Insulation protection device for hot-line work robot in high-temperature and high-humidity environment

A technology for working robots and live work, applied in manipulators, manufacturing tools, etc., can solve problems such as leakage and overheating, and achieve the effect of reducing impact, avoiding interference, and avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

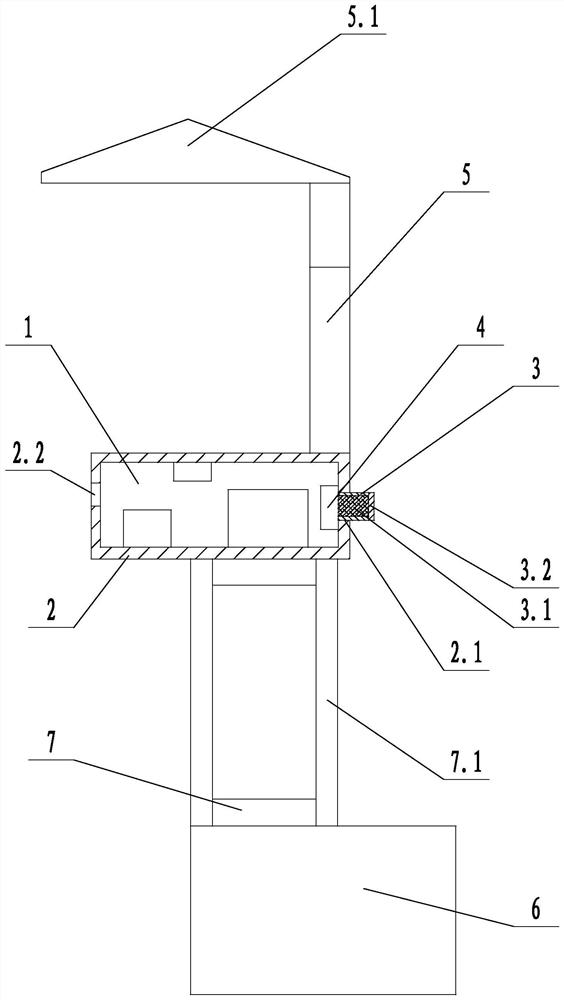

[0024] like figure 1 As shown, a live working robot insulation protection device for a high temperature and high humidity environment includes a working robot body 1, and the working robot body 1 includes a casing 2. The casing 2 is provided with a cooling ventilation inlet 2.1 and a cooling ventilation outlet 2.2. A dehumidification pipe 3 is arranged at the outer position of the inlet 2.1, and a desiccant 3.1 and a semiconductor dehumidification device 3.2 are arranged in the dehumidification pipe 3, and the semiconductor dehumidification device 3.2 is arranged outside the desiccant 3.1. A fan 4 is provided inside the cooling and ventilation inlet 2.1. The working robot body 1 is provided with a shielding mechanism 5 , and the shielding mechanism 5 includes a shielding canopy 5.1 , and the shielding canopy 5.1 is arranged above the working robot body 1 .

[0025] In the above technical solution, the desiccant 3.1 can absorb water vapor in the air, reduce the air humidity bl...

Embodiment 2

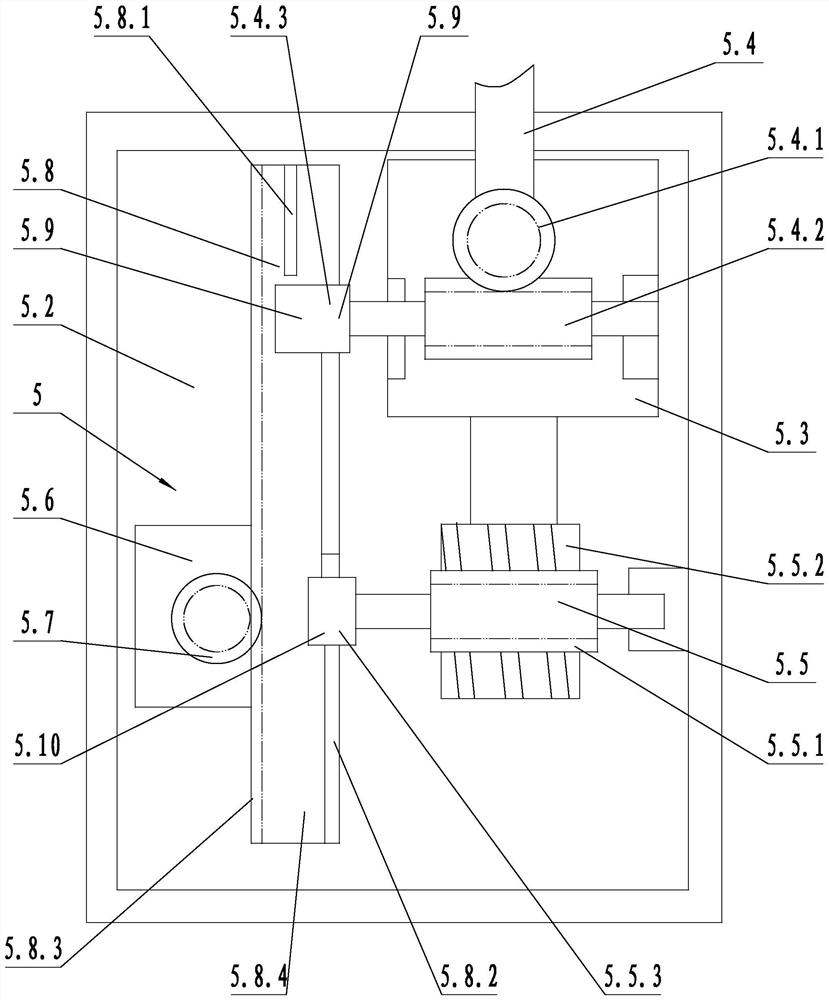

[0027] like figure 2As shown, on the basis of Embodiment 1, the shielding mechanism 5 further includes a fixing frame 5.2, a horizontal turret 5.3, a turning mechanism 5.4, a rotating mechanism 5.5, a driving motor 5.6, a driving gear 5.7, a transmission rack 5.8, a first The transmission gear 5.9, the second transmission gear 5.10, the awning 5.1 and the horizontal turret 5.3 are rotatably connected in the vertical plane, and the turning mechanism 5.4 drives the awning 5.1 to rotate relative to the horizontal turret 5.3, and the horizontal turret 5.3 is rotatably connected with the fixed frame 5.2 And the rotation axis of the horizontal turret 5.3 is vertical, and the rotating mechanism 5.5 drives the horizontal turret 5.3 to rotate relative to the fixed frame 5.2.

[0028] The turning mechanism 5.4 includes a first worm gear 5.4.1, a first worm 5.4.2, and a first rotational drive member 5.4.3. The awning 5.1 is rotatably connected to the horizontal turret 5.3 through a turn...

Embodiment 3

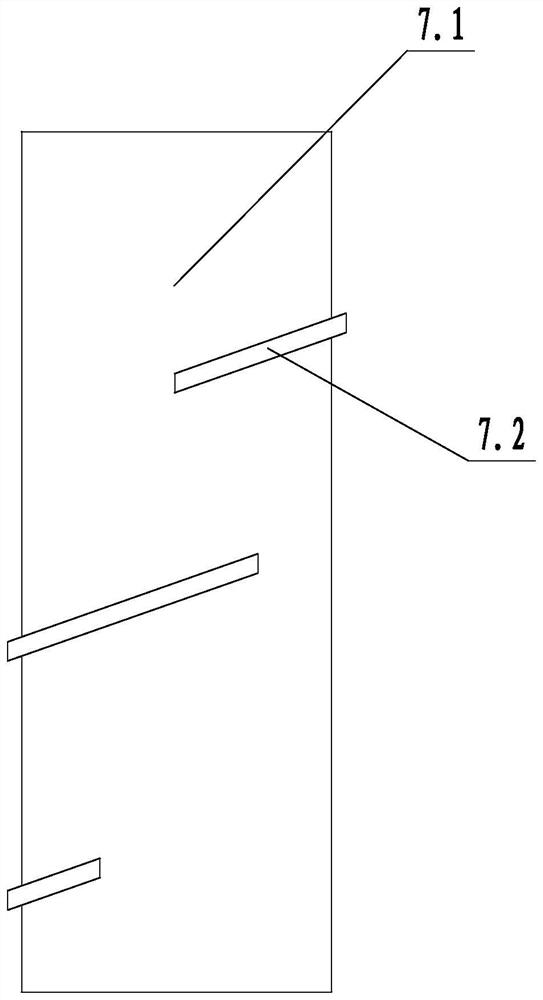

[0032] like image 3 As shown, on the basis of Embodiment 1, it also includes a lifting platform 6. The working robot body 1 and the lifting platform 6 are connected by an insulating frame 7. The insulating frame 7 includes several insulating rods 7.1. Several water-breaking guide bars 7.2 are arranged obliquely on the axis of the insulating rod 7.1. The plurality of water-breaking guide bars are arranged along the axial direction of the insulating rod, and adjacent water-breaking guide bars are staggered on the axial projection plane of the insulating rod. The lower ends of the plurality of water-breaking guide bars are suspended on the insulating rod, and the height of the water-breaking guide bar on the side close to the outer side wall of the insulating rod is higher than the height of the water-breaking guide bar on the side away from the outer side wall of the insulating rod.

[0033] The above-mentioned lifting platform 6 can transport the working robot body 1 to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com