Patents

Literature

35results about How to "Reduce or avoid access to" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

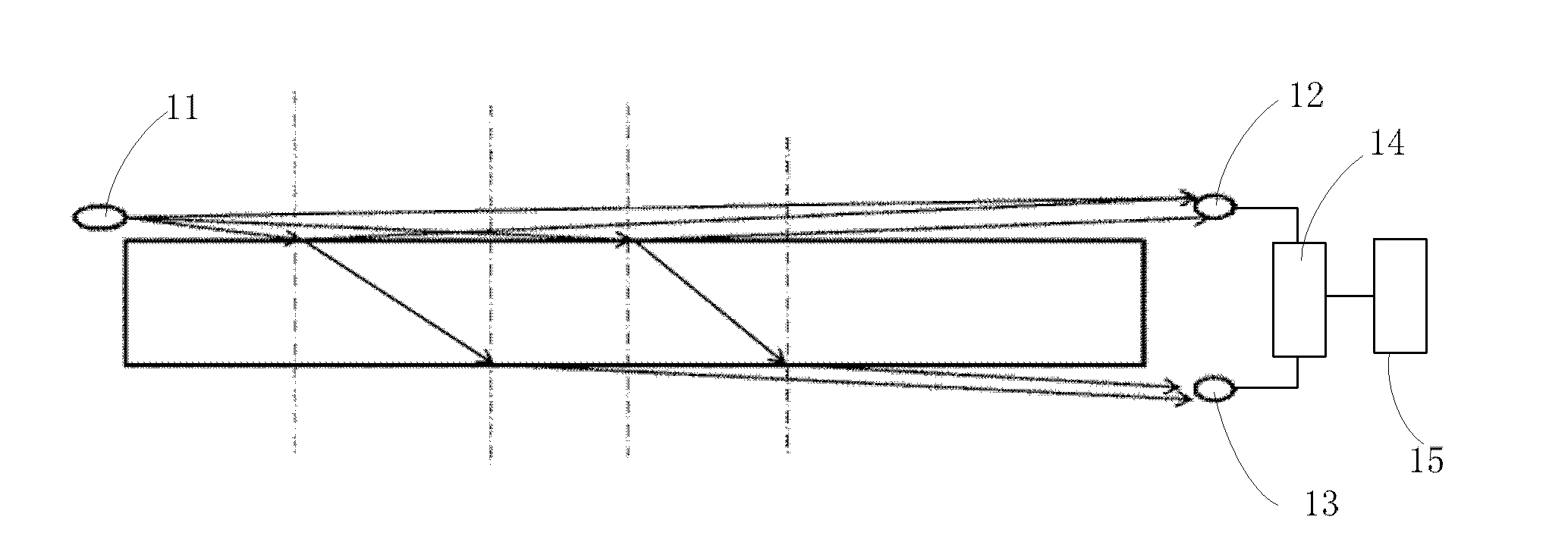

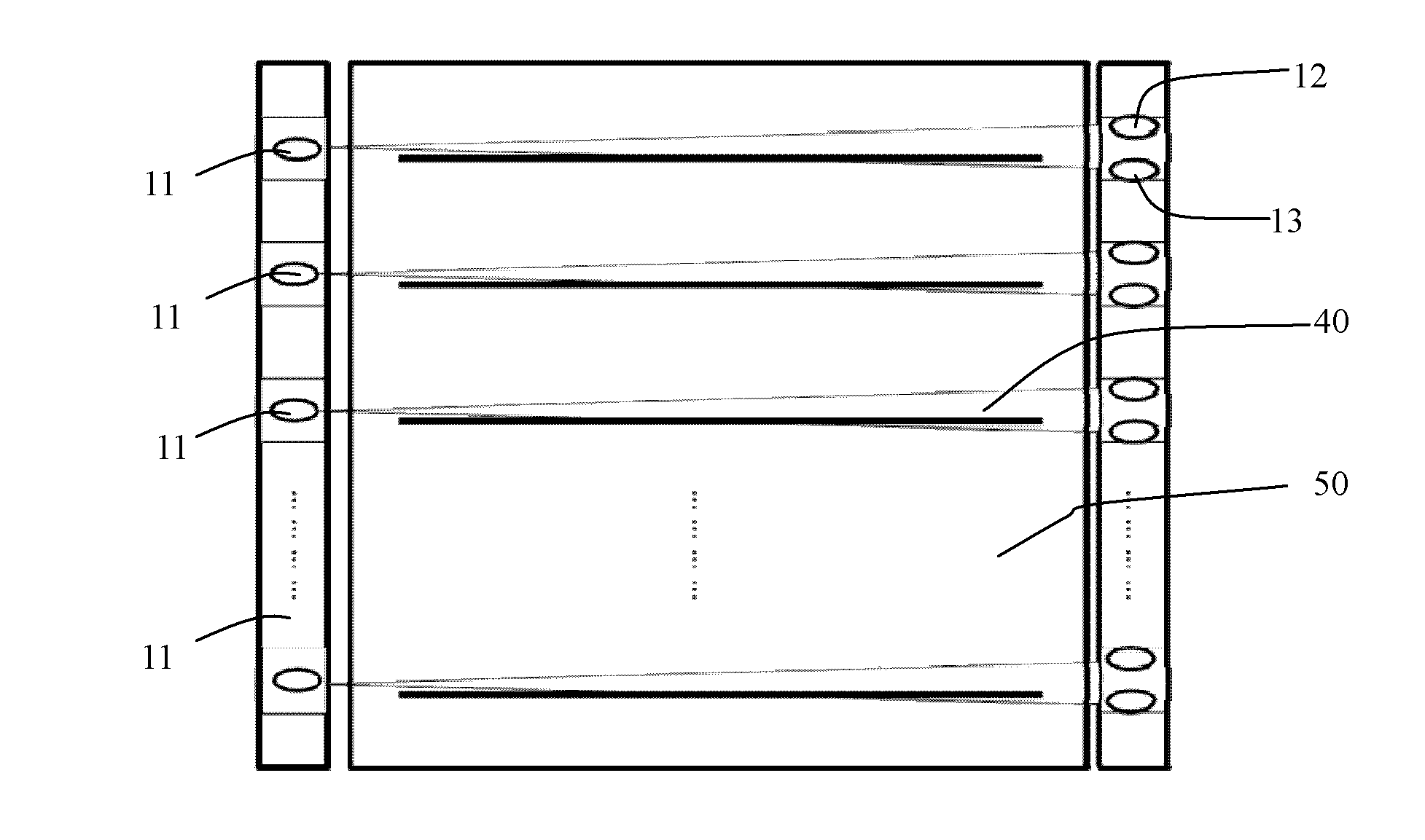

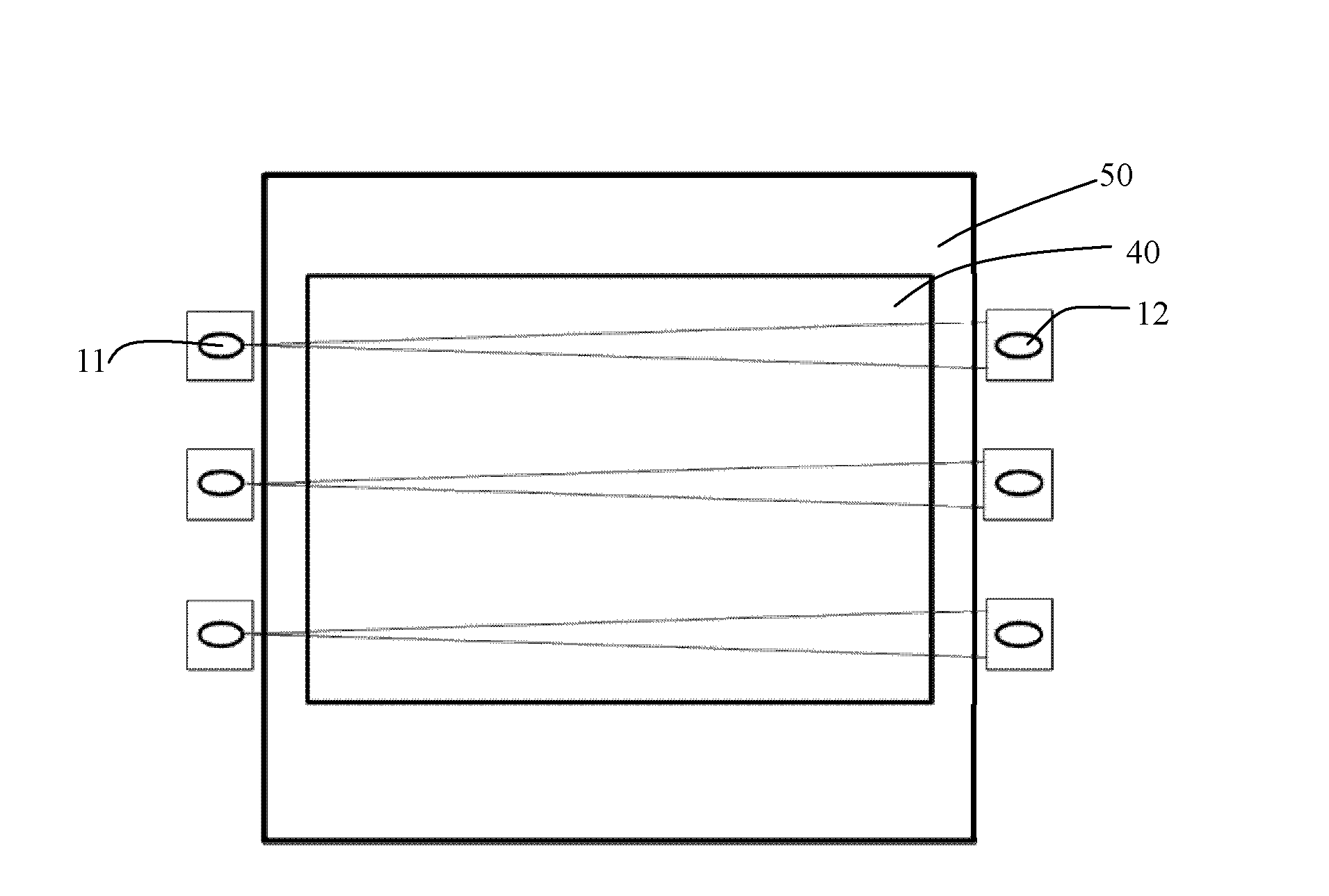

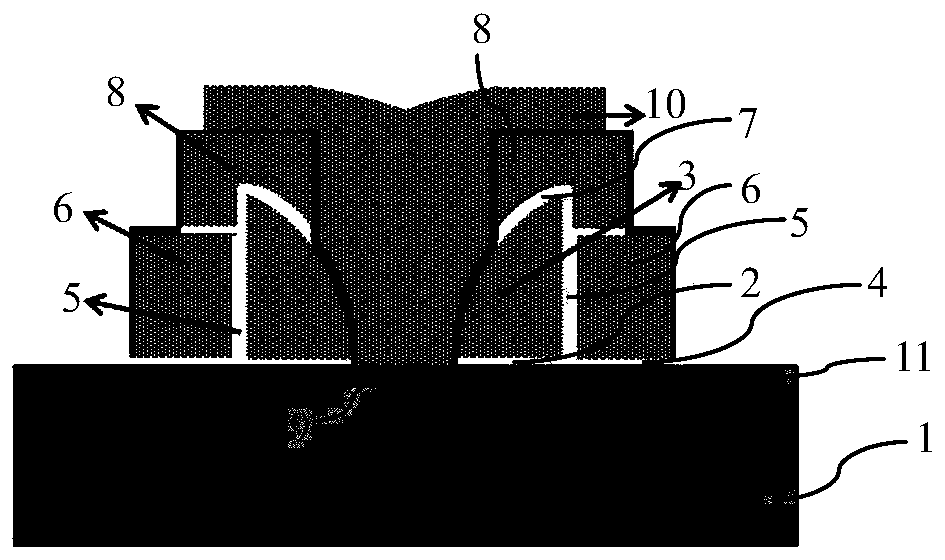

Detection device and detection method for glass substrate

InactiveCN102636498AIncrease productivityReduce the chance of defective finished productsMaterial analysis by optical meansOptoelectronics

The invention provides a detection device and a detection method for a glass substrate, and is used for detecting whether the glass substrate bore in a clamping case is damaged or not. The detection device comprises at least one sensor group and at least one processing unit, wherein the sensor group comprises an illuminating element on one side of the glass substrate and two illuminated elements respectively positioned on the two sides of the glass substrate, and the processing unit is used for judging whether the luminance difference of the luminance of the two illuminated elements is in the preset scope or not; and if the luminance difference is not in the preset scope, the glass substrate to be detected is broken. Through the detection method provided by the invention, the phenomenon that the broken glass substrate enters into a display panel processing line can be reduced or avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

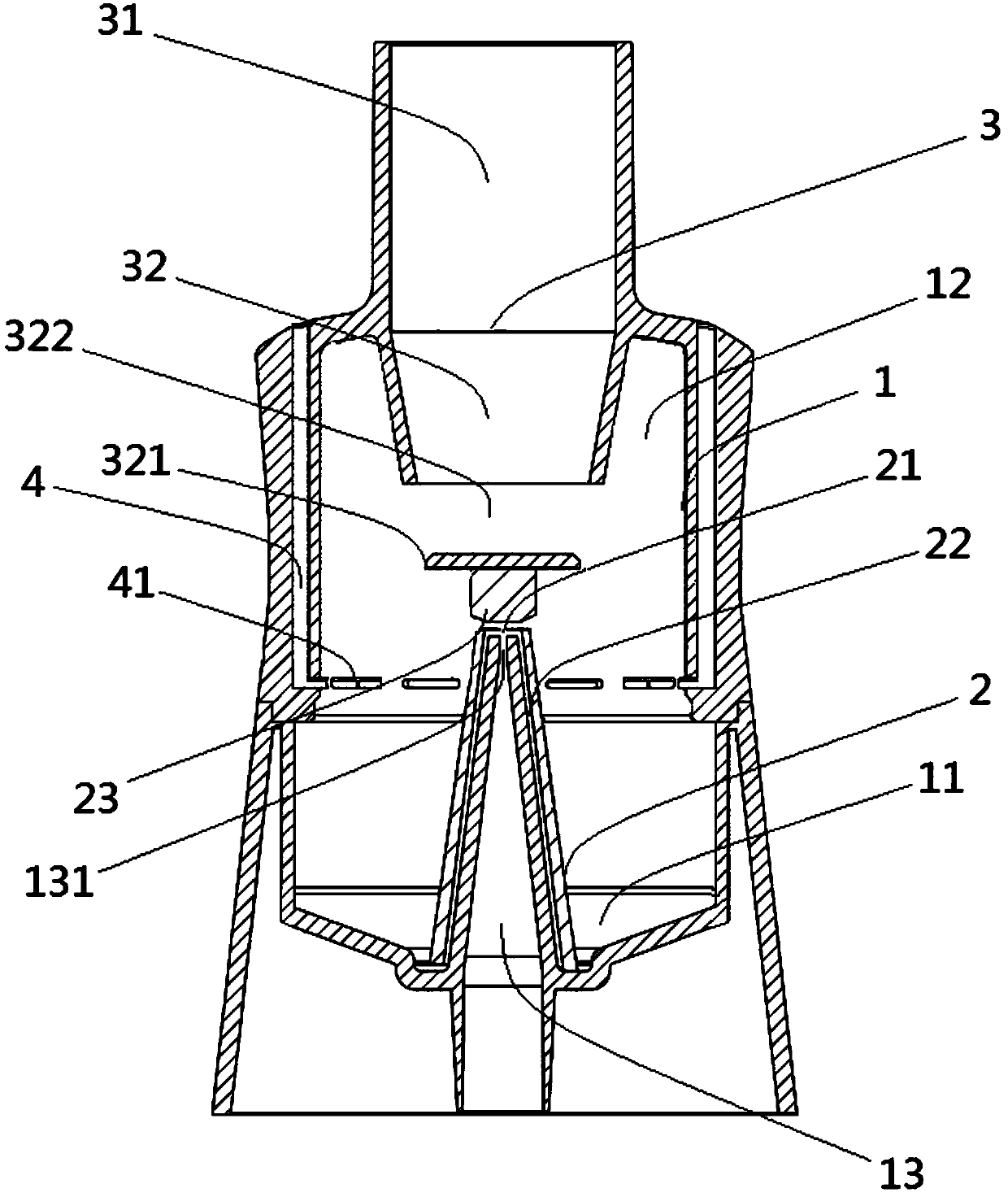

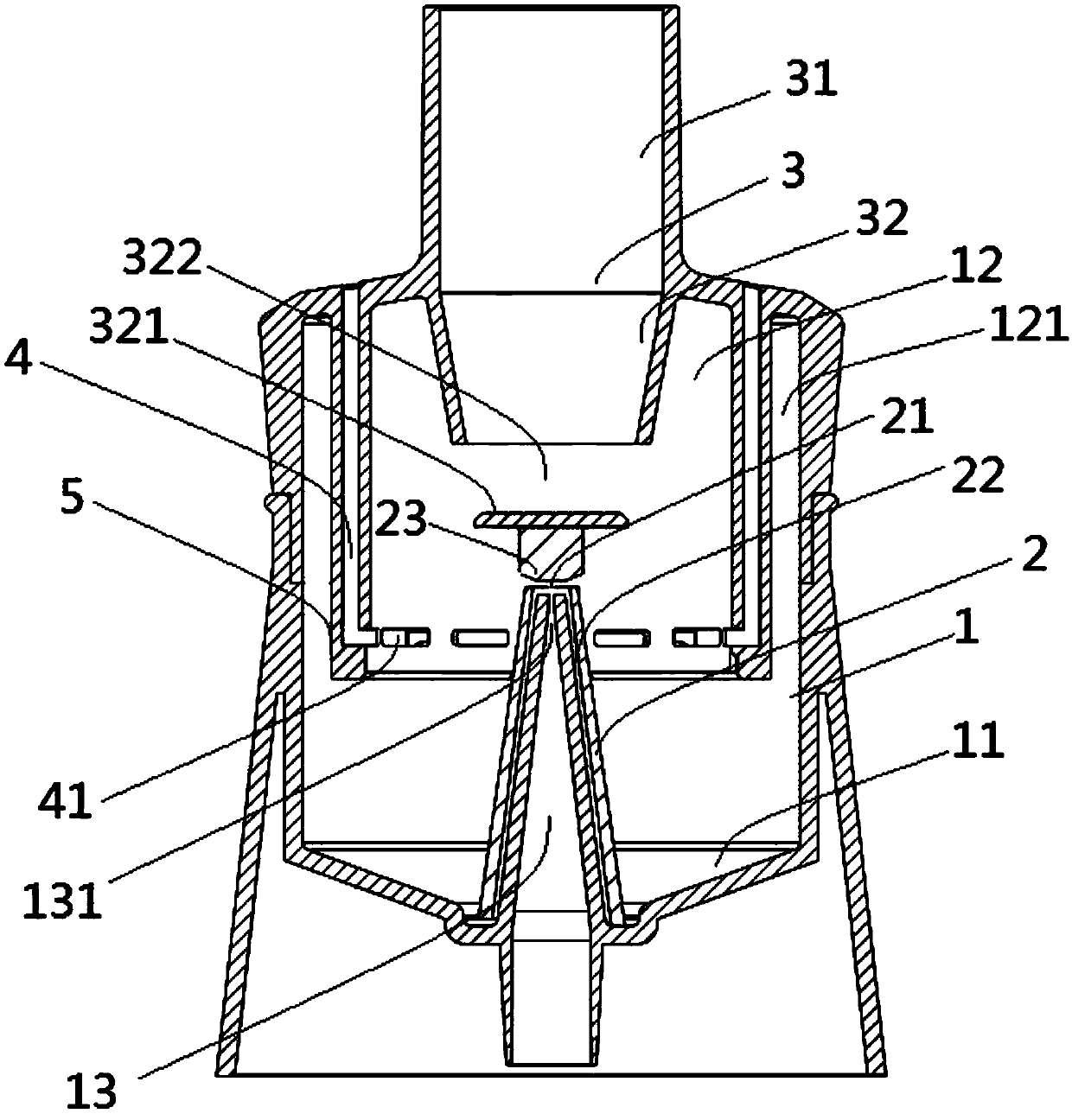

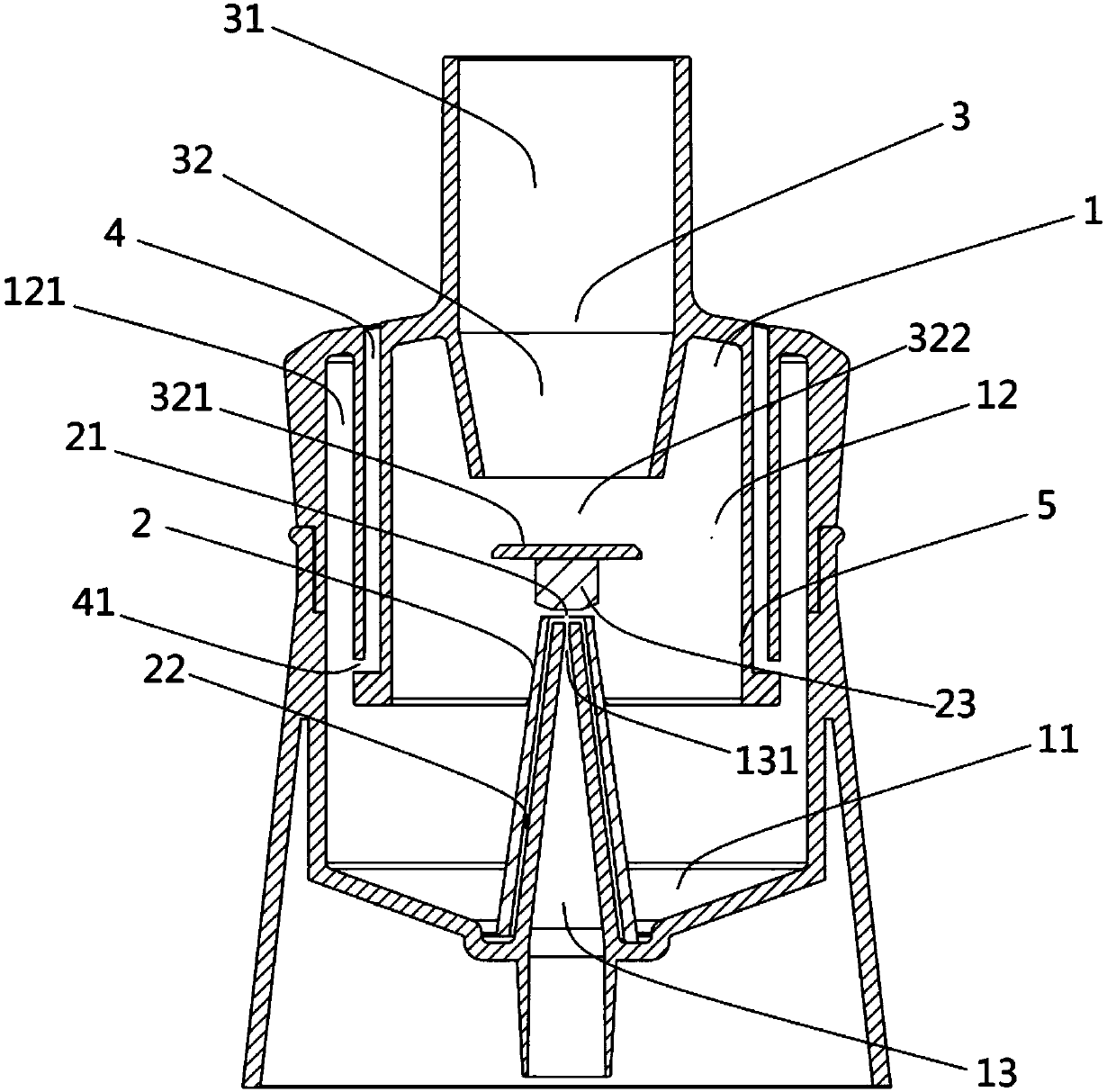

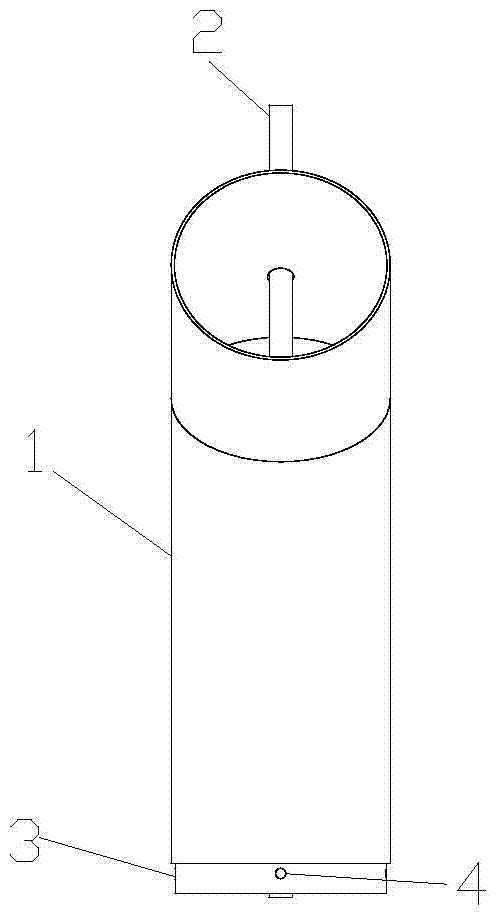

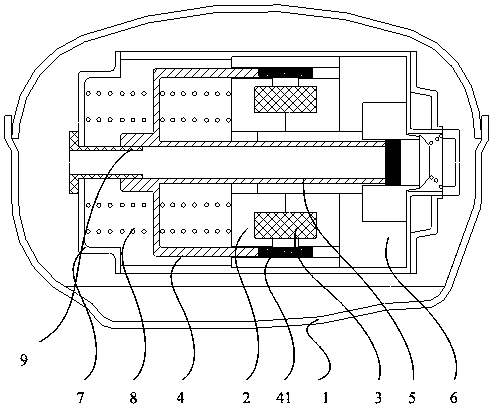

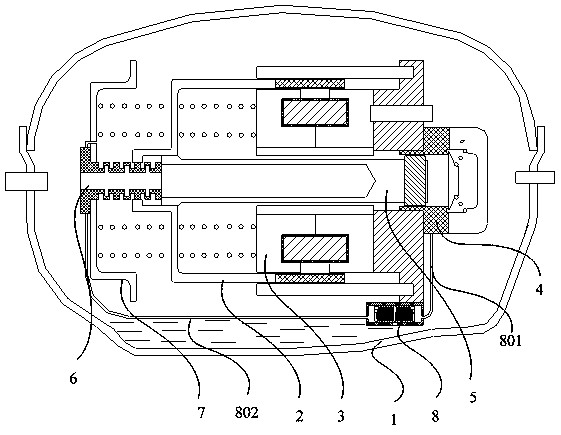

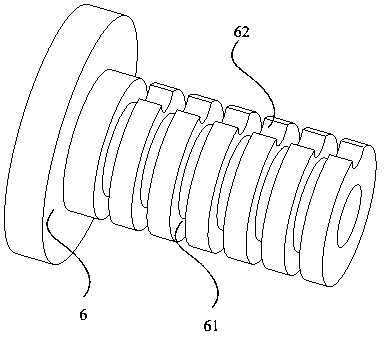

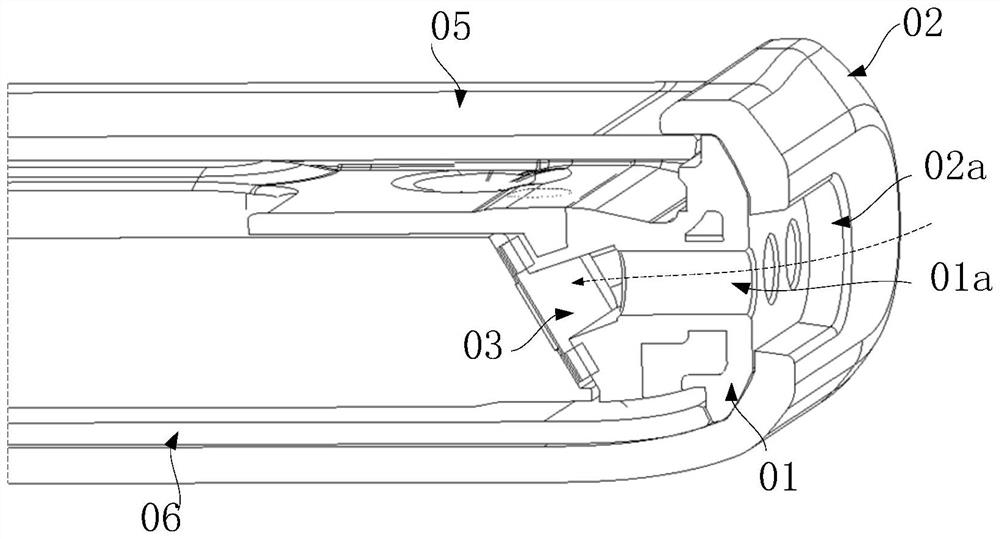

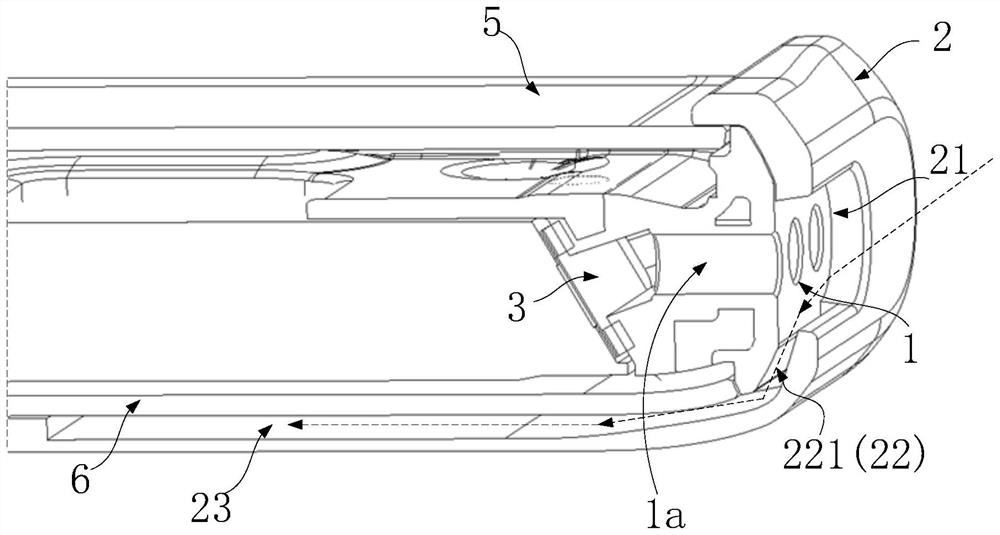

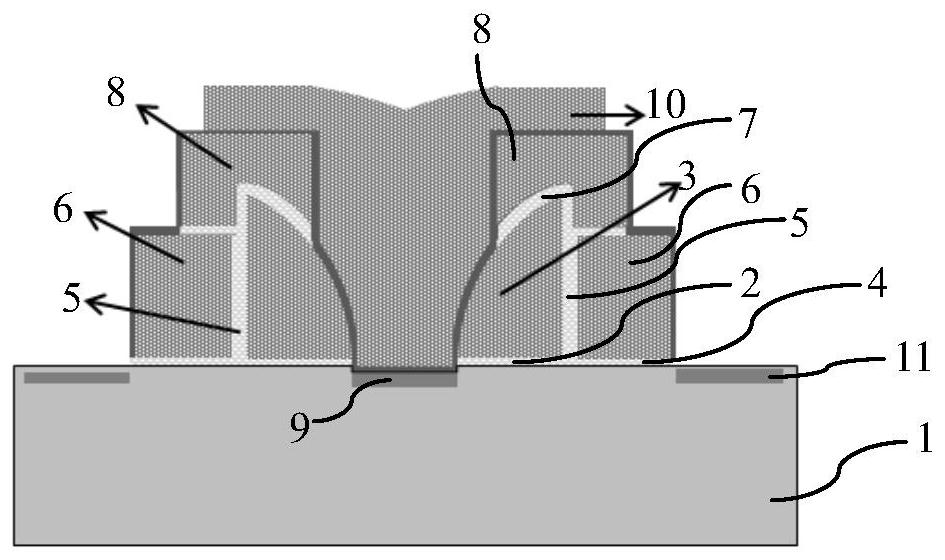

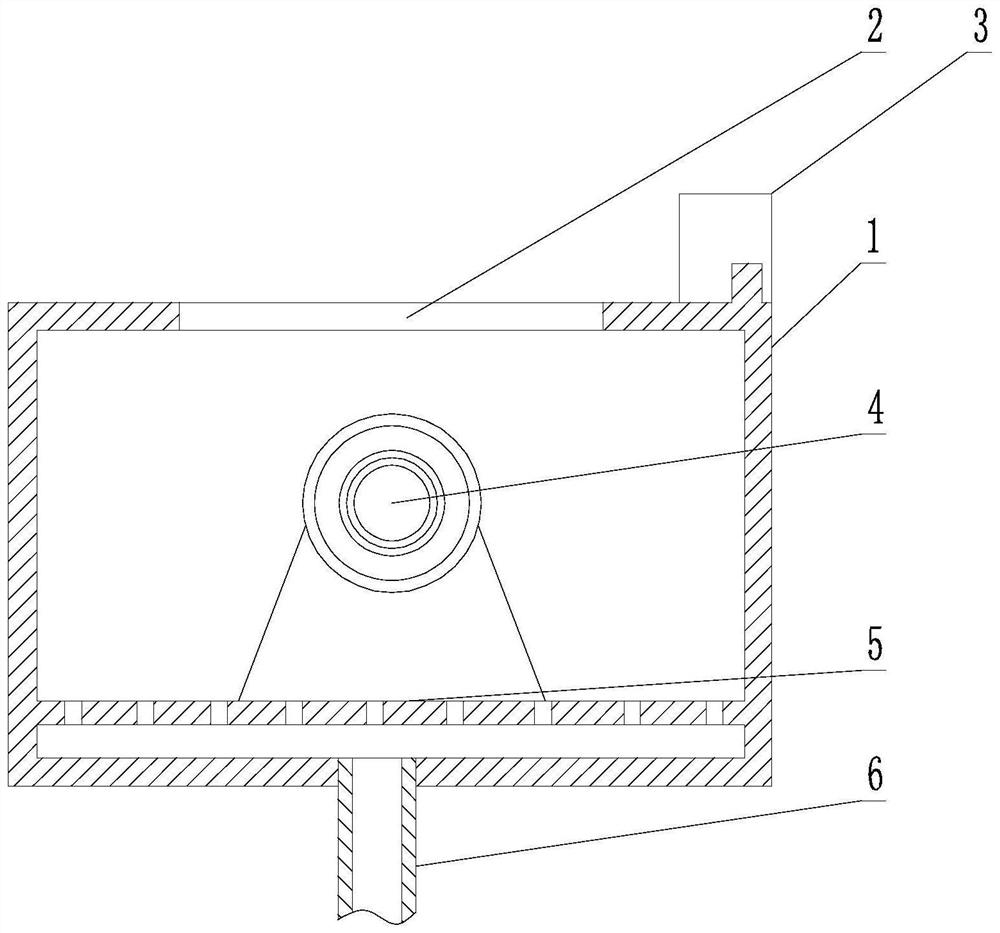

Medical care atomizer with improved inner air currents

The application belongs to the field of medical apparatuses, and particularly relates to a medical care atomizer with improved inner air currents. According to the medical care atomizer disclosed by the application, through a stopping member adopting an inversed truncated cone body structure, a special cavity structure and an outside air entering passage are arranged, so that fog granules with lowparticle diameter can be effectively screened and enter human bodies, and the atomization efficiency can also be improved.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

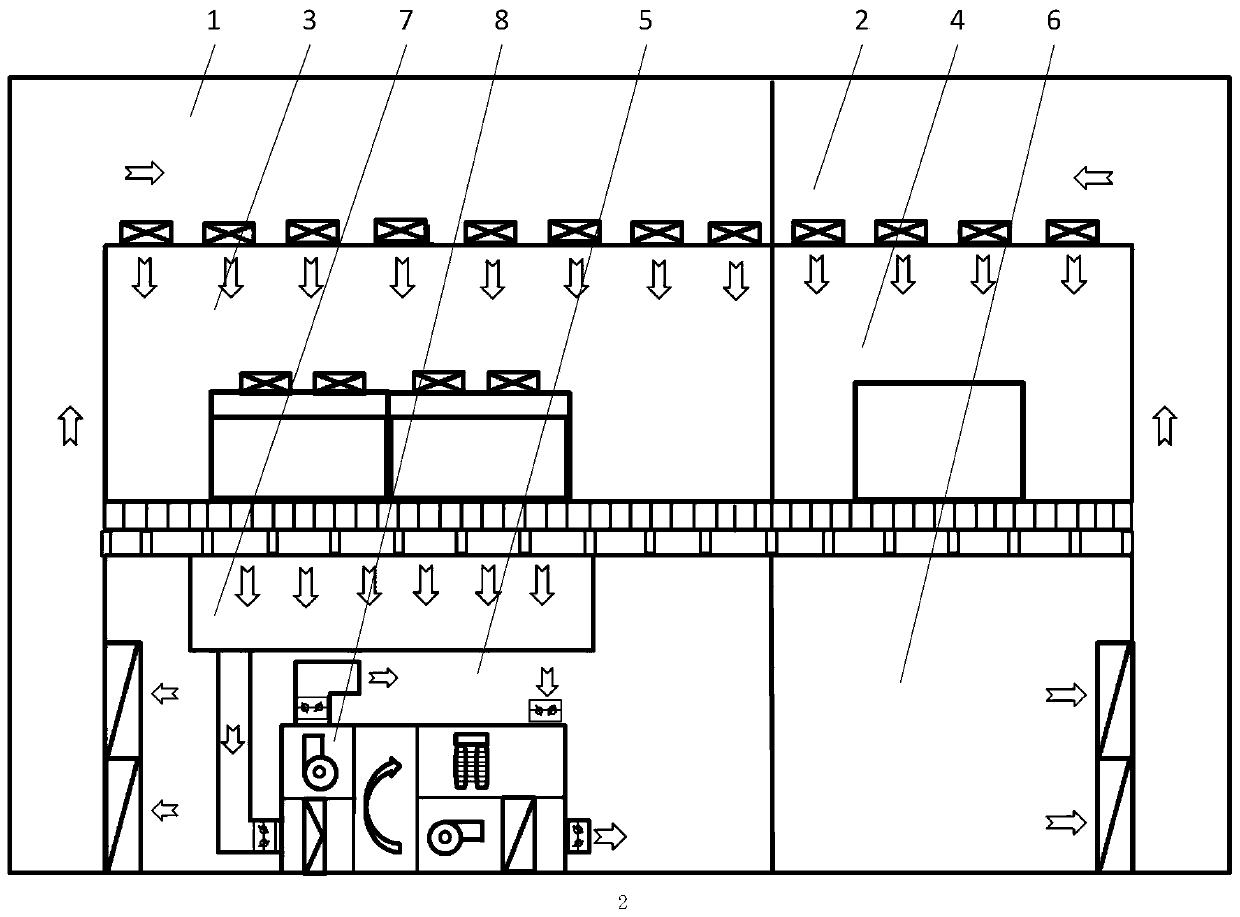

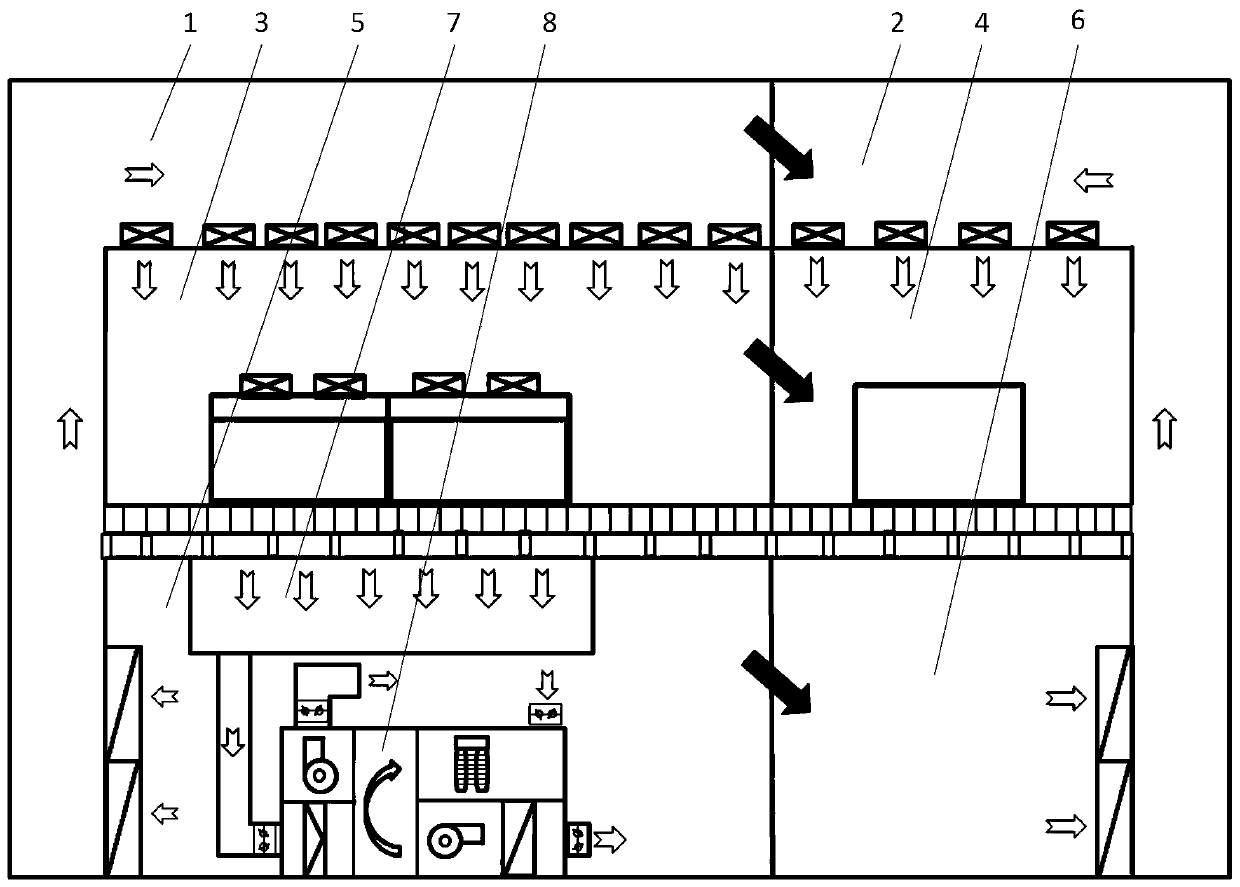

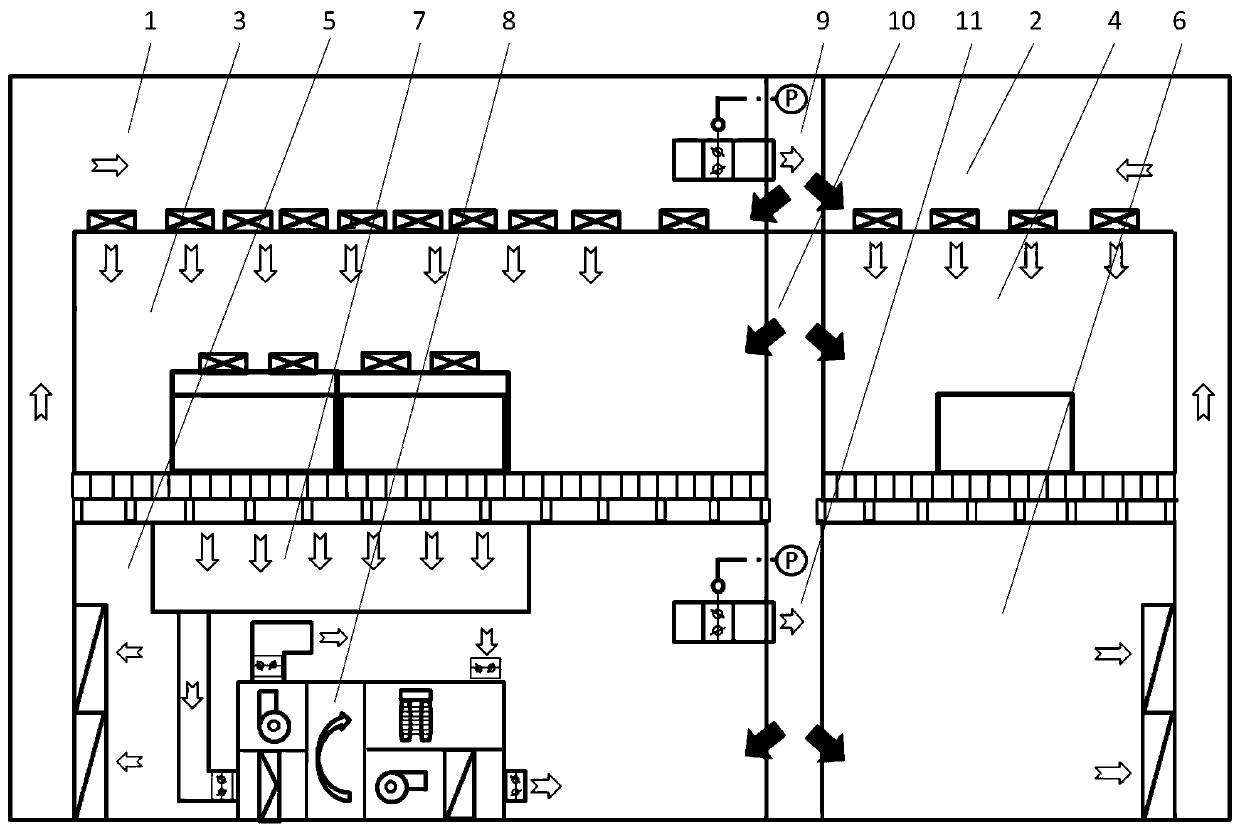

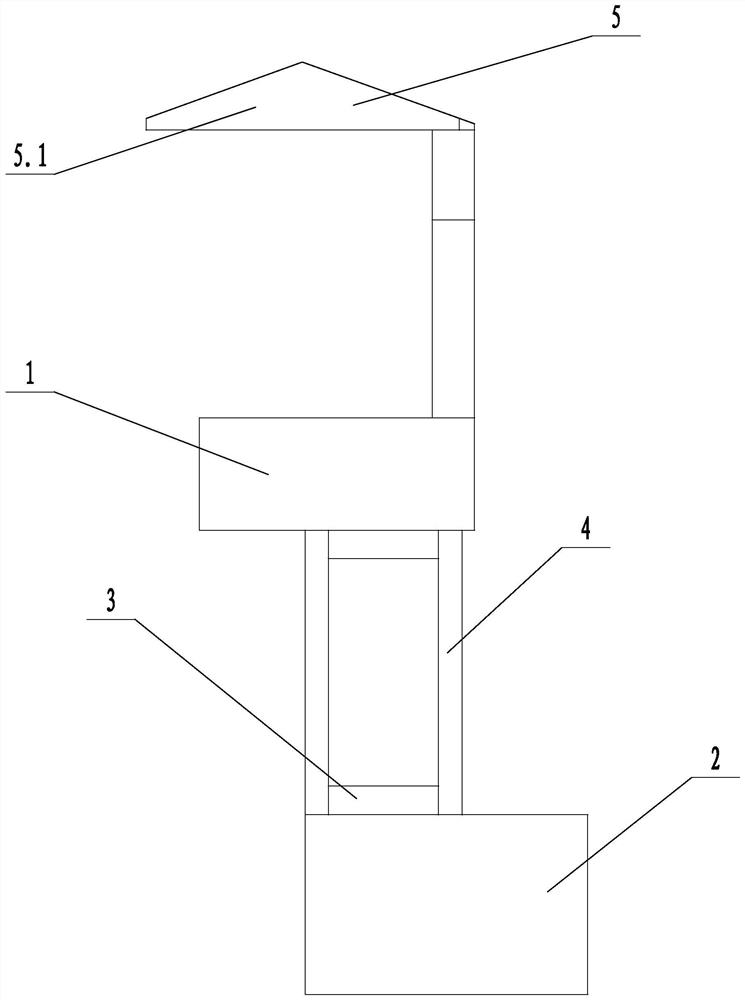

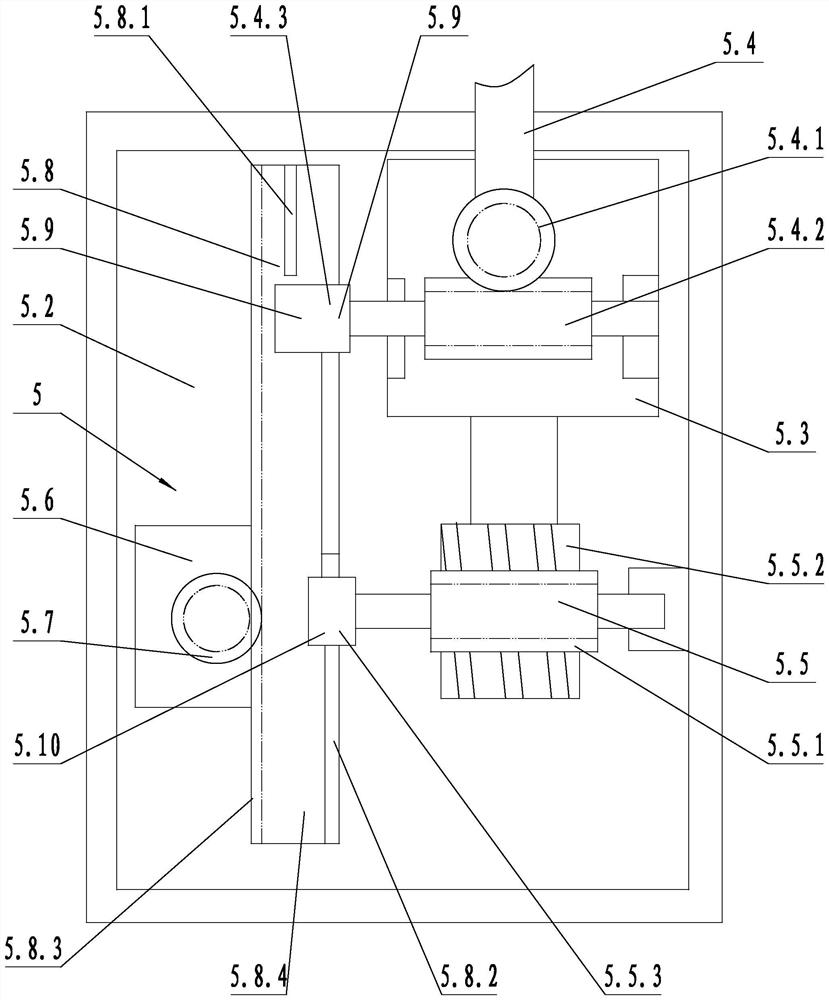

Clean room

PendingCN110439332AReduce or avoid access toImprove yieldDucting arrangementsMechanical apparatusDouble wallEngineering

The invention relates to the technical field of clean plants, and discloses a clean room. The clean room includes a pressure regulating equipment assembly, and the pressure regulating equipment assembly is used for regulating air pressure in a double wall sandwich channel of an upper technical interlayer to make the air pressure in the double wall sandwich channel of the upper technical interlayerhigher than air pressure in an adjacent upper technical interlayer with a pollution source and an adjacent upper technical interlayer without the pollution source when the clean room is in normal production; and / or the pressure regulating equipment assembly is used for regulating air pressure in a double wall sandwich channel of a lower technical interlayer to make the air pressure in the doublewall sandwich channel of the lower technical interlayer higher than that in an adjacent lower technical interlayer with the pollution source and an adjacent lower technical interlayer without the pollution source when the clean room is in normal production, or, make the air pressure in the double wall sandwich channel of the lower technical interlayer less than that in the adjacent lower technicalinterlayer with the pollution source and the adjacent lower technical interlayer without the pollution source when the clean room is in normal production. According to the disclosed clean room, pollutants generated by a production area with the pollution source entering a production area without the pollution source can be lowered or avoided to increase the yield of products in the production area without the pollution source.

Owner:S Y TECH ENG & CONSTR CO LTD +1

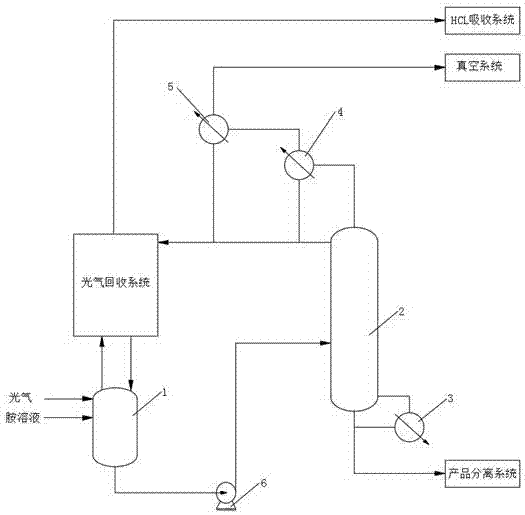

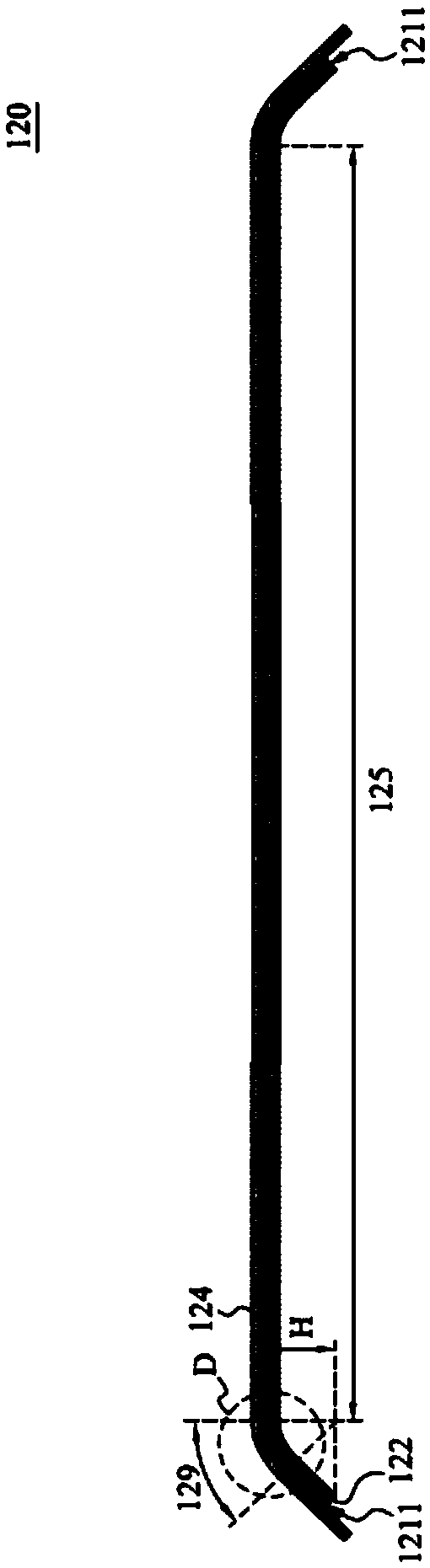

Method for removing phosgene from isophthalylidene diisocyanate

ActiveCN108003060AReduce or avoid access toSolve the difficulty of removalOrganic compound preparationIsocyanic acid derivatives purification/separationBoiling pointProduct gas

The invention discloses a method for removing phosgene from isophthalylidene diisocyanate. The method includes the steps that isophthalylidene diisocyanate (XDI) actinic solution containing a high-boiling-point solvent enters a phosgene removal tower of a negative-pressure operation system, the temperature of the tower is adjusted to be proper to remove residue phosgene, then the temperature of atower top condenser is adjusted to condense the tower top solvent, the phosgene and other mixed gas at the same time, the phosgene is reduced as much as possible or prevented from entering a vacuum system, and tower top condensate serves as an absorbing agent to be used for a phosgene recycling system. The method is suitable for removing the phosgene by using the high-boiling-point solvent and theXDI with a heat sensitivity problem or similar isocyanate. The method is high in phosgene removing capacity, reduces the load of the vacuum system, reduces the consumption of a cryogenic medium, andomits the process that parts of solvents are specially removed to be used for the phosgene recycling system.

Owner:QINGDAO UNIV OF SCI & TECH +1

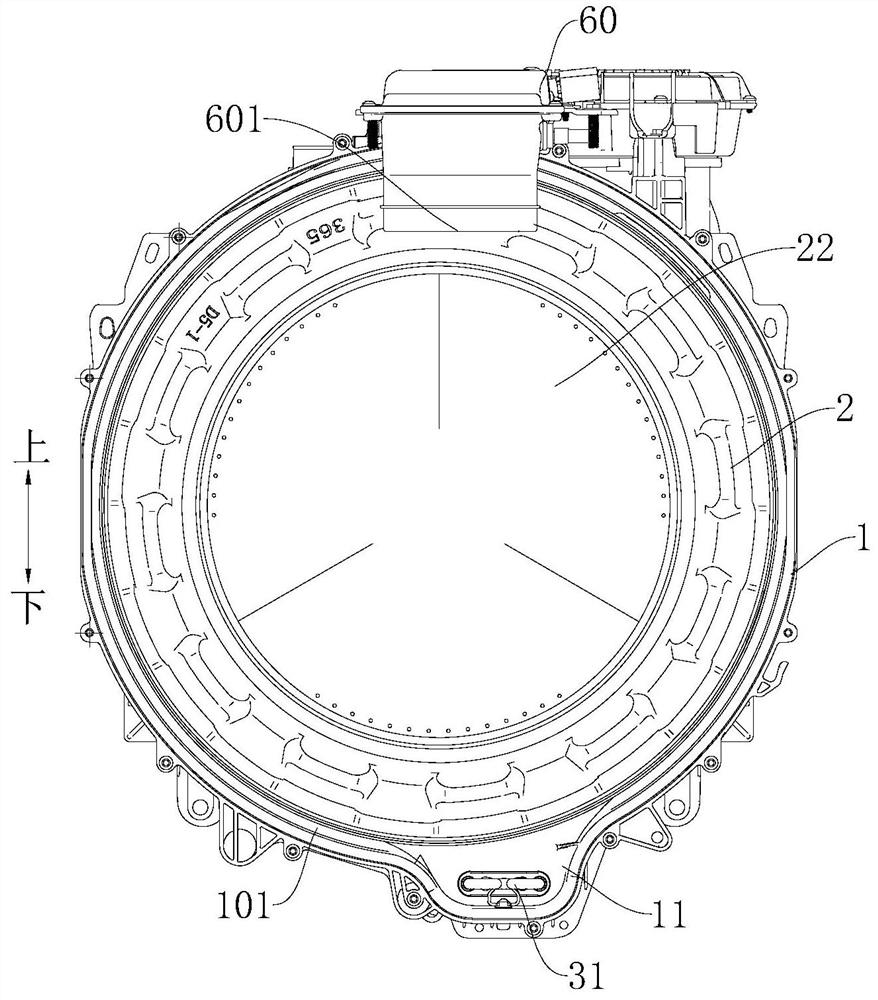

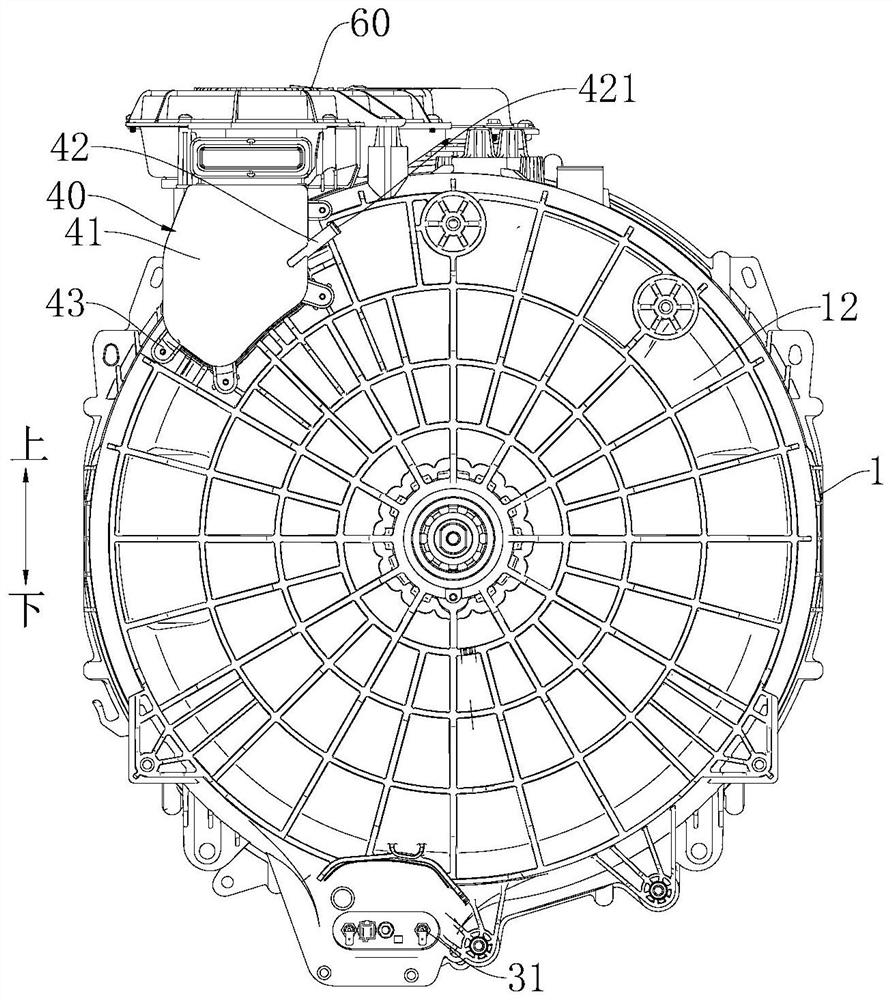

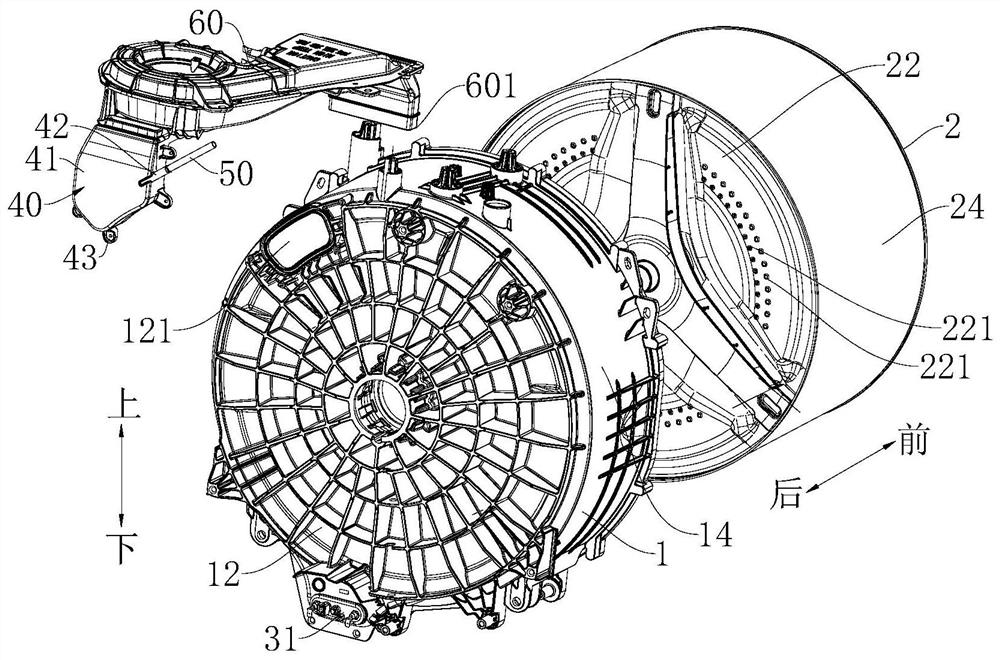

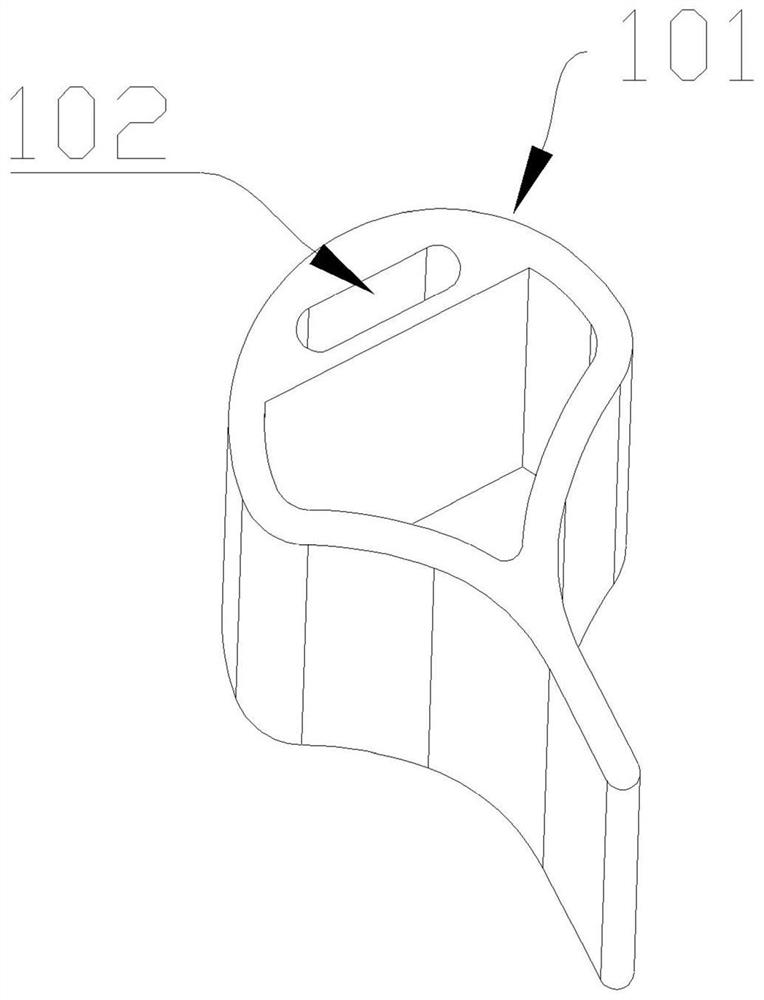

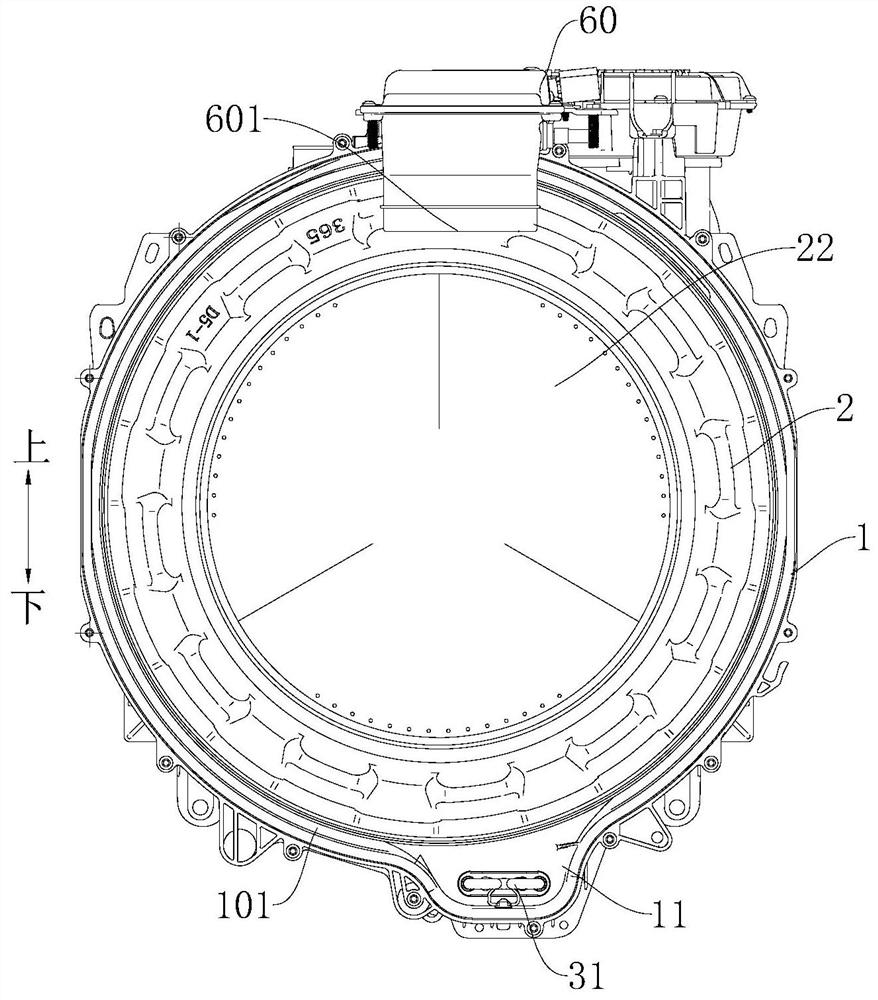

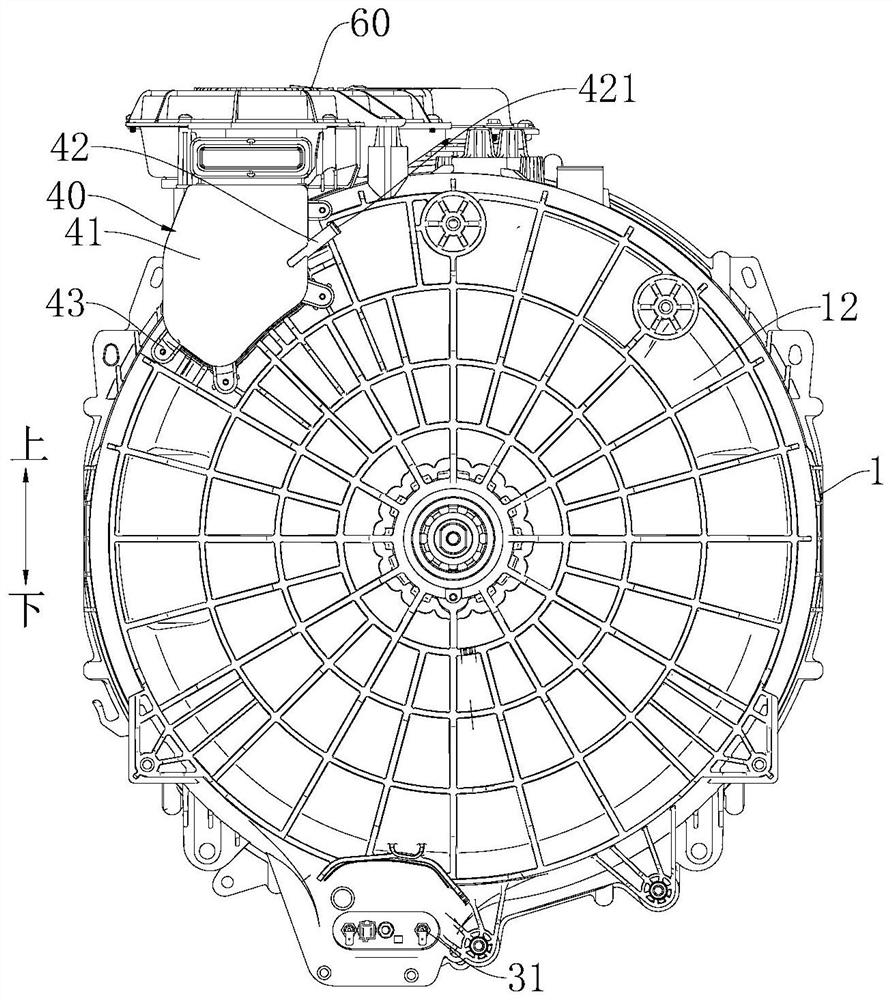

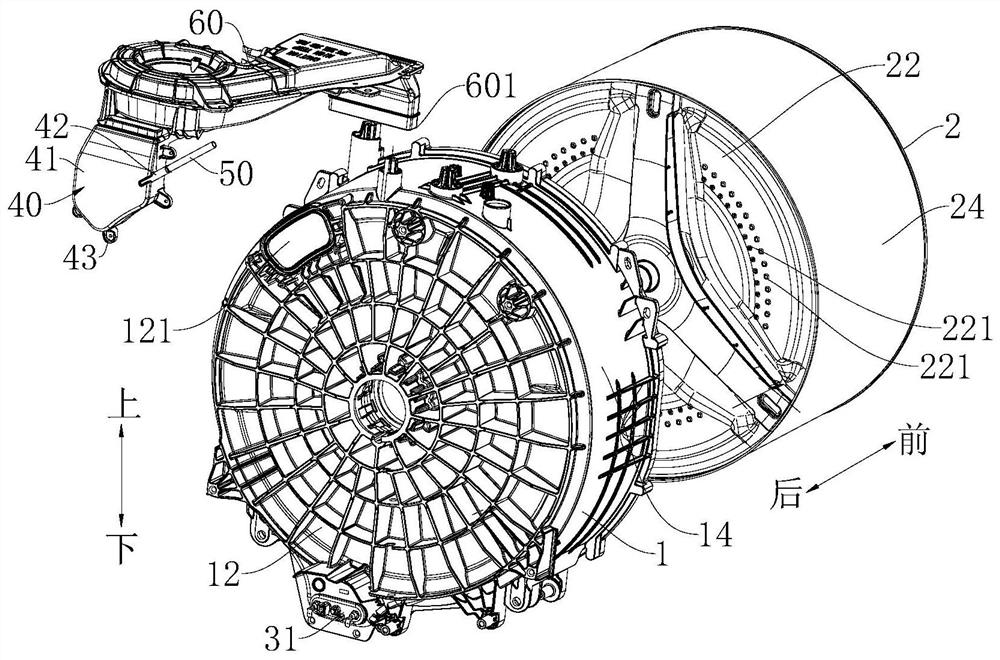

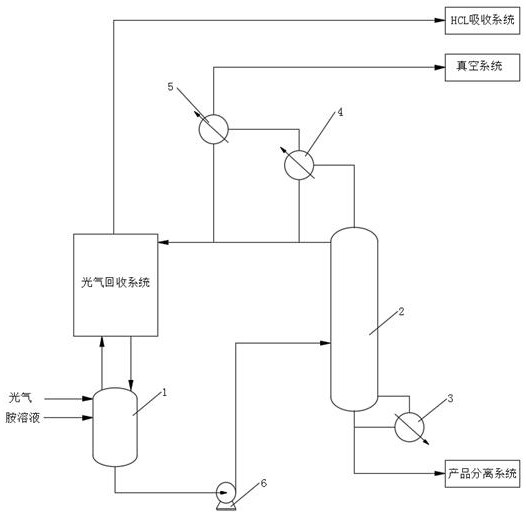

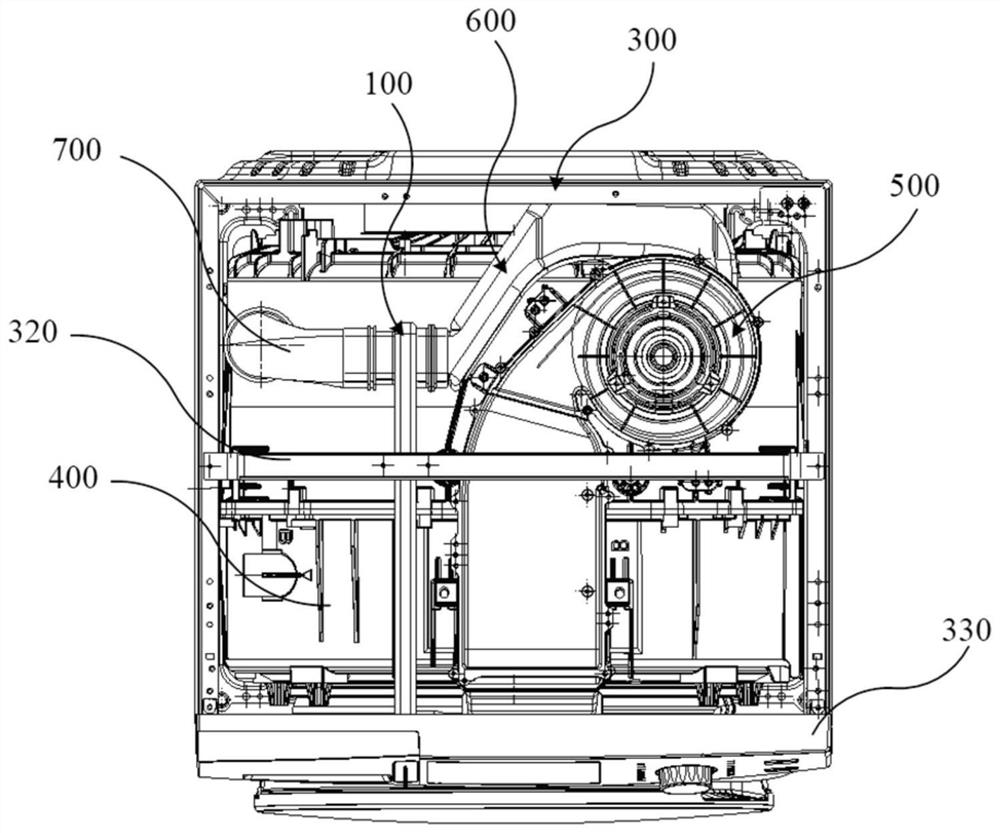

Barrel assembly and clothes processing equipment

ActiveCN113152025AImprove performanceReduce or avoid access toOther washing machinesTextiles and paperWater storageEngineering

The invention discloses a barrel assembly and clothes processing equipment. The barrel assembly comprises an outer barrel, an inner barrel and a first heating part. A water storage area is arranged on the inner lower portion of the outer barrel; a water inlet is formed in the outer barrel; the first heating part is arranged in the water storage area and used for heating water in the water storage area to generate steam; the inner barrel is rotatably arranged in the outer barrel; a partition cavity is defined between the outer barrel and the inner barrel; a communicating hole for communication between a clothes processing cavity and the partition cavity is formed in the inner barrel; and when the inner barrel is located at any angle position, the water inlet and the communicating hole are staggered. According to the barrel assembly in the embodiment of the invention, a steam washing mode can be achieved without additionally arranging a steam generator, and the relative positions of the communicating hole in the inner barrel and the water inlet in the outer barrel are optimally designed, so that the situation that water enters the inner barrel can be reduced or prevented in the process of supplying the water to the water storage area, the situation that the clothes are wetted can be reduced or prevented in the steam washing mode, the requirement for steam washing is met, and the steam washing performance of the whole machine is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

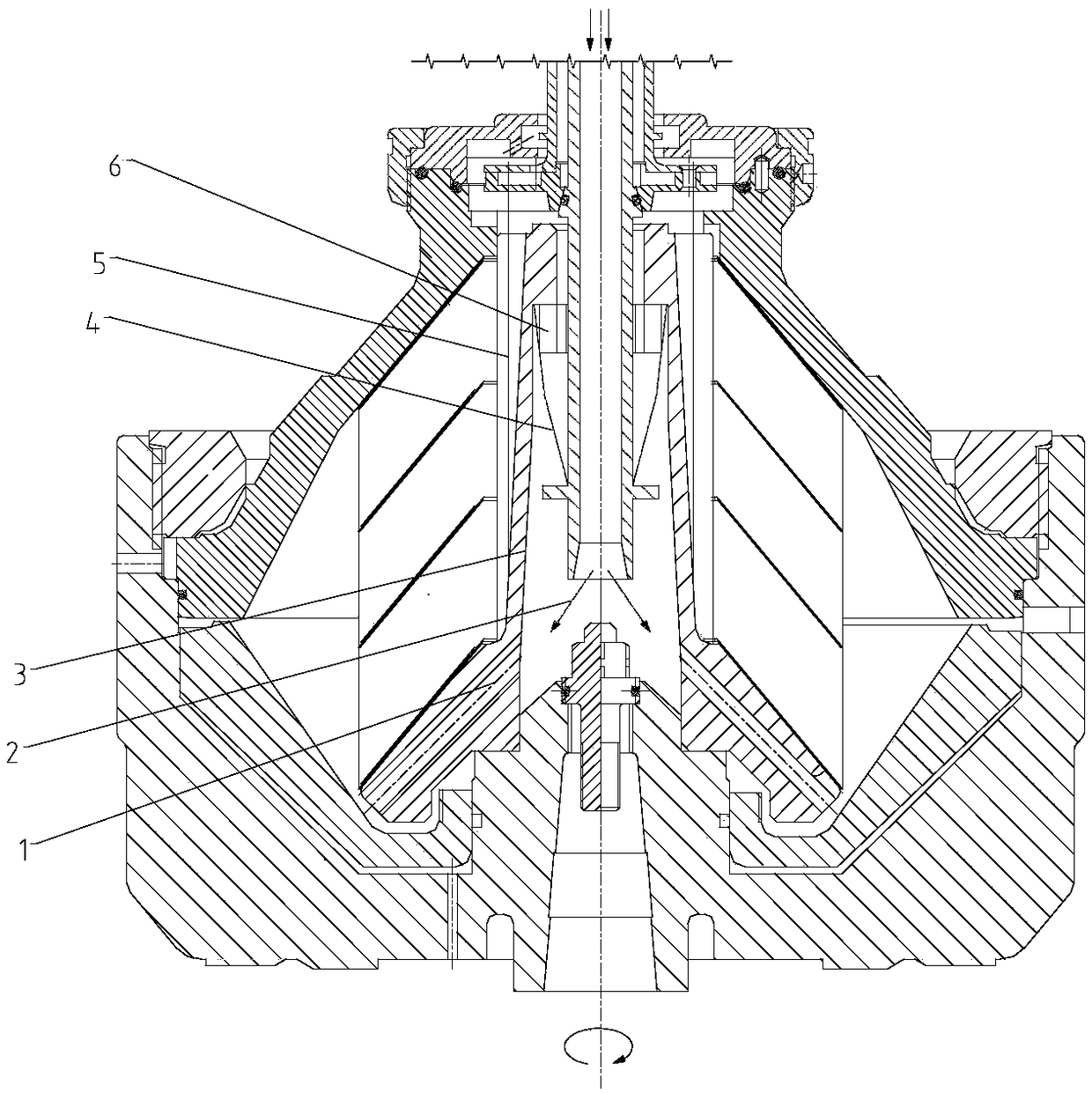

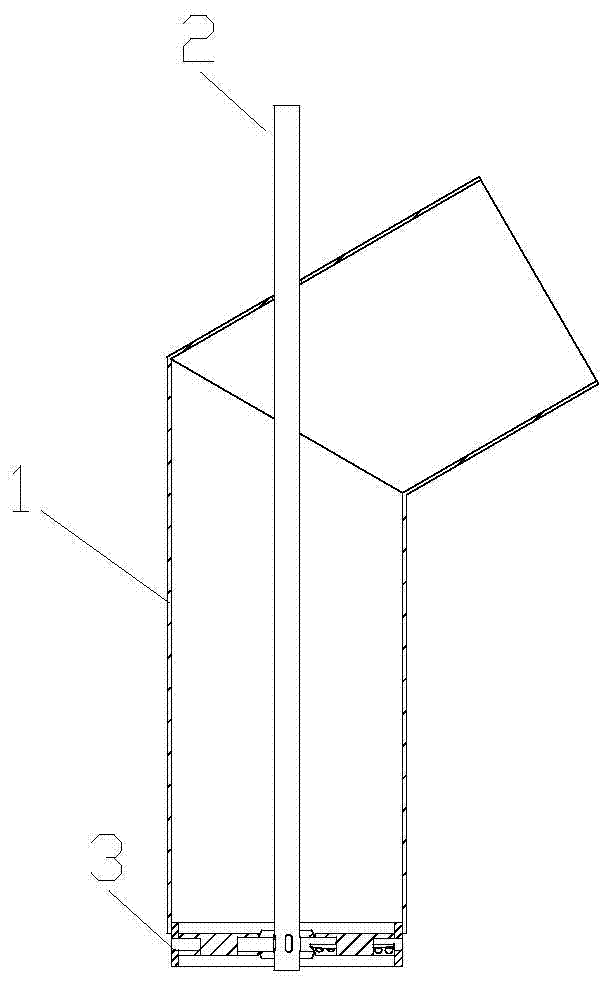

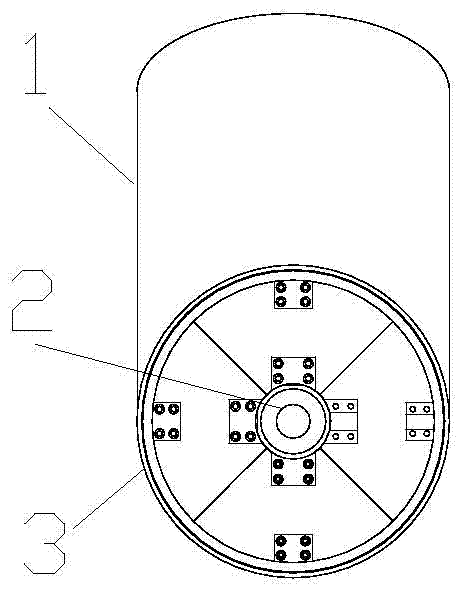

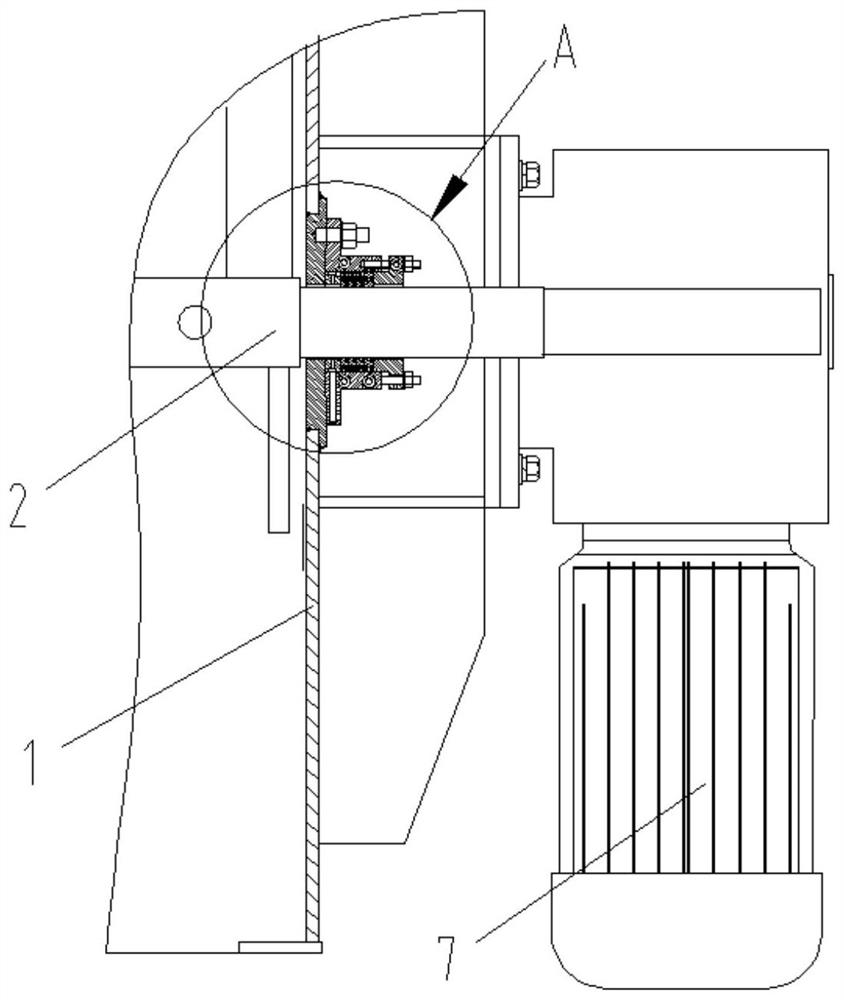

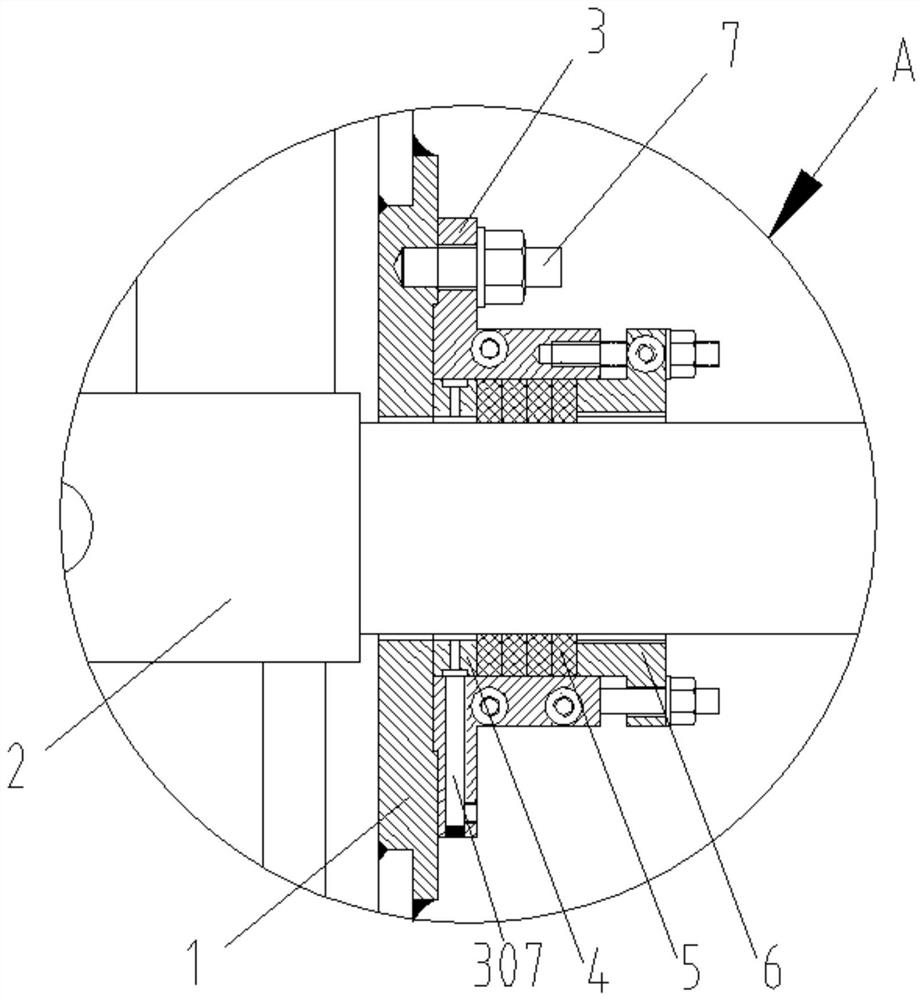

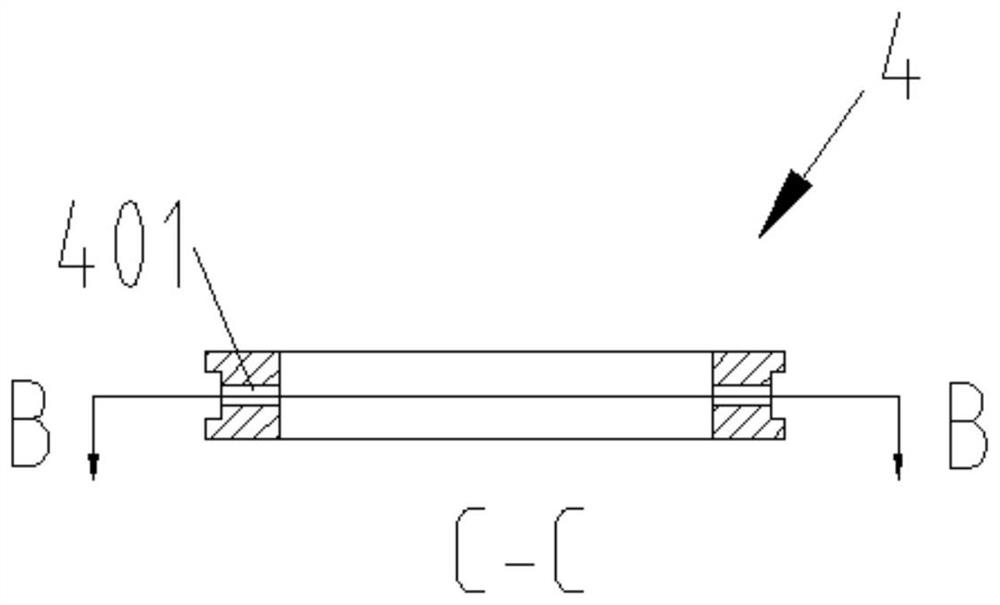

Disc type separator seal feeding device

The invention discloses a disc type separator seal feeding device. A feeding pipe is fixed to a rack of a separator body. A centripetal pump is arranged at the middle section of the feeding pipe in the circumferential direction, and the lower section of the feeding pipe goes deep into the feeding section of a distributor through a through hole in the distributor. A screw plug is located on the lower side of the centripetal pump and is fixedly connected with the distributor. The distributor is arranged on a drum body and connected with a discharging port of the feeding pipe through a feeding hole in the bottom of the distributor. At least four through holes or groove profile runners are evenly distributed in the lower portion in the distributor according to the flow, increasing is conductedwith even number times, and anti-overflow ribs are symmetrically distributed at the upper portion of an inner cavity of the distributor in the axial direction of the feeding pipe. The disc type separator seal feeding device is stable in feeding, a liquid seal layer is stable, the situation that air enters a separation area along with materials is reduced or avoided, and the separation effect is improved.

Owner:CSSC NANJING LUZHOU MACHINE

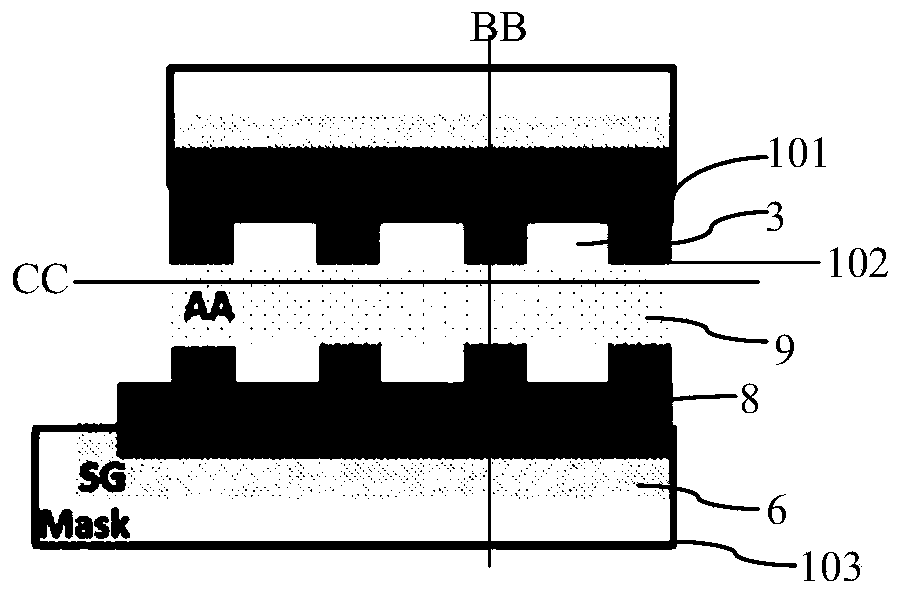

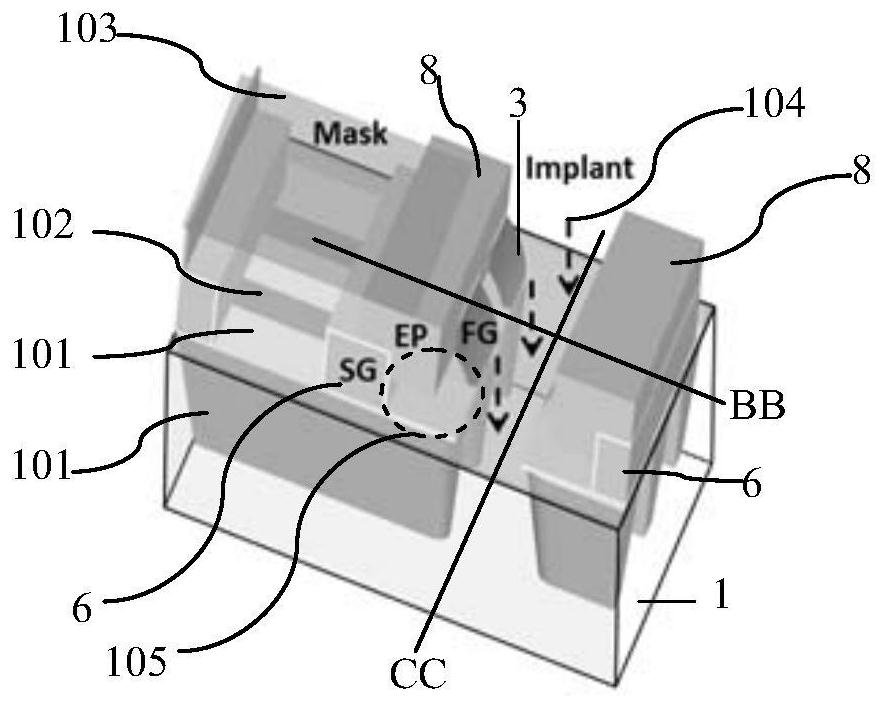

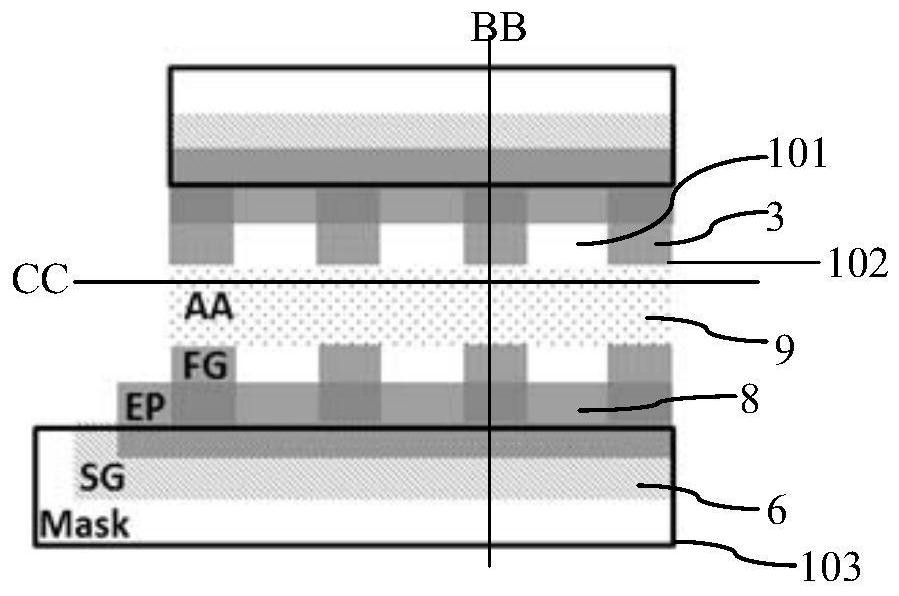

Method for manufacturing split-gate flash memory

ActiveCN109727986AReduce or avoid access toAvoid enteringSolid-state devicesSemiconductor devicesEngineeringMechanical engineering

The invention discloses a method for manufacturing a split-gate flash memory, comprising forming field oxide in a semiconductor substrate and isolating a plurality of active regions, wherein each active region comprises a plurality of active region rows which are strip structures and in parallel, the active region rows corresponding to a source region communicate with one another in a column direction to form an active region column; forming selection gates which are strip column structures and are in parallel; forming floating gates at the active region rows of the first sides of the corresponding selection gates; forming erase gates covering the top surfaces of the first sides of the selection gates and extending to the tops of the floating gates; covering the two sides of each floatinggate vertical to the active region columns with a dielectric layer; forming a photoresist pattern to open the active region column, the partial regions of the erase gates adjacent to the first side, and the floating gates outside the first side; performing source implantation. The method can protect the floating gates in source implantation and prevents the source implantation from affecting channel punchthrough, thereby improving device performance.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

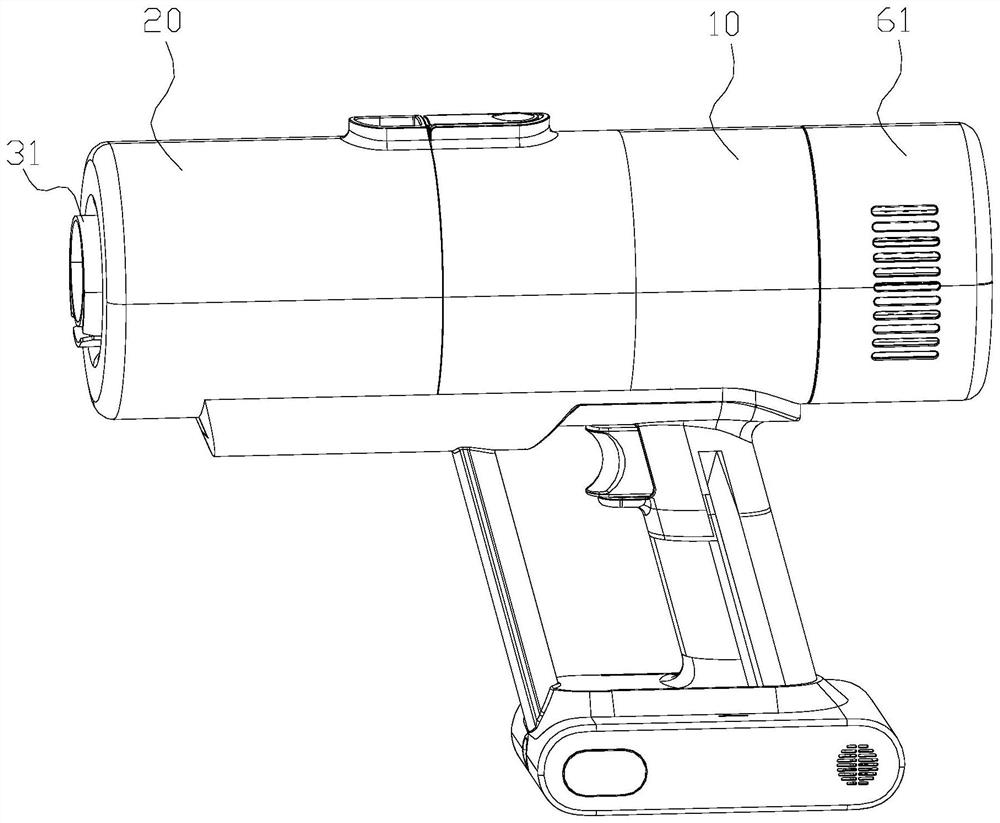

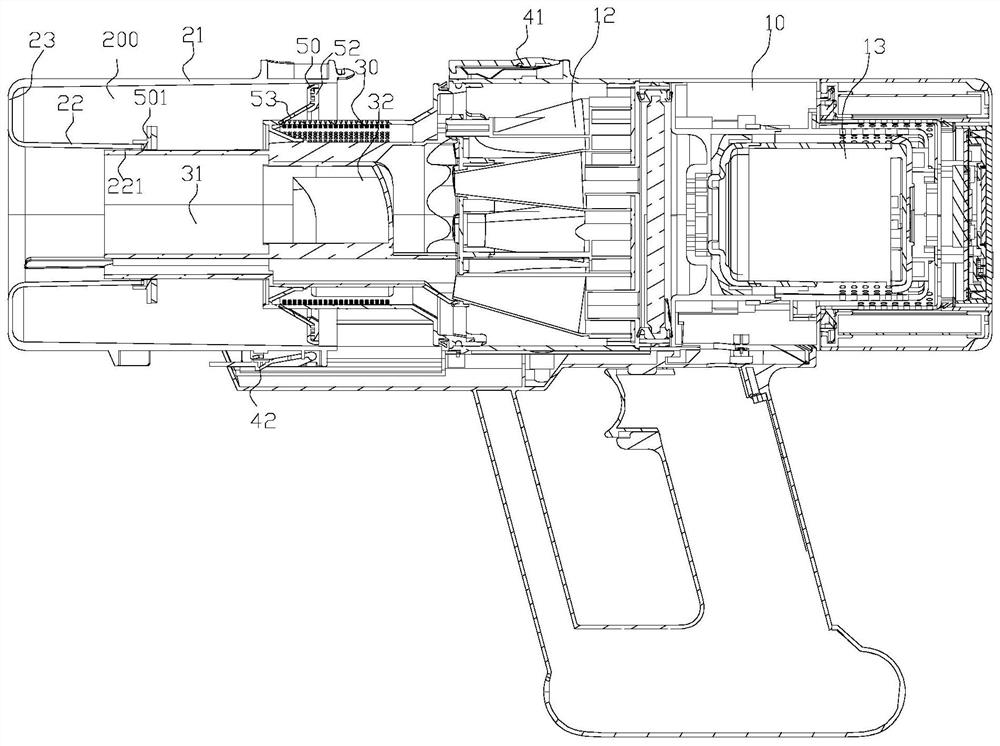

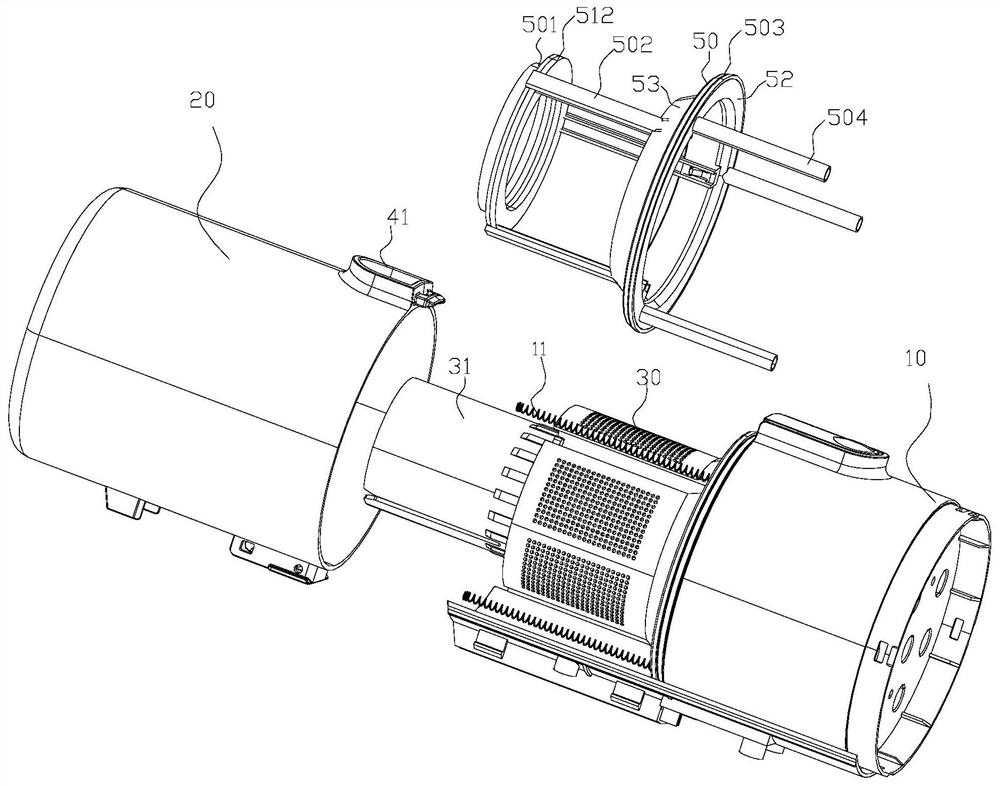

Cleaning device

PendingCN112656291AReduce or avoid access toAvoid enteringCleaning filter meansSuction filtersEnvironmental engineeringMechanical engineering

The present invention provides a cleaning device which comprises a main body part on which a filter for filtering dust air is mounted, and an air inlet pipeline through which the dust air is introduced into the filter; the device also comprises a dust cup which moves close to the air inlet pipeline; and an ejection device, wherein one end of the ejection device is installed on the main body part, the other end of the ejection device abuts against the dust cup, an ash scraping part is installed on the ejection device, and the an ash scraping part abuts against or abuts against the filter; when the ejection device moves, the abutting dust cup is pushed to move, and meanwhile the dust scraping part scrapes the filter. The automatic ash scraping can be achieved while the ejection dust cup moves; in the ejection process of the dust cup, the dust cup is tightly attached to the air inlet pipeline, and an overlapping part exists between the dust cup and the air inlet pipeline, so that dust in a first-stage dust area is reduced or prevented from entering the air inlet pipeline, and dust raising is reduced or avoided; in the ejection process of the dust cup and after ejection, the first-stage dust area between an outer barrel and an inner barrel is always sealed, dust raising is effectively prevented, and the influence on user experience and the dust collection effect is reduced or avoided.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

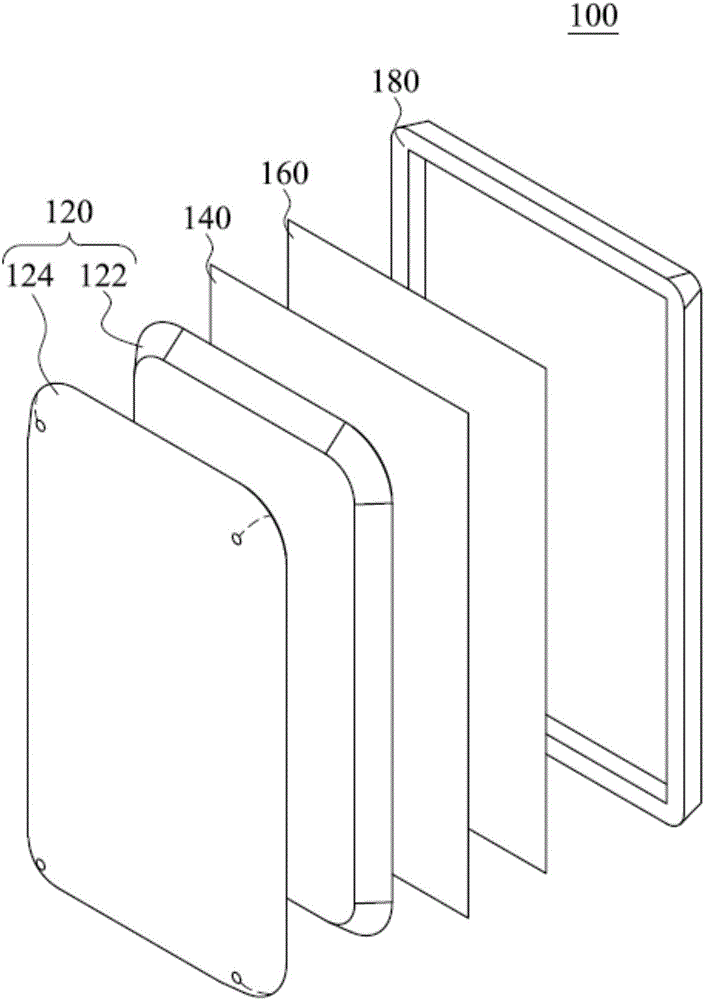

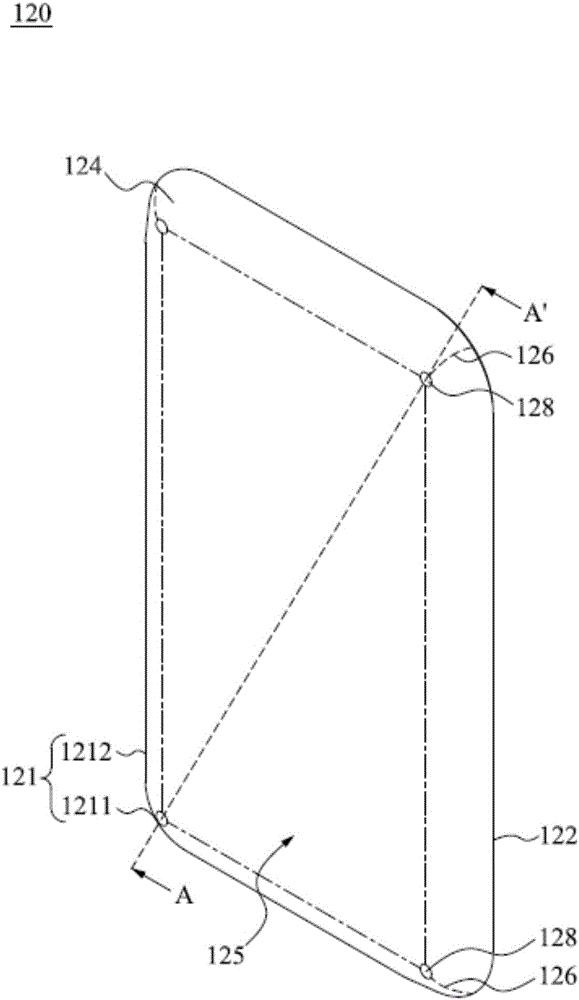

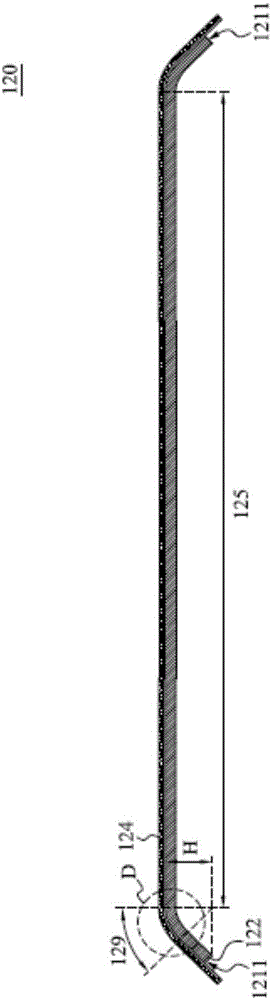

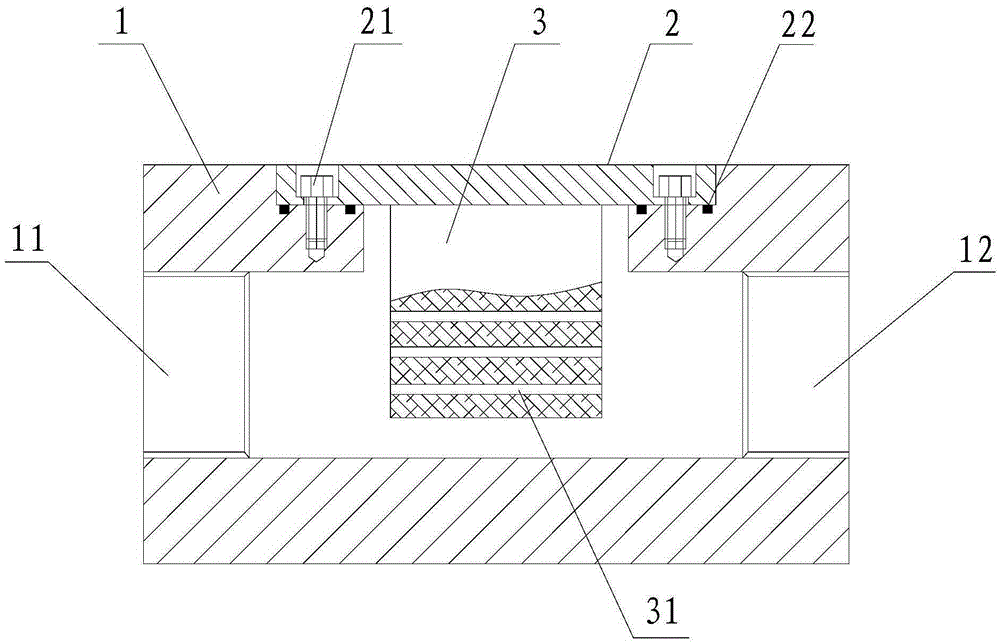

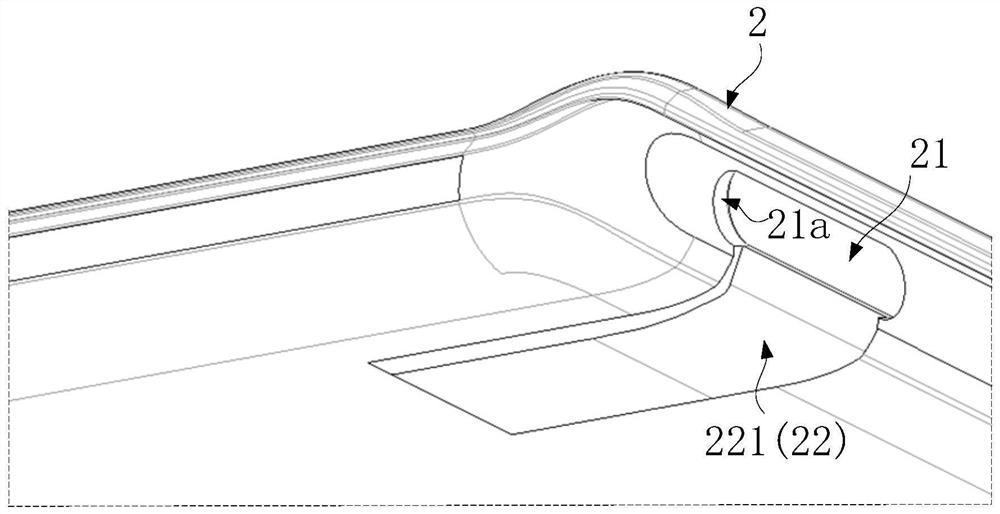

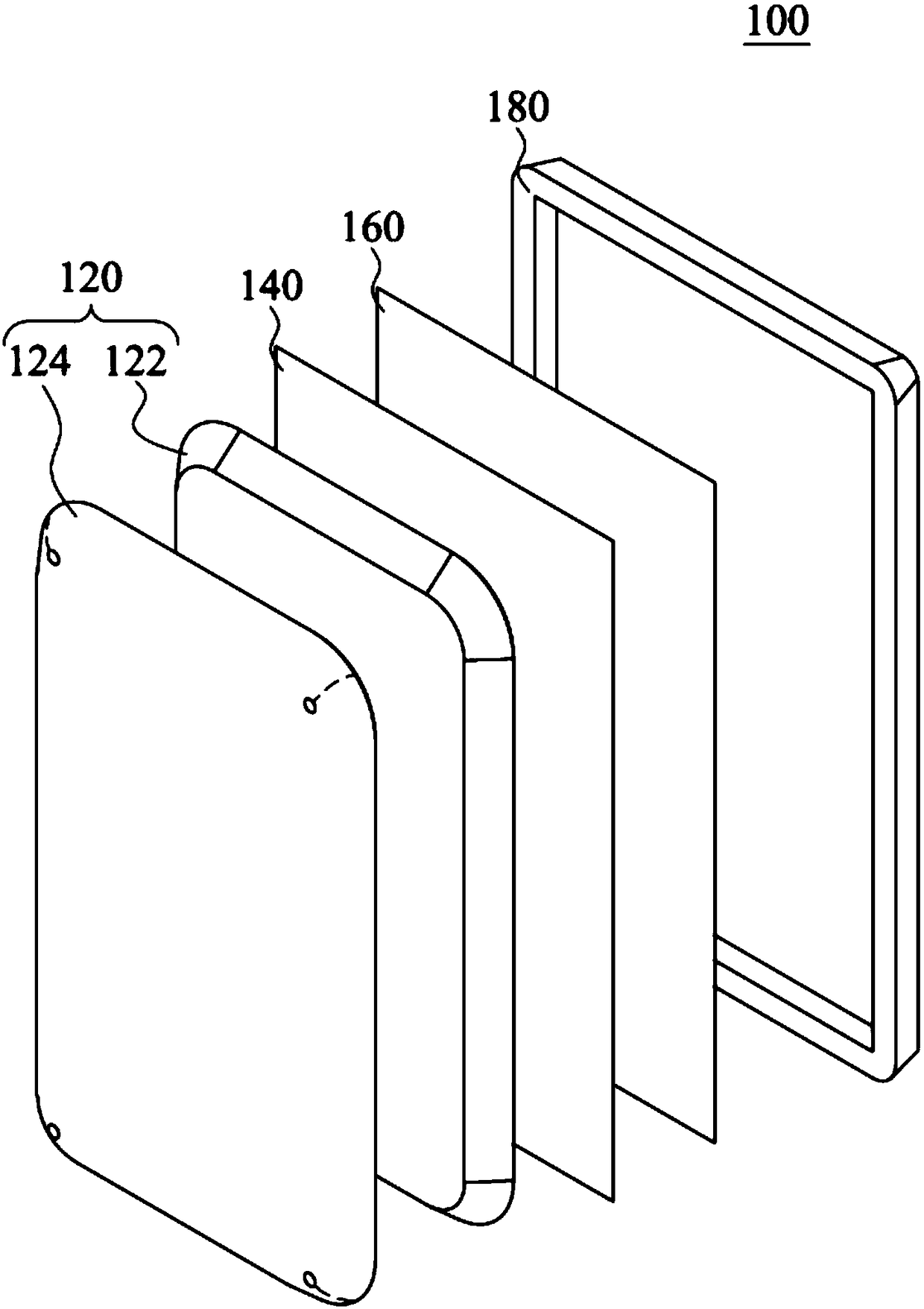

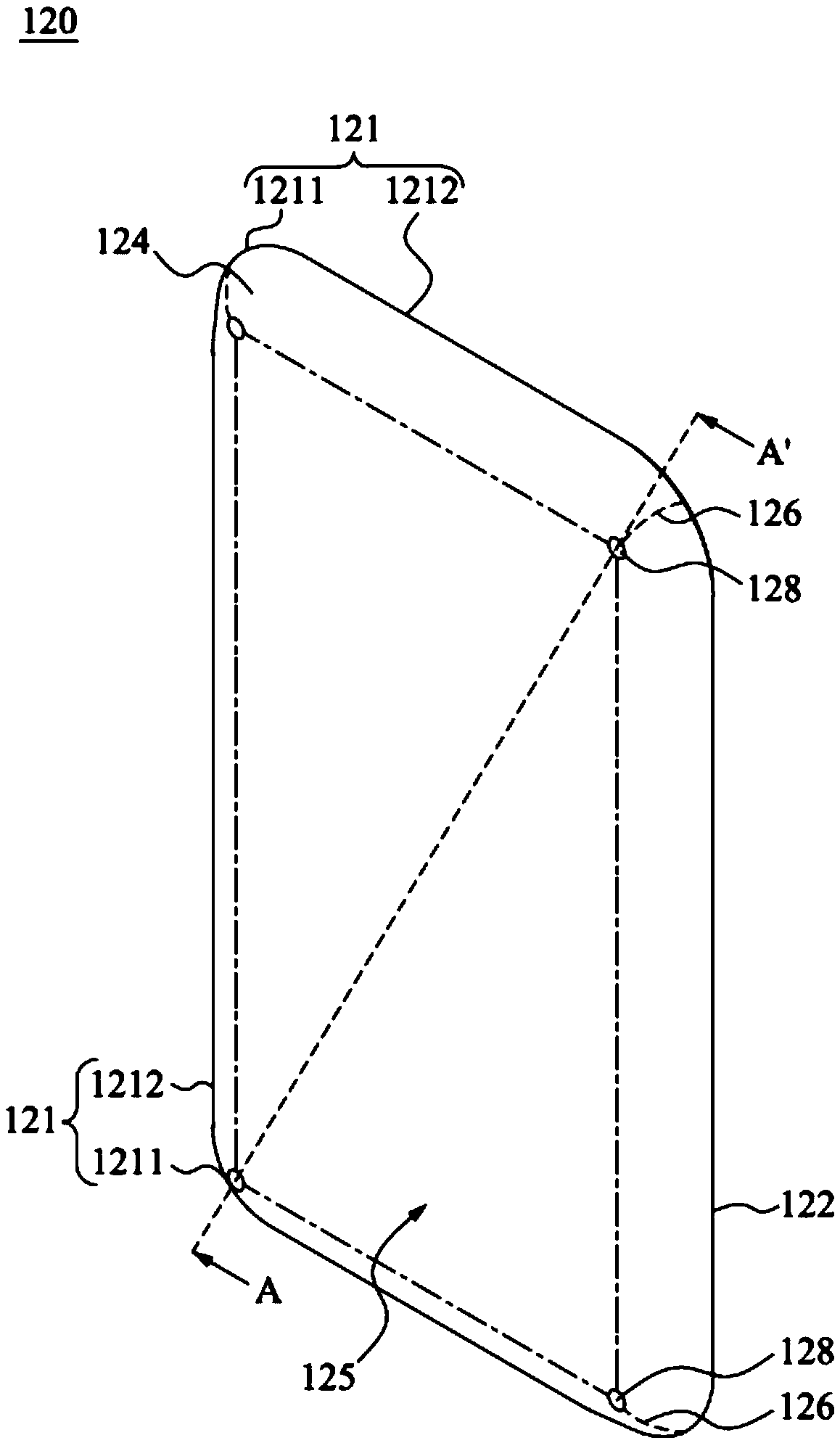

Three-dimensional-curved-surface panel, three-dimensional-curved-surface touch panel with same and three-dimensional-curved-surface touch display panel with same

ActiveCN106564264AImprove yieldAvoid scratchesFlexible coversWrappersTectorial membraneForeign matter

The invention relates to a three-dimensional-curved-surface panel. The three-dimensional-curved-surface panel comprises a covering layer and a protective film. The covering layer is provided with a three-dimensional curved surface. The height of the three-dimensional curved surface changes from the edges of the covering layer to the central area of the covering layer. The protective film is attached to the surface of the covering layer. The protective film is provided with shear lines. The shear lines extend from the edges of the covering layer to the central area of the covering layer. Because the shear lines extending from the edges of the covering layer to the central area of the covering layer are formed on the protective film, thee protective film can be well attached to the covering layer of the three-dimension curved surface. In this way, external influences on the covering layer protected by the protective film can be reduced or avoided; and for instance, external foreign matter is prevented from entering the three-dimensional-curved-surface panel, and the covering layer is prevented from being scratched.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Filter unit applied to plug-pull type hydraulic system

InactiveCN105351286AReduce pollutionReduce or avoid access toFluid-pressure actuator componentsSlagPulp and paper industry

The invention discloses a filter unit applied to a plug-pull type hydraulic system and belongs to the field of hydraulic equipment. The filter unit comprises a hollow shell provided with an inlet and an outlet; the sidewall of the shell is provided with a through hole; the through hole is matched with an end cover; a magnet is mounted on the inner side of the end cover. The filter unit disclosed by the invention has the beneficial effects that the filter unit is connected to a pipeline of the hydraulic system, iron slag in hydraulic oil can be attracted by the magnet so as to be attached to the magnet when the hydraulic oil passes through the filter unit, subsequently iron-containing impurities entering the hydraulic system can be effectively reduced or avoided by just periodically clearing the iron slag on the magnet, and the pollution of the hydraulic oil is alleviated, so the wear degree of the equipment is alleviated, the service life of the equipment is prolonged, the stability of the equipment is improved, the using cost and the maintenance cost of the equipment are effectively lowered.

Owner:RUI STEEL INDAL OF PANZHIHUA GANGCHENG GROUP

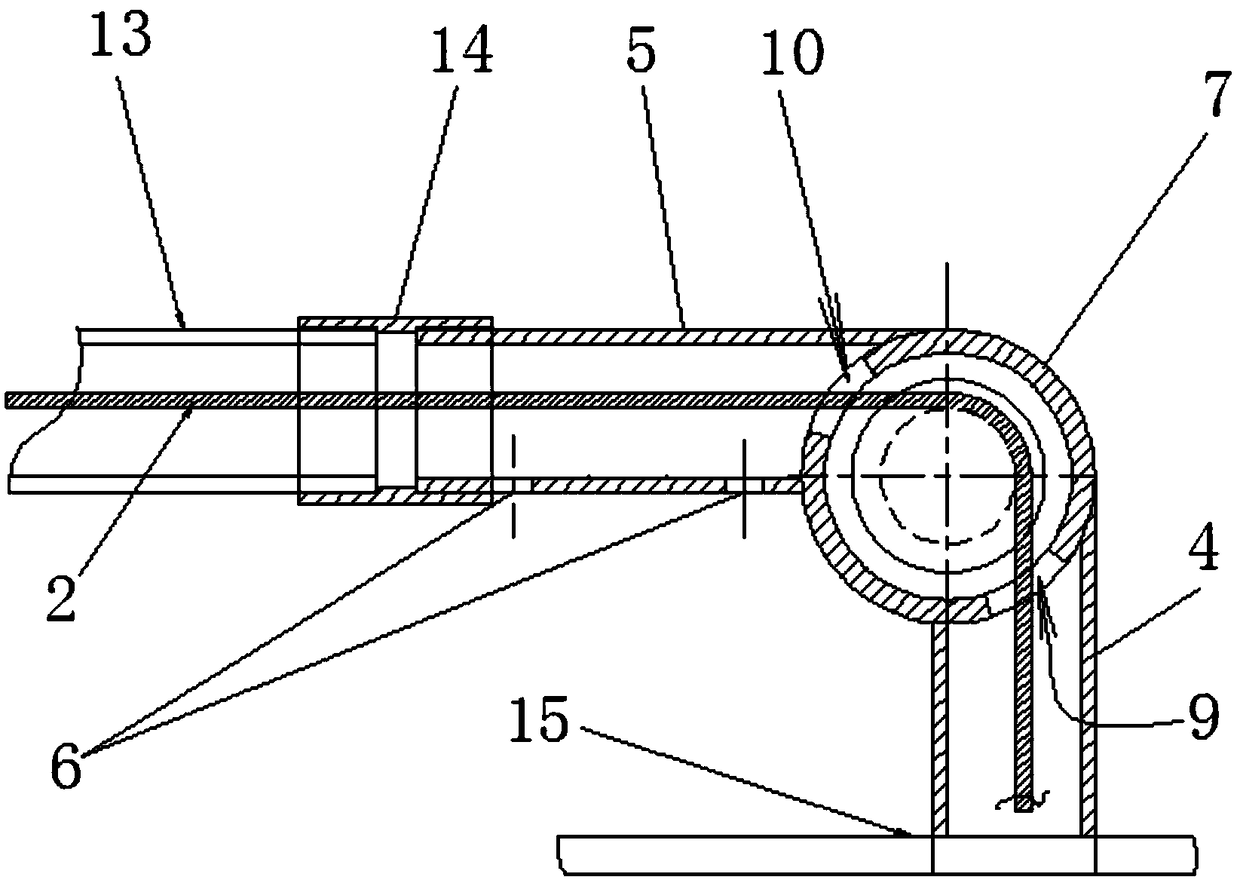

A pea-cannon whistle pistol

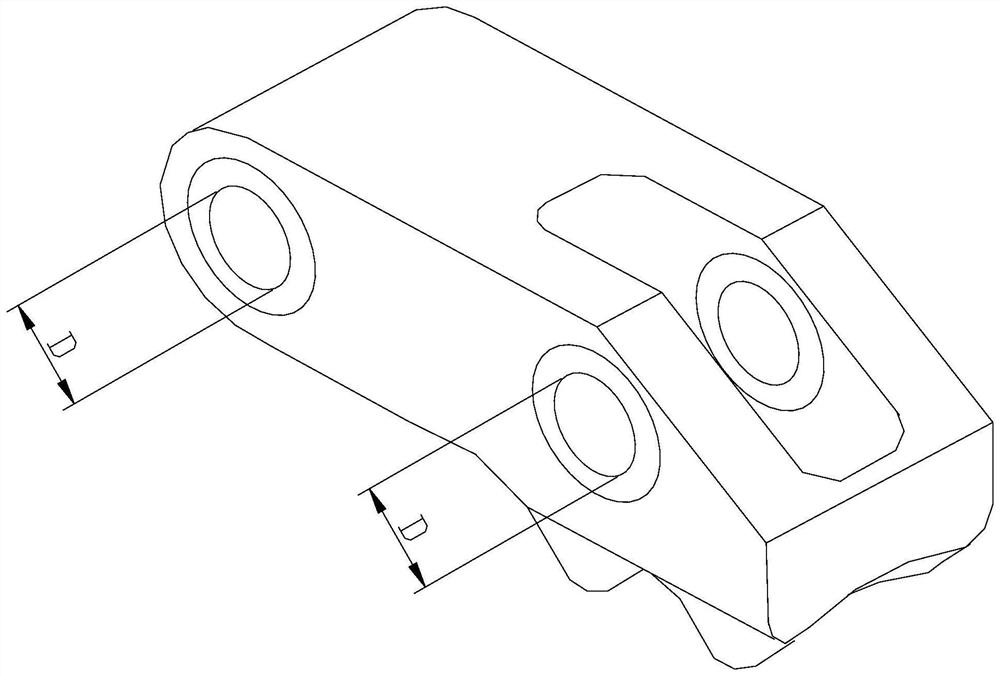

InactiveCN109094751AImprove reliabilityReduce welding distortionAcoustic vessel signallingPulleyIndustrial engineering

The invention relates to the technical field of marine equipment, which discloses a pea cannon type whistle pull pistol, Including pulley block, the inner cavity of the pulley base is provided with arotatable pulley assembly for guiding a whistle pulling rope, The lower end of the pulley seat is connected with a vertical threading pipe communicated with the inner cavity of the pulley seat, a lateral threading pipe communicated with the inner cavity of the pulley seat is arranged on a lateral side of the pulley seat, and a water drop hole is arranged on the lower inner wall of the lateral threading pipe. The invention improves the rain-proof performance of the whistle pulling pistol.

Owner:CHENGXI SHIPYARD

Darkroom detection device and method

The invention relates to the technical field of display, in particular to a darkroom detection device and method, the darkroom detection device comprises a darkroom body, a bearing platform, a drivingmechanism, a shading plate and a detection assembly, the darkroom body is provided with a hollow cavity, and the side surface is provided with an opening part; the bearing platform is used for placing at least one to-be-detected piece; the driving mechanism is used for driving the bearing platform to move horizontally, so that the bearing platform penetrates through the opening part and is arranged inside the hollow cavity or outside the darkroom body; the shading plate is arranged at one end of the bearing platform and used for at least partially covering the opening part when the bearing platform is located in the hollow cavity; and the detection assembly is arranged in the hollow cavity and used for detecting the to-be-detected piece. According to the darkroom detection device, shakingof the darkroom detection device can be reduced, the step of adjusting the shading plate is omitted, and the detection accuracy of the to-be-detected piece is improved.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

A negative pressure device for the production port for organic silicon production

A negative pressure device for the discharge port used in the production of organic silicon, which relates to the field of organic silicon production equipment, including a discharge pipeline, a transmission shaft and a negative pressure mechanism, the negative pressure mechanism is arranged at the bottom of the discharge pipeline, and the The transmission shaft passes through the discharge pipeline and is connected to the negative pressure mechanism through the air-tight auxiliary shaft. The device is equipped with a negative pressure mechanism, which drives the air-tight auxiliary shaft to move through the transmission shaft in the discharge pipeline, thereby driving the air-tight plate to tilt to a certain side. There is an open or closed space between the air-tight plates, so that the material can be sealed and packaged during the entire silicone production material packaging process, reducing or avoiding the gas entering the sealed bag, increasing the amount of silicone material contained in the sealed bag and Material storage time.

Owner:蚌埠市万科硅材料科技有限公司

Environment-friendly steel lattice plate manhole cover

InactiveCN109555215APrevent movementAvoid enteringSewerage structuresArchitectural engineeringDrainage ditch

The invention provides an environment-friendly steel lattice plate manhole cover. The environment-friendly steel lattice plate manhole cover comprises a steel lattice plate and a filtering assembly, the filtering assembly comprises a filter screen and a filter screen framework, the filter screen is installed in the filter screen framework, the filter screen framework is provided with at least twoinstallation columns distributed circumferentially, the steel lattice plate comprises a frame body, and further comprises flat steel and cross rods which are arranged in the frame body in warp and weft arrangement, the outer edge of the bottom side of the frame body uniformly extends downwards in the circumferential direction to form step grooves capable of being used for accommodating the filterscreen framework, step holes are formed in the inner bottom walls of the step grooves, elastic ring bodies are arranged in the thick ends of the step holes, one ends of the elastic ring bodies are fixedly connected with the step positions of the step holes, the step holes correspond to the installation columns one to one, the installation columns penetrate from the thick ends of the step holes through the elastic ring bodies to extend into the thin ends of the step holes, and the elastic ring bodies are in interference connection with the installation columns. According to the environment-friendly steel lattice plate manhole cover, the filter screen framework and the frame body can be fixed, the structure is simple, and installation is convenient, garbage entering to a drainage ditch can be reduced or avoided, and thus the degree of water pollution is decreased.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

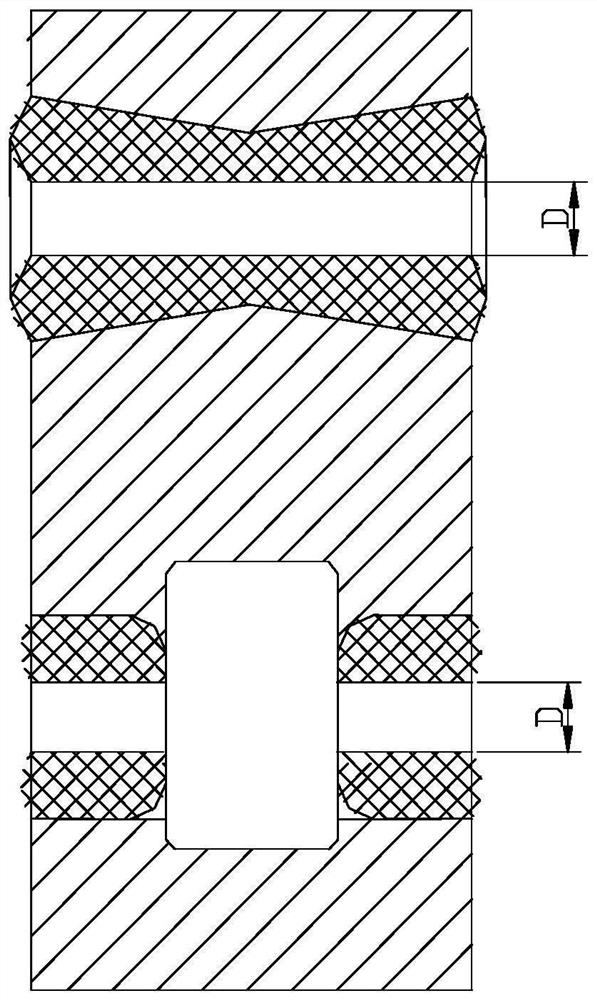

Rotating shaft dynamic sealing structure and method for replacing sealing ring of rotating shaft dynamic seal

PendingCN111895093AReduce or avoid access toExtended service lifeEngine sealsEngineeringBolt connection

The invention discloses a rotating shaft dynamic sealing structure. The rotating shaft dynamic sealing structure includes a shell and a rotating shaft; a shaft hole is arranged on the shell; the rotating shaft passes through the shaft hole; the rotating shaft outside the shell is sleeved with a stuffing box; the stuffing box contains a bottom plate and a cylinder connected to one side of the bottom plate; the middle of the bottom plate is provided with a first circular hole, and the diameter of the first circular hole is larger than the diameter of the rotating shaft; a plurality of first fixing holes are arranged on the edge of the bottom plate; the stuffing box is connected to the shell by bolts; the cylinder is sequentially provided with an air blowing ring, at least two sealing rings and a stuffing box gland from the inside to the outside; the side wall of the air blowing ring is provided with an air blowing hole; the air blowing hole is connected to compressed air; and the inner diameter of the air blowing ring is larger than the diameter of the rotating shaft. The invention also discloses a method for replacing the sealing ring of the rotating shaft dynamic seal. The technical scheme reduces or avoids particle powders entering the sealing ring, and prolongs the service life of the sealing ring; and the structure of semi-stuffing boxes and semi-sealing rings simplifies thesteps of replacing the sealing ring, so that maintenance workload and maintenance time are saved.

Owner:陕西宏达实业有限公司

Linear compressor and refrigerant preheating method

ActiveCN107448372BImprove safety and reliabilityReduce or avoid access toPositive displacement pump componentsLubricating pumpsLinear compressorPetroleum engineering

The invention provides a linear compressor and a refrigerant preheating method. The linear compressor comprises a shell and further comprises a stator, a rotor, an air cylinder, a piston, a spring pressing plate, an air suction barrel and an oil pump which are arranged in the shell, lubricating oil is stored in the bottom of the shell, a main oil supply pipe and a preheating oil supply pipe are connected to the oil pump, the main oil supply pipe is used for feeding the lubricating oil to the air cylinder, and the preheating oil supply pipe is used for feeding the lubricating oil to the air suction barrel. Safety and reliability of the linear compressor are improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

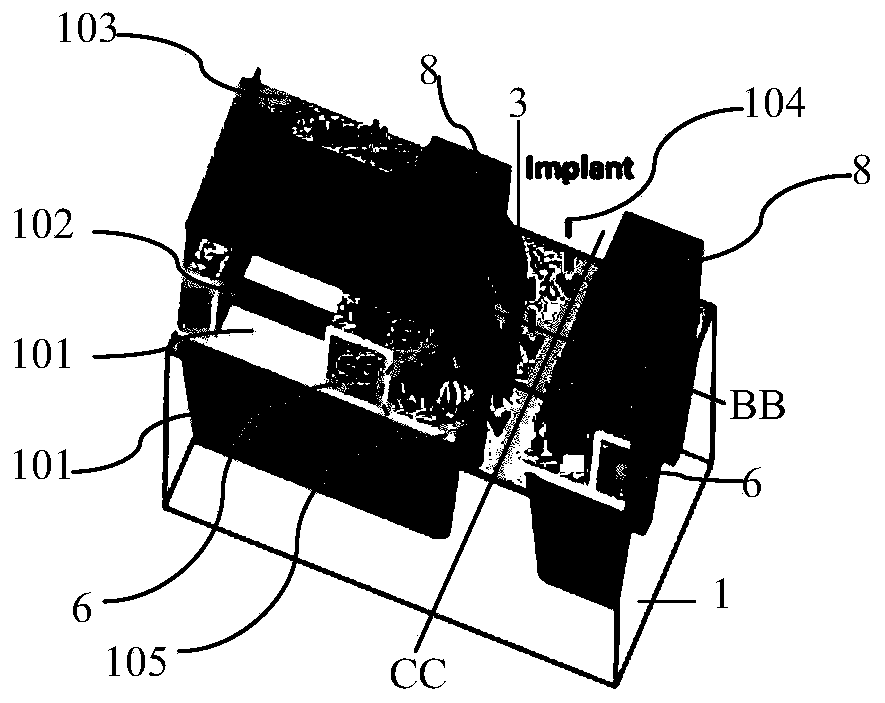

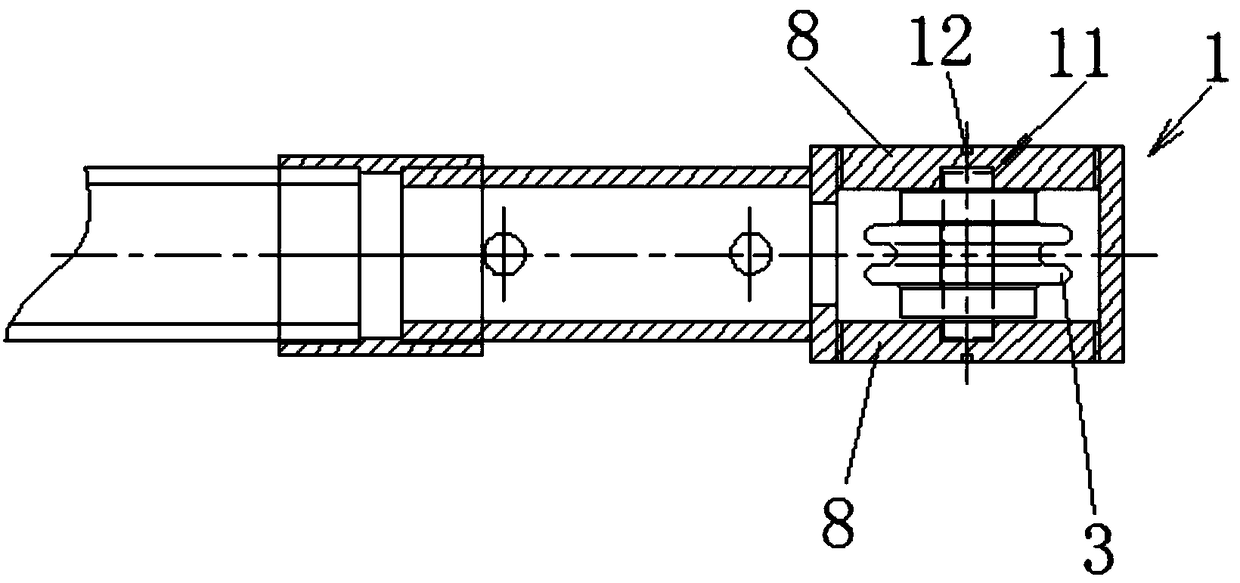

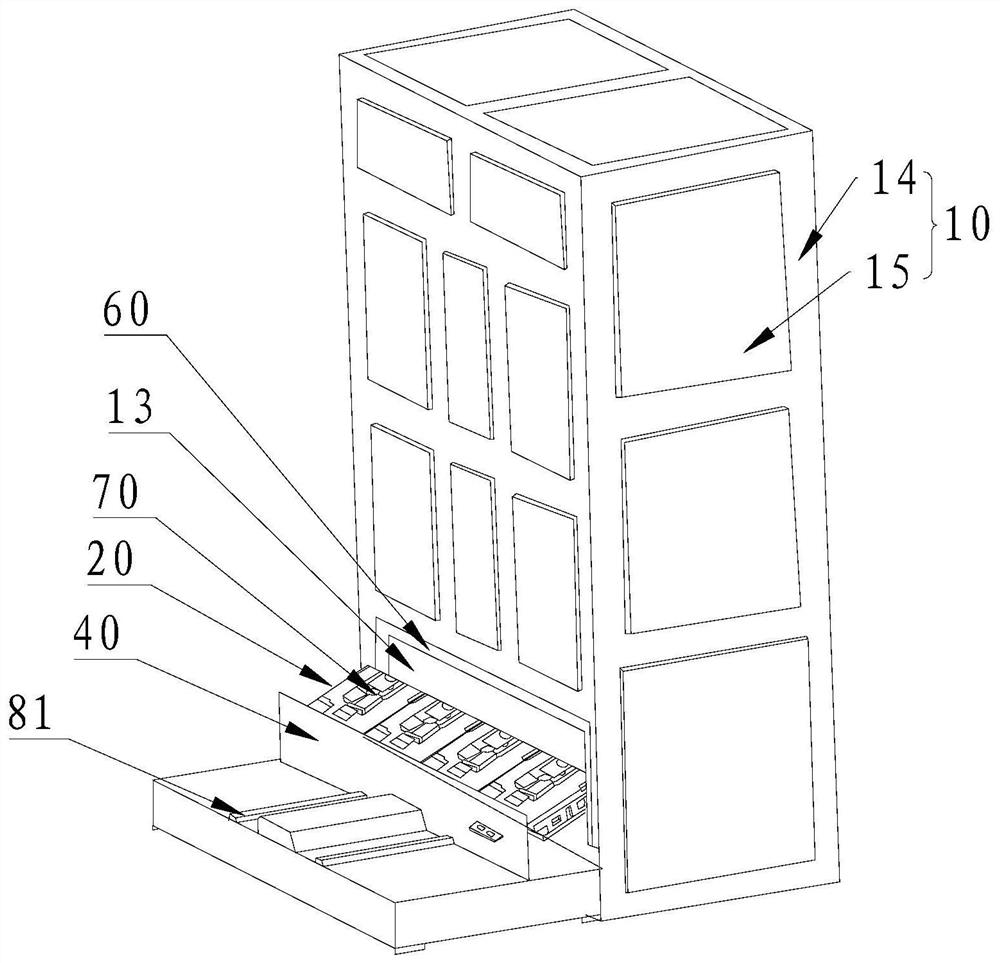

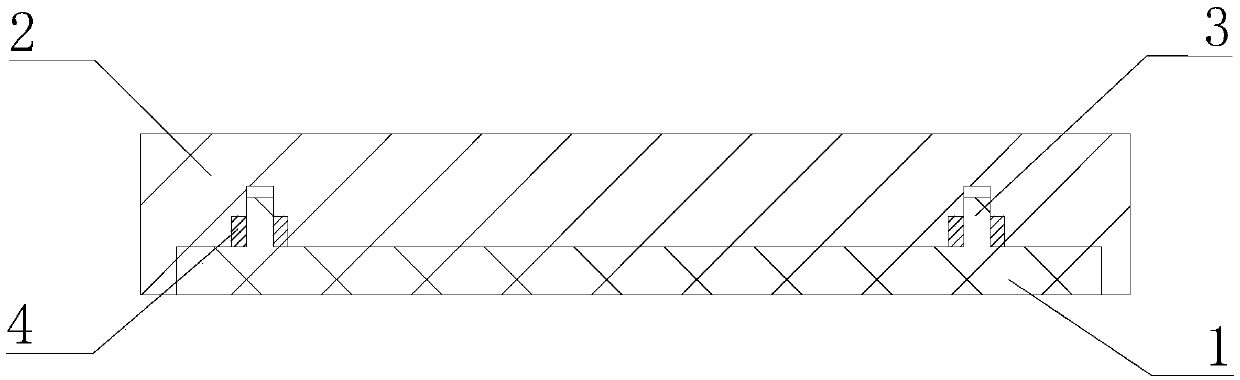

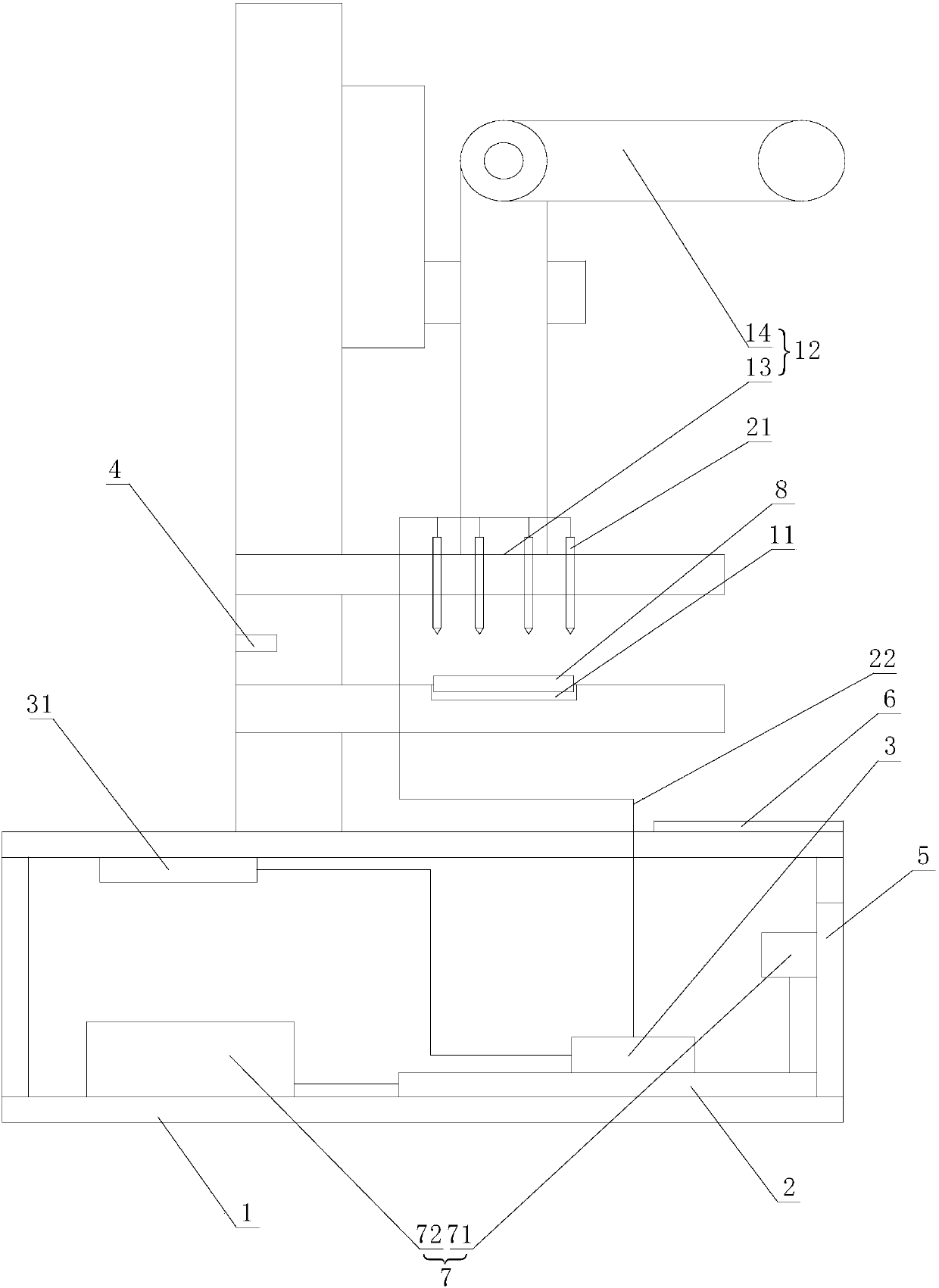

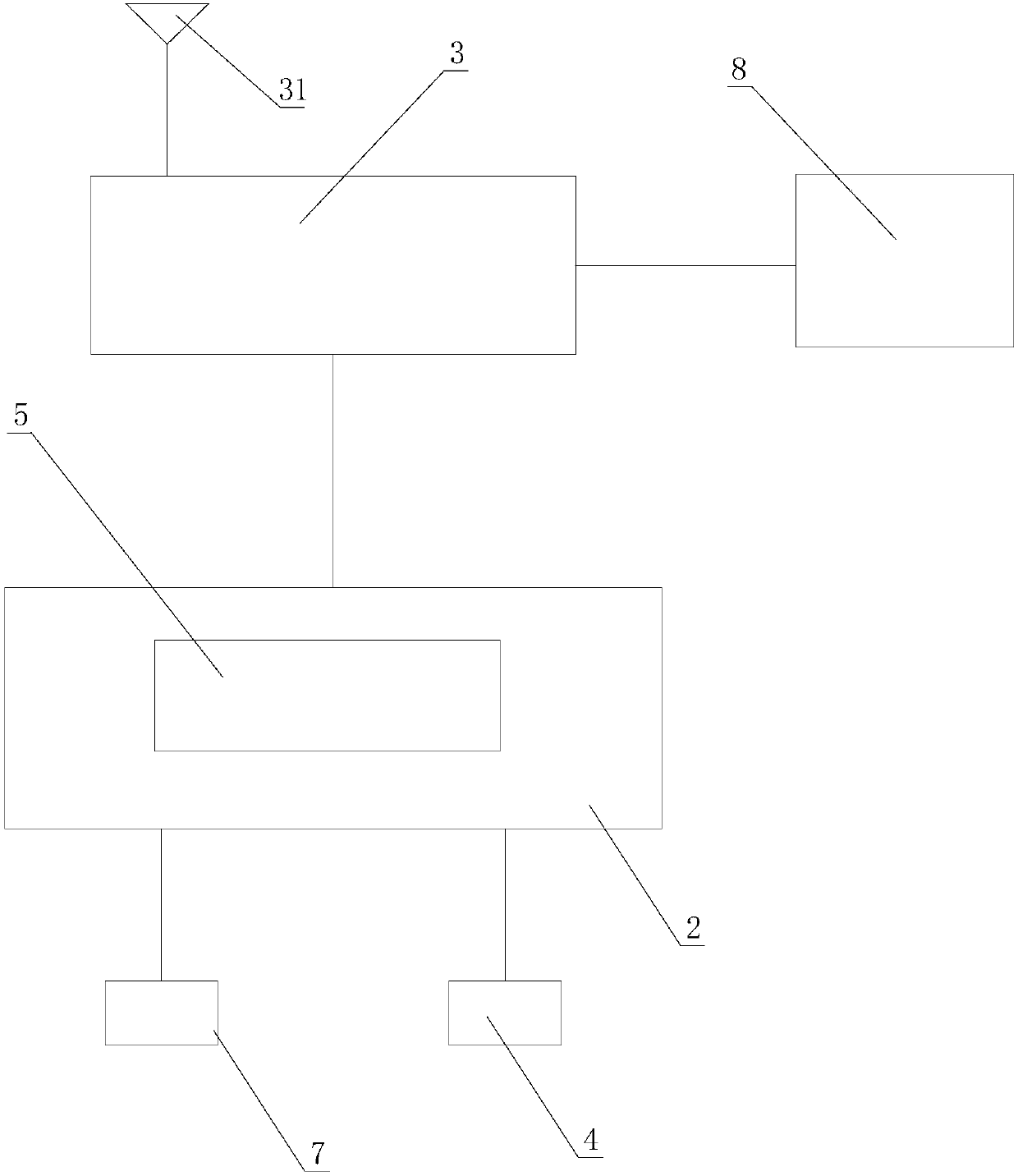

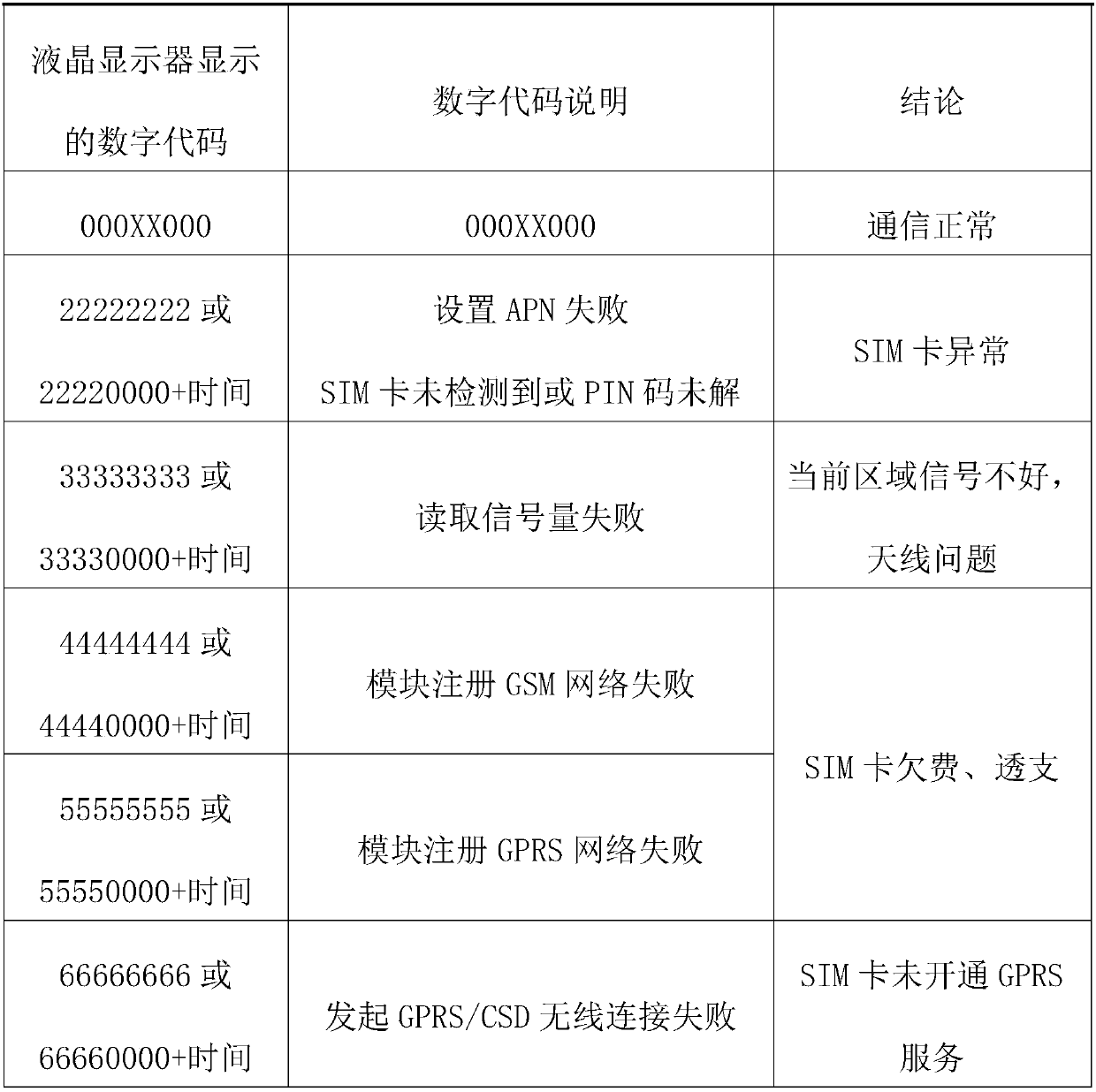

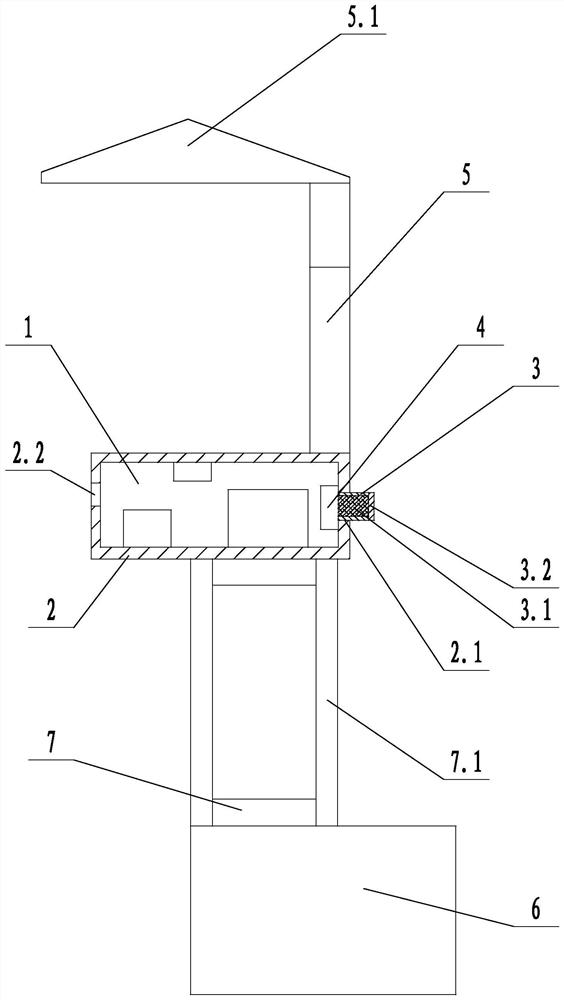

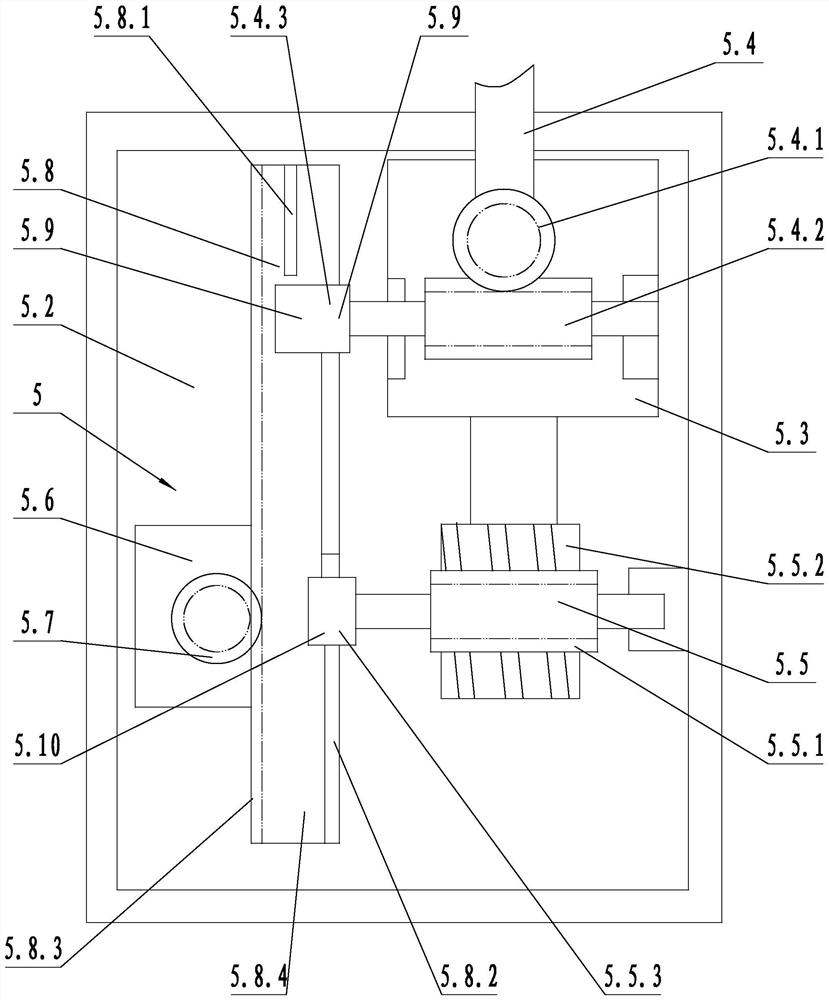

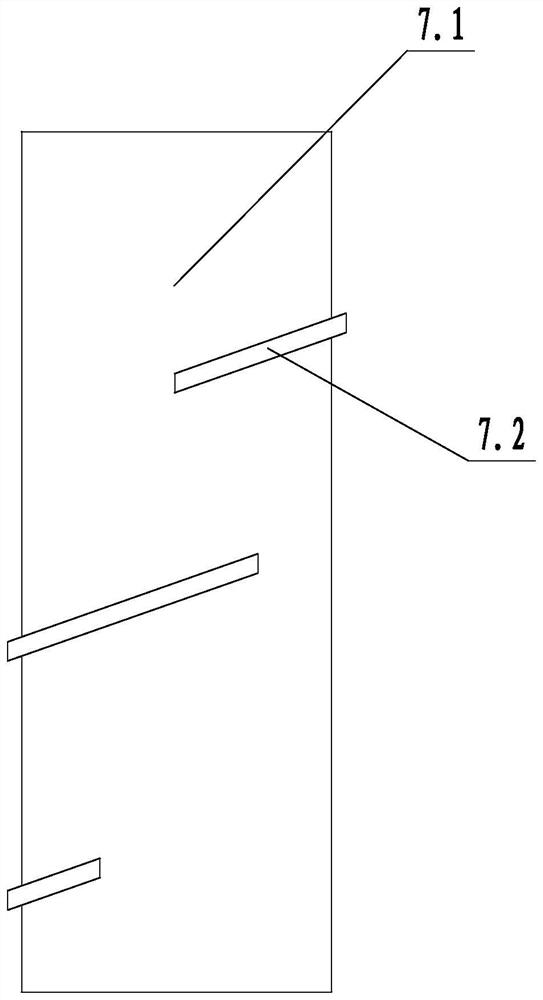

Internet-of-Things instrument paster SIM card performance detection apparatus and method therefor

PendingCN107703393AEasy to detectAvoid reworkMeasurement instrument housingEnvironmental/reliability testsMobile WebNetwork performance

The invention relates to an Internet-of-Things instrument paster SIM card performance detection apparatus and belongs to the technical field of detection apparatuses. The Internet-of-Things instrumentpaster SIM card performance detection apparatus can help solve problems of shutdown of production processes and reworking caused due to exceptions of conventional paster SIM cards. According to a technical solution, the Internet-of-Things instrument paster SIM card performance detection apparatus mainly comprises a work platform, a main control board and a communication module, wherein the main control board is connected with a test pin, the work platform comprises a first installation part and a second installation part, a paster SIM card to be tested is installed on the work platform via the first installation part, the test pin is mounted on the work platform via the second installation part, and a state of the current paster SIM card is determined according to a communication state ofthe communication module and a mobile network; the Internet-of-Things instrument paster SIM card performance detection apparatus is advantageous in that the state of the paster SIM card can be obtained before production, phenomena that abnormal SIM cards enter production processes can be alleviated or prevented, subsequent reworking of the paster SIM cards can be prevented, and the invention alsoprovides an Internet-of-Things instrument paster SIM card performance detection method which is applied to the above apparatus.

Owner:GOLDCARD HIGH TECH

Protective sleeve of electronic product and electronic equipment

PendingCN114257675AReduce entryReduce or avoid access toTelephone set constructionsProtection KITMechanical engineering

The embodiment of the invention discloses a protective sleeve of an electronic product and electronic equipment, the electronic product is provided with a first through hole for communicating external and internal electronic devices, the protective sleeve is provided with a second through hole corresponding to the first through hole, and the protective sleeve is further provided with a flow guide part communicated with the second through hole. When liquid passes through the second through hole, the liquid flows along the flow guide part of the protective sleeve under the action of gravity and viscous force, so that the liquid is reduced and even prevented from continuously flowing to the first through hole of the electronic product, and the liquid is prevented from flowing to a corresponding electronic device in the electronic product through the first through hole; therefore, the liquid is prevented from damaging internal electronic devices, and then the waterproof and oil-proof effects are achieved.

Owner:BEIJING HONOR DEVICE CO LTD

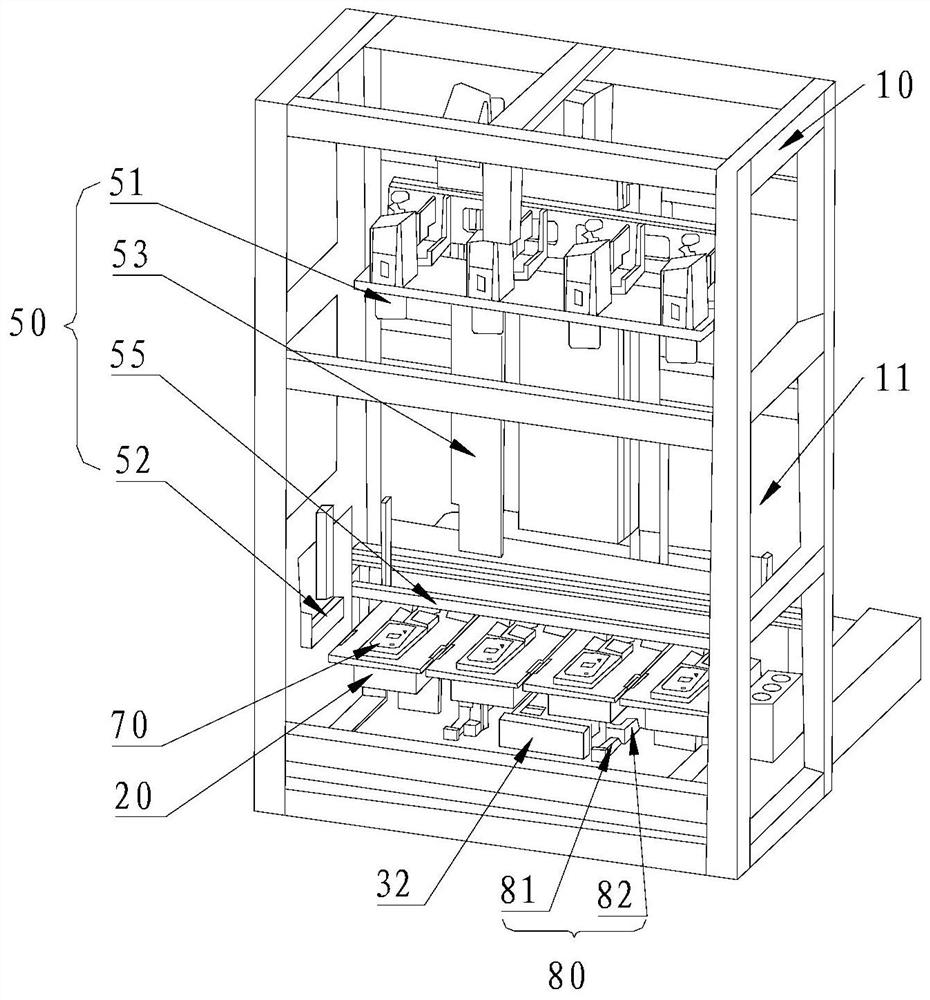

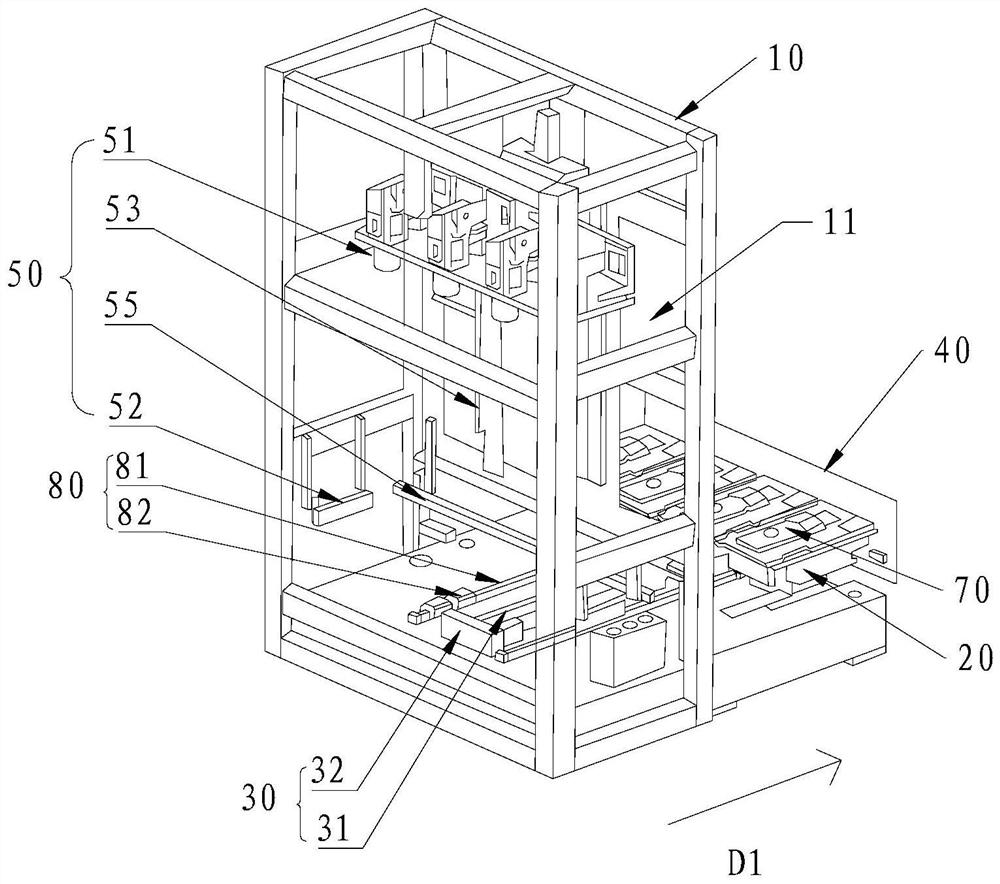

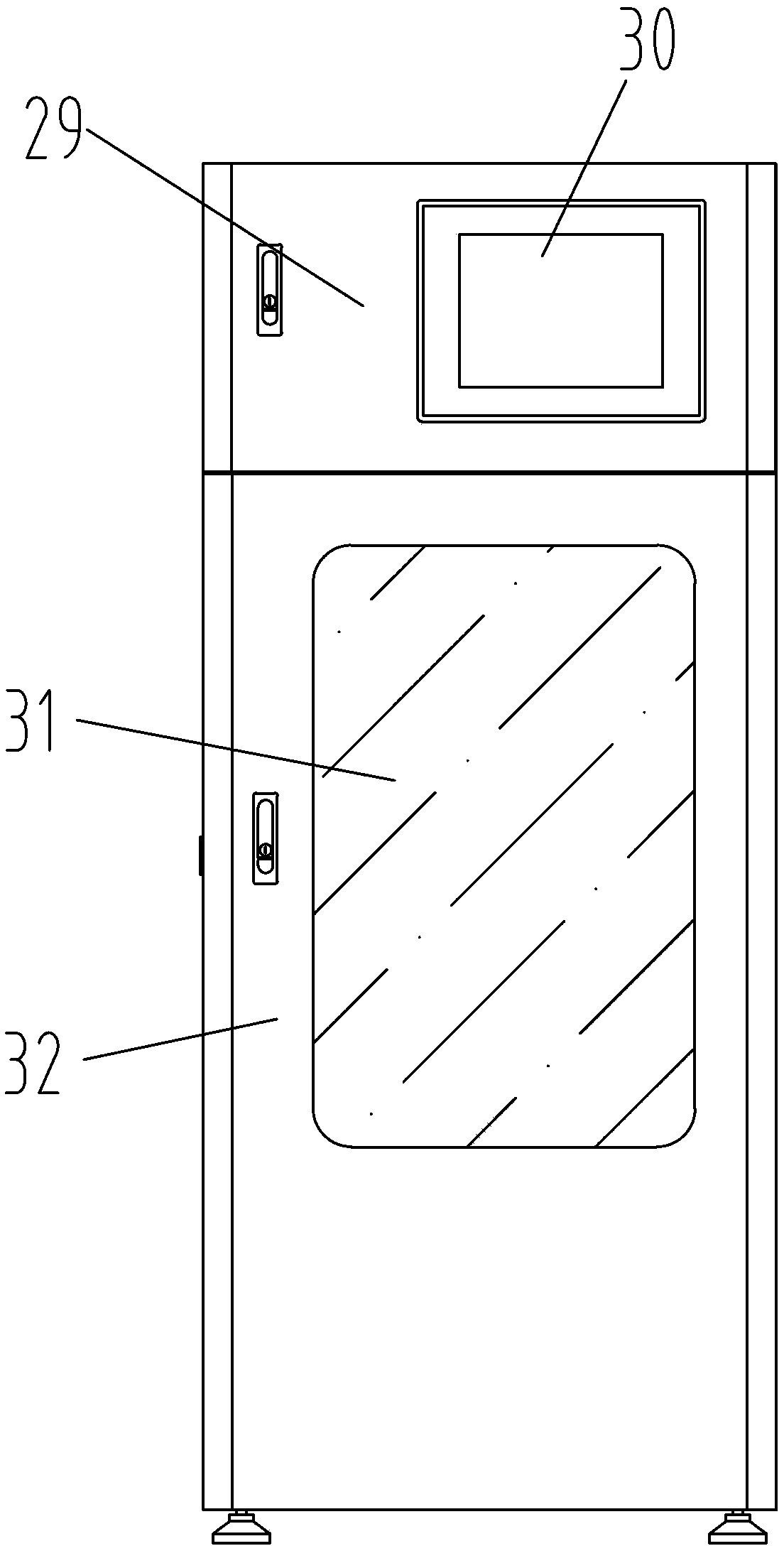

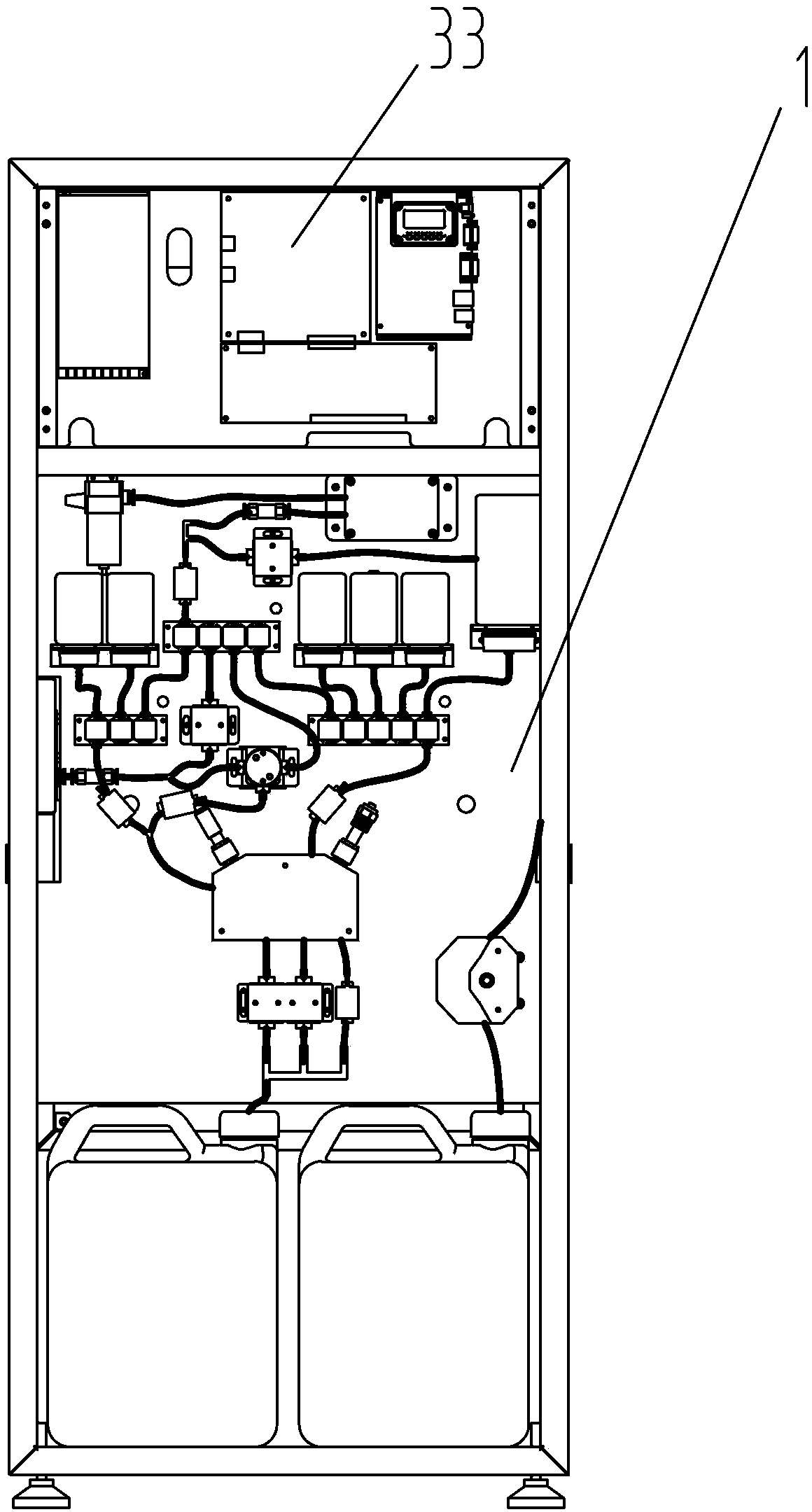

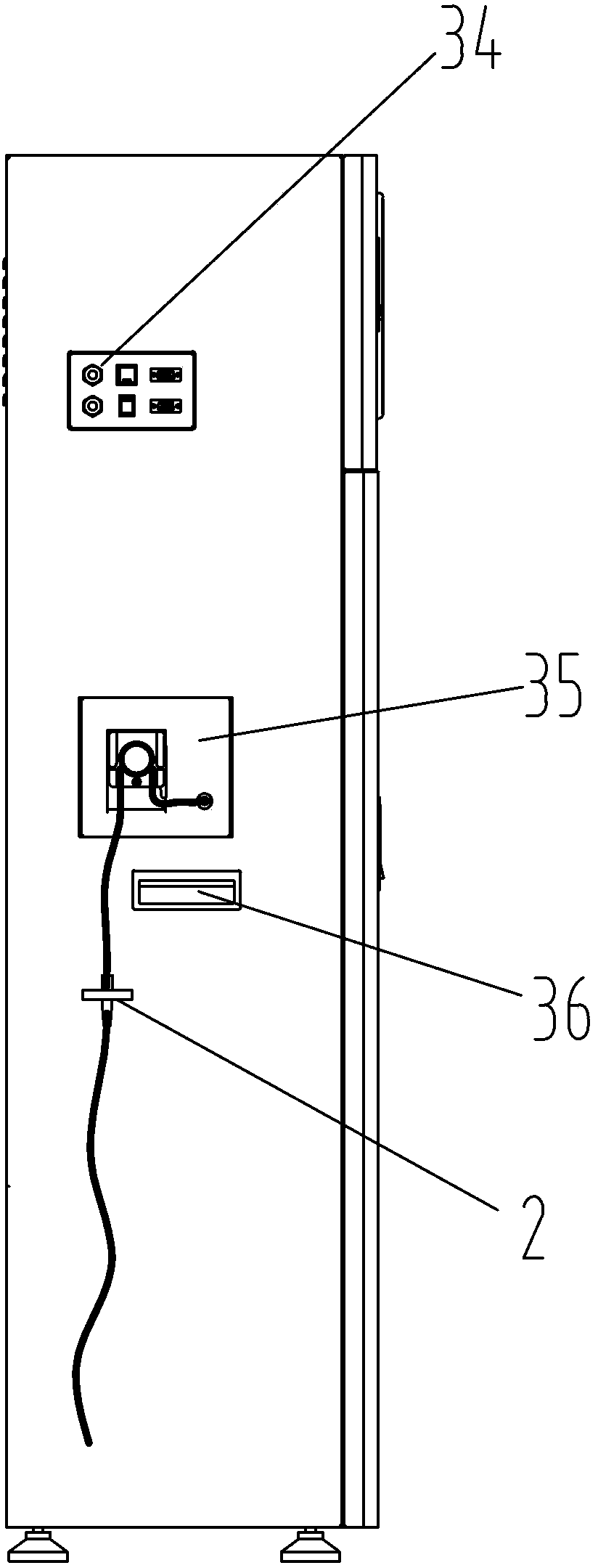

Indoor analysis meter for precipitation sample

ActiveCN103163184BReduce volume requirementsReduce volumeWithdrawing sample devicesMaterial impedancePrecipitationInstrumentation

The invention provides an indoor analysis meter for a precipitation sample, and belongs to the technical field of meteorological watch, aiming at solving the technical problems that detection can not be carried out under small amount of precipitation through manual analysis, the precipitation sample is polluted by insufficient washing, and the like. The indoor analysis meter for the precipitation sample comprises a cabinet, and a water sample pumping pipeline, a pipeline cleaning device, a calibration device, a PH detection electrode, a conductive detection electrode, one detection pool, a main controller and a display which are arranged in the cabinet, wherein the PH detection electrode and the conductive detection electrode are simultaneously arranged in the detection pool. The indoor analysis meter has the advantages of being convenient, low in cost, simple and compact in structure, small in size, and low in requirement on amount of precipitation samples, and capable of improving the detection frequency, increasing the detecting efficiency, accurately obtaining a detecting result and accurately analyzing the precipitation sample.

Owner:ZHEJIANG HENGDA INSTR CO LTD

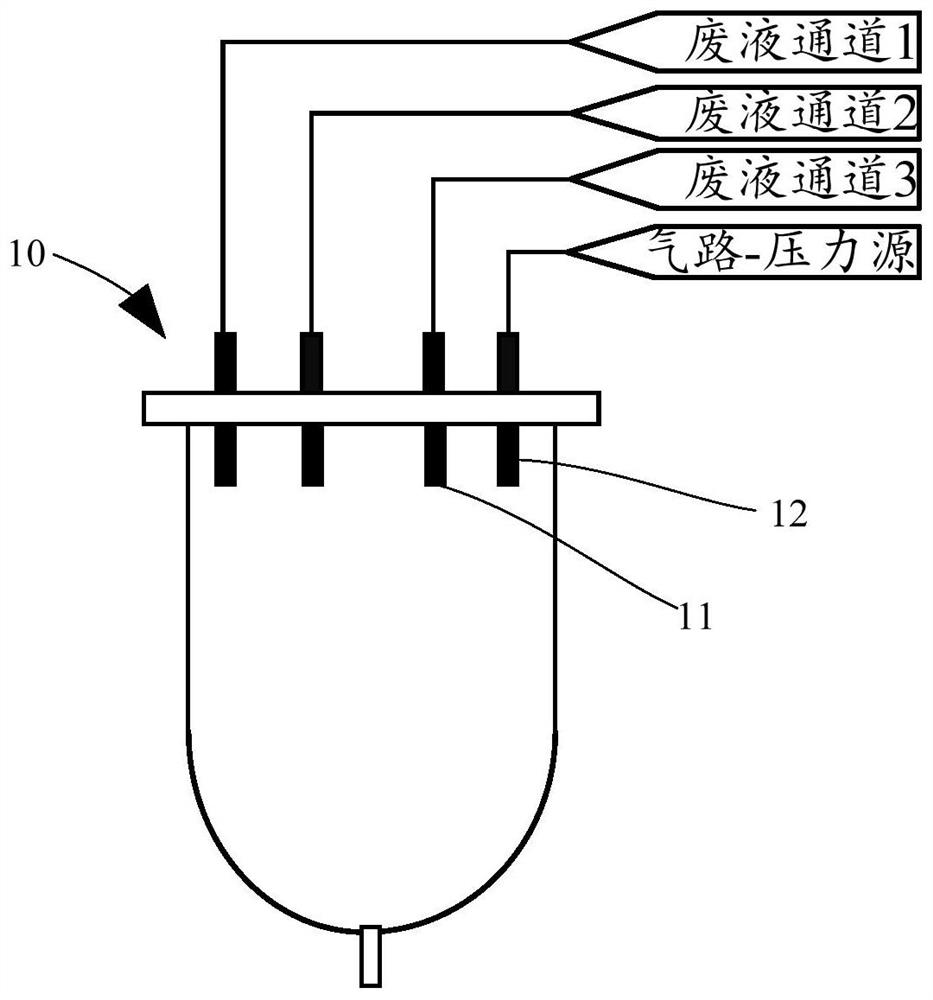

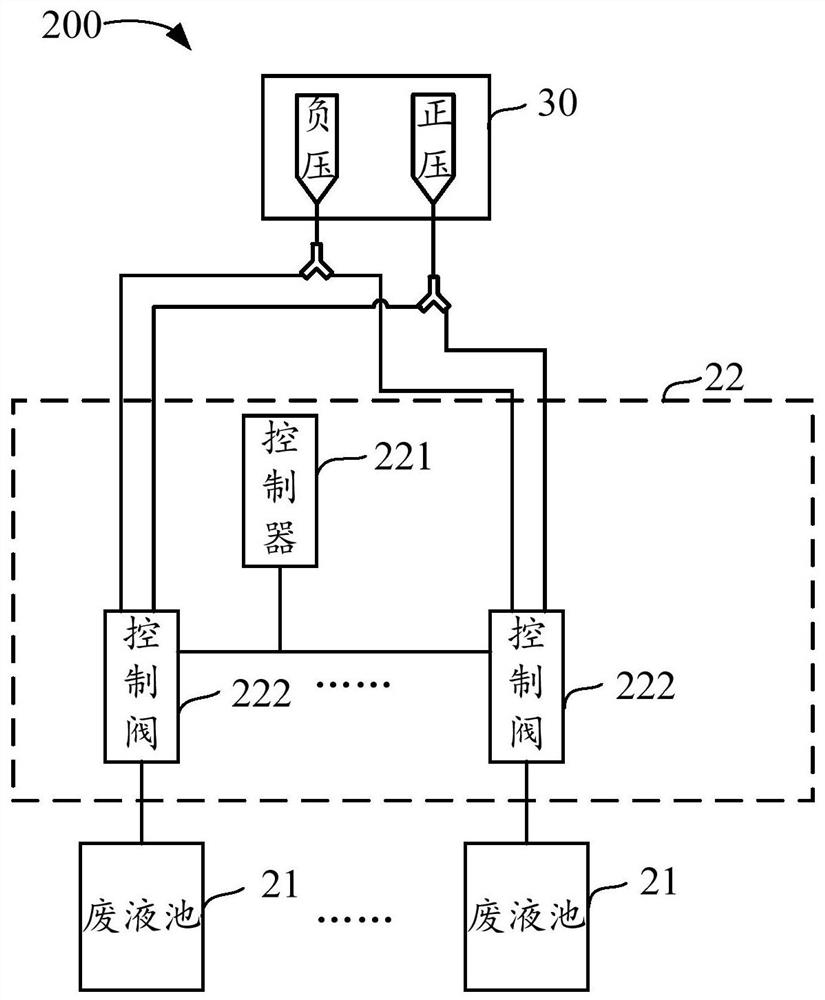

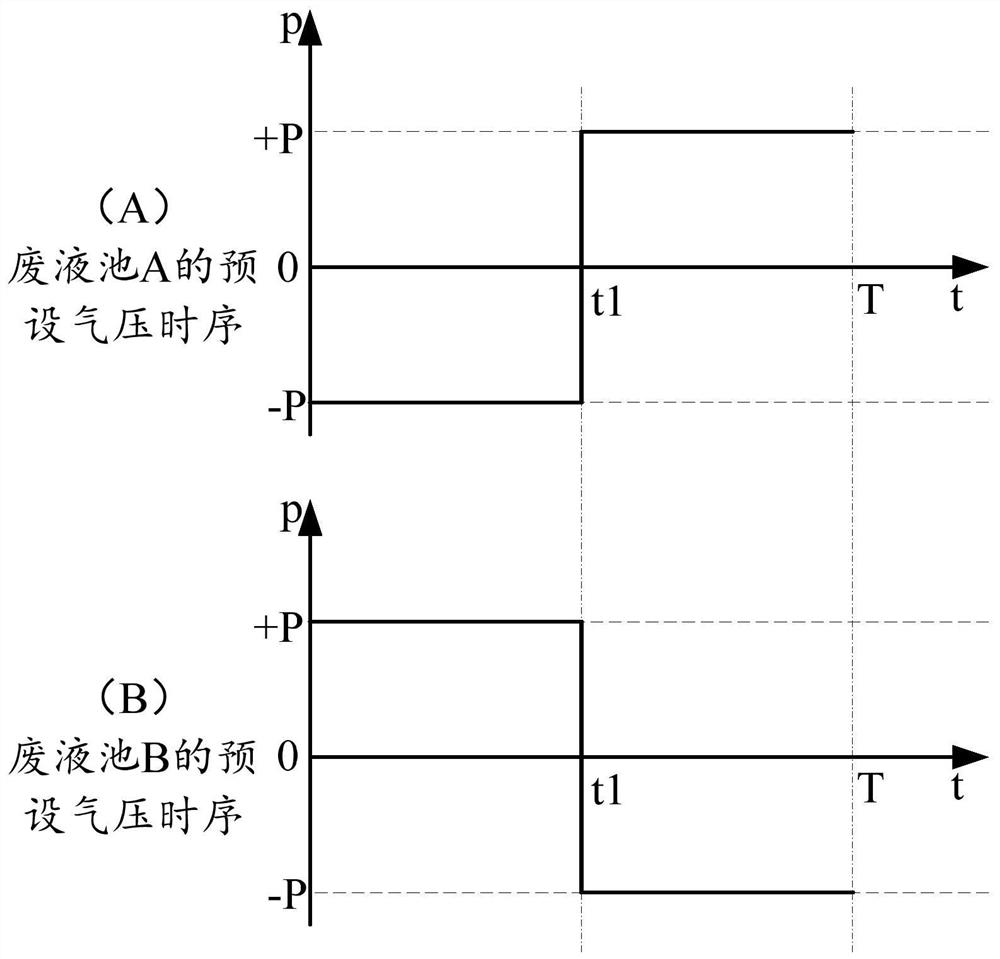

Waste liquid pool, waste liquid treatment device and sample analyzer

ActiveCN113042116AAddress reliabilityReduce or avoid access toBiological testingHazardous material storageEnvironmental engineeringMechanical engineering

The invention provides a waste liquid pool, a waste liquid treatment device and a sample analyzer. The waste liquid pool comprises a body, a cover body and a first baffle, wherein a containing cavity used for storing a waste liquid is formed in the body, a liquid outlet used for discharging the waste liquid is formed in the bottom of the body, the cover body is used for sealing the opening of the body, the side wall of the body and / or the cover body are / is further provided with a ventilation opening, the first baffle is arranged in the containing cavity and located between the ventilation opening and the liquid outlet, at least one liquid inlet is formed in the side wall of the body and located below the first baffle, and the first baffle is used for preventing foam and / or waste liquid in the containing cavity from entering the ventilation opening. The waste liquid pool can prevent foam and / or waste liquid in the containing cavity from entering the ventilation opening, so that the problem of reliability of waste liquid treatment caused by acceleration of the sample analyzer can be effectively solved.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Manufacturing method of split-gate flash memory

ActiveCN109727986BReduce or avoid access toAvoid enteringSolid-state devicesSemiconductor devicesDielectric layerPhotoresist

The invention discloses a method for manufacturing a split-gate flash memory, comprising: forming field oxygen in a semiconductor substrate and isolating a plurality of active regions, each active region comprising a plurality of active regions in a stripe structure and parallel to each other Rows, the rows of active regions corresponding to the source regions are connected to form a whole line in the column direction and form active region columns; select gates are formed, and each select gate is in a strip-shaped column structure and parallel to each other; floating gates are formed, and the floating gates are formed in On the row of the active region on the first side of the corresponding selection gate; forming an erasing gate, each erasing gate covers the top surface of the first side of the selection gate and extends to the top of the floating gate; Covering the vertical sides of the region column with a dielectric layer; forming a photoresist pattern to open the active region column, part of the erasing gate near the first side, and each floating gate outside the first side; performing source injection. The invention can protect the floating gate during the source injection, prevent the source injection from affecting channel penetration, thereby improving the performance of the device.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

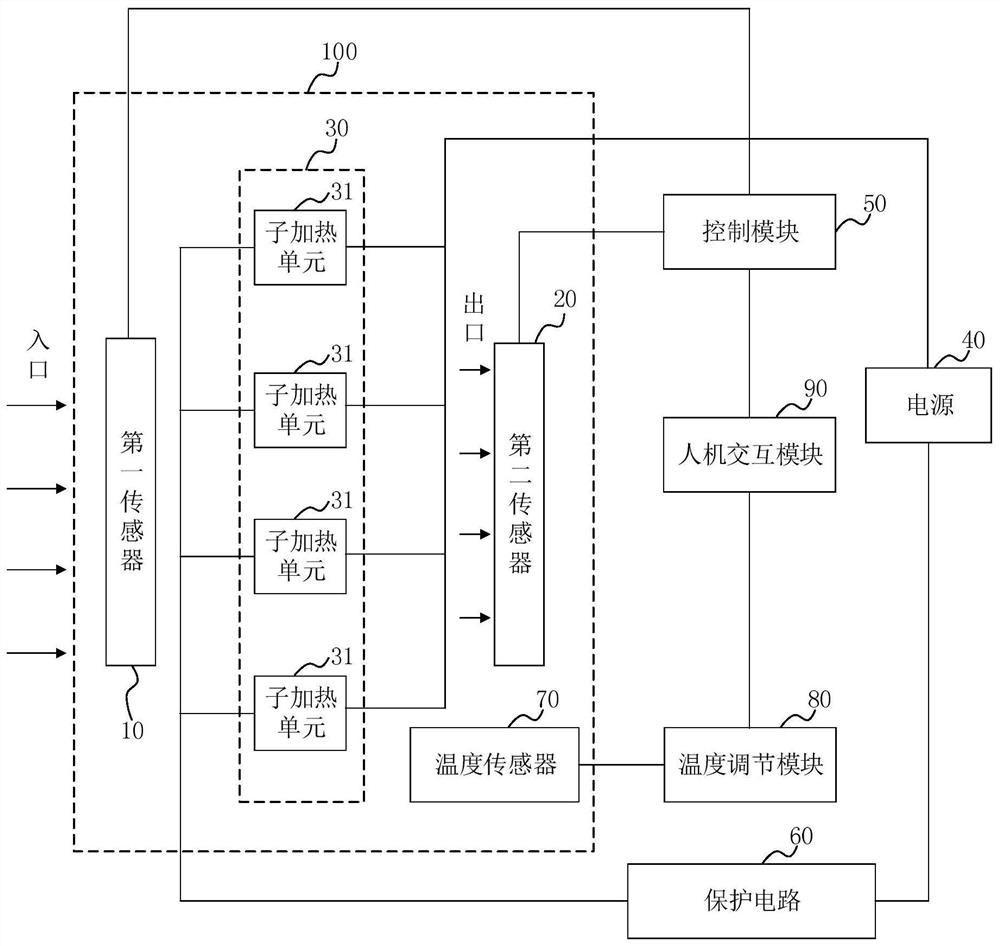

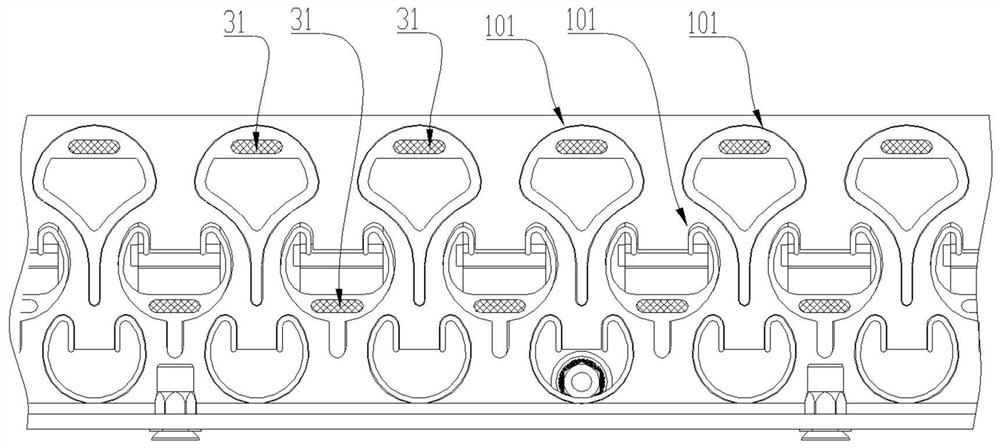

Snow blocking filter device, snow blocking method and locomotive

ActiveCN113476993BReduce or avoid access toAvoid failureDispersed particle filtrationEngineeringMechanical engineering

The present disclosure relates to the technical field of locomotives, and specifically discloses a snow blocking filter device, a snow blocking method and a locomotive. The snow blocking filter device includes a filter chamber and a filter core body arranged in the filter chamber, the chamber has an inlet and an outlet, and further includes: a first sensor, arranged at the inlet of the filter device, for A first signal is output when rain and / or snow is detected; a second sensor is provided at the outlet of the filtering device for outputting a second signal when rain and / or snow is detected; a heating module is provided at the The filter chamber of the filter device is used to generate heat when the power is turned on; the control module is connected to the first sensor, the second sensor and the heating module respectively, and is used for detecting the first sensor, the second sensor and the heating module. When the first signal and the second signal are used, the heating module is activated to control the heating module to heat the filter chamber to melt snow, which can reduce or prevent snow from entering the surface or interior of electrical components.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Tub assembly and laundry treatment equipment

ActiveCN113152025BImprove performanceReduce or avoid access toOther washing machinesTextiles and paperWater storageEngineering

The invention discloses a bucket body assembly and clothes processing equipment. The bucket body assembly includes: an outer bucket, an inner cylinder and a first heating element. The inner lower part of the outer barrel has a water storage area, and a water inlet is formed on the outer barrel. The first heating element is arranged in the water storage area for heating the water in the water storage area to generate steam. The inner barrel is rotatably arranged in the outer barrel A spacer cavity is defined between the inner and outer barrels and the inner cylinder, and a communication hole connecting the clothes processing chamber and the spacer cavity is formed on the inner cylinder; wherein, when the inner cylinder is at any angle position, the water inlet and the communication hole are all staggered. According to the barrel assembly of the embodiment of the present invention, the steam washing mode can be realized without an additional steam generator, and by optimizing the relative position of the communication hole on the inner barrel and the water inlet on the outer barrel, in the water supply and storage area During the water supply process, water can be reduced or prevented from entering the inner cylinder, thereby reducing or avoiding wet clothes in the steam washing mode, which is conducive to meeting the requirements of steam washing and improving the steam washing performance of the whole machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

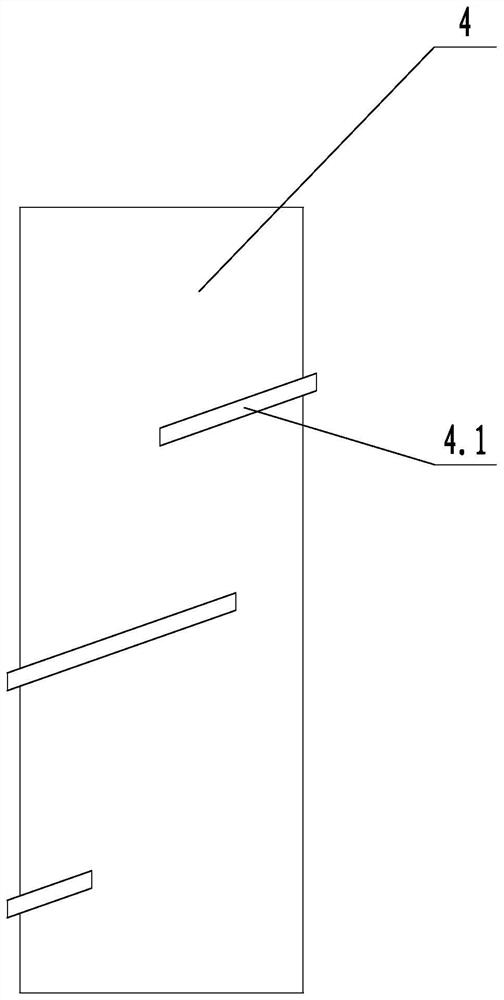

Preparation method and equipment capable of improving manufacturing qualification rate of claws and connecting rods

PendingCN114160912AImprove pass rateReduce or avoid access toGas flame welding apparatusEngineeringStructural engineering

The invention discloses a preparation method and equipment capable of improving the manufacturing qualification rate of claws and connecting rods, and belongs to the technical field of control rod driving mechanism parts. The preparation equipment comprises a surfacing box of a box structure, and the upper portion of the surfacing box is further provided with an opening serving as an opening of the surfacing box; the mounting rack is arranged in the surfacing welding box, a mounting station for mounting the filling rod is arranged on the mounting rack, and the filling rod can rotate around the axis of the filling rod on the mounting station; the opening is used as an operation channel for surfacing a surfacing layer on the filling rod; the outlet end of the gas source pipe is positioned in the surfacing box. The preparation method is based on the preparation equipment. By adopting the preparation equipment and the preparation method provided by the scheme to complete preparation of the claw and the connecting rod, the product manufacturing qualification rate can be effectively improved.

Owner:喻杰

Three-dimensional curved surface panel, three-dimensional curved surface touch panel and three-dimensional curved surface touch display panel using the same

InactiveCN106564264BImprove yieldAvoid scratchesFlexible coversWrappersForeign matterTectorial membrane

Owner:INTERFACE TECH CHENGDU CO LTD +2

A kind of phosgene removal method of m-xylylene diisocyanate

ActiveCN108003060BReduce or avoid access toSolve the difficulty of removalOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneMethylene diisocyanate

The invention discloses a method for removing phosgene from isophthalylidene diisocyanate. The method includes the steps that isophthalylidene diisocyanate (XDI) actinic solution containing a high-boiling-point solvent enters a phosgene removal tower of a negative-pressure operation system, the temperature of the tower is adjusted to be proper to remove residue phosgene, then the temperature of atower top condenser is adjusted to condense the tower top solvent, the phosgene and other mixed gas at the same time, the phosgene is reduced as much as possible or prevented from entering a vacuum system, and tower top condensate serves as an absorbing agent to be used for a phosgene recycling system. The method is suitable for removing the phosgene by using the high-boiling-point solvent and theXDI with a heat sensitivity problem or similar isocyanate. The method is high in phosgene removing capacity, reduces the load of the vacuum system, reduces the consumption of a cryogenic medium, andomits the process that parts of solvents are specially removed to be used for the phosgene recycling system.

Owner:QINGDAO UNIV OF SCI & TECH +1

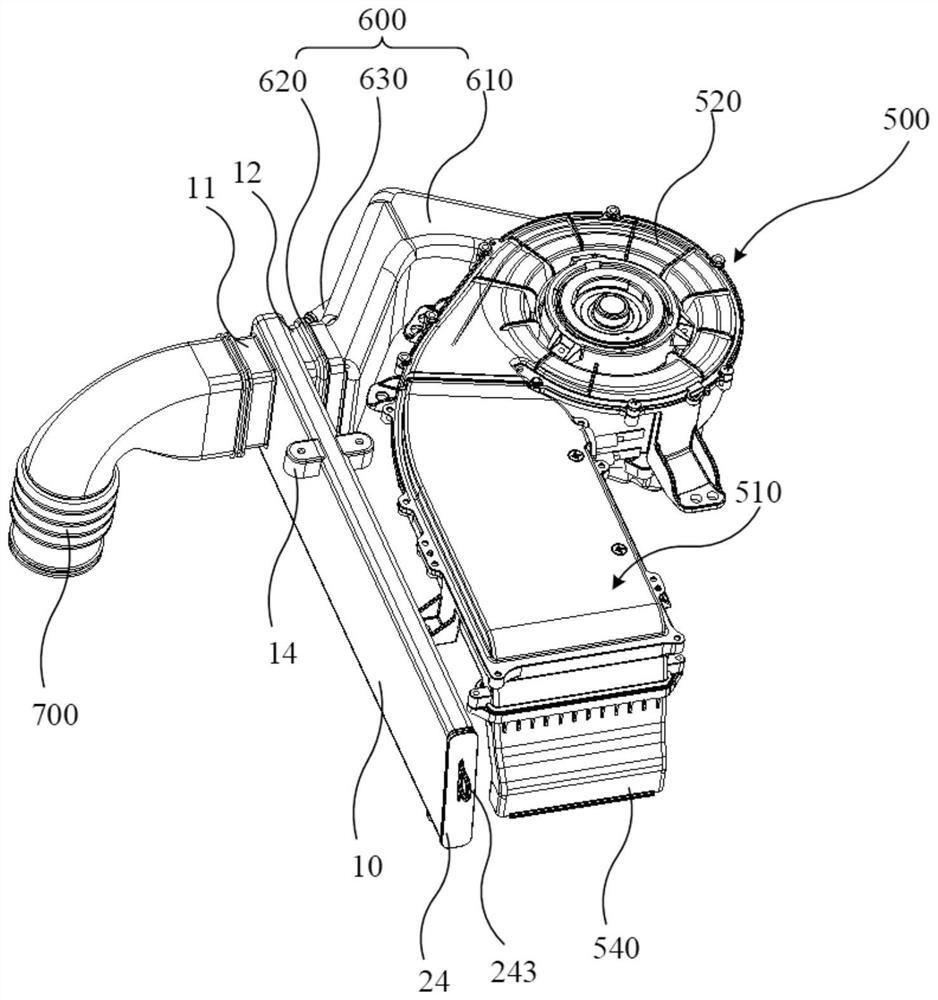

Clothes treatment equipment

ActiveCN112831995ASolve the problem of easy residual fluffReduce or avoid access toTextiles and paperLaundry driersProcess engineeringMechanical engineering

The invention relates to clothes treatment equipment. The clothes treatment equipment comprises a box body, an outer barrel, a drying device, a fluff filtering and collecting device and a condensing device; the drying device communicates with the outer barrel to convey hot air used for drying clothes; the fluff filtering and collecting device communicates with the outer barrel so as to filter and collect fluff in the damp and hot gas discharged by the outer barrel; the fluff filtering and collecting device is arranged in the box body and is at least partially detachable so as to clean the fluff; and the condensing device communicates with the fluff filtering and collecting device and the drying device separately, and the condensing device is used for cooling wet and hot gas and conveying the cooled gas to the drying device. The fluff filtering and collecting device in the clothes treatment equipment can filter and collect fluff in damp and hot gas discharged by the outer barrel, and the fluff entering the condensing device and the drying device along with the gas is reduced or avoided; and at least part of the fluff filtering and collecting device is detachable, so that a user can conveniently clean the fluff; and gas discharged from the fluff filtering and collecting device can enter the drying device to be reused, so that resources are saved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

All-weather self-adaptive live working machine with rainproof structure

PendingCN114536354AIncreased insulation protectionImprove reliabilityClimate change adaptationManipulatorStormwaterElectrical and Electronics engineering

The invention discloses an all-weather self-adaptive live working machine with a rainproof structure, which comprises a machine body, a shielding mechanism is arranged on the machine body, the shielding mechanism comprises a shielding tent, a fixing frame, a horizontal rotating frame, an overturning mechanism and a rotating mechanism, and the shielding tent is rotatably connected with the horizontal rotating frame in a vertical plane. The turnover mechanism drives the shielding tent to rotate relative to the horizontal rotating frame, the horizontal rotating frame is rotationally connected with the fixing frame, a rotating shaft of the horizontal rotating frame is vertical, the rotating mechanism drives the horizontal rotating frame to rotate relative to the fixing frame, and the shielding tent is arranged above the machine body. According to the all-weather self-adaptive hot-line working machine provided with the rainproof structure, rainwater is reduced or prevented from entering the working position in rainy days, insulation protection of the working position is improved, and the hot-line working robot can operate in the rainy days.

Owner:慈溪市输变电工程有限公司 +1

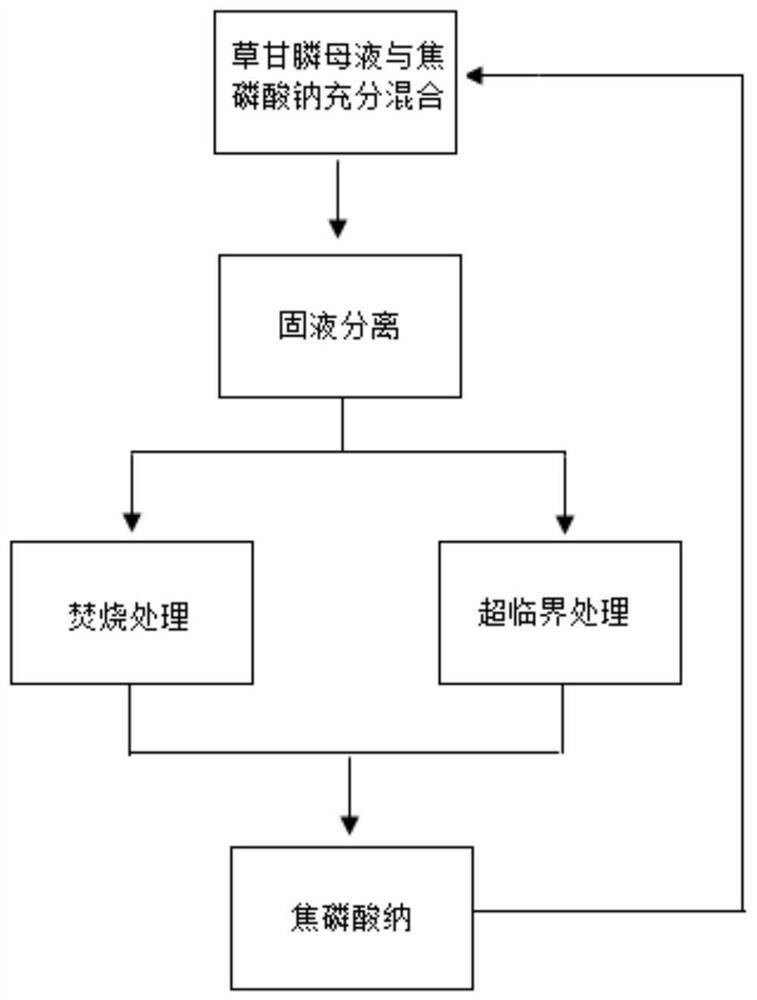

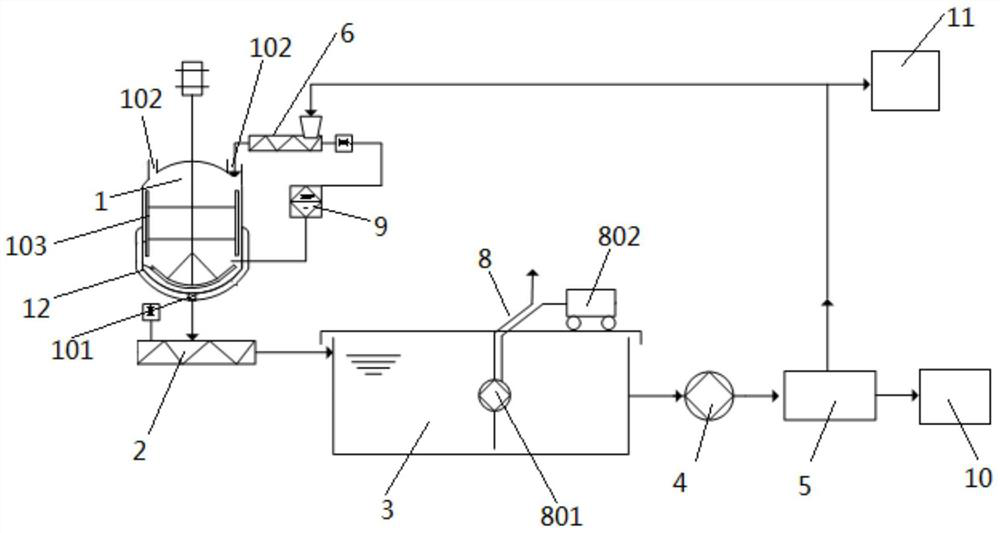

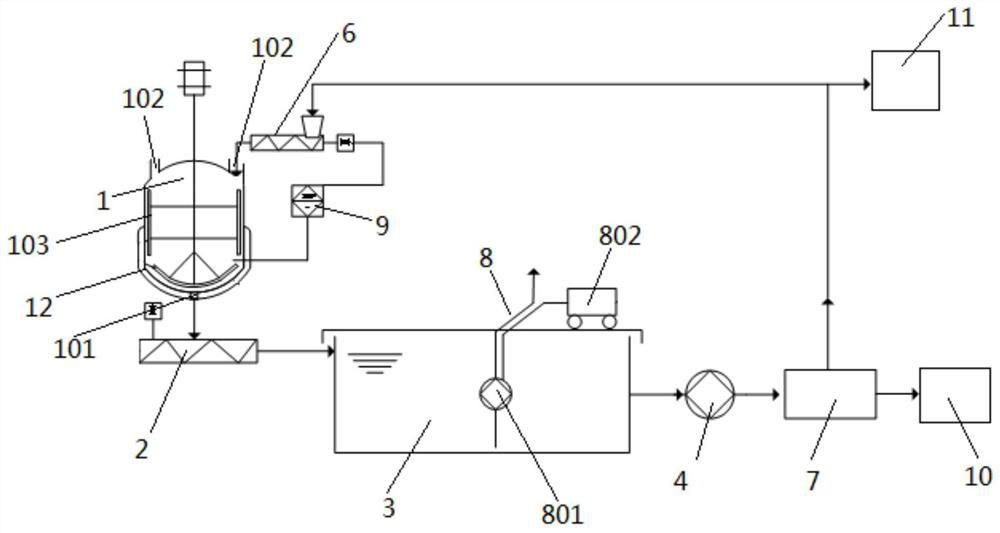

A kind of treatment method and device of glyphosate mother liquor

ActiveCN110812877BAchieving processing powerIncrease productionTransportation and packagingGroup 5/15 element organic compoundsSodium phosphatesGlyphosate

The invention discloses a method and device for treating glyphosate mother liquor, which belongs to the technical field of chemical industry and environmental protection, and overcomes the problem in the prior art that the separation rate of sodium chloride is low during the treatment of glyphosate mother liquor. The device includes a crystallization tank, a rotor pump, a solid-liquid separation device, a delivery pump, an incineration device or a supercritical water oxidation device, and a dosing device connected in sequence; the crystallization tank is provided with a discharge port and at least two feed ports. The feed port is connected with the rotor pump, and any feed port is connected with the dosing device. Based on the same ion effect, sodium pyrophosphate or sodium phosphate is used to introduce sodium ions into the glyphosate mother liquor, which reduces the solubility of sodium chloride in the glyphosate mother liquor, increases the precipitation of sodium chloride, and then improves the Sodium chloride separation efficiency. At the same time, the output of the by-product sodium chloride industrial salt is increased, and the purity of the industrial by-product sodium pyrophosphate or sodium phosphate is guaranteed.

Owner:XI AN JIAOTONG UNIV

Insulation protection device for hot-line work robot in high-temperature and high-humidity environment

The invention discloses a hot-line work robot insulation protection device for a high-temperature and high-humidity environment, and the device comprises a work robot body, the work robot body comprises a housing, the housing is provided with a heat dissipation ventilation inlet and a heat dissipation ventilation outlet, the outer side of the heat dissipation ventilation inlet is provided with a dehumidification pipe, and the dehumidification pipe is internally provided with a drying agent. A fan is arranged on the inner side of the heat dissipation ventilation inlet. According to the hot-line work robot insulation protection device used in the high-temperature and high-humidity environment, effective heat dissipation can be conducted on the work robot body in the high-temperature and high-humidity environment, the influence of high humidity on the interior of a machine is reduced, and the hot-line work robot can be used in the high-temperature and high-humidity environment.

Owner:慈溪市输变电工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com