Patents

Literature

48 results about "Chemical distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical distribution systems are used to convey chemicals over multiple injection points and are used for production, (produced) water treatment, as well as hydrate control chemicals. A chemical distribution system generally consists of an injection rate control device (IRCD), isolation valves, a check valve, and a flow meter.

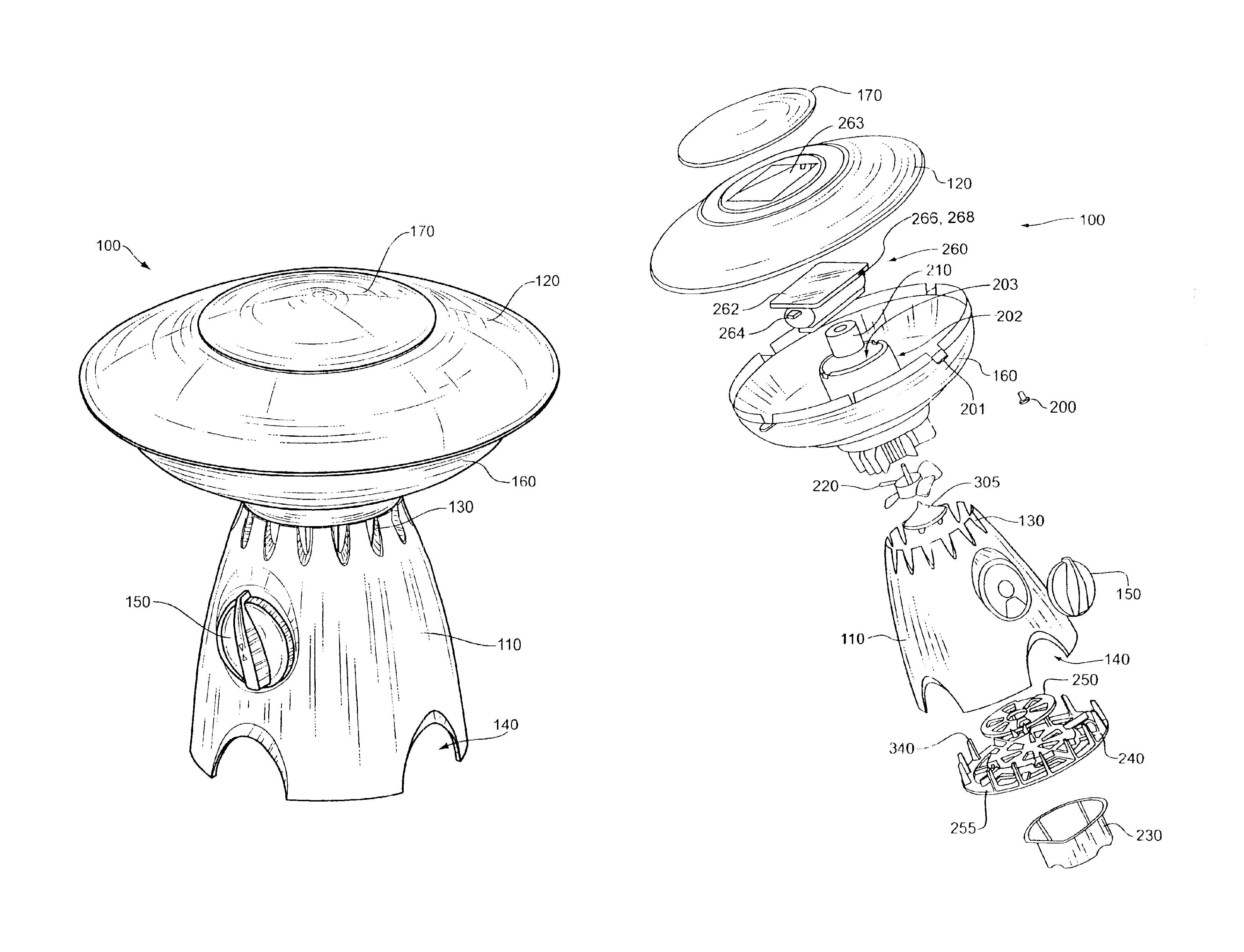

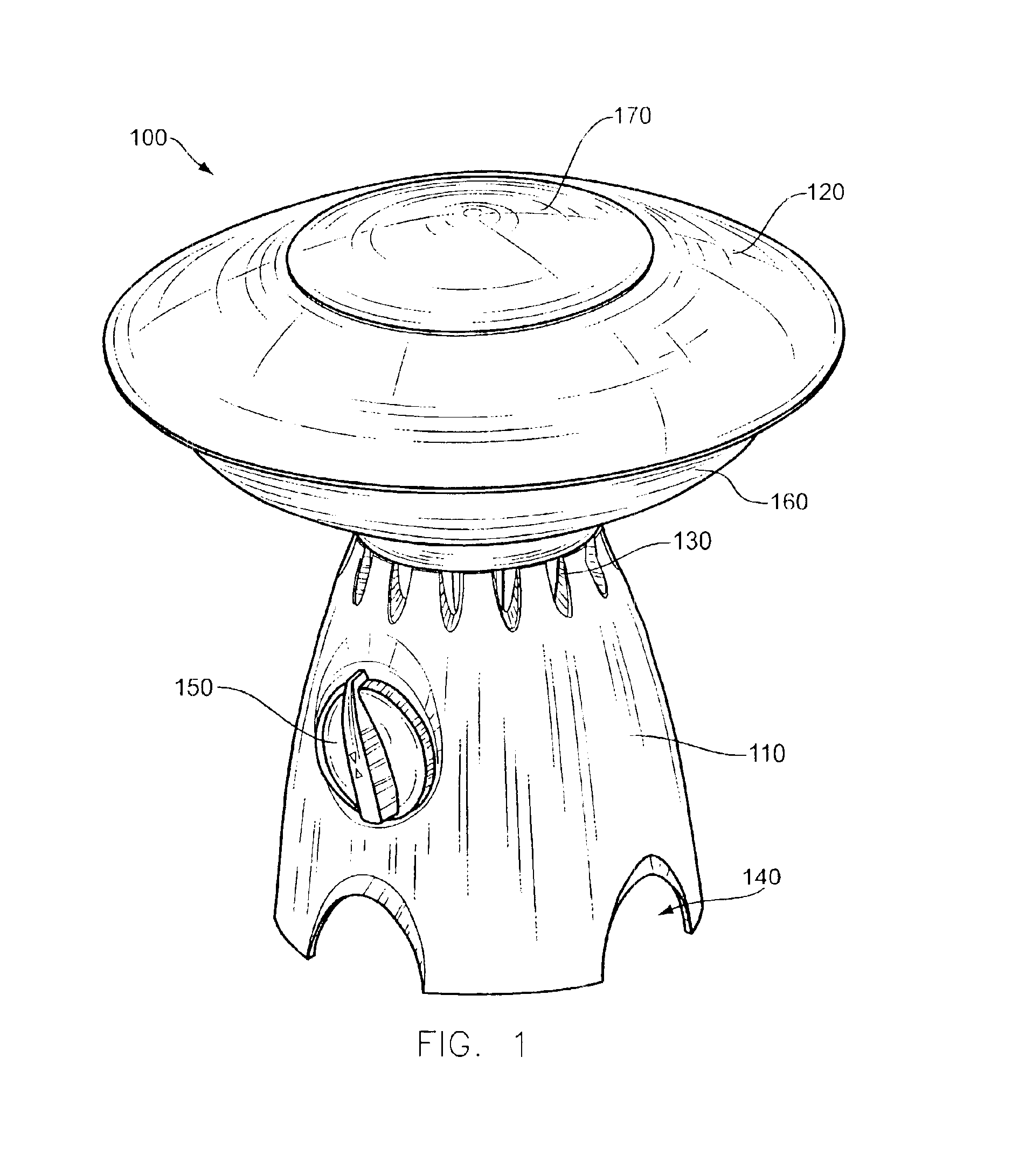

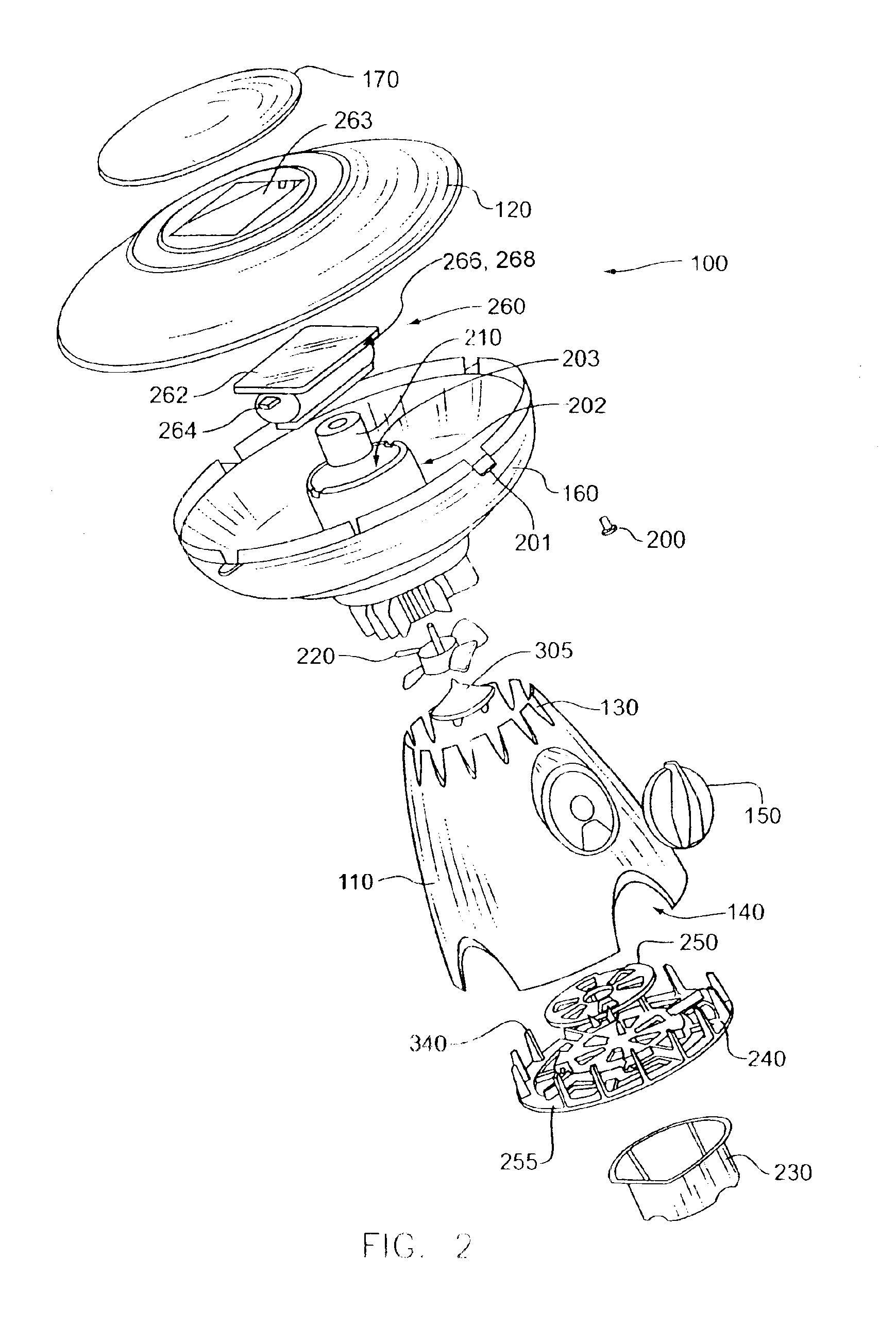

Light fixture and chemical distribution device

InactiveUS6854208B1Prevent discoveryLighting and heating apparatusMixing methodsChemical distributionEngineering

A device is disclosed for distributing chemicals, such as mosquito inhibitor chemicals. The device includes a housing and a light source. The light source is positioned within the housing such that the light source can be used to illuminate objects located near the device. The housing also includes a chemical disperser capable of distributing the chemicals. A solar panel provides power to the device.

Owner:J BAXTER BRINKMANN INT

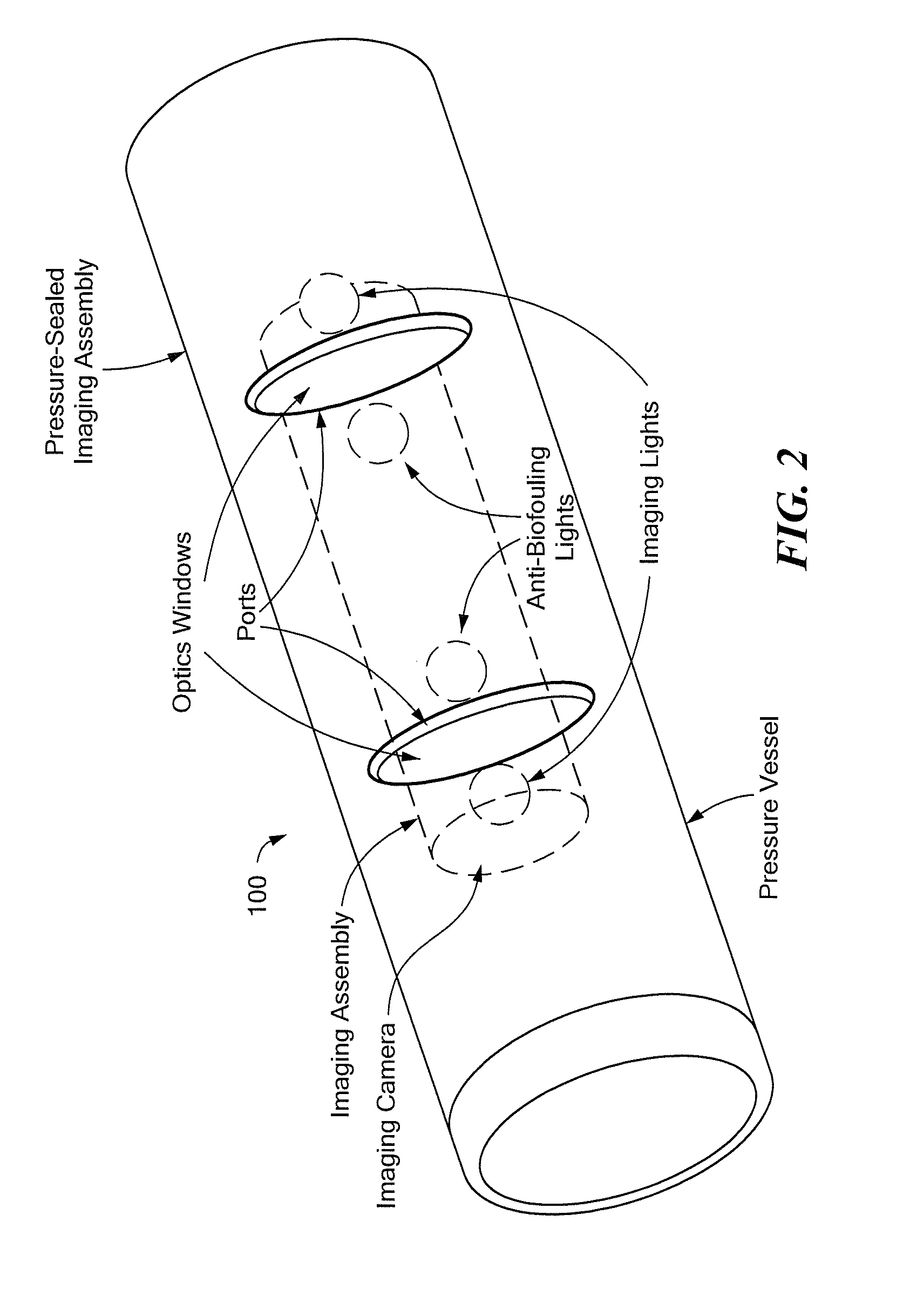

Method and Apparatus for Anti-Biofouling of Optics in Liquid Environments

InactiveUS20120050520A1Avoid biological contaminationVessel cleaningWater/sewage treatment by irradiationUltraviolet lightsEngineering

The present invention provides an apparatus and a method to prevent biofouling of underwater optical systems using ultraviolet light generated from within a pressure vessel and through an optics window, without removing the optical systems from the water and without disbursement of chemicals into the water.

Owner:RAYTHEON CO

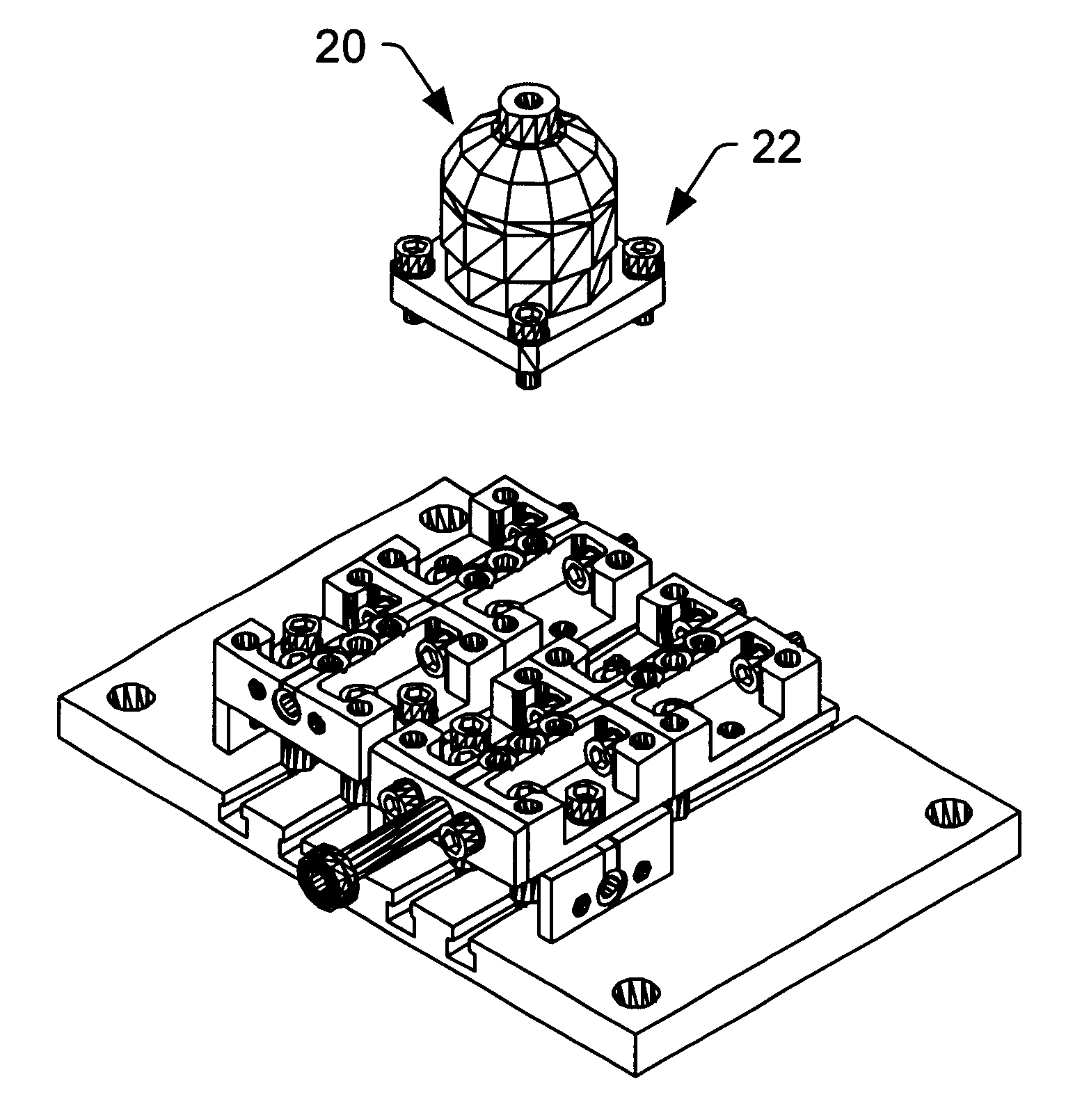

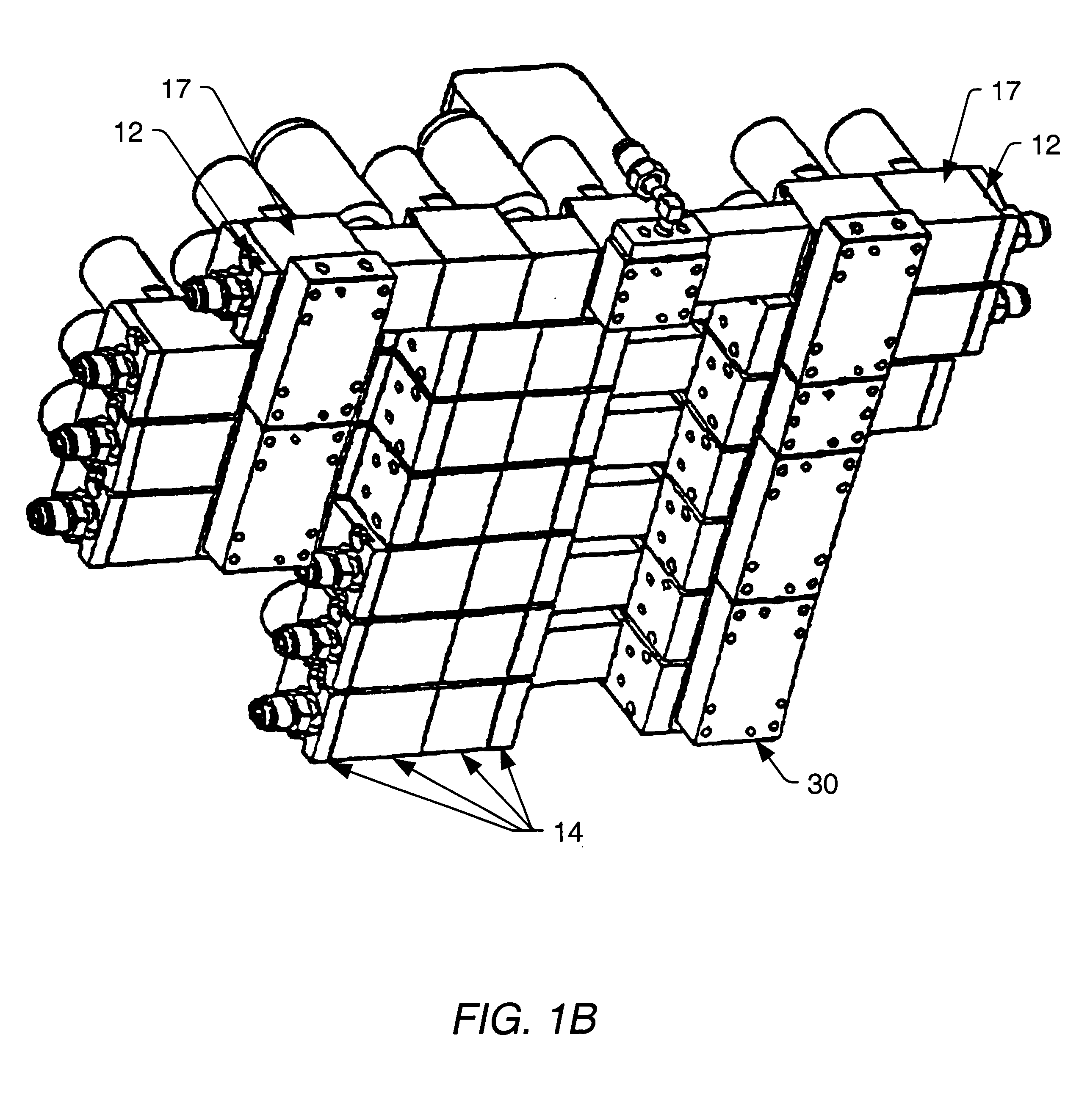

Apparatus for assembling modular chemical distribution substrate blocks

InactiveUS6260581B1Overcome disadvantagesMinimal numberServomotor componentsLift valveComputer moduleCompound (substance)

An apparatus for mechanically connecting modular chemical delivery substrate blocks in single layer and / or multiple lower layer configurations via axial and intermediate locations in such a way that all joint locations (including mounting fixtures to a rigid mechanism for mounting purposes) are completely accessible from the top surface of the assembly for fastening or unfastening the joints of the blocks. A design using the method of the present invention and incorporating current semiconductor standards (such as SEMI 2787) dictates specific mechanical dimensions and fastener localities in order to be properly implemented. Use of this top access fastener design results in minimal numbers of substrate joints in a chemical delivery system being affected when removing any one block from the system.

Owner:HOLLINGSHEAD J GREGORY

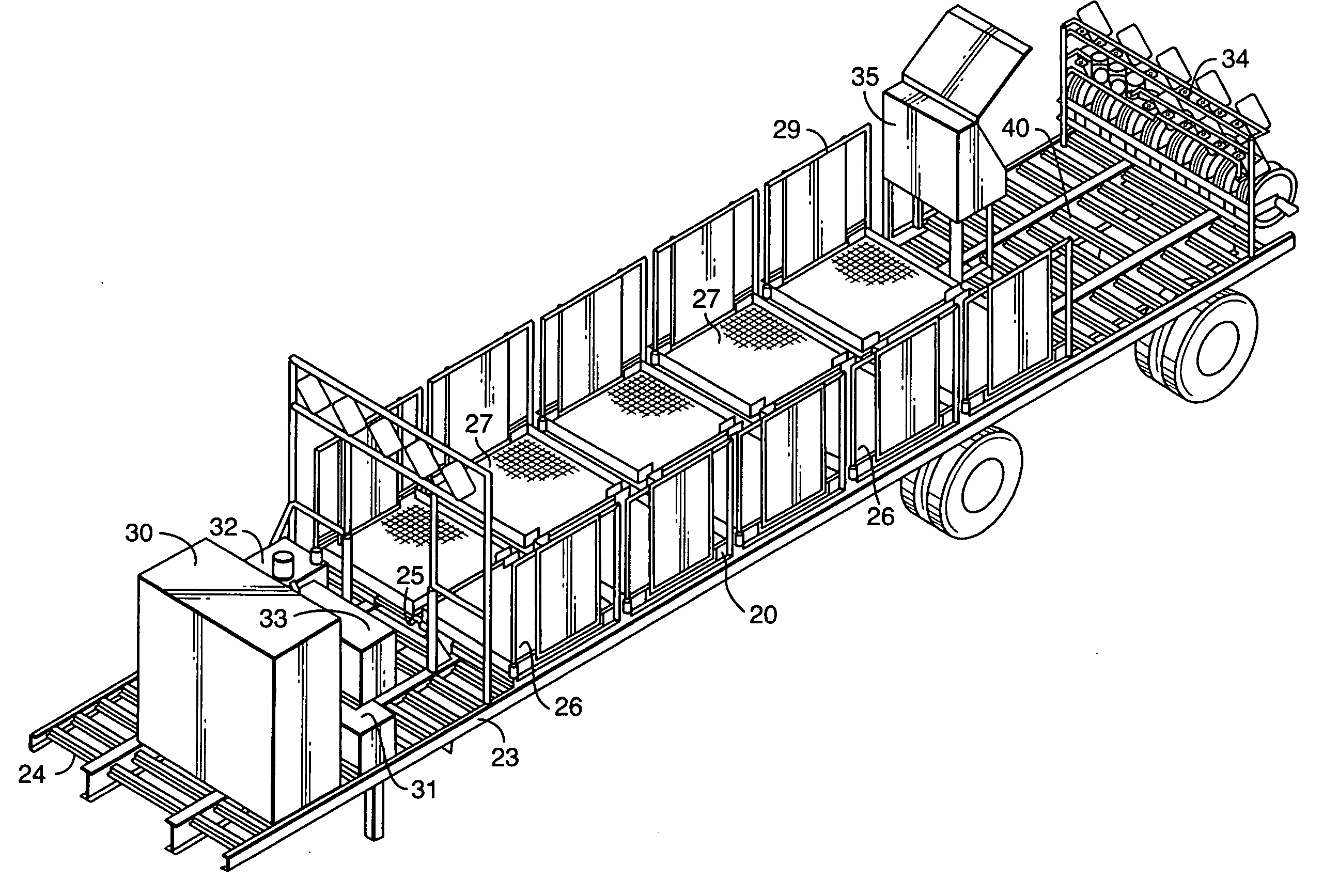

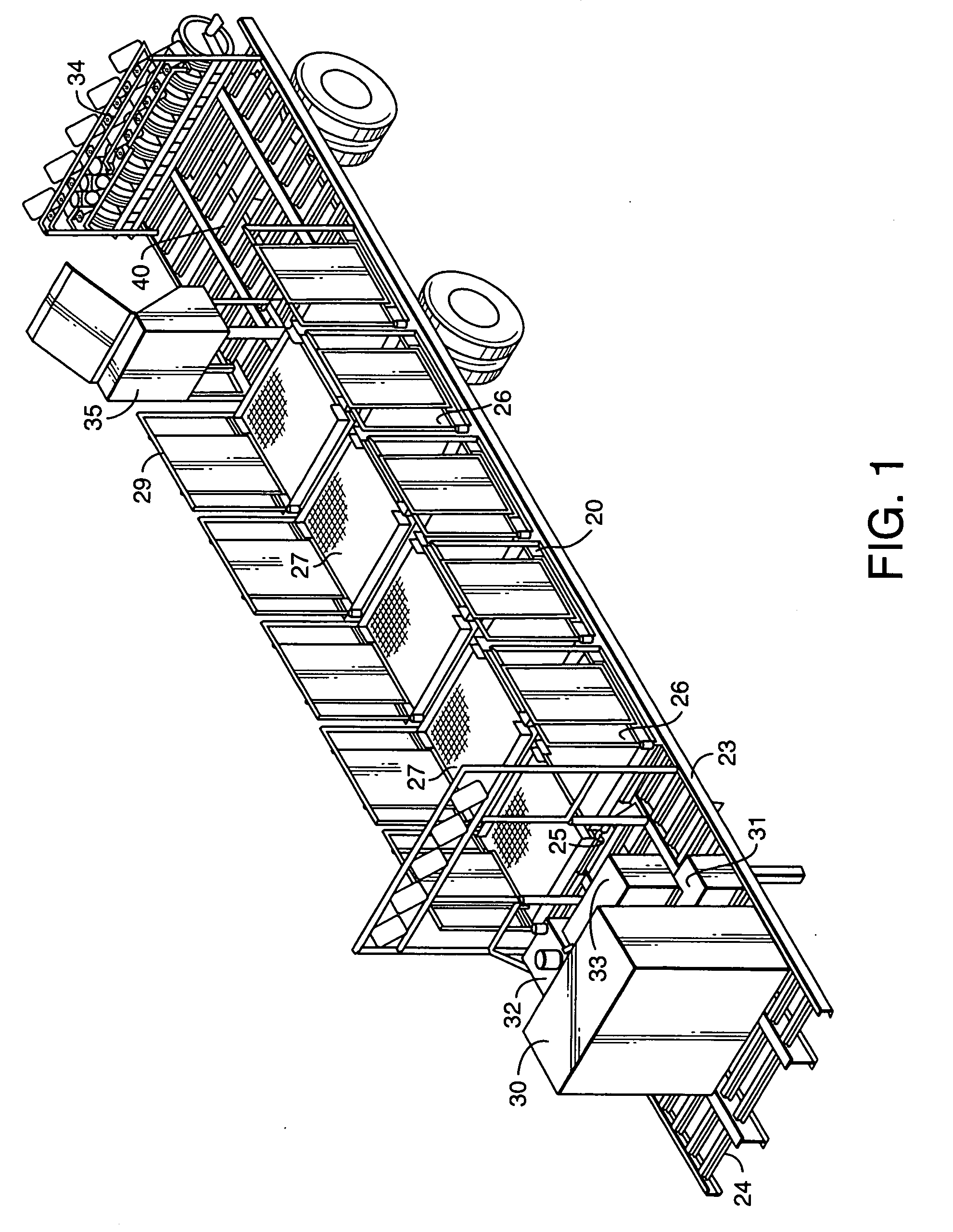

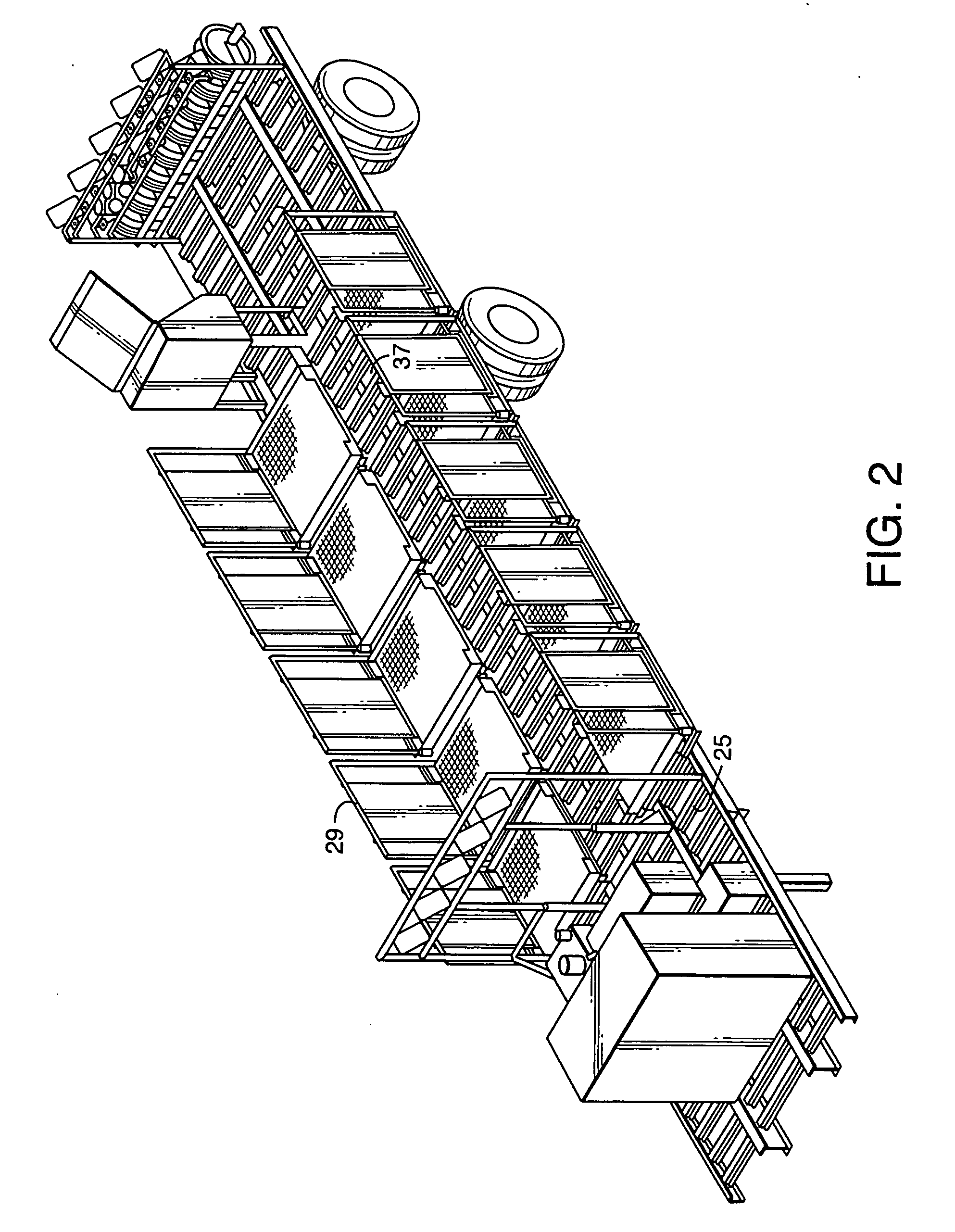

Distribution units and methods of use

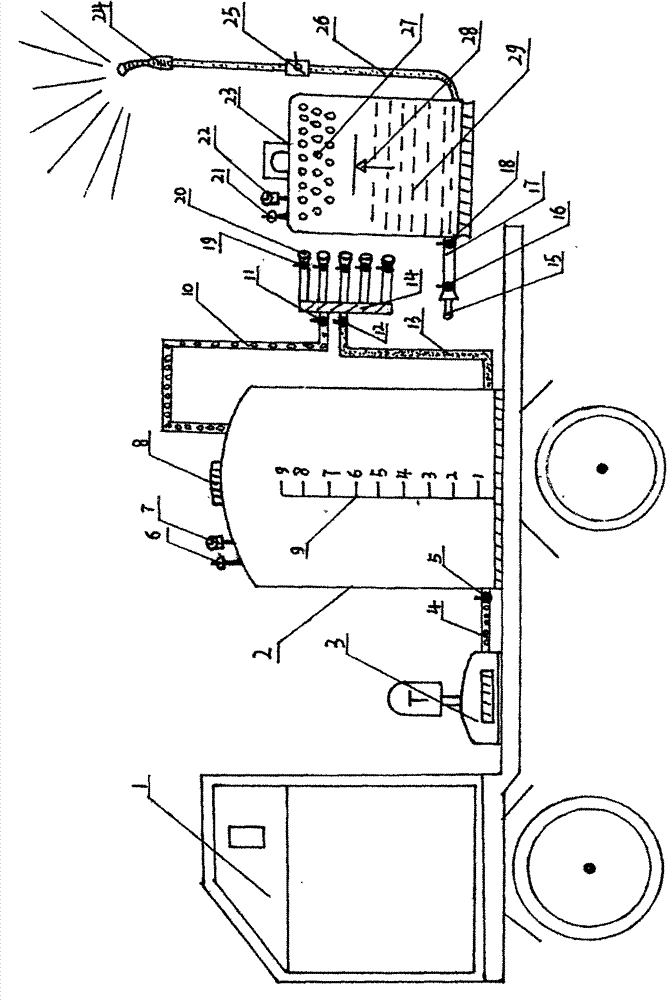

InactiveUS20070116546A1Hand carts with one axisItem transportation vehiclesMarine engineeringDistribution system

The invention relates to distribution systems and methods of their use. In some embodiments, the invention relates to a truck and trailer comprising a platform that is configured to allow movement of containers including, but not limited to, a tank. In some embodiments, the invention relates to chemical distribution units that are configured such that a plurality of chemical tanks, together or individually, can be moved partially over the edge of a platform, including but not limited to, over the edge of a trailer. In another embodiment, the invention relates to a chemical distribution system constructed on the deck of a trailer comprising first plurality of chemical tanks and a second plurality of chemical tanks configured such that the first and second plurality of tanks can be moved sufficiently over the edge of the trailer deck to allow a person to access the top of each of the individual tanks.

Owner:ROLLIGON

Purification of organic solvent fluids

InactiveUS7329354B2Precision productionSmooth connectionIon exchange regulation/controlIon-exchange column/bed processesOrganic solventIon exchange

A chemical distribution system having improved organic solvent fluid purity and consistency includes a vessel containing ion-exchange media positioned within a fluid flow pathway such that the organic solvent fluid passes through the ion-exchange media, thereby effecting removal of undesired impurities. Different embodiments of the invention position the vessel at varying locations within the fluid flow pathway. The chemical distribution system also preferably includes a return chemical flow pathway that recirculates purified organic solvent fluid through the ion-exchange media-containing vessel and thereby enables the system operator to conduct incremental adjustment of the solvent purity until a desired overall purity is attained.

Owner:PPT TECH

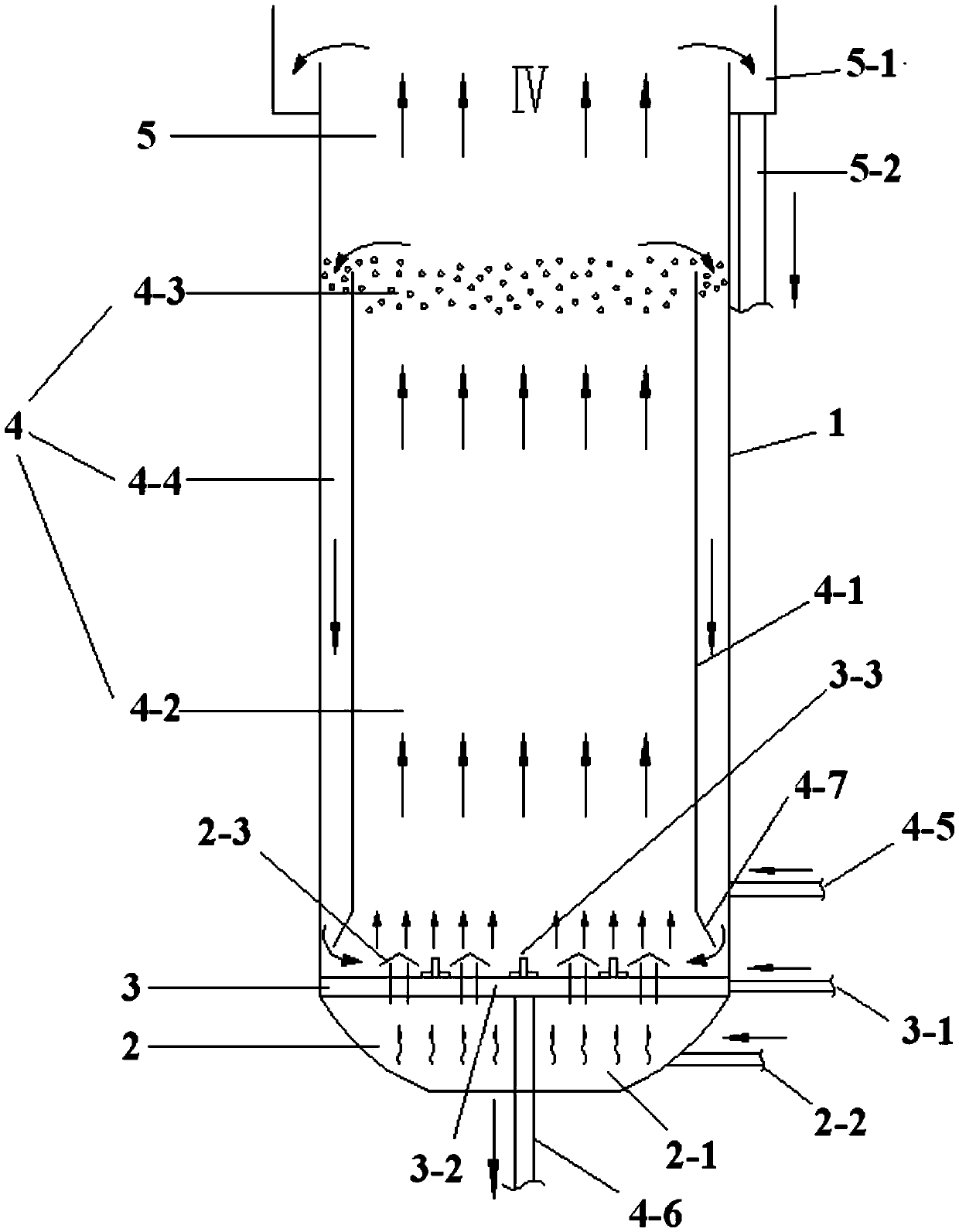

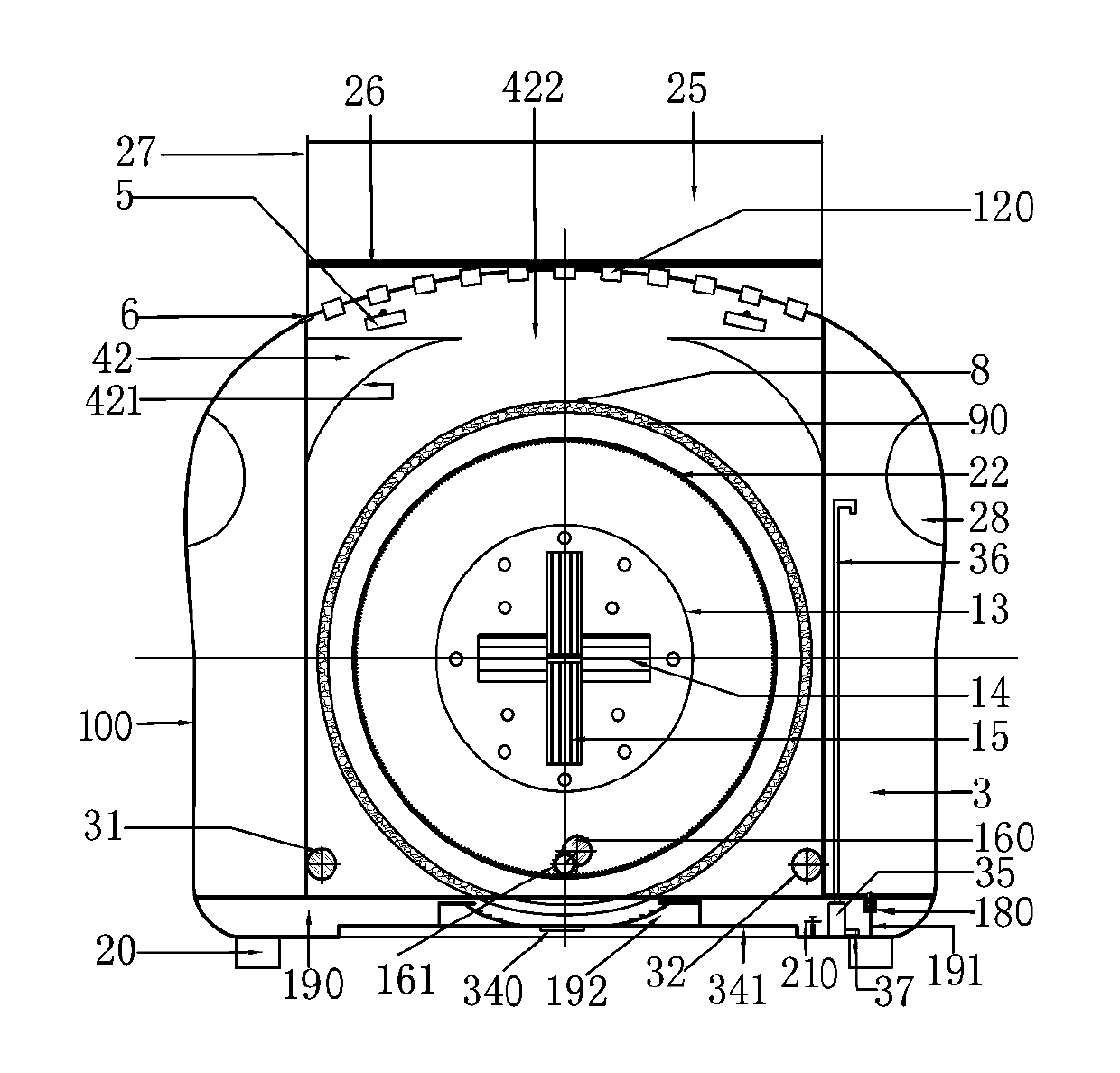

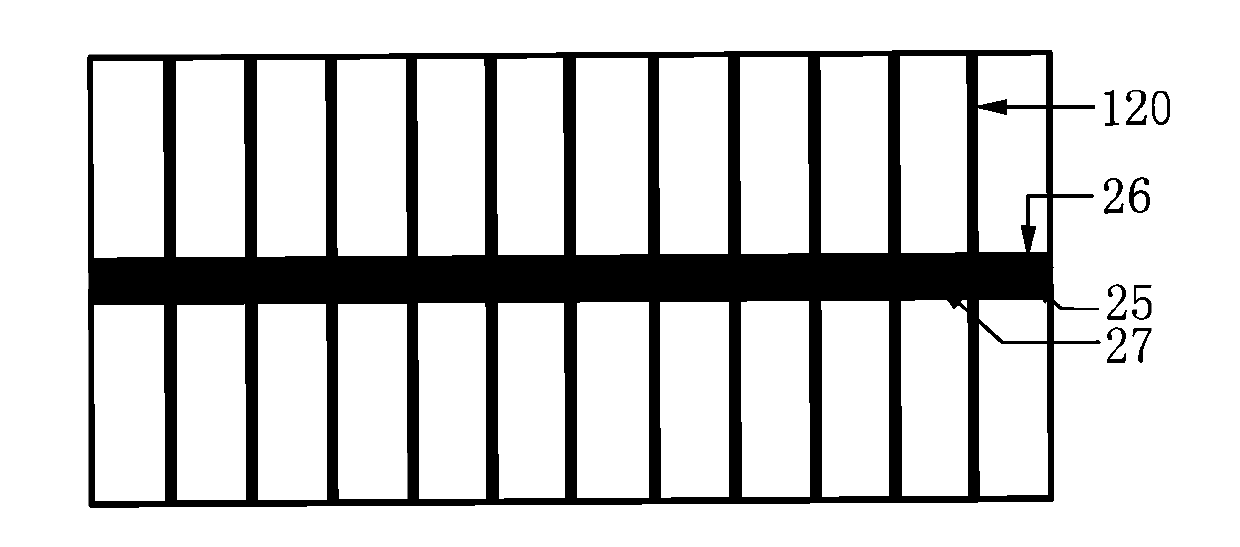

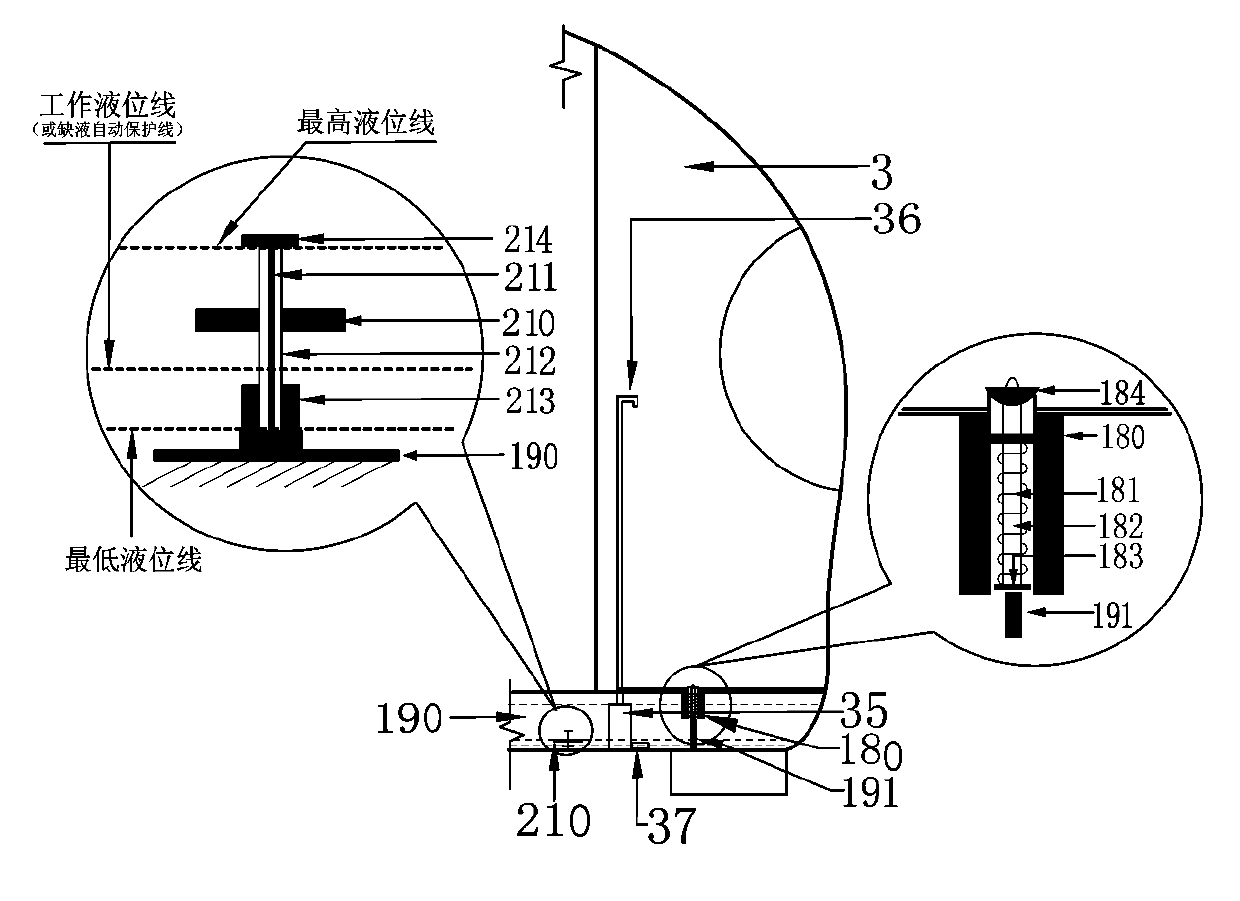

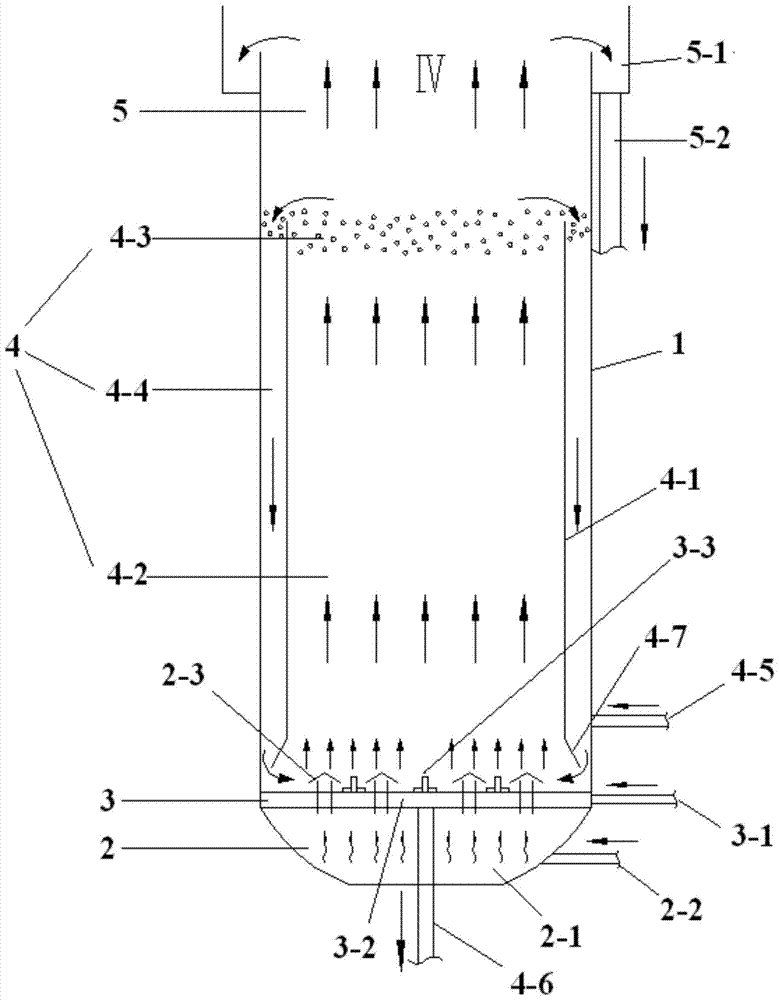

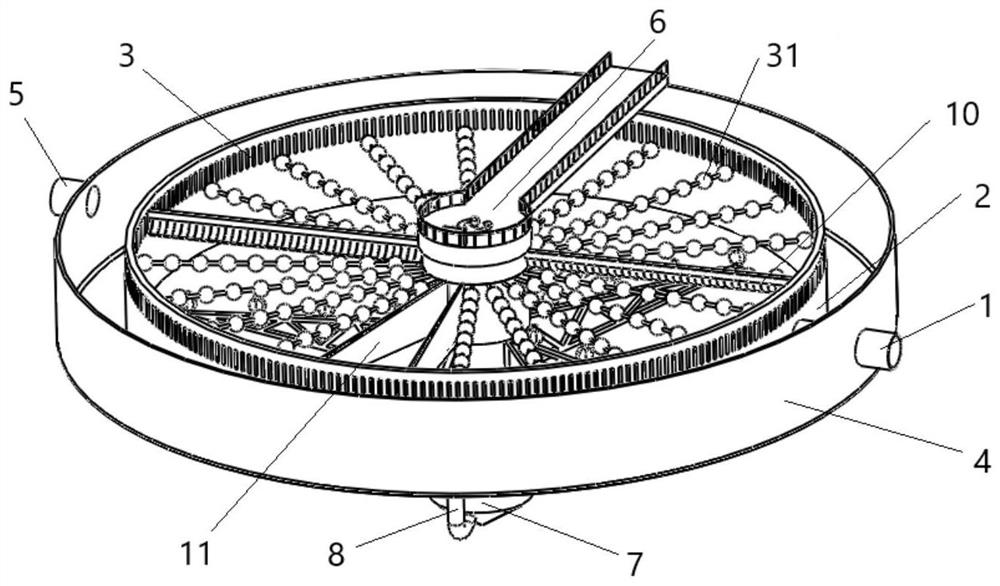

Fluidized bed water treatment device realizing chemical crystallization circulating granulation

ActiveCN105502692AGood processing effectExtended discharge cycleWater contaminantsWater softeningChemical distributionEngineering

The invention provides a fluidized bed water treatment device realizing chemical crystallization circulating granulation. The device is characterized in that a water distribution area, a chemical distribution area, a granulation area and a clear water area are sequentially arranged in a cylinder from bottom to top; the granulation area is divided into three areas by an inner cylinder, an area close to the bottom in the inner cylinder is a fluidization area, an area close to the top in the inner cylinder is a separation area, an interlayer between the inner cylinder and the cylinder is a static settling area; the fluidization area is communicated with a seed crystal adding pipe, seed crystals circularly flow among the fluidization area, the separation area and the static settling area, and ions in water realize the chemical crystallization circulating granulation in the flowing process; the fluidization area is further communicated with a grain discharge pipe, and grains formed through the chemical crystallization circulating granulation are settled to the bottom in the fluidization area and discharged from the grain discharge pipe finally. The overall structure is clear, function units are compactly connected, the plane utilization rate is high, the operation is convenient, a certain single ion in multiple kinds of ions can be removed, and multiple kinds of ions in water can be removed efficiently and synchronously.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

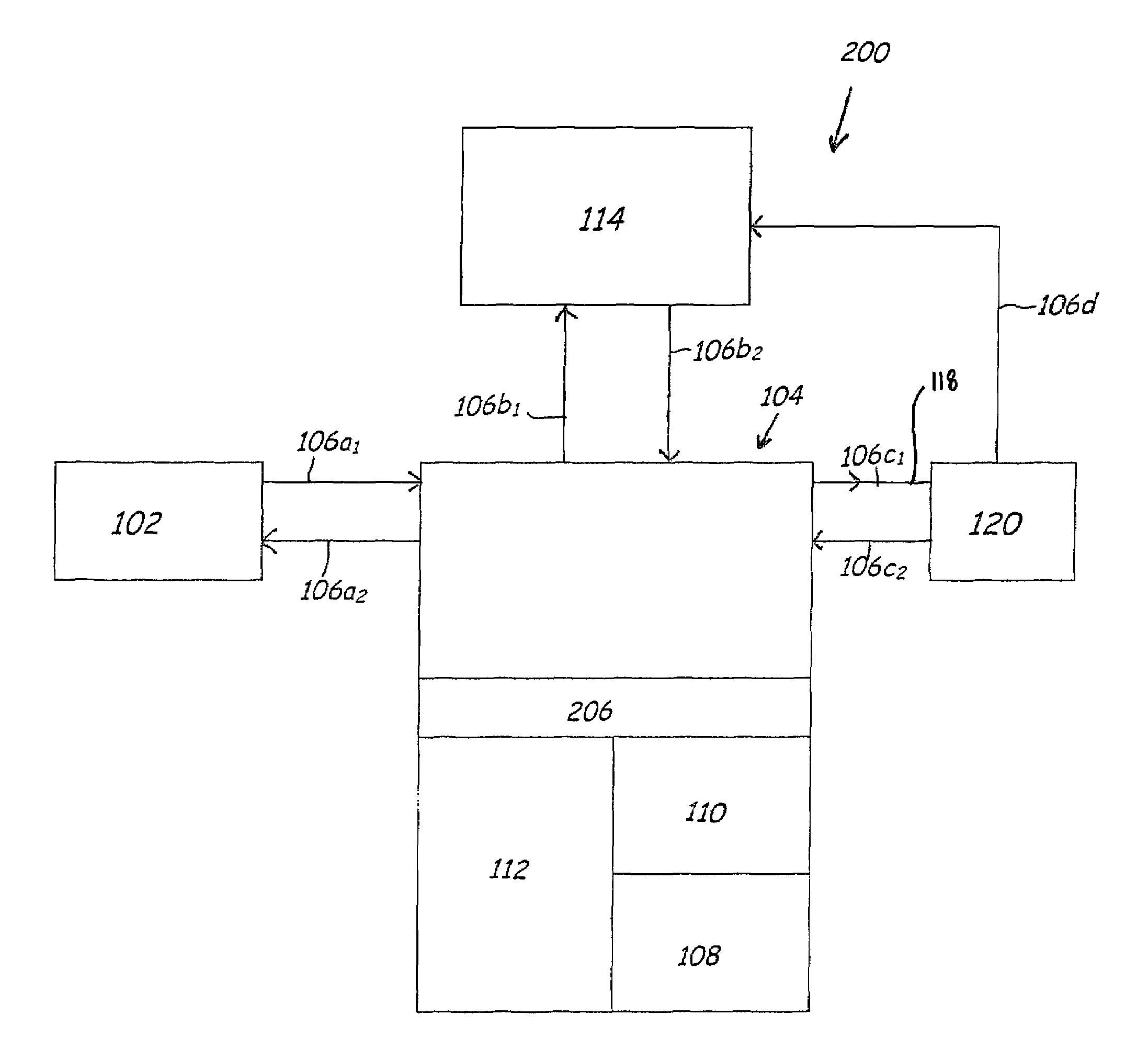

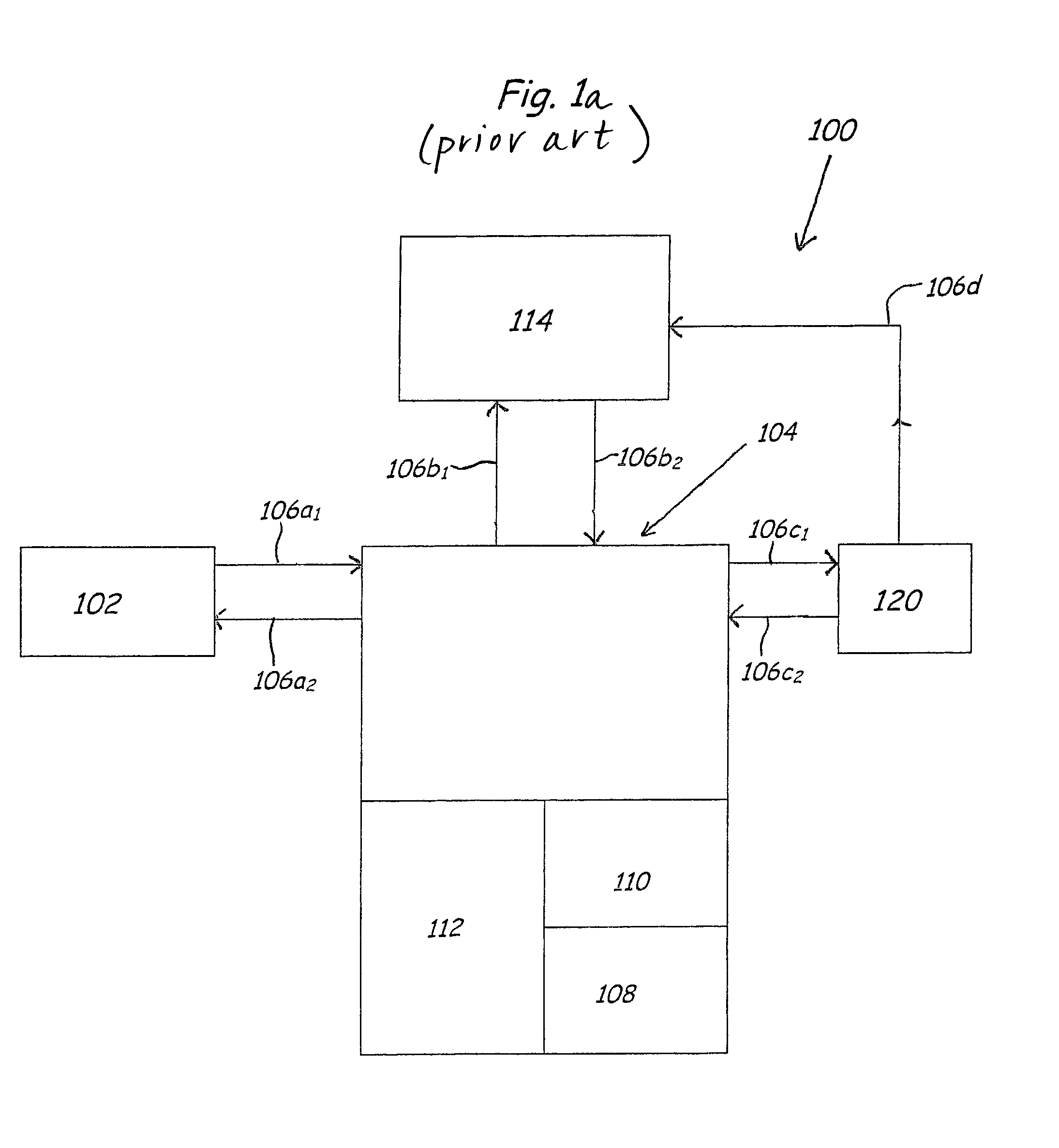

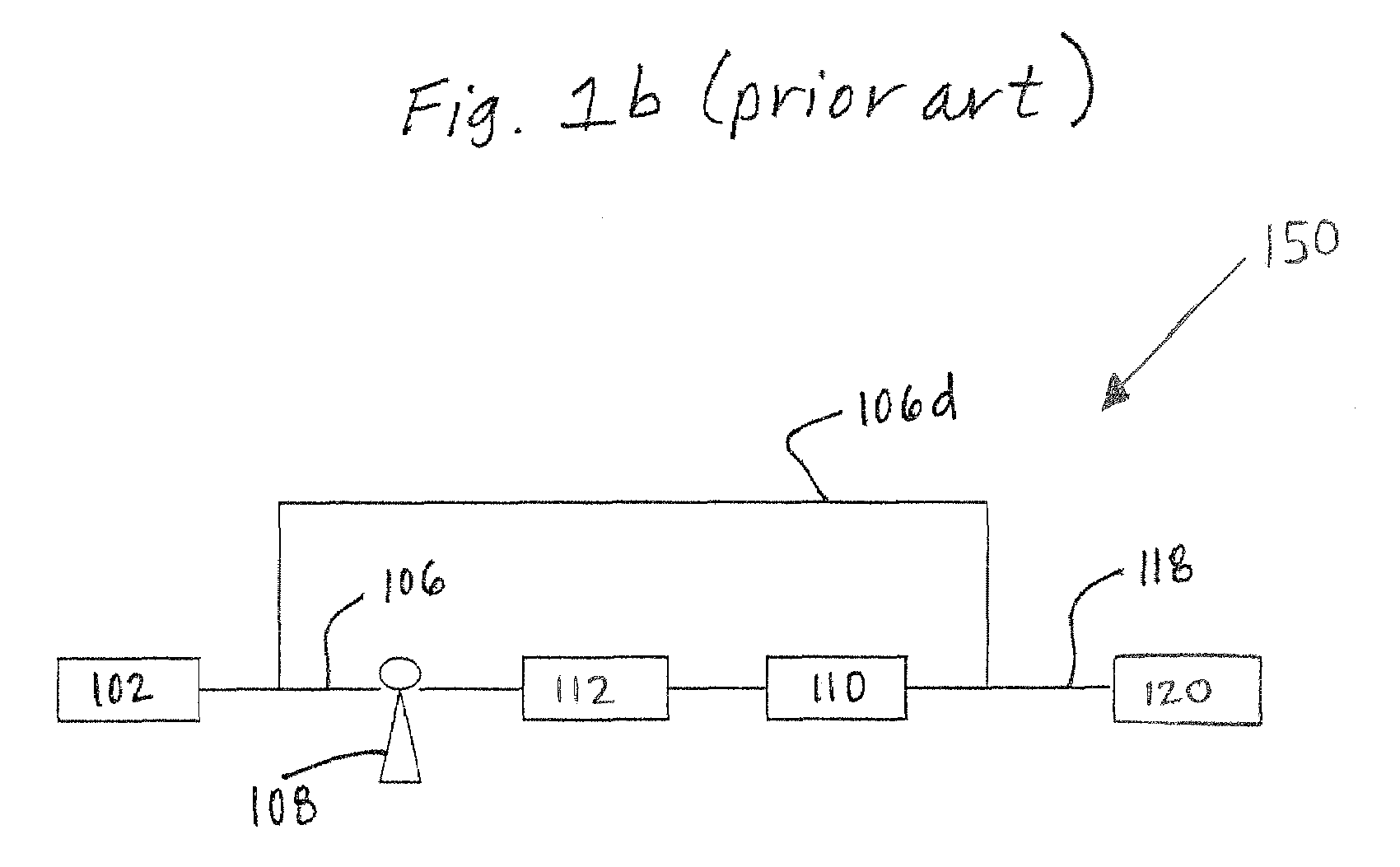

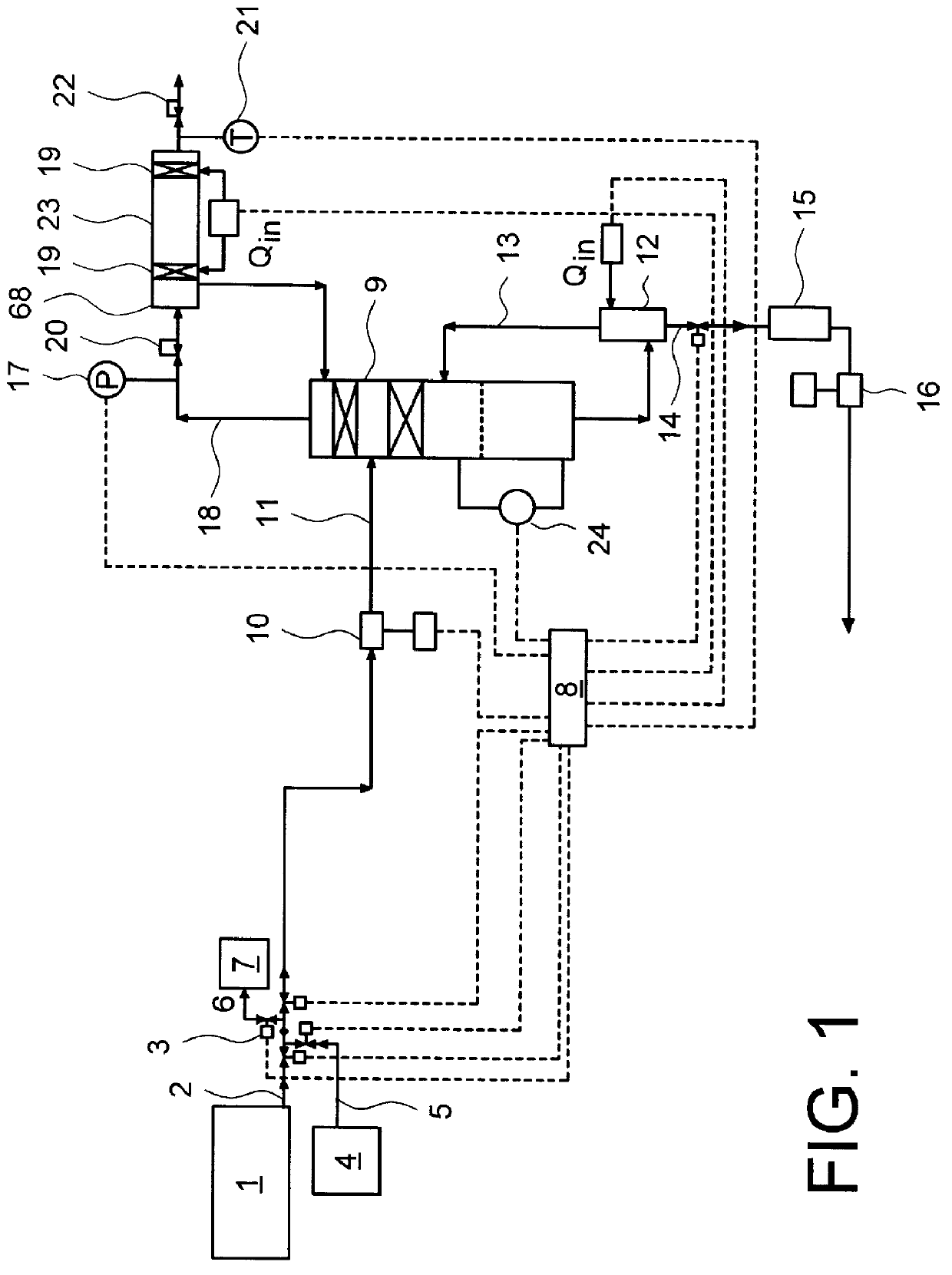

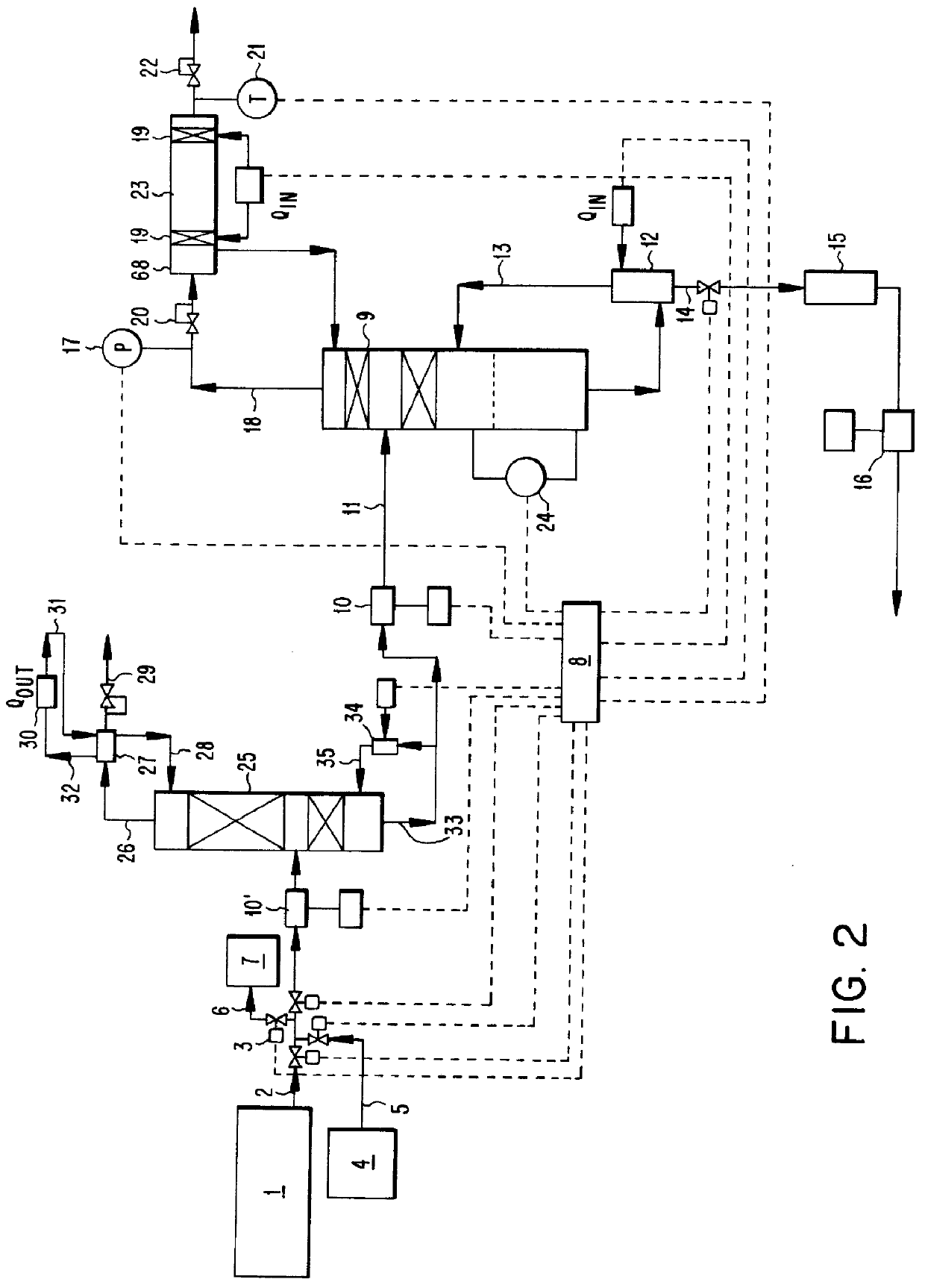

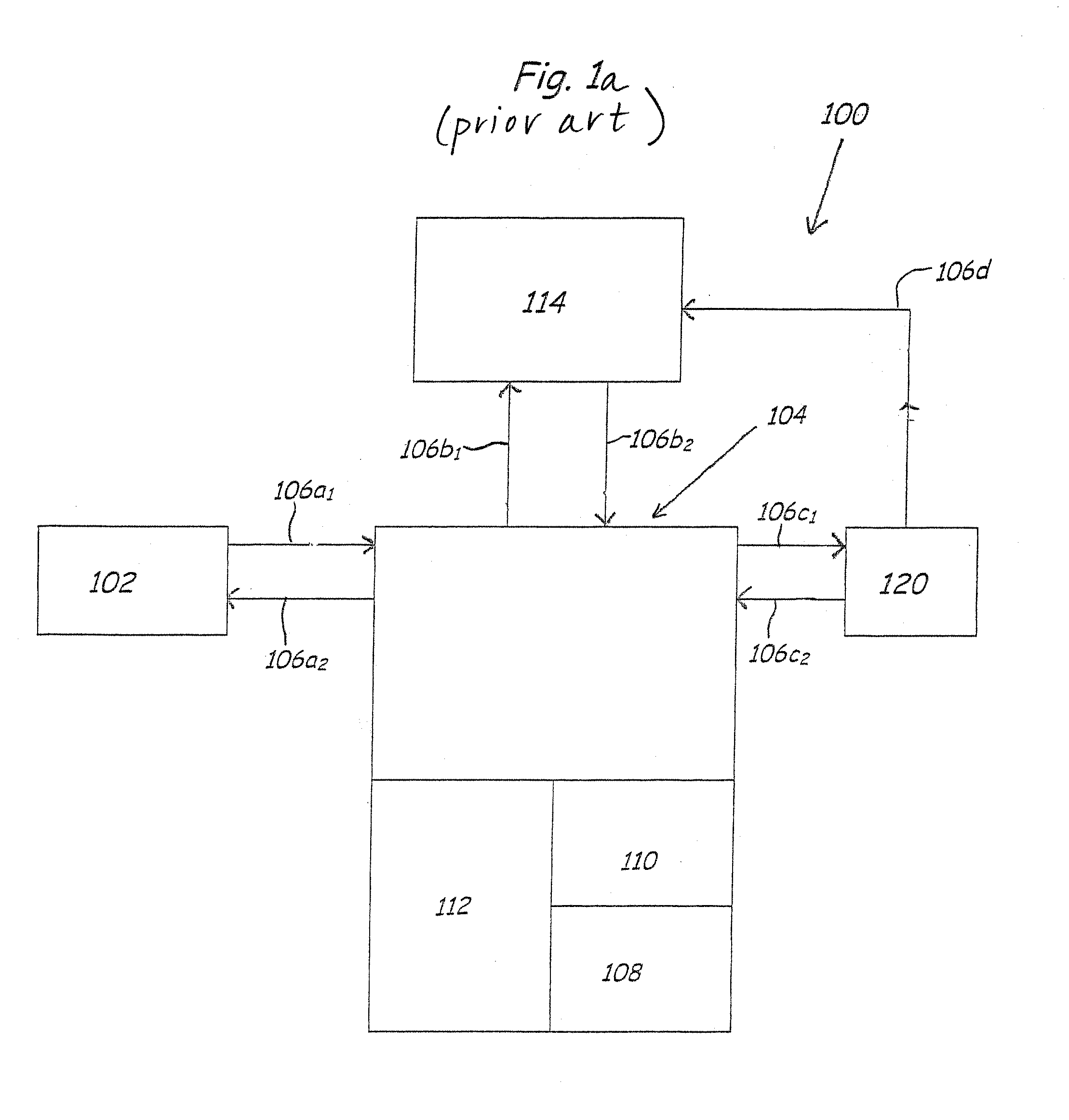

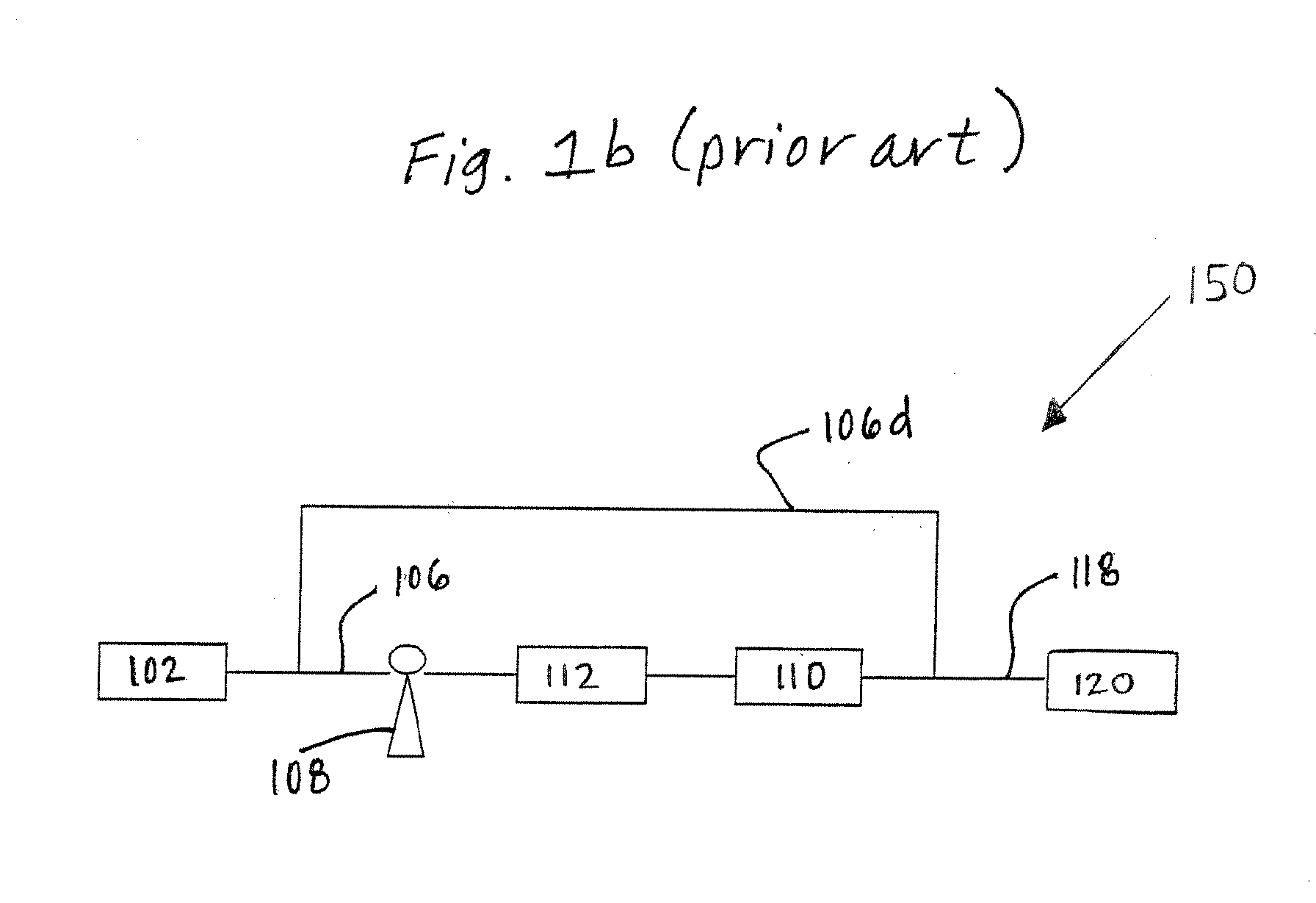

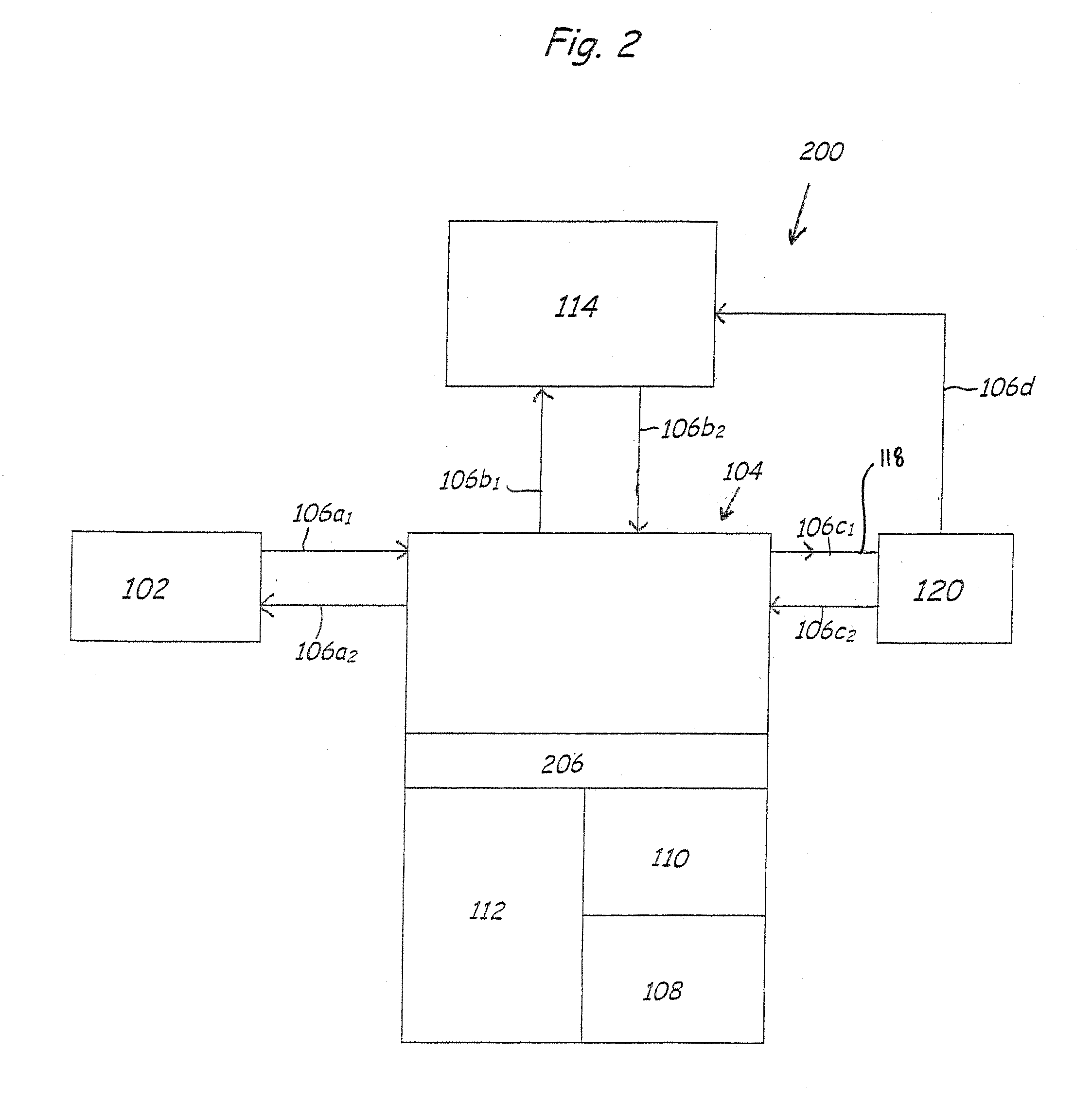

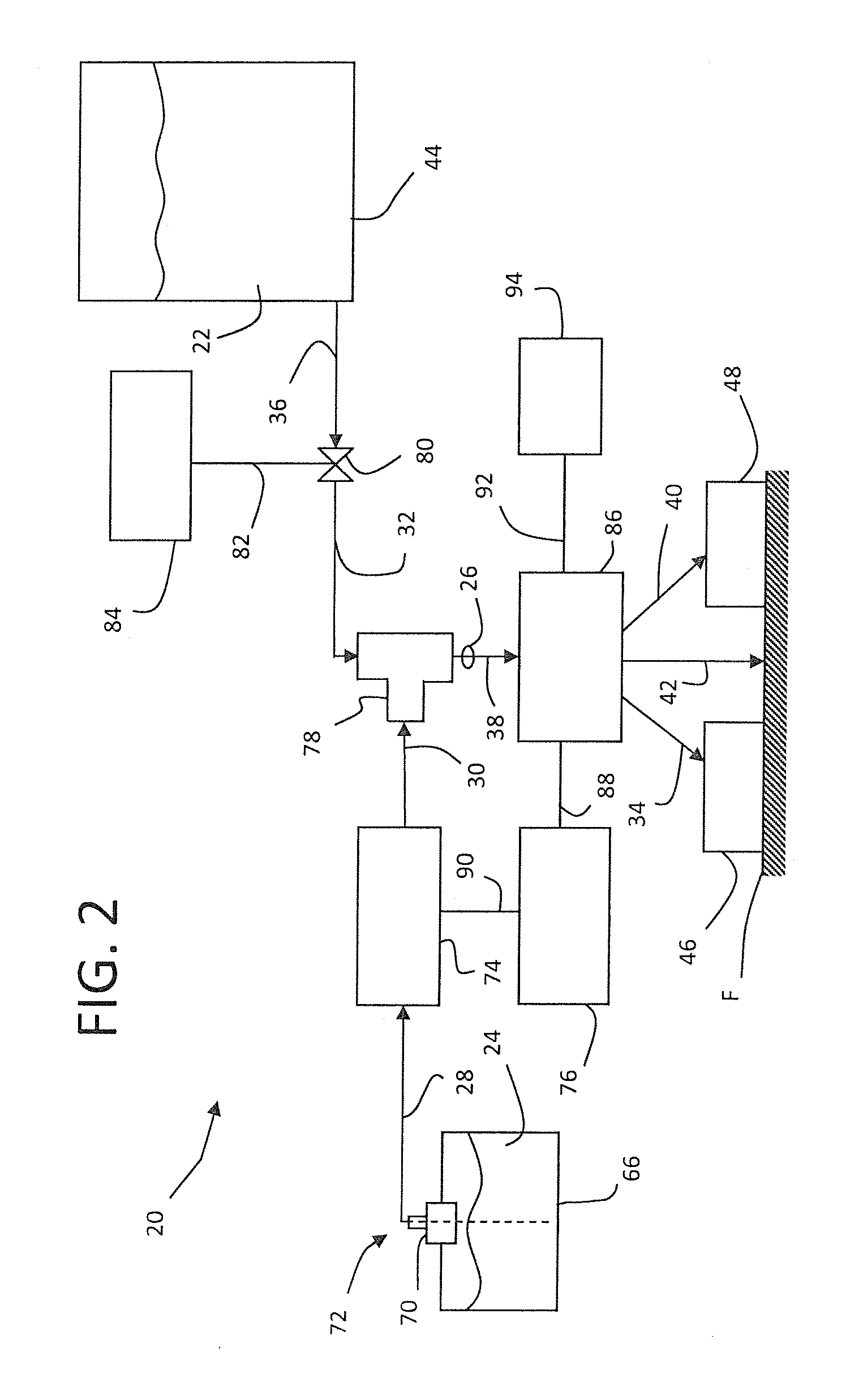

System and method for delivery of a vapor phase product to a point of use

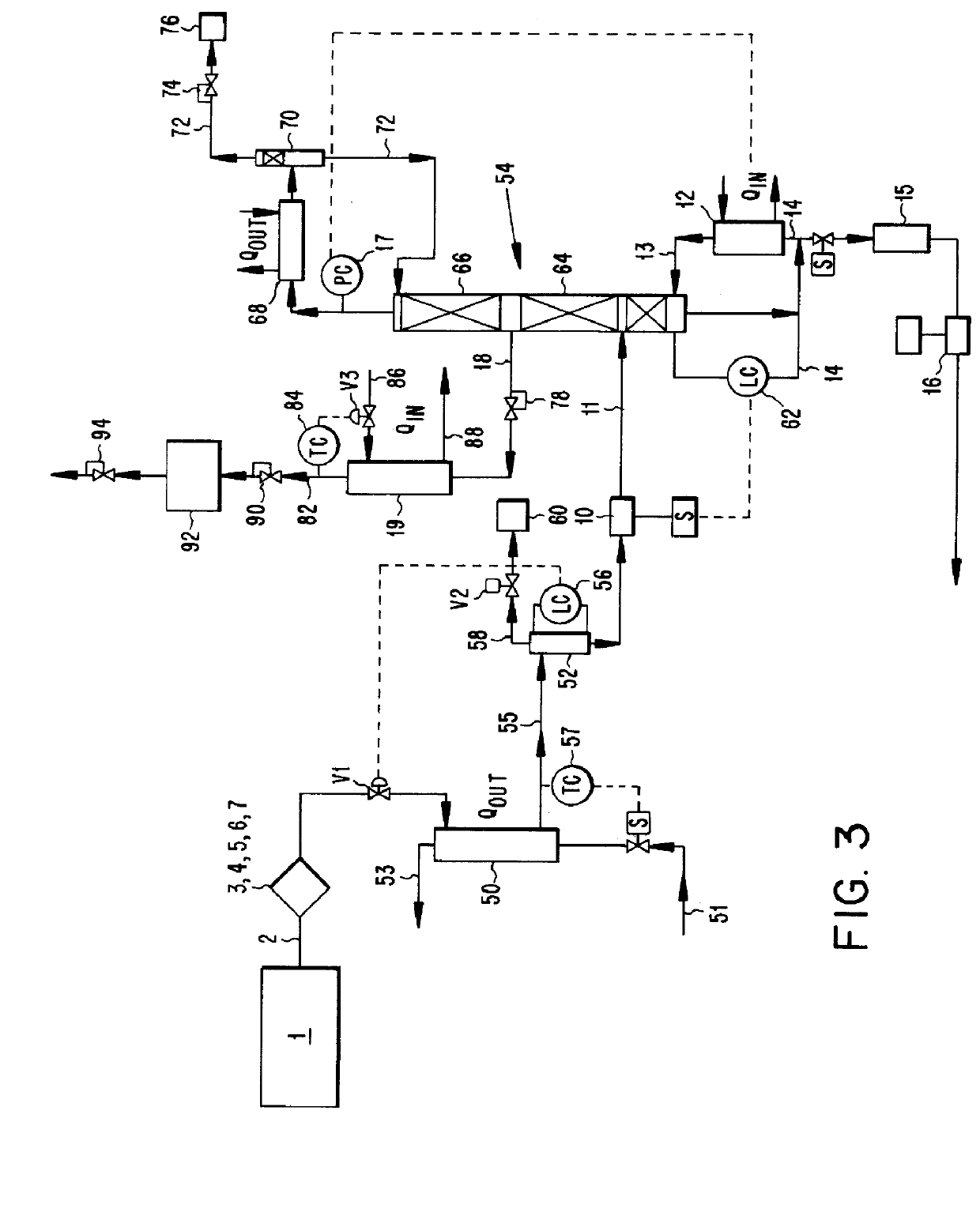

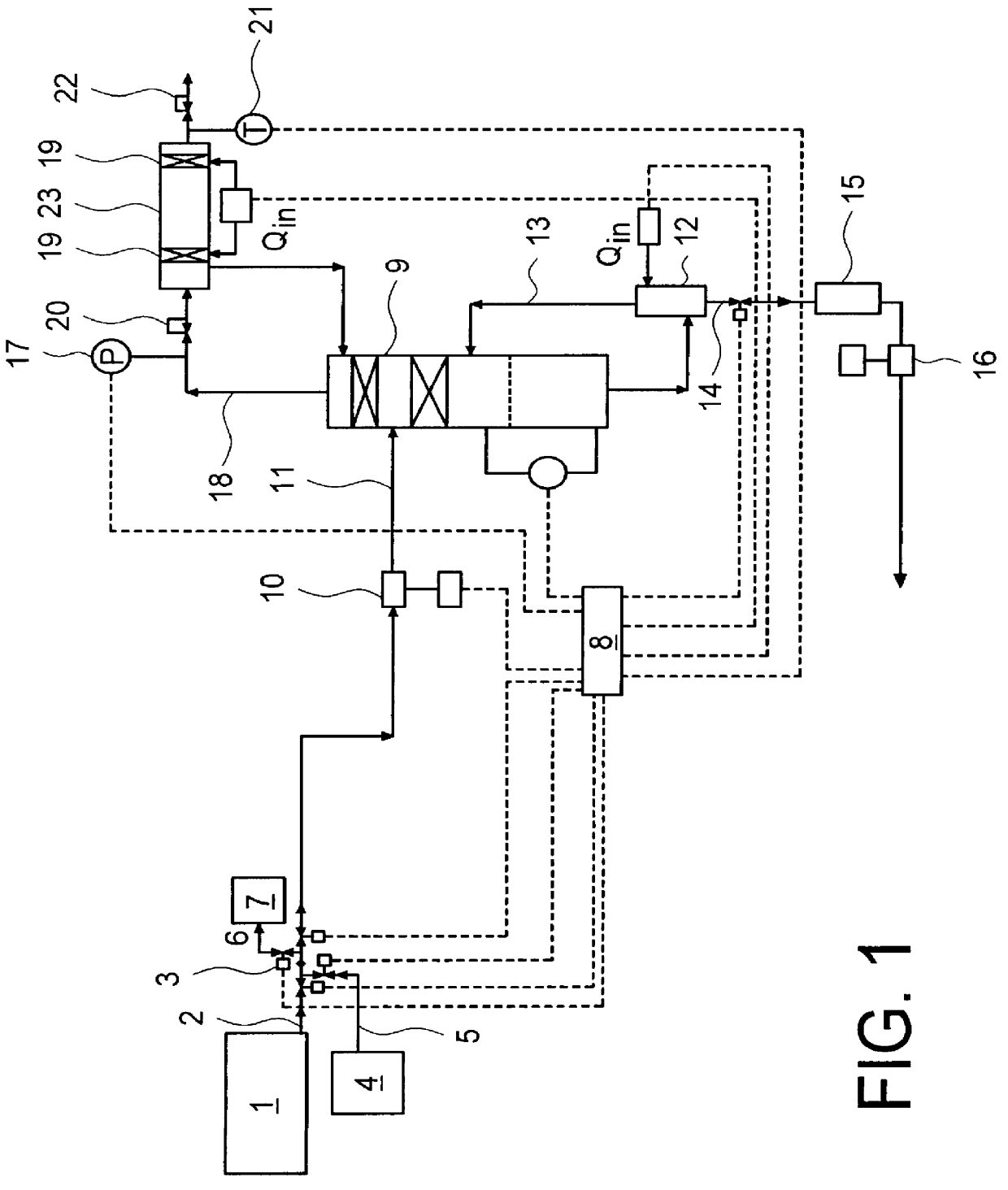

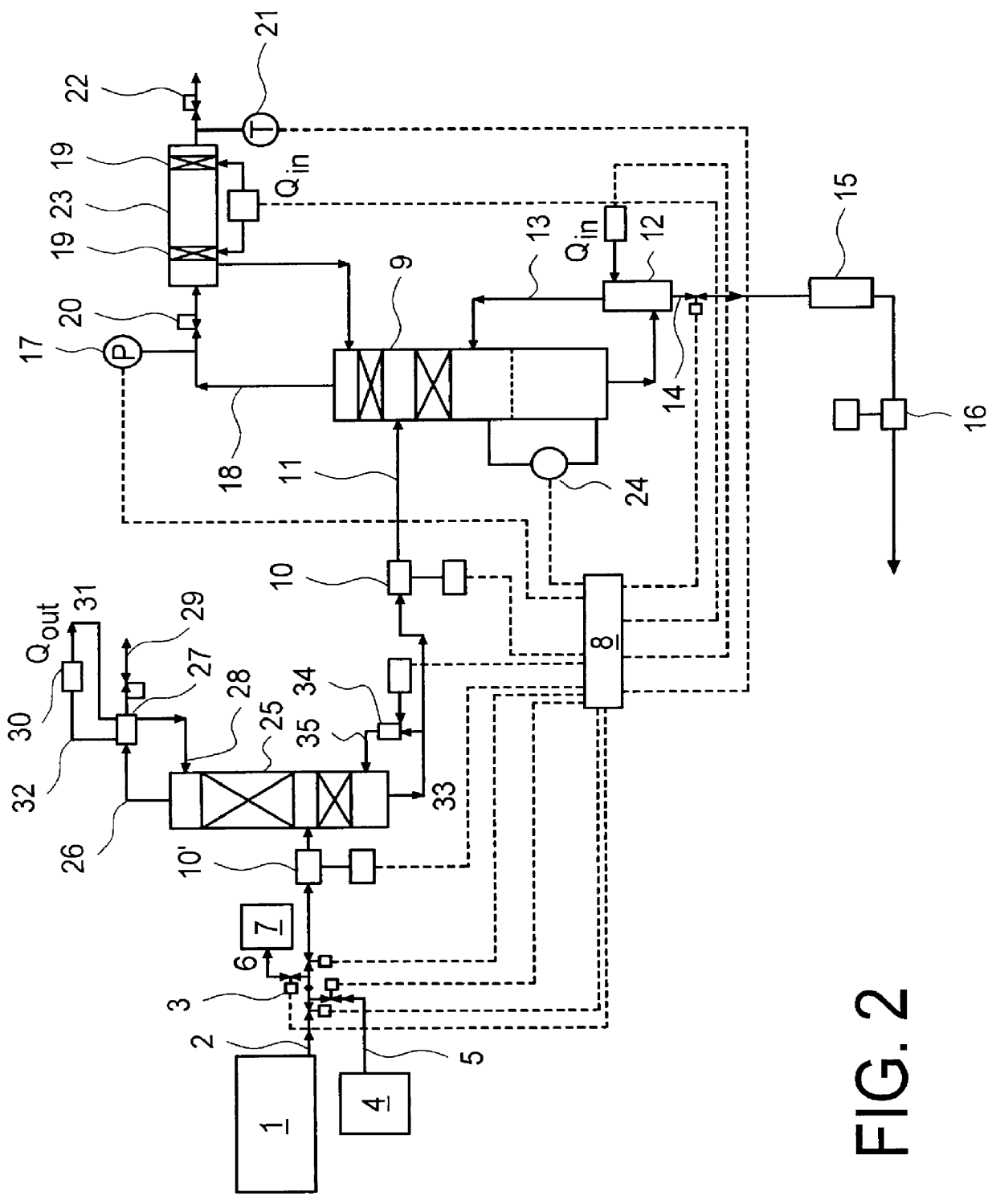

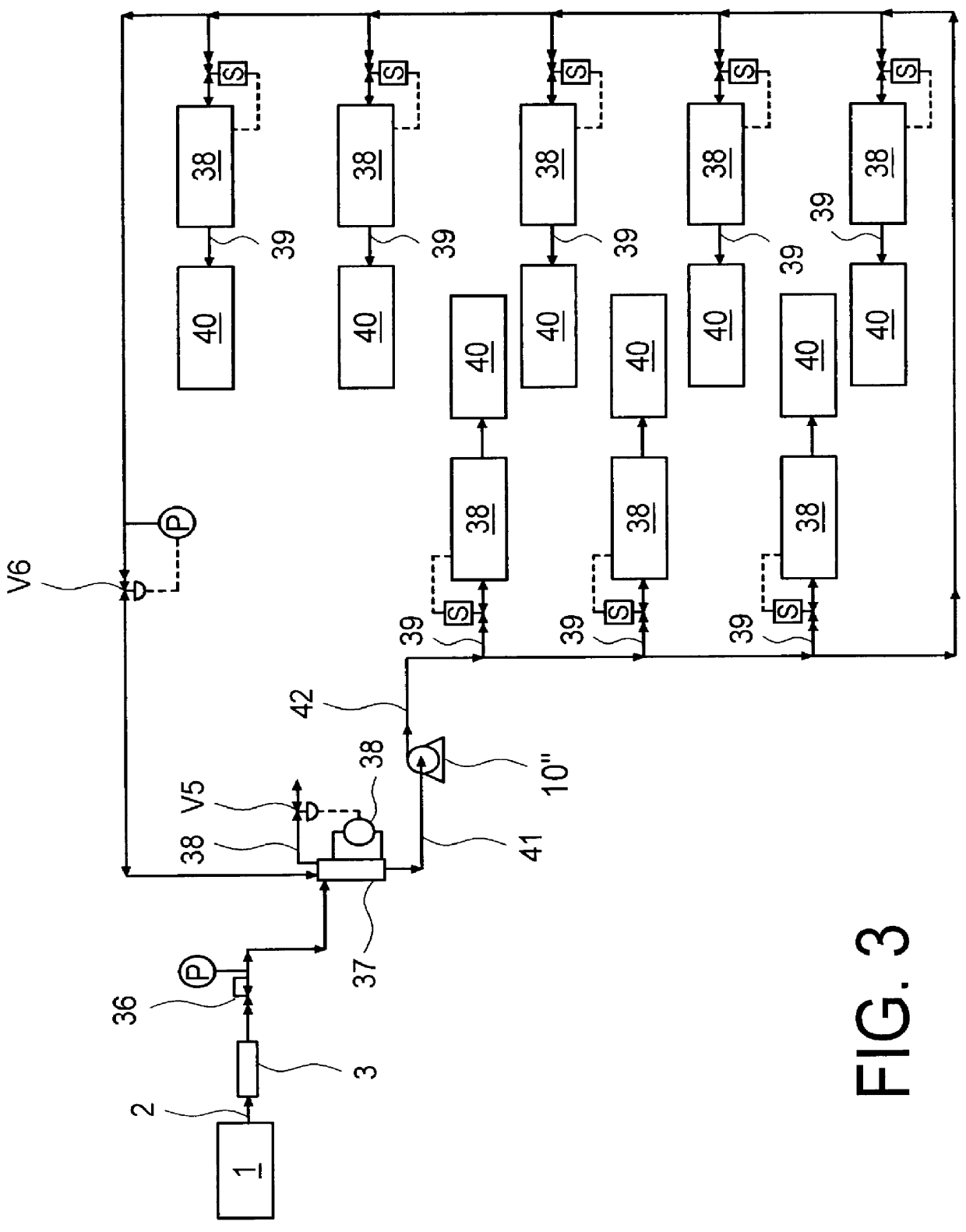

Provided are a novel system and method for delivery of a vapor phase product to a point of use, as well as a novel on-site chemical distribution system and method. The system for delivery of a vapor phase product includes a storage vessel containing a liquid chemical under its own vapor pressure, a column connected to receive the chemical in liquified state from the storage vessel, wherein the chemical is fractionated into a contaminated liquid heavy fraction and a purified light vapor fraction and a conduit connected to the column for removing the purified light vapor fraction therefrom. The system is connected to the point of use for introducing the purified vapor fraction thereto. Particular applicability is found in semiconductor manufacturing in the delivery of electronic specialty gases to one or more semiconductor processing tools.

Owner:AIR LIQUIDE AMERICA INC

System and method for delivery of a vapor phase product to a point of use

Provided are a novel system and method for delivery of a vapor phase product to a point of use, as well as a novel on-site chemical distribution system and method. The system for delivery of a vapor phase product includes a storage vessel containing a liquid chemical under its own vapor pressure, a column connected to receive the chemical in liquified state from the storage vessel, wherein the chemical is fractionated into a contaminated liquid heavy fraction and a purified light vapor fraction and a conduit connected to the column for removing the purified light vapor fraction therefrom. The system is connected to the point of use for introducing the purified vapor fraction thereto. Particular applicability is found in semiconductor manufacturing in the delivery of electronics specialty gases to one or more semiconductor processing tools.

Owner:AIR LIQUIDE AMERICA INC

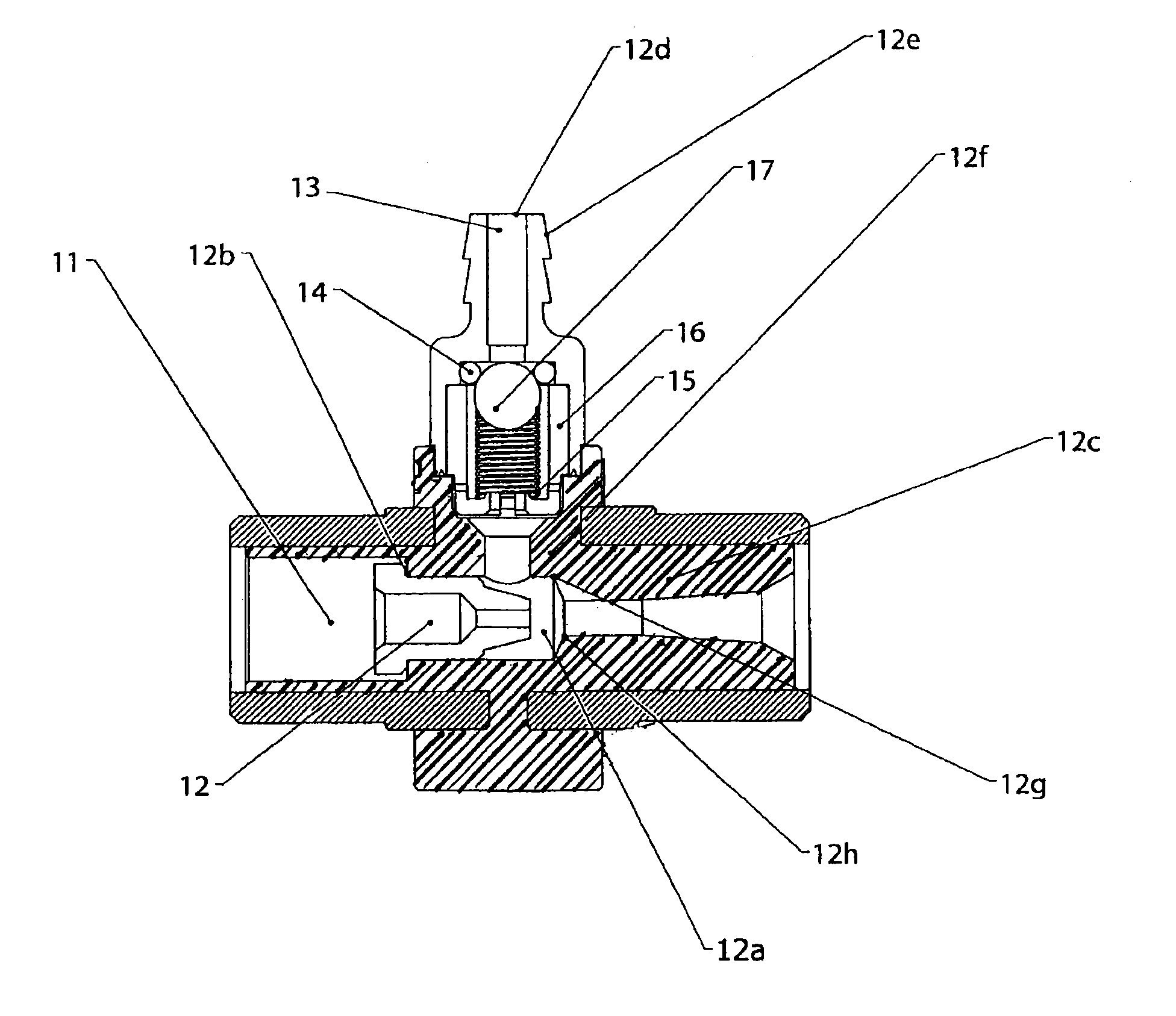

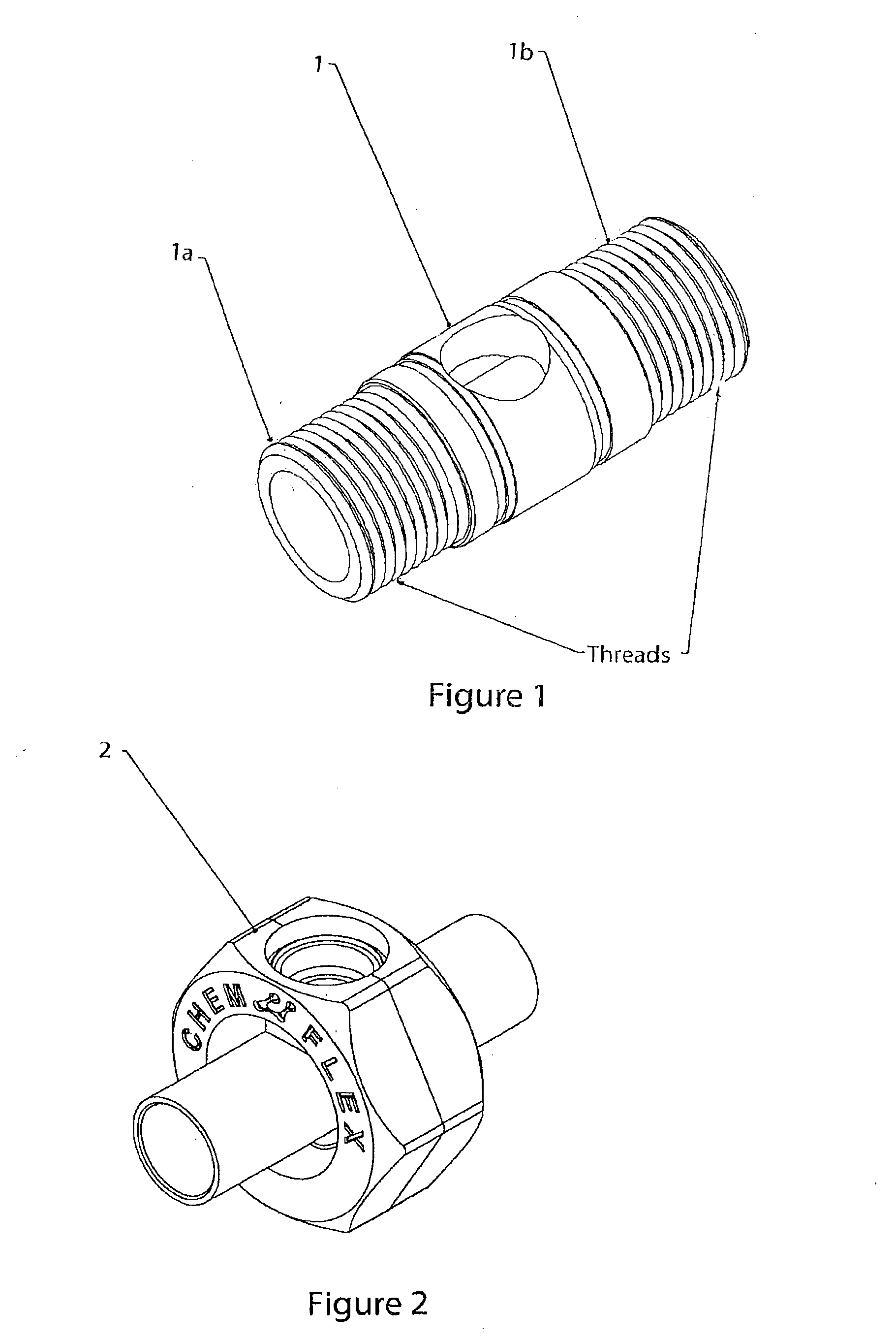

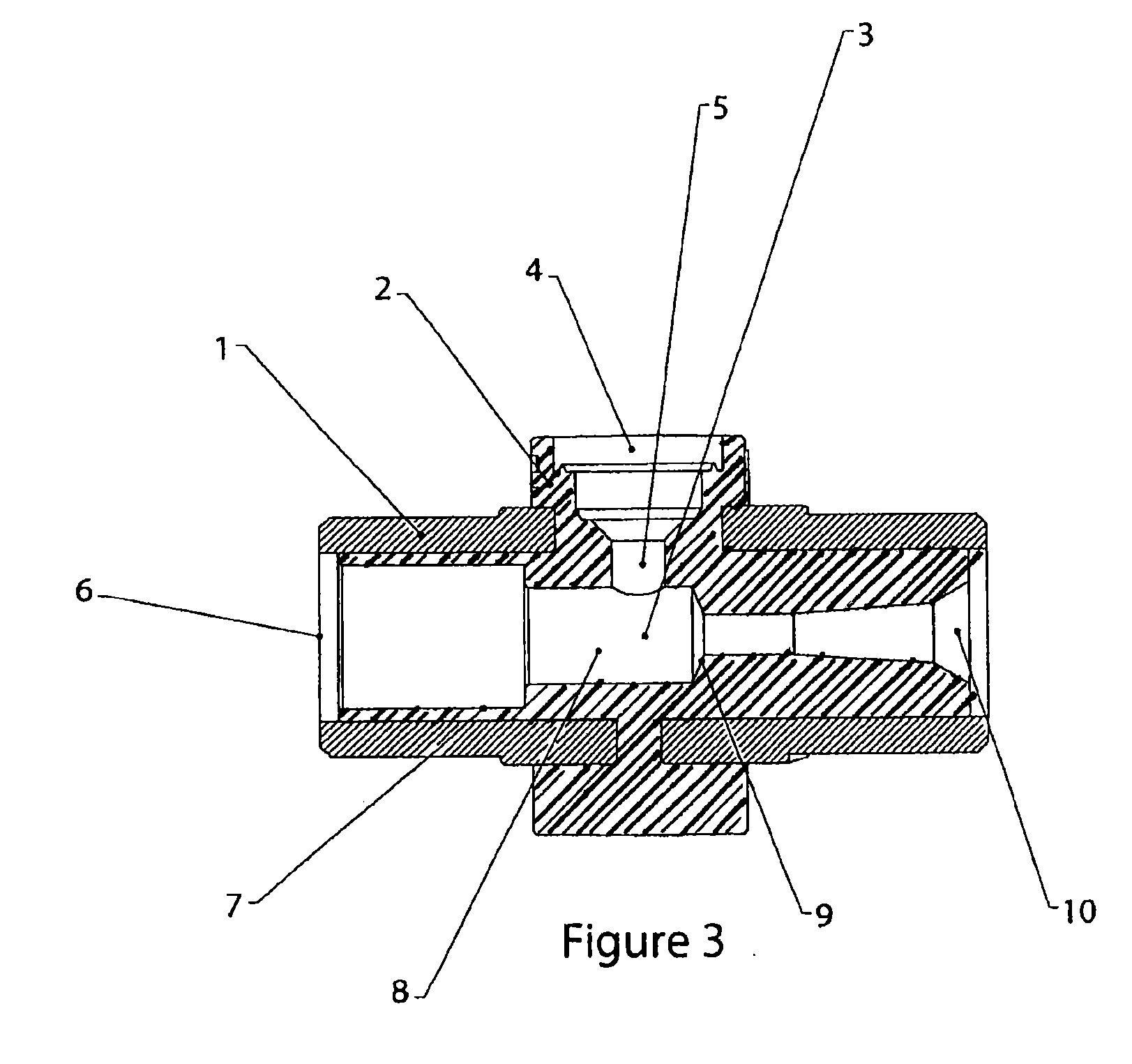

Eductor assembly with dual-material eductor body

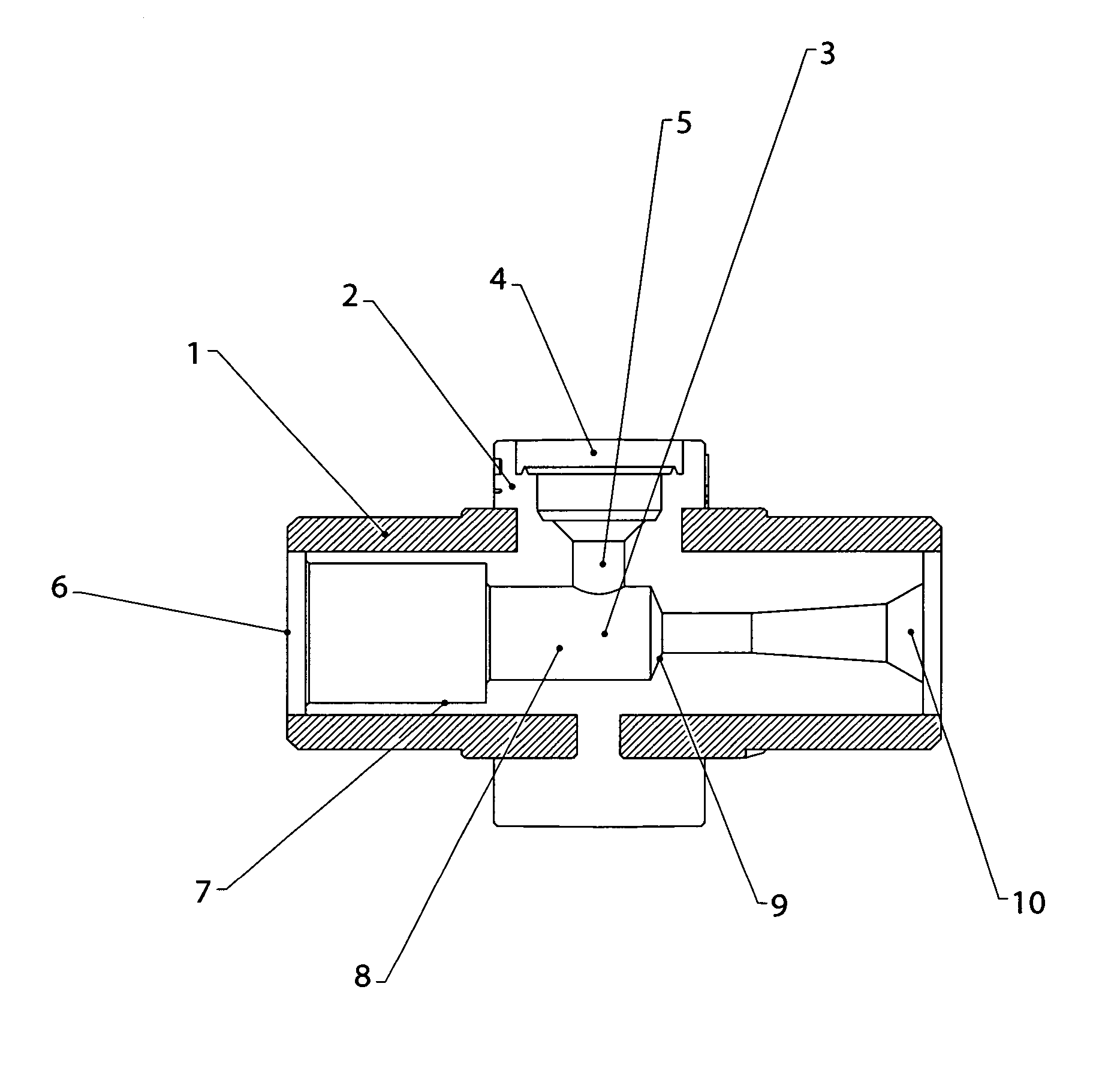

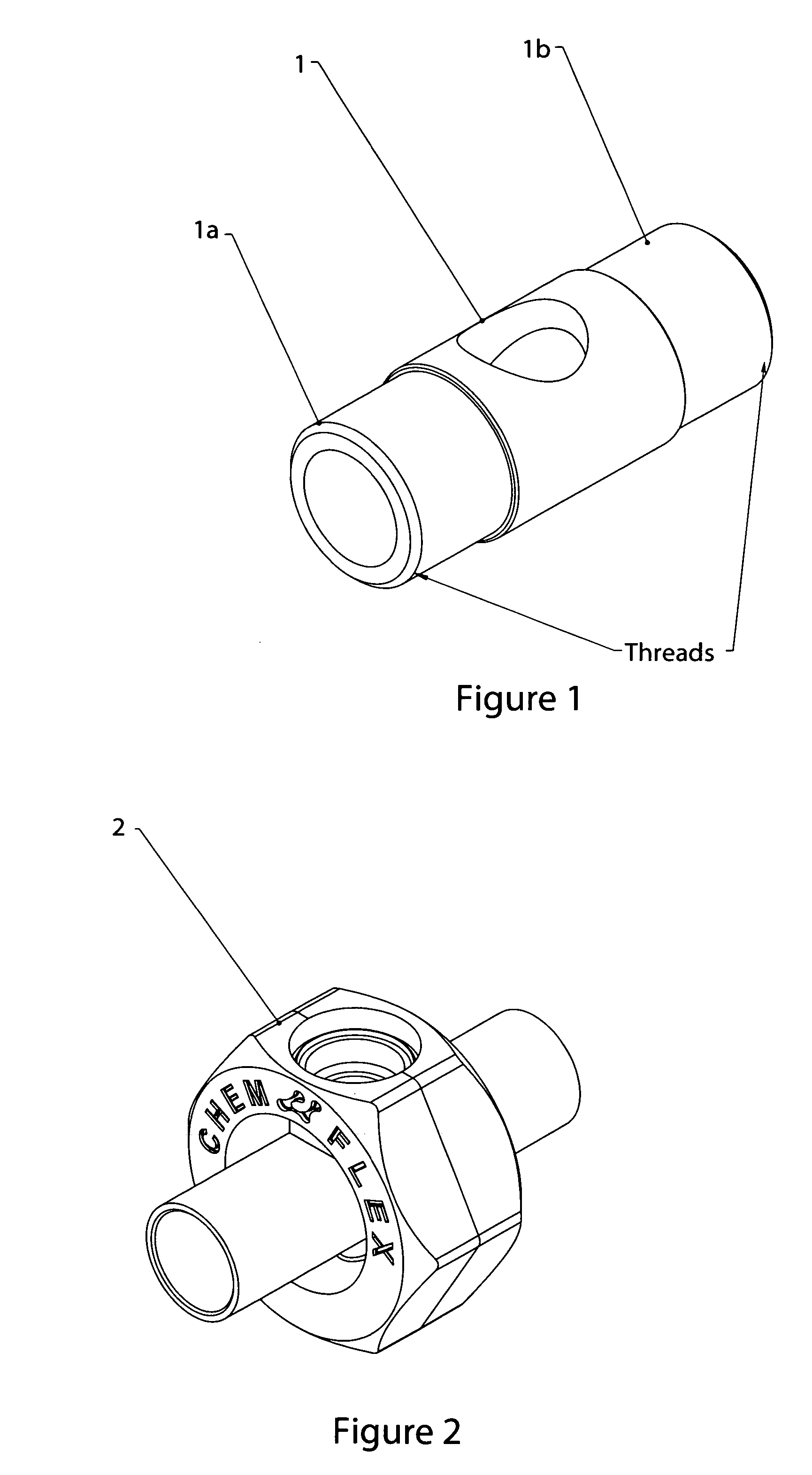

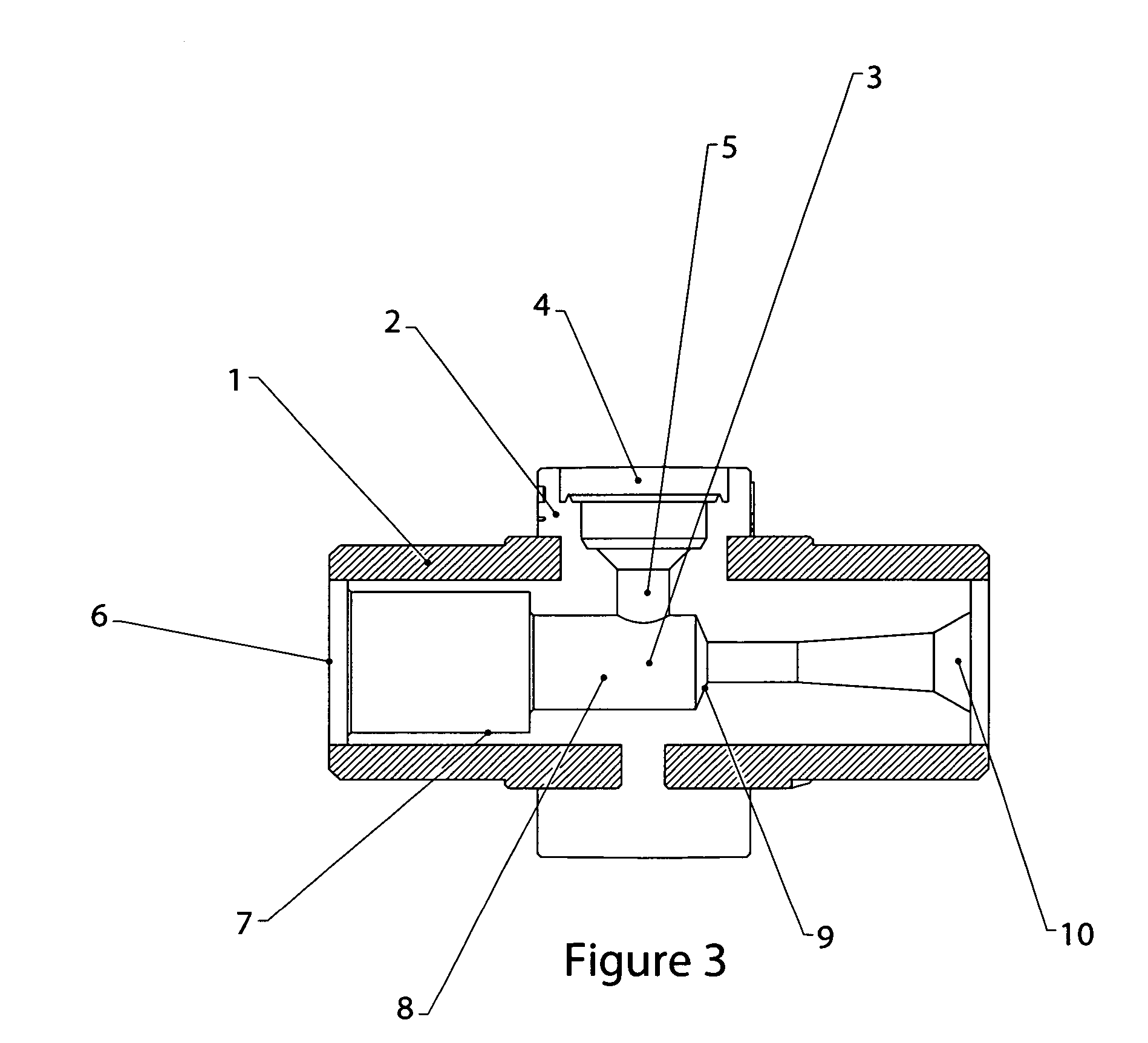

An improved venturi-style eductor apparatus for dispensing chemicals into a motive fluid stream where an eductor body FIG. 3 is manufactured by molding a chemically inert polymer material FIG. 2 around and inside a metallic insert FIG. 1. Opposing ends of the metallic insert may be threaded, flanged, or machined for push-in connection to facilitate mating with a motive fluid source and a dispensing device. By manufacturing an eductor assembly using a single-piece metal insert over-molded with an inert polymer provides improved chemical resistance for aggressive applications and allows improvements in venturi geometry not achievable using traditional machined components. This apparatus reduces manufacturing cost over current state-of-the-art eductor assemblies by using a single molding step to create flow-path geometry in the eductor body while retaining mechanical strength with the metallic insert FIG. 1.

Owner:SONNYS HFI HOLDINGS LLC

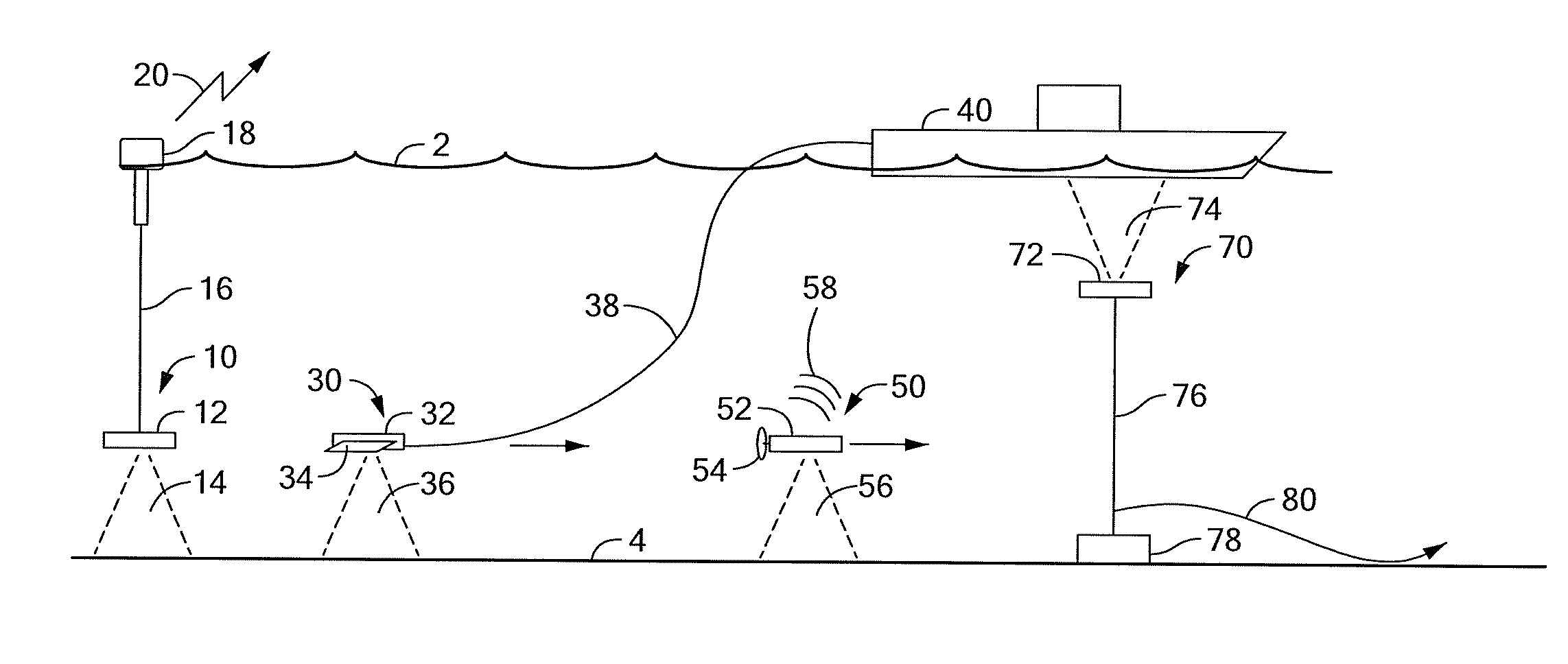

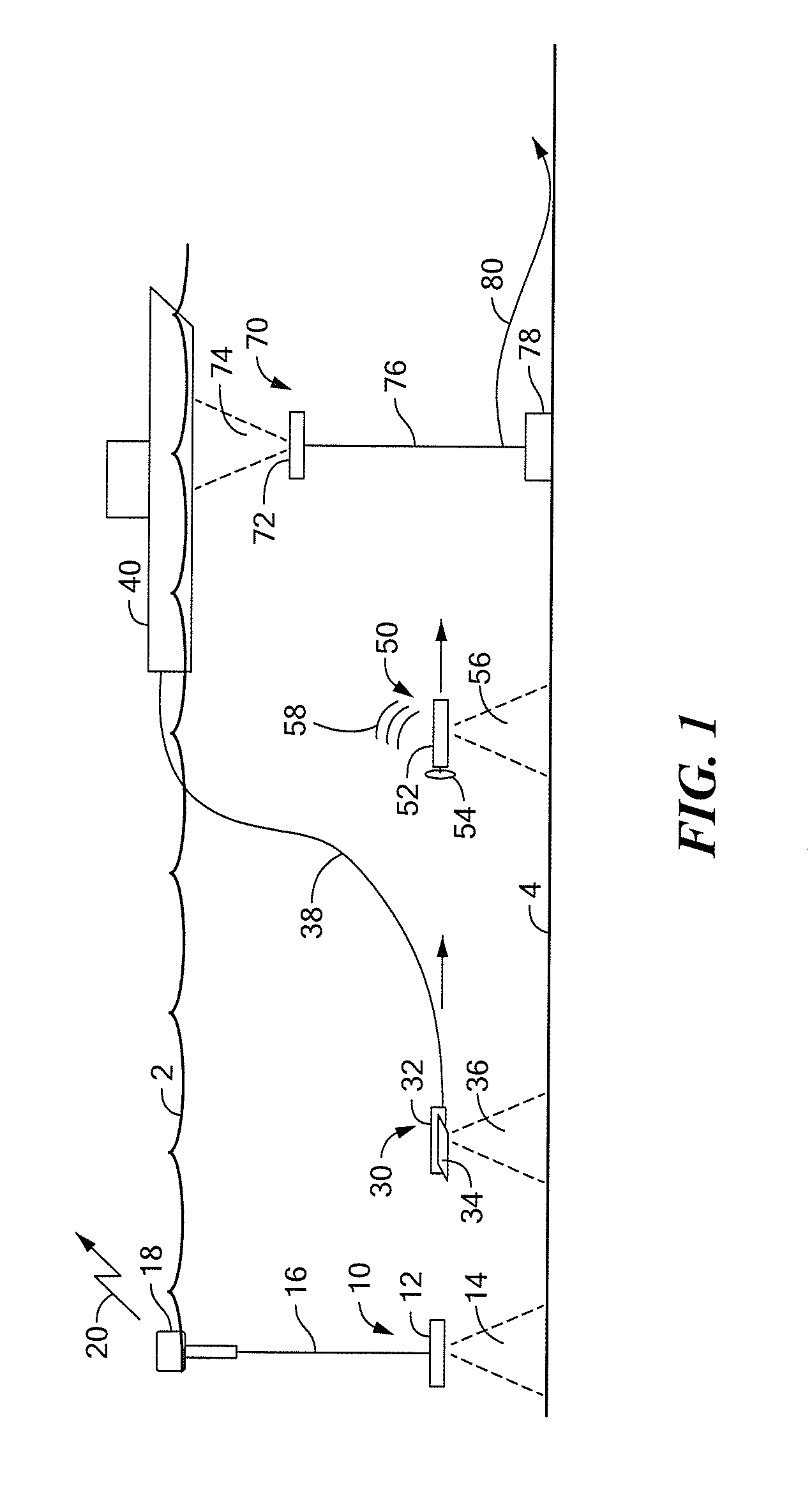

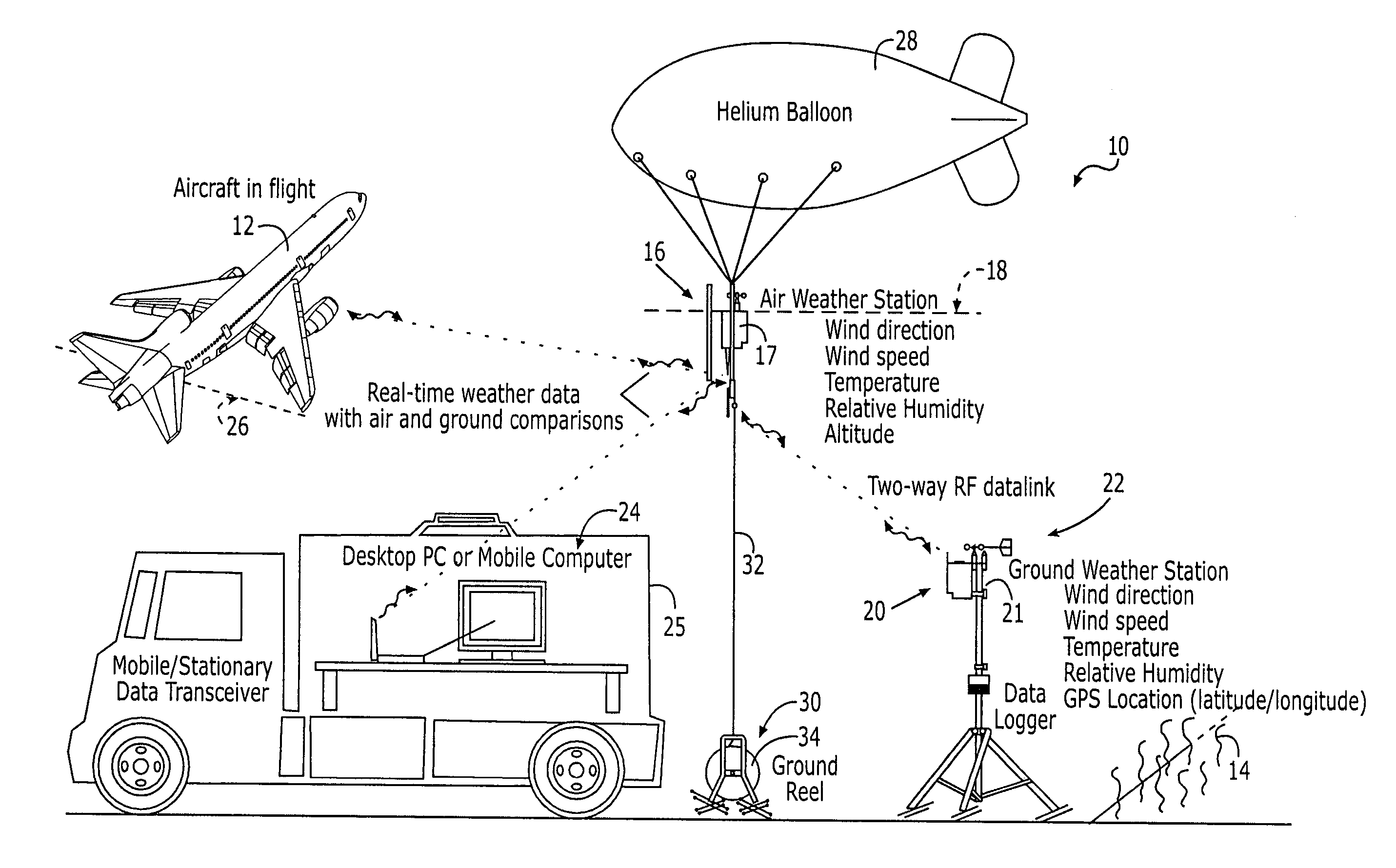

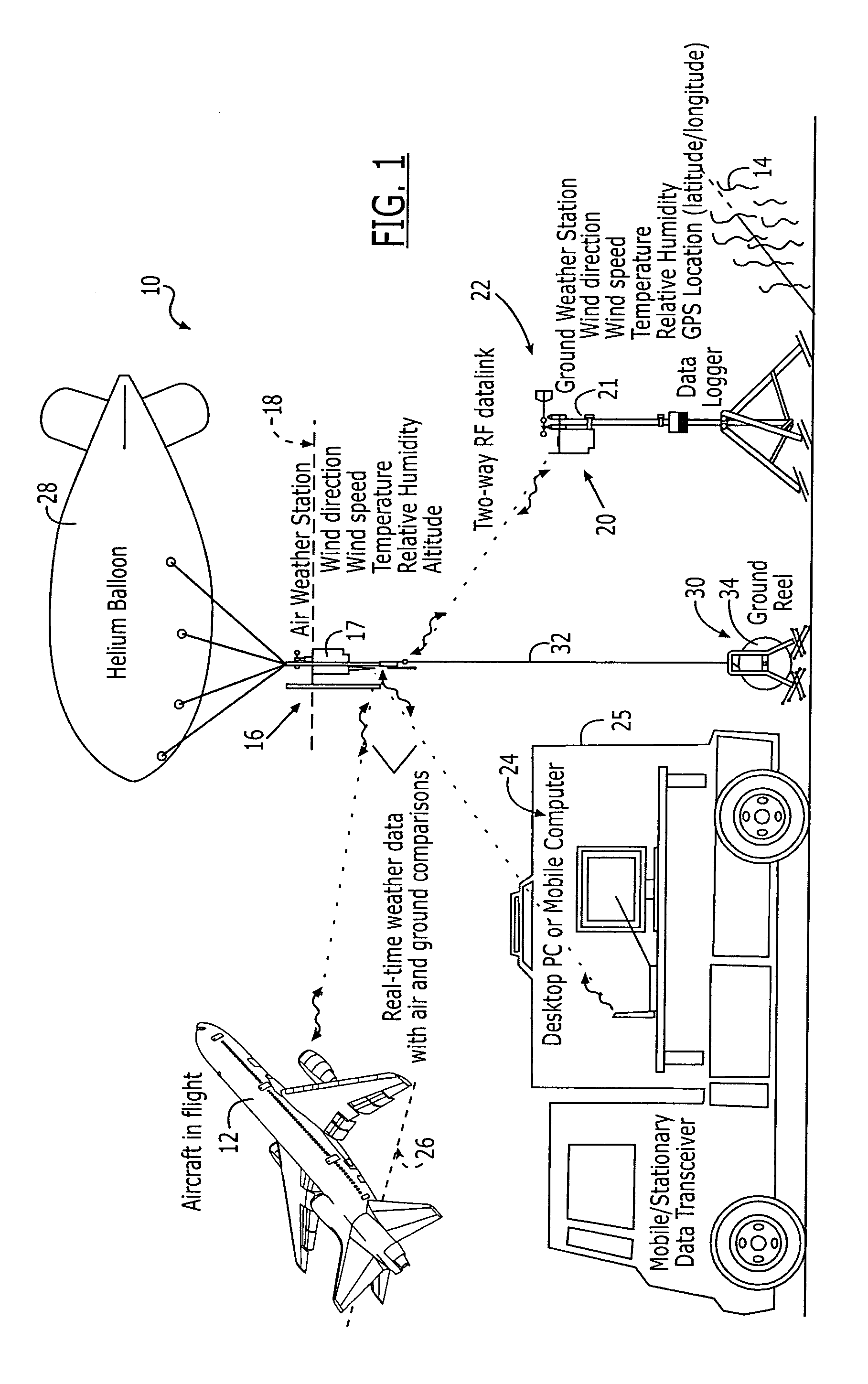

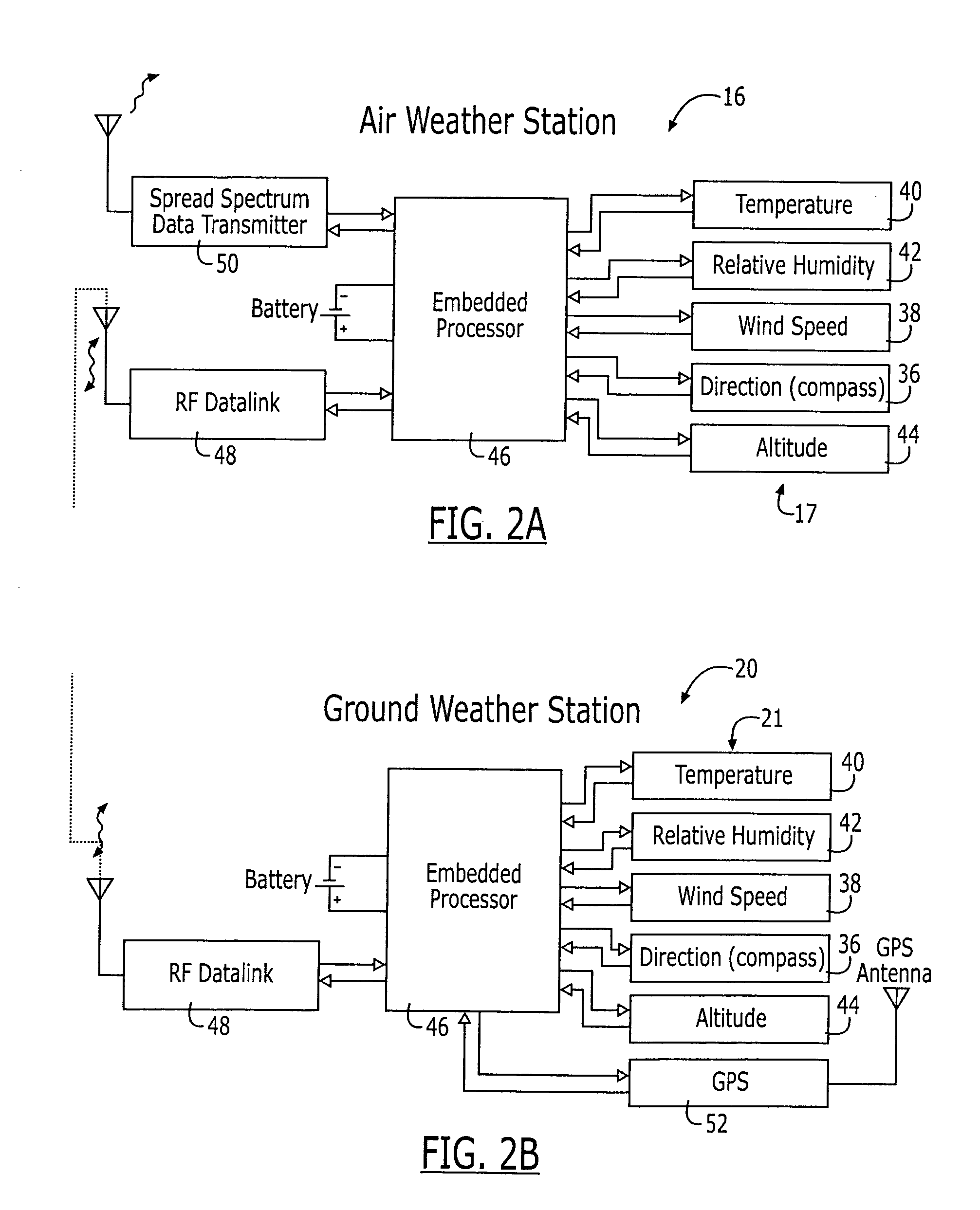

Aerial chemical application and control method

Owner:ADAPCO

Eductor assembly with dual-material eductor body

An improved venturi-style eductor apparatus for dispensing chemicals into a motive fluid stream where an eductor body FIG. 3 is manufactured by molding a chemically inert polymer material FIG. 2 around and inside a metallic insert FIG. 1. Opposing ends of the metallic insert may be threaded, flanged, or machined for push-in connection to facilitate mating with a motive fluid source and a dispensing device. By manufacturing an eductor assembly using a single-piece metal insert over-molded with an inert polymer provides improved chemical resistance for aggressive applications and allows improvements in venturi geometry not achievable using traditional machined components. This apparatus reduces manufacturing cost over current state-of-the-art eductor assemblies by using a single molding step to create flow-path geometry in the eductor body while retaining mechanical strength with the metallic insert FIG. 1.

Owner:HYDRA FLEX INC

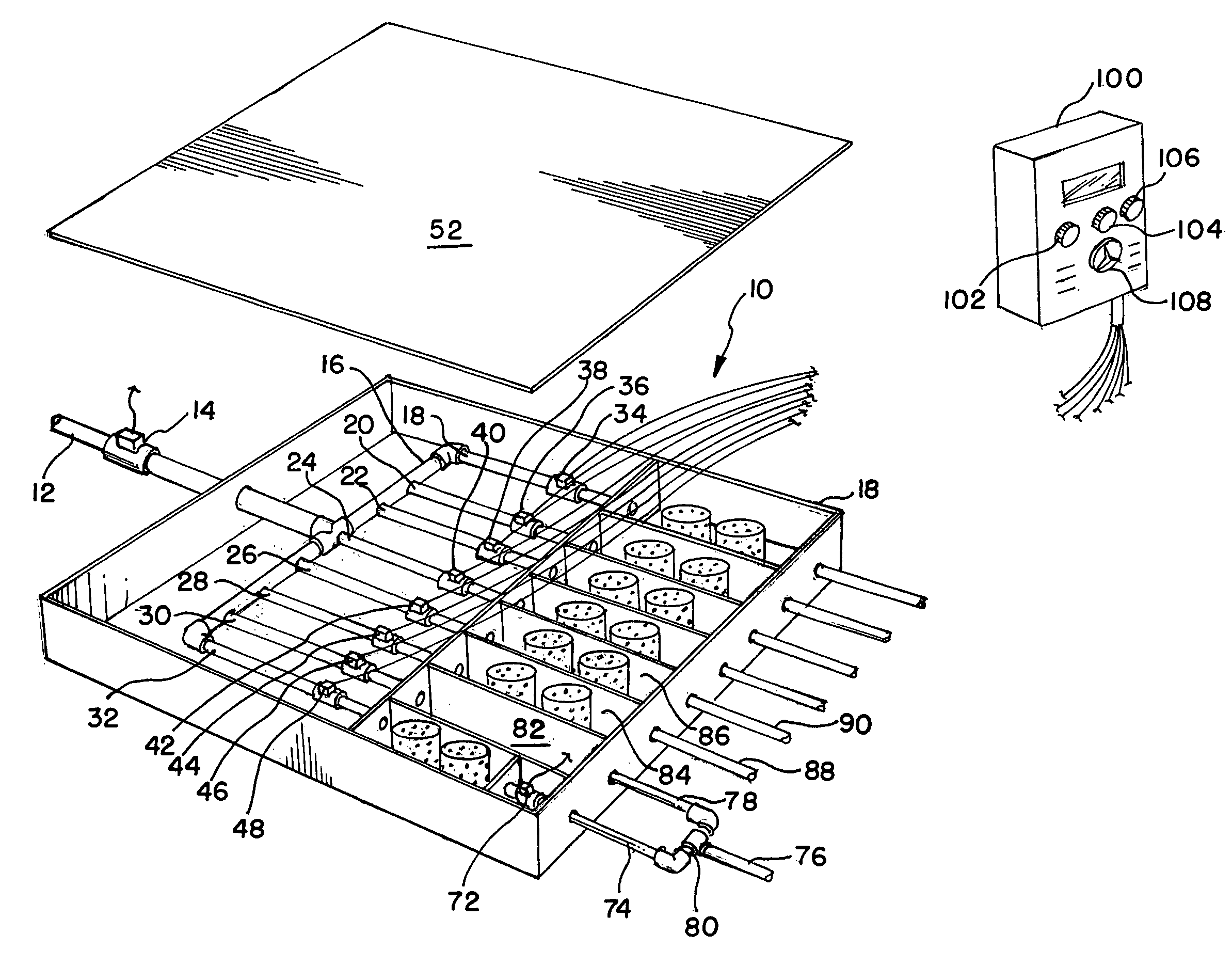

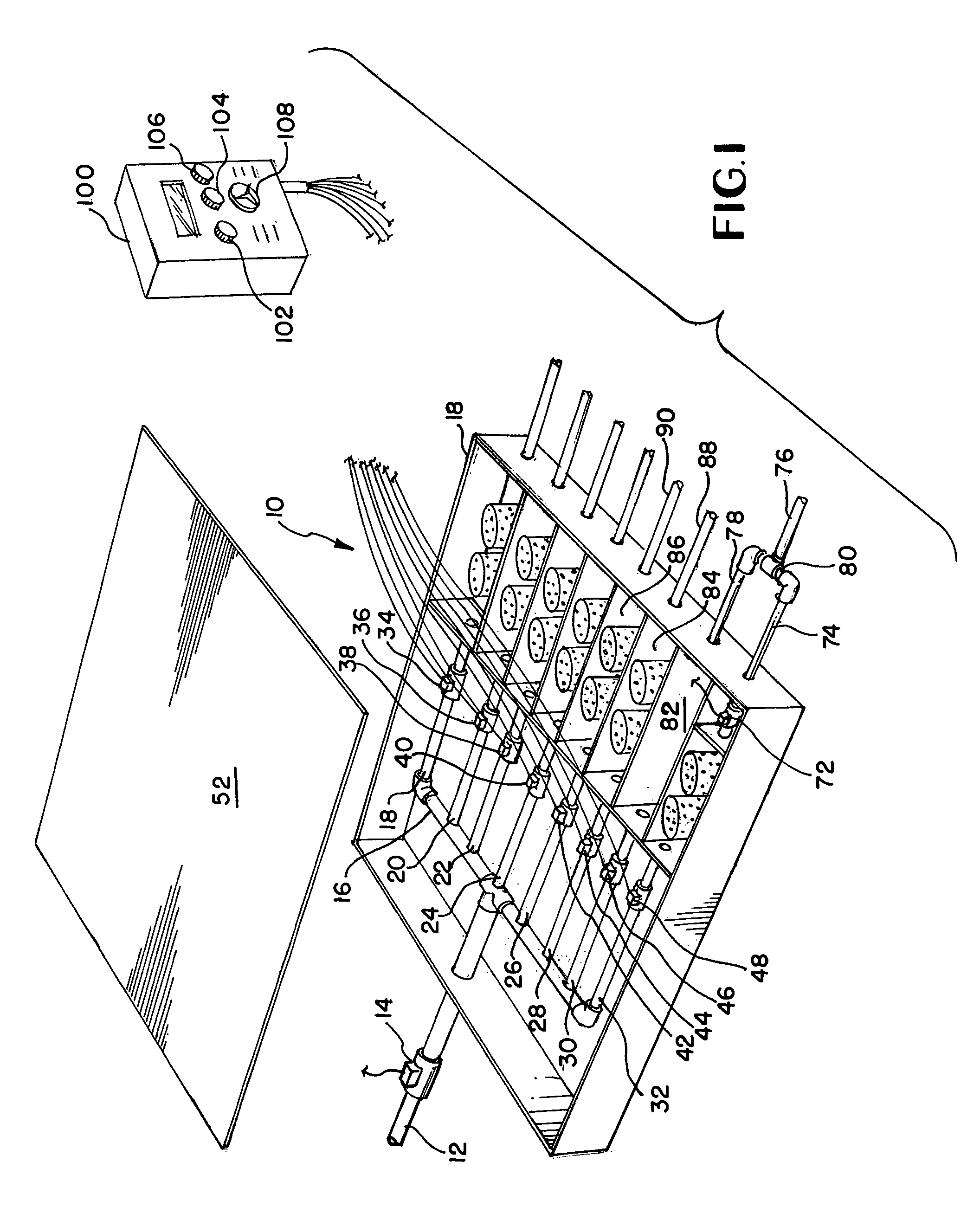

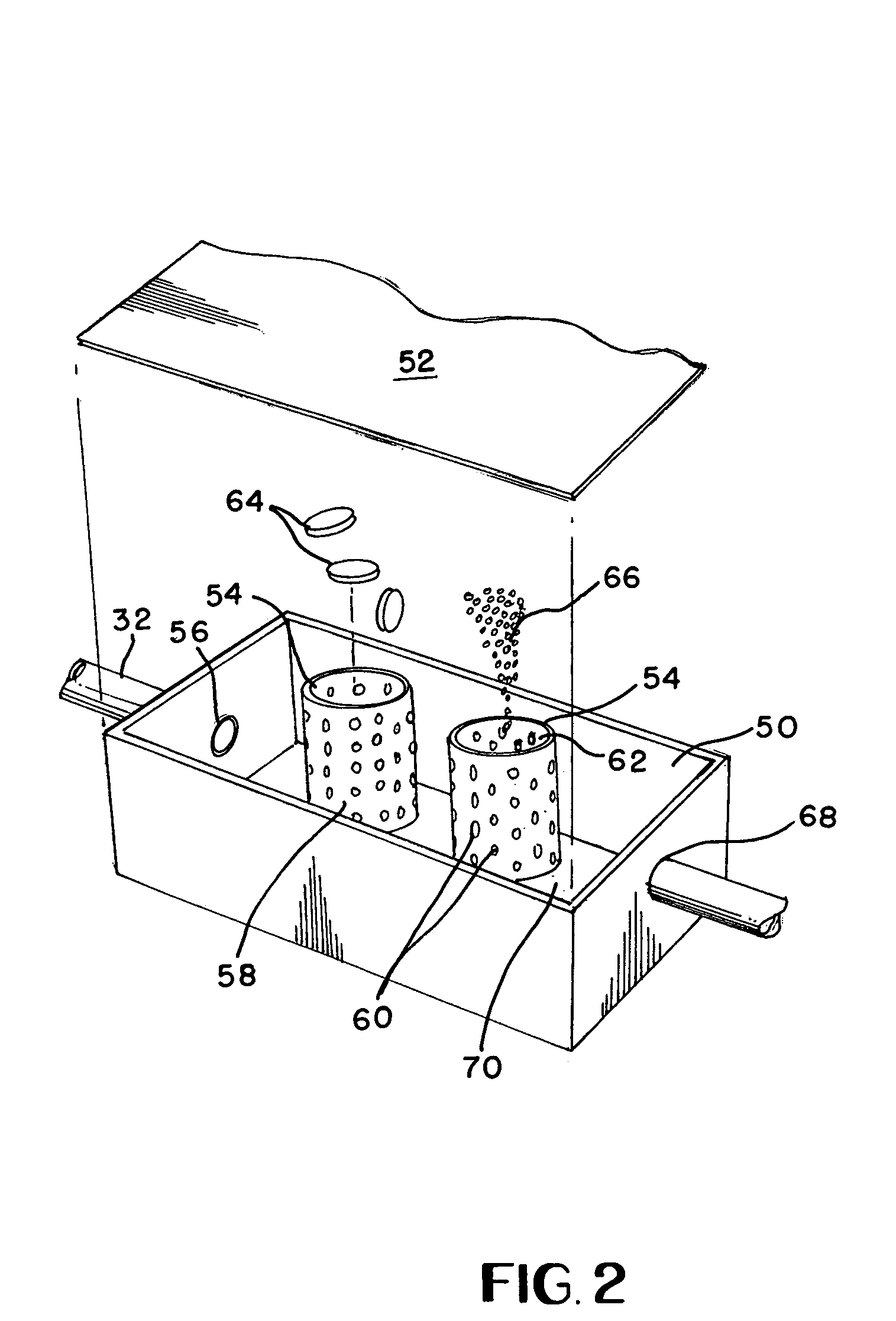

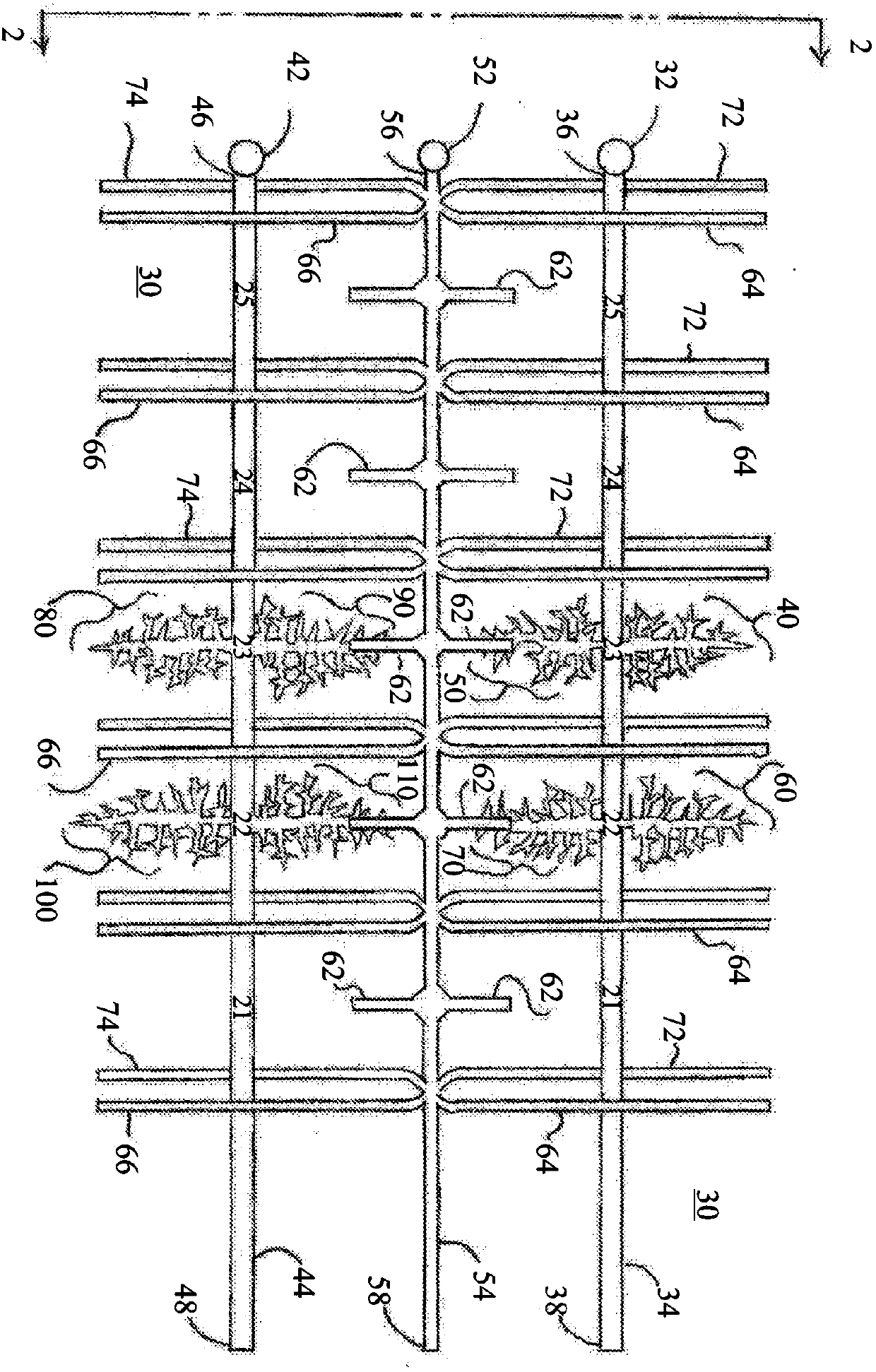

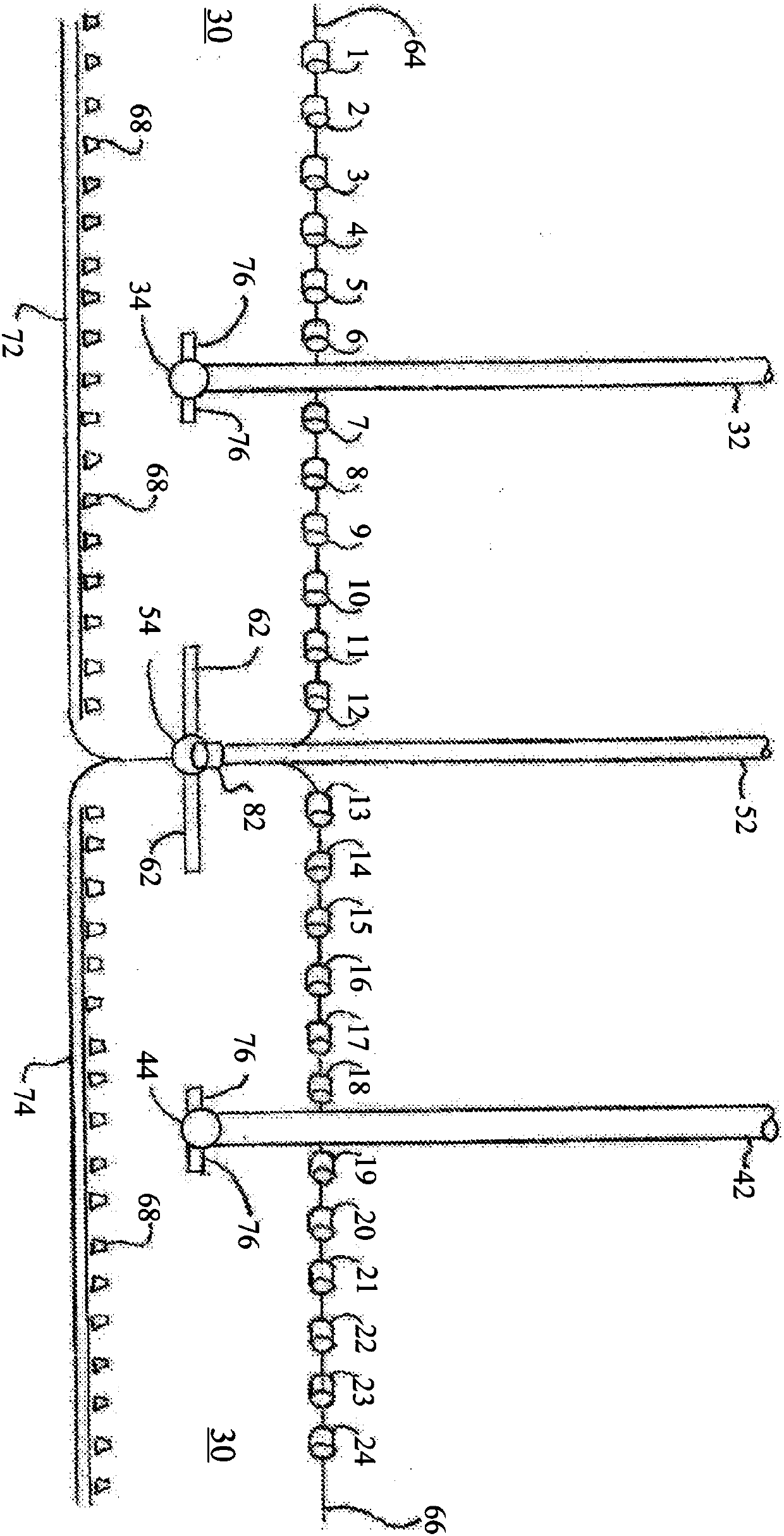

Yard chemical dispensing apparatus

A chemical distribution apparatus contains at least one, and preferably multiple chambers which house magazines which accept solid lawn treatment chemicals such as fertilizers, herbicides, fungicides, insecticides, lime treatments, pre-emergents, post-emergents, and the like. As water is passed into the chemical distribution apparatus, it is preferably selectively controlled by a controller to a particular chamber for distribution of a particular chemical in accordance with a pre-set schedule.

Owner:GRAHAM JR WILLIAM C +1

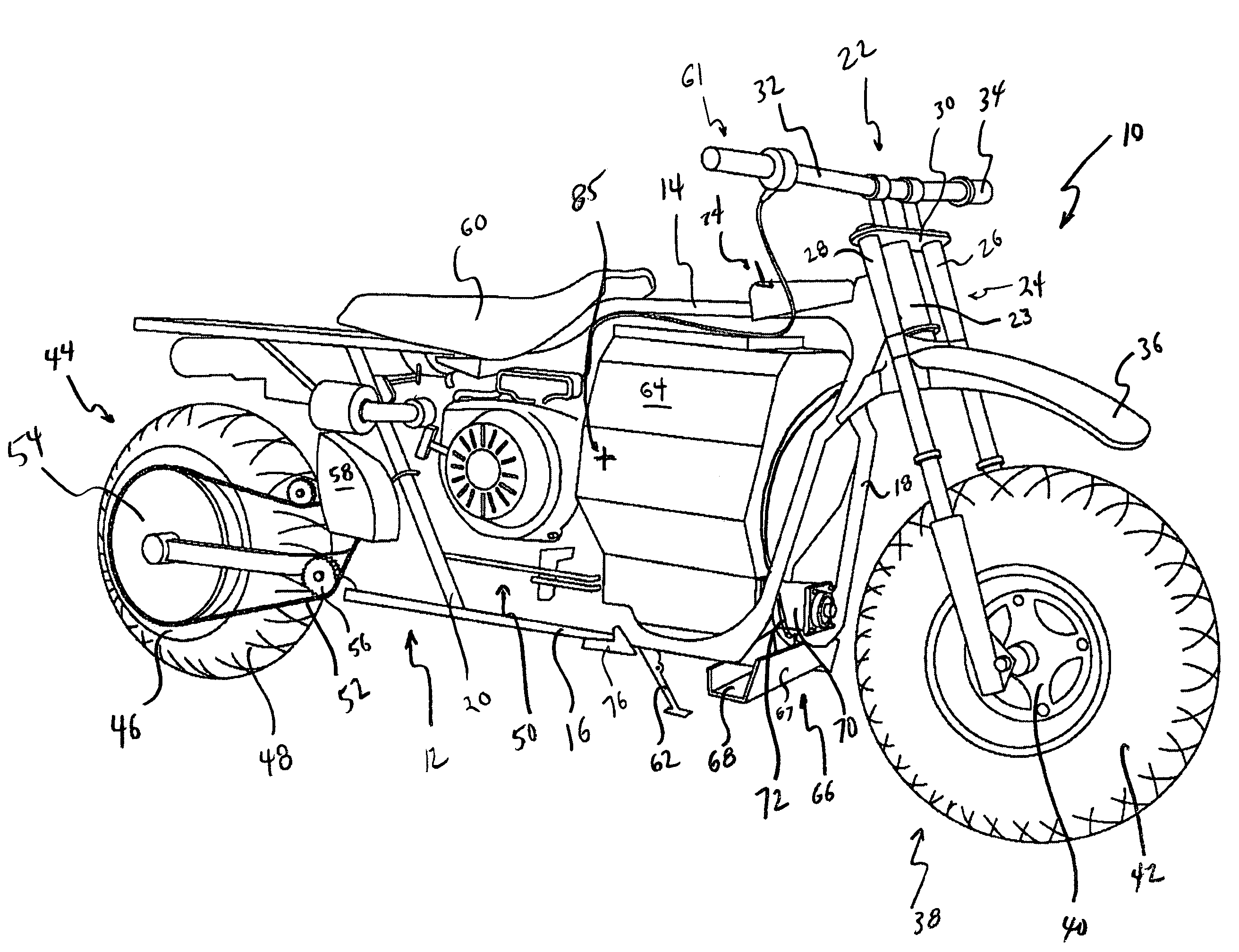

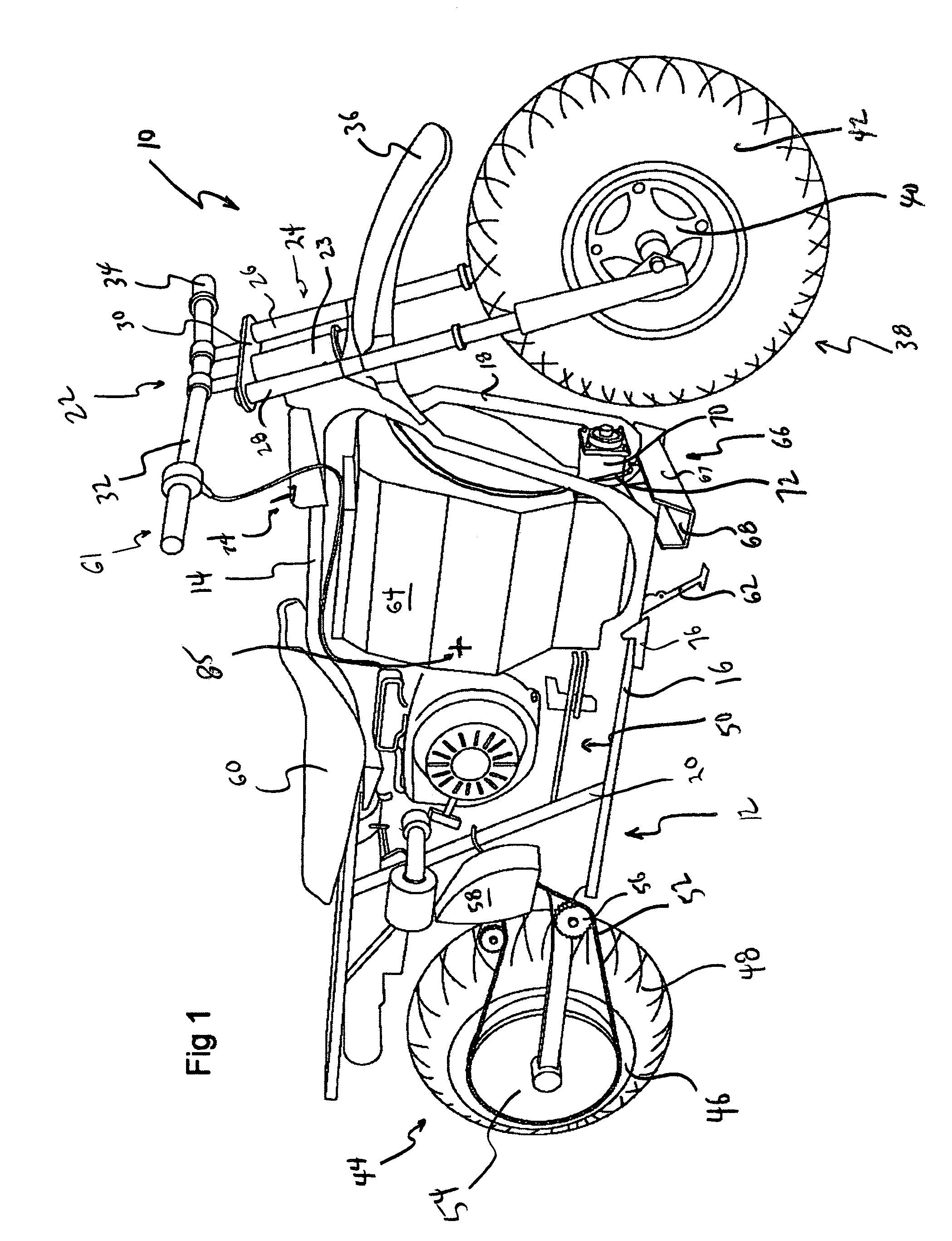

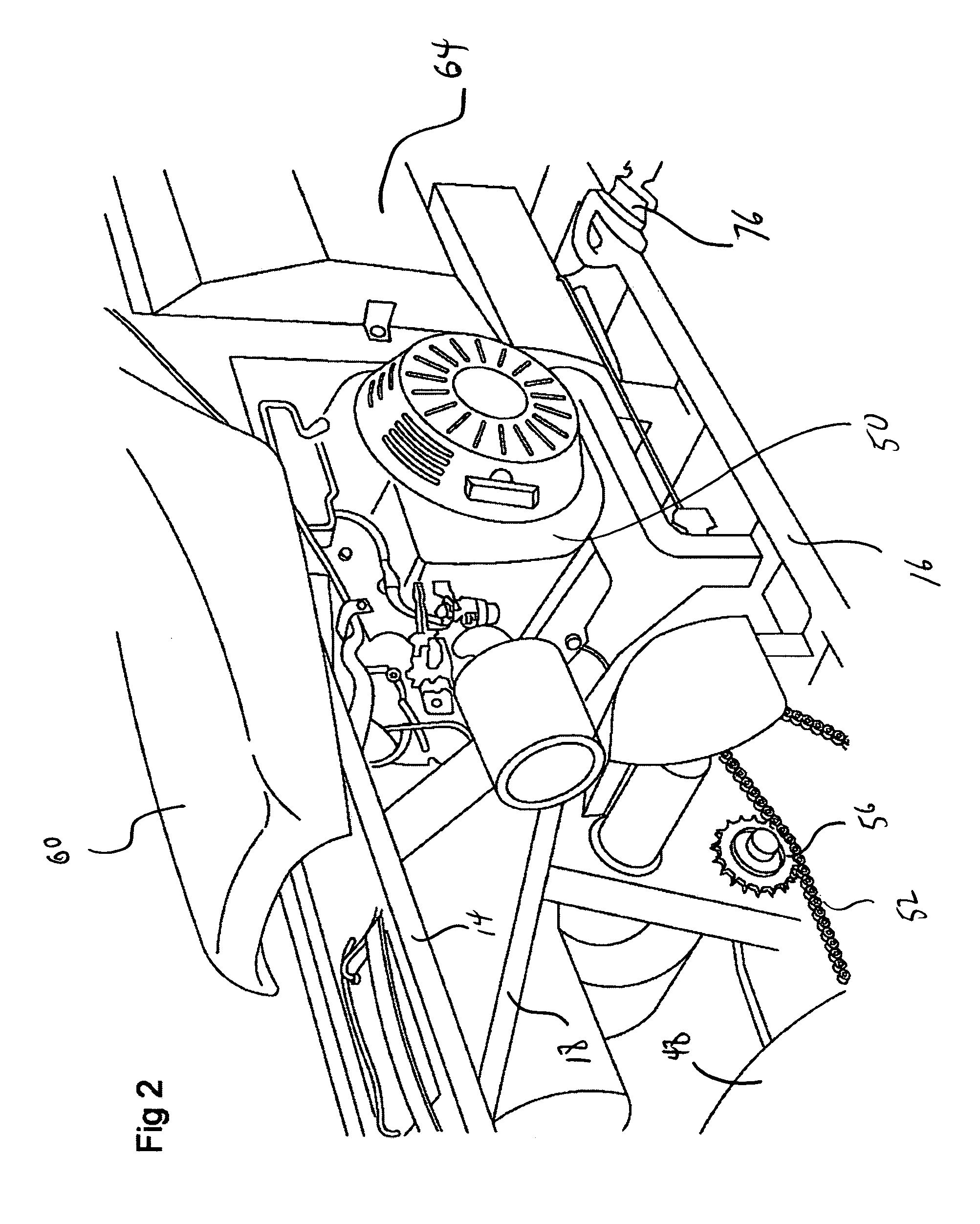

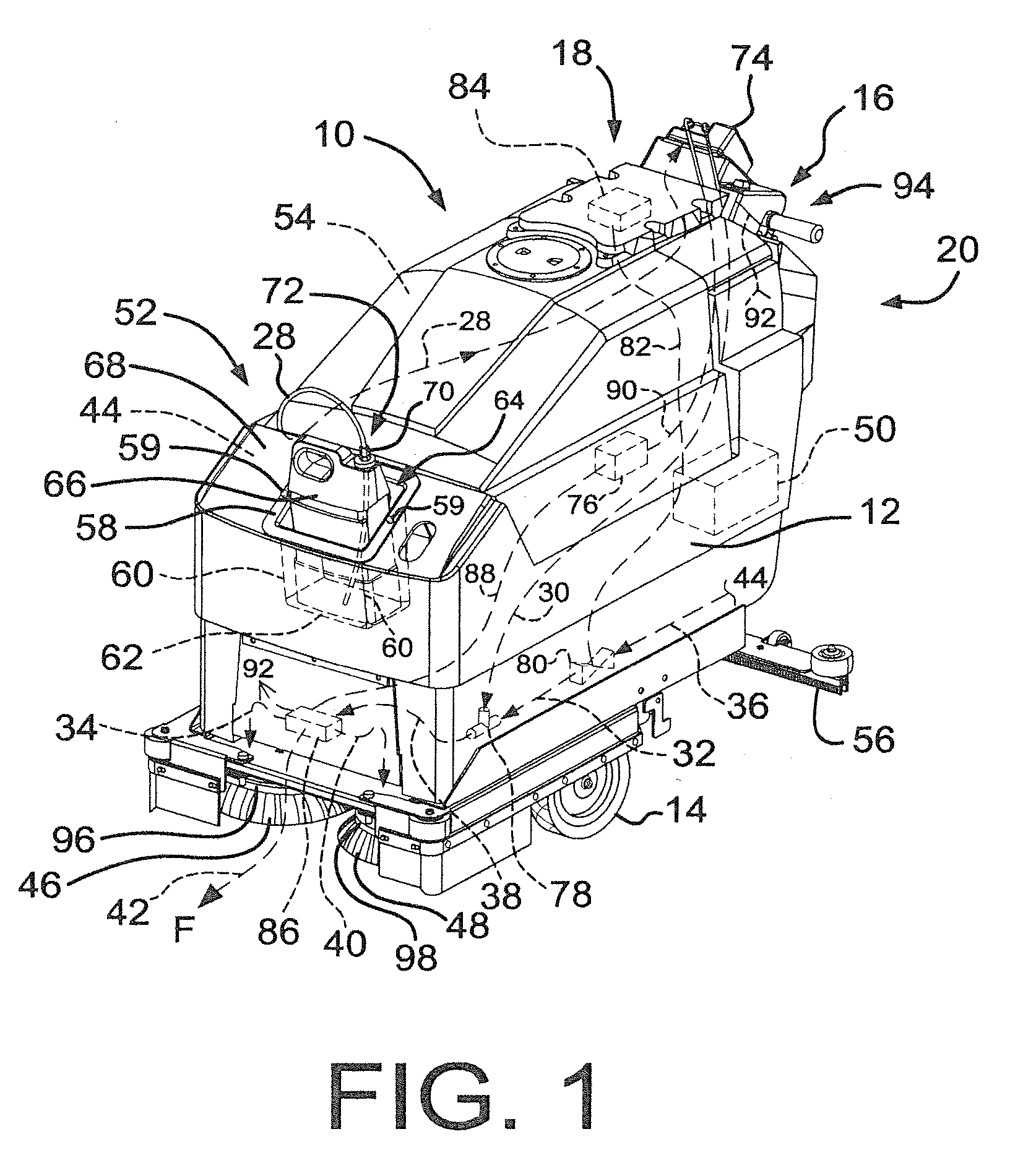

Self-propelled chemical delivery vehicle and dispenser

InactiveUS7275700B2Safe wayImprove controllabilityWatering devicesFertiliser distributersGround contactDrive wheel

Owner:MILES JR D WAYNE

Purification of organic solvent fluids

InactiveUS20070084792A1Cost efficientPrecision productionIon exchange regulation/controlGroup 4/14 element organic compoundsOrganic solventIon exchange

A chemical distribution system having improved organic solvent fluid purity and consistency includes a vessel containing ion-exchange media positioned within a fluid flow pathway such that the organic solvent fluid passes through the ion-exchange media, thereby effecting removal of undesired impurities. Different embodiments of the invention position the vessel at varying locations within the fluid flow pathway. The chemical distribution system also preferably includes a return chemical flow pathway that recirculates purified organic solvent fluid through the ion-exchange media-containing vessel and thereby enables the system operator to conduct incremental adjustment of the solvent purity until a desired overall purity is attained.

Owner:MULLEE WILLIAM H

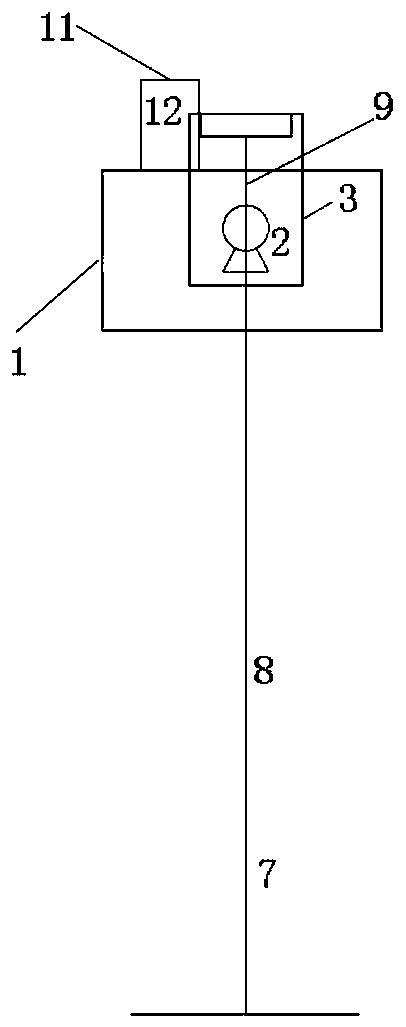

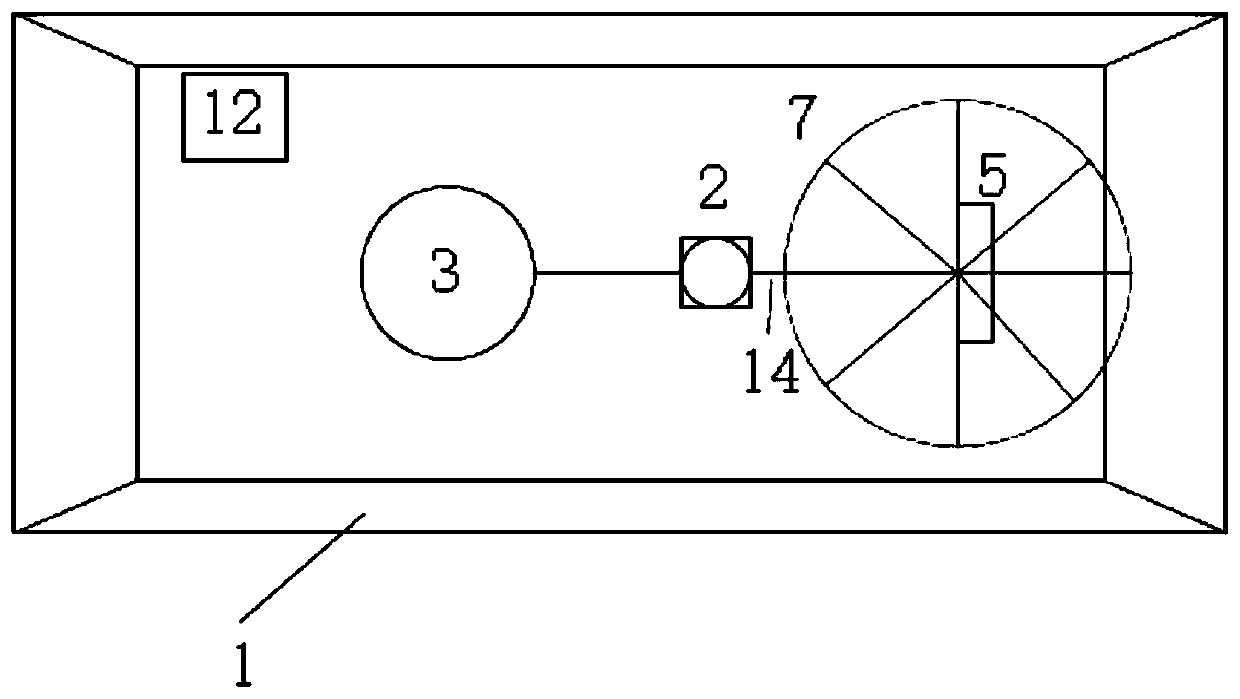

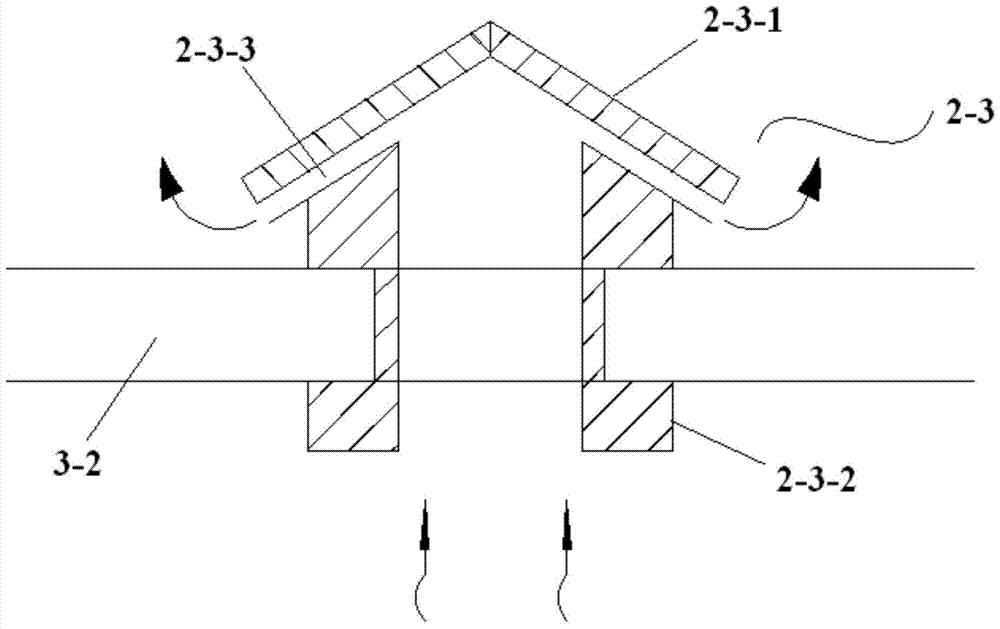

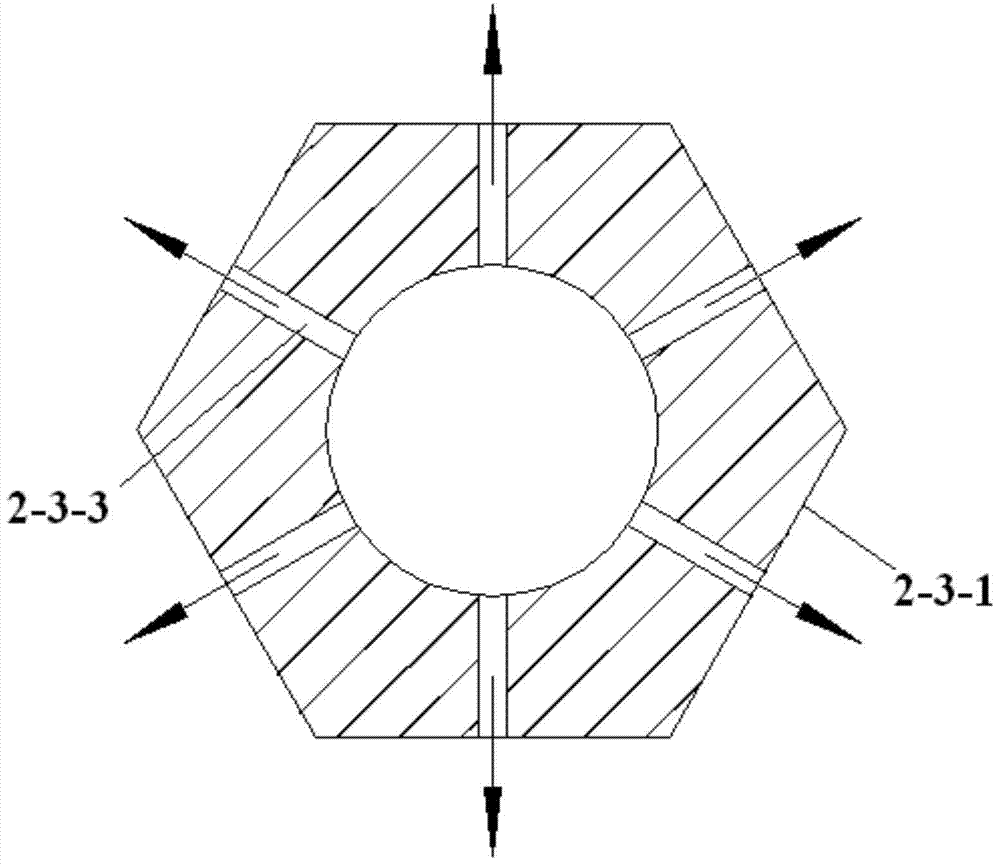

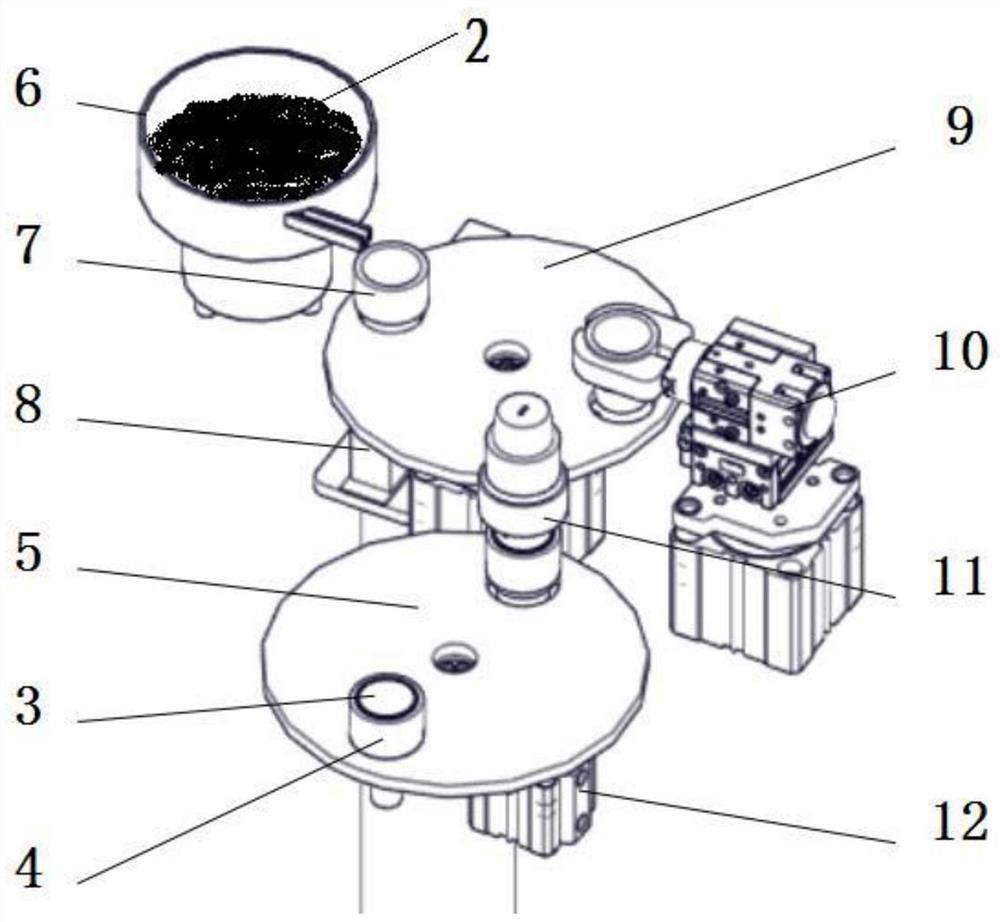

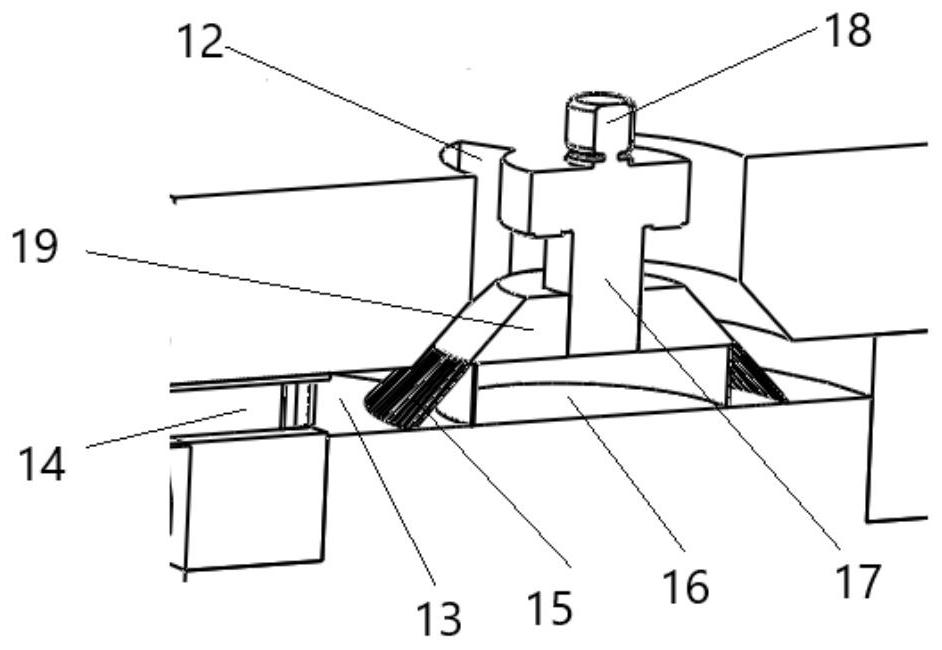

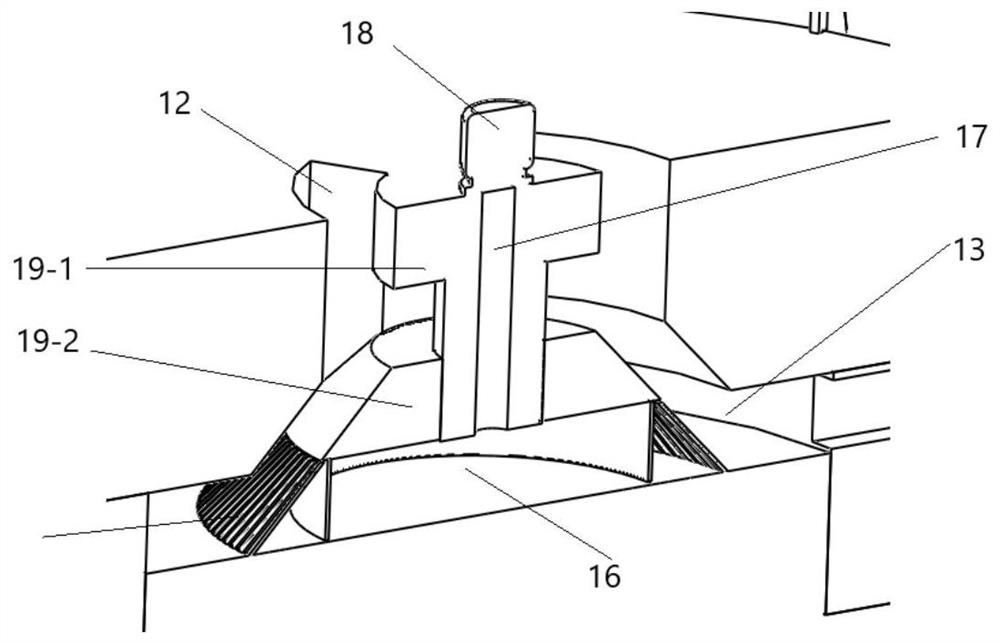

Efficient chemical distributing method and efficient chemical distributing device

InactiveCN103371139AHigh gaseous flow intensityResidue reductionFumigatorsHorticulture methodsWater savingPesticide residue

The invention discloses an efficient chemical distributing method and an efficient chemical distributing device suitable for spraying chemicals in enclosed environments. The efficient chemical distributing method is mainly characterized in that chemicals are prepared into extractable and carriable chemical liquid, then a rotatable carrier with a liquid extraction capability is used for extracting the chemical liquid continuously, meanwhile, hot airflow is provided for heating the carrier, and in the process that the chemical liquid is extracted by the carrier continuously, gaseous flow containing ultrafine chemical particles is continuously formed from the carrier to be applied in an enclosed environment along with the hot airflow and act on a chemical-applied object in a free dispersion manner. The chemicals applied by the method and the device are small in particle size and concentrated in particle spectrum, can be absorbed by a target object effectively, invalid deposit amount of the chemicals is small, and the novel chemical distributing method and the chemical distributing device are less prone to causing chemical residue and waste, integrate many advantages of chemical saving, water saving, labor saving, energy conservation, convenience, environmental friendliness and the like, save chemicals by at least more than 50% as compared with the prior art, and can be widely applied to air purification, disinfection and sterilization, and chemical distribution for various purposes of deinsectization, sterilization, pesticide residue removing and the like for crops or agricultural products in the enclosed environments in the agricultural fields.

Owner:北京中知领见科技有限公司

Defluorination method of fluorine-containing wastewater, and fluidized bed crystallization separator for defluorination

PendingCN110627177ASave materialImprove settlement performanceSpecific water treatment objectivesWater contaminantsTherapeutic effectOperant conditioning

The invention provides a fluidized bed crystallization separator for defluorination. The fluidized bed crystallization separator comprises a cylinder body, a guide cylinder, a screening device, and areturn pipe; a water distribution area, a chemical distribution area, a granulation area and a clear water area are sequentially arranged in the cylinder body from bottom to top; the guide cylinder isarranged in the cylinder body and is designed to be coaxial with the cylinder body; the granulation area is divided into a fluidization area, a separation area and a static settling area; the screening device is arranged in the cylinder body, and between the water distribution area and the medicine distribution area, and comprises a screen and a storage device arranged below the screen; one end of the return pipe is connected with the seed crystal feeding opening, and the other end of the return pipe is connected with the storage device and is used for returning screened particles with smaller sizes to the granulation area for recycling. The invention also provides a fluorine-containing wastewater defluorination method realized by the fluidized bed crystallization separator. The fluidizedbed crystallization separator for defluorination and the fluorine-containing wastewater defluorination method provided by the invention are relatively simple in operation condition, relatively low intreatment cost, good in treatment effect, lower in fluorine ion concentration of effluent, free of sludge dehydration and less in seed crystal dosage.

Owner:国能朗新明环保科技有限公司

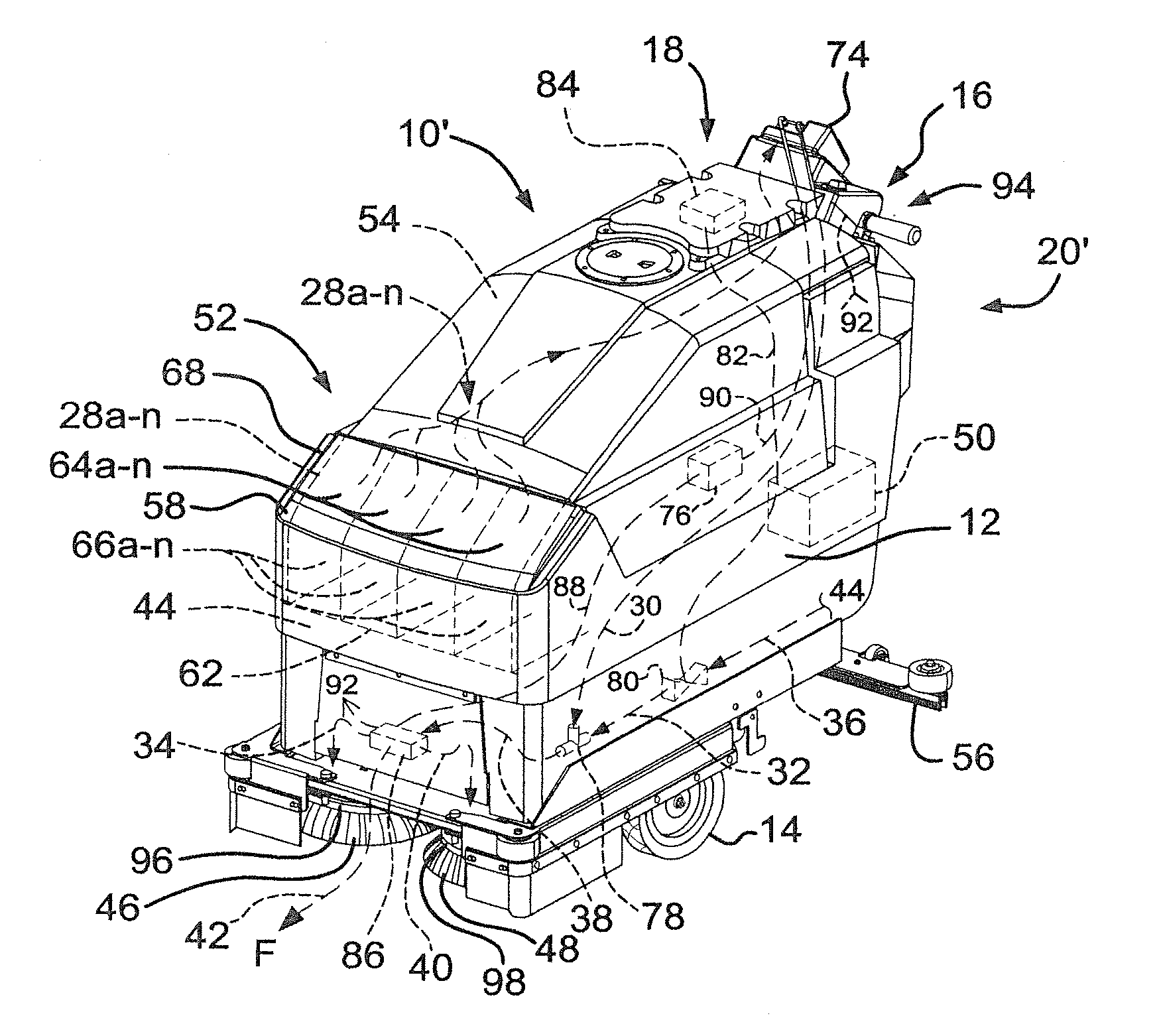

Chemical distribution system for floor cleaning machine

A chemical distribution system for a floor cleaning machine is described. The system utilizes at least one container that is selectively connected to a pump that pumps a cleaning chemical solution from the container into a tee for combining with a fluid from an onboard fluid tank at a rate determined by a machine operator. Chemical containers may be readily and interchangeably connected to the pump to permit various solutions to be selectively utilized to optimize floor cleaning.

Owner:NSS ENTERPRISES INC

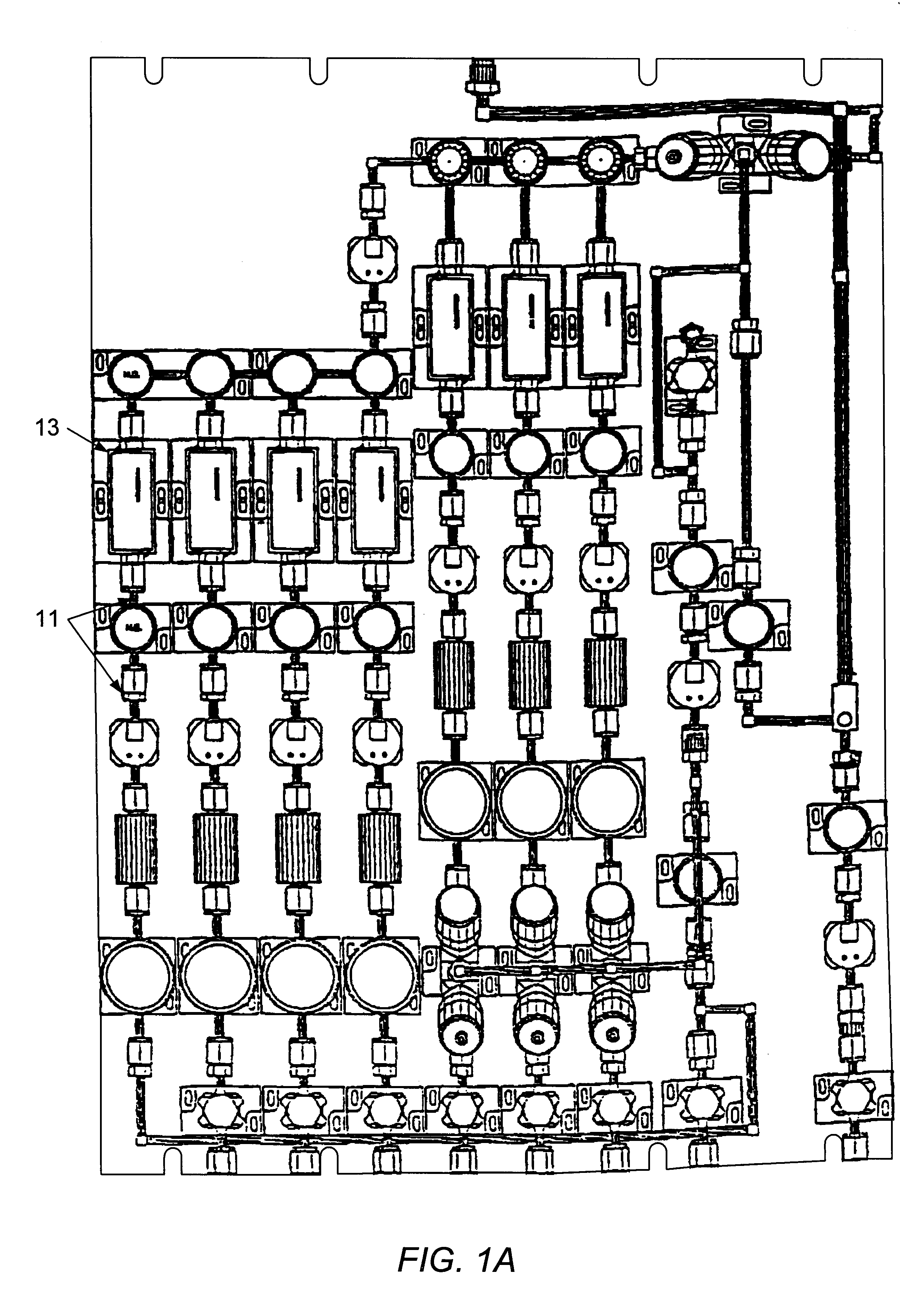

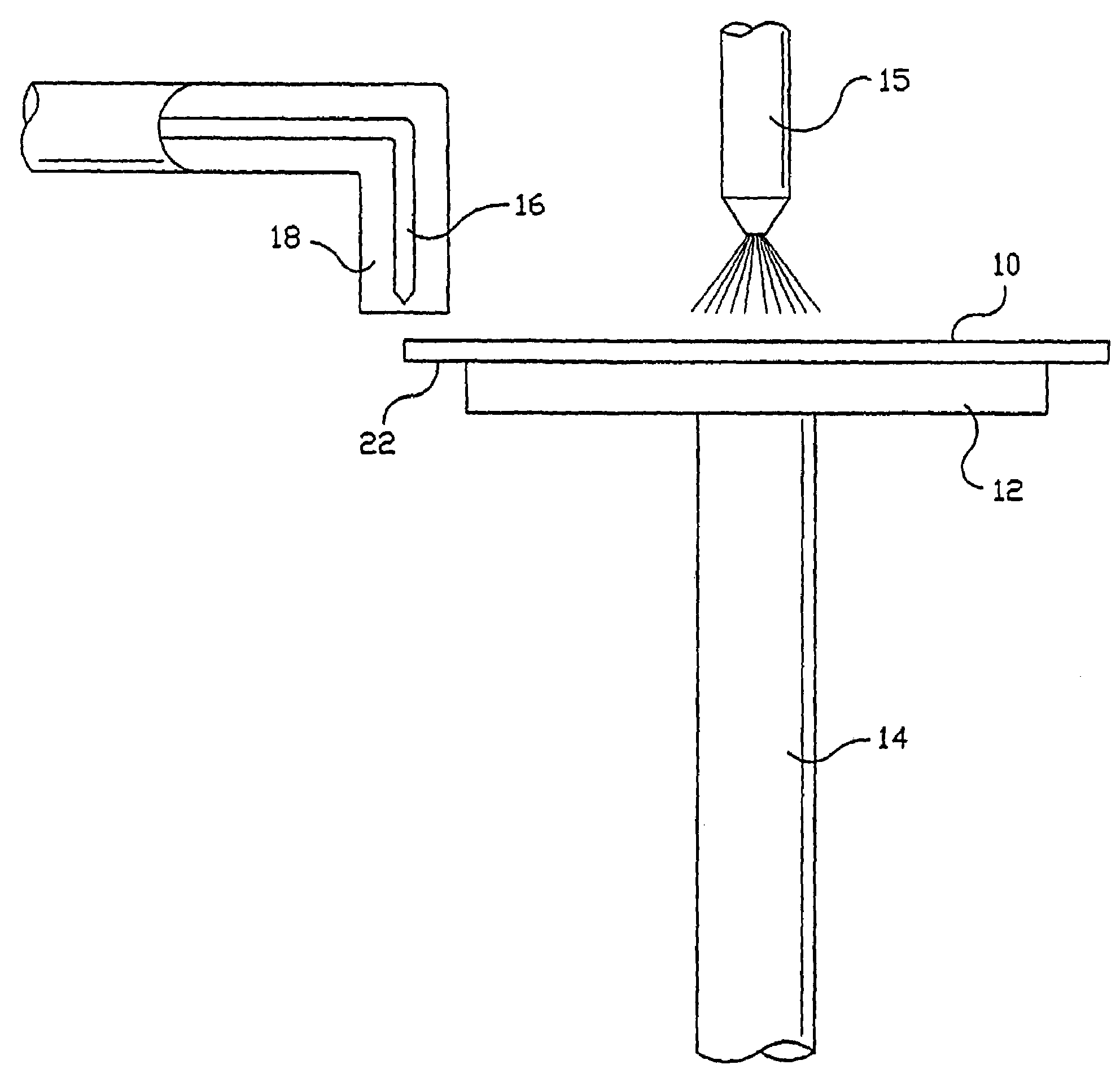

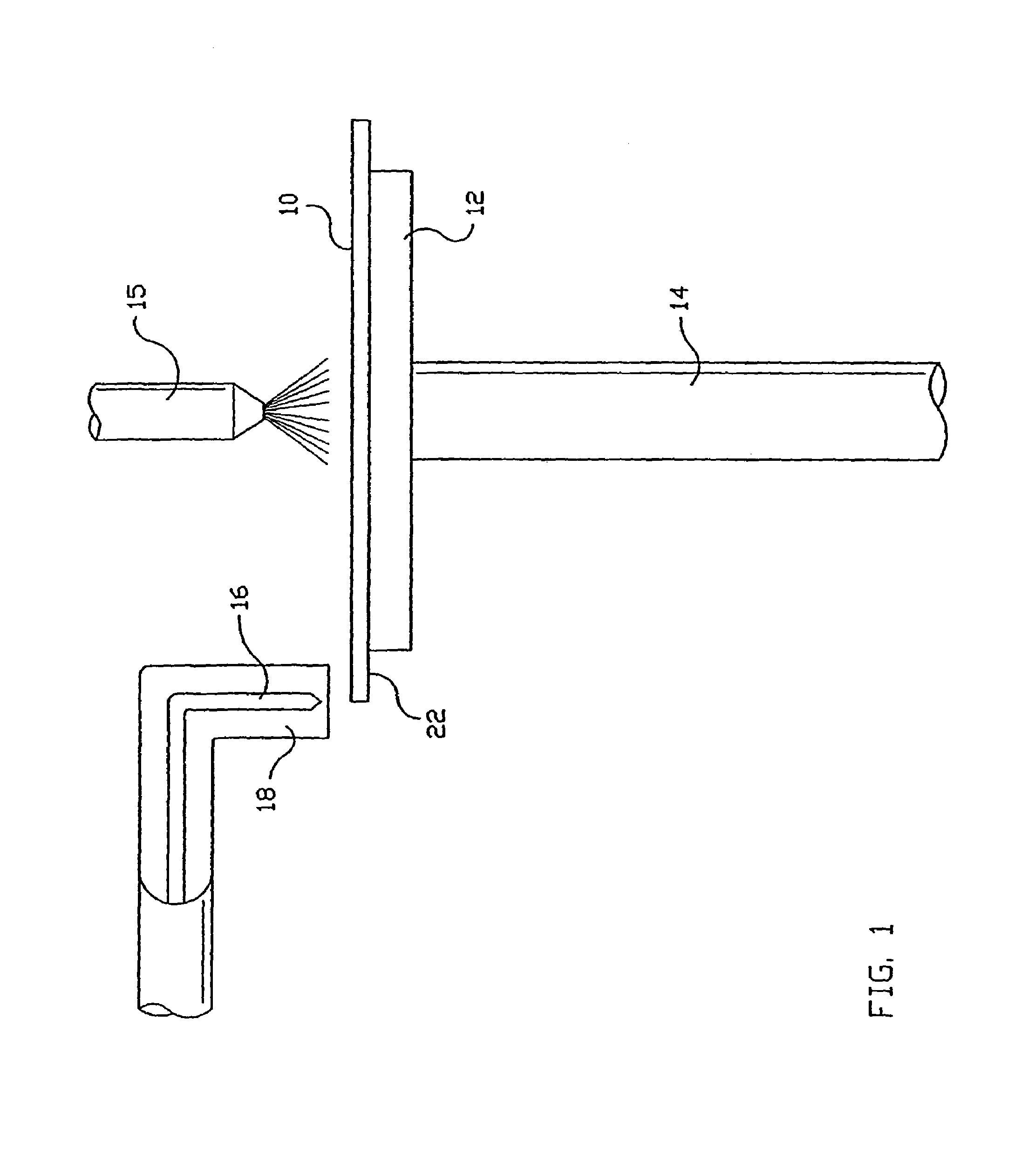

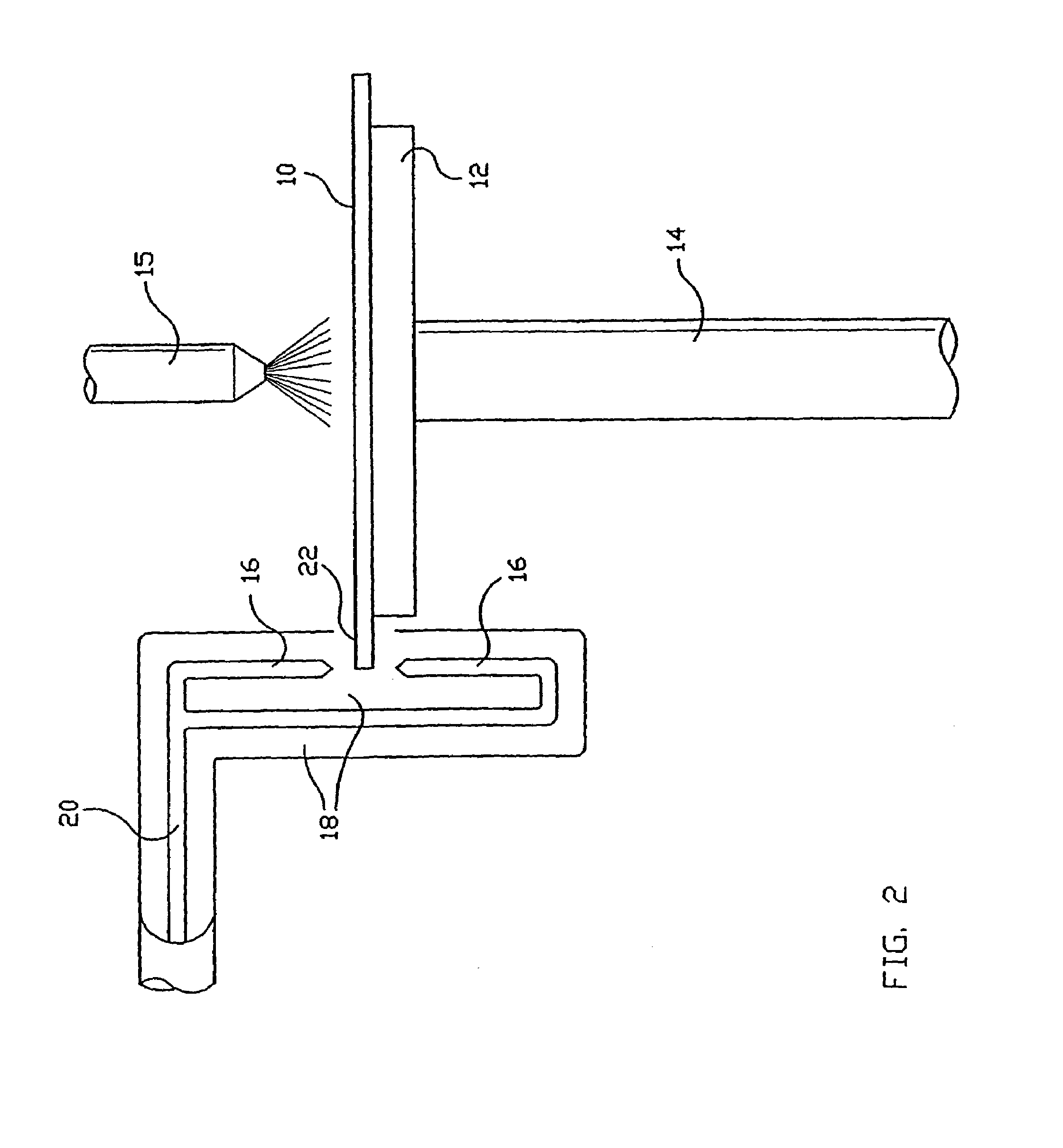

Chemical dispensing system for semiconductor wafer processing

InactiveUS7470344B1Improve efficiencyImproved profilePretreated surfacesSemiconductor/solid-state device manufacturingChemical distributionSolvent

A method for dispensing a chemical, such as an edge bead removal solvent, onto a semiconductor wafer comprising the steps of dispensing the chemical selectively onto the wafer and applying a suction to the area immediately surrounding the location at which the chemical is dispensed onto the wafer. Preferably, the suction is applied substantially simultaneously with the dispensing of the chemical. One specific version of the invention provides an edge bead removal system wherein suction is applied to the area immediately surrounding the solvent dispensing nozzle to remove dissolved coating material and excess solvent from the wafer. In one aspect of this system, an apparatus for removing the edge bead includes a mechanism for dispensing a solvent selectively onto the edge of the wafer, and a mechanism surrounding the dispensing mechanism for vacuuming excess solvent and dissolved coating material from the edge of the wafer. The edge bead removal apparatus preferably also includes mechanisms for spinning the semiconductor wafer and coating material on the spinning wafer. Another aspect of the system provides a method for removing an edge bead of a coating of material that has been spun onto the surface of a semiconductor wafer. The method includes the steps of dispensing a solvent selectively onto the edge of the wafer to dissolve the coating material at the extreme edge of the wafer, and applying a suction to vacuum excess solvent and dissolved coating material from the wafer.

Owner:MICRON TECH INC

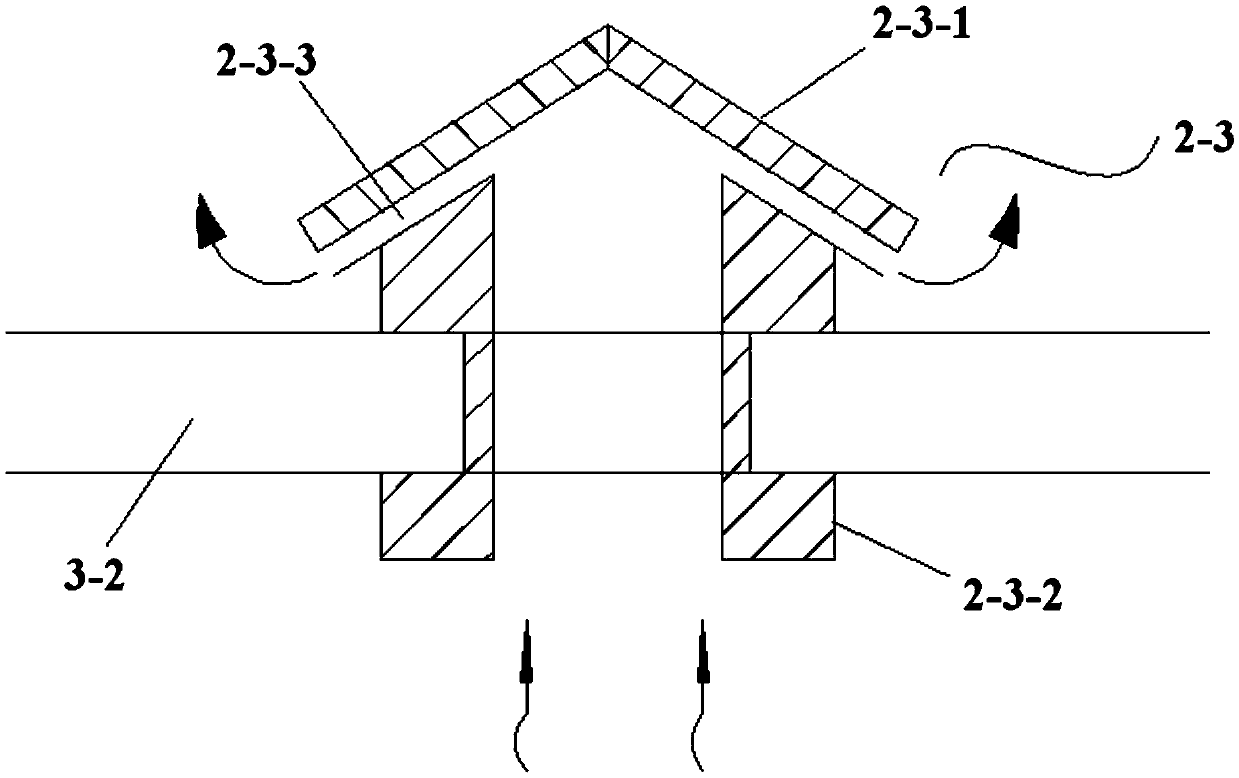

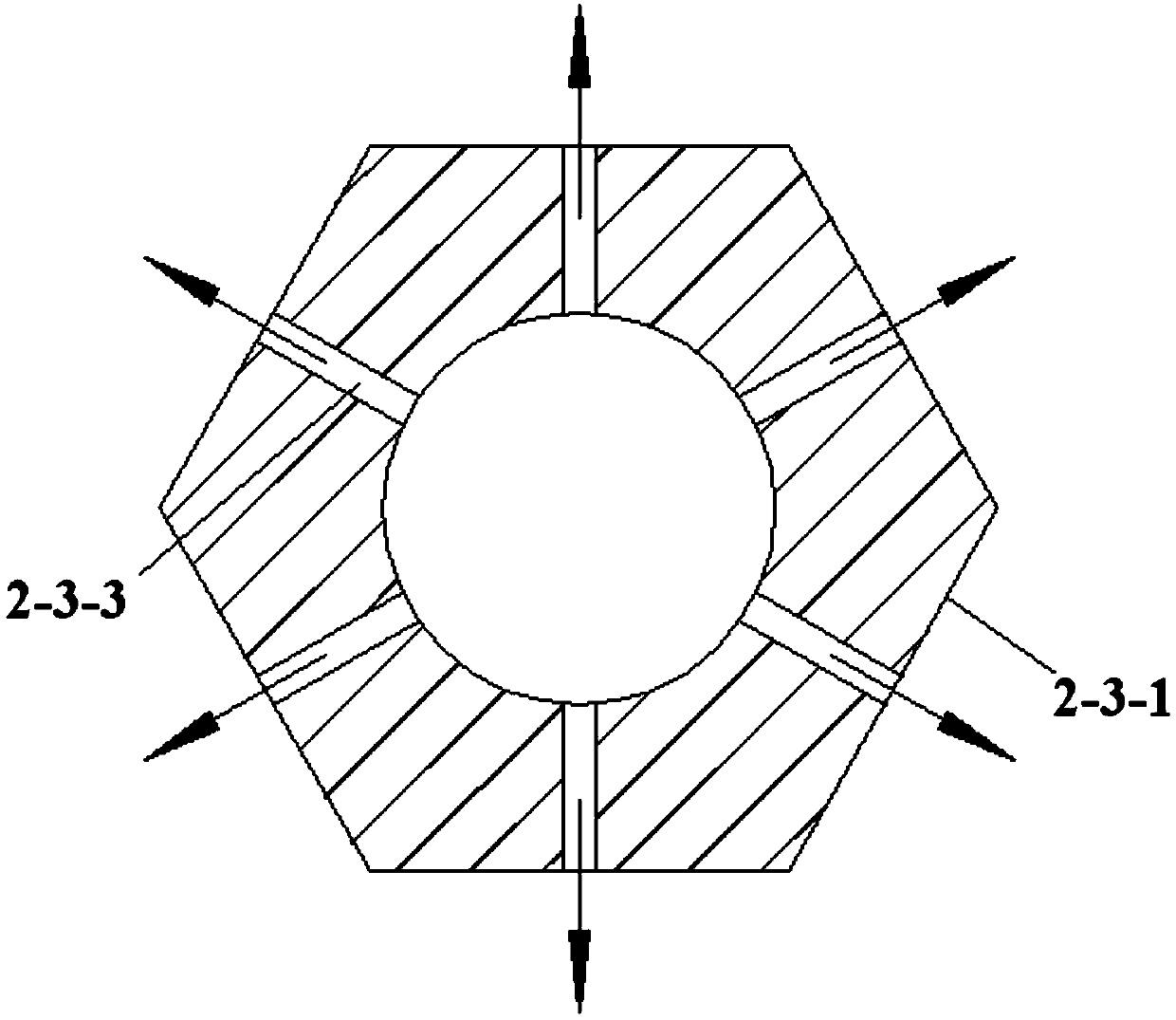

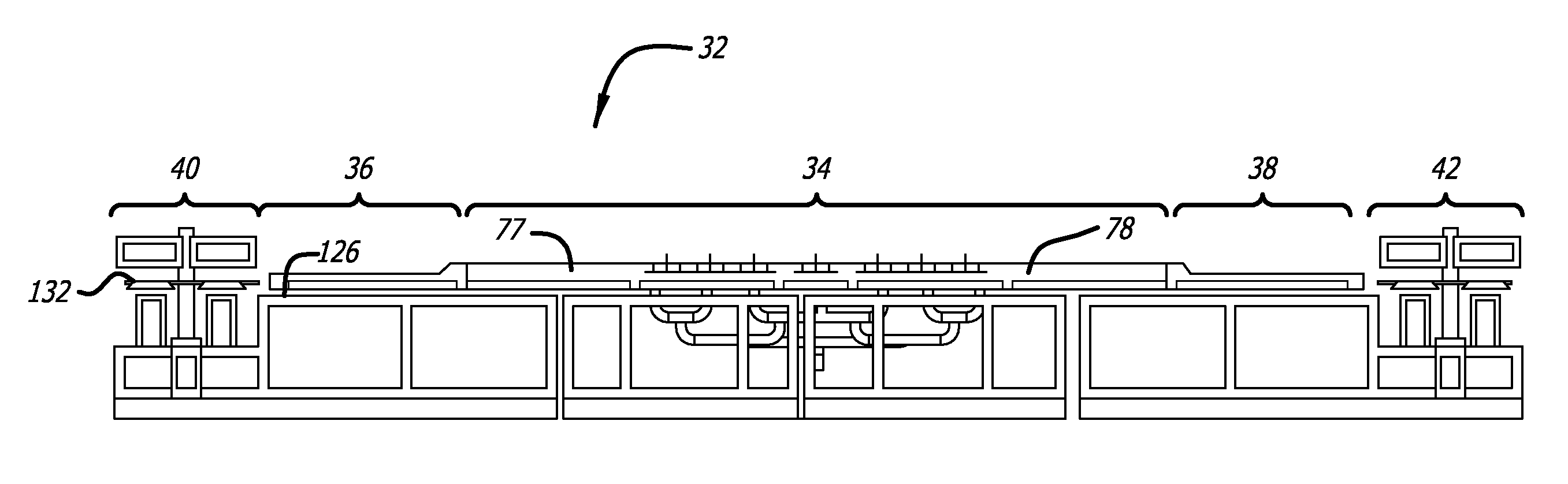

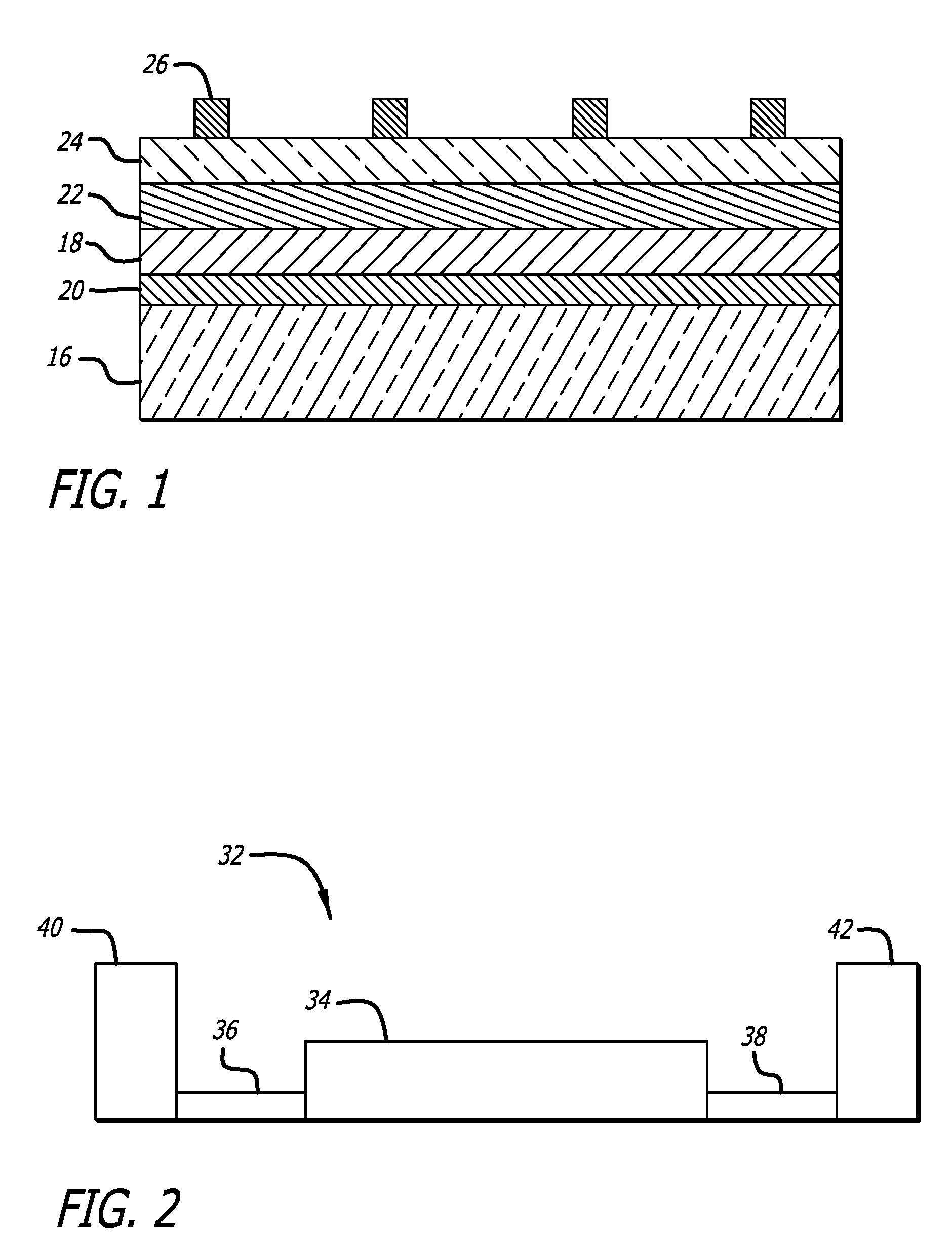

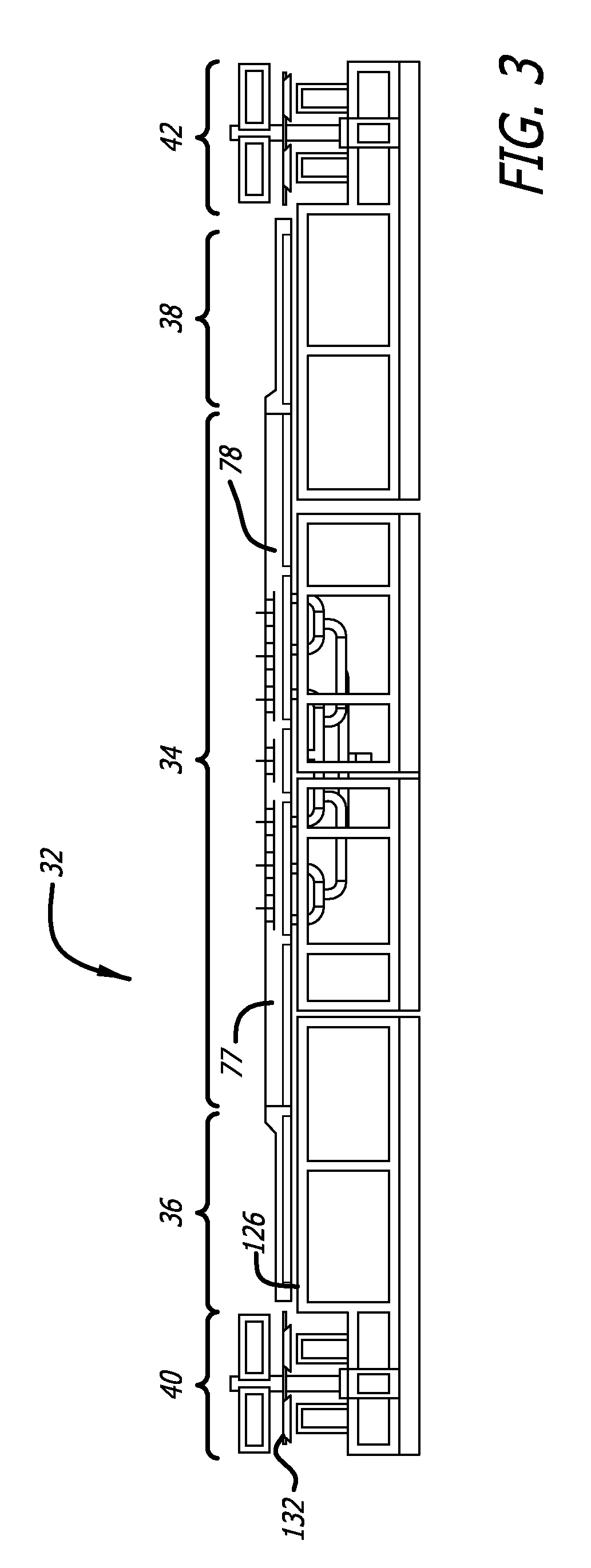

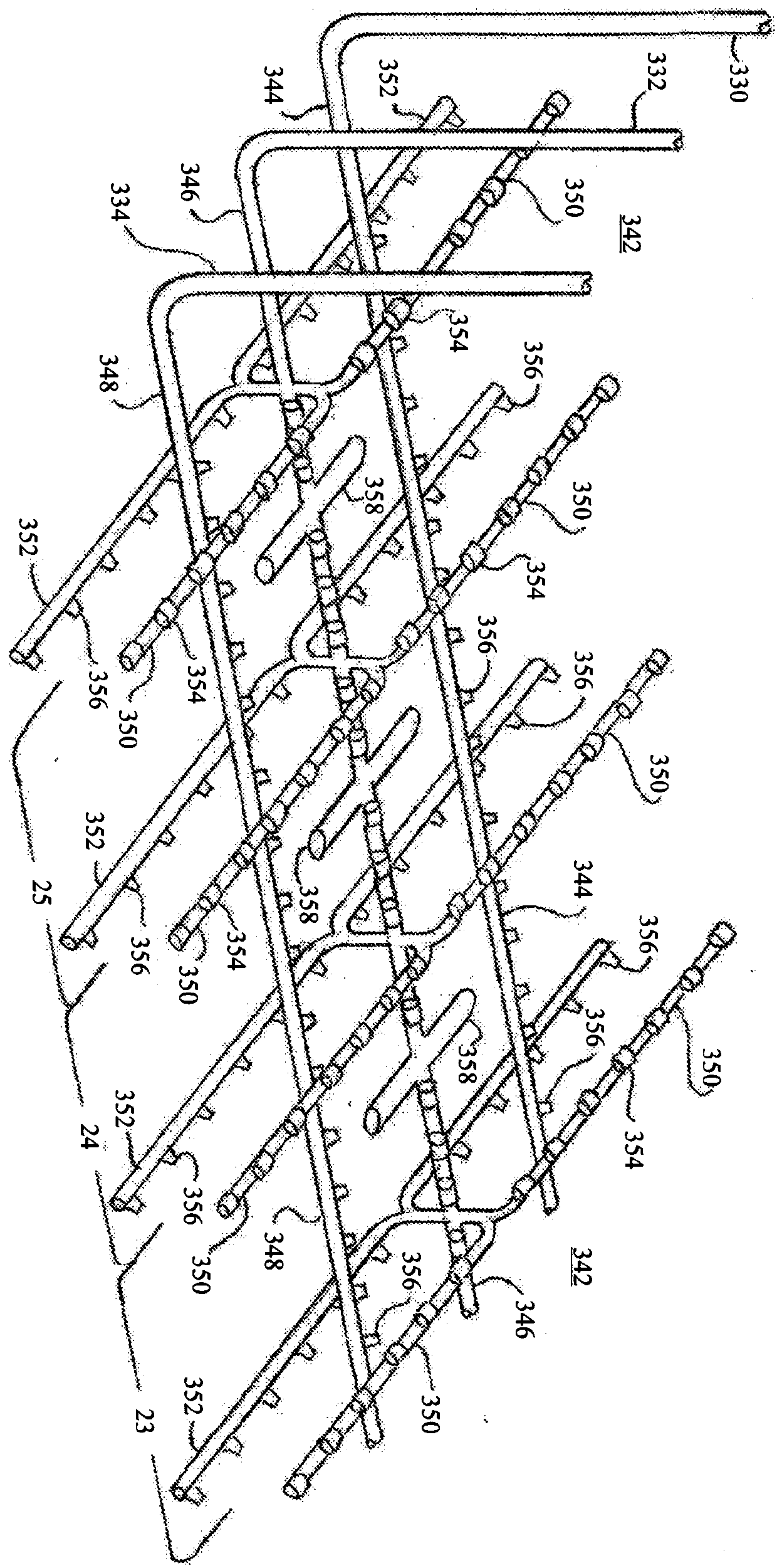

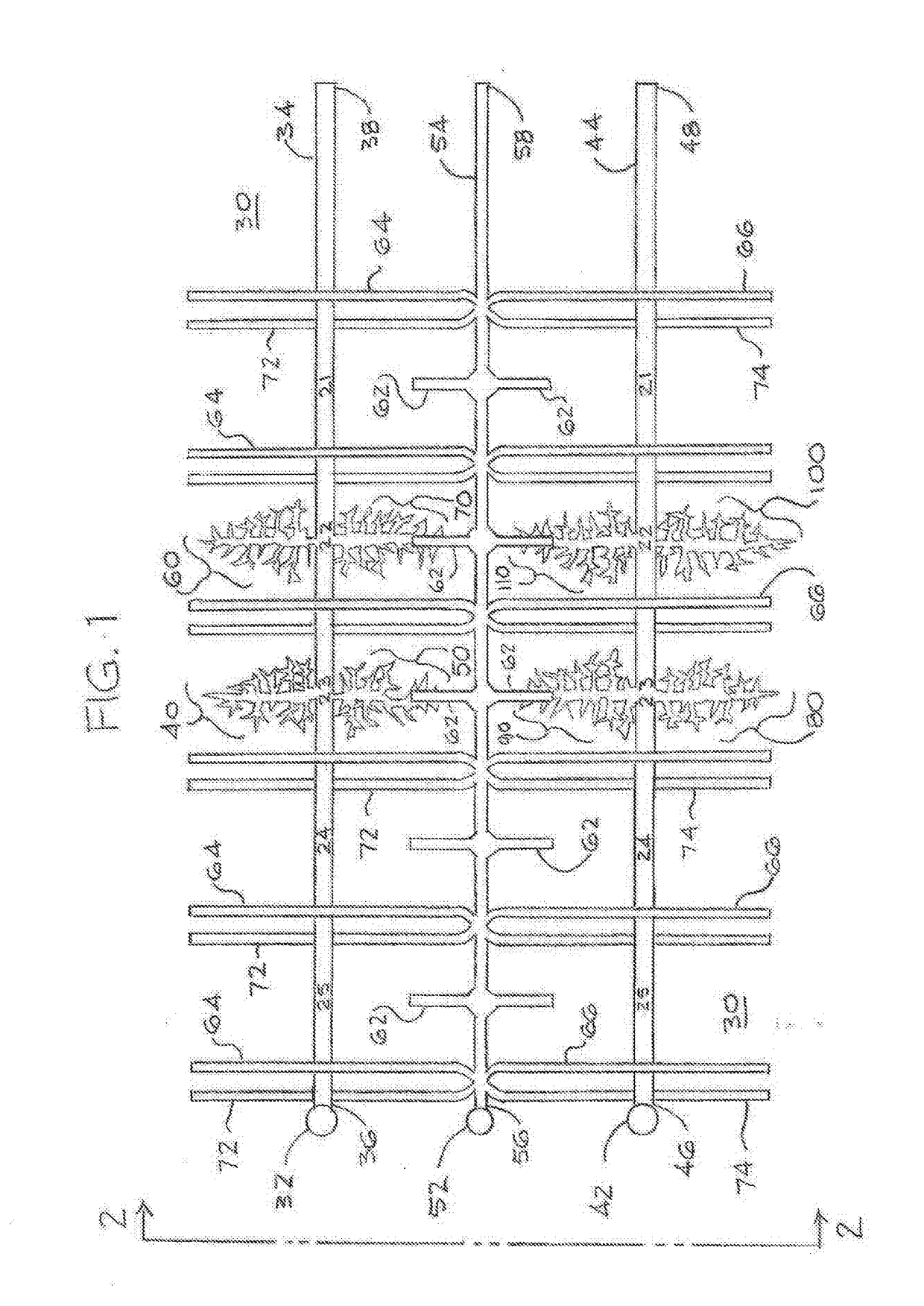

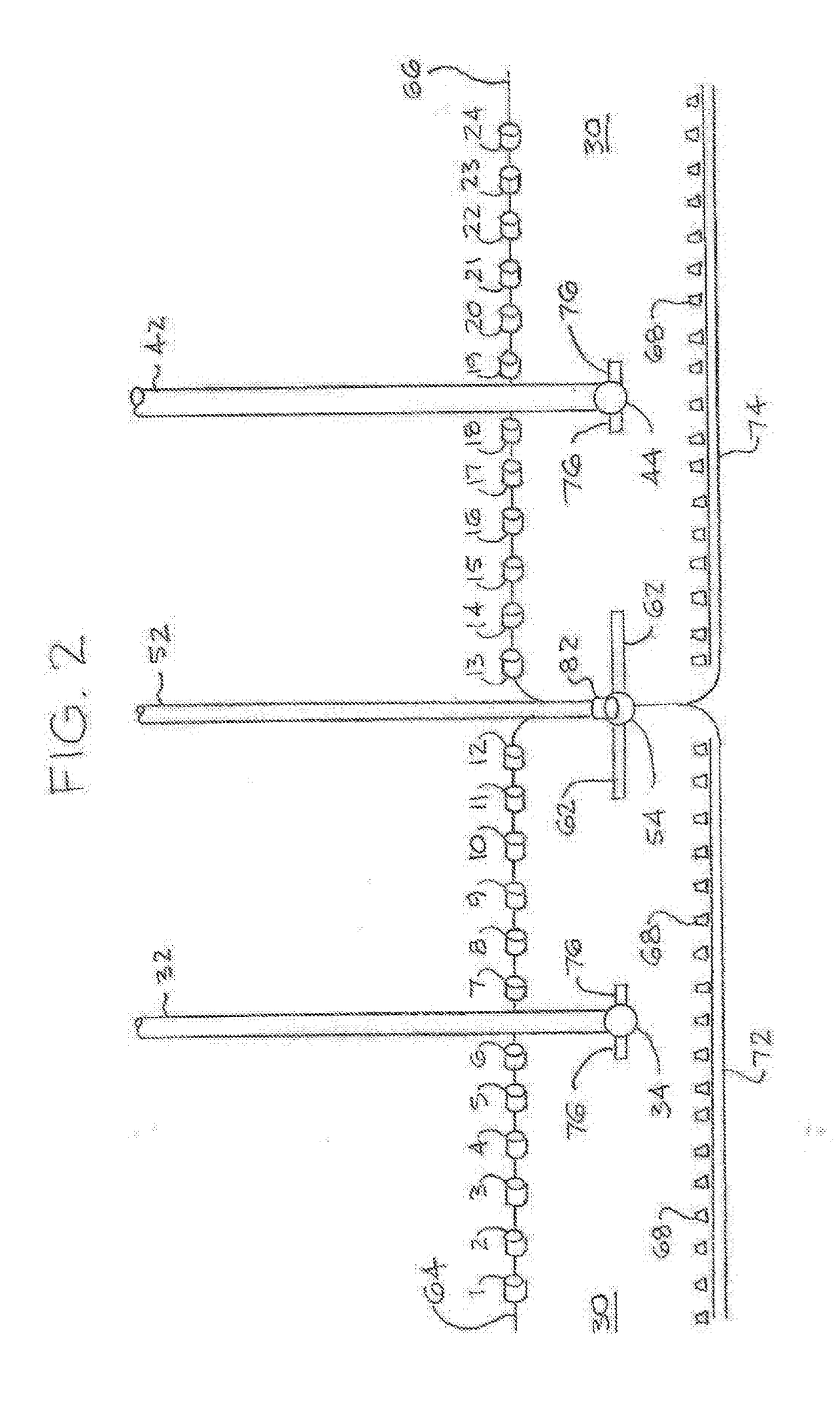

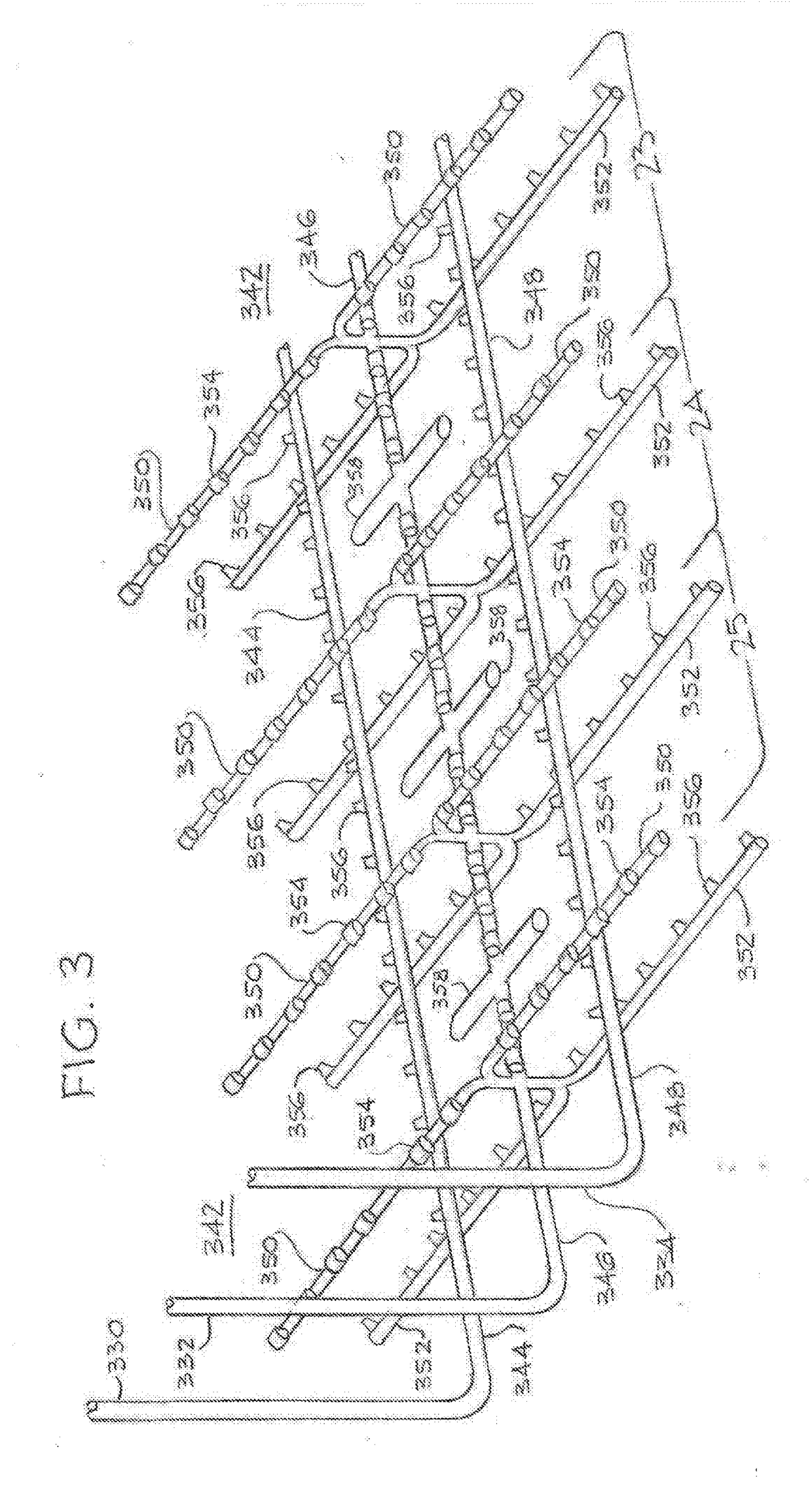

Chemical vapor deposition method and system for semiconductor devices

InactiveUS20100035432A1Final product manufactureSemiconductor/solid-state device manufacturingWater vaporGas phase

A method of and system for chemical vapor deposition of layers of material on substrates for producing thin film semiconductor devices provides for continuous in-line processing. The method and system are adapted for size and potential speed, and for scaling to further increase the rate of production. The method includes continuously conveying a plurality of substrates through a plurality of in-line deposition regions, continuously providing and distributing a chemical vapor at each region to deposit material for the layer, and continuously supplying a flow of chemical material for each region to provide the chemical vapor. The chemical vapor for deposition at each region covers an area that is substantial for substrates, then, also having a substantial area. The chemical vapor may include an organometallic material, such as diethyl zinc vapor, or dimethyl zinc vapor, as well as a material that provides oxygen, such as water vapor or nitrous oxide gas. It may also include a material that provides a dopant. Thus, the layers of material may be a zinc oxide material. The system includes a continuous in-line substrate conveyance apparatus for moving a plurality of substrates through a plurality of deposition regions, a deposition head for providing and distributing a chemical vapor at each of the regions to deposit material for the layers, and a chemical material supply apparatus for providing a flow of chemical materials to each of the heads for the chemical vapor. The chemical vapor deposition head includes an emission and distribution face at the region for the head, and wall structure defining a first plenum layer having a first plenum and a second plenum layer having a second plenum, for receiving chemical materials from the supply apparatus and for maintaining separation of received chemical materials. The head also includes wall structure defining a third plenum layer having a first set of elongated plenums for receiving chemical material from the first plenum and distributing such chemical material to the emission and distribution face, and a second set of elongated plenums for receiving chemical material from the second plenum and distributing such chemical material to the emission and distribution face. One exemplary number of deposition regions is seven.

Owner:INT SOLAR ELECTRIC TECH INC

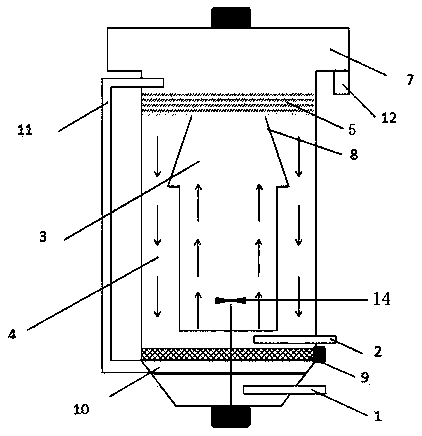

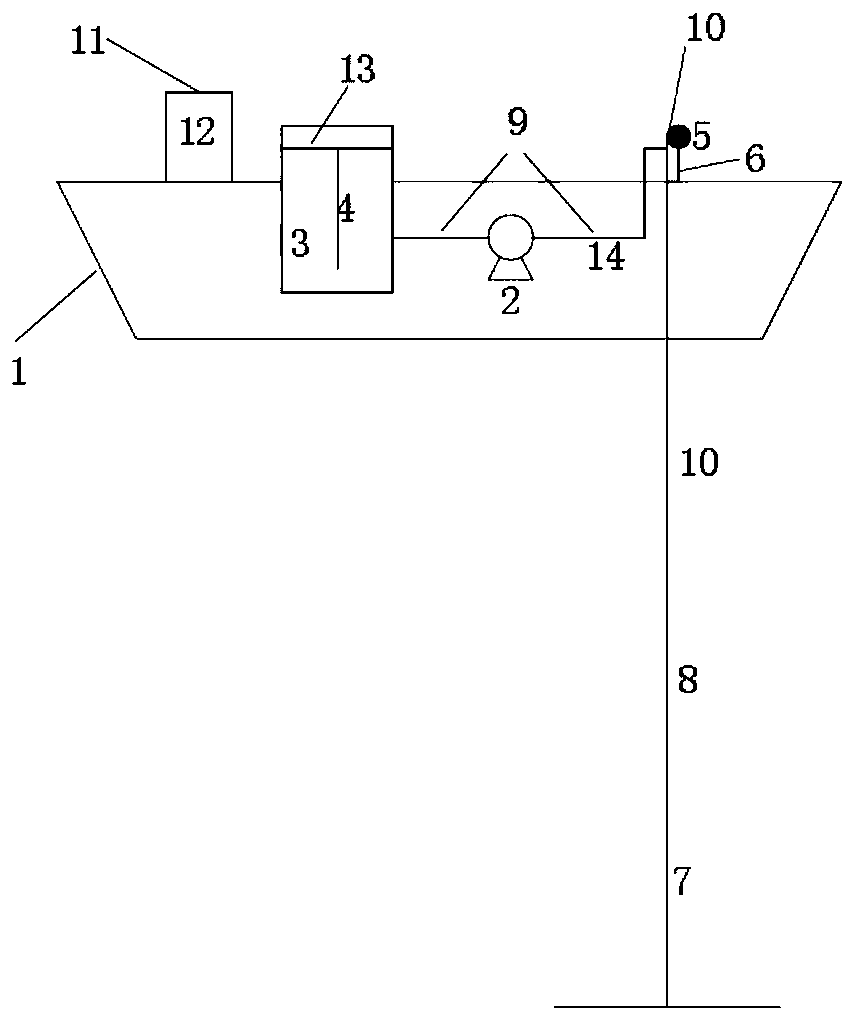

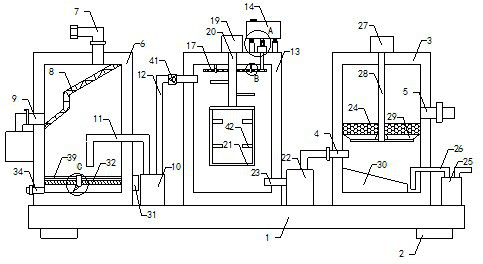

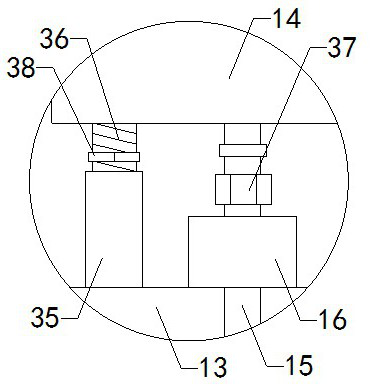

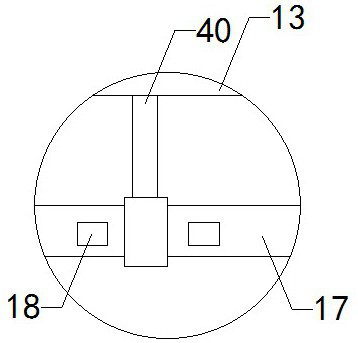

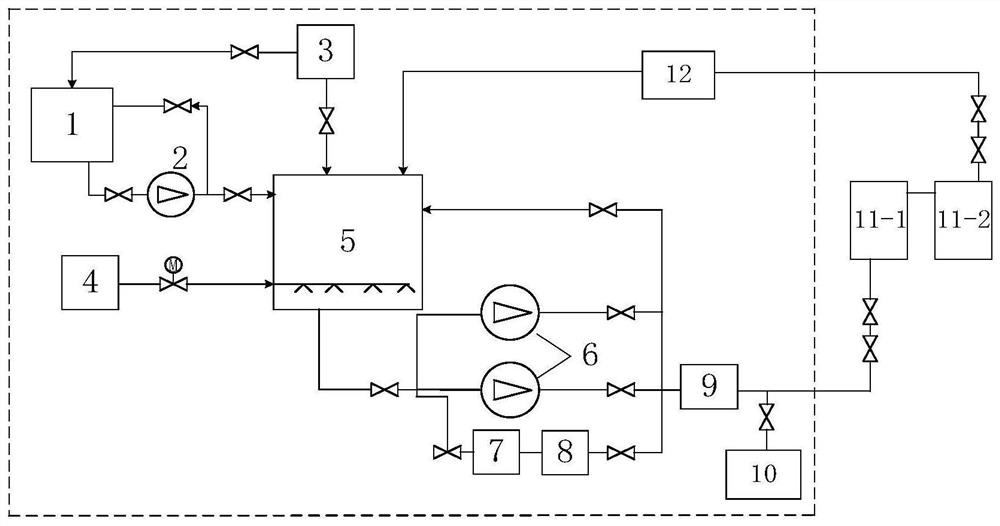

Automatic chemical mixing and feeding integrated device for lake reservoirs

PendingCN110252190AAutomatic and efficient mixingAutomatic and efficient dosingFlow mixersTransportation and packagingEmergency treatmentChemical solution

The invention discloses an automatic chemical mixing and adding integrated device for lake reservoirs. The automatic chemical mixing and adding integrated device comprises a floating body system for providing buoyancy to the integrated device, a chemical dissolution system for dissolving solid chemicals to provide chemical solutions, a feeding system for feeding the chemical solutions into the lake reservoirs, a control system, and a power supply device for powering all electric equipment on the integrated device. The chemical dissolution system and the feeding system are arranged on the floating body system. An inlet of the feeding system is connected with an outlet of the chemical dissolution system through a pipe system. An outlet of the feeding system is connected with a liftable chemical distribution system through a pipe system. The control system is connected with the floating body system to control the movement of the floating body system, is connected with the chemical dissolution system to control the concentration of the chemicals of the chemical dissolution system, and is connected with the feeding system to control feeding of the chemical solutions. By the integrated device, automatic mixing and feeding of the chemicals for emergency treatment of the lake reservoirs are realized.

Owner:唐山市曹妃甸供水有限责任公司 +1

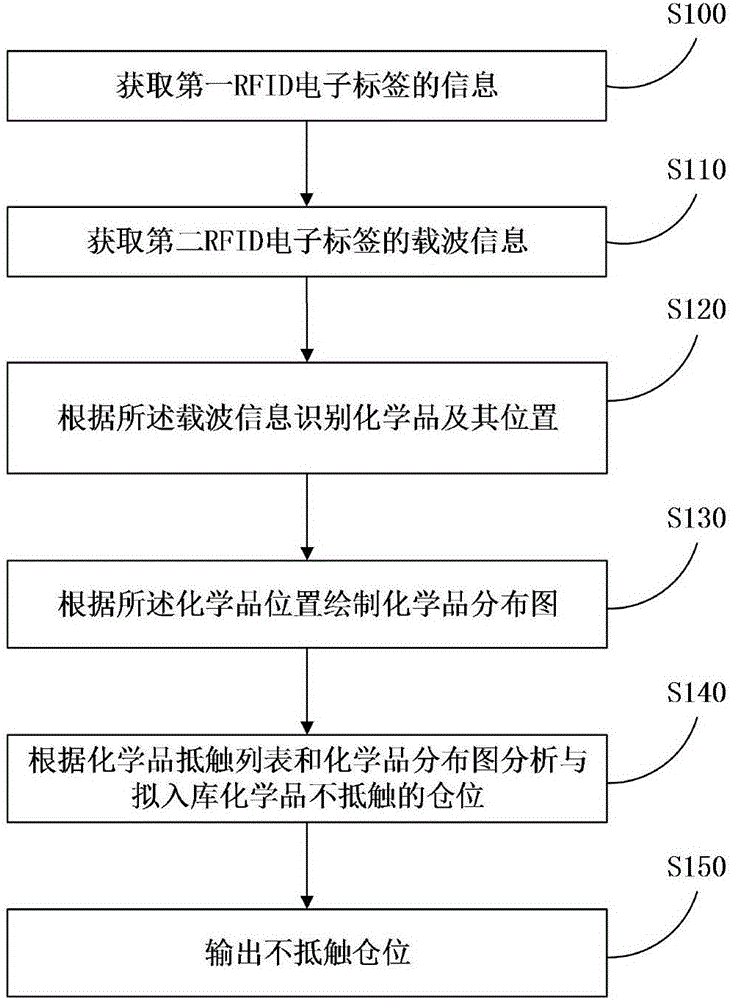

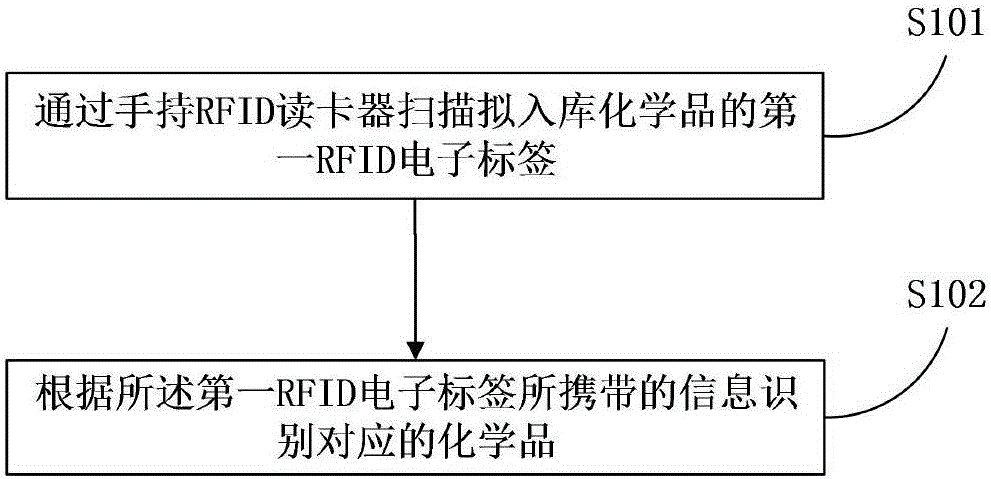

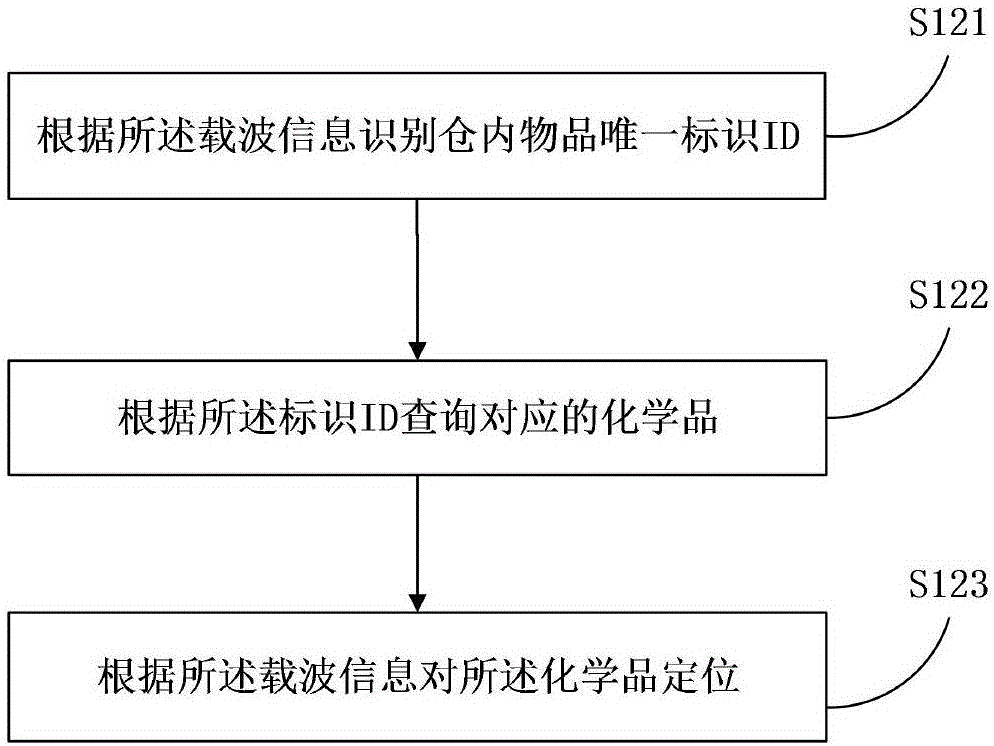

Mixed chemical storage warehouse management method and mixed chemical storage warehouse management system

InactiveCN106384221AEnsure safetyAvoid safety hazardsCo-operative working arrangementsLogisticsChemical storageCarrier signal

The invention provides a mixed chemical storage warehouse management method. The method comprises the steps of acquiring information of a first RFID electronic label; acquiring carrier information of a second RFID electronic label; identifying a chemical and position thereof according to the carrier information; drawing a chemical distribution map according to the chemical position; analyzing a warehouse position which does not conflict with the to-be-stored chemical according to a chemical conflicting list and the chemical distribution map; and outputting the non-conflicting position. The mixed chemical storage warehouse management method settles problems of safety hazards in mixed chemical storage, easy error and low efficiency in artificial management for the chemical position in existing chemical warehouse management technology. The mixed chemical storage warehouse management method can quickly determine whether position conflicting exists and recommend the non-conflicting position. The invention further provides a mixed chemical storage warehouse management system.

Owner:佛山市炫鲸科技有限公司

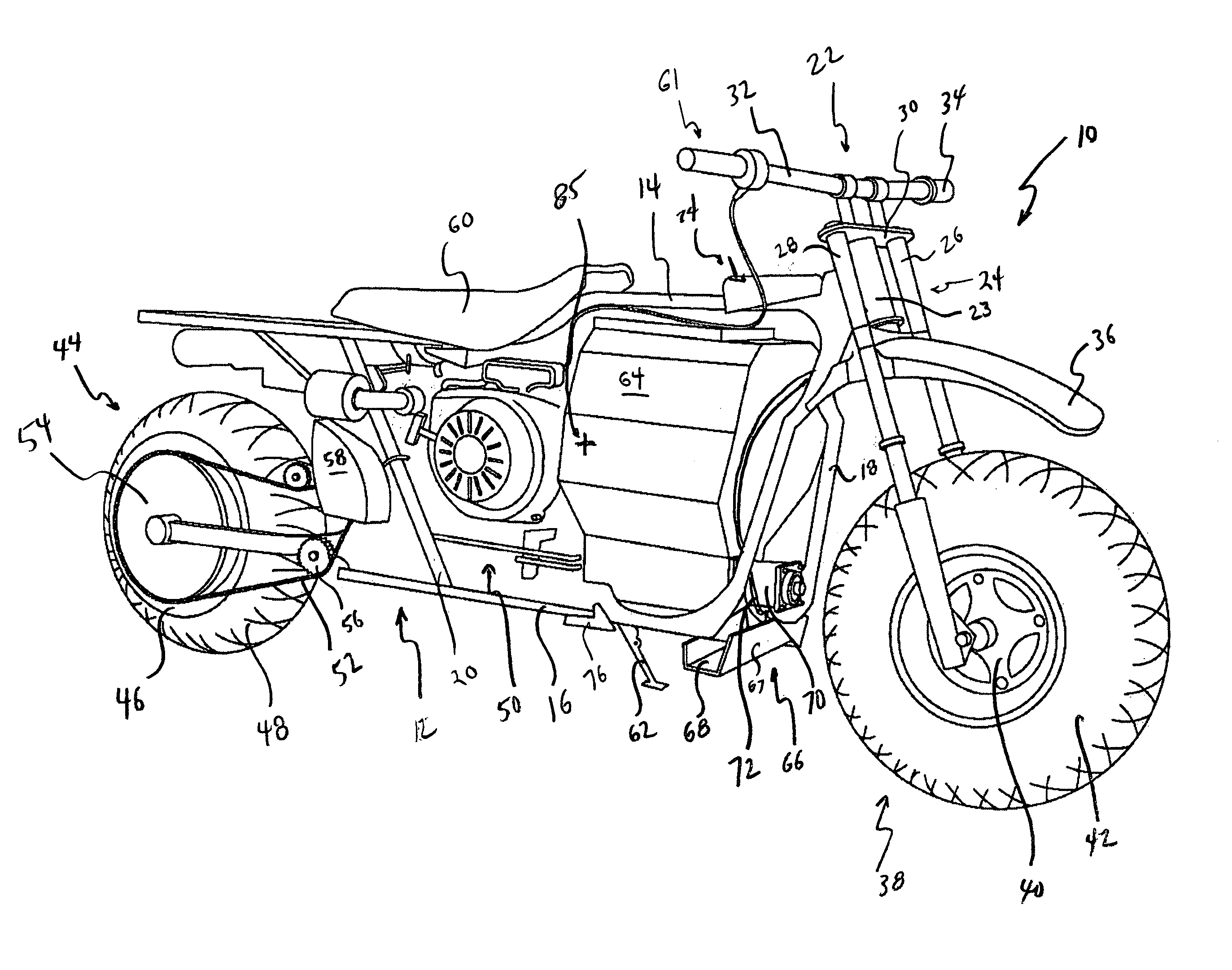

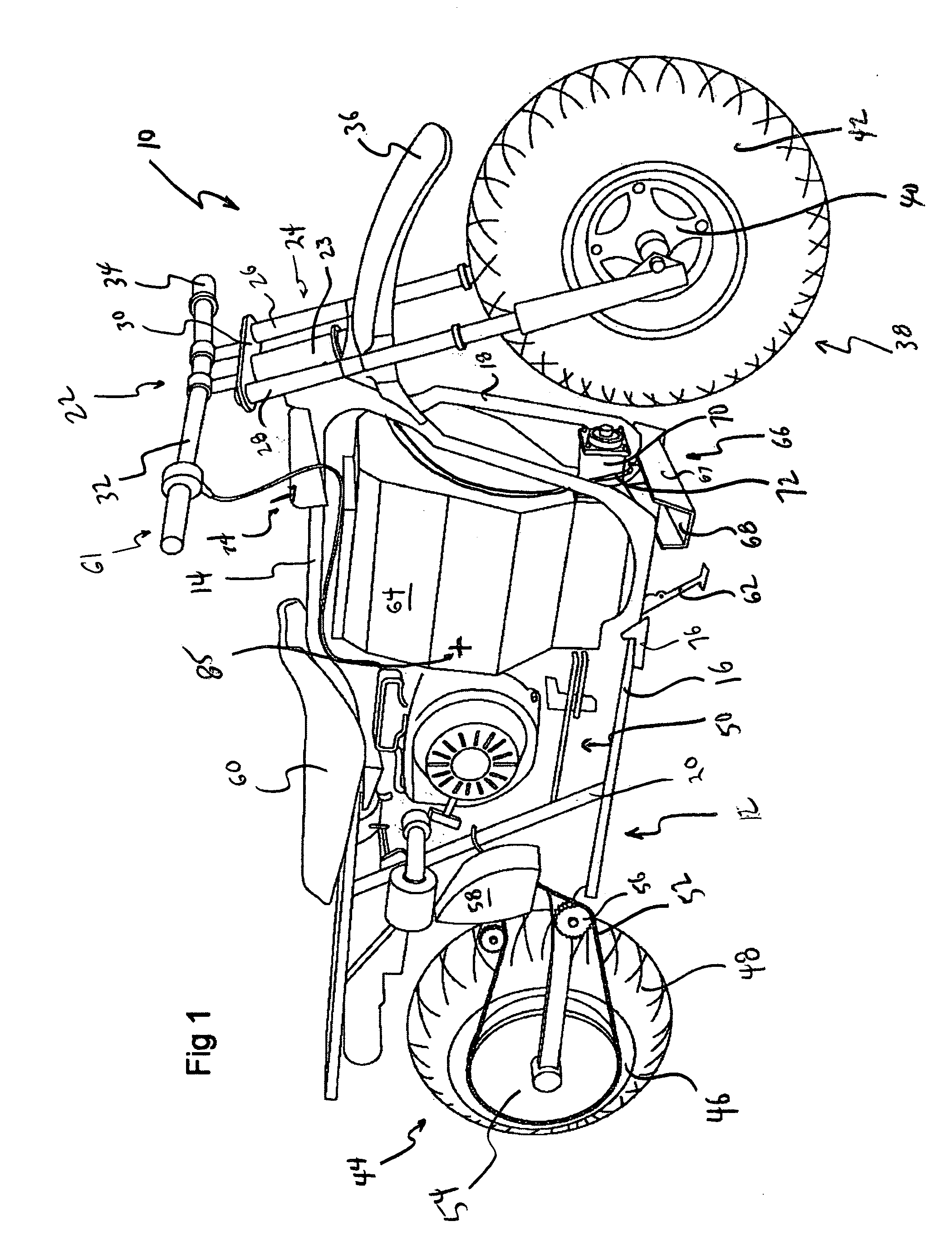

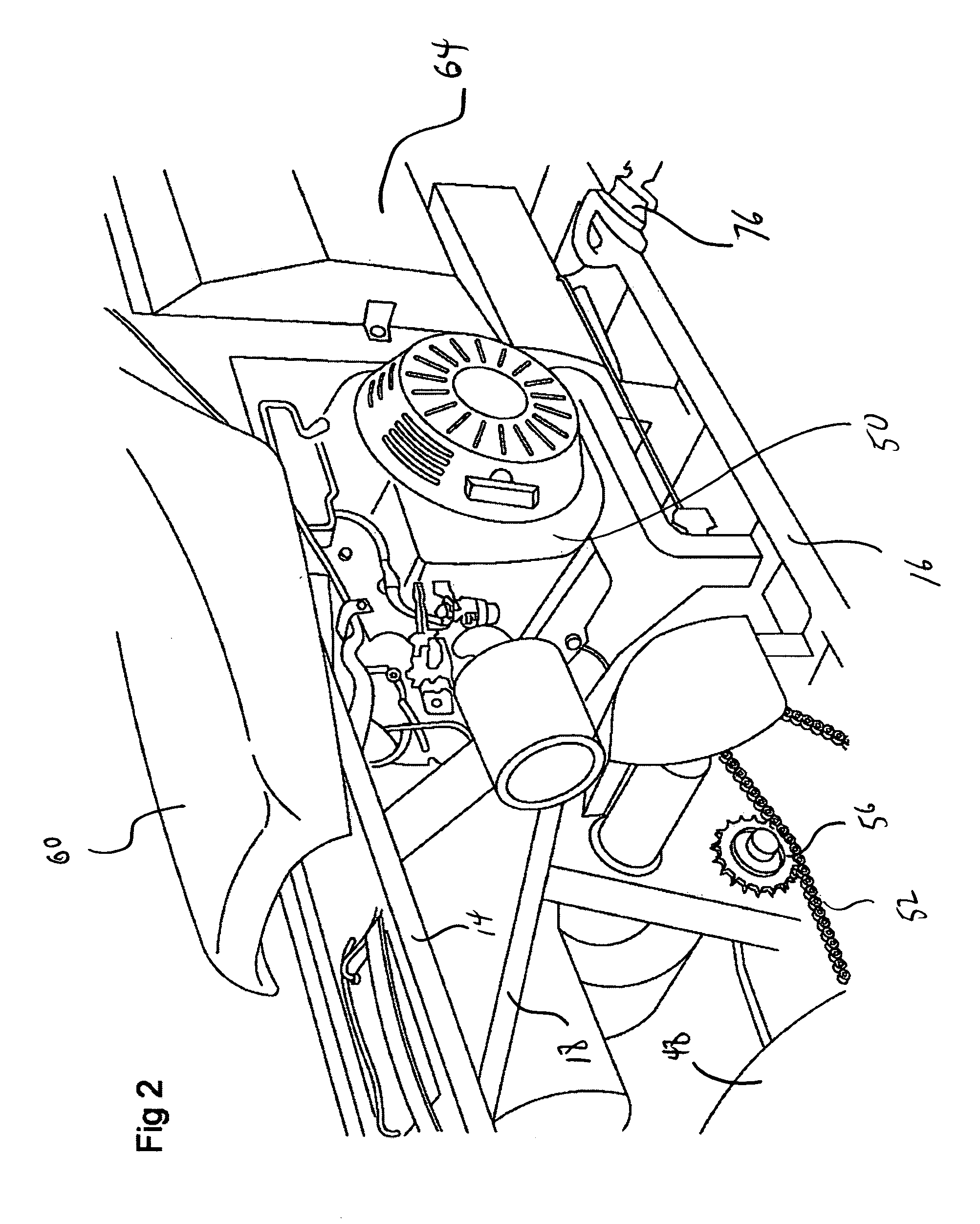

Self-propelled chemical delivery vehicle and dispenser

InactiveUS20060016907A1Safe wayImprove controllabilityWatering devicesFertiliser distributersGround contactDrive wheel

A self-propelled chemical delivery vehicle and dispenser generally for agricultural use includes a frame including first and second vertically spaced support members; a rider support member mounted to the frame; an apparatus for providing motive power mounted to the frame; at least two wheel and tire assemblies, with one of the at least two wheels being a drive wheel, the drive wheel being in communication with the apparatus for providing motive power for application of motive power through the ground contact for vehicle movement with the at least two wheel and tire assemblies being spaced apart in generally longitudinal alignment; and an assembly for directional control of the self-propelled chemical delivery vehicle and dispenser mounted to the frame. Also included is a chemical reservoir mounted to the frame intermediate the first and second vertically spaced support members and intermediate the at least two wheel and tire assemblies; and a chemical delivery assembly mounted to the frame in communication with the chemical reservoir for selective, operator controlled chemical distribution therefrom. In addition, the chemical reservoir is mounted to the frame coincident with the center of gravity of the two-wheeled chemical delivery vehicle and dispenser.

Owner:MILES JR D WAYNE

Methods and materials for evaluating and improving production of geo-specific shale reservoirs

Diagnostic or assisting lateral wellbores can have a significant benefit for injecting and distributing treatment fluids and other materials within complex fracture networks that surpass conventionalinjection at the primary lateral wellbore perforations for acquiring empirical knowledge about the numerous processes that influence shale reservoir production which occur after primary shale reservoir stimulation. Injection of diagnostic treatment fluids or treating chemicals for understanding production optimization, such as water-block removal, fines migration removal, and treating chemicals for prevention of scale and paraffin deposition, can be injected along the diagnostic lateral wellbore or fracture interval lateral wellbores to give broader and / or deeper distribution into the fracturenetwork than by using mono-bore-centric diagnostic injection techniques. Diagnostic lateral treatment techniques can also improve fluid or chemical distribution, such as the use of gas injection to help energize fluid flow to the primary lateral during production optimization treatments, including reverse diversion methodology.

Owner:BAKER HUGHES INC

A chemical crystallization circulating granulation fluidized bed water treatment device

ActiveCN105502692BEasy to handleExtended discharge cycleWater contaminantsWater softeningChemical treatmentEngineering

The invention provides a chemical crystallization circulating granulation fluidized bed water treatment device, in which a water distribution area, a drug distribution area, a granulation area and a clear water area are sequentially arranged in the cylinder from the bottom to the top; the inner cylinder divides the granulation area into three The area near the bottom inside the inner cylinder is the fluidization zone, the area near the top inside the inner cylinder is the separation zone, and the interlayer between the inner cylinder and the cylinder body is the static settling zone; the fluidization zone is connected to the seeding tube , the crystal seed circulates between the fluidization zone, the separation zone and the static settling zone, and the ions in the water realize the chemical crystallization cycle granulation during the flow process; the fluidization zone is also connected with the particle discharge pipe, and the chemical crystallization cycle granulation forms The particles in the fluidized zone settle to the bottom and are finally discharged from the particle discharge pipe. The invention has a clear overall structure, compact connection of functional units, high plane utilization rate, convenient operation, can remove a single ion among various ions, and can simultaneously and efficiently remove various ions in water.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Methods and materials for evaluating and improving the production of geo-specific shale reservoirs

Diagnostic or assisting lateral wellbores can have a significant benefit for injecting and distributing treatment fluids and other materials within complex fracture networks that surpass conventional injection at the primary lateral wellbore perforations for acquiring empirical knowledge about the numerous processes that influence shale reservoir production which occur after primary shale reservoir stimulation. Injection of diagnostic treatment fluids or treating chemicals for understanding production optimization, such as water-block removal, fines migration removal, and treating chemicals for prevention of scale and paraffin deposition, can be injected along the diagnostic lateral wellbore or frac interval lateral wellbores to give broader and / or deeper distribution into the fracture network than by using mono-bore-centric diagnostic injection techniques. Diagnostic lateral treatment techniques can also improve fluid or chemical distribution, such as the use of gas injection to help energize fluid flow to the primary lateral during production optimization treatments, including reverse diversion methodology.

Owner:BAKER HUGHES INC

Metal door processing plant sewage treatment equipment

ActiveCN112279418ASimple structureEasy to operateTreatment involving filtrationMultistage water/sewage treatmentSludgeDrain tube

The invention relates to the technical field of environmental protection equipment, in particular to metal door processing plant sewage treatment equipment which performs multi-step treatment on sewage through a treatment box, a reaction box and a settling box, is simple in overall structure and convenient to operate, pretreats the sewage, removes large-volume impurities influencing subsequent treatment, and uniformly treats heavy metals in the sewage under the stirring of the stirring frame so that the treatment effect is good, and the practicability is high; the equipment comprises a base, abottom column, the settling tank, a water inlet pipe and a drainage pipe; the equipment further comprises the treatment box, a sewage pipe, an impurity removal net, an impurity discharge pipe, a first water pump, a first water pumping pipe, a first water supply pipe, the reaction box, a chemical box, a chemical inlet pipe, a metering pump, a chemical distribution pipe, a chemical outlet head, a first motor, a first rotating shaft, a stirring frame, a second water pump, a second water pumping pipe, a filter net, a sludge pump and a sludge pumping pipe. The impurity removal net is provided witha first inclined section, a vertical section and a second inclined section.

Owner:烟台胜凯门业制造有限公司

Efficient crop protection spraying combined device

The invention discloses an efficient crop protection spraying combined device and belongs to the technical field of liquid spraying equipment. The efficient crop protection spraying combined device comprises a truck, a high-pressure-resistant chemical distribution box, a high-pressure air feed pump, a multi-interface fast splicer and air compressing power sprayers. The high-pressure air feed pump is connected with the high-pressure-resistant chemical distribution box through a high-pressure pipe. The high-pressure-resistant chemical distribution box is connected with the multi-interface fast splicer through a high-pressure-resistant pipe. The multi-interface fast splicer is connected with each air compressing power sprayer through a high-pressure-resistant pipe. Chemicals are pressed into the air compressing power sprayers through the power provided by the high-pressure air feed pump. The efficient crop protection spraying combined device has the advantages that the whole combined device is provided with a large amount of air compressing power sprayers which do not use oil, electricity or manual pressing as power for spraying, a user does not need to prepare spraying water, chemicals and carrier vehicles and add chemicals frequently, labor intensity and preparation procedures can be reduced, and crop protection spraying can be performed in a time-saving, labor-saving and money-saving manner.

Owner:李军

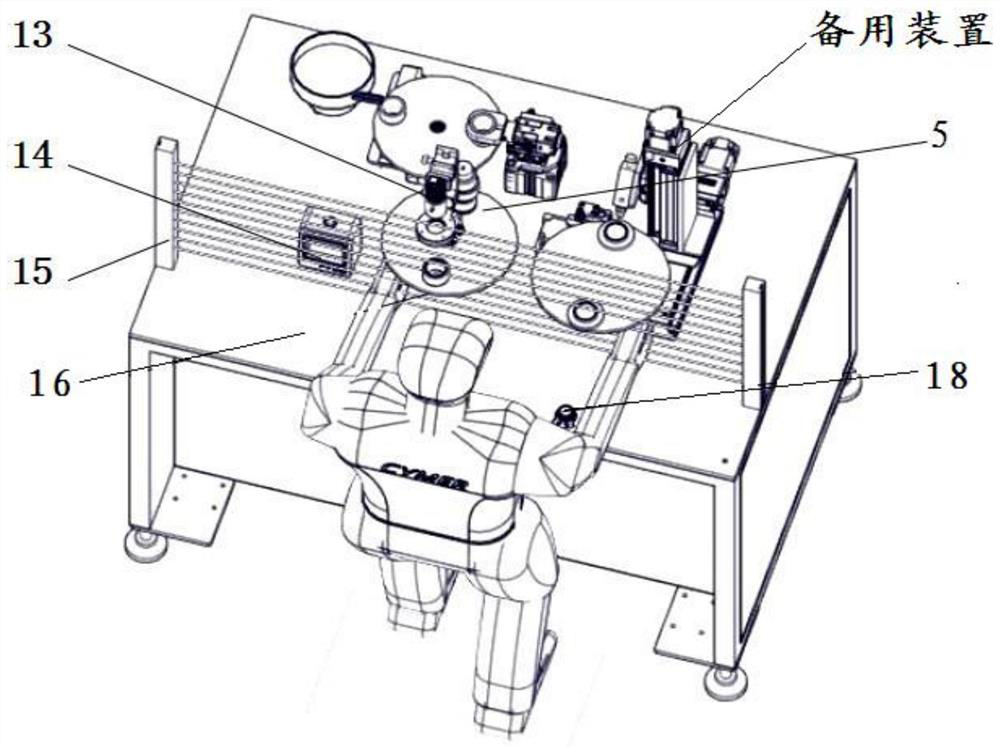

High-precision quantitative automatic charging device for initiating explosive devices such as ignition powder box

ActiveCN112050694ARealize automatic controlRealize judgmentAmmunitionAgainst vector-borne diseasesChemical storageThermodynamics

The invention relates to a high-precision quantitative automatic charging device for initiating explosive devices such as an ignition powder box, and belongs to the technical field of high-precision quantitative charging of black powder. The high-precision quantitative automatic charging device comprises chemicals, a box body, a positioning jig, a positioning rotary disc, a chemical storage bin, two chemical transfer boxes, a weighing module, a rotary disc, a chemical pouring manipulator, a chemical charging hopper, a box body vibrator and an operating platform, wherein the chemicals in the chemical transfer boxes are moved from the rotary disc to the positioning rotary disc through the chemical pouring manipulator and poured into the box body from the chemical transfer boxes; and a camera, a code scanner, a safety grating and a starting button are used for assisting in realizing the recording of the box body and the chemical filling amount and the safety precaution in the working process. According to the high-precision quantitative automatic charging device, the automatic quantitative chemical distribution, automatic charging and automatic shaking and leveling in the assembly process are realized instead of manual operation.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Heavy metal sewage treatment system and heavy metal sewage treatment method

InactiveCN113072220AEfficient removalReduce deliveryWater/sewage treatment by irradiationWater treatment compoundsWater treatment systemSludge

The invention discloses a heavy metal sewage treatment system and a heavy metal sewage treatment method. The heavy metal sewage treatment system comprises a water inlet pipe, a reaction tank, a transition tank and a drainage pipe, wherein the water inlet pipe communicates with the reaction tank, the transition tank is arranged around the outer wall of the reaction tank and communicates with the drainage pipe, a feeding control table is arranged in the middle of the reaction tank and is a cylindrical cement column, the bottom end of the feeding control table is fixed to the bottom of the reaction tank, the bottom of the reaction tank communicates with a sludge storage tank, the bottom of the sludge storage tank is connected to a sludge treatment system through a pipeline, a feeding device is arranged in the table top of the feeding control table, a stirrer is arranged on a column body, close to the tank bottom, of the feeding control table, and the stirrer rotates around the feeding control table. The heavy metal sewage treatment system is more convenient to put chemicals and more uniform in chemical distribution, heavy metal elements in sewage are effectively removed, impurities in sludge are less, and subsequent treatment and resource recovery are facilitated.

Owner:殷富新

Sodium-cooled fast reactor steam generator and superheater heat transfer tube steam-water side chemical cleaning system

PendingCN112344314AUnaffected thermal performanceDoes not affect material propertiesBoiler cleaning control devicesFlush cleaningSuperheaterProcess engineering

The invention discloses a sodium-cooled fast reactor steam generator and superheater heat transfer tube steam-water side chemical cleaning system. An outlet of a chemical preparation box communicateswith an inlet of a chemical distribution pump, an outlet of the chemical distribution pump is divided into two paths, one path of the two paths communicates with an inlet of the chemical preparation box through a return valve, the other path communicates with a water inlet of a cleaning box, a desalted water source communicates with an inlet of the cleaning box and the inlet of the chemical preparation box, a nozzle is arranged in the cleaning box, a steam source communicates with the nozzle, an outlet of the cleaning box is divided into two paths, one path of the two paths communicates with an inlet of a cleaning flow meter through a cleaning pump, the other path communicates with an inlet of the cleaning flow meter through a monitoring pipe and a monitoring pipe flow meter, an outlet ofthe cleaning flow meter is divided into two paths, one path of the two paths communicates with a waste water collecting box through a drain valve, and the other path communicates with the inlet of thecleaning box through a steam generator, a superheater and a chemical sampling device in sequence. The system can achieve chemical cleaning of an evaporator and the superheater in a sodium-cooled fastreactor unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com