Process for producing lithium carbonate magnesium oxide and hydrogen chloride by high magnesium lithium-containing halogen water

A lithium carbonate and magnesium oxide technology, applied in the field of salt chemical industry, can solve the problems of high production cost and low recovery rate, achieve good economic and social benefits, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

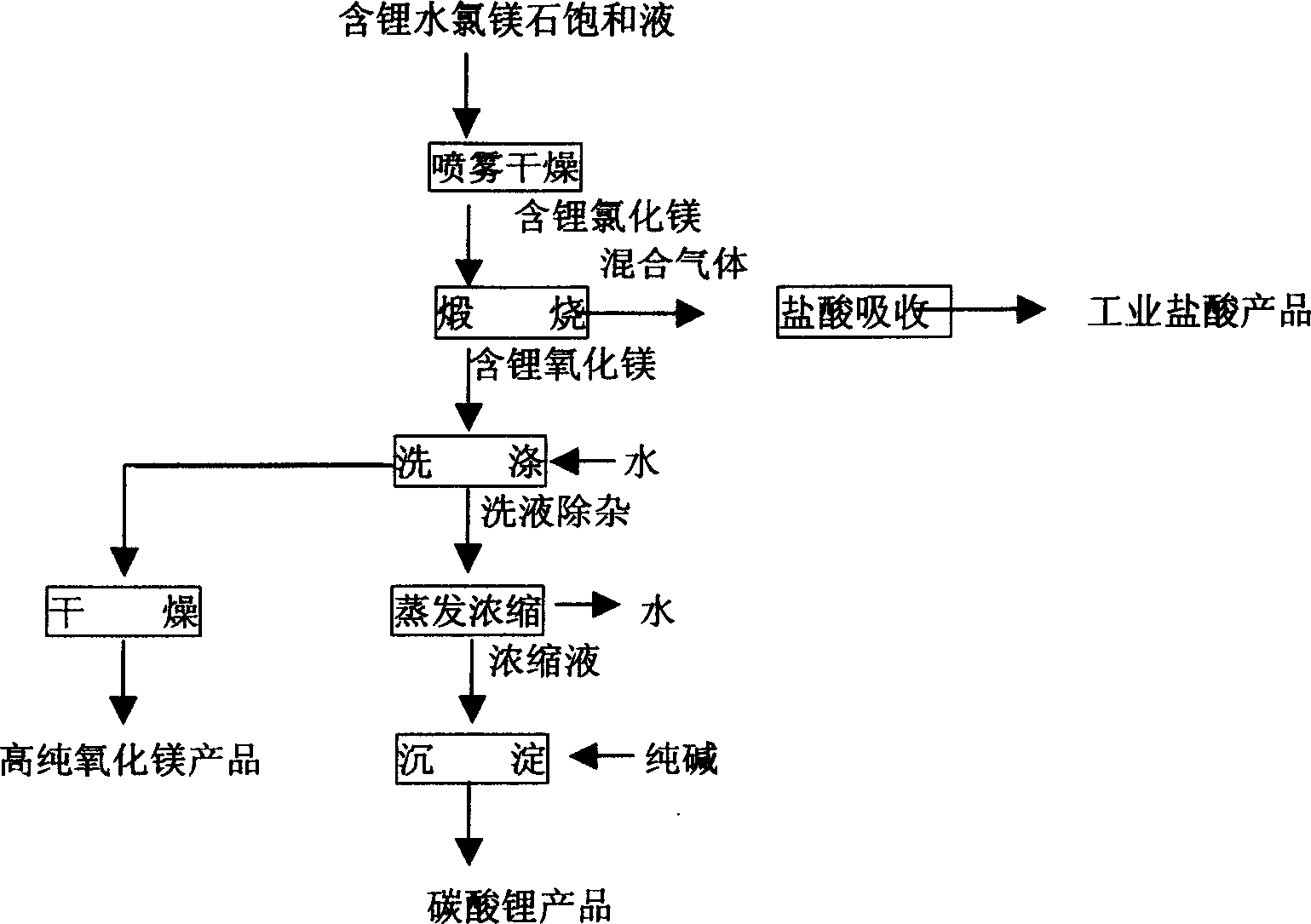

[0007] Example 1: Using high-magnesium lithium-containing brine as raw material, after precipitation removes insoluble matter in the brine, the feed temperature of the spray drying process is room temperature, the inlet air temperature of the spray drying tower is 450°C, and the outlet air temperature is 240°C The conditions are dry, and the lithium-containing magnesium chloride solid is produced. During calcination, a rotary calciner is used to calcinate at a calcination temperature of 554 ° C for 2.5 hours to obtain a solid lithium-containing magnesia, wherein the pyrolysis rate of magnesium chloride can reach 96%, and the recovery rate of lithium can reach 96.5%, washed 3 times countercurrently with fresh water, the filter cake was dried and dehydrated to obtain high-purity magnesium oxide with a MgO content of 99%, and the washing liquid was evaporated and concentrated into brine after removing impurities + When it is 14g / l, after removing the precipitate, add the concentra...

Embodiment 2

[0008] Example 2: Using high-magnesium lithium-containing brine as a raw material, after precipitation and removal of water-insoluble matter in the brine, the feed temperature of the spray drying is 130°C, the inlet air temperature of the spray drying tower is 200°C, and the outlet air temperature is 150°C. Dry under low temperature to obtain lithium-containing magnesium chloride solid. When calcining, use a swirling flow dynamic calciner to calcinate at 1200°C for 0.5 seconds to obtain solid lithium-containing magnesium oxide, then wash it countercurrently with fresh water for 6 times, and the filter cake is obtained by drying and removing water. A high-purity magnesium oxide product with a MgO content of 99.4%, the washing liquid is evaporated and concentrated into brine after removing impurities + When it is 21g / l, remove the precipitate, add excess soda ash to the concentrated solution to precipitate lithium carbonate, and finally separate the precipitated solid to obtain l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com