Method for continuously manufacturing toluene di-isocyanate

A technology of toluene diisocyanate and its manufacturing method, applied in the direction of urethane preparation, organic chemistry, etc., can solve the problems of increased side reactions, equipment abrasion, slow rate of isocyanate, etc., to reduce the amount of production, increase energy consumption, reduce Abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

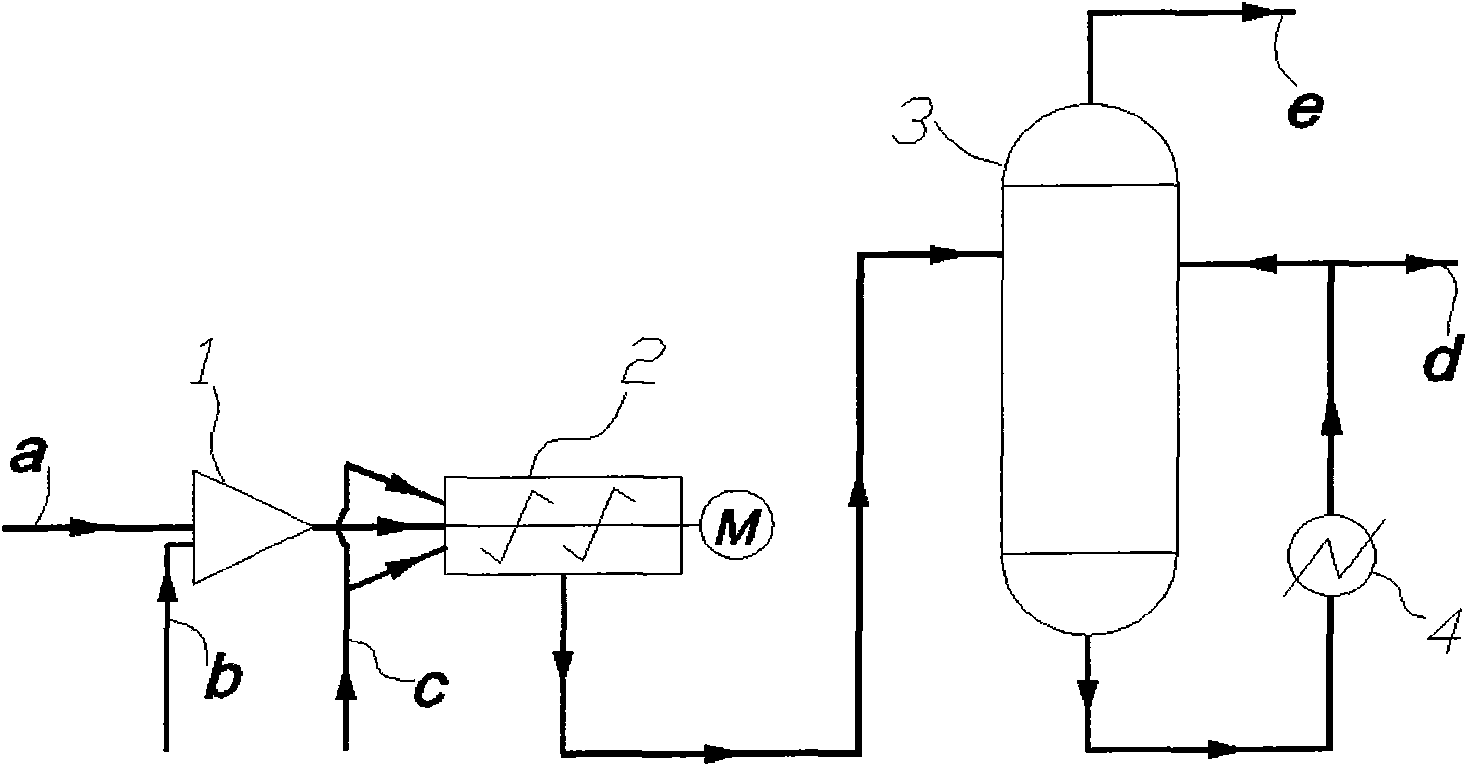

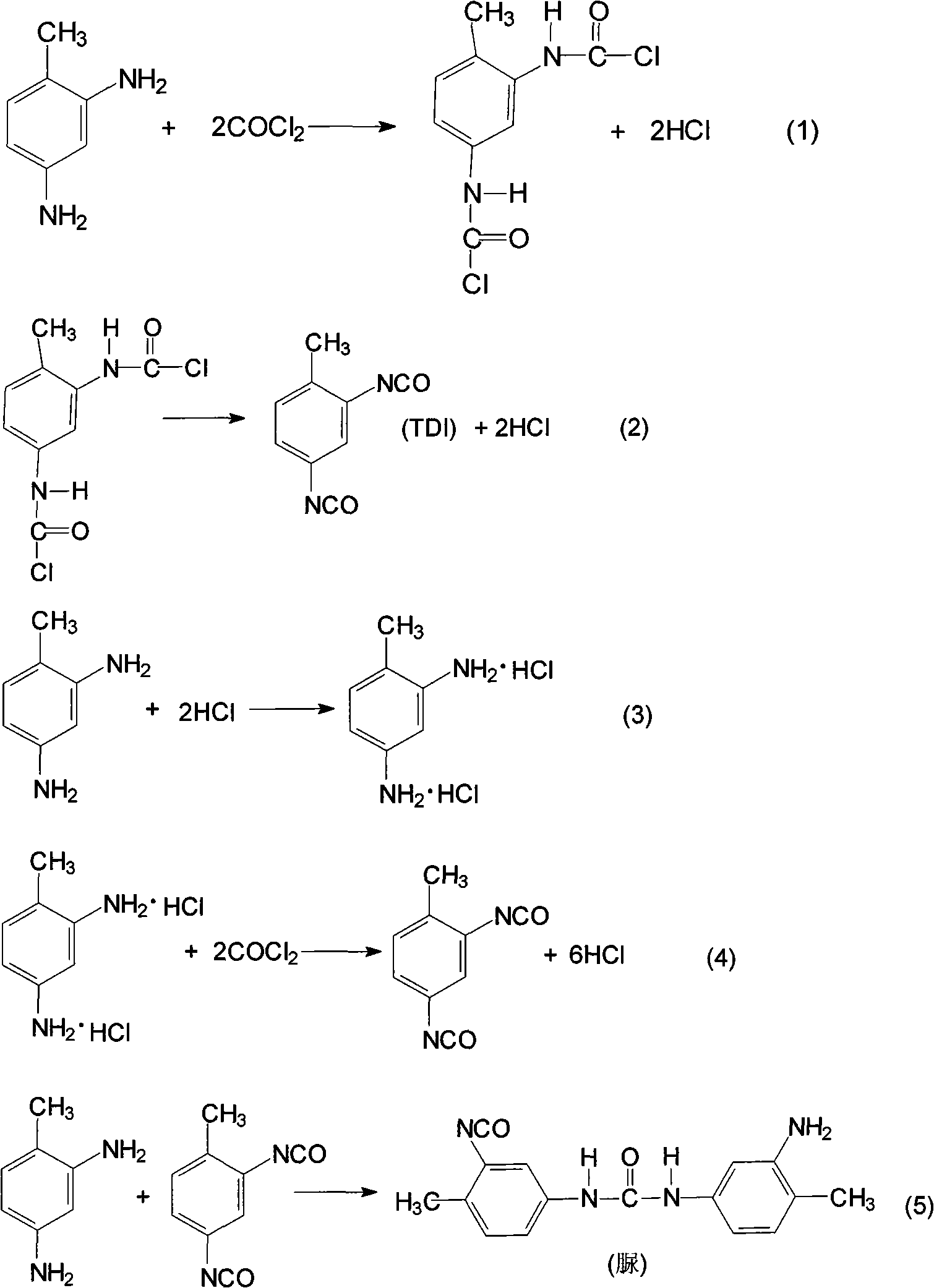

[0043] This embodiment is a continuous production process of toluene diisocyanate (TDI) before improvement, specifically, toluene diamine and phosgene are only mixed in one step, and a jet reactor is used as the phosgenation reactor.

[0044]After heating the organic inert solvent o-dichlorobenzene (ODCB), dilute m-toluenediamine (m-TDA) to a mass concentration of 20%, and control the amount of heating so that the temperature of the m-toluenediamine solution is around 100-140°C. Similarly, fresh phosgene and recycled phosgene are made into a solution with a mass concentration of 40% by using heated o-dichlorobenzene, and the temperature is controlled at 80-100° C. The phosgene solution contains 0.44% hydrogen chloride in mass fraction. Control the molar ratio of amino group and phosgene in the toluenediamine to be 1:3, adjust the reaction temperature to be 100-110° C., and the absolute reaction pressure to be 1.5-1.8 MPa. The crude product of the phosgenation reaction is passe...

Embodiment 2

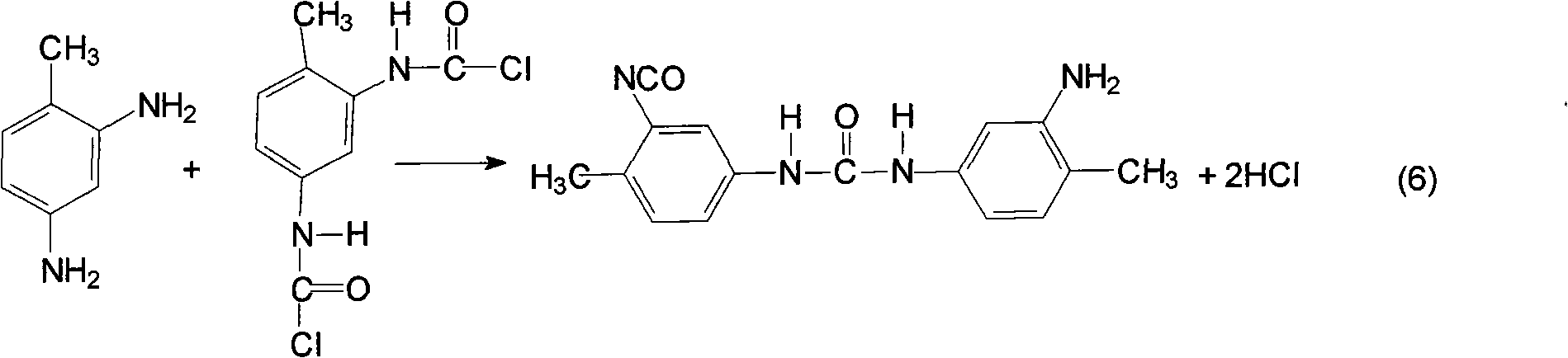

[0046] A continuous manufacturing method of toluene diisocyanate, comprising the steps of:

[0047] (1) After heating the organic inert solvent o-dichlorobenzene (ODCB), dilute m-toluenediamine (m-TDA) to a mass concentration of 20%, and control the amount of heating to dissolve the m-toluenediamine solution. In the phosgene refining tower, fresh phosgene and non-condensable gas from the top of the phosgenation reaction flasher and degassing tower are absorbed into 35% to 40% phosgene ortho-dichlorobenzene with heated o-dichlorobenzene Benzene solution, wherein the hydrogen chloride mass fraction is less than 0.1%, its temperature is controlled at 40-50 ° C, according to the molar ratio of amino group and phosgene in m-toluenediamine is 1: 2, the o-dichlorobenzene solution of m-toluenediamine Mix and react with phosgene o-dichlorobenzene solution with a mass content of less than 0.1% hydrogen chloride in a jet mixer, the reaction temperature is 50-60°C, and the absolute pressu...

Embodiment 3

[0052] A continuous manufacturing method of toluene diisocyanate, comprising the steps of:

[0053] (1) With an impingement flow mixer, the chlorobenzene solution of 5% toluenediamine with a mass concentration and the phosgene with a mass concentration of 5% to 10% that contain a mass fraction of 0.1% hydrogen chloride at a temperature of 40 to 50°C The chlorobenzene solution is pre-mixed and reacted, the reaction temperature is 70-80°C, the absolute reaction pressure is 0.5-0.7MPa, and the average residence time of the material in the impinging flow mixer does not exceed 10s; in the impinging flow mixer, toluene diamine The molar ratio of amino group and phosgene is 1:1.5;

[0054] (2) Input the reacted mixture into the high-shear reactor, and continue to add the low-temperature 140-160° C. Continue to mix and react in the phosgene chlorobenzene solution with a mass concentration of 0.5% hydrogen chloride of 40% to 45%, and control the reaction temperature to 130 to 140°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com