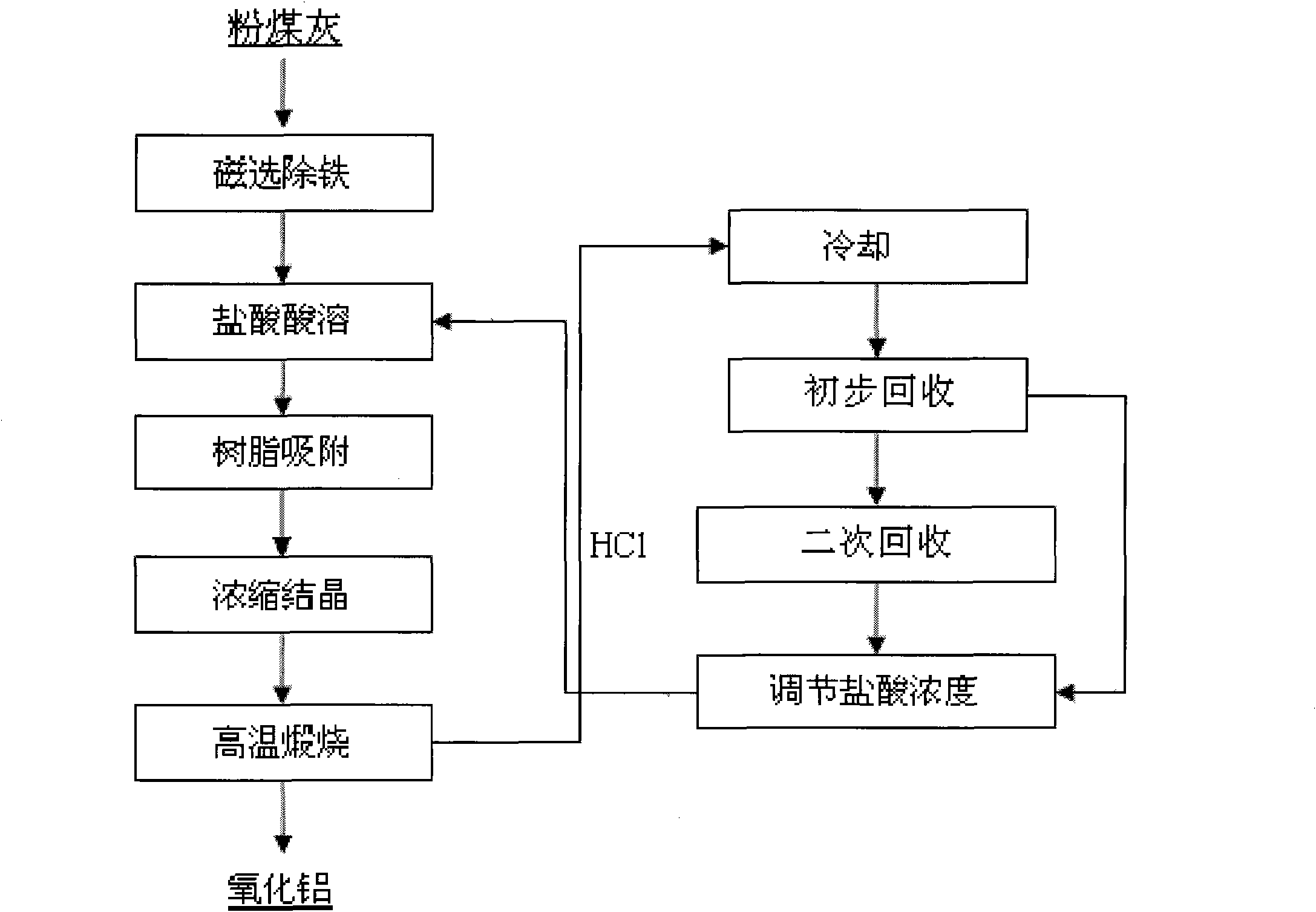

Method for recycling acid in process of producing alumina from fly ash by acid method

A technology for fly ash and alumina, which is applied in the removal of alumina/aluminum hydroxide, chlorine/hydrogen chloride, solid waste, etc., achieves the effects of simple process, low production cost, and easy control of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

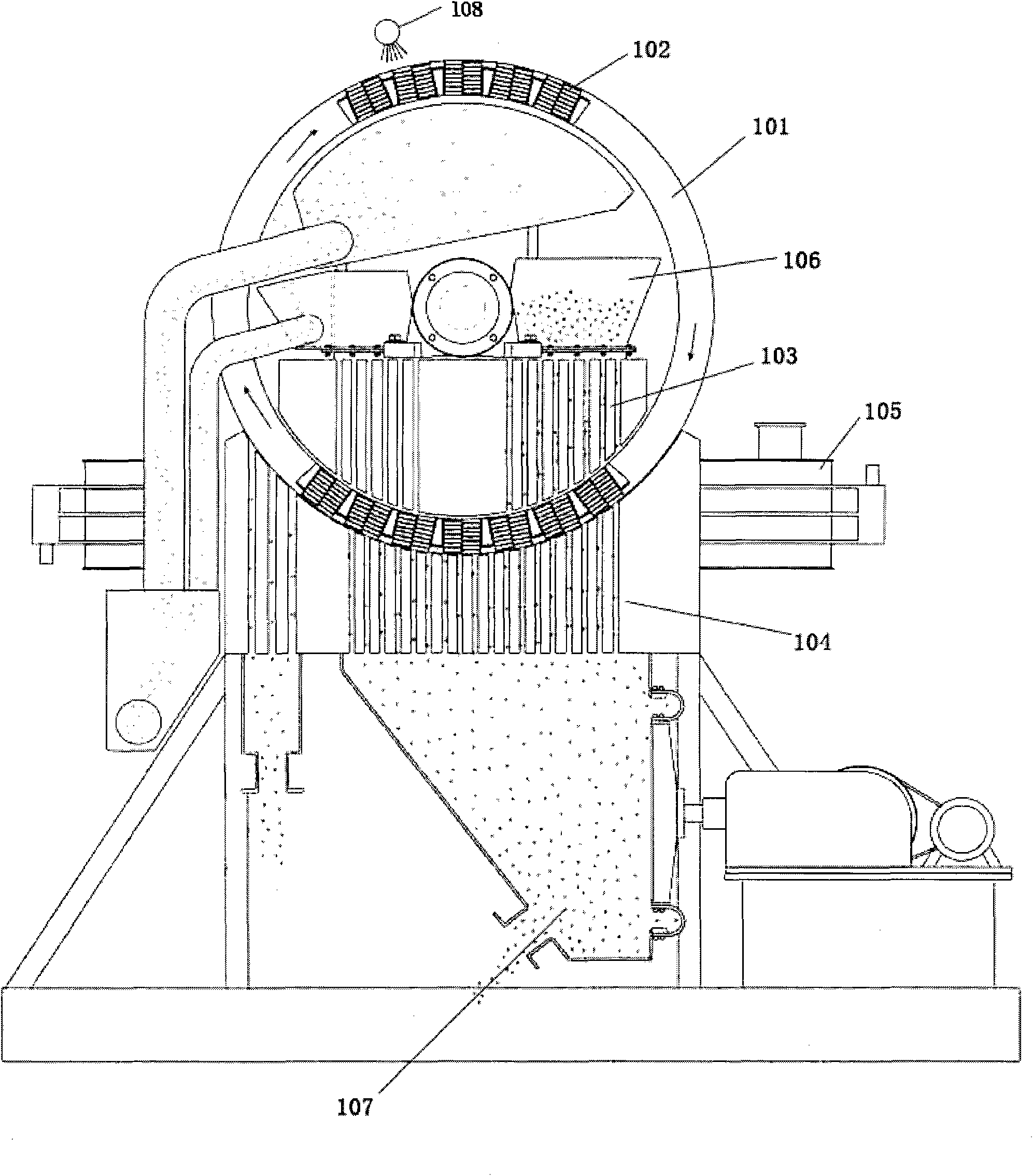

[0025] Take the fluidized bed fly ash and crush it to 150 mesh, add water to make a slurry with a solid content of 30wt%, magnetically separate it on a vertical ring magnetic separator with a magnetic separation field strength of 15,000 Gs, and magnetically separate it three times until the pulverized coal The content of iron oxide in the ash is 0.8wt%. After pressing with a basket filter press, a filter cake with a solid content of 34.5 wt% was obtained. Put the filter cake into an acid-resistant reactor, add 22wt% hydrochloric acid for acid dissolution, the molar ratio of HCl in hydrochloric acid to alumina in ash is 5:1, the reaction temperature is 150°C, the reaction time is 2 hours, and the reaction pressure is 1.0 MPa. The aluminum chloride solution obtained by acid dissolution is passed into a resin column to remove iron. The resin column is in a single column mode. The resin used is D001 (Anhui Wandong Chemical Plant), the treatment temperature is 60 ° C, and the flow ...

Embodiment 2

[0028] The main process conditions for preparing metallurgical grade alumina with circulating fluidized bed ash are the same as in Example 1. Wherein the acid dissolution step adds hydrochloric acid concentration to be 26.5wt%.

[0029] The hydrogen chloride gas produced by calcination is cooled to 90°C through the cooling tower, and then enters the acid absorption tower, and the water injection speed in the acid absorption tower is controlled to 120L / min for preliminary acid gas recovery. The acid gas not fully absorbed in the absorption tower is introduced into the vacuum circulation acid storage tank, and its vacuum degree is controlled at -0.07KPa for secondary recovery of hydrochloric acid. The acid absorption liquid was weighed and chemically analyzed to obtain a concentration of hydrochloric acid of 26.9 wt%, and a recovery rate of hydrogen chloride of 99.75%. Finally, release the absorption acid in the absorption tower and acid storage tank, add water to adjust its co...

Embodiment 3

[0031] The main process conditions for preparing alumina from circulating fluidized bed ash are the same as in Example 1, wherein the concentration of hydrochloric acid added in the acid dissolution step is 30 wt%.

[0032] The hydrogen chloride gas produced by calcination is cooled to 94°C through the cooling tower, and enters the acid absorption tower. The water injection speed in the acid absorption tower is controlled to 110L / min for preliminary acid gas recovery. The acid gas not completely absorbed in the absorption tower is introduced into the vacuum circulation acid storage tank, and its vacuum degree is controlled at -0.06KPa for secondary recovery of hydrochloric acid. The acid absorption liquid was weighed and chemically analyzed to obtain a concentration of hydrochloric acid of 25.4 wt%, and a recovery rate of hydrogen chloride of 99.69%. Finally, release the absorption acid in the absorption tower and acid storage tank, add hydrochloric acid with a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cycle efficiency | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com