Method for recovering phosgene in continuous production process of toluene di-isocyanate

A technology of toluene diisocyanate and production process, which is applied in the field of phosgene recovery in the continuous preparation process of toluene diisocyanate, can solve the problems of high risk, high cost of phosgene recovery process, poor operation stability, etc., and achieve low cost and reduced Operation and maintenance costs, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

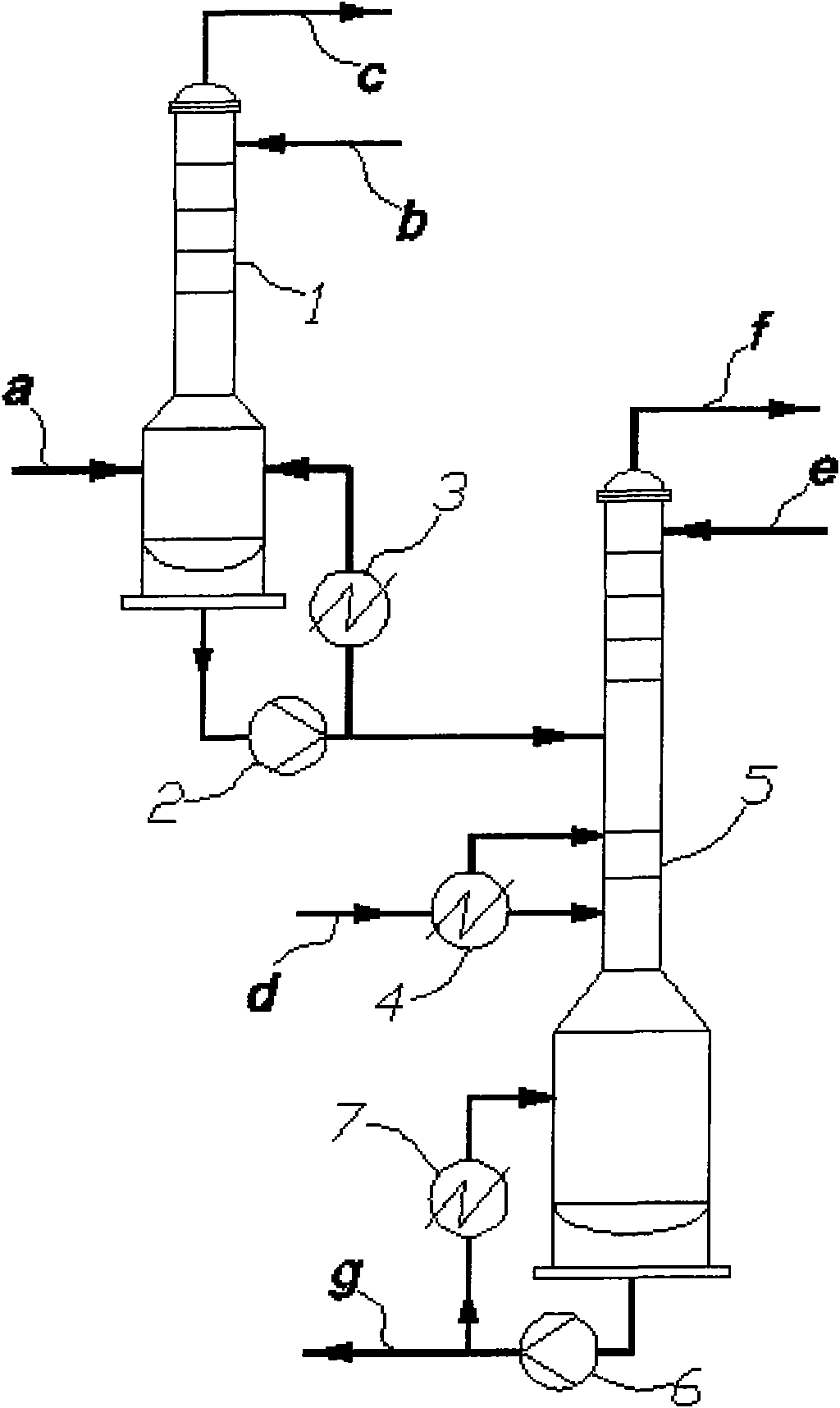

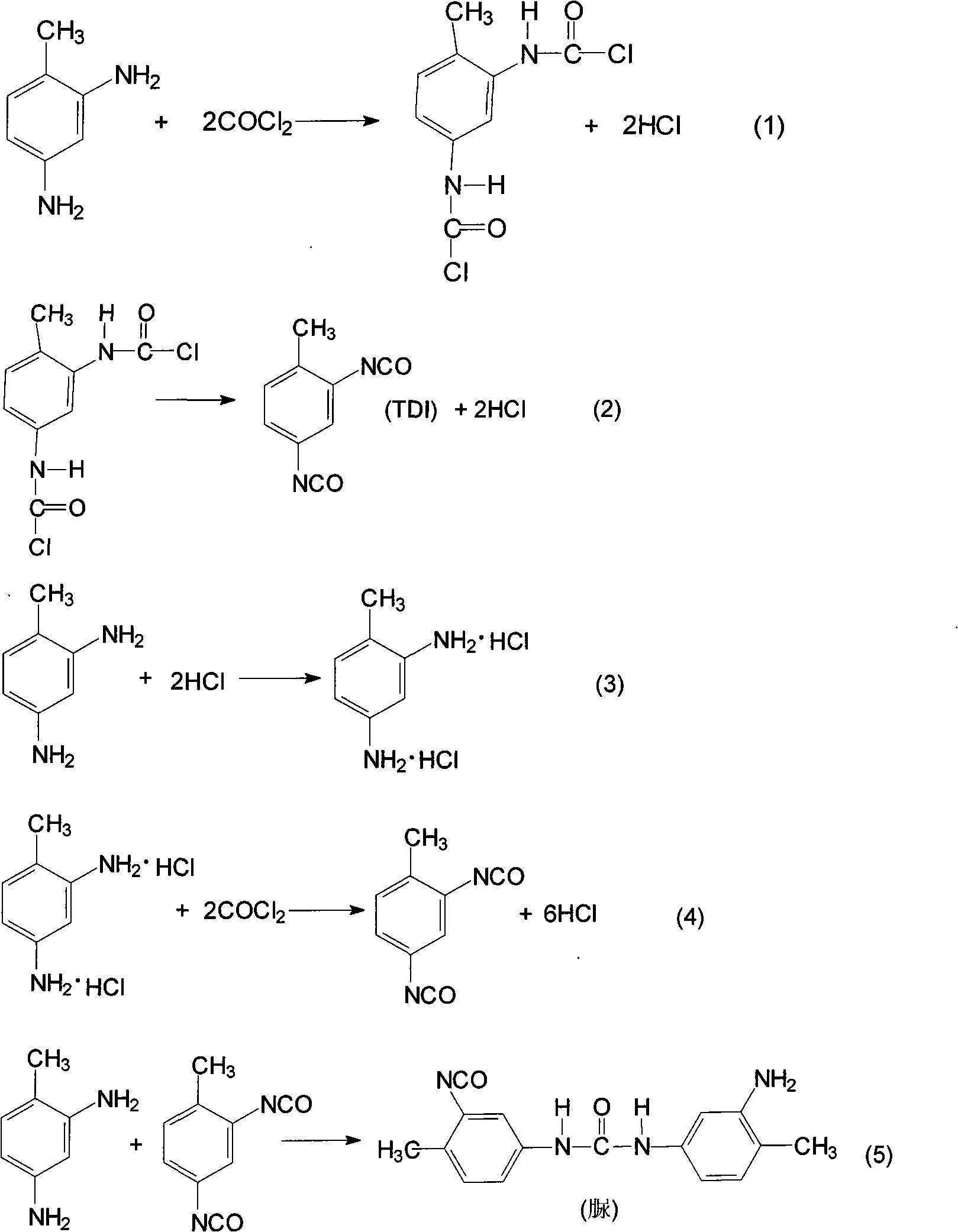

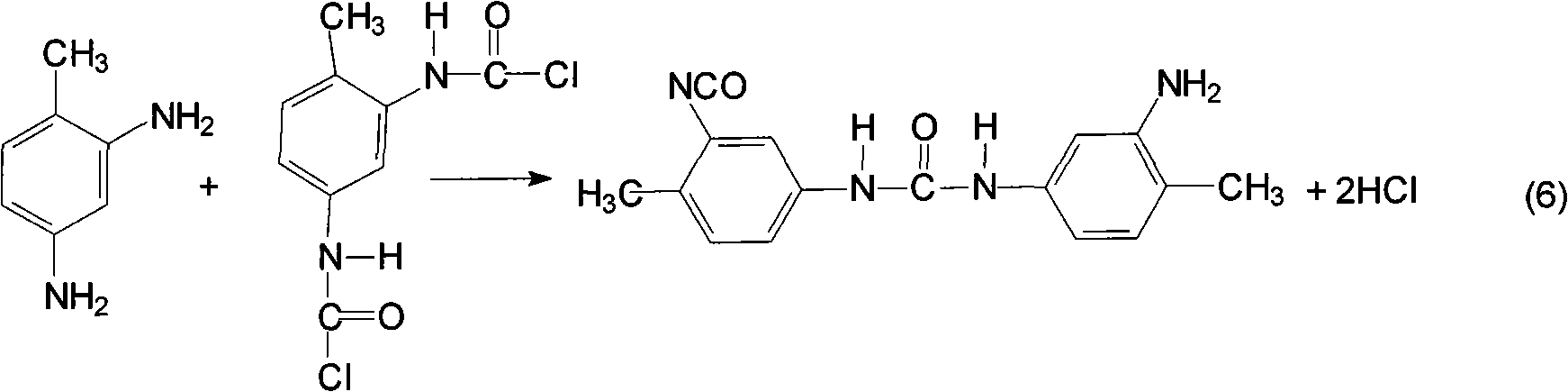

[0030] This example relates to the recovery of phosgene during the continuous preparation of toluene diisocyanate (TDI) by liquid-phase phosgenation of toluene diamine in o-dichlorobenzene (ODCB). The percentage composition in each stream refers to the mass percentage.

[0031] The first phosgene absorption tower is a packed tower with 10 theoretical plates. Gas stream a rich in phosgene, hydrogen chloride and a small amount of impurities (from the degassing tower and the hydrogen chloride stripping tower in the production process of toluene diisocyanate, the temperature is 5 ℃, the absolute pressure is 120kPa, and its mass flow rate is 5000kg / hr, Containing 81.9% phosgene, 17.4% hydrogen chloride, 0.6% carbon tetrachloride and a small amount of ODCB and carbon dioxide) enter from the bottom of the first phosgene absorption tower; -10 ℃, ODCB with an absolute pressure of 110kPa enters from the top of the tower at 20000kg / hr Enter;

[0032] The first phosgene absorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com