Patents

Literature

330results about How to "Reduce shading area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-viscosity solar cell front side silver paste and method for producing the same

InactiveCN101271928AIncrease aspect ratioImprove photoelectric conversion efficiencyFinal product manufactureNon-conductive material with dispersed conductive materialScreen printingSilver paste

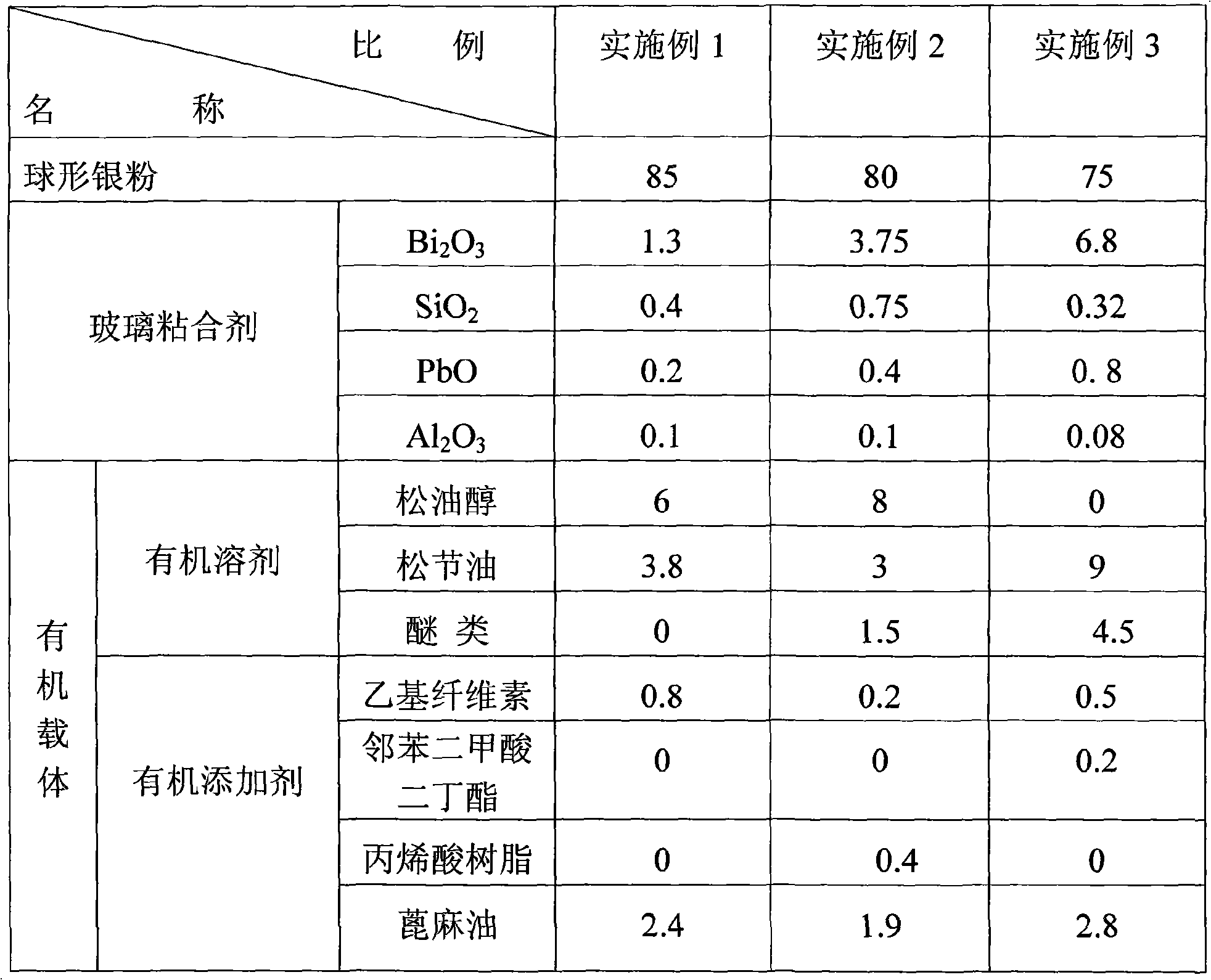

The invention relates to a high viscosity solar cell front silver serum and a preparation method thereof. The composition and the weight ratio of the high viscosity solar cell front silver serum are that conductive silver powder accounts for 75-85 percent, glass glue accounts for 2-10 percent, organic carrier accounts for 5.5-20 percent, the particle size of the conductive silver powder is 0.2-2mum; the composition and the weight ratio of the glass glue are that Bi2O3 accounts for 65-85 percent, SiO2 accounts for 5-20 percent, PbO accounts for 1-15 percent and Al2O3 accounts for 1-5 percent. After such processes are carried out by the serum as screen printing, low temperature drying and high temperature sintering, the aspect ratio of a conducting electrode formed on the surface of solar cell is high, the solar cell produced by using the method has small front shading area and high photoelectric conversion efficiency.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Method for preparing front electrodes of solar cells

InactiveCN101562217AReduce surface recombinationHigh aspect ratioFinal product manufactureSemiconductor devicesStencil printingChemical plating

The invention relates to a method for preparing front electrodes of solar cells, which comprises the following steps: firstly preparing discontinuous dot electrodes; and then connecting the dot electrodes by electroplating technology to realize that the electrodes collect and transport current but dielectric films still exist between the dot electrodes to have the function of passivation. The discontinuous dot electrodes are prepared by photoetching, evaporation and dissection methods, or firstly printed by silkprint, stencil printing or ink jet printing and then prepared by a sintering method. The electroplating is photoinductive electroplating or chemical plating. The dot electrodes effectively reduce surface recombination; and the adopted electroplating technology not only simply and accurately realizes the connection of the dot electrodes, but also effectively reduces the width of grid lines, namely reduces electrode shading areas and further reduces the surface recombination so as to contribute to improving battery efficiency.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

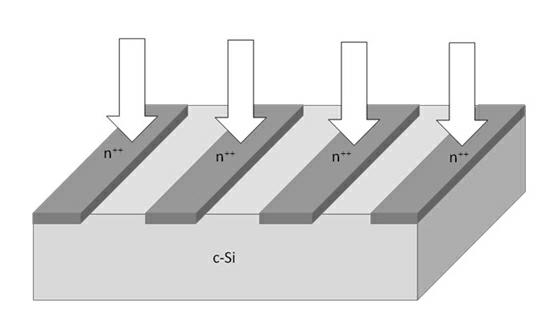

Technology for manufacturing interlaced back contact (IBC) crystalline silicon solar battery with ion implantation

ActiveCN102222726ASimple preparation processHigh feasibilityFinal product manufactureSemiconductor devicesSilicon solar cellOptoelectronics

A technology for manufacturing an interlaced back contact (IBC) crystalline silicon solar battery with ion implantation comprises the following steps: (1) selecting a crystalline silicon base body to perform surface texturing; (2) forming a homotype doping layer having the same electrical property with the base body on the positive surface; (3) forming n+ doping regions and p+ doping regions interlaced to each other on the back surface of the crystalline silicon by the ion implantation; (4) insulating the n+ doping regions and the p+ doping regions on the back surface of the crystalline silicon base body; (5) performing annealing in order to eliminate crystalline damage caused by iron implantation to the crystalline silicon base body, and performing thermal oxidation to form a SiOx oxide layer; (6) forming a passive anti-reflecting film on the positive surface of a silicon chip; (7) forming a passive film on the back surface of the silicon chip; and (8) forming an emitter and a metal contact electrode of a base electrode on the back surface, and forming the ohmic contact of the metal electrode with the n+ doping regions and the p+ doping regions after one sintering. The method canaccurately control concentration, depth and position of the doping, and the technological process is simple, and easy to operate.

Owner:JA SOLAR TECH YANGZHOU

Low-cost efficient solar cell electrode grid line structure

The invention discloses a low-cost efficient solar cell electrode grid line structure which comprises two parts of main grid lines and thin grid lines, wherein the main grid lines are symmetrically distributed by taking a silicon wafer center as a center, the thin grid lines are equidistantly distributed in the way of being vertical to the main grid lines in parallel, the main grid lines adopt a sectional type design, and all the subsections are connected by thin lines. The electrode grid line structure adopts a design that the grid lines are thinned, the shading areas of the grid lines are reduced, the number of the grid lines is increased so that the lateral transmission loss of a carrier is lowered and the collection efficiency of the carrier is increased; moreover, the main grid lines are divided into sections, thinned and hollowed out additionally, so the silver usage is reduced, the manufacturing cost of a solar cell is reduced, meanwhile, the contact area compound is lowered, accordingly, the open-circuit voltage of the solar cell is increased, and the cost is greatly lowered; and compared with the widespread products of the industry, in the design scheme which is obtained by optimizing the scheme, the shading area of the grid lines on the front side of the solar cell is reduced by about 1%, the conversion efficiency is improved by 0.2-0.3%, and the silver paste consumption is reduced by about 35%.

Owner:JA SOLAR TECH YANGZHOU

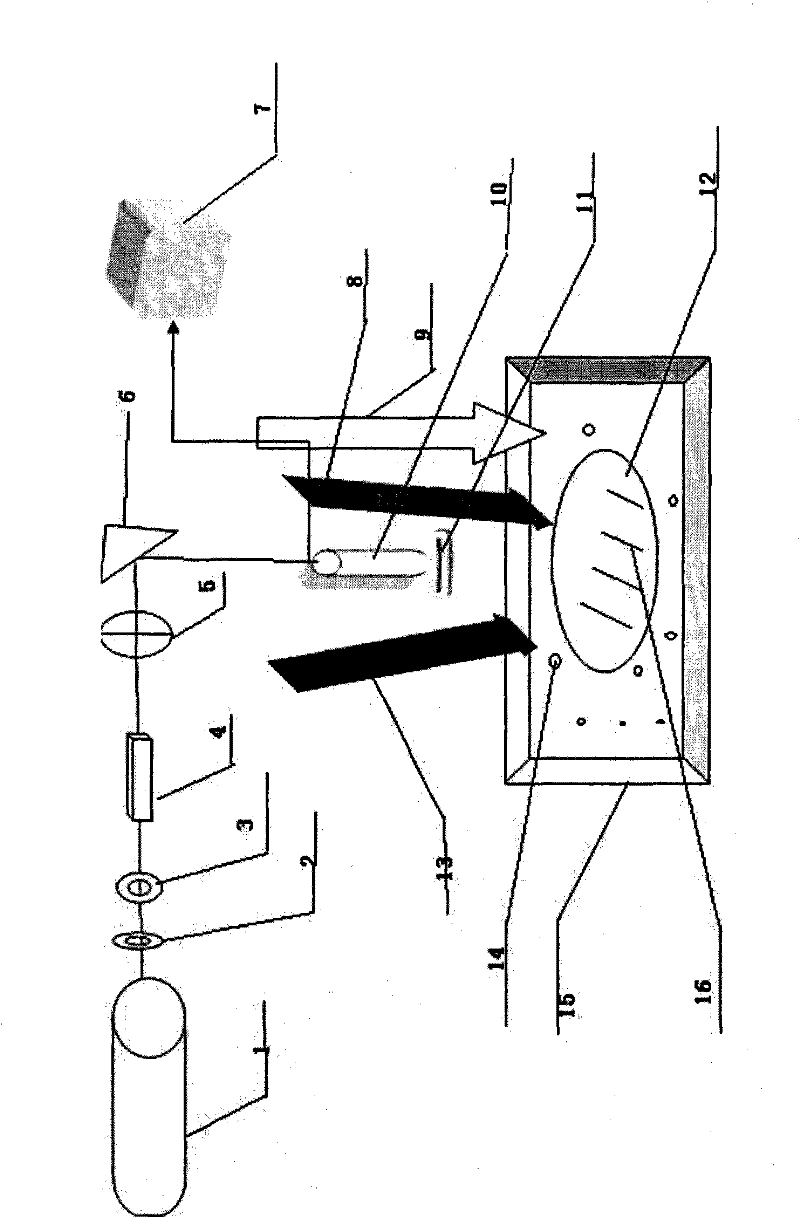

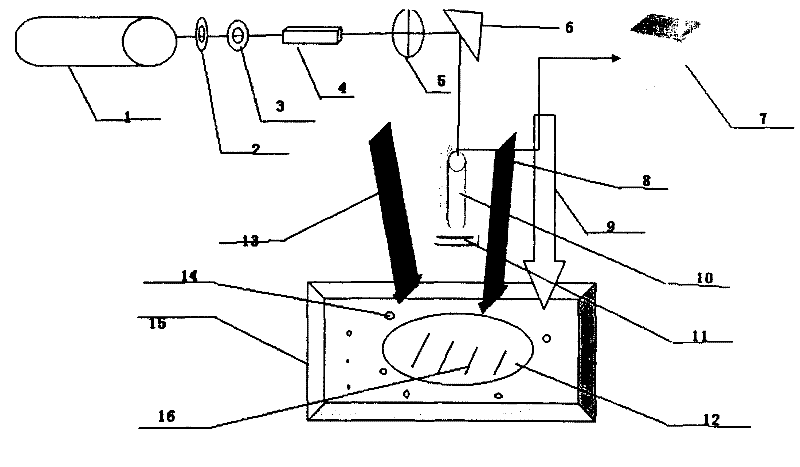

High-speed precision crystal silicon laser etching apparatus and method

InactiveCN102201493AEasy to controlNo pollution in the processLaser beam welding apparatusSemiconductor devicesHeat-affected zoneAutomatic control

The invention provides a high-speed precision crystal silicon laser etching apparatus and method. The method comprises the following steps: (A) placing a single crystal silicon wafer or a polycrystalline silicon wafer on a four-dimensional precision moving platform for laser processing by using a specific manipulator, with the aid of an observation and monitoring CCD system; (B) precisely focusing a laser beam on the surface of the silicon wafer, scanning the surface of the silicon wafer at a high speed by using a three-dimensional dynamic focusing vibration mirror in cooperation with a specific telecentric field lens, rising the surface etching temperature of the silicon wafer, and feeding phosphorous paste or phosphoric acid to a high-speed laser etching line at the same time; and (C) removing the manipulator for the silicon wafer and fixing next silicon wafer at the same time, and repeating the above drilling mode at. The method has the following advantages: laser has the characteristics of non-contact, no environment pollution and easy controllability, and can achieve the automatic control; since the laser focusing spot is in a micrometer size or smaller, thereby achieving high silicon wafer etching accuracy, small heat affected zone at the edge, and little damage to the substrate; and the power generation efficiency of the crystal silicon is further improved, and the production cost is further reduced.

Owner:周明

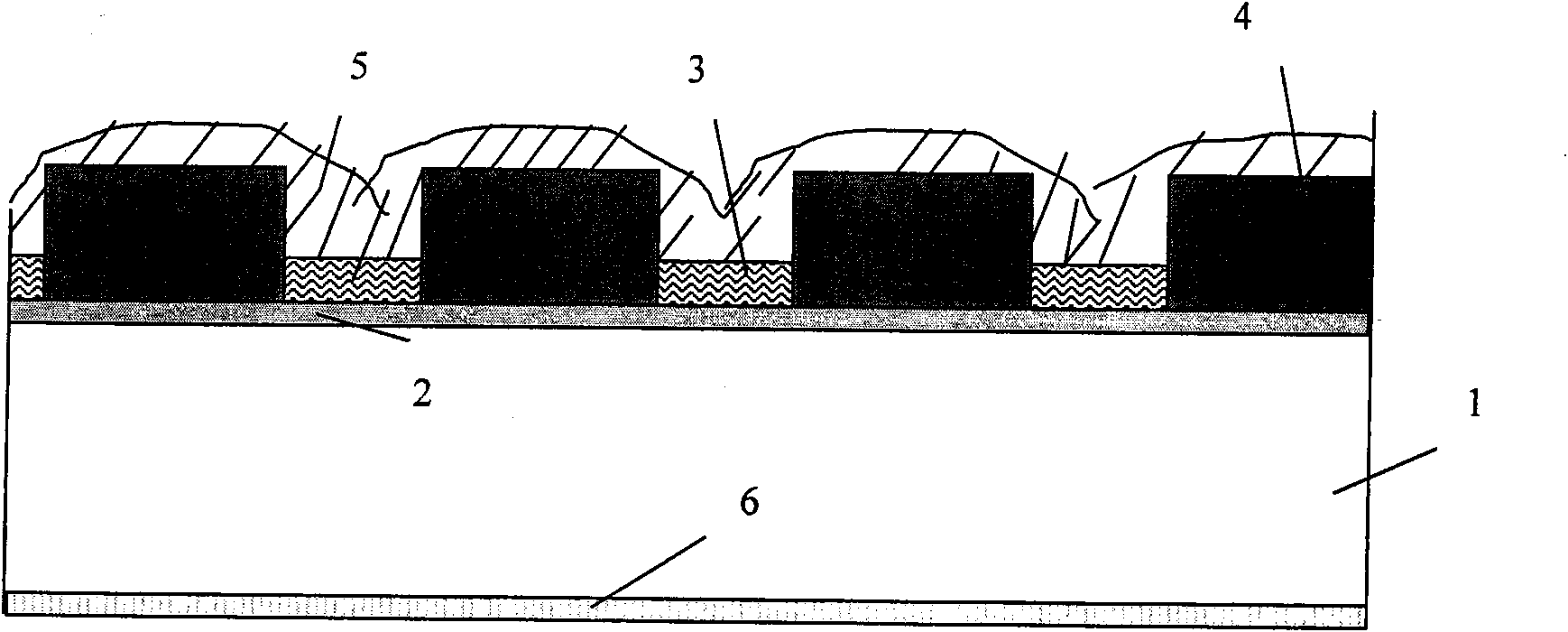

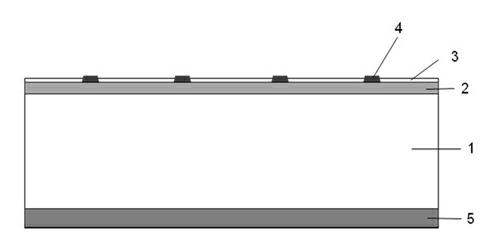

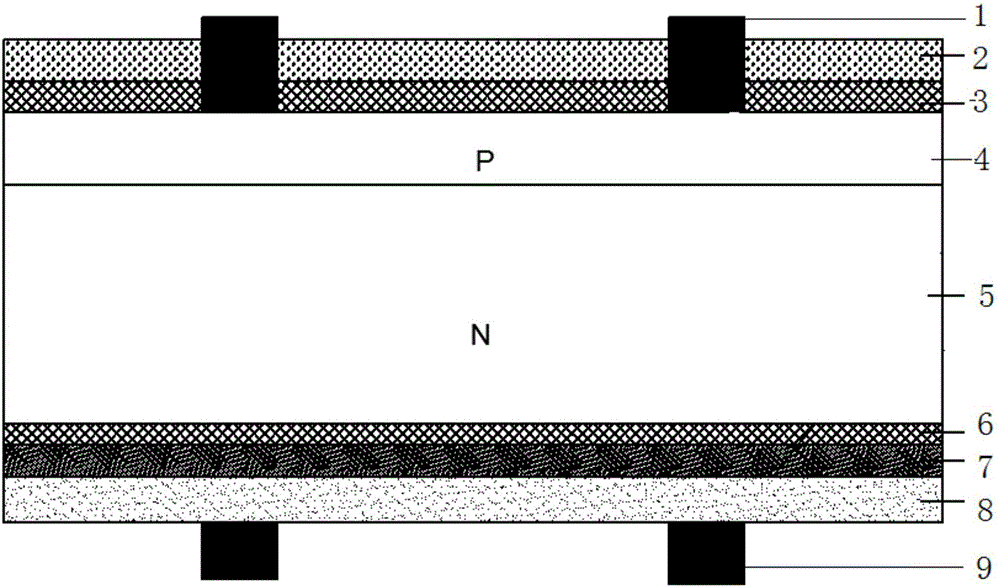

Silicon solar battery

InactiveCN101710596AIncrease power generation per unit areaReduce shading areaPhotovoltaic energy generationSemiconductor devicesBack surface fieldSlurry

The invention discloses a silicon solar battery which comprises a silicon substrate, wherein a silicon nitride film is deposited on the front surface of the silicon substrate; a group of auxiliary grid lines are arranged on the silicon nitride film; an aluminum-back surface field (Al-BSF) made of aluminum slurry is coated on the back surface of the silicon substrate; a main grid line is arranged on the Al-BSF; a plurality of conducting through holes which penetrate through the silicon substrate are arranged on the silicon substrate; conducting slurry is filled in the conducting through holes; the auxiliary grid lines and the main grid line are respectively connected with two ends of the conducting slurry; and an insulation tank for isolating the Al-BSF from the main grid line is arranged at the periphery of the main grid line. The invention has the advantages that by arranging the main grid line on the back surface of the silicon substrate, arranging the conducting through holes on the silicon substrate and filling the conducting slurry into the conducting through holes, each auxiliary grid line is mutually conducted with the main grid line through the conducting slurry, and the current generated by the battery under the condition of illumination passes through the auxiliary grid lines and then passes through the conducting slurry to be converged onto the main grid line to be derived. In the battery with the structure, as the main grid line for converging current is arranged on the back surface of the silicon substrate, the effective illumination surface of the front surface of the battery is increased.

Owner:SUN EARTH SOLAR POWER

Electrode construction for enhancing photoelectric transforming efficiency of silicon solar cell

InactiveCN101483199AIncrease the number ofIncrease the arrangement densitySemiconductor devicesTransformation efficiencyEngineering

The invention discloses an electrode structure for improving a crystal silicon solar battery photoelectric transformation efficiency characterized by arranging parallely set gate lines on a light interception face of the crystal silicon solar battery substrate, and arranging at least two solder joints between each gate line and the crystal solar battery substrate light interception face, wherein the gate lines are conductive gate lines. The invention cancels split-gate lines in a background technique, uses the solder points between the metal gate lines and the crystal solar battery substrate to gather light currents of the crystal silicon solar battery light interception face and guides the currents gathered by the solder points by using the metal gate lines. Because said structure, the invention not only reduces a lightproof area of the light interception face gate line of the crystal silicon solar battery, but also reduces a series resistance of the crystal silicon solar battery, thereby improving the conversion efficiency of the crystal silicon solar battery and facilitating the interconnect of multi-block single batteries.

Owner:JIAWEI SOLAR WUHAN

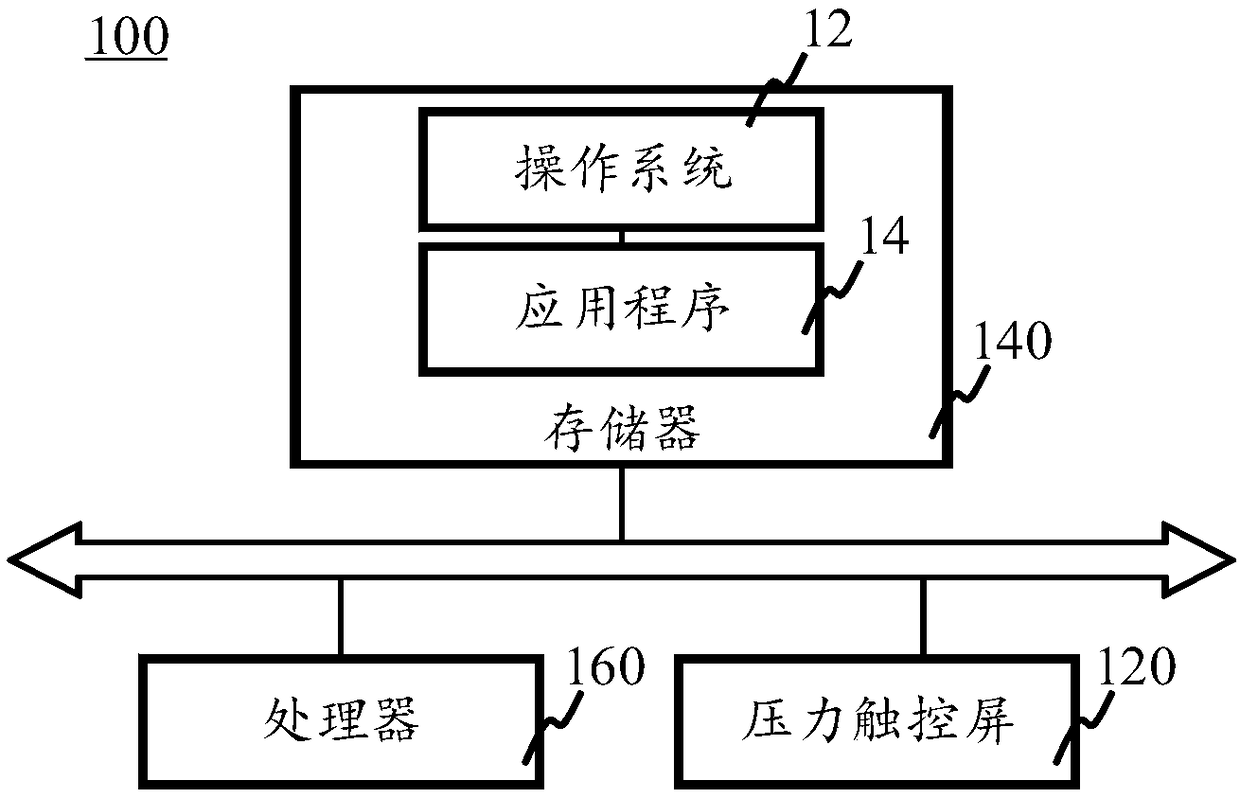

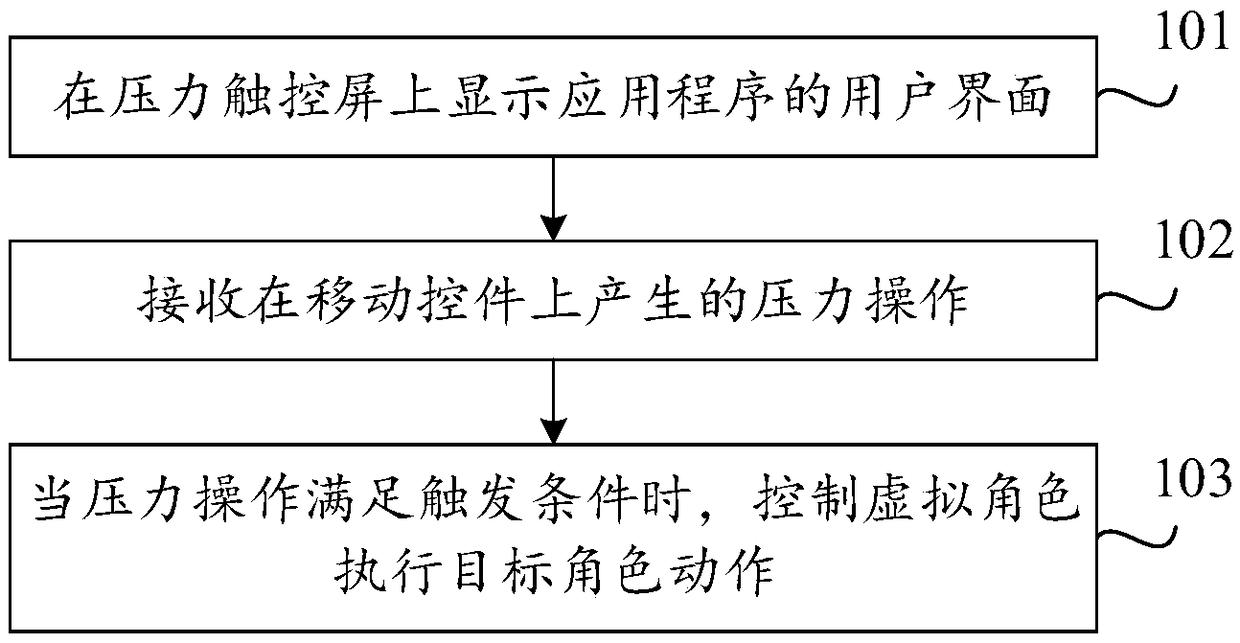

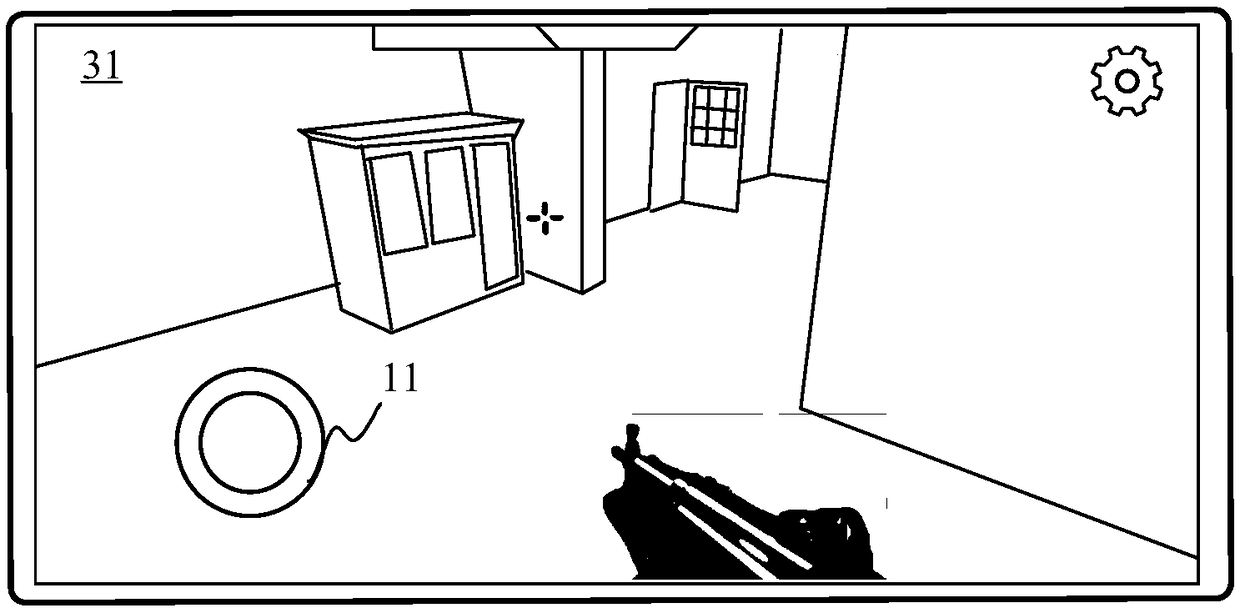

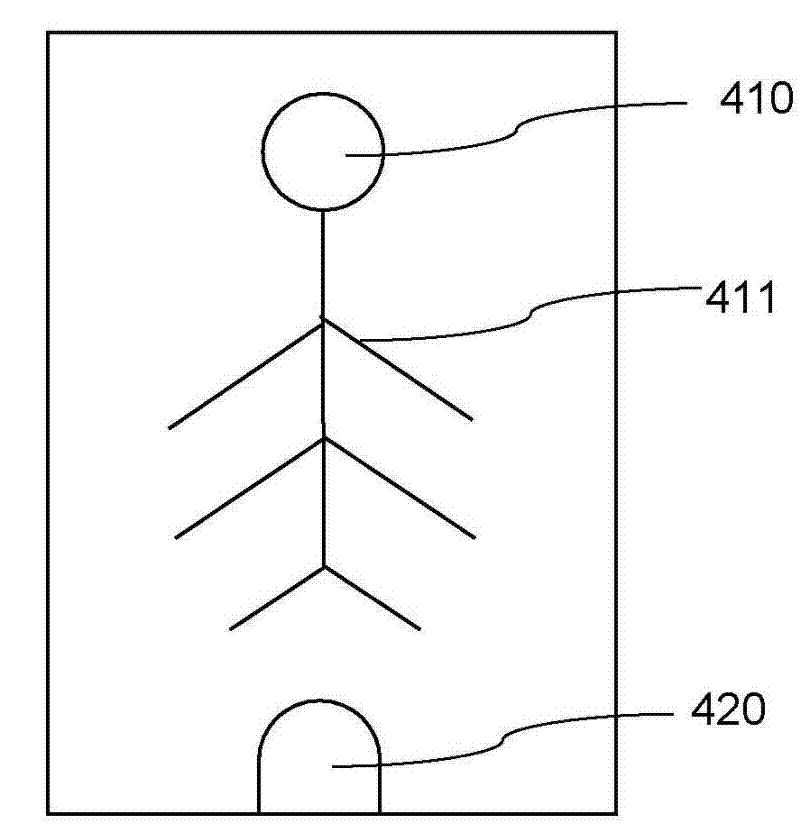

Method, device, apparatus and storage medium for controlling virtual role

This invention discloses a method, device, apparatus and storage medium for controlling a virtual role, and relates to the field of human-computer interaction. The method includes the following stepsof: displaying a user interface of an application on a pressure touch screen; receiving a pressure operation generated on a moving control element; when the pressure operation meets the trigger condition, controlling the virtual role to perform a target role action. According to the invention, by detecting the pressure value of the pressure operation on the moving control element, two different control operations can be achieved on the moving control element, a pressure threshold is used as a dividing line, and two different control operations can be achieved on the moving control element, which can reduce the setting of some control elements. Thus, the area of the virtual environment screen, blocked by the control elements, is reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Method for manufacturing silicon solar cell

InactiveCN101783374ALow sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesMetallic electrodeOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the purpose of industrialized production better.

Owner:SUN EARTH SOLAR POWER

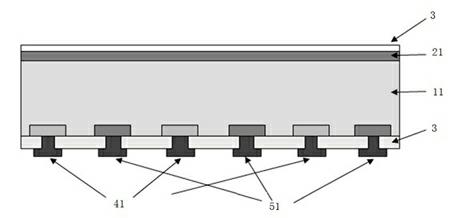

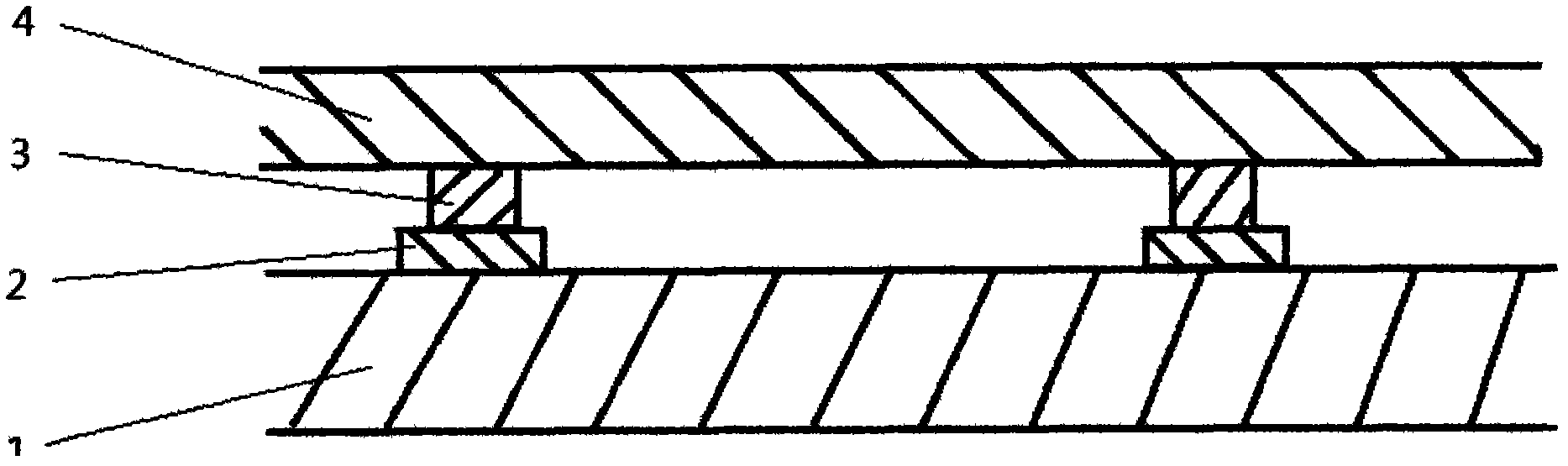

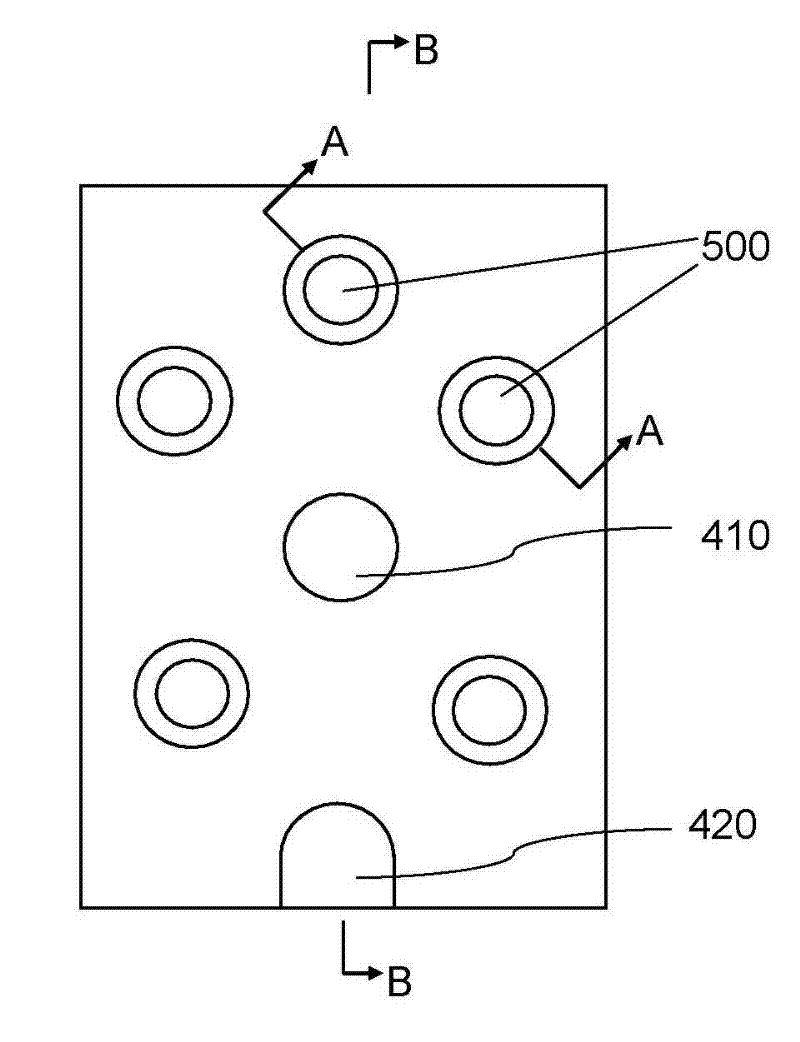

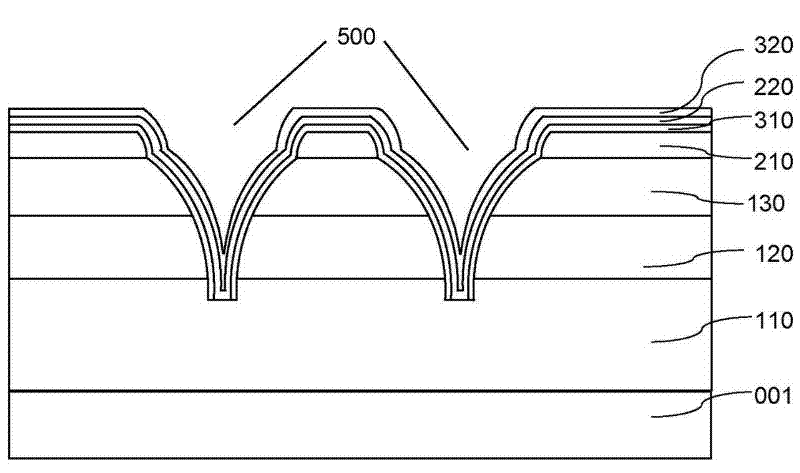

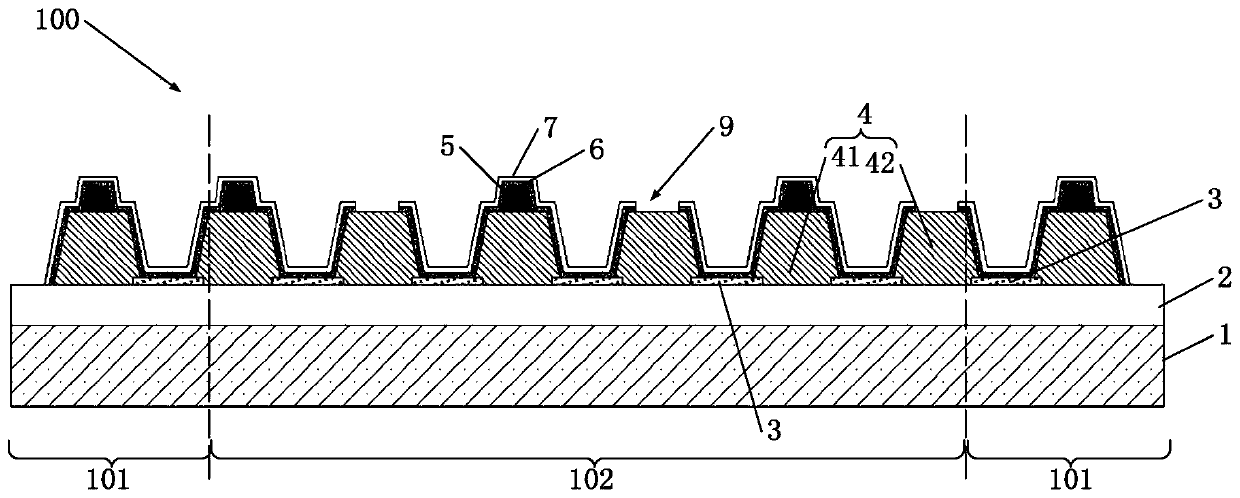

Rear surface passivation contact battery electrode structure and preparation method thereof

InactiveCN105870215AImprove conversion efficiencyImprove conductivityFinal product manufactureSemiconductor devicesBack structureTransparent conducting film

The invention discloses a rear surface passivation contact battery electrode structure and a preparation method thereof. A battery back structure comprises a tunneling layer which is arranged on the rear surface of a crystal silicon wafer and used for providing a passivation effect on the rear surface of a battery, the tunneling layer is provided with an N type doped crystal silicon layer used for a charge vertical conducting layer, the N type doped crystal silicon layer is provided with a transparent conducting film for an electric charge horizontal conducting layer, and the transparent conducting film is provided with a rear surface metal electrode for electric charge collection and a connection effect between battery pieces. According to the rear surface passivation contact battery electrode structure, the transparent conducting film / metal combination electrode is adopted so as to replace a conventional grid line electrode or an all metal back field electrode, so that the rear surface of the battery can serve as a light receiving surface, a shading area and the usage amount of conductive metal are remarkably reduced on the premise of guaranteeing good conductivity of the electrode, and the conversion efficiency of the battery is improved.

Owner:LONGI SOLAR TECH CO LTD

Display panel and display device

ActiveCN108806578AHigh precisionReduce the amount of occlusionUnauthorised/fraudulent call preventionStatic indicating devicesCapacitanceDisplay device

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

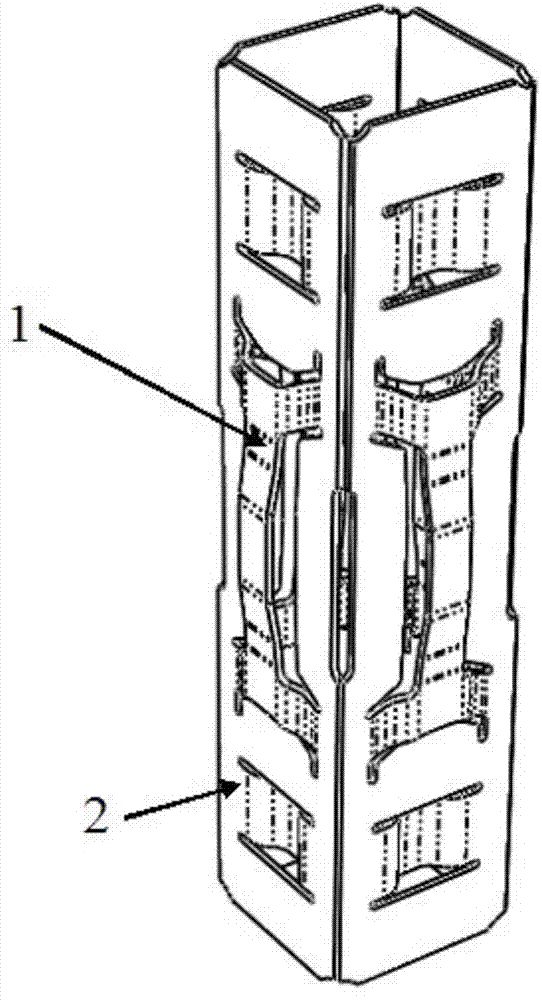

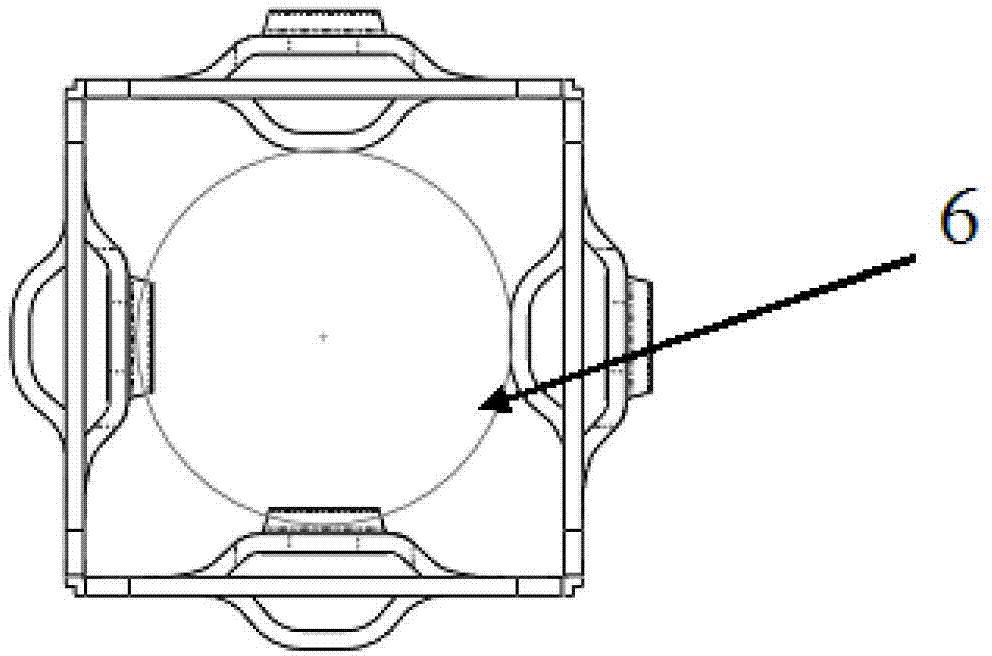

Fuel assembly positioning grid capable of preventing fuel rod from being scratched and subjected to vibrating abrasion

ActiveCN103177776ASmall pressure dropReduce shading areaNuclear energy generationFuel element assembliesWhole bodyEngineering

The invention provides a fuel assembly positioning grid capable of preventing a fuel rod from being scratched and subjected to vibrating abrasion. An upper rigid dimple and a lower rigid dimple are uniformly distributed on the side wall of each grid cell; a positioning grid spring is arranged between every two rigid dimples; the whole body of each positioning grid spring is of an I-type and each positioning grid spring comprises two arched primary springs which are arranged at the upper part and the lower part, as well as a strip-shaped secondary spring; the two primary springs are arranged transversely; the height of each primary spring is smaller than the spacing between a cladding surface and the side wall of the positioning grid when the fuel rod is located in the center of the positioning grid; the secondary spring is arranged longitudinally; and the two ends of the secondary spring are respectively connected to the centers of the primary springs and are slowly raised up to form two slopes, and the middle of the secondary spring is a top plane which is in direct contact with the surface of the fuel rod. The structure of the fuel assembly positioning grid is capable of effectively preventing the surface of the fuel rod from being scratched by the springs of the positioning grid and reducing the vibrating abrasion of the spring to the fuel rod, thereby improving the whole safety of a fuel assembly.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

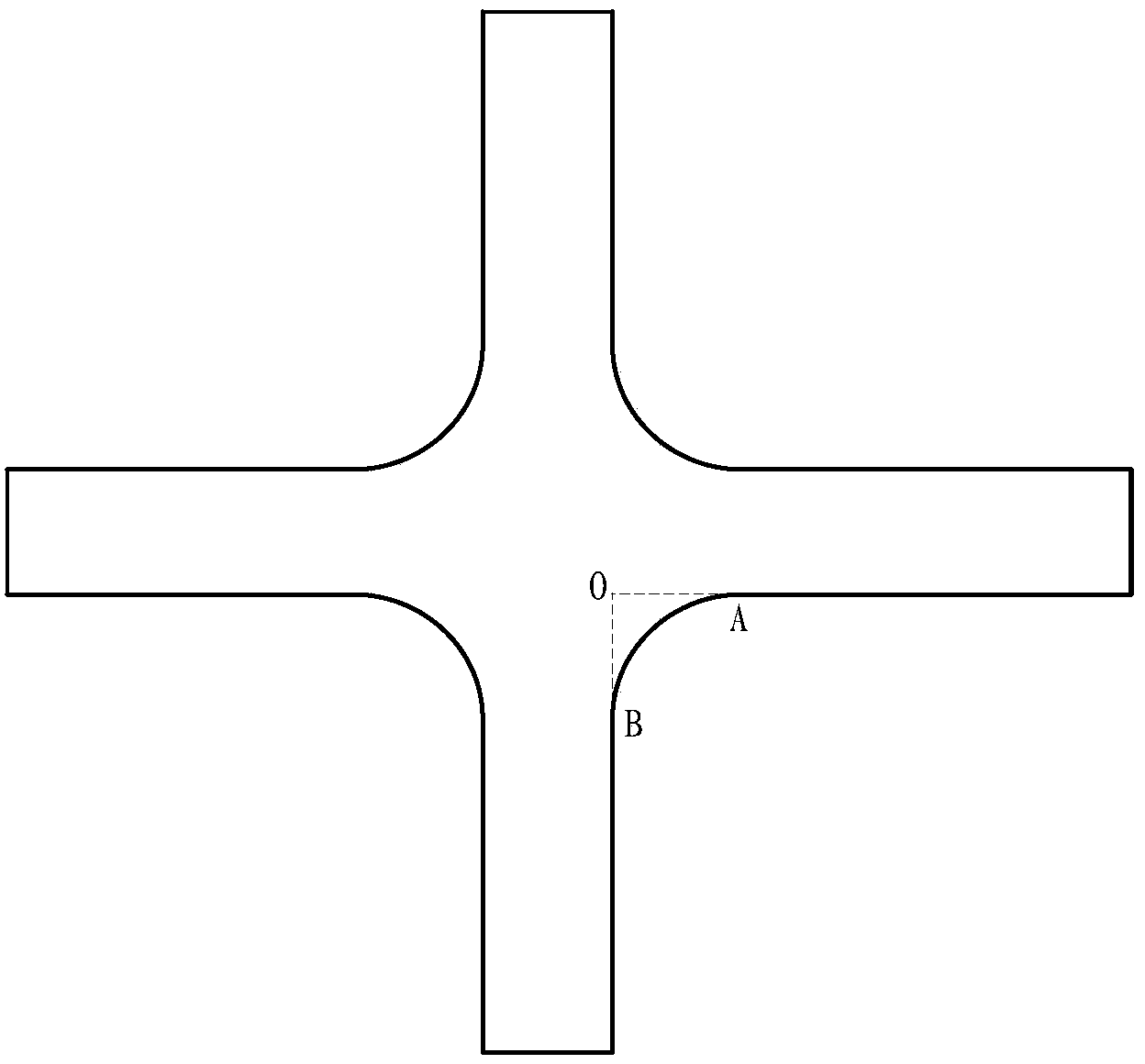

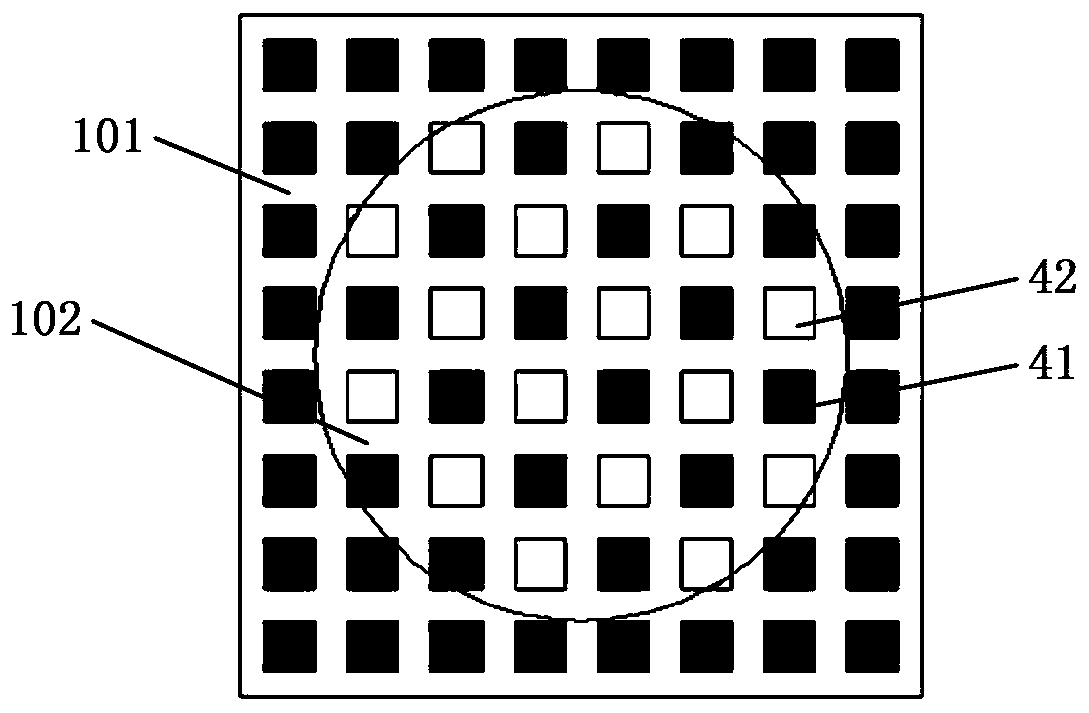

Mask plate

InactiveCN104281000AIncrease opening ratioImprove transmittanceOriginals for photomechanical treatmentTransmittanceBlack matrix

The invention provides a mask plate which comprises a plurality of rectangular shading regions which are arranged in an array, wherein clearances between the multiple rectangular shading regions form light leakage regions; the light leakage regions comprise a plurality of transverse light leakage strips and longitudinal light leakage strips which are staggered transversely and longitudinally; an auxiliary shading region is also arranged on the mask plate and can shade light rays at corners of the rectangular shading regions, so that the light intensities of the light rays at the corners of the rectangular shading regions are in right-angle distribution. According to the mask plate with the structure, the light intensity distribution of the shading regions at the corners of the light leakage regions is of a right angle or is close to the right angle, so that the mask plate can form a black matrix with right-angle corners; therefore, the shading areas of the corner regions of the black matrix are reduced, the aperture opening ratio of the black matrix is increased, and the aim of increasing the light ray transmittance rate of a display panel is achieved.

Owner:BOE TECH GRP CO LTD +1

Front electrode of solar cell

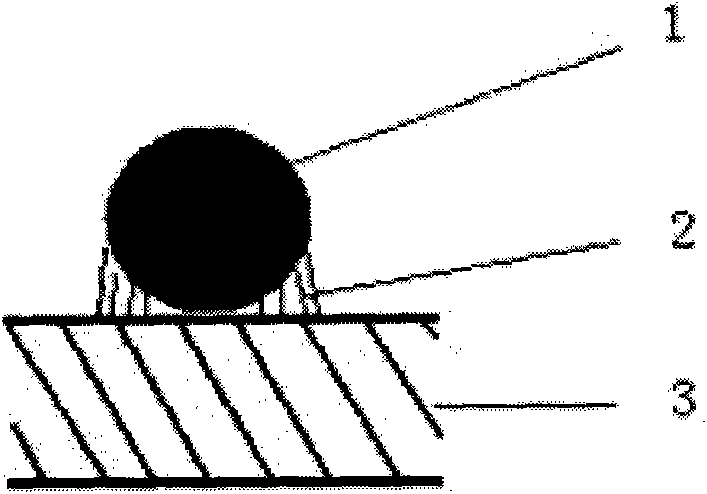

The invention relates to a point-contact front electrode structure of a solar cell. The front electrode structure is a bridge structure. The bridge structure comprises a bridge foundation, bridge piers and a bridge girder; the bridge foundation is weldable, silver paste or nickel paste is sintered to form the bridge foundation, and the bridge foundation is in excellent ohmic contact with a semiconductor of a substrate; solder paste is melted by heat to form the bridge piers, and the bridge girder can be conductively and mechanically connected with the bridge foundation by the bridge piers; the bridge girder comprises conducting metal wires, and currents of the various bridge piers can be gathered and led out by the aid of the bridge girder. The front electrode structure has the advantages that points of a point-contact electrode can be connected with one another by the metal wires, so that the total area of an electrode region is reduced, photon-generated carriers which are composited with one another on the surface of the cell are effectively reduced, the illumination shielding area of the electrode can be effectively reduced owing to the suspended metal wires, light injection is effectively increased, an open-circuit voltage and a short-circuit current are increased, and the conversion efficiency of the solar cell is improved; consumption of expensive silver is reduced owing to the structure, and accordingly the production cost of the solar cell is lowered.

Owner:陕西众森电能科技有限公司

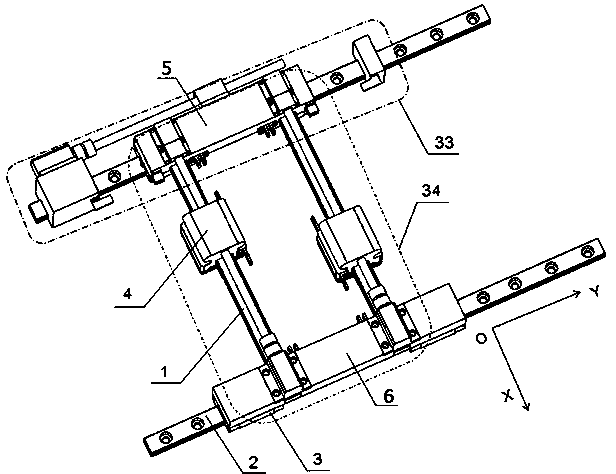

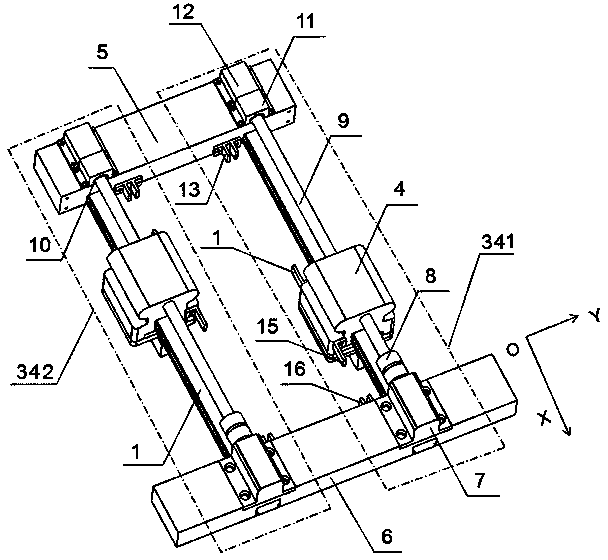

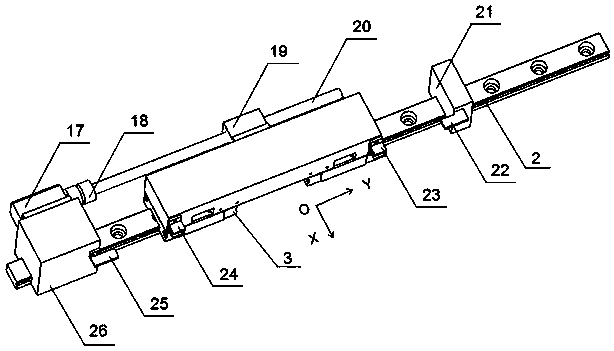

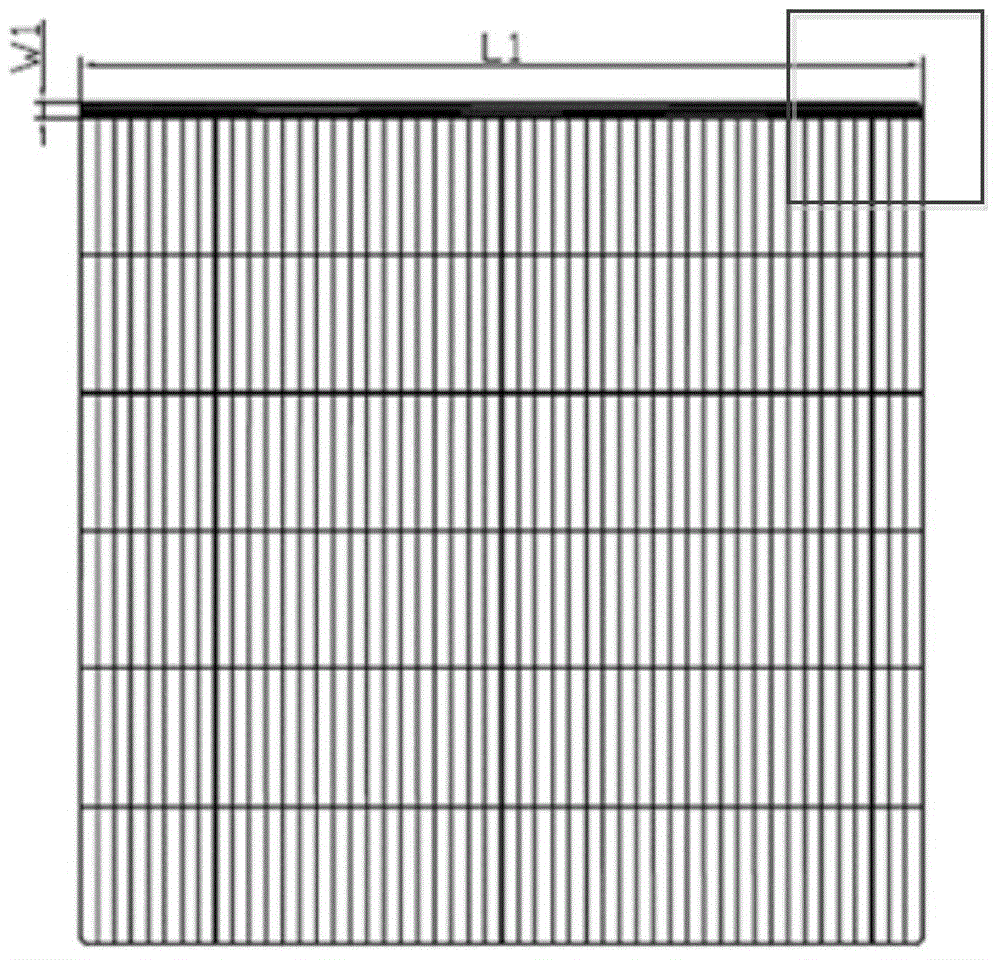

Ink jet device for preparing superfine primary/secondary grid line of solar cell

ActiveCN103625114AReduce shading areaIncrease productivityTypewritersPower drive mechanismsElectricityEngineering

The invention discloses an ink jet device for preparing a superfine primary / secondary grid line of a solar cell. The invention aims to improve the conversion efficiency of the solar cell by reducing the shielding area of an antireflection coating and realizing a high depth-to-width ratio. The ink jet device comprises linear guide rails, and a transverse positioning mechanism and a longitudinal positioning mechanism arranged on each set of linear guide rail; each set of transverse linear guide rail comprises a transverse linear slide rail and a transverse-sliding slide block; each set of longitudinal linear guide rail comprises a longitudinal linear slide rail and a longitudinal-sliding slide block; each longitudinal-sliding slide block is fixedly provided with a guide rail installation seat; the bottom end of each transverse-sliding slide block is provided with a micro-moving positioning platform which consists of a planar micro displacement mechanism and a plurality of piezoelectric ceramics; the bottom end of each planar micro displacement mechanism is fixedly provided with a ink jet printing head array. With the adoption of the ink jet device disclosed by the invention, high positioning accuracy of the ink jet printing head can be met, and the preparation of the orthogonal superfine primary and secondary grid lines can be completed at one step; the ink jet device has the advantages that the mechanism is flexible and adjustable, the operation is reliable, the production efficiency of printing the grid lines can be improved, and the fragment rate of cell pieces can be reduced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

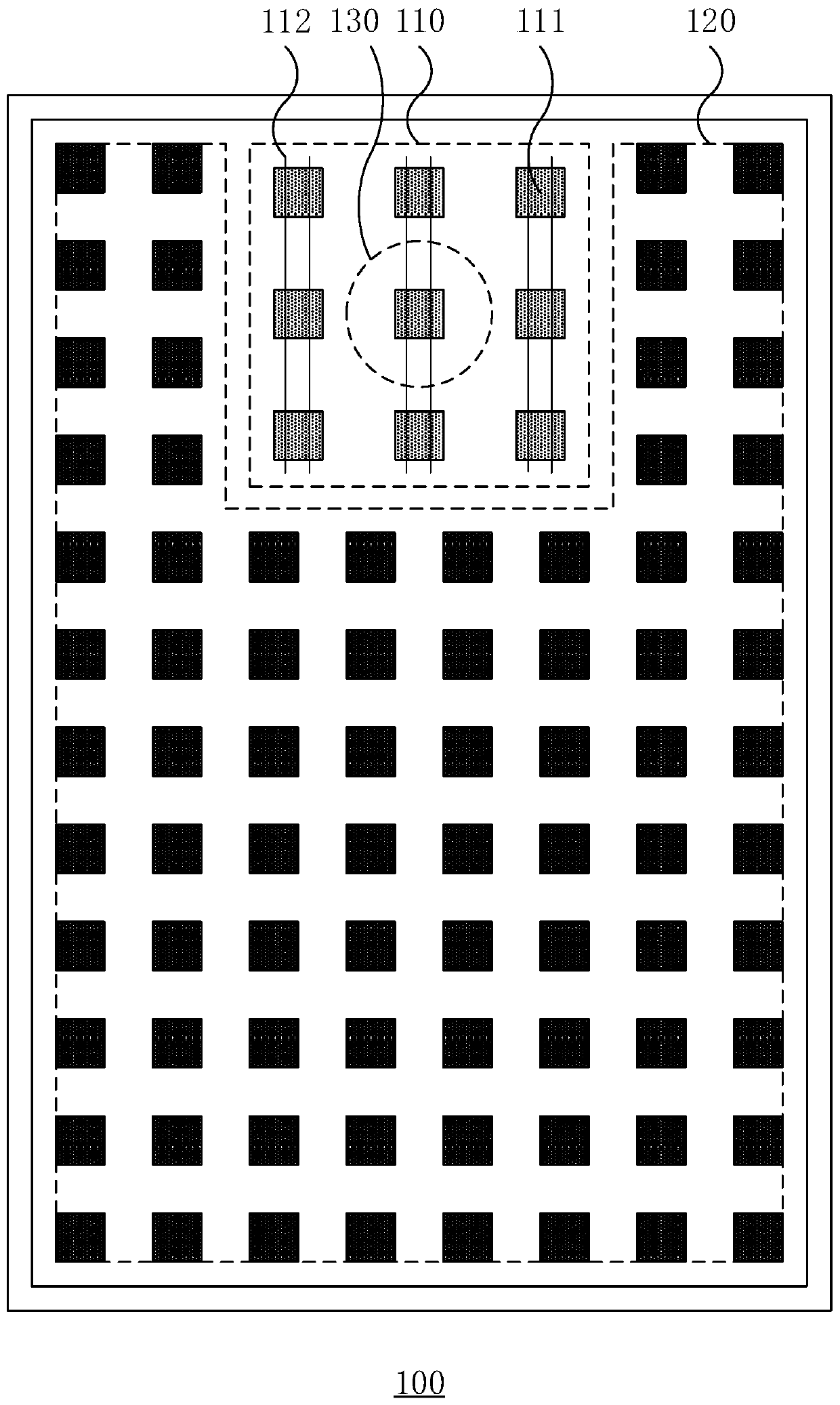

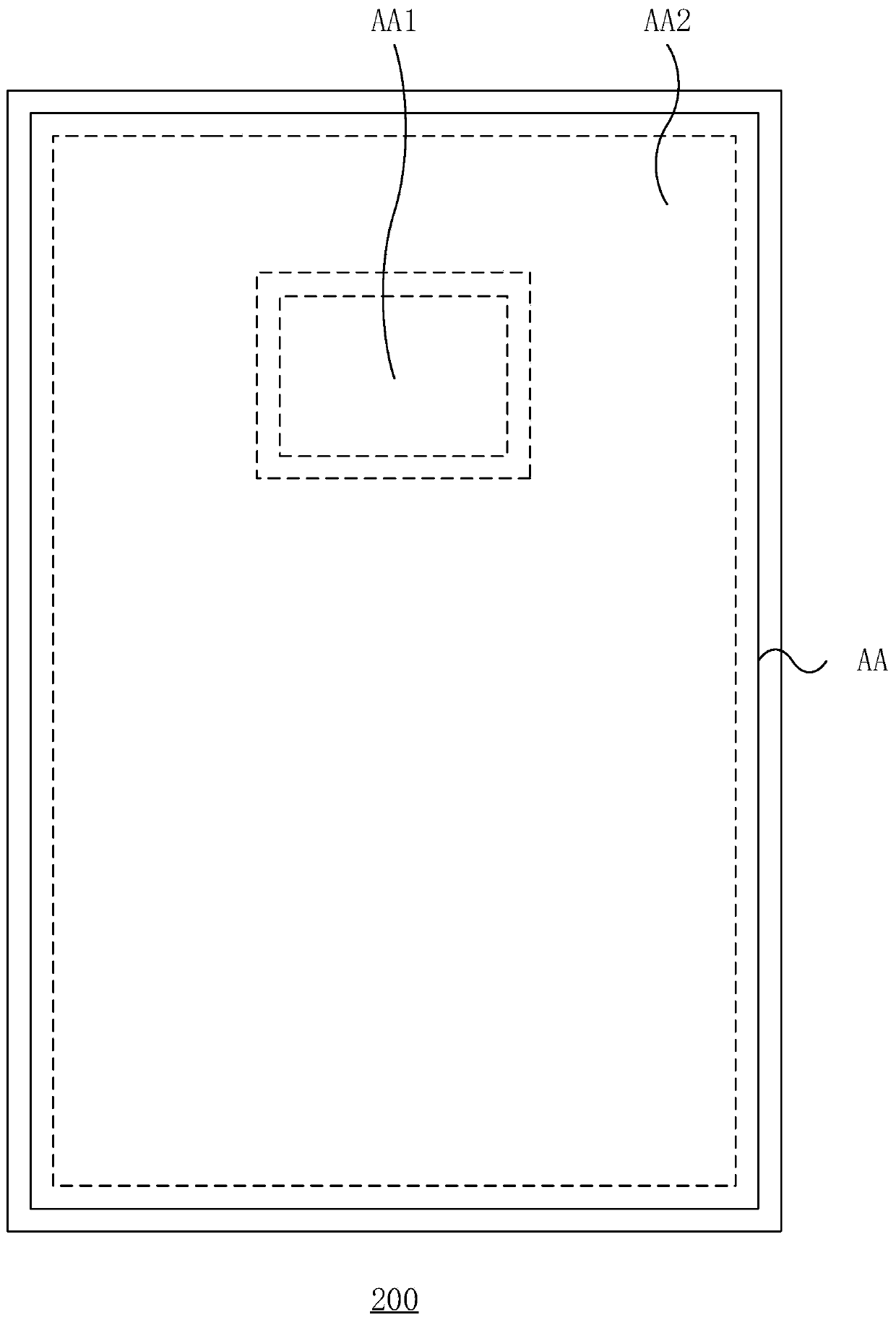

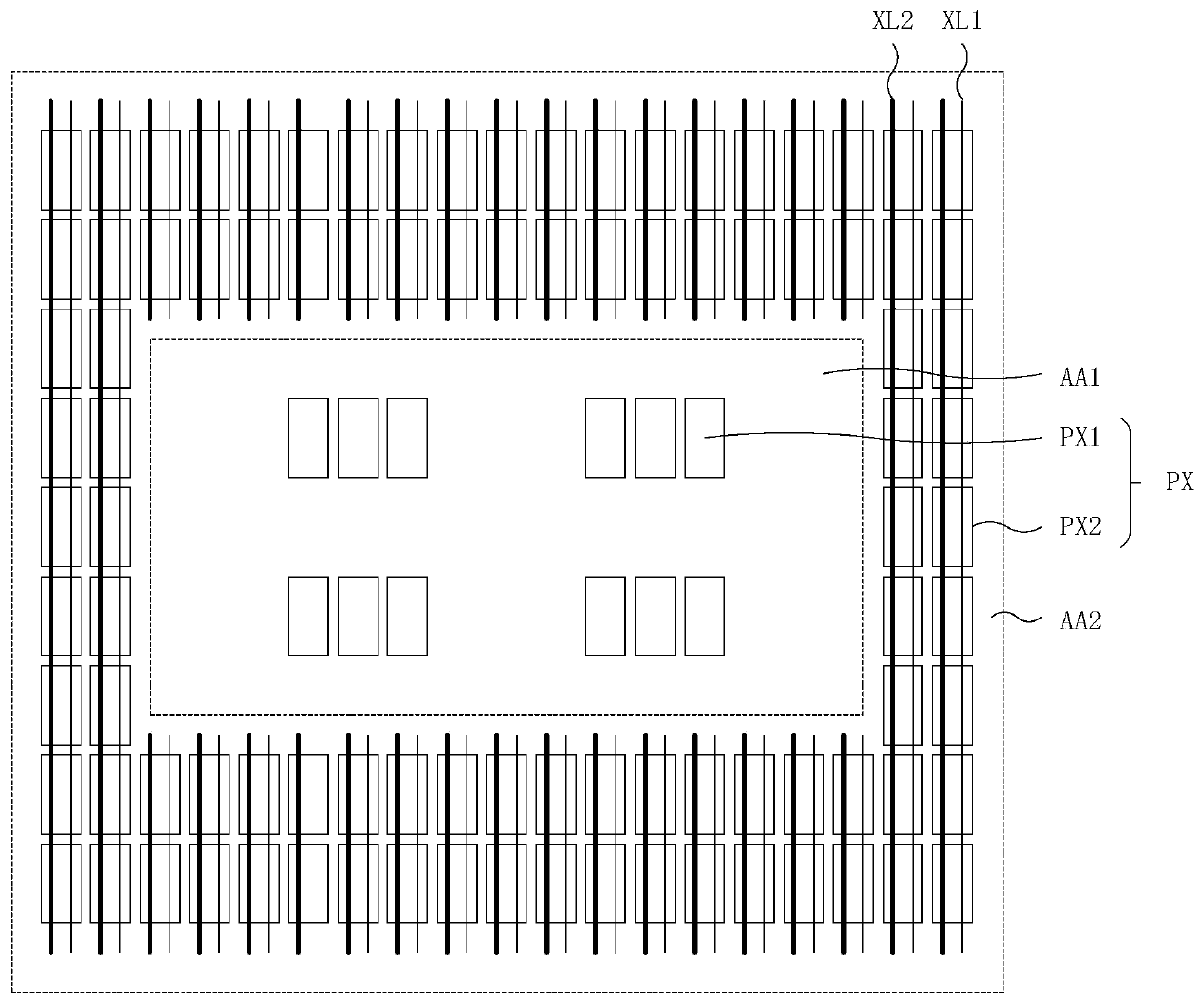

Display panel and device

ActiveCN110288915AHigh light transmittanceThe light transmittance is higher than that of the second sub-display areaTelevision system detailsCharacter and pattern recognitionPixel densityTransmittance

The invention provides a display panel and device. The display panel includes a plurality of pixels, a display area, first signal lines and second signal lines, wherein the multiple pixels include a first pixel and a second pixel; the display area includes a first sub-display area and a second sub-display area, the first pixel is located in the first sub-display area, the second pixel is located in the second sub-display area, and the pixel density of the first sub-display area is less than that of the second sub-display area; the first signal lines and the second signal lines are insulated and extend in the same direction; the first sub-display area includes a pixel setting area and a lining concentrated area, and the first pixel is located in the pixel setting area; in the pixel setting area, the horizontal distance between every two adjacent first signal lines is a, in the lining concentrated area, and the horizontal distance between every two adjacent first signal lines is b, wherein a>b>0; and in the direction perpendicular to the plane of the display panel, at least parts of lining sections of the second signal lines are overlapped with the first signal lines in the lining concentrated area. According to the display panel and device, the transmittance of the first sub-display area is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Front electrode structure of solar battery and manufacturing method of front electrode structure

InactiveCN102214729AReduce widthReduce shading areaFinal product manufactureSemiconductor devicesSilver pasteSolar cell

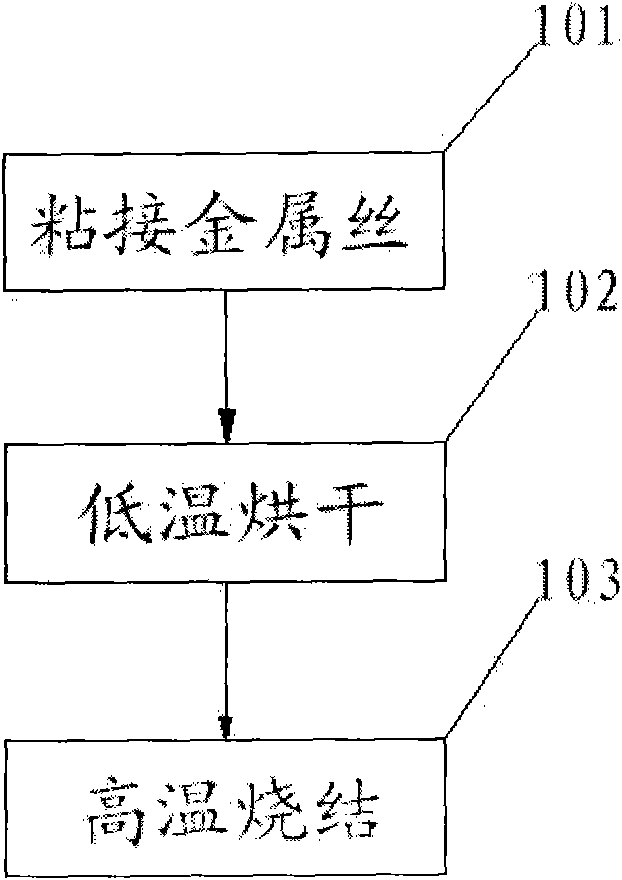

The invention relates to the field of solar batteries, in particular to a front electrode structure of a solar battery and a manufacturing method of the front electrode structure. The manufacturing method comprises the following steps of: bonding, namely pasting silver paste on a metal wire and bonding the metal wire with the silver paste on the surface of a silicon slice so as to form a thin grid wire; drying, namely drying the silicon slice bonded with the metal wire at the temperature of 200 to 400 DEG C; and sintering, namely sintering the dried silicon slice at the temperature of 700 to 900 DEG C, so that high ohm contact is formed between the silver paste and the silicon slice, and the silver paste and the metal wire are sintered into a complete conductor. The structure comprises the silicon slice and the metal wire which are bonded with each other through the silver paste. In the invention, the metal wire is used for replacing the thin grid wire on the original silicon slice, so the thin grid wire is narrowed; therefore, the light shield area of the thin grid wire is reduced greatly and the conversion efficiency of the solar battery is improved.

Owner:陕西众森电能科技有限公司

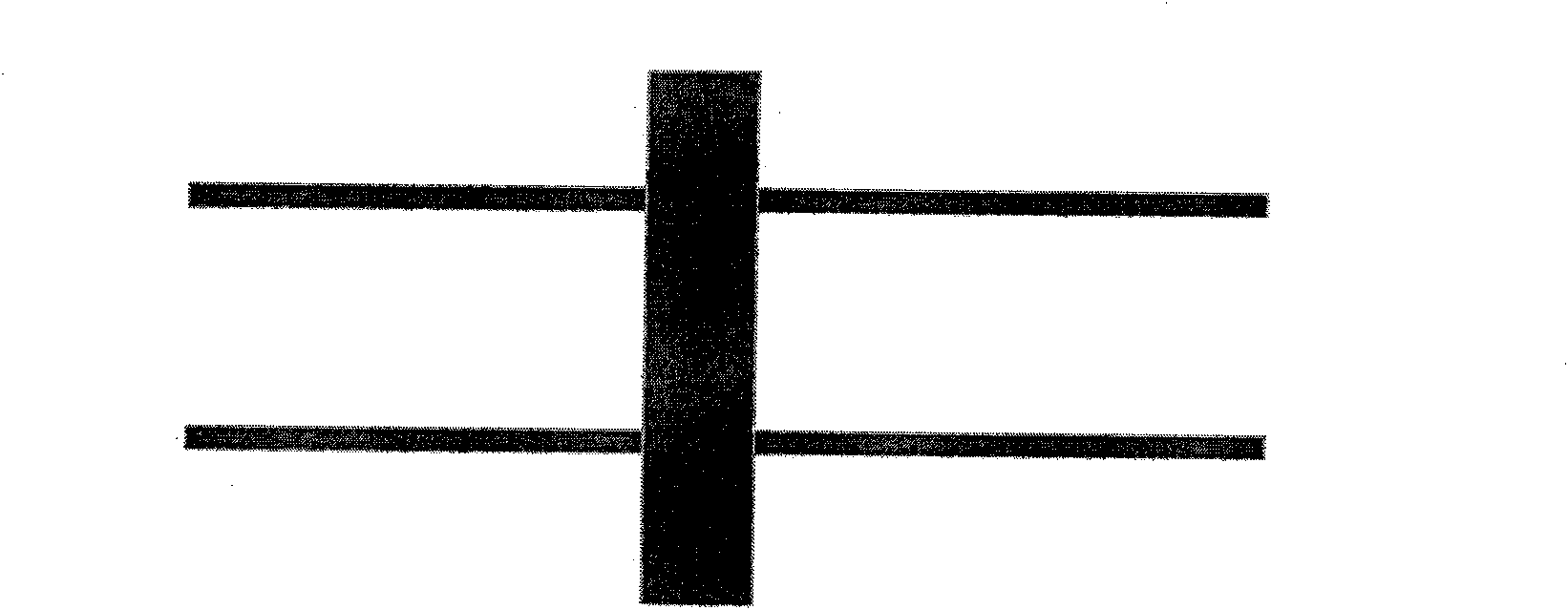

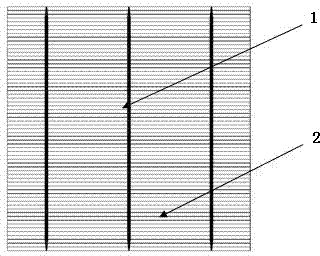

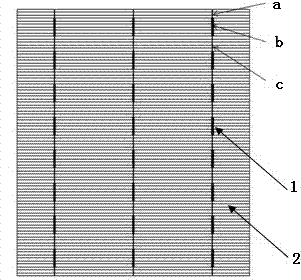

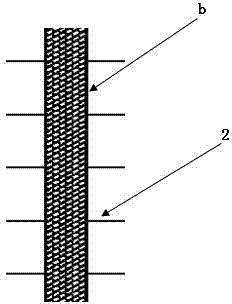

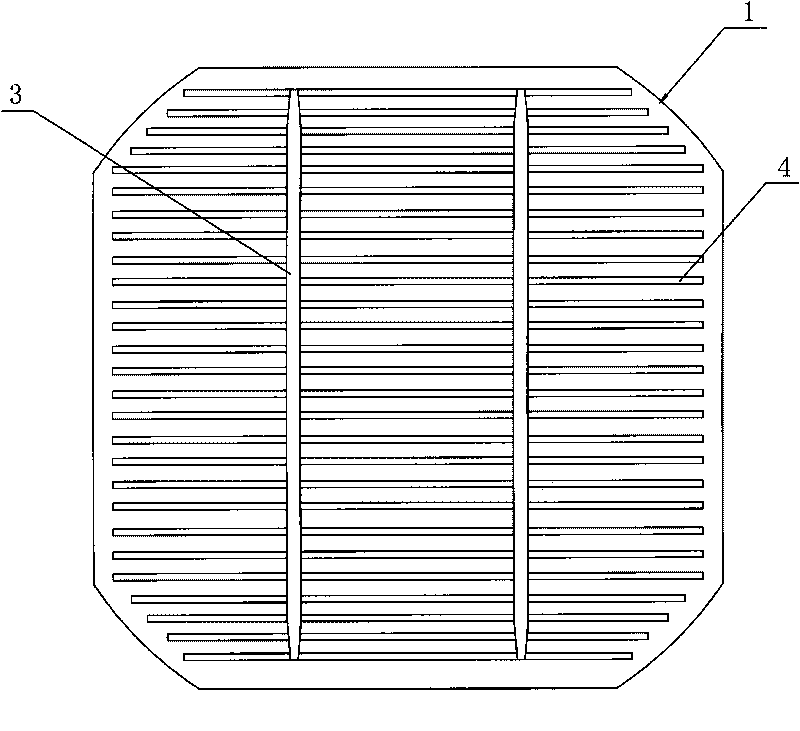

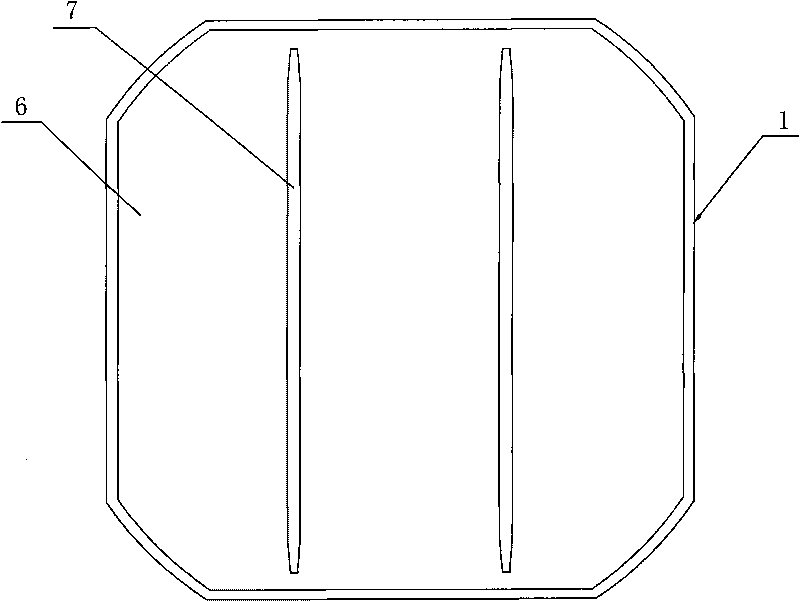

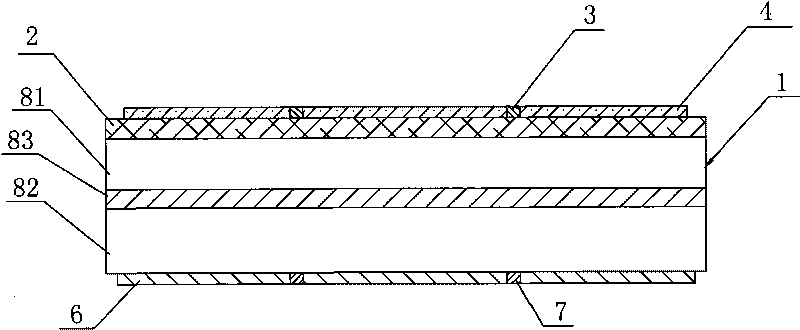

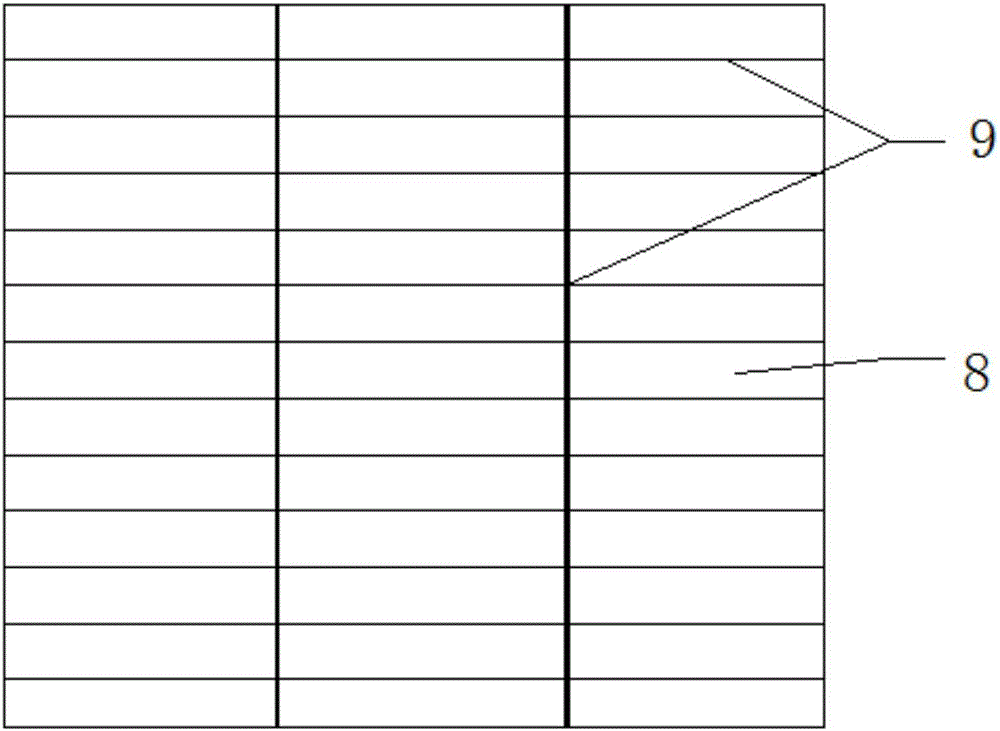

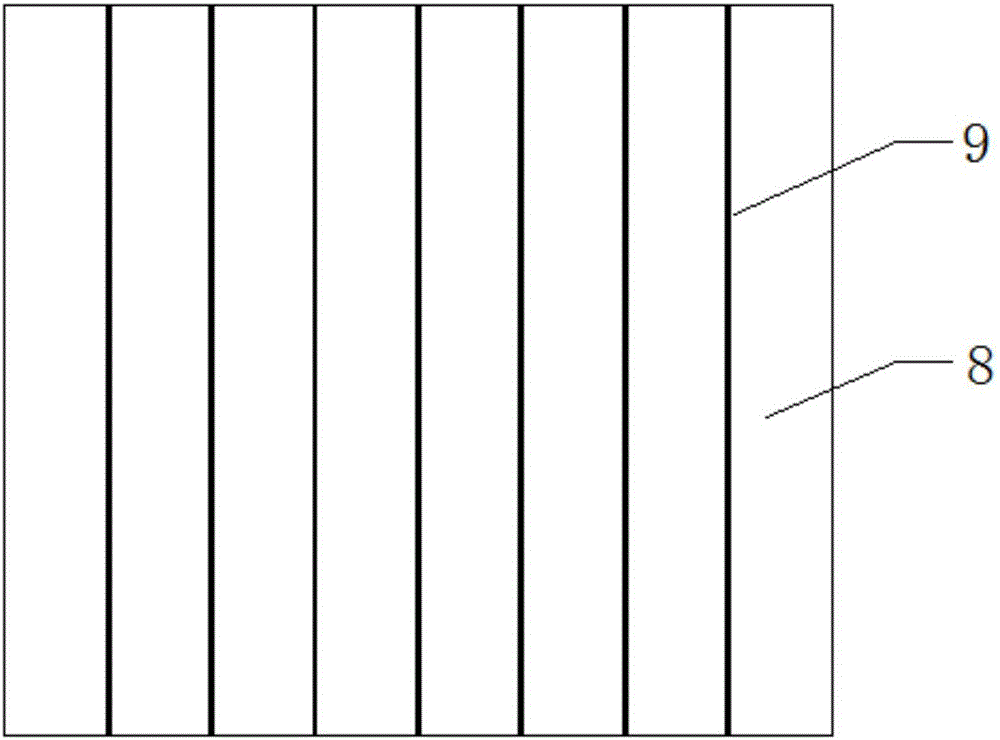

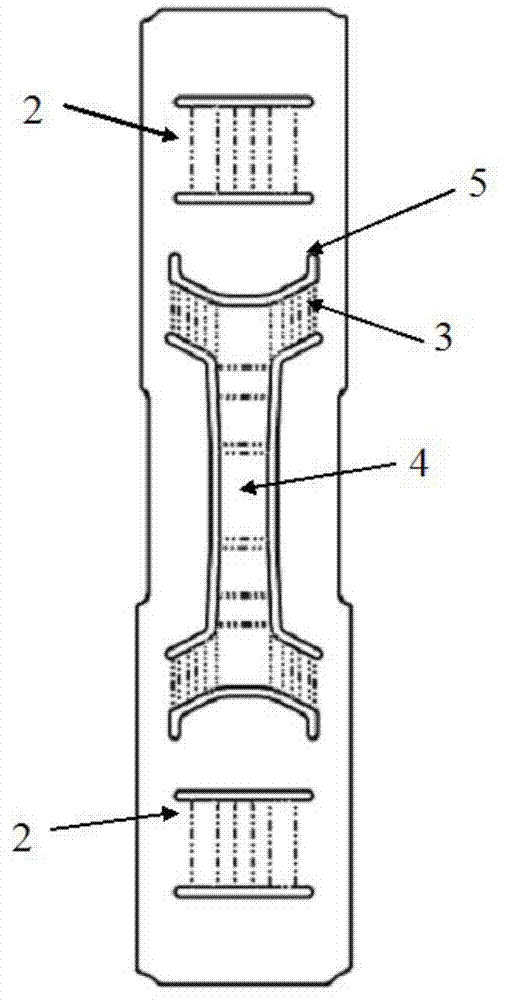

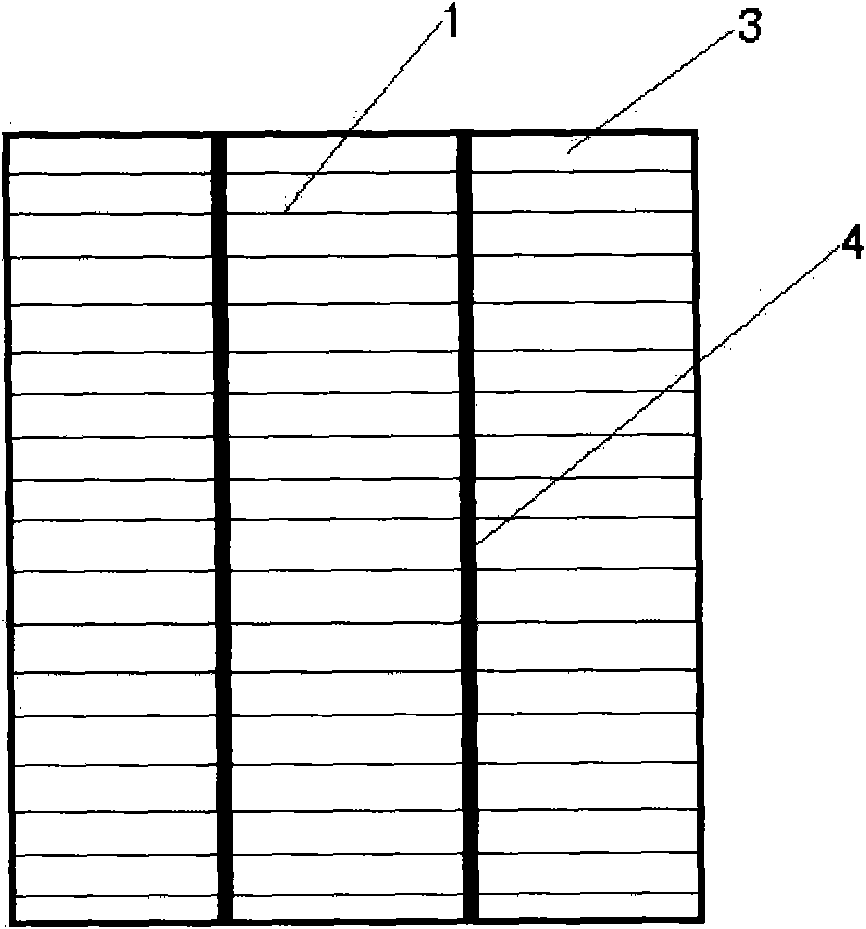

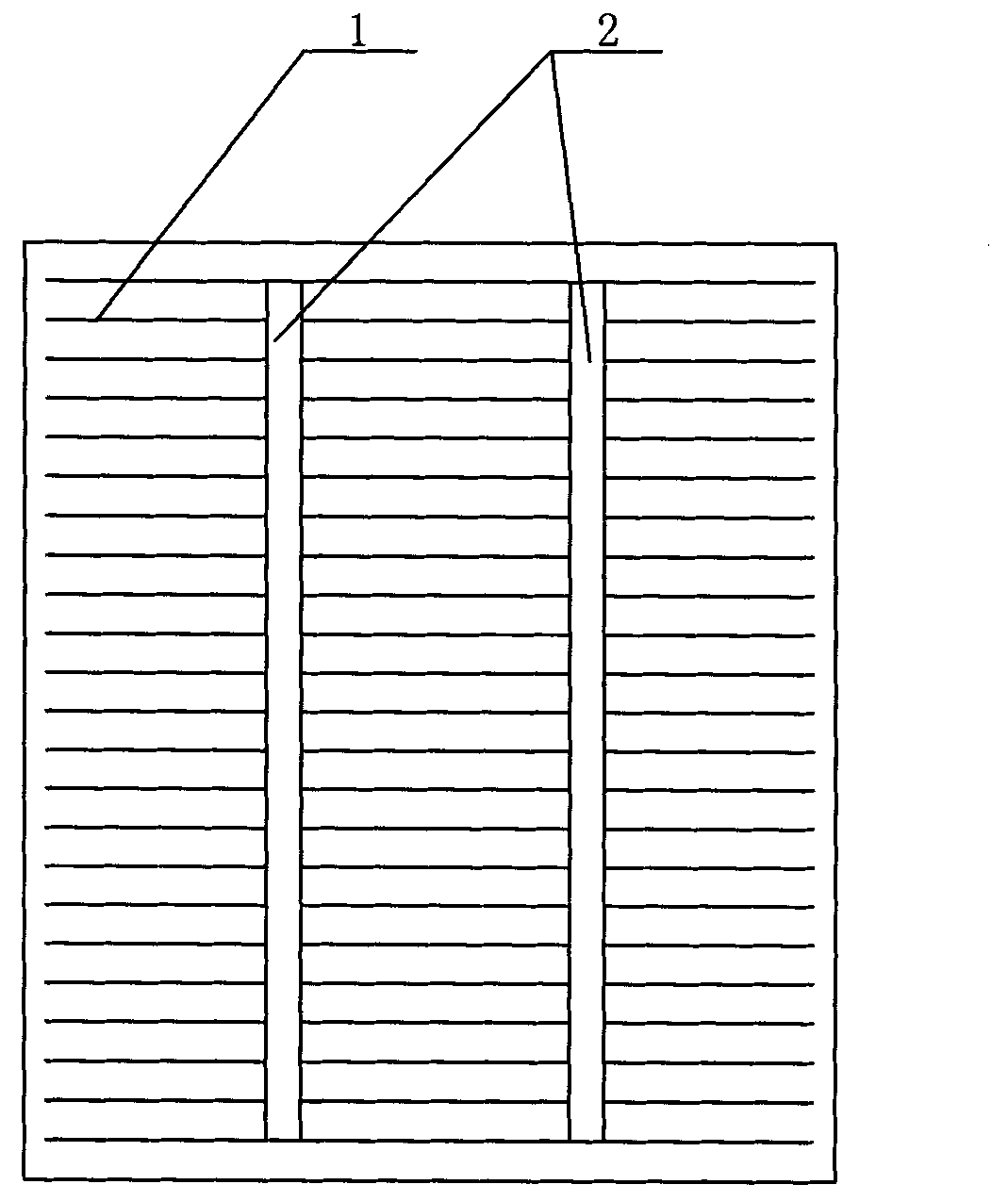

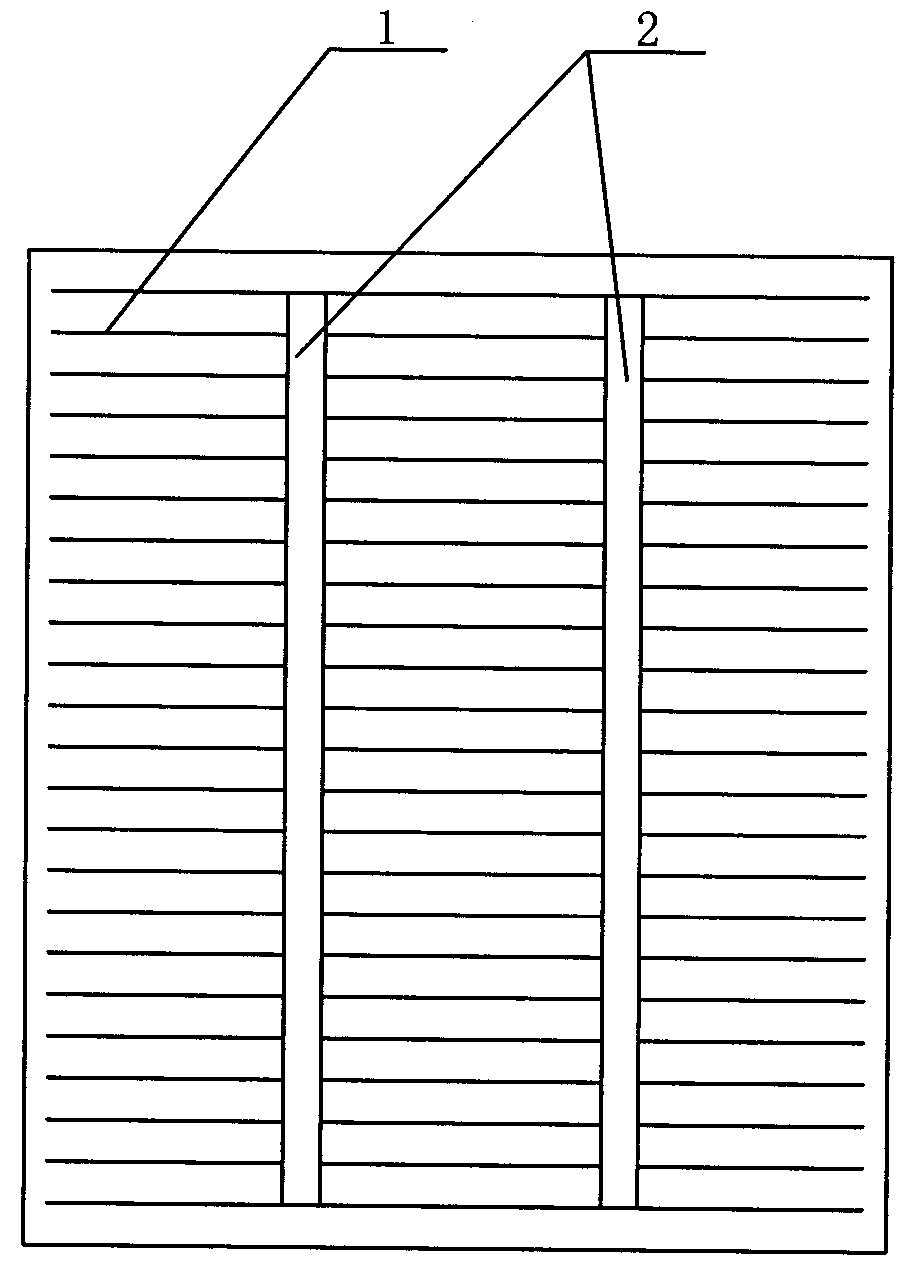

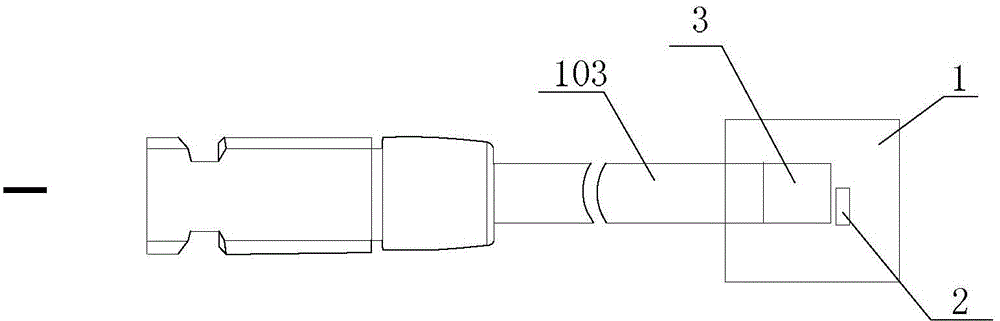

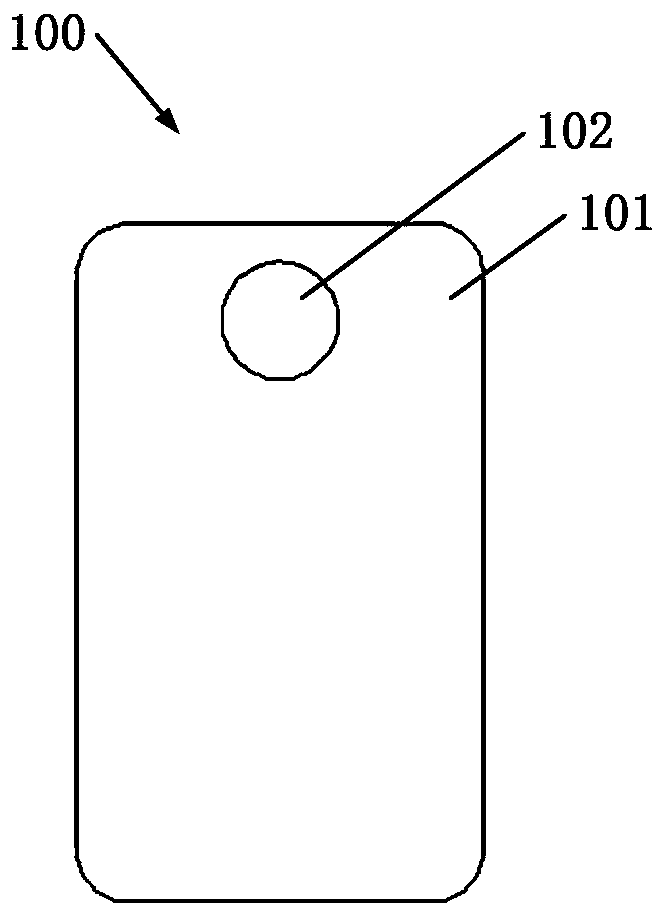

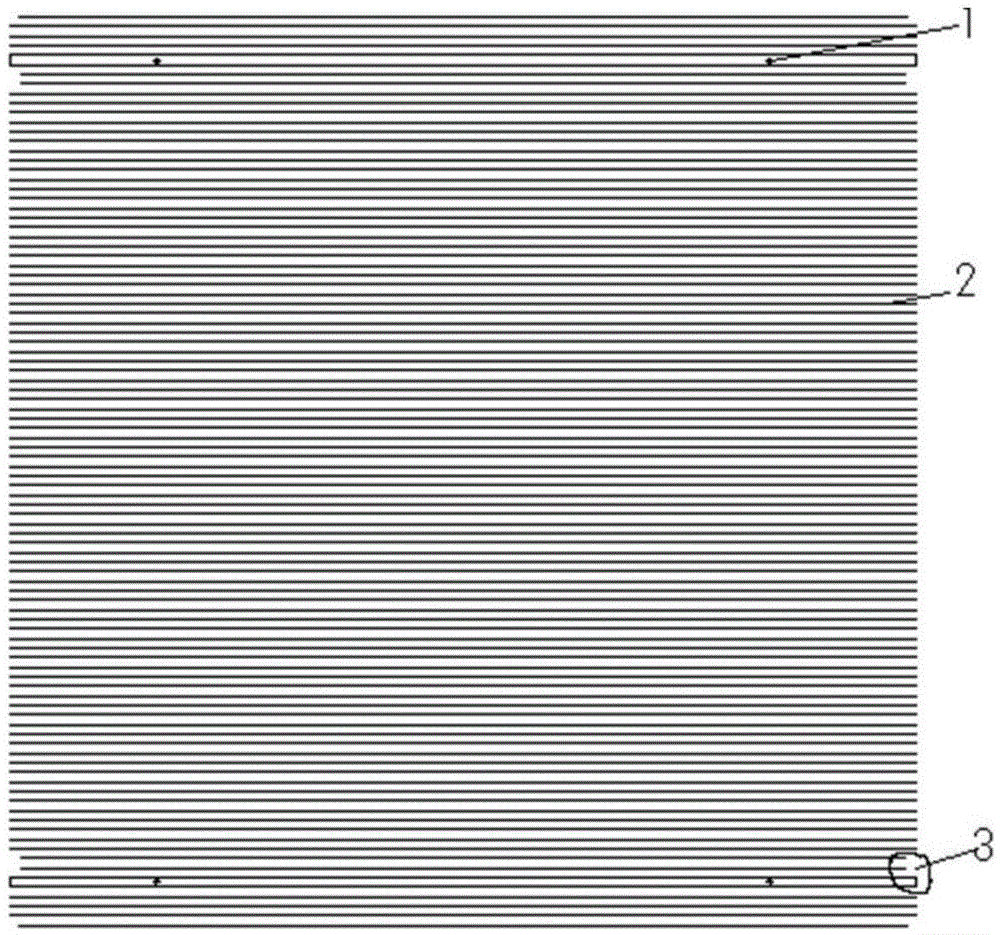

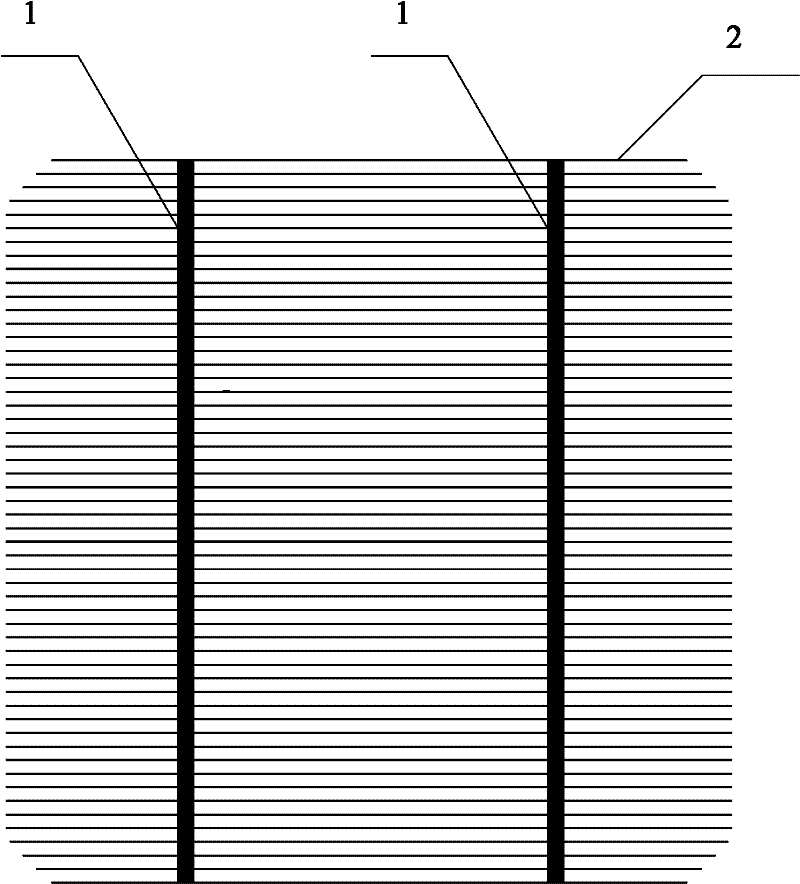

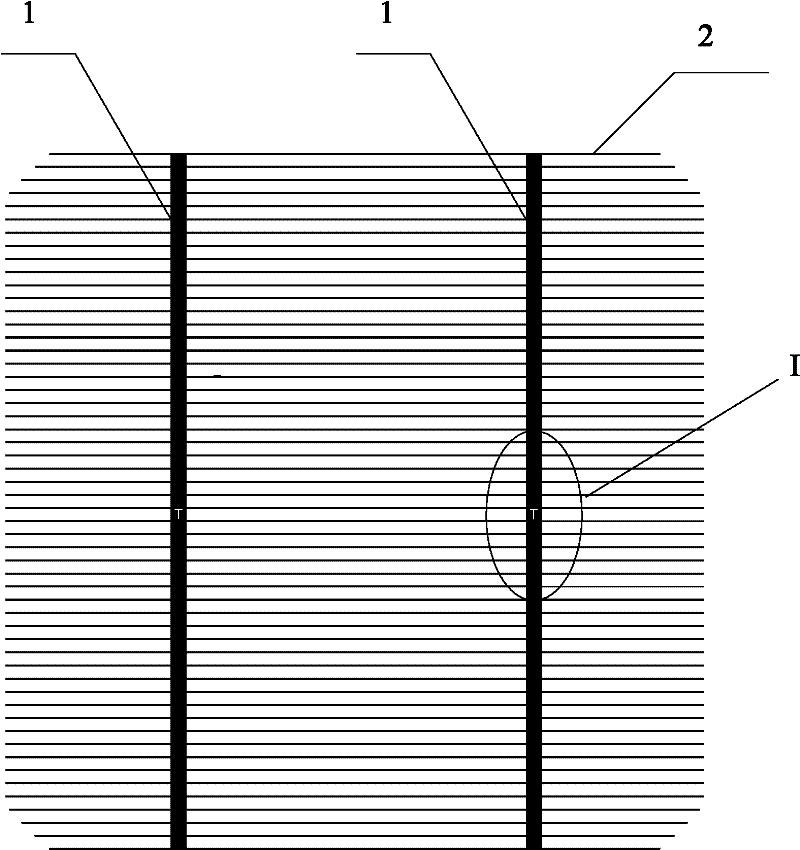

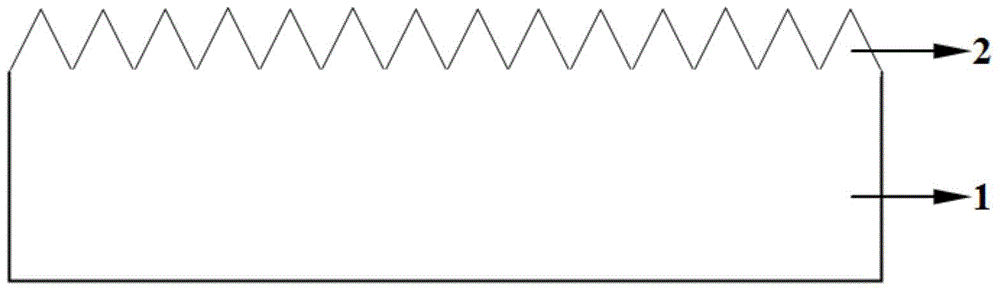

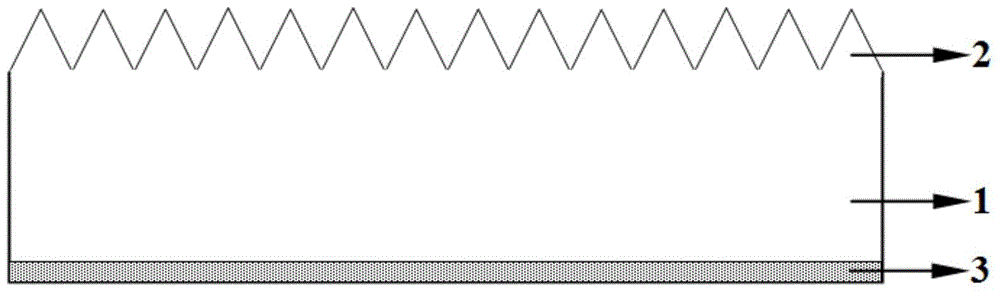

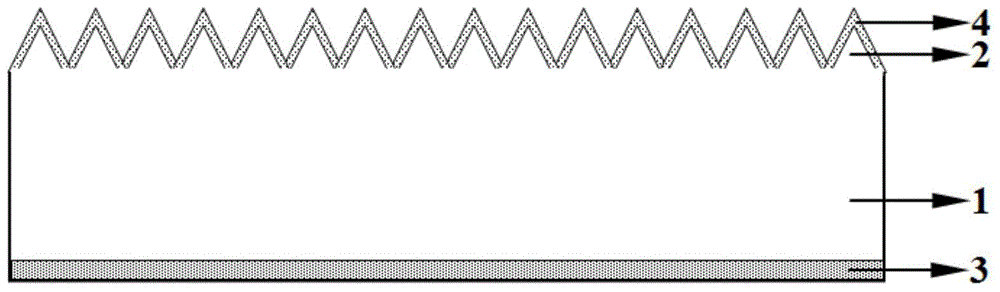

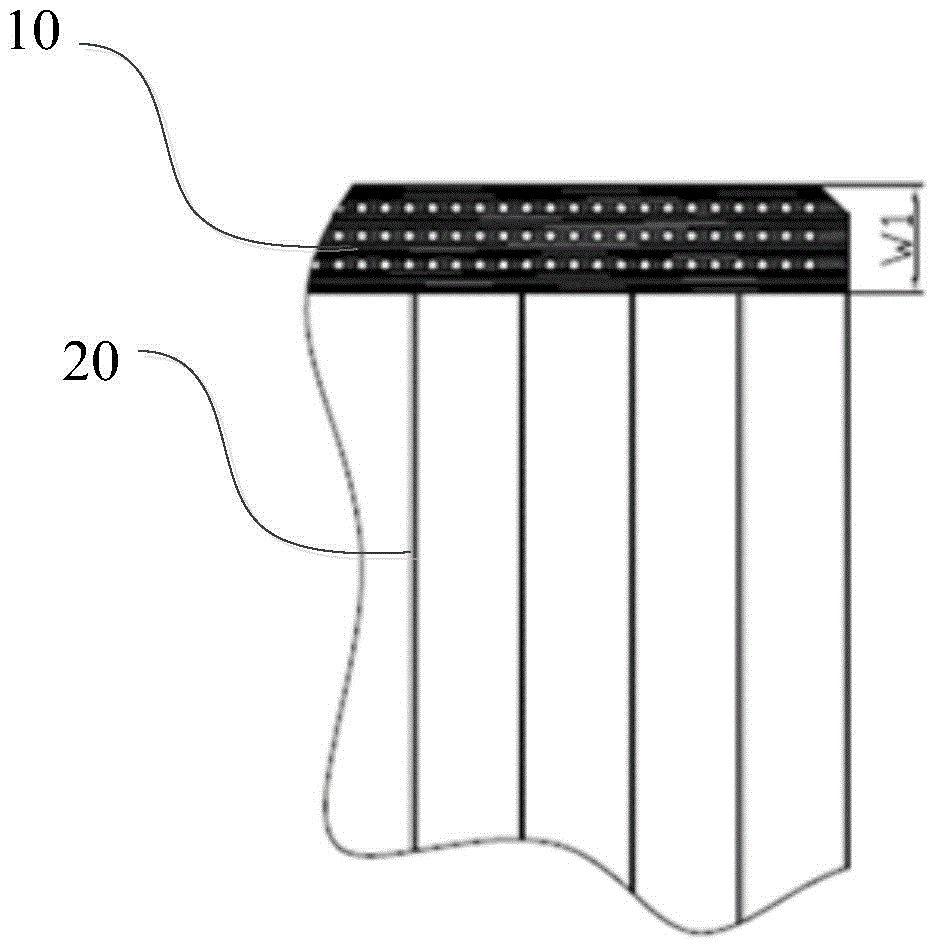

Method for preparing semiconductor secondary grid-metal primary grid crystalline silicon solar battery

InactiveCN101826573AReduce shading areaReduce usageFinal product manufactureSemiconductor devicesScreen printingSolar battery

The invention relates to the technical field of a metal electrode of a crystalline silicon solar battery, in particular to a method for preparing a semiconductor secondary grid-metal primary grid crystalline silicon solar battery. The semiconductor secondary grid-metal primary grid crystalline silicon solar battery consists of a plurality of strips of semiconductor secondary grids (1) and a plurality of strips of metal electrode primary grid lines (2). The method has the advantages of completely utilizing the advantages, such as simpleness, low cost, high yield and high automation degree, of a screen printing process, effectively reducing the light-shading area of the metal electrode of the solar battery, and improving the conversion efficiency of the metal electrode of the solar battery.

Owner:EOPLLY NEW ENERGY TECH

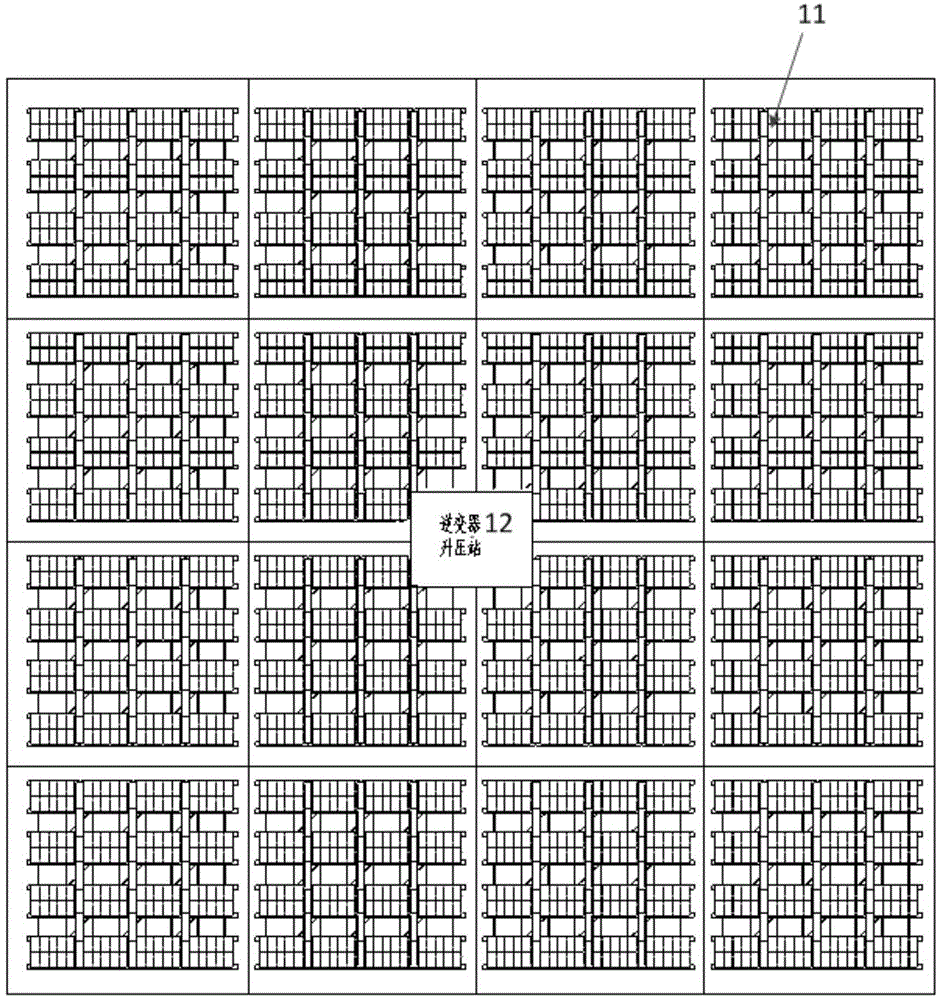

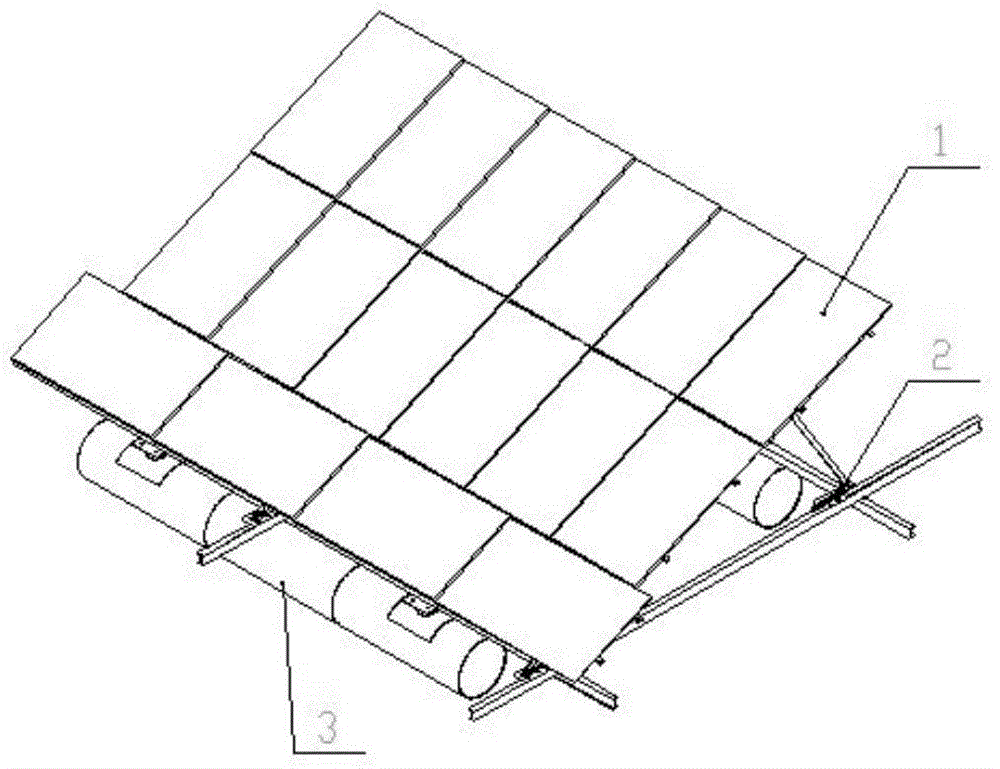

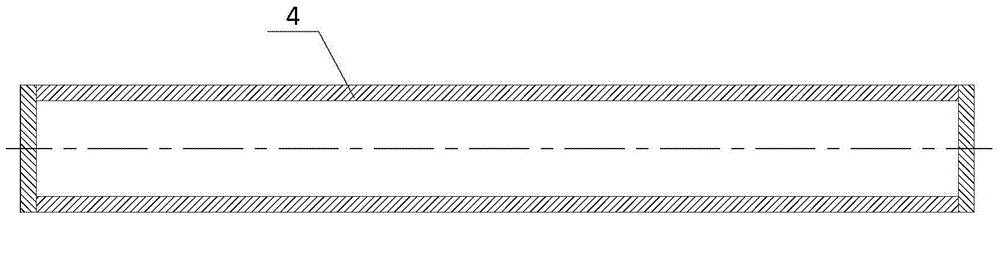

Waterborne solar generating platform

ActiveCN104828216ALower transmission costsImprove energy efficiencyPhotovoltaic supportsSolar heating energyFloating platformCells panel

Disclosed in the invention is a waterborne solar generating platform comprising at least one floating unit. Each floating unit is formed by mutual connection of floating body units by connecting elements; and the floating units are mutually connected by trusses to form a floating platform. The trusses are fixed at the floating body units floating over water. The floating platform is provided with a repairing channel and several kinds of connectors for fixing a cell panel, an electrical device, and an auxiliary device. The floating body units contain sealed shells and reinforced bodies arranged in the sealed shells. The rigidity of each floating body unit meets the following conditions: the maximum radial deformation value does not exceed the one percent of the diameter of the unit and the maximum axial deformation value does not exceed the 0.5% of the length when the unit carries a load; the mass of the floating body unit is between 32KG and 950 KG; and a buoyancy force larger than 3.84KN is generated during floating in water. The provided platform has advantages of high stability, good wave-resistant performance, and high wind-resistant stability.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Fine metal mask and manufacture method thereof

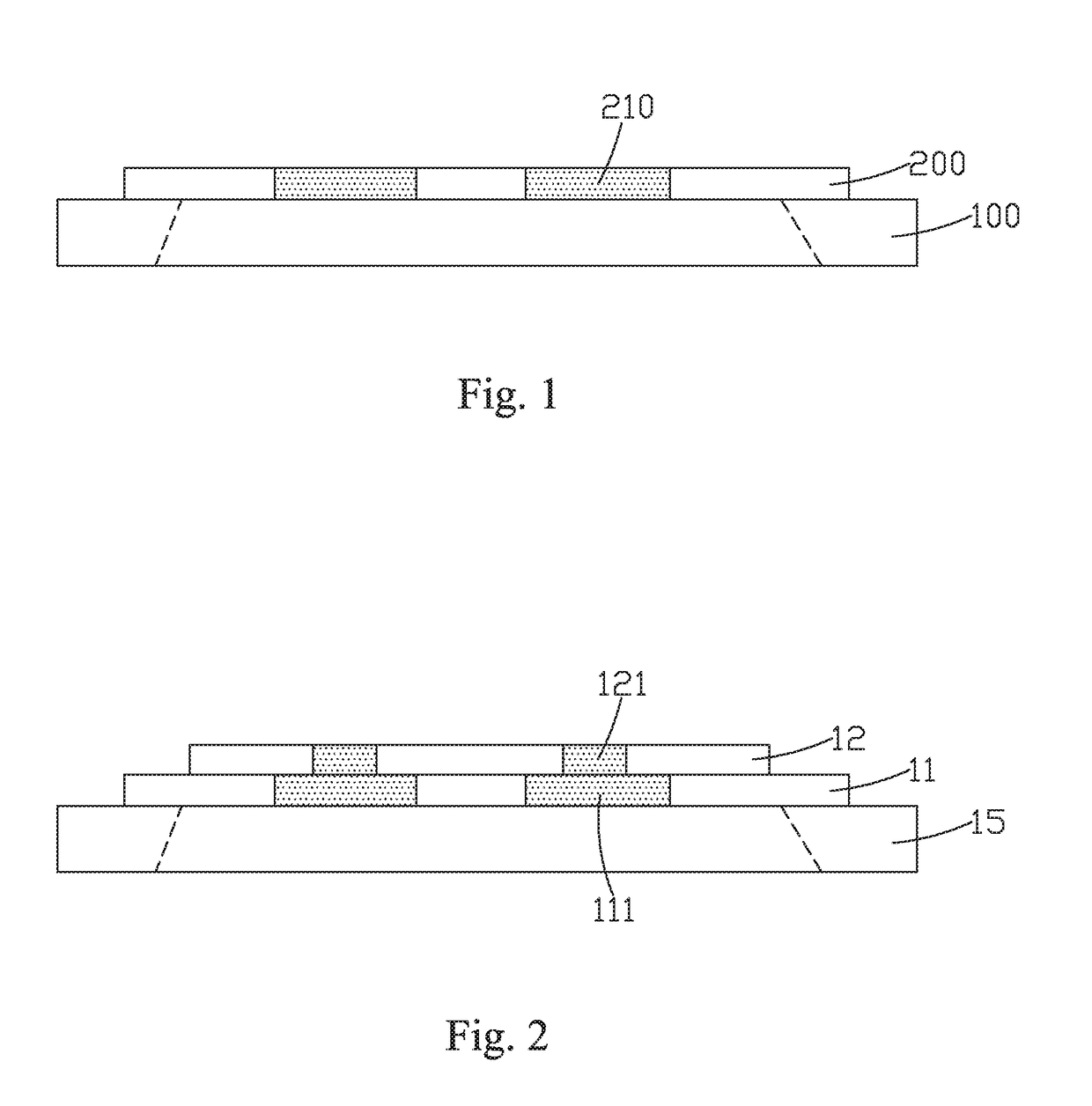

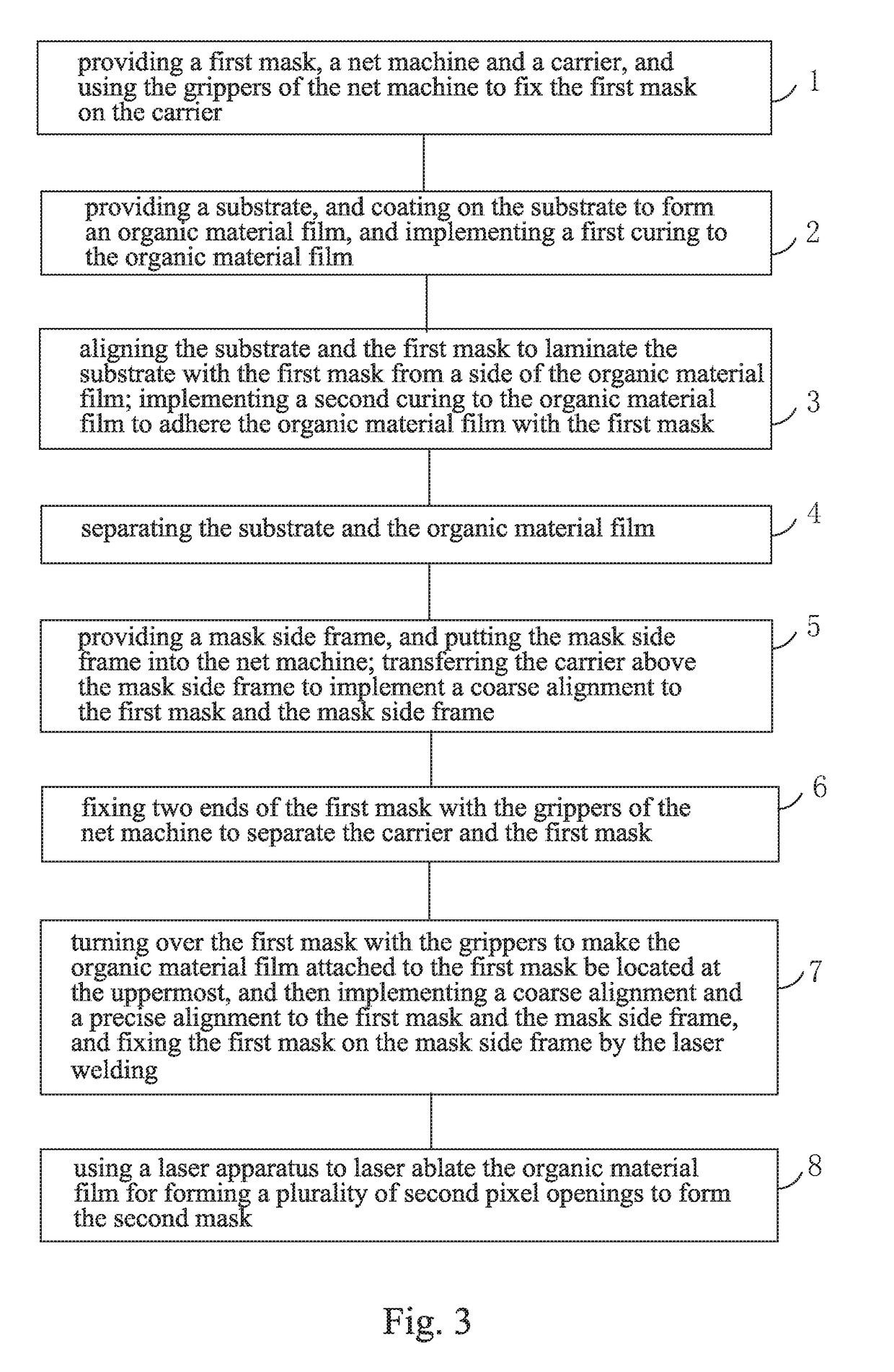

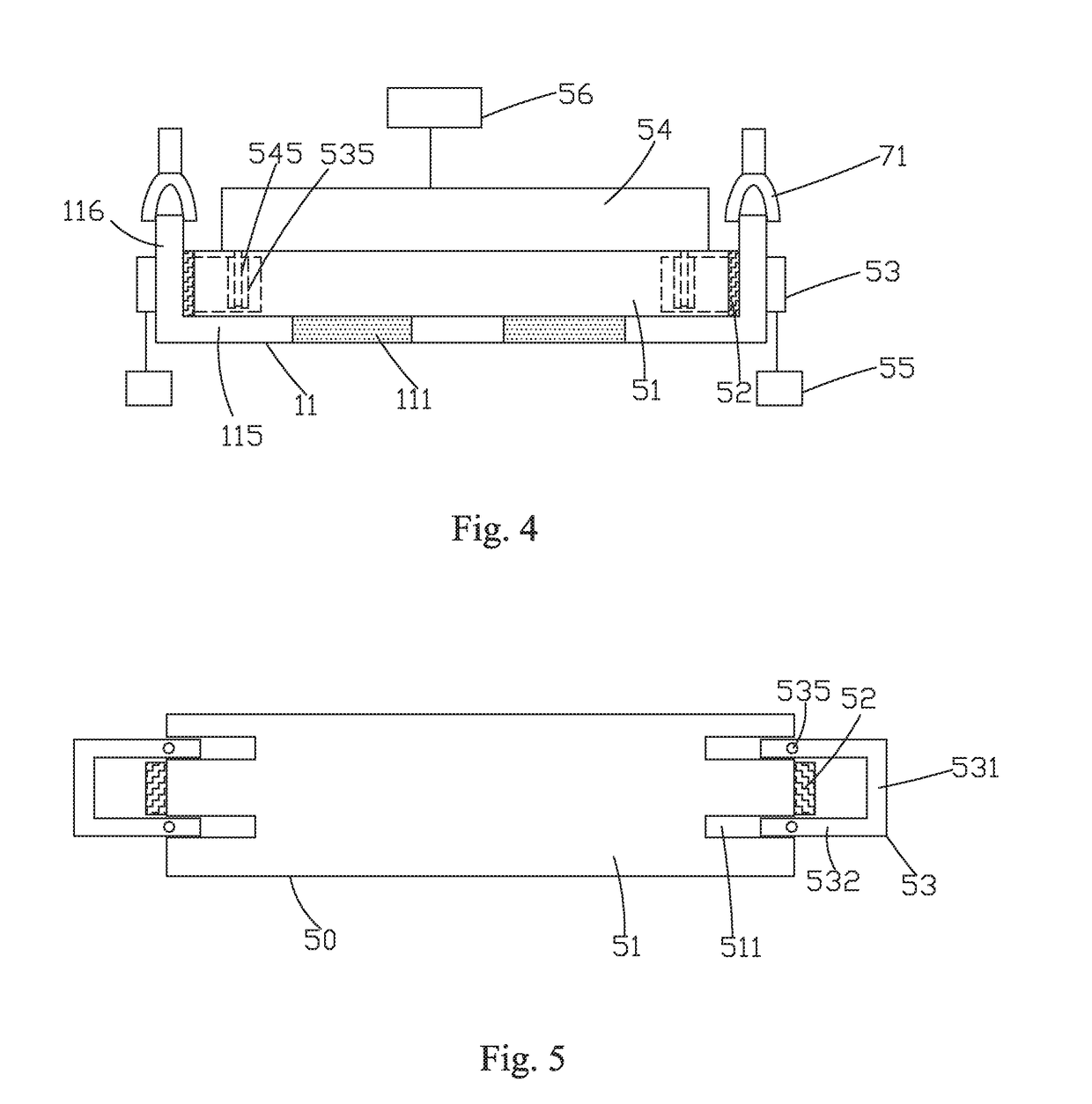

InactiveUS20180355466A1Small sizePromote resolutionSolid-state devicesVacuum evaporation coatingImage resolutionOptoelectronics

The present invention provides a fine metal mask and a manufacture method thereof. The fine metal mask comprises a mask side frame, a first mask of metal material and a second mask of an organic material; the first mask comprising first pixel openings; the second mask comprising one or more second pixel openings corresponding to an area of each first pixel opening, and because the second pixel openings are arranged in the area corresponding to the first pixel openings, in comparison with prior art, the present invention can provide the pixel openings with a smaller size to manufacture the OLED elements with a smaller size to raise the resolution of the OLED display product; meanwhile, the opening wall slope of the second pixel openings can be controlled to be smaller to make the incident angle of the evaporation material at the second pixel opening edge smaller.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Gallium nitride based light emitting diode and manufacturing method thereof

InactiveCN102420279AImprove luminous efficiencyIncrease the number of holesSemiconductor devicesGallium nitrideElectrically conductive

The invention discloses a gallium nitride based light emitting diode and a manufacturing method thereof. In the invention, a double-layer transparent conducting layer structure is designed, a first transparent extension layer is formed on a p type semiconductor layer, a p electrode is provided at a center area of an epitaxial structure layer, peripheral of the p electrode is provided with a hole structure, and a second transparent extension layer is formed in the hole structure and is connected with an n electrode to form an equipotential surface. After current is injected from the p electrode, the current diffuses to a whole light emitting surface through the first transparent extension layer and flows to an n type layer through the p type semiconductor layer, and since the second transparent extension layer and the n electrode are in a same electric potential, the current diffuses to the second transparent extension layer to reach the n electrode finally. According to the gallium nitride based light emitting diode and the manufacturing method, in a process that the current flows to the n electrode from the p electrode, the current is uniformly distributed on an epitaxial luminescent layer, a current flow through path of a P layer is shorter, simultaneously, structure of partial light emitting surface is changed, and luminescence efficiency is effectively raised.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

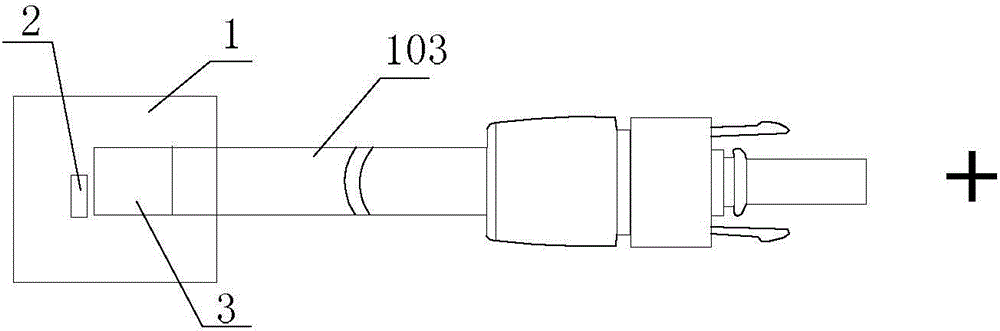

Heat-dissipation split-type conjunction box used for solar assembly and solar cell assembly thereof

ActiveCN105280739ASimple structureWill not blockPhotovoltaicsPhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a heat-dissipation split-type conjunction box used for a solar assembly. The heat-dissipation split-type conjunction box comprises a cathode wire box, intermediate wire boxes and an anode wire box which are mutually independent. The intermediate wire boxes are arranged between the cathode wire box and the anode wire box, and each wire box comprises a box body and a box cover which is capable of covering the box body. The heat-dissipation split-type conjunction box is characterized in that the cathode wire box is arranged at a cathode initiating terminal of the solar cell assembly, the box body is only internally provided with one binding post used for being connected with an assembly leading-out wire, and the binding post is simultaneously connected with a cathode terminal of a photovoltaic connector through a cable; the anode wire box is arranged at an anode initiating terminal of the solar cell assembly, the box body is only internally provided with one binding post used for being connected with an assembly leading-out wire, and the binding post is simultaneously connected with an anode terminal of the photovoltaic connector through a cable; and the number of the intermediate wire boxes is three. In addition, the invention further discloses the solar cell assembly using the heat-dissipation split-type conjunction box used for the solar assembly.

Owner:TRINA SOLAR CO LTD

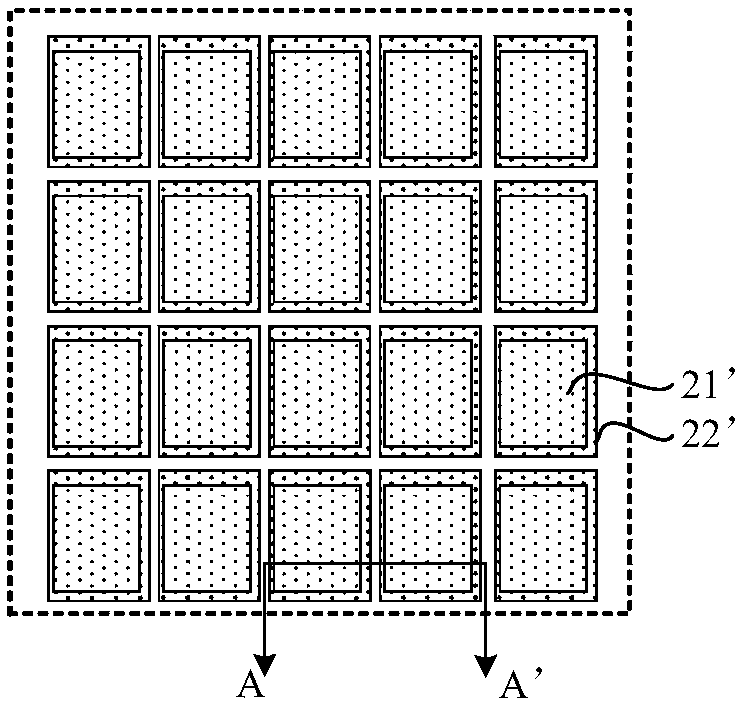

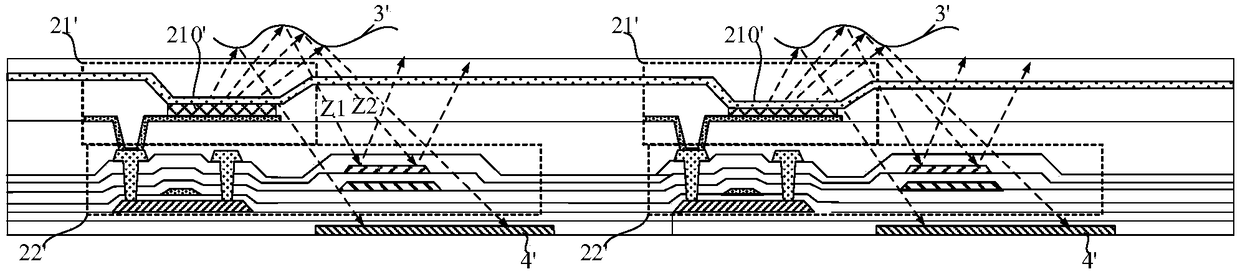

OLED display device and fabrication method thereof

ActiveCN110048005AReduce shading areaImprove transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceDisplay device

The invention relates to an OLED display device and a fabrication method thereof. The OLED display device comprises a substrate, a functional layer, a positive electrode, a pixel defining layer, a first isolation vertical post, a light emitting layer and a negative electrode. An upper surface of the negative electrode on a second pixel defining layer is locally sunken until a groove is formed in abottom surface of the light emitting layer, so that the shielding area of the negative electrode is reduced, the transmittance of the negative electrode is improved, the lighting effect of a camera under a screen is finally improved, and the imaging effect is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

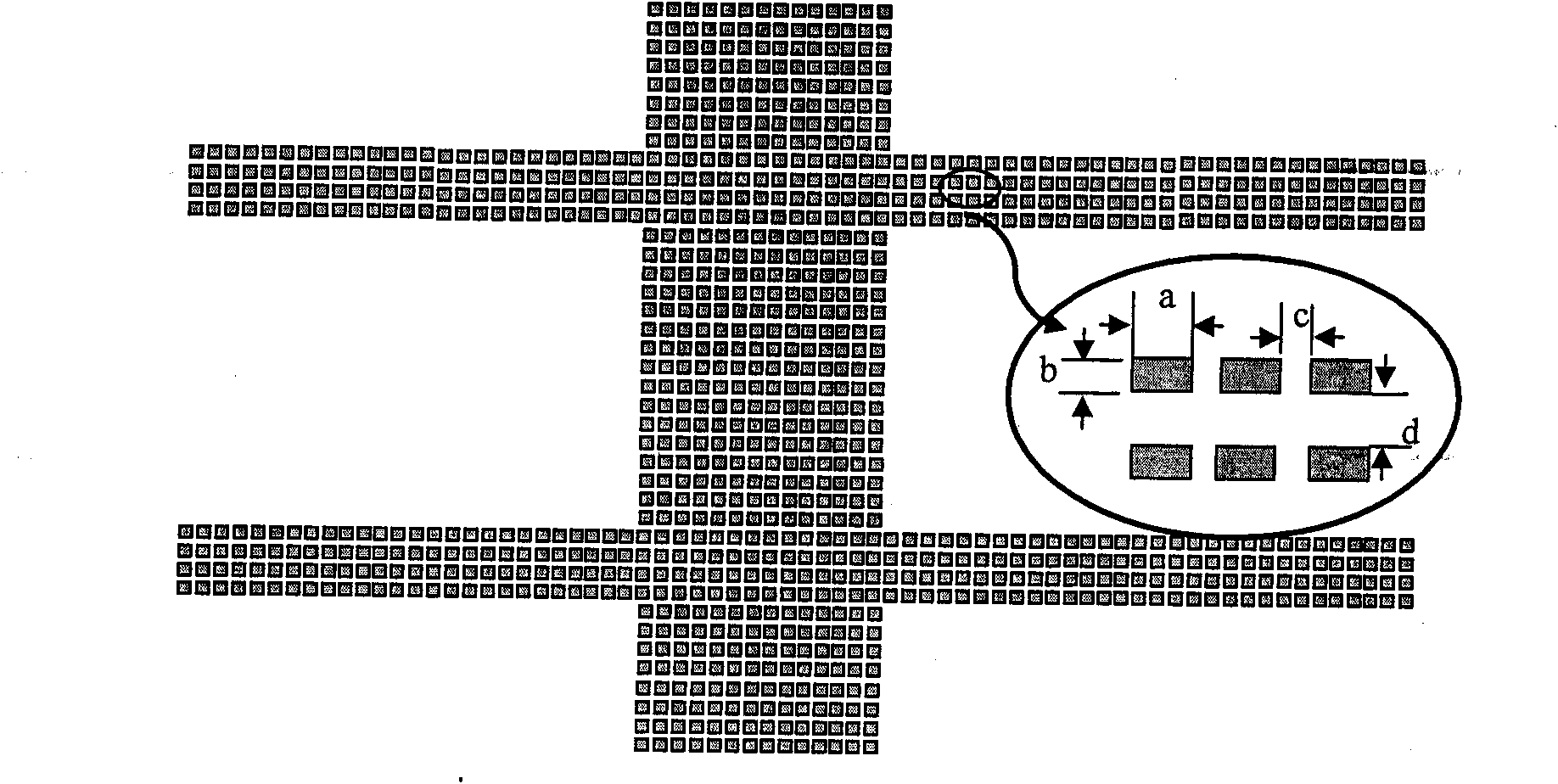

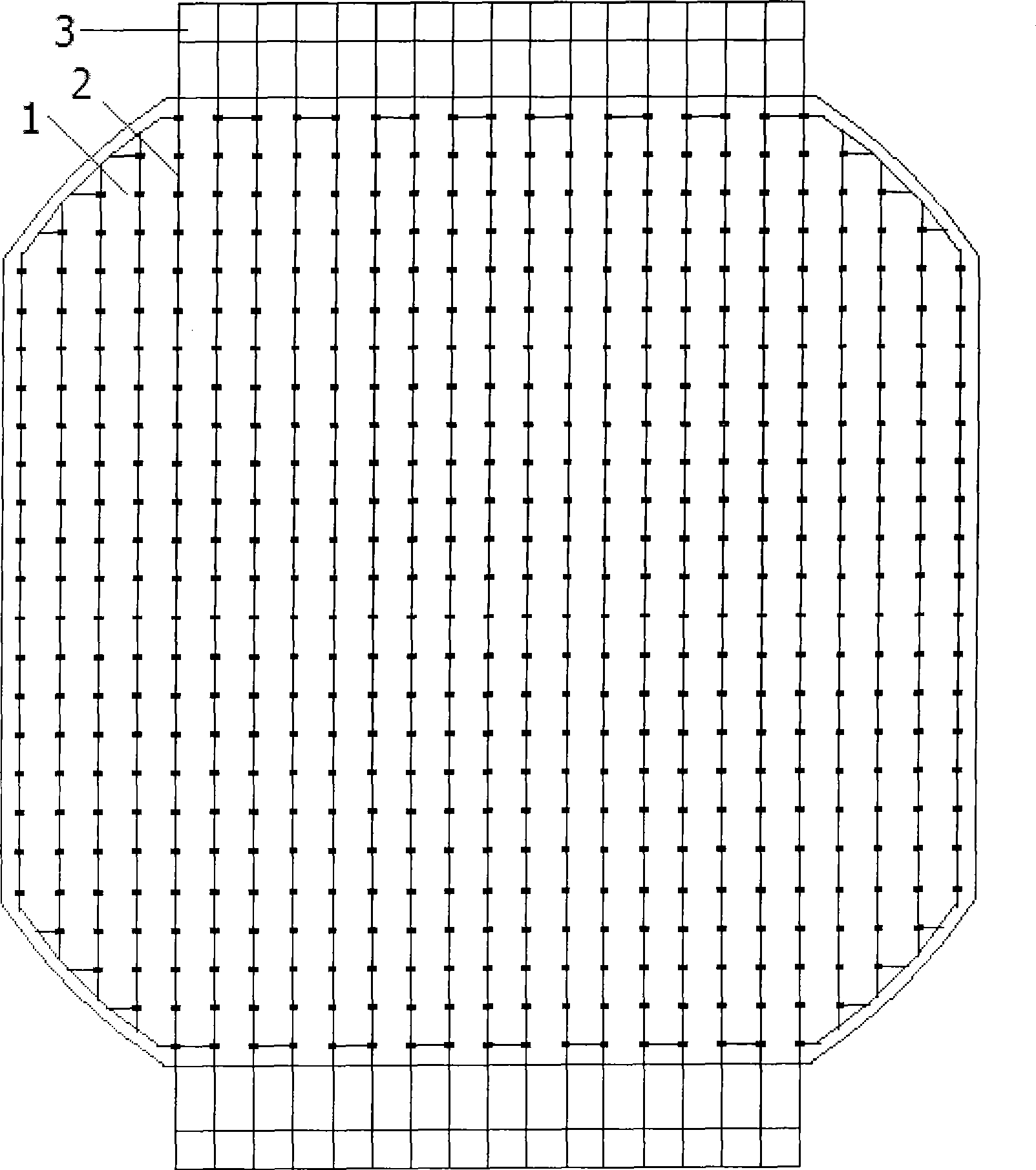

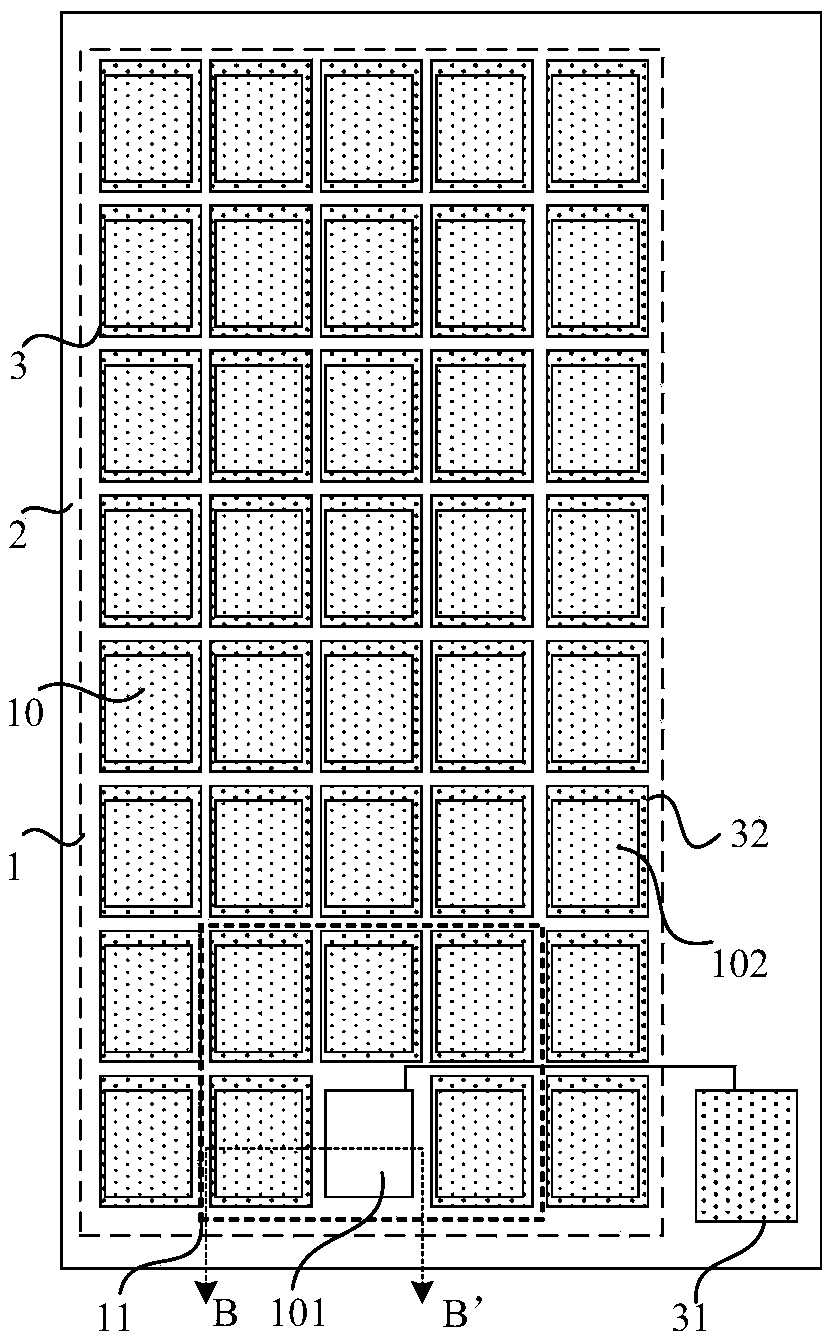

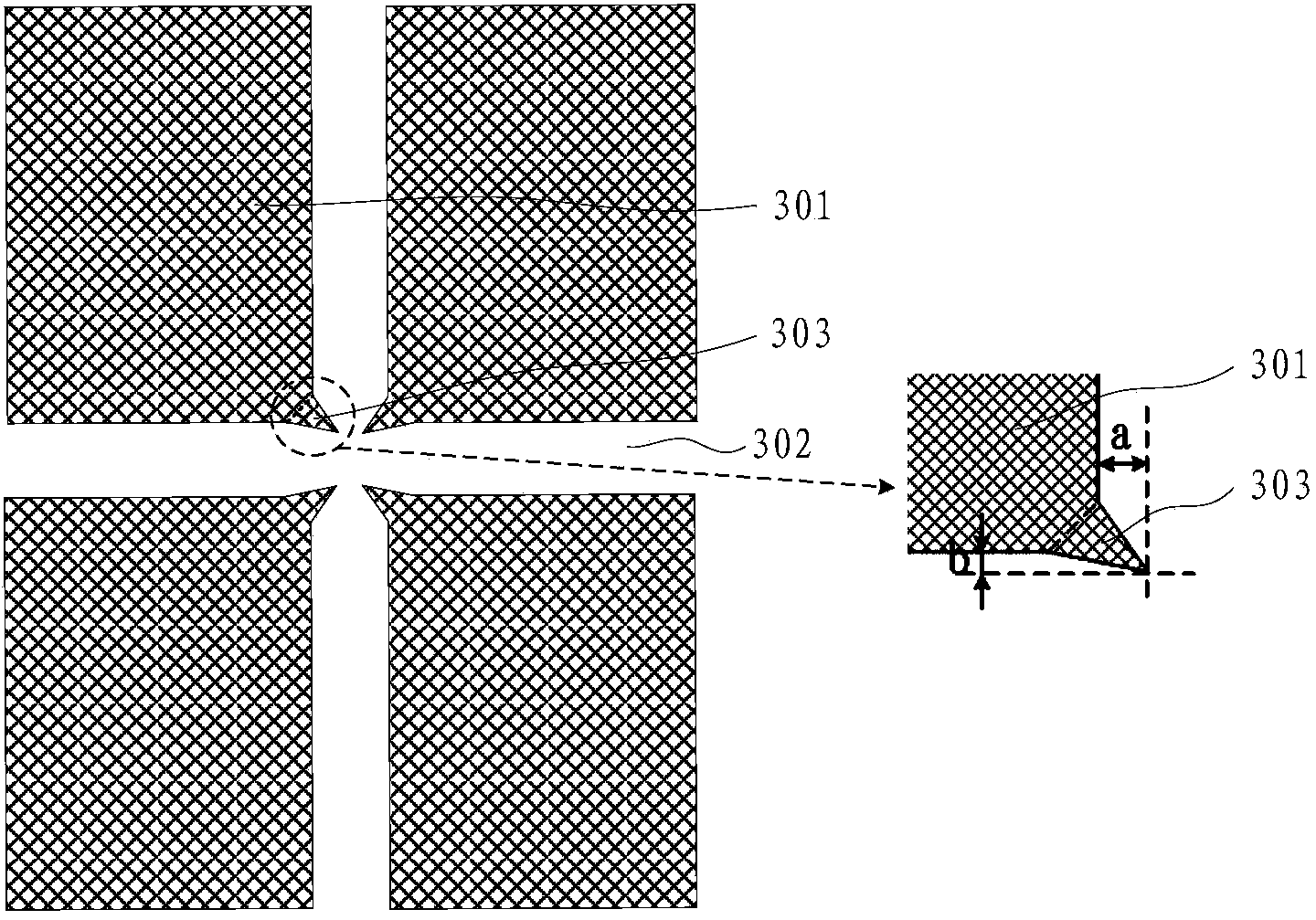

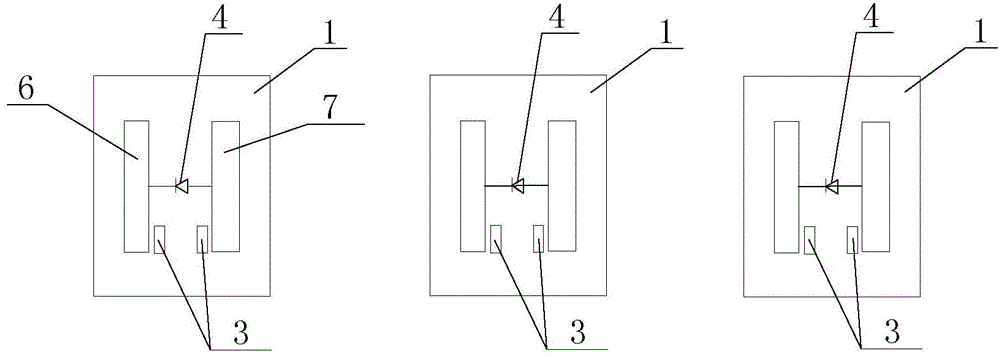

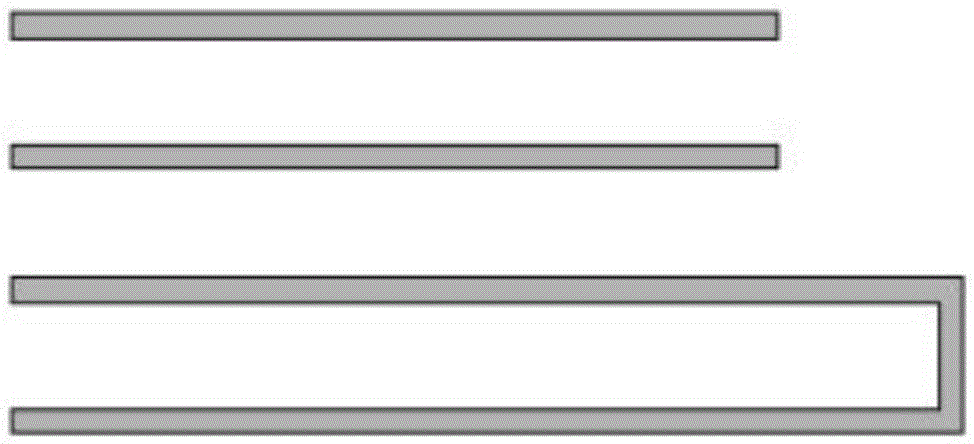

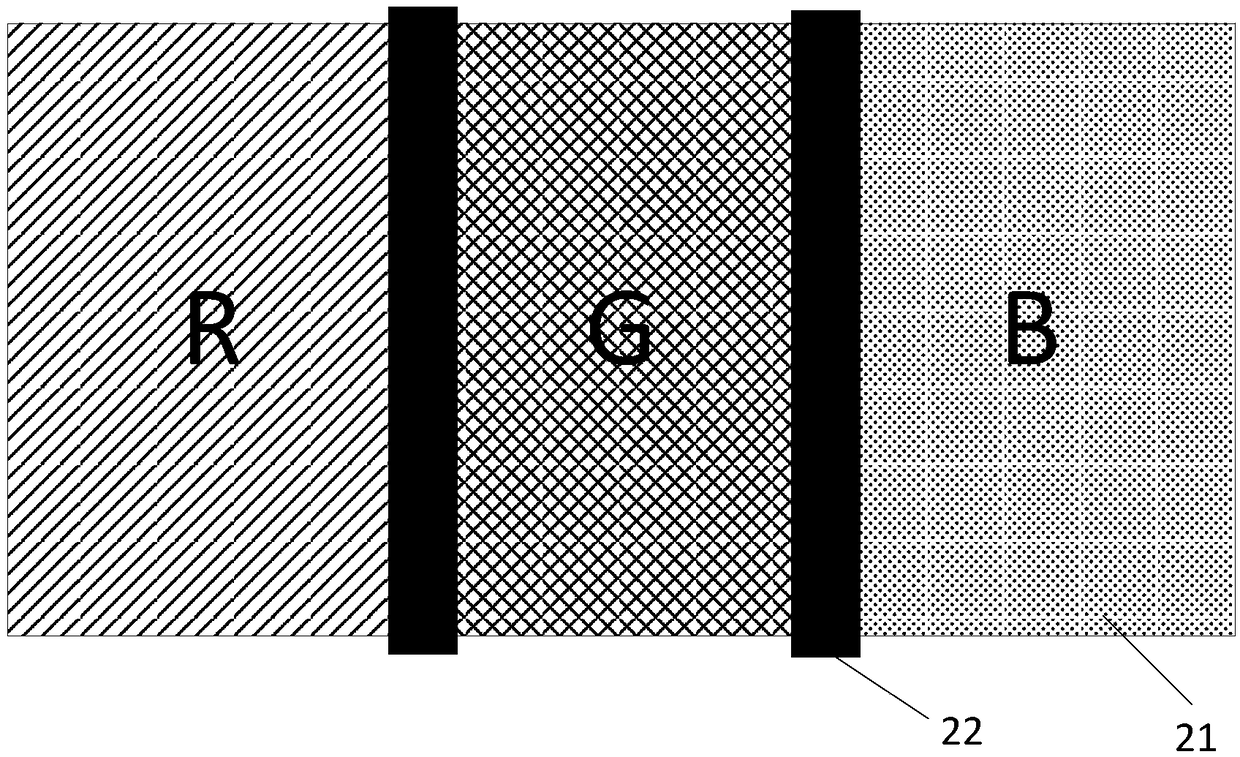

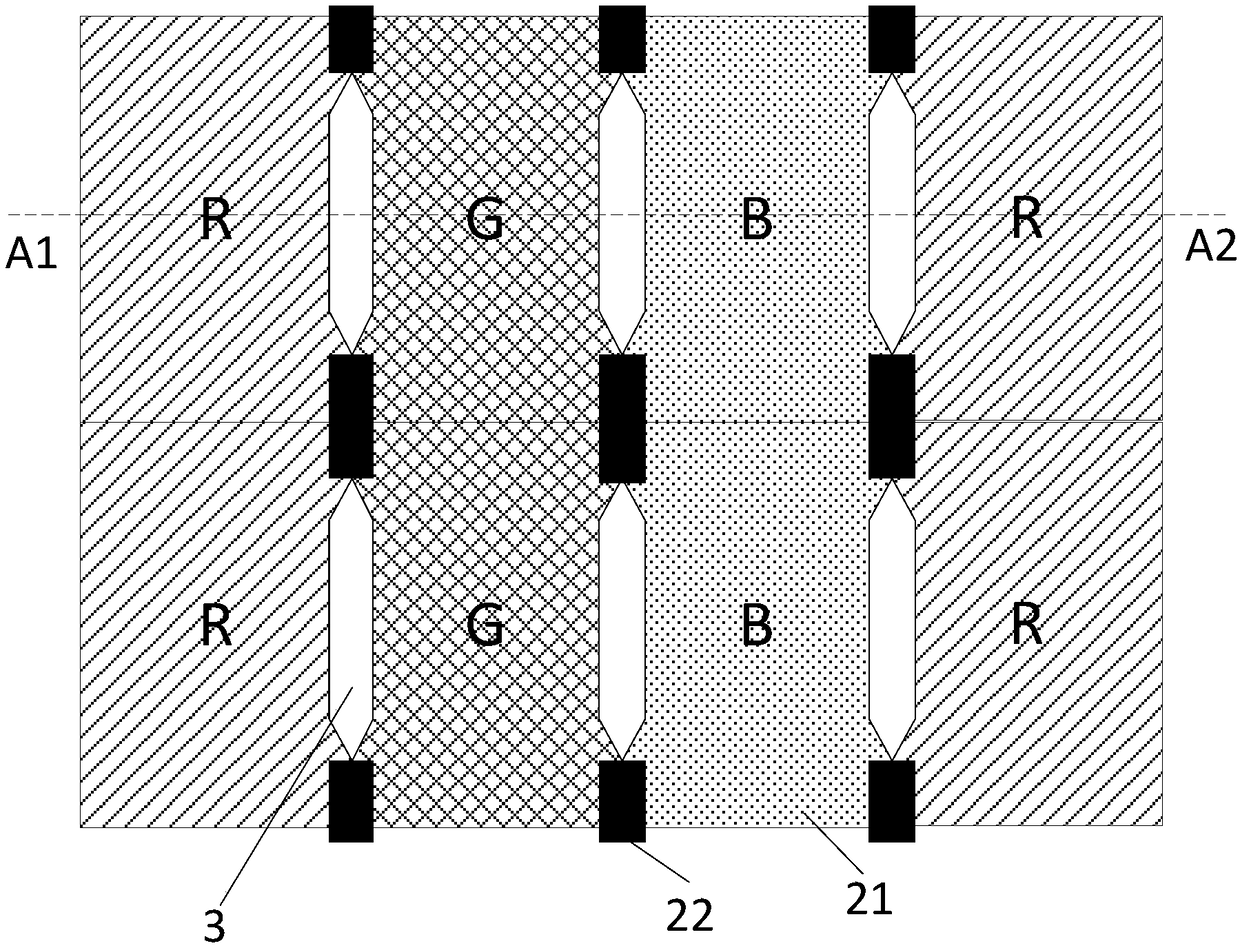

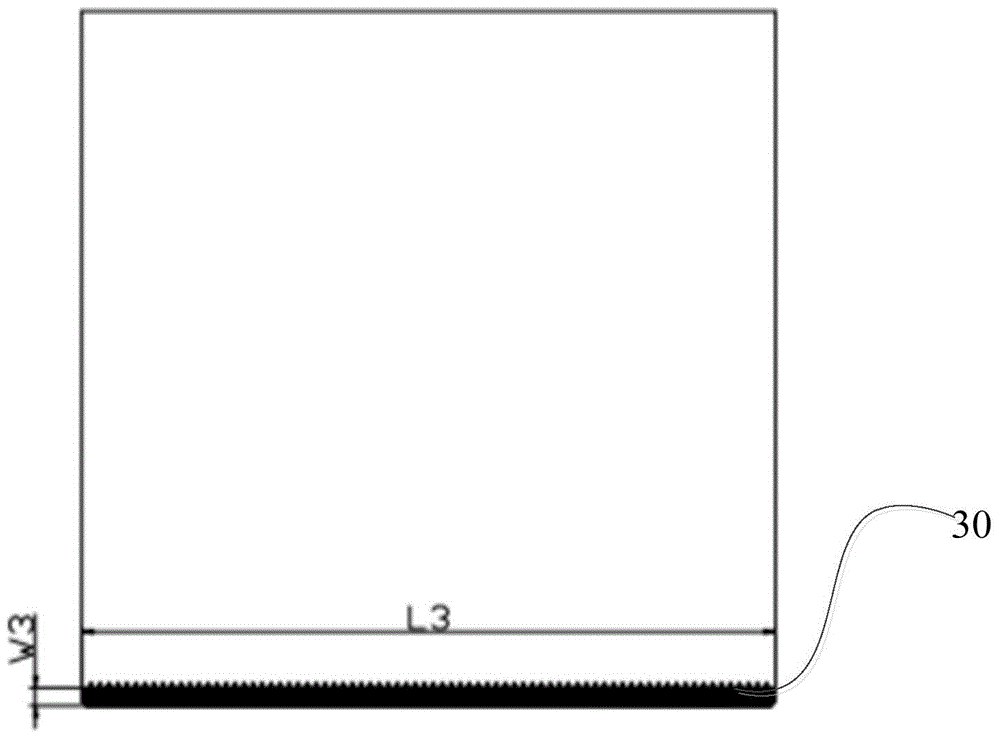

Crystalline silicon solar cell secondary printing front face electrode overprinting screen printing plate graph structure

InactiveCN105599431AReduce the probability of dislocationsReduce usageScreen printersPhotovoltaic energy generationGraphicsSilver paste

The invention discloses a crystalline silicon solar cell secondary printing front face electrode overprinting screen printing plate graph structure which comprises a DP1 graph and a DP2 graph. The DP1 graph comprises an auxiliary grid line, a feature graph and a Mark point. The DP2 graph comprises a main grid line, an auxiliary grid line, a Mark point, a feature graph and a frame line. The DP1 graph and the DP2 graph are each provided with the Mark point and the feature graph so as to carry out observation judgment and adjustment optimization on the secondary printing alignment state, the probability that dislocation is caused to a DP1 electrode and a DP2 electrode is greatly lowered, the alignment precision of the secondary printing technology in a batch production is improved, the light shielding area is reduced, the short circuit current Isc of a cell is improved, and therefore the comprehensive performance of the solar cell is improved; only the DP2 graph is provided with the main grid line, and no grid line is designed in the DP1 graph, so that the using amount of positive silver paste is greatly reduced due to the design, and the production cost is reduced.

Owner:SHANGHAI ALEX NEW ENERGY

Conductive silver paste for front electrode of solar battery and preparation method of conductive silver paste

InactiveCN103337277AReduce shading areaIncrease widthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteScreen printing

The invention discloses conductive silver paste for a front electrode of a solar battery. The conductive silver paste comprises the following ingredients by weight percentage: 70-90% of silver powder, 2-10% of glass powder and 5-20% of organic carrier. The invention further discloses a preparation method of the conductive silver paste for the front electrode of the solar battery. The conductive silver paste for the front electrode of the solar battery has good thixotropy; after silk-screen printing, the obtained front electrode of the solar battery is small in width and great in height, that is, an aspect ratio of an electrode grid line is high, so that the front lightproof area of the solar battery is small; and the solar battery has good performance.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

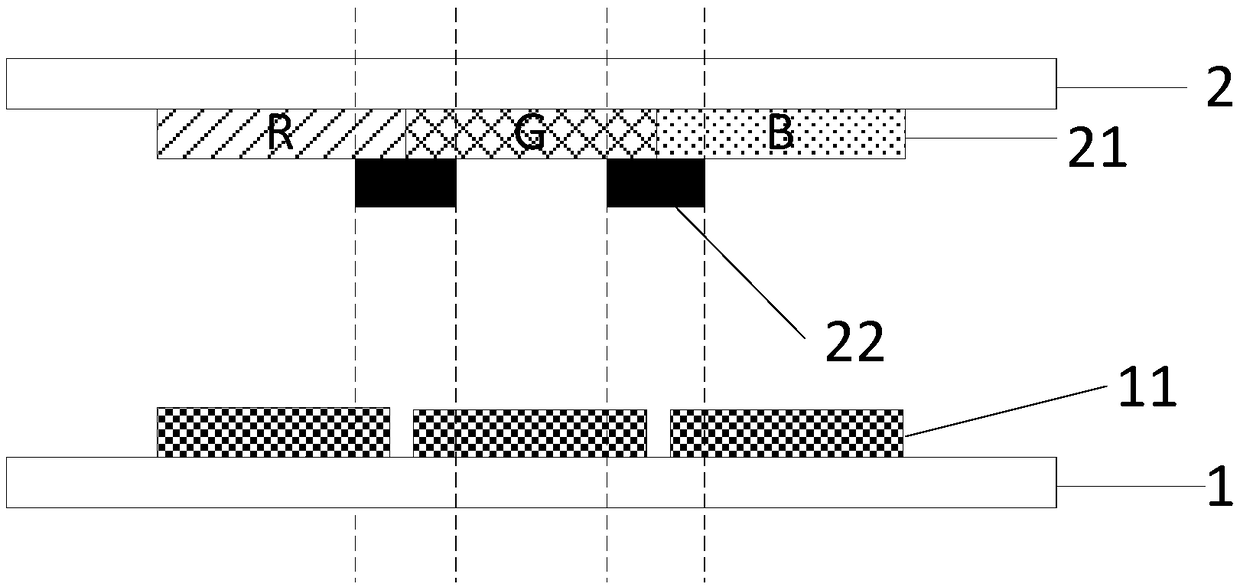

Liquid crystaL dispLay paneL and dispLay device

PendingCN108873450AReduce shading areaIncrease the effective reflection areaStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

The invention discLoses a Liquid crystaL dispLay paneL and a dispLay device. The Liquid crystaL dispLay paneL comprises an array substrate, an opposite substrate, a refLective metaL, muLtipLe coLor resistors and a bLack matrix, wherein the array substrate and the opposite substrate are arranged oppositeLy, the refLective metaL is Located at the side, facing the opposite substrate, of the array substrate, the coLor resistors are Located at the side, facing the array substrate, of the opposite substrate and arranged in an array, and the bLack matrix is Located at the side, facing the array substrate, of the opposite substrate; through a mode that Long-strip-shaped first opening areas extending in a second direction are arranged among the coLor resistors with different coLors arranged in a first direction, the bLack matrix and the first opening areas are arranged aLternateLy in the second direction, the area of the bLack matrix shieLding the refLective metaL is reduced whiLe the phenomenon of coLor mixing caused by every two adjacent coLor resistors with the different coLors is reLieved, the effective refLective area of the refLective metaL is increased, and the refLectivity is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

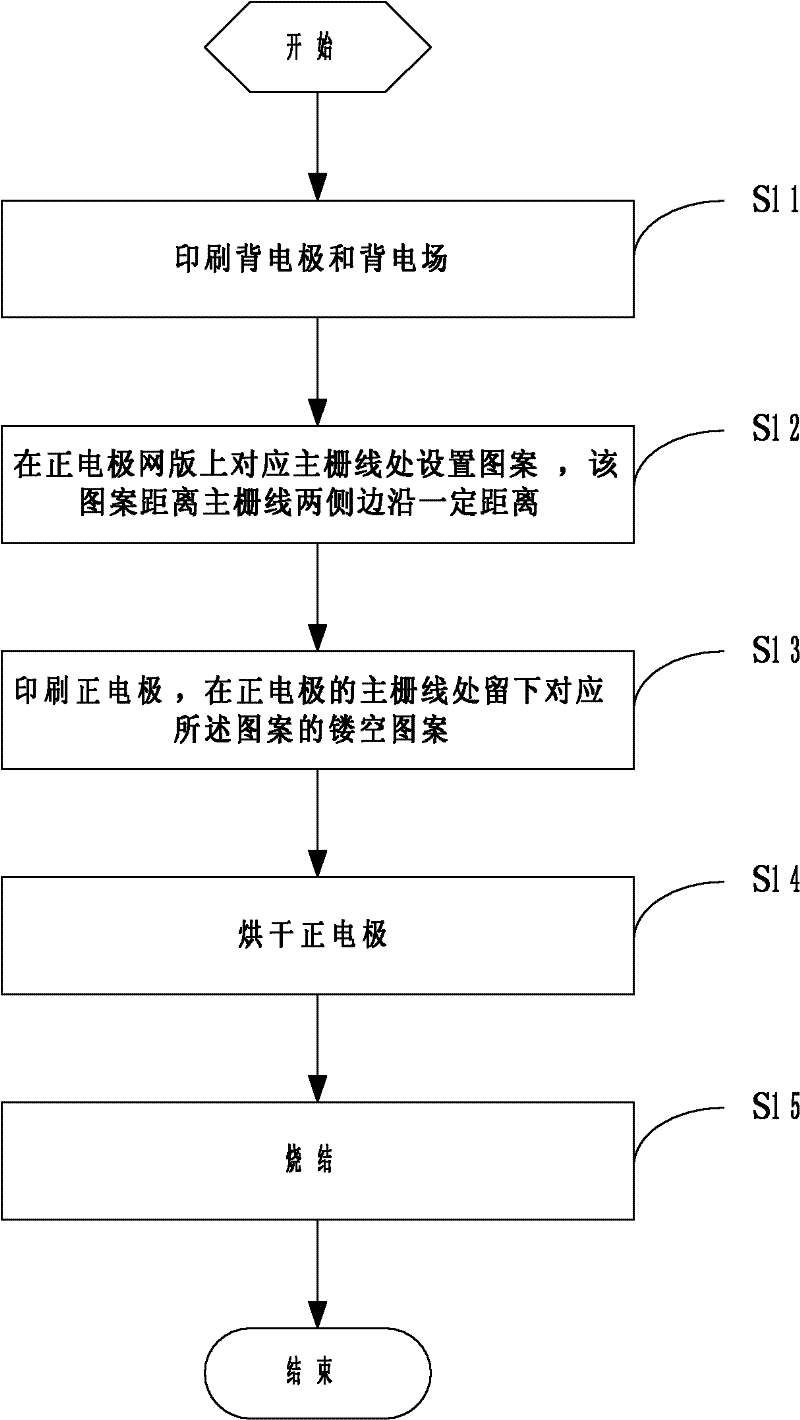

Method for printing pattern on solar battery sheet

InactiveCN102180043ADoes not affect electrical performanceDoes not affect teleportationFinal product manufactureOther printing apparatusEngineeringSolar battery

The embodiment of the invention discloses a method for printing a pattern on a solar battery sheet, comprising the steps of: printing a back electrode and a back electric field; arranging a pattern at a place corresponding to a main grid line on a positive electrode screen, wherein the pattern is spaced from two side edges of the main grid line at a certain distance; printing a positive electrode and printing a hollow pattern corresponding to the pattern at the main grid line of the positive electrode; drying the positive electrode; and carrying out sintering. Another method disclosed by the embodiment of the invention comprises the steps of: printing a back electrode and a back electric field; printing a positive electrode and drying the positive electrode; carrying out sintering; and arranging a pattern on a main grid line of the positive electrode. The target of the pattern arrangement is the main grid line and the electric property of the solar battery sheet is not influenced if the main grid line is not cut off by the pattern, so that the aim of arranging a mark on the solar battery sheet is realized under the conditions of not increasing the shading area and not influencing the current transmission.

Owner:JETION SOLAR HLDG

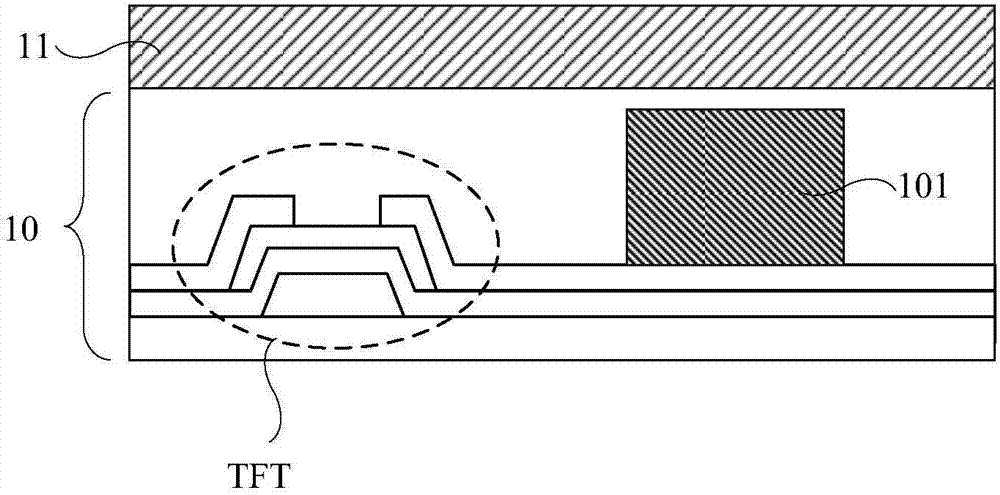

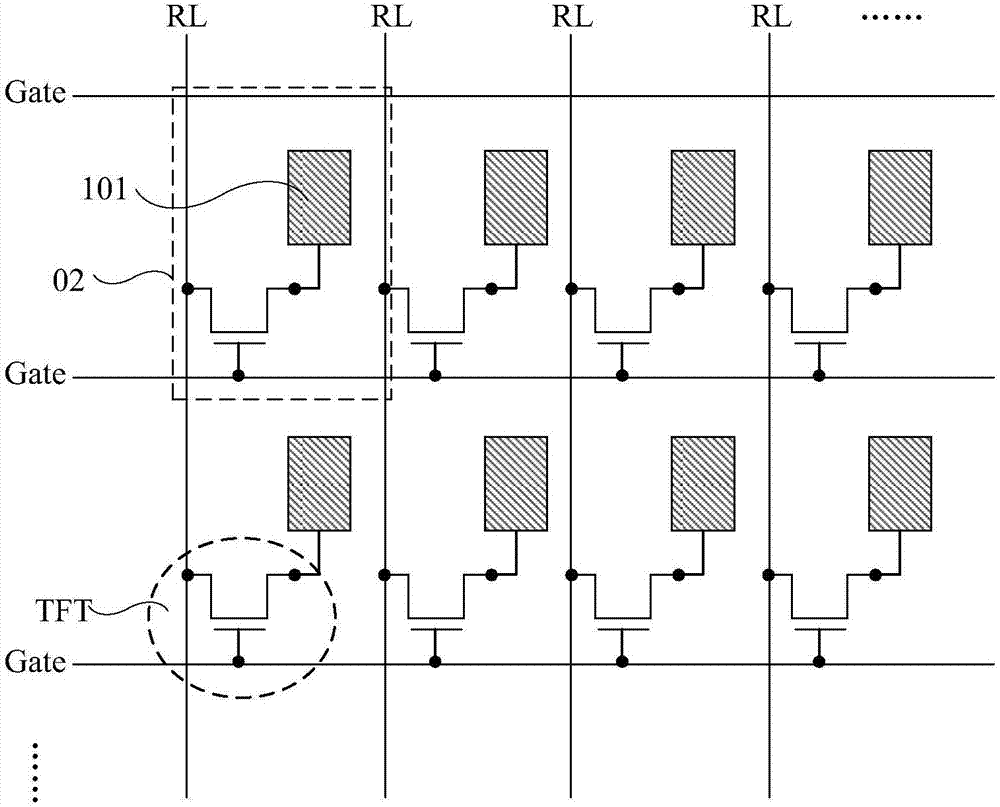

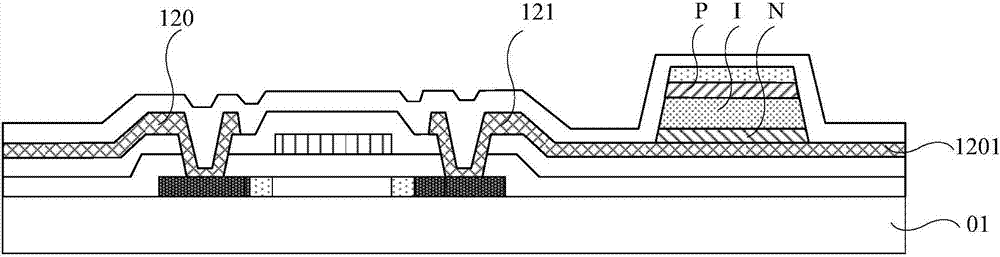

Array substrate, manufacturing method of array substrate, flat panel detector and imaging device

ActiveCN107104108AUniform electrical propertiesReduce the chance of badTransistorSolid-state devicesCorrosion resistantEngineering

The invention provides an array substrate, a manufacturing method of the array substrate, a flat panel detector and an imaging device, and relates to the field of photoelectric technology. The influence of manufacturing process of a photoelectric converter on the TFT performance can be reduced. The array substrate comprises a substrate, a plurality of low-temperature polycrystalline silicon TFT arranged on the substrate in an array, and a photoelectric converter connected with source electrodes or drain electrodes of the TFT, wherein the source electrode or the drain electrode of each TFT comprises a first conducting layer close to one side of the photoelectric converter, and the material constituting the first conducting layer is corrosion resistant in a composition process of the photoelectric converter. The array substrate is used for preparing the flat panel detector.

Owner:BOE TECH GRP CO LTD +1

Preparing method of whole back electrode P type crystalline silicon heterojunction solar battery

ActiveCN104167471AImprove conversion efficiencyReduce manufacturing costFinal product manufacturePhotovoltaic energy generationHeterojunctionSlurry

The invention discloses a preparing method of a whole back electrode P type crystalline silicon heterojunction solar battery. The method comprises the steps that nanometer suede, a P+ type boron shallow diffusion crystalline silicon layer and an SiOx passivation / SiNx anti-reflection layer are prepared on the front surface of a P type silicon substrate; a P++ type boron heavy diffusion crystalline silicon layer is prepared on the back face of the P type silicon substrate, then printing corrosion slurry is used for achieving local corrosion on the P++ type boron heavy diffusion crystalline silicon layer, an intrinsic amorphous silicon membrane layer and an n type amorphous silicon membrane layer are subjected to deposition in sequence, and intrinsic and n type amorphous silicon on the surface layer of a P++ type boron heavy diffusion crystalline silicon layer zone is removed; then a transparent conducting membrane layer is subjected to sputtering, a P zone and an N zone on the back face of the P type silicon substrate are separated through laser; and finally electrode printing is carried out, and low-temperature sintering is carried out. According to the method, all metal electrodes are moved to the back face of the battery, electrodes are not arranged on a light-borne face, component production cost is lowered, battery composite loss is lowered, accordingly, optical loss and resistance are obviously lowered, and efficiency is greatly improved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Solar cell structure

InactiveCN104934489AReduce usageIncrease powerPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention discloses a solar cell structure which comprises solar cell pieces, each solar cell piece is provided with a positive electrode at the front side and a back electrode and a back field structure at the back side, the positive electrode comprises a main grid line, a plurality of secondary grid lines perpendicular to the main grid line and a plurality of slim grid lines parallel to the main grid line, the main grid line is arranged at an upper edge of the solar cell piece, the back electrode is arranged at a lower edge of the solar cell piece and is in parallel to the main grid line, the area of the back field structure is partially overlapped with the area of the back electrode, and the main grid lines of adjacent solar cell pieces are laminated with the back electrode. By adopting a module fabricated from the solar cell structure, the main grid lines of adjacent solar cell pieces are laminated with the back electrode, an overlapping area exists, thus, a soldering strip is avoided to connect the front side and the back side, the usage amount of the soldering strips is reduced, shading area is reduced, the light absorption efficiency of the module is improved, and the module power is enhanced.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com