Patents

Literature

204results about "Preparation from carbamates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Making Carbamates, Ureas and Isocyanates

InactiveUS20100113819A1Improve production yieldShort timeUrea derivatives preparationCarbamic acid derivatives preparationCarbamatePyrolysis

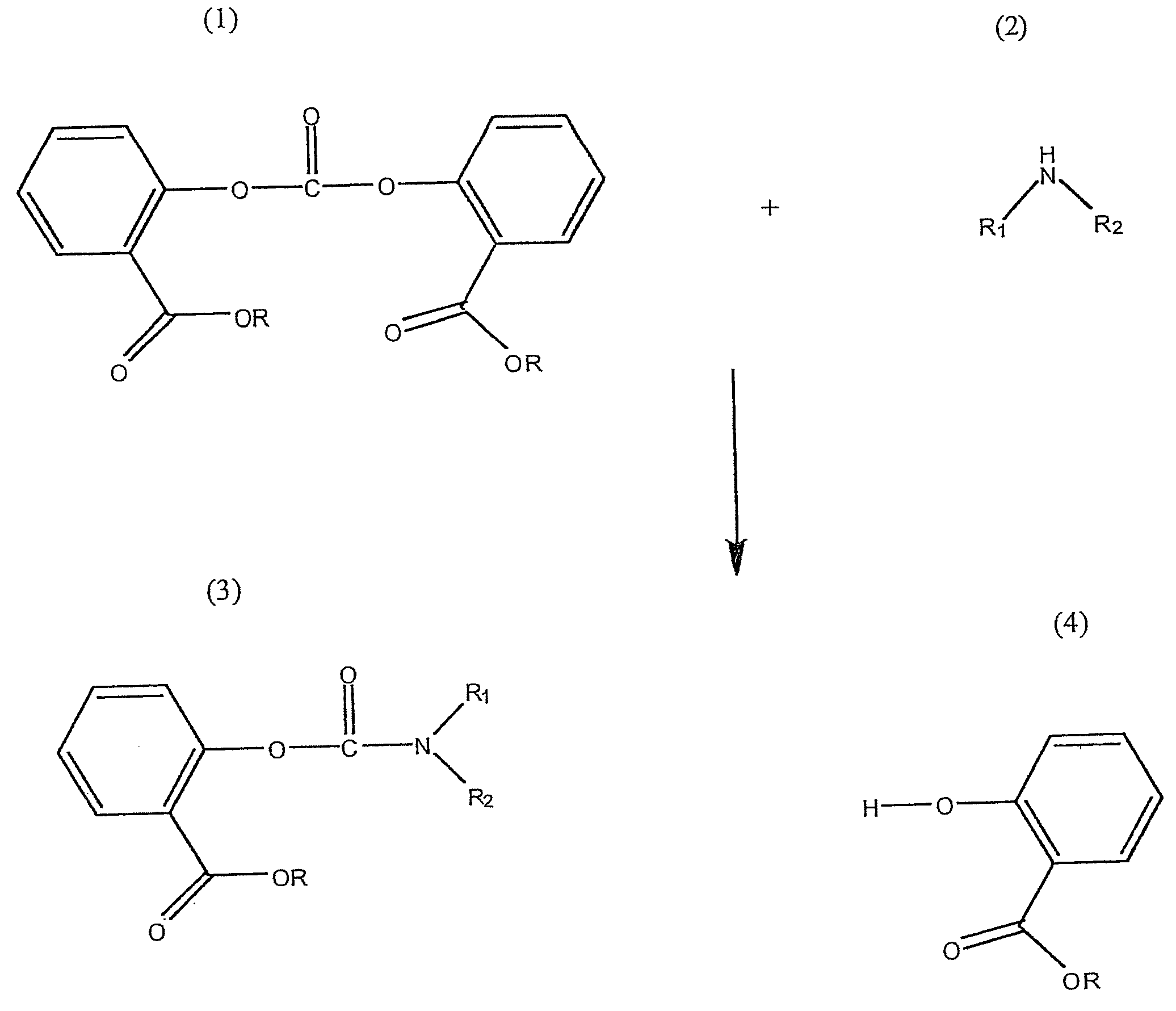

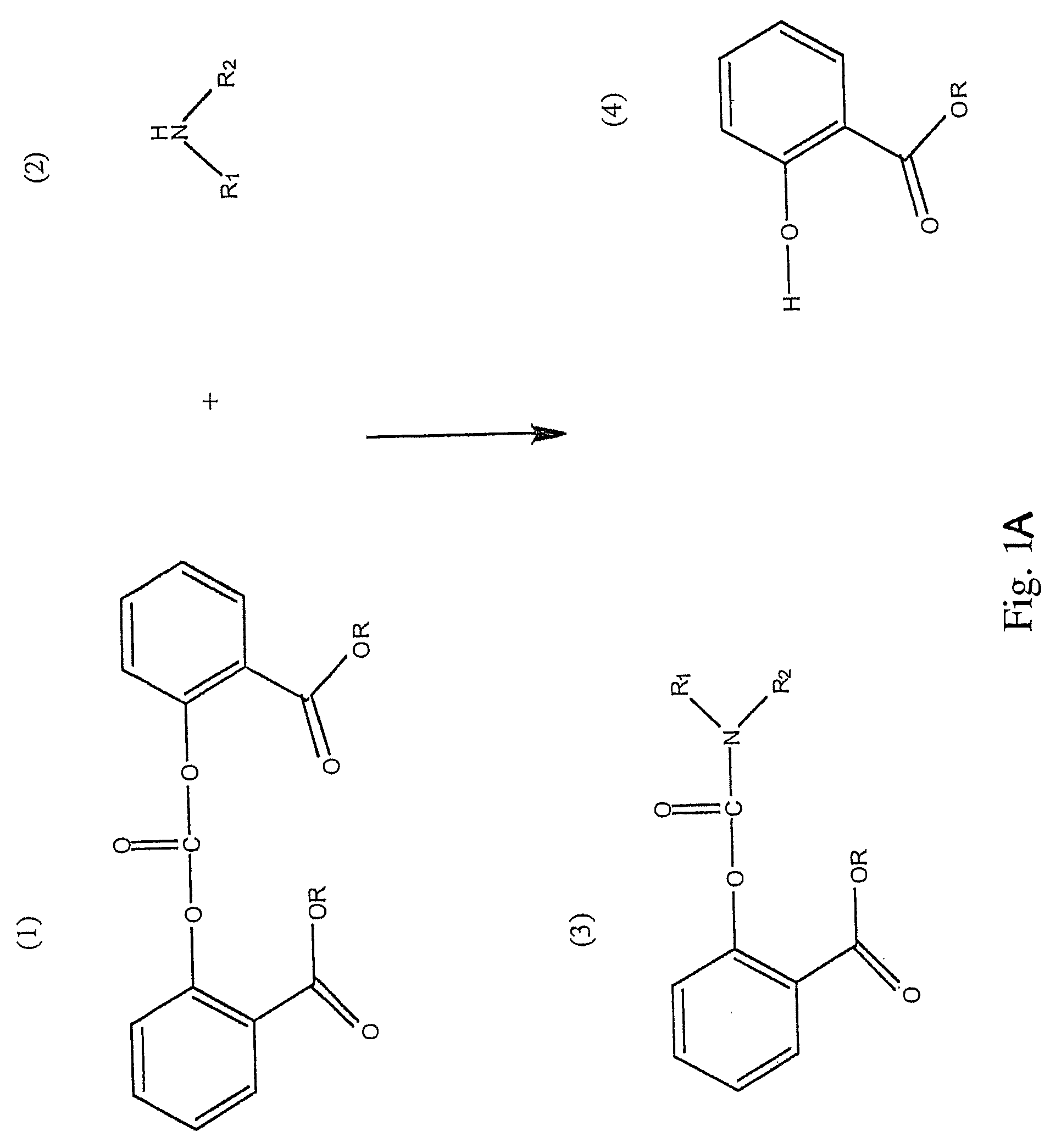

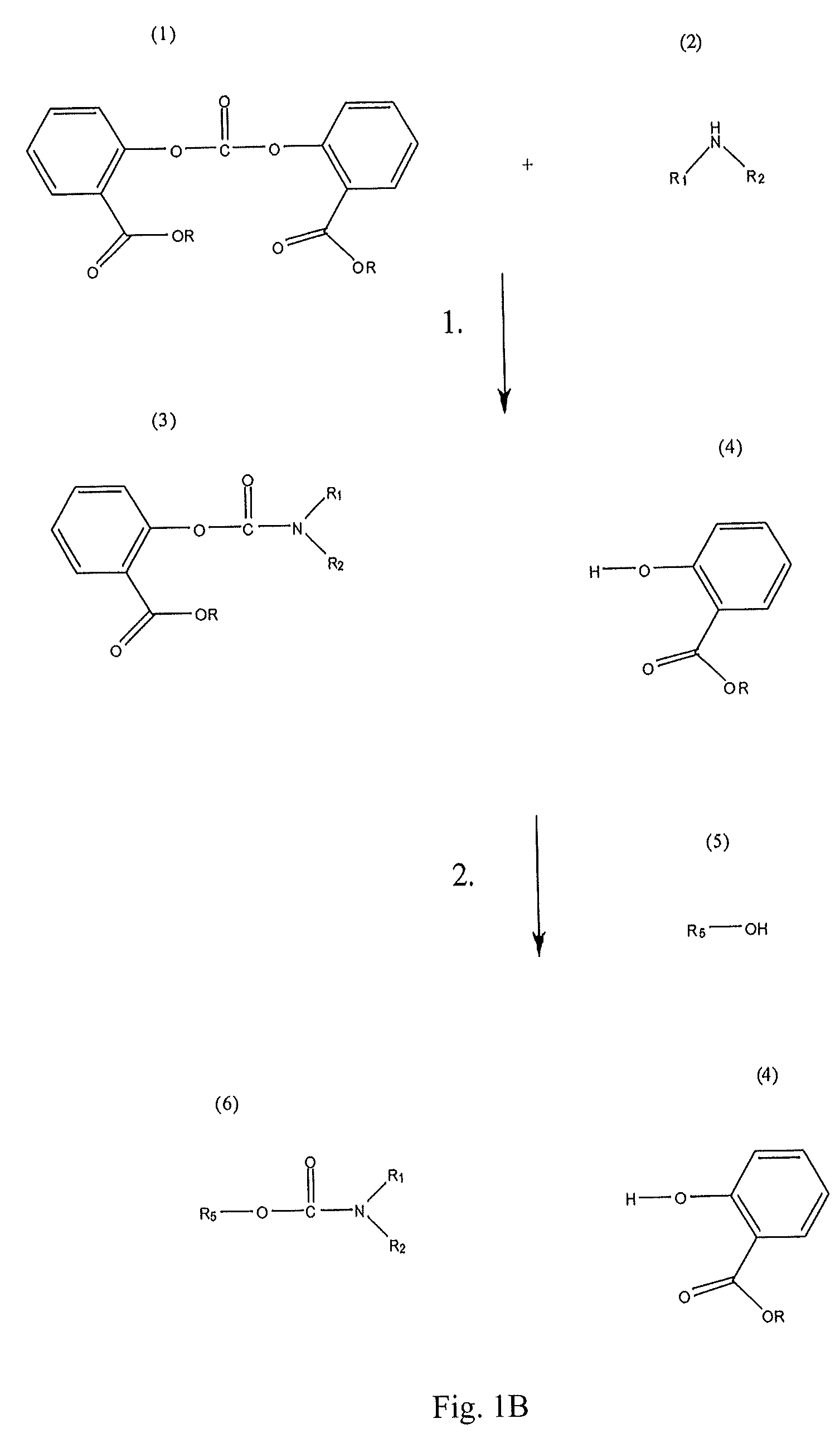

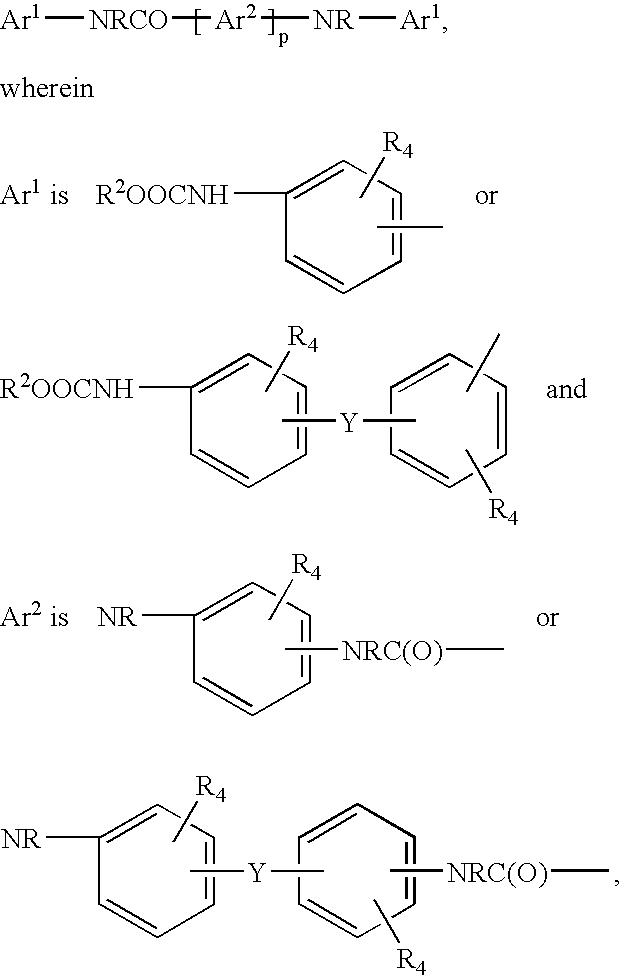

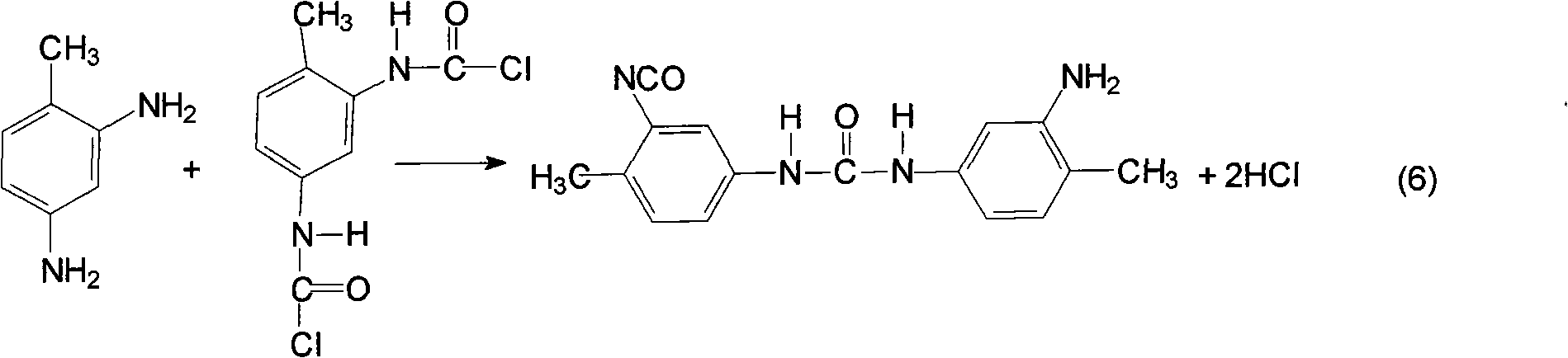

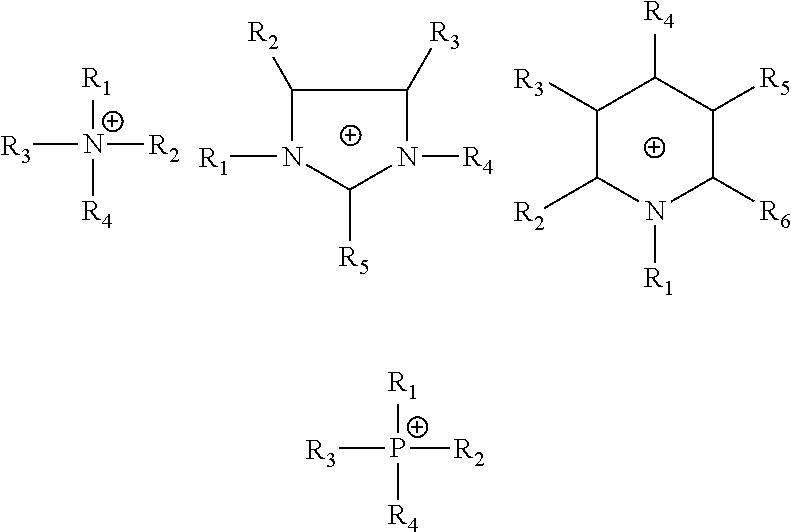

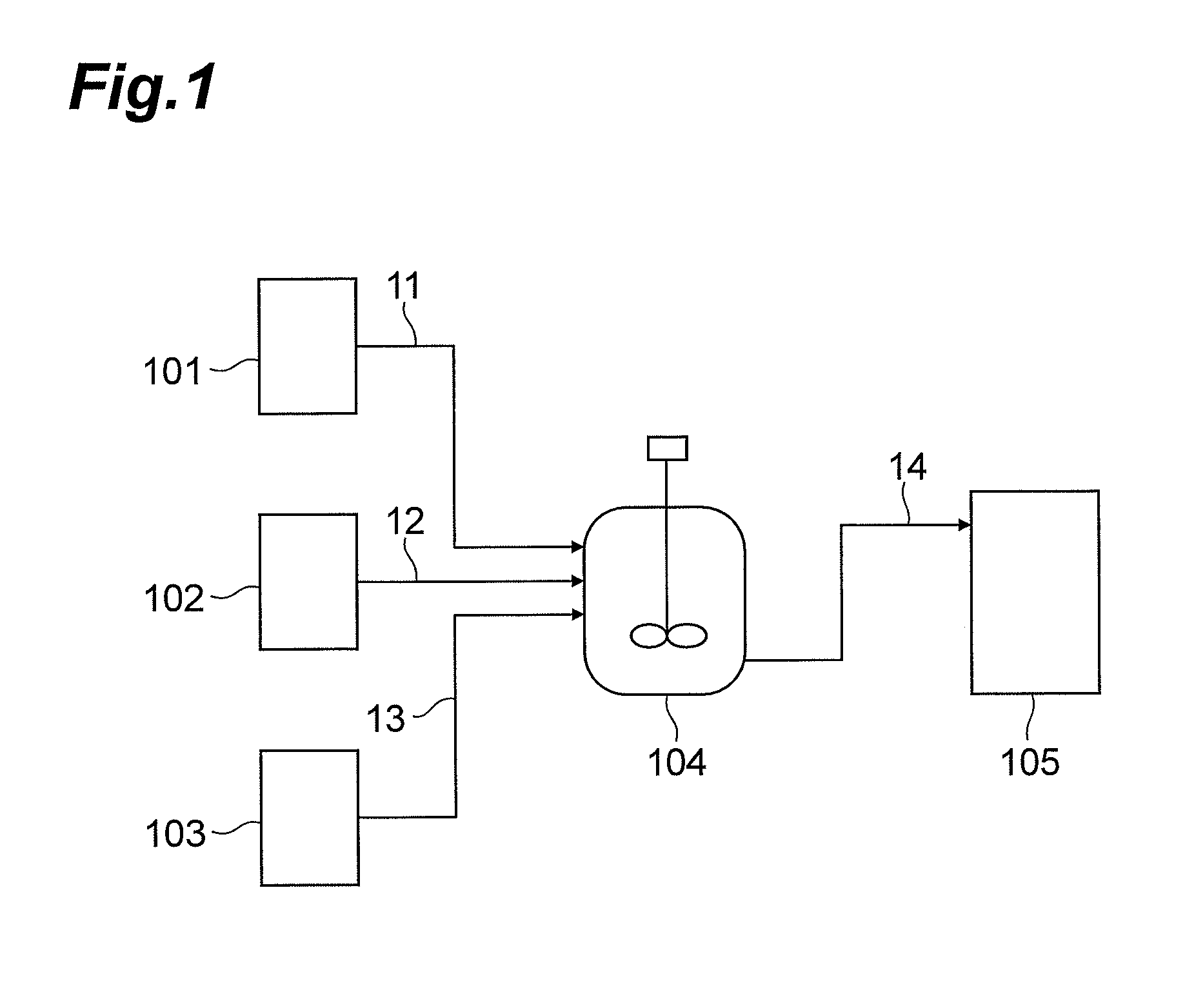

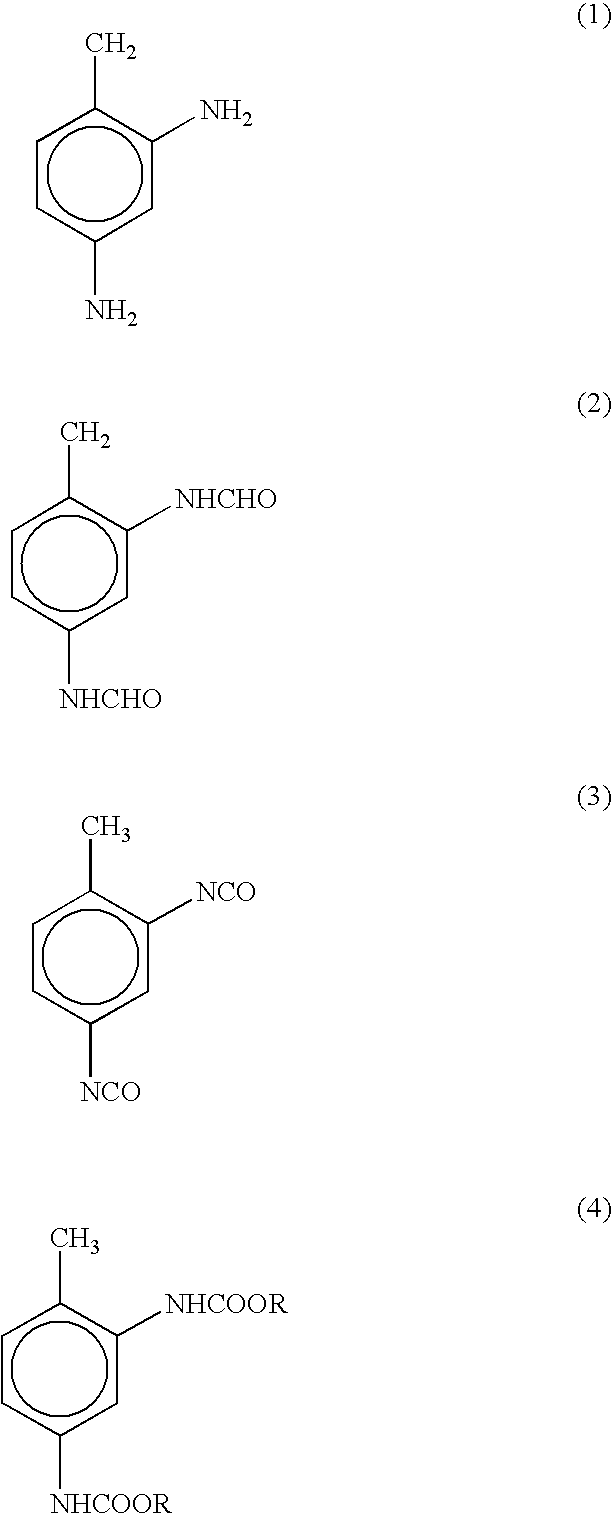

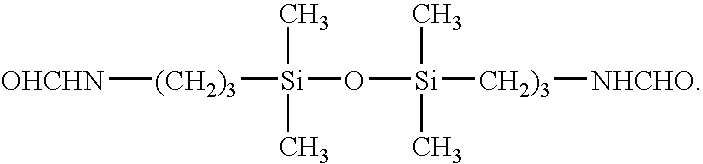

The present invention provides methods of forming carbamates, ureas, and isocyanates. In certain embodiments these methods include the step of reacting an amine with an ester-substituted diaryl carbonate to form an activated carbamate which can be further derivitized to form non-activated carbamate or a urea. The urea or carbamate can be subjected to a pyrolysis reaction to form isocyanate.

Owner:SABIC GLOBAL TECH BV

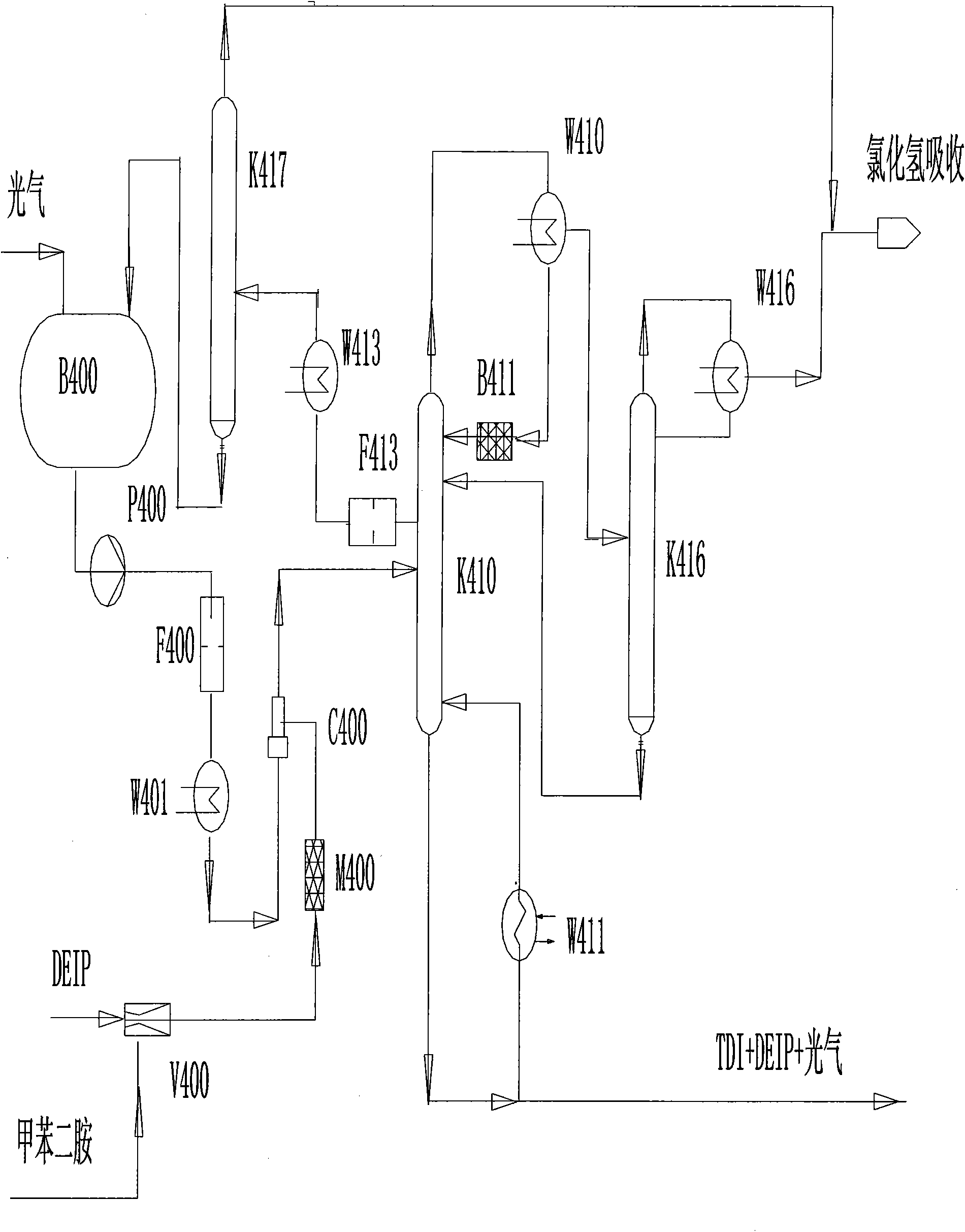

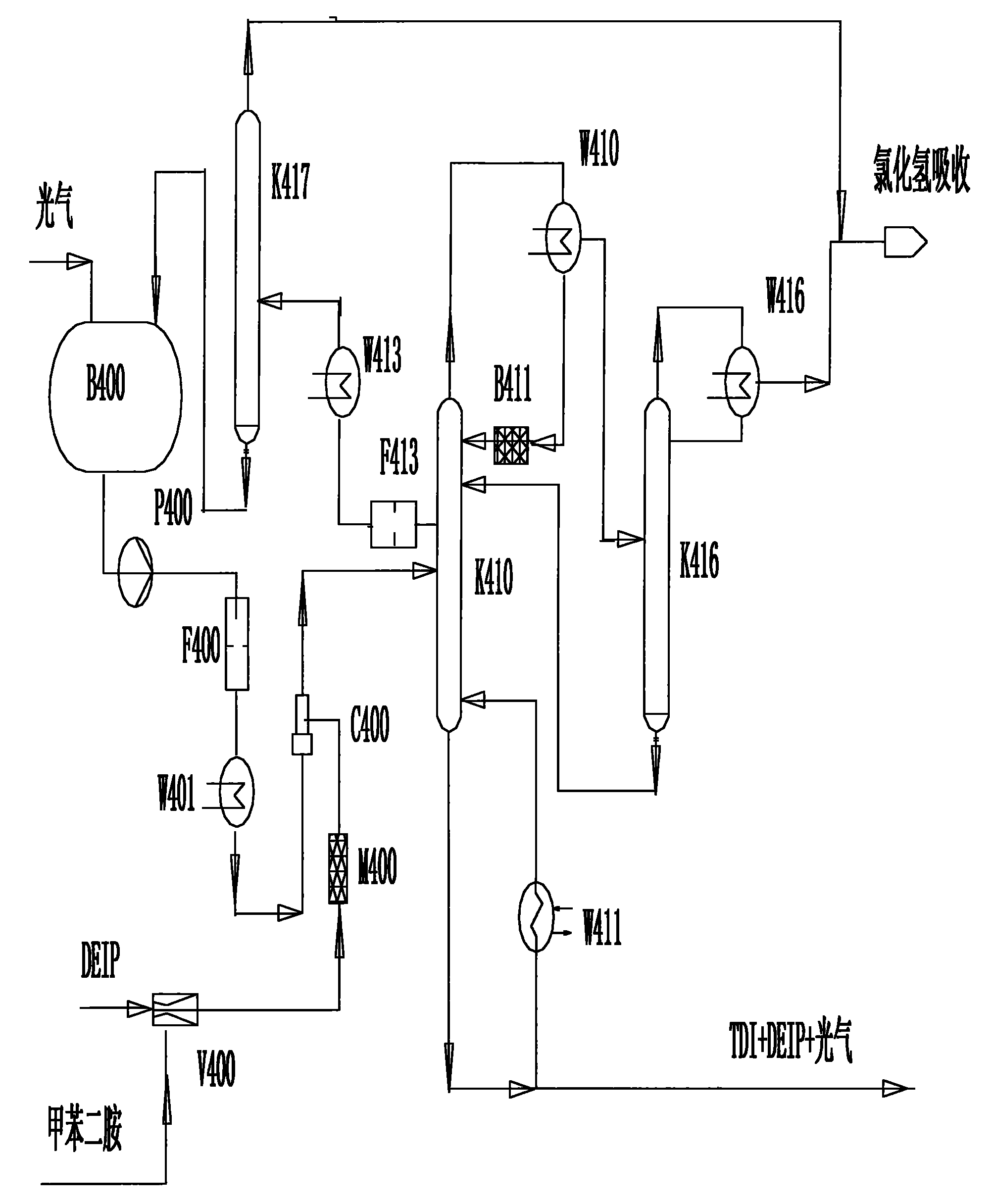

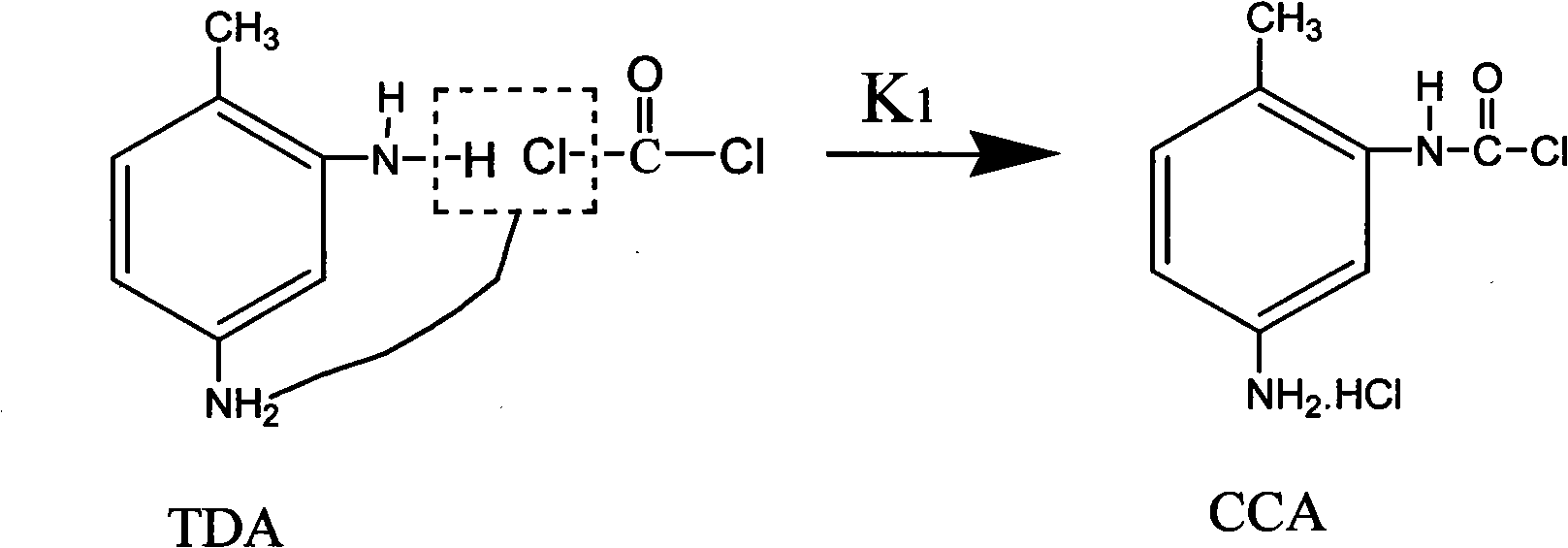

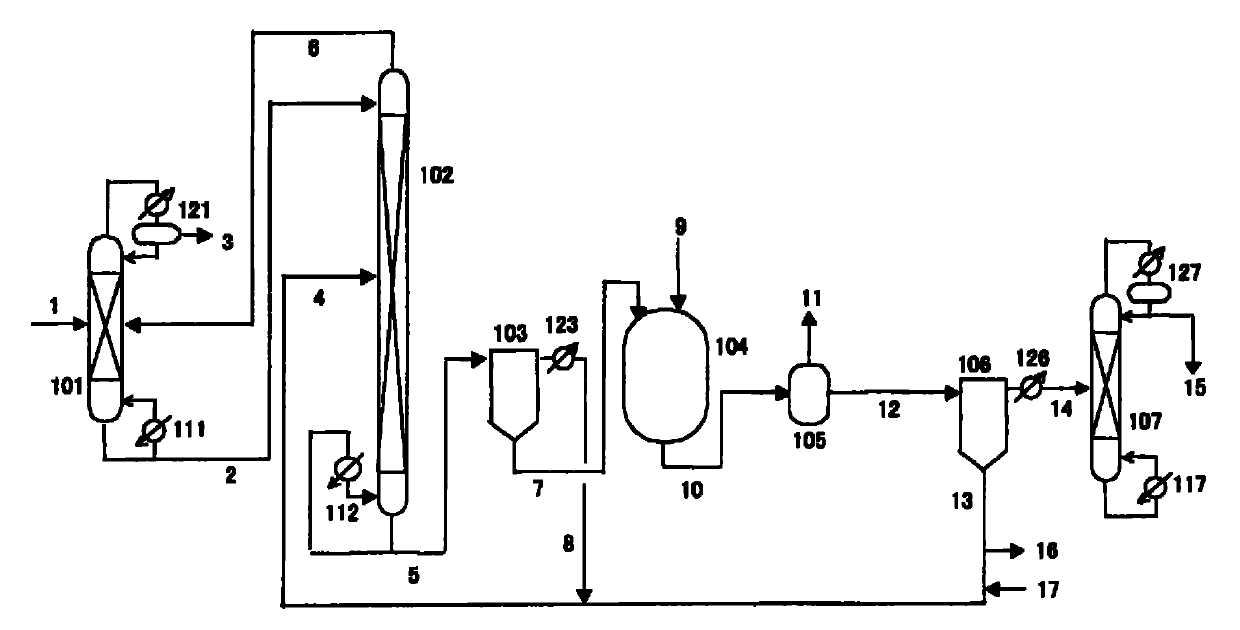

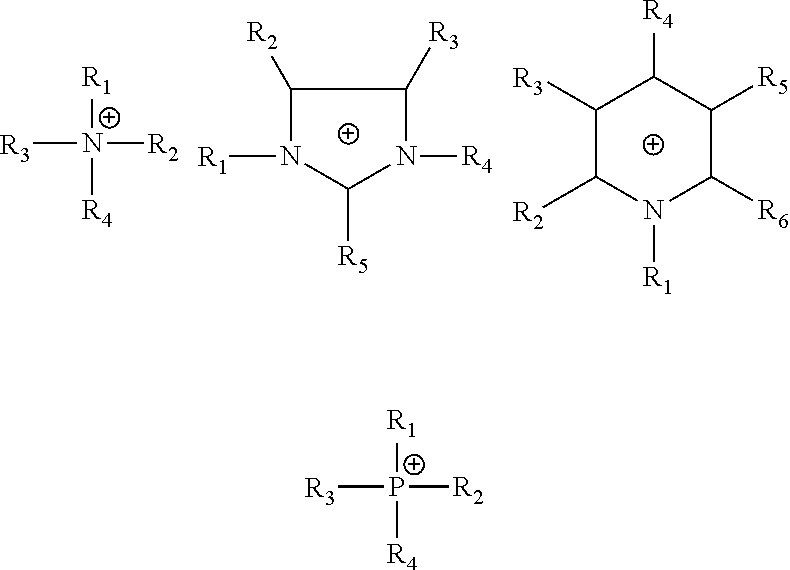

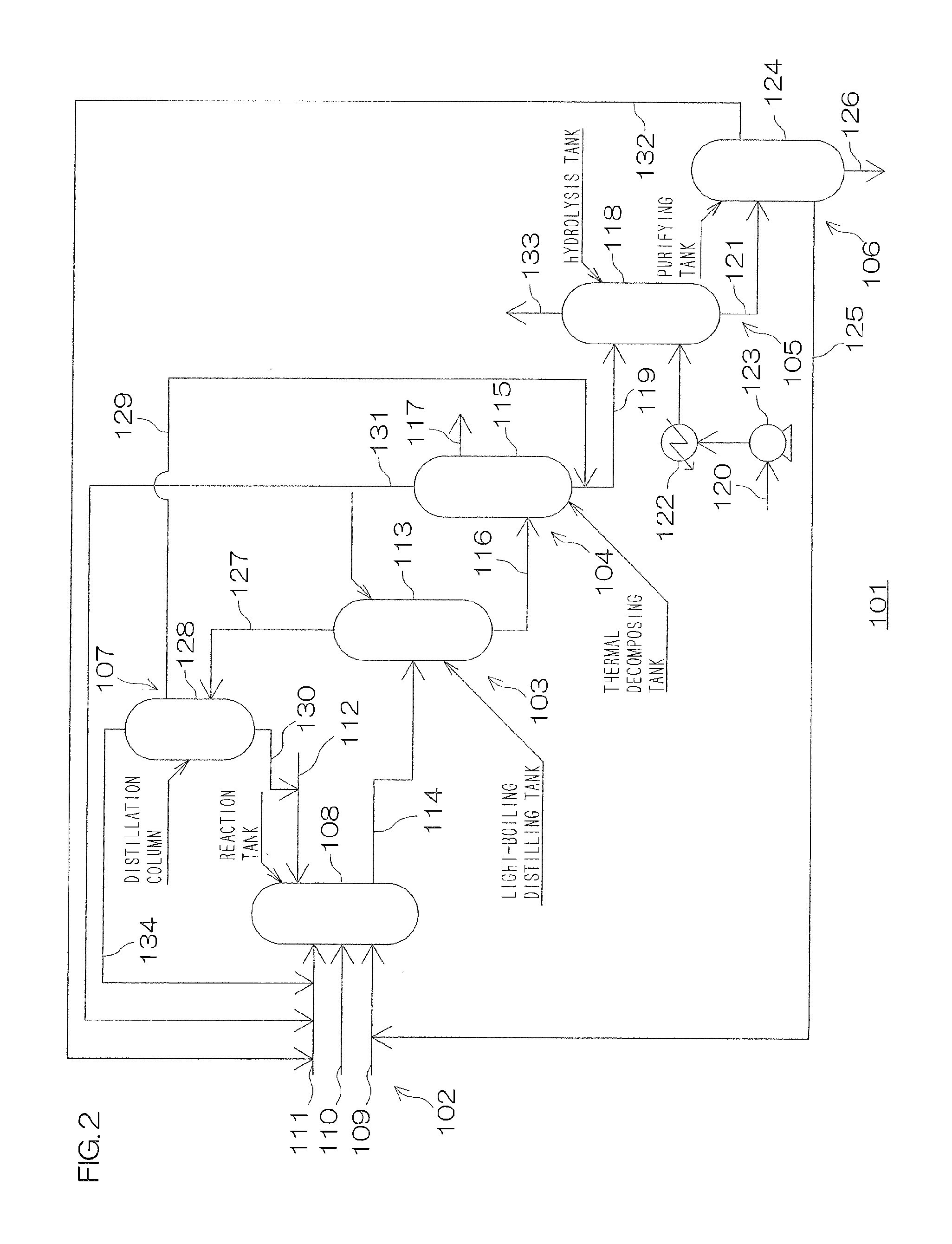

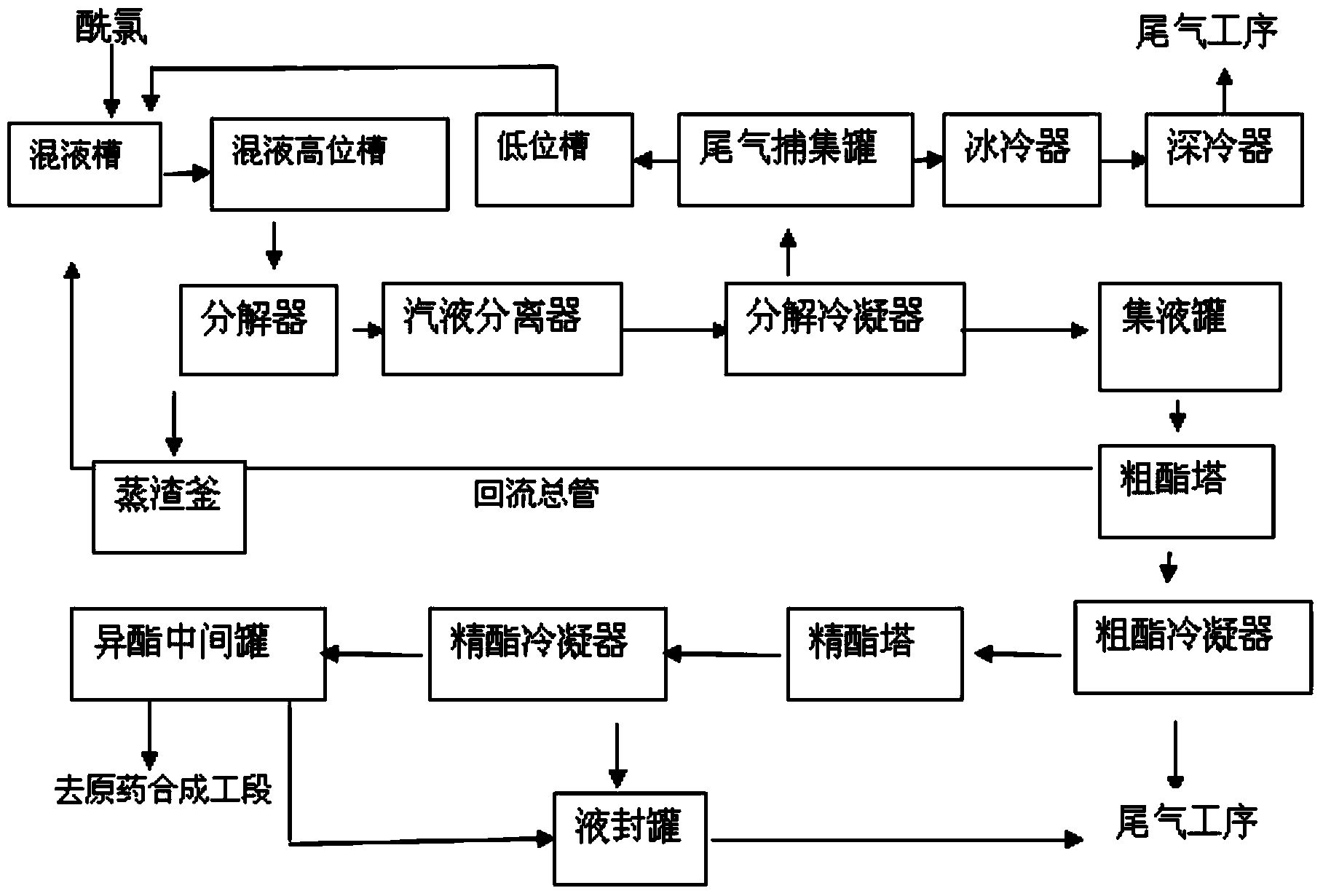

Method for continuously preparing toluene diisocynate

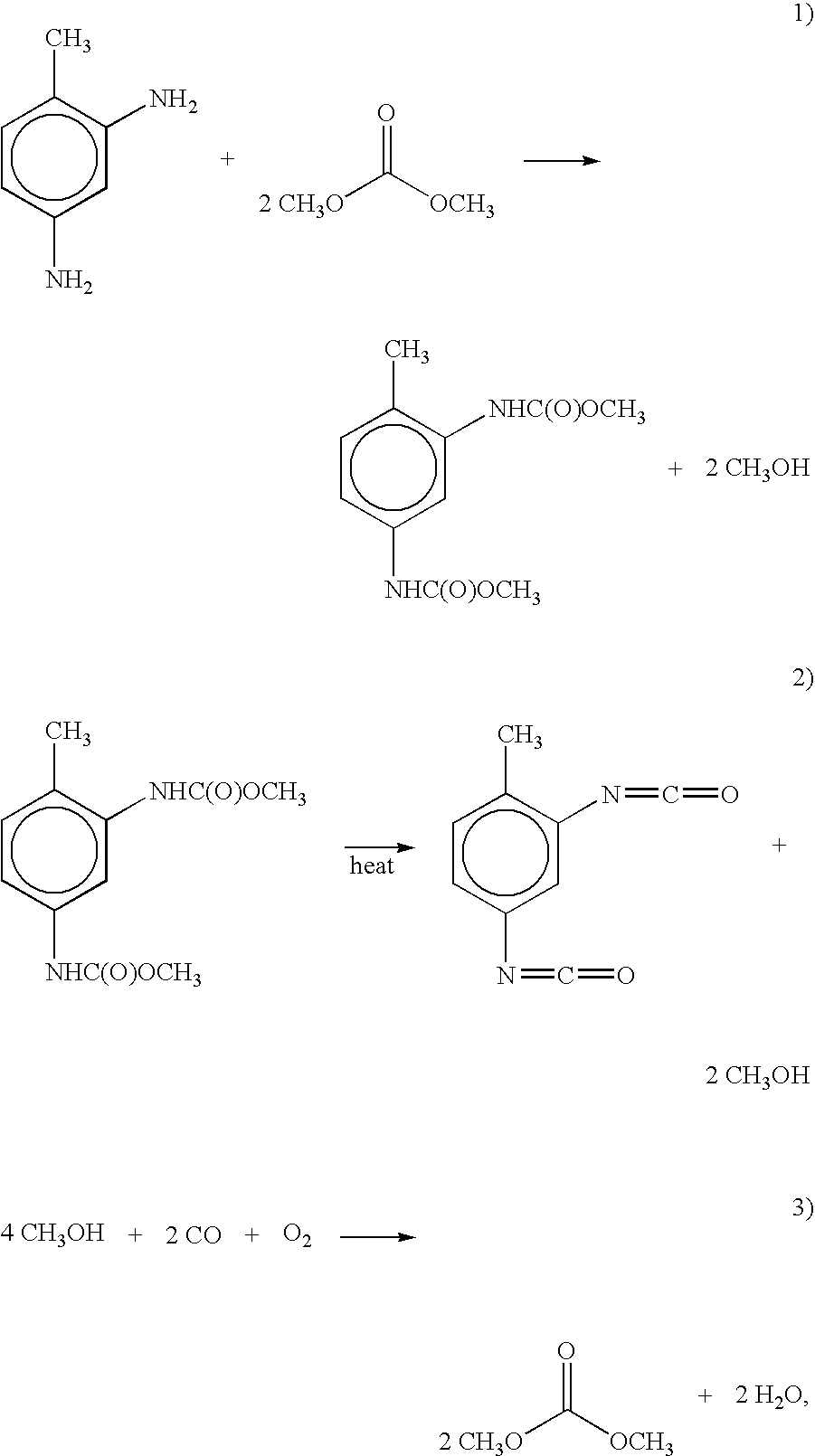

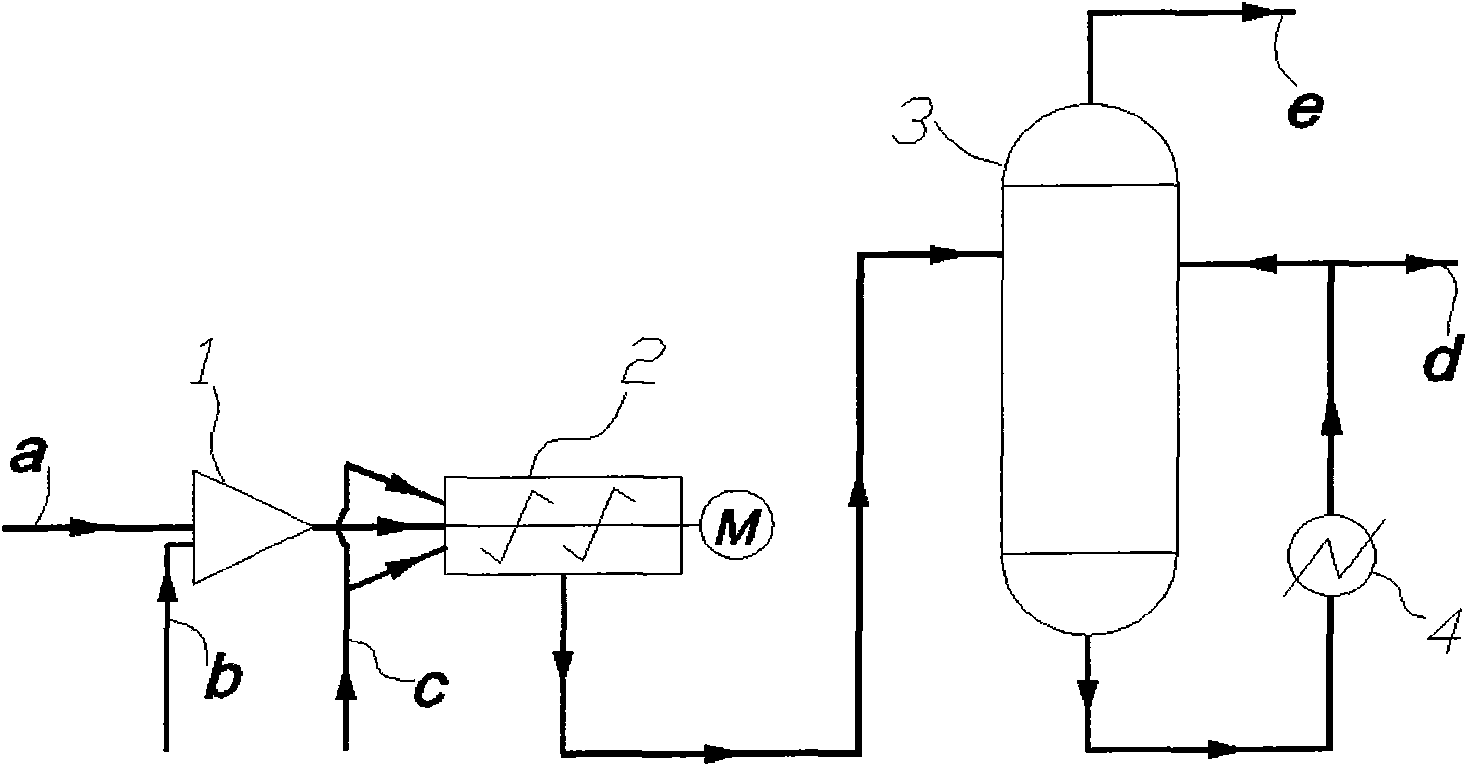

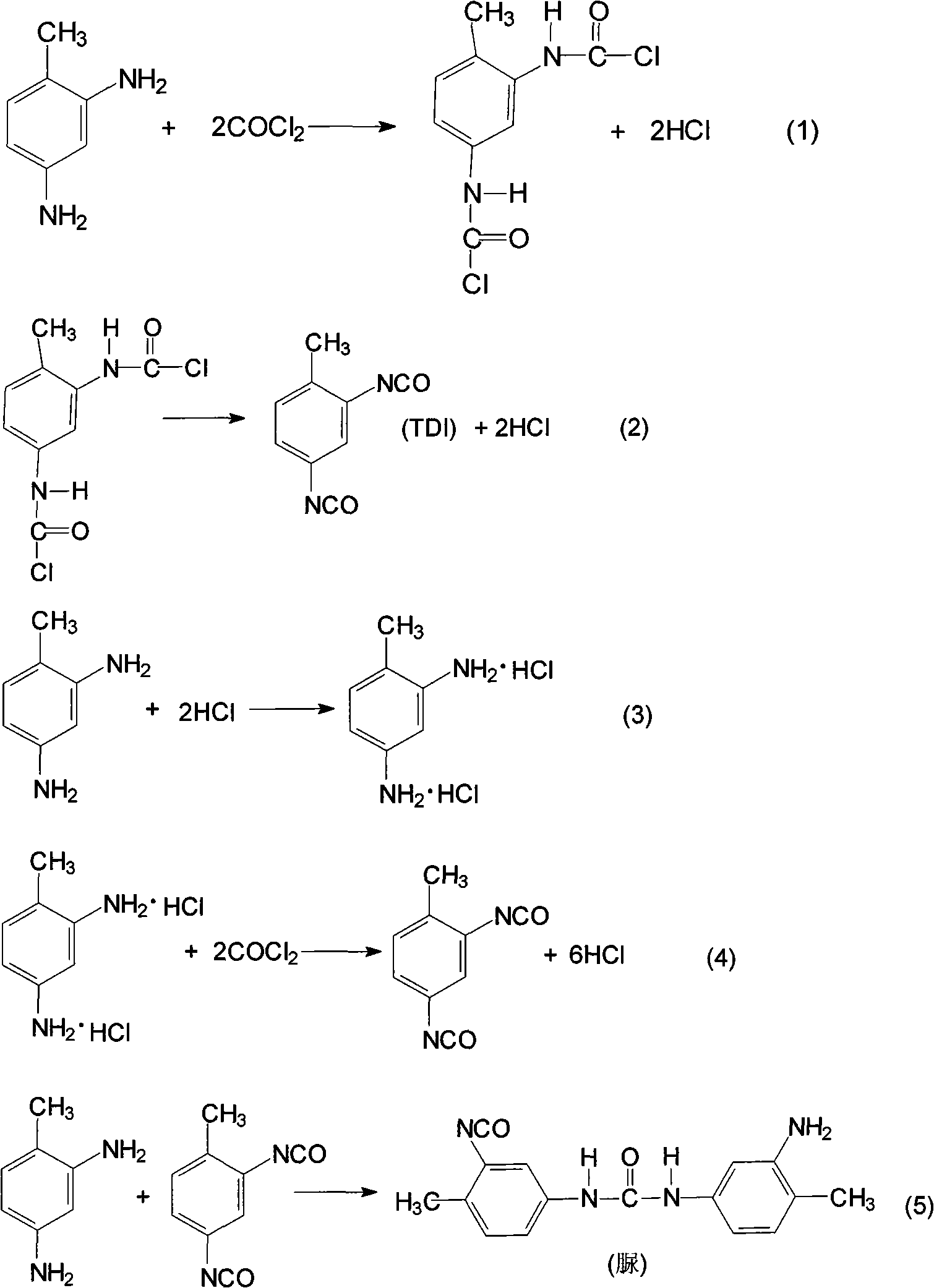

The invention relates to a method for continuously preparing toluene diisocynate, in particular to a method for preparing coarse toluene diisocynate by a phosgene method. The method comprises the following steps: mixing toluene diamine and DEIP solvent, performing low-temperature photochemical reaction on the mixture and excessive liquid phosgene in a jet reactor, heating and cracking a reaction product in a photochemical reaction tower to further decompose toluene dicarbamic chloride serving as an intermediate product to form the toluene diisocynate, recycling the reclaimed phosgene and the DEIP solvent, and delivering the hydrogen chloride gas serving as a side product to a hydrogen chloride absorption system.

Owner:甘肃银光聚银化工有限公司

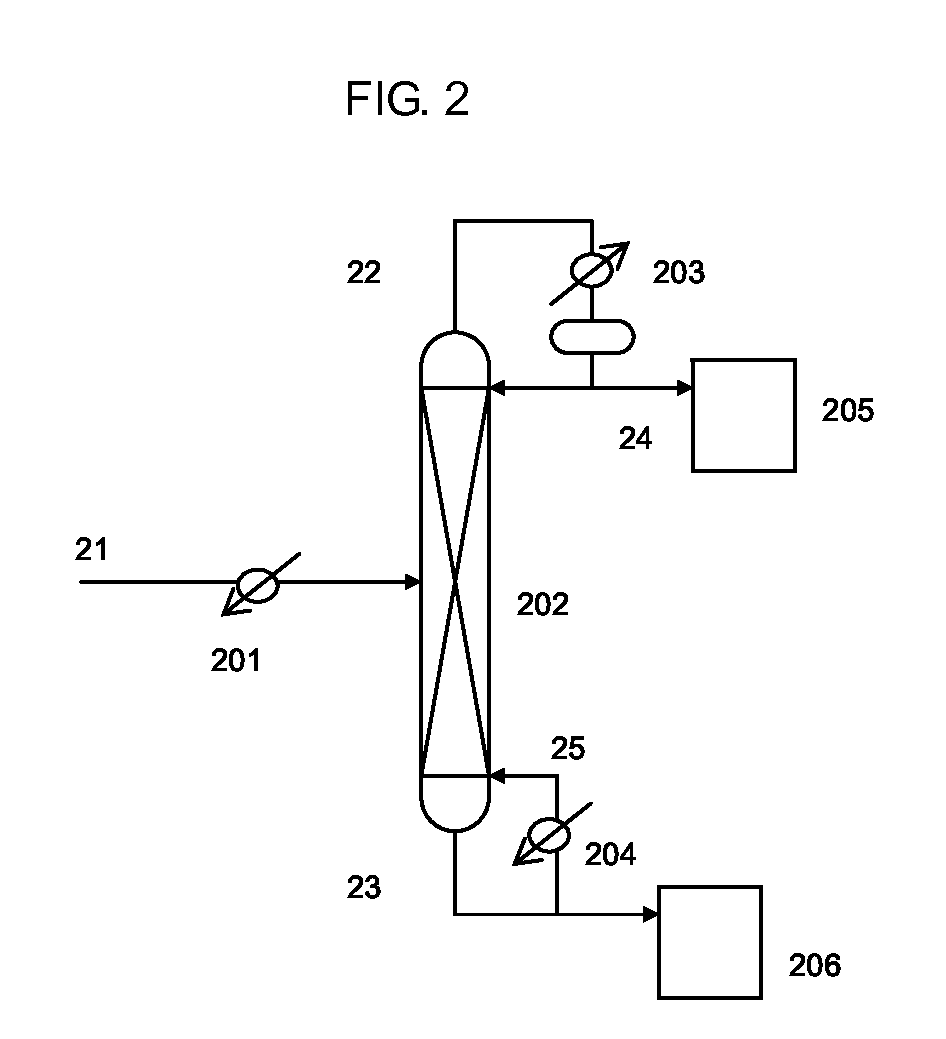

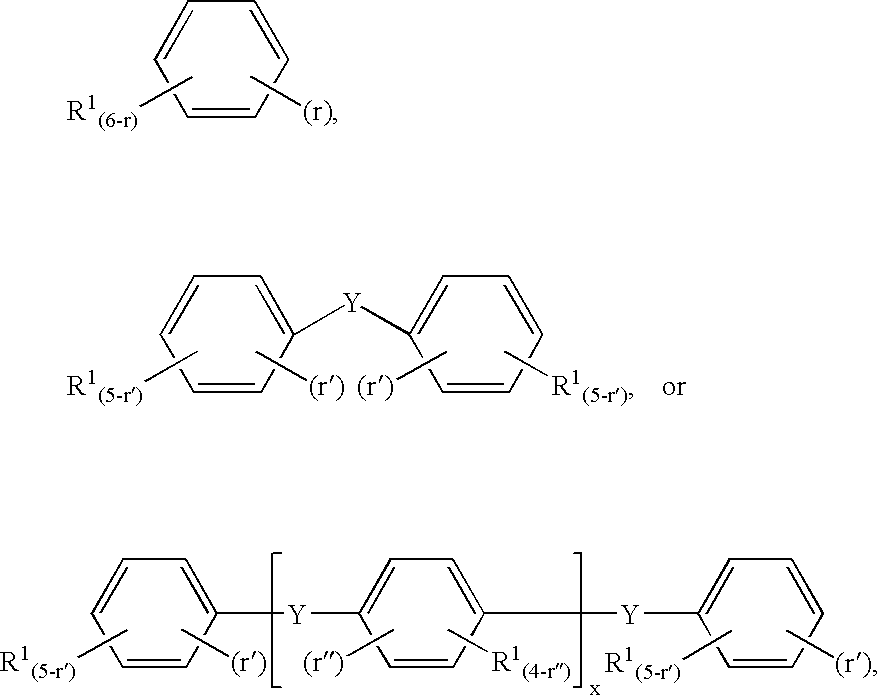

Process for producing isocyanates

ActiveUS20100029981A1Efficient productionCarbamic acid derivatives preparationOrganic compound preparationCarbamateDecomposition

An object of the present invention is to provide a process that enables isocyanates to be stably produced over a long period of time at high yield without encountering various problems as found in the prior art when producing isocyanates without using phosgene. The present invention discloses a process for producing an isocyanate, comprising the steps of: reacting a carbamic acid ester and an aromatic hydroxy compound to obtain an aryl carbamate having a group derived from the aromatic hydroxy compound; and subjecting the aryl carbamate to a decomposition reaction, wherein the aromatic hydroxy compound is an aromatic hydroxy compound which is represented by the following formula (1) and which has a substituent R1 at least one ortho position of a hydroxyl group:(wherein ring A represents an aromatic hydrocarbon ring in a form of a single or multiple rings which may have a substitute and which have 6 to 20 carbon atoms;R1 represents a group other than a hydrogen atom in a form of an aliphatic alkyl group having 1 to 20 carbon atoms, an aliphatic alkoxy group having 1 to 20 carbon atoms, an aryl group having 6 to 20 carbon atoms, an aryloxy group having 6 to 20 carbon atoms, an aralkyl group having 7 to 20 carbon atoms or an aralkyloxy group having 7 to 20 carbon atoms, the group containing an atom selected from a carbon atom, an oxygen atom and a nitrogen atom; and R1 may bond with A to form a ring structure).

Owner:ASAHI KASEI CHEM CORP

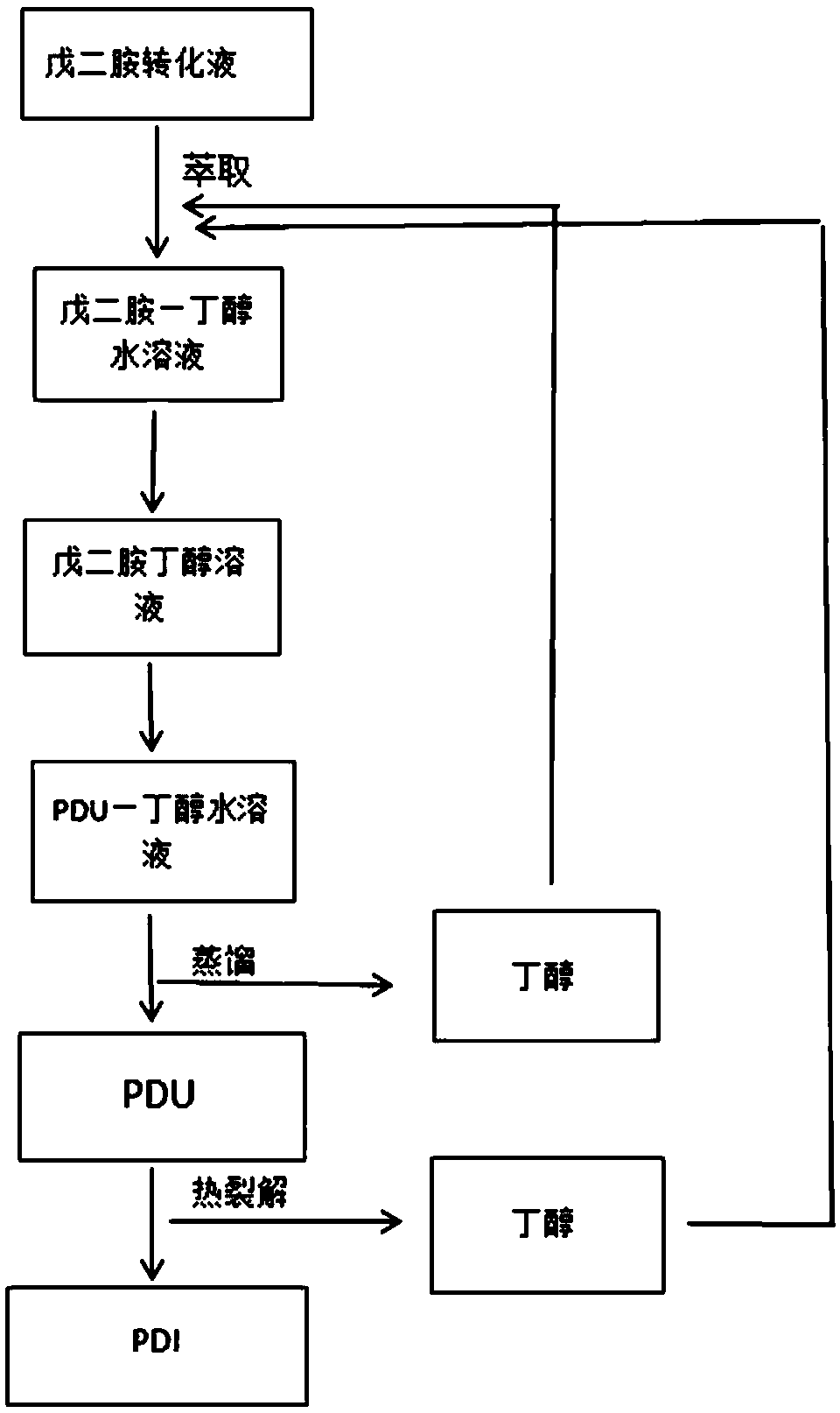

1, 5-pentyl diisocyanate preparation method

InactiveCN108689884AReduce consumptionAchieve recyclingCarbamic acid derivatives preparationOrganic compound preparationHeat carrierDistillation

The invention discloses a 1, 5-pentyl diisocyanate preparation method which includes the steps: (1) mixing 1, 5-pentane diamine transfer solution and extracting solvents, extracting 1, 5-pentane diamine and dewatering extracting solution to obtain mixed solution of the 1, 5-pentane diamine transfer solution and the extracting solvents; (2) adding catalysts and urea into the mixed solution of the 1, 5-pentane diamine transfer solution and the extracting solvents, supplementing an appropriate quantity of extracting solvents to form a reaction system, performing carbamic acid esterification on the 1, 5-pentane diamine and recycling excessive extracting solvents in the reaction system by reduced pressure distillation to obtain PDU; (3) mixing the PDU, heat carriers and the catalysts and performing thermal cracking reaction and separation to obtain the extracting solvents and PDI. According to the method, a large quantity of salts in the transfer solution can be removed by extracting solvent extraction, the extracting solvents can serve as raw materials for synthesizing the PDU, the PDI can be prepared by thermal cracking, and the extracting solvents serving as by-products can be recycled.

Owner:NANJING UNIV OF TECH

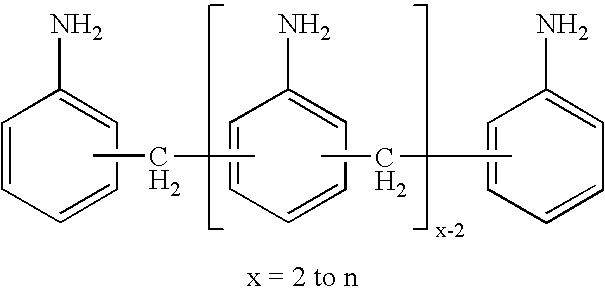

Process for the preparation of di- and polyamines of the diphenylmethane series

InactiveUS20060094897A1Organic compound preparationDiaryl/thriaryl methane dyesDiphenylmethaneAniline

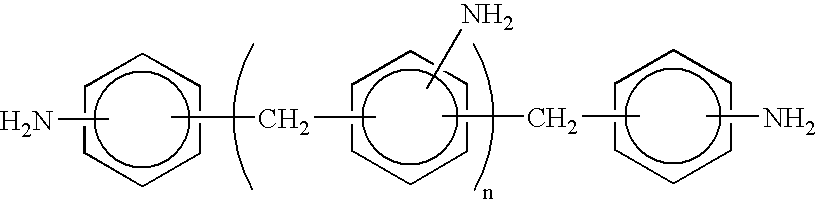

The present invention relates to a process for the preparation of di- and polyamines of the diphenylmethane series, and to the preparation of di- and polyisocyanates of the diphenylmethane series from these di- and poly-amines. The di- and poly-amines of the diphenylmethane series are prepared by the reaction of aniline and formaldehyde in the presence of hydrochloric acid. In with the present invention, the hydrochloric acid employed contains less than 0.001 wt. % of metal ions which are divalent and / or more than divalent.

Owner:BAYER MATERIALSCIENCE AG

Process for producing isocyanates using diaryl carbonate

ActiveUS20110054211A1Efficient productionOrganic compound preparationPreparation from carbamatesArylCarbamate

An object of the present invention is to provide a process that enables isocyanate to be produced stably over a long period of time and at high yield without encountering problems of the prior art during production of isocyanate without using phosgene. The present invention provides an isocyanate production process including the steps of: obtaining a reaction mixture containing an aryl carbamate having an aryl group originating in a diaryl carbonate, an aromatic hydroxy compound originating in a diaryl carbonate, and a diaryl carbonate, by reacting a diaryl carbonate and an amine compound in the presence of a reaction solvent in the form of an aromatic hydroxy compound; transferring the reaction mixture to a thermal decomposition reaction vessel; and obtaining isocyanate by applying the aryl carbamate to a thermal decomposition reaction, wherein the reaction vessel in which the reaction between the diaryl carbonate and the amine compound is carried out and the thermal decomposition reaction vessel for the aryl carbamate are different.

Owner:ASAHI KASEI CHEM CORP

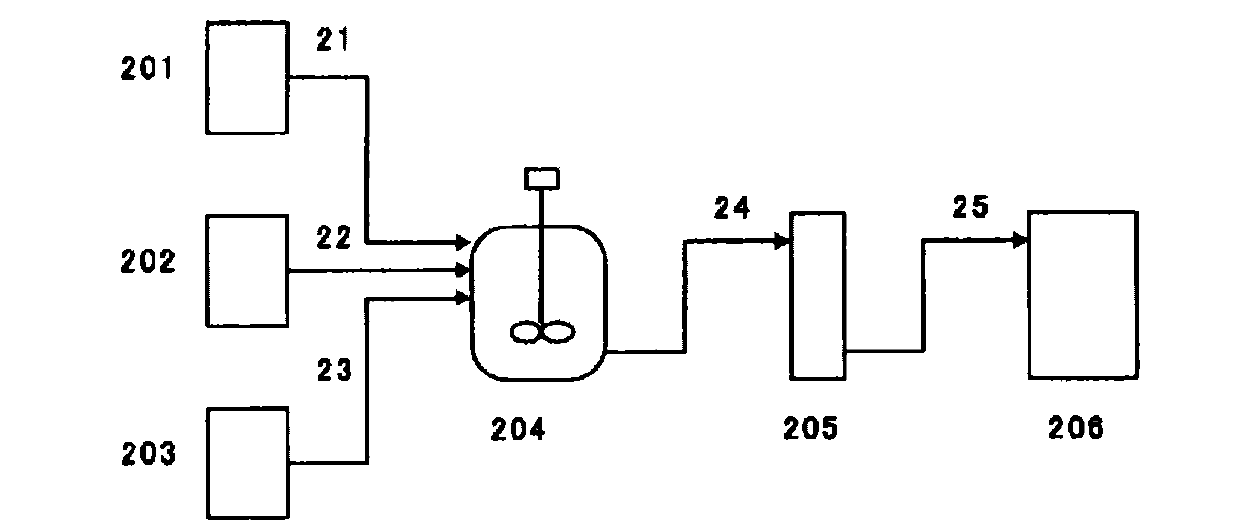

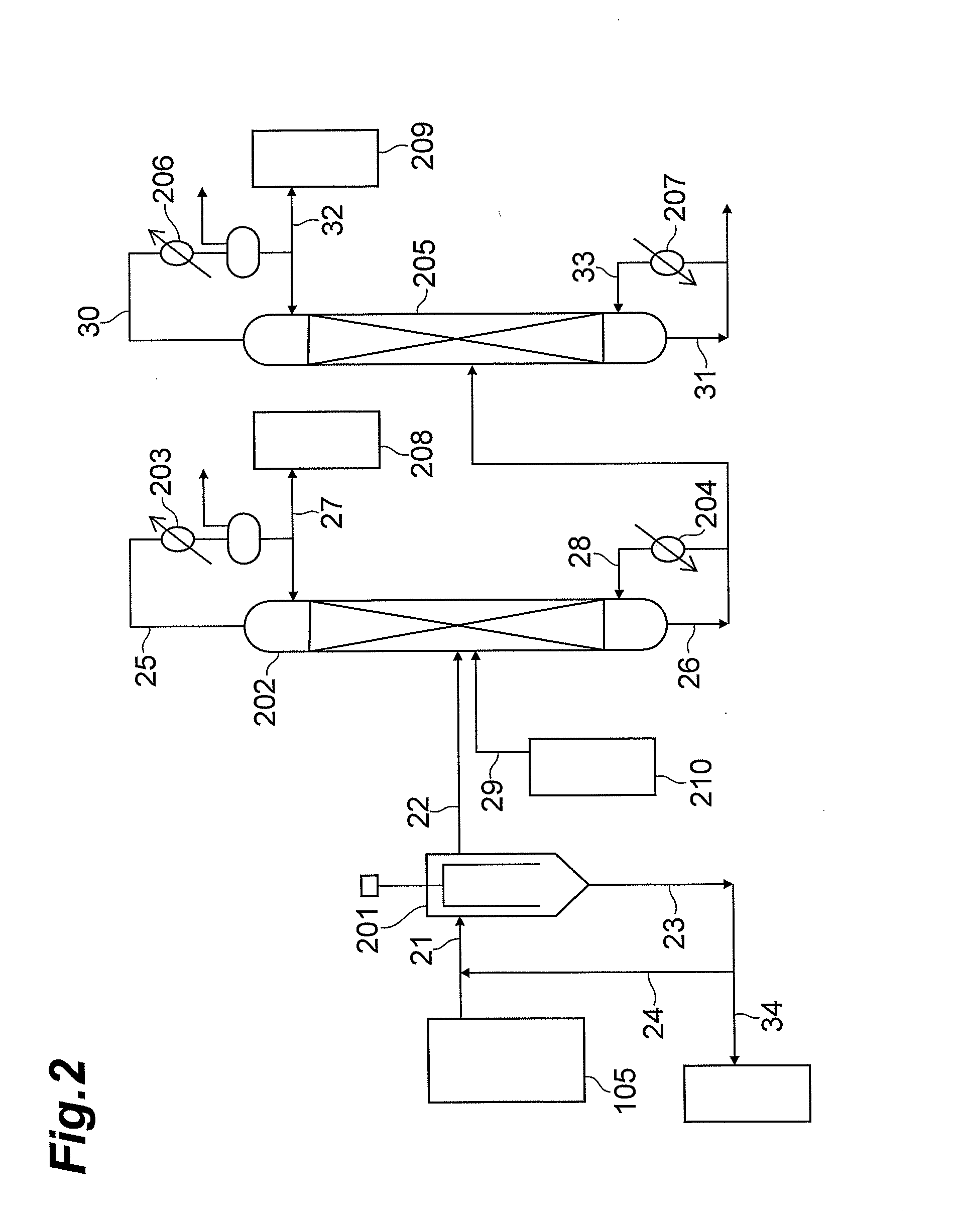

Multistage continuous preparation of cycloaliphatic diisocyanates

InactiveUS20050043563A1Speed up the processAvoid disadvantagesOrganic compound preparationPreparation from ureasPolymer sciencePhosgene

The invention relates to a multistage process for continuous and phosgene-free preparation of cycloaliphatic diisocyanates.

Owner:DEGUSSA AG

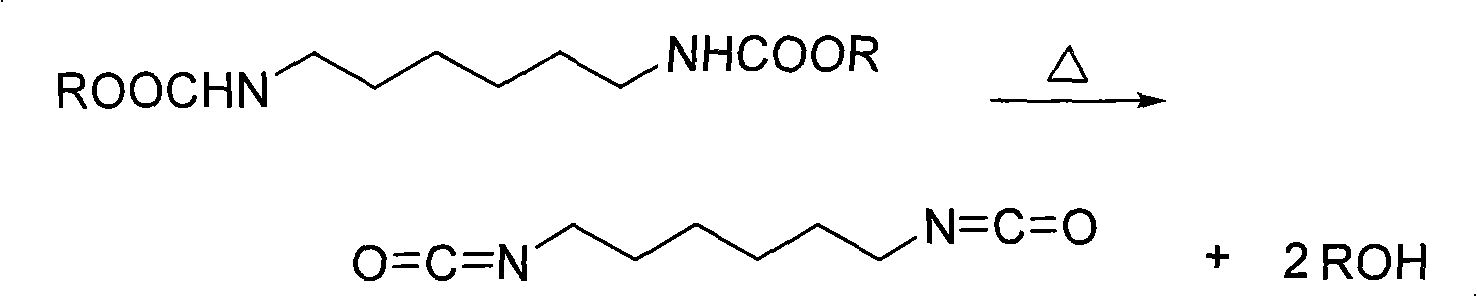

Process for the continuous preparation of (cyclo) aliphatic diisocyanates

InactiveCN101234998AAvoid spendingReduce the use effectCarbamic acid derivatives preparationOrganic compound preparationCarbamateAlcohol

The invention relates to a multi-stage process for the continuous, phosgene-free preparation of (cyclo)aliphatic diisocyanates that comprises the conversion of (cyclo)aliphatic diamines into the corresponding (cyclo)alkylene biscarbamates and the thermal cleaving of the latter into the (cyclo)alkylene diisocyanates and alcohol. The urea used in accordance with the invention and also the urea employed for the preparation of urea equivalents (e.g. alkyl carbonates, alkyl carbamates) as a possible precursor for the synthesis of the (cyclo)aliphatic biscarbamates is unconditioned.

Owner:EVONIK DEGUSSA GMBH

Method for producing carbamates and method for producing isocyanates

ActiveUS7122697B2High selectivityLow costCarbamic acid derivatives preparationOrganic compound preparationCarbamateAliphatic amine

A method for producing carbamates that enables carbamates to be produced at low costs, with high selectivity and high yield, and in a simple manner, and a method for producing isocyanates that enables isocyanates industrially used to be produced by using the carbamates obtained by the carbamates producing method. Nonaromatic amine selected from the group consisting of aliphatic amine, alicyclic amine, and aralkyl amine is allowed to react with alkylaryl carbonate to thereby produce carbamates. Also, the carbamates thus obtained are thermally decomposed to thereby produce isocyanates. When carbamates are produced in this method, alkyl carbamates can be obtained with high selectivity and at high yield by using simple equipment. Also, when isocyanates are produced in this method, polyisocyanates used industrially as the raw material of polyurethane can be produced in a simple manner and with efficiency.

Owner:QUANTA COMPUTER INC +1

Heterogeneous Supported Catalytic Carbamate Process

InactiveUS20080227999A1Improve processing efficiencyLow costCarbamic acid derivatives preparationOrganic compound preparationCarbamateHomogeneous catalysis

A process for the preparation of aromatic carbamates comprising contacting one or more organic carbonates with an aromatic amine or urea in the presence of a catalyst and recovering the resulting aromatic carbamate product, characterized in that the catalyst is a heterogeneous catalyst comprising a Group 12-15 metal compound supported on a substrate.

Owner:MOLZAHN DAVID C

Multistage continuous preparation of cycloaliphatic diisocyanates

InactiveUS20060025626A1Carbamic acid derivatives preparationOrganic compound preparationPhosgeneDi-isocyanate

The invention relates to a multistage process for continuous and phosgene-free preparation of cycloaliphatic diisocyanates.

Owner:EVONIK DEGUSSA GMBH

Multistage continuous preparation of cycloaliphatic diisocyanates

Cycloaliphatic diisocyanates can be prepared continuously and phosgene-free by reacting at least one cycloaliphatic diamine with at least one carbonic acid derivative and at least one alcohol to give a cycloaliphatic diurethane; freeing the cycloaliphatic diurethane of a low boiler, a medium boiler and mixtures thereof; thermally cleaving the cycloaliphatic diurethane in a cleavage apparatus to give a cycloaliphatic diisocyanate and a cleavage residue; continuously discharging a portion of the cleavage residue from the cleavage apparatus; removing the high boiler components from the discharge to obtain a purified discharge; reurethanizing the purified discharge with alcohol to obtain a reurethanized discharge; and recycling the reurethanized discharge into the process.

Owner:EVONIK DEGUSSA GMBH

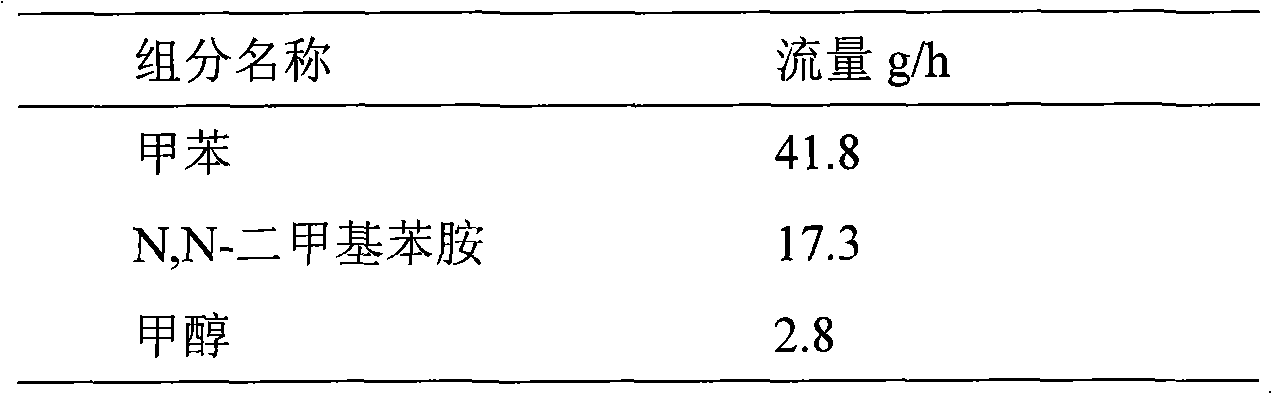

Method for producing 1,6-hexamethylene diisocyanate with hexa-methylene diamino-methyl formate liquid phase thermal cracking

InactiveCN101195590AMild reaction conditionsReduce volatilityPreparation from carbamatesFormateSolvent

The invention relates to a method for preparing corresponding 1, 6-hexadiisocyanate heated and cracked by hexamethylene aminomethyl formate liquid phase, which adopts ion liquid as reaction solvent and supported metal oxide as catalyst. The main character of the method is mild, clean and green in reaction condition, little in volatility, high in purity of the separated and obtained product and relatively less in by-product.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Prepn process of carbamate and prepn process of isocyanate

InactiveCN1432563ACarbamic acid derivatives preparationOrganic compound preparationCarbamateAliphatic amine

A method for producing carbamates that enables carbamates to be produced at low costs, with high selectivity and high yield, and in a simple manner, and a method for producing isocyanates that enables isocyanates industrially used to be produced by using the carbamates obtained by the carbamates producing method. Nonaromatic amine selected from the group consisting of aliphatic amine, alicyclic amine, and aralkyl amine is allowed to react with alkylaryl carbonate to thereby produce carbamates. Also, the carbamates thus obtained are thermally decomposed to thereby produce isocyanates. When carbamates are produced in this method, alkyl carbamates can be obtained with high selectivity and at high yield by using simple equipment. Also, when isocyanates are produced in this method, polyisocyanates used industrially as the raw material of polyurethane can be produced in a simple manner and with efficiency.

Owner:MITSUI TAKEDA CHEM INC

Method for continuously manufacturing toluene di-isocyanate

InactiveCN101671275AHigh energy consumptionReduce generationPreparation from carbamatesHydrogenToluenediamine

The invention discloses a method for continuously manufacturing toluene di-dsocyanate, comprising the following steps: (1) premixing a toluenediamine inert solvent solution with a phosgene inert solvent solution containing a hydrogen chloride with a mass fraction lower than 0.1 percent by a premixer and generating reaction; (2) importing the reacted mixture into a high shear reactor and refillingthe phosgene inert solvent solution containing the hydrogen chloride with the mass fraction lower than 0.5 percent to continue mixing and generating reaction; (3) leading materials in an outlet of thehigh shear reactor into detention equipment, continuing reacting at a temperature of 90-200 DEG C and an absolute pressure of 0.3-1.8 MPa until the solution turns transparent and a crude toluene di-isocyanatel is generated. The method for continuously manufacturing toluene di-dsocyanate is realized by mixing the phosgene with hydrogen chlorides in different contents with the toluenediamine step by step, thereby reducing the generation amount of low amine hydrochloride, improving the yield of the product toluene di-isocyanate and avoiding the addition of the energy consumption in refining phosgene recovering.

Owner:SEDIN ENG +1

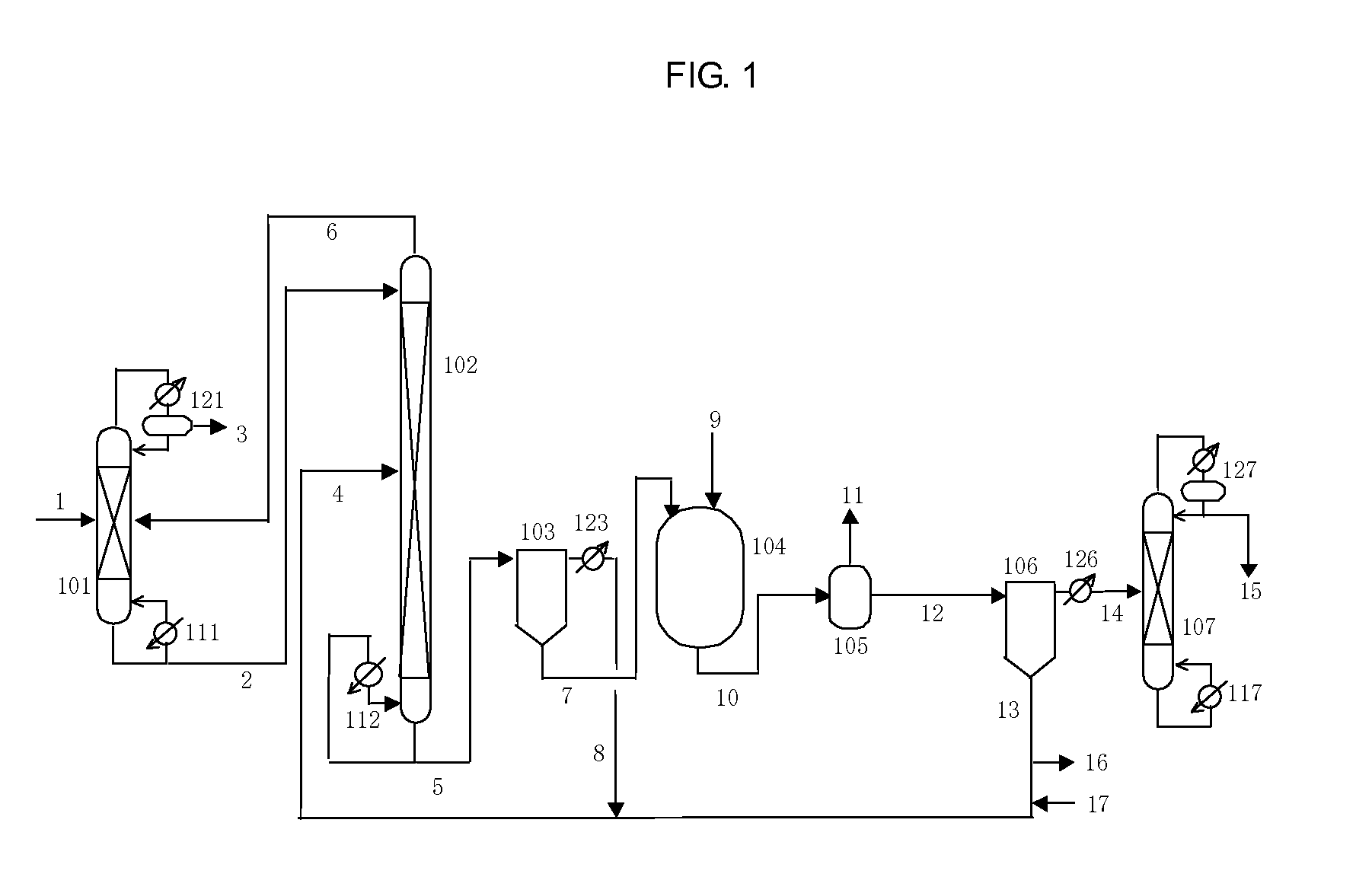

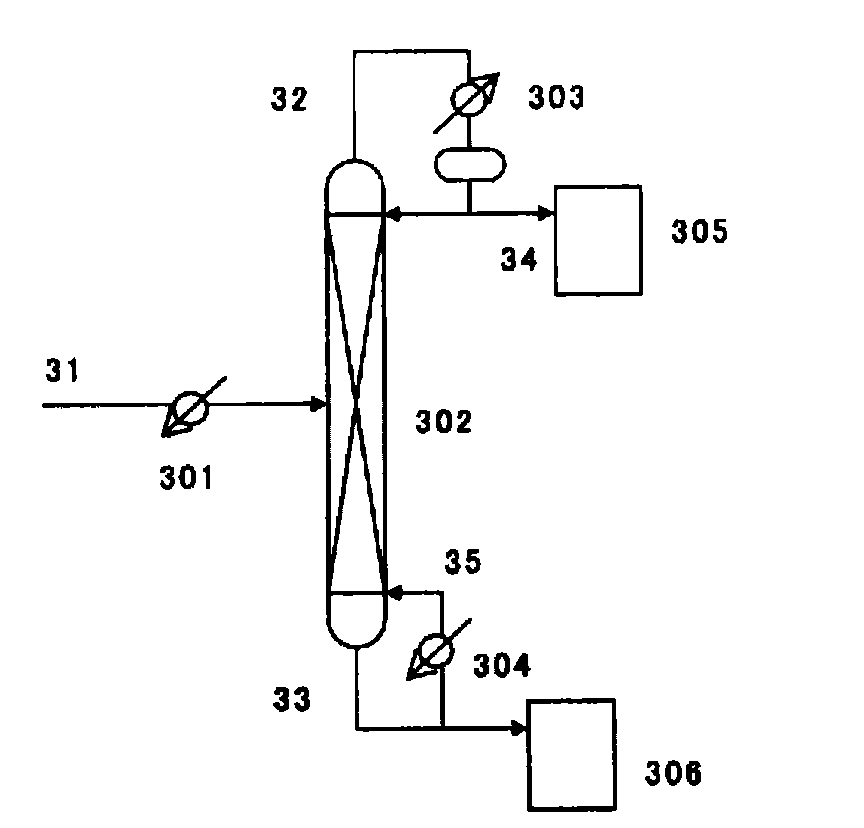

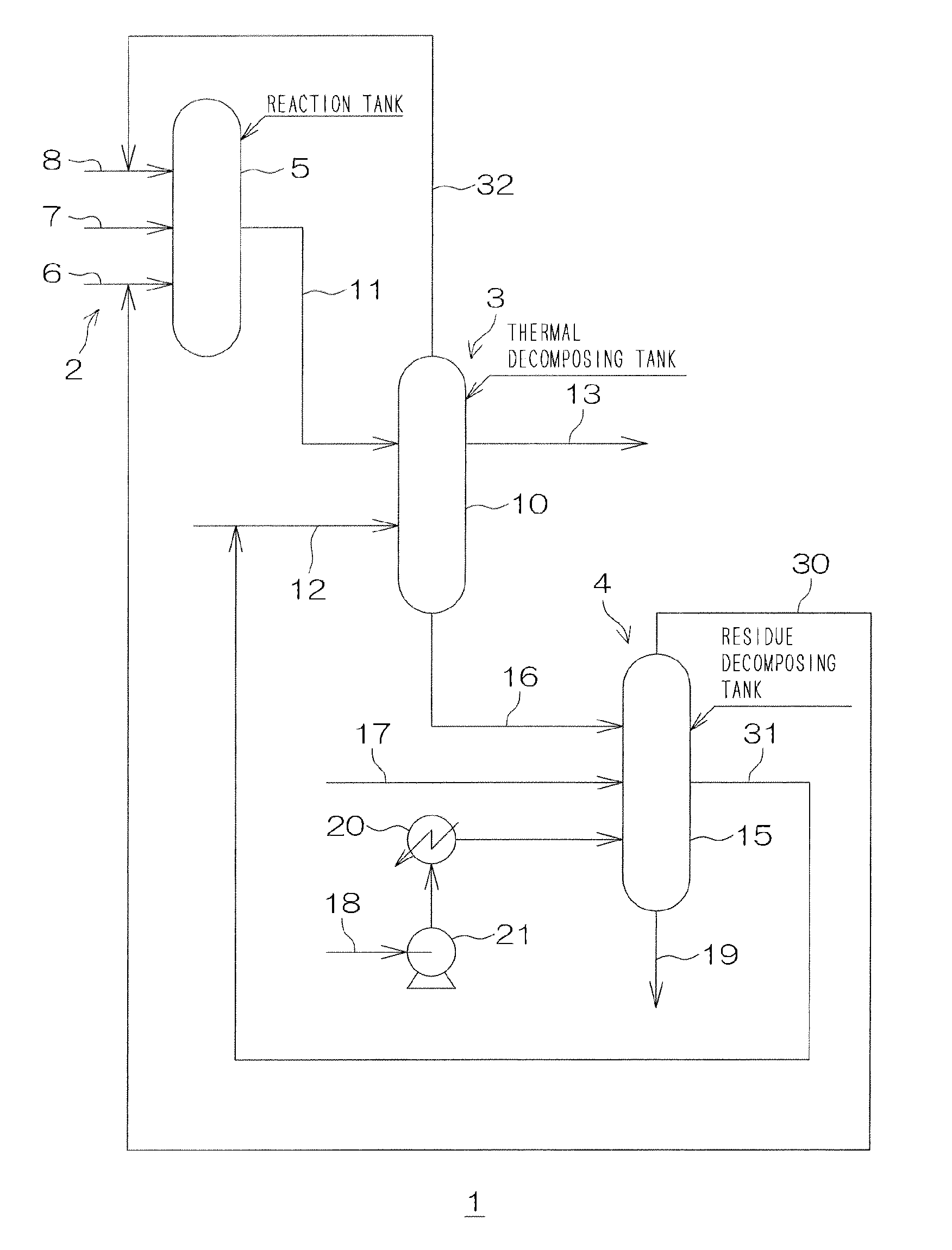

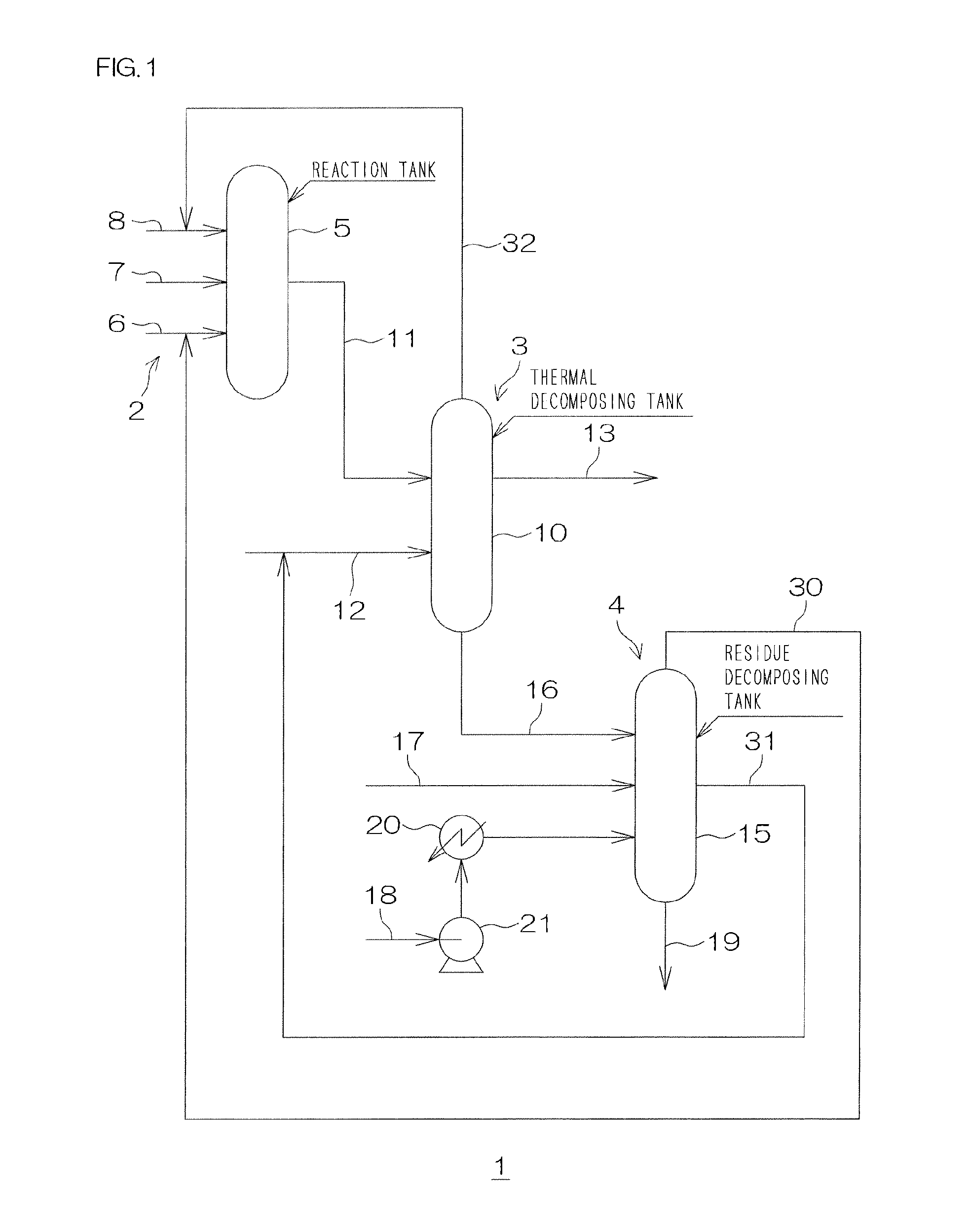

Process for producing isocyanate

ActiveCN102026965AContinuous operationOrganic compound preparationIsocyanic acid derivatives purification/separationCarbamateBoiling point

A process for producing an isocyanate without using phosgene. The process has none of various problems encountered in prior art techniques and enables an isocyanate to be stably produced in high yield for long. The process is for producing an isocyanate by subjecting a carbamic acid ester to pyrolytic reaction. The process includes: a step in which low-boiling ingredients are recovered as a gas-phase ingredient from a pyrolysis reactor where the pyrolytic reaction is conducted; a step in which a liquid-phase ingredient containing the carbamic acid ester is recovered through a bottom part of the pyrolysis reactor; and a step in which part or all of the liquid-phase ingredient is supplied to an upper part of the pyrolysis reactor.

Owner:ASAHI KASEI KK

ZnO/SBA-15 composite nano-catalyst, preparation method and application thereof

InactiveCN101269342AReduce sizeReduce manufacturing costMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsNano catalystAqueous solution

The invention relates to a nano composite catalyst ZnO / SBA-15, which has the mass percentage of compositions as follows: ZnO ranges from 5 to 15 percent; SBA-15 ranges from 85 to 95 percent. SBA-15 ethanol-water suspension is mixed from an ethanol aqueous solution and SBA-15; the SBA-15 ethanol-water suspension, being stirred at the temperature ranging from 60 DEG C to 120 DEG C, is added with the zinc salt-absolute ethanol solution with a concentration of 0.001 to 0.20 mol / L and equivoluminal ethanol solution organic amines with a concentration of 0.01to 1.6 mol / L; then the mixed solution is aged for 1 to 5 hour(s), and then is let stand and filtrated; the sediments are washed by deionized water to be neutral; and the ZnO / SBA-15 catalyst is made by drying and roasting the sediments. The nano composite catalyst has the advantages of simple process, homogeneous distribution of particles, good dispersion, high conversion rate of aromatic isocyanate, good selectivity, etc.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

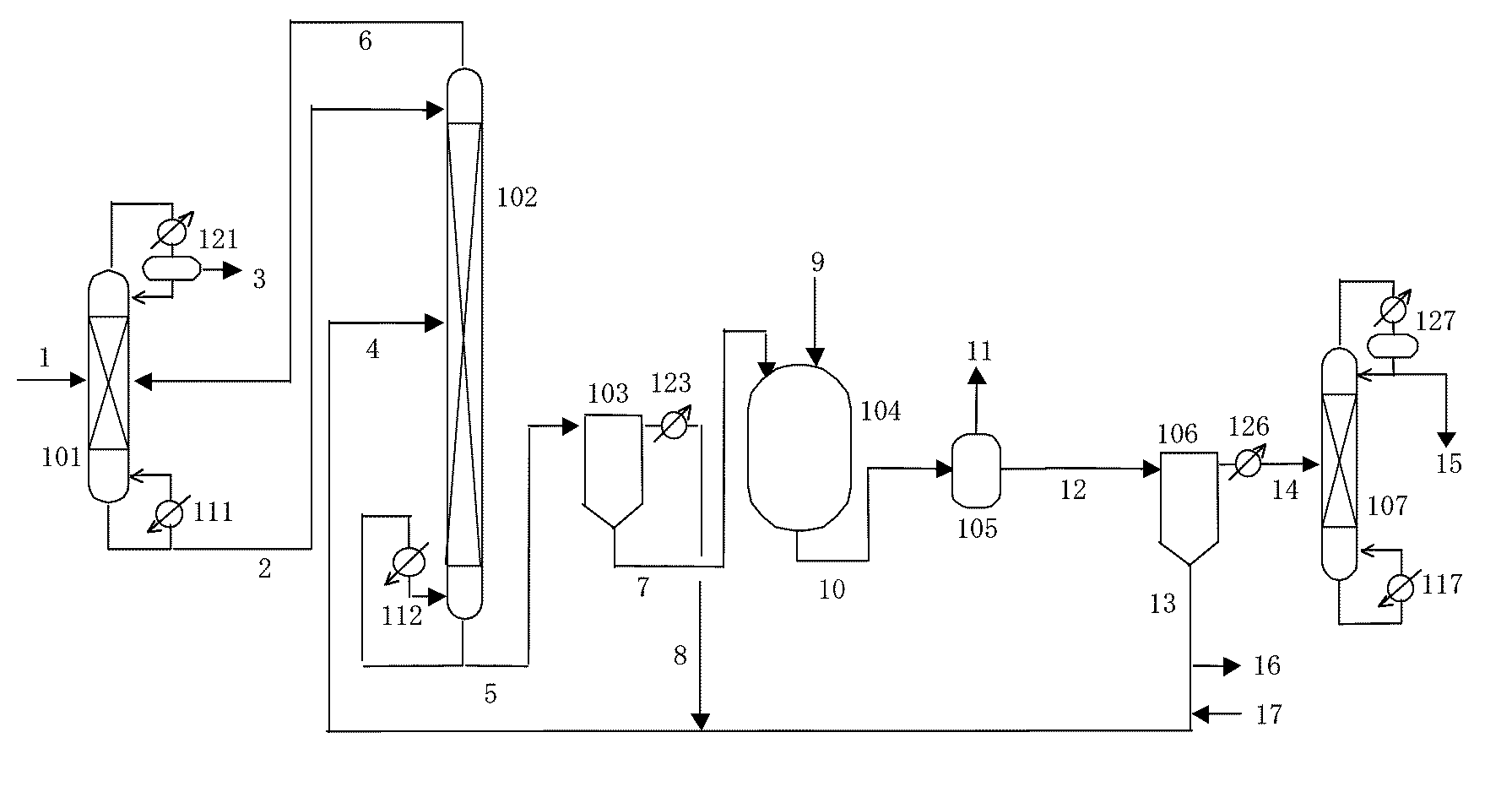

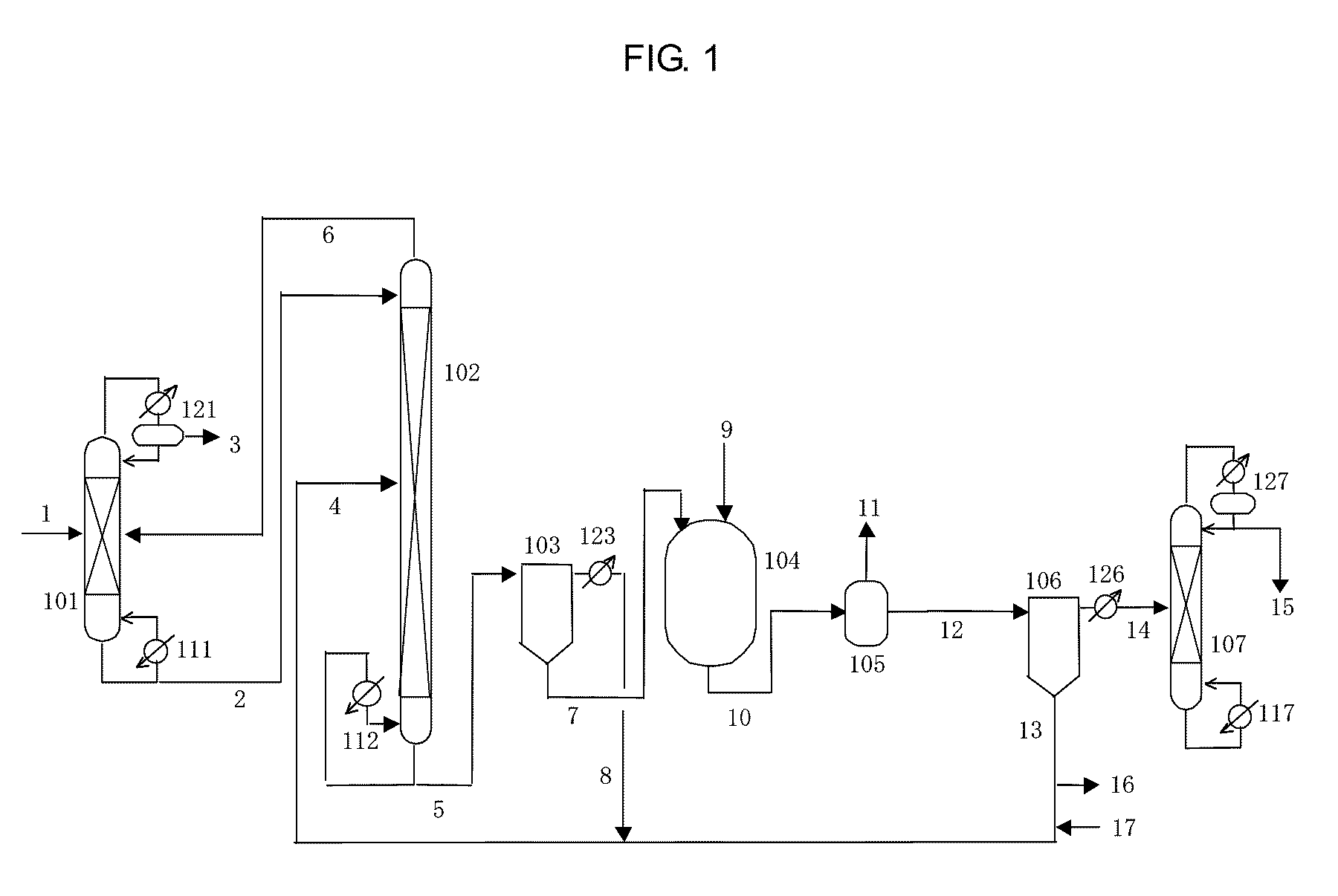

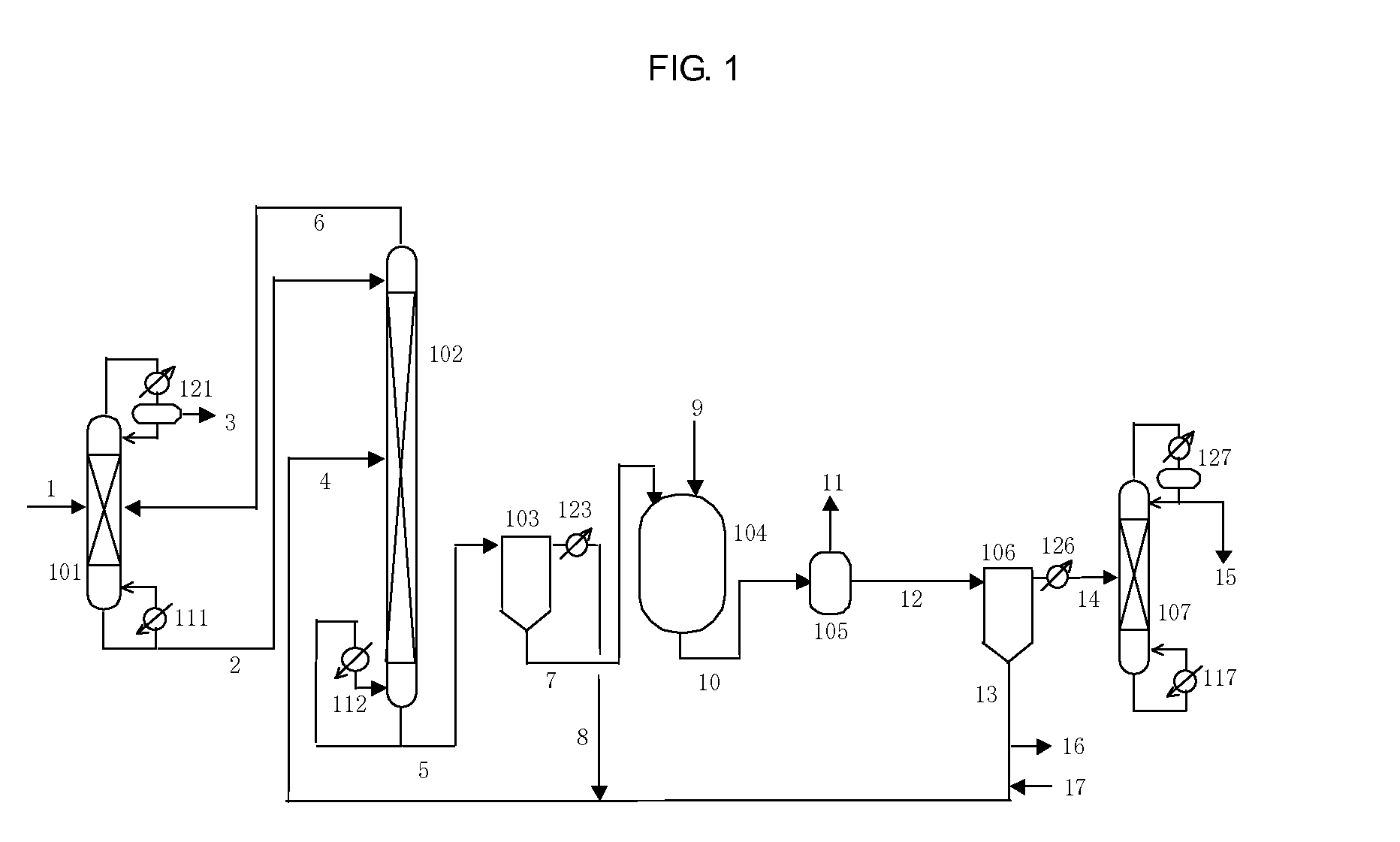

Method for preparing isocyanates by liquid-phase thermal cracking

InactiveUS20110021810A1Reduce loadLarge flowOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsArylReaction temperature

The present invention discloses a method for preparing isocyanates by liquid-phase catalytic thermal cracking. In this method, in a reaction-rectification thermal cracking reactor, using a catalyst composition comprising a superfine powder metal oxide catalyst and an ionic liquid, an alkyl or aryl dialkylurethane, or multialkylurethane being a reactant is liquid-phase thermal cracked for a reaction time of 0.5-3 h under a reaction temperature of 160-220° C. and an absolute pressure of 1000-8000 Pa so as to prepare the corresponding isocyanate. The invention has the characteristics of low thermal cracking temperature, high yield of target products, relatively simple reaction apparatus and good universality for substrates (the yields of HDI, MDI, TDI, HMDI, NDI and IPDI or the like are all >85%) and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

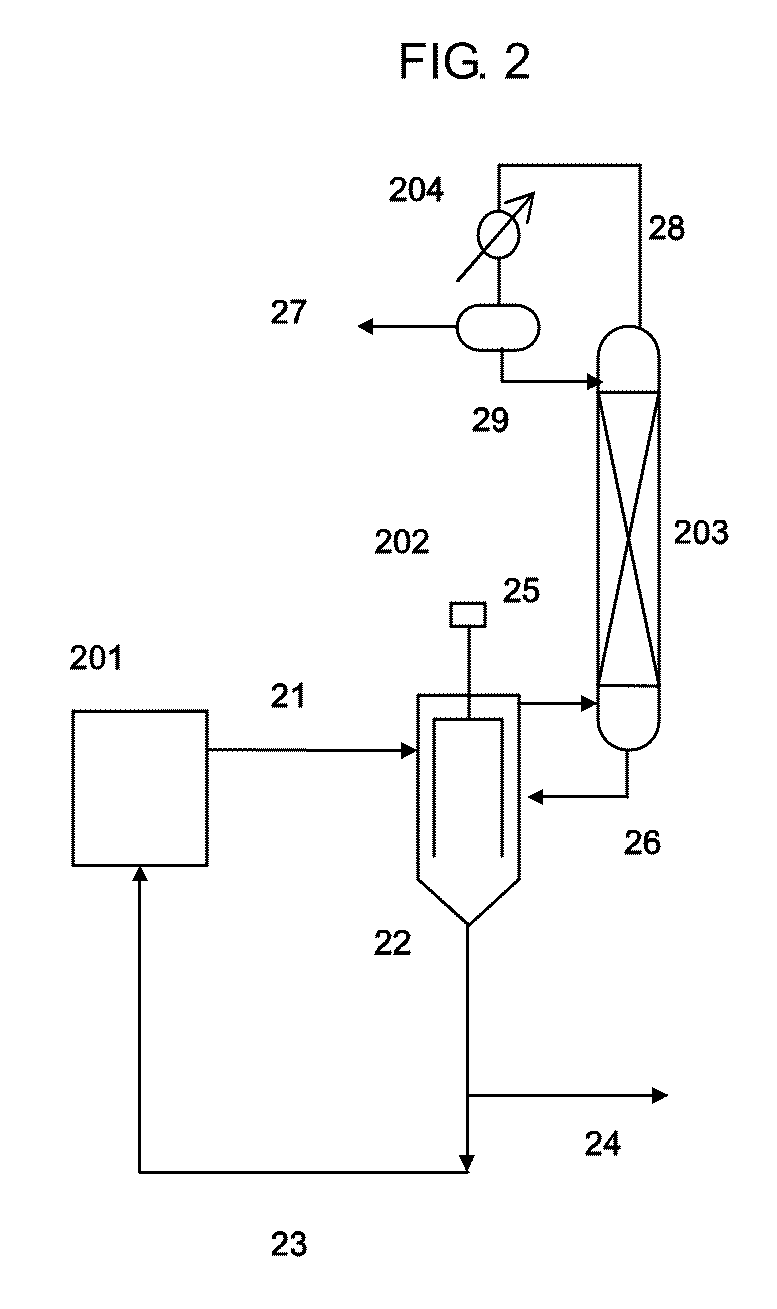

Isocyanate production process

ActiveUS20110092731A1Organic compound preparationIsocyanic acid derivatives purification/separationBoiling pointGas phase

An object of the present invention is to provide a process that enables isocyanate to be produced stably over a long period of time and at high yield without encountering problems of the prior art during production of isocyanate without using phosgene. The present invention discloses a process for producing an isocyanate by subjecting a carbamic acid ester to a thermal decomposition reaction, including the steps of: recovering a low boiling point component in a form of a gaseous phase component from a thermal decomposition reaction vessel in which the thermal decomposition reaction is carried out; recovering a liquid phase component containing a carbamic acid ester from a bottom of the thermal decomposition reaction vessel; and supplying all or a portion of the liquid phase component to an upper portion of the thermal decomposition reaction vessel.

Owner:ASAHI KASEI CHEM CORP

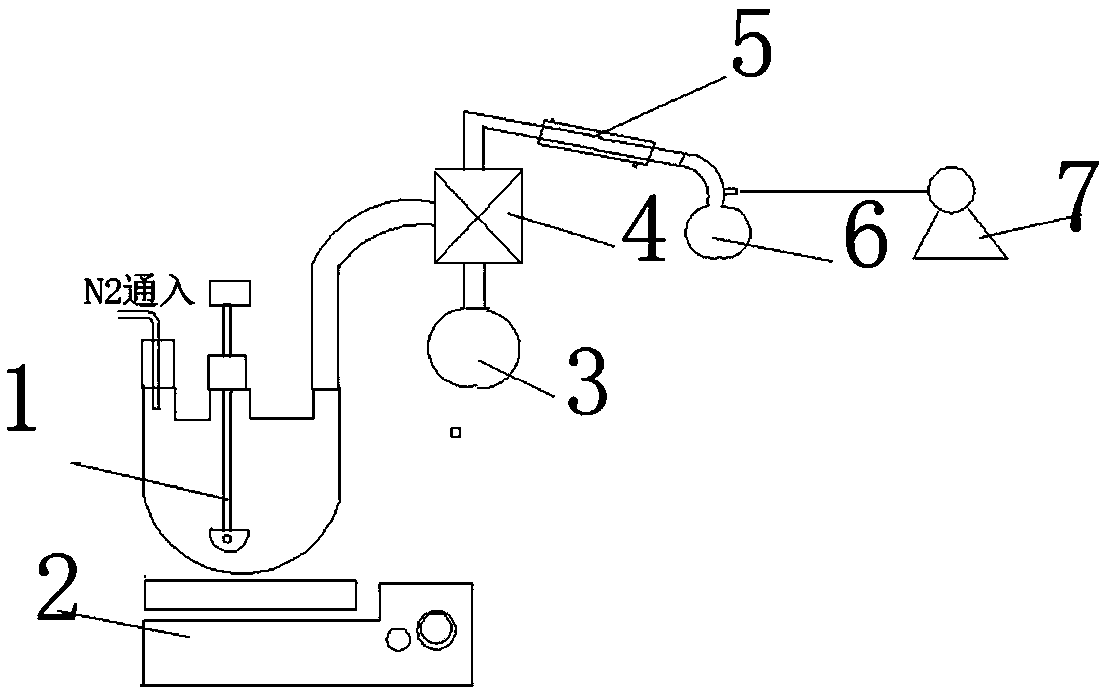

Method for synthesizing pentamethylene diisocyanate

InactiveCN106045882AAccurate measurementAvoid reactionCarbamic acid derivatives preparationOrganic compound preparationHigh pressureMethylene diisocyanate

The invention discloses a method for synthesizing pentamethylene diisocyanate. 1,5-pentanediamine or salt produced by 1,5-pentanediamine and dry carbon dioxide or 1,5-pentanediamine and dry hydrogen chloride reacts with solid-state phosgene, a middle product is produced, carbon dioxide or hydrogen chloride is exhausted, and the middle product is pentamethylene dimethylcarbamoyl chloride. The middle product is decomposed at the high temperature to produce pentamethylene diisocyanate and hydrogen chloride. The synthesis method adopts a solid-state phosgene method for synthesis, and solid-state phosgene is in a solid form at the normal temperature, has a higher melting point and a stable property and can be accurately metered during a reaction; high temperature and high pressure are not required in the technological process, the operation is simple and the cost is low.

Owner:山东崇舜新材料科技有限公司

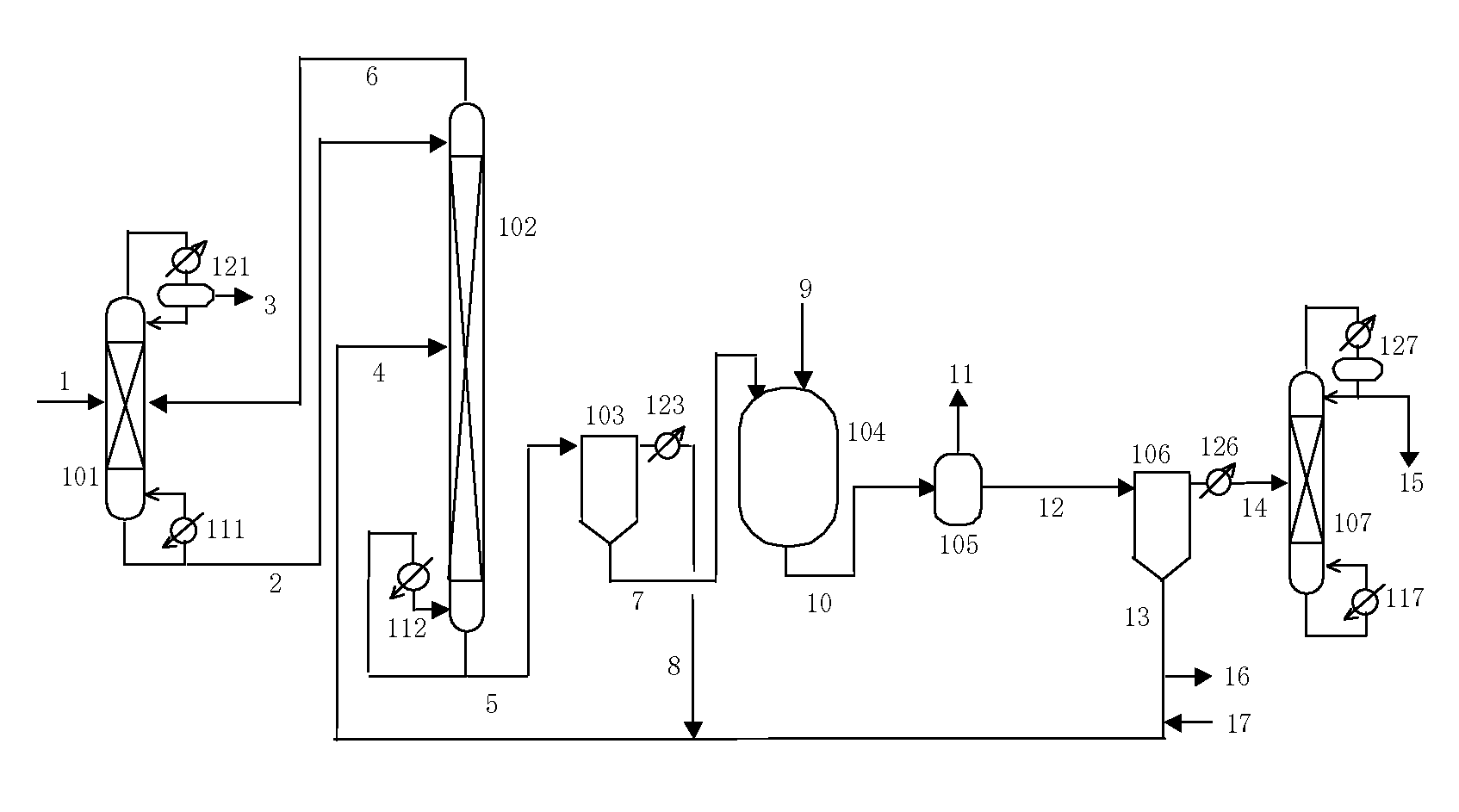

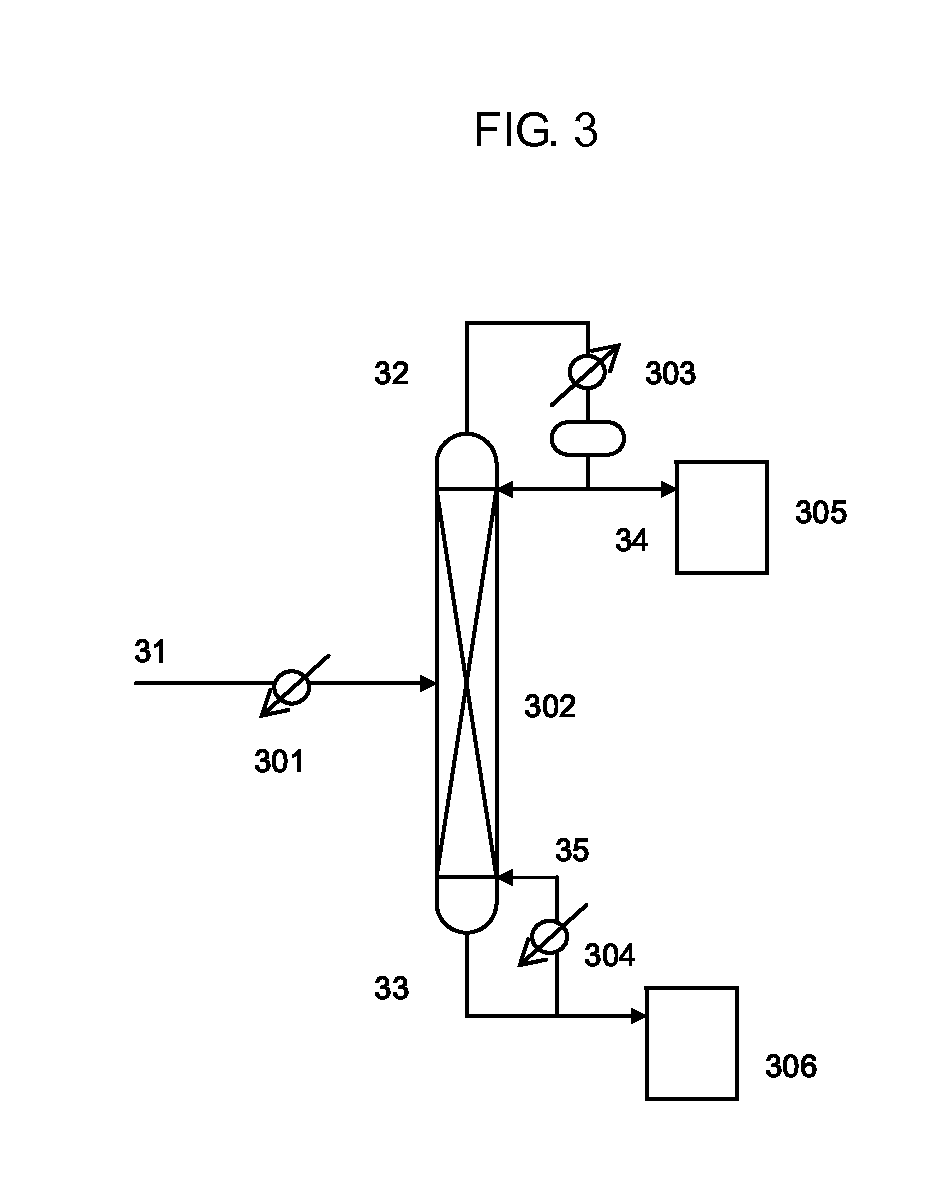

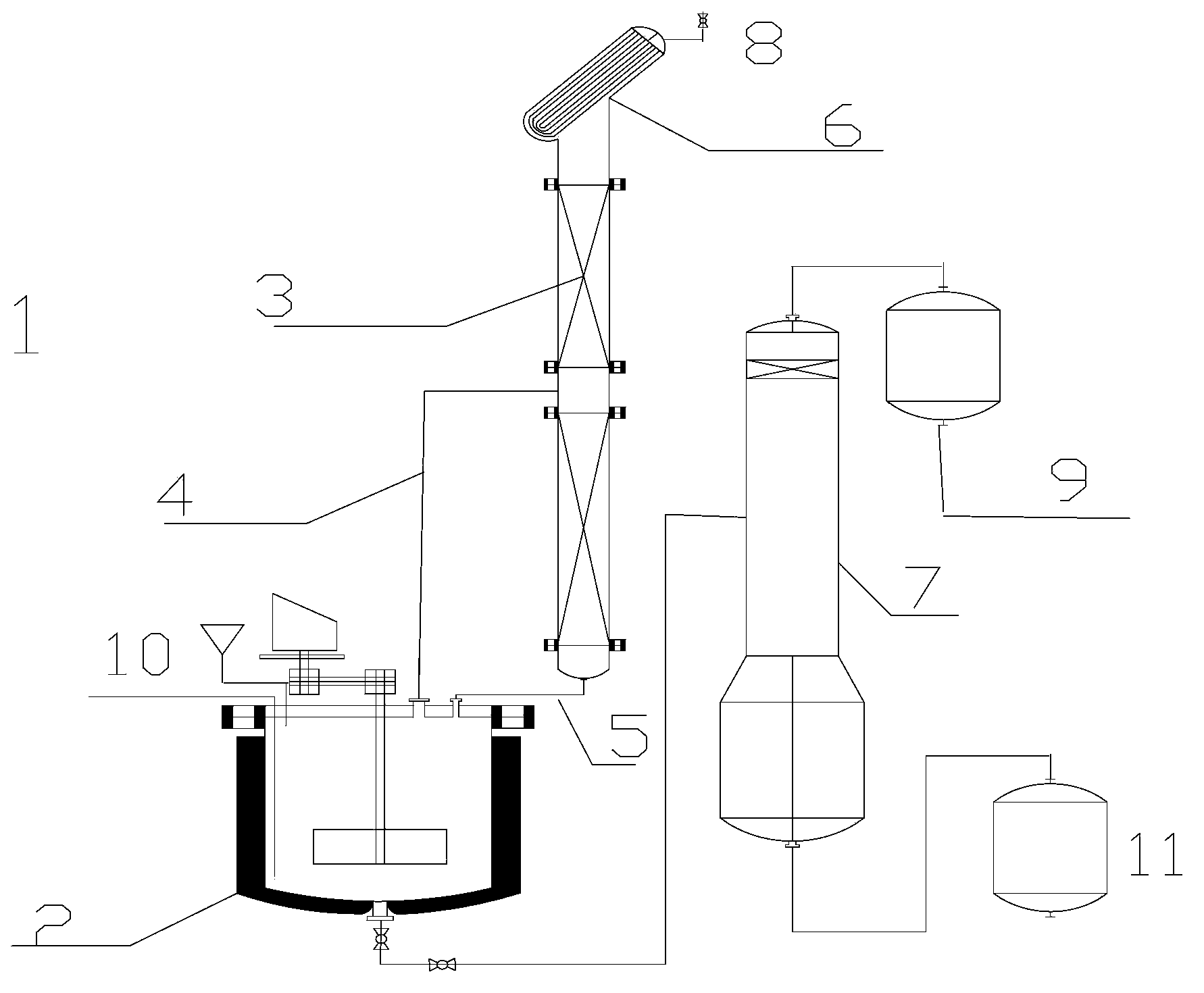

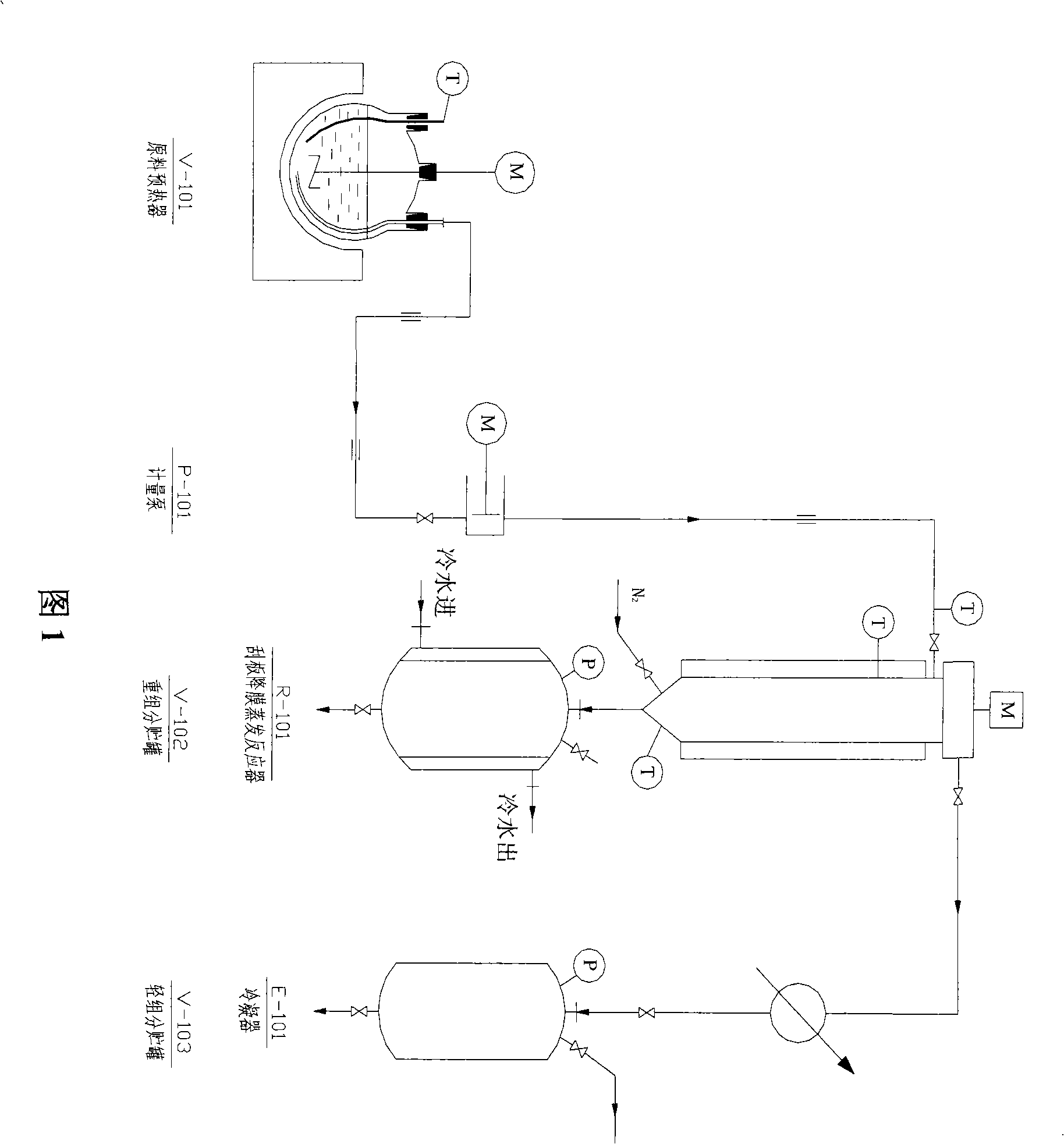

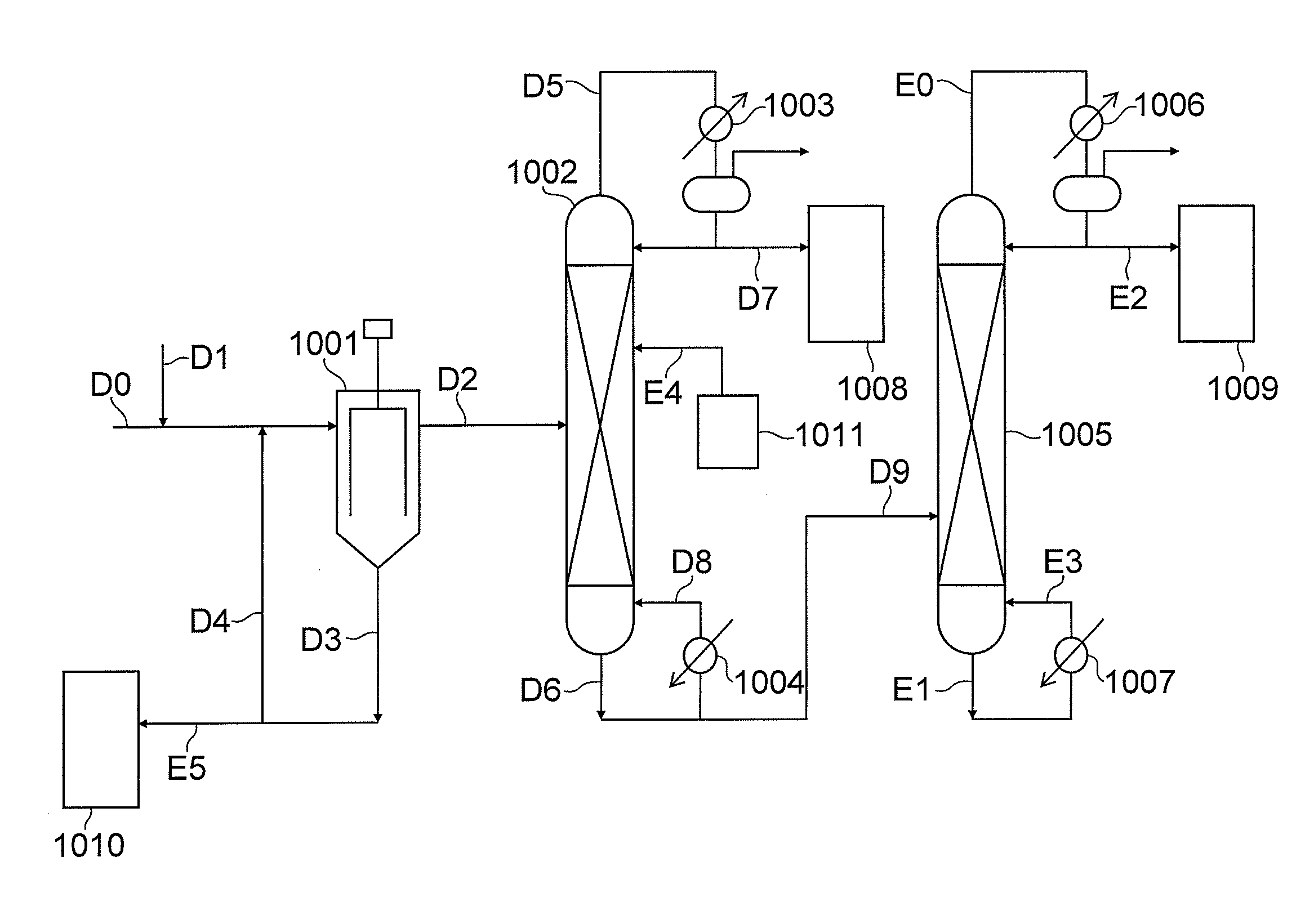

Equipment and method for preparing isocyanate through compression pyrolysis

The invention relates to equipment and a method for preparing isocyanate through compression pyrolysis, and belongs to the technical field of preparation of isocyanate through pyrolysis. The reactor is an integrated reactor of a high pressure pyrolytic reaction kettle and a rectifying tower and comprises a pyrolytic reaction kettle and a rectifying tower; a gas rising pipeline and a liquid return pipeline are connected between the pyrolytic reaction kettle and the rectifying tower; a condenser is arranged on the upper part of the rectifying tower; liquid in the condenser can reflow by inner circulation or outer circulation; a gas outlet is arranged on the upper part for connecting a pressure adjusting system to keep the pressure of the system; and the pyrolytic reaction kettle is simultaneously connected with a liquid phase output discharge processing system. Under the compression pyrolysis condition, solvent can be effectively separated from lower alcohol generated from reaction in the reaction process through separation of the rectifying tower, so that the reaction rate is improved, and the yield of isocyanate is enhanced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for treatment of isocyanate residue, and method for treatment of carbonate

ActiveUS20120271067A1Easy to useIndustrially effectively usedOxygen-containing compound preparationCarbamic acid derivatives preparationCarbamateAlcohol

A method for treating an isocyanate residue, which comprises carrying out a thermal decomposition reaction of a carbamate that is produced by the reaction among an amine, urea and / or an N-unsubstituted carbamic acid ester and an alcohol to produce a decomposition solution, separating an isocyanate and the alcohol from the decomposition solution to produce the isocyanate residue, and bringing the isocyanate residue into contact with high-pressure / high-temperature water to decompose the isocyanate residue into an amine; and a method for treating a carbonate, which comprises bringing the carbonate into contact with high-pressure / high-temperature water to decompose the carbonate into an alcohol.

Owner:MITSUI CHEM INC

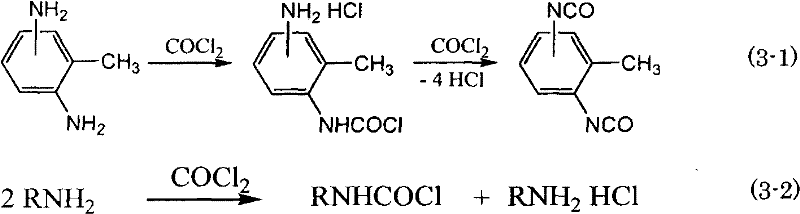

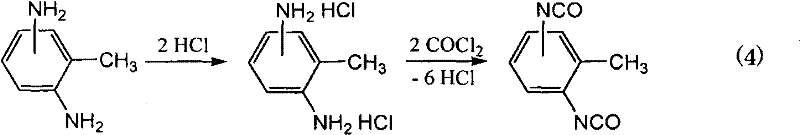

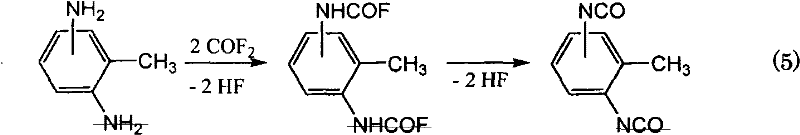

Method for producing isocyanate compound

InactiveCN102056895AIncreased toxicityLow toxicityOrganic compound preparationPreparation from carbamatesCarbonyl fluorideReaction temperature

Disclosed is a method for efficiently producing an isocyanate compound at a low reaction temperature at a low reaction pressure without using a highly toxic phosgene and without going through a complicated process. Specifically, an isocyanate compound is produced by reacting a carbonyl fluoride and an organic amine. A carbamoyl fluoride is produced by reacting the carbonyl fluoride and the organic amine, and then the carbamoyl fluoride is converted into an isocyanate. The carbamoyl fluoride is converted into the isocyanate by heating.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for continuous preparation of 1,6-hexamethylene diisocyanate

InactiveCN101492397AAvoid poisonousAvoid corrosionLiquid-gas reaction of thin-film typePreparation from carbamatesAlcoholSolvent

The invention relates to a method for continuously preparing 1, 6-hexamethylene diisocyanate. Solution dissolved with hexamethylene diurethane is continuously pumped into a scraper falling film evaporator to form a falling film. The thermal cracking reaction is started. The inner wall temperature of the evaporator is controlled at 220 to 245 DEG C, and the reaction pressure is stabilized at 0.2-0.6MPa. Alcohol generated during the reaction together with little solvent evaporates from the top of the evaporator. The 1, 6-hexamethylene diisocyanate together with most of the solvent are produced from the bottom of the evaporator, and the yield is larger than 90 percent.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Solid acid catalyst and use thereof in synthesizing 1,6-hexamethylene diisocyanate

ActiveCN101337189ALight colorHigh reactivityPhysical/chemical process catalystsPreparation from carbamatesCatalytic pyrolysisMethyl carbonate

The invention relates to a solid-acid catalyst, and the application thereof in the synthesis of 1, 6-hexamethylene diisocyanate (HDI). The solid-acid catalyst of the invention is characterized in that SO4<2-> / TiO2-ZnO-ZrO2-Al2O3 is prepared by the reaction of phthalate ester, water soluble zinc salt, water soluble aluminum salt, water soluble zirconium salt and H2SO4; the mole fraction of the phthalate ester is 8-45 percent; the mole fraction of the zinc salt is 30-60 percent; the mole fraction of the zirconium salt is 3-10 percent; and the mole fraction of the H2SO4 is 6-18 percent. The catalyst is applicable to the preparation of the 1, 6-hexamethylene diisocyanate (HDI), has higher reaction activity and higher selectivity, and can adopt the cheaper dimethyl carbonate as the raw material, besides, the aminolysis yield is as high as 95 percent, the pyrolysis yield can reach 88 percent, and the catalytic pyrolysis temperature is especially lower, and can decrease to be not higher than 230 DEG C, thereby obviously reducing the occurrence of side reactions, improving the yielding rate of the product, and enabling the total yielding rate of the product to be 83.6 percent.

Owner:JIANGSU GUOLI CHEM TECH

Production method and equipment of methyl isocyanate

InactiveCN103694190AAvoid downtimeEnsure continuous productionIsocyanic acid derivatives purification/separationPreparation from carbamatesChlorideMethyl isocyanate

The invention discloses a production method of methyl isocyanate. The method comprises the following steps: producing CO from CO2, O2 and coke, producing phosgene from CO and chlorine gas, synthesizing methylaminoformyl chloride from the phosgene and the monomethylamine, decomposing and purifying to prepare the methyl isocyanate. The invention further discloses production equipment of methyl isocyanate. According to the production method and equipment, the energy consumption can be effectively reduced, byproducts are reduced, the production cost is lowered, the product yield is increased, the labor intensity of workers is reduced, the production field environment is improved, the reaction safety is further enhanced, and the three-waste emission is reduced.

Owner:荆州沙隆达控股有限公司

Separation Method and Method for Producing Isocyanate

ActiveUS20130184488A1Efficient separationEfficient collectionOrganic compounds purification/separation/stabilisationOrganic compound preparationHydrogenBoiling point

Disclosed is a method for separating, with a multi-stage distillation column, a mixture containing an active hydrogen-containing compound (A) and a compound (B) that reversibly reacts with the active hydrogen containing compound (A), the method comprising distillation-separating the active hydrogen-containing compound (A) and the compound (B) with the multi-stage distillation column in the presence of an intermediate-boiling-point inactive compound (C) that has a normal boiling point between a normal boiling point of the active hydrogen-containing compound (A) and a normal boiling point of the compound (B) and is chemically inactive for both of the (A) and the compound (B).

Owner:ASAHI KASEI CHEM CORP

Catalyst for preparing isocyanate by thermal decomposition of aryl (alkyl) carbamic acid ester and use thereof

InactiveCN101011657AHigh yieldEasy to separateMetal/metal-oxides/metal-hydroxide catalystsPreparation from carbamatesHalogenCarbamic acid esters

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

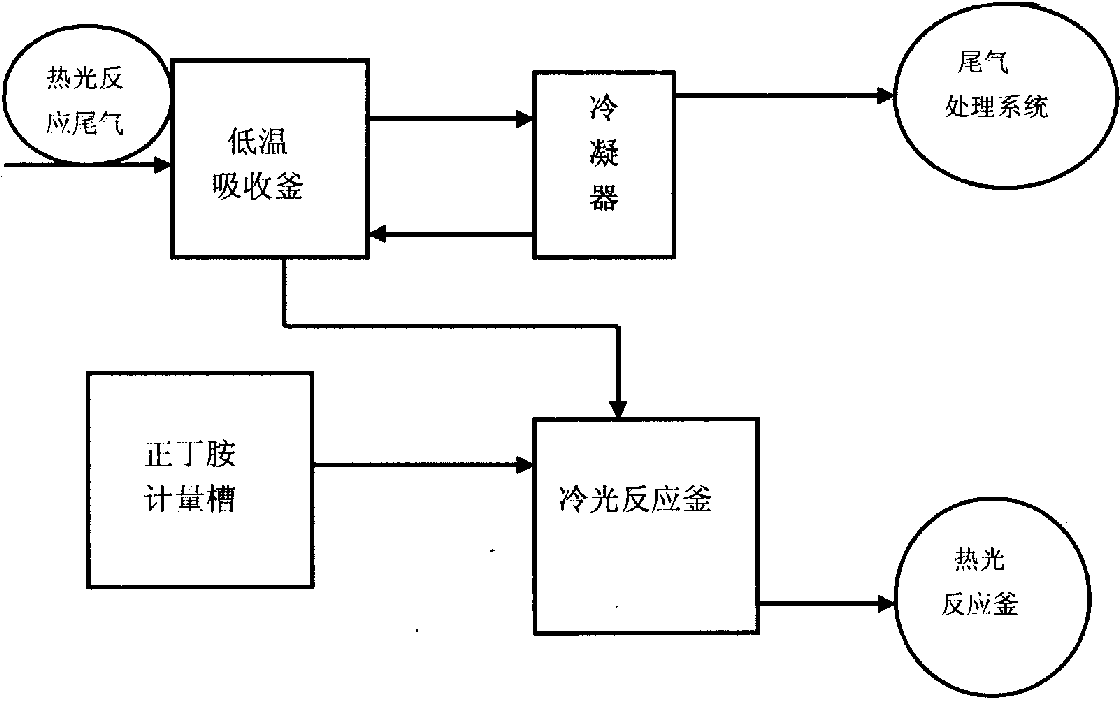

Recycling method for phosgene in tail gas generated in calorescence reaction for synthesizing normal-butyl isocyanate

ActiveCN103638688ATake advantage ofMaximize utilizationDispersed particle separationVapor condensationCalorescenceN-butylisocyanide

The invention relates to a recycling method for phosgene in tail gas generated in calorescence reaction for synthesizing normal-butyl isocyanate. The recycling method comprises the steps of continuously cooling and absorbing the tail gas generated in the calorescence reaction for synthesizing the normal-butyl isocyanate through a low temperature solvent, and condensing the tail gas through a condenser, wherein the non-condensing gas directly enters a tail gas processing system; preparing normal-butyl acyl chloride from the solvent containing the phosgene with certain quality concentration through cold light reaction, metering the phosgene-containing solvent, shifting the solvent into a cold light kettle, dropwise adding n-butylamine at -8 DEG C to -2 DEG C, after the dropwise adding, keeping the temperature for 1 hour so as to obtain the n-butylamine acyl chloride; and resolving the n-butylamine acyl chloride in a calorescence reaction kettle to obtain the normal-butyl isocyanate. The method provided by the invention has the advantages that the phosgene is utilized to the greatest extent, the load of the tail gas generated in the normal-butyl isocyanate calorescence reaction in a tail gas processing system and the alkali charge during tail gas processing are reduced, the production cost of the product is reduced, and the purpose of saving and recycling resources is achieved.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

Non-phosgene route to the manufacture of organic isocyanates

InactiveUS6781010B1Avoid huge wasteEfficient processingCarbamic acid derivatives preparationOrganic compound preparationPhosgeneReaction product

A phosgene-free process for producing organic isocyanates reacts an organic fomamide with a diorganocarbonate and thermolyzing the reaction product to obtain the corresponding organic isocyanate. Byproducts may be cycled back to the reaction or recycled to produce additional starting materials. The process product organic isocyanates in high yield.

Owner:LYONDELL CHEM TECH LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com