Disc type separator seal feeding device

A disc separator and feeding device technology, which is applied to centrifuges and other directions, can solve the problems of poor sealing effect of feeding materials, high maintenance difficulty, high precision requirements, etc., achieve stable liquid seal layer, low production cost, and improve separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

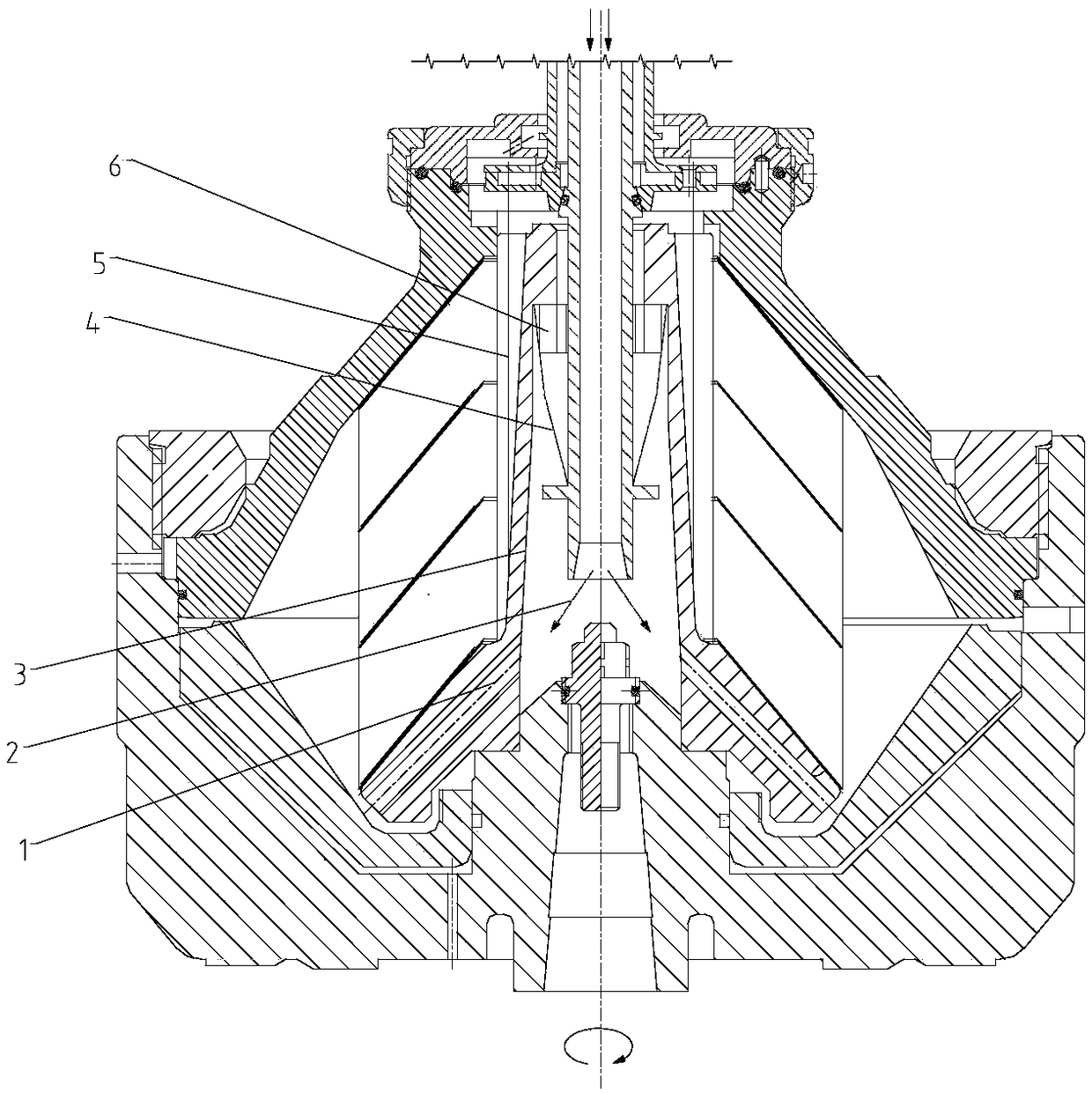

[0017] The invention provides an anti-clogging system for a nozzle-type disc separator, such as figure 1 Shown: The drum components of the separator mainly include drum body, piston, drum cover, disc set, distributor, feed pipe, discharge pump and other parts. The drum body and drum cover are combined to form the base of the drum, which is the main force-bearing part. The piston moves up and down to realize the slag discharge function of the separator; the disc group is the separation function area, which is the main realization area of material separation; Evenly distributed to the disc group, the inside of the distributor plays the function of distribution and feeding buffer; the discharge pump pumps the separated materials out of the machine.

[0018] The feed pipe is fixed on the frame of the separator body, a centripetal pump is installed on the circumference of the middle section of the feed pipe, and its lower section passes through the through hole on the distributor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com