Patents

Literature

622results about "Chlorine/hydrogen-chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

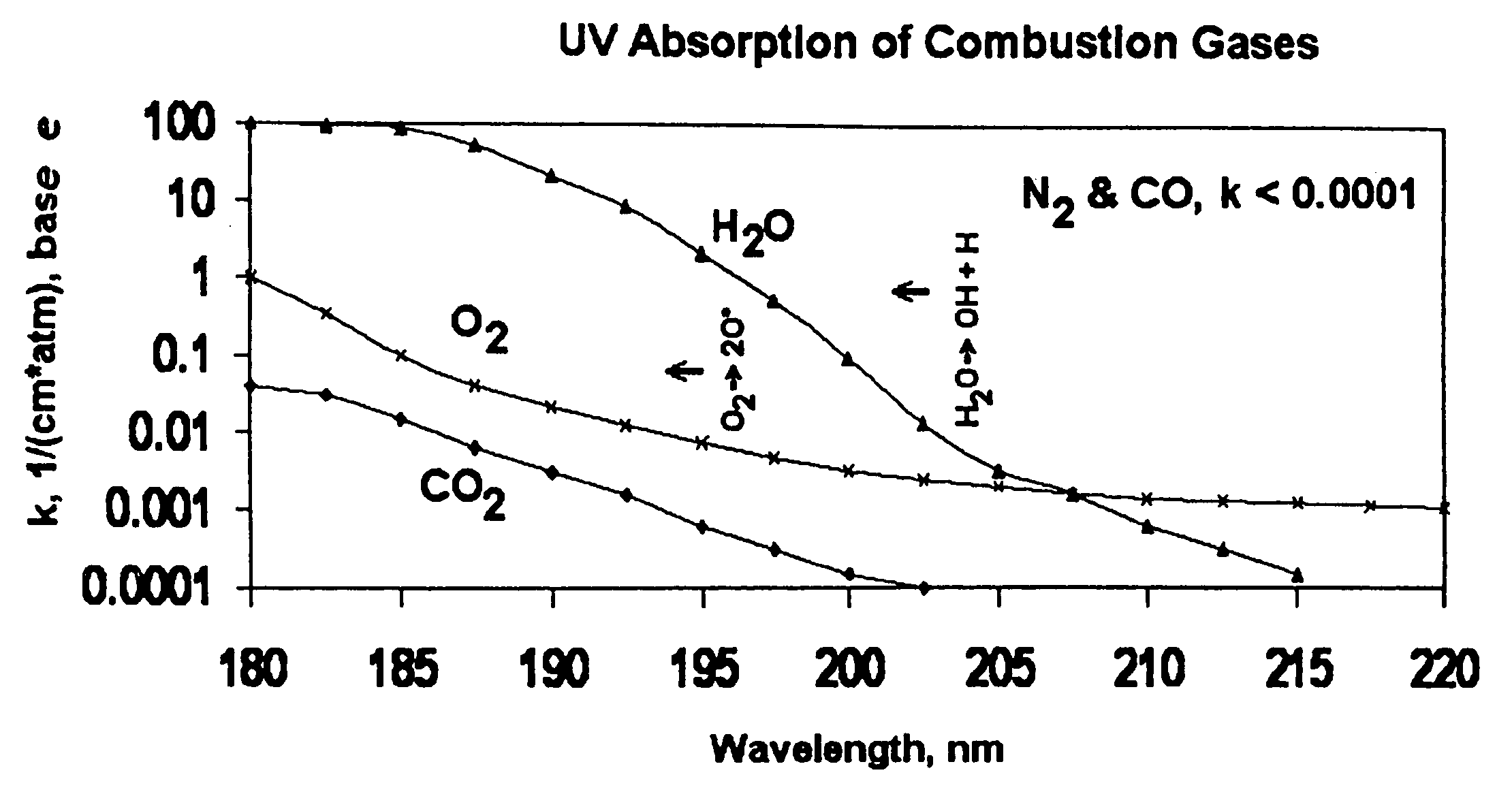

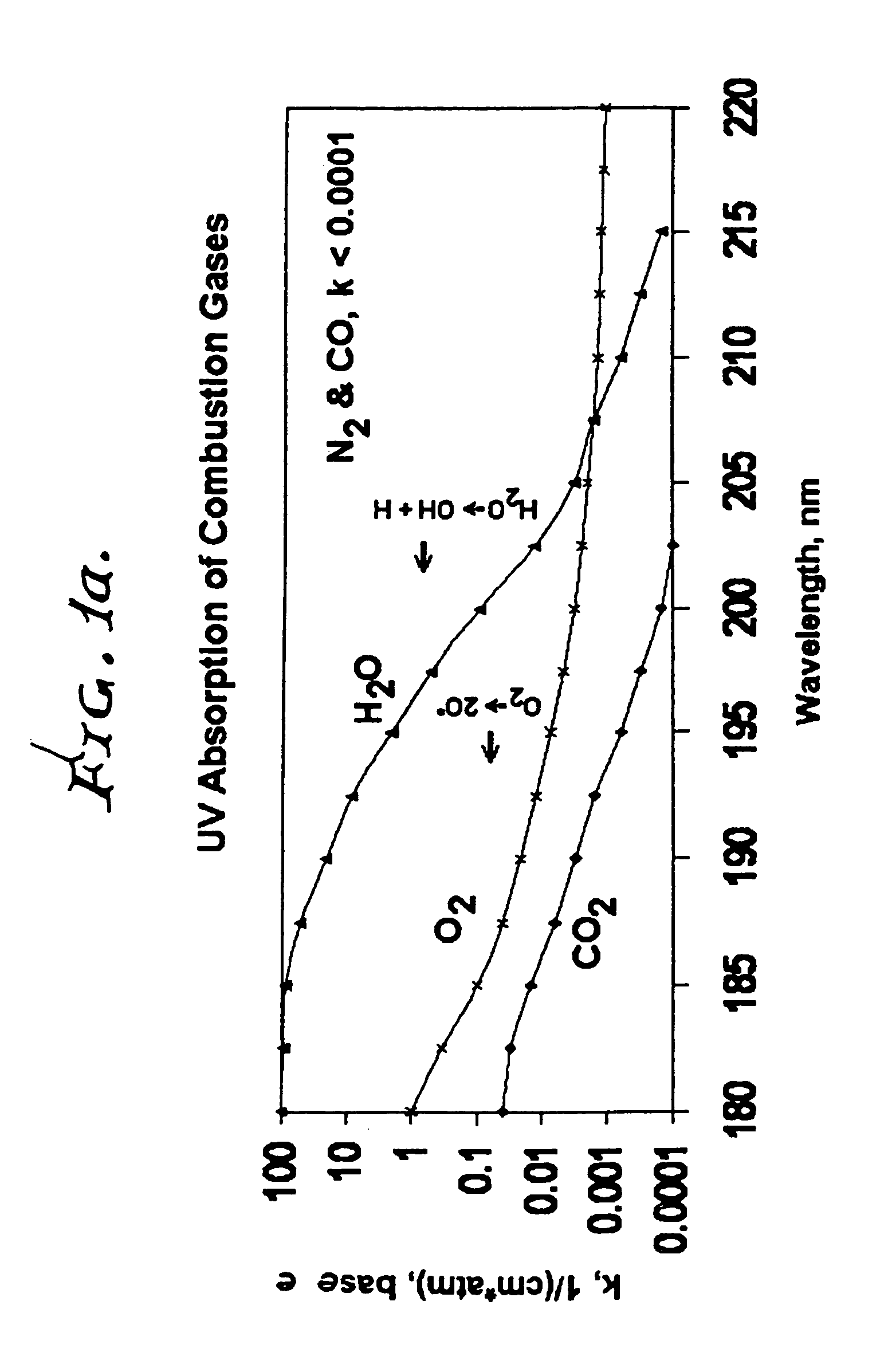

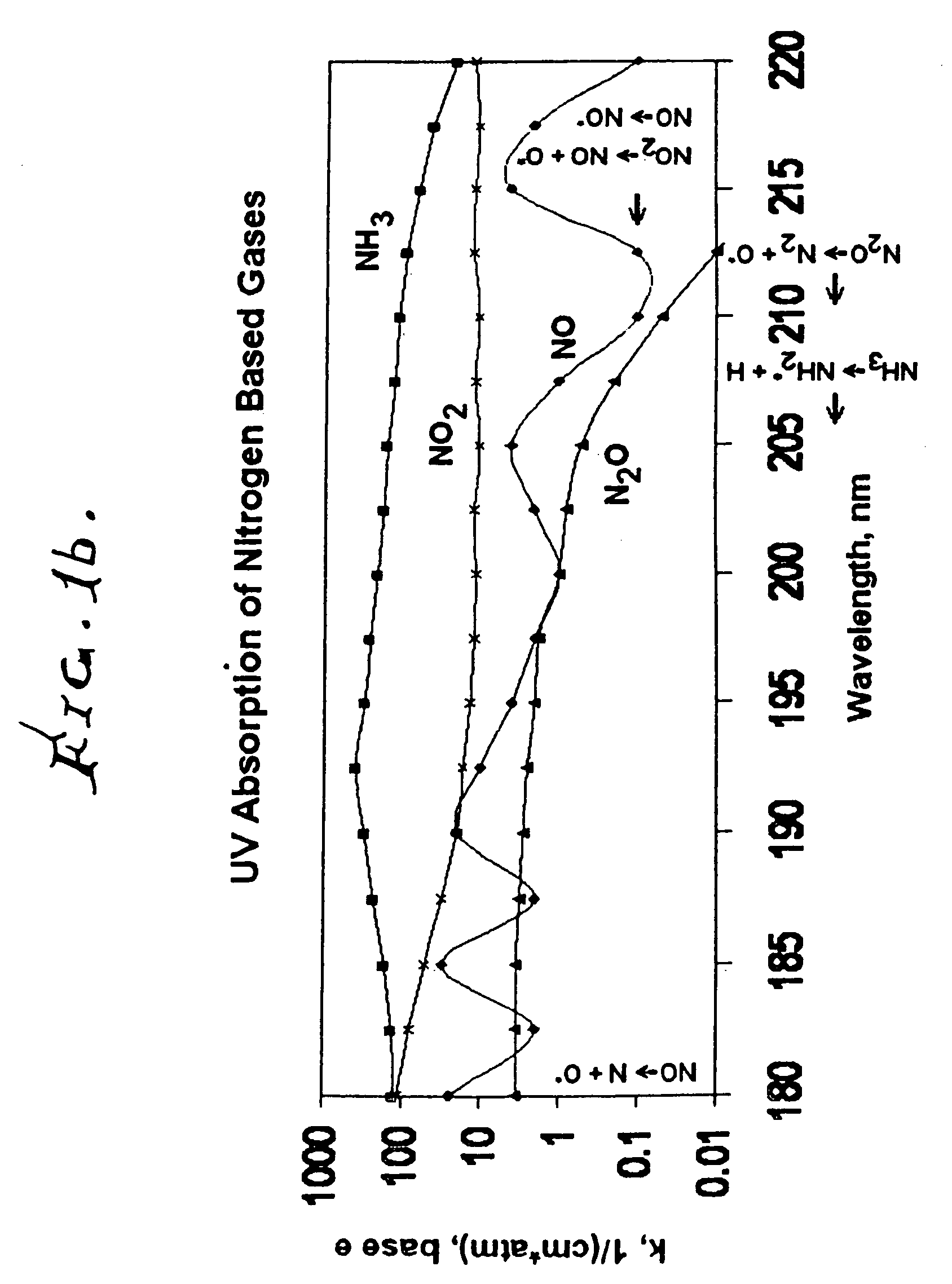

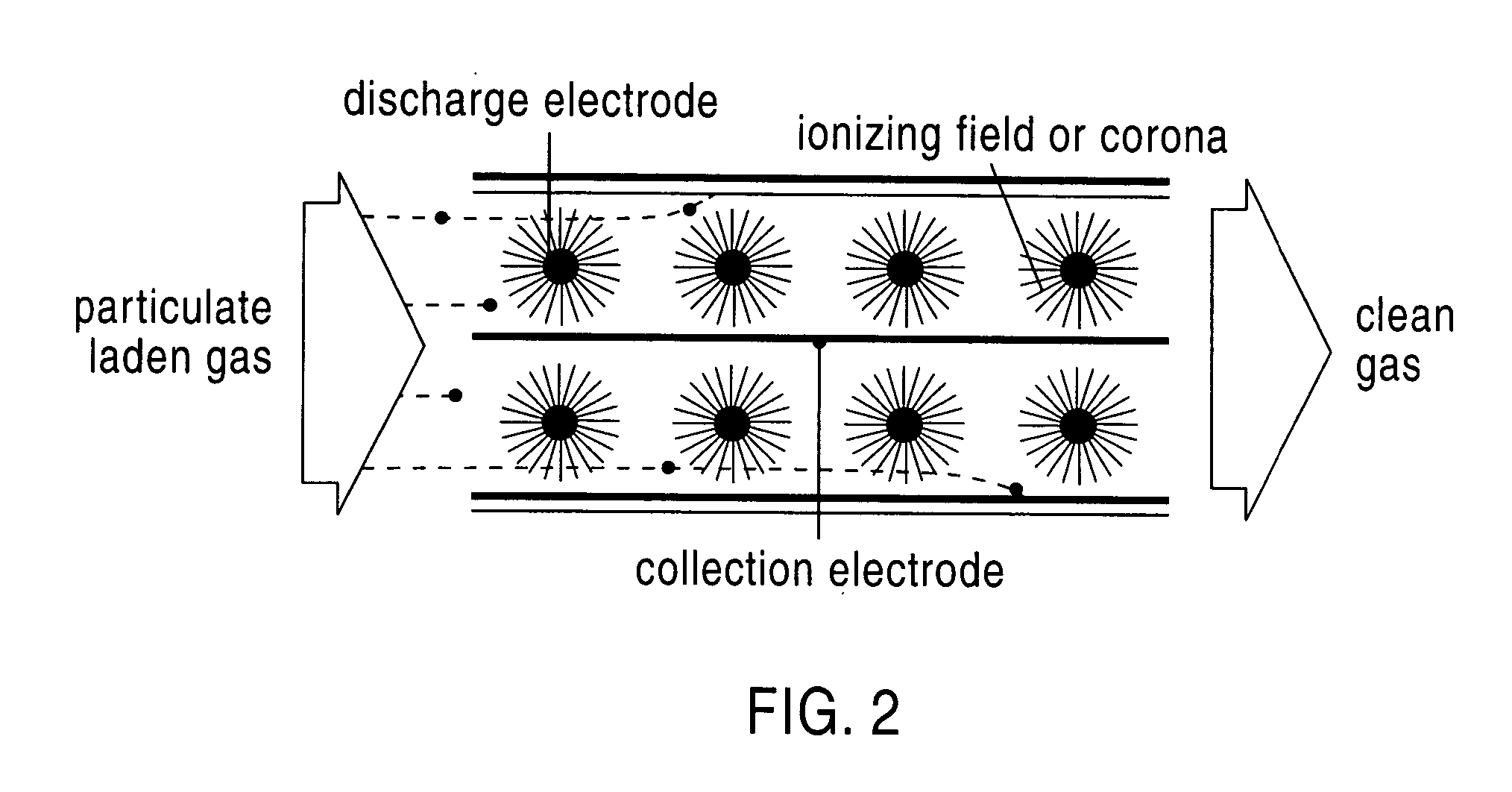

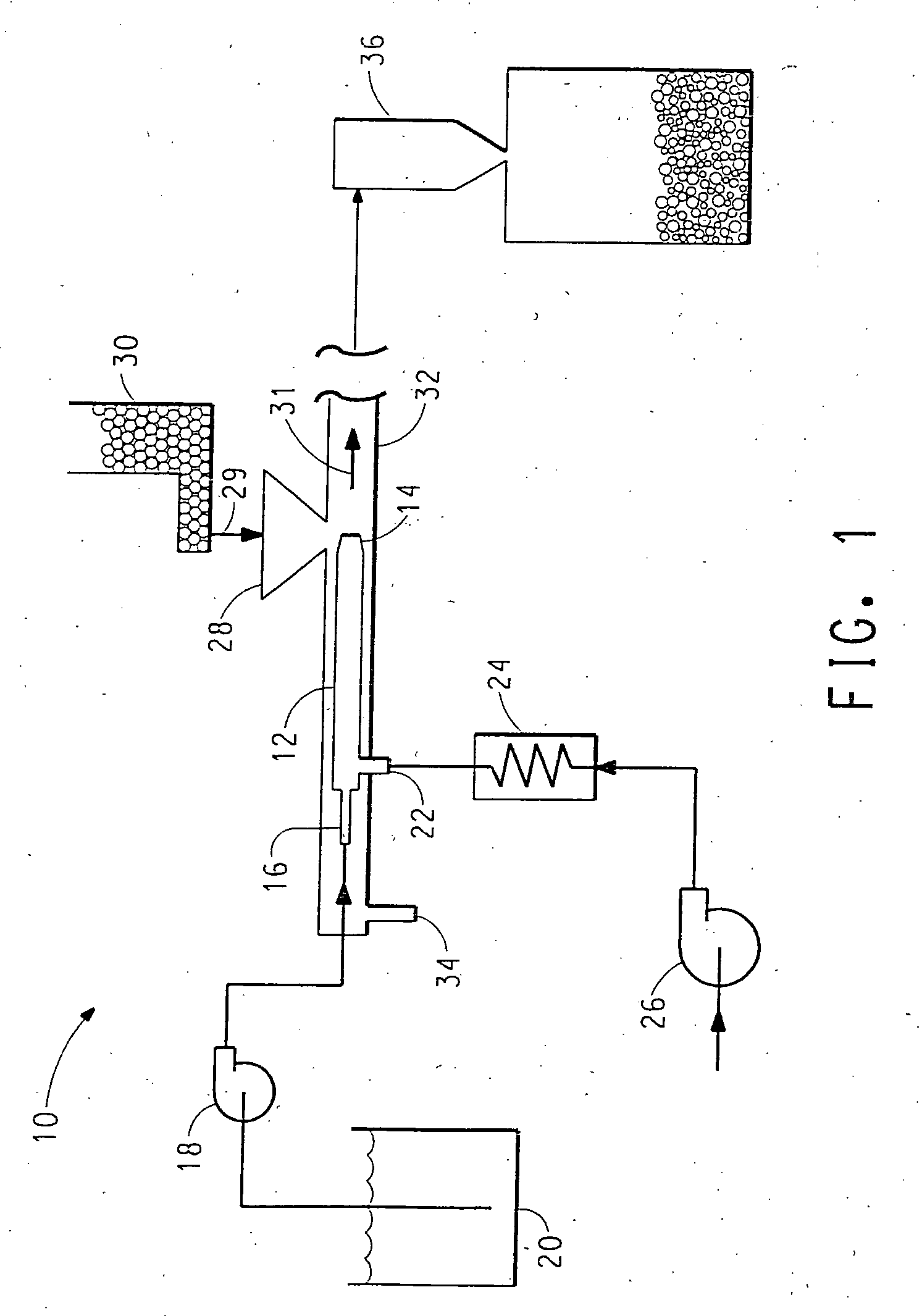

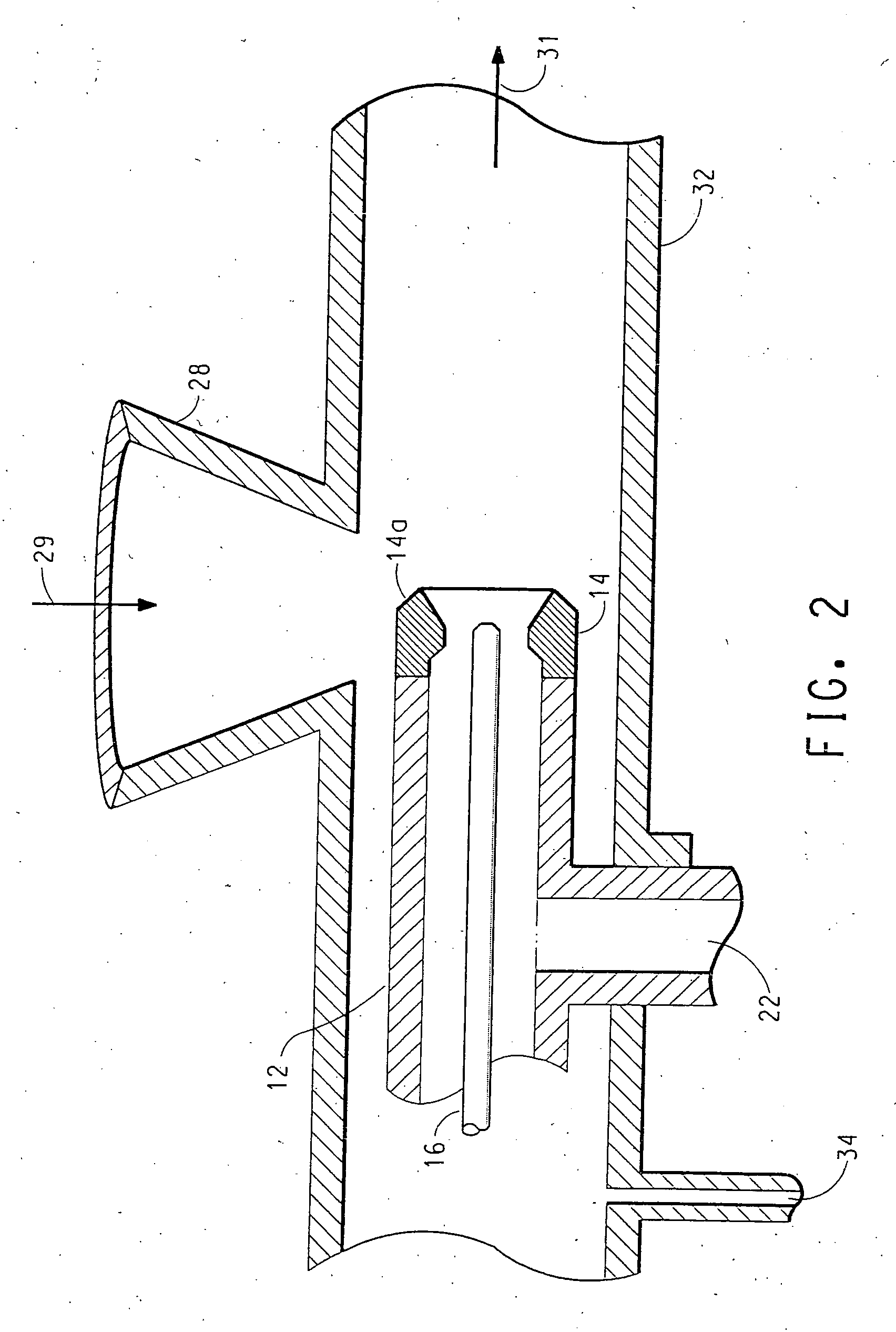

Controlled spectrum ultraviolet radiation pollution control process

InactiveUS7498009B2Cost effectiveEasy to adaptCombination devicesOrganic chemistryEnvironmental engineeringNitrogen oxide

A method for reducing or substantially eliminating oxides of nitrogen from an effluent gas stream, that includes providing a source of ultraviolet radiation with a precise wavelength, adding ammonia or an ammonia based reagent to the effluent stream, upstream of the ultraviolet radiation source, controllably operating the ultraviolet radiation source to irradiate the effluent stream flowing in the duct and substantially reducing or eliminating oxides of nitrogen by promotion a reaction of ammonia with the oxides of nitrogen to produce N2 and H2O, and also thereby destroying any surplus ammonia. This process can also be modified to oxidize carbon monoxide and VOC's to CO2 and H2O.

Owner:DANA UV

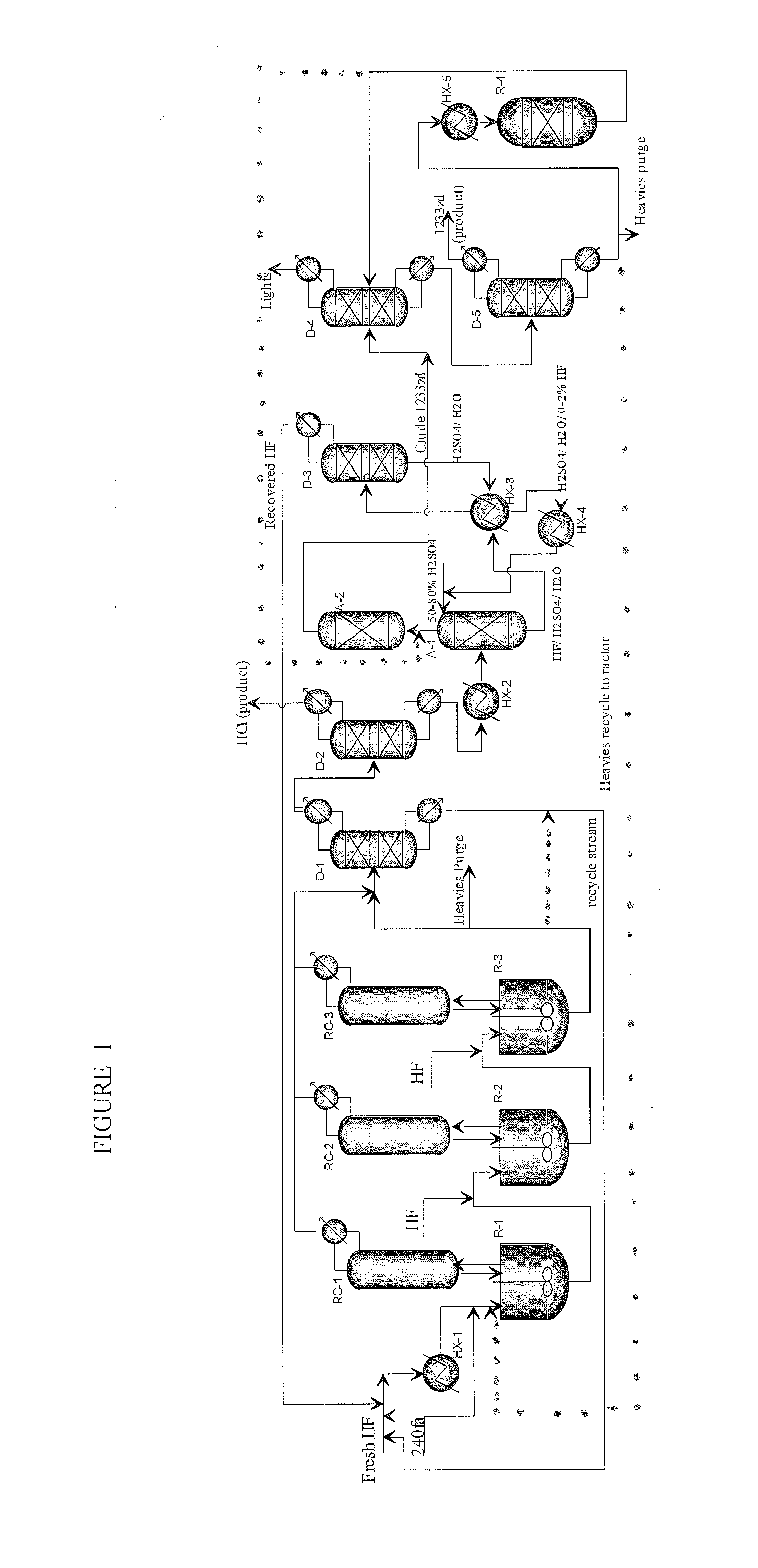

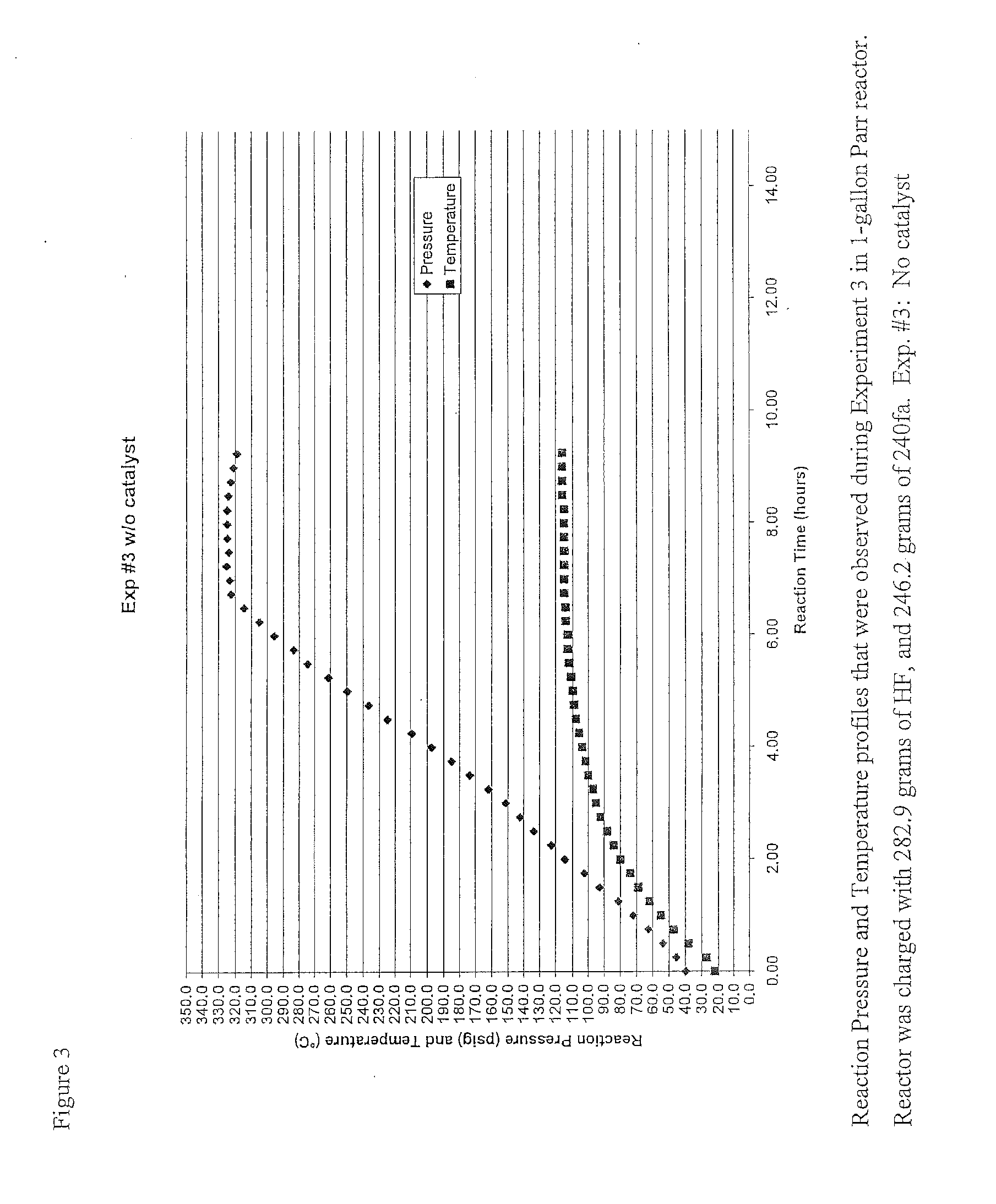

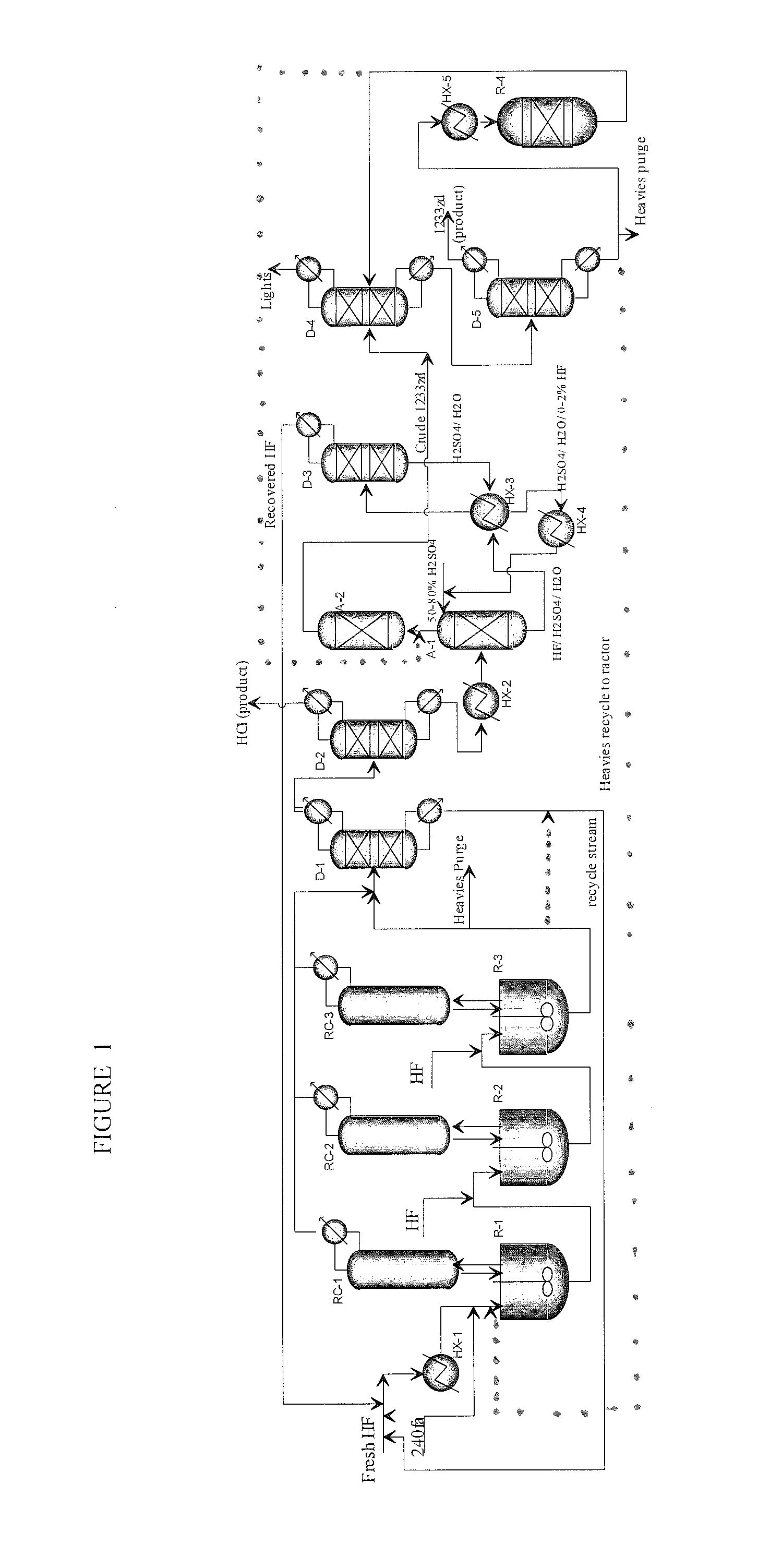

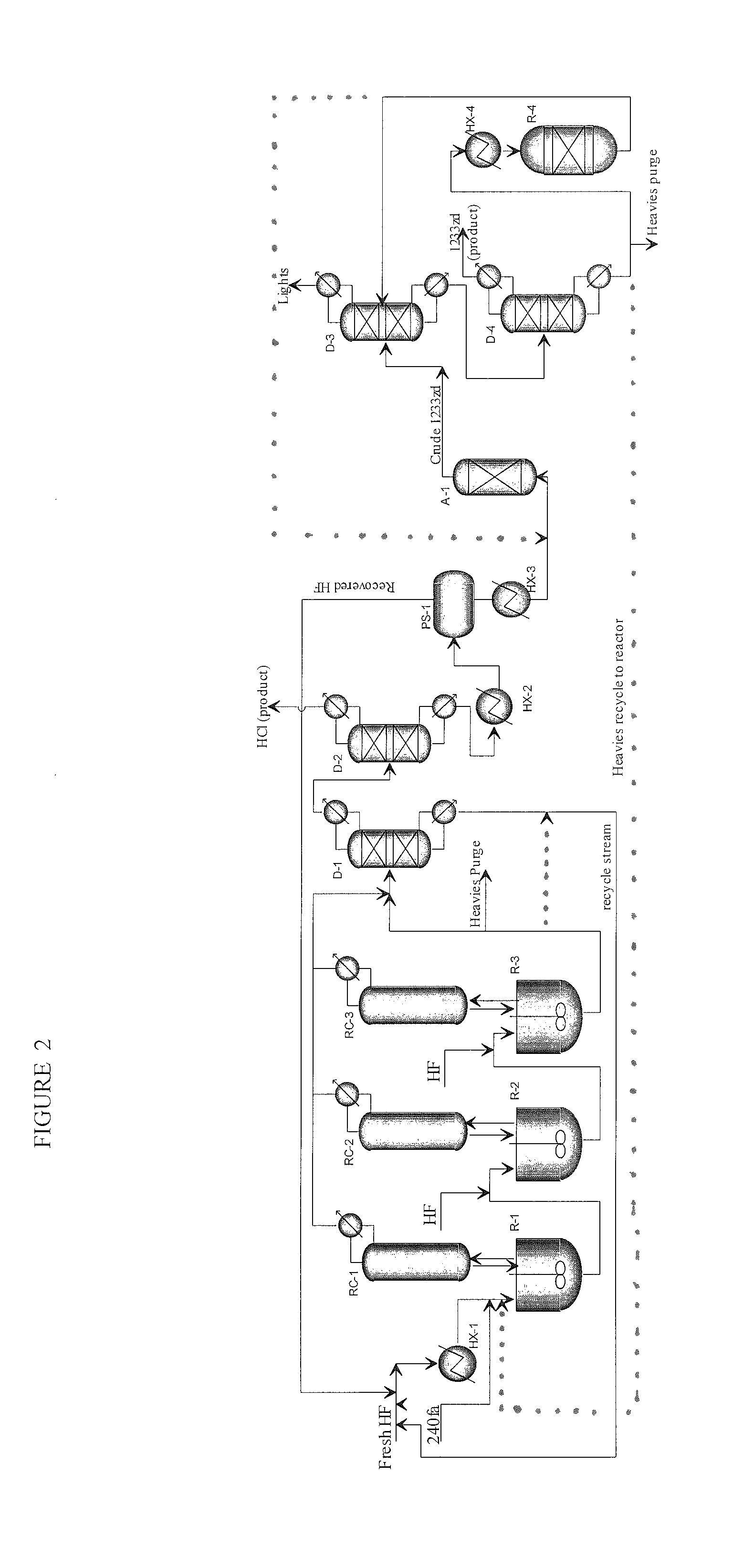

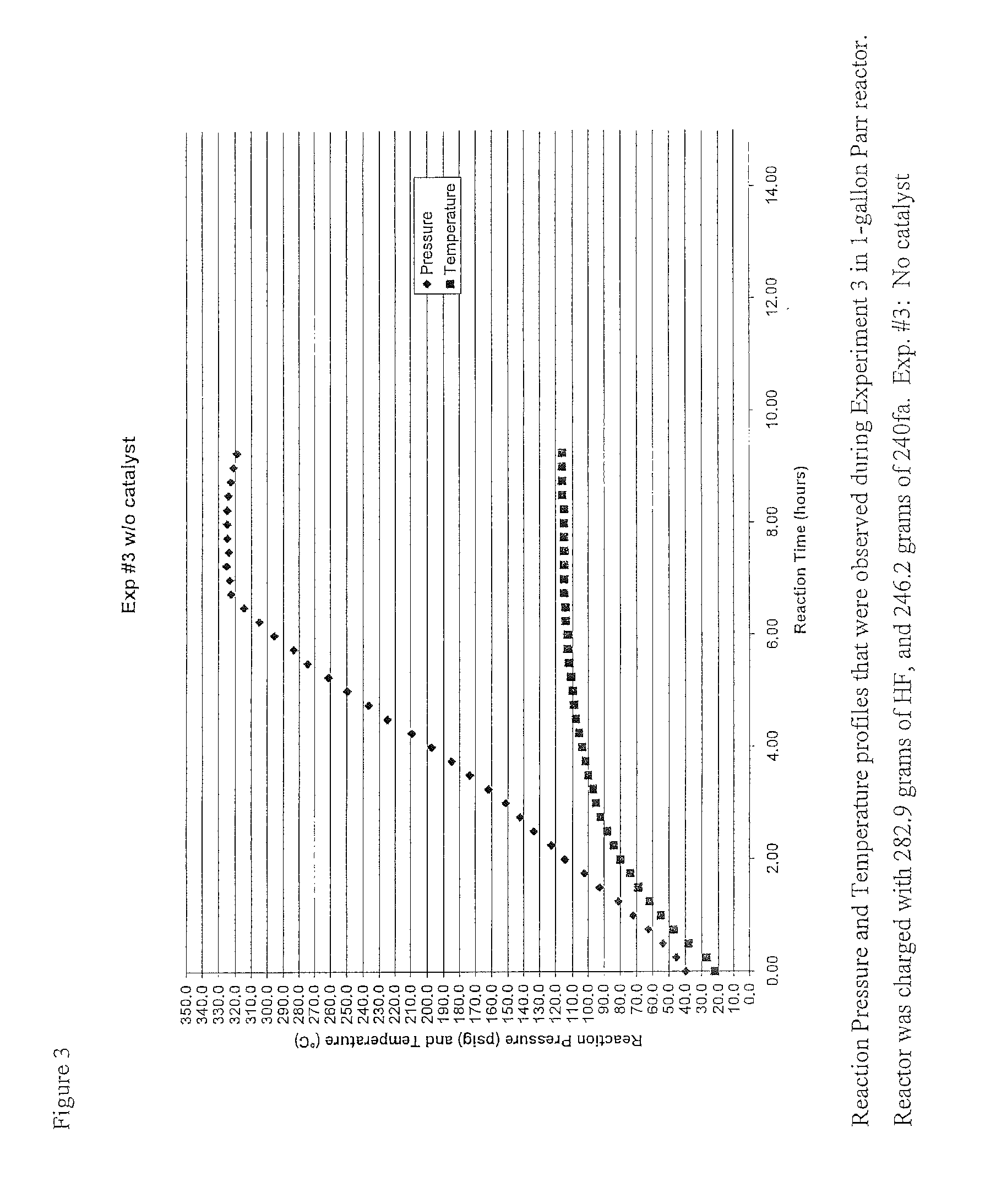

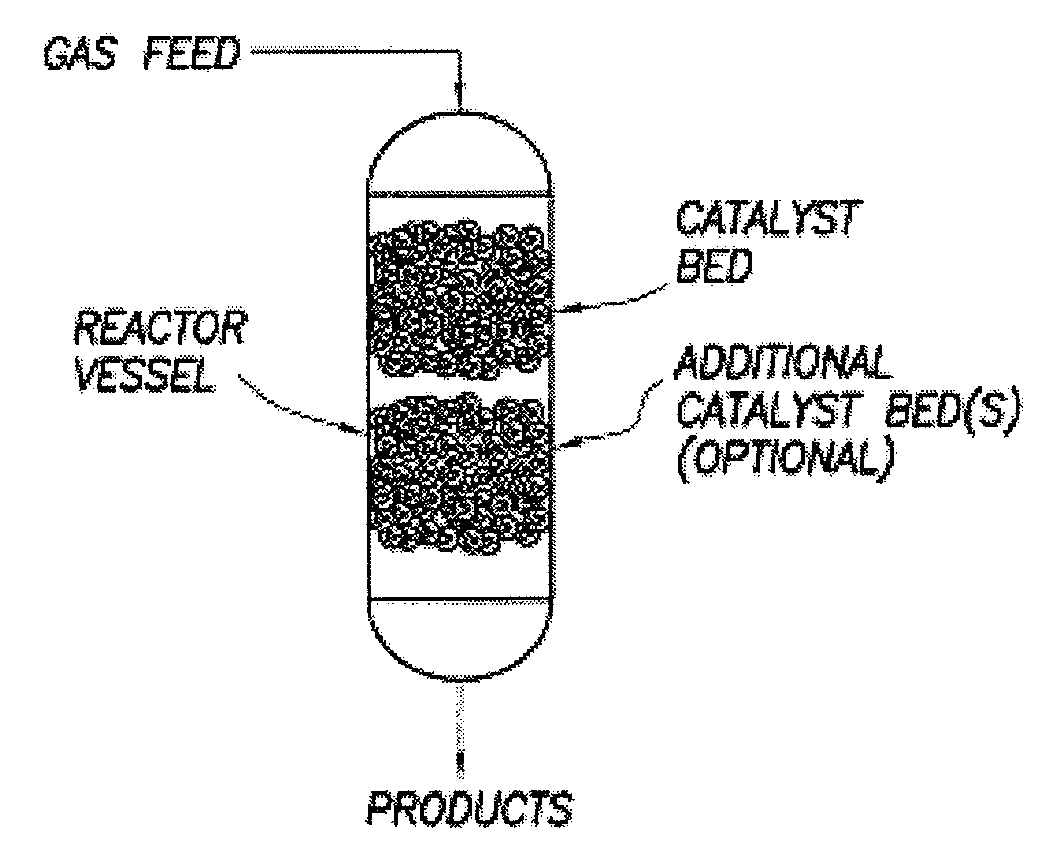

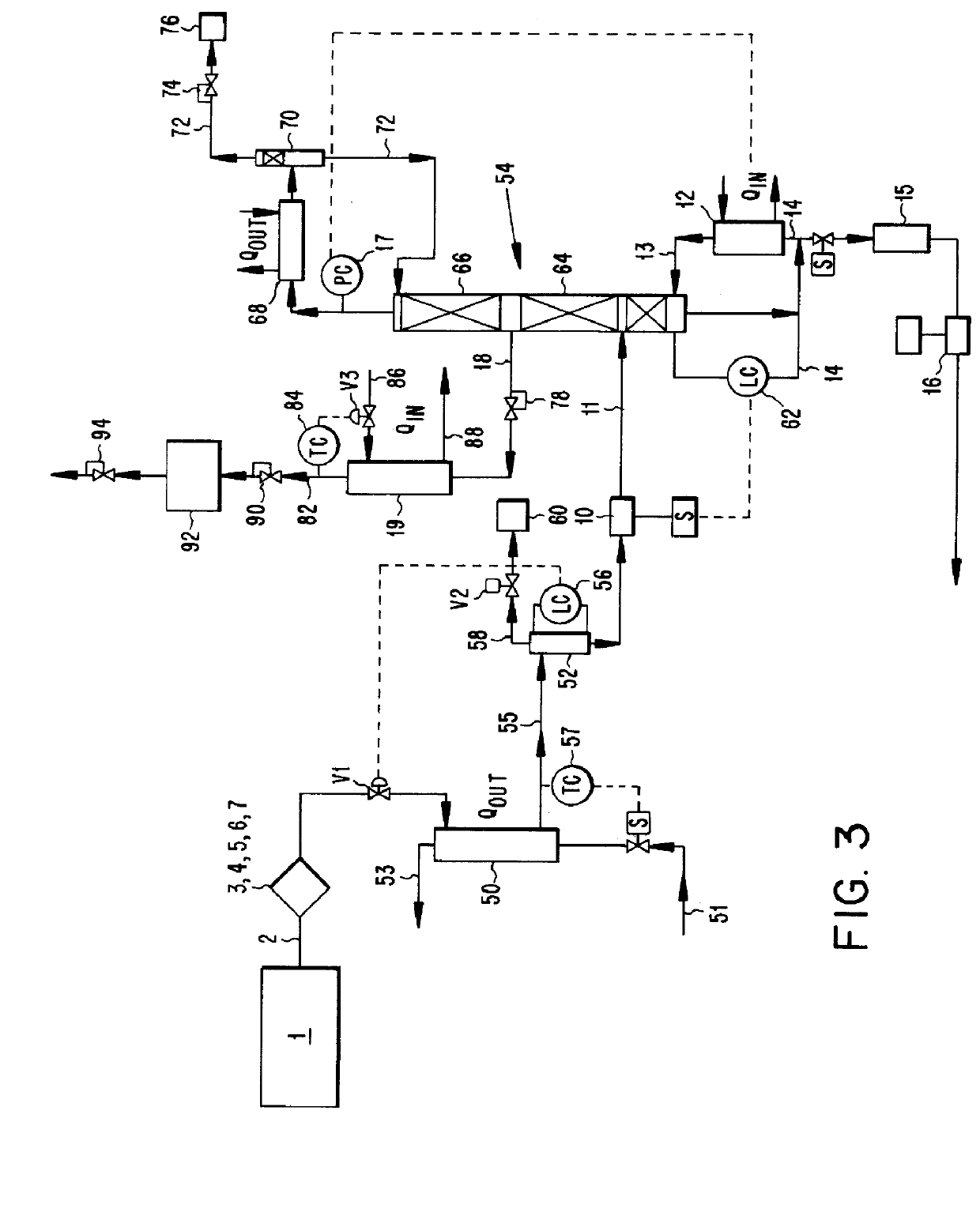

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20120059199A1Slow reaction rateYield maximizationChlorine/hydrogen-chloridePreparation by hydrogen halide split-offIsomerizationUnit operation

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

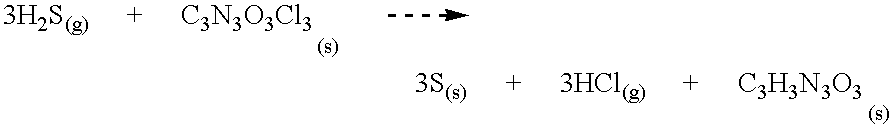

Massive bodies containing free halogen source for producing highly converted solutions of chlorine dioxide

InactiveUS7182883B2Increase conversion rateImprove permeabilityBiocideOrganic chemistryHalogenLiquid water

A massive body, e.g., a tablet, for producing a solution of chlorine dioxide when the massive body is added to liquid water. The massive body comprises a metal chlorite such as sodium chlorite, an acid source such as sodium bisulfate and a source of free halogen such as the sodium salt of dichloroisocyanuric acid or a hydrate thereof. The concentration of free halogen in the solution will be:(a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or(b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:ENGELHARD CORP

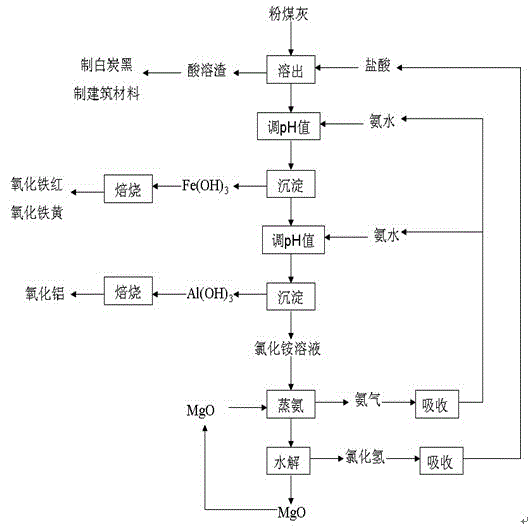

Method for processing fly ash used for circulating fluidized bed

ActiveCN104445212ASolve environmental pollutionHarm reductionChlorine/hydrogen-chlorideSilicaAluminium hydroxideHydrolysis

The invention relates to a method for processing fly ash used for a circulating fluidized bed, which comprises the following steps: dissolving fly ash from the circulating fluidized bed out by hydrochloric acid, filtering to obtain filter residue and a leaching liquid; adjusting pH value of the leaching liquid to 1.5-3.5 by ammoniacal liquor, deposing, filtering to obtain the filter residue and a filtrate, washing filter residue, drying to obtain a compound of iron; adjusting the pH value of the filtrate after extracting iron to 3.8-5.2 by the ammoniacal liquor, deposing, filtering to obtain the filter residue and the filtrate, washing filter residue, drying to obtain aluminium hydroxide, further calcining to obtain metallurgy alumina; adding magnesium oxide in an ammonium chloride solution after extracting aluminium and performing ammonia distilling and hydrolysis reactions to obtain hydrogen chloride gas, ammonia gas and magnesium oxide. According to the invention, stepwise extraction of useful elements such as aluminium, silicon and iron in fly ash can be realized, cycle utilization of the materials can be realized, process is simple, cost is low, and the method opens new approach for high value utilization of fly ash from the circulating fluidized bed.

Owner:GUIYANG AL-MG DESIGN & RES INST

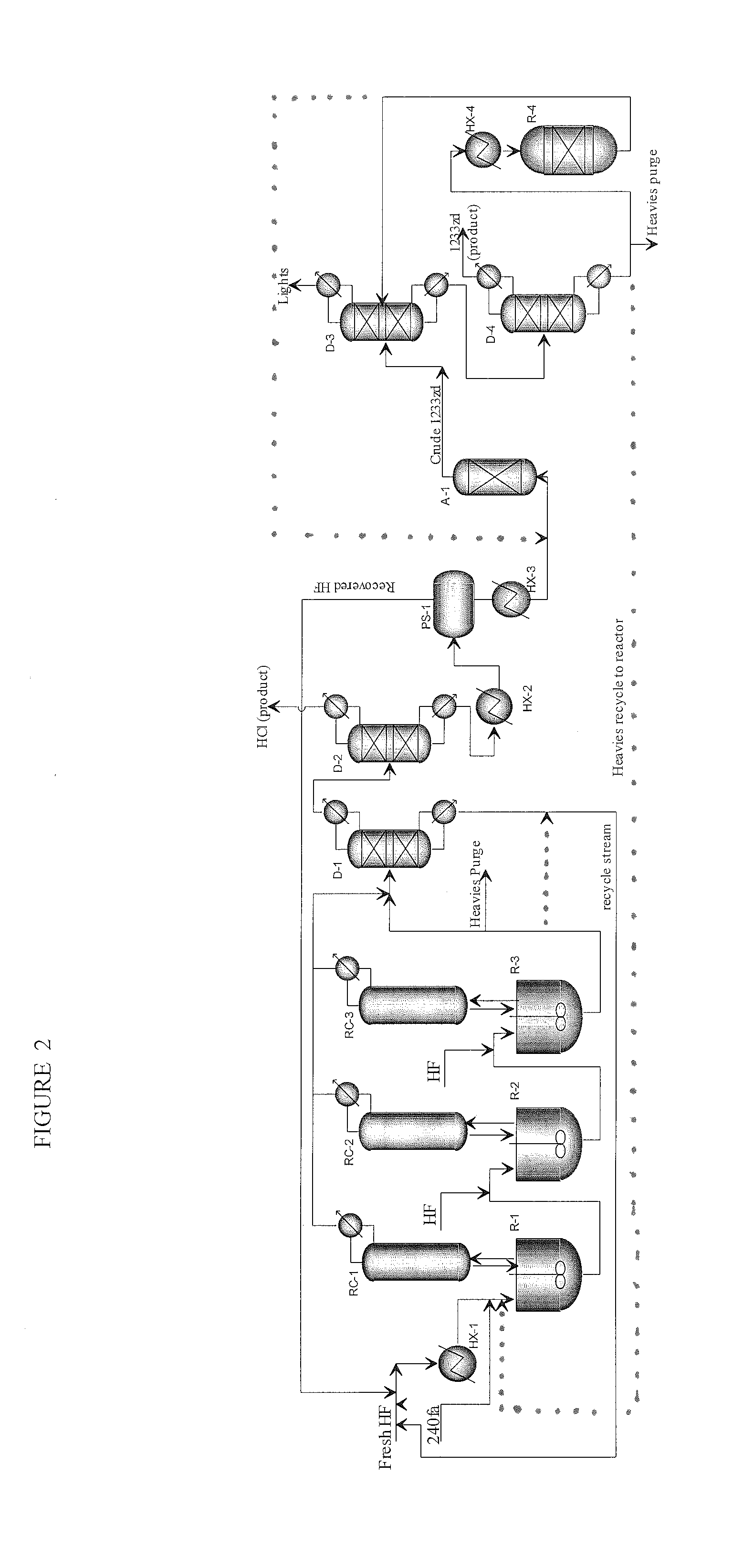

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS8704017B2Yield maximizationChlorine/hydrogen-chlorideHydrocarbon from carbon oxidesIsomerizationUnit operation

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

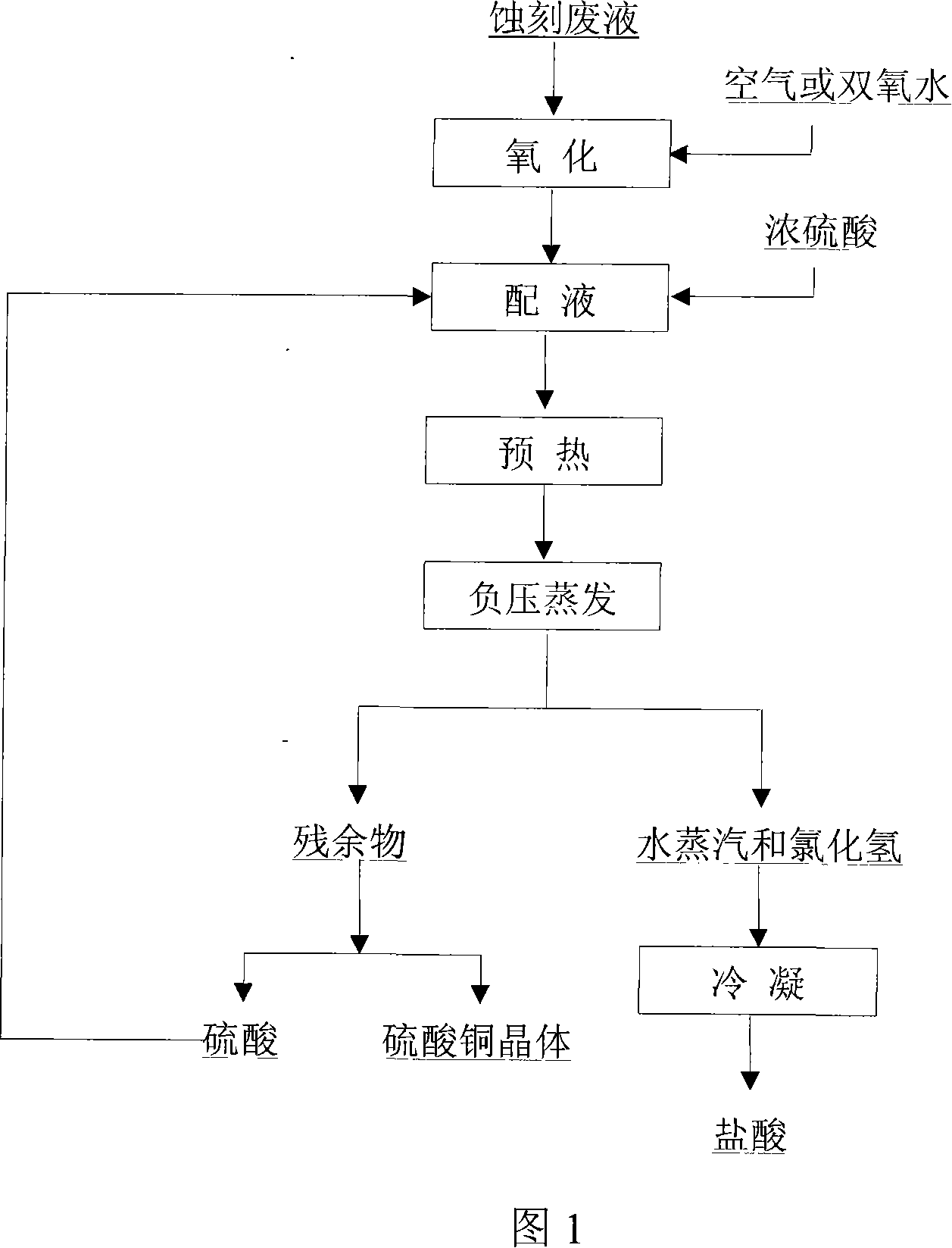

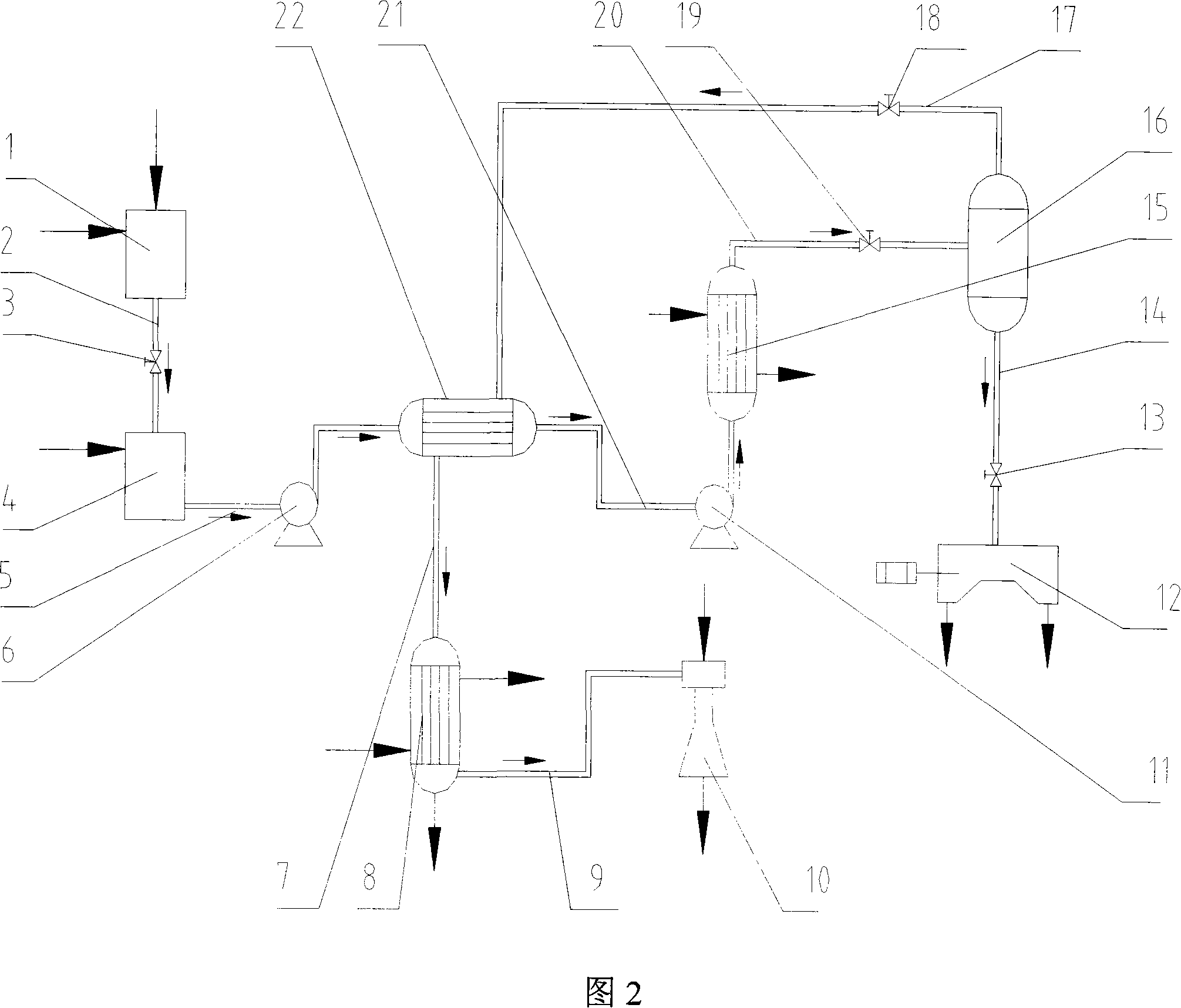

Method and system for reclaiming valuable resource in acidic etching waste liquid

InactiveCN101215062AImprove liquidityReduce cooling energy consumptionChlorine/hydrogen-chlorideMultistage water/sewage treatmentLiquid wasteWater vapor

Provided are system of value resource in acidic corrosion waste fluid and a recycling method. The recycling method of the invention includes the following steps that adding oxidation agent and concentrated sulfuric acid into the corrosion waste fluid, pre-heating and heating the corrosion waste fluid, evaporating out water vapor and hydrogen chloride under negative pressure and recycling hydrochloric acid, the residue separates hydric sulphate from blue copperas crystal via centrifugal filtration and recycle hydric sulphate, washing blue copperas crystal by blue copperas crystal solution and absolute ethyl alcohol and recycling blue copperas. The recycling system comprises an oxidation ditch, a dosage bunker, a pre-heater, a heat booster, an evaporation tank, a filter, a cooler, a spraying and absorbing device and the like. The recycling method of the invention increases the recovery rate of metal copper and hydrogen chloride, with both recovery rates more than 99%. The method can employ scheme of batch operation or continuous recycling, which is adapted for industry utilization.

Owner:郝屿

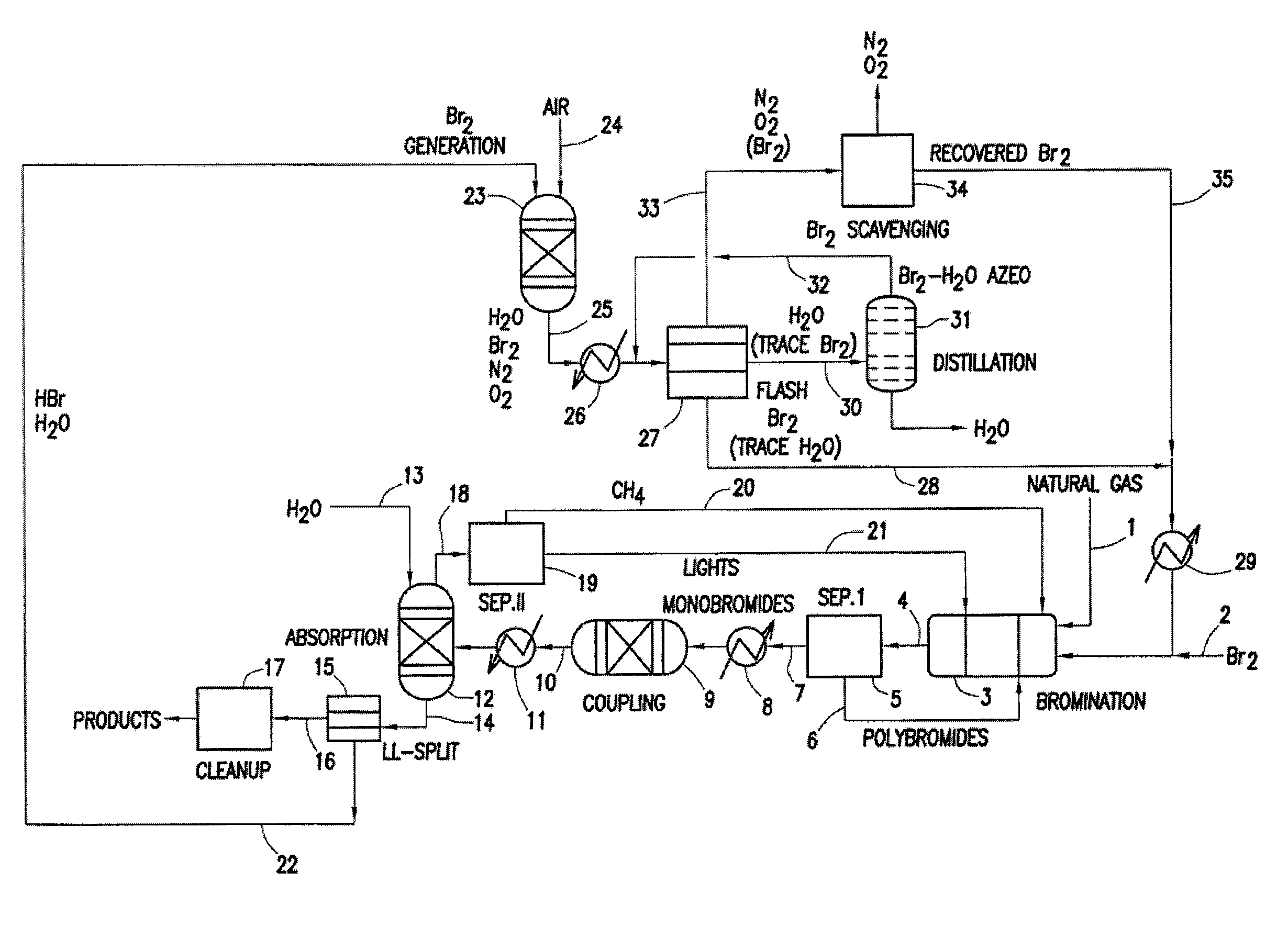

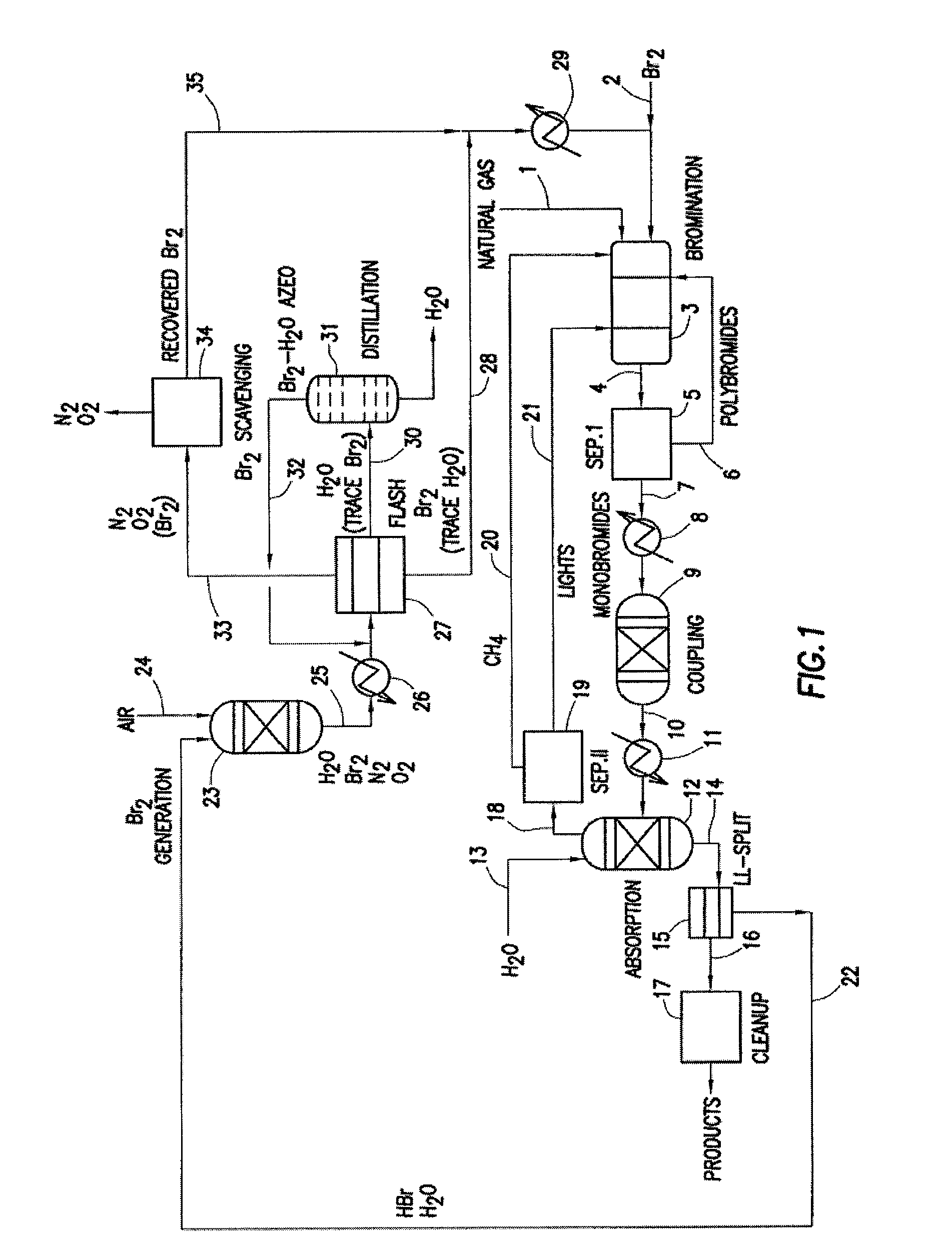

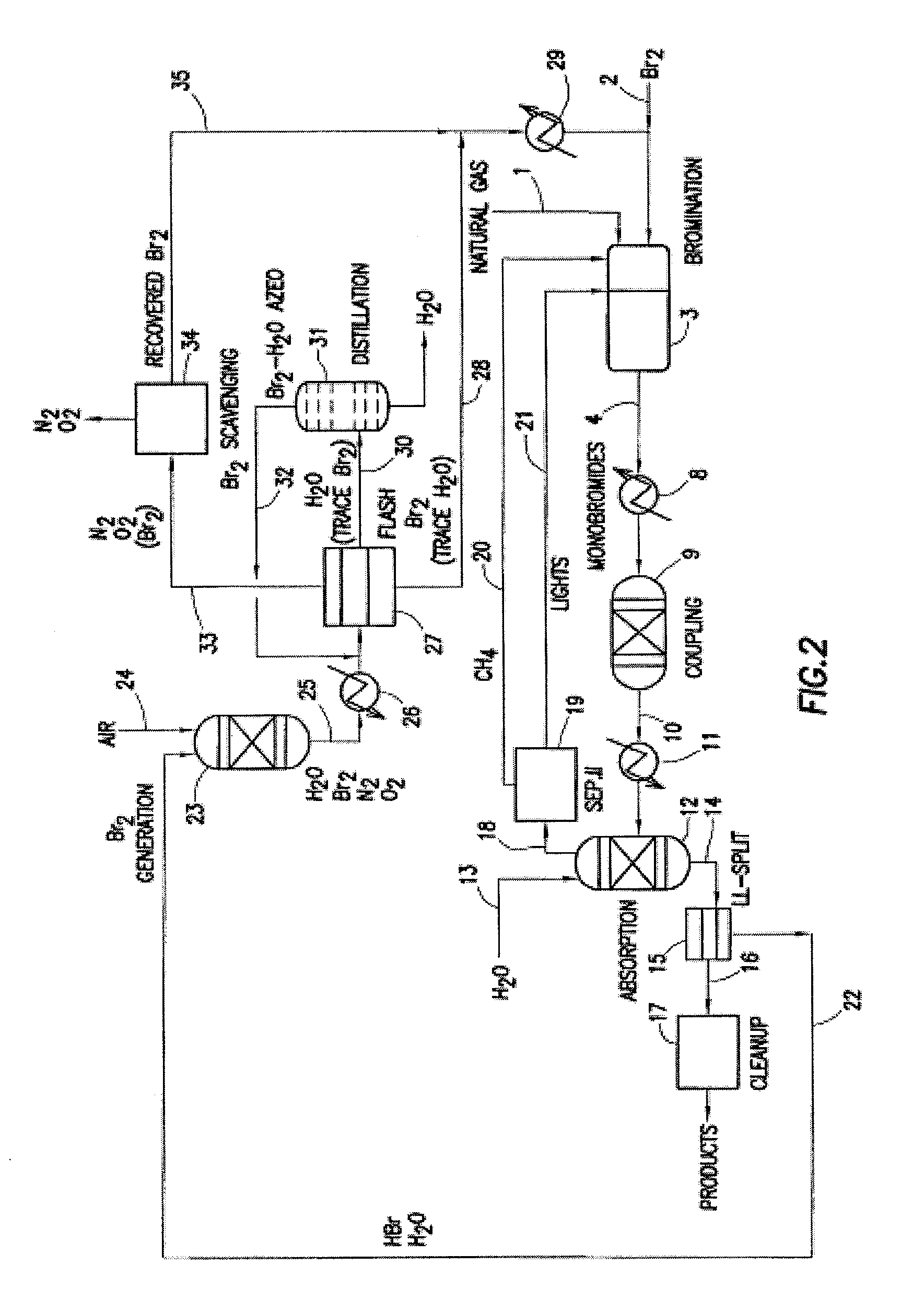

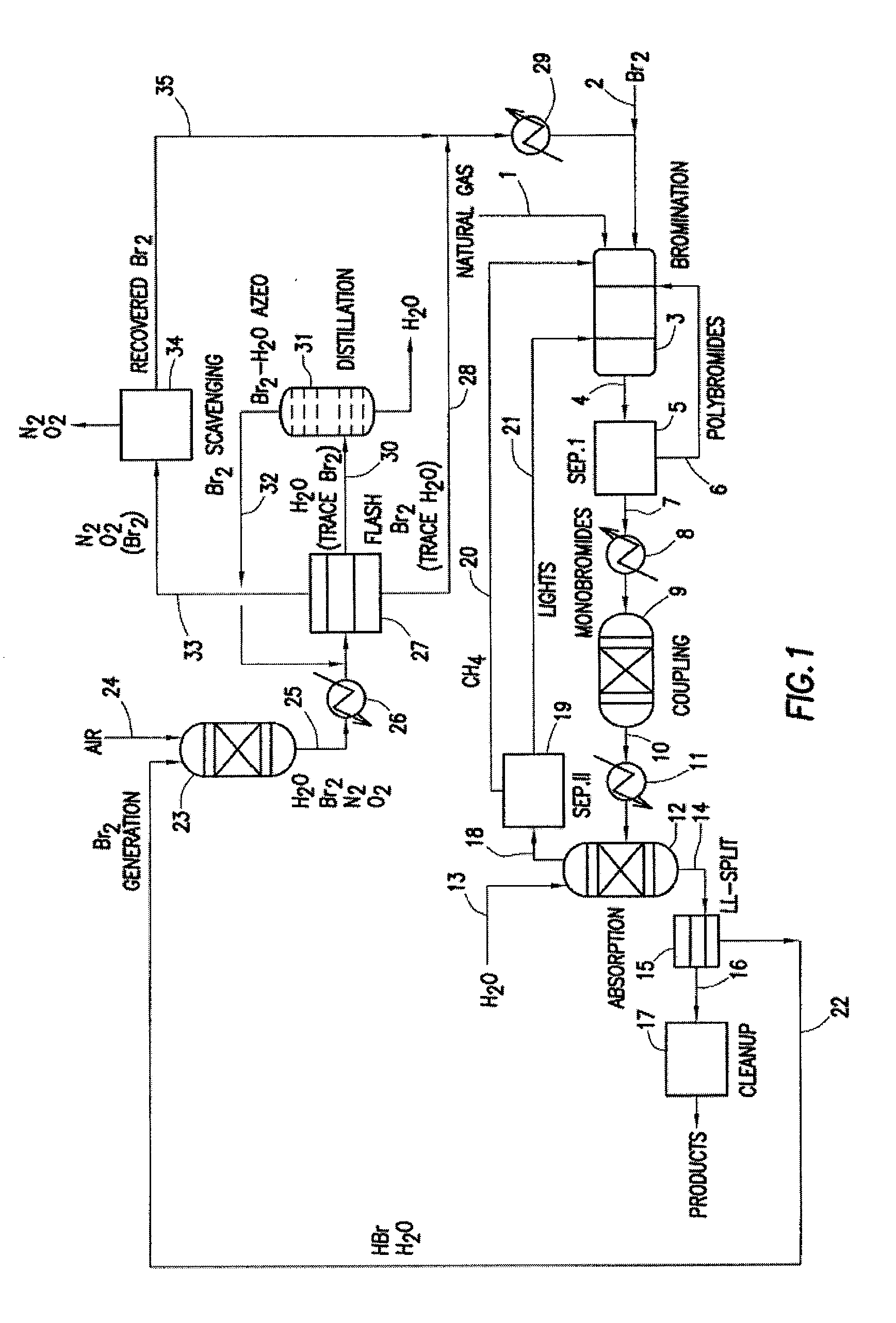

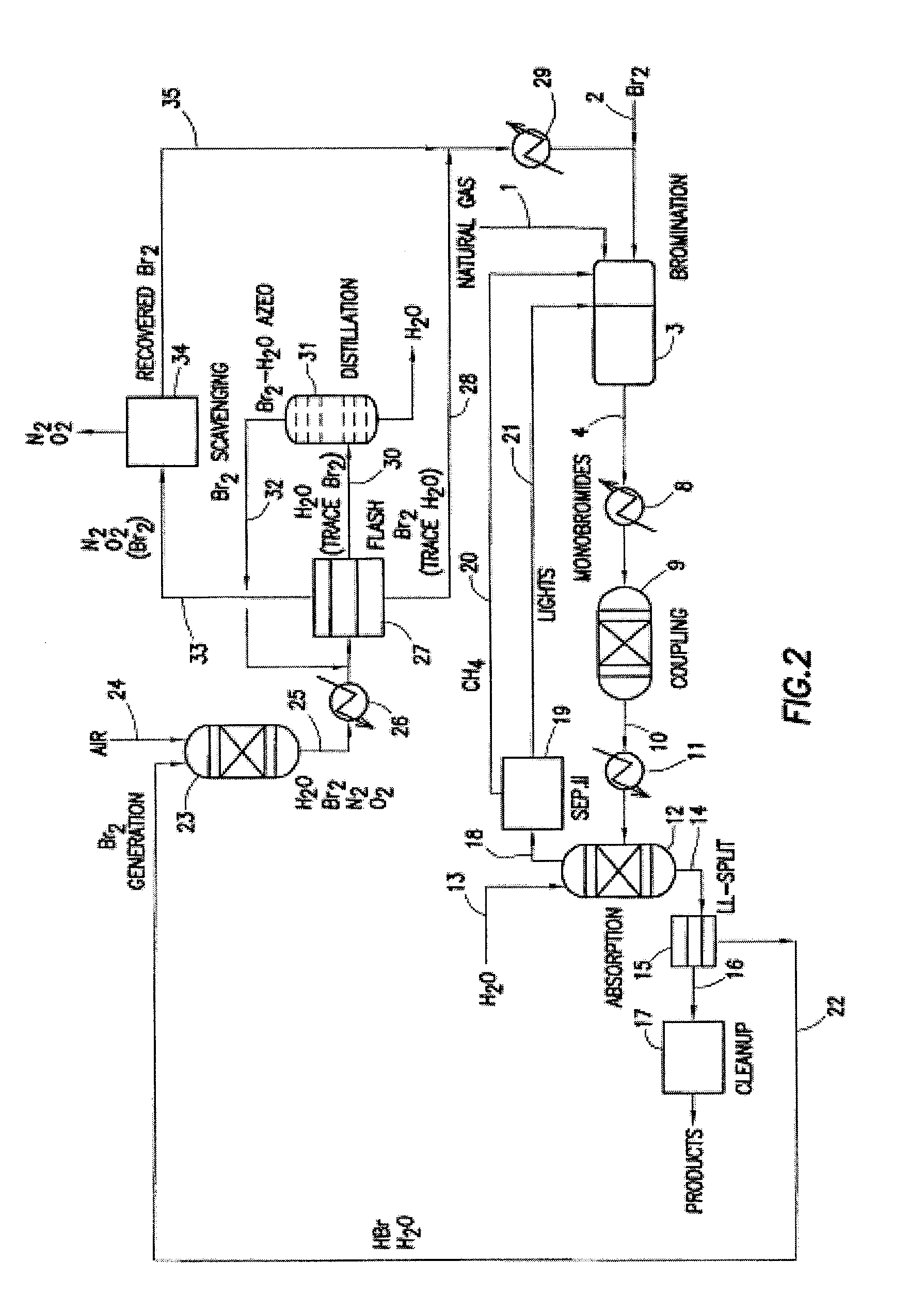

Continuous Process for Converting Natural Gas to Liquid Hydrocarbons

A method comprising: providing an alkyl halide stream; contacting at least some of the alkyl halides with a coupling catalyst to form a product stream comprising higher hydrocarbons and hydrogen halide; contacting the product stream with a solid reactant to remove at least a portion of the hydrogen halide from the product stream; and reacting the solid reactant with a source of oxygen to generate a corresponding halogen.

Owner:REACTION 35 LLC

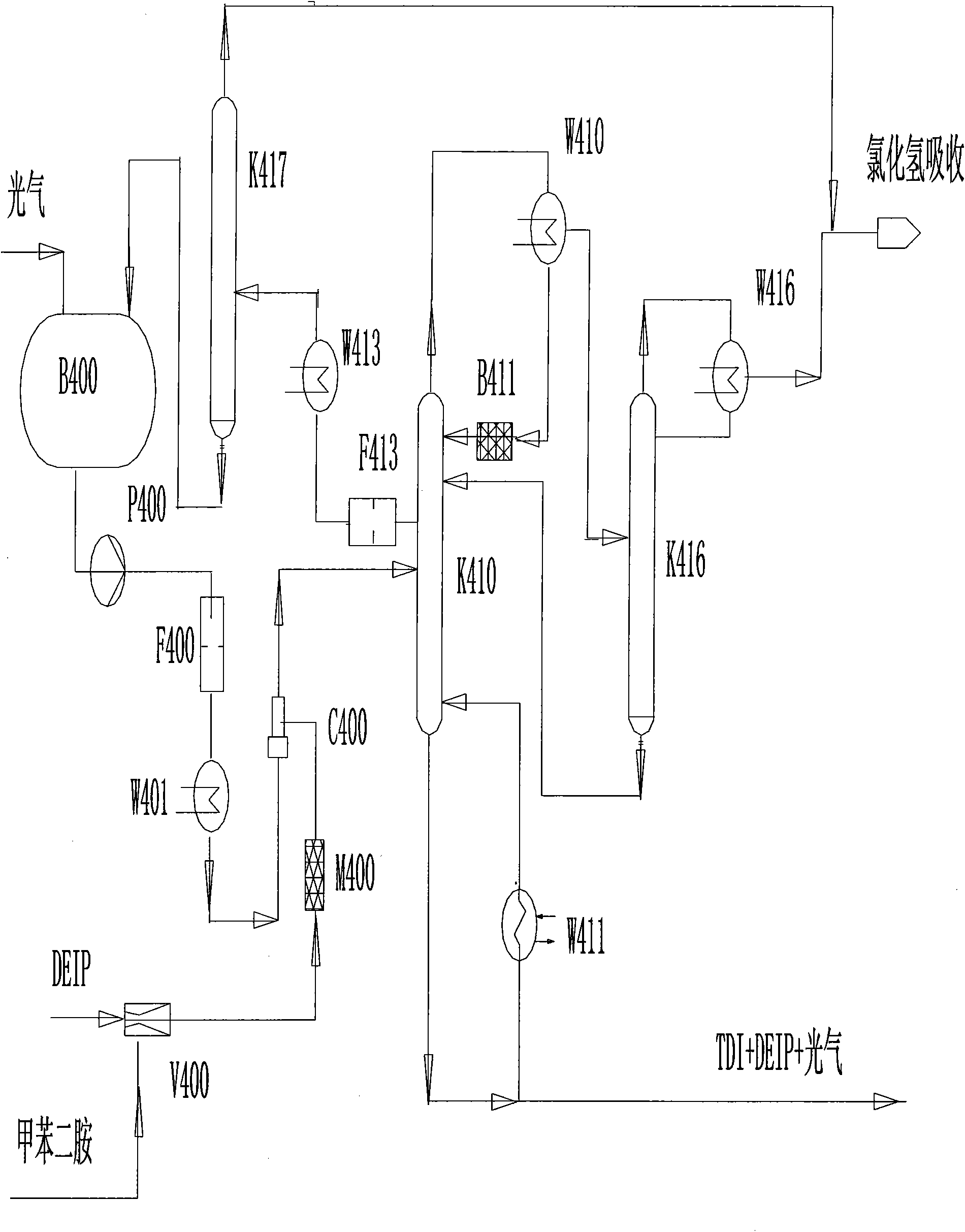

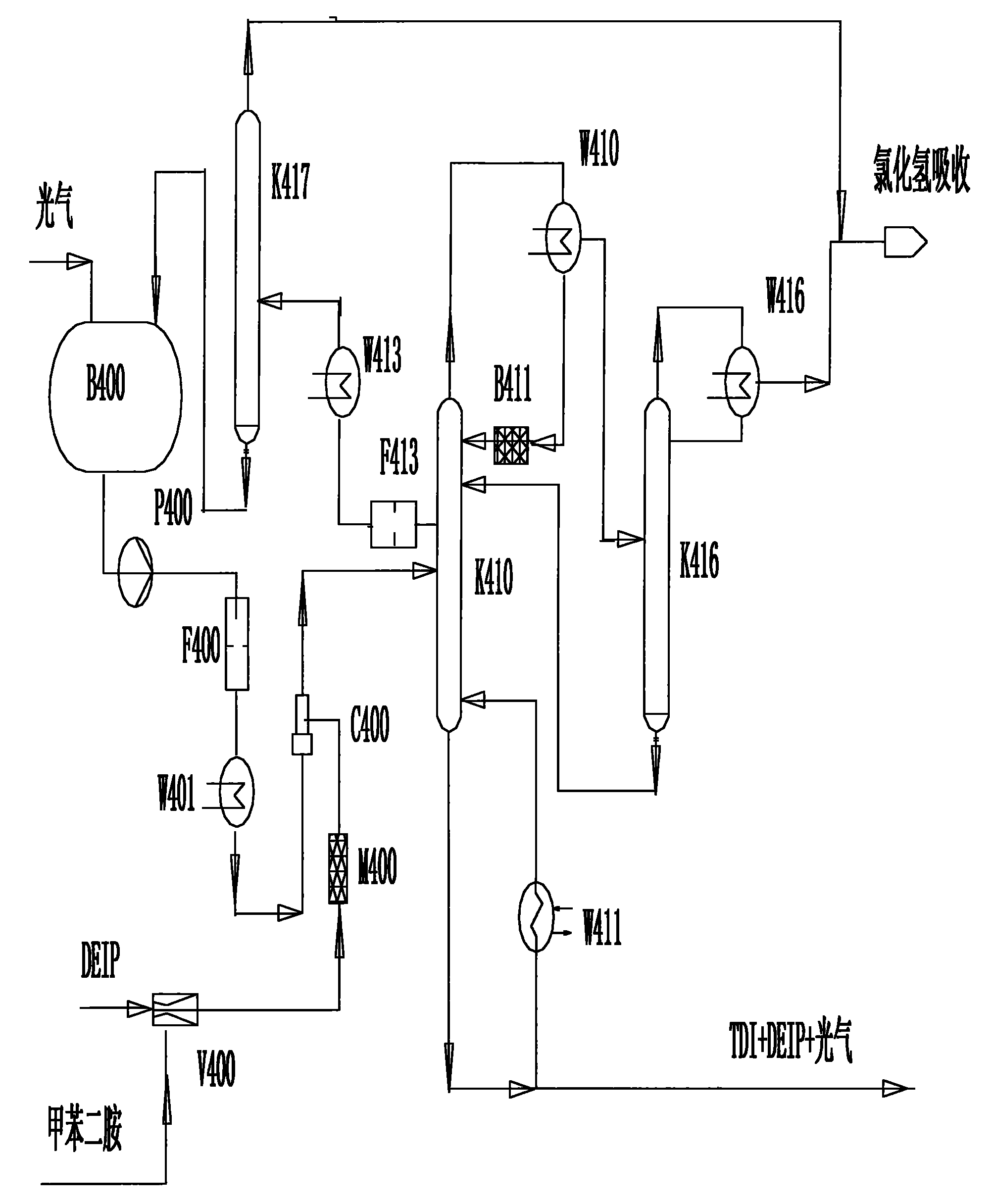

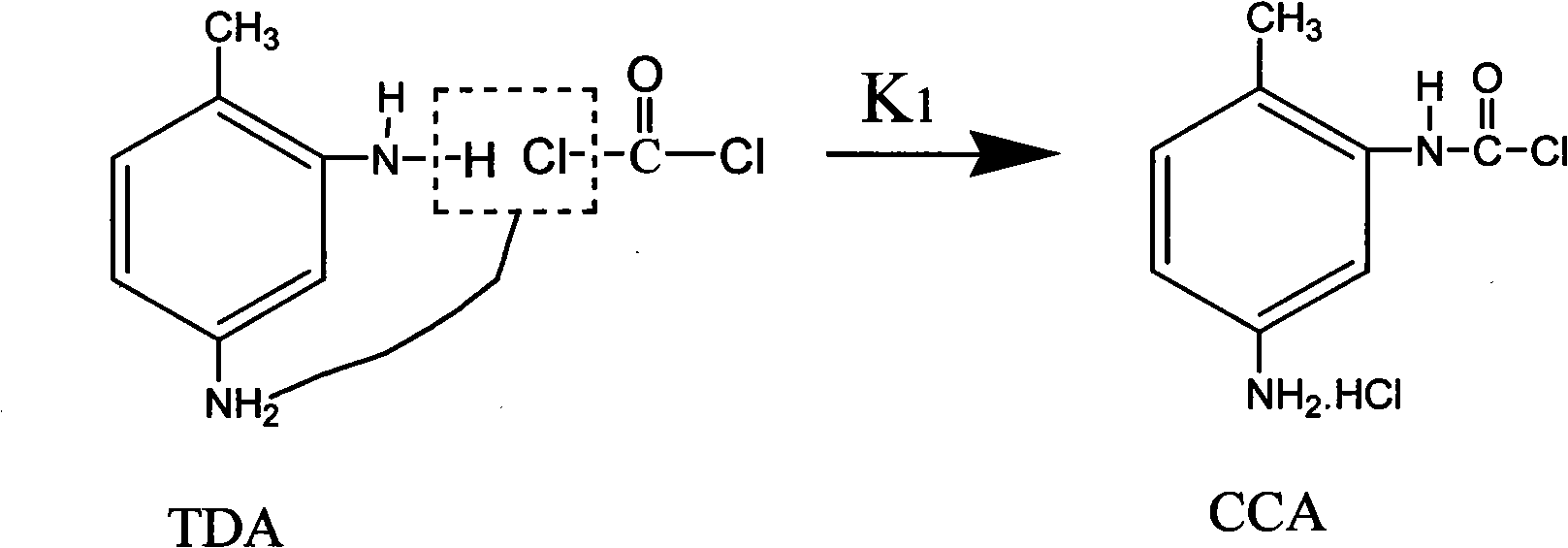

Method for continuously preparing toluene diisocynate

The invention relates to a method for continuously preparing toluene diisocynate, in particular to a method for preparing coarse toluene diisocynate by a phosgene method. The method comprises the following steps: mixing toluene diamine and DEIP solvent, performing low-temperature photochemical reaction on the mixture and excessive liquid phosgene in a jet reactor, heating and cracking a reaction product in a photochemical reaction tower to further decompose toluene dicarbamic chloride serving as an intermediate product to form the toluene diisocynate, recycling the reclaimed phosgene and the DEIP solvent, and delivering the hydrogen chloride gas serving as a side product to a hydrogen chloride absorption system.

Owner:甘肃银光聚银化工有限公司

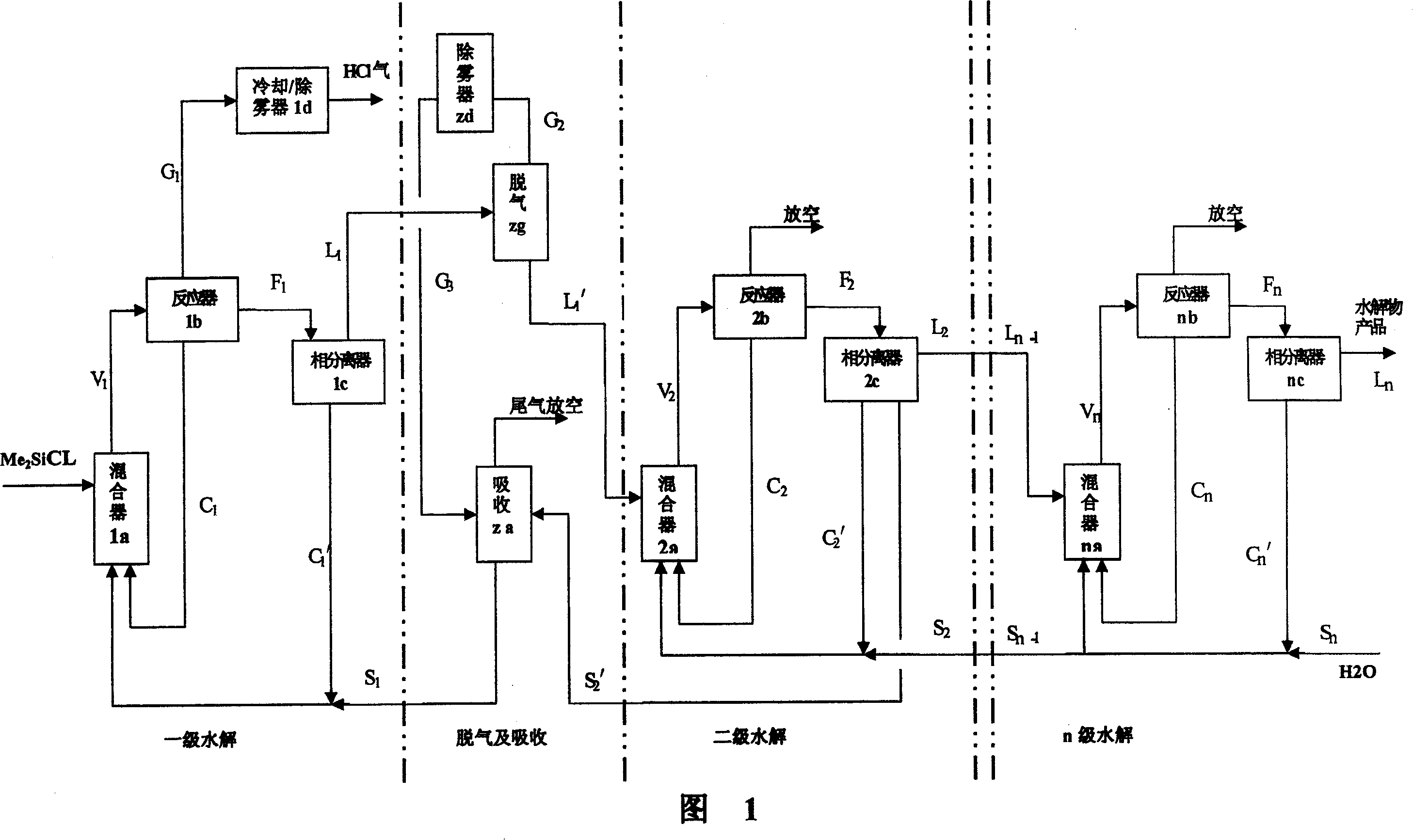

Method for continuous production hydrolysate by methylchlorosilane concentrated acid hydrolyzing

ActiveCN101323666AThe new hydrolysis process is excellentReduce or completely avoid entrainmentChlorine/hydrogen-chlorideDecompositionHydrolysate

The invention relates to a method for hydrolyzing methyl chlorosilane with concentrated acids to obtain hydrolysate, wherein, the methyl chlorosilane and the acidic oil-contained aqueous solution separated from the primary phase separator and the secondary phase separator from the hydrolysate are mixed, pass through a preheater, enter a concentrated-acid hydrolysis reaction system and undergo a circular reaction operation; the hydrogen chloride generated in the hydrolysis reaction is released from the top of a tower, goes through a defroster and a condensator and then becomes qualified HCI gas to be used in the production of methyl chloride. Qualified hydrolysate used for decomposition process is obtained after the hydrolysate of methyl chlorosilane goes through four phase separators and a steam tower.

Owner:BEIJING PETROCHEM ENG +1

Slow release type azophoska compound fertilizer and production method thereof

ActiveCN101503322AIncrease productionImprove qualityChlorine/hydrogen-chlorideAgriculture gas emission reductionDecompositionPhosphate

The invention relates to a slow-release type nitrogen-phosphorus-potassium composite fertilizer and a production method thereof, belonging to a composite fertilizer with slow-release type nutrient. The composite fertilizer is characterized by comprising the following components by weight portions: 5 to 50 of slow-release composition of phosphogypsum and fly ash, 10 to 40 of urea, 10 to 45 of hydrochloric acidified phosphate rock powder, 10 to 35 of mixed potassic fertilizer, 0.5 to 2.0 of slow-release agent and 1 to 5 of trace element compound. The raw materials are mixed evenly, the conventional auxiliary materials are added for granulation, and then lamination is carried out so as to obtain the composite fertilizer. The invention provides an ideal slow-release type nitrogen-phosphorus-potassium composite fertilizer which has comprehensive nutrients, scientific and reasonable matching and slow rate of fertilizer decomposition and nutrient release, is in conformity with the absorption rate of plants for nutrients, can improve the yield and quality of agriculture product, improve utilization rate of fertilizer, reduce rate of fertilizer application and agricultural production cost, and is beneficial to protection of soil and natural environment and a production method thereof.

Owner:SHIKEFENG CHEM IND

Process for producing high purity magnesia

InactiveCN1704337ANo pollutionShort technical routeChlorine/hydrogen-chlorideMagnesium chloridesSulfate radicalsPhysical chemistry

The invention discloses a process for preparing high purity magnesium oxide products, which consists of using brine containing magnesium chloride from sea, lakes or crude magnesium chloride hexahydrate as raw material, purifying the brine through vacuum crystallization method, removing boron, sulfate radicals, calcium ions and soluble impurity substance in the raw material, finally carrying out dynamic calcinations.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

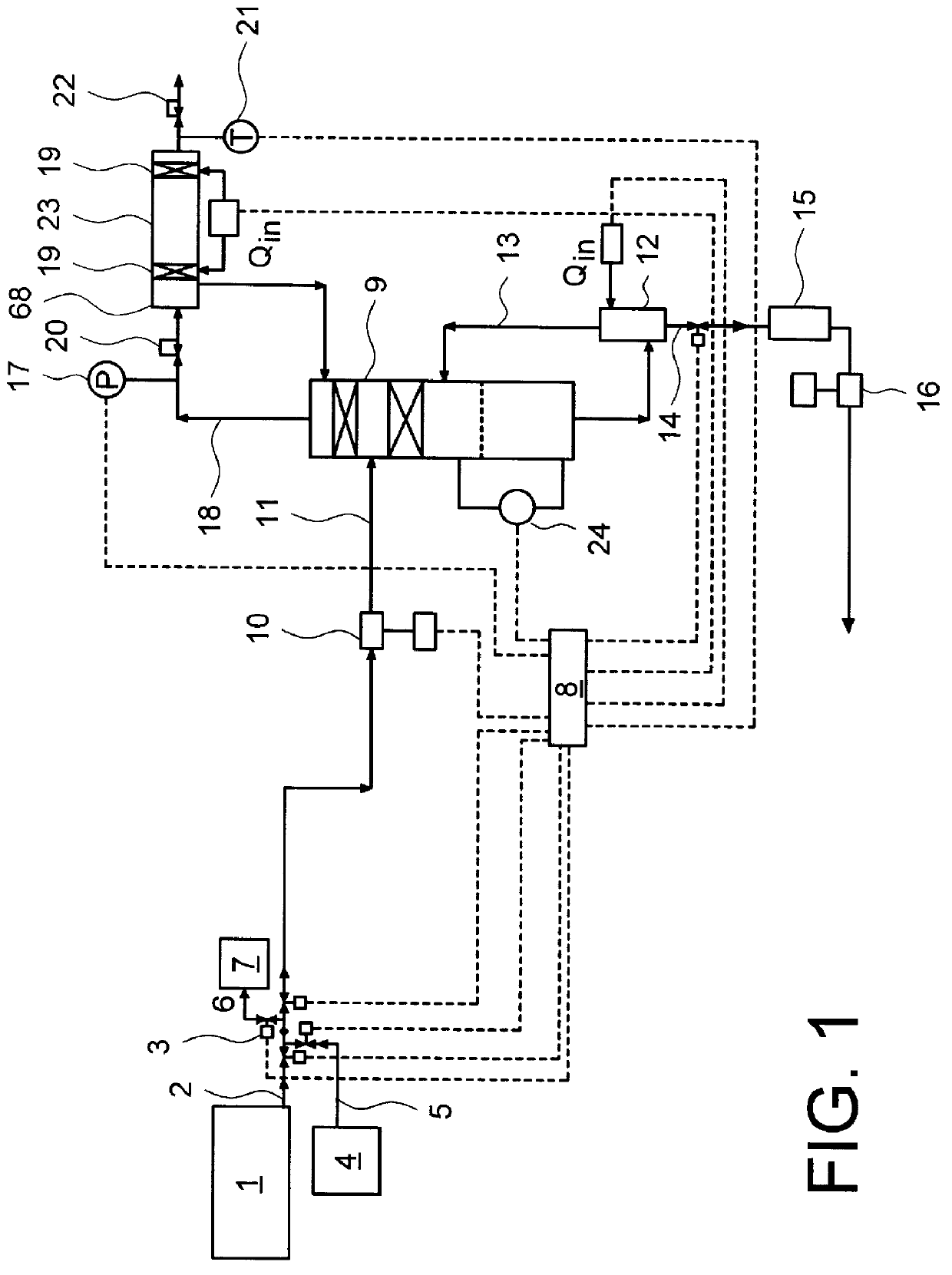

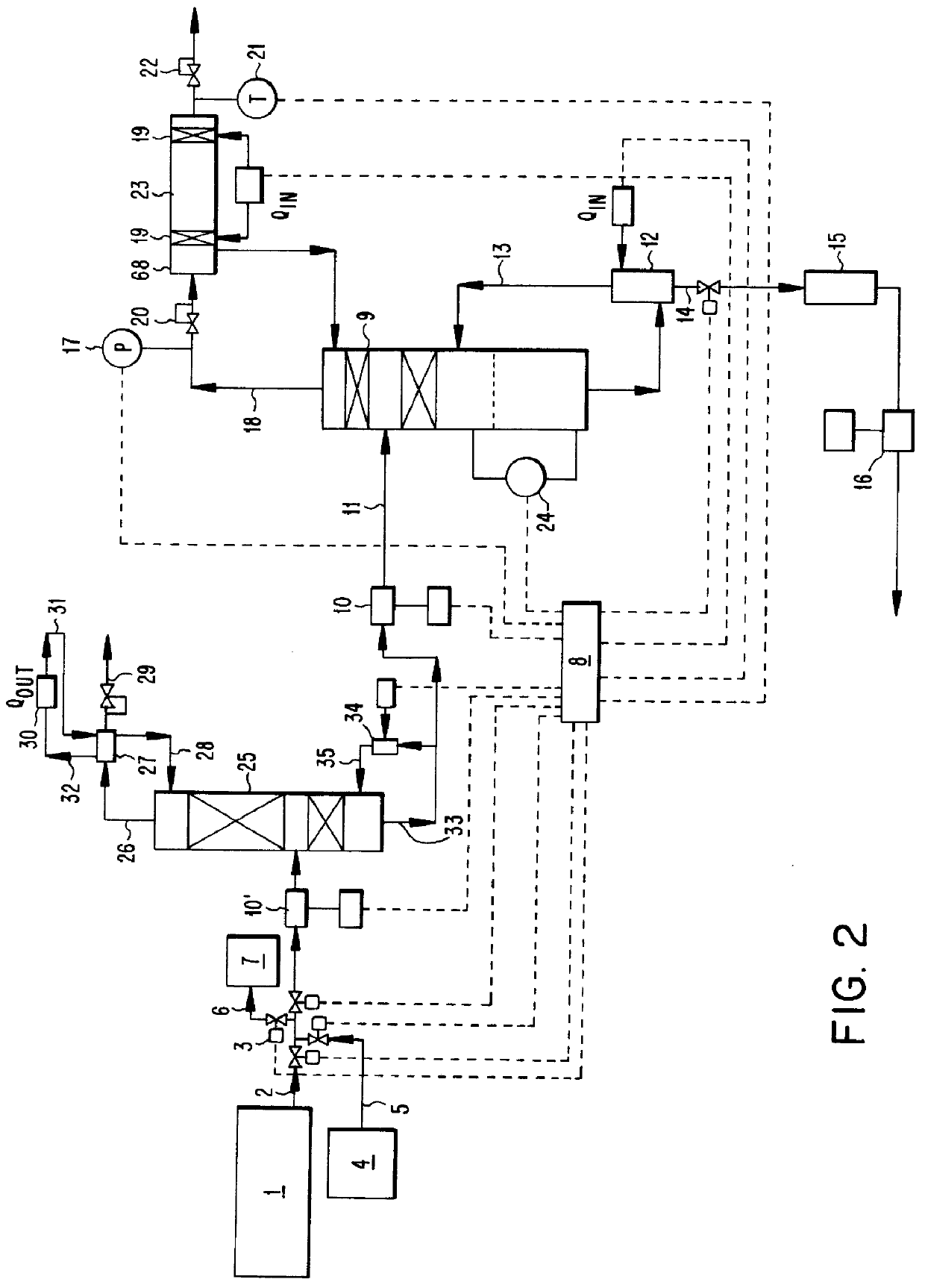

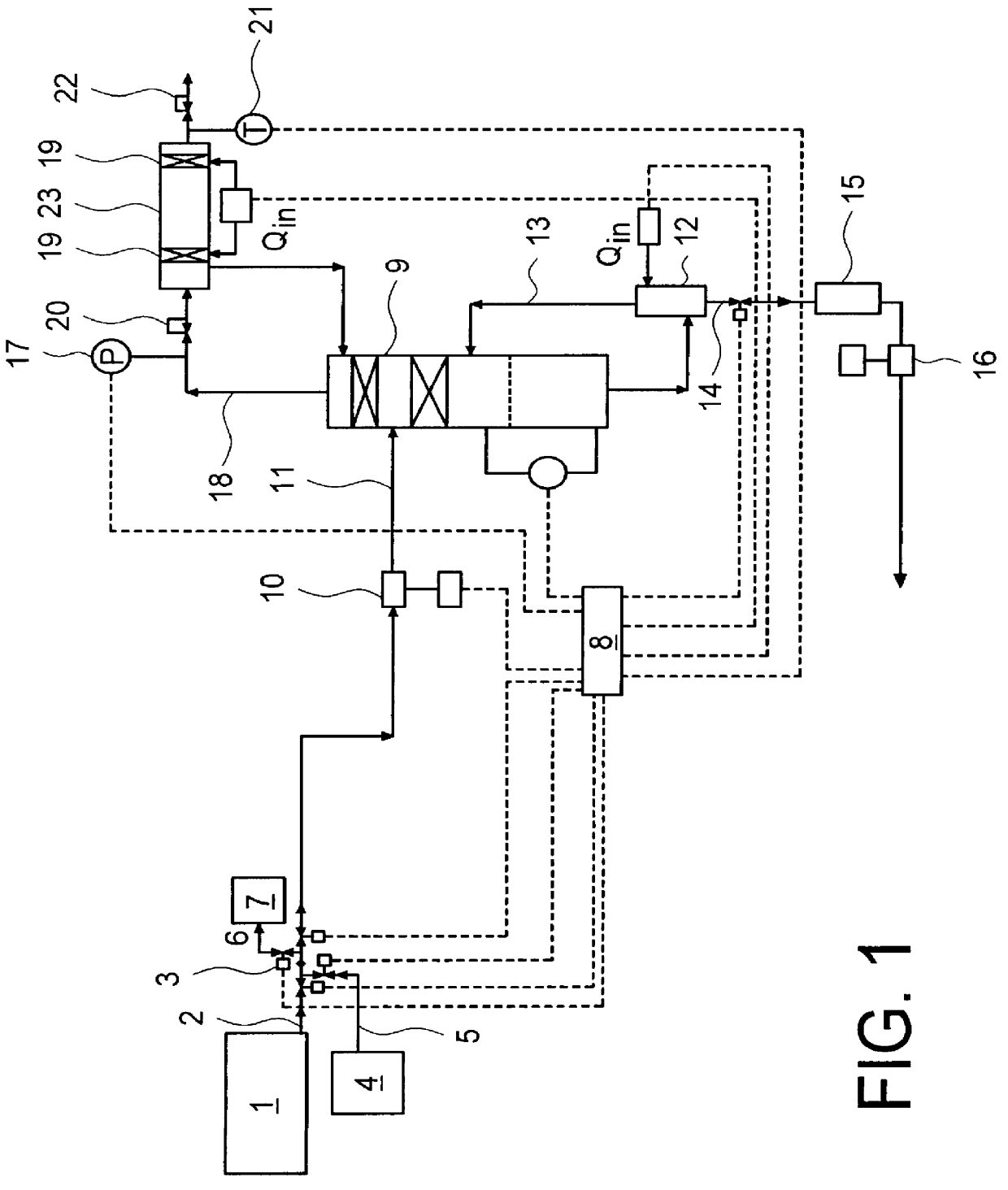

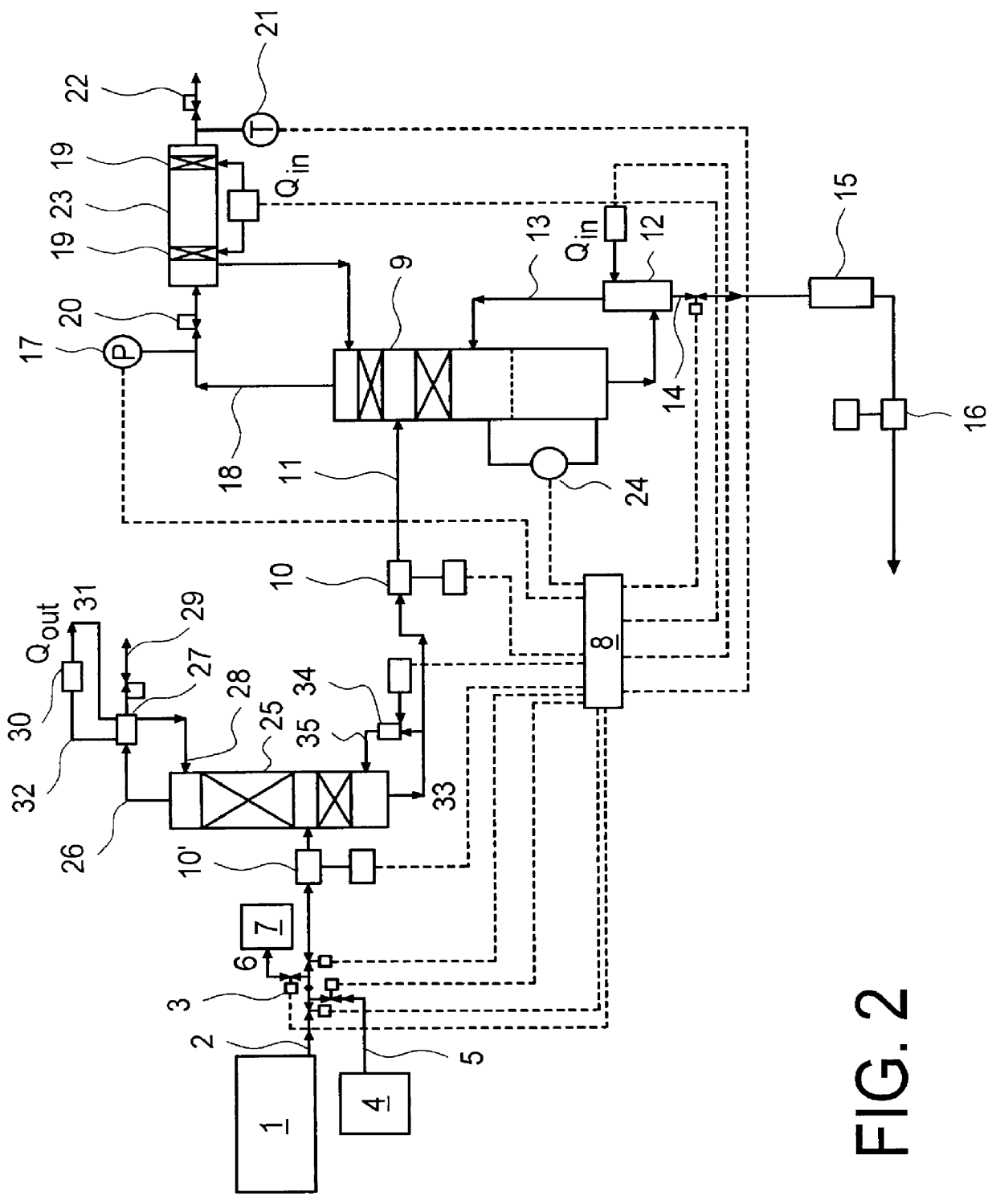

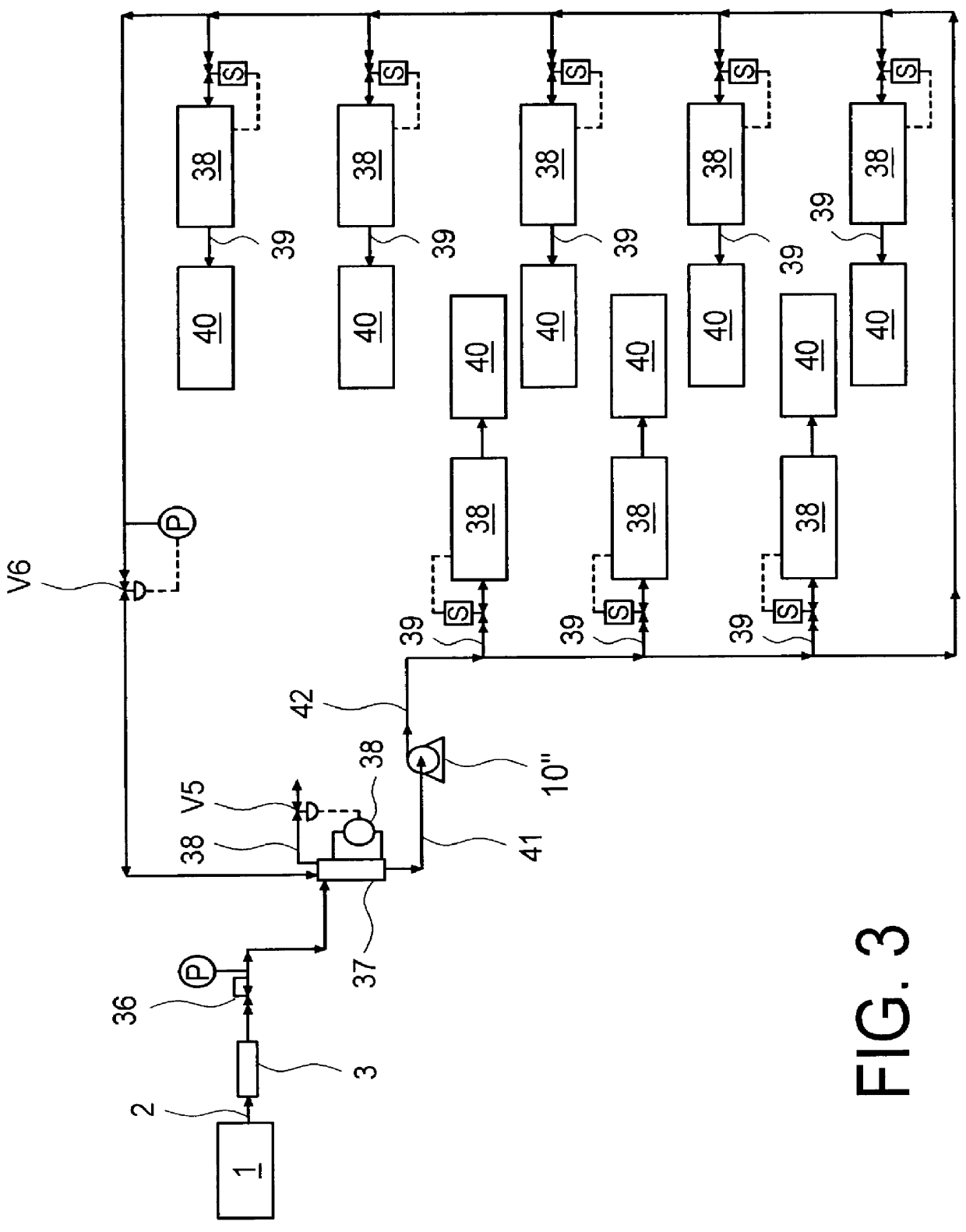

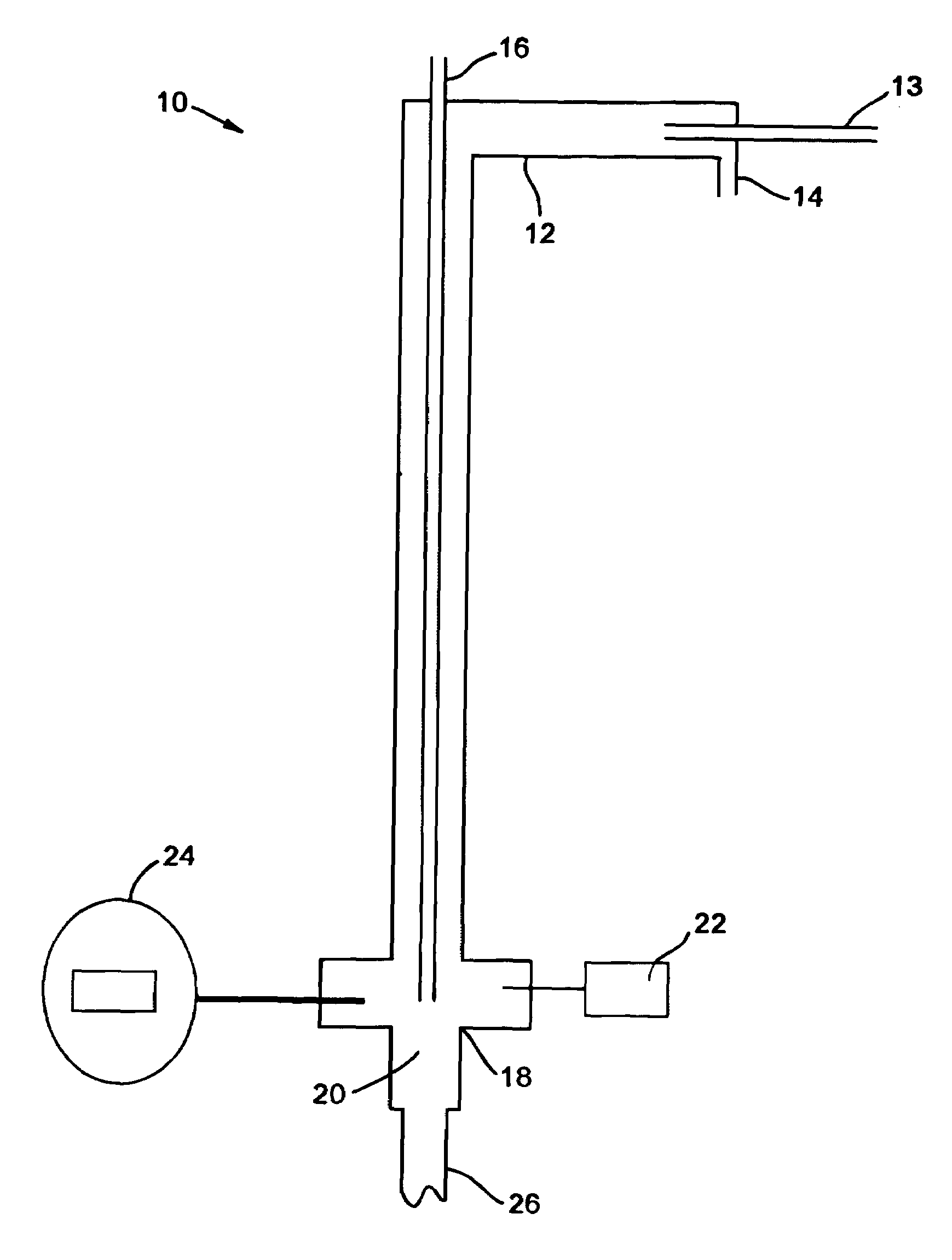

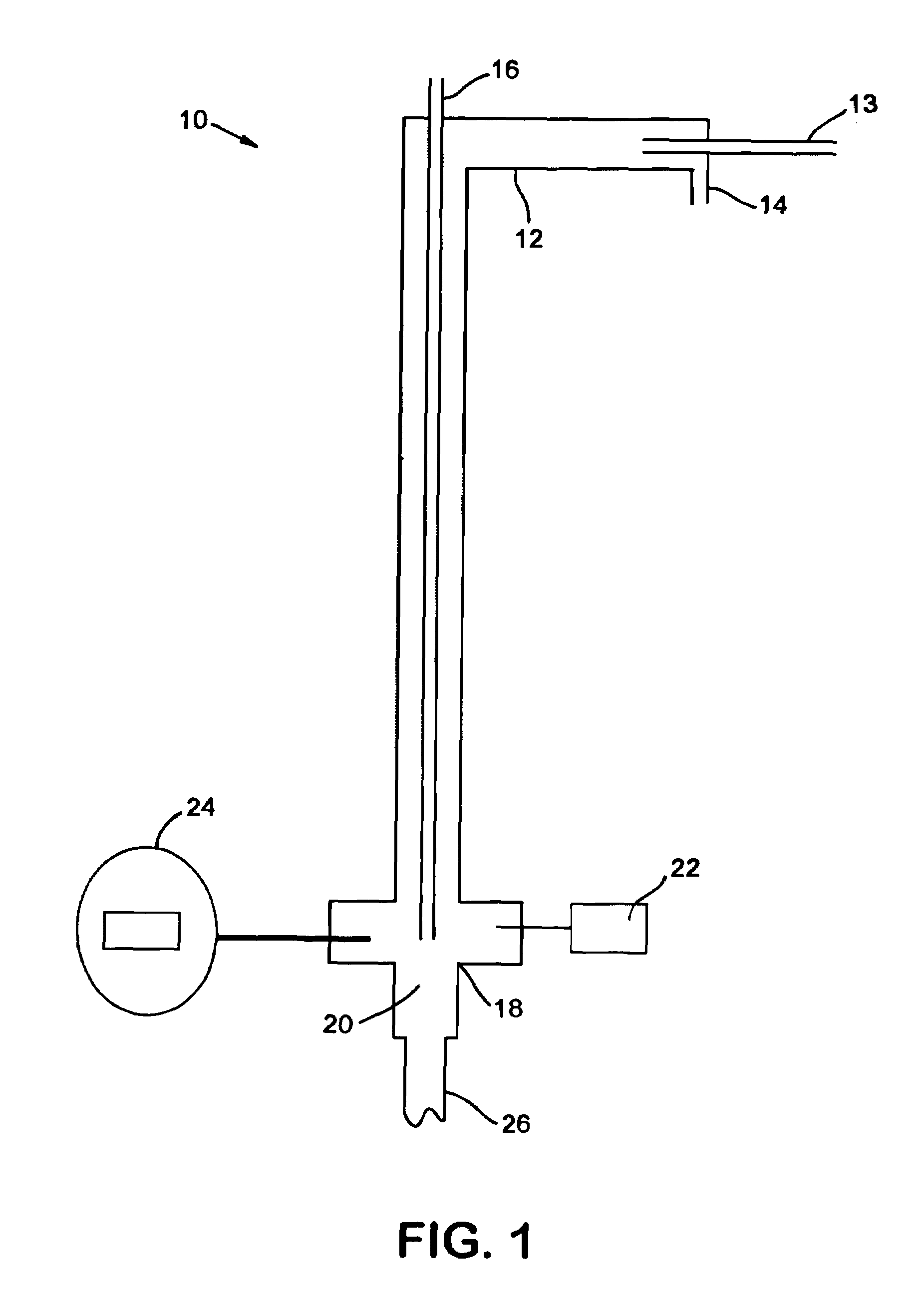

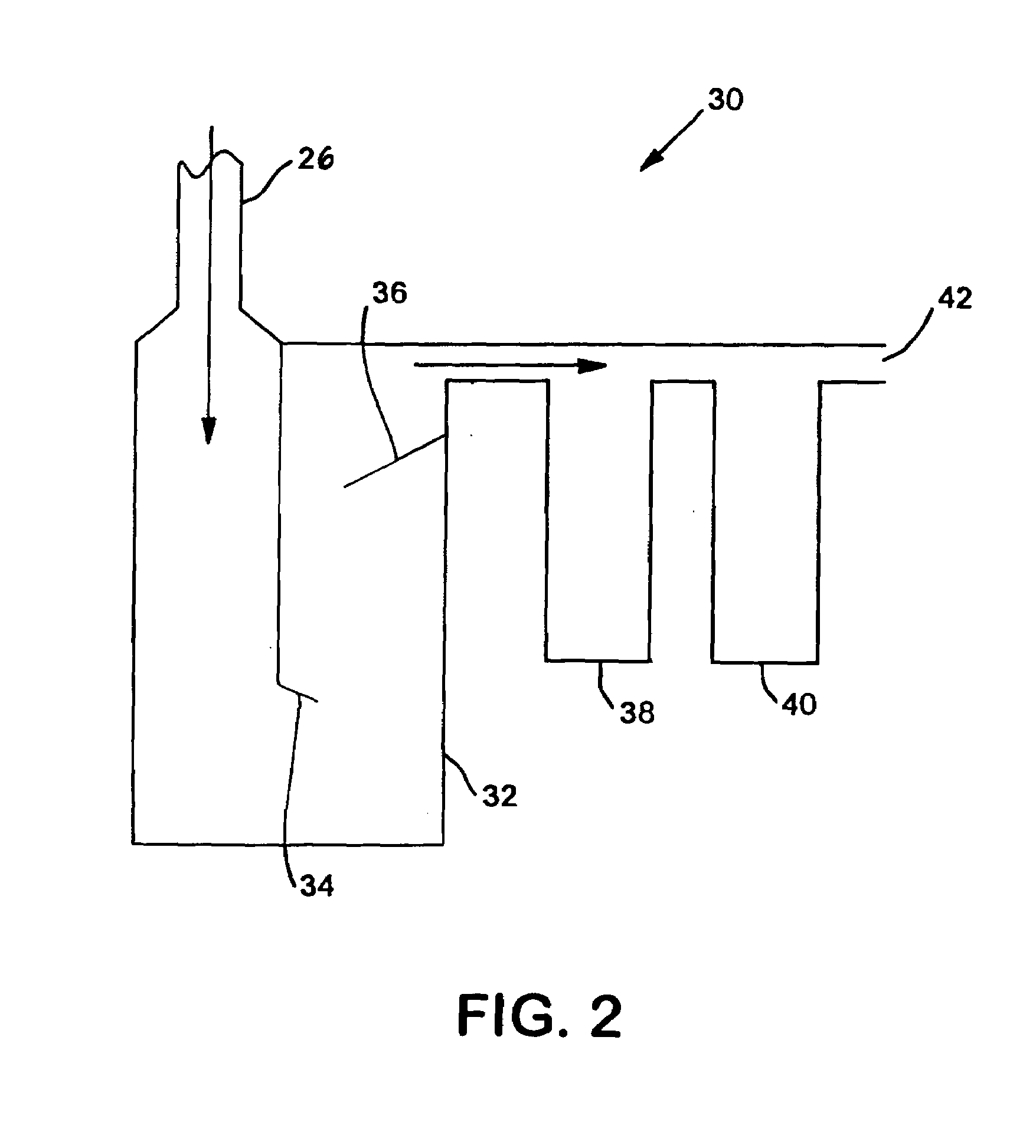

System and method for delivery of a vapor phase product to a point of use

Provided are a novel system and method for delivery of a vapor phase product to a point of use, as well as a novel on-site chemical distribution system and method. The system for delivery of a vapor phase product includes a storage vessel containing a liquid chemical under its own vapor pressure, a column connected to receive the chemical in liquified state from the storage vessel, wherein the chemical is fractionated into a contaminated liquid heavy fraction and a purified light vapor fraction and a conduit connected to the column for removing the purified light vapor fraction therefrom. The system is connected to the point of use for introducing the purified vapor fraction thereto. Particular applicability is found in semiconductor manufacturing in the delivery of electronic specialty gases to one or more semiconductor processing tools.

Owner:AIR LIQUIDE AMERICA INC

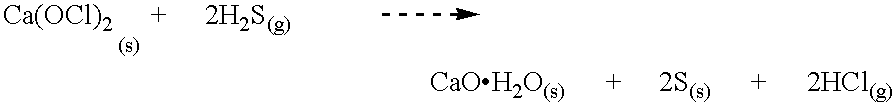

Hydrogen sulfide abatement with scale control and/or well acidizing

InactiveUS6375907B1Avoid disadvantagesLow costHydrogen bromideLiquid degasificationHydrogen halidePower station

The emissions of hydrogen sulfide during the production of natural gas, oil or geothermal fluids from subterranean formations and the subsequent processing of these fluids is reduced by converting the hydrogen sulfide into a hydrogen halide or a halogen acid and then using the hydrogen halide or halogen acid for scale control and / or well acidizing. In a preferred embodiment, hydrogen sulfide produced with geothermal fluids is converted into hydrochloric acid, which is then used to reduce pH and control scale formation during the extraction of energy from geothermal fluids in a geothermal power plant.

Owner:UNION OIL OF CALIFORNIA

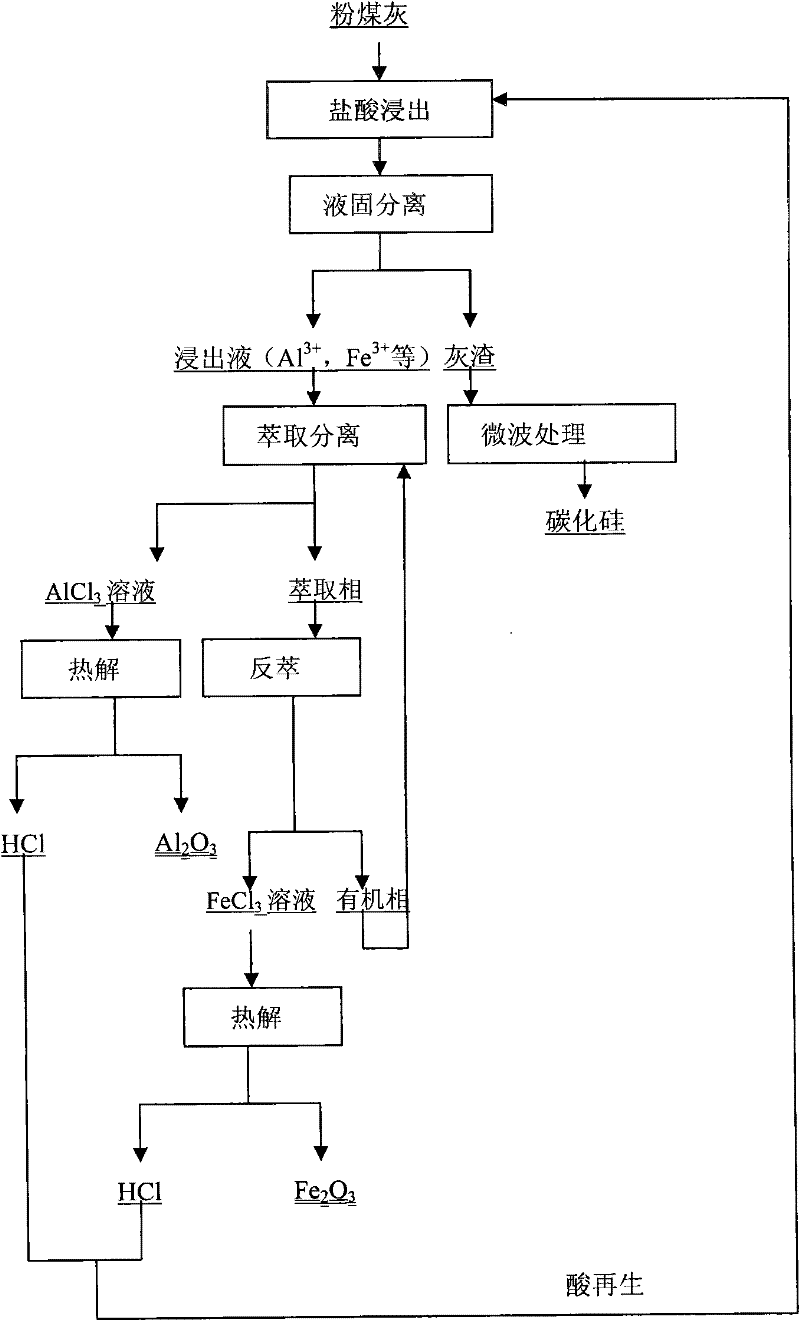

Ecological synthetic utilization method of fly ash

ActiveCN102241410ARealize comprehensive utilizationShort processChlorine/hydrogen-chlorideSolid waste disposalSilicon oxideMaterials science

The invention relates to an ecological synthetic utilization method of fly ash, and the method has the following steps: (1) selecting fly ash which contains aluminum oxide, iron oxide and silicon oxide as a raw material, wherein the mass content of aluminum oxide, iron oxide and silicon oxide are respectively 20-45%, 10-40% and 30-50%, performing a fine grinding and then leaching; (2) filtering and separating to obtain a leaching solution and leaching residue; adding tributyl phosphate and a diluent in the leaching solution to extract, wherein aluminum enters in raffinate phase to form an aluminum chloride solution as well as iron enters in raffinate phase; (3) performing a liquid atomizing pyrolysis to aluminum chloride to obtain aluminum oxide; (4) using water as a re-extraction preparation in raffinate phase for carrying out a re-extraction, wherein iron enters in the re-extraction preparation to form an iron chloride solution; performing a liquid atomizing pyrolysis to iron chloride to obtain iron red. According to the invention, the valuable elements of aluminum, iron, silicon and the like in fly ash are synthetically utilized, the process flow is short and the operation is simple, so that the ecological synthetic utilization method realizes the synthetic utilization of all the valuable elements of aluminum, iron, silicon and the like in fly ash.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

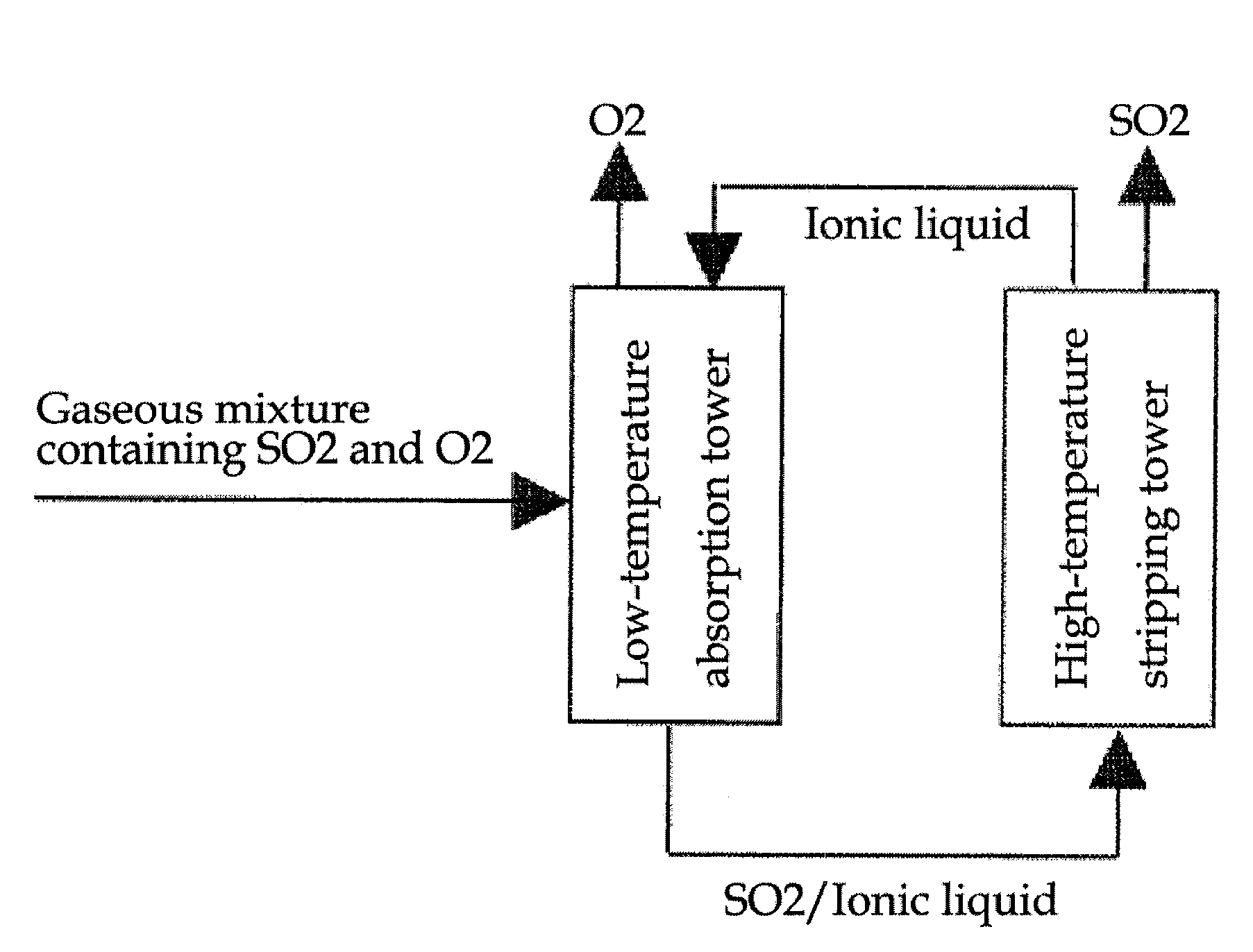

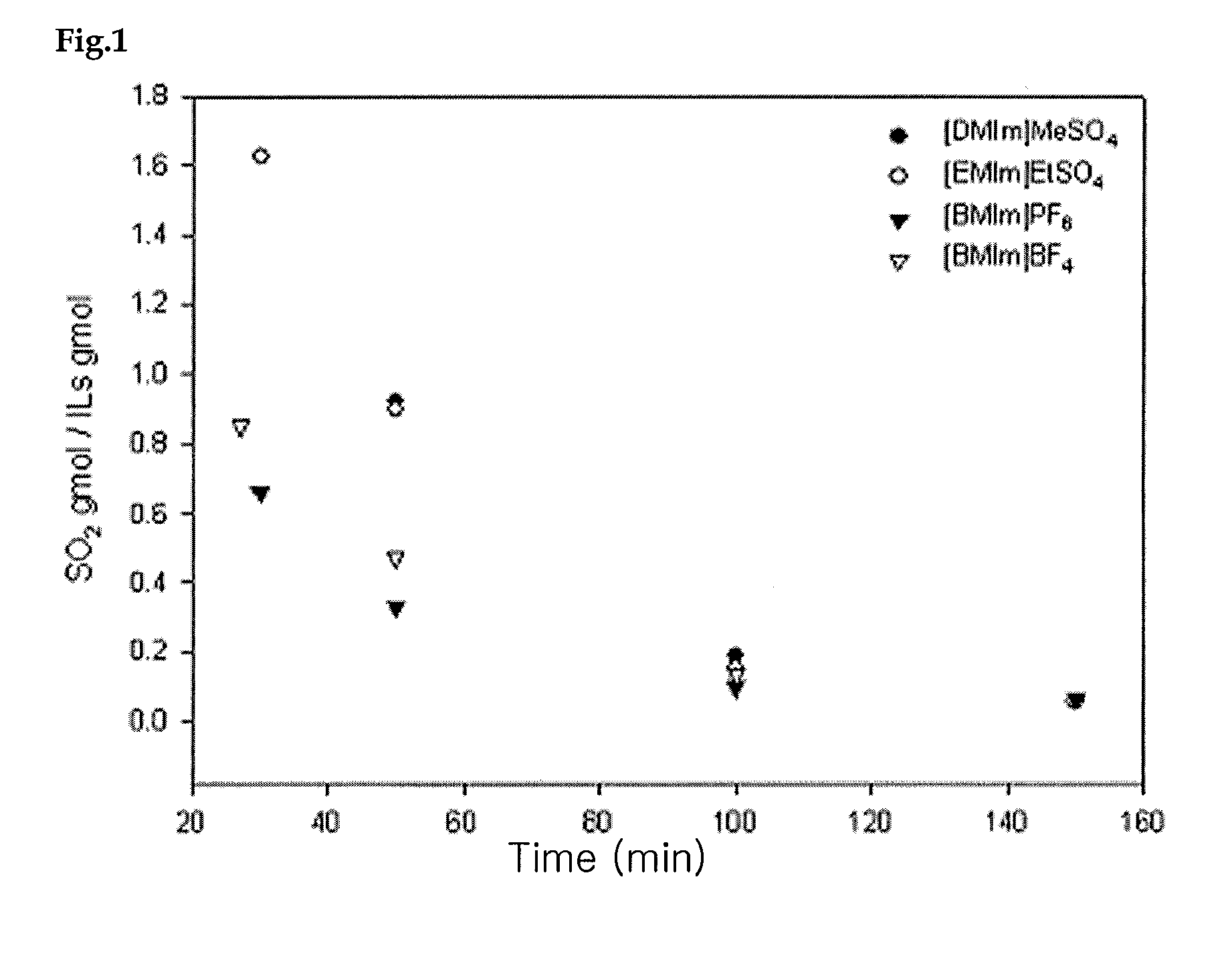

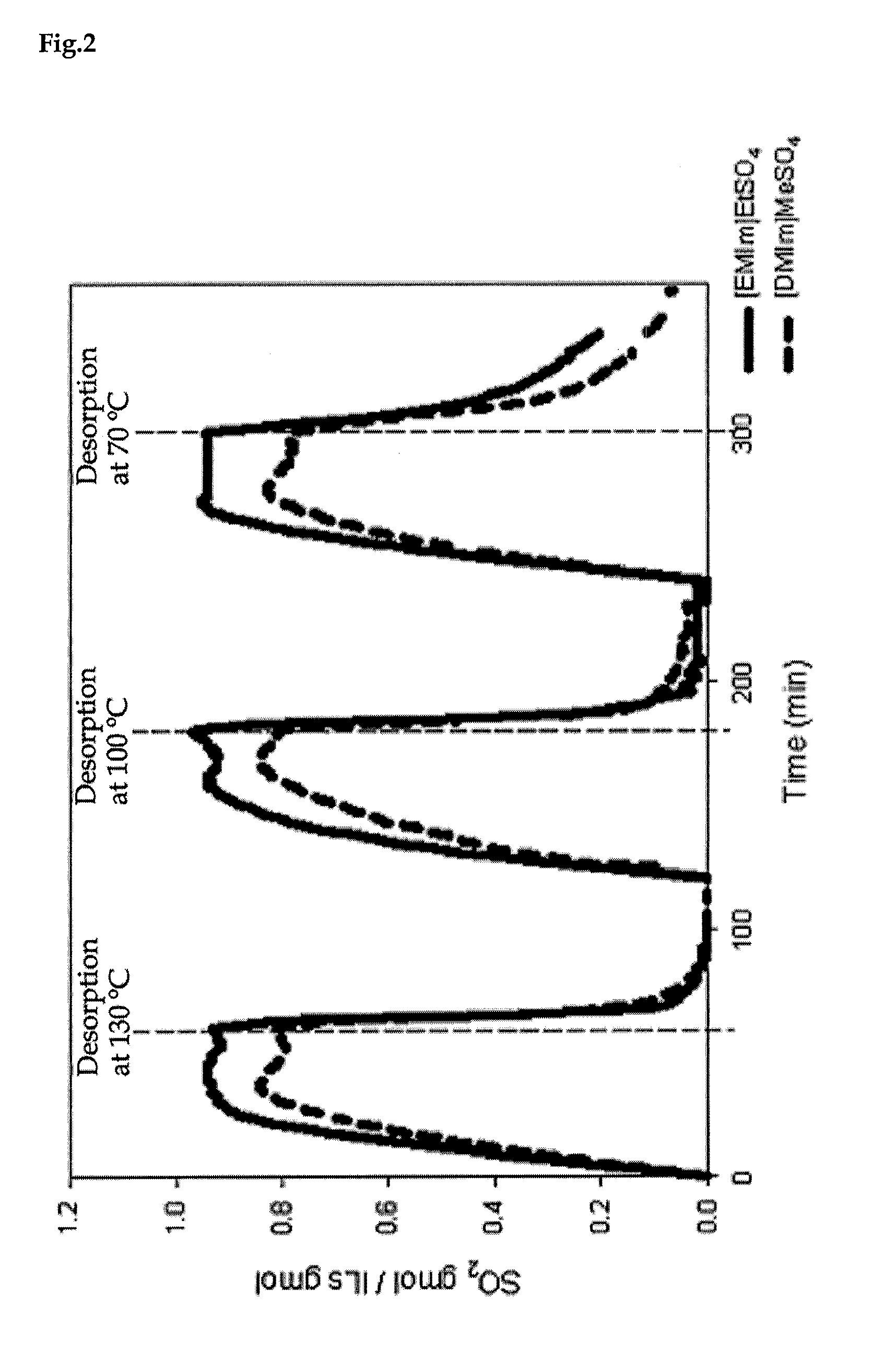

Method for separation and recycle of pure sulfur dioxide from a gaseous mixture in is cycle with ionic liquids

InactiveUS20100015040A1Improve processing efficiencyGood chemical stabilityChlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxidePhysical chemistryIonic liquid

The present invention relates to a method for separation and recycling of pure sulfur dioxide from a gaseous mixture in the IS cycle. More specifically, the present invention relates to a method for separation and recycling of pure sulfur dioxide from a gaseous mixture in the IS cycle using an ionic liquid under a specific condition. When compared with the conventional amine-based absorbent, the use of the ionic liquid enables continuous absorption and stripping of SO2 even at high temperature, and enables a reversible absorption of SO2 without loss, decomposition or degradation of a solvent due to good chemical stability, thereby enabling separation and recycling of pure SO2 from a gaseous mixture in the IS cycle.

Owner:KOREA INST OF SCI & TECH

A comprehensive utilization method of red mud

ActiveCN104340995AEfficient separationAchieve cycleChlorine/hydrogen-chlorideSolid waste disposalFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method of bauxite and particularly relates to a comprehensive utilization method of red mud. The method includes: a step of mixing the red mud with hydrochloric acid, adding the mixture into a hydrochloric acid-resistant reactor, and reacting; a step of cooling after the reaction is finished, performing solid liquid separation and washing; a step of adding the obtained solution into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; a step of preparing the aluminium hydroxide and iron hydroxide solid into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; a step of subjecting the sodium chloride solution to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; a step of returning the sodium hydroxide solution discharged from an ionic membrane cathode zone and recycling; and a step of returning and recycling the obtained hydrogen and the obtained chlorine. The method is obvious in environment protection effects, effectively separates aluminum, iron and silicon in the red mud, and recovers the aluminum, the iron, sodium and other useful elements, thus achieving comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

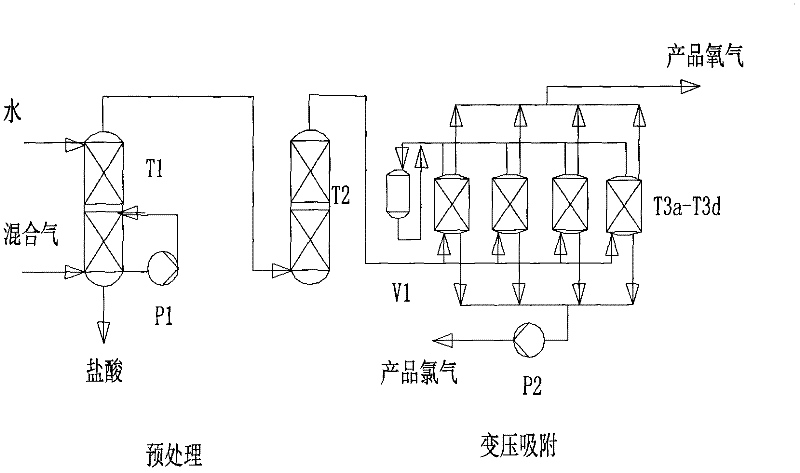

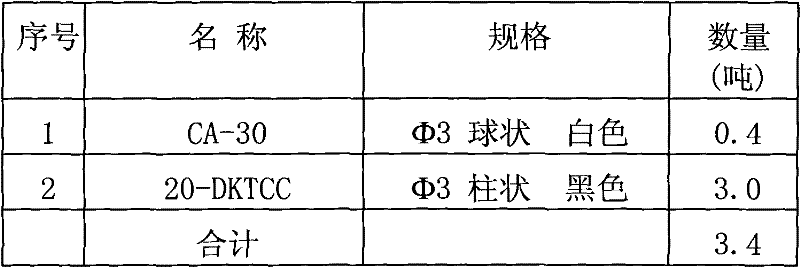

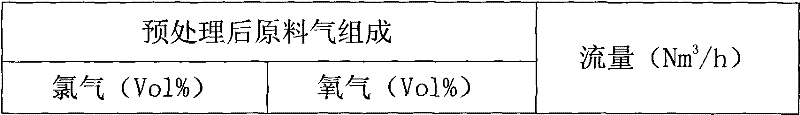

Method for separating and recovering chlorine and oxygen of hydrogen chloride oxidation gas mixture by use of PSA (Pressure Swing Adsorption) technology

ActiveCN102502498AHigh purityChlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxideDesorptionSorbent

The invention relates to a method for separating and recovering chlorine and oxygen of a hydrogen chloride oxidation gas mixture by use of a PSA (Pressure Swing Adsorption) technology and belongs to the technical field of gas separation. The method aims at a gas mixture generated by catalytic oxidation of hydrogen chloride and comprises the following steps of: firstly absorbing unreacted hydrogen chloride with water, dehydrating through concentrated sulfuric acid, and introducing a residual gas mixture into a PSA device so as to be separated, wherein the PSA device comprises at least two absorbing tower units, adsorbents filled in the absorbing tower units are at least one of silica gel and active carbon, and the volume proportion of the active carbon is 0-50%; chlorine with the purity of more than 99.2% is obtained after adsorption, pressure equalizing, flushing and desorption steps are carried out on the gas mixture, adsorption tail gas is oxygen with the purity of more than 99.5%, and the recovery rates of chlorine and oxygen are more than 98.5%. The method for separating and recovering the chlorine and oxygen of the hydrogen chloride oxidation gas mixture by the PSA technology, disclosed by the invention, is especially suitable for separation recovery of the chlorine and oxygen of the hydrogen chloride oxidation gas mixture, and has the advantages of simple process, high recovery rates and purities of chlorine and oxygen, and excellent economical and environmental-friendly benefits.

Owner:甘肃银光聚银化工有限公司 +1

System and method for delivery of a vapor phase product to a point of use

Provided are a novel system and method for delivery of a vapor phase product to a point of use, as well as a novel on-site chemical distribution system and method. The system for delivery of a vapor phase product includes a storage vessel containing a liquid chemical under its own vapor pressure, a column connected to receive the chemical in liquified state from the storage vessel, wherein the chemical is fractionated into a contaminated liquid heavy fraction and a purified light vapor fraction and a conduit connected to the column for removing the purified light vapor fraction therefrom. The system is connected to the point of use for introducing the purified vapor fraction thereto. Particular applicability is found in semiconductor manufacturing in the delivery of electronics specialty gases to one or more semiconductor processing tools.

Owner:AIR LIQUIDE AMERICA INC

Method for reclaiming hydrochloric acid and metal copper from printed circuit acidic etching waste liquid

InactiveCN101125719APromote environmental protectionAchieving a circular economyChlorine/hydrogen-chloridePhotography auxillary processesLiquid wasteElectrolysis

The invention relates to a method to recycle hydrochloric acid and copper from acidic waste etching liquid of printing circuit, comprising the equipment: a heater, an evaporator, a stuffing tower, a separator, a condenser, a liquid receiving tank, an extraction box, a corrosion resistant pump, a flux meter, an electrobath, a commutator, an anode plate and conductive copper strips, etc. The technique steps are: 1. Recycling hydrochloric acid through a distillation method; 2. extracting and repairing copper sulfate through an extraction method. 3. recycling copper through an electrolysis method. The recovery rate of hydrochloric acid of the invention is as high as 80 percent, copper as high as 99.5 percents, which not only is beneficial to environment protection but also can recycle hydrochloric acid and electrolyze copper. The recycled hydrochloric acid can be reused in PCB production line by adding a little etching additive, which realizes the circulation economy model of decreasing pollution and recycling waste in the industry at the same time.

Owner:深圳市中冠环保科技有限公司

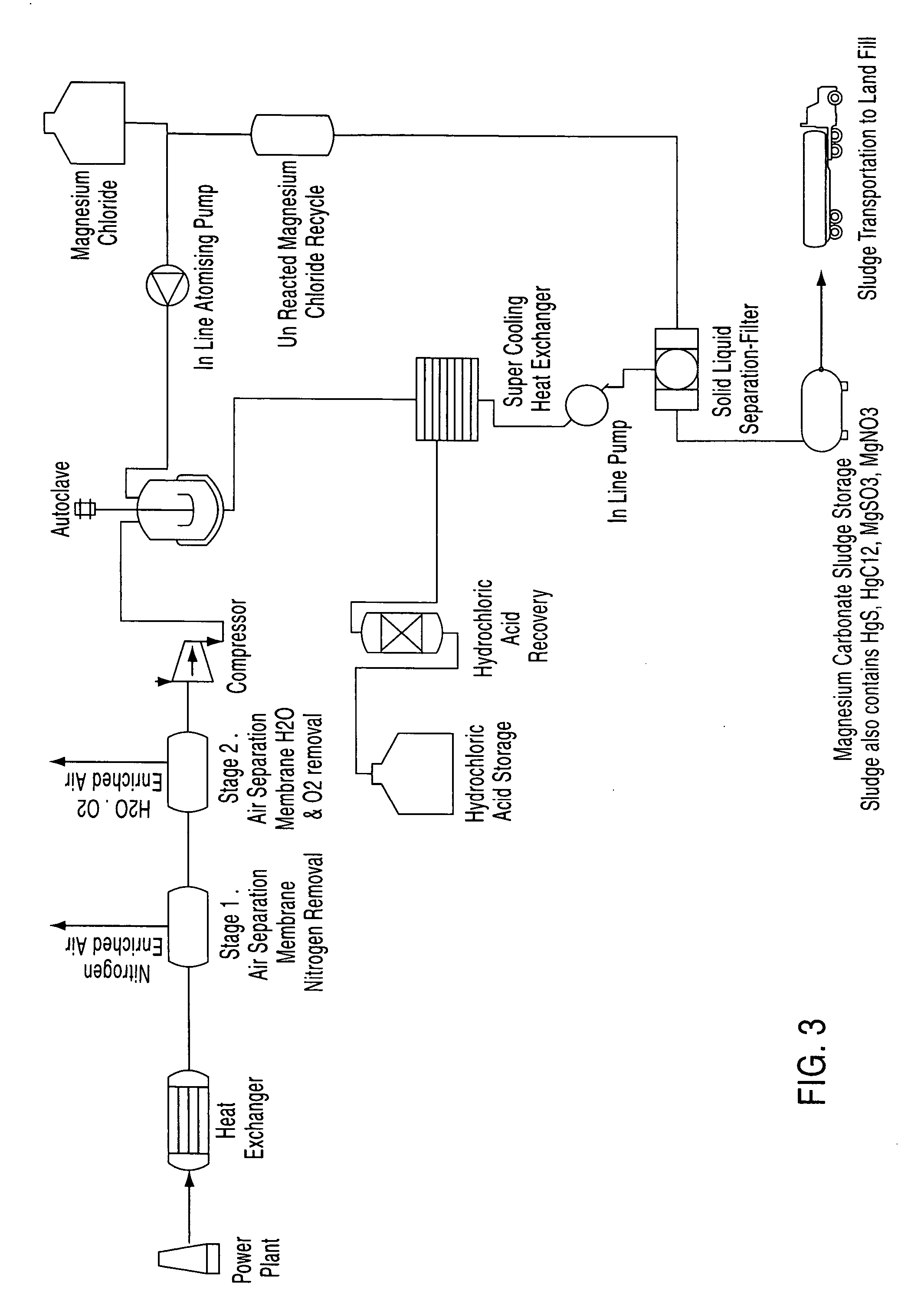

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

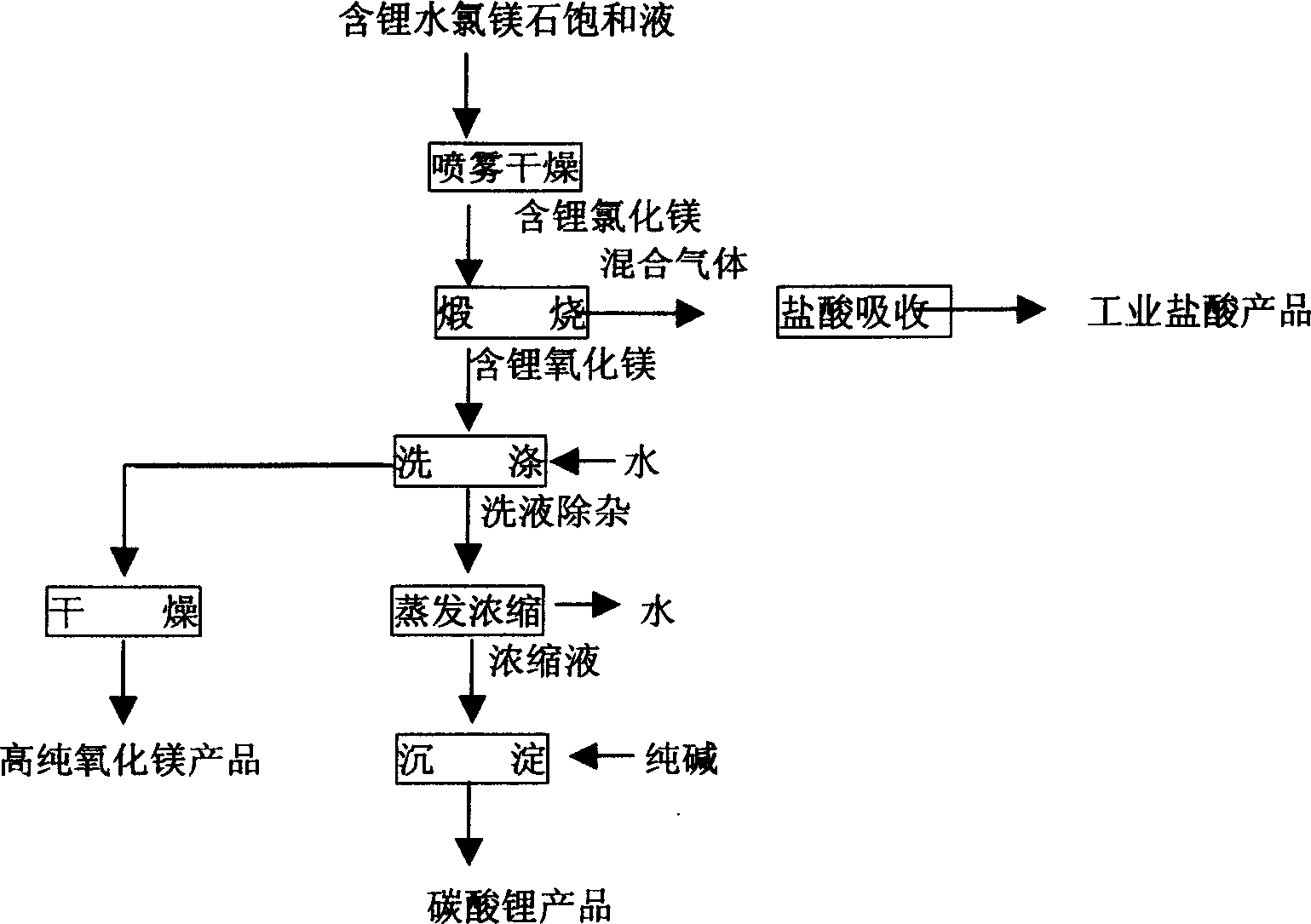

Process for producing lithium carbonate magnesium oxide and hydrogen chloride by high magnesium lithium-containing halogen water

ActiveCN1724372AEfficient use ofSolve the key technical problems in the separation and production of lithium carbonateChlorine/hydrogen-chlorideMagnesiaHigh magnesiumHalogen

A process for preparing lithium carbonate, magnesium oxide and hydrochloric acid from the Li-contained high-Mg bittern includes such steps as spray drying, calcining, water washing evaporation concentrating, depositing to obtain lithium carbonate, absorbing the gas mixture generated during calcining by hydrochloric acid to obtain industrial hydrochloric acid, and drying the filtered cake generated after water washing to obtain high-purity magnesium oxide. The technological parameters for said steps are also disclosed.

Owner:青海中信国安锂业发展有限公司

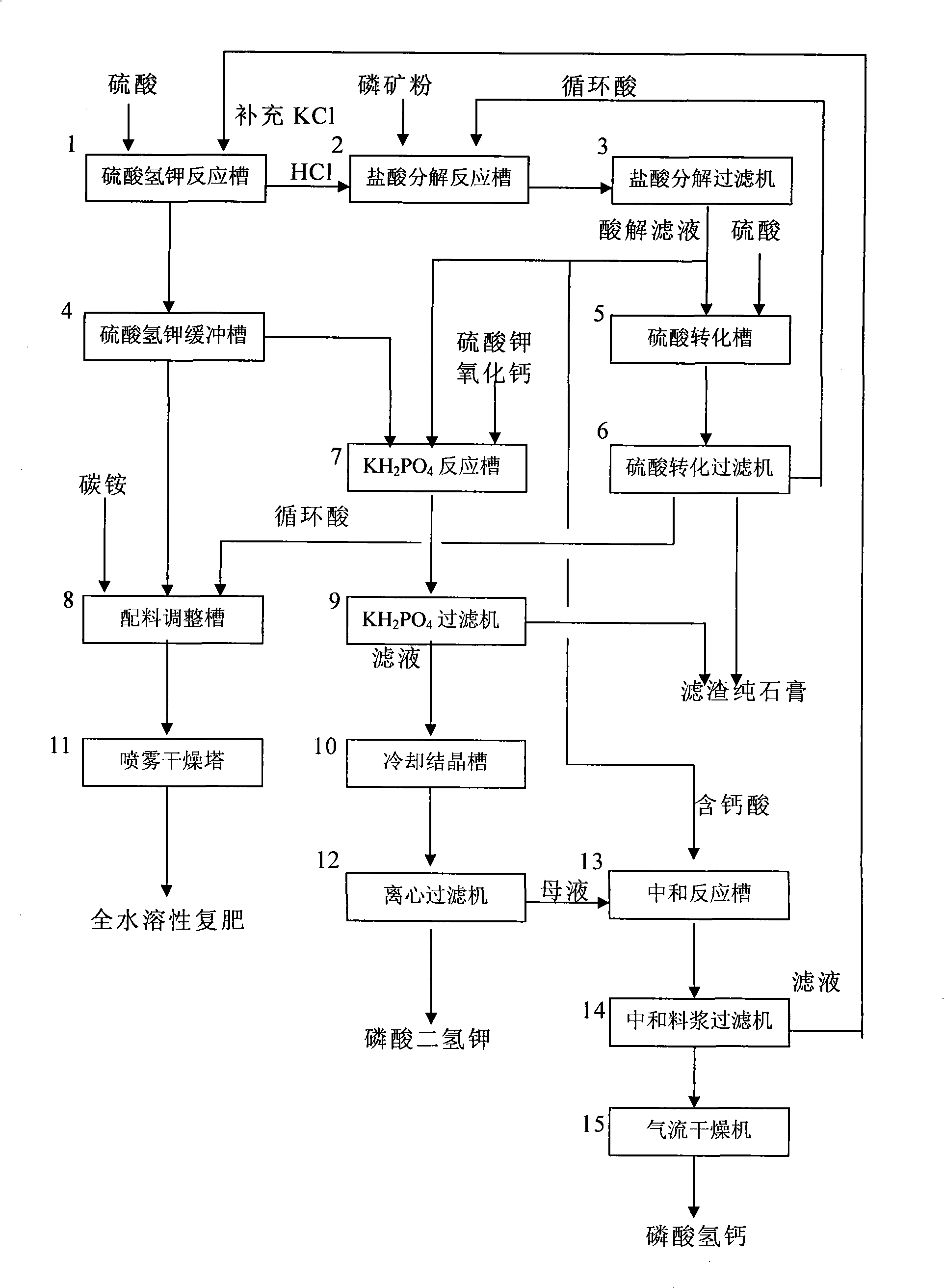

Process for disassembling phosphate ore by mixed acid and coproducing potassium dihydrogen phosphate, hydrogen phosphate and combined fertilizer

InactiveCN101337657ASolve processing problemsSolving Phosphogypsum ProblemsChlorine/hydrogen-chlorideSulfate/bisulfate preparationSolubilitySlurry

A method for the joint production of monopotassium phosphate, calcium hydrophosphate and compound fertilizers through by subjecting phosphorite to mixed acid resolution is characterized in that the method comprises the steps of taking sulphuric acid and potassium chloride to prepare chlorine hydride and acid potassium sulfate; conducting acidolysis reaction after phosphorite slurry absorbs chlorine hydride; preparing monopotassium phosphate through the reaction between an acidolysis filtrate and calcium oxide and lemery; agitating a mixture of the acidolysis fitrate with monopotassium phosphate crystallization mother liquor to neutralize and prepare calcium hydrophosphate; preparing recycle acid through the reaction between the acidolysis filtrate with sulphuric acid; preparing full water-solubility compound fertilizers through the reaction between recycle acid and an acid potassium sulfate solution and ammonium hydrogen carbonate or ammonia, etc. The method can successfully solve the impurity interference problem in the production of phosphate by using phosphorite of middle-low grade, and increase the reclaim rate of phosphorus pentoxide to approximate 100%. The method has the advantages of fully utilizing resources, simplifying process and devices, reducing corrosion, saving energy, reducing acid consumption and cost, eliminating pollution, and achieving good technical and economic effects.

Owner:黄明科 +1

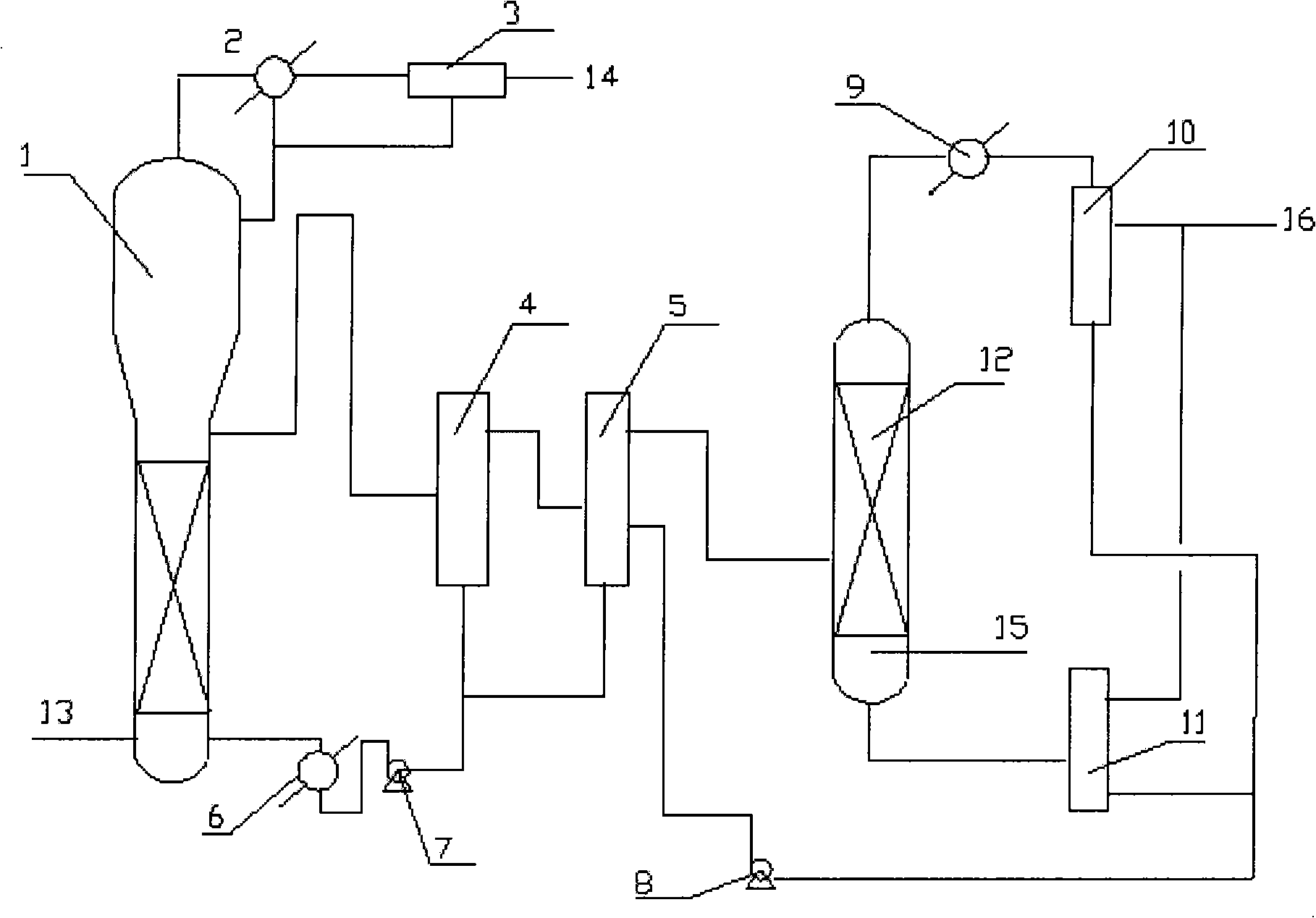

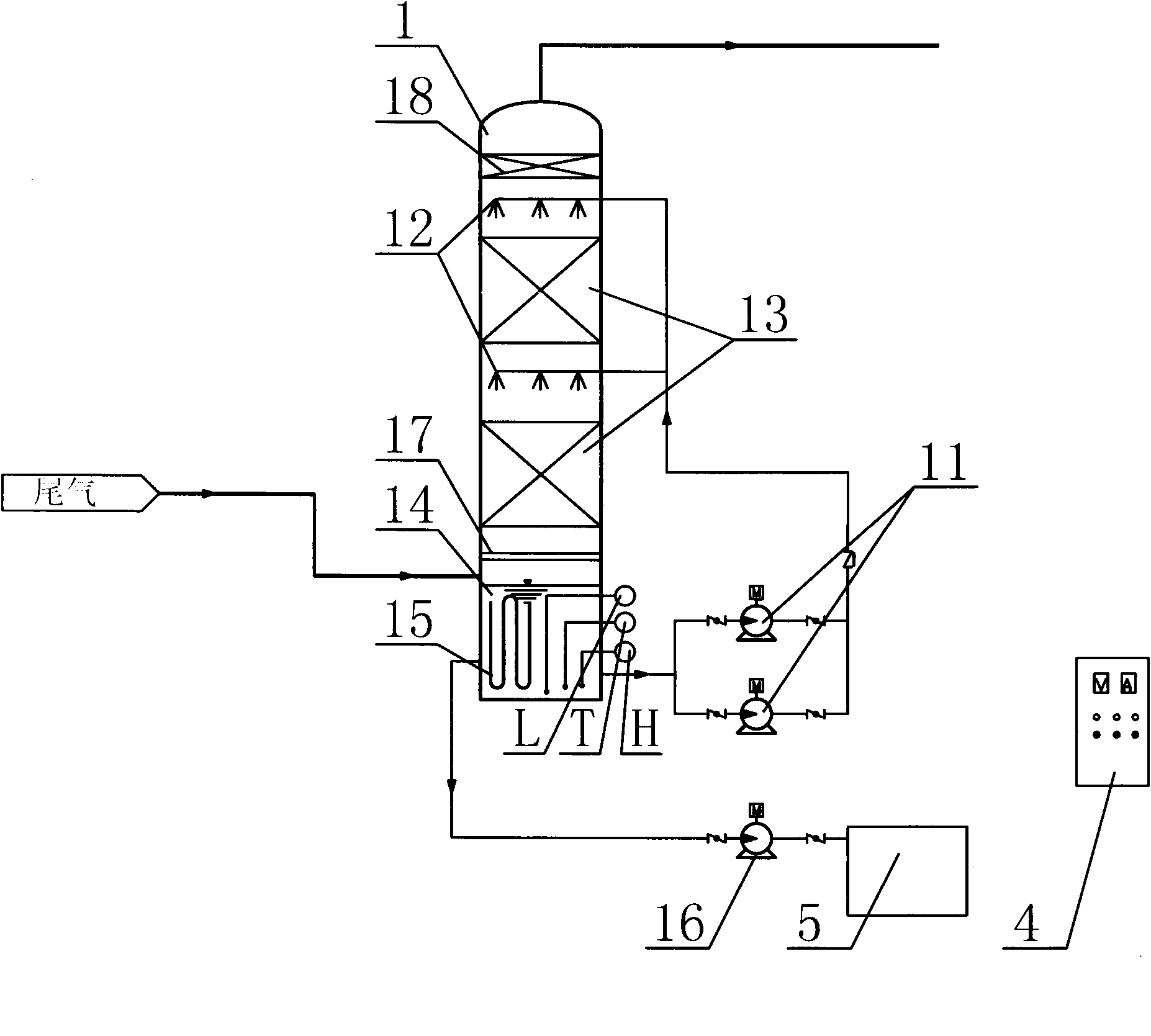

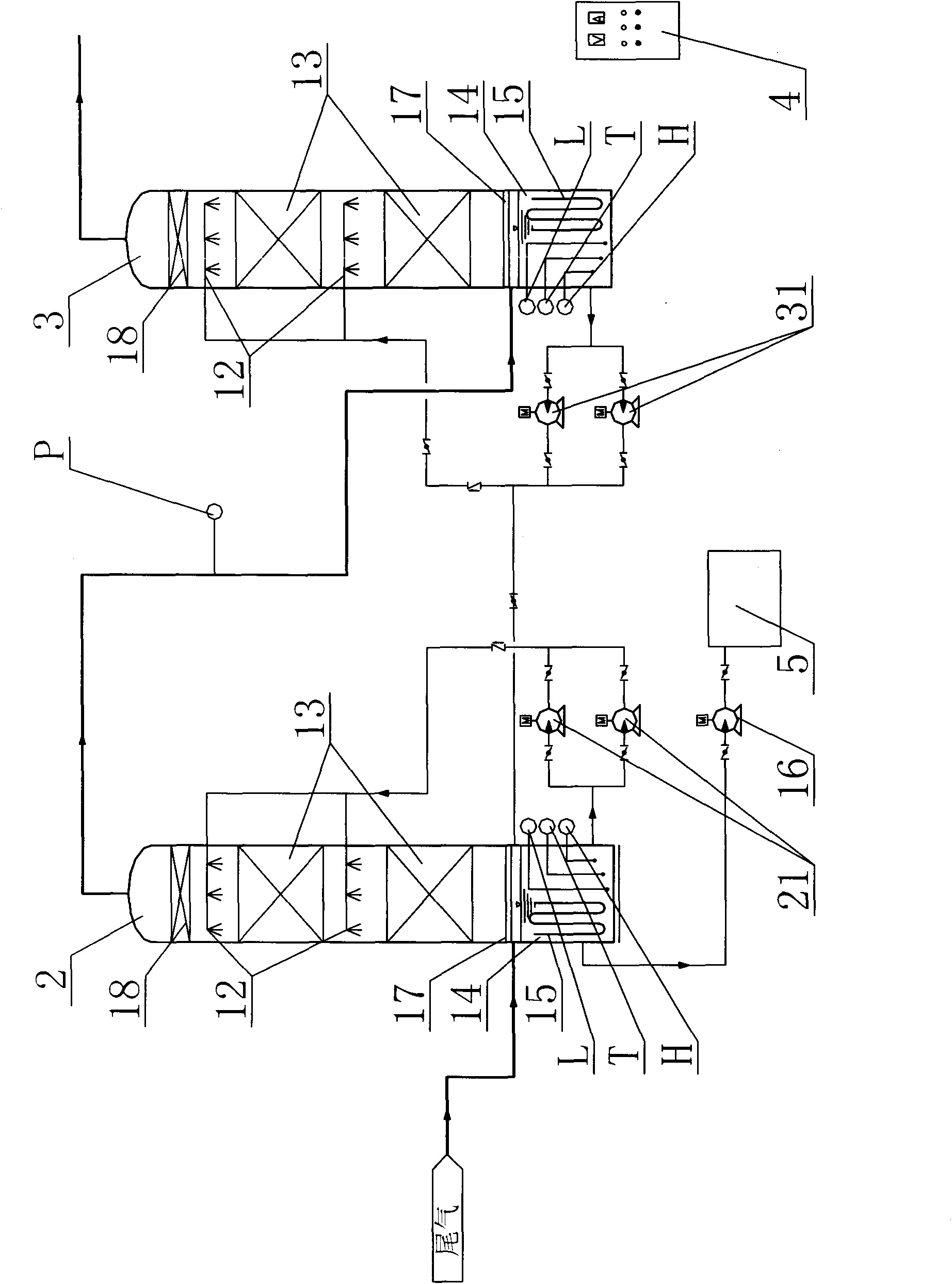

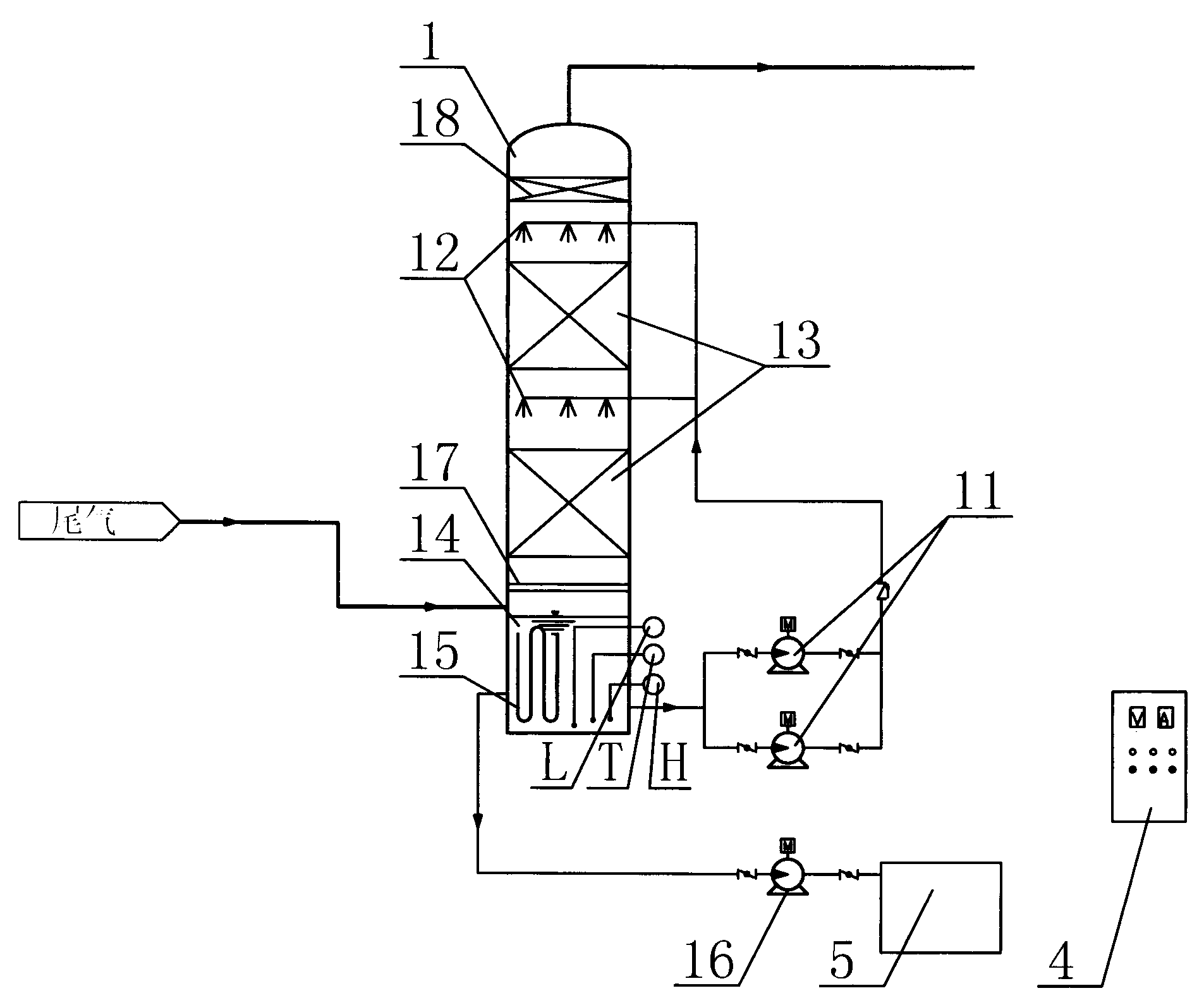

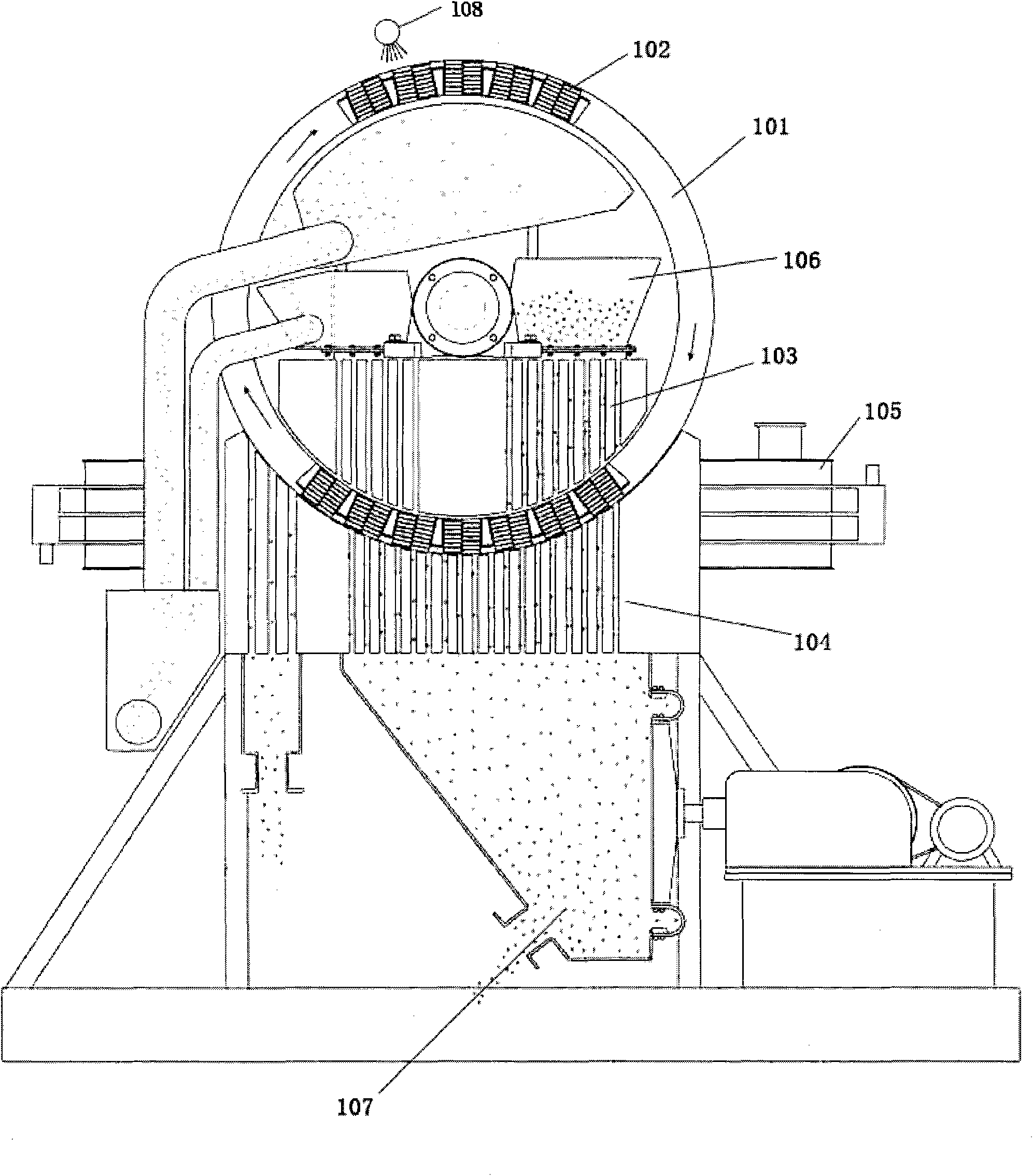

Hydrogen chloride tail gas recovery equipment

InactiveCN102198361ANovel ideaHydrogen chloride works wellChlorine/hydrogen-chlorideDispersed particle separationPhysical chemistryTower

The invention relates to hydrogen chloride tail gas recovery equipment, which is provided with at least one hydrochloric acid recovery tower and an absorption liquid circulating device, wherein a tail gas inlet is formed on the lower part of each hydrochloric acid recovery tower, and a tail gas outlet is formed at the upper end of each hydrochloric acid recovery tower; a secondary spraying devicefor spraying absorption liquid is arranged in each hydrochloric acid recovery tower and comprises two sprayers which are arranged up and down; a filler layer is arranged below each sprayer; a circulating liquid tank for recovering the absorption liquid sprayed from the secondary spraying devices is arranged on the lower part of each hydrochloric acid recovery tower; and the circulating liquid tanks and the secondary spraying devices are in pipeline communication through the absorption liquid circulating device. The hydrogen chloride tail gas recovery equipment has a novel concept, the hydrochloric acid recovery towers are provided with the secondary spraying devices, so the effect of absorbing hydrogen chloride in recovered tail gas is better, and hydrochloric acid products with utilization value can be obtained; and the hydrogen chloride tail gas recovery equipment is electrically controlled and has a high automation degree, and the running cost is far lower than that of a hydrogen chloride tail gas treatment tower.

Owner:JIANGSU HONGYUAN TECHNOLOGY ENGINEERING CO LTD

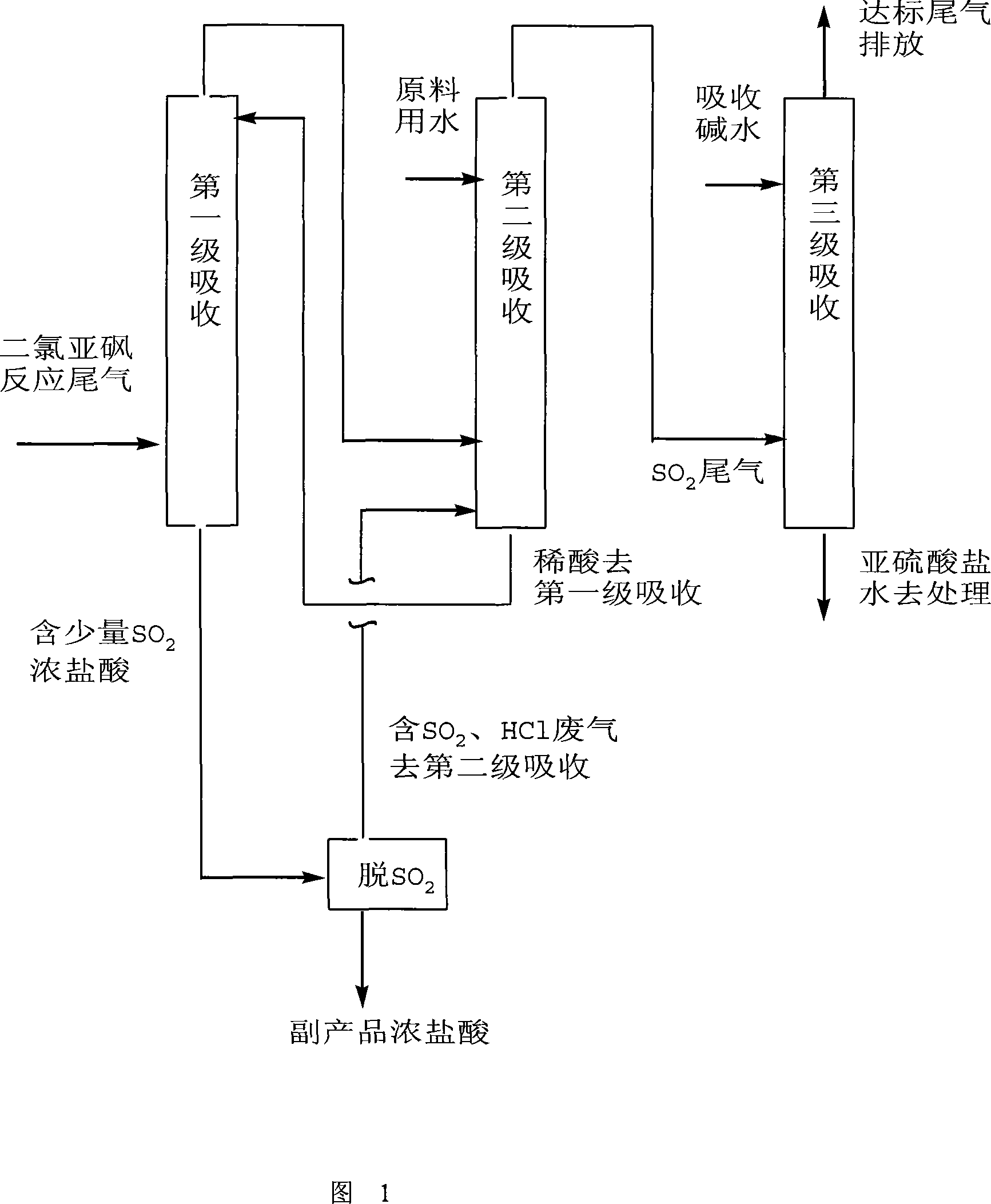

Method for treating tail gas of thionyl chloride chlorination

InactiveCN101121094AFully absorbedReduce dosageChlorine/hydrogen-chlorideSulfur-halogen-hydrogen-oxygen compoundsSulfite saltWastewater

The invention discloses a method for treating tail gas generated in chlorination reaction by using thionyl chloride. The existing traditional tail gas treatment method is costly due to a large amount of alkali consumption, and the pressure on environmental protection is high due to the final generation of a large amount of waste water containing heteroions. In the present invention, by controlling the amount of water, the hydrogen chloride in the tail gas is subjected to two-stage absorption with water, and the concentrated hydrochloric acid with a hydrogen chloride content close to saturation and a small amount of sulfur dioxide is obtained through the first-stage absorption; the second-stage absorption: after the first-stage absorption, the The exhaust gas is subjected to the second-stage absorption, and the added water is not discharged to obtain dilute hydrochloric acid containing a small amount of hydrogen chloride and a small amount of sulfur dioxide. The dilute hydrochloric acid is used as the raw material water for the first-stage absorption; after the above-mentioned secondary absorption treatment, it is then treated with alkali or alkali The third level of water absorption is used to absorb sulfur dioxide in the tail gas to obtain a relatively pure aqueous solution of sodium sulfite. The invention has high treatment efficiency, complete tail gas absorption, and reduces the pressure on environmental protection.

Owner:GAOYOU CITY ORGANIC CHEM FACOTRY

Method for preparing inorganic chemical product using waste produced by polycrystalline silicon

InactiveCN101386415AThe method is simple and practicalTechnology is easy to implementChlorine/hydrogen-chlorideSilicaSilicic acidPhosphate

A method using polysilicon production waste for preparing inorganic chemical products is disclosed. The wastes which are generated in the process of producing polysilicon by an improved Siemens method mainly comprise silicon tetrachloride, trichlorosilane, dichloro-dihydro-silicon, and the like; the method using polysilicon production waste for preparing inorganic chemical products comprises two steps: firstly, polysilicon production waste is hydrolyzed; when the polysilicon production waste is put into the water, the hydrolysis reaction is carried out on the silicon tetrachloride, the trichlorosilane, and the dichloro-dihydro-silicon, thereby generating silicic acid and hydrochloric acid; secondly, the silicic acid and hydrochloric acid are used; the hydrochloric acid is used for being reacted with carbonate to prepare chloride, or the hydrochloric acid is used for being reacted with phosphate to prepare phosphoric acid or acid phosphate; the silicic acid is used for being reacted with alkali to prepare silicate or metasilicate, or the silicic acid is used for preparing silicon dioxide or silica gel by heating and dehydration. The invention has the advantages that by the hydrolysis, silicon tetrachloride becomes 'harmlessness'; by the reuse of the silicic acid and the hydrochloric acid, inorganic chemical products which are needed urgently by the market are prepared, thereby changing the silicon tetrachloride into 'resource' and changing the waster into valuables. The production process achieves 'zero emissions'; the obtained inorganic products have stable quality and high purity; large-scale production can be easily realized; the invention also has the advantages of low energy consumption, low production cost, can be conducive to solve the pollution problem in the polysilicon industry, and has great economic and social benefits.

Owner:魏昭荣

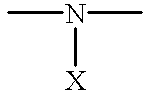

Production of gaseous chloramine

InactiveUS7070751B2Prevent scalingSimple streamlined designCombination devicesExhaust apparatusChloramine BGas phase

The present invention provides a reactor for the gas-phase reaction of commercially available gases in the presence of an inert carrier gas to form product gas. The reactor has a streamlined, compact configuration and at least one solids collection and removal system downstream of the reactor, where solids are efficiently removed from the product gas stream, leaving high purity product gas. The removal system allows for a simple reactor design, which is easy to clean and operates continuously over longer periods of time.

Owner:BRISTOL MYERS SQUIBB CO

Method for preparing polyorganosiloxane and gas phase hydrogen chloride by multi-stage continuously hydrolyzing dichlorosilane

InactiveCN101148510AReduce pollutionReduce manufacturing costChlorine/hydrogen-chlorideDegasserGas phase

The present invention relates to continuous multistage organic dichlorosilane hydrolyzing process for preparing organic siloxane polymer and gaseous hydrogen chloride. Organic dichlorosilane is hydrolyzed continuously in a circulating hydrolysis reaction system with at least thee stages, each of which includes one inner circulating unit and one outer circulating unit. In the relatively independent hydrolysis reaction stages, the hydrolyzed organic siloxane polymer is fed continuously from the upper stage to the lower stage through one degasser to eliminate great amount of free hydrogen chloride, while hydrolyzed hydrochloric acid is replenished from the lower stage to the upper stage. The present invention has low gaseous hydrogen chloride content in each hydrolysis reaction stage, easy operation, stable product quality, high yield and stable pressure of anhydrous gaseous hydrogen chloride.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Composition for controlled sustained release of a gas

InactiveUS20060178445A1High quantity of gasShort stayBiocideCyanogen compoundsBiological activationSodium chlorite

The invention relates to an improved composition for generating at least one gas comprising an energy-activated catalyst capable of being activated by electromagnetic energy, heat and / or moisture and anions capable of being oxidized or reacted to generate at least one gas, the composition, when exposed to electromagnetic energy, heat and / or moisture being capable of generating and releasing the gas after activation of the catalyst and oxidation or reaction of the anions. The process comprises: (a) metering a liquid composition comprising a source of the anions, specifically sodium chlorite, into a flow restrictor; (b) injecting a gas stream through the flow restrictor, concurrently with step (a) to create a zone of turbulence at the outlet of the flow restrictor, thereby atomizing the liquid composition; (c) heating the gas stream prior to injecting the gas stream through the flow restrictor; and (d) adding the energy-activated catalyst, specifically titanium dioxide, to the zone of turbulence concurrently with steps (a) and (b) to contact the energy-activated catalyst with the atomized liquid composition wherein the contacting at the zone of turbulence treats the energy-activated catalyst with the source of the anions. The titanium dioxide can be pigmentary or nano-sized. The composition can be useful in polymeric composition, specifically for making a body covering article.

Owner:EI DU PONT DE NEMOURS & CO

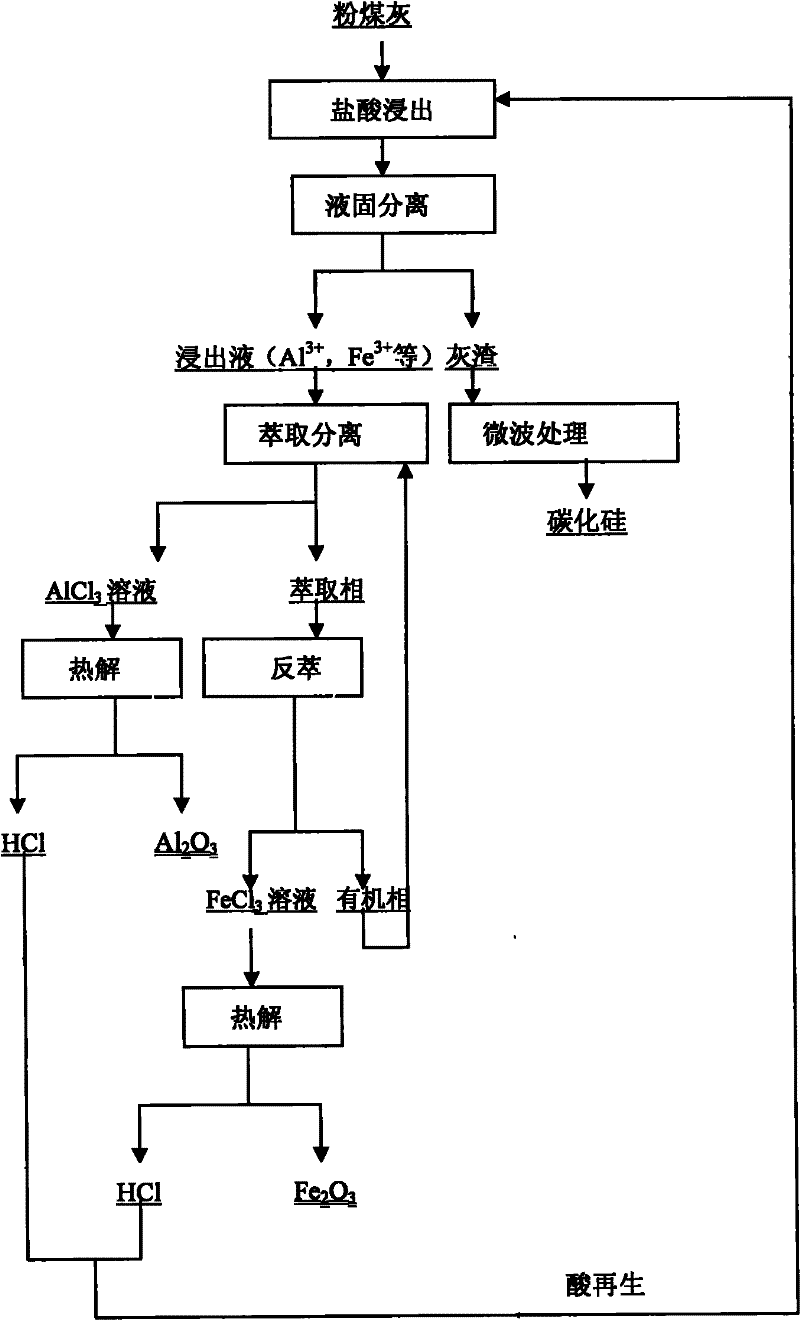

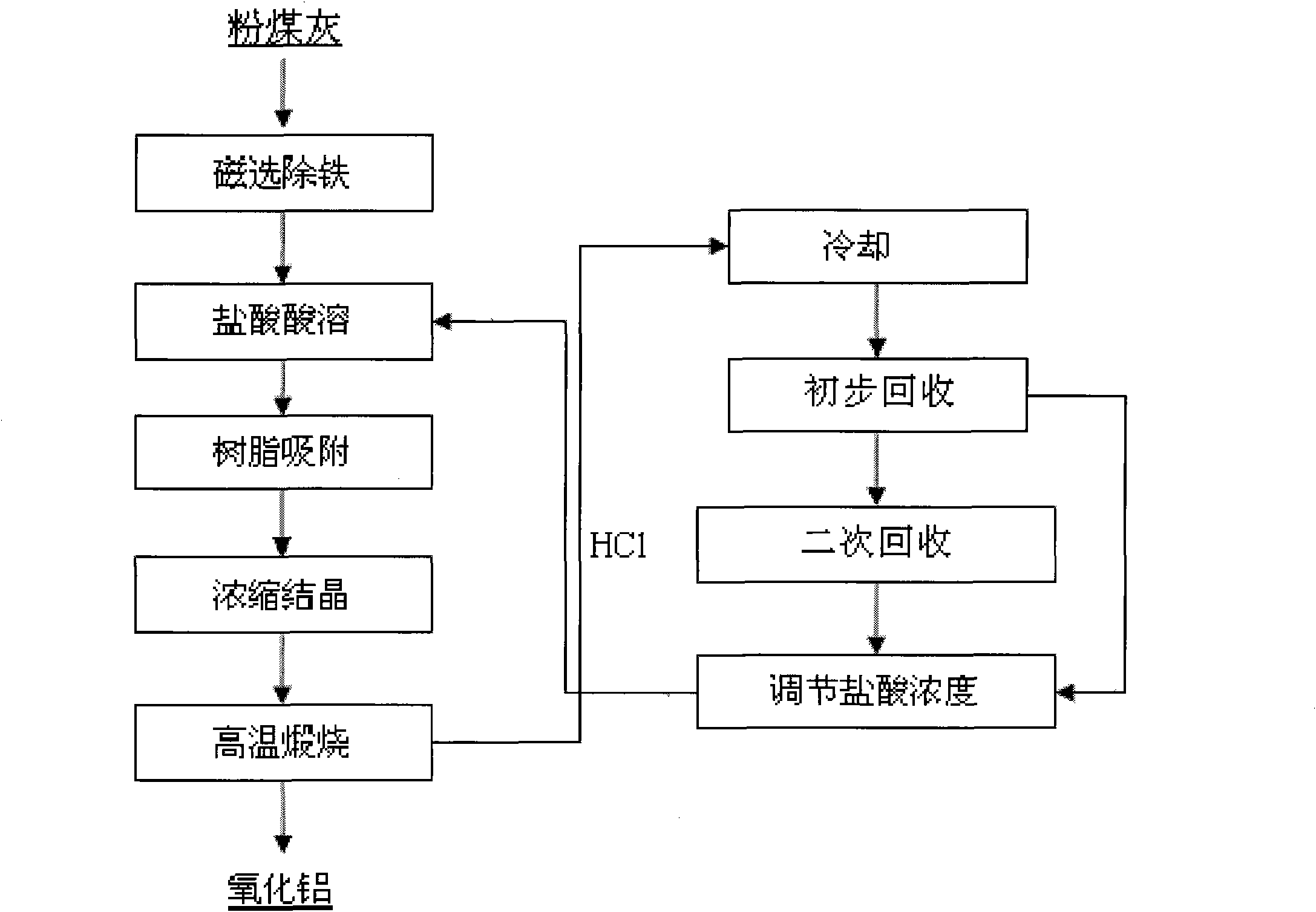

Method for recycling acid in process of producing alumina from fly ash by acid method

InactiveCN101863498ASimple processEasy to controlChlorine/hydrogen-chlorideSolid waste disposalIron removalAcid dissolution

The invention relates to a method for recycling acid in the process of producing alumina from fly ash by an acid method. The method comprises the following steps of magnetic separation and iron removal of the fly ash, acid dissolution, resin adsorption and iron removal, condensation crystallization, calcination, cooling, primary recycle of hydrogen chloride gas, secondary recycle of hydrogen chloride gas, regulation of concentration of recycled hydrochloric acid and application of the obtained hydrochloric acid to the step of acid dissolution. The method has the advantages of simple process, easily controlled production process, low production cost and recyclable adsorbed hydrogen chloride product.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com