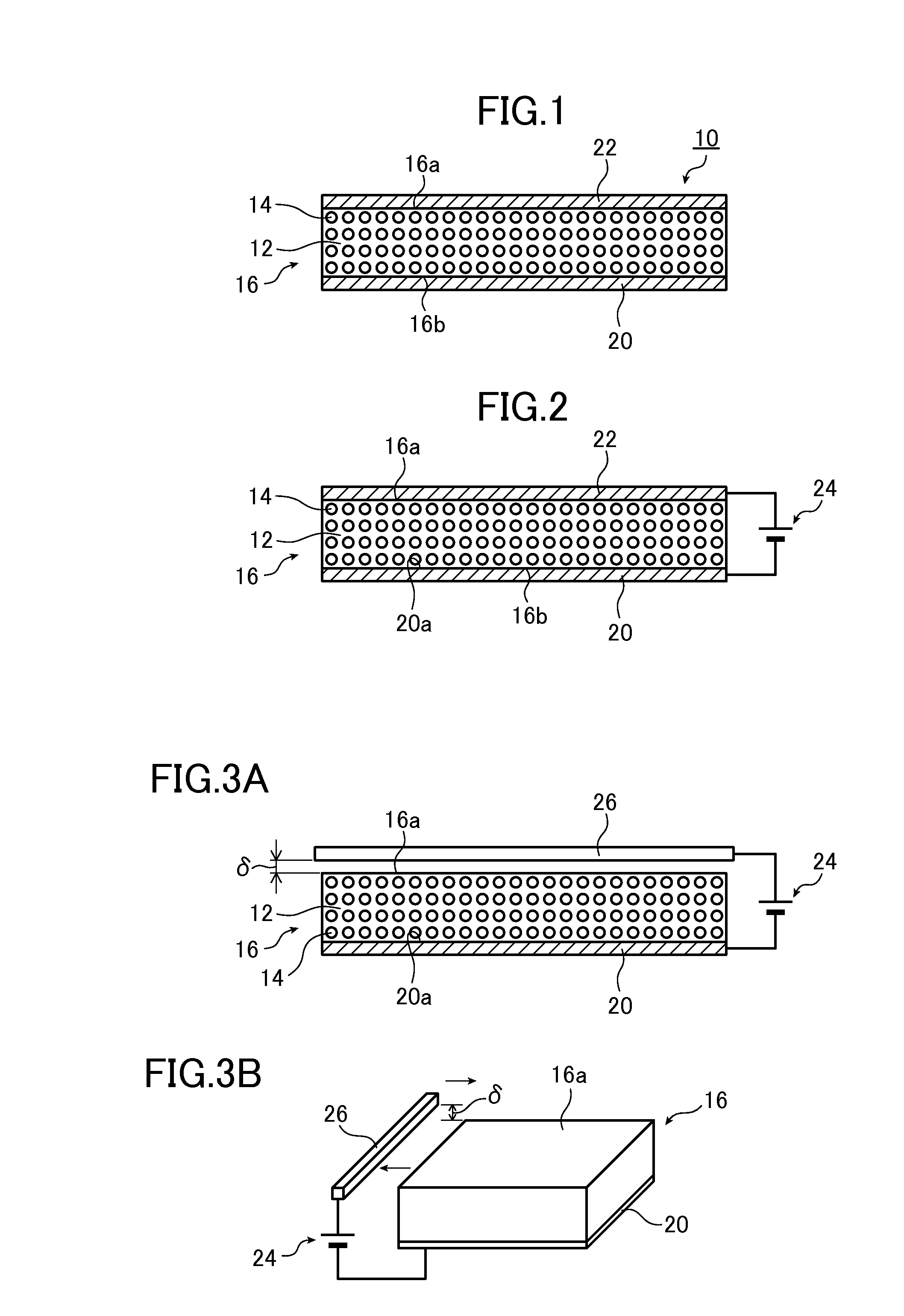

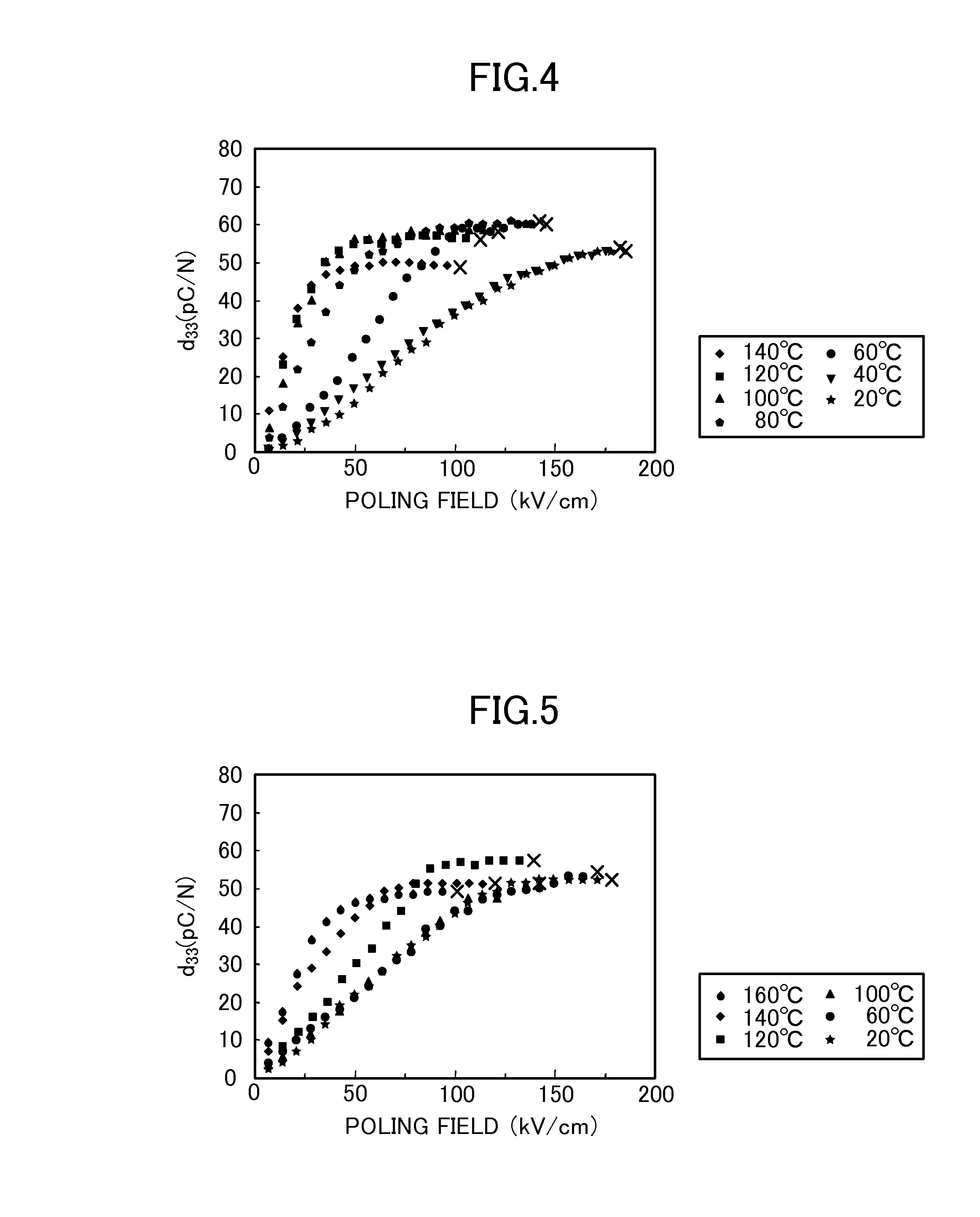

Polymer composite piezoelectric body and manufacturing method for the same

ActiveUS20130256581A1Improve leakage currentSuppress dielectric breakdownPiezoelectric/electrostrictive device manufacture/assemblyPretreated surfacesPolyvinyl alcoholPolymer composites

A polymer composite piezoelectric body is obtained by conducting polarization treatment on a composite having piezoelectric particles uniformly mixed by dispersion in a polymer matrix containing cyanoethylated polyvinyl alcohol.

Owner:FUJIFILM CORP

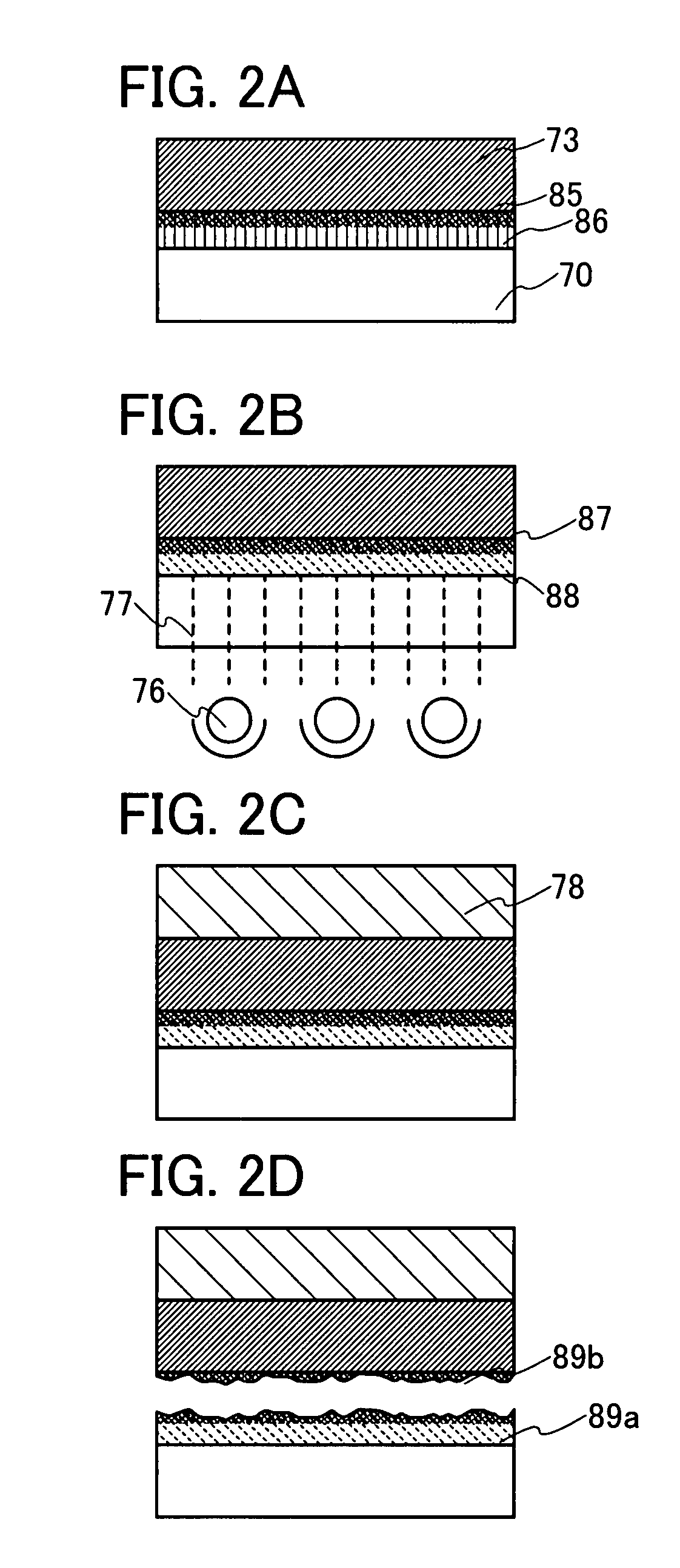

Radiation detecting apparatus, manufacturing method therefor, and radiation image pickup system

InactiveUS7521684B2Simple processIncrease opening ratioPhotometrySolid-state devicesElectrical conductorOhmic contact

The present invention provides a radiation detecting apparatus having a radiation conversion element laminated on a switch TFT, including a gate electrode of the switch TFT; a first insulating layer, a first semiconductor layer, and an ohmic contact layer, which are laminated on the gate electrode in order; and a source / drain electrode of the switch TFT laminated on the ohmic contact layer, which all constitute the switch TFT; and a lower electrode of the radiation conversion element, which is formed on the same layer as the source / drain electrode; a second insulating layer, a second semiconductor layer, and a second ohmic contact layer, which are laminated on the lower electrode in order; and a bias wiring for applying a bias to the radiation conversion element. Also, the invention provides a radiation image pickup apparatus including a photoelectric conversion element having a wavelength converter for converting a radiation into a visible light, a pixel electrode for converting the visible light into an electric signal, an insulating layer, and a semiconductor layer; and a transistor for controlling reading of the electric signal converted by the photoelectric conversion element, the photoelectric conversion element being laminated on the wavelength converter side of the transistor, the pixel electrode being divided for each of plural pixels, and the semiconductor layer extending over the plural pixels.

Owner:CANON KK

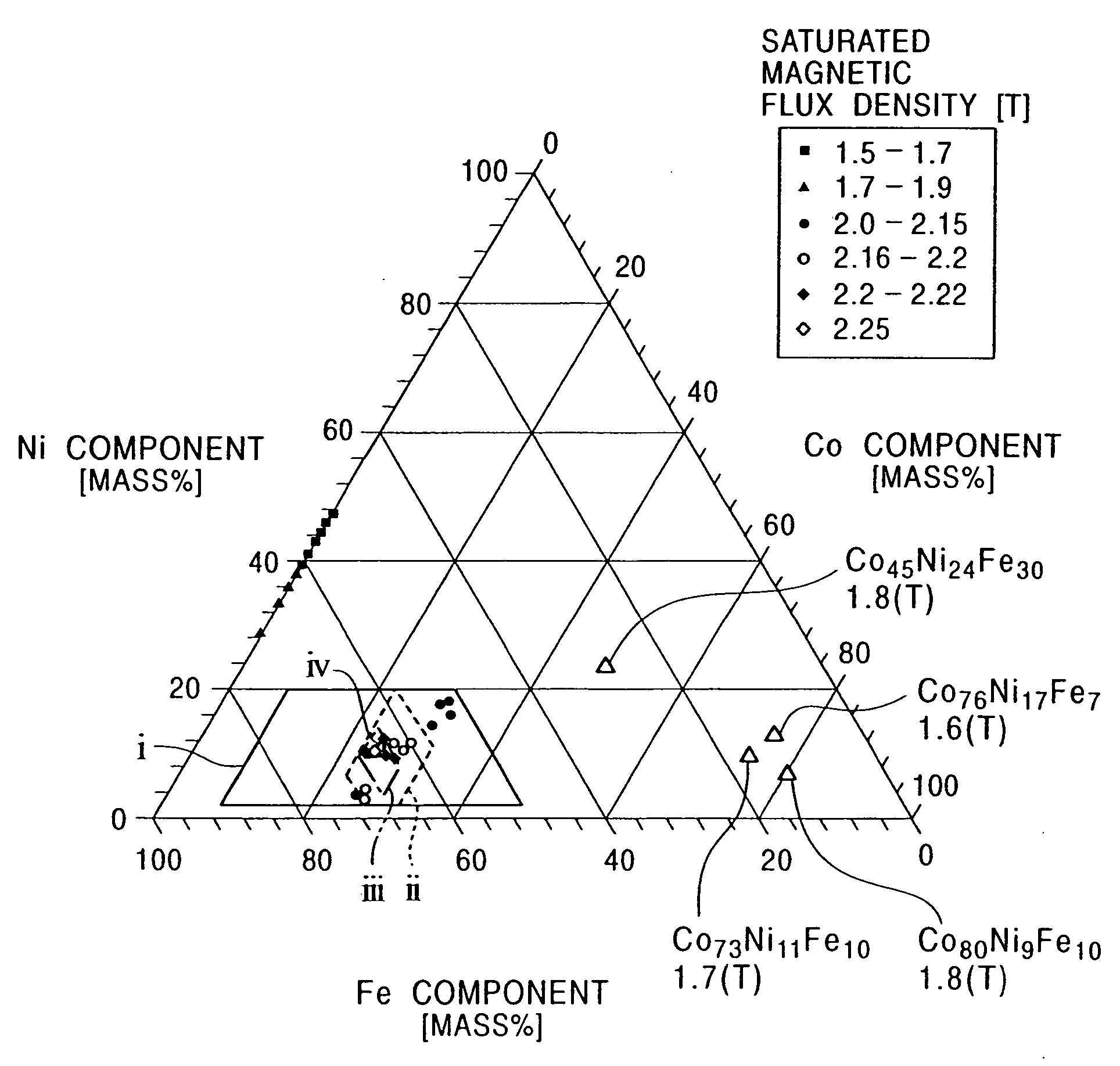

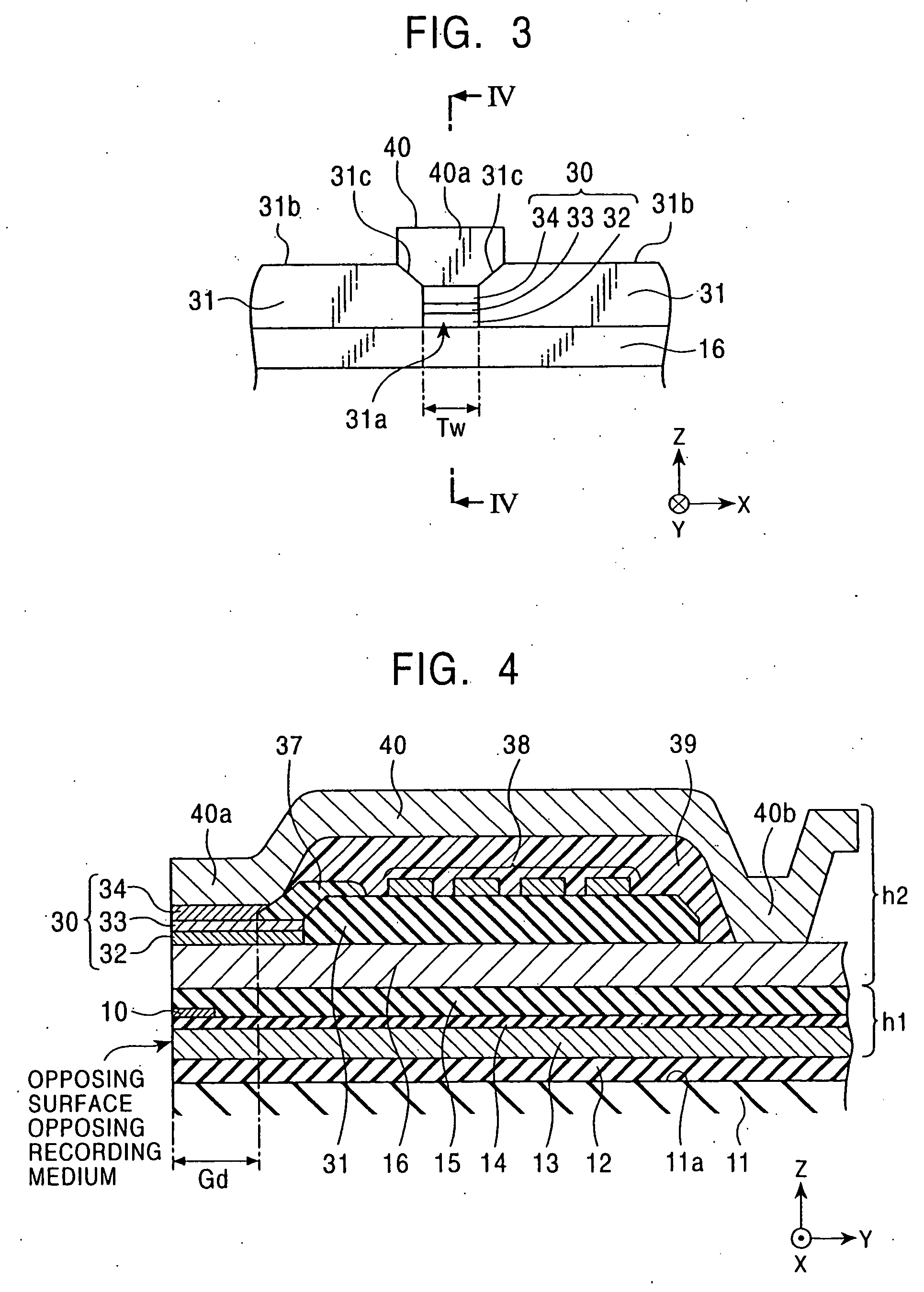

Soft magnetic film having improved saturated magnetic flux density, magnetic head using the same, and manufacturing method therefore

InactiveUS20050011590A1Improve recording densityImprove corrosion resistanceHeads using thin filmsRecord information storageMagnetic polesAlloy

A lower magnetic pole layer and / or an upper magnetic pole layer are formed of a CoFeα alloy in which the component ratio X of Co is 8 to 48 mass %, the component ratio Y of Fe is 50 to 90 mass %, the component ratio Z of the element α (the element α is at least one of Ni and Cr) is 2 to 20 mass %, and the equation X+Y+Z=100 mass % is satisfied. Consequently, the saturated magnetic flux density can be 2.0 T or more, and a thin-film magnetic head have a higher recording density can be manufactured

Owner:TDK CORPARATION

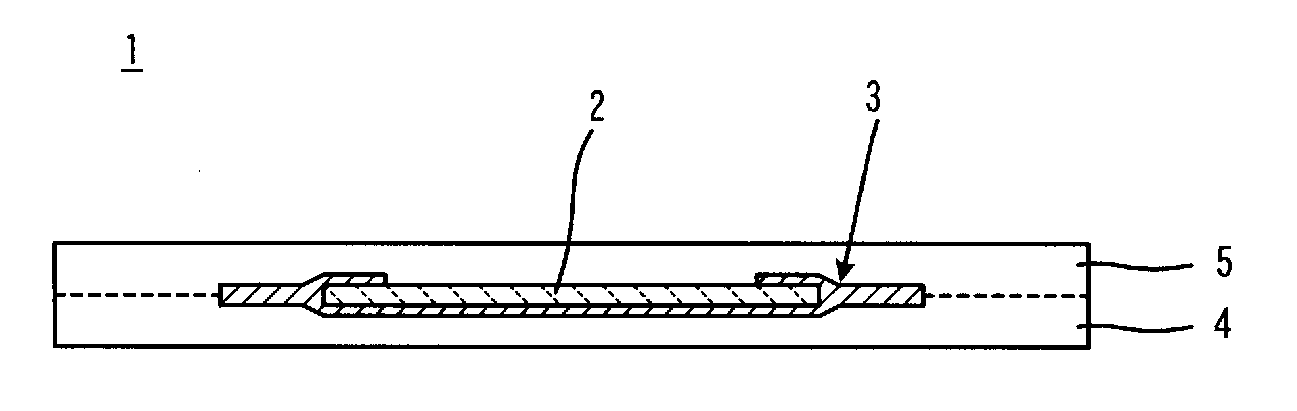

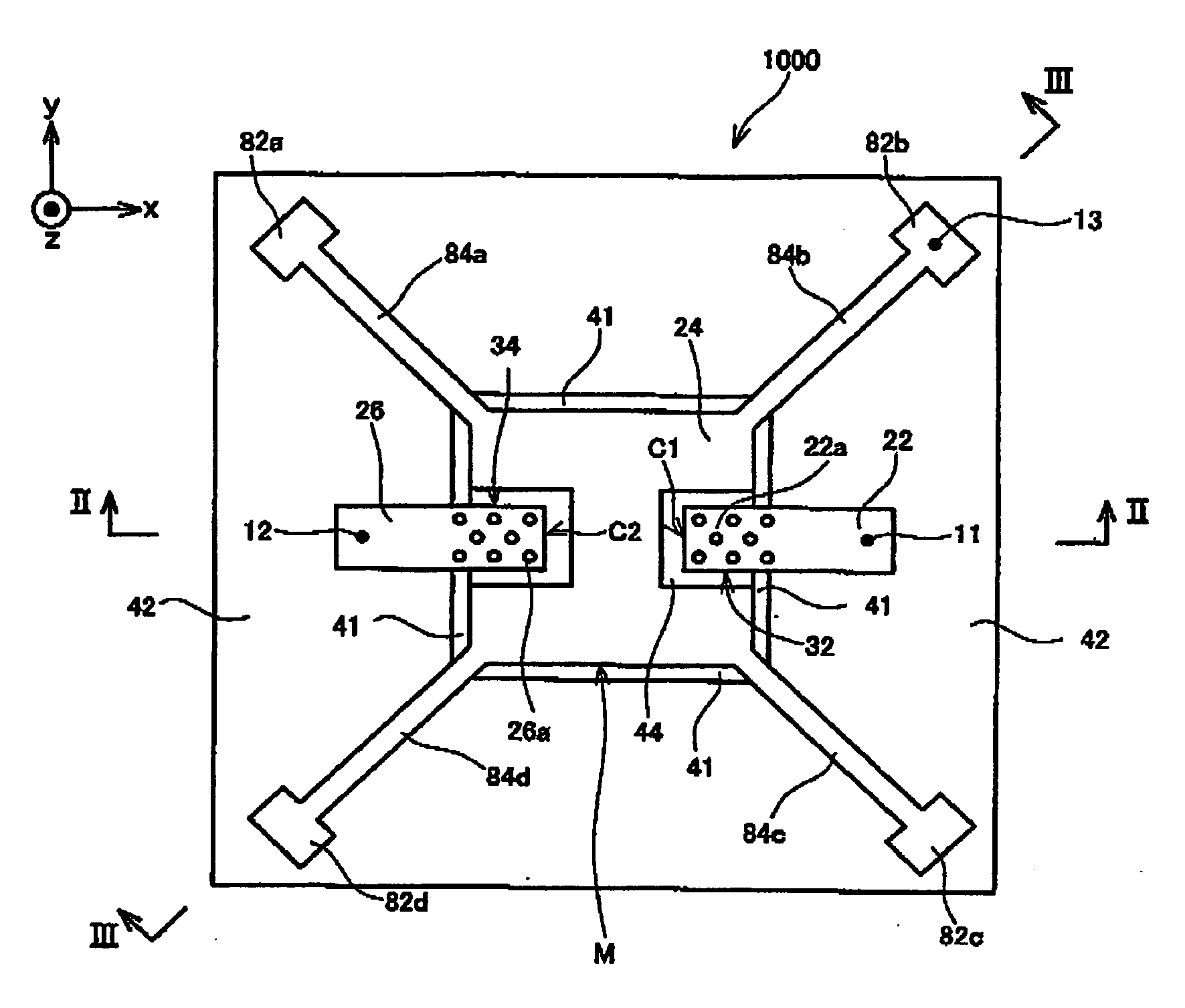

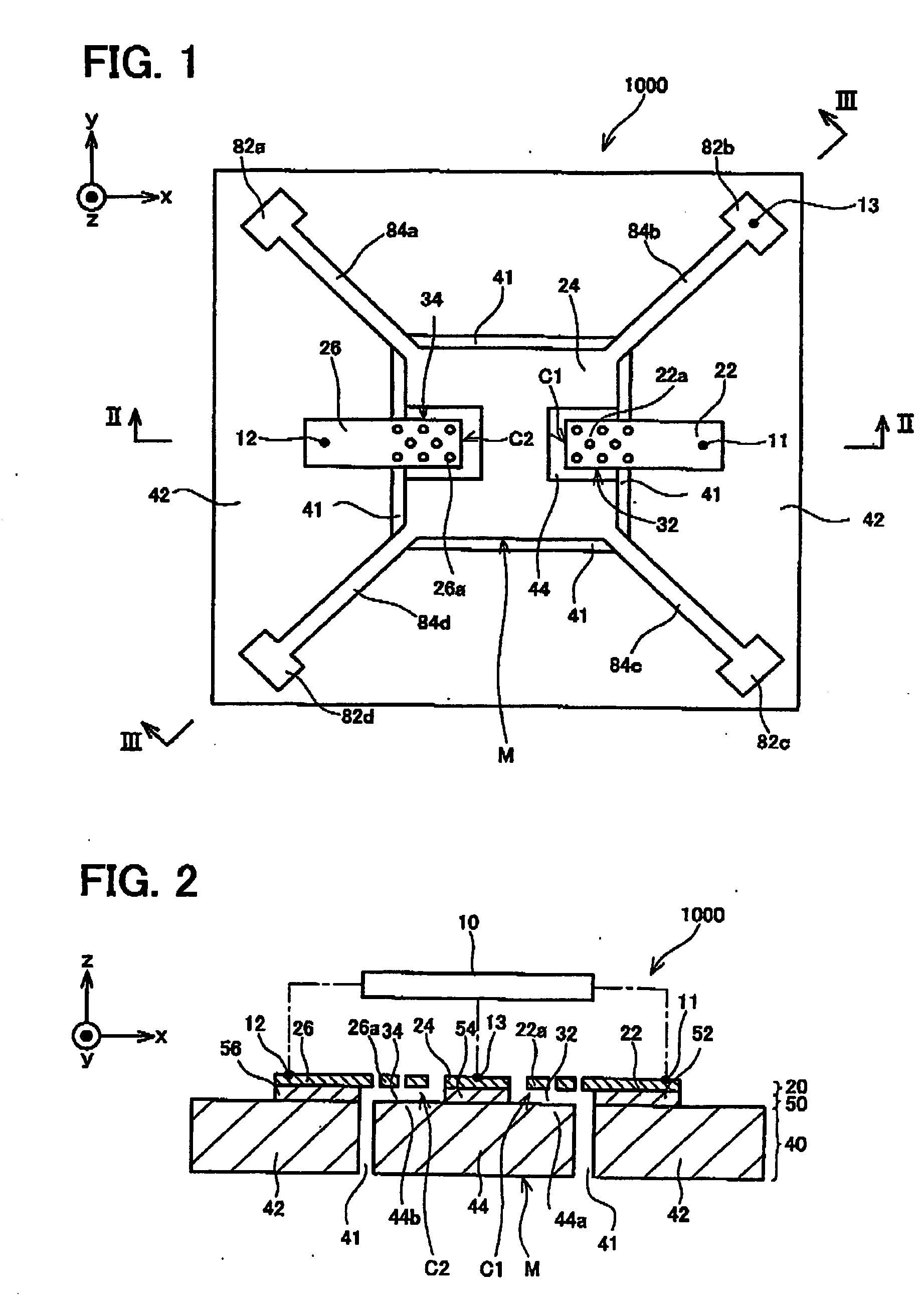

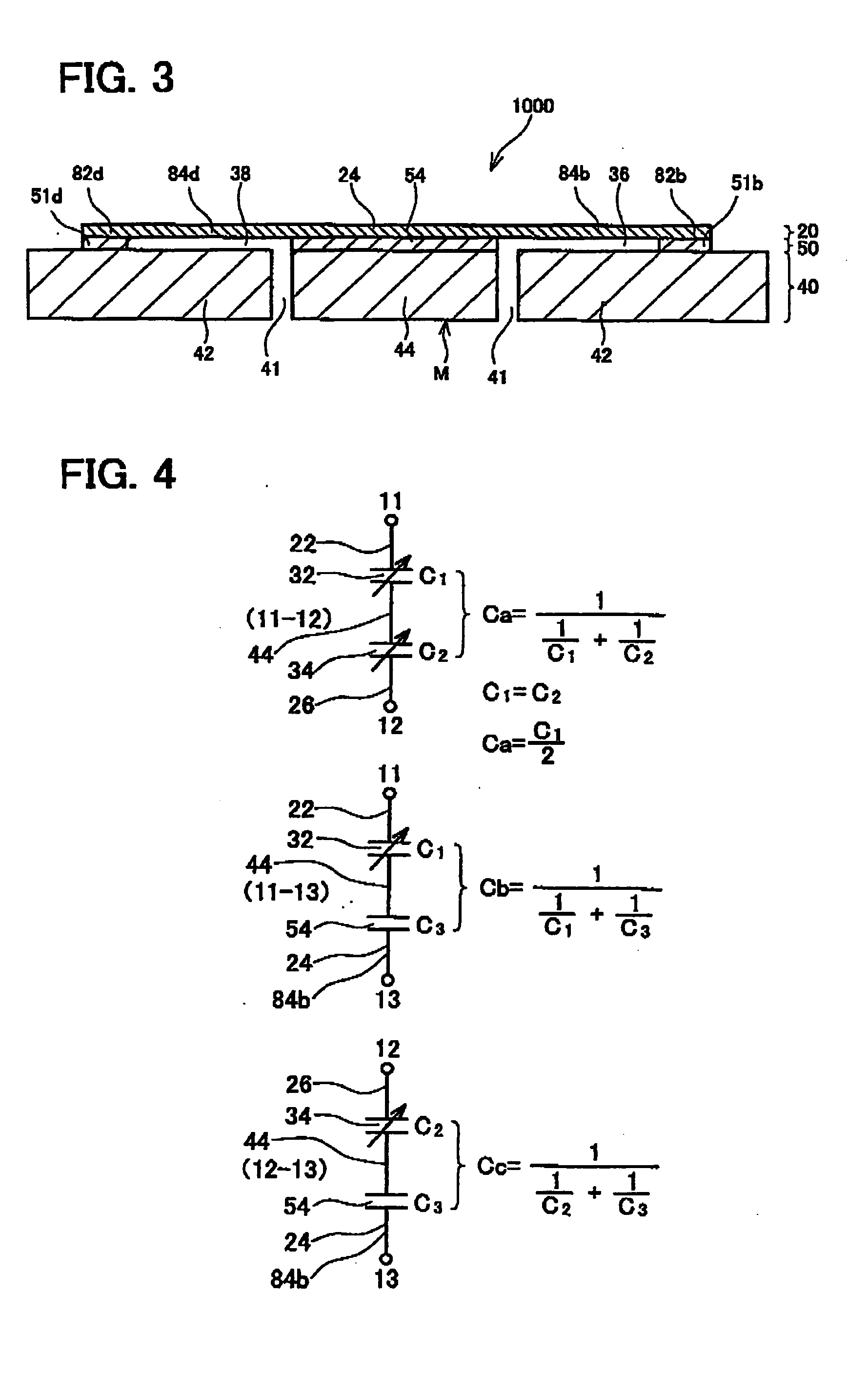

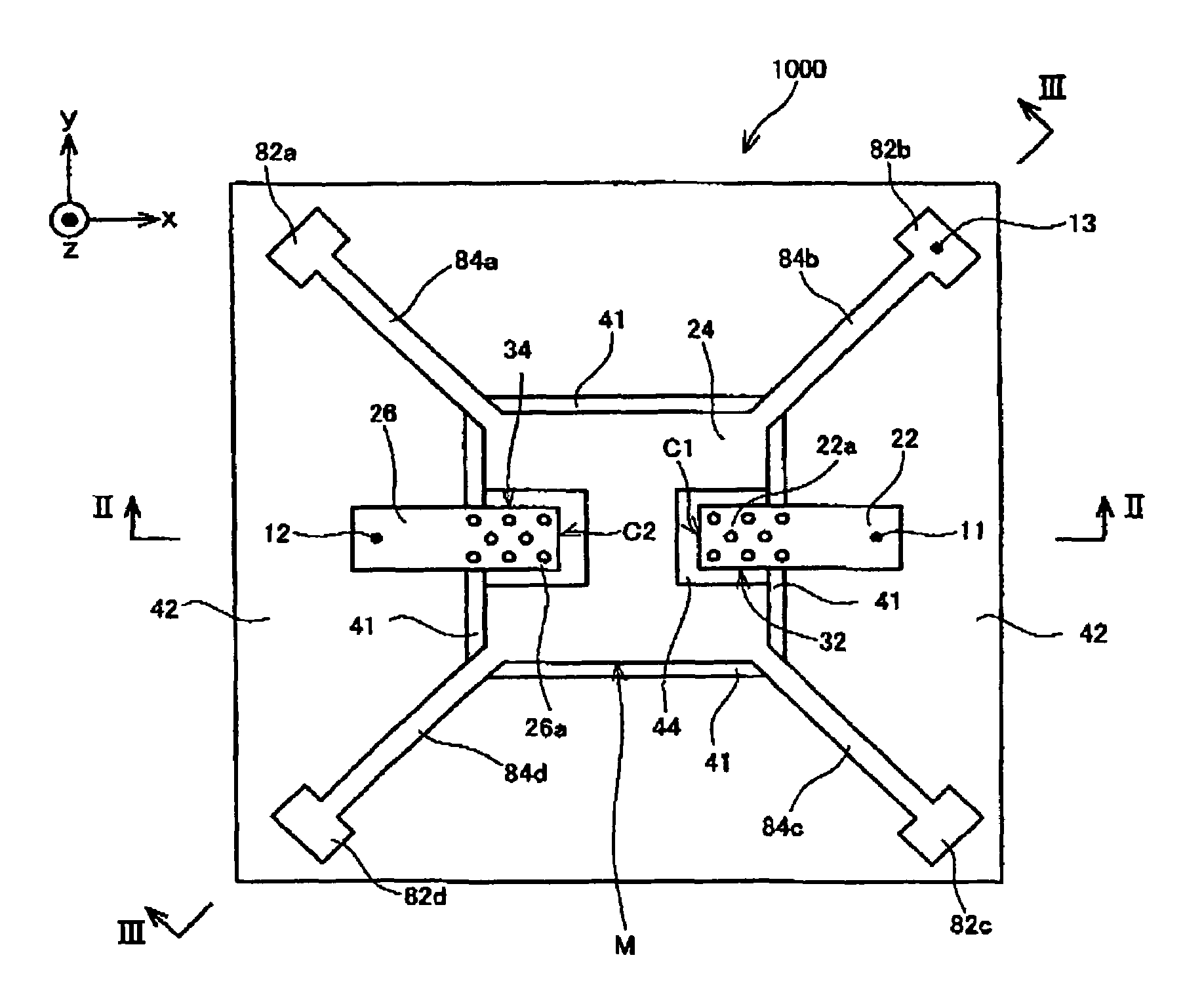

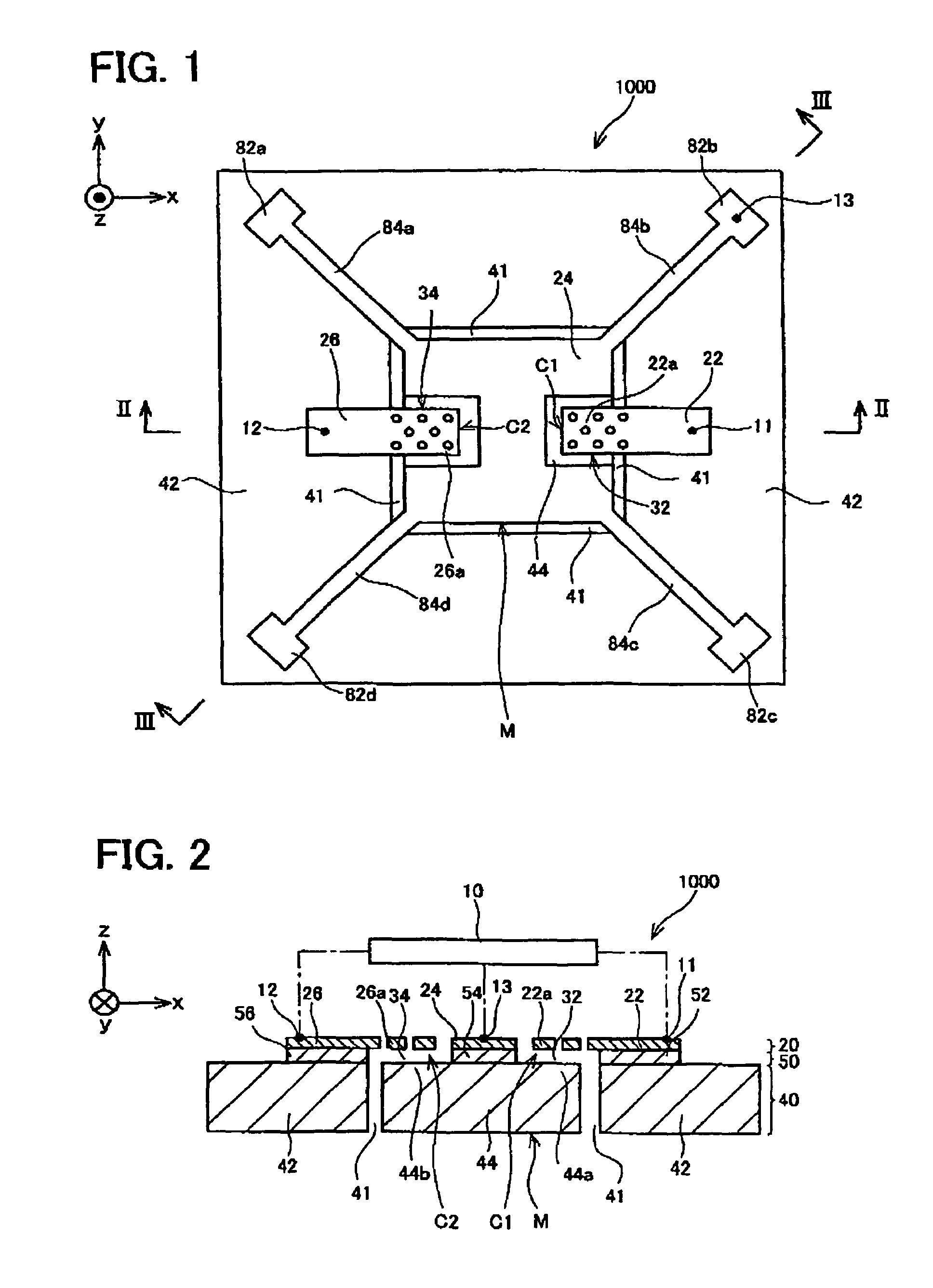

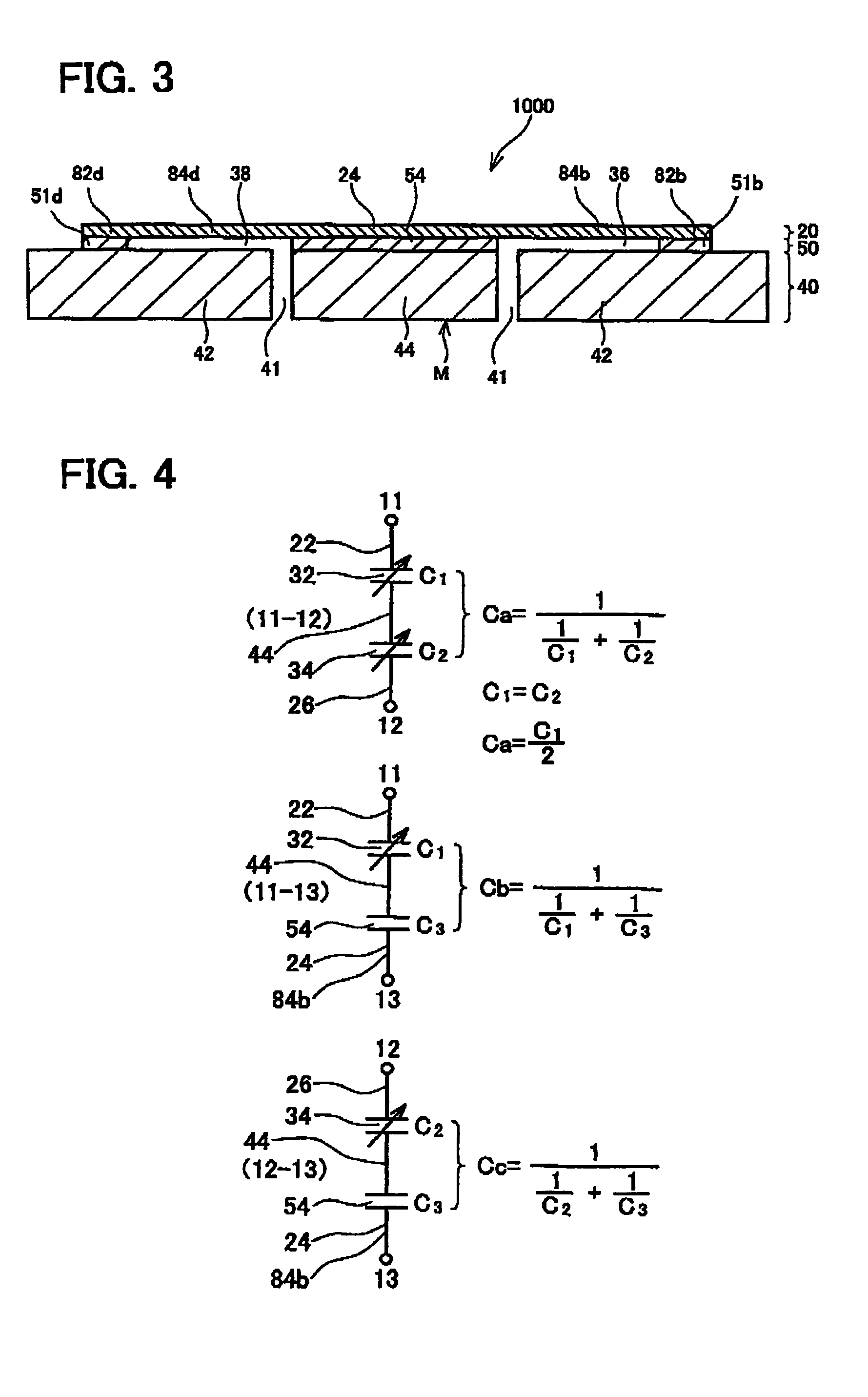

Displacement sensor

InactiveUS20050241364A1Easily manufactureHigh yield manufactureAcceleration measurement using interia forcesResistance/reactance/impedenceElectrical and Electronics engineeringCapacitor

Owner:TOYOTA CENT RES & DEV LAB INC +1

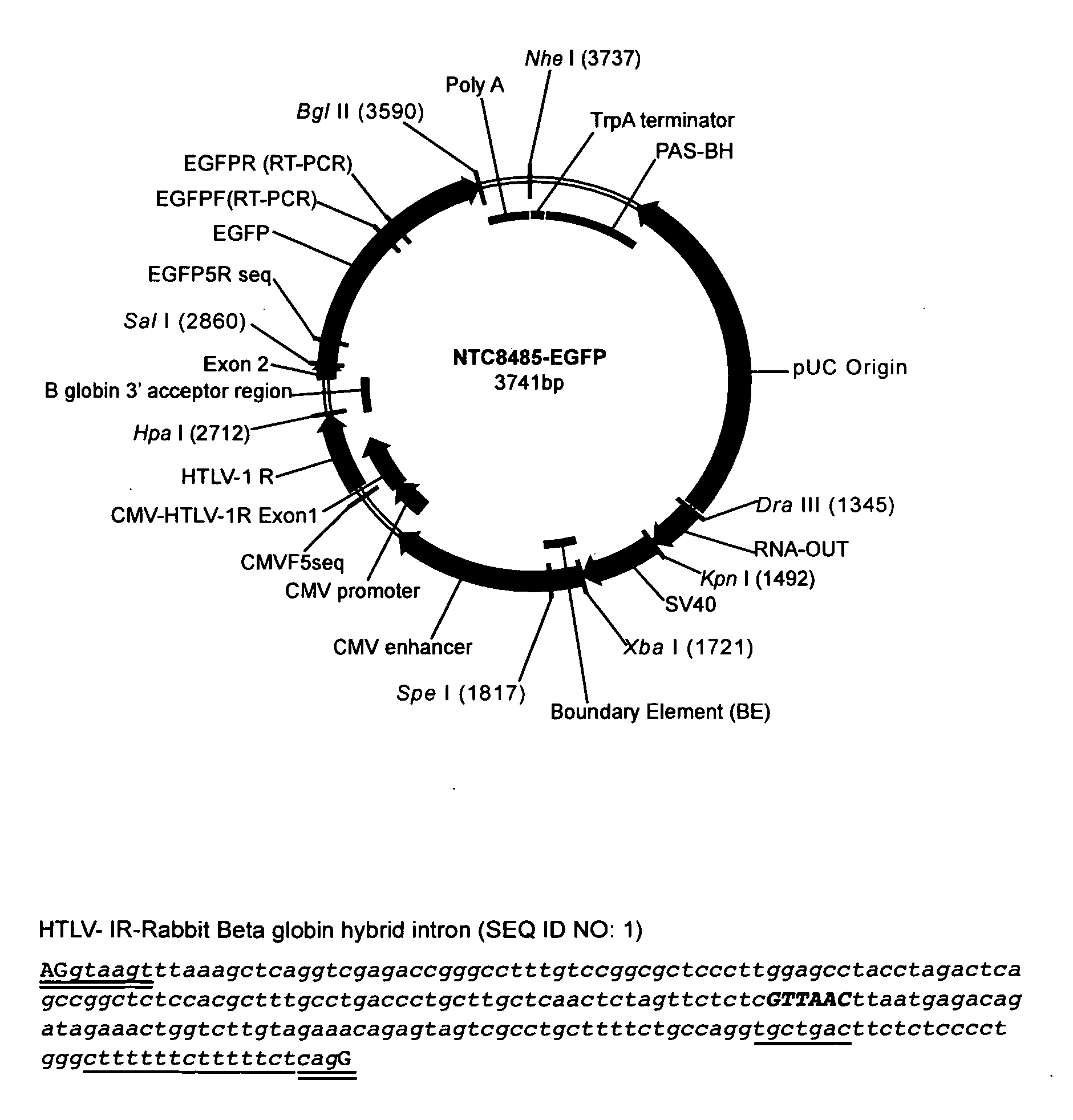

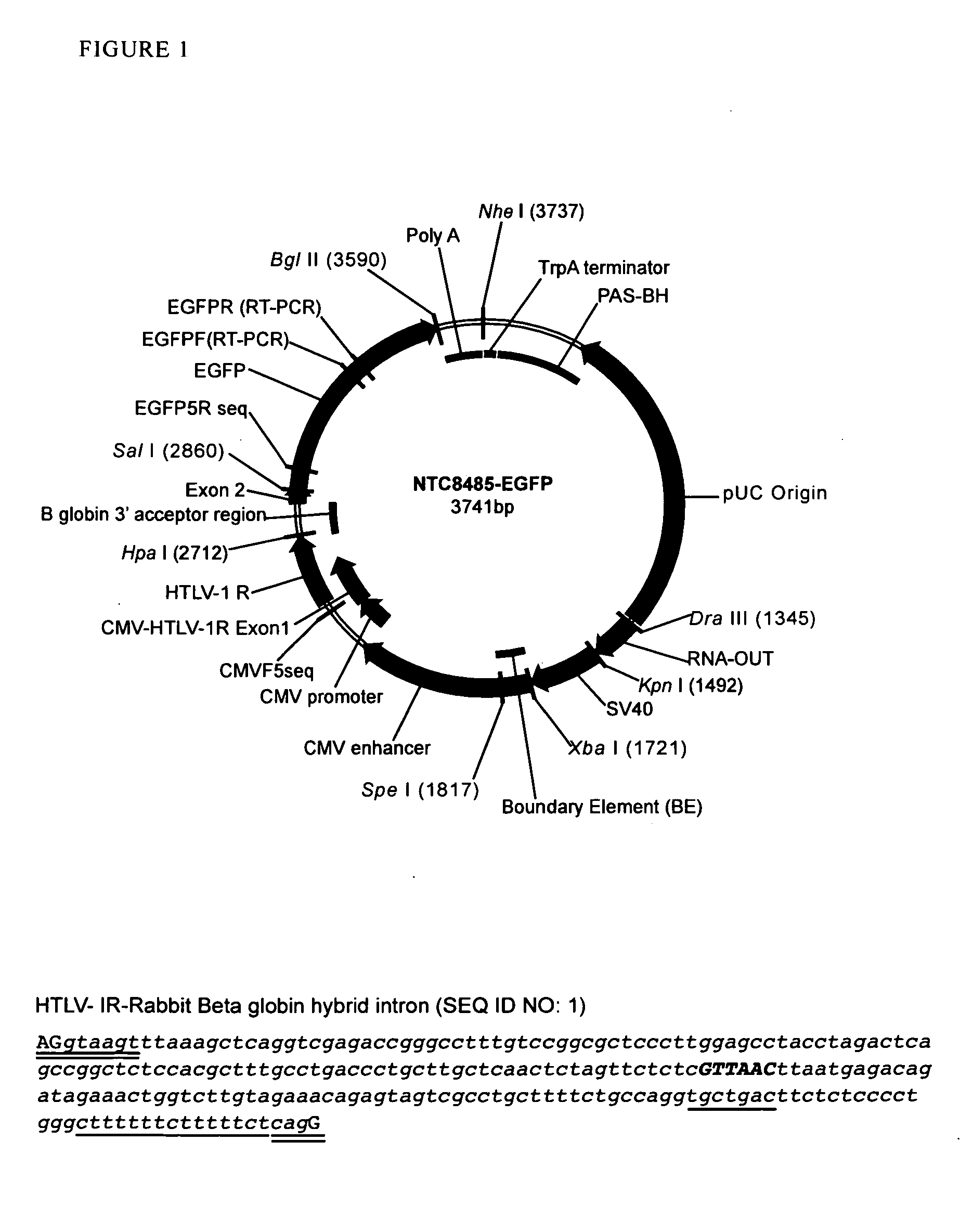

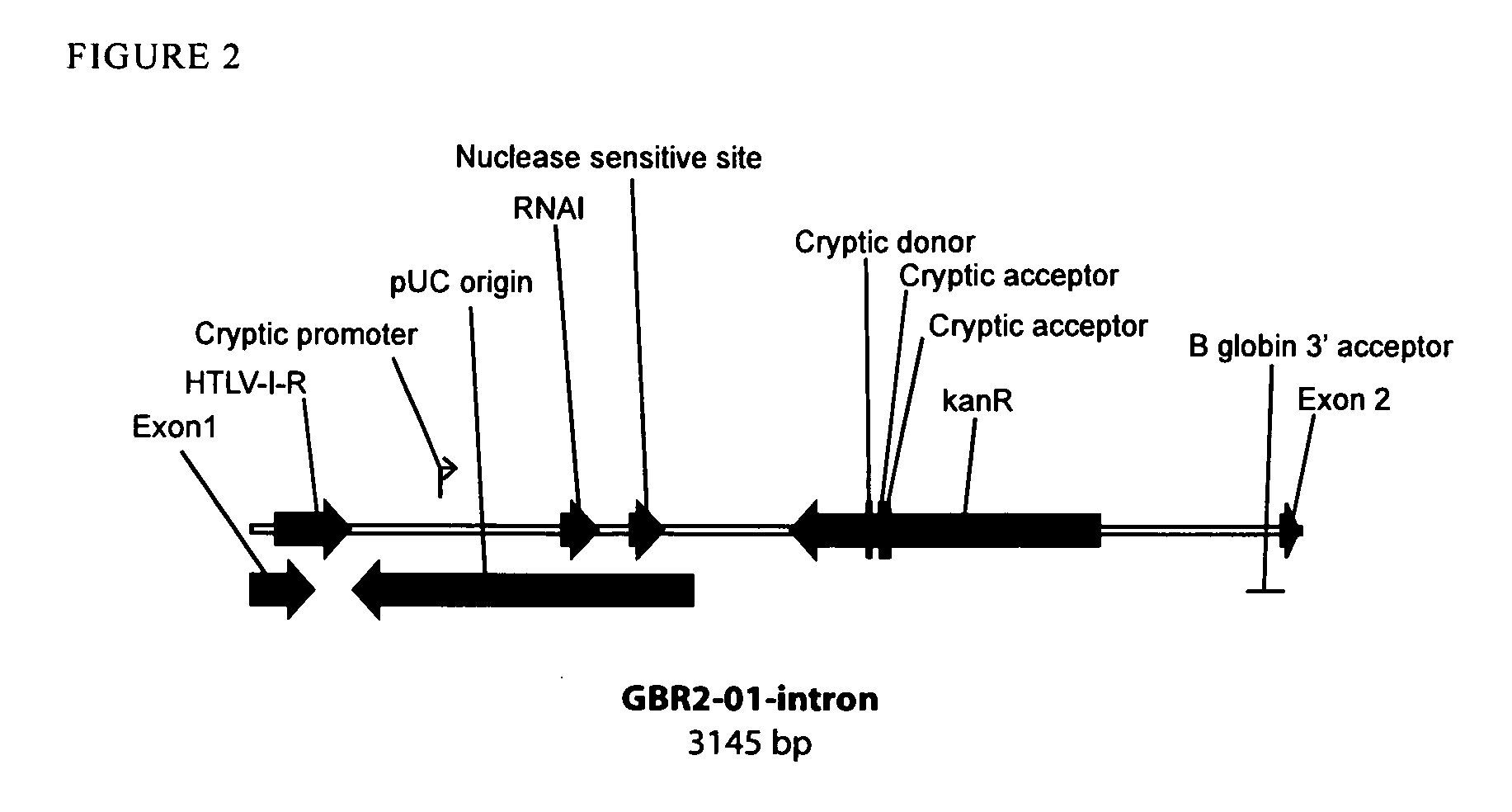

Replicative minicircle vectors with improved expression

ActiveUS20150275221A1Efficient preparationImproved in vivo expressionGenetic material ingredientsNucleic acid vectorBacteriophageViral vector

The present invention relates to the production and use of covalently closed circular (ccc) recombinant DNA molecules such as plasmids, cosmids, bacterial artificial chromosomes (BACs), bacteriophages, viral vectors and hybrids thereof, and more particularly to vector modifications that improve expression of said DNA molecules.

Owner:ALDEVRON LLC

Radiation detecting apparatus, manufacturing method therefor, and radiation image pickup system

InactiveUS20080128630A1Simple processIncrease opening ratioPhotometrySolid-state devicesElectrical conductorOhmic contact

The present invention provides a radiation detecting apparatus having a radiation conversion element laminated on a switch TFT, including: a gate electrode of the switch TFT; a first insulating layer, a first semiconductor layer, and an ohmic contact layer, which are laminated on the gate electrode in order; and a source / drain electrode of the switch TFT laminated on the ohmic contact layer, which all constitute the switch TFT; and a lower electrode of the radiation conversion element, which is formed on the same layer as the source / drain electrode; a second insulating layer, a second semiconductor layer, and a second ohmic contact layer, which are laminated on the lower electrode in order; and a bias wiring for applying a bias to the radiation conversion element. Also, the invention provides a radiation image pickup apparatus including: a photoelectric conversion element having a wavelength converter for converting a radiation into a visible light, a pixel electrode for converting the visible light into an electric signal, an insulating layer, and a semiconductor layer; and a transistor for controlling reading of the electric signal converted by the photoelectric conversion element, the photoelectric conversion element being laminated on the wavelength converter side of the transistor, the pixel electrode being divided for each of plural pixels, and the semiconductor layer extending over the plural pixels.

Owner:CANON KK

Method of manufacturing an LED

InactiveUS20140000793A1Small loadHigh yieldLamination ancillary operationsSolid-state devicesEngineeringPressure sensitive

A method of manufacturing an LED according to an embodiment of the present invention includes back-grinding a substrate of an LED wafer including a light emitting element and the substrate, where the back-grinding includes fixing the LED wafer to a table via a double-sided pressure-sensitive adhesive sheet, and then grinding the substrate.

Owner:NITTO DENKO CORP

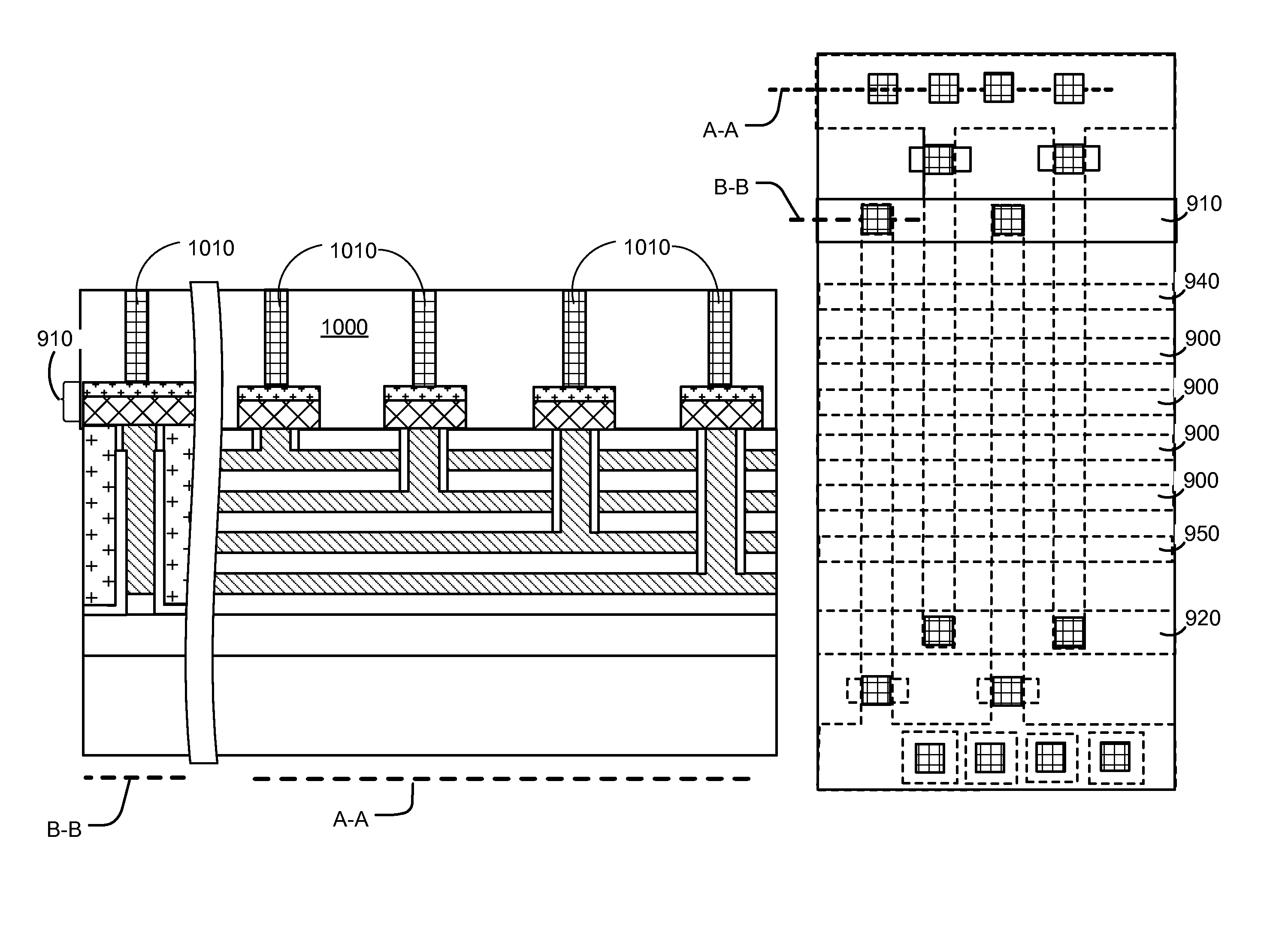

Contact architecture for 3D memory array

A vertical interconnect architecture for a three-dimensional (3D) memory device suitable for low cost, high yield manufacturing is described. Conductive lines (e.g. word lines) for the 3D memory array, and contact pads for vertical connectors used for couple the array to decoding circuitry and the like, are formed as parts of the same patterned level of material. The same material layer can be used to form the contact pads and the conductive access lines by an etch process using a single mask. By forming the contact pads concurrently with the conductive lines, the patterned material of the contact pads can protect underlying circuit elements which could otherwise be damaged during patterning of the conductive lines.

Owner:MACRONIX INT CO LTD

Displacement sensor

InactiveUS7501835B2Easy to adjustHigh yield preparationAcceleration measurement using interia forcesResistance/reactance/impedenceEngineeringCapacitor

Owner:TOYOTA CENT RES & DEV LAB INC +1

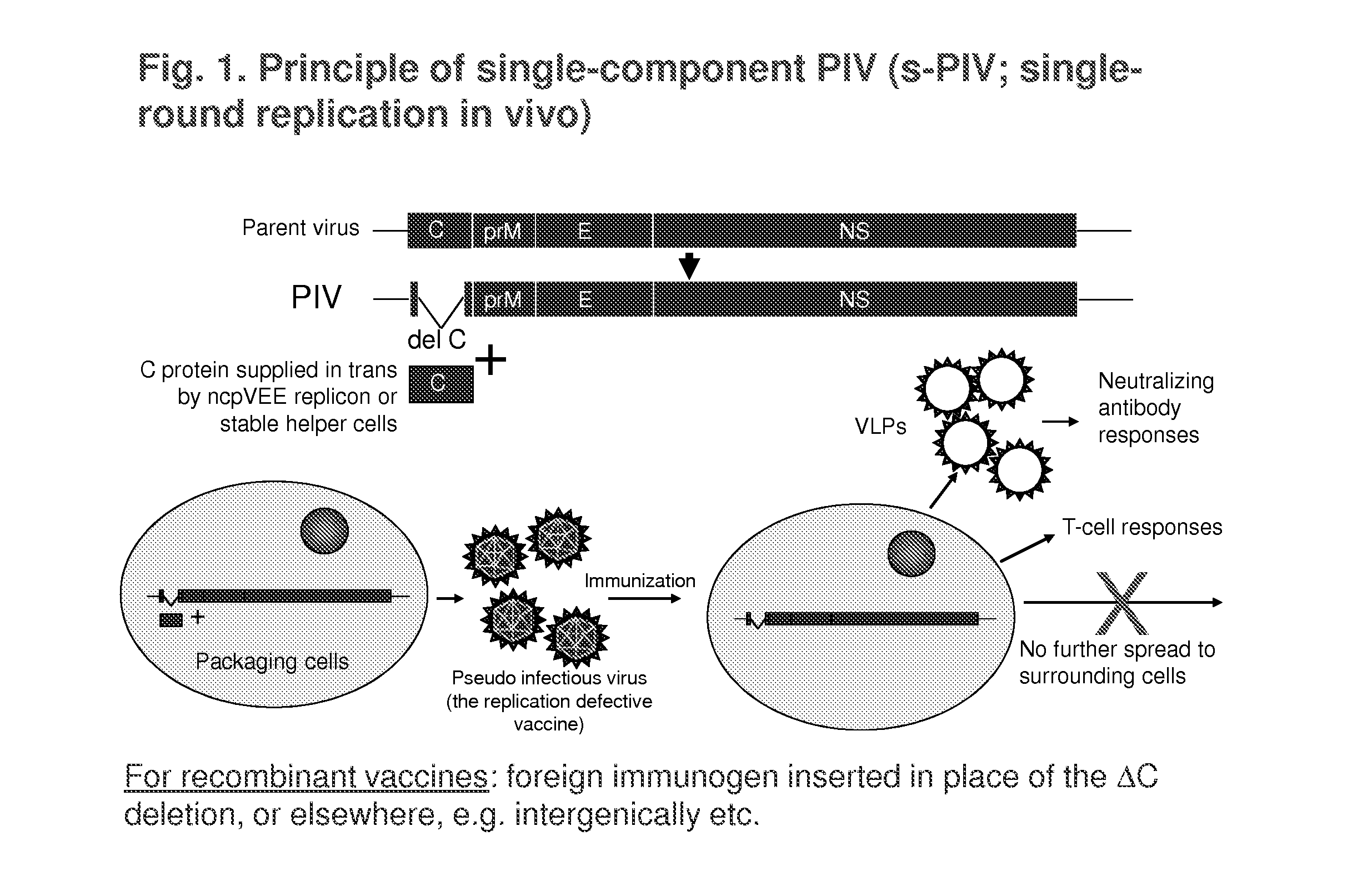

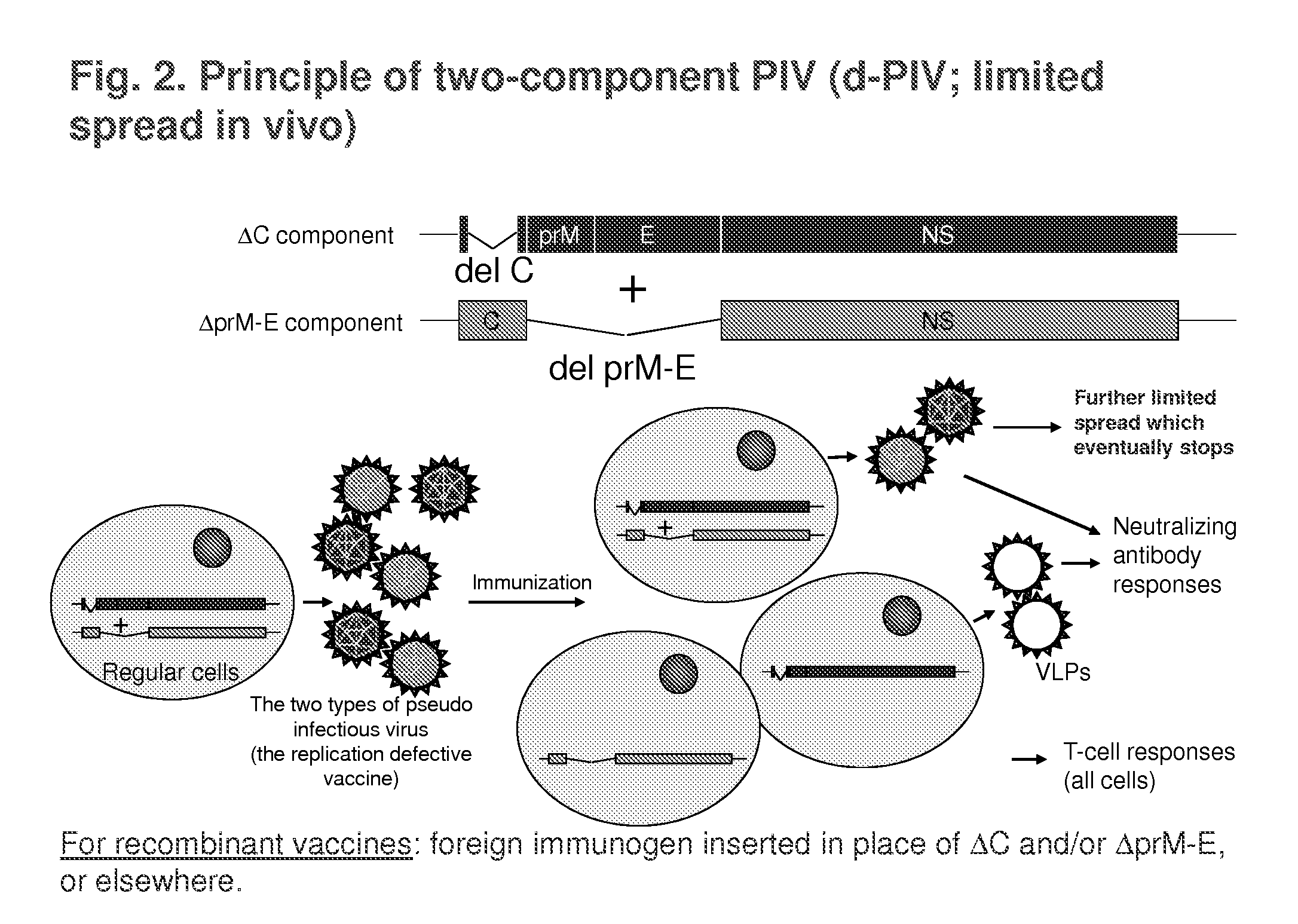

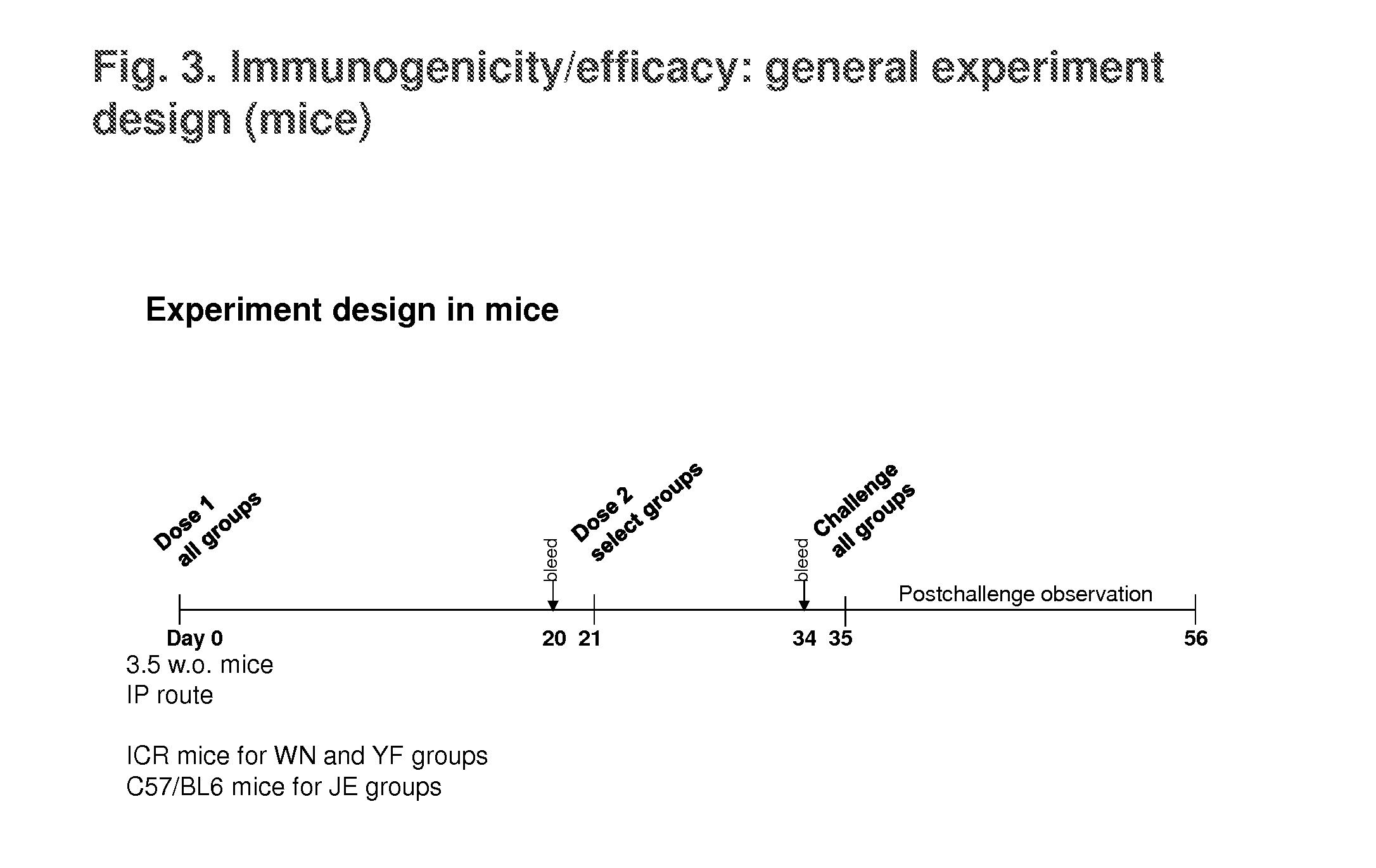

Replication-Defective Flavivirus Vaccines and Vaccine Vectors

InactiveUS20130243812A1Speed up the descentHighly efficaciousSsRNA viruses negative-senseAntibacterial agentsTGE VACCINEBiomedical engineering

This invention provides replication-defective flavivirus vaccines and vaccine vectors, and corresponding compositions and methods.

Owner:SANOFI PASTEUR BIOLOGICS CO

Dye-sensitized solar cell and dye-sensitized solar cell module

ActiveCN102396101AHigh yield preparationImprove conversion efficiencyElectrolytic capacitorsPhotovoltaic energy generationSurface roughnessSolar cell

Provided is a dye-sensitized solar cell wherein at least a catalytic layer, a porous insulating layer containing an electrolyte inside thereof, a porous semiconductor layer wherein a sensitizing dye is adsorbed and the electrolyte is contained therein, and a second conductive layer are laminated on a first conductive layer. The contact surface of the adjacently laminated porous insulating layer or catalytic layer of the porous semiconductor layer or second conductive layer has an uneven shape having a surface roughness coefficient (Ra) of 0.05-0.3 [mu]m.

Owner:SHARP KK

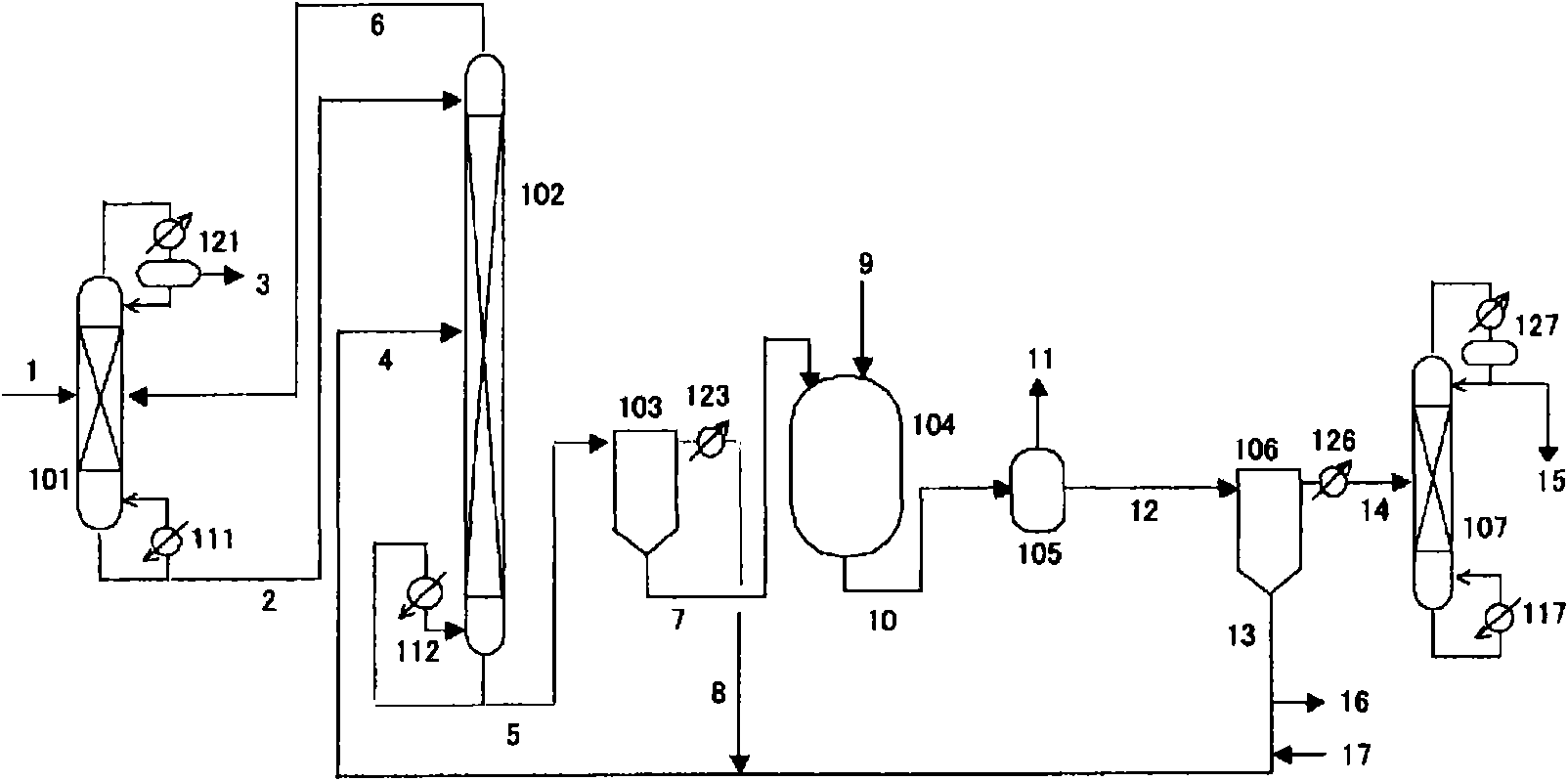

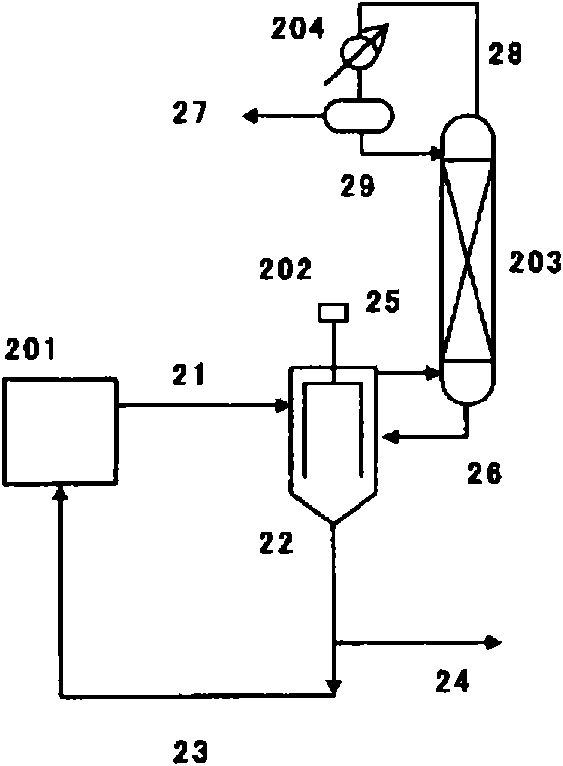

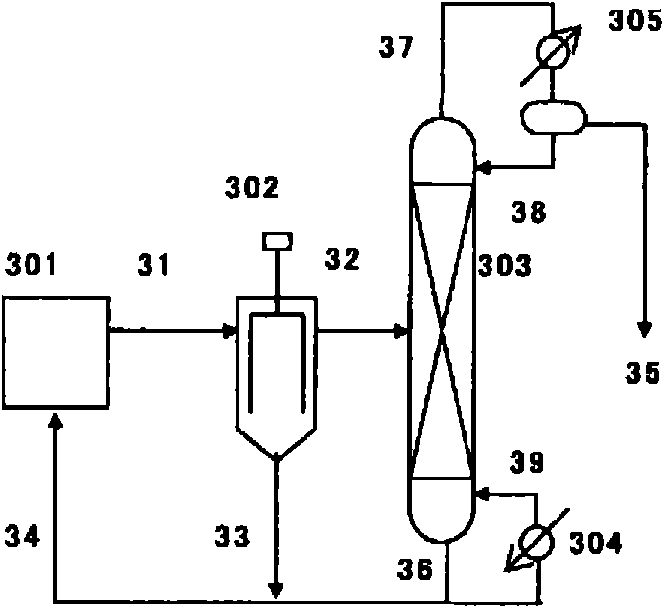

Method for producing isocyanate

ActiveCN101589022AManufactured with high yieldHigh yield preparationPreparation from carbamatesAromatic hydroxylationDecomposition

Disclosed is a method for stably producing an isocyanate with high yield for a long time without using phosgene. This method for producing an isocyanate does not cause the problems involved in the prior art. Specifically disclosed is a method for producing an isocyanate, which comprises a step wherein a carbamic acid ester is reacted with an aromatic hydroxy compound, thereby obtaining an aryl carbamate having a group derived from the aromatic hydroxy compound, and a step wherein the aryl carbamate is subjected to a decomposition reaction. This method for producing an isocyanate is characterized in that the aromatic hydroxy compound is an aromatic hydroxy compound represented by the formula (1) below, which has a substituent R<1> at at least one ortho-position of the hydroxyl group. In the formula, ring A represents an optionally substituted monocyclic or heterocyclic aromatic hydrocarbon ring having 6-20 carbon atoms; R<1> represents a group other than a hydrogen atom, which is an aliphatic alkyl group having 1-20 carbon atoms, an aliphatic alkoxy group having 1-20 carbon atoms, an aryl group having 6-20 carbon atoms, an aryloxy group having 6-20 carbon atoms, an aralkyl group having 7-20 carbon atoms or an aralkyloxy group having 7-20 carbon atoms, each containing an atom selected from a carbon atom, an oxygen atom and a nitrogen atom; and R<1> and A may combine together to form a ring structure.

Owner:ASAHI KASEI KK

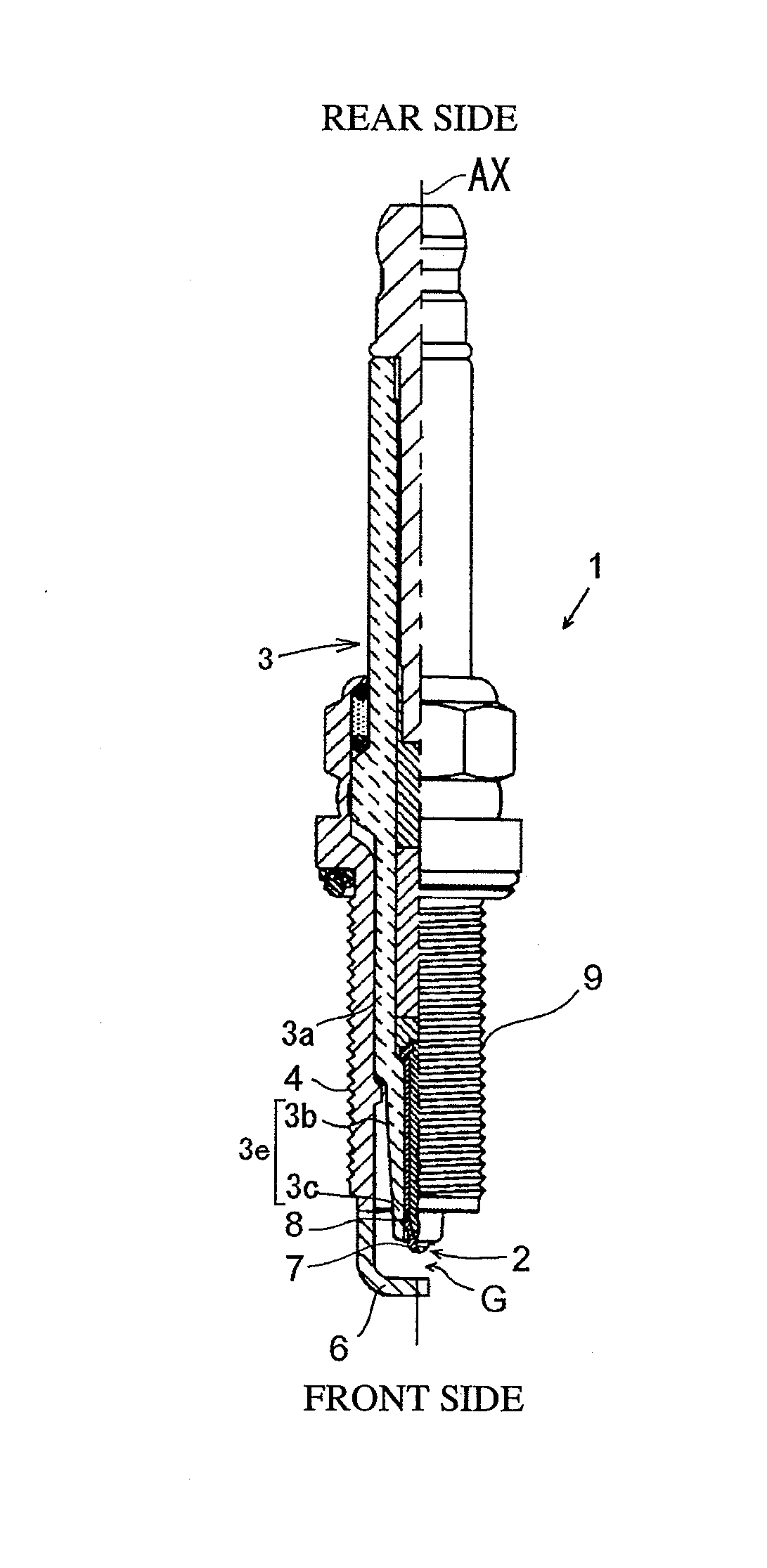

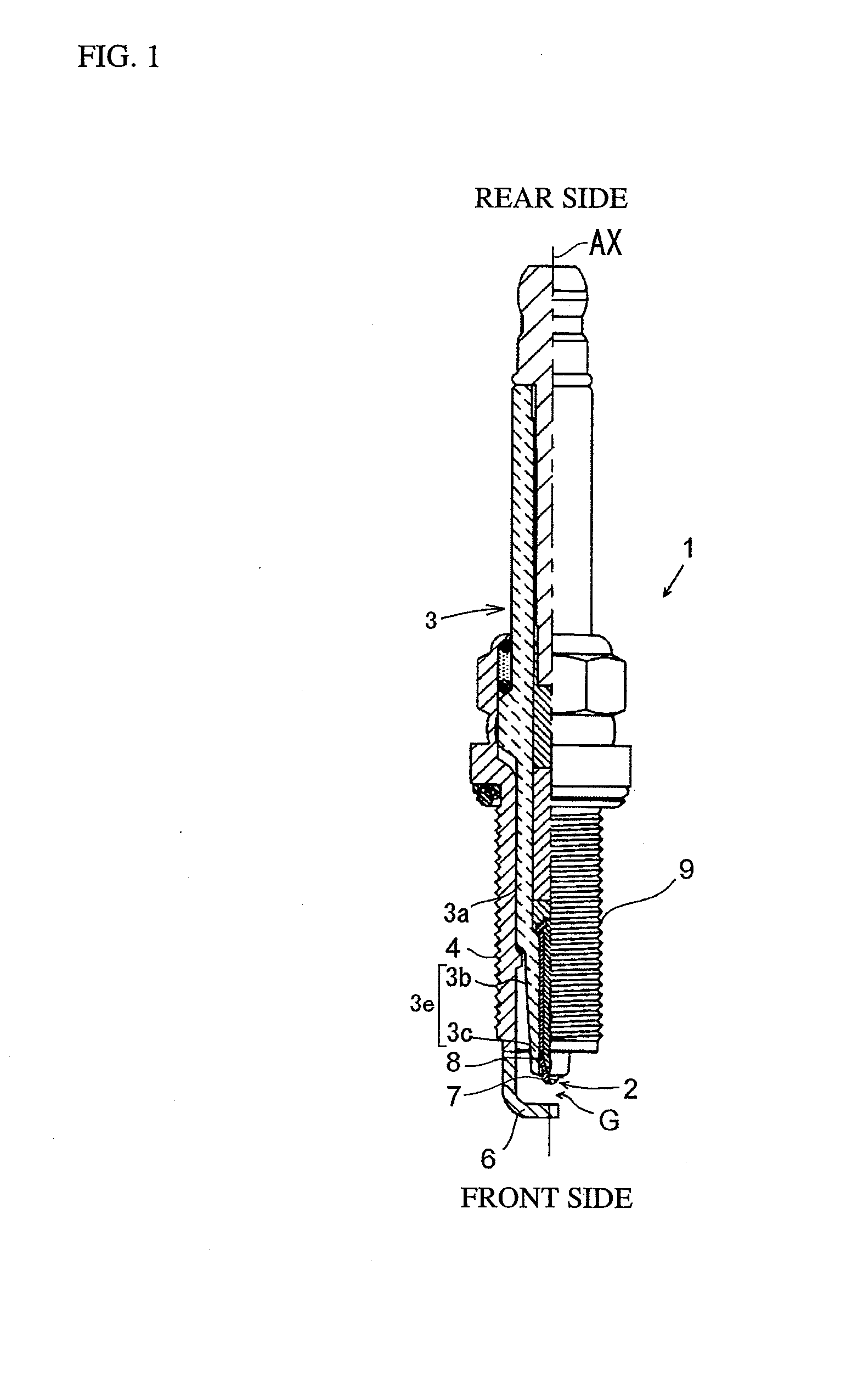

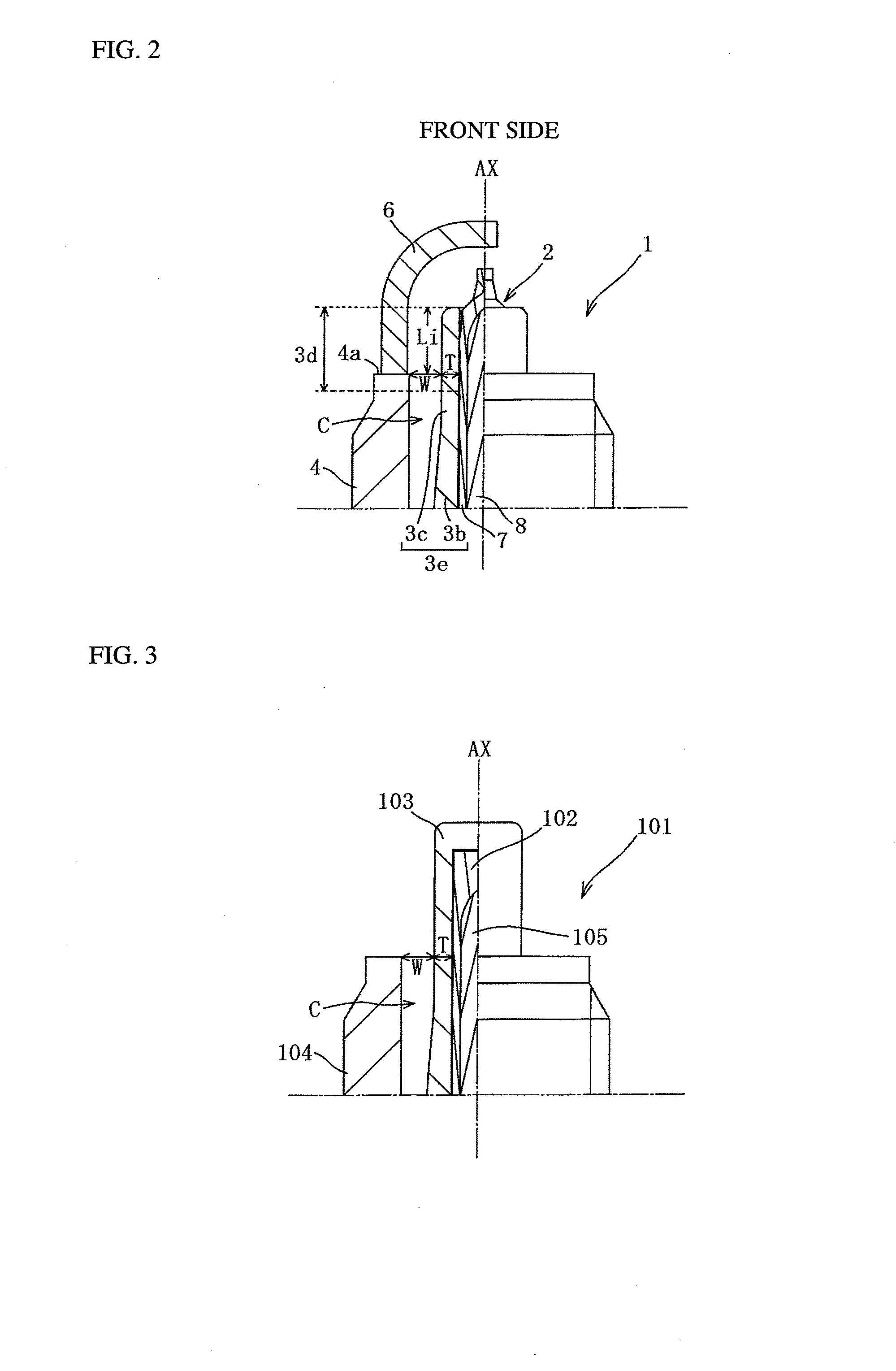

Spark plug and method for manufacturing spark plug

ActiveUS20120319556A1Avoid leakage currentGood combustible-gas ignitabilitySpark gapsFuel injection apparatusRare-earth elementMass ratio

The present invention relates to a spark plug having good combustible-gas ignitability even when the spark plug is downsized and to a method for high-yield manufacturing of a spark plug with good combustible-gas ignitability. There is provided according to one aspect of the present invention a spark plug 1 having a center electrode 2, an insulator 3 and a metal shell 4 and satisfying the following conditions (1) to (5). There is provided according to another aspect of the present invention a manufacturing method of a spark plug including the step of producing an insulator by preparing a raw material powder in such a manner that the particle size distribution ratio (90% volume diameter / 10% volume diameter) between particles of 10% volume diameter and particles of 90% volume diameter in the raw material powder is 3.6 to 5.2, and then, press-forming and sintering the prepared raw material powder.Condition (1): The insulator has a wall thickness T of 0.3 to 1.1 mm at an imaginary plane including a front end face of the metal shell.Condition (2): A region of the insulator extending from a front end of the insulator to at least 2 mm rear from the imaginary plane is formed of an alumina-based sintered body containing a Si component, a rare earth element component and at least two kinds of Group 2 element components and being substantially free from a B component.Condition (3): The mass ratio RRE of a mass of the rare earth element component to a total mass of the Si component, the Group 2 element components and the rare earth element component in the alumina-based sintered body is 0.15 to 0.45.Condition (4): The mass ratio R2 of a total mass of the components of the Group 2 elements to a mass of the Si component in the alumina-based sintered body is 0.25 or greater.Condition (5): The alumina-based sintered body includes, in a grain boundary phase thereof, an aluminate crystal containing the rare earth element component.

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com