Patents

Literature

349 results about "Axial projection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

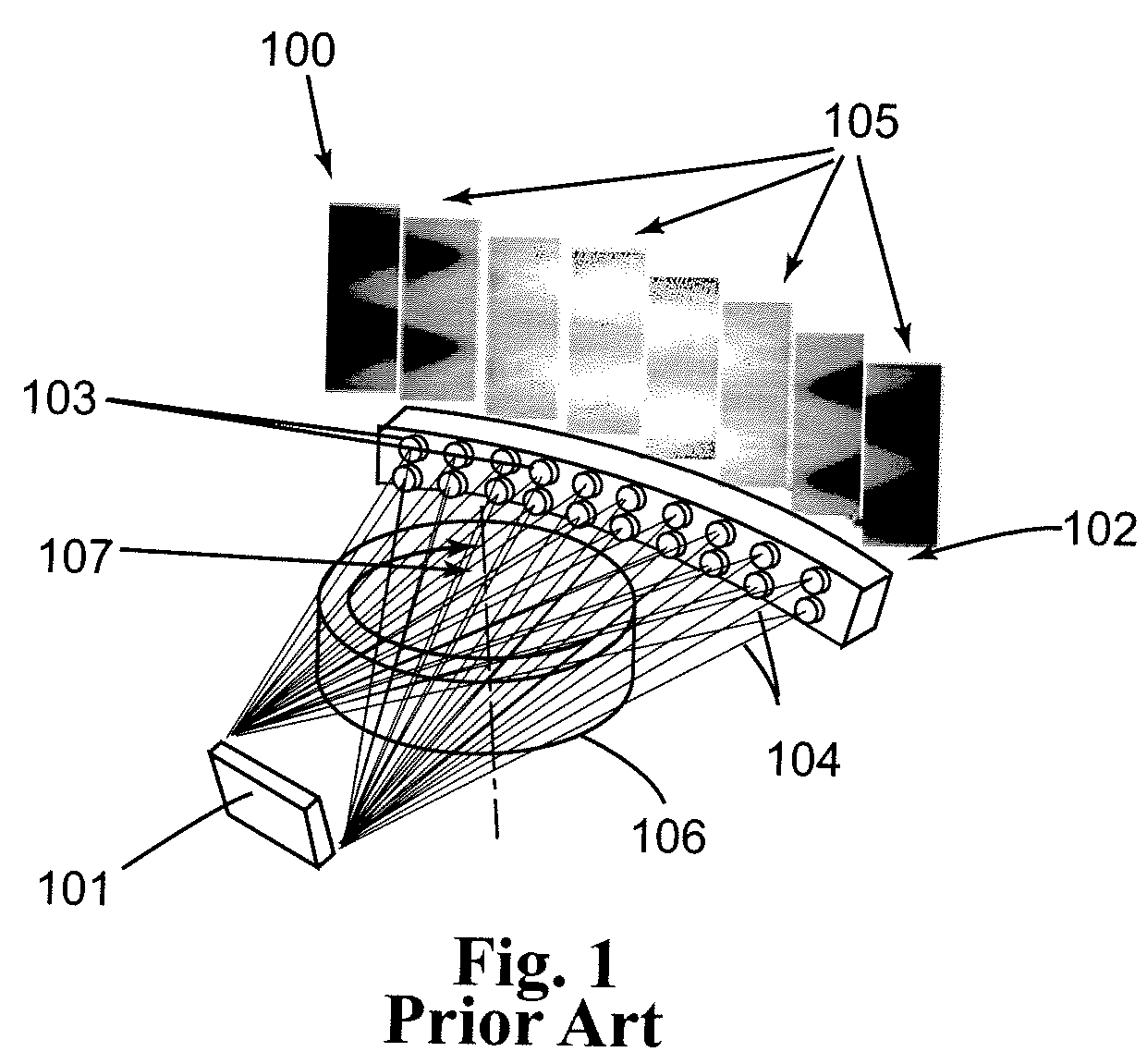

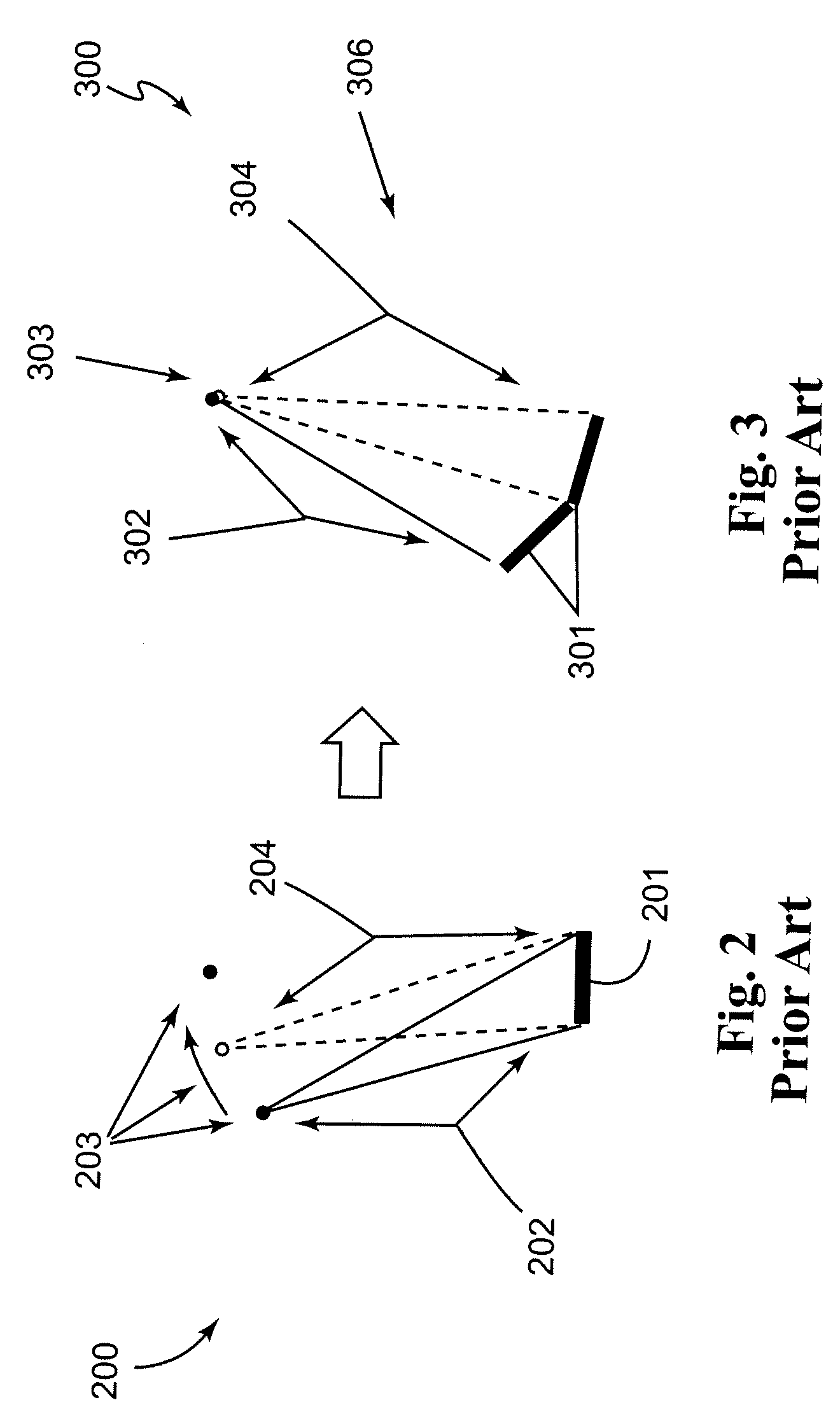

Radial, axial and tangential projections of the contact zone between the roller and work are made, then the radial projection area Sr, axial projection area Sz and tangential projection area St can be obtained, as shown in the Figure 3 ~ 5.

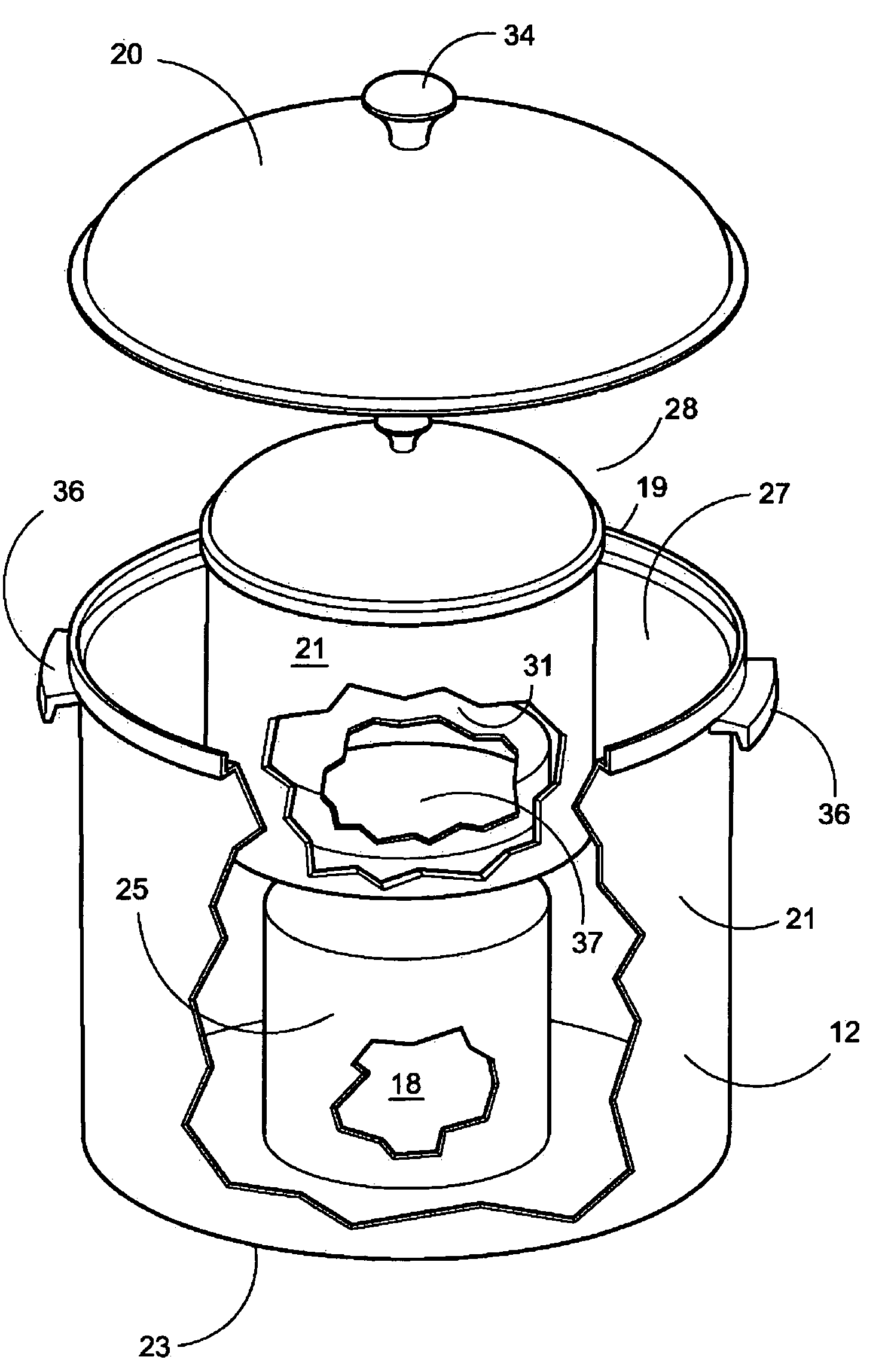

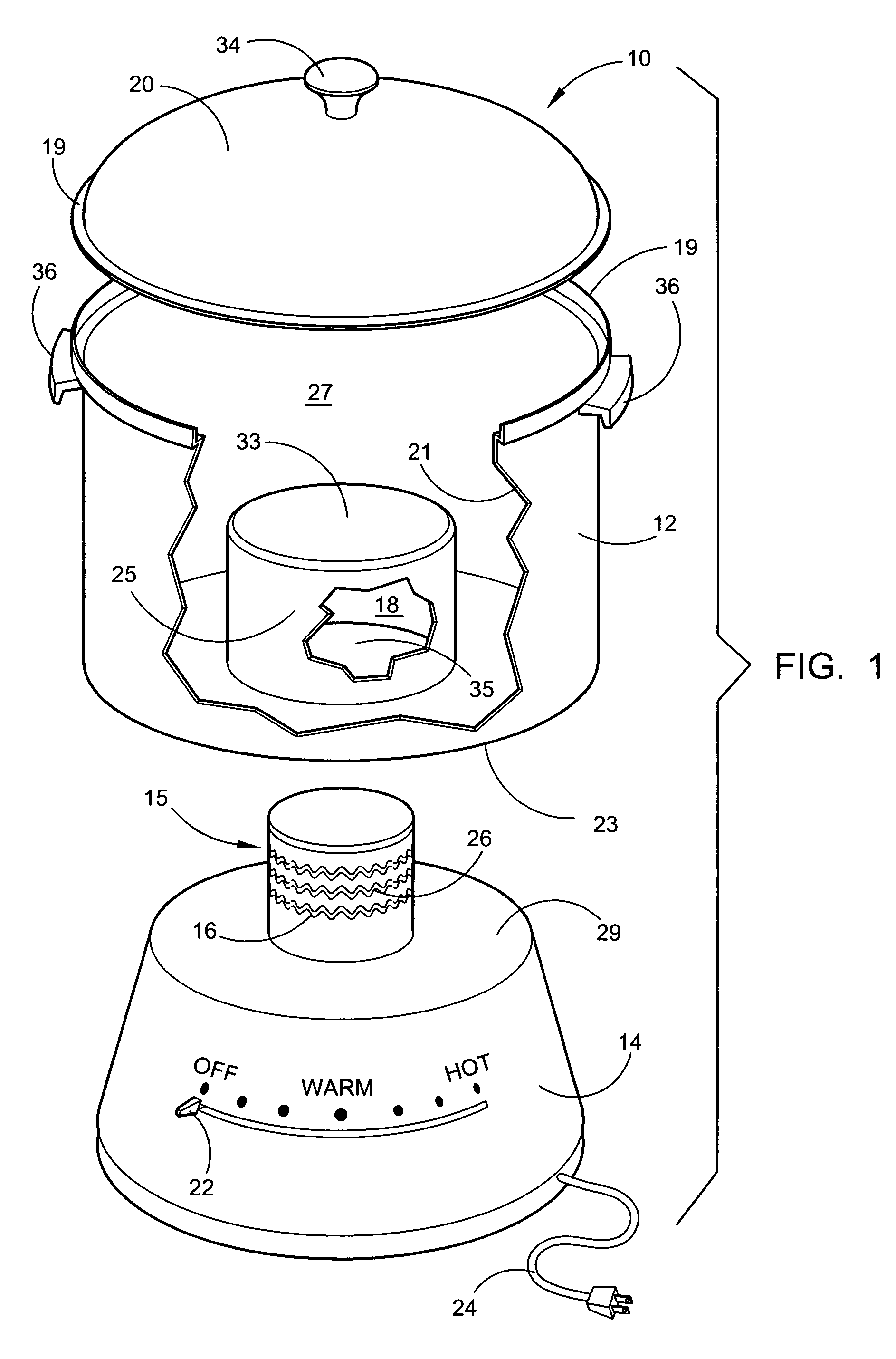

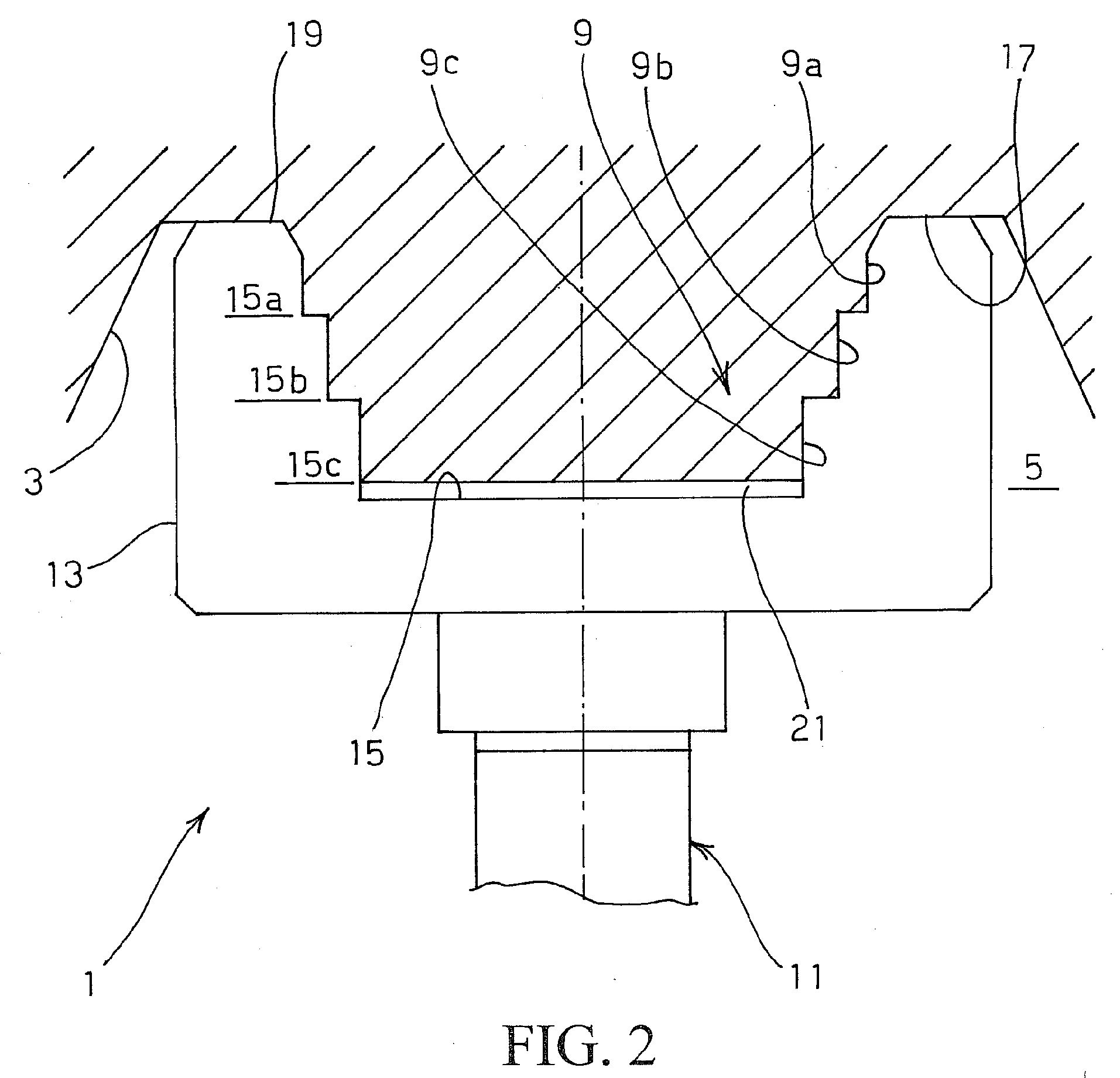

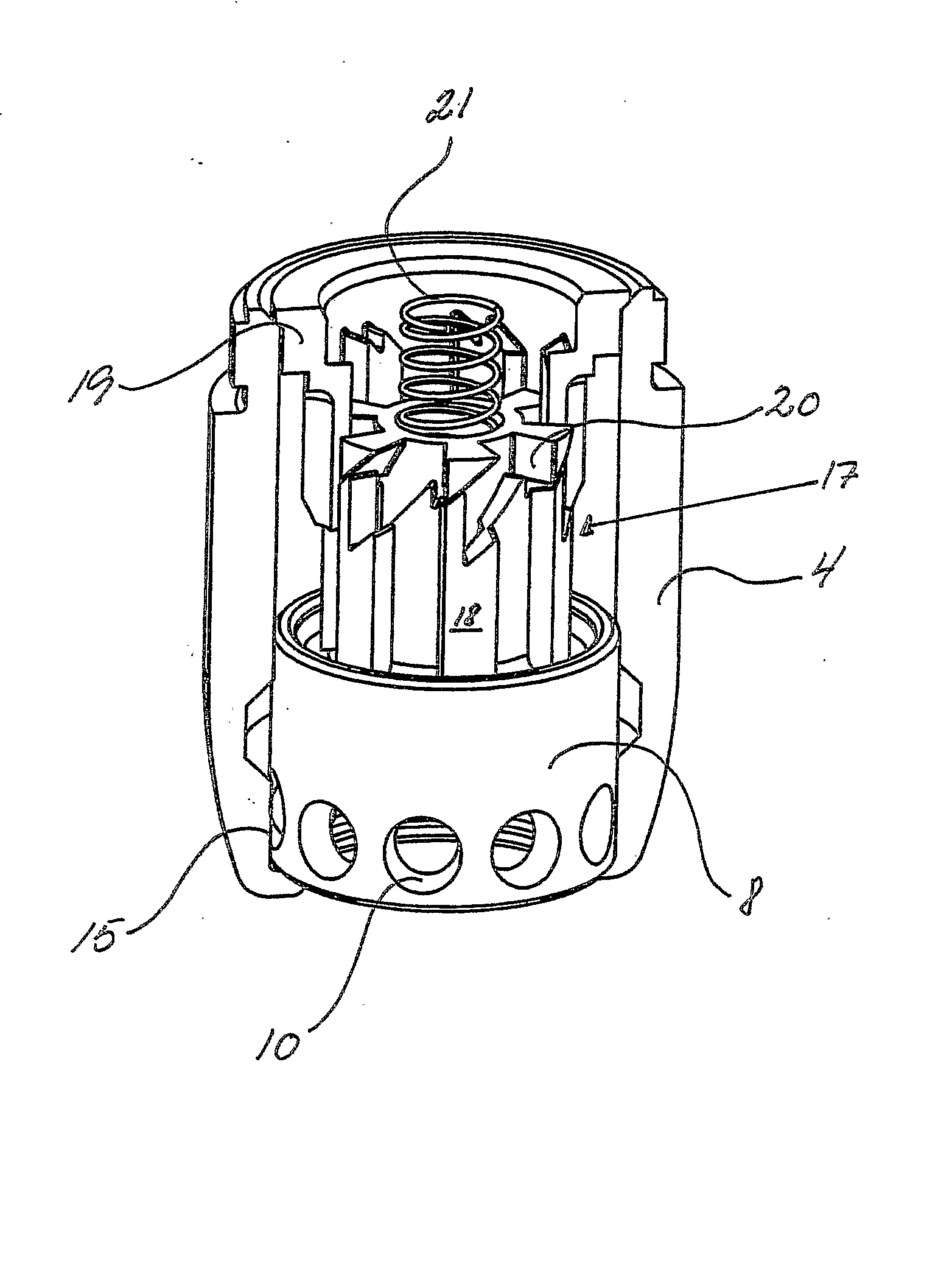

Cooking apparatus employing centrally located heat source

InactiveUS7166822B1Transmission control/equlisationBoiling over preventionEngineeringAxial projection

Owner:MIRAMA ENTERPRISES

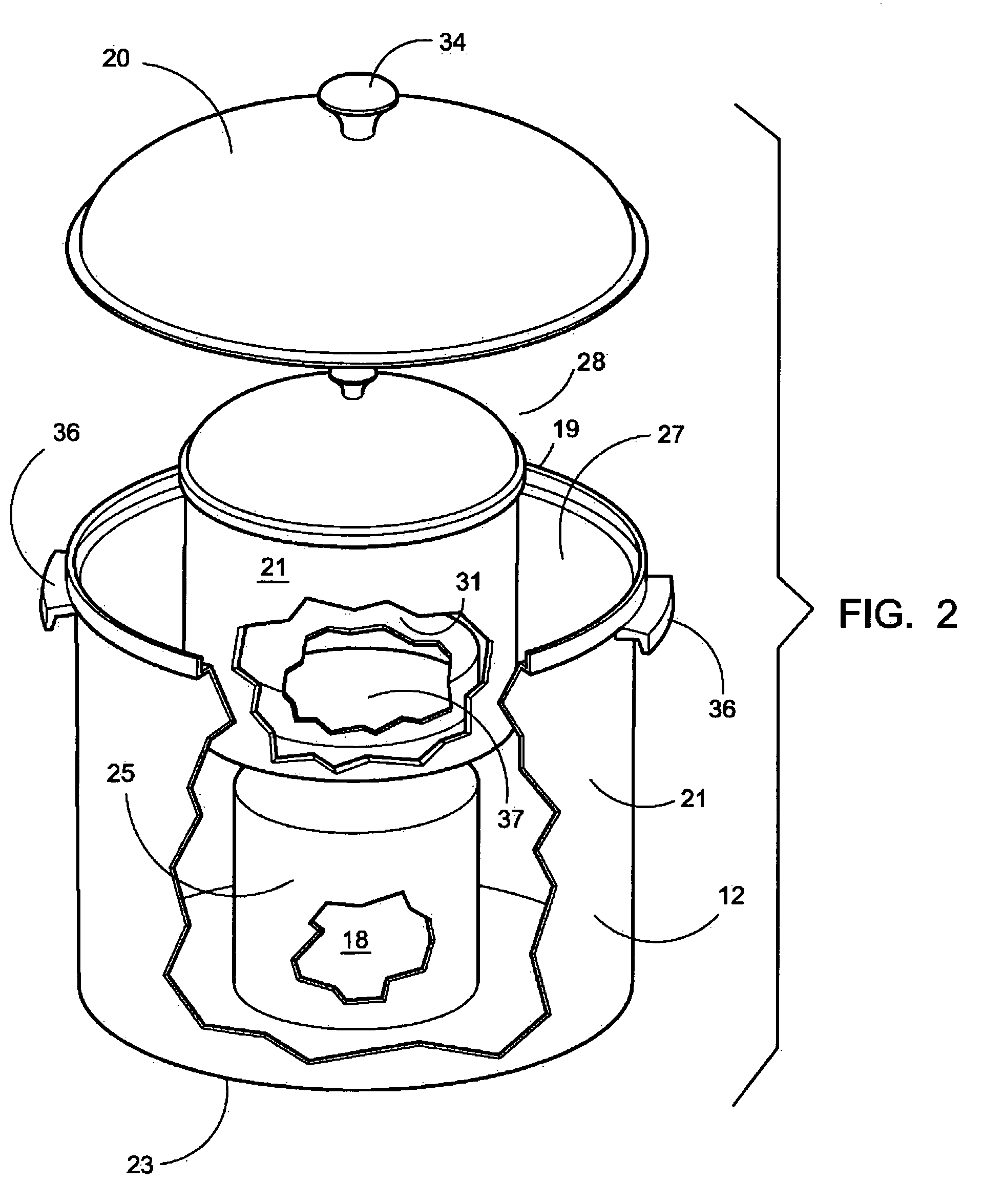

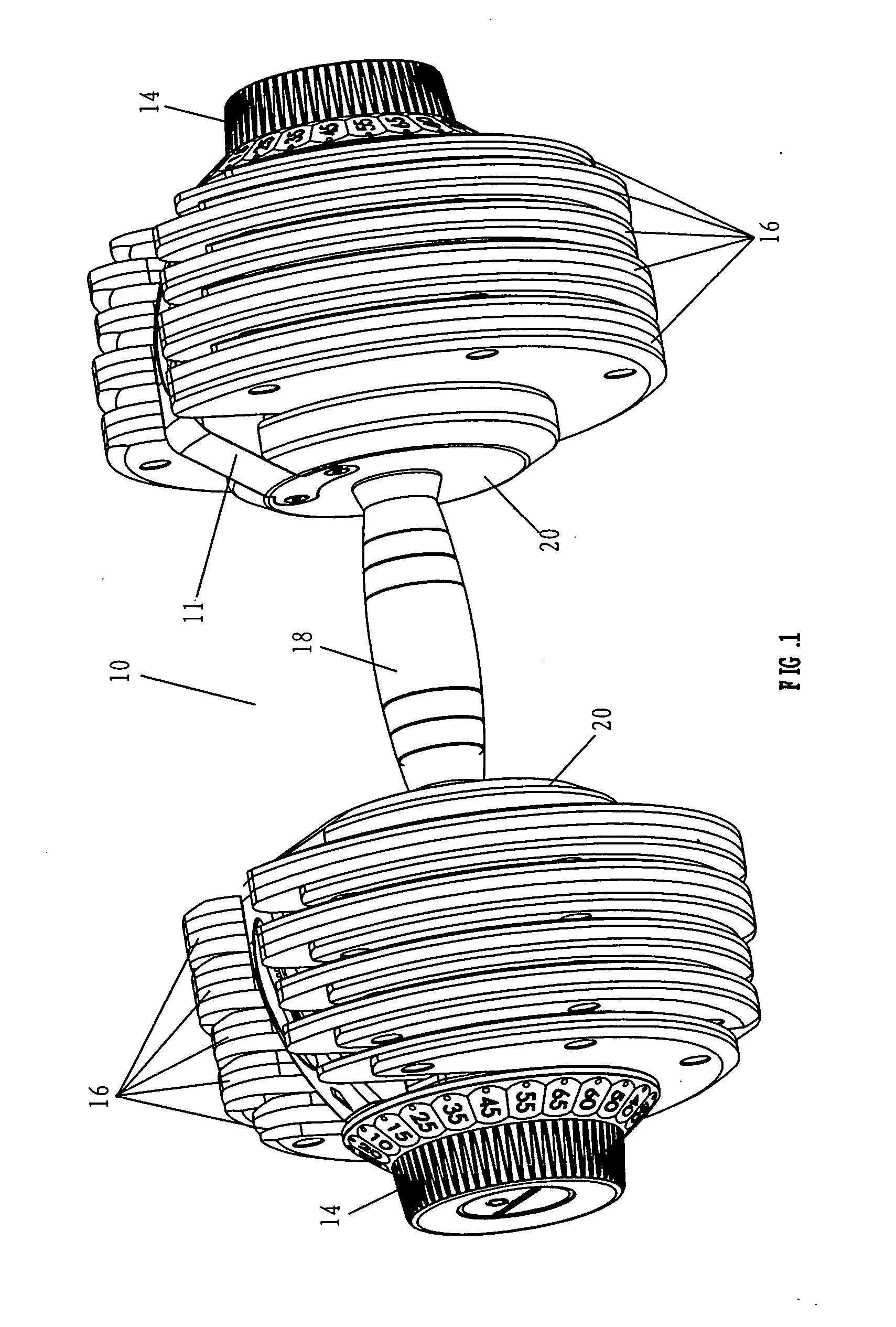

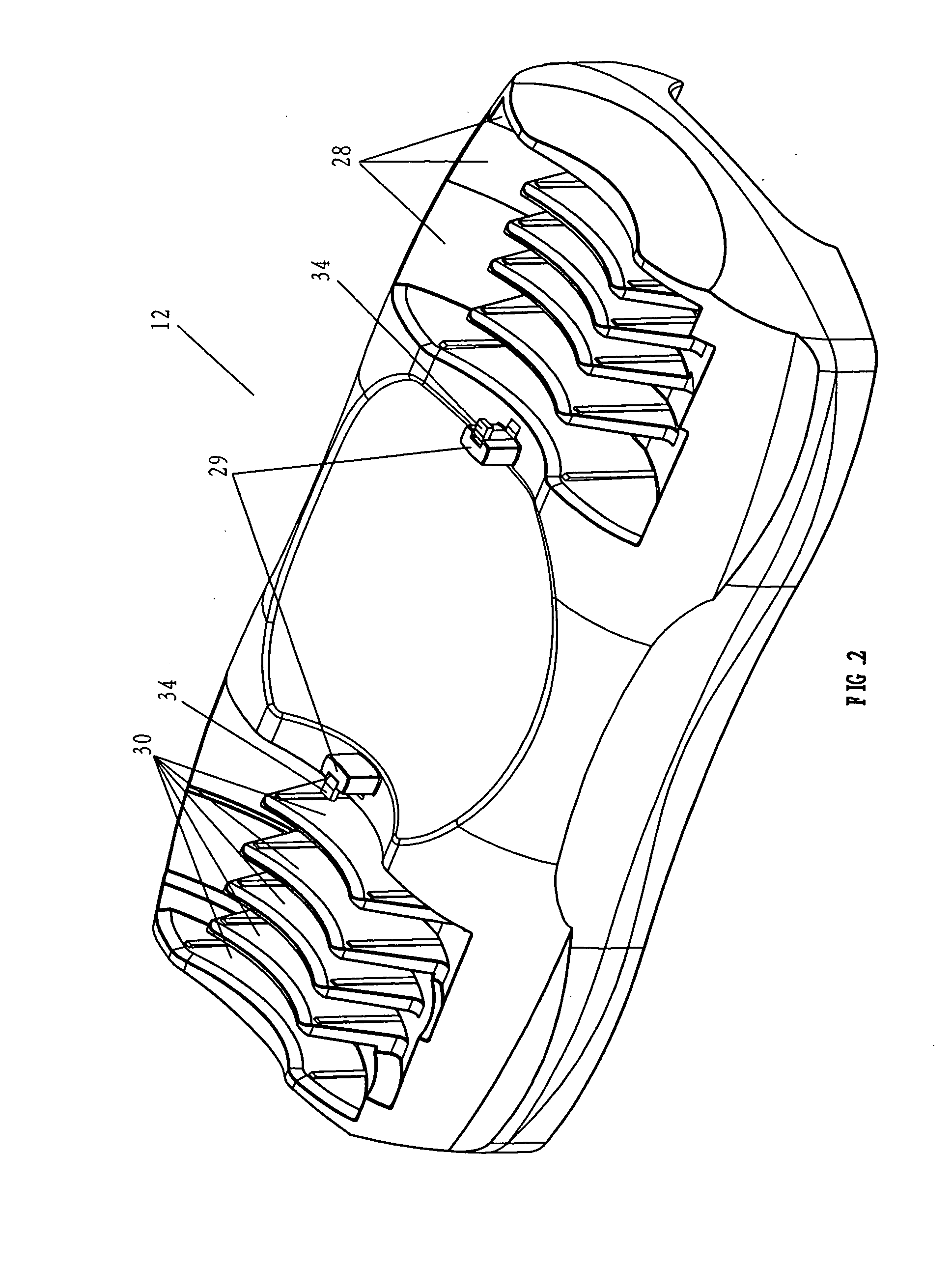

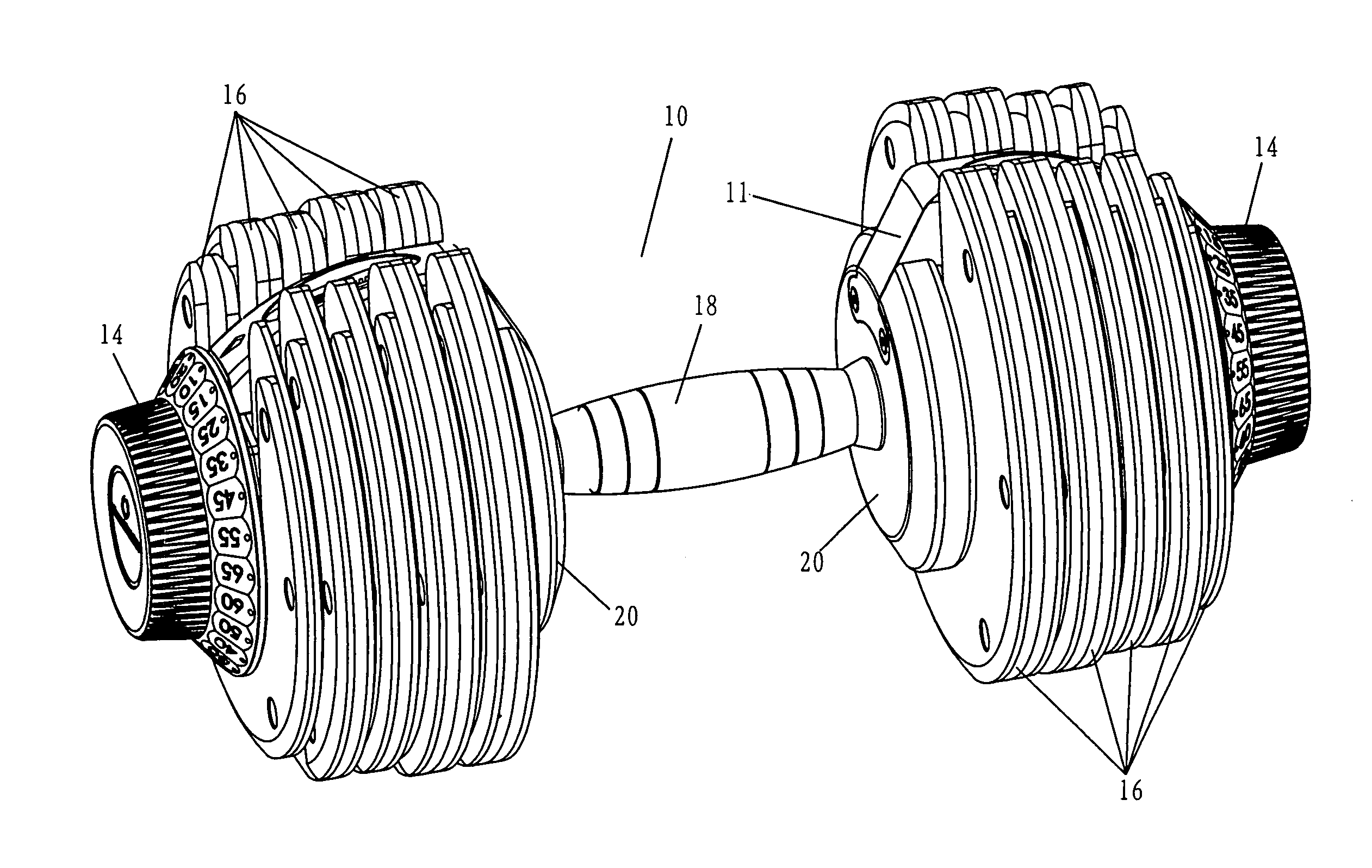

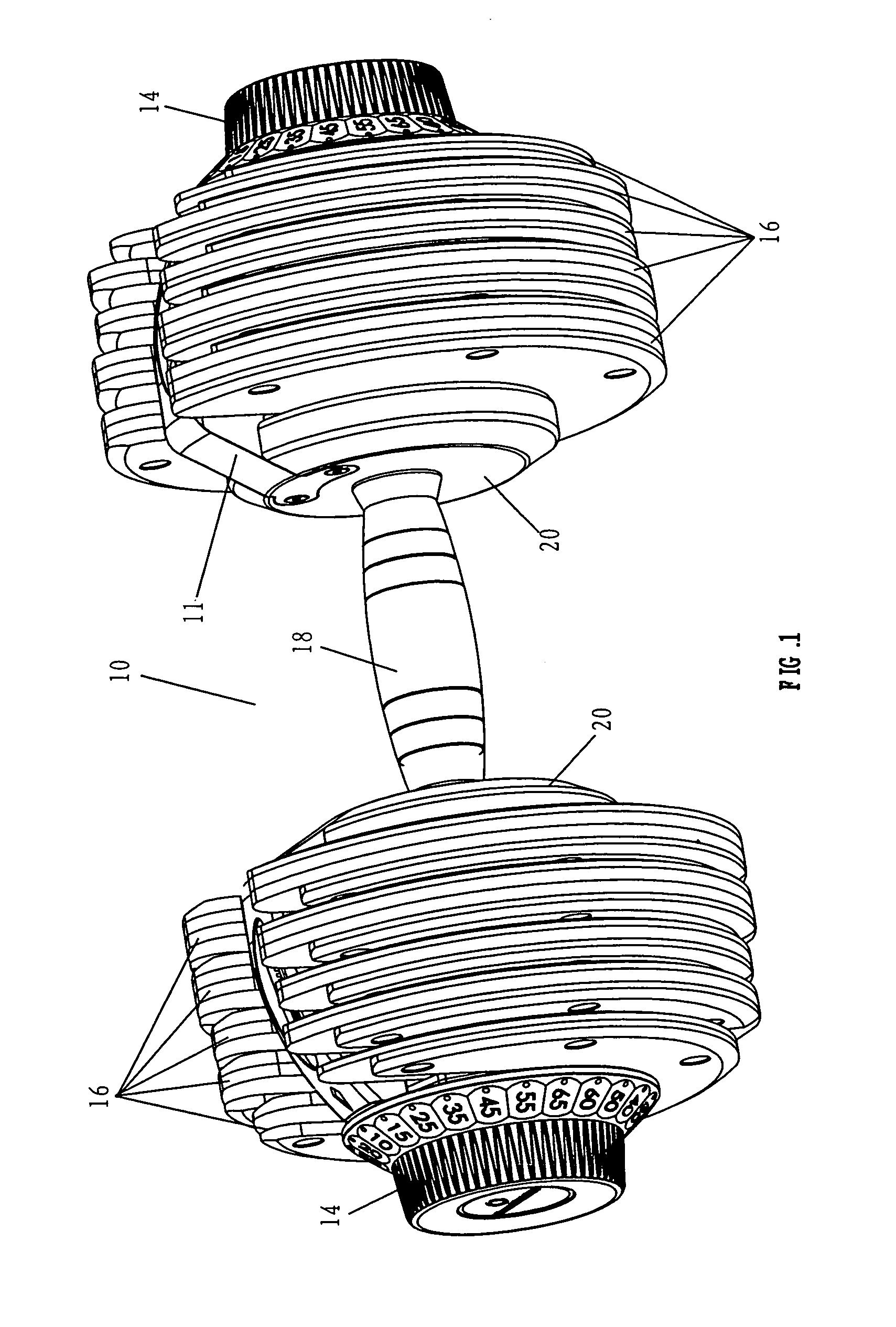

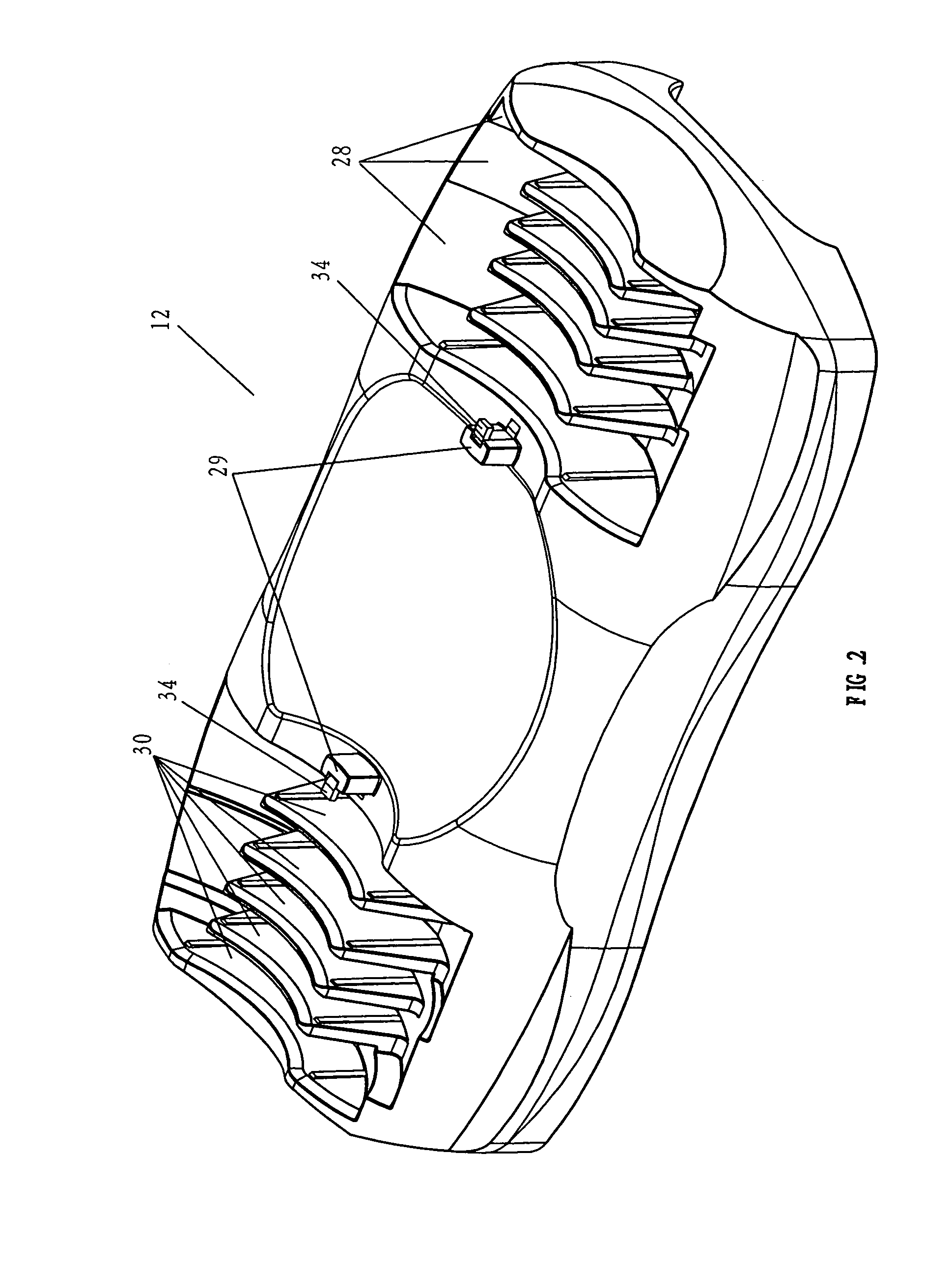

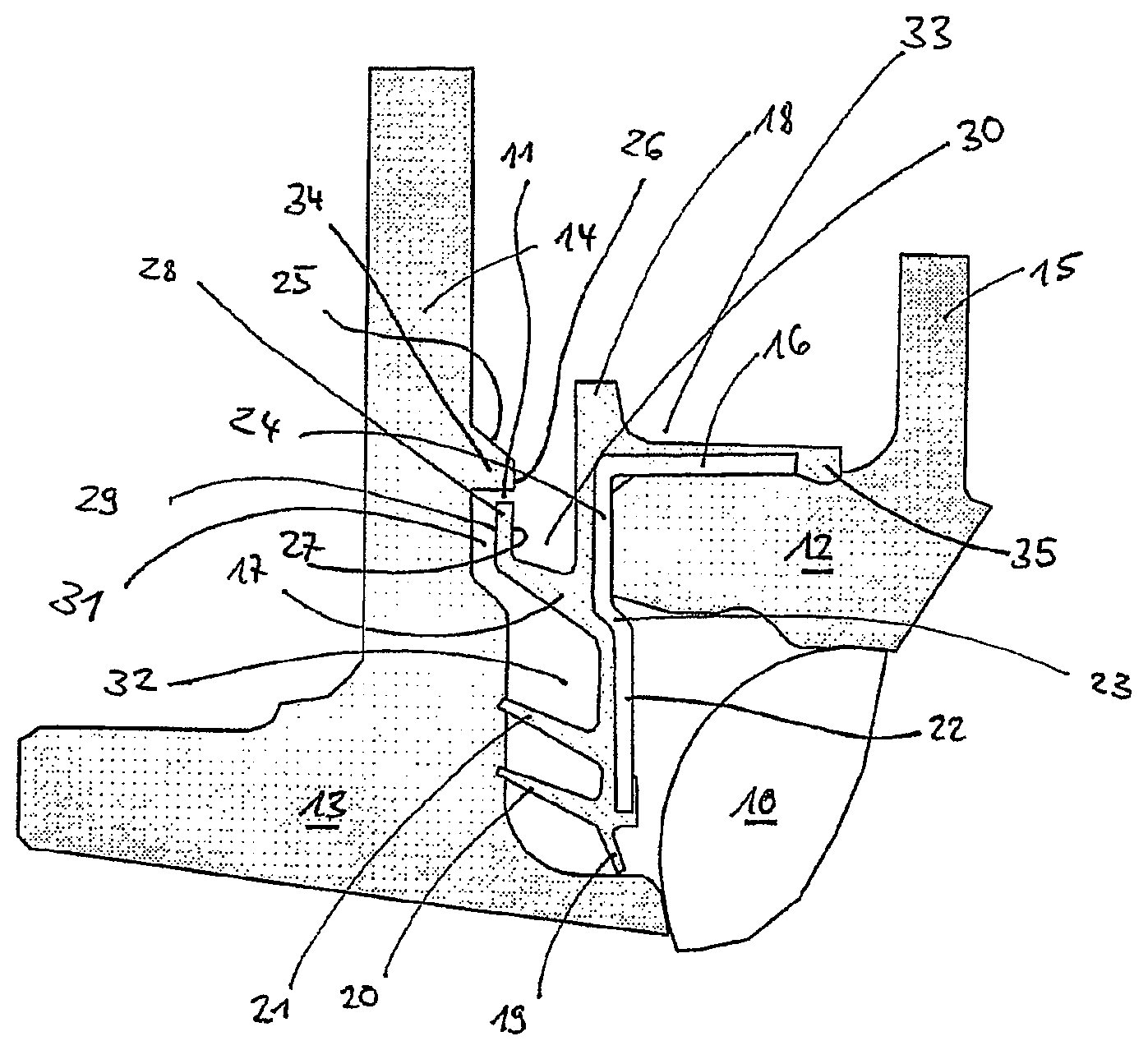

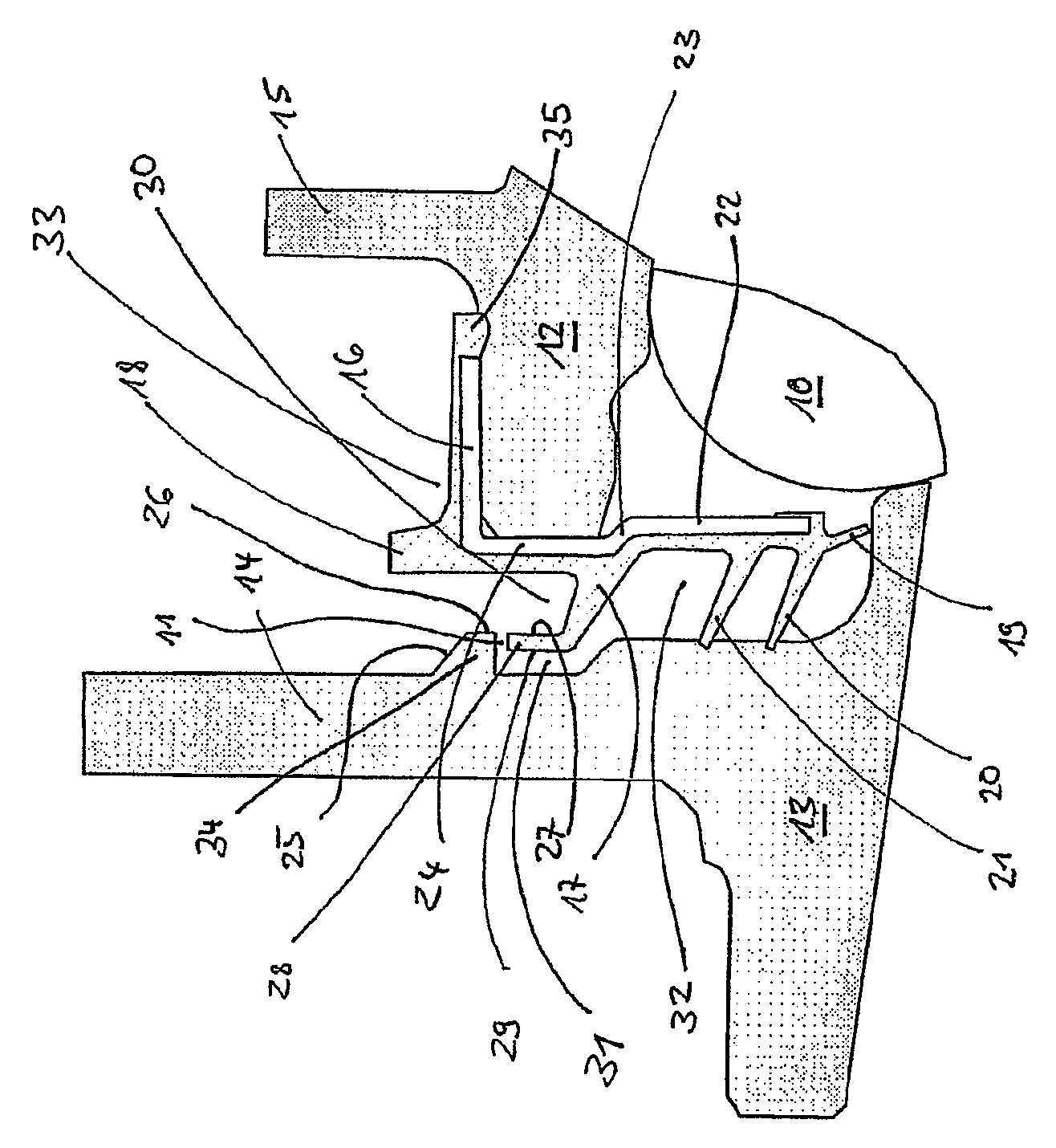

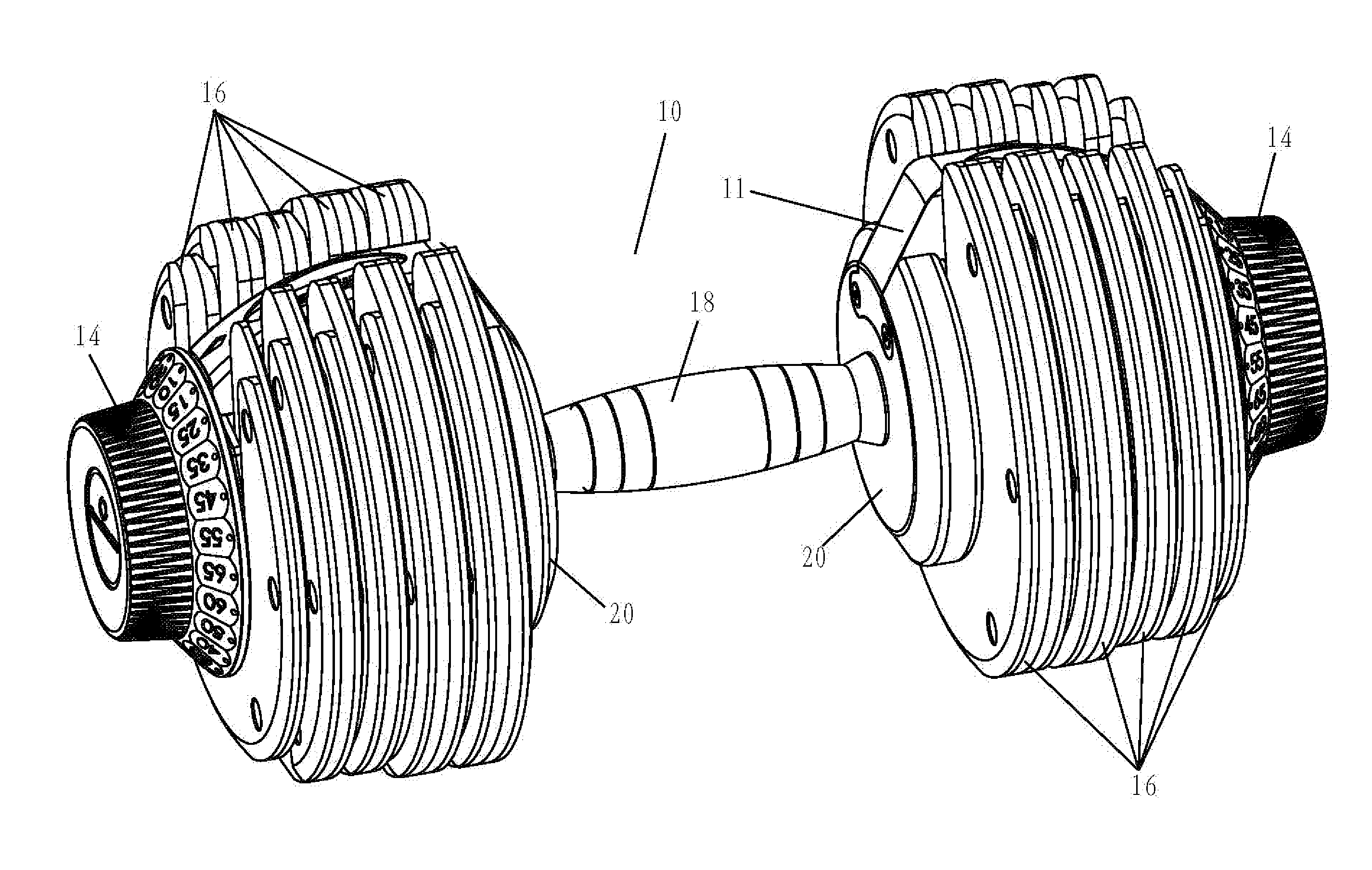

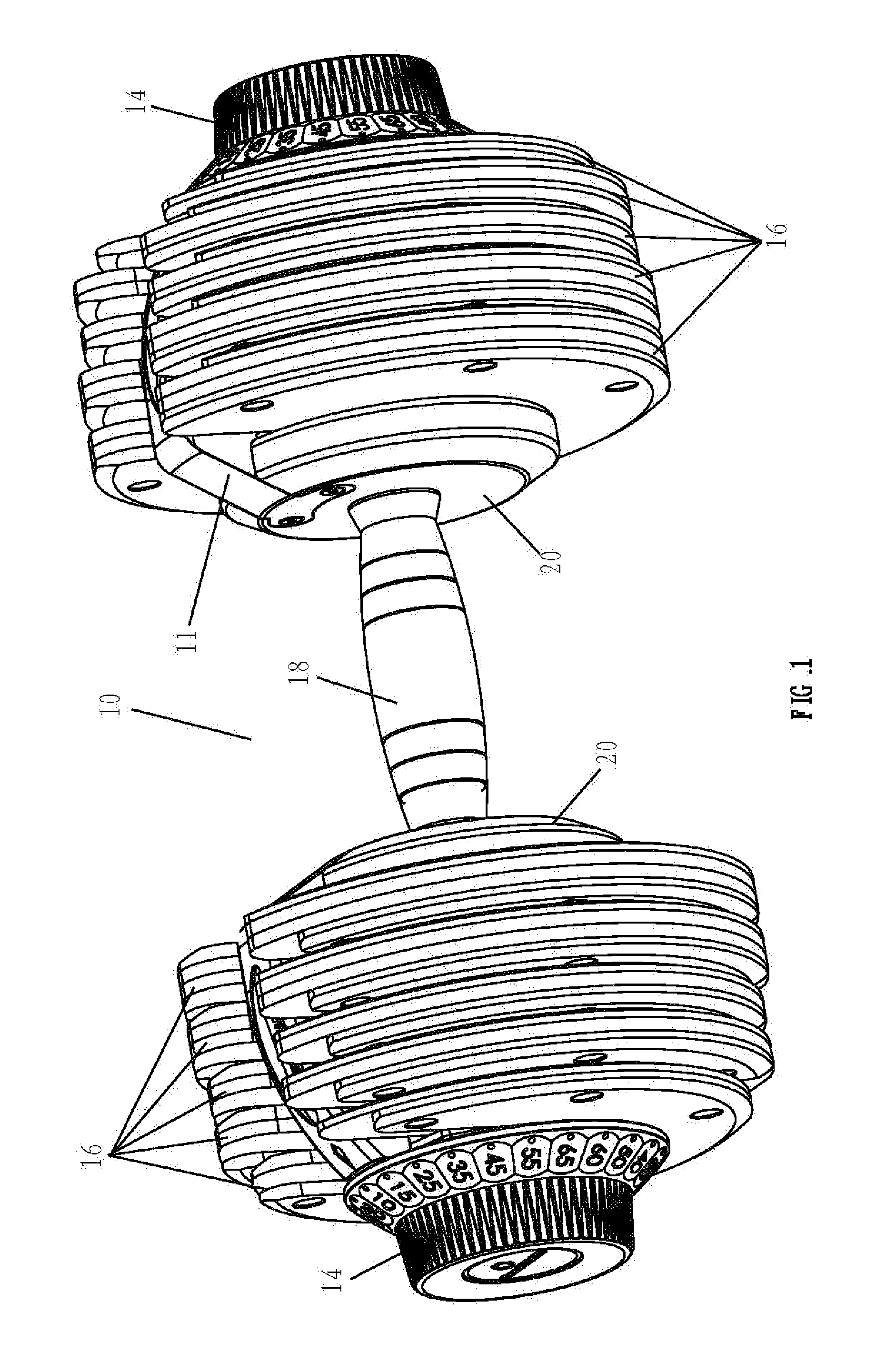

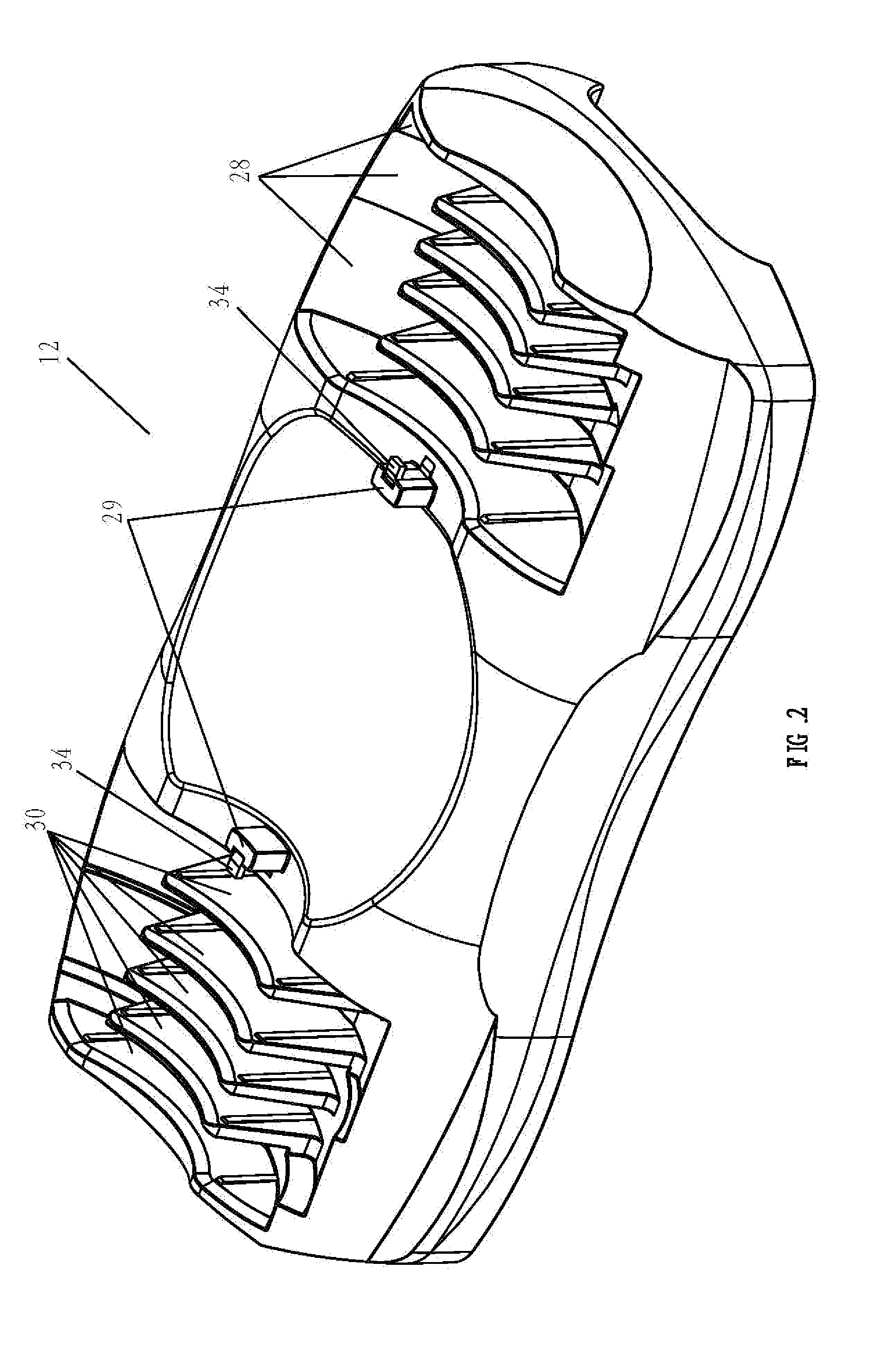

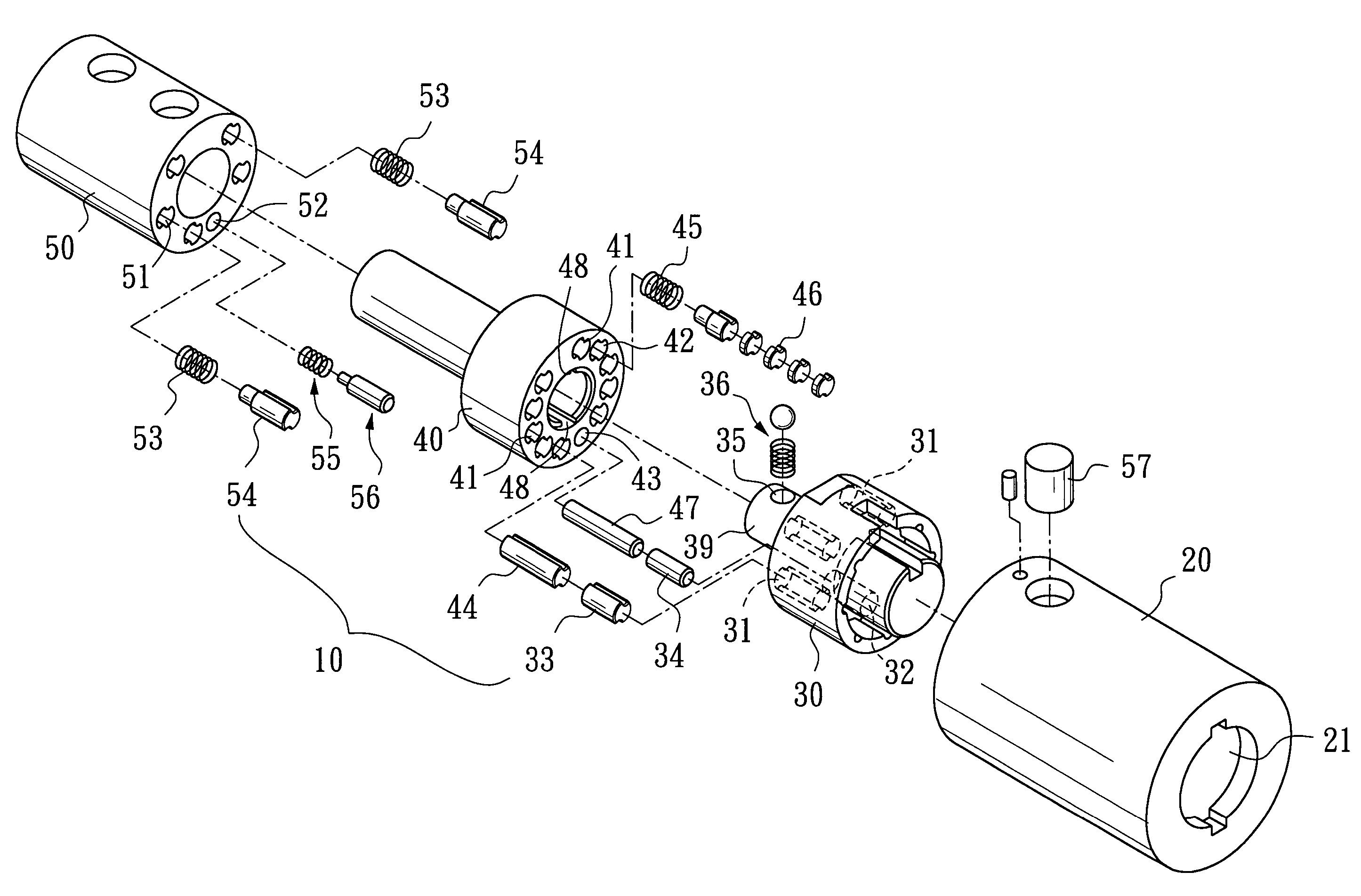

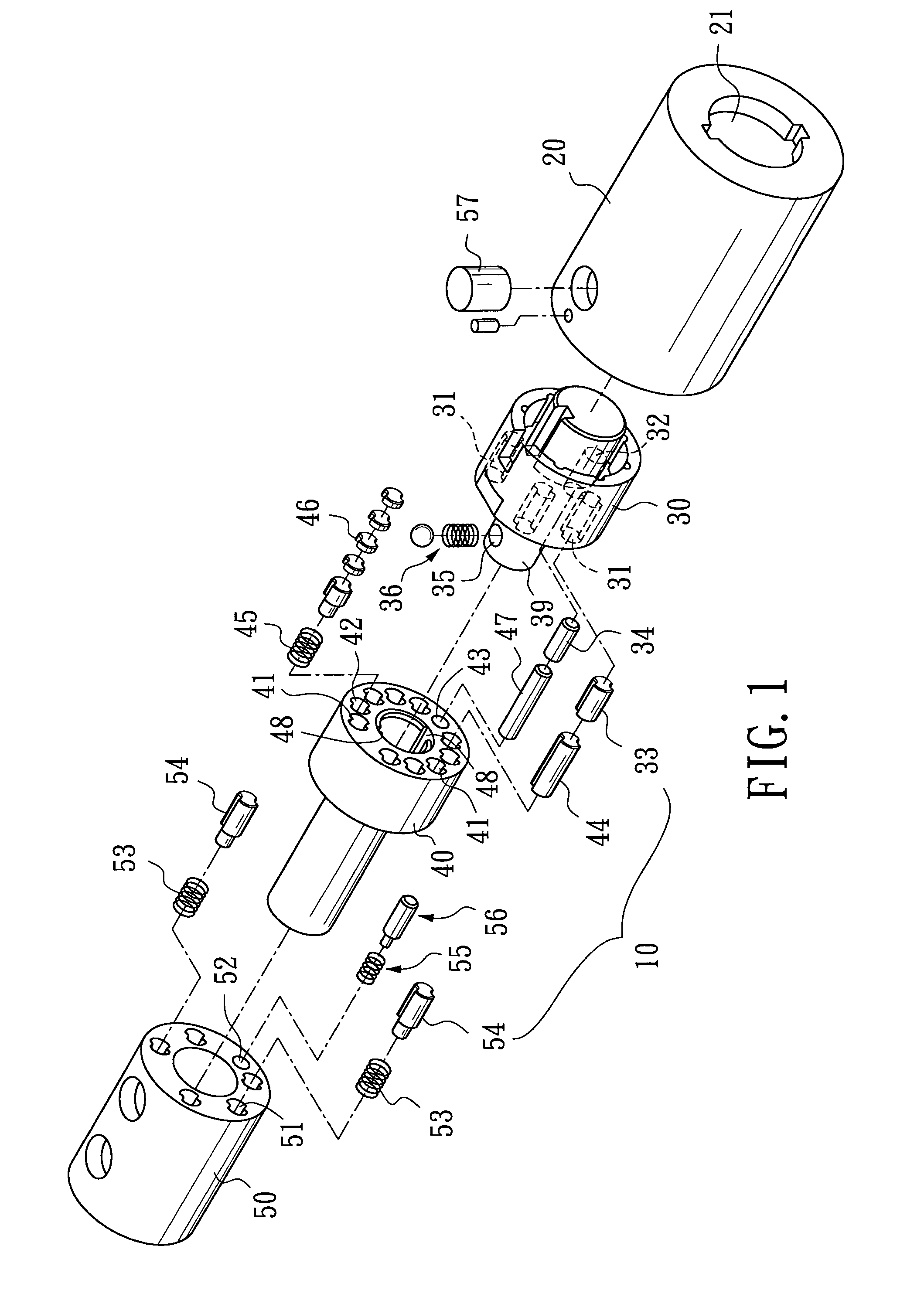

Adjustable dumbbell system

ActiveUS20090042700A1Easy and efficient to manufactureDurable and reliable constructionDumb-bellsDumbbellCoil spring

A handle has opposed ends and a central extent. A grip rotationally receives the central extent of the handle. An adjustment wheel is secured to each end of the handle. A side cover is fixedly secured to each end of the grip. A dowel disk is on the handle adjacent to one side cover with fingers and spaces. A plurality of cam bits are supported on the handle. A safety lock is within the side cover adjacent to the dowel disk. The safety lock has a first end extent and a second end extent with a radial recess and a central extent with an axial projection. A coil spring within the radial recess urges the safety lock radially outwardly.

Owner:LIU PING

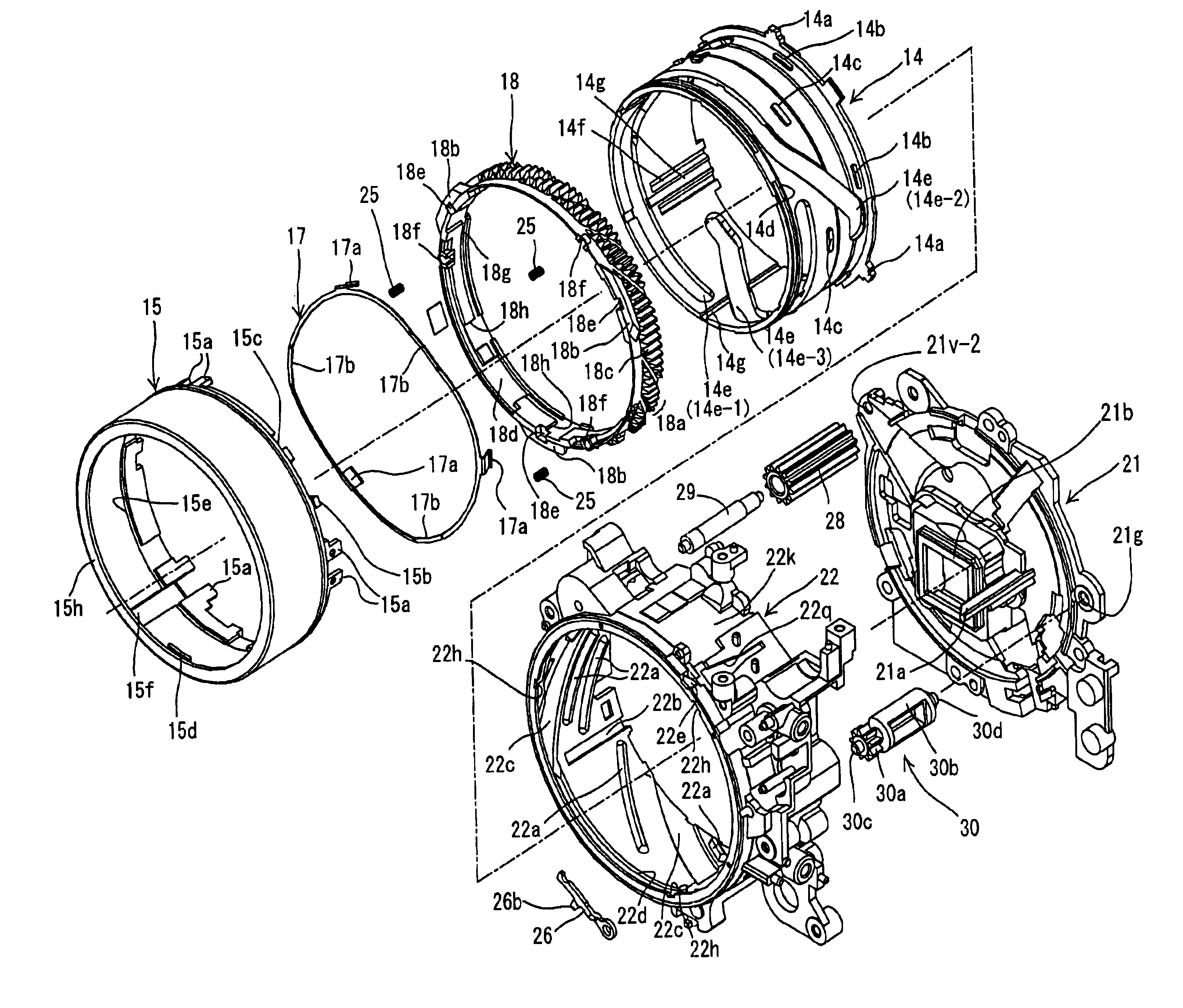

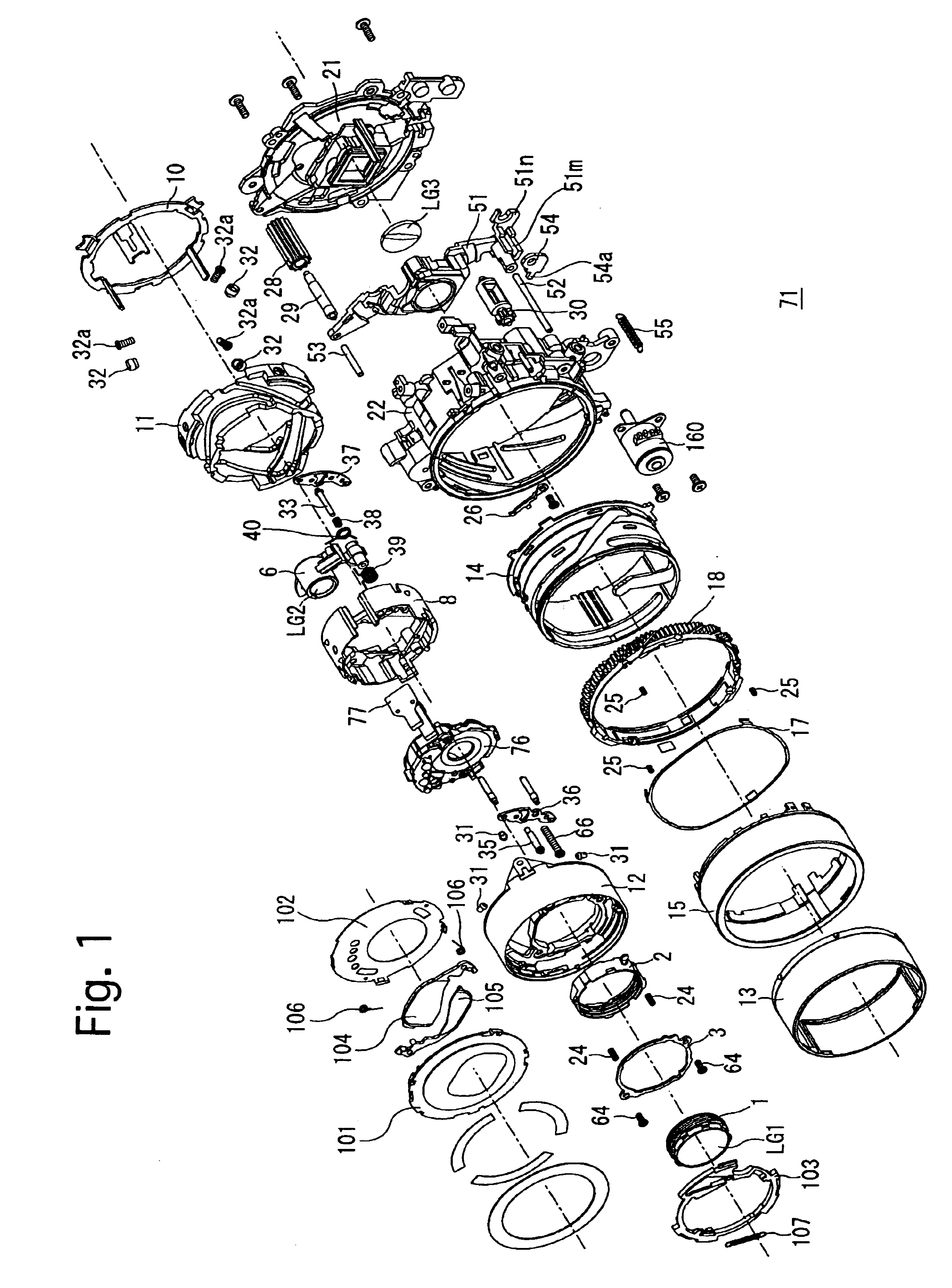

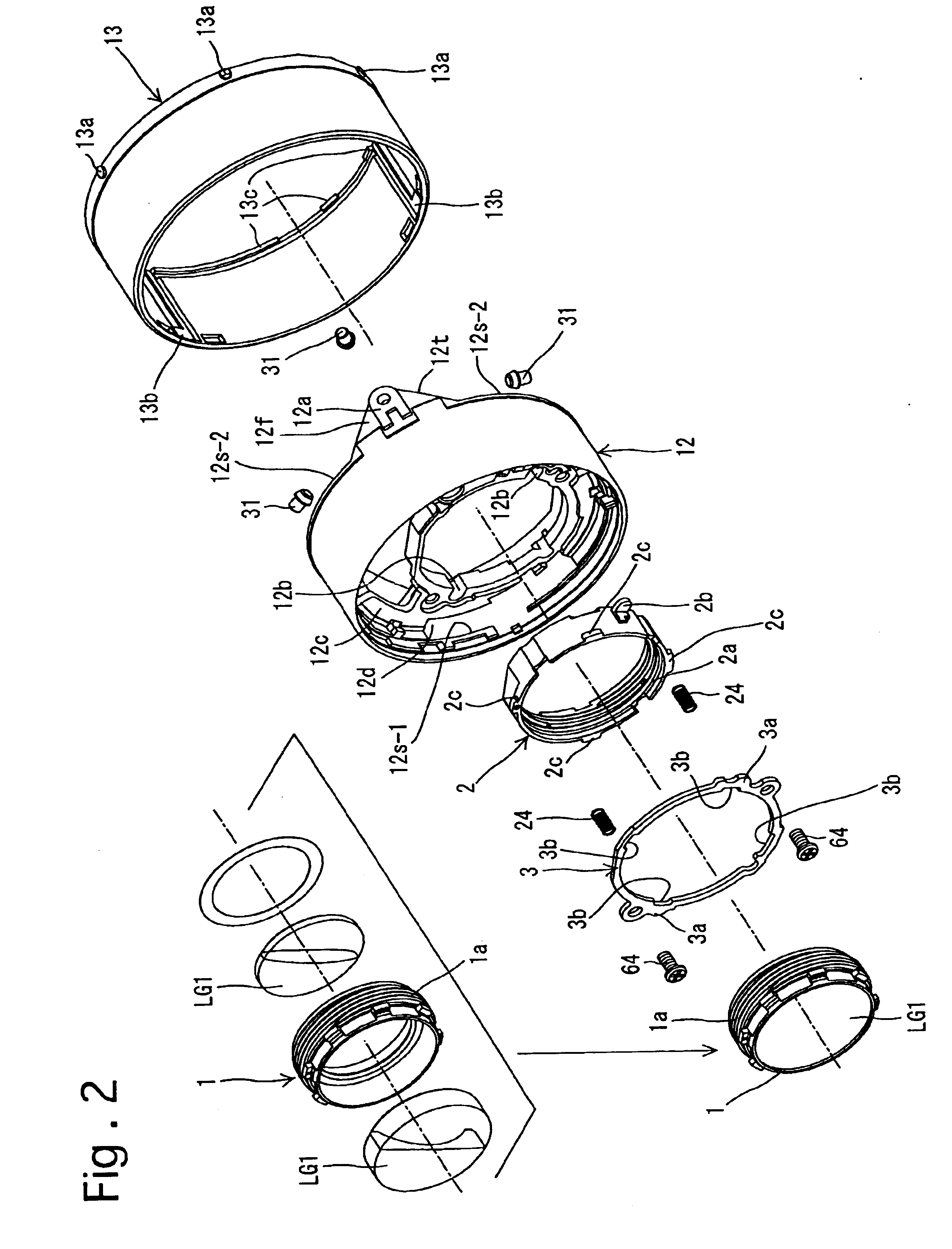

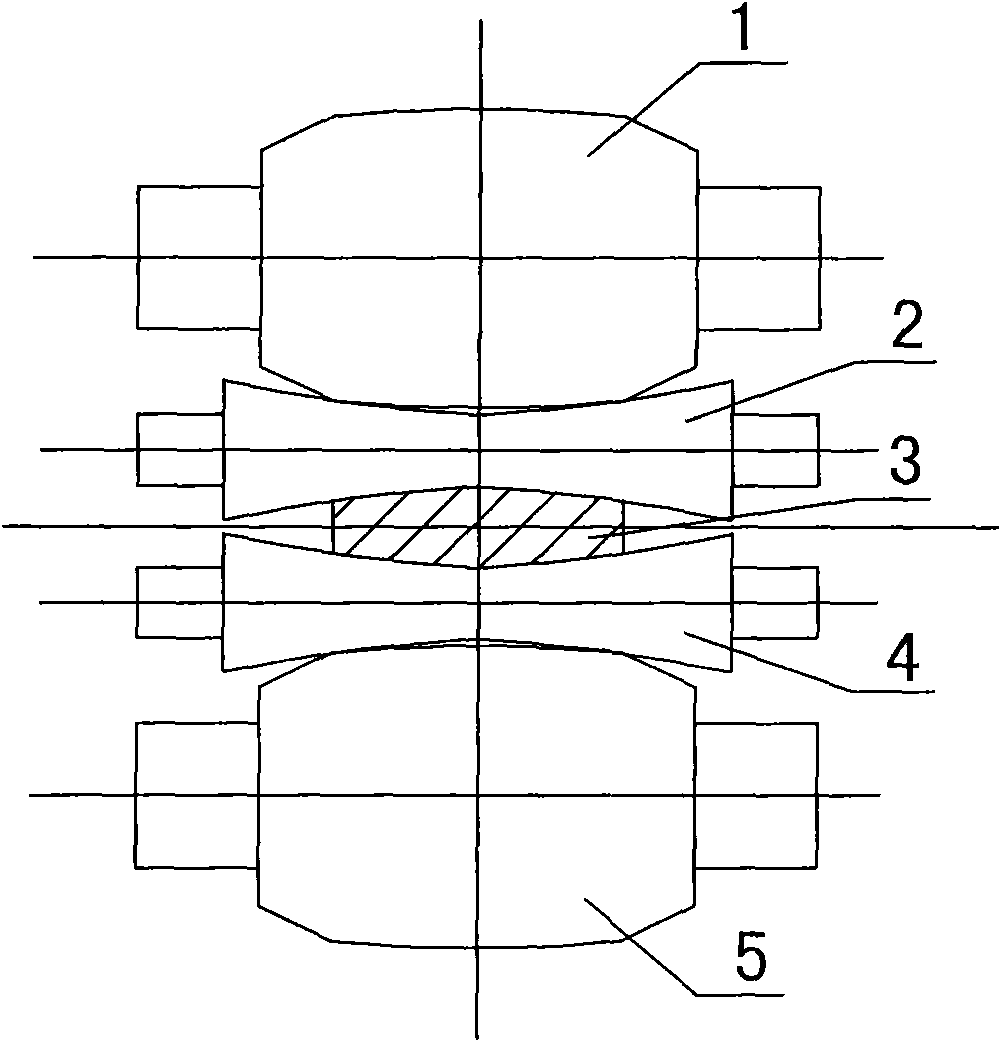

Lens barrel incorporating the rotation transfer mechanism

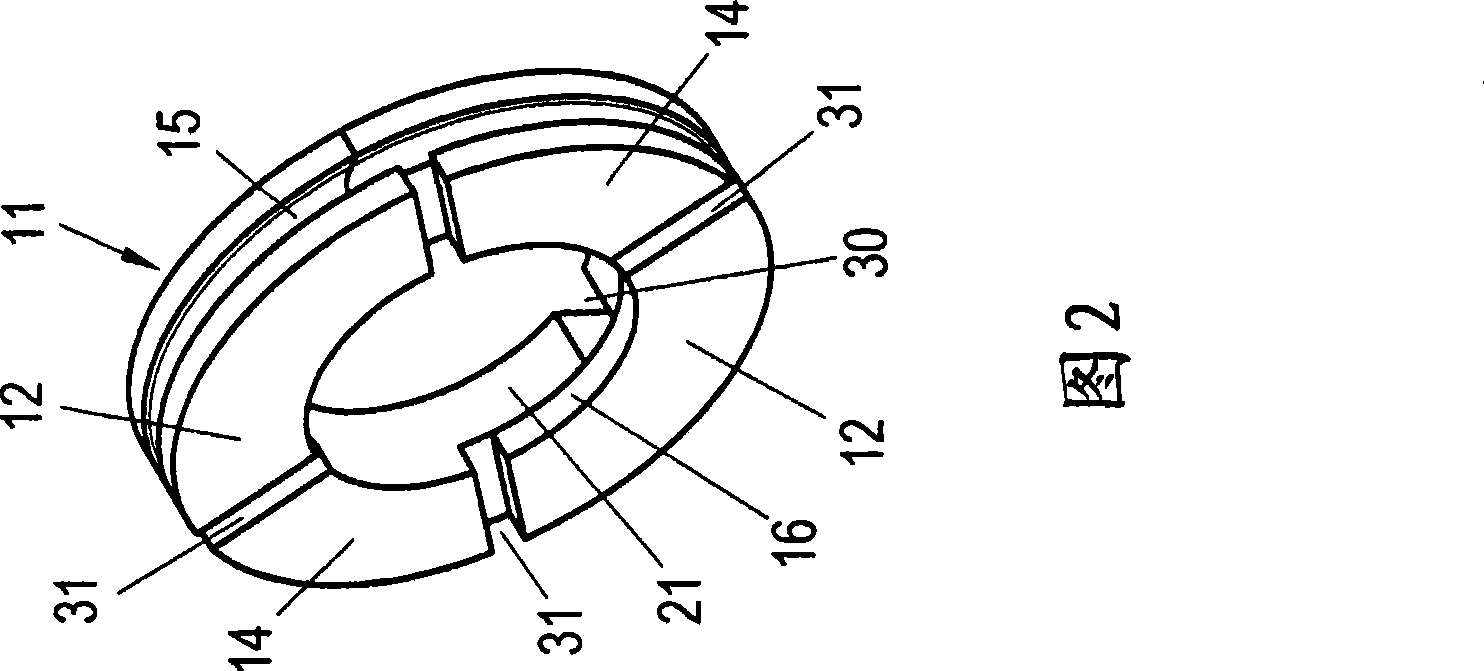

A rotation transfer mechanism of a lens barrel includes a pair of rotatable rings, adjacent ends of which are opposed to each other; an axial-direction projection extending in the rotational axis direction; an axial-direction recess in which the axial-direction projection is positioned; a rotation transfer groove located on an inner peripheral surface of the one of the rotatable rings that has the axial-direction projection, wherein a circumferential position of the rotation transfer groove corresponds to a circumferential position of the axial-direction projection; a driven rotational member having a rotation transfer protrusion engaged in the rotation transfer groove, the rotation transfer protrusion slidably movable in the rotation transfer groove in the rotational axis direction and configured to transmit rotation of the rotatable ring to the driven rotational member; and at least one optical element configured to be driven by the driven rotational member.

Owner:ASAHI KOGAKU KOGYO KK

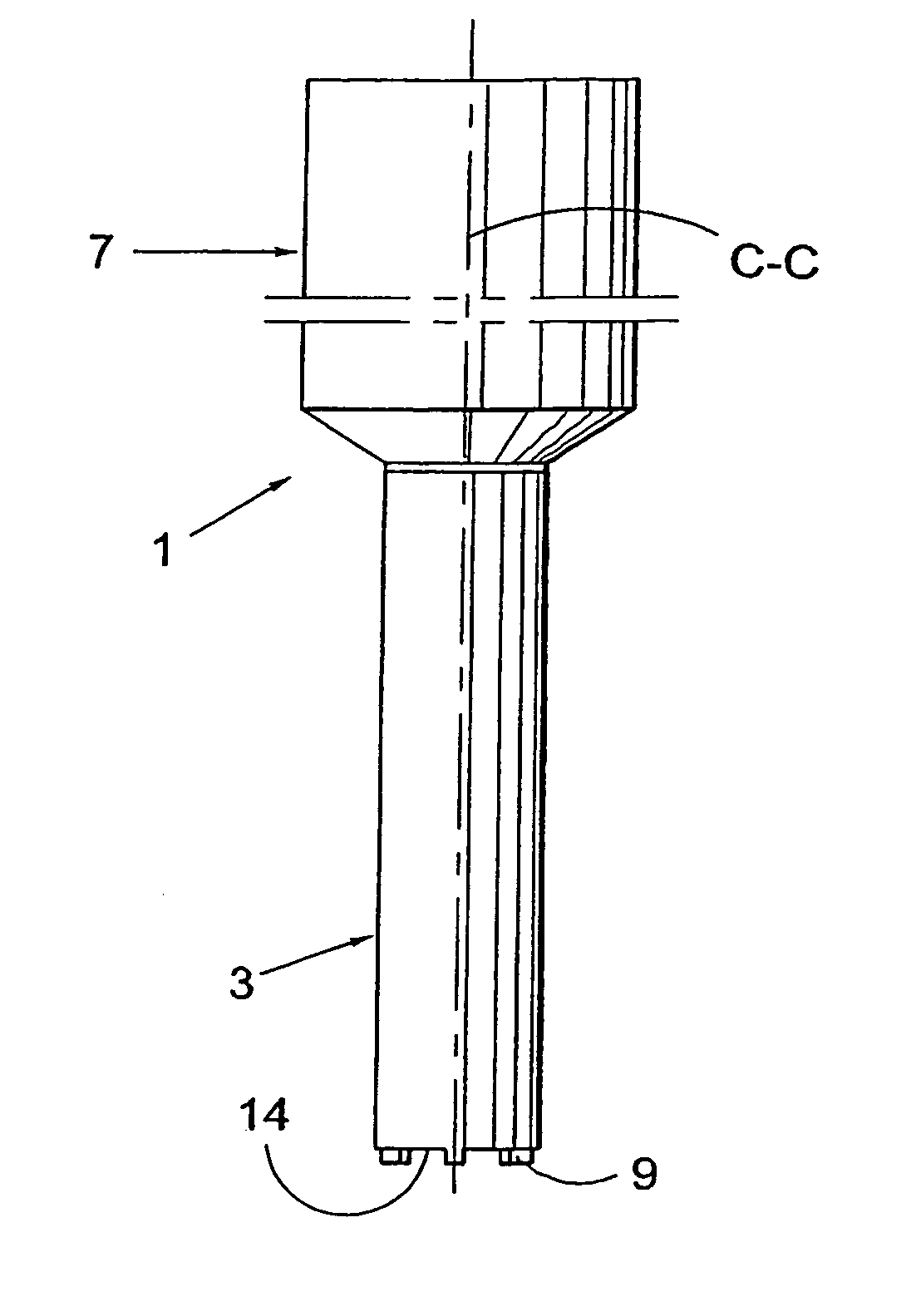

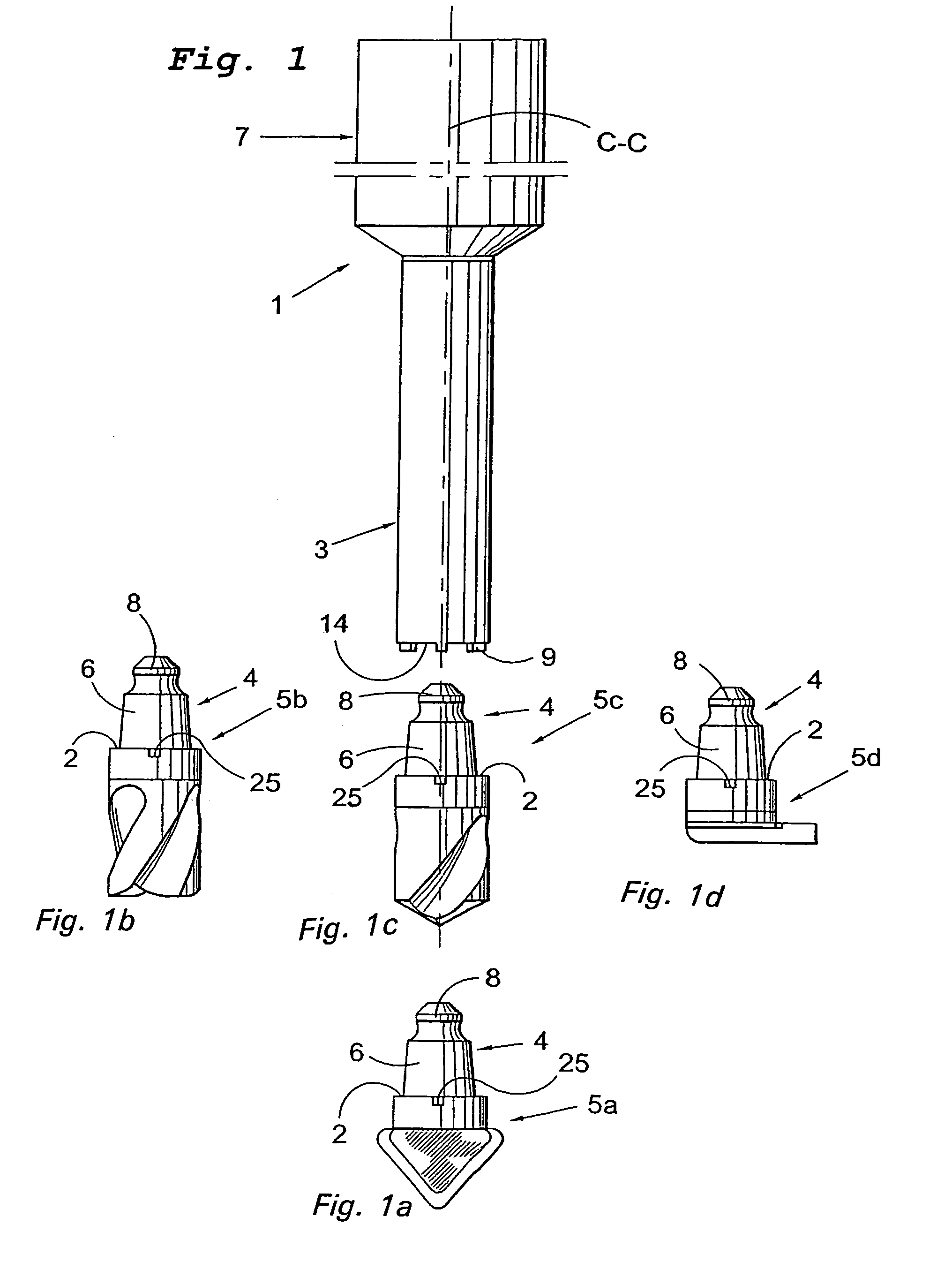

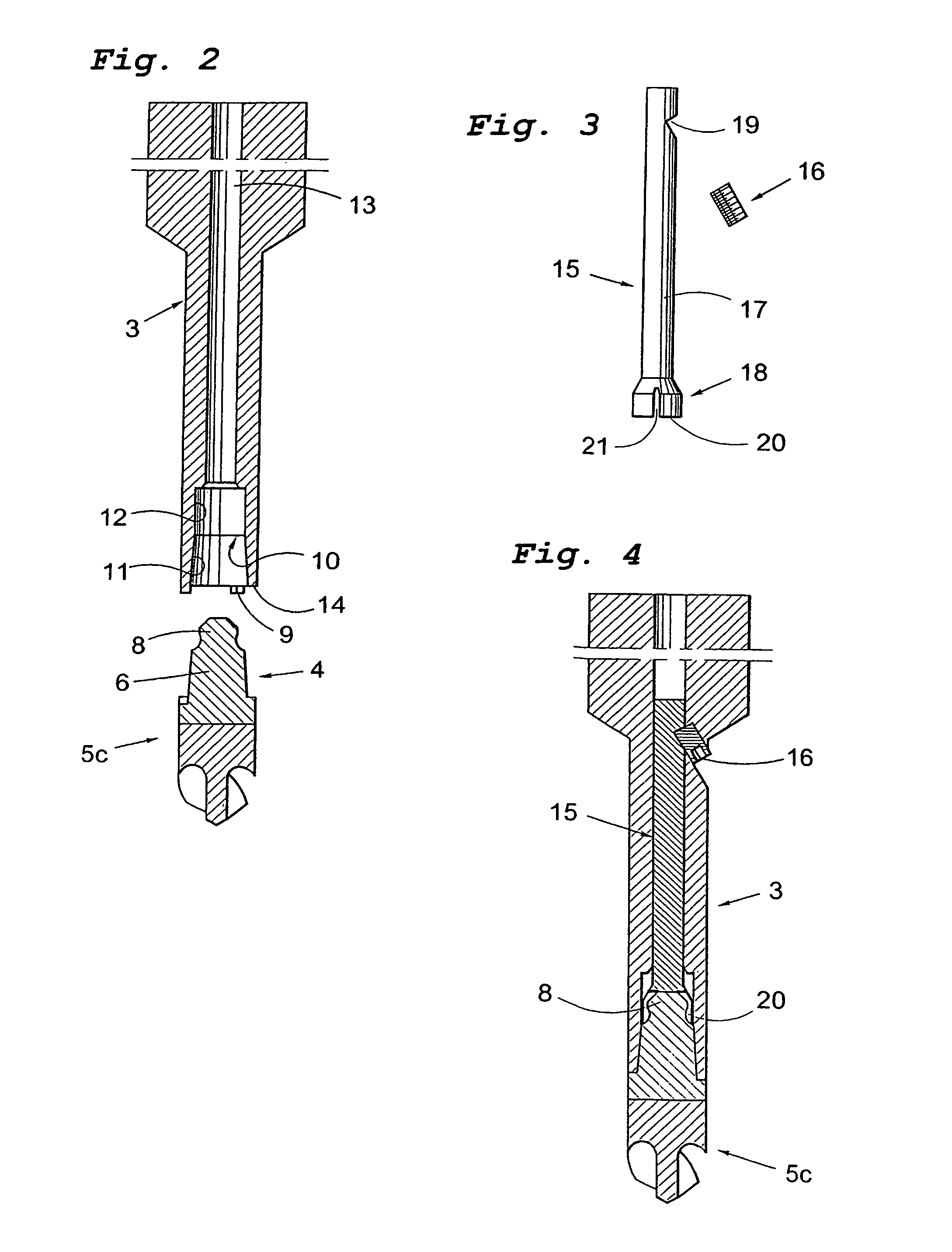

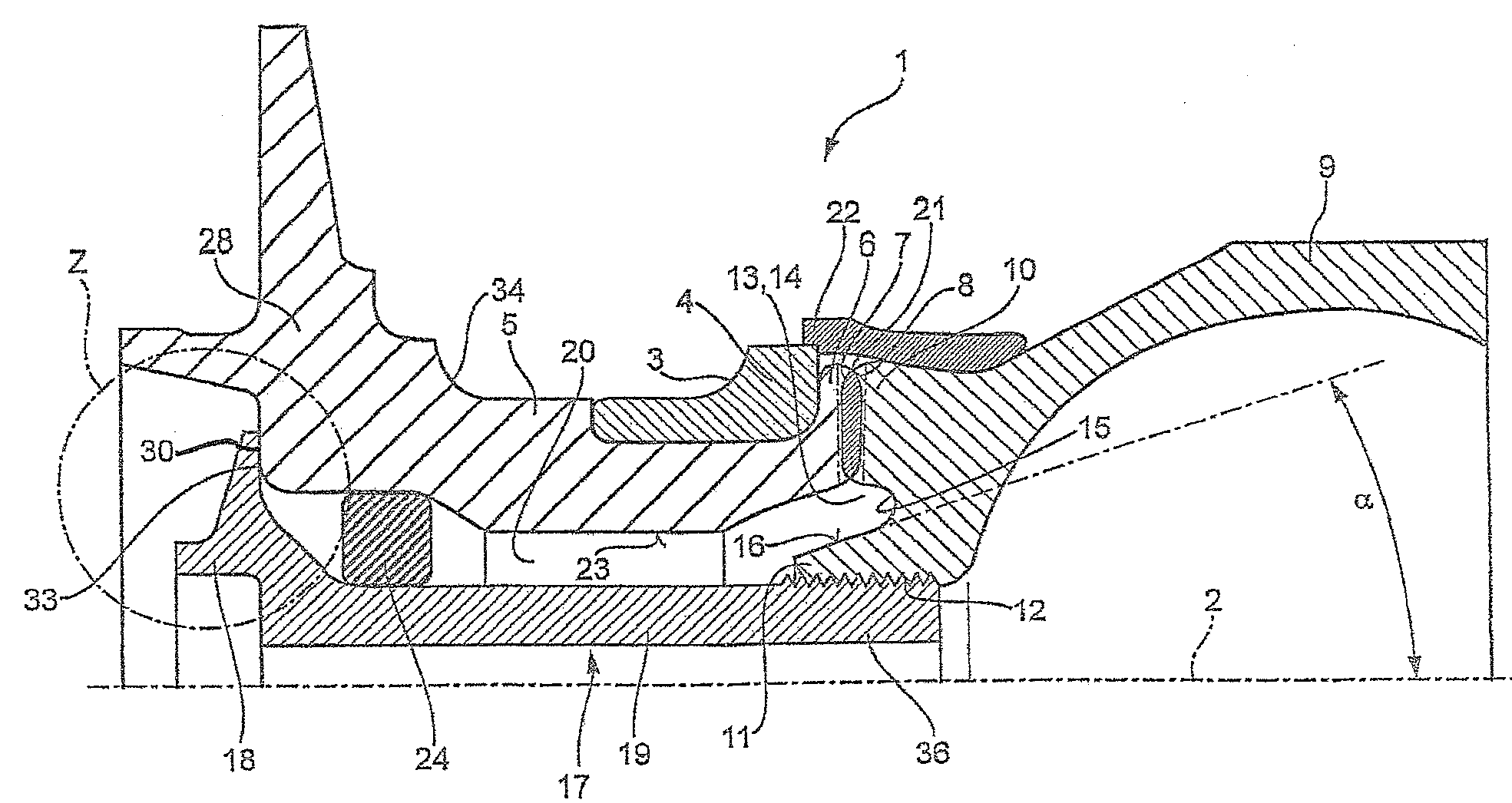

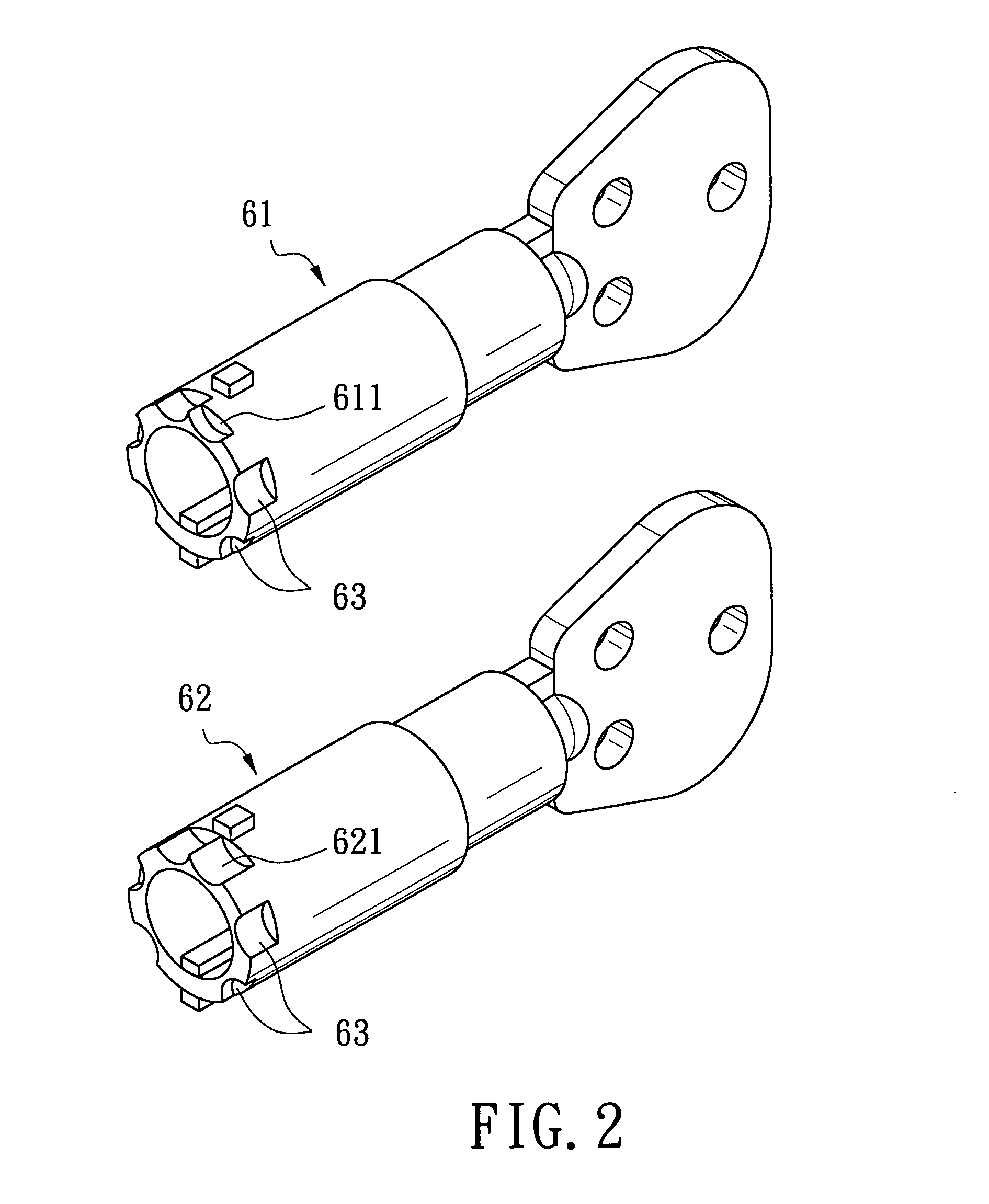

Cutting tool and cutting head thereto

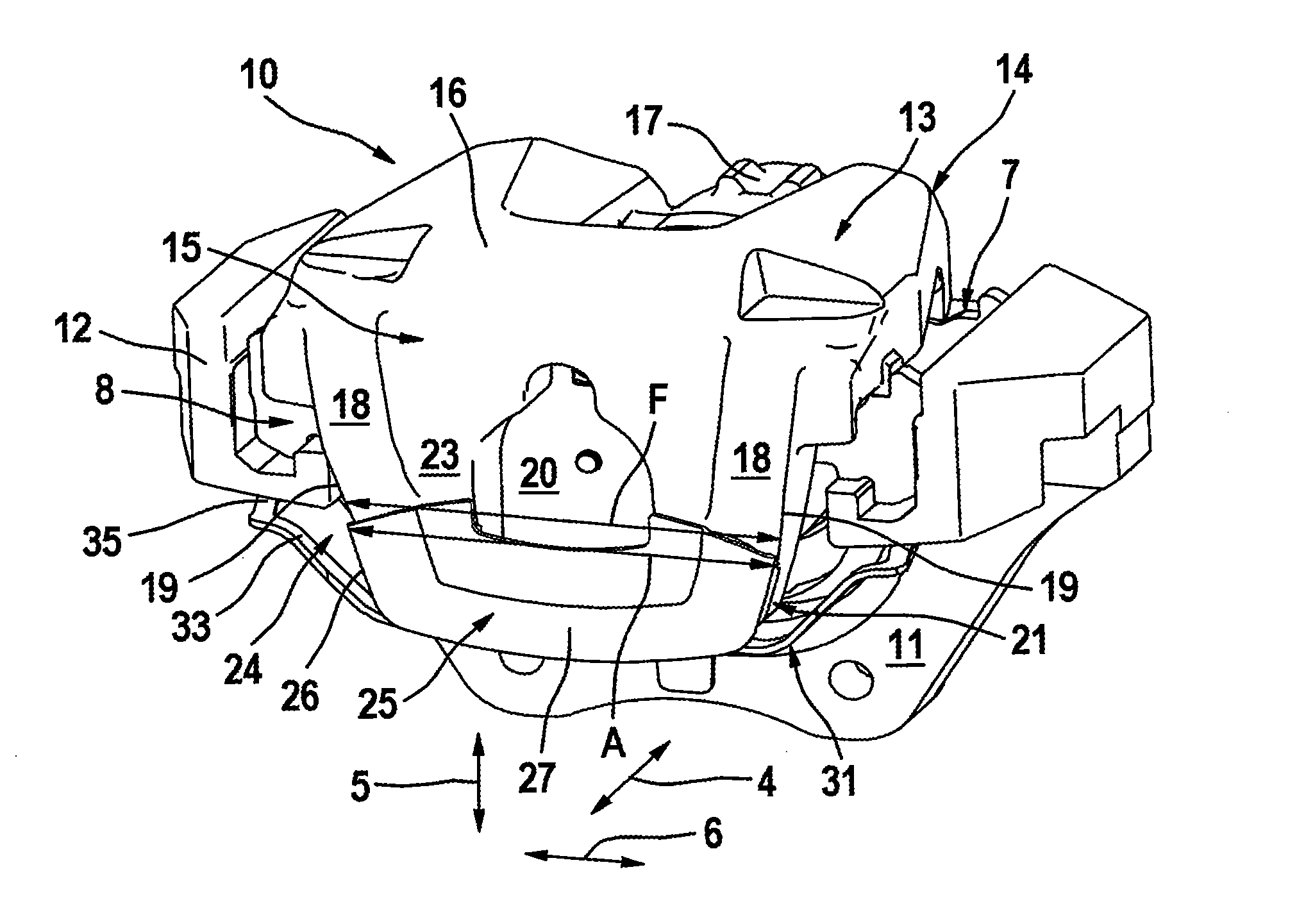

InactiveUS7101128B2Improve stabilityThread cutting machinesTransportation and packagingEngineeringAxial projection

A tool such as a milling or drilling tool includes a shaft having a front recess in which a cutting head is disposed. A drawbar disposed in the shaft includes a plurality of flexible tongues disposed in the recess. The tongues form a recess in which a rear knob of the cutting head is received. A retainer urges the drawbar axially rearwardly to retain the cutting head in the recess. The shaft includes axial projections at its front end which are received in respective rearwardly open recesses of the cutting head to prevent relative rotation between the shaft and the cutting head.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

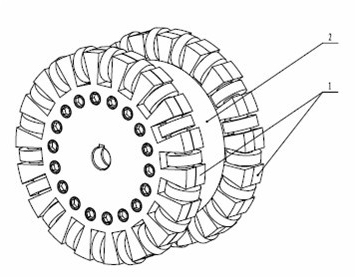

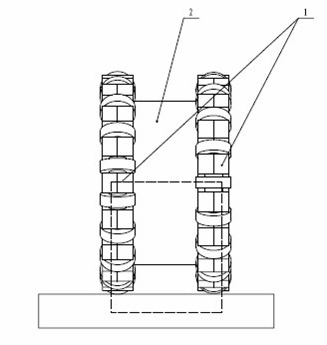

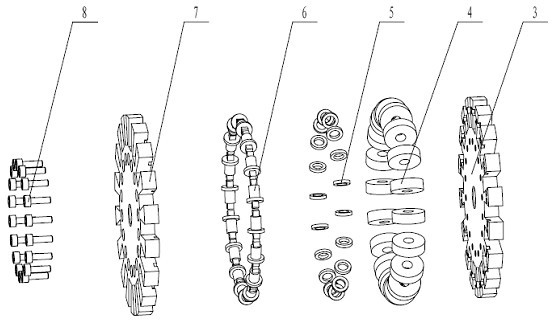

Novel universal rolling magnet-wheel device for magnetic adsorption climbing robot

The invention belongs to the technical field of robots and particularly relates to a novel universal rolling magnet-wheel device for a magnetic adsorption climbing robot. The novel universal rolling magnet-wheel device comprises an annular permanent magnet, all-dimensional wheels are arranged on two sides of the annular permanent magnet, and each all-dimensional wheel comprises a first hub, rollers, a sleeve, a roller shaft and a second hub which are sequentially arranged. The structure of the all-dimensional wheels is that the rollers capable of rotating around self axles are arranged on the peripheries of the hubs, the rollers are evenly distributed on the peripheries of the hubs, the axles of the rollers are orthogonal to axles of the hubs, and the all-dimensional wheels on the two sides are arranged in stagger to enable axial projection of the rollers of the all-dimensional wheel on one side to be located in the middle of the two rollers of the all-dimensional wheel on the other side. The novel universal rolling magnet-wheel device has the advantages that when wheels have axial movement trends along the wheels, the rollers of the all-dimensional wheels on the two sides are contacted with the ground and rotate around the self axles to enable the wheel to keep in a pure rolling state and improve flexibility of movement of the wheels.

Owner:中国东方电气集团有限公司

Adjustable dumbbell system

ActiveUS7604578B2Prevent rotationEasily and efficiently manufactured and marketedDumb-bellsDumbbellCoil spring

A handle has opposed ends and a central extent. A grip rotationally receives the central extent of the handle. An adjustment wheel is secured to each end of the handle. A side cover is fixedly secured to each end of the grip. A dowel disk is on the handle adjacent to one side cover with fingers and spaces. A plurality of cam bits are supported on the handle. A safety lock is within the side cover adjacent to the dowel disk. The safety lock has a first end extent and a second end extent with a radial recess and a central extent with an axial projection. A coil spring within the radial recess urges the safety lock radially outwardly.

Owner:LIU PING

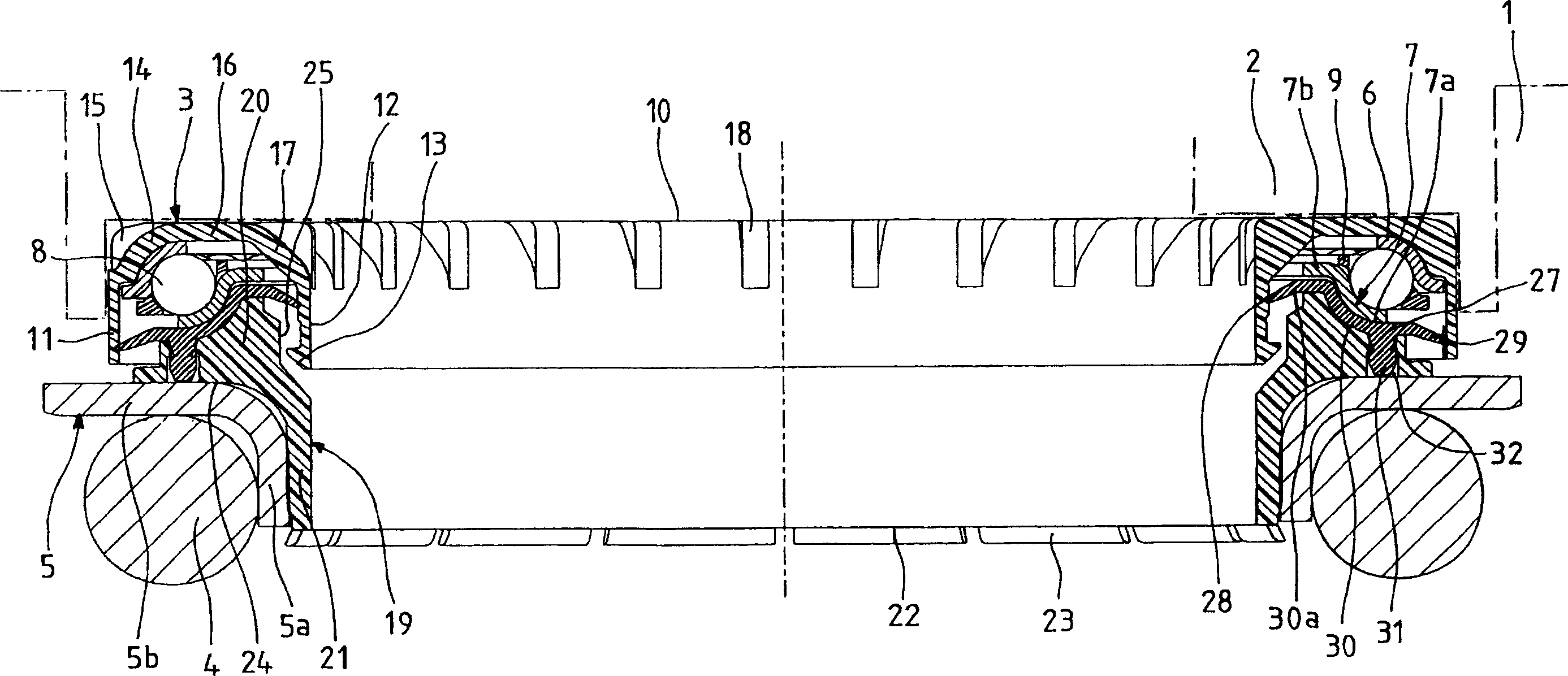

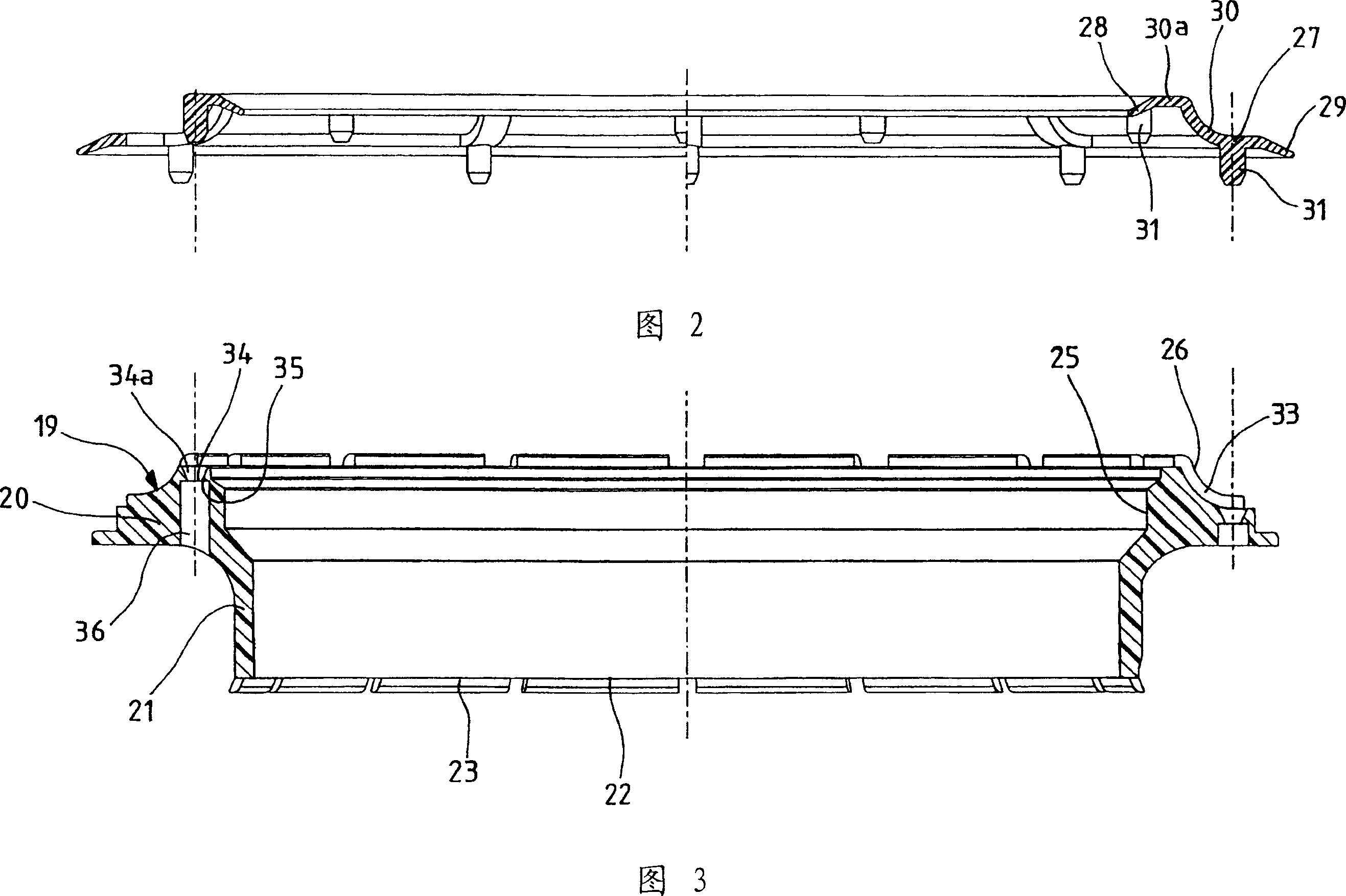

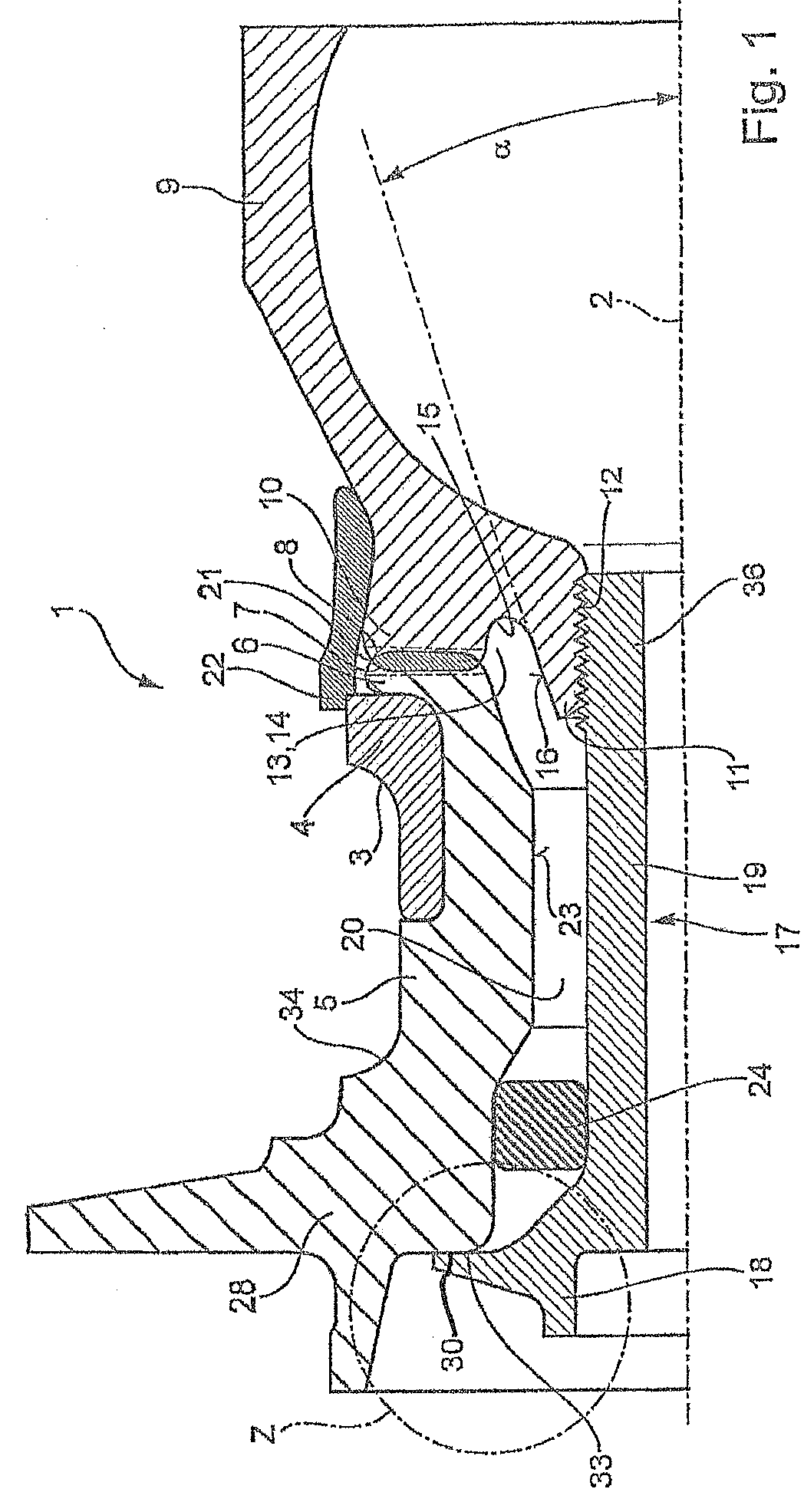

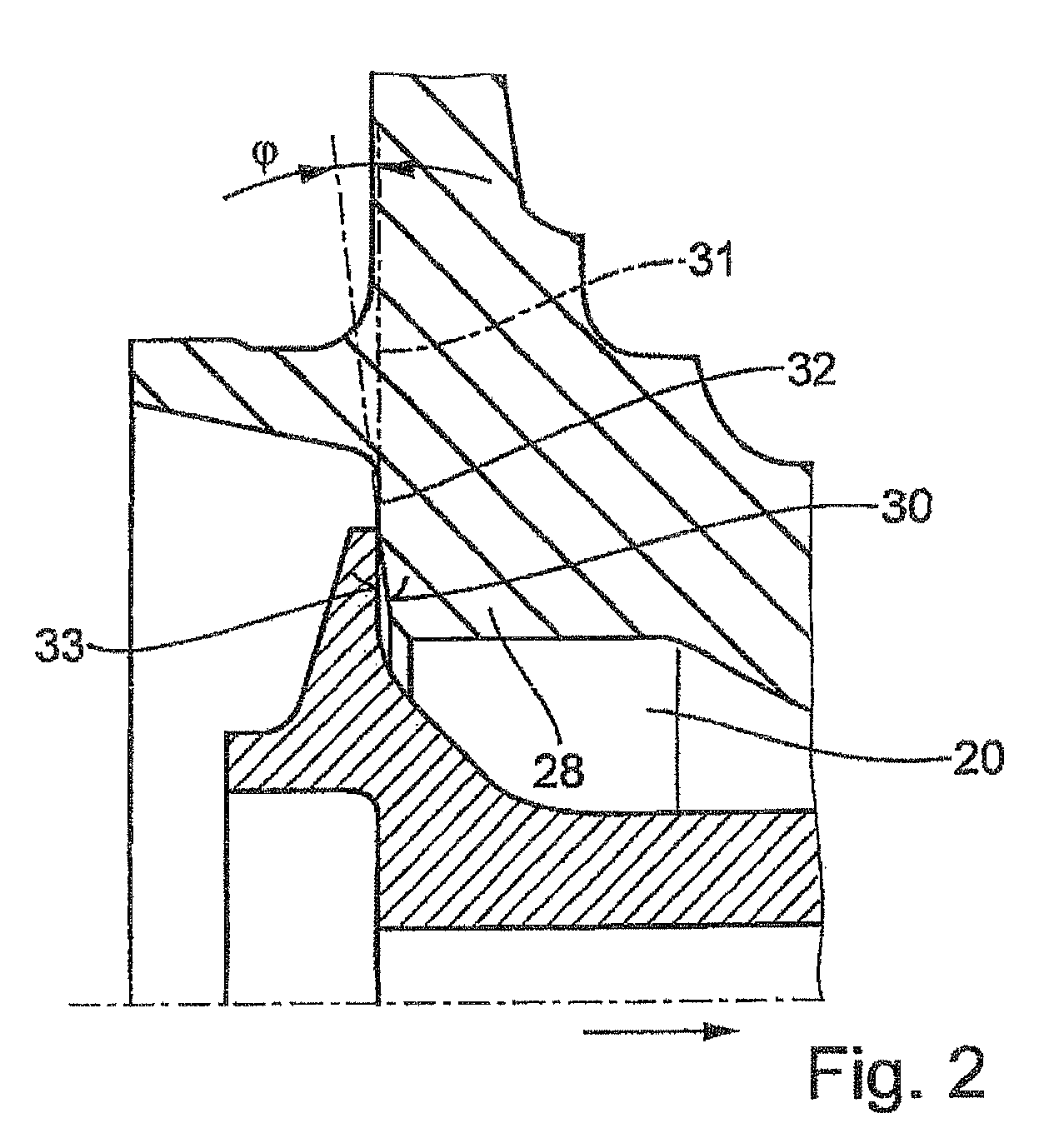

Labyrinth seal of a radial rolling contact bearing having a radial flange

InactiveUS8979385B2Improve sealingReduce coefficient of frictionRolling contact bearingsCastorsRolling-element bearingEngineering

A seal assembly for sealing a radial rolling contact bearing, having a first sealing ring and a second sealing ring, wherein the two sealing rings can be rotated relative to each other about a common axis of rotation and together form a labyrinth seal, wherein a sealing gap of the labyrinth seal that extends substantially radially with respect to the axis of rotation is covered radially by an axial projection of the second sealing ring, and the sealing gap at the axial projection opens axially into a first catch channel of the first sealing ring. A hub of the radial rolling contact bearing forms the second sealing ring. Therefore, the second sealing ring is integrated into the hub flange, which means that the hub flange performs the function of the second sealing ring and to some extent helps to form the labyrinth seal.

Owner:SCHAEFFLER TECH AG & CO KG

Torque coupling assembly

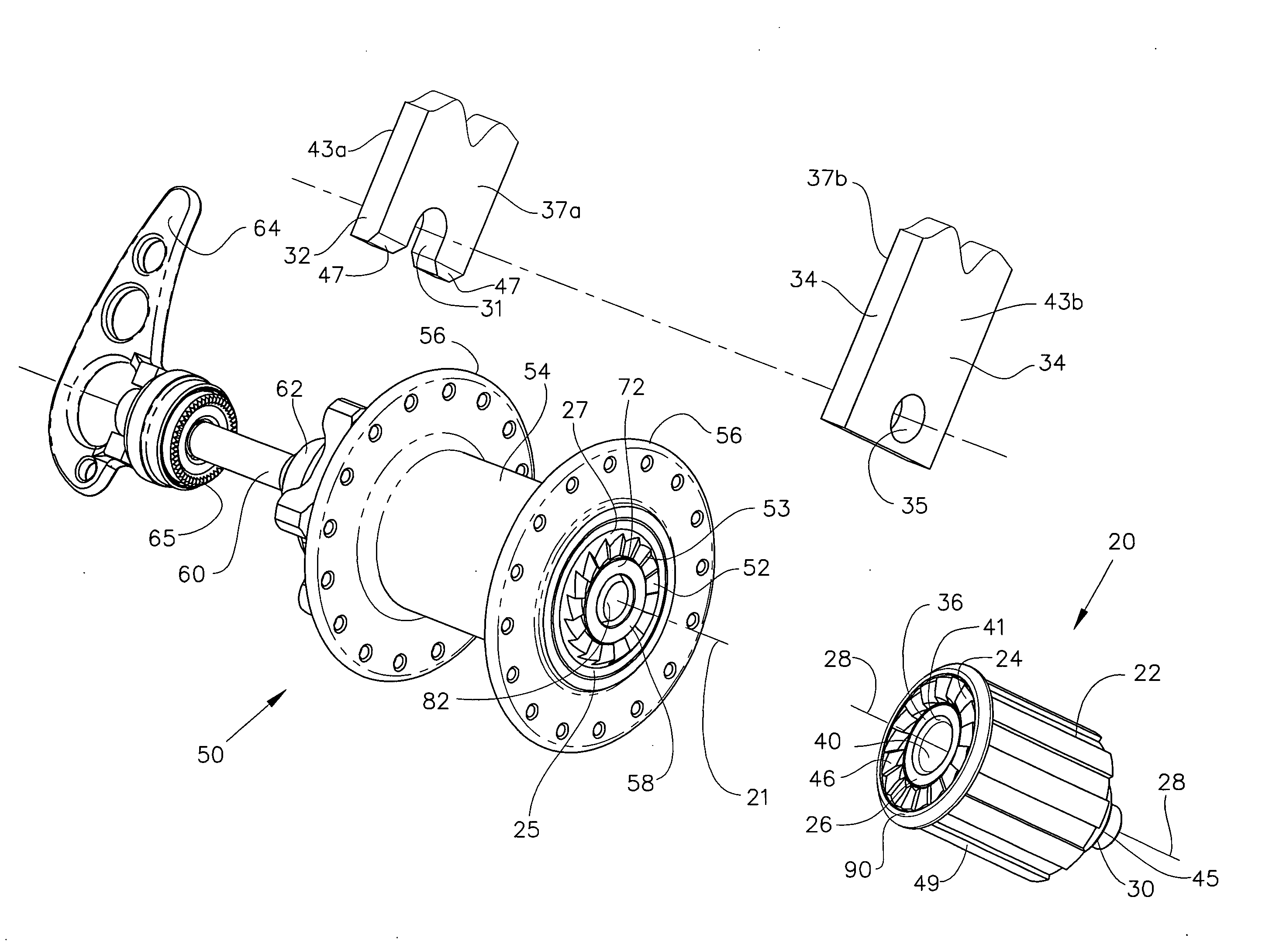

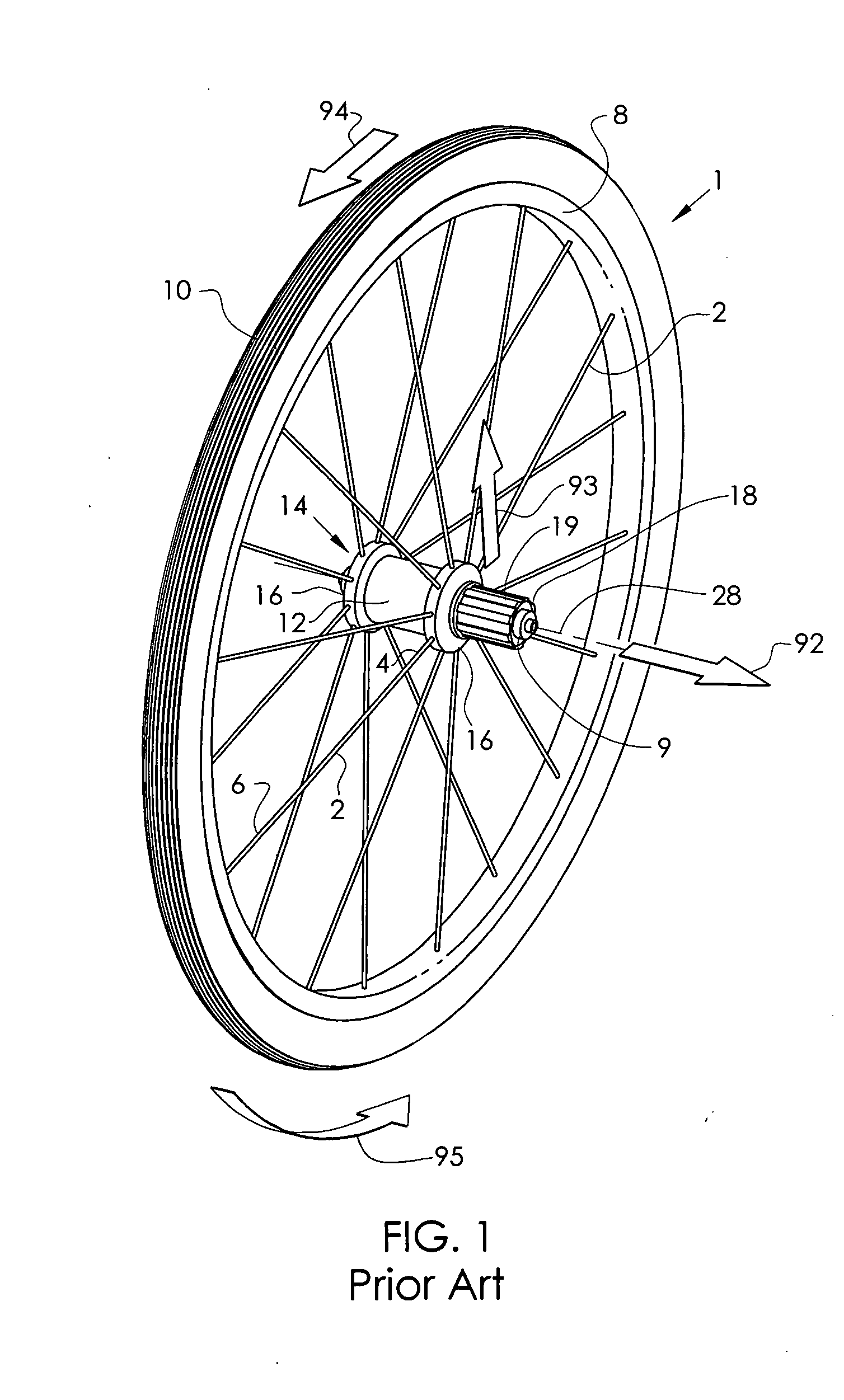

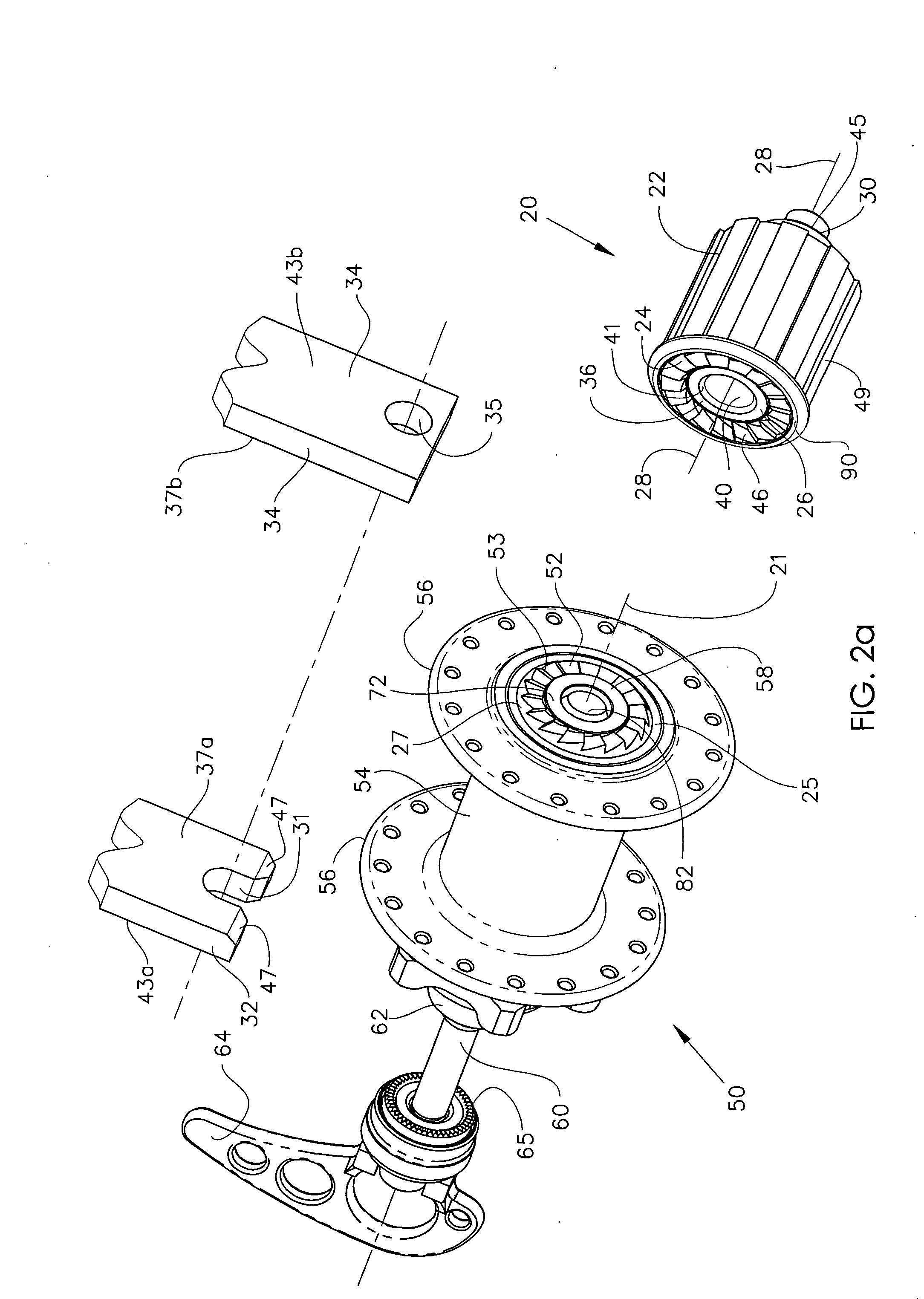

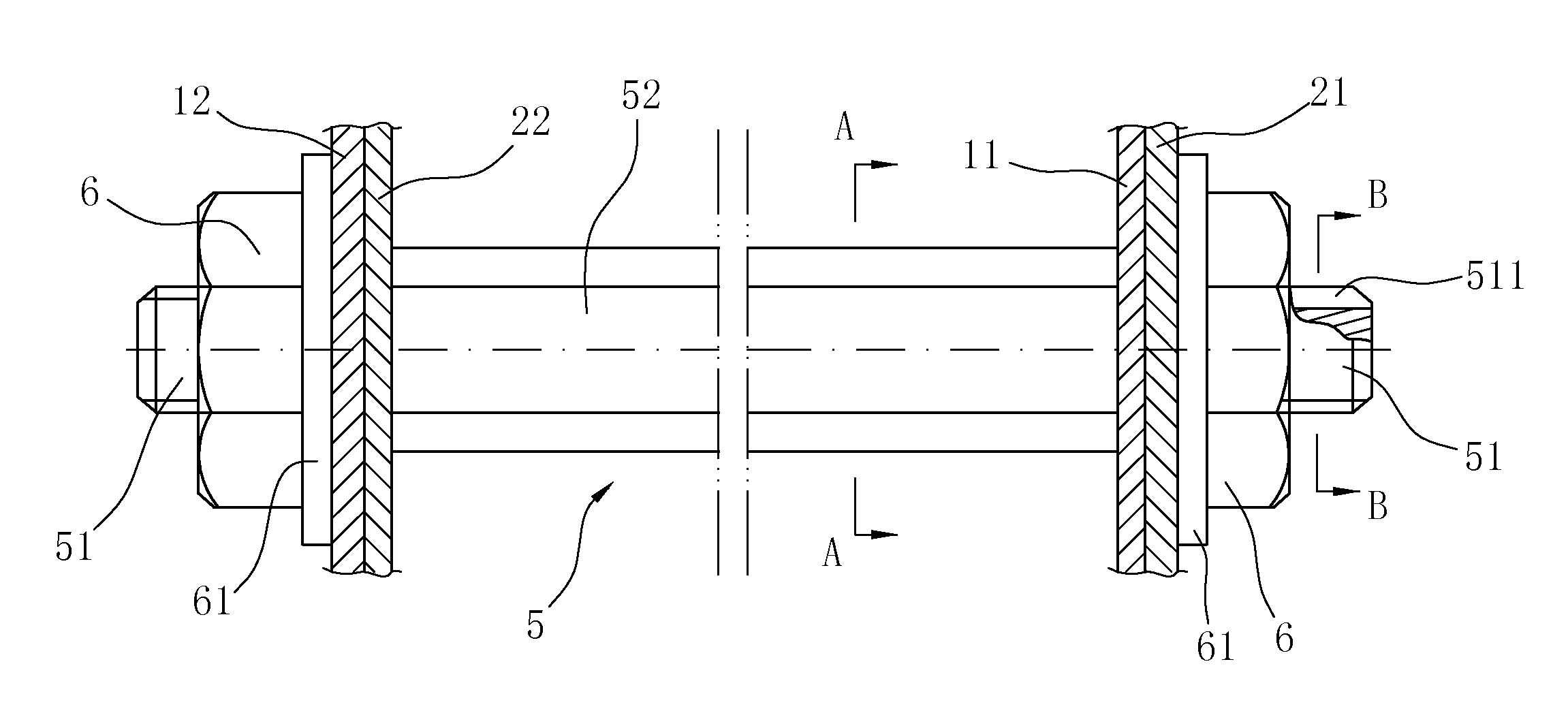

InactiveUS20100170762A1Easy to assembleEasily and simultaneously disassembledHubsFriction clutchesCouplingEngineering

A torque coupling assembly that includes a rotationally driving assembly with a rotationally fixed driving axle element and a rotatable driving shell element, and an axial axis of rotation; a rotationally driven assembly, with a rotationally fixed driven axle element and a rotatable driven shell element, and an axial axis of rotation; a frame element with at least two axially spaced mounting elements for mounting of said torque coupling assembly; where the rotatable driving shell includes an axial projection anchored thereto, with a tip portion located axially distal from the driving shell and a root portion axially proximal to the driving shell, and an axially relieved portion circumferentially adjacent the axial projection; where the rotatable driven shell includes an axial projection anchored thereto, with a tip portion located axially distal from the driven shell and a root portion axially proximal to the driven shell, and an axially relieved portion circumferentially adjacent the axial projection; where, in an assembled or installed position, the driving assembly and the driven assembly are both connected to the frame the axial projection of the driving shell is aligned to engage the axial projection of the driven shell with an axial overlie engagement to rotatably transmit torque between the driving shell and the driven shell; where, in a removed or uninstalled position, one of the driving assembly and the driven assembly may be displaced in a generally radial direction relative to the frame and the other of the rotational driving assembly and the rotational driven assembly; where at least one of the driving assembly and the driven assembly includes ramped lead-in geometry adjacent the axial projection(s); and optionally where at least one of the driving assembly and the driven assembly includes shielding geometry adjacent and the axial projection, where the shielding geometry extends to axially overlap at least a portion of the axial projection.

Owner:SCHLANGER RAPHAEL

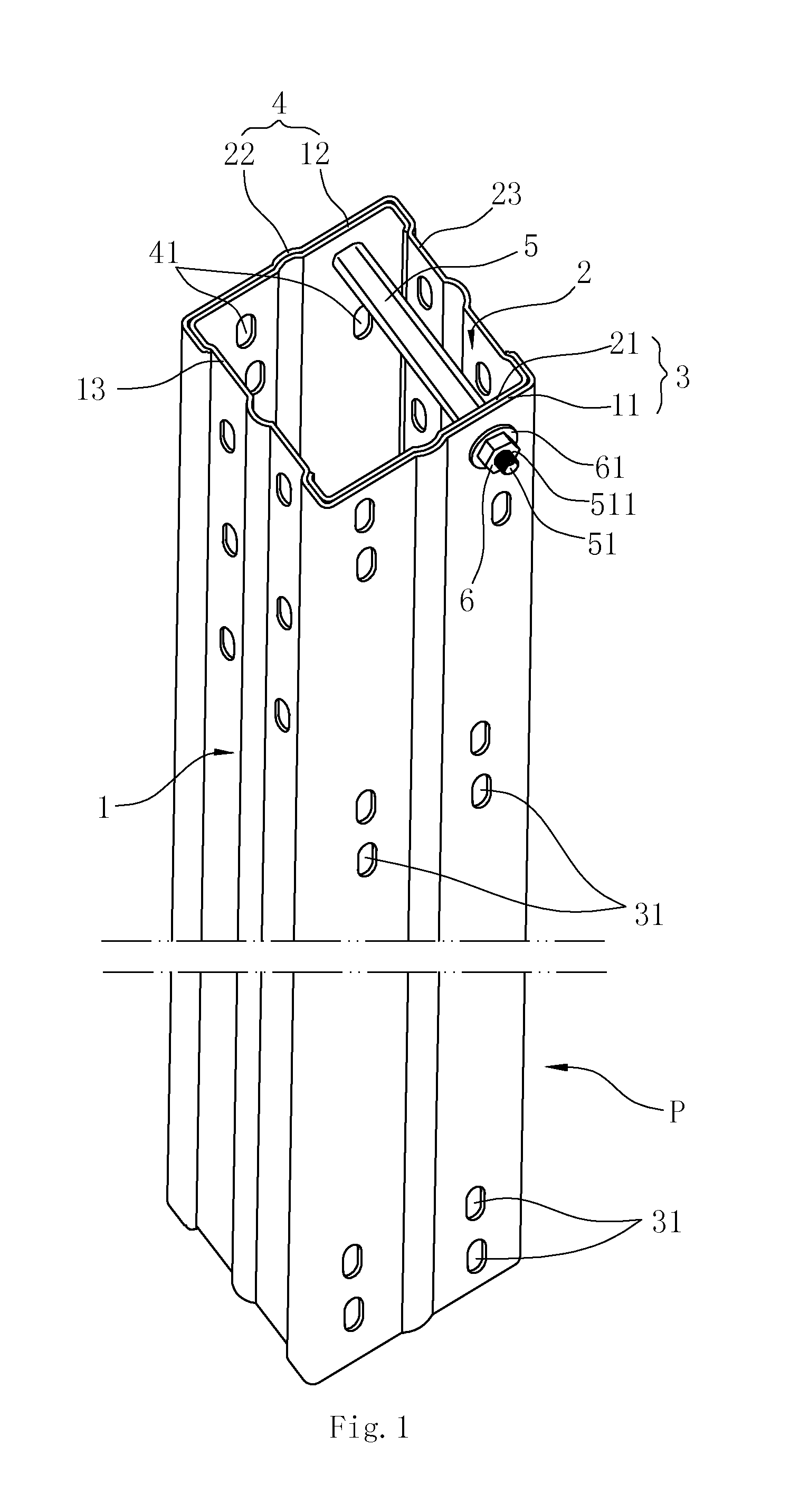

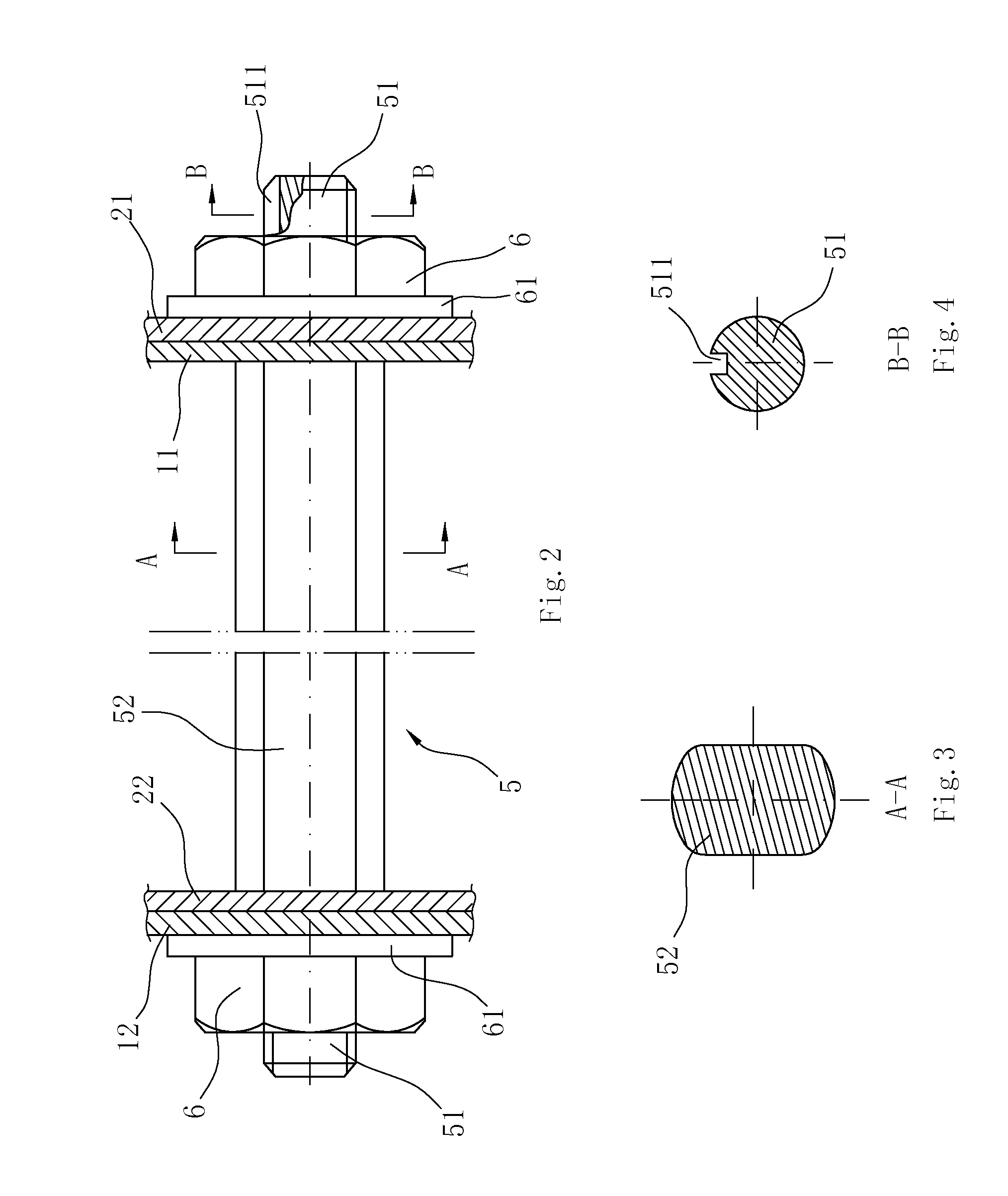

Unconventional Bolt and a Fastening Device Using the Unconventional Bolt Thereof

An unconventional bolt includes a main body having two heads, and two threaded rods respectively formed at the external surface of each head coaxially with the main body, wherein the cross section of each head has a noncircular shape, and the axial projection of the cross section of the middle of the main body is located in the noncircular axial projection of each head of the main body. The unconventional bolt has a simple structure and a convenient assembly, and can improve the strength and rigidity of the nested profiled components after the connection; and the fastening device using the unconventional bolt can not only support the component but also reinforce it, thus effectively preventing the nested profiled components from transforming.

Owner:NINGBO BANGDA INDAL

Axial rolling bearing for a suspension

Owner:AB SKF

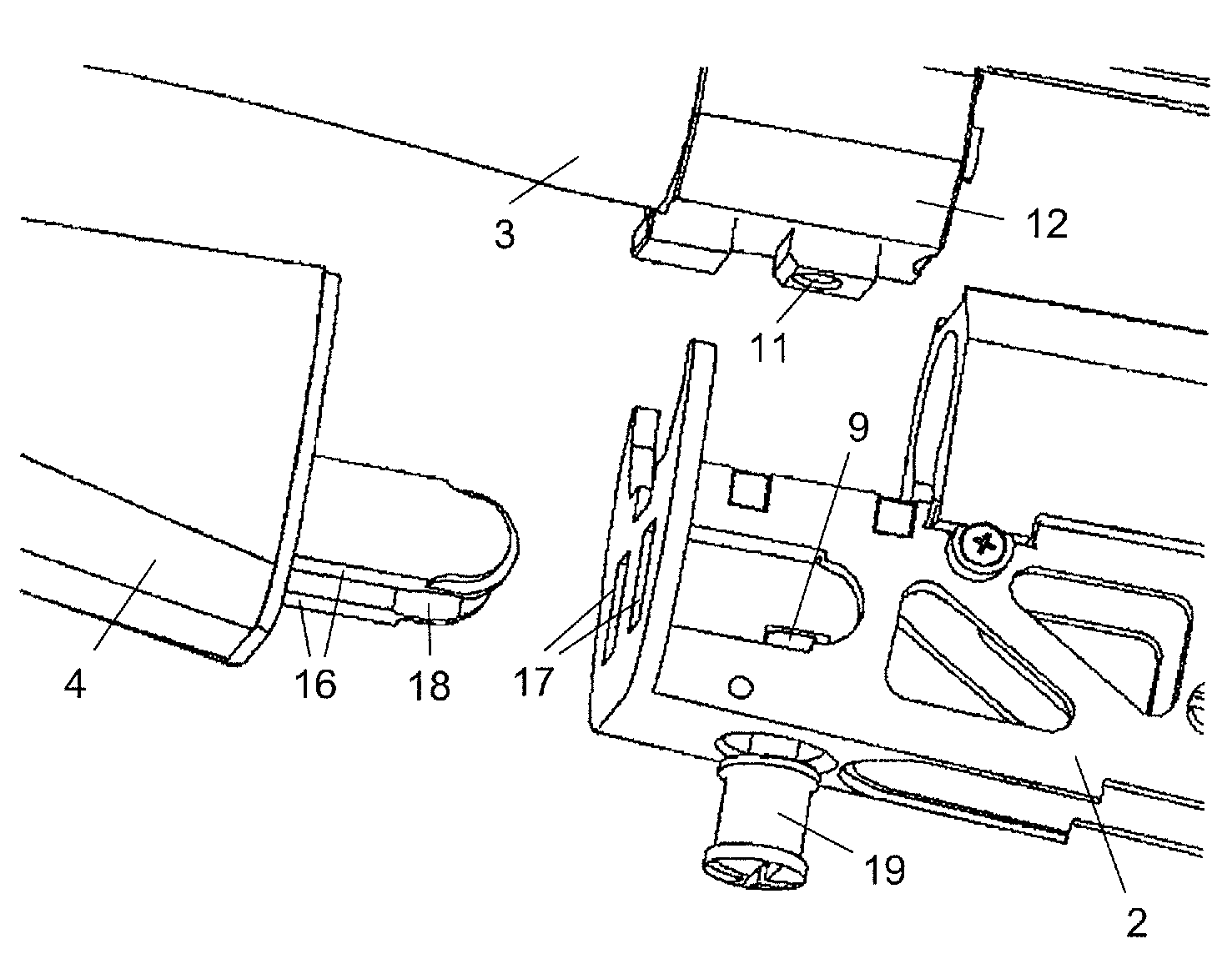

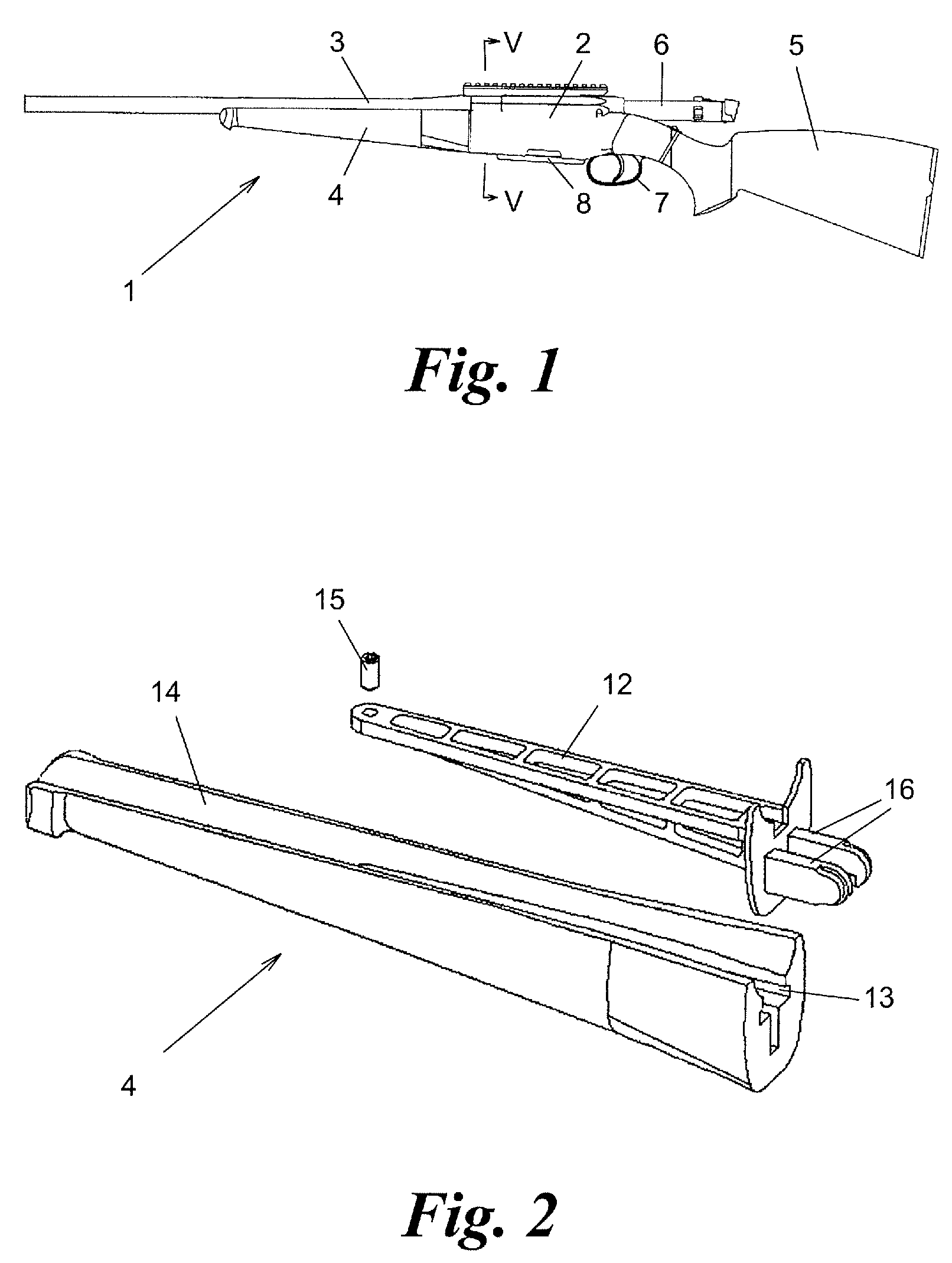

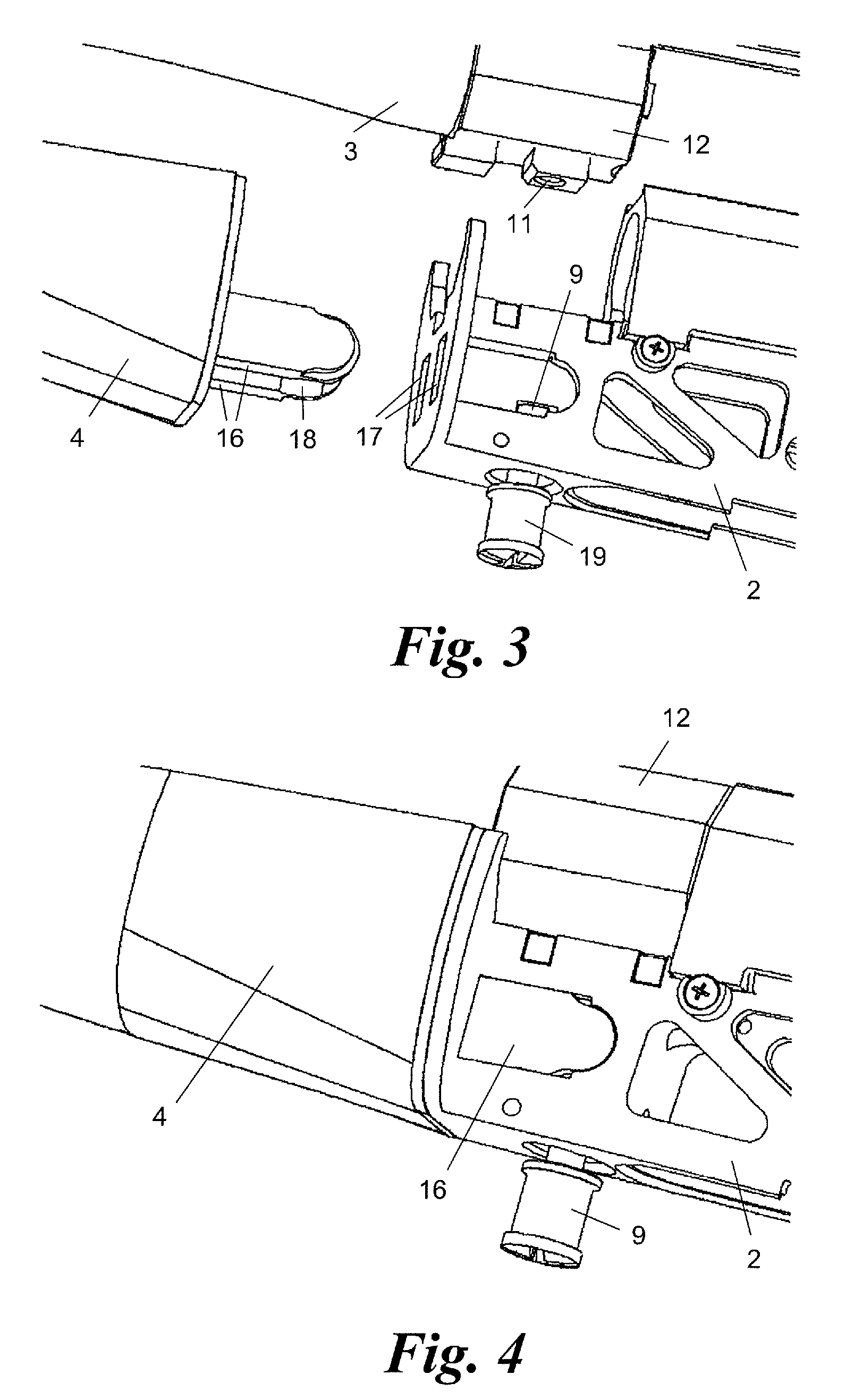

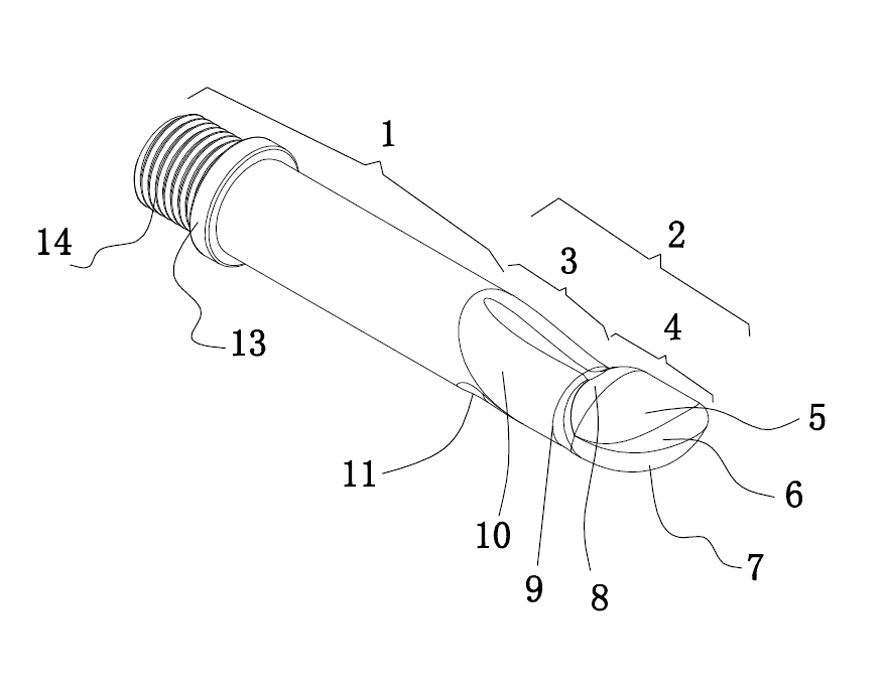

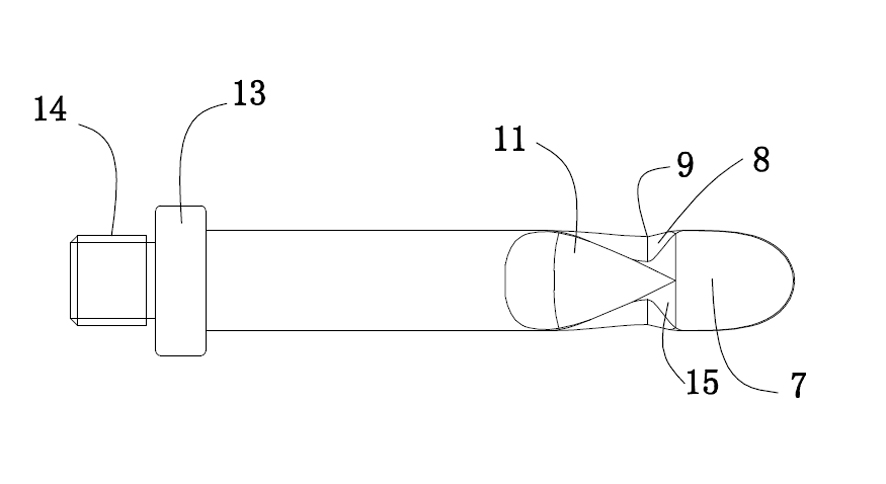

Rifle

InactiveUS7685757B2The process is simple and effectiveRobust structureWeapon assembly/disassemblyCollapsible gunsEngineeringRifle

A rifle comprising a housing, a barrel anchored thereon and a forearm extending below the barrel. The barrel is anchored by a fastening element which extends through a cross hole of the housing. The forearm has at least one axial projection that detachably engages into a seat of the housing. The cross hole for anchoring the barrel and the seat for fastening the forearm intersect and the forearm comprises a snap-in recess for the fastening element to snap in when the barrel is anchored.

Owner:STEYR MANNLICHER

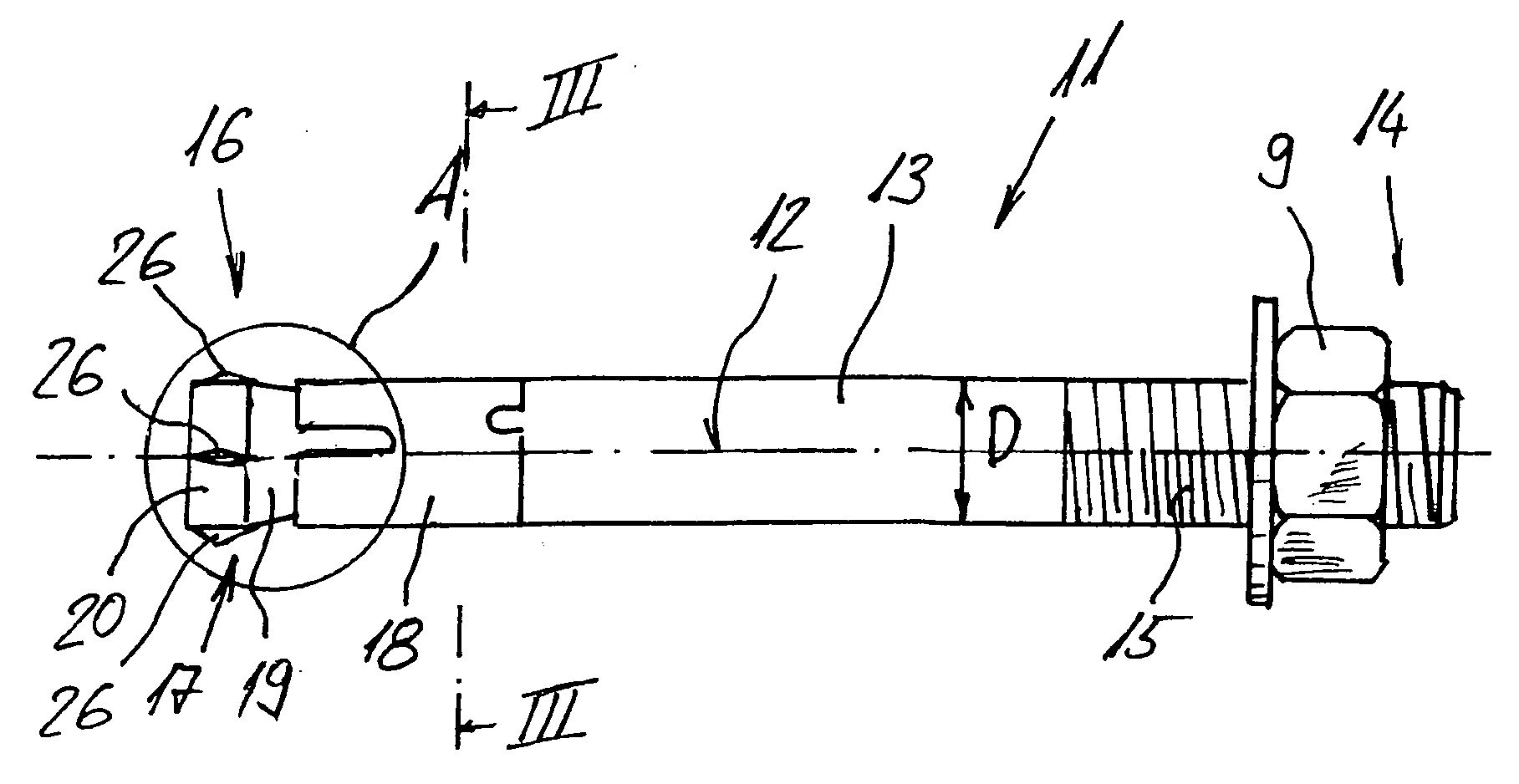

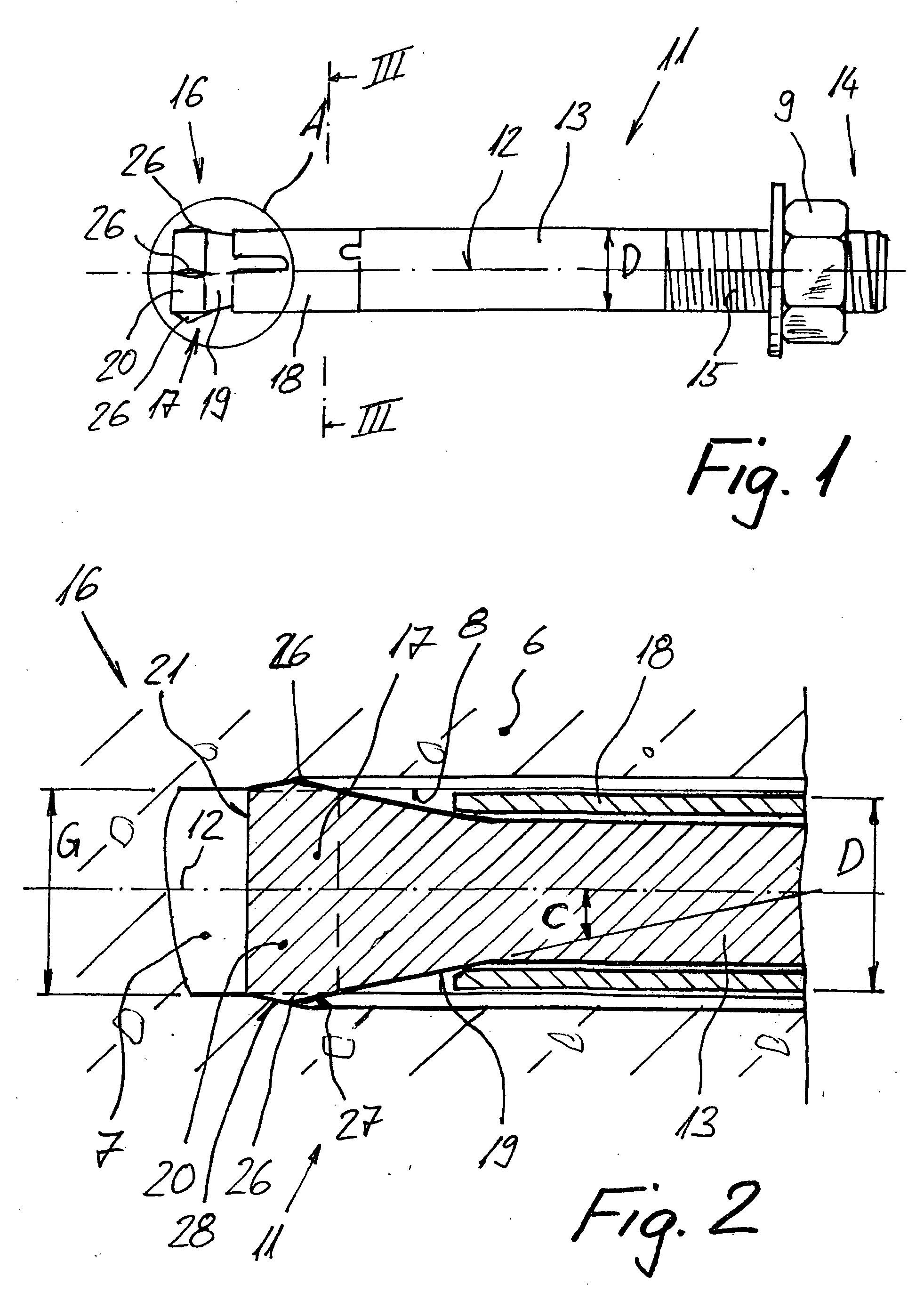

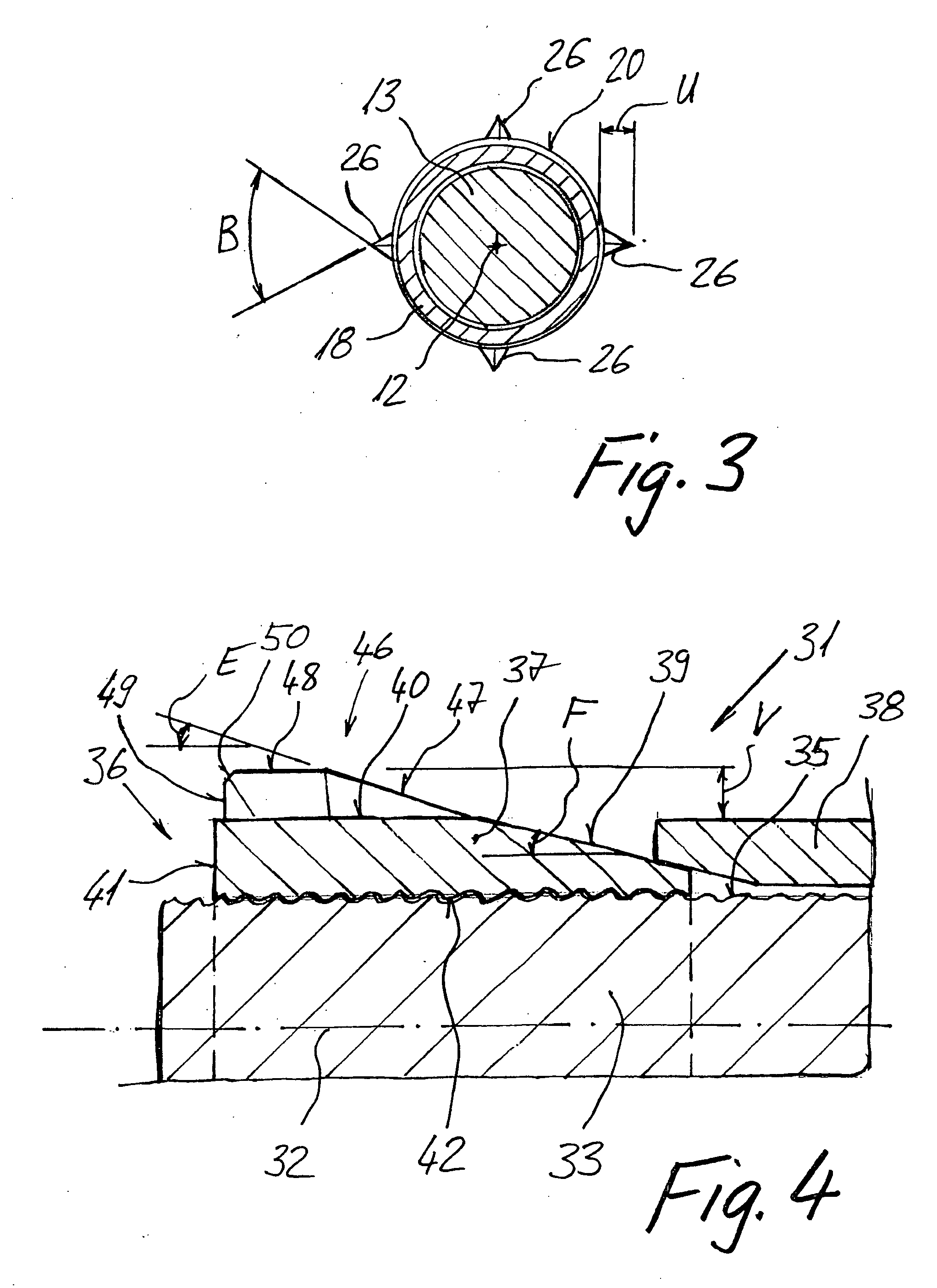

Fastening element

InactiveUS20070224015A1Facilitates formation of furrowGood introductionDowelsEngineeringExpansion joint

A fastening element for constructional components, includes an anchor bolt and an expansion sleeve (18, 38), with the anchor bolt having a load application element (15) at its first end region (14) of the anchor stem (13, 33), and at a second, opposite end region (16, 36) an expansion portion (17, 37) having a conical section (19, 39) that expands in a direction of a free end of the second end region, and a cylindrical section (20, 40) that adjoins the conical section (19, 39) and has a shaped profile formed by ribs (26, 46) extending parallel to the longitudinal axis (12, 32) of the stem with the ribs (26, 46), projecting beyond an axial projection of an outer profile of the expansion sleeve (18, 38) by a distance (U. V).

Owner:HILTI AG

Wheel bearing joint unit

Owner:SCHAEFFLER TECH AG & CO KG

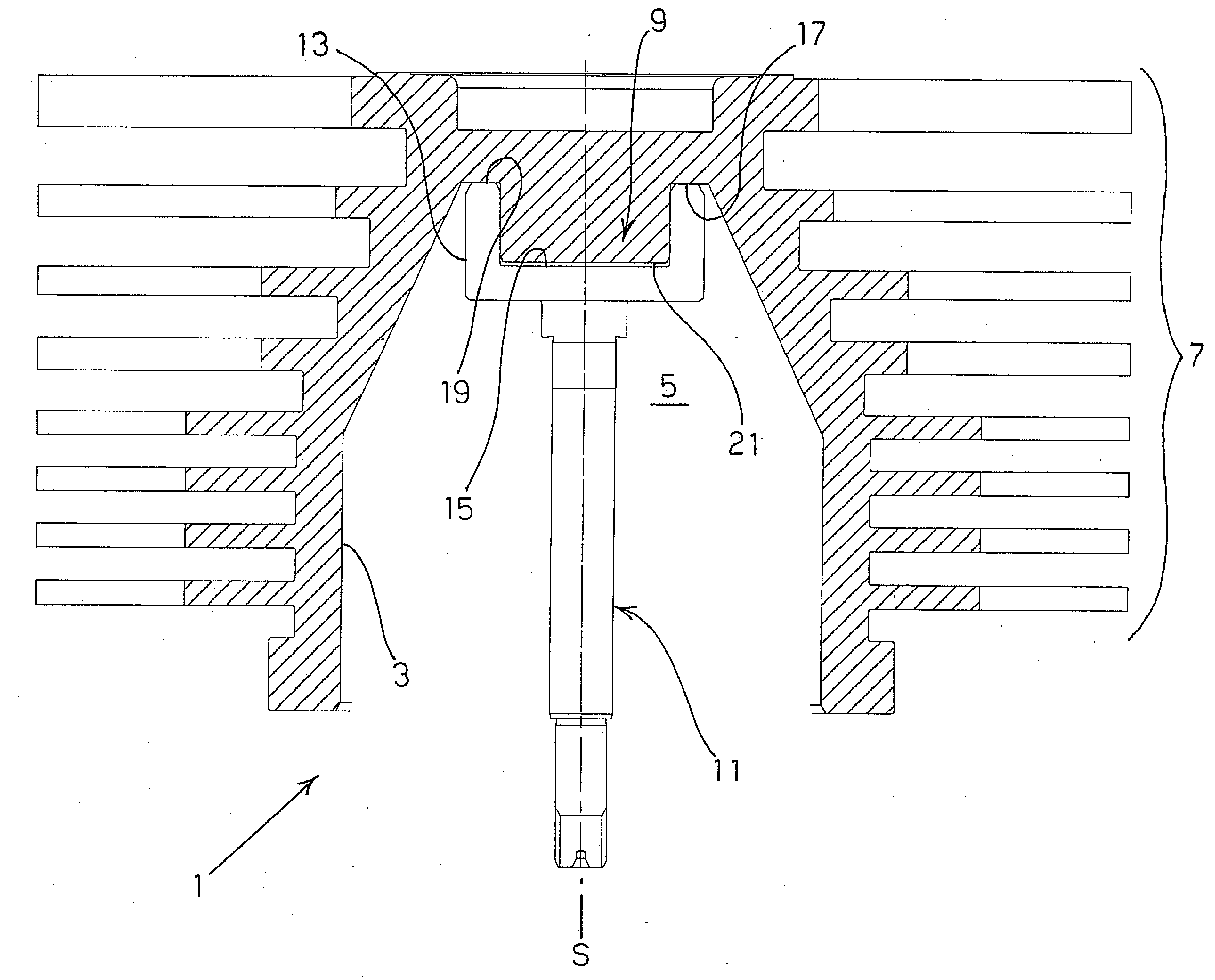

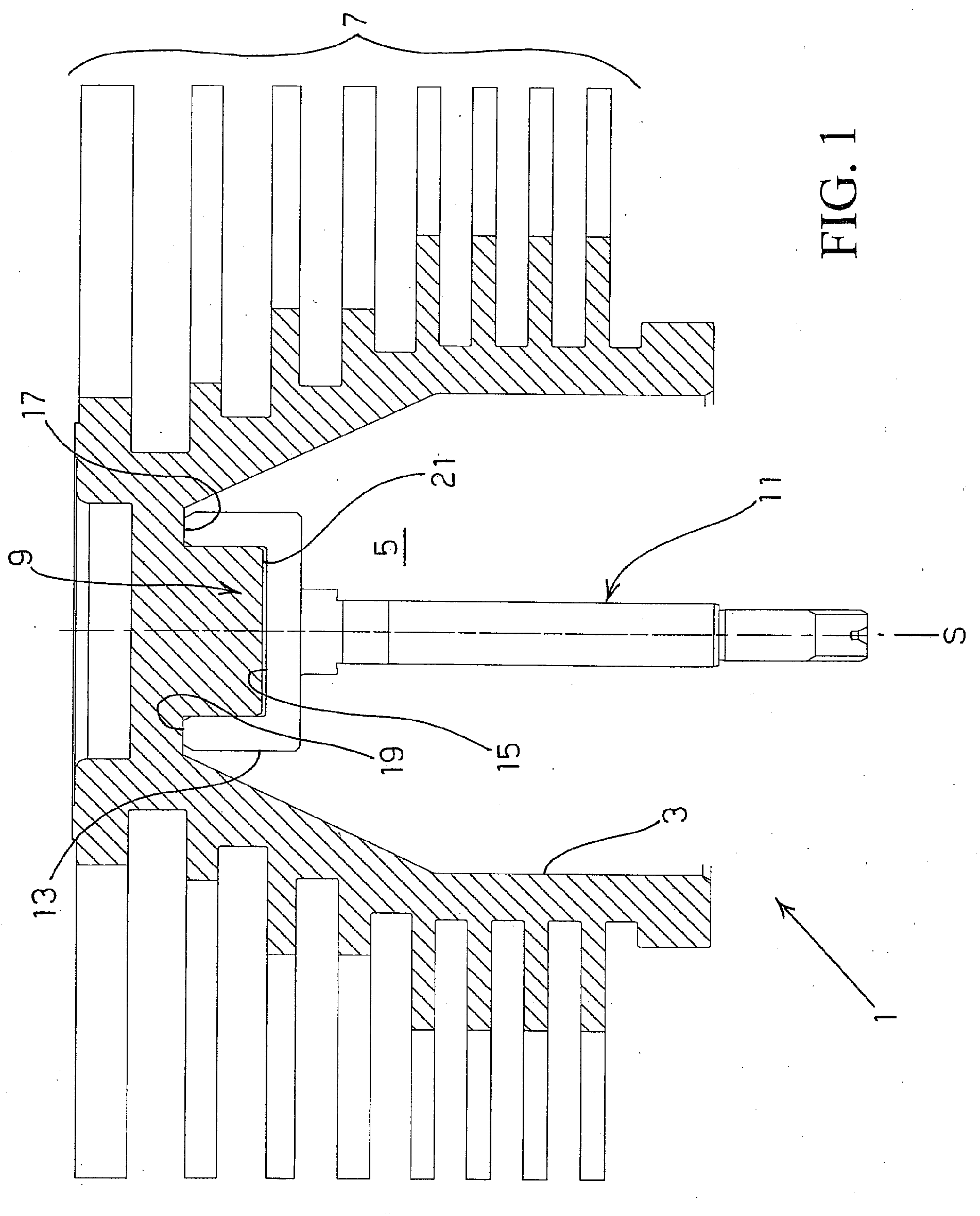

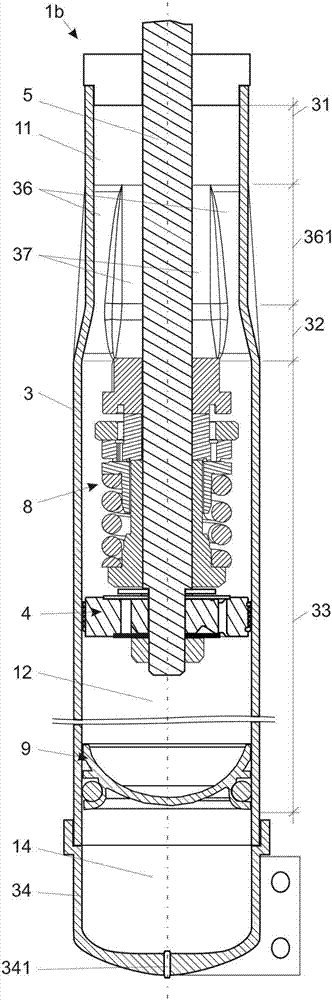

Method for manufacturing the rotor assembly of a rotating vacuum pump

ActiveUS20090214348A1Reduce processing costsEasily reversiblePump componentsBlade accessoriesVacuum pumpAxial projection

A rotor assembly for rotary vacuum pumps has improved mechanical characteristics and low manufacturing cost due to a one-step thermal coupling of a rotor having a male axial projection and its supporting shaft having an end portion comprising a female cavity with a shape and size for receiving the male projection with interference at an ambient temperature. The rotor and the shaft are made of different materials. Heating of the end portion of the shaft provides expansion of the female cavity and allows for inserting the mail projection of the rotor into the female cavity of the shaft. By cooling the end portion to the ambient temperature the contraction of the cavity is obtained forming fixed interference coupling between the shaft and the rotor, where the end portion of the shaft contracts and compresses about the male axis projection of the rotor.

Owner:AGILENT TECH INC

Adjustable dumbbell system

InactiveUS20160166873A1Easy and efficient to manufactureDurable and reliable constructionDumb-bellsDumbbellUnsafe condition

A handle has opposed ends and a central extent. A grip rotationally receives the central extent of the handle. An adjustment wheel is secured to each end of the handle. A side cover is fixedly secured to each end of the grip. A dowel disk is on the handle adjacent to one side cover with fingers and spaces. A plurality of cam bits are supported on the handle. A safety lock is within the side cover adjacent to the dowel disk. The safety lock has a first end extent and a second end extent with a radial recess and a central extent with an axial projection. A coil spring within the radial recess urges the safety lock radially outwardly. A safety indicator may be seen on one side cover that changes from red to green as the weight selection wheel is turned, indication proper weight selection when green and a potential unsafe condition when red.

Owner:LIU PING

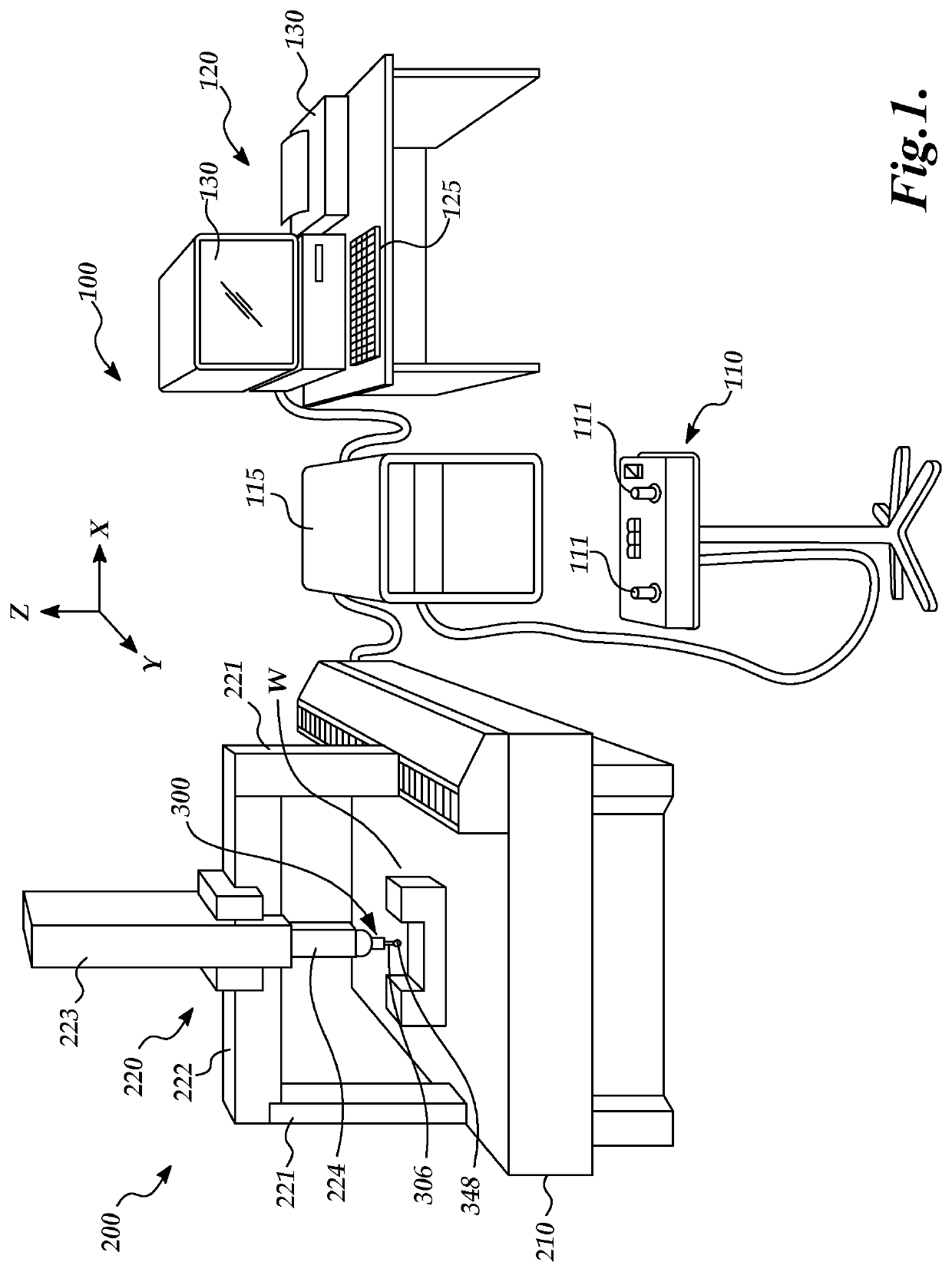

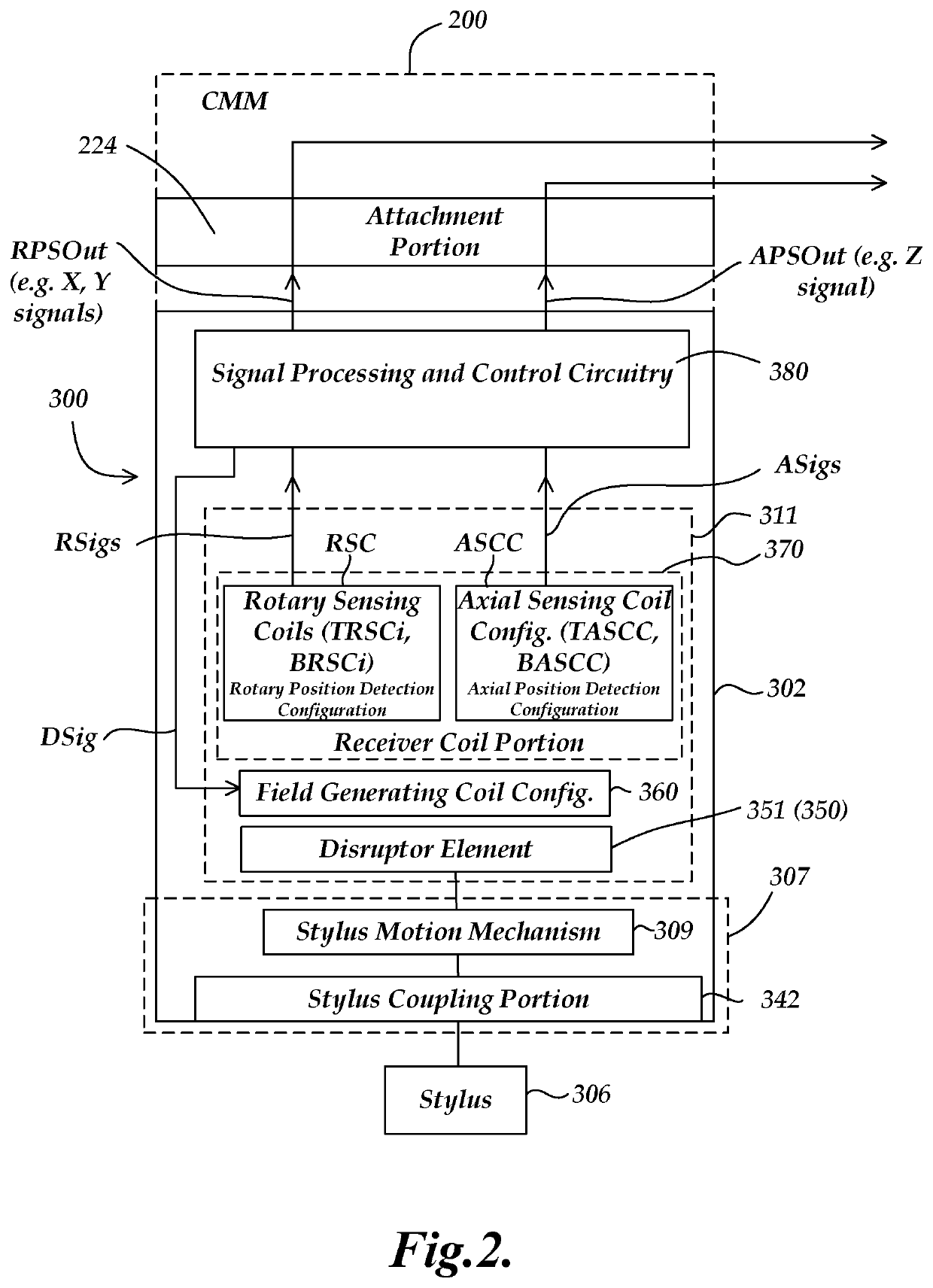

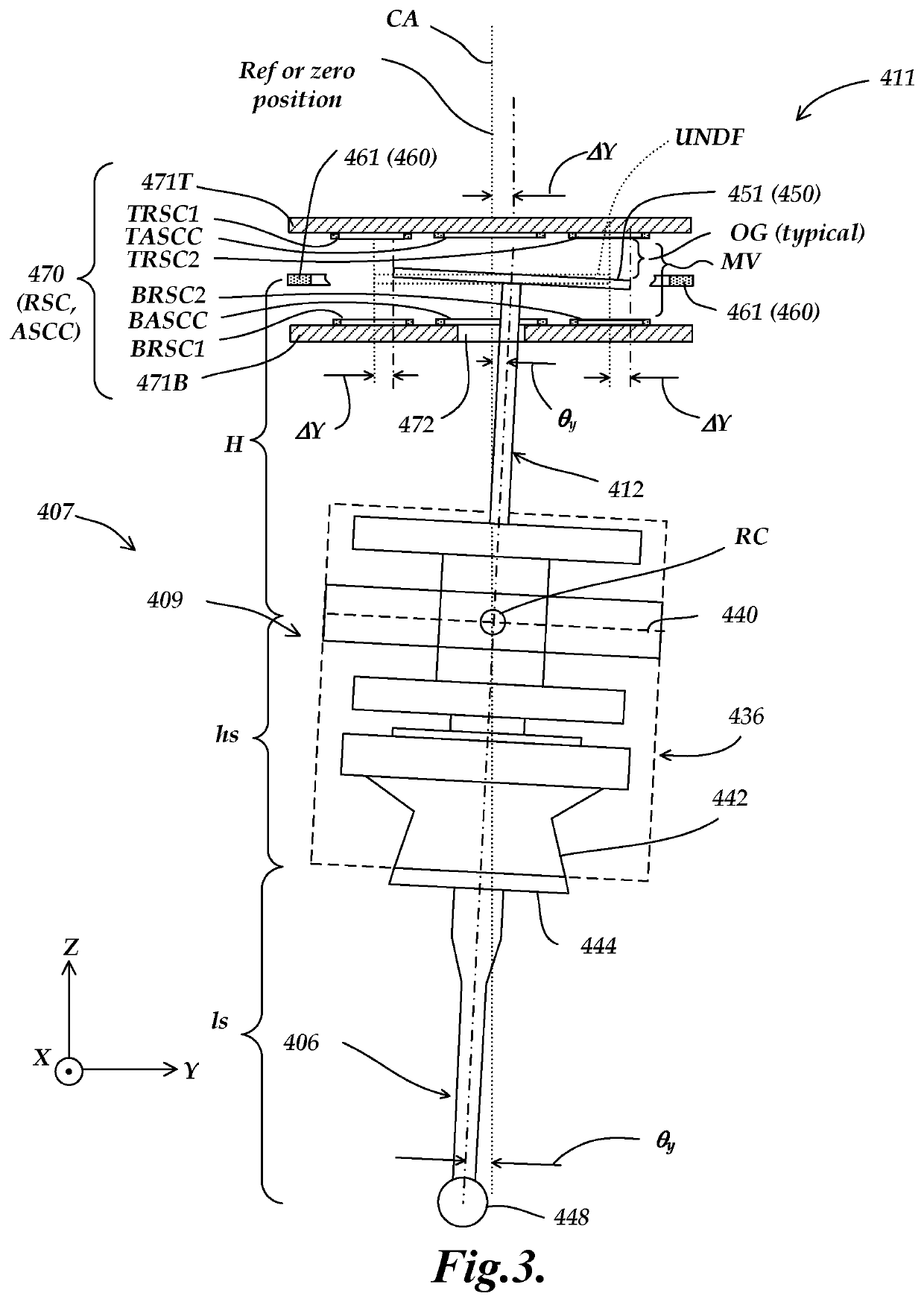

Inductive position detection configuration for indicating a measurement device stylus position

ActiveUS20200141714A1Reduce positioning accuracyImprove accuracyUsing electrical meansConverting sensor output electrically/magneticallyMeasurement deviceEngineering

An inductive position detector (IPD) for stylus position measurement in a scanning probe comprises two substrates located along a central axis in the probe with a motion volume therebetween, each including N rotary sensing coils (RSCs) and respective axial sensing coil configurations (ASCC). A stylus-coupled conductive disruptor moves along Z (axial) and X-Y (rotary) directions in the motion volume. A generating coil (GC) generates a changing magnetic flux encompassing the disruptor and coils, and coil signals indicate the disruptor and / or stylus position. Axial projection of the disruptor defines axial sensing overlap area (ASOA) with the ASCC, and rotary sensing overlap areas (RSOAs) with respective RSCs. The IPD is configured such that the ASOA is independent of disruptor position, and N complementary pairs (CPs) of RSCs are provided, wherein the magnitude of the change in the RSOA in the two coils of a CP is the same for any disruptor displacement.

Owner:MITUTOYO CORP

Labyrinth seal of a radial rolling contact bearing having a radial flange

InactiveUS20140003753A1Improve sealingReduce coefficient of frictionRolling contact bearingsCastorsRolling-element bearingEngineering

A seal assembly for sealing a radial rolling contact bearing, having a first sealing ring and a second sealing ring, wherein the two sealing rings can be rotated relative to each other about a common axis of rotation and together form a labyrinth seal, wherein a sealing gap of the labyrinth seal that extends substantially radially with respect to the axis of rotation is covered radially by an axial projection of the second sealing ring, and the sealing gap at the axial projection opens axially into a first catch channel of the first sealing ring. A hub of the radial rolling contact bearing forms the second sealing ring. Therefore, the second sealing ring is integrated into the hub flange, which means that the hub flange performs the function of the second sealing ring and to some extent helps to form the labyrinth seal.

Owner:SCHAEFFLER TECH AG & CO KG

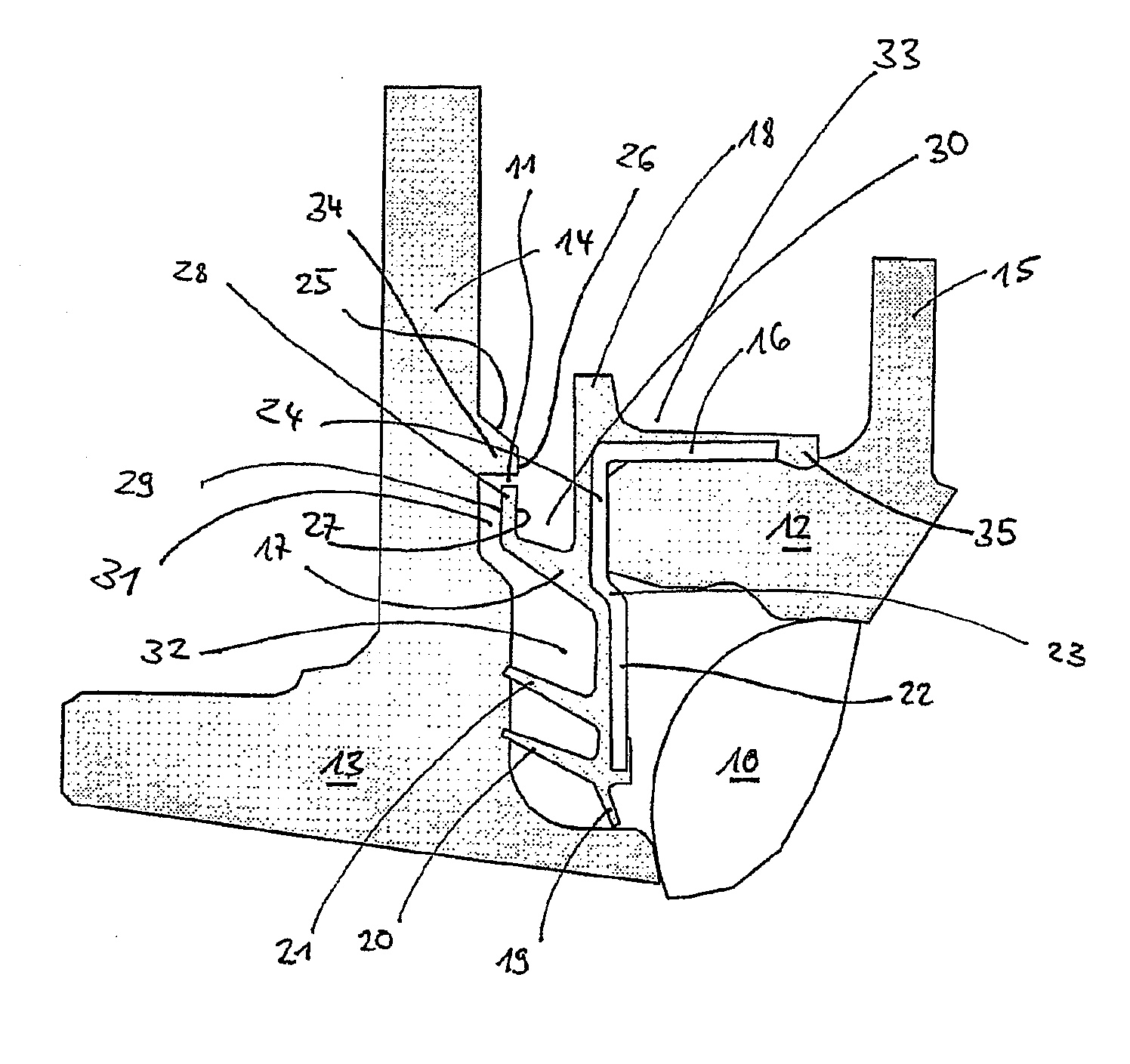

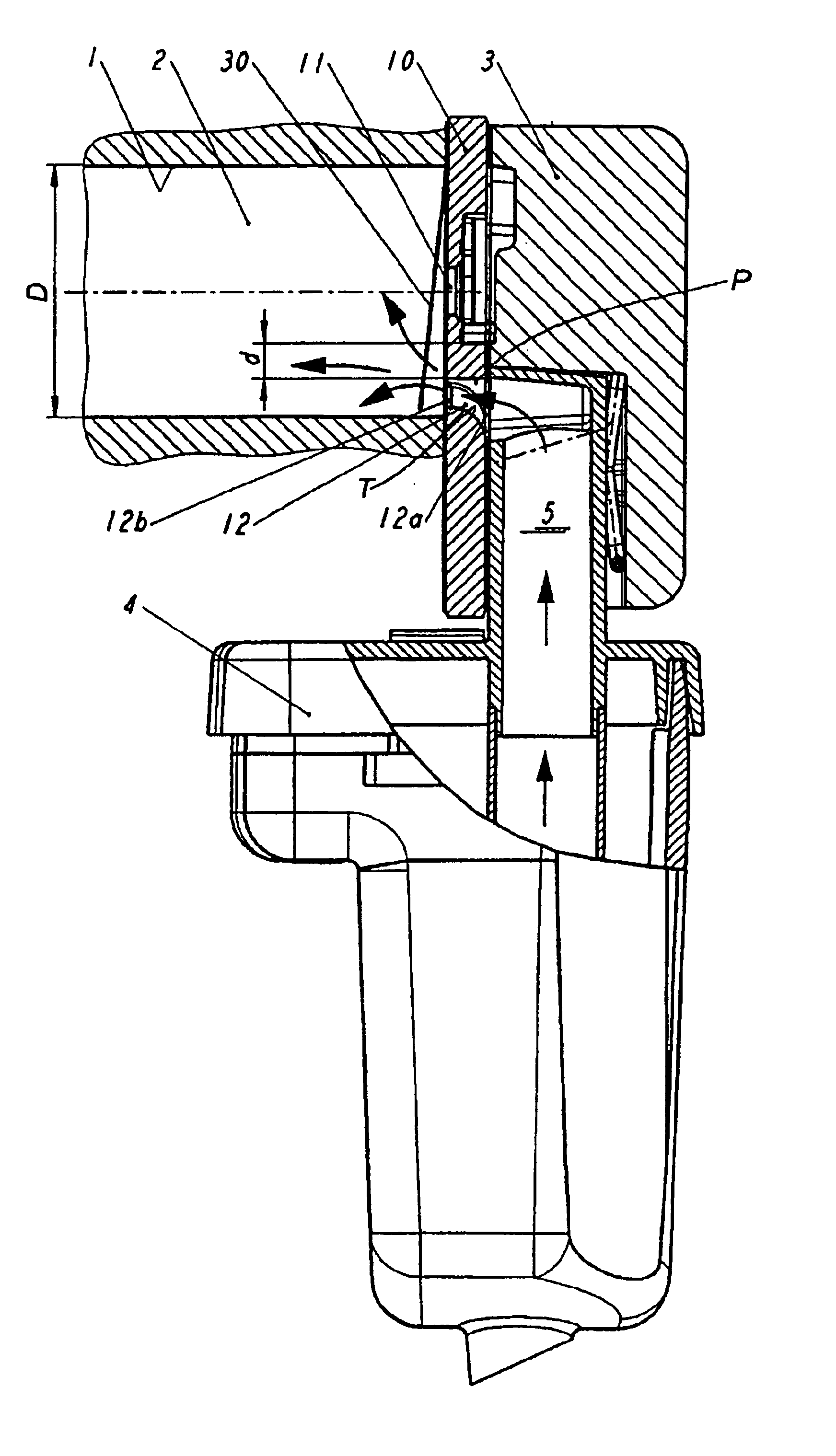

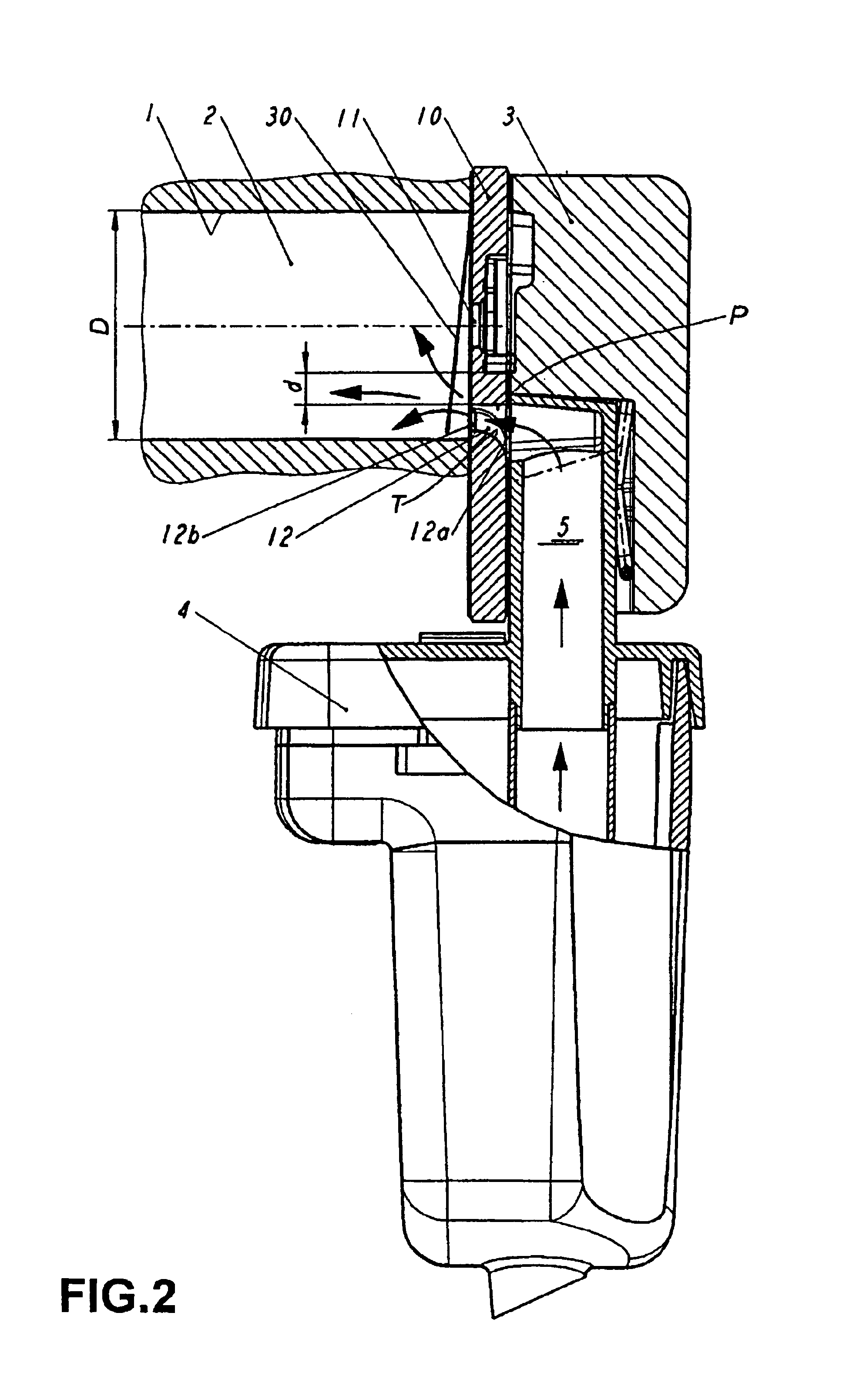

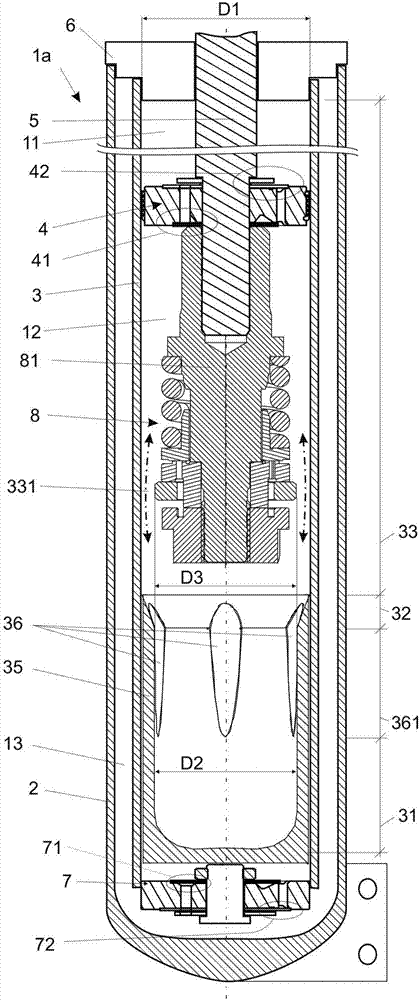

Valve arrangement for a small hermetic compressor

InactiveUS7083400B2Minimizes pressure differentialReduce load lossPositive displacement pump componentsCheck valvesEngineeringAxial projection

A suction and discharge valve arrangement for a small hermetic compressor of the type presenting a compression cylinder (1), which has an end closed by a valve plate (10) and which has a suction pipe (5) adjacent to the valve plate (10) and substantially orthogonal to the cylinder axis, the valve plate (10) being provided with a discharge orifice (11) substantially centralized in relation to the axial projection (20) of the internal contour of the compression cylinder (1), and with at least one suction orifice (12), which is internal to said axial projection (20) of the internal contour of the compression cylinder (1), and defining at least part of the extension of a suction passage (P), with an end opened to the inside of the compression cylinder (1) and an opposite end opened and connected to the suction pipe (5) by means of a transition portion (T), which is configured to minimize load losses.

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

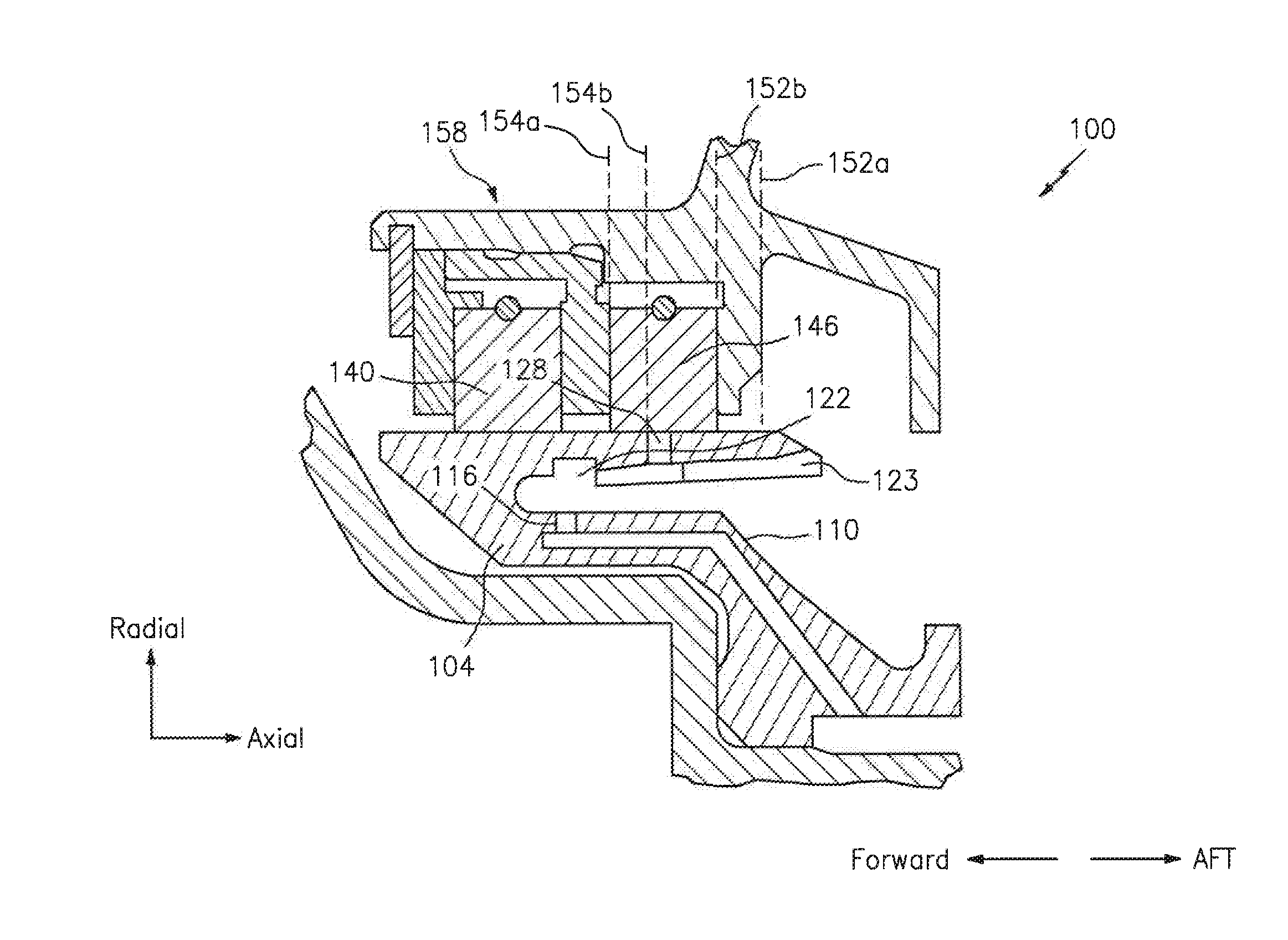

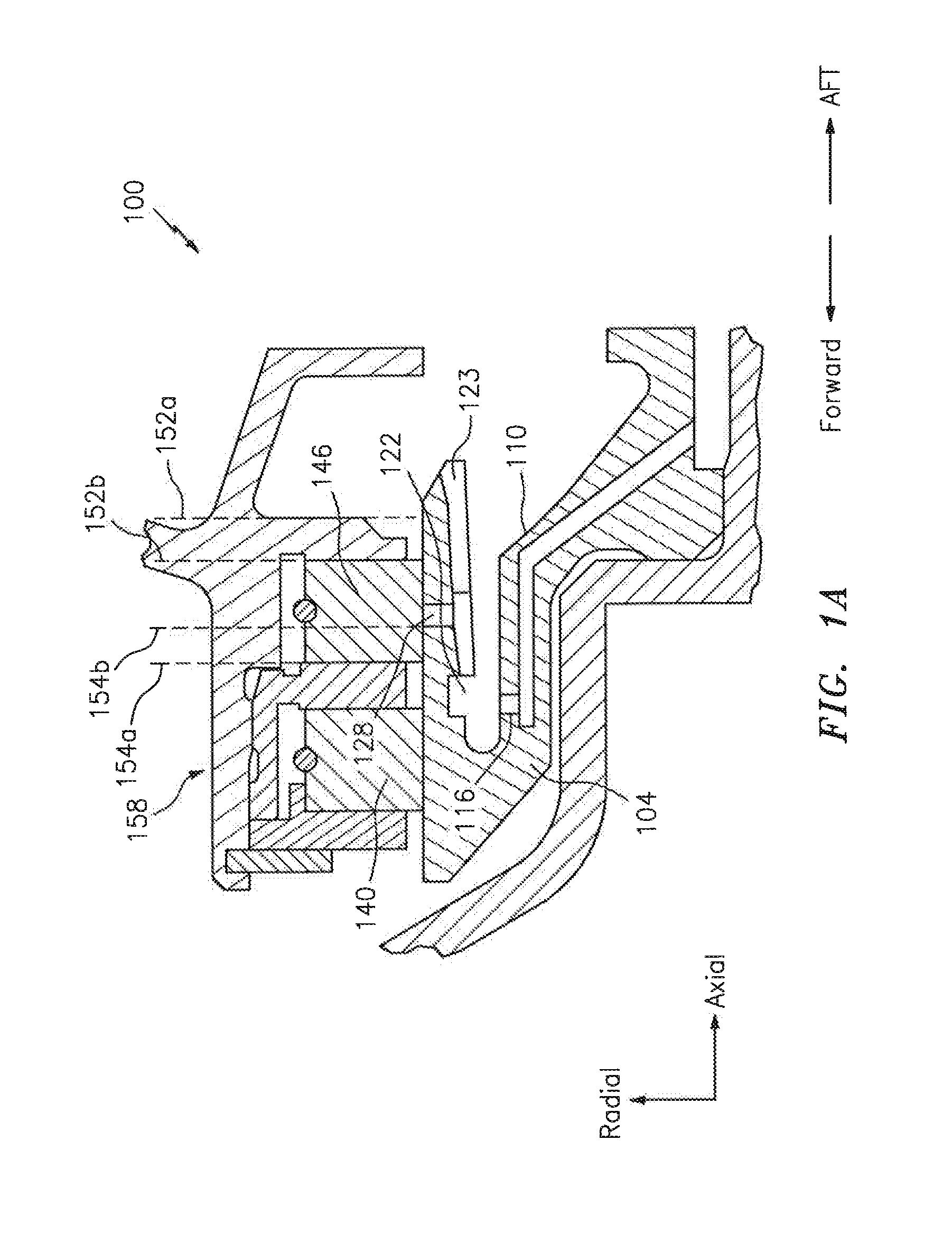

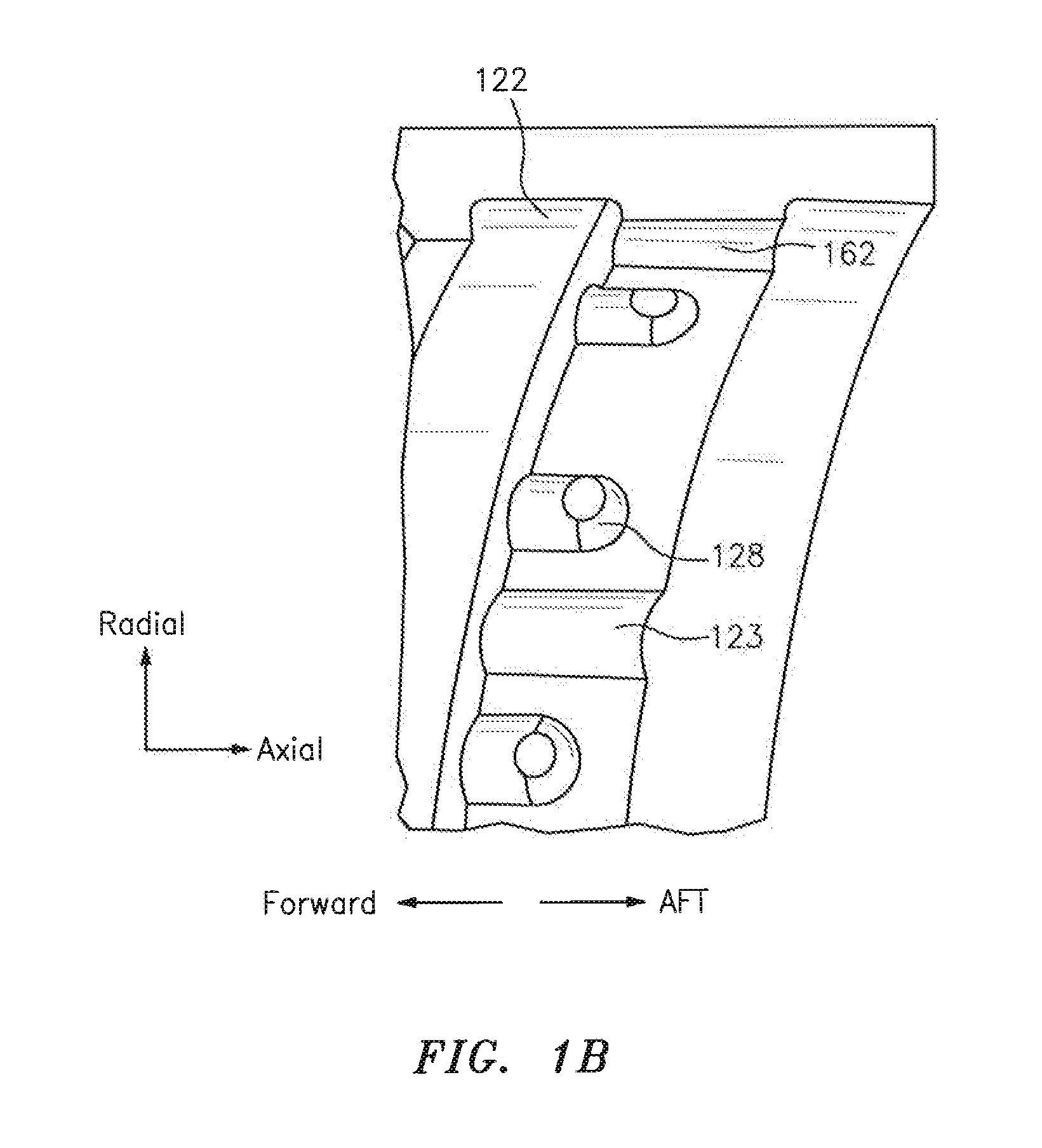

Seal runner with controlled oil lubrication

A system is provided associated with an engine of an aircraft. The system includes a ring, a runner and at least one radially-oriented hole associated with the runner that is configured to supply oil to an interface between the runner and the ring. The at least one hole is contained within an axial projection of the ring.

Owner:RAYTHEON TECH CORP

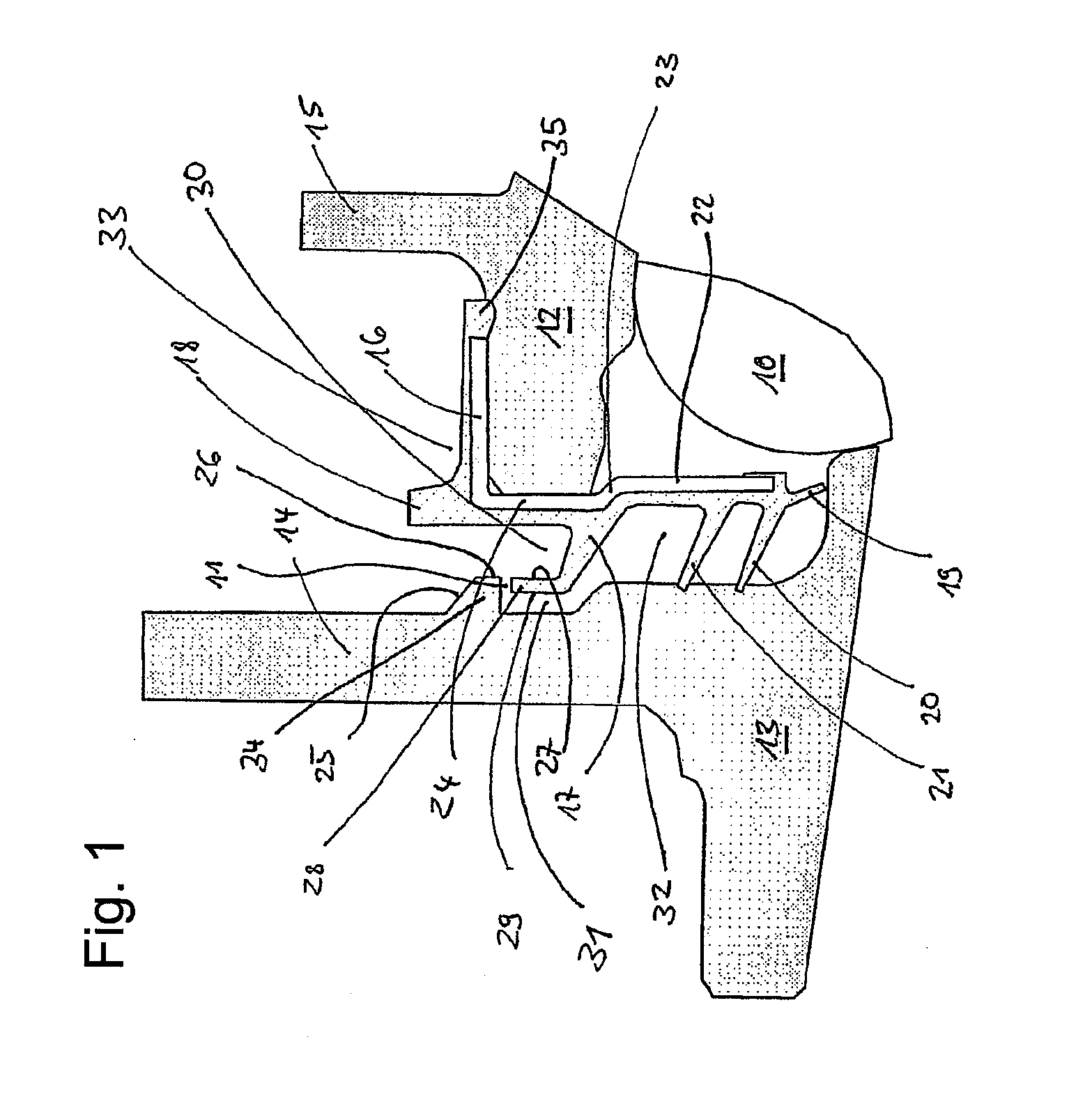

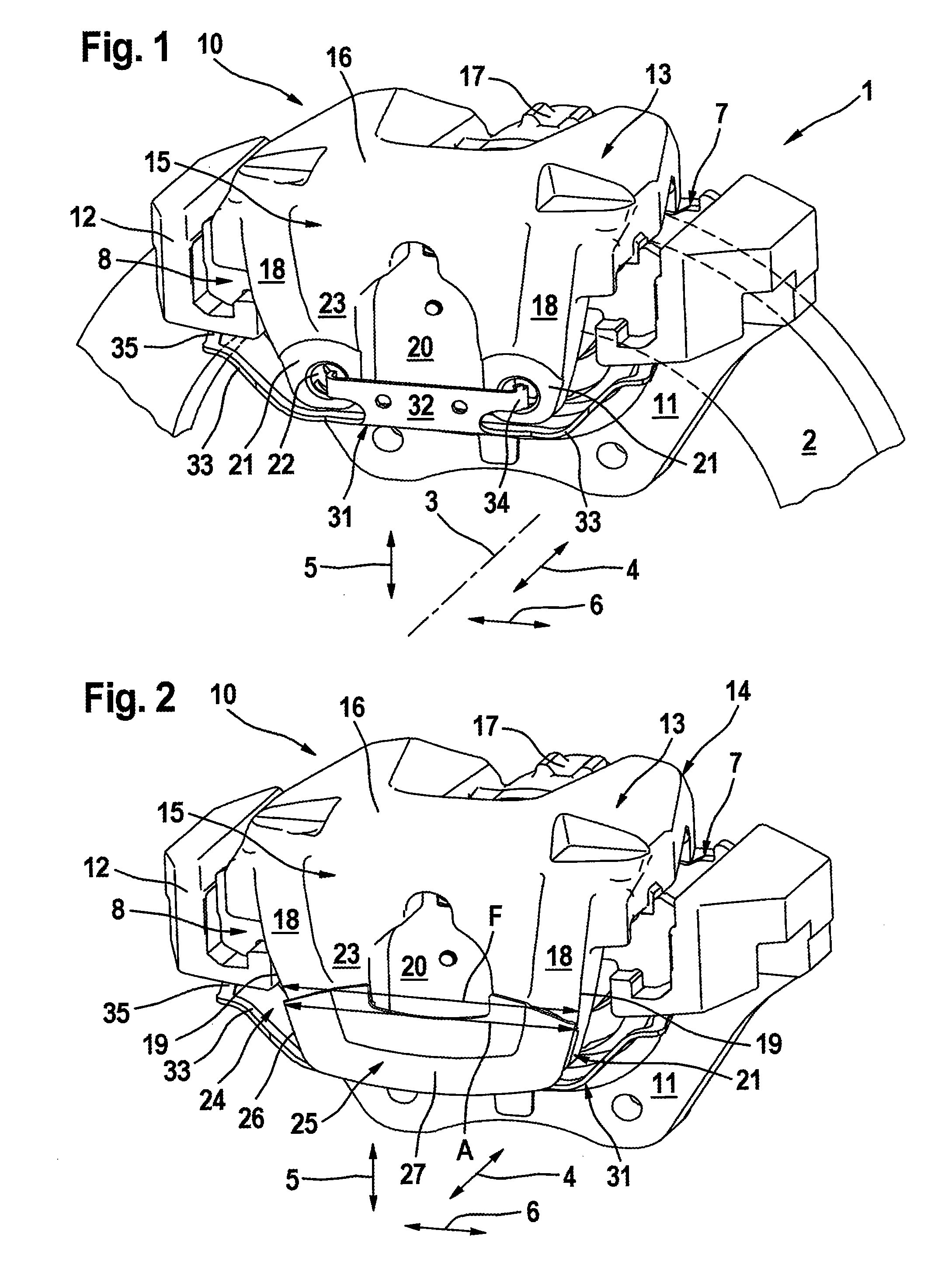

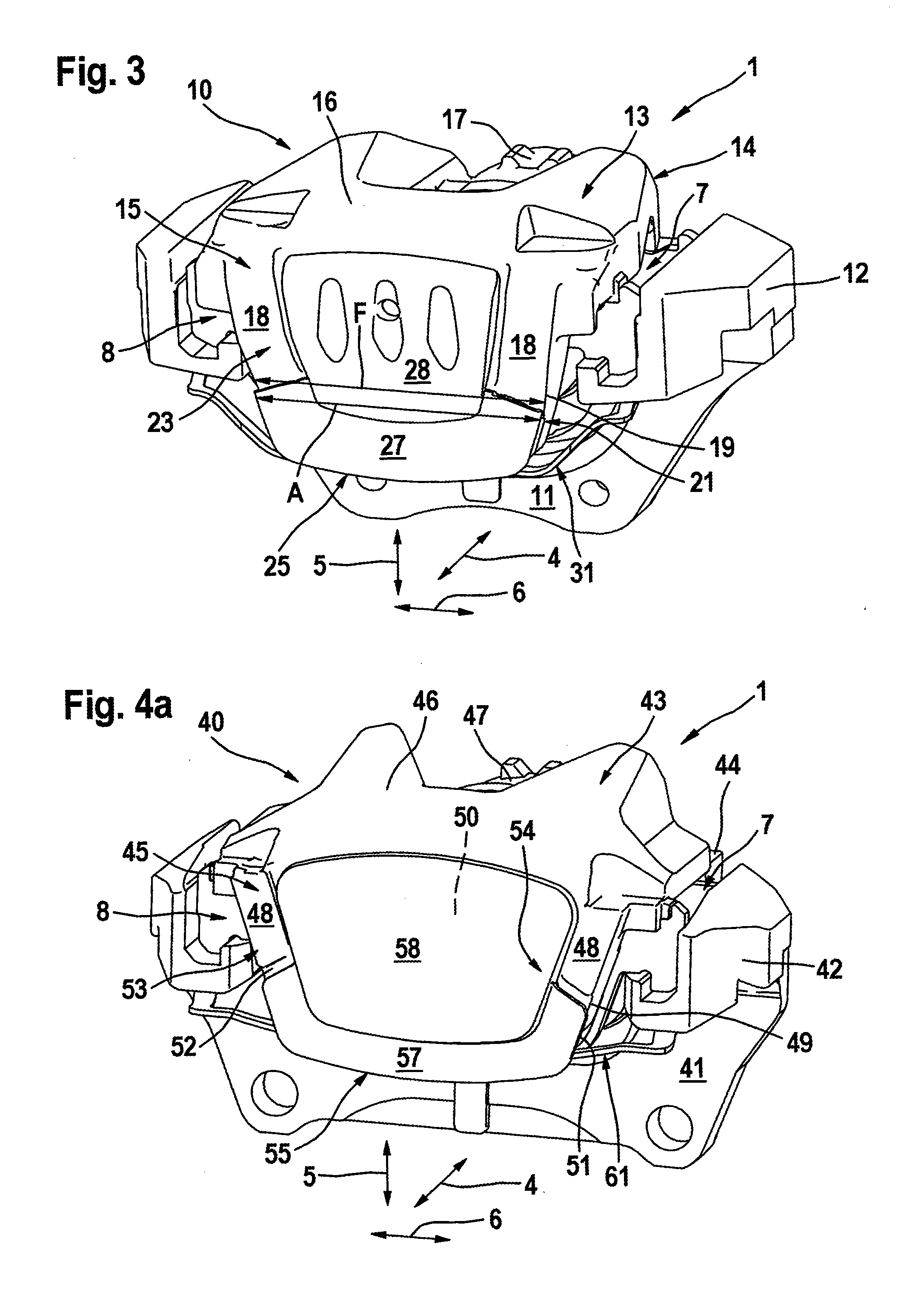

Disk Brake

InactiveUS20100163350A1Protected against external mechanical effectRealize the designAxially engaging brakesBrake actuating mechanismsRotational axisEngineering

A disk brake having a brake disk, a brake caliper including a bracket, a caliper housing and a brake lining. The bracket and the caliper housing engage axially around the brake disk, with the caliper housing and the brake lining movable in an axial direction. The caliper housing has outer housing limb comprising two housing fingers which run substantially in a radial direction and which span a limb window situated between them and which is open in the direction of the rotational axis, with the housing fingers having one end section facing the rotational axis. A protective screen covers end sections of the housing fingers and conceals a section of the limb window that faces the rotational axis, with an outer dimension of the protective screen in a circumferential direction such that a transition between the protective screen and the housing fingers is substantially stepless in an axial projection.

Owner:CONTINENTAL TEVES AG & CO OHG

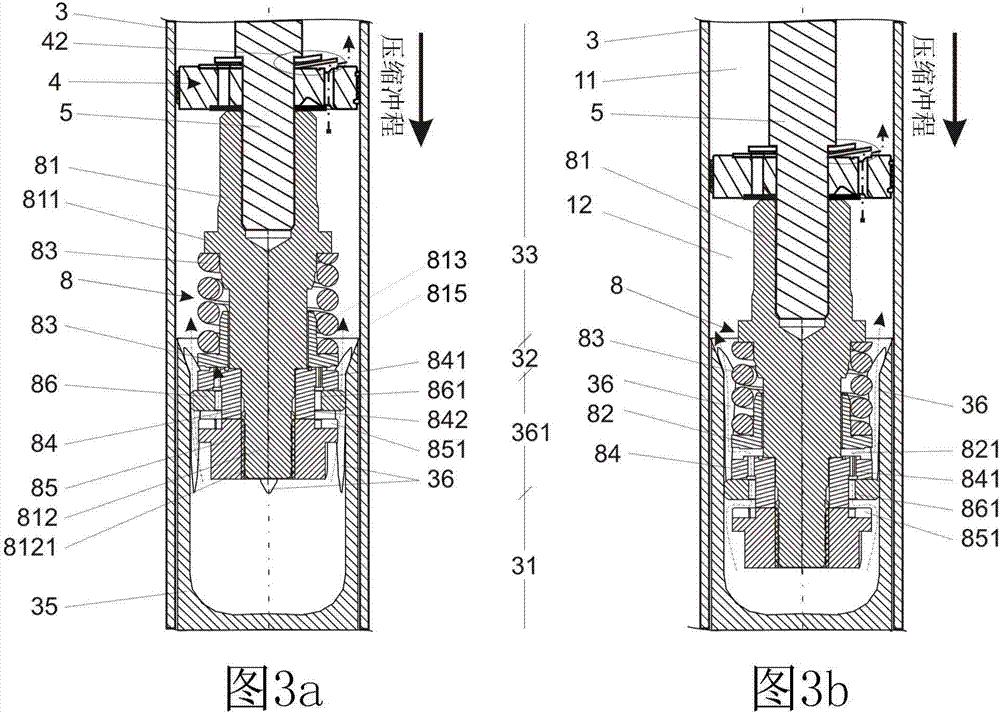

Hydraulic damper with hydraulic stop

Provivded is a hydraulic damper with a hydraulic stop. A hydraulic damper for a motor vehicle includes a tube having a main section and a narrowed section. The main piston assembly is disposed inside the main section. The main piston rod is attached to the main piston assembly. The secondary lever is coupled to the main piston rod. The spring seat is disposed about the secondary lever. The spring engages the spring seat and preloads the spring seat. The secondary piston is disposed about the secondary pole and is coupled to the secondary pole. The secondary piston has an axial projection and an annular projection abutting said spring seat. The annular protrusions define a plurality of axial grooves. The retaining member is fixed to the secondary pole and has an outer surface defining a plurality of radial grooves. The seal ring is slidably disposed about the axial projection. The annular passage is radially defined between the seal ring and the axial projection.

Owner:BEIJING WEST IND CO LTD

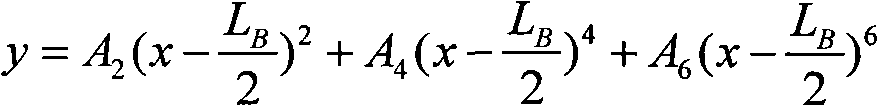

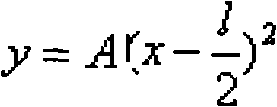

Roller of four-high rougher

InactiveCN101837369AExtended service periodImprove shape qualityCounter-pressure devicesRollsWork rollRoll forming

The invention relates to a roller of a four-high rougher, belonging to the technical field of a production process of hot rolled strips. The roller comprises two working rolls which symmetrically prop against a roughing mill and two supporting rolls which are in contact with the two working rolls, wherein the generatrix of the working rolls is a median-concave continuous curve determined by a curvilinear equation; and the generatrix of the supporting rolls comprises three sections, the middle section is a median-convex continuous curve determined by a polynomial equation, and the two end sections are symmetrical chamfer lines of an axial projected length L. The invention can inhibit the deviation of strip steel in the rough rolling process by the negative-convexity roll forming of the working rolls, equalize contact stresses among the rolls and eliminate the disadvantage of overlarge stress caused by the contact of the edges of the working rolls and supporting rolls, thereby prolonging the service cycle of the supporting rolls and improving the strip quality of an intermediate blank at the outlet of the roughing mill.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

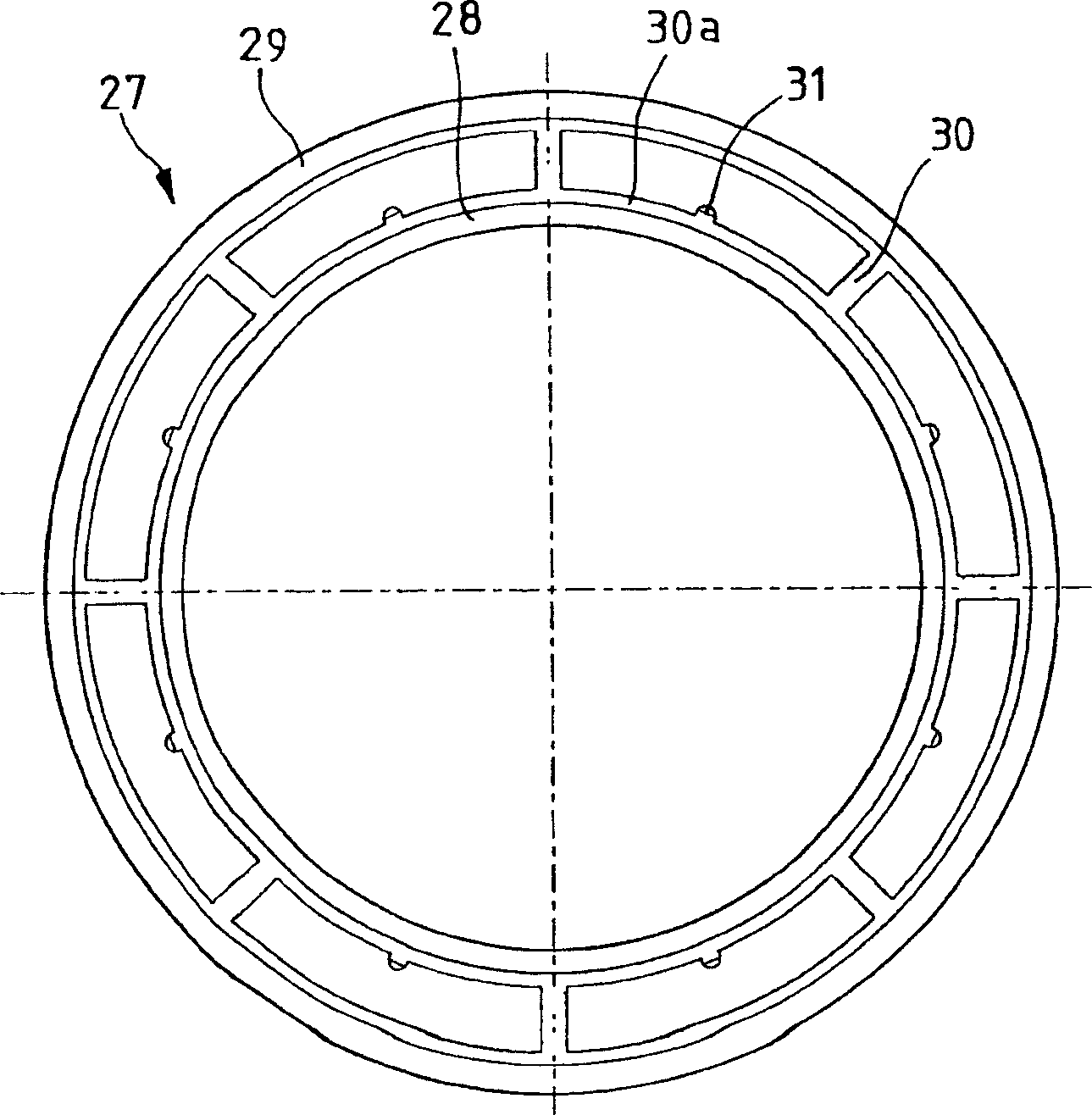

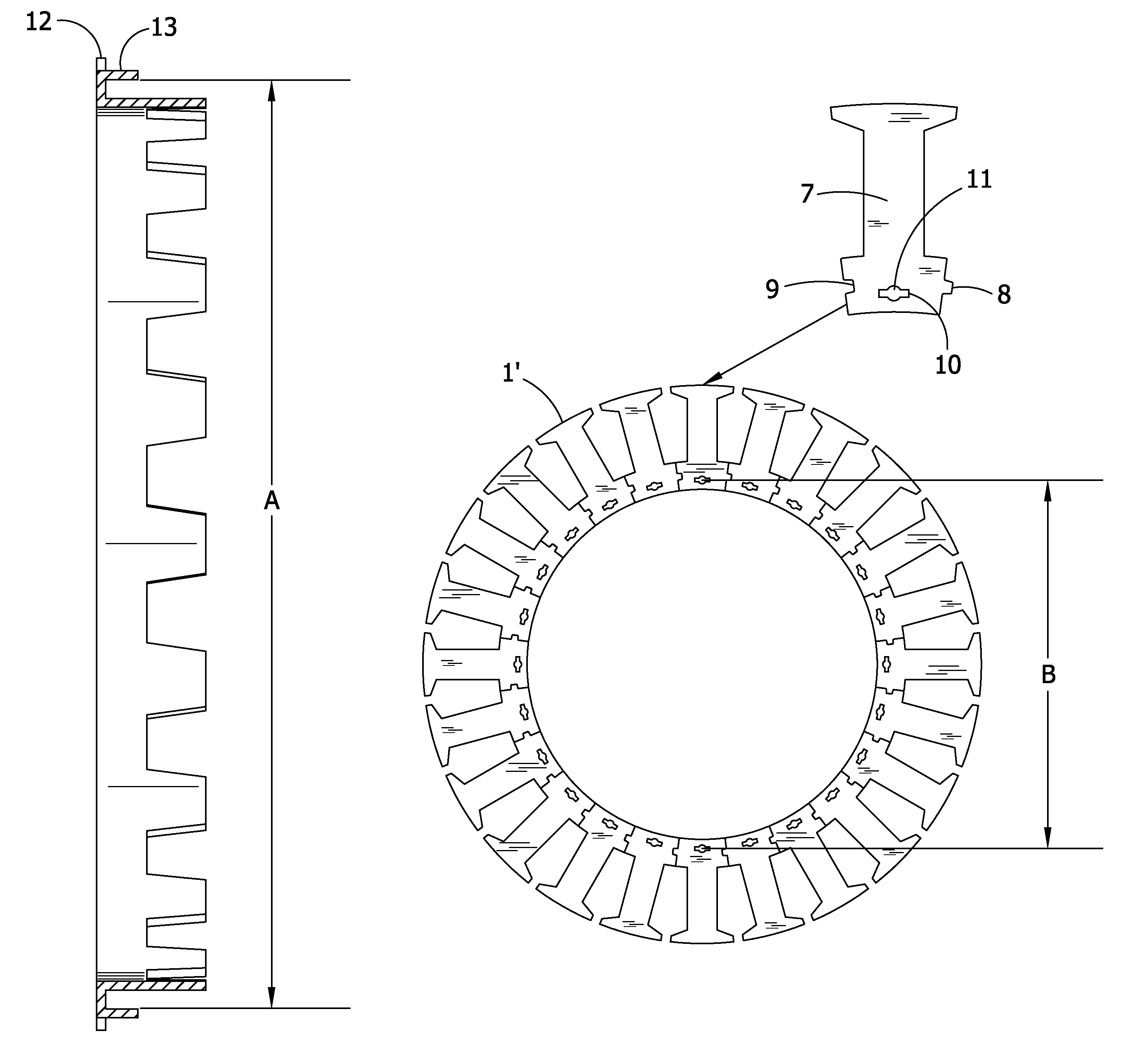

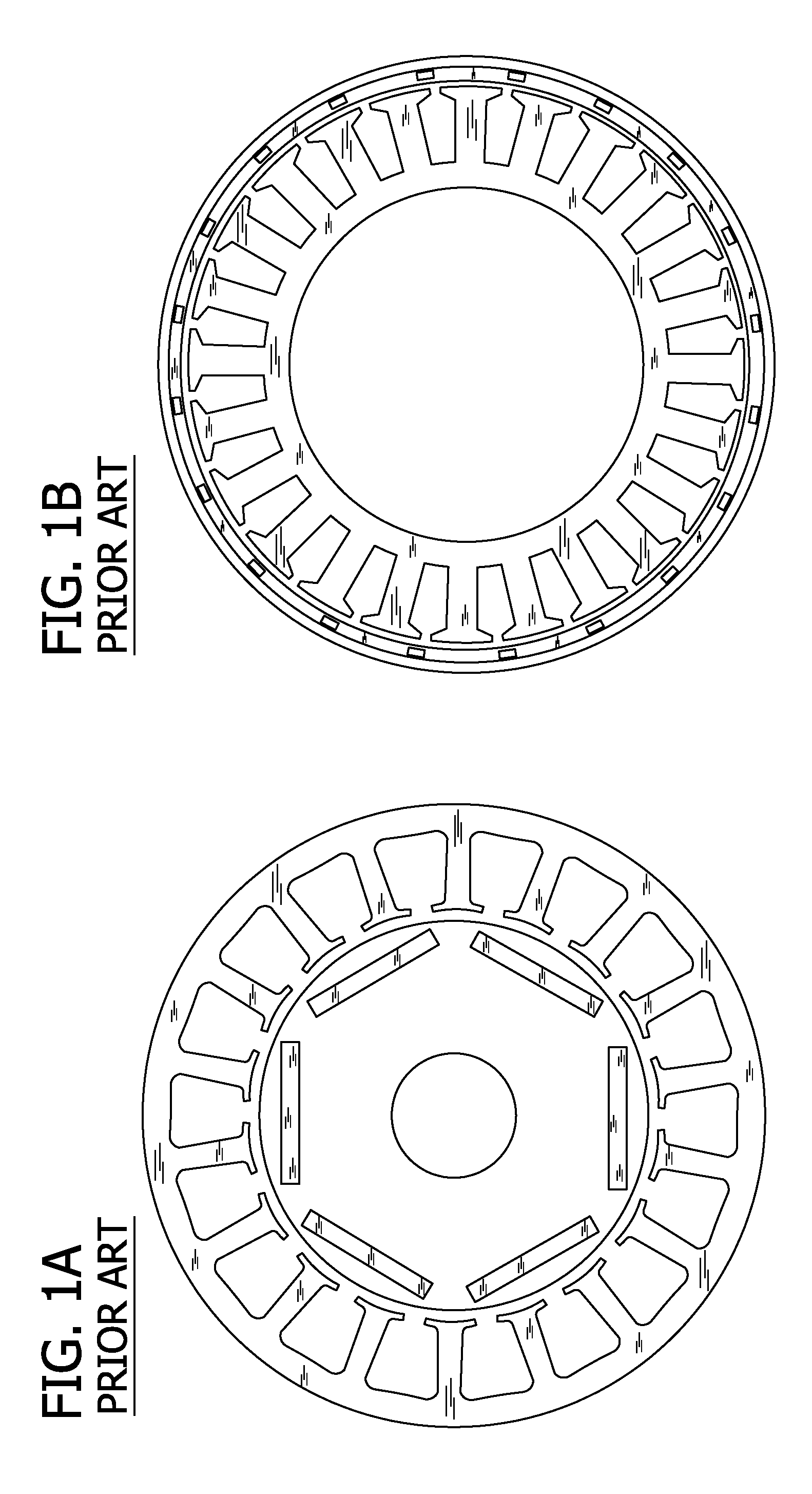

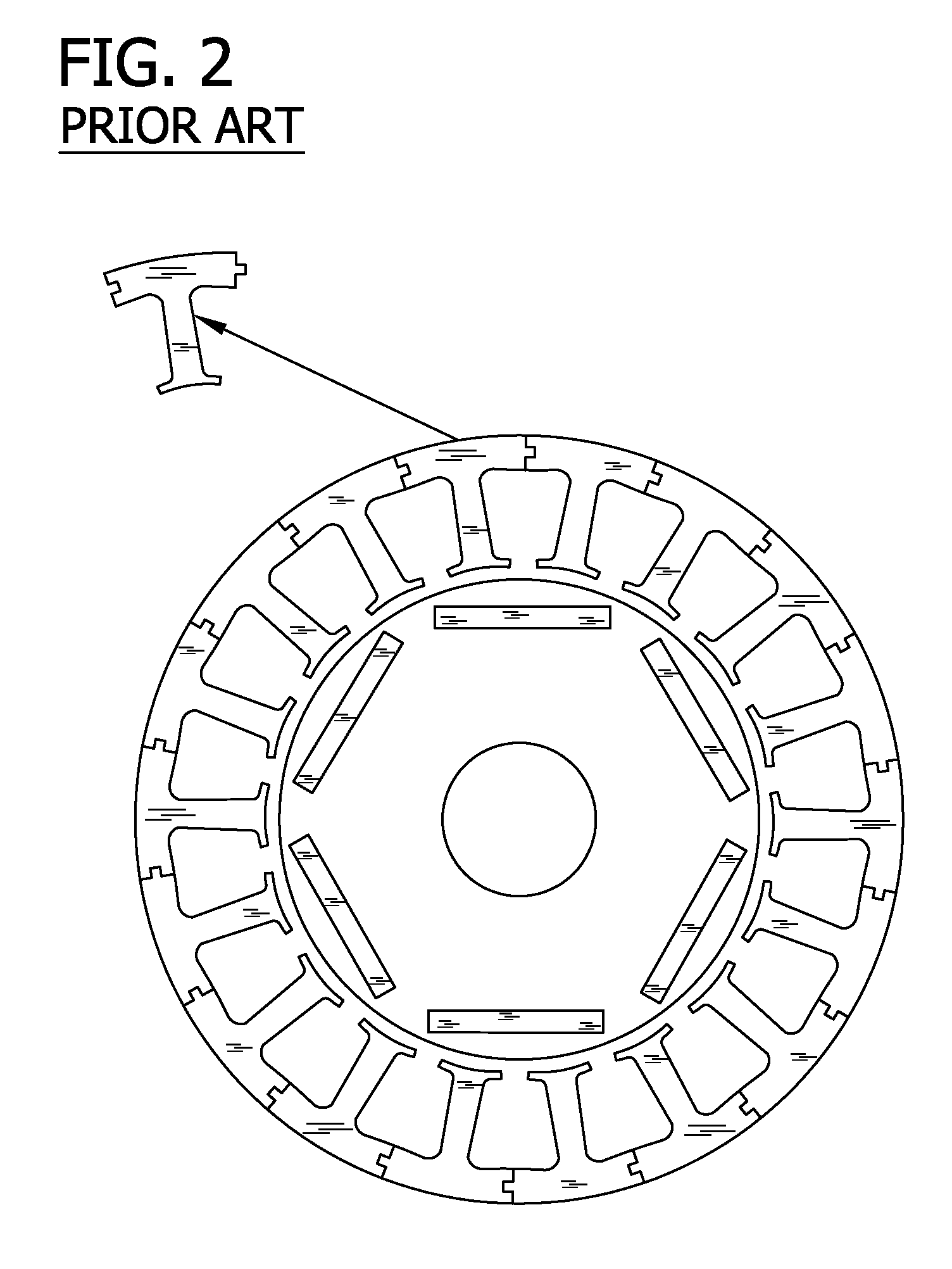

Segmented inner stator and brushless permanent magnet motor with the same

InactiveUS7615907B2Reduce material costsEasy to fillMagnetic circuit stationary partsPermanent magnet motorConductor Coil

Owner:NIDEC MOTOR CORP

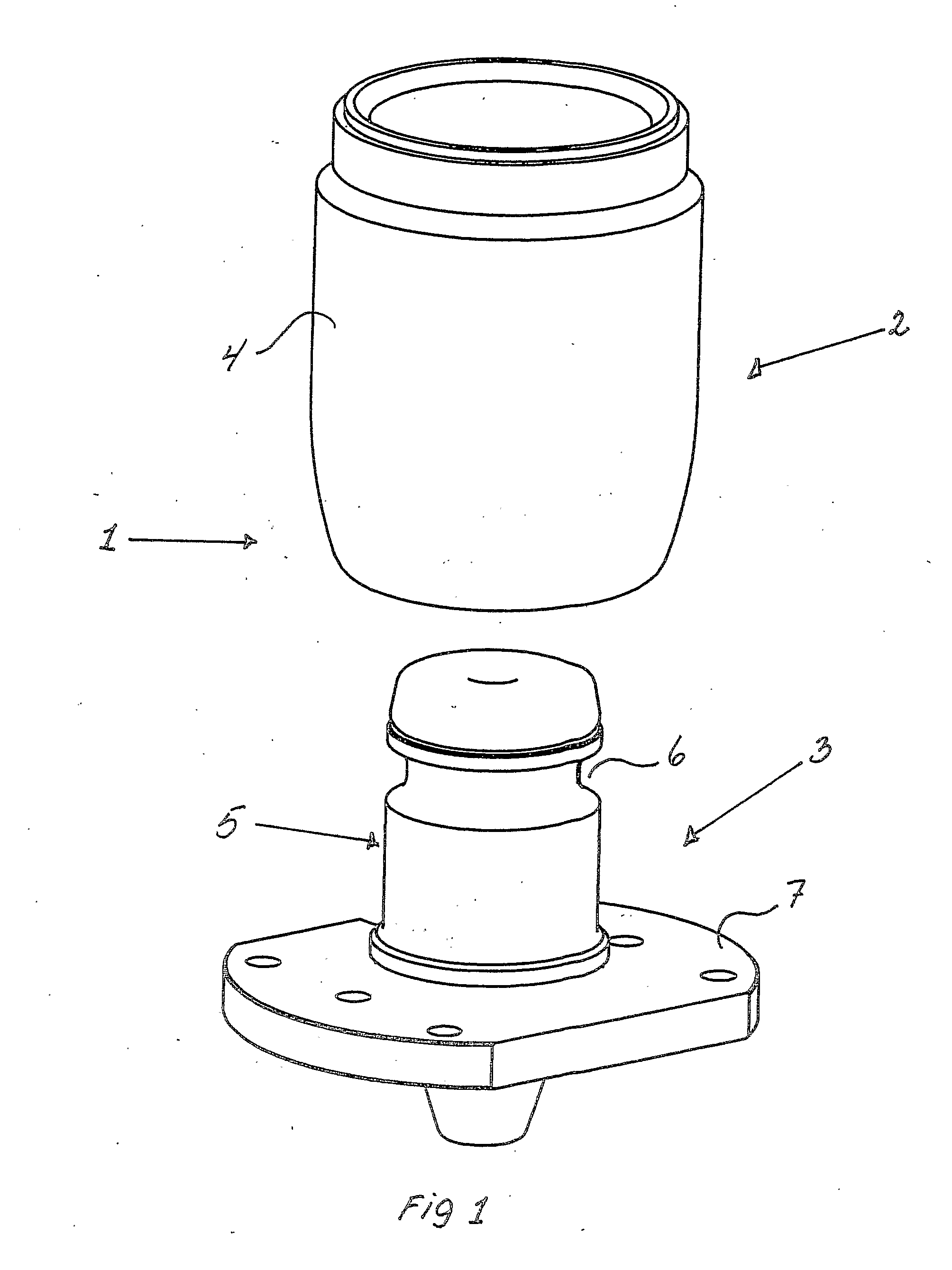

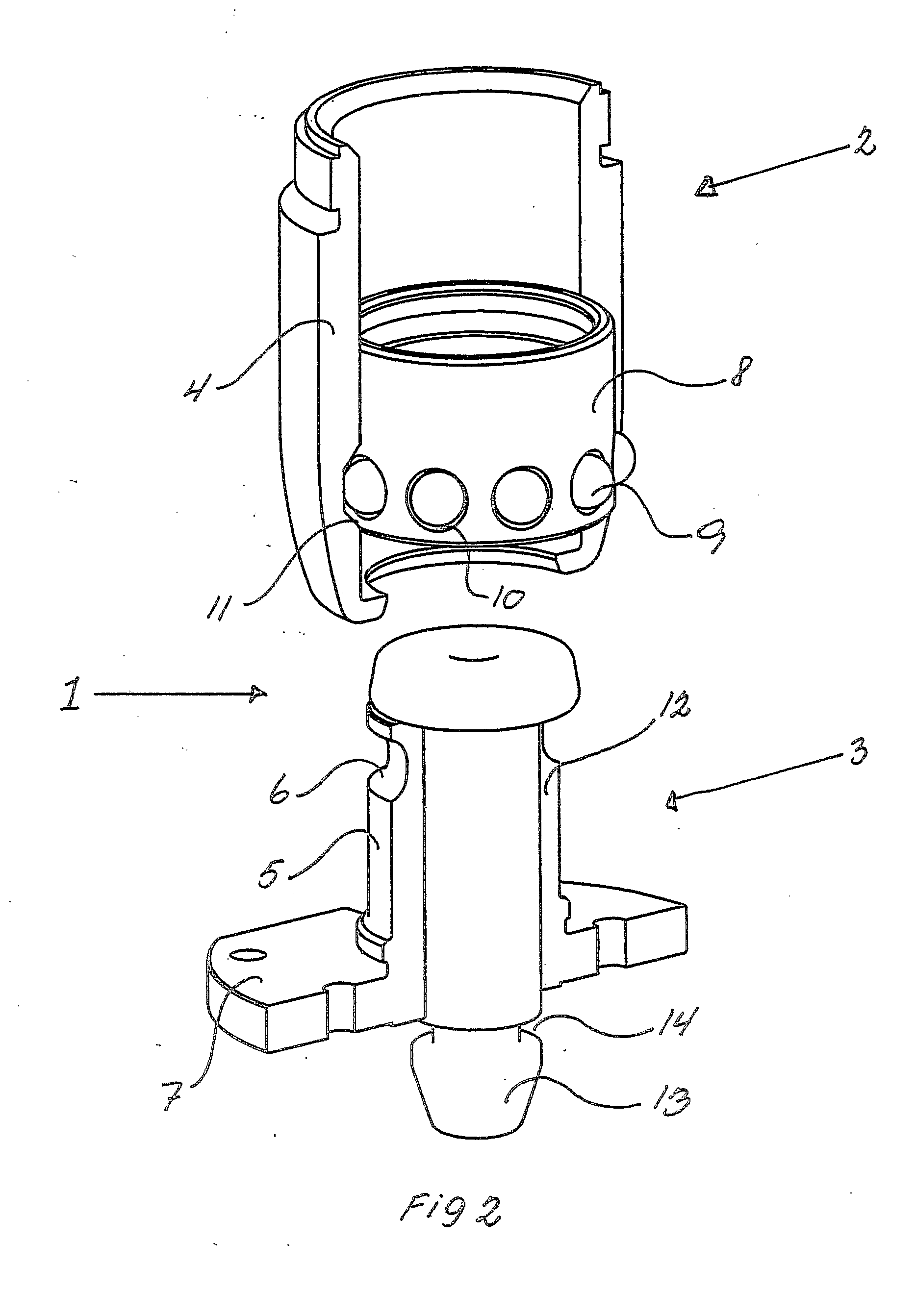

Coupling

The present invention concerns a coupling (1) including a first part (2) and a second part (3), where the first part (2) includes a housing (4) in which is arranged a displaceable locking ring (8) with locking means (9), where the locking ring (8) in a known way is arranged for receiving and fixing a projecting part (5) of the second part (3) which is complementary to the locking ring (8), where the housing (4) in an internal cylindric surface is provided with an annular recess (11) which is arranged for accommodating the locking means (9), and where the locking ring (8) is connected with a spring-biased locking unit (17) which is arranged for moving and locking the locking ring (8) in at least two positions in the housing (4), and where the locking unit (17) includes an insert (18) which at one end is connected to the locking ring (8), and which at an opposite end is provided with a number of series of continuing, oblique teeth (23), the insert (18) having internal and external, respectively, axial projections (24, 25), a guide ring (19) surrounding the insert (18) and having internally a design which is complementary to the axial projections (25), and being provided with a number of sets of oblique teeth (26) disposed between the external projections (25), and a rotor (20) provided at one end with a number of radial teeth (28) and which at an opposite end provided with a number of stops (29) that interact with the internal projections (24), the rotor (20) seated internally in the insert (18) so that the teeth (28) interact with the oblique teeth (23, 26).

Owner:V GULDMANN AS

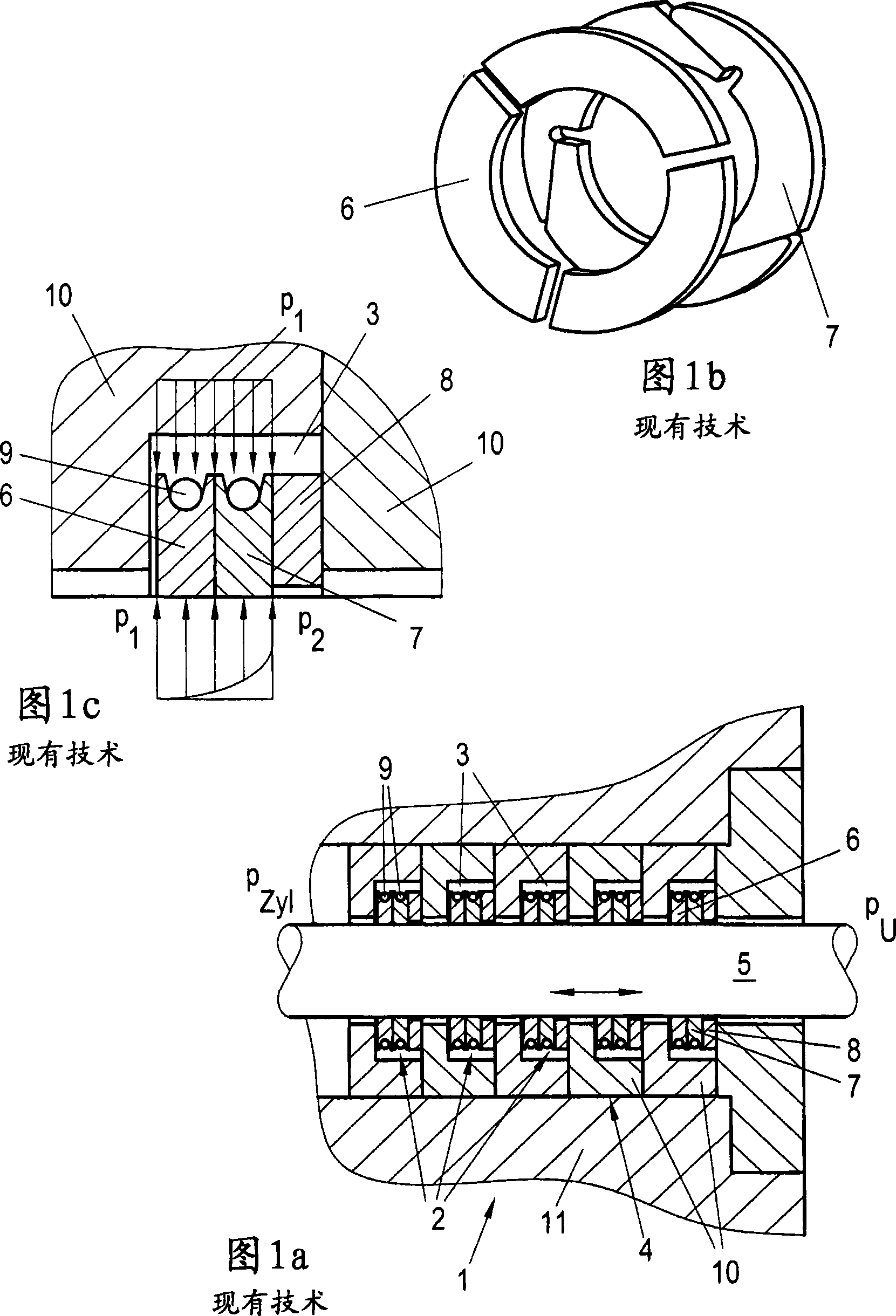

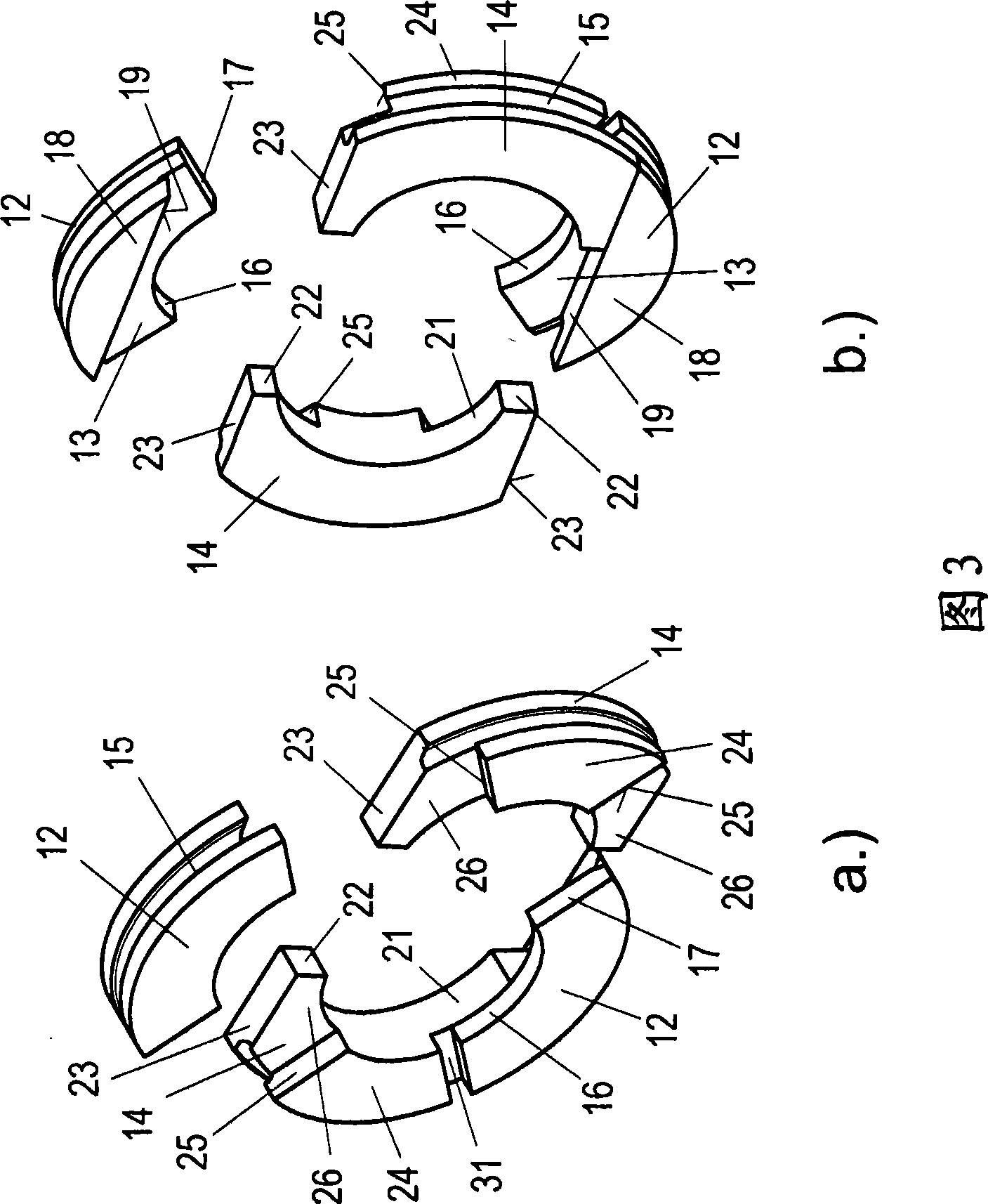

Multipart packing ring

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

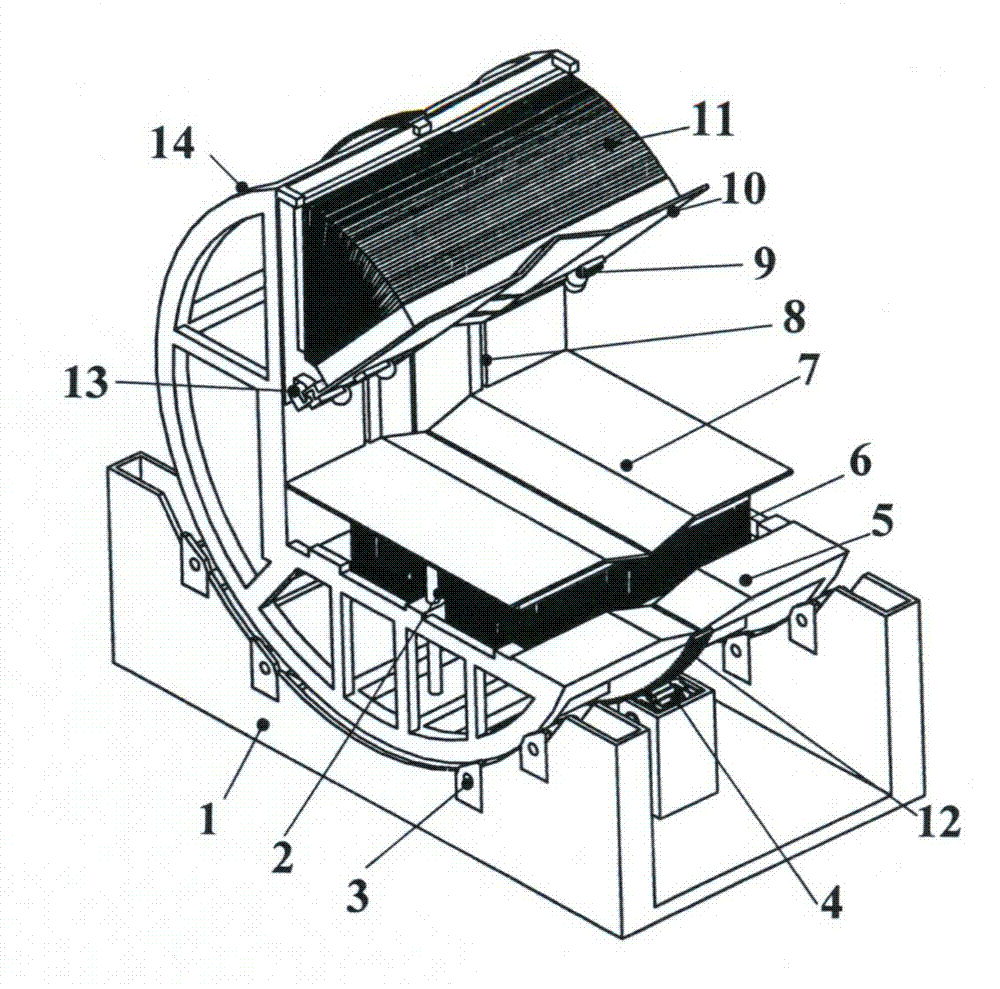

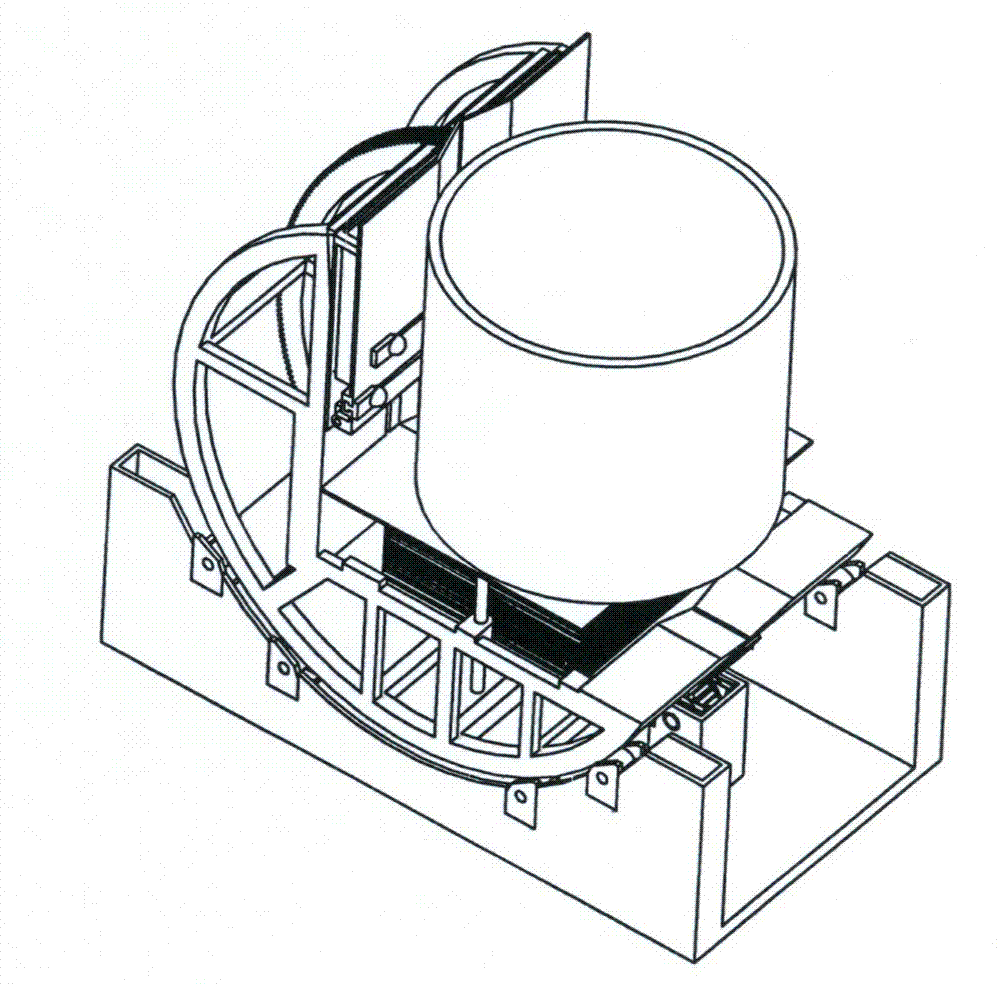

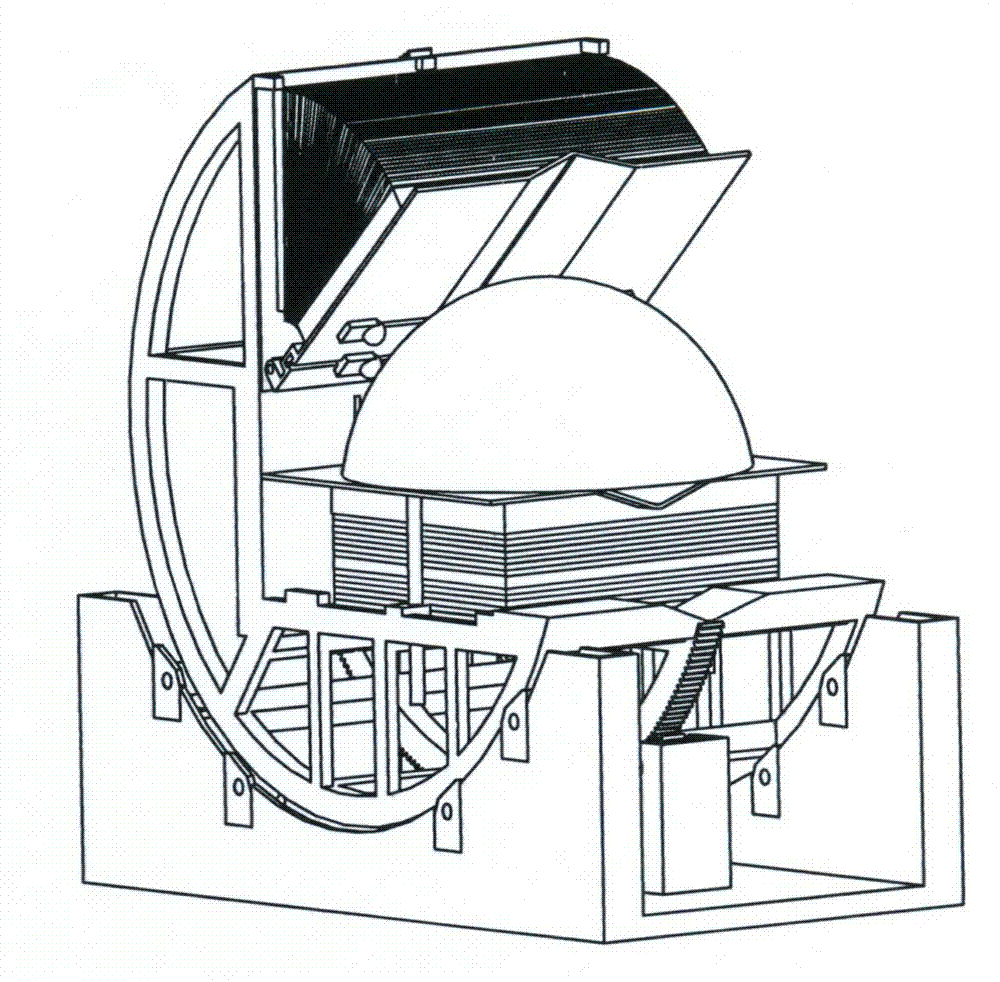

Respectively moving and turning double-air-bag three degree-of-freedom 90/180 degree turnover machine

InactiveCN102785113ASimple structureReduce the overall heightMetal working apparatusThree degrees of freedomDegrees of freedom

The invention relates to a respectively moving and turning double-air-bag three degree-of-freedom 90 / 180 degree turnover machine. The turnover machine comprises a base and a turnover machine body, and is characterized in that a curved base roller bed is arranged at each of the two ends of the base respectively; a carrier roller is arranged on each of the roller beds; a driving gear is arranged on the base; the turnover machine body is of a cylindrical welding structure and is provided with a worktable of which the axial projection is L-shaped; a circular supporting track is fixedly connected to each of the two ends of the excircle of the turnover machine body respectively; a curved machine body gear ring is arranged in the middle of the turnover machine; a turnover working platform is hinged on a vertically fixed working surface of the L-shaped worktable; a turnover driving air bag is formed between the turnover working platform and the vertically fixed working surface; and the horizontally fixed working surface of the L-shaped worktable is provided with a vertically moving platform by a vertically moving air bag. The turnover machine has the advantages of strong bearing capability, capability of implementing a turnover of 90 and 180 degree for workpieces of various shapes and sizes without accessories, simple structure, small whole height, convenience in manufacturing, low cost, and safety and reliability.

Owner:YANSHAN UNIV

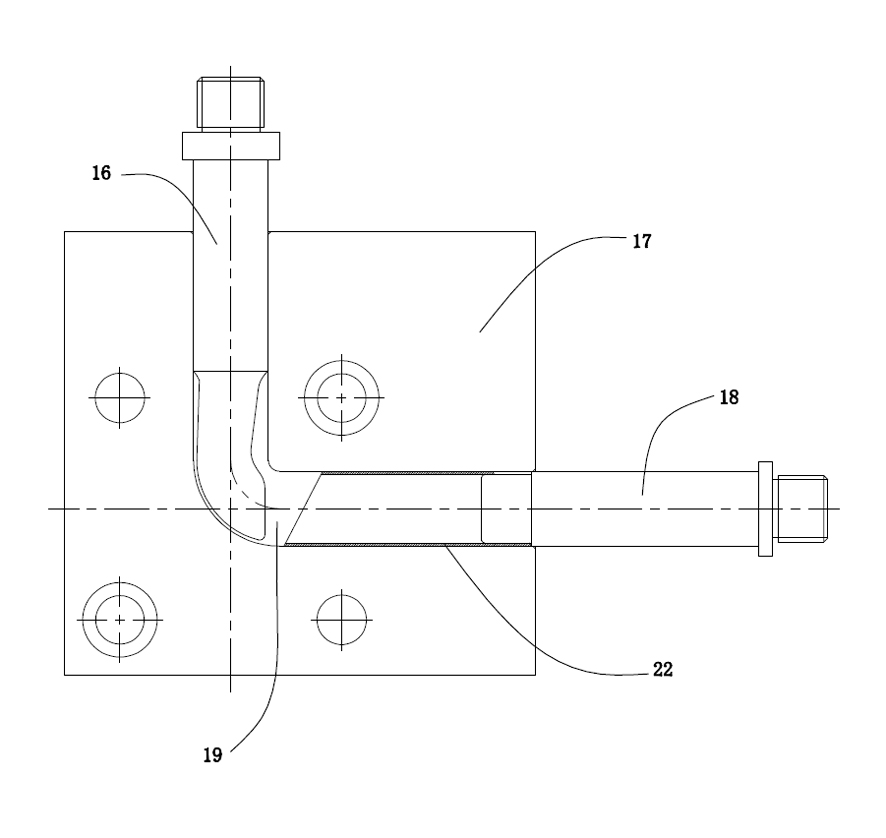

Metal elbow cold extrusion molding device

InactiveCN101954389ALess bending timeEasy to operateExtrusion diesExtrusion mandrelsPipe fittingMaterials science

The invention relates to a metal elbow cold extrusion molding device for processing metal pipe fittings. The invention solves the defects of serious loss of filters, long process time and high bending cost of pipe fittings in the traditional pipe bending technology which needs filling. The metal elbow cold extrusion molding device comprises an extrusion mold core which can be inserted into a mold cavity and a core pushing stick for pushing the pipe fittings to be processed. The extrusion mold core comprises a basic shaft and a working end. The basic shaft is adapted to the inner diameter of the mold cavity, at least one gap equal with the wall thickness of the pipe fitting is arranged between the working end and the inner wall of the mold cavity, the projection of the working end along with the axial direction of the basic shaft is of a round shape, and the round shape is consistent with the inner diameter of the pipe fitting to be processed. The axial projection of the working end is of the round shape, then the pipe fitting can be repaired when the working end exits, the end part of the pipe fitting is of the round shape, the pipe fitting is formed by extruded and bended one-step molding and does not need cooling, the bending time is short, the operation is simple, the efficiency is high, the shape of the end part of the final pipe fitting is more in line with requirements, and the precision is higher.

Owner:ZHE JIANG TIAN XING PIPE

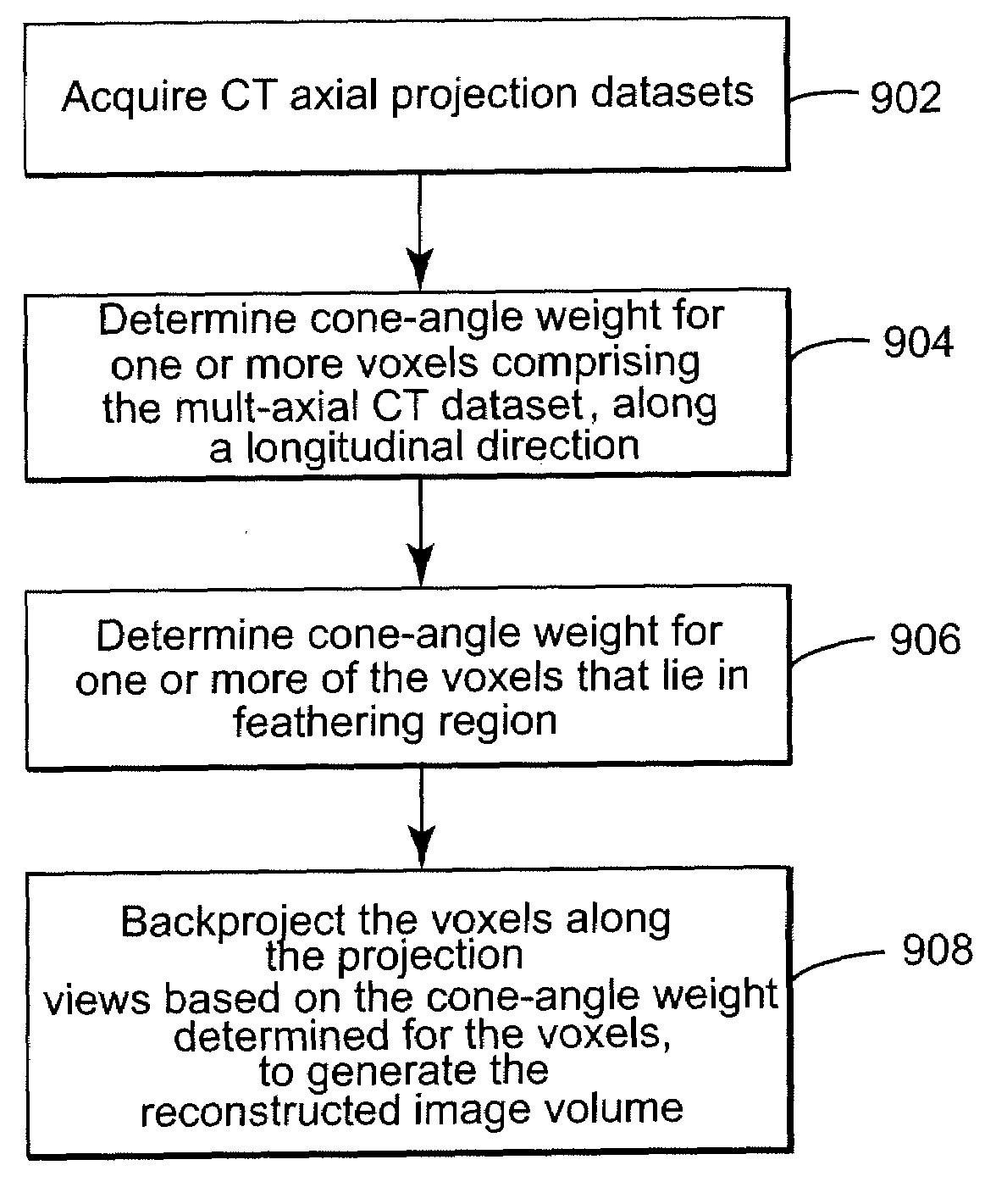

Method for analytic reconstruction of cone-beam projection data for multi-source inverse geometry ct systems

ActiveUS20090110259A1Need be addressReconstruction from projectionMaterial analysis using wave/particle radiationData setVoxel

A method for analytically reconstructing a multi-axial computed tomography (CT) dataset, acquired using one or more longitudinally-offset x-ray beams emitted from multiple x-ray sources is provided. The method comprises acquiring one or more CT axial projection datasets, wherein the CT axial projection datasets are acquired using less than a full scan of data. The method further comprises reconstructing the CT axial projection datasets to generate a reconstructed image volume. The reconstruction comprises backprojecting one or more voxels comprising the multi-axial CT dataset, along one or more projection views, based upon a cone-angle weight determined for the voxels, wherein the cone-angle weight for the voxels is determined along a longitudinal direction.

Owner:GENERAL ELECTRIC CO

Resettable tumbler lock

A resettable tumbler lock includes: a lock housing; a sleeve mounted rotatably in the lock housing and formed with a plurality of tumbler bores; a cylindrical latch-connecting part mounted rotatably in the lock housing and formed with a plurality of tumbler holes and a plurality of blind holes; and a plurality of spring-biased tumbler units. The sleeve is rotatable relative to the latch-connecting part between first and second angular positions. At least one of the tumbler bores in the sleeve has an axial projection that does not coincide with that of an aligned one of the tumbler holes in the latch-connecting part when the sleeve is disposed at a predetermined position between the first and second angular positions.

Owner:LIN SHENG TING

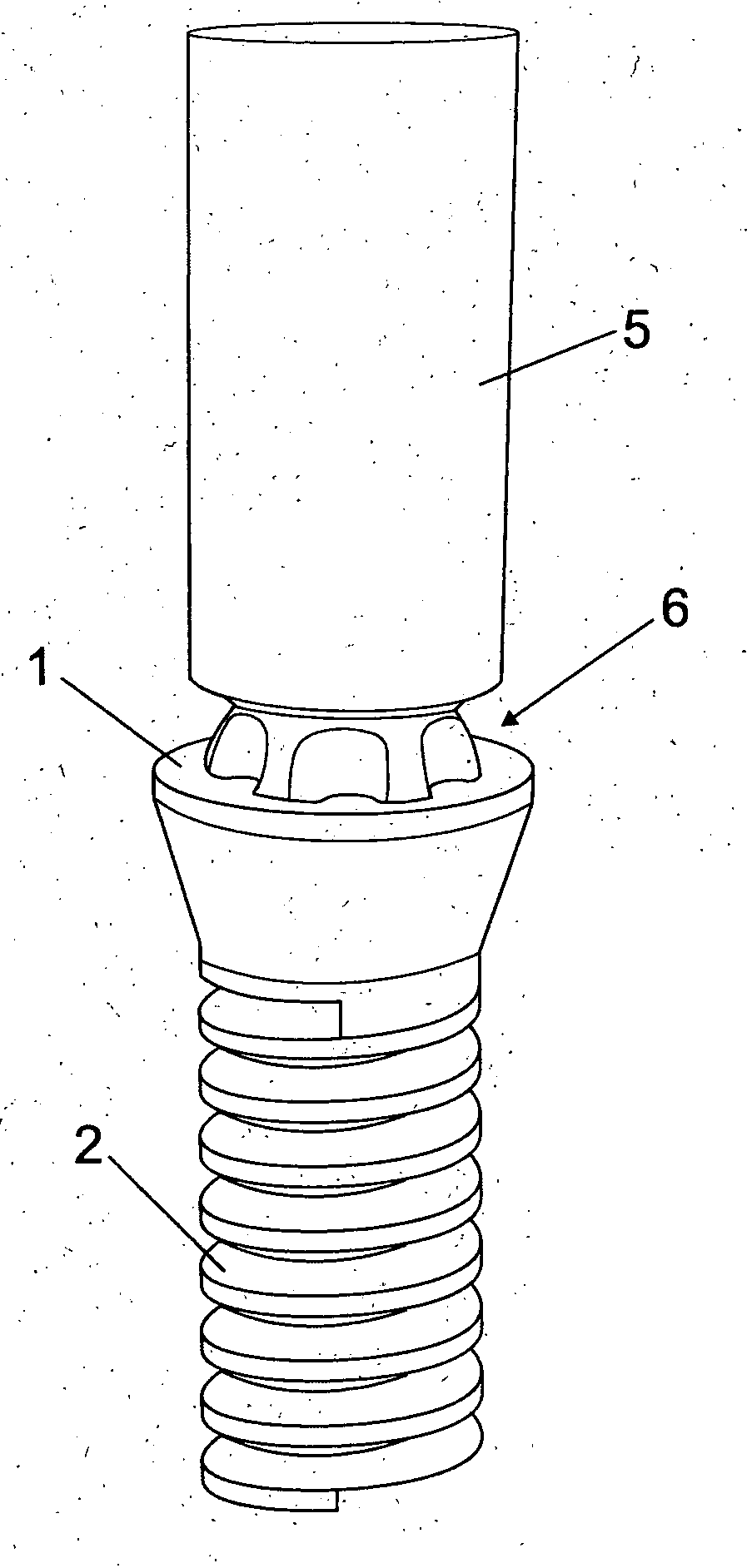

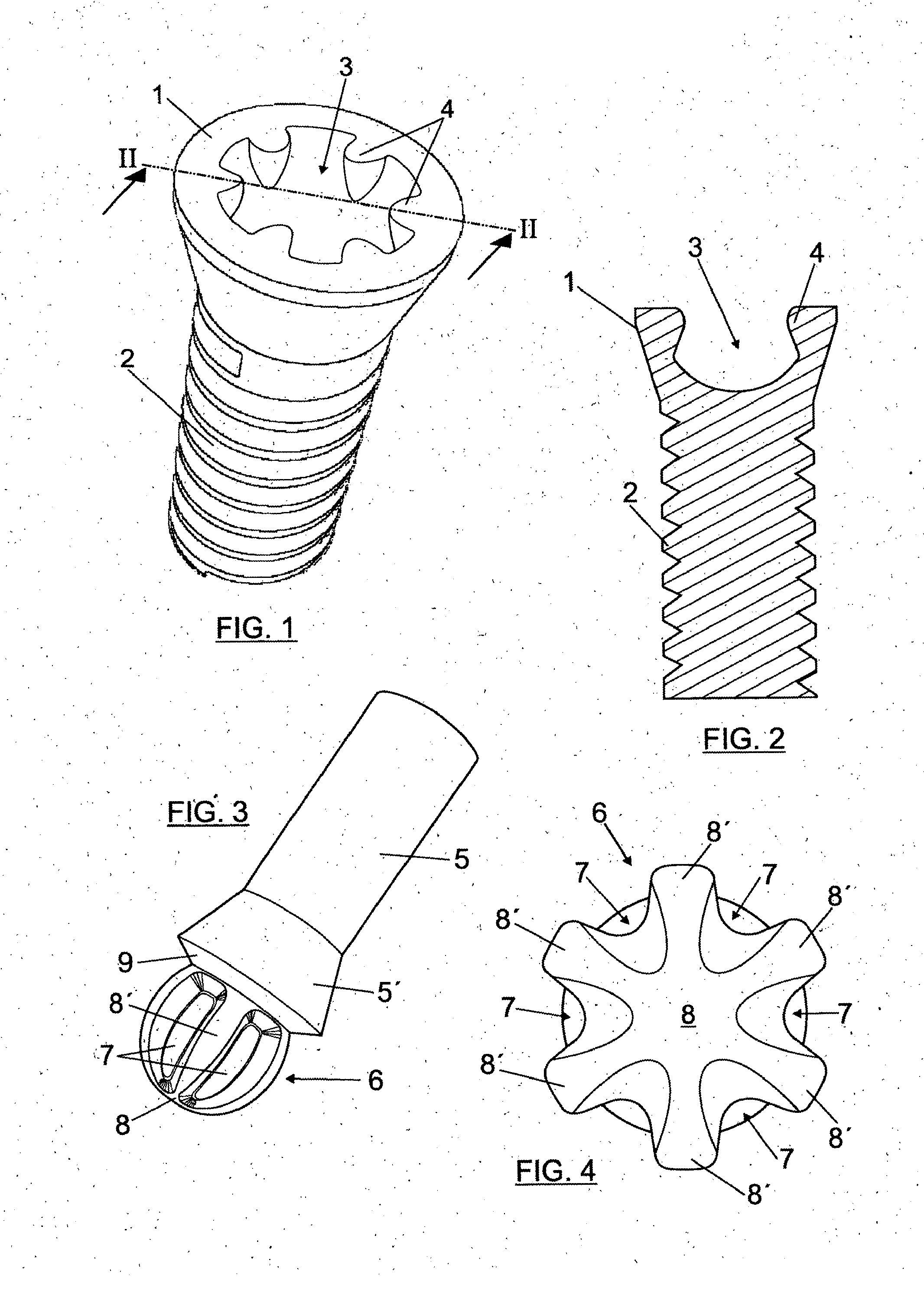

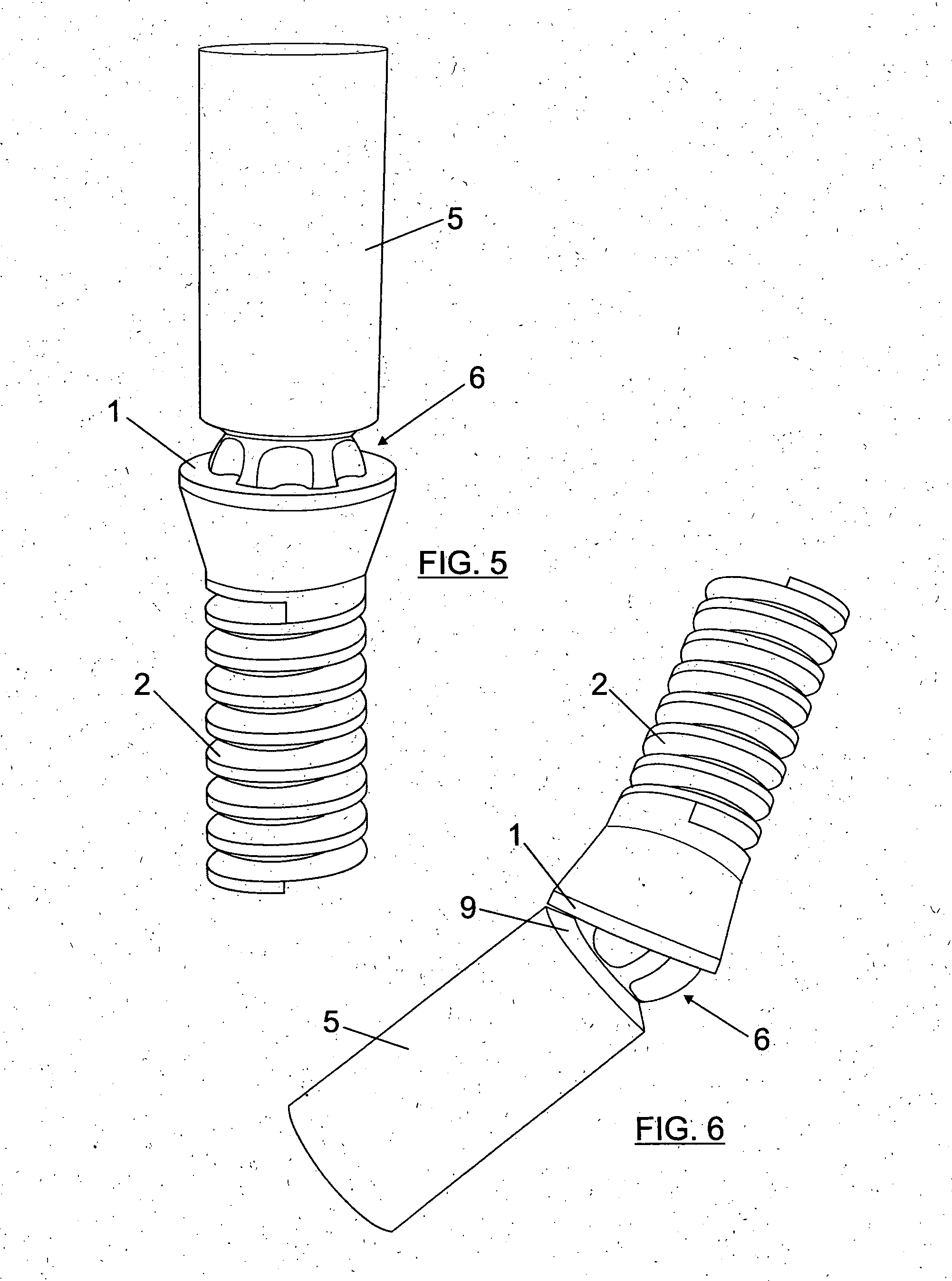

Coupling structure between screw head and tightening tool

ActiveUS20120103147A1High tightening torque on the screwRisk is exacerbatedBoltsSpannersSurface finishCoupling

A coupling structure between a screw head and a tightening tool includes a recess (3) with a curved concave surface on the free base of the head (1) of the screw (2) and a protuberance (6) with a curved convex surface finishing the end of the tool (5). The recess has axial projections (4) internally and the protuberance (6) has meridional grooves (7).

Owner:UNIVERSAL BALL HEAD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com