Preparation method of MWT (Metal Wrap Through) solar cell

A solar cell and one-sided technology, applied in the field of solar cells, can solve problems such as unfavorable large-scale mass production, and achieve the effects of simplified battery preparation process, strong feasibility, and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

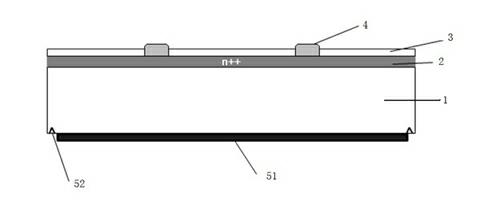

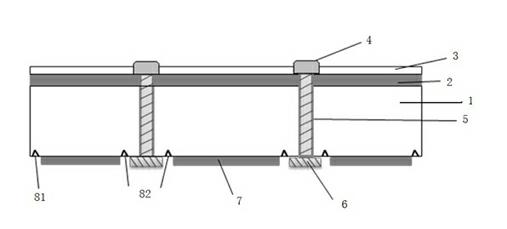

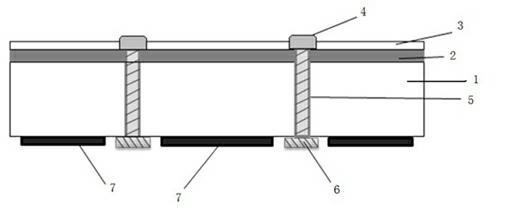

[0057] The MWT solar cell provided by this embodiment, such as image 3 As shown, it includes a p-type polysilicon substrate 1, and an emitter 2, a passivation anti-reflection layer 3 and an emitter contact grid line 4 are arranged on the front surface (light-receiving surface) of the p-type polysilicon substrate 1 from bottom to top. Between the front surface and the rear surface (back surface) of the silicon substrate, a plurality of conductive through-holes 5 penetrating the substrate are provided, and the plurality of conductive through-holes are filled to connect the emitter electrode and the emitter contact electrode 6 ( That is, the negative pole), the base contact electrode 7 (that is, the positive pole) that forms an ohmic contact with the silicon substrate in the region that is not provided with the emitter contact electrode on the back of the crystalline silicon substrate, the gap between the emitter contact electrode and the base contact electrode provides Insulati...

Embodiment 2

[0078] The preparation method of MWT solar cell in the present embodiment comprises the following steps:

[0079] (1) Texture corrosion

[0080] Texture corrosion is usually: select a p-type single crystal silicon substrate (sheet) with a resistivity of 1.0-3.0 Ω cm, place the silicon sheet at a temperature of 80-95 ° C, and a volume percentage of 1-10% alcohol The surface is corroded in sodium hydroxide solution to form uneven suede. The weight percentage of sodium hydroxide solution is 0.5-1.5%. The textured silicon wafer was soaked in 10% dilute hydrochloric acid for 2 minutes, and then rinsed with deionized water.

[0081] (2) Phosphorus diffusion

[0082] Phosphorus diffusion is usually as follows: using phosphorus oxychloride liquid source, diffusion is carried out in an industrial tubular diffusion furnace, so that the temperature in the constant temperature zone is 800~900°C, the diffusion time is 30~60 minutes, and the diffusion resistance is controlled at 40~80Ω ...

Embodiment 3

[0098] The preparation method of MWT solar cell in the present embodiment comprises the following steps:

[0099] (1) Texture corrosion

[0100] Select a p-type polysilicon substrate (sheet) with a resistivity range of 1.0-3.0 Ω·cm, and place the silicon substrate piece by piece in an acidic texturing solution at a temperature of 8-10°C (by HF, HNO 3 , H 2 O composition) solution for one-sided corrosion of the front surface to form a rough suede surface and then rinsed with deionized water.

[0101] (2) Phosphorus diffusion

[0102] The liquid source of phosphorus oxychloride is used to diffuse in an industrial tubular diffusion furnace, so that the temperature in the constant temperature zone is 800-900°C, the diffusion time is 30-90 minutes, and the diffusion resistance is controlled at 40-80Ω / □; this implementation In the example, the temperature in the constant temperature zone is 850°C, the diffusion time is 70 minutes, and the diffusion square resistance is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com