Patents

Literature

38results about How to "Reduce the chance of bad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

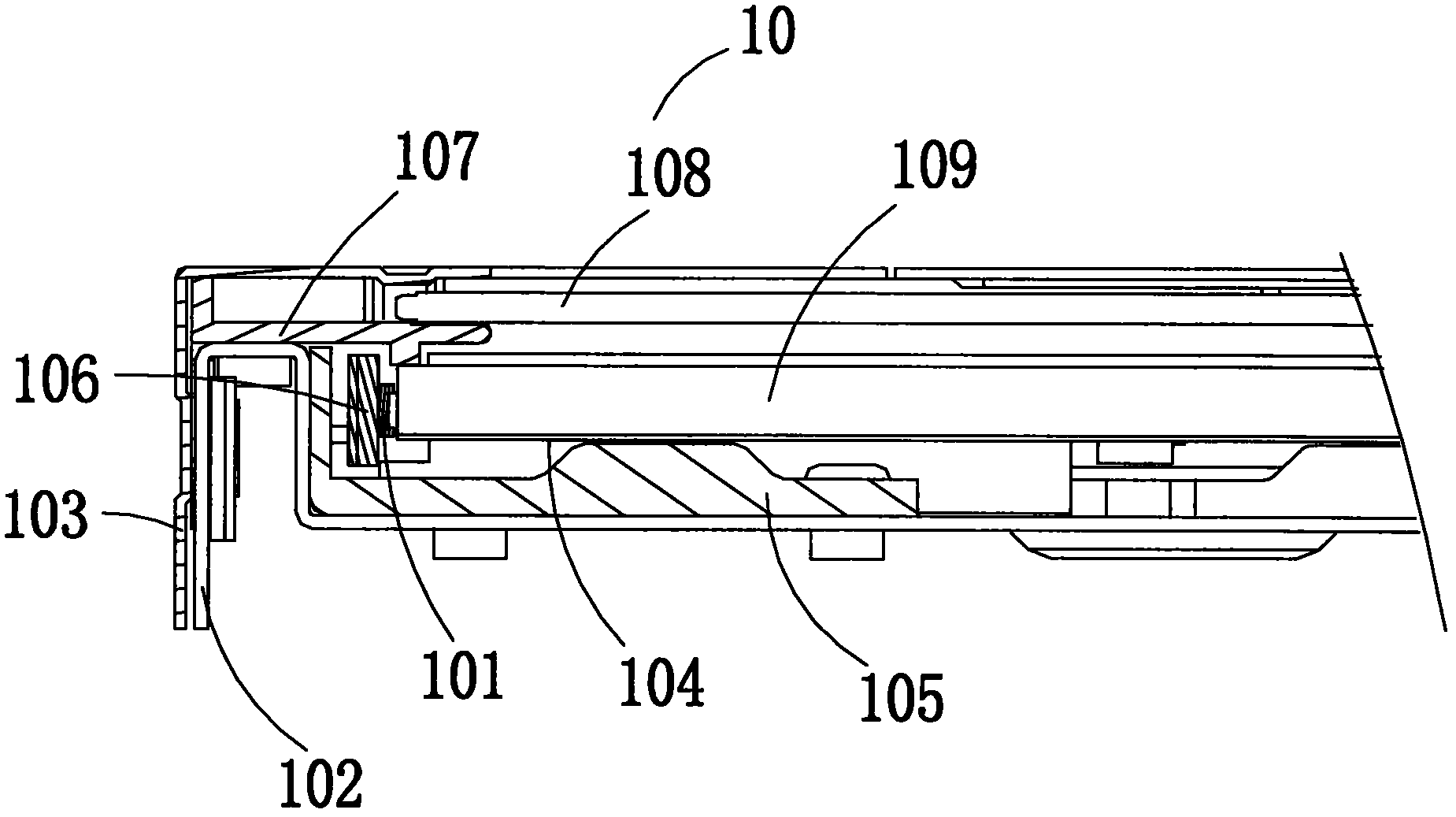

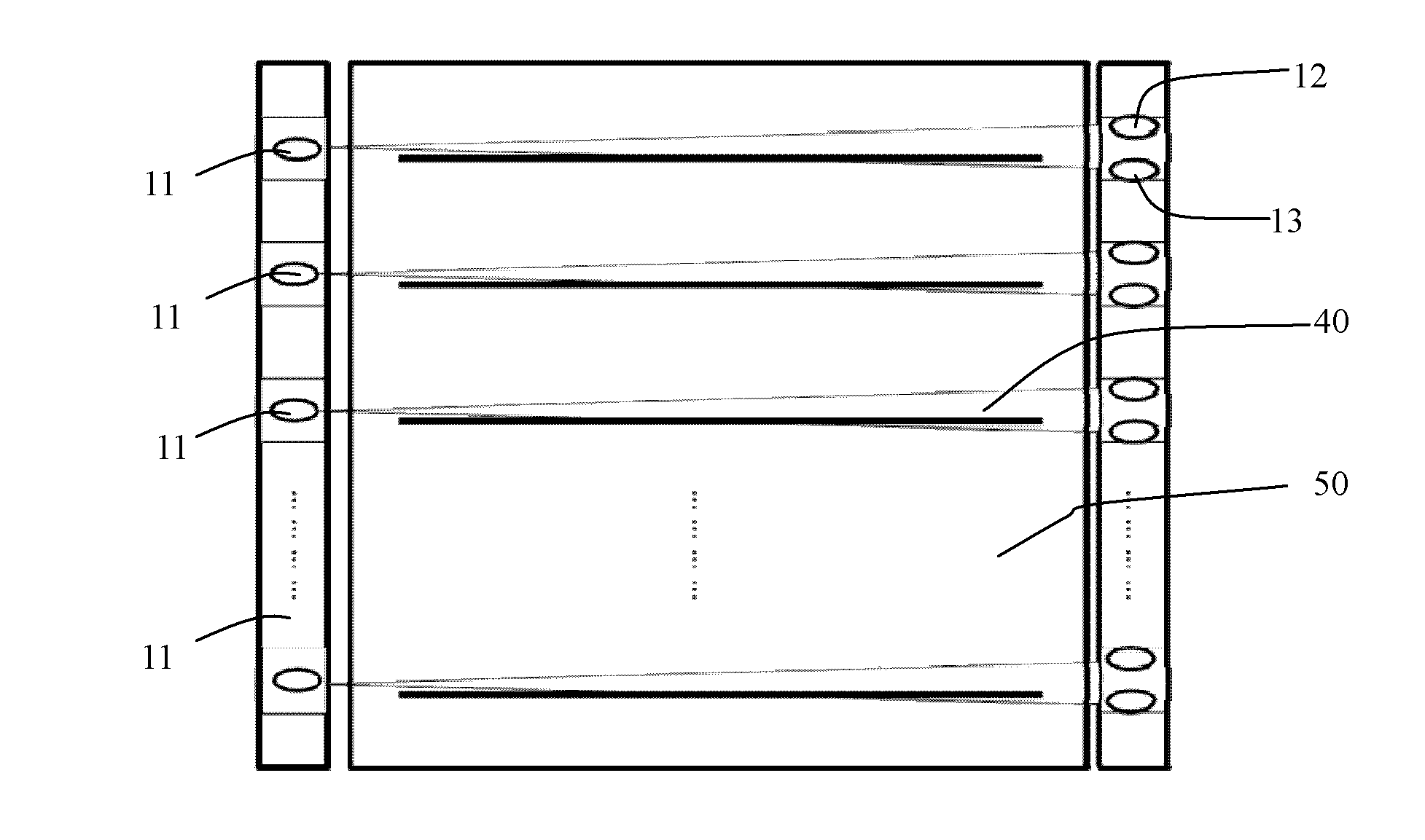

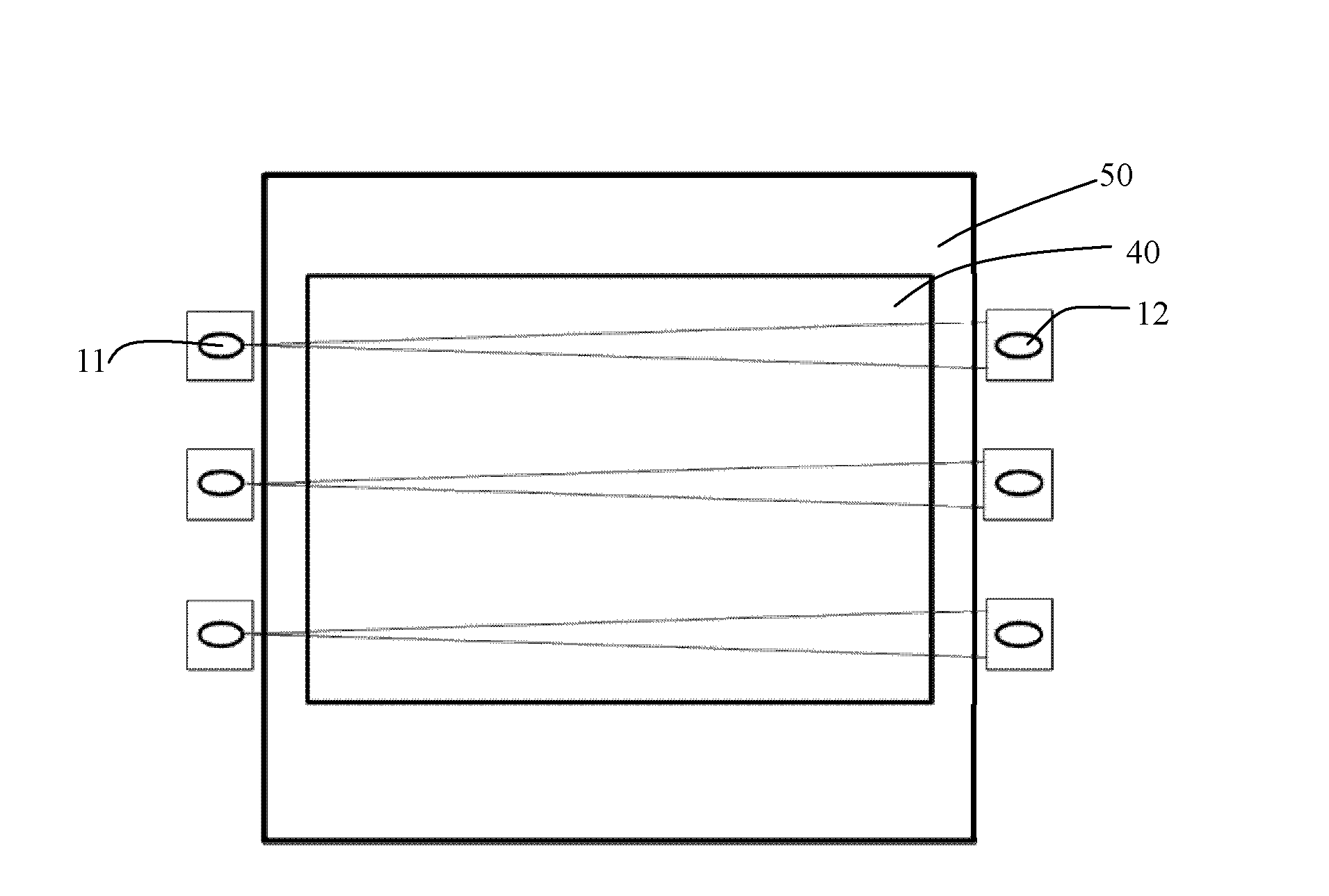

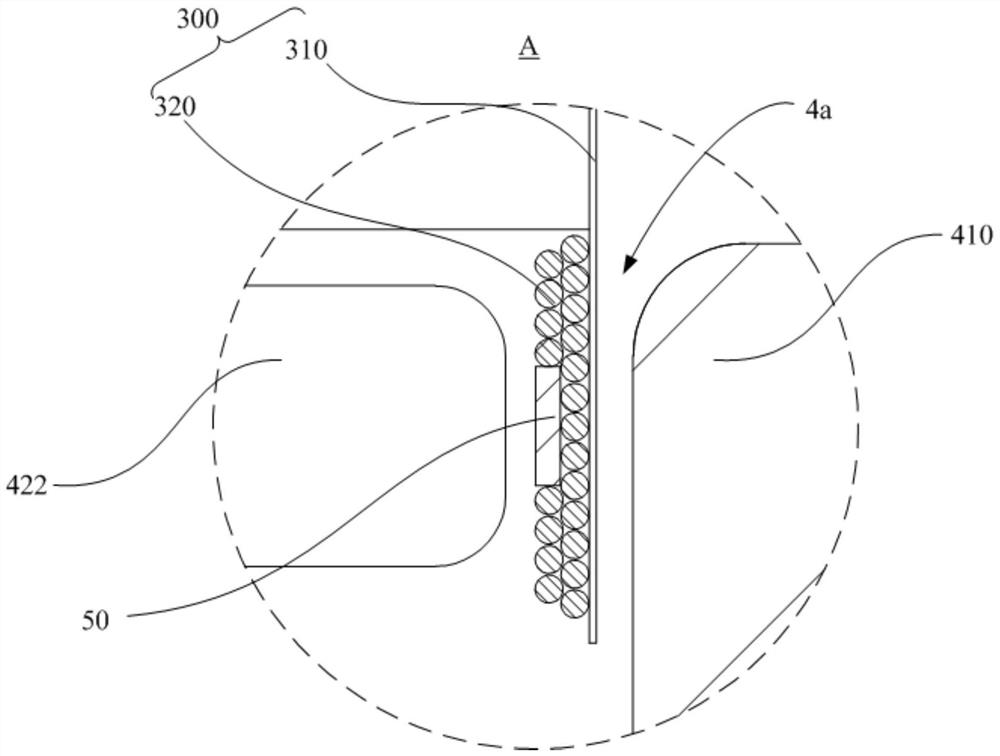

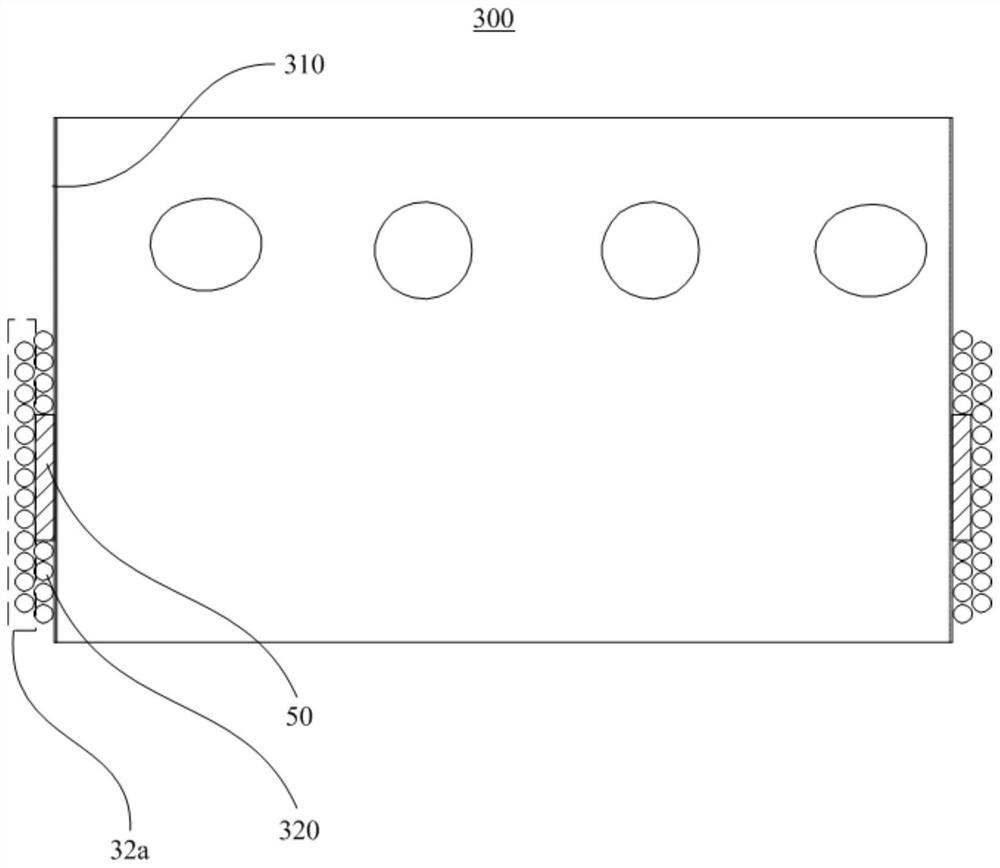

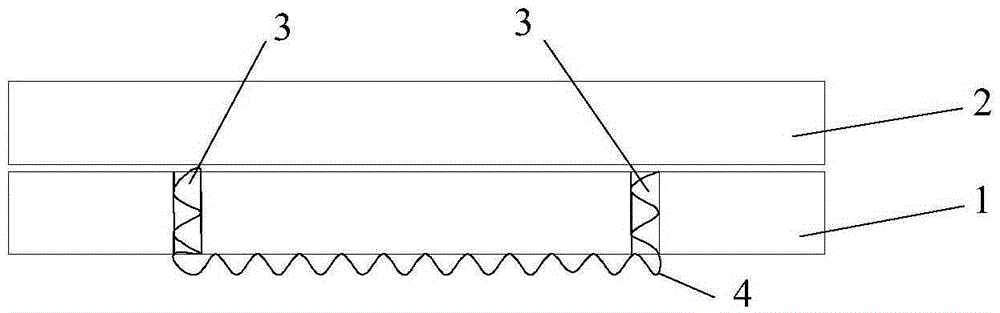

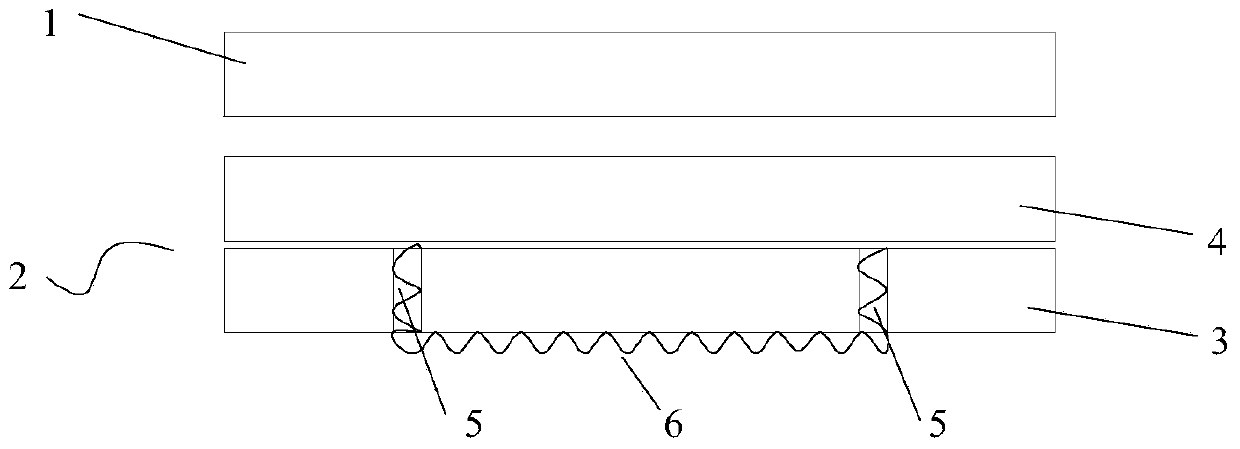

Lateral light-entering type LED liquid crystal backlight module

InactiveCN102588848AQuick dismantlingReduce the chance of badPoint-like light sourceLight fasteningsLight guideEngineering

The invention discloses a lateral light-entering type LED liquid crystal backlight module, which comprises an outer frame, a middle frame, liquid crystal glass, a back plate, a reflective sheet, a light guide plate, an optical diaphragm, a radiating plate and an LED light bar. The back plate comprises a bearing surface and a radiating surface, the reflective sheet, the light guide plate and the optical diaphragm are sequentially stacked on the bearing surface of the back plate from bottom to top, the radiating plate is fixed to the radiating surface of the back plate, the radiating plate is close to the edge of the light entering side of the light guide plate, a light bar fixing portion is arranged on the light guide plate in a projecting manner, and the LED light bar is fixed to the light bar fixing portion. The radiating plate can be rapidly detached from the back plate, the LED light bar is replaced by a non-defective light bar, rework process is greatly simplified, rework time is shortened, the probability of leading other materials to be defective during rework can be greatly reduced, and radiating effects are greatly improved owing to the designed structure.

Owner:SKYWORTH LCD SHENZHEN CO LTD

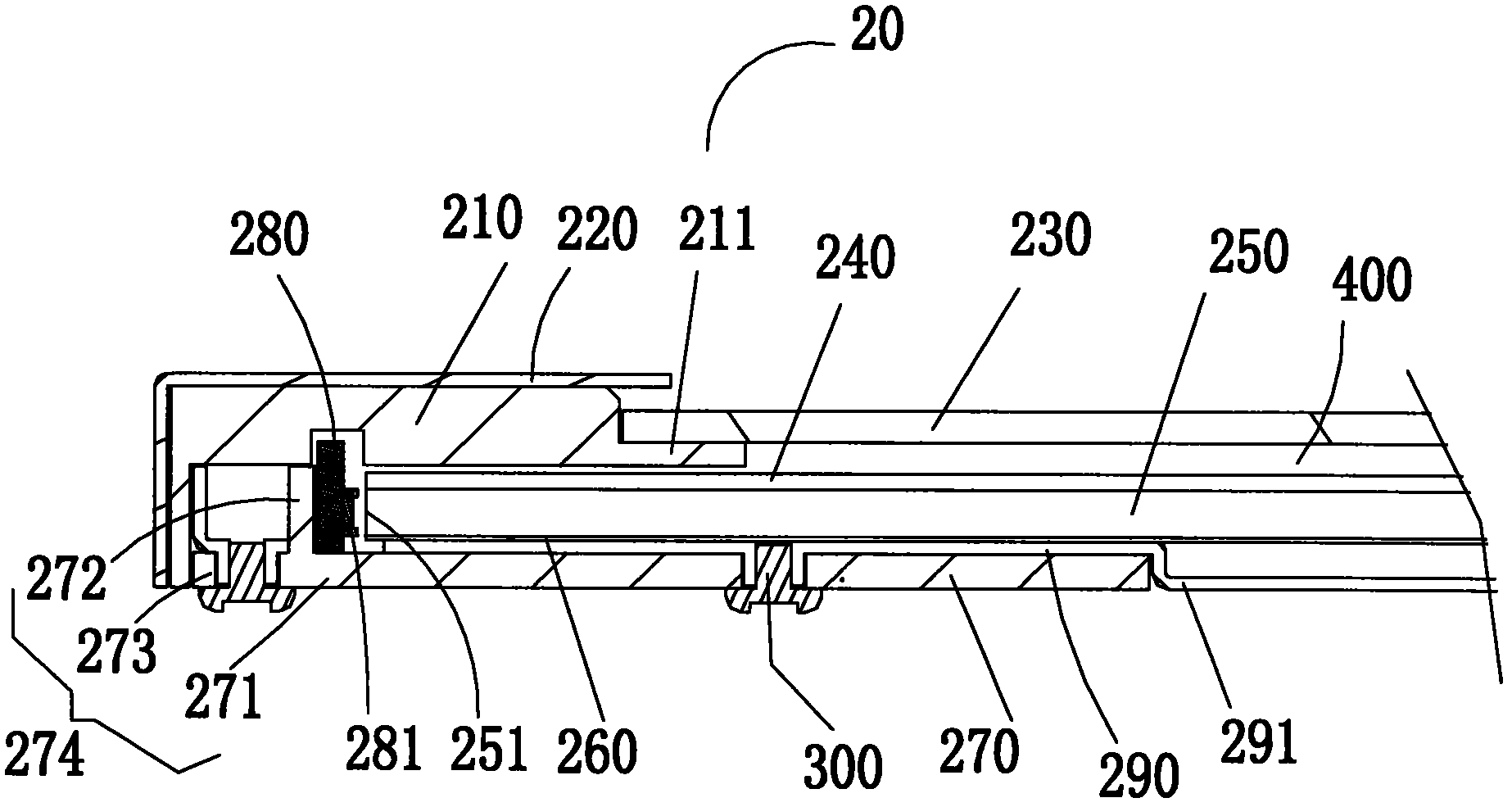

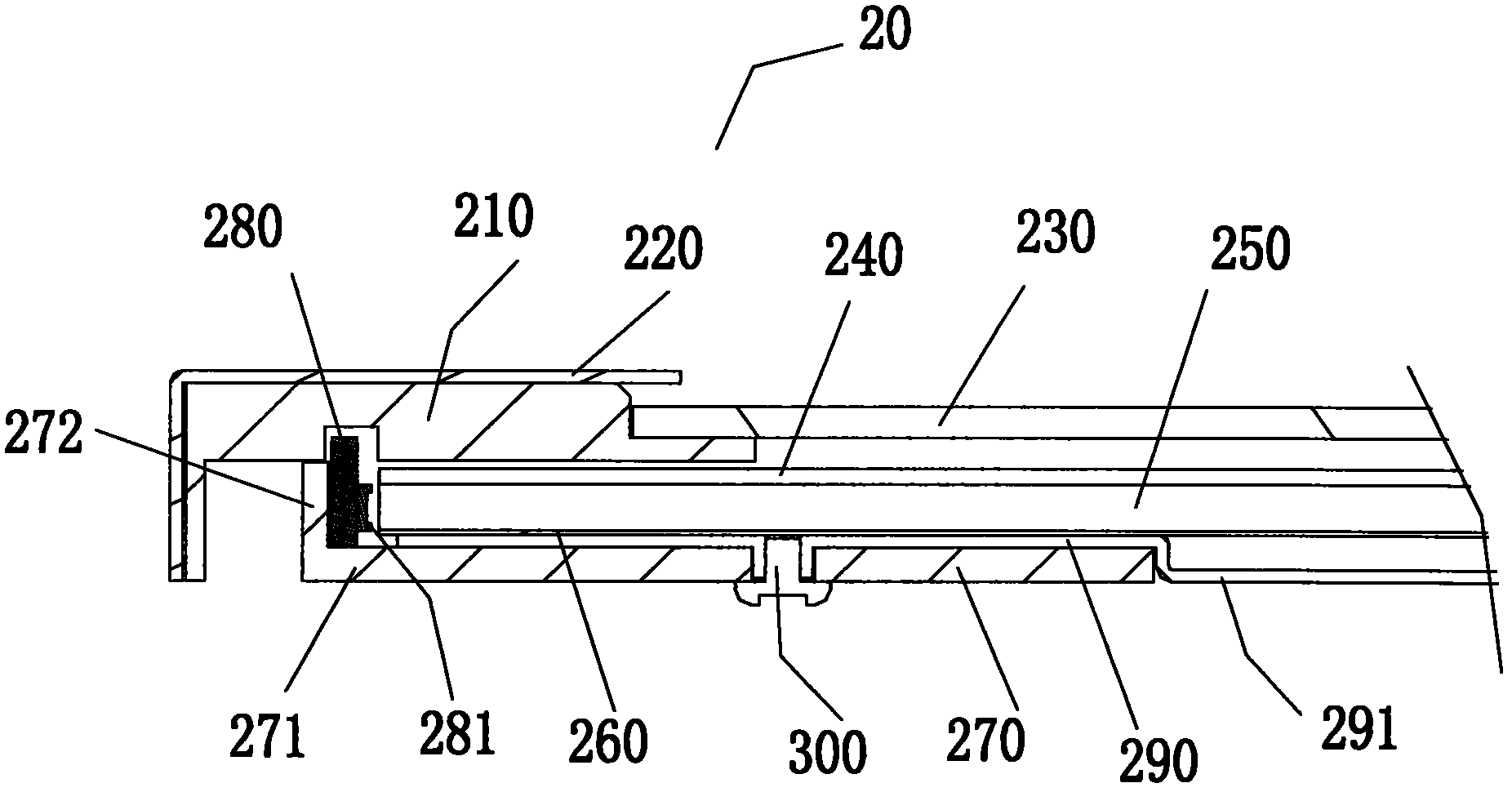

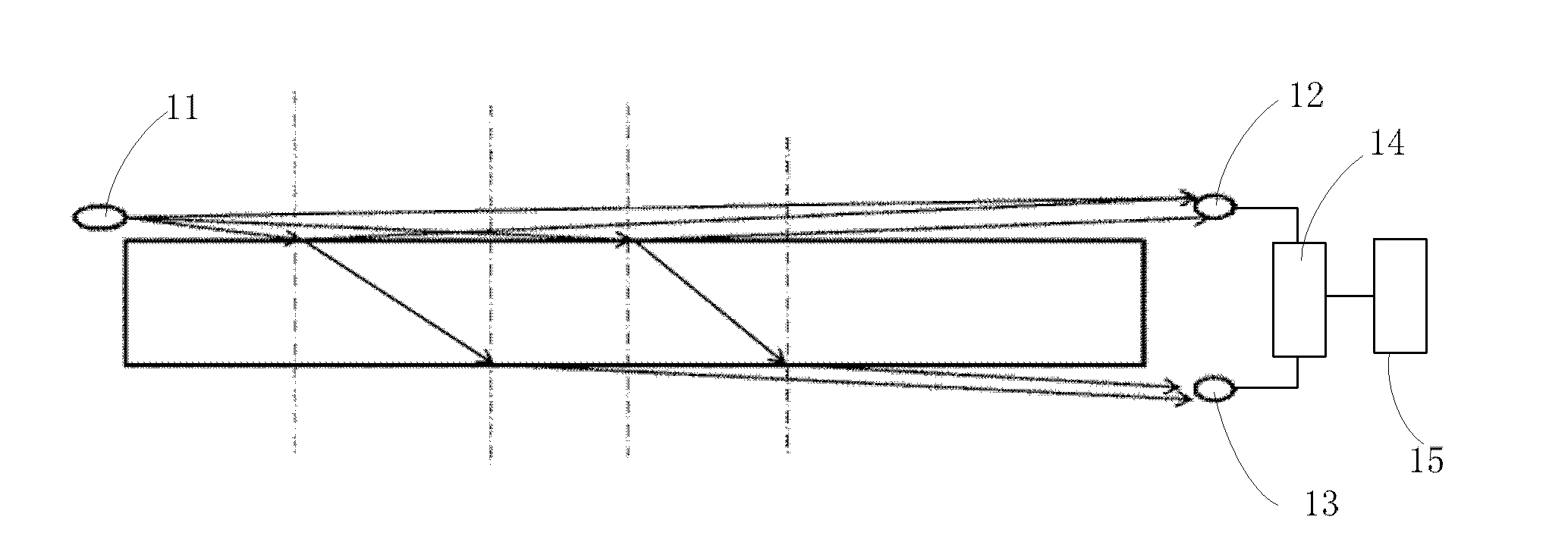

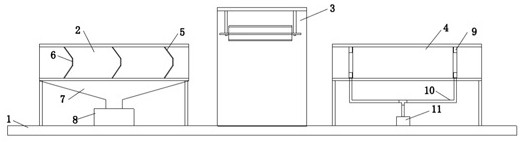

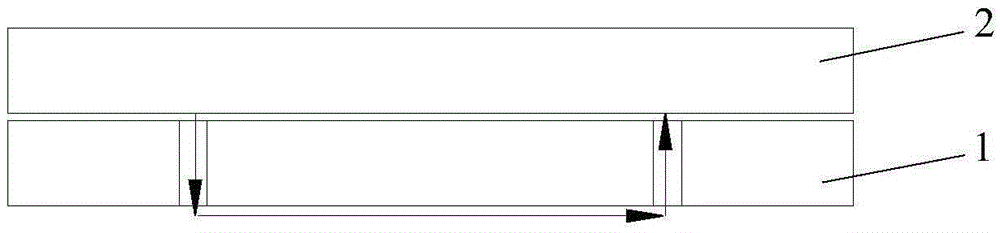

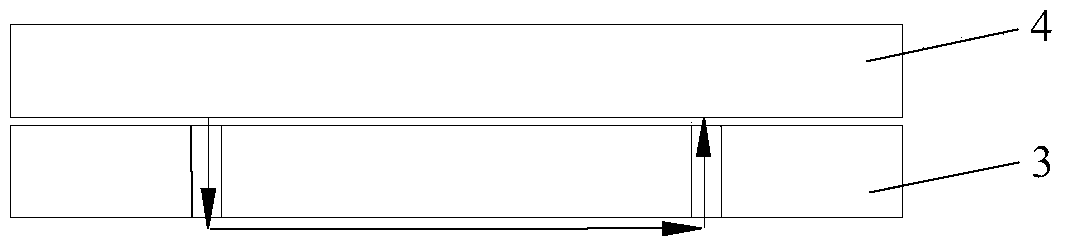

Detection device and detection method for glass substrate

InactiveCN102636498AIncrease productivityReduce the chance of defective finished productsMaterial analysis by optical meansOptoelectronics

The invention provides a detection device and a detection method for a glass substrate, and is used for detecting whether the glass substrate bore in a clamping case is damaged or not. The detection device comprises at least one sensor group and at least one processing unit, wherein the sensor group comprises an illuminating element on one side of the glass substrate and two illuminated elements respectively positioned on the two sides of the glass substrate, and the processing unit is used for judging whether the luminance difference of the luminance of the two illuminated elements is in the preset scope or not; and if the luminance difference is not in the preset scope, the glass substrate to be detected is broken. Through the detection method provided by the invention, the phenomenon that the broken glass substrate enters into a display panel processing line can be reduced or avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

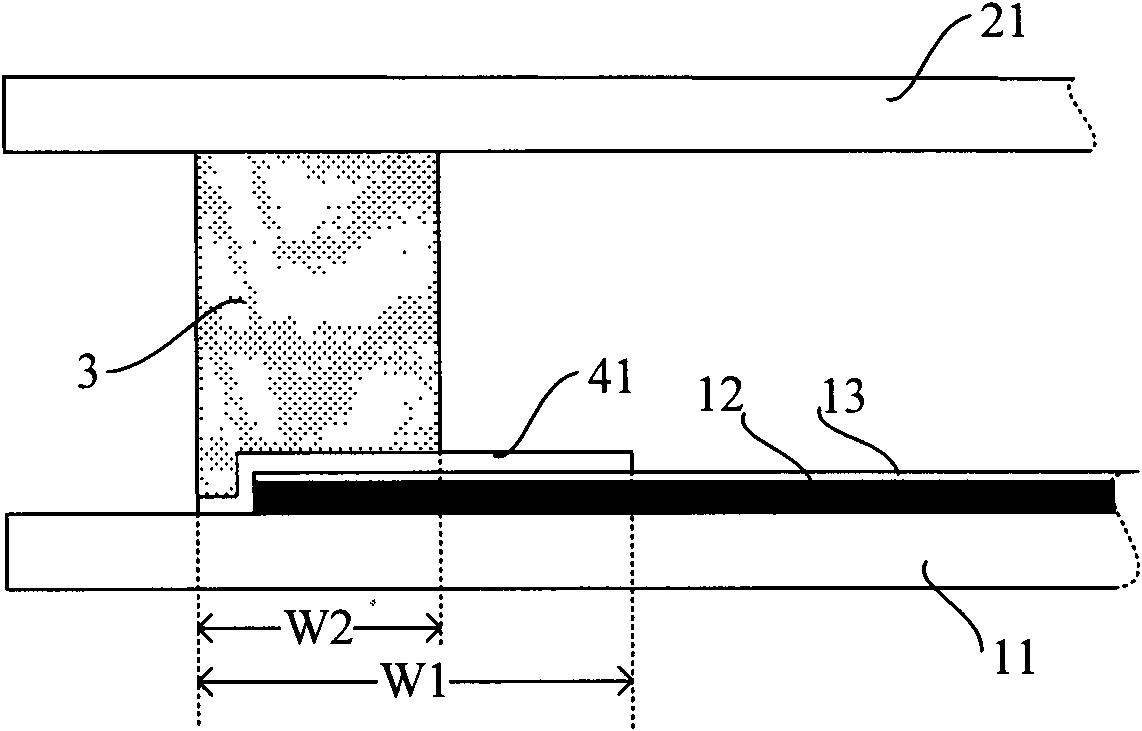

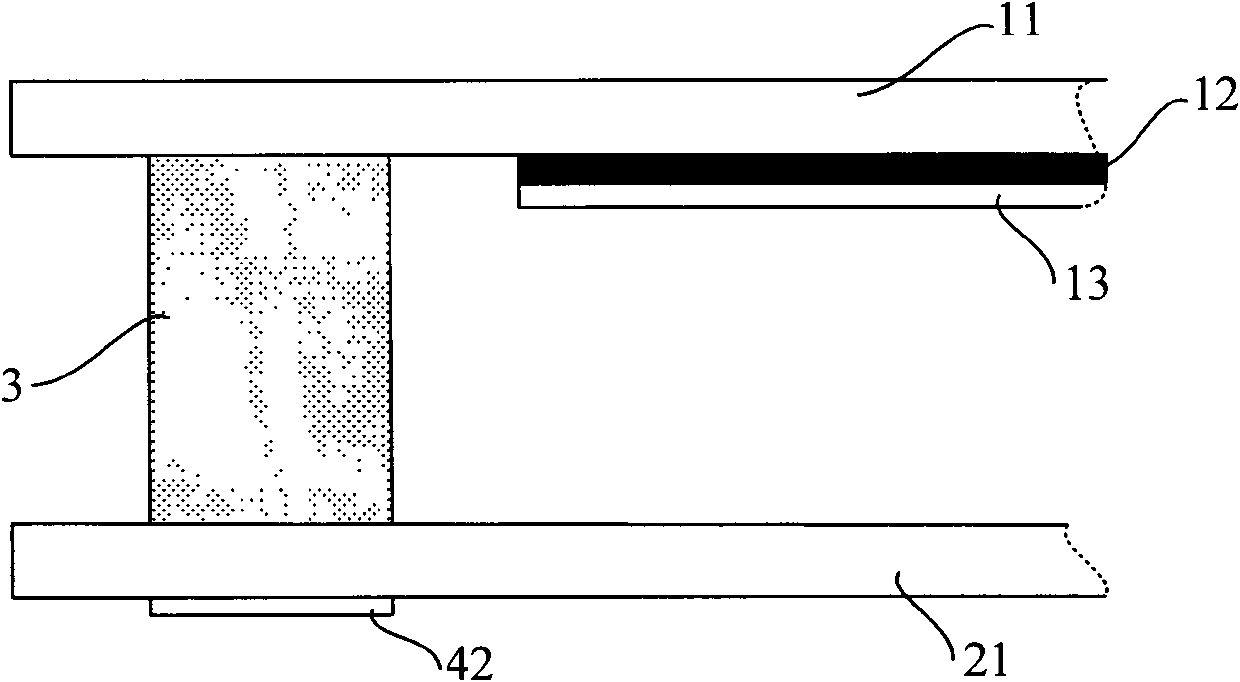

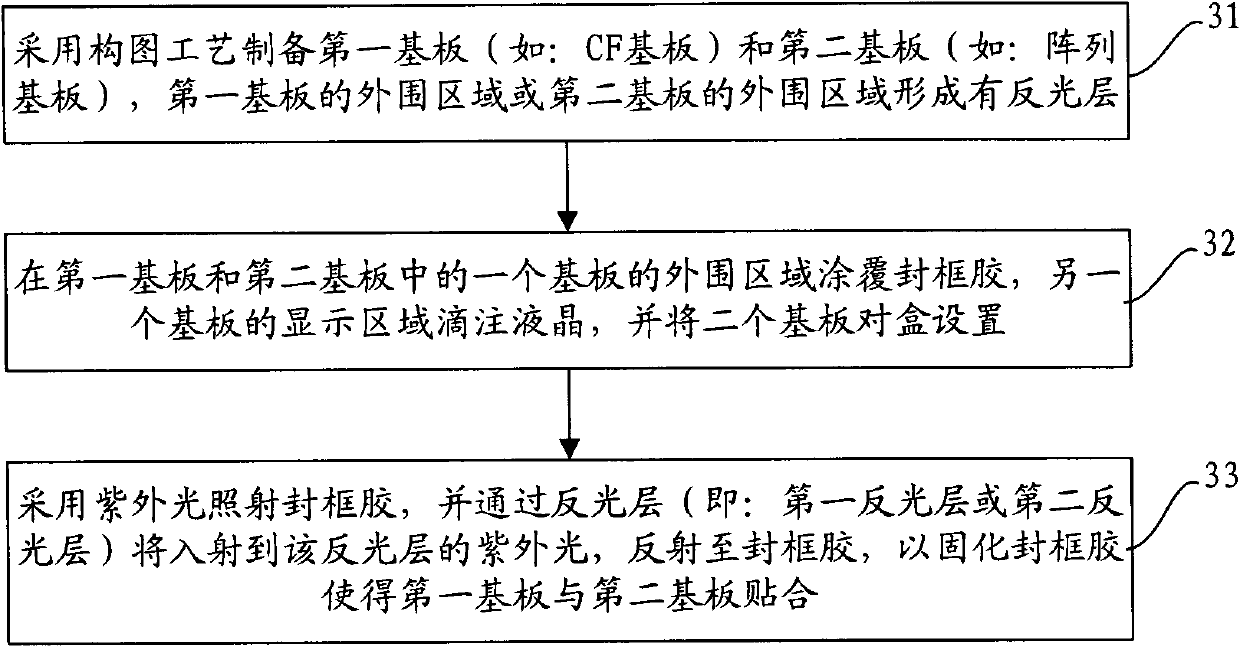

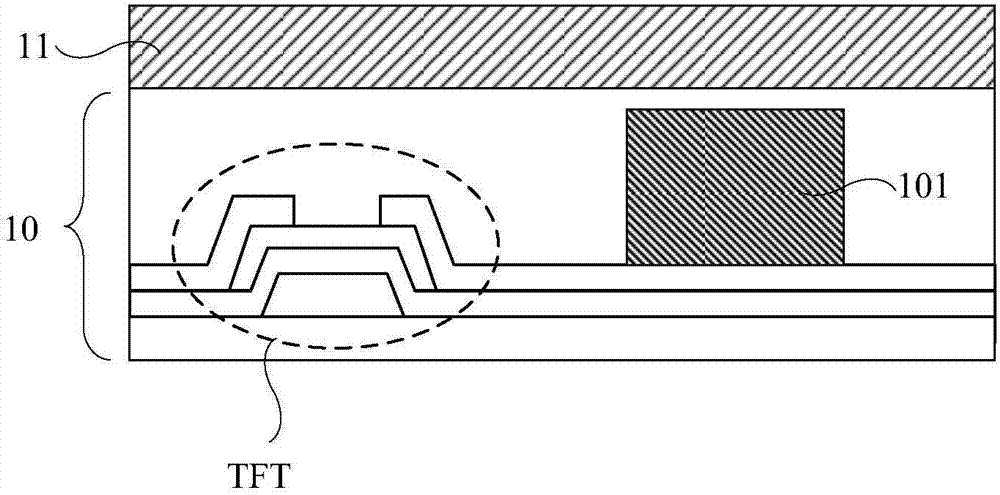

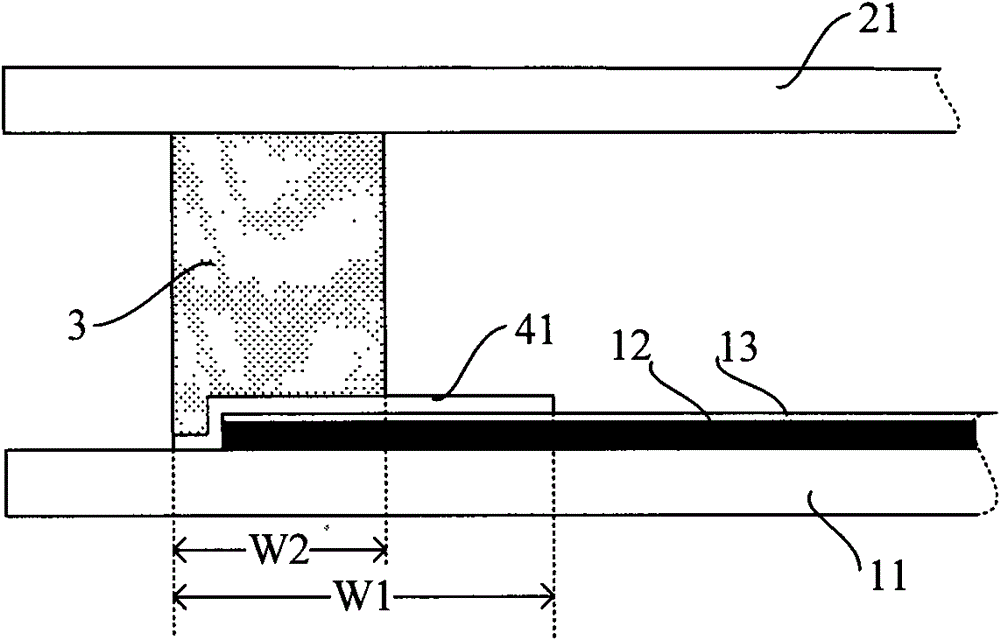

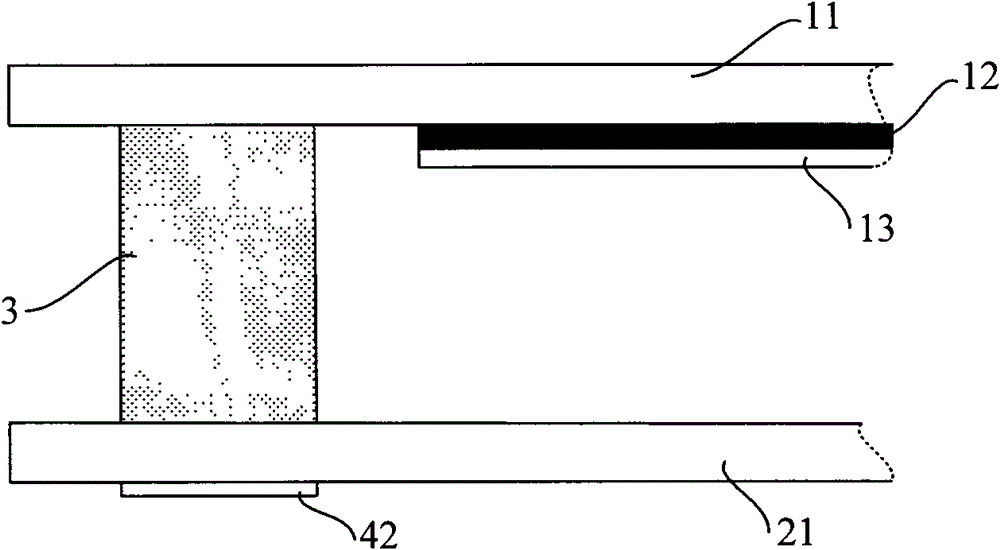

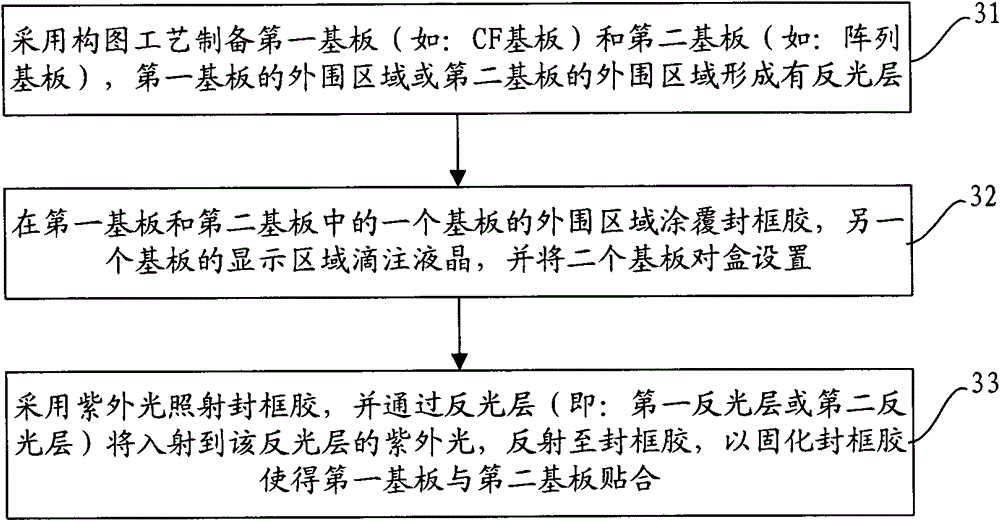

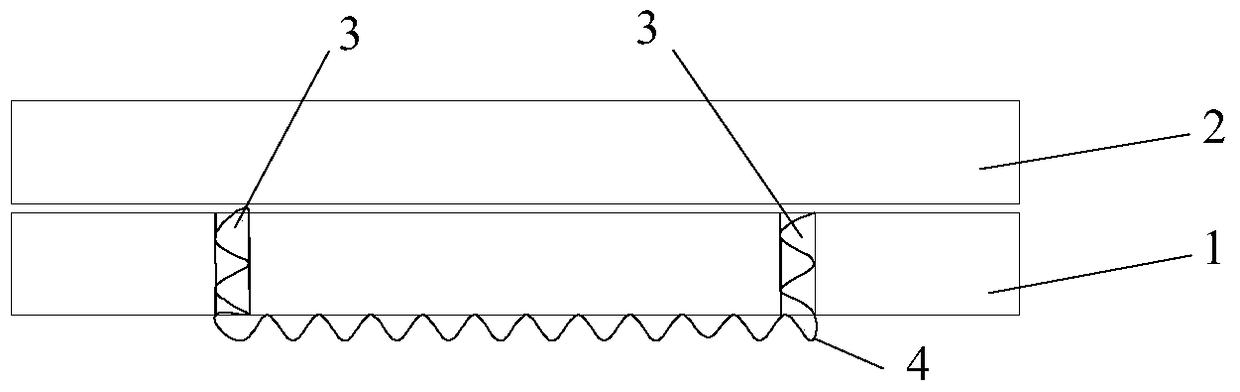

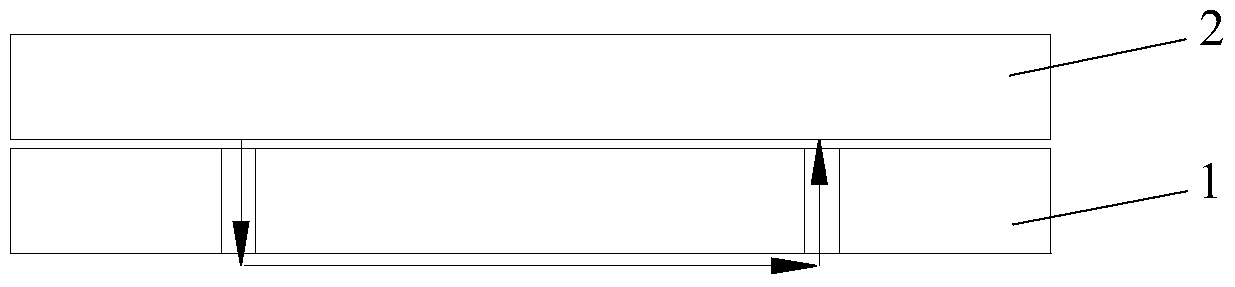

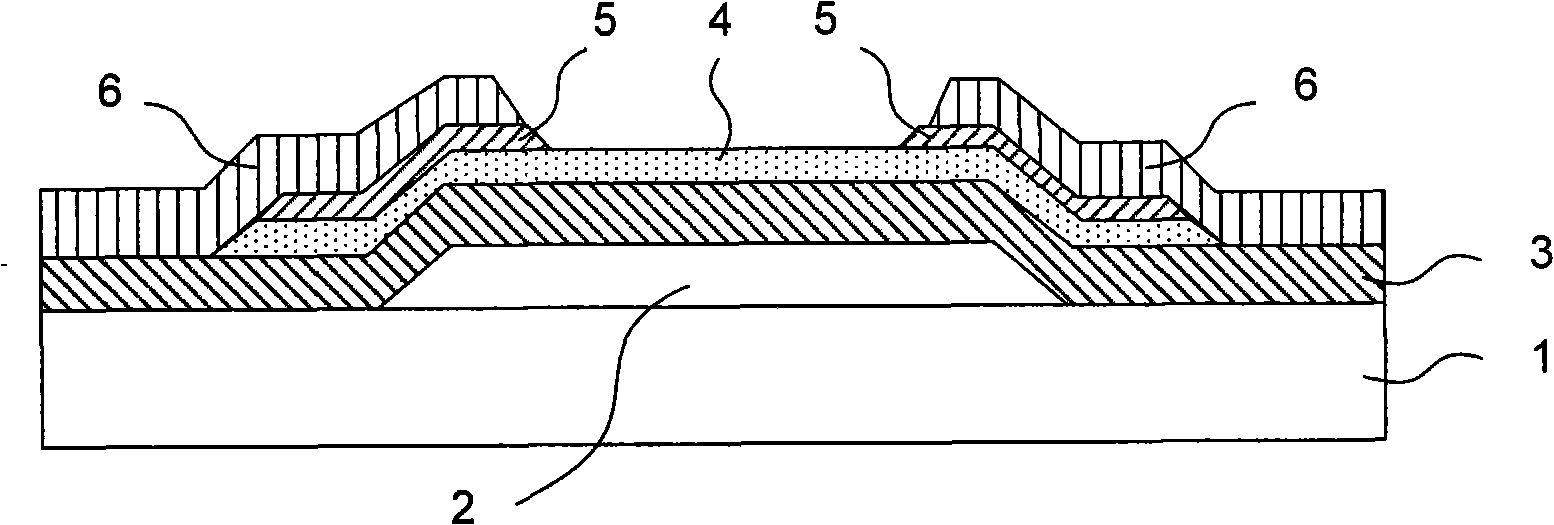

Liquid crystal display panel and method for producing same

ActiveCN102023406AReduce the chance of badImprove the utilization rate of ultraviolet lightNon-linear opticsLiquid-crystal displayUltraviolet lights

The present invention relates to a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises a first substrate and a second substrate that are assembled opposite to each other; liquid crystal is filled between the display area of the said first substrate and the display area of the said second substrate; sealing glue is formed between the peripheral area of the said first substrate and the peripheral area of the said second substrate; a reflection layer is formed on the peripheral area of the said first substrate or the peripheral area of the said second substrate. The said reflection layer is used to reflect the incident ultraviolet light to the said sealing glue in the process of assembling the said first substrate and the said second substrate. The liquid crystal display panel and the manufacturing method thereof provided in the present invention increase the utilization rate of ultraviolet light in the process of solidifying the sealing glue when assembling the two substrates by arranging reflection layers on the peripheral area of one of the two substrates that constitute the liquid crystal display panel, and helps to lower the probability of defects occurring to the LCD panel.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

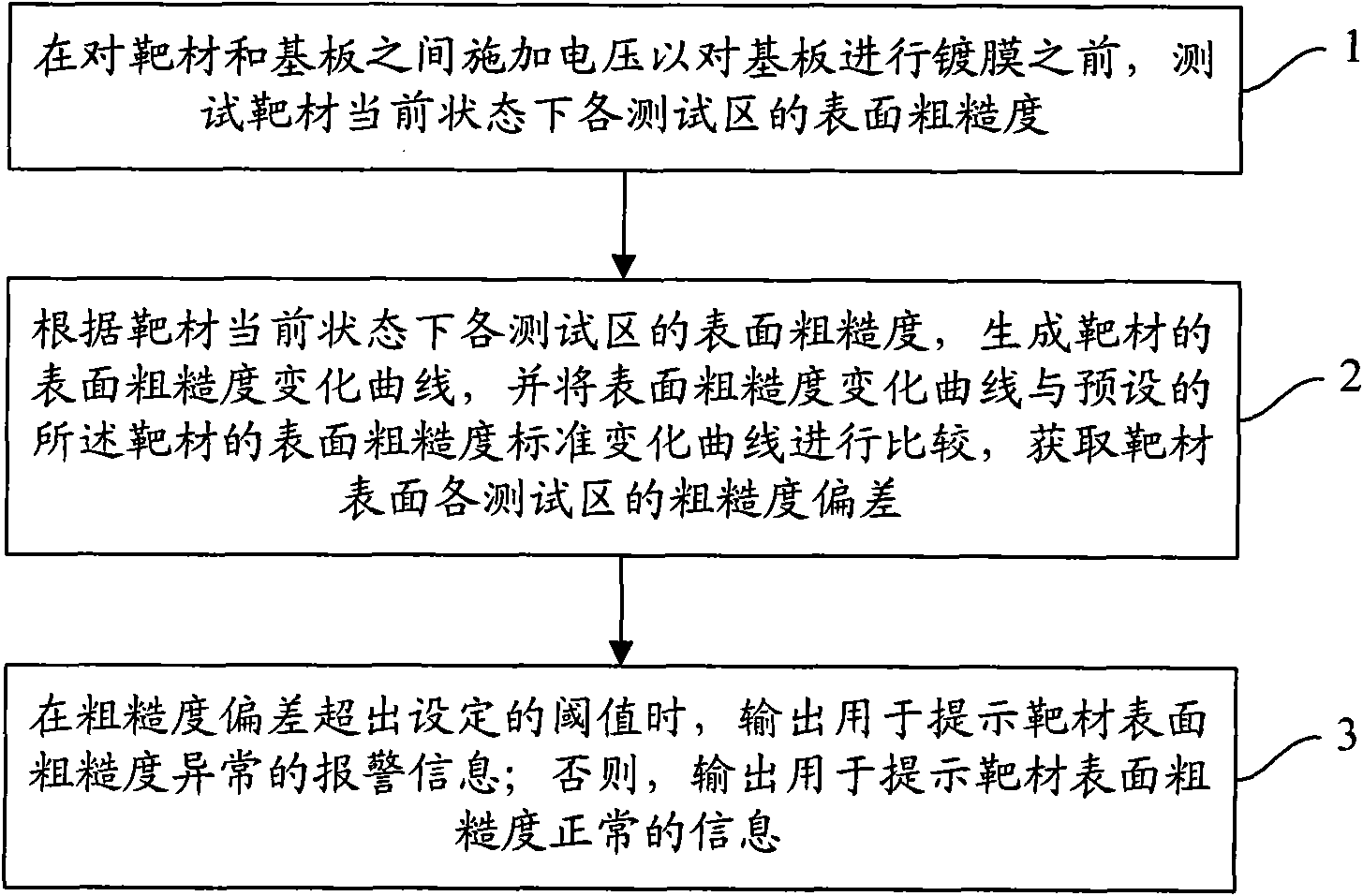

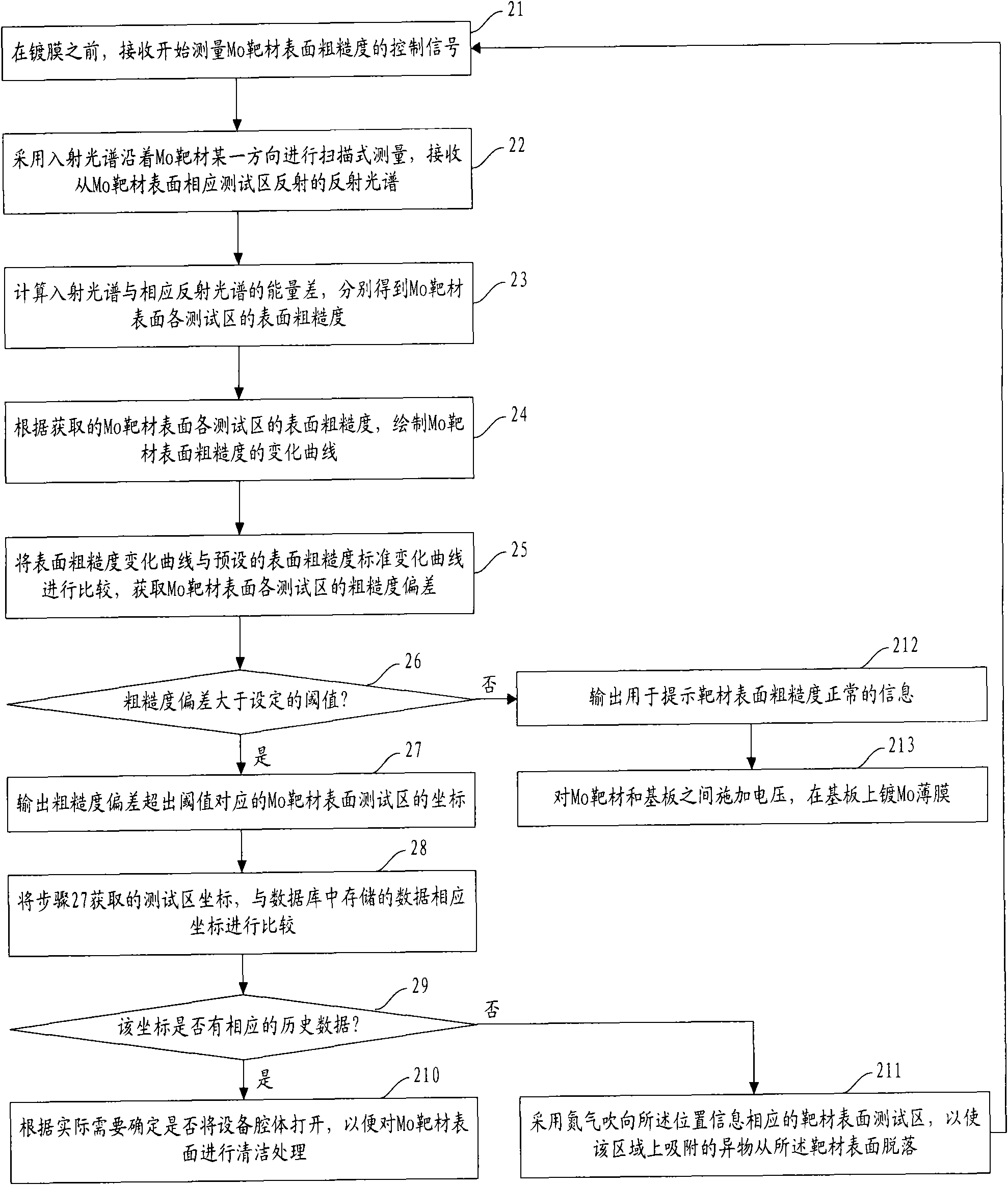

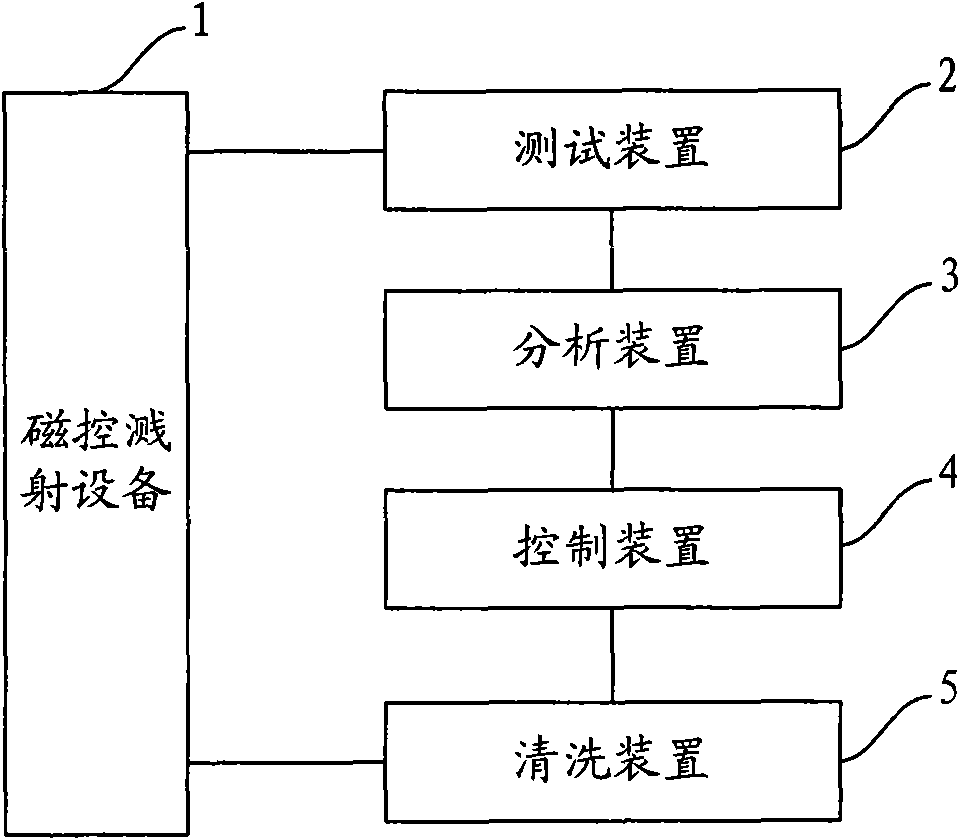

Method and system for monitoring surface roughness of magnetic control spattering target

InactiveCN101819030AReduce the chance of defective productsImprove timeliness and efficiencyVacuum evaporation coatingSputtering coatingPhysicsVoltage

The invention relates to a method and a system for monitoring surface roughness of a magnetic control spattering target. The method comprises the following steps of: step 1, before applying voltage between the target and the substrate to plate a film on the substrate, testing the surface roughness of each testing area of the target in the current state; step 2, according to the surface roughness of each testing area of the target under the current state, generating a surface roughness change curve of the target, and comparing the surface roughness change curve and a preset standard surface roughness change curve of the target to obtain the roughness deviation of each testing area of the target; step 3, when the roughness deviation exceeds a preset threshold, outputting the alarming information for promoting the abnormal surface roughness of the target; otherwise, outputting the information for promoting the normal surface roughness of the target. The invention is favorable for decreasing the rate of defective product caused by the abnormal surface roughness of the target and enhancing the in-time property and efficiency of the monitoring of the surface roughness of the magnetic control spattering target.

Owner:BOE TECH GRP CO LTD +1

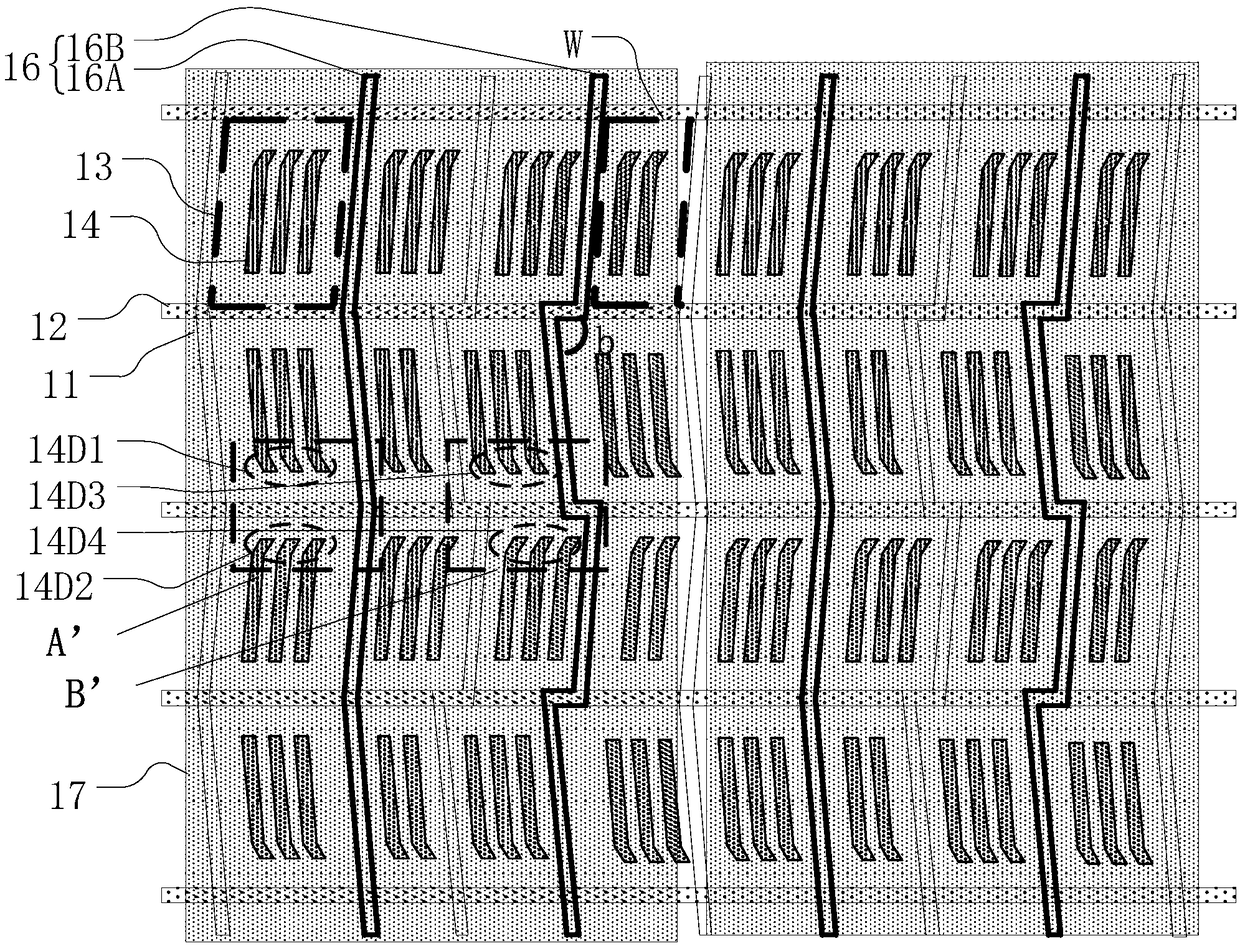

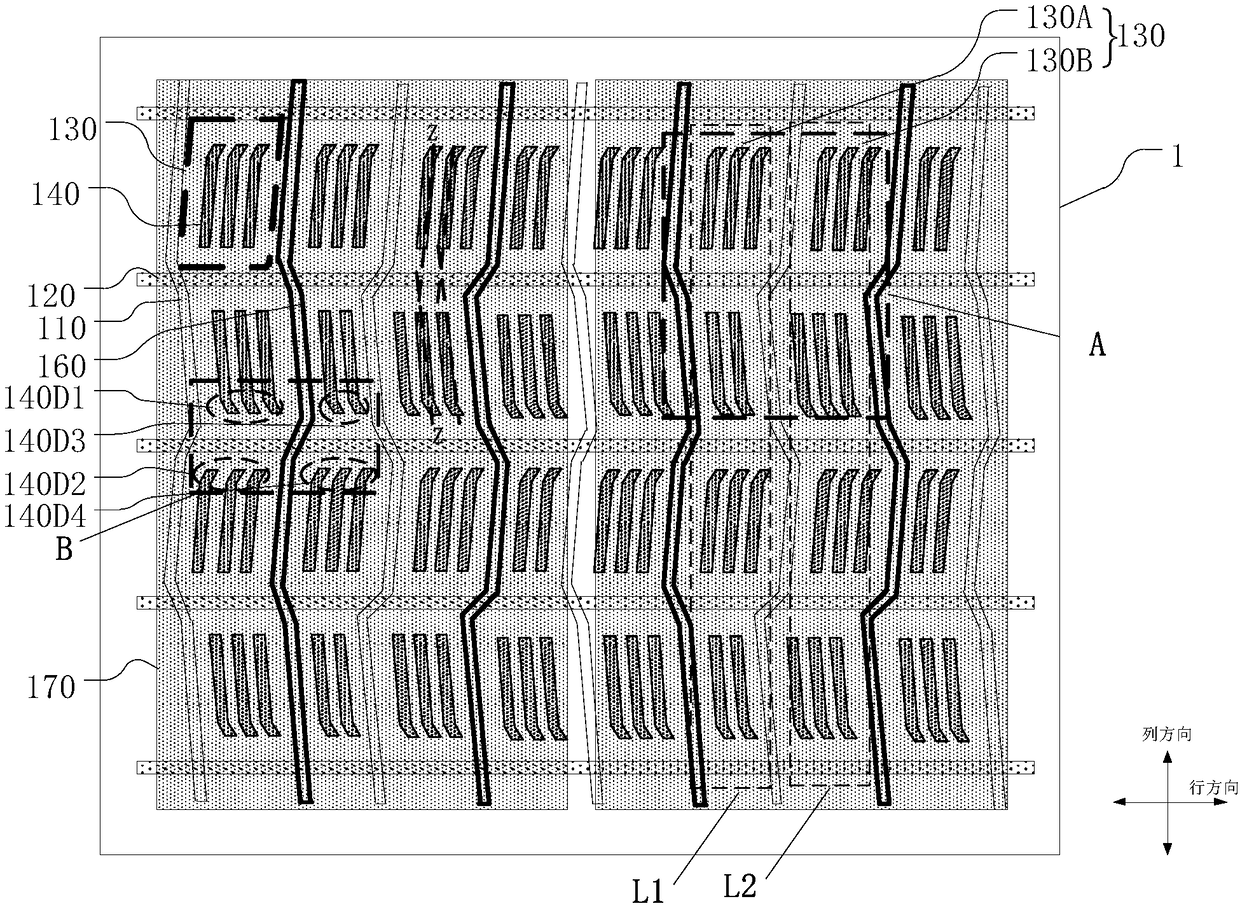

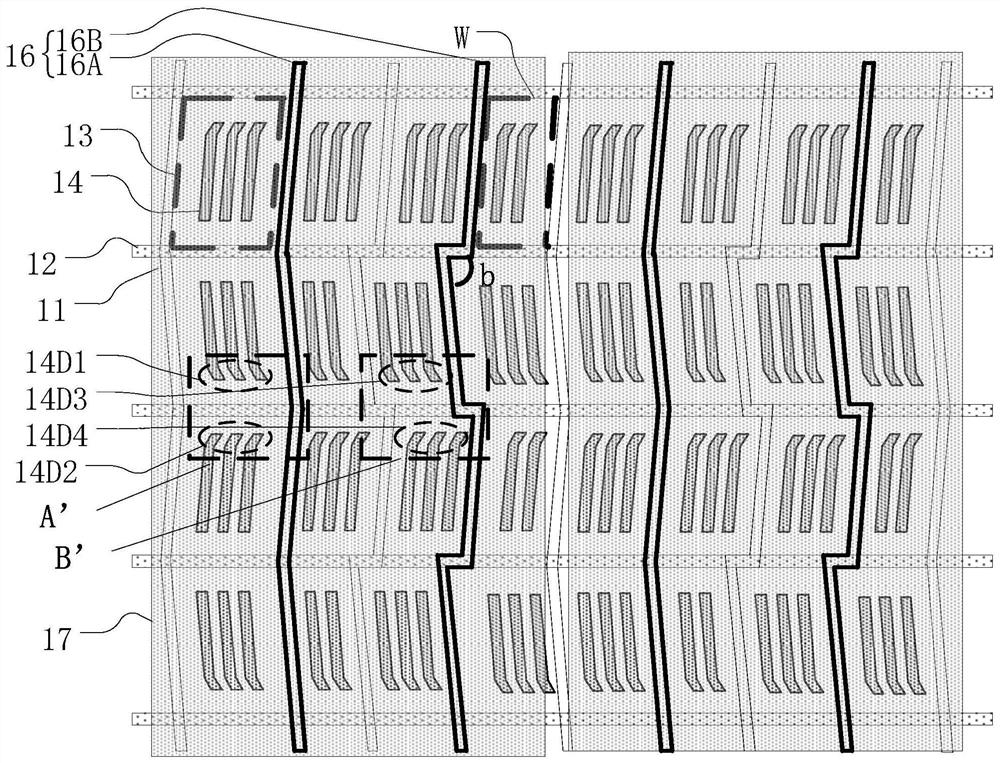

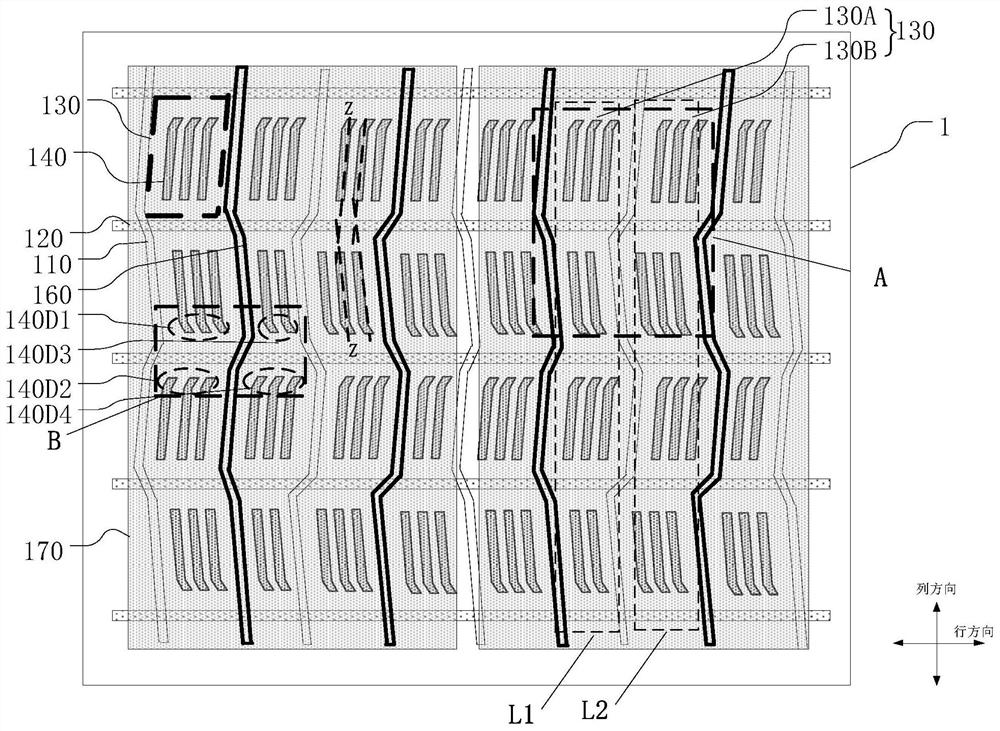

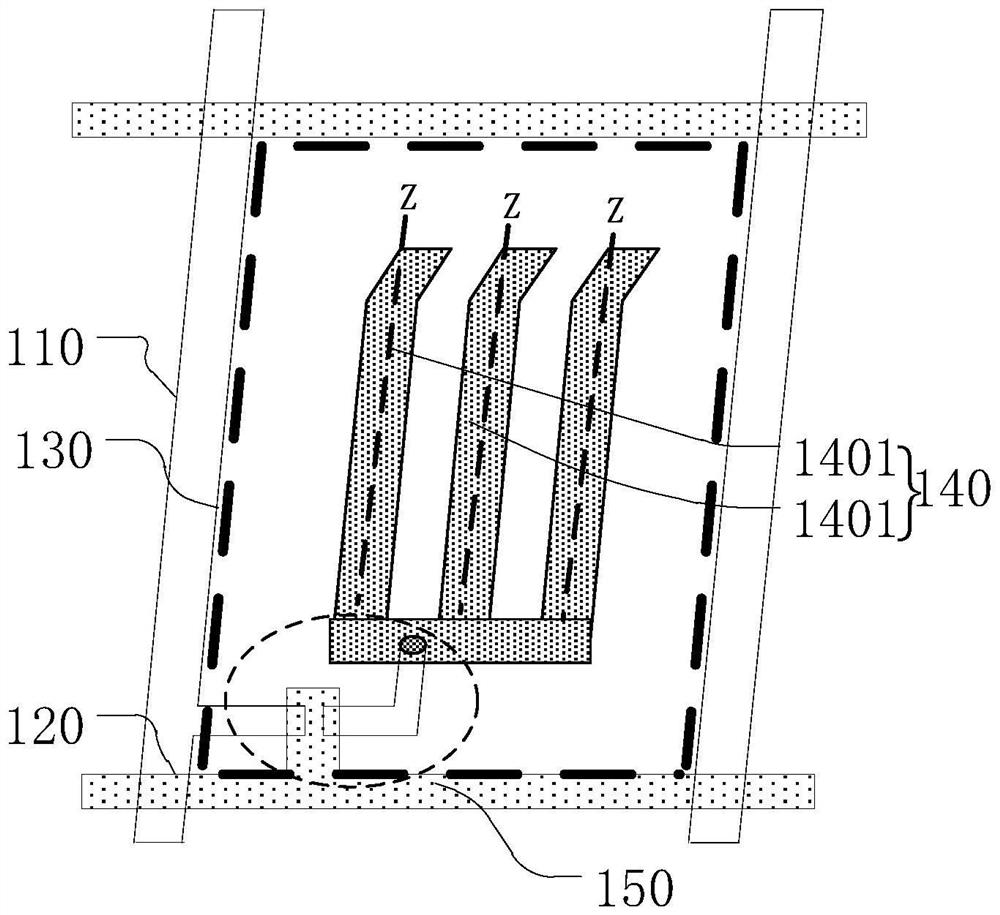

Array substrate and display device

ActiveCN108254987AAvoid severe inhomogeneity of corner amplitudeReduce interferenceNon-linear opticsInput/output processes for data processingLong axisDisplay device

An embodiment of the invention discloses an array substrate and a display device. The array substrate comprises a substrate body, and multiple scanning lines and multiple data lines are arranged on the substrate body to form multiple subpixels in intersection; pixel electrodes arranged in the subpixels include multiple stripline electrodes, long axes of the stripline electrodes in the same row ofthe subpixels are parallelly mutually, and the long axes of the stripline axles in any two rows of the subpixels extend in intersection; each touch electrode is electrically connected with at least one touch signal line, each touch signal line comprises multiple straight line parts and multiple folding line parts, the two neighboring straight line parts are connected through the folding line parts, the straight line parts are parallel to the long axles of the stripline electrodes located in the same raw of the subpixels, extending lines of the folding line parts interact the long axes of the stripline electrodes, and orthographic projection of the folding line parts on the substrate body overlap with that of the scanning lines on the substrate while the folding line parts are not perpendicular to the scanning lines. By the arrangement, the problem that display effect is affected by uneven pressure.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

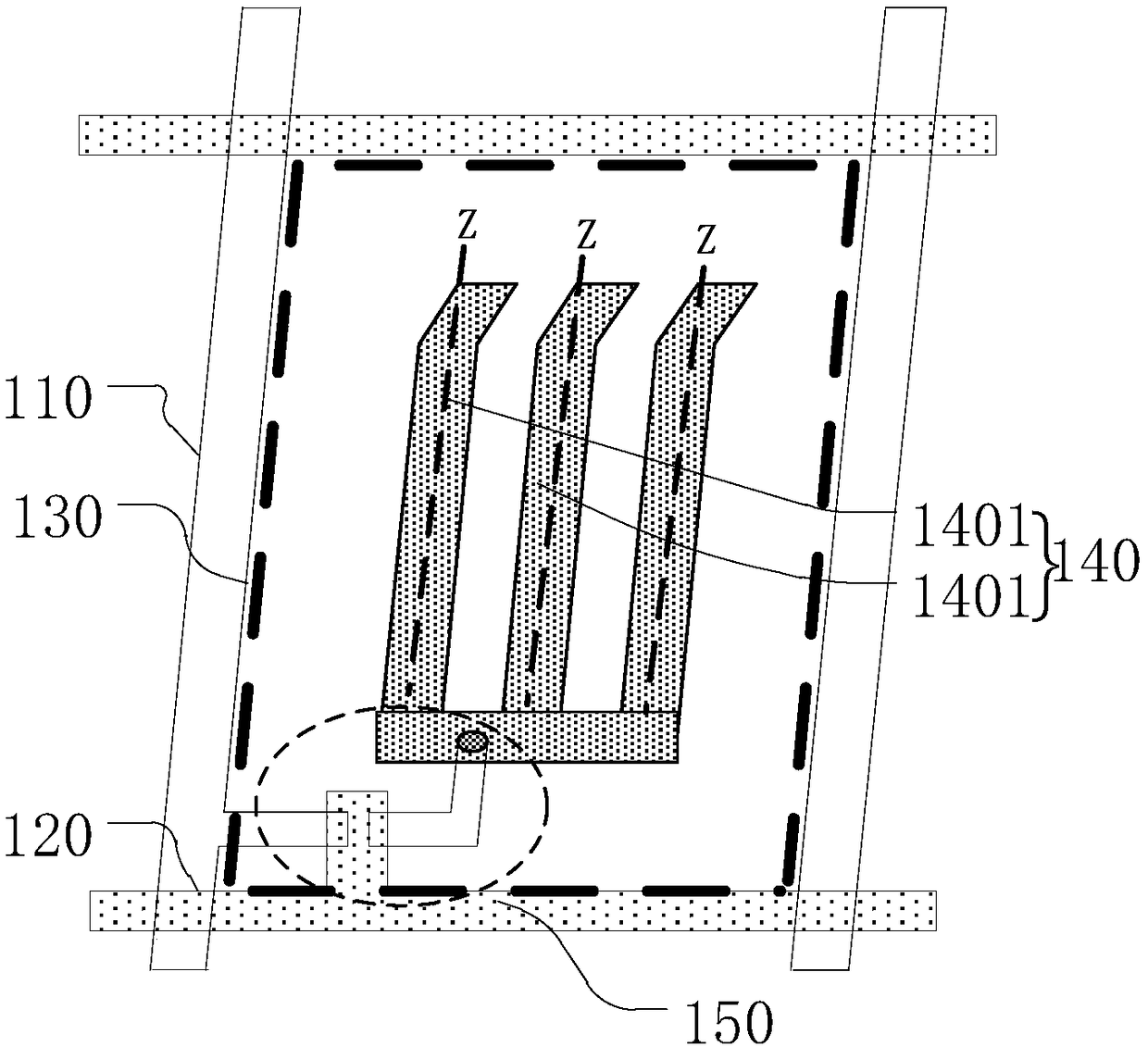

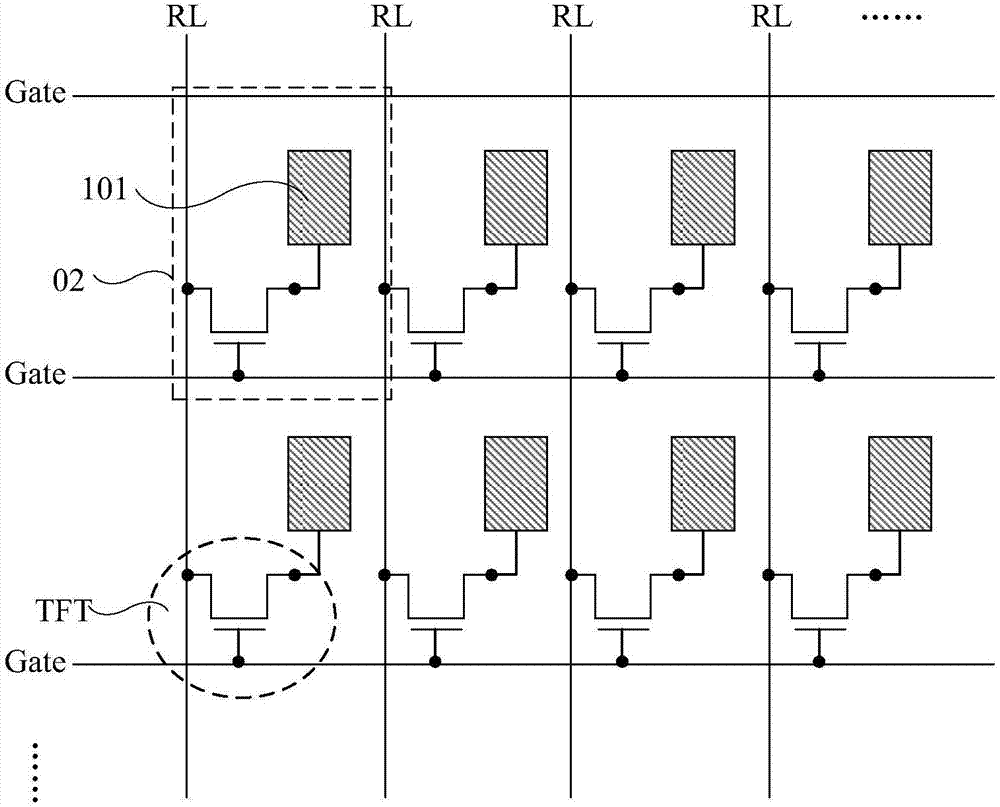

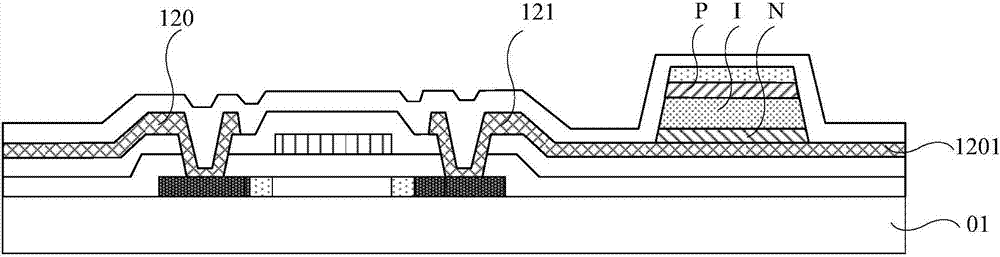

Array substrate, manufacturing method of array substrate, flat panel detector and imaging device

ActiveCN107104108AUniform electrical propertiesReduce the chance of badTransistorSolid-state devicesCorrosion resistantEngineering

The invention provides an array substrate, a manufacturing method of the array substrate, a flat panel detector and an imaging device, and relates to the field of photoelectric technology. The influence of manufacturing process of a photoelectric converter on the TFT performance can be reduced. The array substrate comprises a substrate, a plurality of low-temperature polycrystalline silicon TFT arranged on the substrate in an array, and a photoelectric converter connected with source electrodes or drain electrodes of the TFT, wherein the source electrode or the drain electrode of each TFT comprises a first conducting layer close to one side of the photoelectric converter, and the material constituting the first conducting layer is corrosion resistant in a composition process of the photoelectric converter. The array substrate is used for preparing the flat panel detector.

Owner:BOE TECH GRP CO LTD +1

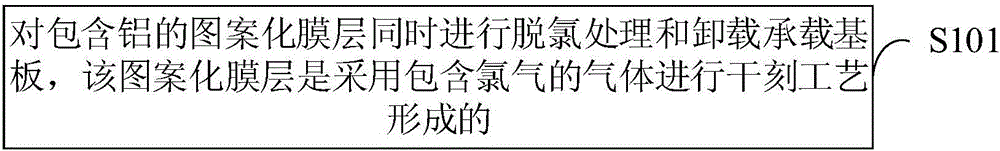

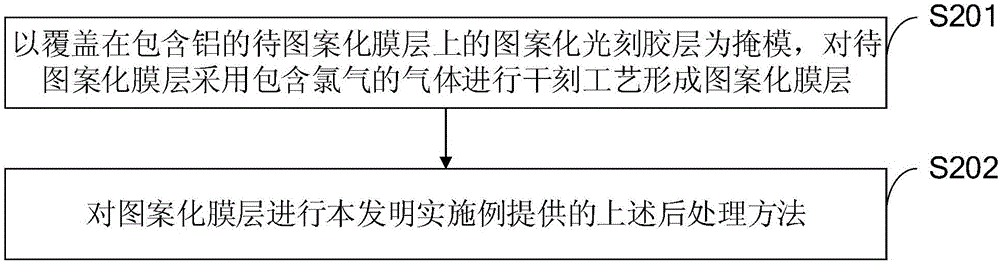

Aluminum-containing film layer pattern, manufacturing method and post processing method therefor

InactiveCN106206290AAvoid damageReduce usageSemiconductor/solid-state device manufacturingPhotoresistDry etching

The invention discloses an aluminum-containing film layer pattern, a manufacturing method and a post processing method therefor. A patterned photoresist layer which covers a to-be-patterned aluminum-containing film layer is used as a mask, and the to-be-patterned film layer is subjected to a dry-etching process through chlorine-including gas; and then the formed patterned aluminum-containing film layer is subjected to dechlorination treatment and uninstalling of a bearing substrate at the same time. Due to that the dechlorination treatment and the uninstalling of the bearing substrate are carried out at the same time, the intermediate equipment waiting time is omitted, so that the processing duration of the overall post processing process is shortened, and the productivity can be improved; in addition, the dosage of the gas in the dechlorination treatment and the uninstalling of the bearing substrate can be reduced, so that the cost can be lowered; moreover, due to that the dosage of the gas in the dechlorination treatment and the uninstalling of the bearing substrate is reduced, the damage to the patterned photoresist layer can be lowered, suspension particles generated by attachment in equipment cavities are reduced, the probability of adverse residue generation in the subsequent substrate dry-etching process is lowered, and the daily maintenance period of the equipment is prolonged consequently.

Owner:BOE TECH GRP CO LTD +1

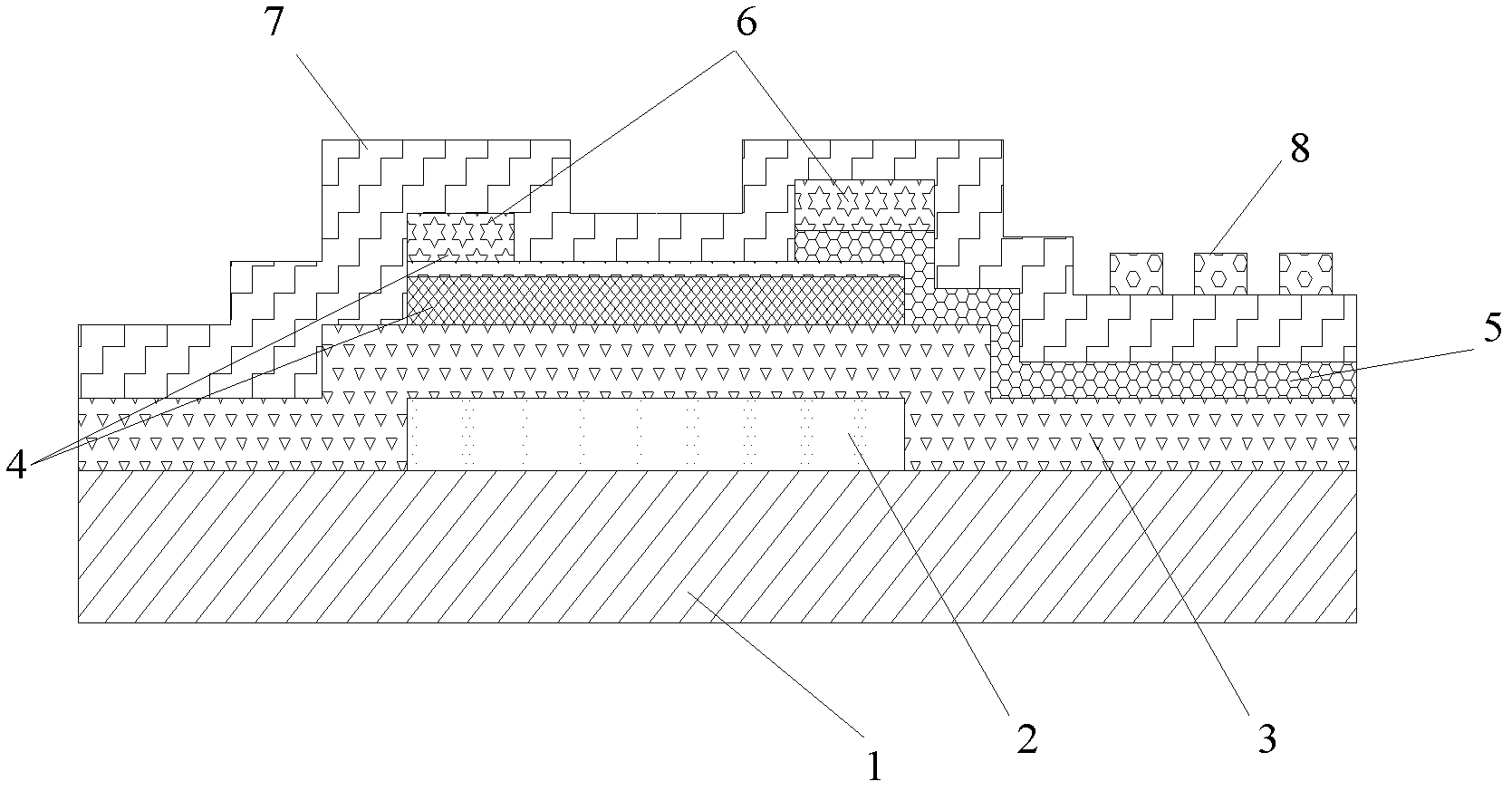

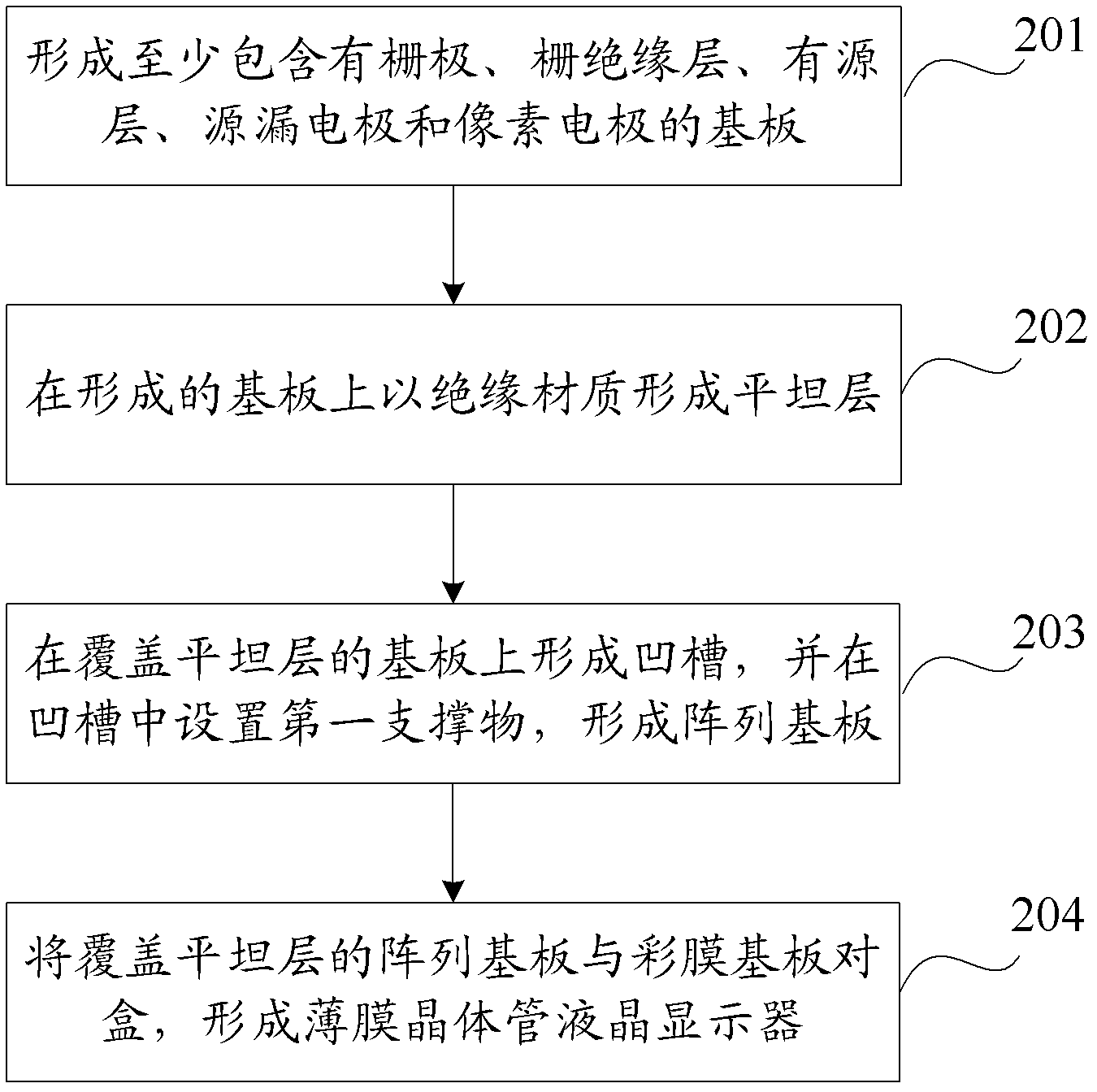

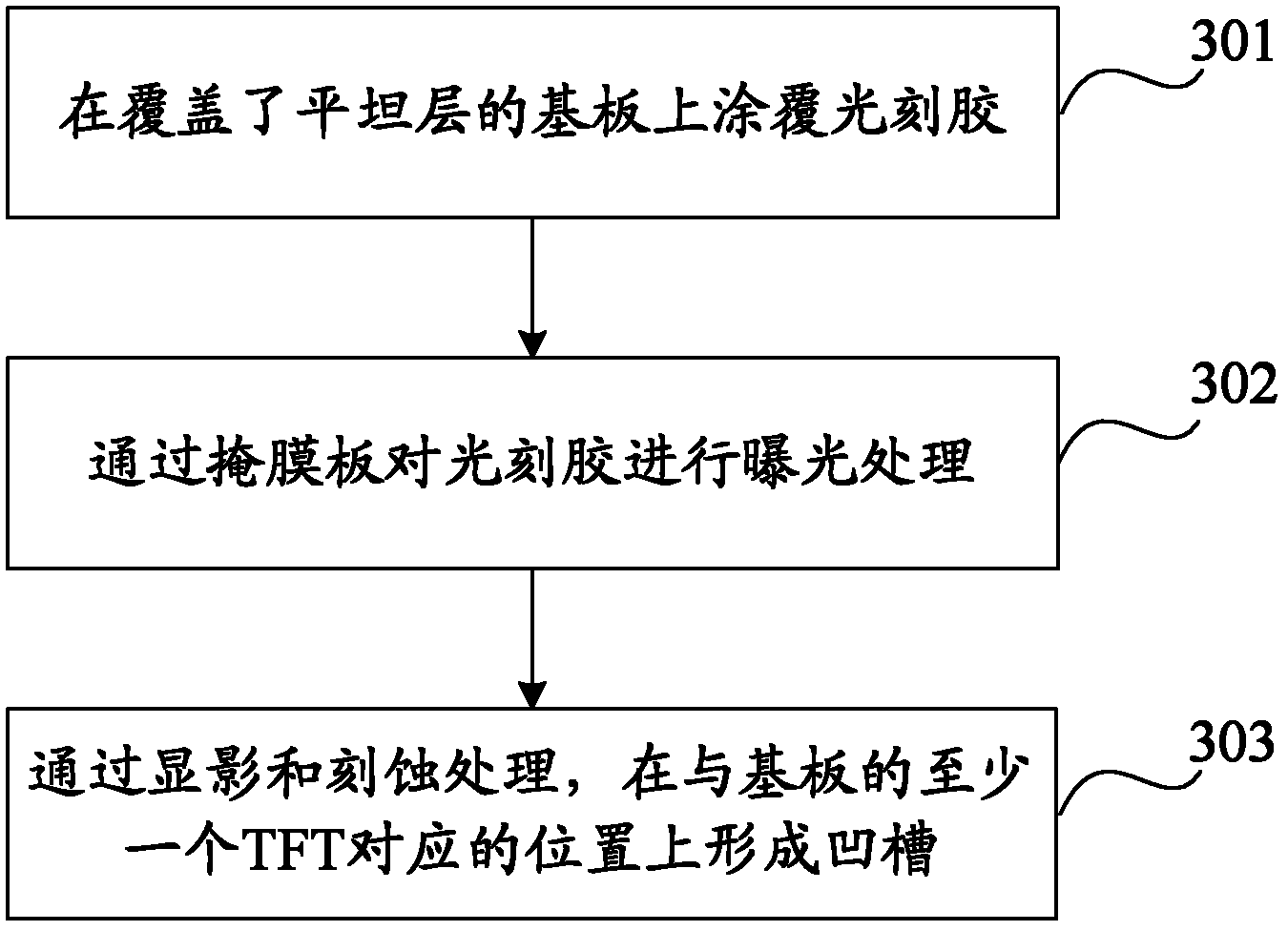

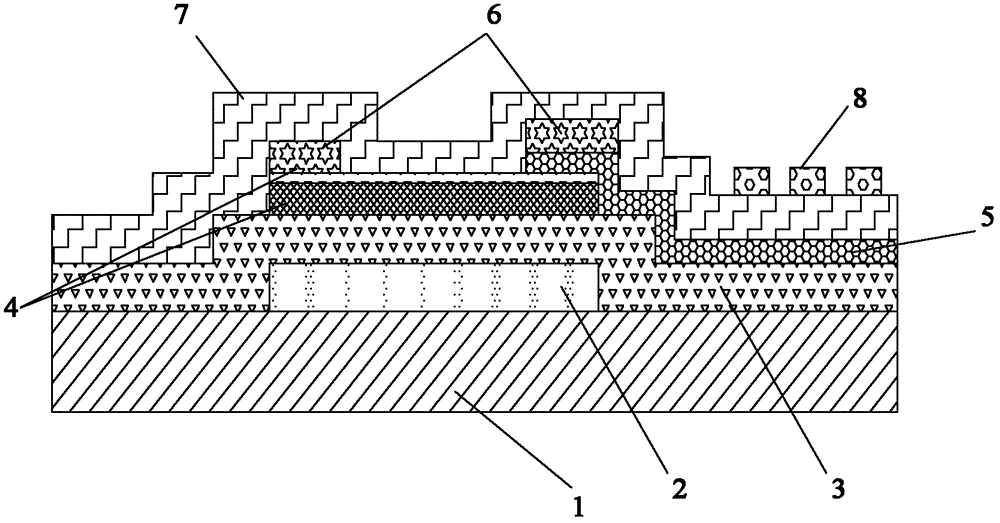

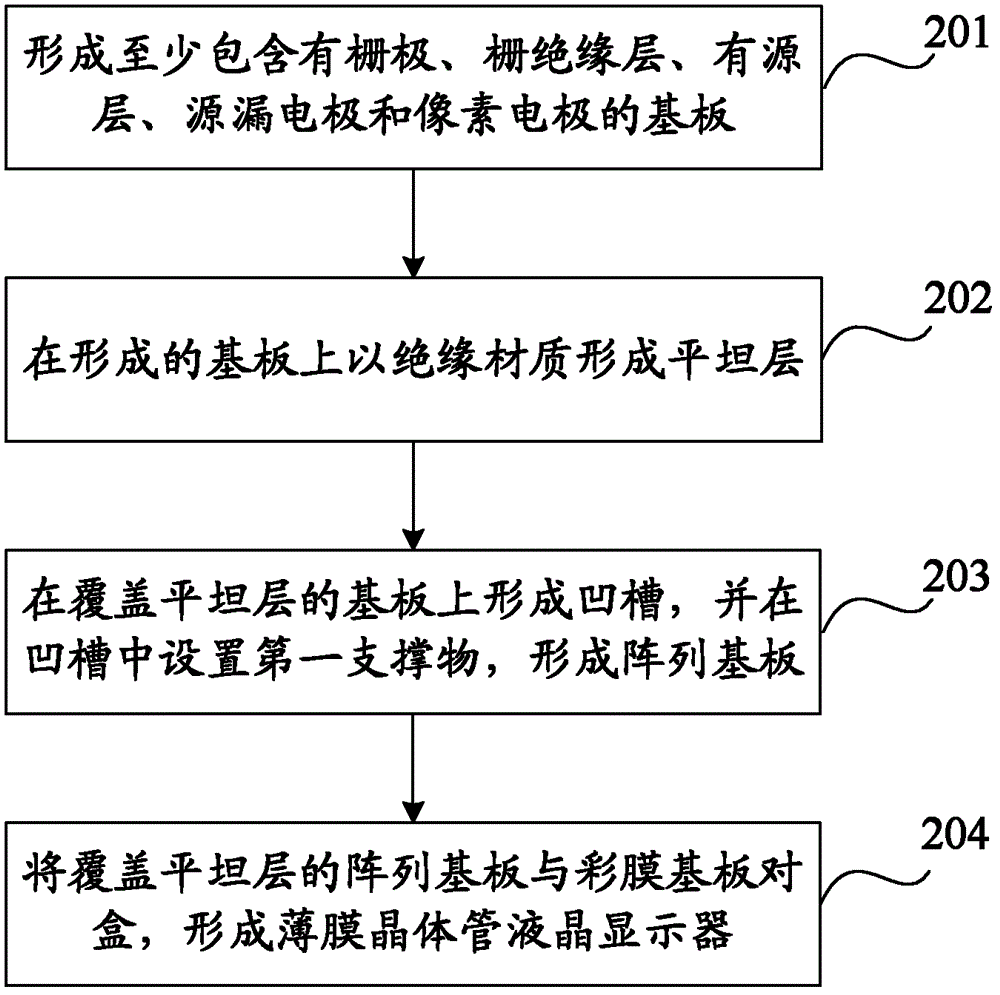

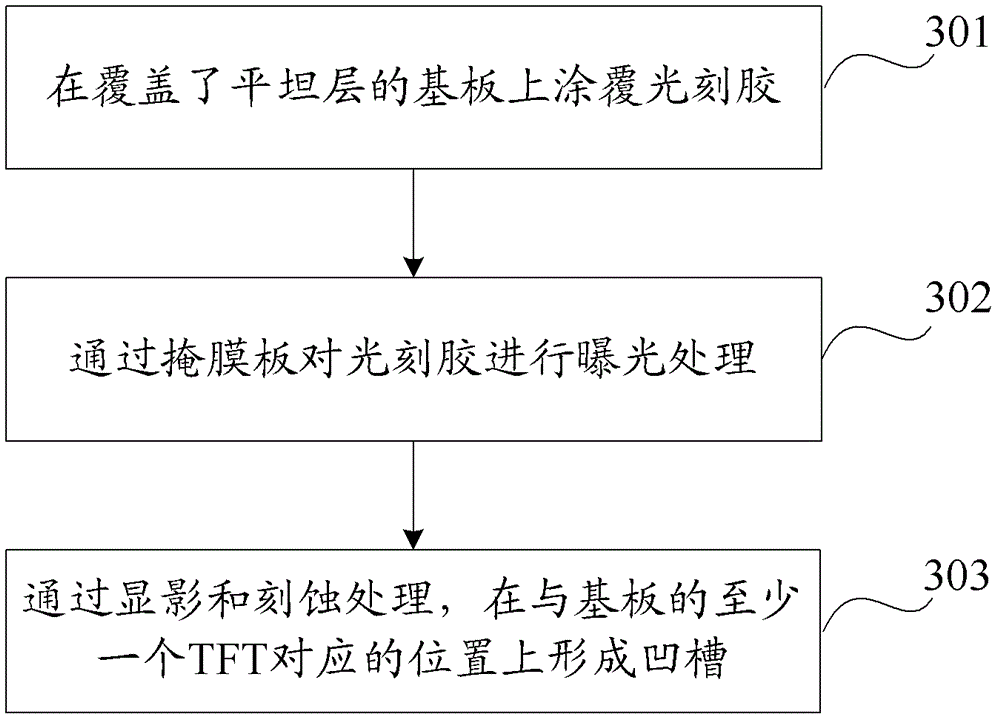

Manufacturing method of array substrate, array substrate and liquid crystal display

ActiveCN102629583AReduce movementReduce the chance of movingSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerLiquid-crystal display

The invention discloses a manufacturing method of an array substrate, an array substrate and a liquid crystal display, thereby improving a picture quality of a thin film transistor liquid crystal display (TFT-LCD). The method comprises the following steps: forming a substrate at least containing a gate electrode, a gate insulation layer, an active layer, s source electrode, a drain electrode and a pixel electrode; forming a flat layer on the substrate; forming a groove on the flat layer; and arranging a first support in the groove.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

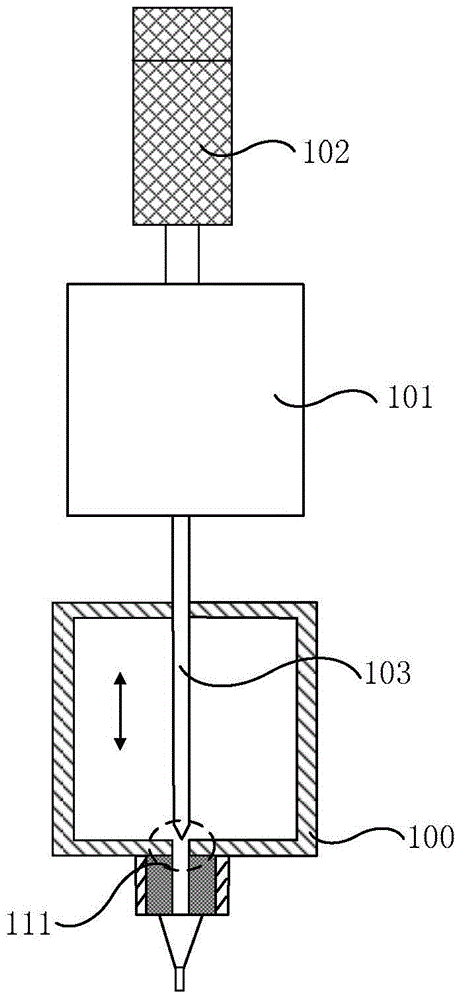

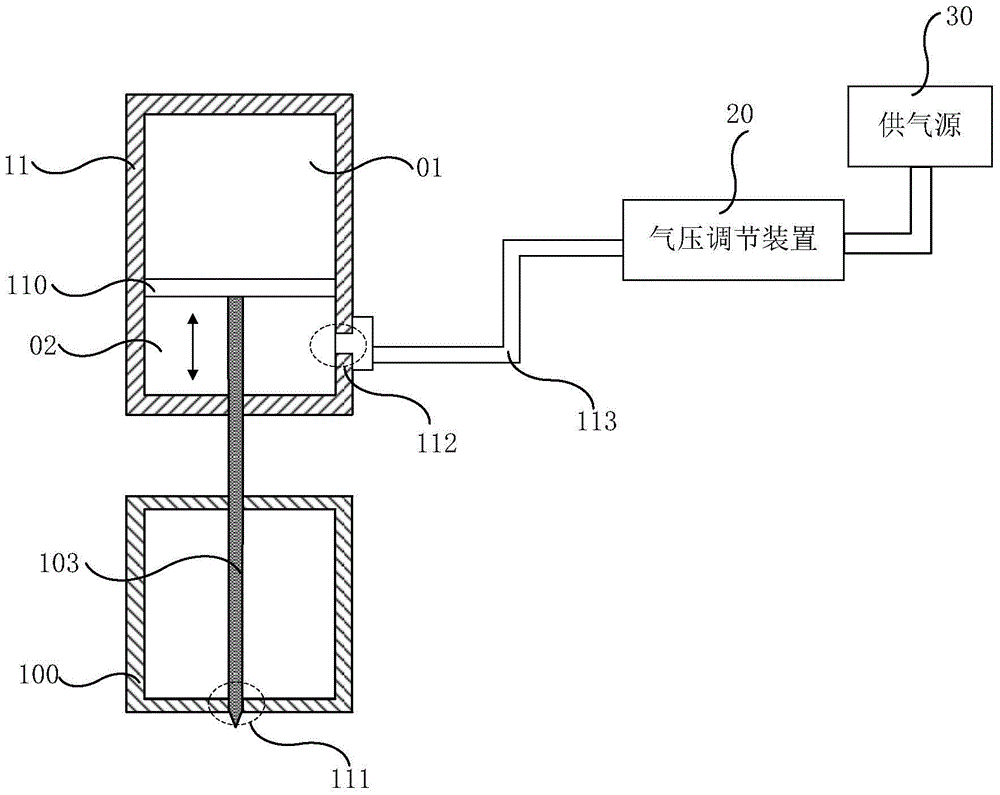

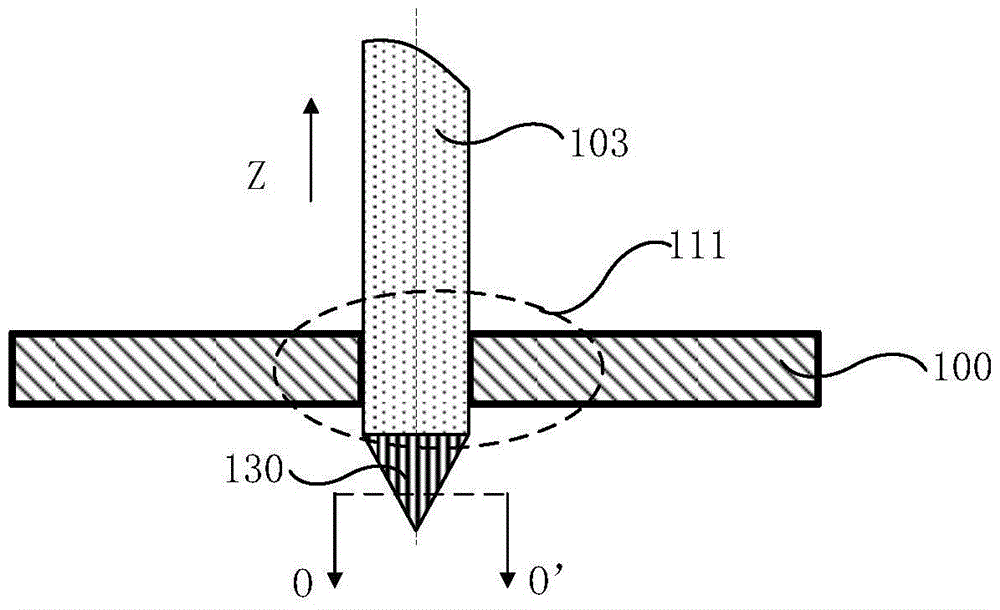

Material coating equipment and control method thereof

InactiveCN105710003AReduce the chance of badHigh control precisionLiquid surface applicatorsCoatingsDisplay deviceProviding material

The embodiment of the invention provides material coating equipment and a control method thereof, relates to the field of preparation of display devices, and can improve the control precision of silica gel coating flow. The material coating equipment comprises a storage cavity, an air pressure cavity, a flow adjusting rod, an air pressure adjusting device and an air supply source. The flow adjusting rod penetrates through the storage cavity, and is provided with an adjusting head at one end near a discharge port of the storage cavity; and one end, deviated from the discharge port, of the flow adjusting rod is connected with a piston in the air pressure cavity. An output end of the air pressure adjusting device is connected with the air pressure cavity, and an input end of the air pressure adjusting device is connected with the air supply source for receiving a preset material flow of the discharge port to convert the preset material flow into a preset air pressure value, matched with the preset material flow, of the air pressure cavity and controlling the flow of gas output to the air pressure cavity by the air supply source according the preset air pressure value. The material coating equipment is used for coating materials.

Owner:BOE TECH GRP CO LTD +1

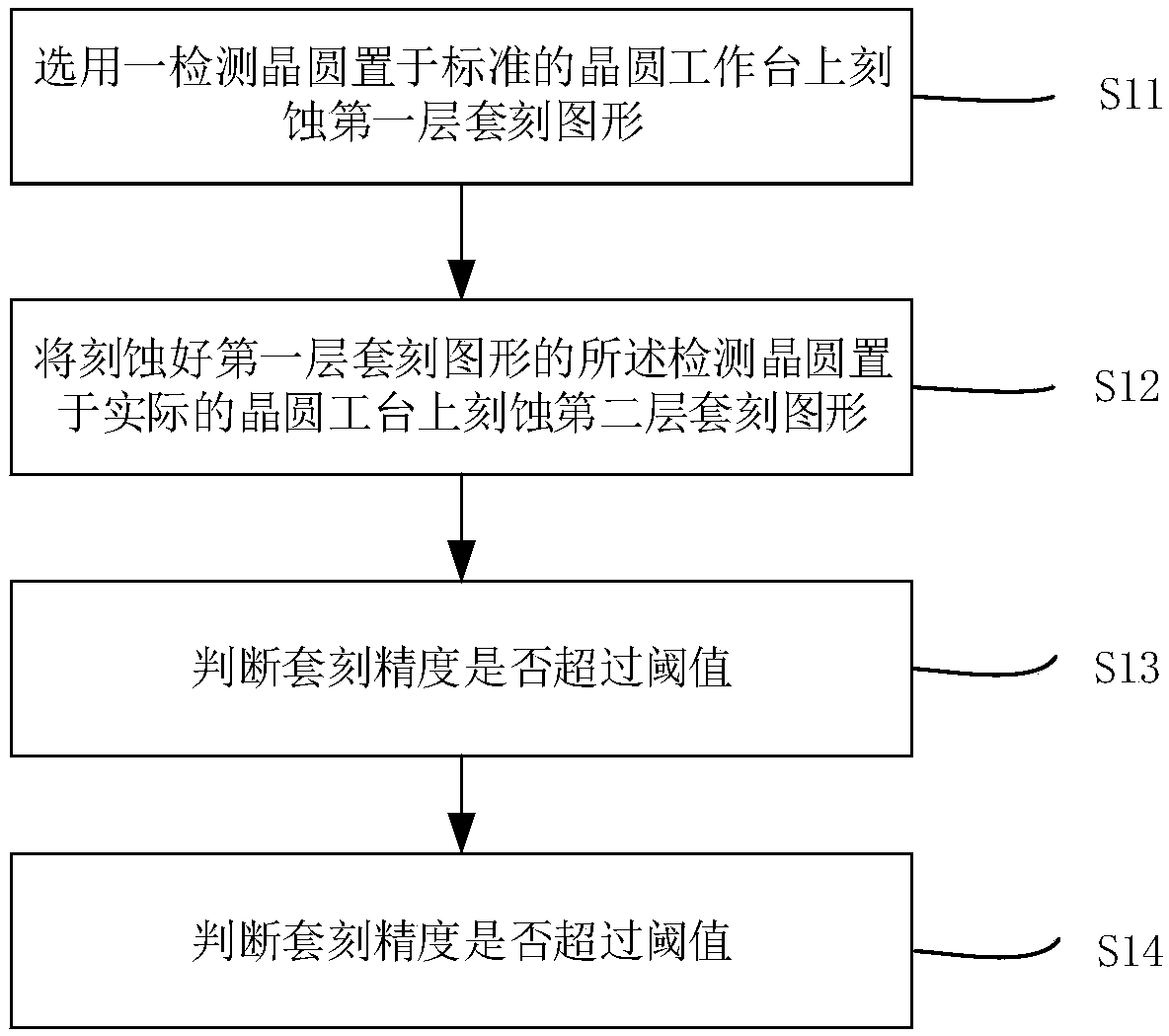

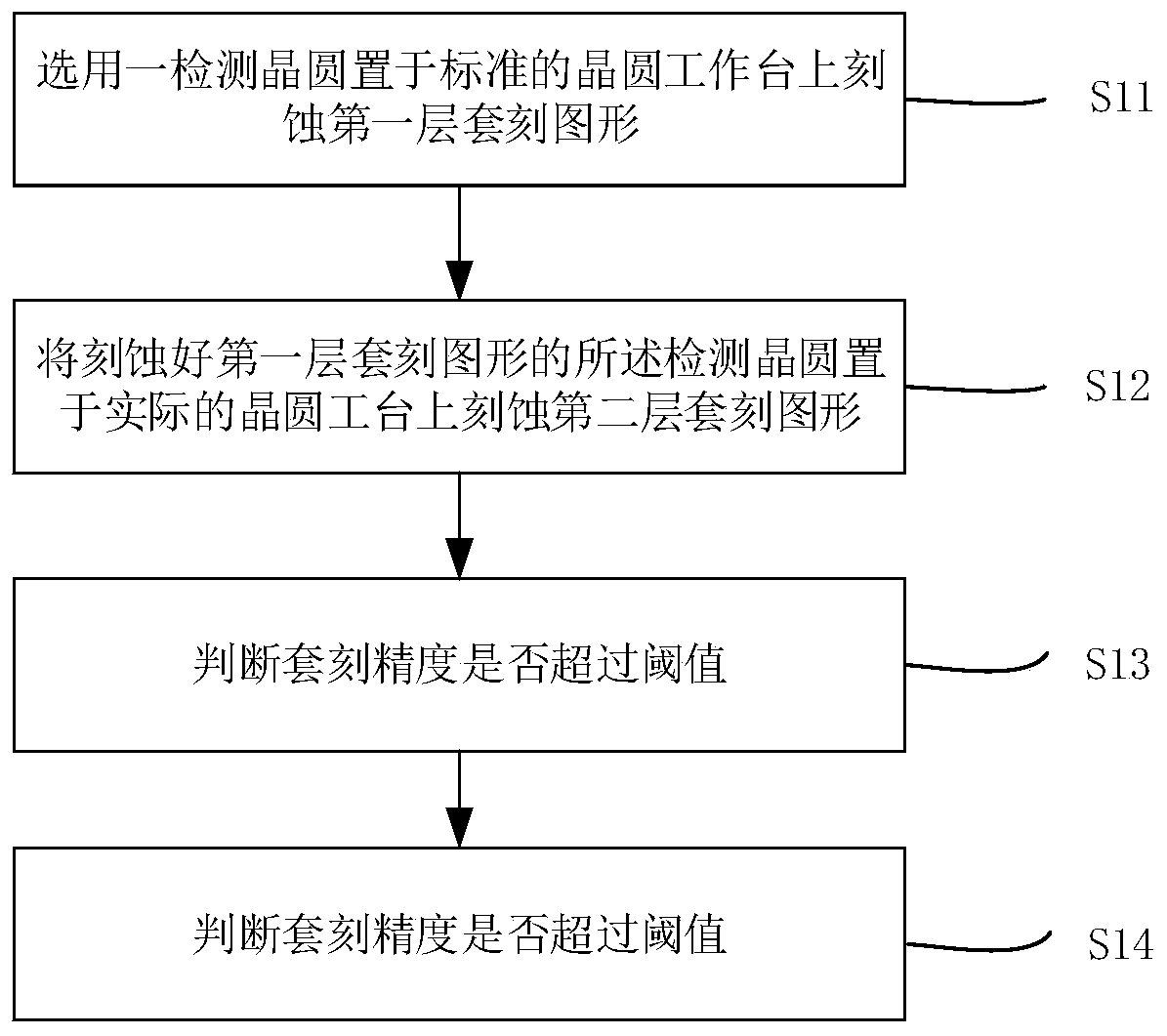

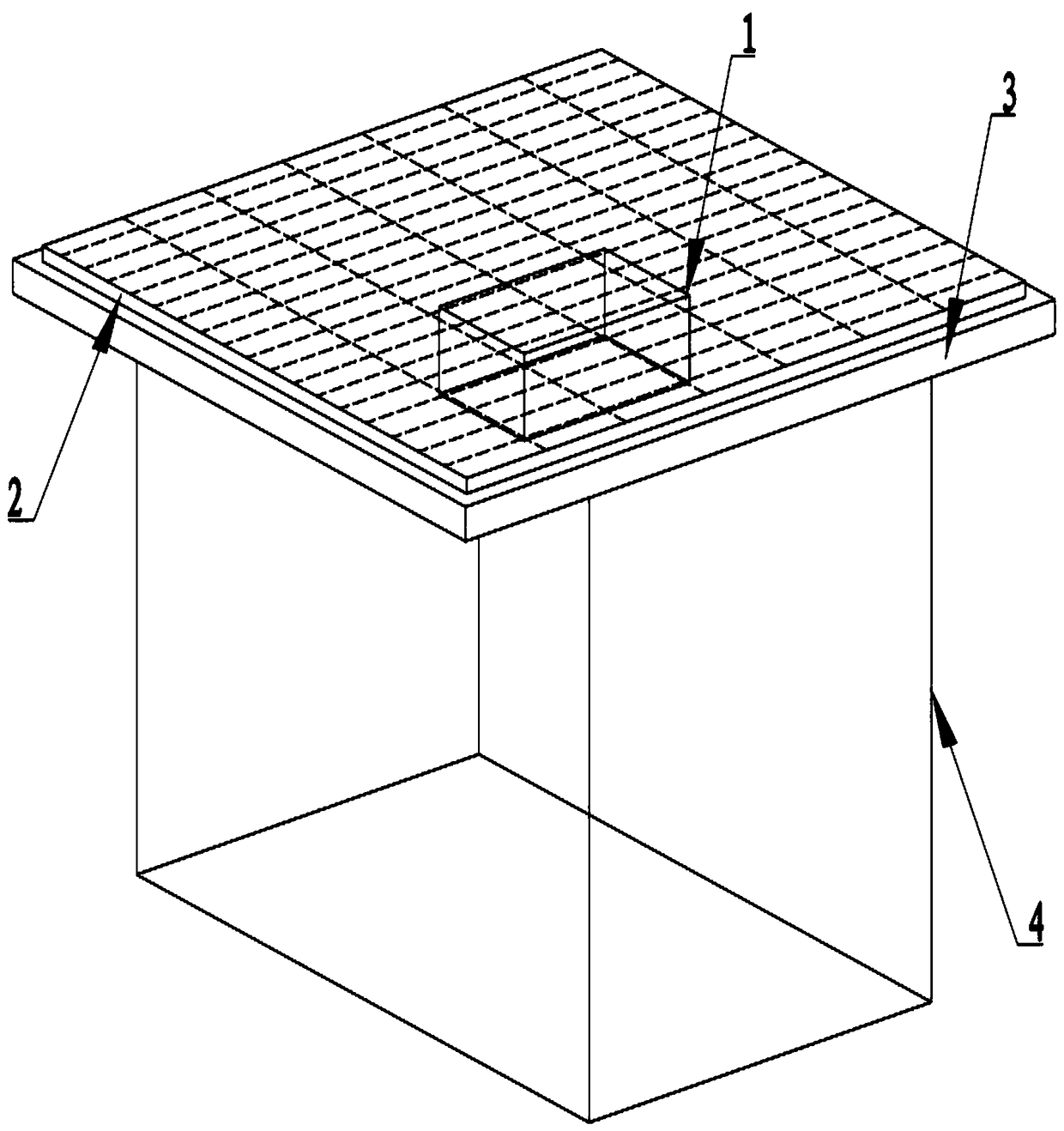

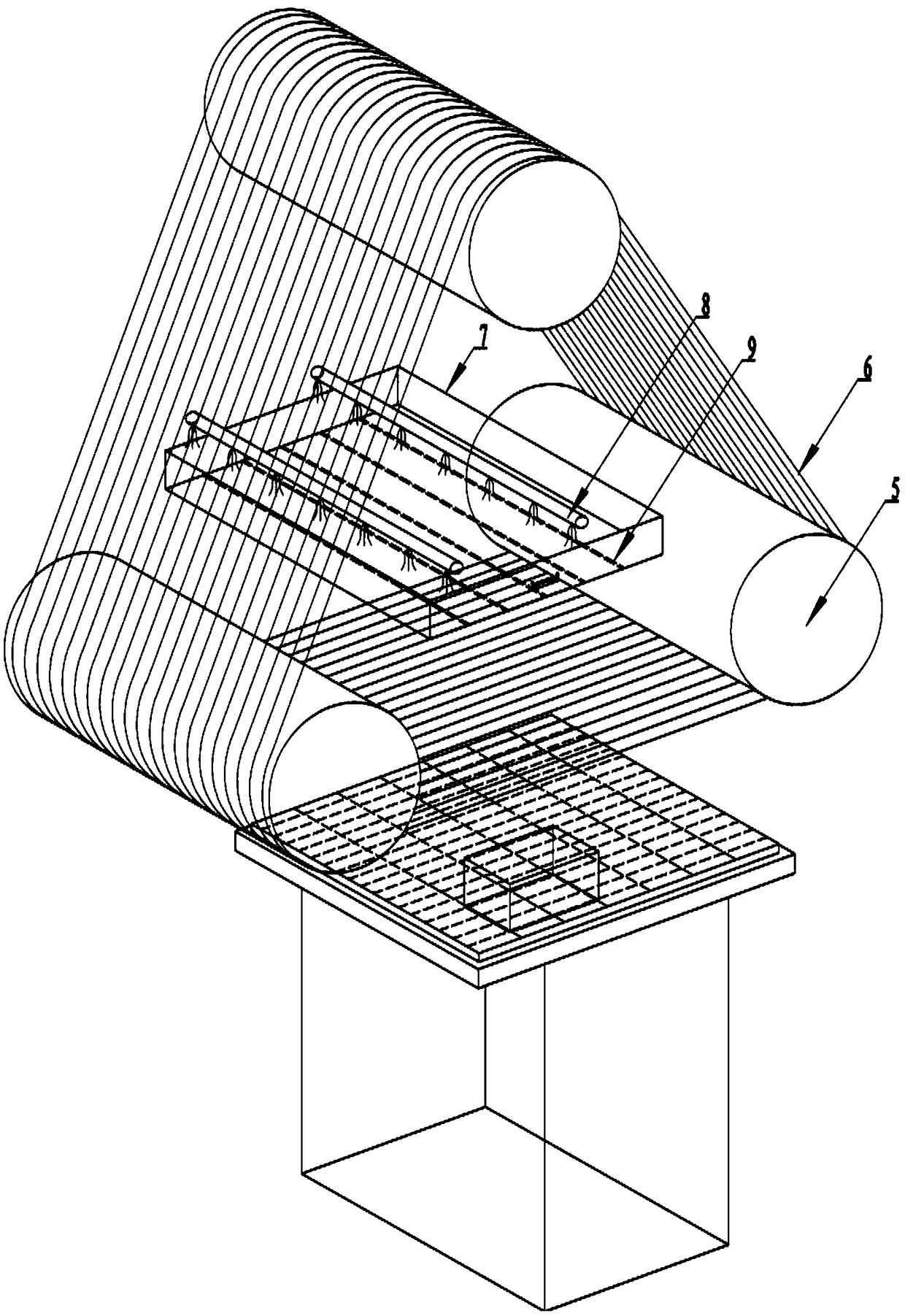

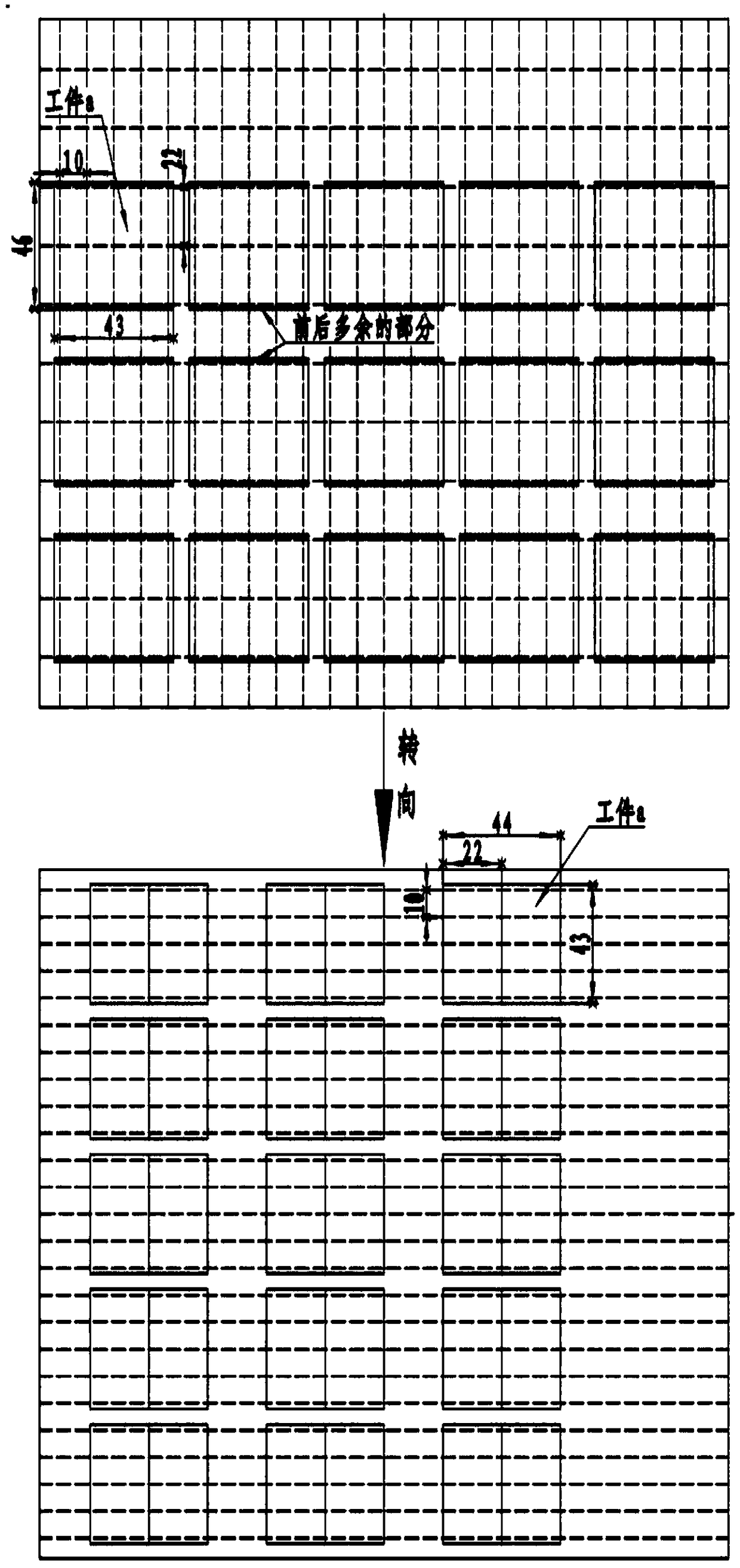

Method for detecting flatness of wafer table

ActiveCN108766901AReduce the chance of badMeasurement devicesSemiconductor/solid-state device testing/measurementGraphicsComputer science

The invention provides a method for detecting the flatness of a wafer table. The method comprises the steps of putting a selected detection wafer on a standard wafer table and etching a first layer ofnesting graphics; putting the detection wafer etched with the first layer of nesting graphics on an actual wafer table and etching a second layer of nesting graphics; calculating the nesting accuracyof the second layer of nesting graphics relative to the first layer of nesting graphics; and comparing the calculated nesting accuracy with a threshold, and if the nesting accuracy exceeds the threshold, judging that the flatness of the wafer table does not reach a standard value. According to the method for detecting the flatness of the wafer table provided by the invention, the value of the nesting accuracy is calculated and recorded through measuring the nesting accuracy of the wafer, and whether the wafer table needs to be cleaned or not is judged through judging whether the nesting accuracy exceeds the threshold or not. According to the method, the flatness of the wafer table can be detected, so that the probability of a bad wafer caused by the flatness is finally reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

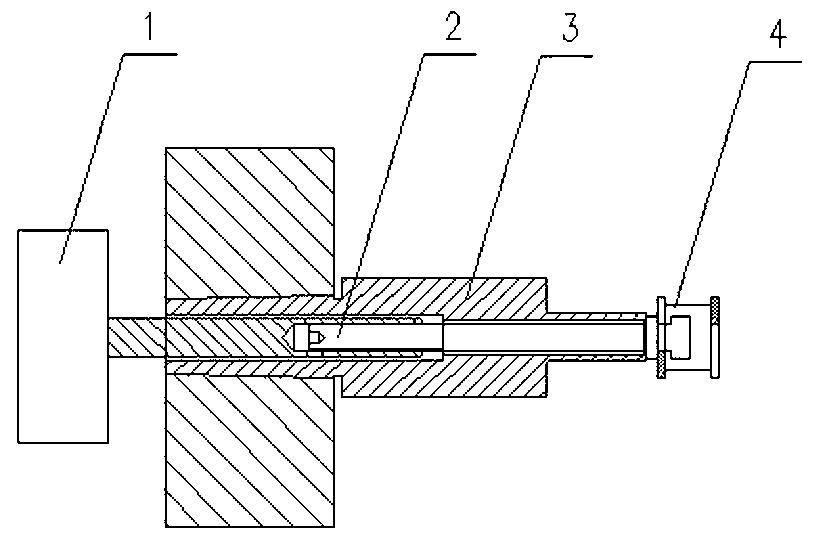

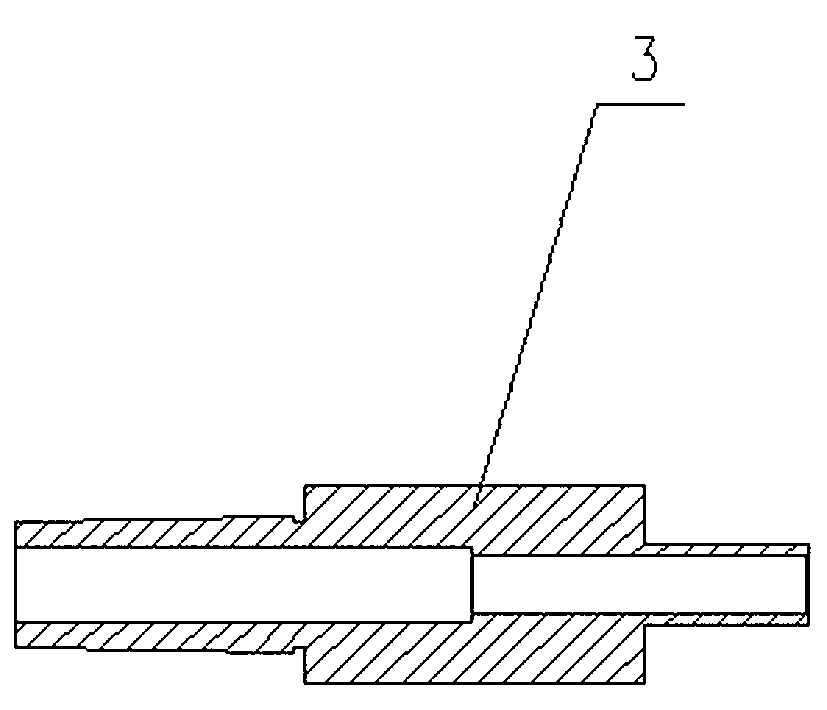

Fixture for machining outer circle of commutator

InactiveCN103341771AReduce the number of repeated targetingReduce machining errorsPositioning apparatusMetal-working holdersCommutatorEngineering

The invention discloses a fixture for machining an outer circle of a commutator. The fixture for machining the outer circle of the commutator is characterized by comprising an air cylinder (1), a pull rod (2), a positioning mandrel and a positioning block (4), wherein the pull rod (2) is connected with the air cylinder, the pull rod is arranged in the positioning mandrel, the tail portion of the pull rod (2) is arranged to be of an I-shaped groove structure, and the positioning block (4) is placed in a groove. According to the fixture for machining the outer circle of the commutator, the head portion of the positioning mandrel (3) is arranged in an inner hole of the commutator in a sleeved mode, the positioning block (4) is placed in the I-shaped groove of the pull rod (2), the pull rod (2) tensions the positioning block (4) under the action of tension of the air cylinder (1), and thus positioning of the commutator is carried out. By the adoption of the mode, turning can be directly carried out on the outer circle and the end face of the commutator, and the purpose of one-time forming is achieved. Meanwhile, repeated positioning errors of repeated machining of commutator products are reduced, and machining efficiency of the products can be effectively improved.

Owner:瑞安博宇科技股份有限公司

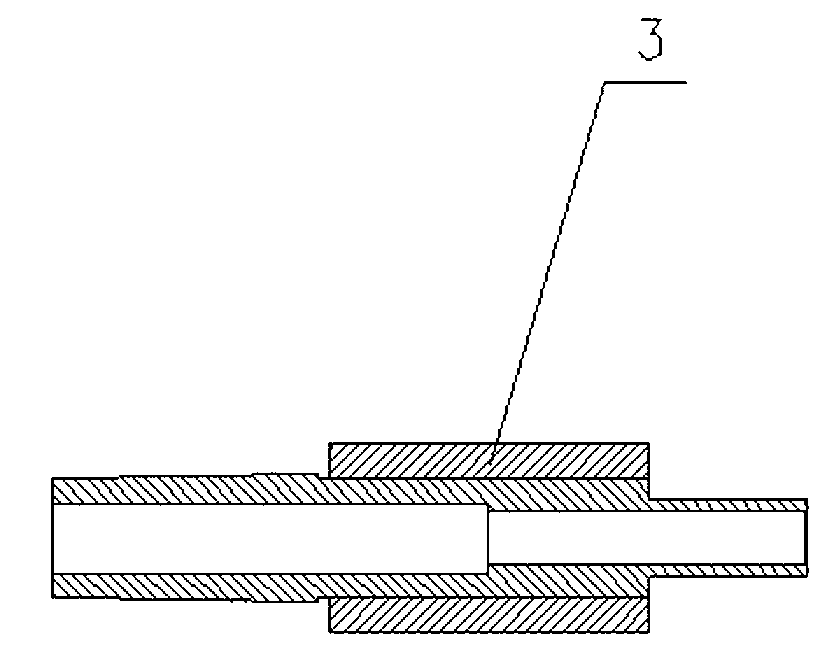

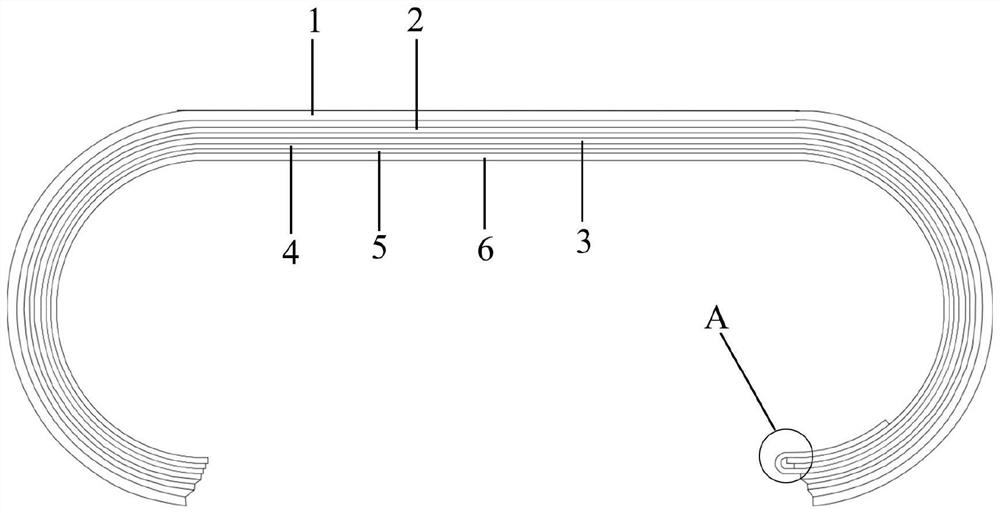

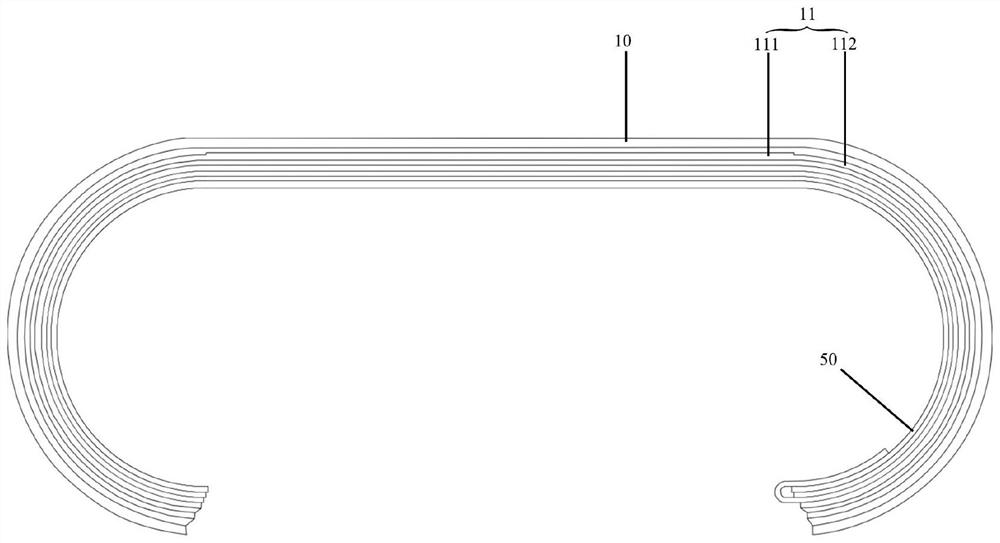

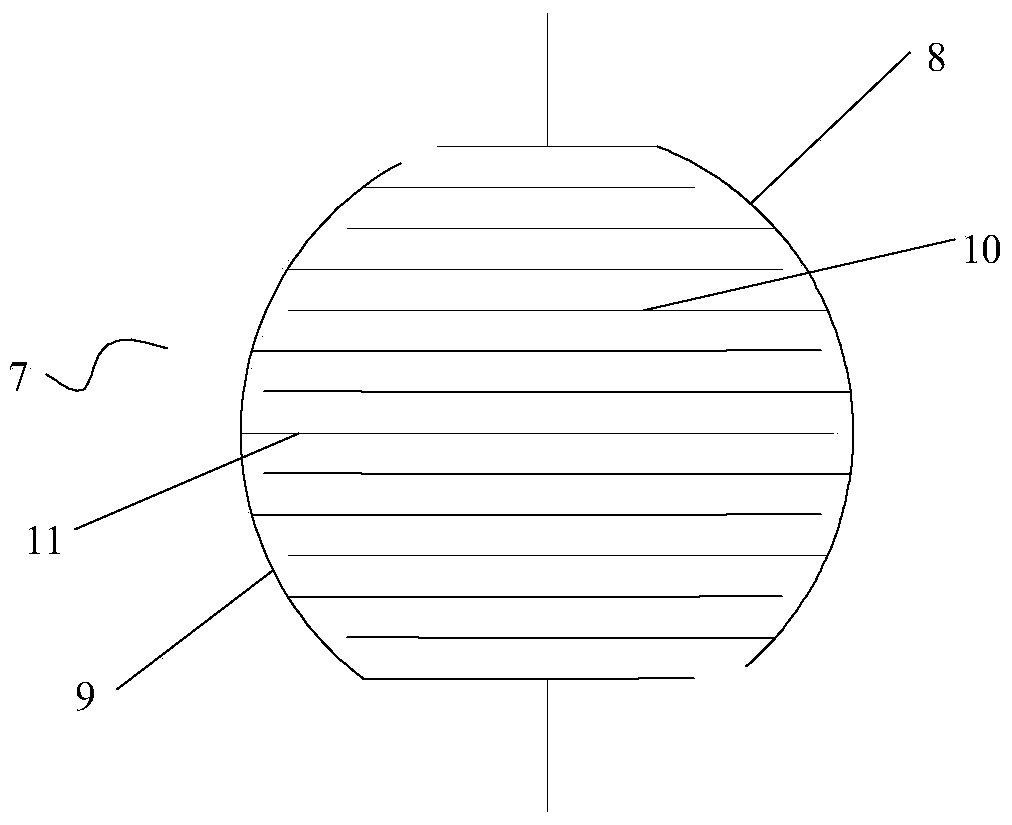

Intrauterine adhesion prevention and treatment device

PendingCN106667556AReduce the chance of badPlay a supporting roleMedical devicesSuction drainage systemsGynecologyUterus

The invention discloses an intrauterine adhesion prevention and treatment device which comprises a uterus-shaped ring and a thin film. The uterus-shaped ring has elasticity, the shape and the size of the uterus-shaped ring adapt to the periphery of the inner wall of the uterus, circular holes are formed in the upper portion and the lower portion of the thin film respectively, the radius of the circular hole formed in the lower portion is small and is located in the center line position; the radius of the circular hole formed in the upper portion is large and is located at the left of the center line. According to the intrauterine adhesion prevention and treatment device, the intrauterine adhesion can be effectively prevented and treated; meanwhile, by means of asymmetrical circular hole design, the uterus-shaped ring placing mode is changed, placement of the uterus-shaped ring is easier and more convenient, and the requirement for the cervical relaxation degree is lowered. In addition, raw materials are saved to a certain extent, and the device is assisted in lowering the cost and the treatment cost of a patient.

Owner:徐大宝

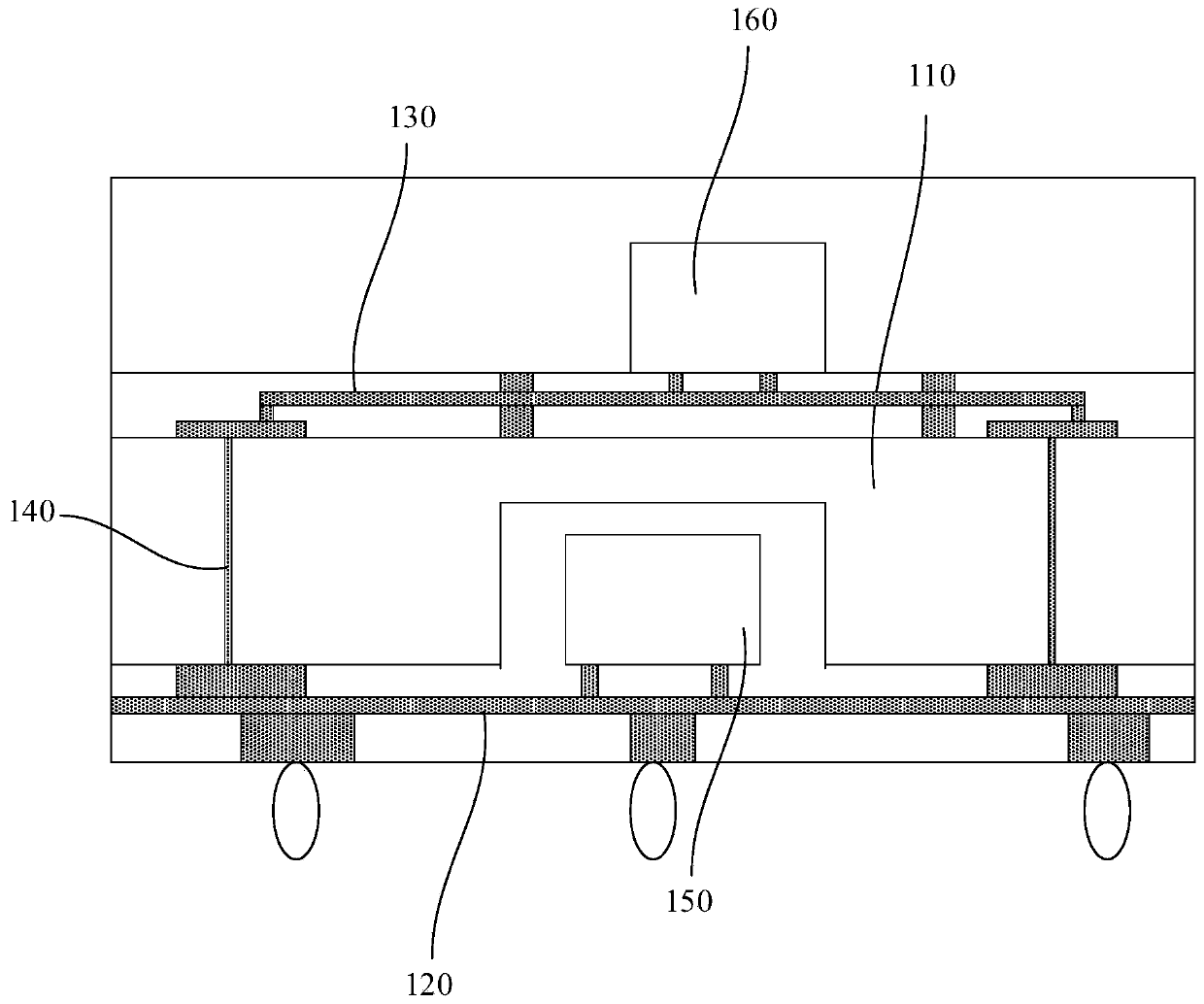

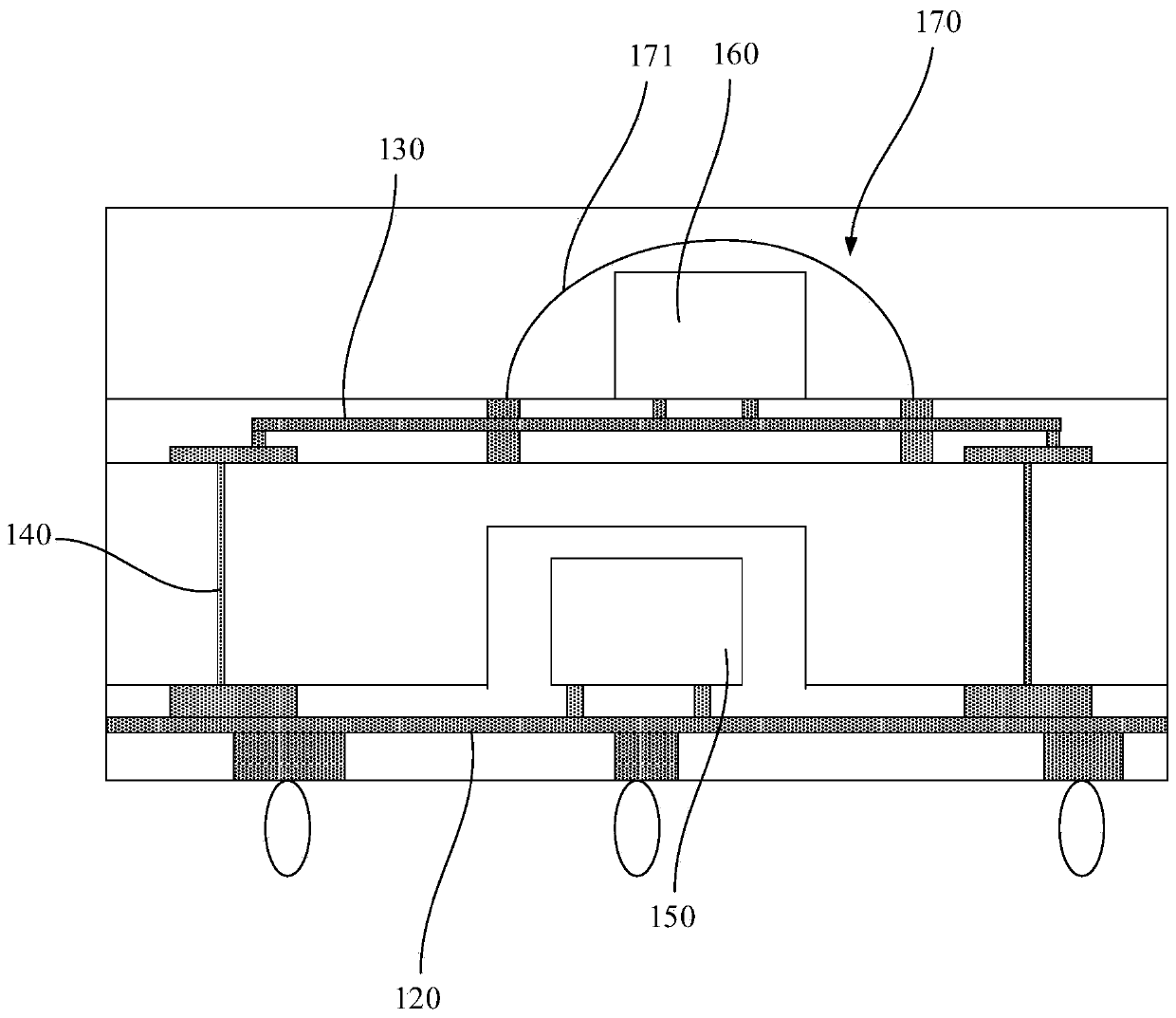

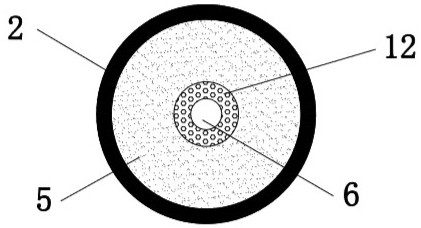

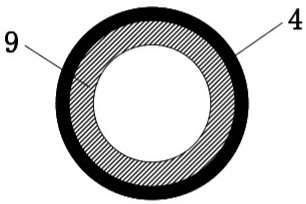

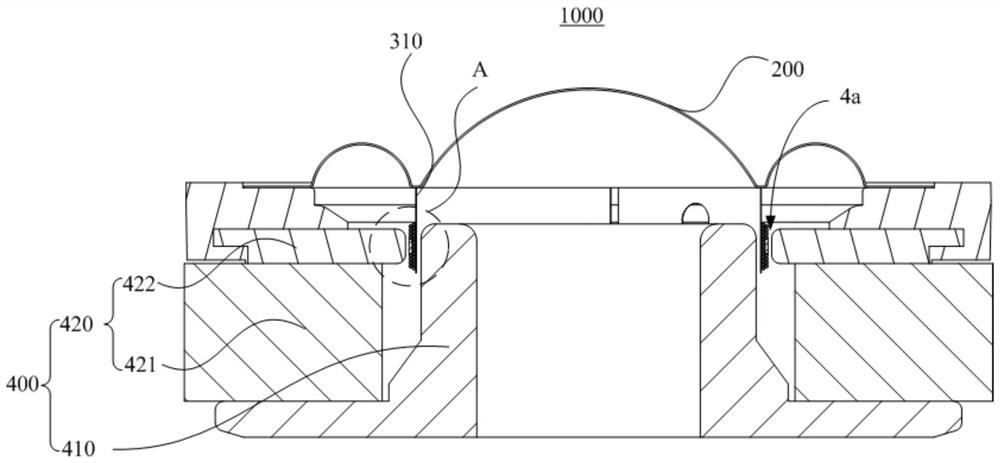

Fan-out type packaging structure and packaging method

ActiveCN111564436AImprove cooling effectReduce the chance of badSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringMechanical engineering

The invention provides a fan-out type packaging structure and a fan-out type packaging method, and belongs to the technical field of chip packaging. The fan-out type packaging structure comprises a plate-shaped base material, an accommodating groove is formed in a plate surface at one side of the plate-shaped base material, a first rewiring layer and a second rewiring layer are respectively formedon two side plate surfaces of the plate-shaped base material; the first rewiring layer and the second rewiring layer are connected through a conductive column. The conductive columns penetrate through the plate-shaped base material; a first chip is accommodated in the accommodating groove; a circuit bonding pad of the first chip is located at the side far away from the bottom of the accommodatinggroove and is connected with the first rewiring layer; a first shielding body is arranged in the accommodating groove, the periphery of the first chip is covered with the first shielding body, the side, away from the plate-shaped base material, of the second rewiring layer is connected with a second chip, a second shielding body is formed on the second rewiring layer, and the periphery of the second chip is covered with the second shielding body. The packaging structure can shield electromagnetic interference between chips so as to avoid badness caused by mutual interference between the chipsand improve the product performance of the packaging structure.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

Liquid crystal display panel and manufacturing method thereof

ActiveCN102023406BReduce the chance of badImprove the utilization rate of ultraviolet lightNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display panel and a manufacturing method thereof are provided. The liquid crystal display panel comprises: a first substrate and a second substrate bonded to each other; a liquid crystal layer filled between a display region of the first substrate and a display region of the second substrate; and a sealant formed between a periphery region of the first substrate and a periphery region of the second substrate. A reflective layer is formed in the periphery region of the first substrate or in the periphery region of the second substrate, and the reflective layer is adapted to reflect UV light to the sealant in a process of assembling the first substrate and the second substrate.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

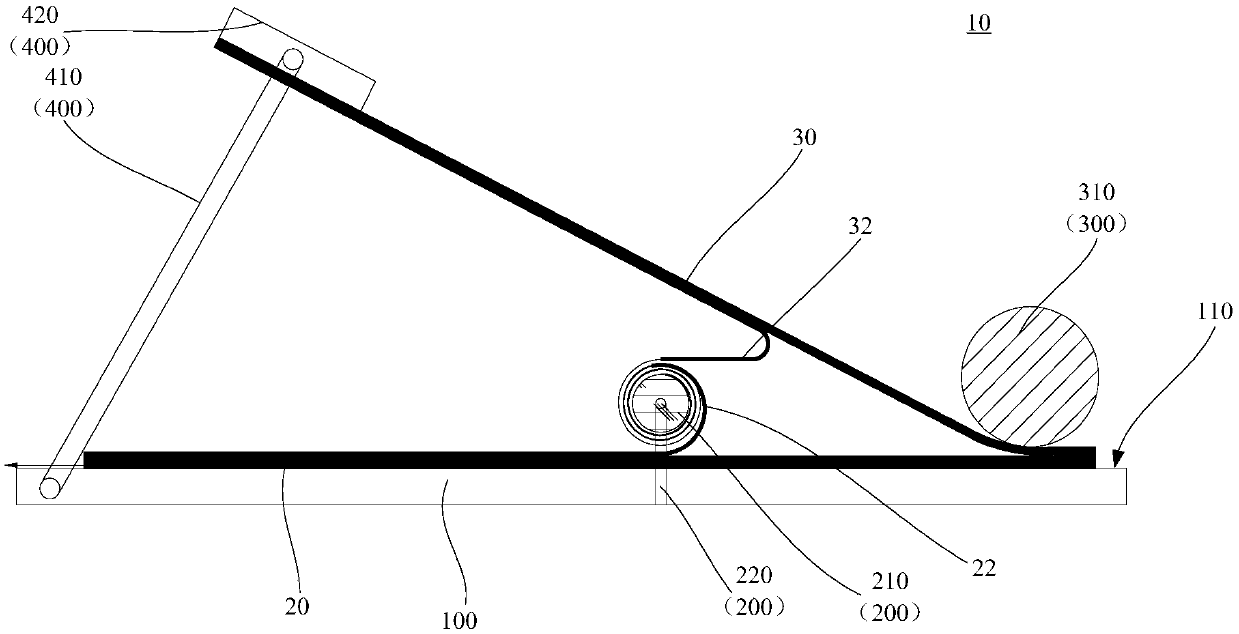

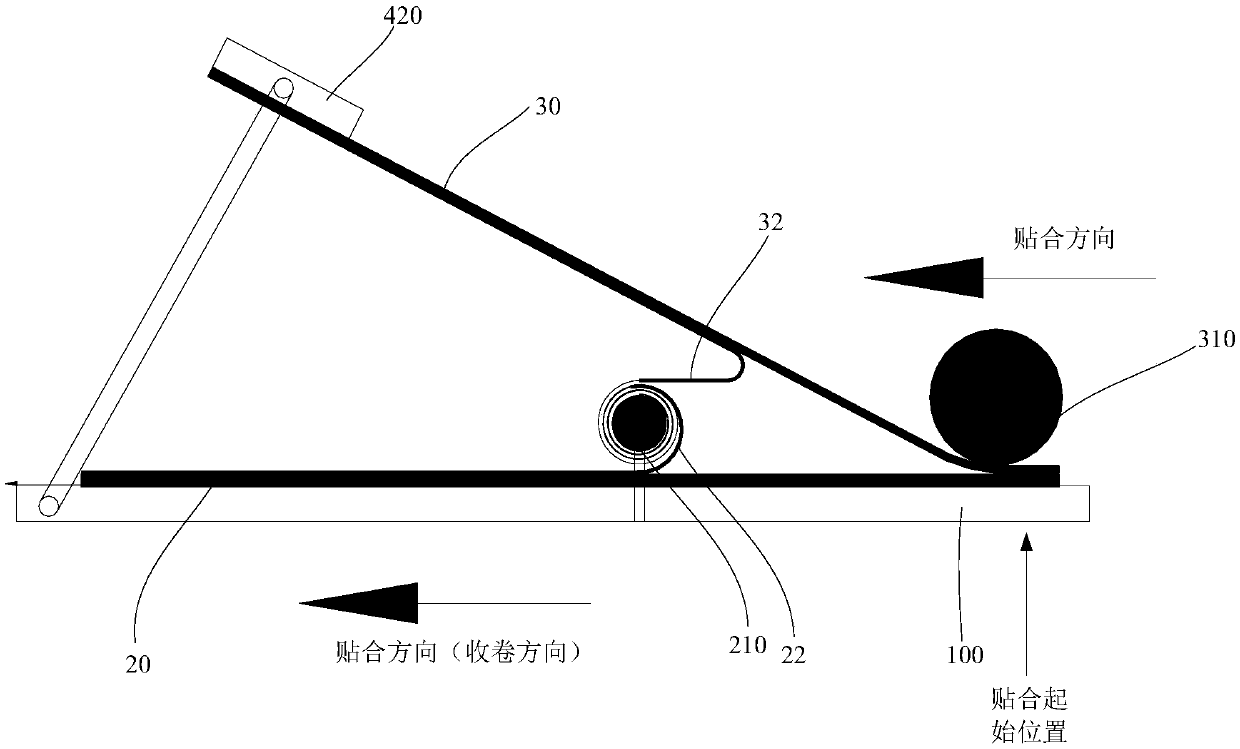

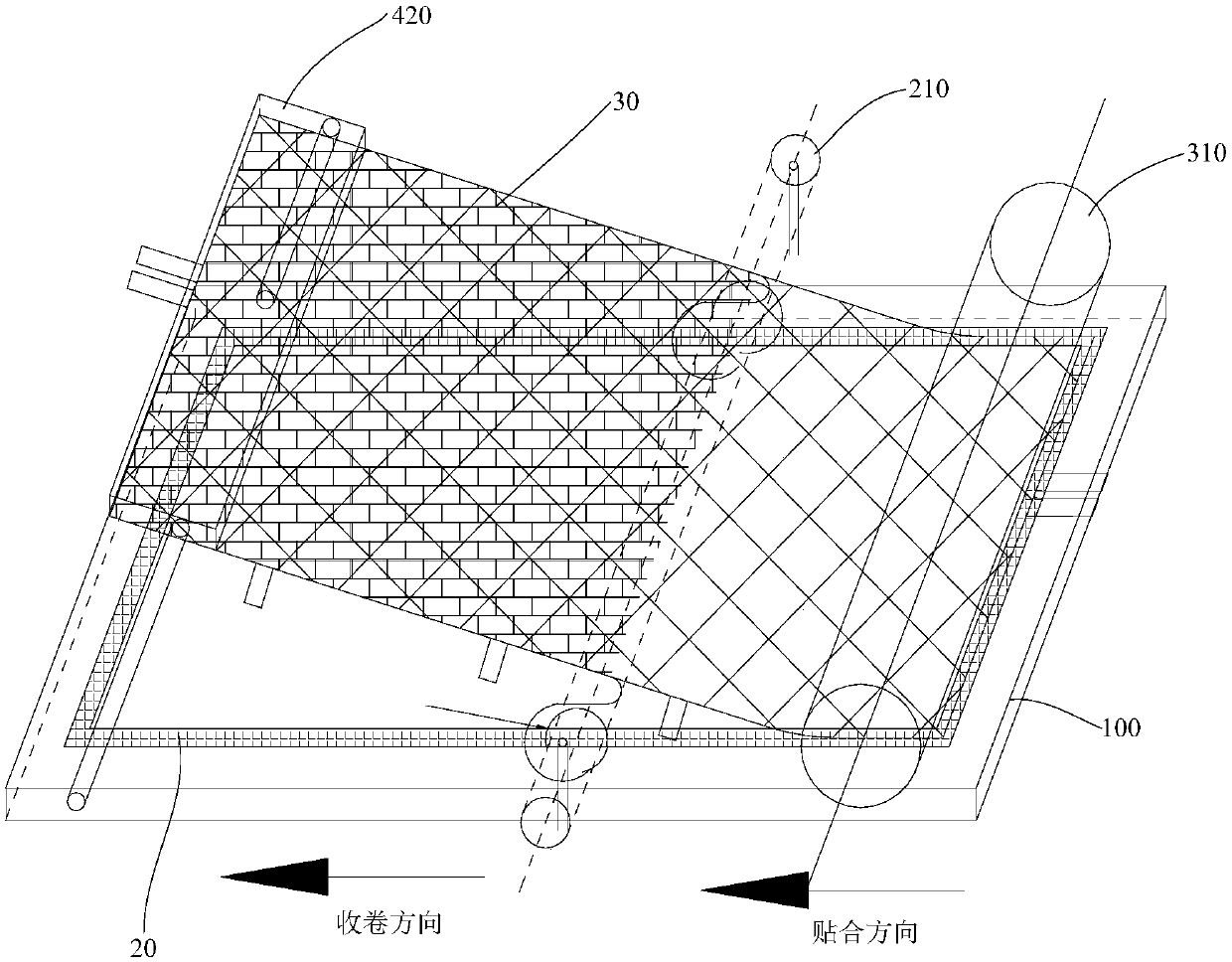

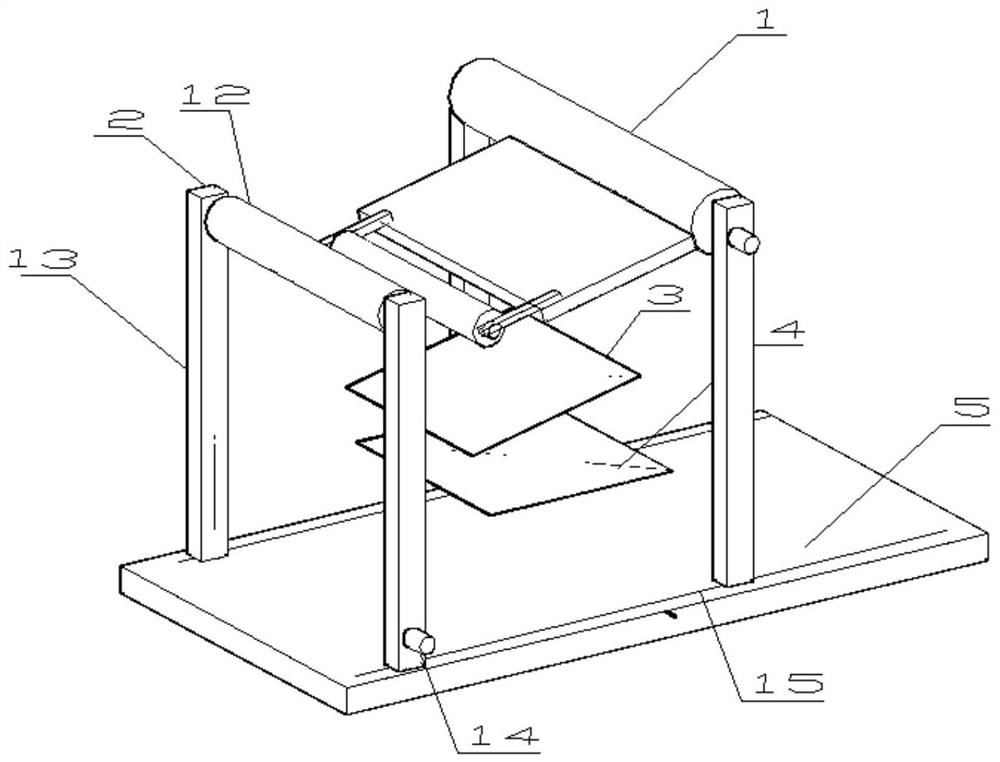

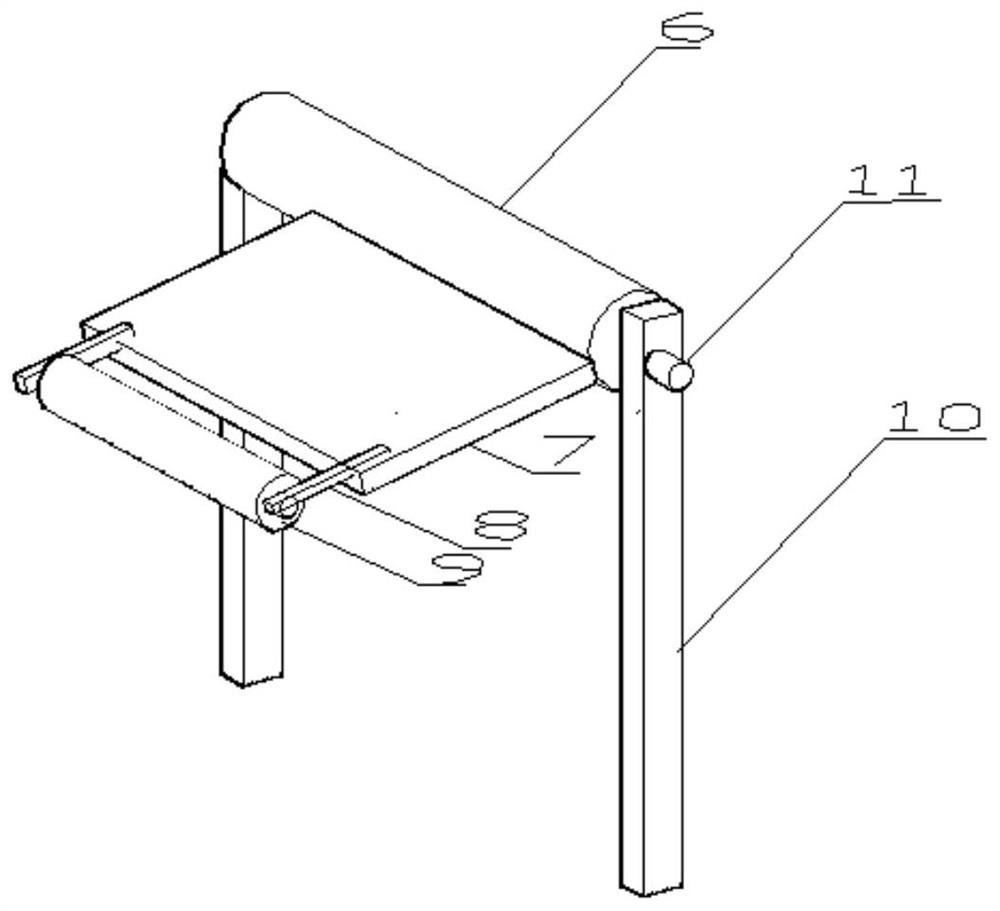

Diaphragm laminating device and method, display module and touch diaphragm

PendingCN109094001AReduce labor costsIncrease productivityInput/output processes for data processingEngineeringPrinting ink

The invention relates to a diaphragm laminating device and method, a display module and a touch diaphragm. The diaphragm laminating device comprises a base, a traction mechanism and a laminating mechanism. According to the diaphragm laminating device and method, when a second laminating object is laminated to a first laminating object, manual dragging and diaphragm tearing are not needed, and a protection diaphragm is gradually rolled automatically or manually through the corresponding traction mechanism, so that the labor cost is saved, the production efficiency is improved, the rate of defective products in the manual diaphragm tearing process is lowered, and the yield rate of products is improved. In the laminating process, the bending angle of the second laminating object can be stillkept smaller than 90 degrees, so that the problems of breakage of the second laminating object or breakage of surface coatings or printed ink due to excessive bending are solved, and the yield of theproduct is further better improved. The diaphragm laminating device and method are particularly suitable for laminating of large-dimension diaphragm products, and have the advantages of being high inlaminating efficiency, stable and reliable in laminating process and the like.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

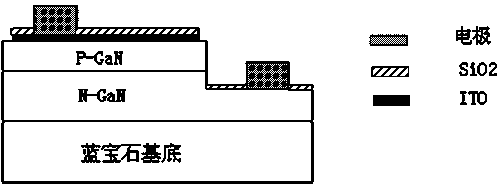

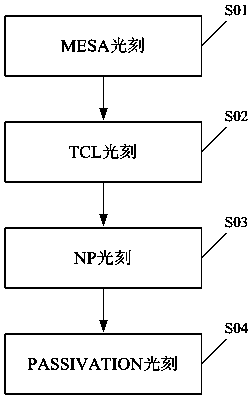

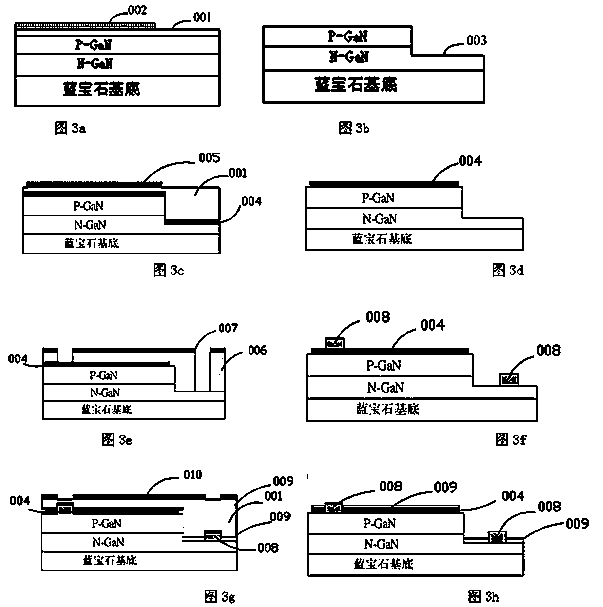

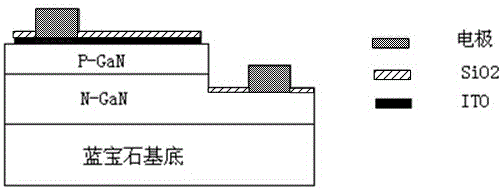

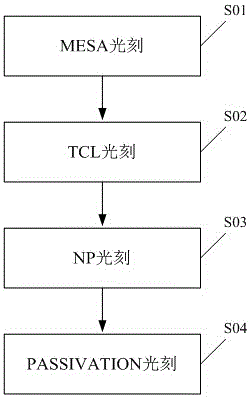

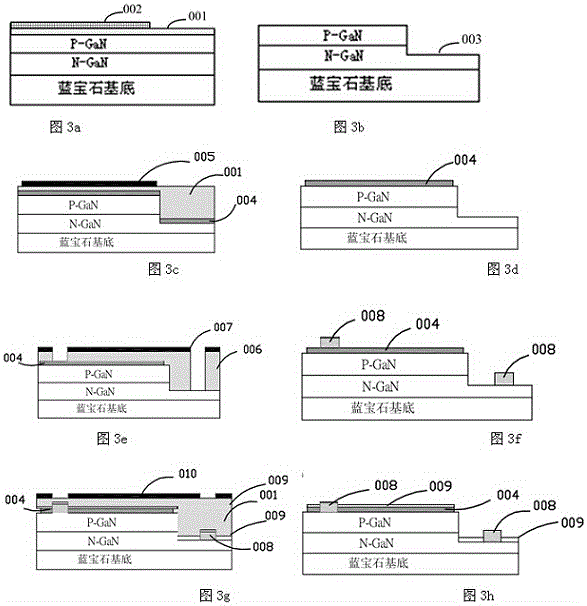

Novel method for manufacturing LED chips

ActiveCN104362226AUsage cut in halfReduce the number of photolithographySemiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyIndium tin oxide

The invention discloses a novel method for manufacturing LED chips. The novel method includes performing MESA photoetching and NP (negative and positive) photoetching, and particularly includes performing vacuum evaporation on the surfaces of epitaxial slices to obtain ITO (indium tin oxide) layers, then coating photoresist on the surfaces of the epitaxial slices, then performing MESA photoetching on the epitaxial slices to obtain photoresist layers with MESA pattern layers, etching ITO of the ITO layers and downwardly etching the surfaces of the epitaxial slices; removing the photoresist layers with the MESA pattern layers; performing vacuum evaporation on steps of the ITO layers and N-GaN layers to obtain SiO<2> layers, coating photoresist on the steps of the ITO layers and the N-GaN layers, and performing NP photoetching on the photoresist layers to obtain photoresist layers with NP patterns; etching the SiO<2> layers; forming P electrodes and N electrodes in regions obtained after the SiO<2> layers are etched; removing the photoresist layers with the NP pattern layers. The novel method has the advantages that the production cost can be effectively reduced, the production cycle can be shortened, and the yield can be increased.

Owner:SHANDONG CHENGLIN PHOTOELECTRIC TECH +1

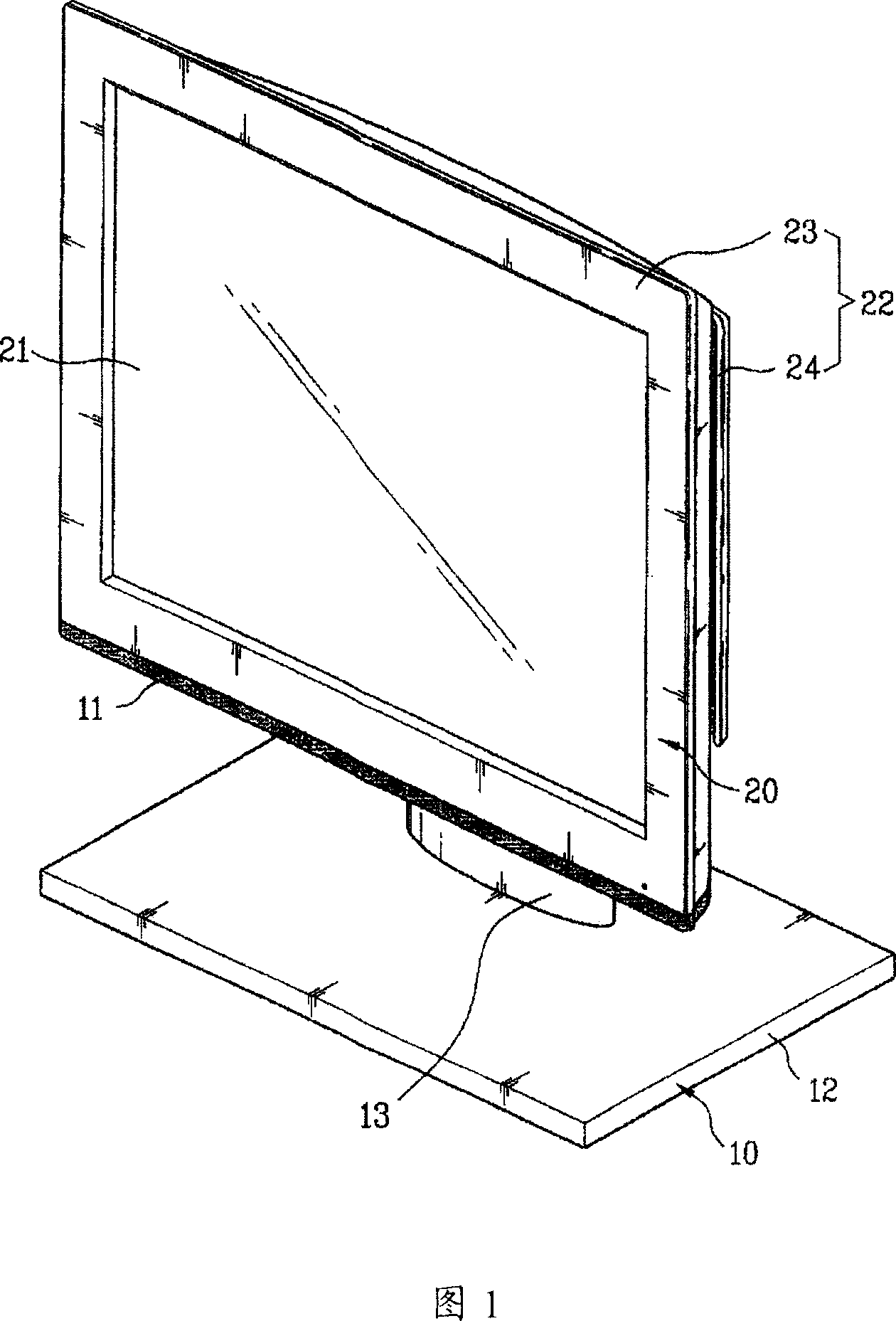

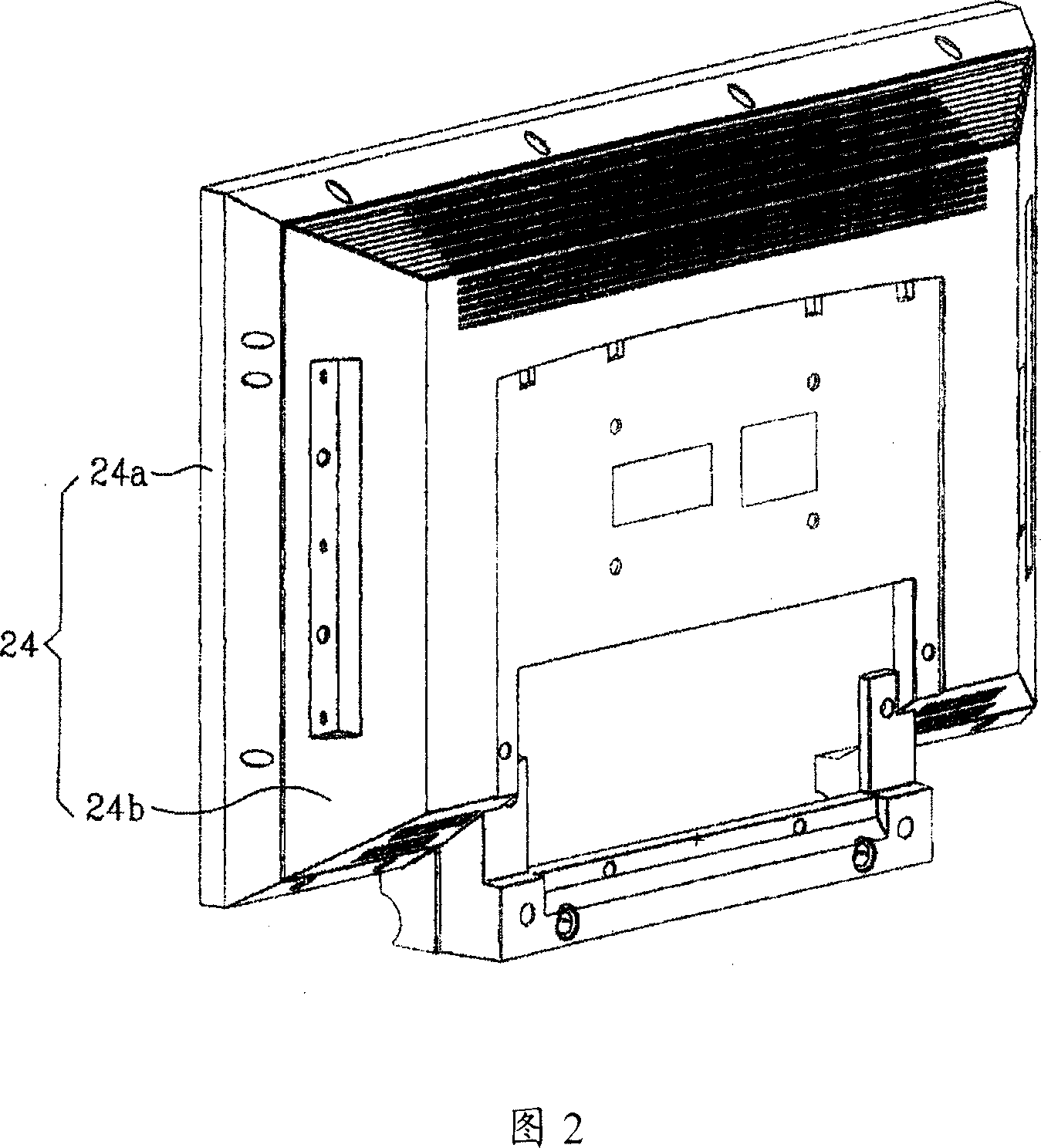

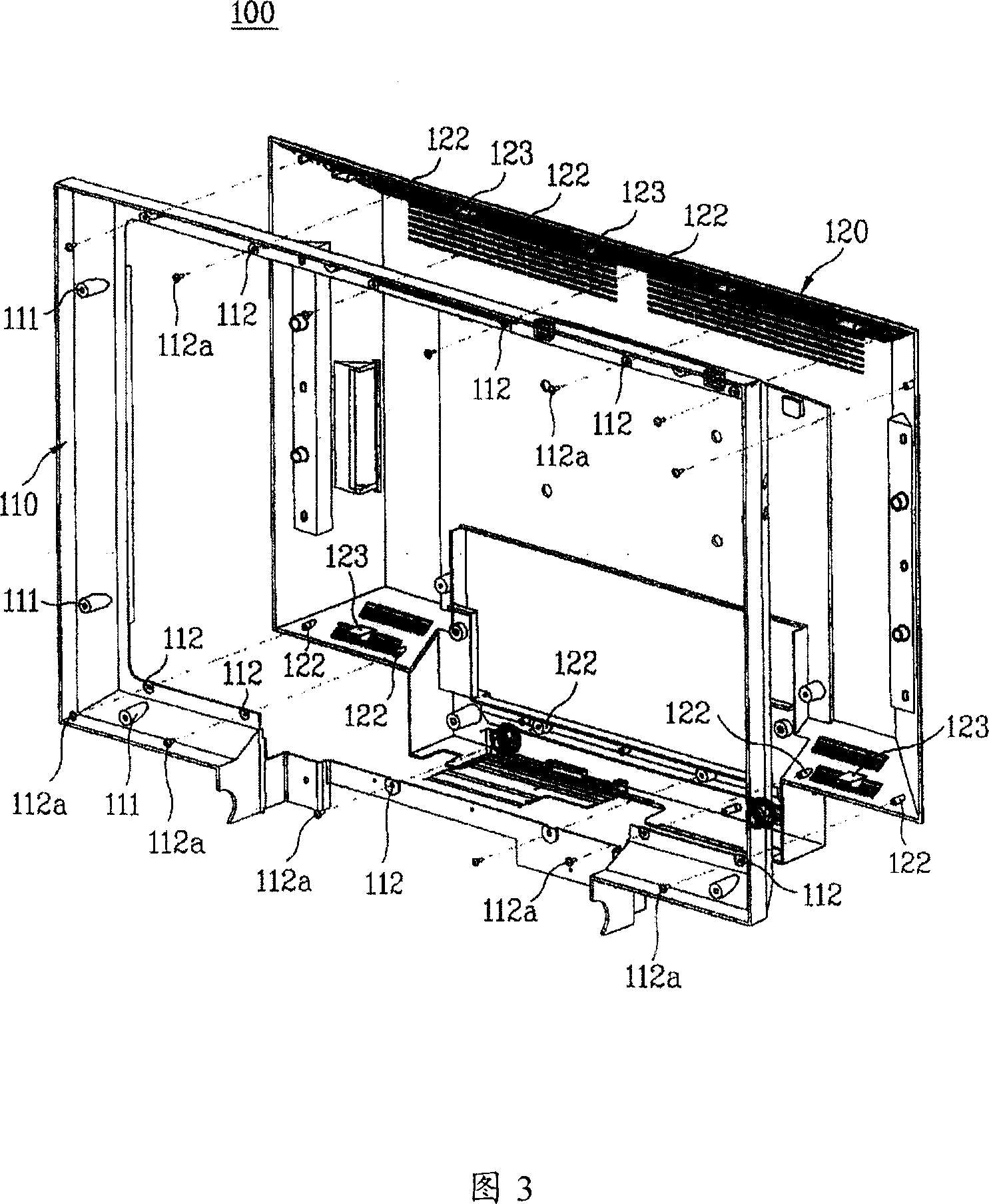

Flat-type image displaying device rear-lid

InactiveCN1980544AReduce the chance of badReduce delaysCasings/cabinets/drawers detailsIdentification meansEngineeringFront cover

The purpose of the invention is to provide a back cover for a kind of flat plate image indication device that can be processed the color coating procedure easily with low fraction defective, therefore, among the back cover that is provided by this invention for the flat plate image indication device, the flat plate image indication device includes two parts said in the following: (1) the front cover that is connected with the front section of the display that is used to display image; (2) the back cover that is connected with the aforesaid front cover that is used to protect the rear of the display. But the aforesaid back cover includes also the following several parts: (1) the No. 1 cover that is connected with the front cover; (2) the No. 2 cover that can be inserted and pulled up on the aforesaid No. 1 cover.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

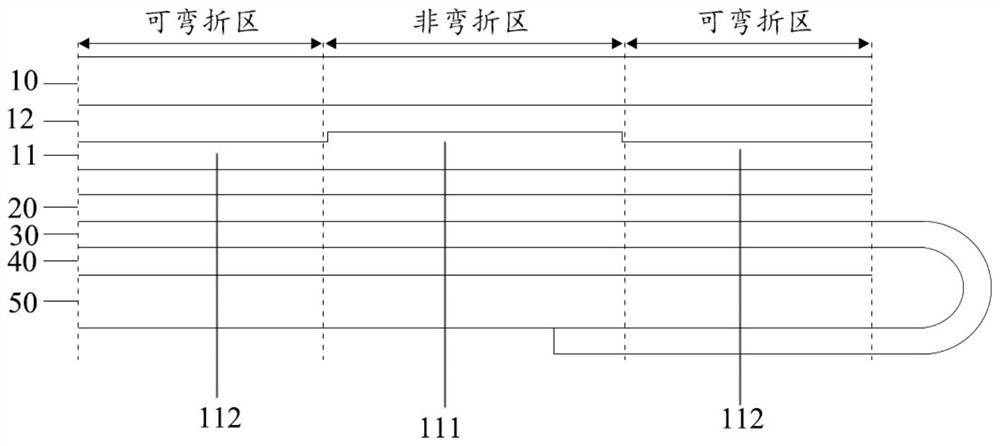

Cover plate structure of flexible display module, flexible display module and flexible display equipment

PendingCN114333594ASmall resilienceReduce the chance of damageIdentification meansStructural engineeringFlexible display

The invention relates to a cover plate structure of a flexible display module, the flexible display module and flexible display equipment. The cover plate structure of the flexible display module comprises an organic cover plate layer and a flexible glass layer which are attached to each other, the flexible glass layer is provided with a first part and a second part, the first part is located in an area, corresponding to a bendable area of the flexible display module, on the cover plate structure, and the second part is located in an area, corresponding to a non-bending area of the flexible display module, on the cover plate structure; the first part of the flexible glass layer is thicker than the second part; or the flexible glass layer is only arranged in the area, corresponding to the non-bending area of the flexible display module, of the cover plate structure. According to the scheme, the overall resilience force of the flexible display module can be reduced when the flexible display module is bent, and attachment between the layers of structures can be better maintained. In addition, the dislocation amount of the edge of the supporting layer when the flexible display module is bent can be reduced, and therefore the probability that a Pad bending area of the flexible display module is damaged in a jacking mode is reduced.

Owner:BOE TECH GRP CO LTD

How to make a new LED chip

ActiveCN104362226BUsage cut in halfReduce the number of photolithographySemiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyIndium tin oxide

The invention discloses a novel method for manufacturing LED chips. The novel method includes performing MESA photoetching and NP (negative and positive) photoetching, and particularly includes performing vacuum evaporation on the surfaces of epitaxial slices to obtain ITO (indium tin oxide) layers, then coating photoresist on the surfaces of the epitaxial slices, then performing MESA photoetching on the epitaxial slices to obtain photoresist layers with MESA pattern layers, etching ITO of the ITO layers and downwardly etching the surfaces of the epitaxial slices; removing the photoresist layers with the MESA pattern layers; performing vacuum evaporation on steps of the ITO layers and N-GaN layers to obtain SiO<2> layers, coating photoresist on the steps of the ITO layers and the N-GaN layers, and performing NP photoetching on the photoresist layers to obtain photoresist layers with NP patterns; etching the SiO<2> layers; forming P electrodes and N electrodes in regions obtained after the SiO<2> layers are etched; removing the photoresist layers with the NP pattern layers. The novel method has the advantages that the production cost can be effectively reduced, the production cycle can be shortened, and the yield can be increased.

Owner:SHANDONG CHENGLIN PHOTOELECTRIC TECH +1

Manufacturing method of array substrate, array substrate and liquid crystal display

ActiveCN102629583BReduce movementReduce the chance of movingSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerLiquid-crystal display

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Wooden product deburring and film covering device

InactiveCN112207671AImprove processing efficiencyReduce the chance of badEdge grinding machinesGrinding carriagesStructural engineeringAir heater

The invention discloses a wood product deburring and film covering device. The device comprises a working platform, a deburring cylinder, a film covering structure and a tightening cylinder, the deburring cylinder, the film covering structure and the tightening cylinder are sequentially installed on the end face of the working platform through a support, the deburring cylinder and the tightening cylinder are transversely located on the same plane, bucket-shaped friction plates are fixedly arranged in the deburring cylinder, penetrating holes are formed in the centers of the friction plates, the bottom of the deburring cylinder is of a hollowed-out structure, the position, corresponding to the hollowed-out position, of the bottom of the deburring cylinder is wrapped with a draught hood, theinput end of the draught hood communicates and is connected with an exhaust fan, a heat conveying ring with the interior of a hollow structure is arranged in the tightening cylinder, a heat conveyingpipe is connected into the heat conveying ring in a communicating mode, and the input end of the heat conveying pipe is connected with an air heater in a communicating mode.

Owner:徐州光头强木业有限公司

Array substrate and display device

ActiveCN108254987BAvoid severe inhomogeneity of corner amplitudeReduce interferenceNon-linear opticsInput/output processes for data processingScan lineDisplay device

An array substrate includes a substrate; scan lines and data lines arranged on the substrate and intersecting one another to define sub-pixels, each of which includes a pixel electrode including strip-like electrodes whose long axes of a same row are parallel to one another. Extension lines of long axes of strip-like electrodes in sub-pixels in any two adjacent rows intersect one another. The touch electrode is electrically connected to at least one touch signal line. Each touch signal line includes straight-line portions and fold-line portions. Two adjacent straight-line portions are connected by one fold-line portion. Any straight-line portion is parallel to long axes of strip-like electrodes in sub-pixels in a same row. Extension lines of fold-line portions intersect long axes of strip-like electrodes. Orthographic projections of fold-line portions on the substrate overlap orthographic projections of scan lines on the substrate. Fold-line portions are not perpendicular to scan lines.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Hot melt film one-time forming laminating process method and device

PendingCN113031322AReduce exposure timeIncrease productivityNon-linear opticsProcess engineeringHot melt

The invention provides a hot melt film one-time forming laminating process method and device. The process method comprises the following steps: 1) fusing a laminating part and a hot melt part on one piece of equipment; the three working procedures of fusion fitting, defoaming and hot melting fitting being one fitting working procedure, so that a working mode of synchronously finishing fitting and hot melting is realized; (2) designing the equipment into a double-wheel structure, the hot melt film being accurately attached to the surface of a product through a pressing roller of the attaching part, completely exhausting gas between attaching faces to enable the attaching faces to be free of bubble residues, and heating the hot melt film and performing edge sealing through a hot melt roller along with pressure. The device adopts a double-wheel structure, deaeration and hot pressing are completed in one step, and the problems that due to product structure factors, a traditional technology and traditional equipment must adopt the technology of firstly attaching, then deaeration and finally hot melting and pressing, the production efficiency is influenced, inconsistency is generated due to long retention time of products, and the product reliability is influenced are solved. The manufacturing time is shortened, and the stability of the product is improved.

Owner:奇新光电股份有限公司

Loudspeaker and electronic equipment

PendingCN113660584AImprove reliabilityImprove performanceElectrical transducersEngineeringLoudspeaker

The invention discloses a loudspeaker and electronic equipment. The loudspeaker comprises a magnetic circuit system and a vibration system, and the magnetic circuit system comprises a first magnet part and a second magnet part which are spaced to form a magnetic gap; the vibration system comprises a vibrating diaphragm and a voice coil for driving the vibrating diaphragm to vibrate, and at least part of the voice coil is located in the magnetic gap; the voice coil comprises a skeleton, a voice coil wire and a magnetic conductive sheet; the voice coil wire is wound on the skeleton so as to form at least one coil layer on the outer side wall of the skeleton in the radial direction of the skeleton; and the magnetic conductive sheet is arranged around the skeleton and is embedded in one or more coil layers. According to the invention, the probability of occurrence of undesirable phenomena such as ring rubbing caused by inclination of the voice coil is reduced, and the reliability of the loudspeaker is improved.

Owner:潍坊歌尔丹拿电子科技有限公司

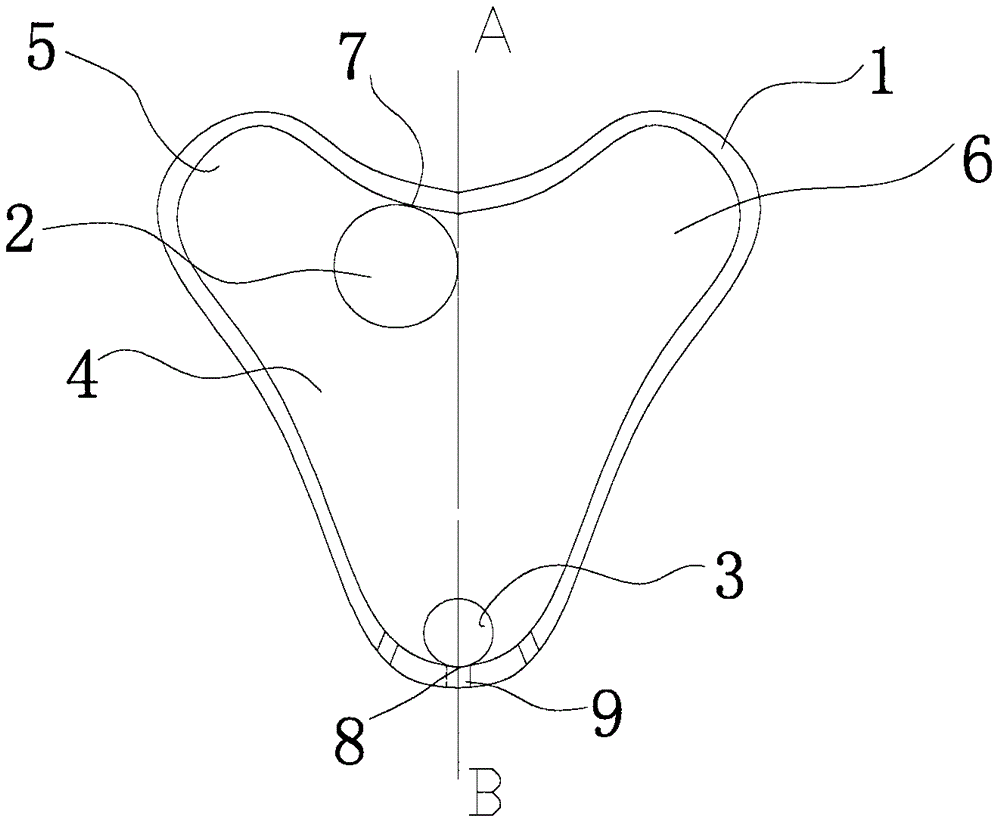

Circuit boards and their applications

ActiveCN105430875BReduce the chance of badReduce production processLegendsPrinted circuit aspectsLight guideConductive coating

The invention relates to a circuit board and application thereof. The circuit board comprises a substrate and an etching metal circuit located over the substrate. The substrate is provided with at least one pair of through holes, inside of the through holes and substrate base between the two through holes are provided with a conductive coating, and the substrate and the etching metal circuit form a conducted closed loop. According to the circuit board provided by the invention, the etching metal circuit is arranged over the substrate to replace the conventional circuit formed by printing silver circuits on the substrate, conductive circuits are compactly concentrated on a metal layer, probability of generating defective circuits while printing is reduced, and yield is increased; and the substrate is drilled, the inside of the through holes and the substrate base are provided with the conductive coating, the formed conducted closed loop can replace the existing jumper technology, production processes can be decreased, difficulty in process is reduced, and production cost is saved greatly. Application of the circuit board provided by the invention comprises using the circuit board as a light guide plate of an illuminant keyboard, and just by directly using the circuit board in cooperation with a light-emitting diode, light emitting at base of the keyboard can be realized.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

Circuit board and application thereof

ActiveCN105430875AReduce the chance of badReduce production processLegendsPrinted circuit aspectsLight guideConductive coating

The invention relates to a circuit board and application thereof. The circuit board comprises a substrate and an etching metal circuit located over the substrate. The substrate is provided with at least one pair of through holes, inside of the through holes and substrate base between the two through holes are provided with a conductive coating, and the substrate and the etching metal circuit form a conducted closed loop. According to the circuit board provided by the invention, the etching metal circuit is arranged over the substrate to replace the conventional circuit formed by printing silver circuits on the substrate, conductive circuits are compactly concentrated on a metal layer, probability of generating defective circuits while printing is reduced, and yield is increased; and the substrate is drilled, the inside of the through holes and the substrate base are provided with the conductive coating, the formed conducted closed loop can replace the existing jumper technology, production processes can be decreased, difficulty in process is reduced, and production cost is saved greatly. Application of the circuit board provided by the invention comprises using the circuit board as a light guide plate of an illuminant keyboard, and just by directly using the circuit board in cooperation with a light-emitting diode, light emitting at base of the keyboard can be realized.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

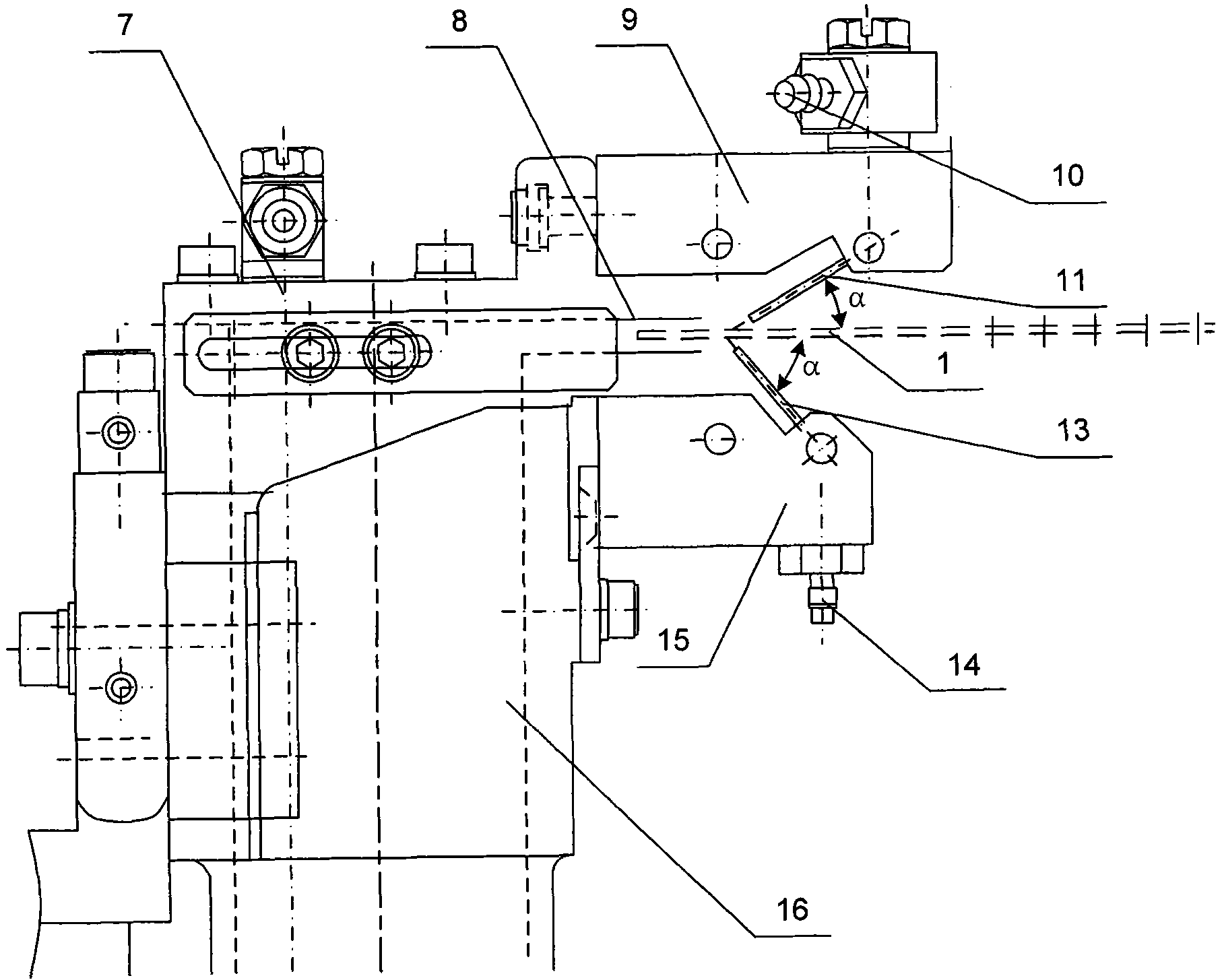

Photoresist apparatus for removing edge

ActiveCN101373341BReduce the chance of badSputtering fastPhotosensitive material processingNon-linear opticsEngineeringNitrogen gas

The invention relates to an edge-removing optical resist device which comprises a device main body. A racking pipe for pumping residual liquid on the edge of a glass substrate through negative pressure is arranged in the device main body; an upper spray needle and a lower spray needle for spraying chemical liquid medicine at the end part of the glass substrate in a sloping direction from the upper part and the lower part are connected to the device body. By changing an inlet pipe duct and the spray direction of the chemical liquid medicine, and arranging the racking pipe with the negative pressure, the invention avoids gas liquid interference appearing in the use of the prior device, reduces ill probability formation caused by sputtering the chemical liquid medicine on the glass substrate, saves nitrogen at the same time, and reduces manufacture cost.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Method for Detecting Flatness of Wafer Worktable

ActiveCN108766901BReduce the chance of badMeasurement devicesSemiconductor/solid-state device testing/measurementGraphicsAlgorithm

The invention provides a method for detecting the flatness of a wafer table. The method comprises the steps of putting a selected detection wafer on a standard wafer table and etching a first layer ofnesting graphics; putting the detection wafer etched with the first layer of nesting graphics on an actual wafer table and etching a second layer of nesting graphics; calculating the nesting accuracyof the second layer of nesting graphics relative to the first layer of nesting graphics; and comparing the calculated nesting accuracy with a threshold, and if the nesting accuracy exceeds the threshold, judging that the flatness of the wafer table does not reach a standard value. According to the method for detecting the flatness of the wafer table provided by the invention, the value of the nesting accuracy is calculated and recorded through measuring the nesting accuracy of the wafer, and whether the wafer table needs to be cleaned or not is judged through judging whether the nesting accuracy exceeds the threshold or not. According to the method, the flatness of the wafer table can be detected, so that the probability of a bad wafer caused by the flatness is finally reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Turning to multi-wire cutting method and equipment

ActiveCN106738392BReduce turnaround timeReduce the chance of badWorking accessoriesFine working devicesTurnover timeWire cutting

Owner:京磁材料科技股份有限公司

membrane switch

ActiveCN105390318BReduce the chance of badReduce production processElectric switchesInsulation layerConductive coating

Owner:JIANGSU TRANSIMAGE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com