Hydraulic damper with hydraulic stop

A hydraulic damper and secondary technology, applied in the field of hydraulic dampers, can solve problems such as high load and excessive damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

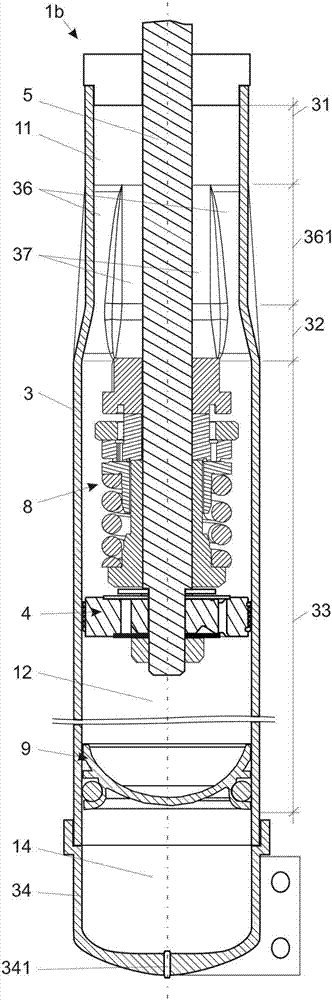

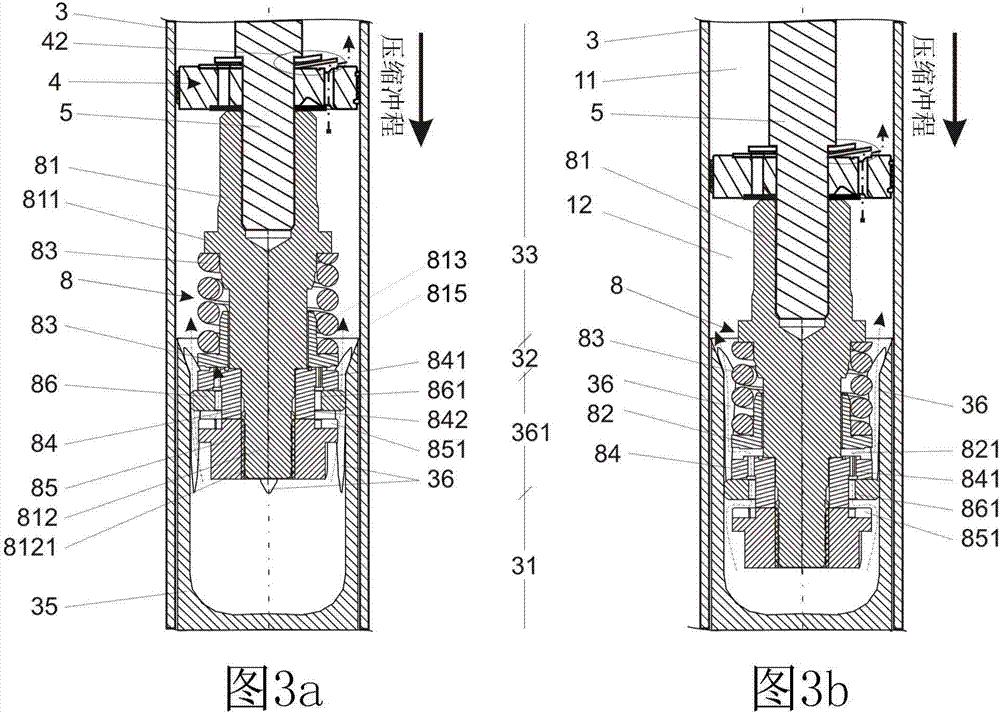

[0032] The reference numbers of functionally equivalent elements remain the same on all figures of the drawings, wherein where appropriate, the reference numbers are supplemented with an additional suffix (a, b) to distinguish functionally identical but structurally different elements.

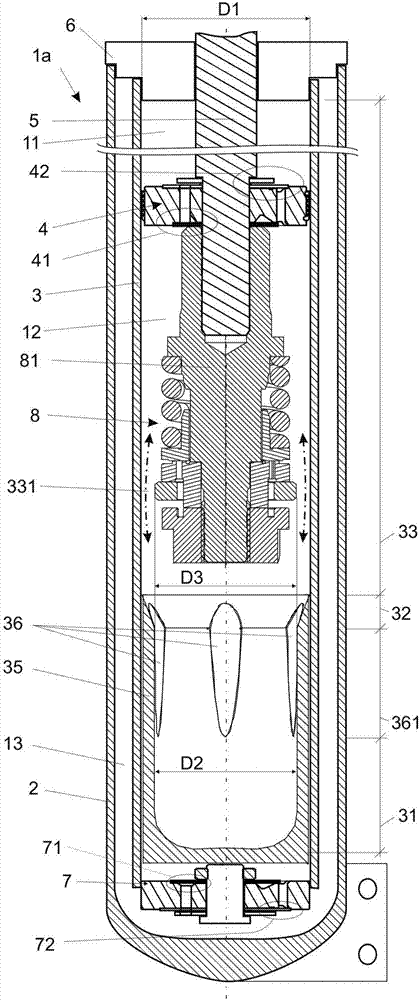

[0033] figure 1 One embodiment of a twin-tube damper 1 a according to the invention is presented that can be employed in a typical motor vehicle suspension. The damper 1a includes an outer tube 2 and a main tube 3 filled with a viscous working fluid. A movable main piston assembly 4 is provided in the main pipe 3 . The main piston assembly 4 is attached to the main piston rod 5 which leads to the outside of the damper 1 a through a sealed piston rod guide 6 . The damper 1 a is also provided with a base valve assembly 7 which is fixed at the other end of the main pipe 3 . The main piston assembly 4 is slidably positioned against the inner surface of the main pipe 3 and divides the tube 3 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com