Patents

Literature

99 results about "Toluene di-isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material

InactiveCN101445583ASolve the problem of poor flexibilityHigh bonding strengthPolyurea/polyurethane coatingsDiphenylmethaneWear resistant

The invention discloses a preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material. Polyether dihydroxy alcohol having a degree of functionality of 2 and an average relative molecular weight of 1200 to 2200 is reacted with toluene di-isocyanate or diphenylmethane-4,4'-diisocyanate prepared for preheating to synthetize polyether dihydroxy alcohol polyurethane performed polymer for reservation; one of bisphenol A E-44 and E-51 after pre-dehydration is selected for reservation; polyurethane modified epoxy is formed through polyaddition reaction in which a mass ratio of polyether dihydroxy alcohol polyurethane performed polymer to epoxide resin is 15 to 70: 100. The polyurethane modified epoxy obtained by the technology has high bonding strength, good flexibility and shock resistance with basal bodies of spare parts, totally without using plasticizers, such as dibutyl phthalate, dioctylphthalate, etc., without using or using less plasticizers, such as polysulfide rubber, liquid acrylonitrile butadiene rubber, etc., thereby not only solving the problem that general epoxide resin has bad flexibility but also saving the production cost.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

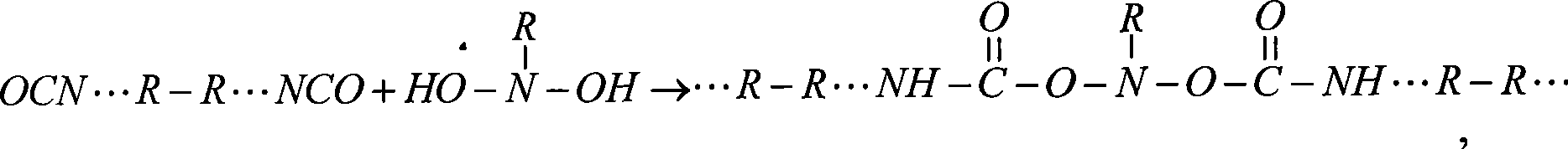

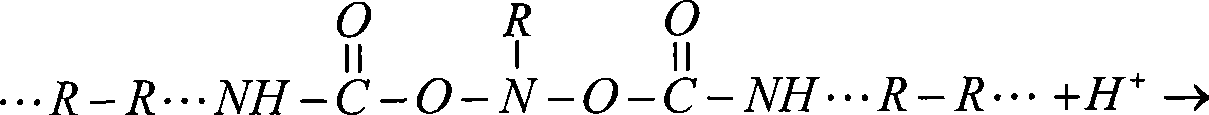

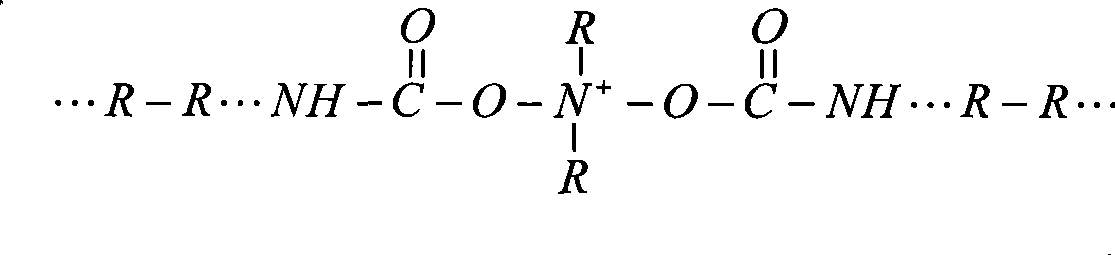

Preparation and use of cation aqueous polyurethane emulsion

InactiveCN101440152ASave energyEasy to processWater-repelling agents additionPulp material addition processesPolyesterPolyethylene glycol

The invention relates to a method for preparing cationic waterborne polyurethane surface sizing agent capable of being used as paper and paperboard surface sizing agent. Toluene di-isocyanate (TDI), polyester dibastic alcohol, polyethylene glycol, 1,4-butanediol and N-methyldiethanolamine as a hydrophilic chain extender are selected to synthesize a cationic waterborne polyurethane emulsion by an internal emulsification method. The prepared polyurethane emulsion can be well used in cooperation with aluminum sulfate, poly aluminum and other aluminum salts. When the prepared polyurethane emulsion is used in cooperation with starch, aluminum salts and the like for the surface sizing of paper and paperboards, good sizing effects can be obtained, and the correlation of the paper and the paperboards can be greatly improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Immobilized carrier of nano-attapulgite clay compounded hydrophilic urethane foam microorganisms

InactiveCN101619310AHigh affinityImprove mass transfer effectImmobilised enzymesSustainable biological treatmentN dimethylformamideRaw material

The invention relates to an immobilized carrier of nano-attapulgite clay compounded hydrophilic urethane foam microorganisms, which consists of the following raw materials in parts by weight: 100 polyether, 36-55 toluene di-isocyanate, 3.1-3.9 polyisocyanate, 0.5-5 nano-attapulgite clay, 0.45-1.2 silicon oil, 0.14-0.25 tertiary amine, 0.14-0.20 organotin, 1.0-2.7 water, 1.6-4.5 methylene dichloride and 0-80 N, N-dimethylformamide. The polyisocyanate and the nano-attapulgite clay are added in the foaming process of common polyether urethane, thereby the common polyether urethane has a water absorbing surface with crosslinked network structure and strong polarity, meanwhile has great adsorption capacity and hydrophilicity of nanomaterials, improves the compatibility and the mass transfer performance of a foam carrier to the microorganism, and simultaneously strengthens the physicochemical performance and the stability of the materials, thereby improving the sewage treatment efficiency.

Owner:LANZHOU JIAOTONG UNIV

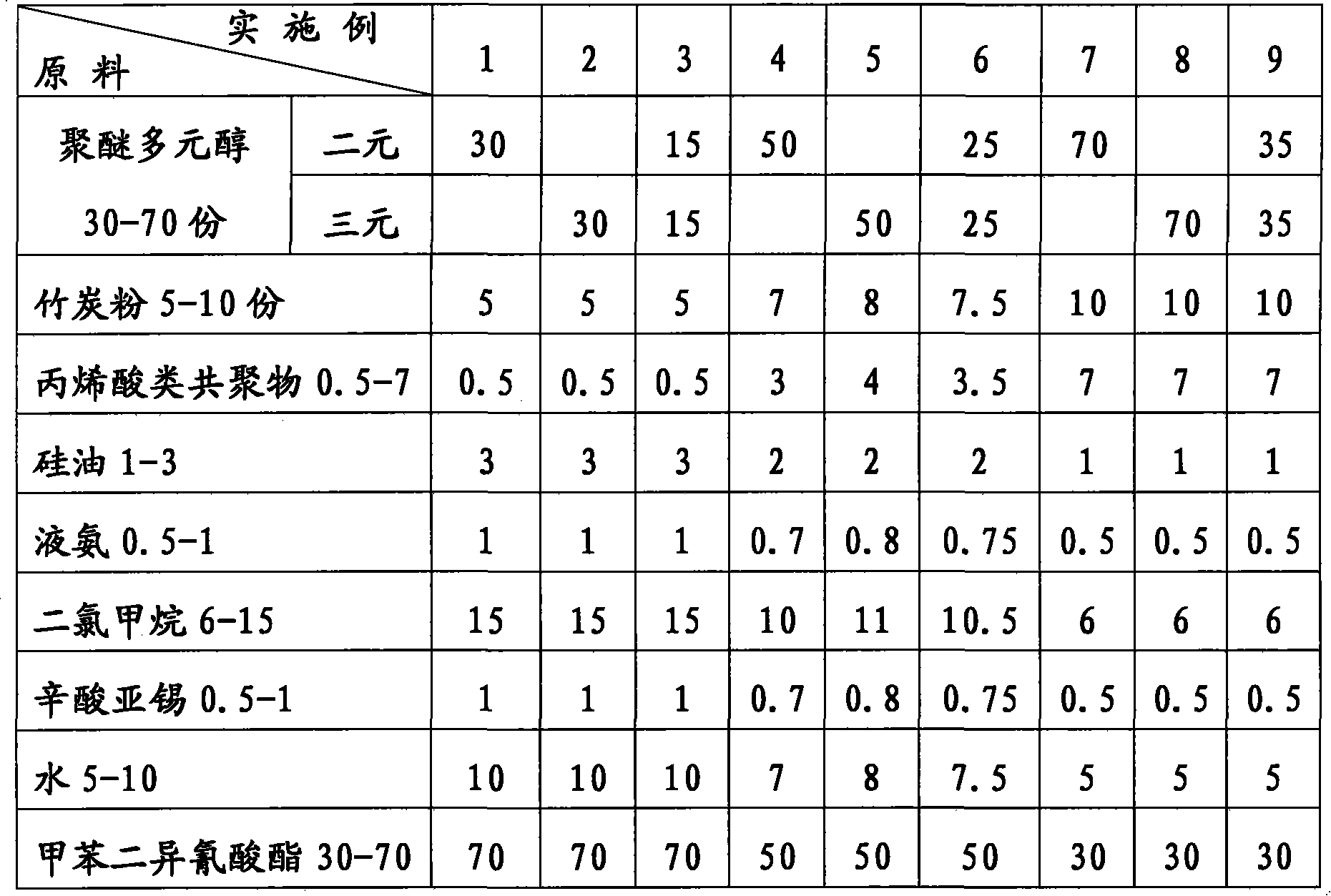

Bamboo charcoal polyurethane foam composite material and production method thereof

The invention relates to a bamboo charcoal polyurethane foam composite material, which comprises the following raw materials in portion by weight: 30 to 70 portions of polyether polyol, 30 to 70 portions of toluene di-isocyanate, 5 to 10 portions of bamboo charcoal powder and a dispersing agent thereof, and a certain amount of mold-release agent, catalyst, blowing promoter and the like. The production method comprises four production steps of the production of the bamboo charcoal powder, the preparation of composite bamboo charcoal powder, the preparation of a prepolymer, and the preparation of the foam composite material. The bamboo charcoal polyurethane foam composite material is suitable for manufacturing compartment sandwich materials, sofas, seat cushions, mattresses and the like, is soft and comfortable and is rich in elasticity, has the advantages of strong performances of absorbing free formaldehyde, releasing negative ions and emitting far infrared rays, and is advantageous for the health of human bodies.

Owner:ZHEJIANG FORESTRY ACAD +1

Modified waterborne polyurethane resin for artificial leather and preparation method thereof

InactiveCN101580577AAddress water resistanceSolve the softness problemTextiles and paperPropanoic acidSolvent

The invention relates to a modified waterborne polyurethane resin for artificial leather and a preparation method thereof. The modified waterborne polyurethane resin comprises formulation: the combination of any two in 6% of polyether polyol N210 with the molecular weight of 1000, 9-14% of polyether polyol N220 with the molecular weight of 2000 or 6% of polyether polyol N240 with the molecular weight of 4000; 6.5-9% of toluene di-isocyanate (TDI), 1.5-1.8% of dimethylol propionic acid, 2-4% of hydroxyl saturated polyester resin, 0.0-1% of dibutyl tin laurate, 0.8-1.5% of diethylene glycol, 0.9-1.3% of triethylamine, 0.4-0.5% of isophorone diamine, 0.5-2% of hydroxyl polyether modified siloxane with the hydroxyl value of 56 and the rest of water. The invention has the advantages of high tensile strength, good elasticity, strong adhesive force, excellent water resistance, solvent resistance and chemical resistance, better leather feeling, high cold resistance and folding strength, good combination property and remarkable environmental protection.

Owner:建德市顺发化工助剂有限公司

Method for producing environmental-protection type sound-absorbing and flame-retardant sponge

InactiveCN101805513AVarious sound absorption and noise reduction effectsMeet the requirements of sound absorption and noise reductionFoaming agentBromine

The invention discloses a method for producing an environmental-protection type sound-absorbing and flame-retardant sponge. The method comprises the following steps of: (1) raw material proportioning: weighting the following raw materials in parts by weight: 50 parts of toluene di-isocyanate, 100 parts of polyether, 3.7 parts of water, 1.2 parts of stabilizer, 0.5 part of catalyst, 2 parts of foaming agent, and 15 parts of flame retardant; (2) mixing reaction, adding the toluene di-isocyanate and polyether into a stirring tank, and uniformly stirring; delivering the water, stabilizer, catalyst, foaming agent and flame retardant and the uniformly mixed toluene di-isocyanate and polyether into a mixing head to carry out mixing reaction at the temperature of 21 DEG C-23 DEG C under the pressure of 0.25Pa; (3) foaming, punching the mixture into a foaming box, and carrying out chain extension, foaming, crosslinking and solidifying to obtain the finished sponge. The produced sound-absorbing and flame-retardant sponge has multiple sound-absorbing and flame-retardant effects, thereby satisfying the multiple sound-absorbing and flame-retardant requirements; the sound-absorbing and flame-retardant property is stable, the bromine is eliminated, and the heavy metal content achieves the environment protection requirement; and the service life is prolonged.

Owner:WUXI JINGSHANG FOAM

Vertical type single-component polyurethane waterproof coating and preparation method thereof

InactiveCN101818022AReduce labor costsTo achieve the purpose of thickeningPolyurea/polyurethane coatingsBenzeneAlcohol

The invention provides a vertical type single-component polyurethane waterproof coating. The coating is prepared from the following components in parts by weight: 15-25 parts of polyether trihydric alcohol, 3-5 parts of toluene di-isocyanate, and 0.3-1.0 part of amine curing agent. The invention also provides a method for preparing the waterproof coating. The waterproof coating has the advantages of high strength, high extension, high adhesion property, no benzene or coal tar, safety, environment protection and the like, can be coated on the vertical surface with the thickness of 0.5-1.0mm each time, has no flowing and dropping, and only needs to coat 2-3 times for the vertical surface to reach the thickness of 2mm.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Production of renewable aromatic compounds

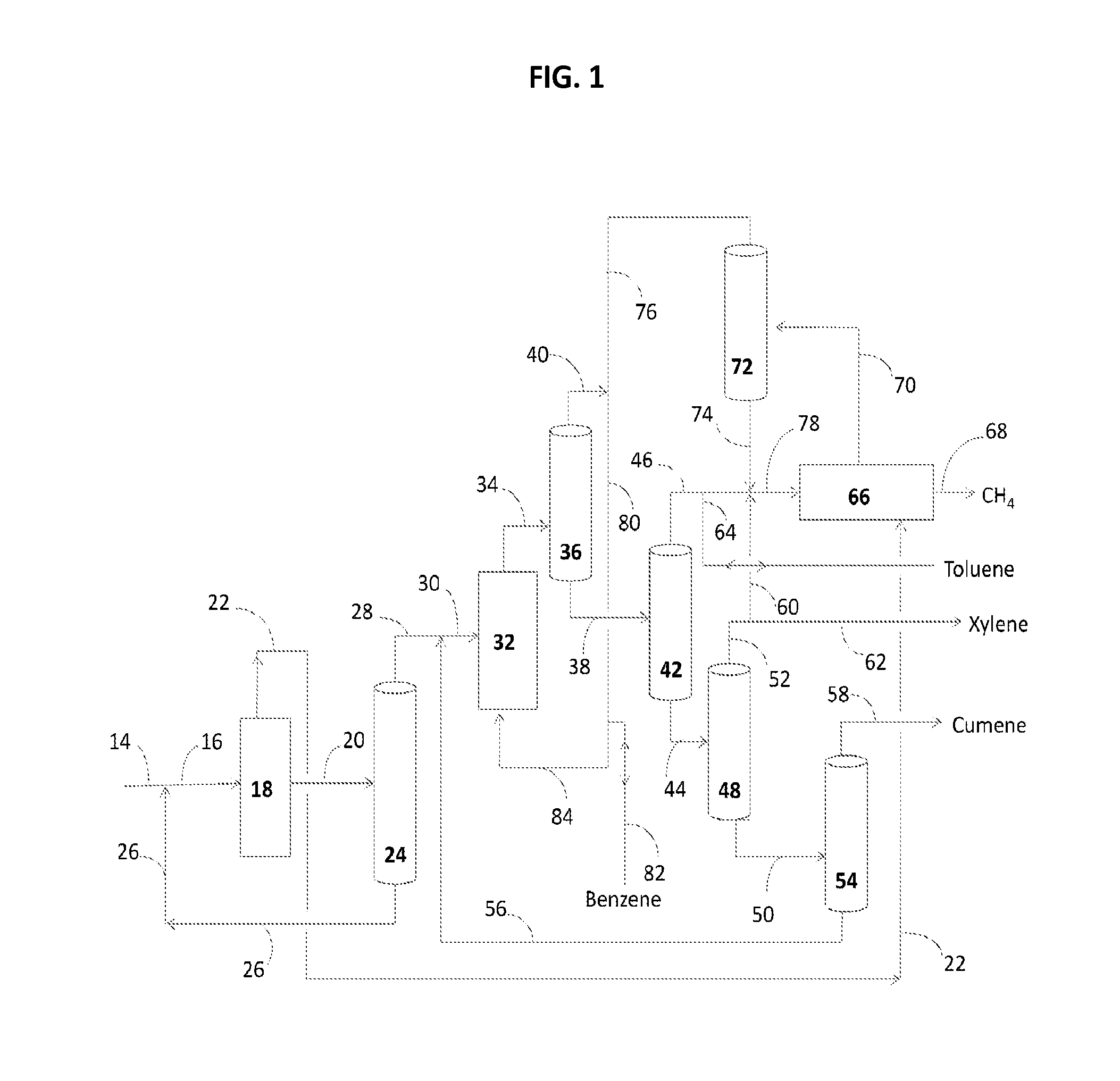

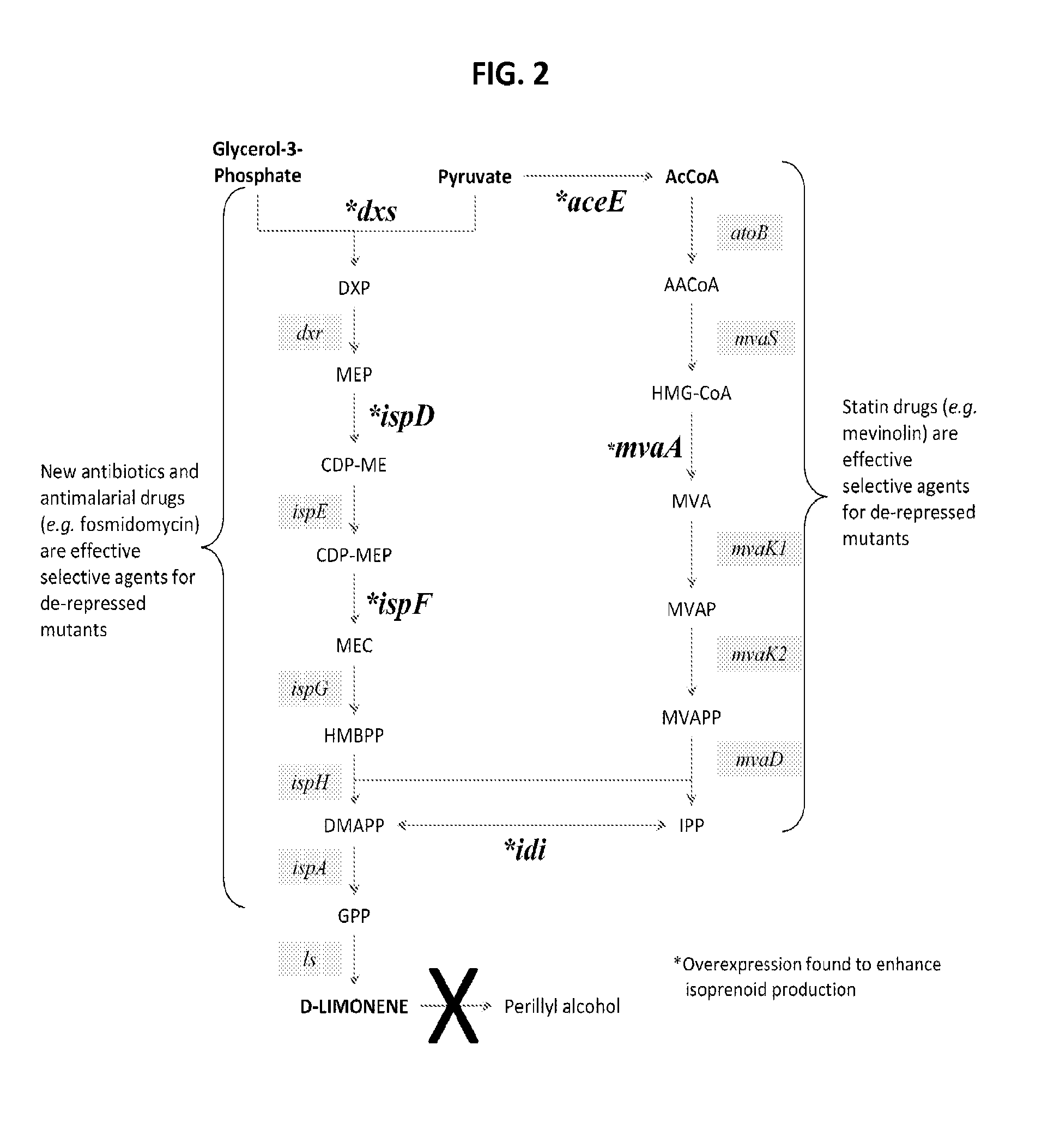

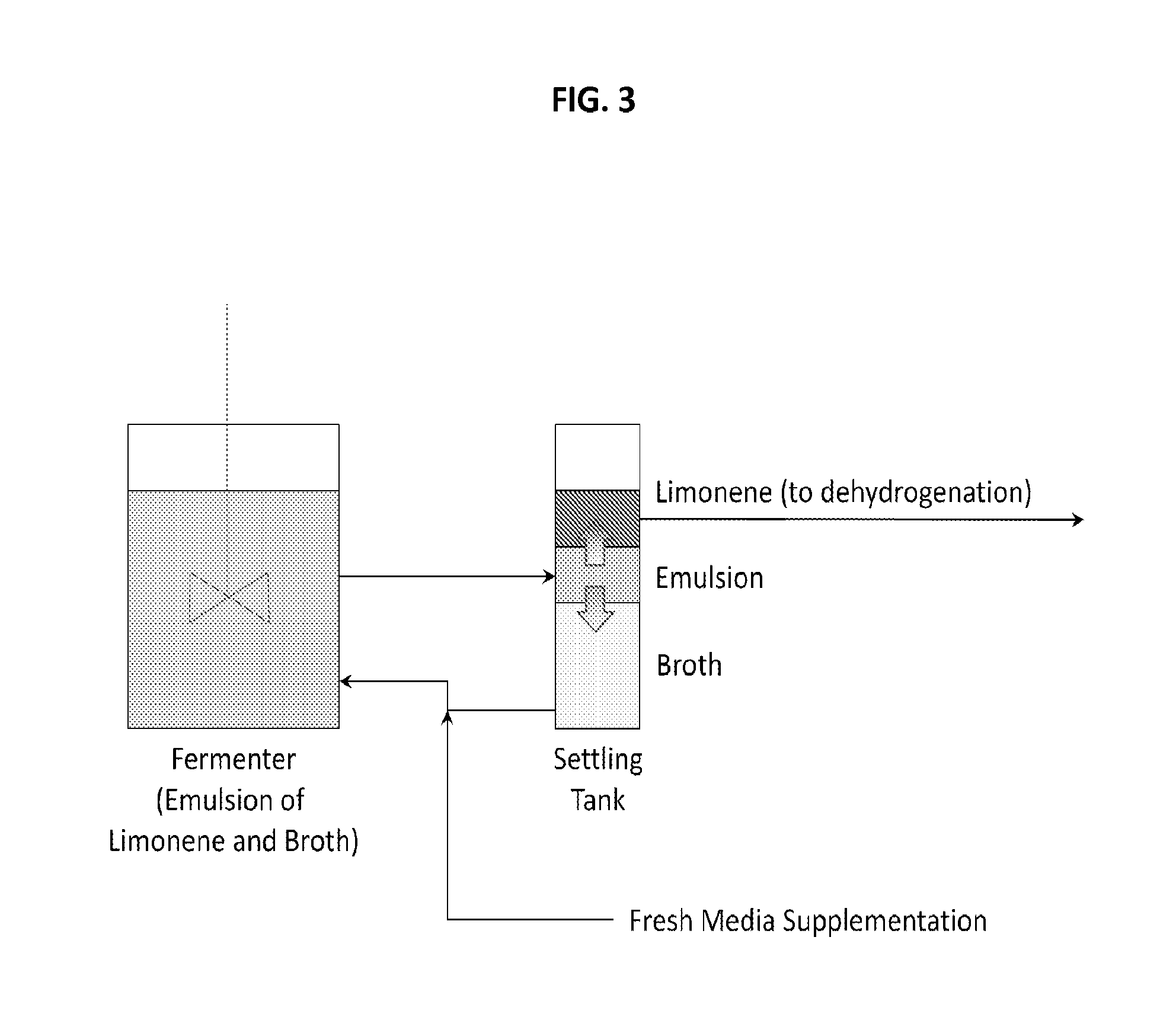

InactiveUS20130130345A1Hydrocarbon by isomerisationOrganic chemistry methodsBenzoic acidCyclohexanone

The invention provides a process for producing a variety renewable aromatic compounds such as benzene, toluene, xylenes, and cumene, as well as compounds derived from these including, for example, aniline, benzoic acid, cresol, cyclohexane, cyclohexanone, phenol and bisphenol A, toluene di-isocyanate, isophthalic acid, phthalic anhydride, terephthalic acid and dimethyl terephthalate. The invention also provides for renewable forms of these aromatic compounds.

Owner:JNF BIOCHEM

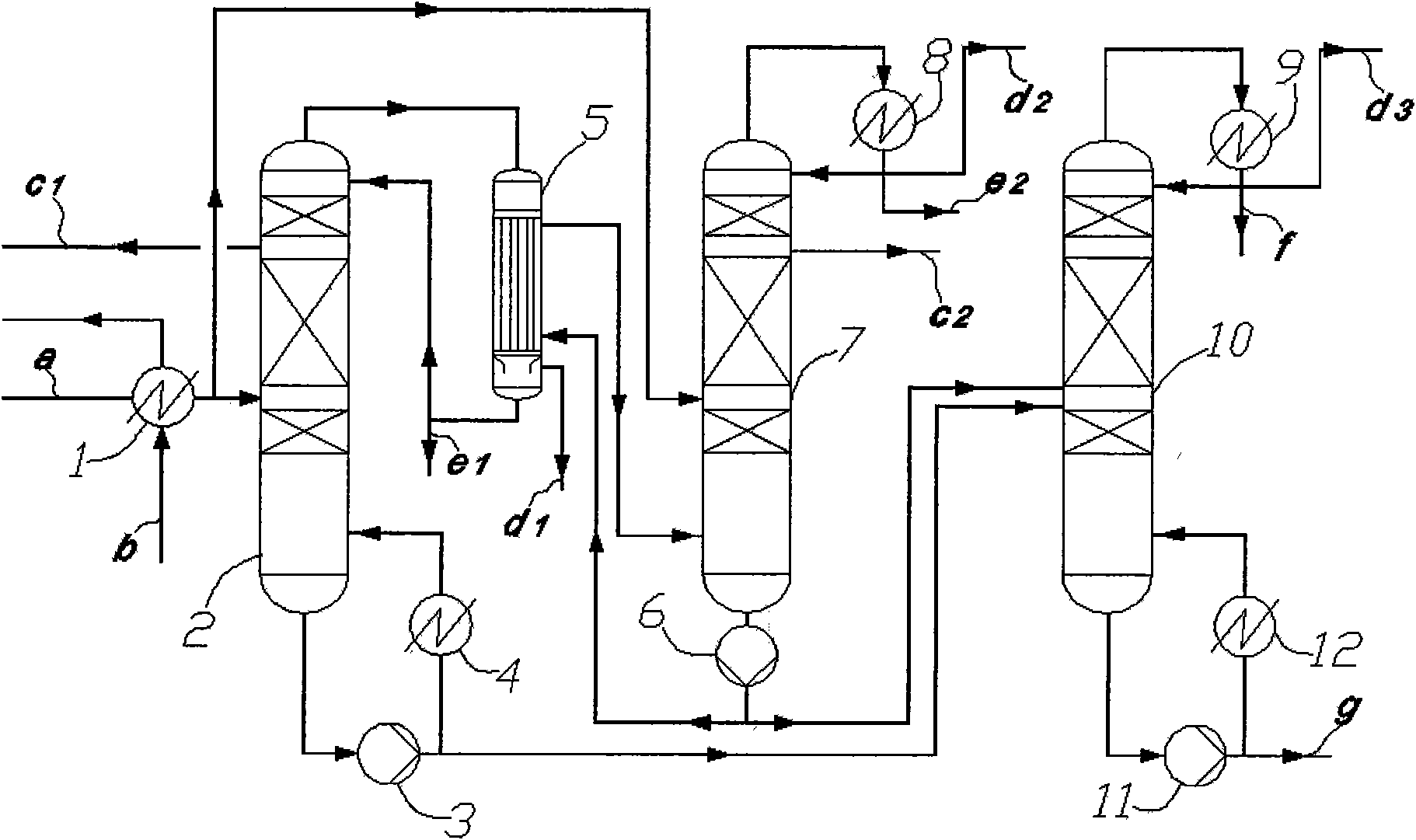

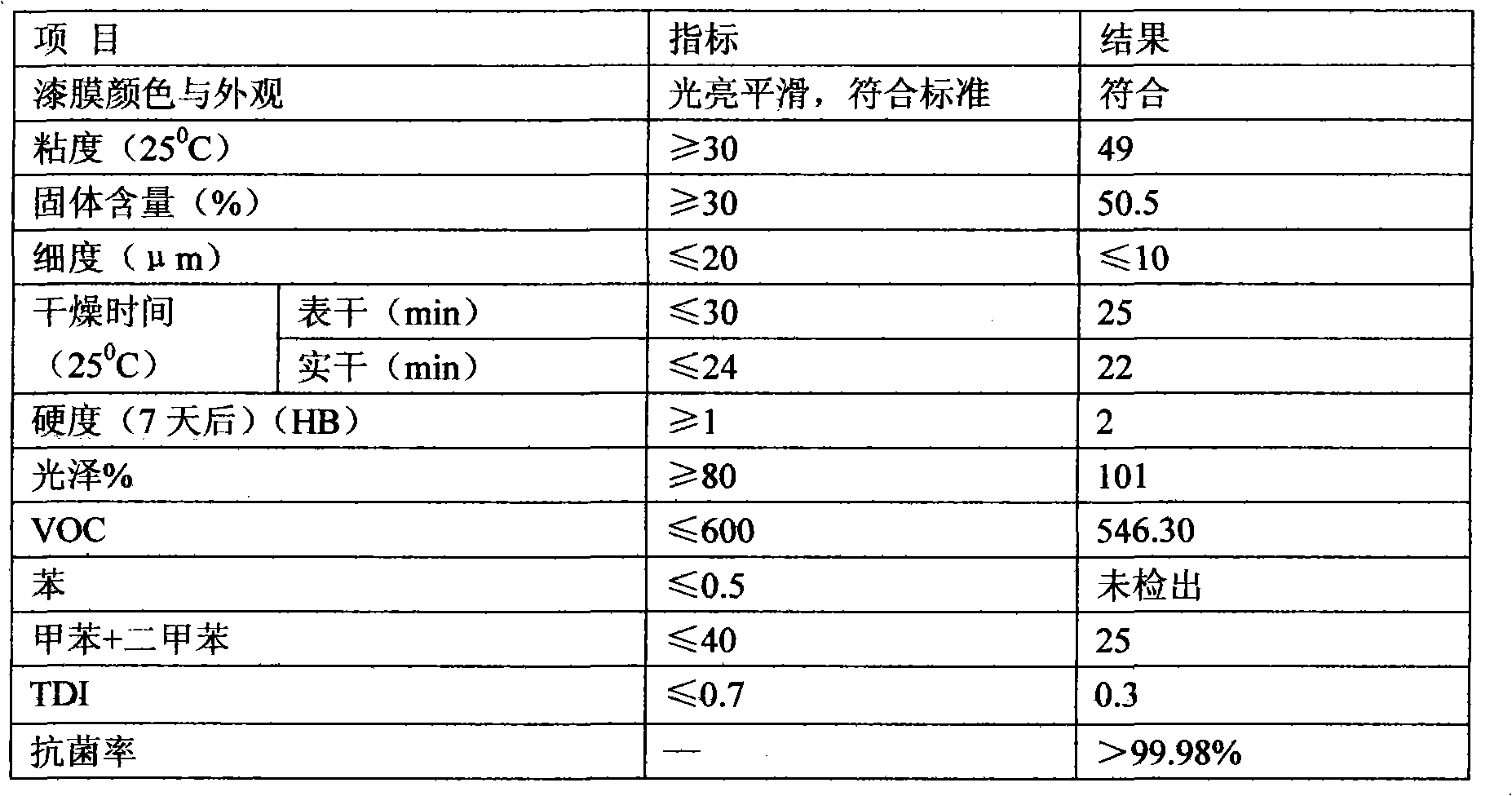

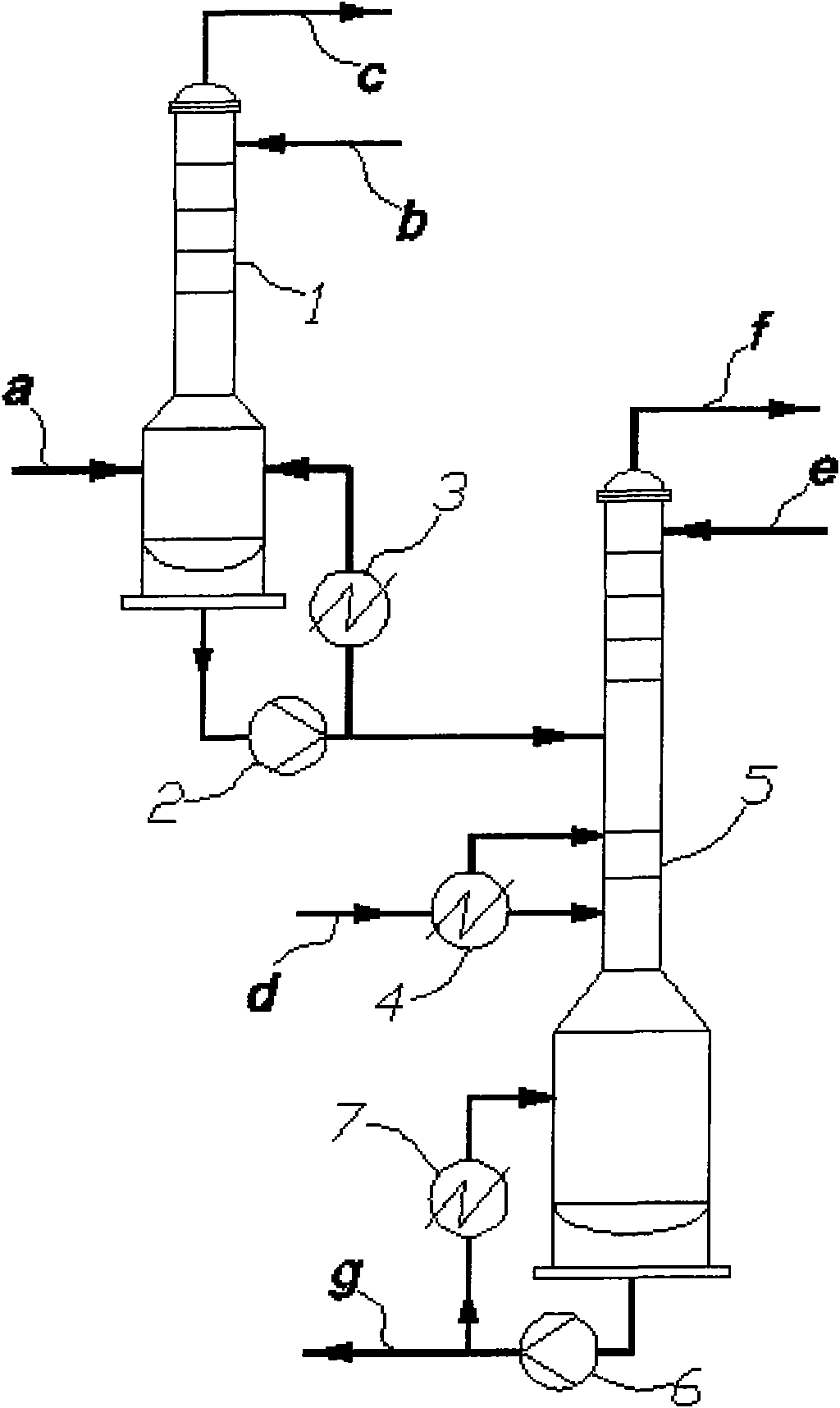

Method for recovering heat integrated solvent in continuous production of toluene di-isocyanate

ActiveCN101671277AReduce energy consumptionReduce manufacturing costChemical industryIsocyanic acid derivatives purification/separationOrganic solventDistillation

The invention discloses a method for recovering heat integrated solvent in the continuous production of toluene di-isocyanate, comprising the following steps: respectively importing materials to be distilled, which contains the toluene di-isocyanate and an inert organic solvent, to a first solvent eliminating tower with higher operation pressure and a second solvent eliminating tower with lower operation pressure to carry out distillation; leading steam from the top of the first solvent eliminating tower into a first condenser and leading part of tower bottom liquid in the second solvent eliminating tower into the first condenser to carry out heat transferring; and leading part of the tower bottom liquid from the first solvent eliminating tower and the second solvent eliminating tower intoa third solvent eliminating tower to carry out distillation. The method can obviously reduce the energy consumption in the production of the toluene di-isocyanate, thereby reducing the production cost of a unit toluene di-isocyanate product.

Owner:TIANJIN UNIV +1

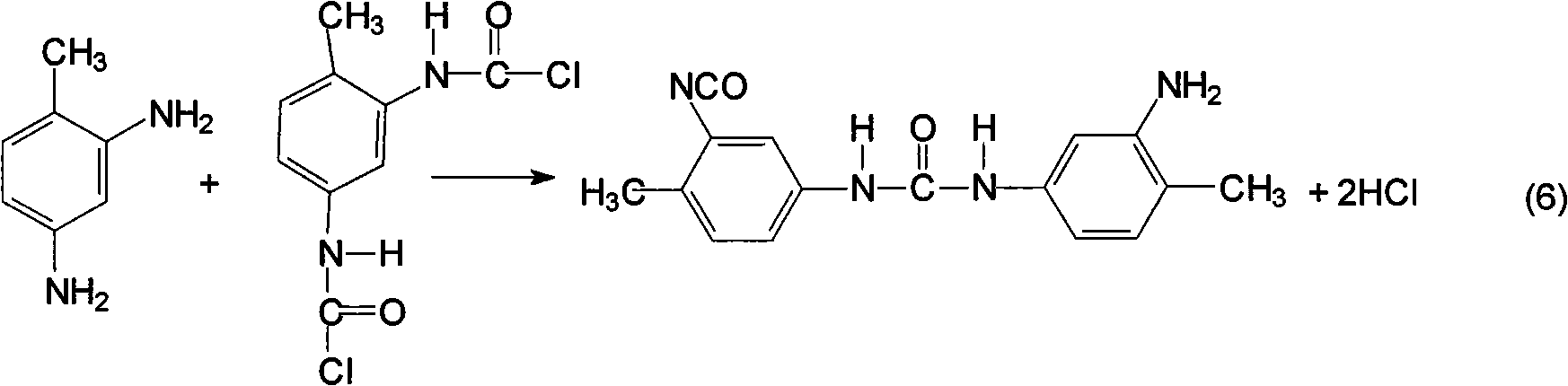

Antibacterial polyurethane wood floor paint

InactiveCN101555380AImprove fullnessHigh glossAntifouling/underwater paintsPaints with biocidesCyclohexanoneHazardous substance

The invention discloses antibacterial polyurethane wood floor paint which comprises two parts: a hydroxyl group component A and a NCO component B. The antibiotic polyurethane wood floor paint is characterized in that the hydroxyl group component A is prepared by mixing and dispersing coconut oil alkyd resin, castor oil alkyd resin, cyclohexanone, n-butyl acetate, dimethylbenzene, antimicrobial, foam killer, flatting agent and drier at high speed; the NOC component B is obtained by evenly mixing and stirring dimethylbenzene, n-butyl acetate, toluene di-isocyanate and trimethylolpropane copolymer solution and preserving heat for 1h; and the weight proportion of the A component and the B component is 1:0.8-1.2. Aiming at overcoming the defects existing in the prior art, the invention provides the polyurethane wood floor paint which has excellent antibacterial performance, good application property and low hazardous substance content and has a paint coat with good wear resistance, shock resistance and adhesive force.

Owner:广东花王涂料有限公司

Composition for preparing sponge powder puff and preparation method of composition

ActiveCN102942673AImprove hydrophilicityImprove comfortPackaging toiletriesPackaging cosmeticsPolyolFoaming agent

The invention belongs to the field of polymer synthesis and particularly relates to a composition for preparing sponge powder puff and a preparation method of the composition. The composition consists of prepolymer ingredients and foaming agent ingredients according to a mass ratio being 100:(50-100), wherein the prepolymer ingredients are prepared from polyether polyol, reaction type hardening agents and toluene di-isocyanate through reaction, NCO is 5.5 to 7.0 percent, and the foaming agent ingredients consist of distilled water and organic silicon surfactants. The preparation method comprises the steps that the polyether polyol and the reaction type hardening agents are placed in a reaction kettle for dehydration, the temperature reduction is carried out, toluene di-isocyanate is added, the temperature rise reaction is carried out, and materials are discharged and are stored in a sealed way; the distilled water and the organic silicon surfactants are mixed, the uniform stirring is carried out, and the mixture is stored in a sealed way; and the prepolymer ingredients and the foaming agent ingredients are uniformly mixed and are cast into a mold for curing, and products are obtained. The sponge powder puff prepared by the composition has the advantages that excellent hydrophily and the hand feeling comfort are realized, the bubble holes are fine, dense and uniform, the powder affinity performance is high, and the use is convenient. The preparation method is simple, and the operation is easy.

Owner:SHANDONG INOV POLYURETHANE

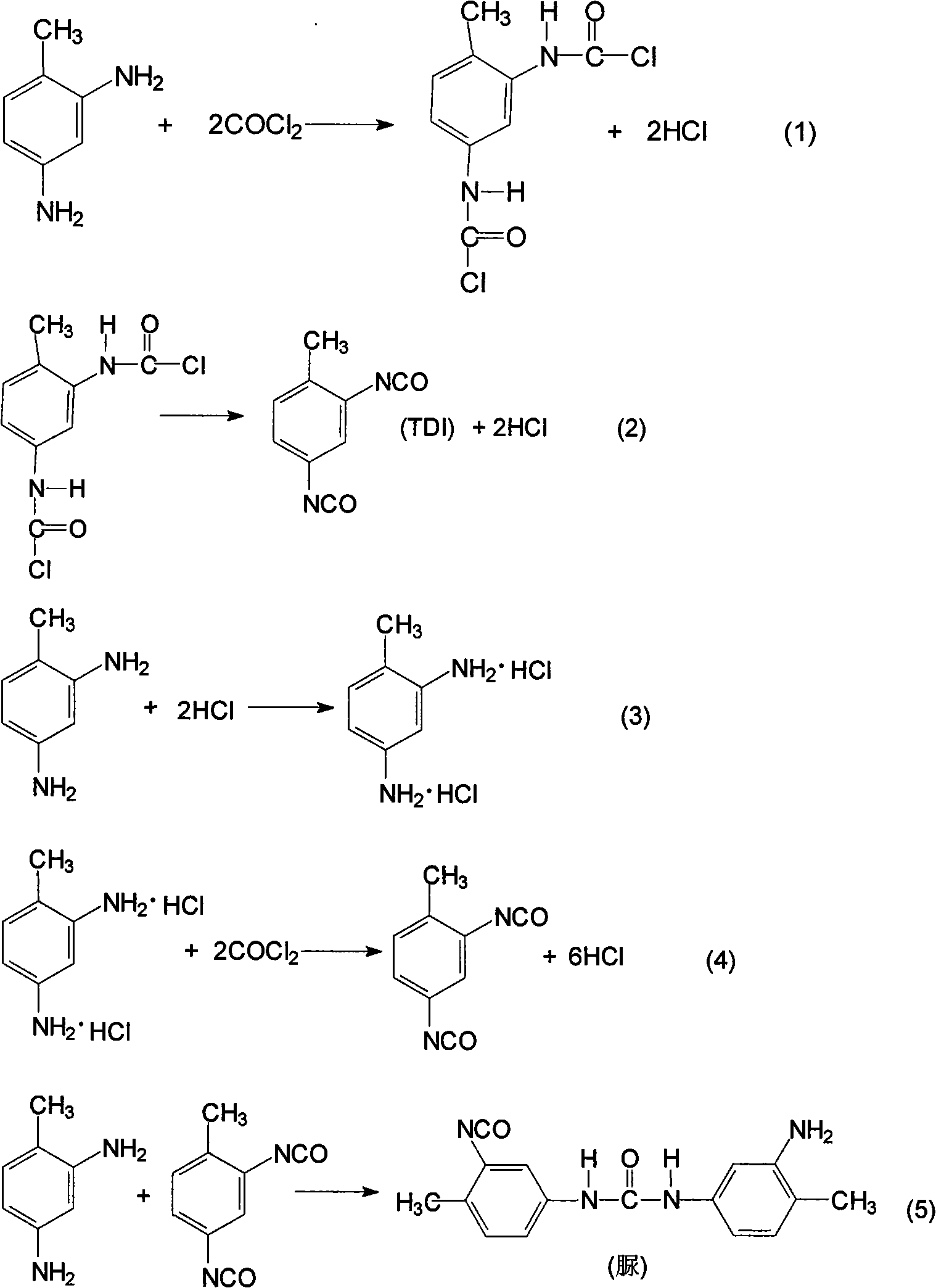

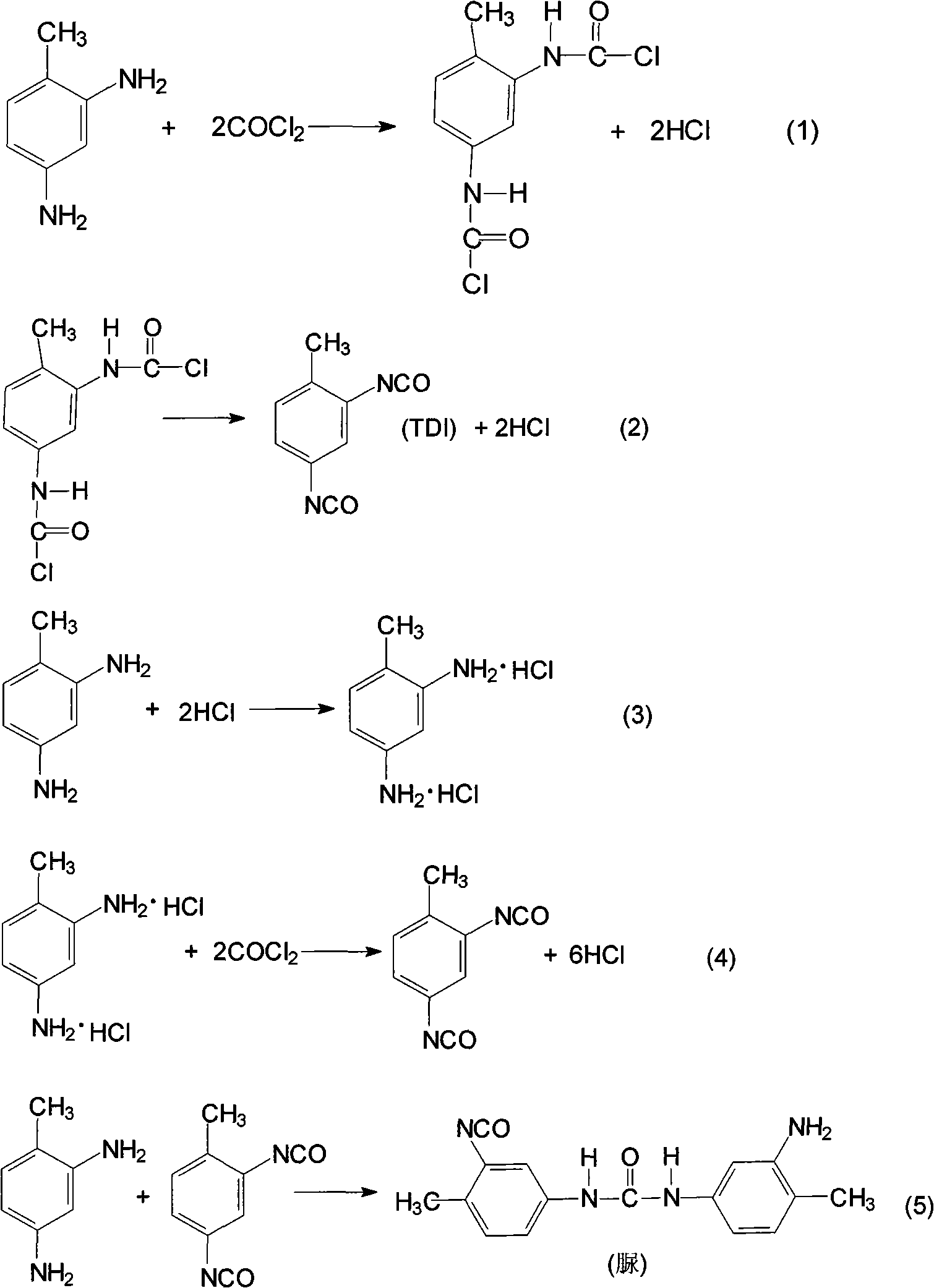

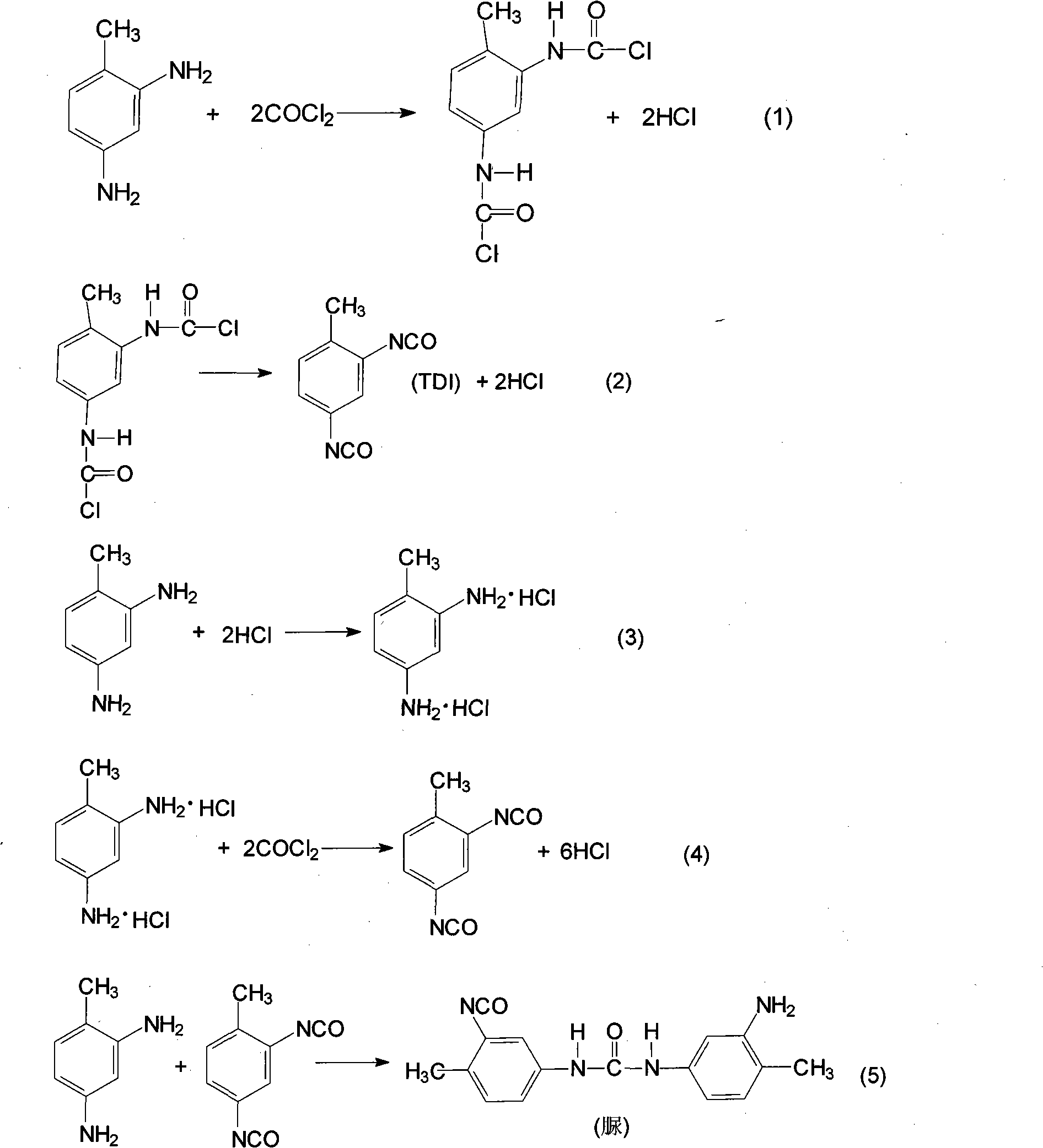

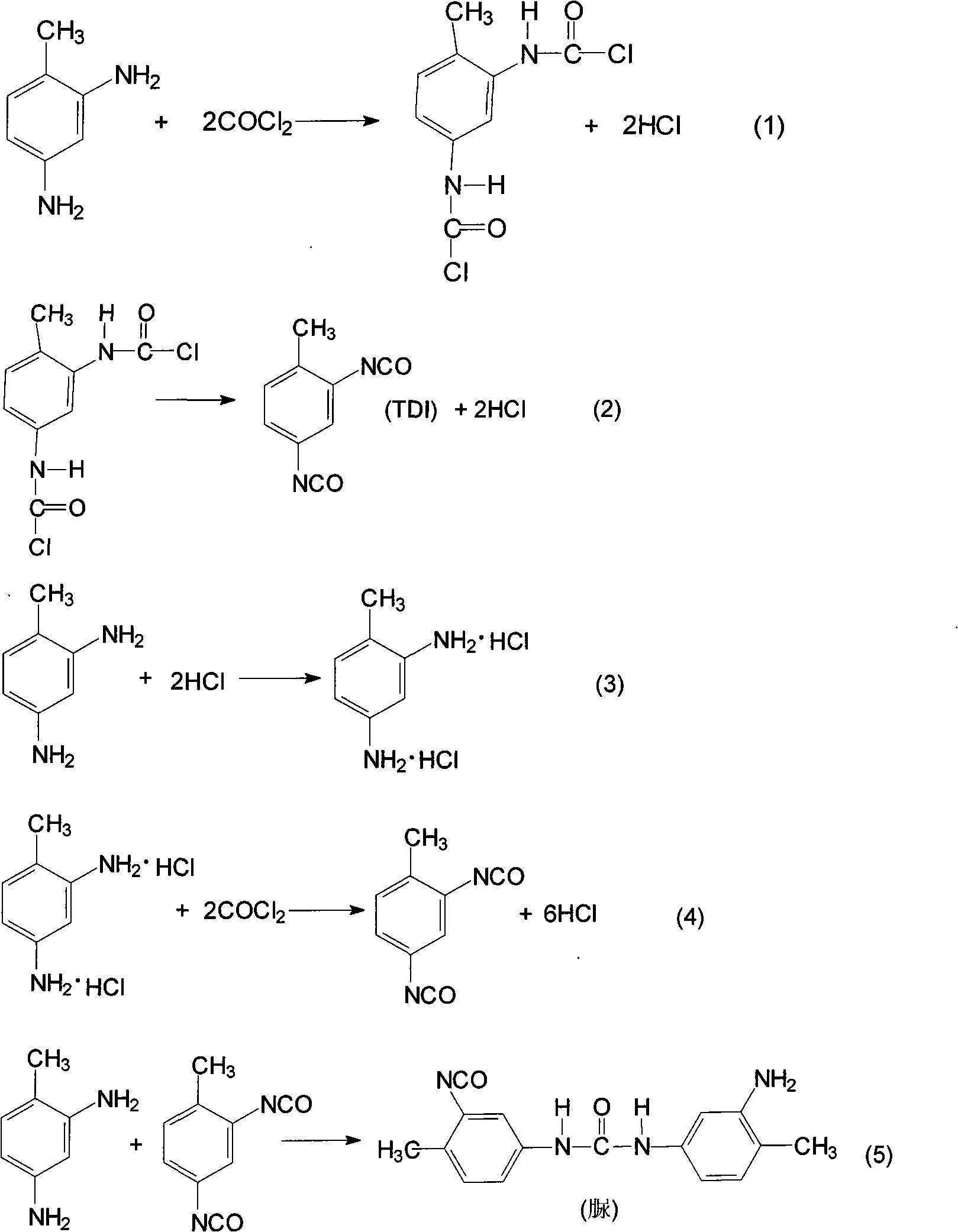

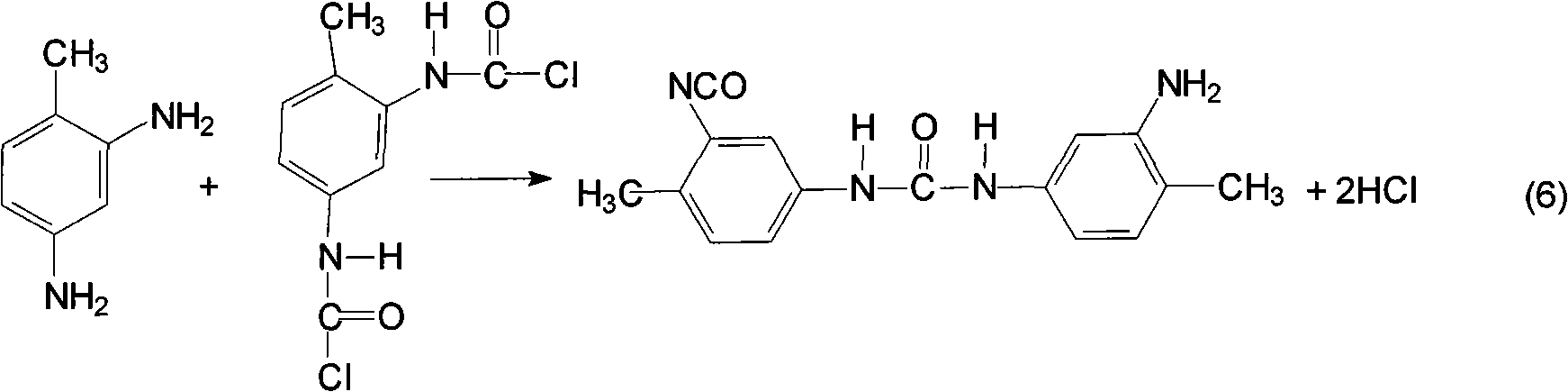

Method for continuously manufacturing toluene di-isocyanate

InactiveCN101671275AHigh energy consumptionReduce generationPreparation from carbamatesHydrogenToluenediamine

The invention discloses a method for continuously manufacturing toluene di-dsocyanate, comprising the following steps: (1) premixing a toluenediamine inert solvent solution with a phosgene inert solvent solution containing a hydrogen chloride with a mass fraction lower than 0.1 percent by a premixer and generating reaction; (2) importing the reacted mixture into a high shear reactor and refillingthe phosgene inert solvent solution containing the hydrogen chloride with the mass fraction lower than 0.5 percent to continue mixing and generating reaction; (3) leading materials in an outlet of thehigh shear reactor into detention equipment, continuing reacting at a temperature of 90-200 DEG C and an absolute pressure of 0.3-1.8 MPa until the solution turns transparent and a crude toluene di-isocyanatel is generated. The method for continuously manufacturing toluene di-dsocyanate is realized by mixing the phosgene with hydrogen chlorides in different contents with the toluenediamine step by step, thereby reducing the generation amount of low amine hydrochloride, improving the yield of the product toluene di-isocyanate and avoiding the addition of the energy consumption in refining phosgene recovering.

Owner:SEDIN ENG +1

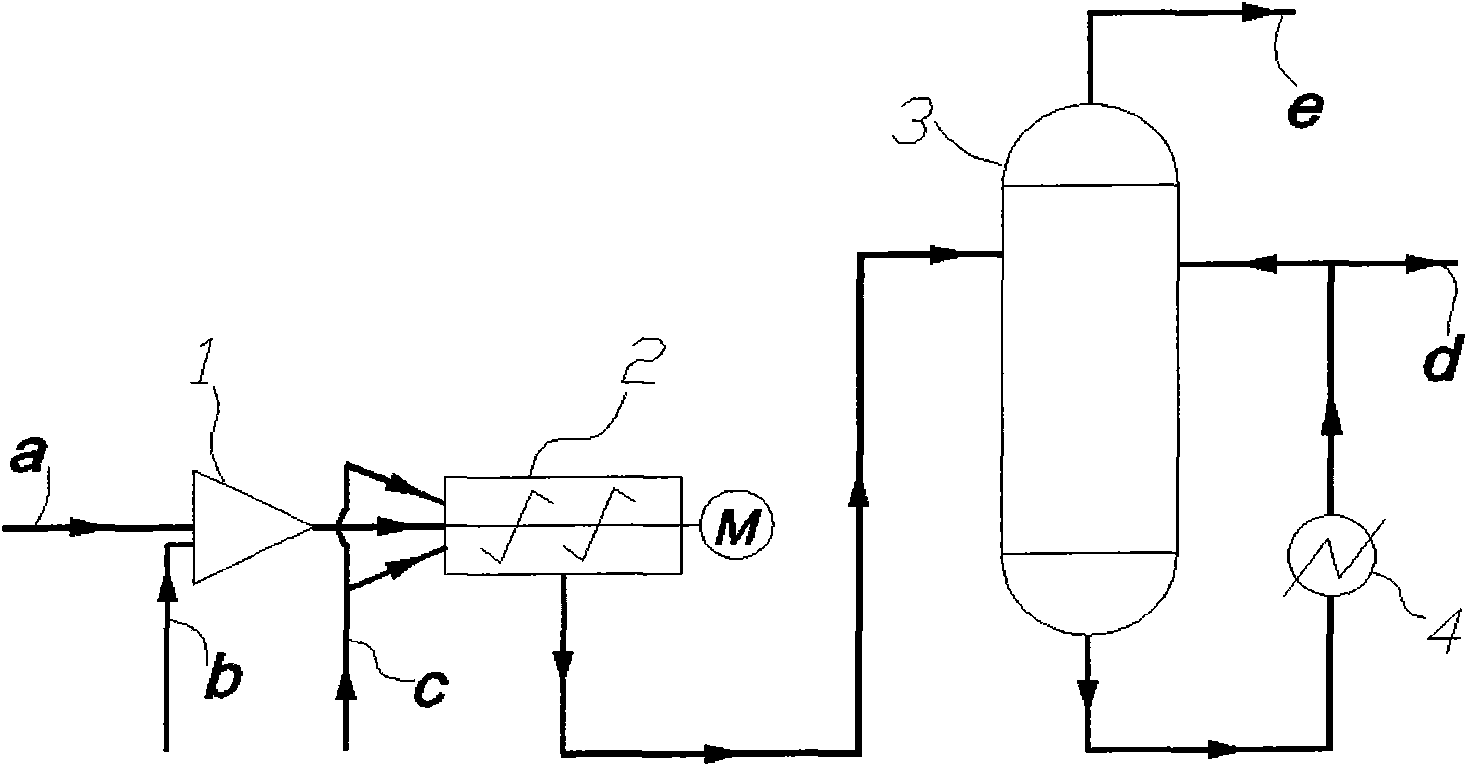

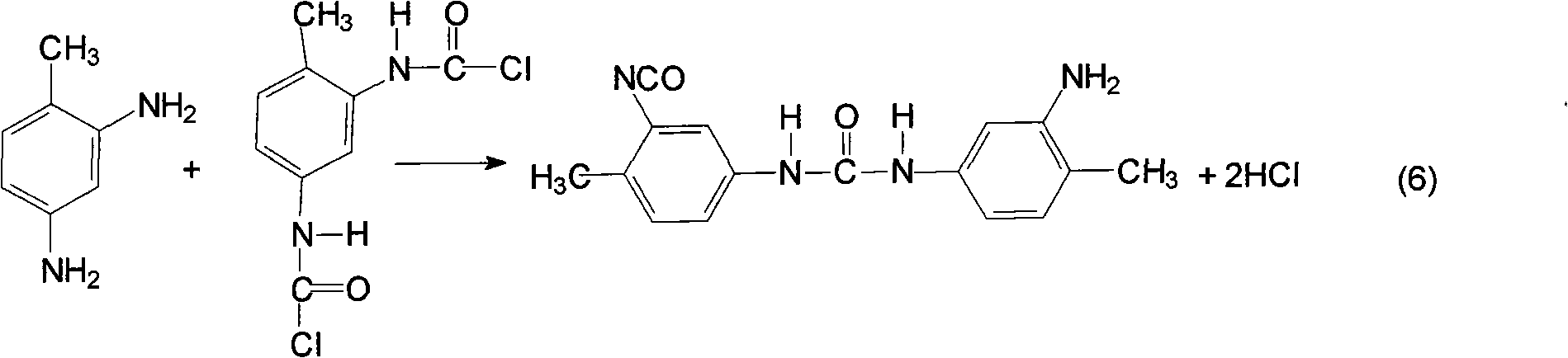

Method for recycling phosgene in continuous production process of toluene di-isocyanate

ActiveCN101671273ALow costLess investmentChlorine/hydrogen-chlorideIsocyanic acid derivatives preparationOrganic solventTower

The invention discloses a method for recycling phosgene in a continuous production process of toluene di-isocyanate, comprising the following steps: importing gas streams generated in the preparationprocess of the toluene di-isocyanate to the bottom of a first phosgene absorption tower and leading in inert organic solvent to the first phosgene absorption tower to absorb; separating the gas streams exhausted from the top of the first phosgene absorption tower by a phosgenation reaction flash separator lead in by a liquid ejector pump and leading the acquired gas streams into a second phosgeneabsorption tower; leading part of tower bottom absorption solution in the first phosgene absorption tower which is pressurized by the tower bottom liquid pump of the first phosgene absorption tower tothe second phosgene absorption tower and leading in inert organic solvent to the second phosgene absorption tower to absorb; and reusing the phosgene inert organic solvent solution acquired from thebottom of the second phosgene absorption tower to the continuous production process of the toluene di-isocyanate. The method reduces the investment on a large-scale compressor and reduces the cost onoperation and maintenance, thereby achieving the purpose of recycling the phosgene at a lower cost.

Owner:TIANJIN UNIV +1

Carrier sponge for medical framework accessory and preparation method thereof

The invention belongs to the technical field of sponge, in particular to carrier sponge for a medical framework accessory and a preparation method thereof. The method comprises the following steps: mixing and uniformly stirring 0.5 to 1 part of silicon oil, 0.1 to 0.3 part of triethylene diamine and 2 to 4 parts of water; adding 10 to 20 parts of polyether polyol and 70 to 100 parts of polymer polyol to be uniformly stirred; then, adding 0.1 to 0.3 part of stannous octoate to be uniformly stirred; and finally, adding 30 to 50 parts of toluene di-isocyanate to be uniformly stirred, and pouring the mixture into a mold to be cured at a room temperature for obtaining the carrier sponge for the medical framework accessory. The carrier sponge provided by the invention has the advantages of high hardness and better pressure resistance intensity, has a coarse hole structure and can be used as a carrier for the medical framework accessory.

Owner:东莞市源聚德实业有限公司

Non-granule plastic rubber material

InactiveCN101456943AImprove wear resistanceImprove anti-aging propertiesGround pavingsBenzoic acidRubber material

The invention discloses a non-particle plastic material, which comprises primer and top adhesive, and the component of which is divided into component A and component B; wherein the component A has the composition by weight of: 77.4 percent of polyether polyol, 22.57 percent of toluene di-isocyanate, and 0.03 percent of chloro-benzoic acid; the component B has the composition by weight of: 19.83 percent of polyether polyol, 5.33 percent of methylene diphenylamine, 0.07 percent of oxine copper, 0.36 percent of white carbon black, 6.67 percent of kaolin, 34.8 percent of talcum powder, 30 percent of chlorcosane, 0.13 percent of antioxidant, 0.13 percent of ultraviolet absorbent, and 2.67 percent of paint. The components are prepared by the following steps: the component A undergoes reaction for 2-3h at 85-90 DEG C after being mixed according to a prescription ratio; the component B is grinded into viscous glue solution after being mixed according to prescription ratio. The premier is prepared by mixing the component A and the component B according to the proportion of 1: 4 and adding the black colloidal particles and the catalyst respectively with the weight percent of 30-35 percent and 8 percent of the sum of the mixture of the component A and the component B; the top adhesive is prepared by mixing the component A and the component B according to the proportion of 1:3.

Owner:GUANGZHOU JRACE ATHLETIC FACILITIES

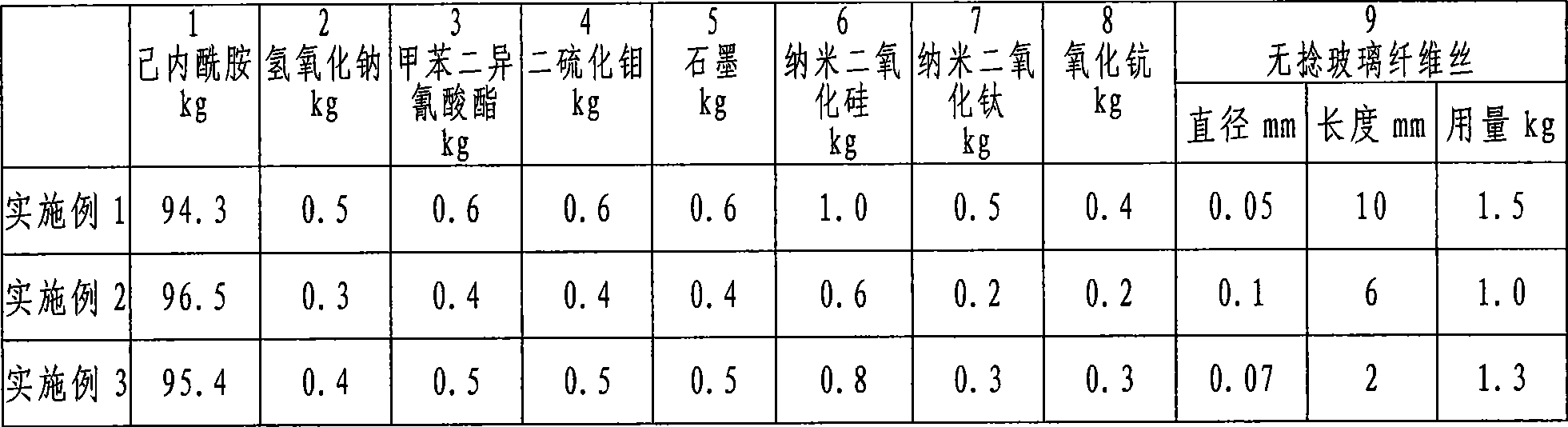

Nylon polymerization member water lubricating bearing for ship

The invention discloses a nylon polymer piece water lubricated bearing for ships. Caprolactam is taken as a main component, nanometer level silicon dioxide and titanium dioxide are added into the raw materials, and each component and the usage percentage (weight) thereof are as follows: 94.3-96.5 of caprolactam, 0.3-0.5 of sodium hydroxide, 0.4-0.6 of toluene di-isocyanate, 0.4-0.6 of a molybdenum disulfide, 0.4-0.6 of graphite, 0.6-1.0 of nano-silicon dioxide, 0.2-0.5 of nano-titanium oxide, 0.2-0.4 of scandium oxide, and 1.0-1.5 of zero twist fiberglass yarn. The bearing is used as ship bearing or bushing, each component develops a synergic effect in polymerization, and the density, hardness and wear resistance of the polymer piece are improved, thus improving the performance of the products and prolonging the service life. Furthermore, the polymer piece has the advantages of smooth surface, small friction coefficient, absence of metal powder, lubrication with water only and a wide application.

Owner:贾明君 +1

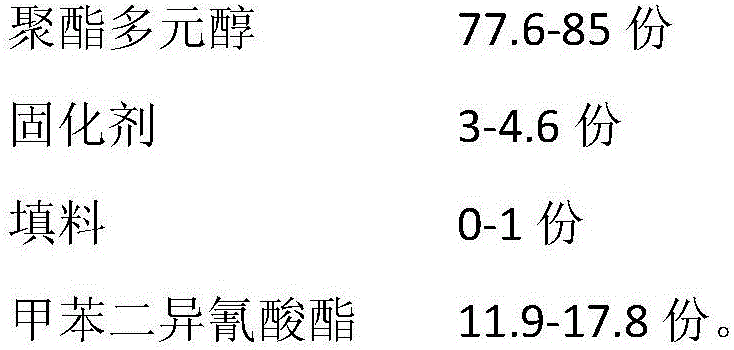

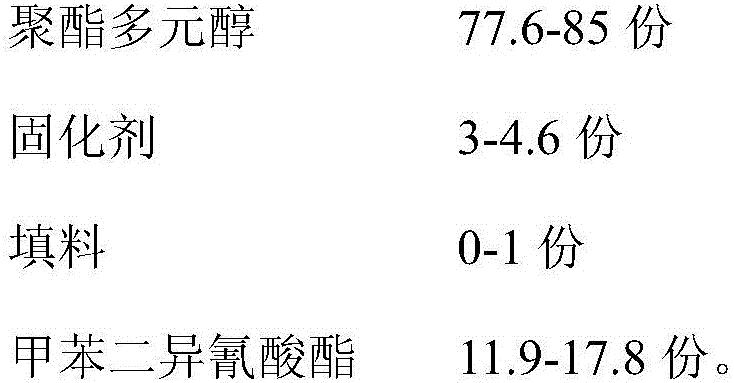

Low-hardness polyurethane rubber roll material and preparation method thereof

The invention relates to a low-hardness polyurethane rubber roll material and a preparation method thereof. Through being metered in parts by weight, the low-hardness polyurethane rubber roll material is prepared from the following raw materials including 77.6 to 85 parts of polyester polyol, 3 to 4.6 parts of curing agents, 0 to 1 part of filling materials and 11.9 to 17.8 parts of toluene di-isocyanate. The low-hardness polyurethane rubber roll material has the advantages that the operation is convenient; the defective rate of the rubber roller is low; the industrial production is easy; no catalyst is used in a curing agent system; no catalyst is remained; the hardness reduction by a plasticizing agent addition mode is not used; the environment-friendly effect is good; the service life is long. In addition, bio-ethylene glycol, propanediol and butanediol are used as raw materials for preparing the polyester polyol; the carbon residue is reduced; the environment is protected; the obtained rubber roller has good wear resistance and long service life.

Owner:SHANDONG INOV POLYURETHANE

Epoxy resin modified by isocyanate terminated silicon rubber and preparation method thereof

The invention discloses epoxy resin modified by isocyanate terminated silicon rubber and a preparation method thereof. The epoxy resin modified by the isocyanate terminated silicon rubber consists of the isocyanate terminated silicon rubber, epoxy resin and a catalyst, wherein the isocyanate terminated silicon rubber consists of silicon rubber with end hydroxyl group, toluene di-isocyanate and a catalyst. The preparation method for the epoxy resin modified by the isocyanate terminated silicon rubber comprises two steps of preparing the isocyanate terminated silicon rubber and preparing the epoxy resin modified by the isocyanate terminated silicon rubber. In the preparing process, the flexible isocyanate terminated silicon rubber is compounded with the epoxy resin to increase the toughness of the epoxy resin, and simultaneously hydroxyl group on the epoxy resin is chemically bonded with isocyanate group on the isocyanate terminated silicon rubber to increase the tensile strength of the epoxy resin, so the impact strength and the tensile strength of the epoxy resin modified by the isocyanate terminated silicon rubber are all obviously improved compared with those of common epoxy resin under the same curing condition.

Owner:大岩(上海)建筑材料有限公司

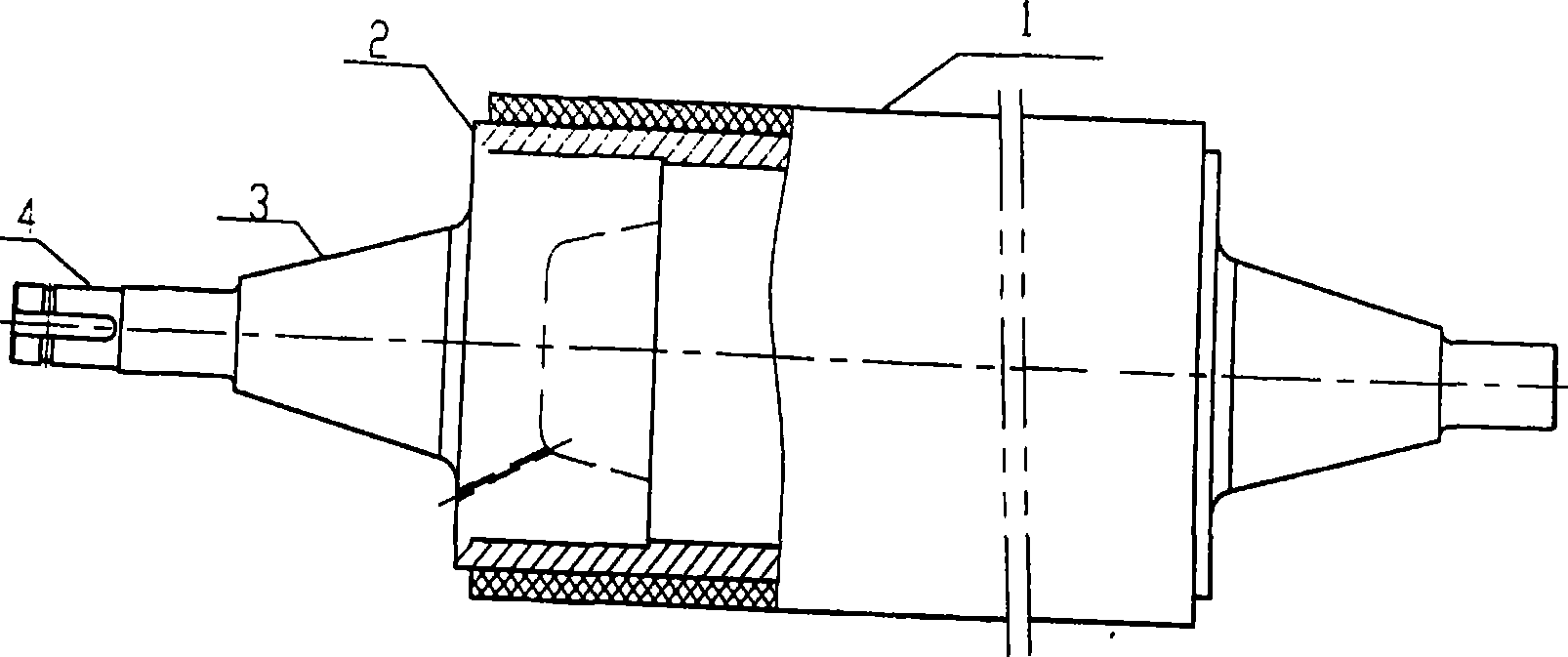

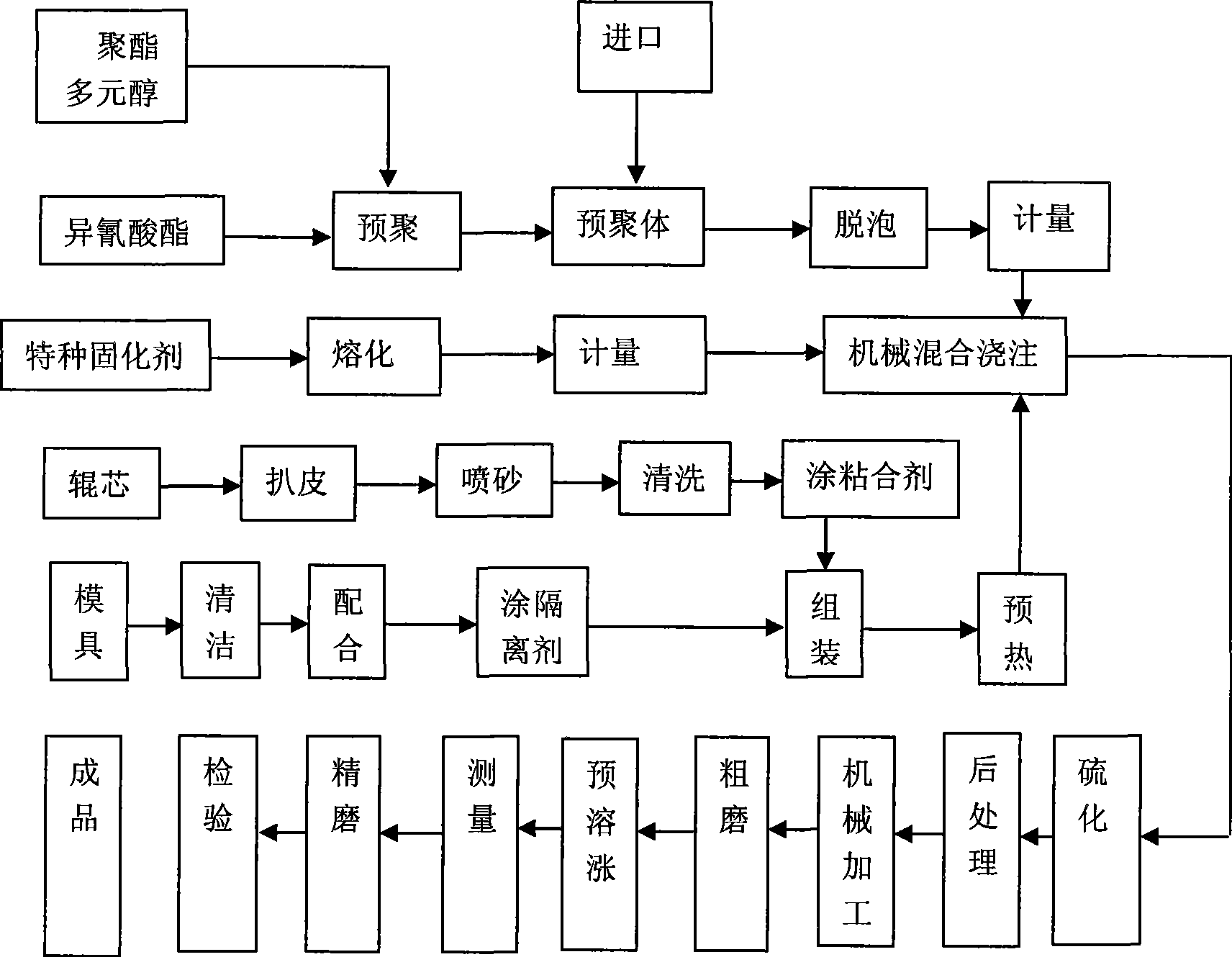

Polyurethane coating roller and manufacture method thereof

A polyurethane coating roller comprises a glue layer which comprises 50 percent to 60 percent of polyester dibasic alcohol, 20 percent to 30 percent of toluene di-isocyanate, 7 percent to 10 percent of prepolymer and 8 percent to 15 percent of curing agent. The manufacture method of the glue layer comprises the steps of: a) prepolymerization step, carrying out dehydration on the polyester dibasic alcohol, adding the toluene di-isocyanate to be mixed with the dehydrated polyester dibasic alcohol, carrying out prepolymerization reaction by adding the prepolymer, and then adding melted curing agent for mechanical mixing; b) pouring step, pouring the mixture on the roller core surface coated with adhesive; and c) post-treatment step, curing and machining the poured mixture. Therefore, the obtained polyurethane coating roller has stable glue roller hardness, excellent physical and mechanical properties such as tensile resistance, rebound and the like and excellent solution resistance property.

Owner:BAOSHAN IRON & STEEL CO LTD

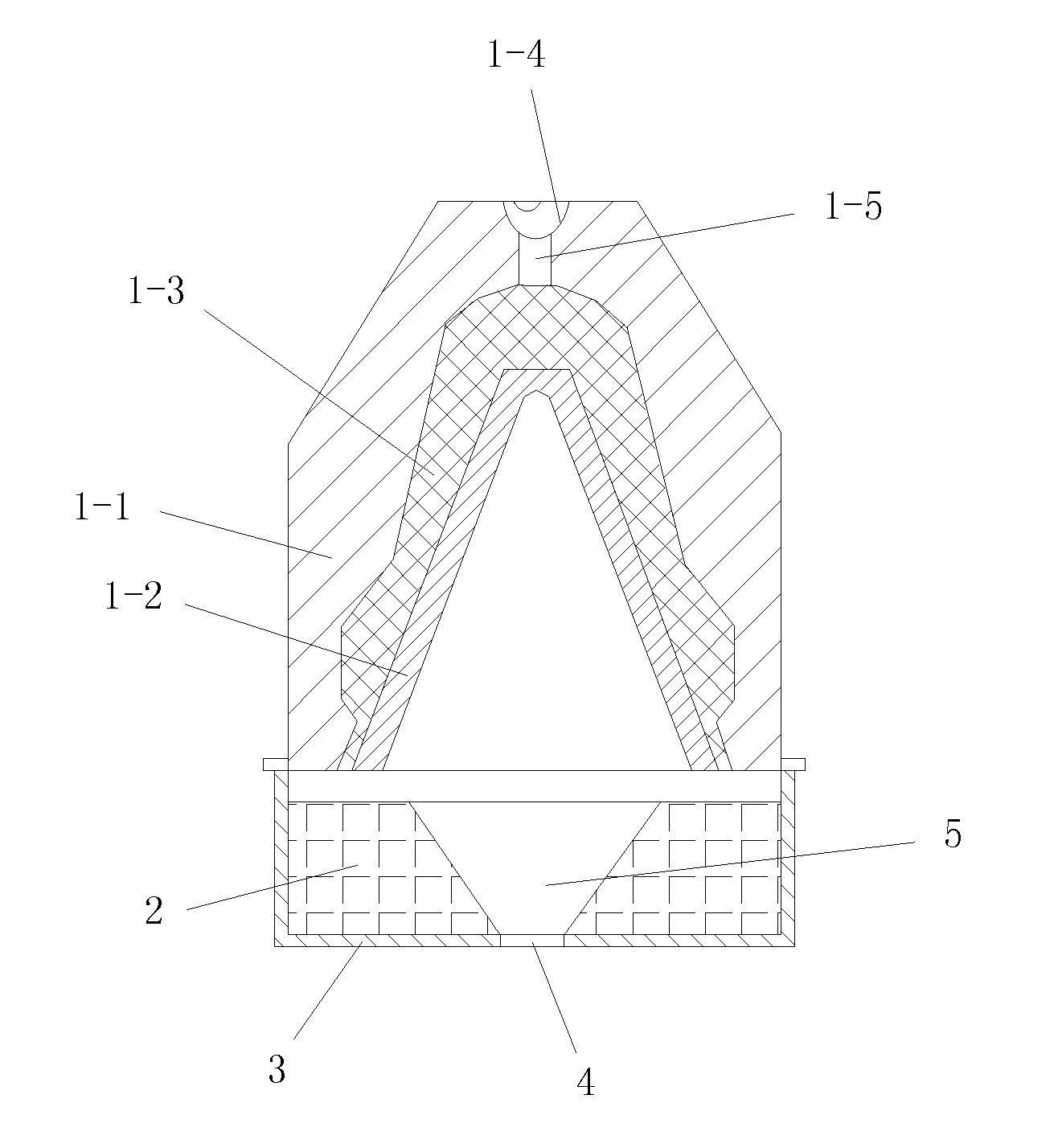

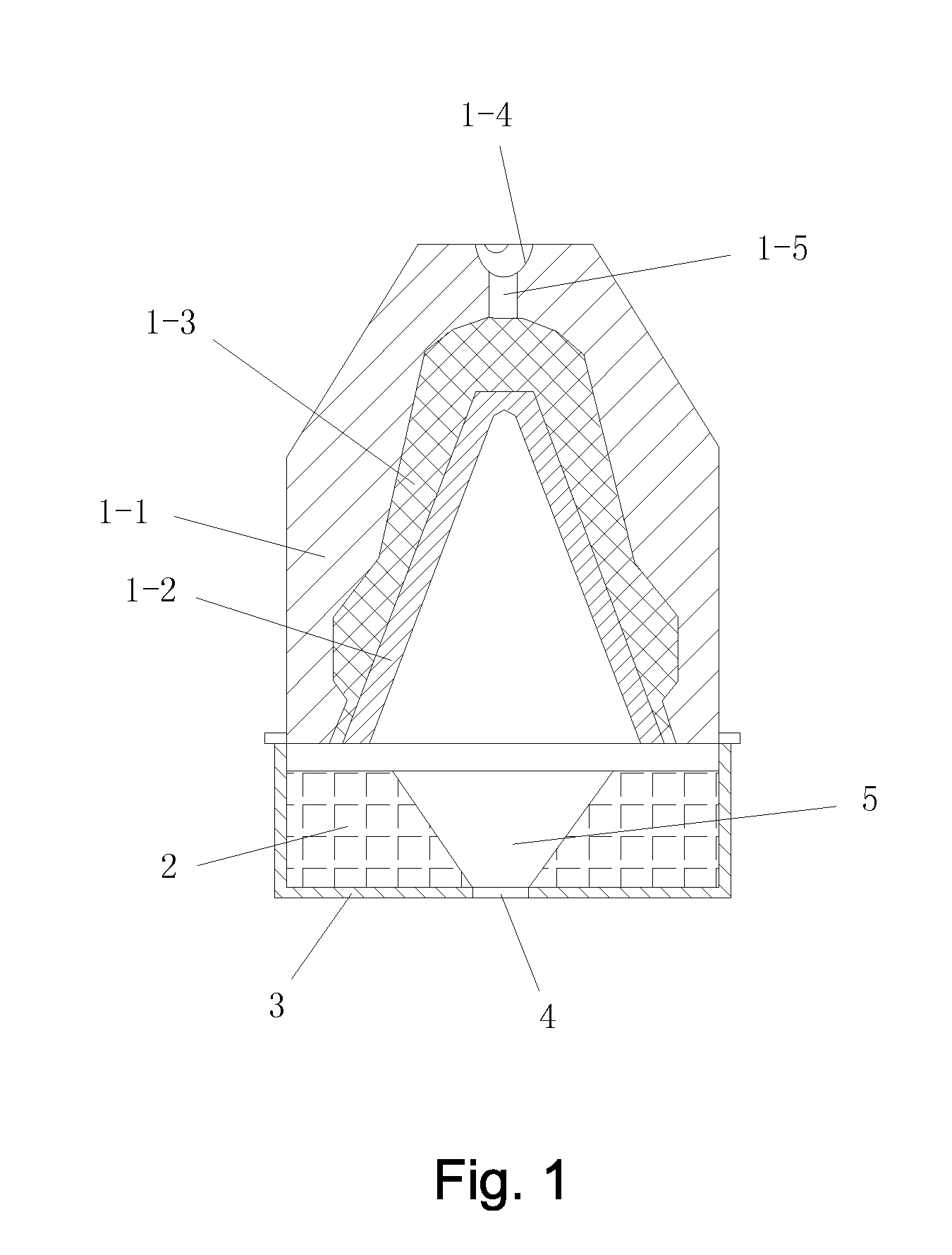

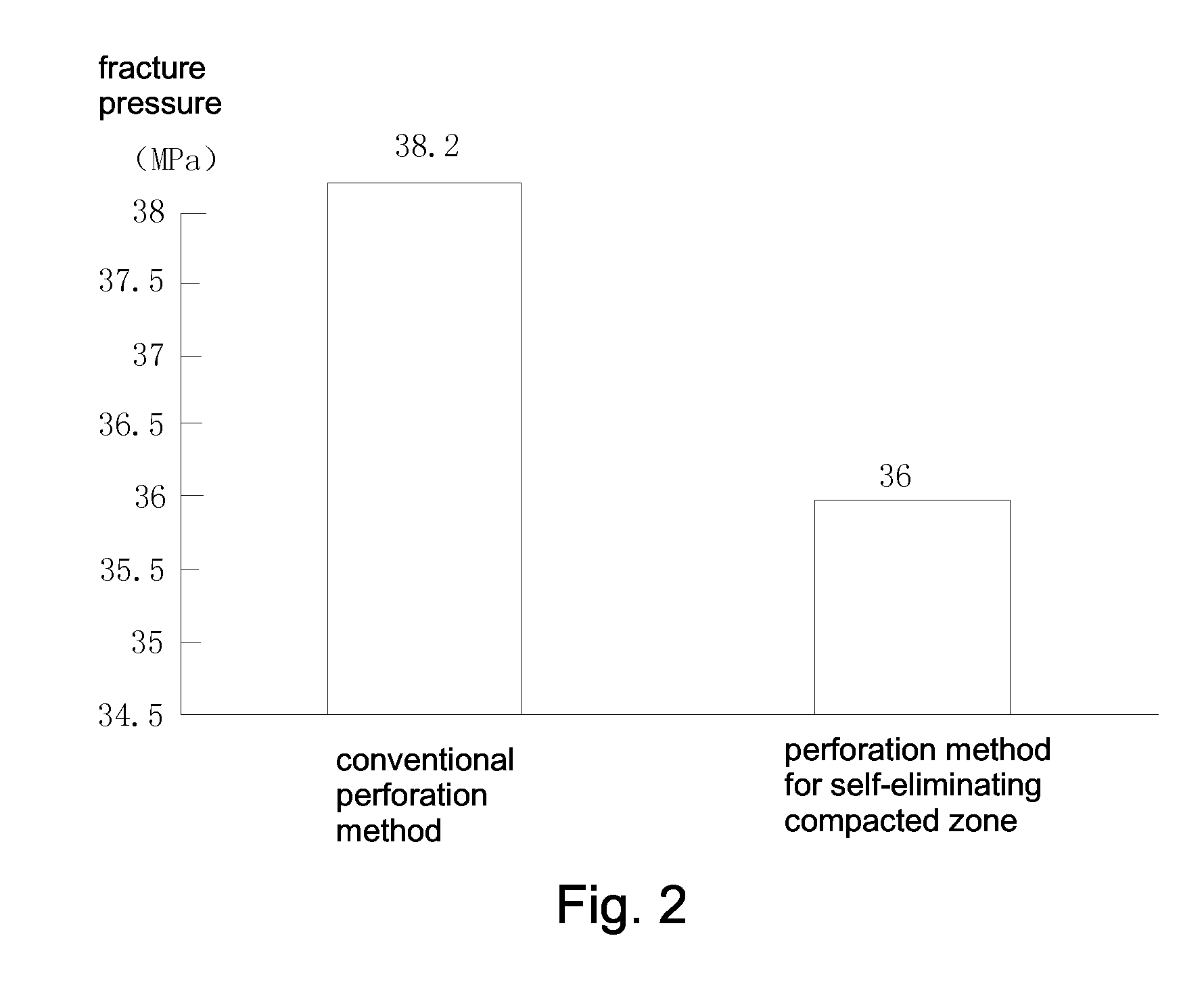

Coaxial perforating charge and its perforation method for self-eliminating compacted zone

ActiveUS20160186536A1Simple structureConvenient manufactureAmmunition projectilesExplosive chargesShaped chargeAmmonium perchlorate

A coaxial perforating charge includes a shaped charge and a container having a fracture explosive pack inside. The container is coaxially provided at a front end of the shaped charge; the fracture explosive pack is a ring-shaped explosive pack formed by impregnating a fracture explosive for eliminating a compacted zone into the container; the fracture explosive pack is coaxially arranged with the shaped charge. The fracture explosive includes ammonium perchlorate, aluminum powder, additive, and dioctyl sebacate; the additive is hydroxyl-terminated polybutadiene (HTPB), or a mixture of HTPB, N,N′-diphenyl-p-phenylenediamine and toluene di-isocyanate. A perforation method thereof, for self-eliminating a compacted zone, includes steps of: running a jet perforating gun downward; perforating while self-eliminating a compacted zone. The charge and its perforation method are reasonably designed, convenient, safe, reliable, well performed, and able to perforate while self-eliminating the compacted zone, which effectively eliminates an impact on rock permeability of the compacted zone.

Owner:XIAN RUITONG ENERGY TECH

Process for the production of toluene diisocyanate

ActiveUS20070287857A1Less coloringReduce colorAmino compound purification/separationOrganic compound preparationToluene diisocyanateToluenediamine

The invention relates to a process for the production of toluene diisocyanate, in which the crude toluenediamine obtained from the hydrogenation is purified and then phosgenated. The purification step reduces the total amount of cyclic ketones to less than 0.1% by weight, based on 100% by weight of the toluenediamine.

Owner:COVESTRO DEUTSCHLAND AG

Anion anti-oxidation coating for automotive leaf spring and preparation method of anion anti-oxidation coating

ActiveCN104356931AImprove anti-corrosion performanceImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyester

The invention discloses an anion anti-oxidation coating for an automotive leaf spring and a preparation method of the anion anti-oxidation coating, and belongs to the field of anti-oxidation coatings. The epoxy resin is improved by adopting polyurethane resin, so that the anticorrosion ability and the hydrolysis resistance are improved, and the oxidation resistance of the product is excellent. Butyl hydroxy polyurethane adopted by the invention is synthesized by olefine dihydric alcohol and toluene diisocynate; and relative to polyether or polyester polyurethane, butyl hydroxy polyurethane has relatively good stability, hydrolysis resistance and corrosion resistance due to stable main chain structure. The tourmaline contained in the coating can automatically release anions, has the environment-friendly function, can be used or effectively removing harmful pollutants in air, and is beneficial to air purification and human health; and the anion anti-oxidation coating is simple in preparation process, convenient to operate and low in cost.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

Raw materials formula for producing single-shell sulfur microcapsule

The invention discloses a raw material formulation for manufacturing single lamella sulfur microcapsules, which comprises sublimed sulfur, toluene di-isocyanate, water, quadrol and diethylenetriamine. The single lamella sulfur microcapsule is prepared with the formulation by an interface polymerization method, gives off sulfur under a certain temperature and plays a role in sulfuration. The single lamella sulfur microcapsule, the mass fraction of the sulfur of which ranges from 5-53%, can be prepared by changing the matching of the raw materials.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Aqueous polyurethane wood lacquer

InactiveCN101519567ASolve residual problemsLow costPolyurea/polyurethane coatingsEmulsion paintsPropanoic acidLacquer

The invention relates to an aqueous polyurethane wood lacquer (latex) which aims at solving the problems of poor adhesive attraction on wood, poor resistance to weather, weak ultraviolet radiation resisting ability, higher cost, and the like of a prior product. The aqueous polyurethane wood lacquer is prepared by the steps of sufficiently stirring polyether dihydric alcohol and toluene di-isocyanate to form a performed polymer, adding dimethylol propionic acid dmpa, trimethylolpropane, diglycol and acetone to the preformed polymer to carry out viscosity-reducing and chain extension reaction, adding triethylamine to carry out quaterisation, adding deionized water to disperse emulsification, and stripping acetone.

Owner:HANGZHOU ECEGE ENVIRONMENTAL TECH

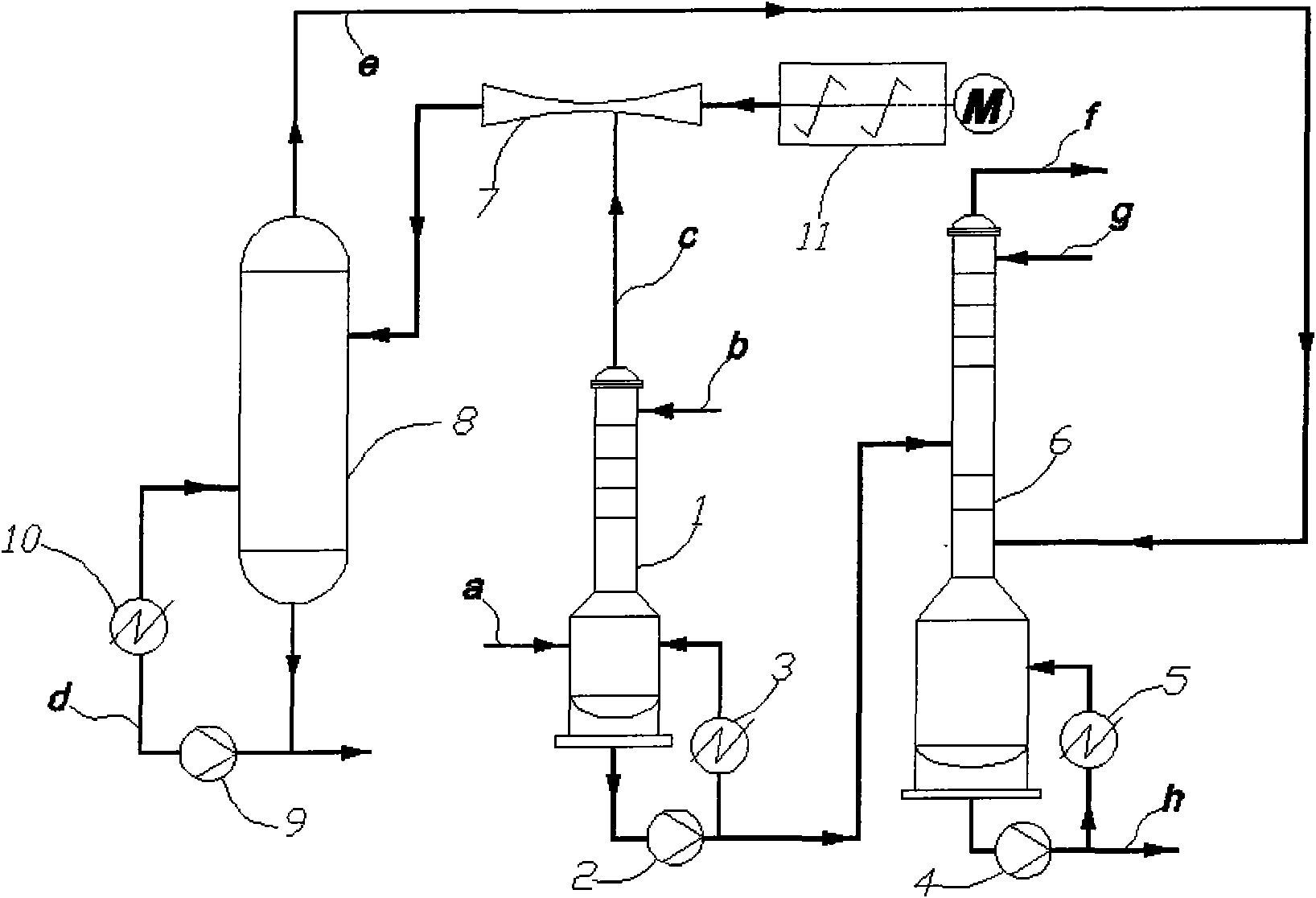

Method for recovering phosgene in continuous production process of toluene di-isocyanate

ActiveCN101671276ALess investmentLow costChlorine/hydrogen-chlorideIsocyanic acid derivatives preparationOrganic solventTower

The invention discloses a method for recovering phosgene in continuous production process of toluene di-isocyanate, comprising the following steps: importing a gas stream with an absolute pressure of0.08-0.2 MPa, which is generated in a preparation process of the toluene di-isocyanate, into the bottom of a first phosgene absorption tower and leading inert organic solvent into the first phosgene absorption tower to absorb; leading part of tower bottom absorption liquid in the first phosgene absorption tower into a second phosgene absorption tower after being boosted by a tower bottom liquid pump; importing another gas stream with the absolute pressure of 0.5-0.8 MPa, which is generated in the preparation process of the toluene di-isocyanate, into the second phosgene absorption tower, and continuing absorbing through adding the inert organic solvent from the top of the second phosgene absorption tower; and reusing the phosgene inert solvent solution acquired from the bottom of the second phosgene absorption tower in the continuous production process of the toluene di-isocyanate. The method avoids using large-sized compressors, reduces the cost on operation and maintenance and achieves the purpose for recovering the phosgene at lower cost.

Owner:SEDIN ENG +1

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

InactiveCN101864671BImprove wear resistanceImprove washabilityFibre treatmentPolyesterMoisture permeation

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol(with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Solvent-free polyurethane nanometer attapulgite composite membrane and preparation method thereof

The invention relates to a solvent-free polyurethane nanometer attapulgite composite membrane and a preparation method thereof. The method comprises the steps of taking polyethyleneglycol and attapulgite nanometer particles; performing heating and stirring; performing uniform scattering through ultrasound or emulsification; after the composite emulsion is cooled to the room temperature, adding toluene di-isocyanate; uniformly stirring the mixture at a high speed; coating the composite emulsion onto release paper fixed on a horizontal plate; taking out the release paper; drying the materials into a baking oven to form a membrane. The solvent-free nanometer attapulgite polyurethane prepared by the method provided by the invention has the advantages that a conventional organic solvent production process and aqueous production process are replaced; the problem of the serious ecological environment pollution caused by the volatilization of a great number of organic solvents used in the production process can be solved; the nanometer attapulgite material is introduced, so that the fire-resistance performance is obviously improved.

Owner:JIAXING HEXIN CHEM IND +1

Solvent-free type polyurethane nanometer TiO2 composite membrane and preparation method thereof

The invention relates to a solvent-free type polyurethane nanometer TiO2 composite membrane and a preparation method thereof. Polyethyleneglycol and TiO2 nanometer particles are heated and stirred; the materials are uniformly scattered through ultrasound or emulsification; after the materials are cooled to the room temperature, toluene di-isocyanate is added; the materials are uniformly stirred at a high speed; the composite emulsion is coated onto release paper fixed on a horizontal plate; the release paper is taken down and is dried to form a membrane in a baking oven. The method provided by the invention is used for replacing a conventional organic solvent production process and an aqueous production process; the serious ecological environment pollution problem due to volatilization of a great number of organic solvents used in the production process is avoided; the nanometer TiO2 is modified, so that a hollow structure is realized; the water steam permeability and the ventilation performance are obviously improved.

Owner:JIAXING HEXIN CHEM IND

Preparation method of heat-resistant flame-retardant polyurethane

InactiveCN105860502AImprove mechanical propertiesImprove hydrolysis resistanceGlutaric acidTrimethylolpropane

The invention discloses a preparation method of heat-resistant flame-retardant waterborne polyurethane. The method comprises the following steps of stirring gamma-(Trimethoxysilyl)-3-aza-hexylamine, N, N-dimethylcyolohexlemine and tetrahydrofuran, and then adding phenyl dichlorophosphate; after the reaction, obtaining a P-N-Si flame retardant; performing a heat insulation reaction on dibromoneopentyl glycol, m-phthalic acid-5-stannous octoate, and then adding the terephthalic acid, glutaric acid and trimethylolpropane; performing heating and stannous octoate, and adding dimethyl benzene until the materials are fused; performing backflow reaction to obtain polyester polyol; adding the polyester polyol and toluene di-isocyanate into a reaction device; adding 1, 4-butylene glycol after the reaction; after the reaction, adding the P-N-Si flame retardant, expansible graphite, multiwalled carbon nanotube and triethylamine; after the reaction, adding acetone; obtaining a finished product after the treatment. The preparation method of heat-resistant flame-retardant polyurethane provided by the invention has the advantages that the steps are simple; the conditions are mild; the obtained composite material has high intensity, excellent flame-retardant performance and good heat resistance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com