Chemical distribution system for floor cleaning machine

a technology for cleaning machines and chemicals, applied in carpet cleaners, instruments, photosensitive materials, etc., can solve the problems of ineffective and inefficient cleaning of floors of the and the above-described first type of scrubber is not optimized for dealing with various types and amounts of dirt and debris,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

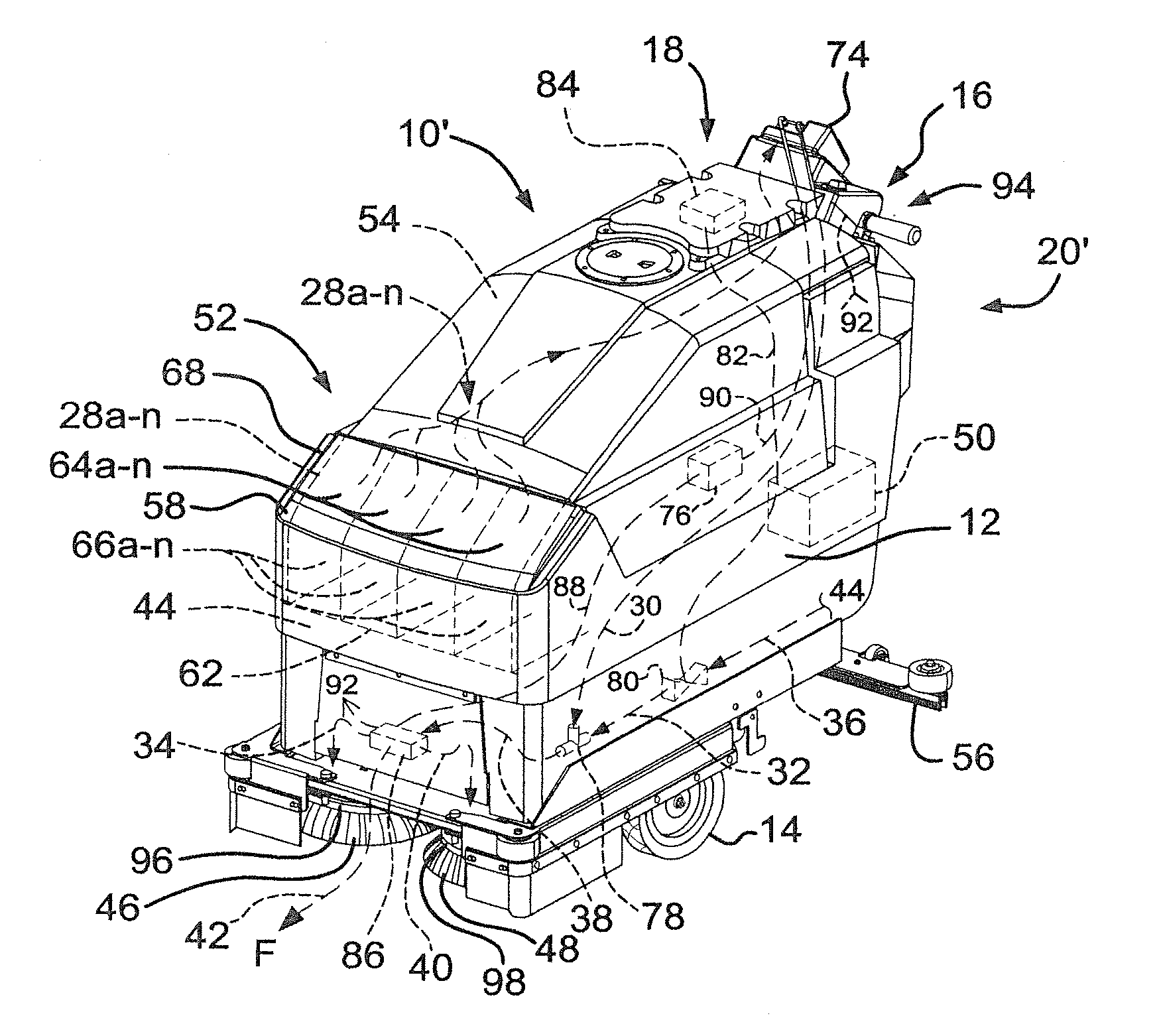

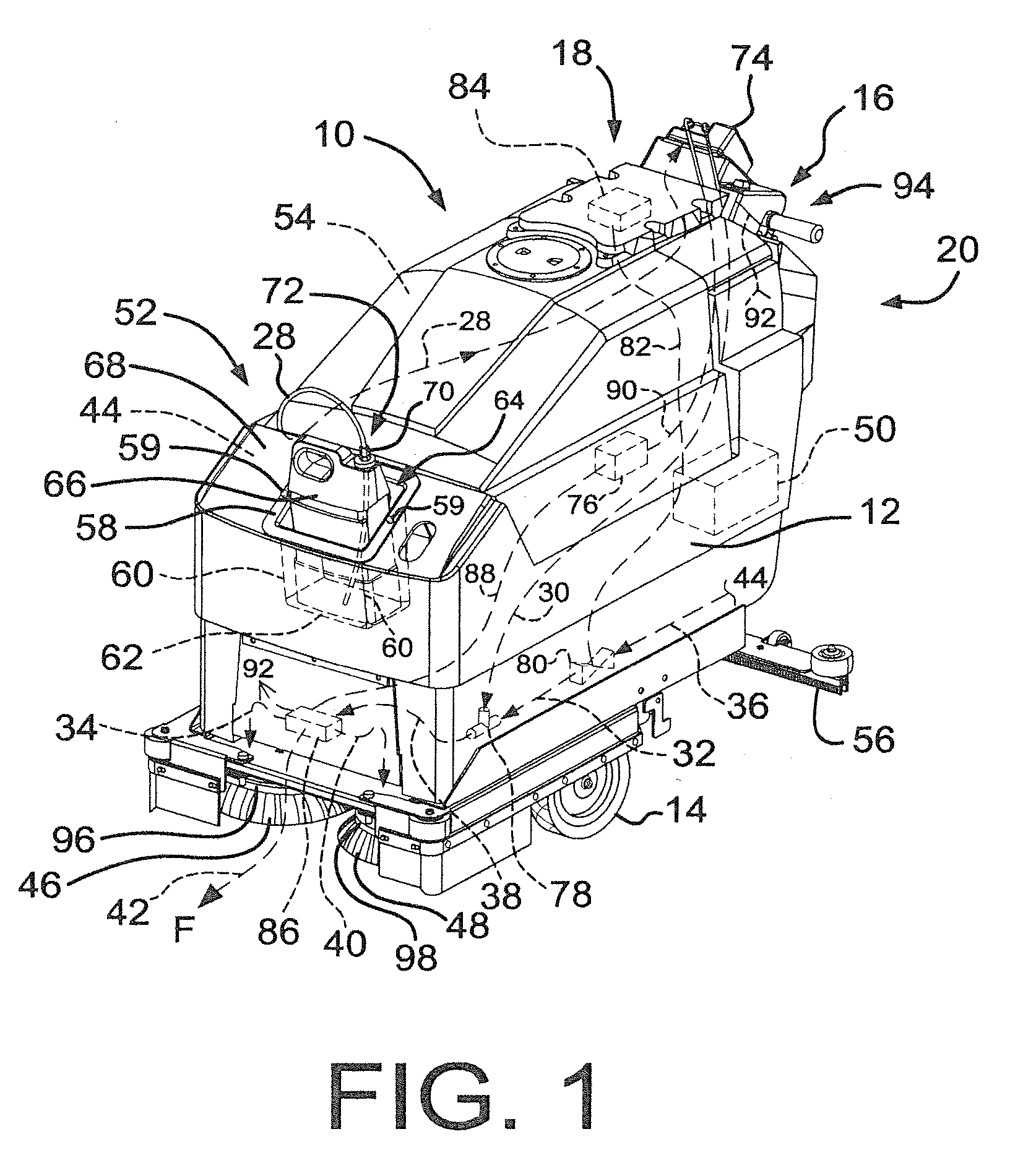

[0021]FIGS. 1 and 2 depict a floor cleaning machine 10, with a chemical distribution system 20, utilized with the present invention. The floor cleaning machine 10 of FIG. 1 is an automatic floor scrubber but the present invention is not limited to floor scrubbers. Instead, the present invention maybe used with any floor cleaning machine known to those skilled in the art.

[0022]The automatic floor scrubber 10 is constructed of a body portion 12 mounted on a set of wheels 14 (one or more not shown but common in the art) that permits the body portion 12 to be moved over a floor F. Machine controls 16 are provided for an operator to turn the machine 10 on and off, to steer and control the speed of the machine 10 and monitor machine performance, among other functions provided by automatic scrubbers in general. The machine controls 16 are provided at a rear portion 18 of the machine 10, where the operator is located.

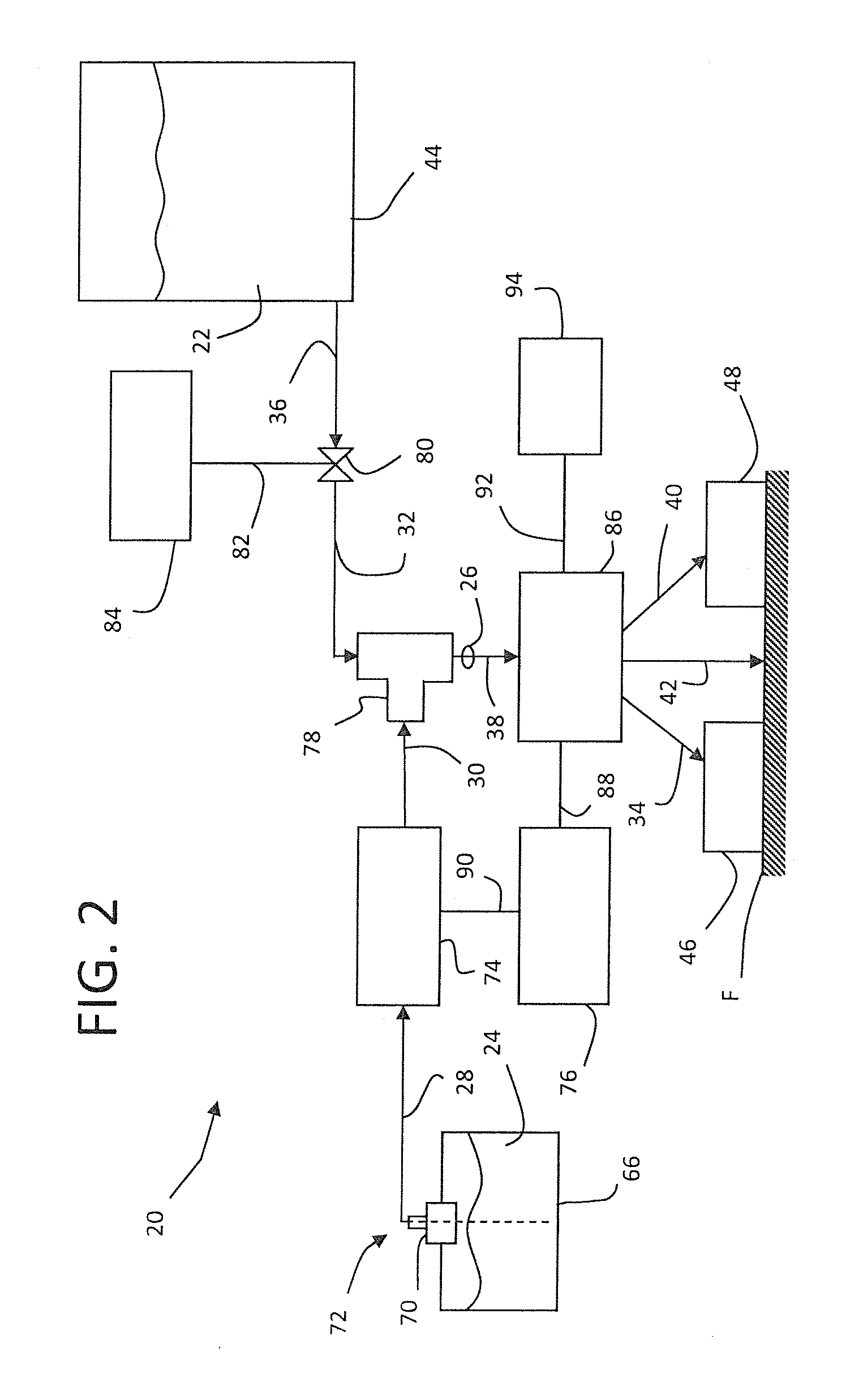

[0023]In general, the flow of fluids 22, 24, 24a-n, 26, 26′ throughout FIG...

embodiment 10

[0030]FIG. 1 further depicts a container receptacle 58 in the forward portion 52 of the body portion 12. In the depicted embodiment 10, the container receptacle 58 is attached to or formed at least partially within the outer surface 68 of the scrubber 10. Therefore, a portion of the volume of the solution tank 44 is reduced approximately by the volume of the container receptacle 58. This is not problematic, however, because the volume of the solution tank 44 is large and the volume taken up by the container receptacle 58 is relatively small in comparison.

[0031]The container receptacle 58 may be a separate component that is attached to the body portion 12 or it may be integrally formed, one-piece and unitary with the body portion 12. In the depicted embodiment 10, the container receptacle 58 is a separate component that is attached to the body portion 12 with mechanical fasteners 59, like screws that are common in the art. Other means, in addition to or separately from mechanical fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com